Protective liquid for preventing oxidation of copper powder, and preparation method and using method thereof

A technology of oxidation protection and protection solution, which is applied in chemical instruments and methods, compositions for inhibiting chemical changes, fibrous fillers, etc., can solve problems such as short protection period, and achieve the effects of convenient operation, strong activity and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

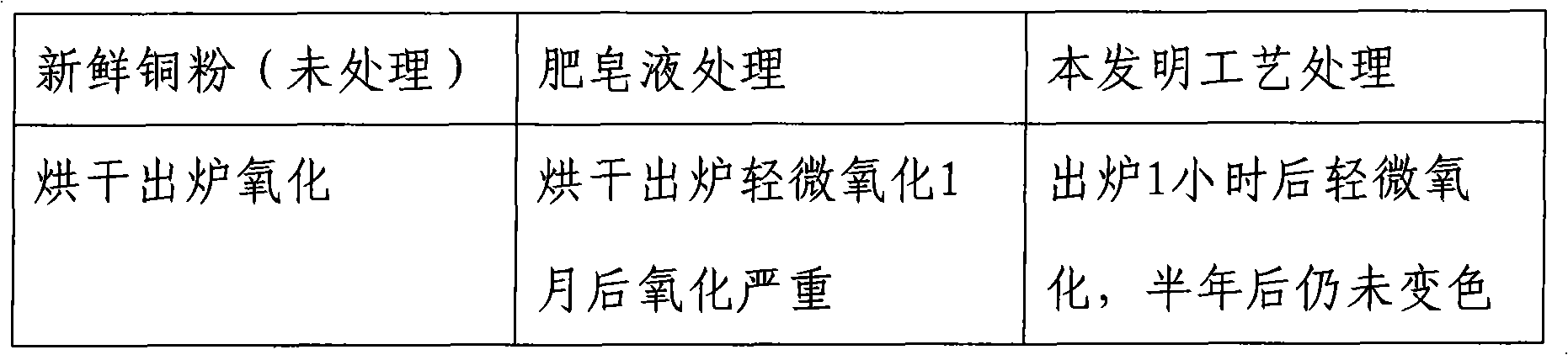

Examples

Embodiment Construction

[0019] The protective solution for preventing copper powder oxidation and discoloration of the present invention comprises (1) 100-200 grams of benzotriazole BTA, (2) 50-100 milliliters of absolute ethanol; (3) 3-4% soap solution 80-120 ml.

[0020] The benzotriazole BTA is firstly dissolved in the ethanol solution, the BTA is completely dissolved in the absolute ethanol, and then the solution is dissolved in 3-4wt% soap liquid.

[0021] The copper powder to be treated is immersed in the protective solution of the technical formula of the present invention for anti-oxidation treatment, and after stirring for a certain period of time, the protected copper powder is obtained by dehydration, washing and drying. Among them, the washing is washed three times with ordinary tap water, and then put into vacuum drying after dehydration. For example:

[0022] An electrolytic copper powder mainly has a dendritic structure, the particle size is mostly concentrated around -250 mesh, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com