Syntactic foam and preparation method thereof

A technology of syntactic foam and plastic foam, which is applied in the field of flame retardant materials, can solve the difficult problems of polystyrene foam droplet and other problems, and achieve the effect of solving burning droplet, low smoke generation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

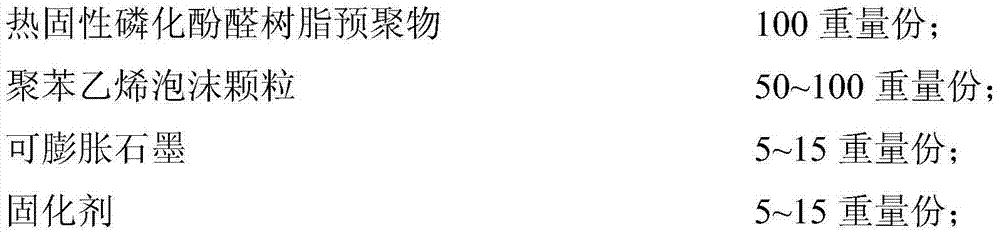

Method used

Image

Examples

Embodiment 1

[0025] Preparation of thermosetting phosphating phenolic resin prepolymer: Weigh 100g of phenol and 58g of phosphoric acid, put them in a 500ml three-neck flask, heat up to 135°C for dehydration and esterification for 5h, then depressurize (vacuum degree -0.08MPa) for 2h, cool to 70°C, use 30% sodium hydroxide solution to adjust the pH value to 10-11, add 130g of 38wt% formaldehyde solution, 1.2g of zinc acetate, heat up to 95°C for 3.5h, then cool down to 65°C, vacuum evaporate with water pump After removing moisture, a thermosetting phosphating phenolic resin prepolymer is obtained.

[0026] The deployment of curing agent: take 30wt% of phenolsulfonic acid, 25wt% of phosphoric acid, 15wt% of sulfuric acid, and 30wt% of water, stir and dissolve for later use;

[0027] Uniform coating of polystyrene foam particles: take 10L of polystyrene foam particle base material (16g / L), add 200g of the above-mentioned curable thermosetting phosphating phenolic resin prepolymer (prepared a...

Embodiment 2

[0030] The deployment of curing agent: take p-toluenesulfonic acid 30wt%, phosphoric acid 10wt%, sulfuric acid 30wt%, water 30wt%, stir and dissolve for later use;

[0031] Uniform coating of polystyrene foam particles: Take 10L polystyrene foam particle base material (density 14g / L), add 140g of the above thermosetting phosphating phenolic resin prepolymer, stir well and add expandable graphite (expansion degree 60ml / g) 7g, after stirring evenly, add 7g of the above-mentioned curing agent, and continue stirring until evenly coated polystyrene foam particles are obtained;

[0032] Compression molding: Add the above-mentioned polystyrene foam particles evenly coated with thermosetting phosphating phenolic resin prepolymer into the steam hot pressing mold, close the mold, feed high-pressure steam with a pressure of 0.05MPa, and keep the pressure for 40s , pressure relief, cooling, and mold opening to obtain polystyrene / phosphorized phenolic resin / graphite composite foam, and th...

Embodiment 3

[0034] The deployment of curing agent: take 30wt% phenolsulfonic acid, 20wt% phosphoric acid, 10wt% p-toluenesulfonic acid, 20wt% sulfuric acid, 20wt% water, stir and dissolve for later use;

[0035] Uniform coating of polystyrene foam particles: Take 10L polystyrene foam particle base material (16g / L), add 250g of the above-mentioned thermosetting phosphating phenolic resin prepolymer (prepared according to Example 1), stir well, add Expandable graphite (expansion degree 180ml / g) 25g, after stirring evenly, add 32g of the above curing agent, continue stirring until evenly coated polystyrene foam particles are obtained;

[0036] Compression molding: Add the above-mentioned polystyrene foam particles evenly coated with thermosetting phosphating phenolic resin prepolymer into the steam hot pressing mold, close the mold, feed high-pressure steam with a pressure of 0.05MPa, and keep the pressure for 40s , pressure relief, cooling, and mold opening to obtain polystyrene / phosphorize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com