Patents

Literature

725results about How to "Achieving Flame Retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

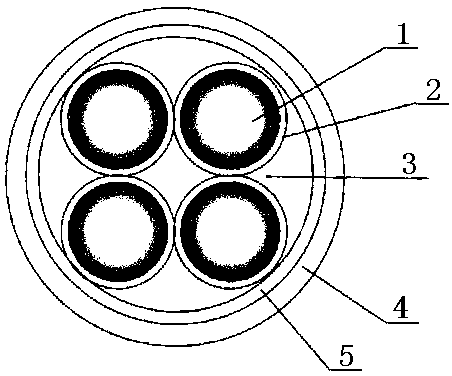

Fireproof and flame retardant mineral compound filling material and cable containing the same

ActiveCN103102134ANo harmImprove fire performanceInsulated cablesInsulated conductorsPolymer scienceFirming agent

The invention relates to a fireproof and flame retardant mineral compound filling material for cables. The filling material comprises a silicon-containing binder; an inorganic flame retardant compound; and a mineral compound. The filling material also can include a silicate modifier, a silicate curing agent and a pigment. Being free of any flammable substance, the fireproof and flame-retardant mineral compound filling material provided in the invention has an excellent fireproof effect, can lose moisture and absorb a lot of heat so as to achieve the flame retardant effect. With good flexibility, the fireproof and flame retardant mineral compound filling material has no hazard to the nature after it is abandoned.

Owner:上海宏胜电线电缆有限公司 +1

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

Water-soluble non-combustible ceramic anti-radiation coating and preparation method thereof

InactiveCN102585570AReduce pollutionHigh durability, impervious and waterproofFireproof paintsReflecting/signal paintsCrack resistanceBrick

The invention relates to a water-soluble non-combustible ceramic anti-radiation coating and a preparation method thereof. The coating comprises an active material, an inorganic filler, a shrinkage reducing agent, a thickening agent, a flame retardant, a silicate binder, a reflection reinforcing agent and an aid in a mass ratio of (2-2.8):(0.5-1):0.40:(0.01-0.04):(0.4-0.8):2.13:(0.067-0.2):0.3. The coating is formed by fully mixing the components uniformly and can be used for painting or spraying, and a layer of modified fluoro-silicone emulsion is painted on the surface of the coating after the coating is surface-dried. The coating can be used as an exterior wall coating (base coat), and also can be used as a protective coating for the surfaces of an exterior wall thermal insulation plate, mortar, a sintered brick and a building enclosure structure; and the water-soluble ceramic coating has the characteristics of high durability, light weight, high strength, high efficiency, flame retardance, fire resistance, controllable quality, water resistance, alkali resistance, freezing and thawing resistance, cracking resistance, falling resistance and the like.

Owner:WUHAN UNIV OF TECH

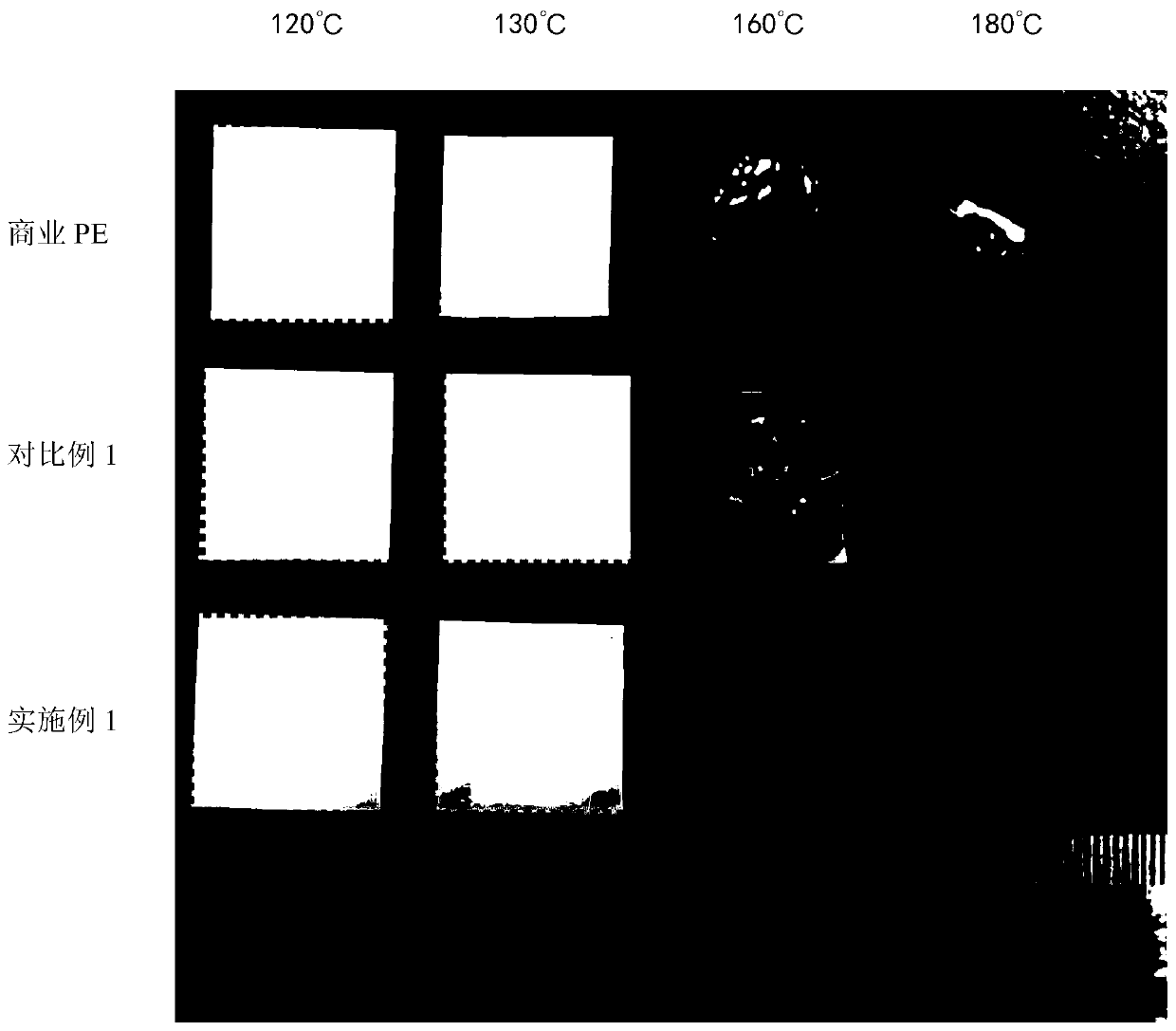

Method for preparing flame-retardant anti-dripping fibre or fabric and flame-retardant anti-dripping fibre or fabric

ActiveCN101353863AMaintain propertiesThe problem of reaching burning dripsFibre treatmentPolymer scienceElectron radiation

The invention provides a preparation method of flame retarding and anti-droplet fiber or textile, and the flame retarding and anti-droplet fiber or textile prepared by utilizing the preparation method. In the preparation method of the invention, fiber or textile is padded and grafted with a monomer solution, and subsequently grafted by electron radiation; then, the fiber or the textile is padded with a cross linker solution and treated with baking so as to cause a fibre-forming polymer to form three-dimensional net type structure. Both of the monomer solution and the cross linker solution can contain flame-retarding elements, and at least one of the two contains the flame-retarding elements so as to lead the synthetic fibers or textiles to realize the dual effects of droplet resistance and flame-retarding. The method of the invention is characterized by strong adaptability to processed objects and good flame-retarding and anti-droplet performance, and the industrialization of the method of the invention is easy to be fulfilled.

Owner:CHINA PETROLEUM & CHEM CORP +1

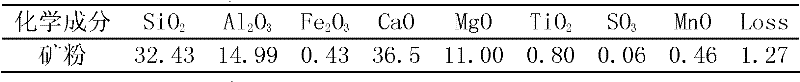

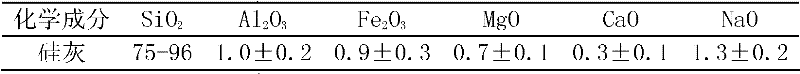

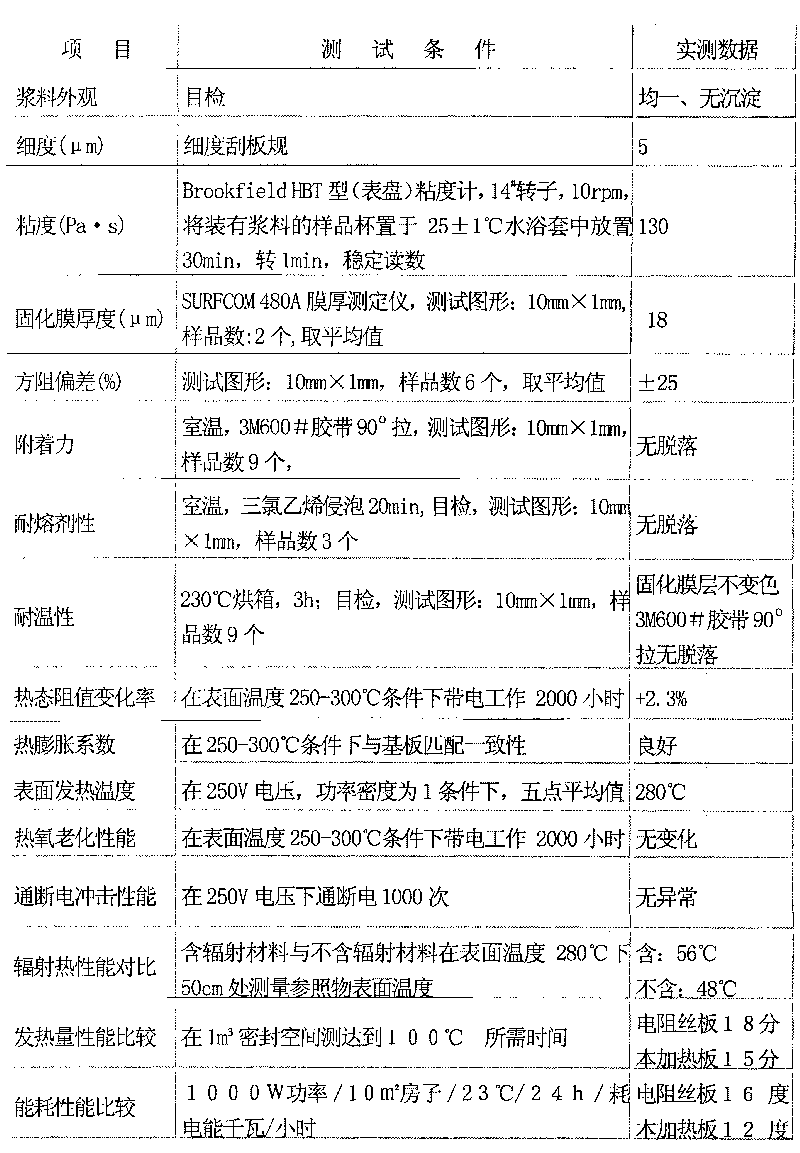

Electrothermal organic power resistance slurry for heater

InactiveCN101735561ALow temperature curingWith high temperature useHeating element materialsLow temperature curingUltra fine

The invention relates to an electrothermal organic power resistance slurry for a heater. The main formula of the slurry comprises the following components by weight percent: 28%-60% of resin I, 5%-13% of flame-retardant heat-resistant polymer containing boron element, 3%-6% of latent curing agent, 1%-2% of latent curing accelerator, 0-30% of resin II, 10%-15% of nano-carbon series conductive filler, 4%-5% of temperature coefficient adjustment additive, 0-5% of ultra-fine base metal alloy powder conductive filler, 0-3% of silicon series far infrared radiating material and 0-4% of ultra-fine mica powder, in addition to the main formula, the slurry further contains a small amount of function auxiliary phase. The slurry can solve the problems that the ordinary slurry is difficult to realize thinness, light weight or special shape; furthermore, the slurry has the properties of low temperature curing and high temperature use and can be directly used for printing or spraying and meet the technical development requirements of an electric heater on the trends of miniature, thinness, light weight and (shape and purpose) special shape.

Owner:西安宏星电子浆料科技股份有限公司

Flame-retardant polypropylene composition with high glow-wire ignition temperature

The invention discloses a flame-retardant polypropylene composition with high glow-wire ignition temperature (GWIT). The composition is characterized by comprising the following components in percentage by weight: 35.0 to 66.5 percent of polypropylene, 15.0 to 20.0 percent of brominated flame retardants, 3.0 to 8.0 percent of flame-retardant synergist, 15.0 to 35.0 percent of high-efficiency composite flame retardant, 0.1 to 0.5 percent of primary antioxidant, 0.1 to 0.5 percent of auxiliary antioxidant and 0.3 to 1.0 percent of processing aid. The composition has the advantages that: a) the composite flame retardant can achieve a microcapsule coating effect around the composite flame retardant, and the heat is taken away and the heat conduction is reduced by isolating oxygen; b) ultrafine magnesium hydroxide can generate metal oxide to reduce heat conduction in the heating process of a glow wire, and produce steam which can take away the heat, and the surface treatment of the precipitated ultrafine magnesium hydroxide slightly affects the mechanical properties of the flame-retardant modified polypropylene composition; and c) an organosiloxane polymer with high polymerization degree can form a silicon carbide gel isolation layer to isolate oxygen and achieve a flame-retardant effect, the GWIT is higher than required 750 DEG C, and the composition is widely applied to the fields of machinery, industry and the like.

Owner:KINGFA SCI & TECH CO LTD +2

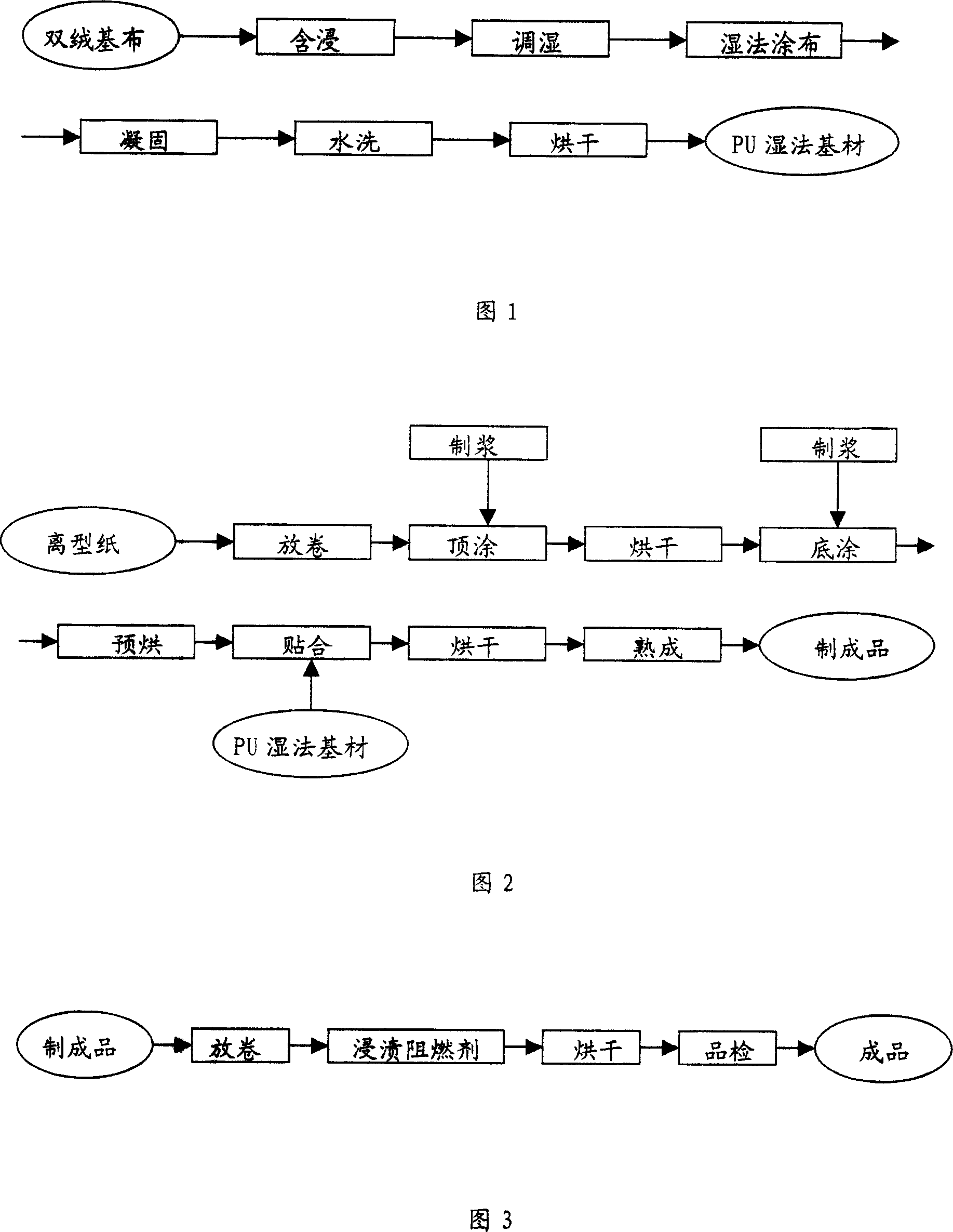

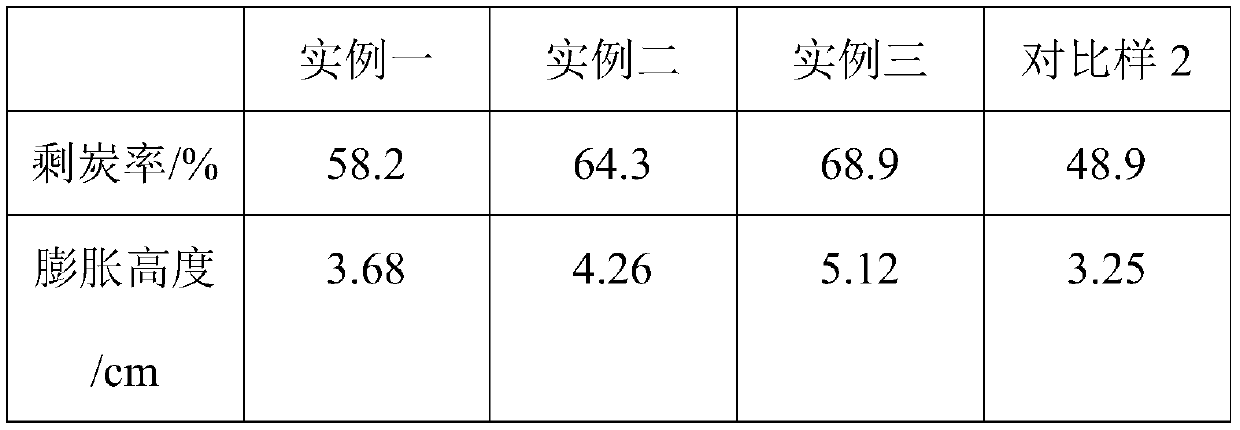

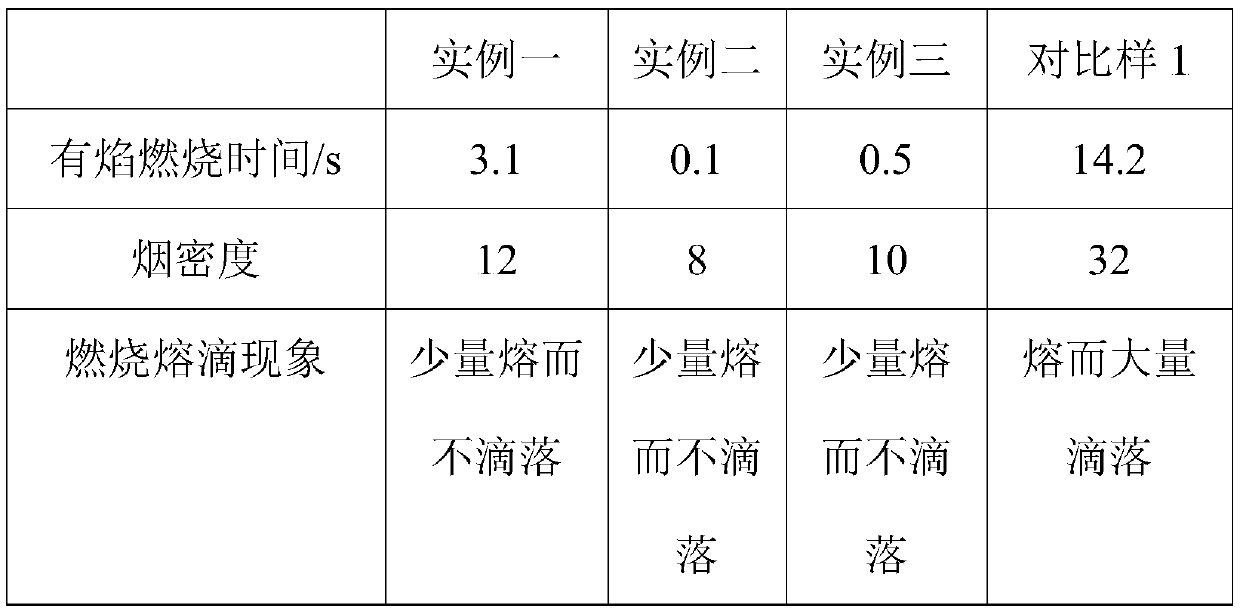

Process of producing fireproof sofa artificial leather

ActiveCN101021045AImprove flame retardant performanceImprove fire protectionTextiles and paperWater basedSlurry

The process of producing fireproof sofa artificial leather includes the following steps: 1. wet coating polyurethane layer on the base fabric; 2. dry adhering surface polyurethane layer on the semi-finished product; and 3. soaking the fabric in water-base environment friendly fire retardant solution and stoving to obtain the product. In the step 1, the polyurethane resin is polyether or polycarbon type polyurethane resin and has phosphate fire retardant added into the wet slurry; and in the step 2, the polyurethane resin is polycarbon type polyurethane resin with fatty resin, the adhering layer is of aromatic resin and the dry slurry has phosphate fire retardant added. The sofa artificial leather has excellent fireproof function, antiageing performance and antiwear performance.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

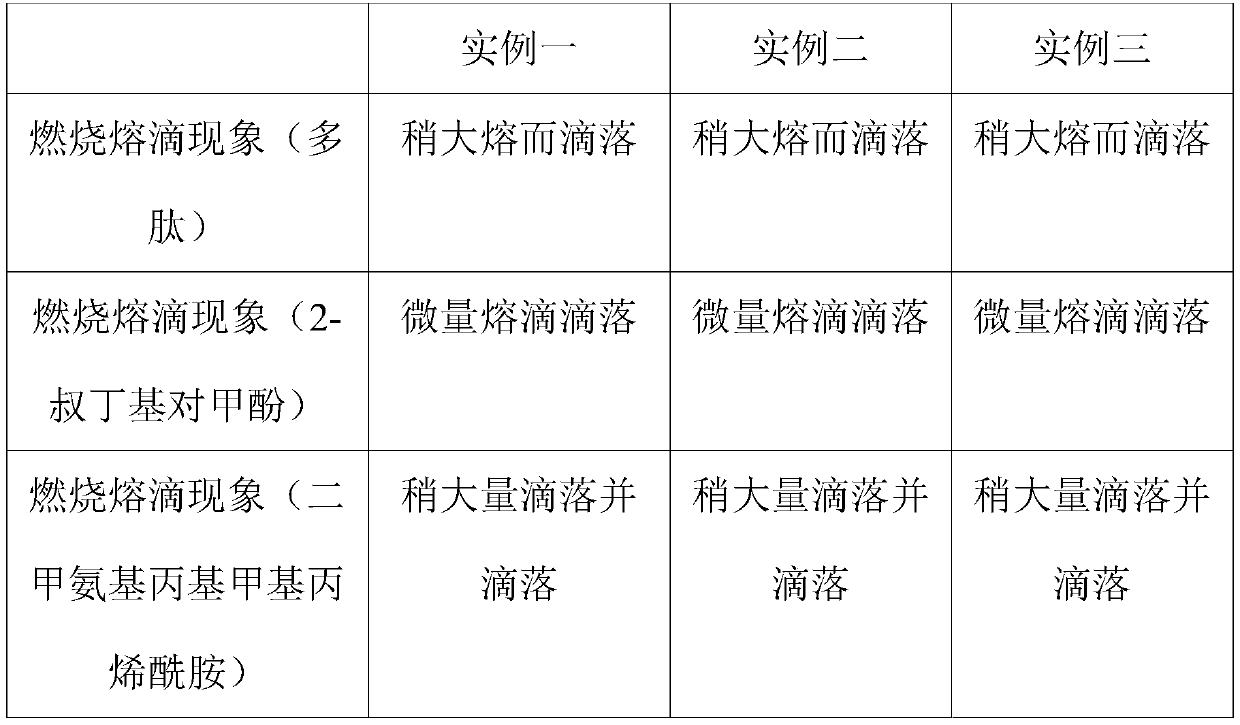

Nitrogen-phosphorus expanded type flame retardant and preparation method for application in aqueous polyurethane coating

ActiveCN110343413AImprove flame retardancyKeep the original natureFireproof paintsGroup 5/15 element organic compoundsChemistrySodium methoxide

The invention relates to preparation of a nitrogen-phosphorus expanded type flame retardant and a method for application in preparing an aqueous polyurethane coating. The method comprises the following steps: mixing dimethyl phosphate, and alkali catalysts, namely sodium methoxide and acrylamide, performing a reaction so as to obtain an intermediate, adding a charcoal formation agent and a substance A, keeping the pH value of the solution to 6.5-7.0 in the stirring process, further adding a substance B and a substance C, performing a continuous stirring reaction, and performing concentration so as to obtain the nitrogen-phosphorus expanded type flame retardant; and preparing the aqueous polyurethane coating from the nitrogen-phosphorus expanded type flame retardant. By adopting the flame retardant provided by the invention, flame can be rapidly choked, and the flame retardancy of the nitrogen-phosphorus expanded type flame retardant can be improved by releasing smoke, controlling flamecombustion time and controlling densities of charcoal layers. In addition, the nitrogen-phosphorus expanded type flame retardant is grafted with polyurethane, so that the flame retardancy of the polyurethane can be further improved.

Owner:YANTAI UNIV

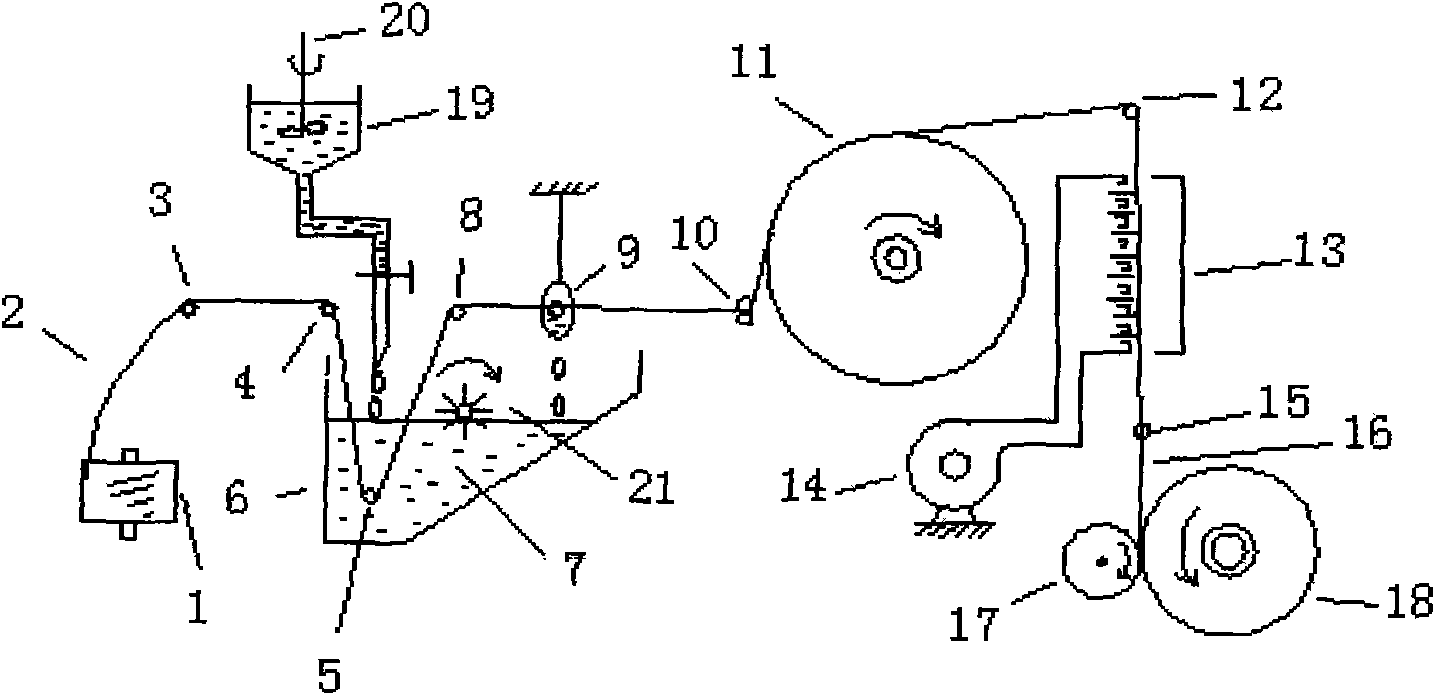

Silk-coating method for PVC/PU coating polyester industrial yarns and device thereof

The invention discloses a silk-coating method for PVC / PU coating polyester industrial yarns and a device thereof. The method comprises the following steps: using polyester industrial yarns as raw materials and a core layer structure; adopting a PVC-coating adhesive as a surface structure; dipping the polyester industrial yarns in the PVC-coating adhesive so that the adhesive is stuck to the silk;extruding the silk; scraping the adhesive; then, winding the silk in a spiral shape and baking; and drying, cooling the dried silk by cold air and coiling so that the coating adhesive is deeply permeated and coated on the core layer structure to form the silk of the coating polyester industrial yarns. The composite silk material has the advantages of high strength, good toughness, corrosion resistance, aging resistance, and the like. A melting point of PVC, PU or PE coating adhesive on the surface is lower than that of core-layer polyester yarns, woven fabrics in a stretching state are baked at high temperature or thermally rolled, shaped and processed, and warp yarns and weft yarns are melted and fused by the coating adhesive so that mesh fabrics are integrally smooth and stiff and meshesare uniform and stable.

Owner:绍兴顺金纺织窗材有限公司

Preparation method of coated halogen-free flame-retardant foamable polystyrene

InactiveCN102977402AAvoid fireWith flame retardant functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoyl peroxideThermal insulation

The invention belongs to the field of expandable polystyrene heat insulating materials, and particularly relates to a preparation method of coated halogen-free flame-retardant foamable polystyrene. The method comprises the following steps: adding polyvinyl alcohol and tricalcium phosphate into deionized water, and evenly mixing to obtain a mixed solution A; adding ammonium polyphosphate, melamine polyphosphate or PNP intumescent flame retardant into styrene, and adding benzoyl peroxide to obtain a mixed solution B; adding the mixed solution B into the mixed solution A to react, and adding a foaming agent to react to obtain halogen-free flame-retardant foamable polystyrene granules; and adding the prepared granules into a phenol formaldehyde resin or melamine resin binding agent containing small amounts of alkali silicate water solution and smoke inhibitor to carry out coating, thereby finally obtaining the coated halogen-free flame-retardant foamable polystyrene granules. The coated halogen-free flame-retardant foamable polystyrene has the advantages of excellent thermal insulation and heat shielding properties, and outstanding flame retardancy and smoke inhibition property, and can be used a flame-retardant architectural thermal insulation material.

Owner:LIAONING TECHNICAL UNIVERSITY

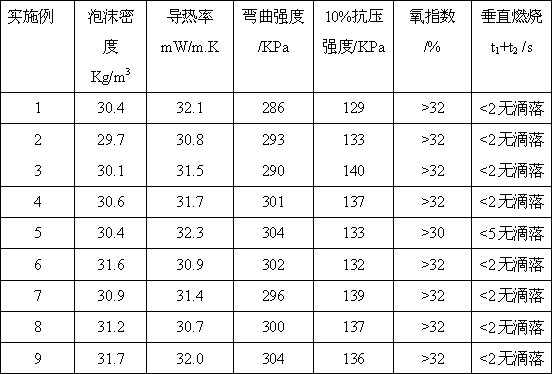

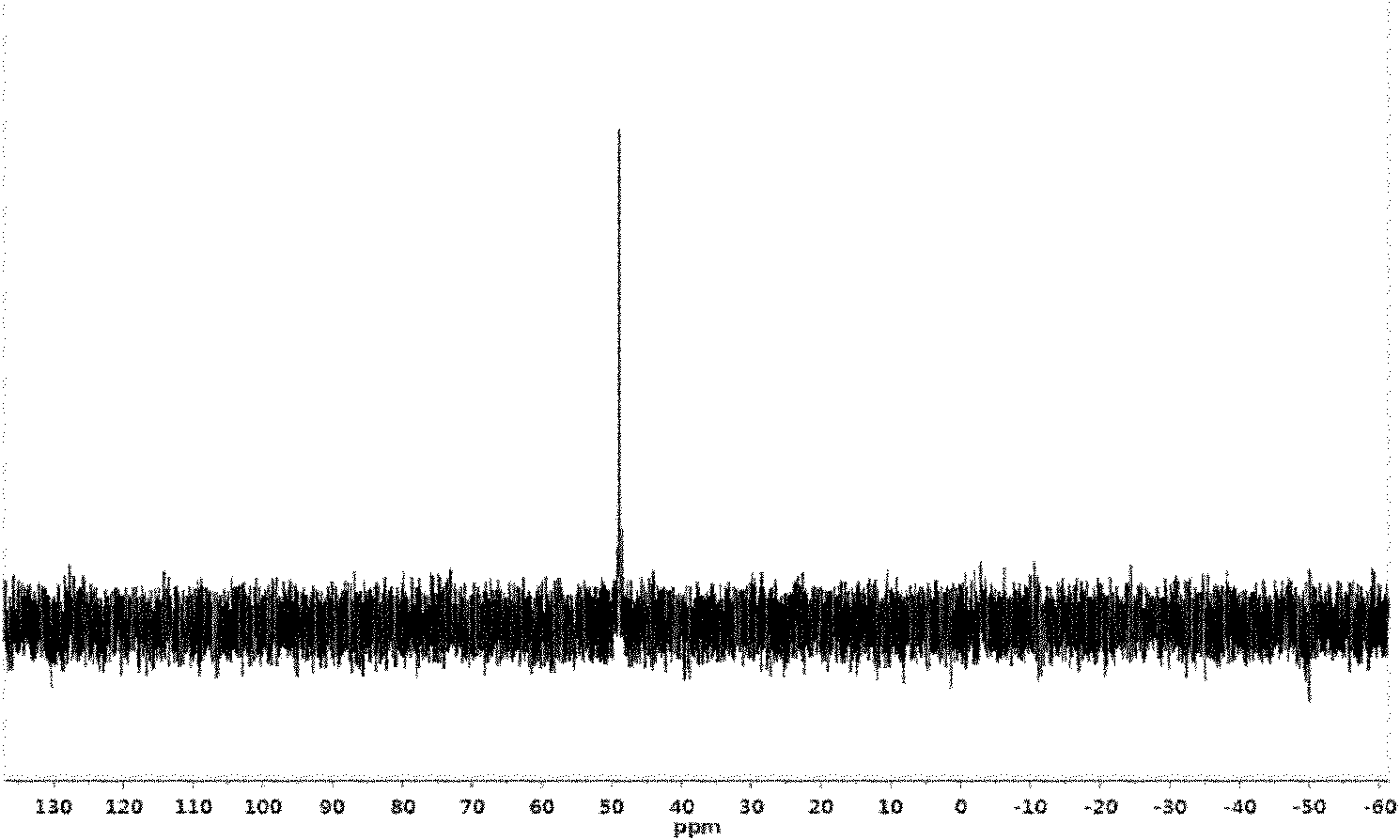

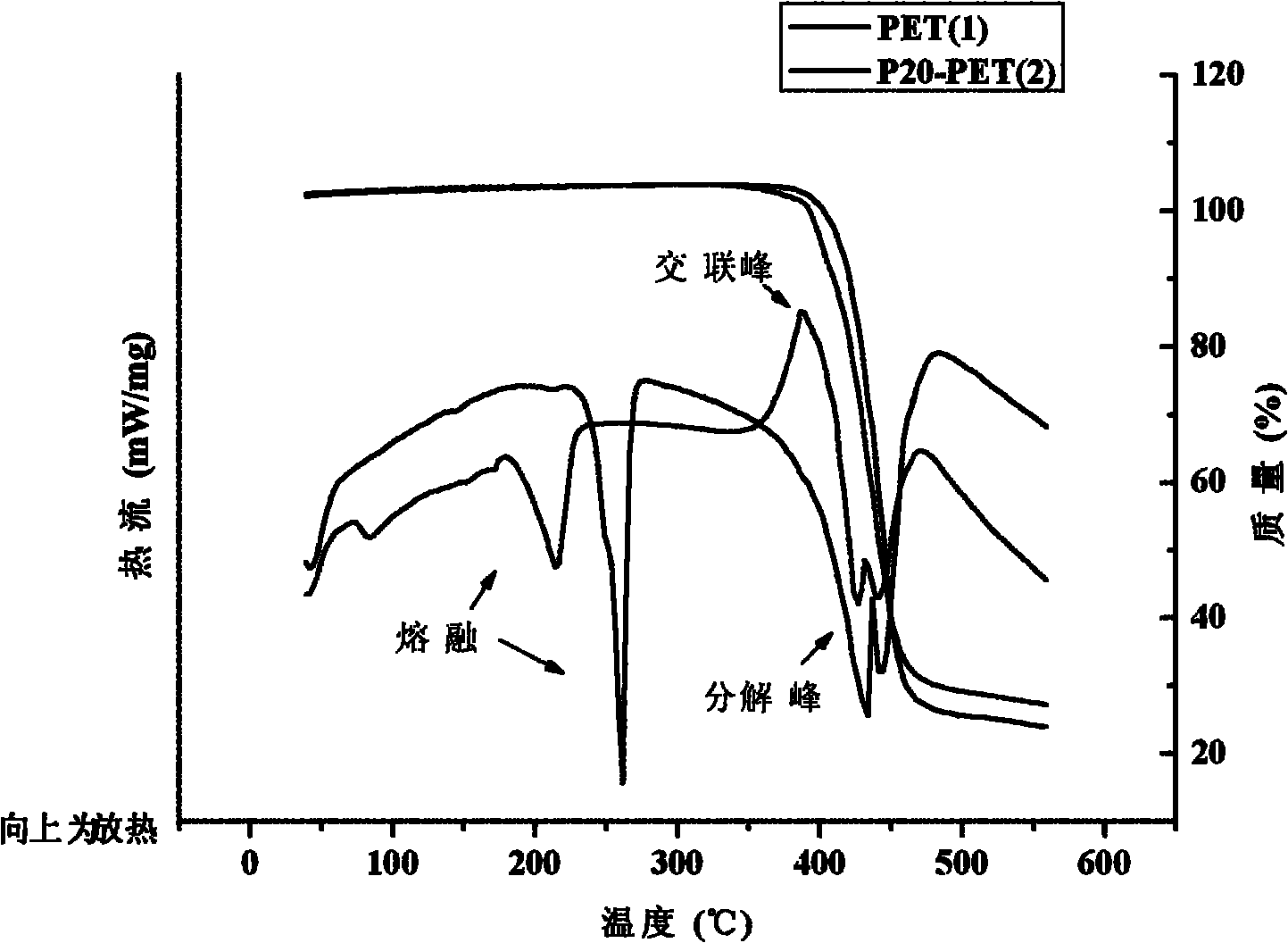

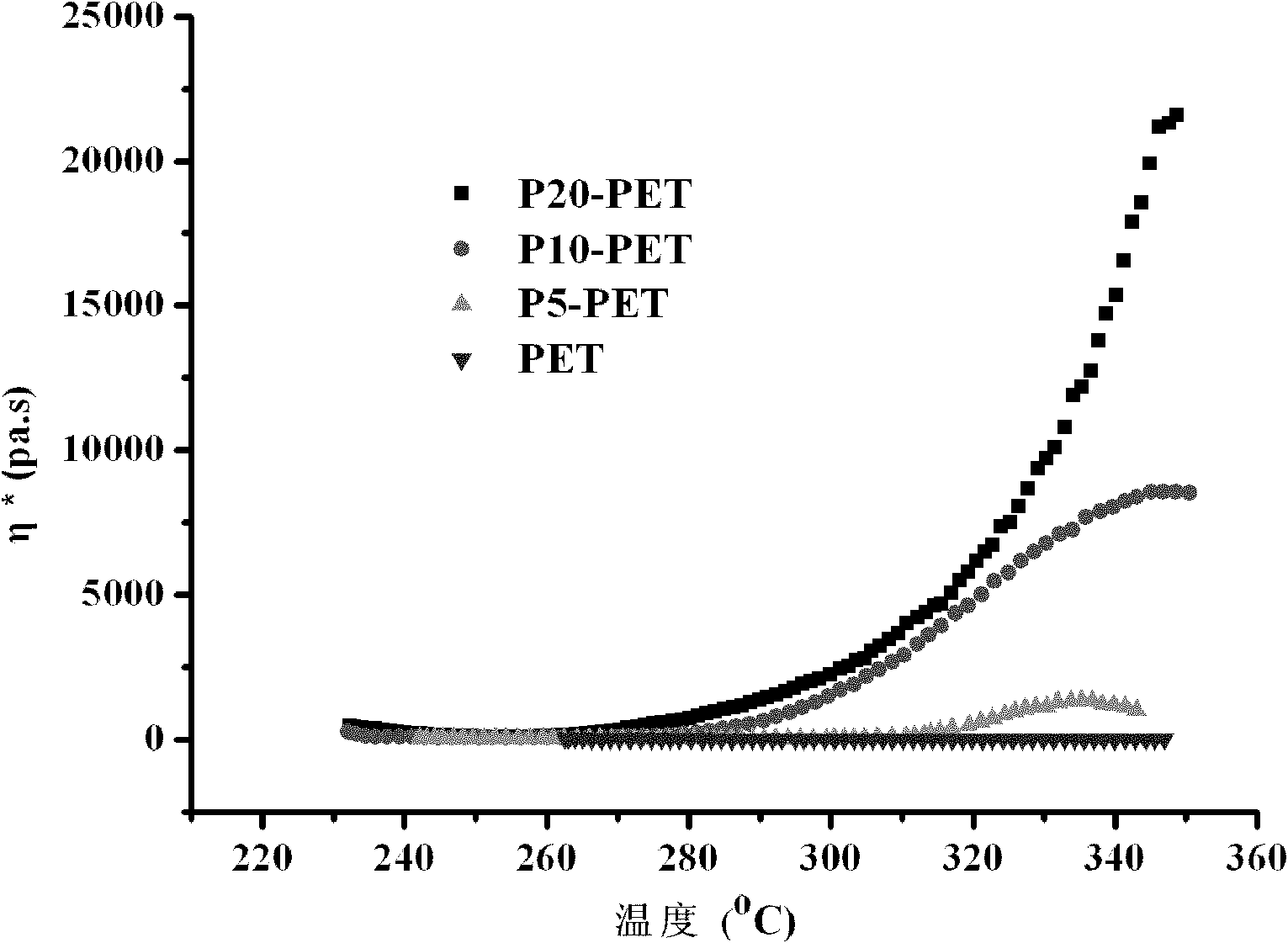

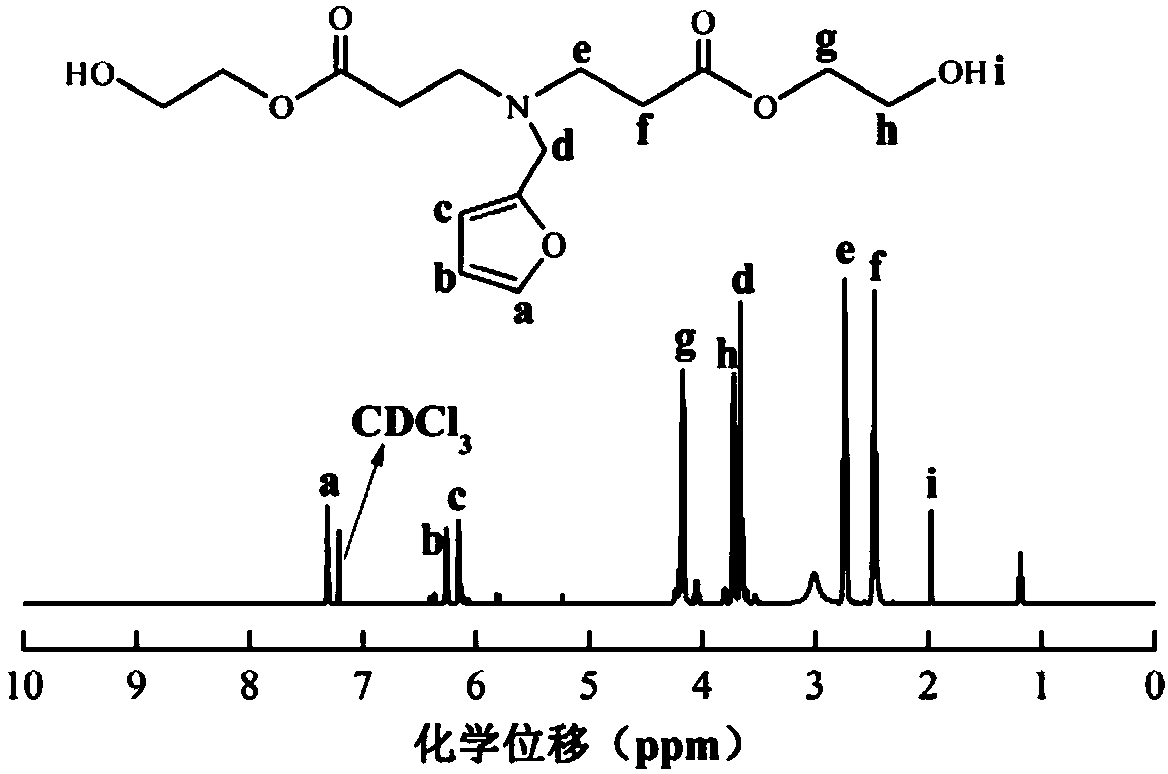

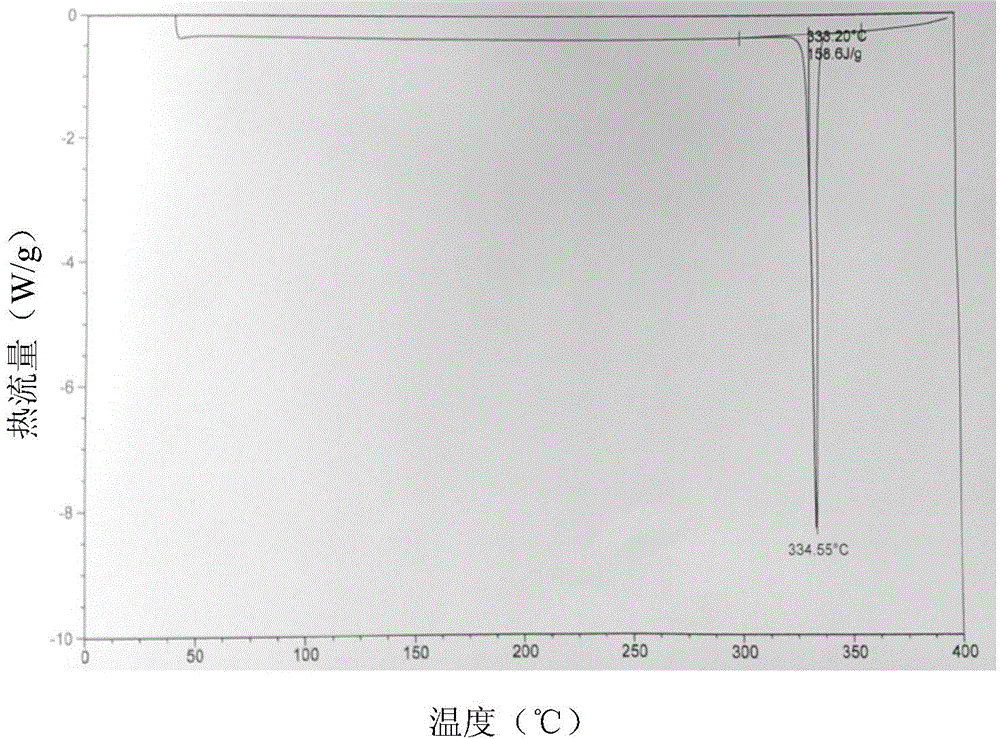

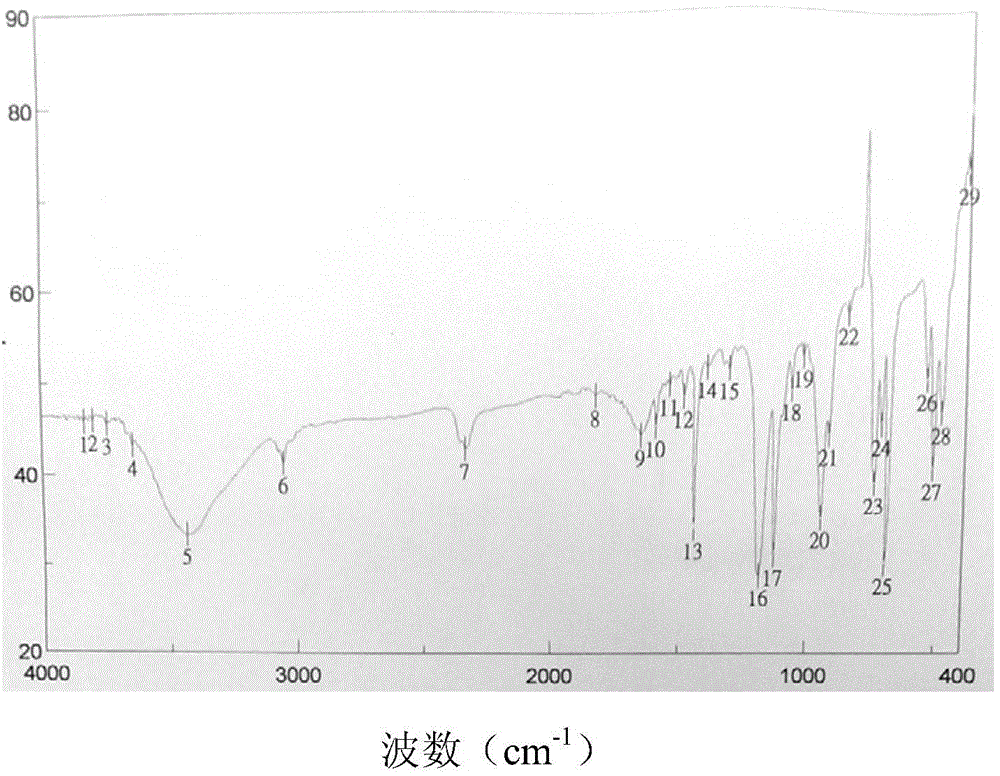

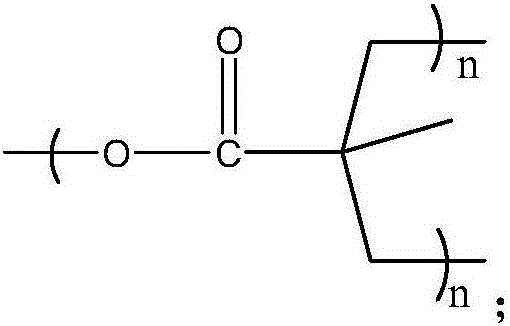

High-temperature self-crosslinking flame-retardant anti-dripping copolyester and preparation method thereof

The invention discloses a high-temperature self-crosslinking flame-retardant anti-dripping copolyester which is prepared by introducing a structural unit shown as IV in the specification or introducing structural units shown as III and IV in the specification by random copolymerization on the basis of structural units of synthetic polyester shown as I and II in the specification, and the intrinsic viscosity [eta] of the prepared high-temperature self-crosslinking copolyester is 0.25-1.25dL / g. The invention also discloses the preparation method of the high-temperature self-crosslinking copolyester. Because the crosslinking group introduced in the invention is a high-temperature self-crosslinking group, on the premise of not affecting the preparation and forming of the polyester, self-crosslinking can be realized at higher temperature, and the melt viscosity of the polyester is improved through the char formation effect and stable chemical crosslinking of the self-crosslinking group, thereby performing combined action with the phosphorus-containing flame-retardant structural unit IV and endowing the polyester with better flame-retardant and anti-dripping properties.

Owner:SICHUAN UNIV

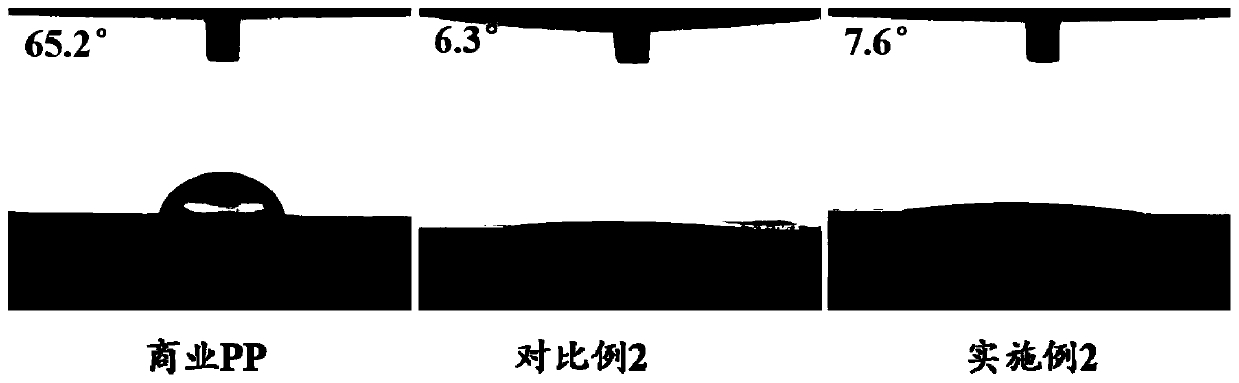

Environment-friendly and flame-retardant polypropylene material and preparation method thereof

The invention relates to the field of preparation of polypropylene composite materials, in particular to an environment-friendly and flame-retardant polypropylene composite material. The environment-friendly and flame-retardant polypropylene composite material is prepared from 100 parts of polypropylene, 0.1-2 parts of modified graphene, 0.5-3 parts of modified carbon nano tubes, 10-20 parts of an inorganic flame retardant, 5-10 parts of a compatilizer, 3-10 parts of a toughening agent, 0.1-0.3 parts of an antioxidant and 0.1-0.3 parts of a heat stabilizer. Graphene, the carbon nano tubes and the inorganic flame retardant are added to polypropylene resin, and a brand-new flame retardant system is formed; dispersing performance of graphene in a polymer system is improved through modification of graphene; migration of combustible matter in a polymer matrix can be effectively inhibited; a compact protective carbon layer is formed on the surface of the polymer matrix by graphene in the burning process of the composite material, and finally, the flame-retardant effect is achieved.

Owner:JIANGSU CHANGHAI COMPOSITE MATERIALS CO LTD

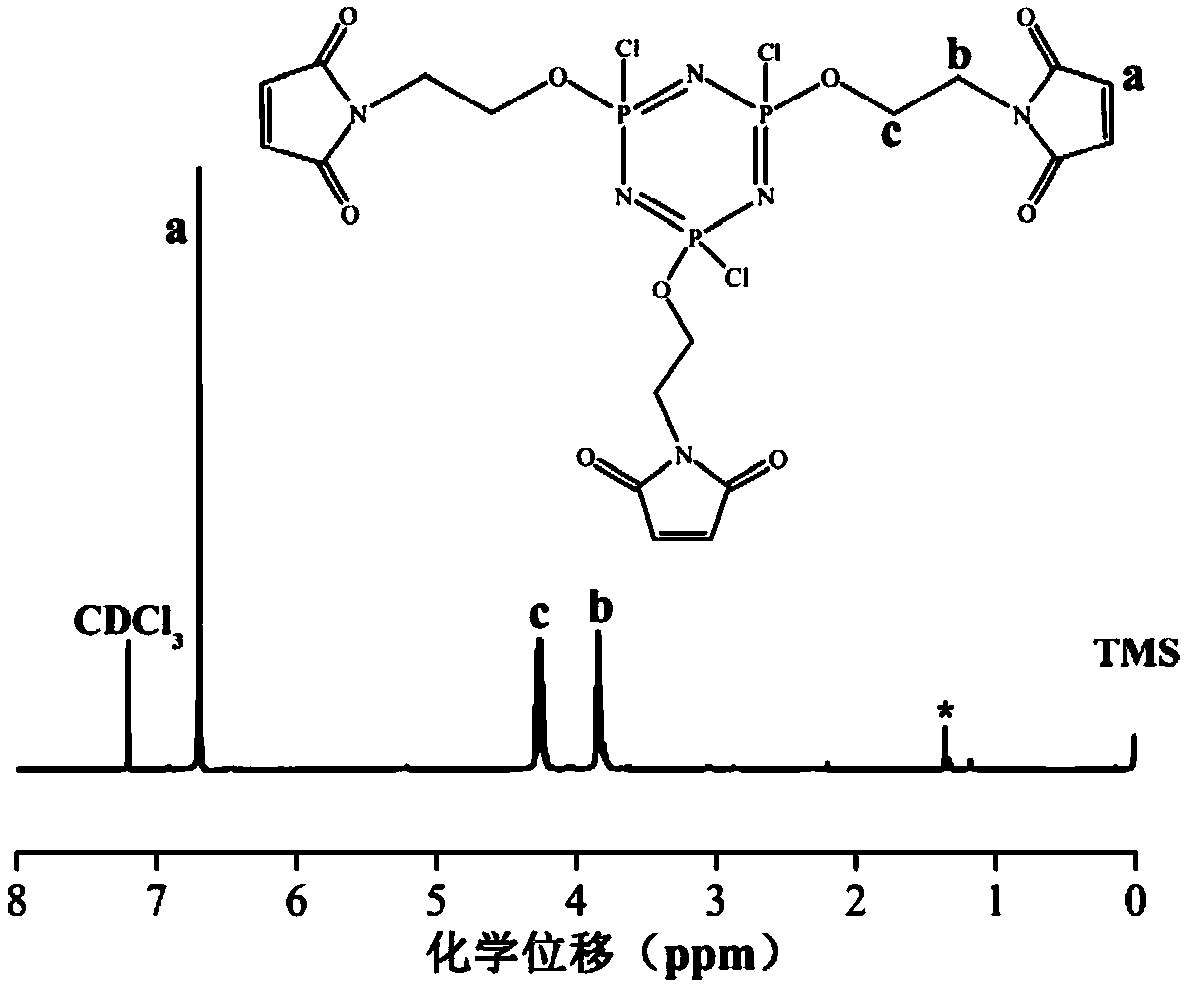

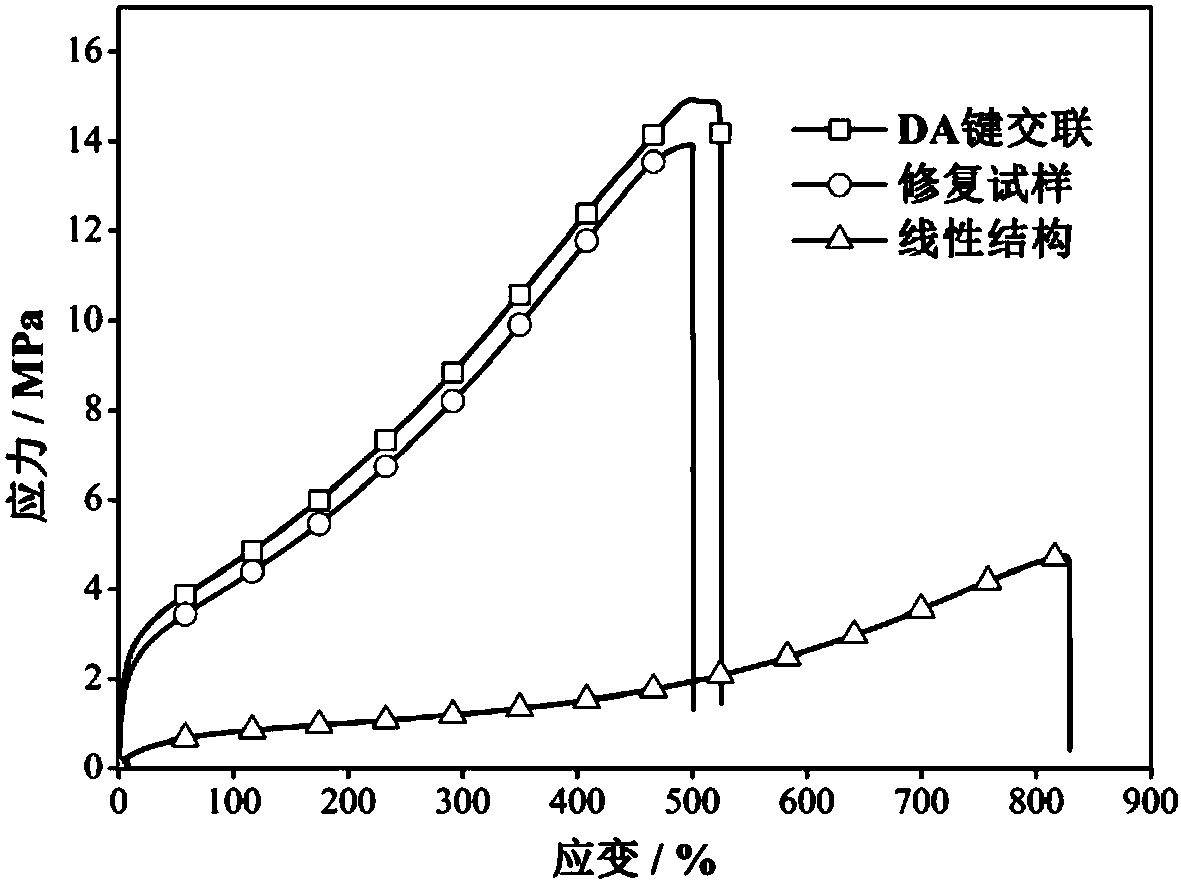

Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer and preparation method thereof

The invention provides a Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer and a preparation method of the Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer. The structural formula of the polyurethane elastomer is shown in the specification. The preparation method of the polyurethane elastomer is as follows: (1) preparing dihydric alcohol having a furan functional group; (2) preparing a linear-structure polyurethane solution comprising a furan functional group on a side chain; (3) preparing a maleimide modified phosphonitrilic chloride trimer flame retardant; and (4) preparing the Diels-Alder bond containing self-repairing flame retardant polyurethane elastomer.

Owner:SICHUAN UNIV

Thermostable, flame-resistant and oil-proof rubber sizing material and production method thereof

InactiveCN101250290AAchieve high temperature performanceAchieving Flame RetardancyFootwearAcrylonitrileUltra fast

The invention discloses rubber compound which is high temperature resistant, fire-proof and grease-proof and a production process, which is formed by raw materials with following weight: 100phr acrylonitrile butadiene, 2-3phr vulcanizing agent, 5-7phr zinc oxide, 2-3phr octadecanoic acid, 1-2phr medium accelerator, 3-4phr ultra fast accelerator, 30-40phr carbon black, 15-25phr softening agent 3-6phr anti-aging agent and 70-100phr halogen-free flame retardant. High temperature resistant and fire-proof sizing material which is produced through the sizing material formulation and the process realizes the high temperature resistance and fire-proof properties of acrylonitrile butadiene at the premise of non halogen-free environmental protection, is used to shoemaking production, and is suitable for work footwear under the condition of high temperature and temporary open flame.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Halogen-free flame-retardant sheath material for class-1E K3 cable used for nuclear power station

The invention provides a halogen-free flame-retardant sheath material for a class-1E K3 cable used for a nuclear power station. The halogen-free flame-retardant sheath material mainly comprises the following components: ethylene-vinyl acetate copolymer, maleic anhydride-grafted polyolefin, inorganic fire retardant, a synergistic fire retardant, melamine urate, micro-capsulated red phosphorus, an anti-oxidant, an ultraviolet ray absorber, an aqueous graphene solution, a crosslinking sensitizer and a lubricant, wherein the mass percentage of vinyl acetate in the ethylene-vinyl acetate copolymer is about 20 to 40%, a compatilizer is at least one selected from the group consisting of maleic anhydride-grafted ethylene-vinyl acetate copolymer, maleic anhydride-grafted ethylene-octylene copolymer and maleic anhydride-grafted polyethylene, and the ultraviolet ray absorber is at least one selected from the group consisting of 2-(2'-hydroxy-3',5'-di-tert-pentyl-phenyl)benzotriazole and 2-(2'-hydroxy-3',5'-tert-octyl-phenyl)benzotriazole. The halogen-free flame-retardant sheath material has good flame retardation performance, oil resistance, electrical performance and mechanical performance and can meet the requirement on a generation-III nuclear power station for service life of 60 years.

Owner:中广核三角洲(江苏)塑化有限公司 +1

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

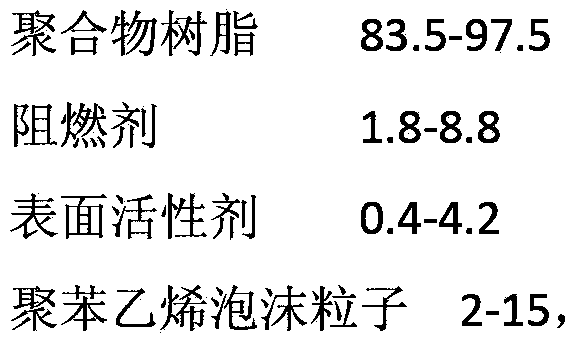

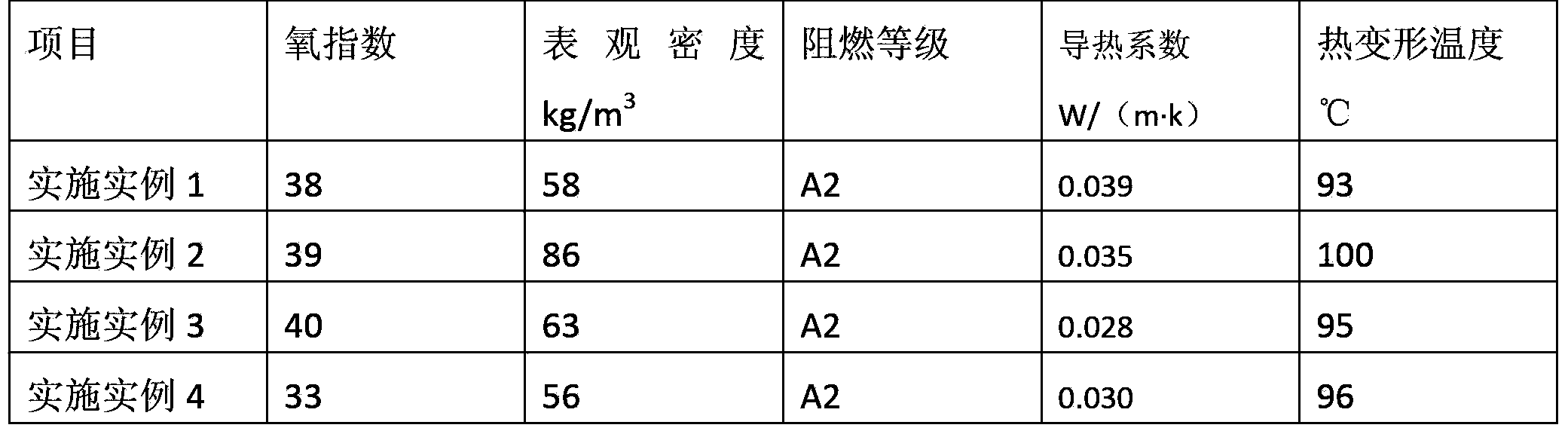

High-molecular flame-retardant foam material and preparation method thereof

InactiveCN103408891ALow thermal conductivityGood flame retardant performanceThermal insulationSurface-active agents

The invention provides a high-molecular flame-retardant foam material which is prepared by mixing the following components in parts by weight: 83.5 to 97.5 parts of polymer resin, 1.8 to 8.8 parts of flame retardant, 0.4 to 4.2 parts of surface active agent and 2 to 15 parts of polystyrene foam particles. The preparation method of the high-molecular flame-retardant foaming heat insulating material comprises the following steps: the polymer resin, the flame retardant and the surface active agent are mixed uniformly to prepare a high-molecular organic flame-retardant adhesive, then after being mixed, the high-molecular organic flame-retardant adhesive and a curing agent are added into the polystyrene foam particles, and the high-molecular flame-retardant foaming heat insulating material can be formed quickly through hot pressing. The high-molecular flame-retardant foam material provided by the invention synthesizes the characteristic of low heat conductivity coefficient of the foam particles and efficient flame-retardant effect of the high-molecular organic flame-retardant adhesive, really achives integration of flame retardance and heat preservation, and uses various flame-retardant compounds for mixing to form the flame retardant, and the prepared high-molecular flame-retardant foaming heat insulating material is better in flame retardant property, better in thermal insulation effect, and higher in oxygen indexes.

Owner:南通南京大学材料工程技术研究院

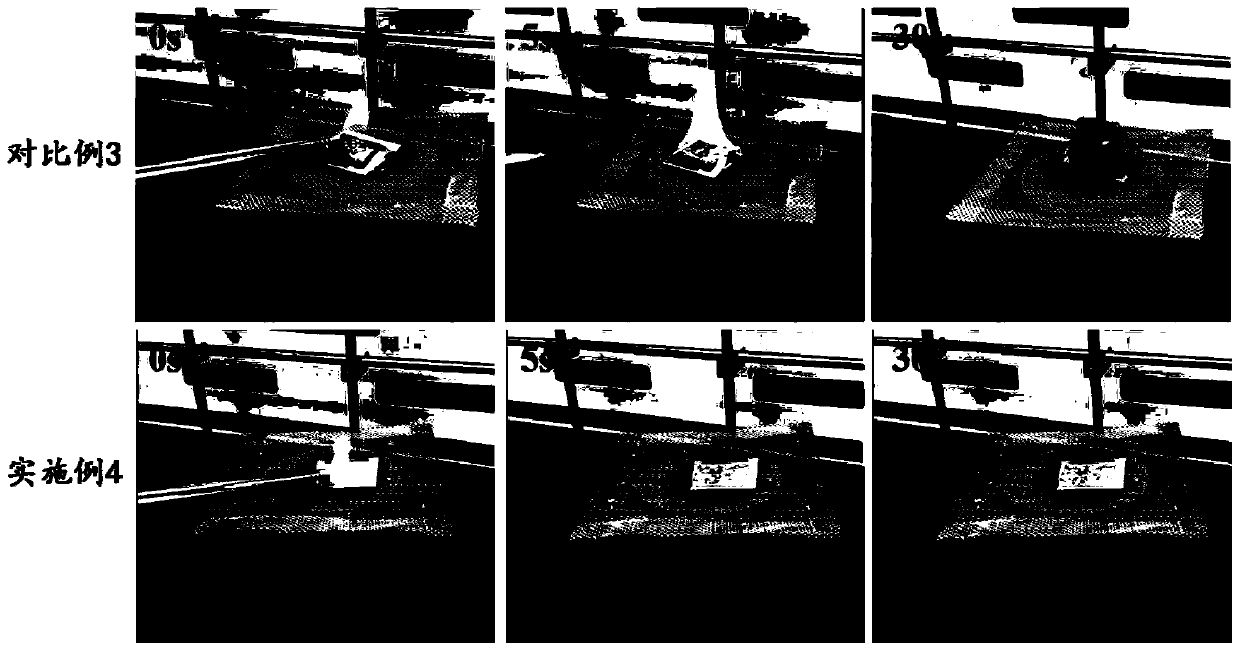

Method of in-situ self-assembly in solid wood to prepare polyurethane reinforced wood

ActiveCN103586947AImprove water resistanceExcellent anti-corrosion and mildew resistancePressure impregnationPolymerisation impregnationSolid woodPolymer science

The invention discloses a method of in-situ self-assembly in solid wood to prepare polyurethane reinforced wood. The method comprises the following steps: utilizing a vacuum high-pressure technology to impregnate isocyanate monomers, vacuum dehydrated polyalcohol, a chain extender, a cross-linking agent, a catalyst and other modifiers which are uniformly mixed to inside of the wood; then ageing, homogenizing and taking a polymerization reaction by heating or microwave to allow the isocyanate and the polyalcohol to take the polymerization reaction on the internal surface of the wood pores, so as to forming the polyurethane reinforced wood. The wood prepared with the method is of the excellent performances of wood and polyurethane, can be applied to various fields, and has high additional value and market prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

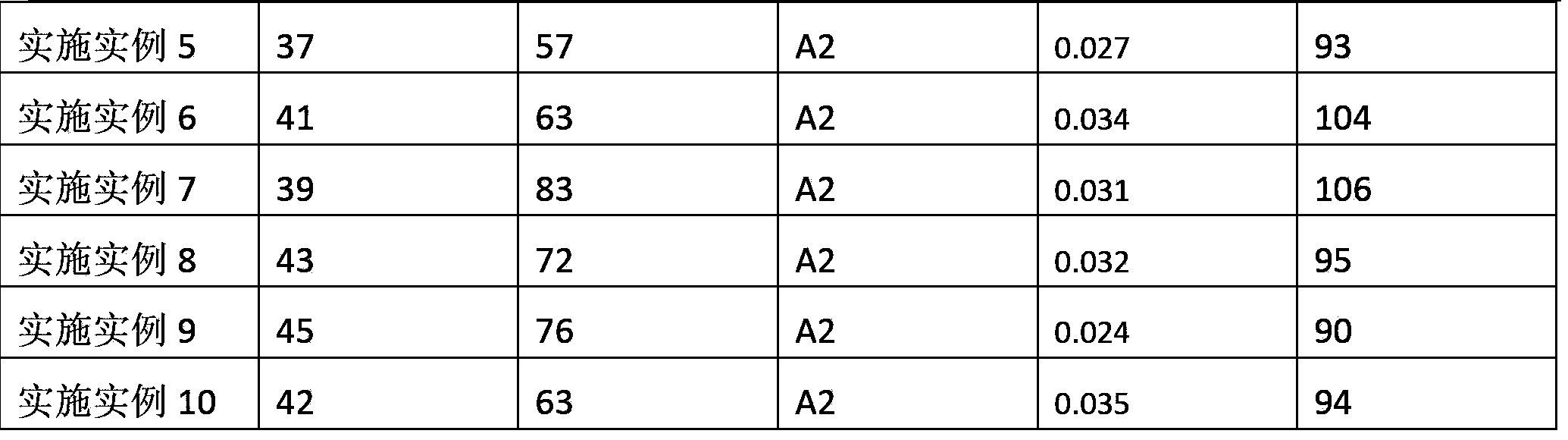

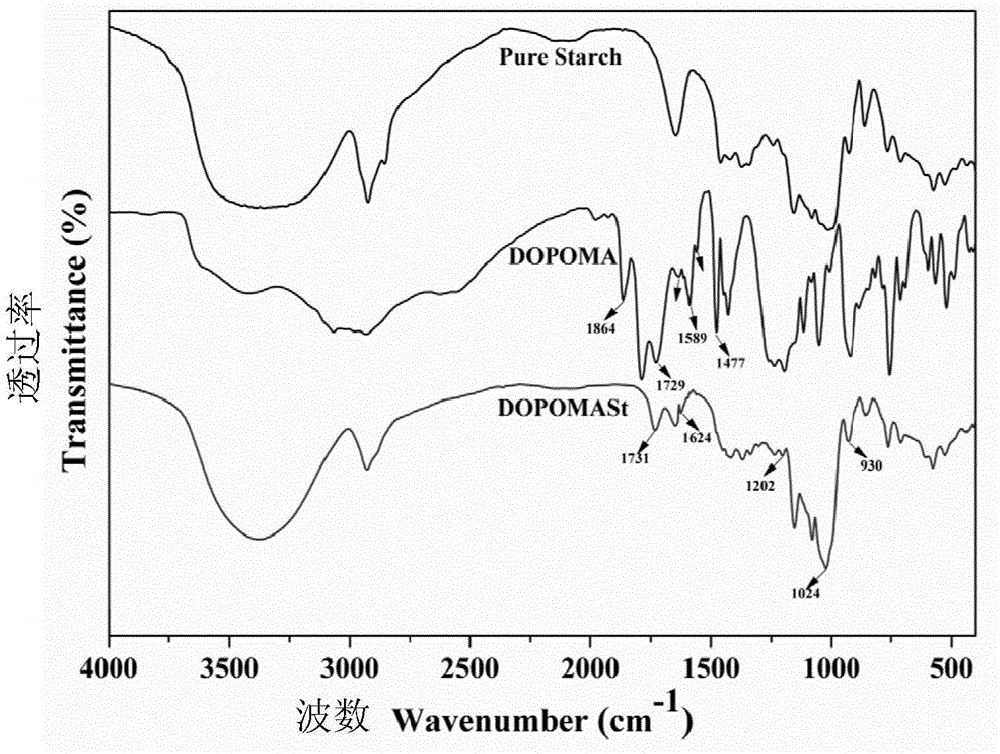

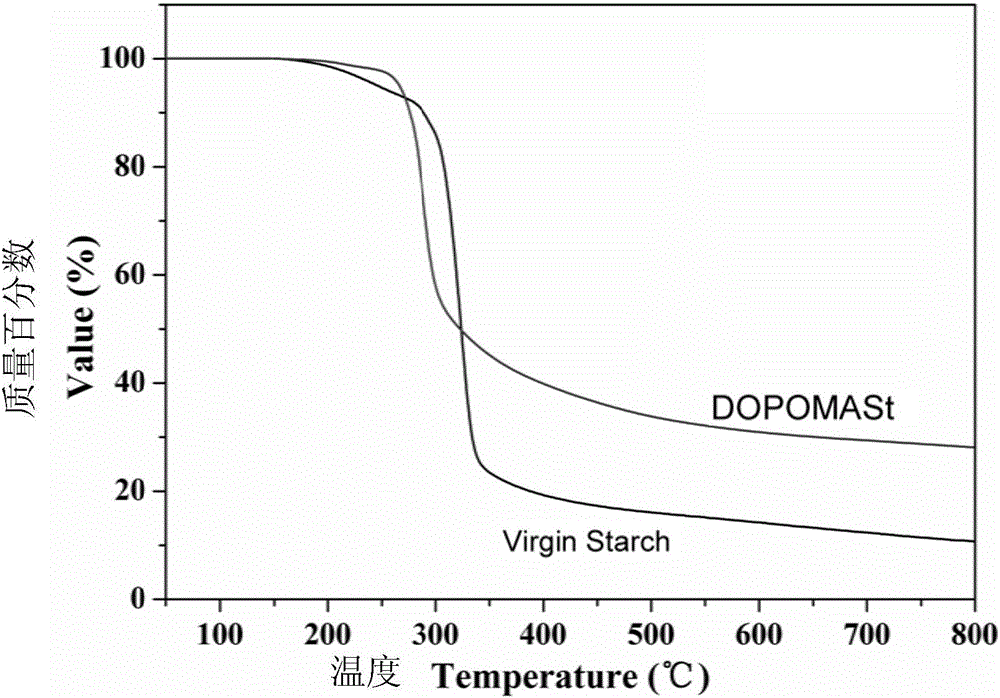

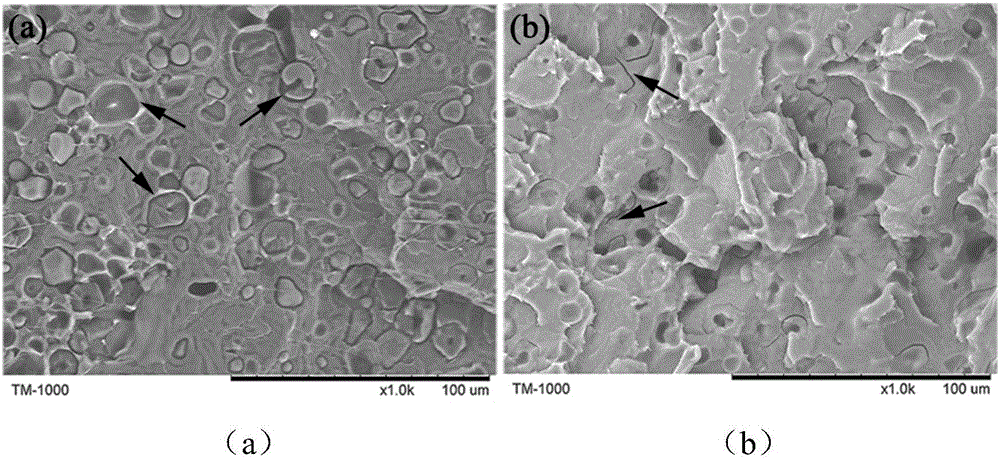

Polylactic acid/starch expansion flame-resistant composite material, and preparation method thereof

ActiveCN106496975AImprove charcoal abilityImprove high temperature thermal stabilityMaleic anhydrideChemistry

The invention discloses a polylactic acid / starch expansion flame-resistant composite material with excellent flame resistance, and a preparation method thereof. The polylactic acid / starch expansion flame-resistant composite material is composed of, by weight, 60 to 89% of polylactic acid, 5 to 30% of an acid source, 5 to 30% of a modified starch, and 1 to 15% of a gas source. In a preferred embodiment, the modified starch is phosphorized maleic anhydride grafting modified starch (bio-based phosphorus containing starch). According to the preparation method, polylactic acid possesses excellent compatibility with the modified starch; synergistic effect of the acid source, the carbon source (the modified starch), and the gas source is capable of improving charring forming capability of the polylactic acid matrix, and improving high temperature stability and flame resistance of polylactic acid greatly. According to the preparation method, adoption of an existing double-screw extruder is enough for production; preparation is simple and convenient; and the preparation method is convenient for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

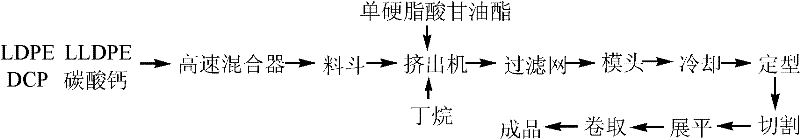

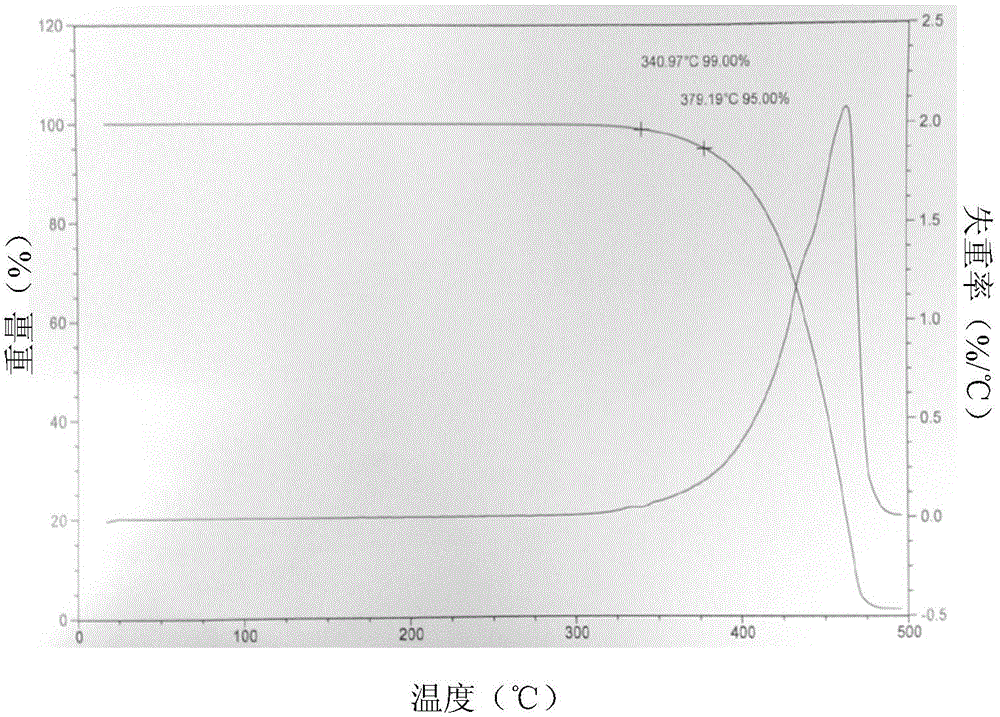

Preparation method of high performance expanded polyethylene product

ActiveCN102558647AHigh densityHigh surface hardnessLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method of a high performance expanded polyethylene product. The material of the invention comprises the following component in parts by weight: 50 parts of LDPE (low-density polyethylene) and LLDPE (linear low-density polyethylene), 0.01-1 parts of peroxide, 0.3-2 parts of talcum powder and / or calcium carbonate, 0.02-0.06 parts of antishrinking agent and 0.1-0.4 parts of foaming agent. In the invention, butane is used as the foaming agent, and the LDPE and the LLDPE are used as resin raw materials. The expanded polyethylene prepared by the preparation method of the invention has the advantages of high density and high surface hardness, the density of the expanded polyethylene is 60-400g / m<3> and the surface hardness is 40-70 degrees. The high performance expanded polyethylene product has good anti-scraping performance and puncture resistance as well as good rebound resilience and anti-quake effect. The high performance expanded polyethylene product meets the requirements of high performance of current packaging materials and fully protecting the substances being packaged. In addition, the high performance expanded polyethylene product has theadvantage of long sustainable using time as a panel and good market potential.

Owner:XIAMEN SANDEXIN SCI&TECH CO LTD

Phosphorus-containing flame retardant low-dielectric resin composition and preparation method and application thereof

ActiveCN105440645AExcellent dielectric propertiesHigh melting pointSynthetic resin layered productsHigh frequency circuit adaptationsPolymer scienceDielectric loss

The present invention belongs to the technical field of low-dielectric resin compositions, and discloses a phosphorus-containing flame retardant low-dielectric resin composition and a prepreg, a resin film, a laminated board and a circuit board prepared on the basis of the phosphorus-containing flame retardant low-dielectric resin composition. The resin composition comprises the following components: (A) a phosphorus-containing flame retardant; and (B) a vinyl compound. The phosphorus-containing flame retardant has the structure shown in the formula (I). The phosphorus-containing flame retardant prepared by derivation of diphenylphosphine oxide has no reactive functional group, and has better dielectric properties and a high melting point, a substrate with low thermal expansion coefficient, high heat resistance, high glass transition temperature and low dielectric constant and dielectric loss is prepared from the resin composition prepared by collocation of the vinyl compound, under the premise of no use of a halogen flame retardant, UL94V-0 level flame retardant effect can be effectively achieved, and the resin composition can be used for making the prepreg, the resin film, a resin coated copper foil, a flexible resin coated copper foil, the laminated board and the circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

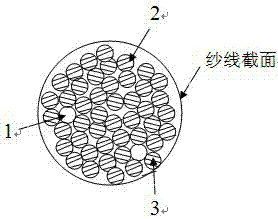

Flame-retardant antistatic yarn and fabric thereof

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Biomass graphene-modified fire retardant and master batch and preparation method

The invention provides a biomass graphene-modified fire retardant and master batch and a preparation method thereof. The biomass graphene-modified fire retardant is mainly prepared from biomass graphene, a fire retardant and a coupling agent. The fire retardant is used as a disperse medium for the biomass graphene. By simple physical mixing, bond joint of the biomass graphene with the fire retardant and uniform dispersion of the biomass graphene are realized, thus finally playing a synergistic flame retardant effect in a polymer matrix. By the adoption of the Biomass graphene-modified fire retardant for preparation of high-molecular polymer master batch, the dispersion problem of biomass graphene is solved, and it is possible to effectively raise fire resistance under the condition of low addition amount of the fire retardant. For practical application fields of different fire-resistant high-molecular polymer materials, anti-dripping, enhancing, ultraviolet-resistant and coloring functions can be obtained simultaneously by the adoption of the master batch product.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Flexible heat-preserving tapestry brick and preparation method thereof

ActiveCN103113057AAchieve compositeImprove mechanical propertiesSolid waste managementFiberCross-link

The invention discloses a flexible heat-preserving tapestry brick and a preparation method of the flexible heat-preserving tapestry brick. The raw material of the brick is sizing agent or dry power formed by evenly mixing mud powder, a hollow filler, crylic acid monomers, a cross-linking agent, reinforced fibers, a solvent, an initiator and a fire retardant according to a certain proportion. The preparation method comprises the following steps of: forming in a mould in a heating way, drawing, drying, trimming and the like to obtain the flexible tapestry brick with the functions of heat preservation and flame retardance. The flexible heat-preserving tapestry brick has the characteristics of being flexible, heat-preserving, water-resistant, fire-resistant, anti-stain, anti-aging, scrubbing-resistant, low in specific gravity, simple in production process, low in cost and the like, thereby being widely applicable to the decoration indoors and outdoors.

Owner:南通南京大学材料工程技术研究院

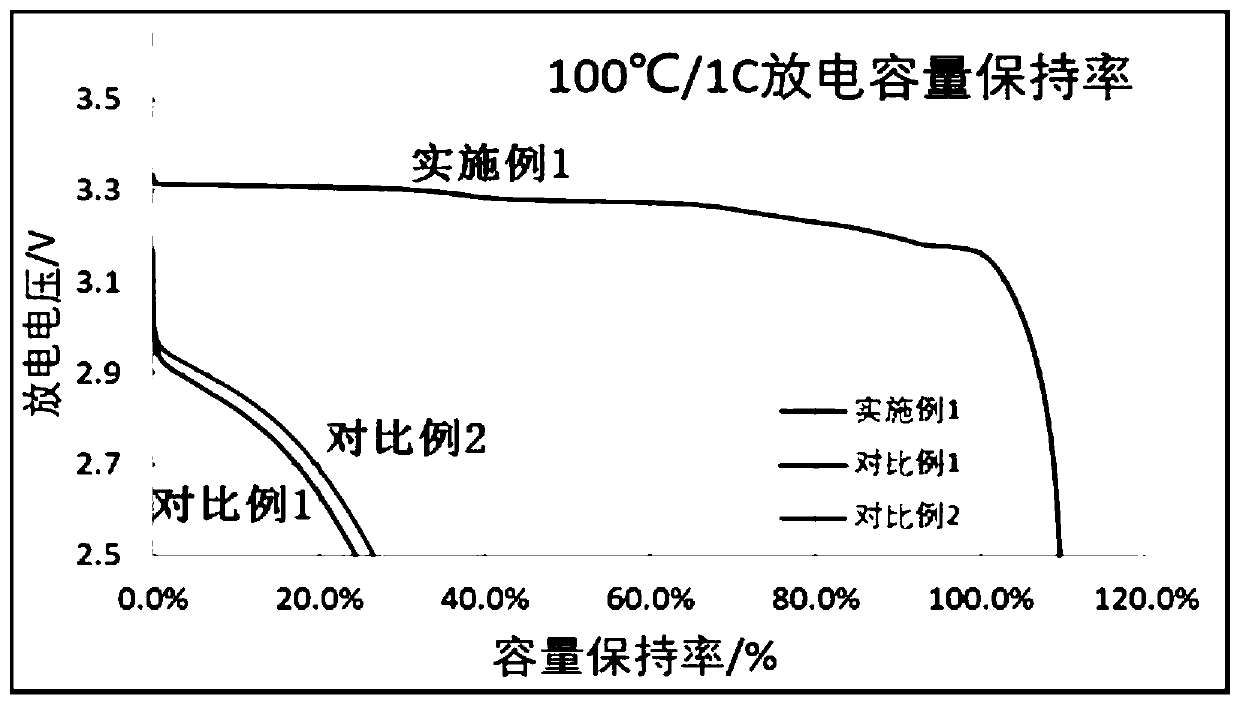

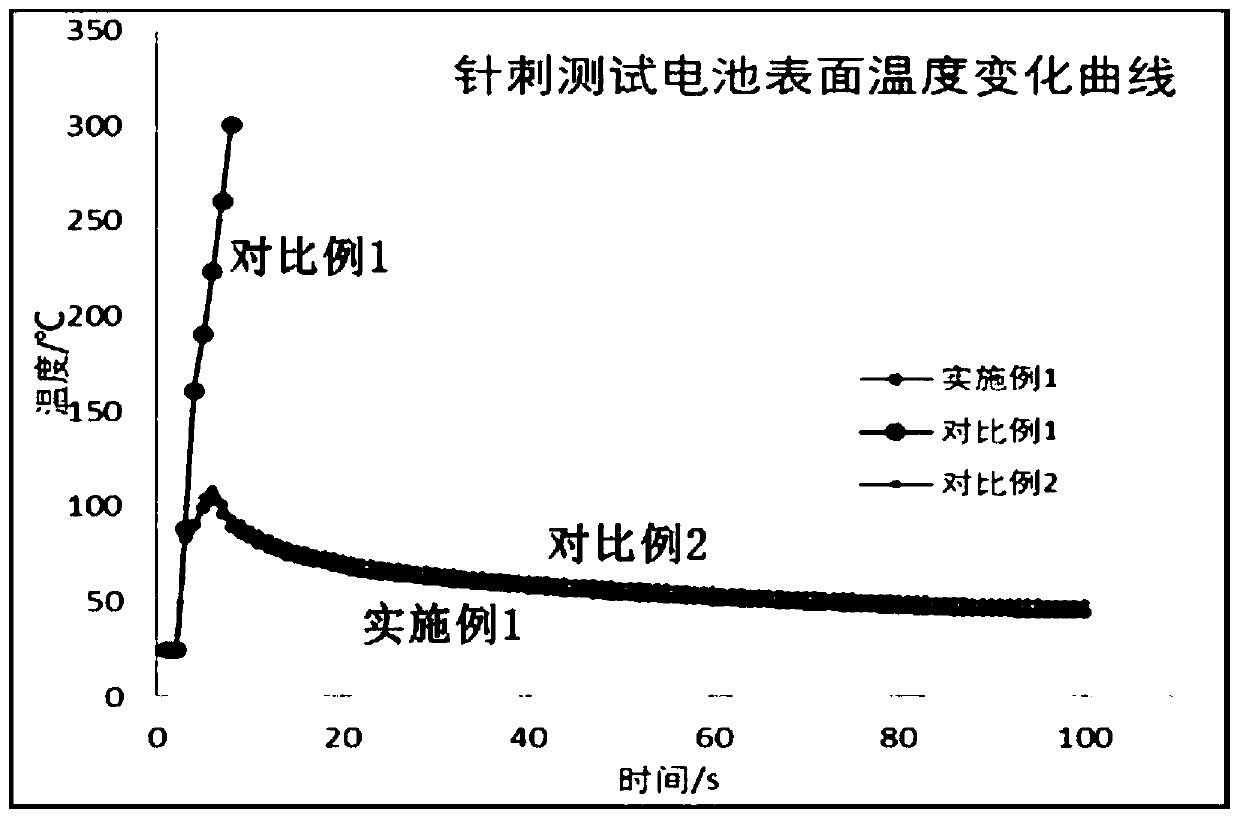

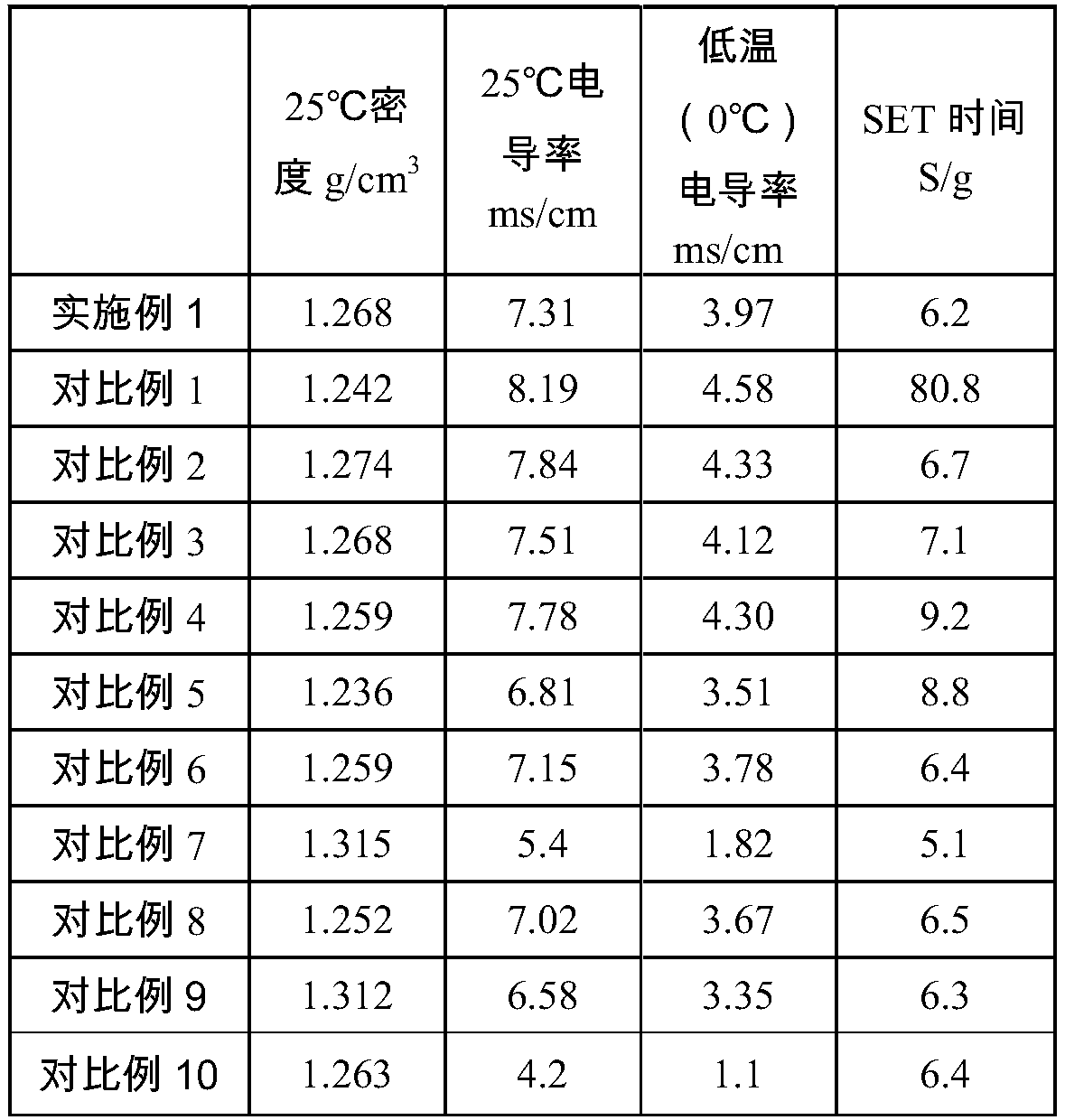

Ultra-high-temperature safe lithium ion battery electrolytic solution and lithium ion battery using electrolytic solution

ActiveCN111564665AImprove high temperature stabilityImprove thermal stabilityFinal product manufactureFire rescueTrifluoromethylOrganosolv

The invention discloses an ultrahigh-temperature safe lithium ion battery electrolytic solution and a lithium ion battery using the electrolytic solution. The electrolytic solution comprises 10-15% ofa lithium salt, 1-5% of a high-temperature film-forming additive, 1-10% of a flame-retardant additive and the balance of an organic solvent, wherein the lithium salt is one or a mixture of more thantwo of hexafluorophosphoric acid, lithium bis (fluorosulfonyl) imide or lithium bis (trifluoromethylsulfonyl) imide, the organic solvent is formed by mixing carbonic ester, carboxylic ester and a fluoroether solvent according to a certain proportion, the carbonic ester accounts for 30%-70% of the total amount of the lithium ion battery electrolytic solution, the carboxylic ester accounts for 0%-10% of the total amount of the lithium ion battery electrolytic solution, and the fluoroether accounts for 0%-10% of the total amount of the lithium ion battery electrolytic solution. According to the invention, the electrolytic solution disclosed by the invention is a high-temperature solvent and lithium salt with excellent thermal stability, and a film-forming additive with excellent film-formingthermal stability and a proper flame-retardant additive are added to realize the flame-retardant effect of the electrolytic solution; and the lithium ion battery disclosed by the invention can be normally used under the ultrahigh temperature condition of 100 DEG C while the battery has excellent safety performance.

Owner:广东金光高科股份有限公司

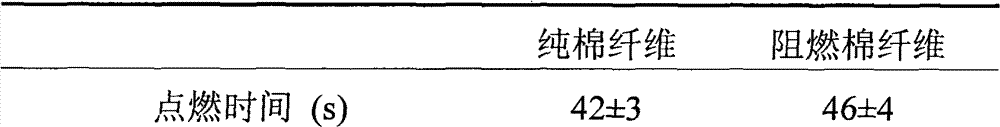

Flame-retardant cotton fiber and preparation method thereof

The invention discloses a flame-retardant cotton fiber and a preparation method thereof. An intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating contains an intumescent flame retardant, polyvinyl alcohol and montmorillonoid. The intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating is prepared by adopting the following step of: carrying out layer-by-layer self-assembly on a polyvinyl alcohol aqueous solution with the intumescent flame retardant and montmorillonoid suspension liquid dispersed in water to obtain the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating. The flame-retardant cotton fiber is obtained by treating the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating. According to the flame-retardant cotton fiber and the preparation method thereof, the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating is prepared by the adoption of a layer-by-layer self-assembly technology; and through the synergistic flame-retardant effect of the intumescent flame retardant and montmorillonoid, the flame retardance of cotton fibers is improved, so that the usage amount of the flame retardant for cotton fabrics is reduced, therefore the cost of flame-retardant cotton fibers is lowered.

Owner:TAIZHOU UNIV

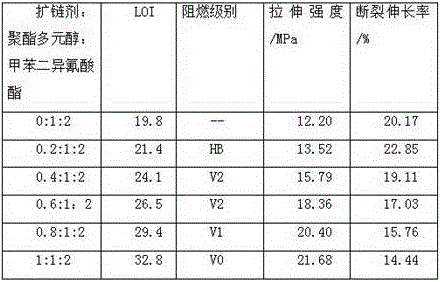

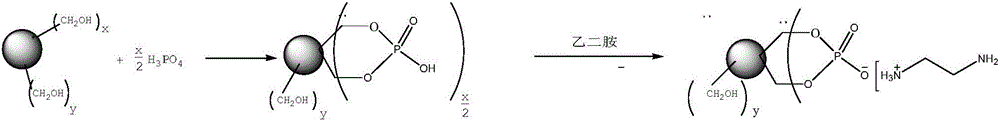

Preparation method and application of three-source integrated hyperbranched structure flame retardant

The invention discloses a preparation method of a three-source integrated hyperbranched structure flame retardant. The preparation method of the three-source integrated hyperbranched structure flame retardant comprises the following steps: 1, adding hydroxyl terminated hyperbranched polyester and phosphoric acid into a reactor, and further adding a catalyst, namely phosphotungstic acid or p-toluenesulfonic acid; 2, heating to the temperature of 80 DEG C, and reacting for 4 hours under a vacuum condition; 3, washing with ethanol, and dissolving in acetone after drying; 4, adding ethylenediamine of which the molar ratio is equal to that of phosphoric acid to be reacted for 30 minutes, obtaining a precipitate, washing with ethanol for 3 times, and drying to obtain light yellow powder. The flame retardant obtained by adopting the method is mixed with acrylic acid, PP and the like, so that polyurethane flame-retardant PP with low viscosity and high mechanical properties can be obtained. The invention further discloses application of the three-source integrated hyperbranched structure flame retardant used as a polymer material.

Owner:东莞市震亚精密技术有限公司

Halogen-free flame retardant cable material

InactiveCN104341666AImprove performanceExtended service lifeRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneDihydrocapsaicin

The invention discloses a halogen-free flame retardant cable material which is prepared from the following raw materials in parts by weight: 60-80 parts of LDPE (Low-Density Polyethylene) resin, 15-25 parts of EPDM (Ethylene-Propylene-Diene Monomer) resin, 5-15 parts of EVA (Ethylene Vinyl-Acetate Copolymer) resin, 70-90 parts of aluminium hydroxide, 6-8 parts of red phosphorus, 25-30 parts of magnesium hydroxide, 2-3 parts of hydrotalcite, 5-10 parts of maleic anhydride grafting, 1-2 parts of antioxidant and 1-1.5 parts of silicon-copper powder. The invention aims at overcoming the defects in the prior art; the magnesium hydroxide as a flame retardant is added in the cable material, so the flame-retardant effect is achieved; by adding abamectin, asarinin and dihydrocapsaicin, the condition that the cable is bitten by termite can be effectively prevented; the silicon-copper powder as a lubricating agent, the maleic anhydride grafting as a compatilizer, the antioxidant and the other components are also added, so that various properties of the flame-retardant material are improved, and the service life of the flame-retardant material is prolonged.

Owner:ANHUI TIANYUAN CABLE

Low smoke antiflaming high shield cable sheath material

ActiveCN103897292AAvoid generatingAvoid catalytic decompositionRubber insulatorsPlastic/resin/waxes insulatorsShielded cableAntioxidant

The invention discloses a low smoke antiflaming high shield cable sheath material. The low smoke antiflaming high shield cable sheath material is prepared from the following raw materials in parts by weight: 45-60 parts of poly vinyl chloride resin base material, 40-50 parts of ethylene-vinyl acetate rubber, 1.5-2.3 parts of multifunctional rare earth thermal stabilizer, 1.5-1.8 parts of zinc borate, 21-24 parts of main plasticizer, 4-6 parts of secondary plasticizer dioctyl sebacate, 2-4 parts of secondary stabilizer calcium stearate, 0.6-0.9 part of antioxidant, 11-13 parts of filing modification material, 0.3-0.5 part of lubricating agent stearic acid, 0.7-1.2 part of conductive carbon black, 3-6 parts of graphite powder and 30-45 parts of magnesium hydroxide. The low smoke antiflaming high shield cable sheath material has excellent antiflaming effect and excellent conductive and shielding properties and can release less smoke and harmful gas when being burned.

Owner:江苏鑫海腾线缆有限公司

Thermal-resistant and flame-retardant membrane and preparation method thereof, and applications

ActiveCN110233224APrevent internal short circuitAvoid burning and explosionCell component detailsSecondary cells servicing/maintenancePhysical chemistryThermal stability

The present invention discloses a thermal-resistant and flame-retardant membrane and a preparation method thereof, and applications. According to the preparation method, the cost is controllable, theoperation of the preparation process is simple, and thus the preparation method is suitable for mass production. The prepared thermal-resistant and flame-retardant membrane has a double-layer composite structure with both thermal stability and flame retardancy, the membrane can prevent internal short circuit of a battery at a lower temperature, so that severe thermal runaway of the battery is prevented, and thus safety accidents, such as burning and explosion are prevented; the membrane can effectively prevent the battery from burning and exploding after the thermal runaway of the battery occurs under the conditions of overcharge, puncture and abuse; and the membrane has good applications in the chemical power supply system, especially in lithium ion batteries.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com