Washing-resistant non-melted-dripping flame-retardant curtain and processing method thereof

A processing method and non-melting droplet technology, applied in the direction of textile and viscose rayon, yarn, etc., can solve the problems of poor flame retardancy, threat to life and health, and flammable curtains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

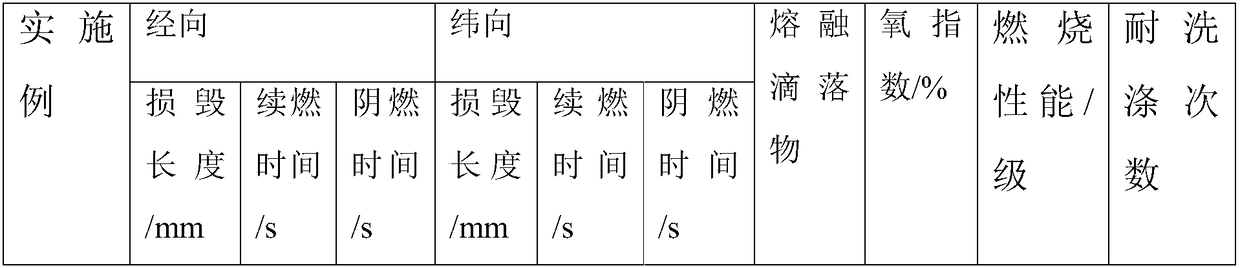

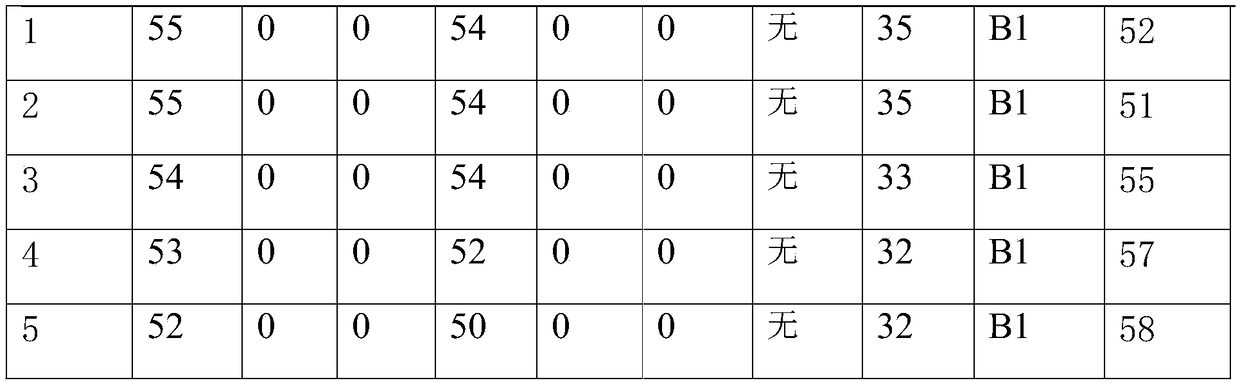

Embodiment 1

[0022] This embodiment provides a washing-resistant non-melting drop flame-retardant curtain processing method and the washing-resistant non-melting dripping flame-retardant curtain obtained by this method. , carding, drawing, roving, spun yarn, setting, twisting, winding, setting, warping and weft winding, weaving, of which:

[0023] The cotton blending is to blend 10 parts by weight of cotton and 10 parts by weight of aramid fiber as the warp direction, 5 parts by weight of cotton and 10 parts by weight of flame-retardant viscose fiber, the length of the aramid fiber is 50mm, and the fineness is 1.6dtex; the flame-retardant viscose fiber length is 35mm, and the fineness is 1.6dtex; wherein the flame-retardant viscose fiber spinning solution and the cotton fiber are all added with 0.2 parts by weight of flame retardant and 0.2 parts by weight of reinforcing agent, so Include 0.1 weight part of strengthening agent in the above-mentioned aramid limit spinning solution; Describe...

Embodiment 2

[0028] This embodiment provides a washing-resistant non-melting drop flame-retardant curtain processing method and the washing-resistant non-melting dripping flame-retardant curtain obtained by this method. , carding, drawing, roving, spun yarn, setting, twisting, winding, setting, warping and weft winding, weaving, of which:

[0029] The blended cotton is blended with 15 parts by weight of cotton and 20 parts by weight of aramid fiber, 20 parts by weight of cotton and 20 parts by weight of flame-retardant viscose fiber, the length of the aramid fiber is 60mm, and the fineness is 1.7dtex; The flame-retardant viscose fiber has a length of 40mm and a fineness of 1.7dtex; wherein the flame-retardant viscose fiber spinning solution and the cotton fiber are all added with 0.3 parts by weight of a flame retardant and 0.25 parts by weight of a reinforcing agent, and the aramid fiber 0.2 parts by weight of a strengthening agent is included in the limit spinning solution; the flame ret...

Embodiment 3

[0034] This embodiment provides a washing-resistant non-melting drop flame-retardant curtain processing method and the washing-resistant non-melting dripping flame-retardant curtain obtained by this method. , carding, drawing, roving, spun yarn, setting, twisting, winding, setting, warping and weft winding, weaving, of which:

[0035] The cotton blending is respectively blending 13 parts by weight of cotton with 15 parts by weight of aramid fiber, 10 parts by weight of cotton and 15 parts by weight of flame-retardant viscose fiber, the length of the aramid fiber is 55 mm, and the fineness is 1.65 dtex; The flame-retardant viscose fiber has a length of 37 mm and a fineness of 1.5 dtex; 0.25 parts by weight of a flame retardant and 0.23 parts by weight of a reinforcing agent are added to the spinning solution of the flame-retardant viscose fiber and the cotton fiber, and the aramid fiber 0.15 parts by weight of reinforcing agent are included in the limiting spinning solution; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com