Cotton blending machine

A technology of cotton blending machine and body, which is applied in the fields of fiber mixing, textile and papermaking, fiber processing, etc., can solve the problems of cotton accumulation in the machine, no fire extinguishing device, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

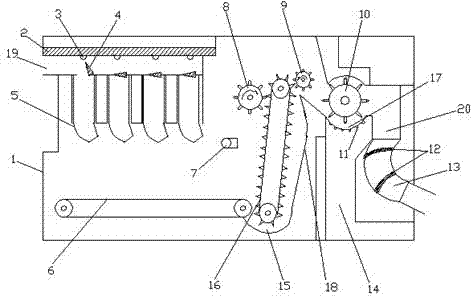

[0011] refer to figure 1 The cotton mixing machine shown includes a body 1, the front end of the body 1 is provided with a cotton inlet chamber 19, and a cotton distribution pipe 5 is provided below the cotton inlet chamber 19, and a water pipe 2 is provided above the cotton inlet chamber 19, The water pipe (2) is provided with a plurality of spouts 3, and the upper end of the cotton distribution pipe 5 is provided with a movable block 4, which can close the cotton distribution pipe 5, and the lower end of the cotton distribution pipe 5 is curved. The cotton tube 5 is rotatable, and the cotton feeding conveyor belt 6 is arranged below the cotton distribution tube 5, and the corner nail curtain 15 is arranged behind the cotton sending conveyor belt 6, and the corner nail curtain 15 is arranged obliquely, and the corner nail curtain 15 is arranged in front of the corner nail curtain 15. Cotton equalizing roller 8 is provided, and stripping roller 9 is provided at the rear upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com