Rubber assembly material for bellows drainpipe of roller washing machine and manufacturing process thereof

A drum washing machine and bellows technology, which is applied in other washing machines, applications, washing devices, etc., can solve the problems of soap liquid resistance, copper ion resistance, high temperature resistance, product odor, etc., and achieve safe and reliable laundry Environment, good steam resistance, good sealing performance and the effect of safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

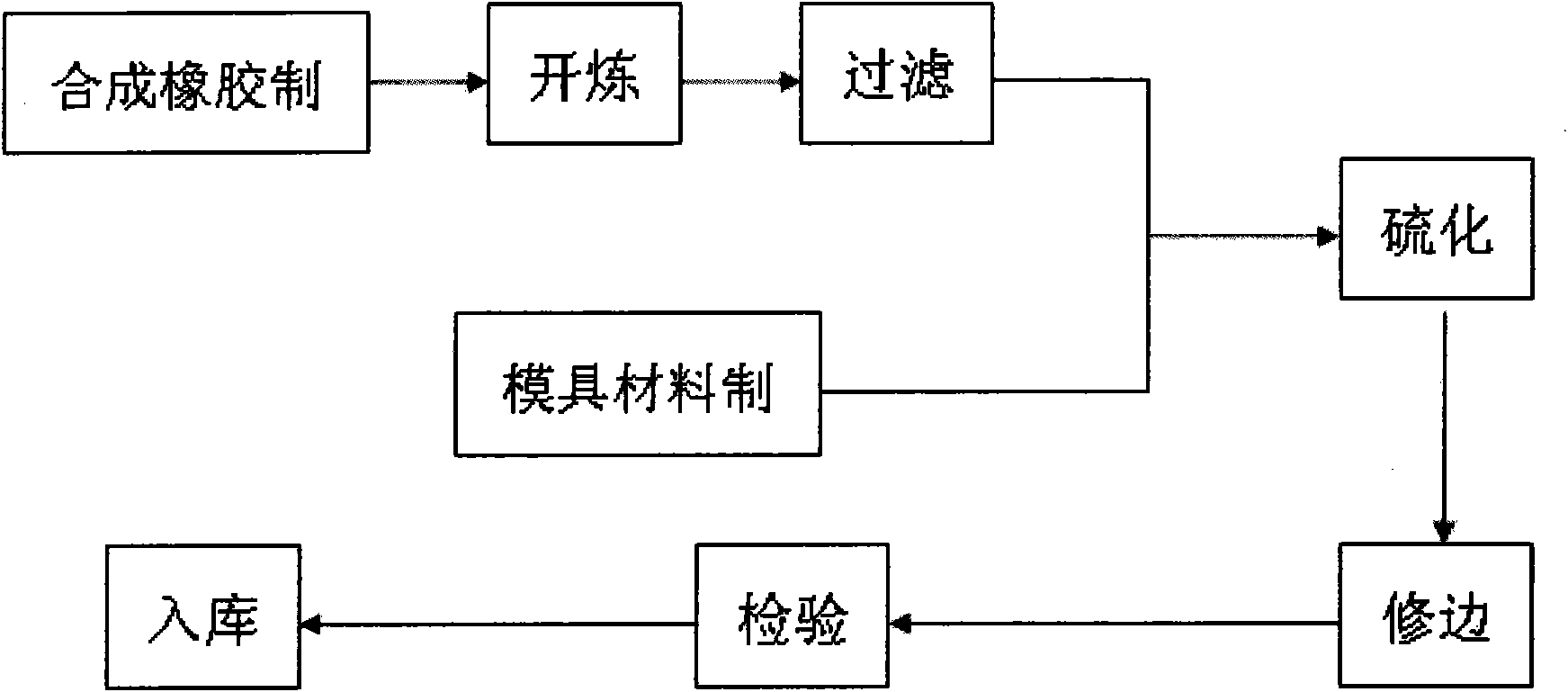

Method used

Image

Examples

Embodiment 1

[0032] The ratio of materials for the rubber component of the drain bellows on the drum washing machine is as follows in parts by weight:

[0033] EPDM: 150 Clay: 70

[0034] Carbon black: 30 NKL-9: 40

[0035] Paraffin oil: 20 Indirect zinc oxide: 4

[0036] Stearic acid: 1 Anti-aging agent RD: 1

[0037] Lubricant WB42: 2 Sulfur: 0.5

[0038] Accelerator CZ: 1 Accelerator M: 0.5

[0039] Accelerator TBZTD: 0.5 Accelerator TL: 0.5.

Embodiment 2

[0041] The ratio of materials for the rubber component of the drain bellows on the drum washing machine is as follows in parts by weight:

[0042] EPDM: 175 Clay: 80

[0043] Carbon black: 40 NKL-9: 45

[0044] Paraffin oil: 25 Indirect zinc oxide: 5

[0045] Stearic acid: 1.5 Anti-aging agent RD: 1.5

[0046] Lubricant WB42: 3 Sulfur: 0.6

[0047] Accelerator CZ: 1.5 Accelerator M: 1

[0048] Accelerator TBZTD: 0.8 Accelerator TL: 0.5.

Embodiment 3

[0050] The ratio of materials for the rubber component of the drain bellows on the drum washing machine is as follows in parts by weight:

[0051] EPDM: 200 Clay: 90

[0052] Carbon black: 50 NKL-9: 50

[0053] Paraffin oil: 30 Indirect zinc oxide: 6

[0054] Stearic acid: 2 Anti-aging agent RD: 2

[0055] Lubricant WB42: 4 Sulfur: 0.8

[0056] Accelerator CZ: 2 Accelerator M: 1.5

[0057] Accelerator TBZTD: 1 Accelerator TL: 0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com