Patents

Literature

710results about How to "Avoid small quantities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

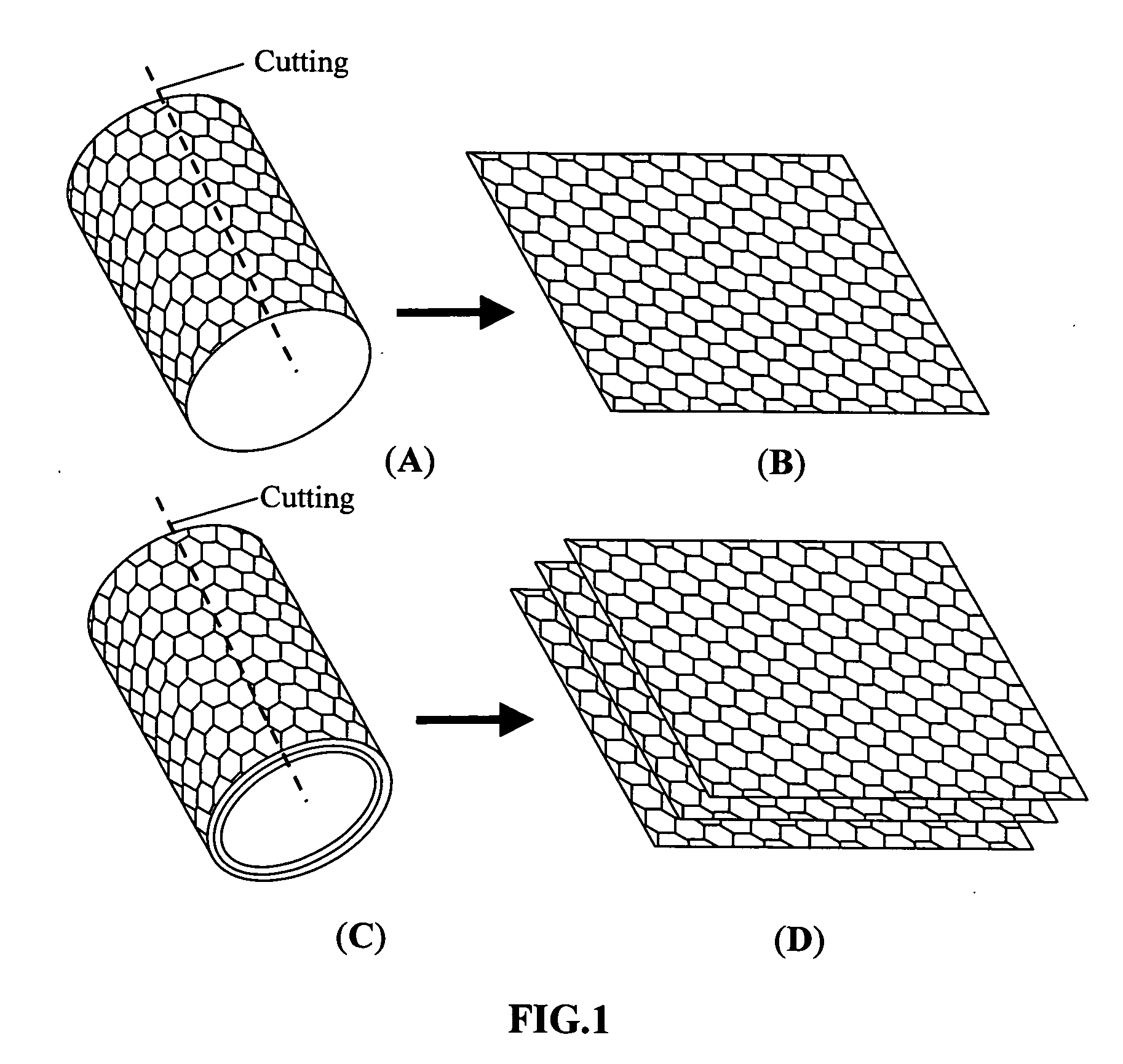

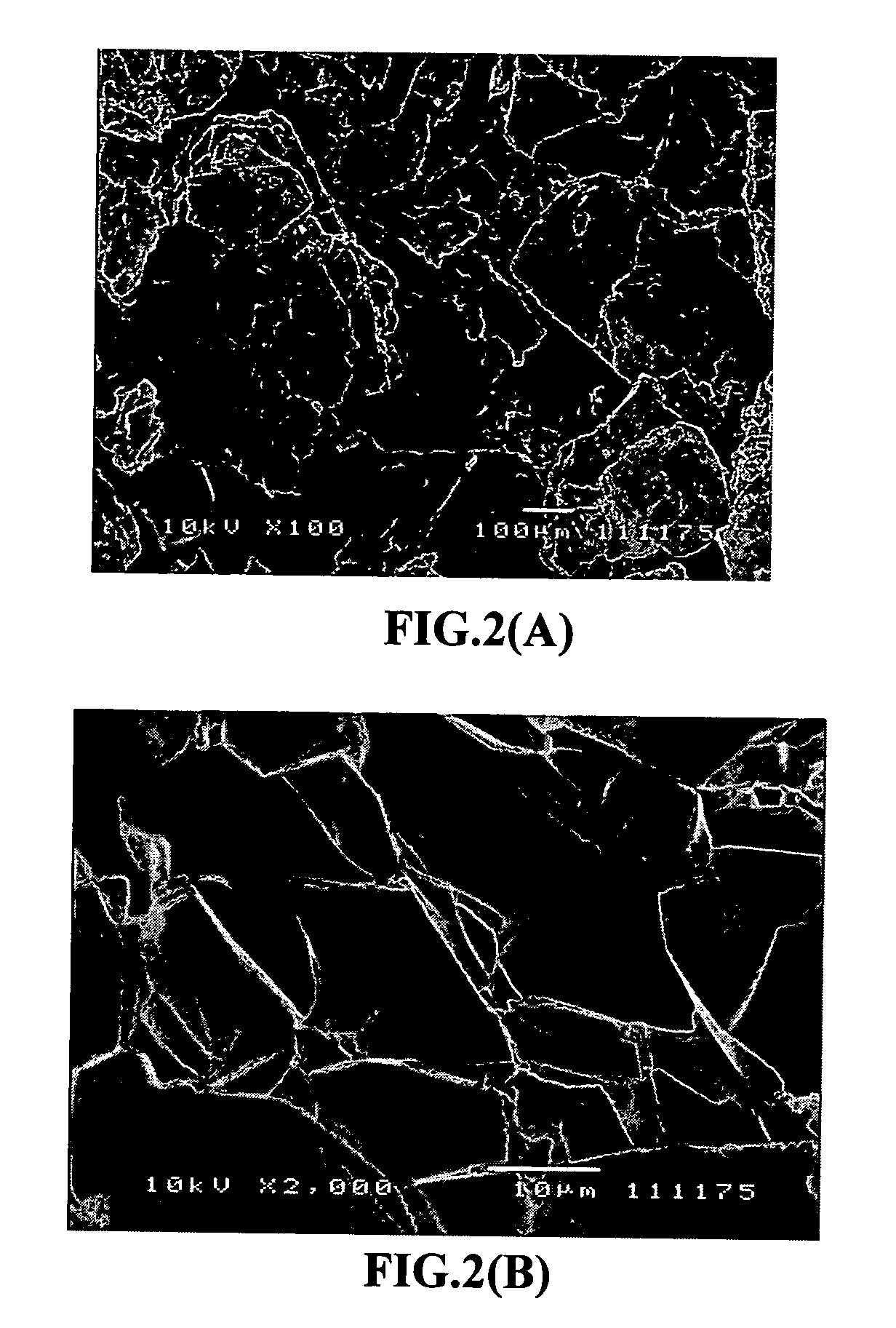

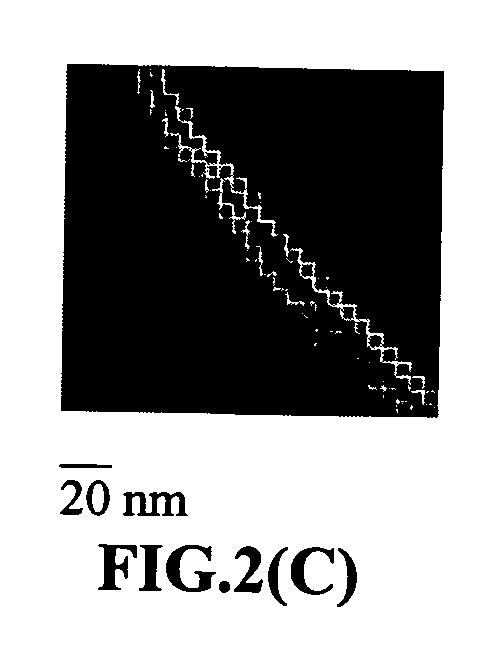

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

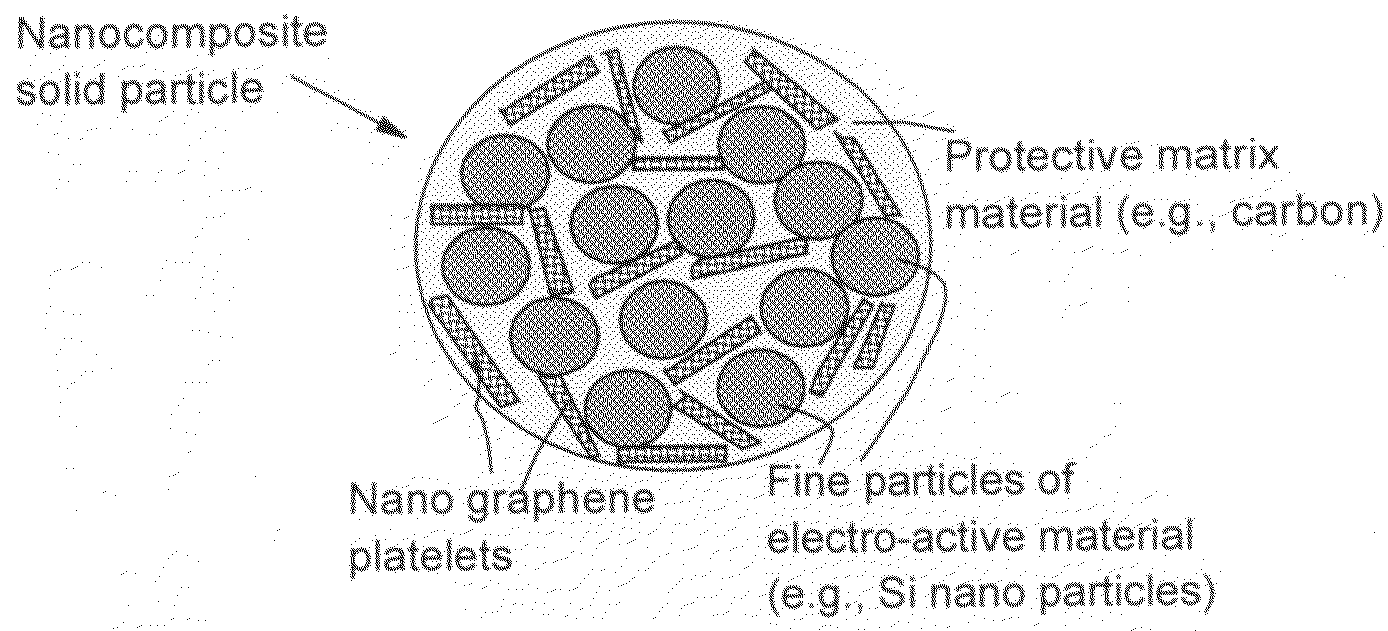

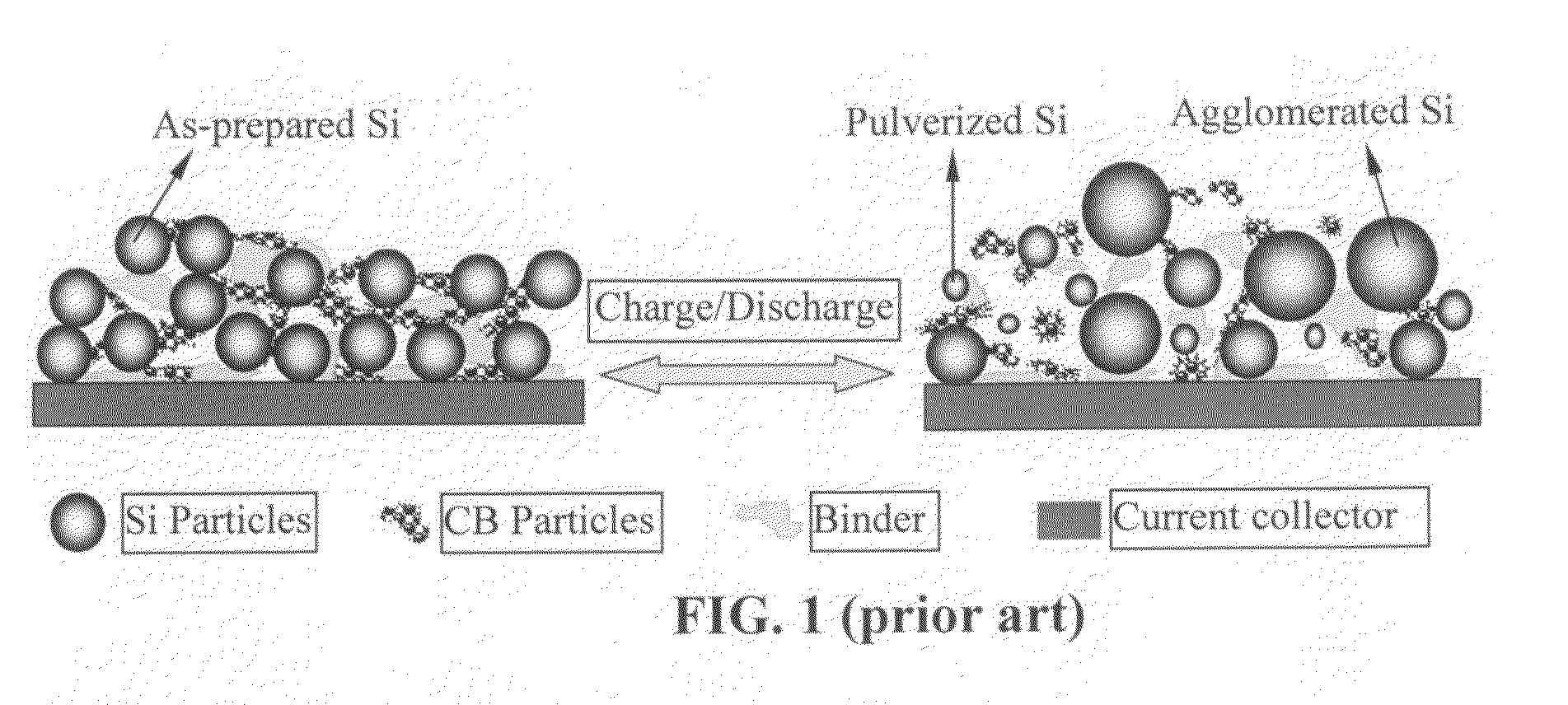

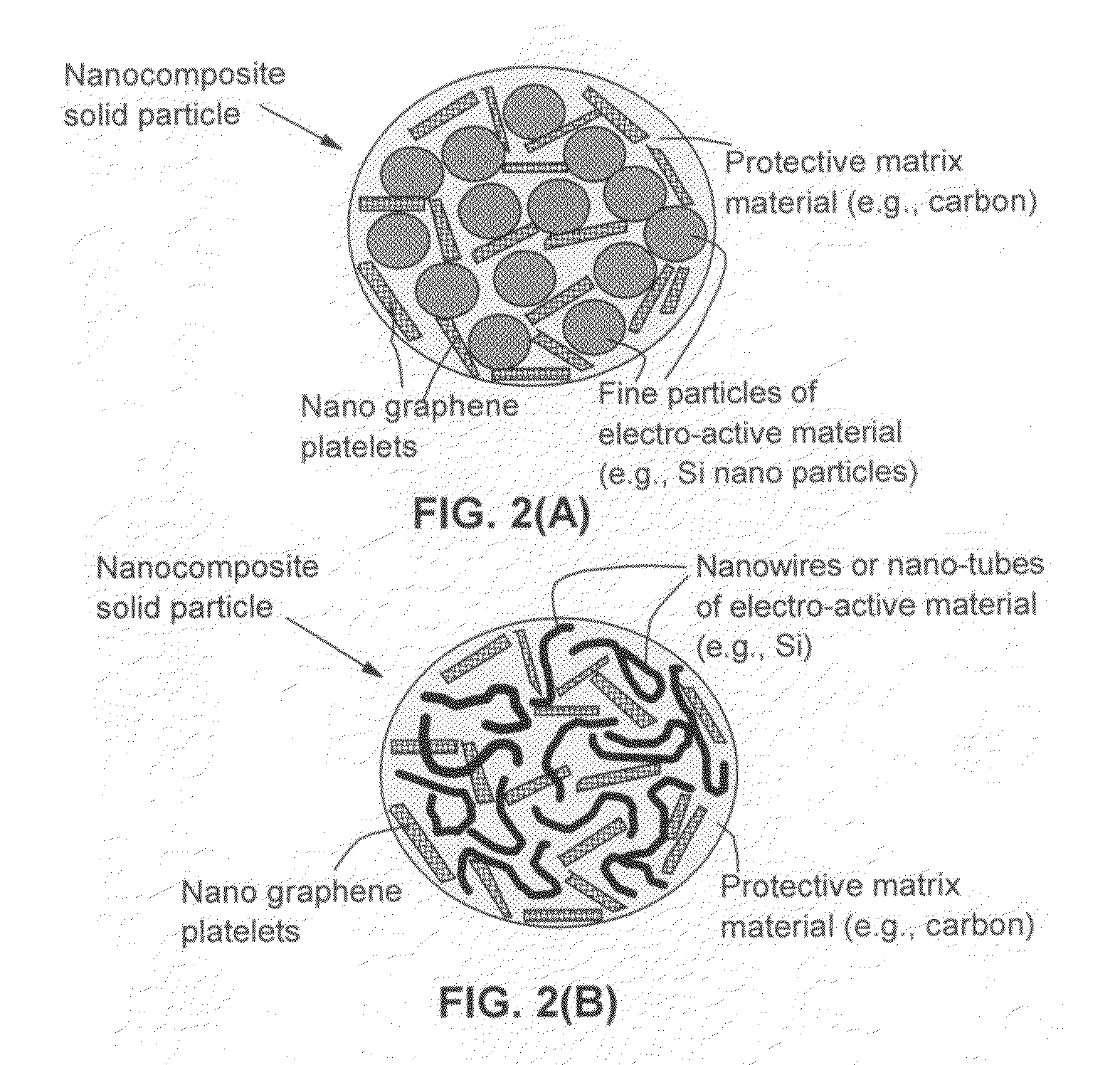

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

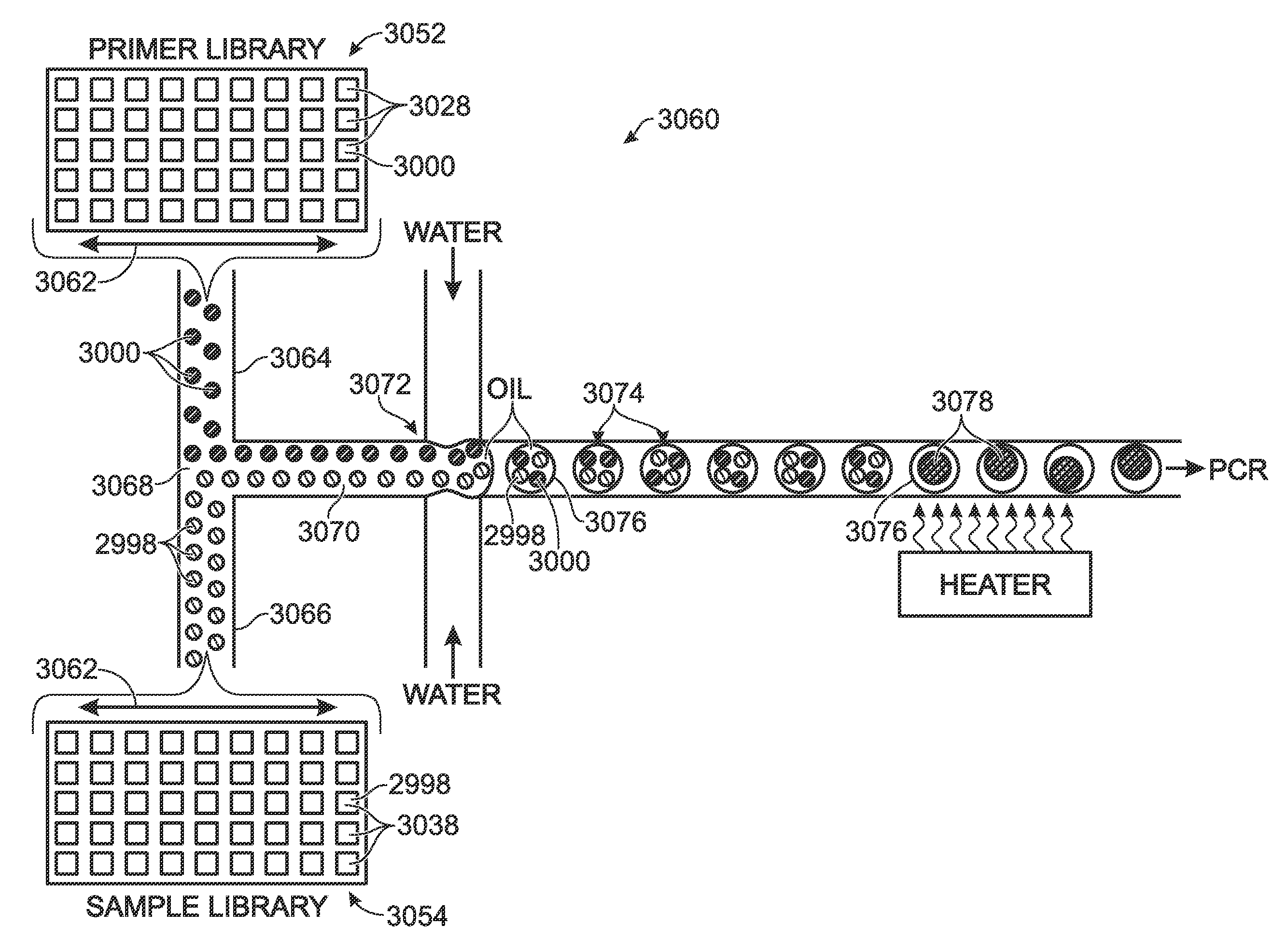

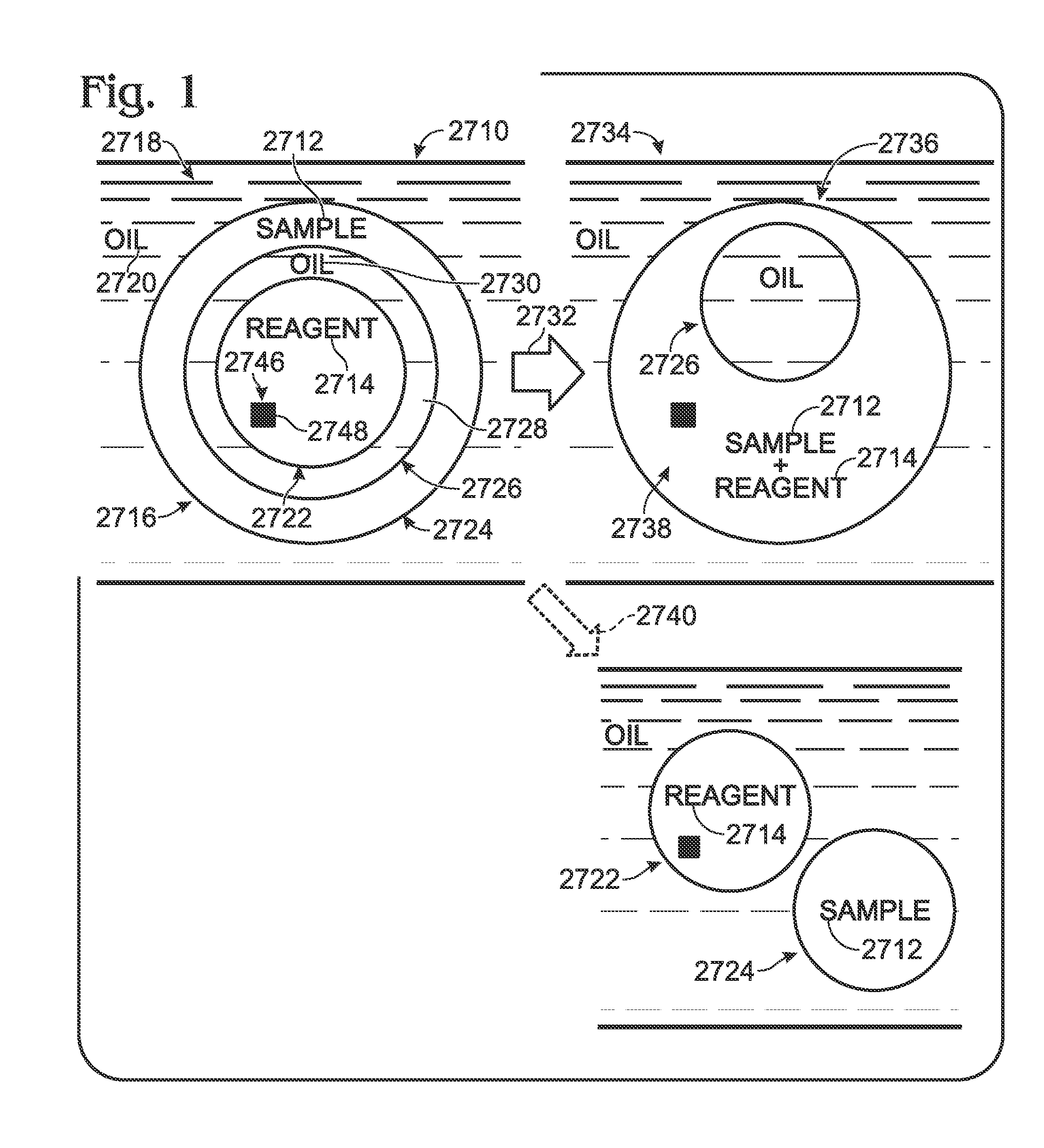

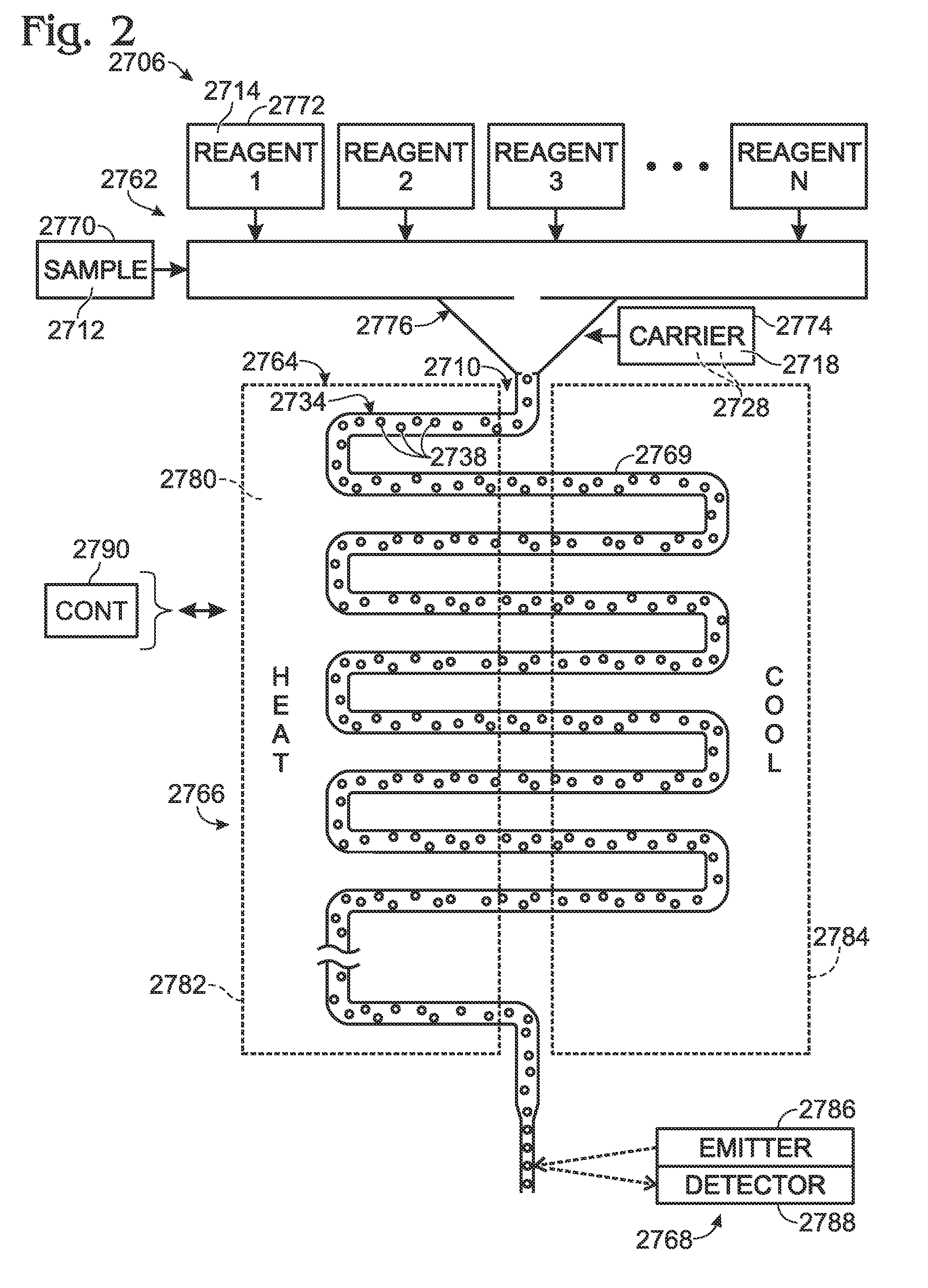

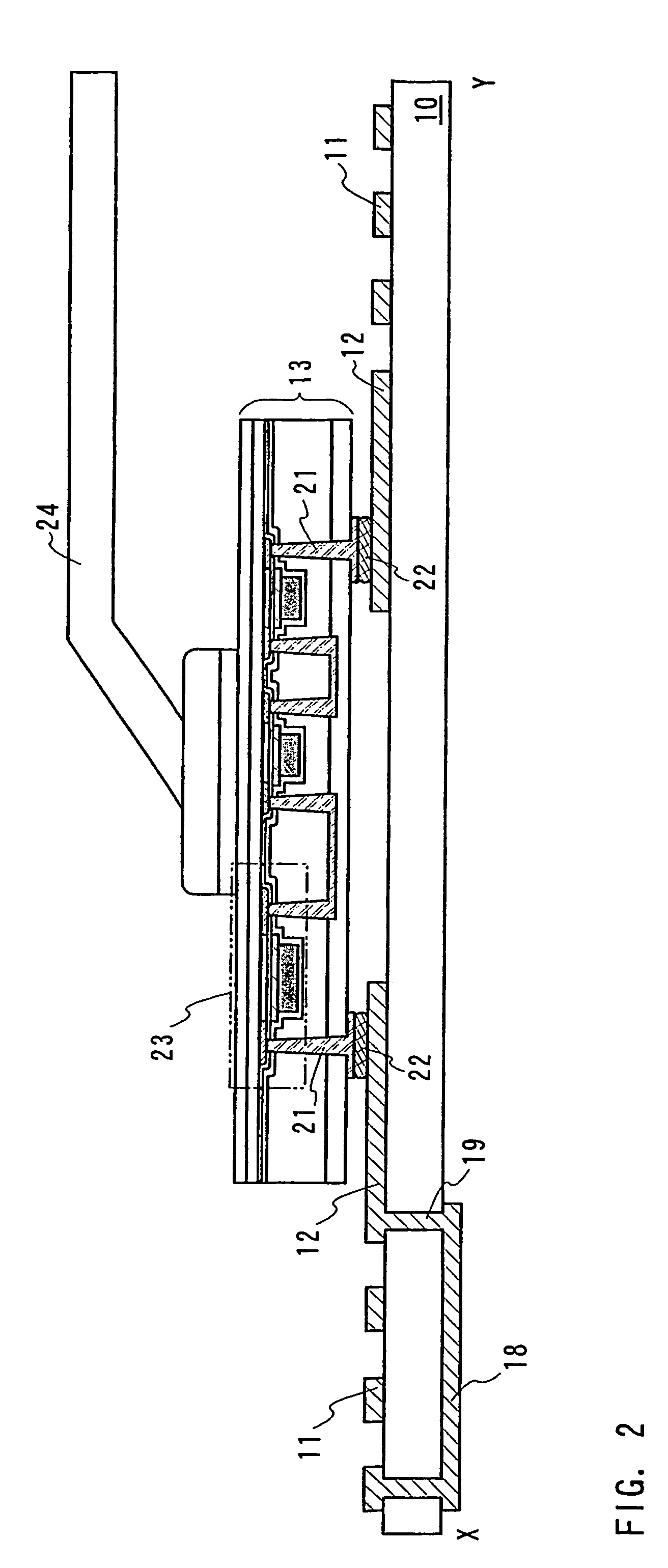

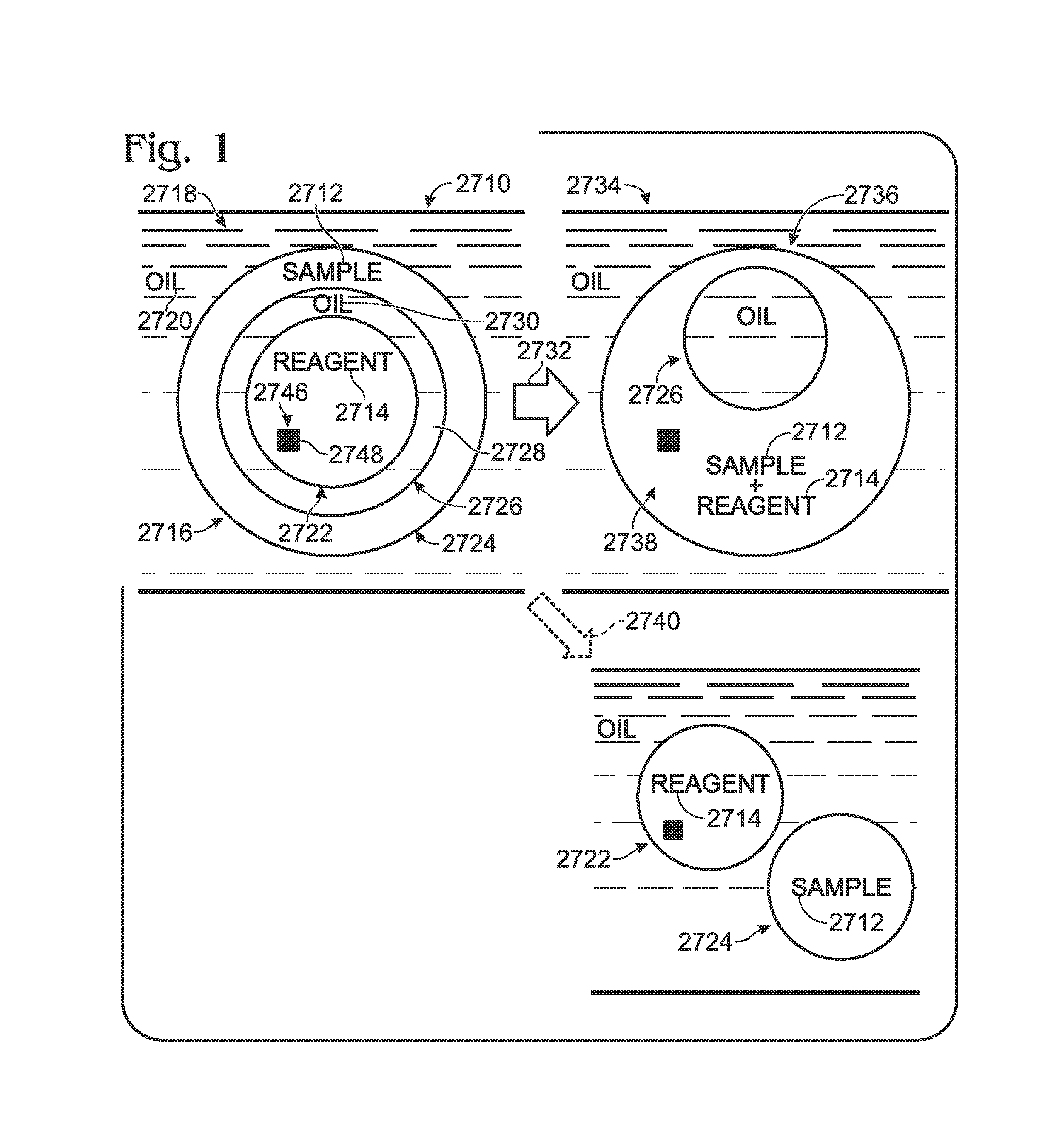

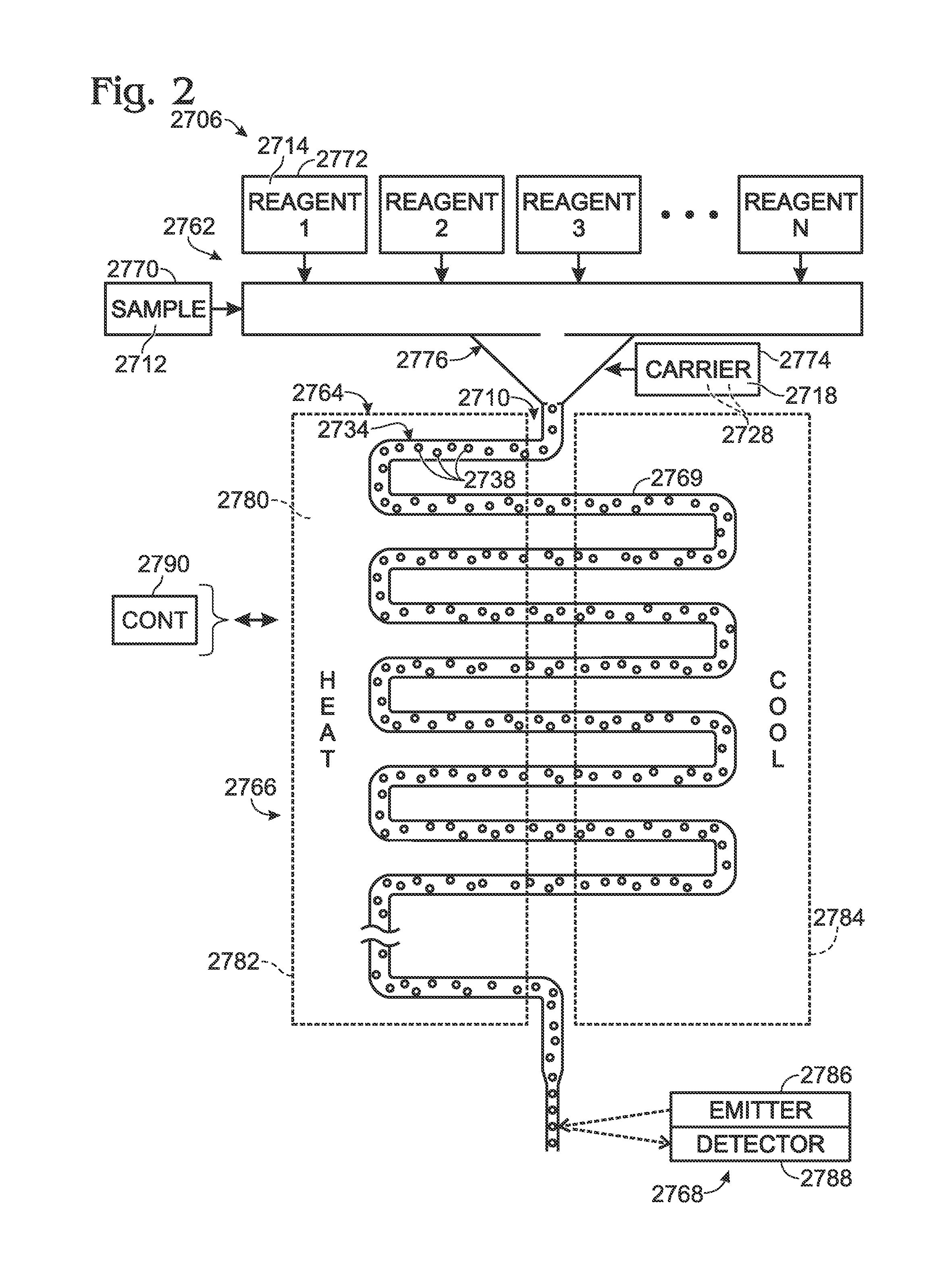

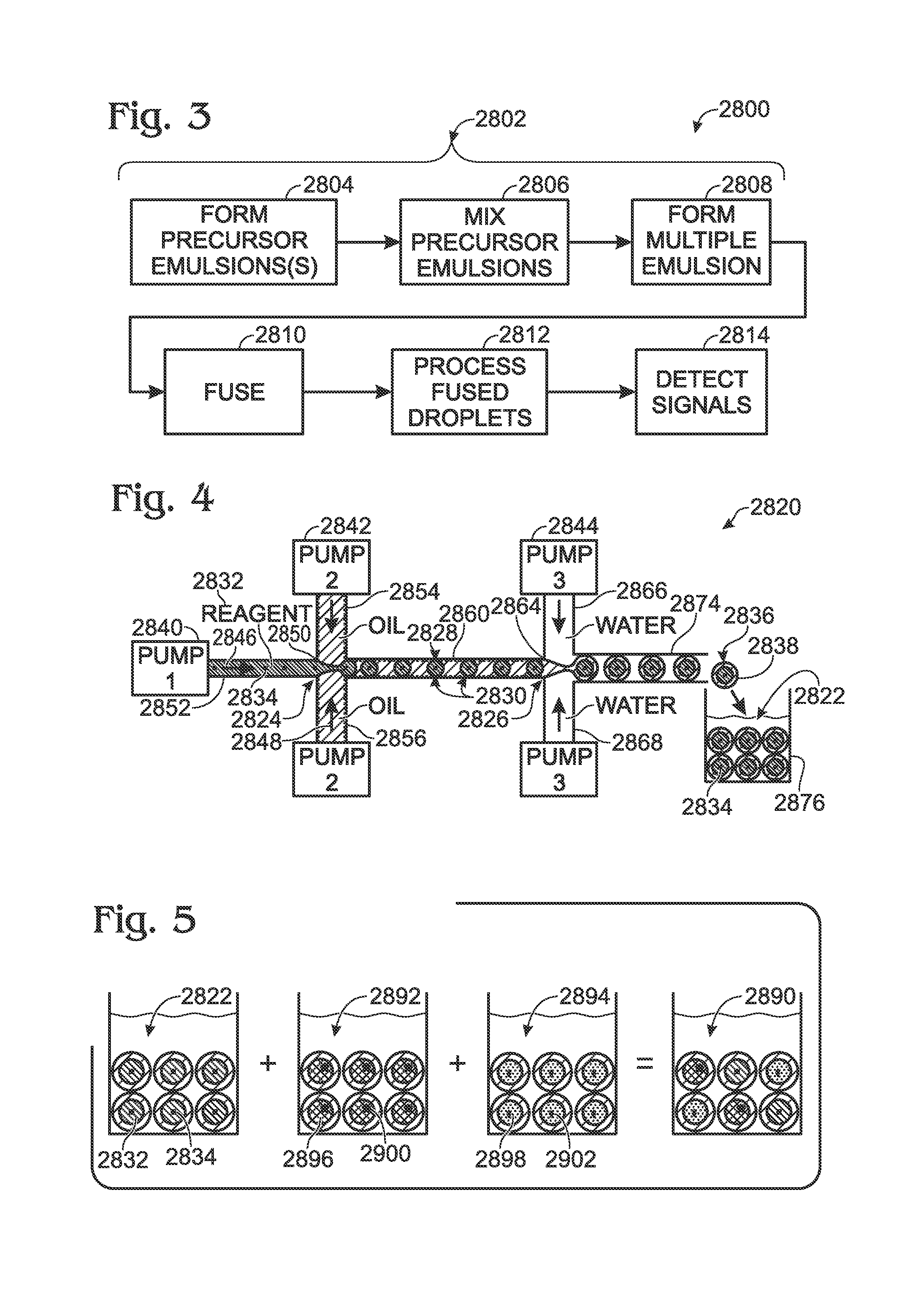

System for mixing fluids by coalescence of multiple emulsions

ActiveUS20110053798A1High-confidence resultLower the volumeSequential/parallel process reactionsHeating or cooling apparatusEmulsionChemistry

System, including methods, apparatus, compositions, and kits, for the mixing of small volumes of fluid by coalescence of multiple emulsions.

Owner:BIO RAD LAB INC

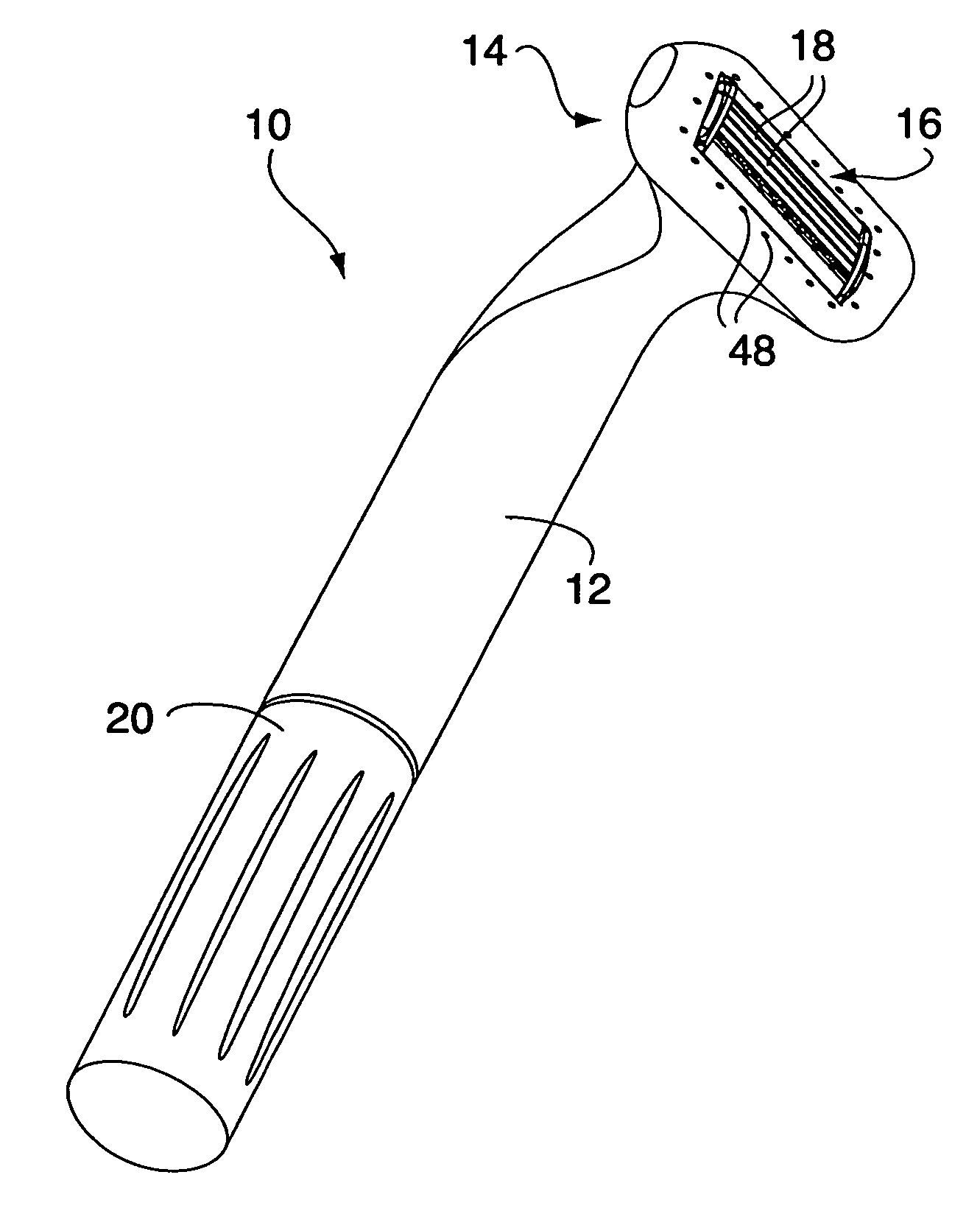

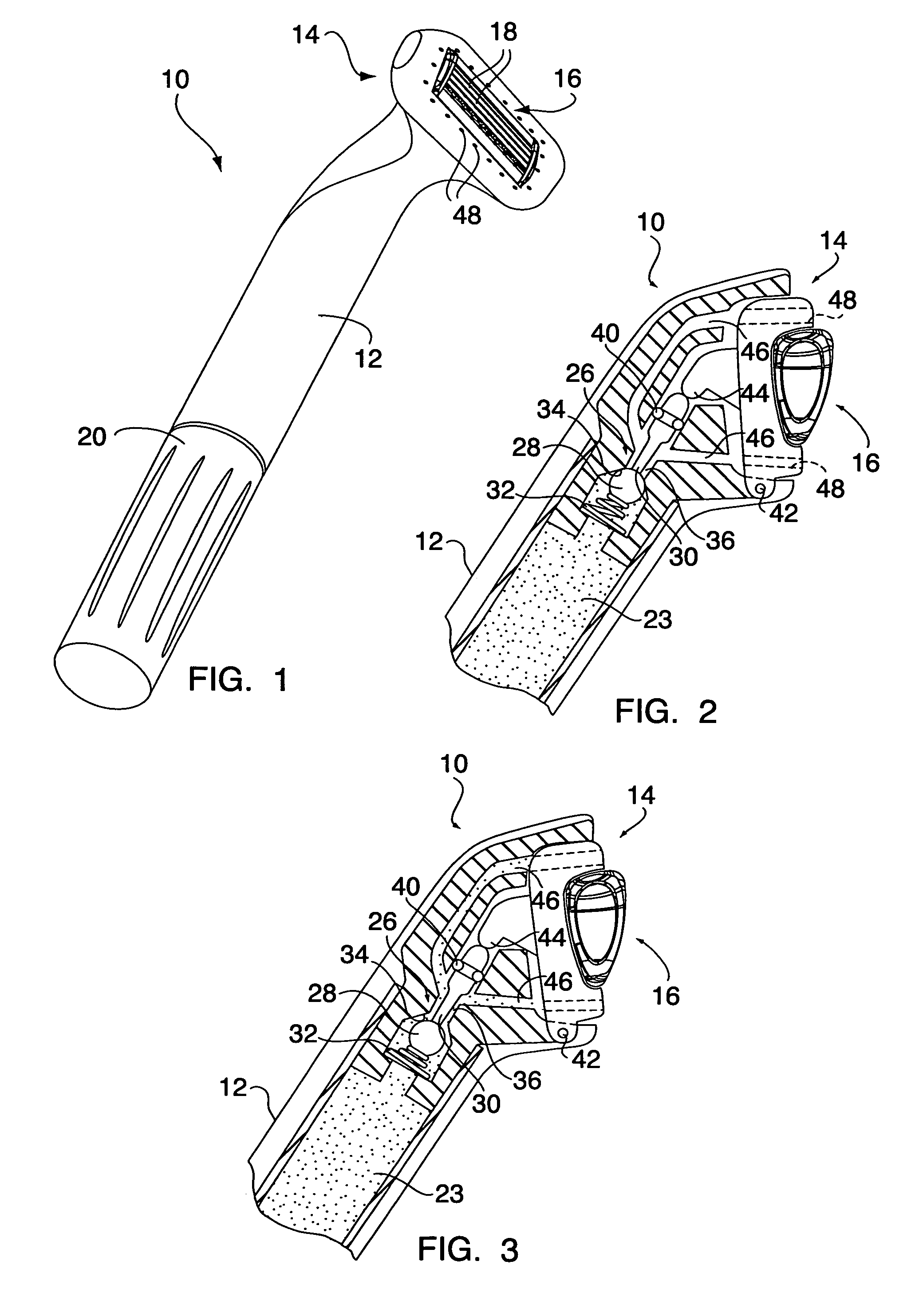

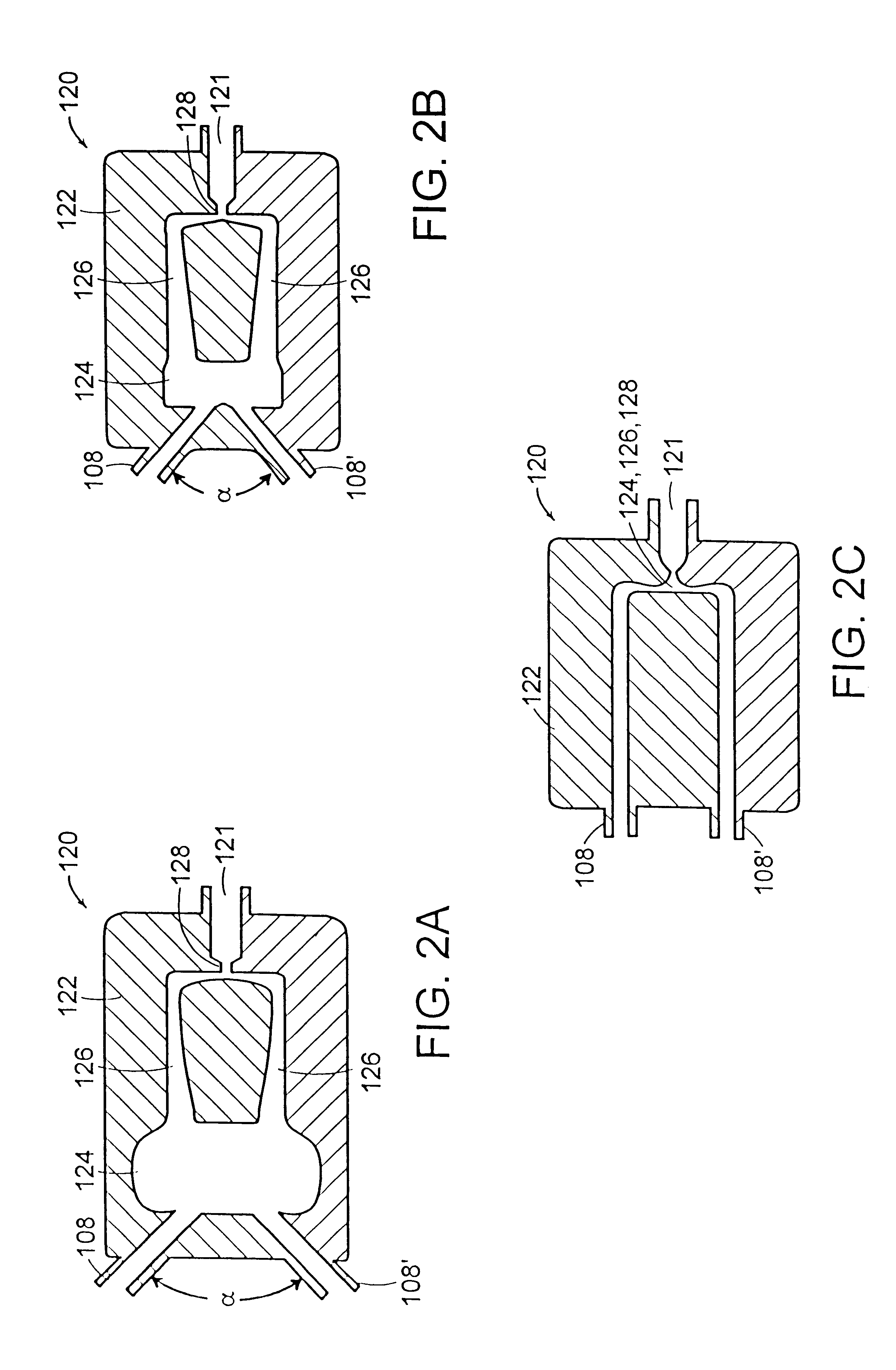

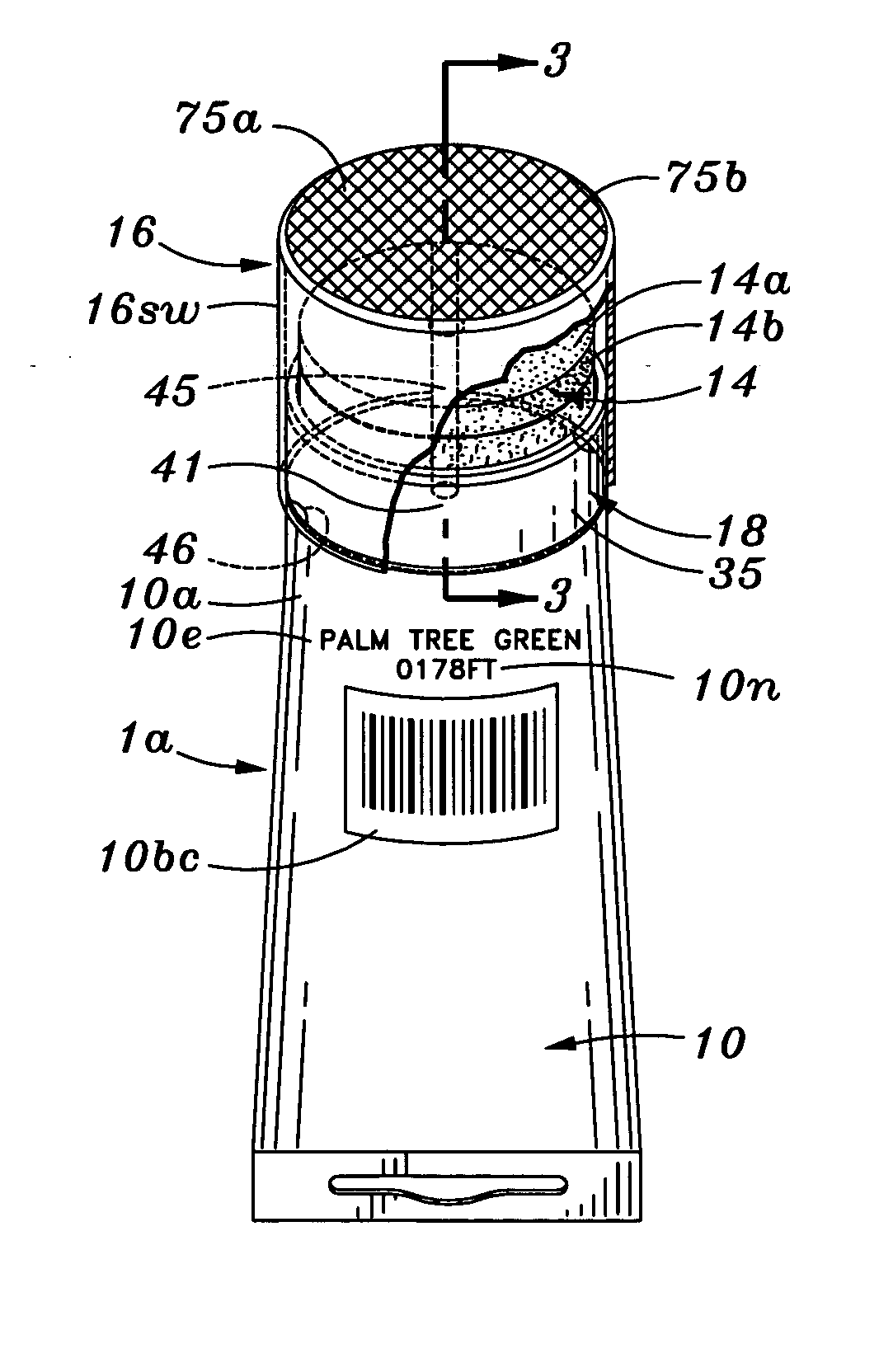

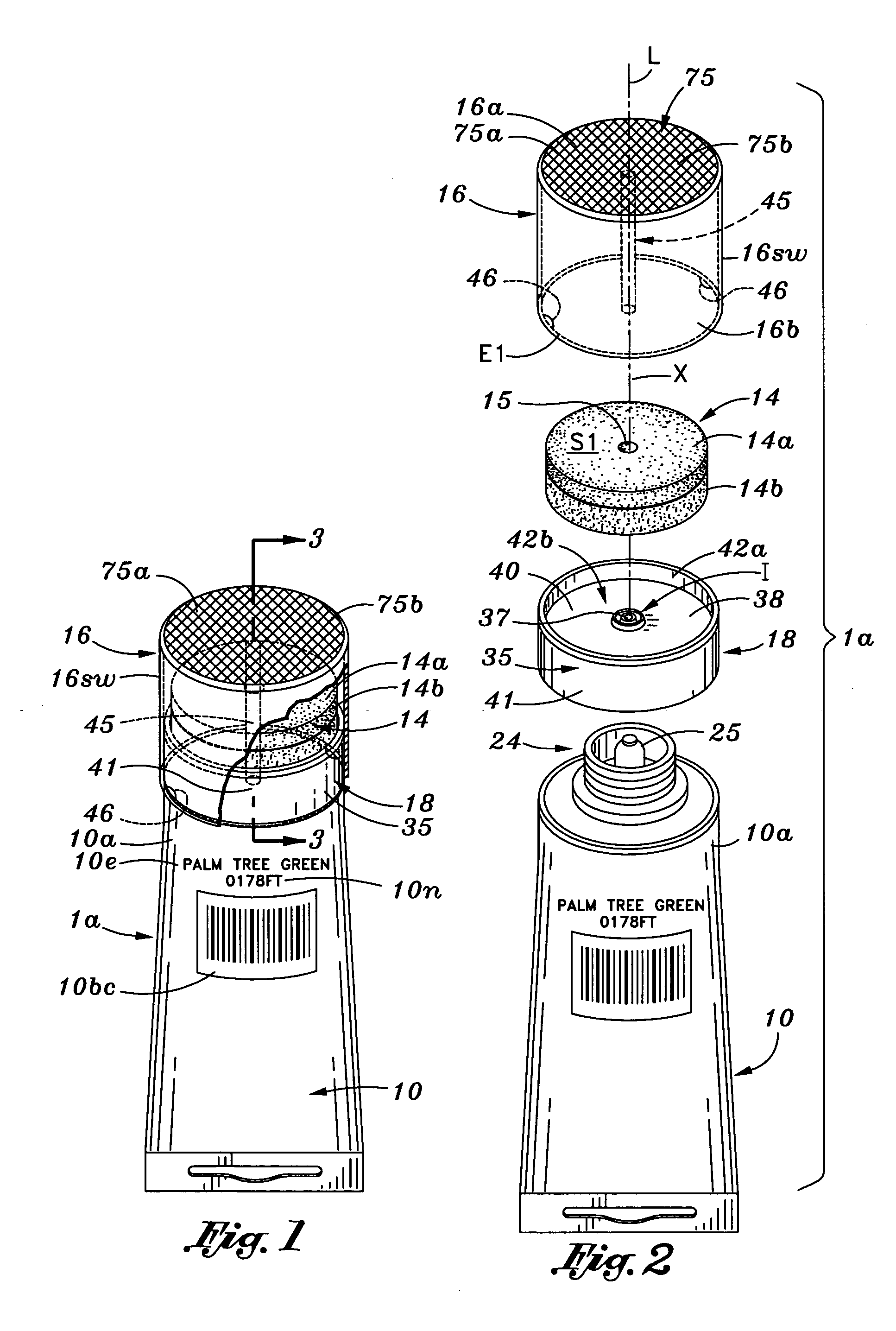

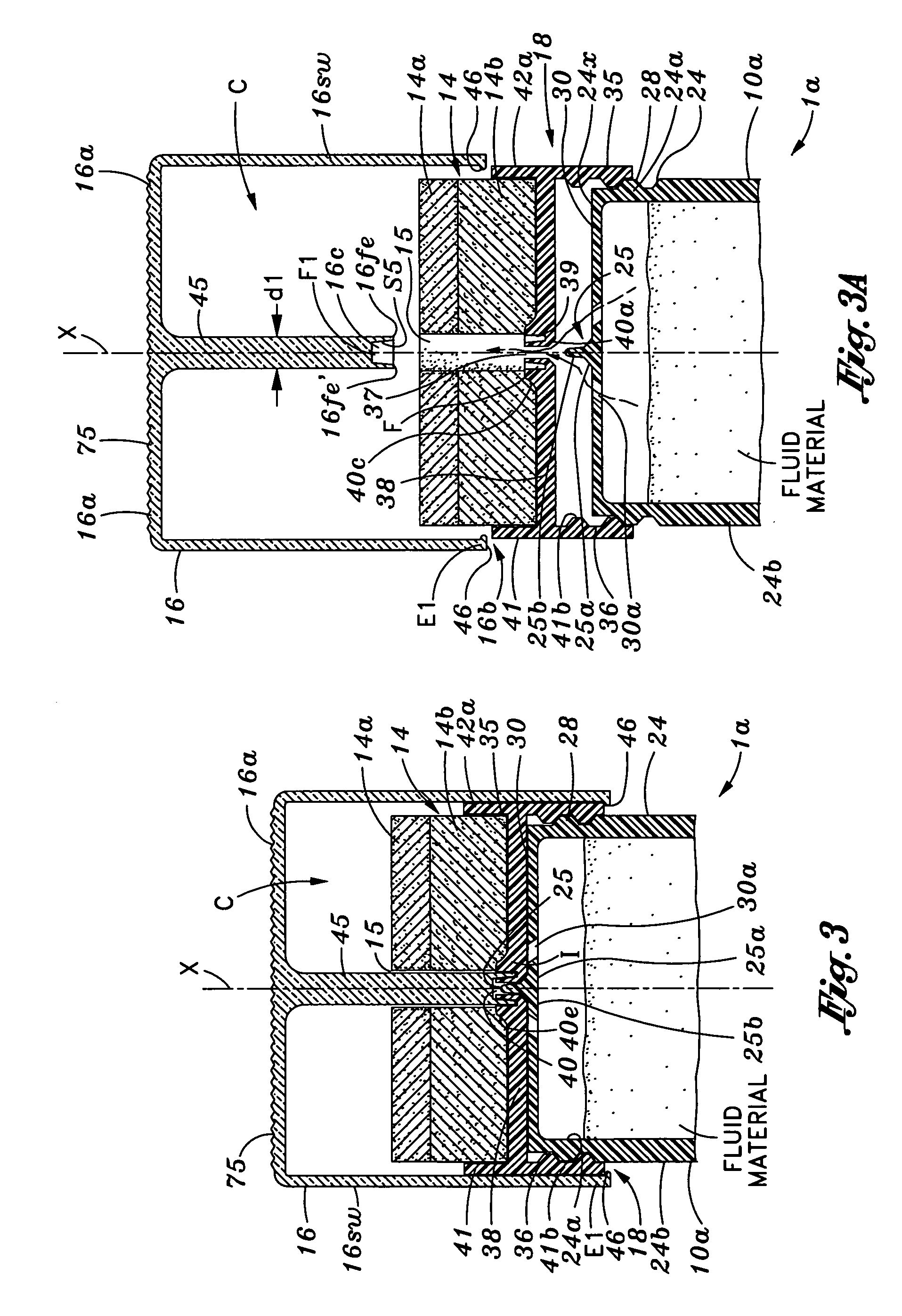

Shaving apparatus with pivot-actuated valve for delivery of shaving aid material

InactiveUS7121754B2Prevent materialObstruct passageCarpet cleanersFloor cleanersEngineeringRazor Blade

A shaving apparatus includes a reservoir for storing a shaving aid material, a razor cartridge having at least one razor blade, and a valve selectively actuatable by movement of the razor cartridge between a first position and a second position. In the first position the valve permits passage of a shaving aid material from the reservoir, and in the second position the valve substantially prevents the passage of the shaving aid material from the reservoir.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

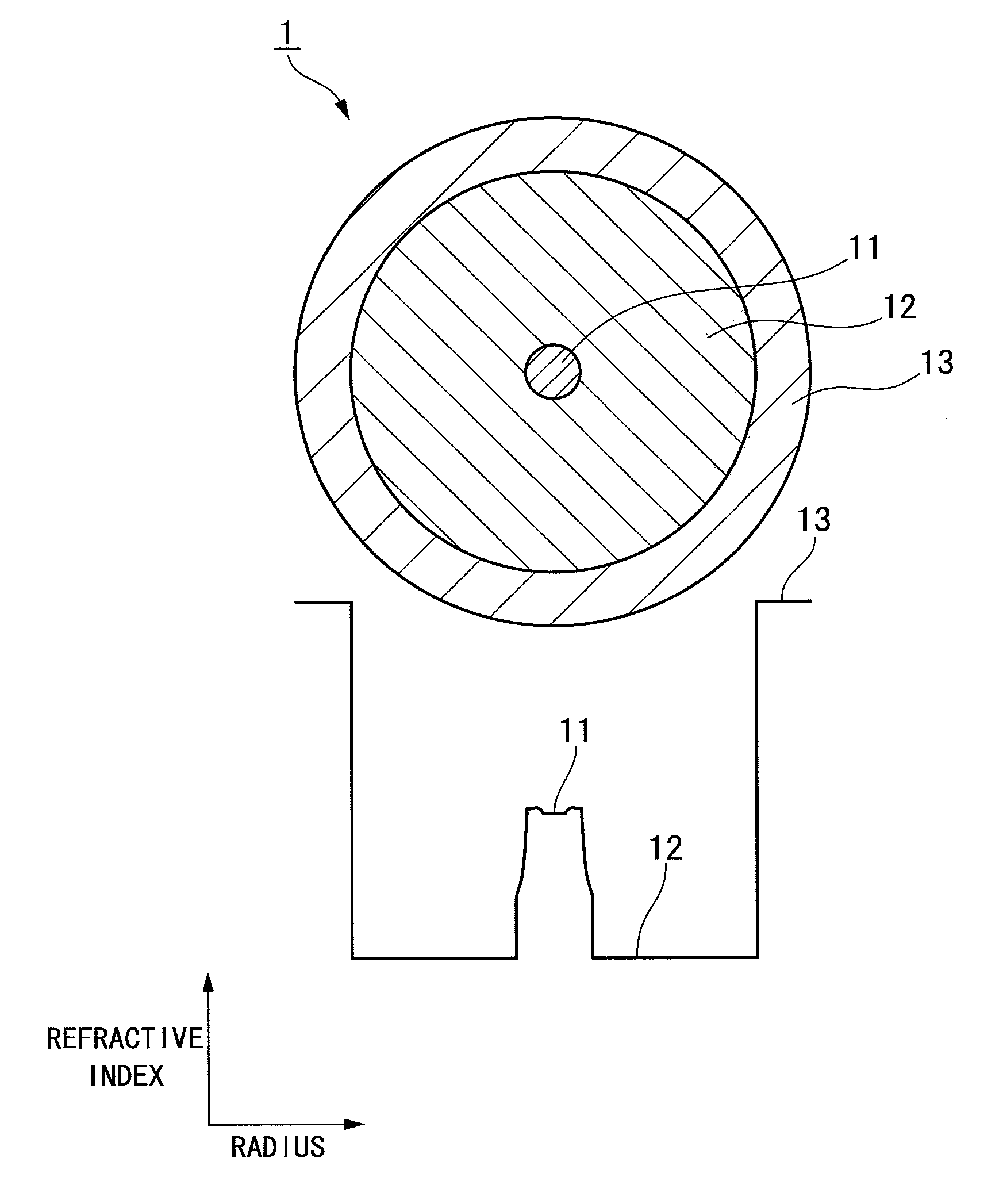

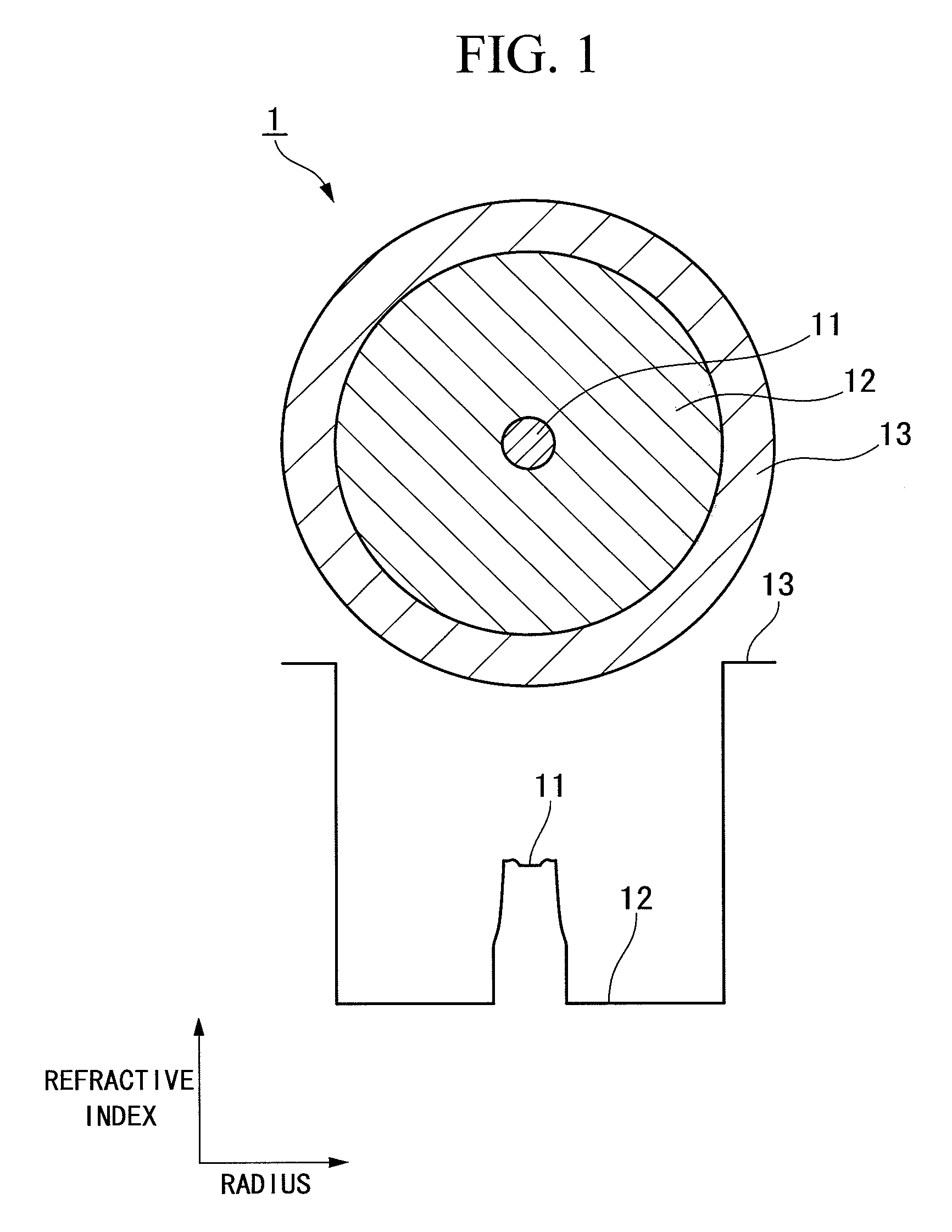

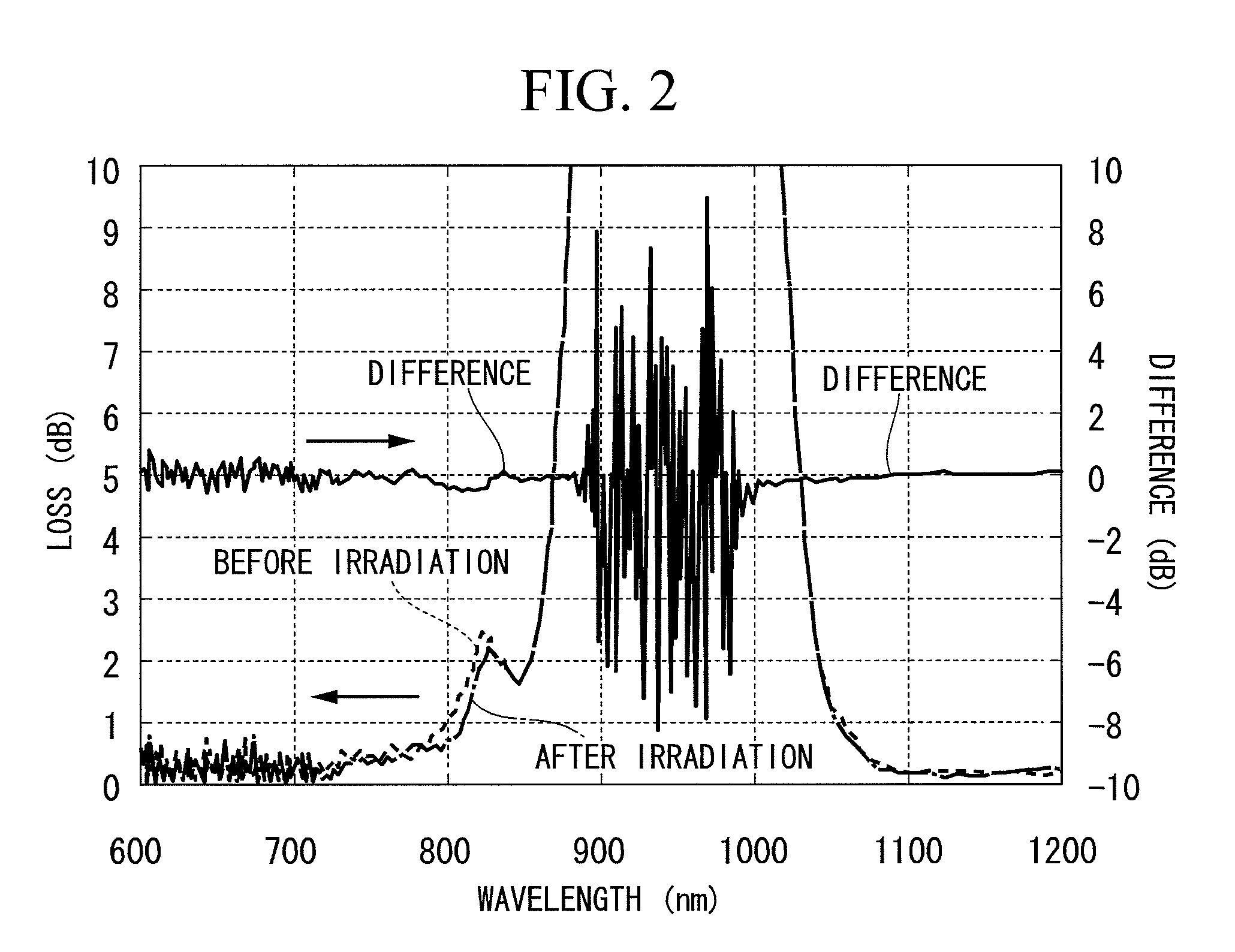

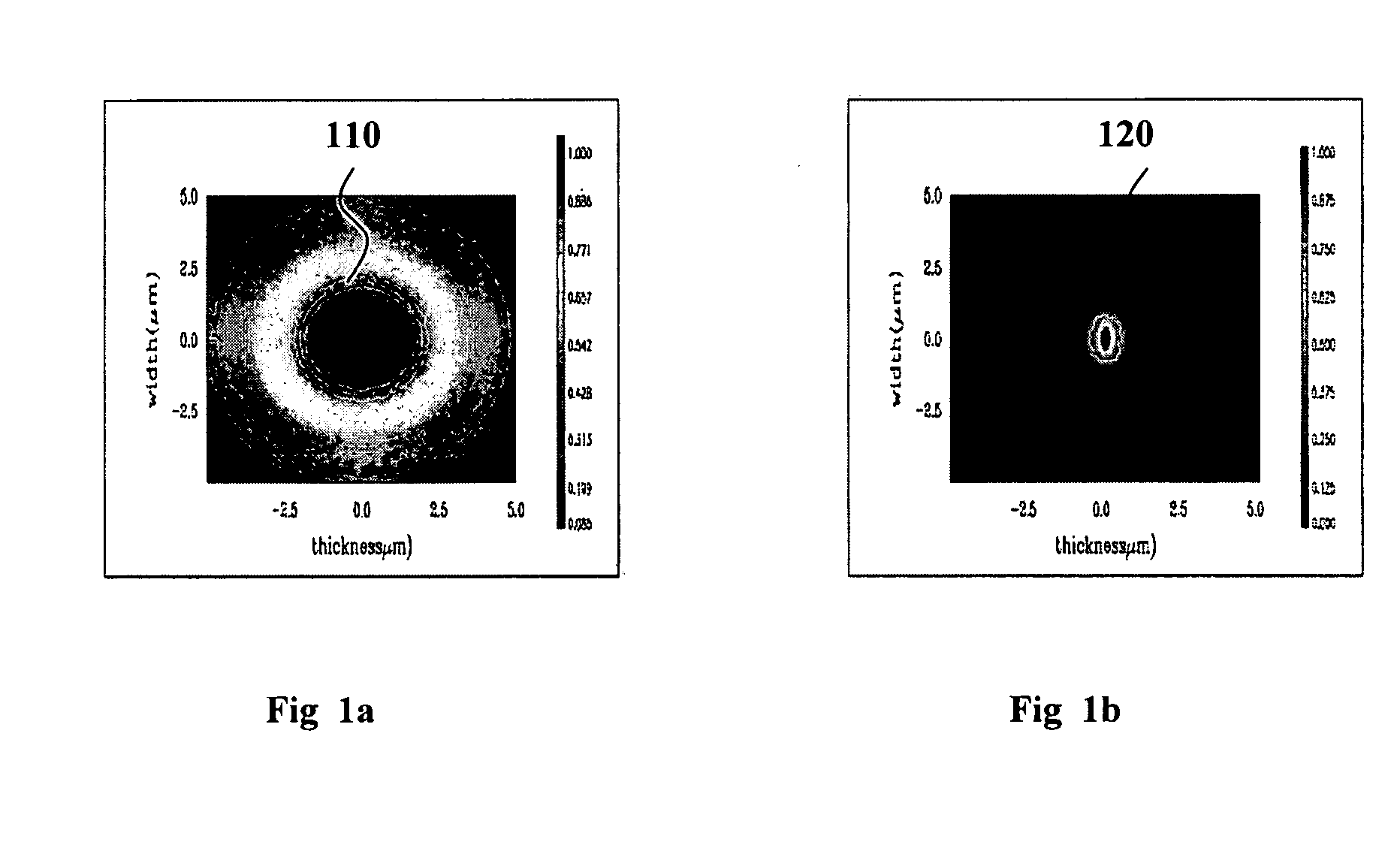

Ytterbium-doped optical fiber, fiber laser, and fiber amplifier

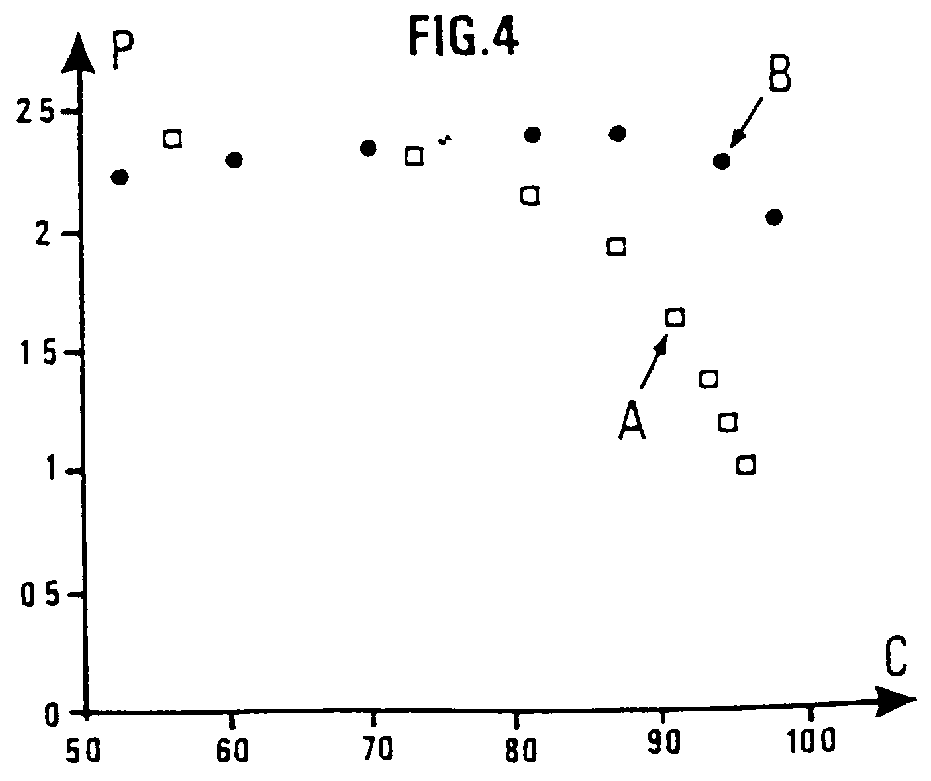

ActiveUS8363313B2Avoid small quantitiesSuperior optical amplificationLaser using scattering effectsOptical fibre with polarisationYTTERBIUM OXIDEDiphosphorus

An ytterbium-doped optical fiber of the present invention includes: a core which contains ytterbium, aluminum, and phosphorus and does not contain germanium; and a cladding which surrounds this core. The ytterbium concentration in the core in terms of ytterbium oxide is 0.09 to 0.68 mole percent. The molar ratio between the phosphorus concentration in the core in terms of diphosphorus pentoxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 30. The molar ratio between the aluminum concentration in the core in terms of aluminum oxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 32. The molar ratio between the above aluminum concentration in terms of aluminum oxide and the above phosphorus concentration in terms of diphosphorus pentoxide is 1 to 2.5.

Owner:FUJIKURA LTD

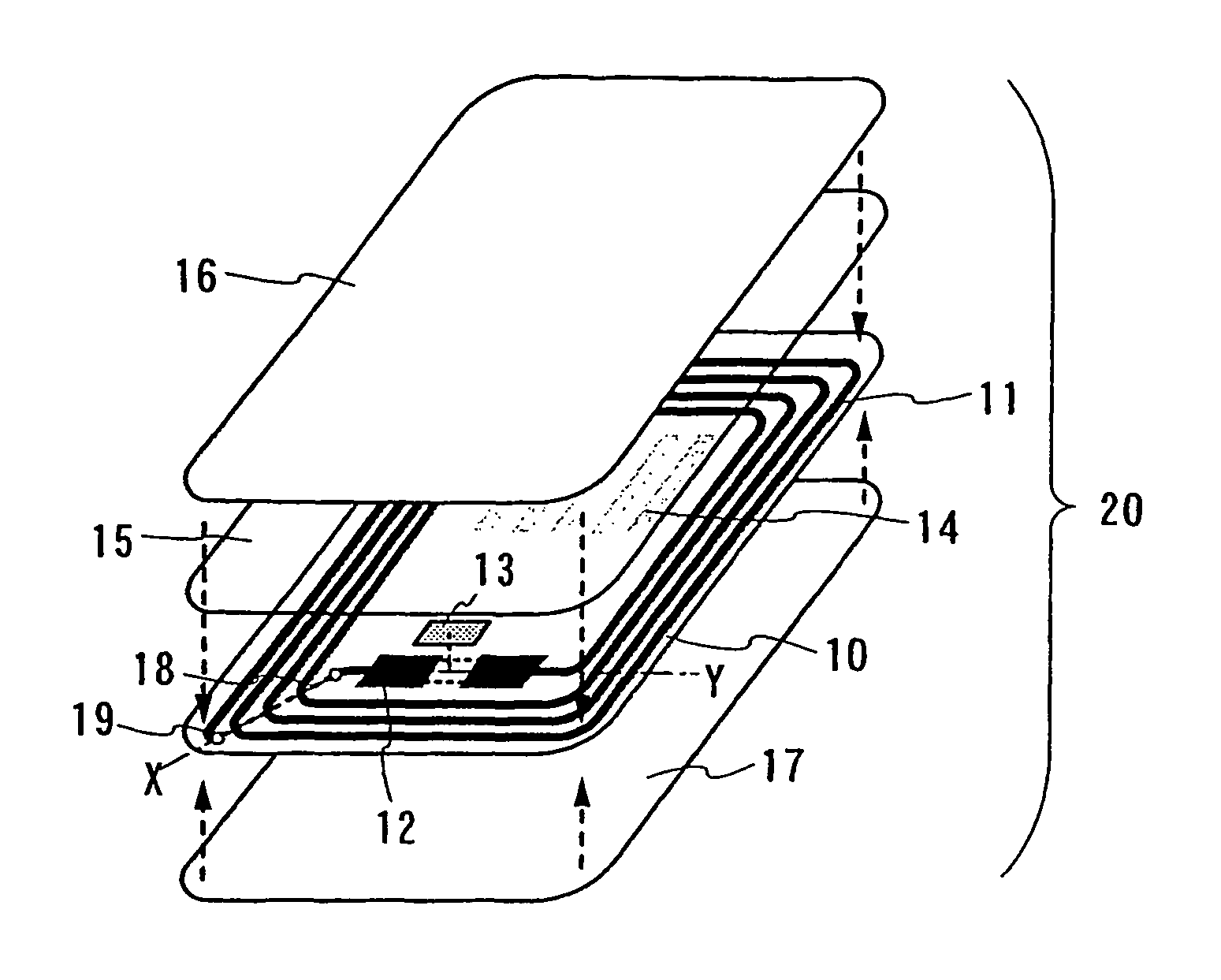

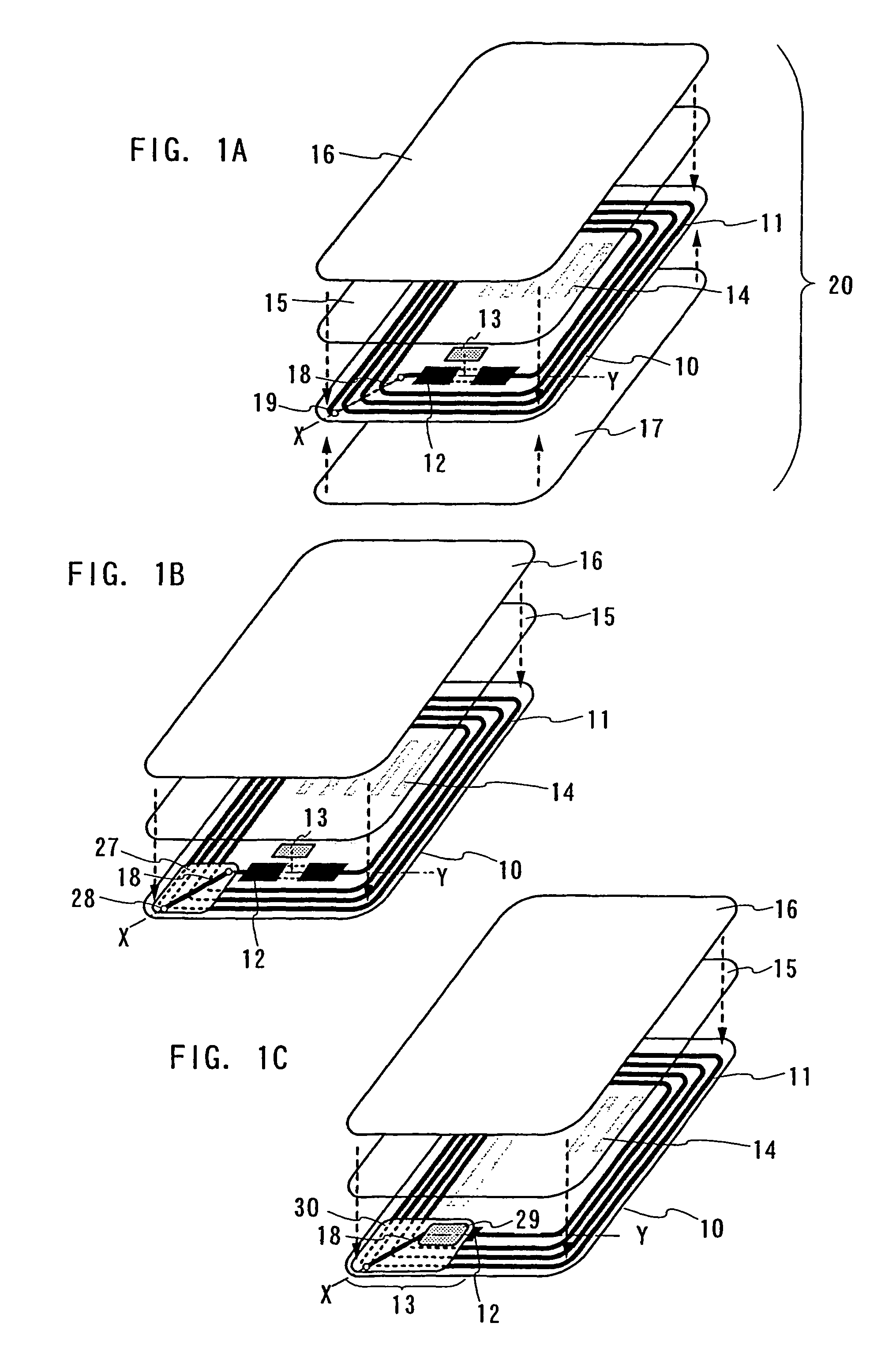

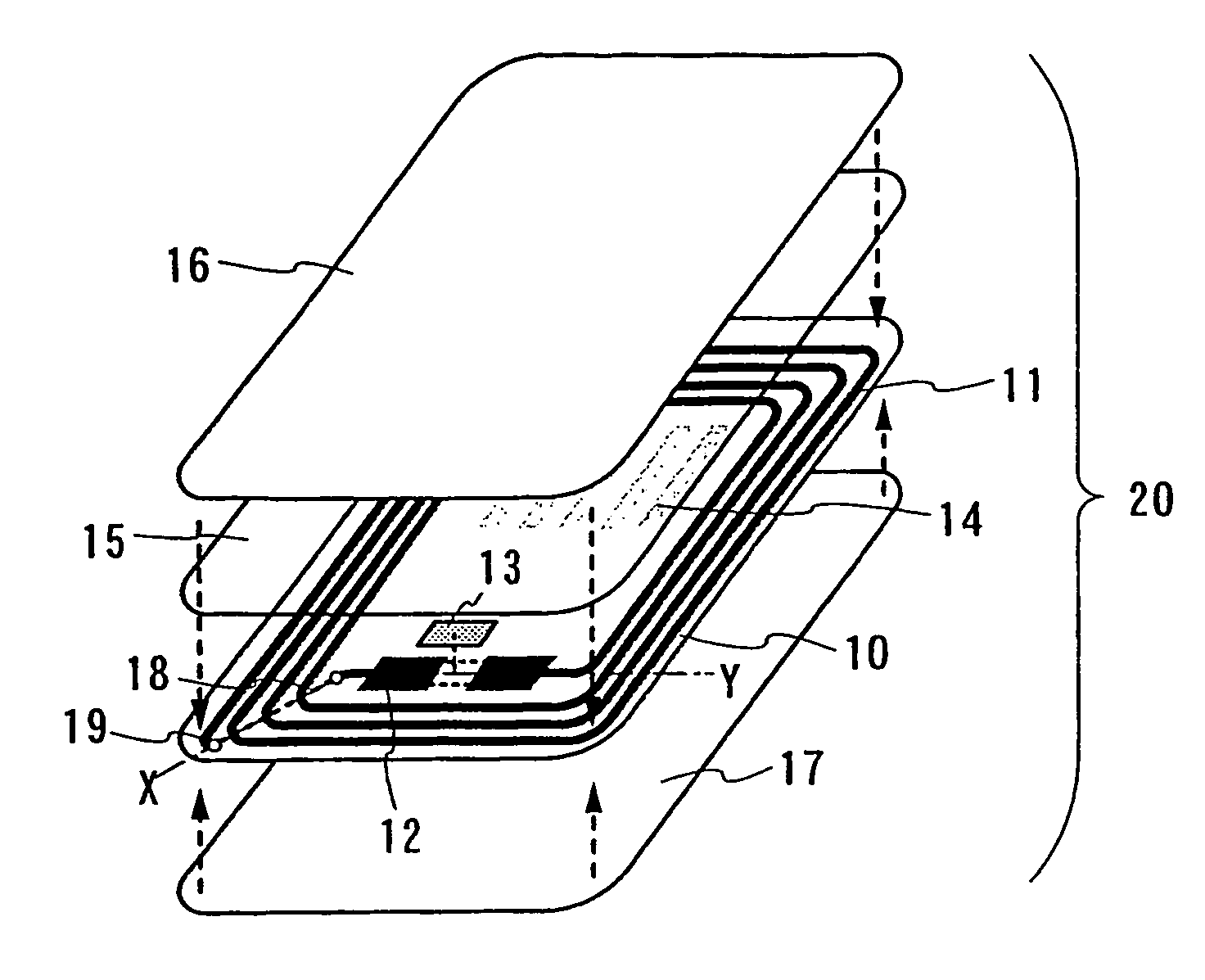

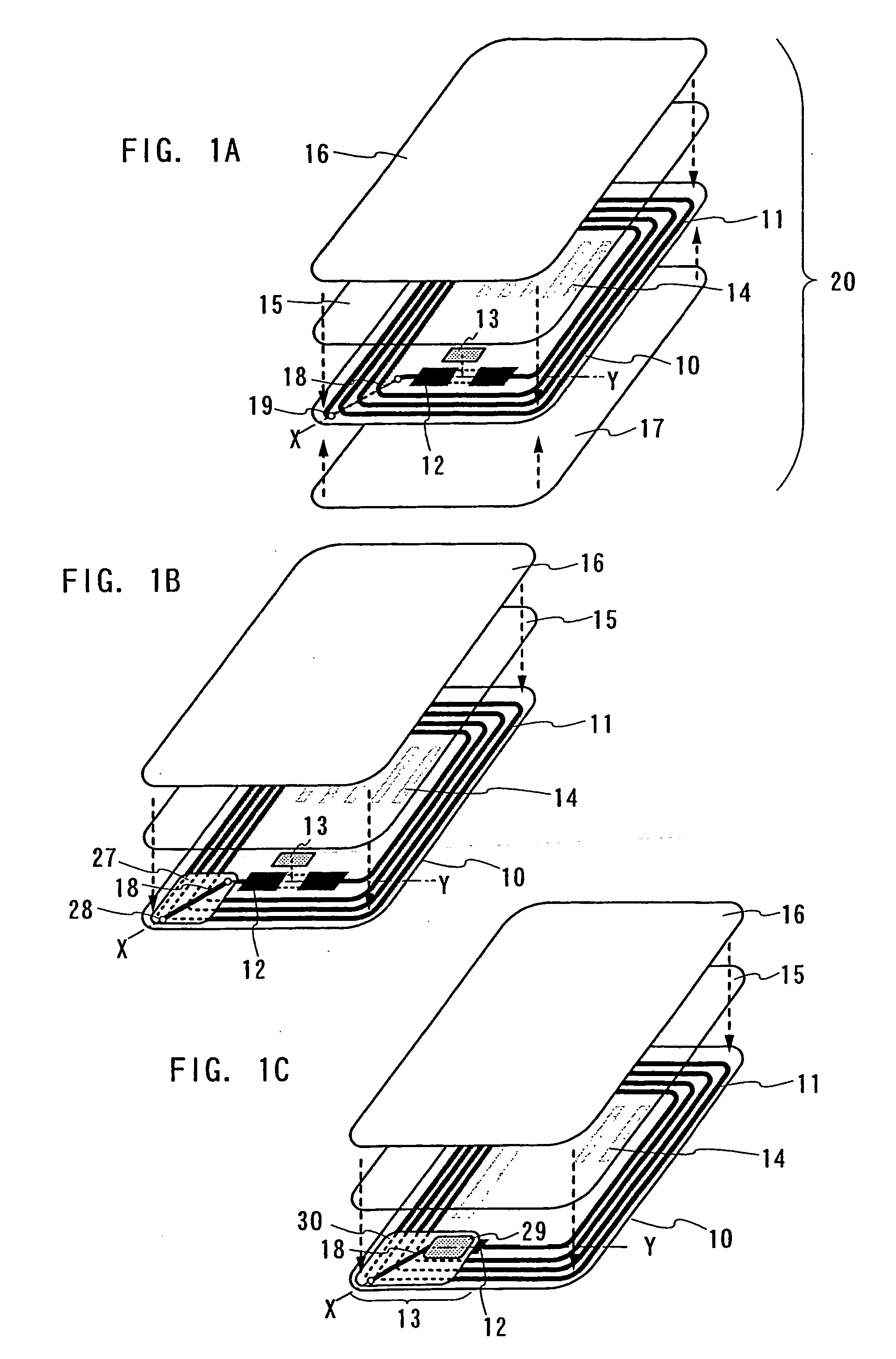

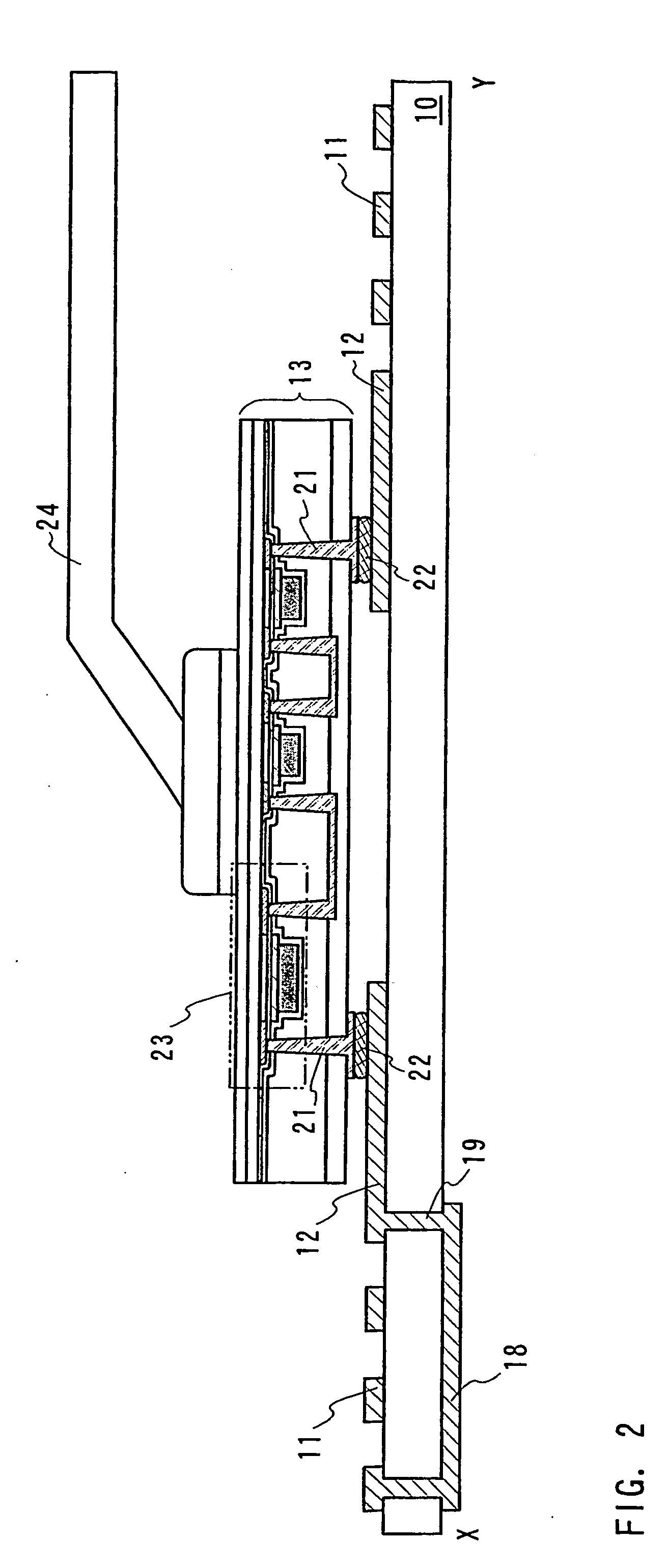

ID label, ID card, and ID tag

As a non-contact ID label, ID tag and the like being widespread, it is required to manufacture a considerable quantity of ID labels at quite a low cost. An ID label attached to a product is, for example, required to be manufactured at 1 to several yens each, or preferably less than one yen. Thus, such a structure and a process are demanded that an ID label can be manufactured in a large quantity at a low cost. A thin film integrated circuit device included in the ID label, the ID card, and the ID tag of the invention each includes a thin film active element such as a thin film transistor (TFT). Therefore, by peeling a substrate on which TFTs are formed for separating elements, the ID label and the like can be manufactured in a large quantity at a low cost.

Owner:SEMICON ENERGY LAB CO LTD

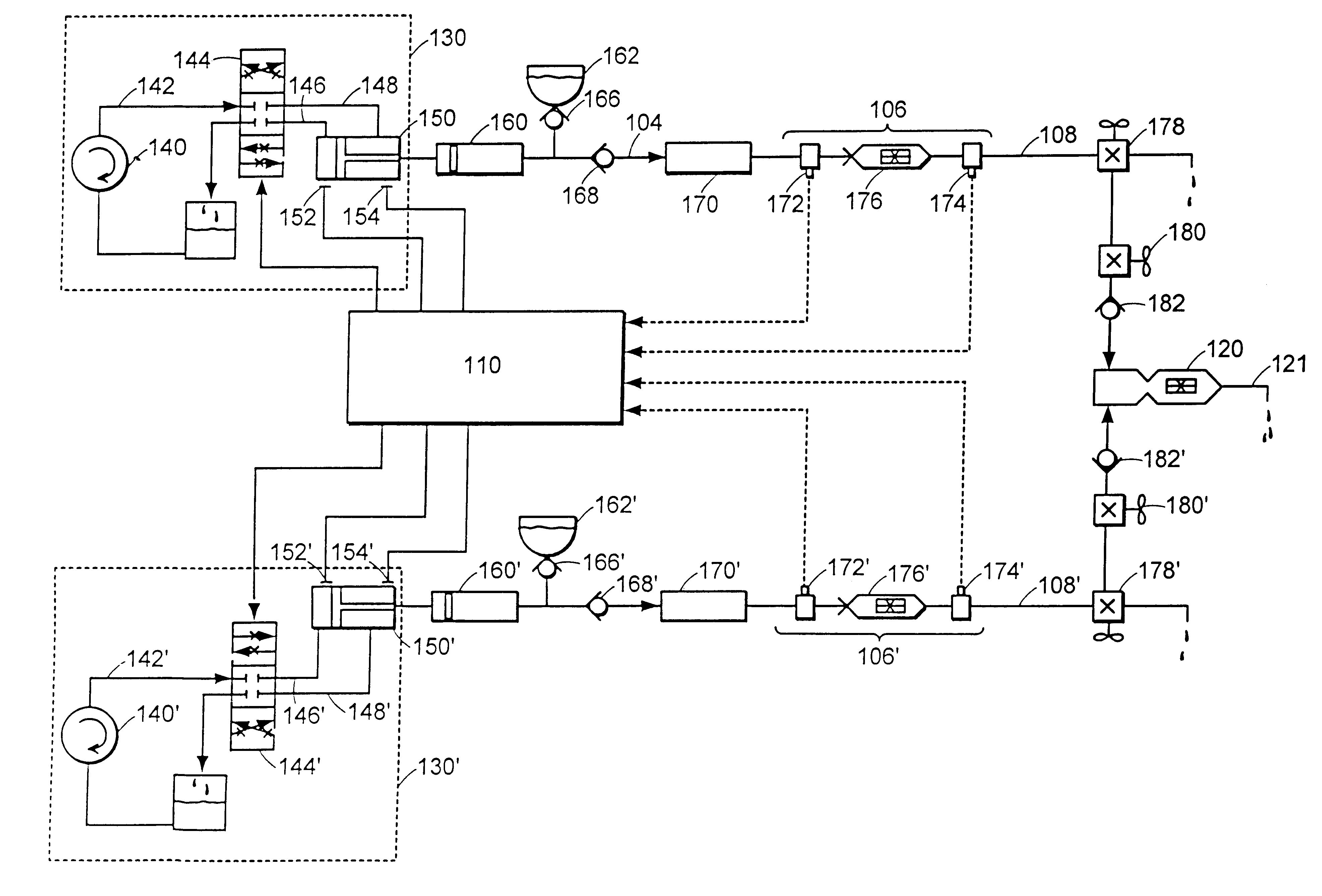

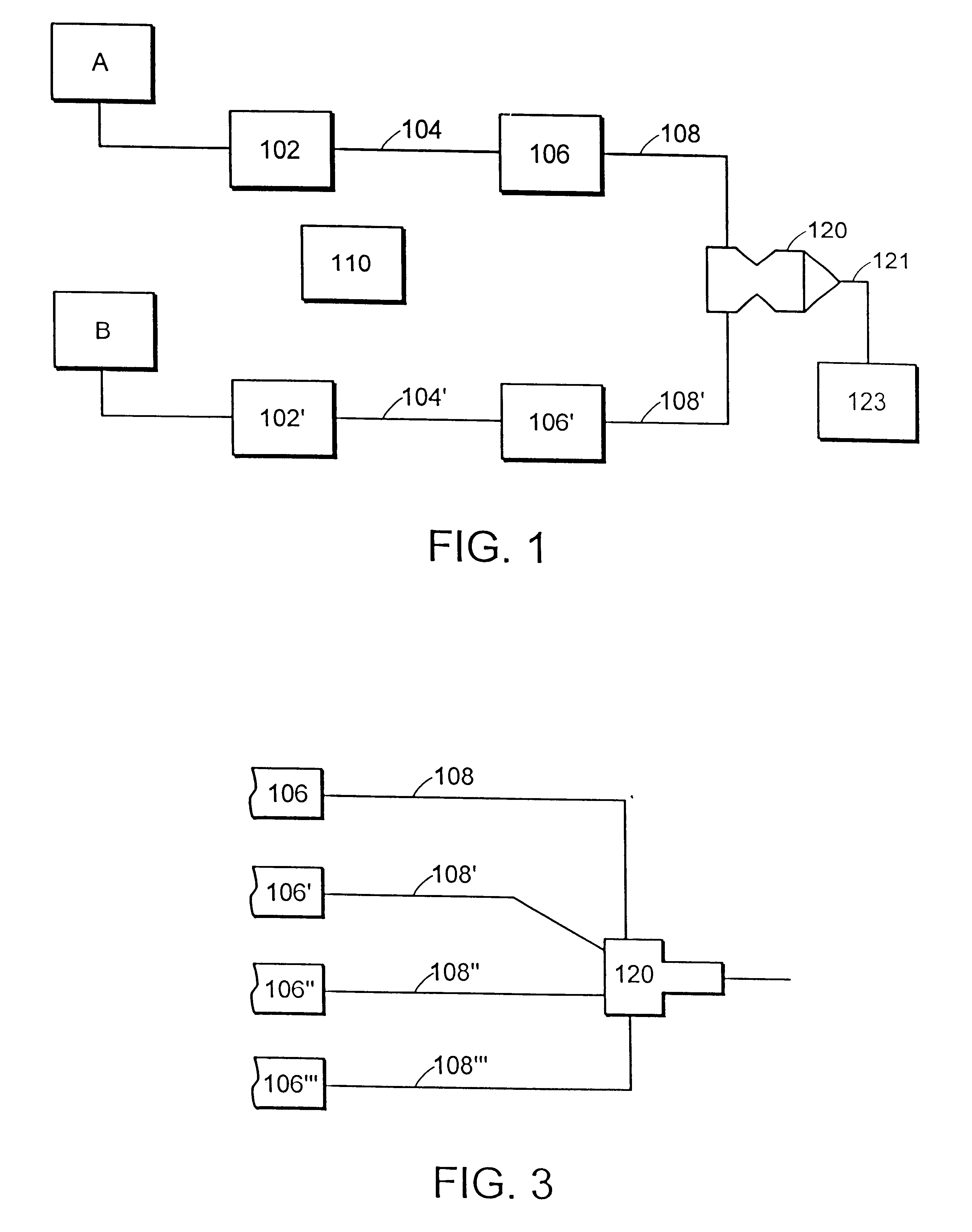

Multiple stream high pressure mixer/reactor

InactiveUS6221332B1Improve reliabilityFew and less partCalcium/strontium/barium carbonatesPressurized chemical processStream flowLow density

Enhanced macromixing, mesomixing, and micromixing of multiple discrete reactant streams, particularly for precipitation reactions of low density pumpable fluids, are obtained by controlled continuous high pressure multiple reactant streams flowing into a chemical mixer / reactor. Individual reactant streams are pressurized to about 8,000 to 50,000 psi and achieve velocities up to about 250 meters / second in the final stage of the chemical mixer / reactor. Reactant flows are controlled by a combination of a fixed restriction and a variable driving pump.

Owner:MICROFLUIDICS INT

Fiber containing filter media

InactiveUS20040038014A1Efficient removalLow efficiencySynthetic resin layered productsUltrafiltrationPolymer scienceFilter media

Improved filtration media or filter bodies can be made from fine fiber and can be formed into a filtration structure having no internal defects. The filter media or filter body comprises a collection of spot in fiber with defined fiber diameter, layer thickness and media solidity. The fine fiber is formed into a media body and obtains substantial flux and filtration efficiency. The filtration media or body can comprise single or multiple layers of fine fiber combined into the improved filter body.

Owner:DONALDSON CO INC

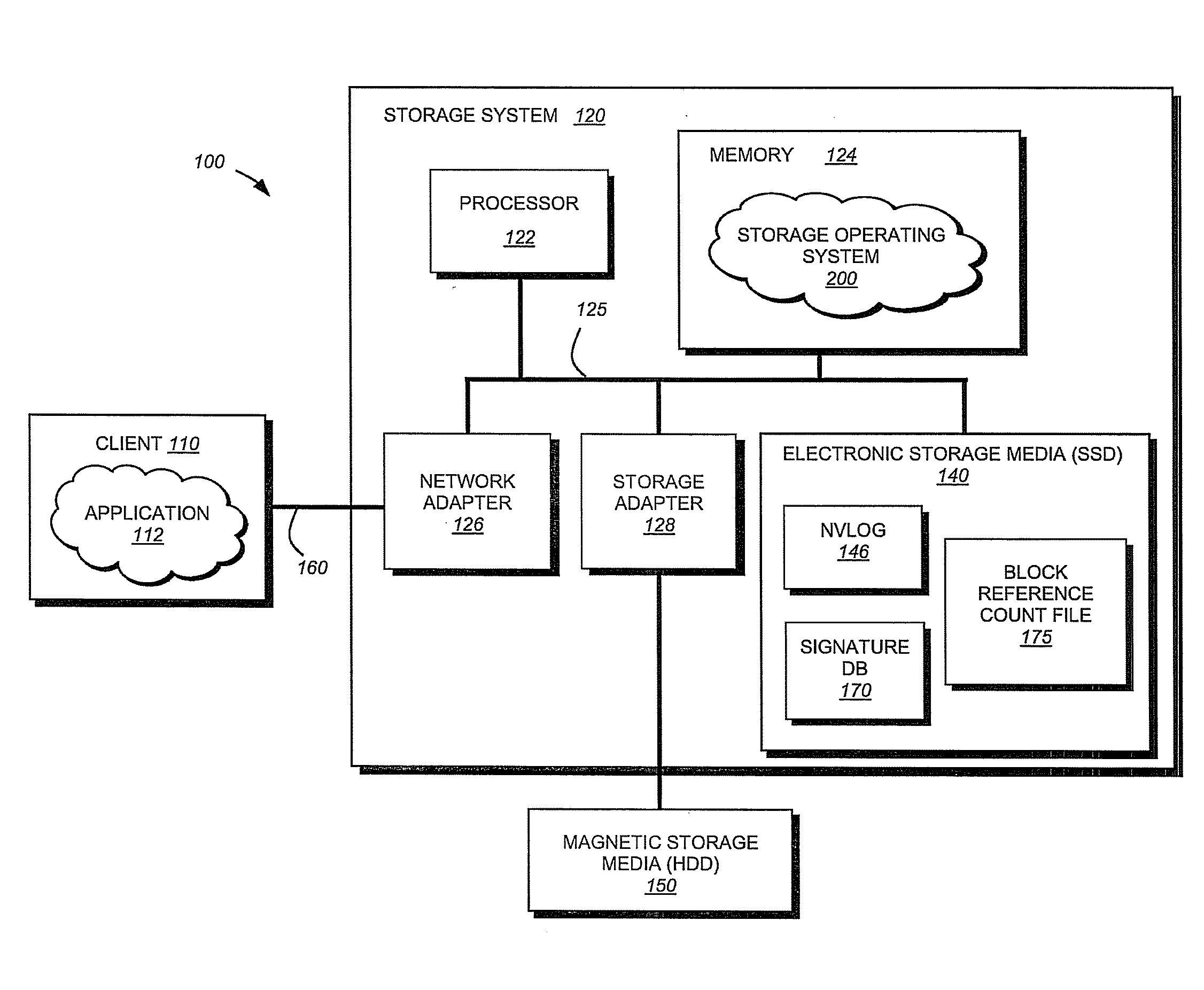

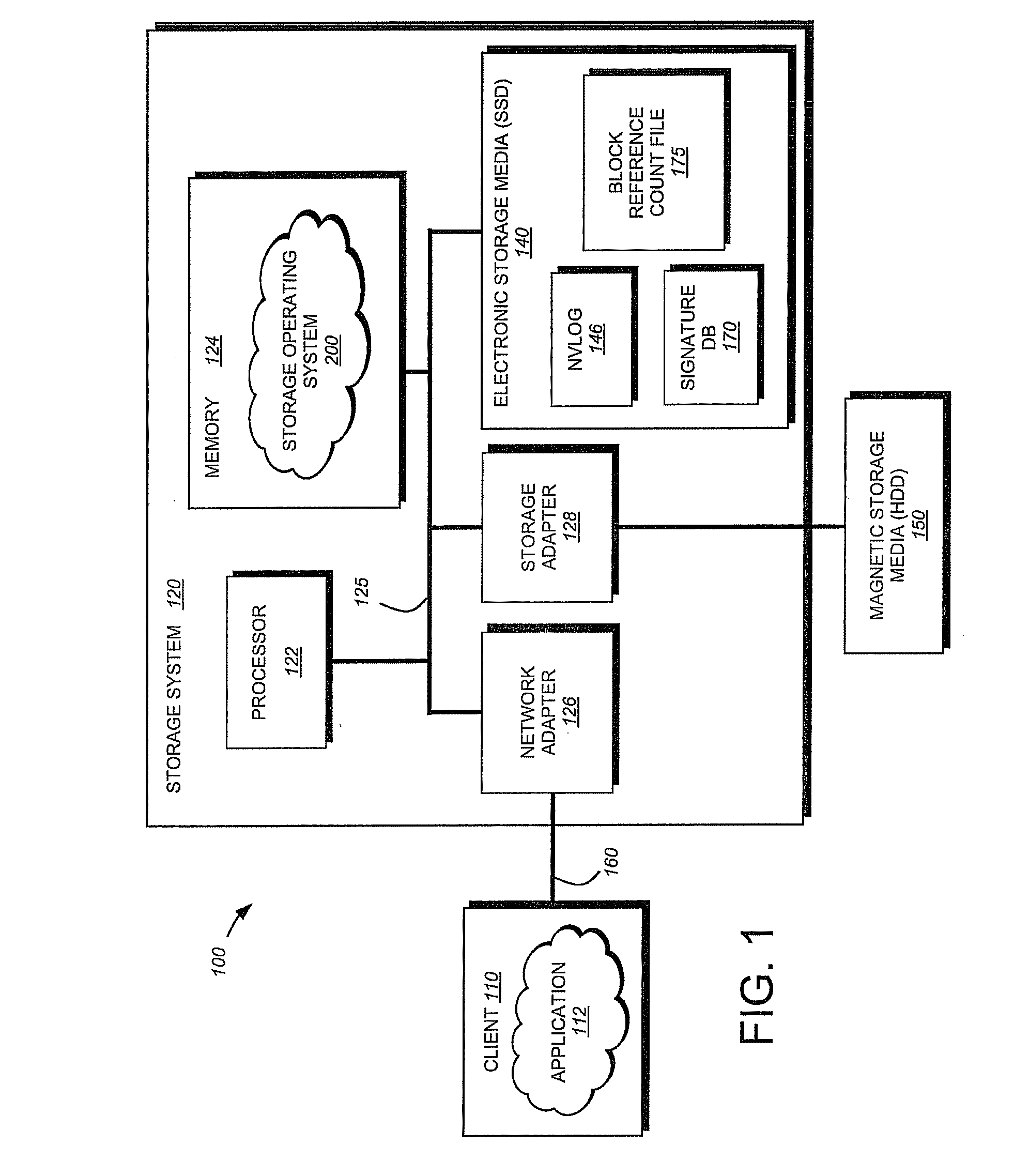

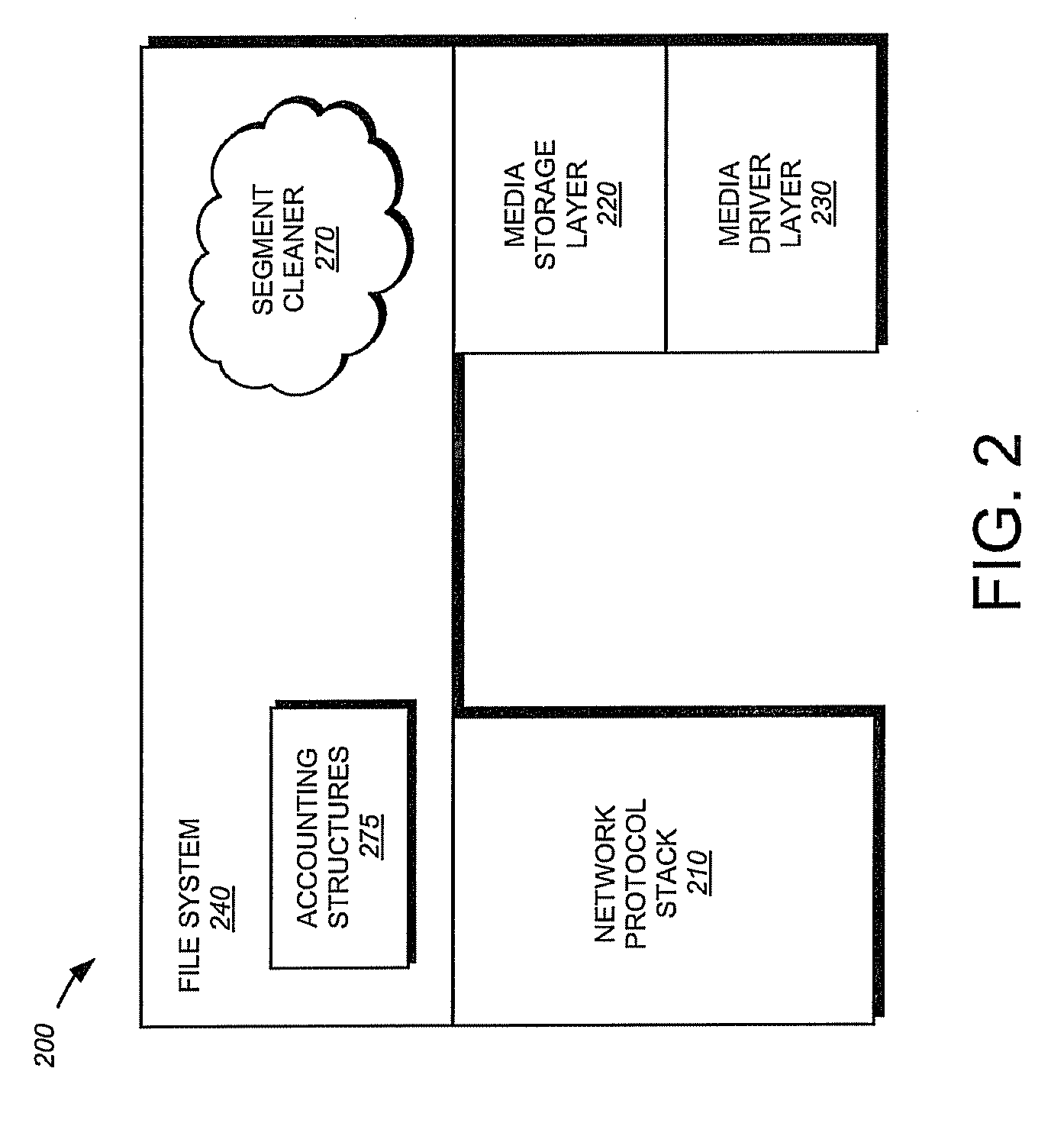

Flash-based data archive storage system

InactiveUS20100281207A1Large capacityMore capacityEnergy efficient ICTMemory loss protectionMass storageMagnetic tape

A flash-based data archive storage system having a large capacity storage array constructed from a plurality of dense flash devices is provided. The flash devices are illustratively multi-level cell (MLC) flash devices that are tightly packaged to provide a low-power, high-performance data archive system having substantially more capacity per cubic inch than more dense tape or disk drives. The flash-based data archive system may be adapted to employ conventional data de-duplication and compression methods to compactly store data. Furthermore, the flash-based archive system has a smaller footprint and consumes less power than the tape and / or disk archive system.

Owner:NETWORK APPLIANCE INC

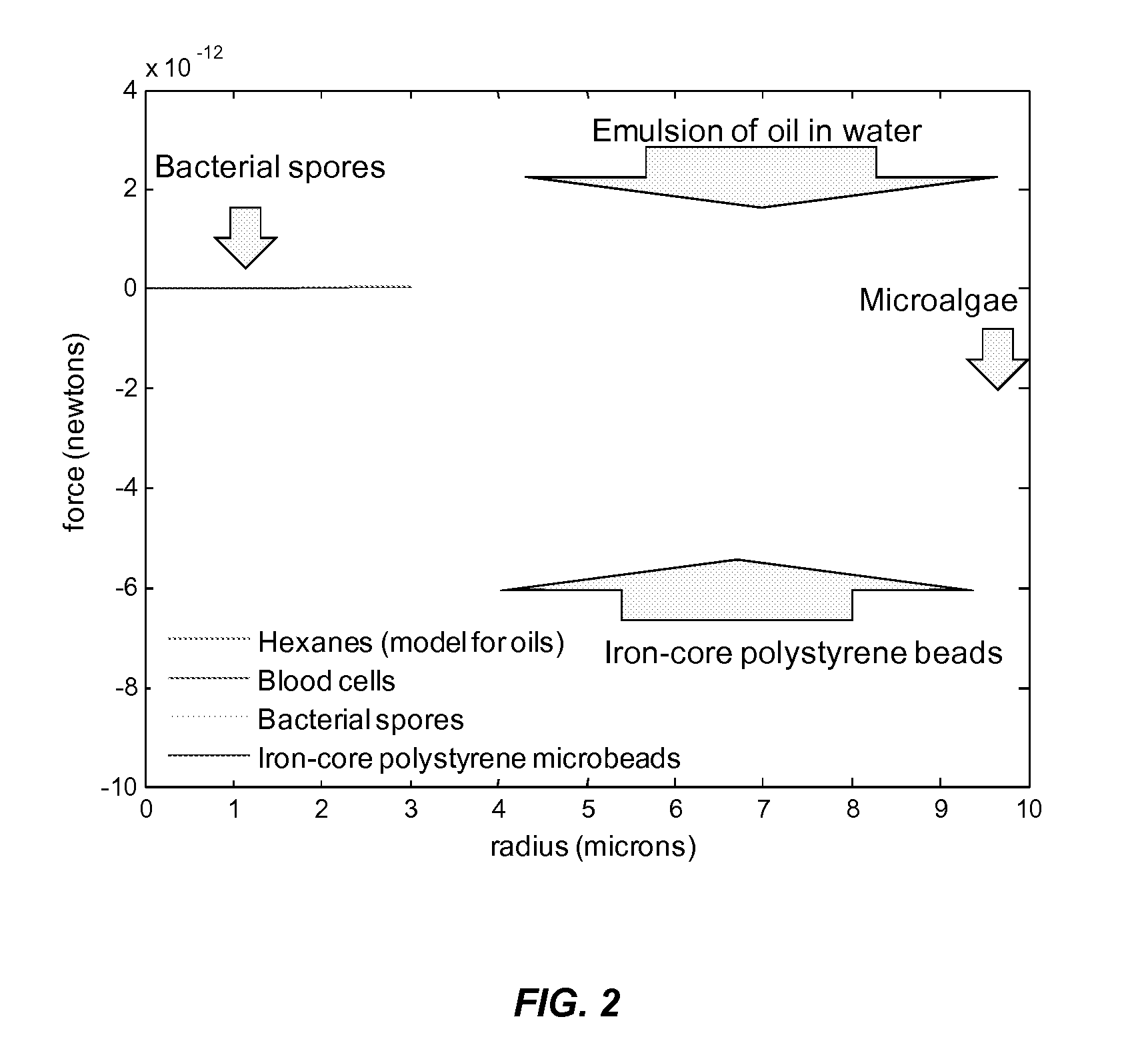

Ultrasound and acoustophoresis for water purification

InactiveUS20110123392A1Low separationEfficiently separateSeawater treatmentBlast furnace detailsStanding waveChemistry

Provided herein are systems and methods for separation of particulate from water using ultrasonically generated acoustic standing waves.

Owner:FLODESIGN SONICS

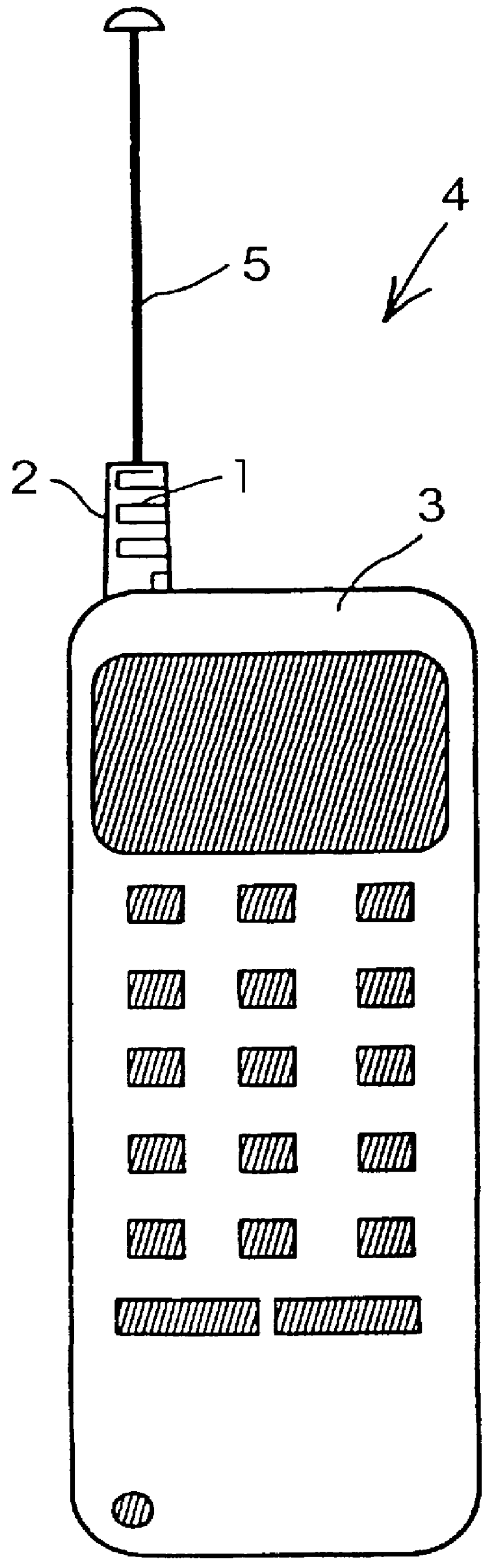

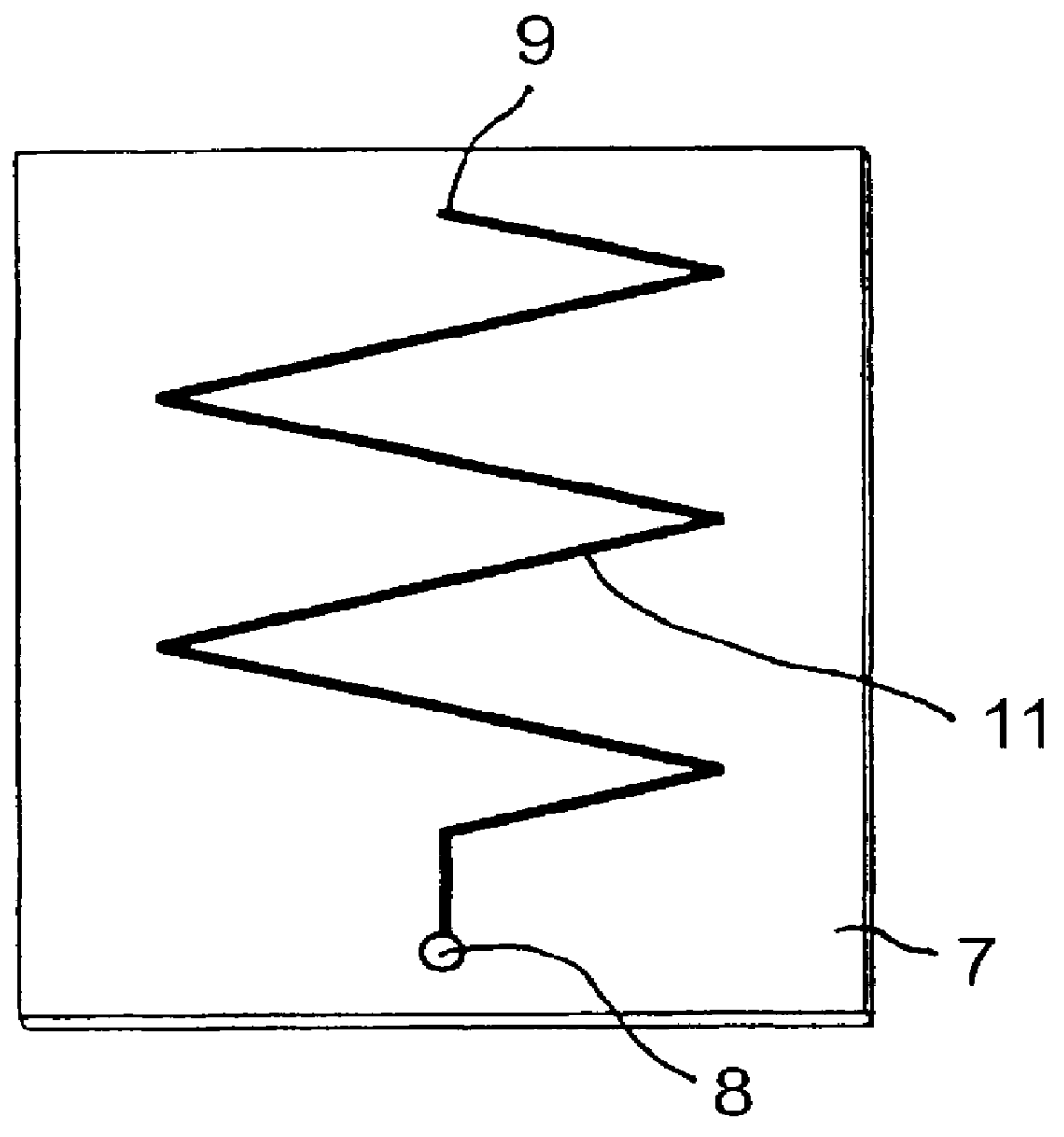

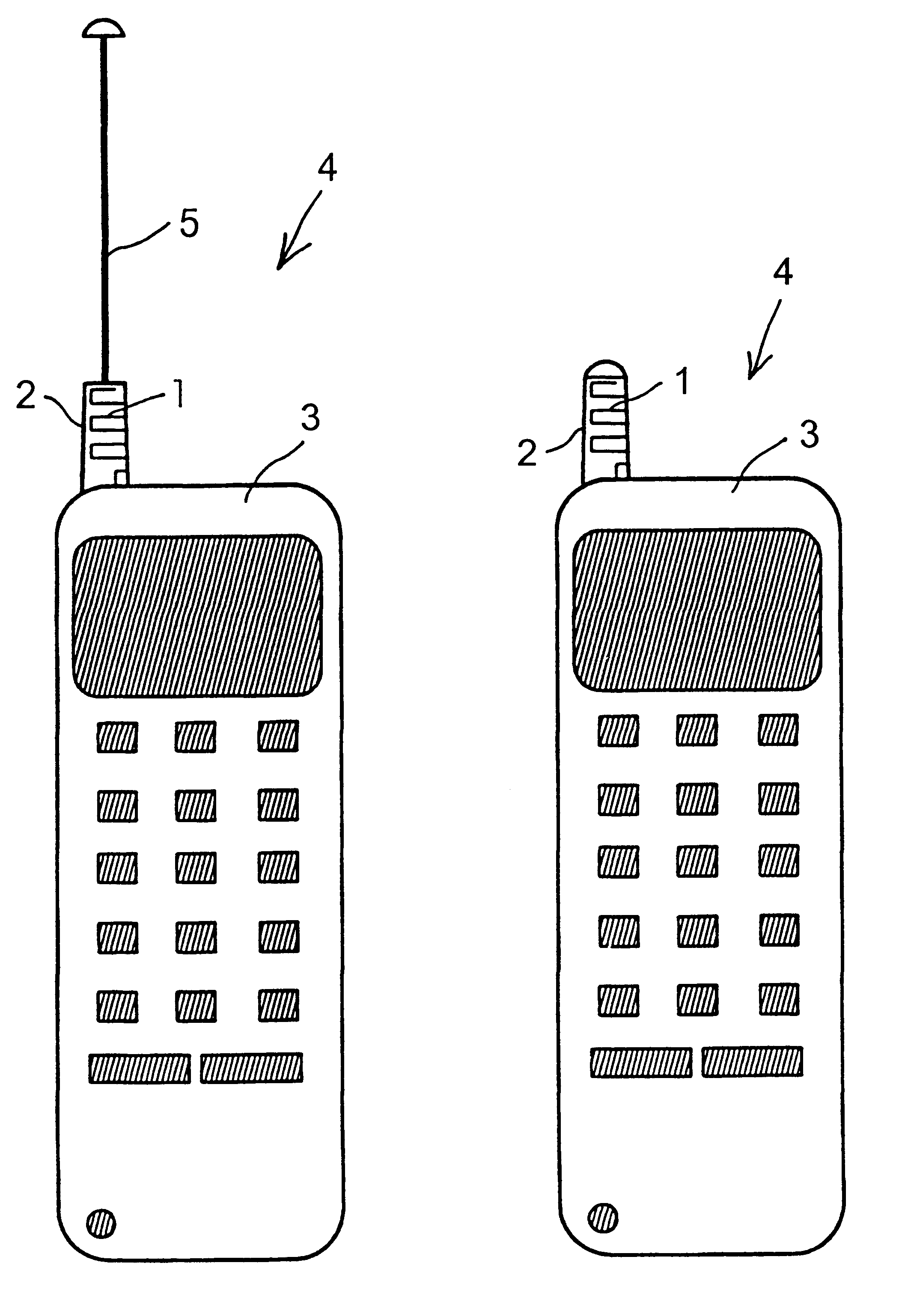

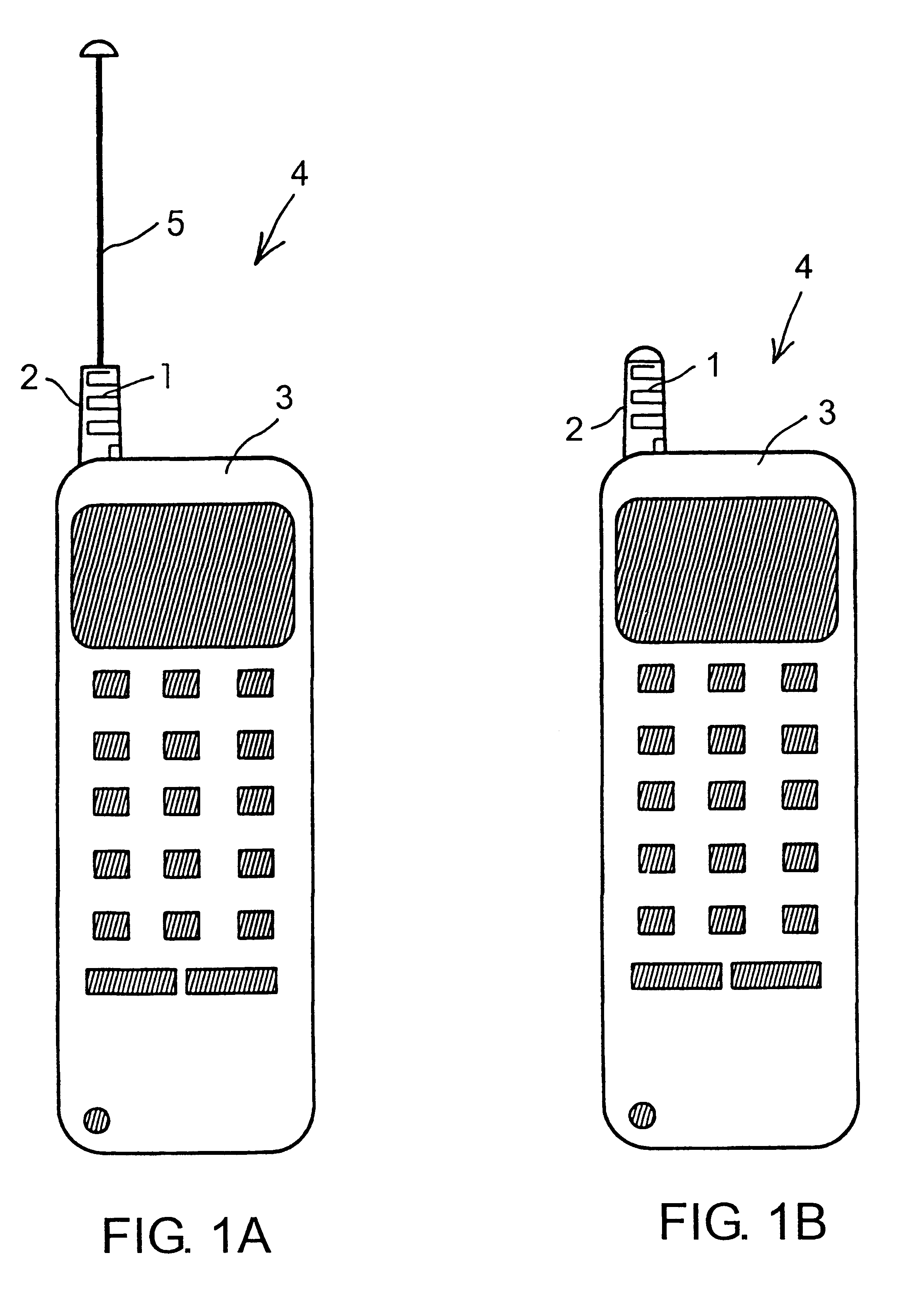

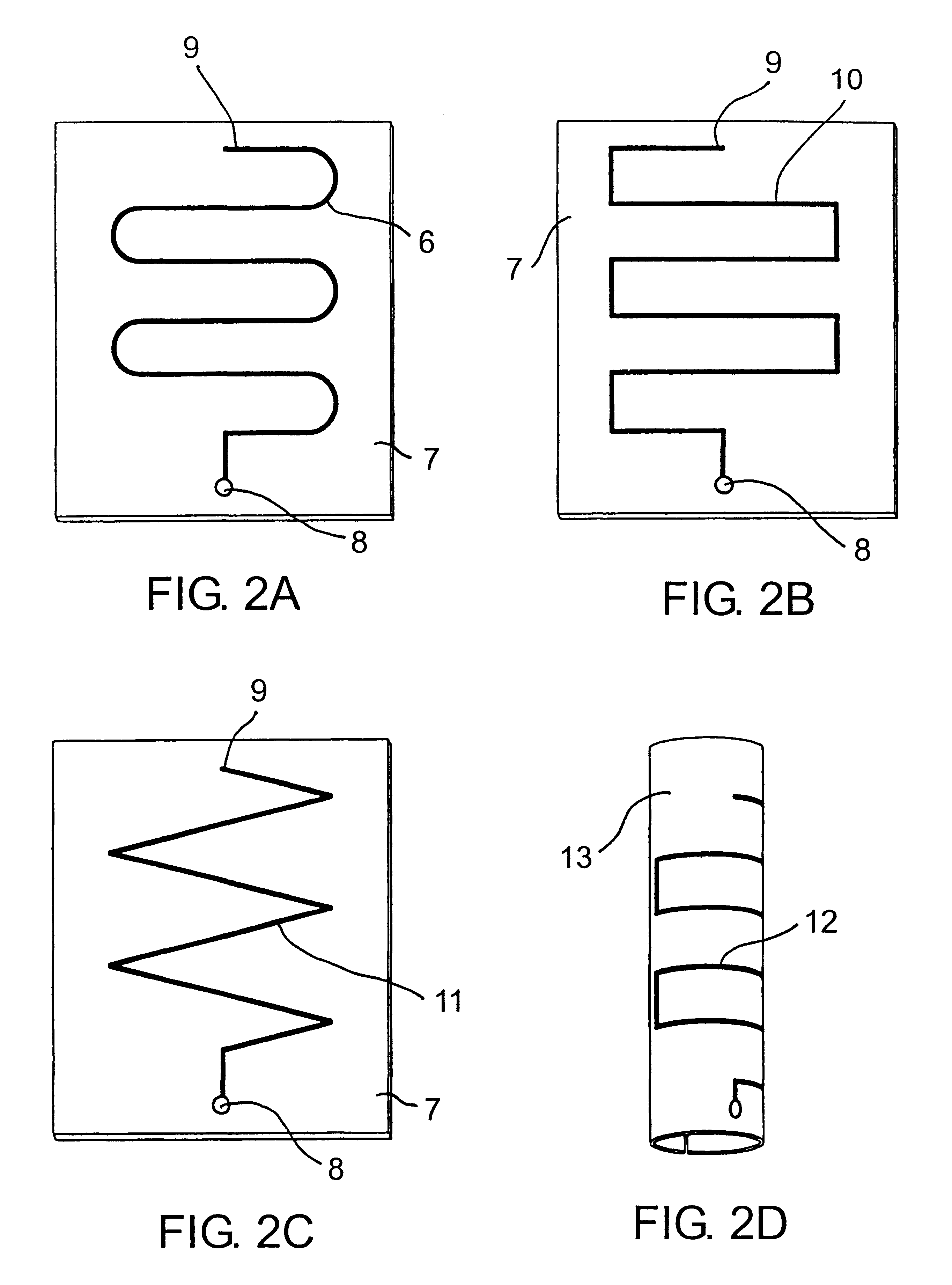

Meander antenna device

InactiveUS6069592AImprove antenna performanceEfficient and impedanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandMeander

An antenna means for a portable radio communication device, in particular a hand-portable mobile telephone, having at least one radiating element that has a meandering and cylindrical configuration. This structure is specifically advantageous in combination with an extendable and retractable whip antenna and, when having two or more meandering radiating elements, in multi-band radiating structures. The antenna device is suitable for manufacturing in large quantities, for example by a flexible printed circuit board technique.

Owner:LAIRD TECH AB (SE)

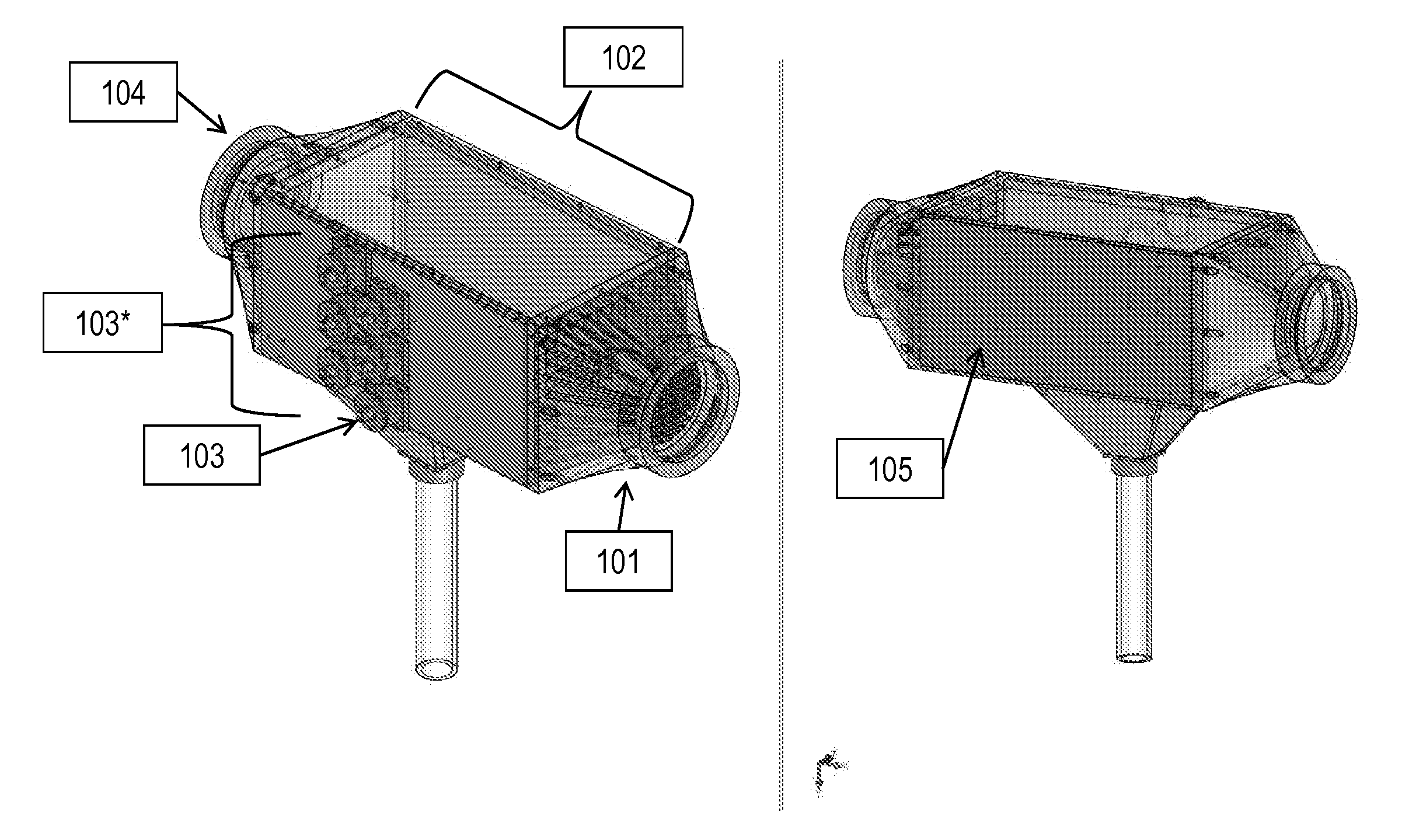

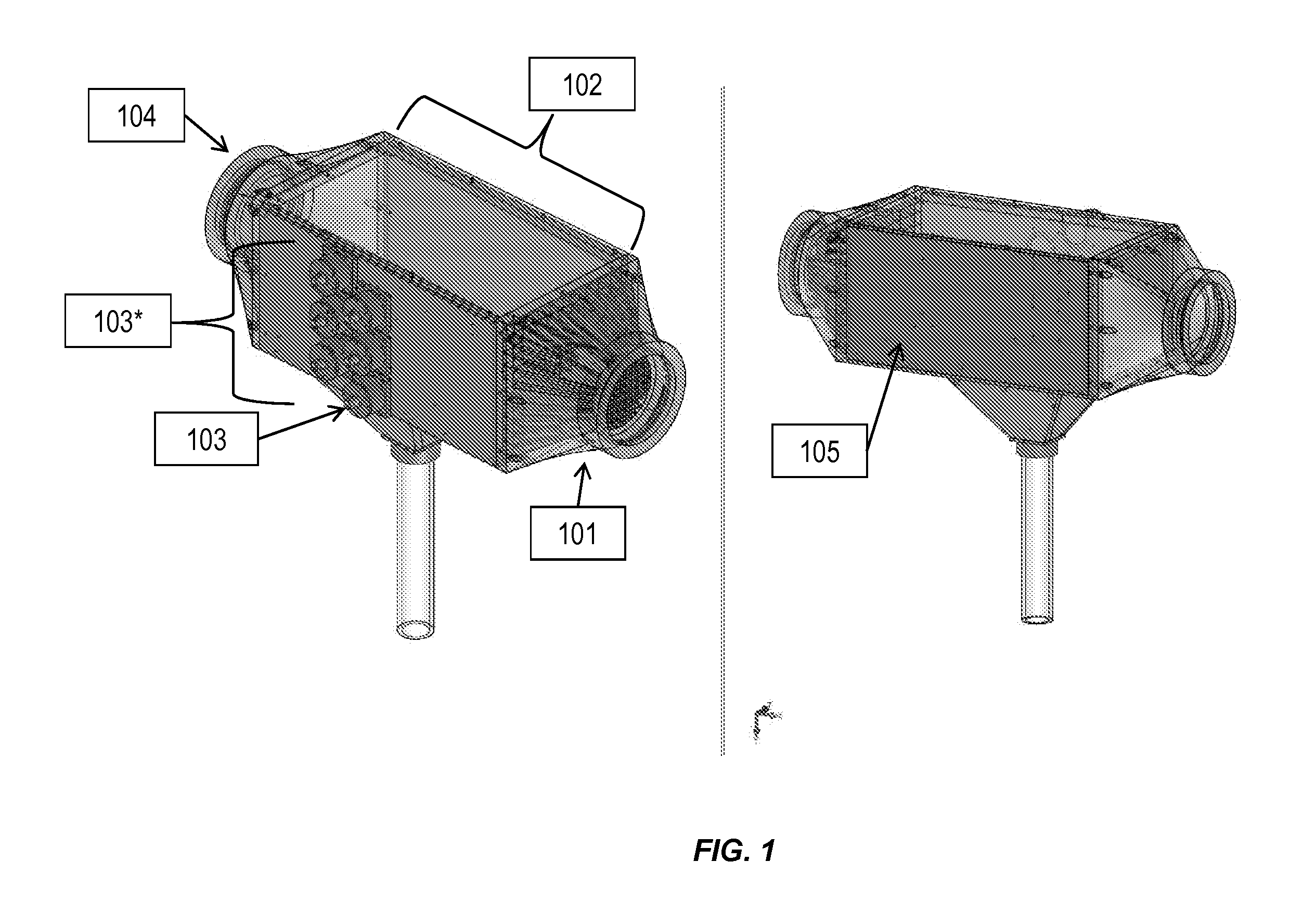

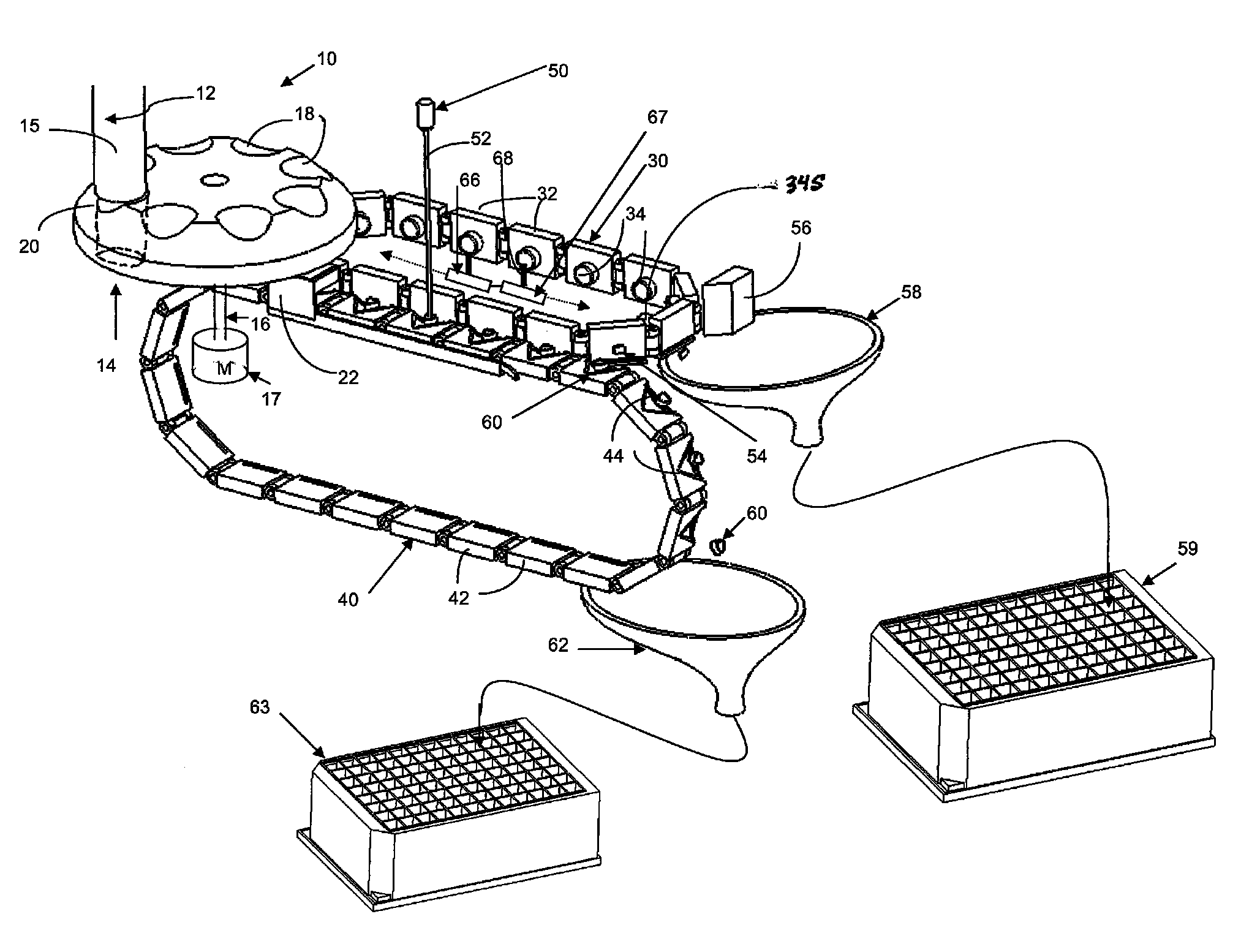

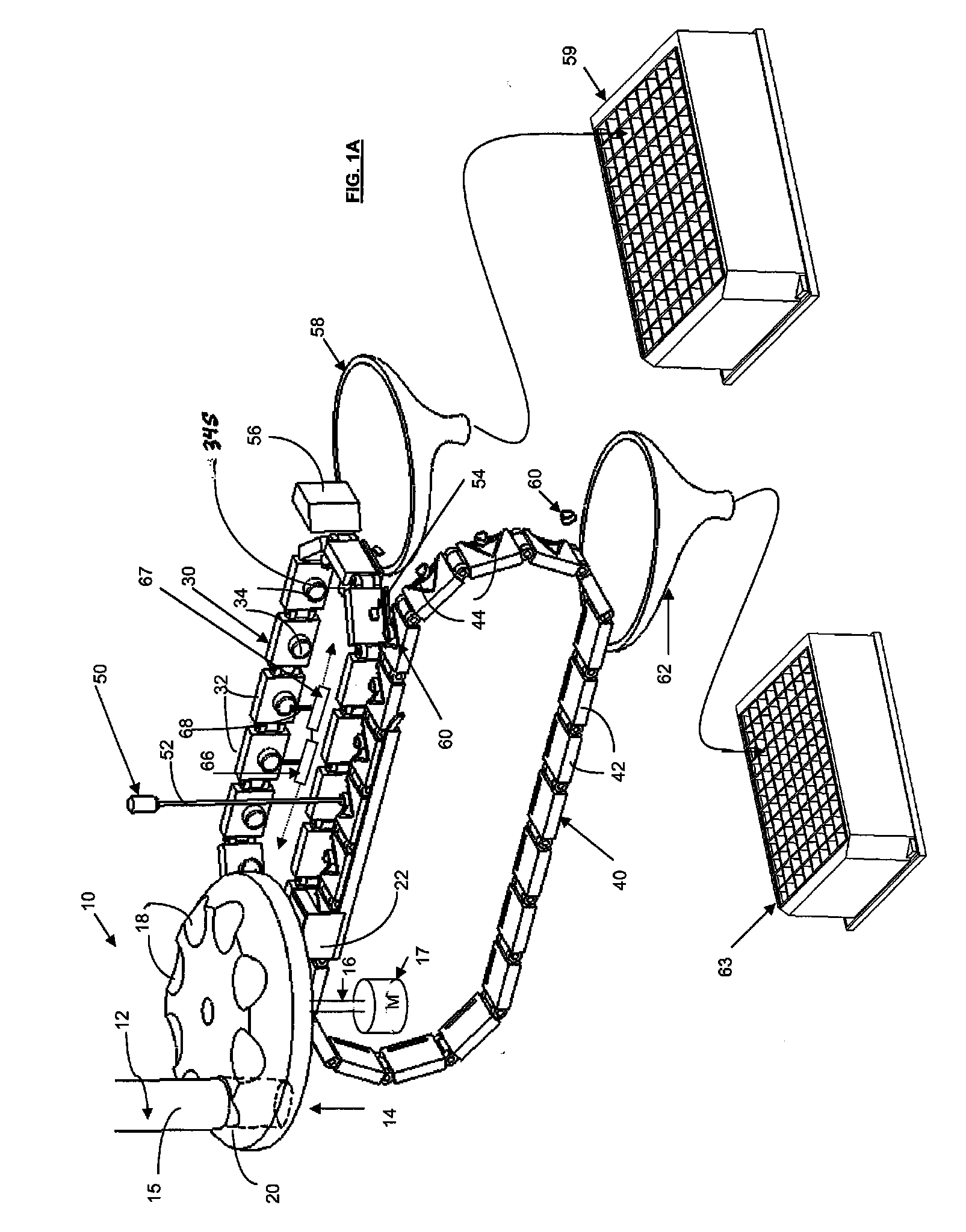

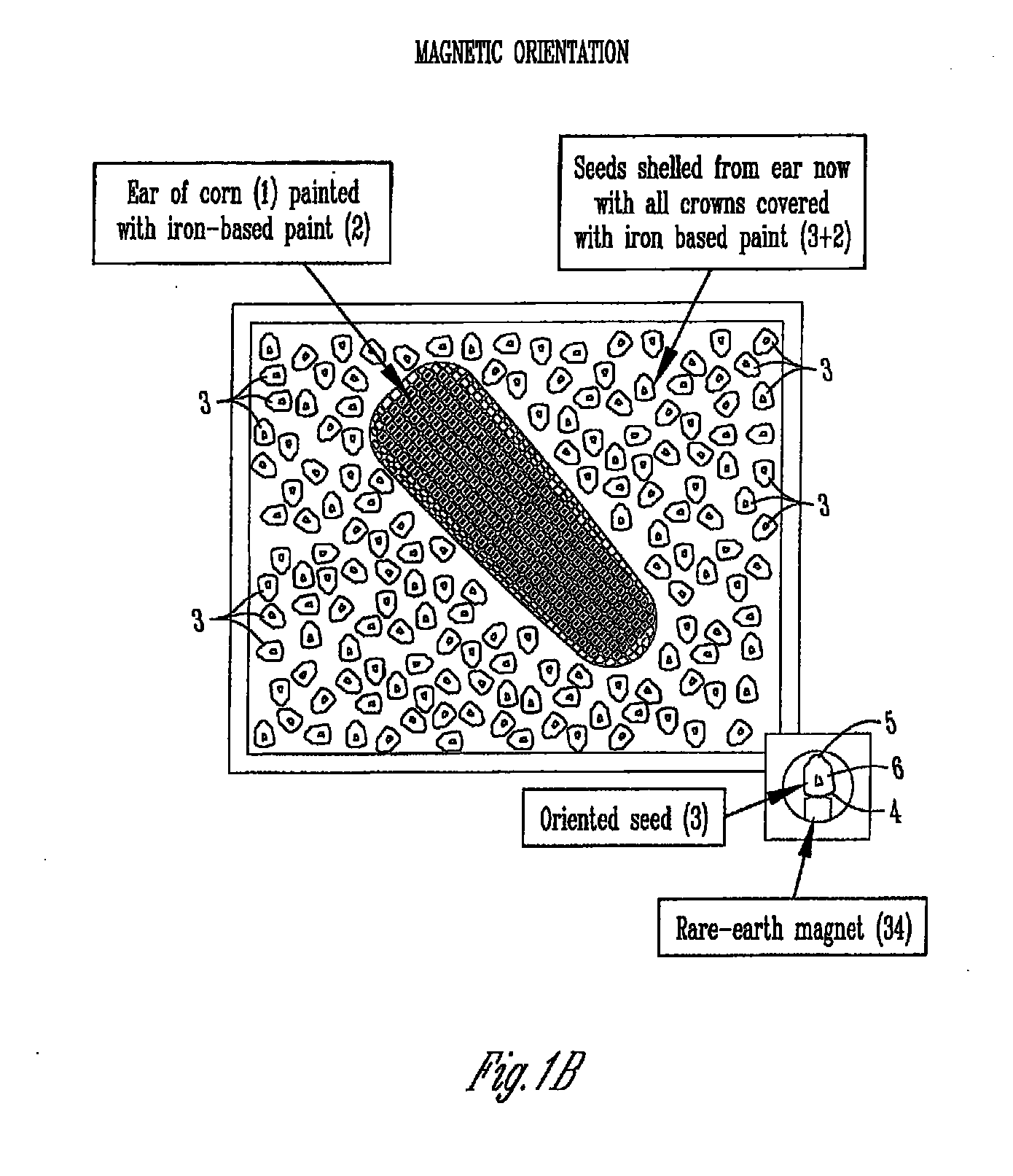

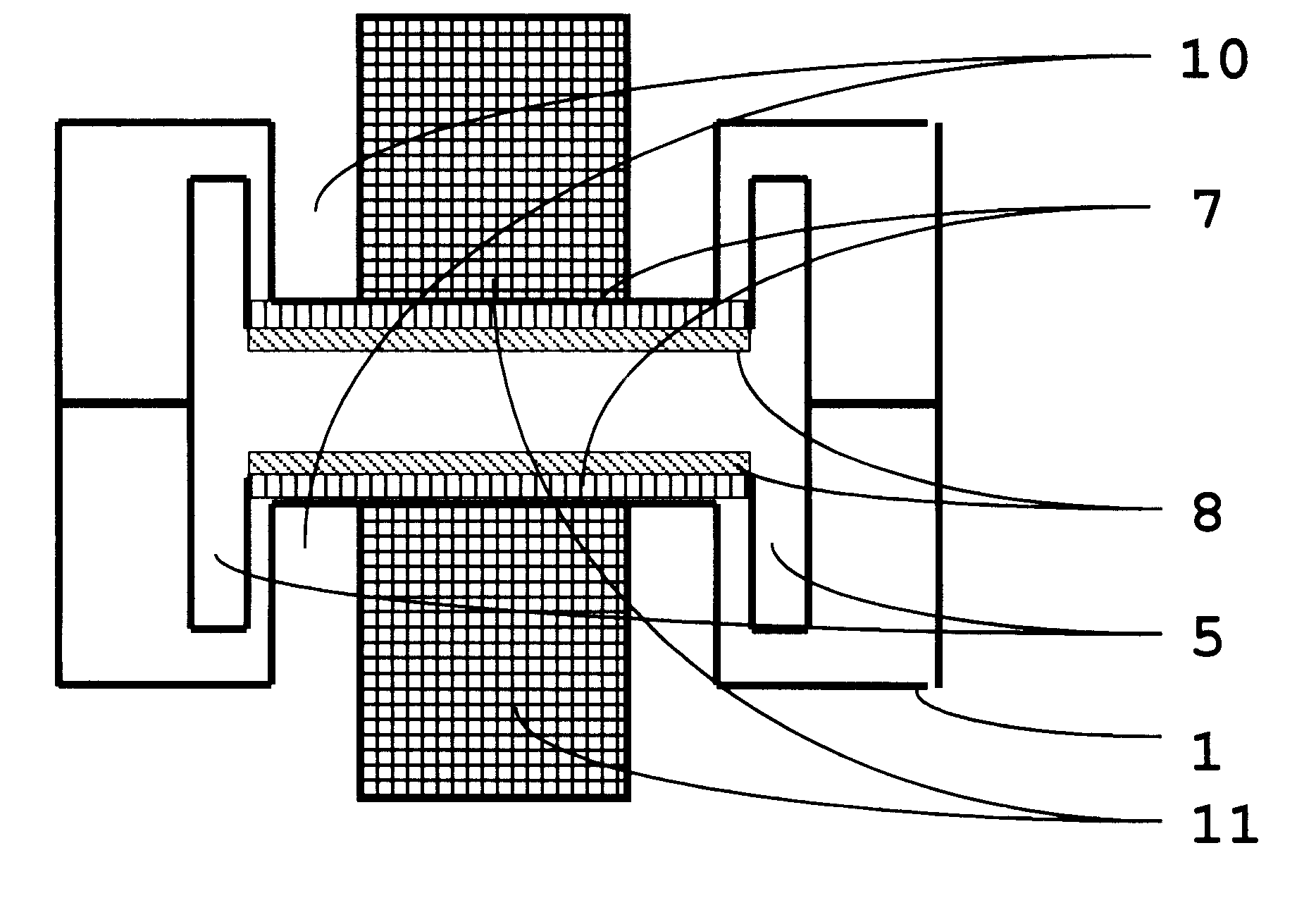

Apparatus, method and system for handling, positioning, and/or automatically orienting objects

InactiveUS20080131254A1Avoid small quantitiesMaximum flexibilityWithdrawing sample devicesPreparing sample for investigationEngineeringComputer vision

A method and apparatus for automatic positioning and / or orientation of an object. The method includes applying a substance or component to an object, or takes advantage of a substance or component already on or associated with an object. The substance or component has a characteristic that can be utilized to automatically attract the substance or component. That characteristic is used to position, move, and / or orient the object automatically, without requiring manual handling. The object can then be further processed or handled. In one embodiment, the substance or component is a magnetically active substance or component. The attraction can be actuated by a magnet.

Owner:PIONEER HI BRED INT INC

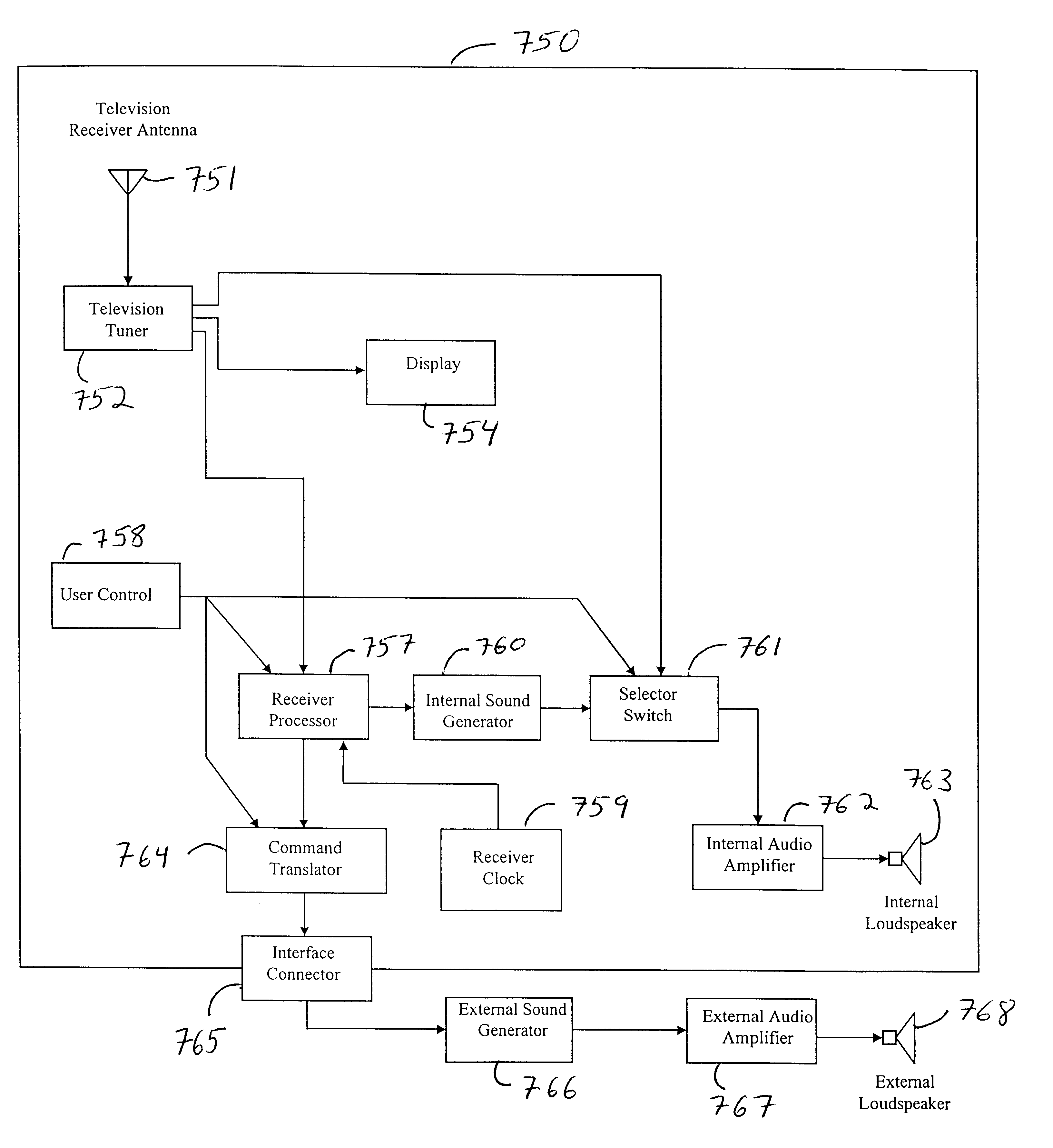

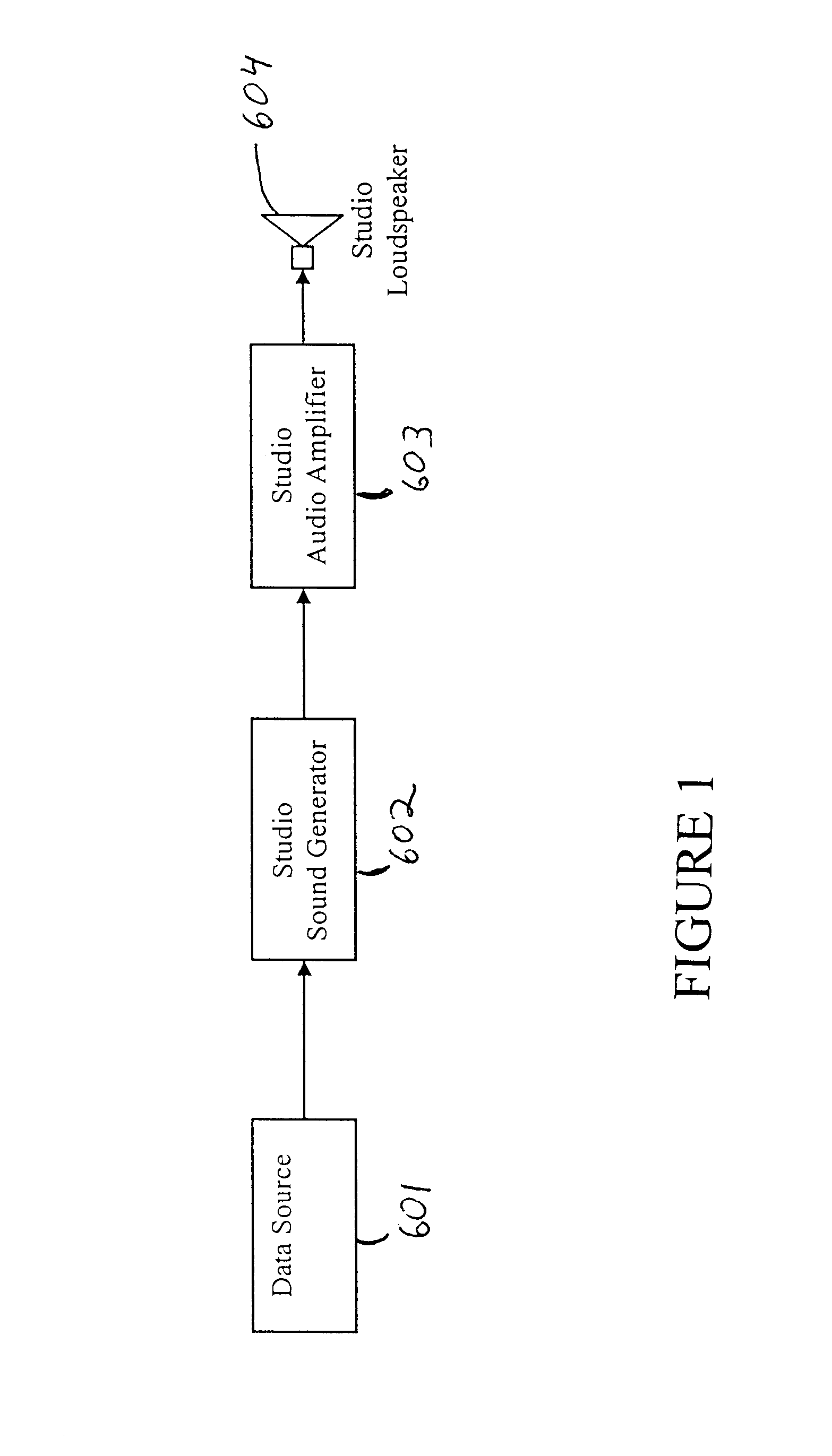

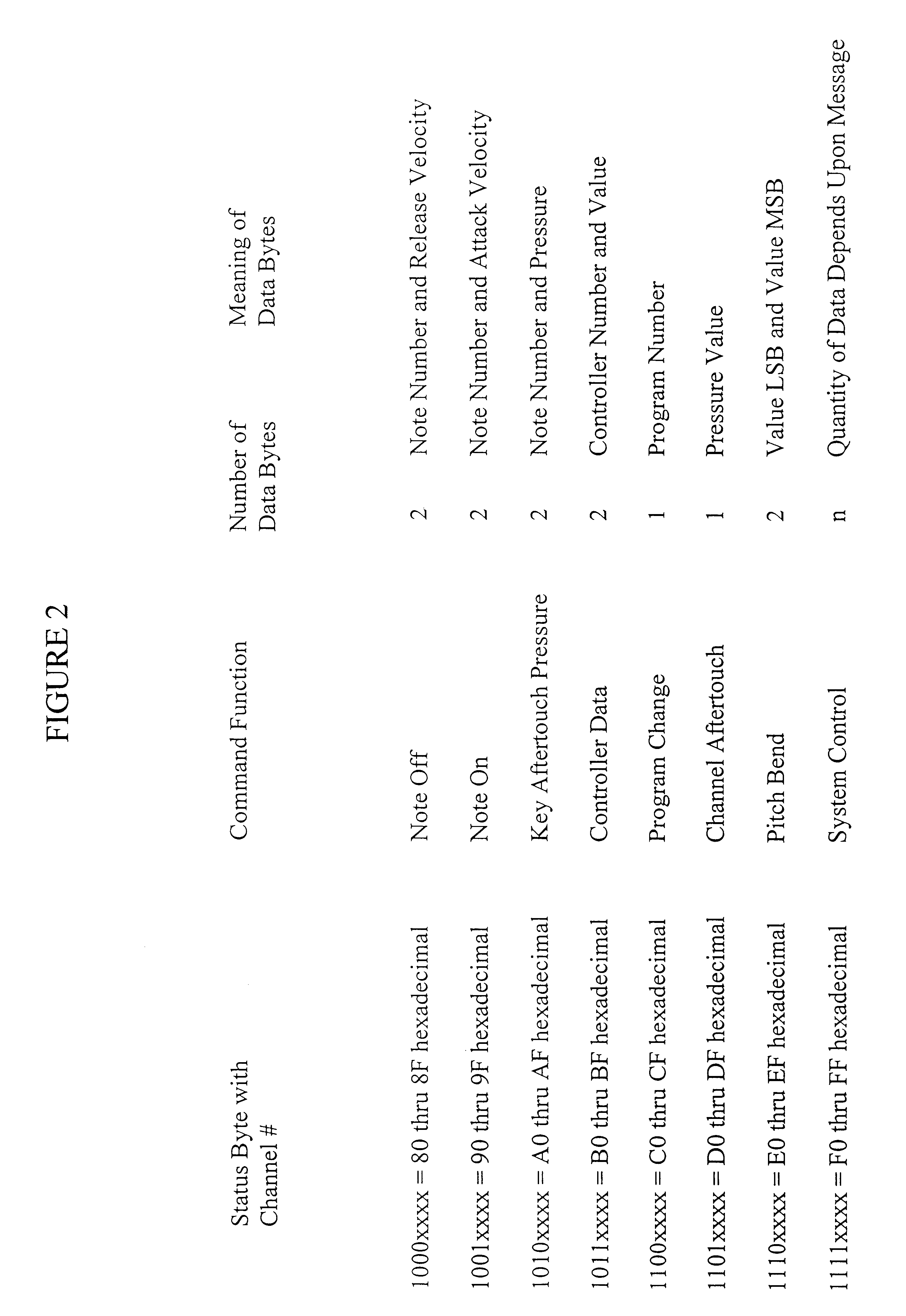

Method and apparatus for audio broadcast of enhanced musical instrument digital interface (MIDI) data formats for control of a sound generator to create music, lyrics, and speech

InactiveUS6462264B1Inhibit outputImprove speech clarityElectrophonic musical instrumentsCode conversionCarrier signalData format

A method and apparatus for the transmission and reception of broadcasted instrumental music, vocal music, and speech using digital techniques. The data is structured in a manner similar to the current standards for MIDI data. Transmitters broadcast the data to receivers which contain internal sound generators or an interface to external sound generators that create sounds in response to the data. The invention includes transmission of multiple audio data signals for several languages on a conventional radio and television carrier through the use of low bandwidth data. Error detection and correction data is included within the transmitted data. The receiver has various error compensating mechanisms to overcome errors in data that cannot be corrected using the error correcting data that the transmitter sent. The data encodes for elemental vocal sounds and music.

Owner:ELAM CARL

Twist-open dispenser with applicator & method of applying skin care products & method of merchandising paint

A dispenser cap with an applicator is connected to a container and a detachable enclosure protects the applicator when the dispenser is not in use. When attached to the cap, the enclosure has a pin that blocks an opening in the cap. The container may hold any fluid material, for example, a skin care product, deodorant, paint, etc. The container may contain various means of identifying the color of paint contained therein, and only a small amount of paint is within the container. This enables a consumer to obtain a number of containers each holding a paint of a different color to apply to a test surface.

Owner:PLATINUM INNOVATIONS

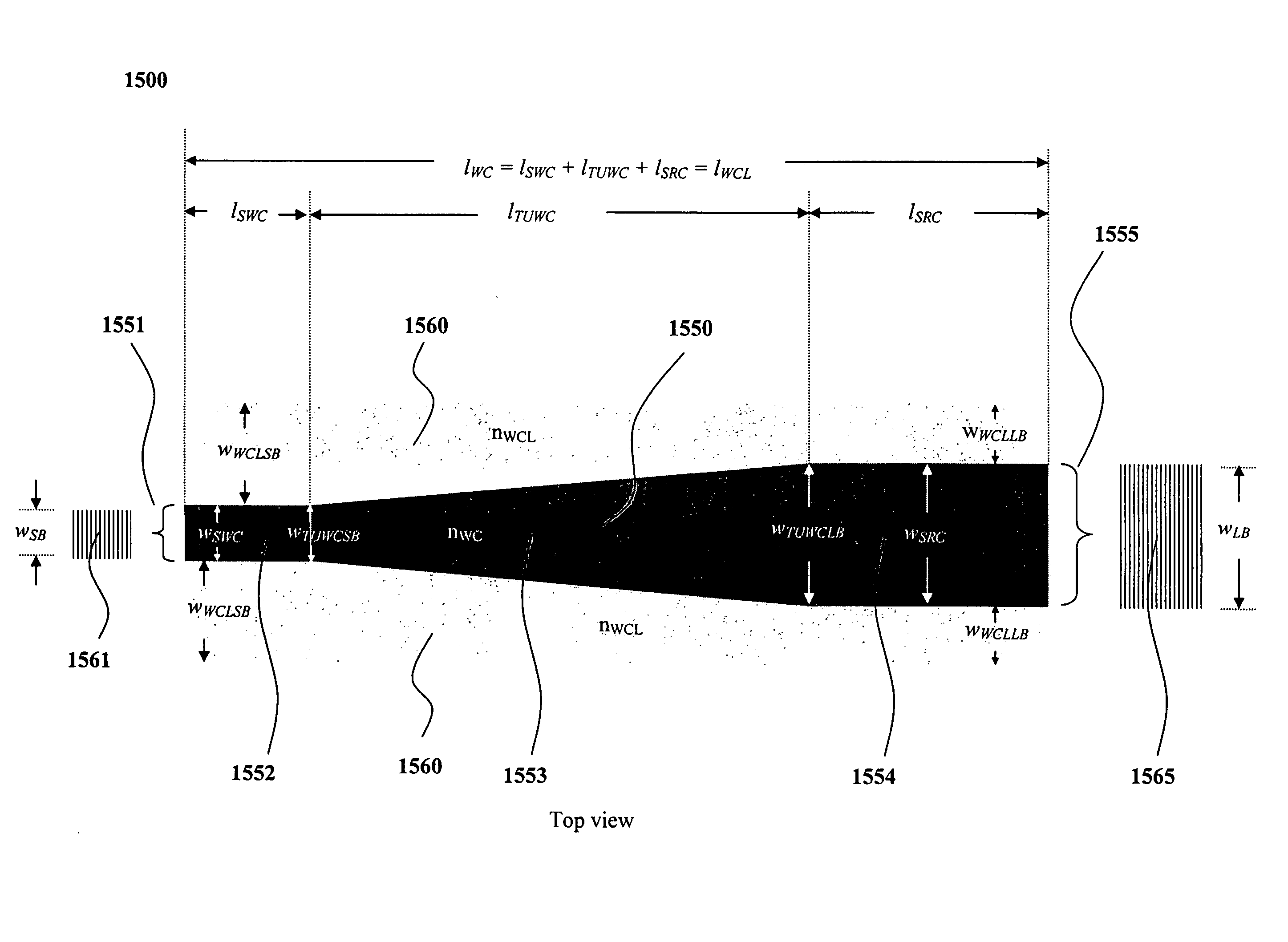

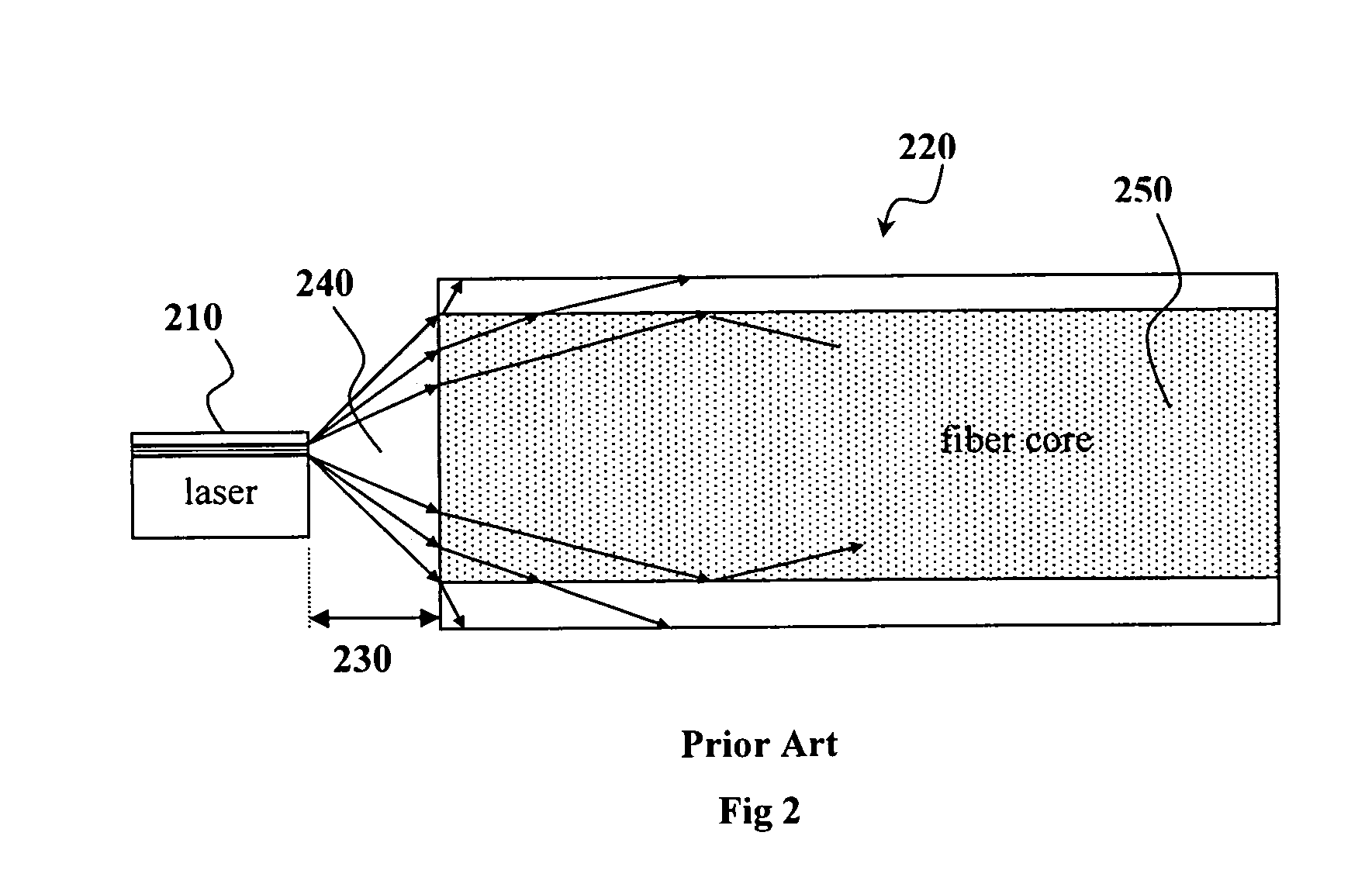

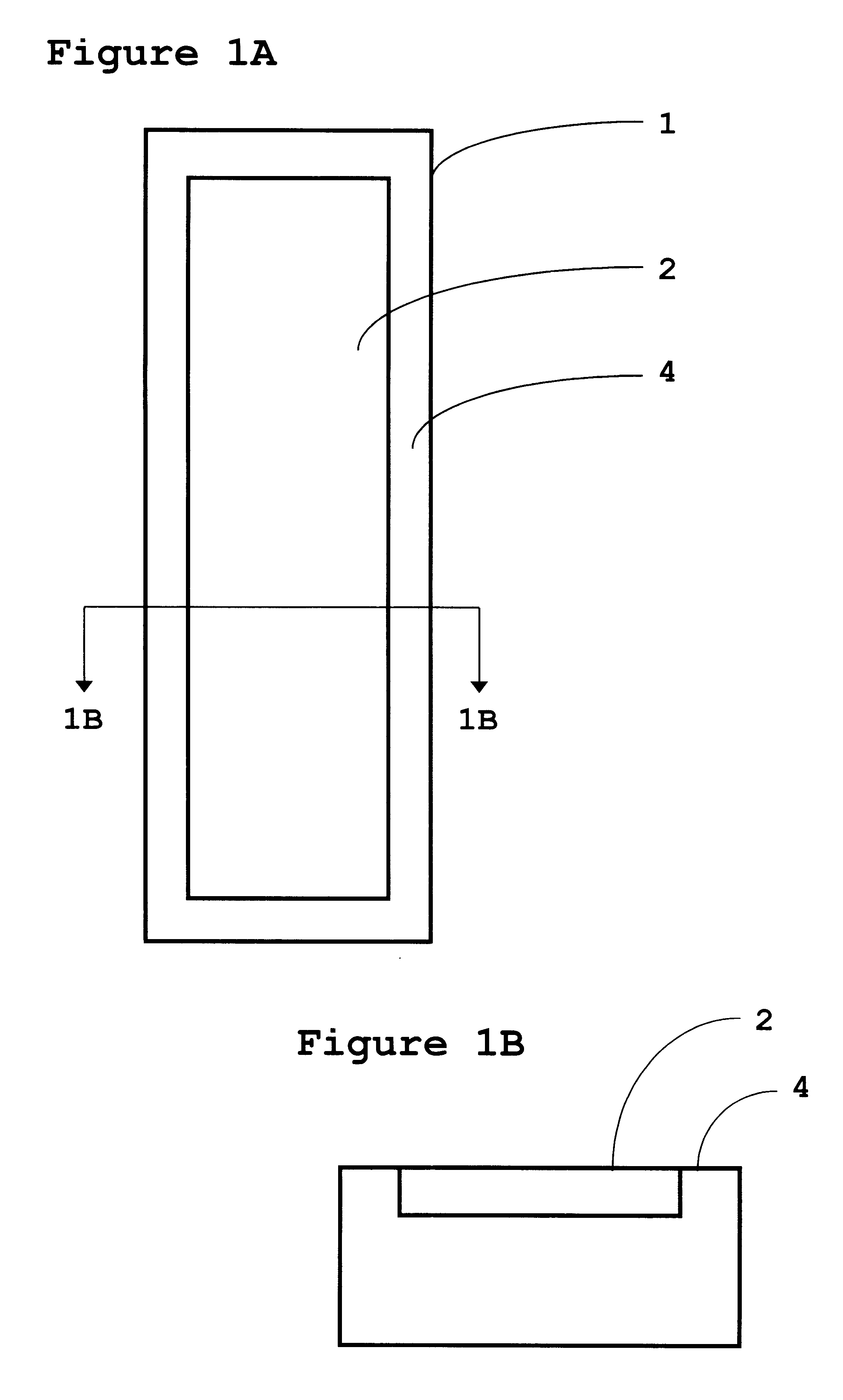

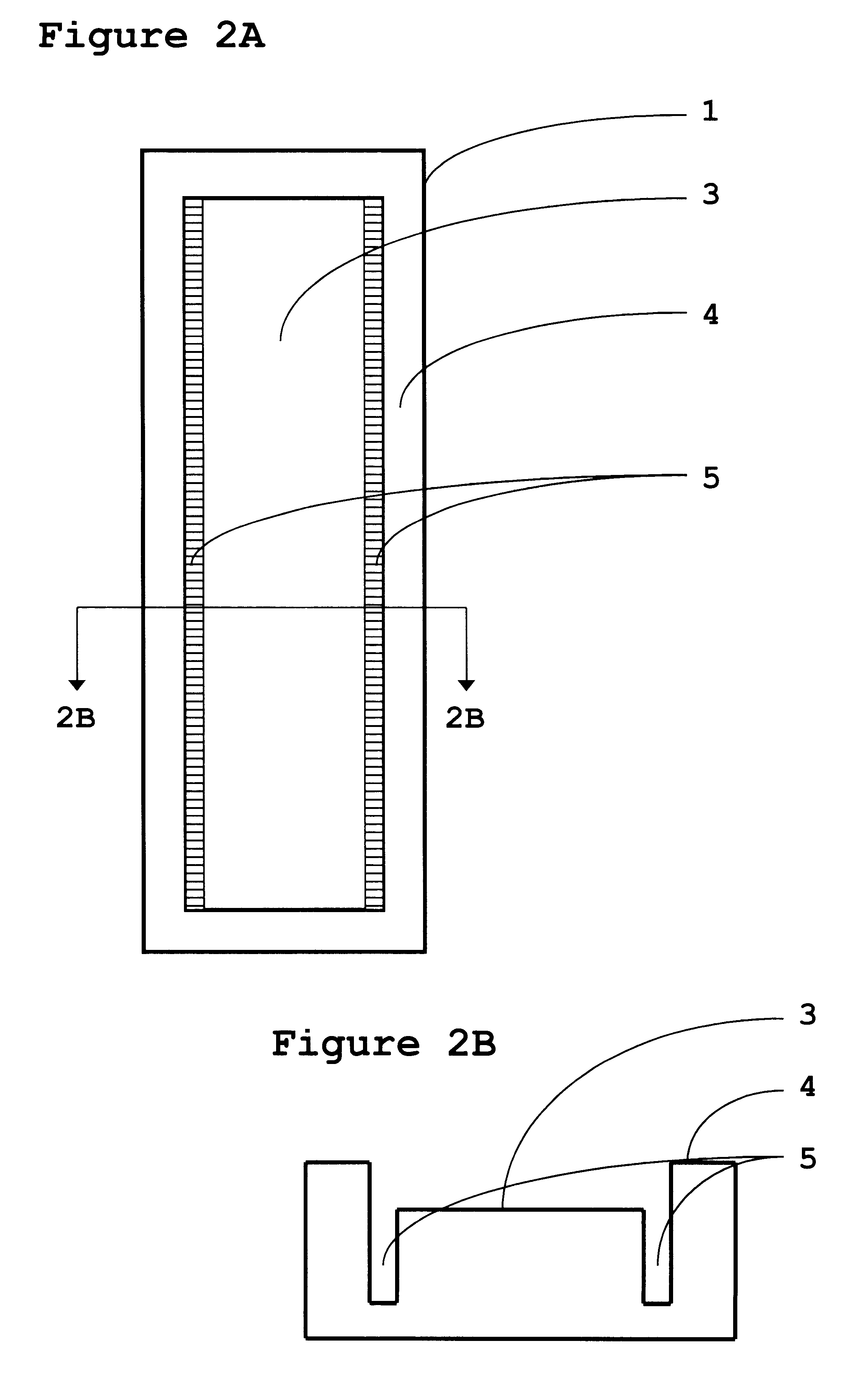

Integrated planar composite coupling structures for bi-directional light beam transformation between a small mode size waveguide and a large mode size waveguide

InactiveUS7218809B2Reduce manufacturing costReduce sensitivityCoupling light guidesOptical waveguide light guideFiberRefractive index contrast

Composite optical waveguide structures or mode transformers and their methods of fabrication and integration are disclosed, wherein the structures or mode transformers are capable of bi-directional light beam transformation between a small mode size waveguide and a large mode size waveguide. One aspect of the present invention is directed to an optical mode transformer comprising a waveguide core having a high refractive index contrast between the waveguide core and the cladding, the optical mode transformer being configured such that the waveguide core has a taper wherein a thickness of the waveguide core tapers down to a critical thickness value, the critical thickness value being defined as a thickness value below which a significant portion of the energy of a light beam penetrates into the cladding layers surrounding the taper structure thereby enlarging the small mode size. This primary tapered core structure may be present in either a vertical or horizontal direction and may be combined with further up taper or down taper structures in the directions transverse to the primary taper direction. Another aspect of the present invention is directed to a non-cylindrical graduated refractive index (GRID) lens structure. The non-cylindrical GRIN structure has a graded refractive index having a maximum value at its core and a minimum value at its outer edges. The grading of the refractive index is provided in a either the vertical or horizontal directions and may have either a fixed refractive index or a graded refractive index in the transverse directions. Yet another aspect of the present invention is directed to composite optical mode transformers that are combinations of the taper waveguide structures and the non-cylindrical graduated refractive index structures. Yet another aspect of the present invention is the further integration of the mode transformers with V-grooves for multiple input / output fibers and alignment platform for multiple input / output photonic chips or devices.

Owner:HO SENG TIONG

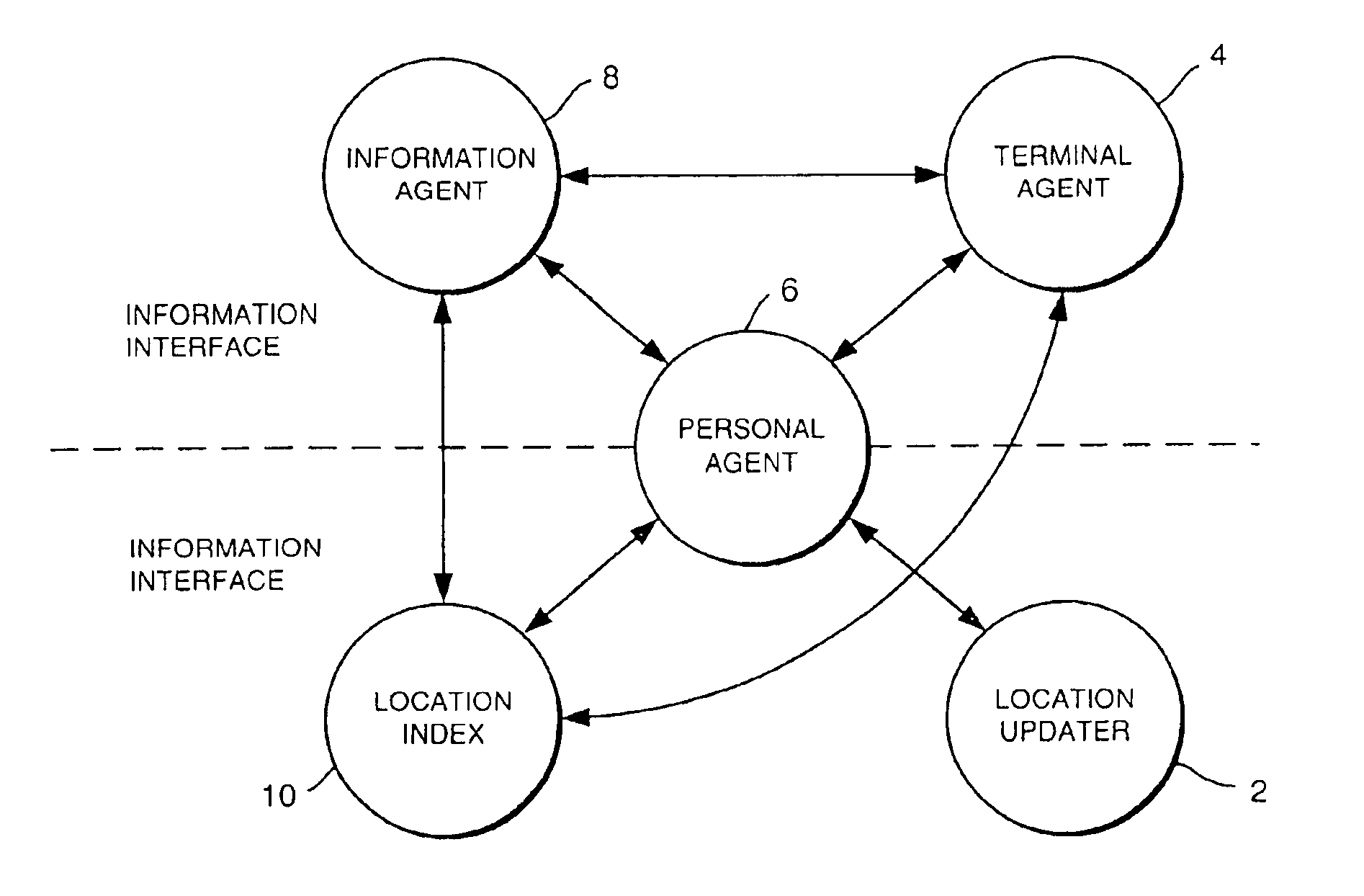

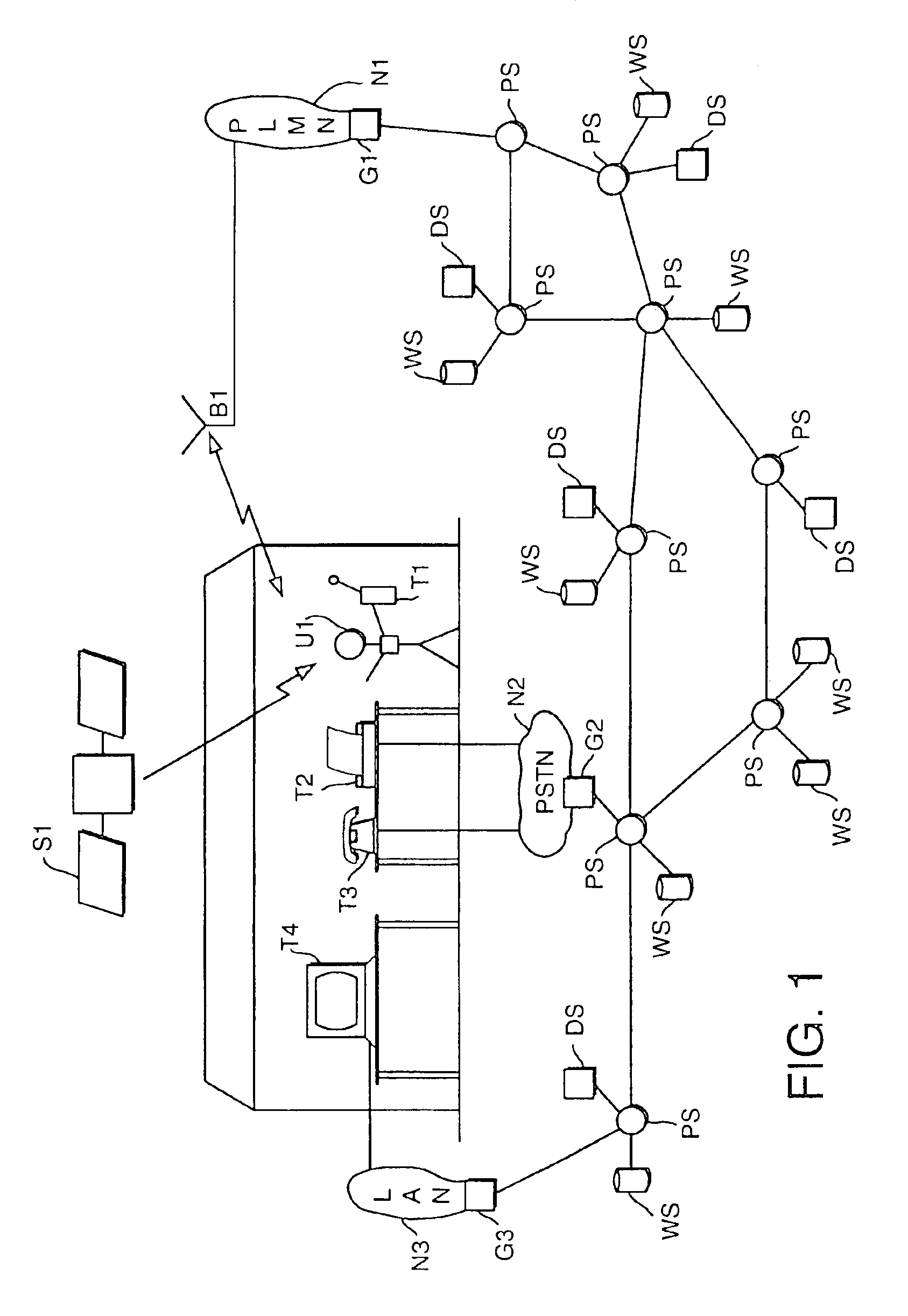

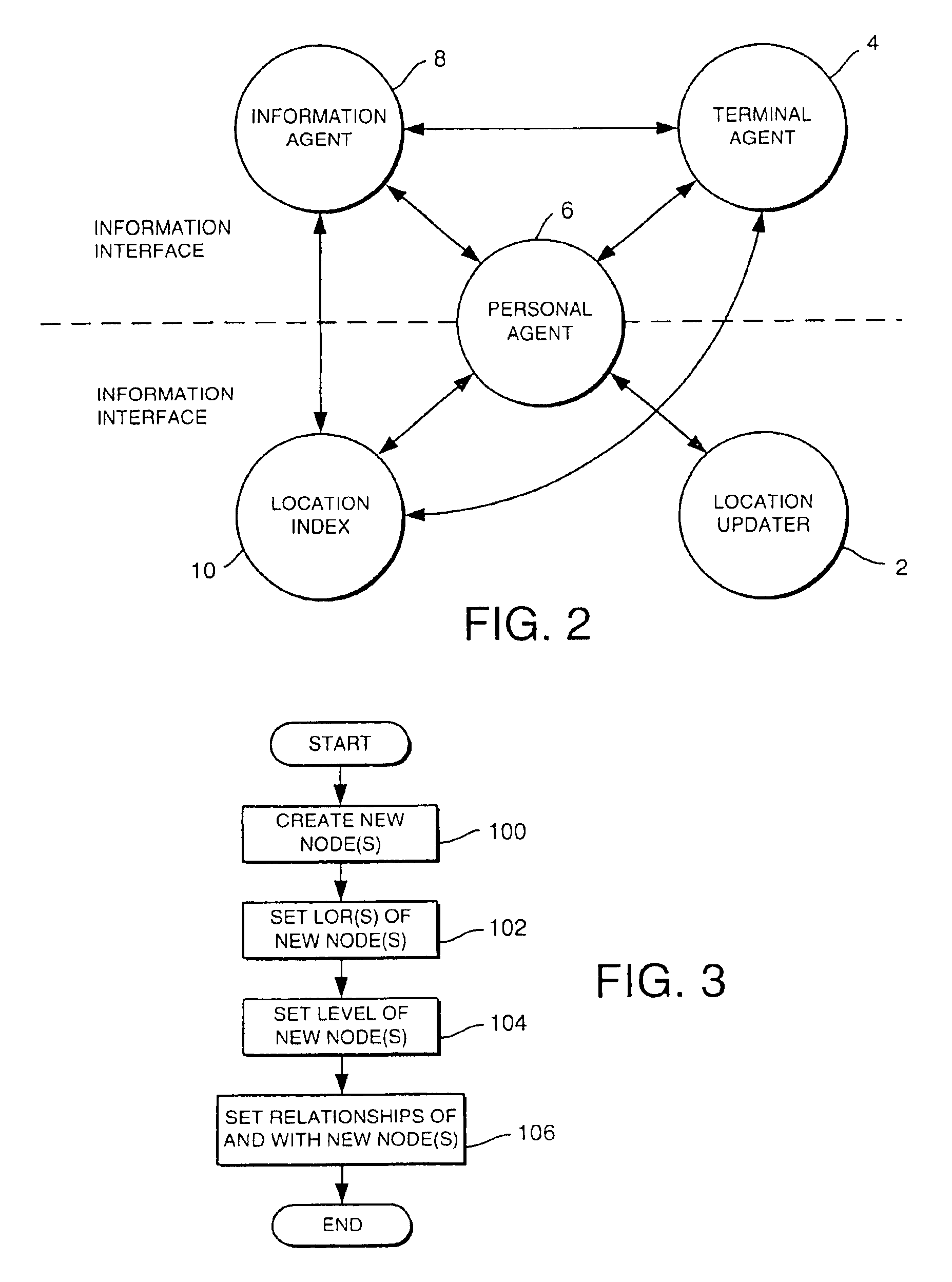

Storage and retrieval of location based information in a distributed network of data storage devices

InactiveUS6826598B1Avoid small quantitiesSufficient specificityRoad vehicles traffic controlMultiple digital computer combinationsLocation based informationComputer terminal

A method of storing and / or retrieving location-based information comprises: storing, in a distributed network of data storage devices accessible simultaneously from a plurality of remote user terminals, data defining a plurality of first localities in relation to which information storage is accessible, and selecting ones of the first localities to represent second localities for which information is to be stored and / or retrieved such that i) the first and second localities bear a predetermined locational relationship, and ii) the first and second localities bear a predetermined relationship in size.

Owner:BRITISH TELECOMM PLC

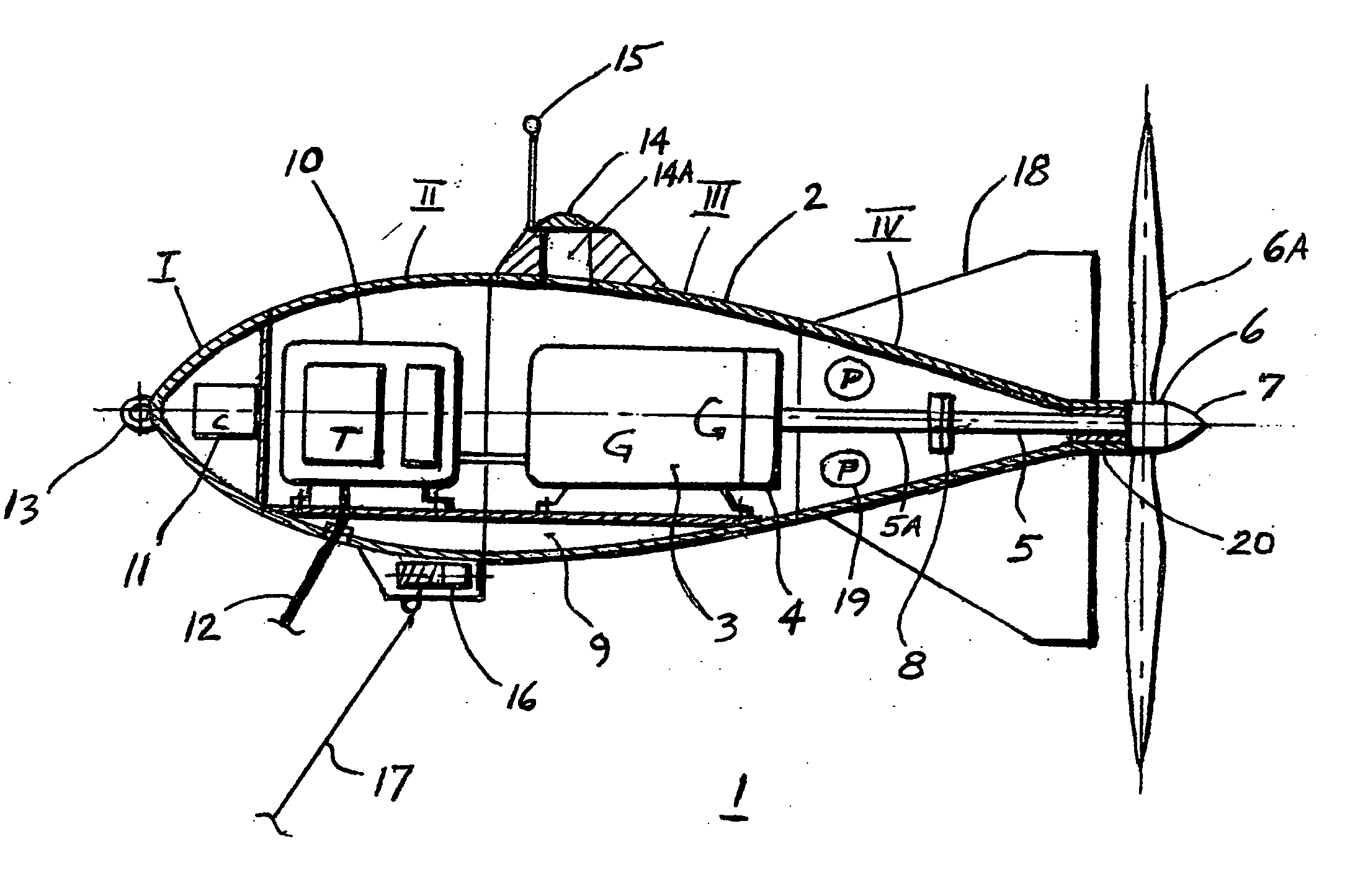

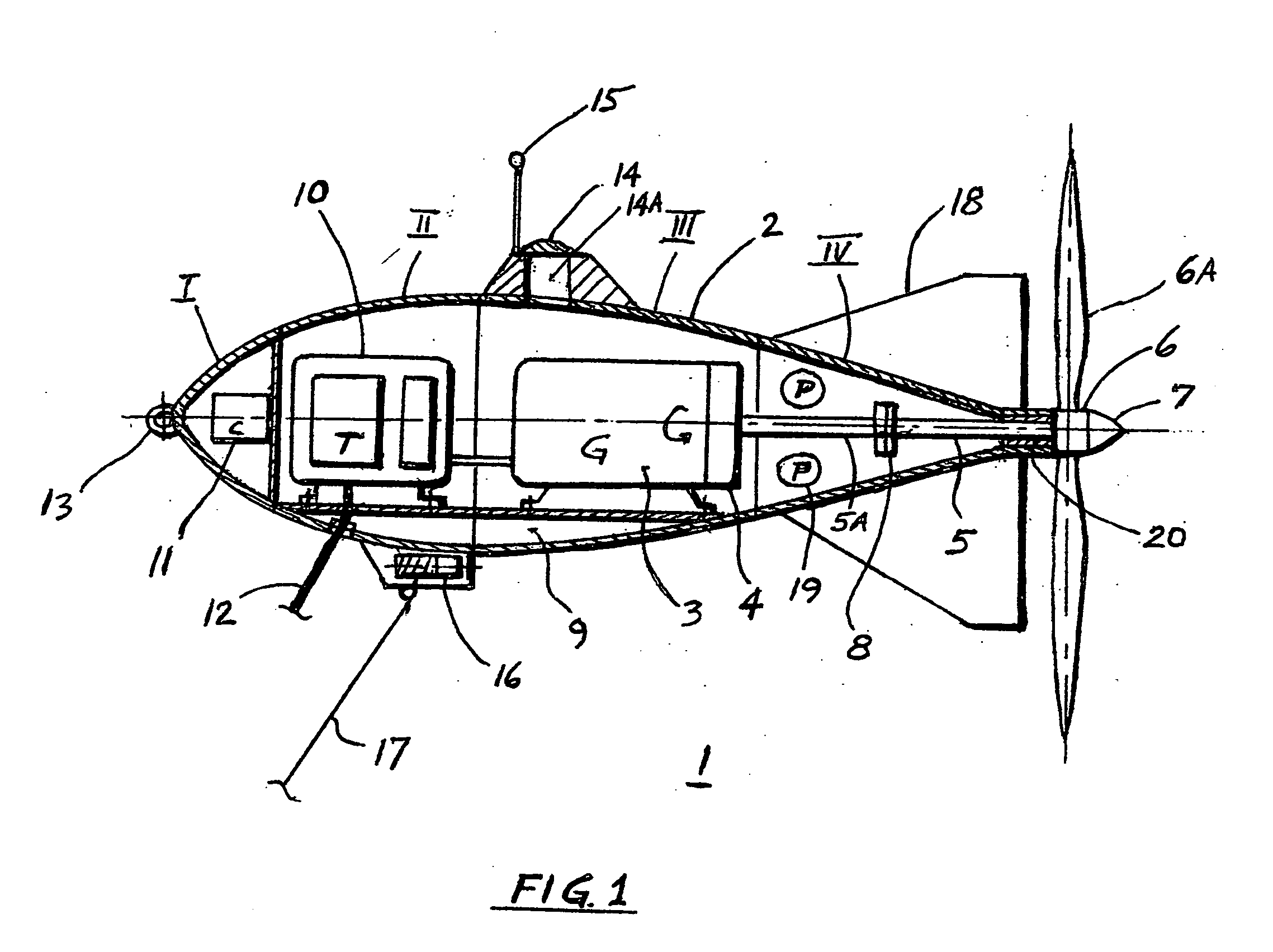

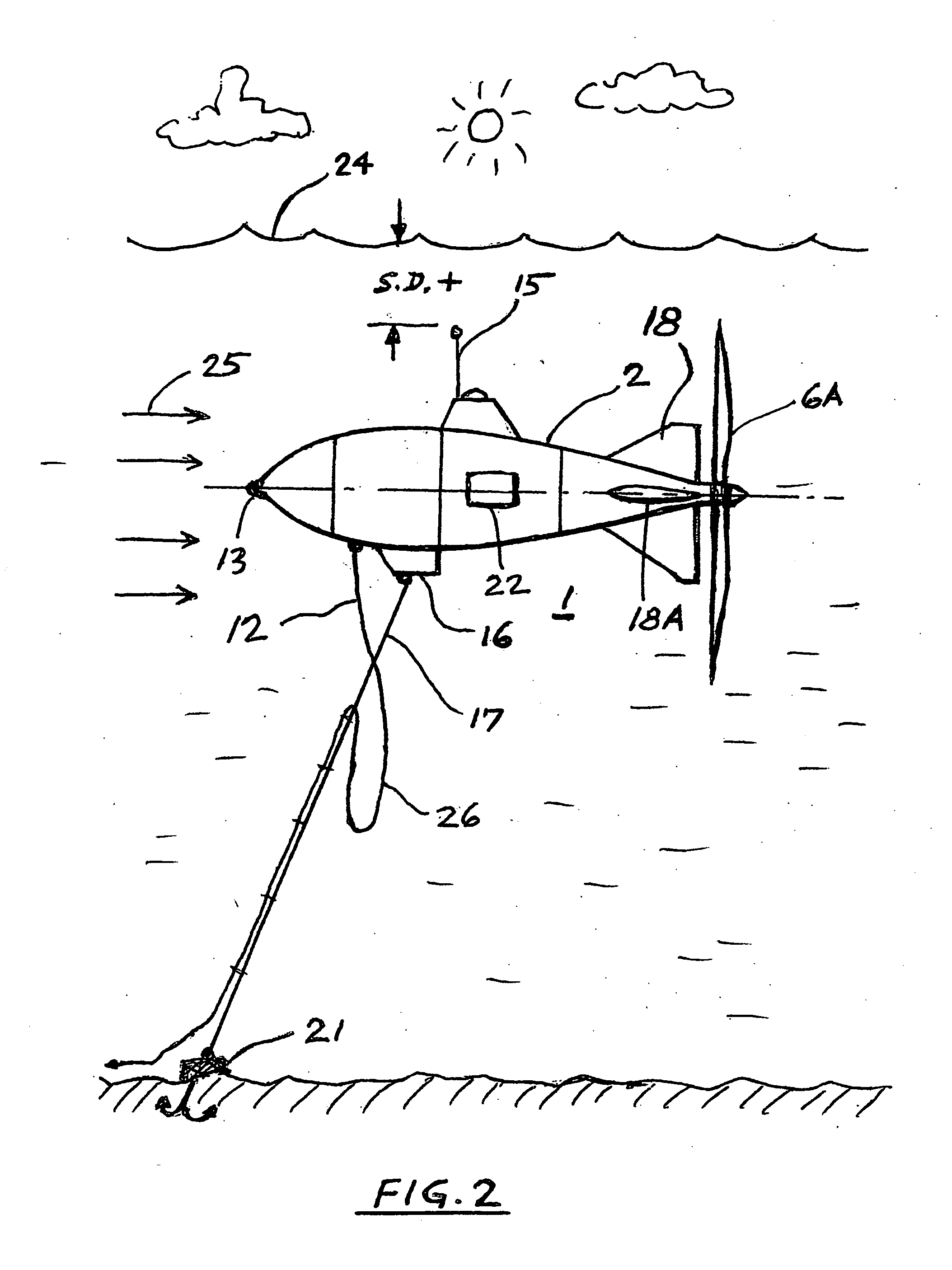

Deployable submarine-hydroelectric generator for sea currents energy harvesting

InactiveUS20090140524A1Easy to harvestReduce global warmingFinal product manufactureGas turbine plantsOcean bottomElectrolysis

Deployable submarine hydroelectric generator for conversion of kinetic energy of deep ocean currents into electricity by having an electric generator mounted in a sealed hydrodynamic, buoyant vessel with tail fins, and connected by a shaft to a rotary turbine blades at the tail end of the submarine vessel, which vessel is anchored at desired depth to the bottom of the ocean by a cable. The drag of the turbine blades causes the vessel to self-steer against the direction of the ocean current. An electric cable is also provided, connecting said electric generator with electric grid on the land. Such generator is out of sight, unlike windmills, and is environmentally friendly to the sea life, due to slow rotating blades. This clean electricity can also be used for production of low cost hydrogen by electrolysis of sea water.

Owner:KEJHA JOSEPH B

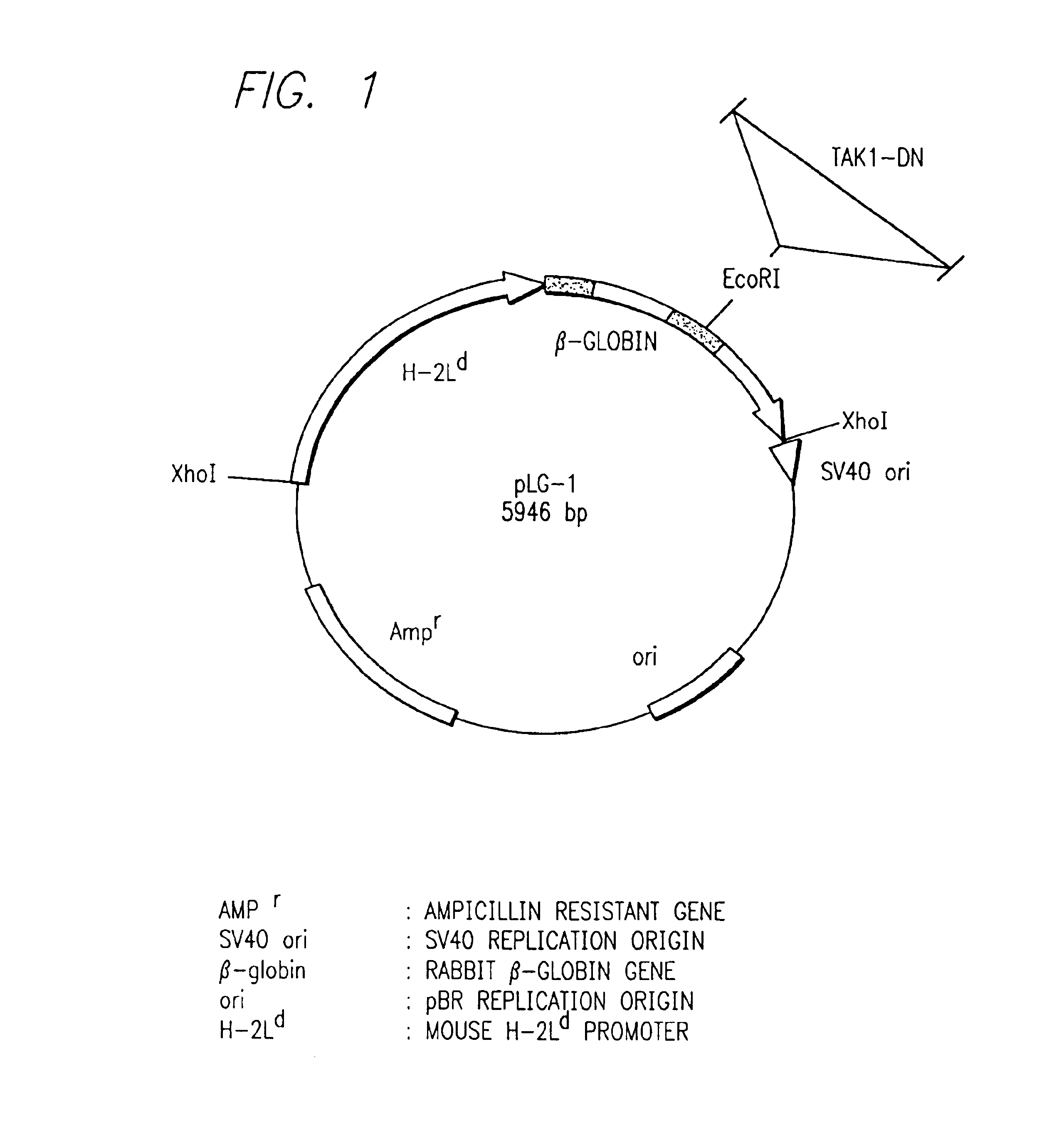

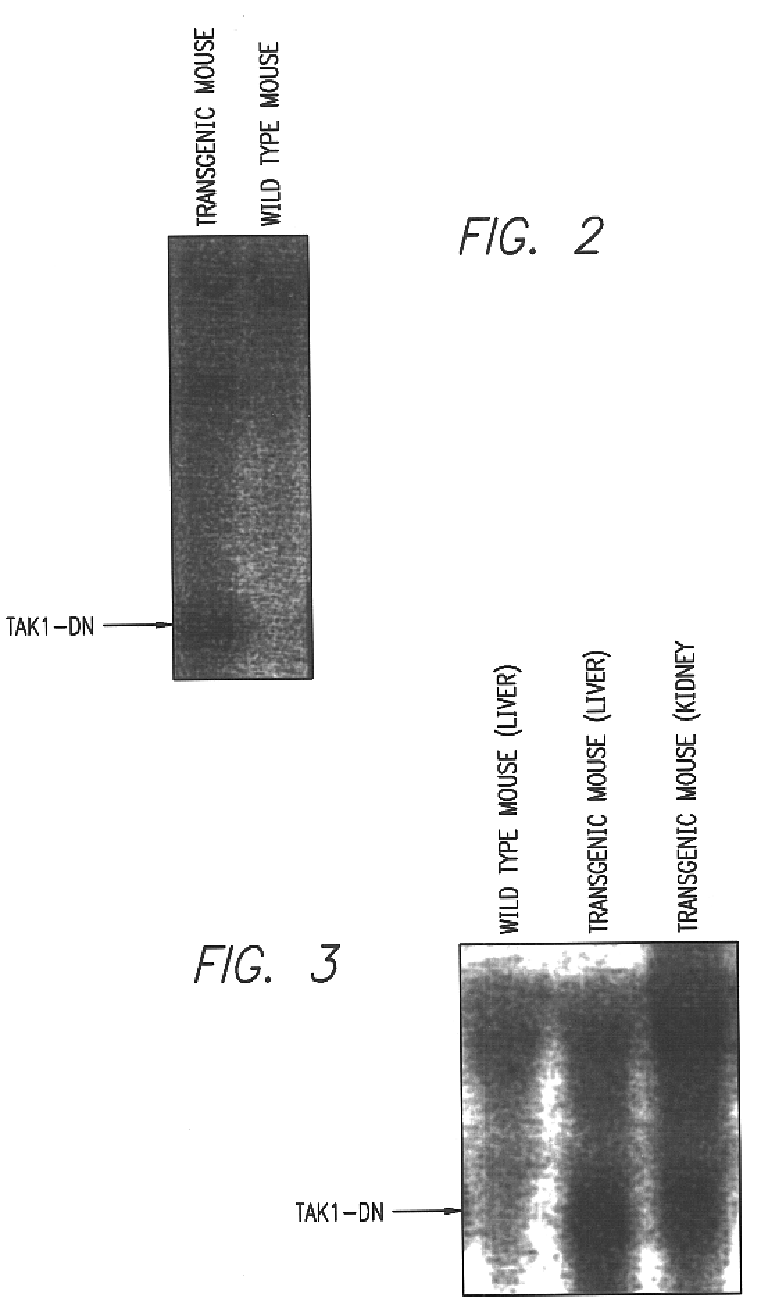

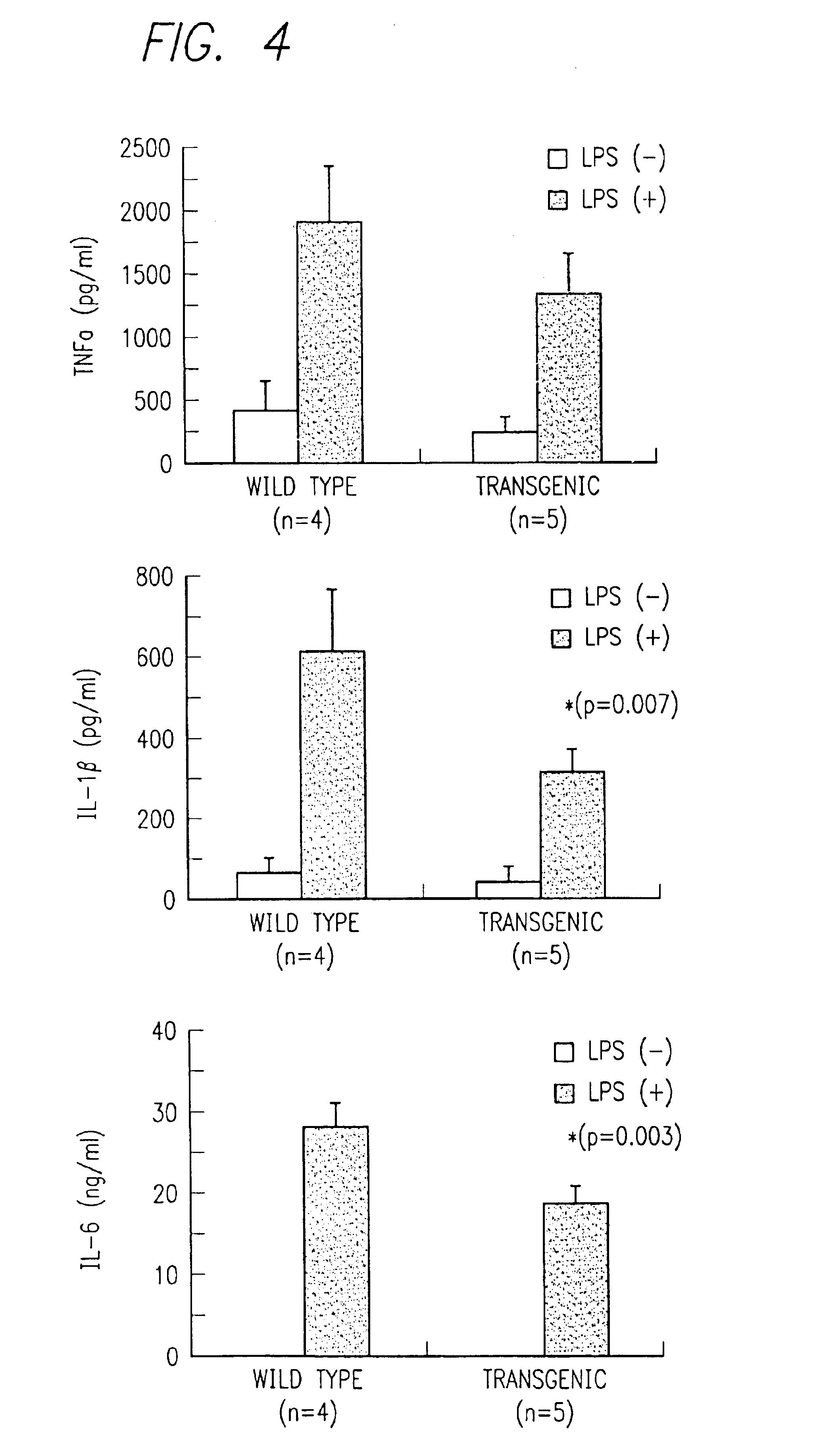

Method for screening compounds inhibiting signal transduction through inflammatory cytokines

InactiveUS6989244B1Avoid low activityHigh activityCompound screeningApoptosis detectionCytokineProinflammatory cytokine

The present invention relates to methods of screening for compounds that inhibit signal transduction by inflammatory cytokines. The methods include providing a sample that contains a TAK1 and a TAB1; contacting the sample with a compound; detecting binding between the TAK1 and the TAB1; and selecting the compound if binding between the TAK1 and TAB1 is inhibited in the sample compared to a control.

Owner:CHUGAI PHARMA CO LTD

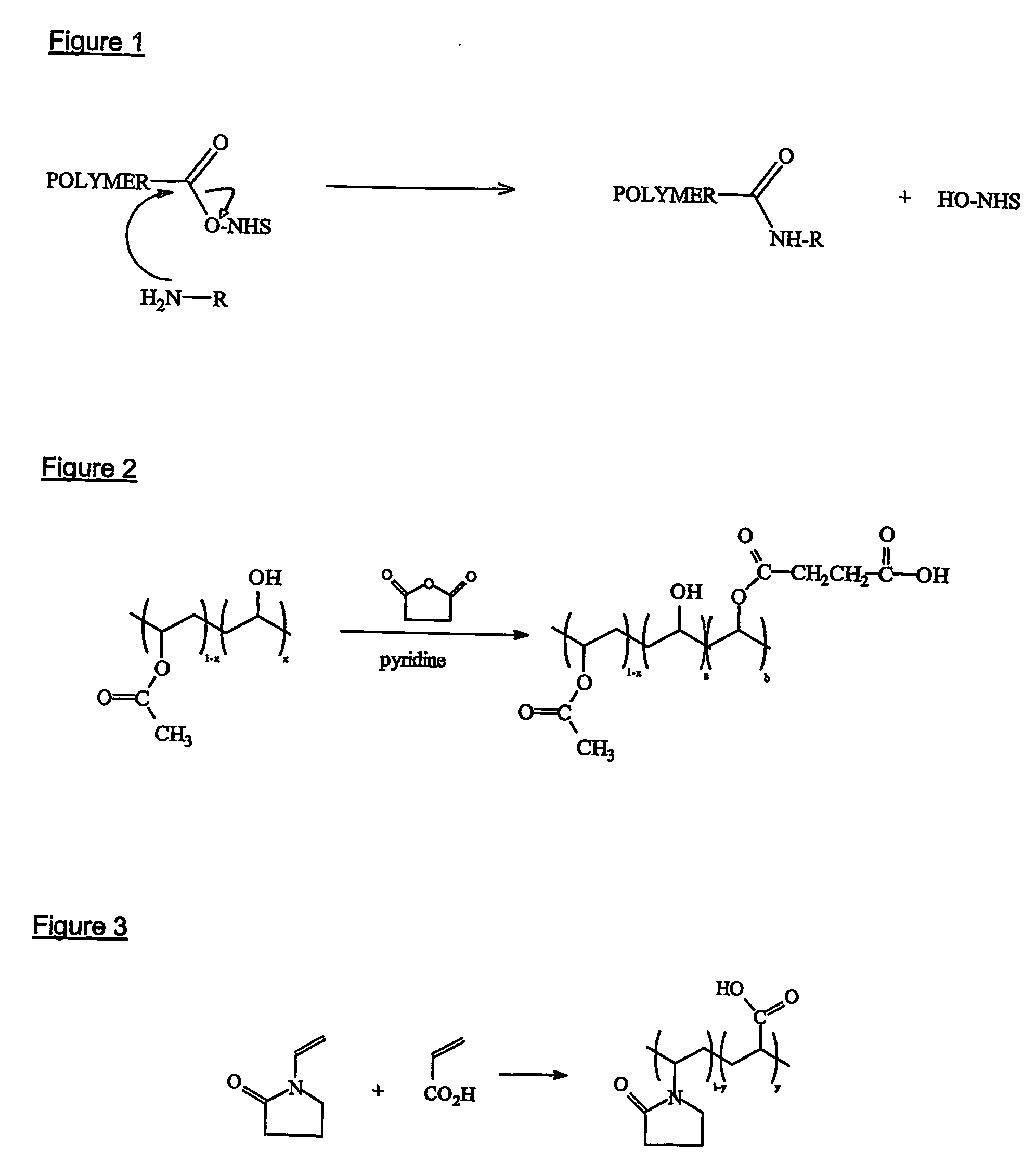

Tissue-adhesive formulations

InactiveUS20060105026A1Efficient use ofGood initial adhesionSurgical adhesivesAbsorbent padsParticulatesMedicine

A tissue-adhesive formulation consists of a naturally occurring or synthetic polymerisable and / or cross-linkable material in particulate form, the polymerisable and / or cross-linkable material being in admixture with particulate material comprising tissue-reactive functional groups. The formulation may be used in the preparation of a tissue-adhesive sheet, by applying the formulation to at least one side of a core of a naturally occurring or synthetic polymeric material.

Owner:TISSUEMED LTD

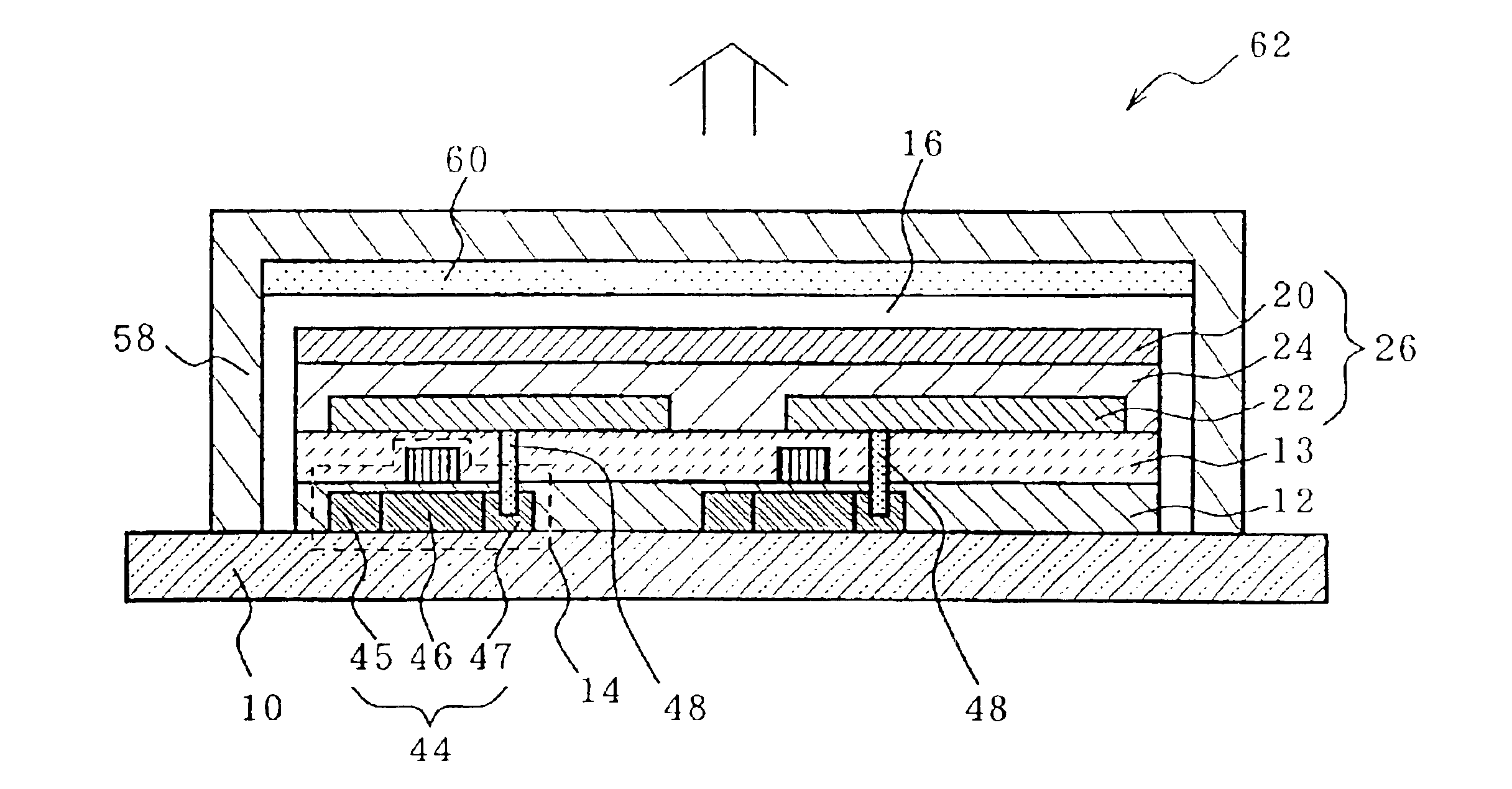

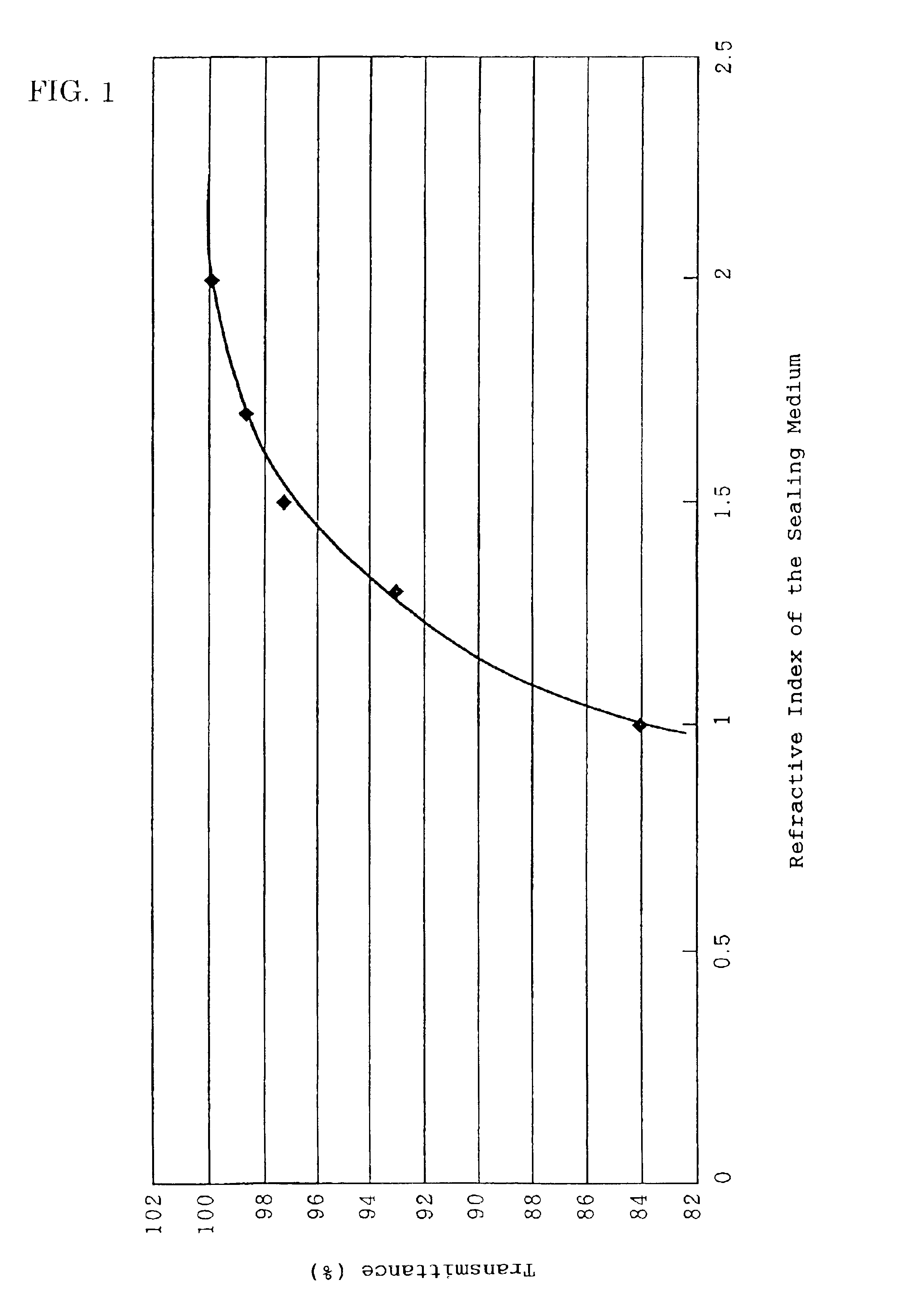

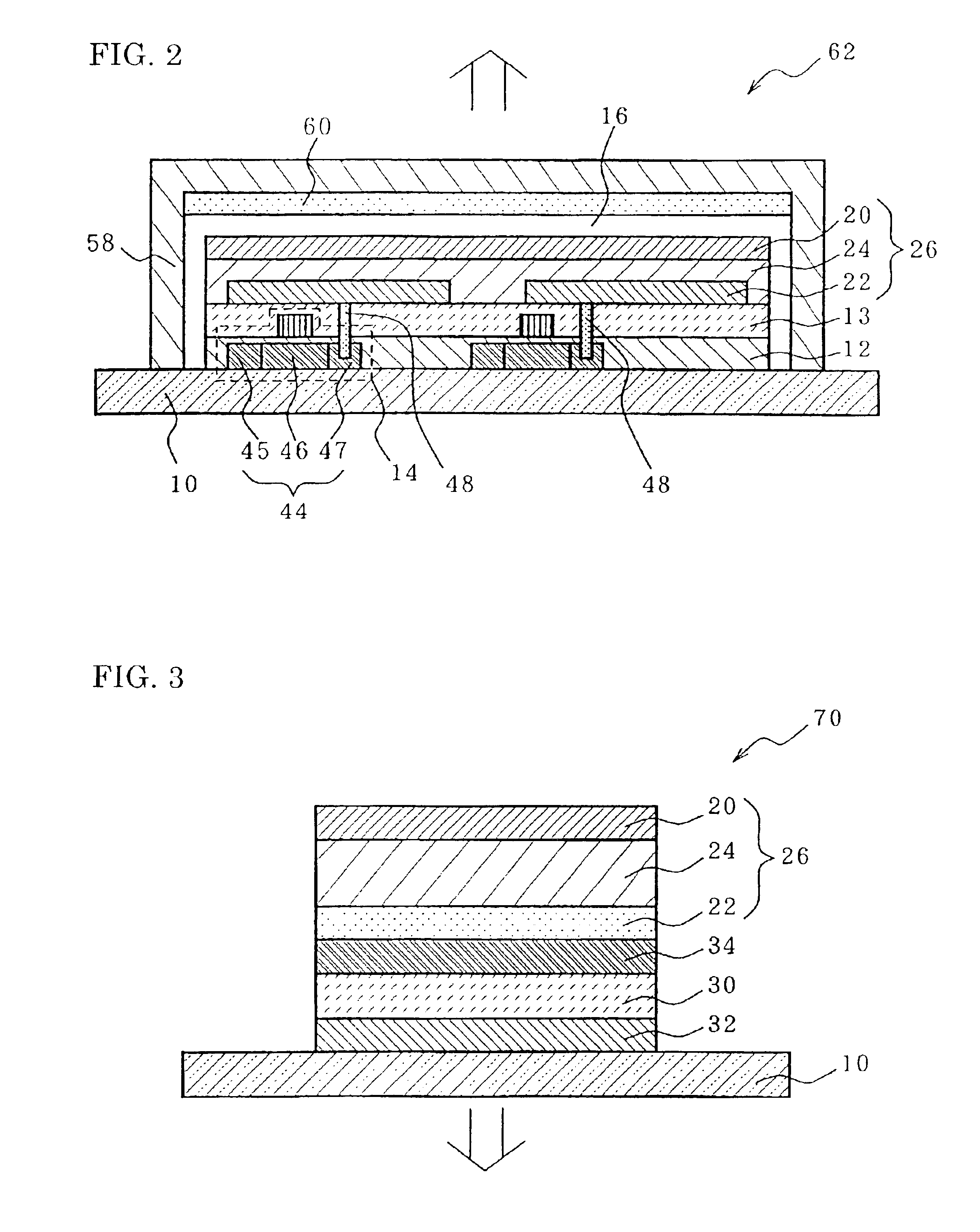

Organic EL display device having certain relationships among constituent element refractive indices

InactiveUS6963168B2Low driving voltageEnhance luminous efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesRefractive indexDisplay device

An organic EL display device having comprises a supporting substrate; and an organic EL element including an organic luminescent medium sandwiched between a lower electrode and an upper electrode thereon. A color changing medium and / or a transparent resin layer are arranged between the supporting substrate and the lower electrode. EL emission is taken out from the lower electrode. Various relationships are indicated among the refractive indices of the various elements of the organic EL display device. In such arrangement, a large quantity of EL emission can be taken to the outside.

Owner:IDEMITSU KOSAN CO LTD

Thermionic generator

InactiveUS6229083B1Reduce manufacturing costAvoid small quantitiesElectric discharge tubesThermoelectric device manufacture/treatmentThermionic converterEngineering

A method for building a thermionic converter comprises providing an electrode and creating a central depression of substantially uniform depth on a face of the electrode. A surface of the central depression is coated with a layer comprising a thermionic material. A second electrode comprising a face is also provided, wherein the face of the second electrode comprises a central depression of substantially uniform depth, wherein the central depression is coated with a layer comprising a thermionic material.

Owner:BOREALIS TECH LTD

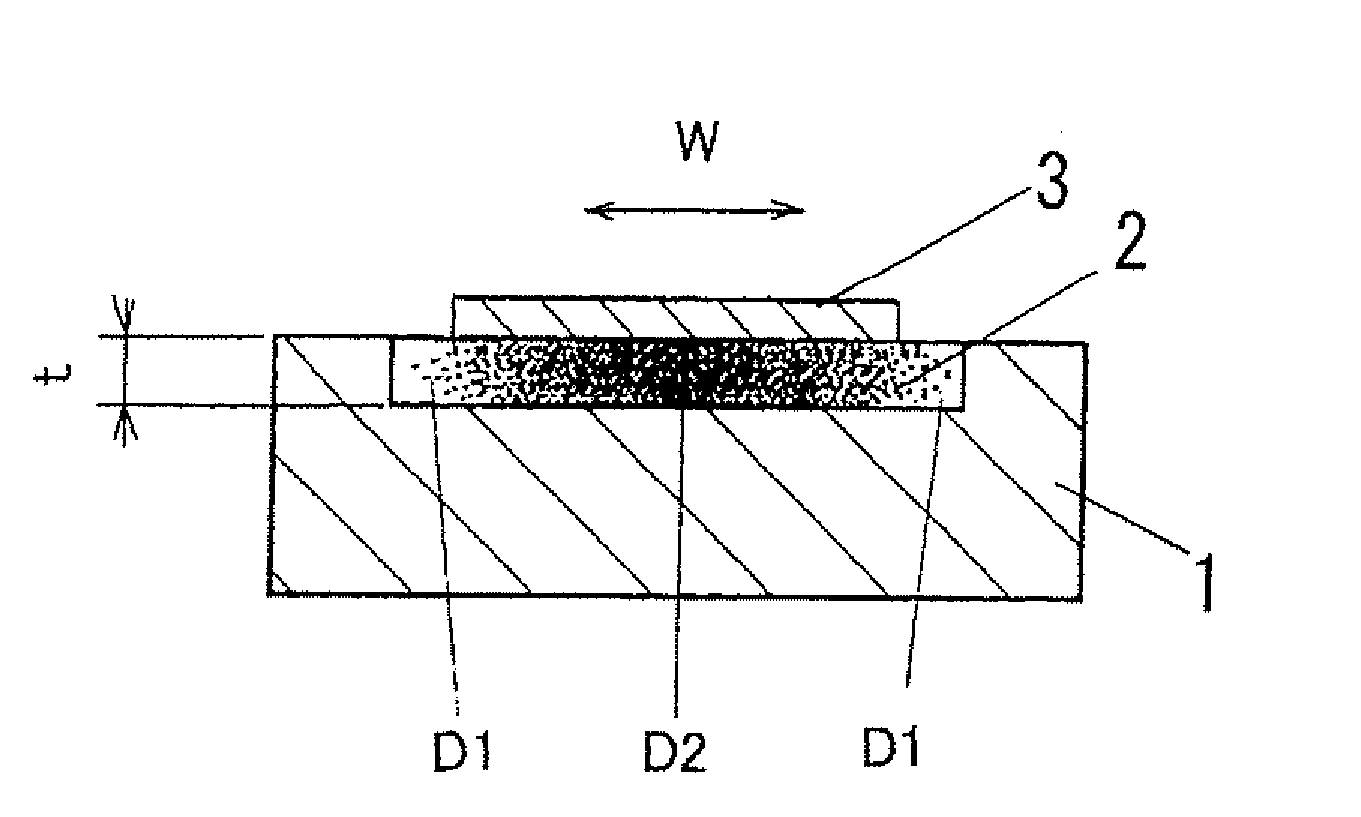

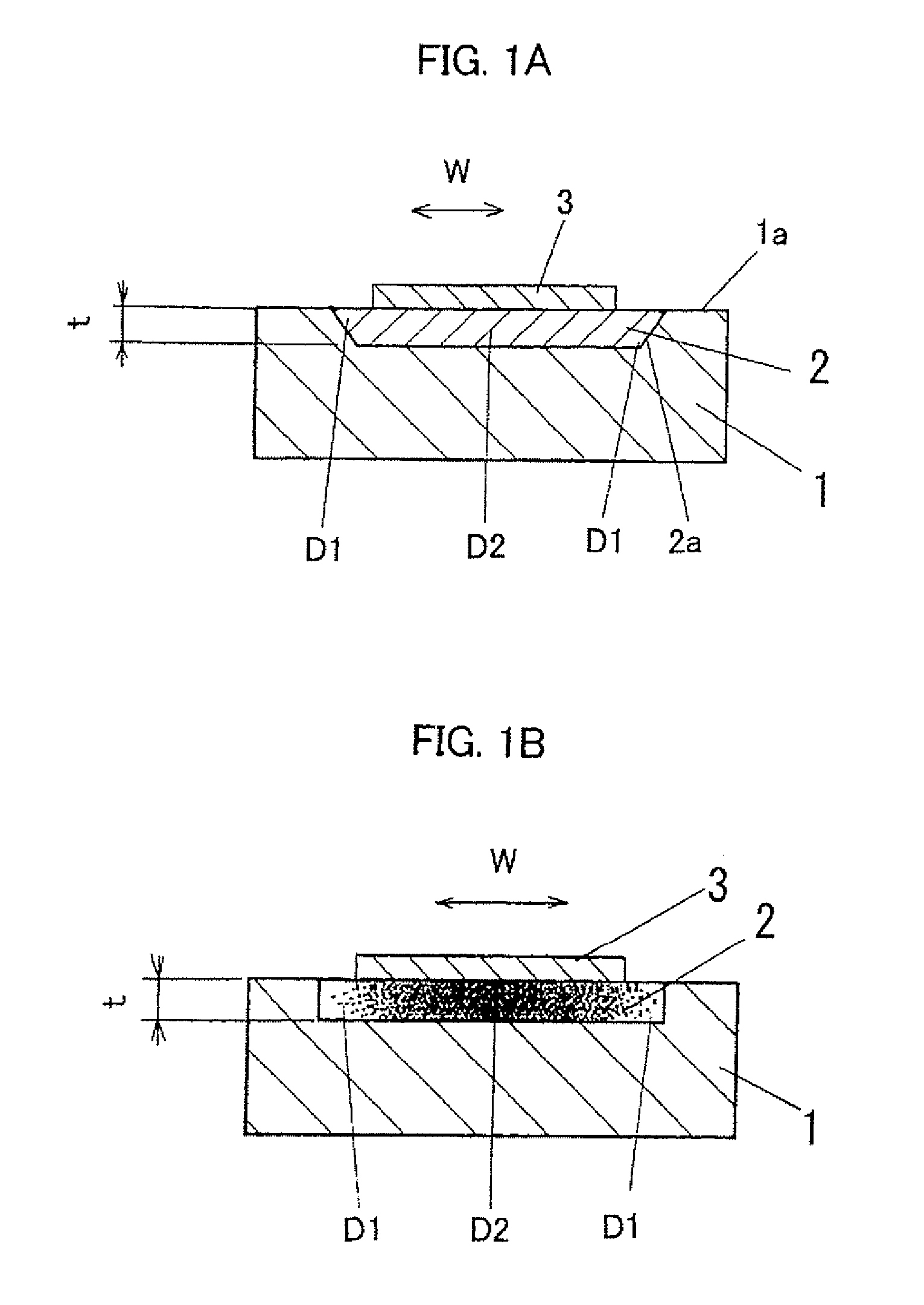

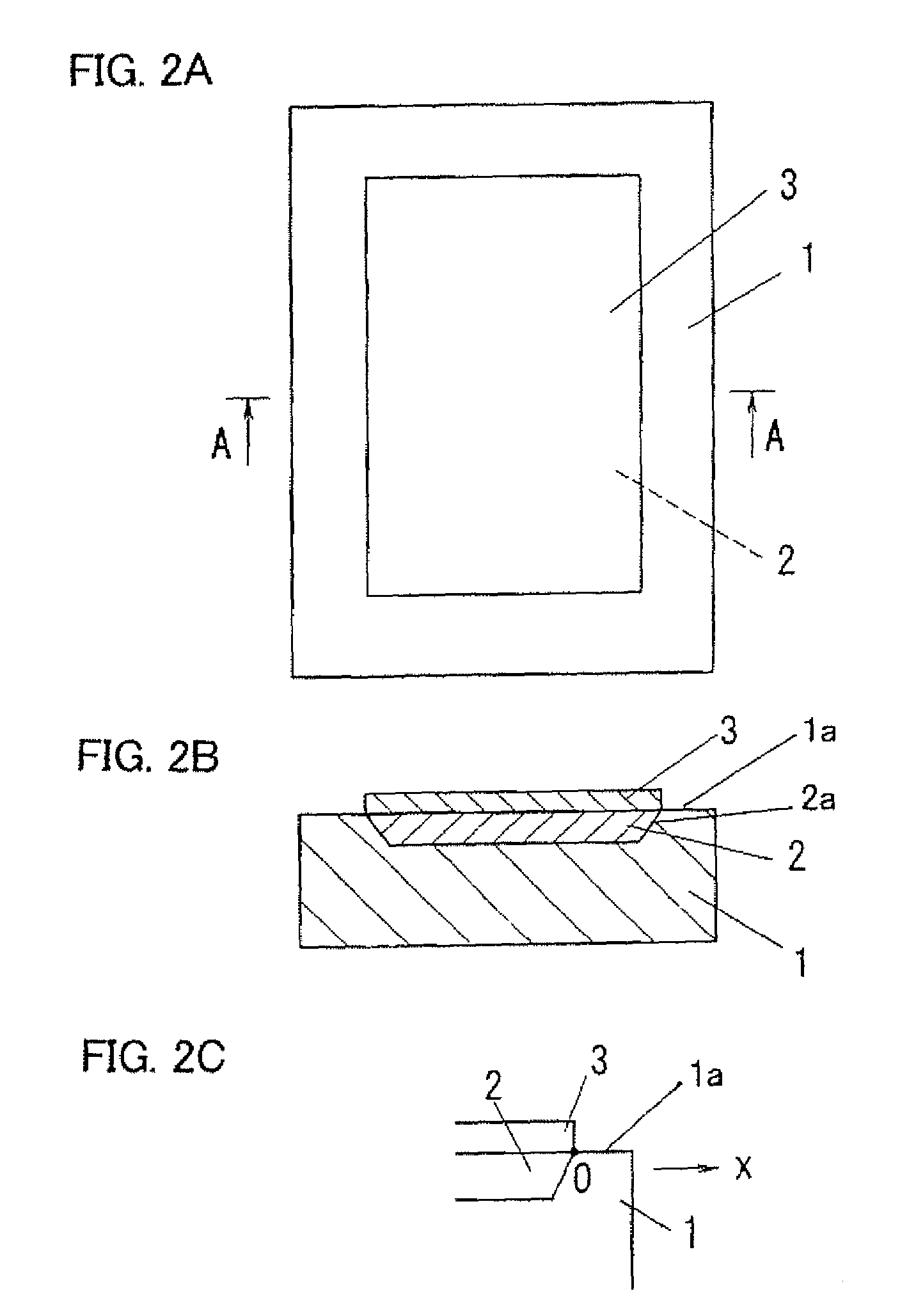

Pressure wave generator and process for manufacturing the same

InactiveUS7474590B2Reduce the likelihood of occurrenceMade smallMicrophonesElectrothermic-effect transistorPorosityElectrical conductor

Even when compression stress is generated because a volume of a thermal insulation layer 2 is expanded due to oxidized by oxygen in the air, occurrence of cracks and fractures of the thermal insulation layer and a heating conductor 3 caused by the cracks are prevented by dispersing the compression stress. A pressure wave generator comprises a substrate 1, the thermal insulation layer 2 of porous material which is formed on a surface of the substrate 1 in thickness direction, and the heating conductor 3 of thin film formed on the thermal insulation layer 2, and generates pressure waves by heat exchange between the heating conductor 3 and a medium. When a thickness at the center of the thermal insulation layer 2 in width direction W is used as a reference thickness, and it is assumed that distribution of thickness of thermal insulation layer in the width direction is averaged with the reference thickness, porosity in an outer peripheral portion of the thermal insulation layer is made smaller than porosity in the center portion. By making the porosity in the outer peripheral portion of the thermal insulation layer 2 smaller, a number of immovable points on the outer periphery of the thermal insulation layer 2 restricted by the substrate 1 is increased and the positions of them are dispersed, so that the compression stress compressed in the outer peripheral portion of the thermal insulation layer 2 can be dispersed.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Id Label, Id Card, and Id Tag

As a non-contact ID label, ID tag and the like being widespread, it is required to manufacture a considerable quantity of ID labels at quite a low cost. An ID label attached to a product is, for example, required to be manufactured at 1 to several yens each, or preferably less than one yen. Thus, such a structure and a process are demanded that an ID label can be manufactured in a large quantity at a low cost. A thin film integrated circuit device included in the ID label, the ID card, and the ID tag of the invention each includes a thin film active element such as a thin film transistor (TFT). Therefore, by peeling a substrate on which TFTs are formed for separating elements, the ID label and the like can be manufactured in a large quantity at a low cost.

Owner:SEMICON ENERGY LAB CO LTD

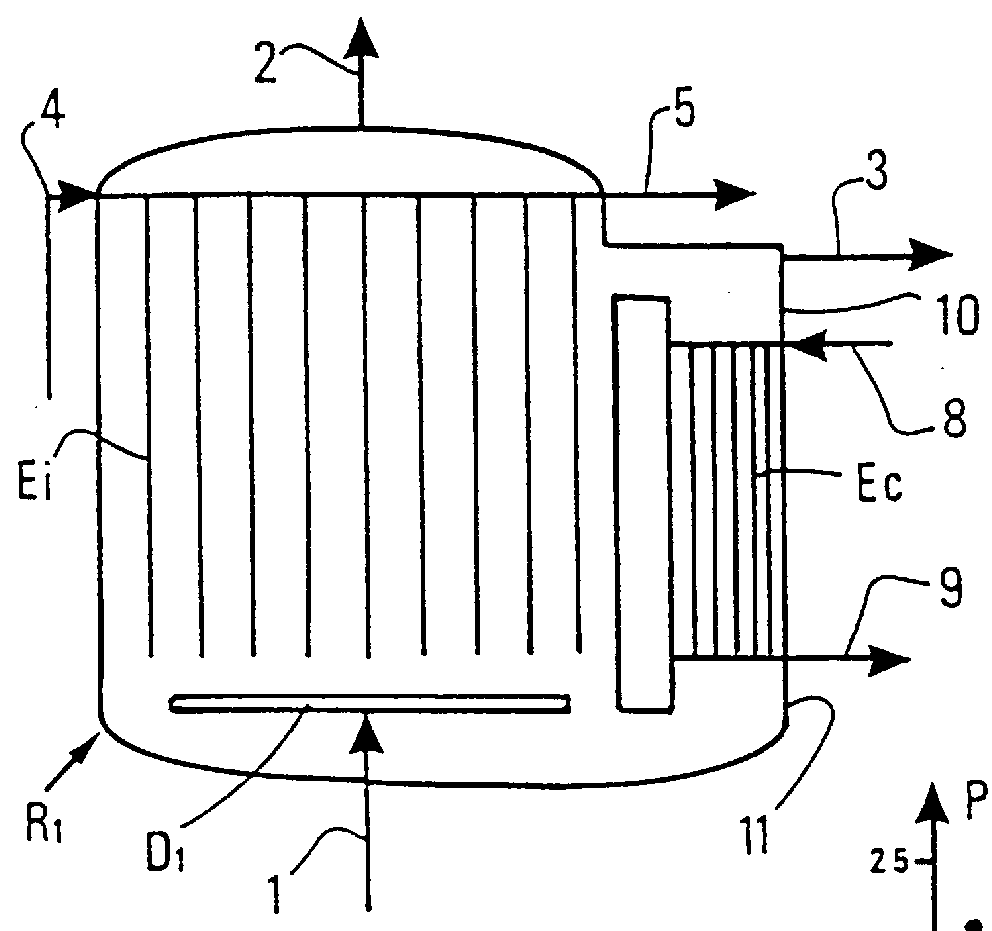

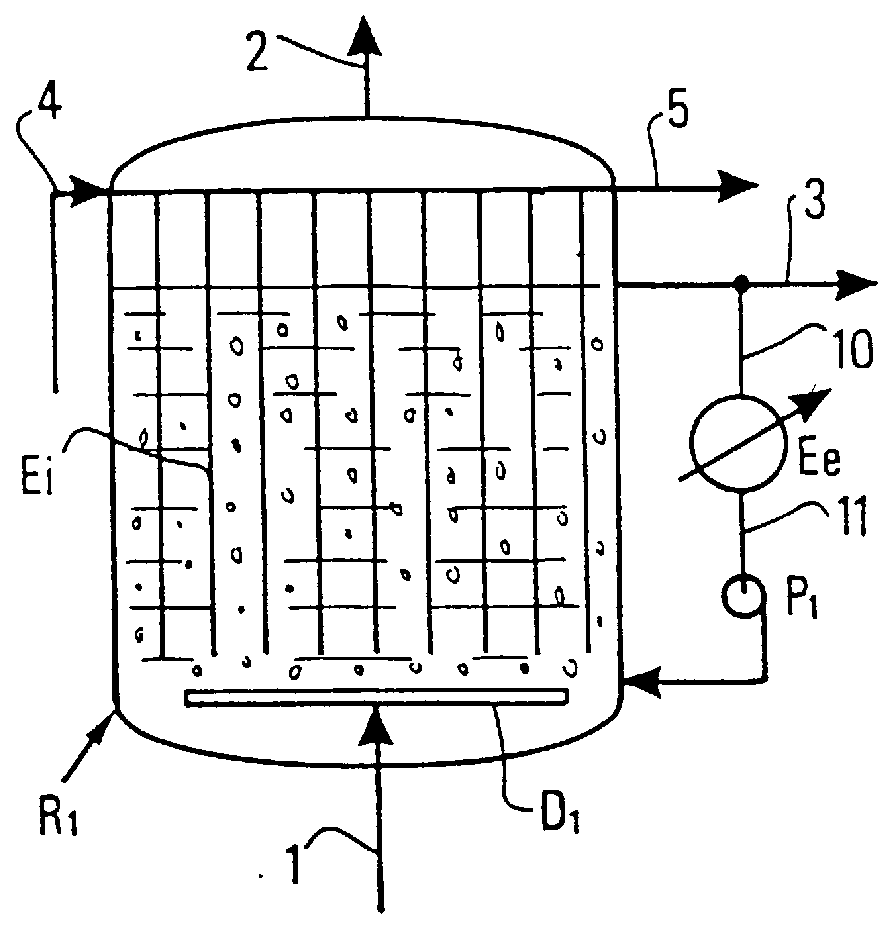

Process and apparatus for operation of a slurry bubble column with application to the fischer-tropsch synthesis

InactiveUS6060524AGuaranteed uptimeAvoid small quantitiesHydrocarbon from carbon oxidesOrganic compound preparationGas phaseBubble column

The invention concerns a process for optimal operation of a slurry bubble column containing a suspension of solid particles in a liquid, characterized in that a gas phase containing the reactant(s) required for the production of the desired products is injected in the form of bubbles close to the lower extremity of said reactor and at least a portion of the liquid fraction and optionally of the solid fraction of said suspension is recirculated, drawn off from close to one extremity of said reactor and reintroduced close to the other extremity of said reactor, with a liquid flow rate U1 in the reactor which is at least equal to and preferably greater than the sedimentation rate Us of the solid particles. The invention also concerns an apparatus for optimal operation of the process. Finally, the invention concerns the use of the process and apparatus in the Fischer-Tropsch synthesis.

Owner:INST FR DU PETROLE +1

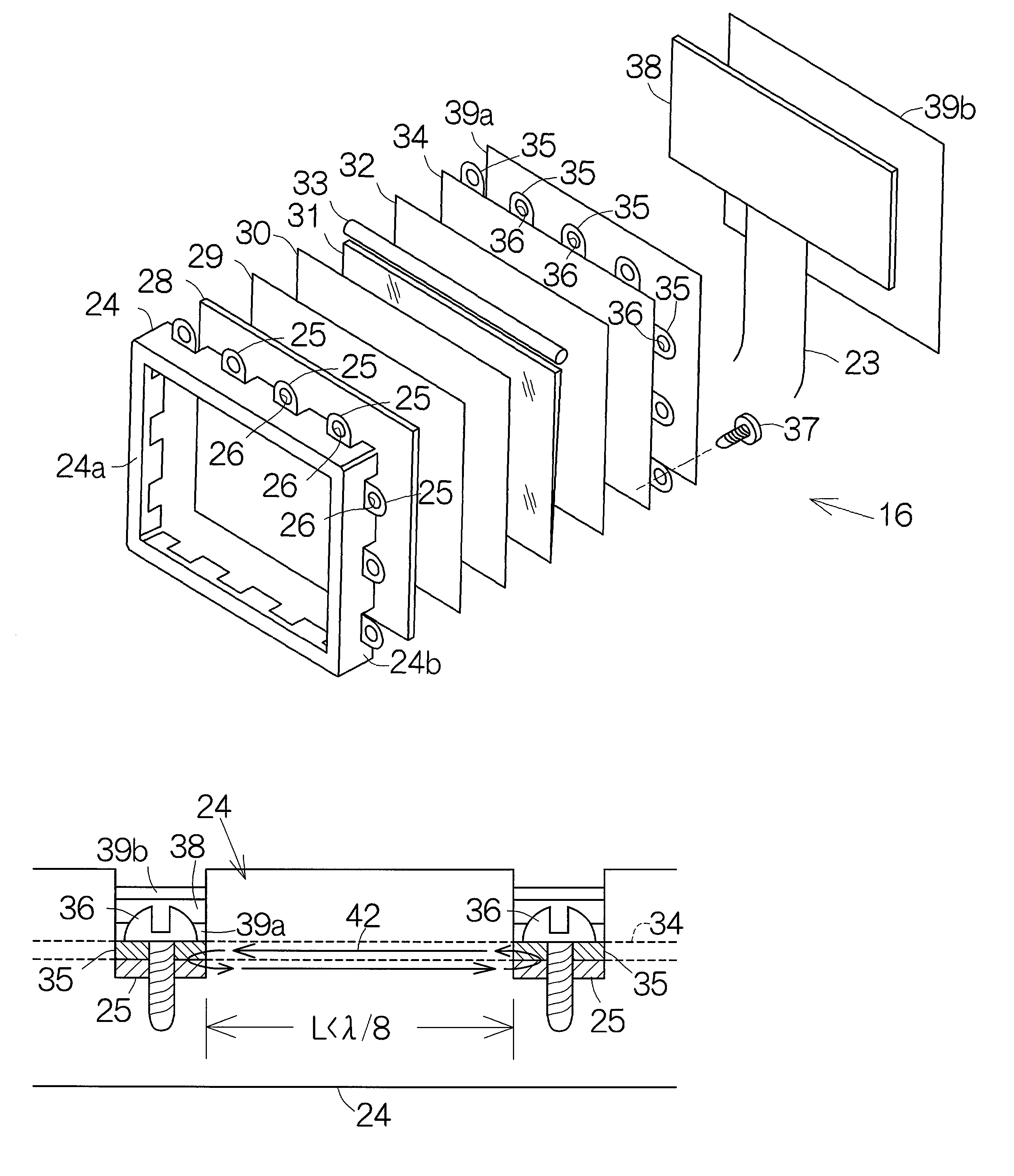

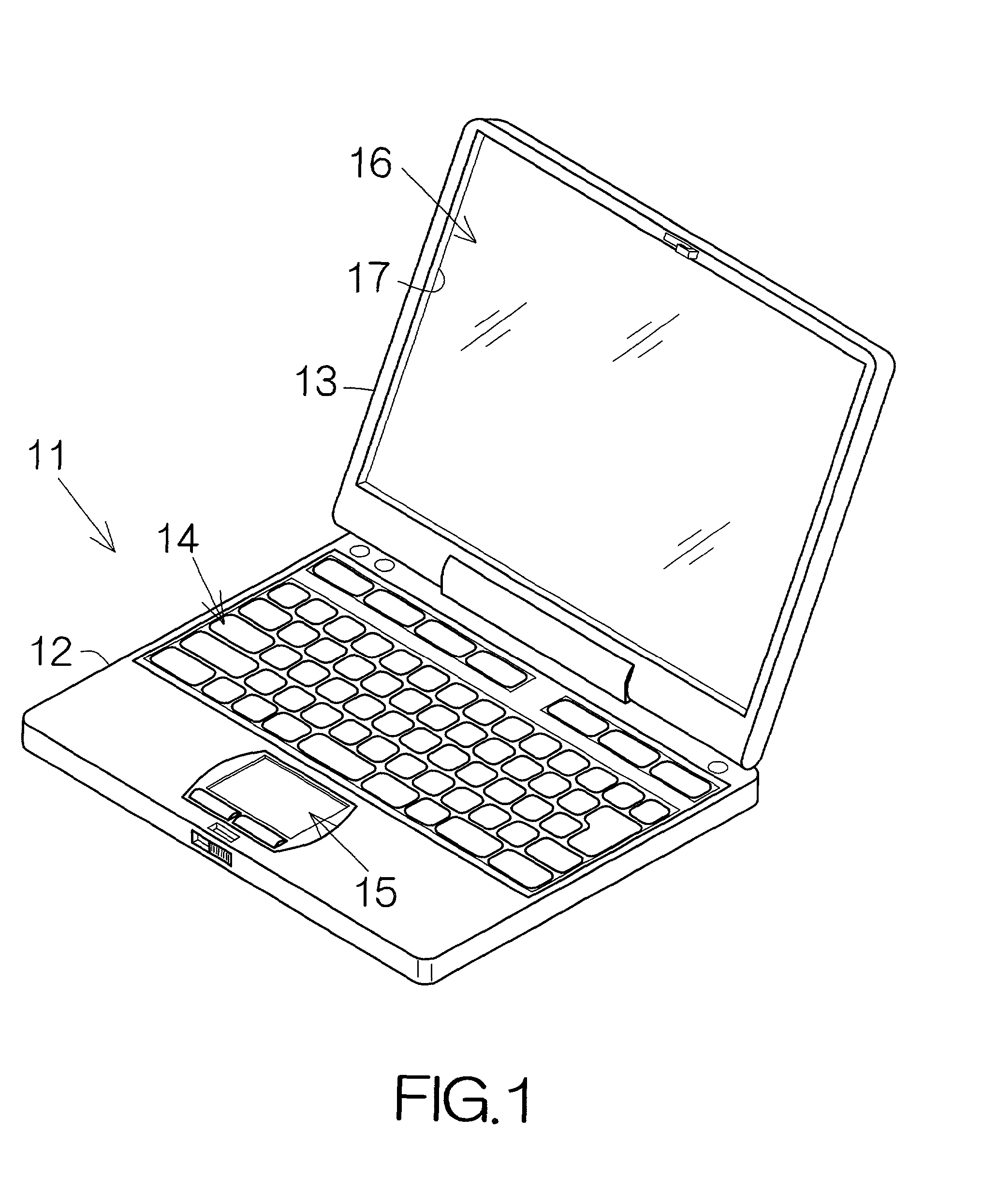

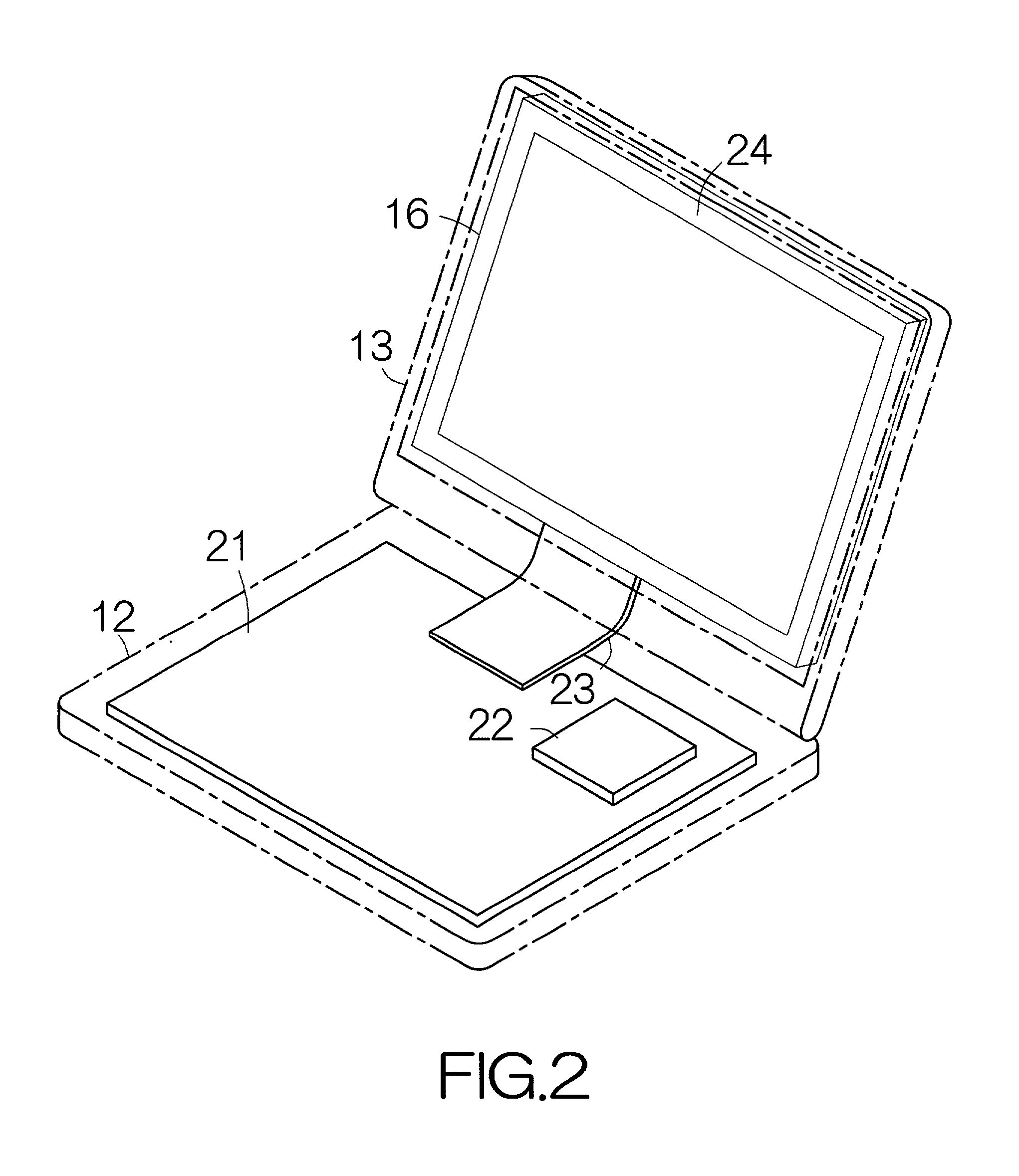

Display panel module of low electromagnetic radiation

InactiveUS20020126236A1Radiation suppressionSuppress electromagnetic radiationNon-linear opticsIdentification meansLiquid-crystal displayElectromagnetic electron wave

A display panel module such as a liquid crystal display (LCD) panel module in an electronic apparatus is designed to receive a driving signal of a predetermined frequency. An electrically conductive frame or bezel of the display panel module tends to suffer from the transmission of electromagnetic waves which are related to the wavelength of the driving signal. An electrically conductive member is located behind the display panel and electrically connected to the electrically conductive frame. The electrically conductive member serves to diverge the electromagnetic waves out of the electrically conductive frame. This divergence of the electromagnetic waves serves to suppress the electromagnetic radiation out of the electrically conductive frame.

Owner:FUJITSU LTD

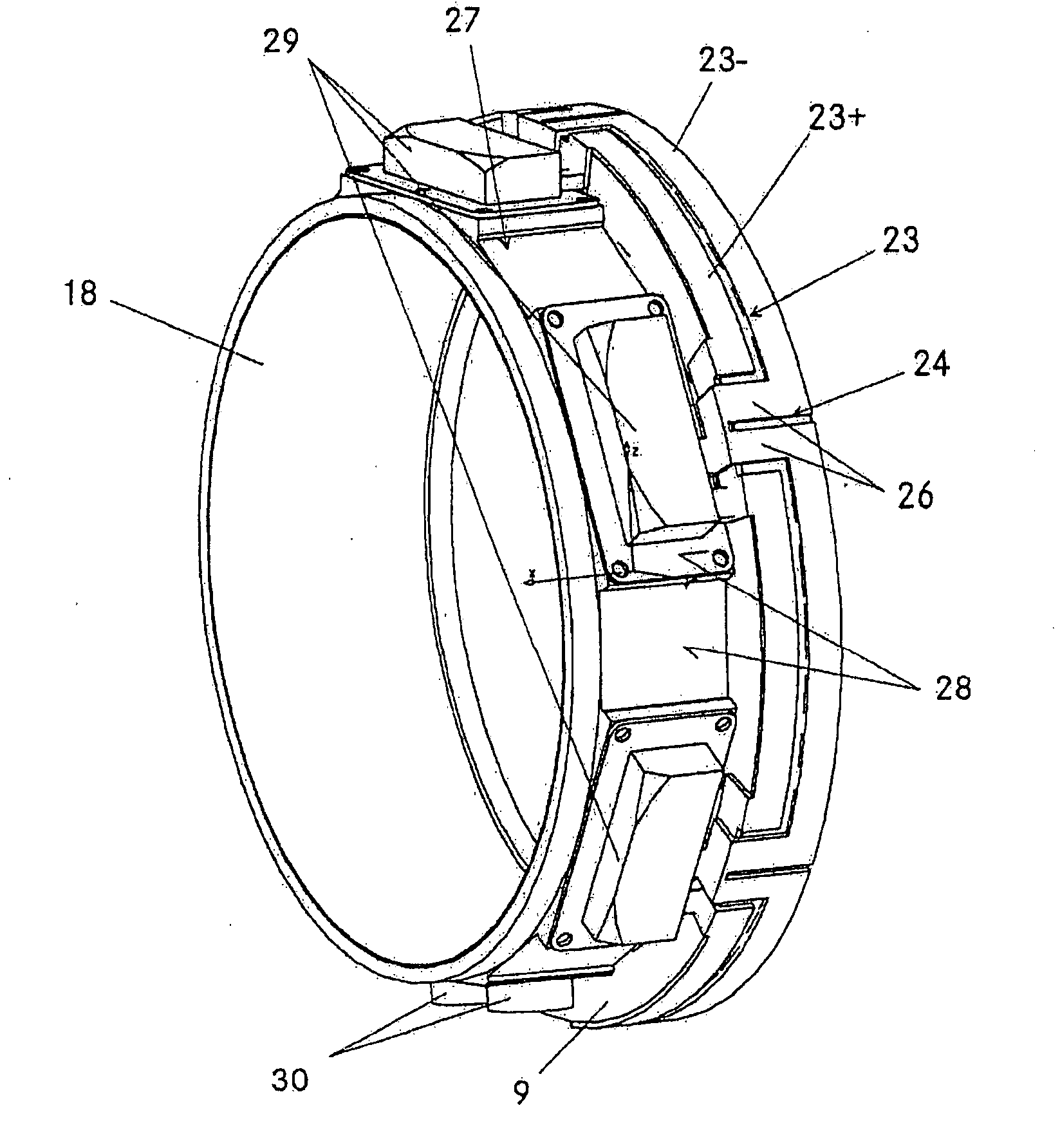

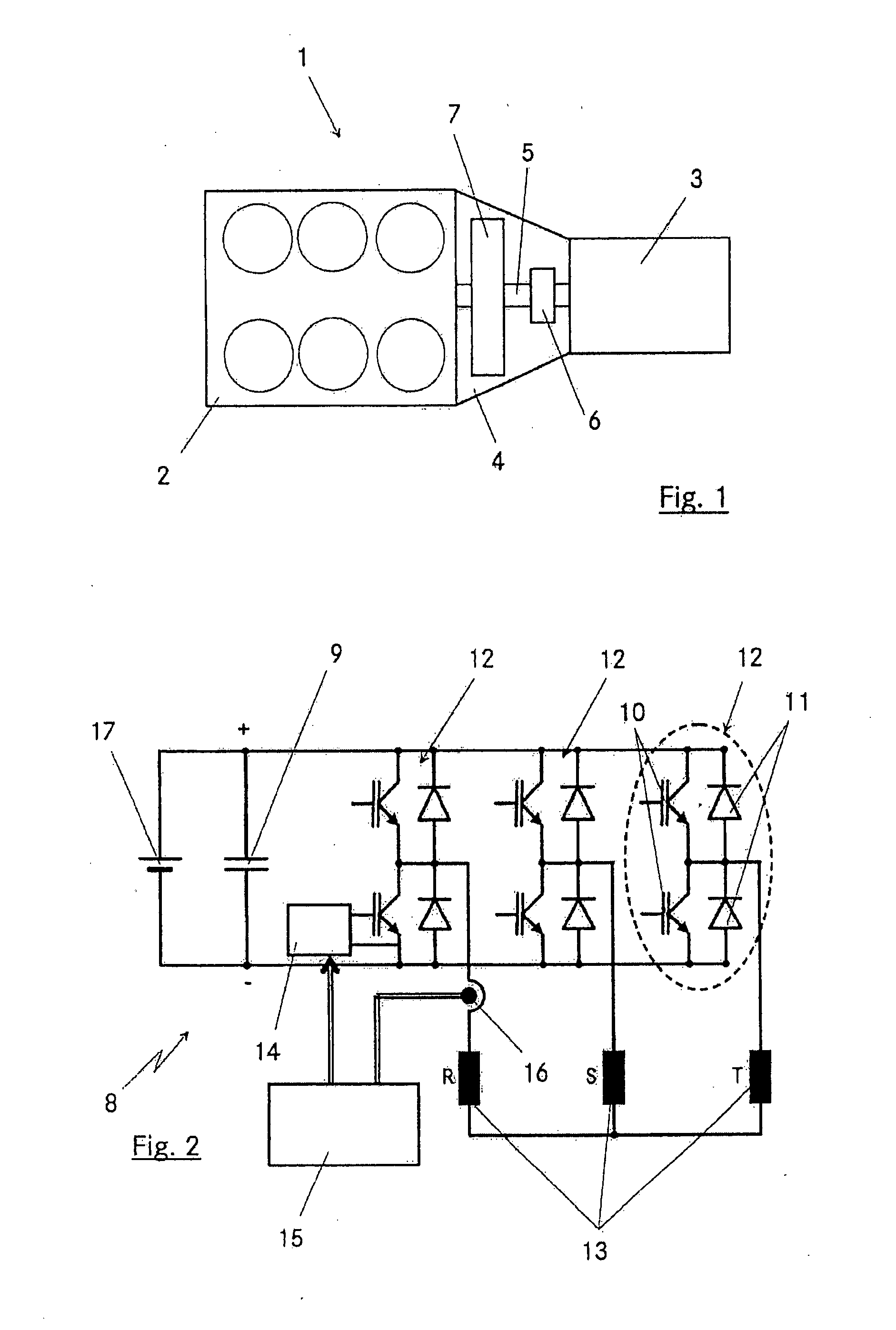

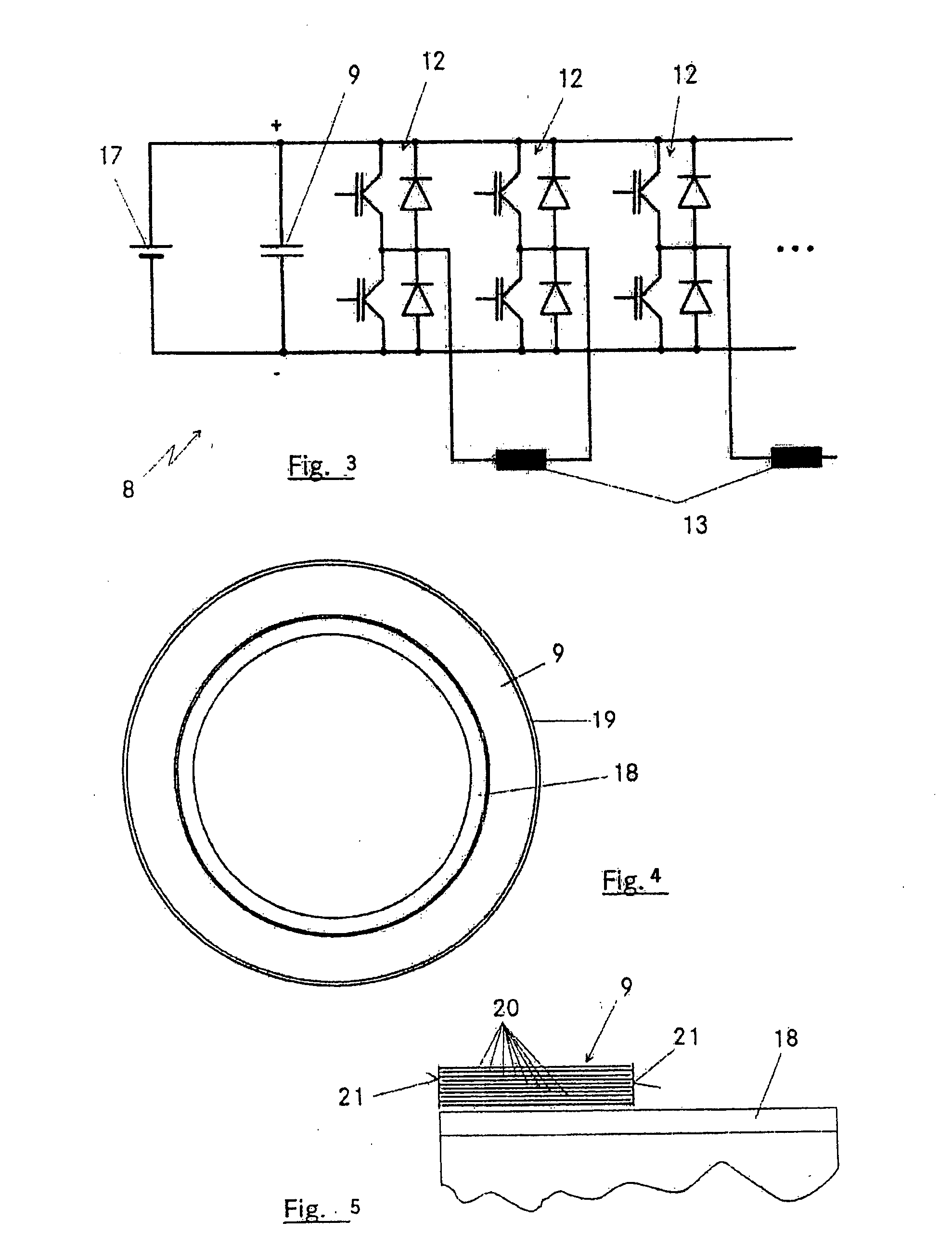

Drive train for a motor vehicle comprising an electric machine

InactiveUS20070284157A1Sufficiently compactReduce module costPropulsion partsSolid-state devicesElectric machineDrive shaft

In a drive train for a motor vehicle, with a converter bell arranged between an internal combustion engine and a transmission, and a drive shaft extending through the converter bell and carrying a clutch device and an electric machine together with a power converter, which comprises at least one capacitor and power electronics which are integrated into the converter bell, the capacitor and the power electronics are arranged between a stator of the electric machine and the converter bell such that they are distributed around the outer circumference of the electric machine in the radial direction and the capacitor and the power electronics are arranged such that they are in thermally conductive contact with the cooling system for the stator of the electric machine.

Owner:DAIMLER AG

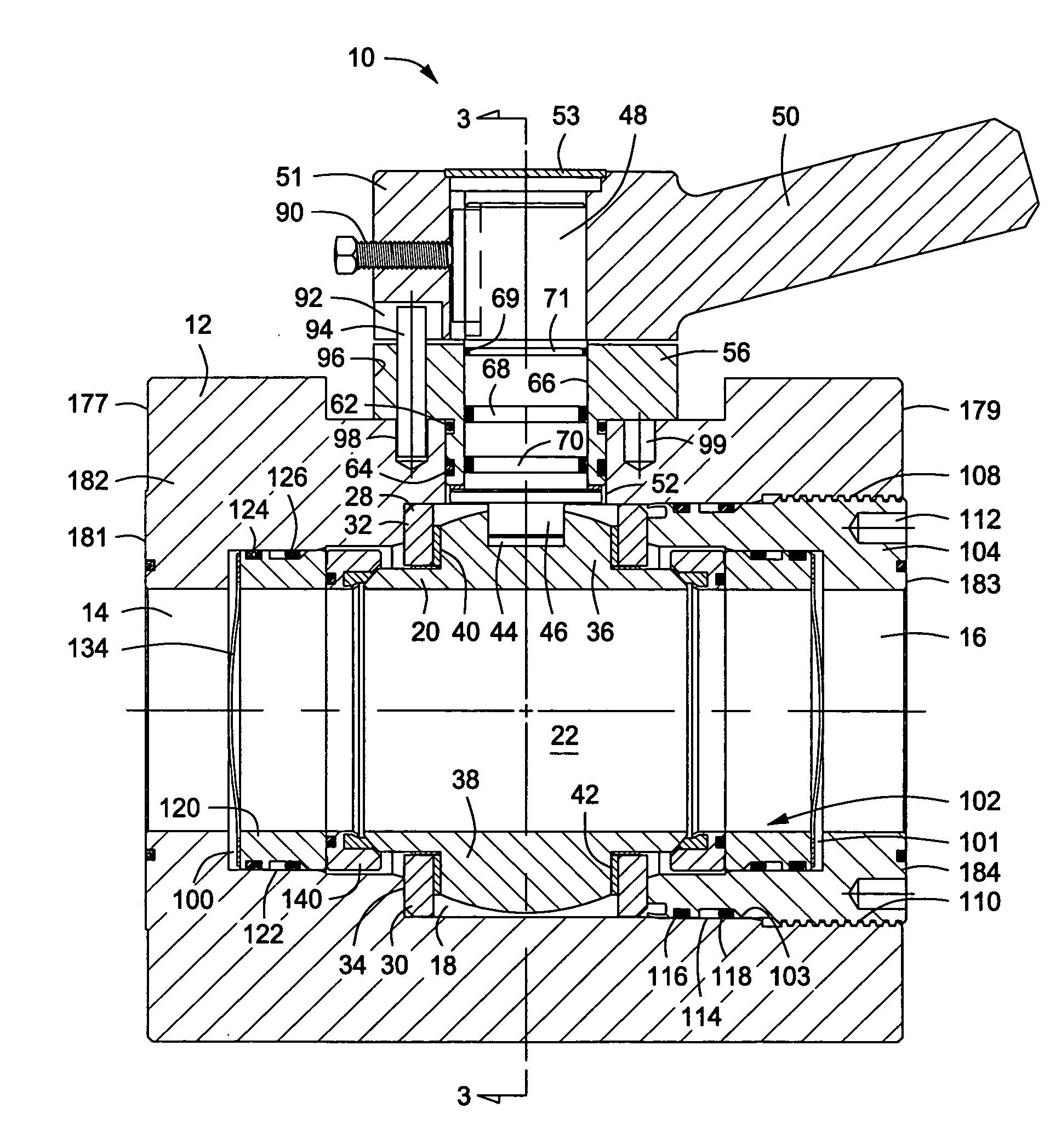

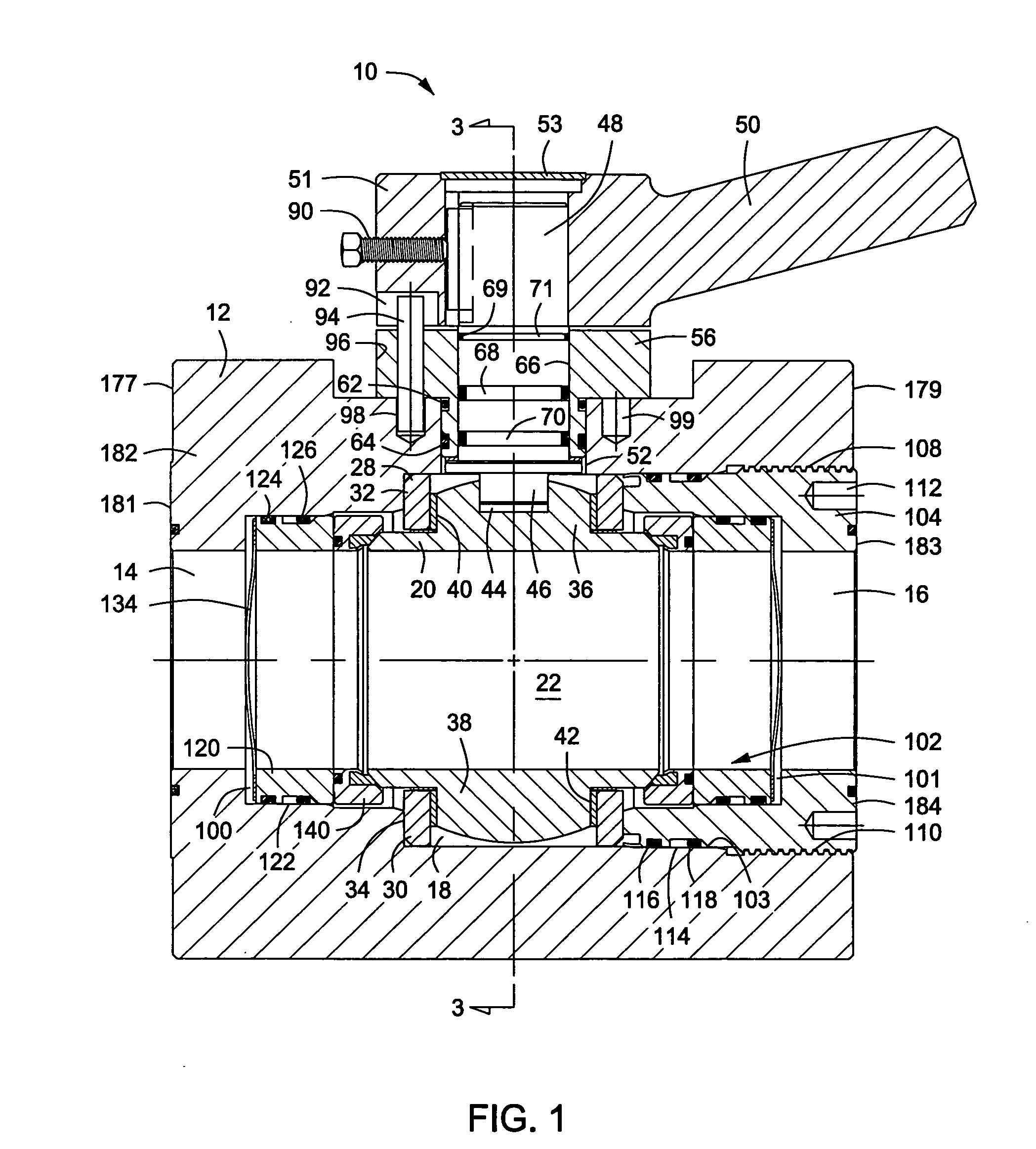

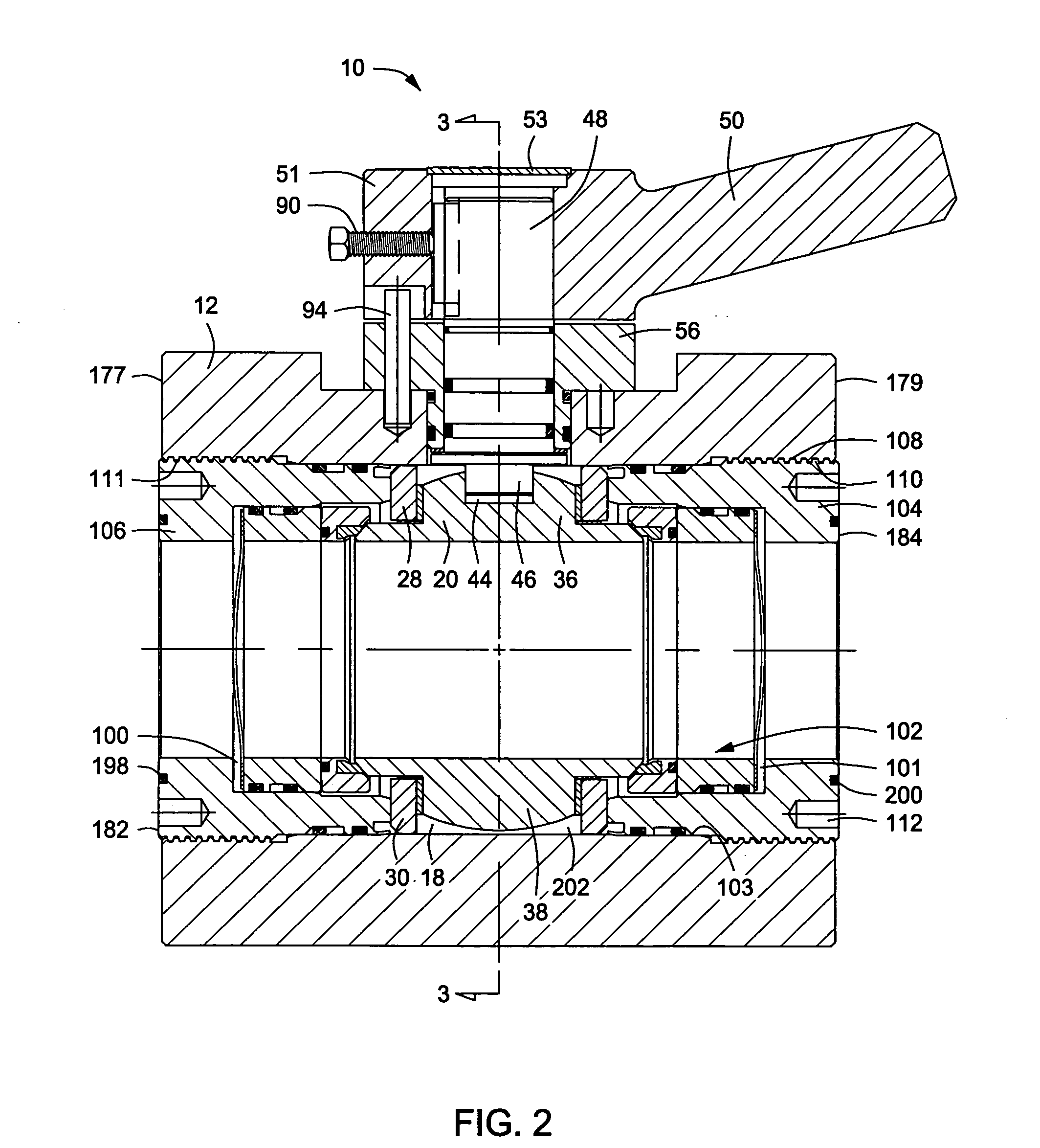

Ball valve having self-centering seats

InactiveUS20090095931A1Improve sealingAvoid small quantitiesPlug valvesValve housingsSpherical formTrunnion

A trunnion type ball valve having valve seats that are laterally moveable within seat recesses of the valve and establish sealing engagement with a valve ball member that is trunnion supported for rotational movement between open and closed positions. The valve seat members are self-centering for optimum sealing engagement with the spherical sealing surface of the ball member. The internal geometry of the seat assemblies are designed to permit optimum flow through the valve mechanism even under circumstances where the seat members are located in laterally off-center relation with respect to the centerline of the flow passages due to self-centering seat movement. The ball valve is readily adapted for fire-safe application via the use of heat resistant seals and metal-to-metal sealing of components to prevent or minimize leakage in the event of seal destruction or degradation by excess heat.

Owner:PHOENIX COMPACT VALVES

Meander antenna device

InactiveUS6351241B1High bandwidthMaintain good propertiesSimultaneous aerial operationsAntenna supports/mountingsMulti bandMeander

An antenna means for a portable radio communication device, in particular a hand-portable mobile telephone, having at least one radiating element that has a meandering and cylindrical configuration. This structure is specifically advantageous in combination with an extendable and retractable whip antenna and, when having two or more meandering radiating elements, in multi-band radiating structures. The antenna device is suitable for manufacturing in large quantities, for example by a flexible printed circuit board technique.

Owner:LAIRD TECH AB (SE)

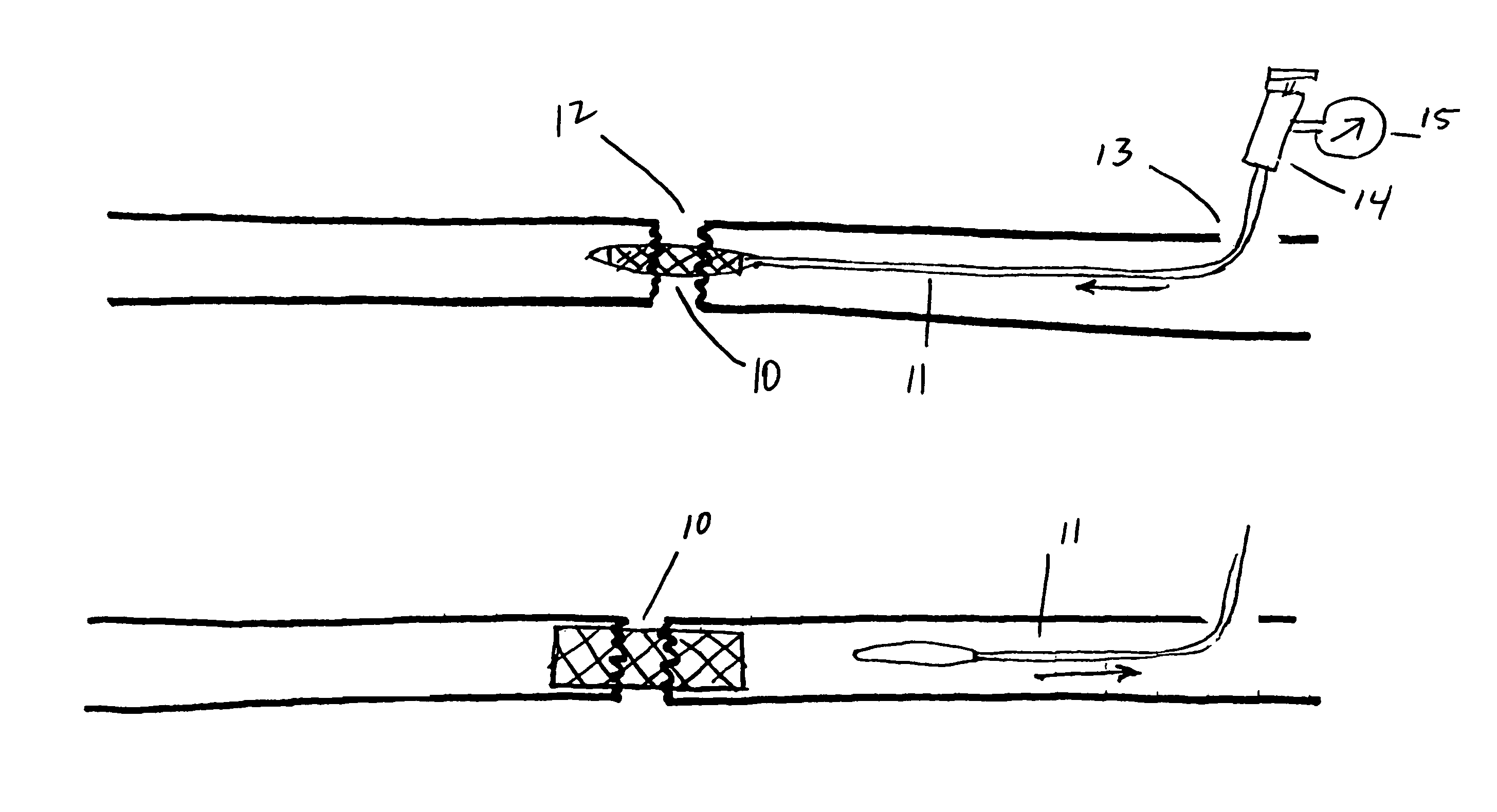

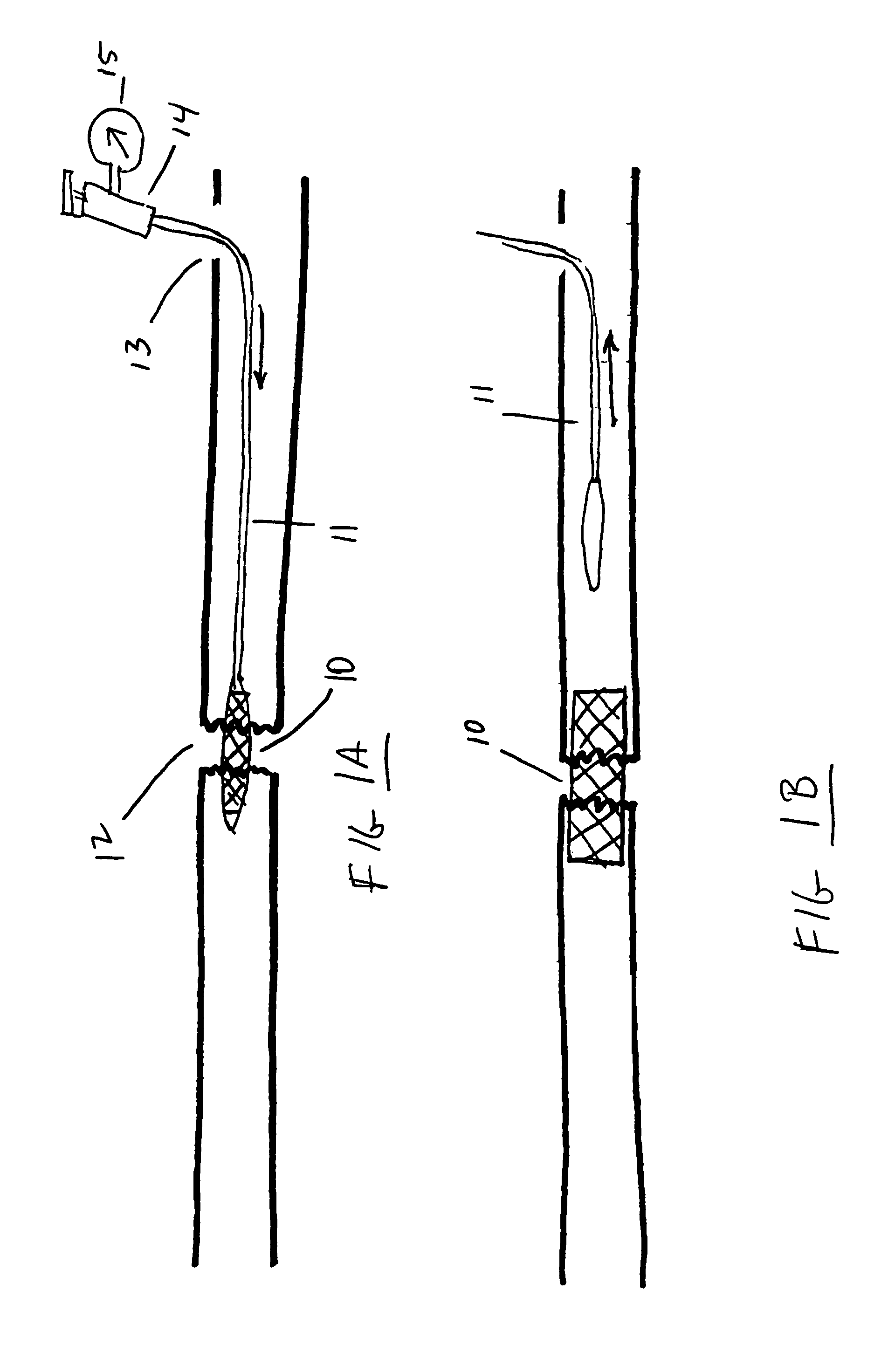

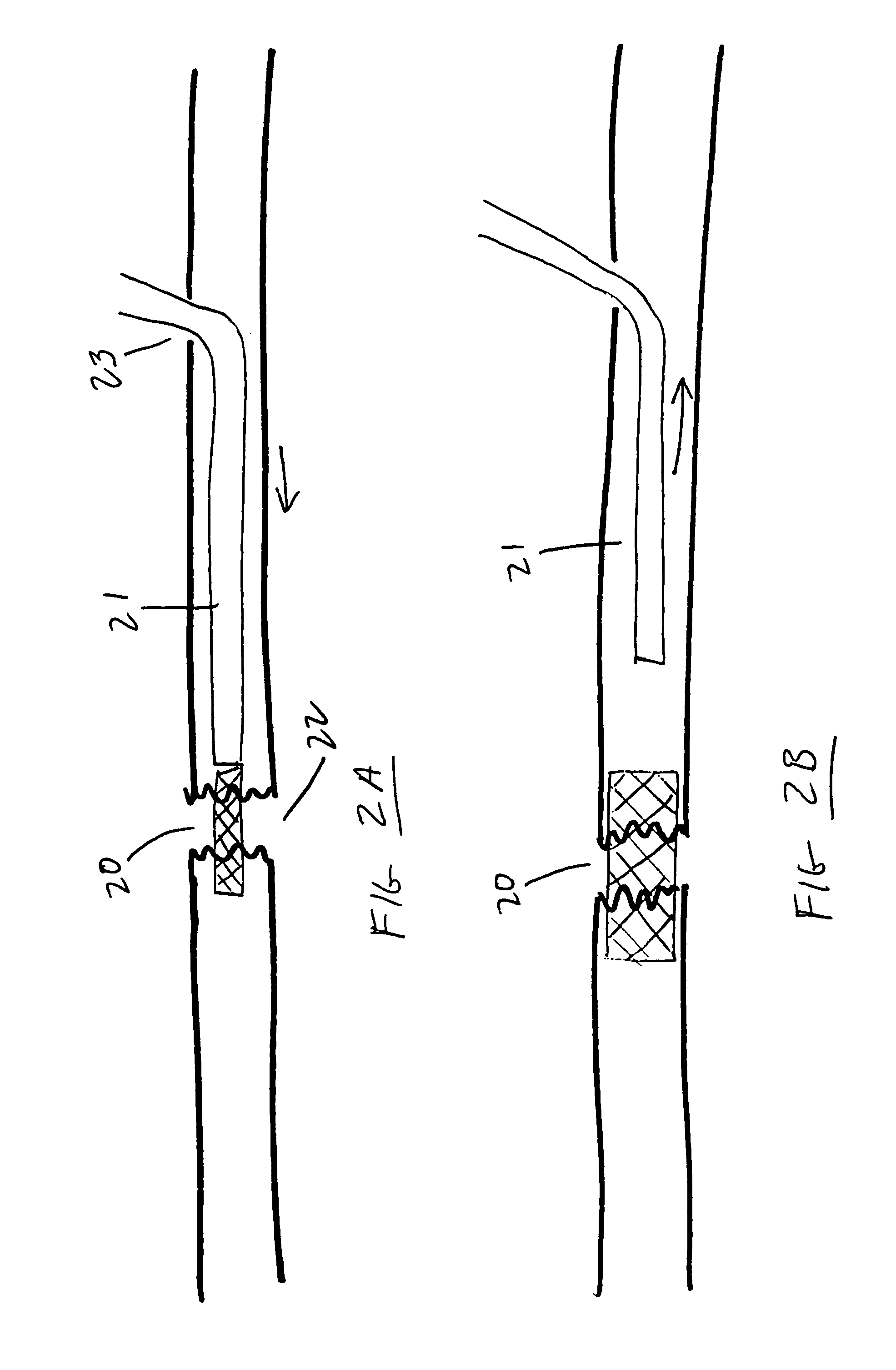

Methods and devices for treatment of bone fractures

InactiveUS8007498B2Low surface area and massLarge quantitySuture equipmentsInternal osteosythesisBiomedical engineeringBone healing

A method and devices for facilitating fixating and joining of bone fractures utilizing expandable devices that are positioned within the bone and across the fracture site. The stress from the expanded may enhance and expedite bone healing.

Owner:MISCHE HANS A

Method of mixing fluids by coalescence of multiple emulsions

ActiveUS9194861B2High-confidence resultLower the volumeSequential/parallel process reactionsHeating or cooling apparatusEmulsionChemistry

System, including methods, apparatus, compositions, and kits, for the mixing of small volumes of fluid by coalescence of multiple emulsions.

Owner:BIO RAD LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com