Cold-resistant rubber cable sheath material and preparation method

A sheath material and rubber cable technology, applied in the direction of insulating cables, cables, circuits, etc., to achieve good flame retardancy, improve low temperature performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] The formula of each component of the material is: 25 kg of chlorinated polyethylene, 15 kg of EPDM rubber, 10 kg of talcum powder, 4 kg of paraffin oil, 5 kg of chlorinated paraffin, 0.1 kg of magnesium oxide, 0.5 kg of lead monoxide, 8 kg of high wear-resistant carbon black, 5 kg of precipitated white carbon black, 20 kg of calcium carbonate, 3 kg of antimony trioxide, 1 kg of paraffin, 0.5 kg of antioxidant N-cumene-N′-phenyl-p-phenylenediamine kg, 0.1 kg of surfactant gamma-aminopropyltriethoxysilane, 1.5 kg of vulcanizing agent dicumyl peroxide, and 1.3 kg of vulcanizing agent triallyl isocyanurate.

[0034] Preparation method: first mix the weighed chlorinated polyethylene and EPDM rubber in an internal mixer at 70°C-80°C for 3min-4min; then add lead monoxide, calcium carbonate, and anti-aging agent according to the corresponding weight N-cumene-N′-phenyl-p-phenylenediamine, antimony trioxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, mix...

specific Embodiment 2

[0039] The formula of each component of the material is: 30 kg of chlorinated polyethylene, 10 kg of EPDM rubber, 10 kg of talcum powder, 4 kg of paraffin oil, 5 kg of chlorinated paraffin, 0.15 kg of magnesium oxide, 0.5 kg of lead monoxide, 5 kg of high wear-resistant carbon black, 5 kg of precipitated white carbon black, 22 kg of calcium carbonate, 4 kg of antimony trioxide, 1 kg of paraffin, 0.5 kg of antioxidant N-cumene-N′-phenyl-p-phenylenediamine Kilogram, 0.1 kilogram of surfactant gamma-aminopropyltriethoxysilane, 1.5 kilograms of vulcanizing agent dicumyl peroxide, 1.25 kilograms of co-curing agent triallyl isocyanurate, preparation method and specific implementation Same as in Example 1.

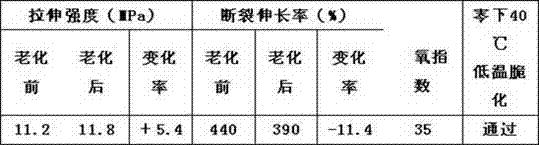

[0040] The performance test data of the low temperature resistant flame retardant rubber sheath material prepared in this example are as follows:

[0041]

[0042] Aging condition: 100±2℃×168 hours

specific Embodiment 3

[0044] The formula of each component of the material is: 30 kg of chlorinated polyethylene, 10 kg of EPDM rubber, 5 kg of talcum powder, 5 kg of paraffin oil, 5 kg of chlorinated paraffin, 0.1 kg of magnesium oxide, 0.5 kg of lead monoxide, 5 kg of high wear-resistant carbon black, 3 kg of precipitated white carbon black, 29 kg of calcium carbonate, 3 kg of antimony trioxide, 1 kg of paraffin, 0.5 kg of antioxidant N-cumene-N′-phenyl-p-phenylenediamine Kilogram, 0.1 kilogram of surfactant gamma-aminopropyltriethoxysilane, 1.5 kilograms of vulcanizing agent dicumyl peroxide, 1.3 kilograms of co-curing agent triallyl isocyanurate, preparation method and specific implementation Same as in Example 1.

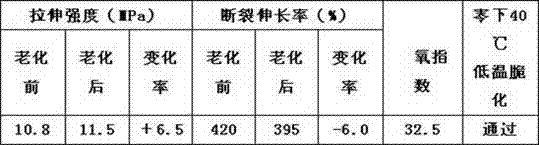

[0045] The performance test data of the low temperature resistant flame retardant rubber sheath material prepared in this example are as follows:

[0046]

[0047] Aging condition: 100±2℃×168 hours

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com