Patents

Literature

98results about How to "No droplet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced toughened halogen-free flame-retardant polypropylene mixture and preparation method thereof

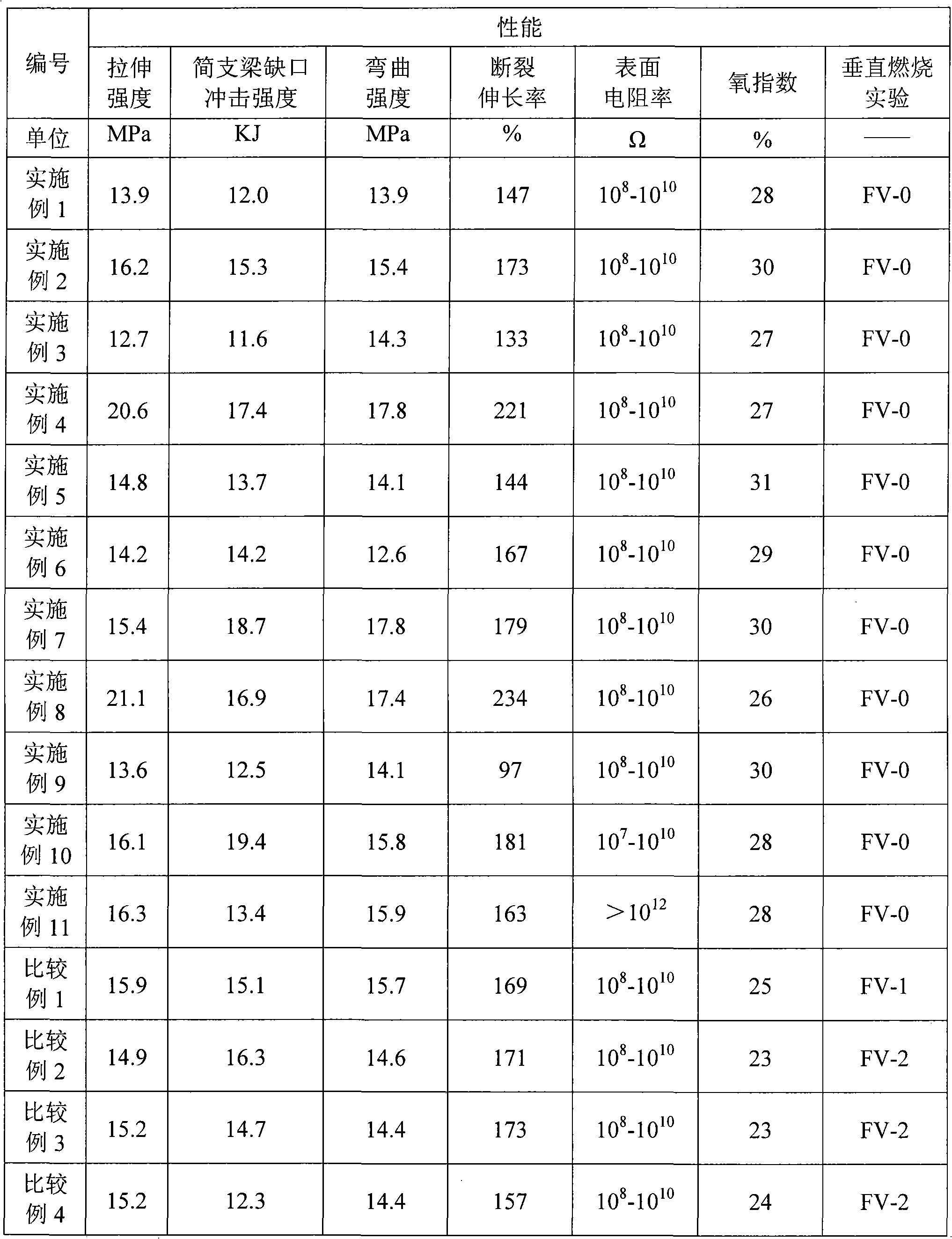

The invention discloses an enhanced toughened halogen-free flame-retardant polypropylene mixture and a preparation method thereof. The method comprises the steps of: diluting 0.5-3 parts by weight of surfactants with 20-30 parts by weight of absolute ethyl alcohol, then adding into 100 parts by weight of alkaline magnesium sulfate whiskers, mixing for 15-30 min in a mixer, and then drying in a dryer to obtain the modified alkaline magnesium sulfate whiskers, wherein the alkaline magnesium sulfate whiskers is required to be 10-60 mum in average length and less than 10 mu m in diameter; adding polypropylene resin firstly on an open type warming mill with double-roll temperature of 170-180 DEG C, sequentially adding an antioxidant, a toughened modifier, the modified alkaline magnesium sulfate whiskers, a synergistic flame retardant, a molten-drop prevention modifier and a compatibilization modifier after the polypropylene resin is molten and covers the rolls, and evenly mixing to obtain the enhanced toughened halogen-free flame-retardant polypropylene mixture. The polypropylene mixture prepared in the invention has the advantages of high strength, good toughness, low smoke, no toxicity, no molten drop, remarkable flame retardant property and the like.

Owner:SOUTH CHINA UNIV OF TECH

Reinforced toughening flame-proof polyolefin resin composition and its preparation method

The invention discloses a flame-proof polyolefin resin component and preparing method in the resin flame resistant modifying domain, which comprises the following parts: a. 9-20% bromine fire retardant with decabran diphenyl ethane or octabromobium ether and heat-stability hexabromide cyclododecane with weight rate at 2: 1-1: 2, b. 3-8% synergic fire retardant with antimony trioxide, c. 3-12% melt resistant melt drip agent with one or more of organic montmorillonite, kaolin and clay.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Low-smoke flame-retardant PVC (polyvinyl chloride) cable material and preparation method thereof

ActiveCN103319802AImprove flame retardant performanceHigh dielectric strengthPlastic/resin/waxes insulatorsOxalatePlasticizer

The invention discloses a low-smoke flame-retardant PVC (polyvinyl chloride) cable material which comprises the following components in parts by mass: 100 parts of PVC, 2-80 parts of a plasticizer, 0.3-15 parts of a heat stabilizer, 0.25-25 parts of a lubricant, 4-60 parts of a flame retardant, 0.5-60 parts of a toughener, 1-5 parts of dicyclopentadienyl iron, 0.5-1.5 parts of magnesia, 0.5-1.5 parts of copper oxalate and 10-20 parts of pottery clay. The oxygen index of the product is up to 55% which is greatly improved compared with the oxygen index (41%) of a product which is obtained in the prior art, the flame-retardant effect is more excellent, and the maximum smoke density is 280; the dielectric strength is up to 30KV / mm which is higher than the dielectric strength (27KV / mm) of the existing product; the tensile strength is 20MPa, the elongation at break is 330-350%, and the brittle temperature is -50 DEG C; the volume resistivity at 20 DEG C is 4*10<14> Ohms.cm, and the volume resistivity at 0 DEG C is 2*10<13> Ohms.cm; and the product is excellent in flame-retardant effect, less in smoke generation, resistant to ultraviolet aging and good in insulation effect and tenacity, does not generate molten drops, can be produced in a large scale, and can be used for replacing the existing material continuously.

Owner:OPTA POLYMER JIANGSU

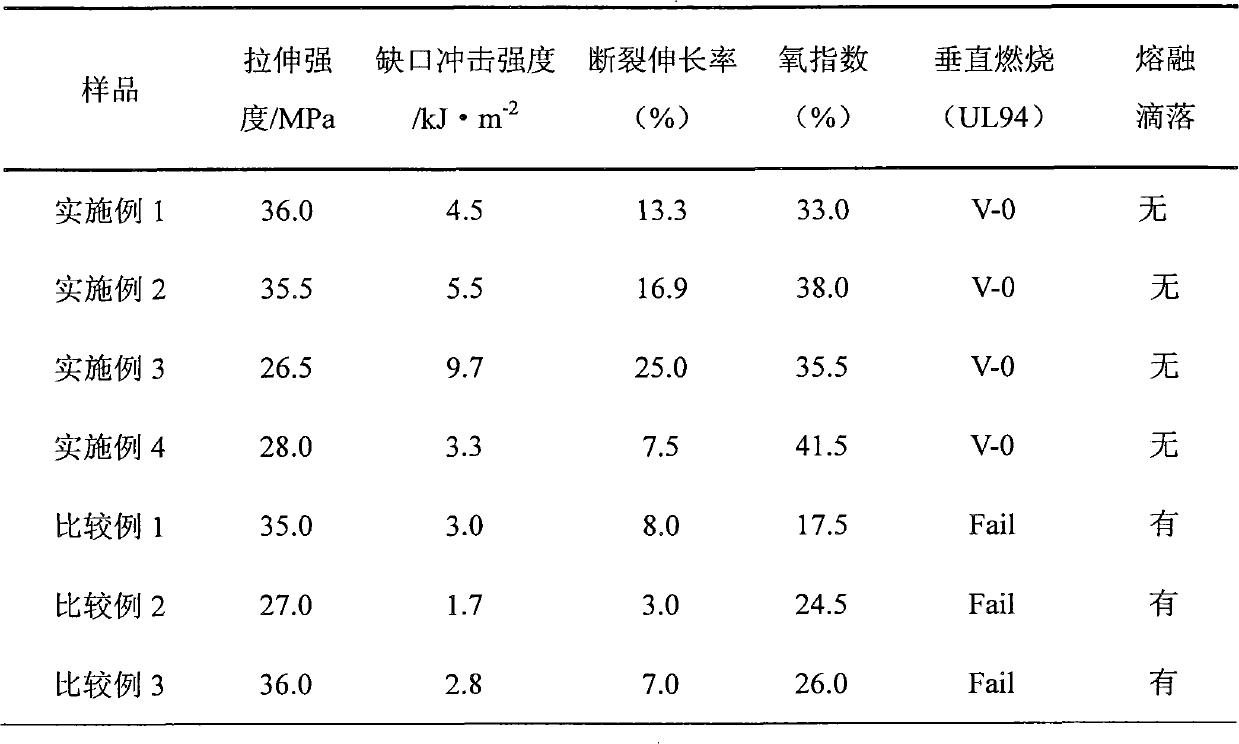

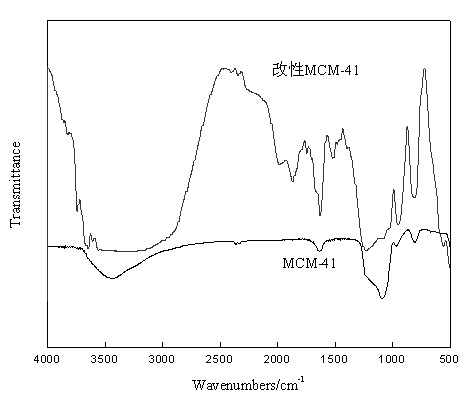

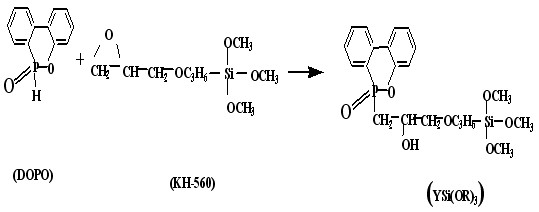

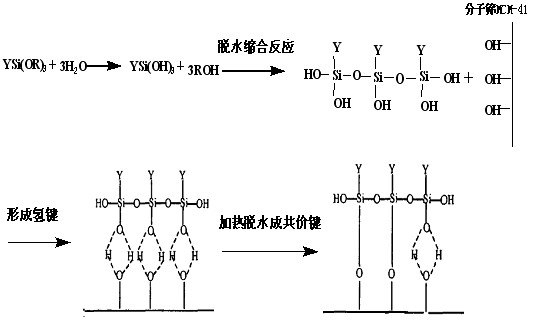

Flame-retardant composite material with DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified nano mesoporous molecular sieve

InactiveCN102675895AImprove compatibilityGood resistance to precipitationMolecular-sieve and base-exchange compoundsPigment treatment with organosilicon compoundsMolecular sieveChemistry

The invention discloses a flame-retardant composite material with DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified nano mesoporous molecular sieve, belongs to the fields of nano mesoporous molecular sieve flame-retardant synergists and halogen-free flame-retardant composite materials, and particularly relates to the preparation method of the DOPO modified nano mesoporous molecular sieve and the flame-retardant composite material with the DOPO modified nano mesoporous molecular sieve. The DOPO is of a hexahydric phosphorus-heterocyclic-ring structure, and is a novel flame retardant intermediate. The nano mesoporous molecular sieve is the flame-retardant synergist. The invention discloses the method for preparing the DOPO modified nano mesoporous molecular sieve and the flame-retardant composite material with the DOPO modified nano mesoporous molecular sieve. Since the compound flame-retardant synergist plays a role in phosphorus / silicon synergistic flame retardance, the obtained product has good expandable carbon forming property, the flame-retardant efficiency of the material is obviously increased, the remaining amount of the residual carbon and the compact degree of a carbon layer are increased, and further the flame redardancy of the composite material is improved to a greater degree.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

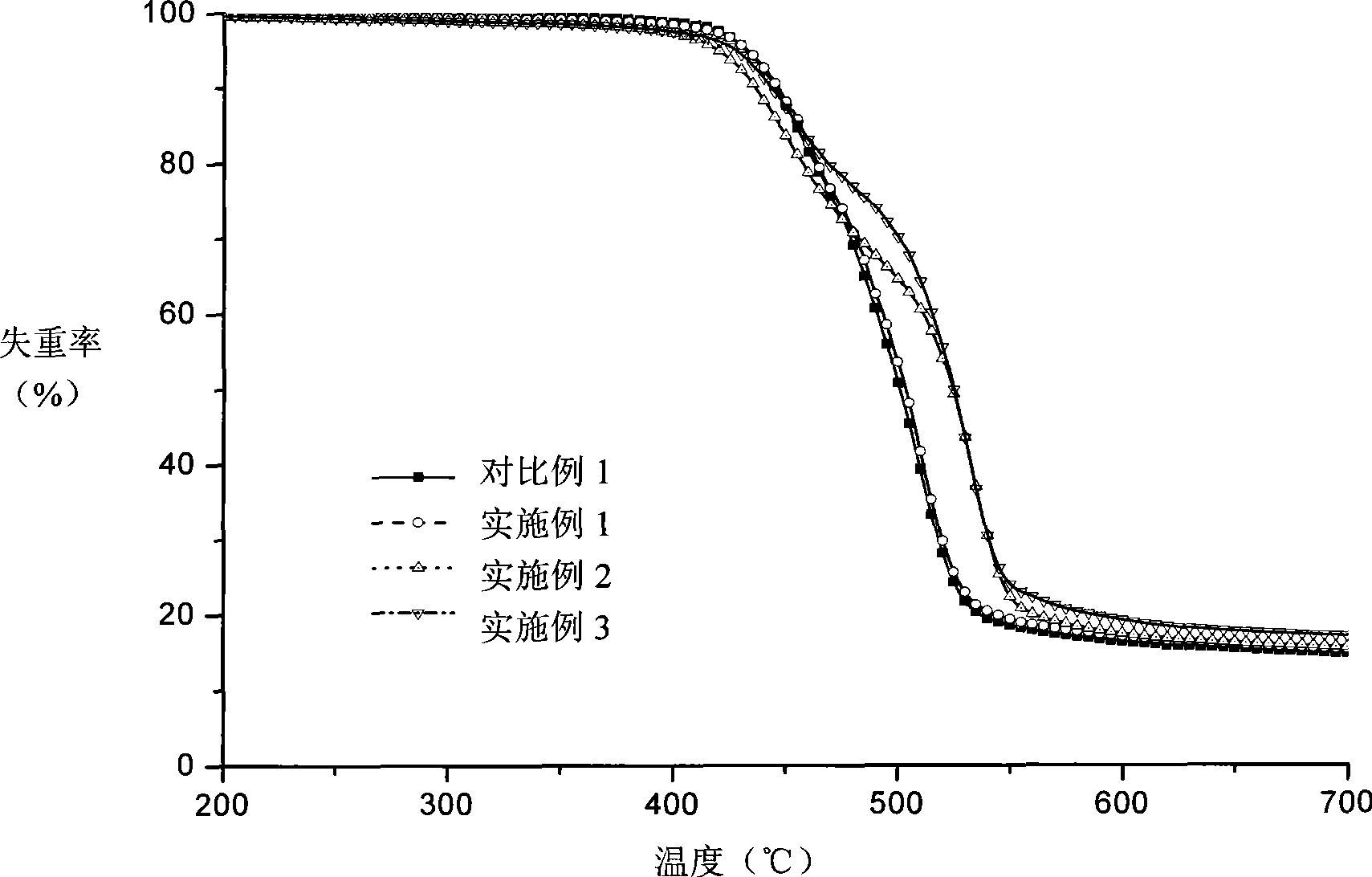

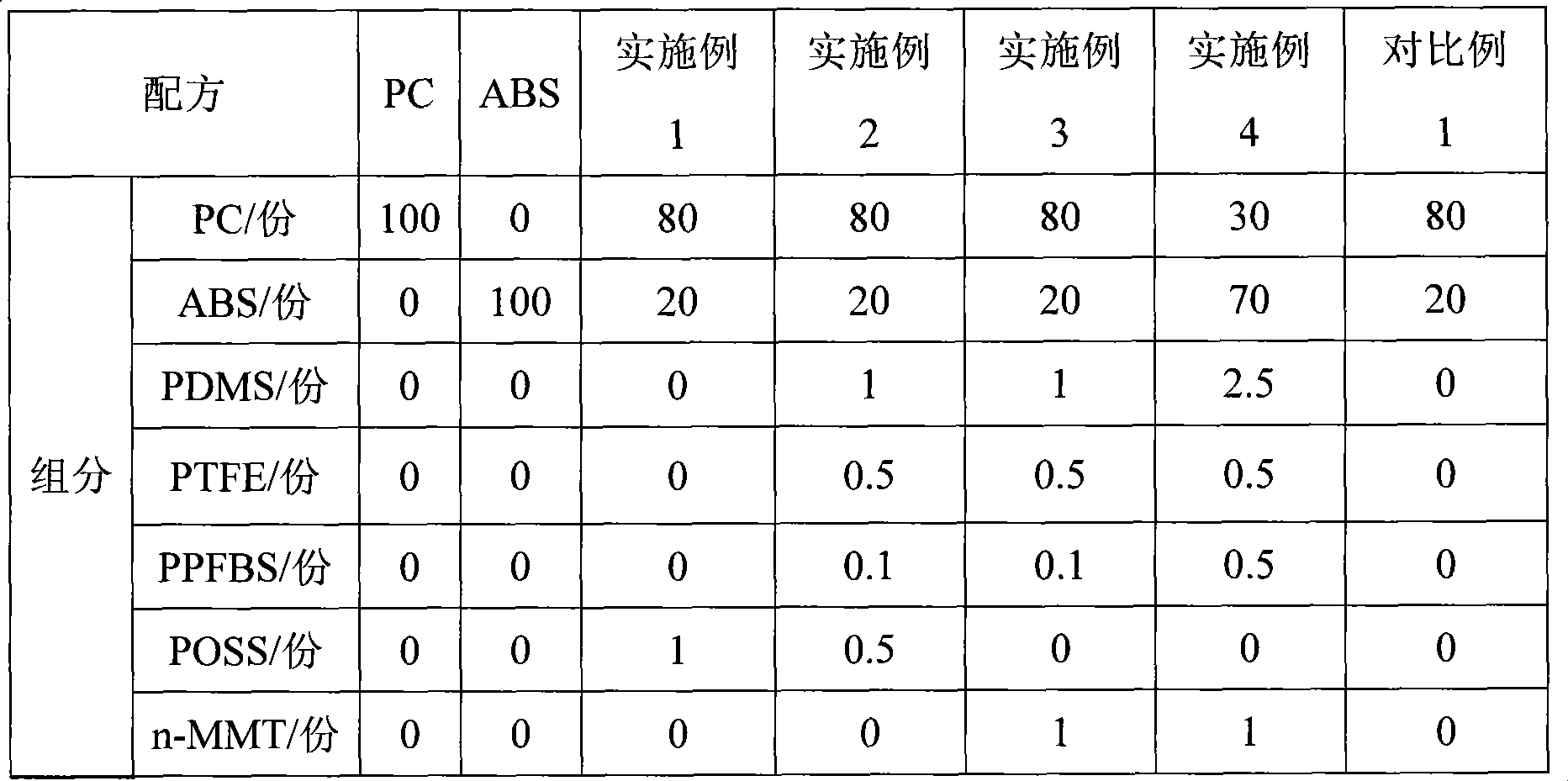

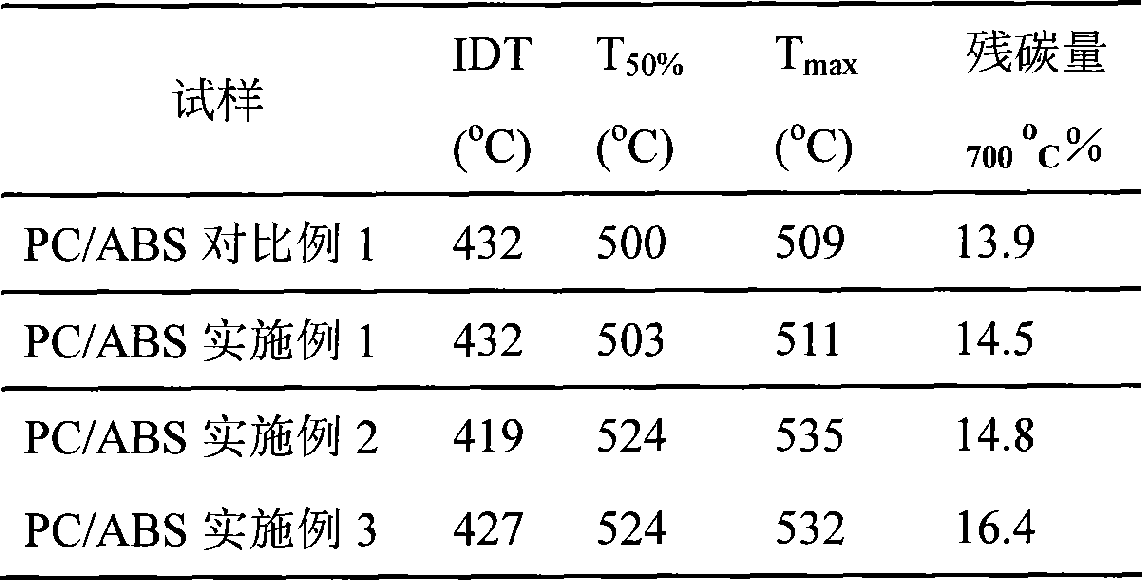

Preparation method of non-halogen flame-retarded makrolan/acrylonitrile-butadiene-styrene copolymer alloy

InactiveCN101445653AFacilitate cross-linkingIncrease the rate of charringPolytetrafluoroethyleneFire retardant

The invention discloses a preparation method of halogen-free flame-retarded makrolan / acrylonitrile-butadiene-styrene copolymer alloy. The following are all showed according to weight portions: the non-halogen flame-retarded makrolan / acrylonitrile-butadiene-styrene copolymer alloy is obtained by drying 20-99 portions of polycarbonate, 80-1 portions of ABS resin, 0.1-1 portion of Teflon, 0.01-4.5 portions of sulphonate series flame retardant, 0.01-5 portions of organic silicon series flame retardant and 0.01-5 portions of nano assistant under the temperature of 85 to 105 DEG C for 4 to 8 hours, then the mixture is uniformly mixed, and added in a double screw extruder, extruding is carried out under the temperature of 230 to 250 DEG C at a rotating speed of 200 to 240 r / min, then cooling, drying and cutting granules are carried out. The preparation method utilizes the complex formulation of the sulphonate series flame retardant, the organic silicon series flame retardant and the nano assistant, thus forming a synergism system co-acted on by a plurality of flame retardants; the alloy obtained is halogen free and the total adding amount of the flame retardants is less; in a vertical burning experiment, the alloy shows effects of self extinguishing, no fused drop and thick and having firm carbon layers and can reach a grade from UL94 V0 to V1. The preparation method has the characteristics that the flame-retarding efficiency is high, the mechanical property is good, and the method is also environmental friendly.

Owner:SHANGHAI JIAO TONG UNIV

Halogen-free flame-proof highly anti-flush polyphenylacetylene composition and method of making the same

The invention discloses a non-bittern flame-proof high-impact polystyrene composition and preparing method in resin flame-proof modified domain, which is characterized by the following: comprising 100 wt high-impact polystyrene resin, 35-80 wt non-bittern combustion inhibitor and 10-30 wt forming carbon agent; setting the non-bitter flame-proof as poly ammonium phosphate pentaerythritol ester; setting the forming carbon agent as poly 2, 6-dimethyl-1, 4 phenyl ether or mixture with mass ratio at 3:1-6:1 poly 2, 6-dimethyl-1, 4 phenyl ester and nanometer caoline; comprising flexibilizer with 10-40 wt; choosing the flexibilizer from at least one of grafts of styrene-butene-styrene terpolymer and maleic anhydride, grafts of octane-ethene binary multipolymer and maleic anhydride and silicon rubber; mixing each component; melting; blending; getting the product. This invention possesses high flame-proof efficiency, which does not generate droplet.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing light, thin, heat-insulating flame-retardant plush fabric

InactiveCN106192176AComfortable to wearGood warmth retentionFabric breaking/softeningWeft knittingYarnPolyester

The invention relates to a method for preparing a light, thin, heat-insulating and flame-retardant plush fabric. The method comprises the steps of weaving a fabric, wherein terry yarn is 98% of 32S / 1 aramid fiber 1313 / 2% of conductive filament, and connecting yarn is 100D / 36F polyester flame-retardant double-sided plush; causing the fabric to undergo dyeing, drying, soft forming, galling, intermediate shaping, combing, shearing and final shaping, and obtaining the light, thin, heat-insulating and flame-retardant plush fabric. The method is short in process and good in stability, the obtained plush fabric insulates heat, is light and thin, has an outstanding flame-retardant effect, does not melt, has no melting drip and does not generate smoke, the afterflame time is 0 s, the smoldering time is 0 s, the plush fabric is permanently resistant to flame and is comfortable to wear and soft in touch, the final finished knitted fabric gram weight is 271 g / m2, the heat-insulating value CLO is 0.5-1.0, and the plush fabric has good application prospects.

Owner:SHANGHAI CHALLENGE TEXTILE

Flame-retardant polymer composite material

The invention discloses a flame retarding polymer composite material which is compounded by resin system, intumescent flame retardant and flame retardant synergist which are melted by a extruding machine or a mill mixer. The intumescent flame retardant comprises a triazine compound and polyphosphate. The flame retardant synergist is silicon magnetism containing inorganic substance. The triazine compound has good thermal stability and water resisting property, is used as carbon source and air source and compounded with ammonium polyphosphate to constitute the intumescent flame retardant which is applied in the flame-retardant polymer which has good flame retardant effect. The obtained coal bed reveals out compact and continuous structure. The silicon magnetism containing inorganic substance is added as the flame retardant synergist, thus promoting the formation of the coal bed, improving the quality of the coal bed, obtaining the flame retarding polymer materials with higher flame retardance in the condition of keeping the same addition of the flame retardant.

Owner:SOUTH CHINA UNIV OF TECH

Halogen-free flame-retardant polyethylene composite material and preparation method thereof

The invention aims to provide a halogen-free flame-retardant polyethylene composite material which is characterized by comprising the following raw materials in parts by weight: 72.0 parts of high-density polyethylene resin, 1.2 parts of mixture of antioxidant 1010 and antioxidant 168 in a ratio of 1.2:1, 0.9 part of pentaerythritol stearate, 28.0 parts of phenoxy polyphosphazene elastomer, 24.5 parts of magnesium hydroxide, 33.0 parts of calcium carbonate and 7.0 parts of rare-earth coupling agent. The invention also provides a preparation method of the material. Compared with the traditional halogen-free flame-retardant polyethylene, the synergic addition of the phenoxy polyphosphazene, nano magnesium hydroxide and calcium carbonate greatly enhances the flame retardancy of polyethylene; and the obtained polyethylene has favorable comprehensive mechanical properties, and does not generate molten drops and has small smoking amount when being combusted.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Novel hot-melt pressure-sensitive adhesive for waterproof materials and preparation method thereof

InactiveCN104946178ANo crackNo flowMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesThermoplastic elastomerHot melt

The present invention relates to the technical field of hot melt adhesives, specifically, to a hot-melt pressure sensitive adhesive used in a waterproof material and a preparation method therefor. By a weight percentage, the hot-melt pressure sensitive adhesive comprises the following components: a thermoplastic elastomer of 30-40%, tackifying resin of 30-50%, rubber softening oil of 15-30% and an auxiliary agent of 0.3-1%. The preparation method comprises: adding the thermoplastic elastomer, the tackifying resin, the rubber softening oil and the auxiliary agent respectively into a closed container, heating and stirring in a condition of 180 degrees centigrade until even, and standing to obtain the hot-melt pressure sensitive adhesive. A purpose of the present invention is to provide the hot-melt pressure sensitive adhesive used in the waterproof material and the preparation method therefor. The hot-melt pressure sensitive adhesive has good low-temperature resistance and good adhesion performance, is safe and environmentally-friendly, and has very good utility value.

Owner:JIANGSU CANLON BUILDING MATERIALS

Low-smoke fireproofing cable material without halide and its preparation method

InactiveCN1951993AAdd lessHigh flame retardant efficiencyInsulated cablesInsulated conductorsAmmonium polyphosphateSmoke

The invention discloses a low-smoke flame-proof non-halogen cable material and preparing method, which comprises the following steps: blending polyphosphoric ammonia and zinc boride evenly; spraying and cladding the composite material through coupler; adding middle-density polyethylene, copolymer, functional nylon, compatible agent, anti-oxidant and lubricant to stir evenly; transmitting composite material into concurrent twin-screw extruder to fuse; graining after winding to obtain the product.

Owner:YUNNAN CHEM RES INST

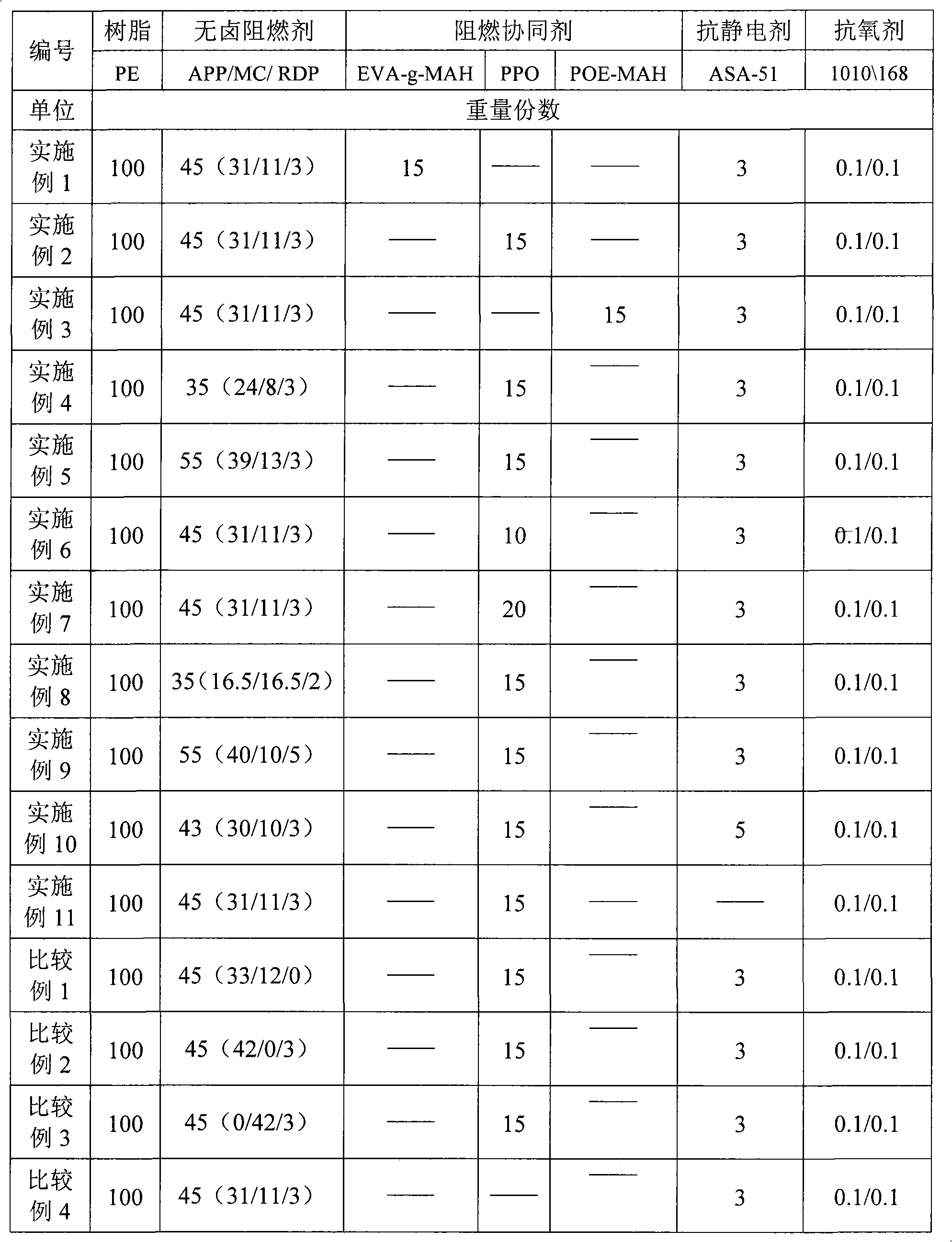

Non-halogen flame-proof polyvinyl composite and method of producing the same

The invention provides a non-halogen flame-retardant polyethylene composition and a preparation method thereof, which relates to the field of the flame-retardance modification of resins. The composition contains 100pbw (parts by weight) of polyethylene resin, 35 parts to 55 parts of non-halogen fire retardants and 8 parts to 20 parts of flame-retardant synergists. The non-halogen fire retardant is compounded by ammonium polyphosphate, melamine cyan urate and hydroxyphenol (diphenyl phosphate), wherein, the total amount of the ammonium polyphosphate and the melamine cyan urate accounts for 32pbw to 50pbw, and the weight ratio of the ammonium polyphosphate and the hydroxyphenol is 1:1 to 4:1; the hydroxyphenol (Diphenyl phosphate) accounts for 3pbw to 5pbw. The flame-retardant synergist can be graft copolymer of vinyl acetic ester and maleic anhydride, or graft copolymer of maleic anhydride and ethylene / octane, or ethylene / octane copolymer or polyphenyl ether. All components are mixed according to the parts by weight and then melted to obtain the polyethylene composition. Under the condition that FV-0 grade is ensured to reached, the polyethylene composition has high flame-retardant efficiency, generates no molten drop, creates small volume of smoke during burning and has good comprehensive mechanical properties.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

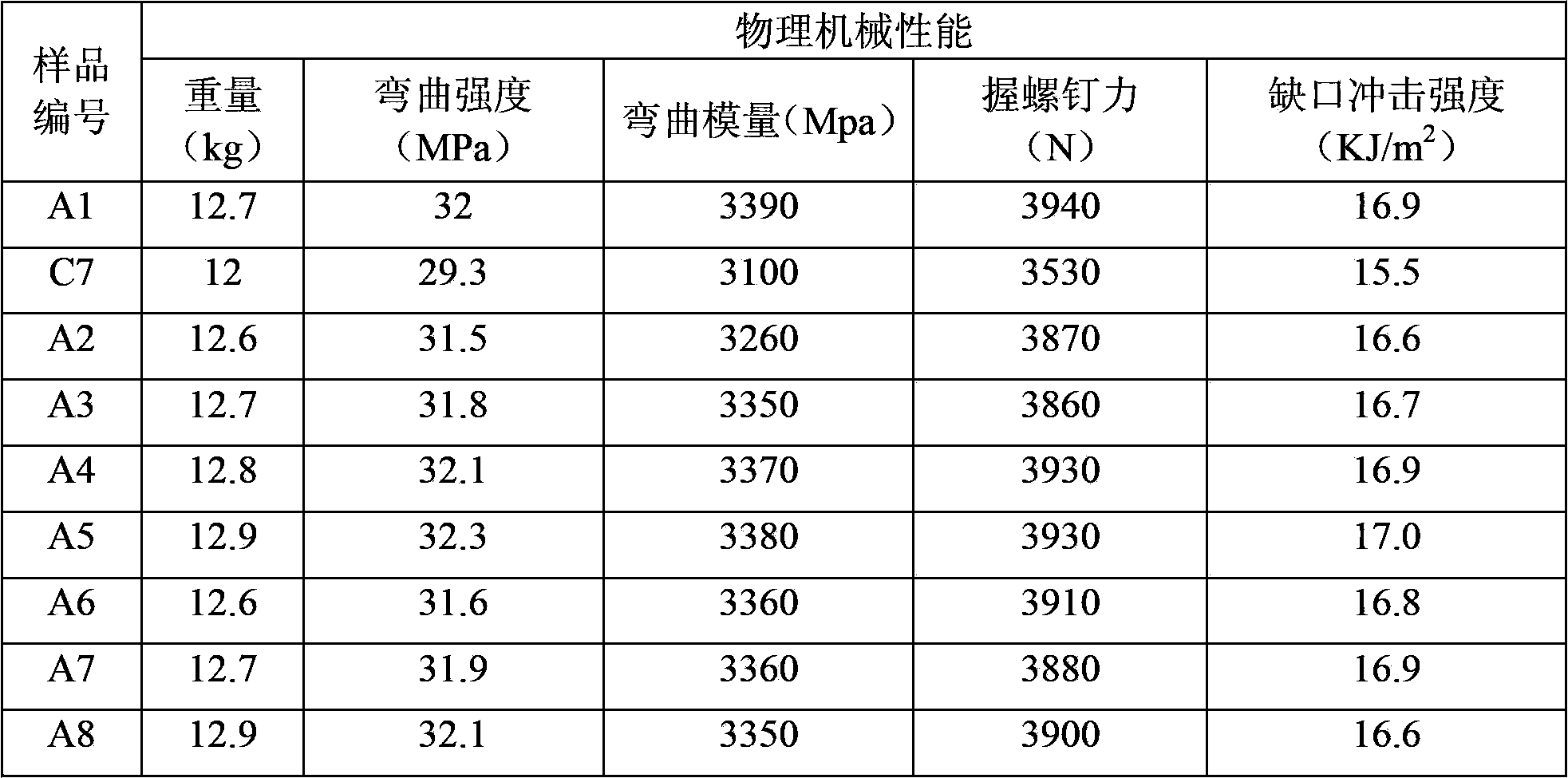

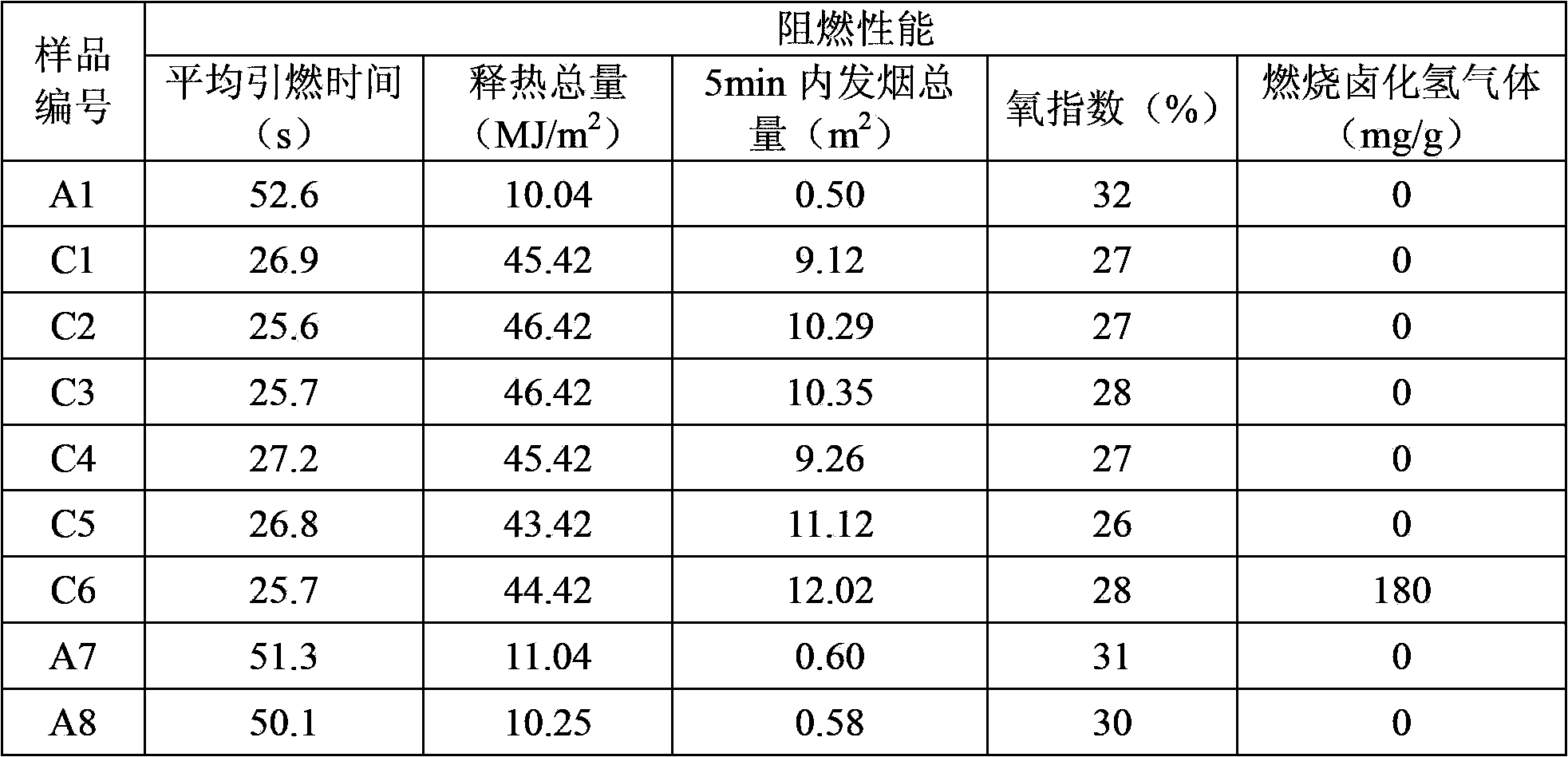

Wood-plastic composite section and preparation method thereof

ActiveCN103422772AImprove flame retardant performanceHigh smoke suppression effectBase framesFiberPolymer science

The invention discloses a wood-plastic composite section and a preparation method thereof. The wood-plastic composite section is characterized by comprising a shell and a light material filled in the shell, the shell is made of a wood-plastic composite, and the density of the light material is lower than that of the wood-plastic composite. A shell preparation method includes uniformly mixing raw materials prior to extrusion molding, and the raw materials include plastic, a wood fiber material and a flame retardant. A flame retardant preparation method includes subjecting phosphoric acid and pentaerythritol to first contact reaction for 0.5-5 hours at the temperature of 100-180 DEG C, adding polyether polyol, ammonium polyphosphate and melamine and / or urea into a product obtained by the first contact reaction, and performing second contact reaction for 0.5-4 hours at the temperature of 100-180 DEG C. The section has excellent flame retardance. In addition, the light material is filled in the shell, so that strength of the section is improved on the premise of not increasing the weight of the section greatly.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Halogen-free flame-retardant wood-plastic composite material and preparation method thereof

InactiveCN103194073AImprove flame retardant performanceHigh smoke suppression effectFiberPentaerythritol

The invention discloses a halogen-free flame-retardant wood-plastic composite material and a preparation method thereof. The method comprises mixing and extrusion molding of the raw materials. The raw materials are characterized by comprising plastic, a wood fiber material and a flame retardant. A preparation method of the flame retardant comprises steps of: conducting a first contact reaction on phosphoric acid and pentaerythritol; and adding polyether polyol, ammonium polyphosphate, melamine and / or urea into reaction products from the first contact reaction to conduct a second contact reaction. The halogen-free flame-retardant wood-plastic composite material provided by the invention has good flame retardancy and smoke suppression, improved average ignition time, heat release, smoke production and oxygen index compared with a halogen flame retardant, and no droplet and good flame retardancy. Besides, the halogen free flame-retardant wood-plastic composite material provided by the invention has the appearance of wood, high physical and mechanical properties, wide application range, simple preparation process, and safe and easily available raw materials.

Owner:东莞市绿美时环保装饰建材有限公司 +1

Flame-retardant anti-static two-faced plush cloth

ActiveCN105019119APermanent Flame RetardancyImprove thermal protection performanceWeft knittingYarnModacrylic

The invention discloses flame-retardant anti-static two-faced plush cloth which is formed by blending the following components in parts by weight: 50-60 parts of modacrylic, 30-40 parts of cotton, 5-15 parts of nylon and 1-3 parts of conductive wires. The two-faced plush cloth includes a first surface and a second surface, wherein both the first surface and the second surface are formed by blending and weaving modacrylic fibers and cotton fibers; the first surface and the second surface are connected with each other through polyamide yarns and the conductive wires; the polyamide yarns are arranged parallel to the conductive wires, the distance between adjacent polyamide yarns is 0.08-0.15 cm, and the distance between adjacent conductive wires is 0.8-1.2 cm. The two-faced plush cloth is knitted fabric and has the characteristics that the cloth is resistant to high temperature, non-combustible, free of molten drops, soft, comfortable and good in heat retention property, and does not lose plush.

Owner:上海俊首安防科技有限公司 +1

Halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke

InactiveCN104479210AReduce migration speedReduce dosagePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideLead phosphate

The invention discloses a halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke. The insulating material is prepared from the following raw materials in parts by weight: 80-150 parts of cross-linked polyethylene, 10-30 parts of magnesium hydroxide, 5-9 parts of aluminium hydroxide, 1-2 parts of lead sulfate tribasic, 0.5-0.9 part of dibasic lead phosphate, 0.3-0.7 part of paraffin, 20-50 parts of phthalate and 5-15 parts of nano-montmorillonite. The insulating material provided by the invention has the advantages of being light in weight, good in toughness, small in flame and low in burning speed, having no molten drop and less smoke, being anti-migration, good in char forming characteristics, easy in processing and the like.

Owner:GUIZHOU MINGHCOO WIRE & CABLE CO LTD

Composite flame retardant in bromine series, preparation method and application

InactiveCN1958720AExcellent flame retardantGood resistance to drippingFireproof paintsPolymer sciencePolyolefin

This invention provides a method for preparing brominated composite flame retardant and its application. The brominated composite flame retardant comprises: brominated flame retardant 100 parts, synergistic flame retardant 30-45 parts, and anti-melting drop 30-60 parts. The brominated flame retardant is a mixture of decabromodiphenyl ethane or octabromo ether and heat-stable hexabromocyclododecane at a weight ratio of (2:1)-(1:2). The synergistic flame retardant is antimony trioxide. The anti-melting drop is one or more of organic montmorillonite, kaolin and clay. The method comprises: adequately mixing the above components according to the formula. The brominated composite flame retardant has a flame retardant grade up to V-0 without melting drop when used in flame retardant modification of polyolefin plastics. Besides, the brominated composite flame retardant has good mechanical properties, and can be used as packaging material for military products and electronic products.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method for environment-friendly anti-flaming anti-static polyethylene pipeline

InactiveCN103073775AImprove flame retardant performanceMake up for the problem of insufficient charcoalRigid pipesElastomerPolymer science

The invention relates to a preparation method for an environment-friendly anti-flaming anti-static polyethylene pipeline. The preparation method comprises the following steps: selecting the following components: high-density polyethylene resin, Mg(OH)2, 35-42 weight parts of phenoxy polyphosphazene elastomer, nanoscale calcium carbonate, nanoscale carbon black, silane coupling agent KH-570, pentaerythritol stearic acid amide, antioxygen 736 and antioxygen 168; preparing polyethylene master batch, mixing through a high-speed mixer, and extruding and pelletizing through a double-screw extruder; and preparing into the pipeline through the steps of extruding through a molding machine, sizing, dragging, cooling-shaping and cutting. The anti-flaming anti-static polyethylene pipeline prepared according to the method provided by the invention has the advantages that the fire retardant is high in anti-flaming efficiency, the additive amount is small, no molten drop is generated during combustion and fuming volume is small, no harmful gas is generated, and the pipeline is anti-flaming while the comprehensive mechanical property is excellent.

Owner:CHONGQING XINGTELONG IND CO LTD

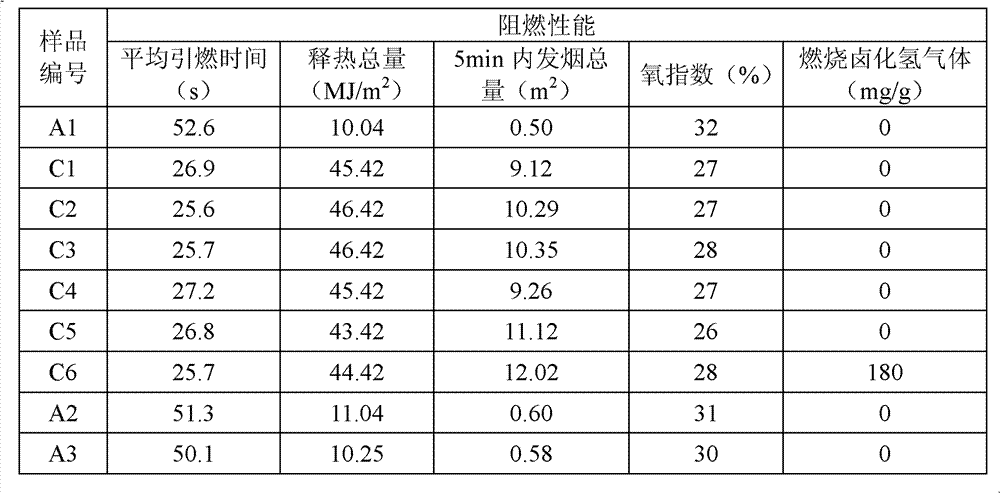

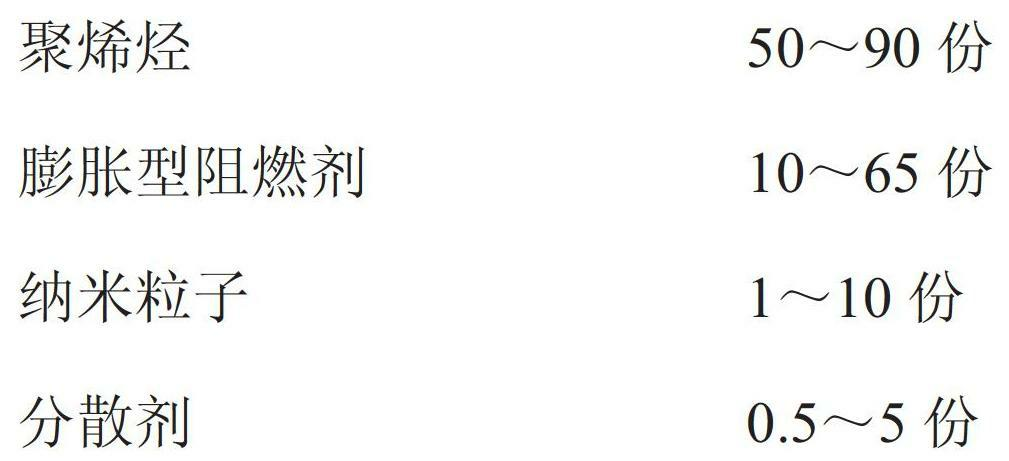

Nano halogen-free flame retardant polyolefin material and preparation method thereof

InactiveCN102643464AImprove mechanical propertiesImprove flame retardant performancePolymer sciencePolyolefin

The invention relates to a nano halogen-free flame retardant polyolefin material and a preparation method thereof. The nano halogen-free flame retardant polyolefin material is prepared by melting and mixing 50-90 parts of polyolefin, 1-10 parts of nano particles, 10-65 parts of expansion type flame retardant and 0.5-5 parts of dispersing agent according to reasonable proportion. According to the nano halogen-free flame retardant polyolefin material and the preparation method thereof, the nano particles are added based on the expansion type halogen-free flame retardant polyolefin, the cooperation flame retardant effect is achieved, the negative influence on the mechanical property of the polyolefin caused by the heavy addition of the flame retardant can be overcome, and compared with the polyolefin material with pure expansion type flame retardant, the nano halogen-free flame retardant polyolefin material has the advantages of good flame retarding effect and excellent mechanical property. The material can be applied to fields of electric wires and cables, automobiles, sports goods and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

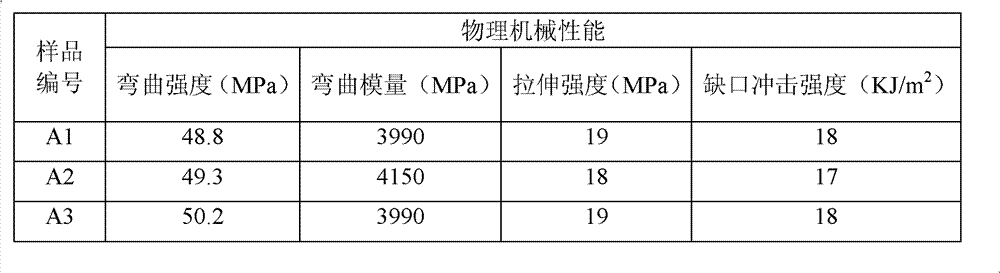

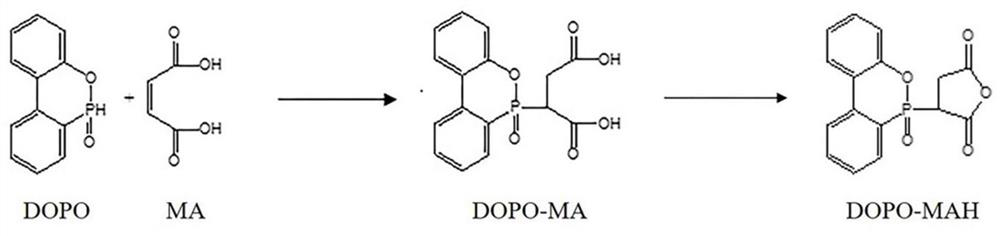

Flame-retardant epoxy resin as well as preparation method and application thereof

PendingCN113461907AImprove flame retardant performanceImprove mechanical propertiesPolymer scienceFirming agent

The invention relates to the technical field of epoxy resin for fiber composite materials, in particular to flame-retardant epoxy resin as well as a preparation method and an application thereof. According to the preparation method of the flame-retardant epoxy resin provided by the invention, epoxy silicate resin is taken as a matrix, and the epoxy resin is subjected to flame-retardant modification according to a P-N-Si synergistic flame-retardant principle under the action of an anhydride curing agent, a phosphorus-containing flame-retardant curing agent and a synergistic flame retardant. The DOPO-MAH is selected as a flame-retardant curing agent, so that poison gas generated by combustion of a halogen flame retardant is avoided, and the problem that an additive flame retardant is poor in dispersity and compatibility is solved; meanwhile, an imidazole curing accelerator is selected, so that the curing temperature can be reduced, and the effect of a synergistic flame retardant can be achieved. According to the invention, DOPO and silicon-oxygen bonds are introduced into a resin system through chemical bonds, and the modified silicon element can cooperate with nitrogen and phosphorus elements, so that the flame retardant property of the epoxy resin is improved, and the mechanical property of the epoxy resin can also be improved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

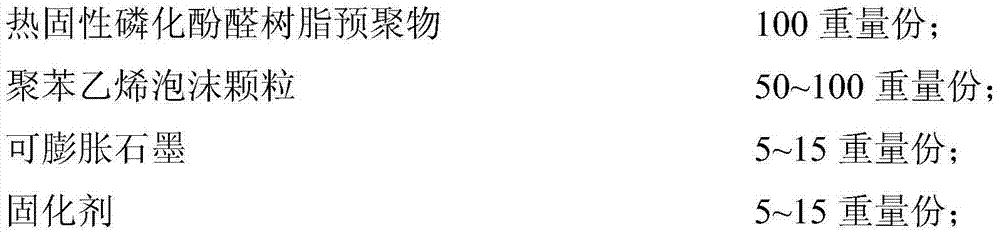

Syntactic foam and preparation method thereof

InactiveCN103709594ASolve the problem of burning dropletsImprove flame retardant performanceCoatingsGraphitePolystyrene particle

The invention relates to syntactic foam and a preparation method thereof, specifically relates to a polystyrene / phosphatized phenolic resin / graphite syntactic foam, and a preparation method thereof, and belongs to the field of flame retardant materials. A formula for the syntactic foam comprises polystyrene foam particles, a thermoset phosphatized phenolic resin prepolymer, expandable graphite and a curing agent. The preparation method of the syntactic foam comprises the steps of coating the thermoset phosphatized phenolic resin prepolymer on surfaces of preset polystyrene foam particles; adding the expandable graphite and the curing agent; and then preparing the polystyrene / phosphatized phenolic resin / graphite syntactic foam under proper temperature and pressure. The syntactic foam has the characteristics of high flame retardant property, low smoke production amount, low cost and excellent performances. Fire melting drip of polystyrene is solved fundamentally; and novel selection is provided for exterior wall thermal insulation materials.

Owner:林百川

High-moisture-penetrability waterproof fabric

ActiveCN104015445AHigh strengthReduce hairinessFibre treatmentSynthetic resin layered productsOxidePhosphate

The invention discloses a high-moisture-penetrability waterproof fabric which comprises basic cloth and a coating layer positioned on one side of the basic cloth, wherein a second priming coating is obtained by drying slurry consisting of the following components by weight percent: 100 percent of polyurethane resin, 38-42 percent of bromoethane, 19-21 percent of antimonous oxide, 4.5-5.5 percent of zinc borate, 4-5 of a bridging agent, 1.6-2 percent of a promoting agent, 1.4-1.6 percent of an anti-washing agent and 9-11 percent of phosphate antiflaming fuel; a surface coating is obtained by drying slurry consisting of the following components in percent by weight: 100 percent of polyurethane resin, 9-11 percent of bromoethane, 4.5-5.5 percent of antimonous oxide and 0.9-1.1 percent of zinc borate; antiflaming acrylic yarns consist of the following components in percent by weight: 4 percent of acrylic, 3.5-4.5 percent of cotton and 0.9-1.1 percent of aramid fibers; the bridging agent is isocyanic acid ester; the promoting agent is an organic ammonia salt; the anti-washing agent is trimethylolpropane poly-material. The high-moisture-penetrability waterproof fabric is long in antiflaming time, small in smoke generation amount, and good in antiflaming effect and has the washing-resistant effect, and the hydrolysis of antiflaming substances is avoided.

Owner:南通东屹纺织科技有限公司

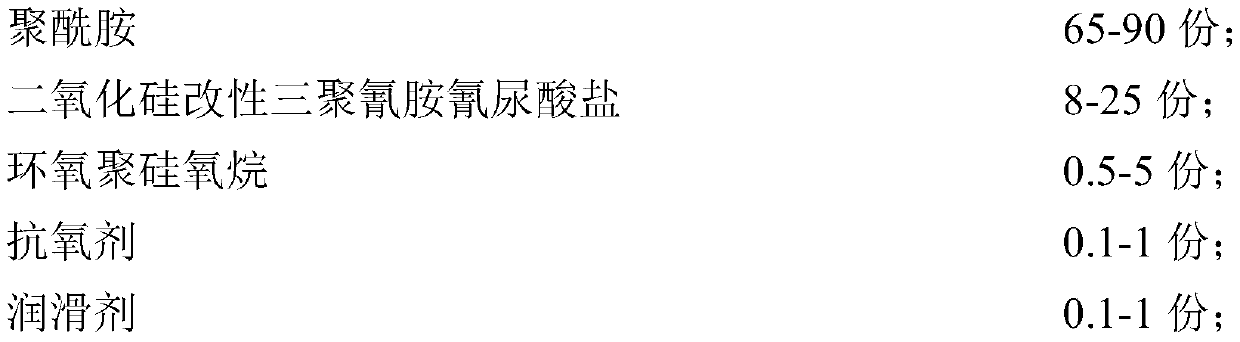

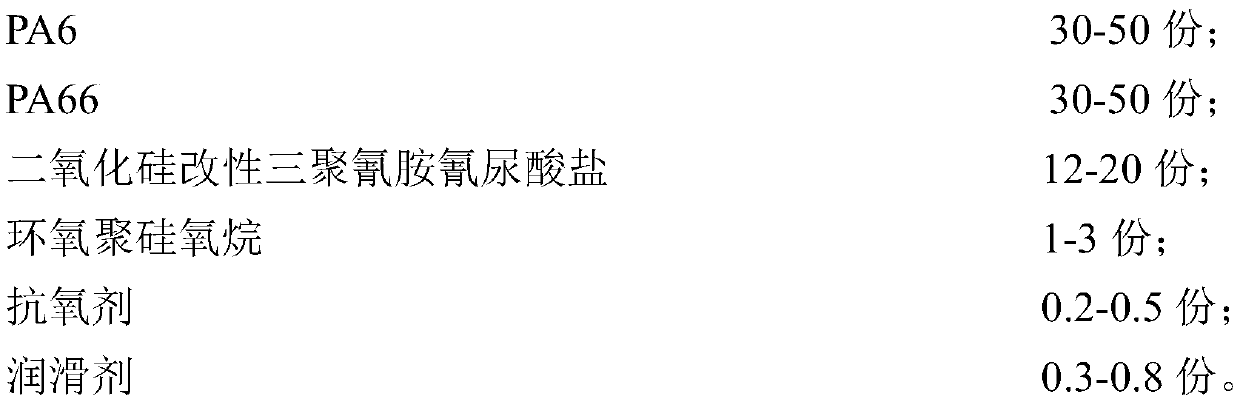

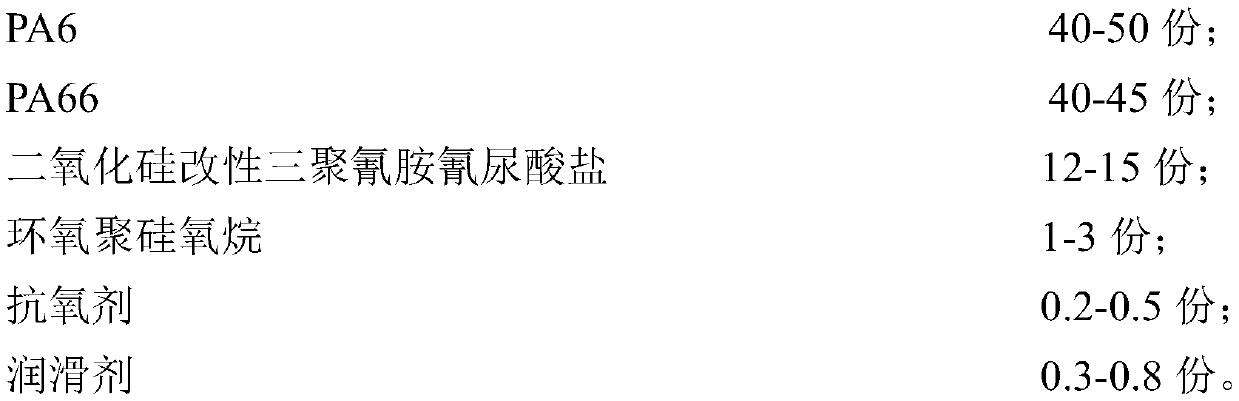

Immersing precipitation-resistant halogen-free flame-retardant polyamide composite material and preparation method thereof

The invention discloses an immersing precipitation-resistant halogen-free flame-retardant polyamide composite material and a preparation method thereof. The immersed and precipitation-resistant halogen-free flame-retardant polyamide composite material is prepared from, by weight part, 65-90 parts of polyamide, 8-25 parts of silicon dioxide modified melamine cyanurate, 0.5-5 parts of epoxy polysiloxane, 0.1-1 part of antioxidant and 0.1-1 part of lubricant through double-screw extrusion and pelletizing. The prepared immersing precipitation-resistant halogen-free flame-retardant polyamide composite material has the advantages of being high in flame-retardant efficiency, good in tenacity, resistant to immersing precipitation, easy to process and the like and can be widely applied to the electronic and electrical field.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

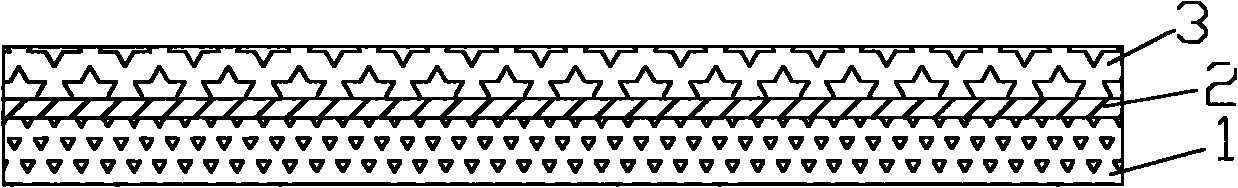

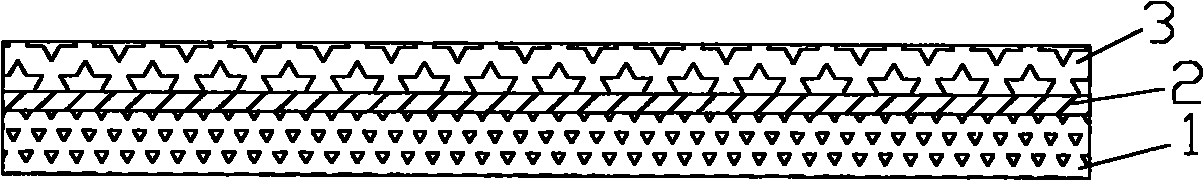

Thermal radiation resistance and high temperature resistance fabric

InactiveCN102152544AHigh strengthImprove wear resistanceMetal layered productsHigh resistancePolyester

The invention relates to a thermal radiation resistance and high temperature resistance fabric. An inner layer of the fabric is an aluminium silicate fiber layer. An intermediate layer of the fabric is an adhesion layer. An outer layer of the fabric is a high temperature resistance protective layer. The three layers are compounded into one whole body. The adhesion layer is made of a polyurethane adhesive. The thickness of the adhesion layer ranges from 2 to 6mum. The protective layer is made of a polyester aluminizing thin film. The thickness of the protective layer ranges from 20 to 25mum. The thermal radiation resistance and high temperature resistance fabric has high strength, high wear resistance and high stability. In case of fire, the thermal radiation resistance and high temperature resistance fabric is not molten down, and no molten drop is generated. No toxic gas is generated. By thermal radiation resistance and high temperature resistance fabric, the heat can be isolated from being transferred at a high temperature. The thermal radiation resistance and high temperature resistance fabric has elasticity and is ventilated and soft and comfortable to wear.

Owner:WUJIANG FEIXIANG WARP KNITTING TEXTILE

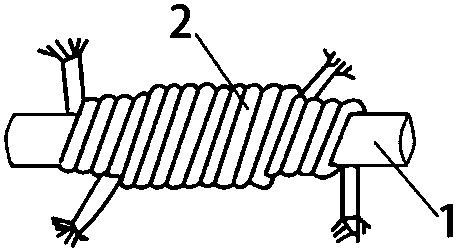

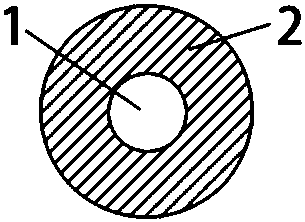

Thermal-radiation-resistant high-temperature-resistant sweat-absorbing T-shirt

InactiveCN103110210AEffective absorptionComfortable to wearGarmentsSynthetic resin layered productsYarnFiber

The invention relates to a thermal-radiation-resistant high-temperature-resistant sweat-absorbing T-shirt. The T-shirt comprises a T-shirt body (1), wherein armpit portions, the front chest portion, and the back portion of the T-shirt body (1) are all provided with sweat-absorbing cloth (2), the sweat-absorbing cloth (2) is arranged on the inner layer of the T-shirt body (1) and is made of a bamboo and jute fiber blended yarn knitted fabric, and the fabric is sewn to form the T-shirt body (1). The inner layer of the fabric is aluminum silicate fiber layer, the middle layer of the fabric is an adhesive layer, the outer layer of the fabric is a high-temperature-resistant protective layer, the three layers are compounded to form a whole, and the adhesive layer is a polyurethane adhesive layer. Due to the fact that the armpit portions, the front chest portion and the back portion of the T-shirt body (1) are all provided with the sweat-absorbing cloth (2), sweat can be effectively absorbed, people feel comfortable to wear the T-shirt, and the T-shirt is thermal-radiation-resistant and high-temperature-resistant.

Owner:周忠平

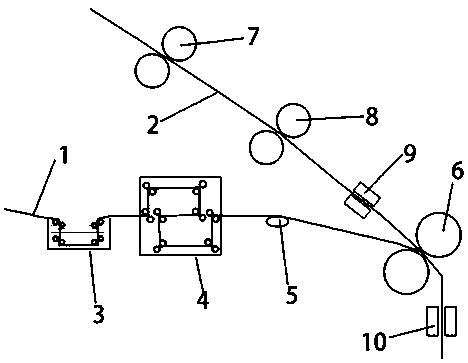

Method for producing flame-retardant fiber from vinylon production line and obtained flame-retardant fiber

ActiveCN107557897AAchieve flame retardant functionHigh strengthFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolyvinyl alcohol

The invention relates to a method for producing a flame-retardant fiber from a vinylon production line and an obtained flame-retardant fiber. The method comprises the following steps: a) dissolving polyvinyl alcohol in water so as to obtain a spinning solution; b) adding an aqueous solution of a tetrahydroxymethyl phosphorus compound; c) spinning by using a mirabilite wet method, and performing condensation and stretching so as to obtain a primary fiber; d) drying the primary fiber obtained in the step c) so as to obtain a flame-retardant precursor fiber; e) performing ammonia fumigation on the flame-retardant precursor fiber obtained in the step d) so as to obtain an ammonia fumigation fiber; f) oxidizing the ammonia fumigation fiber obtained in the step e); and g) randomly performing washing, oiling and drying, thereby obtaining the flame-retardant fiber.

Owner:宁夏全宇新材料有限公司 +1

Pre-oxidized fiber core spun yarn and manufacturing method thereof

ActiveCN110453330AImprove flame retardant performanceImprove thermal stabilityFibre typesConjugated synthetic polymer artificial filamentsTextile technologyFiltration

The invention discloses a pre-oxidized fiber core spun yarn and a manufacturing method thereof, and belongs to the technical field of textiles. The manufacturing method of the pre-oxidized fiber corespun yarn comprises the following steps that common polyacrylonitrile resin is mixed with high-isotacticity polyacrylonitrile resin to obtain mixed resin; the mixed resin and dimethylformamide are placed under a high temperature condition for mixing, then filtration is carried out, and a spinning solution is obtained; firstly, the spinning solution is treated into a nascent fiber, and pre-oxidation treatment and spinning processing are performed in sequence to obtain a pre-oxidized filament; then, after a gelatin sizing agent is used for performing sizing pretreatment on the pre-oxidized filament, drying treatment is carried out; finally, a staple fiber rough yarn is used for wrapping the dried pre-oxidized filament, twisting and desizing are carried out in sequence, and the pre-oxidized fiber core spun yarn can be obtained. The obtained pre-oxidized fiber core spun yarn not only has high flame retardancy and excellent thermal stability, but also has higher mechanical strength and suitable textile processing performance.

Owner:义乌市恒达织带有限公司 +1

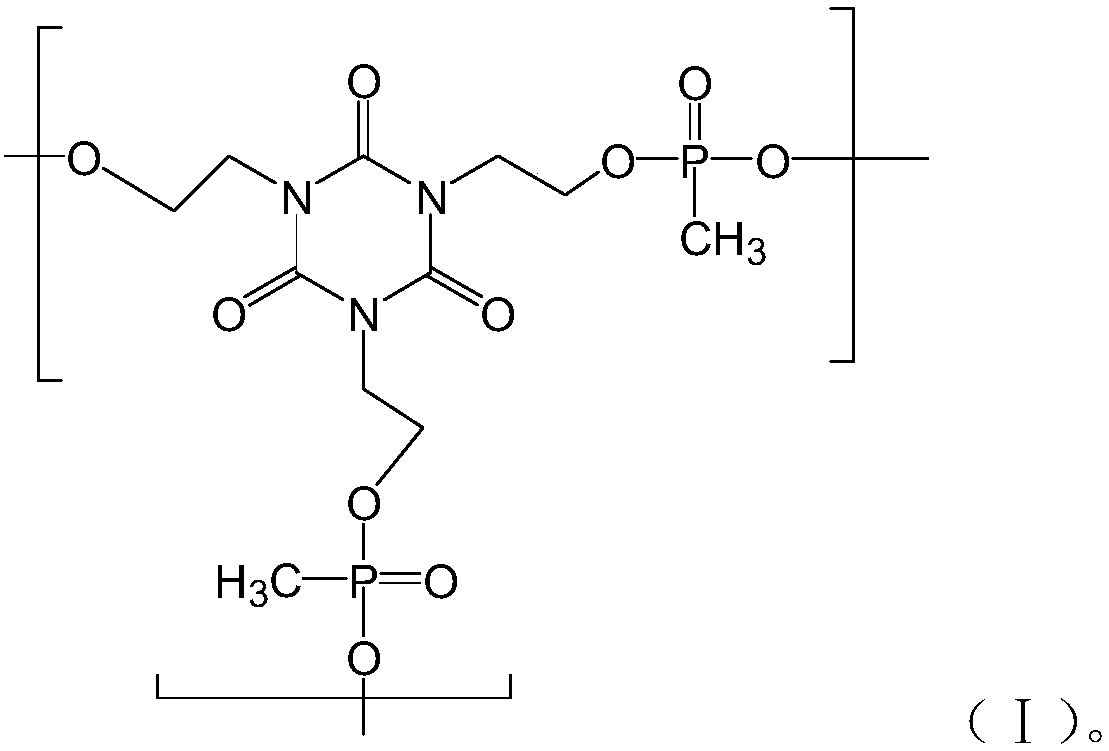

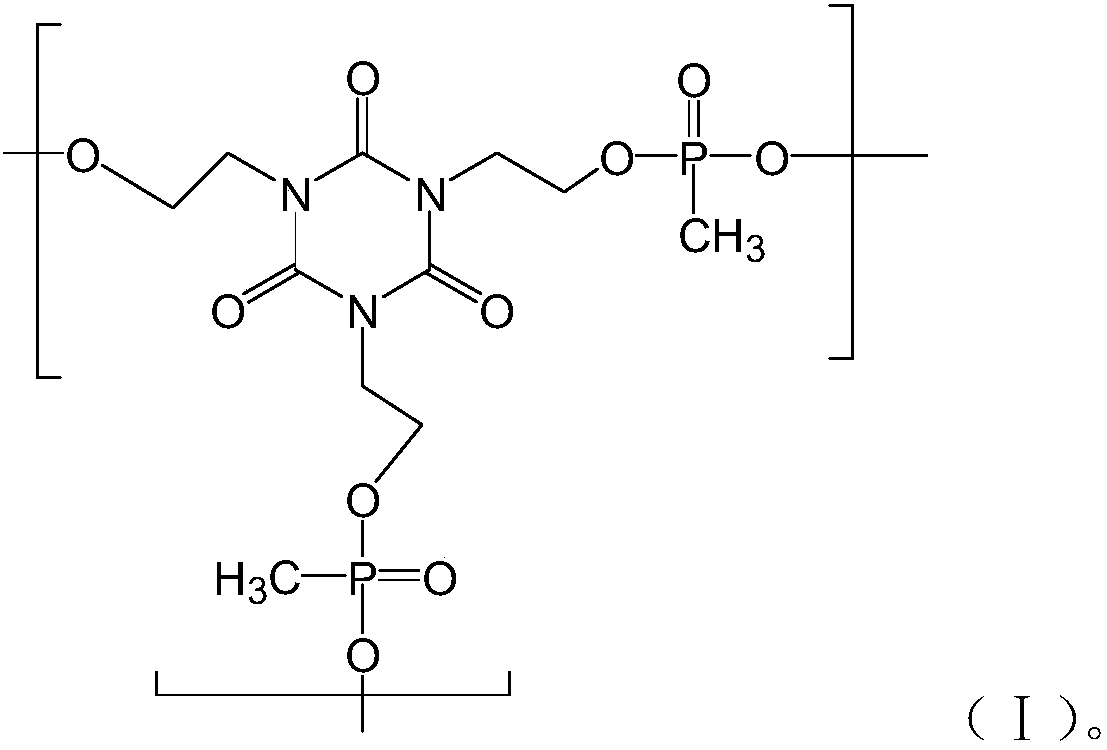

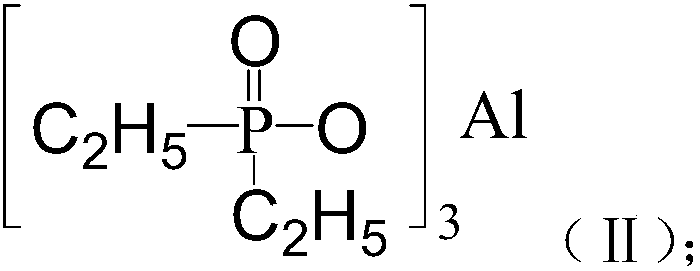

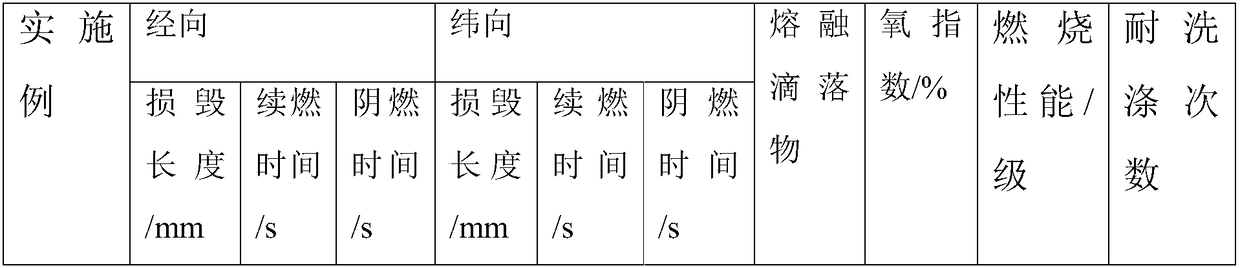

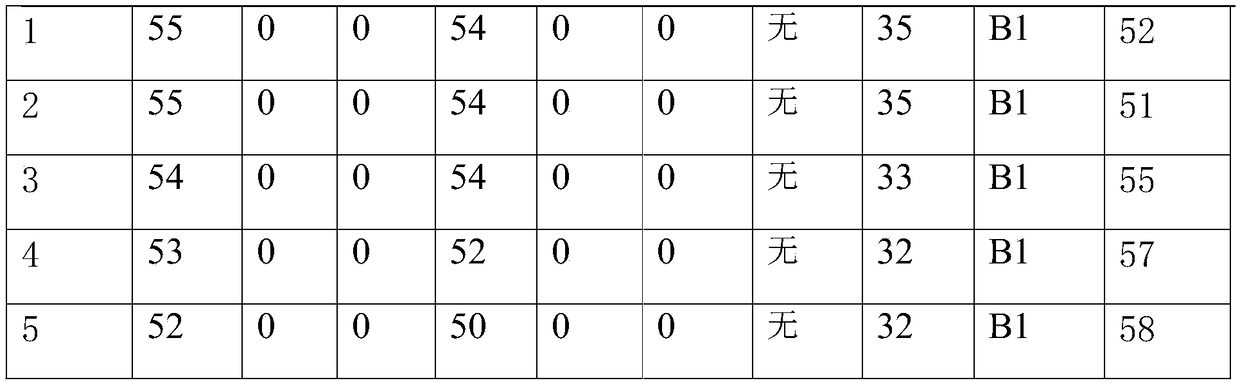

Halogen-free flame-retardant TPU elastomer composition used for electric wires and cables, and preparation method thereof

ActiveCN107892808ANo dropletNo resistance to migrationPlastic/resin/waxes insulatorsChemistryAluminium

The invention discloses a halogen-free flame-retardant TPU elastomer composition used for electric wires and cables. The halogen-free flame-retardant TPU elastomer composition used for electric wiresand cables comprises, by weight, 65 to 90% of a TPU matrix material, 10 to 30% of a phosphor nitrogen composite flame retardant system, and 1 to 5% of an auxiliary agent; the phosphor nitrogen composite flame retardant system comprises diethyl aluminium hypophosphite and a carbon forming component; the carbon forming agent is an insoluble infusible crosslinked polymer, and the crosslinking point structure is represented by formula I. The halogen-free flame-retardant TPU elastomer composition possesses molten drop resistance, high flame resistance, migration resistance, wear resistance, and oilresistance, is soft, and can be used for preparing wires and cables in the fields of new energy vehicle with requirements on high flame resistance, oil resistance, softness, and wear resistance.

Owner:江苏利思德新材料股份有限公司

Washing-resistant non-melted-dripping flame-retardant curtain and processing method thereof

InactiveCN108660586ANo dropletSoft touchArtificial filaments from viscoseWoven fabricsFire retardantWear resistance

The invention provides washing-resistant non-melted-dripping flame-retardant curtain. The curtain is prepared from, by weight, 20-30 parts of cotton fiber, 10-20 parts of aramid fiber and 10-20 partsof flame-retardant viscose, wherein 0.2-0.3 part by weight of fire retardant is added into a flame-retardant viscose spinning liquid and the cotton fiber respectively. The washing-resistant non-melted-dripping flame-retardant curtain has the advantages that the used raw materials of cotton, aramid and viscose are all fibers without melted dripping when burned, so that the curtain made from the same does not have melted dripping either; a blended fabric of aramid and flame-retardant viscose has the excellent characteristics that the hand feeling is soft, the fluffiness, drapability and moisturepermeability are good, the strength and wear resistance are high, the fabric surface perfection and color fastness are good, and the fabric is not melted to drip when carbonized by catching fire, andthe quality requirements of curtain upholstery fabrics can be met.

Owner:应急管理部四川消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com