Method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres

A technology of benzobisoxazole and poly-p-phenylene is applied in the field of spinning of poly-p-phenylene benzobisoxazole fibers, which can solve the problems of entanglement, noil and pulling, and achieve smooth surface and less neps. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

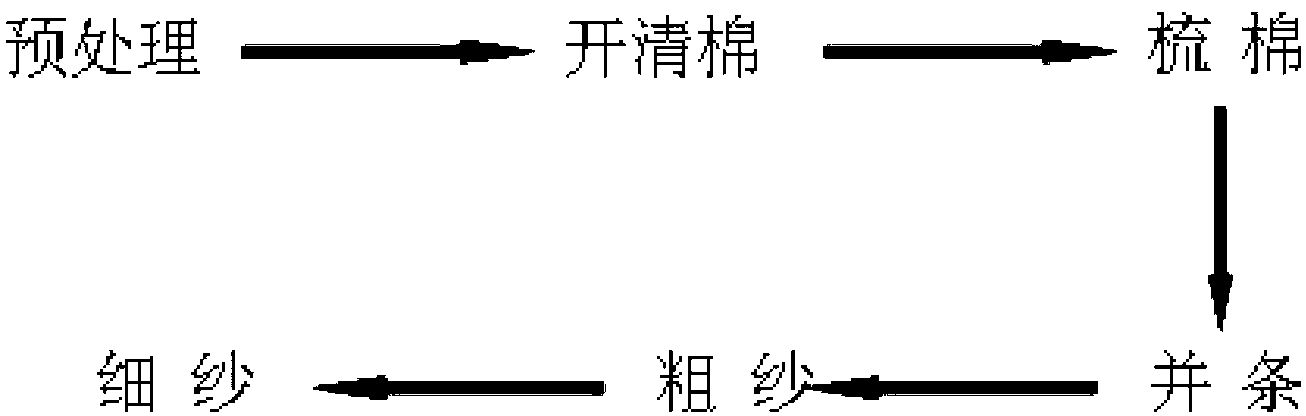

Method used

Image

Examples

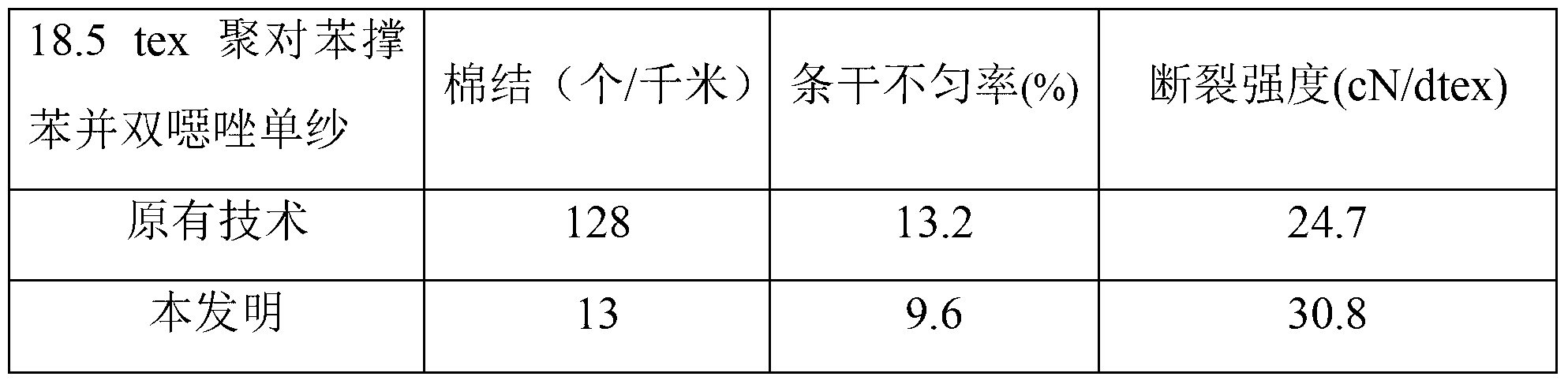

Embodiment 1

[0054]The loose poly-p-phenylene benzobisoxazole fibers are loosened and paved at a temperature of 18°C and a humidity of 70%. Add antistatic agent FC-1 at a mass ratio of 4:1000, and store for 48 hours; put the poly-p-phenylenebenzobisoxazole fiber obtained above into the carding needle at a beating speed of 480r / min, and the winding roller at a speed of 10r / min It is processed in the opening and cleaning unit of the cotton lap, and the cotton lap that the cotton lap quantitative is 170g / meter is made; The cotton lap that is obtained above is 36mm by the length of the working surface, and the angle of the inclined plane is 12 °. The feeding cylinder speed is 200r / min, the licker-in speed is 330r / min, the doffer speed is 10r / min, and the cover plate speed is 20mm / min in the carding machine, open and card to obtain raw sliver; put the raw sliver obtained above into the front The holding distance of the district rollers is 52mm, the draft ratio in the rear area is 1.7 times, a...

Embodiment 2

[0059] The loose poly-p-phenylene benzobisoxazole fibers are loosened and paved at a temperature of 18°C and a humidity of 70%. Add antistatic agent FC-1 at a mass ratio of 4:1000, and store for 48 hours; put the poly-p-phenylenebenzobisoxazole fiber obtained above into the carding needle at a beating speed of 480r / min, and the winding roller at a speed of 10r / min It is processed in the opening and cleaning unit of the cotton lap, and the cotton lap that the cotton lap quantitative is 170g / meter is made; The cotton lap that is obtained above is 36mm by the length of the working surface, and the angle of the inclined plane is 12 °. The feeding cylinder speed is 210r / min, the licker-in speed is 360r / min, the doffer speed is 13r / min, and the cover plate speed is 20mm / min in the carding machine, open and card to obtain raw sliver; put the raw sliver obtained above into the front The holding distance of the district rollers is 52mm, the draft ratio in the rear area is 1.7 times, ...

Embodiment 3

[0061] The loose poly-p-phenylene benzobisoxazole fibers are loosened and paved at a temperature of 18°C and a humidity of 70%. Add antistatic agent FC-1 at a mass ratio of 6:1000 and store for 48 hours; put the poly-p-phenylenebenzobisoxazole fiber obtained above into the carding needle at a beating speed of 480r / min, and the winding roller at a speed of 10r / min It is processed in the opening and cleaning unit of the cotton lap, and the cotton lap that the cotton lap quantitative is 170g / meter is made; The cotton lap that is obtained above is 36mm by the length of the working surface, and the angle of the inclined plane is 12 °. The feeding cylinder speed is 230r / min, the licker-in speed is 380r / min, the doffer speed is 15r / min, and the cover plate speed is 30mm / min in the carding machine, open and card to obtain raw sliver; put the raw sliver obtained above into the front The holding distance of the district rollers is 52mm, the draft ratio in the rear area is 1.7 times, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com