Patents

Literature

54results about How to "Fewer neps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for regenerating spinnable fibers from blended worn-out garments

InactiveCN103924326ASolve pollutionSolve environmental problemsTextile disintegration and recoveryFibre disintegrationFiberSquare Millimeter

The invention relates a method for regenerating spinnable fibers from blended worn-out garments. The method includes: sterilizing the worn-out garments, removing buttons, cutting the garment into cut cloth 50-100 square millimeters, using a feeding roller and an opening licker-in to continuously perform opening twice so as to allow the large tangled fibers of the cut cloth to be opened into small or bunchy fibers, using the feeding roller and a carding licker-in to continuously perform disintegration and carding for four times so as to allow the fibers of the cut cloth to be further disintegrated and carded, and obtaining the reusable spinnable fibers. The method has the advantages that the problem that manual operation is high in cost is solved, production efficiency is increased by dozens of times, high automation level is achieved, intelligent production is preliminarily achieved, the problem of impurity pollution is solved, environmental protection is achieved, the whole process is clean and environmentally friendly, and the obtained spinnable fibers are longer and fewer in nep as compared with the fibers processed by traditional processing processes.

Owner:北京中民慈善项目发展中心 +1

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

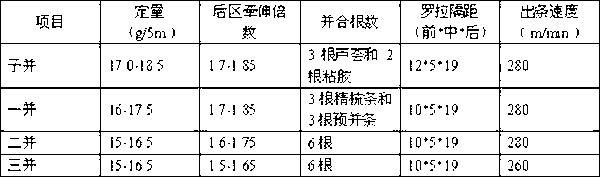

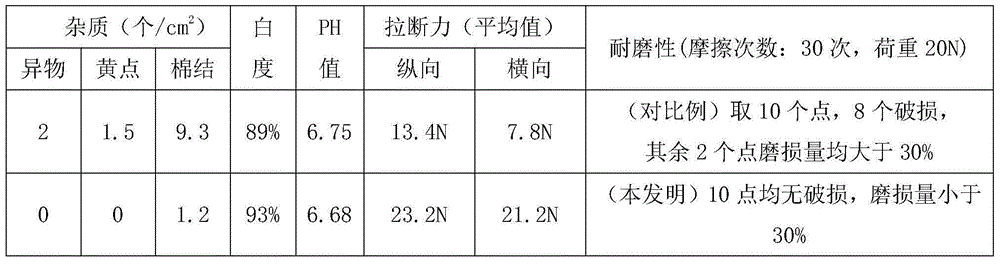

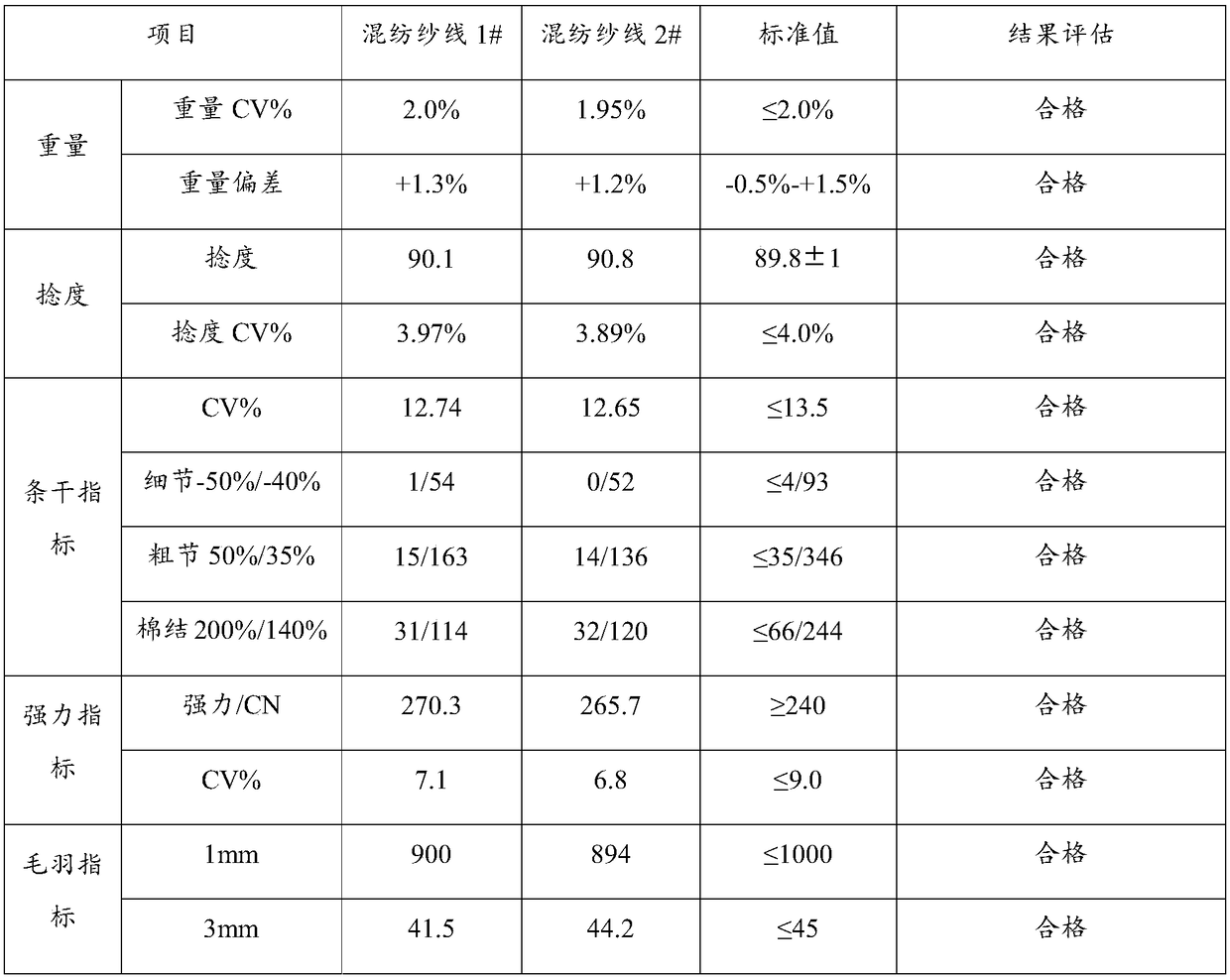

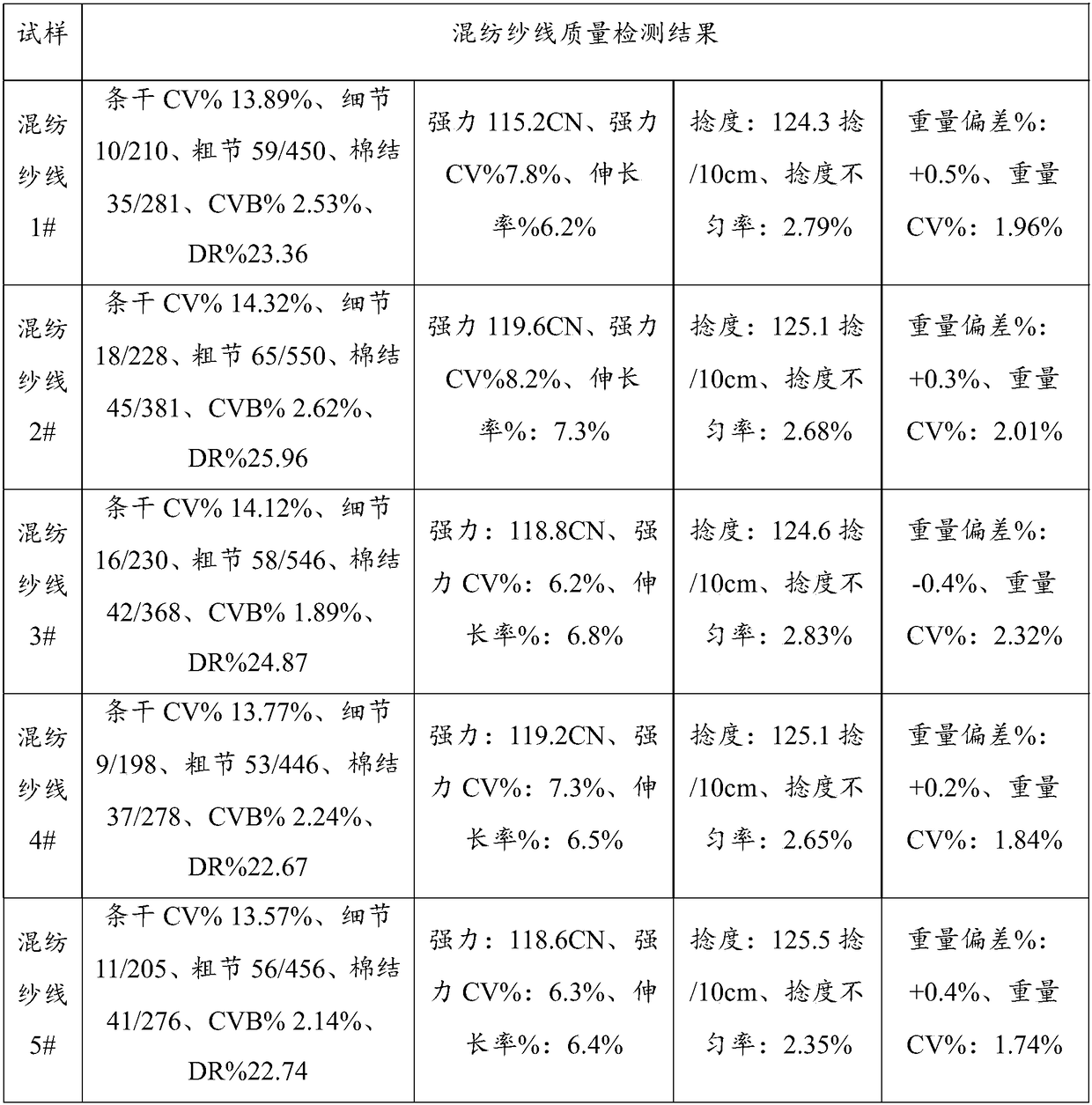

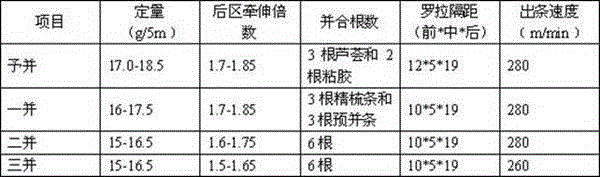

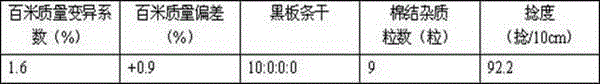

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

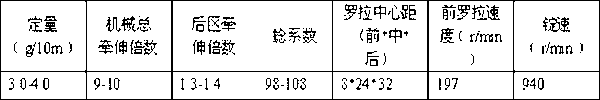

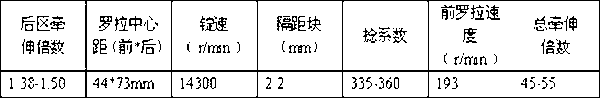

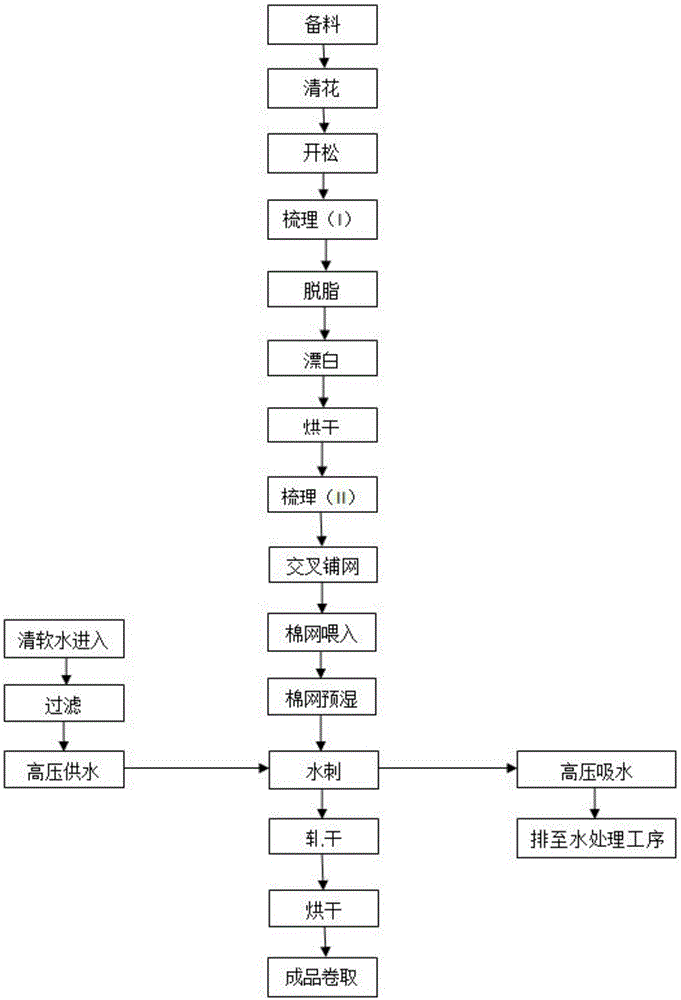

Production method for all-cotton spunlace non-woven fabric for medical health

Owner:湖北欣柔卫生用品股份有限公司

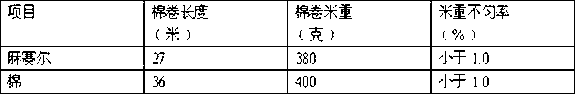

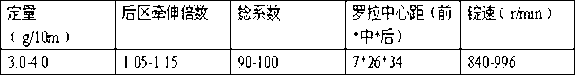

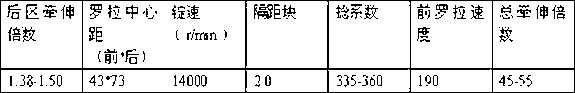

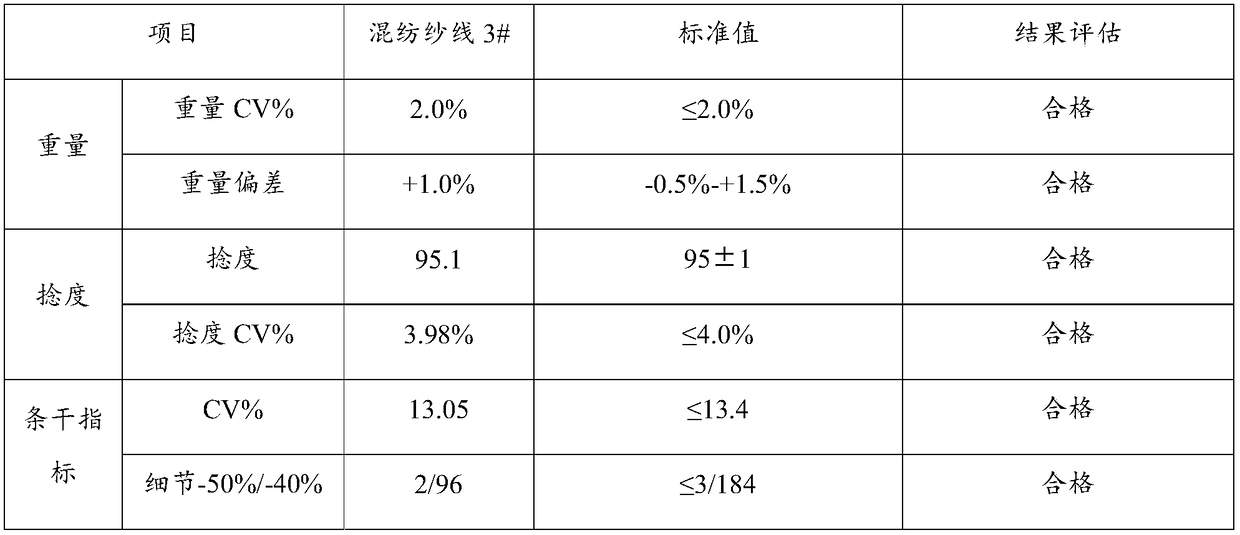

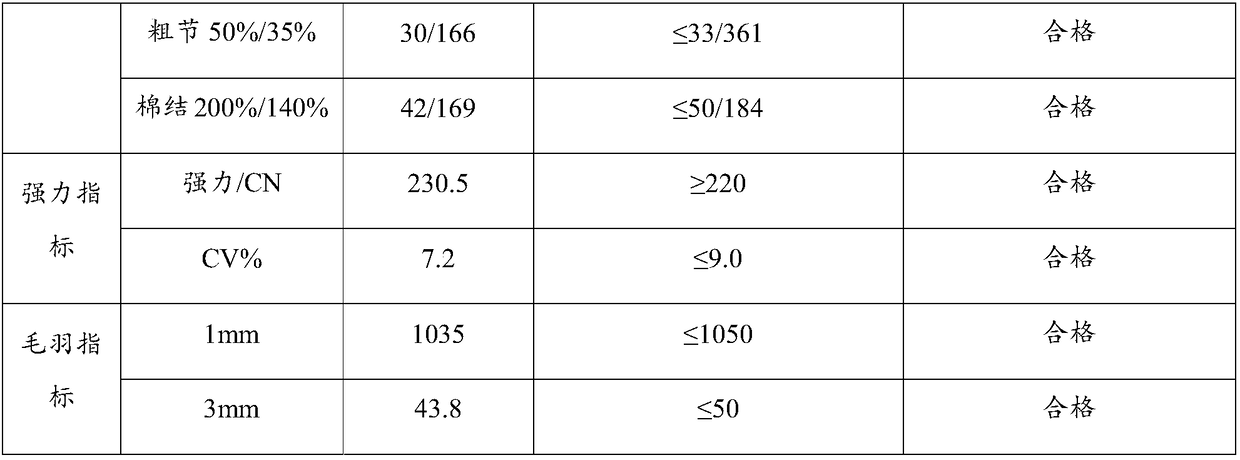

Cotton fiber and jutecell fiber blended yarn and spinning process thereof

The invention discloses a cotton fiber and jutecell fiber blended yarn and a spinning process thereof. The blended yarn comprises jutecell fiber with fiber content blending ratio as 70% and 30% fine staple cotton. The fibers are spun into yarns through the blended spinning process. Raw materials of the yarns are composed of the jutecell fiber and the fine staple cotton. Compared with the prior art where long staple cotton and jutecell fiber are used for blended spinning, the process is low in cost and high in cost performance. The blending mode of one pre-blending and three mixed-blending is adopted, so that the blending spinning ratio is accurate, and components are even. The blended yarns produced in the production process are high in single yarn strength, even in yarn levelness and few in nep and yarn fault. The yarn structure can further improve textile comfortableness, improve textile hand feel and improve lining grade.

Owner:山东超越纺织有限公司

Silver-element fibre spinning technology

The invention relates in particular to a new sliver-element fibre spinning technology, belonging to the spinning engineering field of textile industry production, comprising the following steps: pre-opening silver-element fibre to 80% by an opening machine; maintaining the blowing integrated beater speed in the blowing process of less than 600r / m and the beater frequency of sliver-element fibre per gram of less than 0.55; blocking the noil airdraft opening when carding cotton; using a flatbed drawing frame and a wool-top-proof conducting bar device with the drawing funnel caliber of 5.2mm; keeping the roving cycles of 33-38 cycle / 10cm, spinning frame guide stroke of 3-6mm; maintaining the groove drum speed in spooling less than or equal to 700 meter / minute and using a photoelectric type flaw-cutting device. Compared with the existing technology, the invention has the advantages of effective control of noil rate of blowing and cotton carding, small fibre damage, little nep, removal of belt roller wound by drawing and roving, smooth passage and winding, less broken ends, higher intrinsic quality of semi-manufactured goods, less flaws and better resultant yarn quality.

Owner:SHANGHAI FEILIAN TEXTILE

Apocynum venetum fiber blending antibiosis, cool and comfortable yarn and preparing method thereof

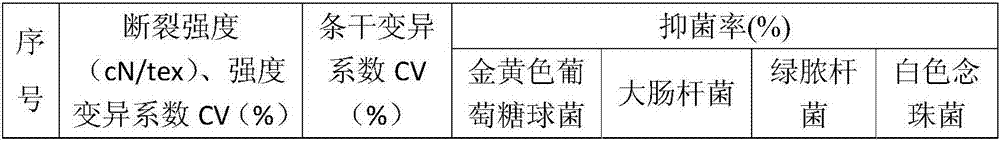

The invention discloses apocynum venetum fiber blended antibiosis, cool and comfortable yarn and a preparing method thereof. The apocynum venetum fiber blended antibiosis, cool and comfortable yarn comprises, by weight, 15-30 percent of apocynum venetum fiber, 35-50 percent of aloe viscose and 35-45 percent of milk fiber. The performance indexes of the blended yarn comprise the single-yarn breaking strength ranging from 11.5 cN / tex to 21.2 cN / tex, the single-yarn breaking strength variable coefficient Cv value ranging from 7.9 percent to 17.0 percent, and the yarn evenness variable coefficient Cv value ranging from 13.5 percent to 19.6 percent. The apocynum venetum fiber blended antibiosis, cool and comfortable yarn has the advantages that the fabric made of the blended yarn has the healthcare functions of antibiosis, antiphlogosis, skin protection, body building, face beautifying, skin moistening and the like, the fabric is high in strength, good in wet absorbing and breathable performance and dyeing performance, soft in hand feeling, good in moistening performance and mold-proof and moth repellency and wide in product usage range, and the fabric can be used for manufacturing various clothes, bedclothes, underwear, sportswear, fitness clothes and other various knitted or woven healthcare textiles.

Owner:ZHONGYUAN ENGINEERING COLLEGE

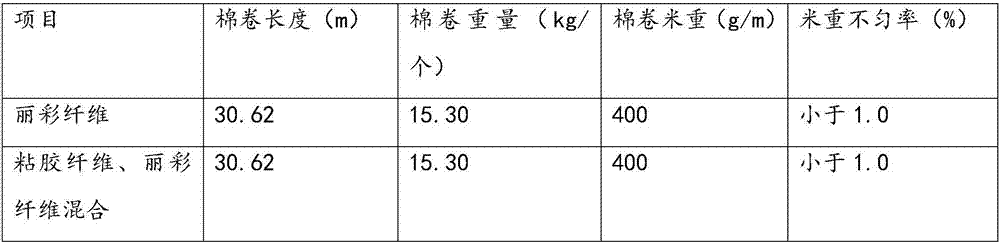

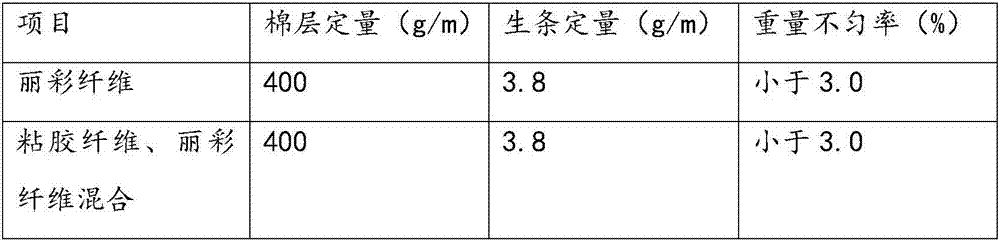

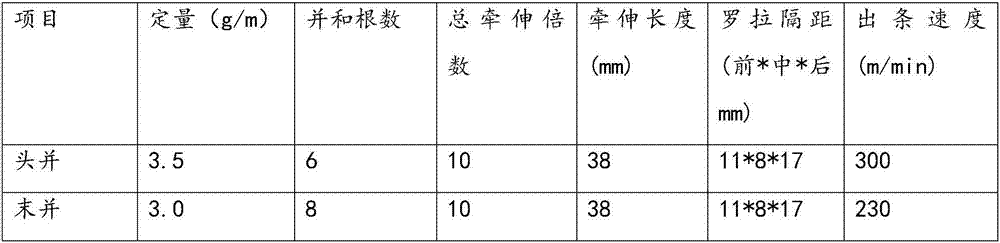

Viscose fiber and leecy fiber blended yarn and spinning technology thereof

The invention discloses a viscose fiber and leecy fiber blended yarn and a spinning technology thereof. The blended yarn comprises viscose fibers with the fiber content blending ratio of 60-70%, and leecy fibers with the fiber content blending ratio of 30-40%. The fibers are woven into the yarn through the spinning technology. Firstly, after the leecy fibers are subjected to opening and picking and cotton carding, the leecy fibers and the viscose fibers are mixed, then opening and picking and cotton carding are carried out, and the leecy fibers and the viscose fibers can be mixed to be uniform; due to the fact that the leecy fibers with the durable physical bacteriostasis function are added, the viscose fiber finished products can be prepared into the yarn with the antibacterial function directly through the following spinning technology, it is not needed to independently carry out antibacterial treatment on the viscose fiber finished products, the technology is simplified while the antibacterial effect is guaranteed, the production cost is reduced, fabric woven from the viscose fiber and leecy fiber blended yarn can be rapidly dyed, the colors are gorgeous, gradually varied and rich in layering sense after the fabric is colored, and multiple colors can be obtained through one time of dyeing.

Owner:宜宾恒丰丽雅纺织科技有限公司

Blended yarn of Shu elastic silk fibers and cotton fibers and spinning process thereof

The invention relates to a blended yarn of Shu elastic silk fibers and cotton fibers and a spinning process thereof. The blended yarn has the advantages of the Shu elastic silk fibers and cotton, is transcendental in size stability, natural, soft, high in air permeability and abrasive resistance, capable of being widely applied in the fields of cowboy costume, formal clothes, sport suit, knitted underwear and home textile, and broad in market prospect. According to the preparation process, the difficulties that the Shu elastic silk which serves as raw material fibers is high in elasticity and uneasy to reel separately and has too much crimps are overcome, the Shu elastic silk fibers and the cotton fibers are blended according to a blending proportion, and a cotton carding process, a roving process and a spun yarn process in the later period are completed. According to the process, the spun yarn process is adjusted, and the problem is solved that since the rebound resilience of the Shu elastic silk is high, coiling strips serving as raw materials are difficult to shape; a big-ration high-drafting process is achieved, the supply in the early period and the supply in the later period can be ensured, and the prepared blended yarns are high in single yarn intensity, small in variable coefficient and high in stability of fiber strength, show excellent rebound resilience, and meet demands of downstream manufacturing.

Owner:威海魏桥科技工业园有限公司

Technique of blending colored regenerated flake yarns

The invention relates to the technical field of spinning with regenerated cotton, in particular to a technique of blending colored regenerated flake yarns, which sequentially includes steps: firstly, preparing cotton; secondly, performing blowing; thirdly, carding the cotton, namely making recycled polyester into neps on a cotton card, collecting the cotton neps, dyeing the cotton neps into colored neps, placing a hopper above a web of the cotton card, and using the hopper to scatter the colored neps onto the web to make colored regenerated blended flake slivers; fourthly, performing drawing; fifthly, performing roving; and sixthly performing spinning. Compared with the prior art, the technique has the advantages that the regenerated cotton, the fine staple cotton and the recycled polyester are blended, the recycled polyester is made into the neps in the cotton carding phase, the neps are dyed and scattered onto the web through the hopper so as to generate colored flakes, and accordingly, the colored regenerated blended flake yarns have the good environment protection function, forming strength of the colored regenerated blended flake yarns is improved, the cotton neps are reduced, and moisture conductivity, breathability and attractiveness of the colored regenerated blended flake yarns are all improved.

Owner:SHANGHAI SHENAN TEXTILE

Blended yarn and preparation method and application thereof

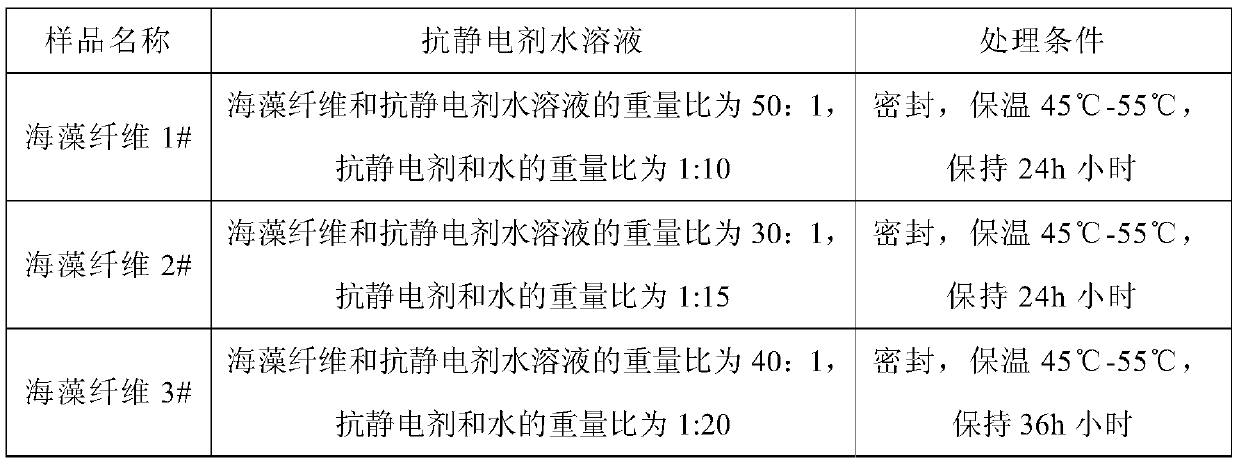

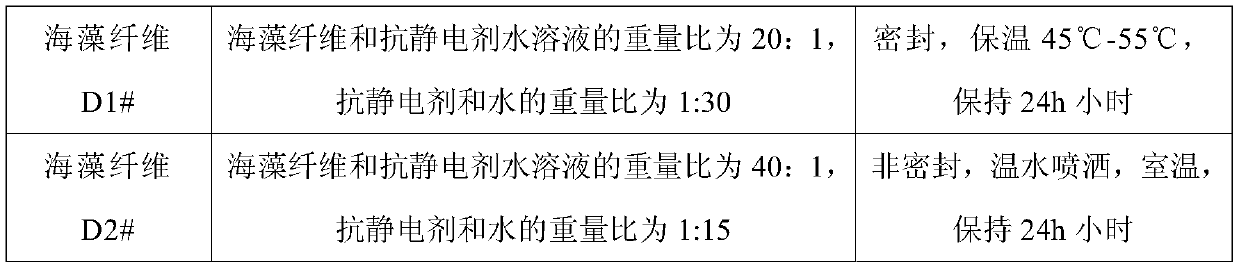

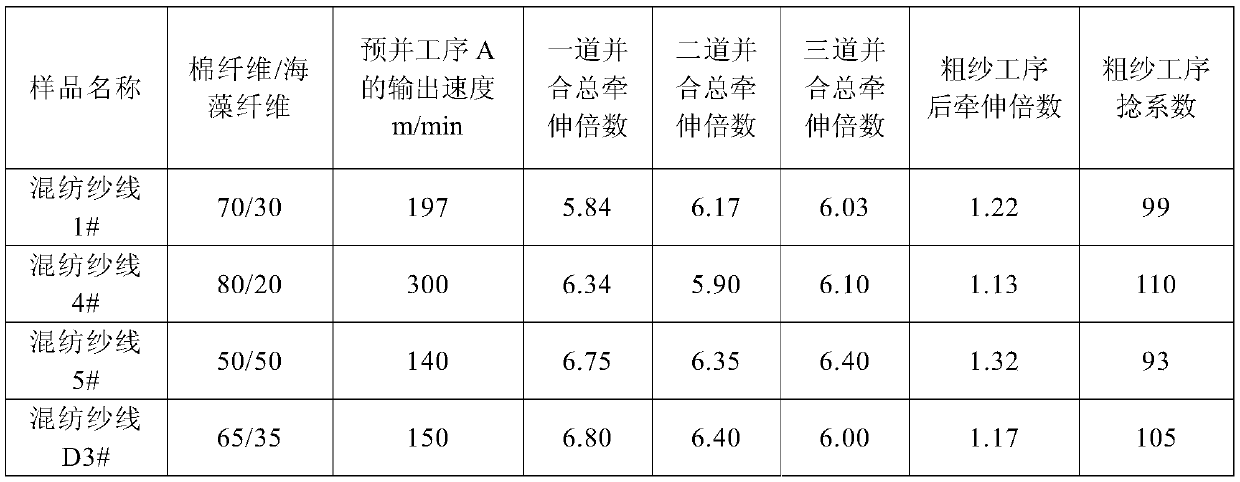

The invention relates to the technical field of textiles, in particular to a blended yarn and a preparation method and application thereof. The method comprises the following steps that pretreated seaweed fibers are subjected to treatment of a blowing process A, a carding process A and a pre-drawing process A to obtain pre-drawn seaweed fiber raw slivers A; cotton fibers are subjected to treatmentof a blowing process B, a carding process B, a pre-drawing process B, a winding process B and a fine combing process B to obtain finely combed cotton slivers B; the prepared pre-drawn seaweed fiber raw slivers A and the finely combed cotton slivers B are subjected to treatment of a mixing process, a roving process and a spinning process to obtain the blended yarn. The blended yarn can be used formanufacture of a knit or a fiber product. The blended yarn is good in single yarn evennes and has few neps and yarn defects, and the comfort of a fabric can be further improved, so that the fabric issmooth in surface, exquisite and delicate in texture and clear in pattern.

Owner:WEIQIAO TEXTILE

Yarn blended with silver fiber and cotton fiber and preparation technology

The invention relates to a yarn blended with silver fiber and cotton fiber and preparation technology, and the yarn is blended with silver fiber and combed cotton fiber through blending, wherein, the content of the silver fiber is 1-50%, and the balance is cotton fiber. The preparation technology comprises the steps of flower removing, cotton combing, preparation, fine combing, blending of silver fiber and combed cotton strip of combed cotton fiber, mixing, roving, spinning and automatic winding. The advantages are that the characteristics of both the silver fiber and the cotton fiber are provided; the yarn has high intensity, good wear resistance, moisture absorption, ventilation, strong antibacterial performance, and radiation hardening. The technology has the advantages that the blending ratio is accurate; the components are uniform; the blended yarn manufactured thereby has a strong force of a single thread, little hairiness, uniform strips, little cotton knobs and little yarn defects.

Owner:山东宏儒纺织科技有限公司

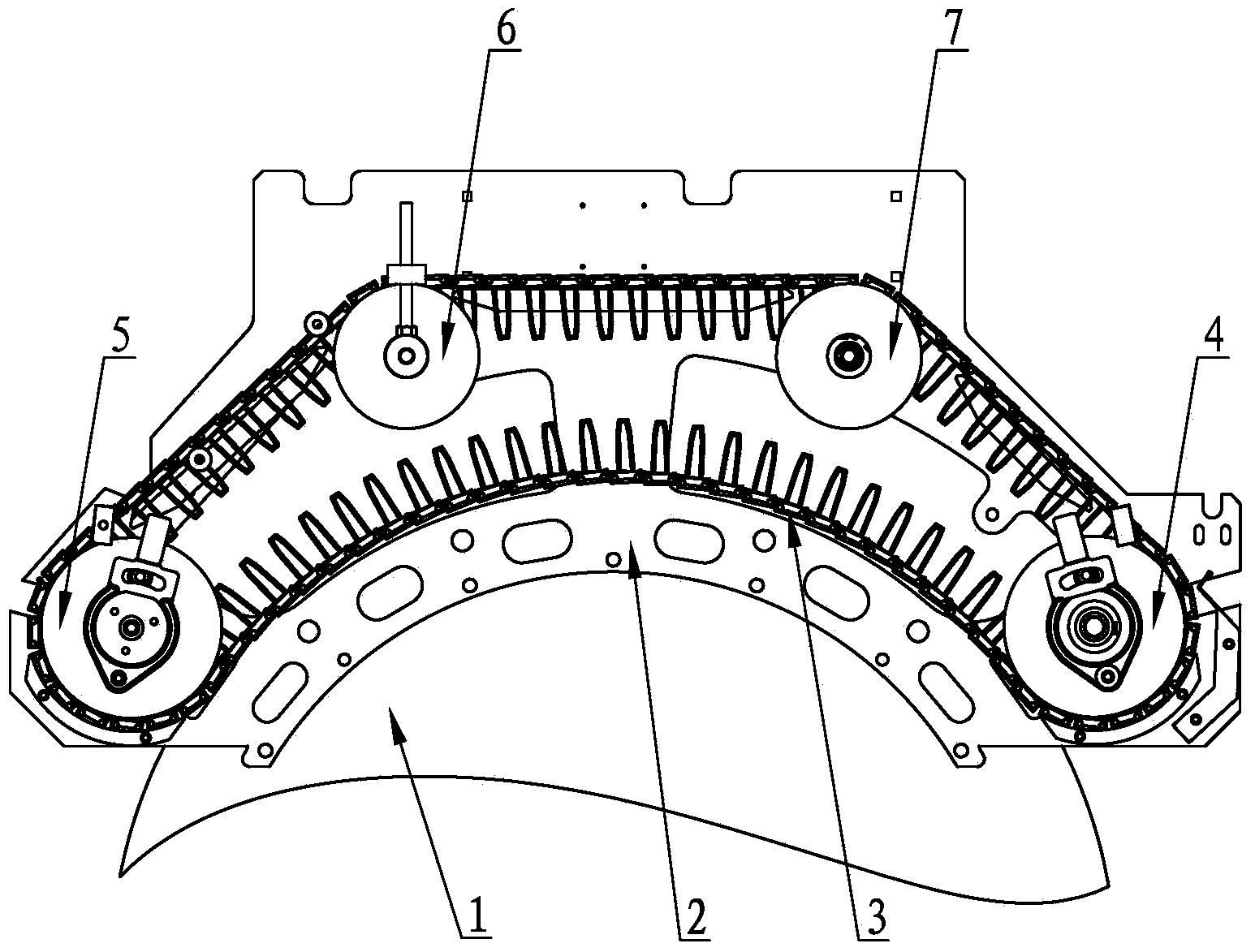

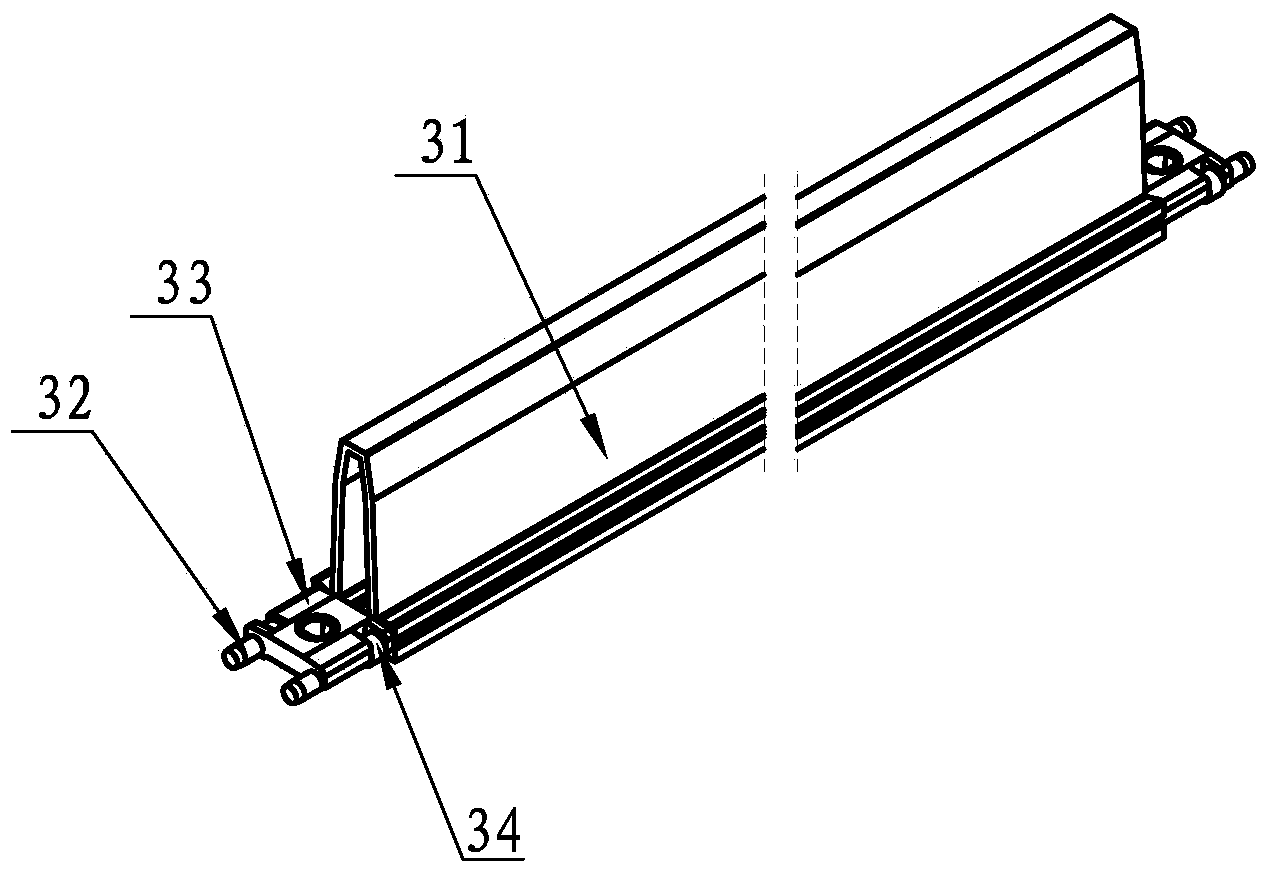

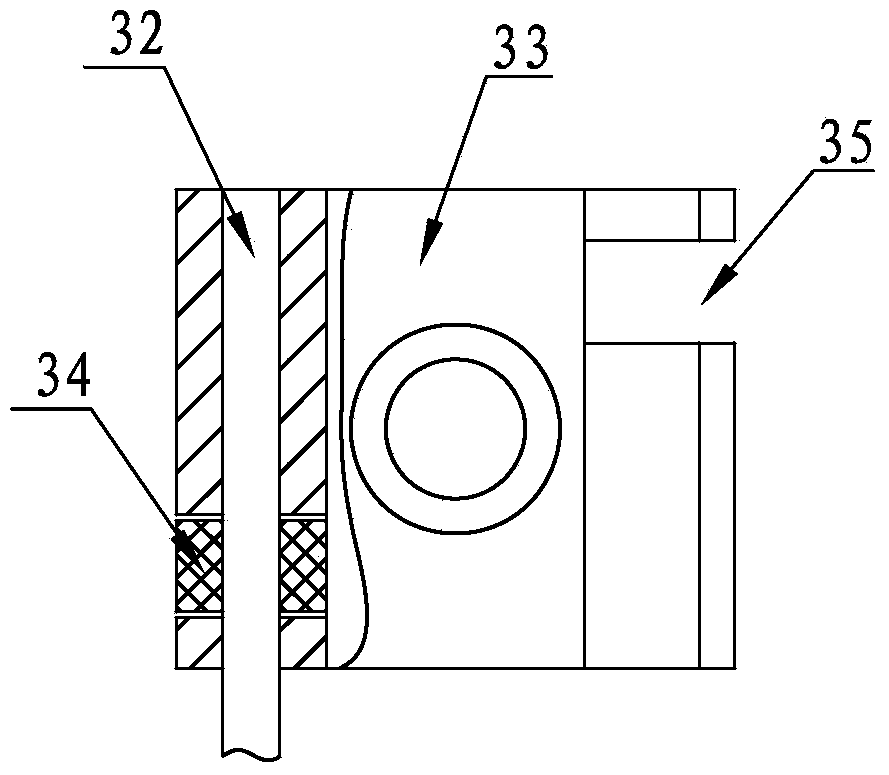

Movable cover board carding device for cotton carding machine

The invention relates to a movable cover board carding device for a cotton carding machine, which comprises a cylinder, a guide rail, a movable cover board, a driving wheel, a driven wheel, a tensioner and a transition wheel. The guide rail is fixedly arranged on a surface plate of the cylinder; the movable cover board comprises a cover board skeleton, cover board hinge pins, fixing blocks and bearing rolling sleeves; the cover board hinge pins are fixedly connected to both ends of the bottom of the cover board skeleton; the cover board hinge pins are sleeved with the fixing blocks; hinge pin holes on the fixing blocks are provided with limiting grooves; the positions of the two limiting grooves are staggered along the axial directions of the hinge pins; the cover board hinge pins in the limiting grooves are sleeved with the bearing rolling sleeves; the bearing rolling sleeves are in rolling contact with the guide rail; the driving wheel and the driven wheel are arranged in round backs at both ends of the movable cover board; and the tensioner and the transition wheel are arranged at the horizontal end of the movable cover board. Due to adoption of the structure, the distance between the movable cover board and the cylinder is stable; the movable cover board carding device is reliable to operate; maintenance cost is reduced; labor intensity is reduced; the device has superior stability in the actual operating process; a small number of neps and cotton impurities in generated cotton slivers are generated; and the cotton slivers have high fiber quality.

Owner:常州金阳纺织机械有限公司

Method for producing extra-fine yarns

The invention relates to the technical field of spinning, and discloses a method for producing extra-fine yarns. The method includes a scutching and combing cotton step by subjecting long stapled cotton to a JWF1009 reciprocate plucker, a JWF0007 type weight separator, a JWF1107 type single-axial flow cotton slitter, a JWF1029 type multi-barn cotton blender, a JWF1115 type fine cotton slitter, a CCH-II type irregular fiber separator, a JWF1171 type feeding hopper and a JWF1203 type carding machine, a combing step completed by a FA306 type drawing frame, a JSFA360 type sliver lap machine and a JSFA388 combing machine, a drawing step completed by an FA326 type drawing frame, a roving step completed by an FA458 type flyer frame, a spinning step completed by a DTM129 type spinning machine, and a winding step completed by an autoconerX5 type automatic spooler. The method ensures low fiber damage level of long stapled cotton, and less short fiber contents and neps impurities and extra-fine yarns produced are high in quality.

Owner:新疆疆棉智能纺织股份有限公司

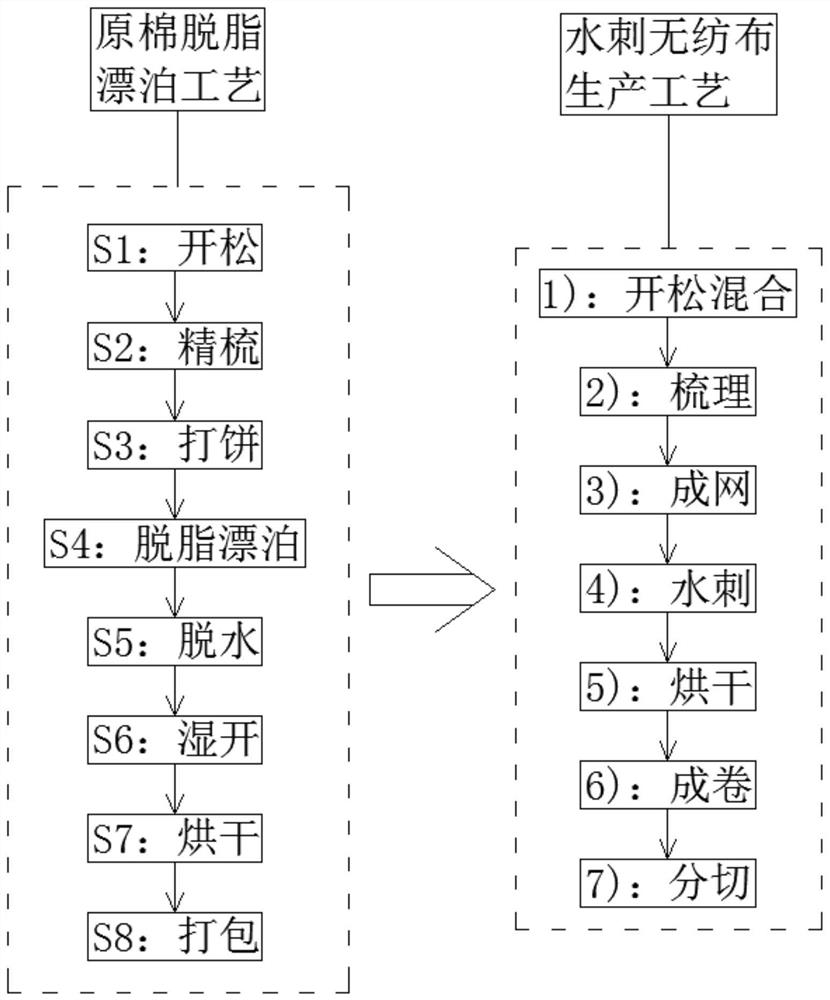

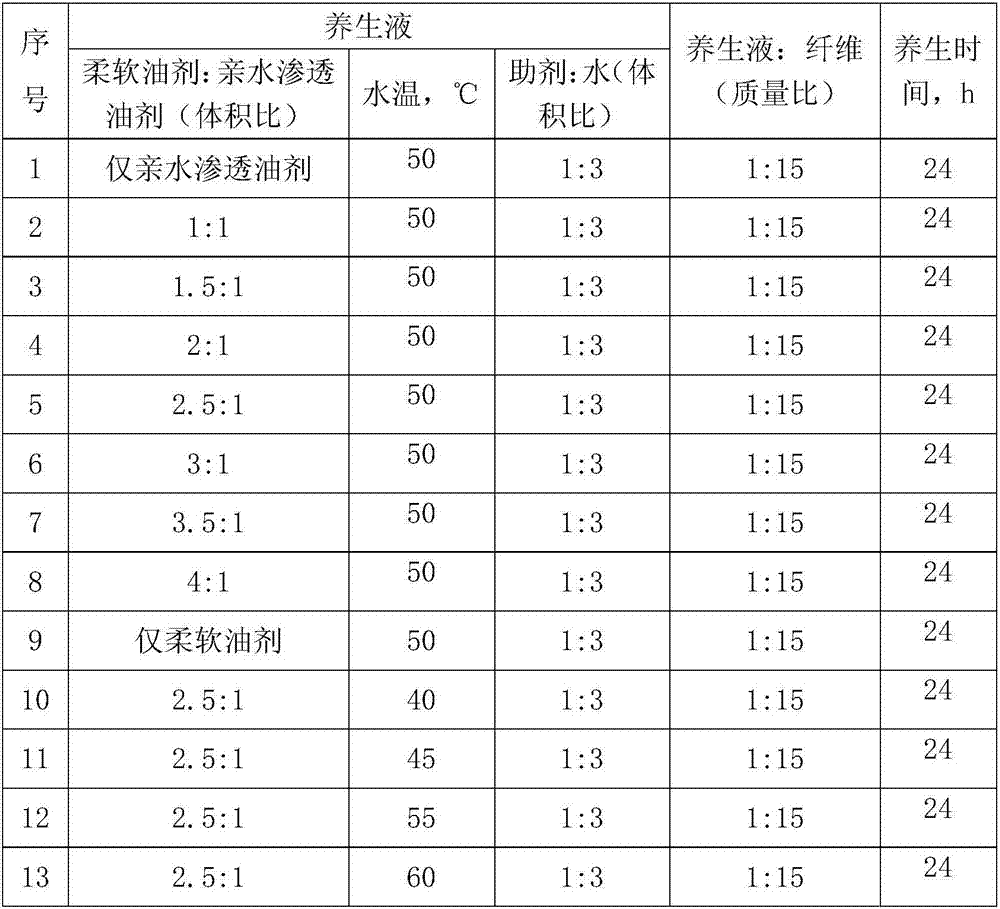

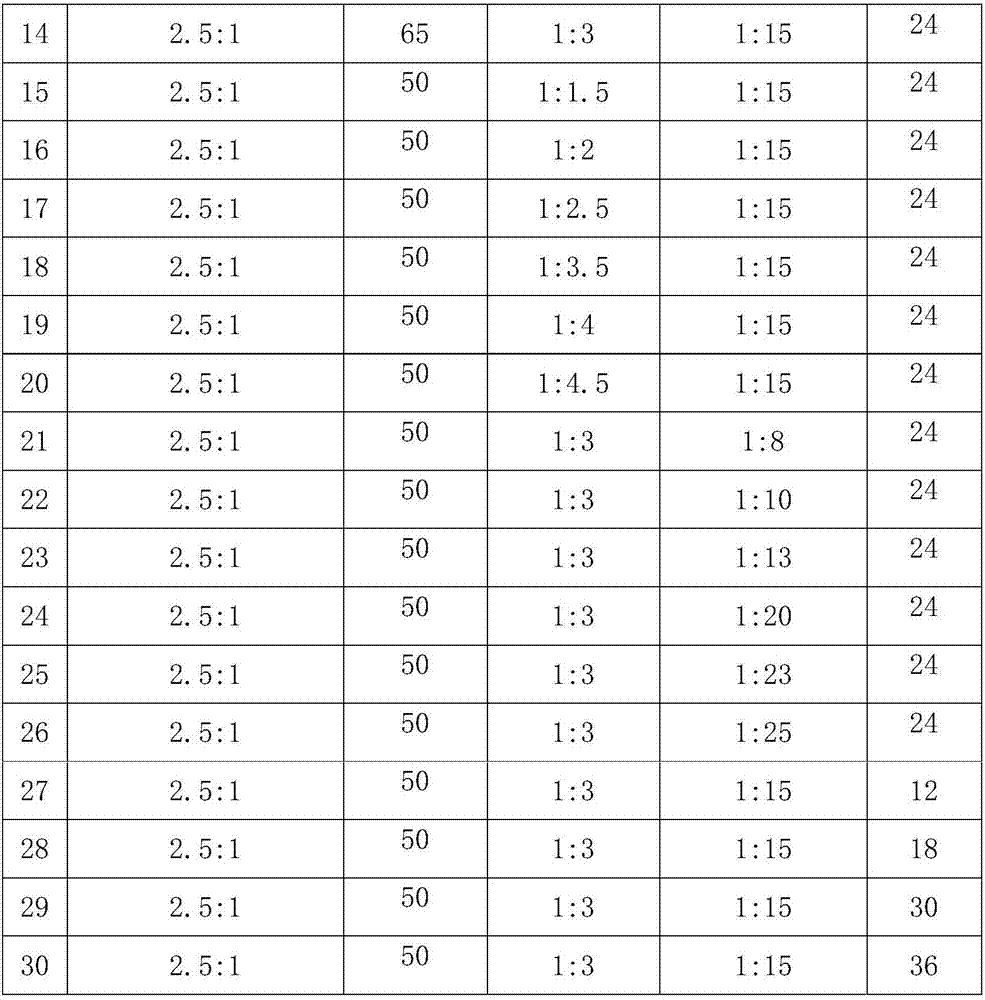

Production method of pre-degreasing-bleaching high-speed high-yield all-cotton spunlace non-woven fabric

The invention discloses a production method of pre-degreasing-bleaching high-speed high-yield all-cotton spunlace non-woven fabric. The method comprises a raw cotton degreasing and bleaching process and a spunlace non-woven fabric production process, wherein the raw cotton degreasing and bleaching process comprises the steps of opening, combing, cake making, degreasing and bleaching, dewatering, wet opening, drying, packaging and the like which are carried out in sequence, and the spunlace non-woven fabric production process adopts degreased and bleached cotton prepared through the raw cottondegreasing and bleaching process for producing the spunlace non-woven fabric, and comprises the procedures of opening and mixing, carding, net forming, spunlace, drying, coiling, slitting and the likewhich are carried out in sequence. The method has the beneficial effects that raw cotton is firstly manufactured into degreased and bleached all-cotton through the degreasing and bleaching process, then the degreased and bleached all-cotton is manufactured into the spunlace non-woven fabric, in the production process, the spunlace non-woven fabric has the advantages of being wide in breadth, highin vehicle speed, high in productivity, few in neps, good in product quality and the like, the labor cost can be effectively reduced, the production efficiency is improved, and the production cost isreduced.

Owner:湖北欣柔卫生用品股份有限公司

Processing method of cotton and copper alginate blended yarn

The invention relates to a processing method of cotton and copper alginate blended yarn and belongs to the technical field of yarn manufacturing processes. Copper alginate fiber and cotton are pretreated respectively, and after the copper alginate fiber and the cotton are mixed evenly, mixed fiber is sequentially subjected to opening picking, carding, combing, drawing, roving and spinning, wherein the opening picking process comprises the steps that the mixed fiber sequentially passes through a bale plucker, a mixing opener, a roller card wire opener, a vibration cotton feeding box and a single beater scutcher to be treated, the roller card wire opener and all beater screens of the single beater scutcher are sealed; a half holding and beating gauge is adopted, and in the carding process, controllable half-hold licker-in opening is adopted; needle teeth small in working angle and low in density are adopted in carding machine card clothing. When applied to processing of the copper alginate fiber and cotton mixed yarn, the method has the advantages that the mixed yarn is less in hairiness, high in strength, less in nep, good in yarn levelness and the like.

Owner:浙江吉麻良丝新材料股份有限公司 +2

Blended yarn of tussah silk and cotton fiber and spinning method of yarn

The invention discloses a blended yarn of tussah silk and cotton fiber and a spinning method of the yarn and belongs to the field of spinning. The blended yarn is formed by blending the tussah silk with the cotton fiber, wherein the content of the tussah silk in the blended yarn is not higher than 60 wt%, and the balance is the cotton fiber; the fineness of the blended yarn is 20-120 S; single-yarn breaking strength of the blended yarn is 430-120 CN, and the size of neps is 5 / 50-150 / 480. The high-quality blended yarn fills up the market blank, is uniformed in component and evenness, high in single-yarn strength and low in hairiness and has few neps and yarn defects. According to the spinning method, combed cotton strips and tussah silk strips are directly subjected to mixed blending, the spinning flow is short, damage caused to the tussah silk is small, the utilization rate is high, the spinning cost is low, and the controlled blending ratio is accurate.

Owner:WEIQIAO TEXTILE

Novel blended yarn and production process thereof

InactiveCN104862842ALess hairyImprove the defect of poor wrinkle resistanceYarnPolymer scienceCotton fibre

The invention discloses novel blended yarn and a production process thereof. The novel blended yarn is formed by blending cotton fibers with the blending ratio being 50%, bamboo pulp fibers with the blending ratio being 40% and soybean protein fibers with the blending ratio being 10%. The novel blended yarn has the advantages that a compact Siro spinning technology is adopted, raw materials are reasonably mixed, the defect of poor crease resistance of the soybean protein fibers is overcome, the soybean protein fibers are prevented from pilling to a large extent, and the size stability of fabric is improved. The problems that the bamboo pulp fibers are poor in hand feel, skin friendliness and cohesive force are solved. The produced yarn is good in strength, high in evenness, good in breathability, fluffy and soft, and has good skin friendliness and health care functions. The three-blending mode is adopted, the blending ratio can be more accurate, ingredients are even, produced single yarn is high in evenness, the strength of the single yarn is high, the number of cotton neps is small, and the number of yarn faults is small. The yarn variety enables fabric to have good breathability, to be fluffy and soft and to have good skin friendliness and a health care function.

Owner:NANTONG YUEDA KNITTING GARMENT

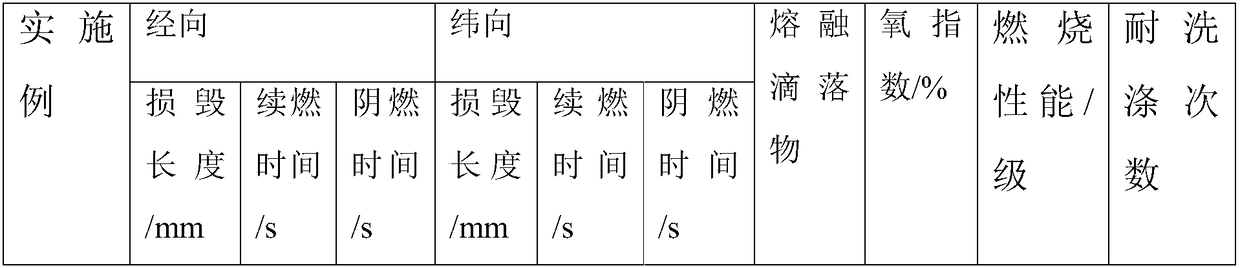

Washing-resistant non-melted-dripping flame-retardant curtain and processing method thereof

InactiveCN108660586ANo dropletSoft touchArtificial filaments from viscoseWoven fabricsFire retardantWear resistance

The invention provides washing-resistant non-melted-dripping flame-retardant curtain. The curtain is prepared from, by weight, 20-30 parts of cotton fiber, 10-20 parts of aramid fiber and 10-20 partsof flame-retardant viscose, wherein 0.2-0.3 part by weight of fire retardant is added into a flame-retardant viscose spinning liquid and the cotton fiber respectively. The washing-resistant non-melted-dripping flame-retardant curtain has the advantages that the used raw materials of cotton, aramid and viscose are all fibers without melted dripping when burned, so that the curtain made from the same does not have melted dripping either; a blended fabric of aramid and flame-retardant viscose has the excellent characteristics that the hand feeling is soft, the fluffiness, drapability and moisturepermeability are good, the strength and wear resistance are high, the fabric surface perfection and color fastness are good, and the fabric is not melted to drip when carbonized by catching fire, andthe quality requirements of curtain upholstery fabrics can be met.

Owner:应急管理部四川消防研究所

Production method of photoelectronic polyester combed cotton compact yarn

The invention discloses a production method of photoelectronic polyester combed cotton compact yarn. Based on weight percentage, the method comprises the steps of combed cotton preparation, blowing mixing of combed cotton and photoelectronic polyester, cotton carding, drawing, roving, spinning and spooling. According to the invention, the photoelectronic polyester fiber and Xinjiang first-class raw cotton are blended and subjected to compact spinning in the spinning process; due to the bundling effect, the strand twisting triangle area is canceled; the hairiness value of single yarn is obviously reduced, and the evenness is remarkably improved; and since the combed cotton is used as a raw material for re-spinning, the neps are remarkably reduced, the quality of the resultant yarn is better, and the functional yarn with brightness, high grade and cooling antibacterial healthcare effect is produced.

Owner:DANYANG DANSHENG TEXTILE

Spinning process of chemical-fiber combed yarn

The invention relates to a spinning process of chemical-fiber combed yarn, comprising an opening picking combination machine process, a cotton carding process, a drawing and roving process, a spinning process and a winding process. A pre-drawing process, a drawing and coiling process and a combing process are added between the cotton carding process and the drawing and roving process. The complete process comprises the following steps of: the opening picking combination machine process, the cotton carding process, the pre-drawing process, the drawing and coiling process, the combing process, the drawing and roving process, the spinning process and the winding process. The invention has the advantages that chemical-fiber yarn produced by utilizing the process flows under the spinning technological condition obviously reduces nubs and neps, improves yarn evenness and strength, thus customers give higher evaluation on yarn quality.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

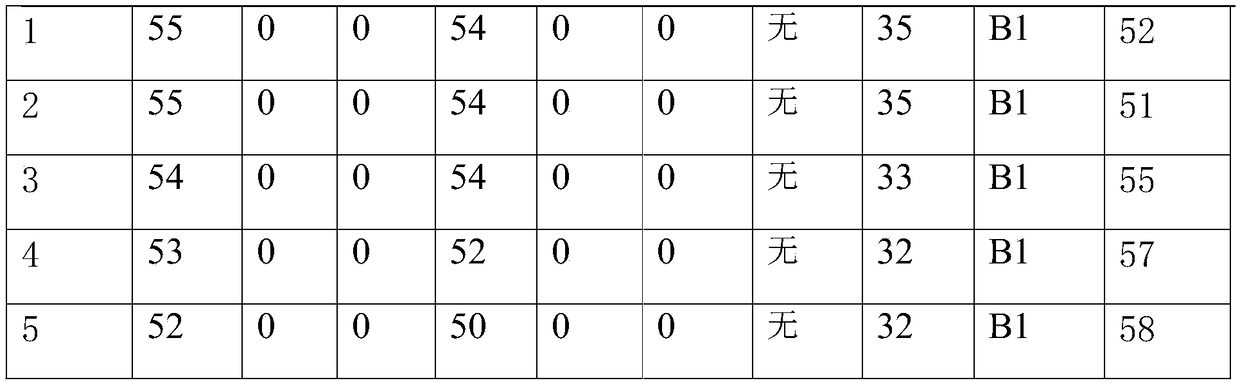

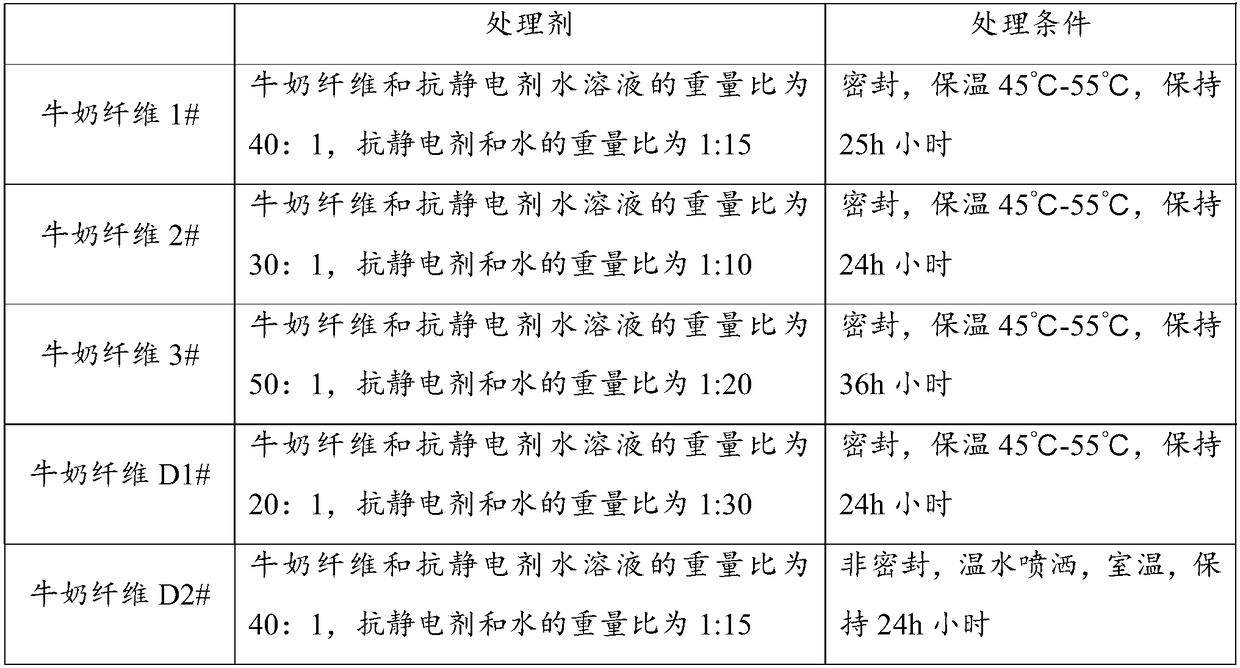

Chinlon carrier milk fiber and cotton fiber blended yarn and spinning process thereof

The invention belongs to the technical field of textile, and particularly relates to chinlon carrier milk fiber and cotton fiber blended yarn and a spinning process thereof. The blended yarn is formedby spinning chinlon carrier milk fibers and cotton fibers through a blending process, wherein the content of the milk fibers is 10%-50%, and the balance is the cotton fibers. The blended yarn is uniform in yarn levelness, few in neps and few in yarn faults, and comfort of fabric can be further improved, so that the fabric is smooth and flat in surface, exquisite and fine in texture and clear in grain.

Owner:WEIQIAO TEXTILE

Blended yarn and preparation method and application thereof

The invention discloses a blended yarn, a preparation method thereof and application thereof, and belongs to the field of textiles. The preparation method of the blended yarn is a yarn blending process, pre-drawing milk fiber strips A and combed cotton strips B are sequentially subjected to a mixing step, a roving step and a spinning step to obtain the blended yarn. The pre-drawing process is carried out on the milk fiber, the weight of pre-drawing strip before mixing is stabilized, therefore, the blending ratio is uniform and stable, and the blended yarn of uniform quality is prepared. The method has the advantages of low preparation cost and high cost performance. According to the invention, a high-count blended yarn prepared by the milk fibers and cotton fibers has yarn evenness, less nep and fewer yarn defects, the blended yarn has the advantages of cashmere and has the advantages of softness and heat preservation, wet permeability and breathability, bacteria inhibition and good sanitation, and the blended yarn is an ideal choice for making home textile products and high-end clothing fabrics.

Owner:WEIQIAO TEXTILE

Combed cotton and chemical fiber blending production process

The invention discloses a combed cotton and chemical fiber blending production process. The specific steps are as follows: ginned cotton is taken out, put into a cotton cleaning and picking area and produced into needed slivers, and after the slivers are predrawn in the first step of drawing, predrawn slivers are obtained; the predrawn slivers are then produced into needed laps by a lap former; the laps are then produced into needed combed slivers by a combing machine and stored for later use; viscose is taken out and put into a cotton cleaning and picking tray, and needed viscose slivers are produced; the produced viscose slivers are taken out and drawn by a first-step drawing frame, so that needed slivers are produced; the obtained slivers and the combed slivers are produced into mixed first slivers; the obtained mixed first slivers are produced into needed mixed final drawn slivers; the obtained mixed final drawn slivers are produced into needed blended yarns. The combed cotton and chemical fiber blending production process is suitable for combed cotton and chemical fiber blending, can effectively improve the uniformity of blending, and reduces neps caused by fiber injuries; original six sections of drawing are changed into five sections, and while capability is the same, a series of problems related to occupied floor area, electricity saving and the like which are caused by equipment investment also can be reduced.

Owner:FUZHOU DEVING ZONE ZHENGTAI TEXTILE

A kind of production method of extra fine special yarn

The invention relates to the technical field of spinning, and discloses a method for producing extra-fine yarns. The method includes a scutching and combing cotton step by subjecting long stapled cotton to a JWF1009 reciprocate plucker, a JWF0007 type weight separator, a JWF1107 type single-axial flow cotton slitter, a JWF1029 type multi-barn cotton blender, a JWF1115 type fine cotton slitter, a CCH-II type irregular fiber separator, a JWF1171 type feeding hopper and a JWF1203 type carding machine, a combing step completed by a FA306 type drawing frame, a JSFA360 type sliver lap machine and a JSFA388 combing machine, a drawing step completed by an FA326 type drawing frame, a roving step completed by an FA458 type flyer frame, a spinning step completed by a DTM129 type spinning machine, and a winding step completed by an autoconerX5 type automatic spooler. The method ensures low fiber damage level of long stapled cotton, and less short fiber contents and neps impurities and extra-fine yarns produced are high in quality.

Owner:疆塑新材料(阿克苏)有限公司

A spinning method for moisture-absorbing and heating fibers

The invention relates to a method for spinning hygroscopic and heat-generating fibers, comprising: pre-treating hygroscopic and heat-absorbing fibers and cotton fibers respectively, and then drawing and mixing to obtain fabrics, wherein the blending ratio of cotton fibers and hygroscopic and heat-generating fibers is 90-60 : 10‑40, the count is 20s‑40s; or mix the hygroscopic heating fiber and the cellulose fiber in a cotton box to obtain a fabric; wherein the blending ratio of the hygroscopic heating fiber and the cellulose fiber is 20‑50:80‑50, the count The numbers are 20s‑40s. By improving the parameters of some steps in the spinning process, the invention compensates for the defects of the fiber itself (such as low fiber strength, low curl, high fiber linear density, high moisture regain, etc.), and achieves the purpose of improving the actual experience of the product.

Owner:SHANGHAI RISOO TECH TEXTILE

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

Two-step color fixing technology for reactive dye fabric dyeing

InactiveCN104562758AReduce dosageFewer nepsLiquid/gas/vapor removalDyeing processCooking & bakingBrightness perception

The invention relates to a two-step color fixing technology for reactive dye fabric dyeing, belonging to the technical field of fabric dyeing. The technology comprises the following steps: (1) firstly, fixing the color in a baking manner, wherein the consumption of sodium carbonate and urea in a dyeing formula is subtracted by about 60 percent, and after the fabric subjected to dyeing liquor padding is baked, the baking color fixing rate can reach 50 to 60 percent; (2) secondly, fixing the color in a steaming manner, wherein after the dyed fabric is baked, the fabric pad-rolls color-fixing liquor (containing appropriate amount of alkaline agent, urea and table salt) steam. In the technology, when in reactive dye deep-color dyeing, the novel two-step color fixing process of baking and steaming is adopted, the consumption of additives can be reduced, the color fixing rate and color yield brightness of the dyed fabric can be improved, and the environmental pollution can be reduced. By adopting the novel color fixing process, the leveling property and dye permeability of the dyed fabric can be improved, cotton neps on the fabric surface can be reduced, and the brightness of the fabric surface can be improved.

Owner:QINGDAO XINYIFA IND & TRADE

Breathable moisture-conductive fabric and manufacturing process thereof

InactiveCN103422218AImprove antibacterial propertiesGood antibacterial effectWoven fabricsYarnCardingEngineering

The invention discloses a breathable moisture-conductive fabric and a manufacturing process thereof. The manufacturing process of the breathable moisture-conductive fabric sequentially comprises opening and cleaning, cotton carding, drawing, roving, spinning, winding and finished product forming. The breathable moisture-conductive fabric has the advantages that bamboo fibers which are used are regenerated cellulose fibers and has good antimicrobial performance, bacteriostasis, ultraviolet-proof performance, soft handfeel, and good hygroscopicity, breathability, quick-drying performance and drapability. Profiled fibers has the advantages of being moisture-conductive, quick-drying, fluffy, breathable, lightweight, soft, not next to the skin and the like. The blended fabric made of the bamboo fibers and the profiled fibers is smooth in handfeel, stiff and neat in appearance, not easy to wrinkle, easy to conduct moisture when being worn, cool, comfortable, good in dyeability and gorgeous in gloss.

Owner:ANZHENG FASHION GROUP

Spinning method of moisture-absorbing and heating fibers

ActiveCN107541828ALittle strengthReduce frizzContinuous processingYarnPolymer scienceCellulose fiber

The invention relates to a spinning method of moisture-absorbing and heating fibers. The method comprises the steps of preprocessing the moisture-absorbing and heating fibers and cotton fibers respectively, and adopting a drawing blending mode to obtain fabric, wherein the blending ratio of the cotton fibers to the moisture-absorbing and heating fibers is (90-60):(10-40), and the count is 20-40 s;or conducting hopper blending on cellulose fibers and the moisture-absorbing and heating fibers to obtain fabric, wherein the blending ratio of the moisture-absorbing and heating fibers to the cellulose fibers is (20-50):(80-50), and the count is 20-40 s. According to the spinning method of the moisture-absorbing and heating fibers, by improving the parameters of some steps in the spinning process, the defects of the fibers are overcome that the fiber strength and the crimpness are low, the fiber line density is high, and the moisture regain is too high, and the purpose of improving the actual experience effect of products is achieved.

Owner:SHANGHAI RISOO TECH TEXTILE

A kind of preparation method of bamboo charcoal fiber blended yarn

ActiveCN106337225BSolve difficult spinningSolve the problems of sticking rolls, broken nets, wrapping rollers and rollers, etc.YarnYarnWinding machine

The invention relates to the technical field of chemical fibers, in particular to a preparation method of bamboo charcoal fiber blended yarns. The method comprises the following steps: (1)preparing bamboo charcoal fibers and viscose fibers into a mixed pre-drawing card silver; (2) pre-drawing the mixed pre-drawing card silver to obtain pre-drawing silver; (3) preparing viscose fiber mono-fiber yarn into viscose card silver; (4) matching the pre-drawing silver and the viscose card silver, and then performing the primary drawing; (5) uniformly mixing the primarily-drawn silver by virtue of secondary drawing and final drawing to obtain a finally-drawn silver; (6) performing coarse-yarn molding for the finally-drawn silver; (7) performing fine yarn molding by adopting compact siro-spinning; and (8) finally forming yarns by adopting an automatic winding machine, removing yarn faults, and bundling. The method is few in yarn forming neps, relatively few in twitty yarns and less in yarn hairness, the difficulty for blending different bamboo charcoal fibers of different specifications is solved, the applicability to the temperature and humidity is greatly improved, and the problems such as roll sticking, net breaking, entangling of leather rollers and rollers and the like are solved.

Owner:YIWU HONGHUI WEAVING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com