Patents

Literature

538results about "Fibre mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-woven sheet, manufacturing method thereof and absorbent article

InactiveUS20130158497A1Increase volumeReduce the amount requiredLayered productsFibre mixingNonwoven fabricBiomedical engineering

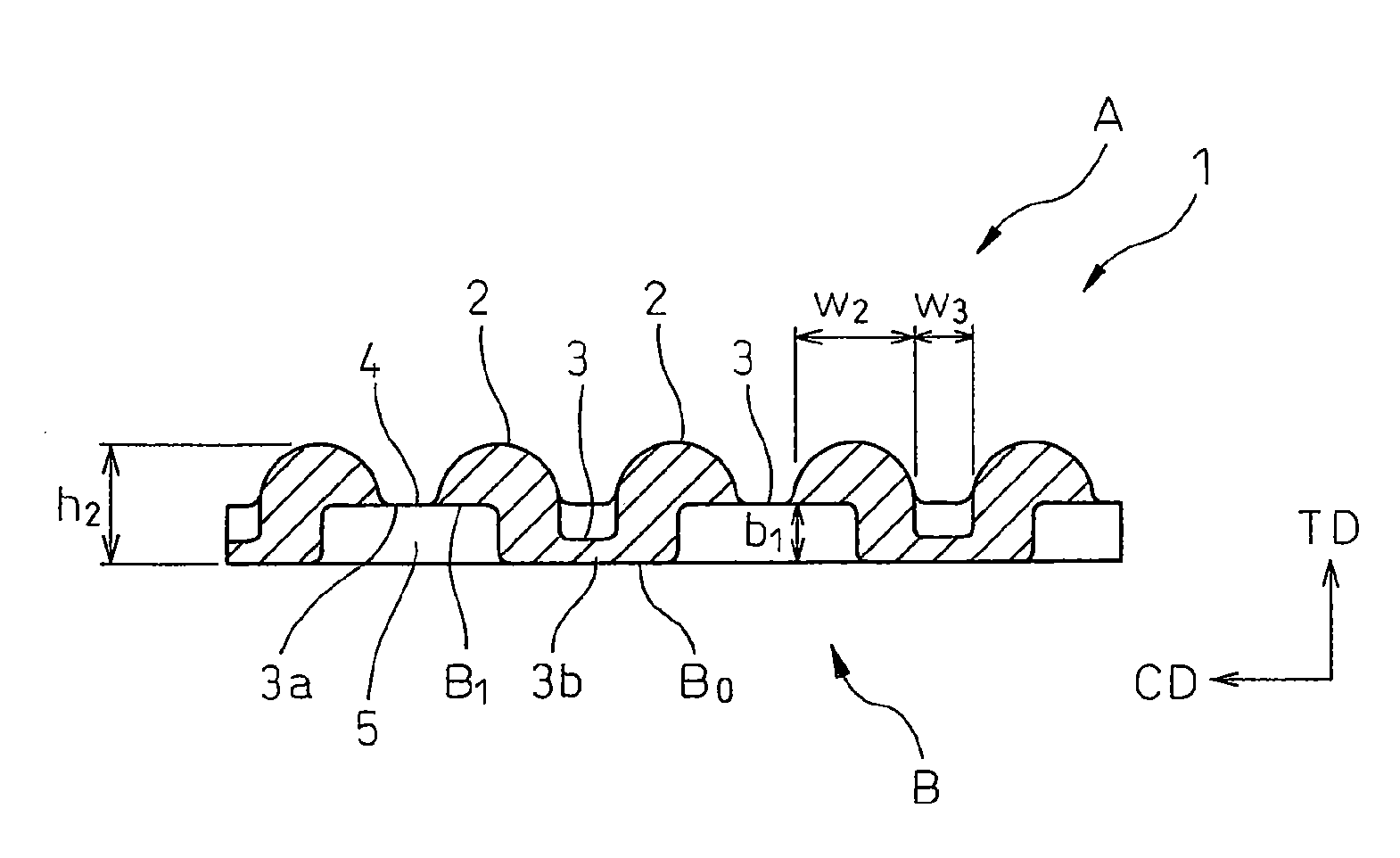

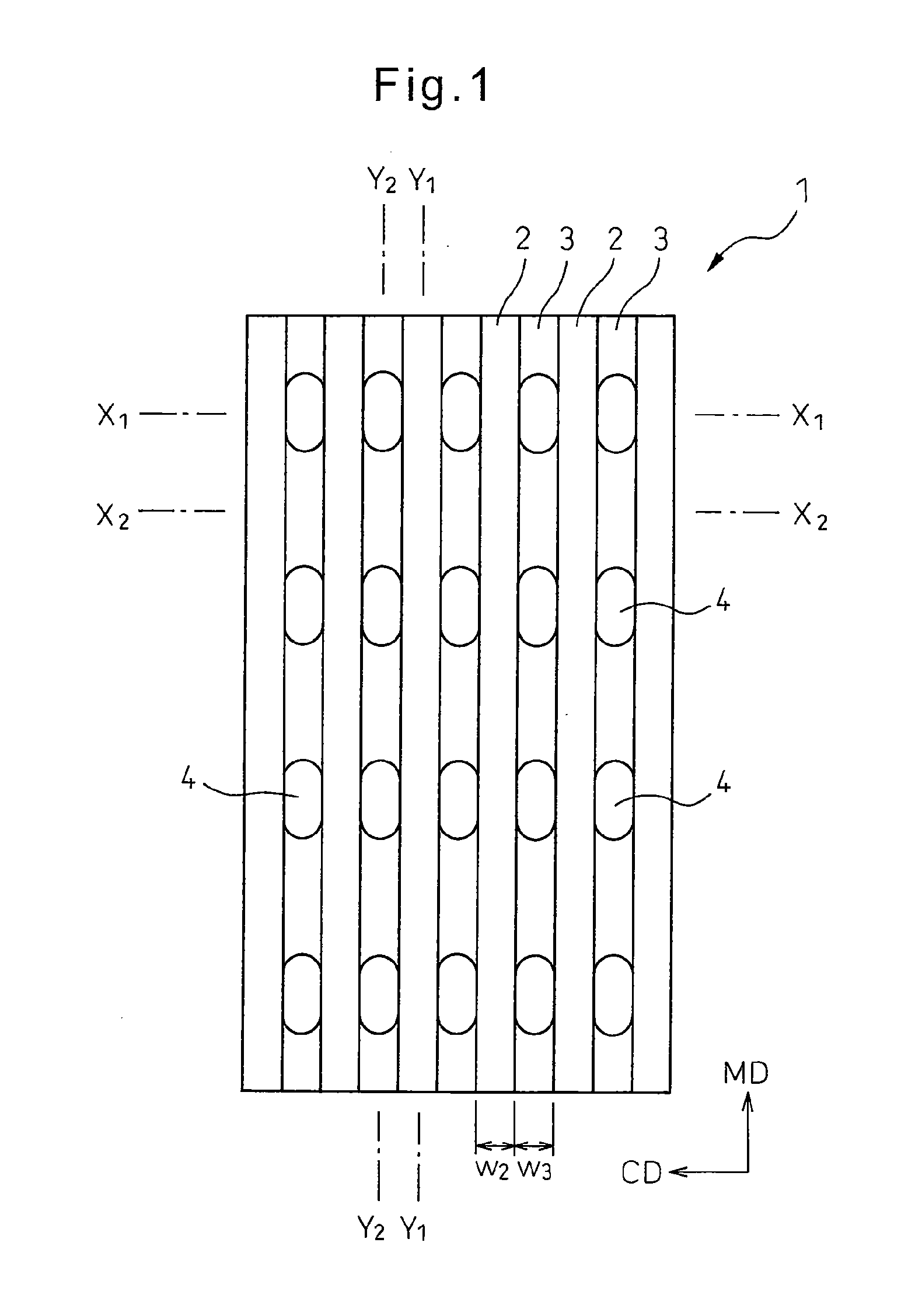

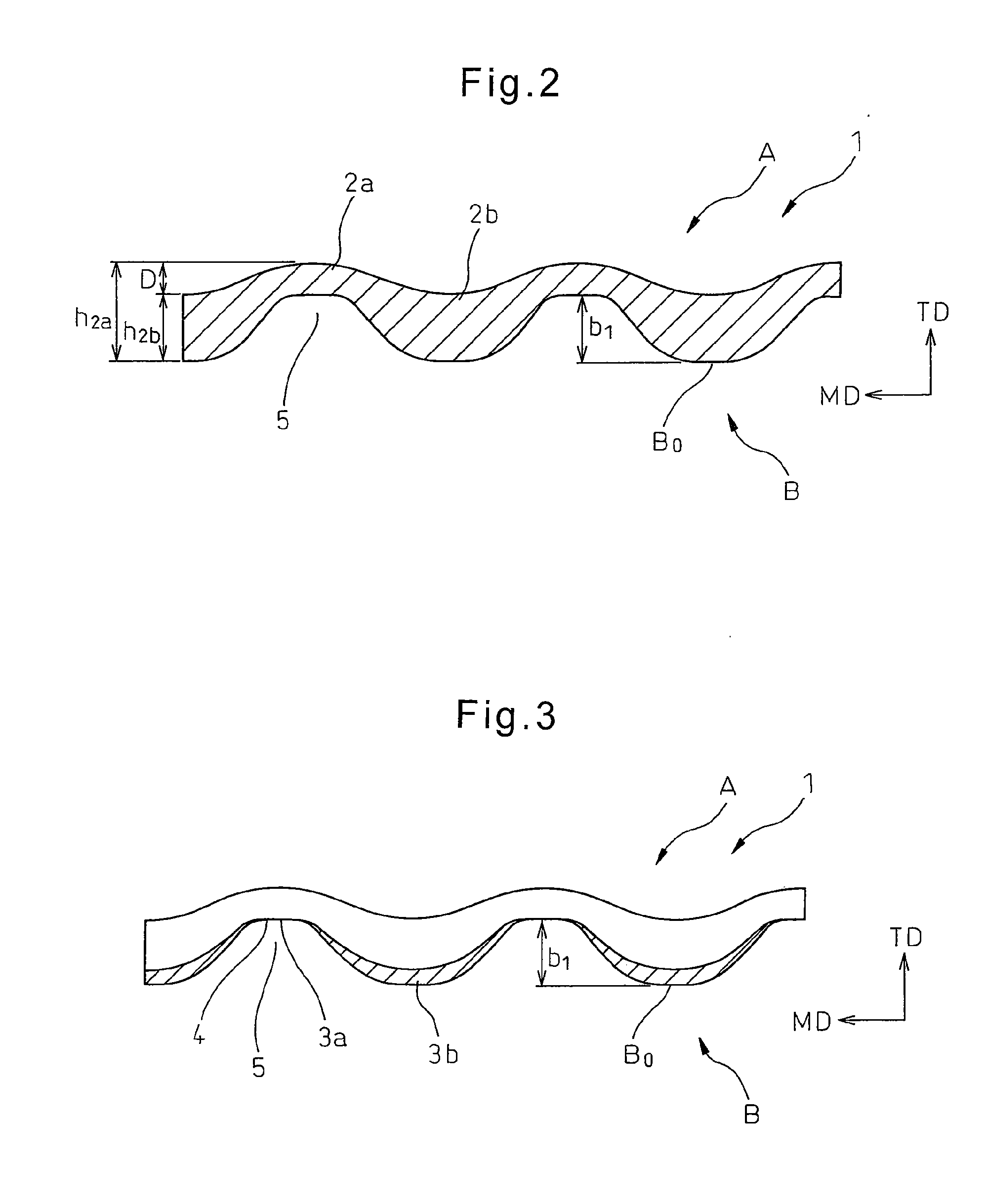

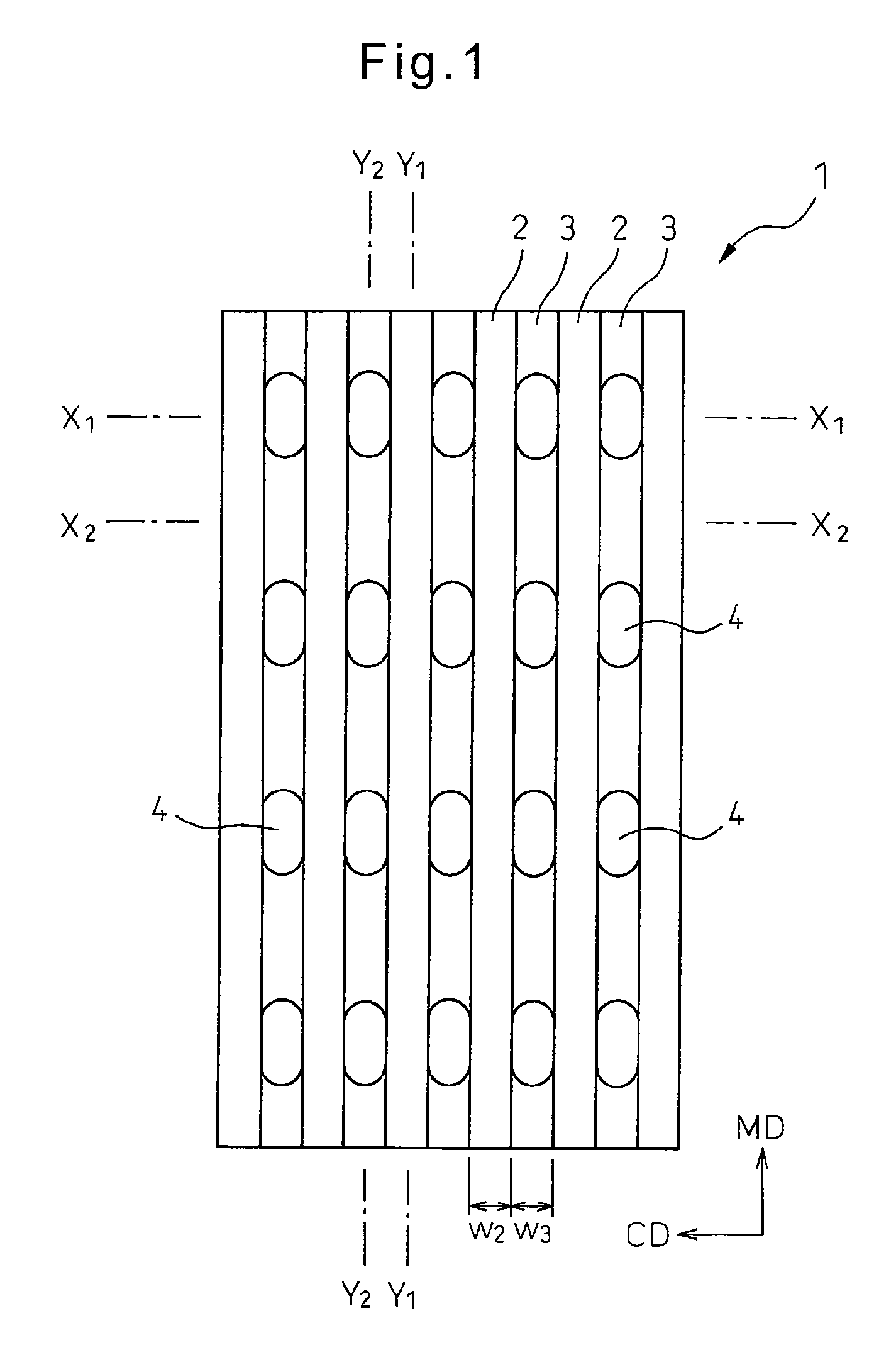

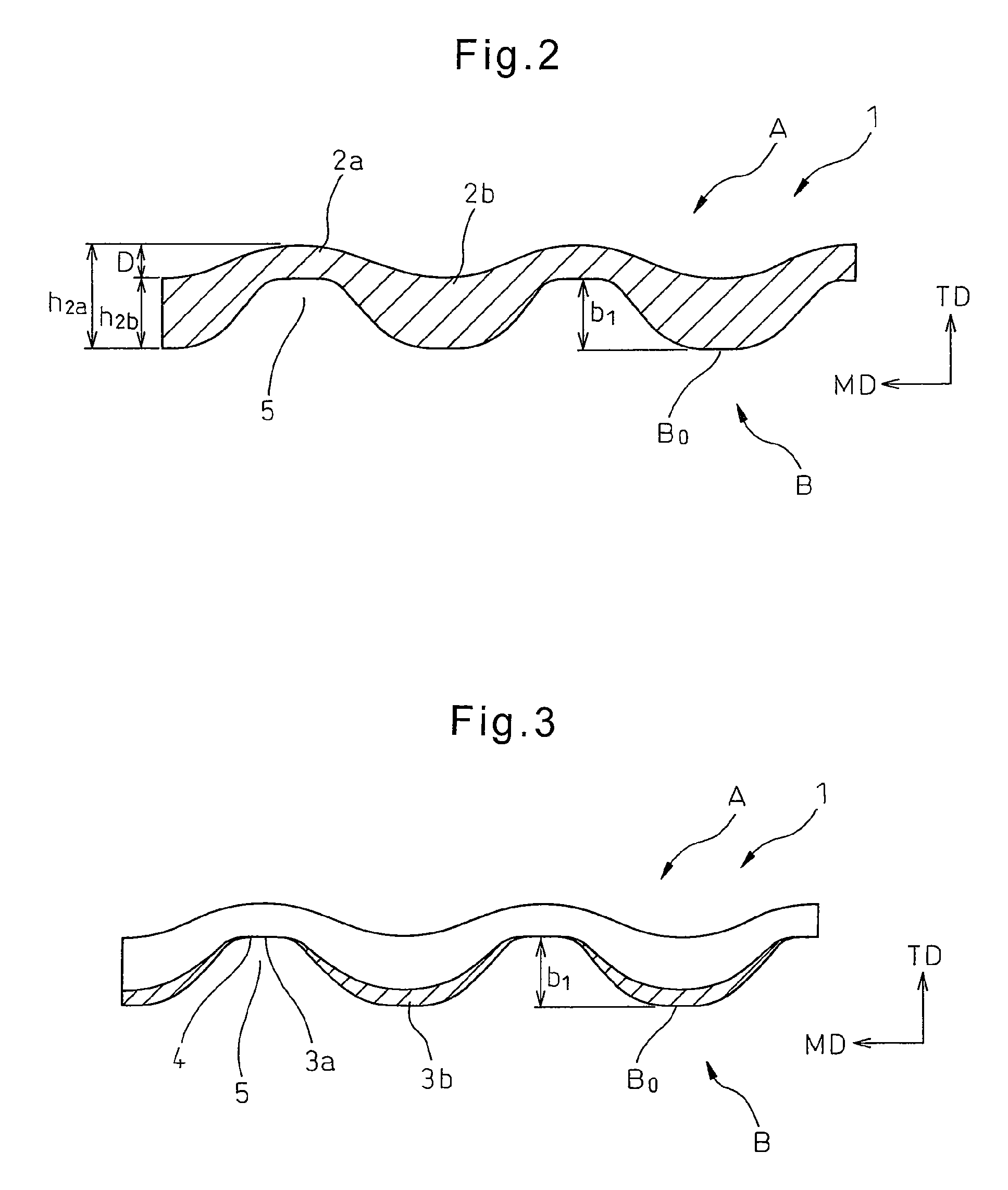

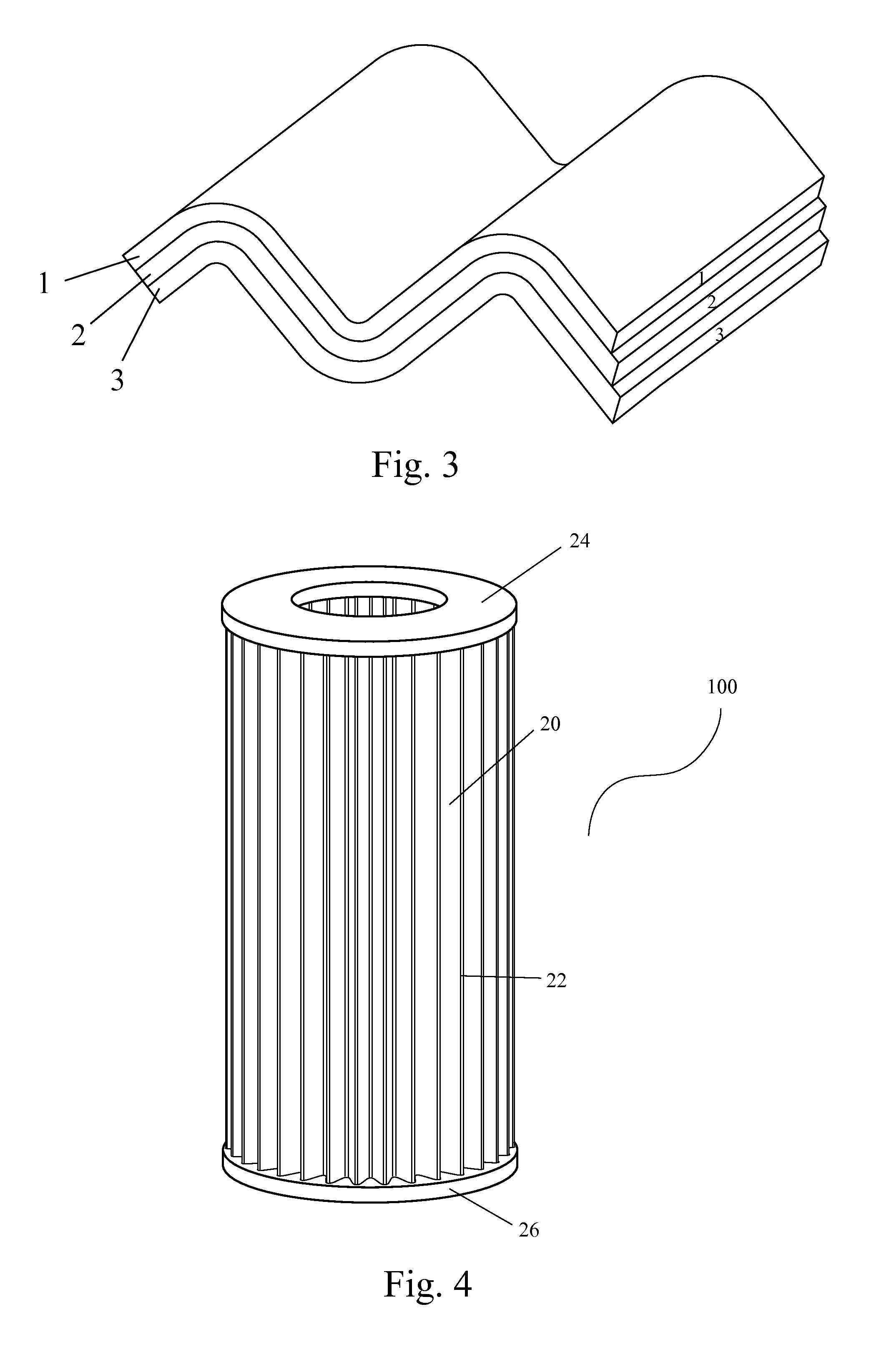

A nonwoven sheet for use in absorbent articles such as disposable diapers which is capable of reducing the range of surface diffusion of, and reducing re-adhesion to the skin of, highly viscous fluid excretion. The nonwoven sheet has mutually perpendicular longitudinal, transverse and thickness directions, and has in the aforementioned thickness direction a front surface and a back surface opposite thereof. Ridges and grooves are formed alternately so as to extend in parallel in the aforementioned longitudinal direction and so as to form repeated undulations in the aforementioned transverse direction. The nonwoven sheet has a bottom surface which, when the aforementioned nonwoven sheet is placed on a horizontal surface with the back surface (opposite of the front surface in contact with the skin of the wearer) down, is the surface that contacts the aforementioned horizontal surface. On the back surface of the aforementioned grooves are formed in the aforementioned longitudinal direction alternately areas where the height from the bottom surface is relatively high and parts corresponding to the bottom surface. Openings are formed at least in the areas where the height from the bottom surface is relatively high, and a space is provided below said openings.

Owner:UNI CHARM CORP

Non-woven fiber assemblies

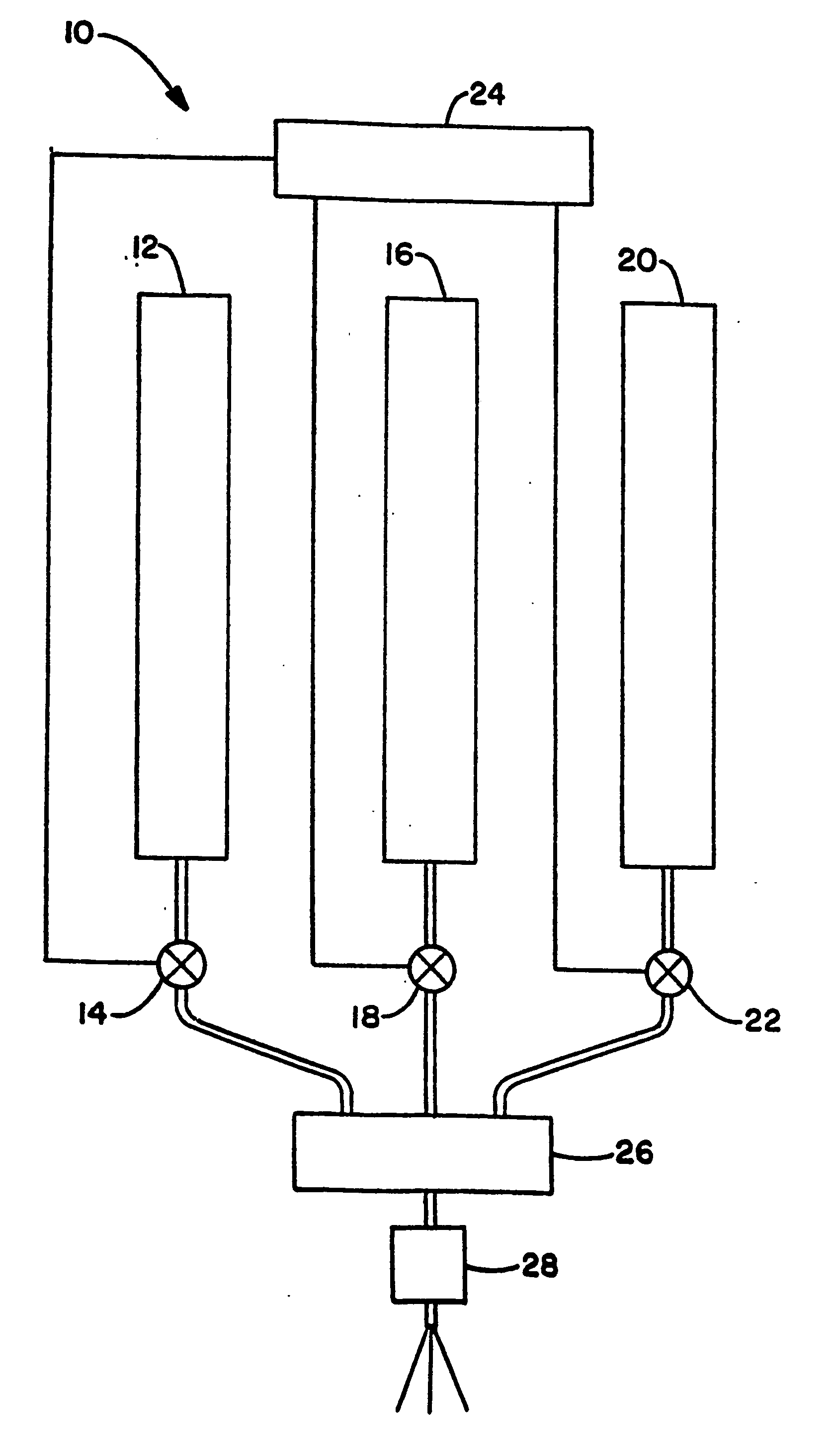

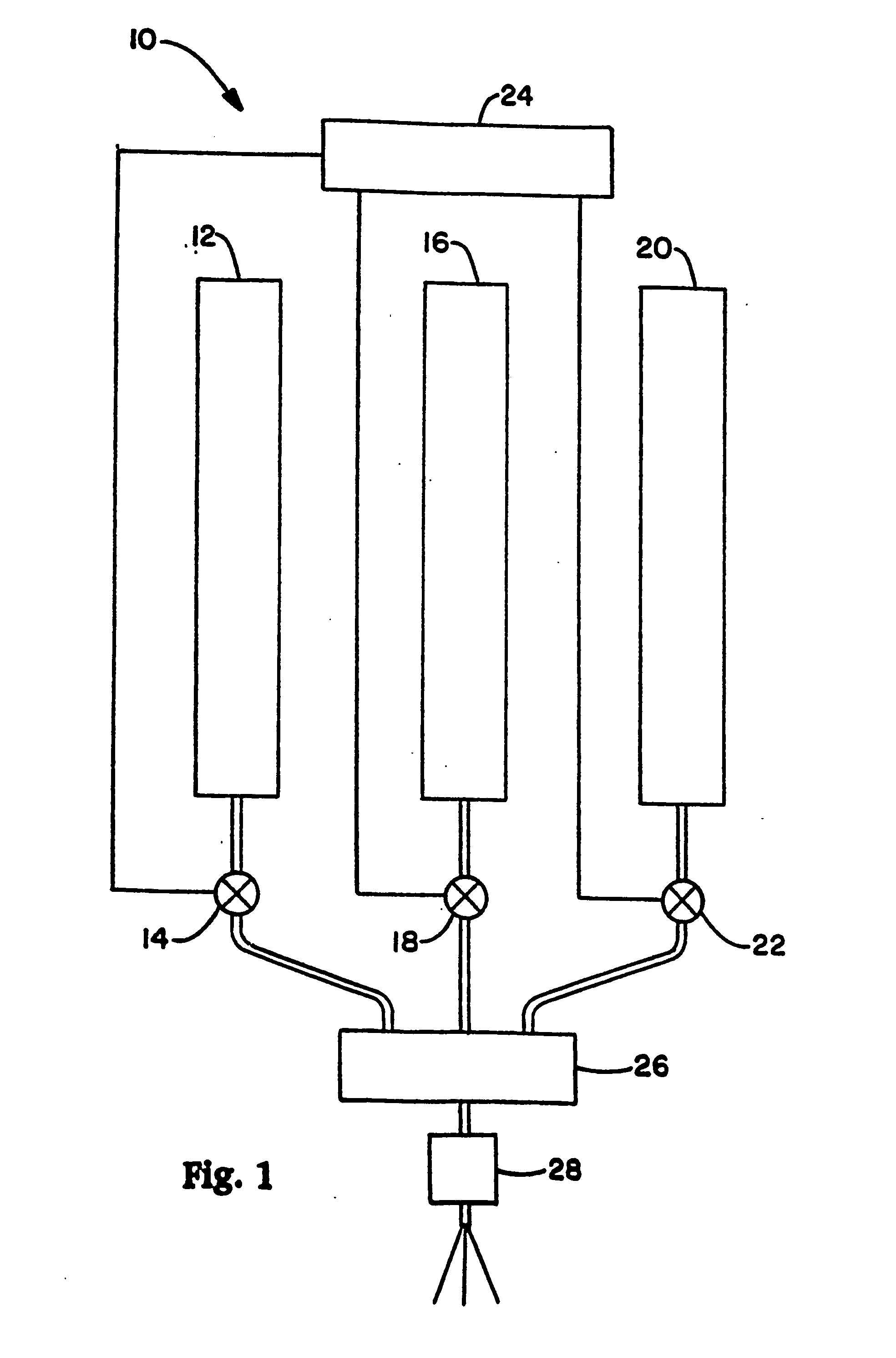

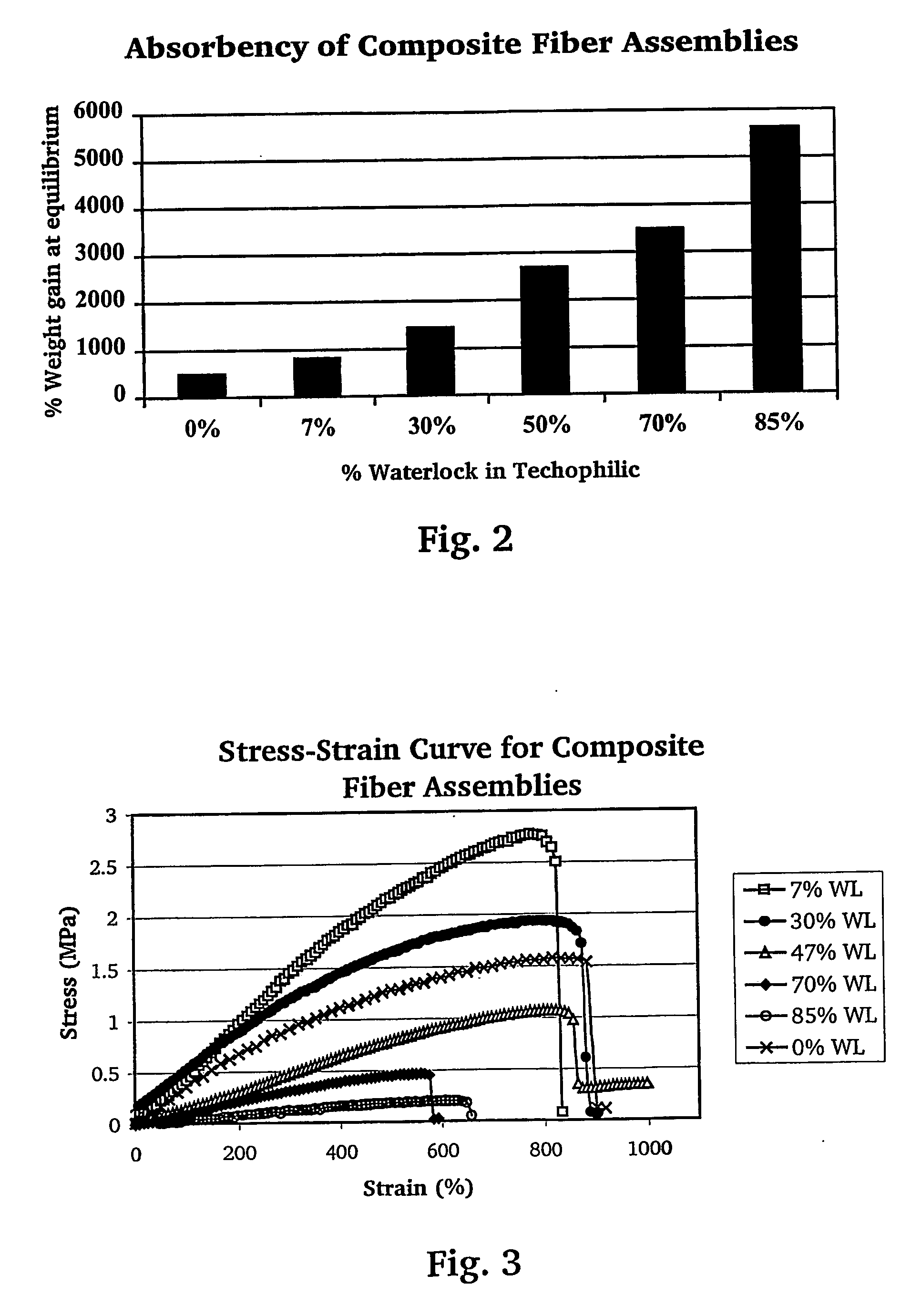

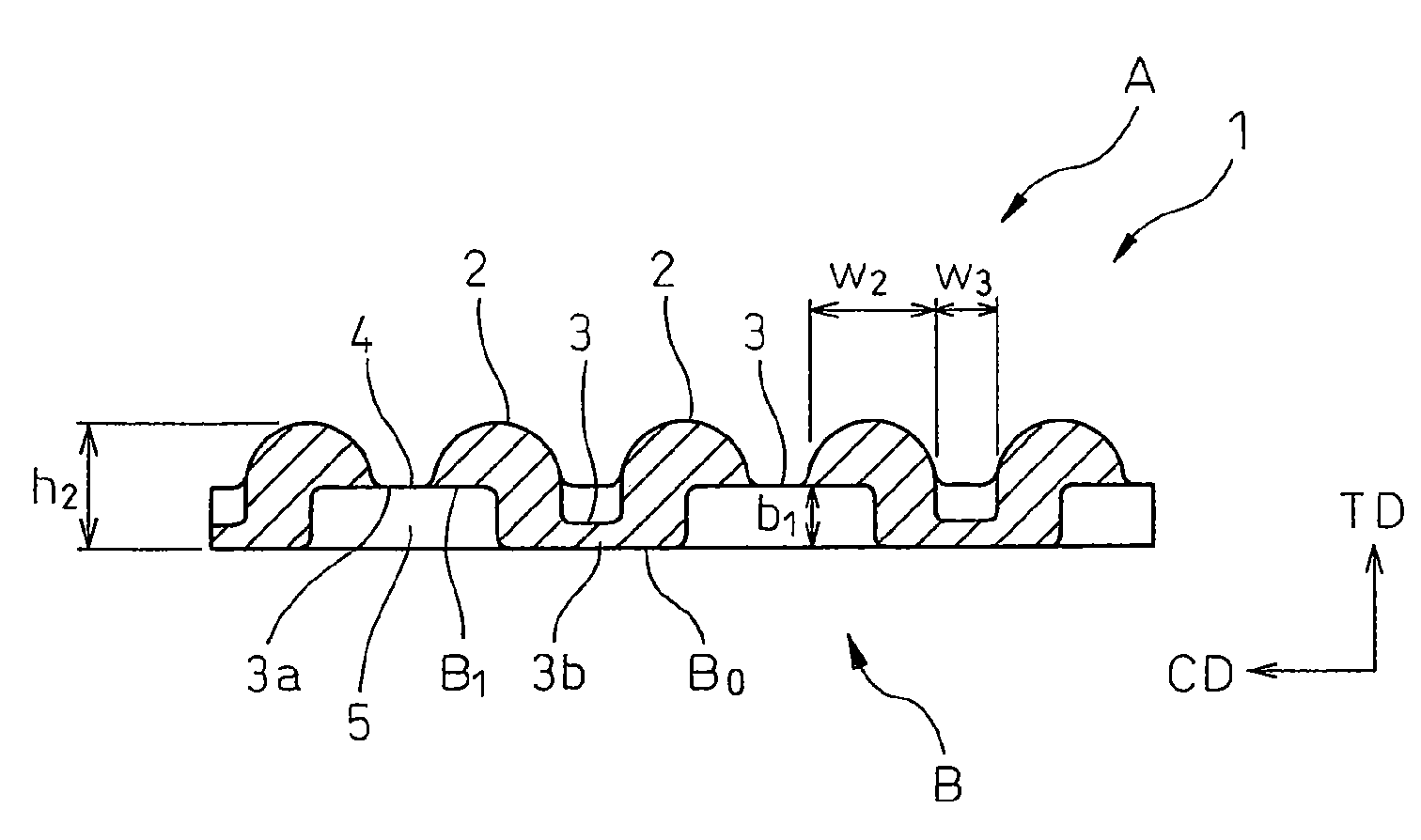

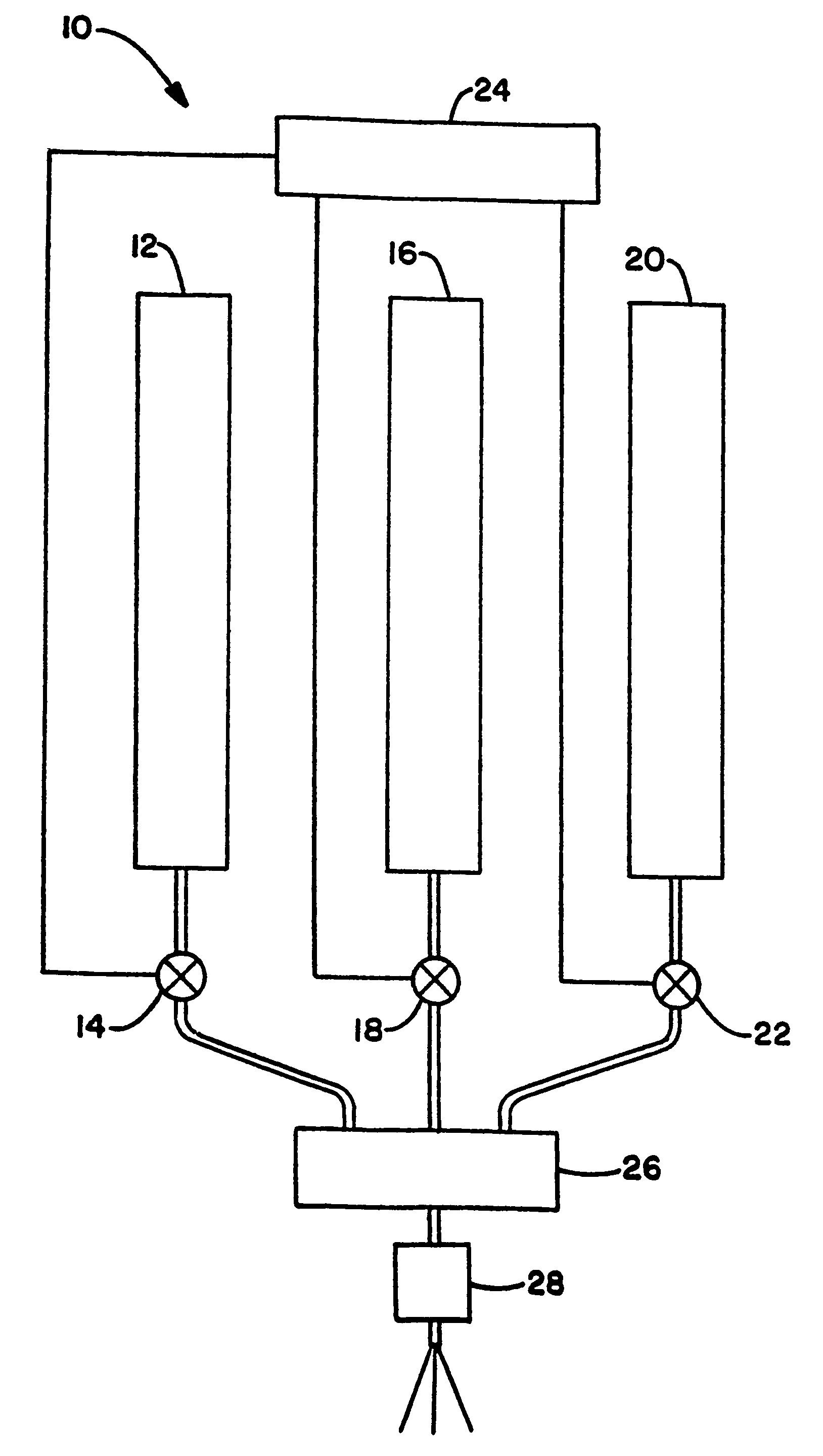

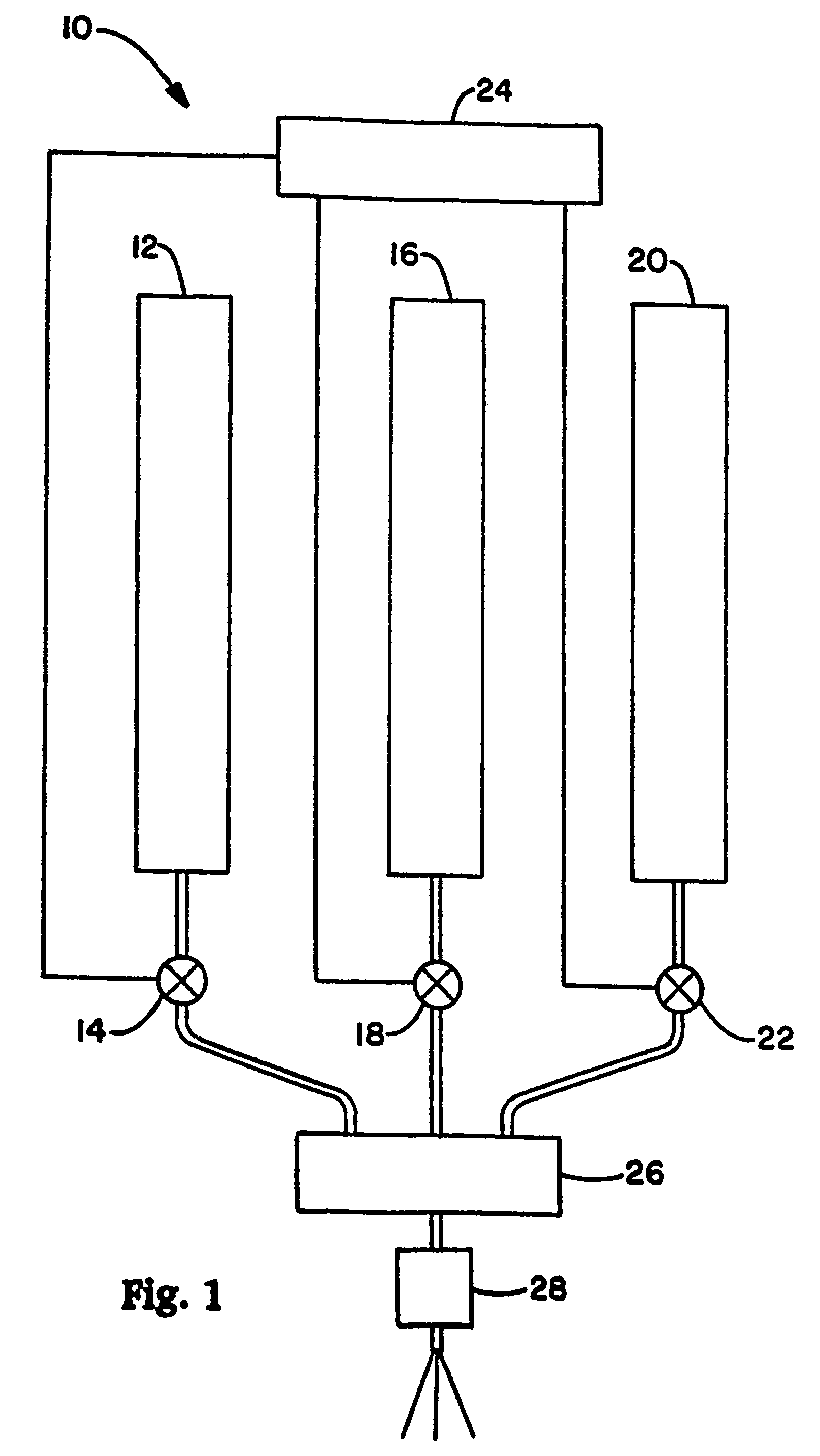

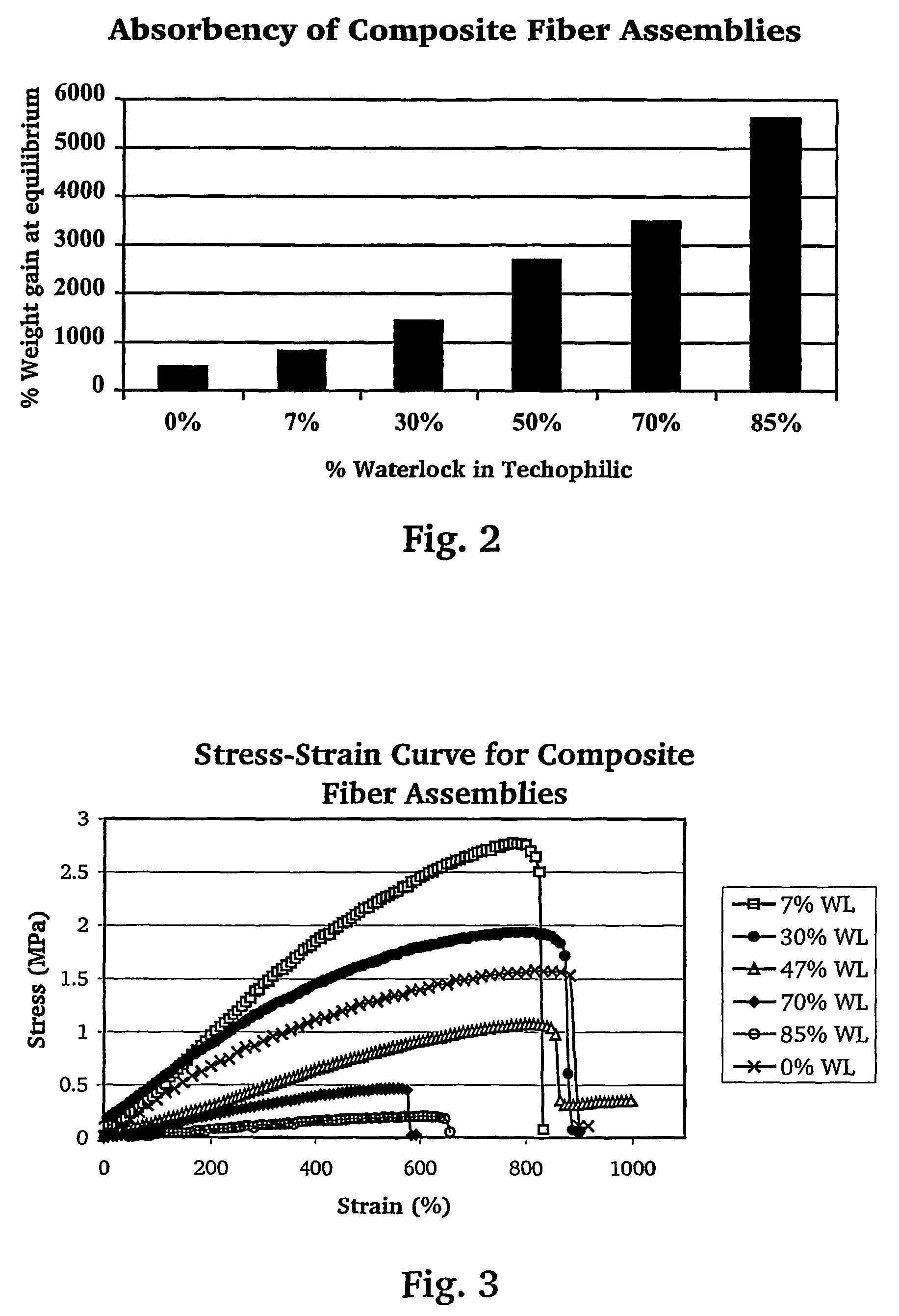

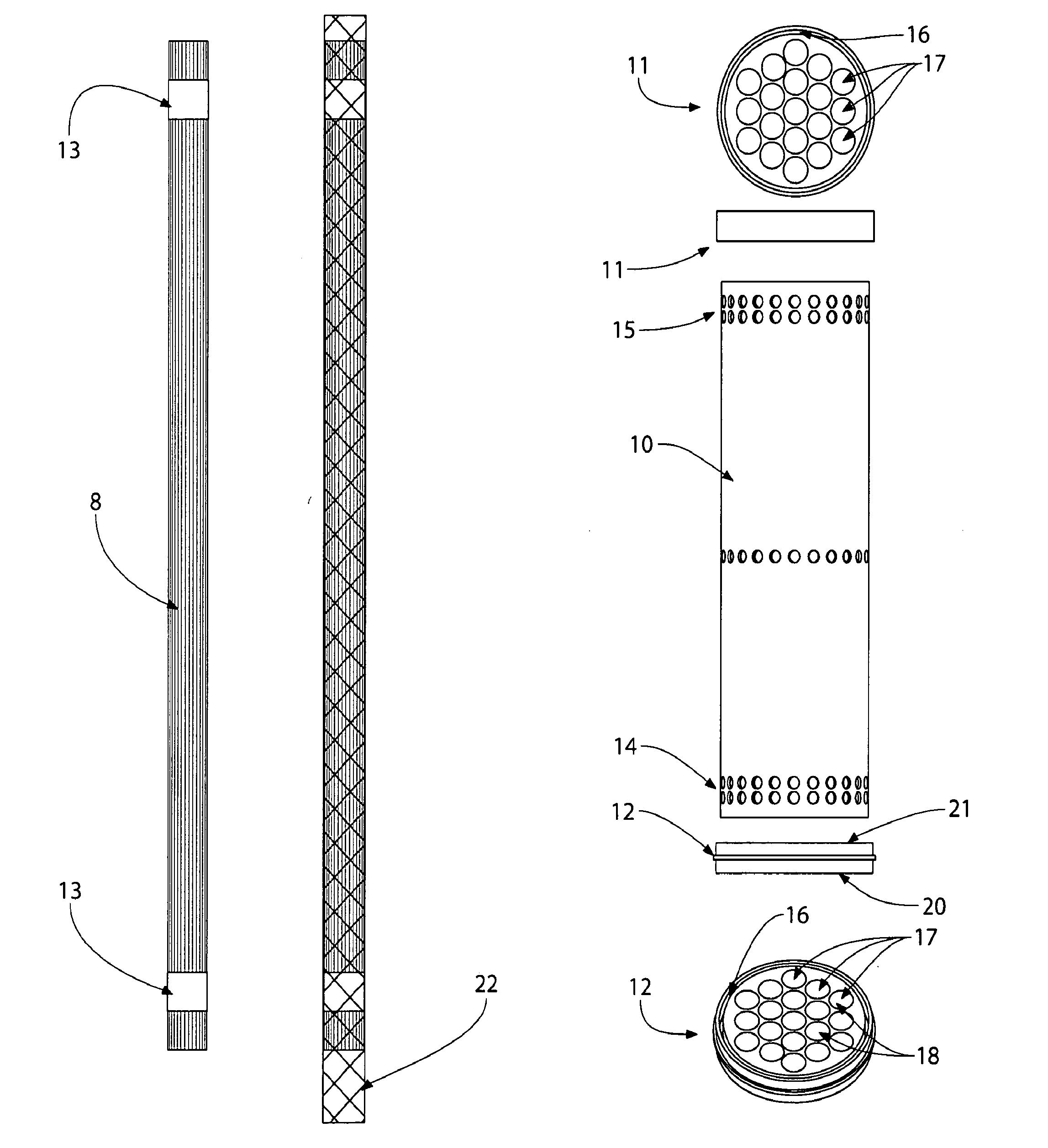

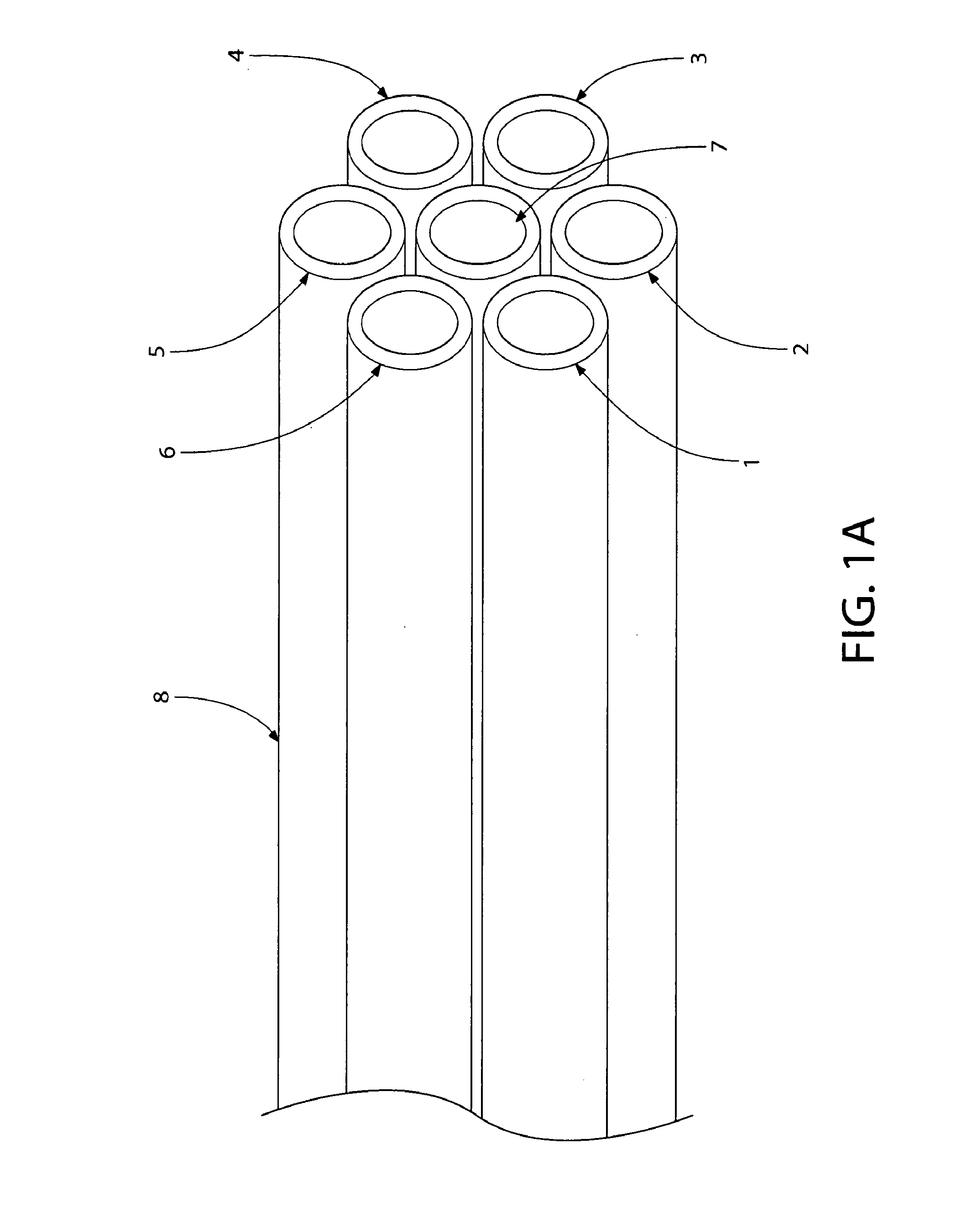

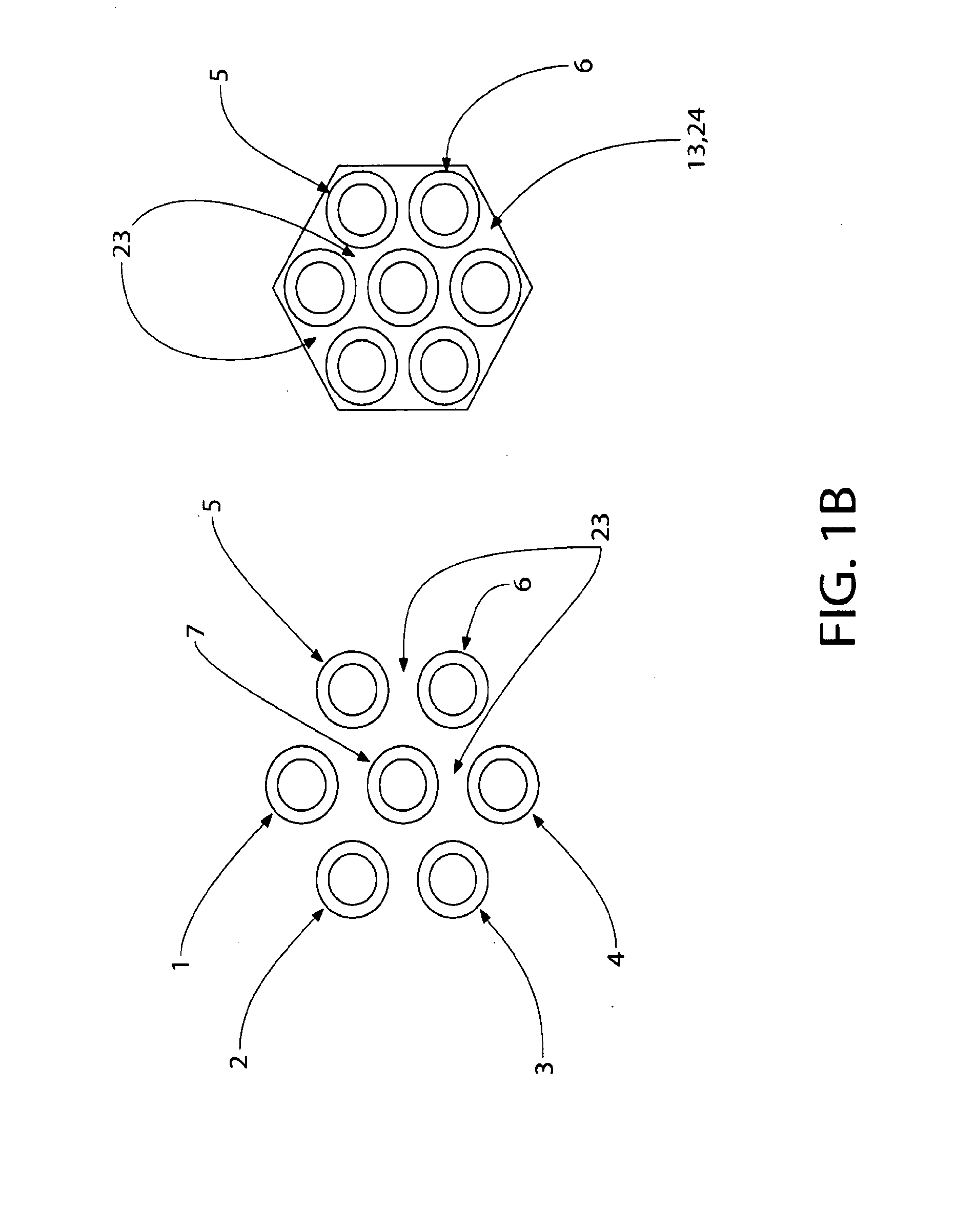

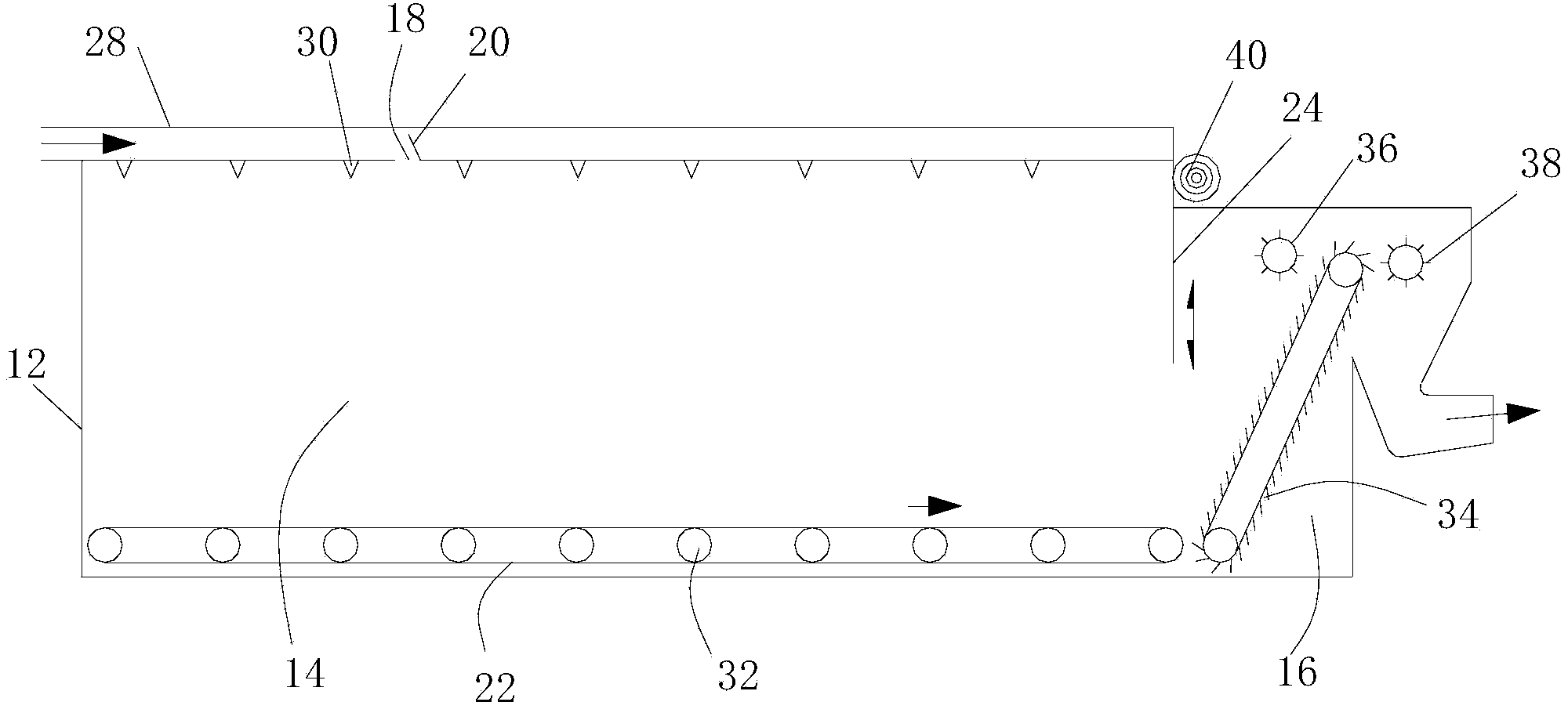

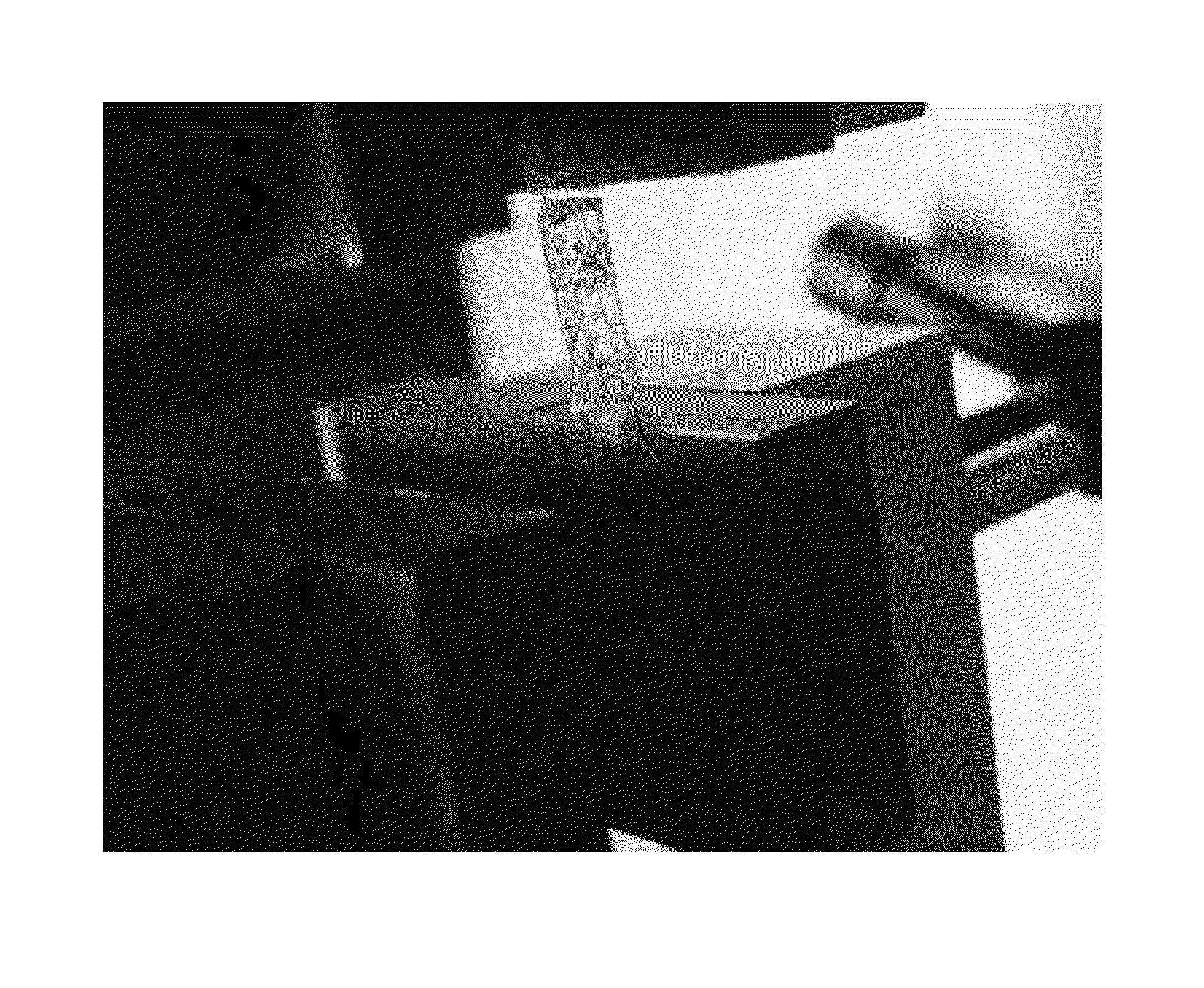

A non-woven fiber assembly comprises one or more fibers containing an adhesive component, an elastomeric component, and a hydrophilic component. A method of making a non-woven fiber assembly comprises the steps of providing one or more fiber-forming materials comprising an adhesive component, an elastomeric component, and a hydrophilic component, and forming said one or more fiber-forming materials into at least one fiber. A method of treating a patient comprises applying a medical dressing comprising the fiber assembly of the present invention to a patient. An apparatus (10) for forming a non-woven fiber assembly comprises a plurality of reservoirs (12, 16, 20) for containing more than one type of fiber-forming material, a plurality of valves (14, 18, 22), each independently in communication with a reservoir, and a fiber-forming device (28) selected from the group consisting of a spinnerette, a NGJ nozzle, and an electrospinning device, in communication with the valves.

Owner:THE UNIVERSITY OF AKRON

Non-woven sheet, manufacturing method thereof and absorbent article

InactiveUS9095477B2Increase volumeReduce the amount requiredLayered productsFibre mixingEngineeringBiomedical engineering

A nonwoven sheet for use in absorbent articles such as disposable diapers which is capable of reducing the range of surface diffusion of, and reducing re-adhesion to the skin of, highly viscous fluid excretion. The nonwoven sheet has mutually perpendicular longitudinal, transverse and thickness directions, and has in the aforementioned thickness direction a front surface and a back surface opposite thereof. Ridges and grooves are formed alternately so as to extend in parallel in the aforementioned longitudinal direction and so as to form repeated undulations in the aforementioned transverse direction. The nonwoven sheet has a bottom surface which, when the aforementioned nonwoven sheet is placed on a horizontal surface with the back surface (opposite of the front surface in contact with the skin of the wearer) down, is the surface that contacts the aforementioned horizontal surface. On the back surface of the aforementioned grooves are formed in the aforementioned longitudinal direction alternately areas where the height from the bottom surface is relatively high and parts corresponding to the bottom surface. Openings are formed at least in the areas where the height from the bottom surface is relatively high, and a space is provided below said openings.

Owner:UNI CHARM CORP

Non-woven fiber assemblies

In one embodiment, the present invention relates to a non-woven fiber assembly comprising one or more fibers wherein each fiber contains: a hydrophilic component; and an elastomeric component, and wherein the non-woven fiber assembly further comprises an adhesive component. In still another embodiment, the present invention relates to a non-woven fiber assembly comprising one or more fibers wherein each fiber contains: a hydrophilic component; an elastomeric component; and an adhesive component, wherein the hydrophilic component, the elastomeric component and the adhesive component are all contained within each fiber. Also disclosed is a method of making the afore-mentioned non-woven fiber assemblies. Additionally, a medical dressing made from the non-woven fiber assemblies of the present invention is disclosed.

Owner:THE UNIVERSITY OF AKRON

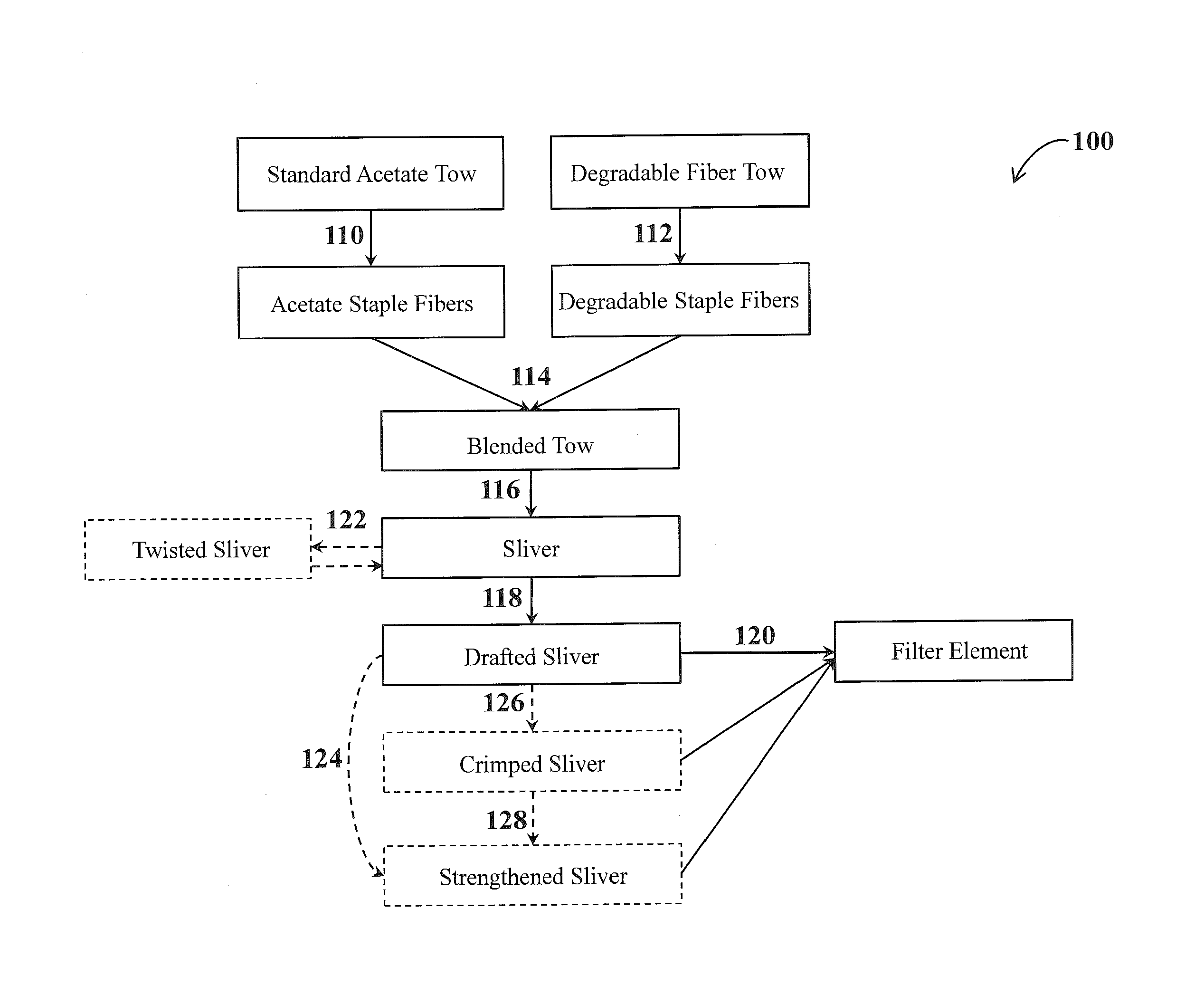

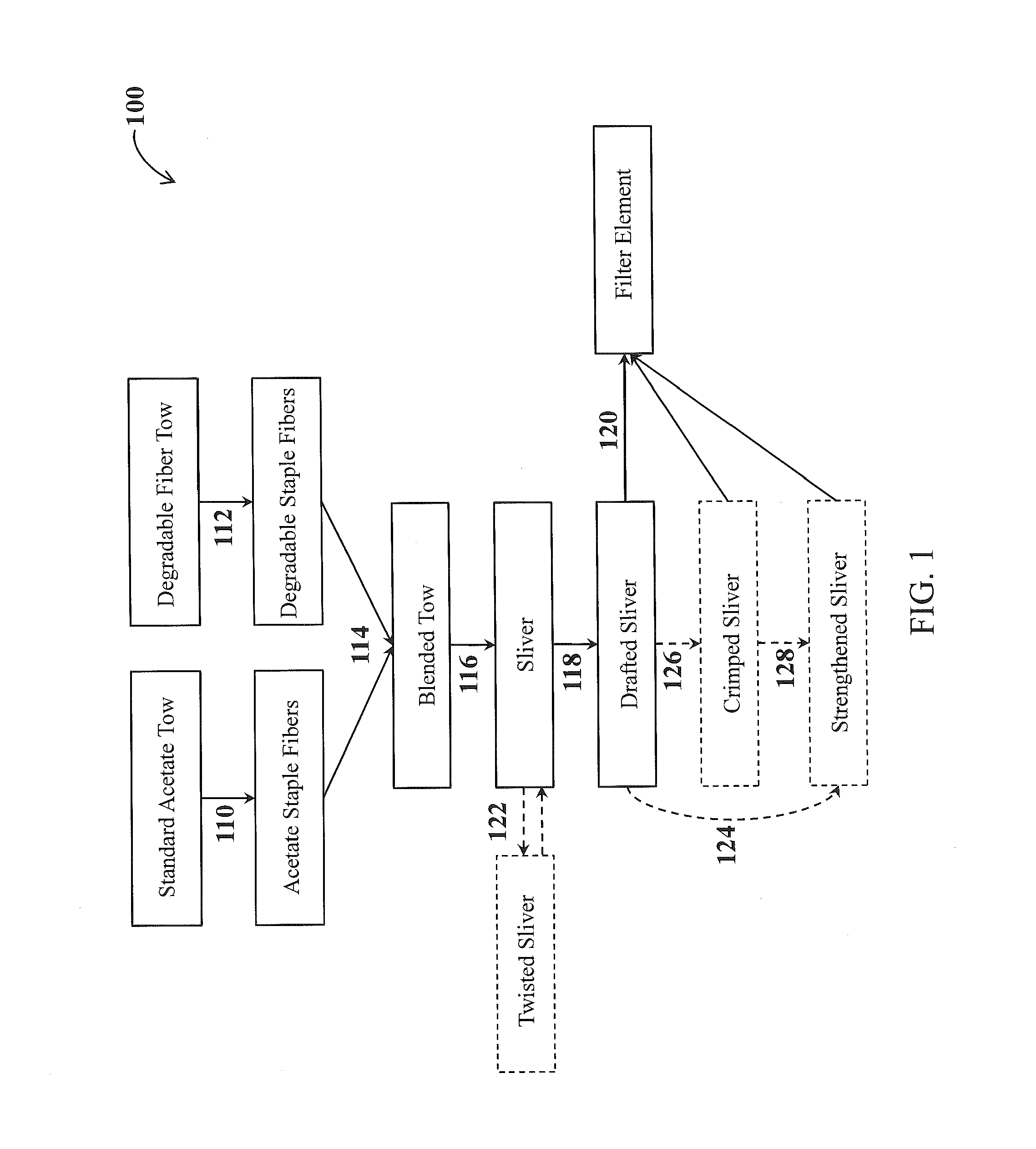

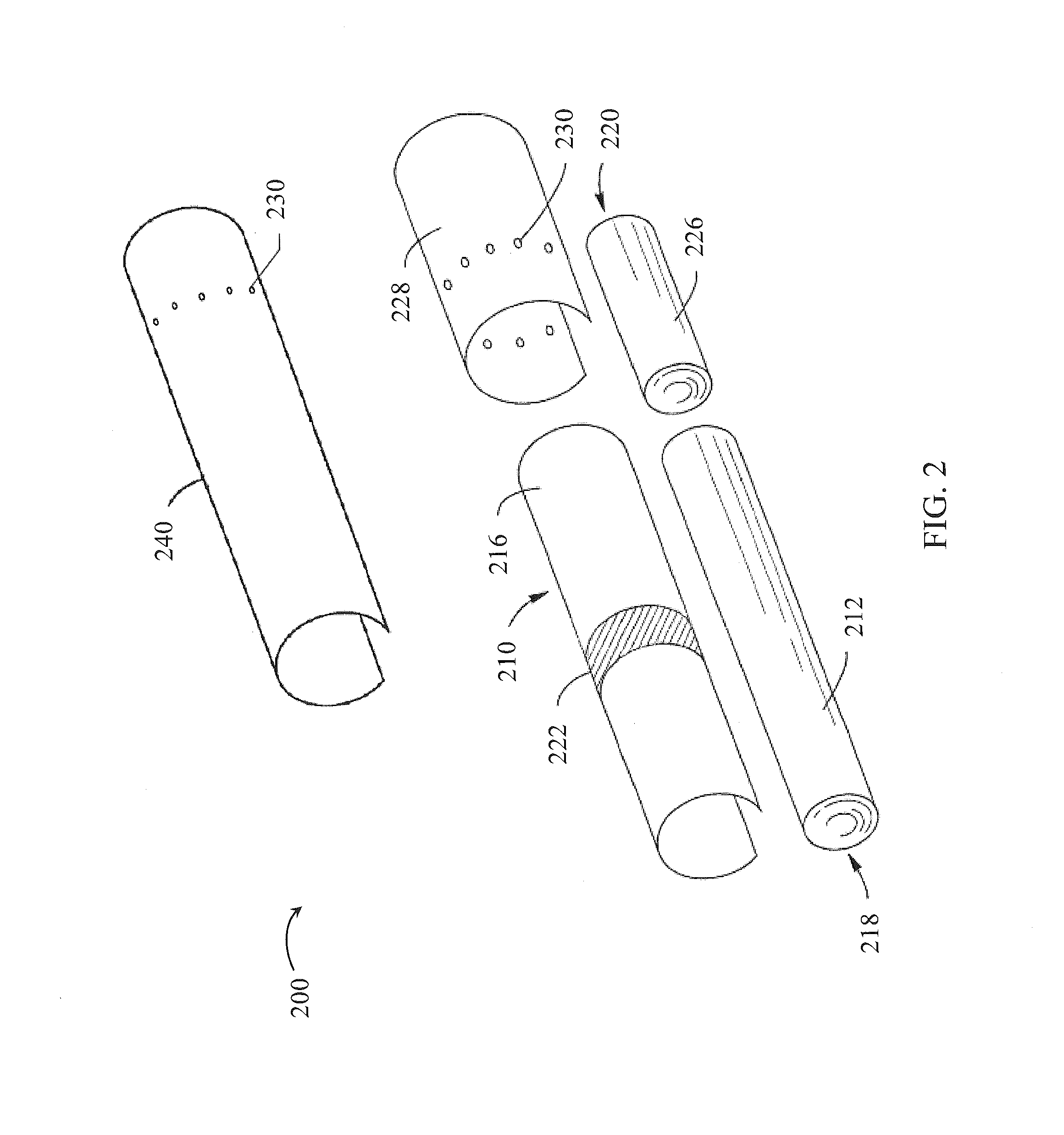

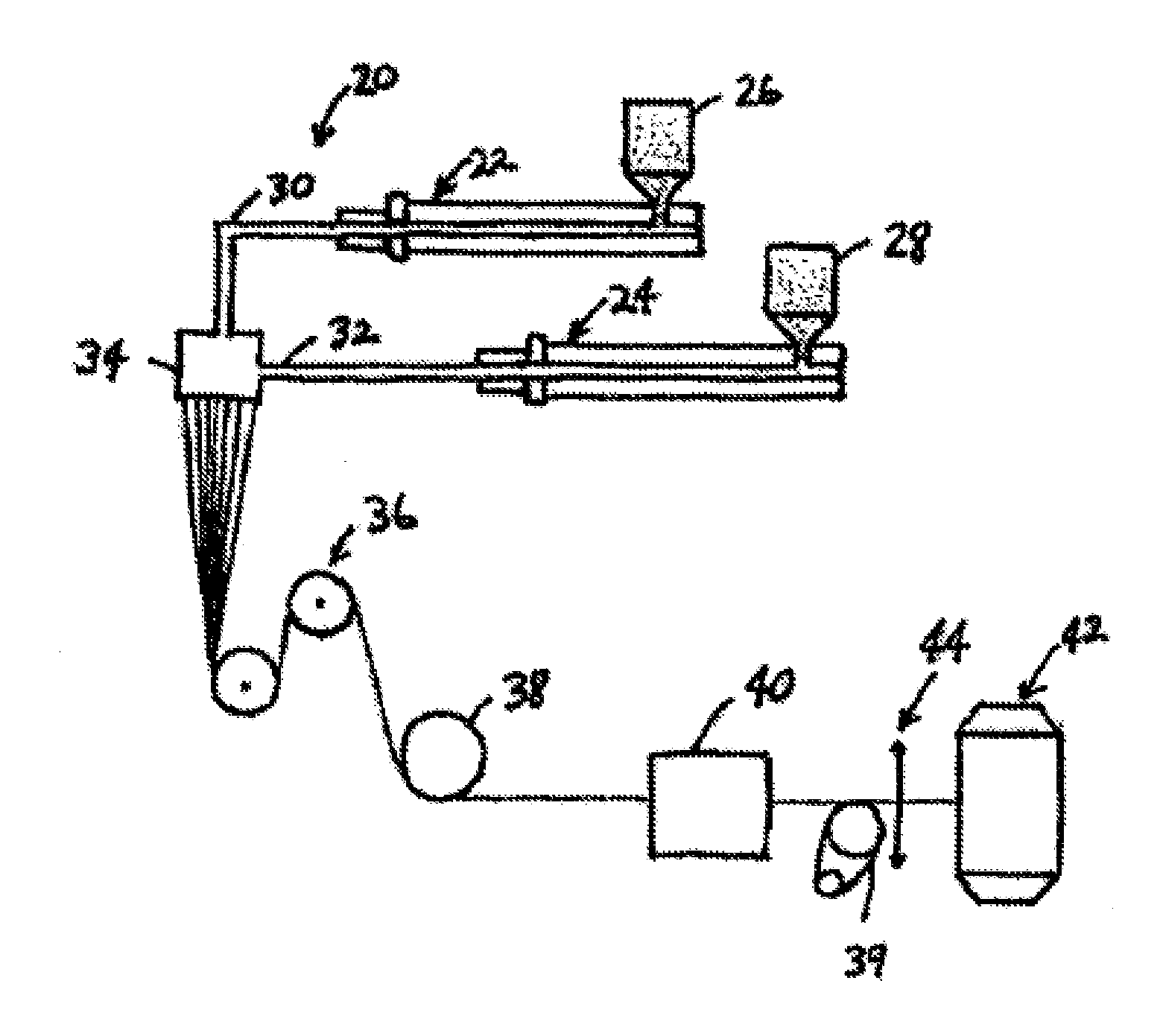

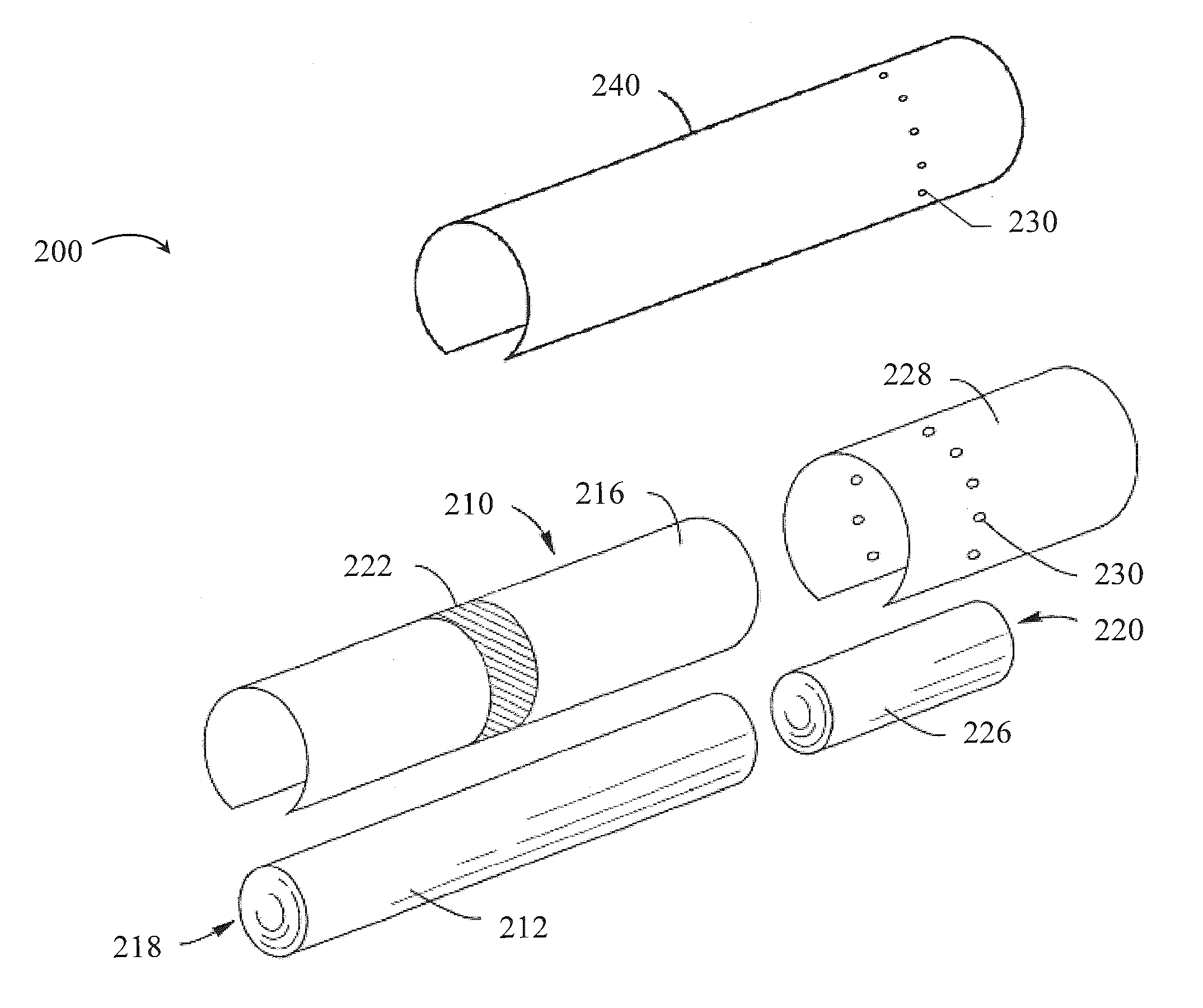

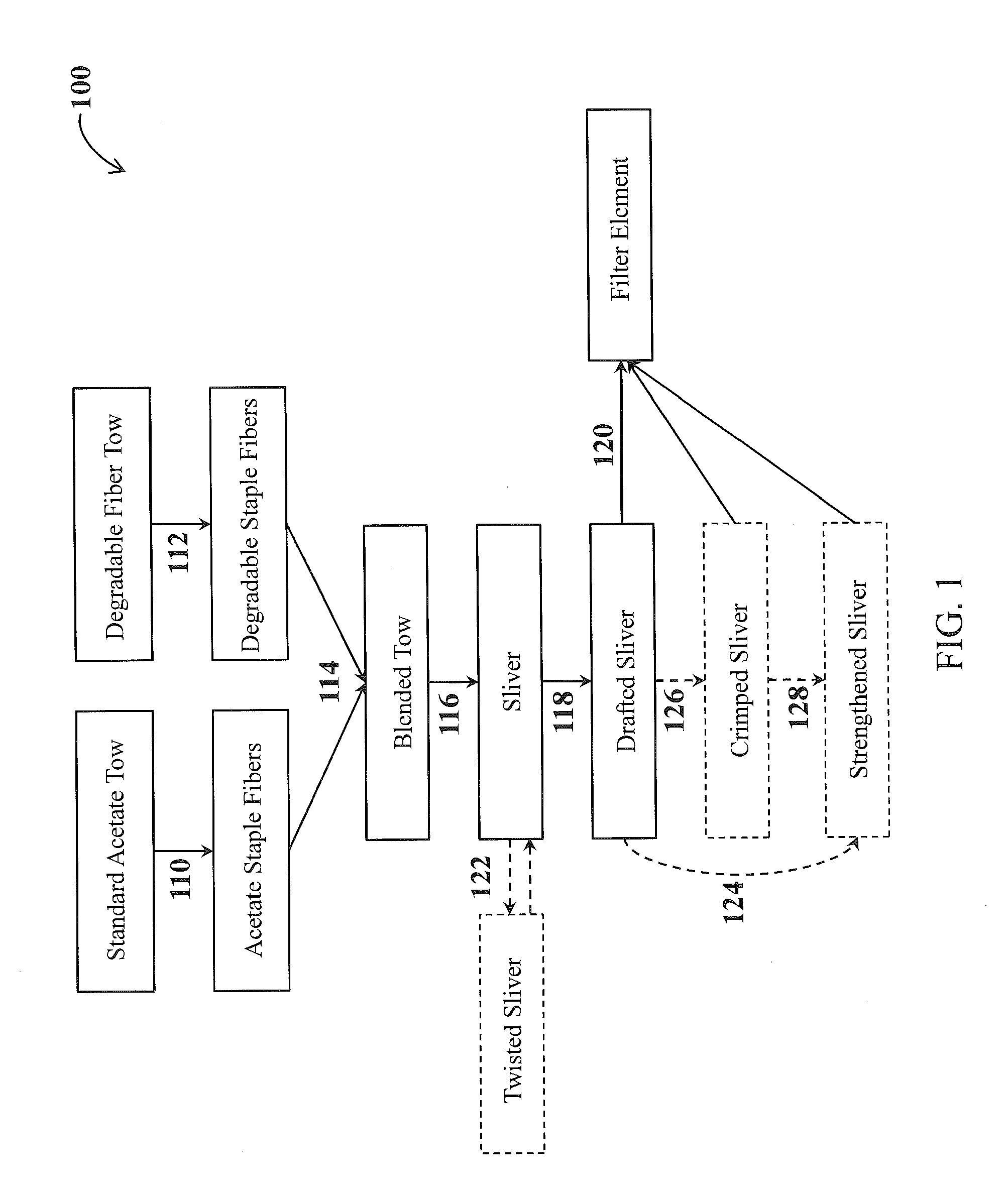

Mixed fiber sliver for use in the manufacture of cigarette filter elements

Smoking articles including filter elements formed from two or more fibrous inputs with different physical properties are provided. The two or more fibrous inputs are provided in the form of staple fibers, which are at least partially entangled with each other to form a mixed fiber sliver. The mixed fiber sliver includes a first plurality of cellulose acetate staple fibers blended with a second plurality of staple fibers comprising a polymeric material different from the first plurality of staple fibers, such as staple fibers of a degradable polymeric material. The entangled fibers of the mixed fiber sliver may be sufficiently separated from one another such that blooming operations typically required in filter element production may not be necessary prior to incorporating the mixed fiber sliver into a filter element. Related methods, apparatuses and mixed fiber products are also provided by the disclosure.

Owner:R J REYNOLDS TOBACCO COMPANY

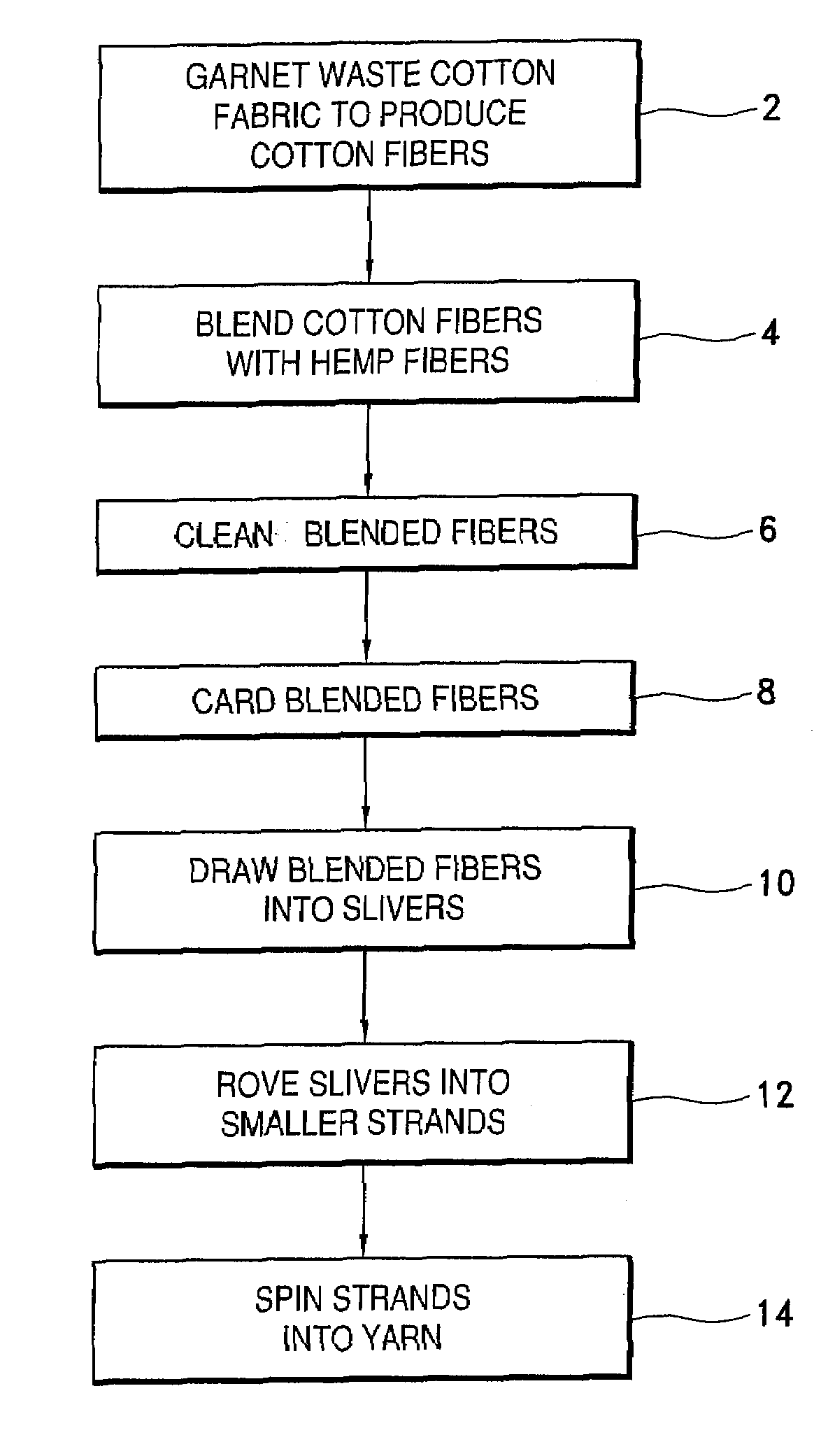

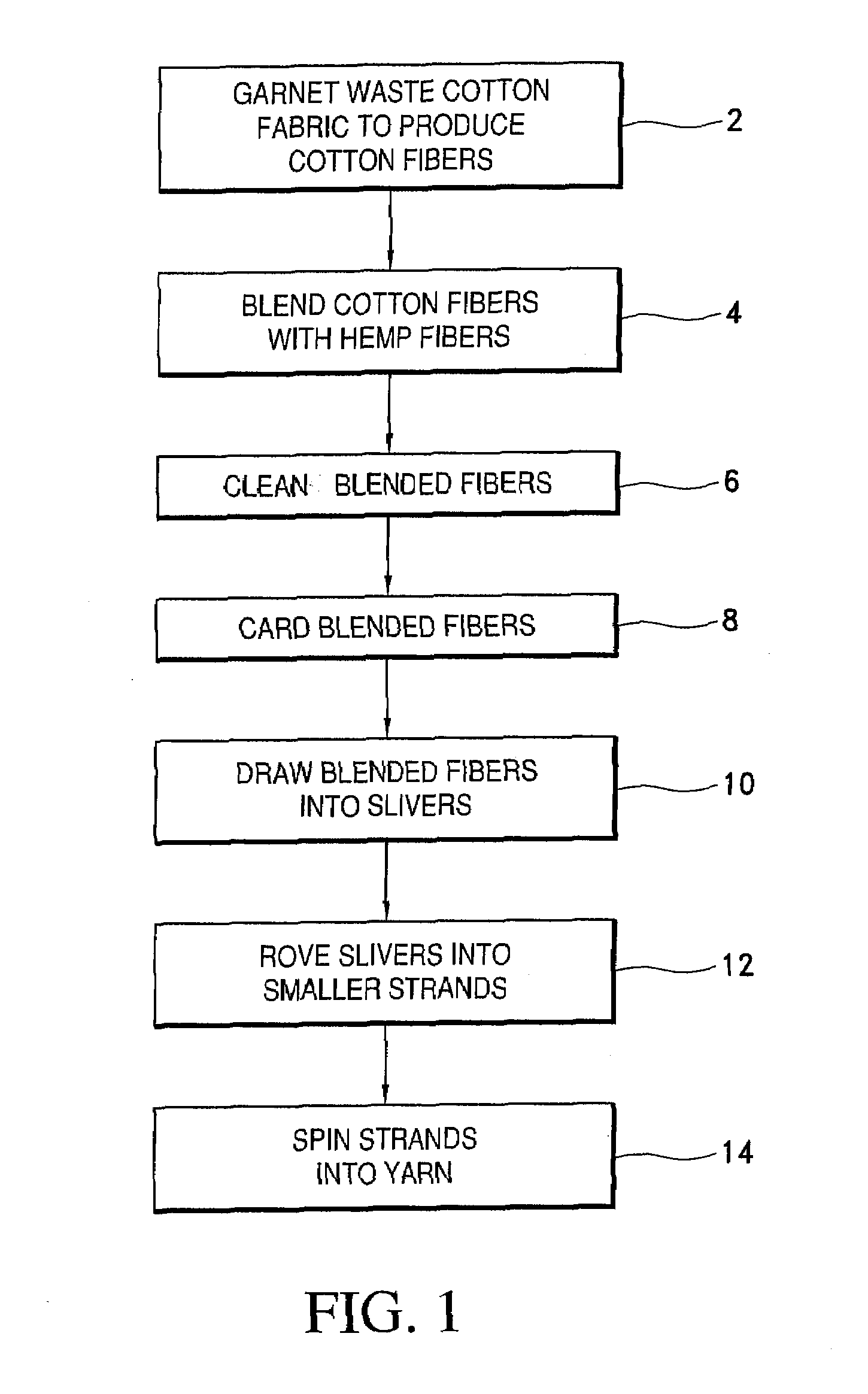

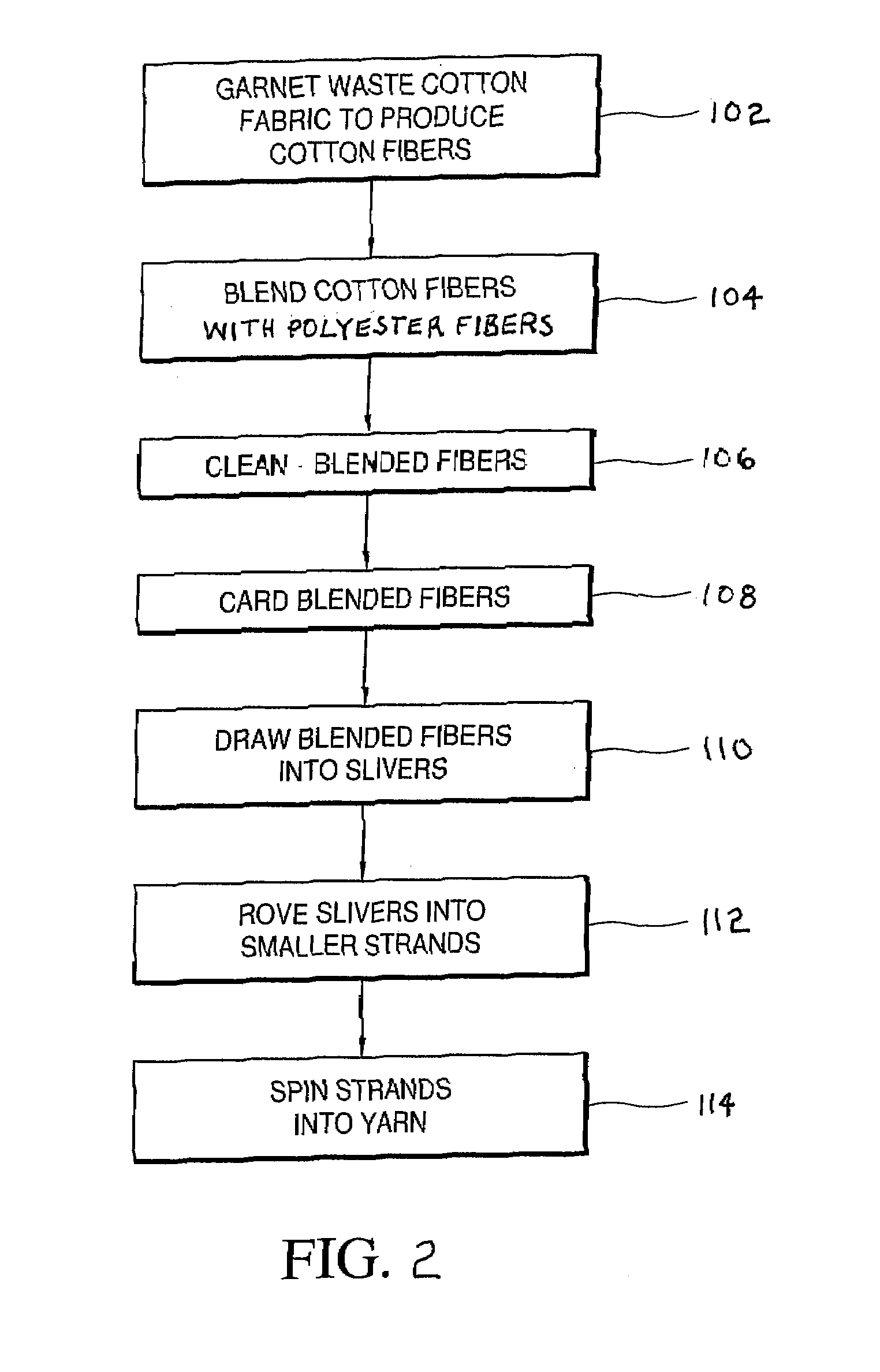

Composite cotton and polyester yarn and method for making same

InactiveUS20090173055A1Reduce impurityFibre mixingTextile disintegration and recoveryCotton fibrePolyester

A composite polyester and cotton yarn is formed by blending polyester fibers with cotton fibers which have been regenerated from waste cotton material such as trimmings and cuttings from the apparel manufacturing industry. The fibers are cleaned and blended, then carded to align the fibers into strands. Depending on the size and texture of the desired yarn, the fibers are stretched and drawn into slivers prior to spinning to join the fibers together. The polyester fibers are preferably recycled polyethylene terephthalate fibers which are up to three time longer than the regenerated cotton fibers, so that the polyethylene terephthalate fibers overlap and braid onto the regenerated cotton fibers during spinning. The resultant yarn is stronger and more absorbent than yarns made solely out of regenerated cotton fibers. The yarn is suitable for producing woven or knit fabric for the production of colorful and functional clothing and home textiles without the need for further bleaching or dyeing.

Owner:SILVER SCOTT

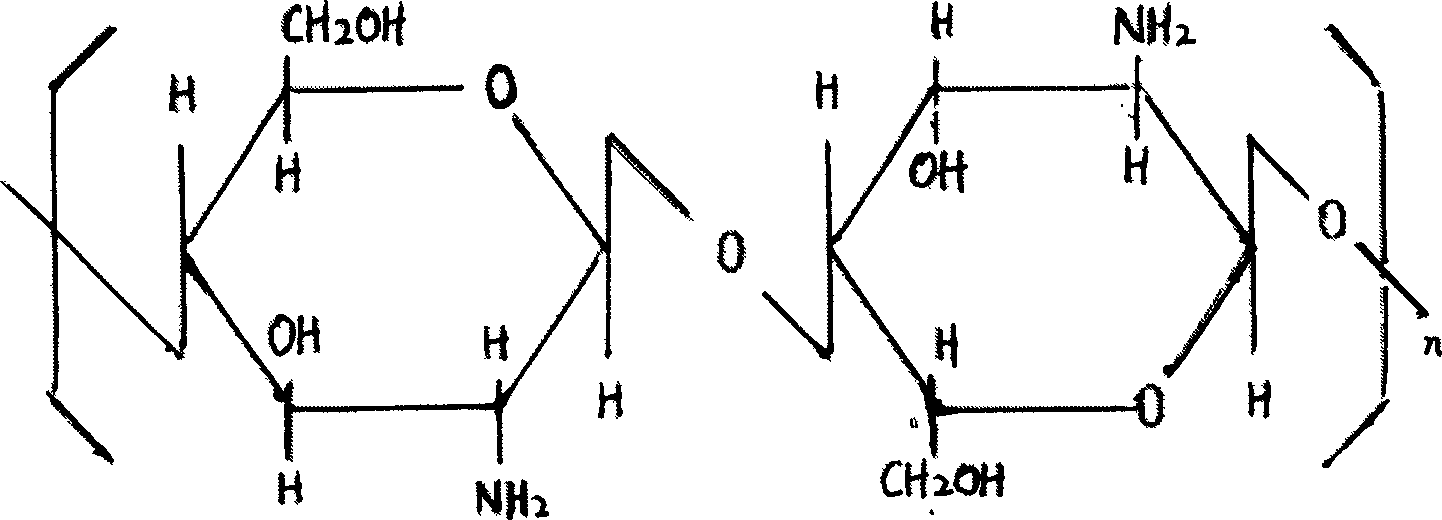

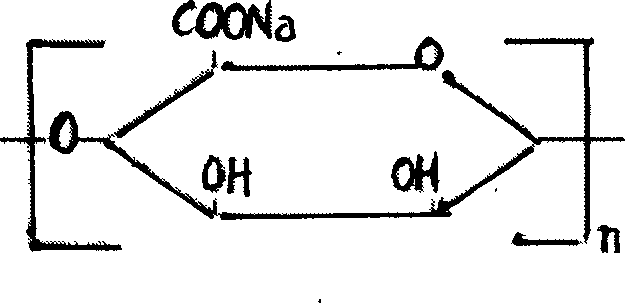

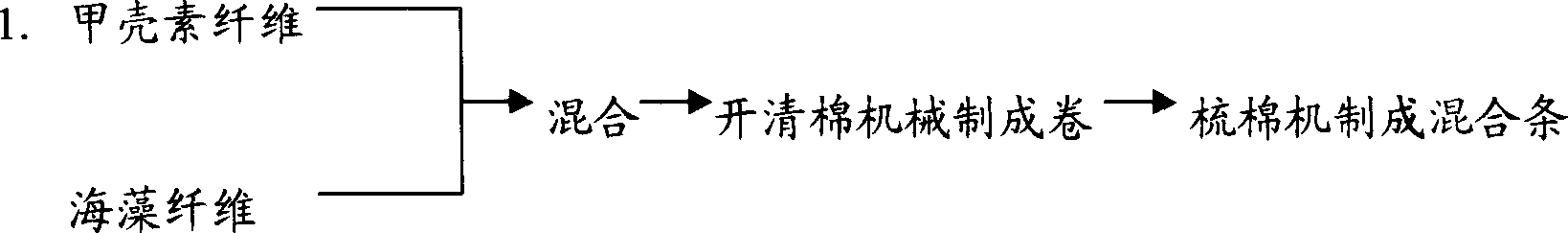

Chitosan fiber, alga fiber and natural fiber blend-spinning yarn and its preparation method and uses

InactiveCN1995512ALong-lasting health careBacteriostaticFibre mixingFibre chemical featuresYarnK pneumoniae

The invention relates to a yarn, especially the manufacturing method for blended yarn of chitin fiber, alginate fiber and tencel fiber, and the application. The blended yarn comprises 5-30 by wt of chitin fiber, 5-40 by wt of alginate fiber and 30-70 by wt of tencel fiber. Merits of invention are that (1) produced blended yarn and the product is environmental protection and degradation material; (2) produced blended yarn and the product is washing resistance and long time for medical and health efficacy; (3) the product is provided with the health action of bacteriostasis, diminishing inflammation, deodorization and so on, and the antibacterial ratio for staphylococcus aureus and Klebsiella pneumoniae bacterium can achieve the standard of national ministry of health; (4) the product is provided with wide application, it can be made into knitting, woven and non-woven fabrics; it can not only be applied in textile for medical treatment but also for ordinary clothes.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

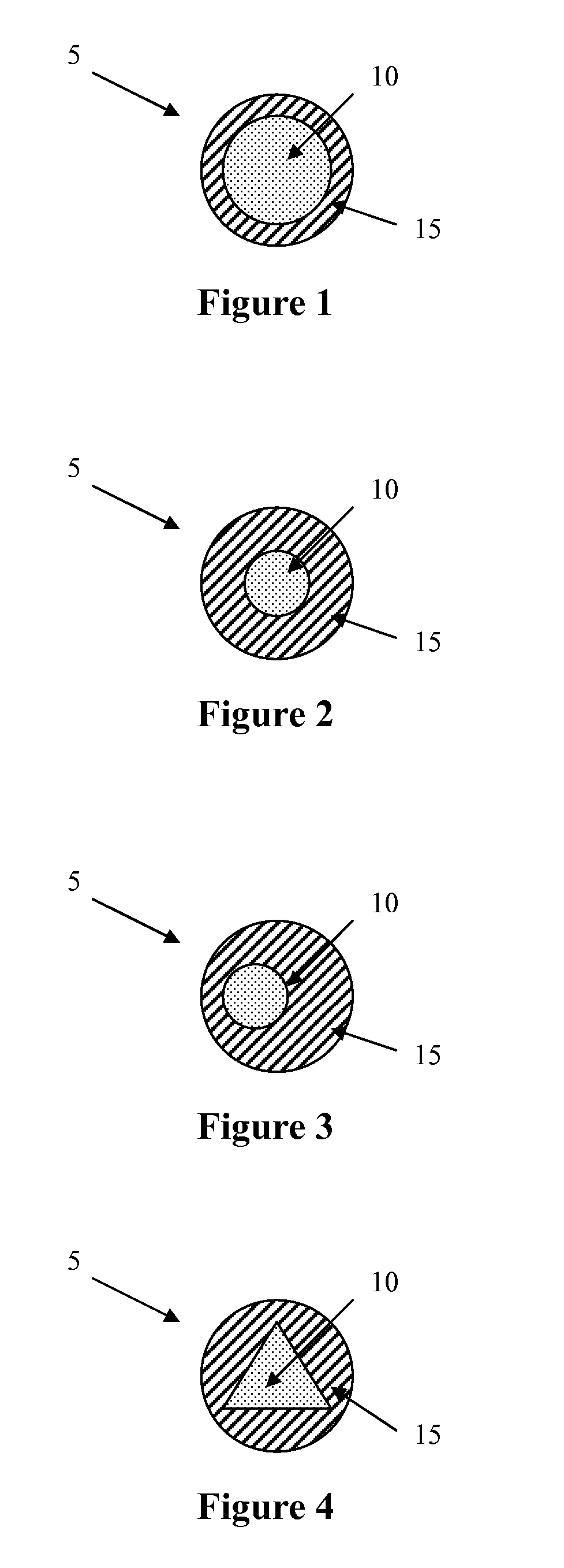

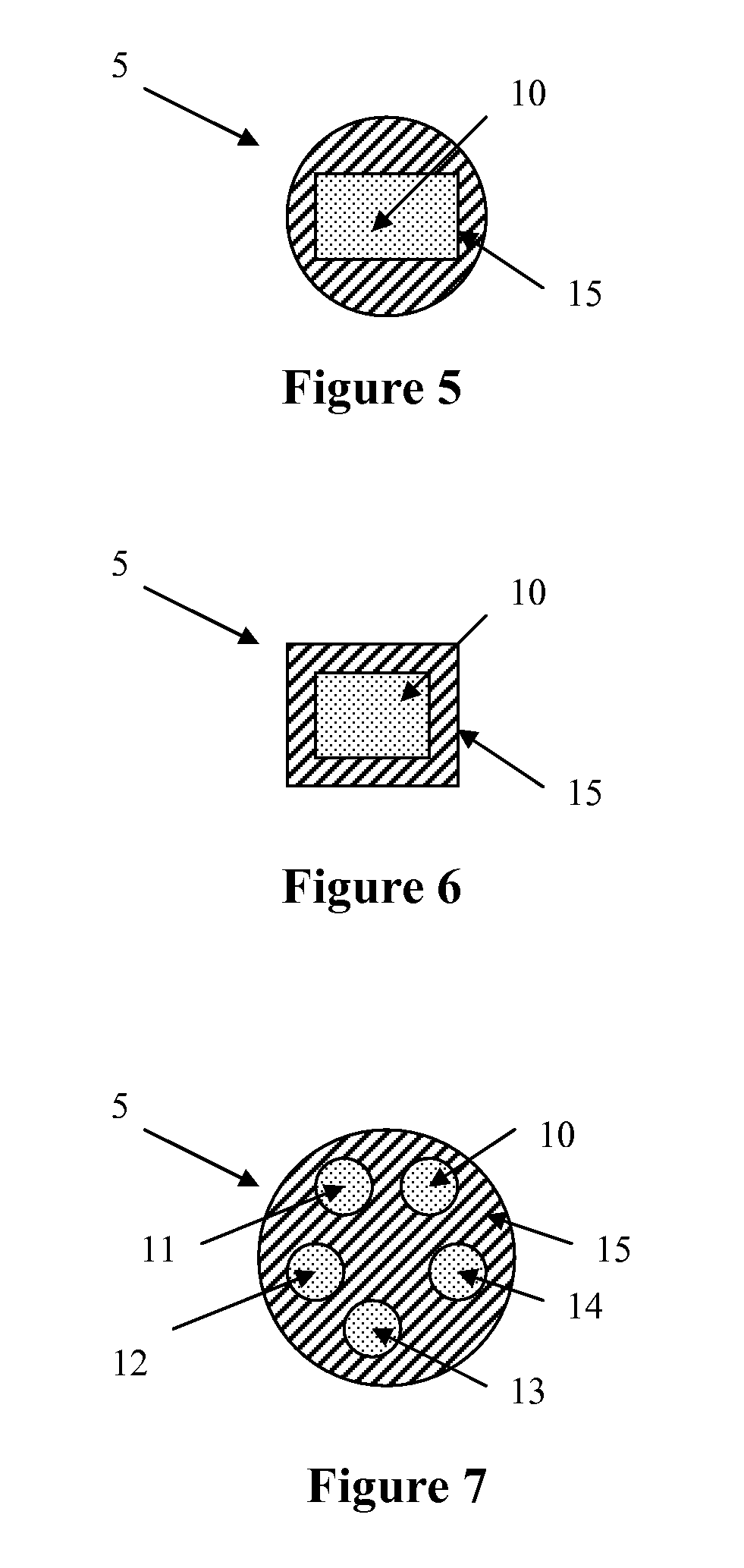

Multicomponent fiber comprising a phase change material

InactiveUS20070089276A1Avoid contactImprove thermal performanceFibre mixingLap-winding devicesFiberPhase-change material

The present invention is a multicomponent fiber comprising a temperature-regulating inner fiber component encapsulated by an outer fiber component. The invention further provides methods of preparing the inventive multicomponent fiber and methods of preparing a temperature-regulating fiber component incorporating at least one phase change material.

Owner:FIBER INNOVATION TECH

Nonwoven fabric

ActiveCN101629358AImprove microcirculationSkin careFibre mixingNon-woven fabricsSurface layerMedicine

The invention relates to a nonwoven fabric. The nonwoven fabric uses pearl fiber as a main raw material and is prepared through a spunlaced method. The nonwoven fabric contains a plurality of amino acids and microelements and has natural affinity for skin and functions of nutrition and health care; and the surface of the nonwoven fabric is smooth and cool, has pearlescent luster and has the functions of bacteriostasis, deodorization, itch relieving, ultraviolet resistance, skin care, fire clearing, toxin removing, inflammation diminishing and the like. The nonwoven fabric can be used for disposably absorbing a surface layer material of articles, mask carriers and other toilet article fields.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

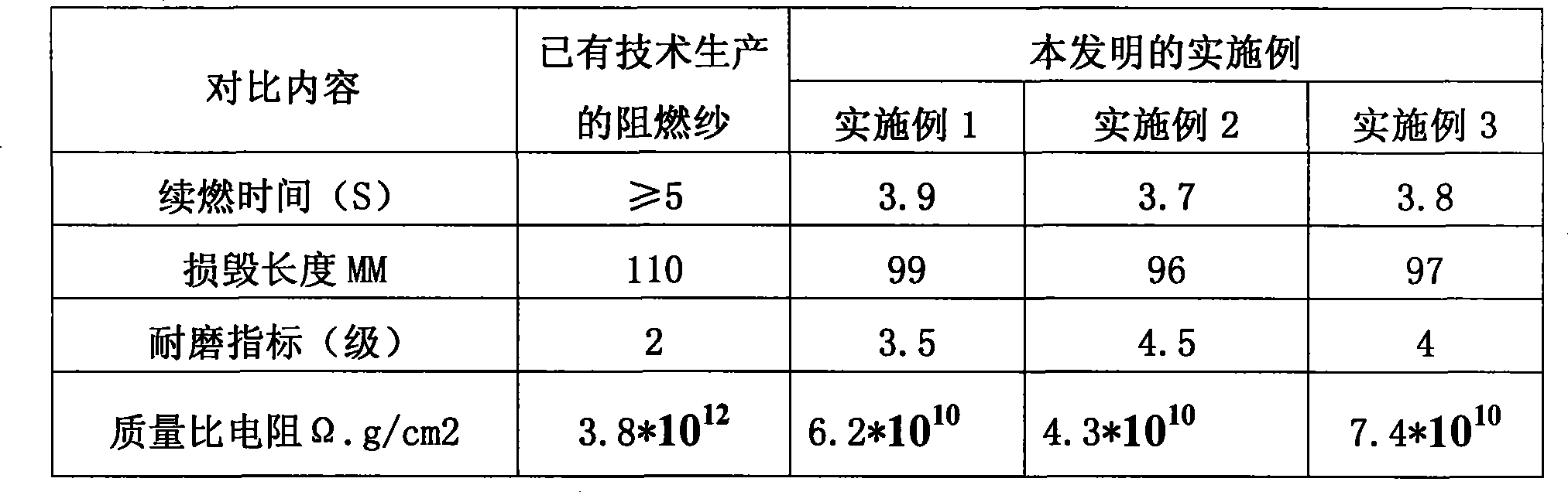

Flame-proof electrostatic resistance yarn and its processing method

InactiveCN101377027AShort afterburn timePermanent and non-fading flame retardancyFibre mixingYarnYarnElectrical resistance and conductance

The invention relates to retardant anti-static yarn and a processing method thereof, which belongs to the technical field of spinning. The yarn is composed of the following materials by the weight percentage: 70 percent to 95 percent of meta aramid fiber, 3 percent to 28 percent of para aramid fiber and 1.5 percent to 4 percent of anti-static fiber. The afterflame time of the retardant anti-static yarn obtained by the disclosed technical proposal is short (shorter than 4S), the damage length is less than 100mm, the wear resistance level is higher than or equal to 3.5, and the mass specific resistance is less than 7.4*10<10>; because of the meta aramid fiber, the para aramid fiber and the anti-static fiber, the retardant and anti-static effect are permanent and do not fade; the recommended process requirements are not harsh and can ensure the technical effect of the retardant anti-static yarn.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

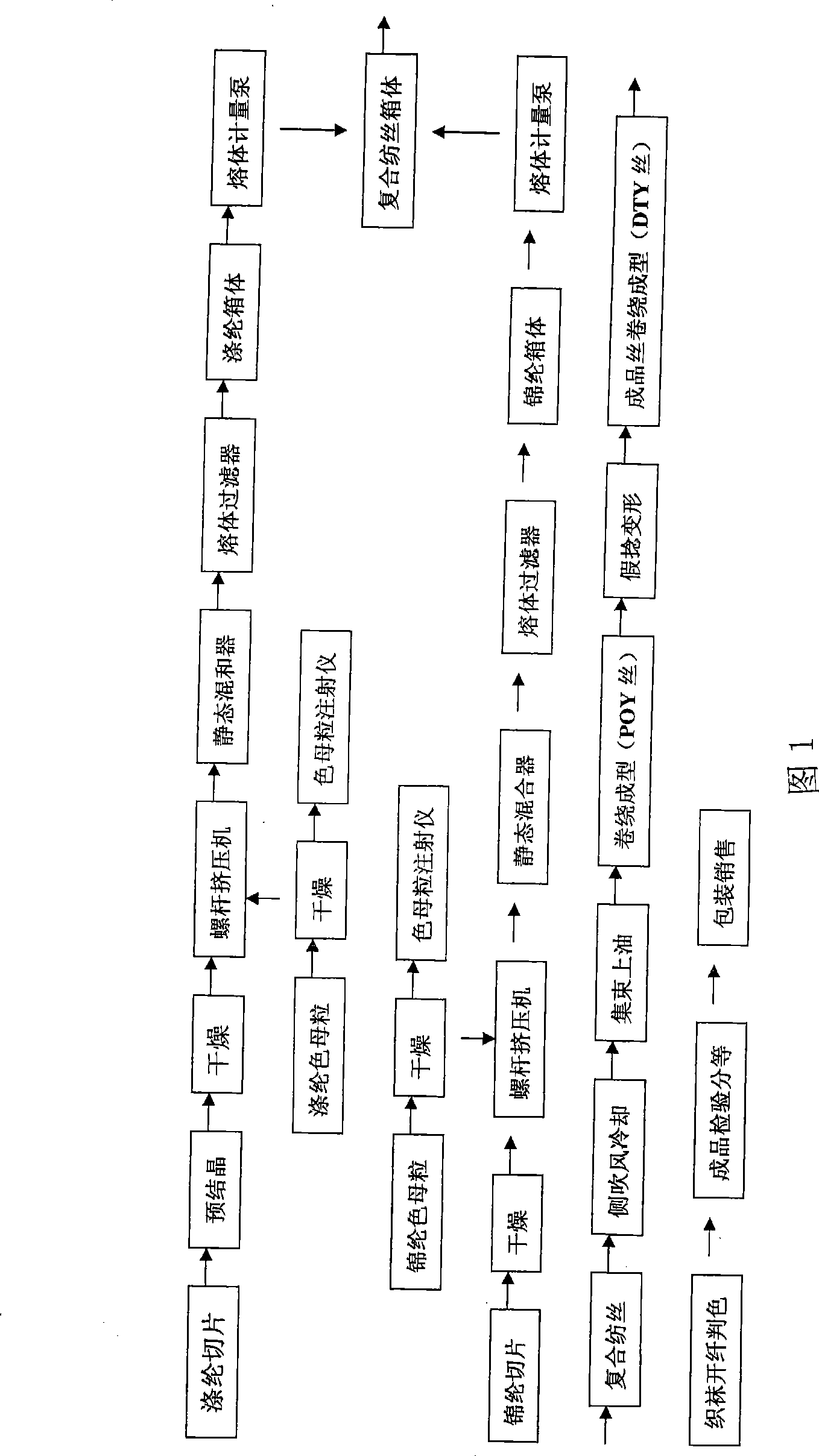

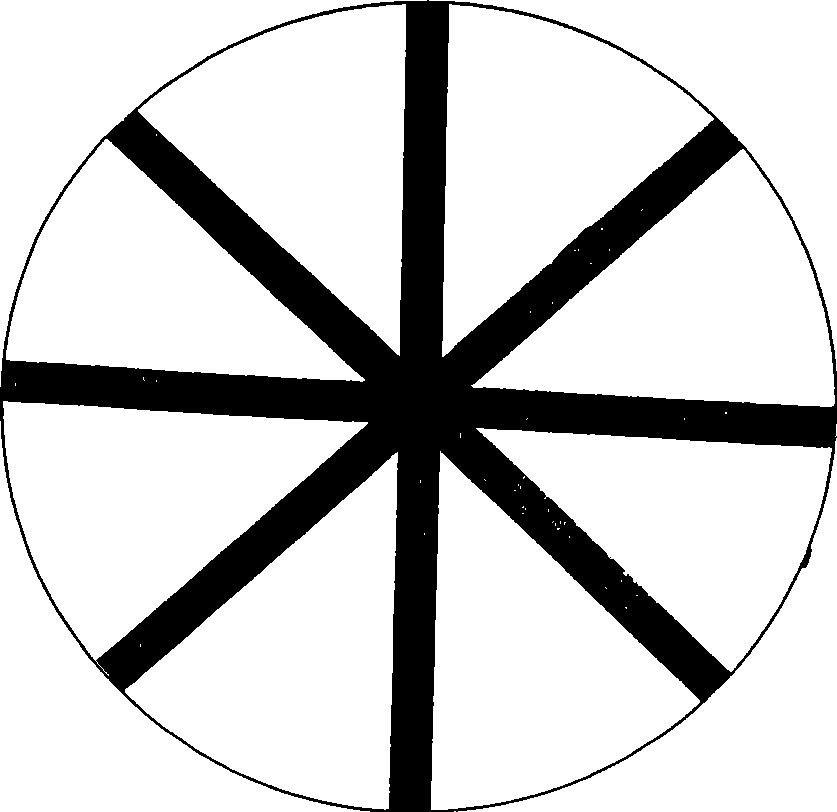

Colour superfine polyester-nylon complex fiber and its processing method

InactiveCN101397698AHigh color fastnessEvenly and fully connectedFibre mixingMelt spinning methodsColour fastnessDark color

The invention relates to a colored ultra-fine polyester / nylon composite fiber and a processing method thereof. The colored ultra-fine nylon / polyester composite fiber is formed by the following materials according to weight part: 62 portions to 82 portions of polyester chips, 15 portions to 35 portions of nylon chips, 1 portion to 3.5 portions of polyester colored master batches and 0.5 portion to 2 portions of nylon colored master batches. The invention has the advantages that: as the polyester colored master batches and the nylon colored master batches are added into the raw material of the polyester chips and the nylon chips, coloring requirement before spinning is met, thus causing spun products not to require dyeing; textile products produced by using the colored ultra-fine polyester / nylon composite fiber has the color fastness much better than that of textile products by dyeing; in addition, the processing method makes up the defect that the textile products of the ultra-fine polyester / nylon composite fiber can not be dyed into dark colors, widens the application scope of the ultra-fine polyester / nylon composite fiber in the field of the textile products; does not need dyeing processing, thus avoiding environmental pollution caused by the textile products due to dyeing; has reasonable processing conditions, and can carry out production with the assistance of the traditional double-component equipment; the colored ultra-fine polyester / nylon composite fiber has all the properties and styles of the ultra-fine polyester / nylon composite fibers with true colors.

Owner:常熟市海欣复合材料有限公司

Easy-to-dye terylene BCF and method for preparing same

InactiveCN101338455AImprove spinnabilitySolve the two major problems of dyeing at room temperatureFibre mixingLap-winding devicesFiberYarn

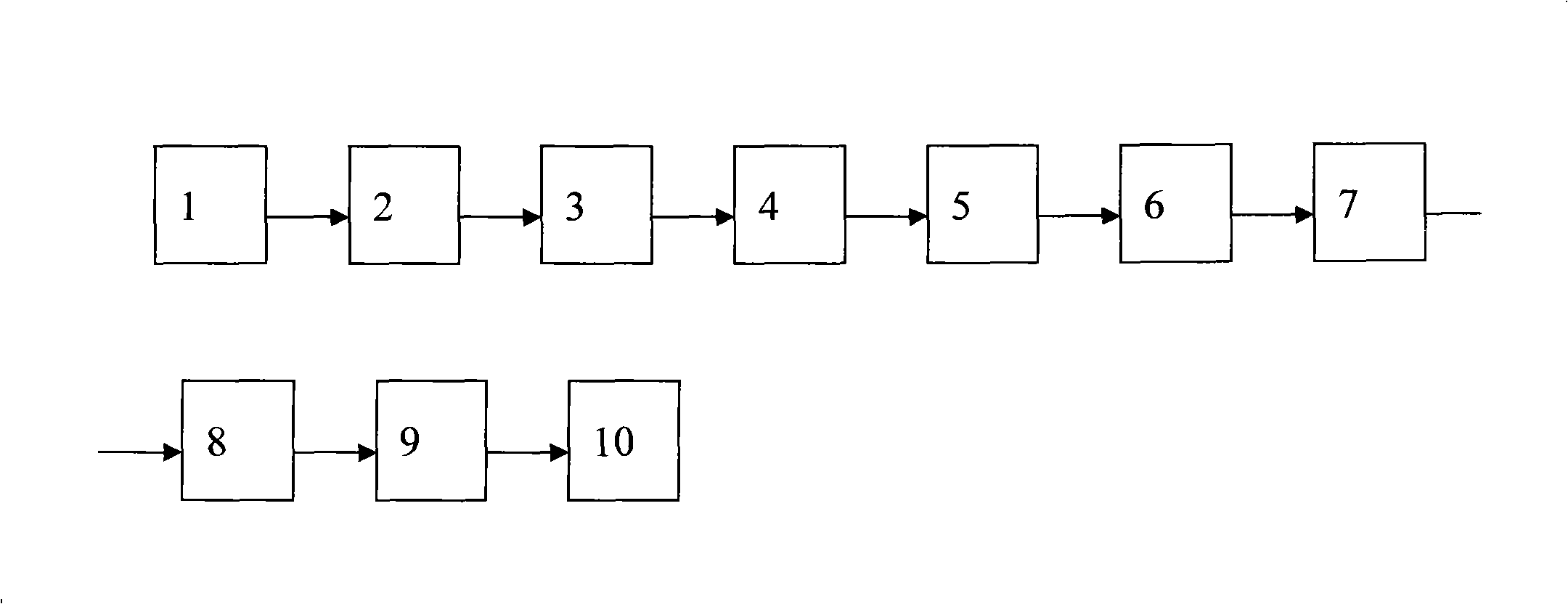

The invention relates to a chromophil terylene BCF and a preparation method thereof, which belong to the technical field of the terylene. The chromophil terylene BCF is characterized in that the terylene BCY is in a tri-leaflet shape which is also called as Y-shaped microcellular structure. The preparation method is characterized in that (1) the slice of raw terylene materials is pre-crystallized and dried by a dryer; (2) the slice of the raw terylene materials are melted by an extruder; (3) multifilament yarn which is in the tri-leaflet shape which is also called as the Y-shaped microcellular structure is sprayed by a tri-leaflet spinneret plate; (4) a tow is cooled to be formed into initial raw silk; (5) oil solution is applied to spinning; (6) the spinning is extended; (7) the spinning undergoes the process of bulking in a deformation box; (8) the spinning is cooled and curled; (9) the spinning undergoes the process of link making; (10) the spinning is rolled into a drum. The chromophil terylene BCF solves two problems that the current BCF has poor spinnability and is difficult to be dyed under normal temperature, provides newly-invented BCF fiber for manufacturing the suede of a blanket and creates conditions for manufacturing the blanket that has good spreadability, beautiful appearance and low manufacturing cost.

Owner:上海繁太实业有限公司

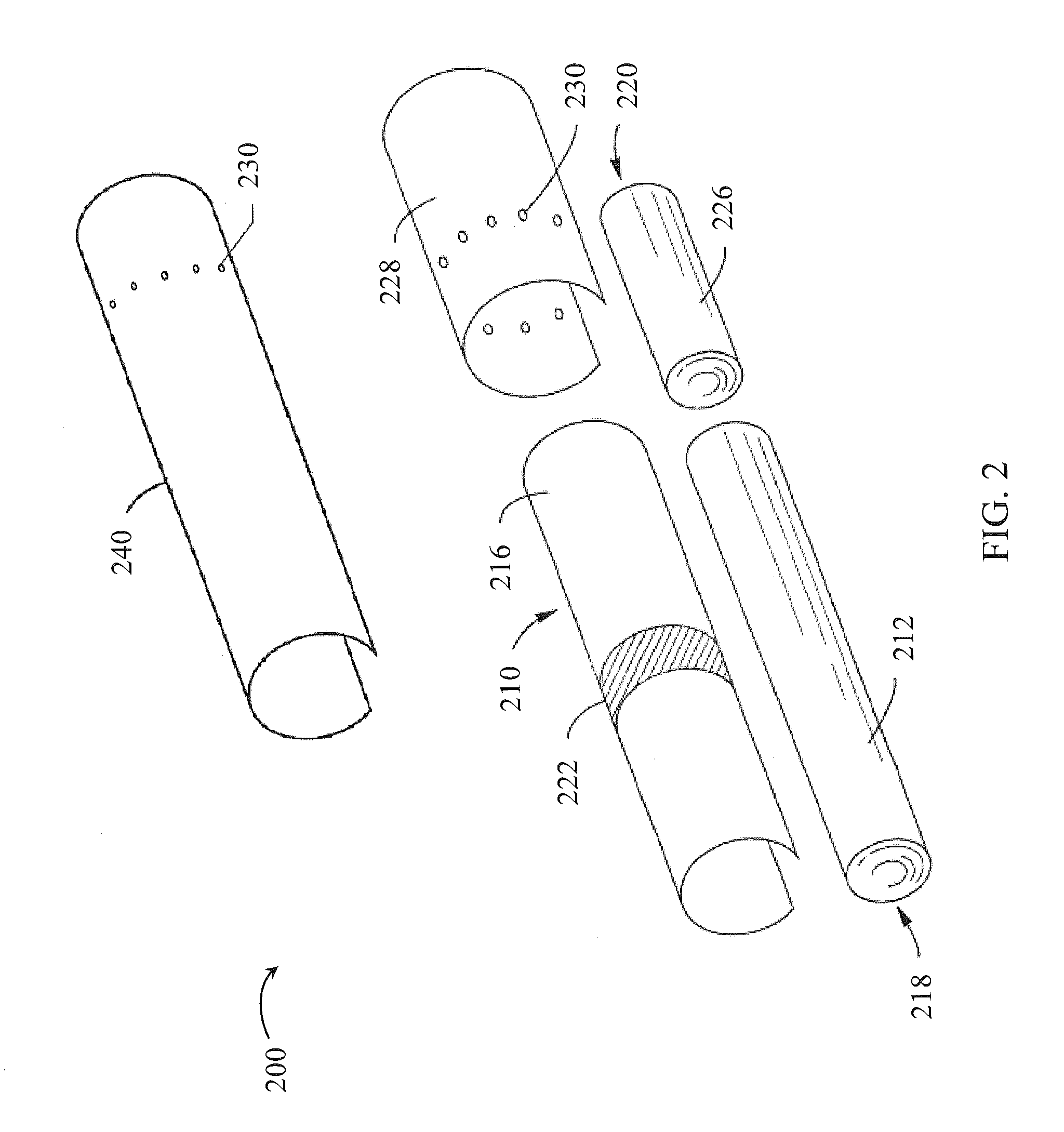

Hollow fiber cartridges and components and methods of their construction

ActiveUS20140319045A1Reduce thermal stressHigh bulk densityMechanical working/deformationFibre mixingHollow fibreFiber

Owner:REFINE TECHNOLOGY LLC

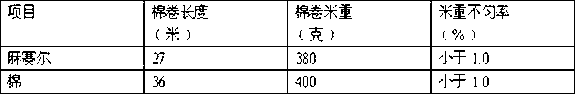

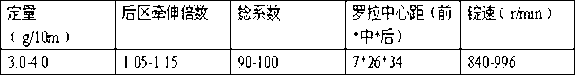

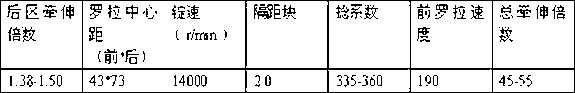

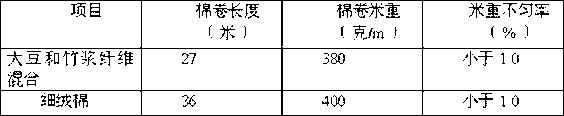

Cotton fiber and jutecell fiber blended yarn and spinning process thereof

The invention discloses a cotton fiber and jutecell fiber blended yarn and a spinning process thereof. The blended yarn comprises jutecell fiber with fiber content blending ratio as 70% and 30% fine staple cotton. The fibers are spun into yarns through the blended spinning process. Raw materials of the yarns are composed of the jutecell fiber and the fine staple cotton. Compared with the prior art where long staple cotton and jutecell fiber are used for blended spinning, the process is low in cost and high in cost performance. The blending mode of one pre-blending and three mixed-blending is adopted, so that the blending spinning ratio is accurate, and components are even. The blended yarns produced in the production process are high in single yarn strength, even in yarn levelness and few in nep and yarn fault. The yarn structure can further improve textile comfortableness, improve textile hand feel and improve lining grade.

Owner:山东超越纺织有限公司

Antimicrobial and Antifungal Polymer Fibers, Fabrics, and Methods of Manufacture Thereof

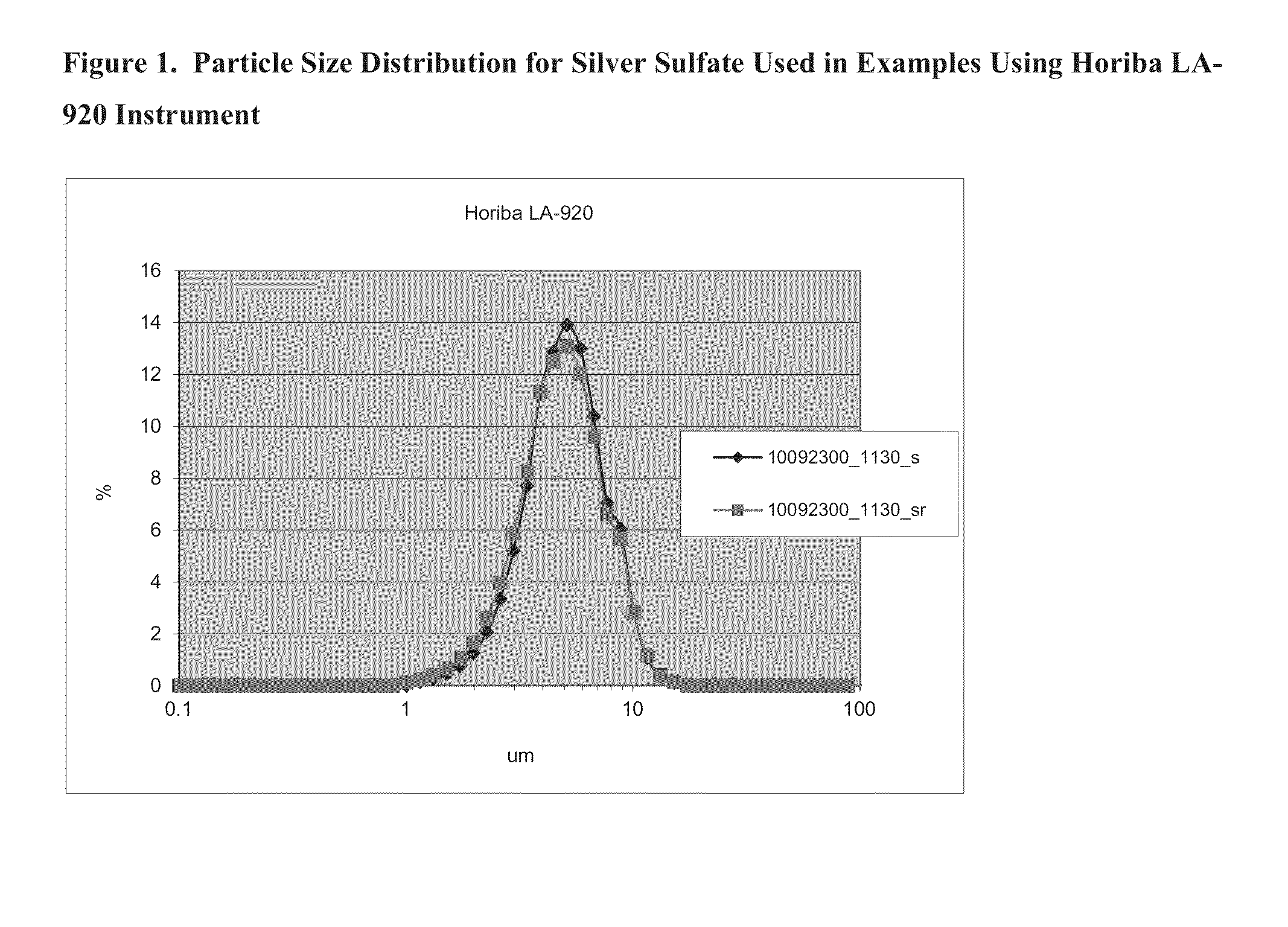

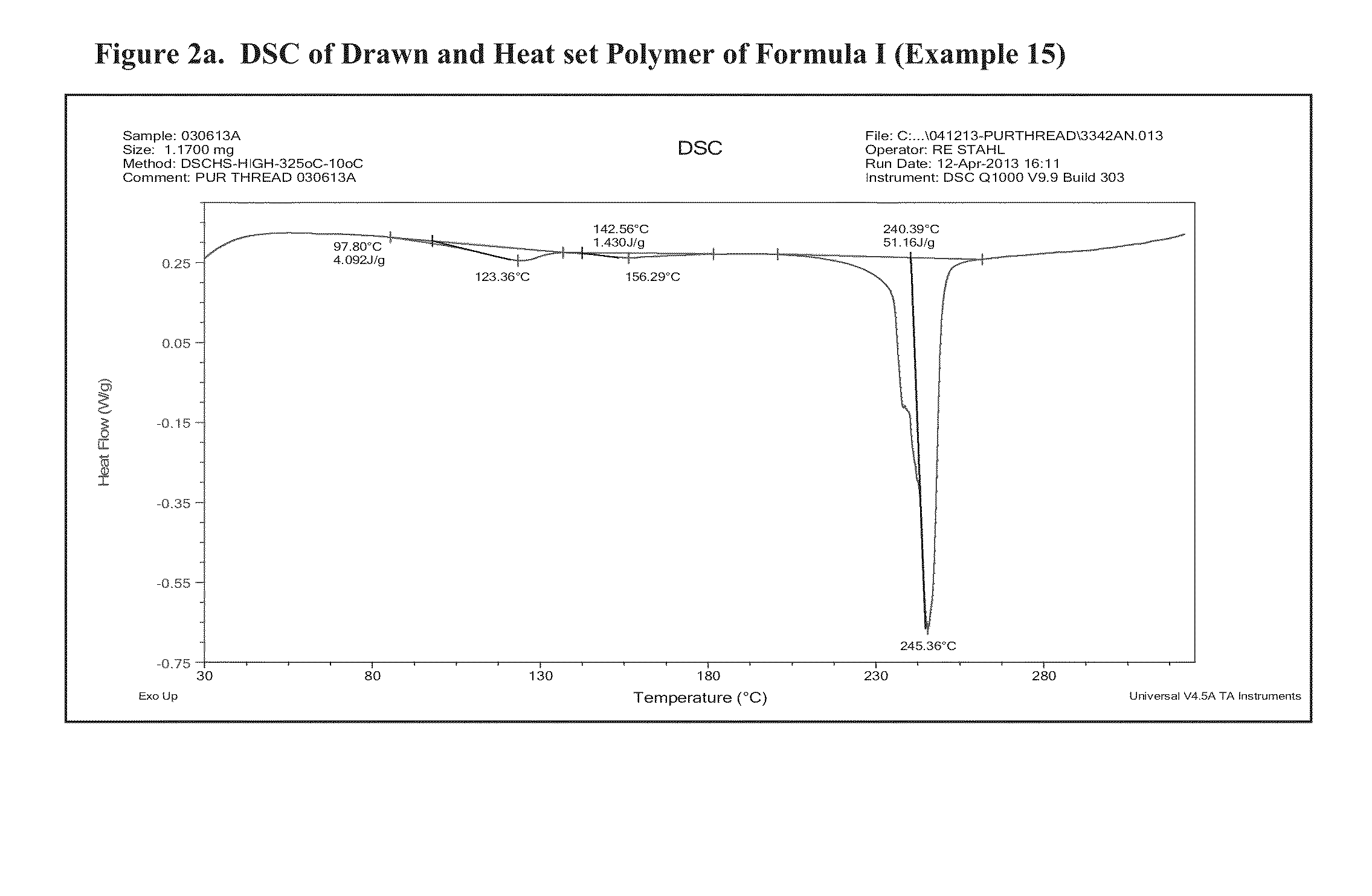

High-melting antimicrobial polymer fibers and antimicrobial fabrics comprising such fibers are prepared by preparing a masterbatch of polymer pellets (e.g., PET), silver and copper salts, and a compounding agent which provides free flowing polymer pellets which can be prepared in advance, with a long shelf life. Polymer masterbatches prepared by the methods of the invention can produce limited color or off-white antimicrobial fibers and fabrics using conventional melt spinning manufacturing methods. Fabrics incorporating fibers of the present invention are potent inhibitors of Athlete's foot fungi, gram negative and gram positive bacteria, and drug resistant pathogens.

Owner:PURTHREAD TECH

Blended yarn and spinning process thereof

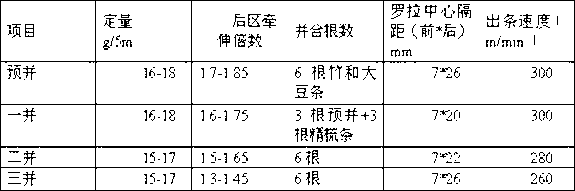

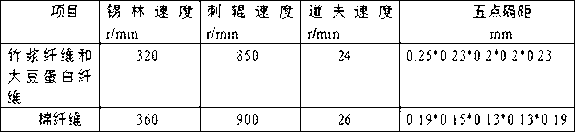

InactiveCN102704107ALess hairyImprove the defect of poor wrinkle resistanceFibre mixingYarnYarnCombing

The invention discloses a blended yarn and a spinning process thereof. The blended yarn comprises the components of 50% of cotton fibers, 40% of bamboo pulp fibers and 10% of soybean protein fibers in a fiber content blending ratio, wherein the fibers are spun into the yarns through using a blending process. The yarn provided by the invention is formed through coating-mixing of the bamboo pulp fibers and the soybean protein fibers, and sliver-mixing of card slivers which are formed through performing steps of scutching, carding and combing with cotton fiber combed slivers. A compact siro-spinning technology and reasonable raw material collocation are employed so that the hairiness of the yarn can be effectively reduced and the shortcoming of poor crumple resistance of the soybean protein fibers is overcome. A mixing manner of one-time pre-drawing and triple mixing is employed, so that the blending ratio is accurate and the composition is even; and a produced single yarn is even, high in strength, few in neps and low in yarn faults.

Owner:山东超越纺织有限公司

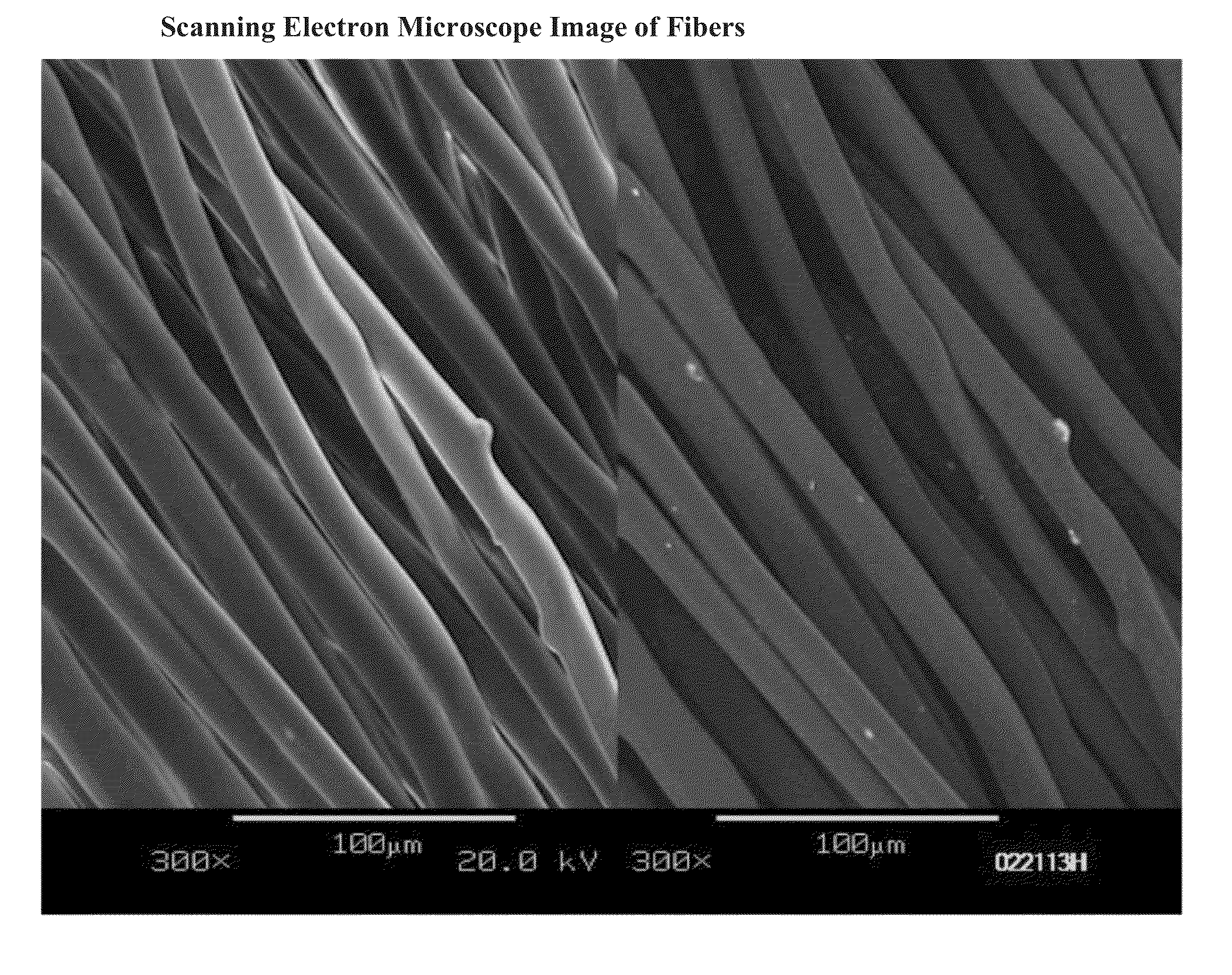

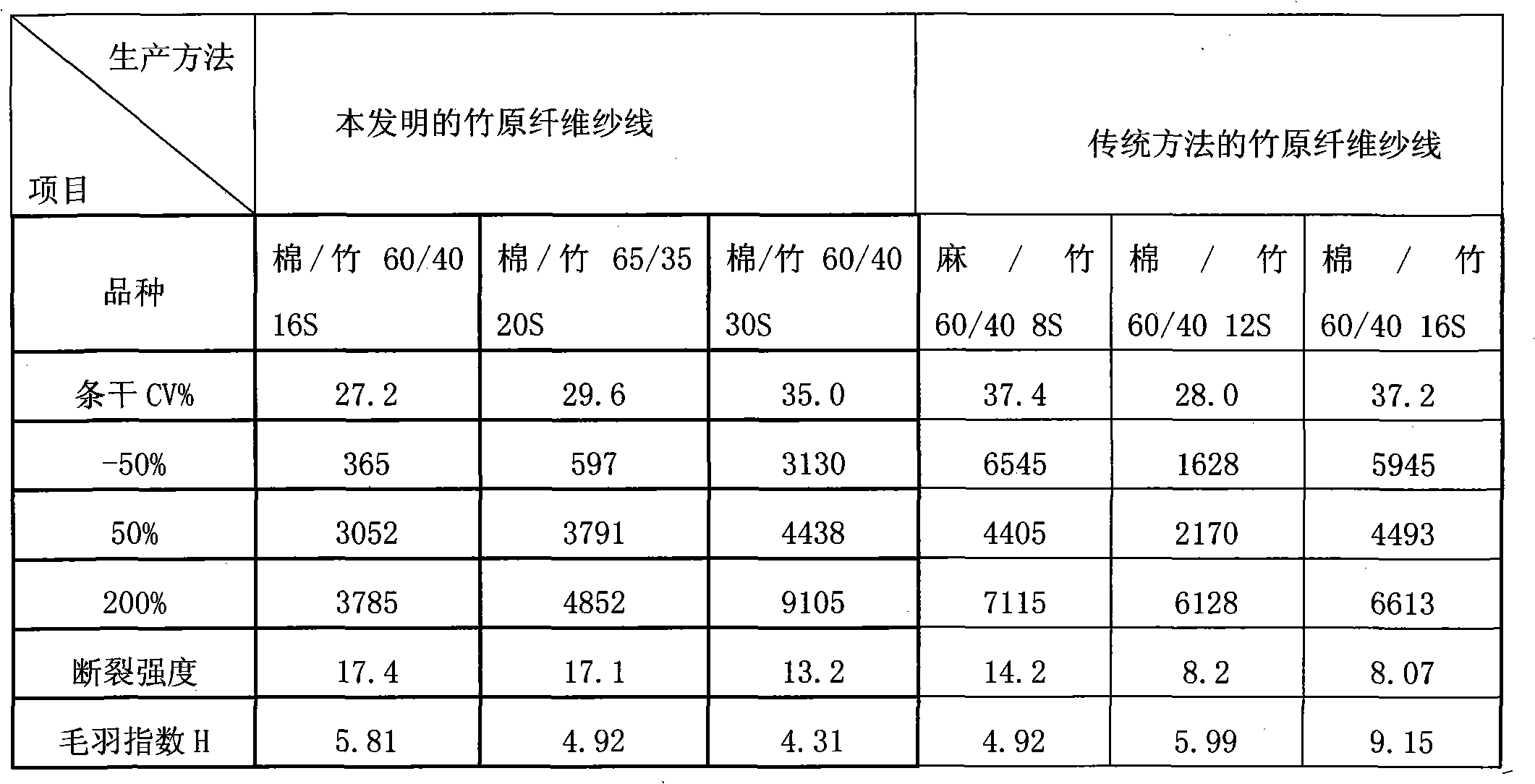

Bamboo fiber yarns and production method thereof

InactiveCN101967710AReduce tensionDecreased elastic strengthFibre mixingYarnEnvironmental resistanceYarn

The invention discloses bamboo fiber yarns and a production method thereof. The bamboo fiber yarns are prepared by spinning the following blended raw materials in part by weight: more than 5 and less than or equal to 95 parts of bamboo fibers (preferably 20 to 40 parts) and 60 to 80 parts of natural fibers (such as cotton) or environmentally-friendly differential fibers. The production method comprises the following steps of: blending slivers made of the bamboo fibers and the natural fibers (such as the cotton) or the environmentally-friendly differential fibers again; and drawing, roving, spinning and spooling for 2 to 3 times to prepare various blended bamboo fiber yarns with low bamboo fiber content, which have naturally antibacterial, bacteriostatic, anti-ultraviolet, hygroscopic, air-permeable characteristics and the like. A plurality of superfine grooves on the surfaces of the bamboo fibers contributes to the improvement on moisture absorption, so that the yarns have the function of dehumidifying. The production method has the advantages of uniqueness, effectiveness, easily controllable manufacturing process, basically no need of equipment replacement, low manufacturing cost and high production efficiency.

Owner:FUJIAN KARTEX TEXTILE

Mixed fiber sliver for use in the manufacture of cigarette filter elements

ActiveUS20140026909A1Promote degradationSuitable for useTobacco treatmentPaper/cardboard wound articlesFiberCellulose acetate

Owner:R J REYNOLDS TOBACCO COMPANY

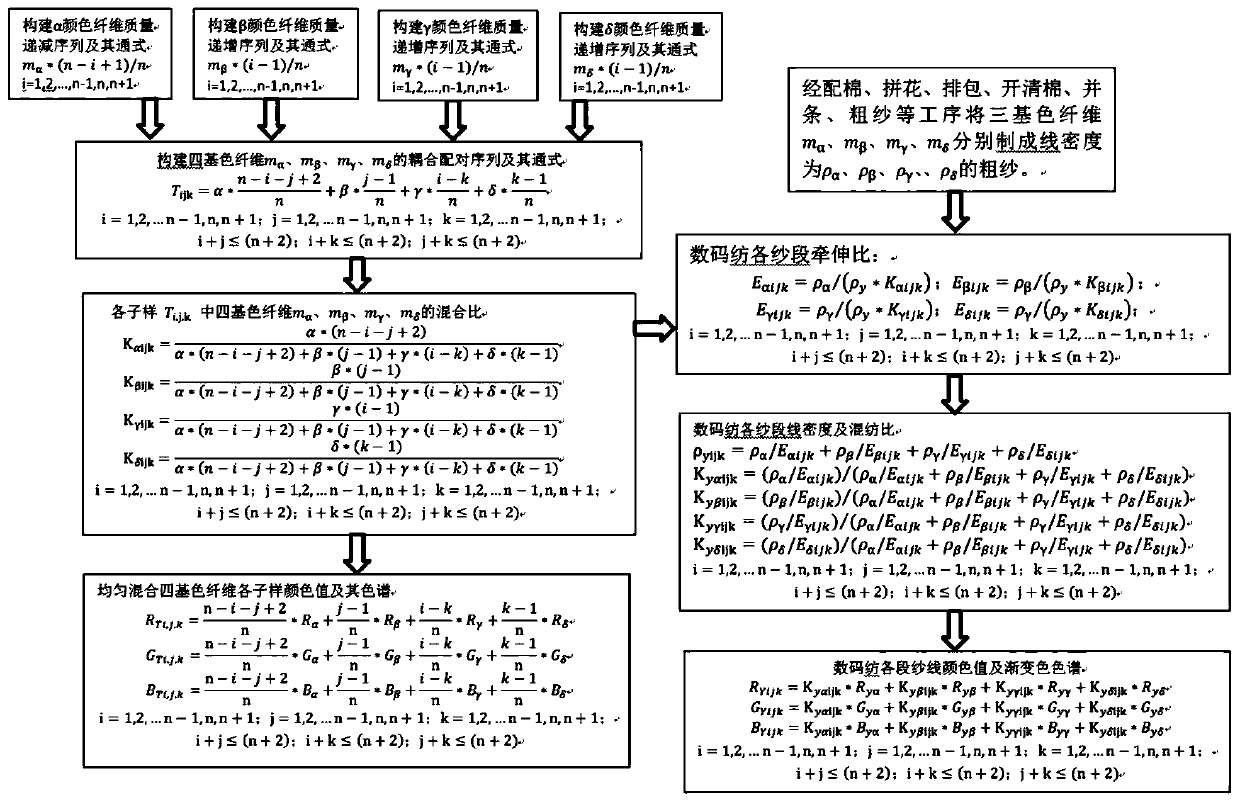

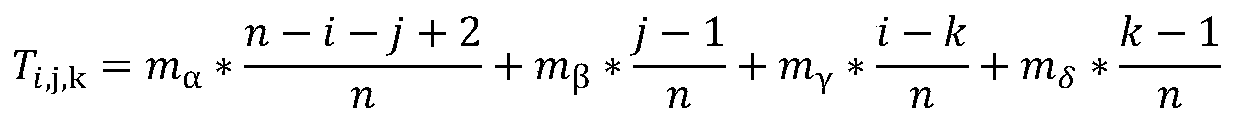

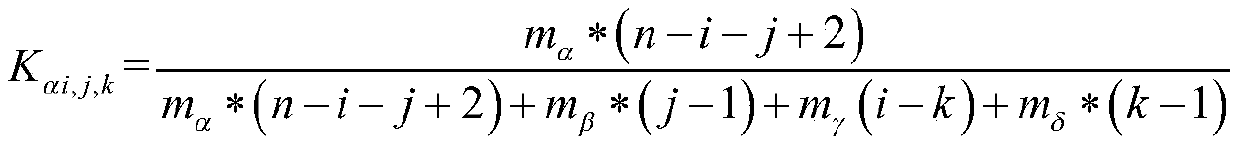

Spinning method for constructing discrete gradient chromatograms and making gradient colored yarns through coupling mixing of fibers in four primary colors

The invention relates to a spinning method for constructing discrete gradient chromatograms and making gradient colored yarns through coupling mixing of fibers in four primary colors. With the mass ofthe fibers in the four primary colors as a carrier, an increasing mass sequence and a decreasing mass sequence are constructed and then combined and paired to serve as a mass coupling mixing and gradient mixing model for the fibers in the four primary colors, the discrete gradient chromatograms of the fibers in the four primary colors and a draft-ratio discrete algorithm for spinning the color discrete gradient colored yarns are constructed according to the model, and the discrete gradient effect of the colors of the yarns is achieved based on coupling mixing of the four primary colors; the method is used for spinning color discrete gradient yarns with color serialization characteristics or spinning the gradient colored yarns with the natural color gradient effect on each yarn. Based on the coupling mass ratio of the fibers in the four primary colors, secondary color matching among fibers in multiple primary colors can be efficiently achieved, discrete gradient serial colors and discrete gradient colors in a full color gamut space are obtained, and therefore the colored yarns in discrete gradient colors corresponding to the fibers in the four colors are accurately obtained.

Owner:YUYUE HOME TEXTILE

Flame-retardant antistatic yarn and fabric thereof

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

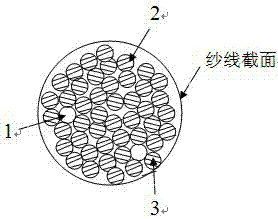

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Cotton fiber and viscose blended yarn and manufacturing method thereof

The invention discloses a cotton fiber and viscose blended yarn and a spinning technology thereof. The blended yarn comprises cotton fiber and viscose, and the fiber blending ratio of the cotton fiber to the viscose is 1:1; and the fibers are spun into yarns through a blending process. Card slivers formed by the processes such as blowing and carding and cotton fiber combed silvers are subjected to silver blending to form yarns, and a compact Silo spinning technology and the reasonable matching of raw materials are adopted, so that the problems such as the viscose can be deformed easily, has low elastic recovery performance and relatively low wear resistance, and is not acidproof are solved, and the advantages of the viscose and the cotton fiber are exerted. A pre-doubling and mixed doubling mixing mode is adopted, so that the accuracy of the blending ratio and the uniformity of ingredients are facilitated, produced single yarns have uniform yarn levelness and high strength, and few neps and yarn faults are produced.

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

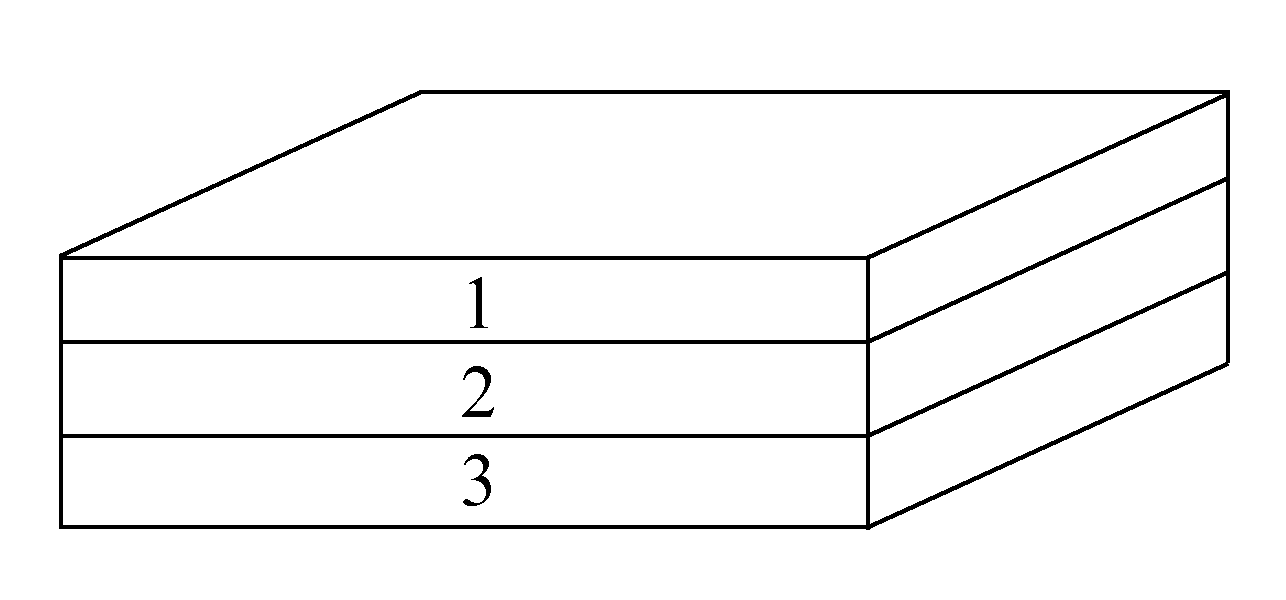

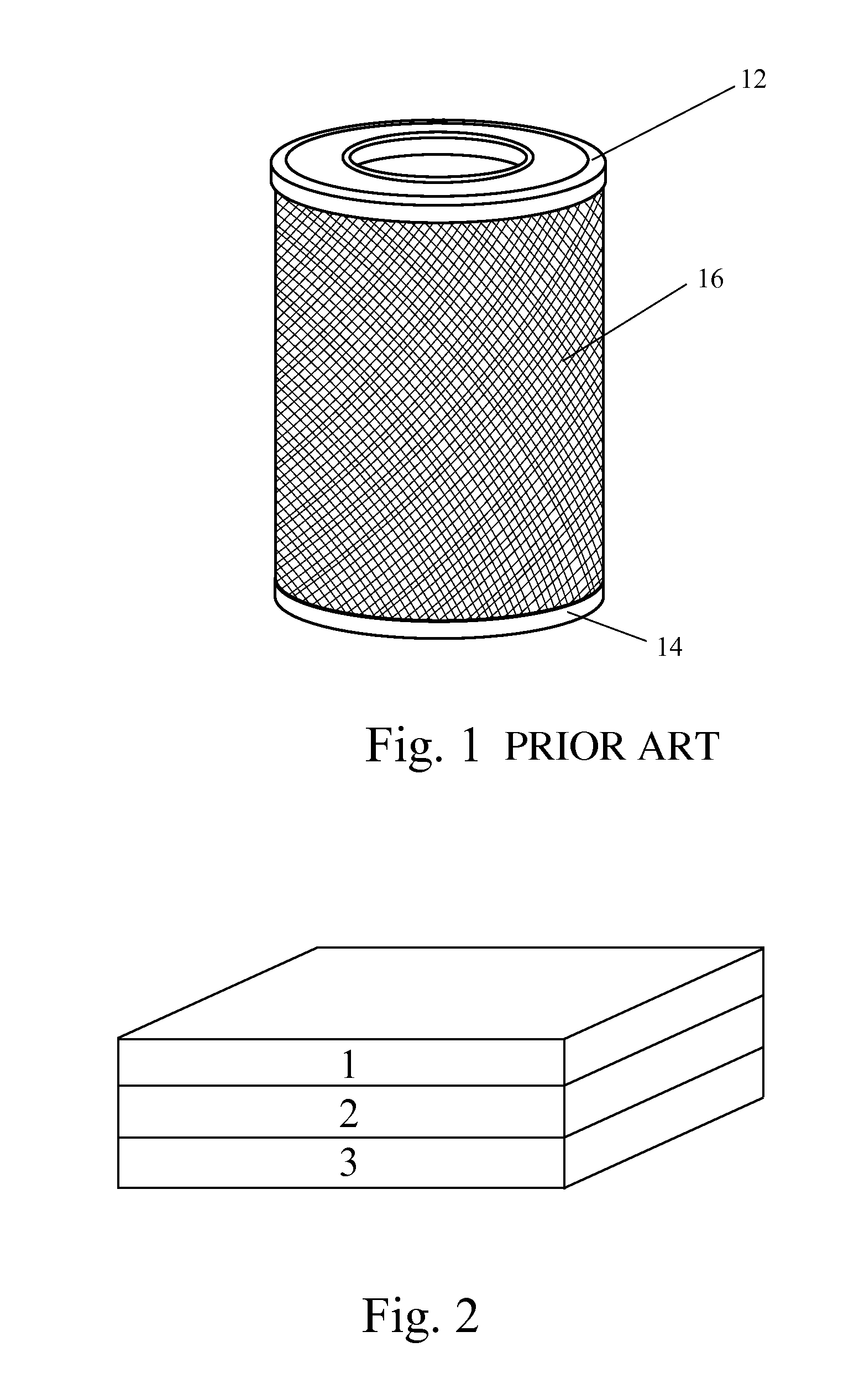

Nonwoven fabric, method for producing the same, and filter formed with the same

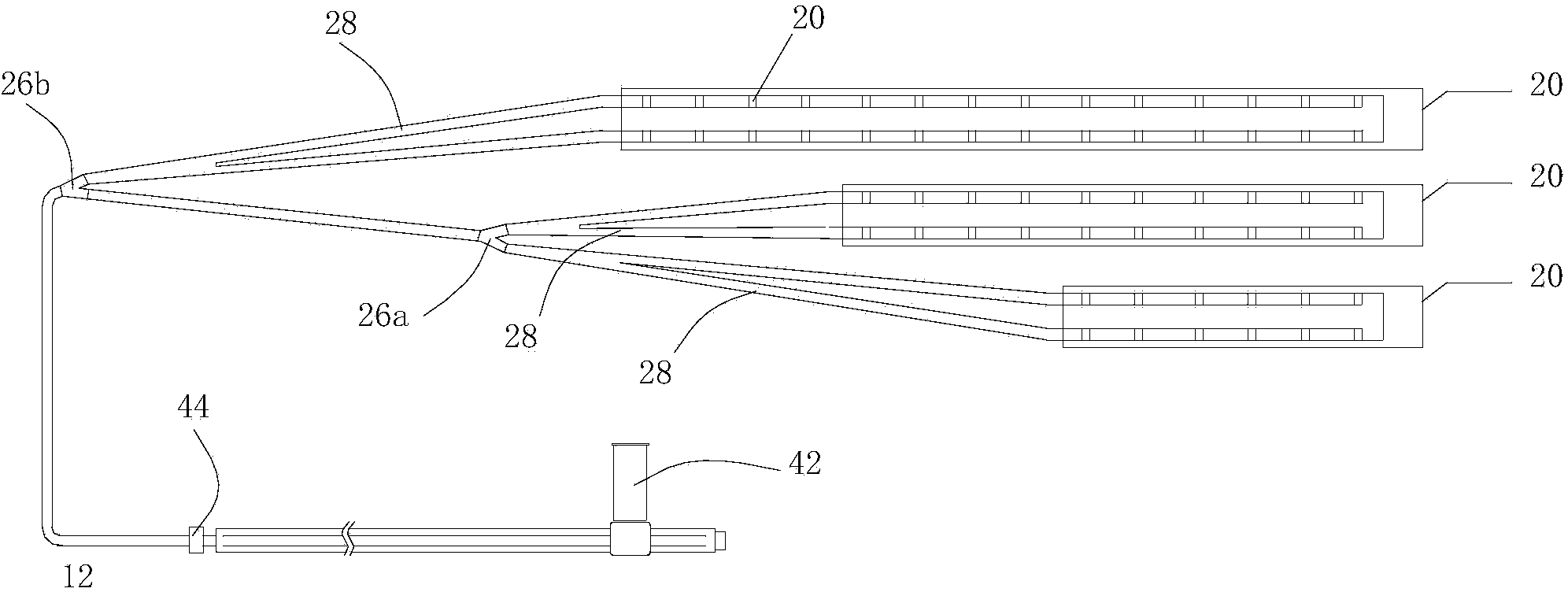

ActiveUS20130193063A1High hardnessIncrease stiffnessFibre mixingMembrane filtersFilter mediaEngineering

The present invention provides a novel nonwoven felt fabric, which is made of at least one low-melting-point short fiber and at least one high-melting-point short fiber of same type or different types, wherein the fabric is stiff enough to be self-sustaining and have the ability of shape maintenance. The felt fabric exhibits excellent pleatability, moldability and compressive strength. The invention also provides a method for producing the felt fabric, and a filter comprising the felt fabric used as the material of a filter medium of the filter, wherein the filter medium requires no support structure to stand alone and persistently retains its shape.

Owner:FAIRTECH INVESTMENT

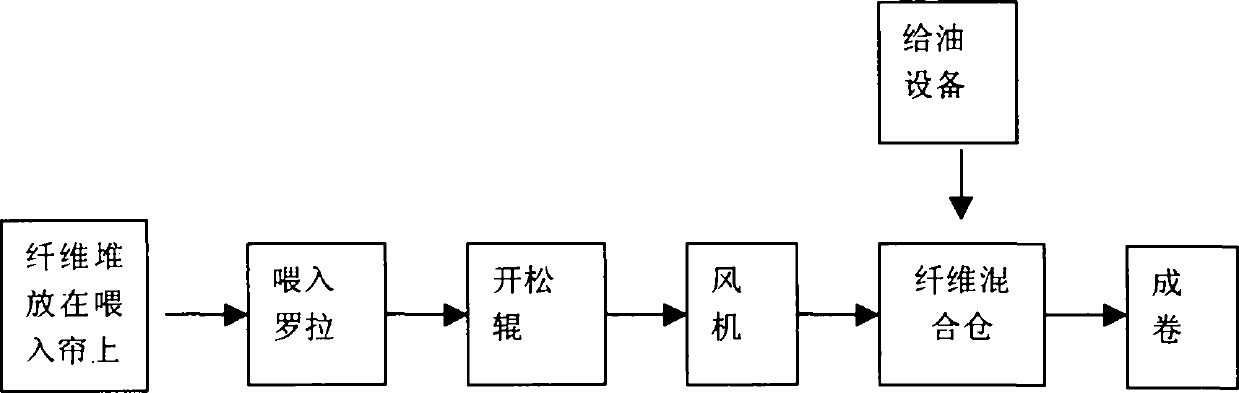

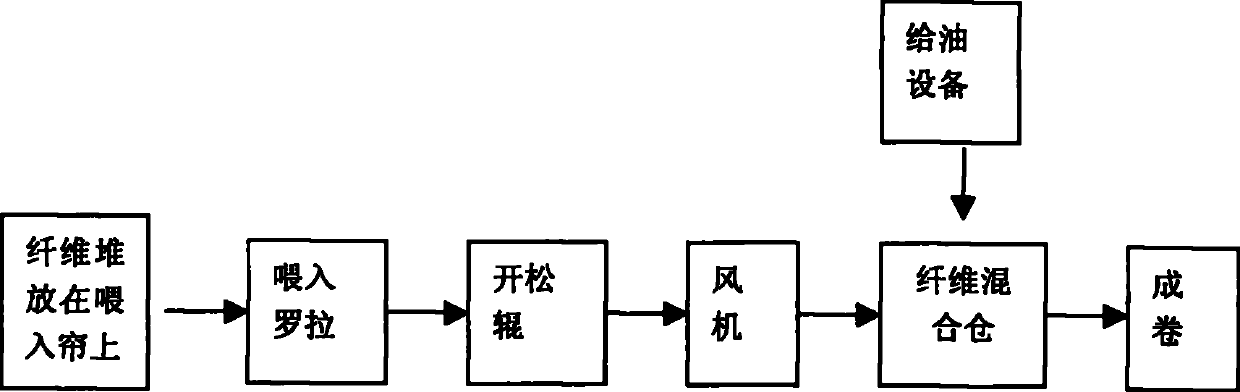

Cotton blending device and cotton blending method

ActiveCN104178854AQuality improvementImprove stabilityFibre mixingContinuous processingFiberEngineering

The invention discloses a cotton blending device and a cotton blending method. The cotton blending device comprises a cotton picker and at least one cotton blending box. Each of the cotton mixing boxes is provided with a cotton spreading area and a cotton picking area arranged at the tail end of the cotton spreading area. The top of the cotton spreading area is provided with cotton inlets. The cotton picker is communicated with the cotton mixing boxes; cotton delivery pipes penetrate the cotton spreading area and pass the cotton inlets; an openable damper is mounted at each cotton inlet; a cotton conveying mechanism in the same direction as the arrangement direction of the cotton inlets is disposed at the bottom of the cotton spreading area. A cotton picking mechanism is disposed in the cotton picking area; an insert plate which can move up and down is disposed between the cotton spreading area and the cotton picking area. According the cotton blending method, an operating mode: laying prior to pick-feeding, laying with no pick-feeding and pick-feeding with no laying is adopted; all cotton fibers in a production batch are blended in all dimensions, blending uniformity quality is far superior to the effect of traditional cotton blending equipment.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +2

Composites comprising collagen extracted from sarcophyton sp. coral

Isolated composites are disclosed comprising collagen fibers isolated from a Sarcophyton sp. coral. An exemplary composite comprises as a first component a bundle of collagen fibers, the collagen fibers being isolated from a Sarcophyton sp. coral, and a second component selected from the group consisting of a polysaccharide, a polypeptide, polylipid, a synthetic polymer, a metal and a mineral, wherein the bundle of collagen fibers comprise woven fibers, twisted fibers, braided fibers, knitted fibers, tied fibers, or sutured fibers. Uses thereof and method of generating are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

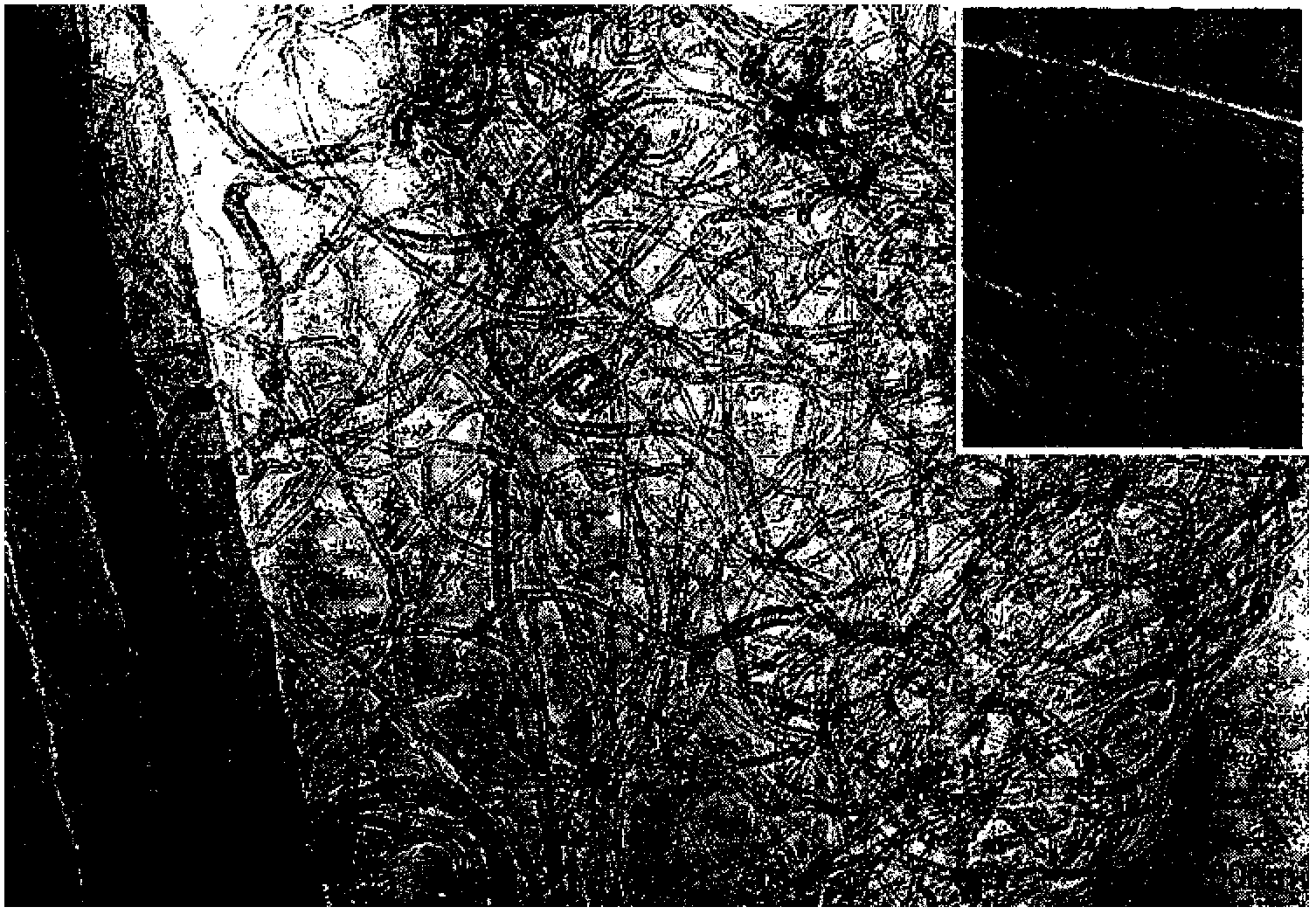

Composite carbon fiber

ActiveCN103523766AGood dispersionEvenly dispersedMaterial nanotechnologyPhysical treatmentFiberCarbon fibers

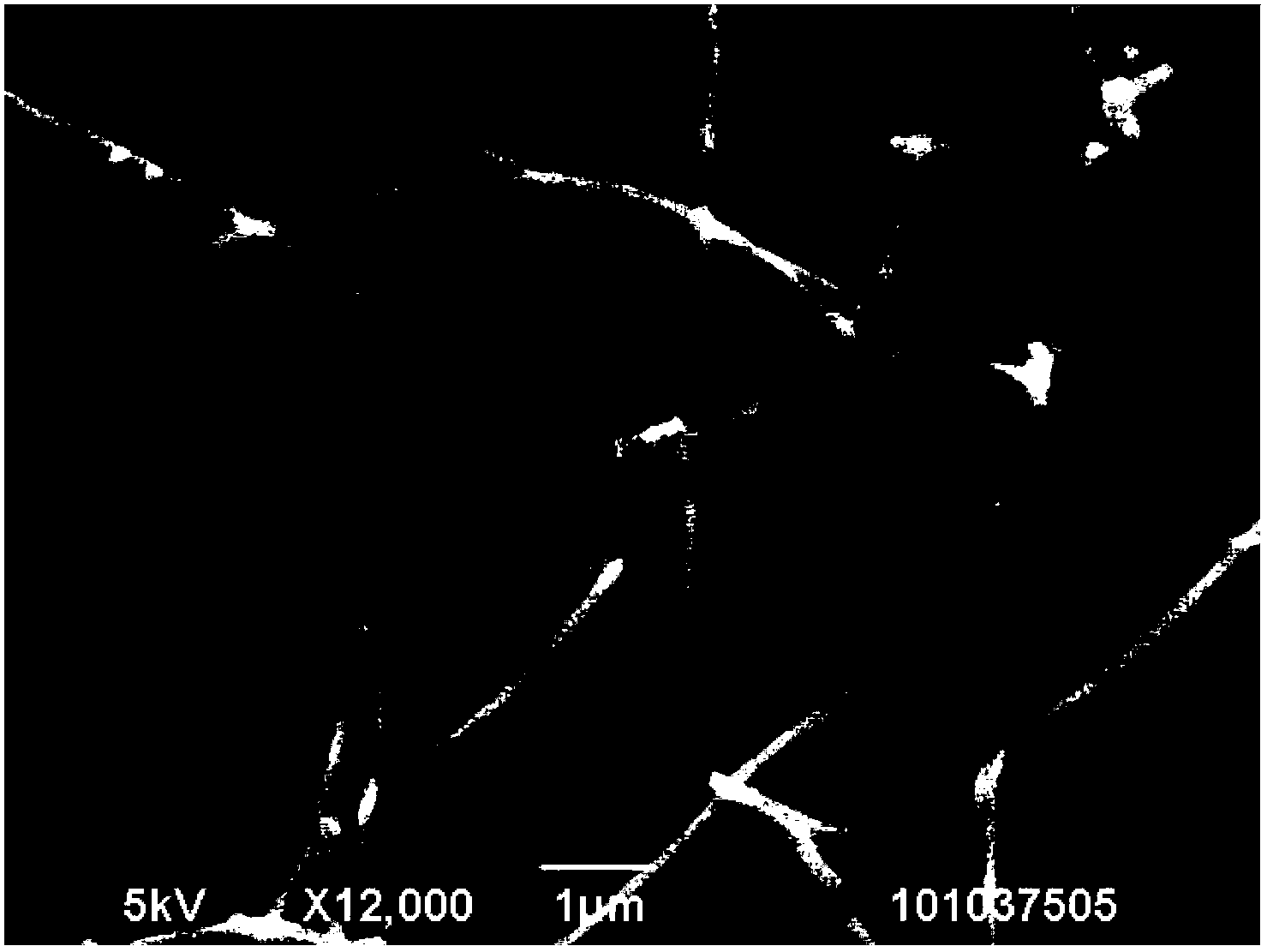

An object of the present invention is to provide composite carbon fibers in which multiwalled carbon nanotubes are homogeneously dispersed between graphitized carbon nanofibers and near the surface of the graphitized carbon nanofibers, the composite carbon fibers being capable of easily being dispersed in a matrix such as resin without leaving aggregates, and also imparting low resistance. Disclosed are composite carbon fibers comprising multiwalled carbon nanotubes having a fiber diameter of 5 nm or more and 30 nm or less and graphitized carbon nanofibers having a fiber diameter of 50 nm or more and 300 nm or less, wherein the multiwalled carbon nanotubes are homogeneously dispersed between the graphitized carbon nanofibers and near the surface of the graphitized carbon nanofibers.

Owner:RESONAC CORPORATION

Cotton blending machine

The invention discloses a cotton blending machine, and belongs to a technology of textile machinery. The technical point is that the cotton blending machine comprises a machine body; a cotton inlet cavity is formed in the front end of the machine body; cotton assorting pipes are arranged below the cotton inlet cavity; a water pipe is arranged above the cotton inlet cavity; a plurality of nozzles are arranged on the water pipe; movable blocks are arranged at the upper ends of the cotton assorting pipes and can close the cotton assorting pipes; the lower ends of the cotton assorting pipes are bent, and the cotton assorting pipes can rotate; a spike lattice is arranged in the machine body; a cotton stripping roller is arranged at the upper rear end of the spike lattice; a cotton cleaning beater is arranged at the rear of the cotton stripping roller; a cotton outlet pipe is arranged at the rear of the cotton cleaning beater; a bent pipe is arranged at the lower part of the cotton outlet pipe; and two magnetic layers are arranged on the inner wall of the bent pipe. The invention aims to provide a cotton blending machine which is safe and uniform in cotton blending.

Owner:谭国演

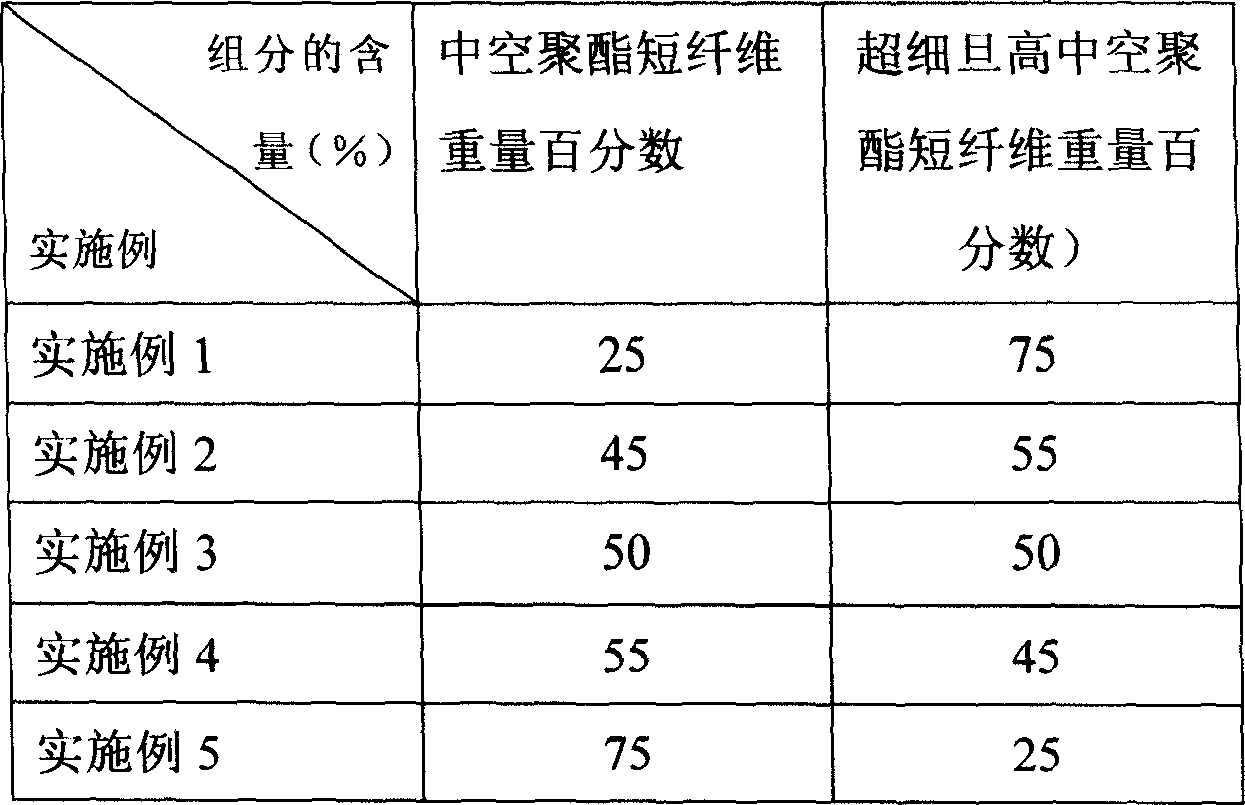

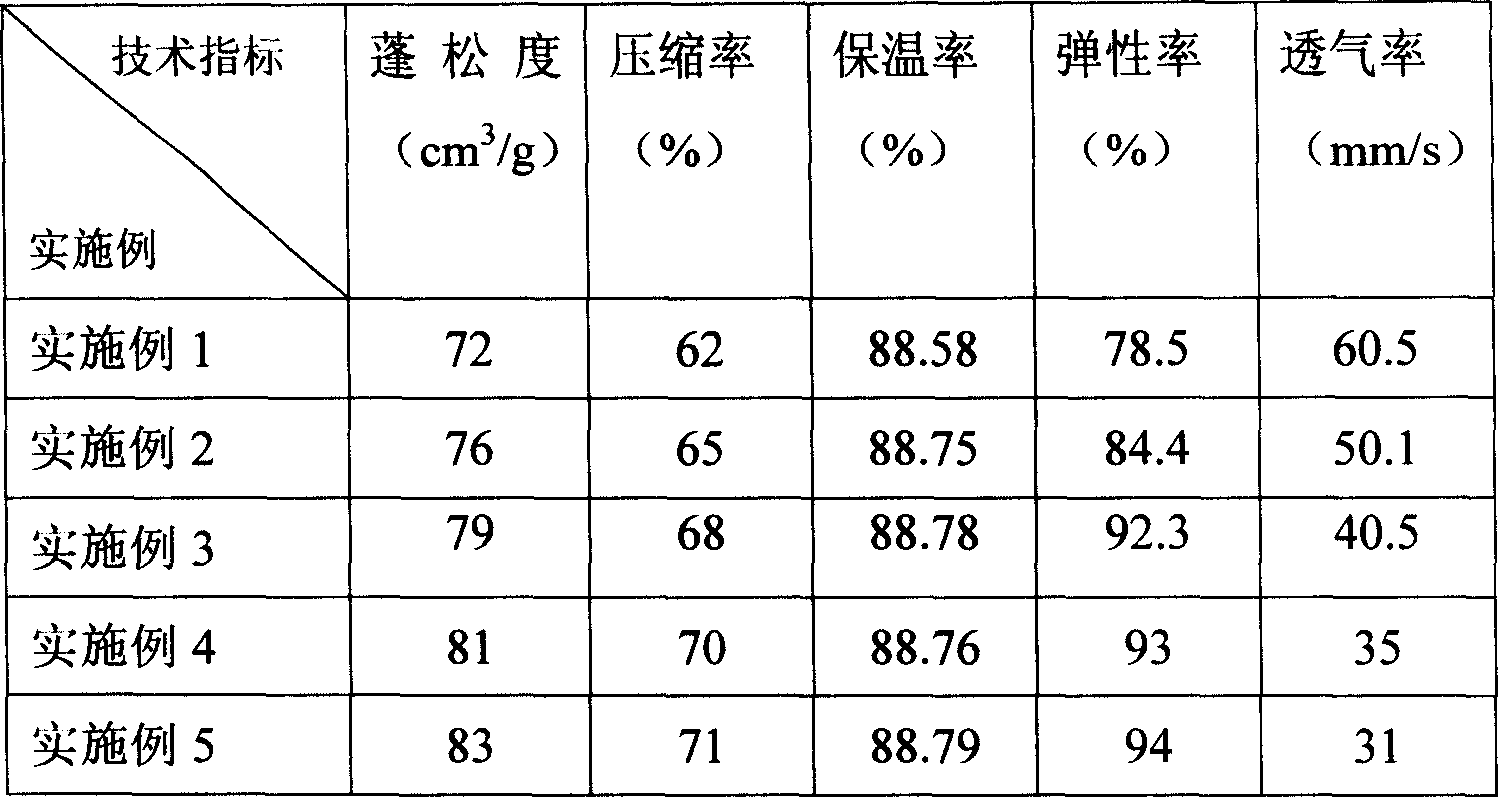

Polyester fiber filling materials and filling process therefor

InactiveCN1966789AWell mixedEvenly filledOakum treatmentHollow filament manufacturePolyesterLife quality

The polyester fiber filler is the combination of the regular hollow cut staple polyester fiber and a superfine super high hollow cut staple polyester fiber. Their weight ratings are hollow cut staple polyester fiber 25%-75%, superfine super high hollow cut staple polyester fiber, with their optimum weight rating of 50%: 50%. It also provides a production process for filling the above said materials through the process of opening picking, mixing, and carding and final air blowing suede. The filled product with this process looks even and trim, it is light, fluffy, sustainable elastic ability, fine heat protection, soft in touching, and provides people with refined living quality.

Owner:上海龙头家纺有限公司

Aromatic polysulphone/antistatic fibre mixed yarn and production method thereof as well as loosening and mixing device

The invention discloses an aromatic polysulphone / antistatic fibre mixed yarn produced in the textile industry and production method thereof as well as a loosening and mixing device adopted in the production. The aromatic polysulphone is 95-99 percent of the mixed yarn, and an antistatic fibre is 1-5 percent of the mixed yarn. In order to solve the problems of uneven permeation of a pretreatment oil agent, which is easily generated in the processing of aromatic polysulphone in a conventional cotton spinning process, and poor cohesive force and serious static electricity in the production of pure aromatic polysulphone, the novel loosening and mixing device is adopted, and the conventional cotton spinning process is improved. In the production process, an aromatic polysulphone fiber and the antistatic fibre are mixed and loosened by the self-designed mixing and loosening device and then carry out the processing procedures of coiling, cotton carding, drawing, roving, fine spinning, spooling, doubling, double-twisting and thermoforming to spin the product. The aromatic polysulphone / antistatic fibre mixed yarn produced by the processing method has even yarn stem, high strength and excellent flame retardant property and antistatic property.

Owner:SHANGHAI TANLON FIBER CO LTD

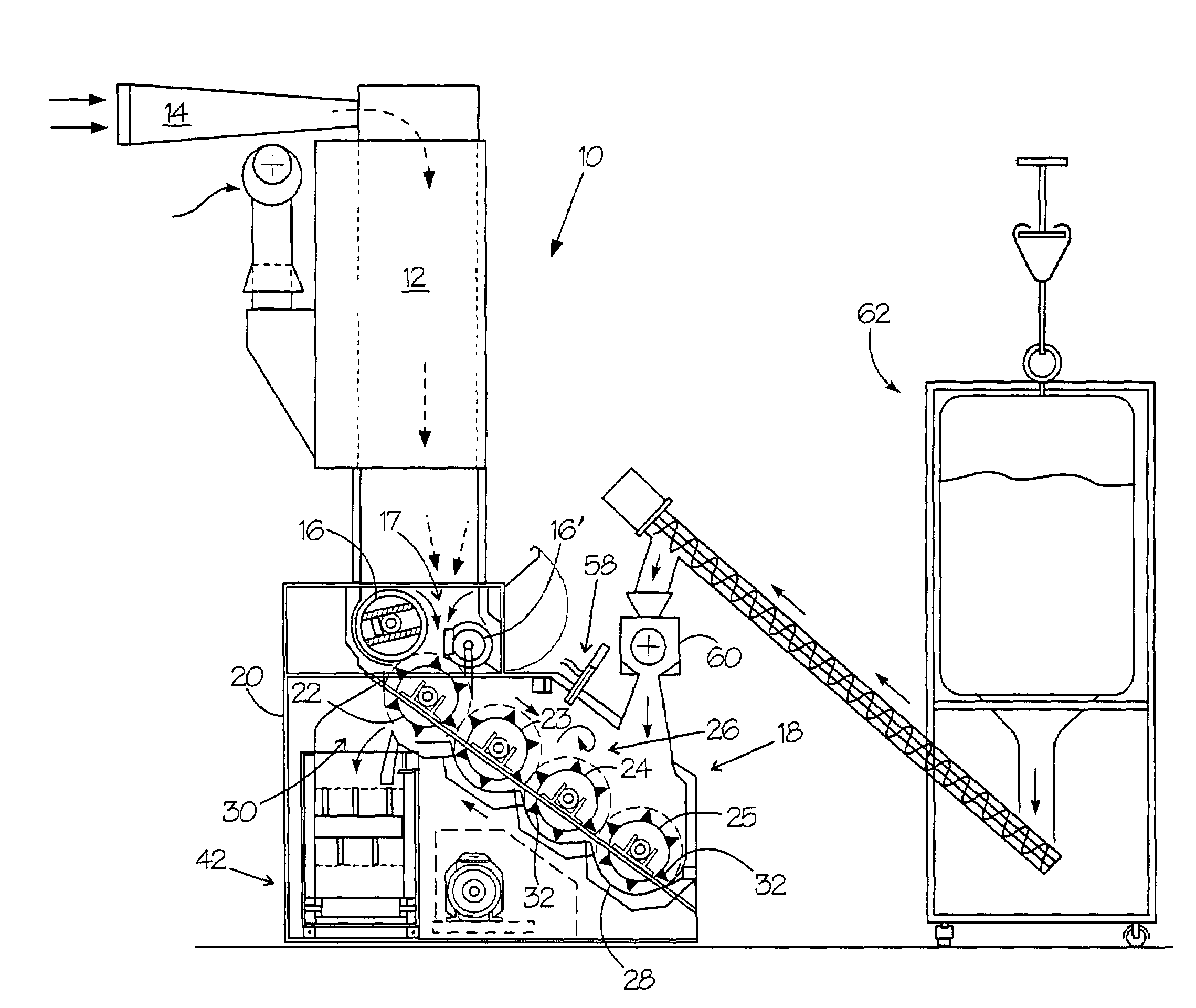

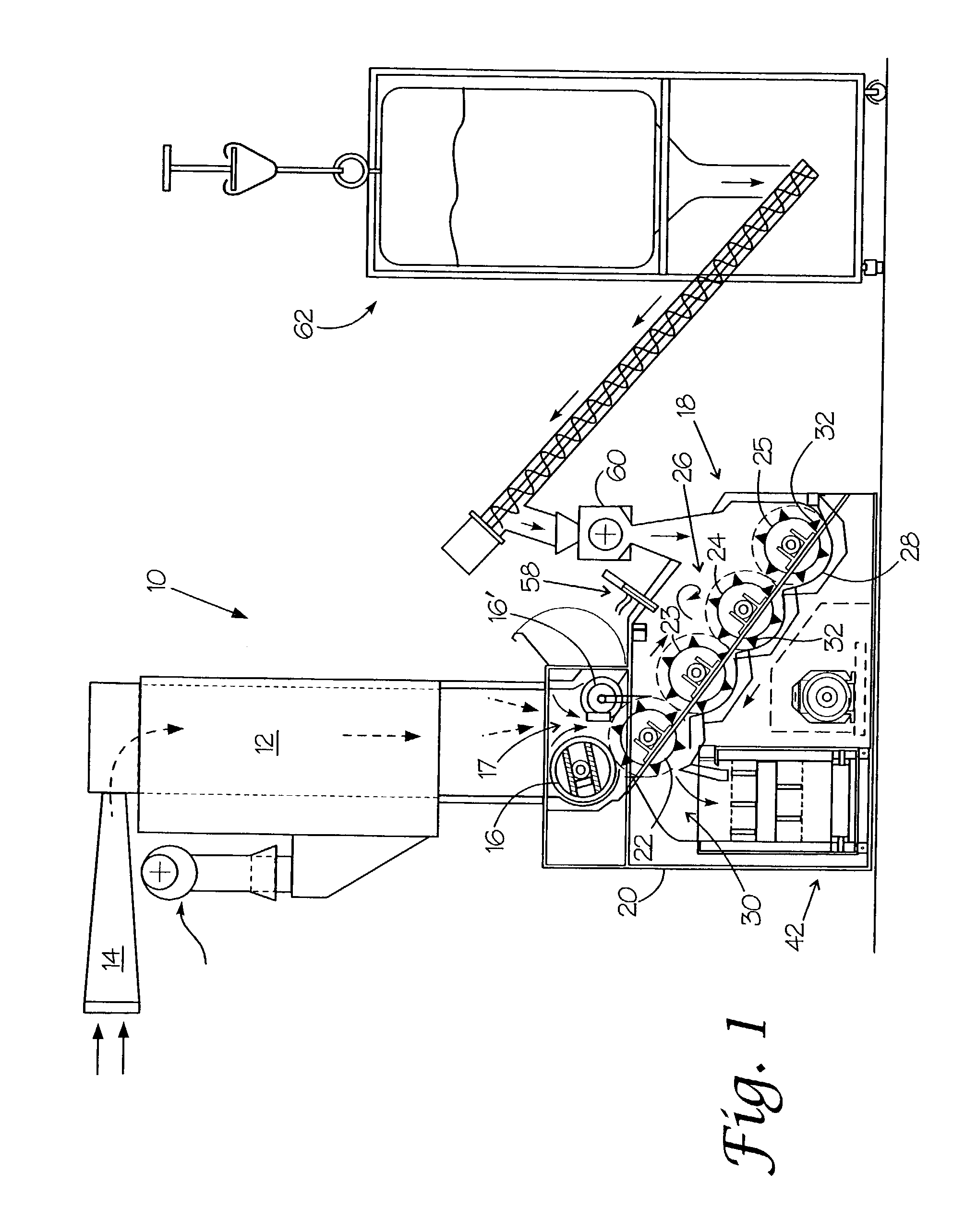

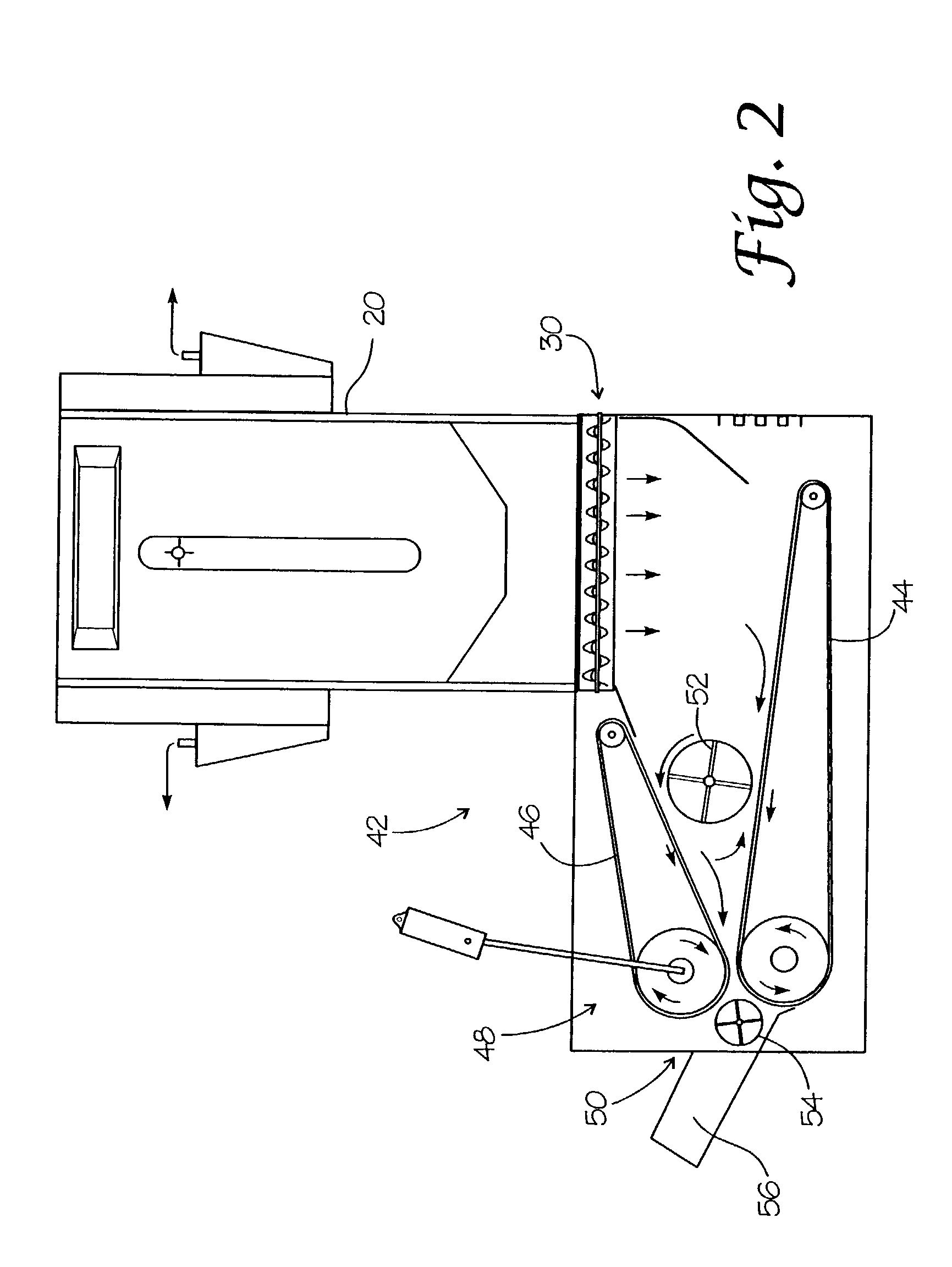

Fiber mixing and opening machine

InactiveUS7032273B2Fibre cleaning/opening by beater armsFibre cleaning/opening by toothed membersFiberMechanical engineering

A fiber blending, opening and cleaning arrangement which includes a feed section for delivering a blend of fibers onto a first opening and blending operation, comprising an array of parallel opening and blending rolls rotating in one direction and arranged along an incline and in adjacent positions. The fibers are passed over the rolls in a first direction and under the rolls in a section direction while being also moved along a sinusoid path. Upon existing the array of rolls, the fibers fall into a fine opening and blending operation which fully mixes the fibers.

Owner:PINTO AKIVA

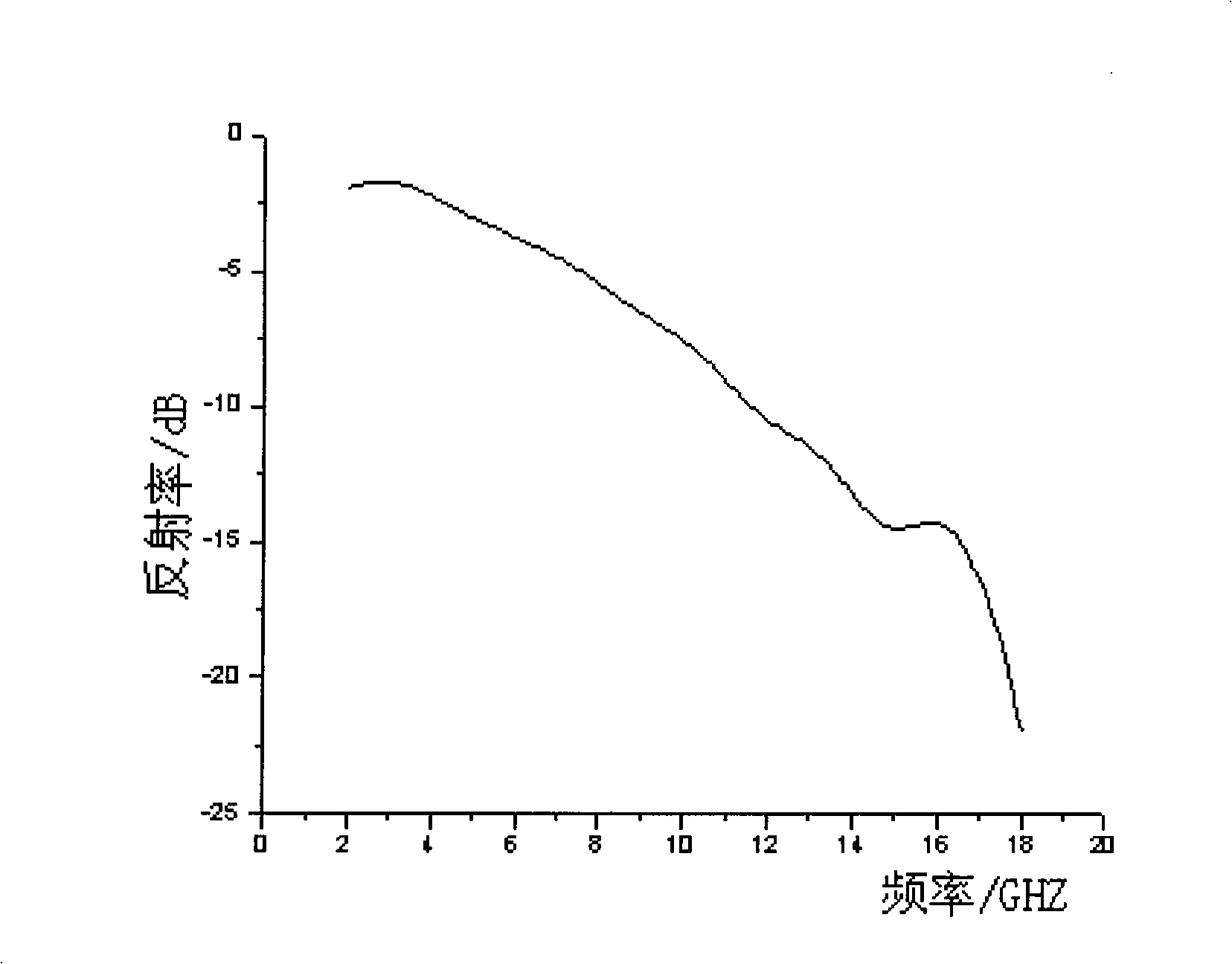

Method for preparing flexible non-weaving suction wave material and product thereof

InactiveCN101407975ASimple processEase of industrial implementationMagnetic/electric field screeningFibre mixingFiberPolyester

The invention relates to a preparation method of flexible non-weaving wave-absorbing materials, and products thereof. The wave-absorbing material is non-weaving cloth of wave-absorbing carbon fiber and polyester through mixed needle punching, wherein, the mass percentage content of the carbon fiber is 5 to 10 percent, and the mass percentage content of polyester fiber is 90 to 95 percent; the preparation method comprises the steps of: (1) the selecting and matching of fiber materials; (2) fiber mixing; (3) carding and netting; (4) lapping; and (5) solidification. The invention has the beneficial effects that: (1) the process of the preparation method is simple, has easy control and easy implement of industrialization, and can guarantee the performance of the product to be reliable, the quality to be stable and the cost to be low; and (2) the products have excellent performance, good wave-absorbing effect, light texture, easy spreading and rolling and storage, convenient use, easy processing into a plurality of forms, and flexible use manner, and are suitable for large-area wave-absorbing layers of tent cover materials, for example, the products can be made into gun covers, tarpaulin, and tents used for armies and warehouses, and the like, and also can be made into a plurality of patterns which can be used as anti-electromagnetic radiation products for civilian use.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com