Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

A technology for laterite nickel ore and nickel-iron concentrate, which can be applied to rotary drum furnaces, furnace types, furnaces, etc., can solve the problems of loss of iron, acid consumption of iron, and increased costs, so as to reduce the cost of smelting, reduce the cost of auxiliary materials, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

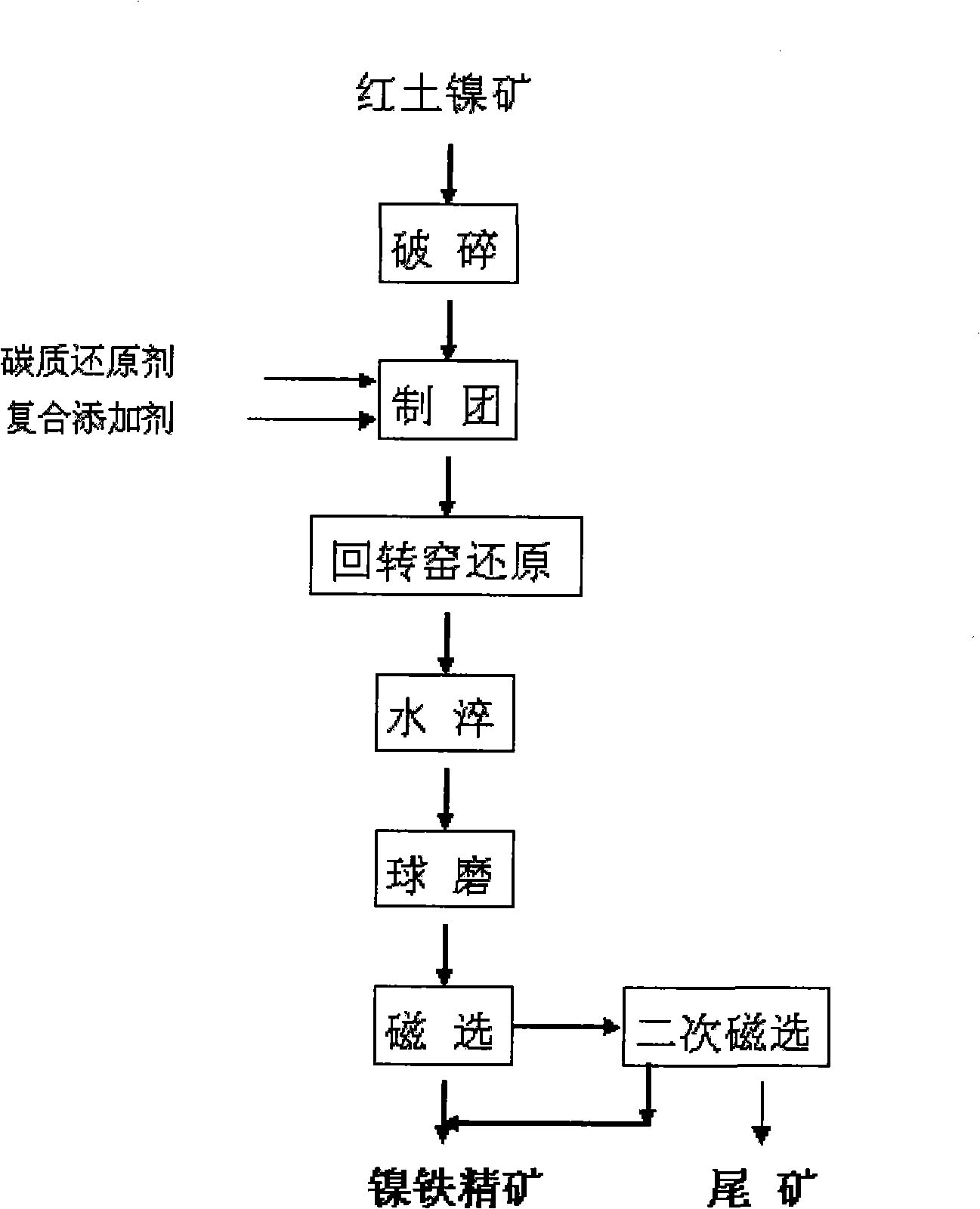

Method used

Image

Examples

Embodiment 1

[0021] 1) The composition of laterite nickel ore in Indonesia is as follows (each component is weight%): Ni 1.67%, Co 0.019%, MgO 15.83%, Fe 2 o 3 15.83%, SiO 2 52.09%, Al 2 o 3 2.99%, Cr 2 o 3 0.39%,

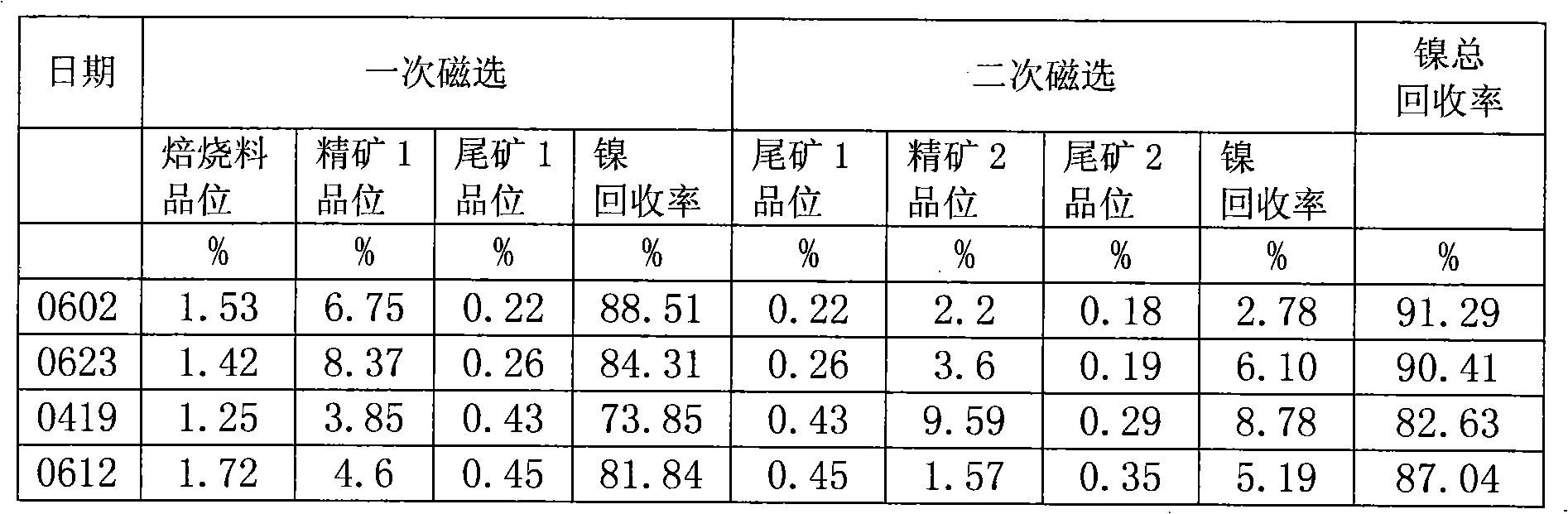

[0022] 2) Process conditions for implementation: 120 tons of laterite nickel ore in Indonesia, Raymond crushed to -120 mesh, accounting for 70%, adding 10% carbonaceous reducing agent by original ore weight, 5% sodium chloride, 5% limestone powder, 0.5% pyrite Mineral powder, stir evenly, add water, enter the ball press machine to press into pellets with a diameter of 50mm, enter the rotary kiln, control the temperature in the high temperature zone at 1150-1200°C and roast for 1.5 hours. The abrasive fineness is controlled to be -120 mesh and 50% to 70% of the content enters the ball mill for treatment, followed by continuous magnetic separation with a magnetic separator. Control the pulp concentration of the magnetic separator to be 20-40%, and the continuous magnet...

Embodiment 2

[0024] 1) The composition of laterite nickel ore in Indonesia is as follows (each component is weight%): Ni 1.12%, Co 0.017%, MgO 15.83%, Fe 2 o 3 20.83%, SiO 2 52.09%, Al 2 o 3 2.99%, Cr 2 o 3 0.39%;

[0025] 2) Process conditions for implementation: 30 tons of Indonesian laterite nickel ore, Raymond crushed to -120 mesh > 60%, add 5% carbonaceous reducing agent, 10% sodium chloride, 5% limestone powder by weight of the original ore, stir well and then add Water enters the ball press machine to press into 40mm pellets, enters the rotary kiln, and roasts at a temperature of about 1150°C for 1 hour. The roasted materials are quenched in water and coarsely broken. 70% enters the ball mill for treatment, followed by continuous magnetic separation by magnetic separator. Control the pulp concentration of the magnetic separator to be 20-40%, and the continuous magnetic separation system processes 5-10 tons of roasted materials every day, and takes samples for analysis eve...

Embodiment 3

[0027] 1) The composition of laterite nickel ore in Indonesia is as follows (each component is weight%): Ni 1.67%, Co 0.019%, MgO 15.83%, Fe 2 o 3 15.83%, SiO 2 52.09%, Al 2 o 3 2.99%, Cr 2 o 3 0.39%;

[0028]2) Process conditions for implementation: 20 tons of laterite nickel ore in Indonesia, Raymond crushed to -120 mesh > 60%, adding 5% carbonaceous reducing agent by original ore weight, 5% sodium chloride, 2% limestone powder, 0.5% pyrite Mineral powder, 0.5% fluorite, stir evenly, add water, enter the ball press machine to press into 50mm pellets, enter the rotary kiln, the temperature in the high temperature zone is controlled at about 1200 ° C for 2 hours, and the roasted materials are quenched by water. After crushing, control the abrasive fineness to -120 mesh and 50% to 70% of the content and enter the ball mill for treatment, followed by continuous magnetic separation with a magnetic separator. Control the pulp concentration of the magnetic separator to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com