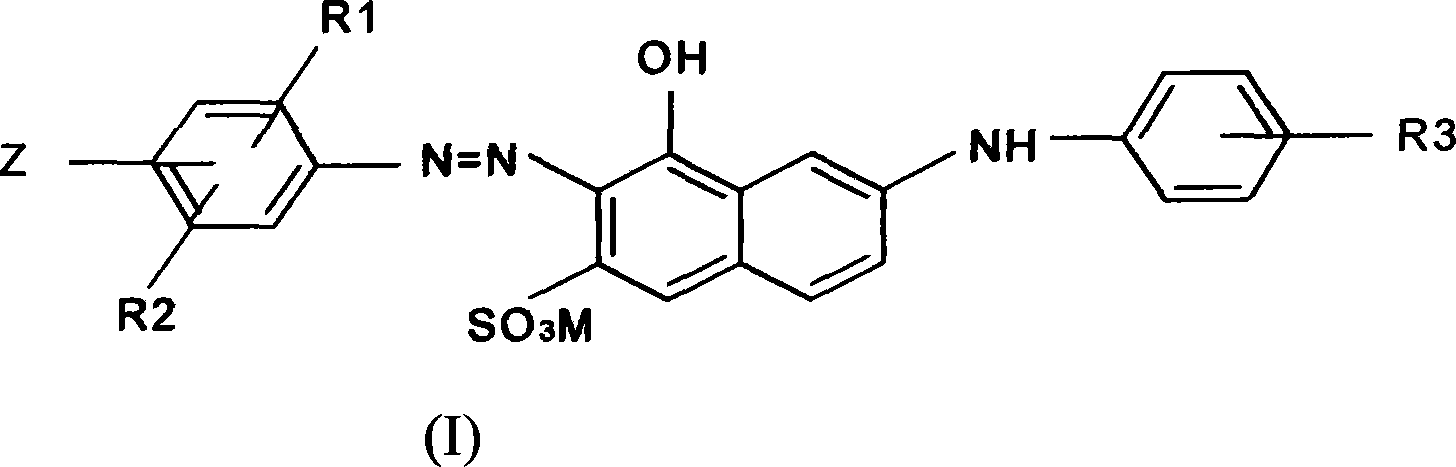

Reactive brown dye and preparation method thereof

A reactive brown and dye technology, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of large color difference, poor stability, color flower, etc., to prevent large head and tail color difference, good comprehensive performance, good light fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

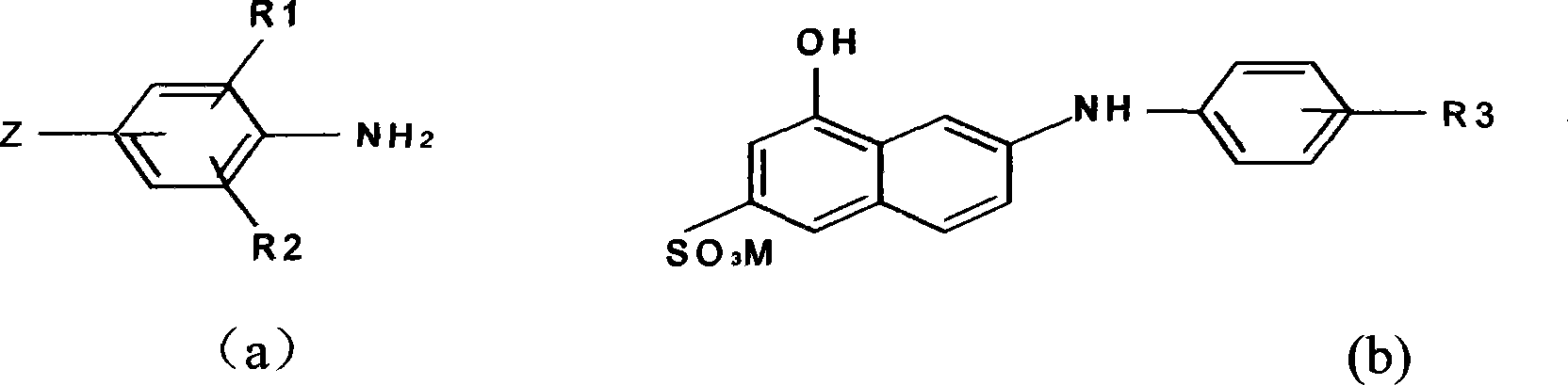

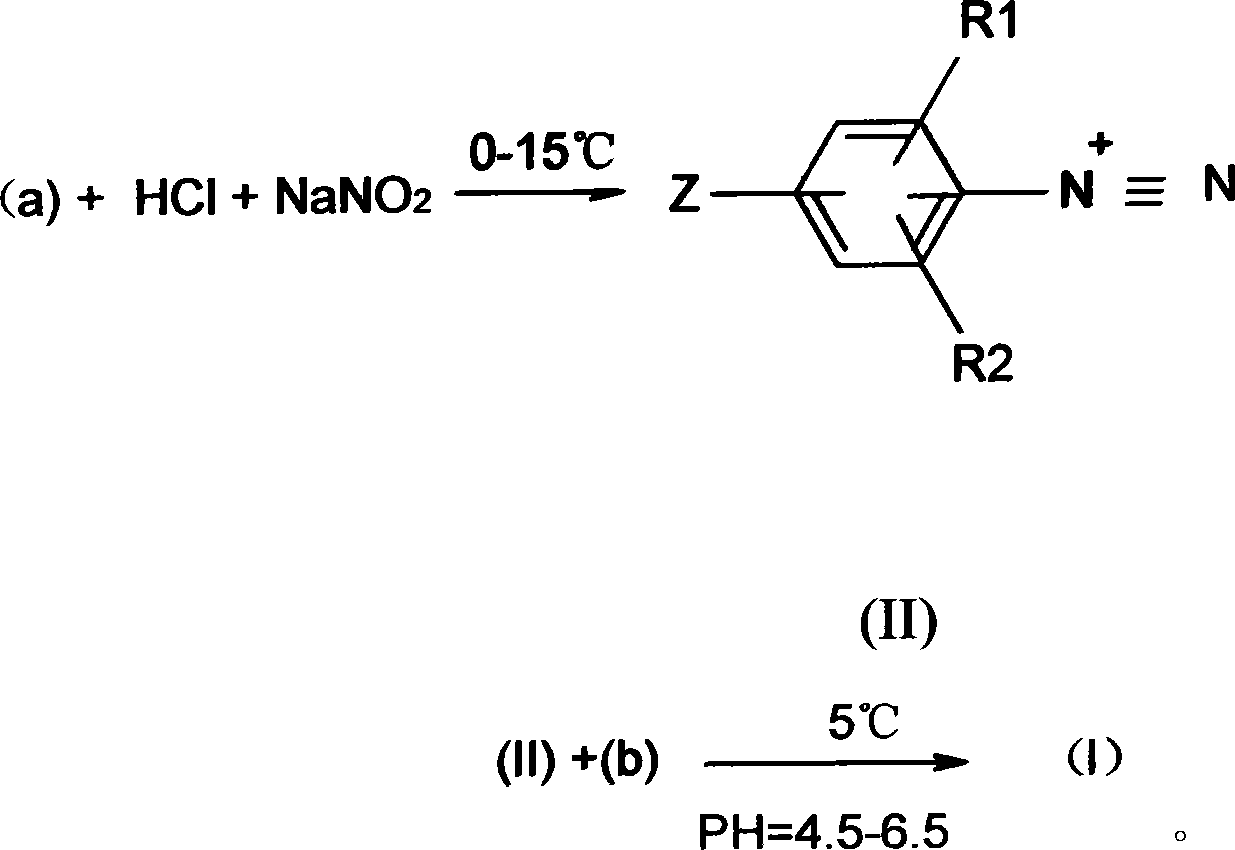

Method used

Image

Examples

Embodiment Construction

[0020] Diazotization: fully stir 100% 28.1 parts of p-ester in 150 parts of ice water, add 13ml of concentrated hydrochloric acid, cool the obtained suspension to 5-10°C, slowly add 100% 6.9 parts of sodium nitrite solution dropwise, Until the potassium iodide starch test paper turns blue, stir at 5-10°C for 1 hour, and remove nitrous acid with sulfamic acid.

[0021] Coupling: 31.6 parts of 100% phenyl gamma acid, add 250 ml of water and stir, add industrial NaOH to adjust pH=6.5 to make it completely dissolved. Then add the p-ester diazonium salt into the phenyl gamma acid solution in a thin stream, and adjust the pH to 6.3-6.5 with soda ash, and control the temperature at 5-10°C. After adding the diazonium salt, stir at 5-10°C for 4 hours Until the diazonium salt disappears, desalination and spray drying give the brown dye of the following formula:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com