Easy-to-dye terylene BCF and method for preparing same

A polyester and polyester slicing technology, applied in the polyester field, can solve the problems of difficult dyeing, low raw material cost and high cost, and achieve the effects of broad market prospects, low material cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

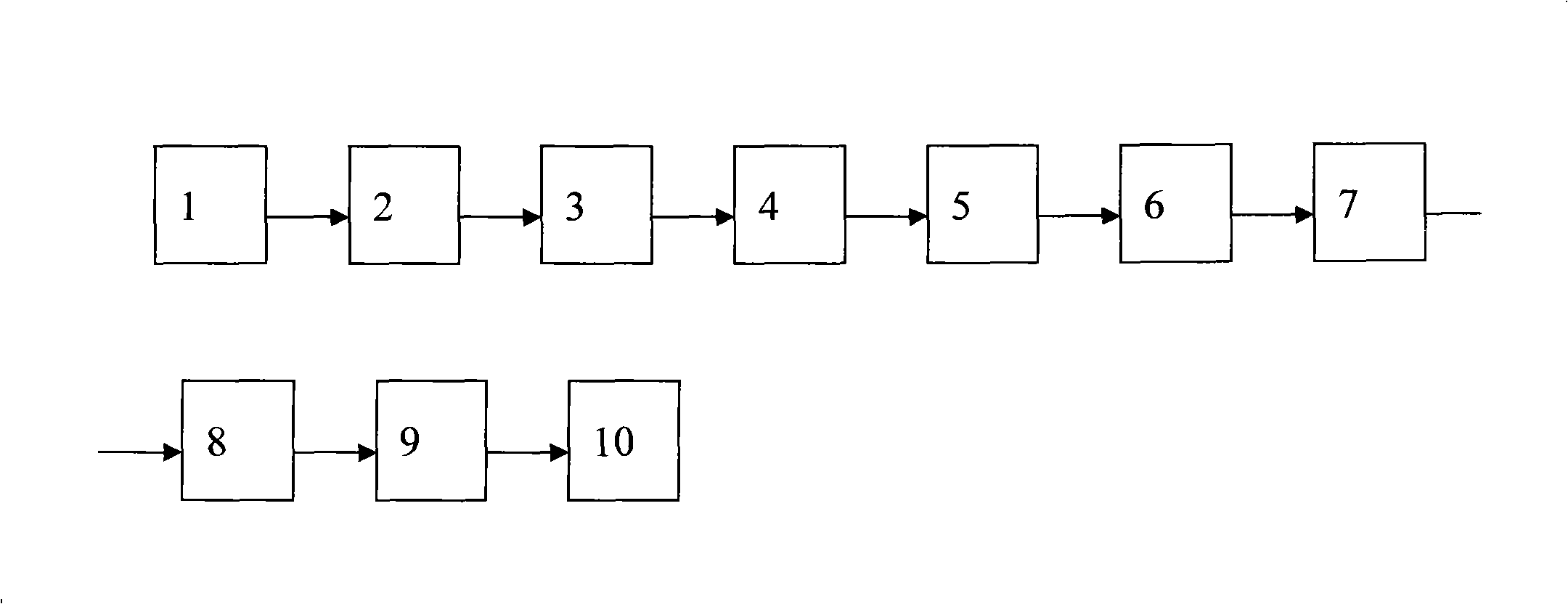

Image

Examples

Embodiment Construction

[0026] Examples of easy-to-dye polyester BCF:

[0027] An easily dyeable polyester BCF is a three-dimensional bulked filament of easily dyeable polyester, and its structure is a trilobal or Y-shaped microporous structure.

[0028] Quality Index:

[0029] 1. Breaking strength: ≥2.5CN / dtex;

[0030] 2. Elongation at break: 30-50%;

[0031] 3. Boiling water shrinkage: ≤5%;

[0032] 4. Hot crimp elongation: ≥16%;

[0033] Easy-to-dye polyester BCF preparation method embodiment:

[0034] (1) Polyester raw material slices are pre-crystallized and dried through a dryer: the polyester raw materials are first sliced, and the polyester slices are pre-crystallized and dried through a dryer so that the moisture content is less than 0.005% (50PPM), and the pre-crystallization temperature is controlled at: 155 °C; the drying temperature is controlled at 142 °C.

[0035] (2) Melting of raw materials: the extruder is set at a temperature 30°C higher than the melting point of the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com