Patents

Literature

717 results about "PARAFFIN HYDROCARBONS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraffin hydrocarbon, also called alkane, any of the saturated hydrocarbons having the general formula CnH2n+2, C being a carbon atom, H a hydrogen atom, and n an integer.

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

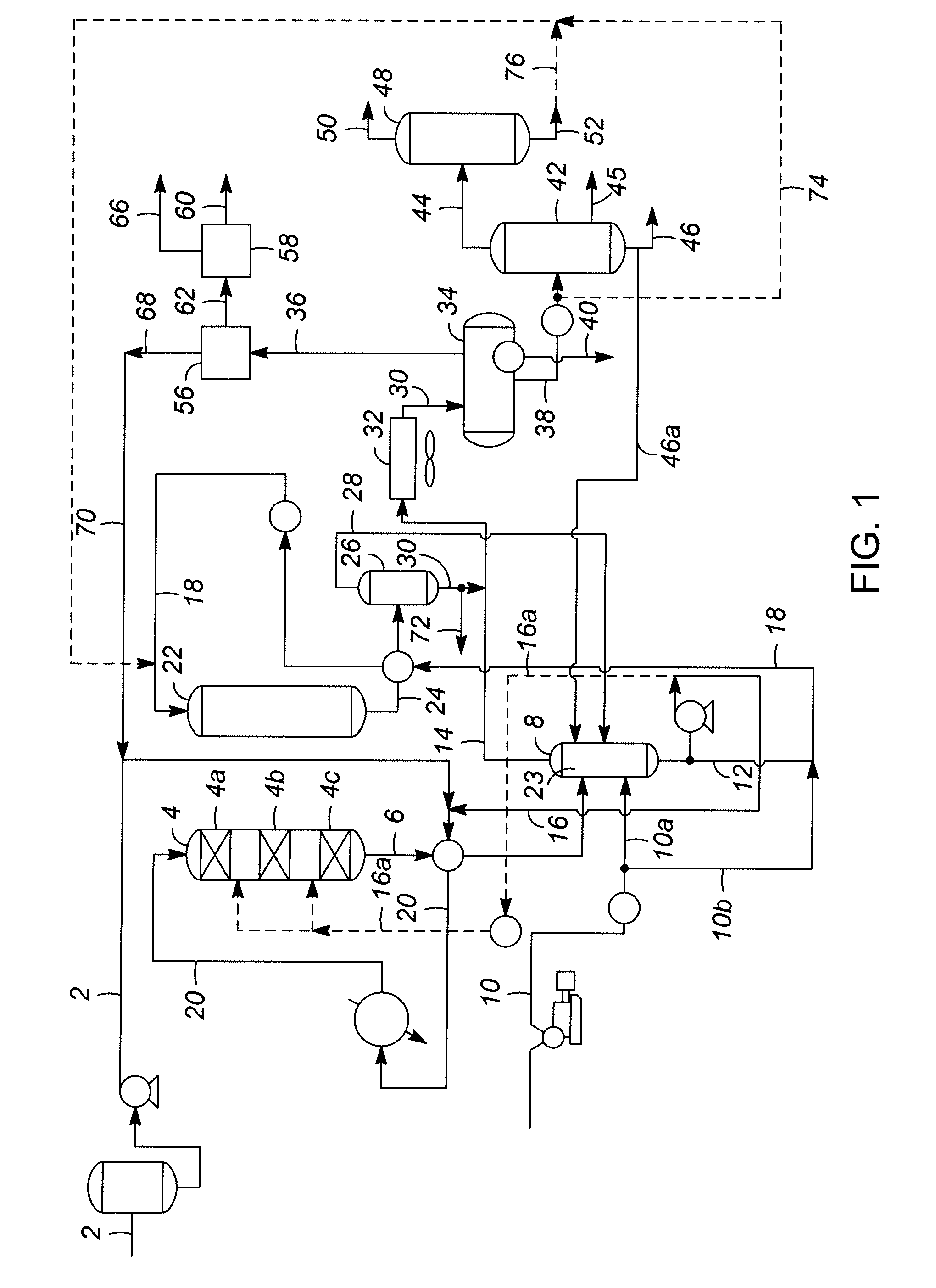

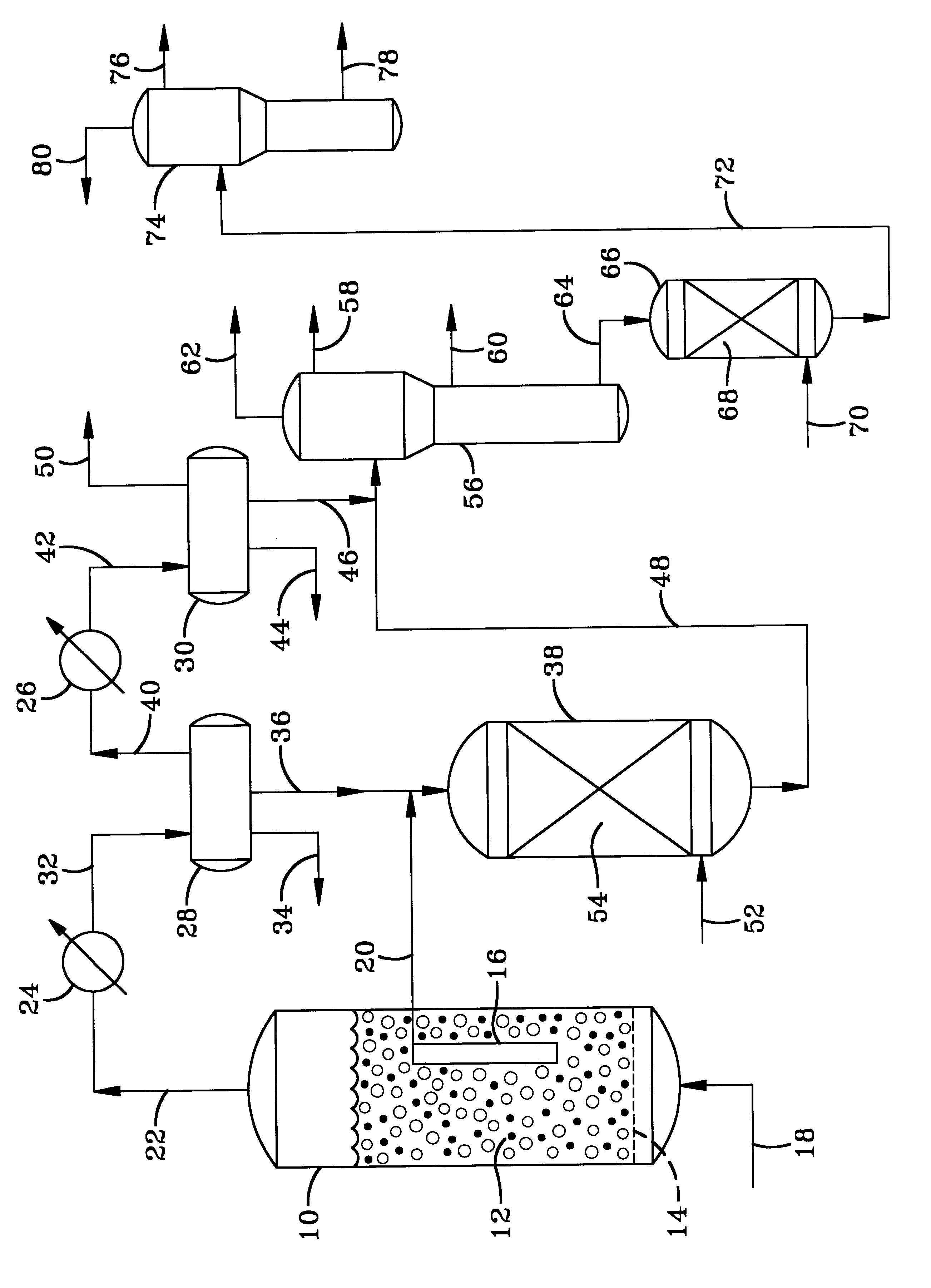

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Premium wear resistant lubricant

A premium synthetic lubricant having antiwear properties comprises a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one antiwear additive. The antiwear additive is preferably at least one of a metal phosphate, a metal dialkyldithiophosphate, a metal dithiophosphate a metal thiocarbamate, a metal dithiocarbamate, an ethoxylated amine dialkyldithiophosphate and an ethoxylated amine dithiobenzoate. Metal dialkyldithiophosphates are preferred, particularly zincdialkyldithiophosphate (ZDDP). The base stock is derived from a waxy, Fischer-Tropsch synthesized hydrocarbon feed fraction comprising hydrocarbons having an initial boiling point in the range of about 650-750 DEG F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The lubricant may also contain hydrocarbonaceous and synthetic base stock material in admxture with the Fischer-Tropsch derived base stock.

Owner:EXXON RES & ENG CO

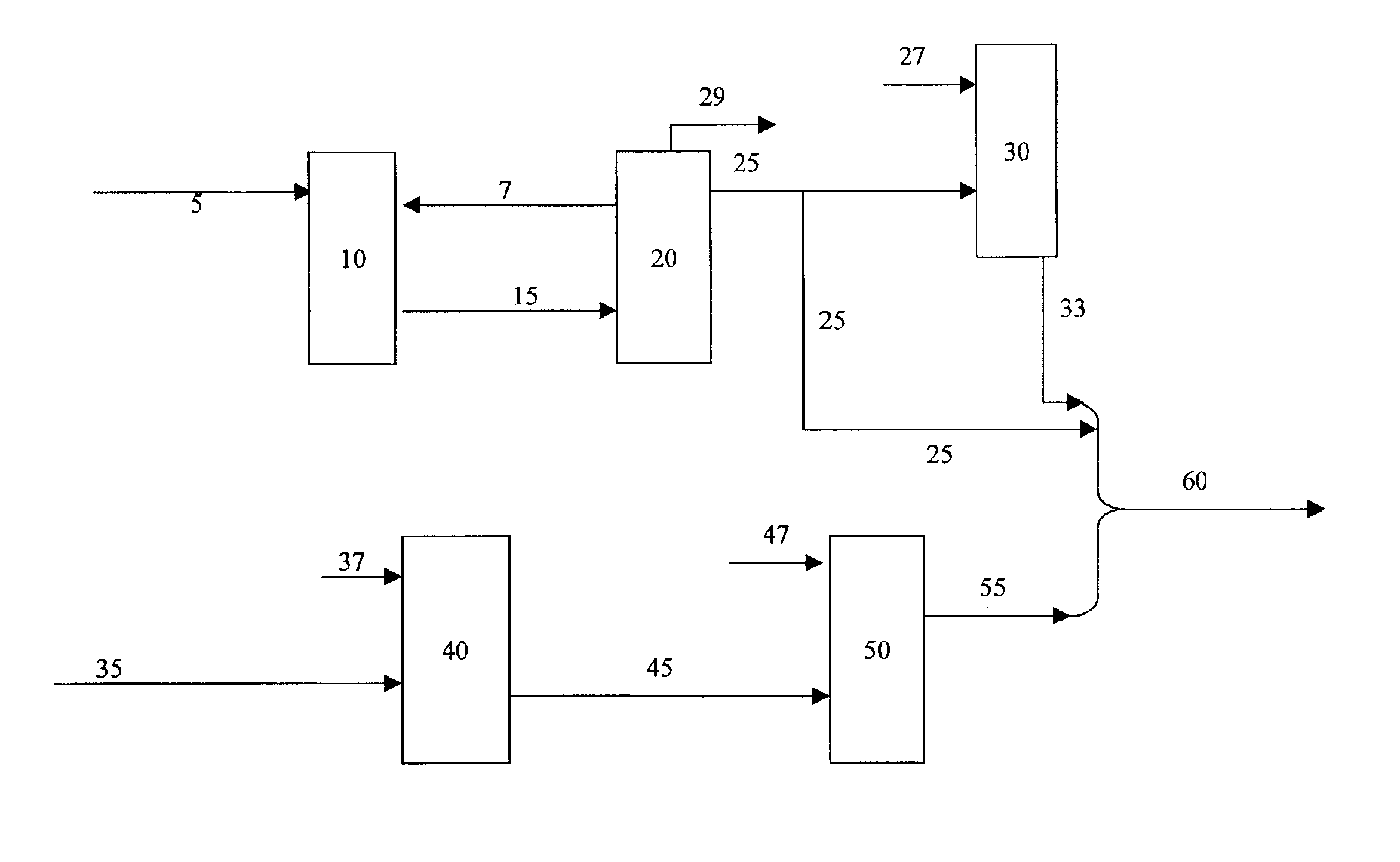

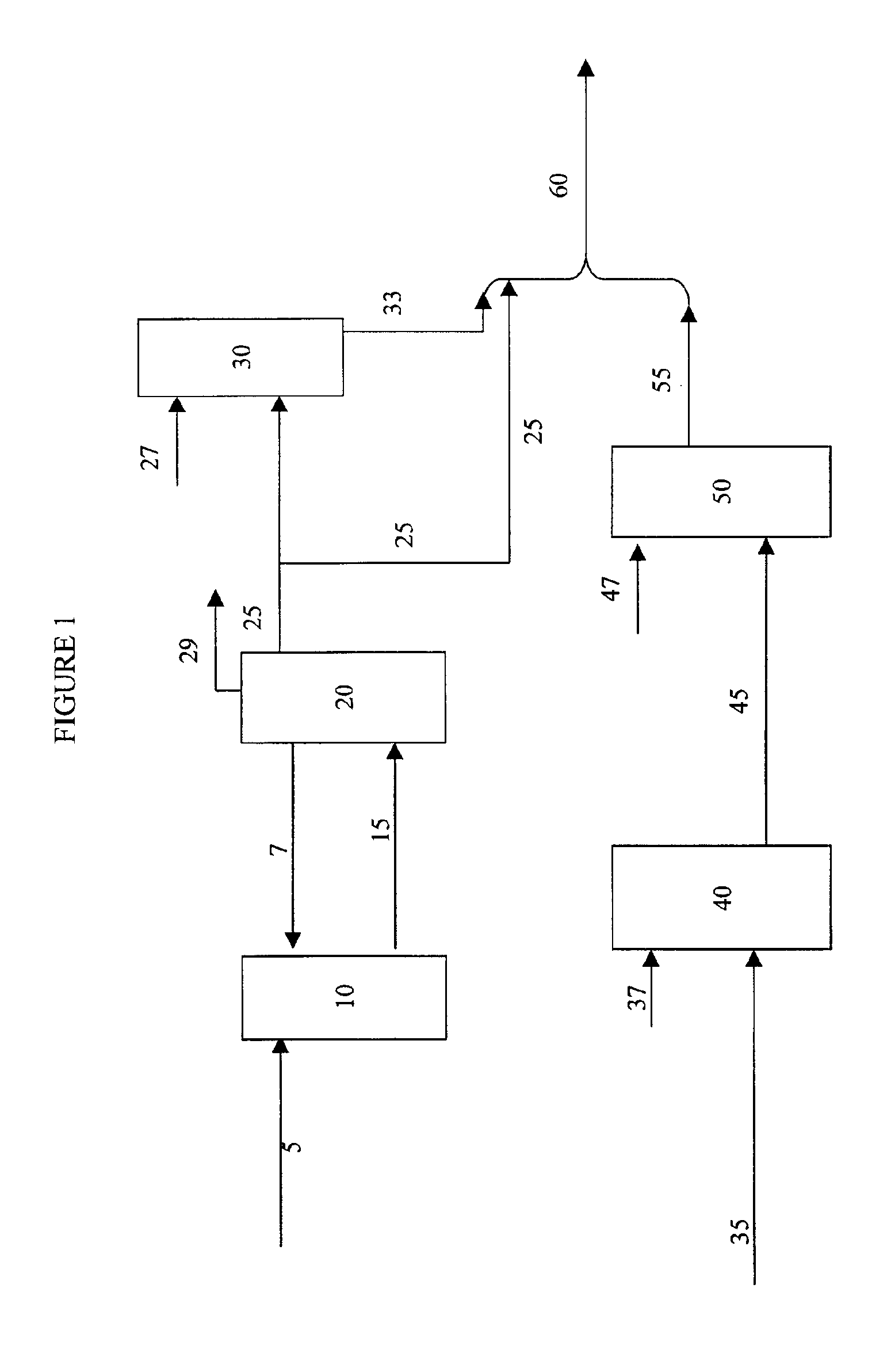

Production of Blended Fuel from Renewable Feedstocks

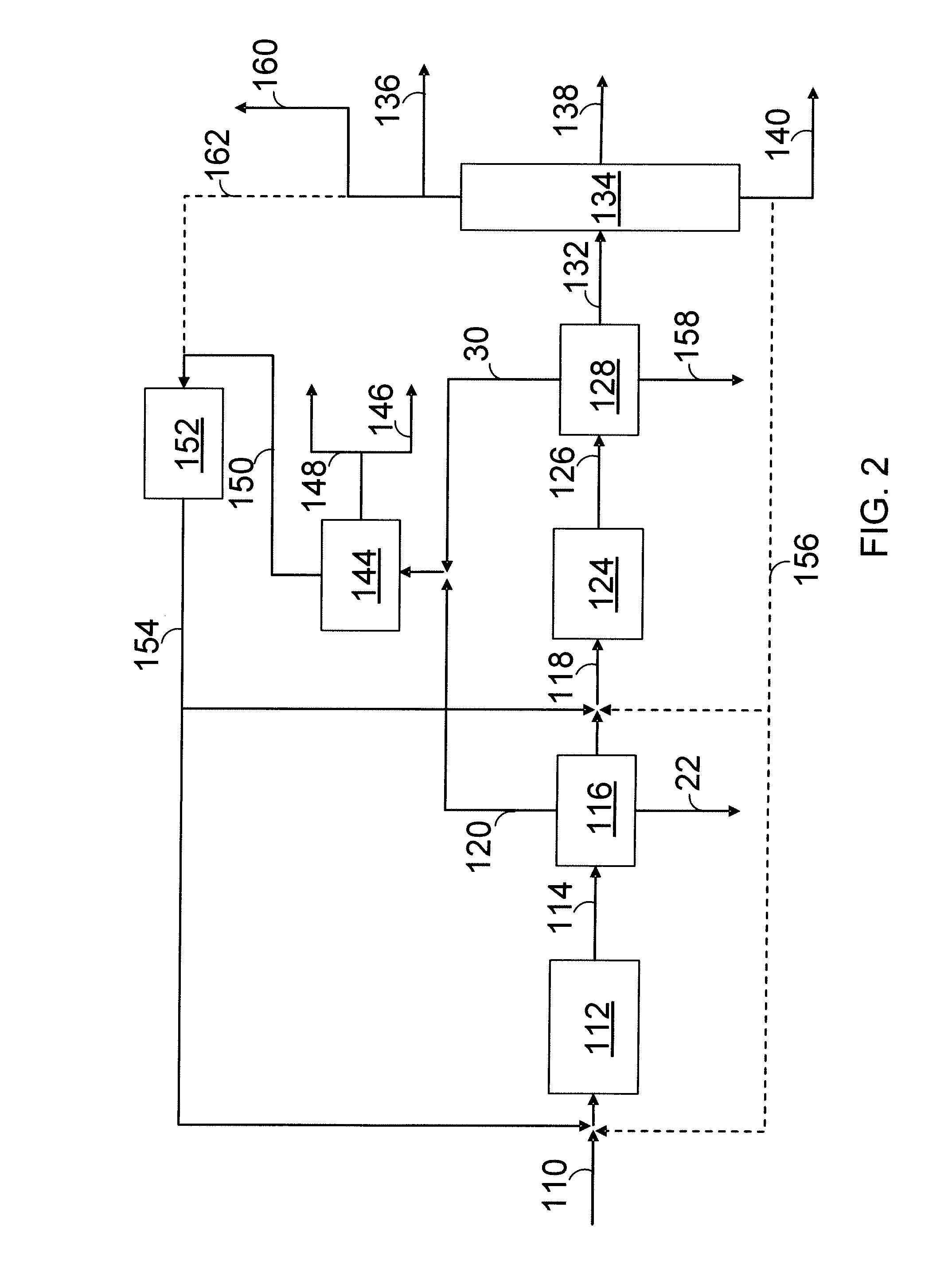

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

Catalyst and process of paraffin hydrocarbon conversion

InactiveUS20040077914A1Improve solubilityEasy to useHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkanePtru catalyst

A catalyst composition and process for the conversion of linear and / or branched paraffin hydrocarbons based on the use of an ionic liquid catalyst in combination with a Brønsted Acid, which provides a catalytic composition with an increased activity compared with said ionic liquid. Under suitable reaction conditions this conversion is leading to paraffin hydrocarbon fraction with higher octane number.

Owner:HALDOR TOPSOE AS

Production of Blended Fuel from Renewable Feedstocks

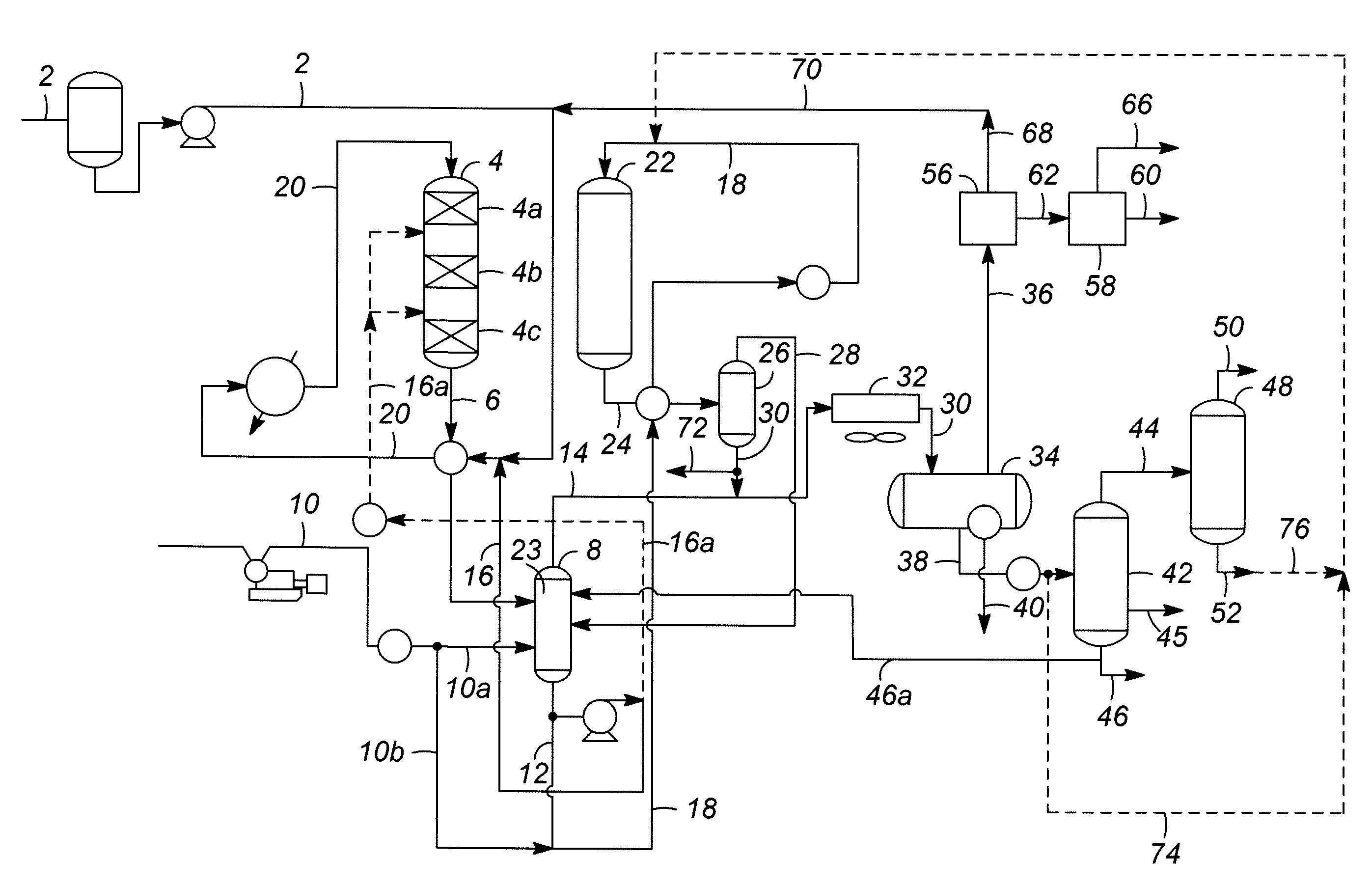

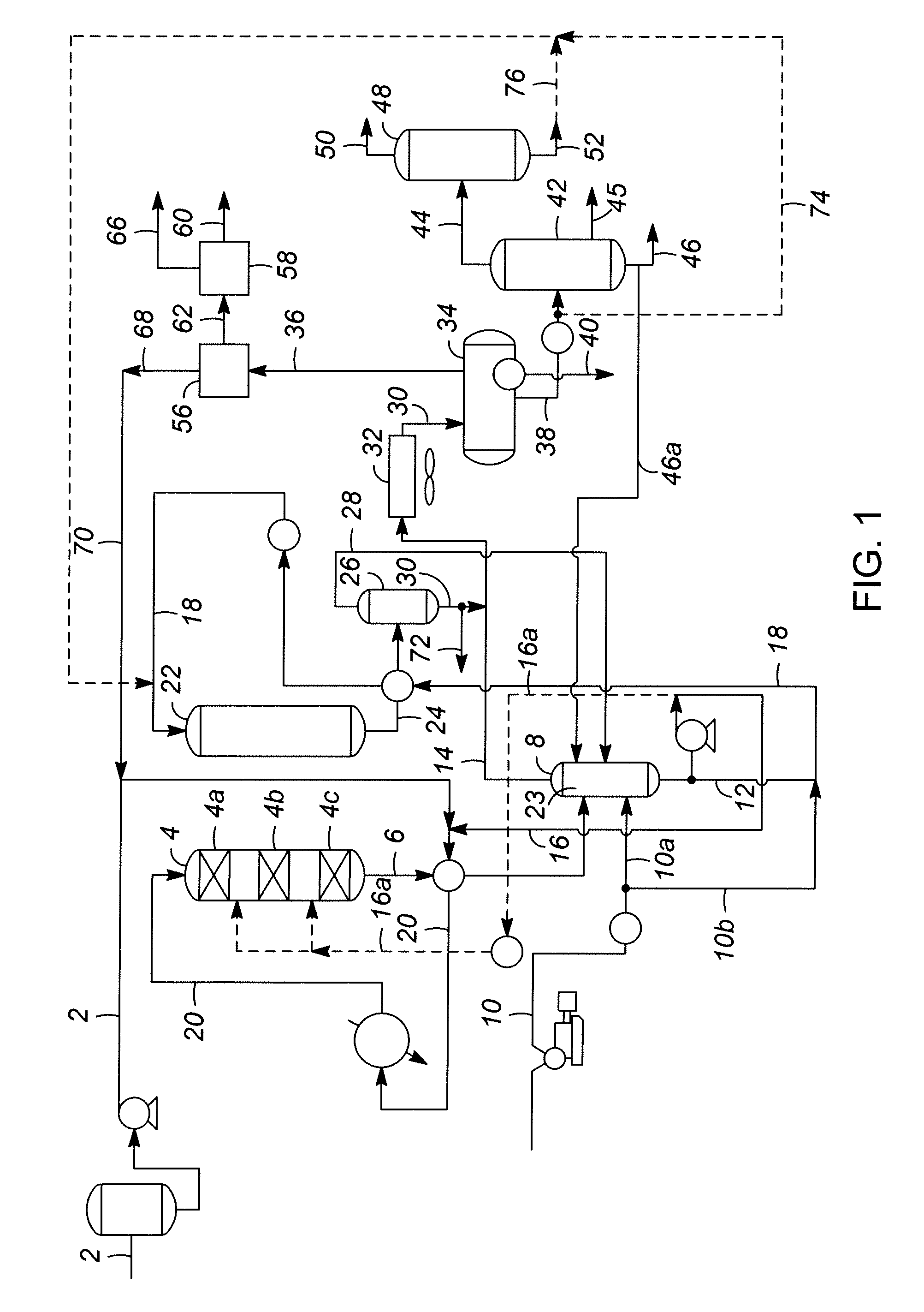

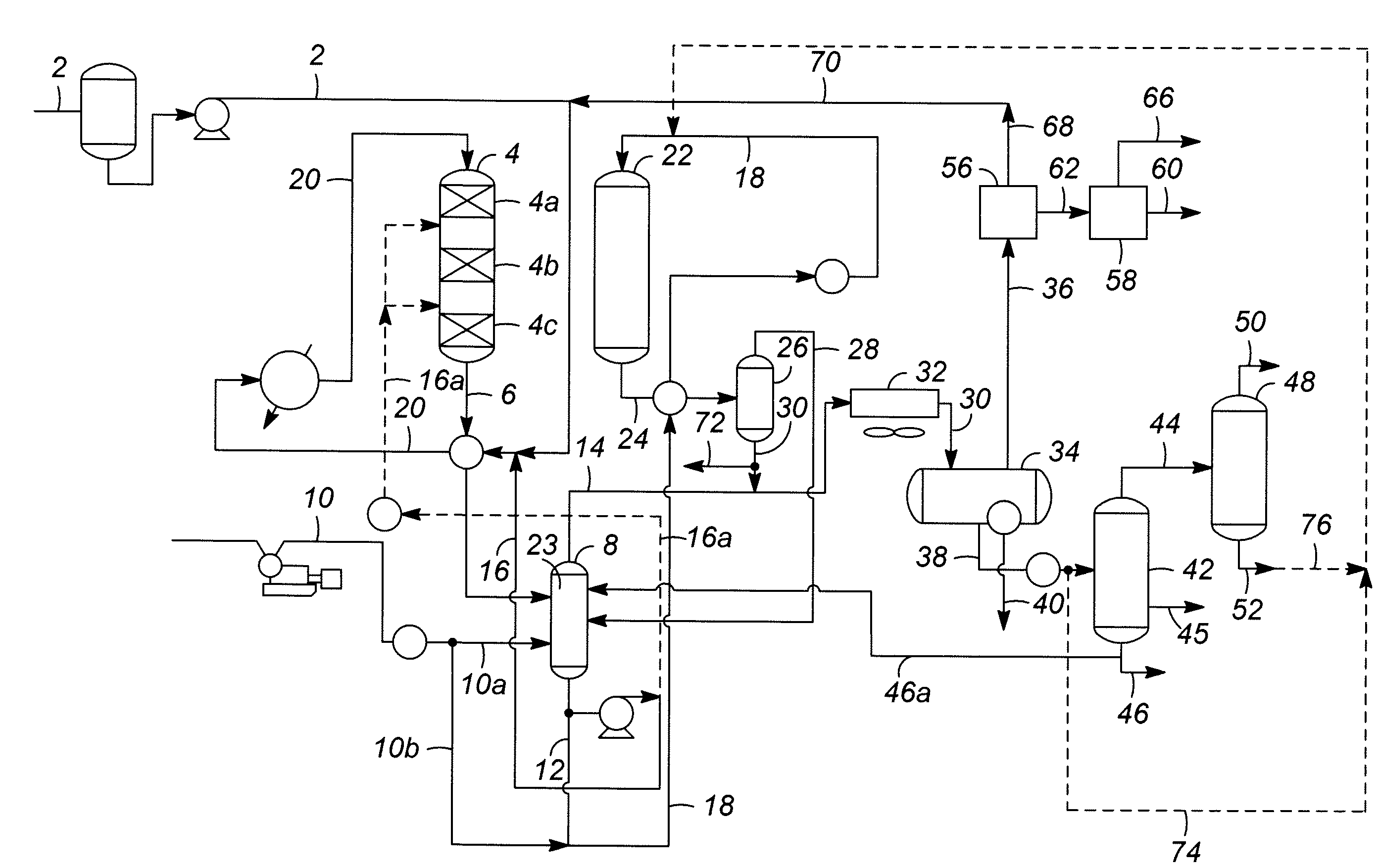

ActiveUS20090301930A1Minimize the numberReduce the amount requiredRefining to change hydrocarbon structural skeletonBiofuelsParaffin waxEngineering

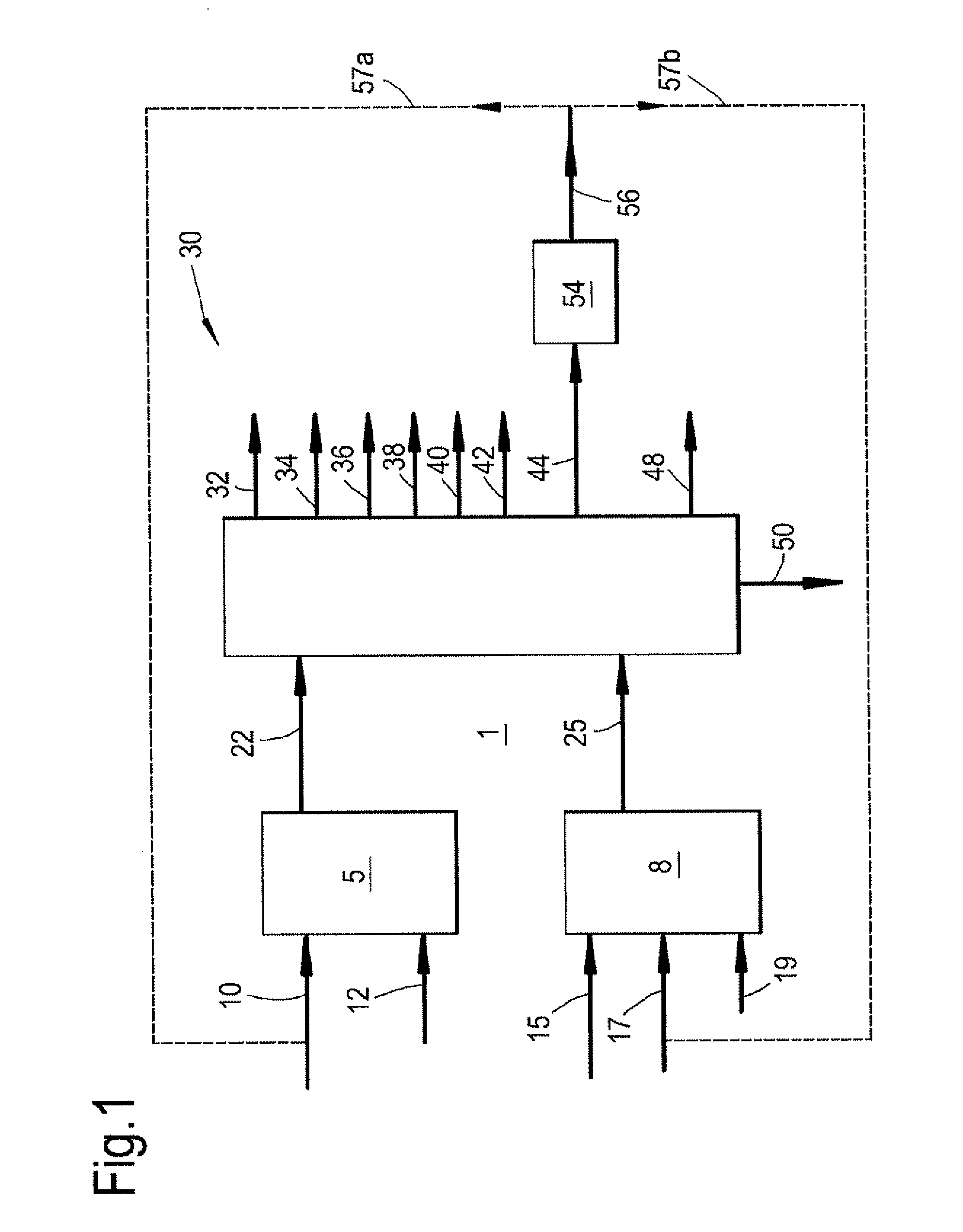

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from glycerides and free fatty acids in feedstocks such as plant and animal oils. The cyclic rich component is generated from biomass derived pyrolysis oil. The source of the animal or plant oil and the biomass may be the same renewable source.

Owner:UOP LLC

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

Process of paraffin hydrocarbon isomerisation catalysed by an ionic liquid in the presence of a cyclic hydrocarbon additive

InactiveUS6797853B2High selectivityHigh degree of branchingHydrocarbon by isomerisationCatalytic crackingAlkaneIonic liquid

Owner:HALDOR TOPSOE AS

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

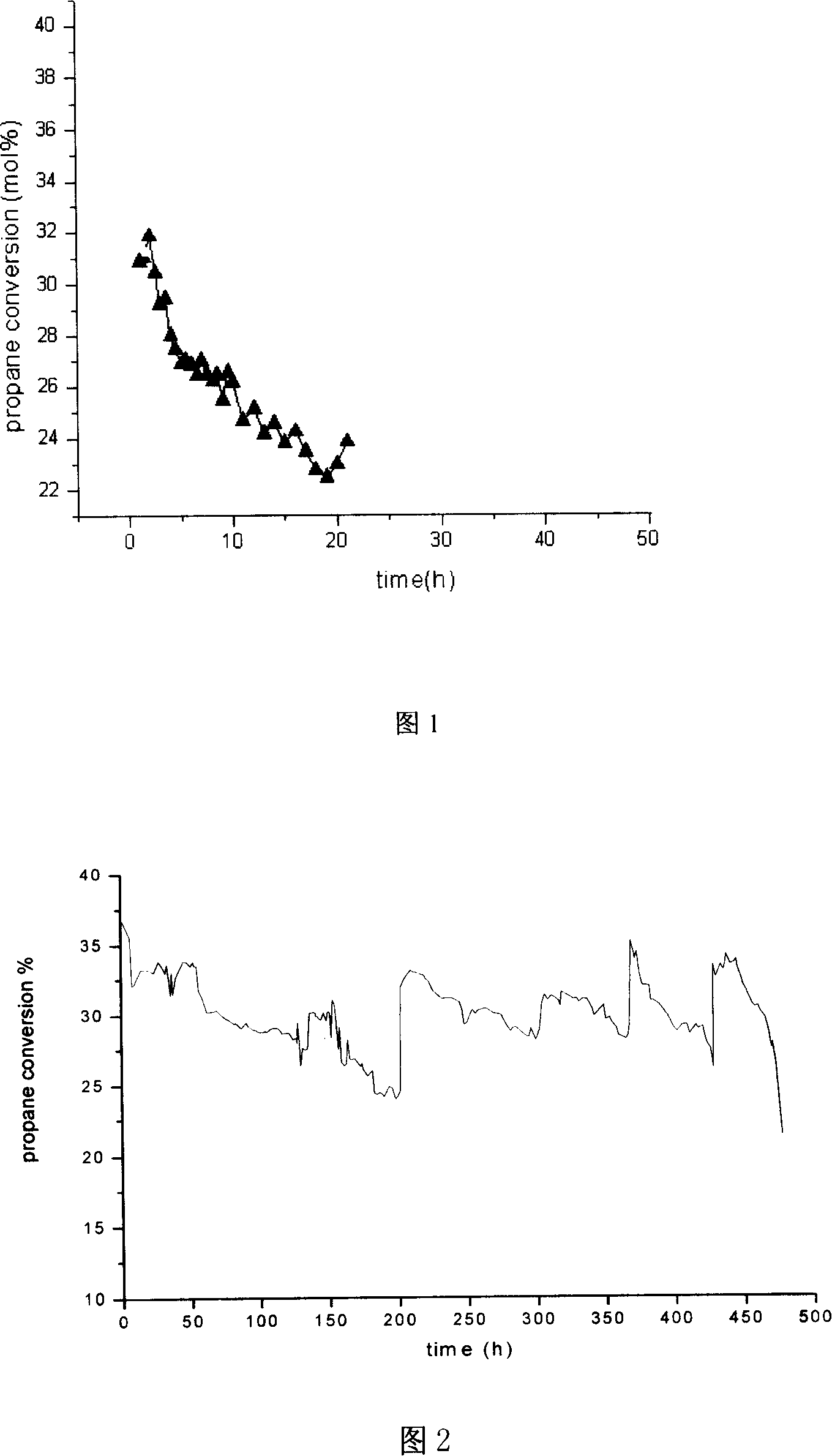

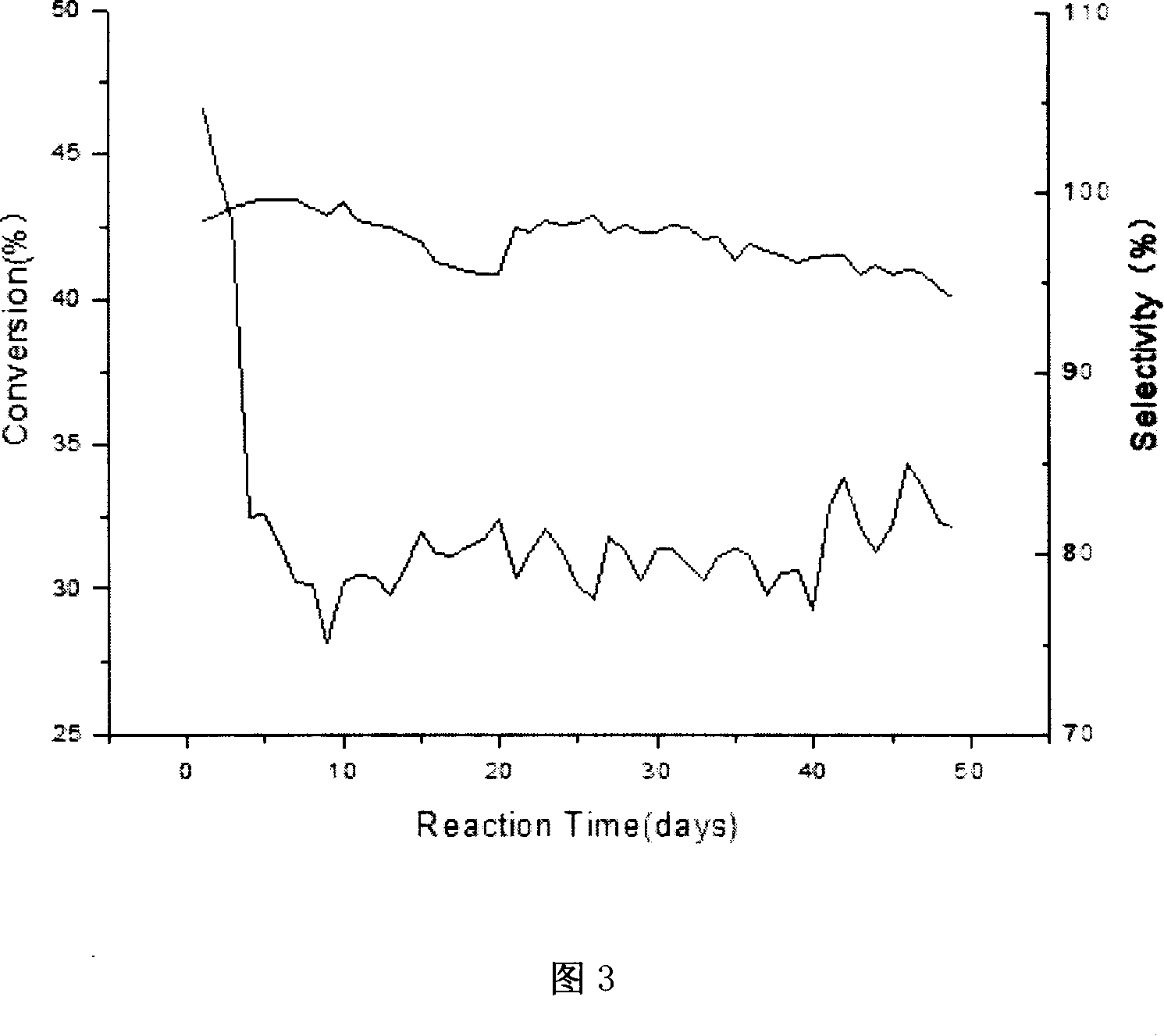

Catalyzer used for low carbon alkane catalytic dehydrogenation and method of manufacturing propylene by paraffin hydrocarbons catalytic dehydrogenation with the same as catalyzer

InactiveCN101108362AReactiveMitigation of heightened demandMolecular sieve catalystsHydrocarbonsAlkaneReaction temperature

The invention relates to a catalyst used for catalyzing and dehydrogenation of low-carbon alkane and the method of producing propylene by alkane catalyzing and dehydrogenation with the catalyst. The former catalyst used for catalyzing and dehydrogenation of low-carbon alkane, each molecule of the hydrocarbon has about 2 to 8 carbon atom, which is characterized in that: the catalyst makes a molecular sieve the carrier, the Pt family metal is loaded on the carrier as the active component, makes the IVA family metal element and alkalinity metal element as additional agent and high temperature standing inorganic oxide as connection agent; when the catalyst is used in producing propylene by alkane catalyzing and dehydrogenation, the reaction temperature is 500 to 700 DEG C., the pressure is 0 to 0.2Mpa, the quality air speed is 2 to 5h to 1, the regenerating temperature of the catalyst is 500 to 700 DEG C., the air speed is 100 to 1000h to 1, the pressure is 0 to 1.0MPa. With adopting the invention, the reaction of producing propylene by alkane catalyzing and dehydrogenation is good, the average transforming rate is 30 per cent, the selectivity above 95 per cent can keep for 50 days.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

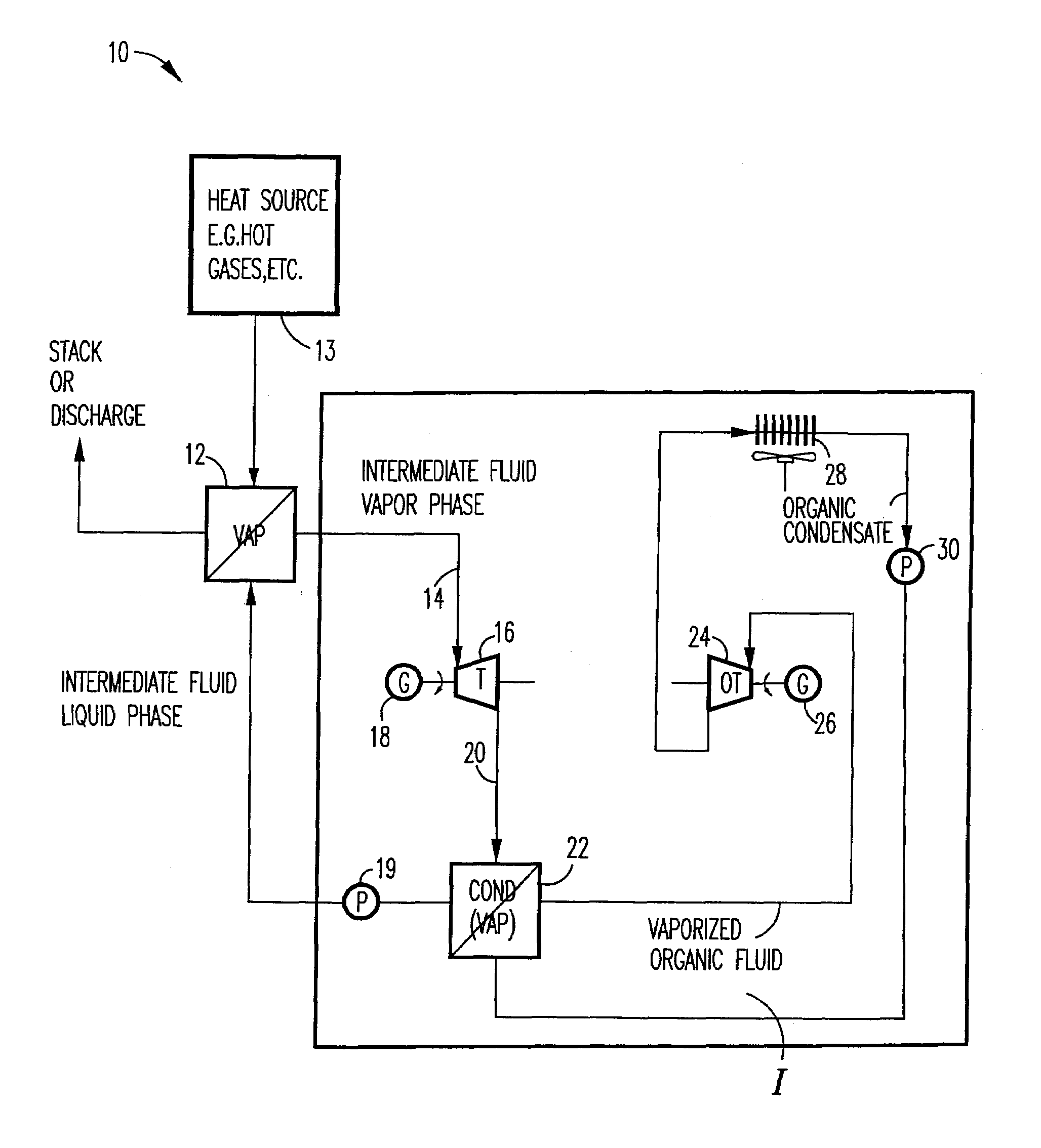

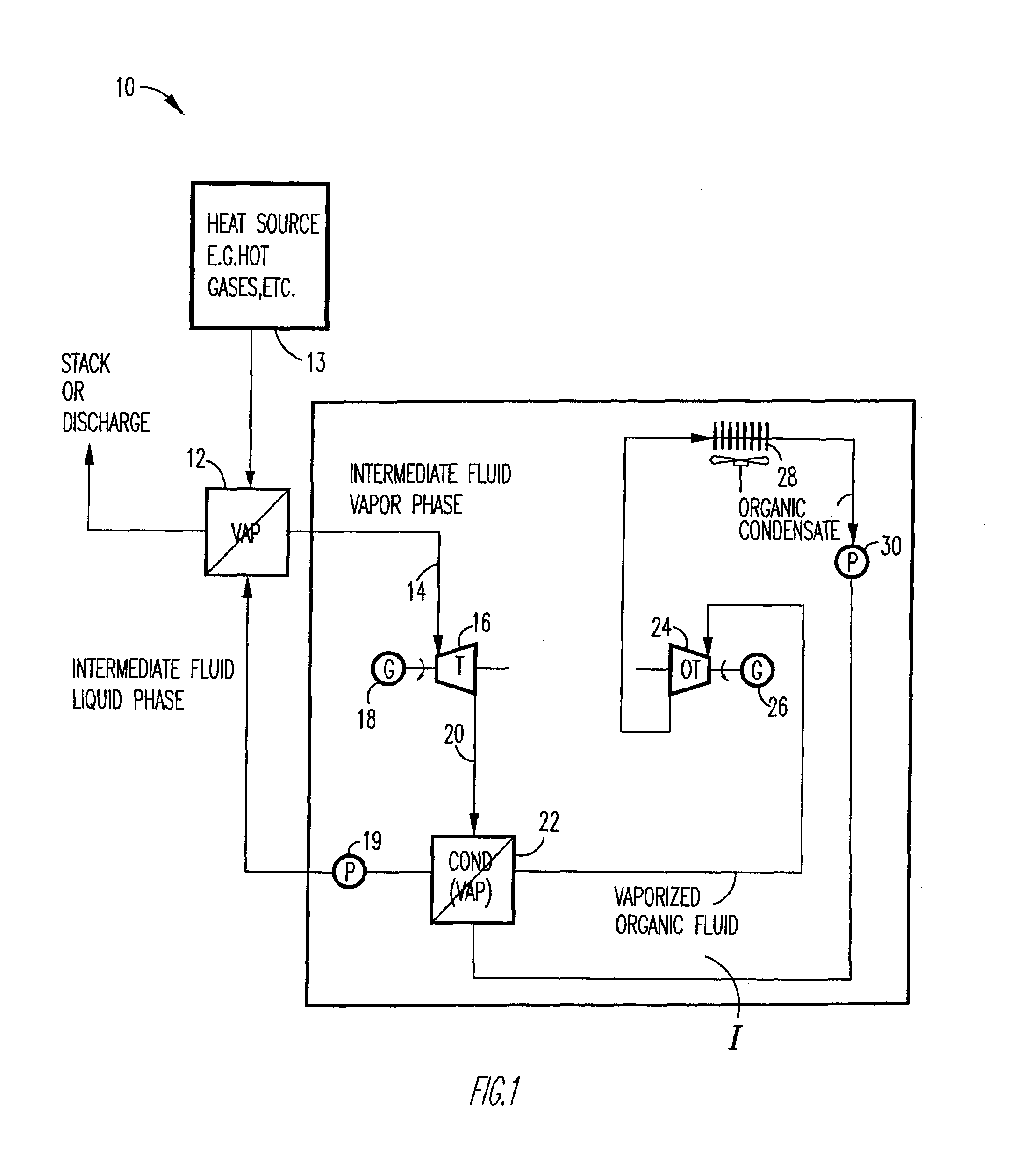

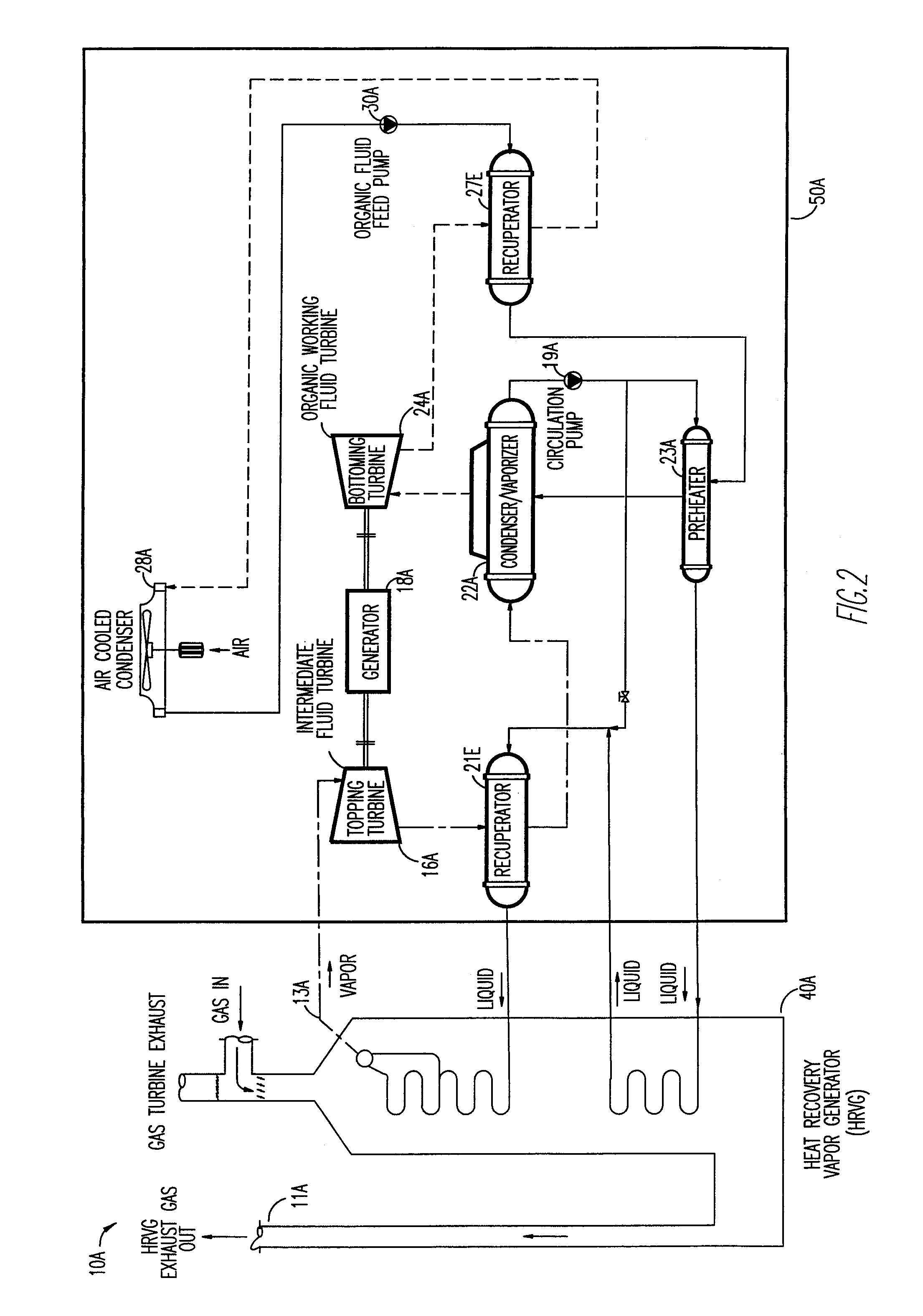

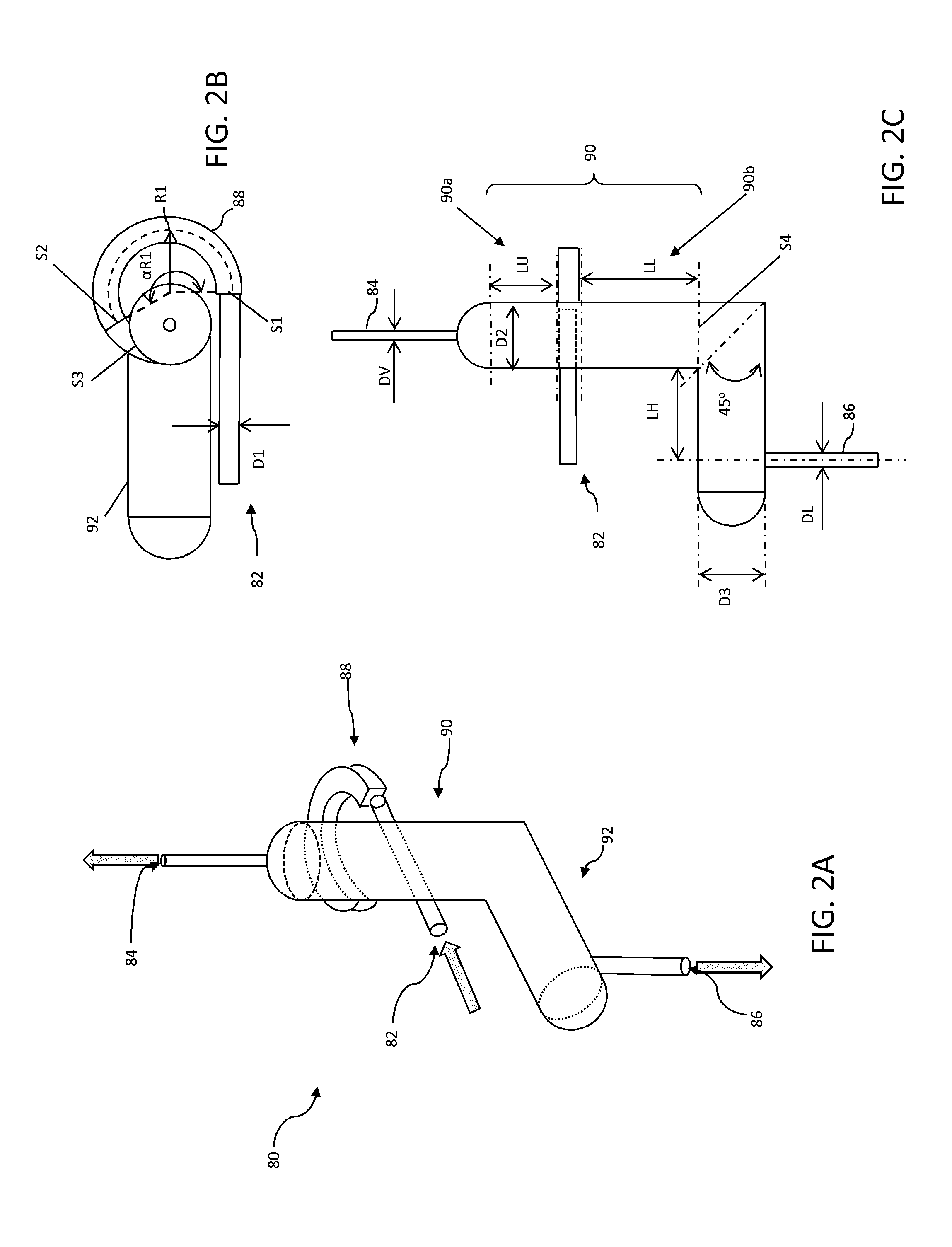

Organic working fluids

ActiveUS7225621B2Improve thermal stabilityStable compoundAuxillary drivesFrom solar energyHuman useAlkane

The present invention provides an improved, commercially available organic working fluid, which is operable under a broad range of temperatures, is thermally stable, has a high auto-ignition temperature, low freezing point and high critical temperature and is benign to the environment, and safe for human use. Such an organic working fluid is useful in organic Rankine cycle (ORC) power plants or units and other systems of the like; as an intermediate fluid for heat-recovery wherein heat from various heat sources is transferred using the intermediate fluid to a further working fluid and converted into work, and the intermediate fluid is also exploited to produce electricity. Such organic working fluids are also operable as heat transfer fluids either in ORC power plants or units or in other heat transfer systems. For this purpose the present invention presents a working fluid comprising at least one highly branched, heavy iso-paraffin hydrocarbons, or a mixture of two or more of such hydrocarbons. Preferably, at least one highly branched iso-paraffin hydrocarbon is present as the major component (i.e. at least 50% by volume) in the working fluid. A preferred sub-class of the class of the branched iso-paraffins which are suitable to be incorporated in organic working fluids of the present invention includes 8 to 20 carbon atom-containing hydrocarbons having at least one methyl radical (CH3) arranged to achieve a highly stable compound.

Owner:ORMAT TECH INC

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

InactiveUS20080312480A1Hydrocarbon from carbon oxidesFatty acid chemical modificationAlkaneVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises molybdenum, a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of even-numbered hydrocarbons to odd-numbered hydrocarbons of at least 2:1.

Owner:EI DU PONT DE NEMOURS & CO

Process for making lubricating base oils with high ratio of monocycloparaffins to multicycloparaffins

InactiveUS20060289337A1Liquid hydrocarbon mixture productionTreatment with hydrotreatment processesMolecular sieveWax

A process for manufacturing a lubricating base oil, comprising dewaxing a substantially paraffinic wax feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve under hydroisomerization conditions including a hydrogen to feed ratio from about 712.4 to about 3562 liter H2 / liter oil, whereby a lubricating base oil is produced having a)a total weight percent of molecules with cycloparaffinic functionality greater than 10, and b) a ratio of weight percent molecules with monocycloparaffinic functionality to weight percent molecules with multicycloparaffinic functionality greater than 30. Also a method for producing a base oil having a high ratio of weight percent molecules with monocycloparaffinic functionality to weight percent molecules with multicycloparaffinic functionality by hydroisomerization dewaxing a selected Fischer-Tropsch wax under hydroisomerization conditions including a hydrogen to feed ratio from about 712.4 to about 3562 liter H2 / liter oil. Also a lubricating base oil manufacturing plant.

Owner:CHEVROU USA INC

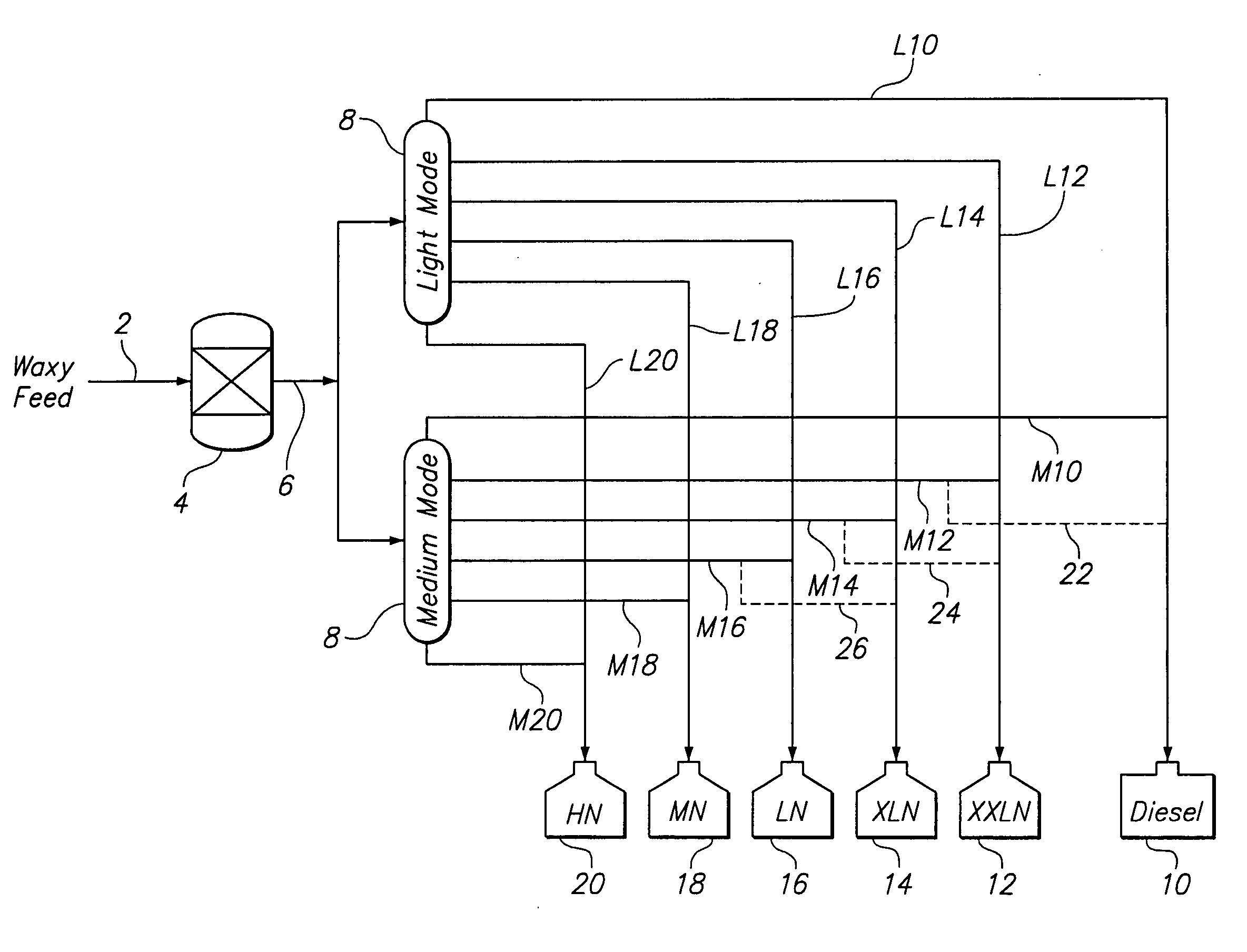

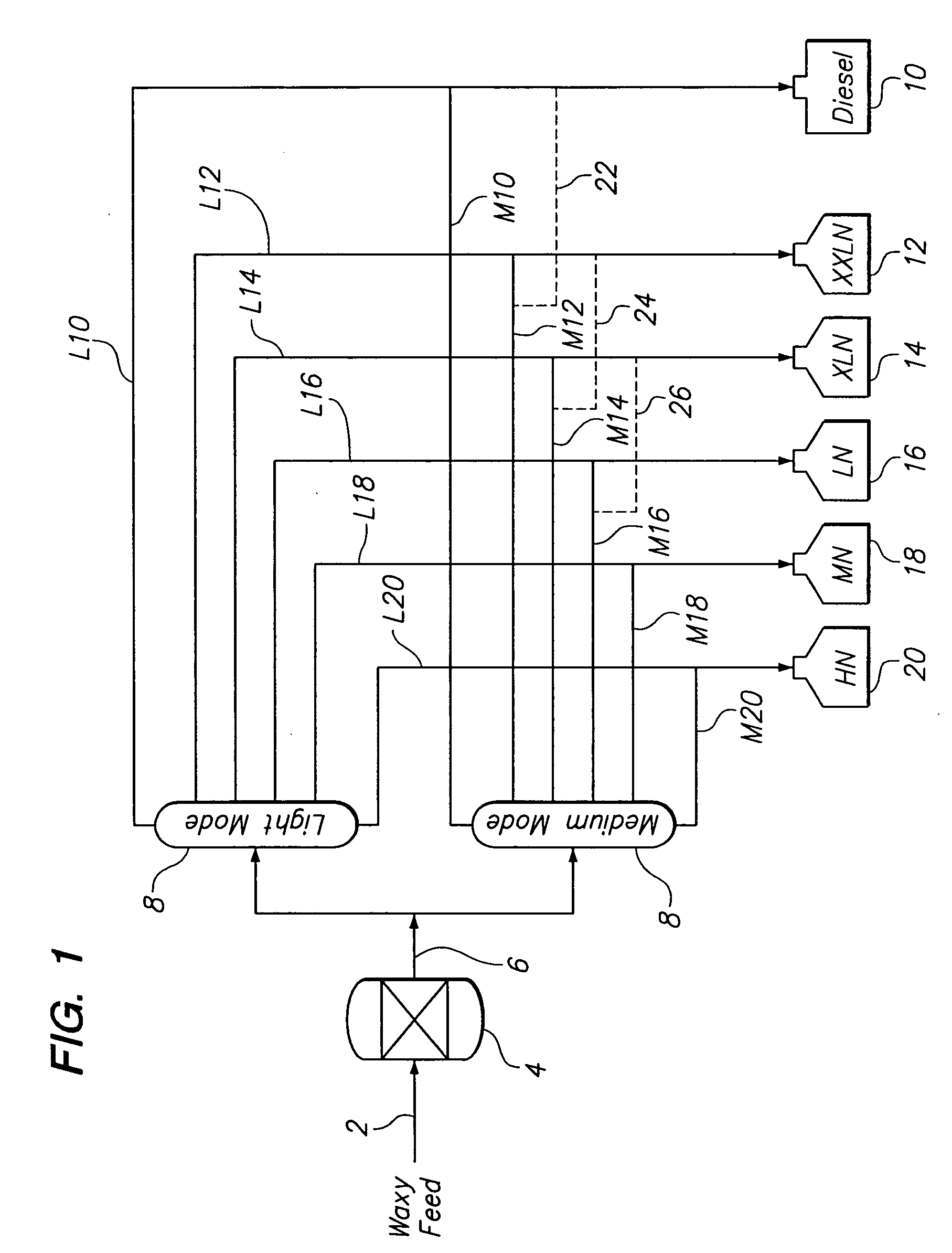

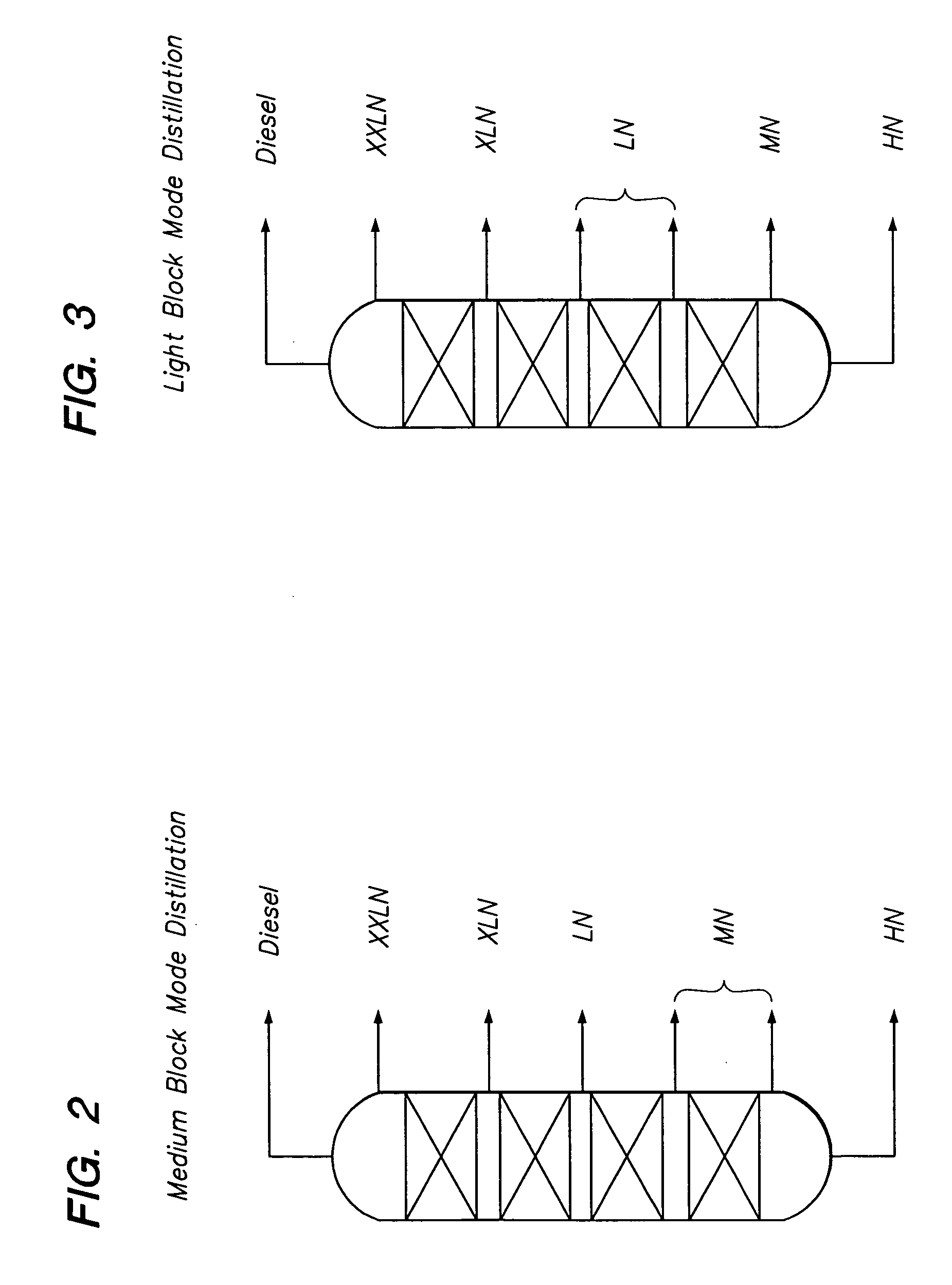

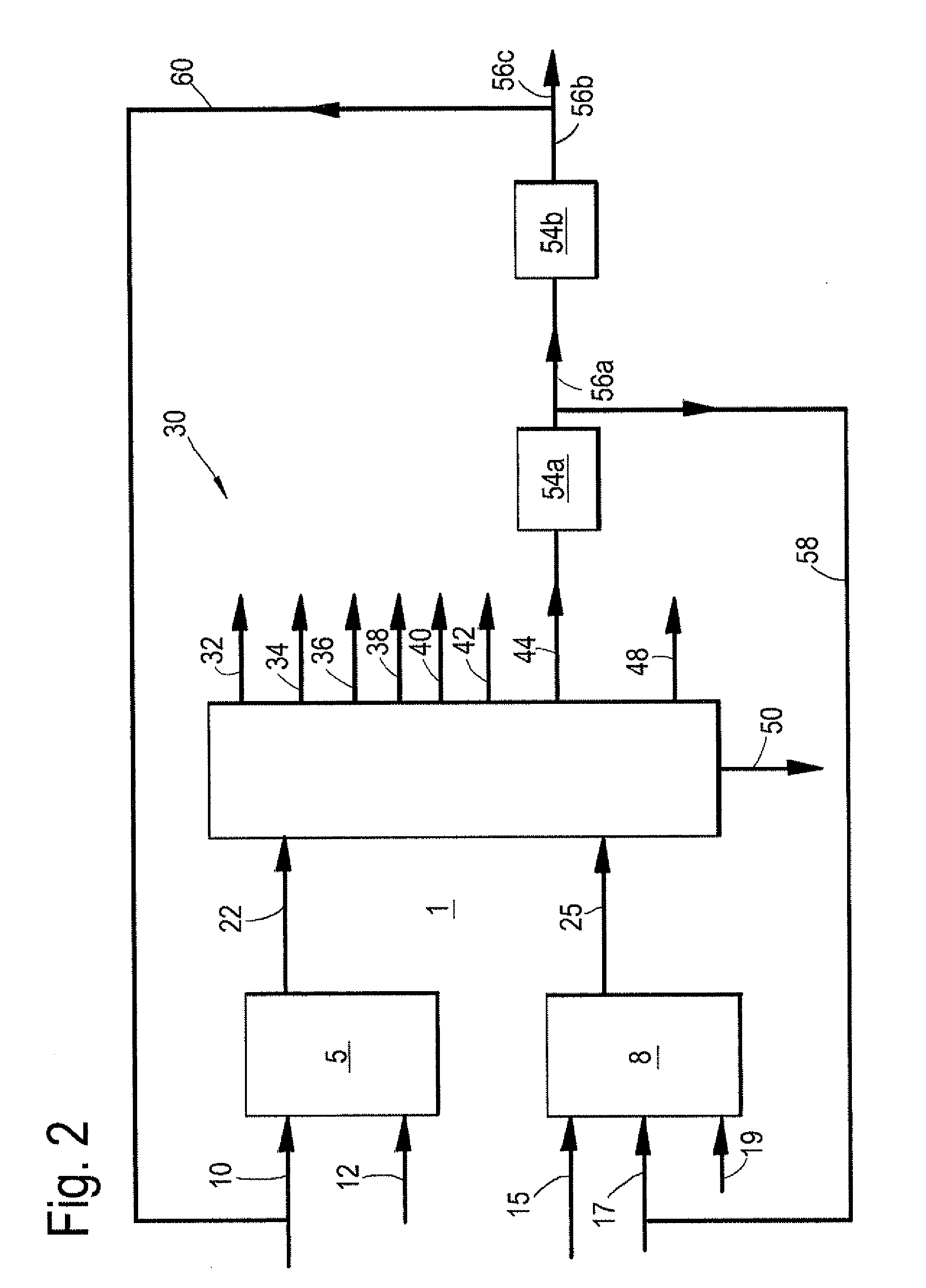

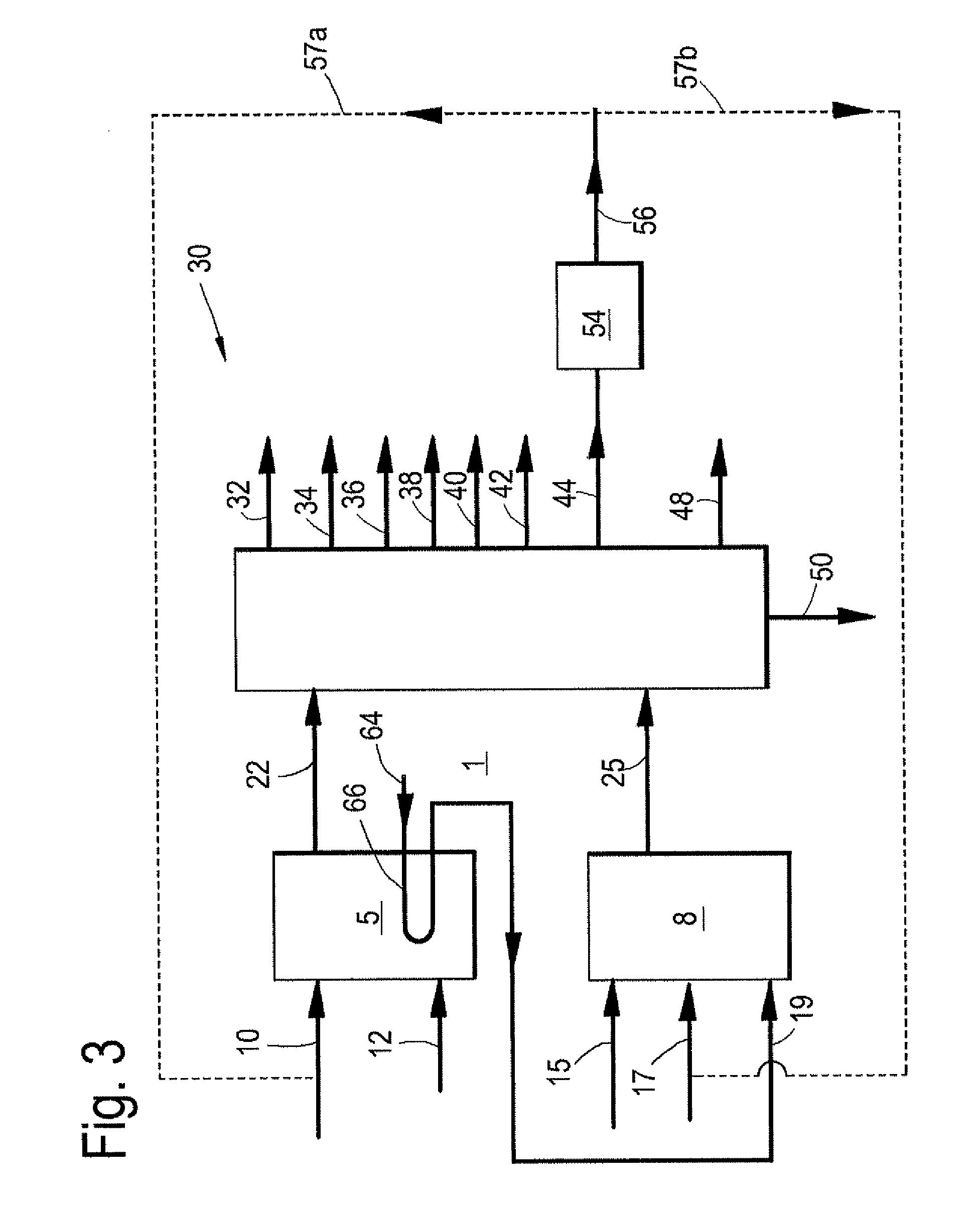

Multiple side draws during distillation in the production of base oil blends from waxy feeds

InactiveUS20060201851A1Refining to change hydrocarbon structural skeletonPetroleum wax refiningIsomerizationDistillation

A process for producing a product slate, which includes at least three base oil grades having kinematic viscosities at 100° C. within the range between about 1.8 cSt and 30 cSt, from a waxy feed having an initial boiling point of about 340° C. or less and a final boiling point of about 560° C. or higher, said process comprising (a) isomerizing at least a portion of the waxy feed, whereby the amount of isoparaffins present are increased; (b) distilling a first portion of the isomerized waxy feed in light block mode operation into at least three base oil fractions having different boiling ranges; (c) distilling a second portion of the isomerized waxy feed in medium block mode operation into at least three base oil fractions having different boiling ranges; and (d) blending at least one base oil fraction produced from light block mode with at least one base oil fraction produced from medium block mode to produce a lubricating base oil blend meeting a target value for at least one pre-selected property.

Owner:CHEVROU USA INC

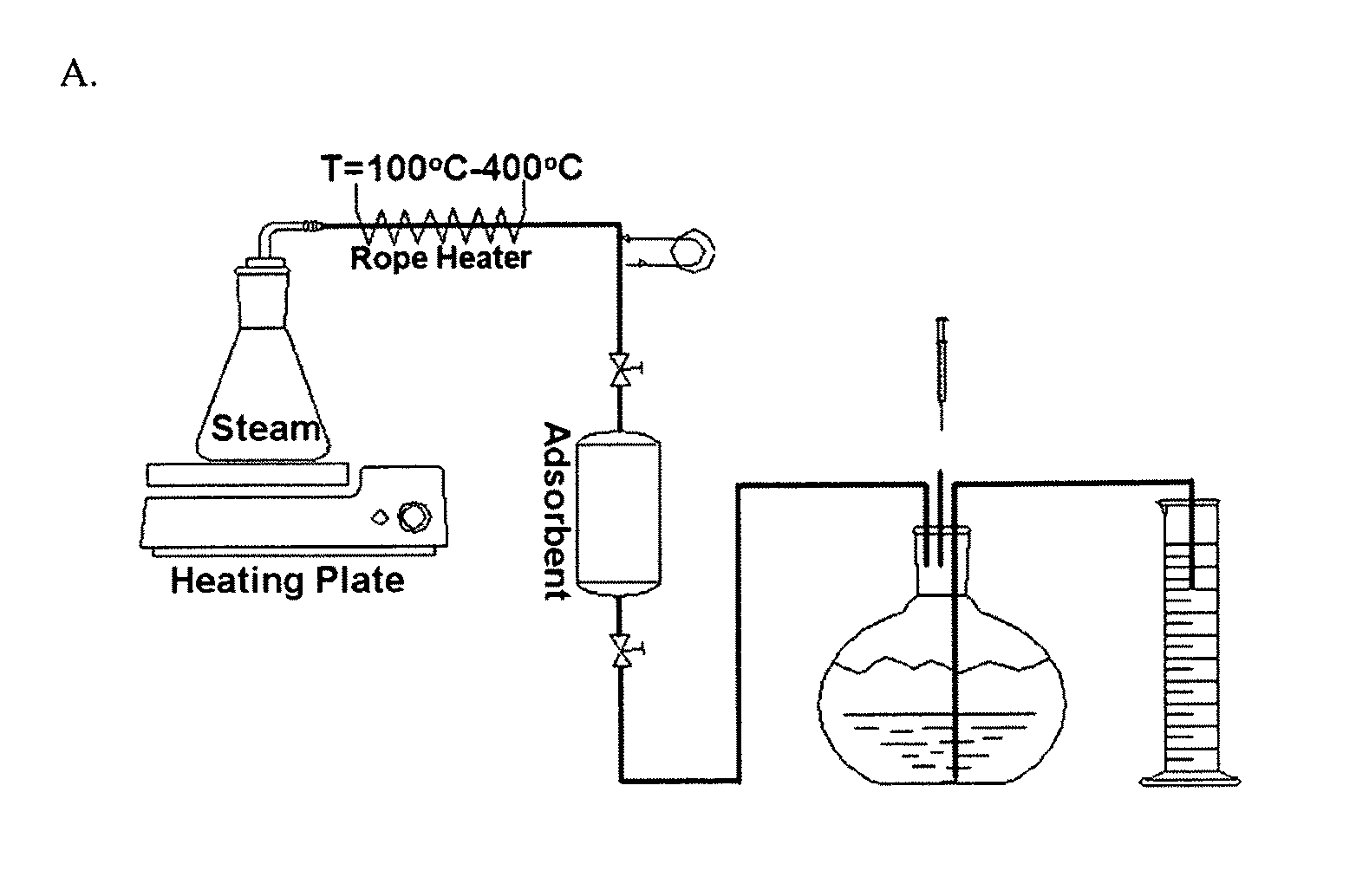

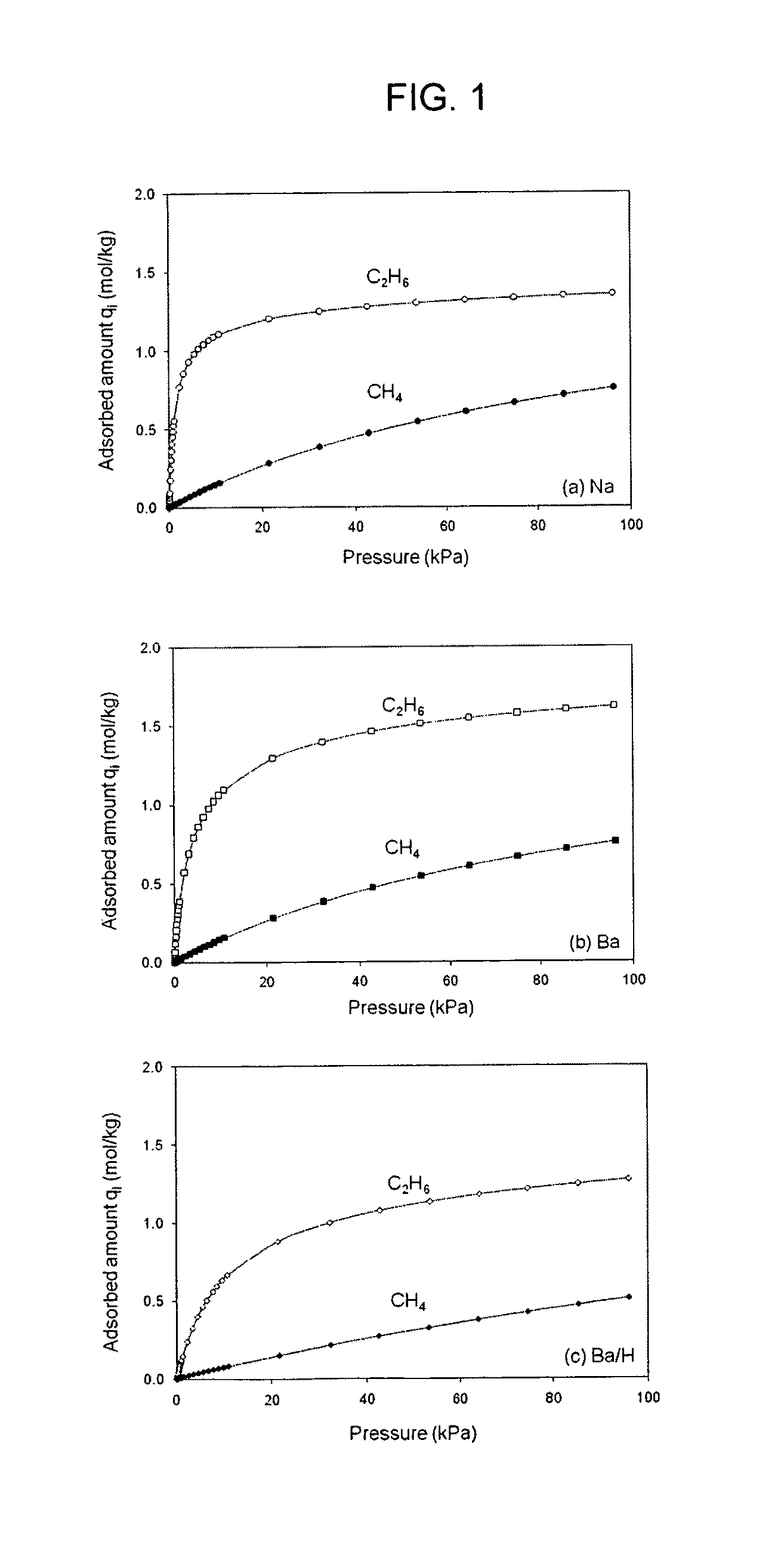

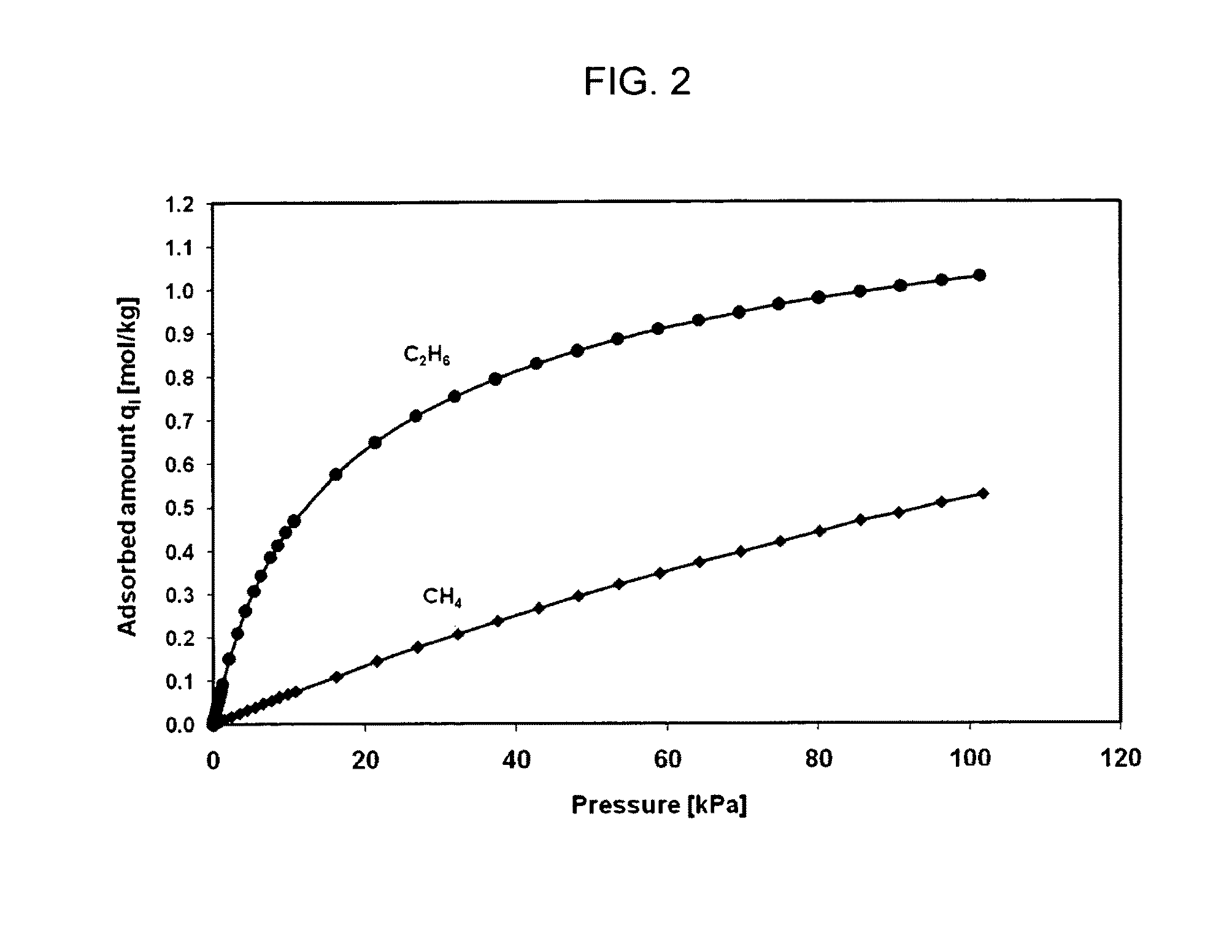

Removal of ethane from natural gas at high pressure

ETS-10 type materials preferentially adsorb ethane and, if present, C3+ paraffins from mixtures comprising methane, ethane and optionally C3+ paraffins at pressures above 200 psia. A process in which ETS-10 type materials are used to separate ethane and C3+ paraffins from natural gas streams at over 200 psia is provided.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

ActiveUS20080308458A1Fatty acid chemical modificationMolecular sieve catalystsParaffin waxVegetable oil

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal a first oxide and optionally a second oxide wherein at least one of the first oxide or second oxide comprises a zeolite, through hydrodeoxygenation and one or both of hydroisomerization and hydrocracking.

Owner:REFINING TECH SOLUTIONS LLC

Distillate fuel blends from Fischer Tropsch products with improved seal swell properties

InactiveUS6890423B2Hydrocarbon by isomerisationCatalytic naphtha reformingPolymer scienceEngineering

The invention provides distillate fuel blend components with improved seal swell and lubricity properties obtained from Fischer Tropsch products. The blends contain a highly paraffinic distillate fuel component and distillate-boiling alkylcycloparaffins and / or distillate-boiling alkylaromatics. The invention further provides processes for obtaining such blends using the products of Fischer Tropsch processes. Finally, the invention provides methods for improving seal swell and lubricity properties for distillate fuels.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

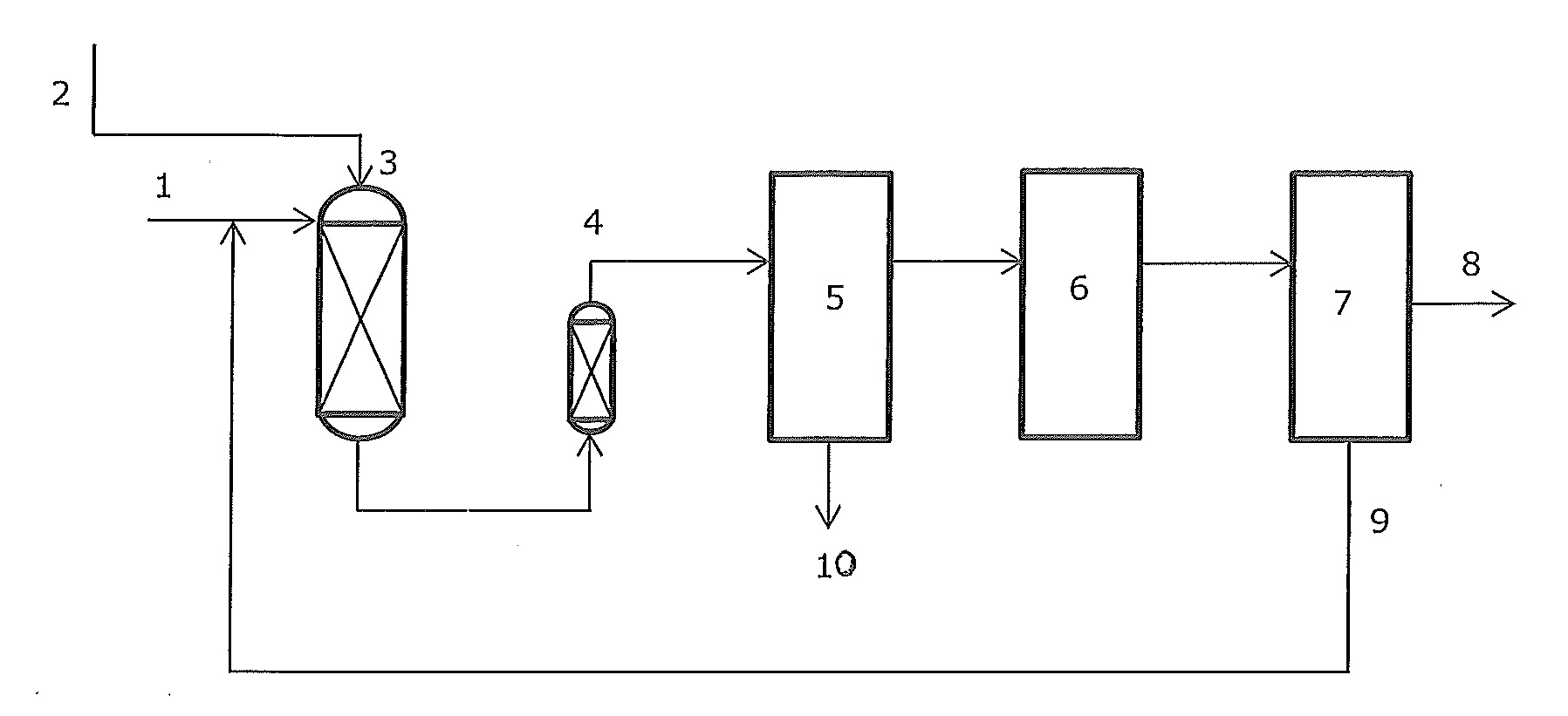

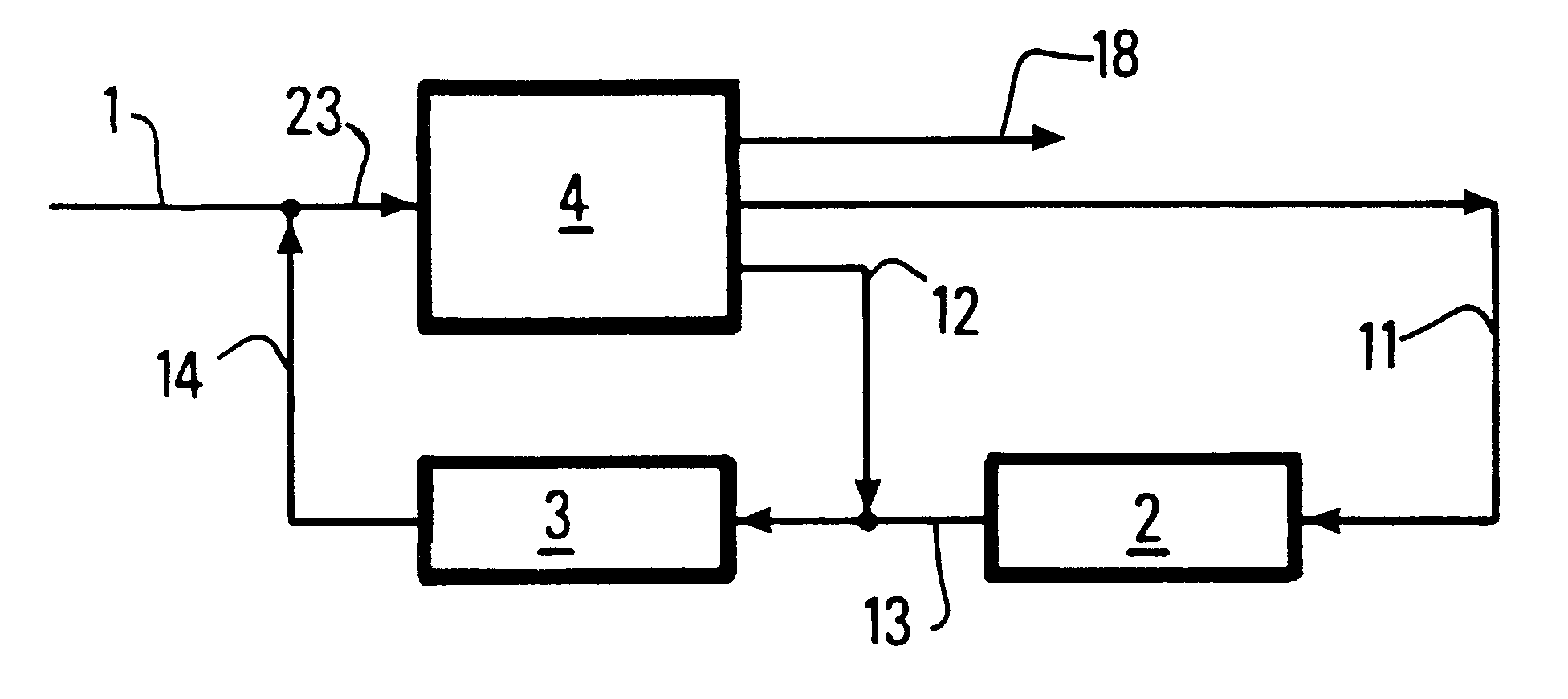

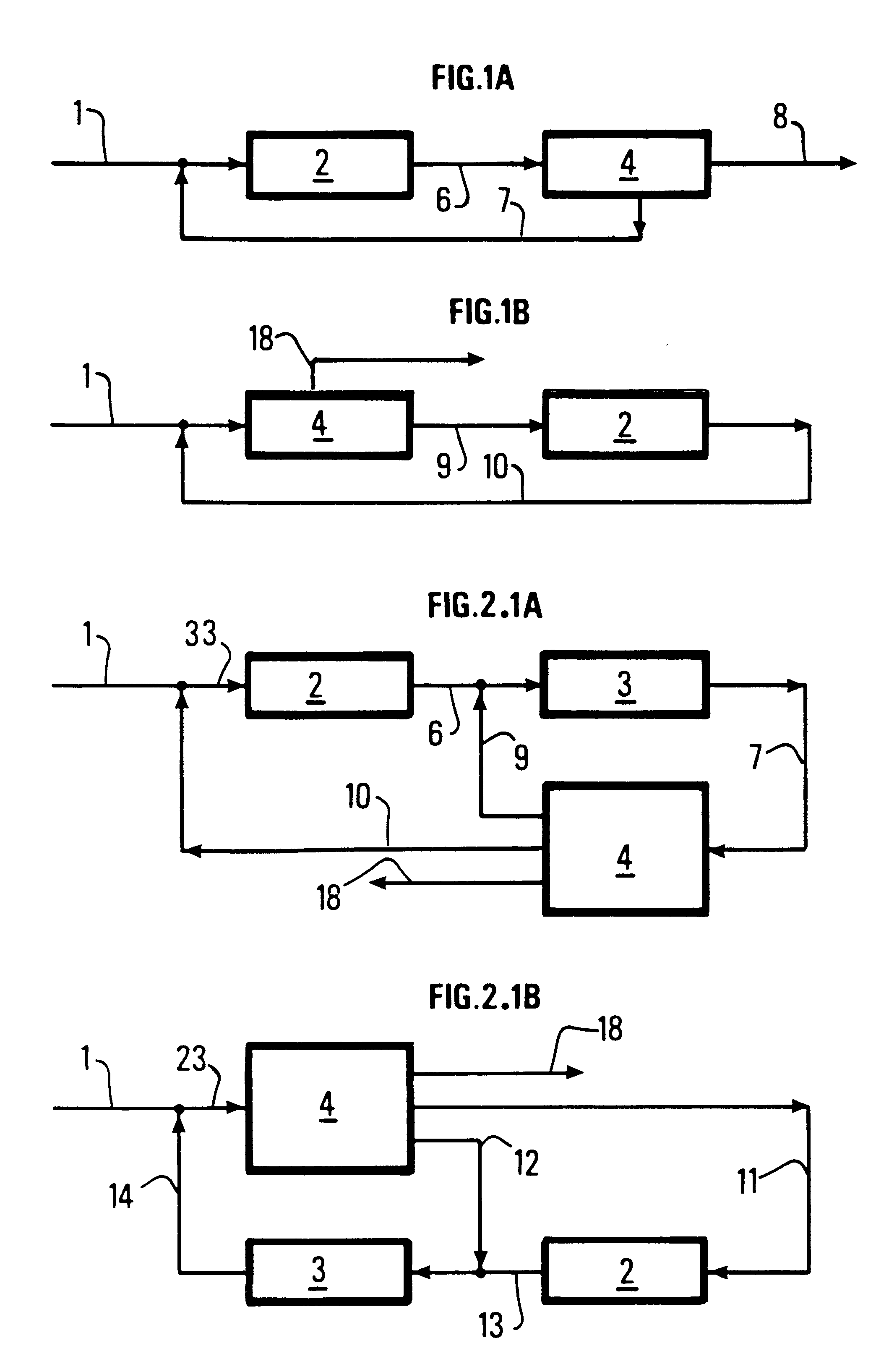

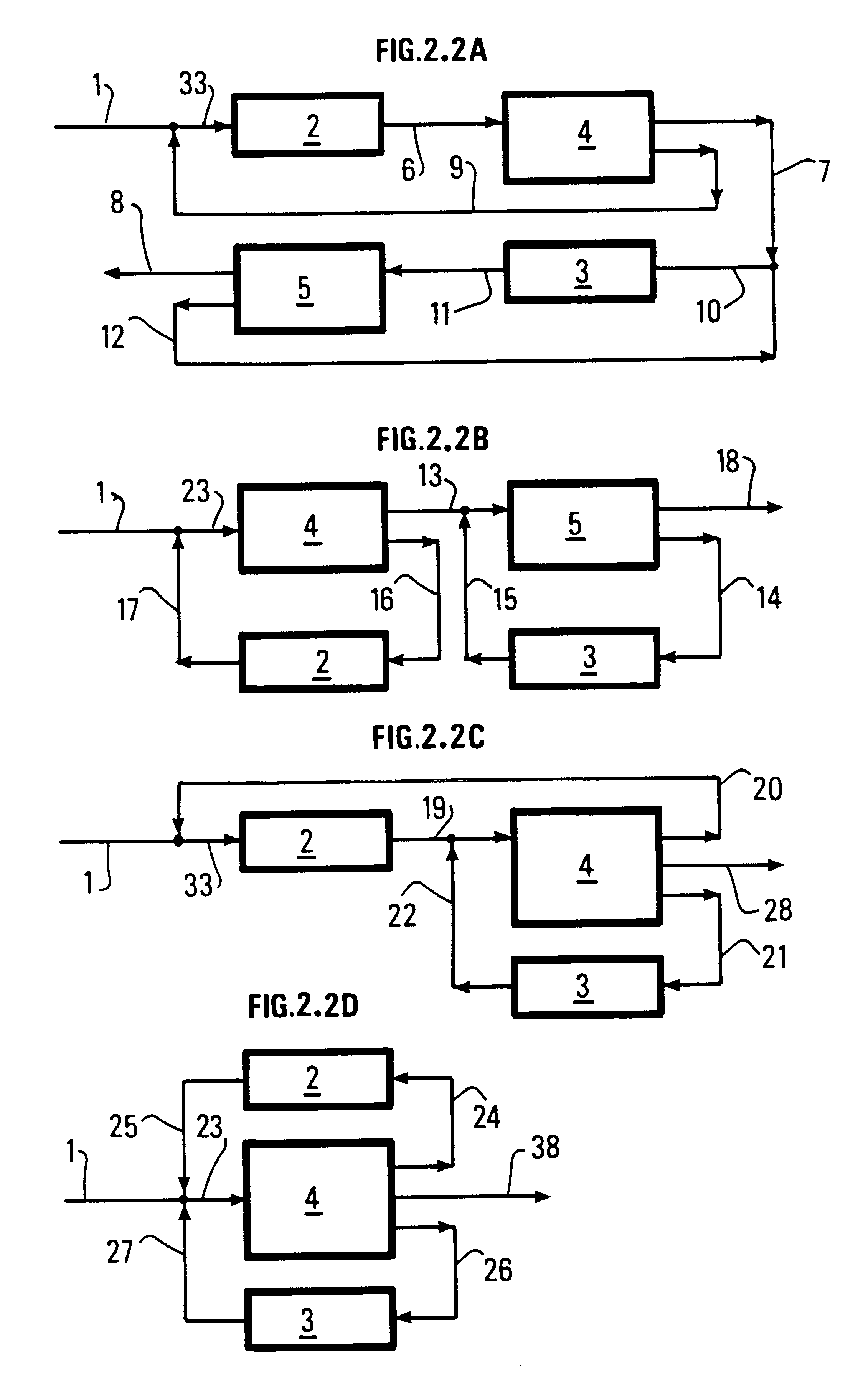

High octane number gasolines and their production using a process associating hydro-isomerization and separation

InactiveUS6338791B1Minimize cracksReduce the amount requiredRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationCyclic alkaneIsomerization

The invention provides a high octane number gasoline pool comprises at least 2% of di-branched paraffins containing 7 carbon atoms, and a process for producing this gasoline pool by hydro-isomerizing a feed constituted by a C5 to C8 cut which comprises at least one hydro-isomerization section and at least one separation section, in which the hydro-isomerization section and at least one separation section, in which the hydro-isomerization section comprises at least one reactor. The separation section comprises at least one unit and produces at least two streams: a first stream which is rich in di- and tri-branched paraffins, and possibly in naphthenes and aromatic compounds which is sent to the gasoline pool; and in a first version of the process, a second stream is produced which is rich in straight-chain and mono-branched paraffins which is recycled to the inlet of the hydro-isomerization section, while in a second version of the process, a second flux is produced which is rich in straight-chain paraffins which is recycled to the inlet of a first hydro-isomerization section and a third stream is produced which is rich in mono-branched paraffins which is recycled to the inlet of a second hydroisomerization section.

Owner:INST FR DU PETROLE

Chemicals from synthesis gas

InactiveUS20040106517A1Increase choiceReduce additionalHydrocarbon from carbon oxidesCatalystsAlkanePtru catalyst

This invention relates to an iron-based Fischer-Tropsch cataylst composition wherein the iron phase is ferrihydrite. The catalyst composition optionally includes a structural promoter which may be selected from manganese or chromium or a mixture thereof and chemical promoters selected from magnesium, zinc, copper and an alkaline or alkali metal such as potassium. The catalyst is best bound to a refractory oxide support such as silica. This catalyst composition produces significant yields of higher parafins, olefins and alcohols.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Integrated hydrotreating and steam pyrolysis process including residual bypass for direct processing of a crude oil

ActiveUS9296961B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlySteam pyrolysisFuel oil

A process is provided that is directed to a steam pyrolysis zone integrated with a hydroprocessing zone including residual bypass to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated hydrotreating and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals comprises separating the crude oil into light components and heavy components; charging the light components and hydrogen to a hydroprocessing zone operating under conditions effective to produce a hydroprocessed effluent reduced having a reduced content of contaminants, an increased paraffinicity, reduced Bureau of Mines Correlation Index, and an increased American Petroleum Institute gravity; thermally cracking the hydroprocessed effluent in the presence of steam to produce a mixed product stream; separating the mixed product stream; purifying hydrogen recovered from the mixed product stream and recycling it to the hydroprocessing zone; recovering olefins and aromatics from the separated mixed product stream; and recovering a combined stream of pyrolysis fuel oil from the separated mixed product stream and heavy components from step (a) as a fuel oil blend.

Owner:SAUDI ARABIAN OIL CO

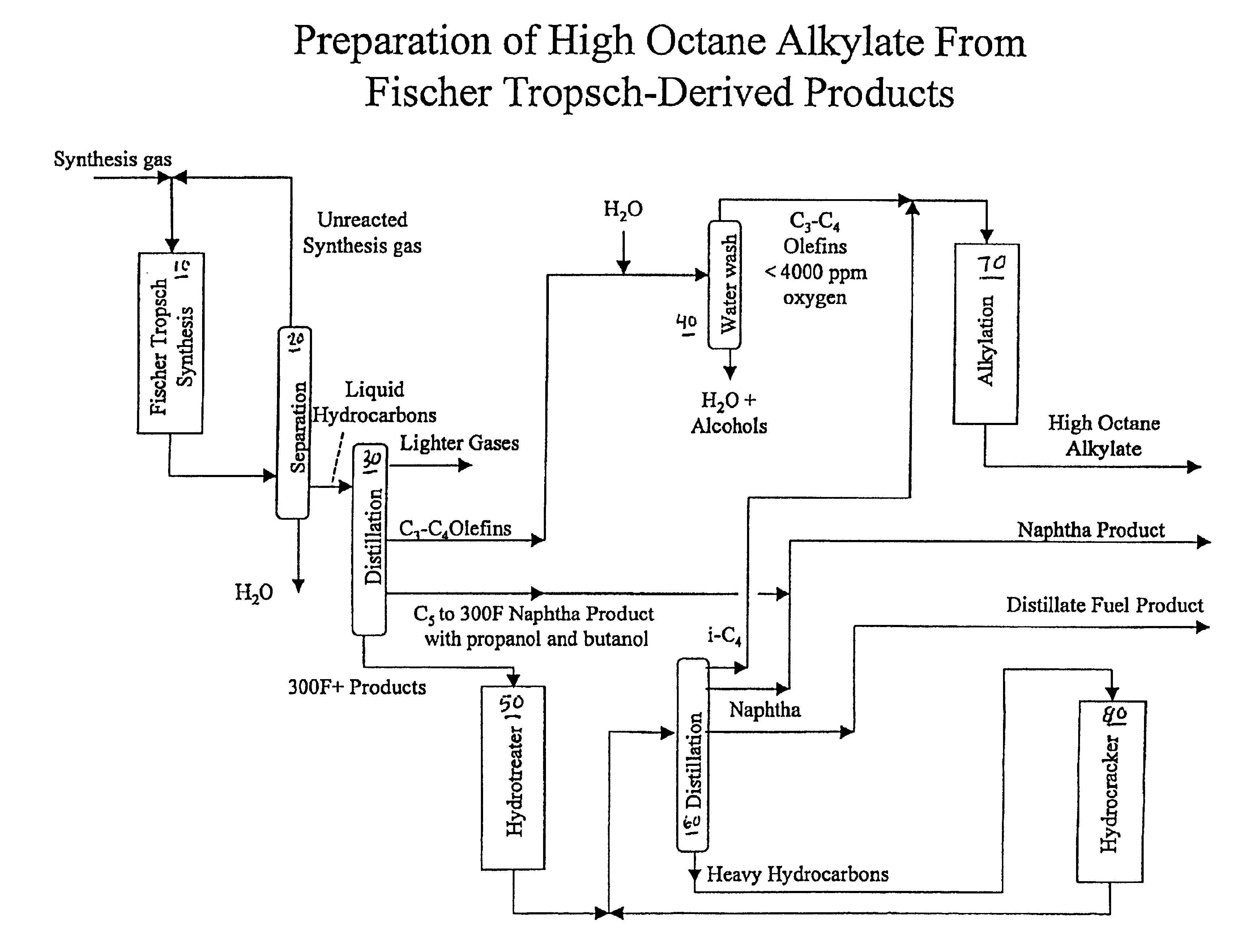

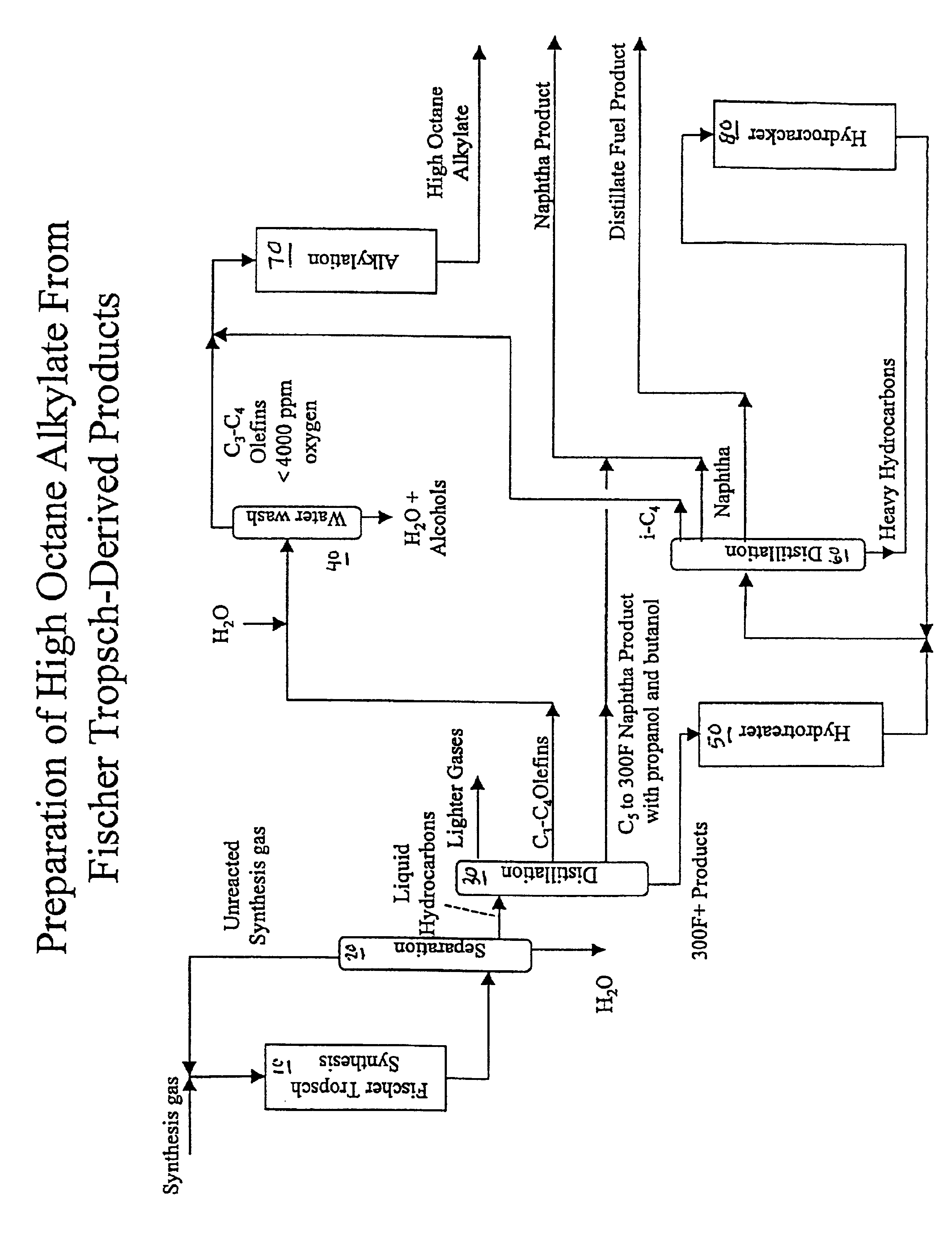

Preparation of high octane alkylate from Fischer-Tropsch olefins

InactiveUS6743962B2Refining to change hydrocarbon structural skeletonOrganic chemistry methodsAlkyl transferGasoline

A Fischer-Tropsch C3-C4 olefin stream is treated to lower the oxygenate content to below 4000 ppm. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane-containing stream. The treated C3-C4 olefin stream is reacted with the isobutane stream in an alkylation reactor to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

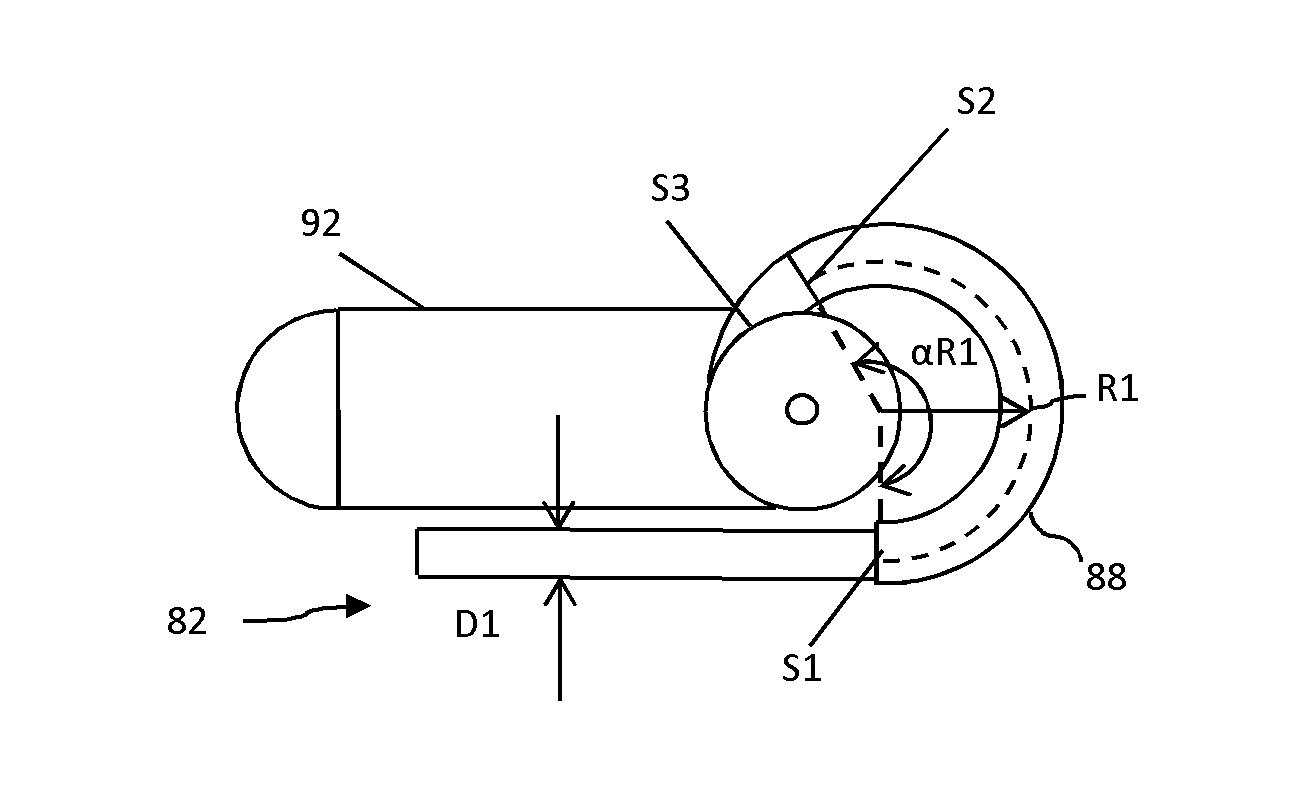

Advances in dehydrogenation catalysis

Provided herein are supported catalysts and processes useful in the dehydrogenation of hydrocarbons. Catalysts made according to the invention possess a unique pore size distribution which provides a favorable balance of selectivity, activity, and thermal stability. In a preferred form of the invention, catalysts made in accordance of the invention are regenerable. Detergent range paraffins may be converted to monoolefins using a catalyst and process provided by the invention.

Owner:INDORAMA VENTURES OXIDES LLC +1

Process of paraffin hydrocarbon isomerization catalysed by ionic liquids

InactiveUS20030109767A1Complicated processingComplicates technologyHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkaneIsomerization

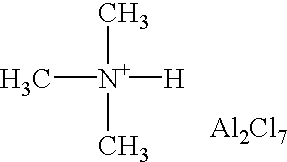

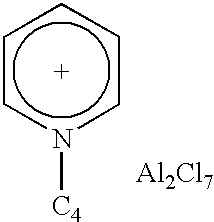

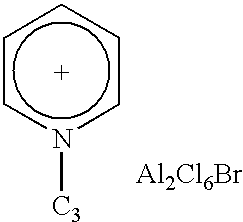

A process for the conversion of paraffin hydrocarbon feed stock via skeletal isomerisation by contacting this feed with a catalyst comprised of an ionic liquid formed from an N-containing heterocyclic and / or N-containing aliphatic organic cation and an inorganic anion derived from metal halides.

Owner:HALDOR TOPSOE AS

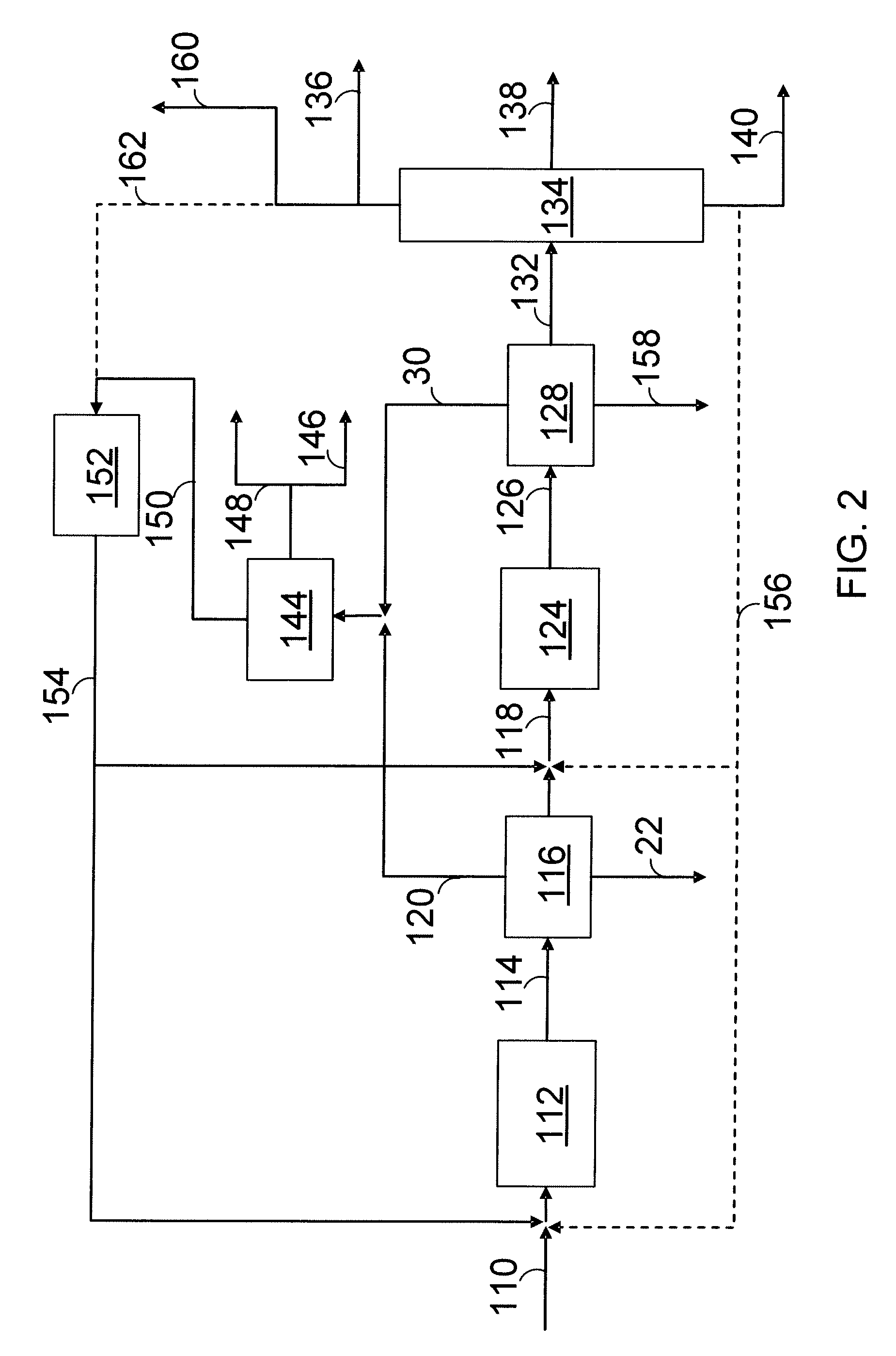

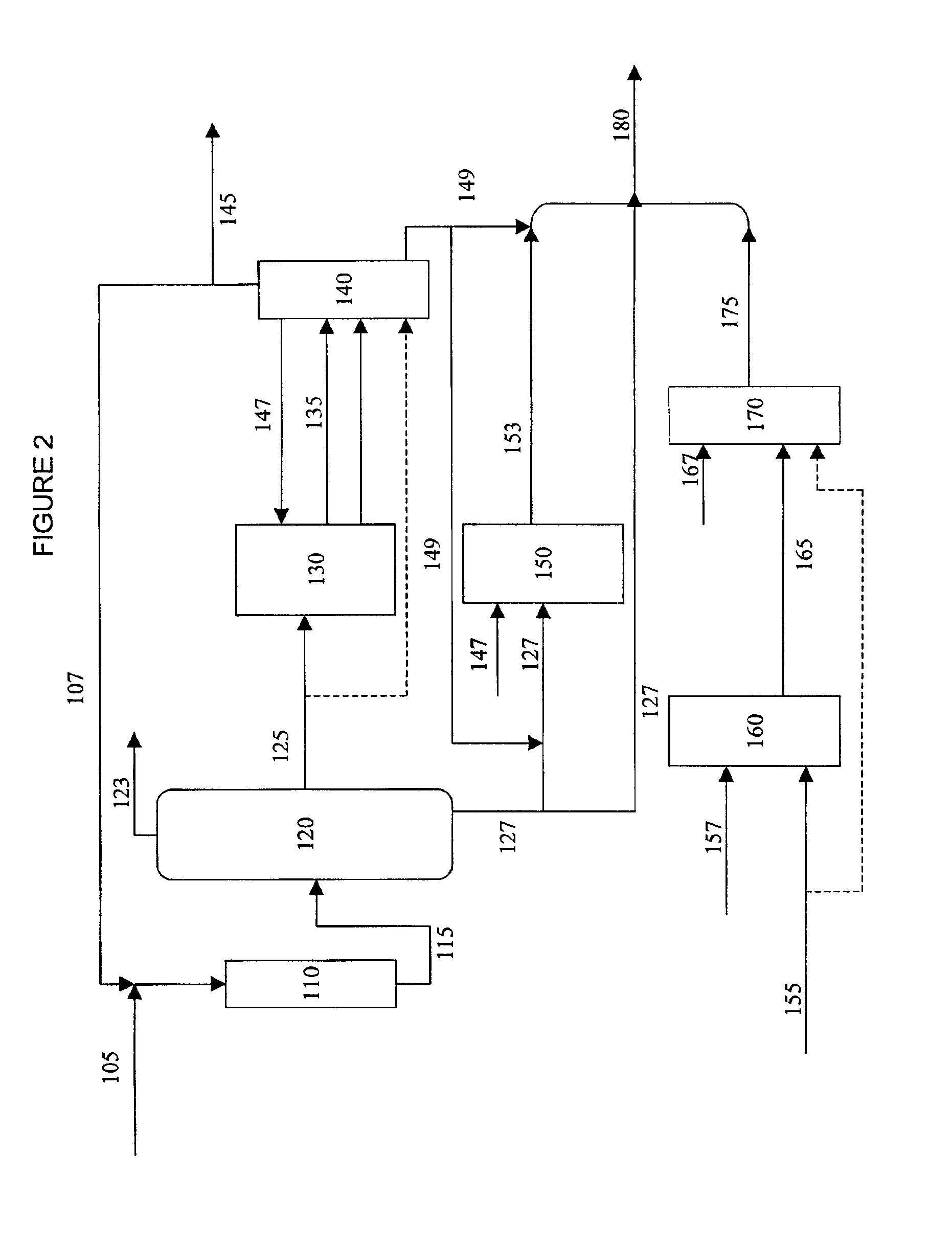

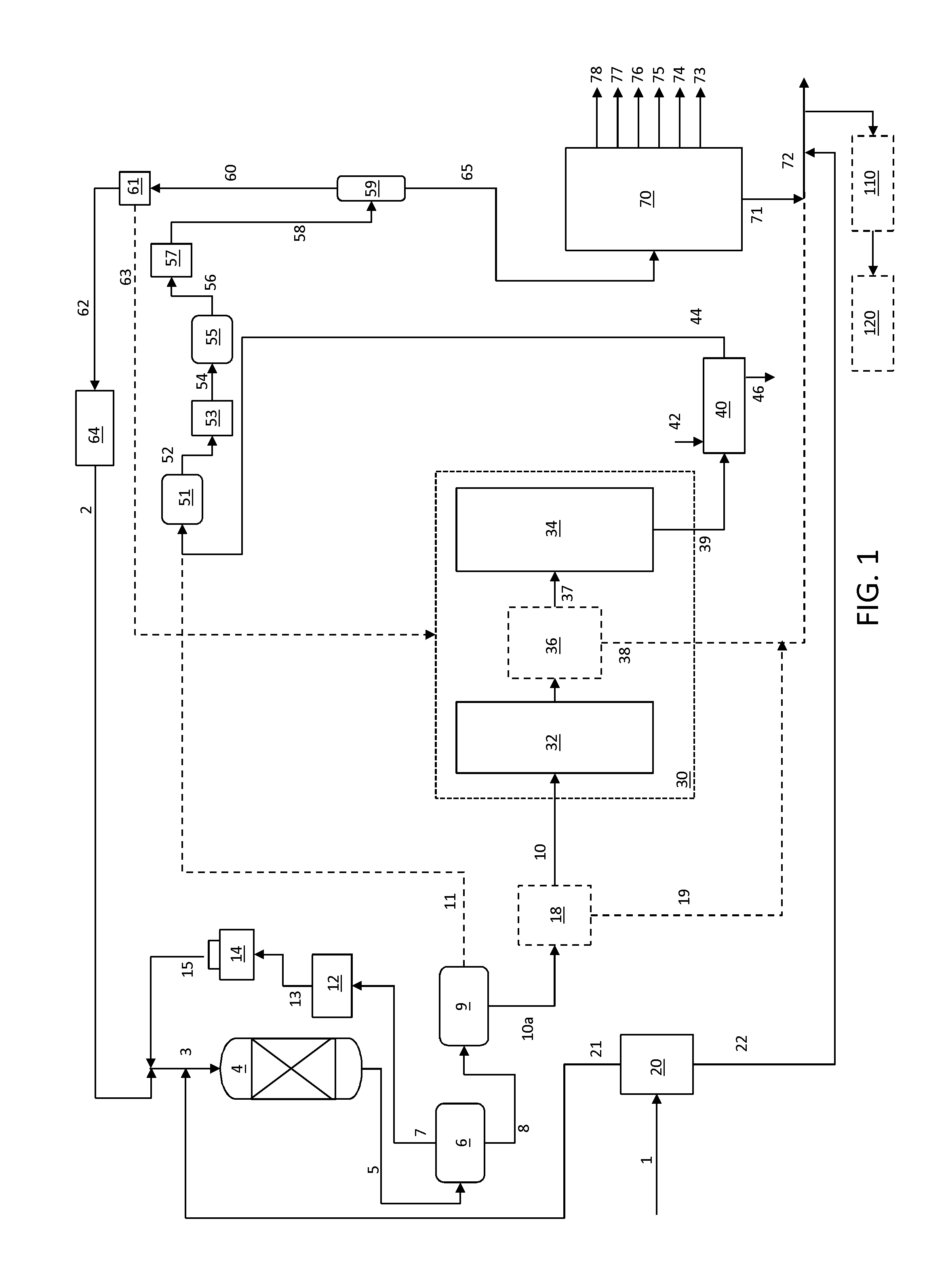

Process and integrated system for the preparation of a lower olefin product

InactiveUS20110112344A1High conversion of feedstockOptimize allocationThermal non-catalytic crackingHydrogenChemistryEffluent

A process for the preparation of an olefin product comprising ethylene and / or propylene, which process comprises the steps ofa) cracking a paraffin feedstock comprising C2-C5 paraffins under cracking conditions in a cracking zone to obtain a cracker effluent comprising olefins;b) converting an oxygenate feedstock in an oxygenate-to-olefins conversion system, comprising a reaction zone in which an oxygenate feedstock is contacted with an oxygenate conversion catalyst under oxygenate conversion conditions, to obtain a conversion effluent comprising ethylene and / or propylene;c) combining at least part of the cracker effluent and at least part of the conversion effluent to obtain a combined effluent, and separating an olefin product stream comprising ethylene and / or propylene from the combined effluent, wherein the cracker effluent and / or the conversion effluent comprises a C4 portion comprising unsaturates, and wherein the process further comprises at least partially hydrogenating at least part of the C4 portion, to obtain an at least partially hydrogenated C4 feedstock; and recycling at least part of the at least partially hydrogenated C4 feedstock as recycle feedstock to step a) and / or step b), and an integrated system for performing the process.

Owner:SHELL OIL CO

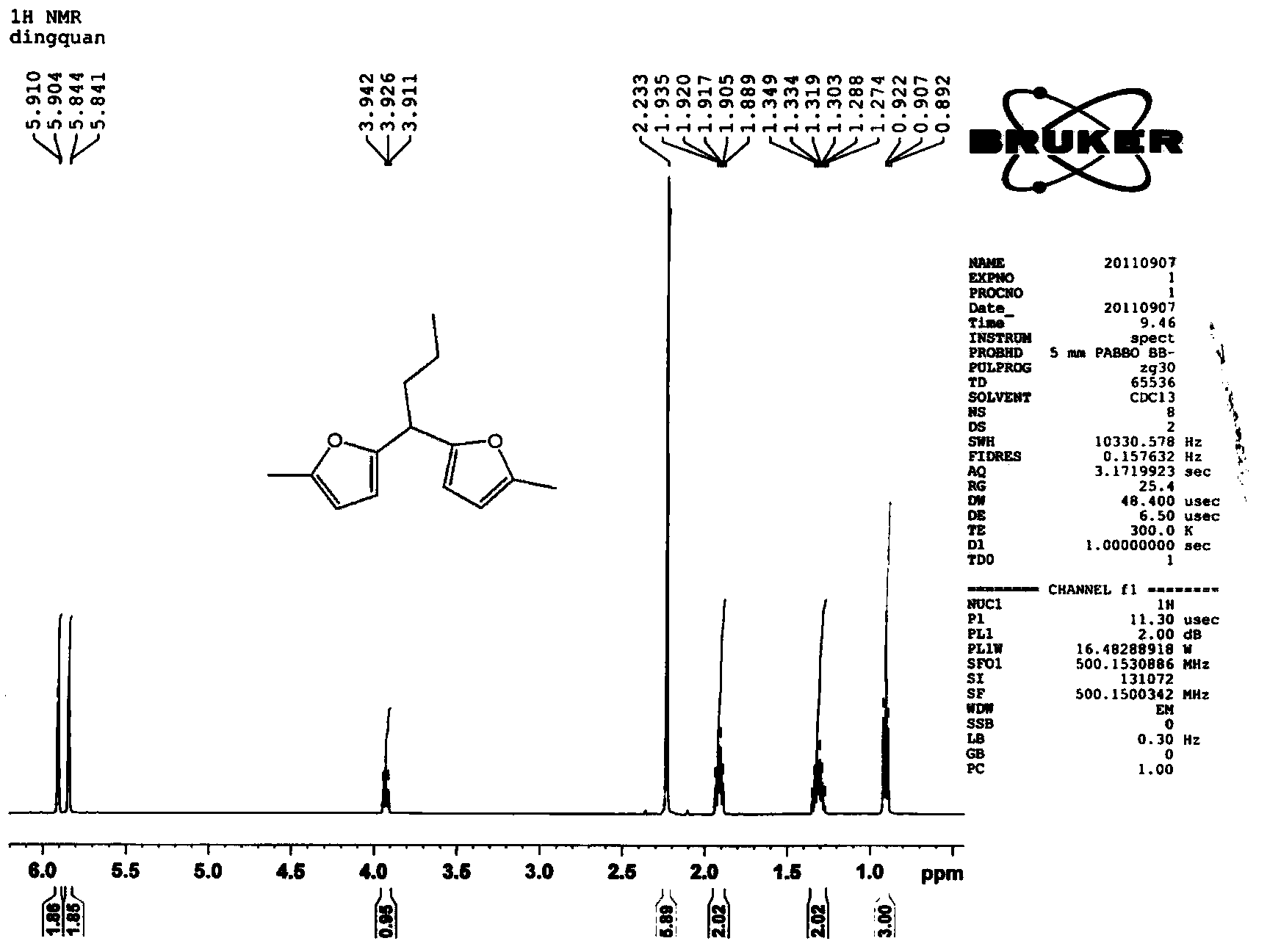

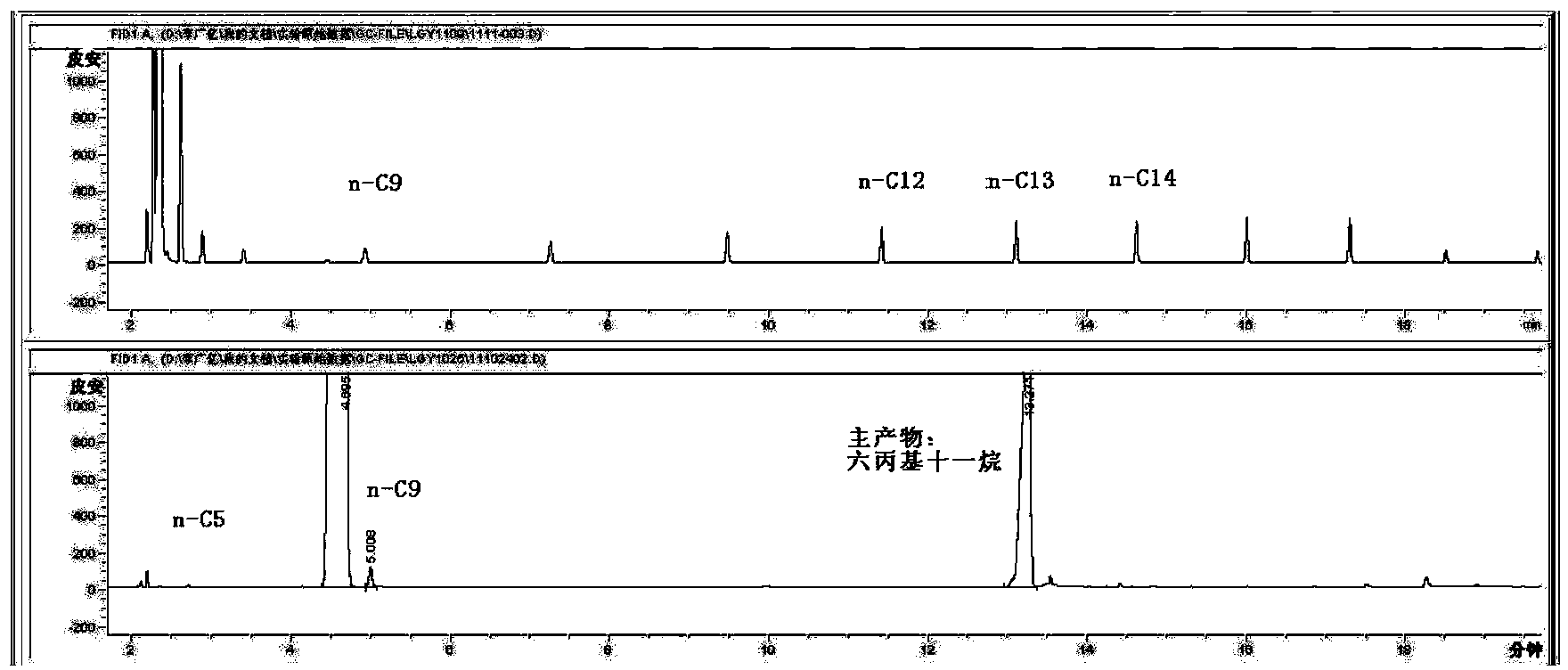

Method for preparing aviation kerosene from furyl oxygen-containing organic compounds by hydrogenation deoxidation

ActiveCN104119943AReduce energy consumptionSimple operation processMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneFuran

The invention relates to a new method for preparing hydrocarbons in the scope of aviation kerosene from C8-C16 furyl oxygen-containing organic compounds as raw materials by hydrogenation deoxidation reaction, wherein the C8-C16 furyl oxygen-containing organic compounds are obtained by C-C coupling of lignocellulose based platform chemical compounds; low temperature direct hydrogenation deoxidation under the condition of no solvent of the furyl oxygen-containing organic compounds can be realized by use of a metal-solid acid dual-functional catalyst to obtain a series of low freezing point branched alkanes having the chain in the length range of the aviation kerosene in high yield. The catalyst is composed of two parts of an active metal A and an acid vector X. The catalyst related in the method ahs the characteristics of being in no need of a solvent, simple in operation process, mild in reaction conditions, good in aviation kerosene (or diesel) selectivity, and the like, and is an ideal hydrogenation deoxidation catalyst for preparing liquid fuels from the furyl oxygen-containing organic compounds by the hydrogenation deoxidation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydroprocessing catalyst and its prepn process

The present invention is hydroprocessing catalyst and its preparation process. The catalyst includes one kind of molecular sieve with TON type structure and active metal component, and the molecular sieve has the features of surface Si / Al ratio higher than the bulk Si / Al ratio, proper acidity and channel structure for paraffin hydrocarbon to generate shape-selective cracking-isomerizing reaction, etc. The catalyst is used in hydroprocessing intermediate fraction oil and heavy fraction product, and has the features of high activity, high isomerizing selectivity, low cracking performance, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

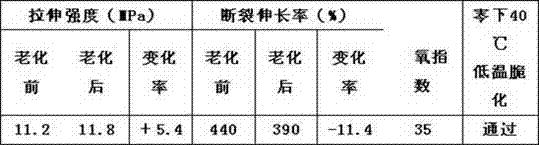

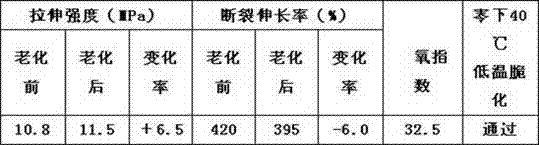

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Dehydrogenation process with water and temperature control

ActiveUS7687676B1Long catalyst lifeLower inlet temperatureHydrocarbon by hydrogenationCatalytic naphtha reformingTemperature controlAlkane

The activity of a dehydrogenation catalyst is improved by increasing the water concentration maintained in the reactants toward the start of the catalyst's life, but after the catalyst has deactivated to the extent that the temperature required to maintain the conversion per pass of paraffinic hydrocarbon through the reaction zone increases by at least 2° C.

Owner:UOP LLC

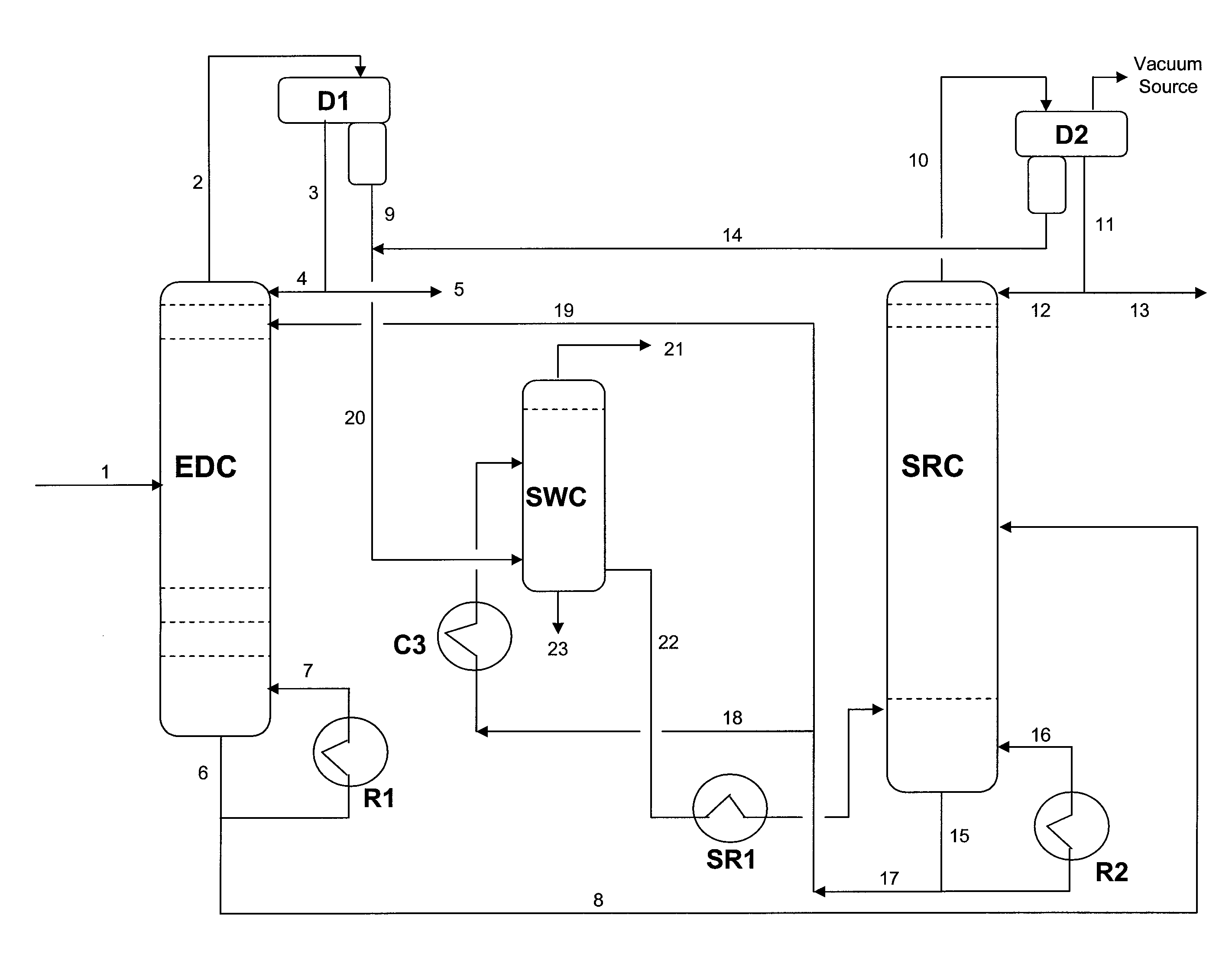

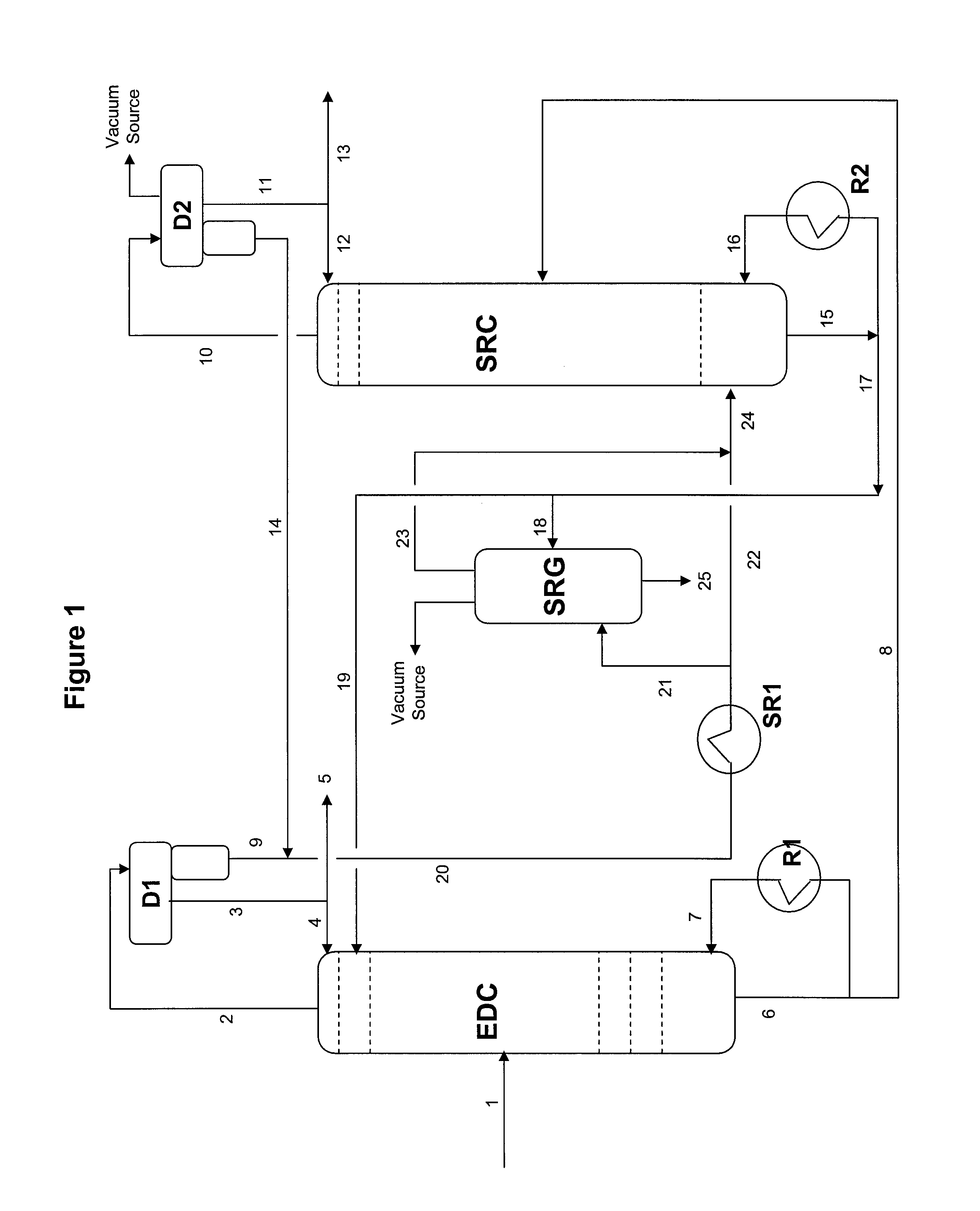

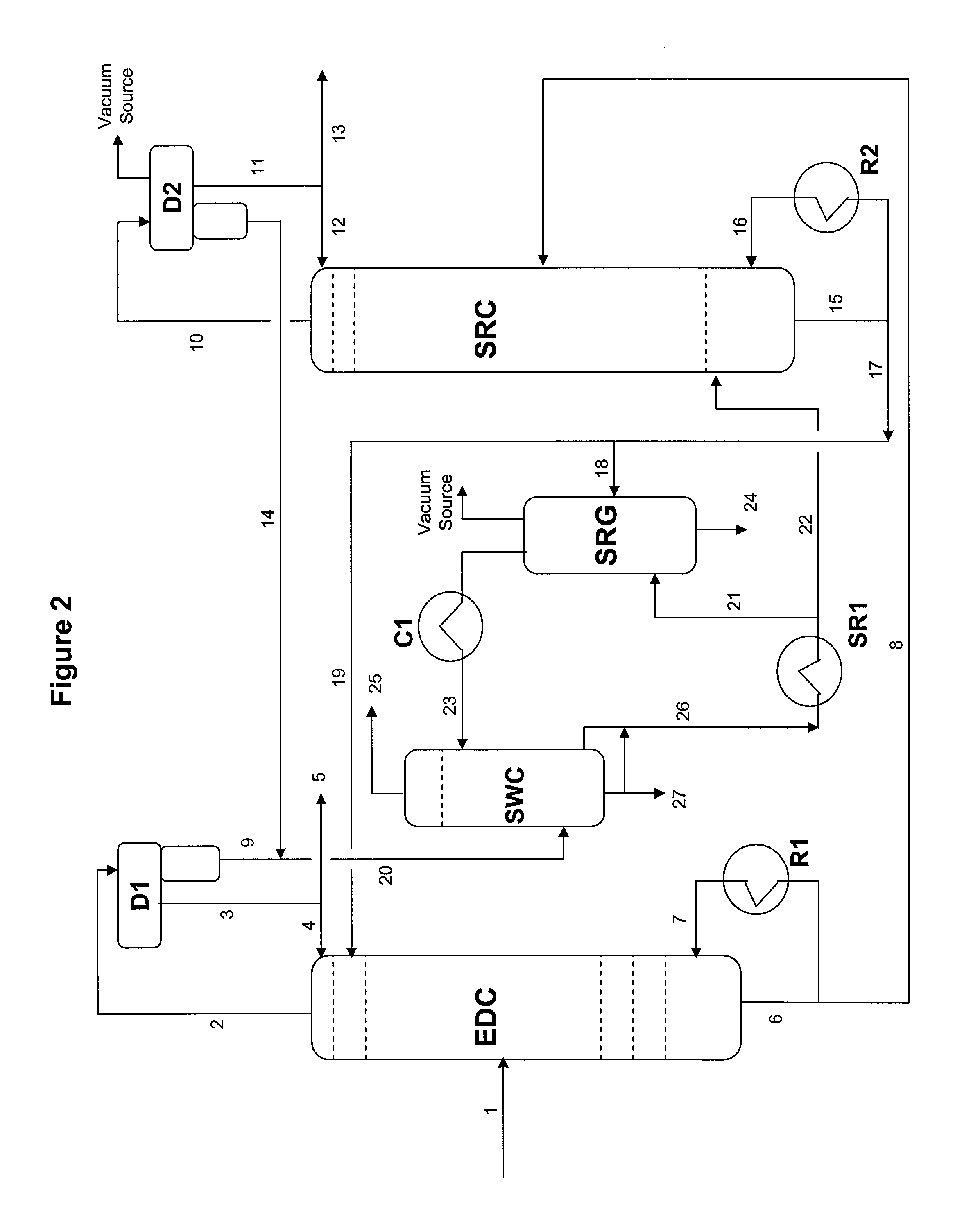

Extractive distillation process for recovering aromatics from petroleum streams

InactiveUS7666299B2Treatment with plural serial cracking stages onlyHydrocarbon oils refiningAlkaneExtractive distillation

A process for recovering polar hydrocarbons from non-polar hydrocarbons, such as aromatics from non-aromatics, naphthenes from paraffins and isoparaffins, or olefins from paraffins and isoparaffins, in feed mixtures containing at least a measurable amount of heavier hydrocarbons. This improved extractive distillation (ED) process recovers aromatic hydrocarbons including benzene, toluene, and xylenes from the C6-C8 petroleum streams containing a measurable amount of C9+ hydrocarbons. The ED process also recovers benzene and toluene from the C6-C7 petroleum streams containing a measurable amount of C8+ hydrocarbons. The ED solvent utilized to recover and purify the aromatic hydrocarbons from the petroleum stream with a heavier than intended feedstock of hydrocarbons is also regenerated and recovered.

Owner:AMT INT INC +1

Wax Emulsion for Use in Building Products

Provided herein are an aqueous wax emulsion, comprising water; a paraffinic hydrocarbon; polyvinyl alcohol and a wax component comprising synthetic olefin wax component. The synthetic olefin wax component may be selected from the group consisting of (i) a synthetic normal α-olefin wax; (ii) a synthetic olefin wax of a carbon chain length of about 20 or more carbon atoms, that is modified by oxidizing and / or by refining through distillation or stripping; and (iii) combinations thereof. Such emulsions are also useful for and disclosed herein are settable gypsum compositions and water-resistant wallboard formed therefrom. Also included herein is a montan wax substitute for use in an aqueous montan-based wax emulsion having paraffinic hydrocarbon, a wax component, water and polyvinyl alcohol wherein the wax component includes the montan wax substitute in place of use of a montan wax in the wax component such that the montan wax substitute is about 1 part to about 100 percent of the wax component and includes a synthetic olefin wax.

Owner:OU HENRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com