Cold printing machine for hexagonal soaps

A printer and hexahedron technology, applied in the direction of forming soap, embossing/polishing soap, etc., to achieve good rigidity, ensure overall precision requirements, and improve response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

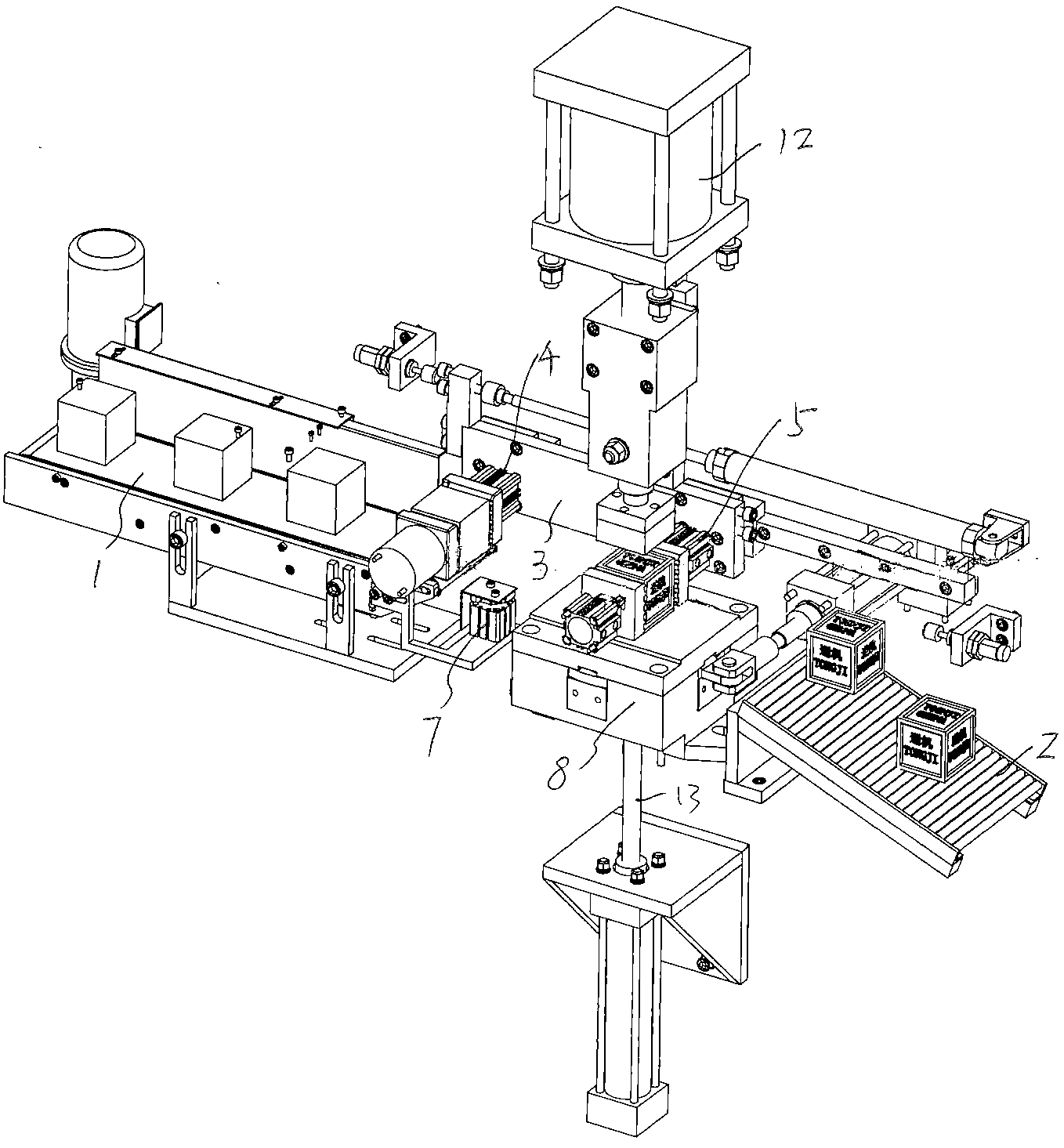

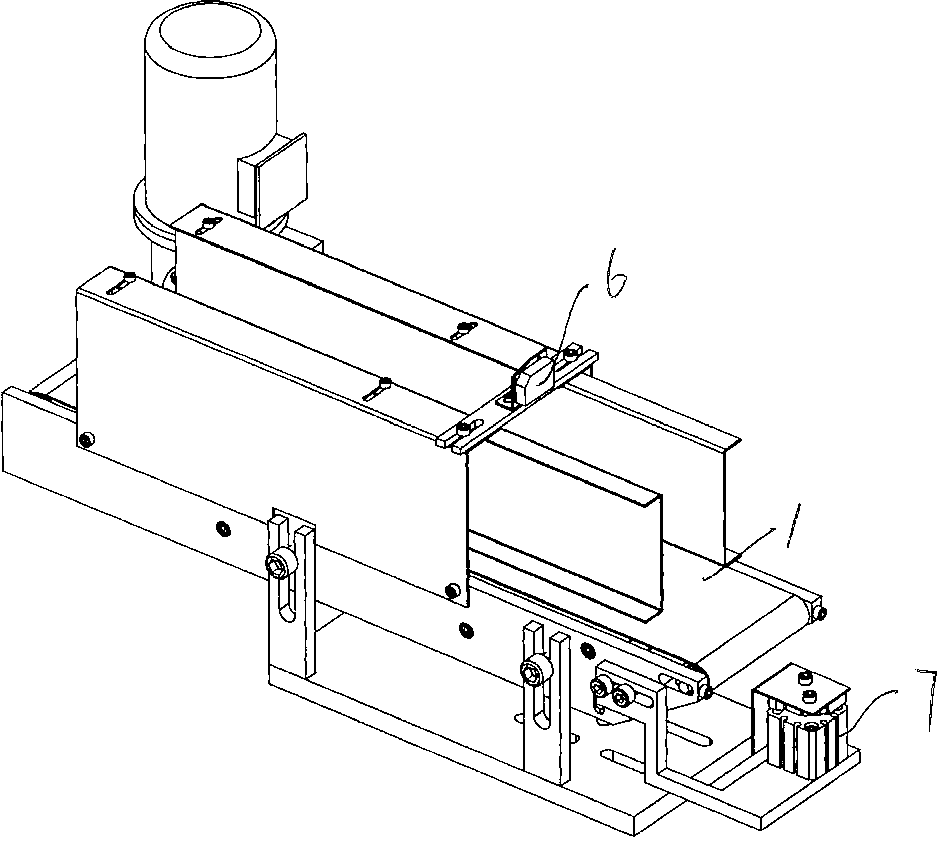

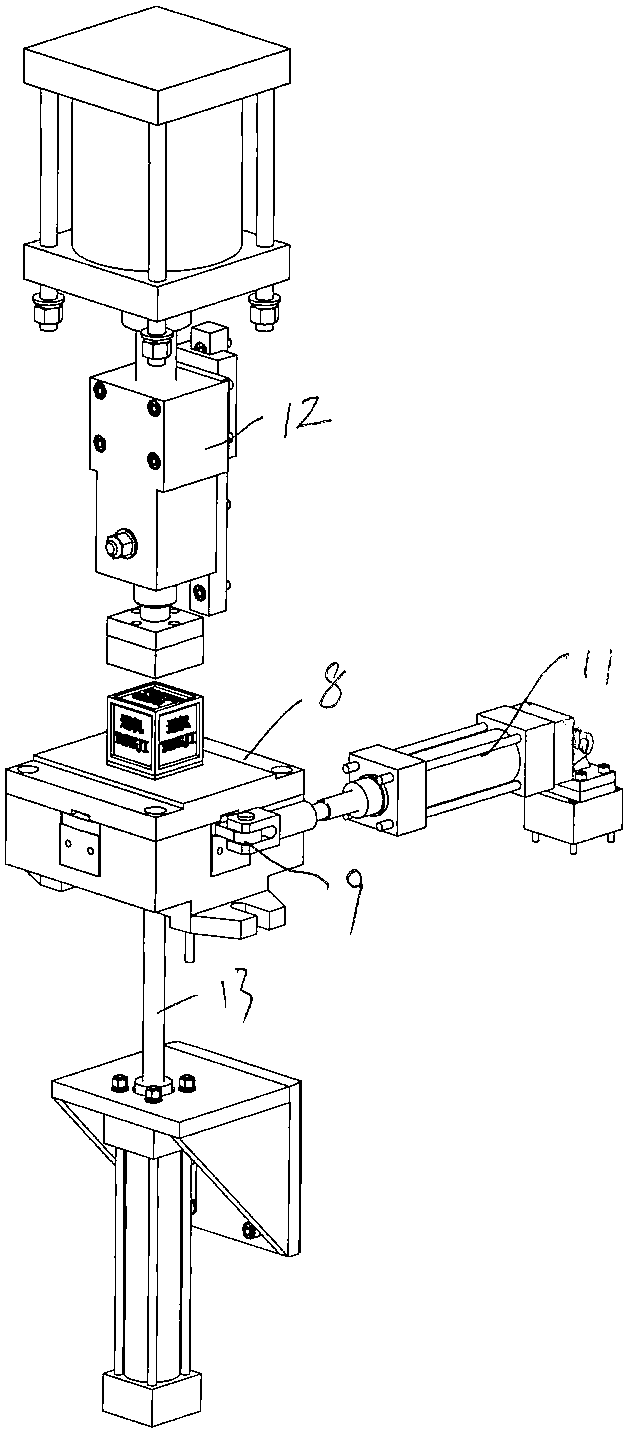

[0018] A hexahedron soap cold printer, including a soap feeding line 1, a forward and backward mobile soap block grabbing mechanism is set at the grabbing position of the soap feeding line, a mold for printing soap bars is set behind the soap bar grabbing mechanism, and a mold is set behind the mold Soap bar output line 2; the front and rear mobile soap bar grabbing mechanism includes front and rear moving parts 3, front and rear soap bar clamping cylinders 4, 5 are fixed on the front and rear moving parts, and the front soap bar clamping cylinders hold the soap bar The soap bar on the block output line is grabbed and sent into the mold cavity of the mold, and the rear soap block clamping cylinder grabs the printed soap bar and sends it into the soap bar output line.

[0019] The position of the soap feeding conveying line is provided with a photoelectric eye 6 for judging the position of the soap block and controlling the operation of the working motor of the soap feeding conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com