Patents

Literature

309results about "Lap-winding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

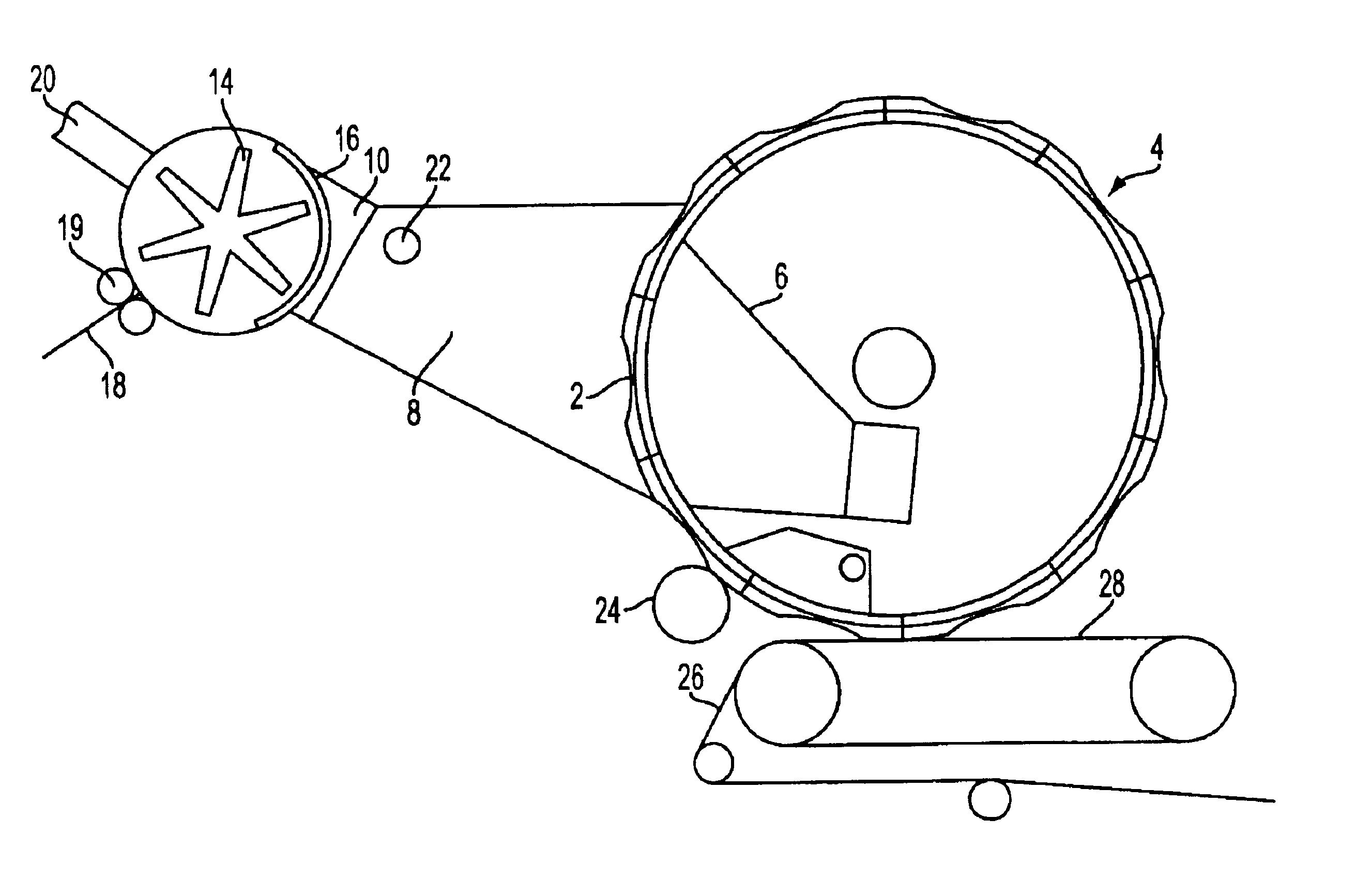

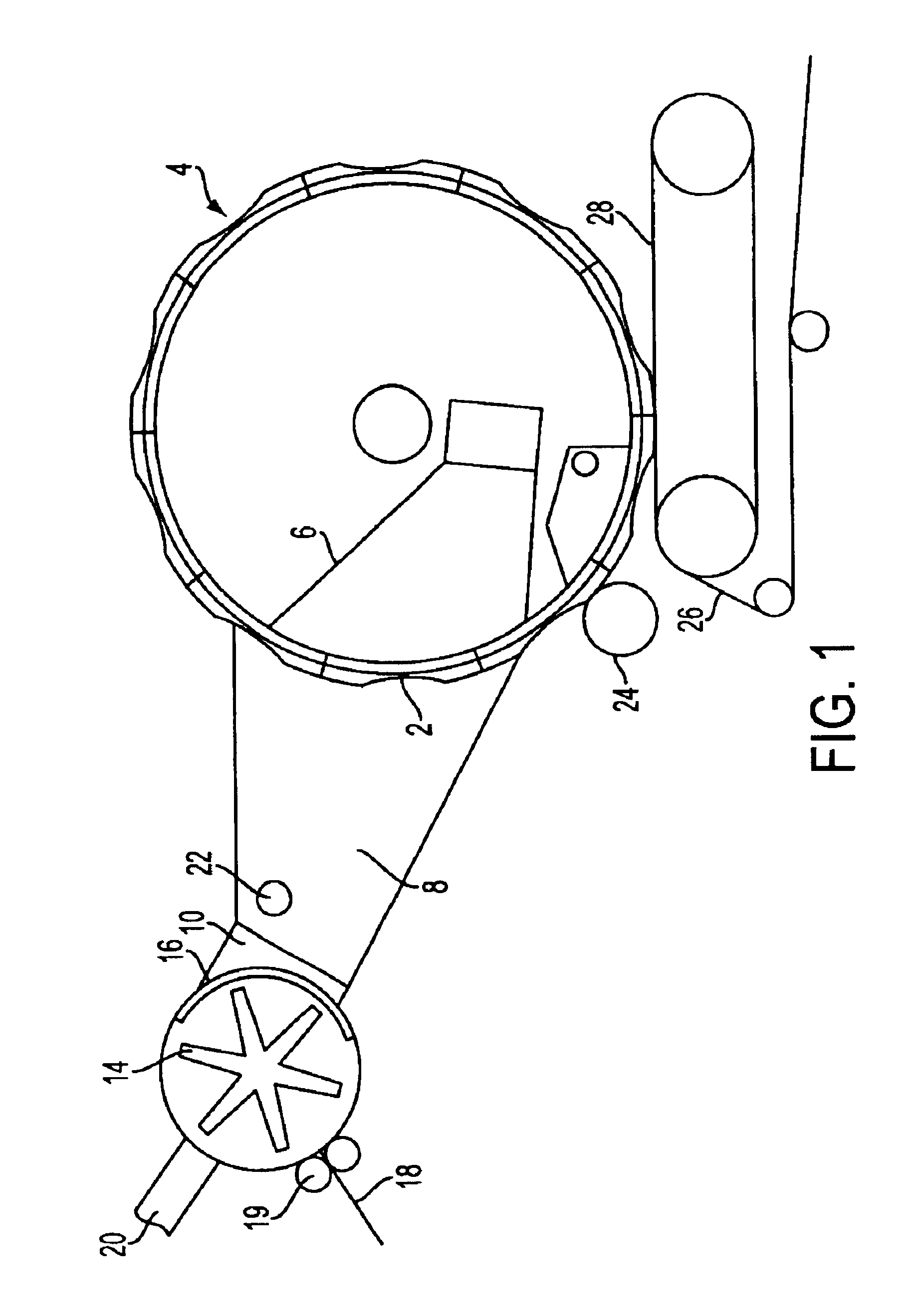

Apparatus for forming controlled density fibrous pads for diapers and the other absorbent products

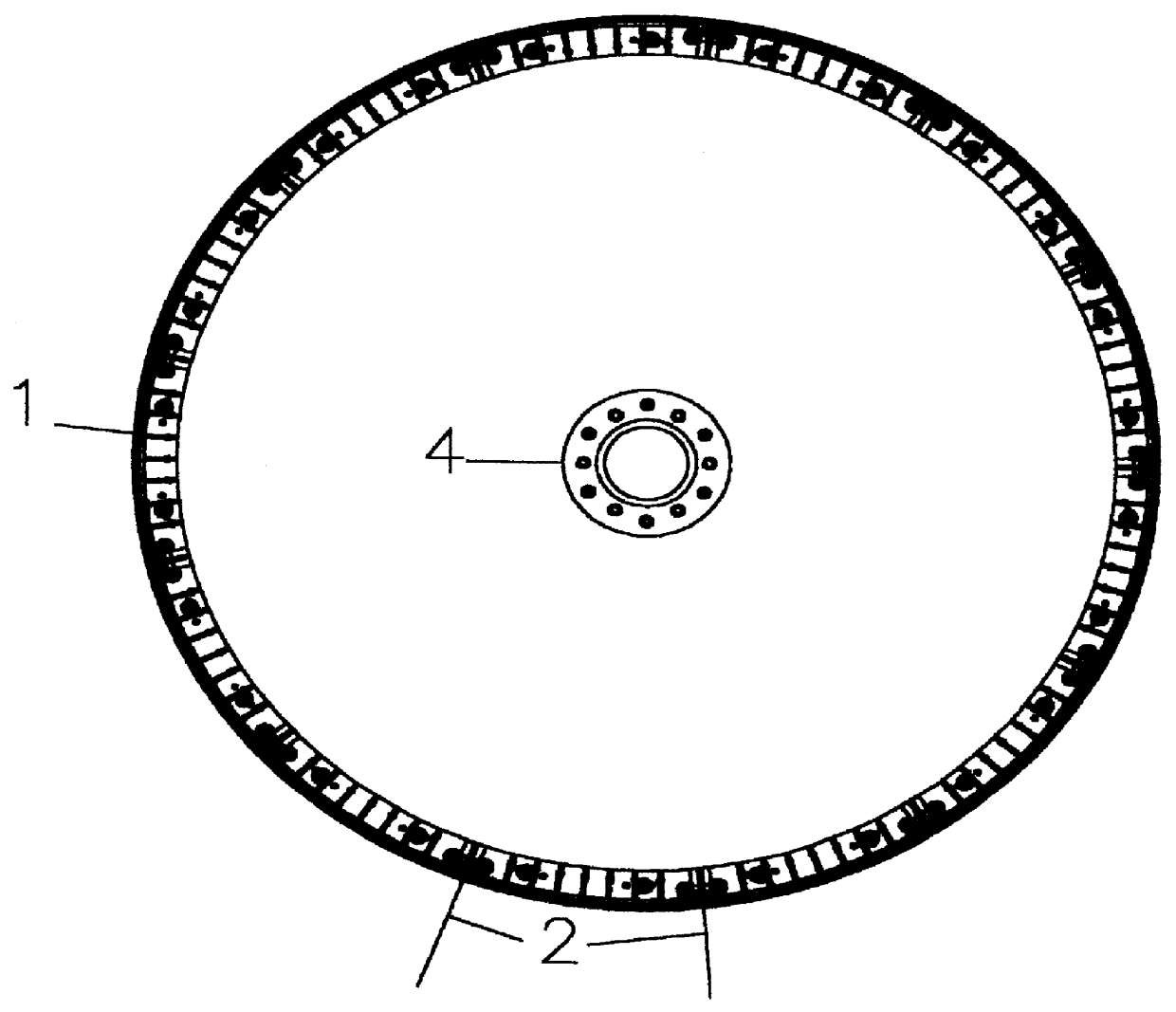

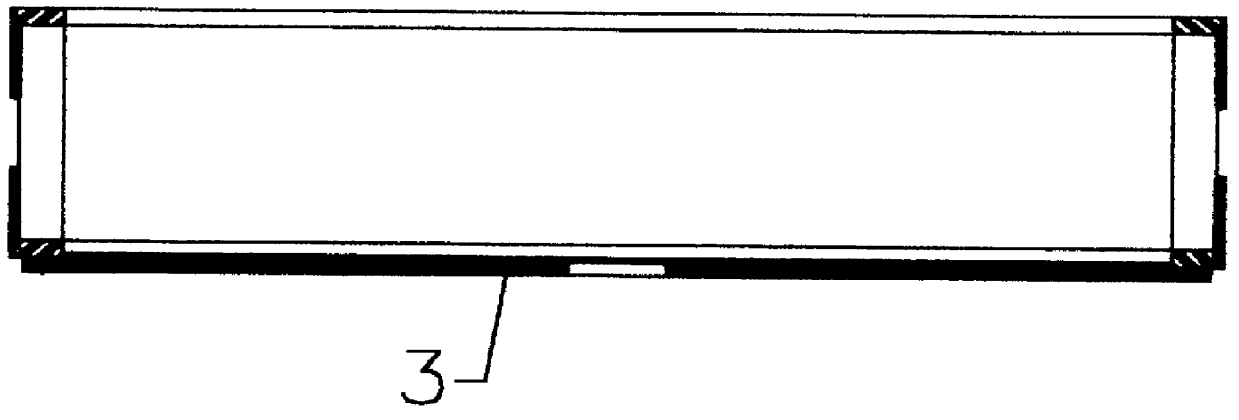

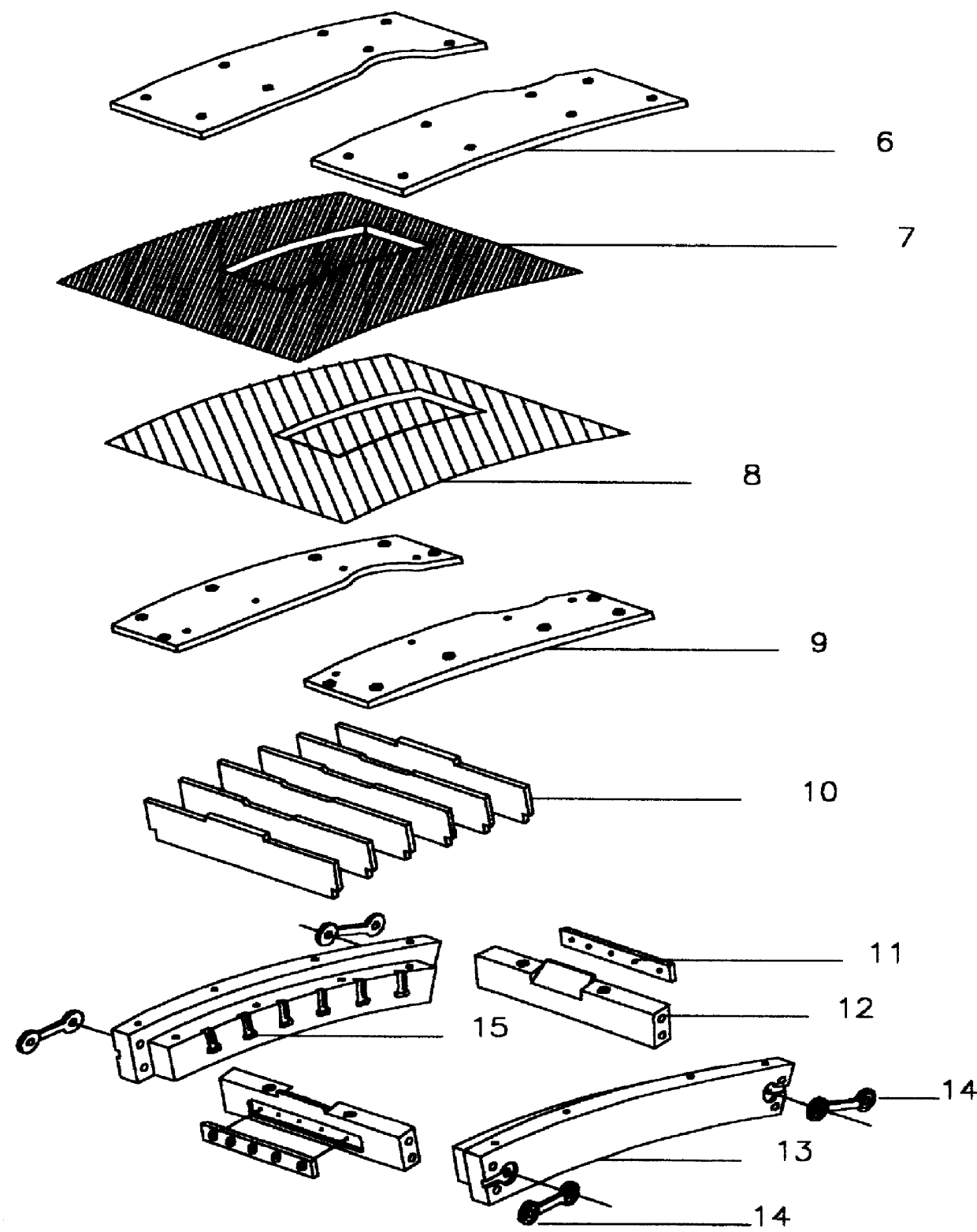

The present invention provides an improved apparatus for forming a fibrous pad for absorbent products with improved density control. Fibers entrained in a high speed air flow are deposited onto the foraminous surface of a spaced, three-dimensional pad-forming pocket. The fine foraminous pad forming screen is supported on its periphery by two top plates, a coarse forming screen, two subplates and end rails which incorporate a device to hold the pad forming screen. A gas flow regulating system consisting of precisely placed cross directional fixed and adjustable airflow control louvers controls the air flow direction and reduces spill over and turbulence during the pad formation and especially during the transition of the forming pocket into and out of the air stream as the rotary former shell rotates through the filling position. Additional control of density and fiber placement is gained through the use of additional gas control innovations including a tapering the pocket ends such that the airflow is streamlined especially during pocket transition through forming sections.

Owner:TONEY JERRY L +3

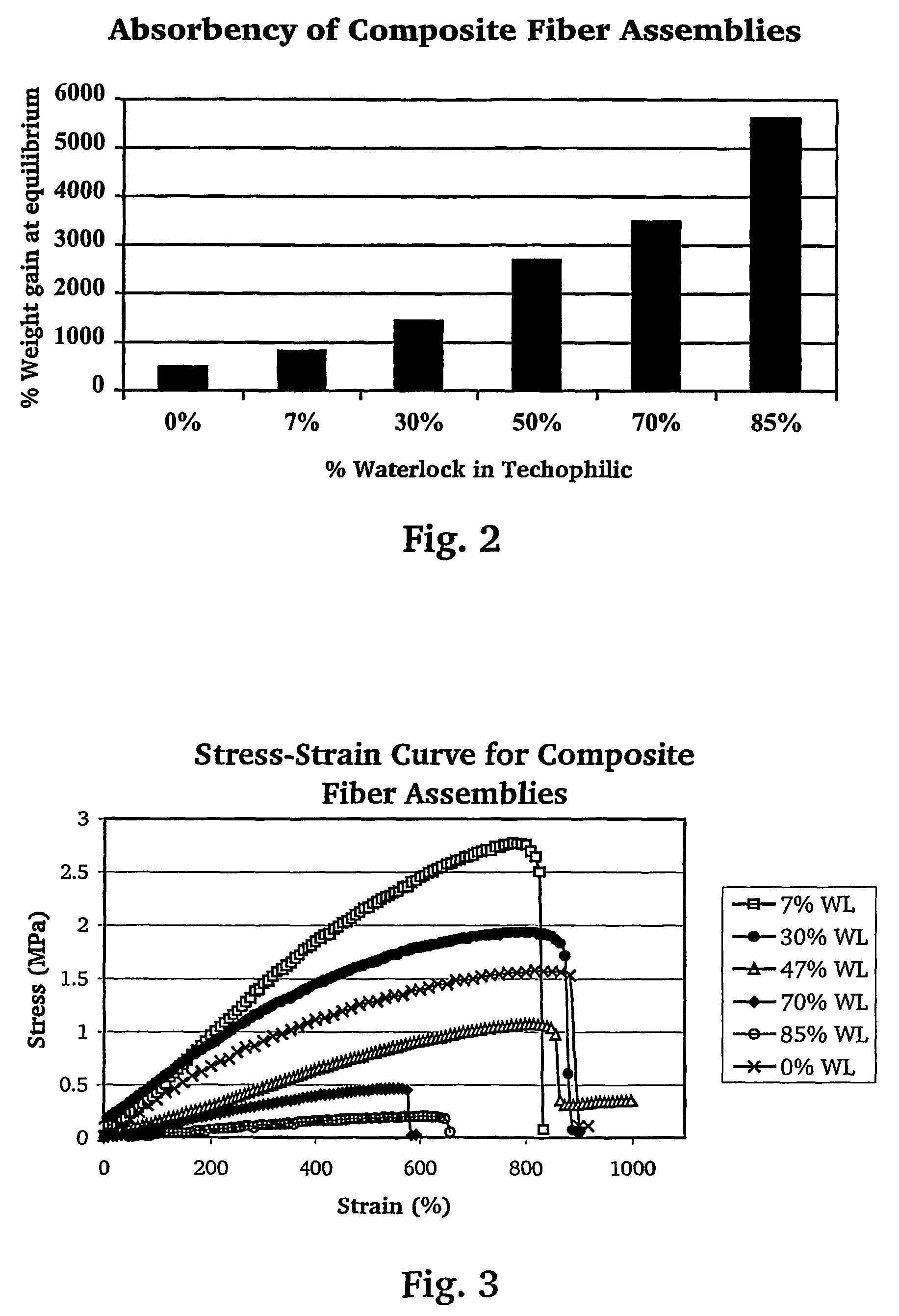

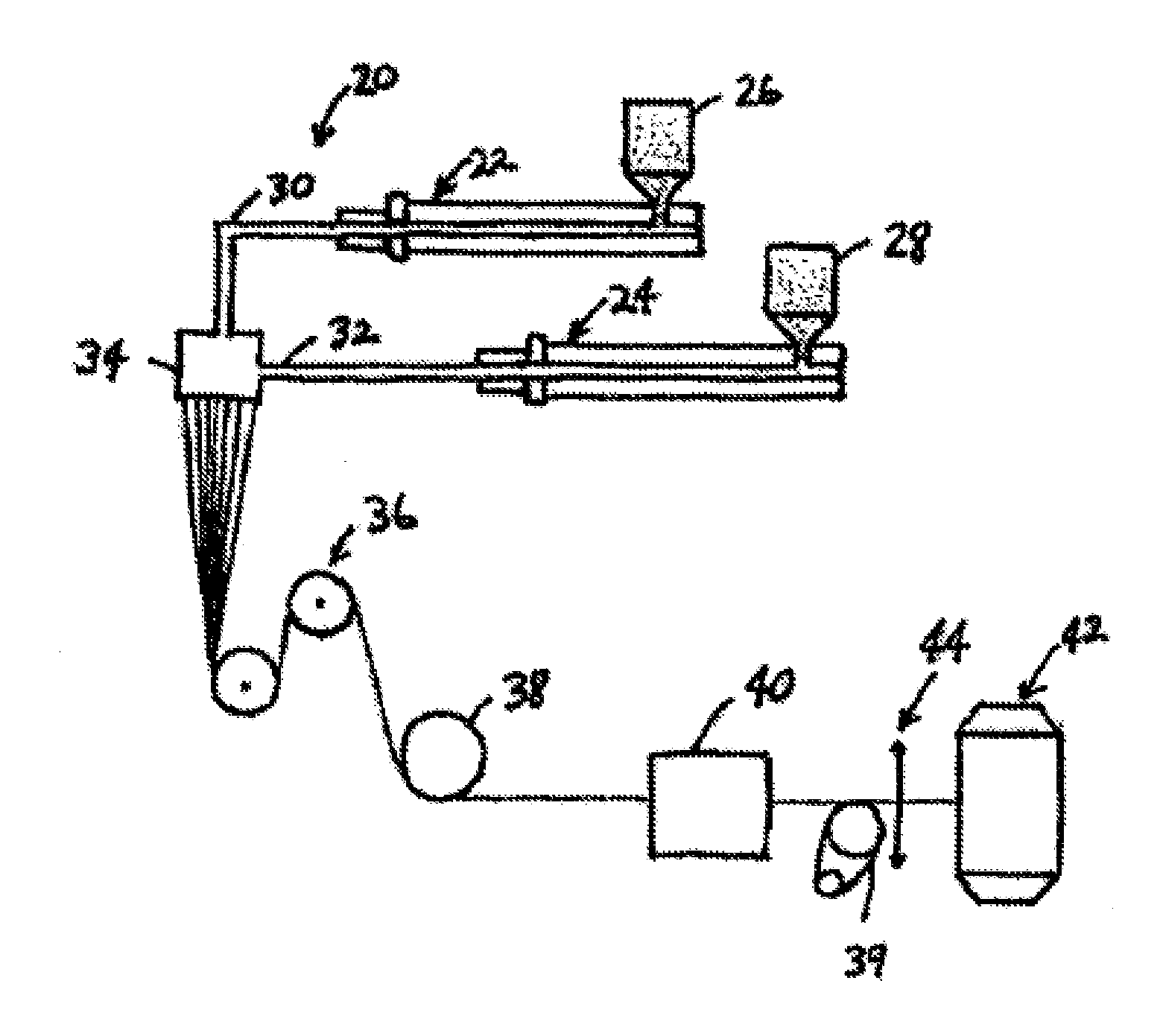

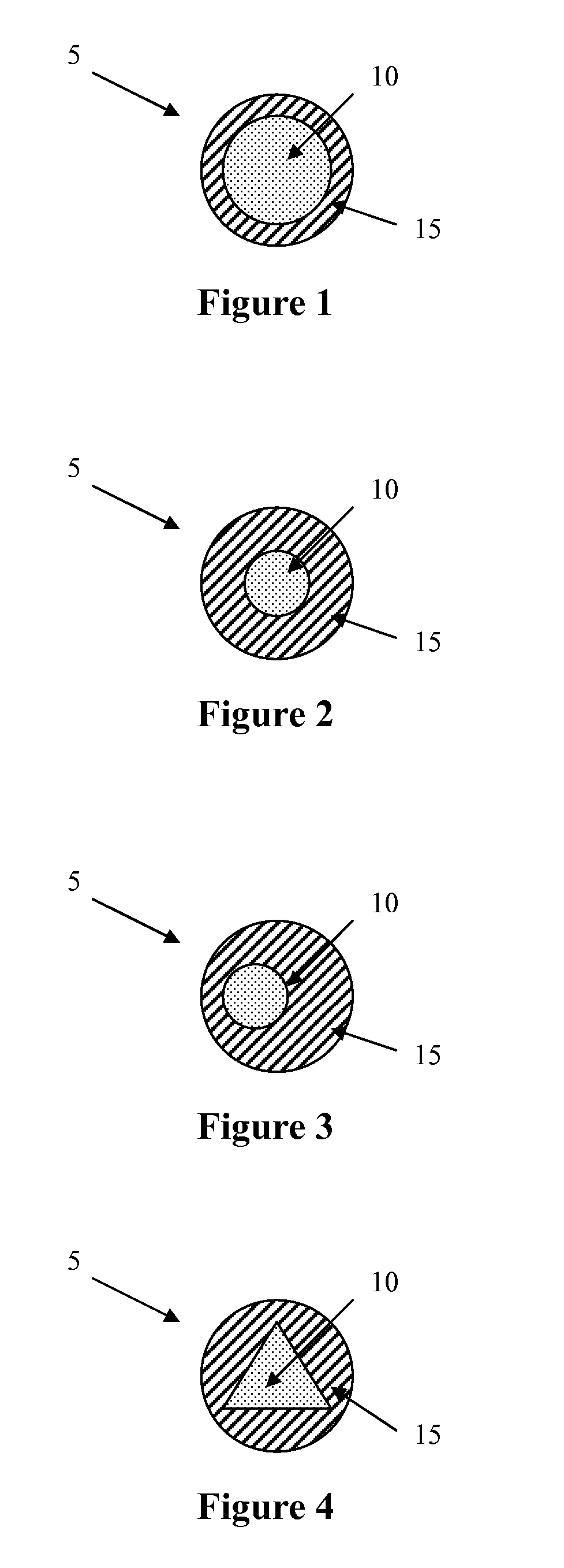

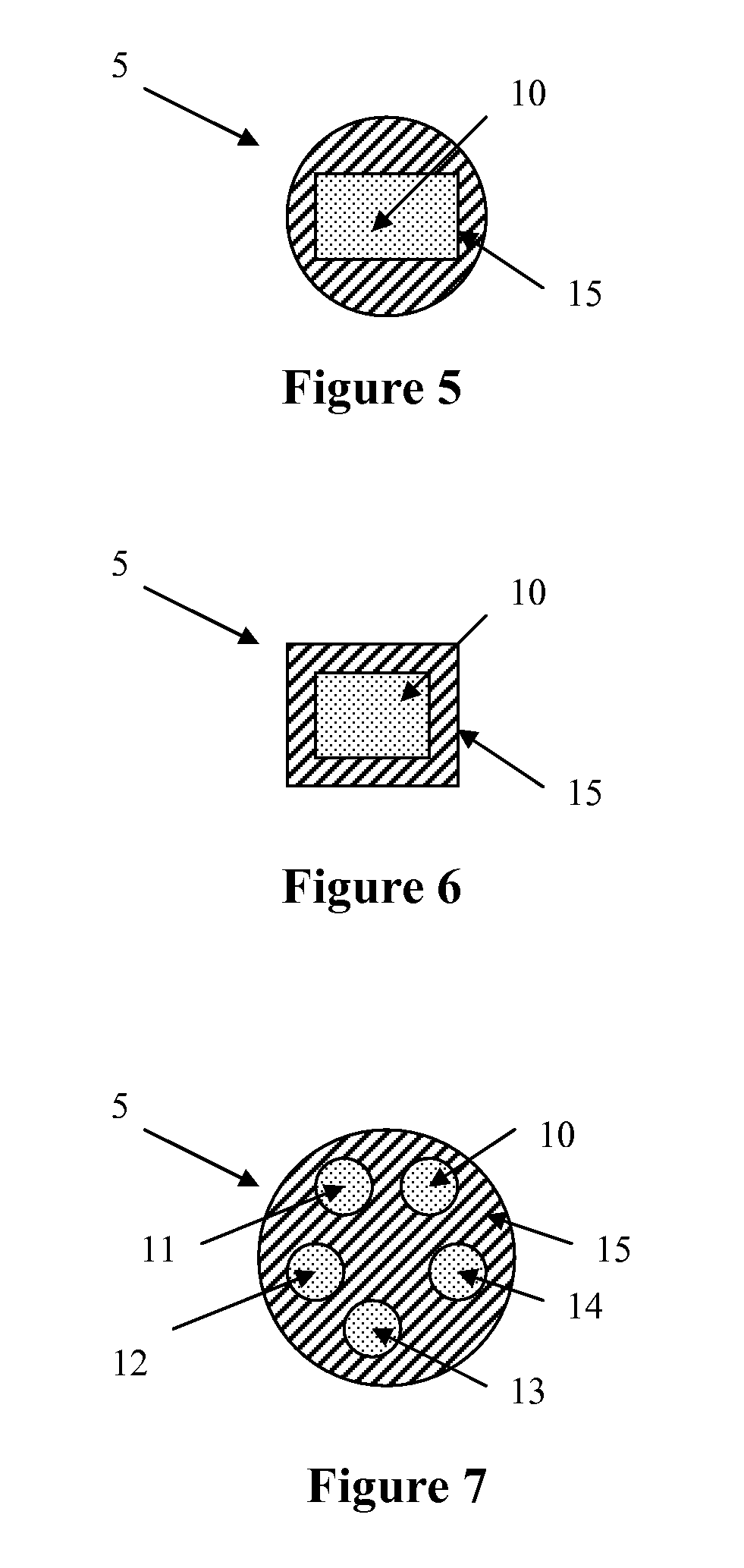

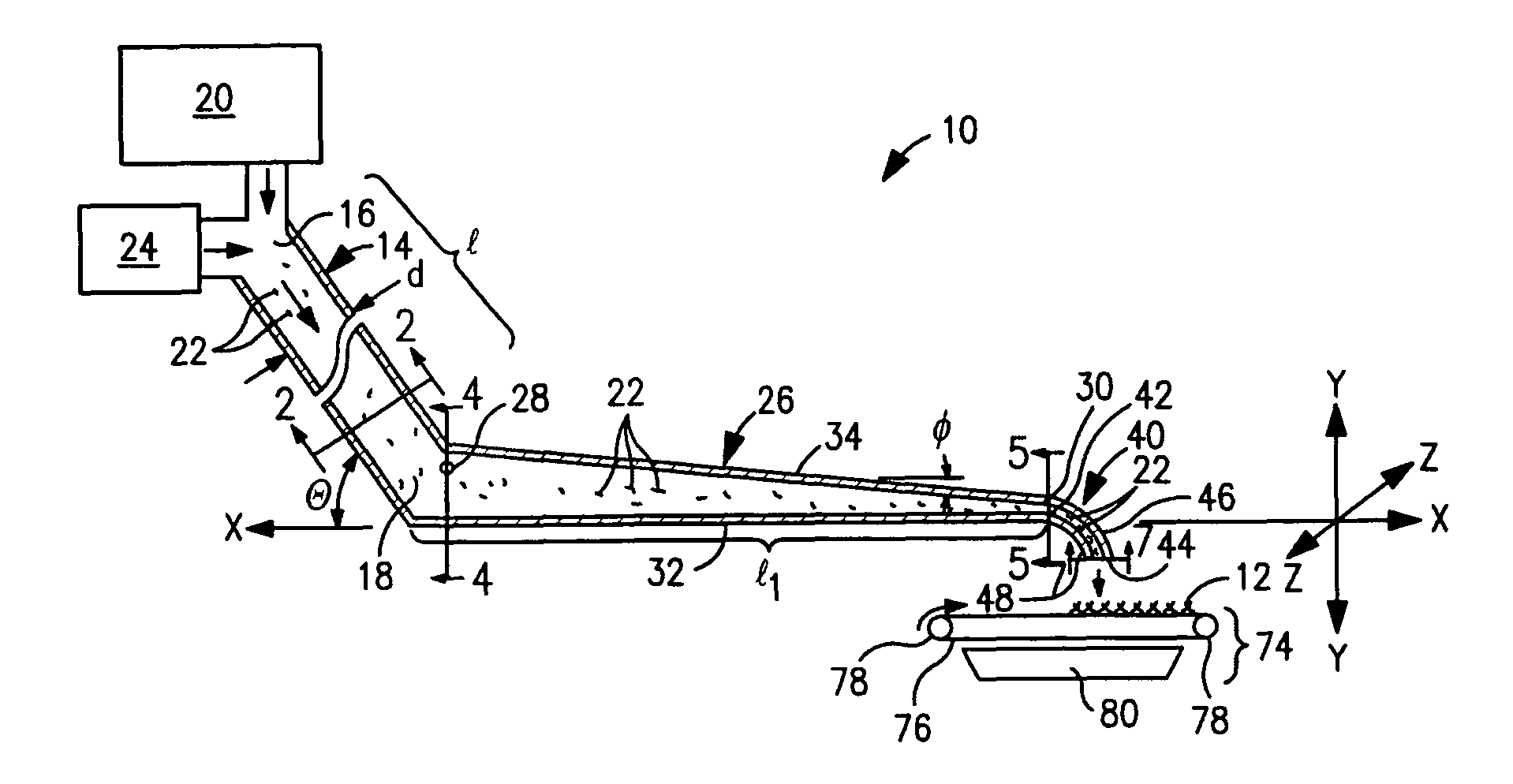

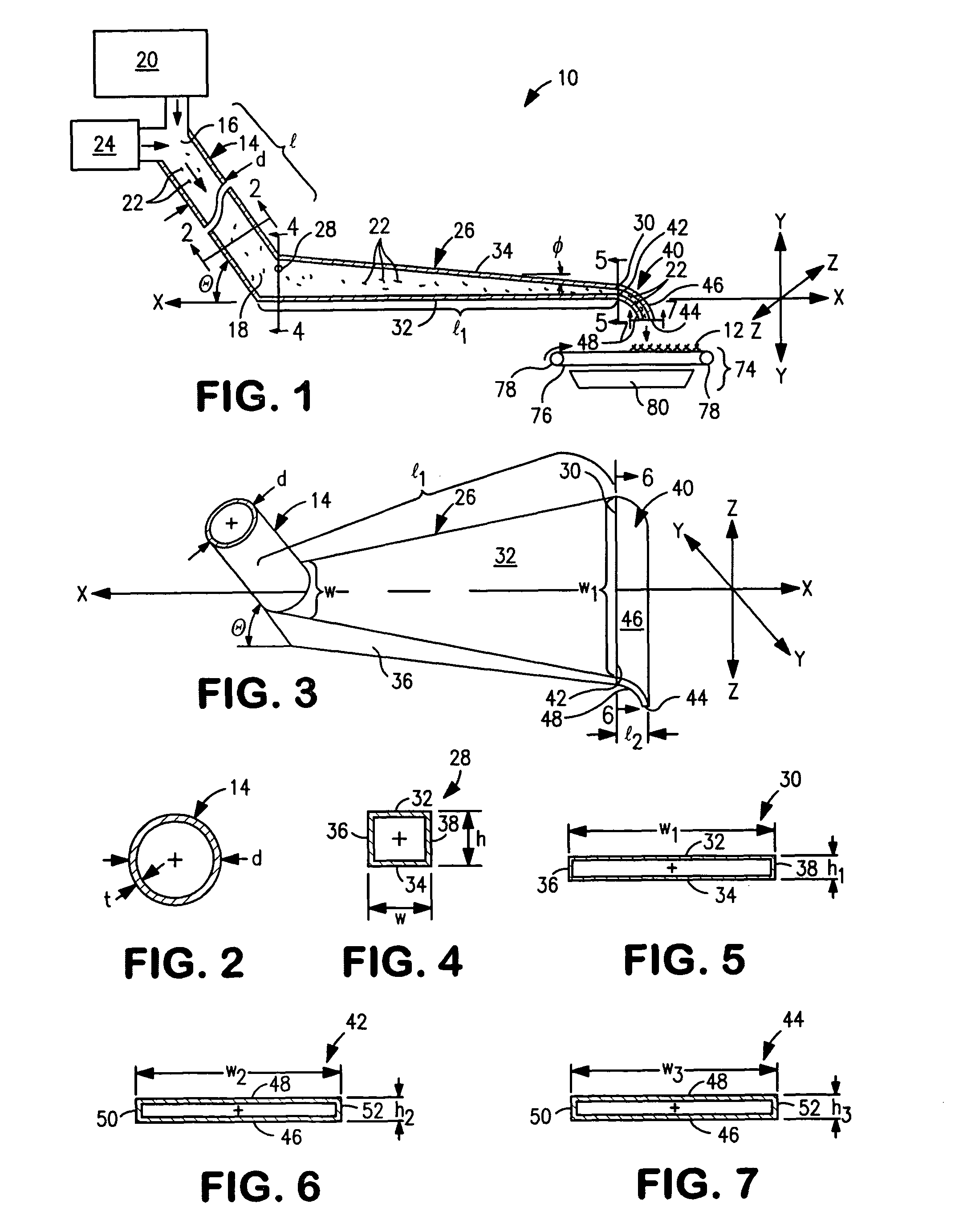

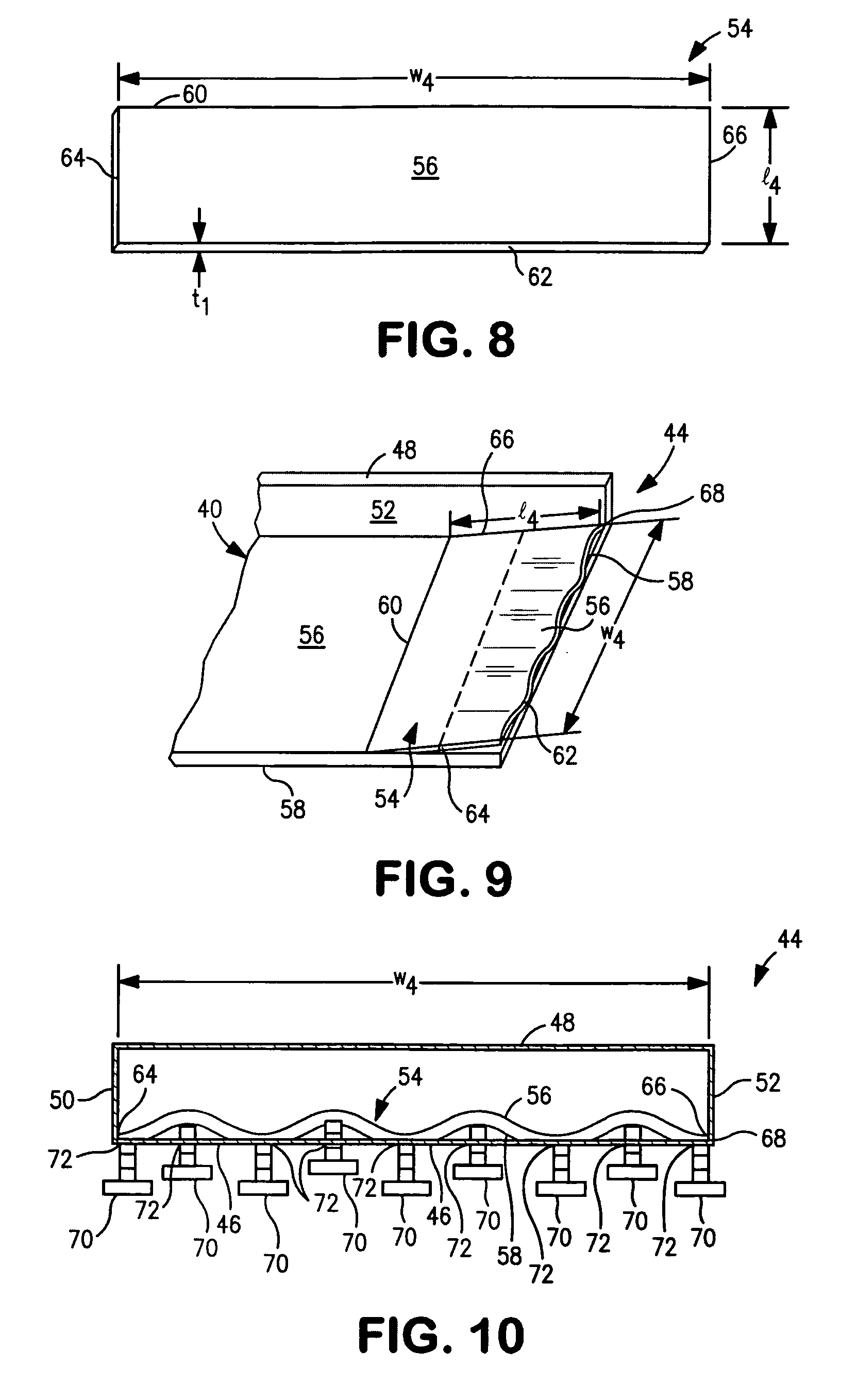

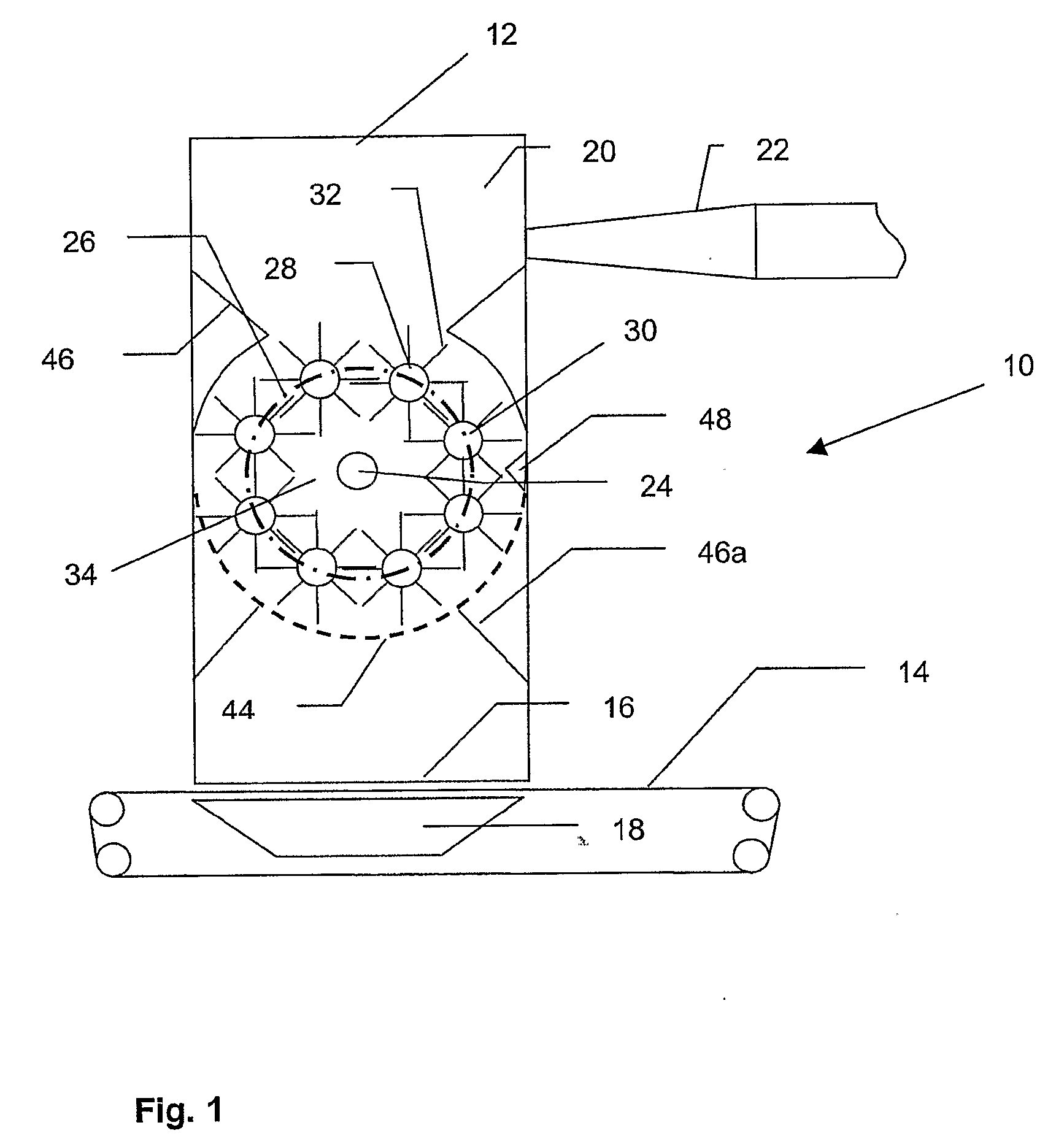

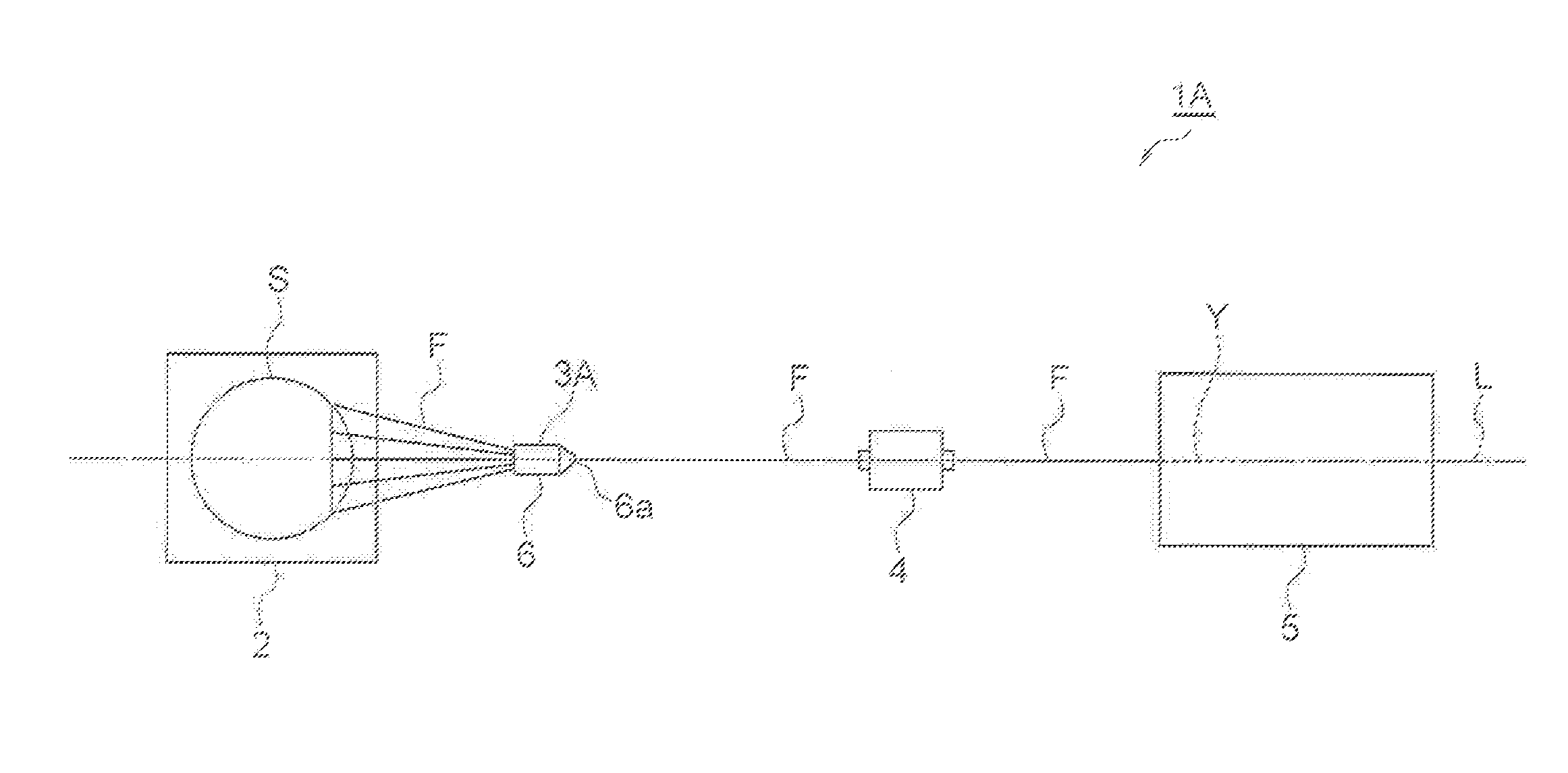

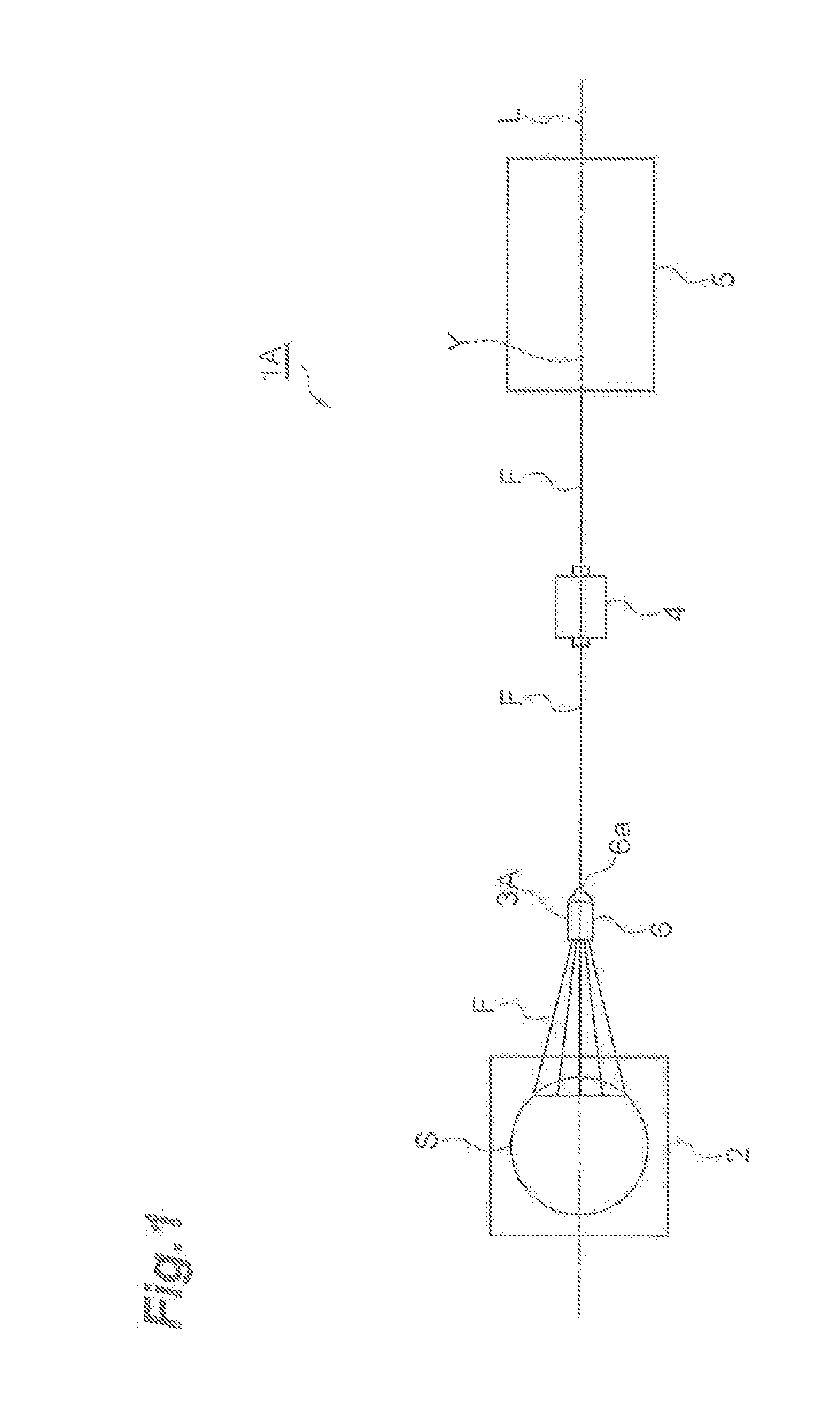

Non-woven fiber assemblies

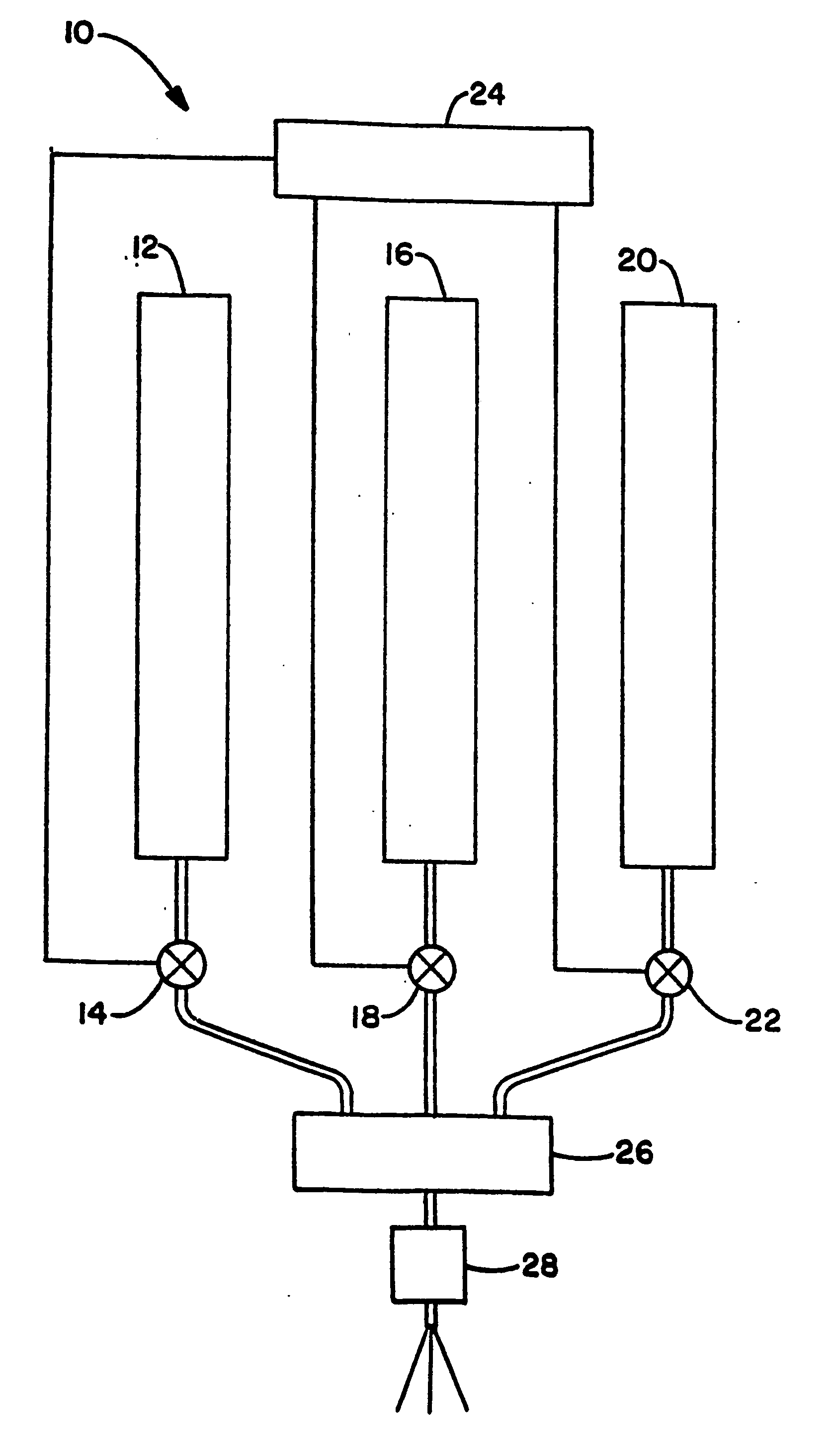

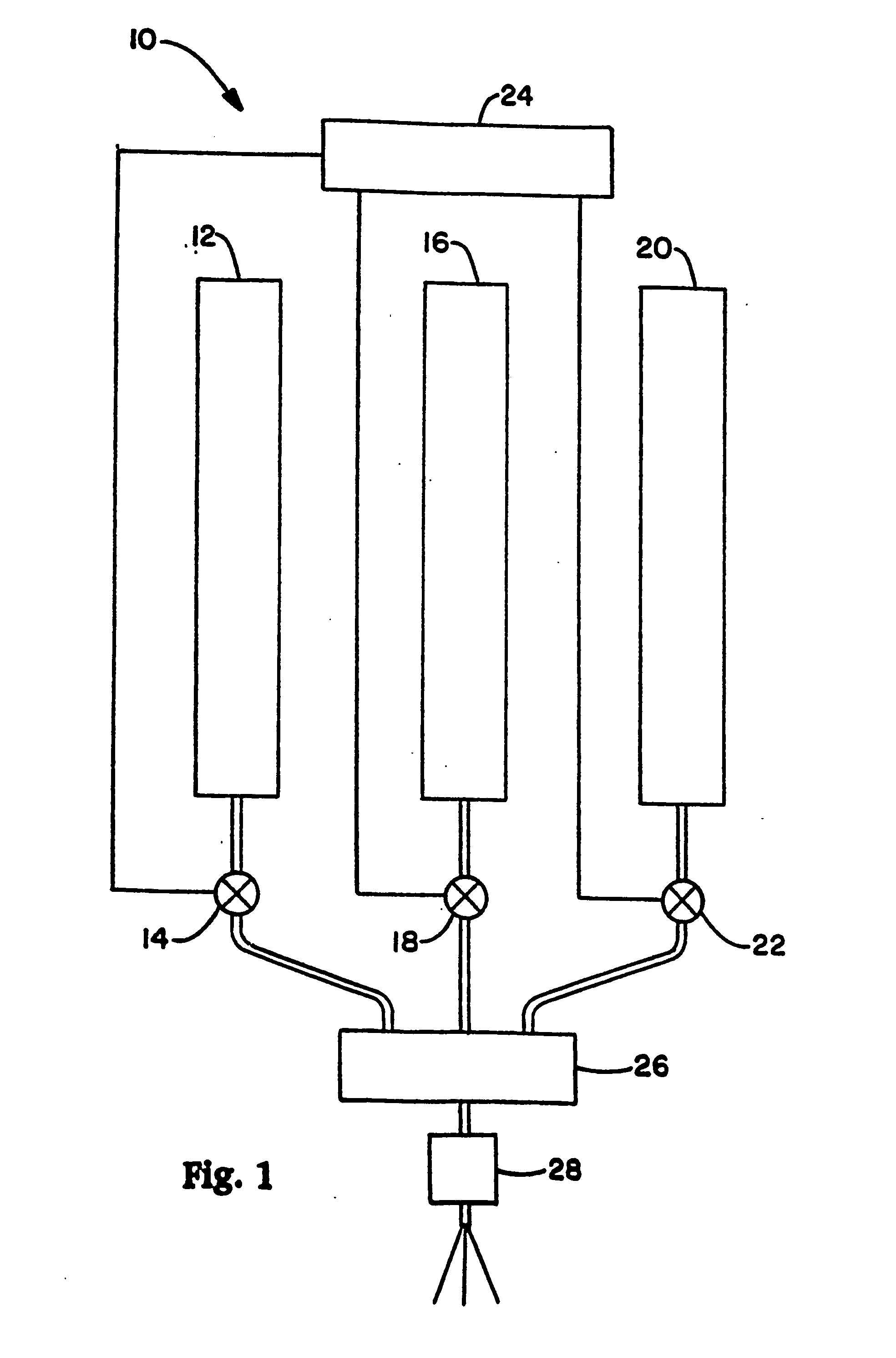

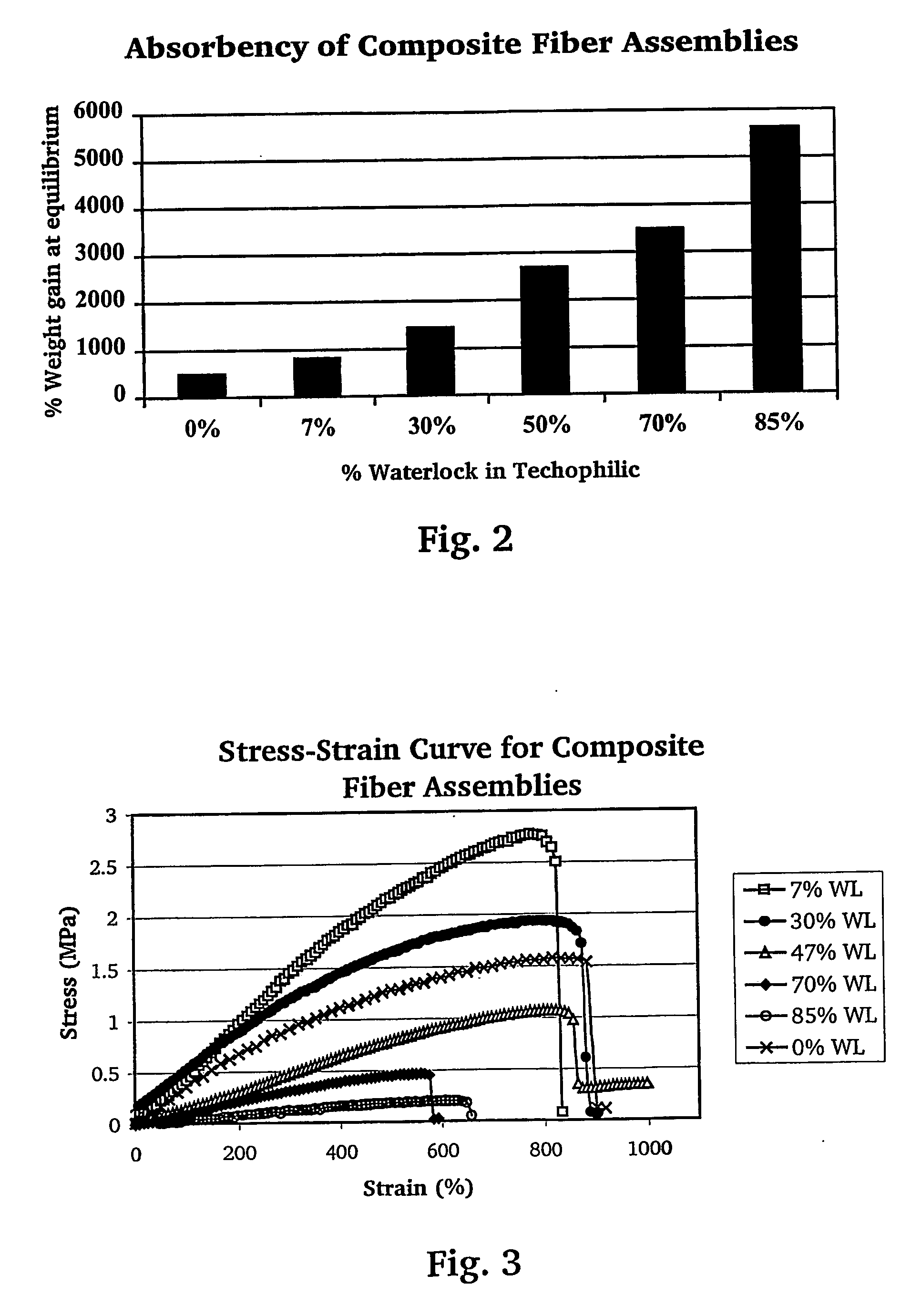

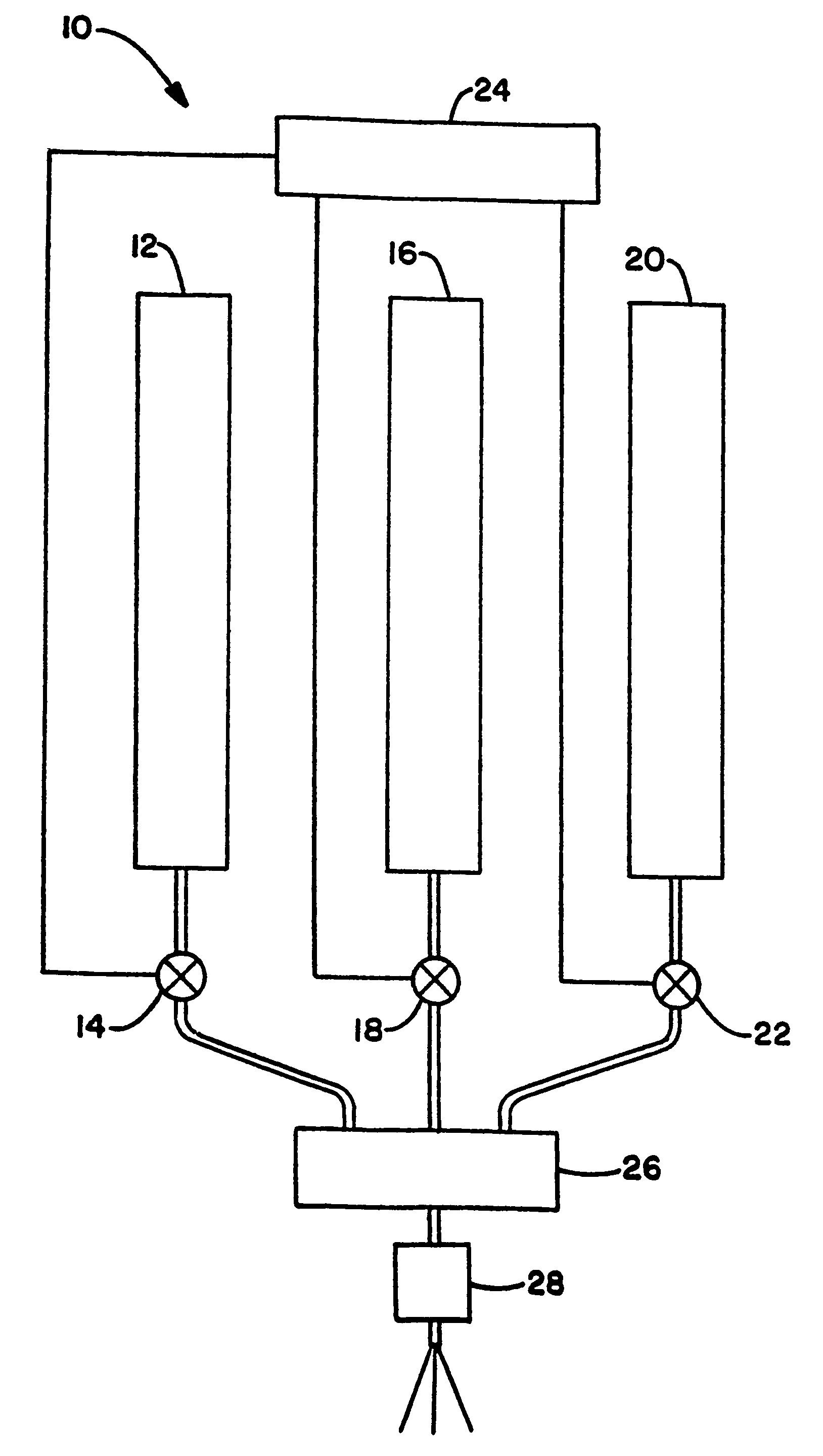

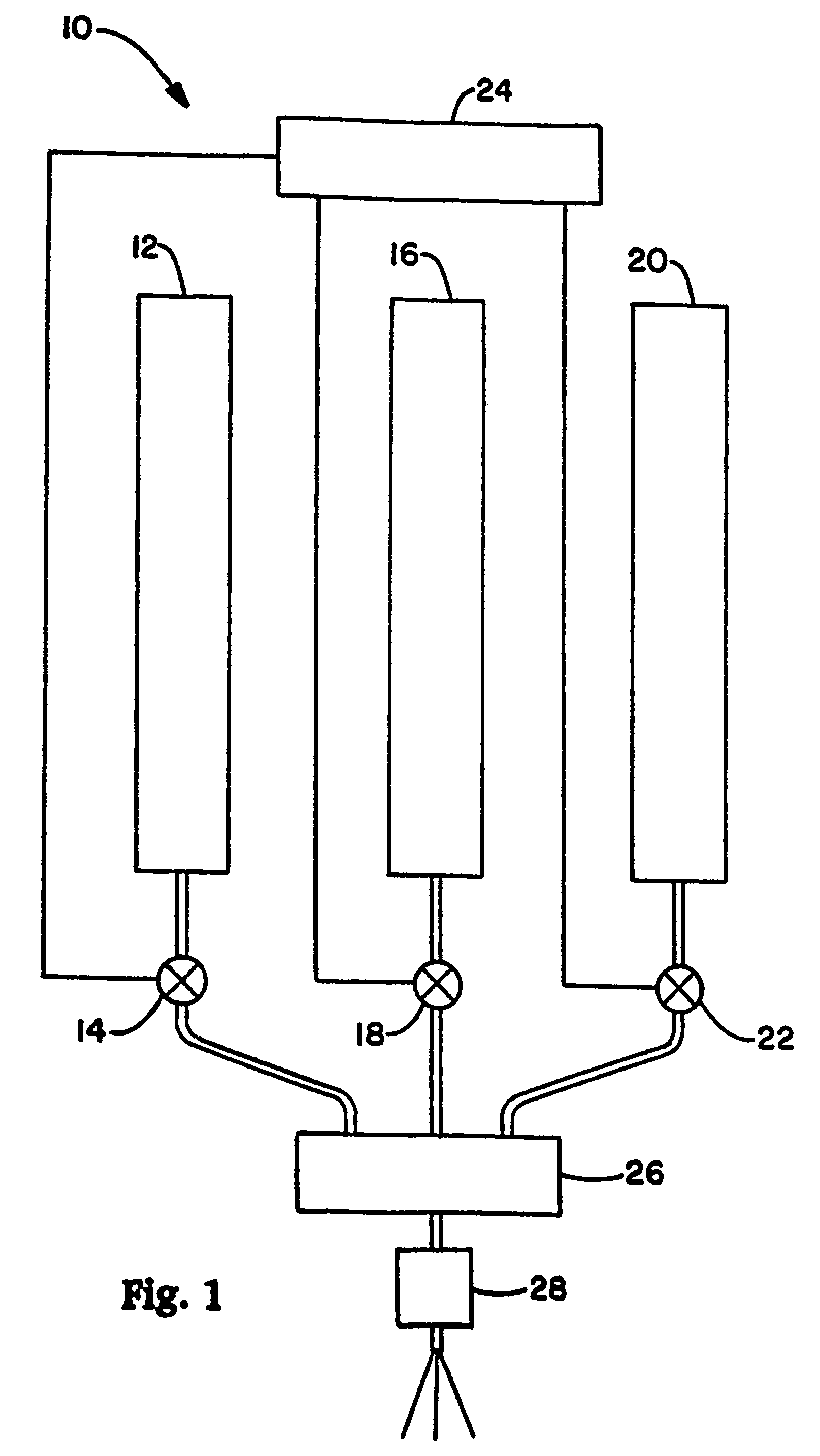

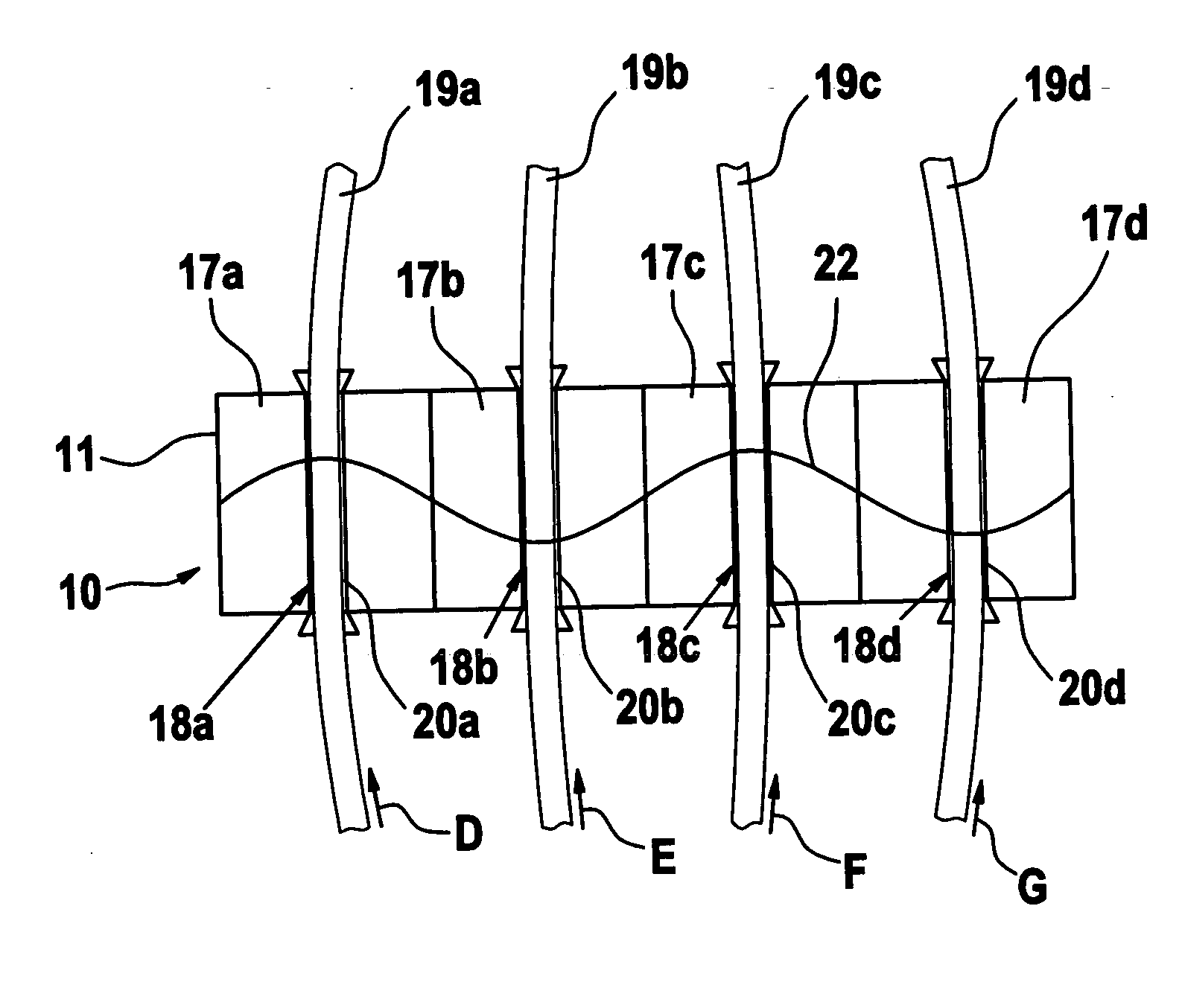

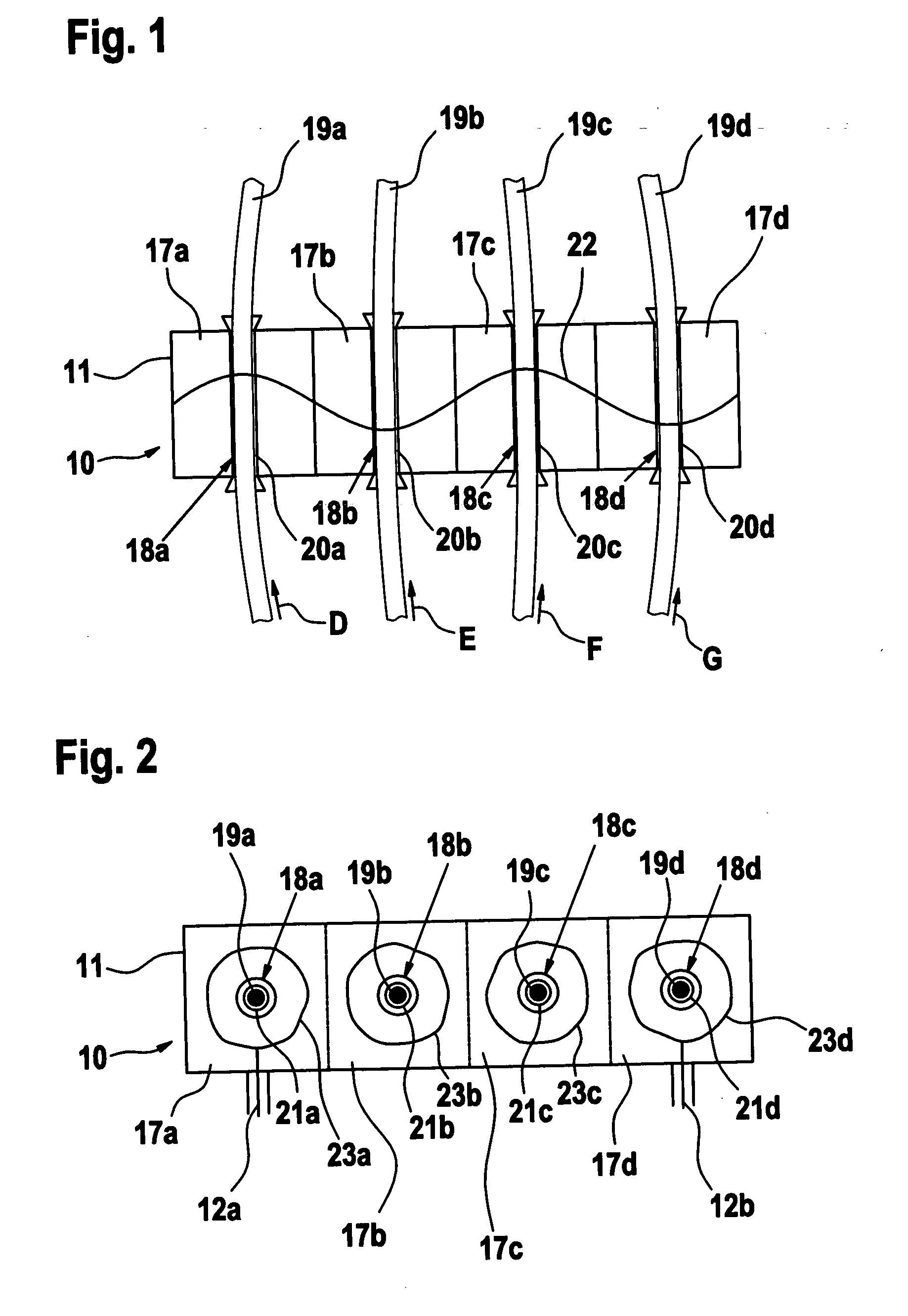

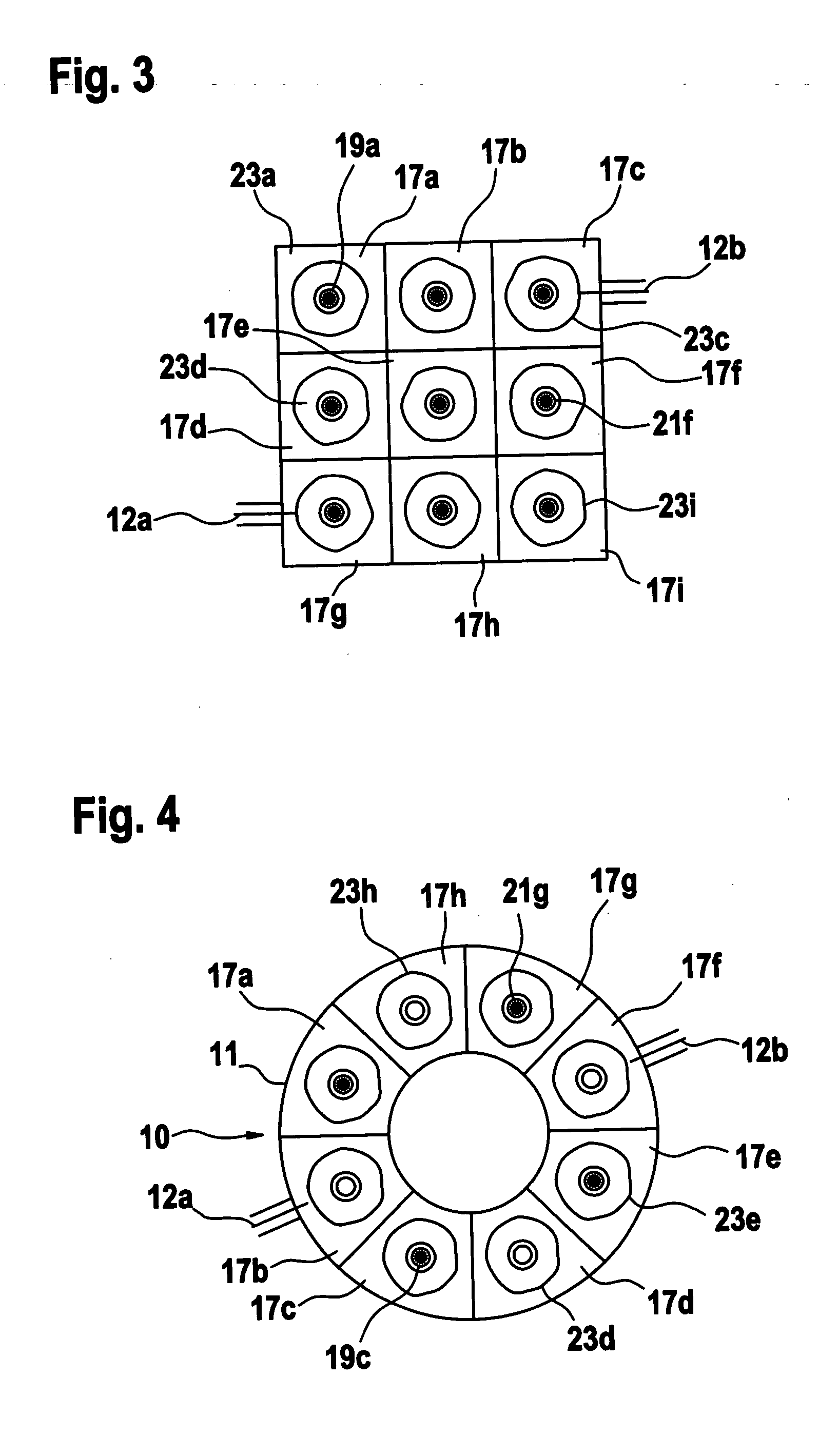

A non-woven fiber assembly comprises one or more fibers containing an adhesive component, an elastomeric component, and a hydrophilic component. A method of making a non-woven fiber assembly comprises the steps of providing one or more fiber-forming materials comprising an adhesive component, an elastomeric component, and a hydrophilic component, and forming said one or more fiber-forming materials into at least one fiber. A method of treating a patient comprises applying a medical dressing comprising the fiber assembly of the present invention to a patient. An apparatus (10) for forming a non-woven fiber assembly comprises a plurality of reservoirs (12, 16, 20) for containing more than one type of fiber-forming material, a plurality of valves (14, 18, 22), each independently in communication with a reservoir, and a fiber-forming device (28) selected from the group consisting of a spinnerette, a NGJ nozzle, and an electrospinning device, in communication with the valves.

Owner:THE UNIVERSITY OF AKRON

Non-woven fiber assemblies

In one embodiment, the present invention relates to a non-woven fiber assembly comprising one or more fibers wherein each fiber contains: a hydrophilic component; and an elastomeric component, and wherein the non-woven fiber assembly further comprises an adhesive component. In still another embodiment, the present invention relates to a non-woven fiber assembly comprising one or more fibers wherein each fiber contains: a hydrophilic component; an elastomeric component; and an adhesive component, wherein the hydrophilic component, the elastomeric component and the adhesive component are all contained within each fiber. Also disclosed is a method of making the afore-mentioned non-woven fiber assemblies. Additionally, a medical dressing made from the non-woven fiber assemblies of the present invention is disclosed.

Owner:THE UNIVERSITY OF AKRON

Multicomponent fiber comprising a phase change material

InactiveUS20070089276A1Avoid contactImprove thermal performanceFibre mixingLap-winding devicesFiberPhase-change material

The present invention is a multicomponent fiber comprising a temperature-regulating inner fiber component encapsulated by an outer fiber component. The invention further provides methods of preparing the inventive multicomponent fiber and methods of preparing a temperature-regulating fiber component incorporating at least one phase change material.

Owner:FIBER INNOVATION TECH

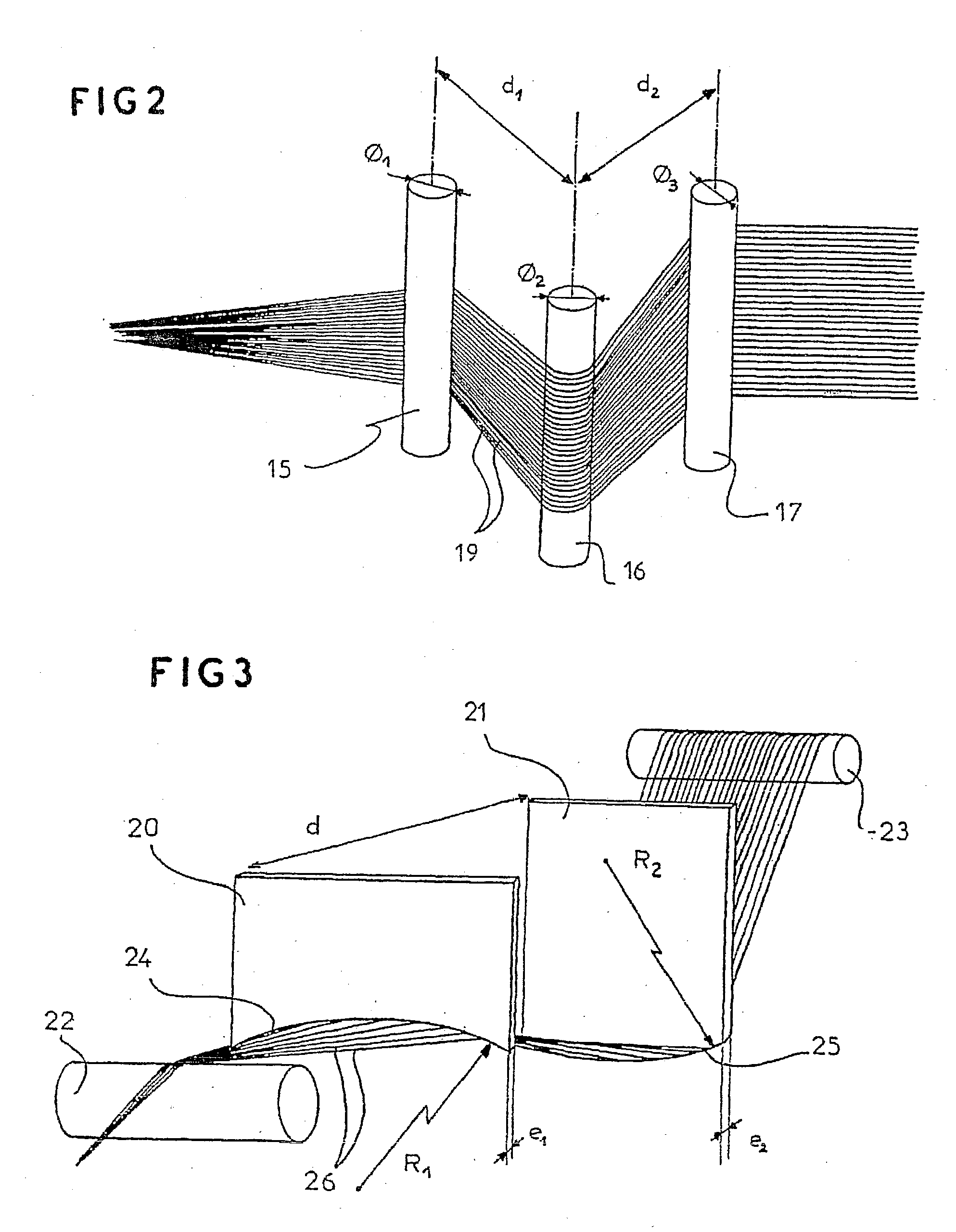

Method for the production of a carbon fiber-based reinforcing element for tires

InactiveUS20040043213A1Reduce riskImprove the lubrication effectCarbon fibresFilament handlingFiberCarbon fibers

A method for the production of a multifilament carbon fibre-based longitudinal reinforcing element, designed to be incorporated in a rubber-based item. Said method comprises the following steps, whereby untwisted carbon fibres are plunged into an impregnating bath contained a solution of resorcinol-formaldehyde resin and rubber latex, the impregnated fibres are then dried and the dried fibres are subsequently twisted. The inventive method is characterised by the fact that it also comprises a step, during the impregnation step, consisting in opening out the carbon fibres by spreading out the constituent filaments thereof in such a way that each fibre has an increased surface area on which the impregnation can be performed.

Owner:SOVOUTRI SOC VOULTAINE DE TRANSFORMES INDS

Easy-to-dye terylene BCF and method for preparing same

InactiveCN101338455AImprove spinnabilitySolve the two major problems of dyeing at room temperatureFibre mixingLap-winding devicesFiberYarn

The invention relates to a chromophil terylene BCF and a preparation method thereof, which belong to the technical field of the terylene. The chromophil terylene BCF is characterized in that the terylene BCY is in a tri-leaflet shape which is also called as Y-shaped microcellular structure. The preparation method is characterized in that (1) the slice of raw terylene materials is pre-crystallized and dried by a dryer; (2) the slice of the raw terylene materials are melted by an extruder; (3) multifilament yarn which is in the tri-leaflet shape which is also called as the Y-shaped microcellular structure is sprayed by a tri-leaflet spinneret plate; (4) a tow is cooled to be formed into initial raw silk; (5) oil solution is applied to spinning; (6) the spinning is extended; (7) the spinning undergoes the process of bulking in a deformation box; (8) the spinning is cooled and curled; (9) the spinning undergoes the process of link making; (10) the spinning is rolled into a drum. The chromophil terylene BCF solves two problems that the current BCF has poor spinnability and is difficult to be dyed under normal temperature, provides newly-invented BCF fiber for manufacturing the suede of a blanket and creates conditions for manufacturing the blanket that has good spreadability, beautiful appearance and low manufacturing cost.

Owner:上海繁太实业有限公司

High performance laminated tapes and related products for ballistic applications

Highly uniform woven fibrous structures formed from fibrous tapes, wherein the tapes constitute the warp and weft tapes of a woven fabric. The individual fibrous tapes may be woven or non-woven, and may be formed as narrow tapes or may be cut from a wider fabric web.

Owner:HONEYWELL INT INC

Non-woven fabric comprising staple fibers and an absorbent article using the same

InactiveUS20020016120A1High densityHigh strengthLap-winding devicesLap forming devicesPolymer scienceSingle fiber

A non-woven fabric comprising staple fibers, having a fiber length of 3 to 25 mm and a single fiber fineness of 1 to 100 denier, and is produced by the fibers being dropped while being dispersed to be accumulated and adhered at the intersection point of the staple fibers. The non-woven fabric has a specific volume of 40 to 200 cm3 / g, and the number of fiber lumps having a volume of not less than 1 mm3 is not more than 5 lumps per 20 g of the non-woven fabric. The bulky non-woven fabric of the present invention in which the sufficient contribution to bulkiness by fibers is exhibited is suitable for sanitary materials, such as disposable diapers, sanitary napkins, incontinence pads, nursing pads or the like, or wipes etc.

Owner:CHISSO CORP

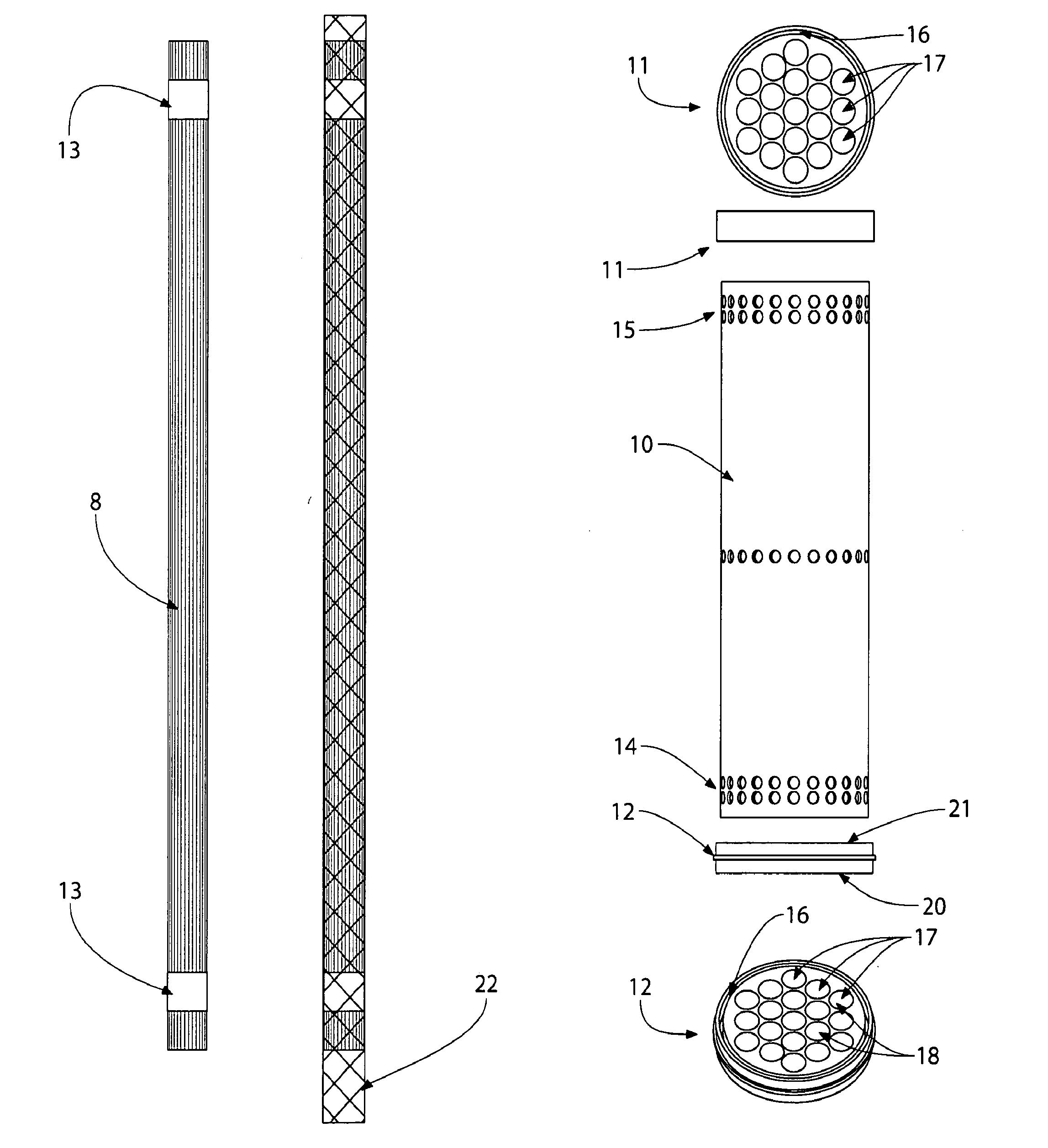

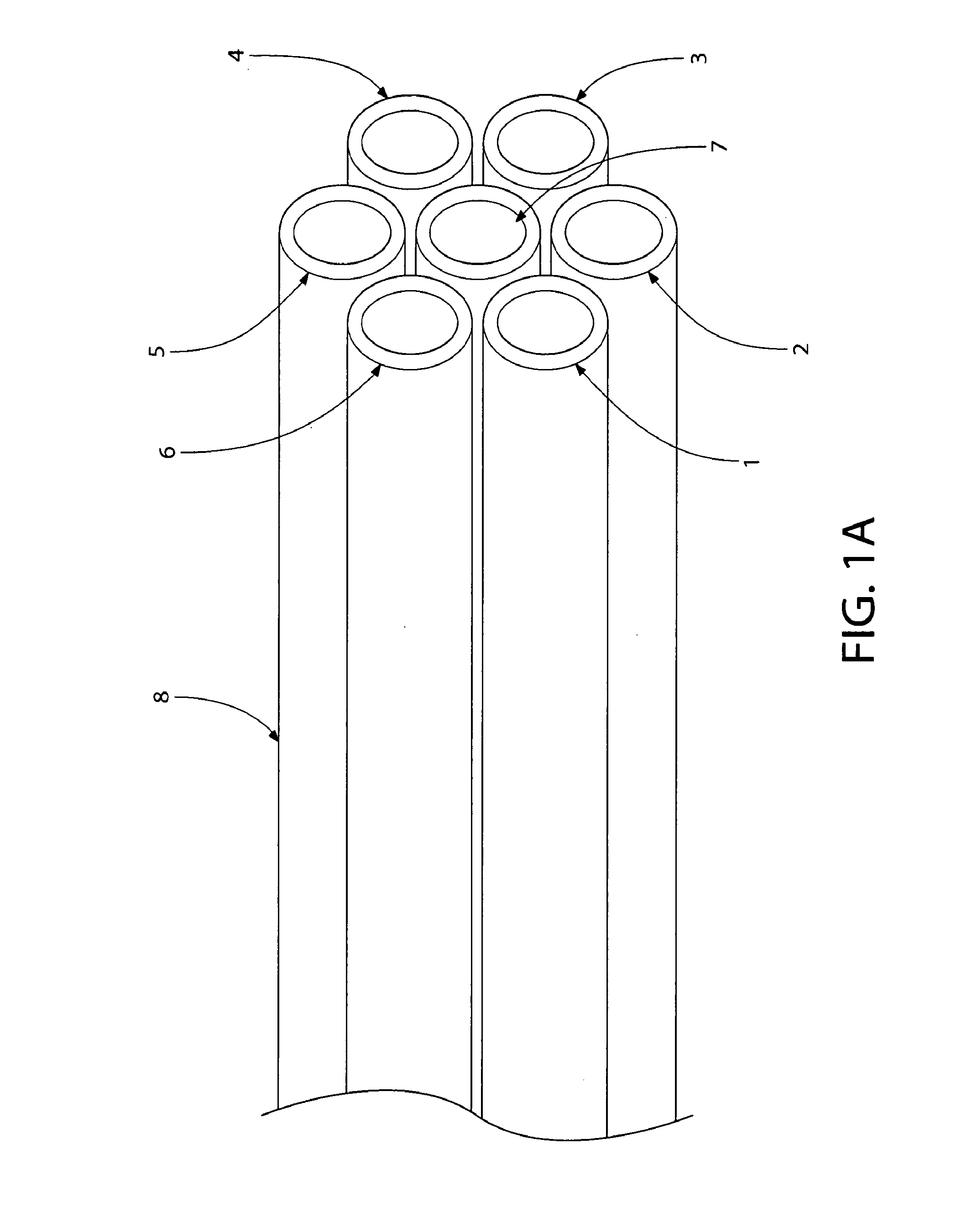

Hollow fiber cartridges and components and methods of their construction

ActiveUS20140319045A1Reduce thermal stressHigh bulk densityMechanical working/deformationFibre mixingHollow fibreFiber

Owner:REFINE TECHNOLOGY LLC

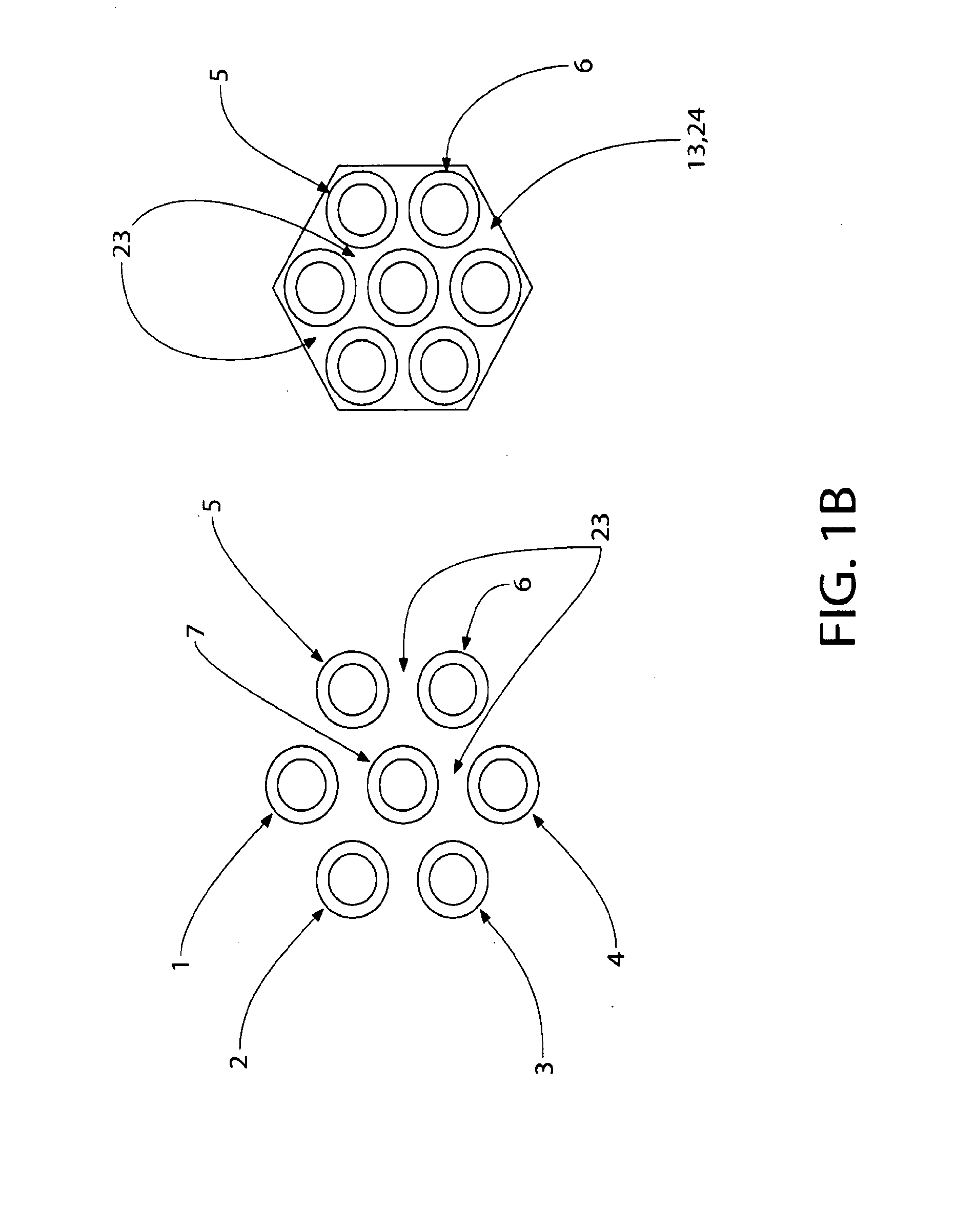

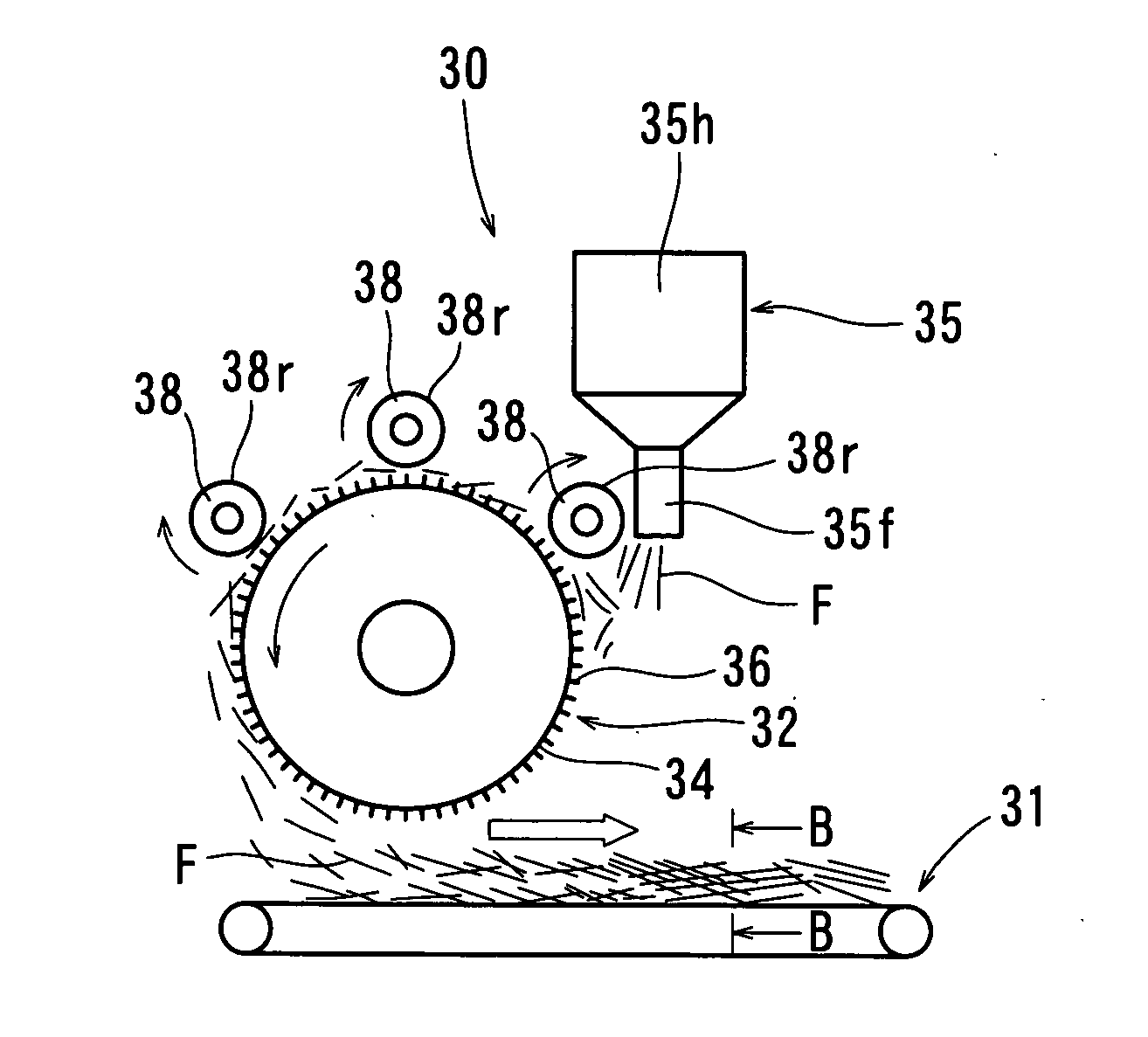

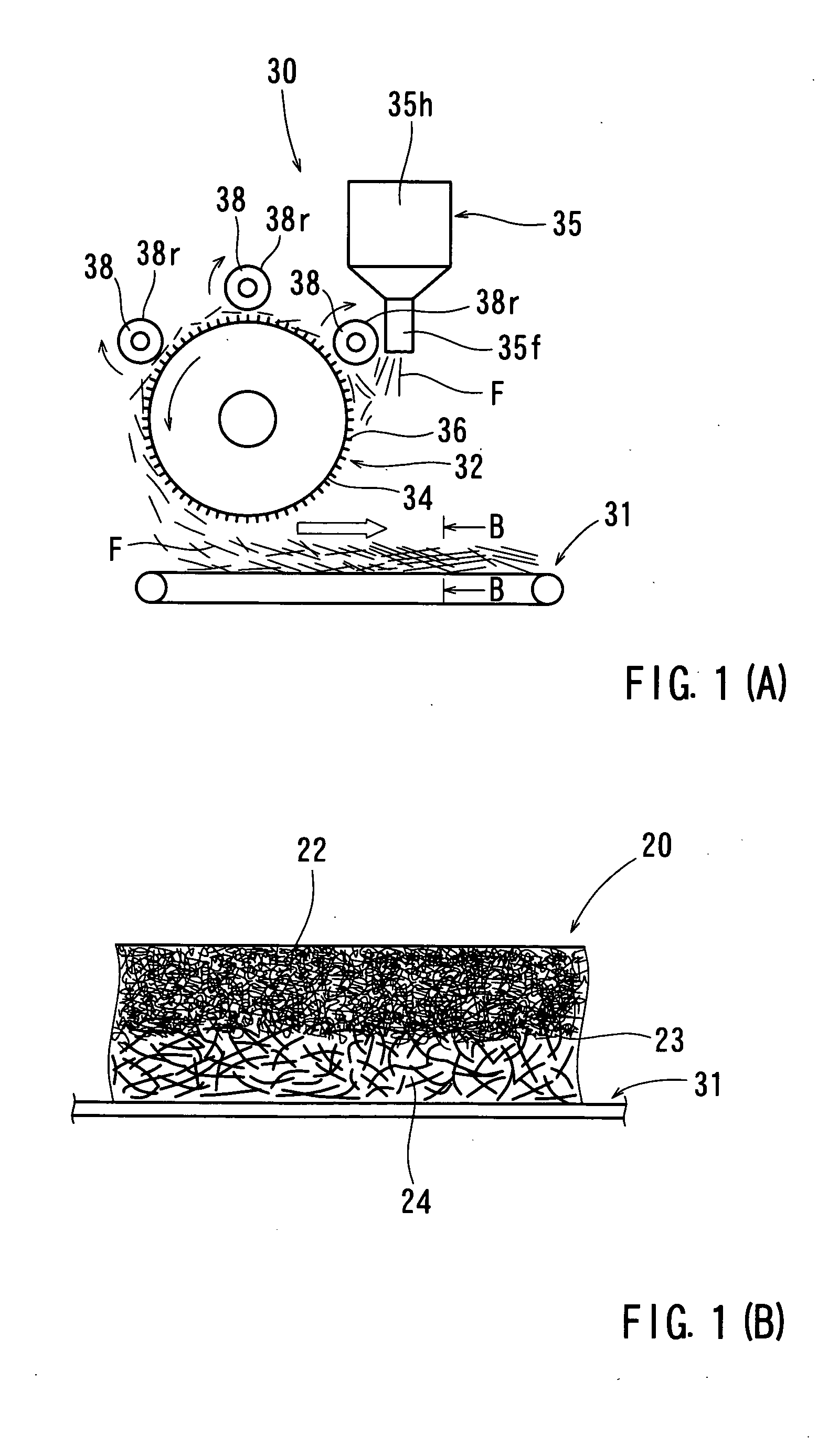

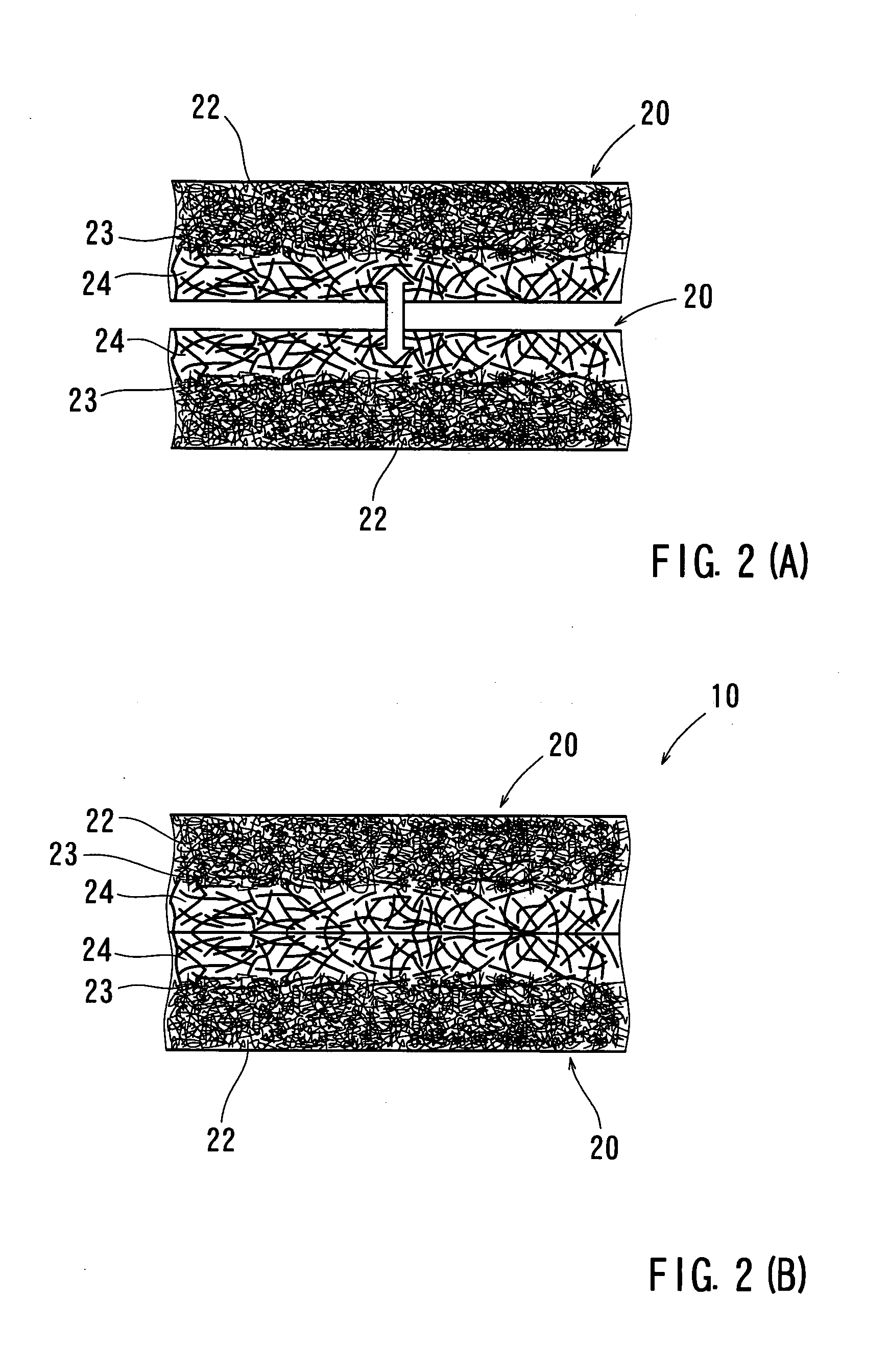

Fibrous formed products and methods for manufacturing such fibrous formed products

InactiveUS20050020164A1Reduce the cost of the whole machineImprove production efficiencyLap-winding devicesPile-fabric loomsFiberHigh density

In a method of manufacturing a fibrous formed product, a mixture of fibers, including thick fibers and thin fibers, is prepared in order to form fibrous mats. The mixed fibers are supplied onto an outer peripheral surface of a roller. As the roller rotates, the mixed fibers are released from the roller and are thrown toward a fiber receiving surface. A fibrous mat is formed on the fiber receiving surface with a low-density layer next to the fiber receiving surface and a high-density layer on top of the low-density layer. Thick fibers mainly form the low-density layer and thin fibers mainly form the high-density layer. First and second fibrous mats are overlaid with one another such that their low-density layers oppose each other.

Owner:TOYOTA BOSHOKU KK +2

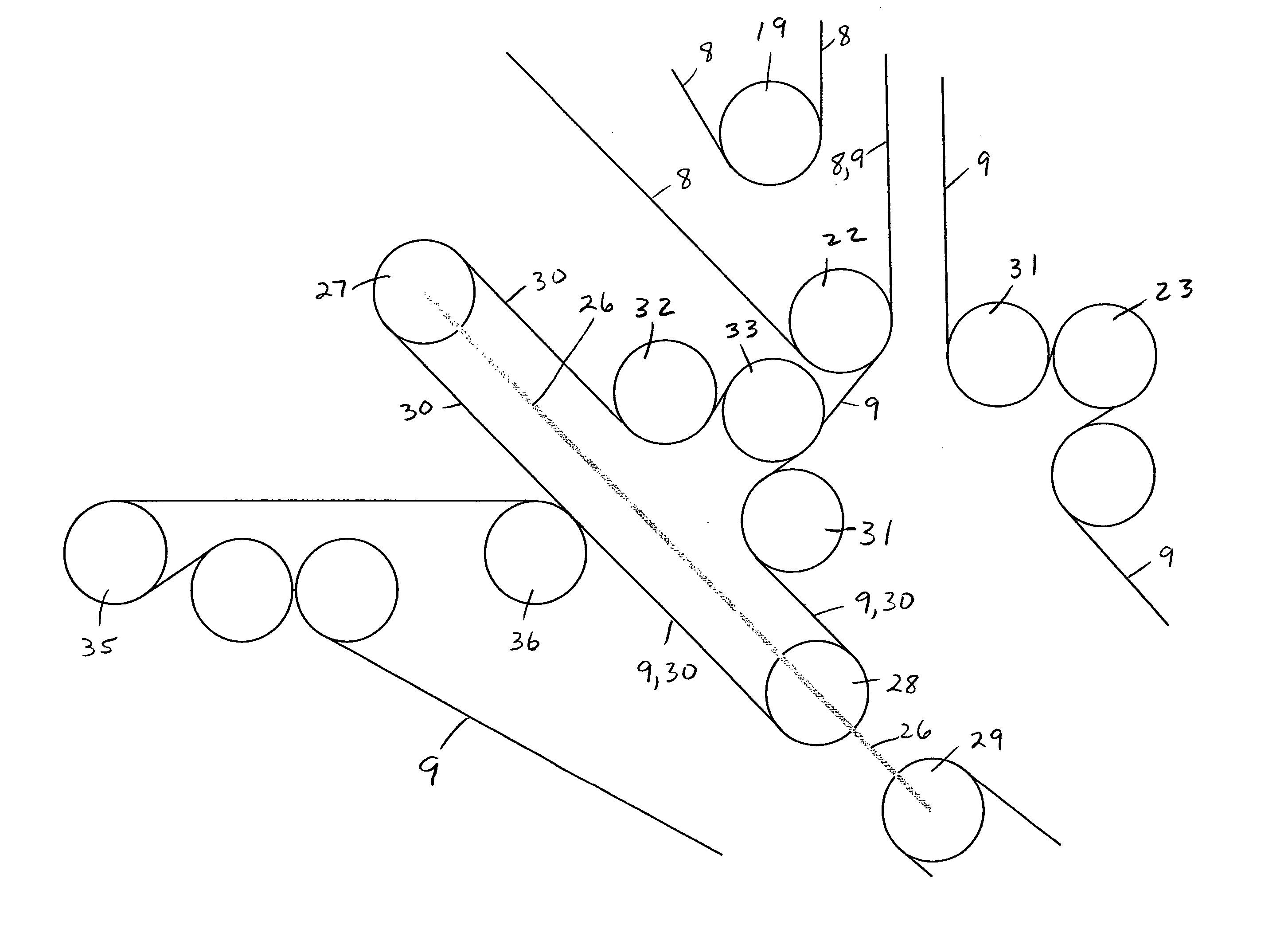

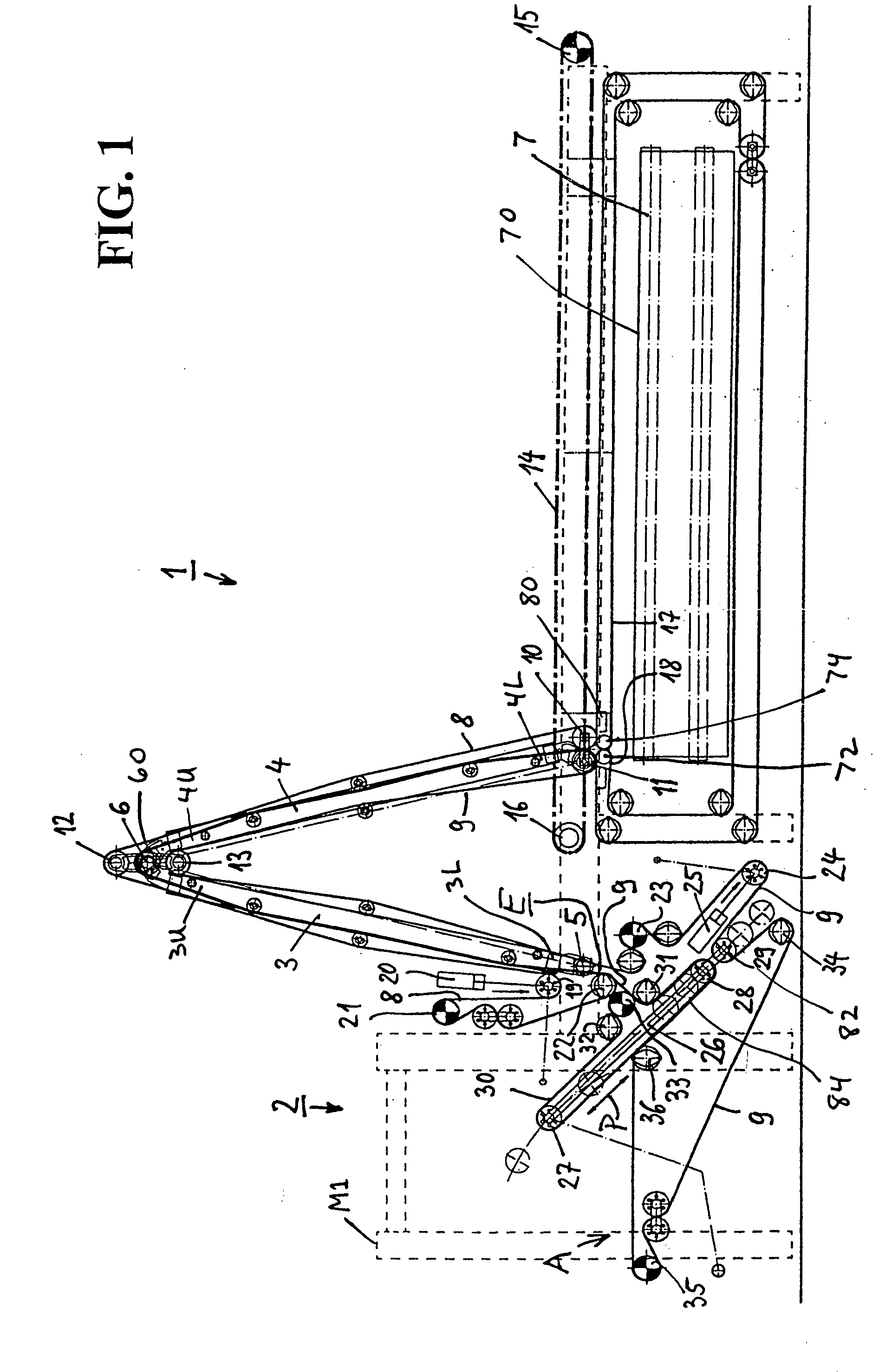

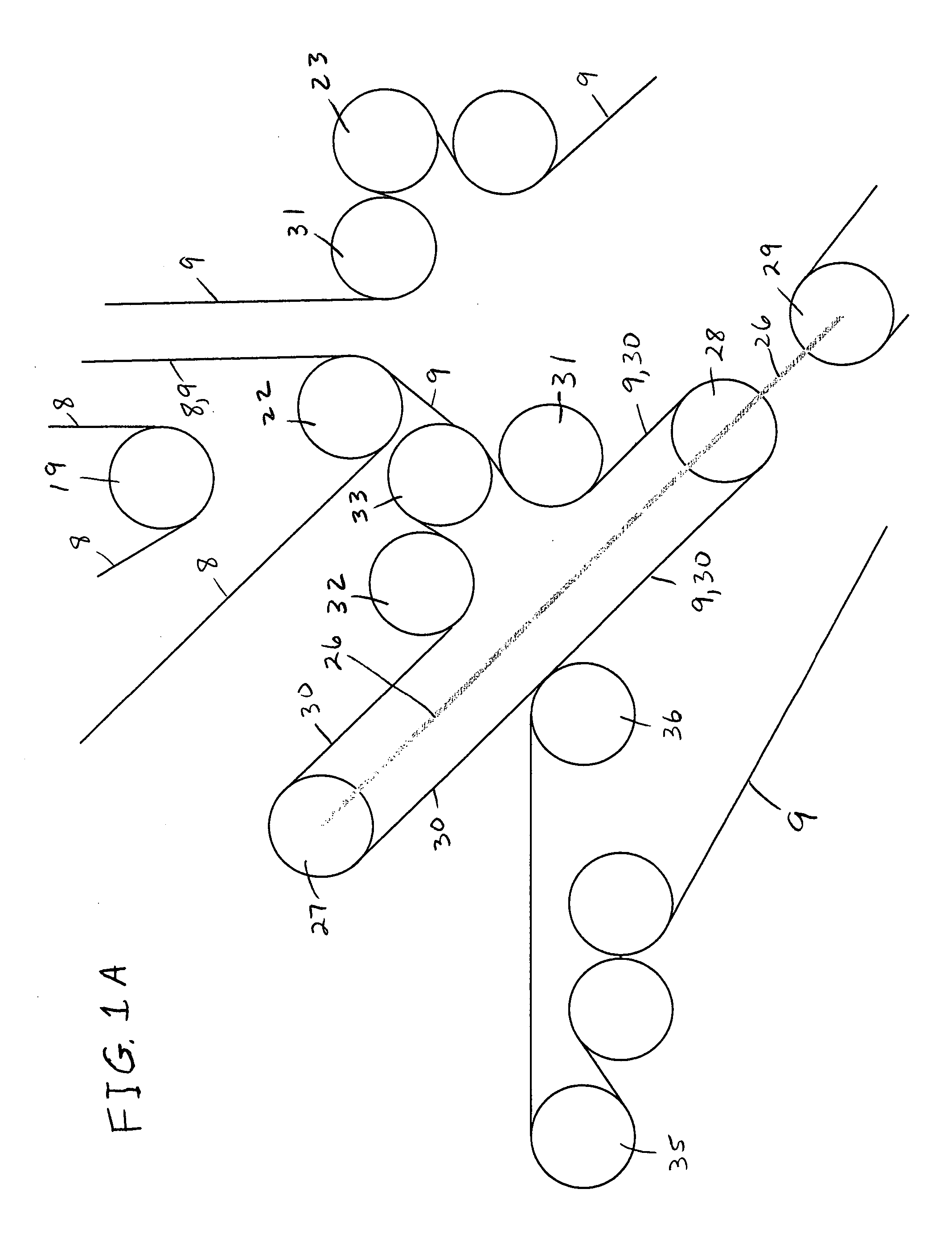

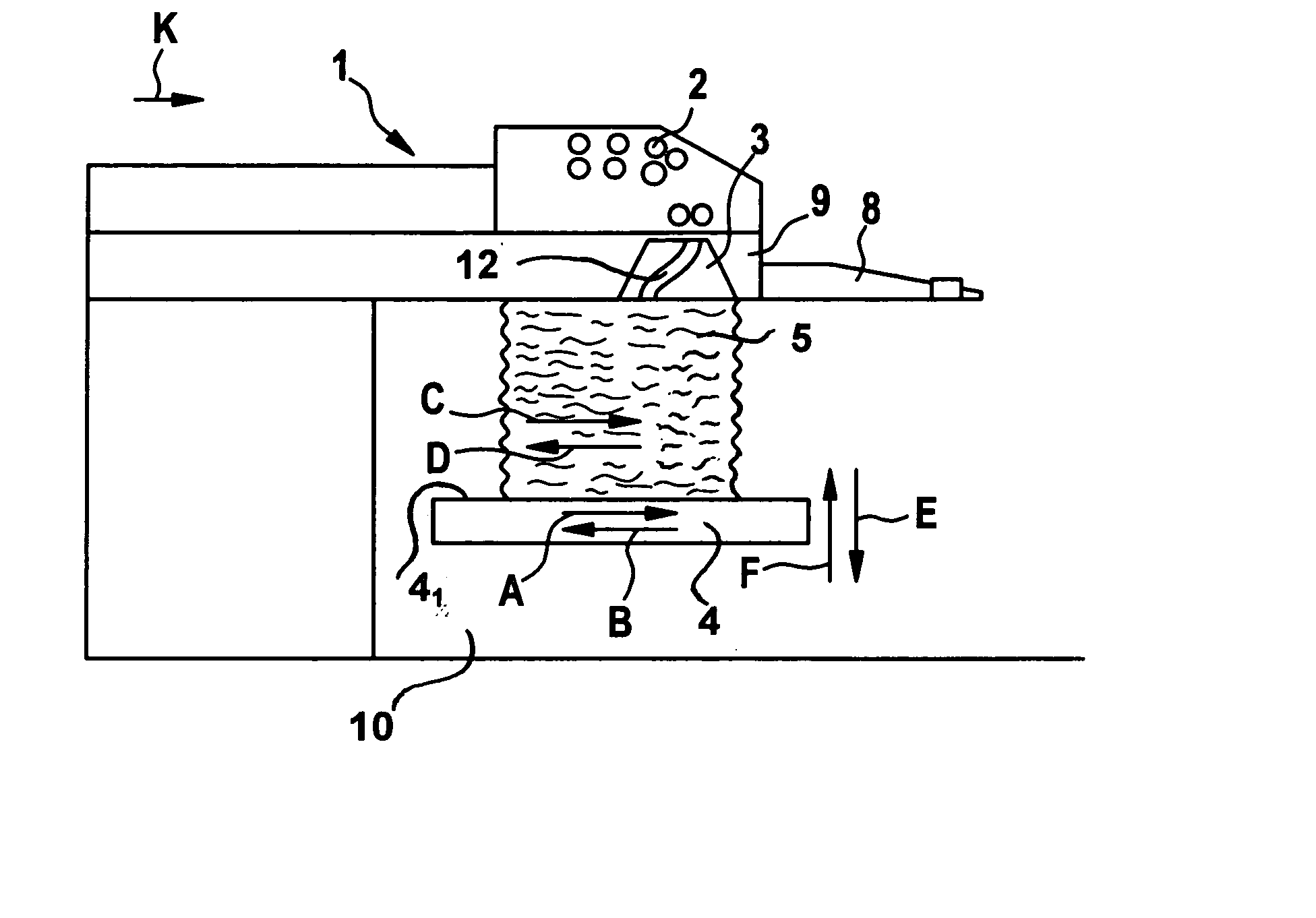

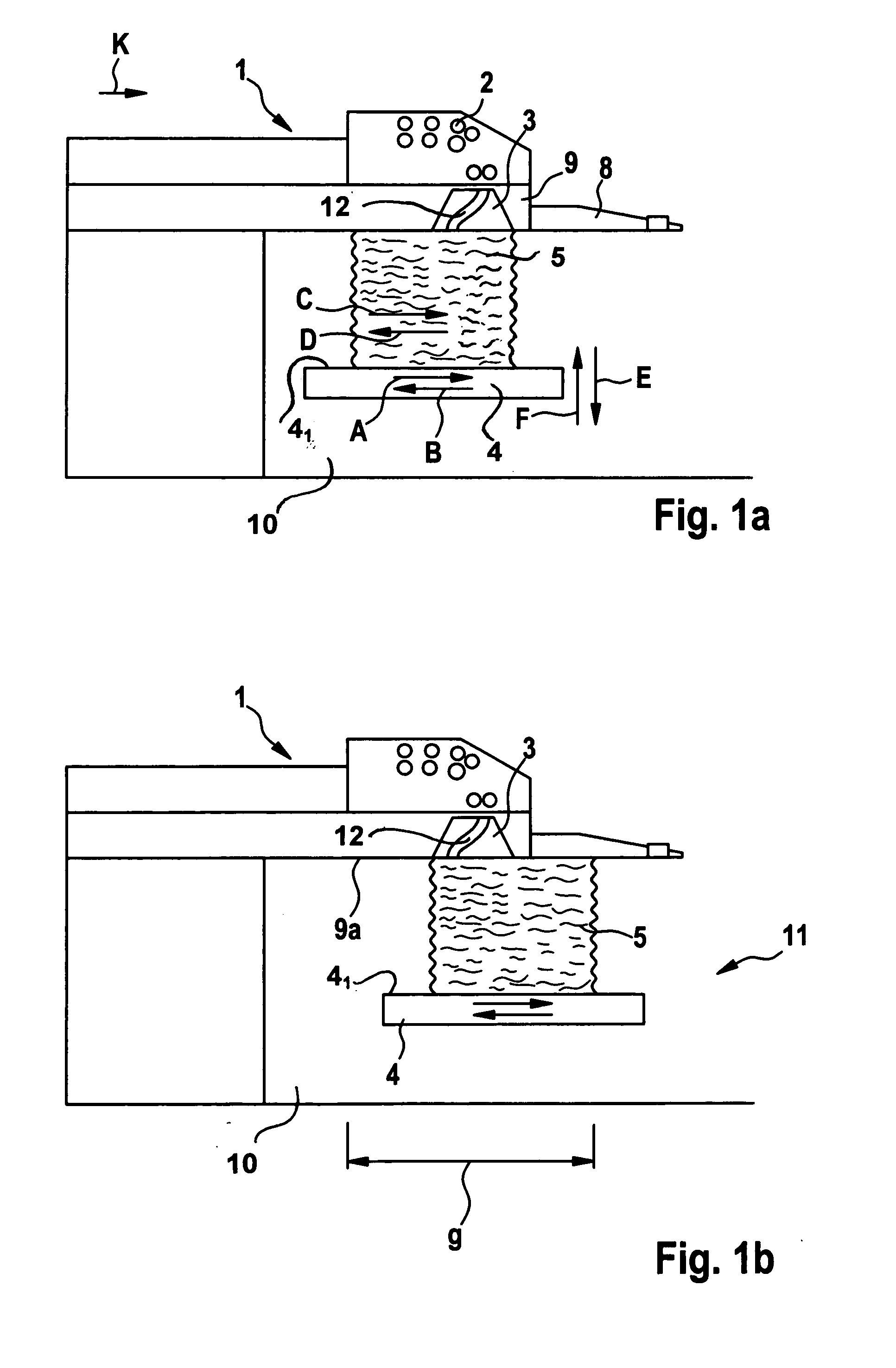

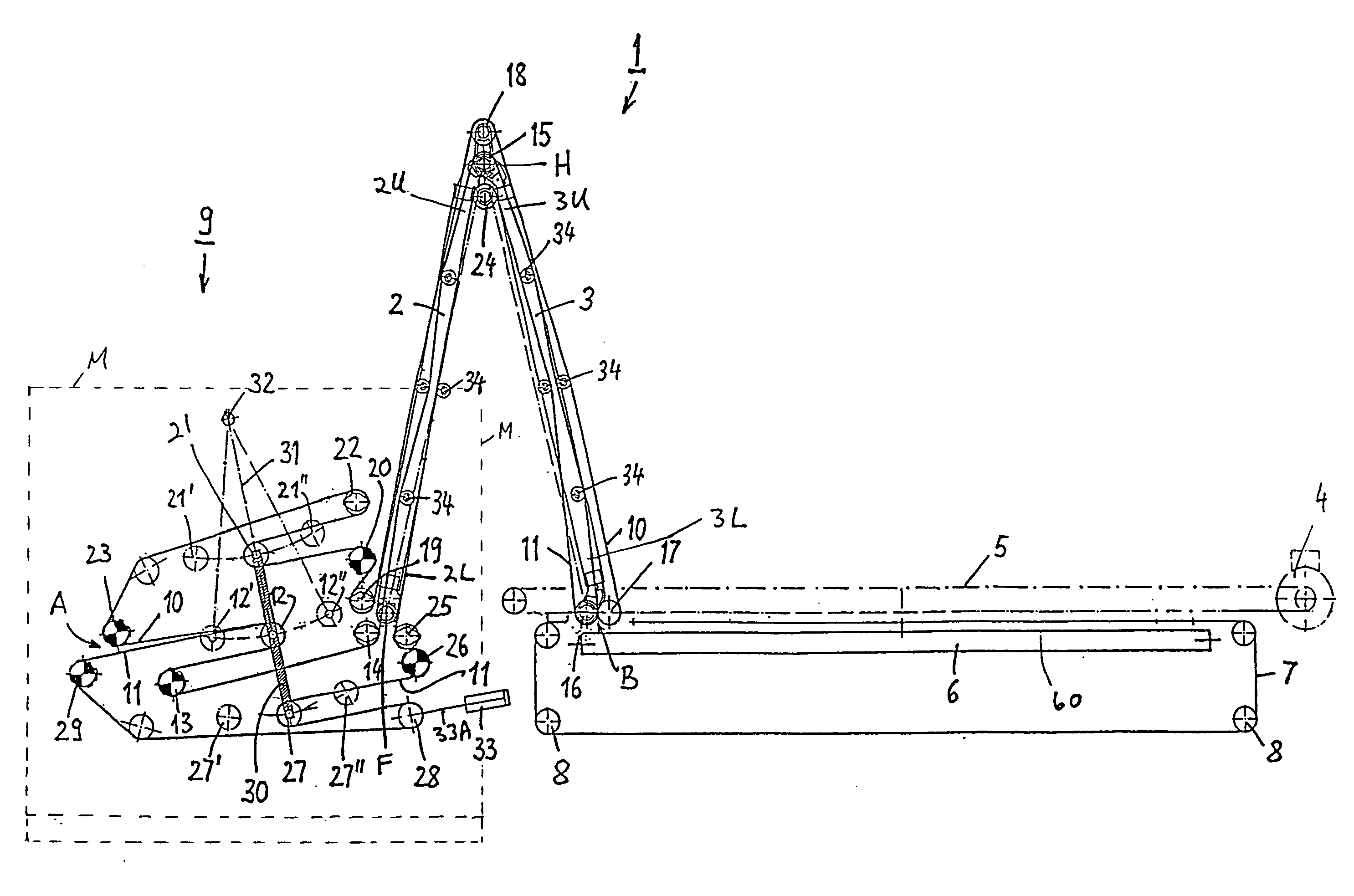

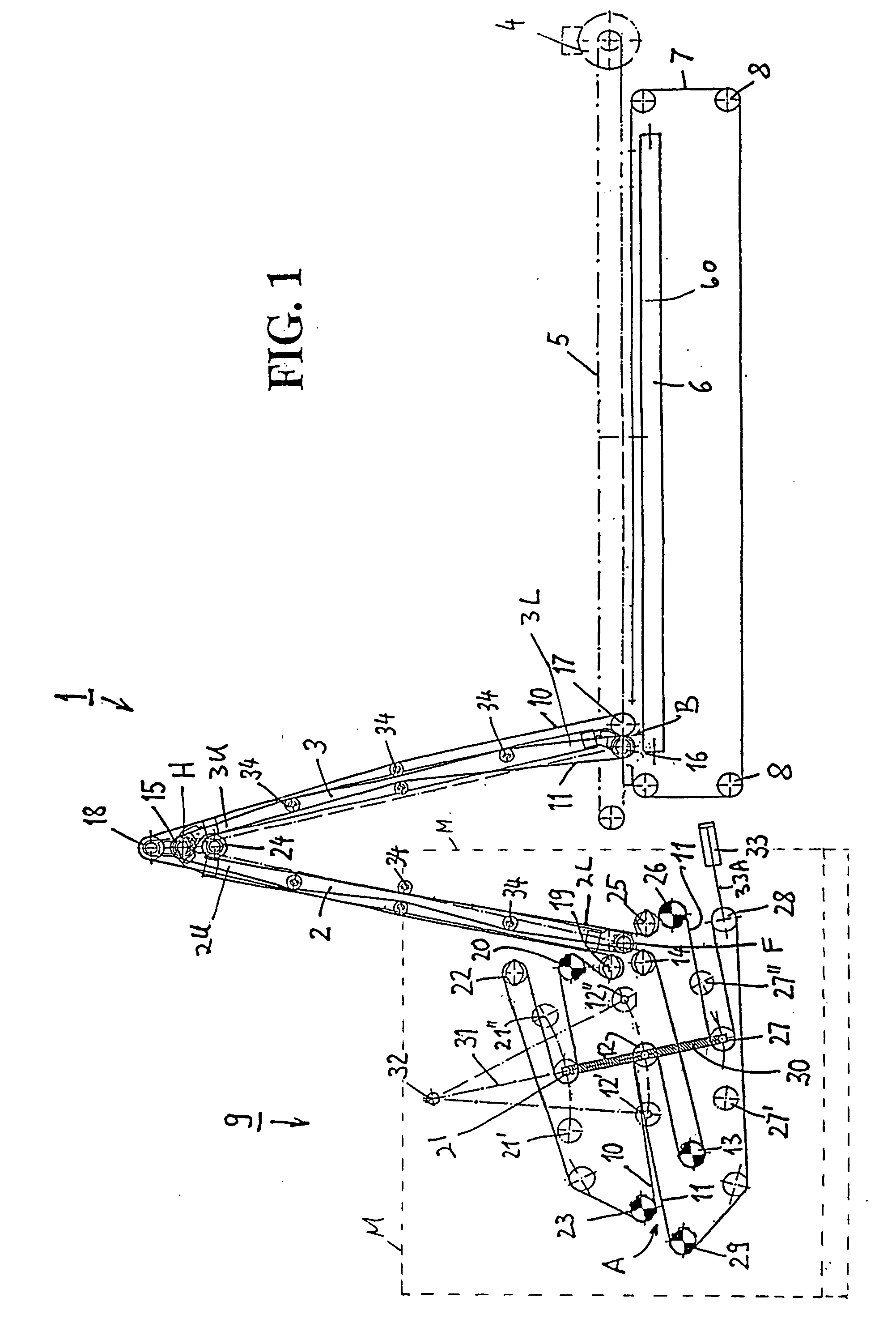

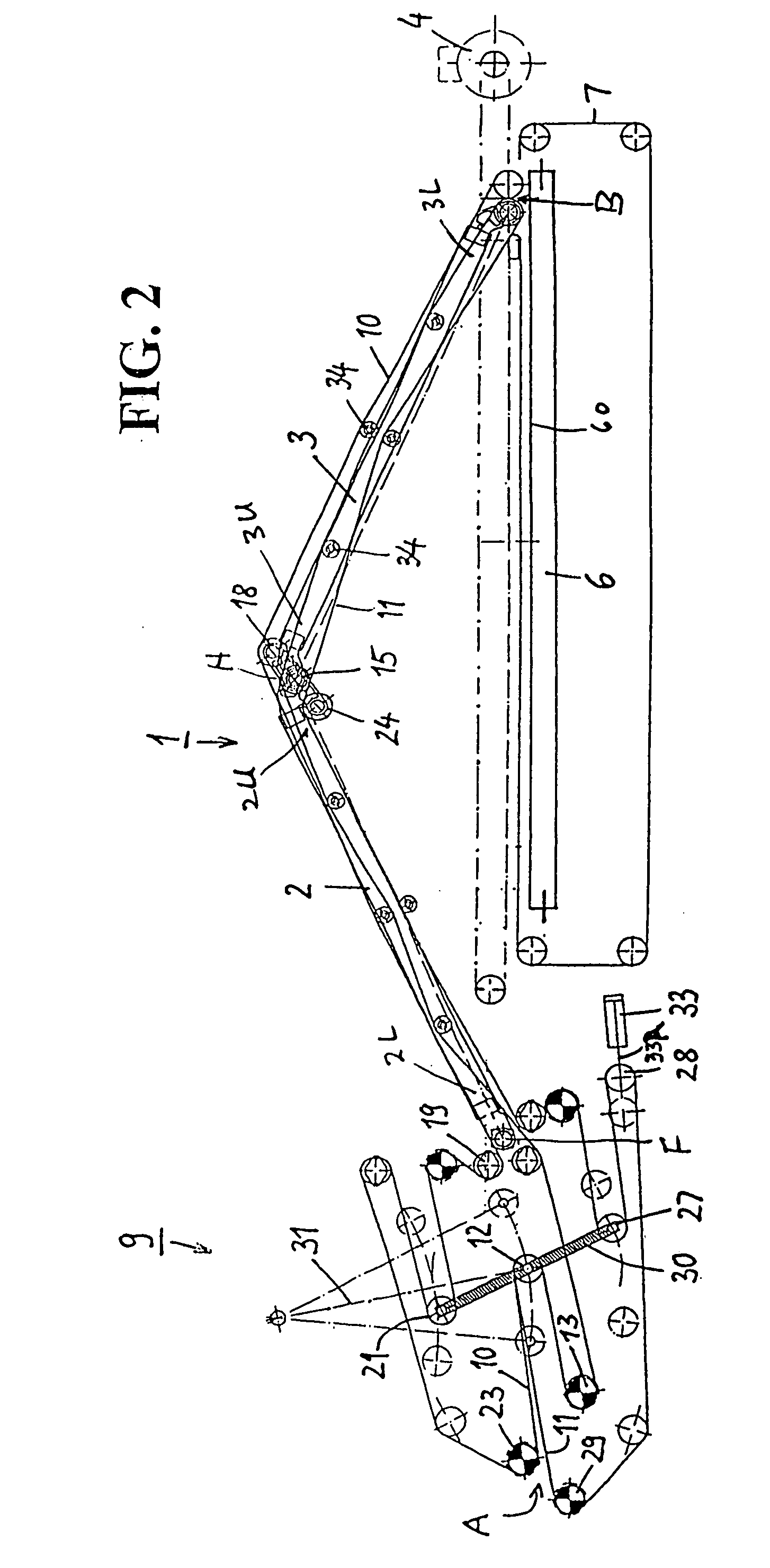

Fleece laying device

InactiveUS20050193525A1Reduce distortion problemsQuality improvementVegetable fibre separation from seedsLap-winding devicesFiberEngineering

A non-woven fiber web laying apparatus including (1) a camel back cross lapper having a supply arm, a layering arm connected thereto, and two delivery transport belts guided in juxtaposed fashion from an infeed zone to a lower end of the layering arm and (2) an upstream web buffering apparatus adapted to hold a web between two take-up transport belts at least one of which is one of the two delivery transport belts, the apparatus sandwiching the web substantially the entire path from the take-up site to the layering-arm lower end. While at least one of the two take-up transport belts of the web buffering apparatus is one of the delivery transport belts of the cross lapper, in one embodiment both of the take-up transport belts are the delivery transport belts. In another embodiment, only one of the take-up transport belts is a delivery transport belt, the other being a pressure belt operating only within the web buffering apparatus.

Owner:DILO MASCHF OSKAR

Silver discharge device

InactiveUS20060027695A1Reduce equipment expenditureSimple processFilament handlingLap-winding devicesEngineeringMechanical engineering

A device is provided on a spinning preparation machine for receiving a sliver from a discharge device of the spinning preparation machine and transporting the sliver to a downstream machine, the spinning preparation machine having a depositing region. The device has a support for receiving the sliver deposited from the discharge device in the depositing region, and a moving device for moving the deposited sliver relative to the discharge device in the depositing region for forming a free standing sliver bundle, and for moving the free standing sliver bundle out of the depositing region for transport to a downstream machine.

Owner:TRUETZSCHLER GMBH & CO KG

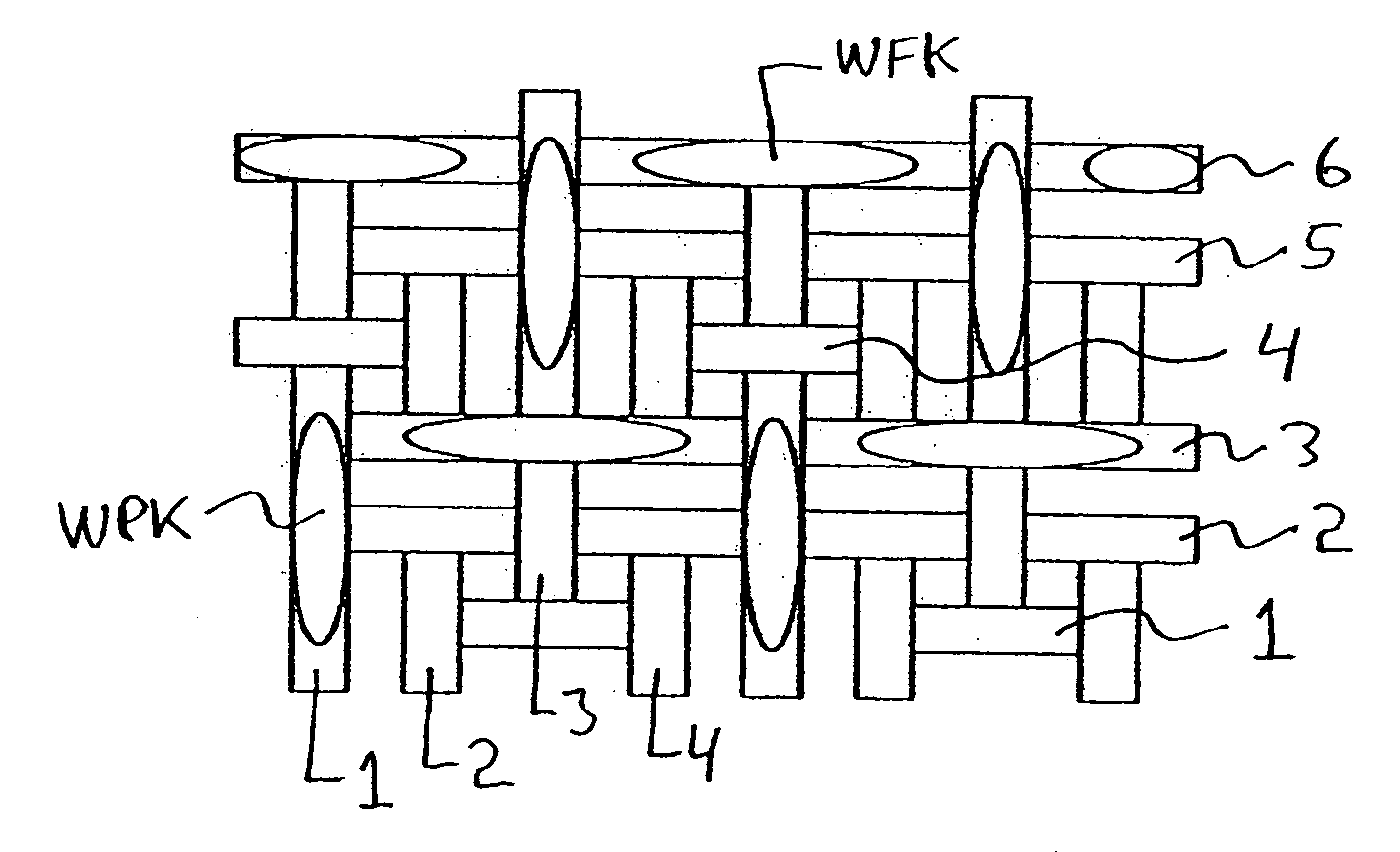

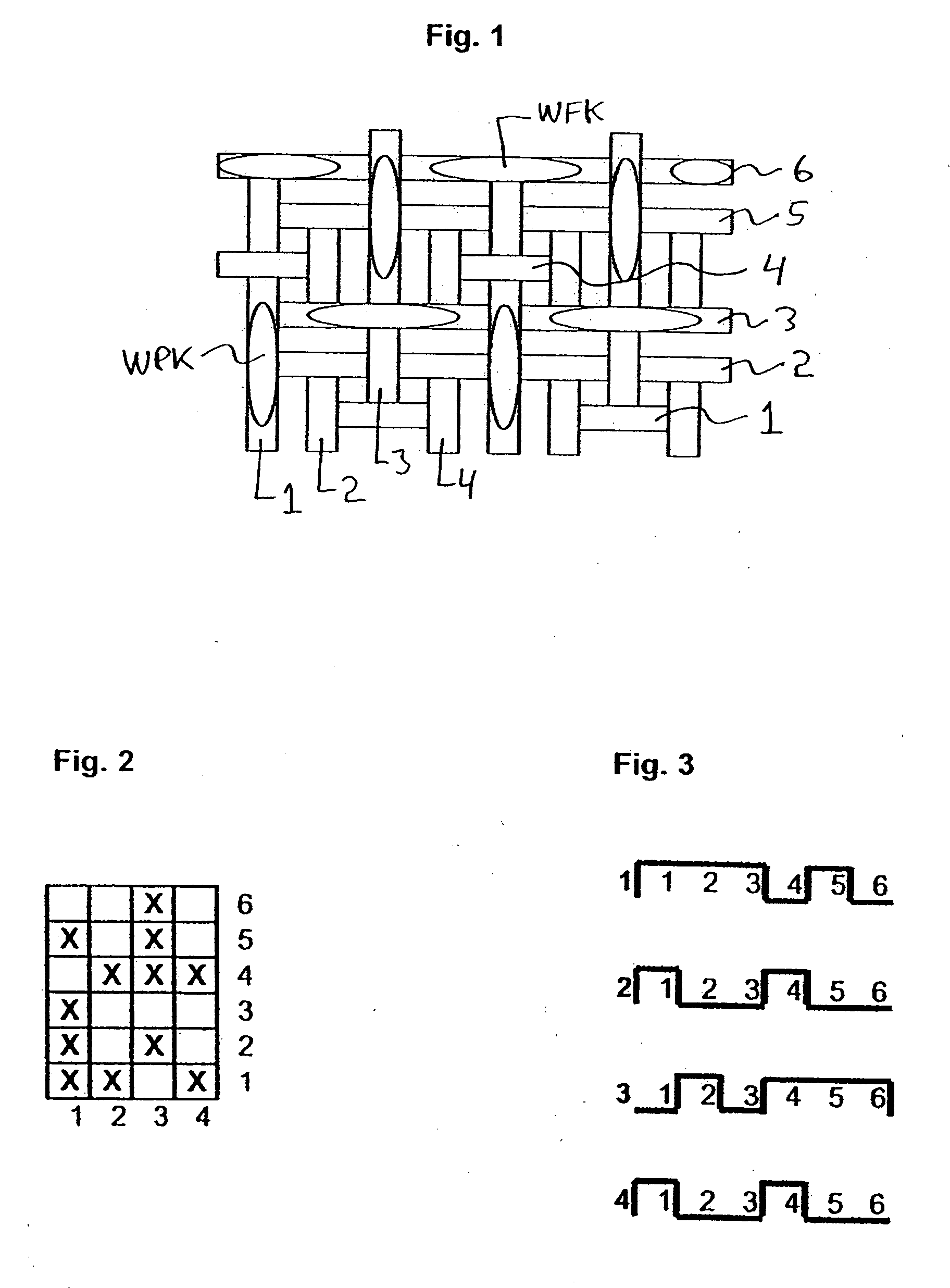

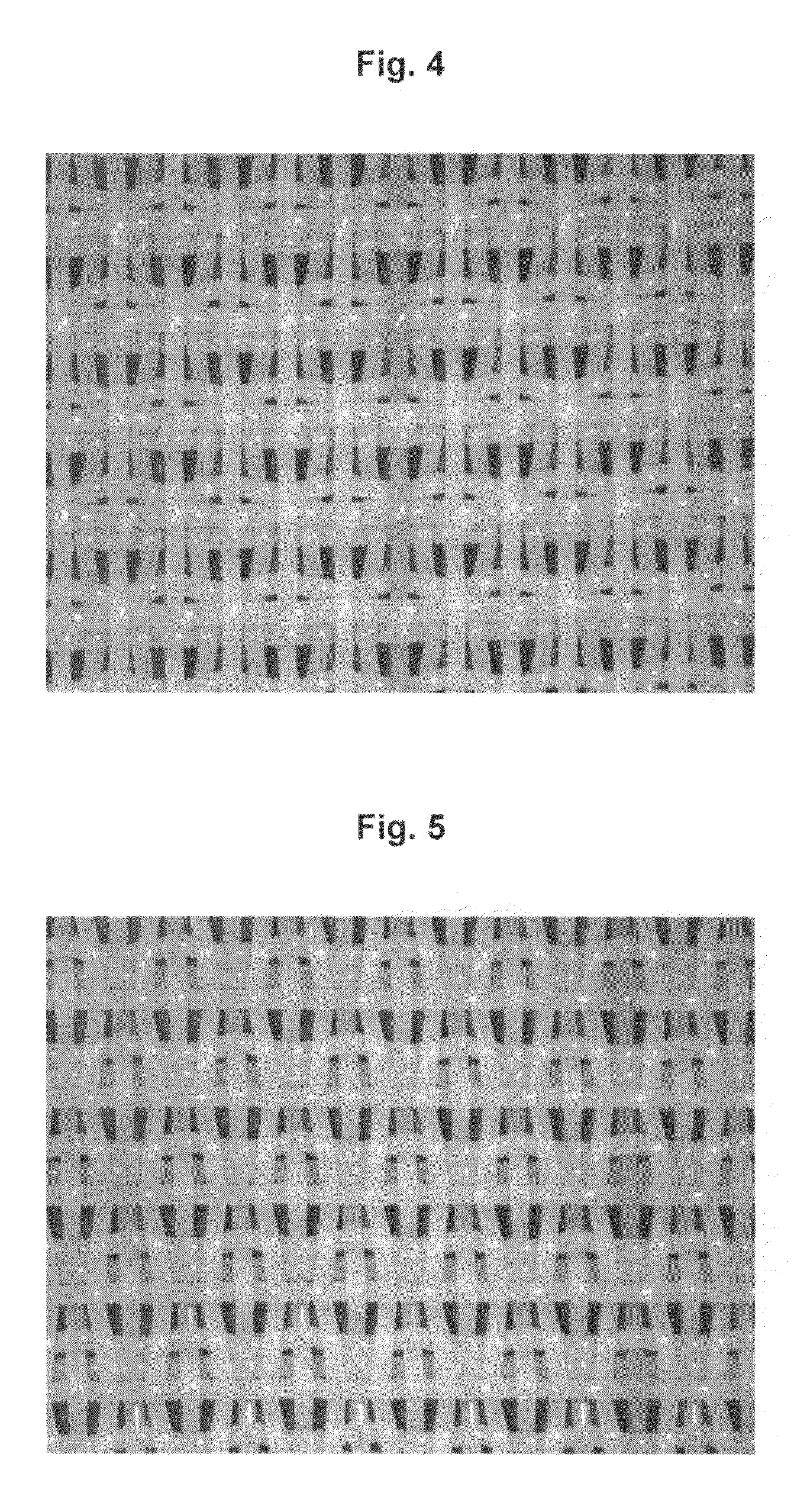

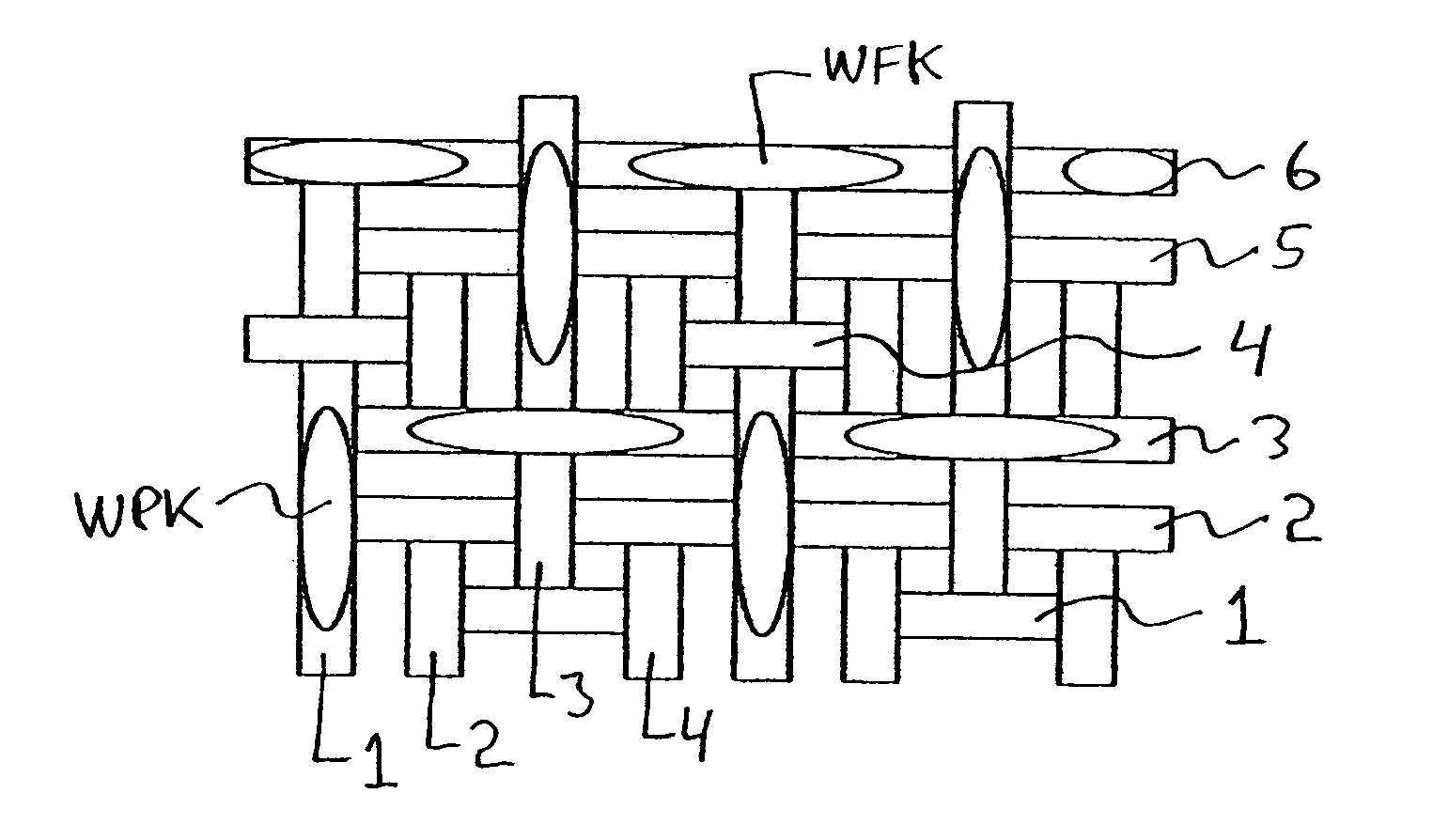

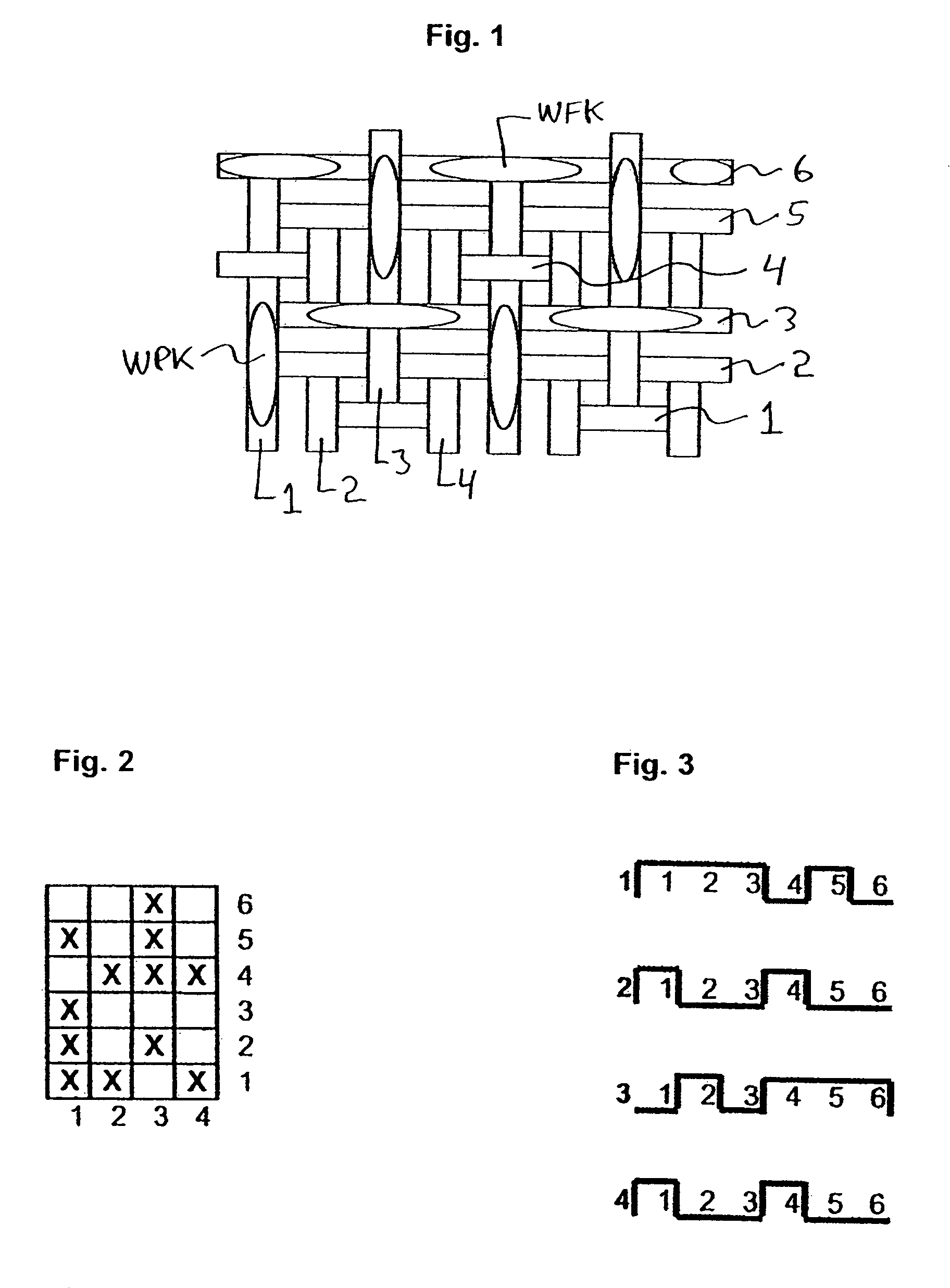

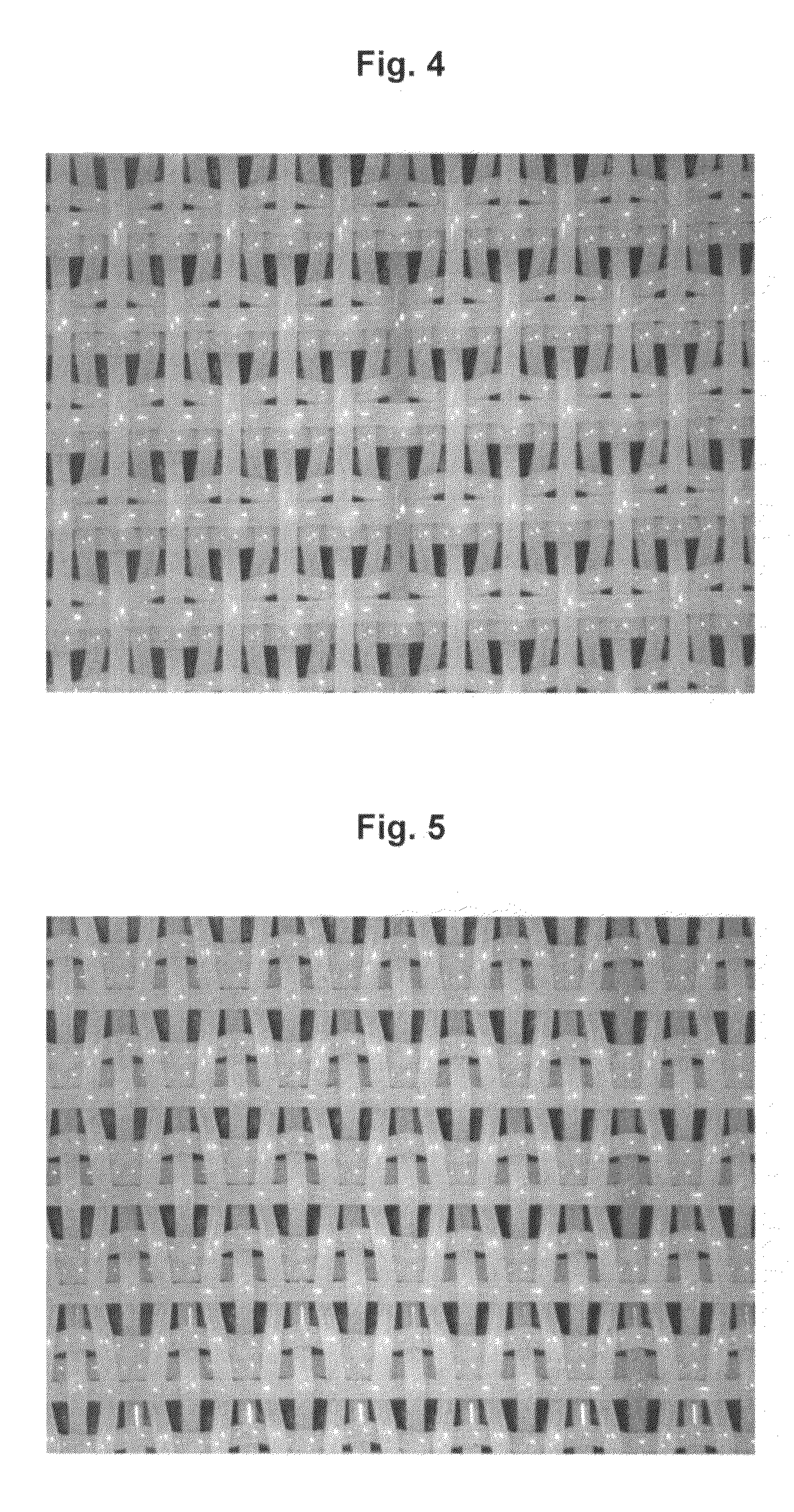

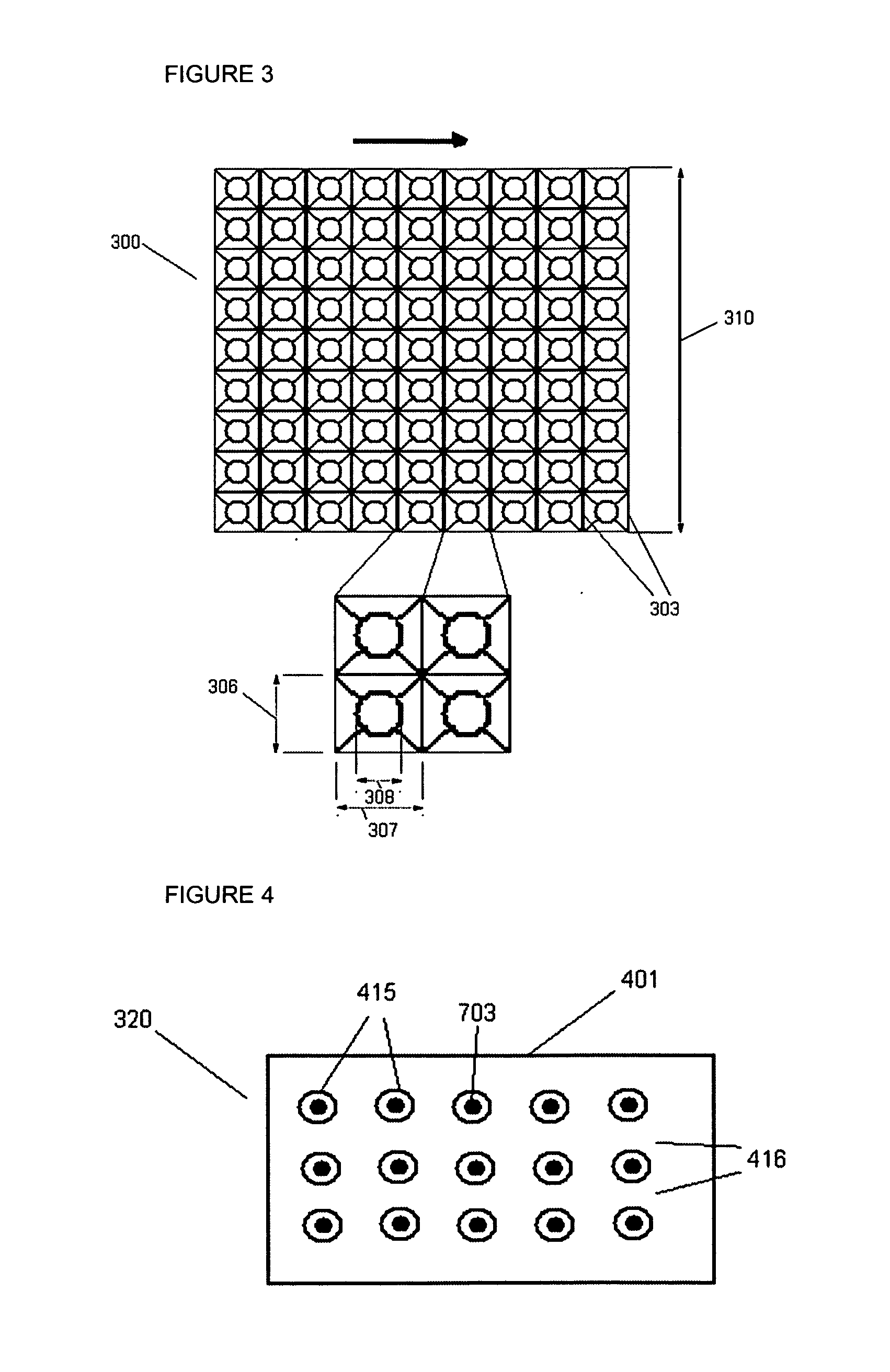

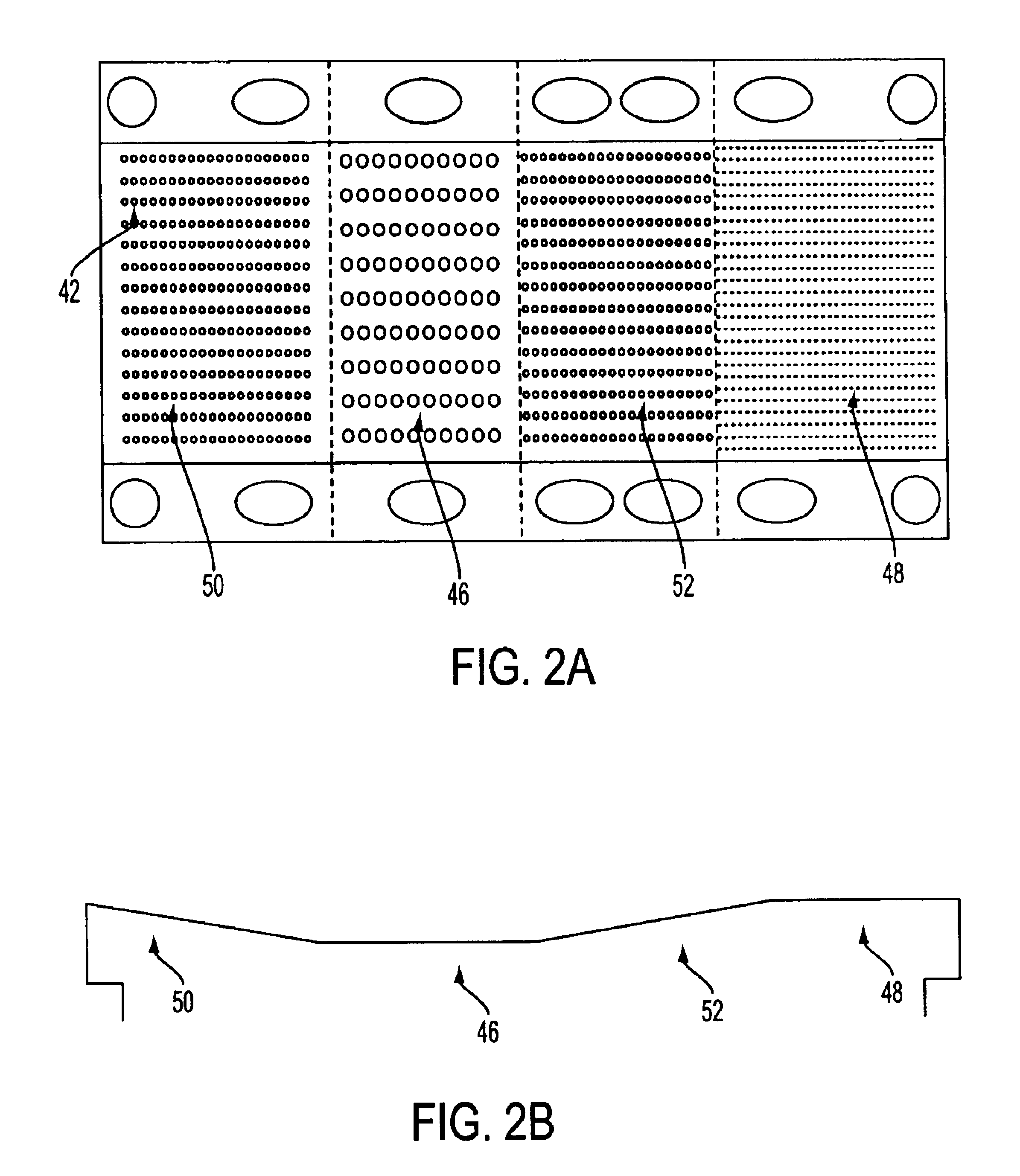

Structured forming fabric and method

InactiveUS20090068909A1Improve system performanceIncreased caliper bulk absorbencyNon-fibrous pulp additionNatural cellulose pulp/paperMechanical engineeringWeft yarn

Forming fabric for making a bulky web. The fabric includes a machine facing side and a web facing side having pockets formed by warp and weft yarns. A bottom of the pockets is formed an exchange of a different number of the warp and the weft yarns. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

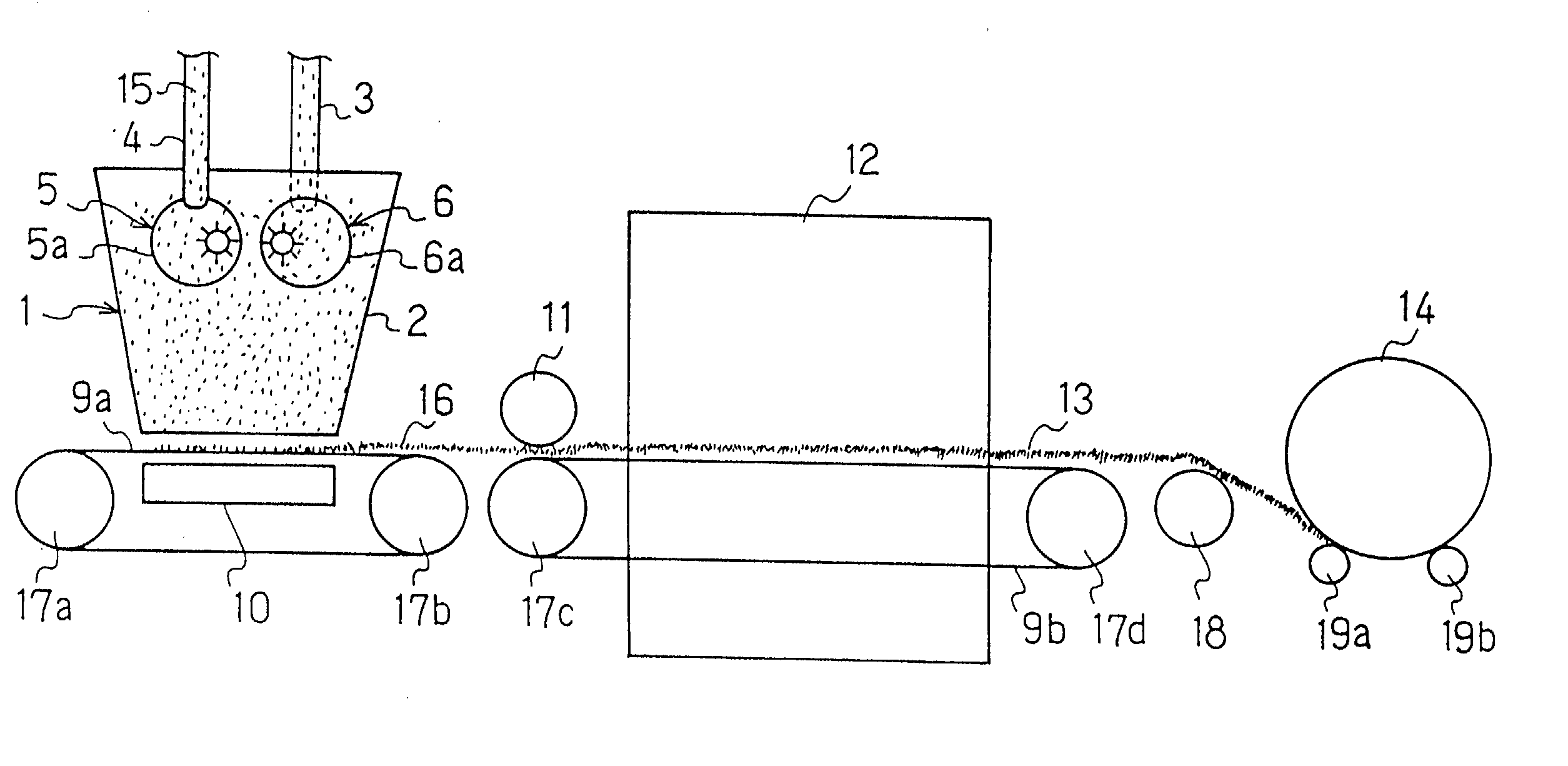

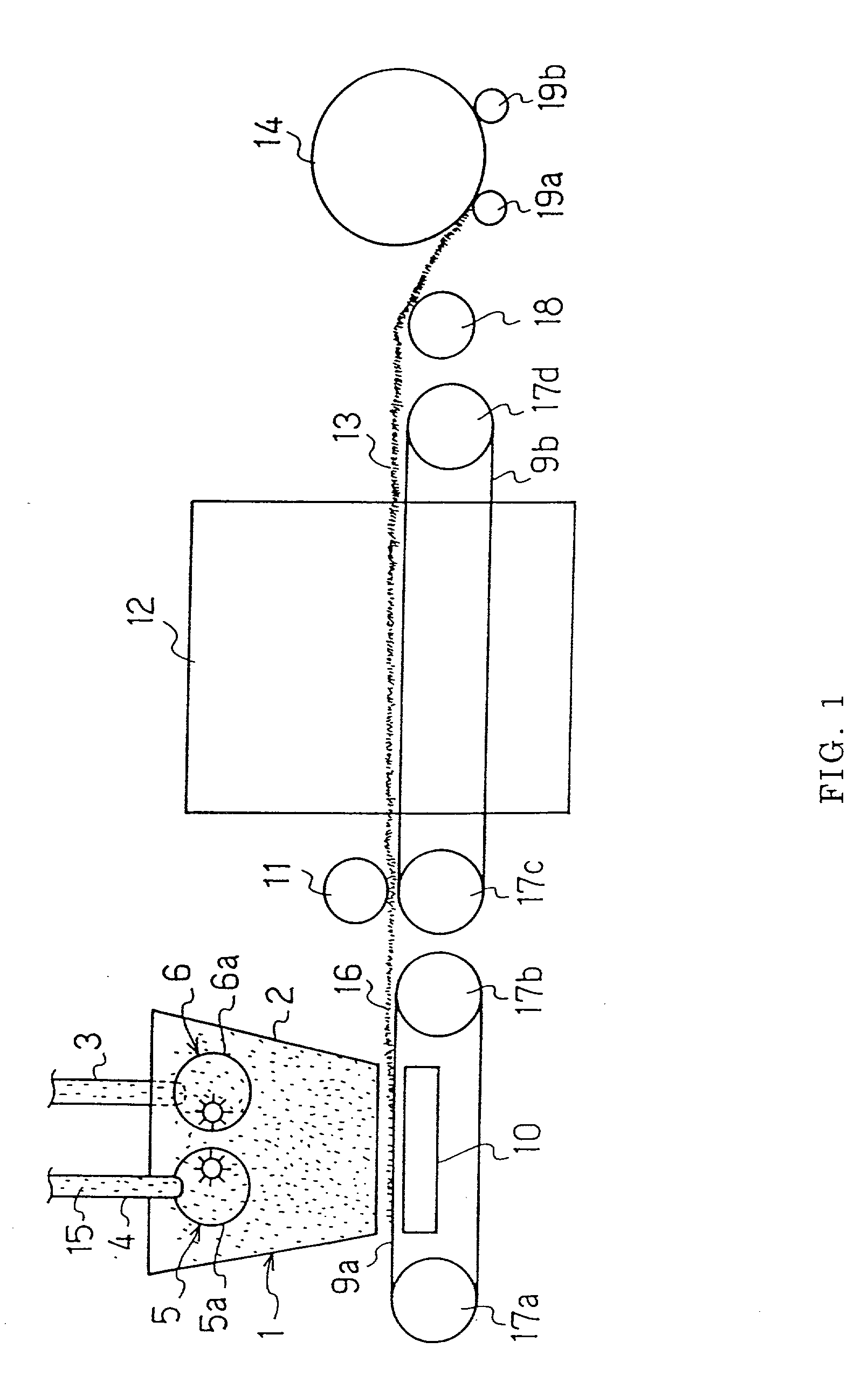

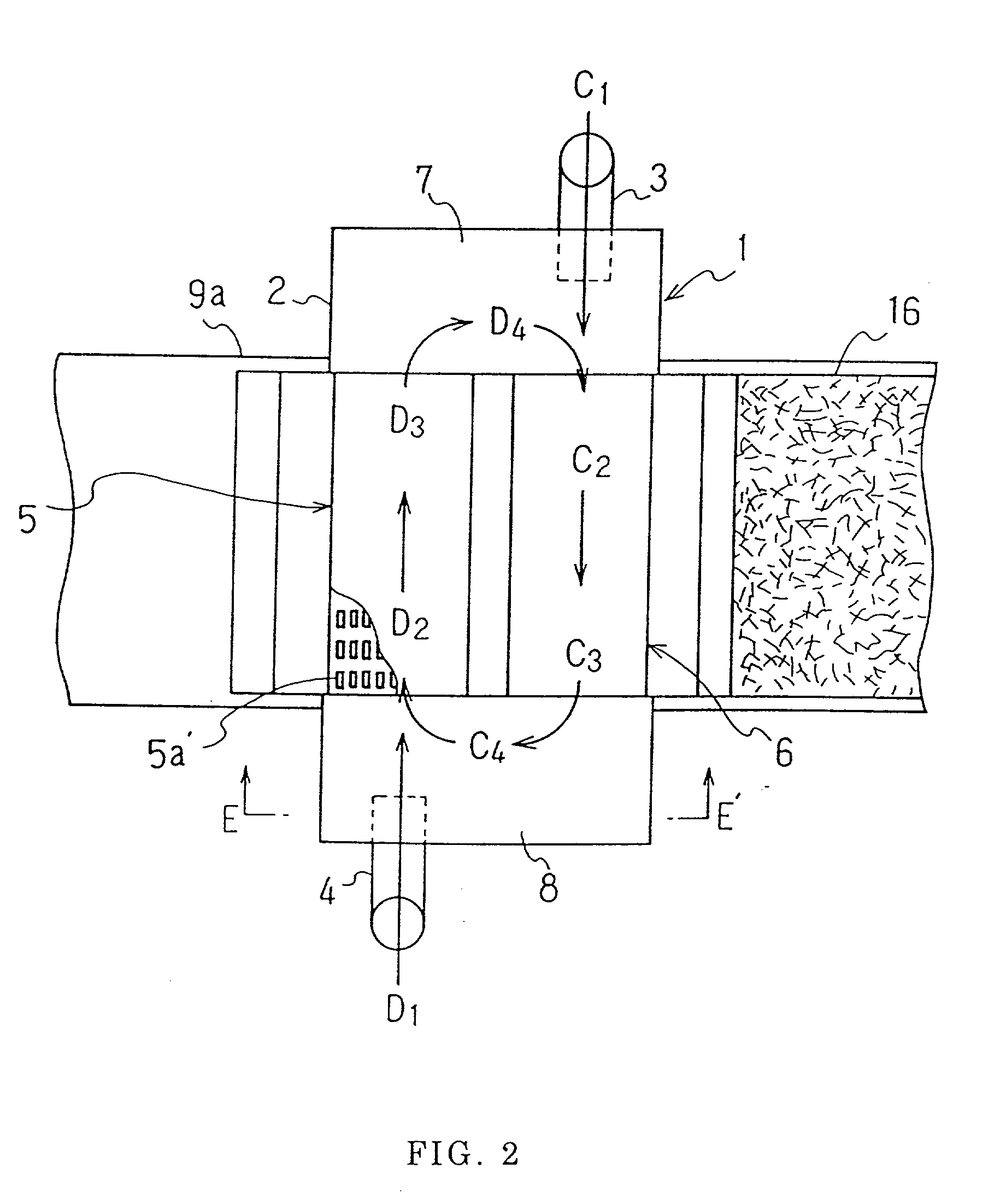

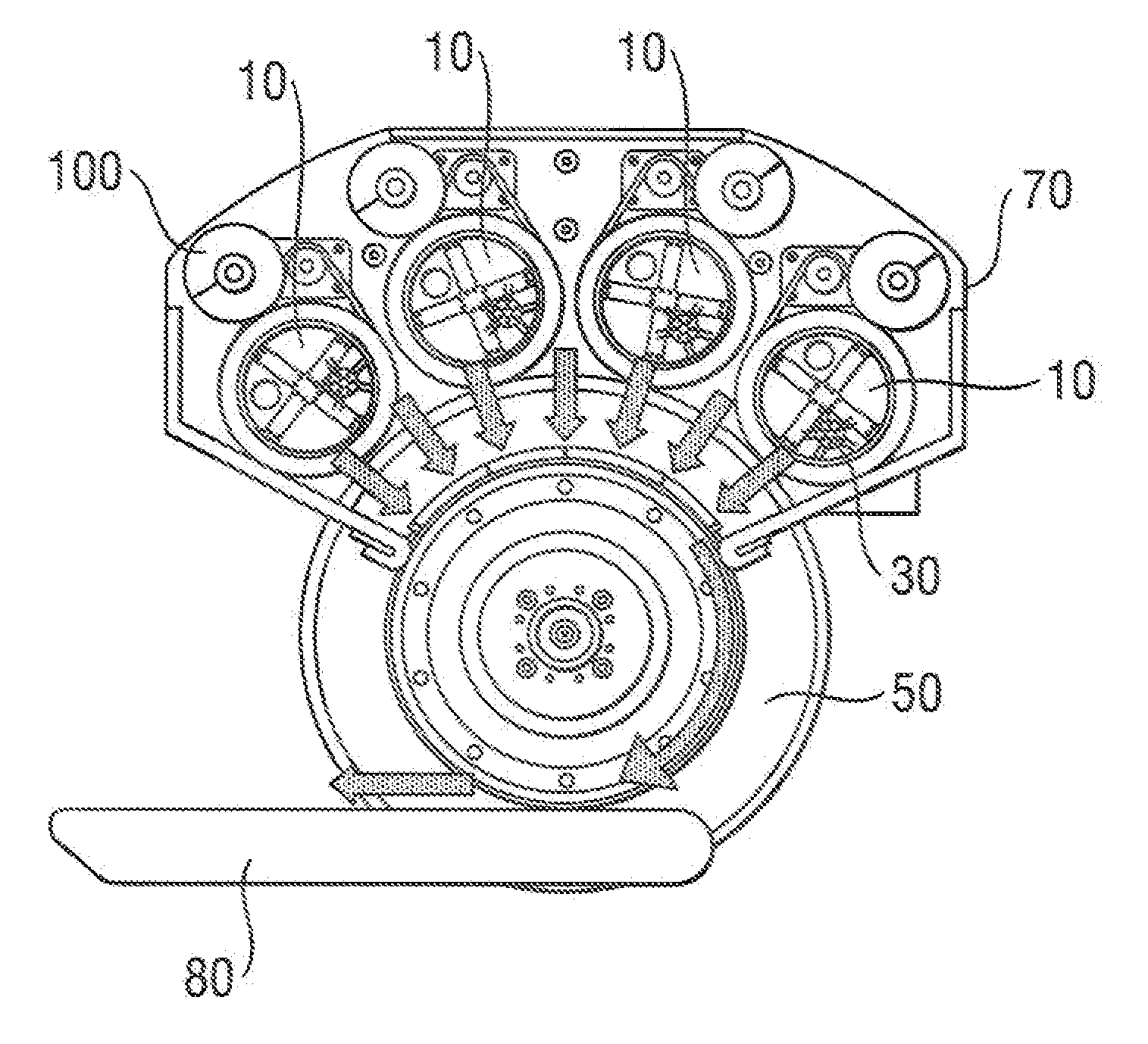

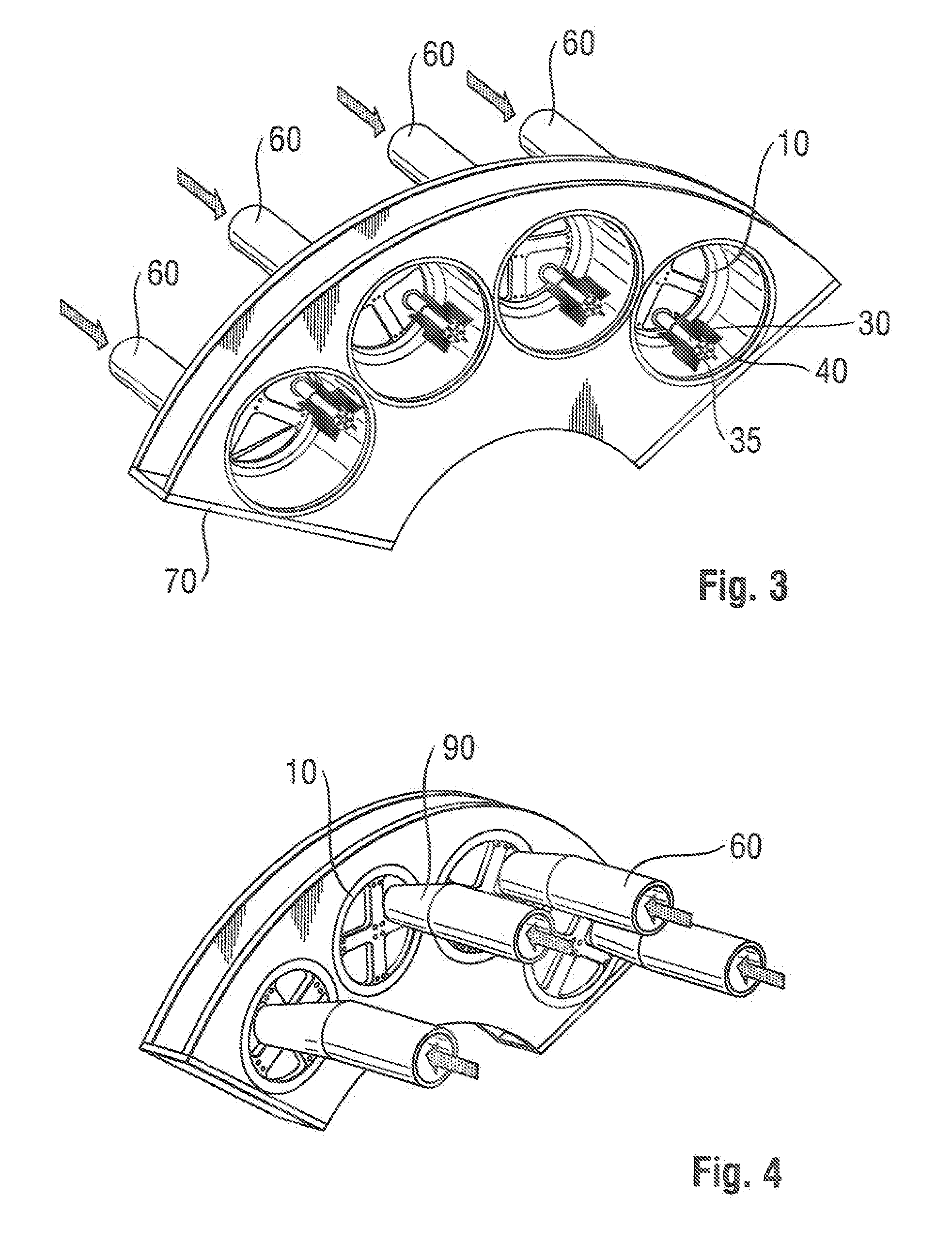

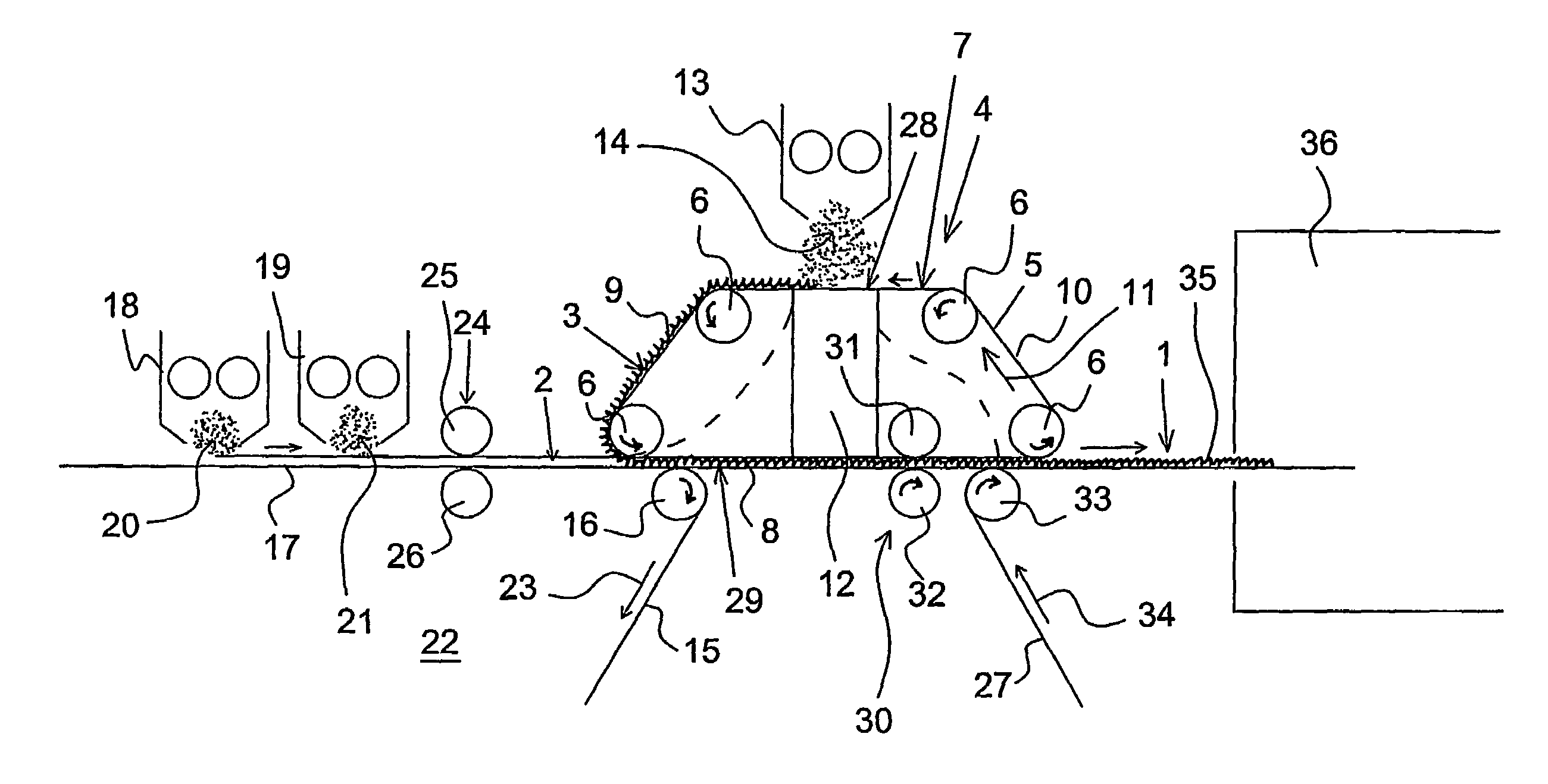

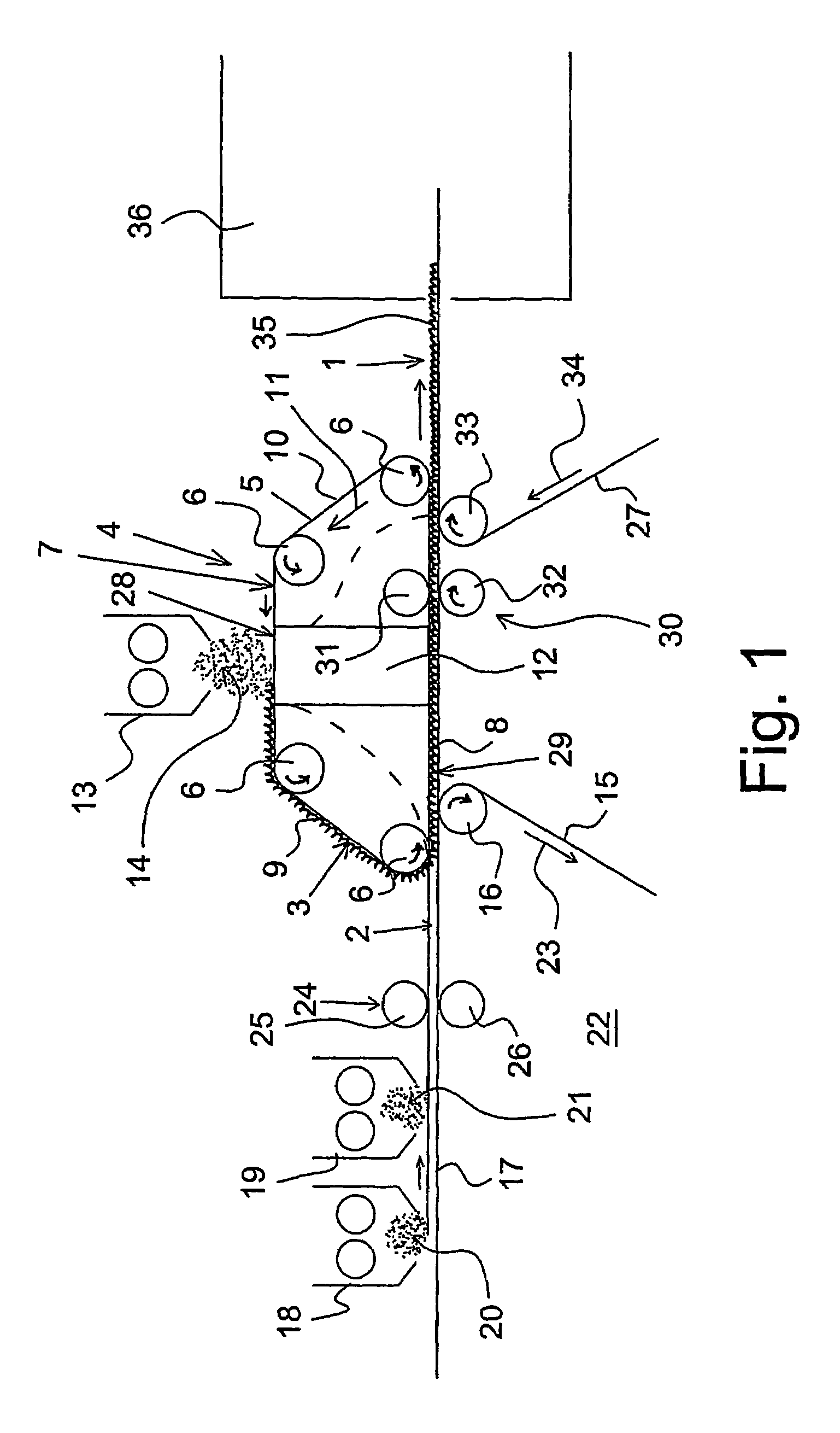

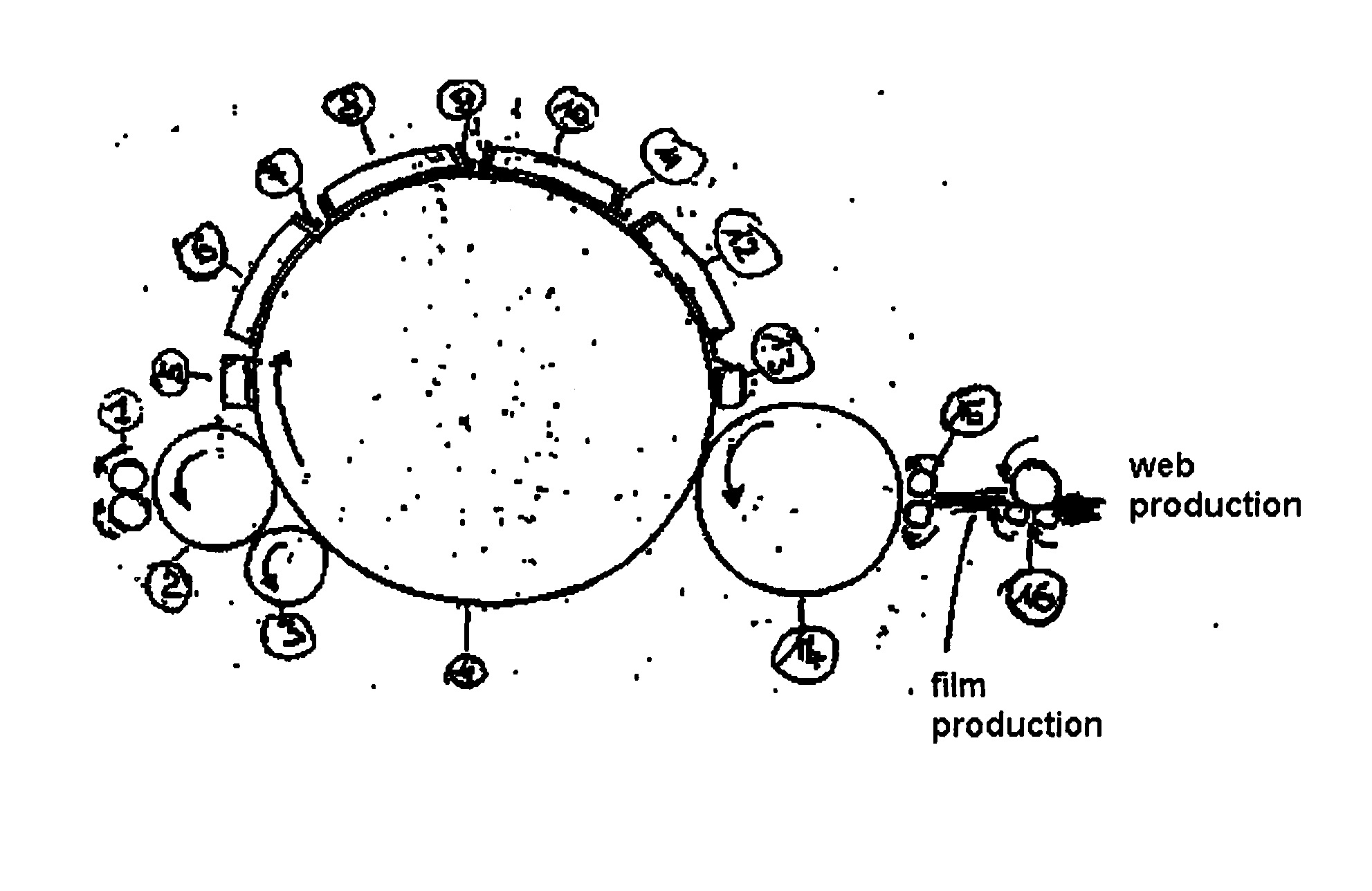

Fiber air-laying process for fibrous structures suitable for use in absorbent articles

The present invention refers to a process of making a fibrous structure, wherein roughly graded material is provided to rotating, apertured drums. The drums have at least one needle roll in their inside. The roughly graded material is agitated inside the drums, whereby fibers or small fiber clusters are separated from each other. These fibers and small fiber clusters are flung through the apertures to the outside of the drum, where they are directed onto a foraminous carrier to form a fibrous structure. The fibrous structures are especially useful in absorbent articles.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus and method for dry forming a uniform non-woven fibrous web

Owner:BIAX FIBERFILM CORP

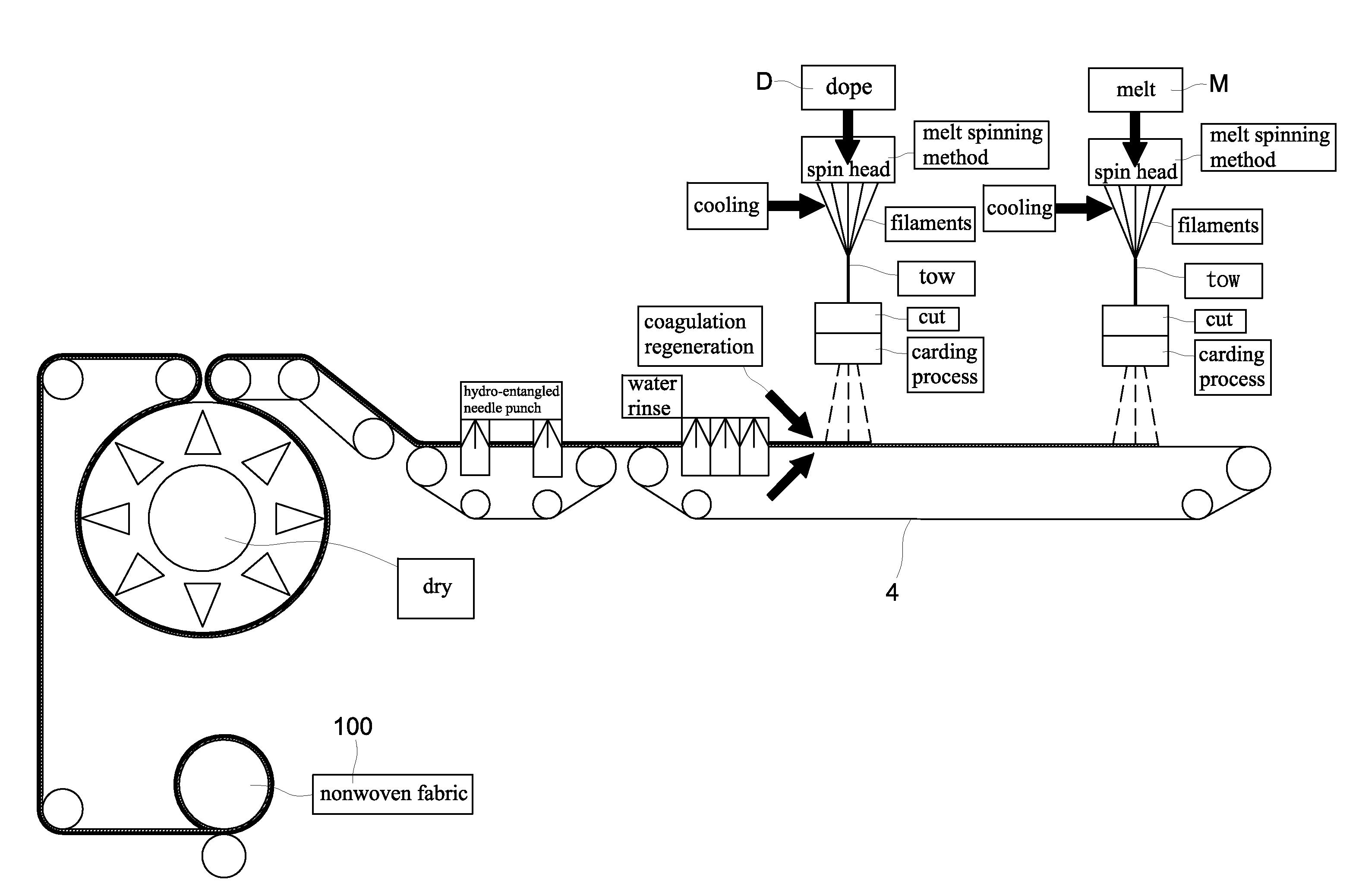

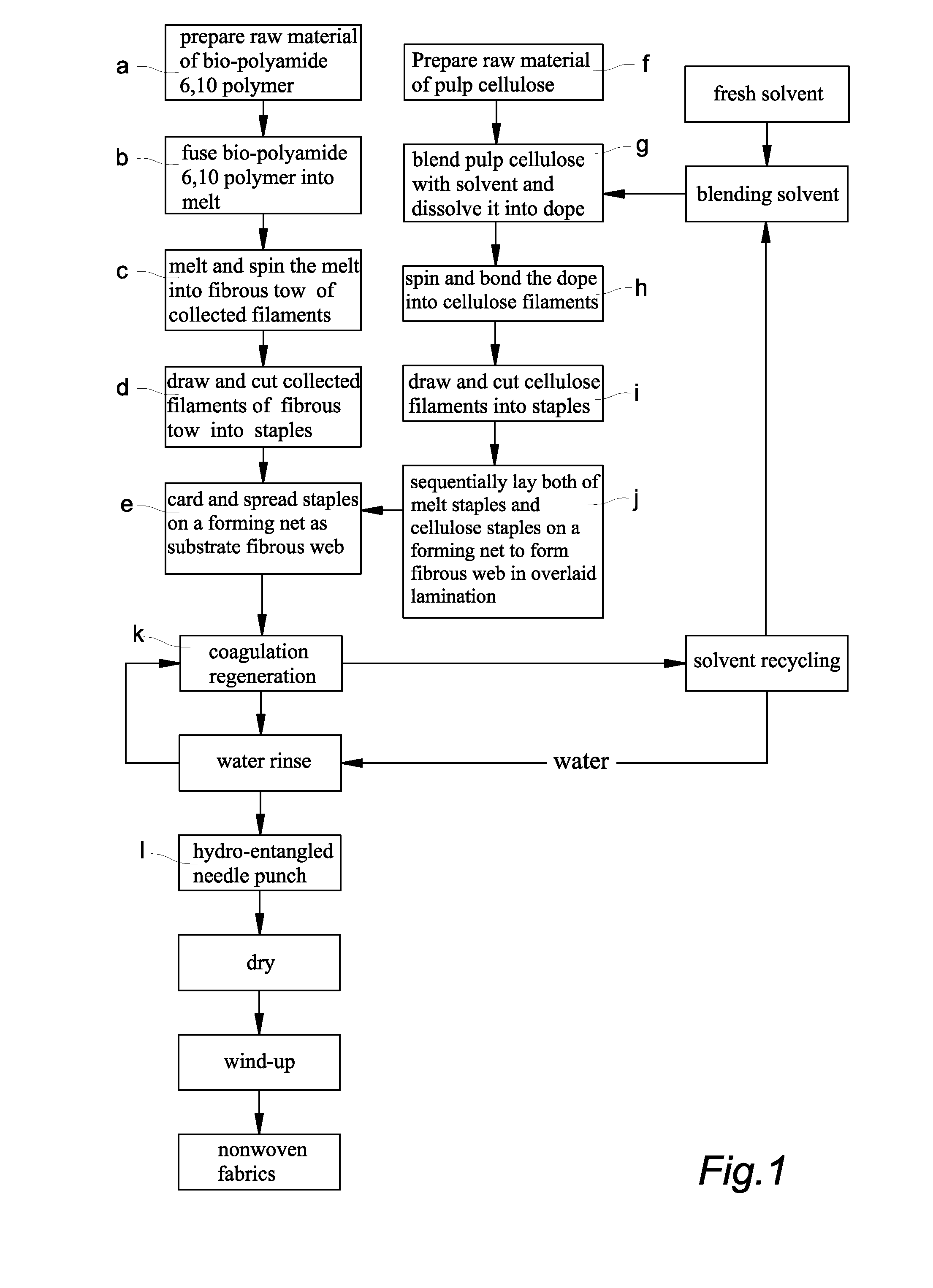

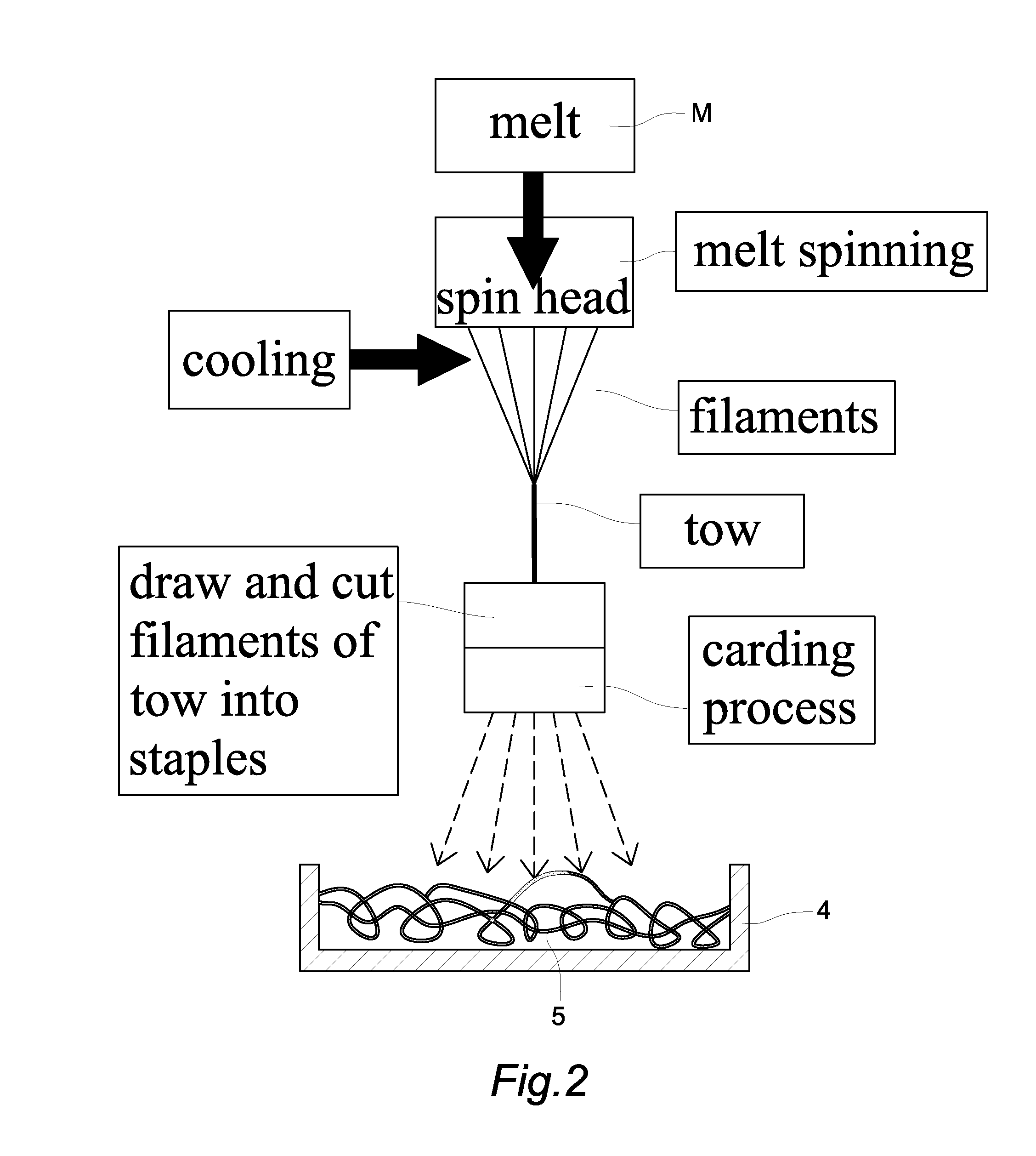

Stapled melt spinning method for producing non-woven fabrics with hygroscopic metastatic feature

ActiveUS20160145781A1Improve water absorptionReduce water contentPattern makingMonocomponent cellulose artificial filamentPunchingPolyamide

A stapled melt spinning method for producing nonwoven fabrics with hygroscopic metastatic feature. Firstly, fuse bio-polyamide 6,10 into melt, extrude and spin it out spin heads of extruder into filaments, cool, draw and collect filaments into tow, then extend, cut and card the filaments into the staples, and spread the staples on a conveyer to form fibrous web. Next, blend and dissolve pulp by N-methylmorpholine N-oxide (NMMO) dissolving solvent, dehydrate it to form dope, and extrude and spin it out spin heads of extruder into filaments, then cool, draw and collect filaments into tow, and extend, cut and card filaments into staples, then overlay the staples over existing fibrous web to form a composite fibrous web of bio-polyamide 6,10 and cellulose filaments. Finally, coagulate, regenerate and convert fibrous composite of bio-polyamide 6,10 and natural cellulose into nonwoven fabric with hygroscopic metastatic feature by hydro-entangled needle punching, drying, winding-up processes.

Owner:LIN CHIH HSIN

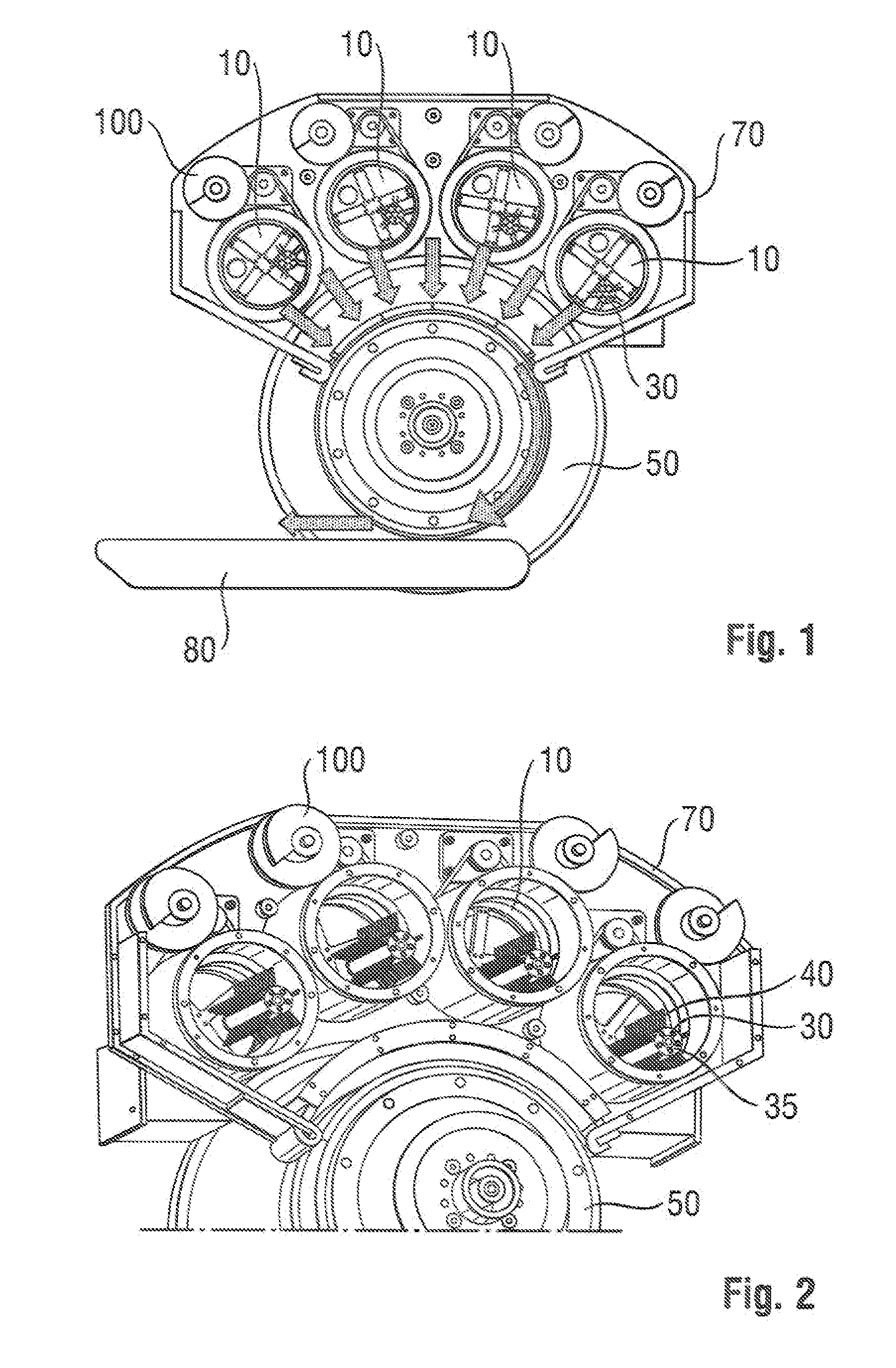

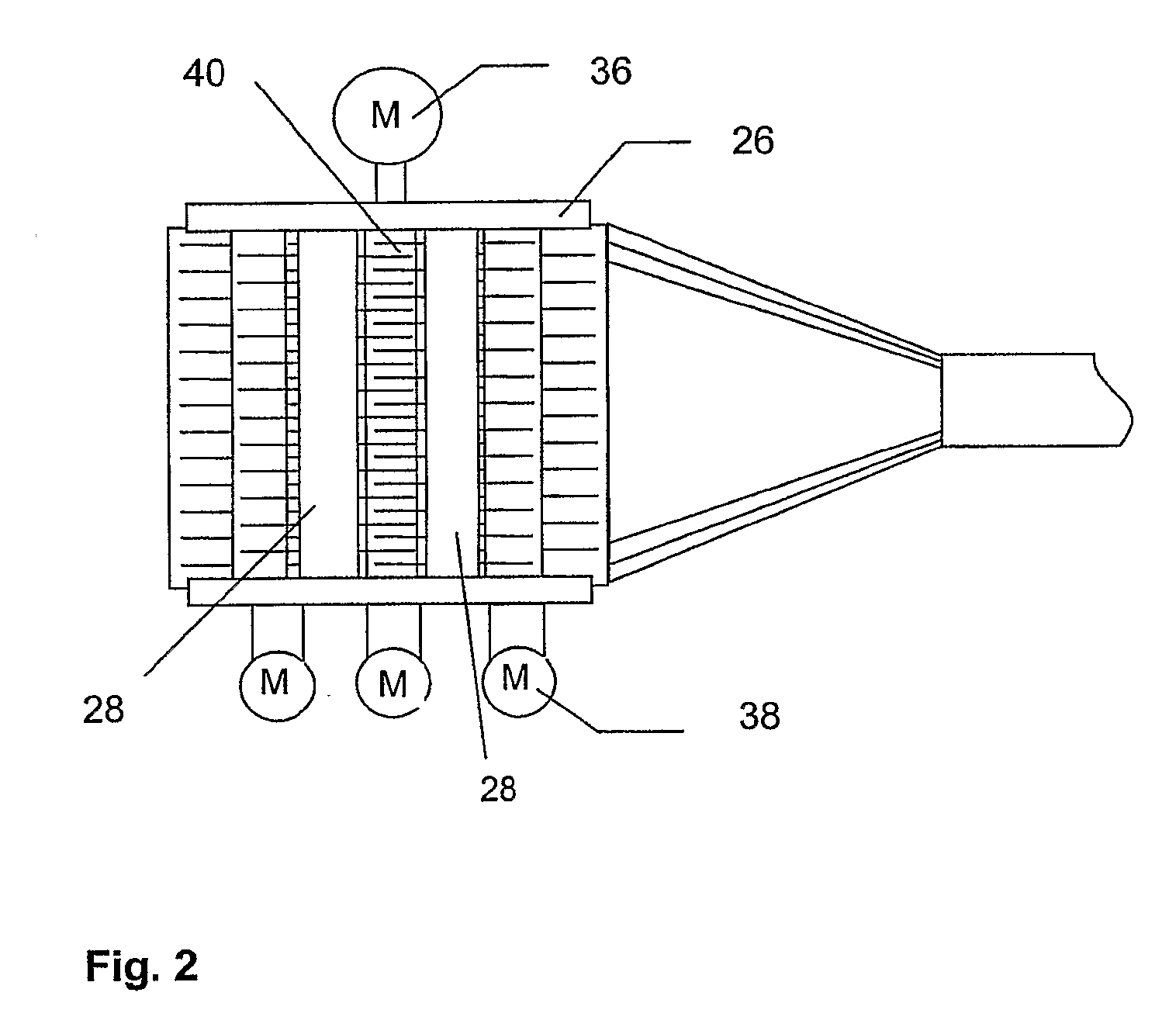

Forming Head and Process for the Production of a Non-Woven Fabric

InactiveUS20080241301A1Great fibre opening capacityEvenly distributedWood working apparatusLap forming devicesNonwoven fabricConveyor belt

The invention concerns a forming head for an apparatus for the production of a non-woven fabric by depositing fibres on a conveyor belt, comprising a fibre feeder which opens into a fibre processing chamber and which has a lower deposit opening for the delivery of fibres, wherein arranged in the fibre processing chamber are interengaging needle rollers with longitudinal axes oriented in mutually parallel relationship, which can rotate about their respective longitudinal axis, and the interengaging needle rollers enclose an inner chamber and are arranged with respect to the fibre feeder and the deposit opening in such a way that fibres fed to the forming head in operation enter the inner chamber by passing through between interengaging needle rollers and leave the inner chamber also by passing through between interengaging needle rollers.

Owner:GLATFELTER FALKENHAGEN GMBH

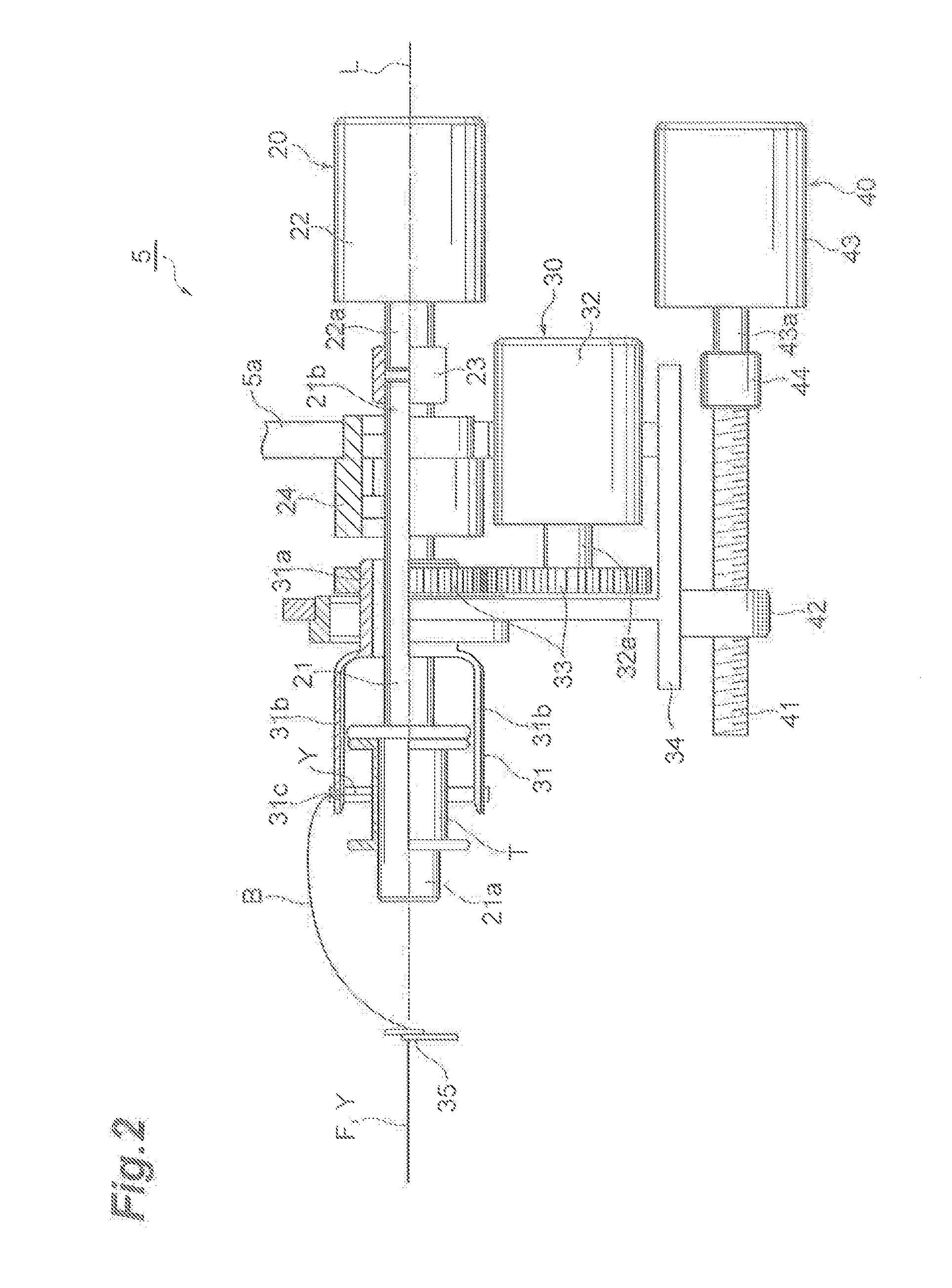

Thread production device

A yarn producing apparatus is an apparatus for producing CNT (carbon nanotube) yarn from CNT fibers while causing the CNT fibers to run. The yarn producing apparatus includes an aggregating unit that aggregates the CNT fibers, and a twisting and winding device that twists the CNT fibers aggregated by the aggregating unit.

Owner:MURATA MASCH LTD

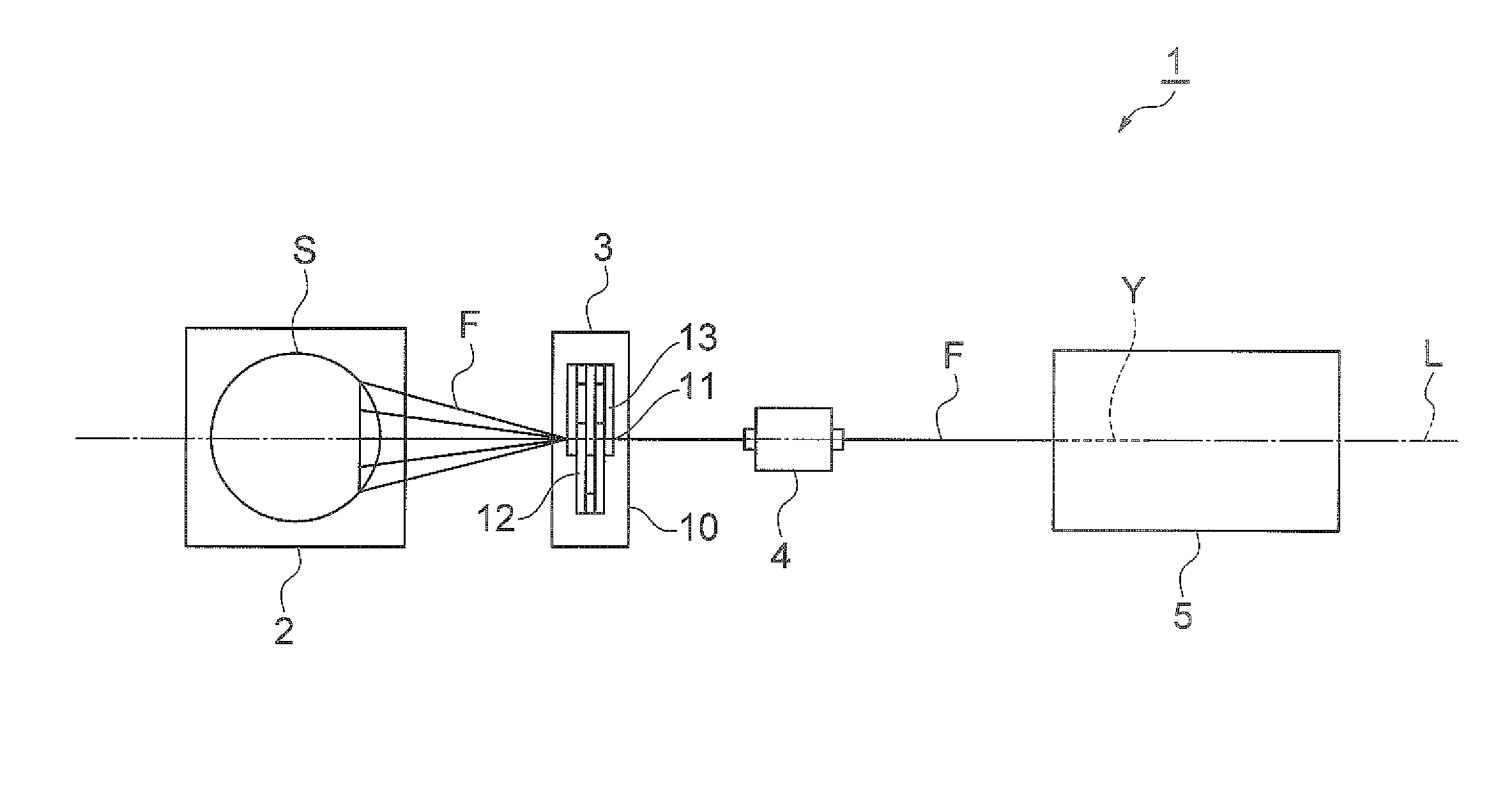

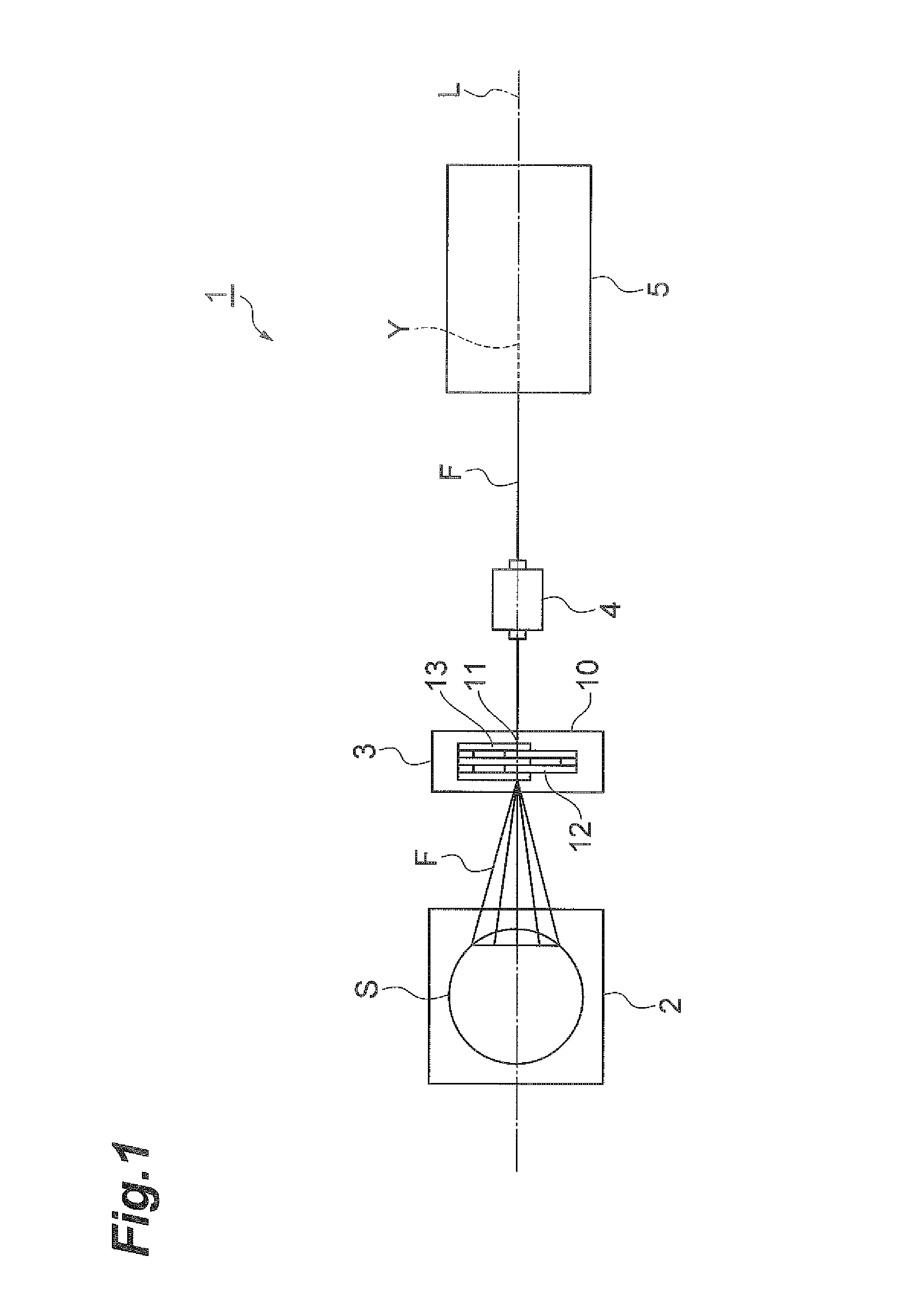

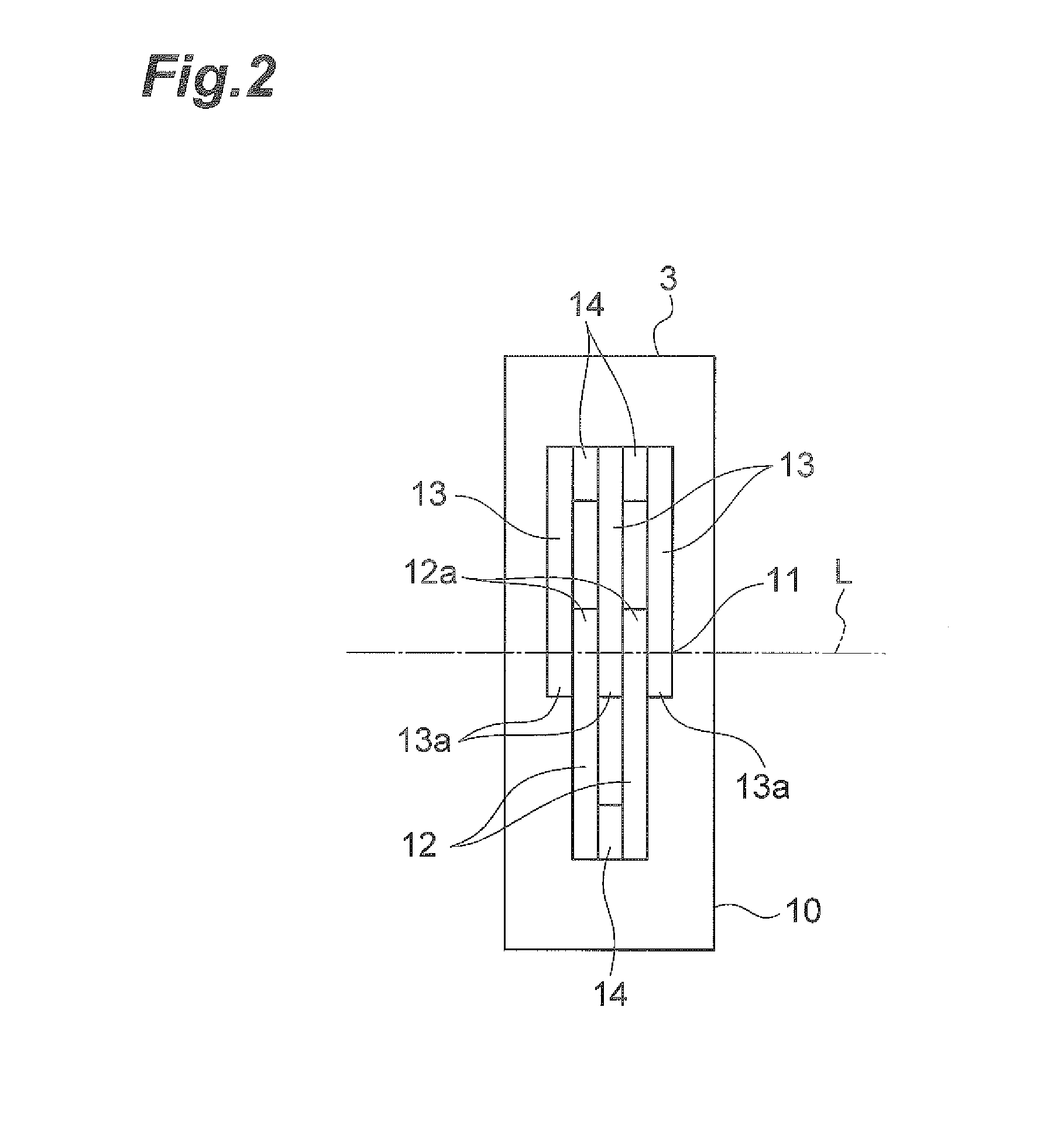

Microwave sensor for measuring a dielectric property of a product

InactiveUS20050179443A1Prevent crashReduce the total massSafety devices for fibre treatmentResistance/reactance/impedenceVolumetric Mass DensityHigh field

The application relates to a microwave sensor for measuring a dielectric property, especially the density and / or moisture content of a product, having a microwave resonator, wherein a product introduced into the resonator interacts with a resonant microwave field generated in the resonator in order to determine suitable measured quantities, and is characterised in that at least two half-waves of the electric field are formed in the resonator in one direction, the product feed being effected in at least one region of high field intensity of one of the half-waves of the electric field.

Owner:TRUETZSCHLER GMBH & CO KG

Structured forming fabric and method

InactiveUS7879195B2Improve system performanceIncreased caliper bulk absorbencyNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringMechanical engineering

Forming fabric for making a bulky web. The fabric includes a machine facing side and a web facing side having pockets formed by warp and weft yarns. A bottom of the pockets is formed an exchange of a different number of the warp and the weft yarns. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

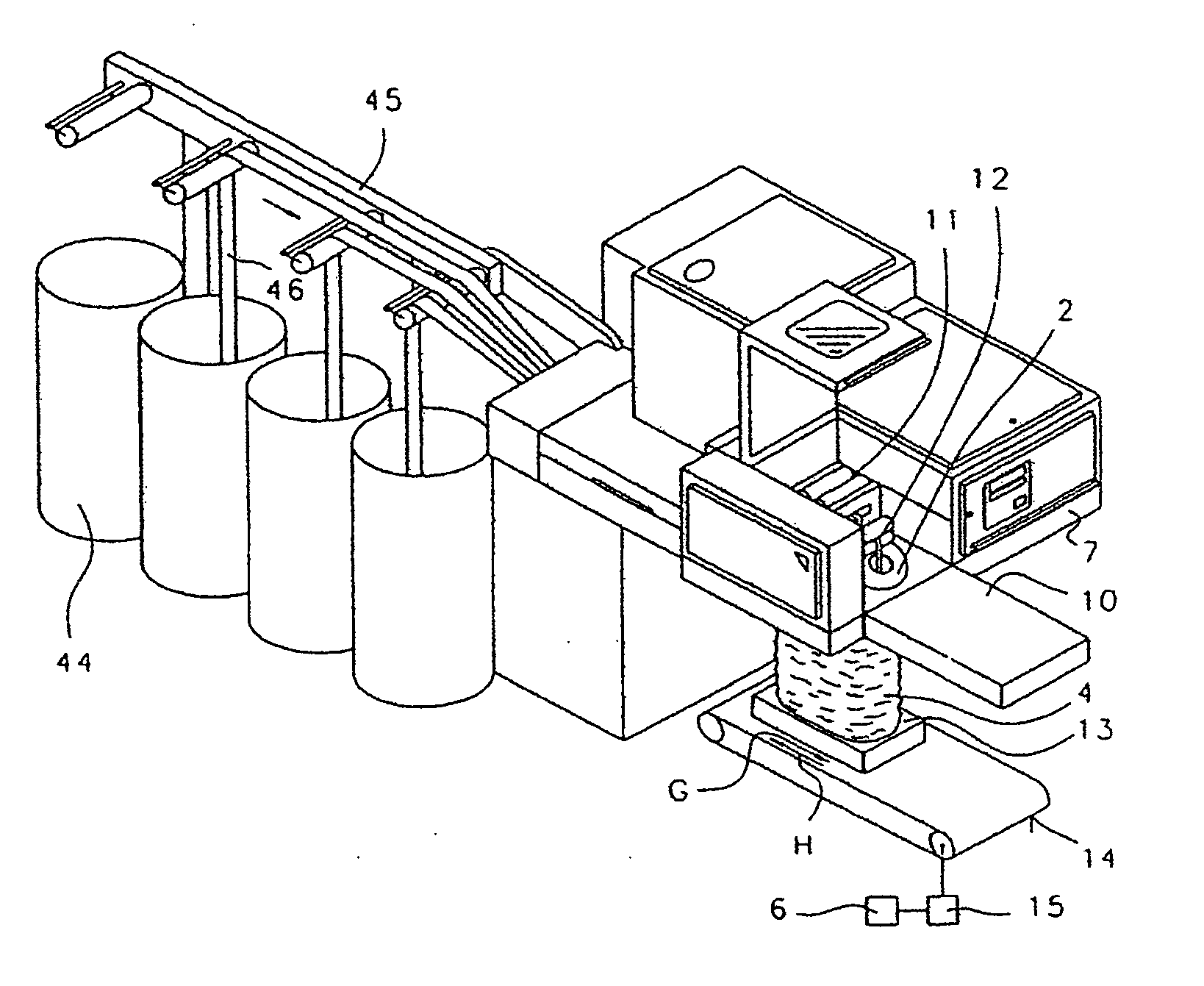

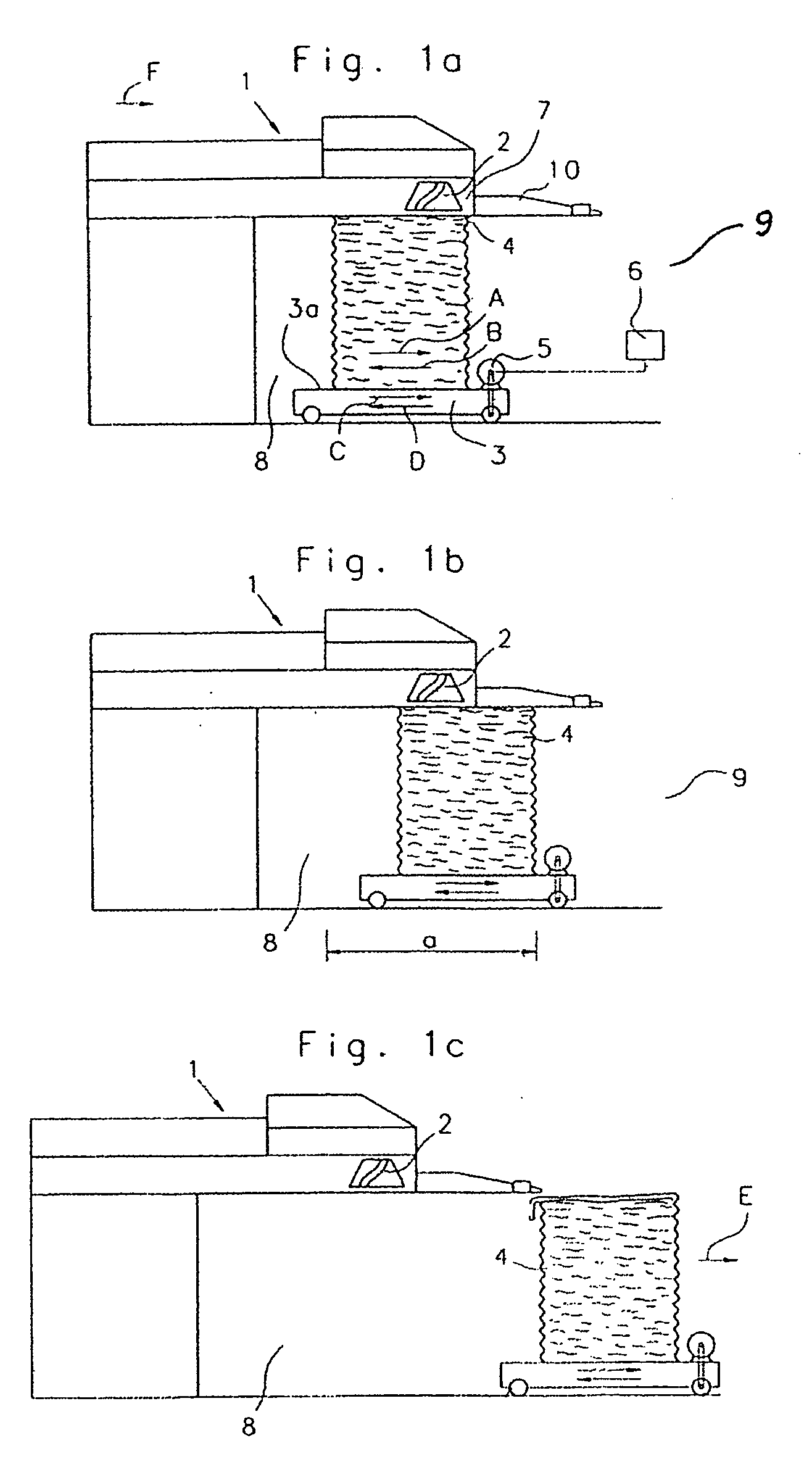

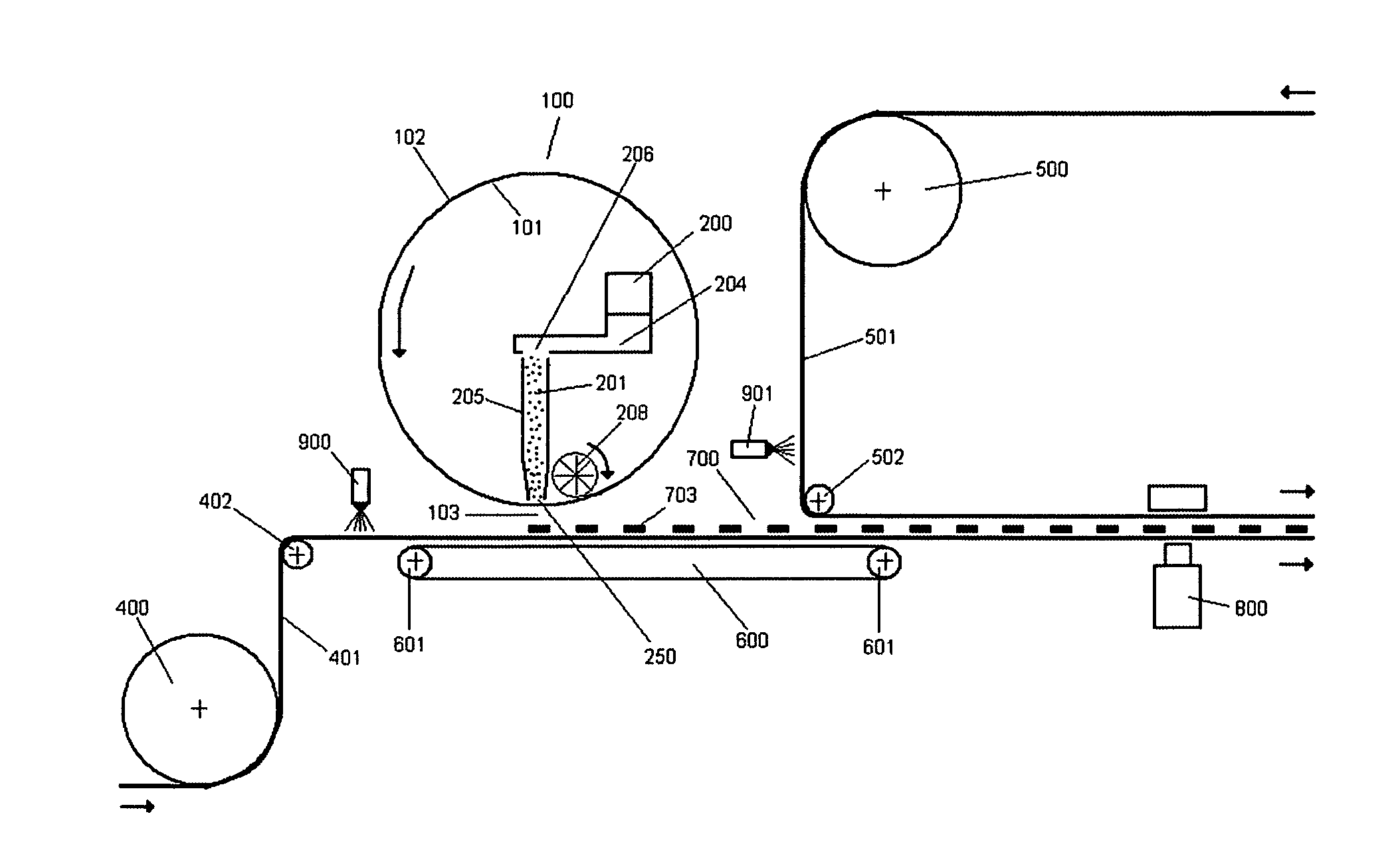

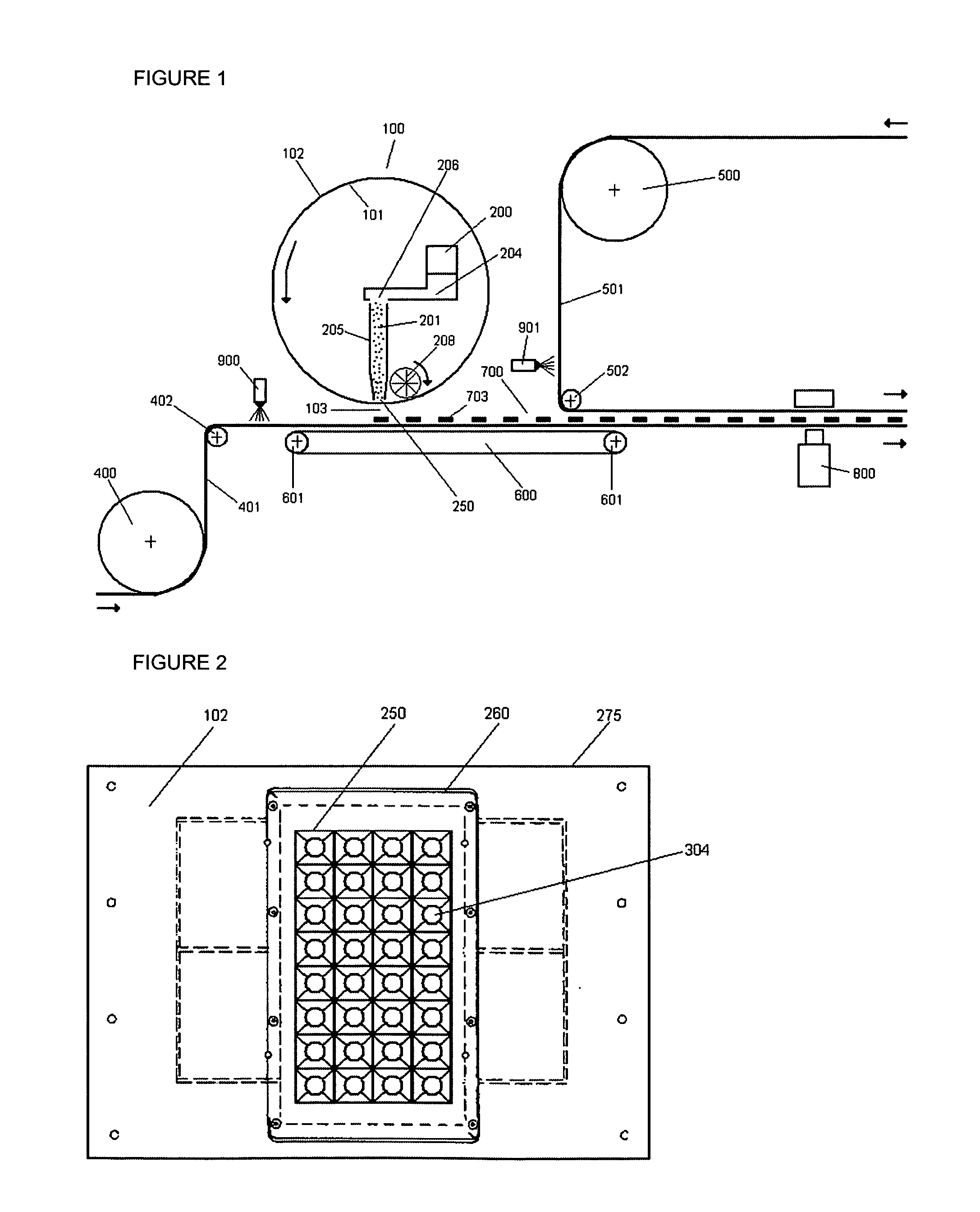

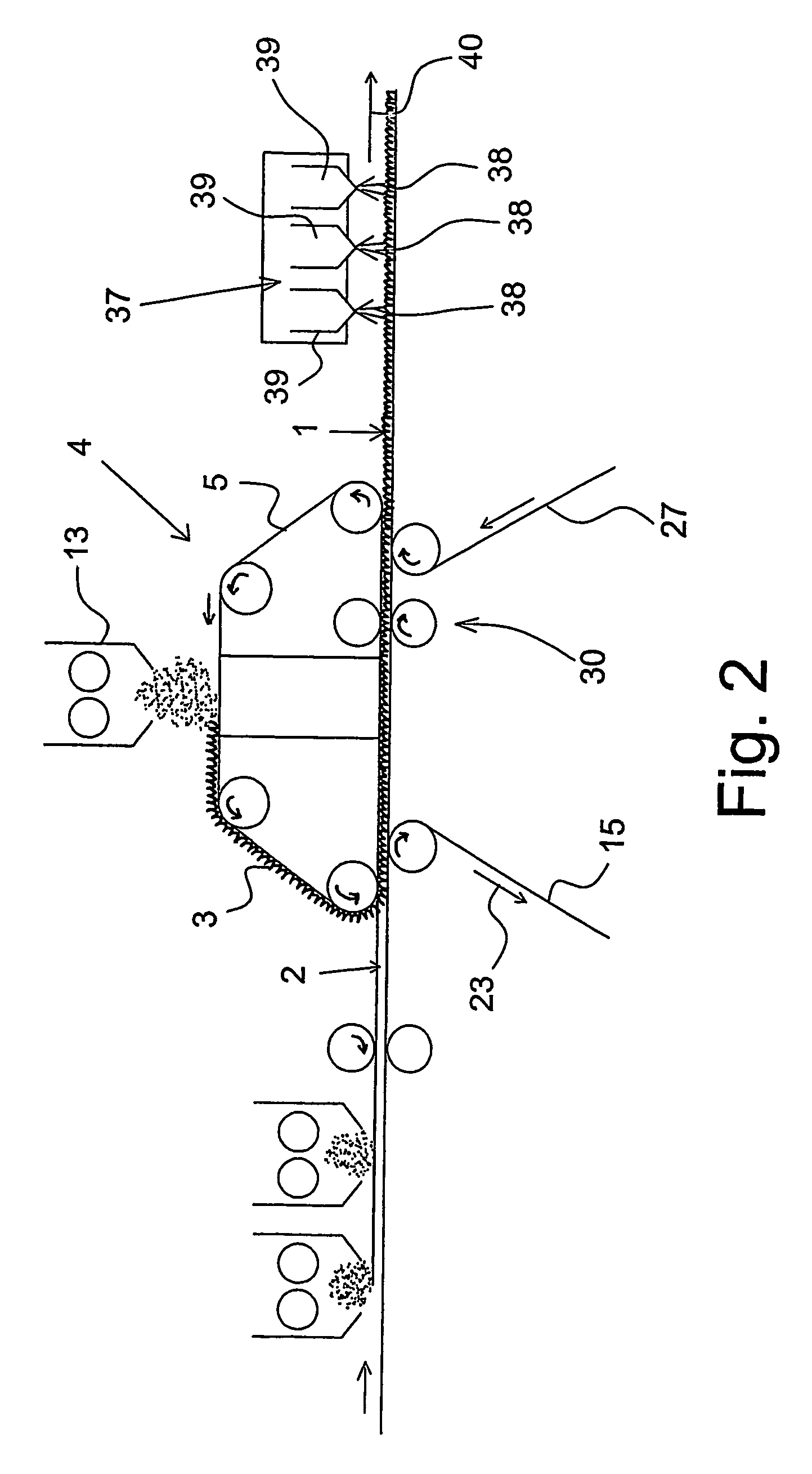

Method and apparatus for producing an environmentally friendly absorbent structure

InactiveUS20140296817A1Prevent overflowImprove accuracyLap forming devicesLap-winding devicesFEMININE HYGIENEBiomedical engineering

The present invention relates to a method and apparatus for forming a composite structure, preferably for use in an absorbent structure used within the personal hygiene industry, such as for instance feminine hygiene garments, baby diapers and pants and adult incontinence garments. The present invention preferably provides a method and apparatus for depositing particulate material in a desired pattern onto a moving carrier layer and positioning it into a pocketing pattern. The method allows accurate forming of a pre-determined pattern of particulate material clusters at high production speed, with reduced raw material usage and relative low cost. As such method allows manufacturing of absorbent structures being substantially cellulose free and substantially glue free, considered technically, economically and environmentally friendly. The present invention foresees in the need for an improved thin, flexible, lightweight particulate material absorbent structure which overcomes the problems of the prior art having optimal absorption, distribution and retention.

Owner:DRYLOCK TECHNILOGIES NV

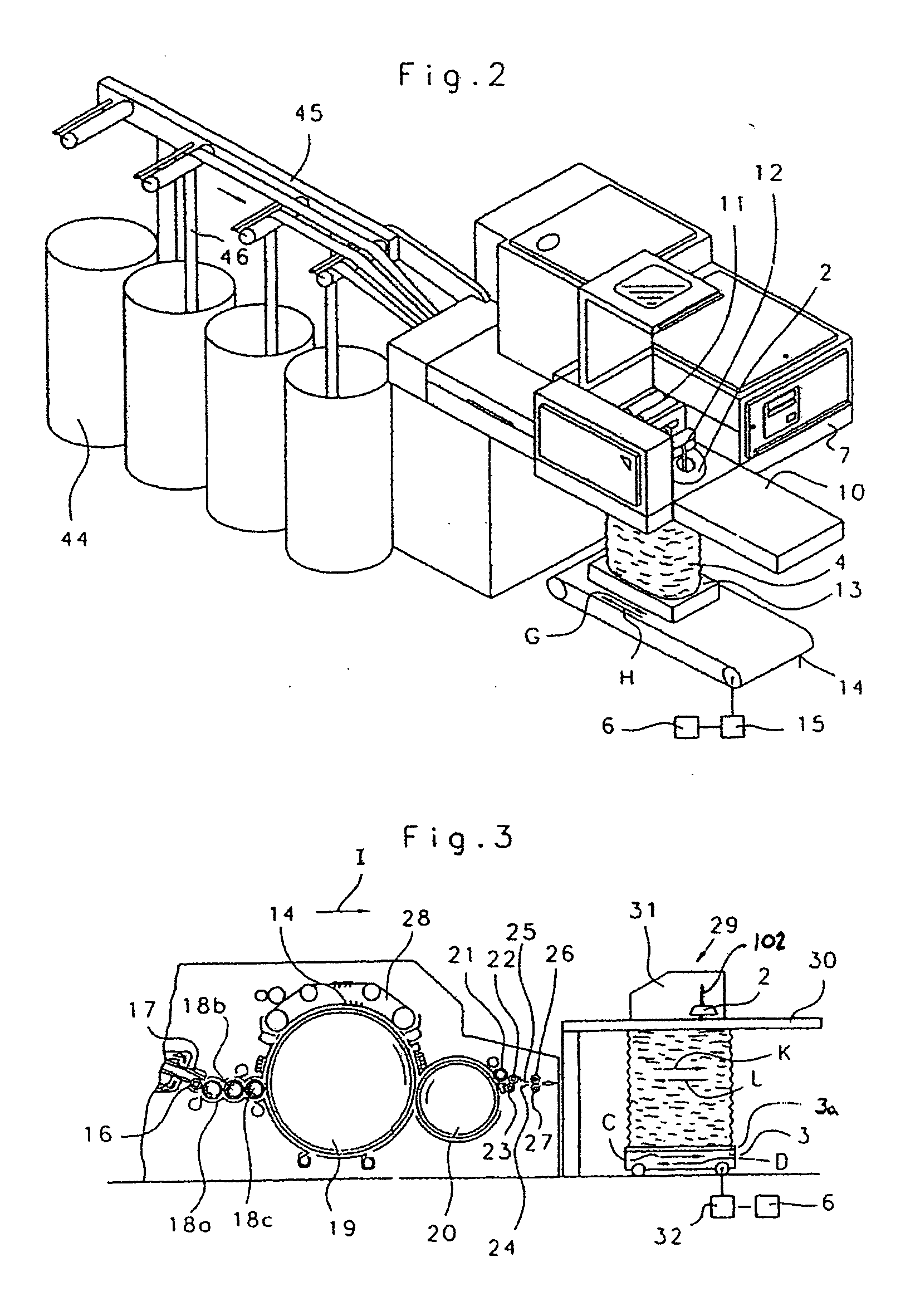

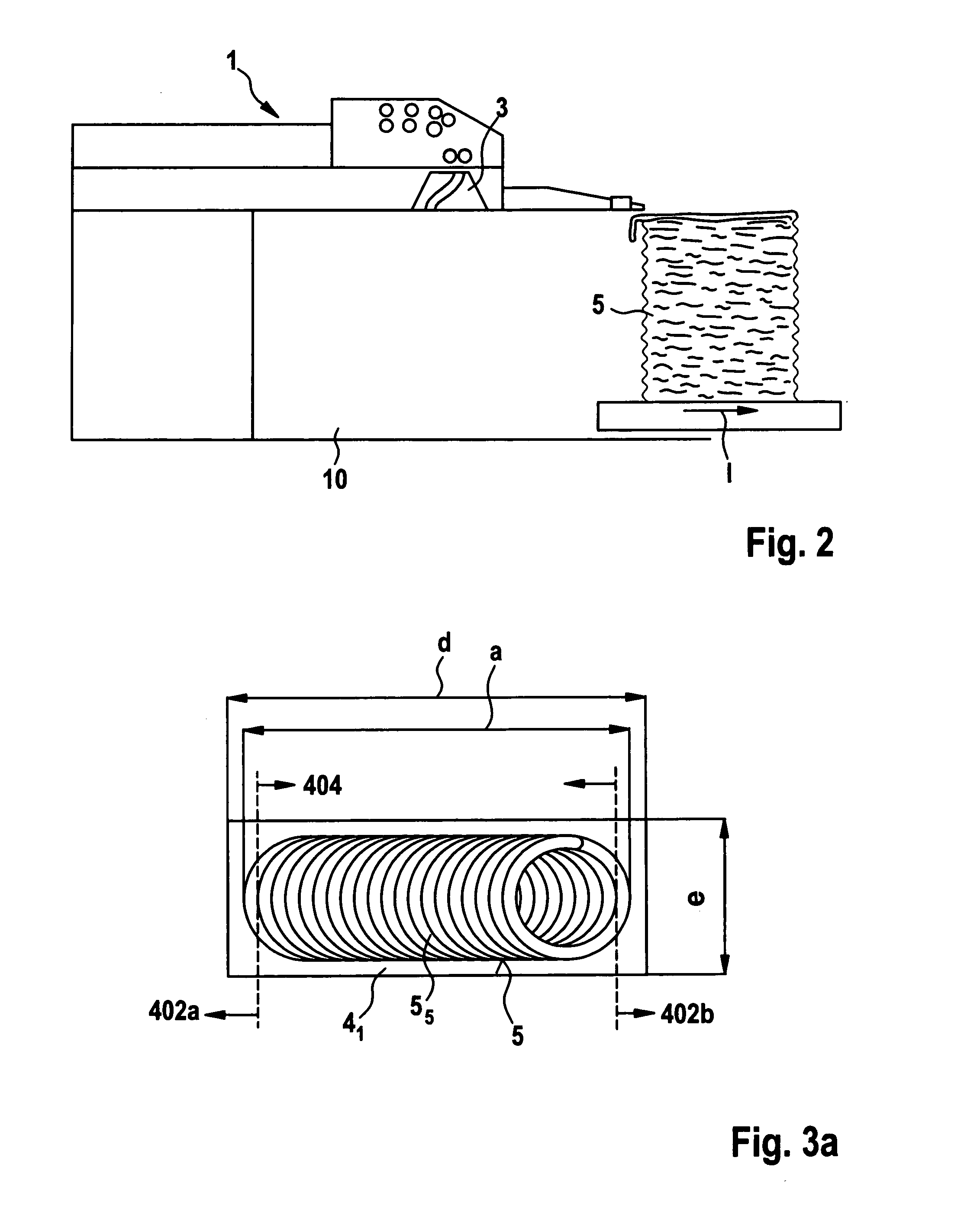

Apparatus in a spinning room for making available a can-less fibre sliver package (feed material) for a sliver-fed spinning machine, for example a draw frame

InactiveUS20070063088A1Simple waySimple and efficient mannerFilament handlingLap-winding devicesFiberEngineering

An apparatus in a spinning room for providing at least one fiber sliver package to a sliver-fed machine having at least one feed position. The apparatus comprises a transport arrangement for transporting one or more fiber sliver packages from an upstream sliver-delivering machine or a storage station to a sliver-fed machine. The transport arrangement is arranged to supply at least one fiber sliver package to a feed position and the fiber sliver package(s) can be stably positioned at the feed position.

Owner:TRUETZSCHLER GMBH & CO KG

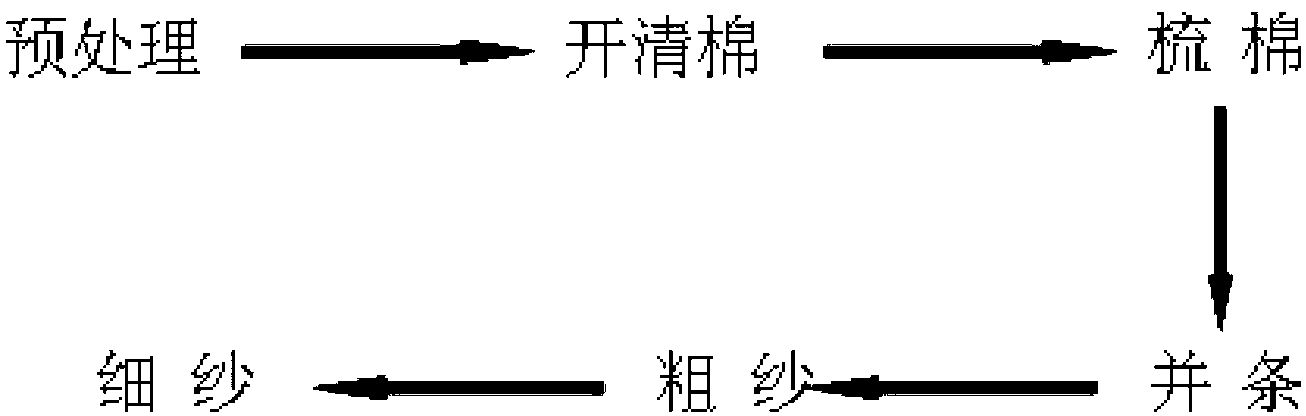

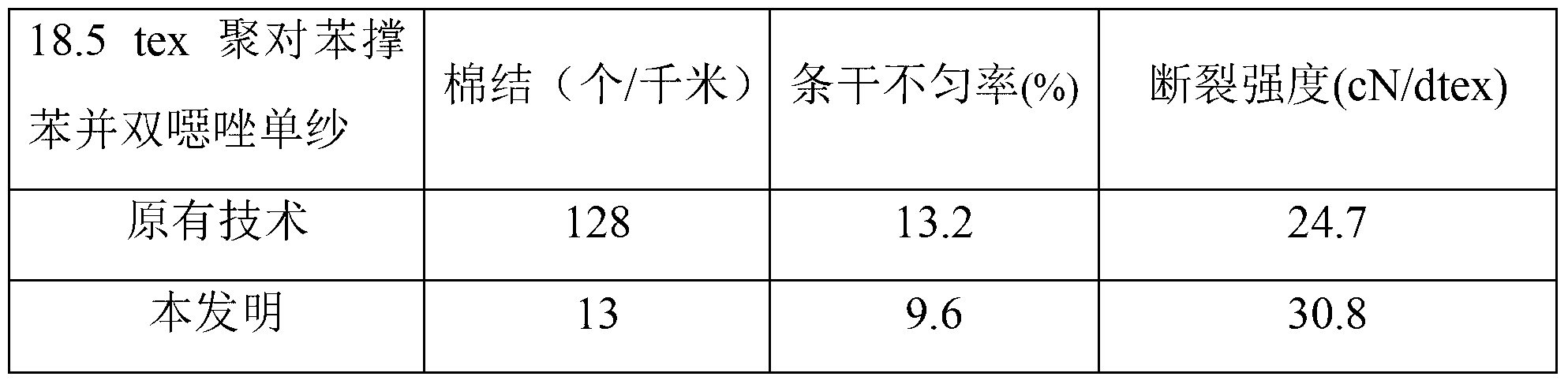

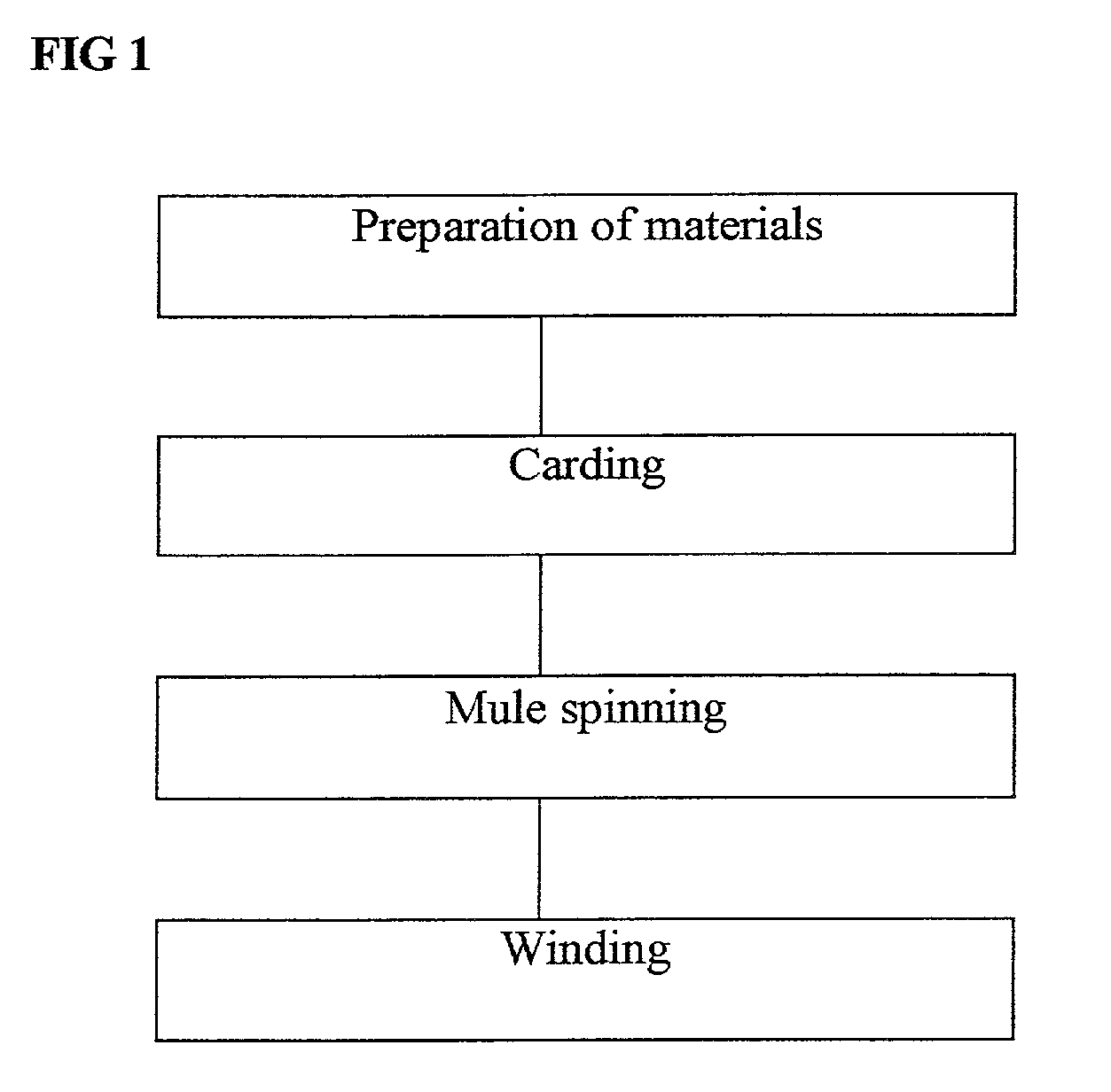

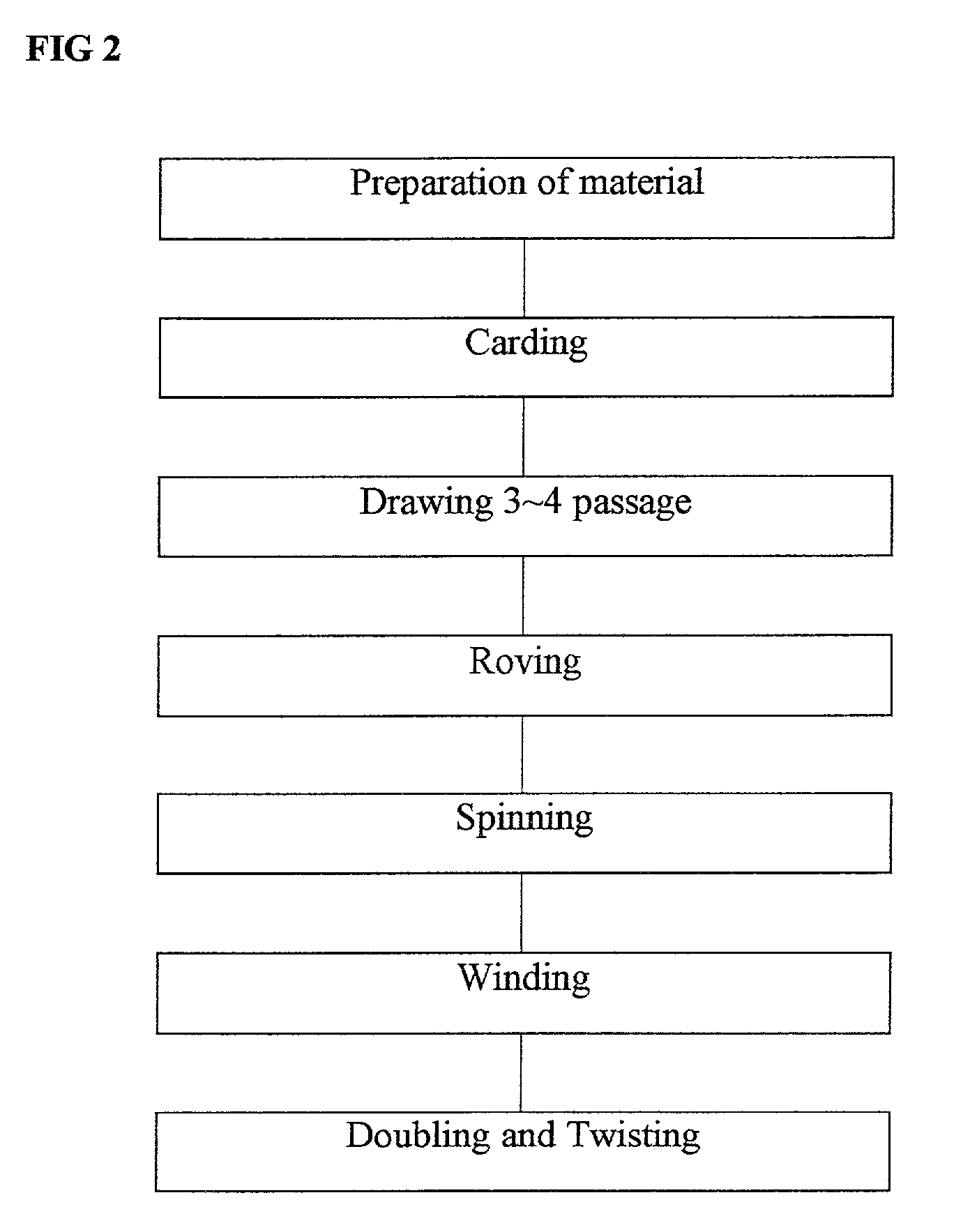

Method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres

The invention discloses a method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres. The method comprises the steps of pre-treatment, cotton opening and picking, cotton teasing, drawing, rough spinning and fine spinning. The method solves the difficult problem of spinning the poly-p-phenylenebenzobisthiazole fibres, and establishes a technical foundation of pure spinning of the PBO fibres, which is performed on cotton spinning equipment; yarns obtained via spinning have the advantages of glabrous surface, smoothness, less neps, uniform evenness and the like, can be widely applied to high-grade protective textiles and industrial textiles.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

Non-Woven Fabric and Method for Fabricating the Same

InactiveUS20140141677A1Desirable mechanical propertyCost-effectivePattern makingLap forming devicesPolymer scienceCellulose fiber

A non-woven fabric includes a filament fiber web and a composite fiber web that is entangled with the filament fiber web and that includes composite staple fibers and cellulose fibers. The composite staple fibers and the cellulose fibers are fusion-bonded together. A method of fabricating a non-woven fabric includes: (a) air laying and thermally treating composite staple fibers and cellulose fibers so as to form a composite fiber web, the composite staple fibers and the cellulose fibers in the composite fiber web being fusion-bonded together, and (b) disposing the composite fiber web between two filament fiber webs followed by subjecting to water-jet treatment such that the composite fiber web and the filament fiber webs are entangled with each other.

Owner:KANG & HSIUNG ENTERPRISE

Absorbent article, method and apparatus for preparing same

Owner:PARAGON TRADE BRANDS

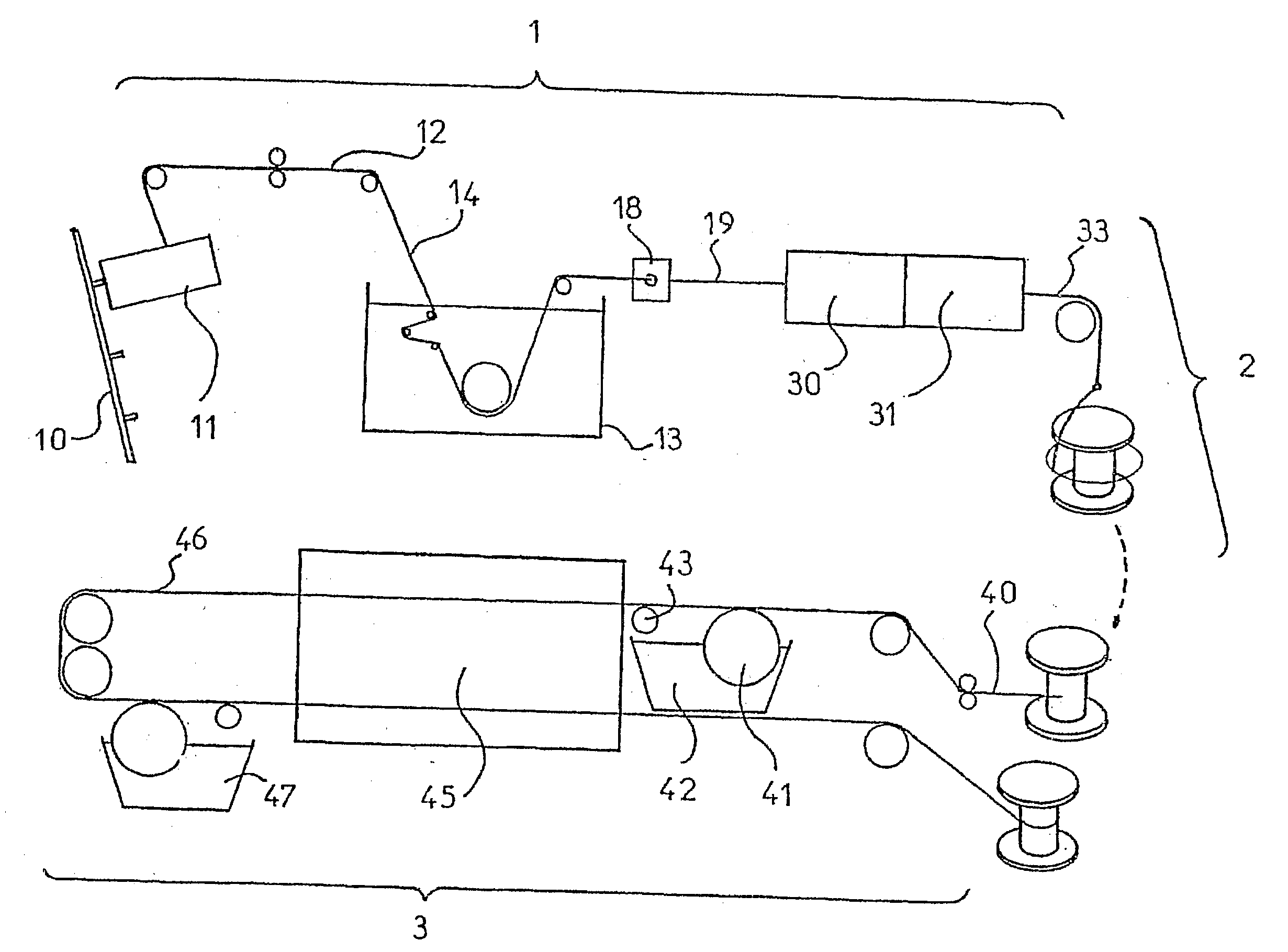

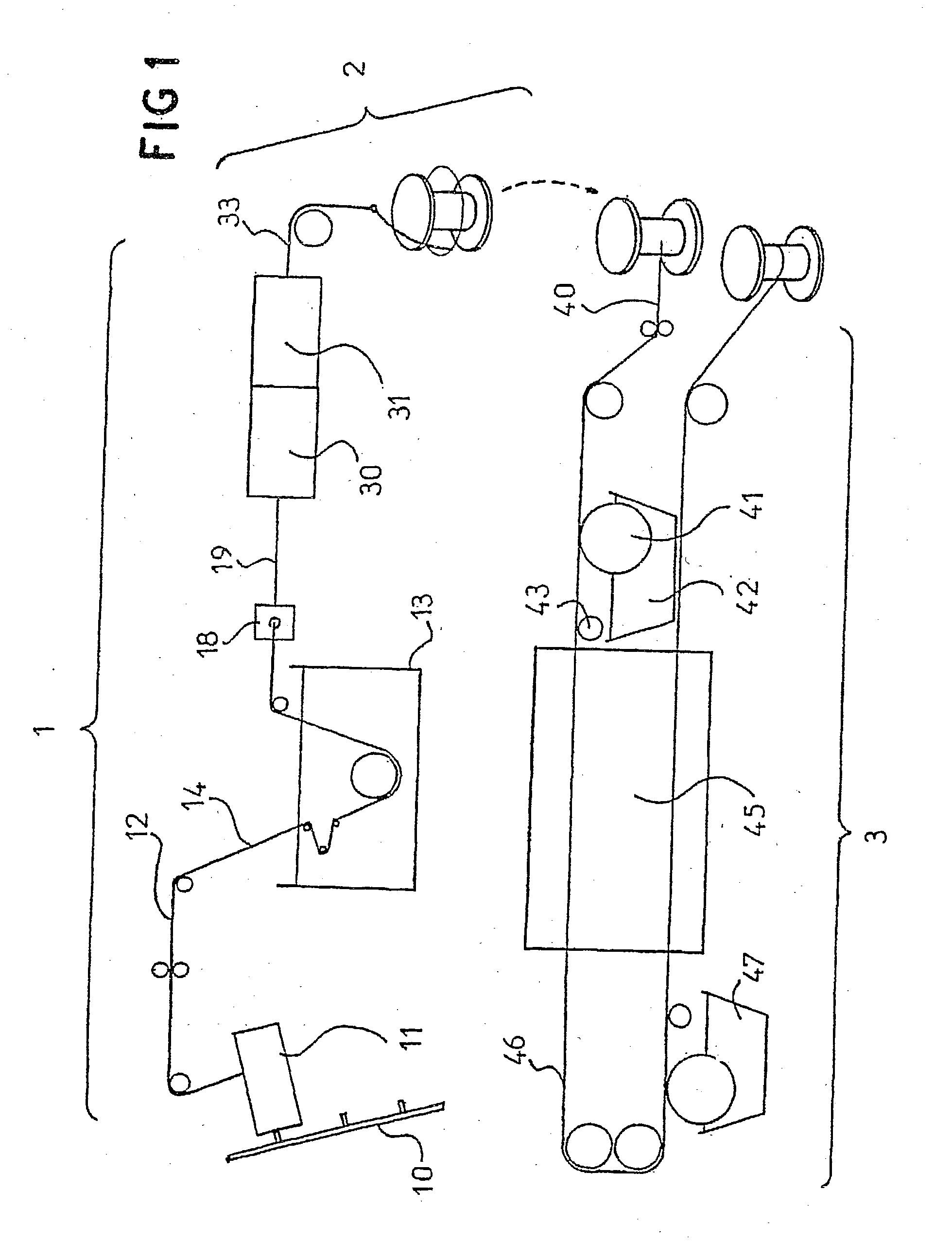

Method and apparatus for dry forming of a fabric

InactiveUS7331089B2Improve relationshipLarge distributionLap forming devicesLap-winding devicesEngineeringNonwoven fabric

A method and apparatus is described for use in dry forming a fabric by at least two non-woven fabrics. The upper run of the transfer wire is used as a forming wire. A forming head is disposed above the transfer wire. An airlaid non-woven fabric is formed on the transfer wire. This non-woven fabric is carried with the transfer wire onto the top side of the first non-woven fabric. The first non-woven fabric is formed on a preceding forming wire and transferred by the transfer wire to a subsequent conveying wire. This subsequent conveying wire can also be a forming wire so further non-woven fabric can be formed before the fabric is consolidated, e.g. by hydroentanglement or latex bonding / fibre bonding.

Owner:DAN WEB HLDG AS

Thread production device, and aggregating part

A yarn producing apparatus produces CNT (carbon nanotube) yarn from CNT fibers while causing the CNT fibers to run. The yarn producing apparatus includes an aggregating unit that aggregates the CNT fibers, and a twisting and winding device that twists the CNT fibers aggregated by the aggregating unit. The aggregating unit includes an adjusting mechanism that adjusts the aggregation state of the CNT fibers.

Owner:MURATA MASCH LTD

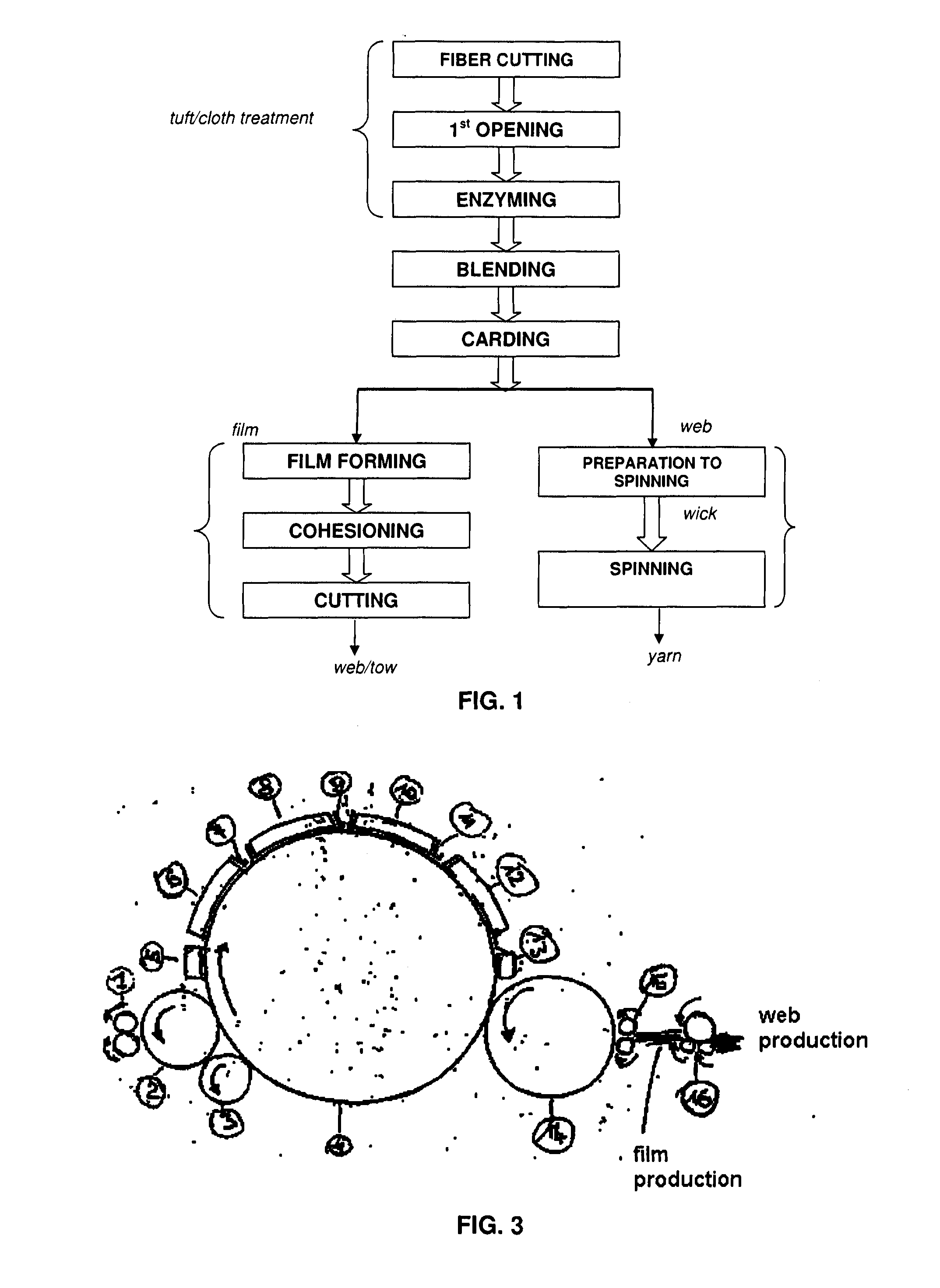

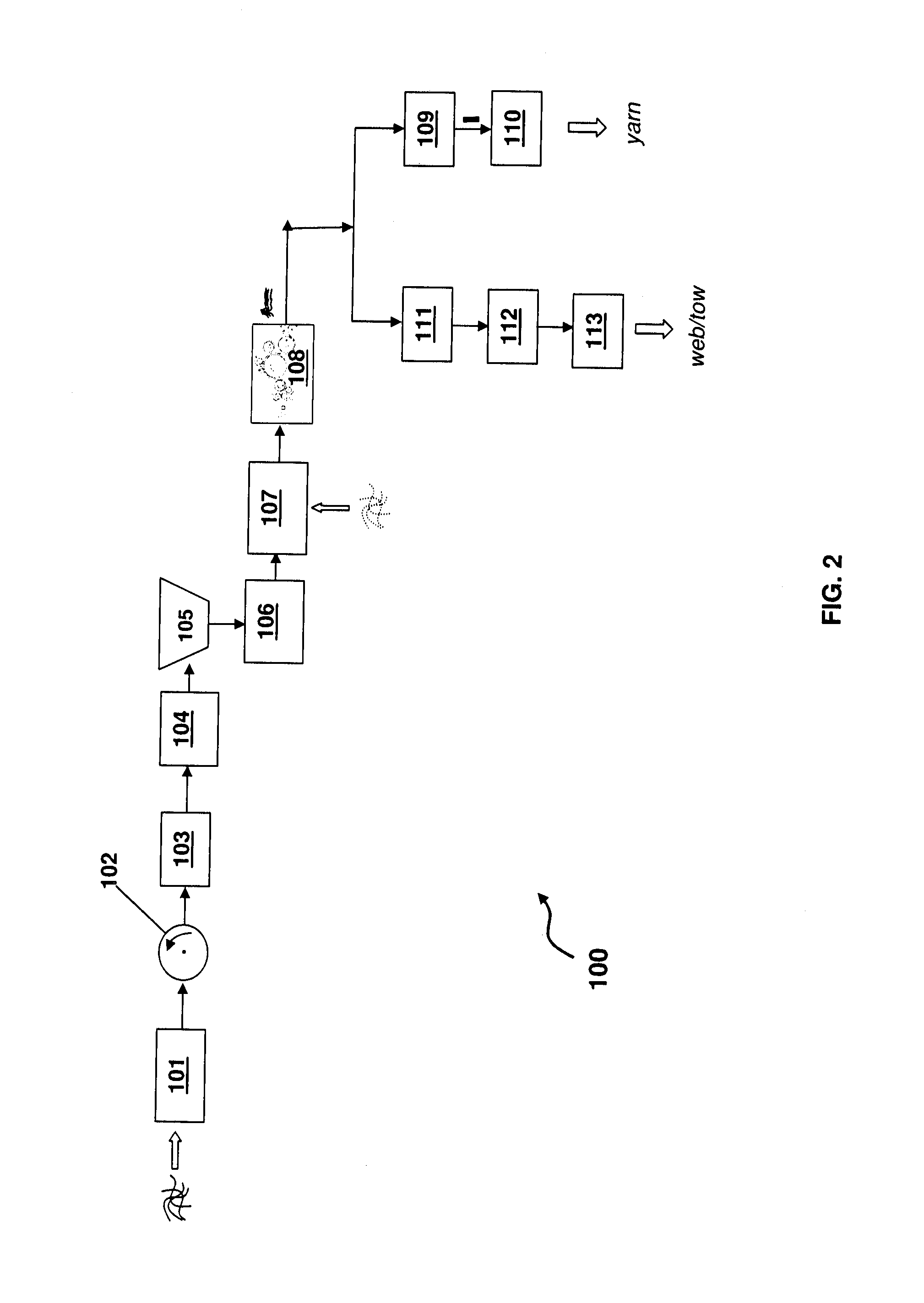

Method for the manufacturing of yarns from recycled carbon fibers

InactiveUS20140245577A1Good molding effectReduce wrinklesContinuous processingCarding machinesYarnCarbon fibers

A method for the manufacturing of textile products in the form of a yarn, web or tow starting from recycled carbon fibers in the form of tuft, cloth or the like, comprising the steps of: • (a) discontinuous cutting of the fibers to obtain dimensionally homogeneous fibers of selected length; • (b) enzyming of the fibers cut in step (a), wherein the latter are additioned with one or more substances; • (c) blending of the fibers treated in step (b) with auxiliary fibers; • (d) double carding of the blended fibers obtained in said step (c); and • (e) feeding a pair of wicks to a spinning machine.

Owner:ENEA AGENZIA NAT PER LE NUOVE TECH LENERGIA E LO SVILUPPO ECONOMICO SOSTENIBILE +1

Web buffering device

InactiveUS20050193526A1Easy to controlEasily interfaceLap-winding devicesLap forming devicesLength variationEngineering

Apparatus for variably buffering a web material, the apparatus having two endless transport belts including feed sections in which the belts are juxtaposed, and return sections, the feed and return sections being of varying lengths. In the feed sections, the belts move through a U-shaped path portion, commonly guided over a deflecting roller. In the return sections, the belts are guided through U-shaped path portions extending opposite to the U-shaped path portion of the feed sections, each belt wrapping separate deflecting rollers. The three deflecting rollers are rotatably supported on a common mounting frame movably held in a machine stand for compensated length variation of the feed and return portions.

Owner:DILO MASCHF OSKAR

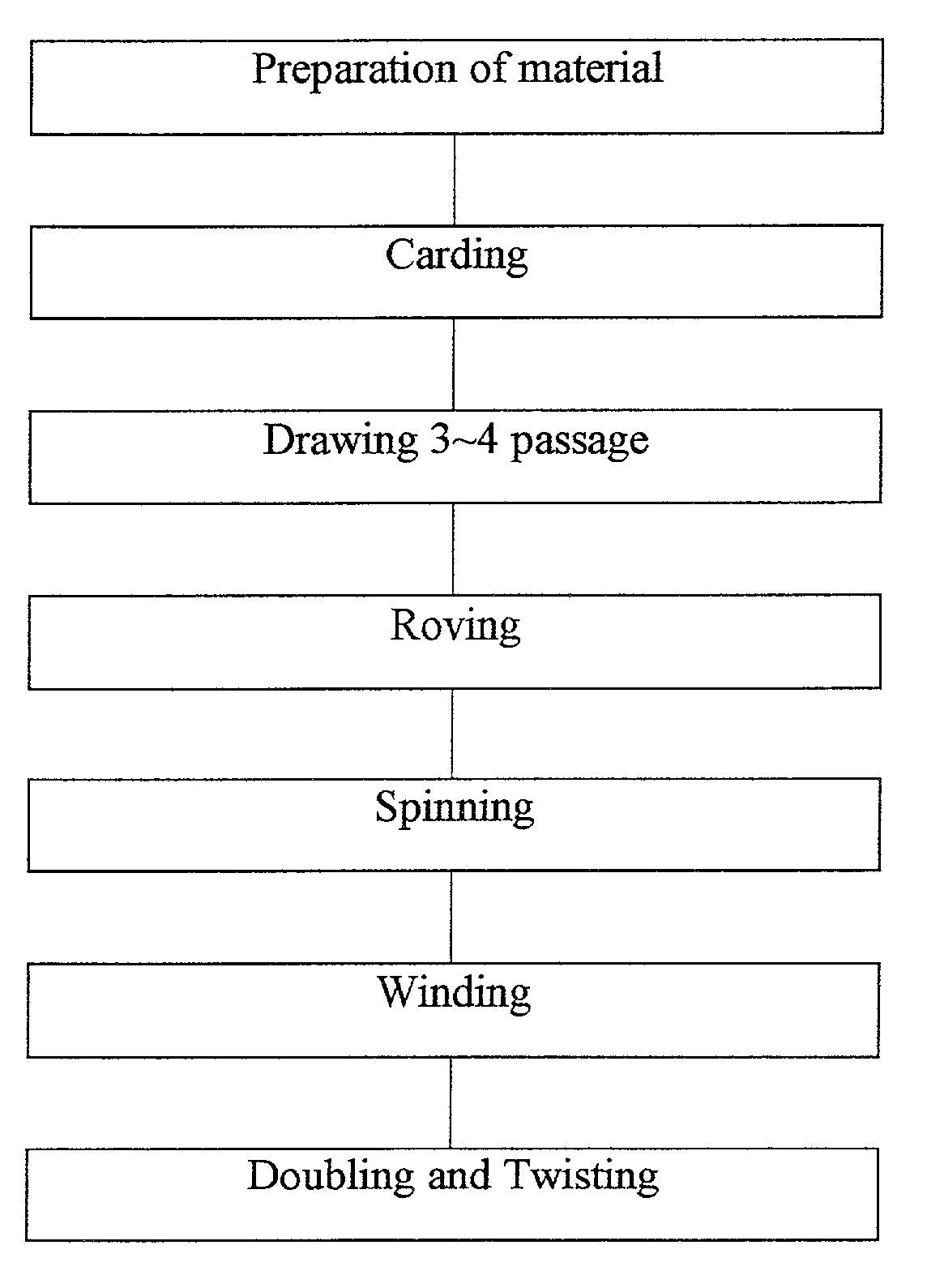

Manufacturing method for carded woolen yarn

Top making apparatus is attached to a woolen card. Materials usually to be processed on a woolen card are fed and the delivered web is guided by the top making apparatus and ball tops are formed by the top making apparatus. This top is processed on cotton spinning system. Finder and evener yam can spun with the top.

Owner:YOUNG NAM TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com