Patents

Literature

40results about "Embossing/polishing soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

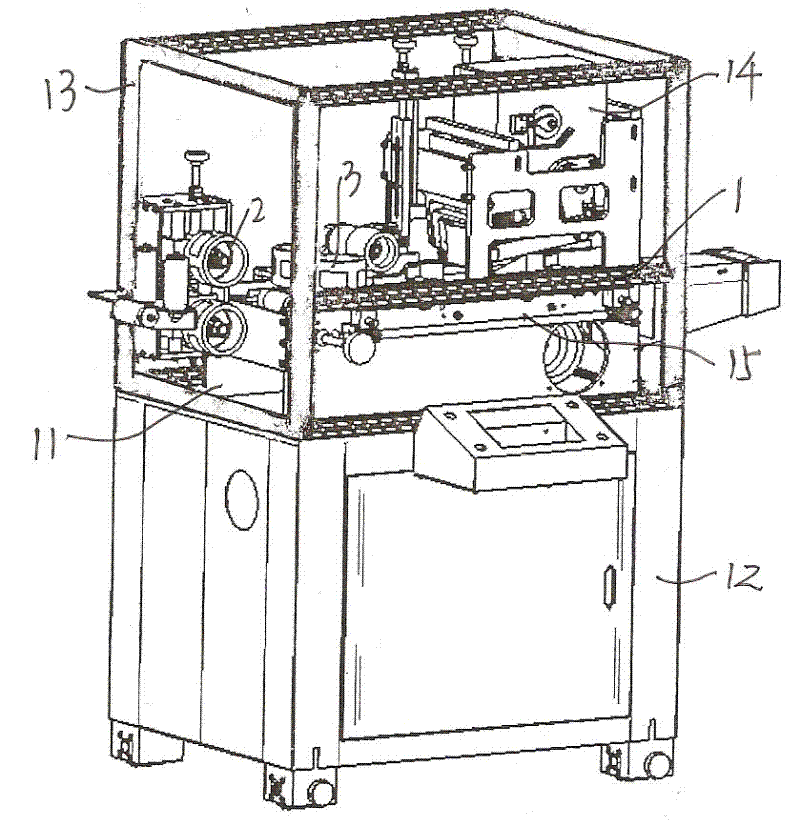

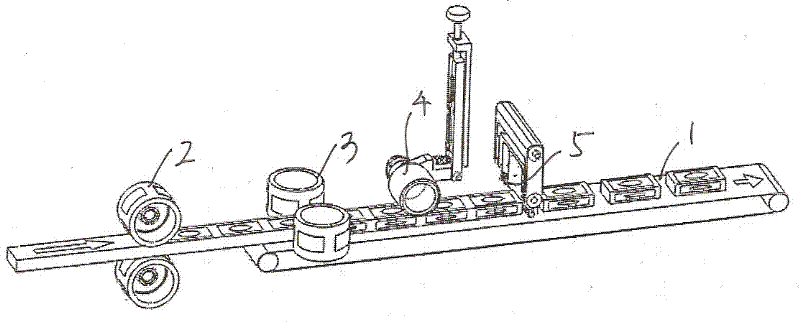

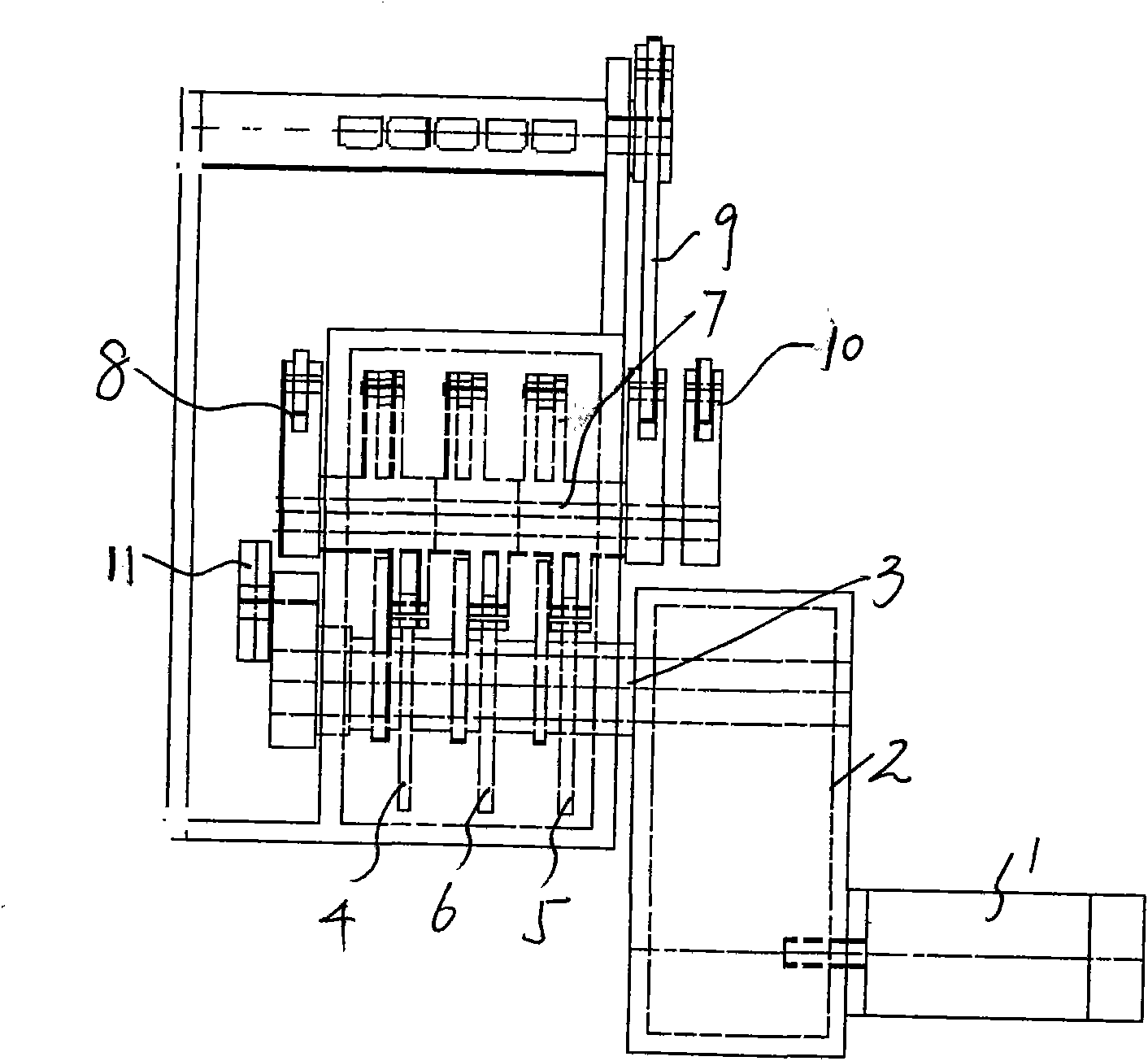

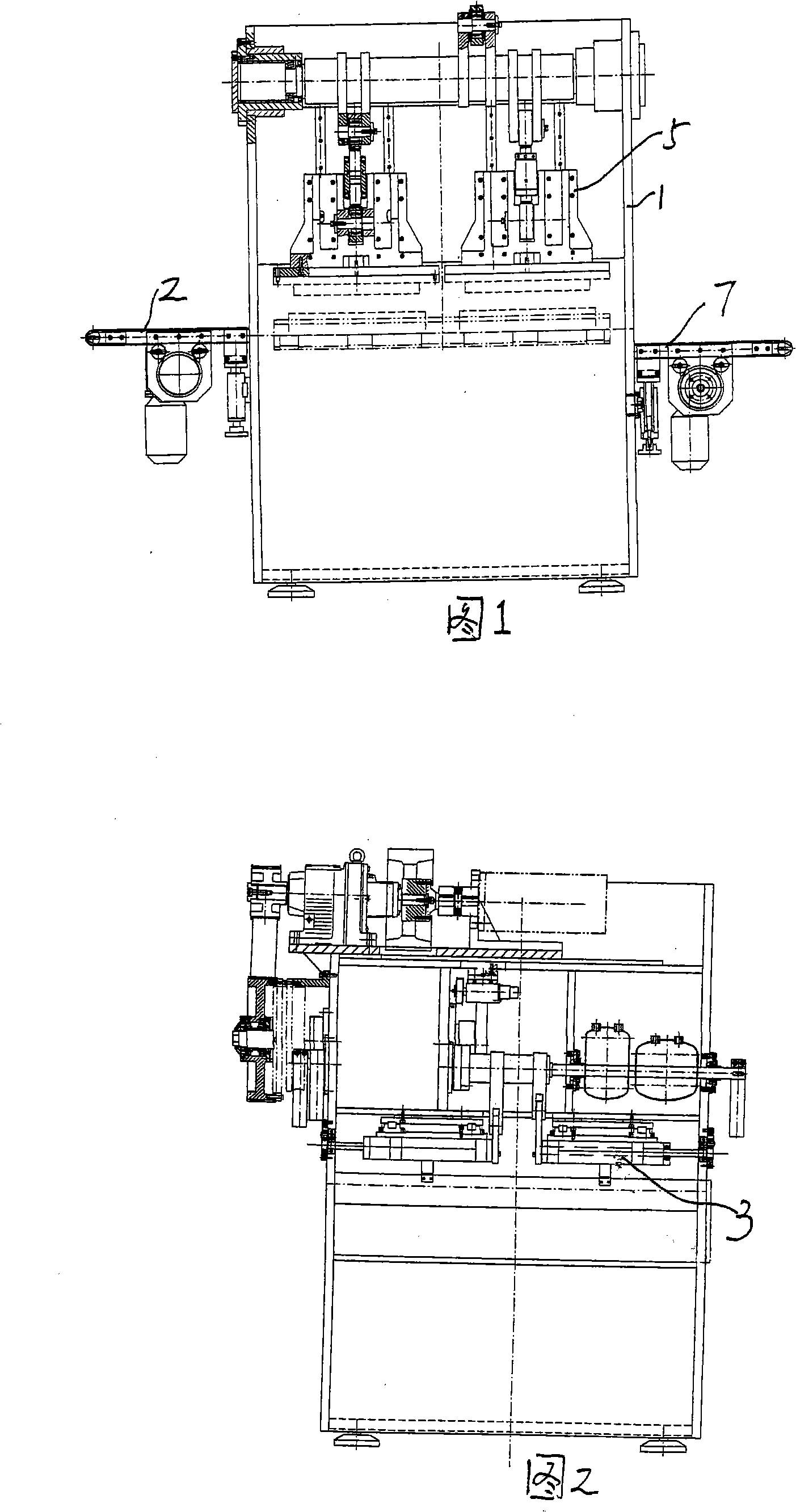

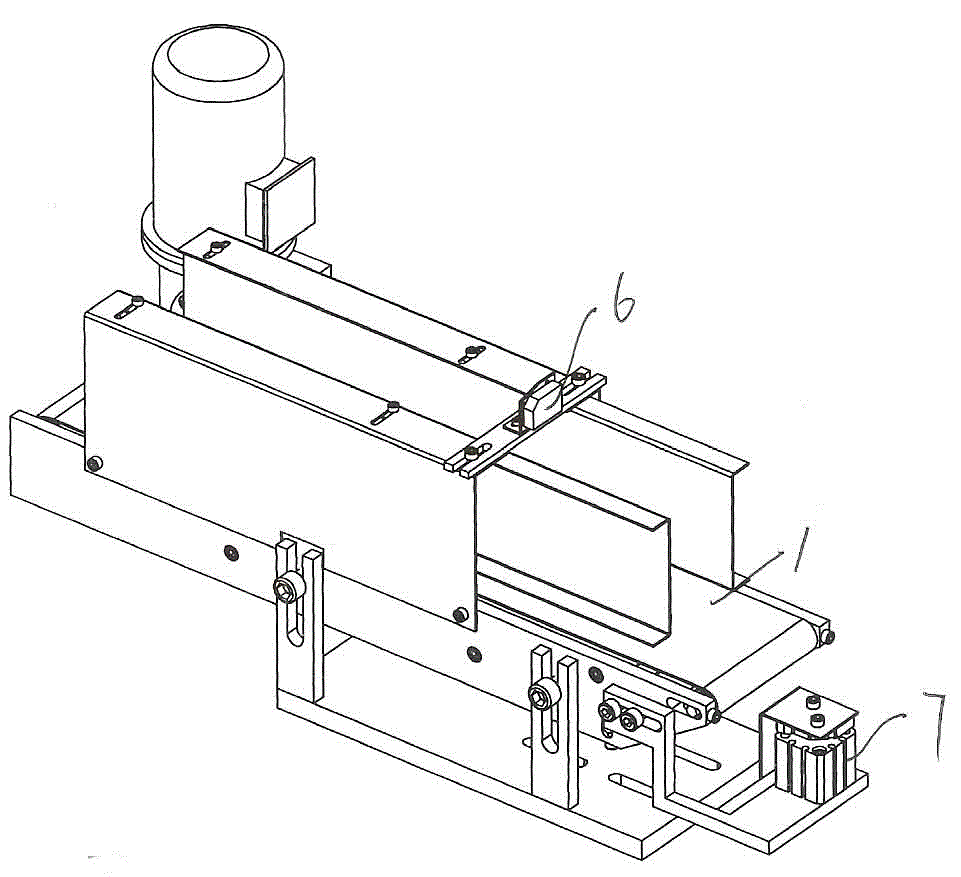

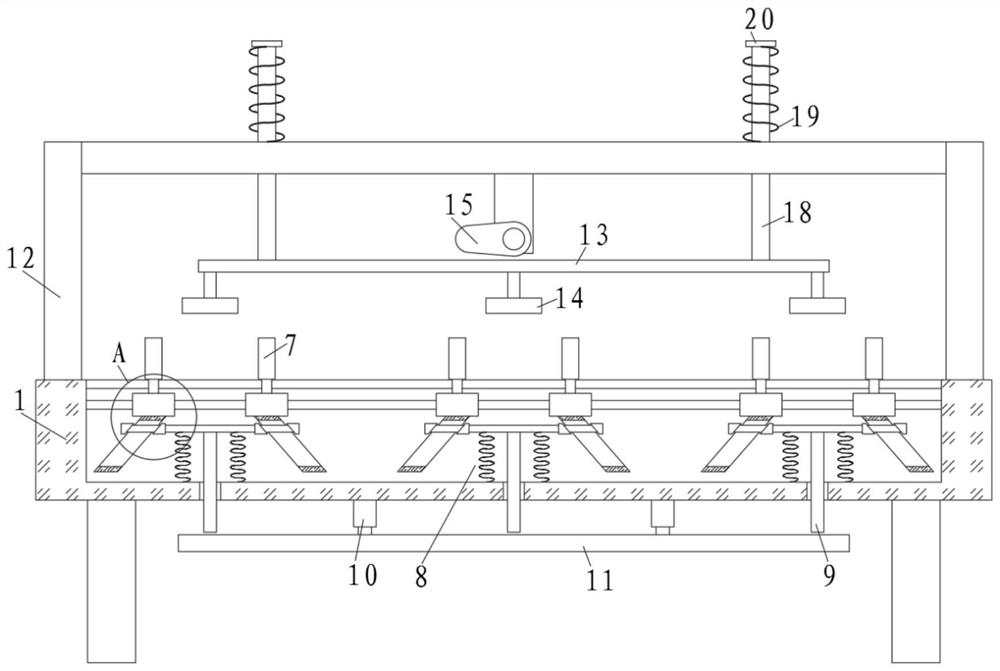

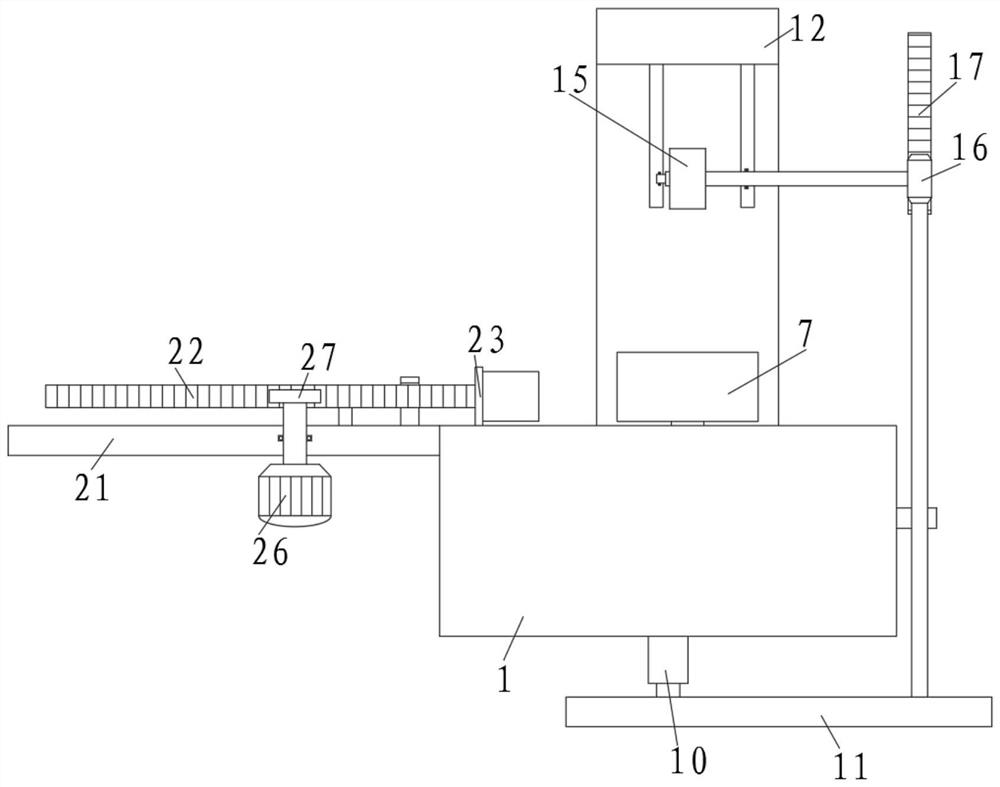

Four-side roll printing block cutting machine

InactiveCN102504987AReasonable designReasonable structureCutting soapEmbossing/polishing soapProduction lineEngineering

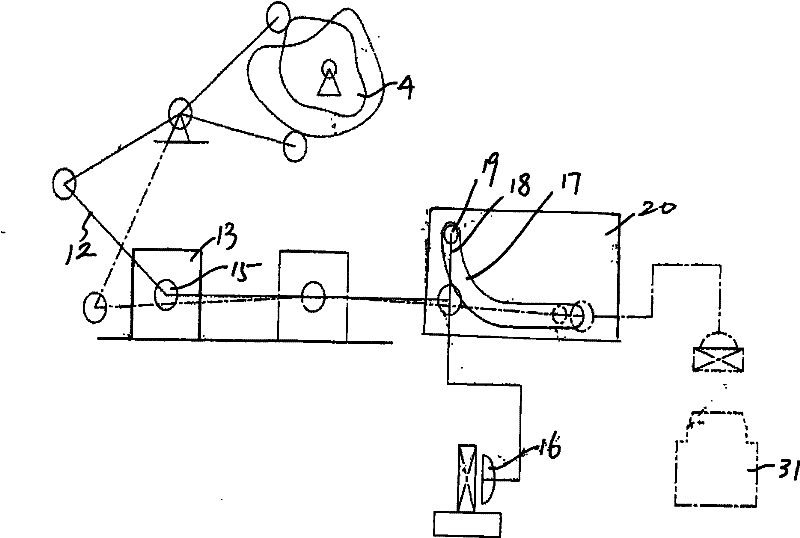

The invention discloses a four-side roll printing block cutting machine. The near side of a soap block conveying line is sequentially provided with an upper and lower roll printing mold device and a left and right roll printing mold device, an encoder capable of outputting pulse signals to a programmable controller during operation is arranged on the upper and lower roll printing mold device and the left and right roll printing mold device, a speed measuring wheel for measuring the speed of the conveying line is arranged behind the left and right roll printing mold device, a speed measuring encoder capable of outputting pulse signals to the programmable controller during the operation is arranged on the speed measuring wheel, a cutting knife for cutting soap strips is arranged behind the speed measuring wheel, and the programmable controller controls the cutting speed of the cutting knife through a transmission system. The four-side roll printing block cutting machine has the advantages that the structure is reasonable and compact, the operation is reliable, and the precision is high; and the double-encoder sampling and speed measuring technology meets the high-precision control requirements of on-line detection, continuous tracking and fixed length cutting. The programmable controller is adopted for control, and in addition, the linkage control with other equipment on a production line can be realized.

Owner:NANTONG UNIVERSAL MACHINERY

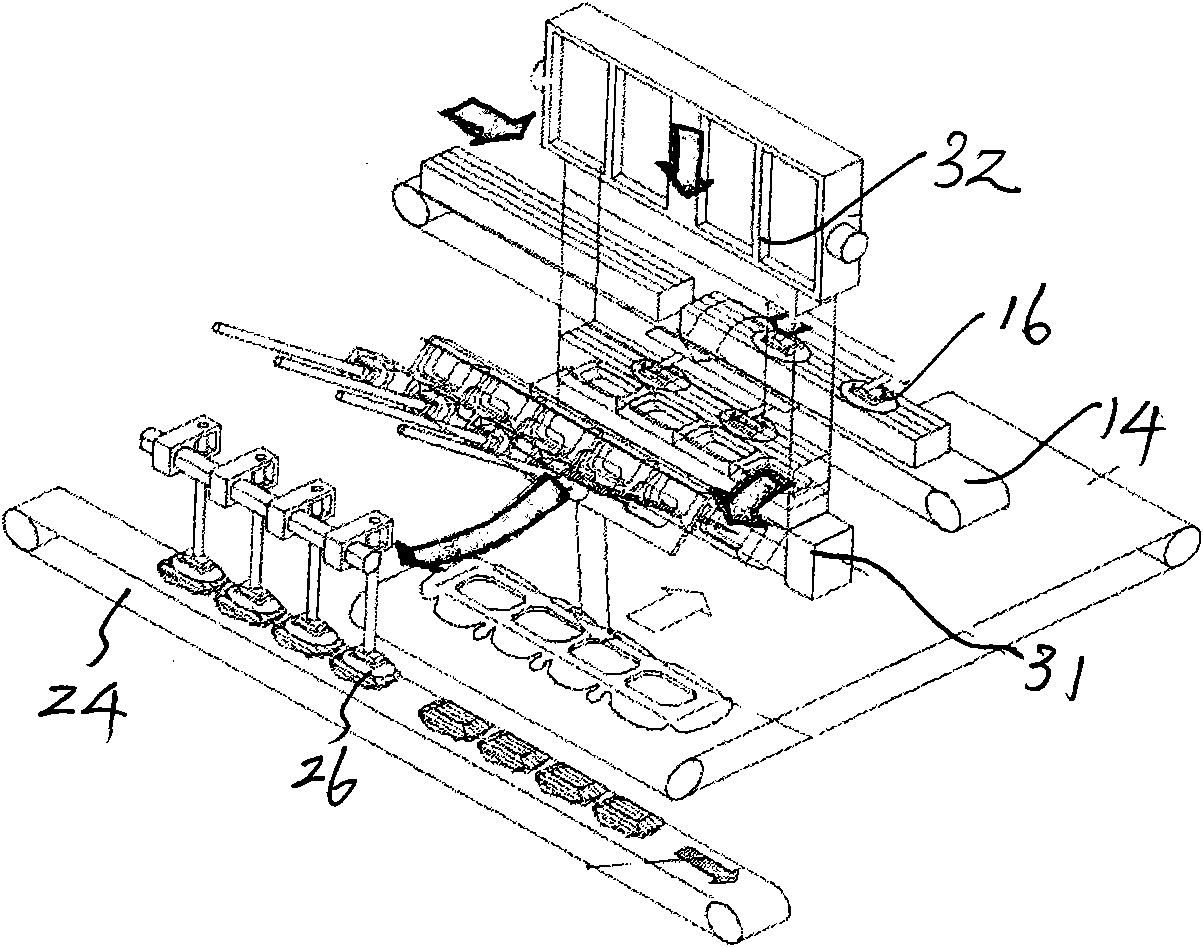

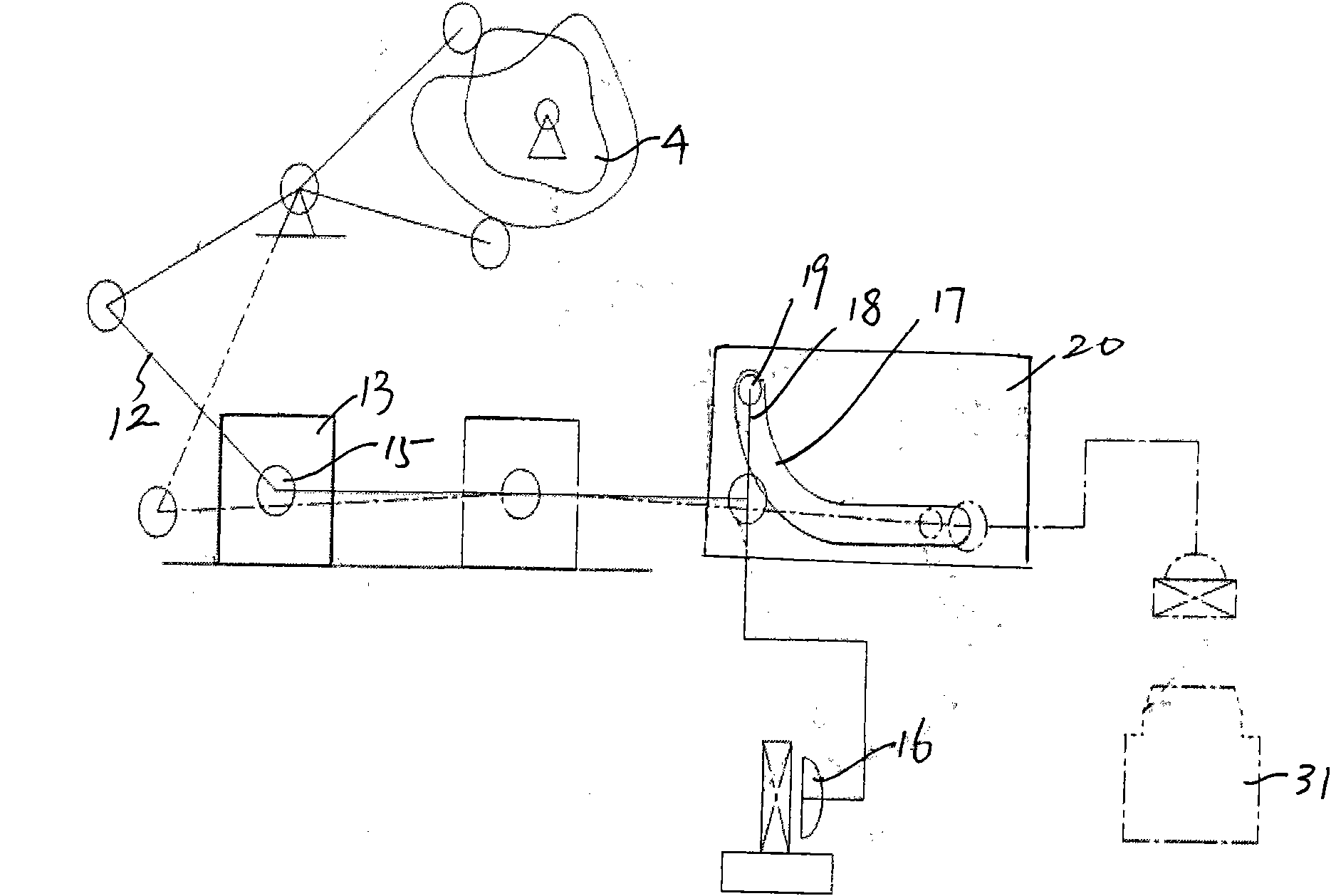

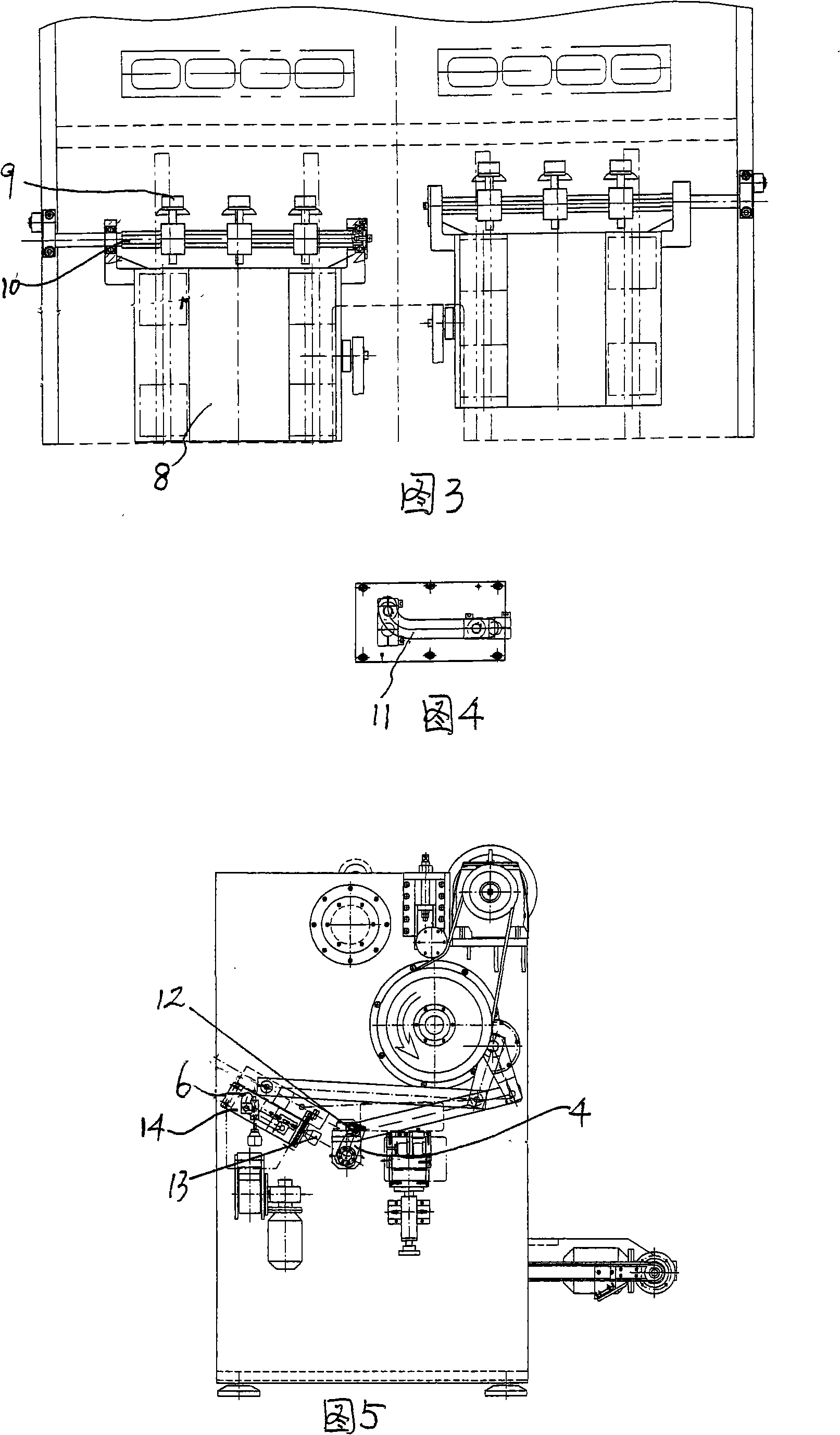

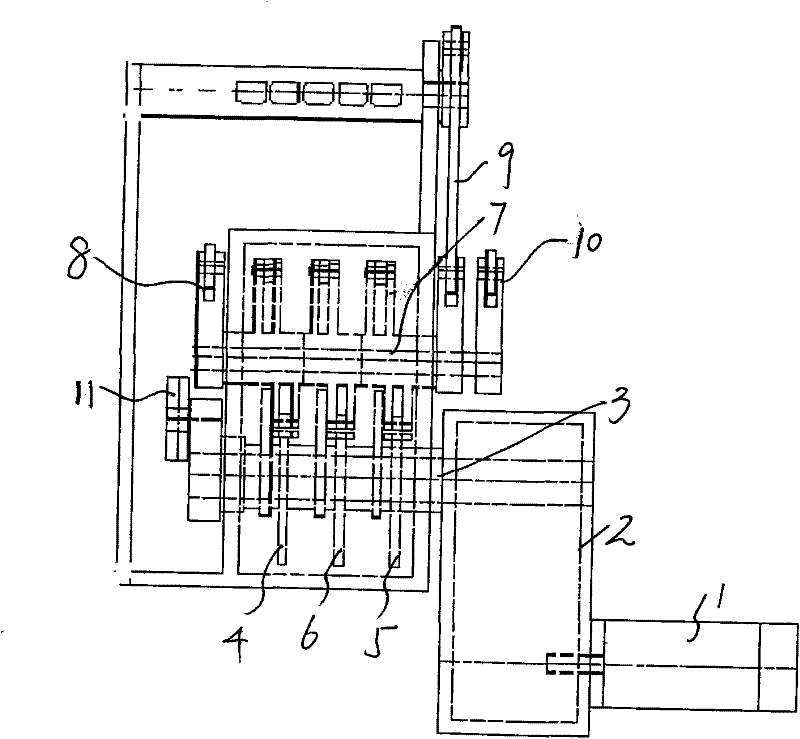

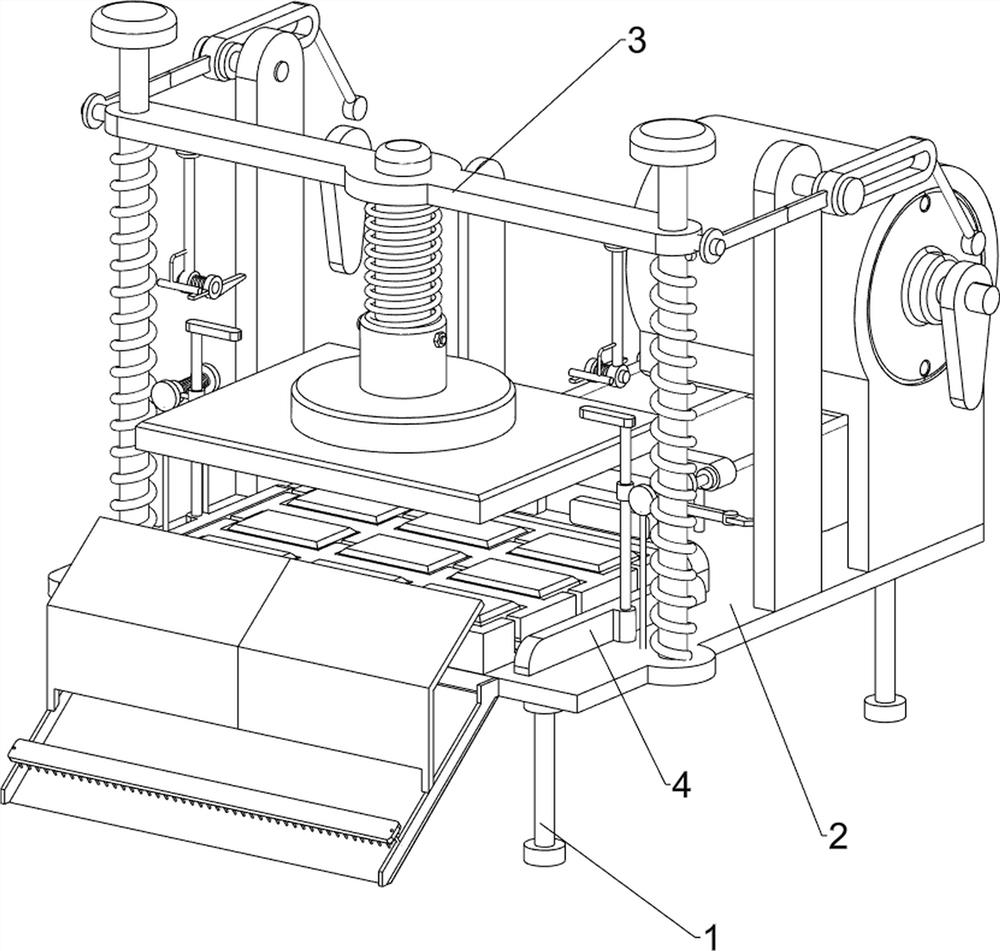

Soap printer

ActiveCN101985589APowerfulImprove reliabilityShaping soapEmbossing/polishing soapMotor driveElectric machine

The invention discloses a soap printer which comprises a motor-driven cam shaft. The cam shaft is provided with three conjugate cams, namely a soap slab cam, a lower mould cam and a soap block cam. The soap slab cam is connected with a first crank slider mechanism which drives a soap slab capturing and turning mechanism to move through a swing rod; the lower mould cam is connected with a crank connection rod mechanism which drives a lower mould turning mechanism to move through a swing rod; the soap block cam is connected with a second crank slider mechanism which drives a soap block capturing and turning mechanism to move through a swing rod; and the cam shaft is provided with a third crank slider mechanism which drives an upper mould to move. The invention has reasonable structure and high working performance.

Owner:NANTONG UNIVERSAL MACHINERY

Cold printer for perfumed soap

InactiveCN101298585AReasonable structureImprove work performanceEmbossing/polishing soapEngineeringMechanical engineering

The invention discloses a cool fragrant soap printer, comprising a frame, wherein, a conveyor device for fragrant soap strips is arranged on the frame; a pick-up and fetching apparatus for fragrant soap strips is positioned above the conveyor device, and can be rotated; a lower molding board that can be rotated is arranged at the lower part outside the pick-up and fetching apparatus for fragrant soap strips; an elevating upper die is arranged above the lower molding board that can be rotated; a fragrant soap taking mechanism that can be rotated is positioned outside the lower molding board that can be rotated; a discharging device is positioned at the lower part of the fragrant soap taking mechanism that can be rotated. The cool fragrant soap printer has the advantages of reasonable structure, excellent working effect and high working efficiency.

Owner:NANTONG UNIVERSAL MACHINERY

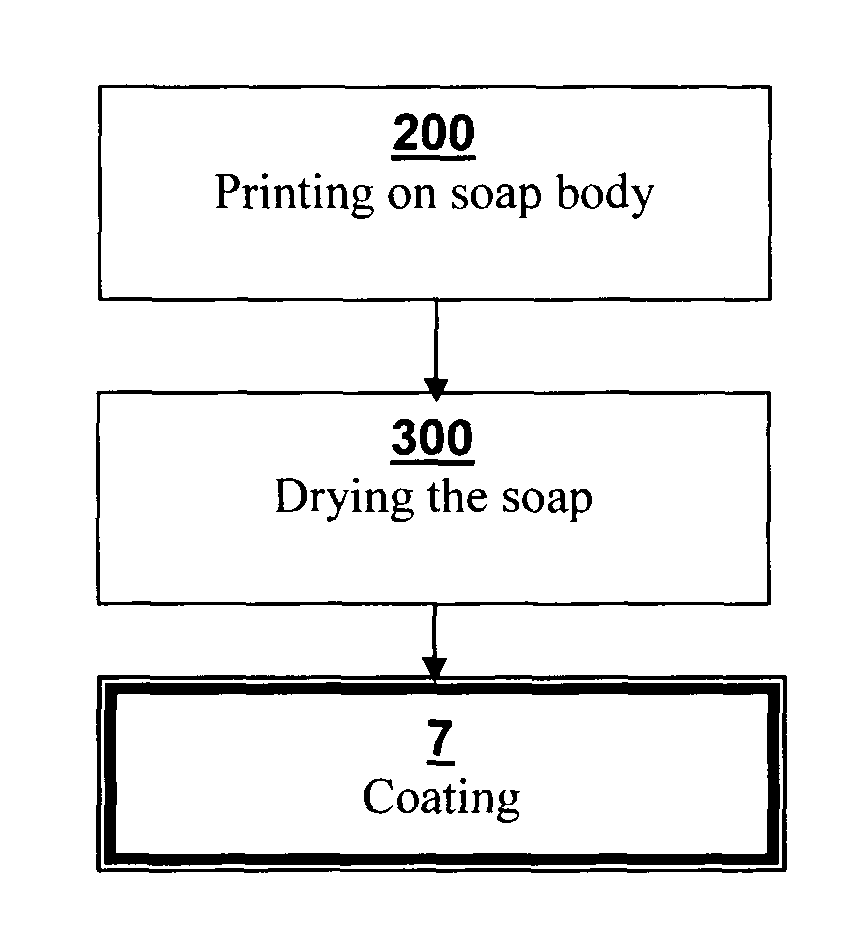

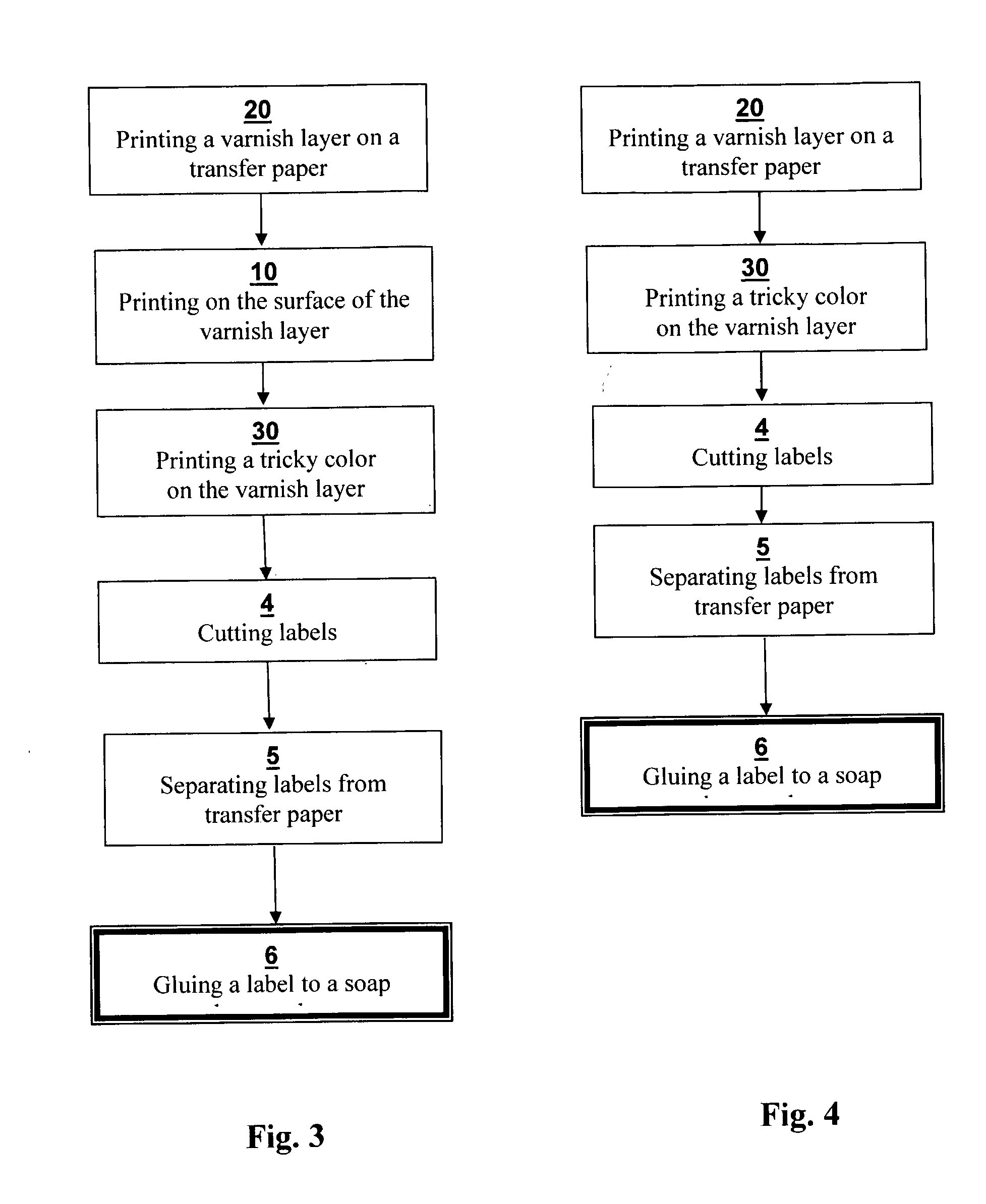

Method of printing upon a soap bar

InactiveUS7743704B2Avoid meltingDissolving, disassembling, decomposing, erodingCylinder pressesOther printing matterWater insolubleDiluent

Owner:PHOTO PRINT SOAP

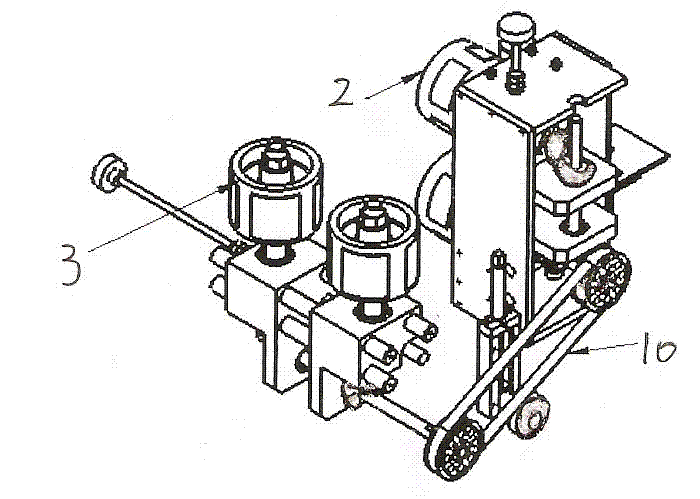

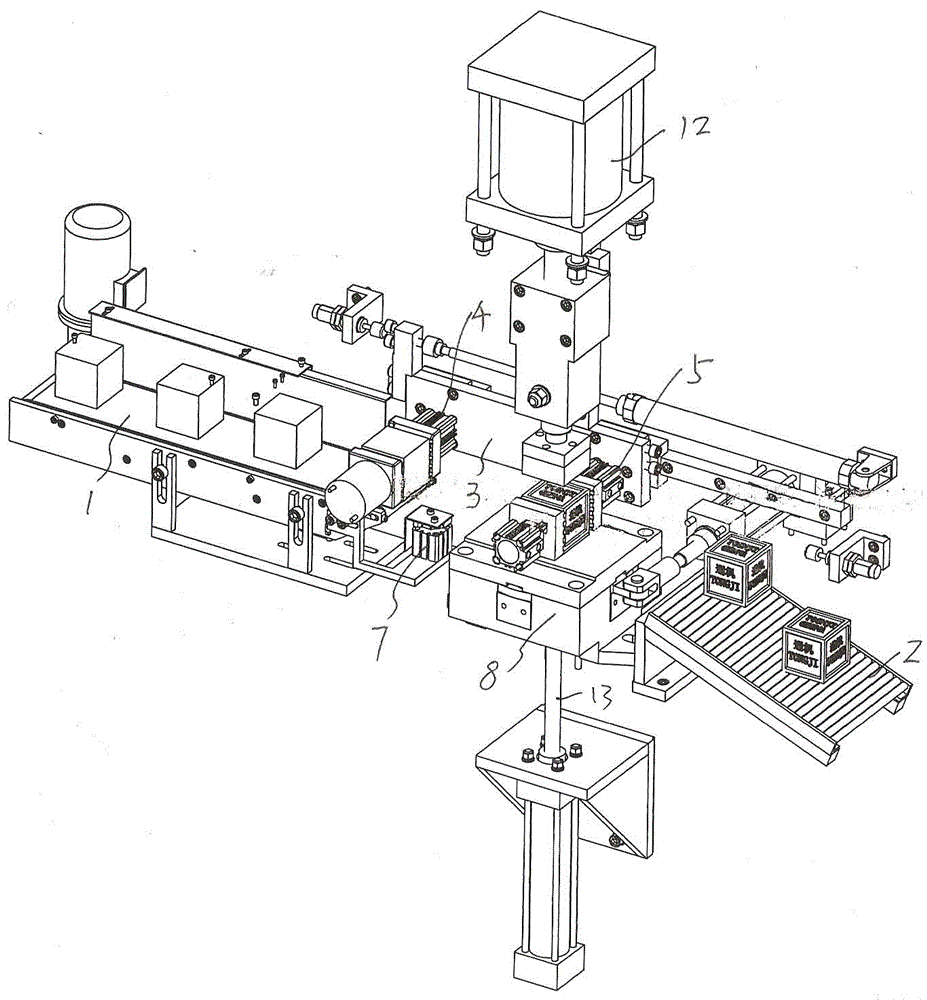

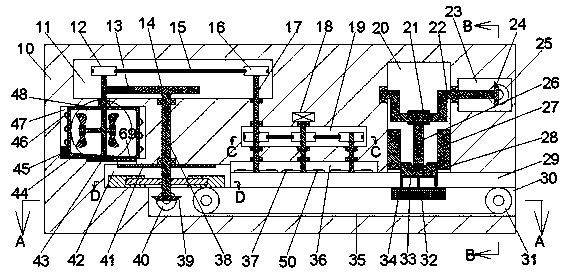

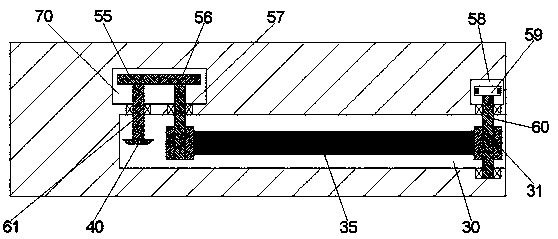

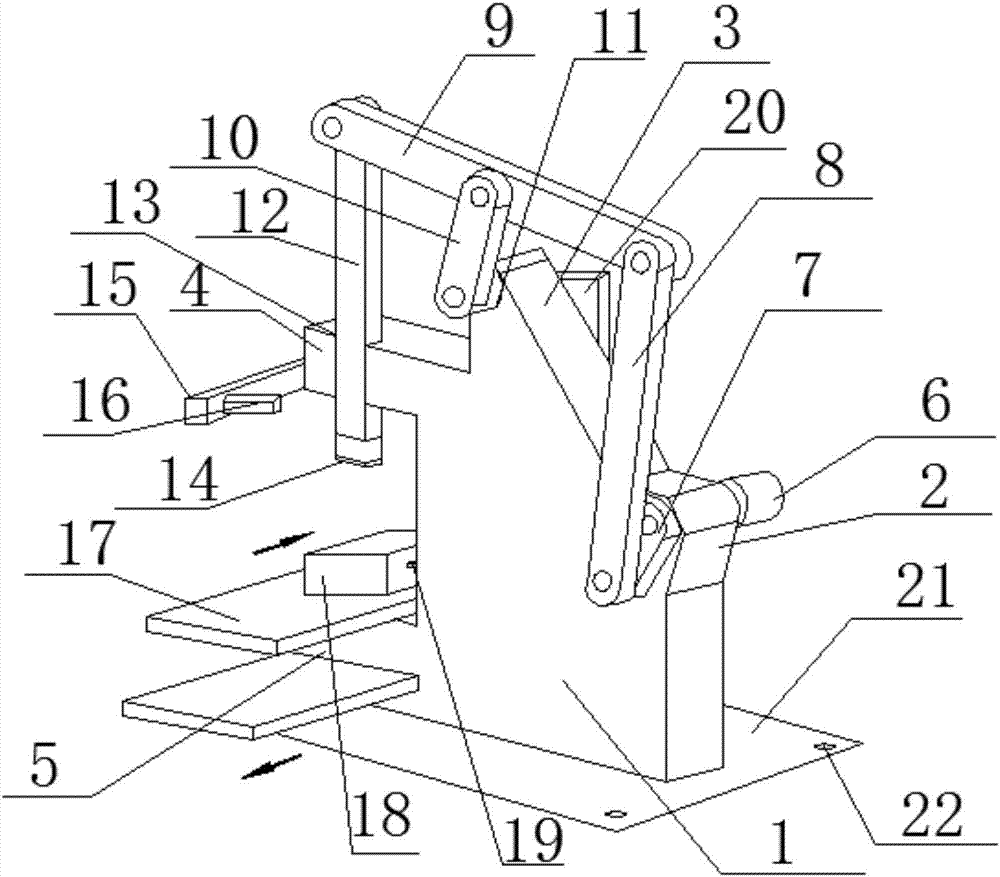

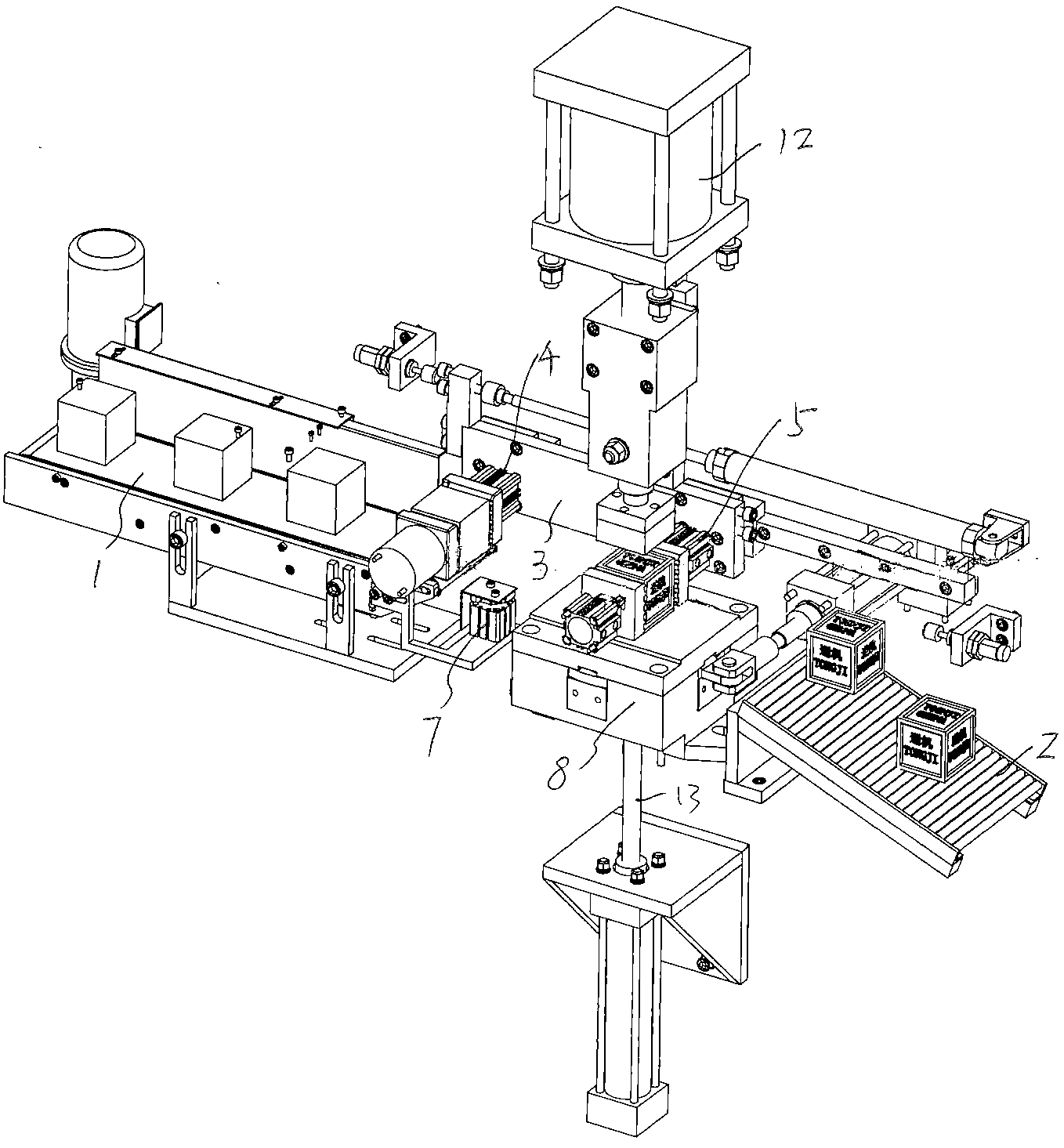

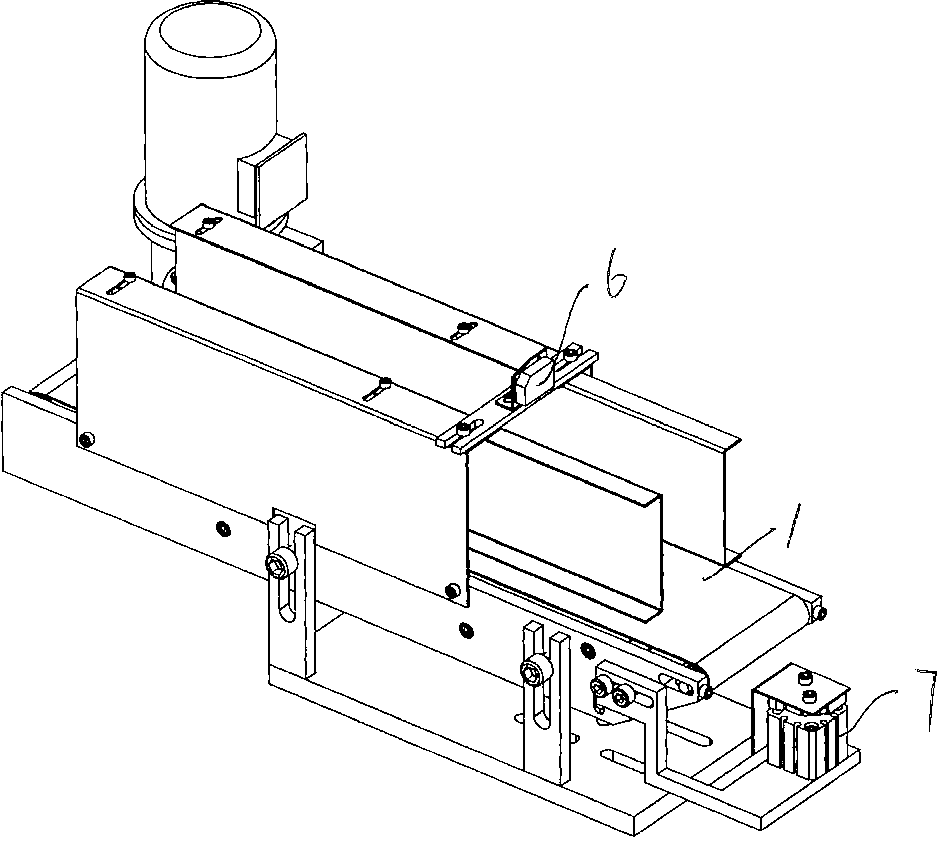

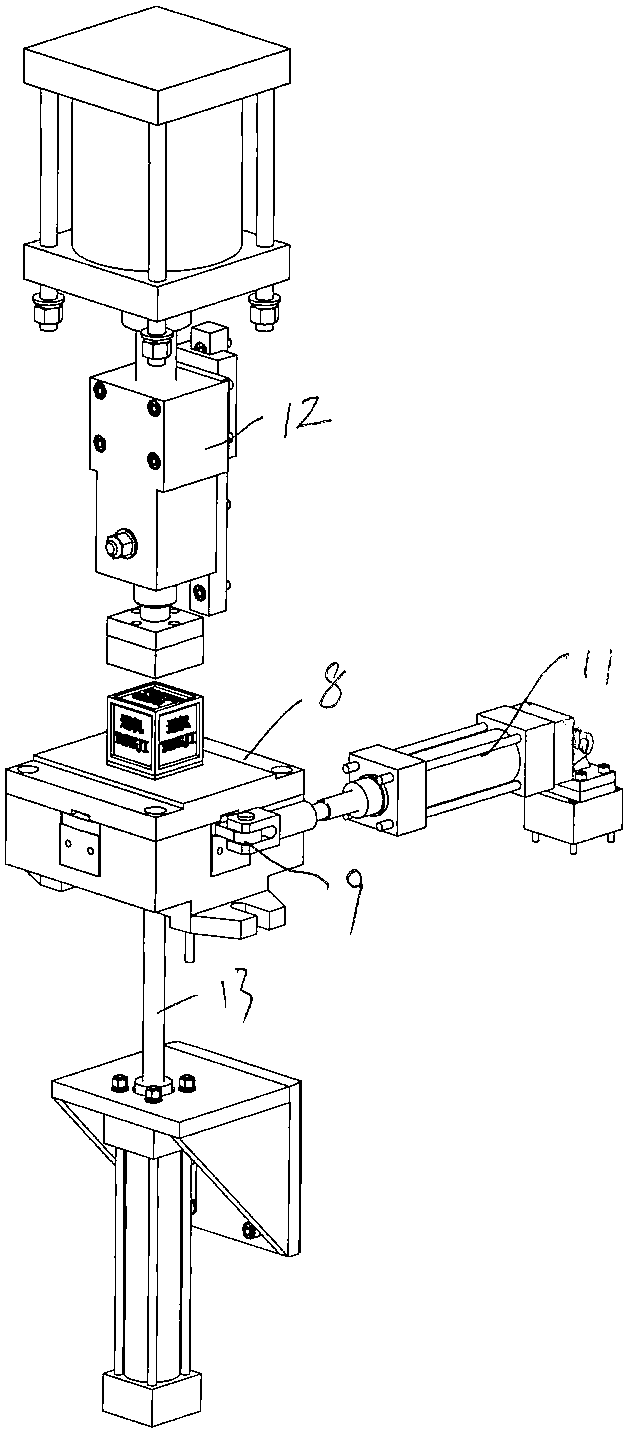

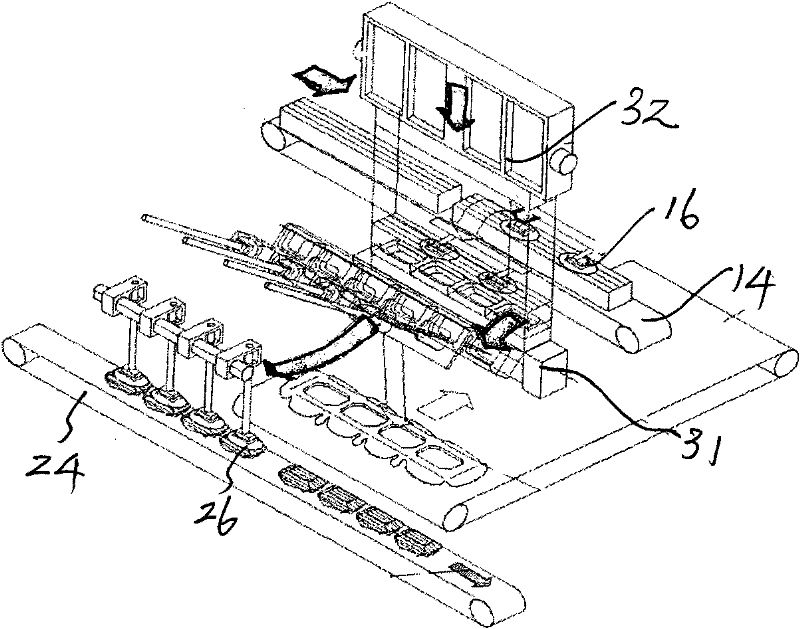

Cold printing machine for hexagonal soaps

ActiveCN102876526AMeet needsReasonable structureShaping soapEmbossing/polishing soapSOAPMoving parts

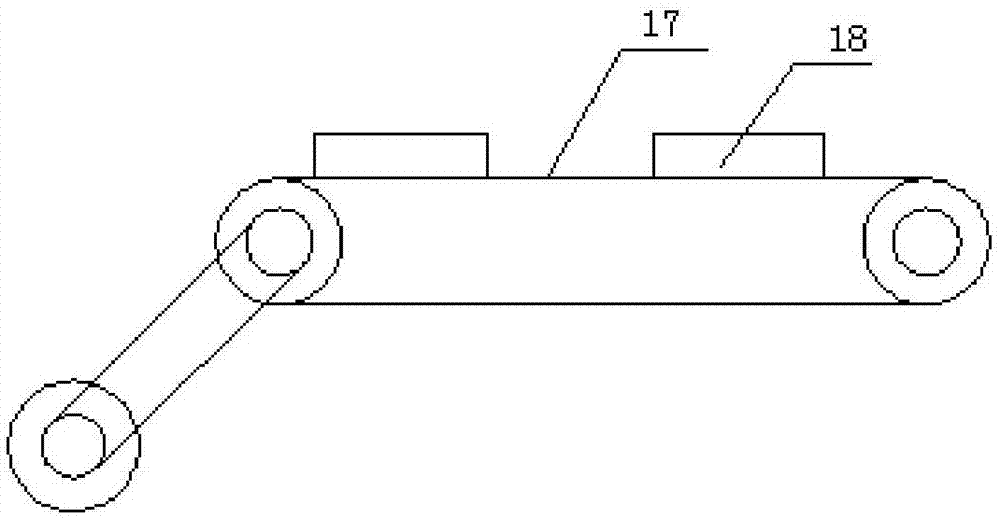

The invention discloses a cold printing machine for hexagonal soaps. The cold printing machine for hexagonal soaps comprises a soap feed conveying line. A back-and-forth moving type soap picking mechanism is arranged at the picking position of the soap feed conveying line, a die for printing the soaps is arranged behind the soap picking mechanism, and a soap discharge conveying line is arranged behind the die. The back-and-forth moving type soap picking mechanism comprises a front moving part and a rear moving part, a front soap clamping cylinder and a rear soap clamping cylinder are fixedly mounted on the front moving part and the rear moving part, the front soap clamping cylinder picks the soaps on the soap discharge conveying line and sends the same into a die cavity of the die, and the rear soap clamping cylinder picks the printed soaps and sends the same to the soap discharge conveying line. The cold printing machine for the hexagonal soaps is reasonable in structure, can print on multiple sides, can meet requirements of different senses of customers on the market for the soaps, breaks through people's conventional concept that soaps are round and opens up a brand-new market.

Owner:NANTONG UNIVERSAL MACHINERY

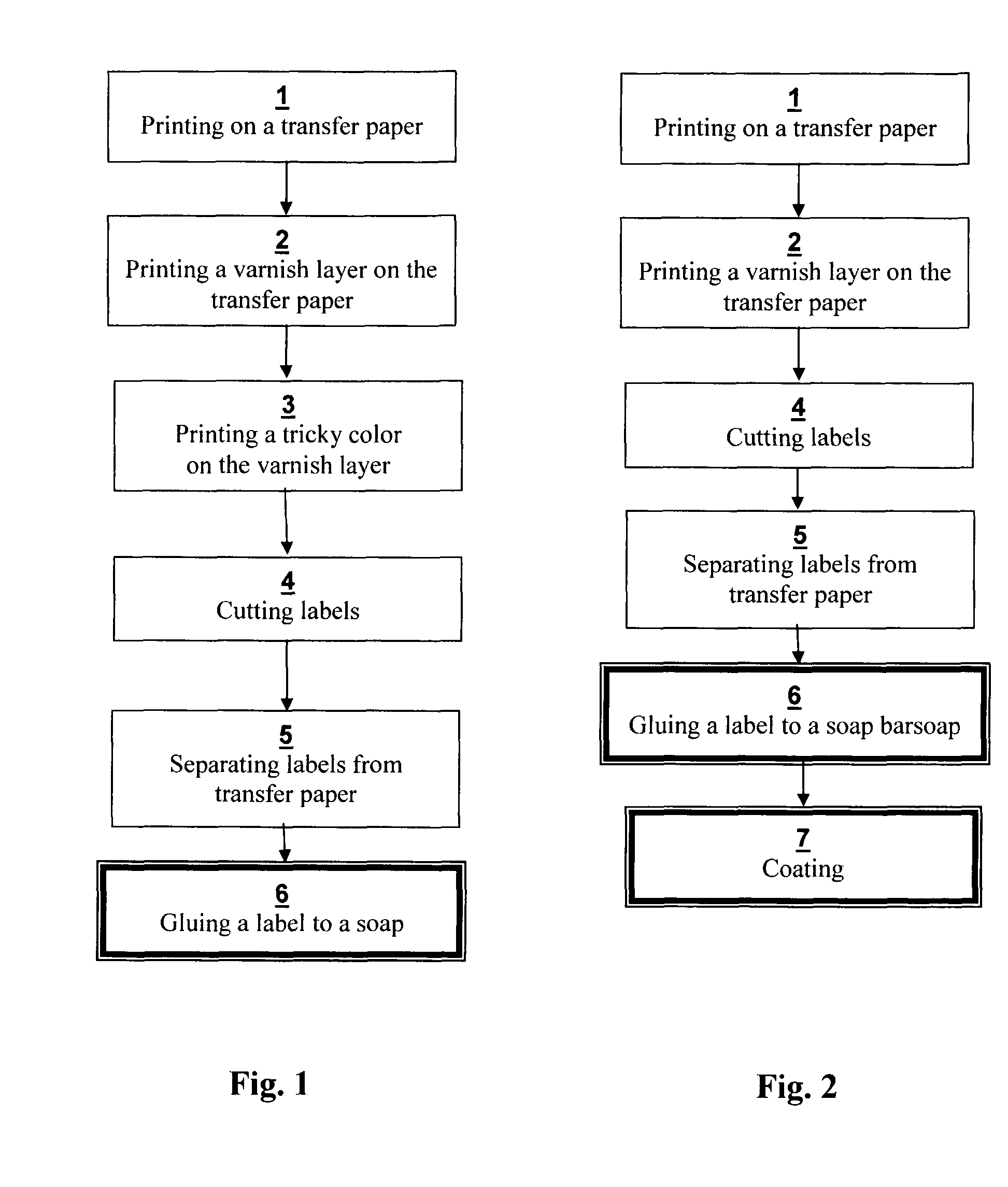

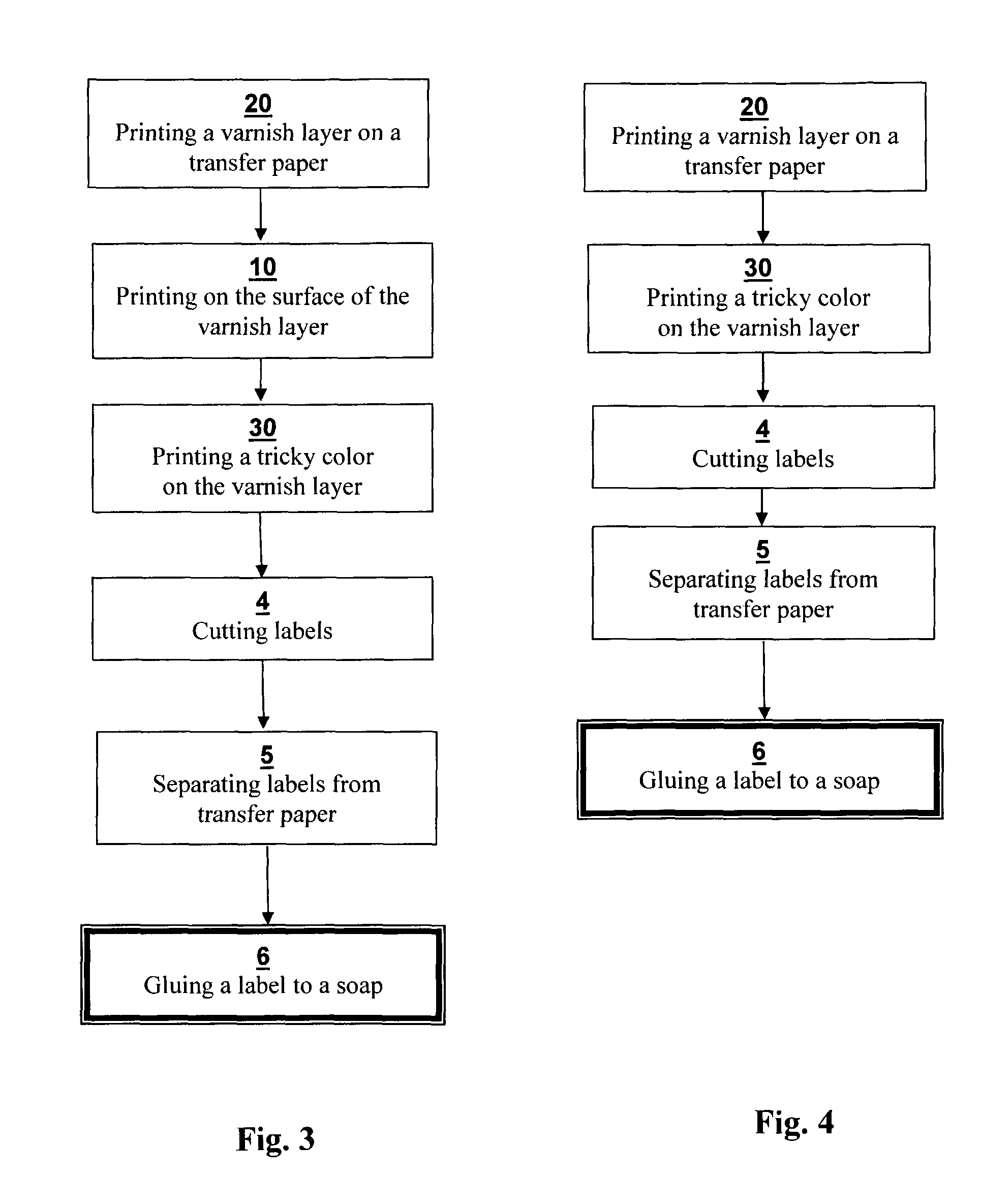

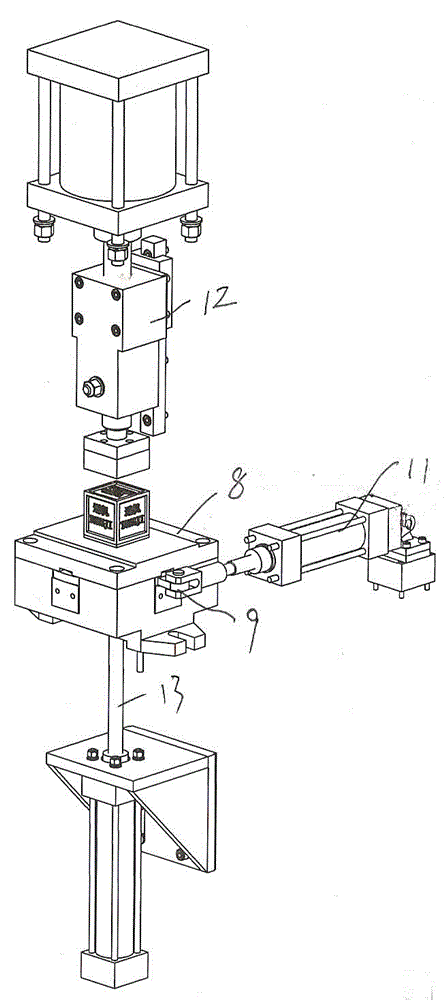

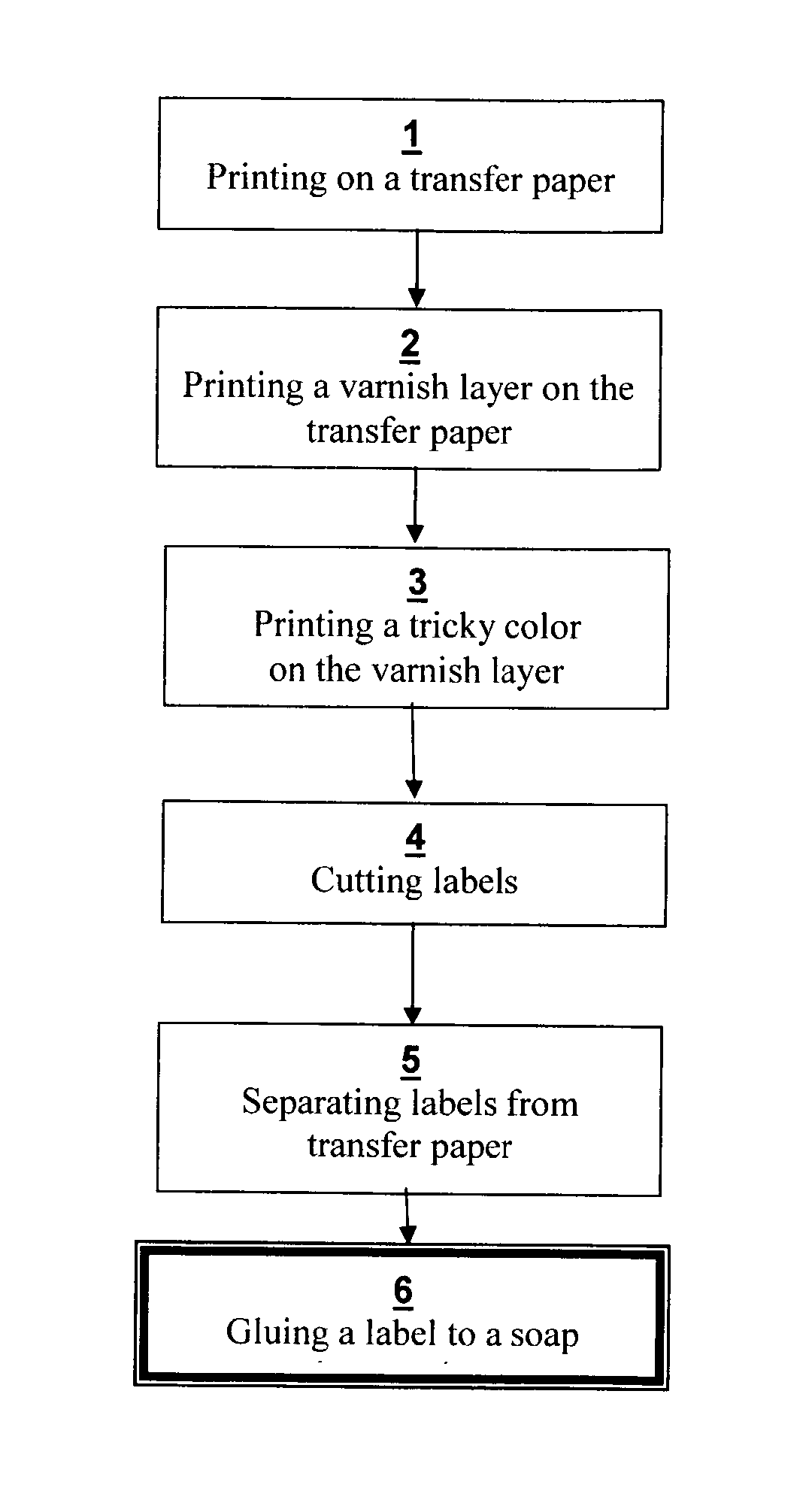

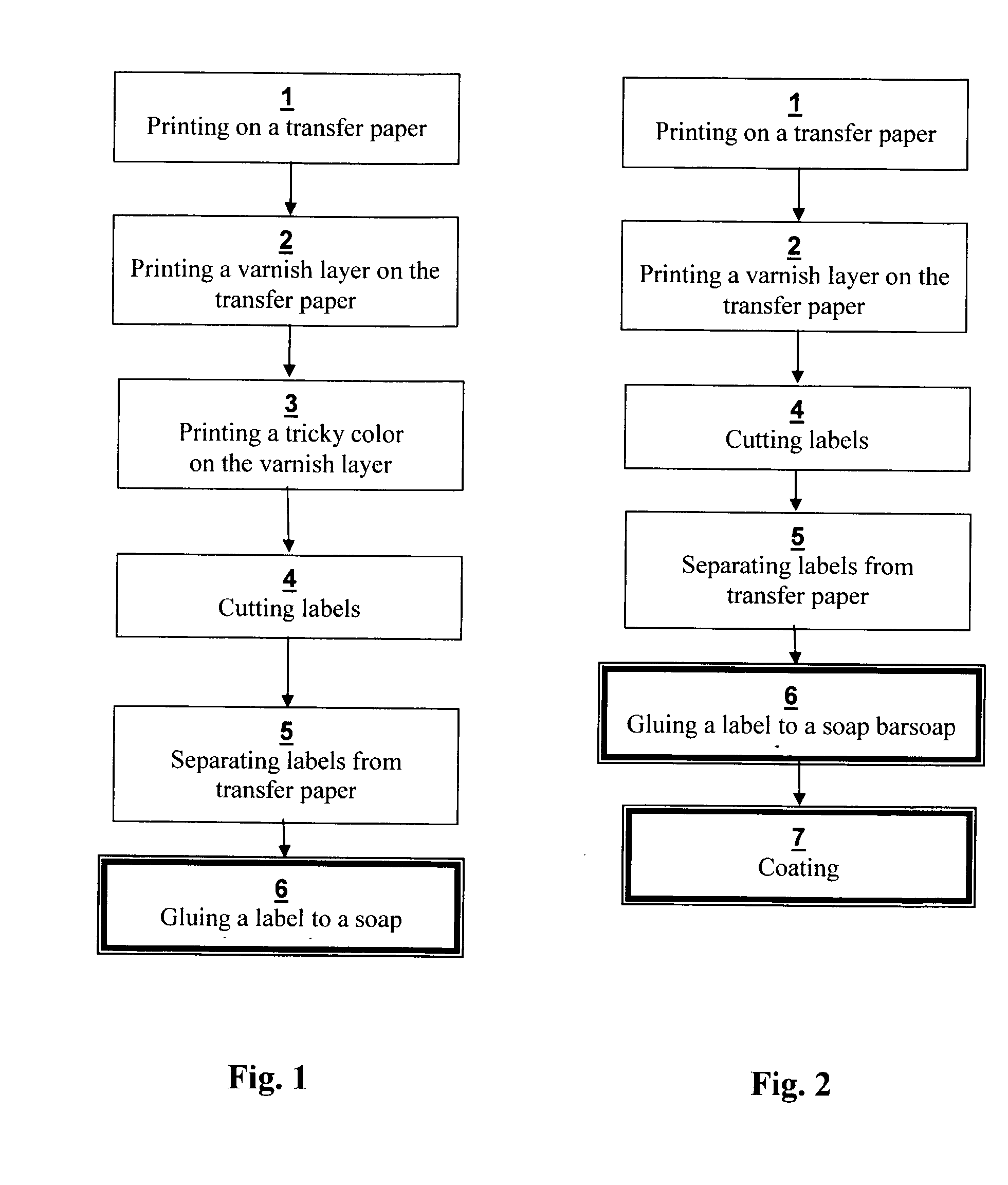

Means And Method Of Printing Upon A Soap Bar

InactiveUS20080064617A1Improve efficiencyAvoid meltingCylinder pressesCosmetic preparationsWaxWater insoluble

The inventors disclose a novel method of imprinting on a soap bar or soap sheet. This method comprises steps of providing printed matter on the surface of said soap and isolating said surface from water contact, such that said printed matter is partially or substantially water-insoluble. Moreover, the invention presents a cost effective soap bar or soap sheet having printed matter on a surface thereon; said surface is protected by at least one protective layer which is partially or substantially water-insoluble. The protective layer can be a varnish layer printed on transfer paper and then glued or otherwise affixed to the soap as a label. It can also be a wax layer, wherein the printed matter is either printed on the soap before coating thereof, or be part of a varnish label to be glued to the soap, which is then coated by a wax layer. The printing color is durable in water or other predetermined diluents and in water-soap solution.

Owner:PHOTO PRINT SOAP

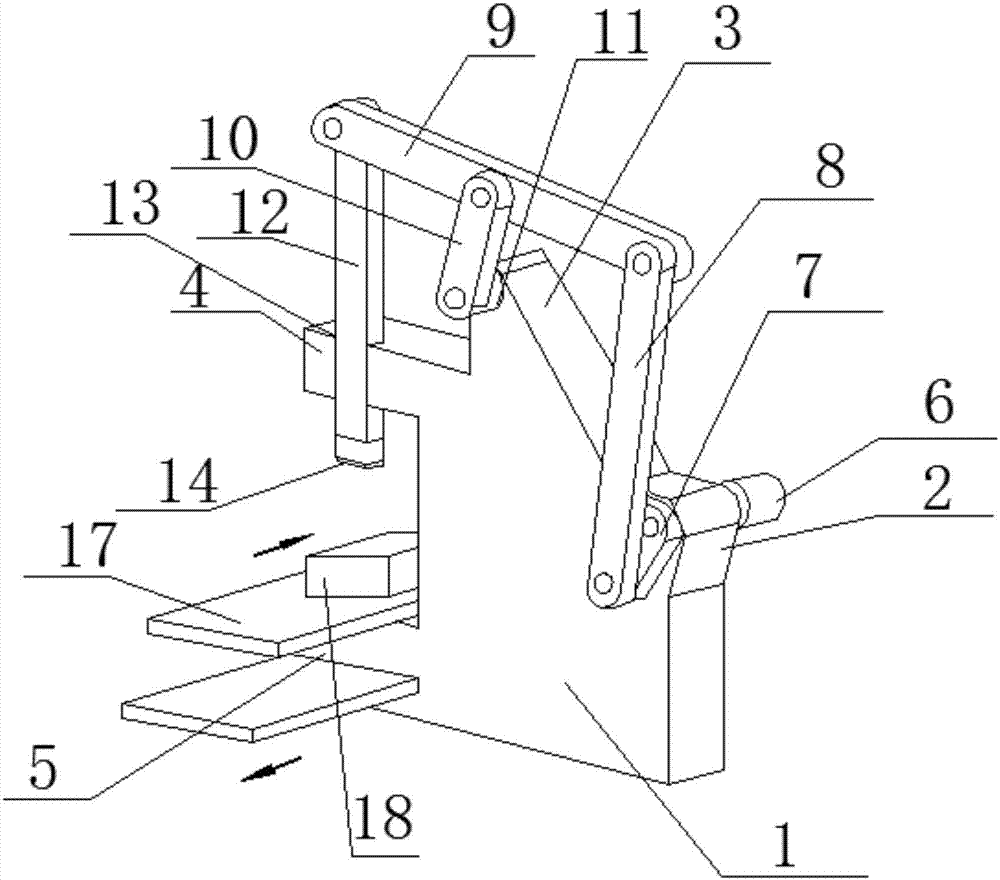

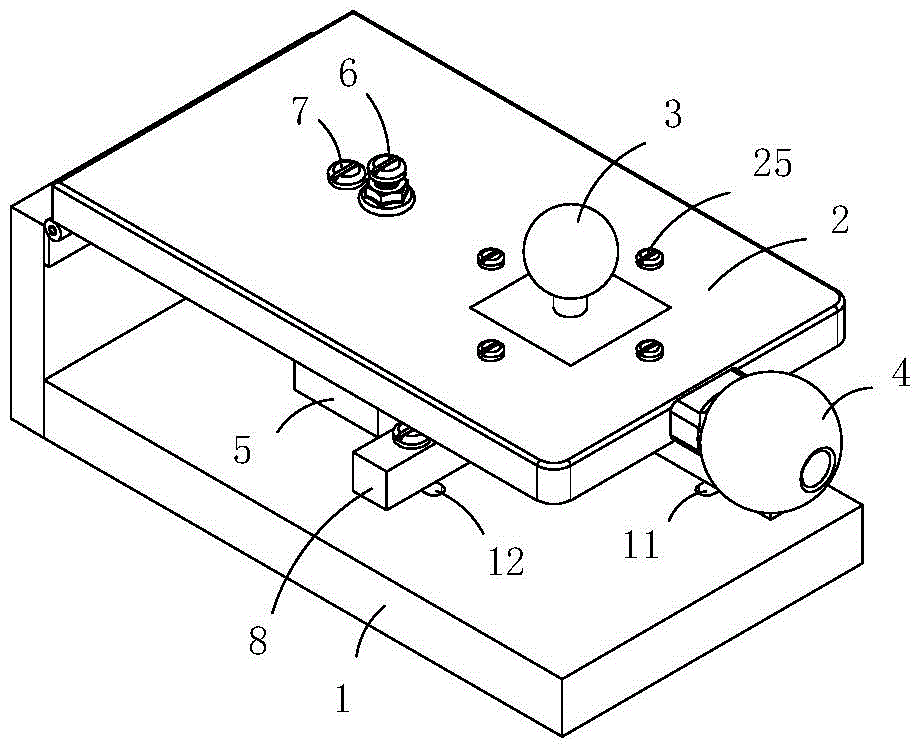

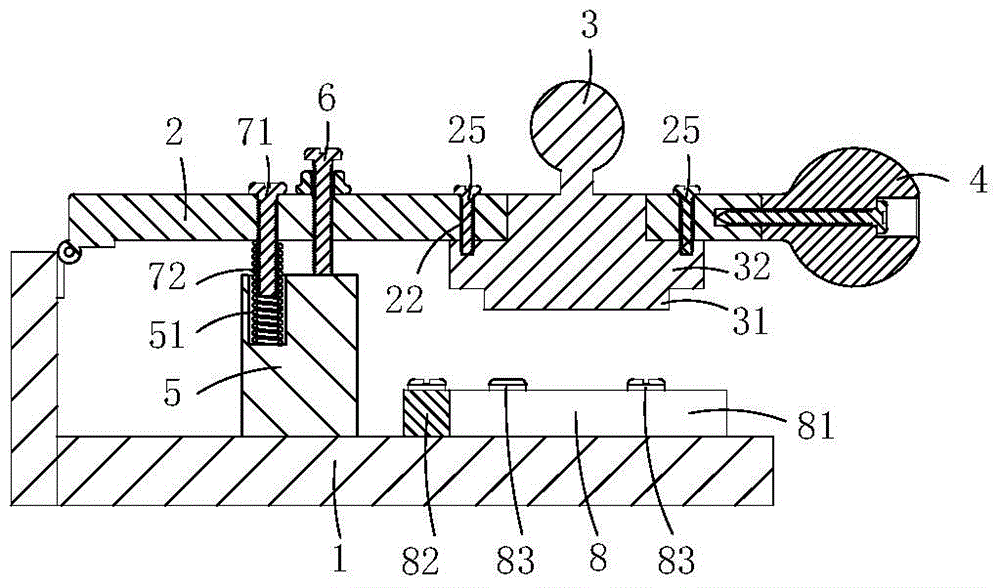

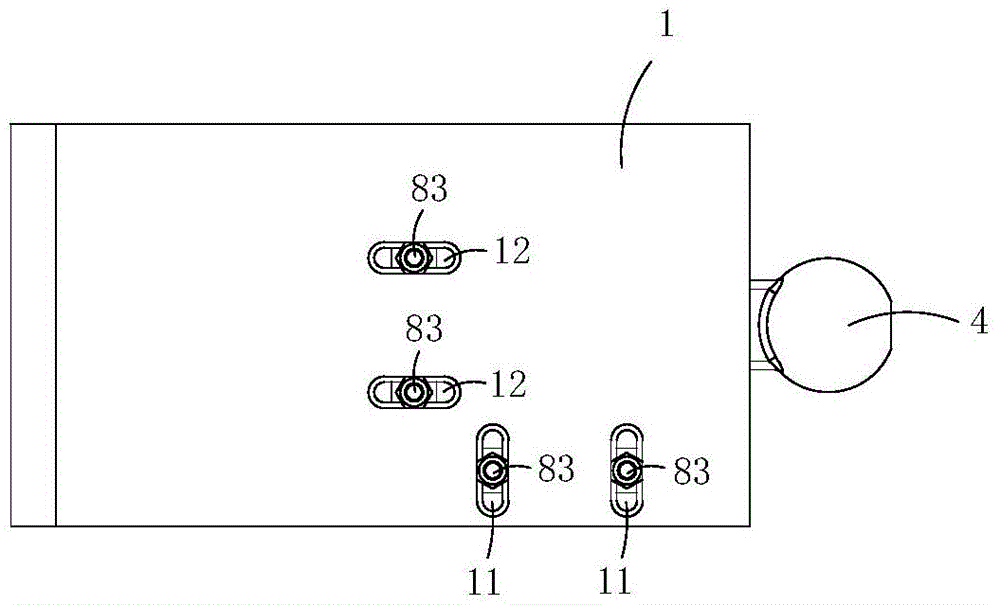

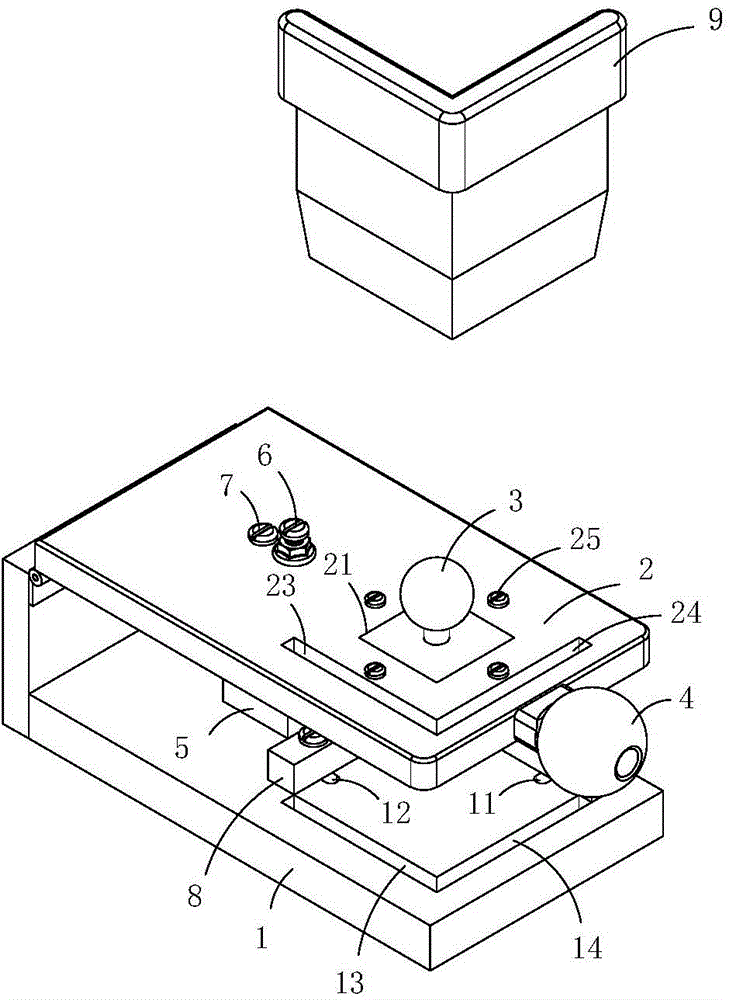

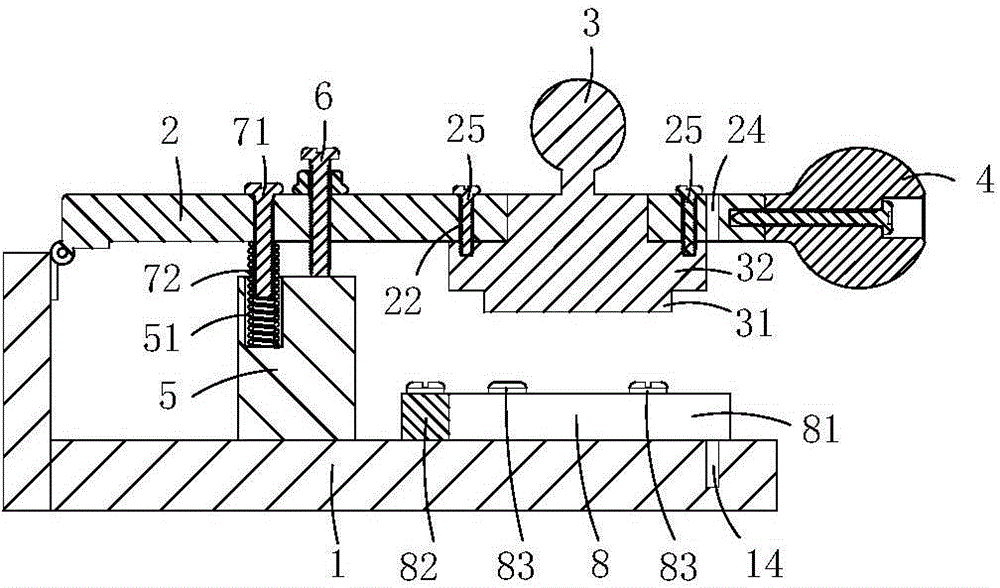

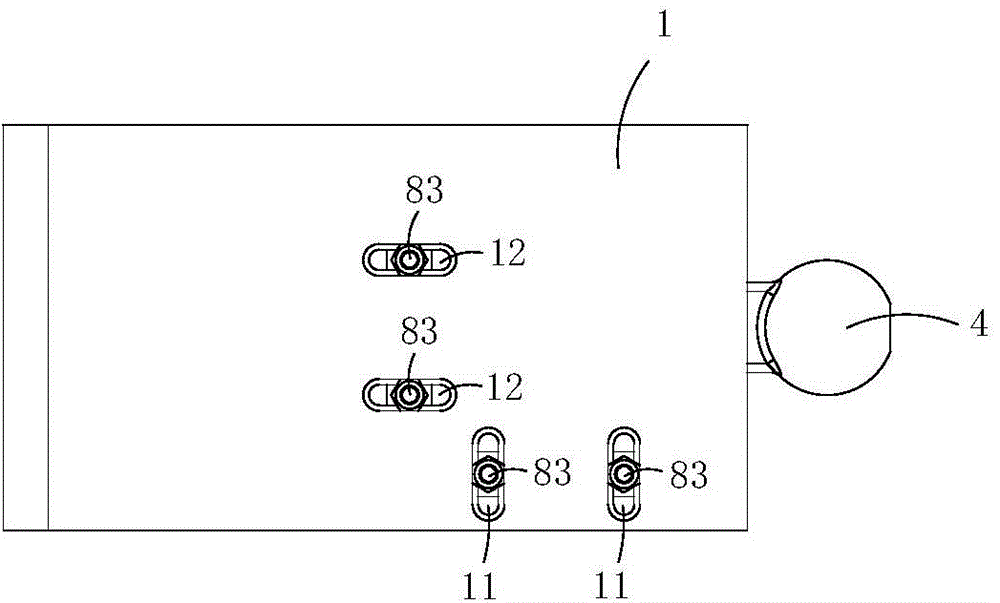

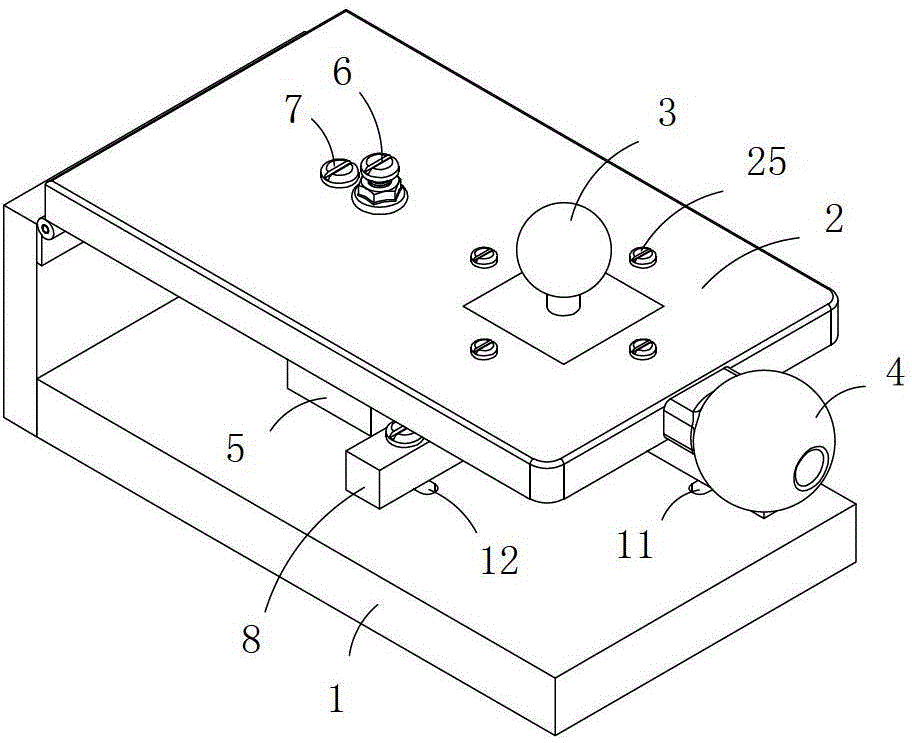

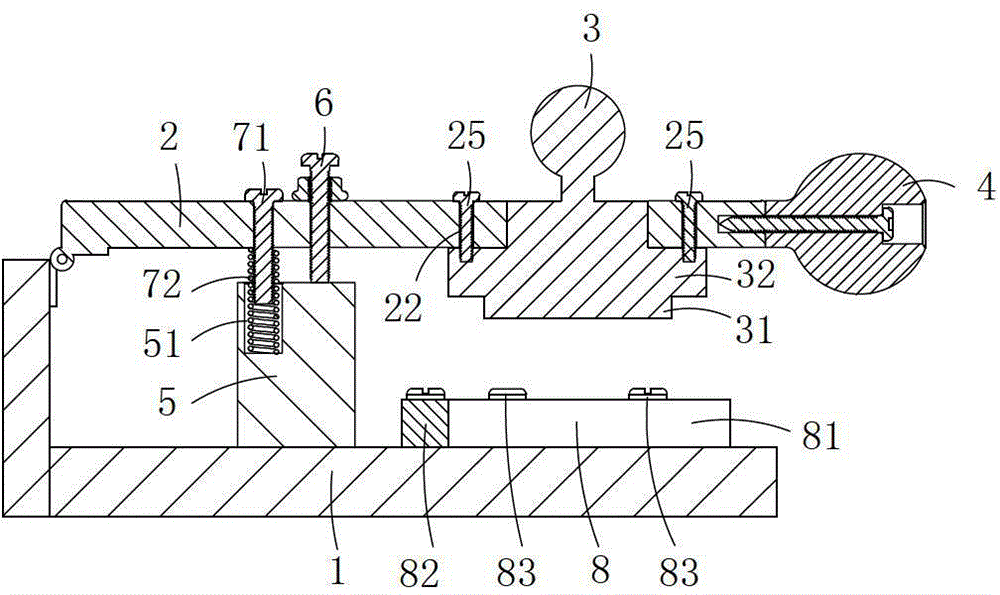

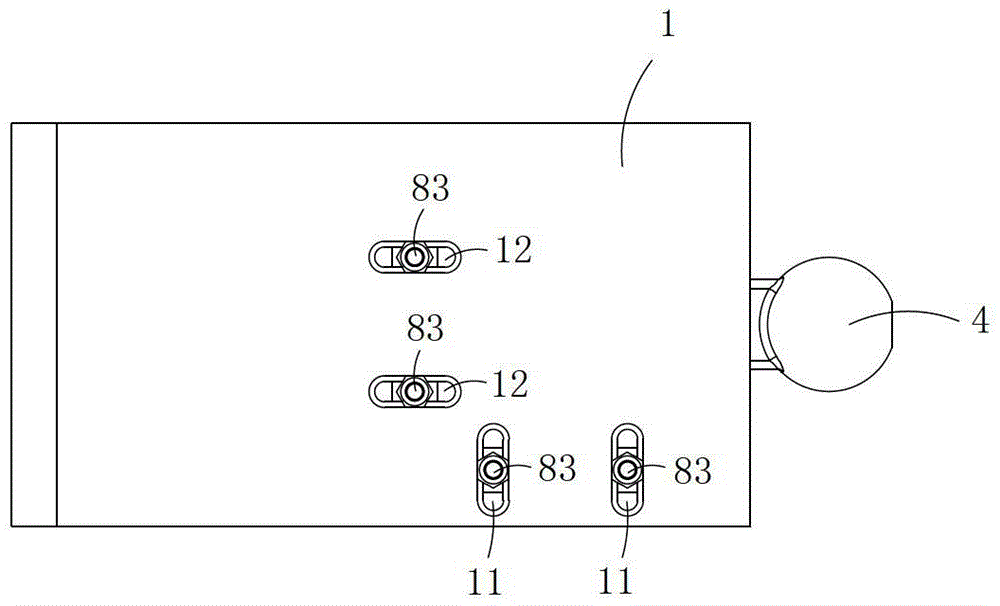

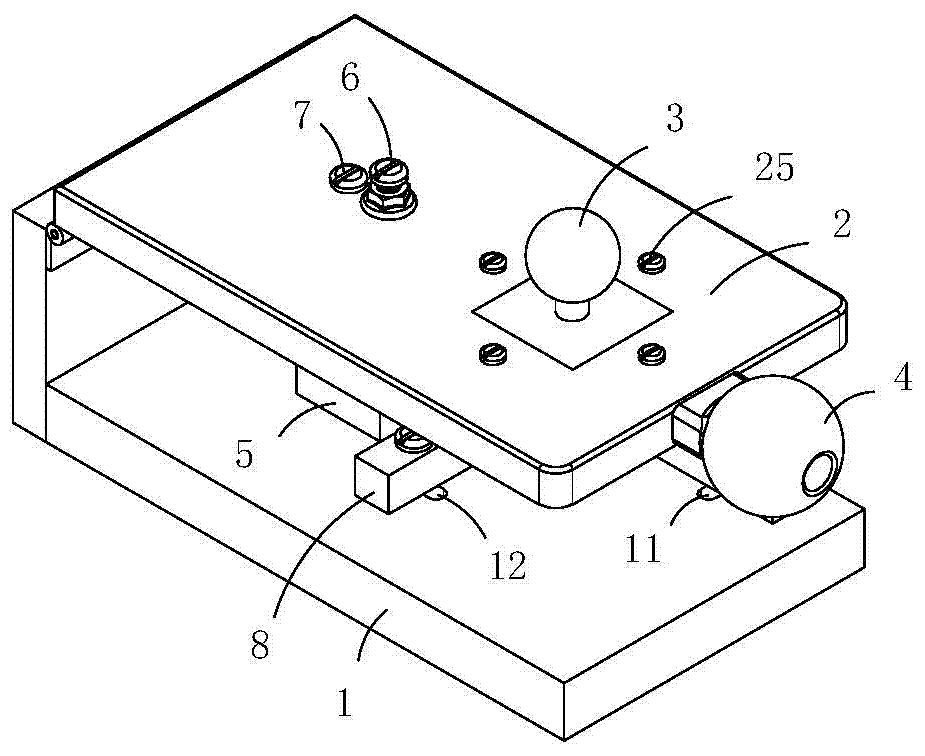

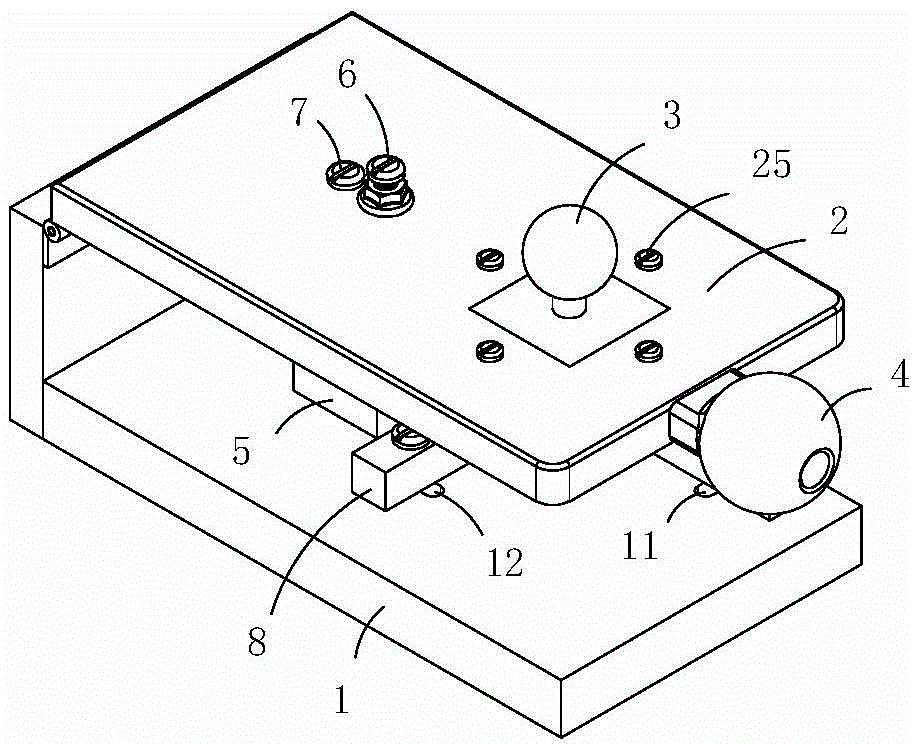

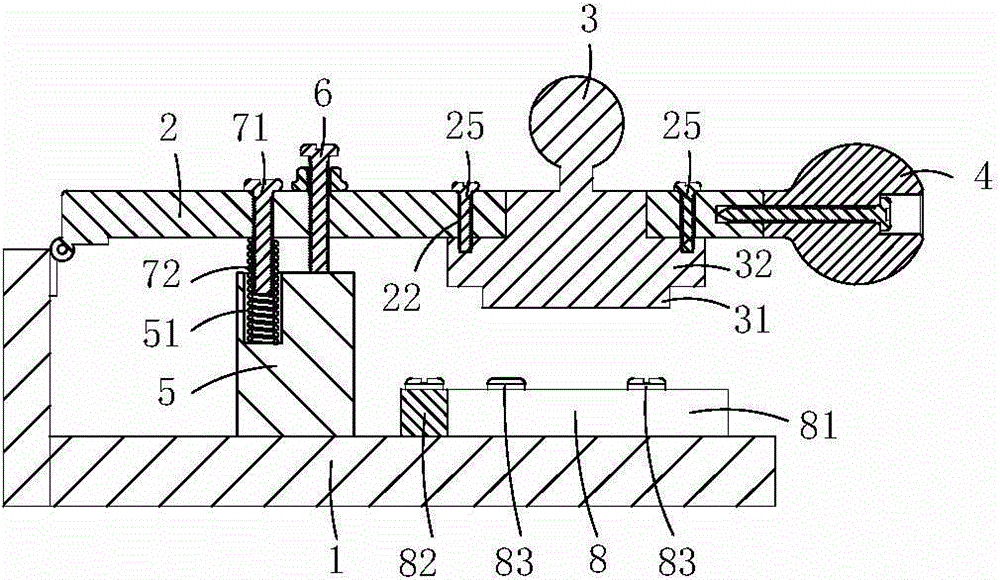

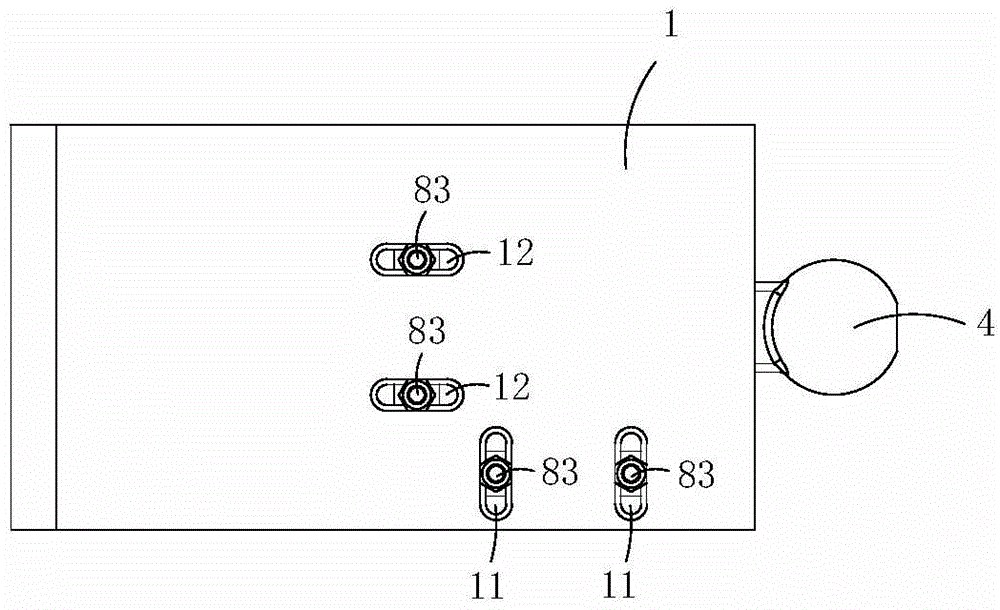

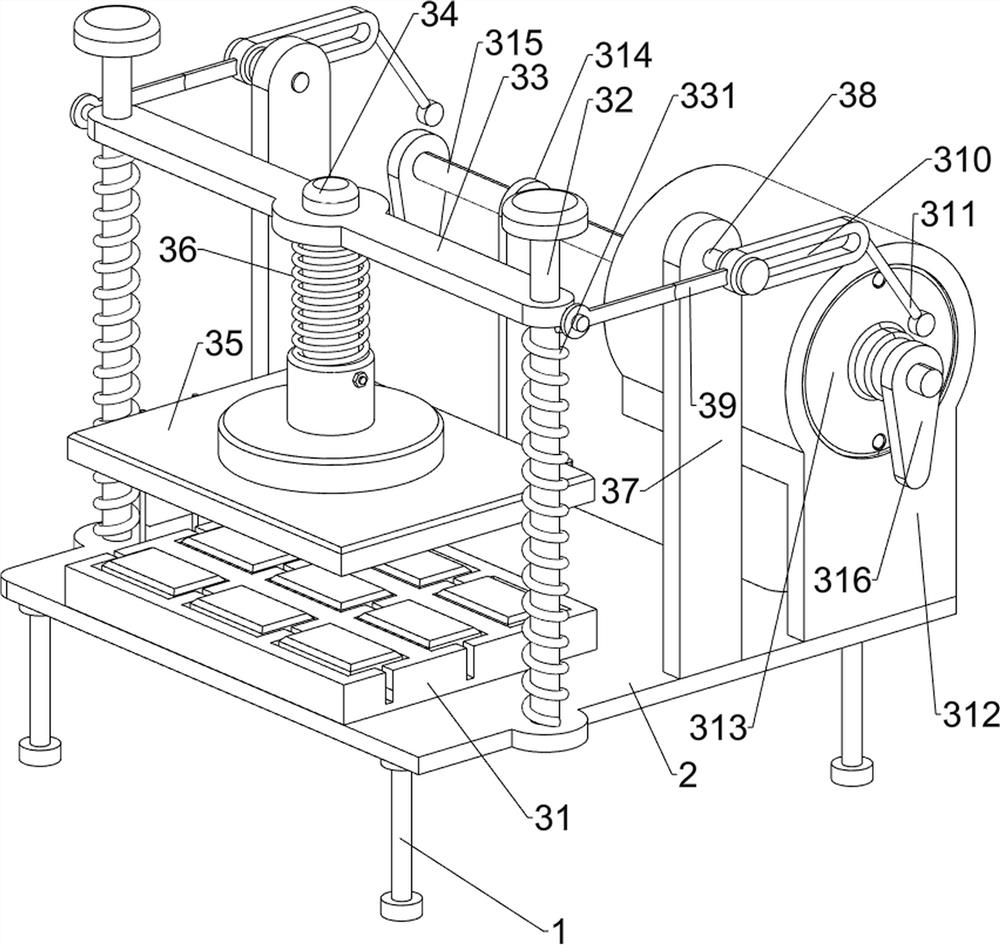

Manually-operated soap imprinting device

The invention discloses a manually-operated soap imprinting device. The manually-operated soap imprinting device comprises a base, a pressing plate, a soap stamp and a handle, wherein the pressing plate is rotationally arranged on the base, the soap stamp is fixed to the pressing plate, and the handle drives the pressing plate to rotate; the pressing plate is provided with a longitudinal-cutting limiting hole and a transverse-cutting limiting hole, the base is provided with a longitudinal-cutting limiting groove and a transverse-cutting limiting groove, the position of the longitudinal-cutting limiting hole is matched with that of the longitudinal-cutting limiting groove, and the position of the transverse-cutting limiting hole is matched with that of the transverse-cutting limiting groove. The manually-operated soap imprinting device is easy and convenient to operate, and can guarantee imprinting quality.

Owner:启东市恒力纺织有限公司

Method for preparing marbled soaps

InactiveCN101709247AReduce usageEasy to prepareShaping soapEmbossing/polishing soapEngineeringHigh pressure

The invention relates to a method for preparing marbled soaps, comprising the conventional procedures of stirring, milling, layering, printing, slab cutting and the like. In the printing procedure, a cylinder of a soap slab machine is provided with an unidirectional flowing high-pressure resisting nozzle; dye is pressed into the cylinder by using a plunger pump, filamentous patterns are formed on a soap base surface, a material body is extruded along with the rotation of a screw rod, the soap is formed through a soap slab cutter or bumper car, and then color patterns can be seen on the surface. The invention is simple, is low in cost, free from pollution and suitable for the industrial production; and the surface of soap obtained has color pattern effect, thereby increasing the beautiful effect of the soap.

Owner:RUGAO YAYA GREASE CHEM

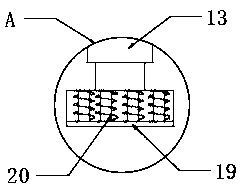

Soap embossing device

The invention discloses a soap embossing device. The device comprises a base, a pressing plate, a soap seal, a handle, a spacing boss and a reset mechanism, wherein the pressing plate is arranged on the base in a rotary manner; the soap seal is fixed on the pressing plate; the handle drives the pressing plate to rotate; the spacing boss is arranged on the base; the reset mechanism returns the pressing plate to an initial position and comprises a reset spacing pillar and a reset spring; the reset spacing pillar is arranged on the pressing plate; the reset spring is sleeved on the reset spacing pillar; the bottom end of the reset spacing pillar extends out of the pressing plate downward; the reset spring is sleeved on the part, extending out of the pressing plate downward, of the reset spacing pillar; a sliding hole is formed in the spacing boss; and when the reset spacing pillar rotates along with the pressing plate, the bottom end of the reset spacing pillar can be inserted into the sliding hole. The device is simpler and more convenient to operate and can ensure the embossing quality.

Owner:启东市华华针布厂

Traditional-Chinese-medicine grinding face cleaning soap with effects of moistening skin and removing wrinkles

InactiveCN106367240AAvoid breakingPromote circulationEmbossing/polishing soapDetergent compounding agentsWrinkle skinOfficinalis

The invention relates to traditional-Chinese-medicine grinding face cleaning soap with the effects of moistening the skin and removing wrinkles. The main constituents of the traditional-Chinese-medicine grinding face cleaning soap are prepared from a mature cold soap and a traditional-Chinese-medicine-liquid decoction agent; the mature cold soap is prepared from, by weight, 100 parts of Macadamia nut oil, 75 parts of sweet almond oil, 175 parts of olive oil, 75 parts of palm oil, 75 parts of coconut oil, 65 parts of sodium hydroxide, 365 parts of traditional-Chinese-medicine liquid and 15 parts of honey; the traditional-Chinese-medicine liquid is prepared from, by weight, 15 parts of radix polygonati officinalis, 10 parts of herba cistanche, 15 parts of radix ophiopogonis, 30 parts of fructus lycii and 20 parts of astragalus membranaceus. According to the manual grinding soap, soap cold preparing is completed, then the following grinding process is added, and the traditional-Chinese-medicine liquid with the effects of moistening the skin and removing wrinkles is added into in the mature cold manual soap; the temperature is not increased in the whole process, the traditional-Chinese-medicine liquid is not prone to damage by strong base, and the effect of the medicine liquid can also be better reserved; manual full grinding is carried out, the finished soap is finer, the washing feeling is gentler, the skin is tender and glossy and can be moist, wrinkles are reduced, and the traditional-Chinese-medicine grinding face cleaning soap has the effects of moistening the skin and removing wrinkles.

Owner:骆志明

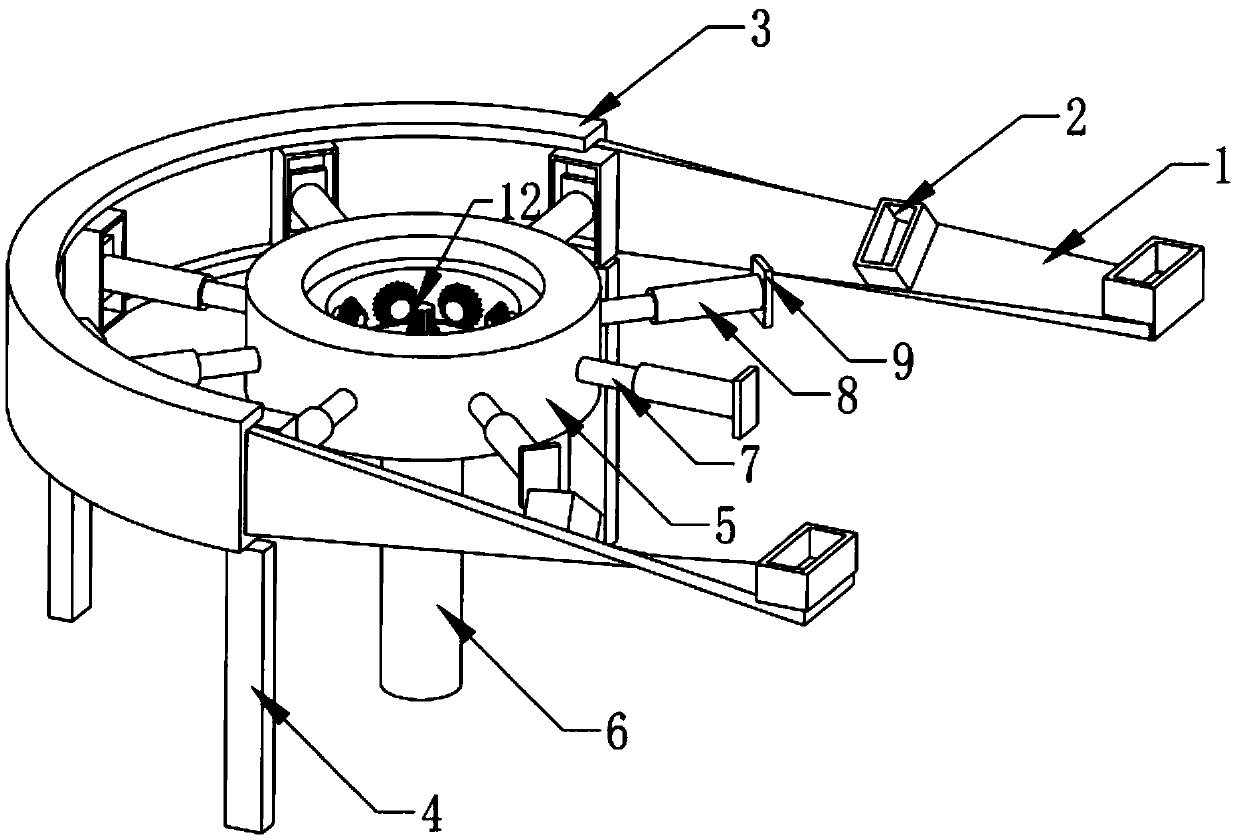

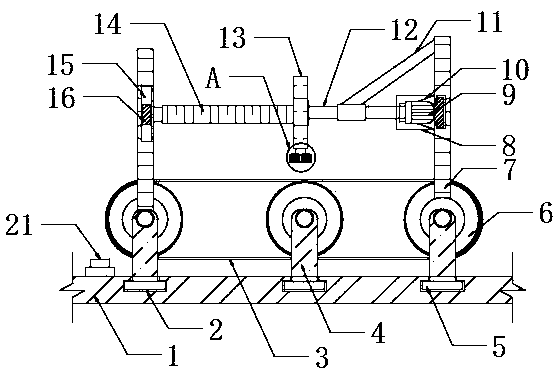

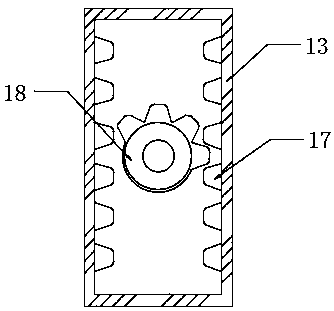

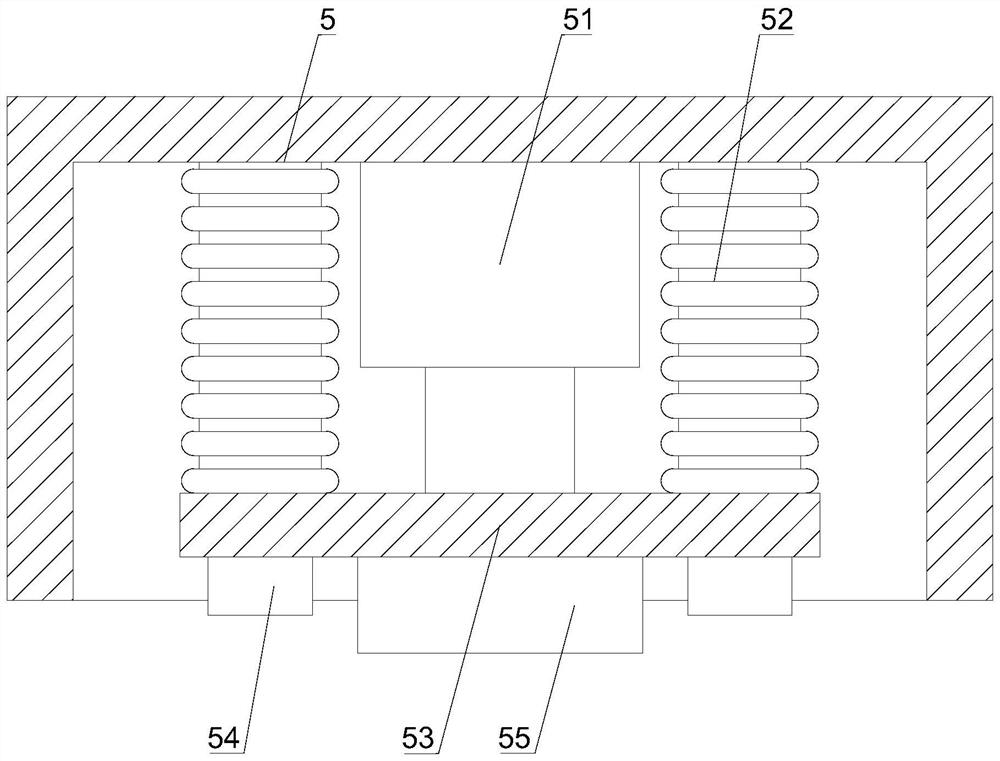

Perfumed soap embossing device

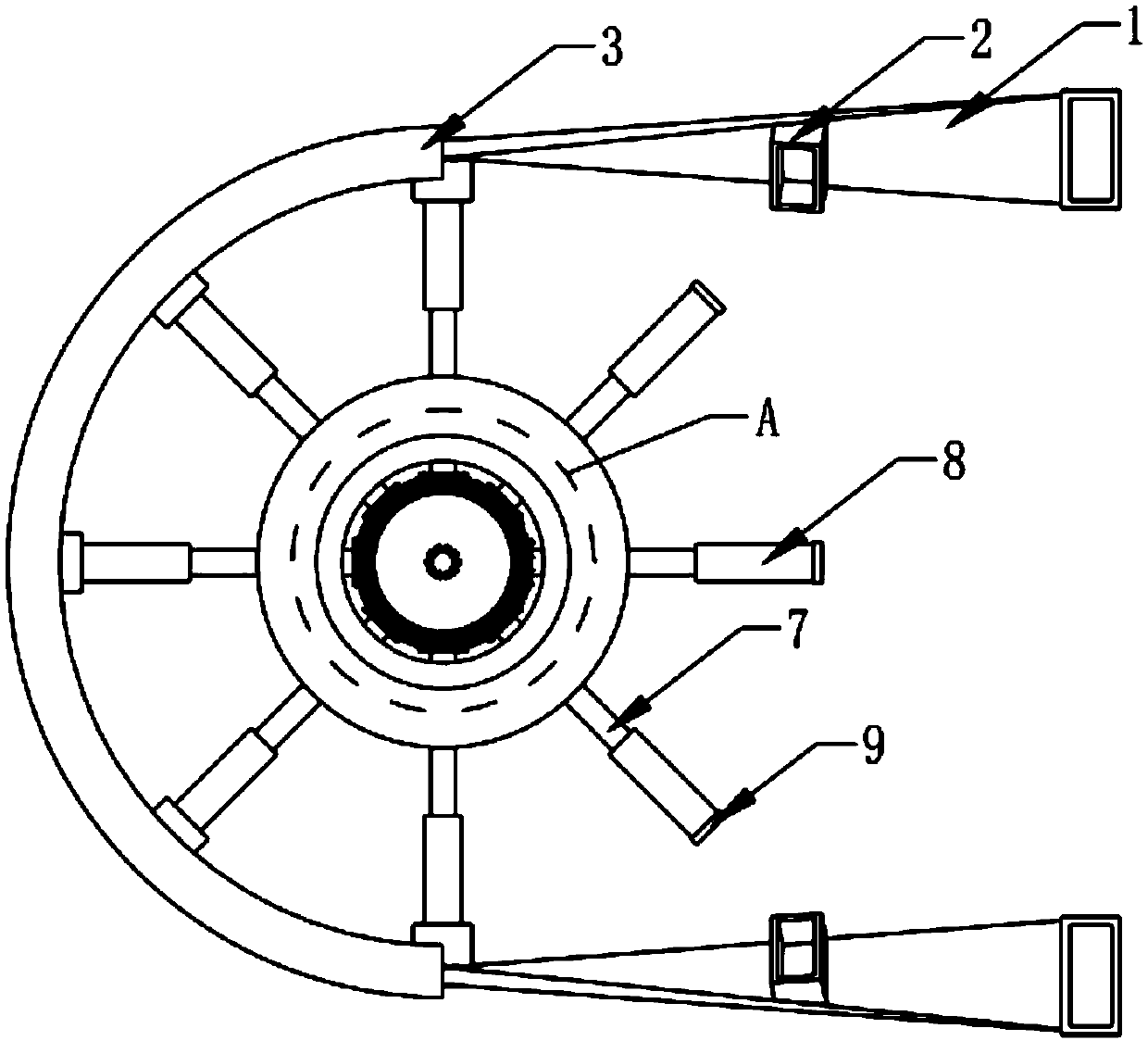

InactiveCN109593617AQuality improvementHigh adjustment accuracyEmbossing/polishing soapDrive wheelSOAP

The invention discloses a perfumed soap embossing device comprising a conveying belt, a turnplate and driving rods; the conveying belt is movably arranged on a circular orbit, and the circular orbit is fixedly arranged on a support frame; the turnplate is fixedly arranged on a driving device for providing power, a main shaft is sleeved with a regulating wheel for synchronously regulating angles ofembossing dies, and a connecting hole is formed in the center of the regulating wheel; and the driving rods are equidistantly arranged on the turnplate in a surrounding way and extend into an inner cavity of the turnplate, one end of each of the driving rods is fixedly provided with a driving wheel, and the other end of each of the driving rods is movably sleeved with a connecting rod; and the other end of the connecting rod is fixedly connected with each of the embossing dies. Due to the arrangement of the conveying belt and the circular orbit, the embossing dies can be kept to be in contactwith a perfumed soap for a certain time, so that the embossing and forming quality is improved; and due to the arrangement of a conical driving wheel and the regulating wheel, the angles of all the embossing dies can be regulated while the conical driving wheel is regulated, so that the regulating precision is high, and regulation is convenient.

Owner:安徽省玉兔日用化学品有限公司

Soap shaping and dicing device

InactiveCN111117818AMix well and evenlySimple structureCutting soapDrying soapEngineeringWater circulation

The invention discloses a soap shaping and dicing device. A stirring mechanism is arranged in a machine body; the stirring mechanism comprises a cooling cavity positioned at the left end in the machine body; fixing blocks are fixed to the upper end wall and the lower end wall in the cooling cavity; a water cooling pipe is wound outside the fixed blocks; a water circulation cooling device which isfixed on the lower end wall of the cooling cavity and is communicated with the water cooling pipe is arranged at the left ends of the fixed blocks; a stirring cavity of which the lower end wall is aninclined surface is formed in the fixed blocks; the rear end of the stirring cavity is provided with a channel, and the channel is communicated with the outside of the machine body and allows materials to enter; air drying is divided into three small parts, the middle part is responsible for absorbing heat, the parts at the two ends are responsible for air drying, and thus the solidification speedis increased; finally, a mold is cut through a cutter, marks are embossed while cutting is conducted, a soap is shaped and transported away, time is saved, and production efficiency is improved.

Owner:FUZHOU GULOU DISTRICT XIARONG TRADING CO LTD

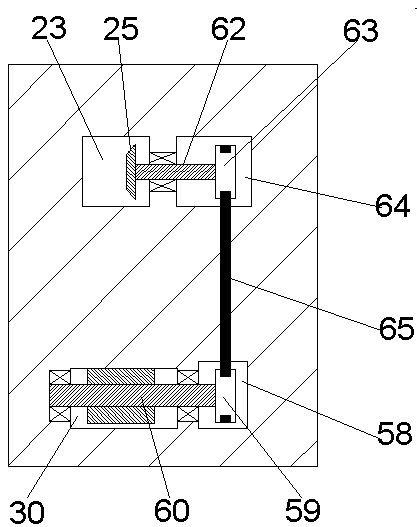

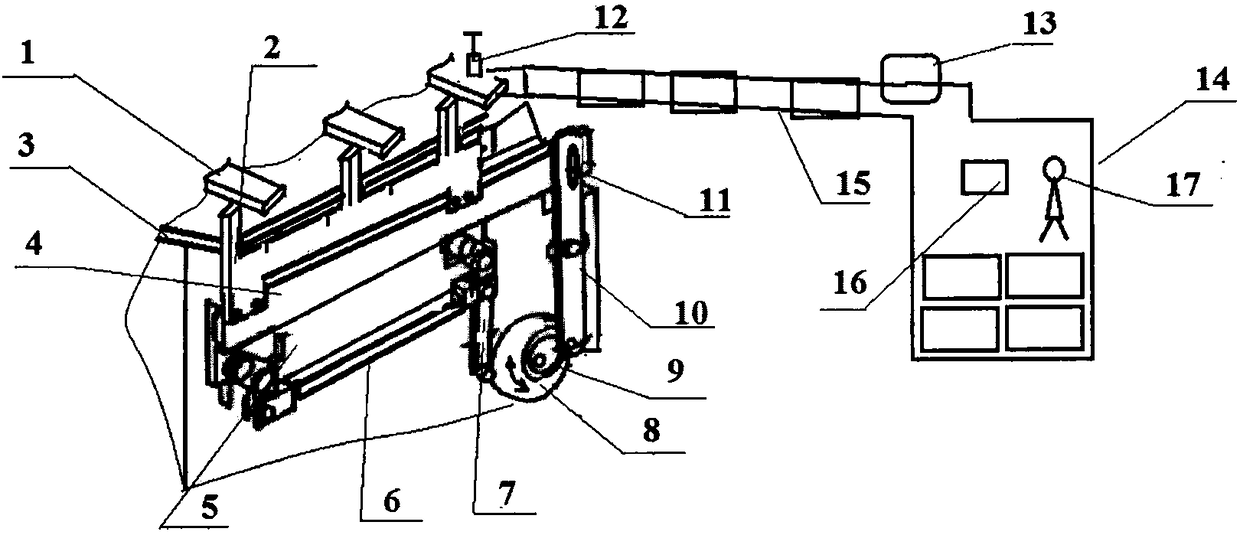

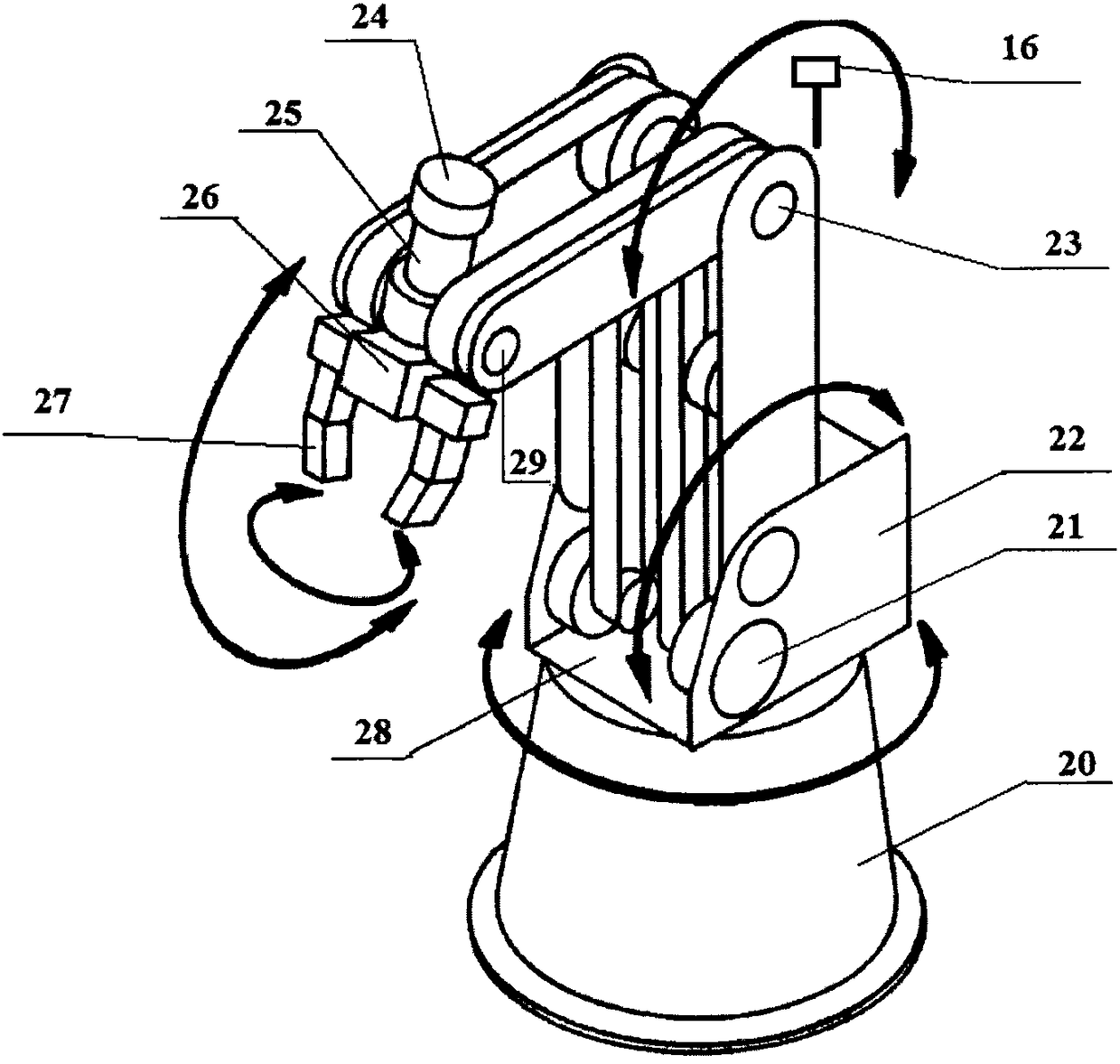

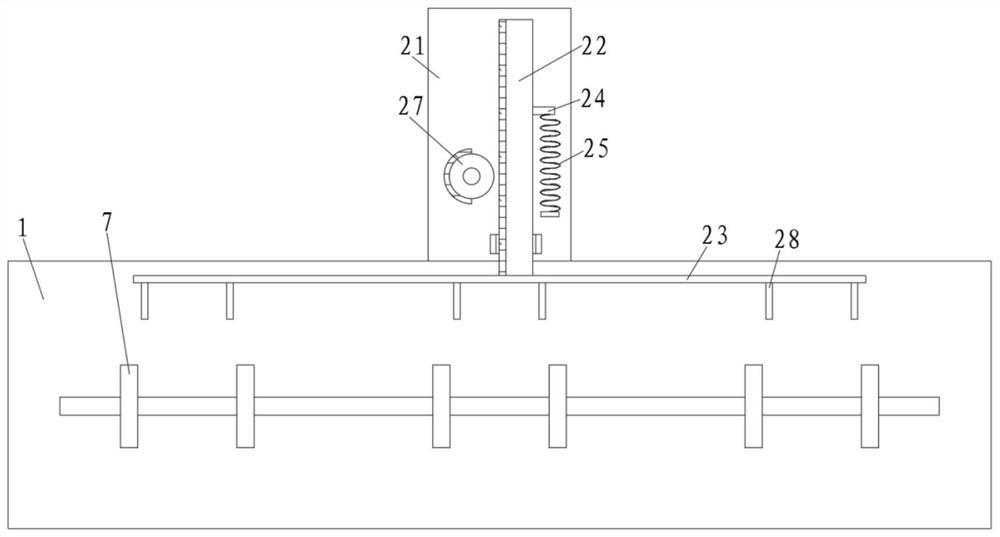

Soap printing and counting integrated equipment

InactiveCN108441366ASimple structureImprove transmission efficiencyEmbossing/polishing soapCounting mechanisms/objectsAutomatic transmissionTransmission belt

The invention relates to integrated electromechanical equipment and in particular relates to soap printing and counting integrated equipment. The equipment is mainly composed of soap, a transmission guide rod, a bracket rail, a left-right transmission plate, a vertical transmission plate, a linkage rod, a small rocking bar, a cam with a sliding groove, a motor, a large rocking bar, a pulling pin,a steel seal, a digital counting device, a box, a transmission belt, a CCD (Charge Coupled Device) camera and a robot, wherein the robot is composed of a robot base, a rotating shaft A, a baffle plate, a rotating shaft B, encoding equipment, a motor, a square block, a robot finger, a robot rotating base and a rotating shaft C; the soap is arranged on the bracket rail; the transmission guide rod ismounted at two sides of the bracket rail; the left-right transmission plate is connected with the large rocking bar through the pulling pin. The soap printing and counting integrated equipment provided by the invention has the advantages of simple structure, automatic transmission, automatic counting, automatic stacking, high transmission efficiency, good quality and low price. The soap printingand counting integrated equipment is very convenient and practical, has a wide popularization and application prospect and can be widely applied to medium-sized and small enterprises.

Owner:李烨

Soap embossing device

The invention discloses a soap embossing device, which relates to the field of soap processing equipment, and comprises a fixed seat and a conveying mechanism, the conveying mechanism includes a conveying belt, an extension plate is provided at the upper end of the fixed seat, and a spacer plate is provided at the lower end, and the extension plate and the spacer plate A conveying channel is formed between them, an aisle is formed between the partition plate and the bottom of the fixed seat, and the conveyor belt passes through the conveying channel and the aisle, the upper end of the fixed seat is provided with a bump one and a bump two, and the first bump is provided with a drive Motor, the output shaft of the driving motor is connected with crank one, one end of crank one is connected with crank two for rotation, one end of crank two is connected with crank three for rotation, one end of crank three is connected with guide rod for rotation, and a connecting shaft is arranged on bump two , the connecting shaft is rotatably connected with crank 4, the side wall of crank 4 is rotatably connected with crank 3, the side wall of the extension plate is provided with a guide chute, and the lower end of the guide rod is provided with an embossing mold. This design is simple, reasonable and easy to operate. , good imprint quality and high efficiency.

Owner:WUHU YIZE SMALL & MEDIUM ENTERPRISE PUBLIC SERVICE CO LTD

Marking device for mechanical automatic soap production

InactiveCN111088128AImprove efficiencyTelecontrol stabilizationEmbossing/polishing soapTransmission beltElectric machinery

The invention discloses a marking device for mechanical automatic soap production. The marking device comprises a working plate. A plurality of mounting grooves are formed in the front end and the rear end of the top surface of the working plate. Mounting blocks are movably mounted in the mounting grooves, and fixed rods are fixedly mounted at the top ends of the mounting blocks. Transmission wheels are movably mounted between the top ends of the fixing rods at the front end and the rear end of the top surface of the working plate through vias. A conveying belt is movably mounted on the transmission wheels. A switch is fixedly mounted on one side of the top face of the working plate. Mounting rods are fixedly mounted at the top ends of the fixed rods on the two sides of the top surface ofthe working plate. A mounting frame is fixedly mounted in the middle of one side of the mounting rod at the top ends of the fixed rods on one side of the top surface of the working plate, and a motoris fixedly mounted on one side in the mounting frame through a mounting base. A pressure head is movably mounted at the bottom end of a rectangular frame body, and multiple resistor heating tubes arefurther movably mounted in the pressure head, so that the marking and marking efficiency and the delivery rate are conveniently improved.

Owner:淮安宝盛德电子有限公司

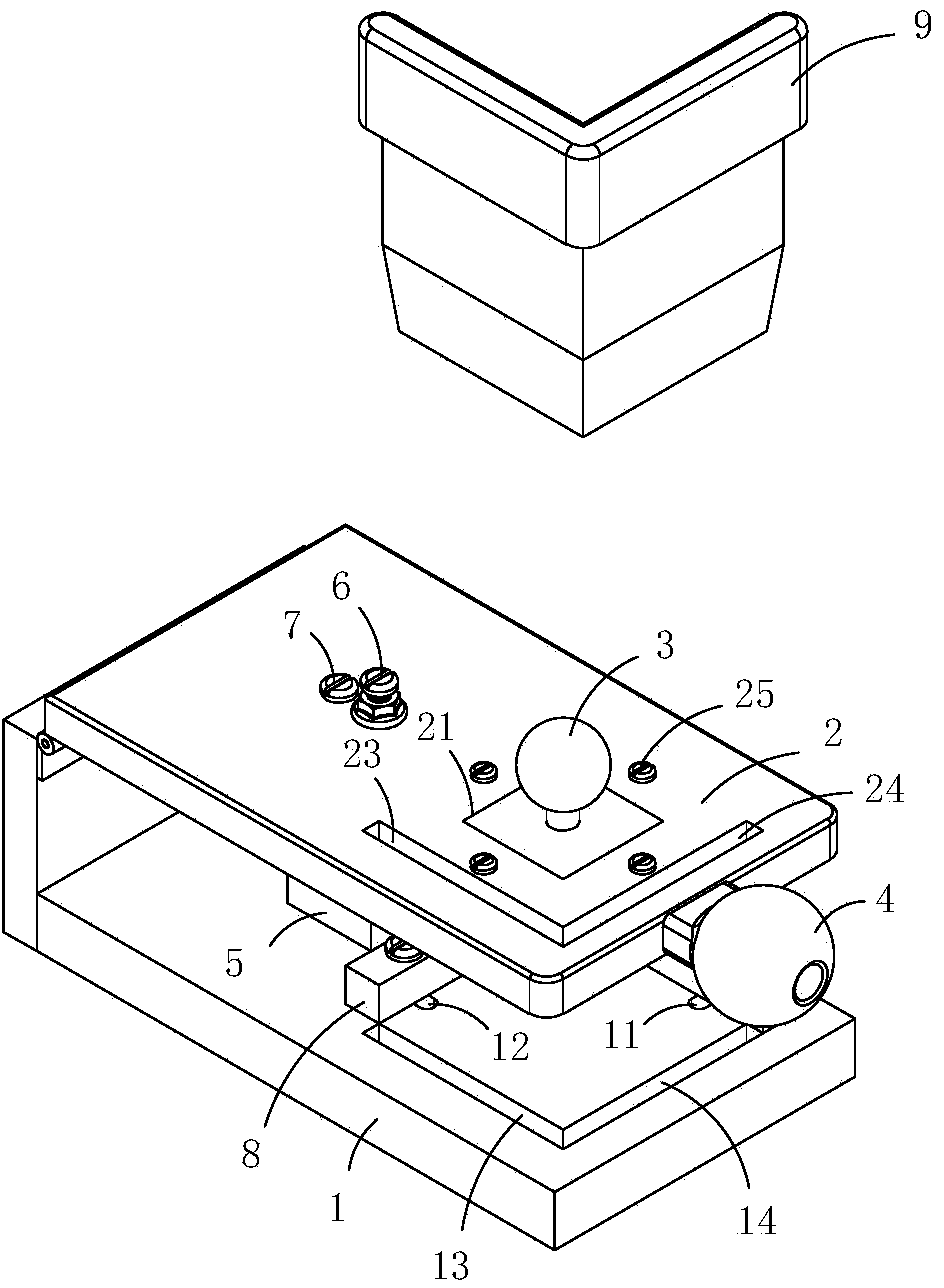

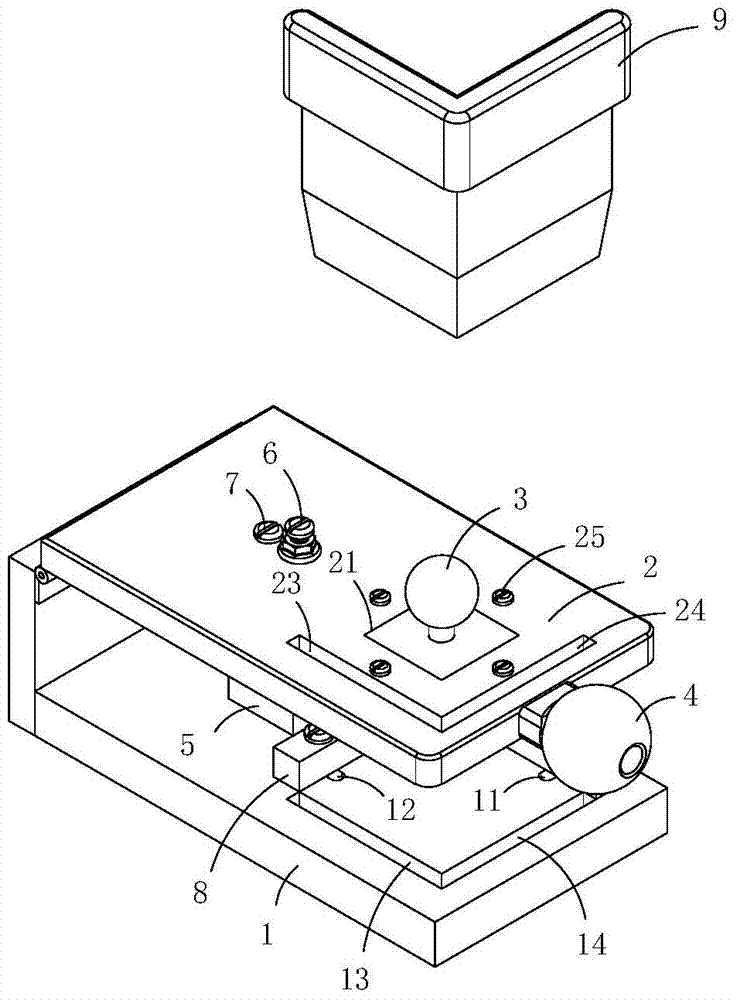

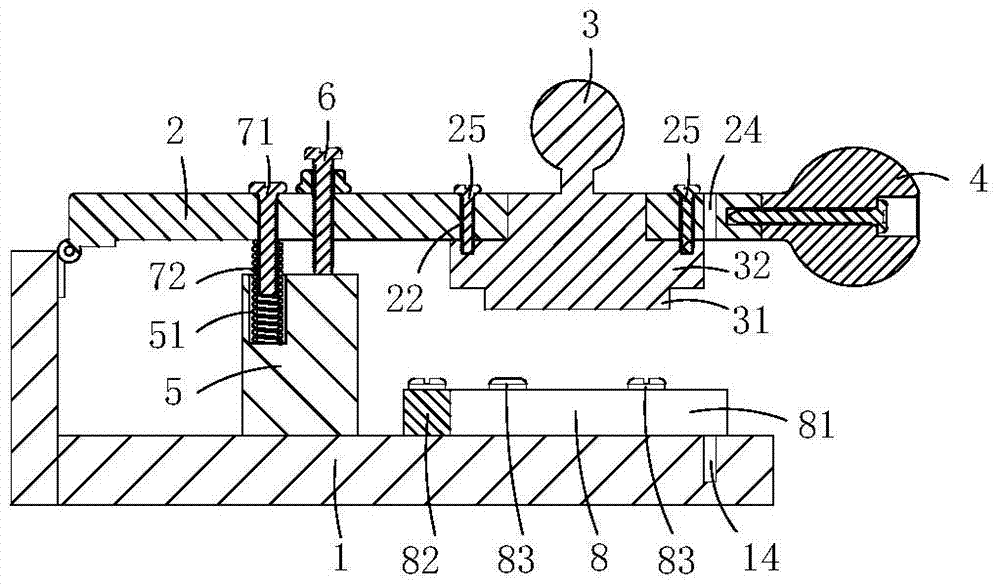

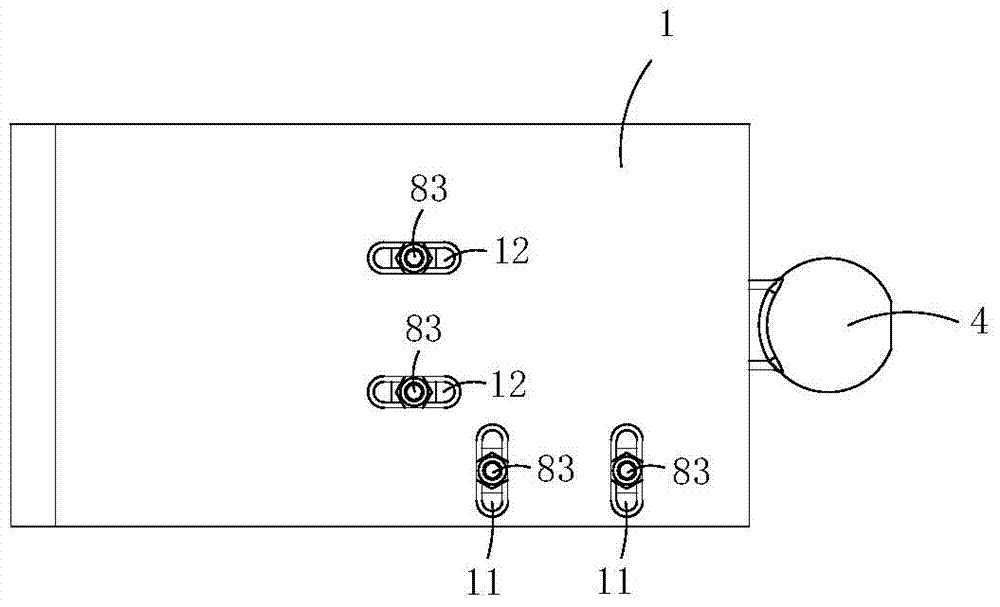

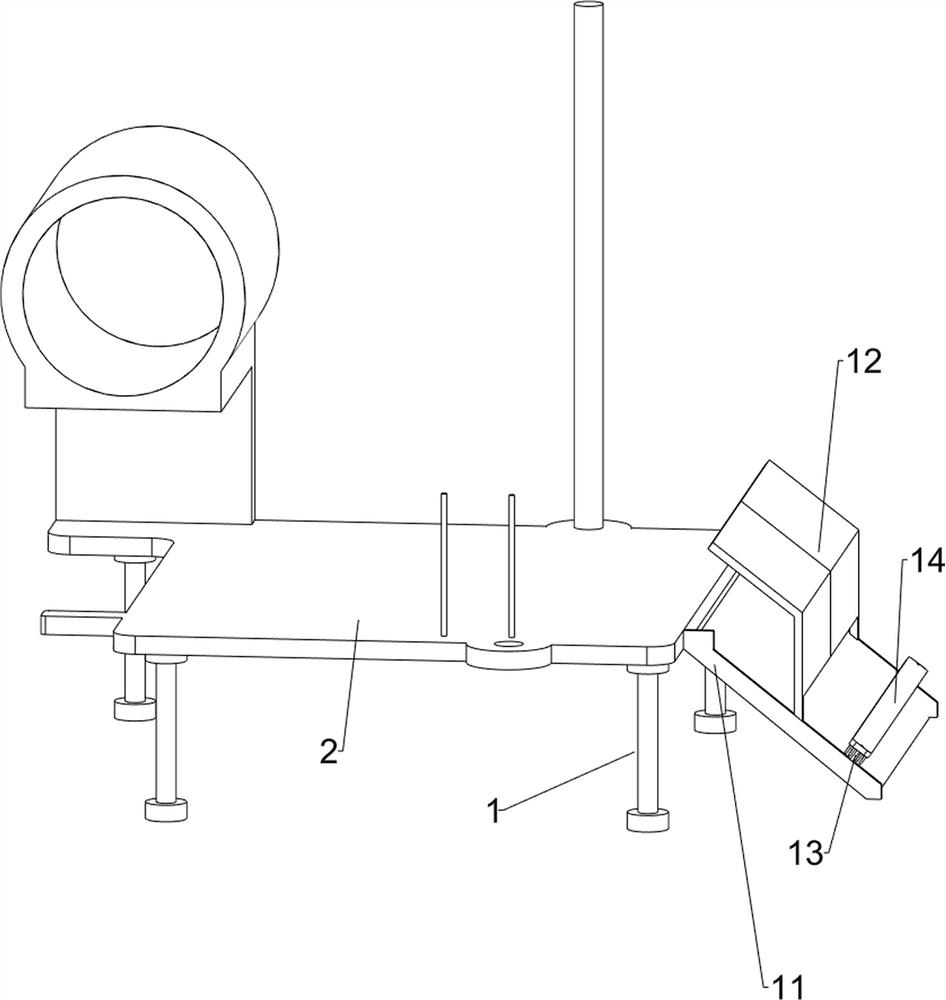

Improved soap printing device

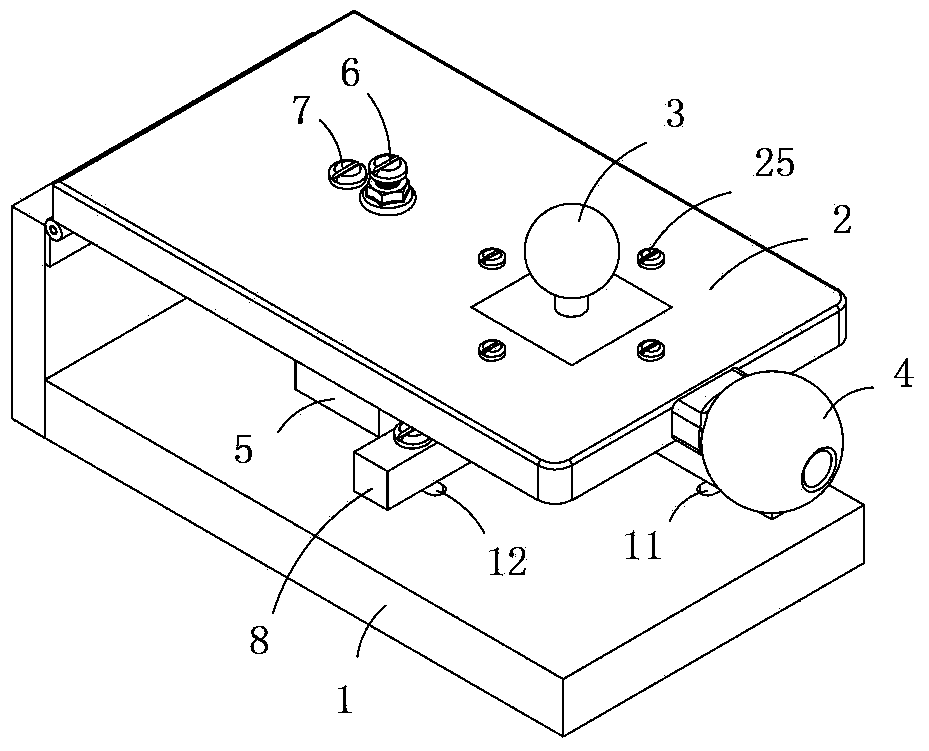

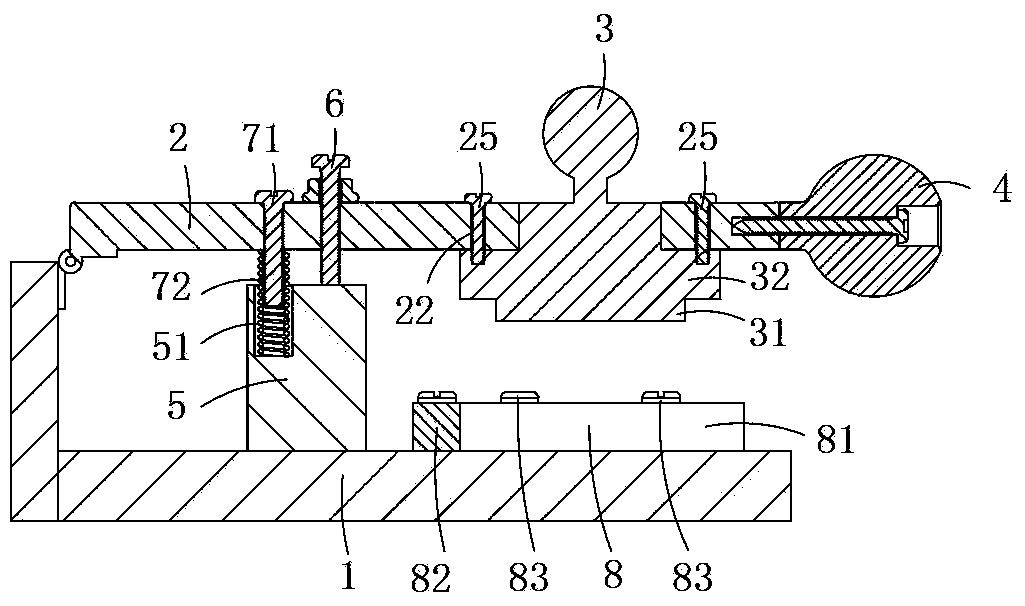

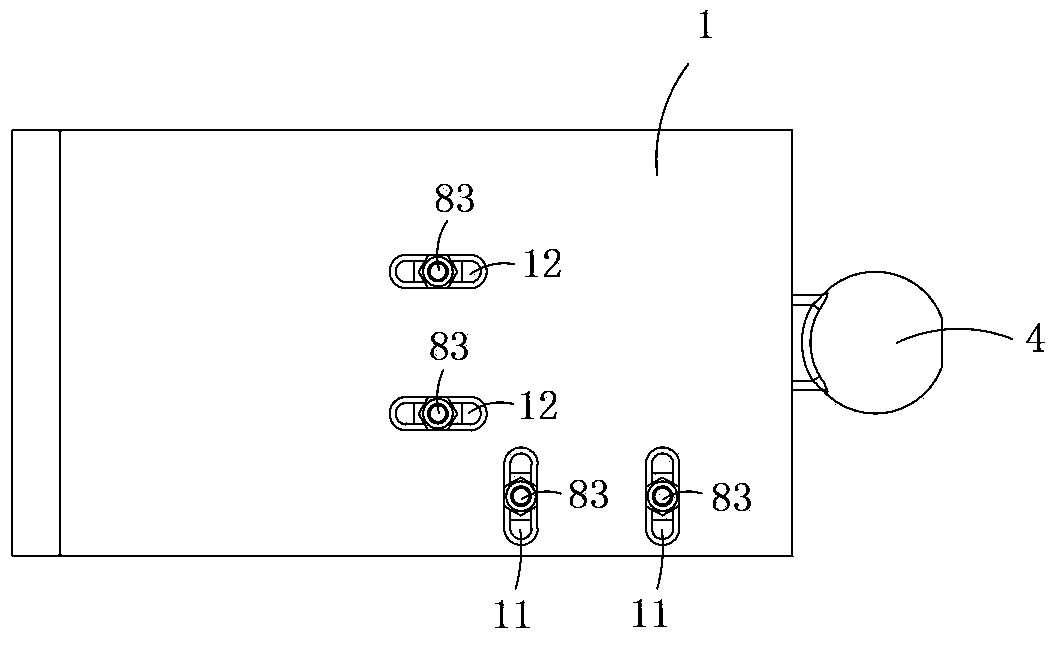

The invention discloses an improved soap printing device which comprises a base, a pressing plate rotatably arranged on the base, a soap stamp fixed on the pressing plate, a handle for driving the pressing plate to rotate, and a positioning mechanism arranged on the base for regulating a location of a soap body to be printed, wherein the positioning mechanism comprises a longitudinal regulating baffle platform extending along the longitudinal direction, a transverse regulating baffle plate extending along the transverse direction, and a plurality of regulating bolt assemblies, longitudinal group installing regulating holes and transverse group installing regulating holes are formed in the base, and are of waist-shaped holes, each longitudinal regulating baffle platform is fixed on the base through a regulating bolt assembly penetrating through each longitudinal group installing regulating hole, and each transverse regulating baffle platform is fixed on the base through a regulating bolt assembly penetrating through each transverse group installing regulation hole. The improved soap printing device is convenient to operate, and is capable of ensuring the printing quality.

Owner:南通华烨塑料工业有限公司

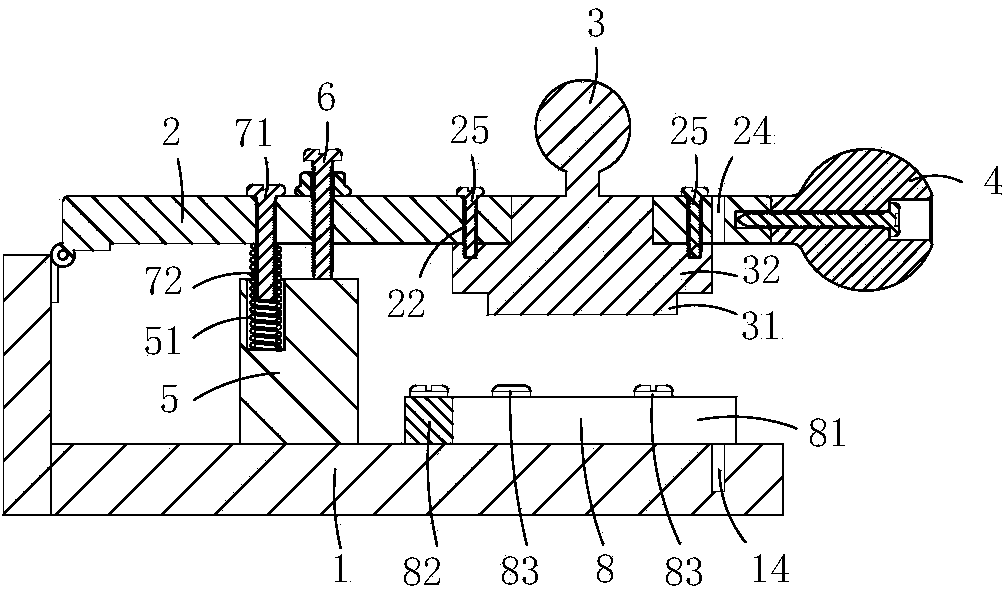

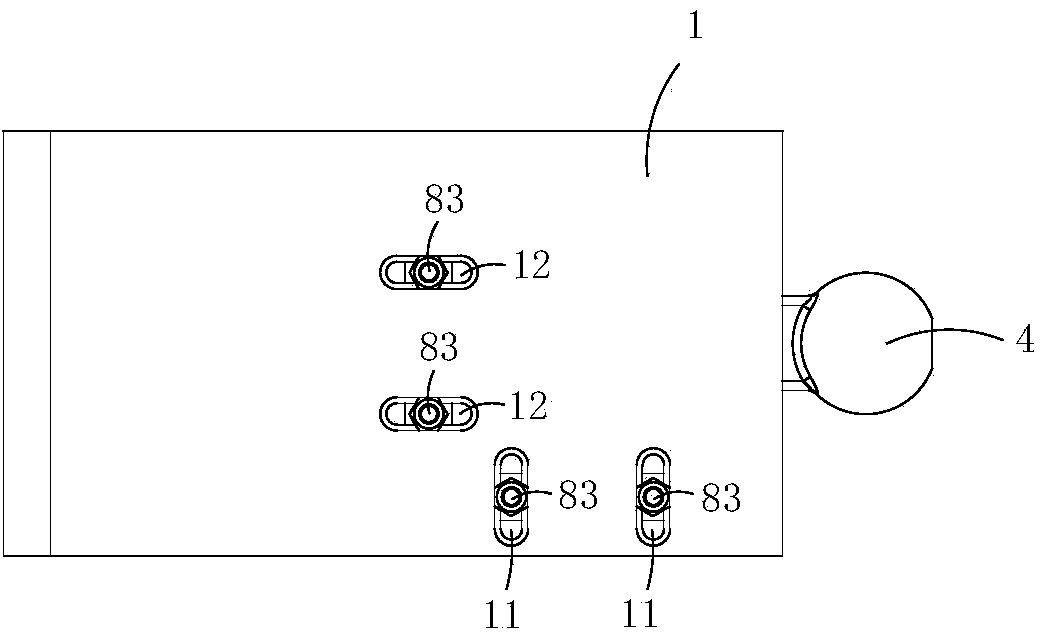

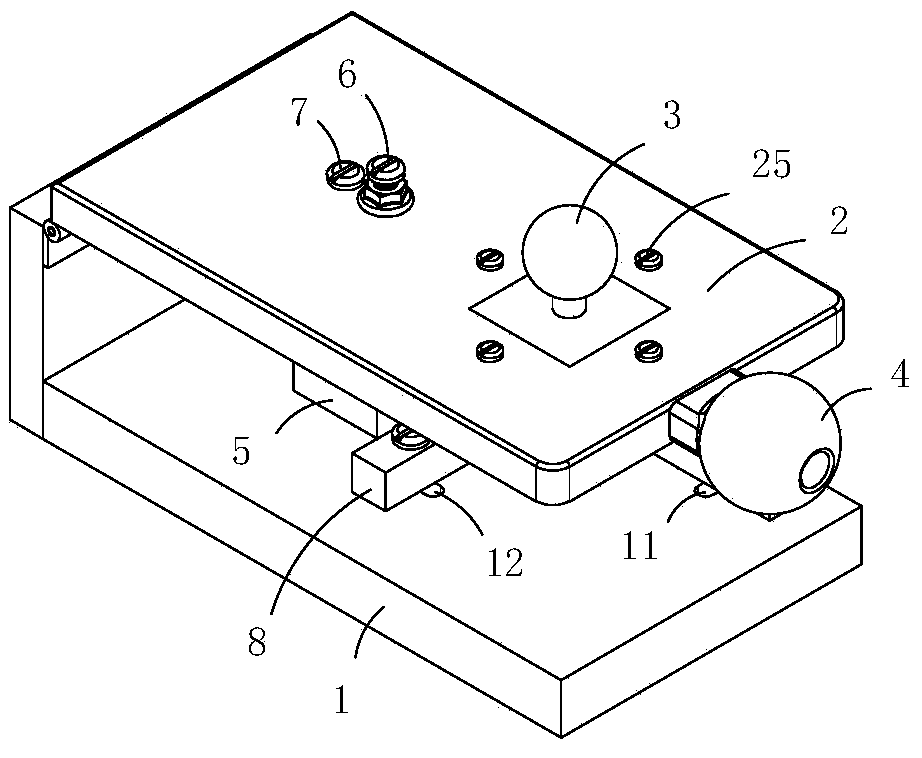

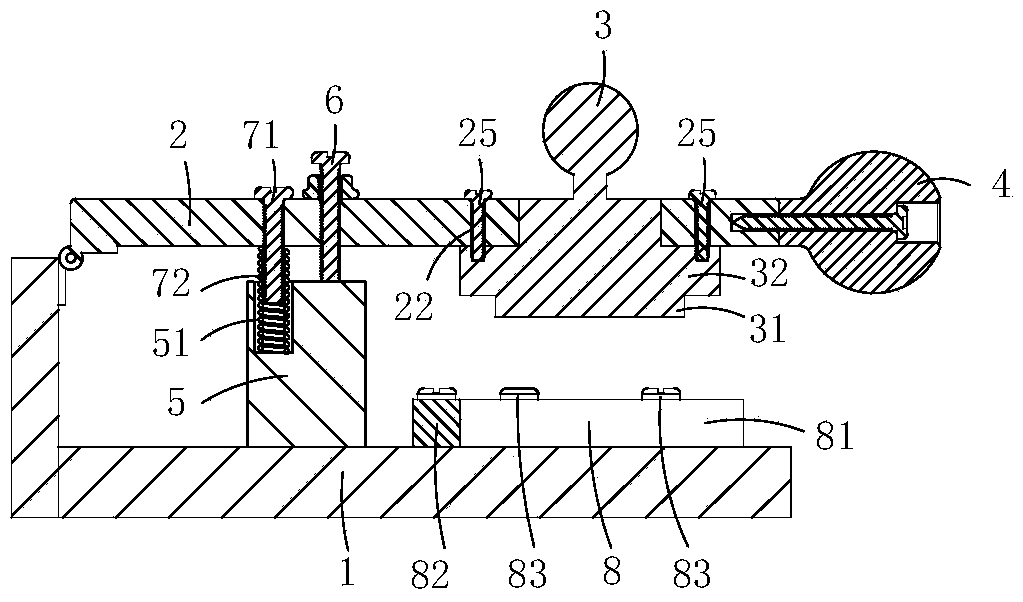

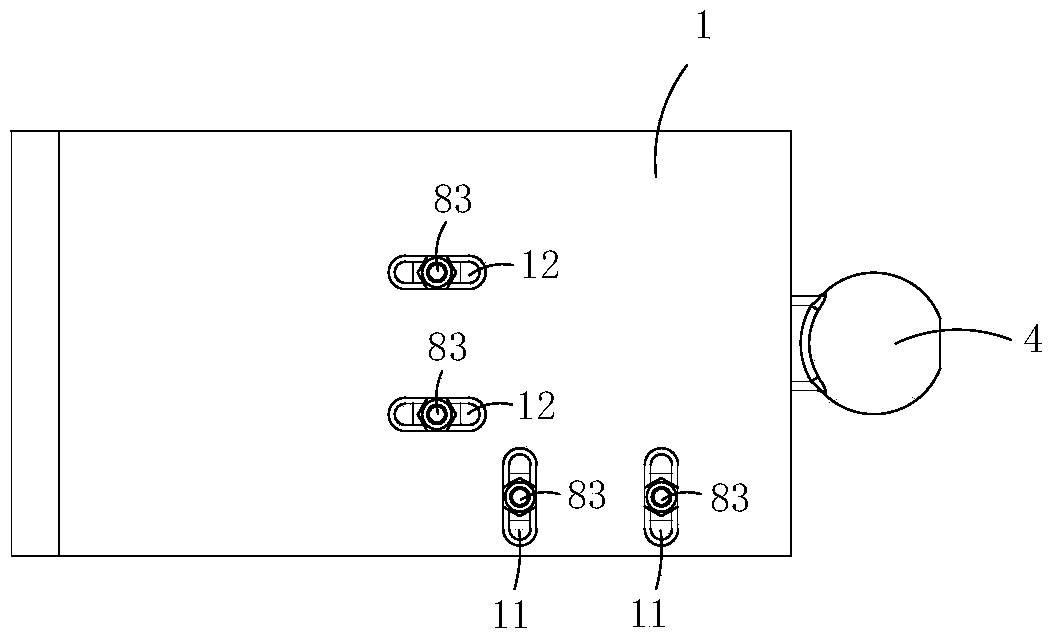

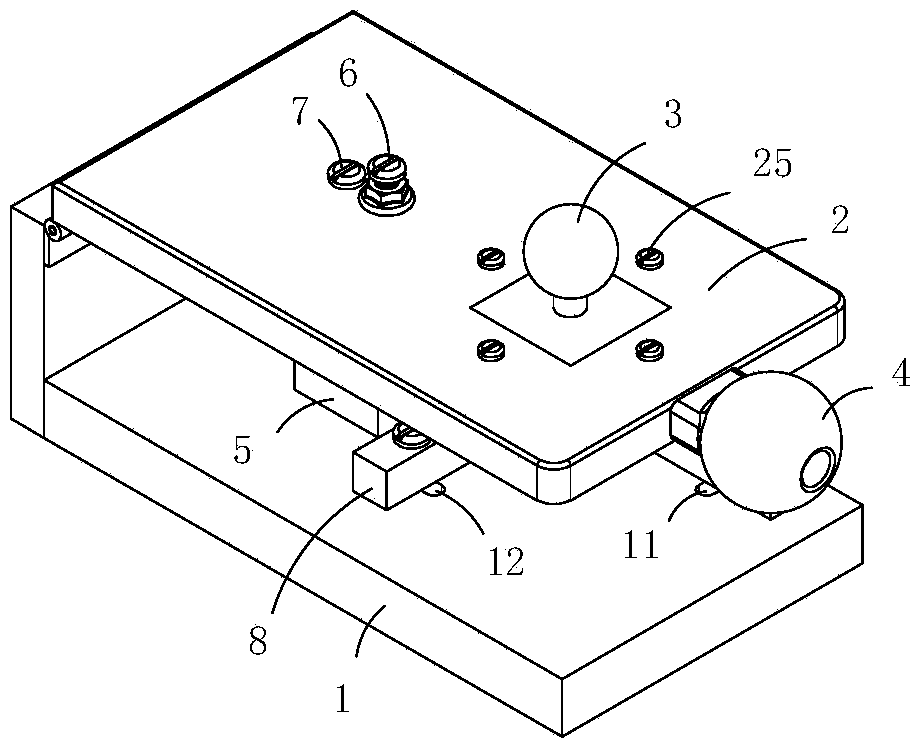

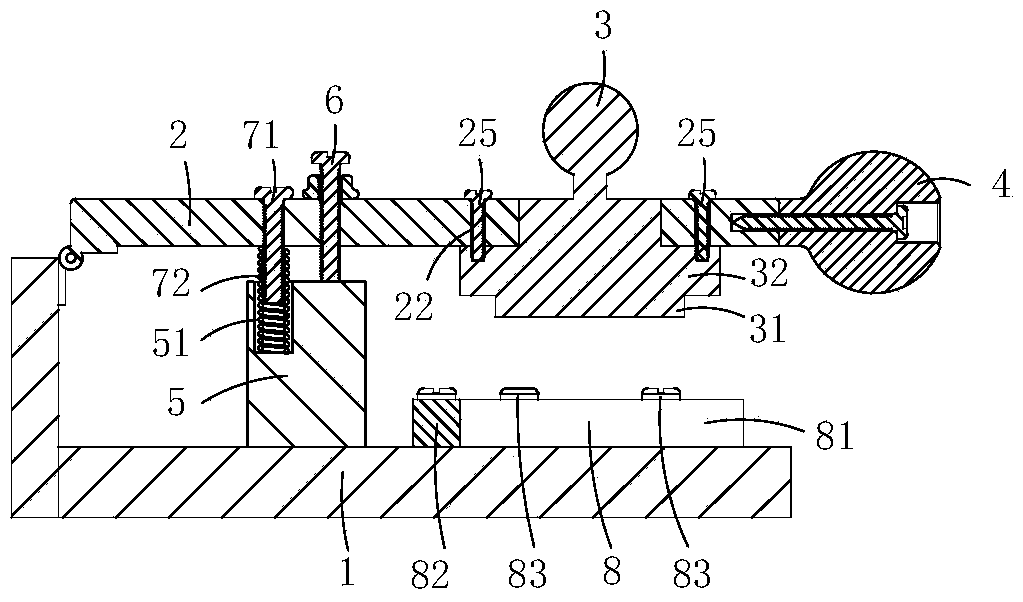

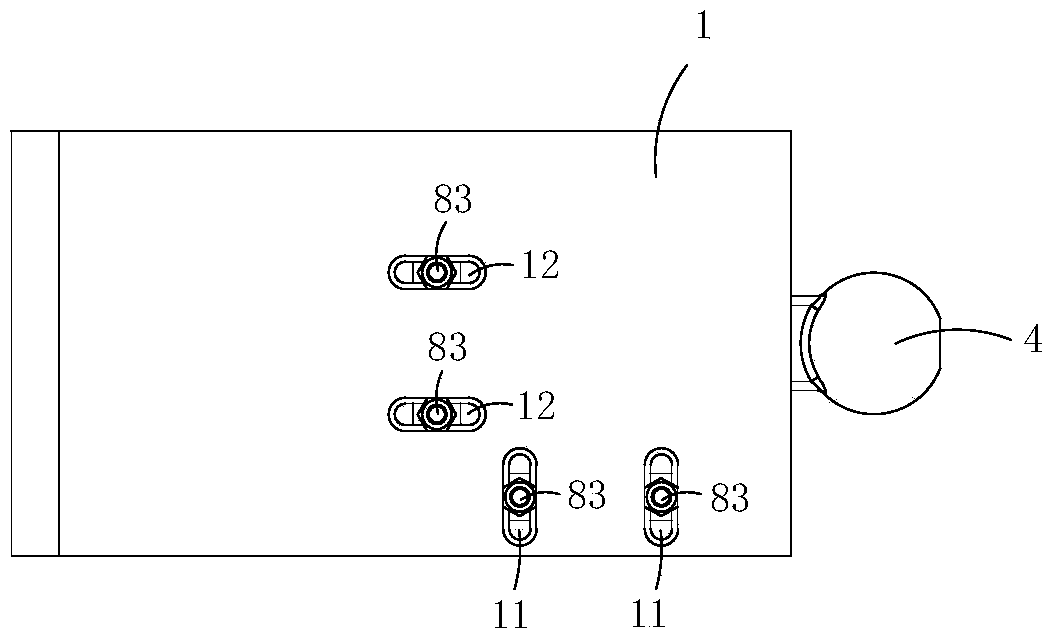

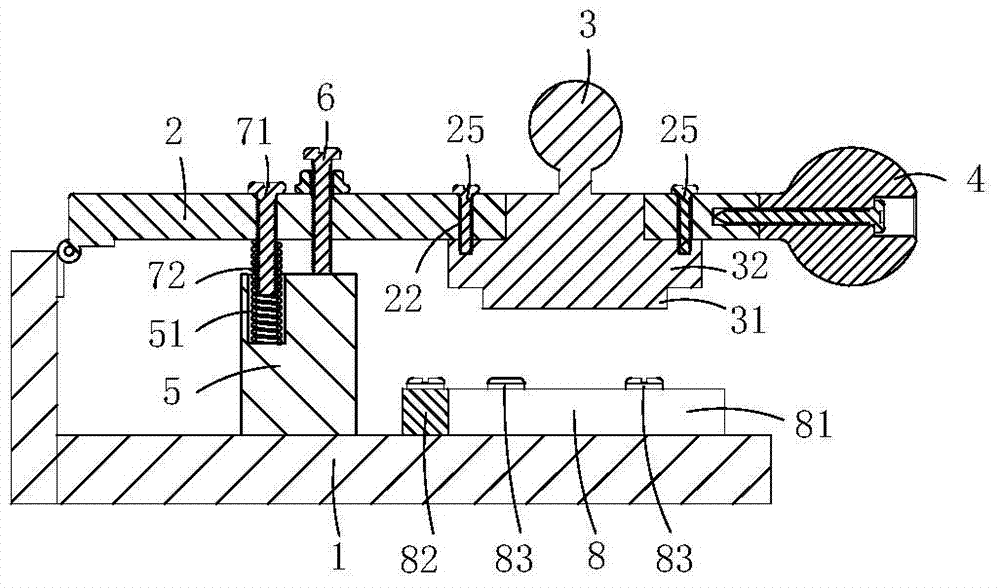

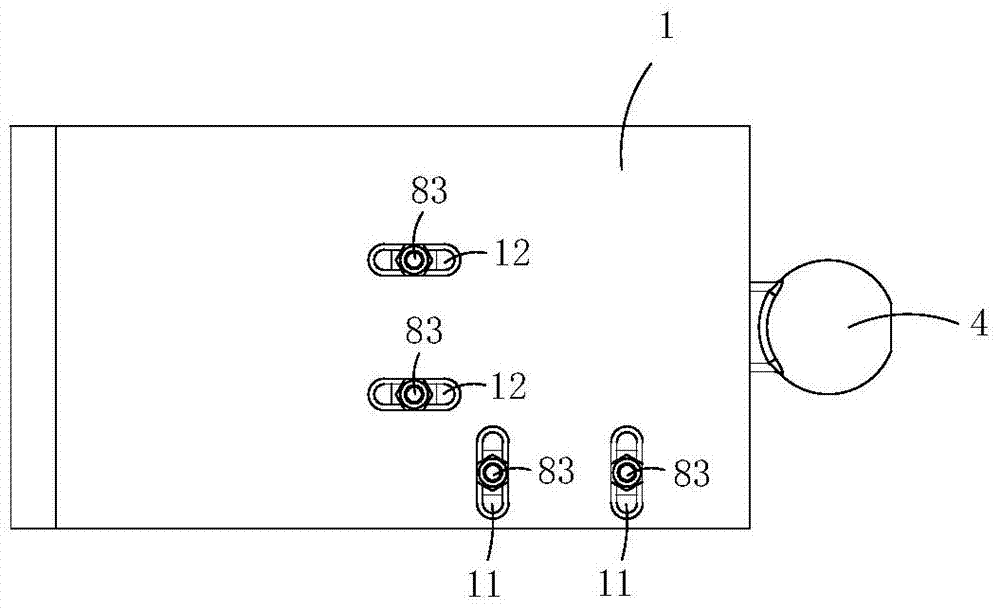

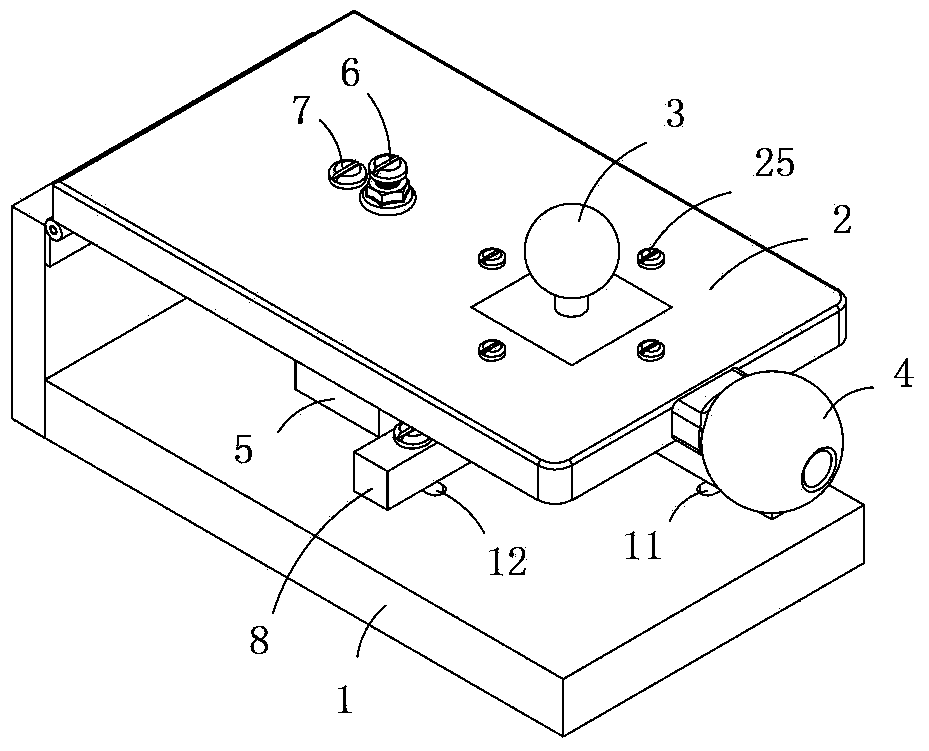

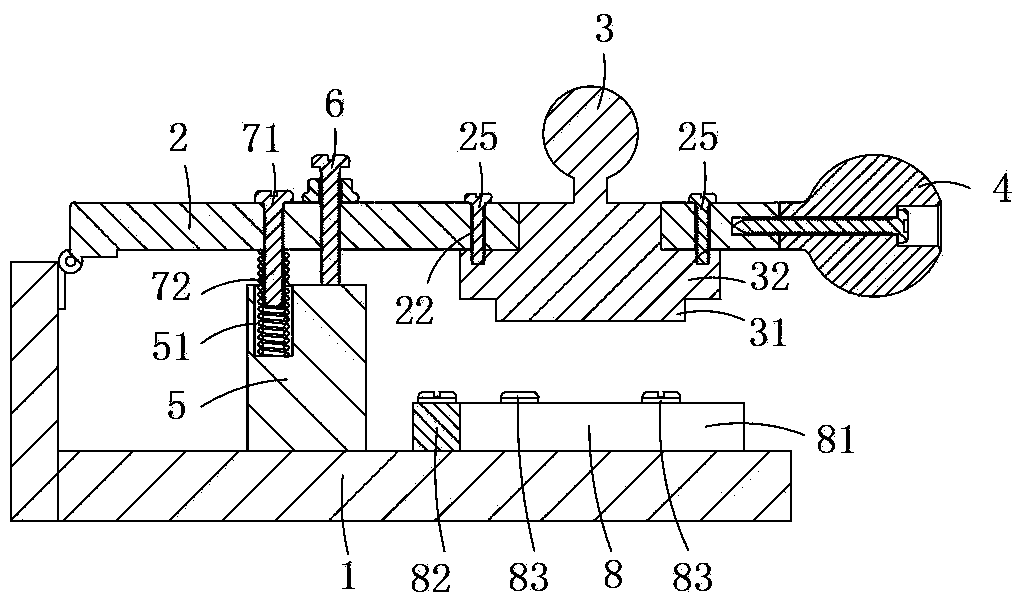

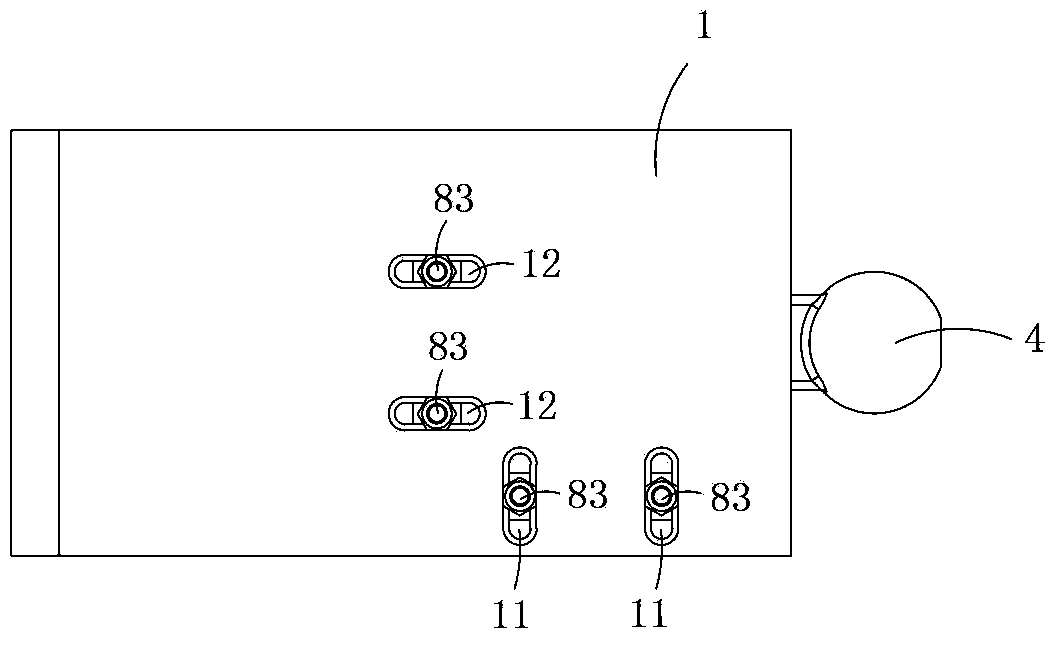

Improved soap printing device

ActiveCN103436396BGuaranteed embossing qualityEmbossing/polishing soapEngineeringMechanical engineering

The invention discloses an improved soap printing device which comprises a base, a pressing plate rotatably arranged on the base, a soap stamp fixed on the pressing plate, a handle for driving the pressing plate to rotate, and a positioning mechanism arranged on the base for regulating a location of a soap body to be printed, wherein the positioning mechanism comprises a longitudinal regulating baffle platform extending along the longitudinal direction, a transverse regulating baffle plate extending along the transverse direction, and a plurality of regulating bolt assemblies, longitudinal group installing regulating holes and transverse group installing regulating holes are formed in the base, and are of waist-shaped holes, each longitudinal regulating baffle platform is fixed on the base through a regulating bolt assembly penetrating through each longitudinal group installing regulating hole, and each transverse regulating baffle platform is fixed on the base through a regulating bolt assembly penetrating through each transverse group installing regulation hole. The improved soap printing device is convenient to operate, and is capable of ensuring the printing quality.

Owner:南通华烨塑料工业有限公司

Manually-operated soap imprinting device

Owner:启东市恒力纺织有限公司

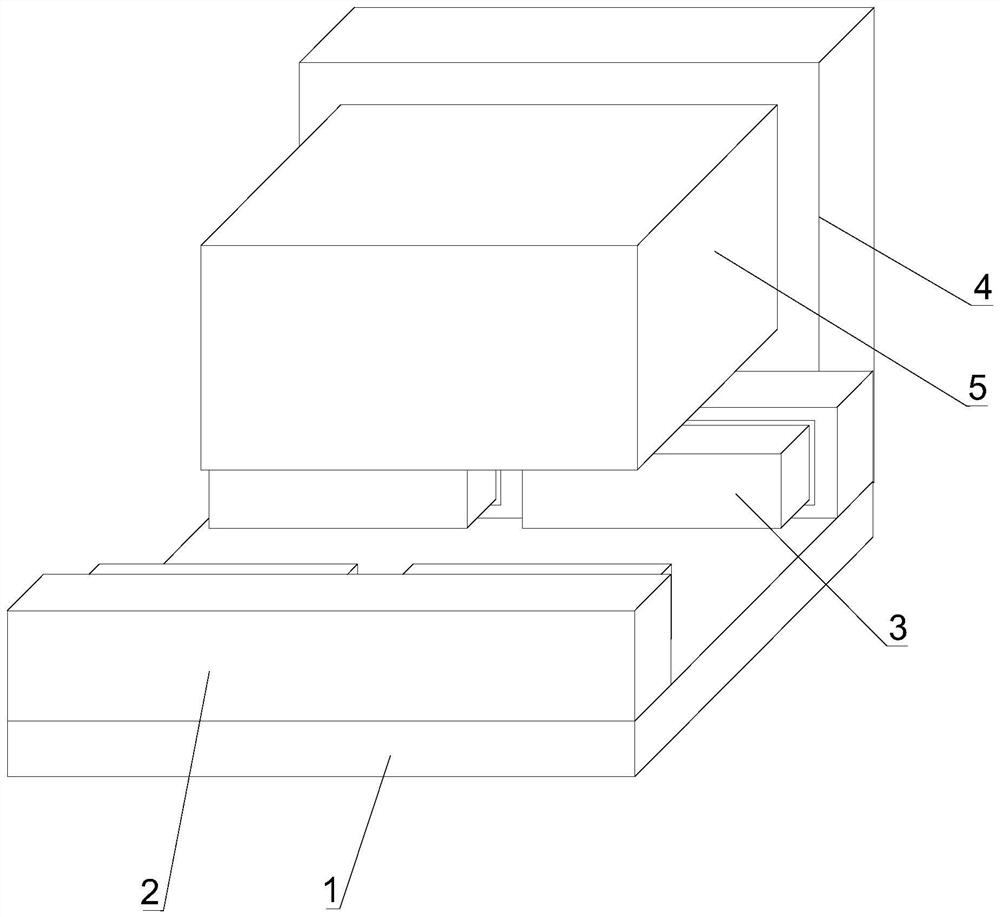

Cold printing machine for hexagonal soaps

The invention discloses a cold printing machine for hexagonal soaps. The cold printing machine for hexagonal soaps comprises a soap feed conveying line. A back-and-forth moving type soap picking mechanism is arranged at the picking position of the soap feed conveying line, a die for printing the soaps is arranged behind the soap picking mechanism, and a soap discharge conveying line is arranged behind the die. The back-and-forth moving type soap picking mechanism comprises a front moving part and a rear moving part, a front soap clamping cylinder and a rear soap clamping cylinder are fixedly mounted on the front moving part and the rear moving part, the front soap clamping cylinder picks the soaps on the soap discharge conveying line and sends the same into a die cavity of the die, and the rear soap clamping cylinder picks the printed soaps and sends the same to the soap discharge conveying line. The cold printing machine for the hexagonal soaps is reasonable in structure, can print on multiple sides, can meet requirements of different senses of customers on the market for the soaps, breaks through people's conventional concept that soaps are round and opens up a brand-new market.

Owner:NANTONG UNIVERSAL MACHINERY

Manual soap embossing device

The invention discloses a manual soap embossing device. The device comprises a base, a pressing plate, a soap seal, a handle and a cutter, wherein the pressing plate is arranged on the base in a rotary manner; the soap seal is fixed on the pressing plate; the handle drives the pressing plate to rotate; a longitudinally cut spacing hole and a horizontally cut spacing hole are formed in the pressing plate; the base is provided with a longitudinally cut spacing groove and a horizontally cut spacing groove; the longitudinally cut spacing groove is fit with the longitudinally cut spacing hole; the horizontally cut spacing groove is fit with the horizontally cut spacing hole; the longitudinally cut spacing hole and the horizontally cut spacing hole intersect to form an L shape; the longitudinally cut spacing groove and the horizontally cut spacing groove also intersect to form an L shape; and the shape of the cutter is L fit with the longitudinally cut spacing hole and the horizontally cut spacing hole. The device is simpler and more convenient to operate and can ensure the embossing quality.

Owner:QIDONG ALPHA VALVE CO LTD

Improved soap embossing device

ActiveCN103409260BGuaranteed embossing qualityEmbossing/polishing soapEngineeringMechanical engineering

The invention discloses an improved soap embossing device. The device comprises a base, a pressing plate, a soap seal and a handle, wherein the pressing plate is arranged on the base in a rotary manner; the soap seal is fixed on the pressing plate; the handle drives the pressing plate to rotate; a containing hole and a plurality of fastening connecting holes formed in a plate body outside the containing hole are formed in the pressing plate; an embossing part, a connecting part and screw holes are formed on the soap seal; the screw holes are formed in the connecting part and are fit with the fastening connecting holes; and the soap seal is fixed on the pressing plate via screws in the fastening connecting holes and the screw holes. The device is simpler and more convenient to operate and can ensure the embossing quality.

Owner:JIANGSU QIHANG LUGGAGE CO LTD

Soap printing device for improving imprinting quality

InactiveCN104726243AEasy to operateImprove quality and efficiencyCutting soapEmbossing/polishing soapMechanical engineeringSOAP

The invention discloses a soap printing device for improving imprinting quality. The soap printing device comprises a base, a pressure plate, a soap print, a handle, a limiting lug boss, an adjusting bolt, a resetting mechanism and a positioning mechanism, wherein the resetting mechanism comprises a resetting limiting column and a resetting spring; the pressure plate extends down out of the bottom end of the resetting limiting column; the resetting spring sleeves on a partial column body, which extends down out of the pressure plate downwards, of the resetting limiting column; a slide hole is formed in the limiting lug boss; the bottom end of the resetting limiting column can be inserted into the slide hole when the resetting limiting column rotates along with the pressure plate; the positioning mechanism comprises longitudinal adjusting baffle tables, transverse adjusting baffle plates and adjusting bolt assemblies; a longitudinal mounting hole group and a transverse assembly mounting hole group are formed in the base and are both waist holes; the longitudinal adjusting baffle tables penetrate through the adjusting bolt assemblies of the longitudinal assembly mounting holes and are fixedly arranged on the base; and the transverse adjusting baffle plates penetrate through the adjusting bolt assemblies of the transverse assembly mounting holes and are fixedly arranged on the base. According to the soap printing device, the imprinting quality and the production efficiency are effectively improved.

Owner:申清章

Soap printer

ActiveCN101985589BPowerfulImprove reliabilityShaping soapEmbossing/polishing soapMotor driveElectric machine

The invention discloses a soap printer which comprises a motor-driven cam shaft. The cam shaft is provided with three conjugate cams, namely a soap slab cam, a lower mould cam and a soap block cam. The soap slab cam is connected with a first crank slider mechanism which drives a soap slab capturing and turning mechanism to move through a swing rod; the lower mould cam is connected with a crank connection rod mechanism which drives a lower mould turning mechanism to move through a swing rod; the soap block cam is connected with a second crank slider mechanism which drives a soap block capturing and turning mechanism to move through a swing rod; and the cam shaft is provided with a third crank slider mechanism which drives an upper mould to move. The invention has reasonable structure and high working performance.

Owner:NANTONG UNIVERSAL MACHINERY

Improved soap embossing device

ActiveCN103409260AGuaranteed embossing qualityEmbossing/polishing soapEngineeringMechanical engineering

The invention discloses an improved soap embossing device. The device comprises a base, a pressing plate, a soap seal and a handle, wherein the pressing plate is arranged on the base in a rotary manner; the soap seal is fixed on the pressing plate; the handle drives the pressing plate to rotate; a containing hole and a plurality of fastening connecting holes formed in a plate body outside the containing hole are formed in the pressing plate; an embossing part, a connecting part and screw holes are formed on the soap seal; the screw holes are formed in the connecting part and are fit with the fastening connecting holes; and the soap seal is fixed on the pressing plate via screws in the fastening connecting holes and the screw holes. The device is simpler and more convenient to operate and can ensure the embossing quality.

Owner:JIANGSU QIHANG LUGGAGE CO LTD

Soap embossing device

Owner:启东市华华针布厂

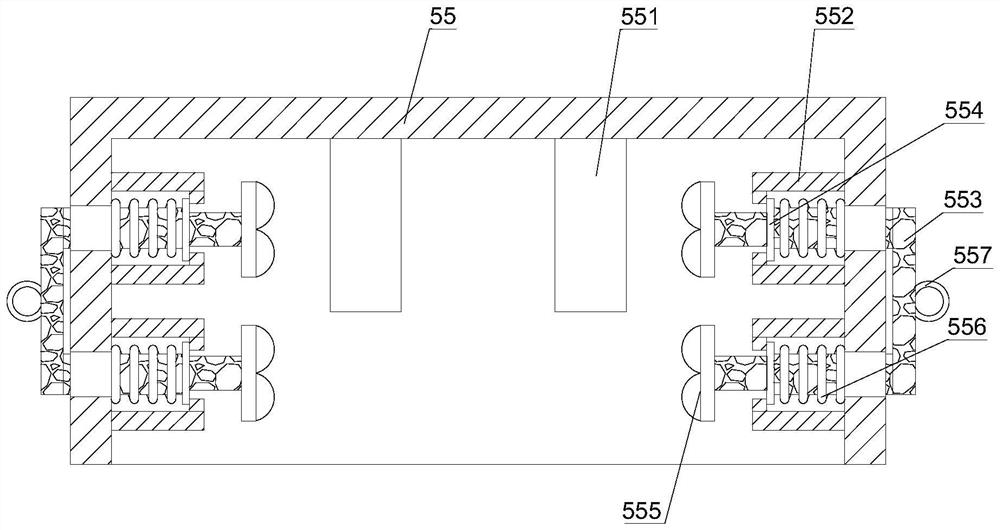

Soap impressing device and use method

ActiveCN114106948AAvoid skewPrevent embedding inEmbossing/polishing soapEngineeringStructural engineering

The invention relates to the technical field of soap production, in particular to a soap coining device which comprises a fixing frame, the fixing frame is provided with multiple sets of fixing mechanisms, and each fixing mechanism comprises a sliding block, an inclined plate, a transverse plate, a through groove, a long plate, a clamping plate and a first spring; a plurality of sets of matched sliding blocks are slidably connected to the top end of the interior of the fixing frame, matched inclined plates are fixedly arranged at the bottoms of the sliding blocks, through grooves are formed in the inclined plates, the inclined plates are slidably connected with transverse plates through the through grooves, and matched long plates are fixedly arranged at the positions, located on the two sides of the inclined plates, of the transverse plates. Materials are prevented from being embedded in the pressing die, the materials are better separated from the pressing die, the clamping plates can automatically adjust the distance according to the width of the materials, universality is high, the pressing die can be matched with the clamping plates for stamping, extra power is not needed, the stamping effect is good, multiple sets of materials only need to be placed in the baffles during stamping through intermittent feeding of the feeding plate, time is saved, and the stamping efficiency is improved. The production efficiency is improved.

Owner:安徽华谊日新科技有限公司

A soap stamping device

The present invention relates to a stamping device, in particular to a soap stamping device. Provided is a soap imprinting device with simple structure, convenient operation and basically the same depth of imprinting on the soap surface. Provided is such a soap stamping device, which includes: a support column, the four corners of the bottom of the workbench are provided with support columns; a stamping mechanism, a stamping mechanism is provided on the top of the workbench; a material removal mechanism, the top of the workbench is provided with Stripping mechanism, the stripping mechanism is located below the stamping mechanism. When the cam rotates and squeezes the pendulum rod clockwise, the first link drives the printing plate to continue to move downward through the circular rod to carry out soap stamping on the upper surface, and the second elastic member and the circular rod can guide and buffer the printing plate.

Owner:HUIZHOU MUSCLE MARGIN BIOLOGICAL POLYTRON TECH INC

Impressing device on soap production line

InactiveCN114350458AReduce scratchesTo achieve the effect of replacementCooling soapEmbossing/polishing soapCold airEngineering

The invention discloses an impressing device on a soap production line, and relates to the technical field of soap impressing, the impressing device comprises a soap production impressing device, lateral top plates, a soap limiting device, a back side working plate and a soap impressing device shell, the lateral top plates are detachably mounted on the front and back side surfaces of the top of the soap production impressing device; and a soap limiting device is detachably mounted on the outer surface of one side of the lateral top plate. The bottom plate is pushed through the pusher, length shrinkage is conducted in cooperation with the telescopic hose, then high-temperature shape and pattern coining is conducted on the surface of soap through the mold sleeve shell, after coining is completed, cold air circulation is conducted on the interior of an exhaust cooling opening in cooperation with the telescopic hose, and the soap subjected to high-temperature coining is rapidly cooled; the soap high-temperature coining and cooling device has the advantages of conducting high-temperature coining and cooling on the soap, solves the problem that cracks appear on the surface of the soap due to traditional hard pressing, and achieves the effects of conducting high-temperature coining and cooling on the soap.

Owner:德清净波日化有限公司

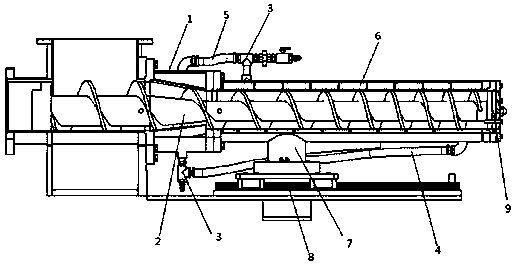

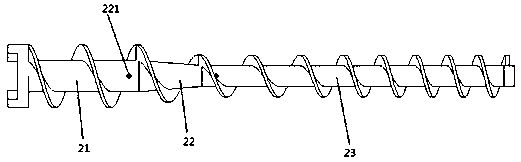

An extended conical lapping extrusion mechanism

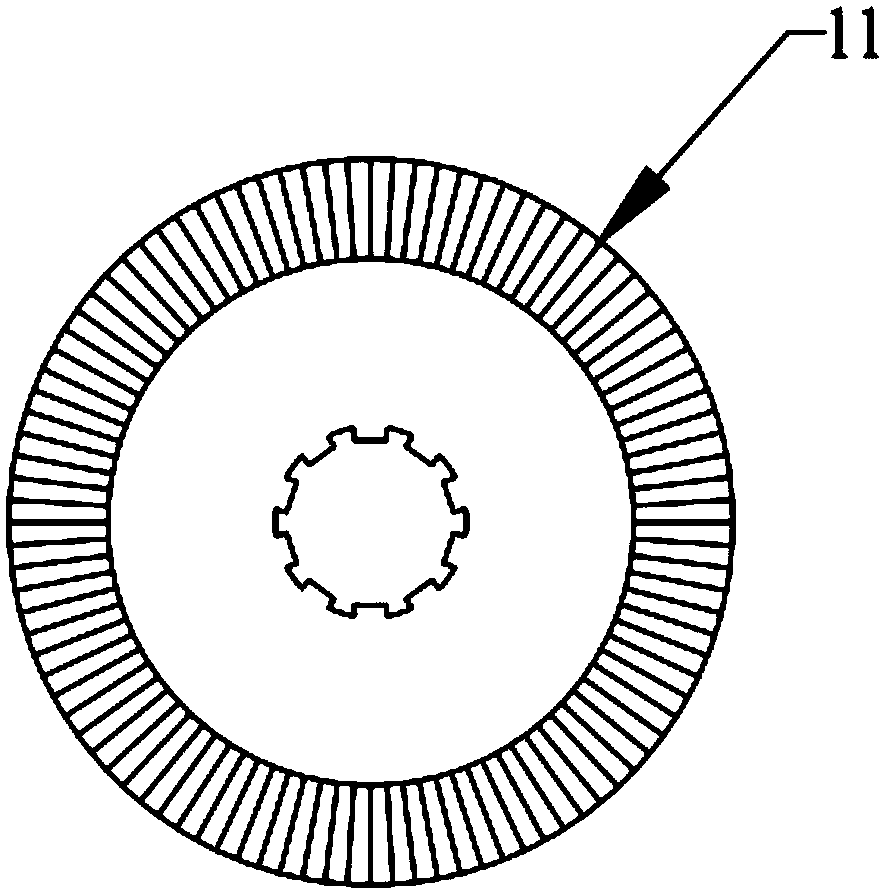

ActiveCN106398928BEffective squeezeEfficient grindingShaping soapEmbossing/polishing soapEngineeringRaw material

The invention discloses a novel lengthened tapered lapping extrusion mechanism, the novel lengthened tapered lapping extrusion mechanism comprises a cylinder body and a screw fixed in the cylinder body, the cylinder body successively comprises, from left to right, a large diameter cylinder, a tapered cylinder and a small diameter cylinder, the screw successively comprises, from left to right, a large diameter screw, a tapered screw and a small diameter screw which are respectively installed in large diameter cylinder, the tapered cylinder and the small diameter cylinder. The novel lengthened tapered lapping extrusion mechanism has the advantages of reasonable and simple structure, easy operation and easy maintenance, can be more effective for extrusion and grinding of soap flakes, can greatly improve the refining effect of the soap flakes, and makes soap grains more refined and uniform, the produced soap grains has high transparency, good gloss and uniform crystal phase structure, and a more high-quality raw material is provided for the subsequent production of high-grade perfumed soap.

Owner:NANTONG UNIVERSAL MACHINERY

Soap embossing device

ActiveCN103409261AGuaranteed embossing qualityEmbossing/polishing soapEngineeringMechanical engineering

The invention discloses a soap embossing device. The device comprises a base, a pressing plate, a soap seal, a handle, a spacing boss and an adjusting bolt, wherein the pressing plate is arranged on the base in a rotary manner; the soap seal is fixed on the pressing plate; the handle drives the pressing plate to rotate; the spacing boss is arranged on the base; the adjusting bolt is arranged on the pressing plate; the bottom end of the adjusting bolt extends out of the pressing plate downward; and when rotating to the lowest position along with the pressing plate, the adjusting bolt pushes against the spacing boss. The device is simpler and more convenient to operate and can ensure the embossing quality.

Owner:QIDONG TIANDI MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com