Patents

Literature

160 results about "Soap solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

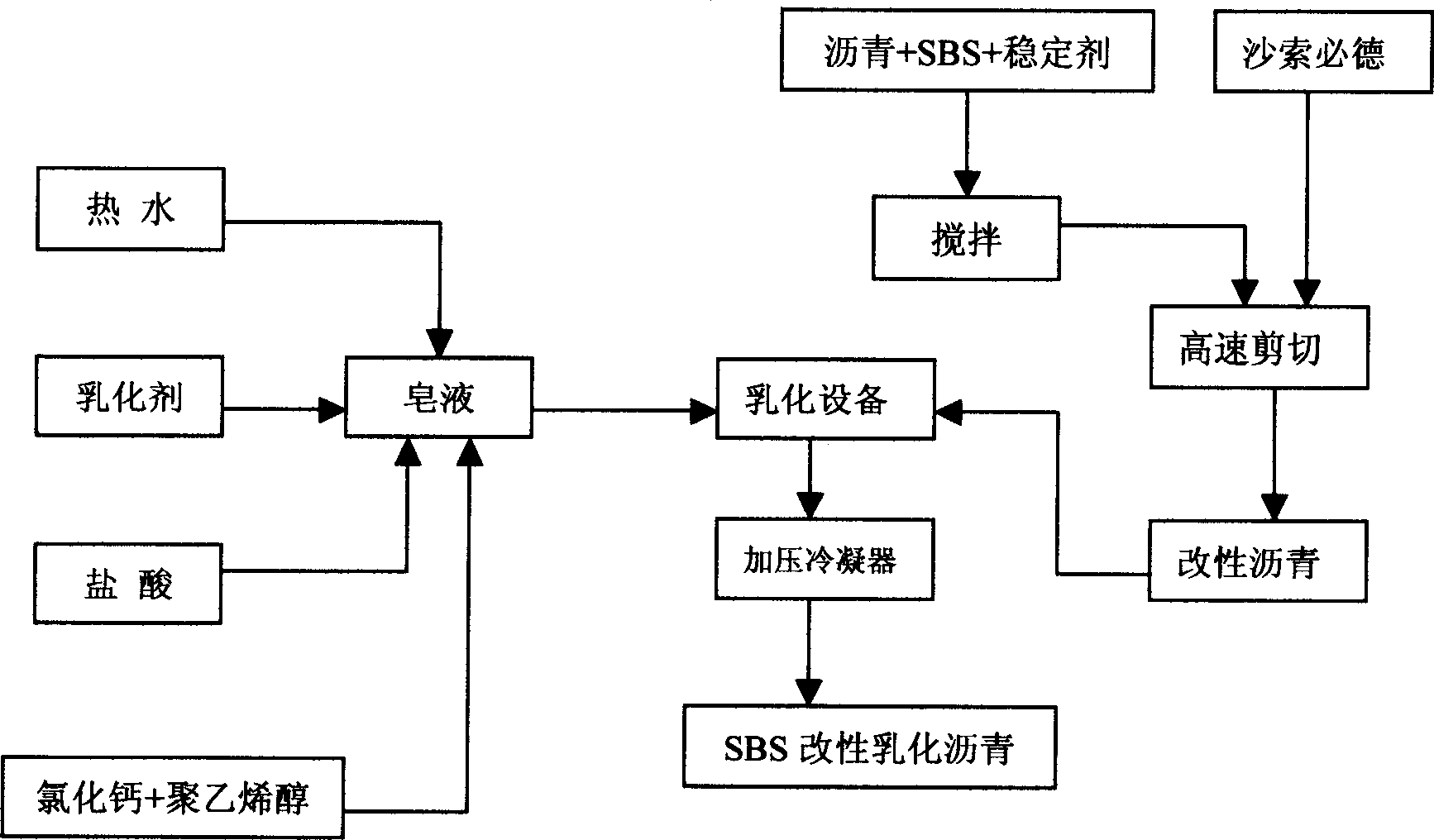

SBS modified emulsifying asphalt and preparation process thereof

InactiveCN1793234AReduce the difficulty of productionImprove high temperature performanceBuilding insulationsPolyvinyl alcoholSoap solution

The invention relates to SBS modification bitumen that is made up from 54-62% base bitumen, 0.3-1.6% Sasobit, 0.06-0.55% WD-3# stabilizer, 1.2-1.8% bitumen positive ion emulsifying agent, 35-40% hot water at 55-60 degree centigrade, 0.4% CaCl2, 0.15% polyvinyl alcohol. The method includes the following steps: heating the base bitumen into 180-190 degree centigrade, adding SBS modifier, whisking for 20min; adding Sasobit cutting for 1-2 hours, adding stabilizer reacting for 15min to gain modified bitumen, adding emulsifying agent, CaCl2 and polyvinyl alcohol into the hot water adjusting pH value to 1.5-3.5 to gain soap solution, emulsifying and dispersing the modified bitumen, pressurizing and cooling. The invention has high softening point. It has low emulsifying point that could decrease the consumption of the device.

Owner:GUANGZHOU UNIVERSITY

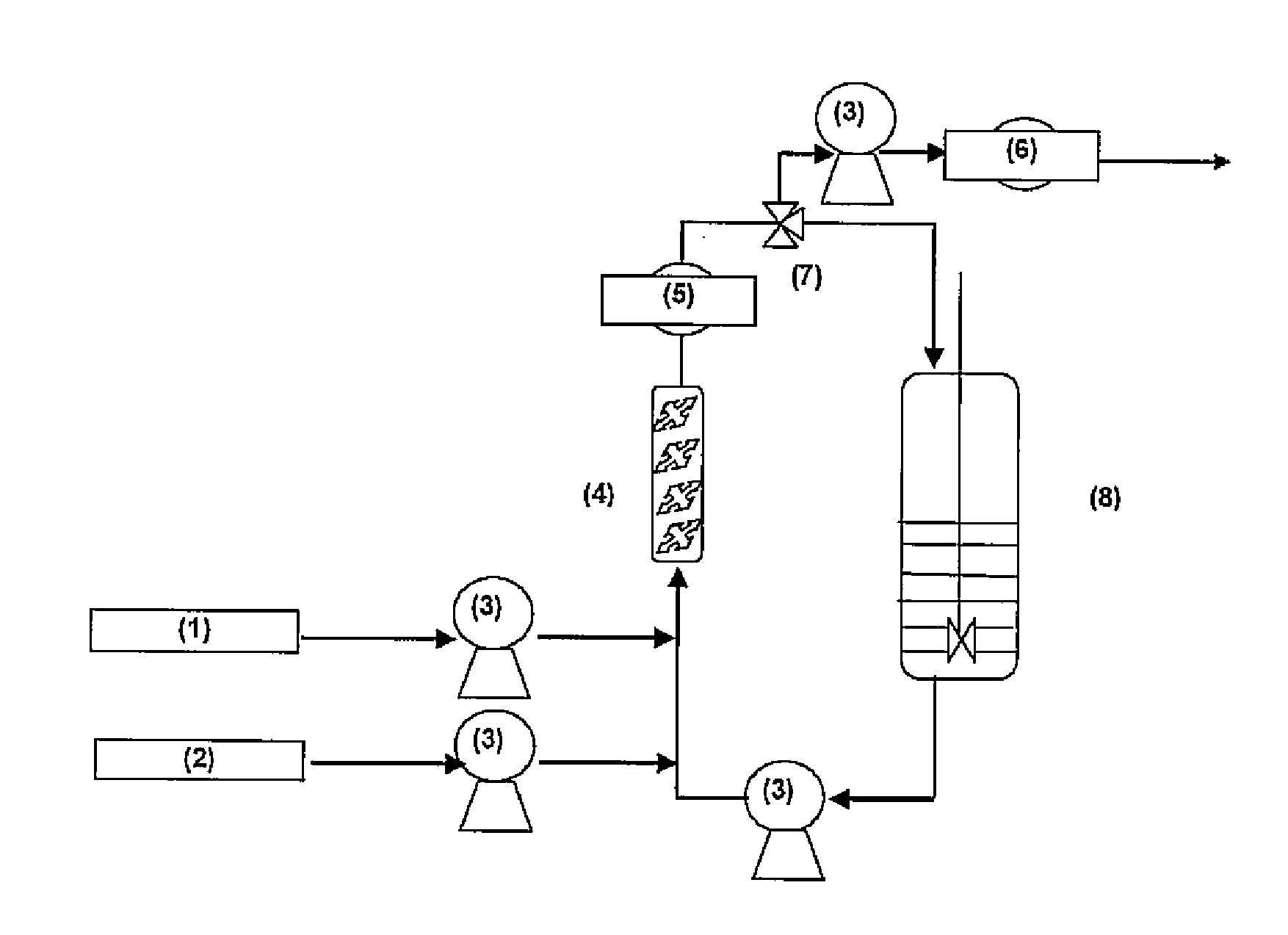

Process for the preparation of an artificial latex

ActiveUS20090281211A1High solid contentOther chemical processesMixing methodsHydrocarbon solventsSoap solution

A process of producing an artificial latex, comprising the steps:(a) cement formation, wherein a rubber is dissolved in a suitable hydrocarbon solvent;(b) emulsification of the cement formed in step (a), together with an aqueous soap solution, thus forming an oil-in-water emulsion;(c) hydrocarbon solvent removal, resulting in a latex of the rubber having particles of a median particle size in the range of from about 0.5 to 2.0 μm, and optionally(d) latex concentration, forming an artificial latex with a higher solids content, characterized in that in step (b) a premix is formed first, which is subsequently homogenized into an oil-in-water emulsion, and wherein the premix is formed by mixing the cement with the aqueous soap solution at a volume ratio of 1:1.5 to 1:3 using at least one homogenizer comprising a stator and a rotor, that is operated at a tip speed of the outer ring of the rotor in the range of from 8 to 16 m / s, and wherein the premix is subsequently homogenized in a rotor / stator homogenizer operated at a tip speed of the outer ring of the rotor in the range of from 16 to 35 m / s.

Owner:CARIFLEX PTE LTD

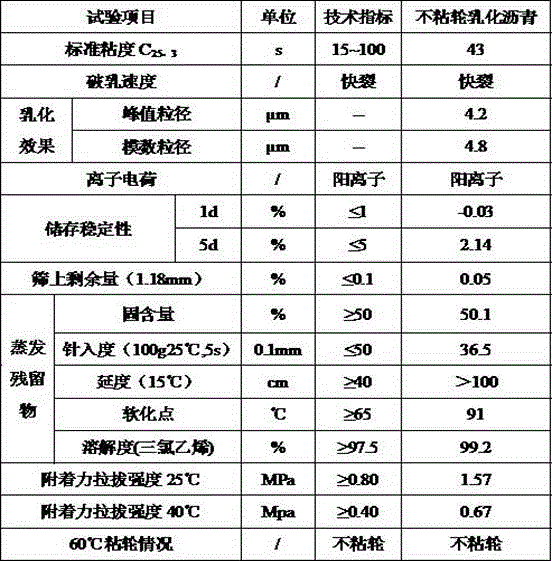

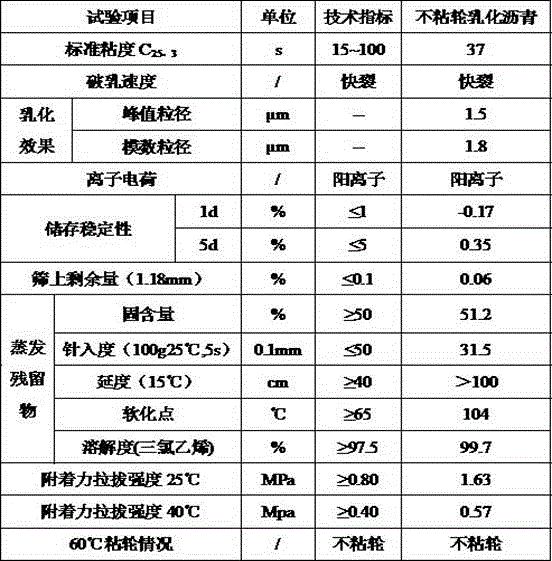

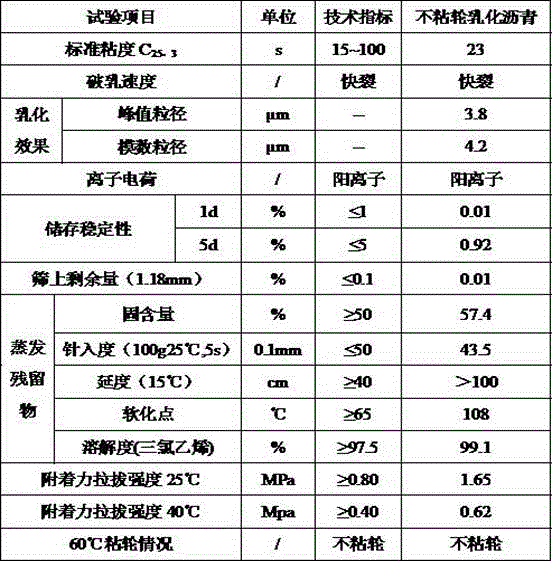

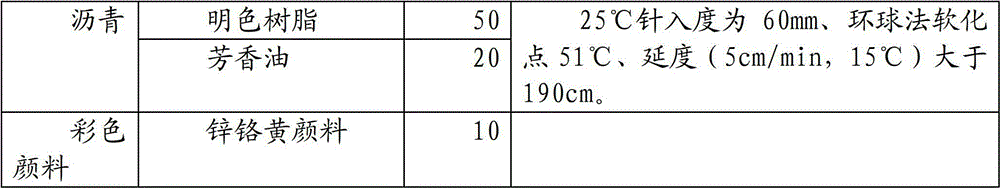

Wheel-sticking-free emulsified asphalt, preparing method, construction technology and application of wheel-sticking-free emulsified asphalt

ActiveCN105924988AHigh bonding strengthAdd a small proportionIn situ pavingsBuilding insulationsPolymer modifiedSoap solution

The invention discloses a wheel-sticking-free emulsified asphalt, a preparing method, a construction technology and application of the wheel-sticking-free emulsified asphalt. The wheel-sticking-free emulsified asphalt is prepared from, by mass, 10-50% of matrix asphalt, 10-50% of hard asphalt, 0-5% of a polymer modifier, 0.3-3% of an asphalt emulsifier, 0-1% of a thickening agent and the balance an acid-base regulating agent and water to reach 100%. The preparing method comprises the steps that firstly, the polymer modifier, the asphalt emulsifier and the thickening agent are added into water, the pH value is regulated, and a soap solution is prepared; then, the matrix asphalt is heated to 150 DEG C, the hard asphalt is heated to 160 DEG C, the matrix asphalt and the hard asphalt are stirred evenly in a stirring state, the obtained mixed asphalt and the soap solution are subjected to high-speed shearing with a colloid mill together, and the emulsified asphalt is obtained, wherein the emulsifying process is simple and practical. The emulsified asphalt has the effect of being free of wheel sticking when serving as road tack coat oil, tack coats are prevented from being damaged by construction equipment or transportation vehicles, the construction efficiency is improved, and the effect of preventing environment pollution is also achieved.

Owner:厦门华特公路沥青技术有限公司

High-permeability emulsion for cold regeneration of waste and old asphalt mixture and preparation method thereof

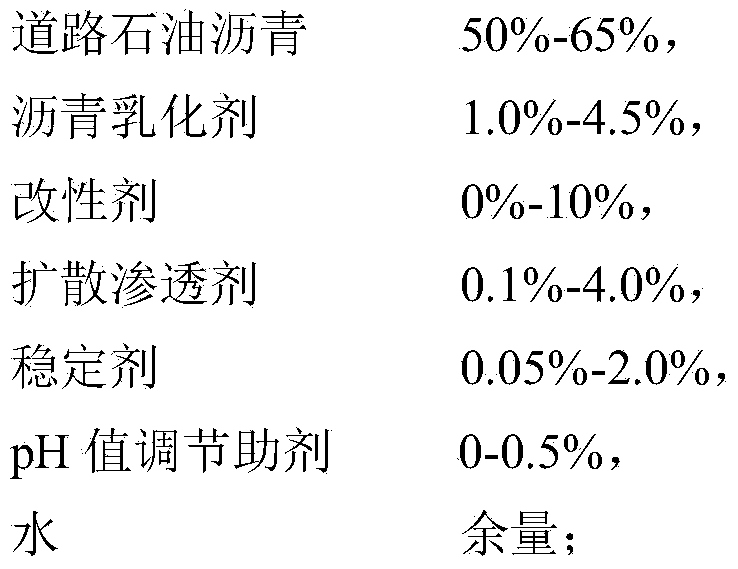

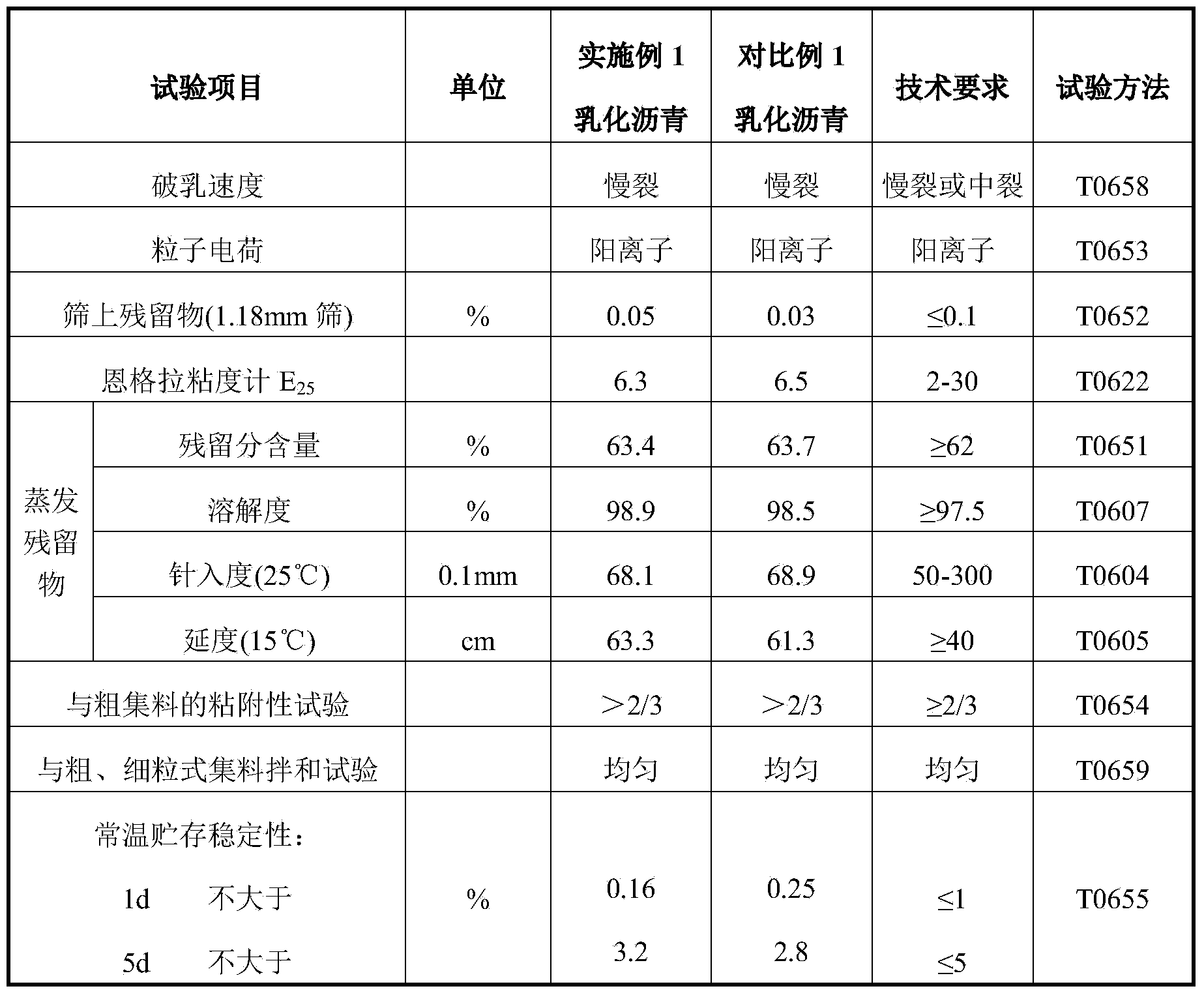

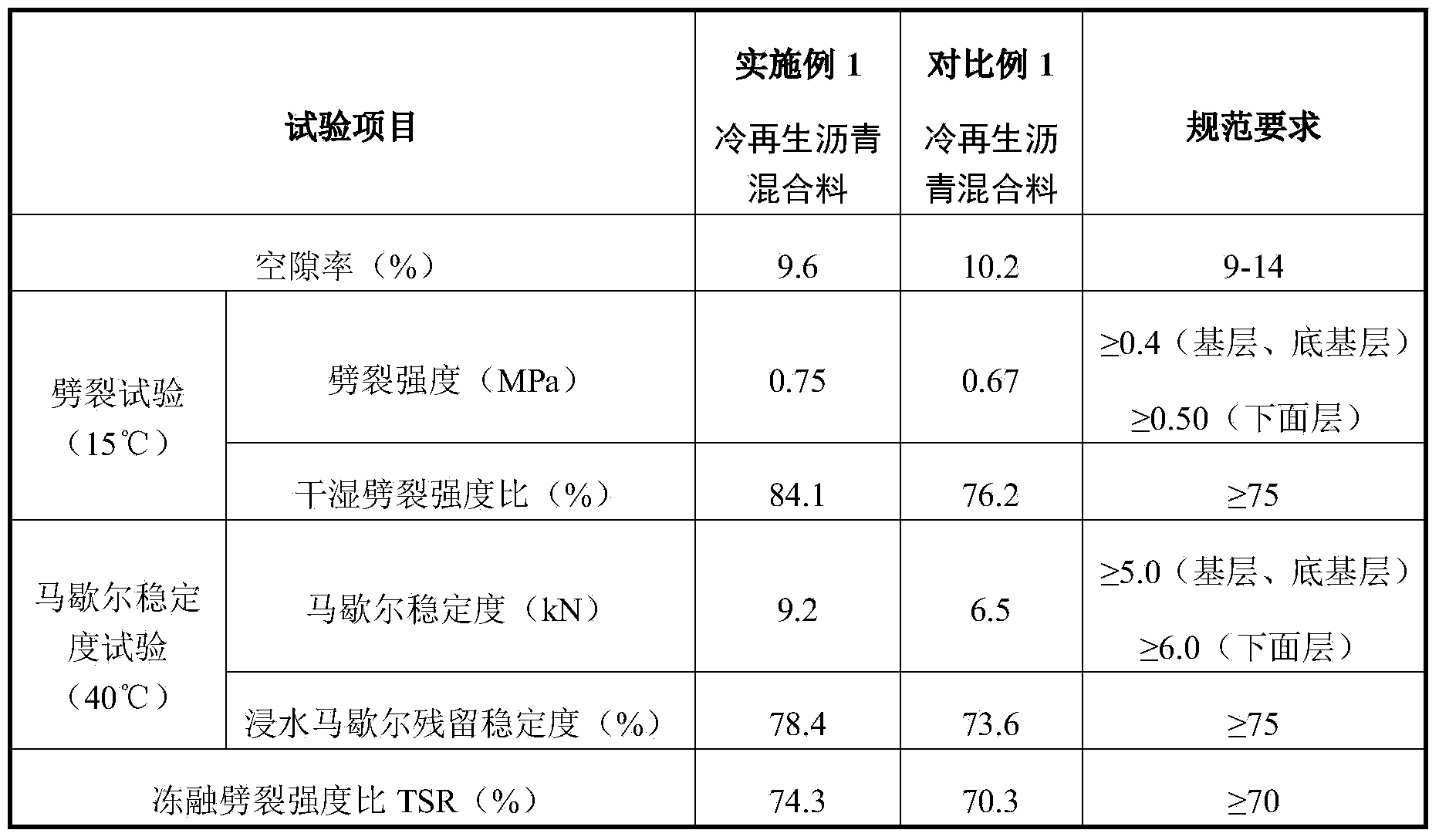

The invention relates to a high-permeability emulsion for cold regeneration of a waste and old asphalt mixture and a preparation method thereof. the emulsion is prepared from the following compositions by mass: 50%-65% of road petroleum asphalt, 1.0%-4.5% of an asphalt emulsifier, 0%-10% of a modifier, 0.1%-4.0% of a penetrating agent, 0.05%-2.0% of a stabilizing agent, 0-0.5% of an auxiliary agent adjusting pH, and the balance water. The preparation method comprises: together dissolving the emulsifier, the modifier, the dispersing penetrating agent, the stabilizing agent and the auxiliary agent adjusting the pH value in water, so as to prepare a soap solution, heating to 40-70 DEG C, adjusting pH to be 1.5-3.0, heating the road petroleum asphalt to 120 DEG C-150 DEG C, and performing emulsification on the soap solution and the asphalt, so as to obtain the high-permeability emulsion for cold regeneration of the waste and old asphalt mixture. After being blended with the waste and old asphalt mixed material, the high-permeability emulsion for cold regeneration of the waste and old asphalt mixture is capable of penetrating and activating aged asphalt in the waste and old asphalt mixed material, thereby improving the effective asphalt content in the cold regeneration mixed material, and further improving the water-damage resistance, endurability and other pavement performances of the cold regeneration mixed material and realizing efficient cold regeneration of the waste and old asphalt mixed material.

Owner:JIANGSU SOBUTE NEW MATERIALS

Preparation method and application of wheel sticking prevention emulsified asphalt for sticky layers

The invention discloses a preparation method and an application of wheel sticking prevention emulsified asphalt for sticky layers. The preparation method comprises the following steps: 1, adding 0-9 parts of a polymeric elastomer material, 0-5 parts of polyethylene wax or ethylene-vinyl acetate wax, 0-5 parts of a viscosity reducer and 0-5 parts of modified asphalt stabilizer to 450-600 parts of asphalt to prepare modified asphalt; 2, adding 1-10 parts of an emulsifier and 0.1-3 parts of an emulsified asphalt stabilizer to 300-500 parts of water, and mixing above materials to prepare a soap solution; and 3, grinding and emulsifying the soap solution and the modified asphalt according to a mass ratio of 1:1 through a modified asphalt colloid mill to prepare the target product, wherein the temperature of the soap solution is 40-60 DEG C, and the emulsification temperature of the modified asphalt is 160-180 DEG C. A high proportion of the polybutadiene elastomer is adopted as the modifier for adjusting the low temperature performances of asphalt, so the softening point of evaporation residues of the prepared wheel sticking prevention emulsified asphalt reaches up to 90 DEG C or above, the penetration degree is greater than 30 cm, and the 15 DEG C ductility is greater than 100 cm.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

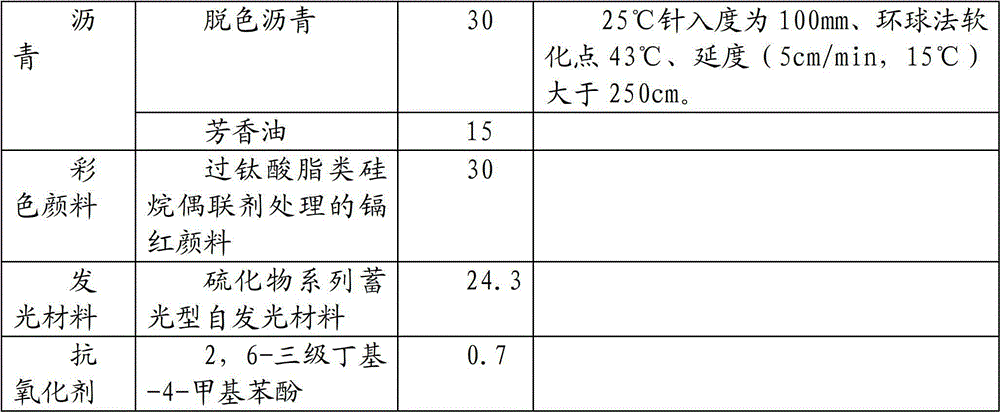

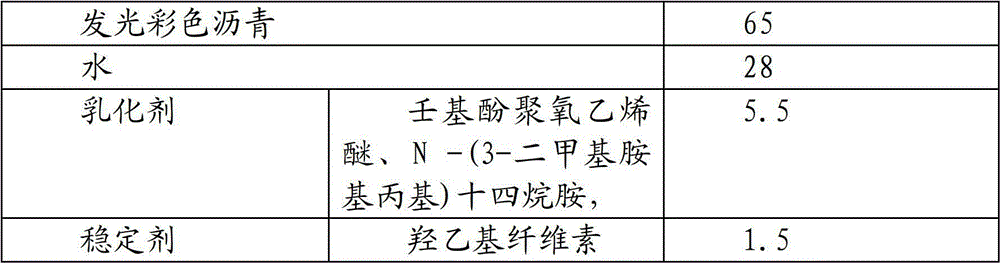

Luminescent colored bitumen emulsion and preparation method thereof

The invention discloses a luminescent colored bitumen emulsion and a preparation method of the bitumen emulsion. The method comprises the steps of: uniformly mixing 10-30 parts by mass of colored pigment, 10-30 parts by mass of luminescent material and 0.5-1.0 part by mass of antioxidant in high-speed stirring equipment, then adding 45-70 parts by mass of 130-160 DEG C bitumen, and stirring uniformly to prepare colored luminescent bitumen; adding 1.5-6.5 parts by mass of emulsifying agent and 1.0-5.0 parts by mass of stabilizer to 28-45 parts of 45-65 DEG C water, and stirring uniformly to prepare soap solution; and injecting the prepared soap solution and luminescent colored bitumen to a colloid mill, and grinding until the emulsion mode has particle size smaller than 5 mum and average grain size smaller than 7 mum. The emulsion contains 50-65 parts of the luminescent colored bitumen, 28-45 parts of water, 1.5-6.5 parts of the emulsifying agent and 1.0-5.0 parts of the stabilizer. The luminescent colored bitumen emulsion is advanced in process and simple in application; and the luminescent colored bitumen emulsion with excellent quality, luminescent effect and gorgeous color can be produced by adopting traditional equipment.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

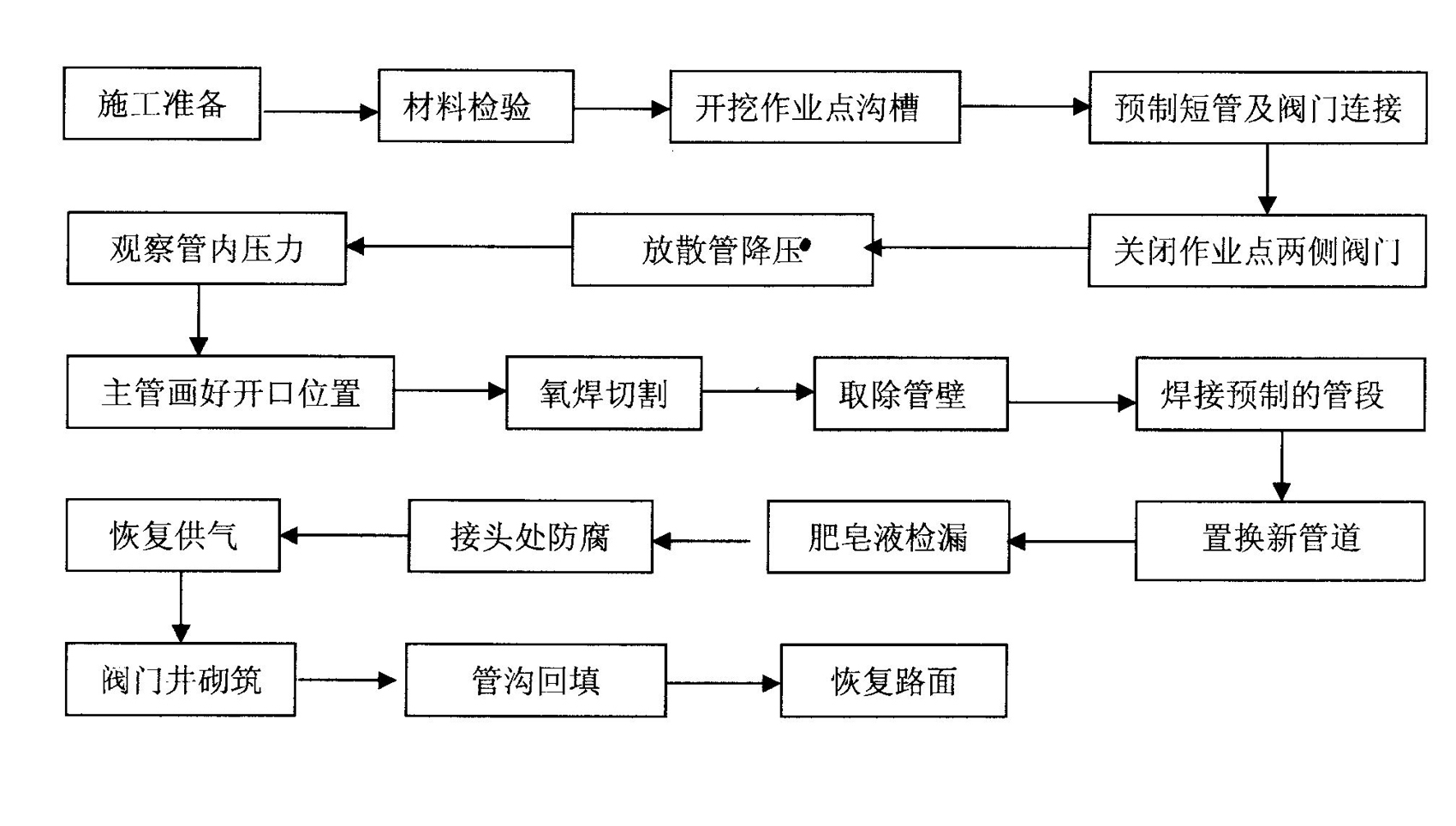

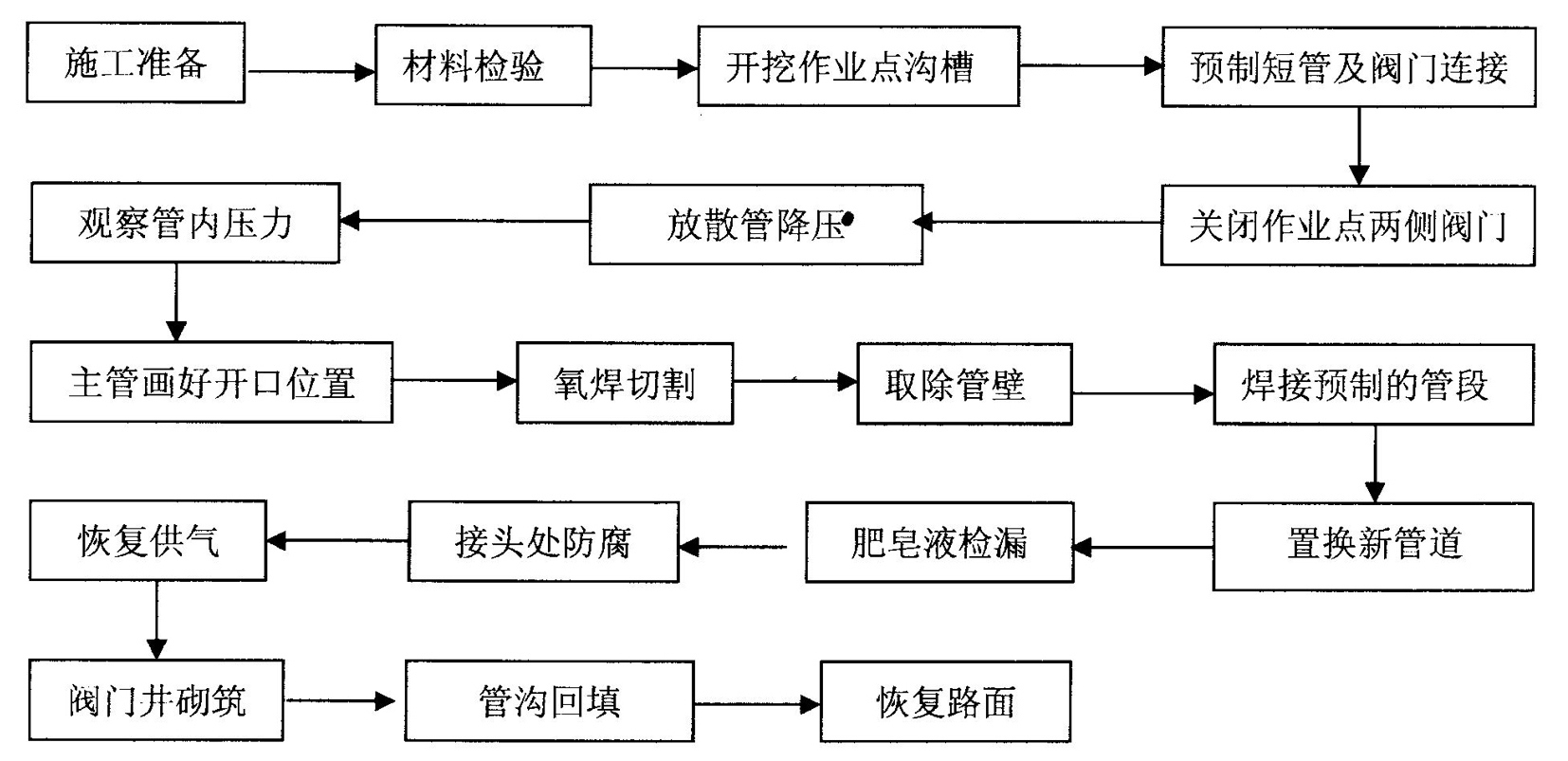

Construction method for connecting natural gas pipelines with gas

ActiveCN101846216ASimple and fast operationLess preparationPipe laying and repairNon-disconnectible pipe-jointsSoap solutionRoad surface

The invention relates to a construction method for connecting natural gas pipelines with gas, which comprises the following steps: excavating an operating spot groove at the selected spot; after excavating the groove to the given requirement, prefabricating stub pipes and junction valves of branch pipes, closing the valves on both sides of the operating spot, putting scattered pipes to reduce pressure, and observing the pressure in the pipes; after the pressure drops to the specified standard, drawing the opening position on the main pipe, carrying out oxweld cutting, removing the pipe wall, welding the prefabricated pipe sections, and replacing with new pipelines; after replacing with the new pipelines, detecting leakage with soap solution, carrying out anti-corrosion treatment at the joints, and restoring gas supply; and finally, laying a valve well, backfilling the pipe groove, and restoring the road surface, thereby completing the whole pipe connecting construction with gas. By using the invention, reliability, economical efficiency, safety and the like of the whole construction process are improved, and the whole construction process is simple in operation, less in preparation work, light in labor intensity and low in labor consumption. Each construction spot only needs about 5 persons, the construction only takes a half day and only needs common equipment, such as welders, electric drills, mobile phones and the like.

Owner:中国化学工程第四建设有限公司

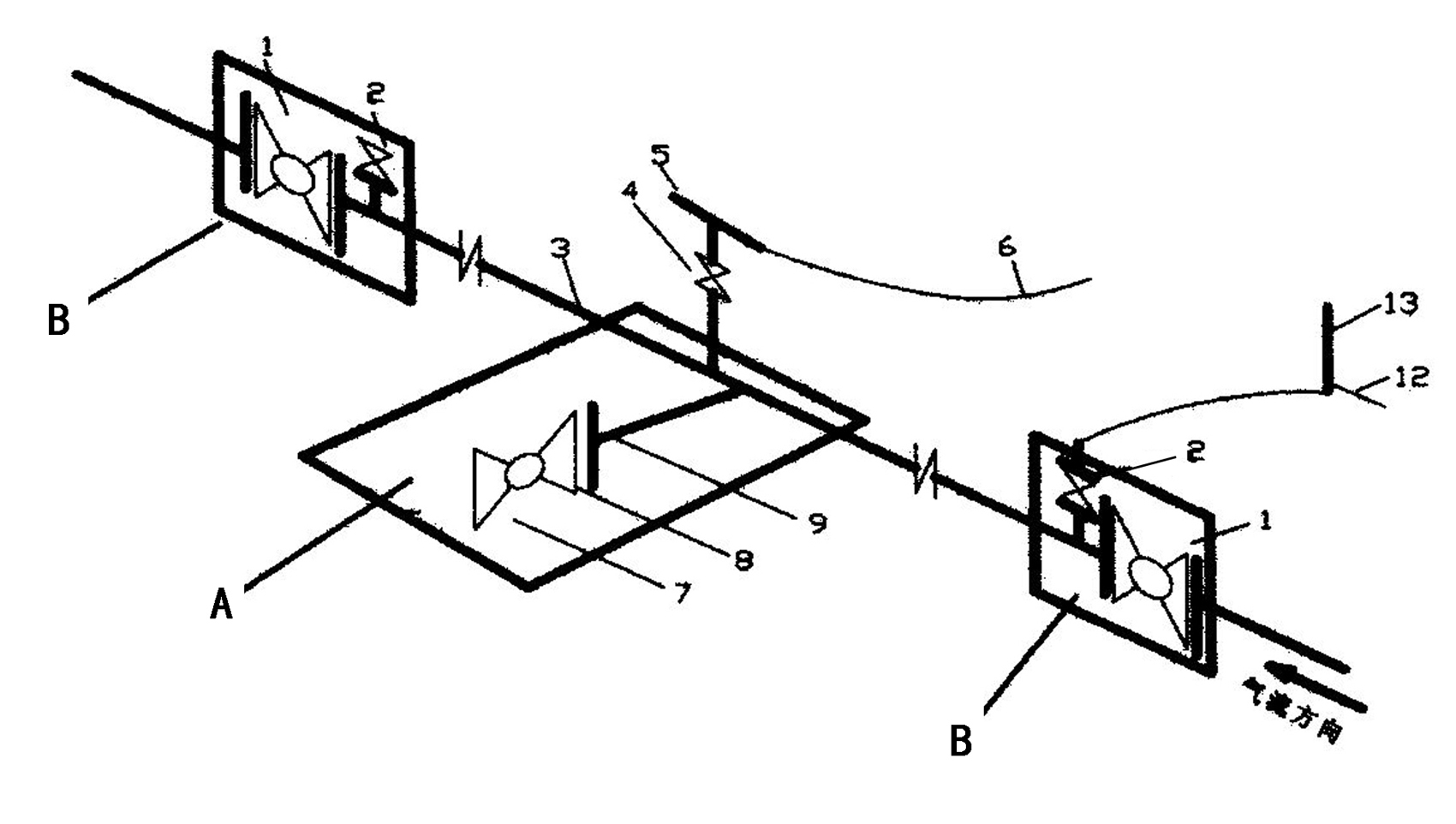

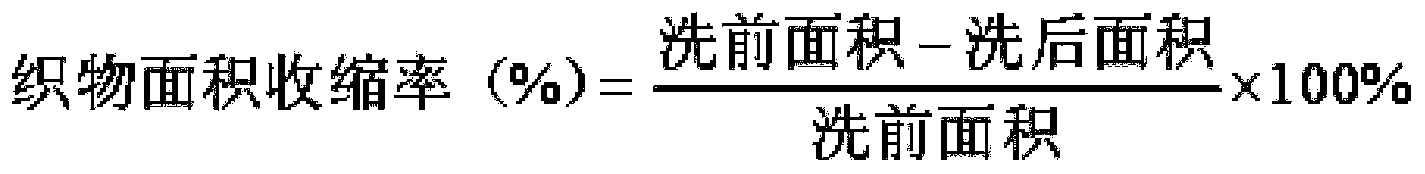

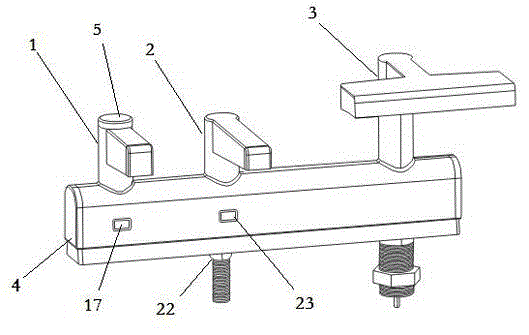

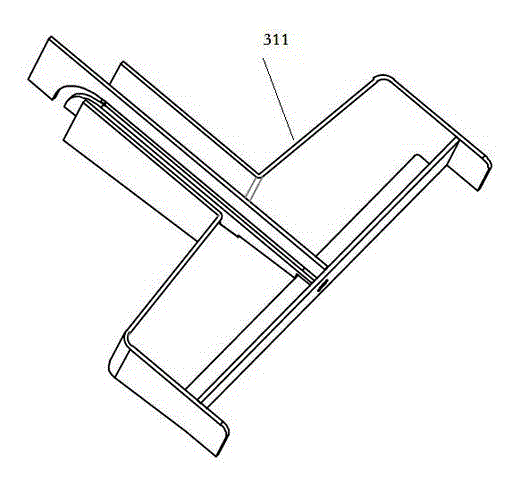

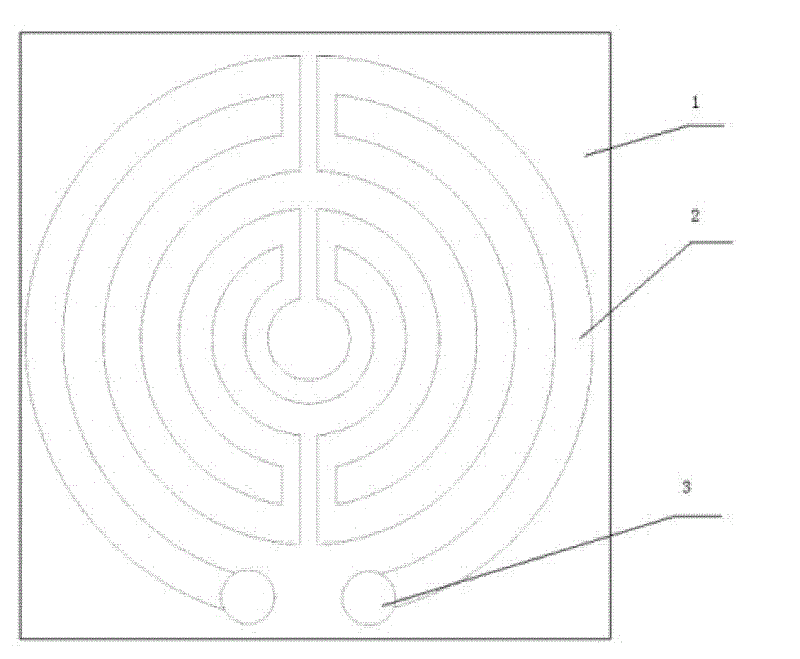

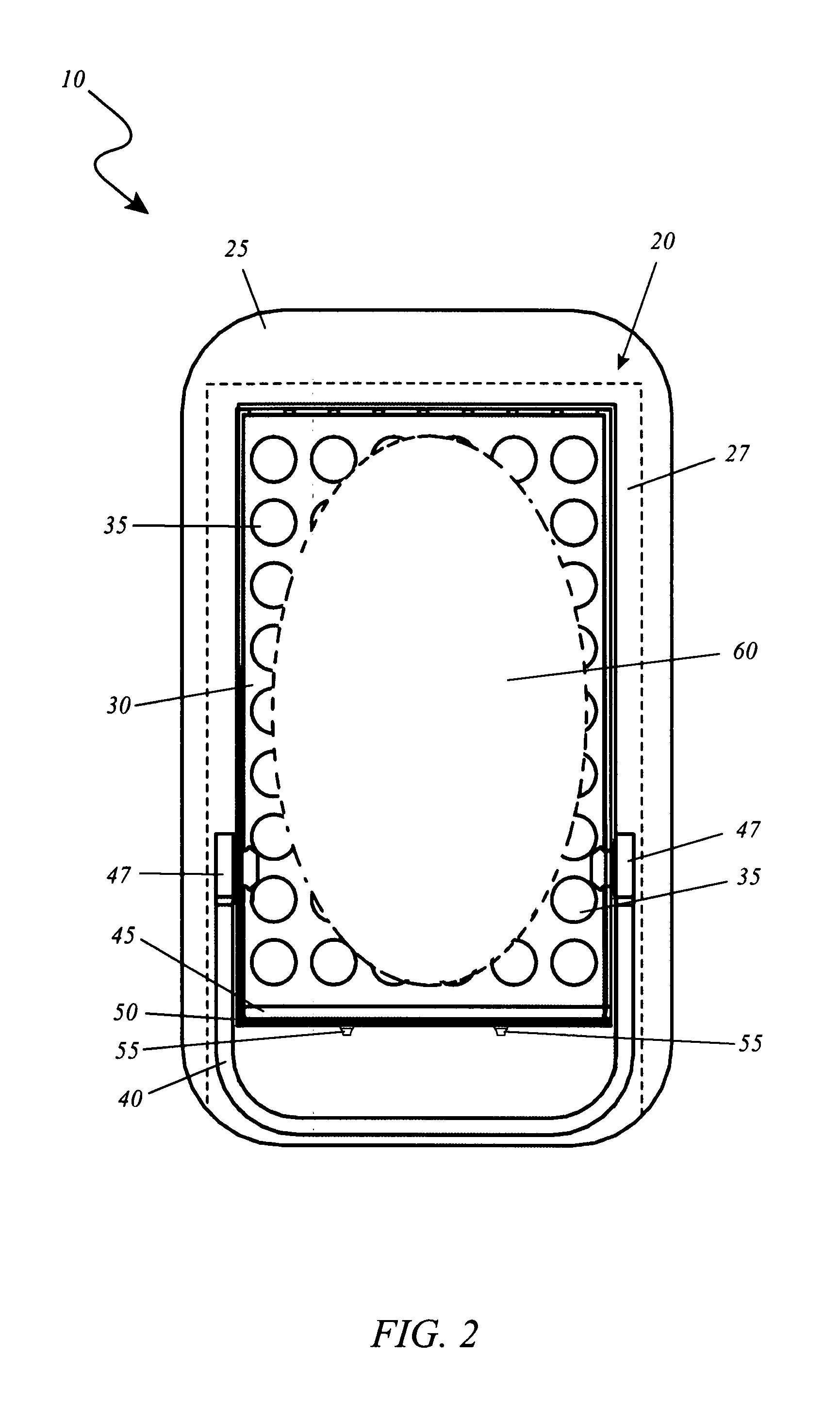

Two-dimensional flow display device

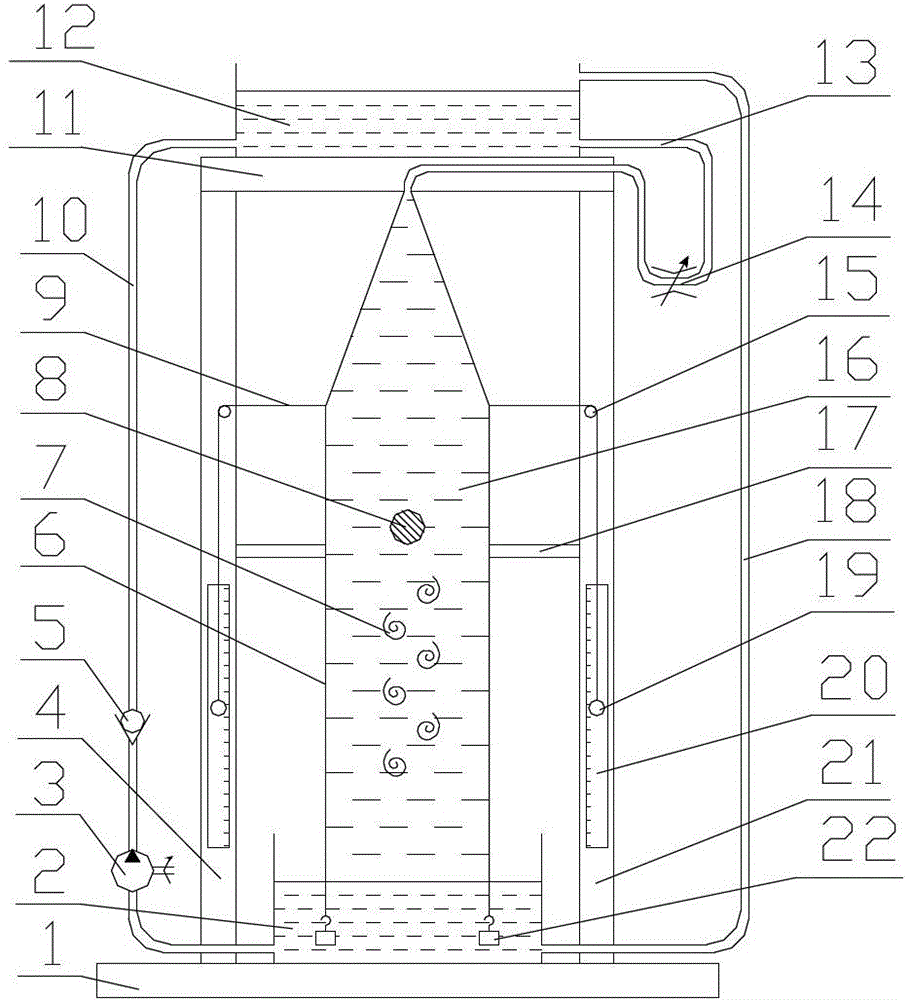

InactiveCN103150946AEasy to makeEasy to moveHydrodynamic testingEducational modelsShortest distanceWater flow

The invention provides a two-dimensional flow display device, relating to flow field display equipment in the fluid mechanics. The two-dimensional flow display device is provided with an integrated framework, a hydraulic loop and a flow display control mechanism, wherein the hydraulic loop is arranged on the integrated framework; the integrated framework is provided with a lower bottom plate, an upper end plate, a left side plate, a right side plate and an experiment table; the hydraulic loop is provided with a lower water tank, a hydraulic pump, a one-way pump, a water transmission pipe, an upper water tank, a throttle valve, a water outlet pipe and an overflow pipe; and the flow display control mechanism is provided with fluid guide wires, pull wires and weights. The two-dimensional flow display device is simple and convenient to manufacture, lower in cost, small in occupied space and convenient to move; a soap solution film flowing perpendicularly and circularly is adopted as a display platform; the width of the soap solution film is adjustable; the flow rate and the speed of the water current at a water outlet are adjustable as well; and therefore, the motion state of the fluid can be clearly exhibited, the partial phenomenon of the fluid can be observed, and the short-distance observance and knowledge about the evolution of a flow phenomenon can be formed.

Owner:XIAMEN UNIV

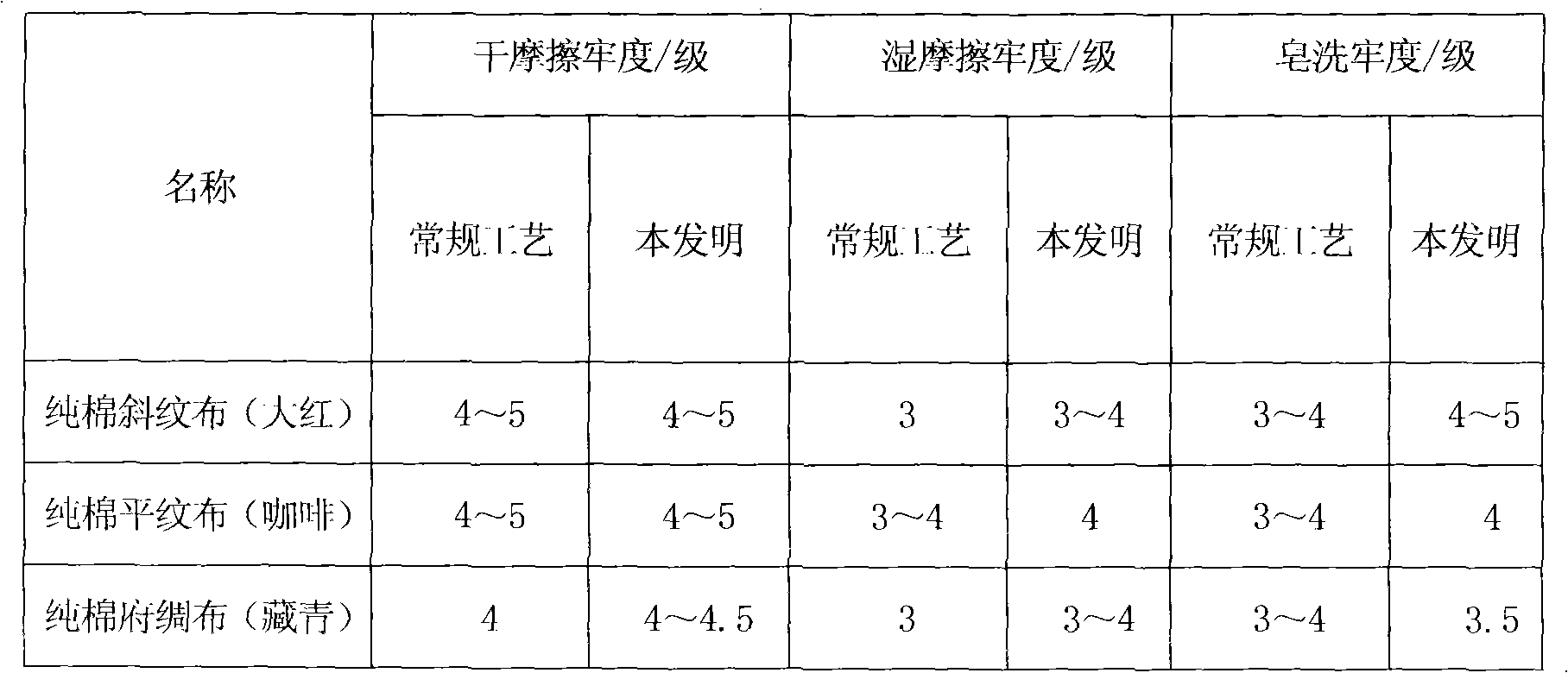

Washing technology of active dye detergent

InactiveCN101787643AReduce dosageConserve waterDry-cleaning apparatus for textilesWarm waterRoom temperature

The invention provides a washing technology of active dye detergent. A dyed product is dried after successively cold wash, acid soap wash, alkali wash, hot wash and warm wash, wherein cold wash is carried out by adopting room temperature water to wash for 1-3 lattices; acid soap wash is carried out by soap in soap wash solution at the temperature of 40-60 DEG C for 1-2 lattices, the pH value of soap wash solution is 3-5, and consumption amount of detergent in soap solution is 0.6-1.2 g / l; alkali wash is carried out by washing in alkaline solution of which the pH is 8-10 at the temperature of 40-50 DEG C; hot wash is carried out by washing in hot water at the temperature of 90-95 DEG C for 1-2 lattices; and warm wash is characterized in washing in warm water at the temperature of 45-60 DEG C for 1-2 lattices. The invention is suitable for washing technology after active dye pad dyeing and has the advantages that the washing technology carries out soap wash at acid condition, has low soap wash temperature and few washing procedures, and can save a great quantity of water and steam. The rubbing fastness and soaping fastness of washed textile are superior to those of conventional washing technology.

Owner:SHAANXI UNIV OF SCI & TECH

Method for testing tightness of welding lines

InactiveCN101726395AImprove work efficiencyImprove and shorten production cycleDetection of fluid at leakage pointVacuum pressureSoap solution

The invention provides a method for testing tightness of welding lines, comprising the steps as follows: selecting a transparent vacuum box which is communicated with a vacuumizer through a pipeline and is provided with a vacuumatic pressure gauge capable of displaying the vacuum degree in the vacuum box; selecting a welding line required to be tested, cleaning the areas respectively about 20mm away from the welding line required to be tested at the right side and at the left side, coating soap solution on the areas, and covering the vacuum box on the welding line coated with the soap solution; compressing the vacuum box, opening the vacuumizer valve, observing whether bubbles belch out of the surface of the welding line or not when the vacuum degree displayed on the vacuumatic pressure gauge is in the range of 0.015-0.02MPa; if so, determining the welding line to be unqualified and rechecking after repair; and if not, determining the welding line to be qualified. The invention has the advantages of reducing workload of tightness test for docks, effectively shortening the production cycle of slipways, optimizing tight working environment, enabling high altitude sealing working to be operated on flat ground, and leading the operation to be more safe; the test method is simple and reliable, namely the test is accurate, the operation is convenient, and the tightness working efficiency is improved effectively.

Owner:浙江东海岸船业有限公司

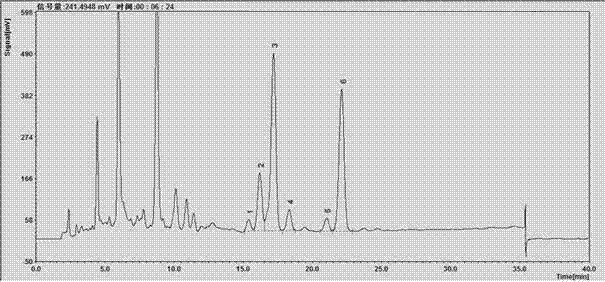

Digital printing process of wool fabric

The invention relates to a digital printing process of a wool fabric. The digital printing process comprises the following steps of (1) carrying out low-pressure plasma pretreatment at the power of 250-350W and the pressure of 20-40Pa for at least 5 minutes; (2) adding alkaline slurry, wherein the alkaline slurry comprises 1-4% of sodium alginate, 5-10% of urea, 0.5-3% of anhydrous sodium sulfate, 0.1-1% of thiourea dioxide, 0.1-0.6% of sodium bicarbonate and 0.5-2% of penetrating agent; (3) carrying out spray printing, and drying at the temperature of 45-70 DEG C for at least 2 minutes; (4) steaming for 50-70 minutes, washing and spraying by using cold water with the temperature of lower than 35 DEG C, and washing by using warm water with the temperature of 40-55 DEG C; (5) soaping at the temperature of 70-90 DEG C, wherein a soaping solution comprises 1-4g / L sodium hydrogen phosphate and 1-6g / L soap flakes, and regulating the pH value of the soaping solution to 8.5-9.5 by using ammonia water; and (6) washing by using warm water with the temperature of 40-55 DEG C, washing by using cold water with the temperature of lower than 35 DEG C, and drying. The printed wool fabric prepared by using the process disclosed by the invention is high in color fastness and uniform in pattern color.

Owner:WUXI DONGXIN WEAVING

Laundry soap solution and preparation method thereof

ActiveCN104818168AEasy to useQuality improvementSurface-active non-soap compounds and soap mixture detergentsFatty alcoholSodium sulfate

The invention belongs to the detergent technical field and provides a laundry soap solution. The laundry soap solution comprises the following components of, by mass, 2 to 15% of mixed fatty acid soap, 2 to 10% of sodium ethoxylated alkyl sulfate, 1 to 5% of fatty alcohol-polyoxyethylene ether, 0.2 to 5% of lauramidopropyl betaine, 0.2 to 5% ofalkyl glycoside, 0.1 to 3% of citrate, 0.1 to 1.0% of chelating agent, 0.5 to 3% of thickening agent, 0.1 to 2% of styrene and acrylate copolymer, 0.1 to 2% of preservative, 0 to 1% of essence and 50 to 90% of water. The laundry soap solution is excellent in detergency and washing performance.

Owner:WALCH GUANGZHOU COMMODITY

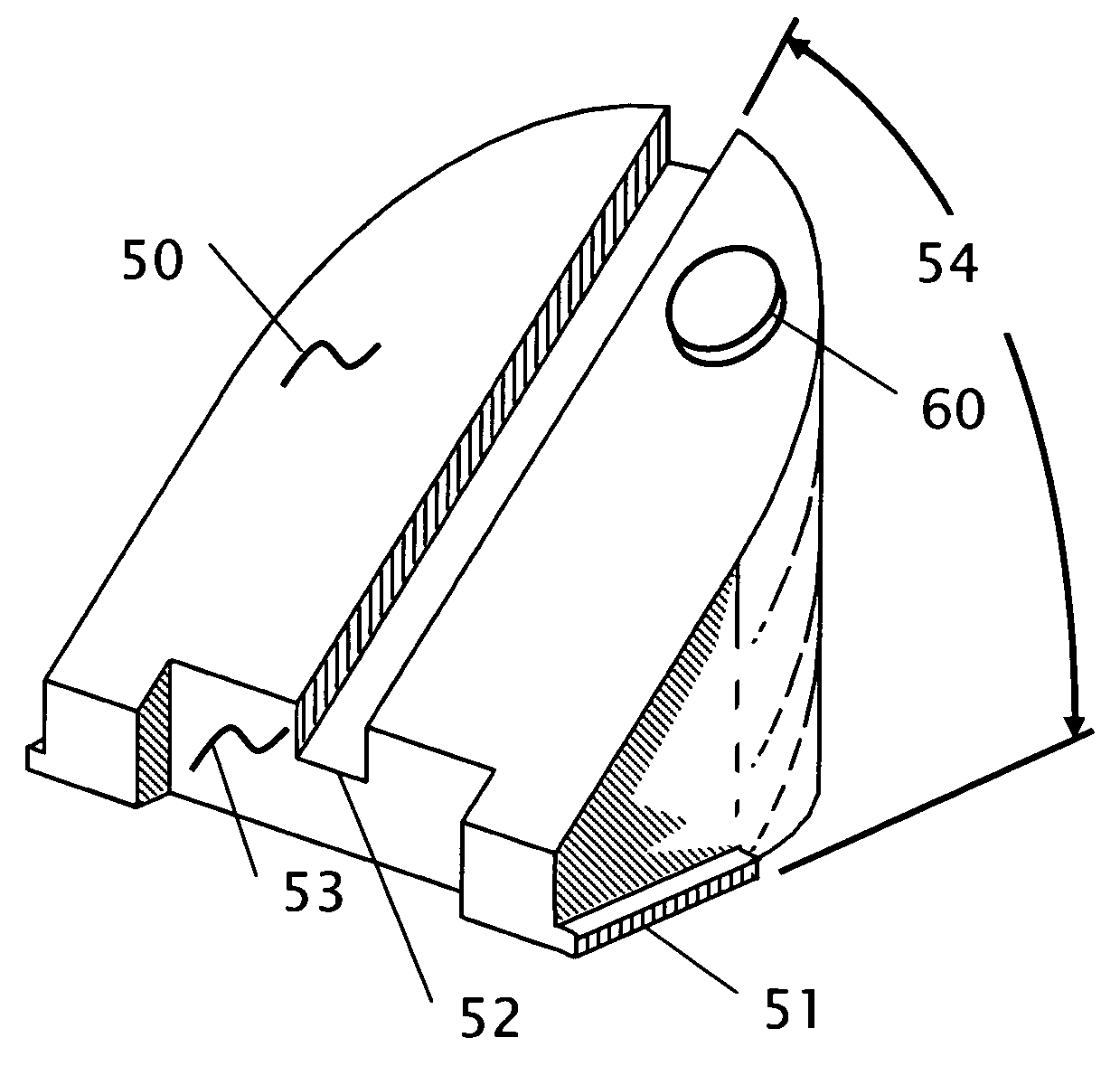

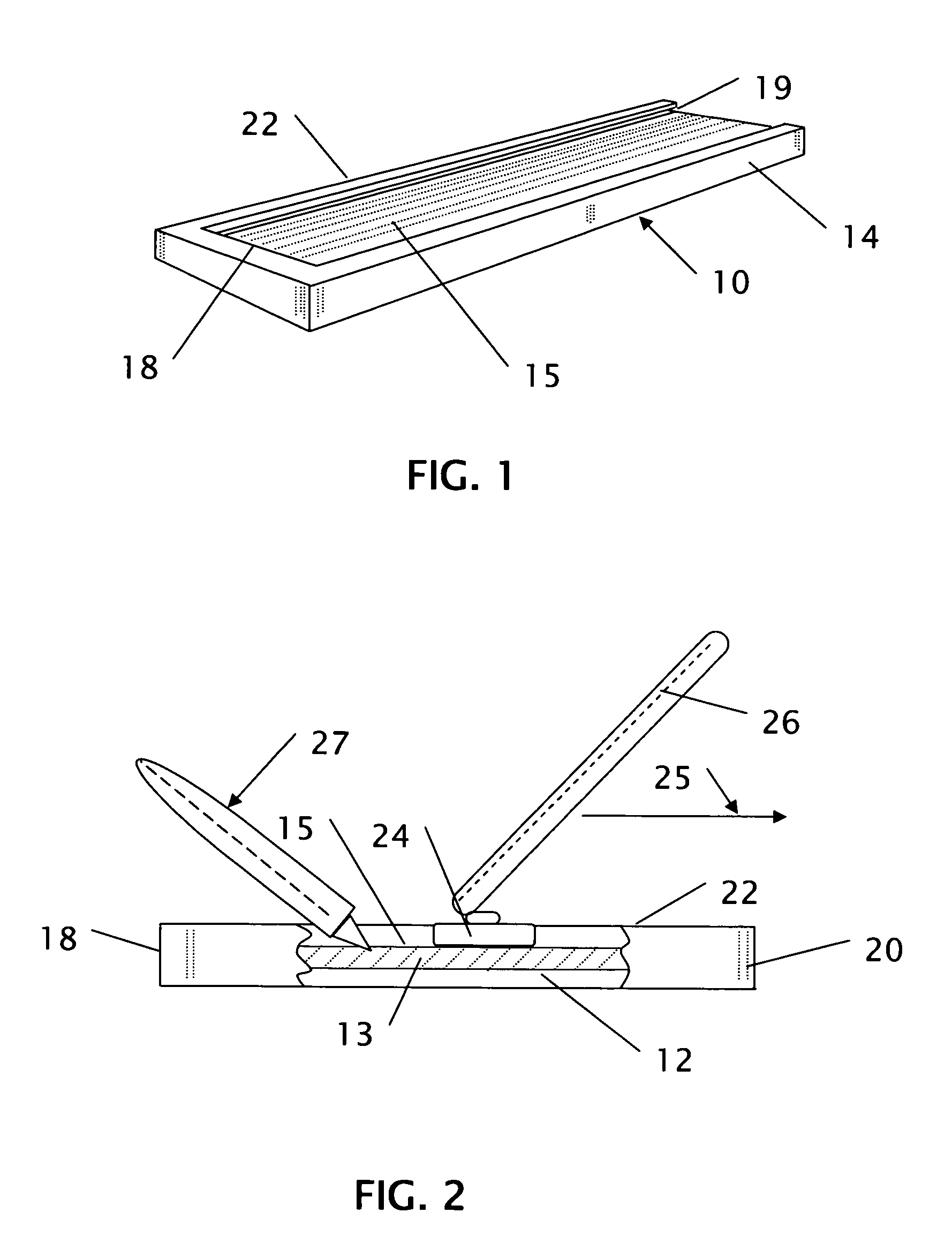

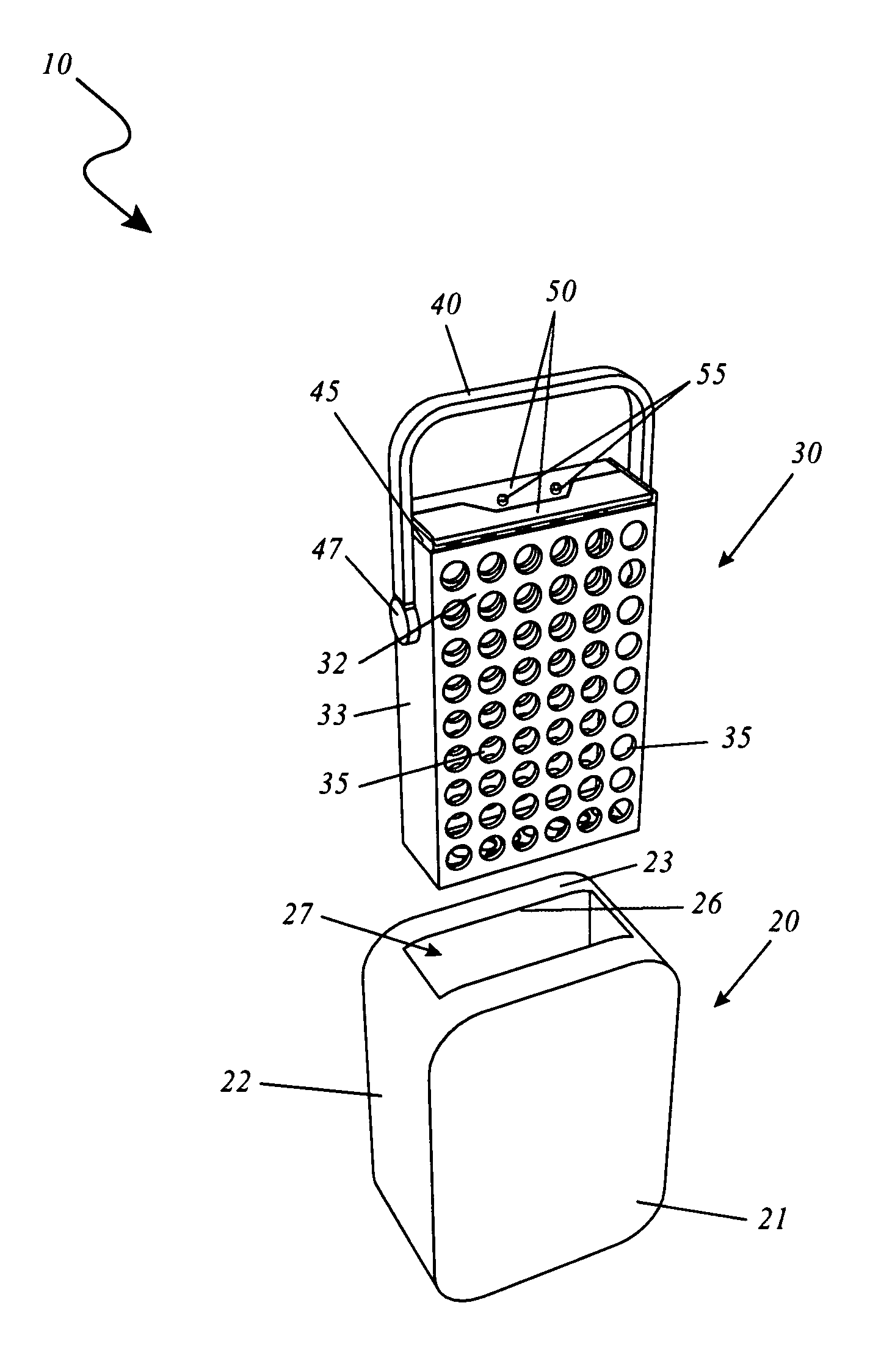

Multi-bladed razor cartridge sharpener with aloe vera gel lubricant

InactiveUS7553218B2Eliminate oxidationRevolution surface grinding machinesCutting toolsRazor stropSoap solution

Apparatus for sharpening and or honing a multi-bladed razor cartridge including a sharpening member, a housing to secure the sharpening member. An aloe Vera or soap solution dispenser provides a lubricant to the sharpening member to lubricate the razor and a housing to limit the travel of the razor on the sharpening member. The sharpening and or honing member is made of a mirrored plate glass secured in a channel within the housing.

Owner:MORITA ANDY

Digital printing process for wool fabric

The invention relates to a digital printing process for a wool fabric. The digital printing process comprises the following steps of (1) carrying out enzyme treatment by using 0.5-1.5g / L protease at the temperature of 45-55 DEG C and the pH value of 7.5-8.5 for 25-60 minutes; (2) adding acidic slurry, wherein the acidic slurry comprises 1-4% of sodium alginate, 5-10% of urea, 3-8% of sodium hydrogen sulfite, 1-6% of ammonium sulfate and 0.5-1.5% of penetrating agent; (3) carrying out spray printing, and drying at the temperature of 45-70 DEG C for at least 2 minutes; (4) steaming for 50-70 minutes, washing and spraying by using cold water with the temperature of lower than 35 DEG C, and washing by using warm water with the temperature of 40-55 DEG C; (5) soaping at the temperature of 70-90 DEG C, wherein a soaping solution comprises 1-4g / L sodium hydrogen phosphate and 1-6g / L soap flakes, regulating the pH value of the soaping solution to 8.5-9.5 by using ammonia water; and (6) washing by using warm water with the temperature of 40-55 DEG C, washing by using cold water with the temperature of lower than 35 DEG C, and drying. The printed wool fabric prepared by using the process disclosed by the invention is high in color fastness and uniform in pattern color.

Owner:WUXI DONGXIN WEAVING

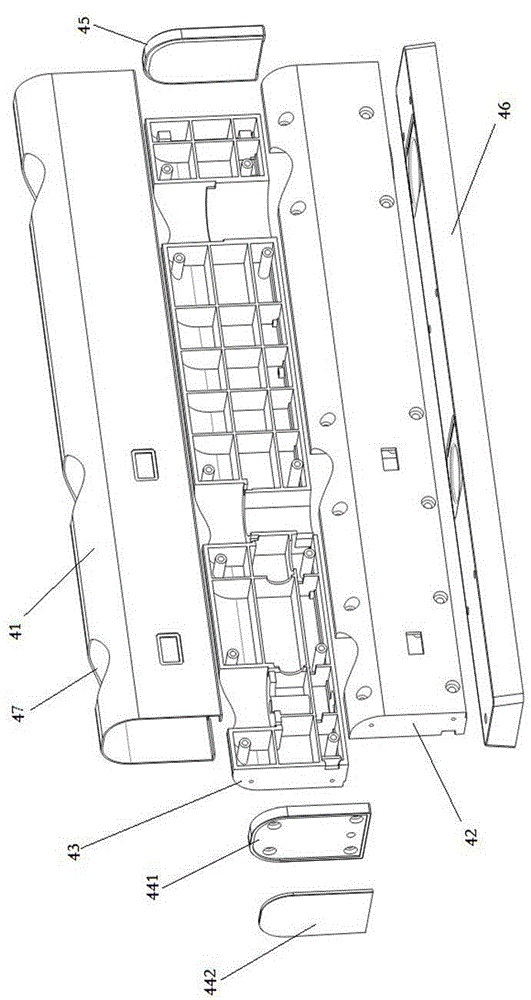

Intelligent hand washing auxiliary equipment

Owner:上方能源技术(杭州)有限公司

Initial refining process of macular cocoons

InactiveCN102134755APromote expansionEasy to spinAnimal materialDe-gumming silkSoap solutionAqueous solution

The invention discloses an initial refining process of macular cocoons, which is characterized in that the initial refining process is performed according to the following steps: soaking the macular cocoons in water solution at the temperature of 100 DEG C, using soda ash to regulate pH value to 10, soaking for 12 hours, soaking the macular cocoons after removing pupae in the water solution at the temperature of 60 DEG C, using the soda ash to regulate the pH value to 7.5, soaking for 10-12 hours, using a scutching machine to scutch the wet macular cocoons after low-temperature soaking, placing cocoon filaments after dehydration into the water solution at the temperature of 60-70 DEG C, adding hydrogen peroxide for bleaching, placing the cocoon filaments after bleaching into a refining cylinder, adding water, heating with steam to 60-70 DEG C, adding 105 textile soap solution which accounts for 2% of the weight of raw materials for refining for 1 hour, flushing the well refined cocoon filaments by using an automatic flushing machine, adding water for soaking the cocoon filaments after dehydration, adding a spun silk finishing agent which accounts for 4% of the weight of the raw materials, soaking for half an hour, drying the cocoon filaments after dehydration with the steam, selecting and removing impurities in the cocoon filaments after drying, and classifying.

Owner:NANCHONG YINHAI SILK

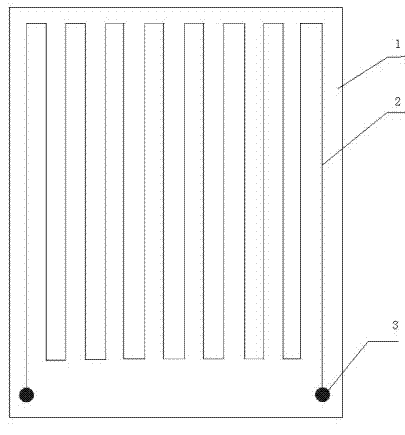

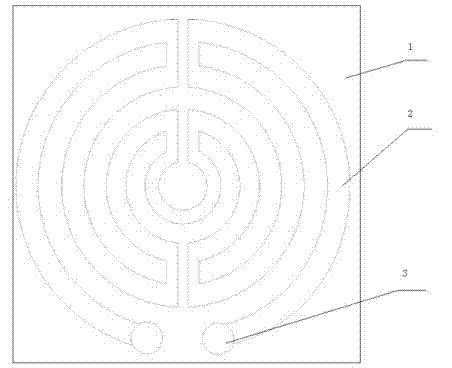

Heating flexible transparent thin film printed with silver paste and carbon paste and production method thereof

InactiveCN103209503AEvenly distributed by designNo corrosionHeating element materialsSilver pasteSoap solution

The invention relates to the technical field of heating thin films and discloses a heating flexible transparent thin film printed with silver paste and carbon paste and a production method thereof. The thermostatic heating flexible transparent thin film comprises a TIE (titanium ethylene) transparent plastic thin film, the conductive silver paste and the carbon paste, the TIE transparent plastic thin film is provided with a conductive heating thin film layer line which is printed with the conductive silver paste and the carbon paste, and the conductive heating thin film layer line is zigzag. The heating flexible transparent thin film printed with the silver paste and the carbon paste is applicable to high-technology applications in the agricultural and the medical fields. The line design of the conductive heating thin film layer is even; after the conductive heating thin film layer is powered for heating, the heat density is large, and the heat is even; the base material thin film is transparent, flexible and foldable; and the thickness can be from 0.02 to 0.05. The printed conductive heating thin film layer cannot drop even being soaked for 24 hours and cannot be eroded in an alkaline soap solution; and no broken line exists after carrying out a plurality of rub tests are carried out, so that the heating flexible transparent thin film printed with the silver paste and the carbon paste has the advantages of low pressure, low temperature, low manufacture cost, usage safety and convenience and , reliable quality and the like.

Owner:LUOYANG CLOUDS NET TECH

Process for extracting silk extract from silkworm cocoon or silk

A process for extracting the silk extract from silkworm cocoon and silk includes adding the silkworm cocoon and silk to weakly alkaline or neutral soap solution, boiling for degumming, and immersing in solution of acetic acid to obtain high-purity silk extract. Its advantages are no damage to silk extract, high purity (more than 98%), short process and low cost.

Owner:周福康

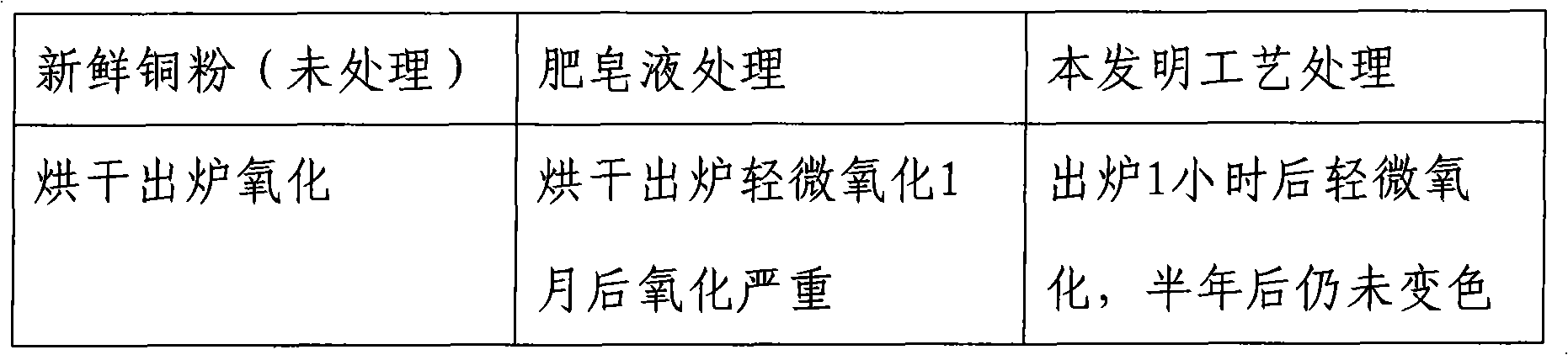

Protective liquid for preventing oxidation of copper powder, and preparation method and using method thereof

InactiveCN101935839AImproves the effect of oxidation discolorationEasy to oxidizePigmenting treatmentChemical inhibitorsAlcoholBenzotriazole

The invention provides conveniently operated and prepared protecting liquid for preventing the oxidation and color change of copper powder, and a preparation method and a using method thereof. The preparation method comprises the following steps of: preparing solution from benzotriazole (BTA) and absolute ethyl alcohol according to a certain proportion; and dissolving the solution into 3 to 4 weight percent of soap solution to prepare the protective liquid. The using method comprises the following steps of: impregnating the copper powder to be treated into the protective liquid, and performing stirring, dehydration, washing and drying to obtain the protected copper powder. The protective liquid can remarkably improve the effect of preventing the oxidation and color change of the copper powder, and is convenient to prepare.

Owner:六安市晖润新材料有限公司

Pure traditional Chinese medicine hand-washing soap solution with skin-care and sterilization effects

InactiveCN104357242AWith washing functionEnhanced EmollientSkin careAlkali/ammonium soap compositionsPotassium hydroxideCoptis chinensis

The invention relates to a pure traditional Chinese medicine hand-washing soap solution with skin-care and sterilization effects, which mainly comprises a traditional Chinese medicine solution and a soap solution raw material. The traditional Chinese medicine solution is prepared from the following components in parts by weight: 40 parts of Coptis chinensis, 40 parts of isatis root, 40 parts of kuh-seng and 40 parts of radix stemonae. The soap solution raw material is prepared from the following components in parts by weight: 125 parts of coconut oil, 100 parts of palm oil, 110 parts of wheat germ oil, 90 parts of sunflower oil, 75 parts of olive oil, 10 parts of tea tree essential oil, 98 parts of potassium hydroxide and 245 parts of water.

Owner:骆志明

Process for producing lysine by soaking water of maize

The invention discloses a producing method lysine through soaping maize, which is characterized by the following: adopting maize soaping solution instead of soy hydrolysate to produce lysine; reducing raw material cost and mating equipment investment; alleviating pressure of effluent disposal in the maize synthetic manufacturing procedure.

Owner:SHANDONG XIWANG SUGAR

Sponge with soap sleeve and method of use thereof

A sponge-like device with an internal cavity for receiving a carrier for liquid and solid soaps. The exterior of the carrier has a variety of design models and shapes; however, the carrier is sized to receive a conventional solid bar of soap or an amount of liquid soap. The carrier has a plurality of drain holes to allow the soap solution, as it mixes with the water during bathing, to drain onto the sponge. The use of the device is for washing oneself, children, invalids, as well as for scrubbing household surfaces like decks and siding, and also for cleaning motor vehicles all without the disadvantages associated with separate sponges and soap material.

Owner:CUTLER RENEE J

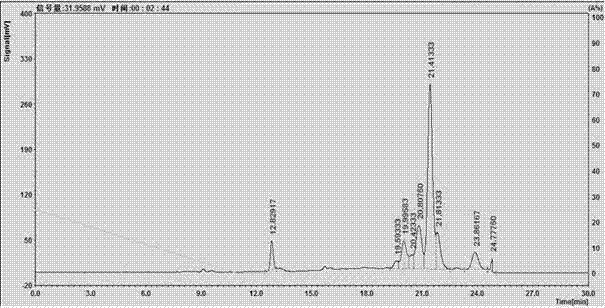

Preparation method for preparing sodium copper chlorophyllin from gingko leaves

ActiveCN104725387APrevent precipitationQuick and complete responseHydroxy compound separation/purificationSolventAbsorbance

The invention relates to a preparation method for preparing sodium copper chlorophyllin from gingko leaves. The preparation method comprises the following main steps: performing extraction and concentration; performing saponification and copper substitution; extracting and removing impurities from the No.6 solvent oil under an alkaline soap solution; removing ginkgolic acid; and forming a salt. According to the preparation method, before, during or after leaching gingko flavones by using a polar solvent, a non-polar solvent is used as a leaching solvent to perform leaching on chlorophyll and other oil-soluble substances; a mixed solvent is adopted as a dissolvent to perform saponification, so that the existence and generation of a deposit in the soap solution are effectively avoided, and then the reaction can be quickly and completely performed; and sodium copper chlorophyllin is prepared by a method comprising the processes of alkaline saponification and copper substitution which are performed simultaneously, so that esterification and deterioration of chlorophyll copper acid during acidic copper substitution are avoided. According to the product obtained by the preparation method provided by the invention, the E1%1cm(405nm+ / -nm) is more than 900, the absorbance ratio is equal to 3.2-3.6, the complex copper content is more than 6%, the nitrogen content is more than 5.5%, and the ginkgolic acid content is less than 50ppm.

Owner:ZHEJIANG DELEKANG FOOD CO LTD

Rust-removing and spot-removing method for synchronizer gear ring

InactiveCN103602998ANo flow marksNo re-corrosionMetallic material coating processesSoap solutionEngineering

The invention discloses a rust-removing and spot-removing method for a synchronizer gear ring. The method comprises steps of removing oil; performing rust-removing and spot-removing treatment by using a rust-removing and spot-removing aqueous solution; rinsing the treated synchronizer gear ring in clear water; dipping the rinsed synchronizer gear ring in an aqueous soap solution; passivating the dipped synchronizer gear ring in a passivation solution; dipping the passivated synchronizer gear ring in water having a temperature of 60-80 DEG C; and drying. The method is simple in operation and low in investment. By the method, the synchronizer gear ring can regain a surface coating with high quality. The synchronizer gear ring treated by the steps is uniform and glossy and free from flow marks and environment pollution, and is passivated without the chromate. The synchronizer gear ring treated by the method cannot be corroded again in a storing process.

Owner:长春永新汽车同步器有限公司

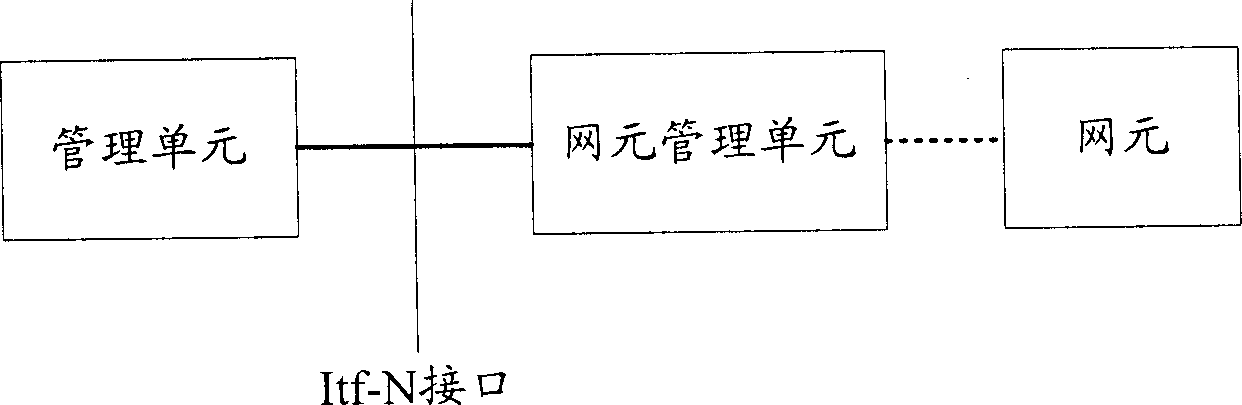

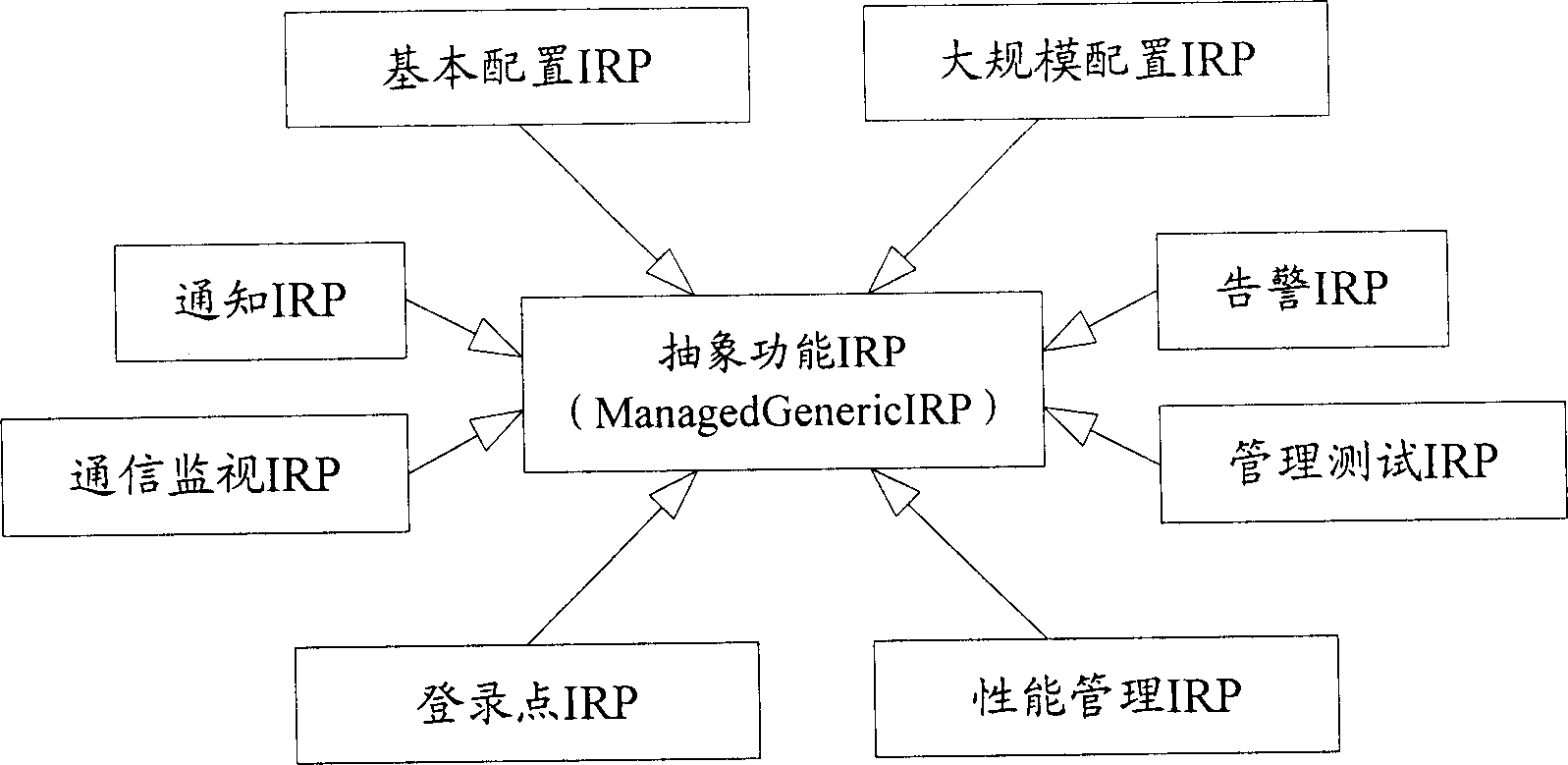

Information service hierarchy inheritance relation realizing method in network management interface

ActiveCN1801739ABasic management operations are called correctlyMeet description requirementsData switching networksSoap solutionSerialization

The invention discloses a realization method for information service hierarchy inheritance relation in network interface used in network management system composed of SOAP interface module and inheritance IRP module with WSDL / SOAP solution scheme. Wherein, defining WSDL document to inherit IRP and realize directly the basic management operation on inheritance IRP module; according to IS hierarchy inheritance relation built in WSDL document, taking sequence / inverse sequence between Web network and IRP module for basic management operation information by SOAP interface module. This invention can satisfy the IS hierarchy description request of IRP.

Owner:HUAWEI TECH CO LTD

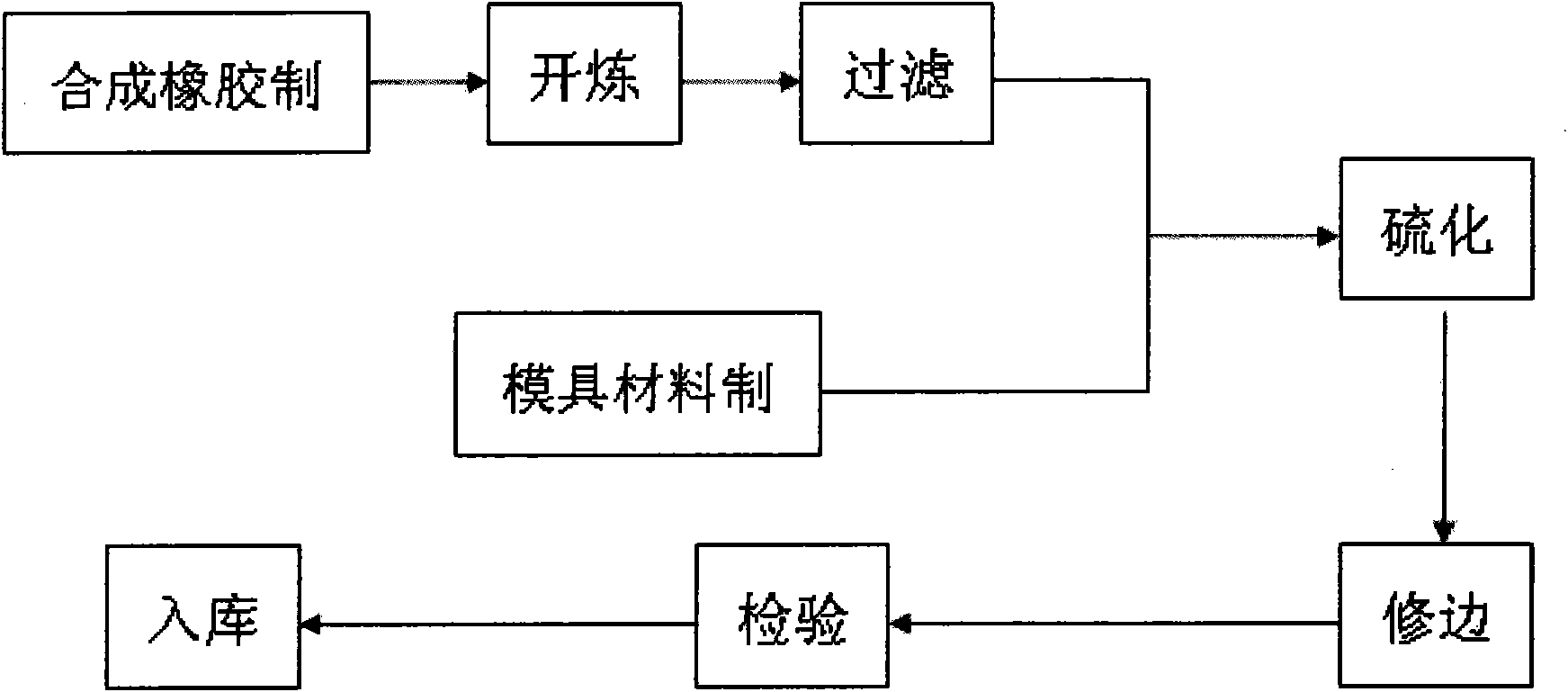

Rubber assembly material for bellows drainpipe of roller washing machine and manufacturing process thereof

InactiveCN101671462AGood soap resistanceGood resistance to copper ionsOther washing machinesTextiles and paperSoap solutionPulp and paper industry

The invention relates to a rubber assembly material for a bellows drainpipe of a roller washing machine and a manufacturing process thereof, and the rubber assembly comprises the main raw materials ofethylene propylene diene monomer (EPDM), pot clay, NKL-9, paraffin hydrocarbon oil and the like. The bellows drainpipe product treated by the process has fine soap solution resistant performance, copper ion resistant performance, vapor resistant performance and good 2500V-resistant insulation resistance performance, thus ensuring nice tightness and safety durability performance. The invention improves soap solution resistance and vapor resistance for the products, solves the technical problems such as copper ion discoloration resistance, punctured 2500V-resistant insulation resistance products and the like. The products conform to environmental directive requirement of EU, provide a safe and reliable clothes-washing environment for consumers, have fine vibration reducing performance, andprovides powerful guarantee for the roller washing machine to develop toward mute direction. The successful development of the products replaces the imported medium-high end roller washing machine bellows drainpipes, realizes products localization and improves the competitive strength for the home-made roller washing machines in the market.

Owner:ANHUI ZHONGDING SEALING PARTS

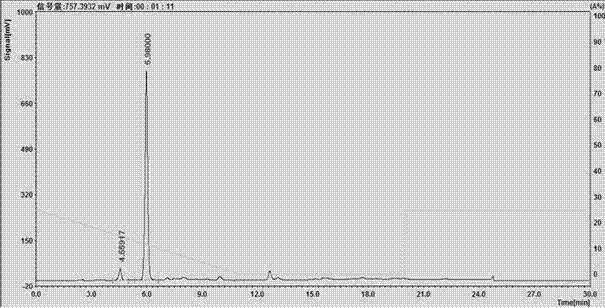

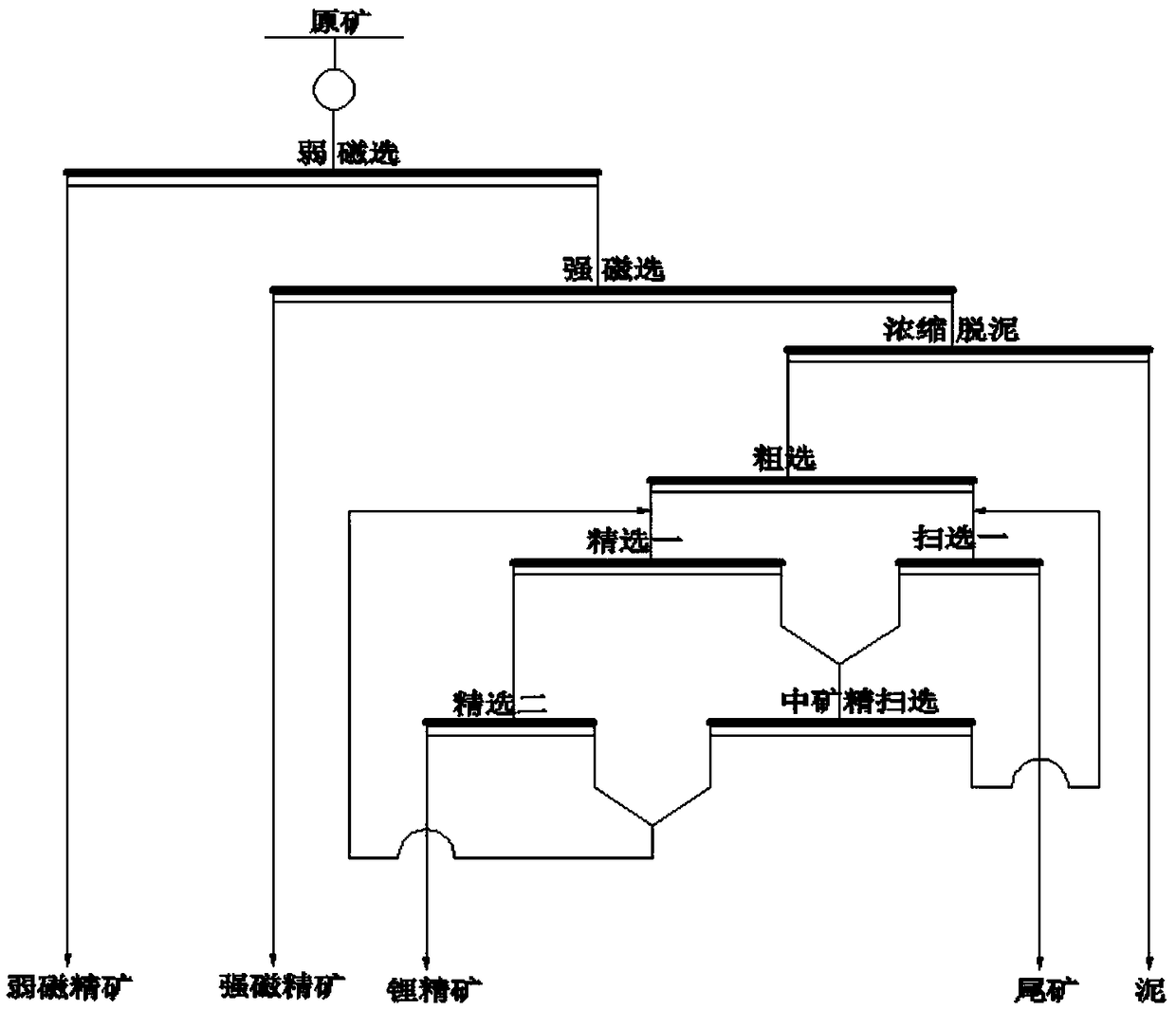

Beneficiation method for spodumene ore

ActiveCN109127117AThe flotation process is stableGood beneficiation indexWet separationDecompositionEngineering

The invention discloses a beneficiation method for spodumene ore. The spodumene ore is crushed and ground, ore pulp obtained after ore grinding is sequentially subjected to low-intensity magnetic separation and high-intensity magnetic separation, and weak-magnetism concentrates and strong-magnetism concentrates are obtained; discharged strong-magnetism tailings are fed to the flotation operation after being subjected to concentration and desliming, and the flotation operation process includes primary roughing, secondary scavenging and secondary fine selecting; calcium fatty acid prepared through the double decomposition reaction of a sodium fatty acid soap solution and a calcium chloride water solution is adopted as a collecting agent, the Li2O grade in the finally-obtained lithium concentrate reaches up to 5.7%-6.2%, and the recycling rate is 78%-88%. According to the beneficiation method, the beneficiation technology process is simple, stability and reliability are achieved, applicability is high, and the laboratory index highly conforms to the industry application index; and the defect that in the existing spodumene ore beneficiation technology, the difference between the industry application index and the laboratory index is large is overcome; and the adopted collecting agent has excellent properties that selectivity is good, the collecting capability is high, and environment friendliness is achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

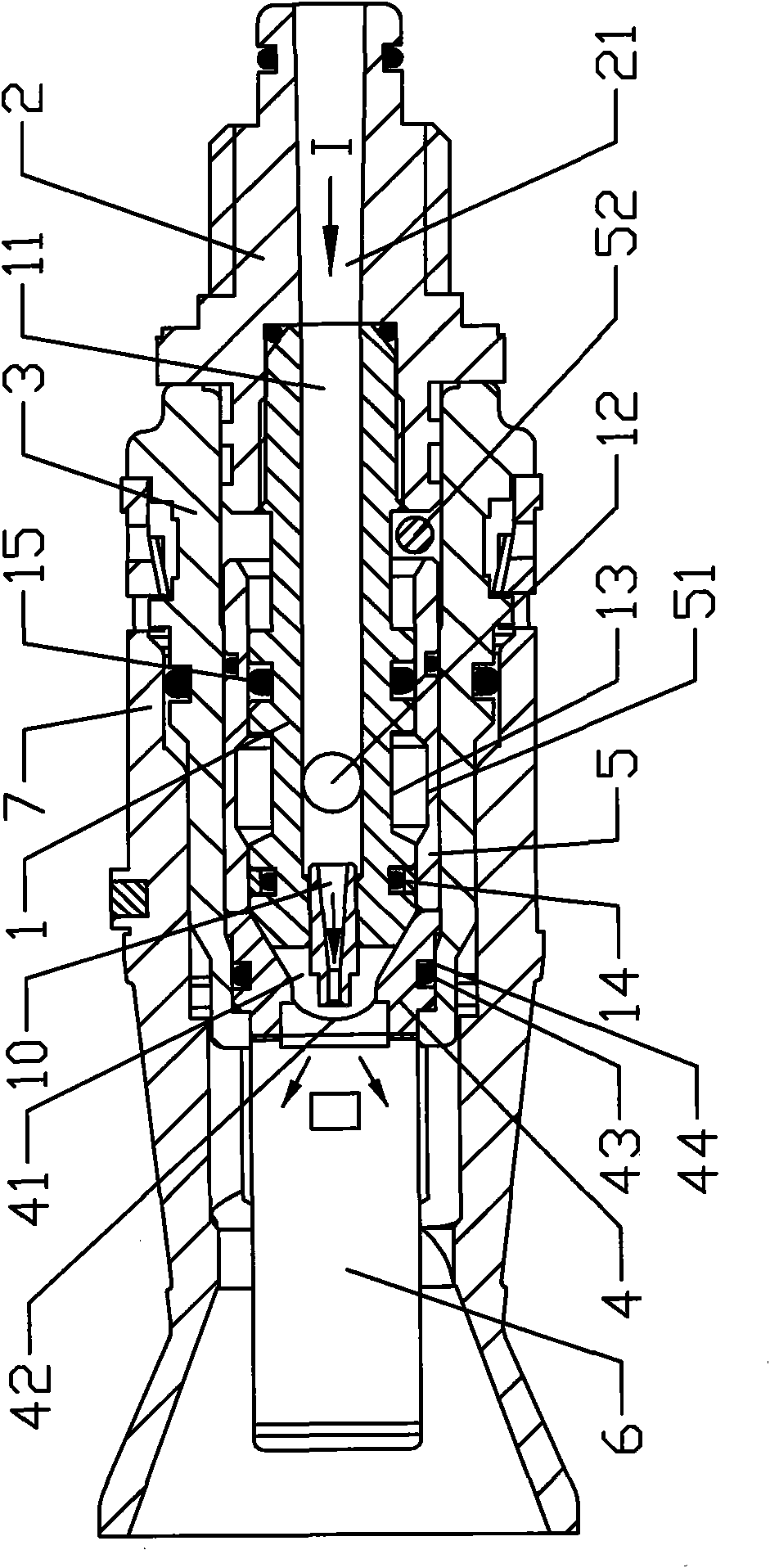

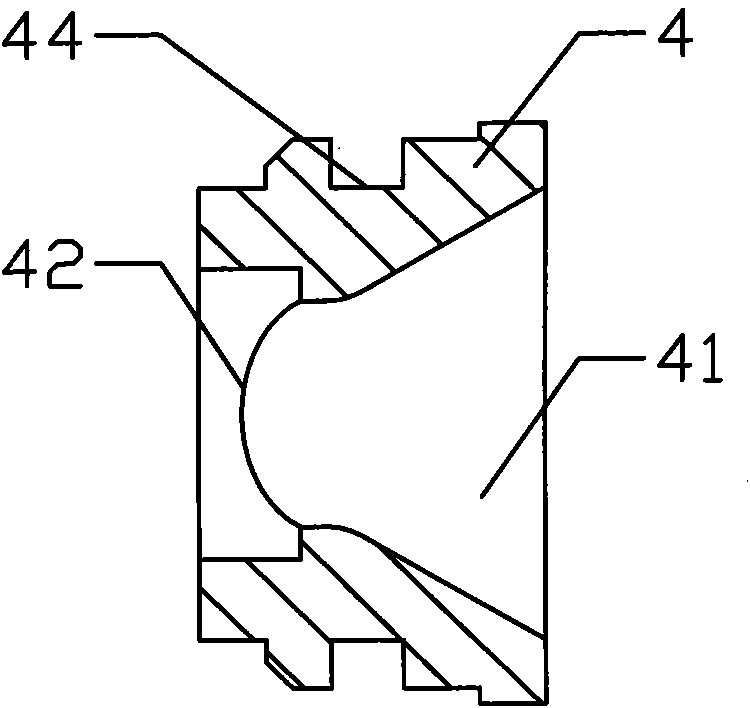

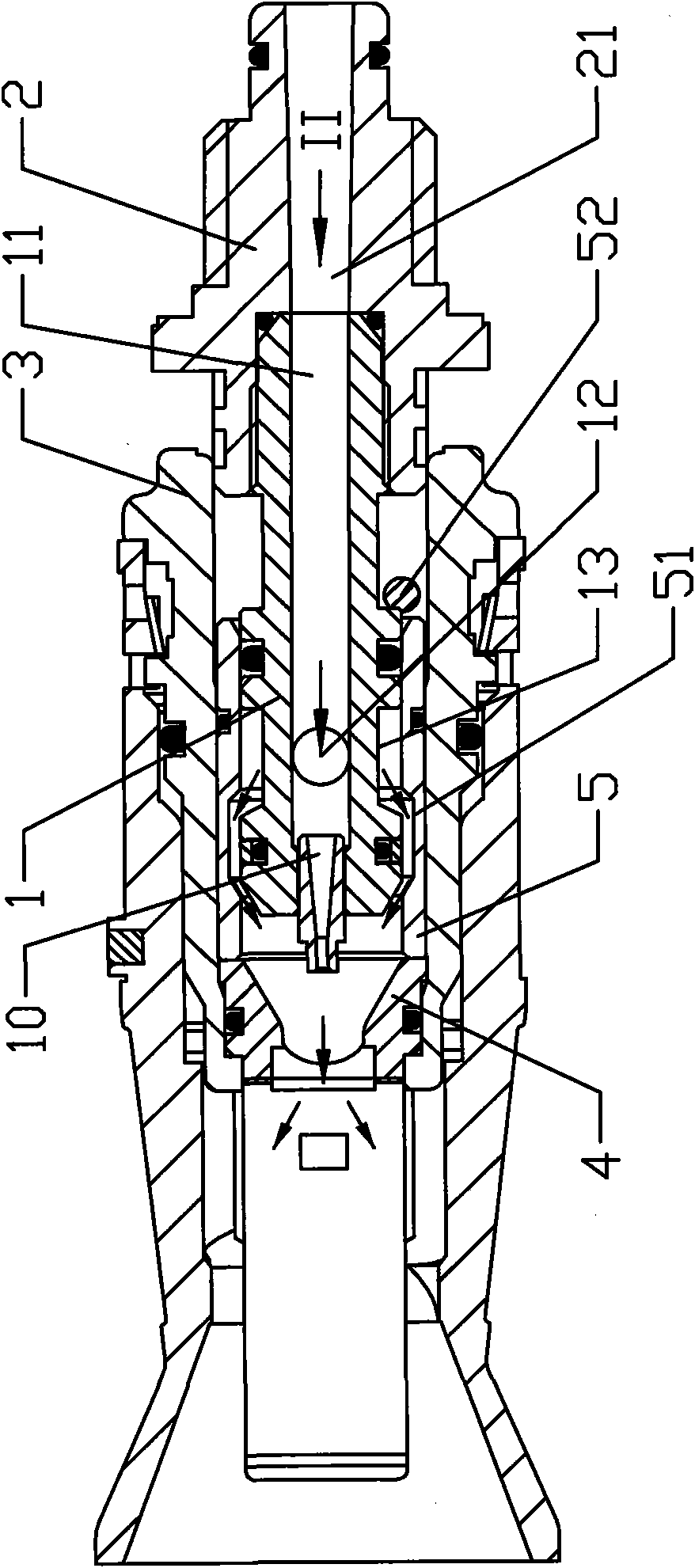

Combined gun head of high pressure gun

InactiveCN102101080ASave resourcesImprove cleaning efficiencySpray nozzlesLiquid spraying apparatusSoap solutionWater resources

The invention discloses a combined gun head of a high pressure gun, which comprises a gun head core and a rear seat connected at the rear end of the gun head core, wherein the front end of the gun head core is provided with a spray head; the gun head core is provided with a gun head sleeve slipping back and forth along the gun head core; the gun head sleeve is propped against the rear seat in a normal state; a passage I through which water flows is formed in the rear seat; a passage II communicated with the passage I is formed in the gun head core; a nozzle matched and fixedly connected with the gun head sleeve is arranged in the gun head sleeve; a nozzle hole is formed in the nozzle and communicated with the outside; the spray head extends into the nozzle hole; and a sealing structure I is arranged between the nozzle and the gun head sleeve. The combined gun head has reasonable structure, is convenient to use, keeps the sprayed water flow more uniformly, saves soap solution and water resource at the same time of improving the cleaning efficiency, and is more energy-saving and environmentally-friendly.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

Moisturizing spot-relieving handmade soap and production method thereof

InactiveCN104774699AHas moisturizing and lightening propertiesReduce exception stackingShaping soapSkin careVegetable oilCutin

The invention discloses a moisturizing spot-relieving handmade soap which is prepared from the following materials in parts by weight: 450-550 parts of base vegetable oil, 64-78 parts of sodium hydroxide, 90-110 parts of distilled water, 22.5-27.5 parts of brown sugar, 22.5-27.5 parts of white poria fine powder, 45-55 parts of honey and 45-55 parts of patchouli extracting solution. The production method of the handmade soap comprises the following steps: saponifying the 38-42-DEG C base vegetable oil with a NaOH water solution with the same temperature, when the soap solution achieves the thick state, adding the patchouli extracting solution, adding the mixture of the brown sugar, white poria fine powder and honey, stirring uniformly, pouring into a mold, keeping the temperature at 38-42 DEG C for 48 hours, demolding and airing. The handmade soap has unique and reasonable material proportioning, has the effects of lightening the skin melanin, mildly eliminating cutin, moistening the skin, keeping the moisture and relieving the spot, and has more obvious spot-relieving effect when being used for a long time.

Owner:SHAANXI UNIV OF TECH

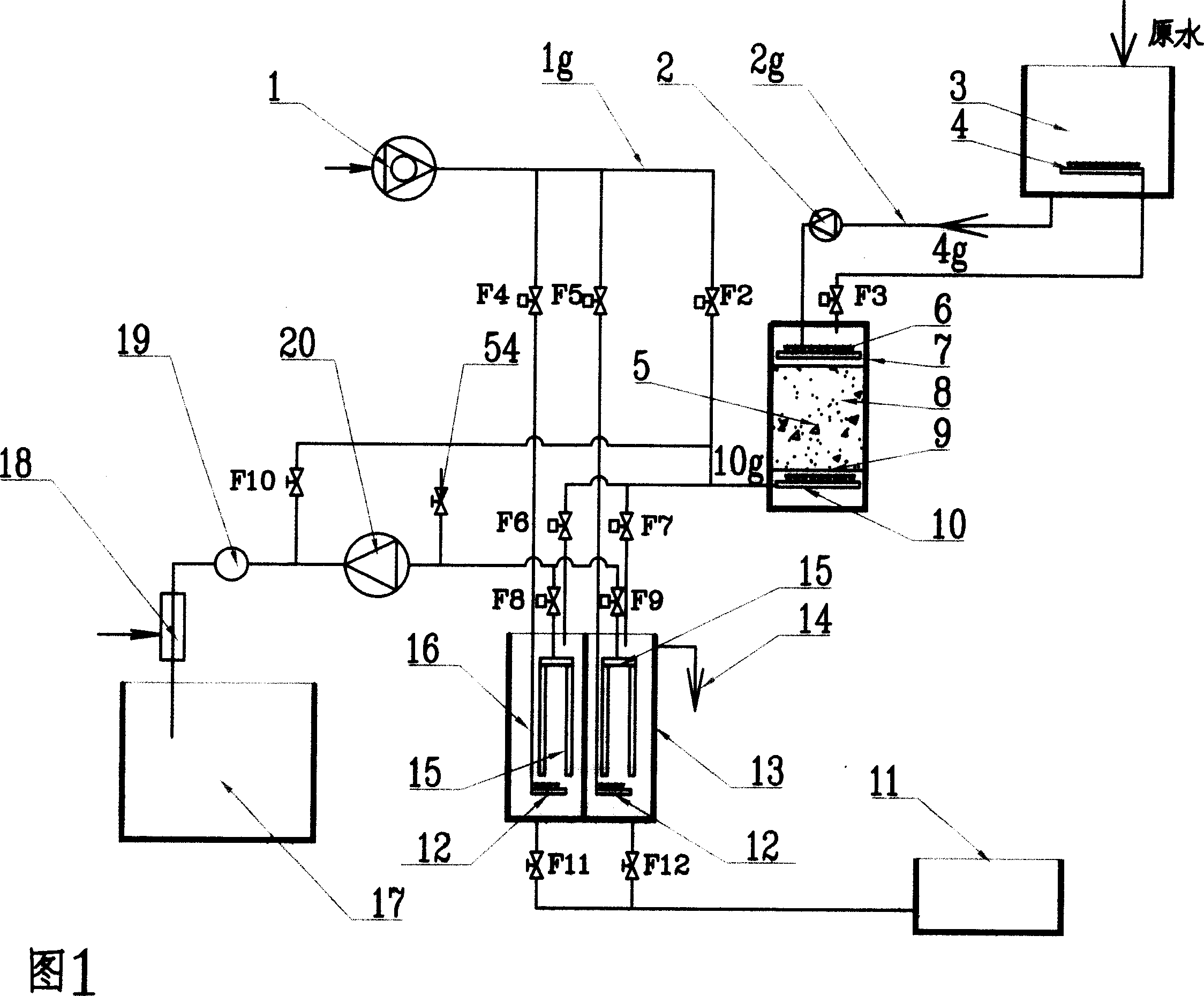

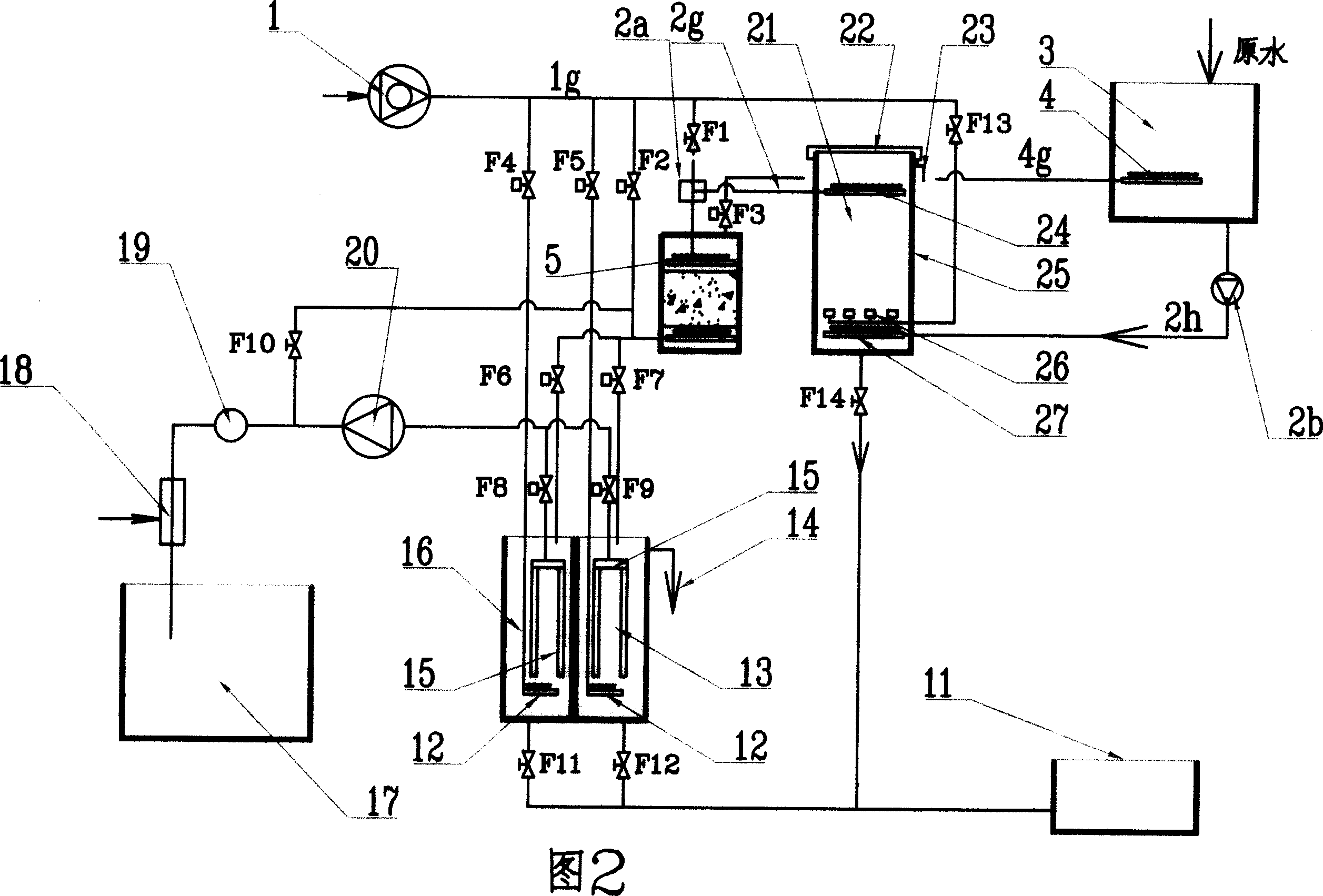

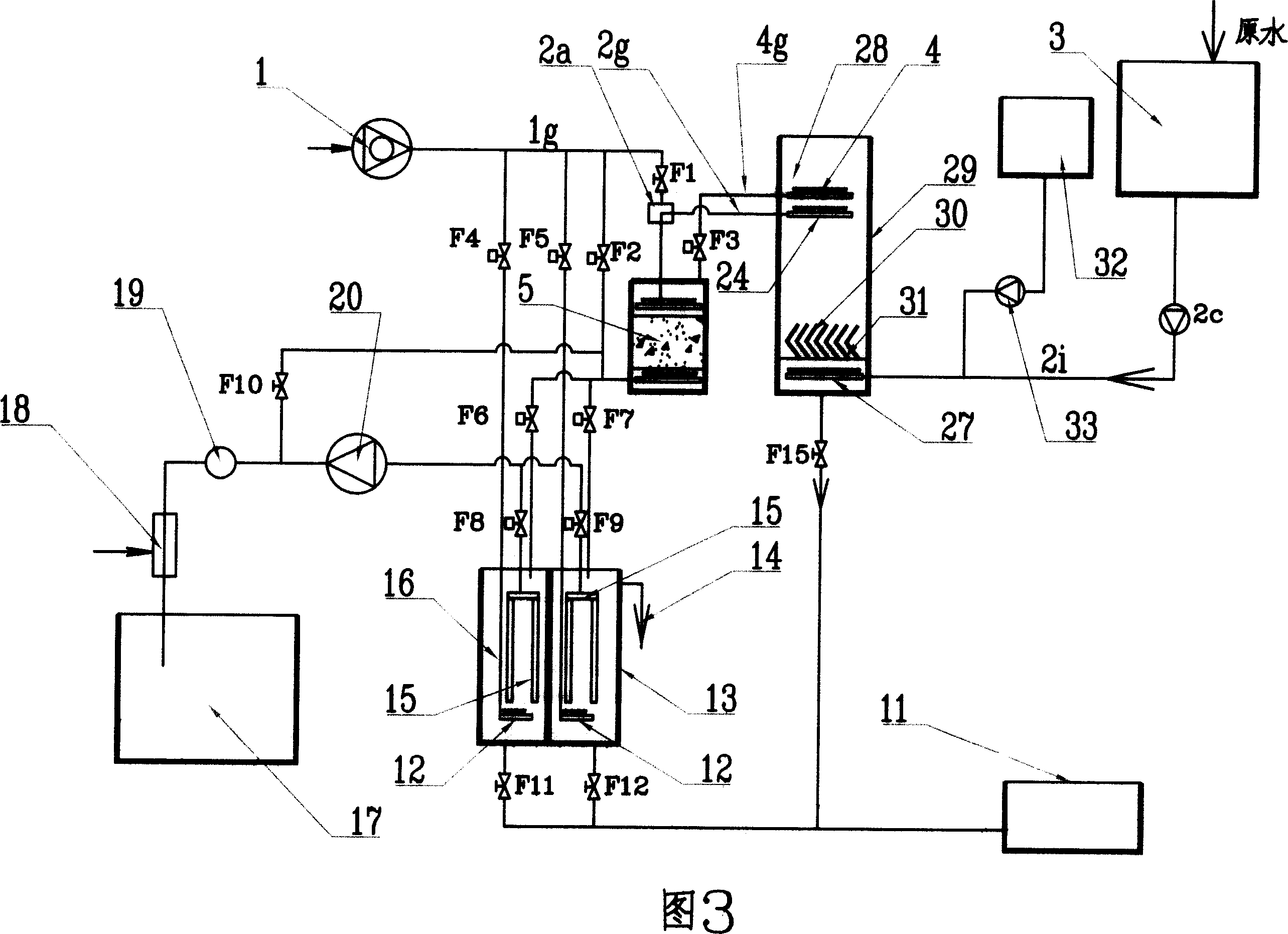

Separator and immersion membrane bioreactor combined water purifying device and system

InactiveCN101033107AAvoid stickingImprove anti-pollution performanceMultistage water/sewage treatmentWaste water treatment from bathing facilitiesFiberAeration system

This invention relates to a clean water device and a system including an immerged film bio-reactor, water, an aeration system, a separator, a technics flow and pipelines, a water safeguarding system, a chemical flush system and a program control system, in which, at least a separator is connected between an original pump of an adjusting basin and the original pipe of the reaction basin of the immerged film bio-reactor, which is suitable for poor water quality with many combos of oil and waste-soap solution with humanbody fat in particular and increases the ability of anti-pollution of the immerged hollow fiber film bio-reactor, and this filter separator can be taken as a generator for collecting and growing biochemical films.

Owner:天津市石化通用机械研究所有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com