Flame-retardant antistatic yarn and fabric thereof

A flame retardant and antistatic yarn technology, which is applied in the manufacture of conductive/antistatic filaments, yarns, textiles, etc., can solve the problems of poor dyeability of ordinary polyester fabrics and poor flame retardancy of polyester fabrics that cannot meet the needs of consumers. and other problems, to achieve the effect of improving static electricity, good flame retardant and antistatic effect, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

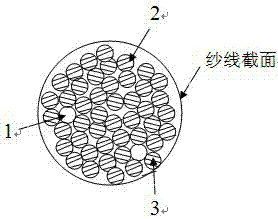

[0043] A 40S flame-retardant and antistatic yarn is obtained by specific spinning technology from 65% cationic polyester flame-retardant fiber [2], 4% graphene-polyester composite fiber [1], and 31% Yacel fiber [3]. , The polyester flame-retardant fiber [2] has a phosphorus content of 7000ppm, a limiting oxygen index of 38, a fineness of 1.4D, and a length of 38mm. The graphene-polyester composite fiber [1] has a fineness of 1.5D and a length of 33mm.

[0044] Graphene-polyester composite fiber [1] is obtained from graphene-polyester spinning composite liquid by wet spinning, and the graphene involved is modified graphene.

[0045] Modified graphene is graphene maleic acid monoester, and its preparation method: adopt hydrogen peroxide to oxidize graphene to obtain graphene with edge hydroxyl, then allow graphene with edge hydroxyl to react with maleic anhydride, and use trifluoromethanesulfonate Rare earth acid salt is used as a catalyst to activate the edge hydroxyl group of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com