Patents

Literature

433 results about "Syntactic foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

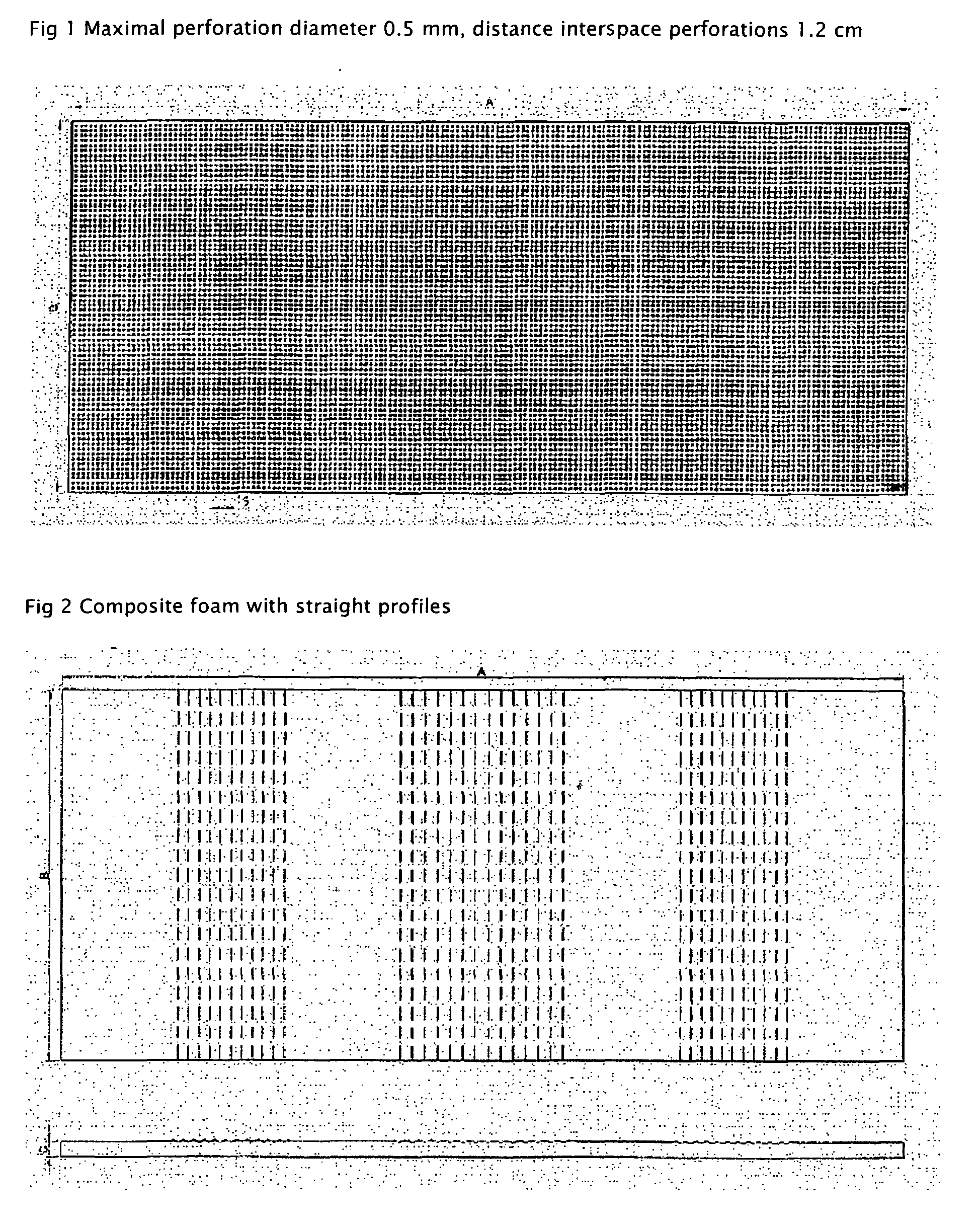

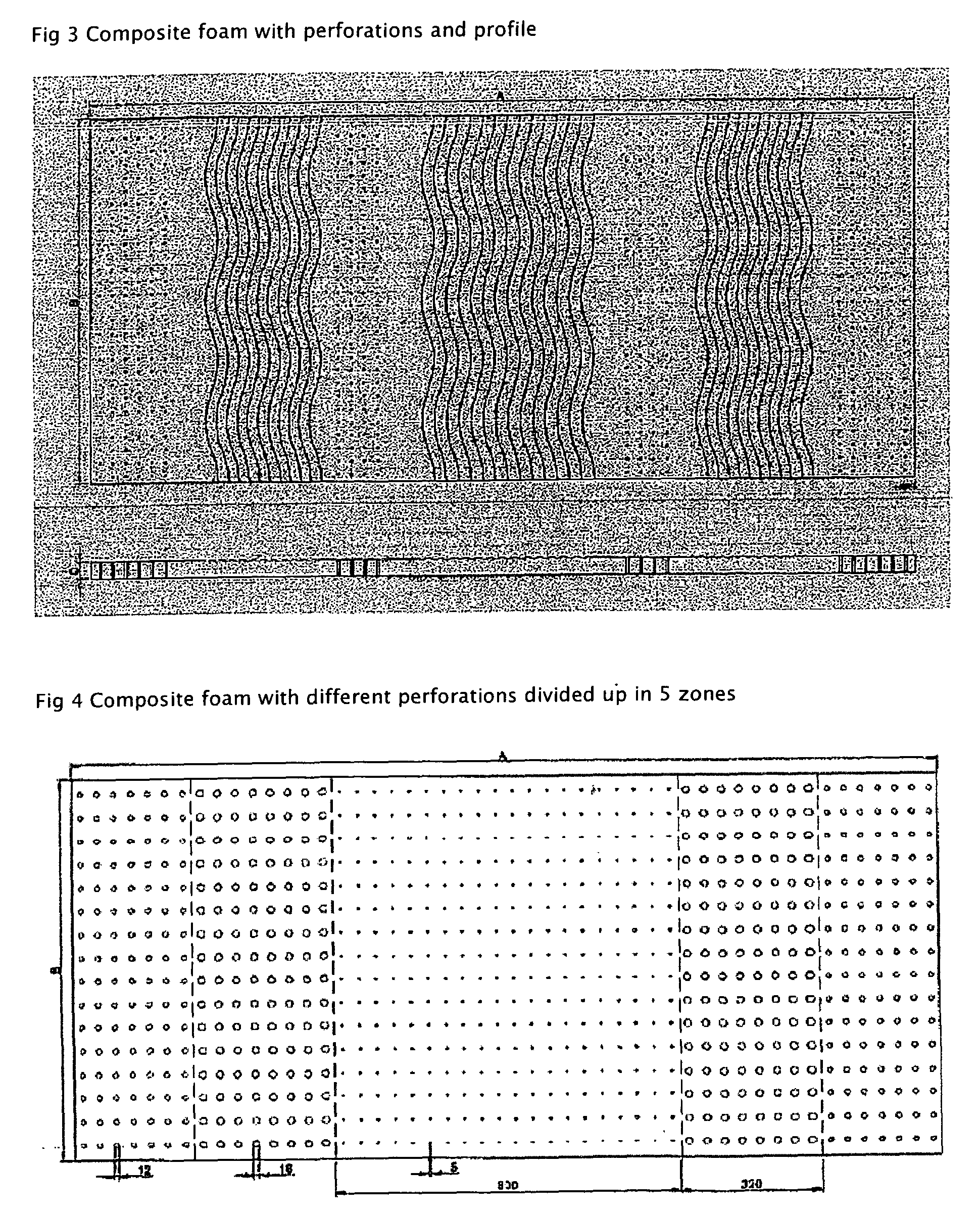

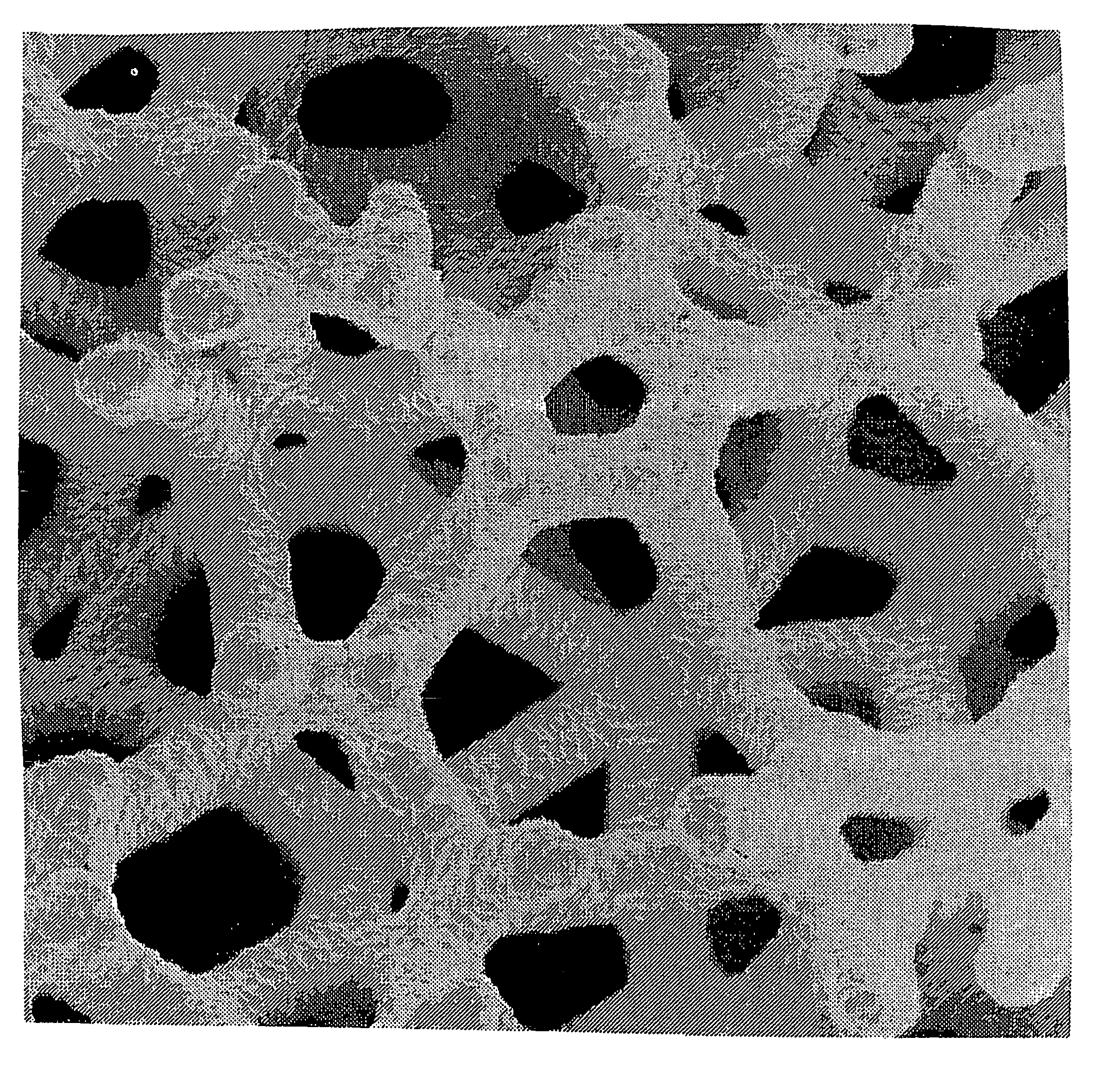

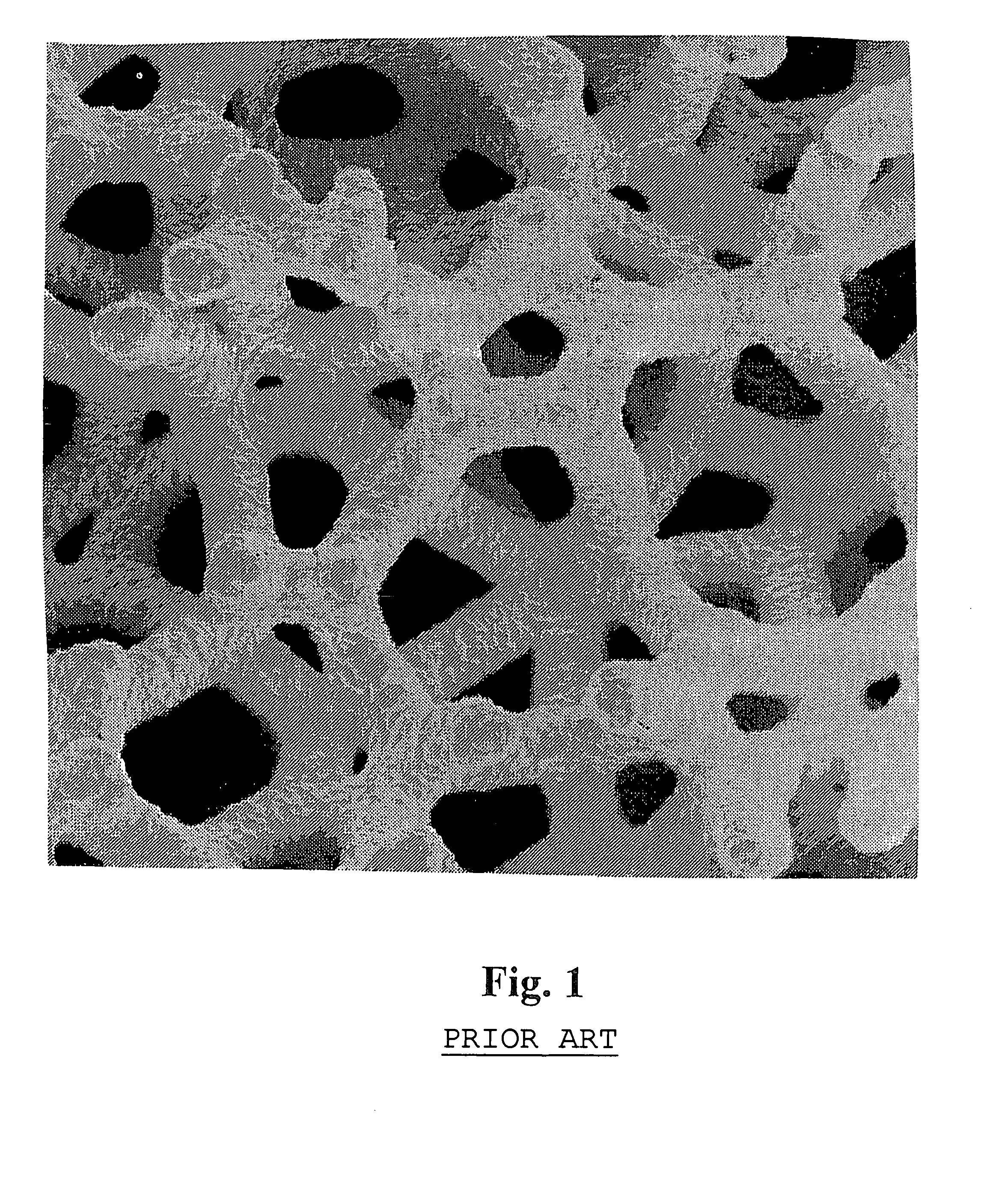

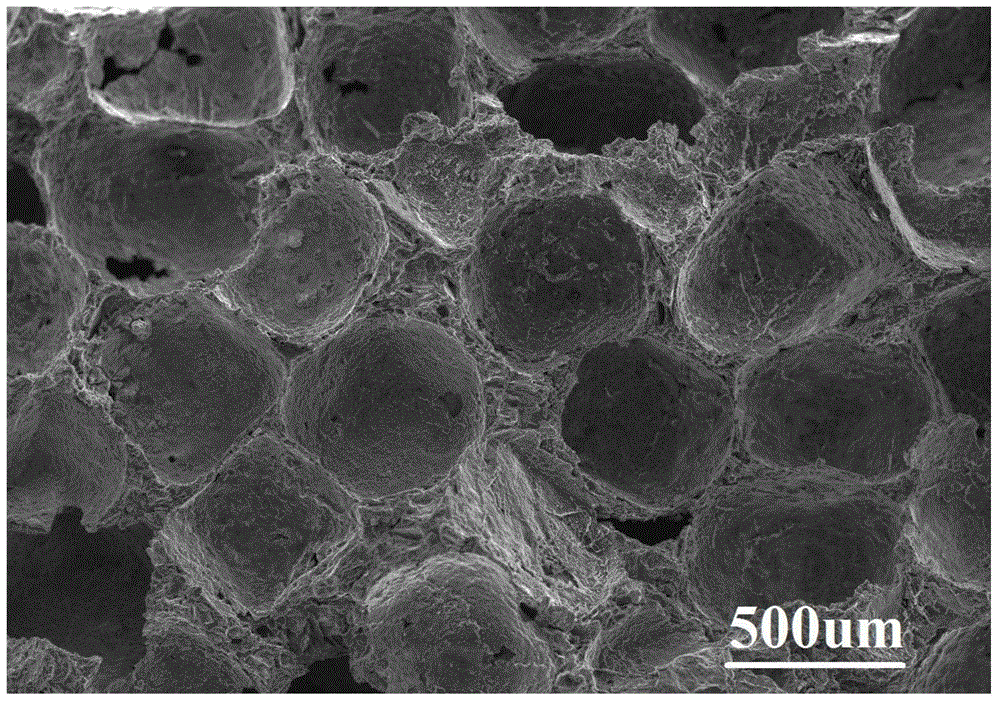

Syntactic foams are composite materials synthesized by filling a metal, polymer, or ceramic matrix with hollow spheres called microballoons or cenospheres or non-hollow spheres (e.g. perlite). In this context, "syntactic" means "put together." The presence of hollow particles results in lower density, higher specific strength (strength divided by density), lower coefficient of thermal expansion, and, in some cases, radar or sonar transparency. A manufacturing method for low density syntactic foams is based on the principle of buoyancy.

Aerogel Based Composites

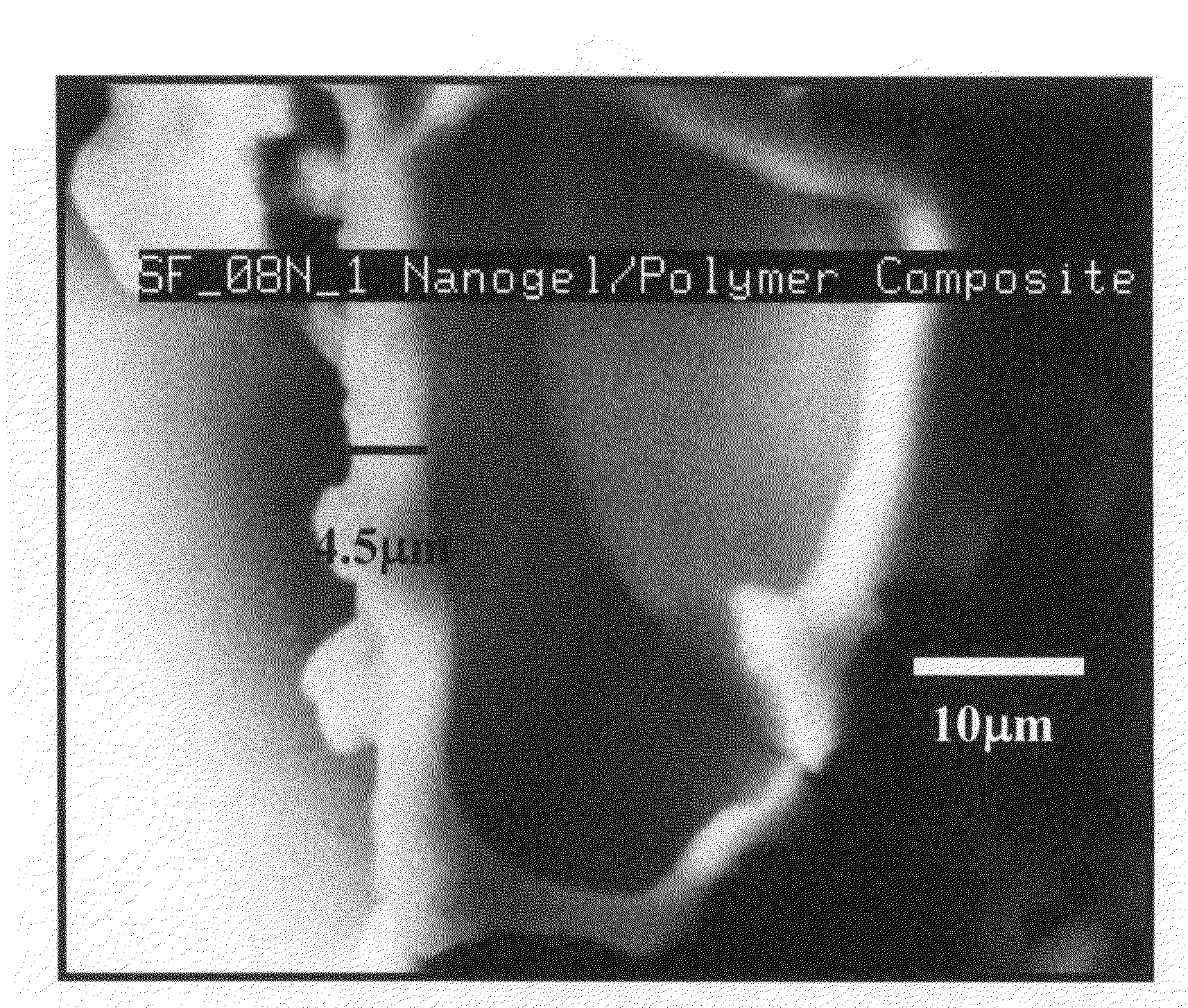

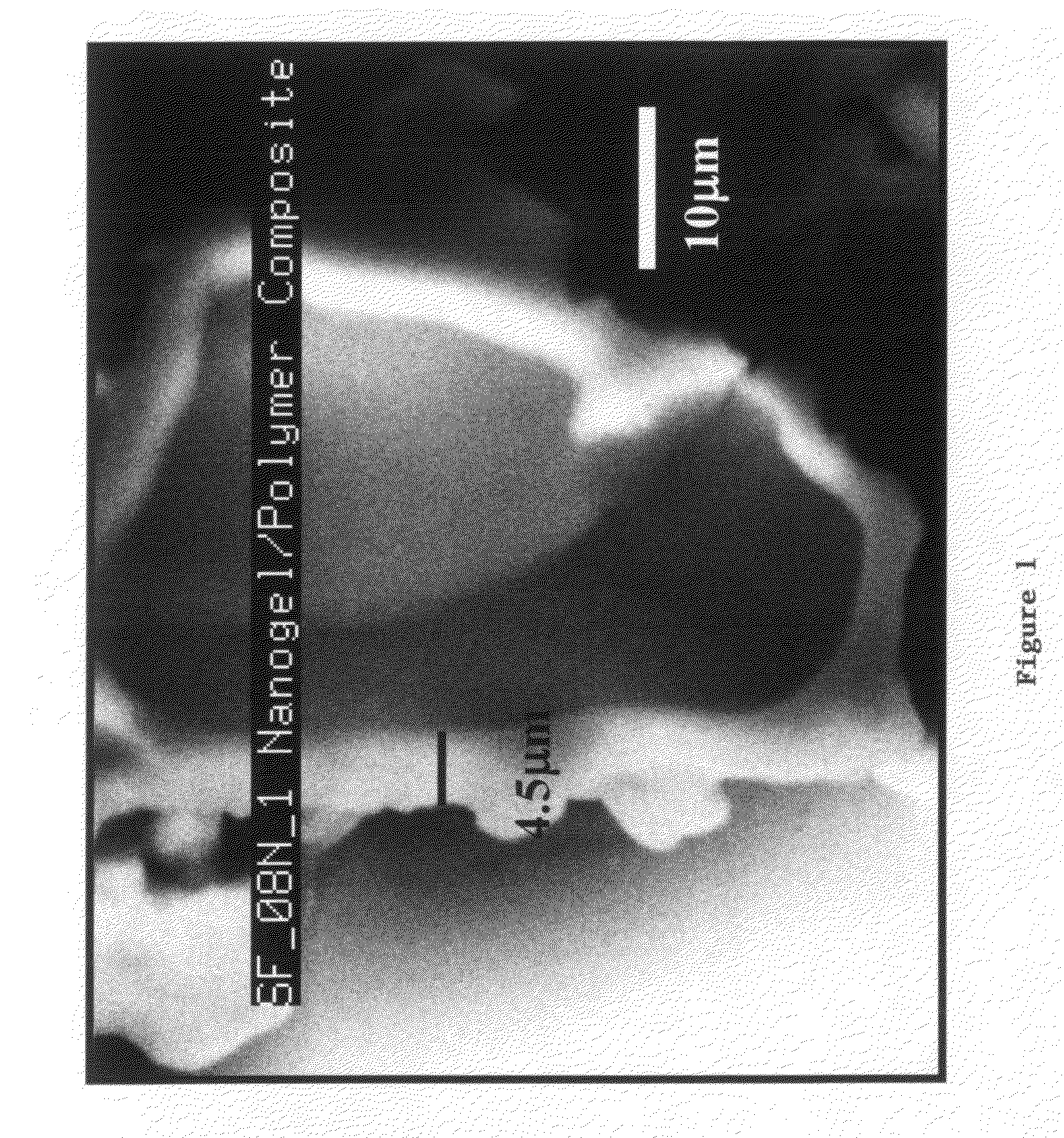

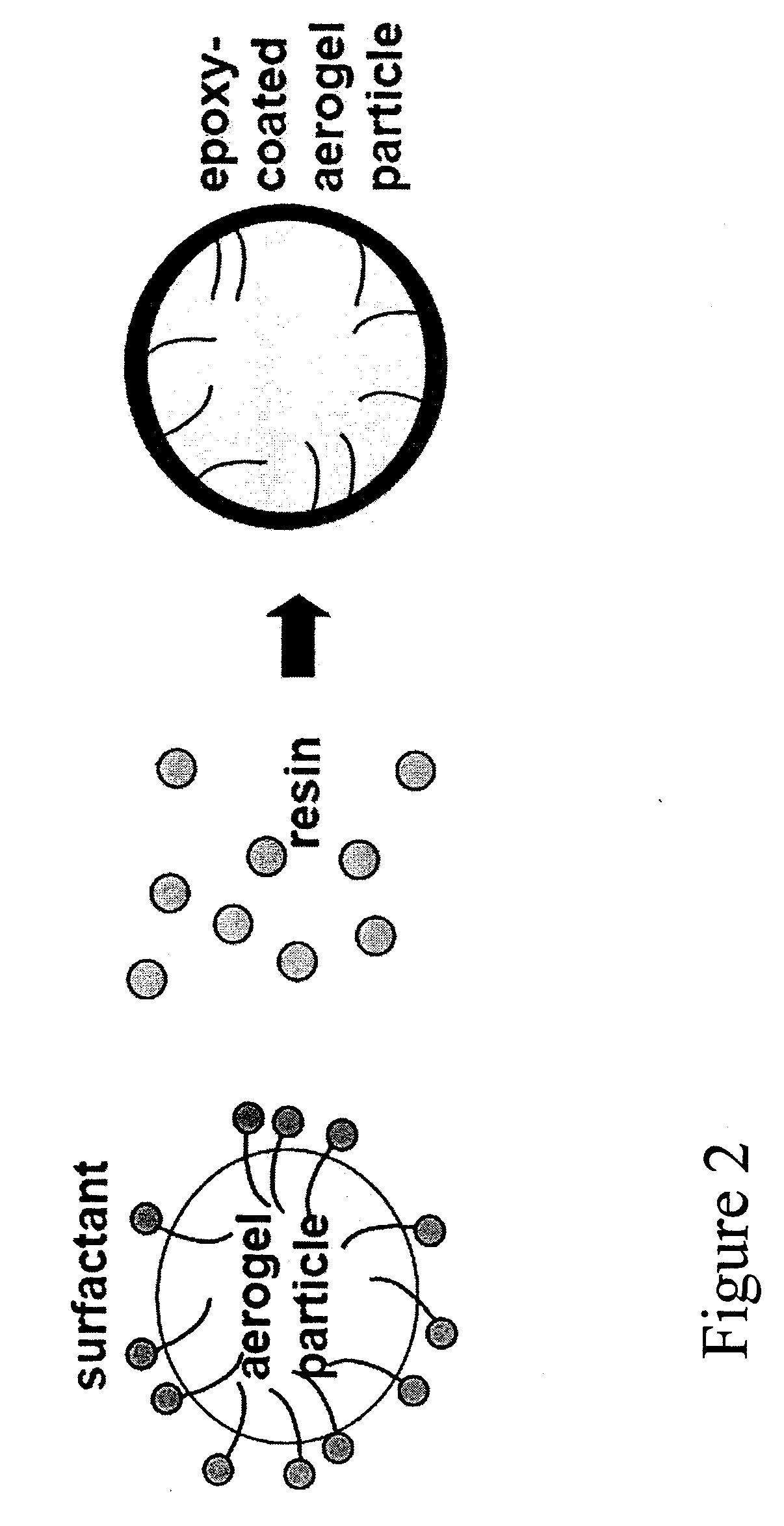

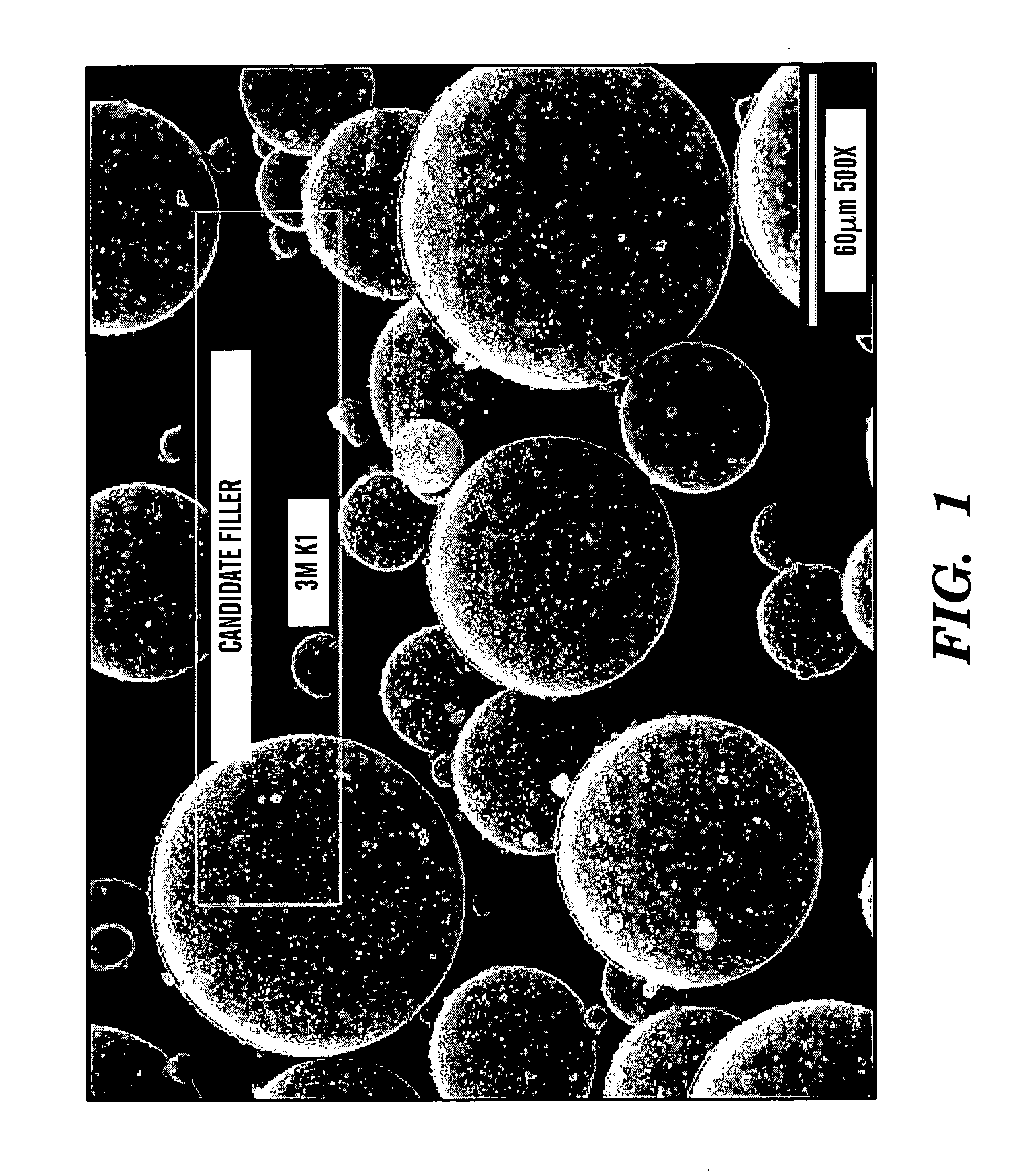

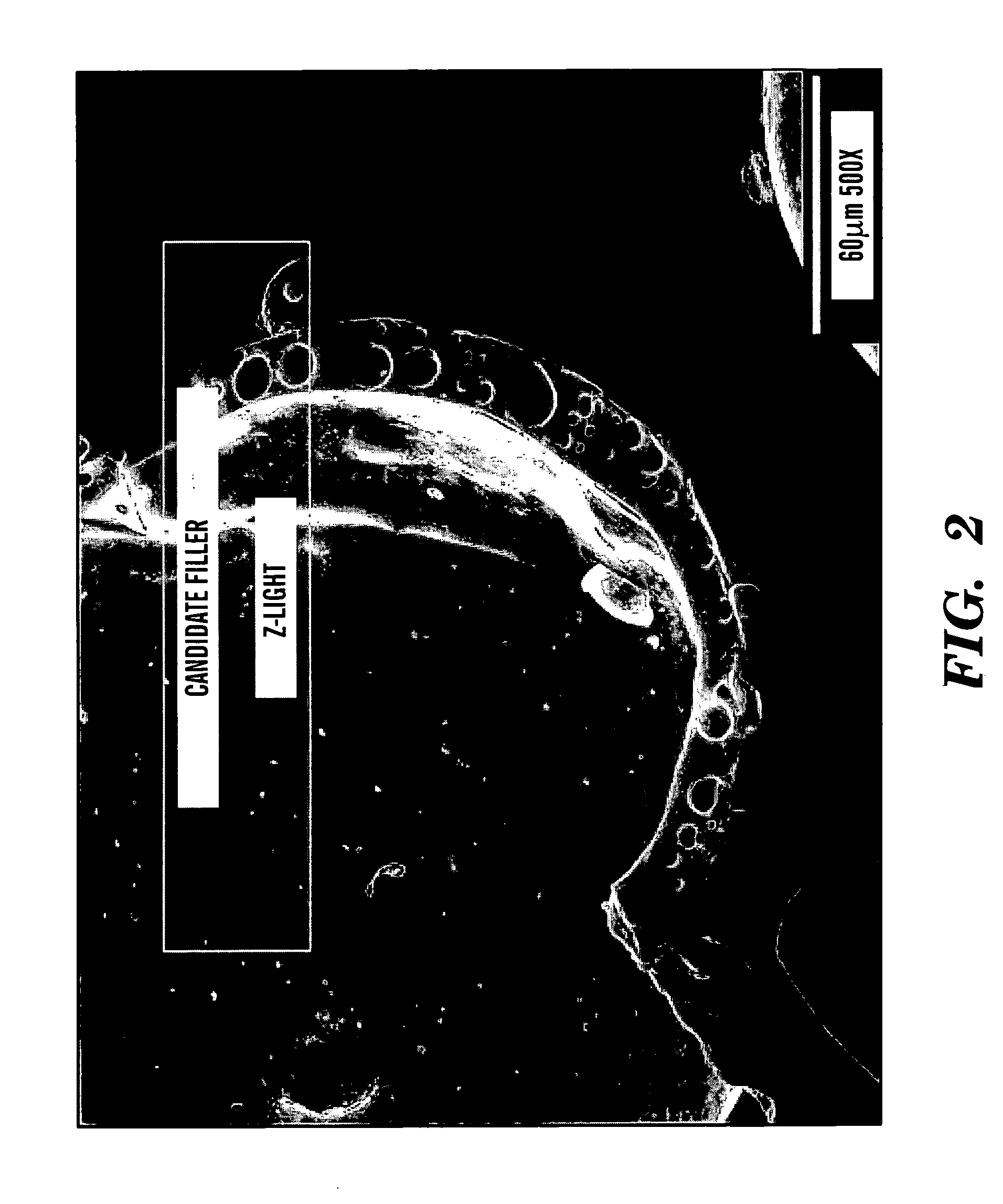

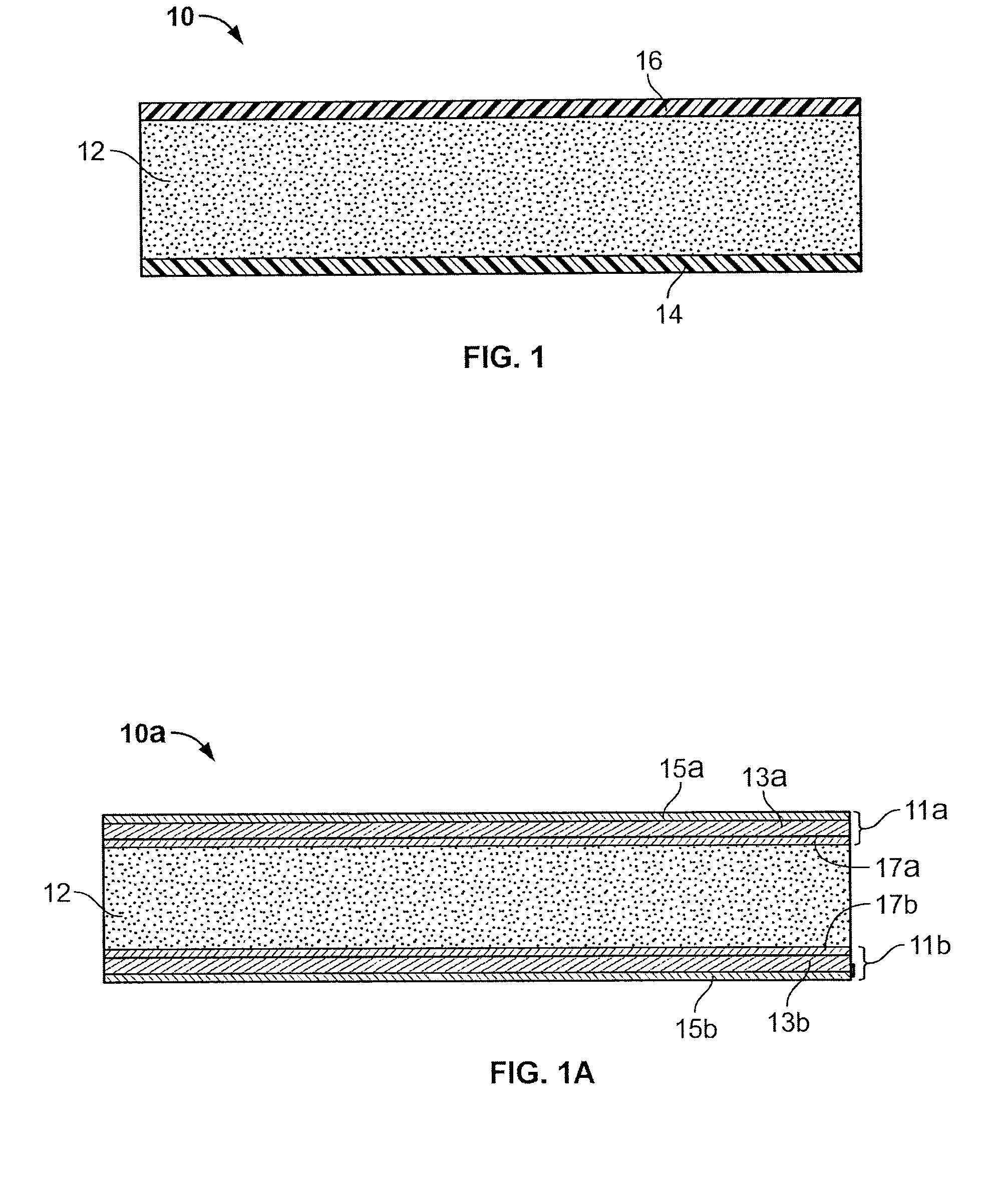

Composites, such as syntactic foams, are described. The composite contains at least one polymer and at least one aerogel. The aerogel is coated with a coating substance to at least substantially prevent the intrusion of the polymer into the pores of the aerogel. Methods of making the composite are also described, as well as uses of the composite.

Owner:CABOT CORP

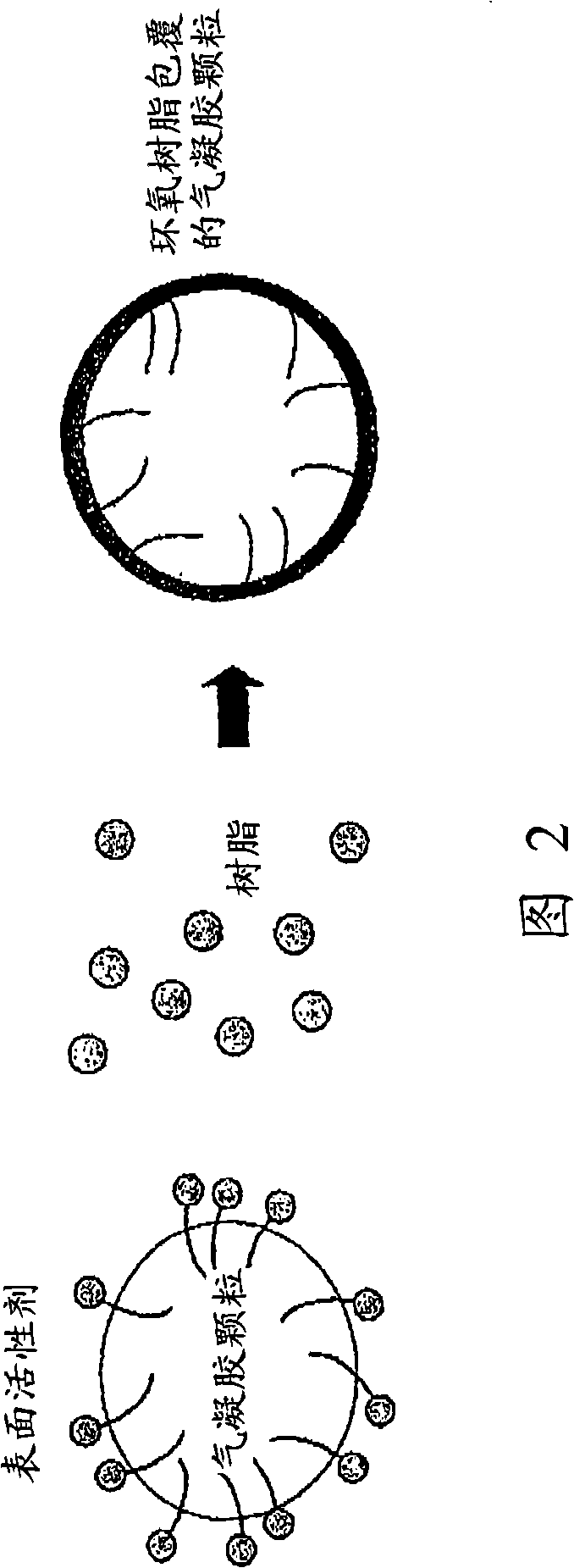

Nanoparticle-added composite foam system used for oil and gas field and preparation method thereof

The invention relates to a nanoparticle-added composite foam system used for an oil and gas field and a preparation method thereof. The composite foam system comprises components of, by mass, 0.3 to 0.5 parts of an anionic surfactant, 1 to 1.5 parts of modified silica nanoparticles, 0.03 to 2.3 parts of counter-ion salt, and 100 parts of water. The method comprises mixing the abovementioned components according to ratio, stirring by using a magnetic stirrer, standing, and then rapidly stirring to form well stable foam using a Waring Blender way. According to the composite foam system, the produced foam has a longer half life than that of foam stabilized by ordinary surfactant, and a larger start-foaming volume than that generated by adding a foam stabilizer The system has advantages of simple formula and preparation technology and good salt tolerance and temperature tolerance, can adapt to complex oil reservoir condition underground, does not pollute stratum, is capable of effectively blocking large channels and improving sweeping efficiency, and thus has good application prospects in oil field exploitation, especially in foam displacement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Latex Based Composite Foams

InactiveUS20080313815A1Improve comfortStuffed mattressesSynthetic resin layered productsPolyesterPolyolefin

A composite foam comprising a top layer of latex foam and a second layer of a foam selected from polyolefin, polyurethane, polystyrene or polyester or visco-elastic latex or mixtures thereof. A bedding such as a mattress or topper comprising said composite foam

Owner:LATEXCO

Composite foam made from polymer microspheres reinforced with long fibers

InactiveUS6864297B2Improved strain energy densityIncrease damage tolerancePolymer scienceMicrosphere

Composite foam based on expandable microspheres reinforced with fibers is described. Also disclosed are methods of making microsphere foam reinforced with fibers and methods of use thereof. The disclosure provides foam that performs equally and better than the performance of most thermoplastic foams commercially available.

Owner:UNIV OF SOUTHERN CALIFORNIA

Early-strength composite foam concrete foaming agent and preparation method thereof

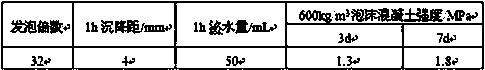

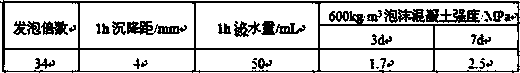

The invention belongs to the technical field of building materials, and particularly relates to an early-strength composite foam concrete foaming agent and a preparation method thereof. The early-strength composite foam concrete foaming agent comprises the following components in percentage by mass: 40%-80% of composite foaming components, 1.0%-5.0% of foam stabilizing components, 3.3%-22% of early-strength components and 10%-45% of water, wherein the composite foaming components are formed by compounding synthesized surface active agent foaming agents and protein foaming agents. The early-strength composite foam concrete foaming agent prepared through the method disclosed by the invention has the advantages of high foam expansion, excellent foam stability and good compatibility with general cement pastes; the early-strength composite foam concrete foaming agent disclosed by the invention is applied to foam concrete; the prepared foam concrete has no recess phenomenon and is fast enhanced in early strength, and the foam concrete with a density grade equal to 300 kg / m<3> or above is more easily prepared.

Owner:中建商品混凝土(福建)有限公司 +1

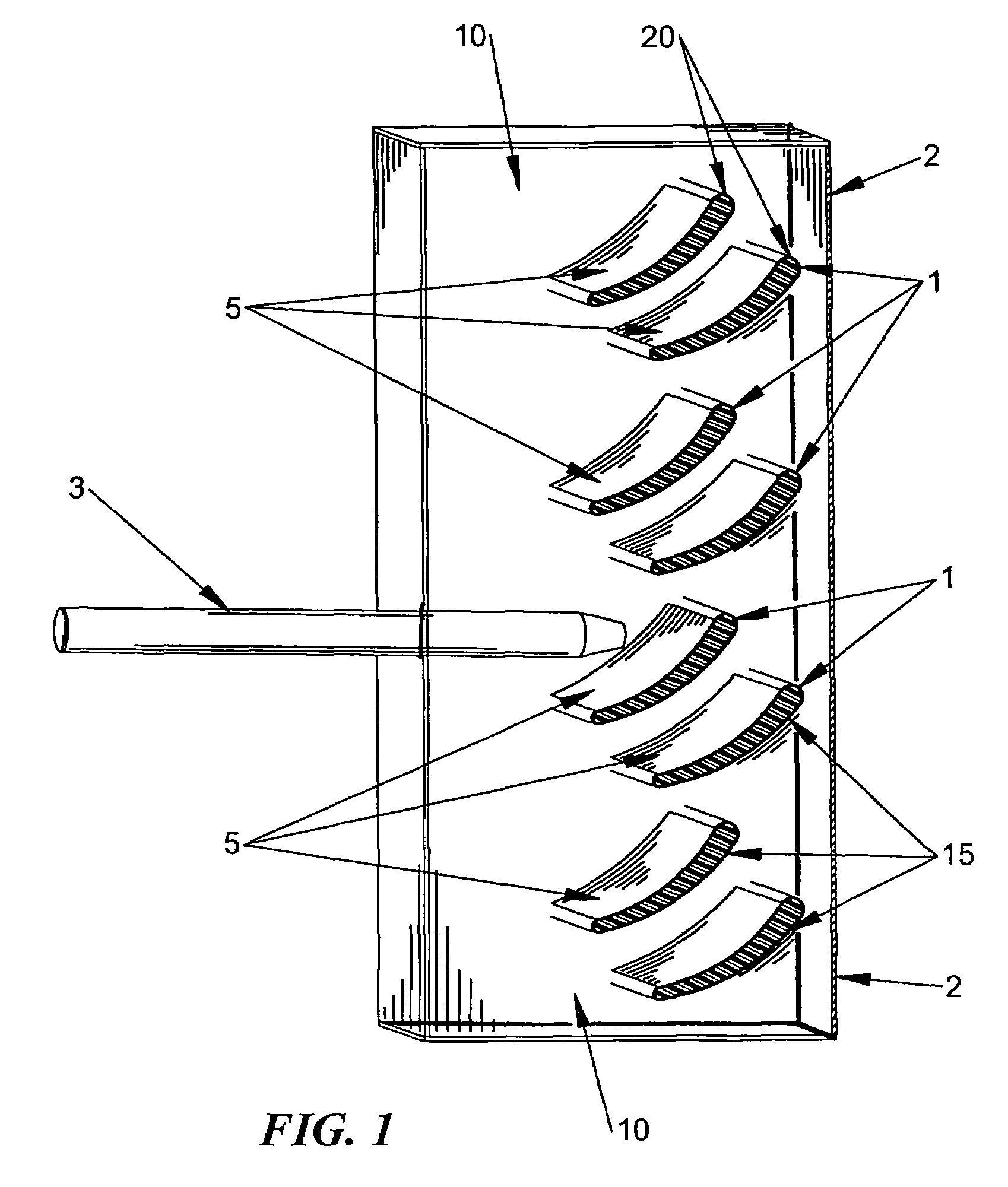

Process for enhancing material properties and materials so enhanced

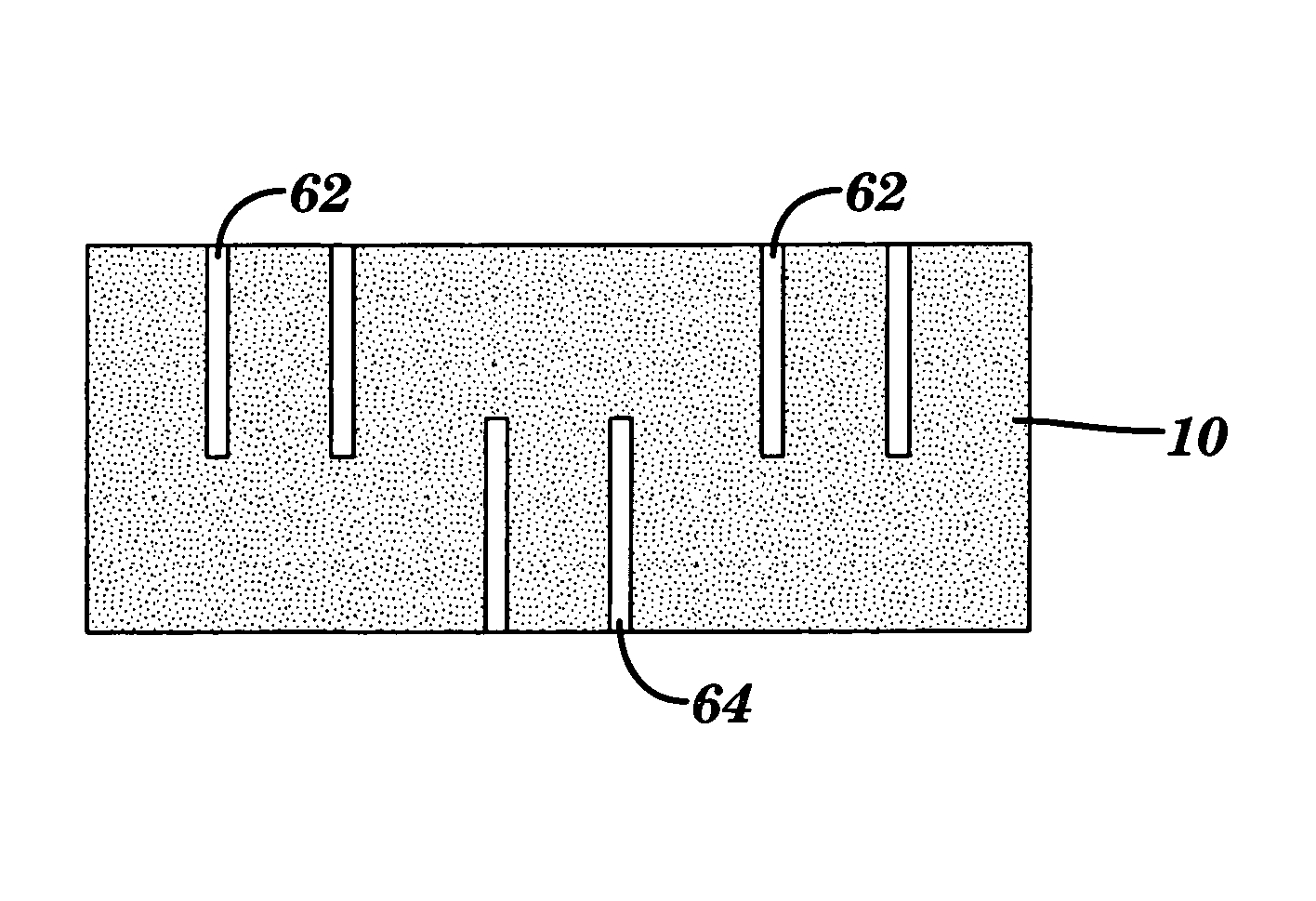

InactiveUS7101607B2Overcome disadvantagesIncrease flexibilityMechanical working/deformationAdhesivesMaterials scienceAerogel

The present invention relates to a composite insulation material. The composite insulation material includes a syntactic foam component and a plurality of aerogel inserts. The present invention also relates to a method of making a composite insulation material. The present invention further relates to a method for enhancing the flexibility of a solid material.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Stone Click Floor Coverings

ActiveUS20130042558A1Precise alignmentSimple preparation processConstruction materialFloorsCouplingAdhesive

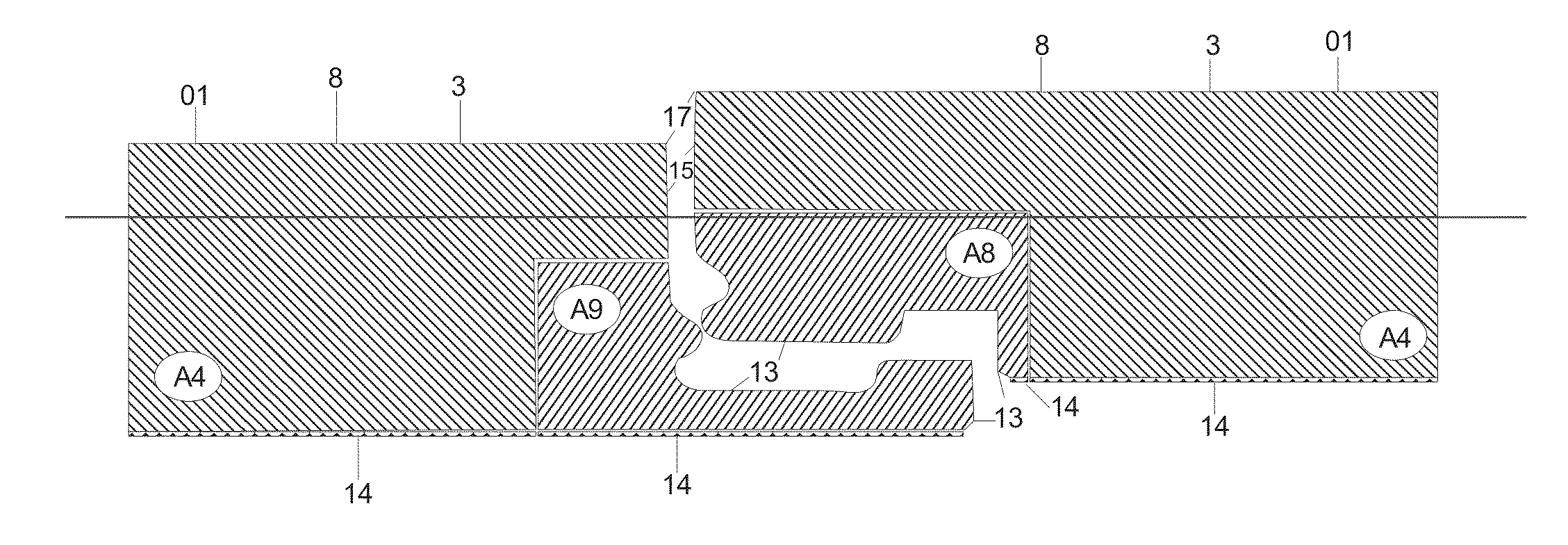

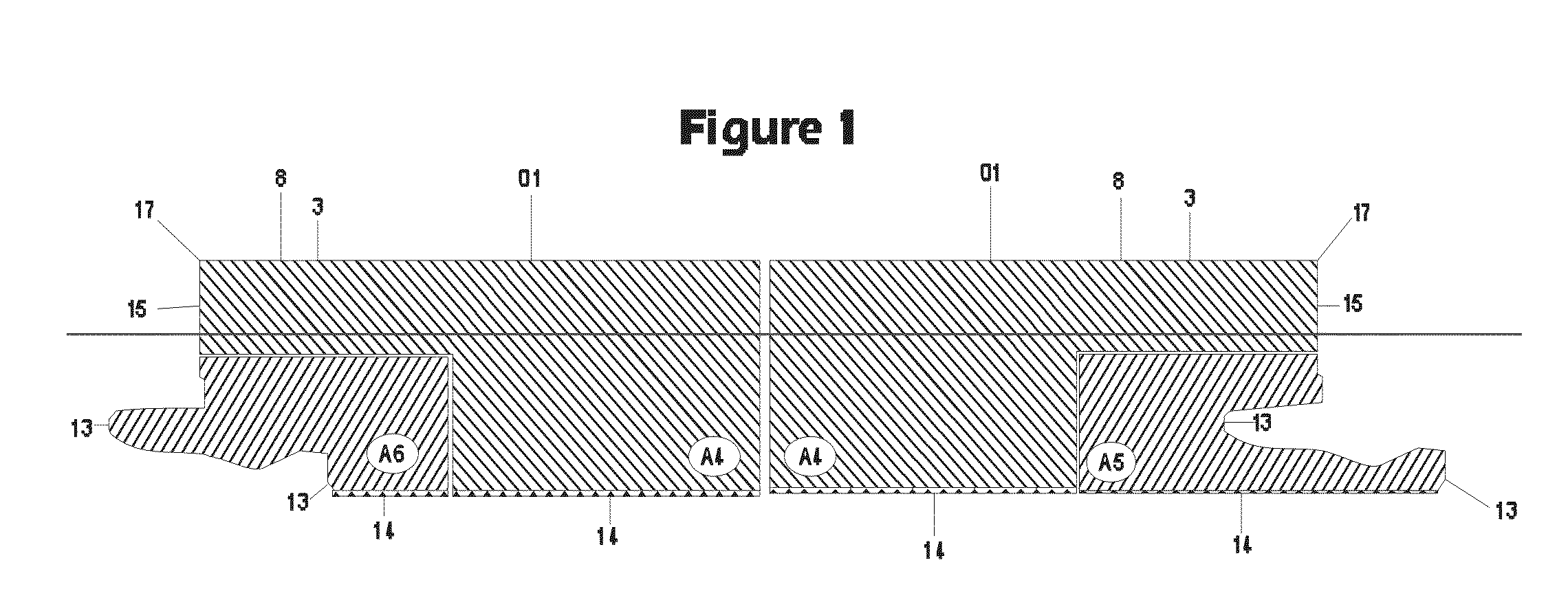

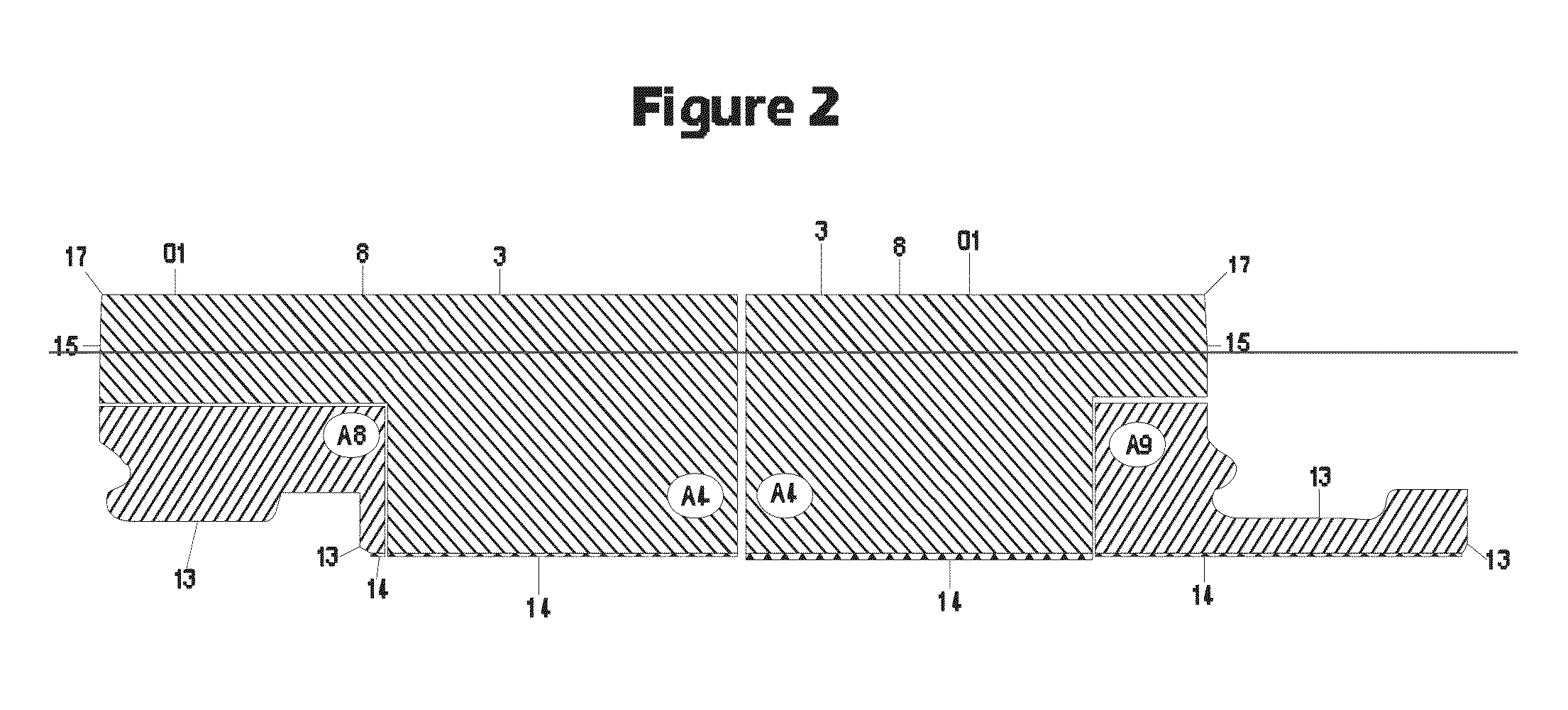

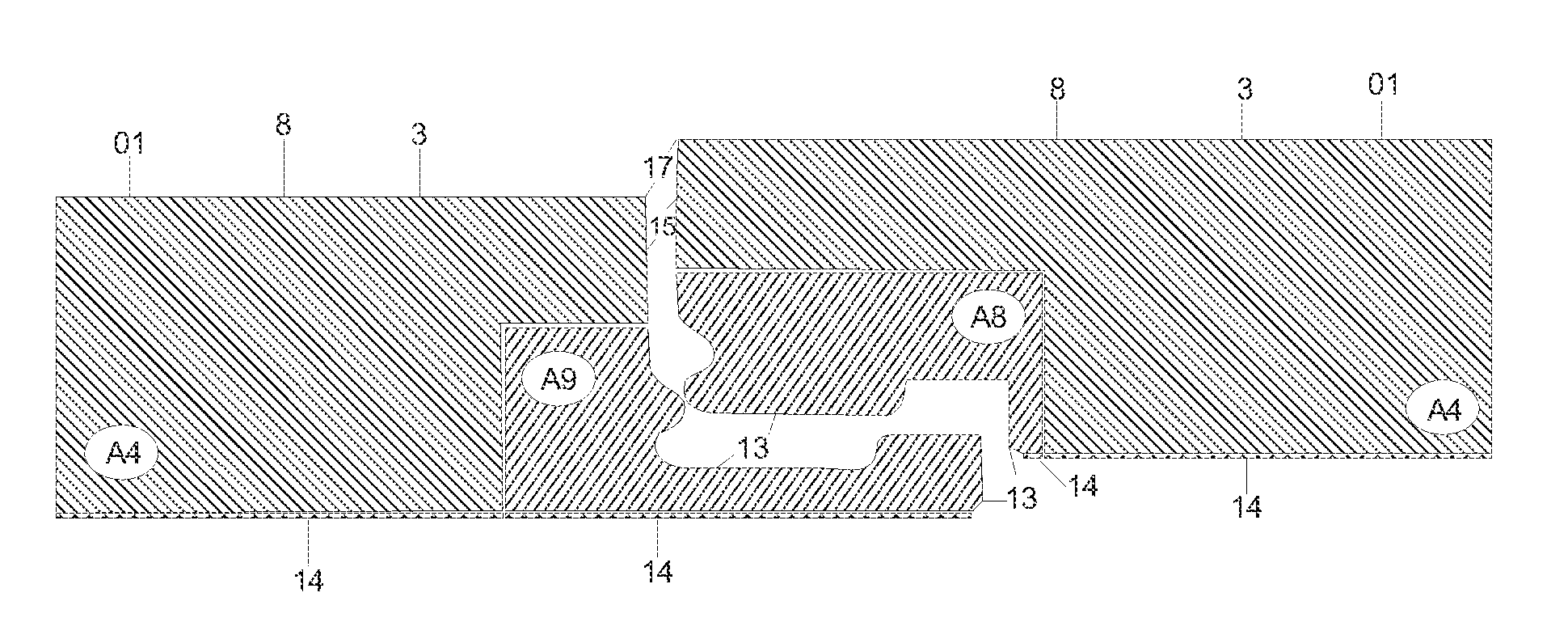

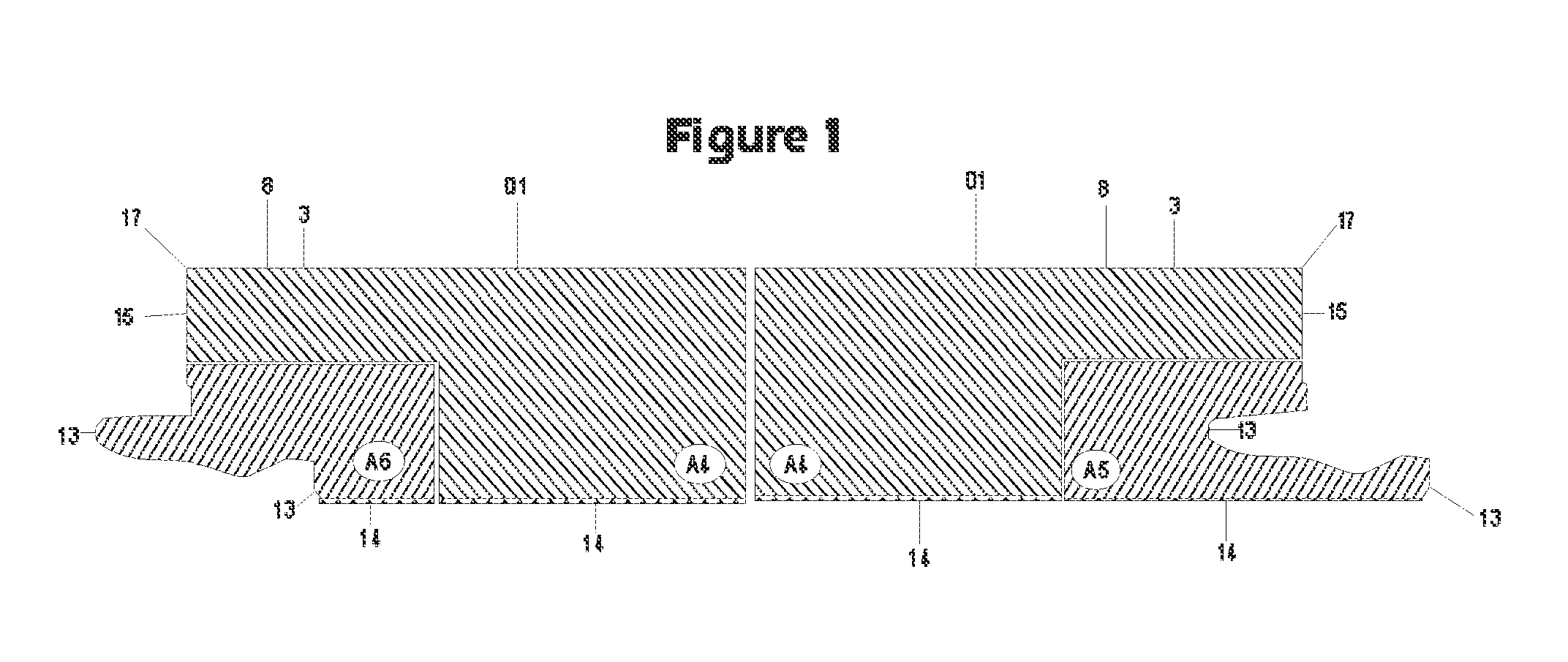

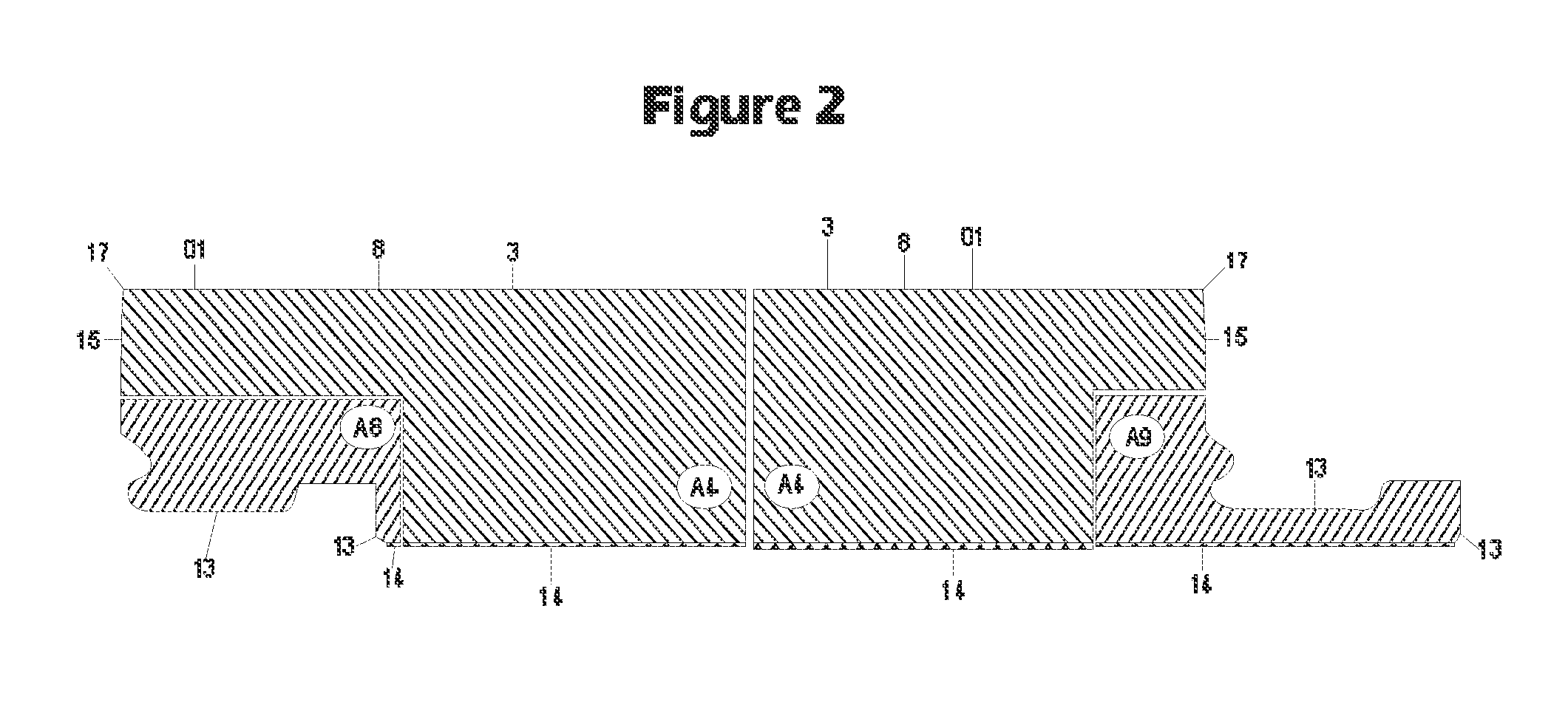

Floor covering (01) material, consisting of Natural Stones, i.e. Marble, Granite, Limestone, Onyx, Travertine and Sandstone, in format of tile slabs, in which the thickness is between 4 mm and 35 mm, in which at the two opposite edges or sides are jointed together and interlocked by mechanical locking means, by connecting or inserting (A6 to A5) and connecting or pressing downward (A8 to A9) using Polyvinyl Chloride (PVC) couplings, connecting in the form of a tongue and a groove which will prevent shifting of two interlocked tiles and or slabs into the opposed direction of each section tile or slab, with an integrated backing layer consisting of cork and / or syntactic foam material, The invention relates to a natural stone core tile slab, allowing for an installation without the use of cement, adhesives or grout, provided with such a mechanical locking system jointed to the core (A4) according to the invention.

Owner:CORDEIRO EURICO JANUARIO

Groutless Tile System

InactiveUS20130212971A1Comfortable feetAcoustical and thermal advantageCovering/liningsFiberAdhesive

Floor, ceiling and wall covering (01) material, consisting of natural stones, i.e. marble, granite, limestone, onyx, travertine and sandstone, cement based tiles, softwood and hardwood, wood fiber HDF, MDF, agglomerated cork, rubber, and composite tile materials, such as stone, quartz or vinyl composition tiles, in format of tile slabs. Which the thickness is between 4 mm and 35 mm in which at the two opposite edges or sides are jointed together and interlocked by mechanical locking means, by connecting or inserting, (A6 to A5) and connecting or pressing downward (A8 to A9) using polyvinyl chloride (PVC) couplings, connecting in the form of a tongue and a groove which will prevent shifting of two interlocked tiles and or slabs into the opposed direction of each section tile or slab, with an integrated backing layer consisting of cork syntactic foam material, The invention relates to a natural stone core tile slab, allowing for an installation without the use of cement, adhesives or grout, provided with such a mechanical locking system jointed to the core (A4) according to the invention.

Owner:CORDEIRO EURICO JANUARIO

Fairing for marine drilling risers

InactiveUS20080025800A1Prevent movementArtificial islandsPipe laying and repairFree rotationEngineering

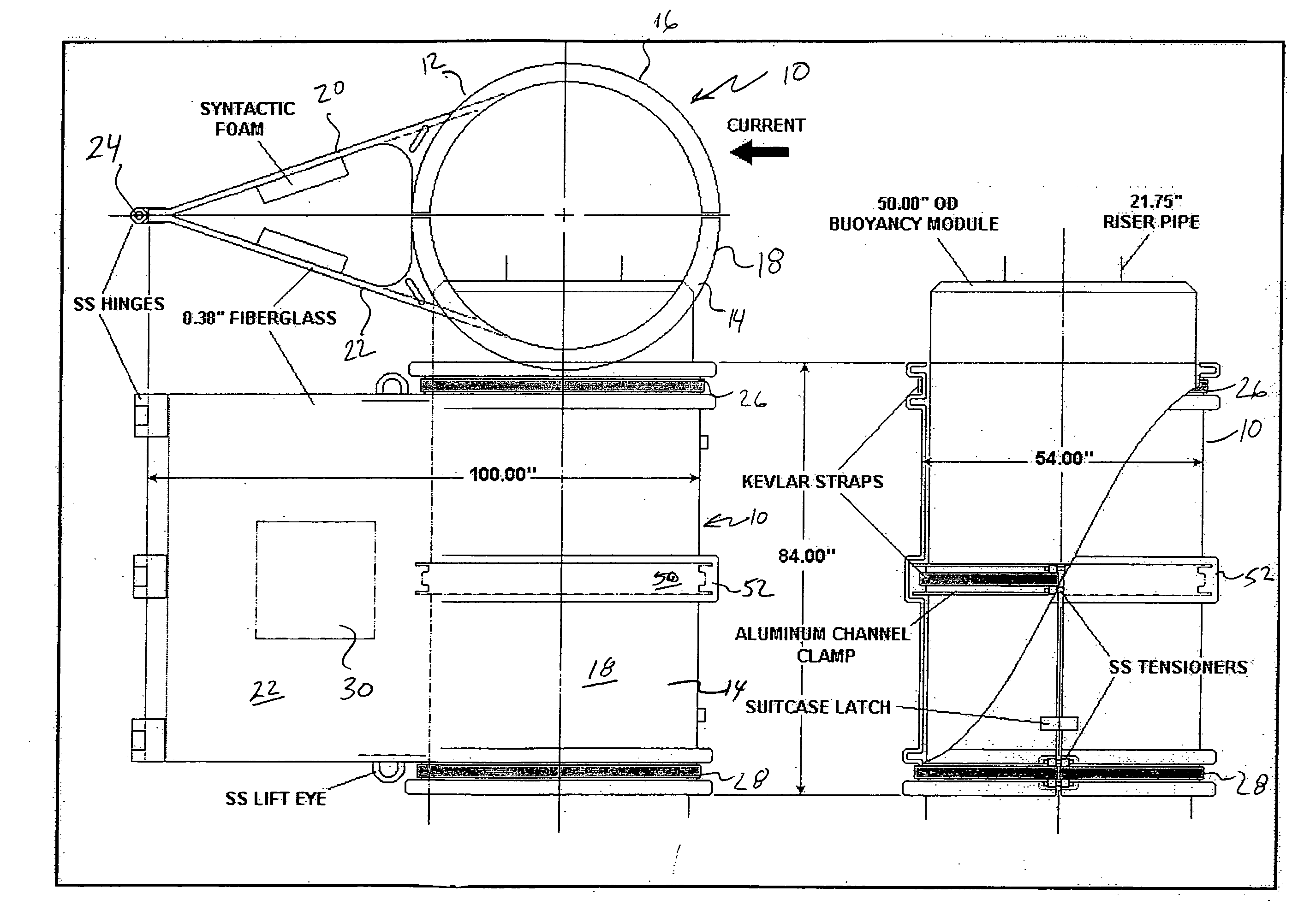

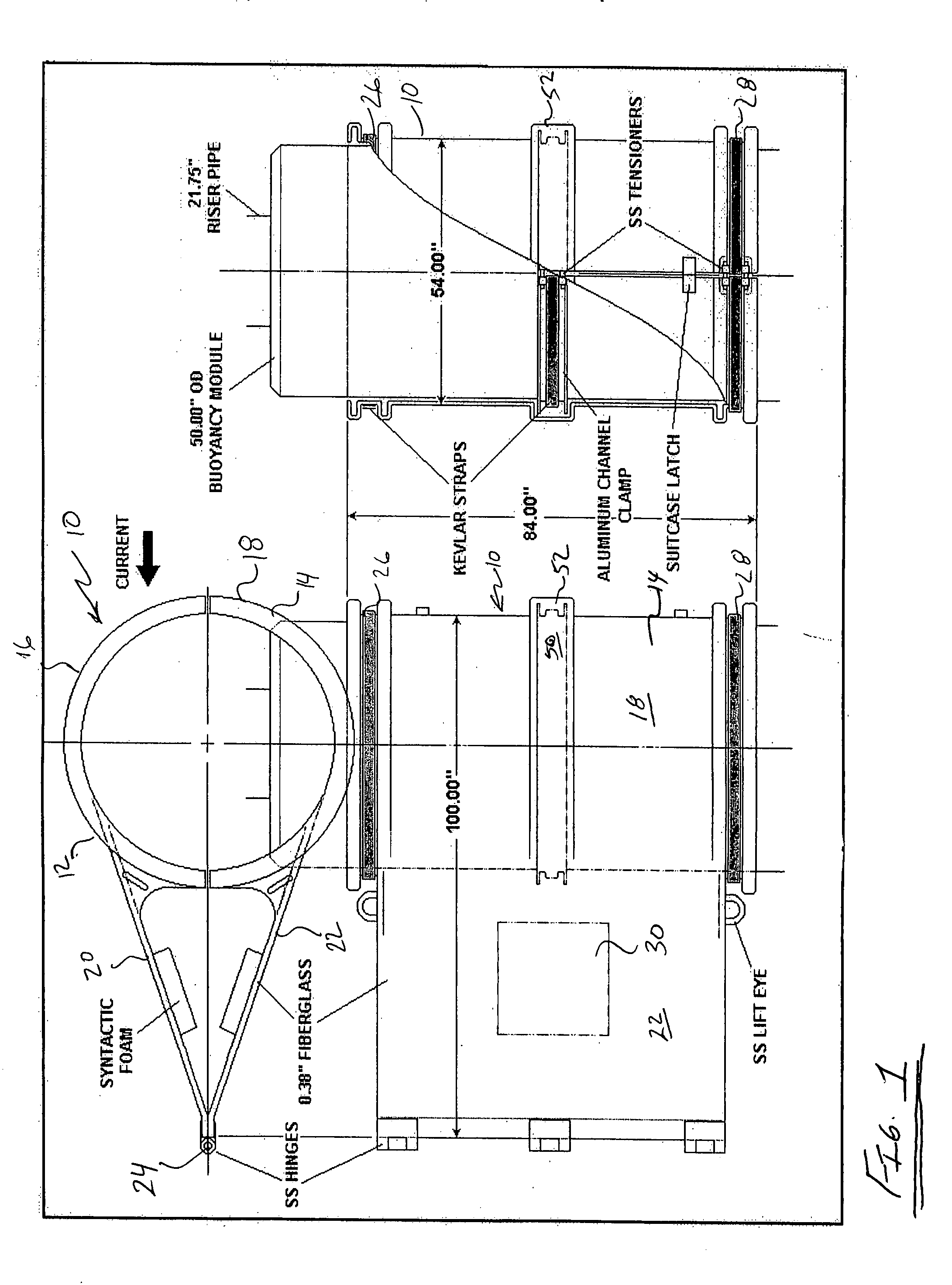

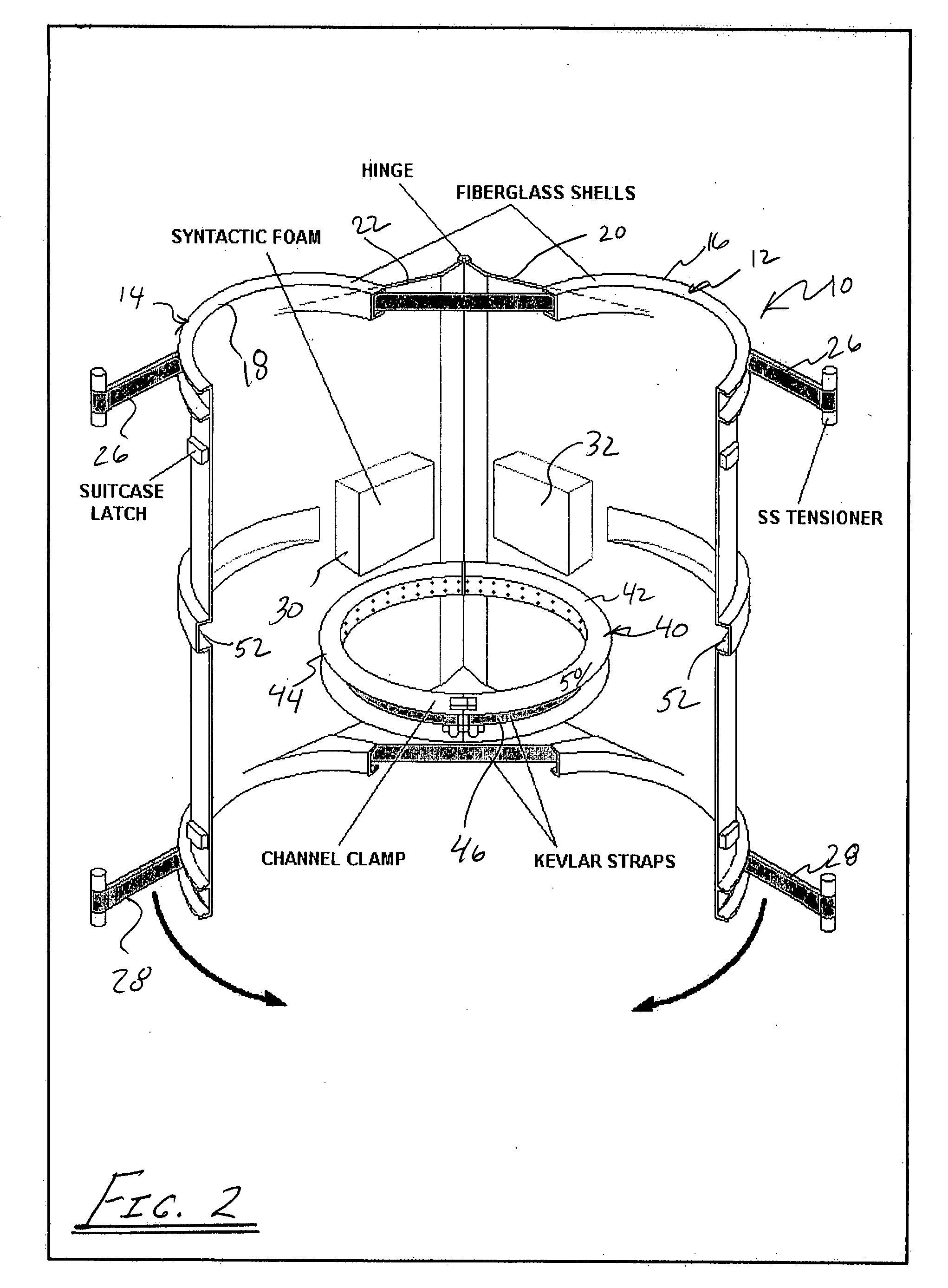

A fairing includes two half-shells of fiber reinforced plastic or fiberglass. The shell halves are shaped to close around the buoyancy modules (e.g., cylindrical syntactic foam buoyancy modules) commonly used on deep-water risers, but with an extended trailing edge. The fairing includes a tail that streamlines the riser and reduces / prevents formation of the vortex, which causes drag and vibration. Hinges at the tail join the halves and enable them to be opened for assembly around the riser pipe as it is being run into the water. The fairing may be fastened together by bolted stainless steel tensioners that tightly draw together straps of high strength aramid fiber, such as KEVLAR®. The fairing is positioned on the riser such that the fairing is free to swivel and rotate into the current, while integral buoyancy blocks support the tail. To prevent movement up or down the riser string, the fairing is held in place by a channel clamp gripping the outside diameter of the syntactic foam buoyancy module.

Owner:CUMING CORP

Wood fiber reinforced inflaming retarding foam material and machining method thereof

InactiveCN102061059AImprove use valueSolve the "Three Rural Issues"Chemical recyclingFirming agentSURFACTANT BLEND

The invention discloses a wood fiber reinforced inflaming retarding foam material and a machining method thereof. The composite foam material is prepared from the following components in parts by weight: 40-95 parts of foaming flame-retarded resin, 0.1-8 parts of curing agent, 0.5-8 parts of surfactant, 1-50 parts of wood fiber and 0.5-10 parts of flexibilizer. The wood fiber is treated by using a coupling agent and then dried, and the coupling agent accounts for 0.15-0.5 percent of the mass of the wood fiber. A naturally expanded foaming method or die foaming method is adopted. The wood fiber reinforced inflaming retarding foam material can be widely applied to fields of insulation of building outer wall bodies, architectural ornament, traffic vehicles, water ships, aerospace, electromechanical equipment, industrial sound absorption, heat preservation and shock absorption and the like, and is a composite foaming material with actual application value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

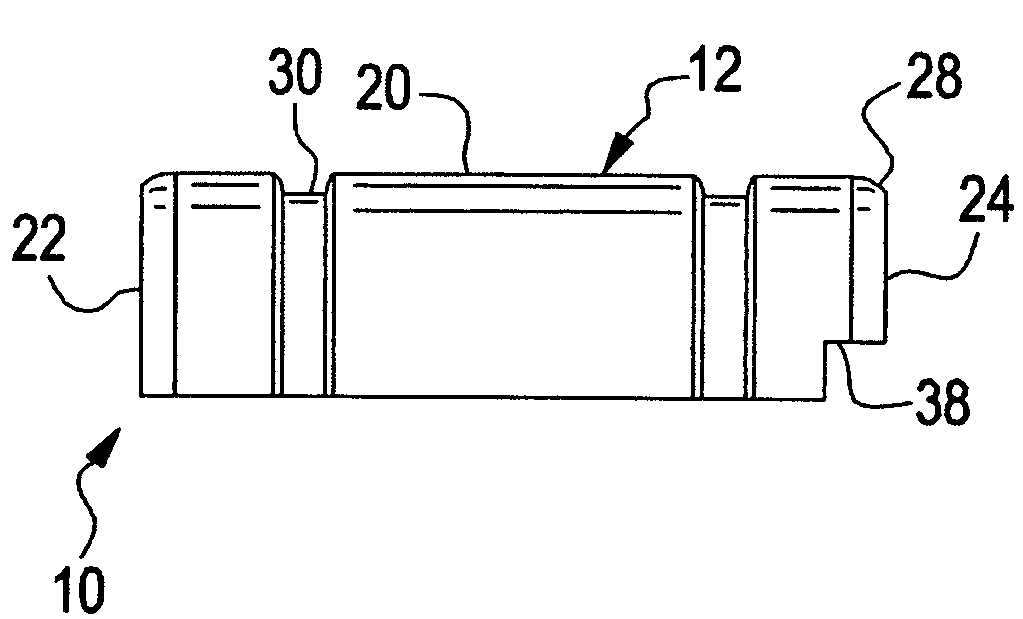

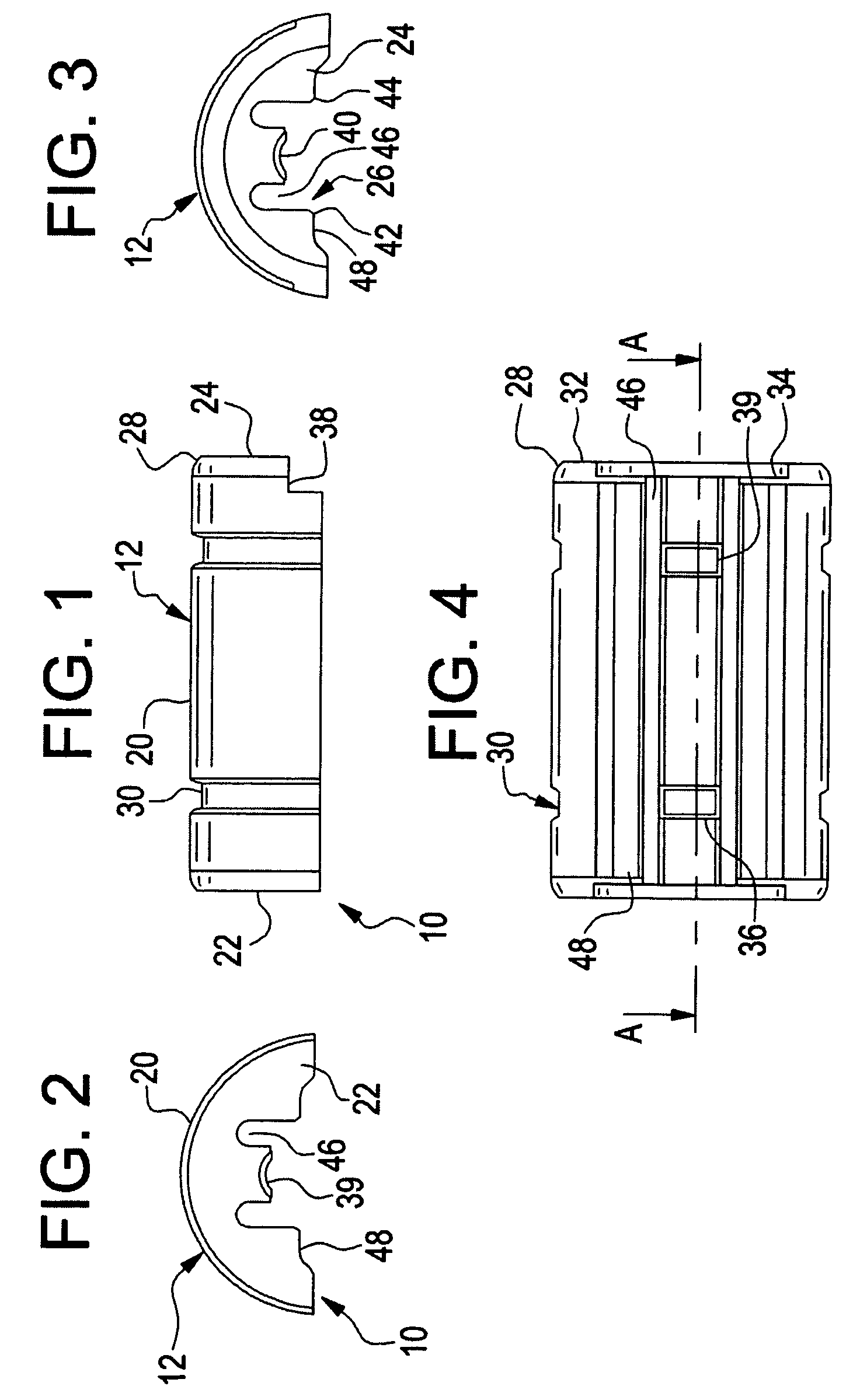

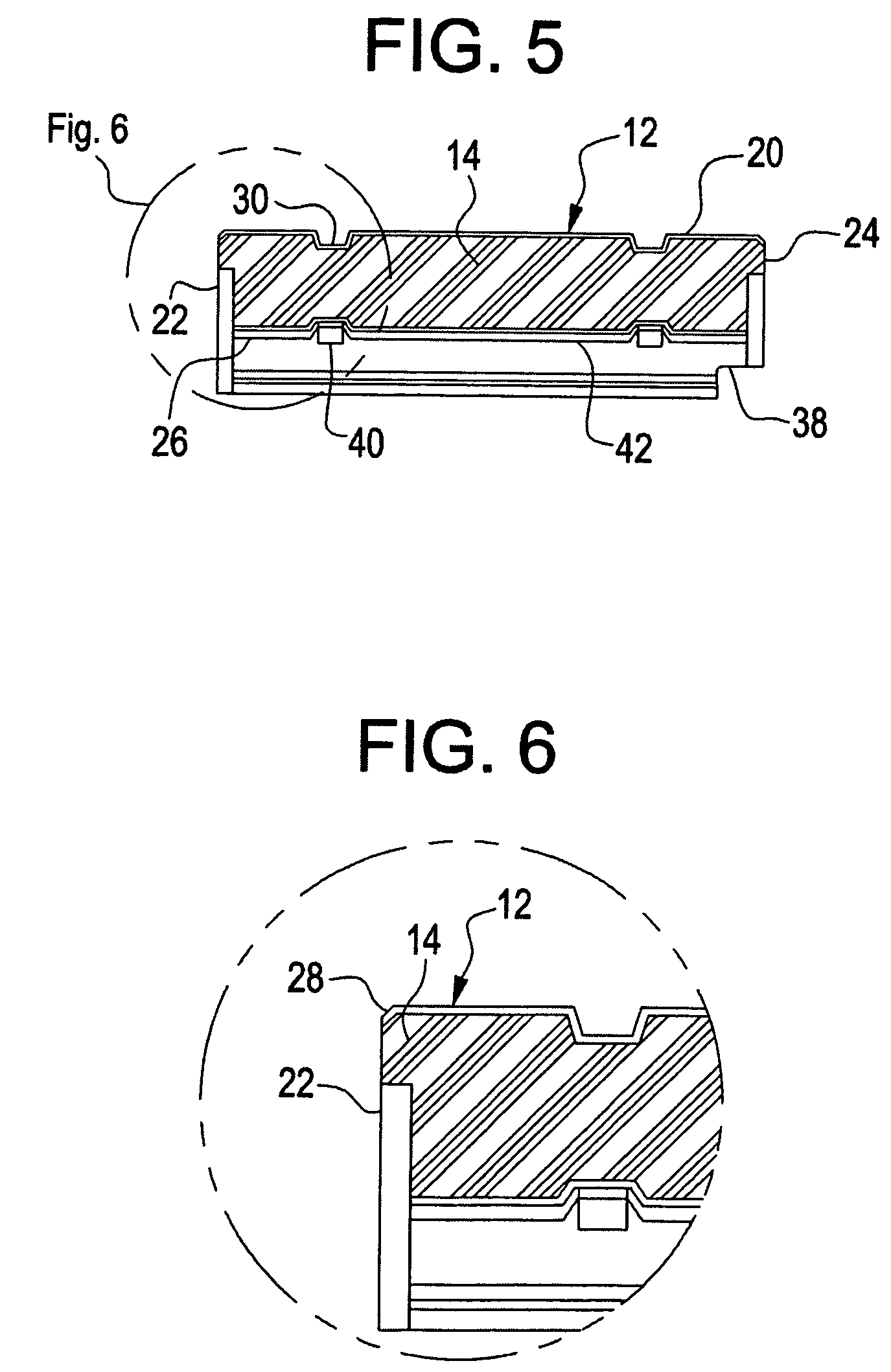

Drilling riser buoyancy modules

InactiveUS7628665B1Improve manufacturabilityImprove performanceArtificial islandsDrilling rodsFiberContact pad

Buoyancy modules for subsea riser pipes are made of syntactic foam solid cores covered with tough high density polyethylene shells. Inner surfaces have partial semi-cylindrical surfaces to fit the riser pipes. Internal radial grooves hold flexible contact pads. Recesses in the inner surfaces hold auxiliary lines. Flat surfaces between the inner and outer semi-cylindrical surfaces have complementary longitudinally extending semi-cylindrical grooves to position choke and kill lines. Grooves in the outer semi-cylindrical surfaces hold composite fiber tensioning straps directly outward from the flexible contact pads. Flat areas of the grooves hold tensioning hardware. Tensioning the straps grips the riser pipe with the pads and grips the choke and kill lines in the semi-circular grooves. Cavities in the ends allow the buoyancy module halves to be assembled on the riser pipe around clamps which hold the accompanying lines.

Owner:CUMING CORP

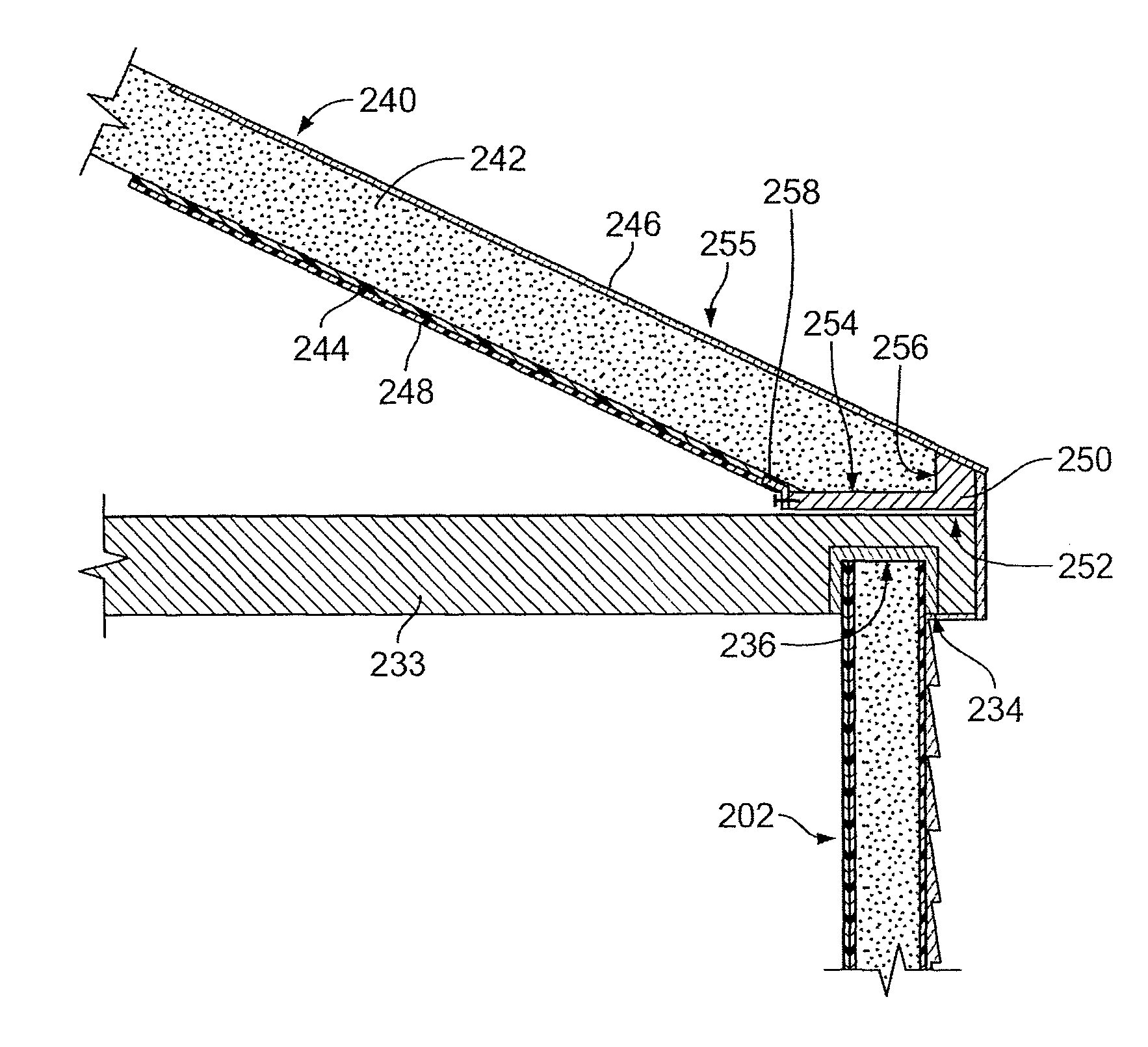

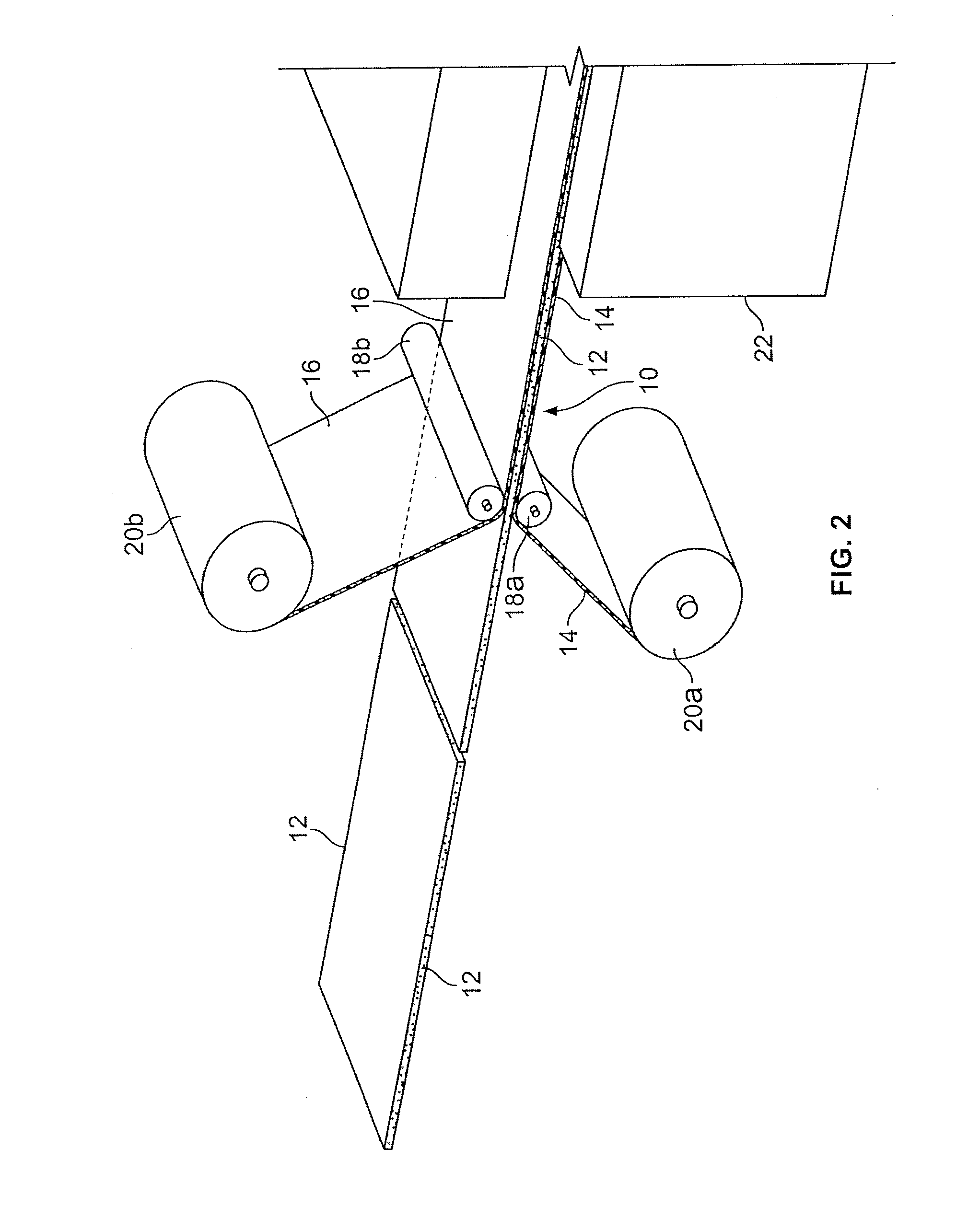

Modular building system utilizing composite, foam core panels

A system for constructing a structure comprises a plurality of composite panels having a laminate structure comprising a foam core to which are attached cover layers of the same or different material. One or both of the cover layers may be comprised of composite sub-layers. The system includes a number elongate and preferably extruded components for connecting the panels to form walls, roofs or floors for the structure. The system is modular, thereby allowing for a time and cost efficient means of erecting a structure.

Owner:INNOVATIVE COMPOSITES INT

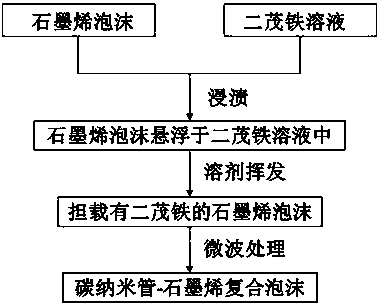

Preparation method for carbon nano tube-graphene composite foam

InactiveCN103738953ASimple processRaw materials are cheap and easy to getMaterial nanotechnologyCarbon compoundsPtru catalystNanotube

The invention belongs to a preparation method of a nano composite material and particularly relates to the field of a microwave preparation method for a grapheme-based composite material. A preparation method for carbon nano tube-graphene composite foam comprises the following steps: firstly, loading ferrocene on graphene foam; and then carrying out microwave treatment on the graphene foam loaded with the ferrocene and decomposing the ferrocene on the graphene foam by a high temperature which is instantly generated, so as to generate a catalyst and a carbon source to realize carbon nano tube in-situ growth and obtain the carbon nano tube-graphene composite foam. A carbon nano tube in the composite material vertically and epitaxially grows on the surface of a hole wall of the graphene foam; the super-hydrophobic and super-lipophilic surface chemical characteristics are represented; the preparation method has a wide application prospect in the aspects of adsorption, oil-water separation and the like; the method has the characteristics that operation is simple and convenient, cost is low, and industrial production is easily realized, and is an important preparation method for nano carbon materials.

Owner:DALIAN UNIV OF TECH

Phenolic foam plastic composite product and its production and forming process

The present invention discloses a phenolic foam plastic composite product and its forming process. Said composite product can be composite foam sandwich plate material or pipe material (single-sided or double-sided composite), and the sandwich material of composite product adopts fire-retardant, low-toxic, low-smoke and high-temp.-resistant phenolic foams, said invention adopts low-temp. foaming method, can be applicable to continuous or intermittent production and in-situ pouring production mode of mechanical foaming machine (two components or more than two components), and the foams and various face materials combined plate materials and pipe materials can be used as sound-proofing, decorative, cold-retaining and heat-insulating materials, also can be used as wall body and roofing material of light factory building.

Owner:GUANGZHOU HUADE NEW MATERIAL

Composite foam structures

InactiveUS6929866B1Weight increaseReduce porosityMolten spray coatingCeramic layered productsPorous substrateThermal spraying

A composite rigid foam structure that has a skin or coating on at least one of its surfaces. The skin is formed in situ by thermal spray techniques. The skin is bonded substantially throughout the surface of the porous substrate to the peripheries of the pores. The skin on the average does not penetrate the surface of the substrate by more than the depth of about 2 to 5 pores. Thus, thermal spraying the skin onto the rigid foam produces a composite that is tightly and uniformly bonded together without unduly increasing the weight of the composite structure. Both thermal conductivity and bonding are excellent.

Owner:ULSTREETCARET

Aerogel based composites

Composites, such as syntactic foams, are described. The composite contains at least one polymer and at least one aerogel. The aerogel is coated with a coating substance to at least substantially prevent the intrusion of the polymer into the pores of the areogel. Methods of making the composite are also described, as well as uses of the composite.

Owner:CABOT CORP

Enhanced light weight armor system with reactive properties

InactiveUS7322267B1Prevent penetrationDissipate energyReactive armourDynamic armourThin metalNanoparticle

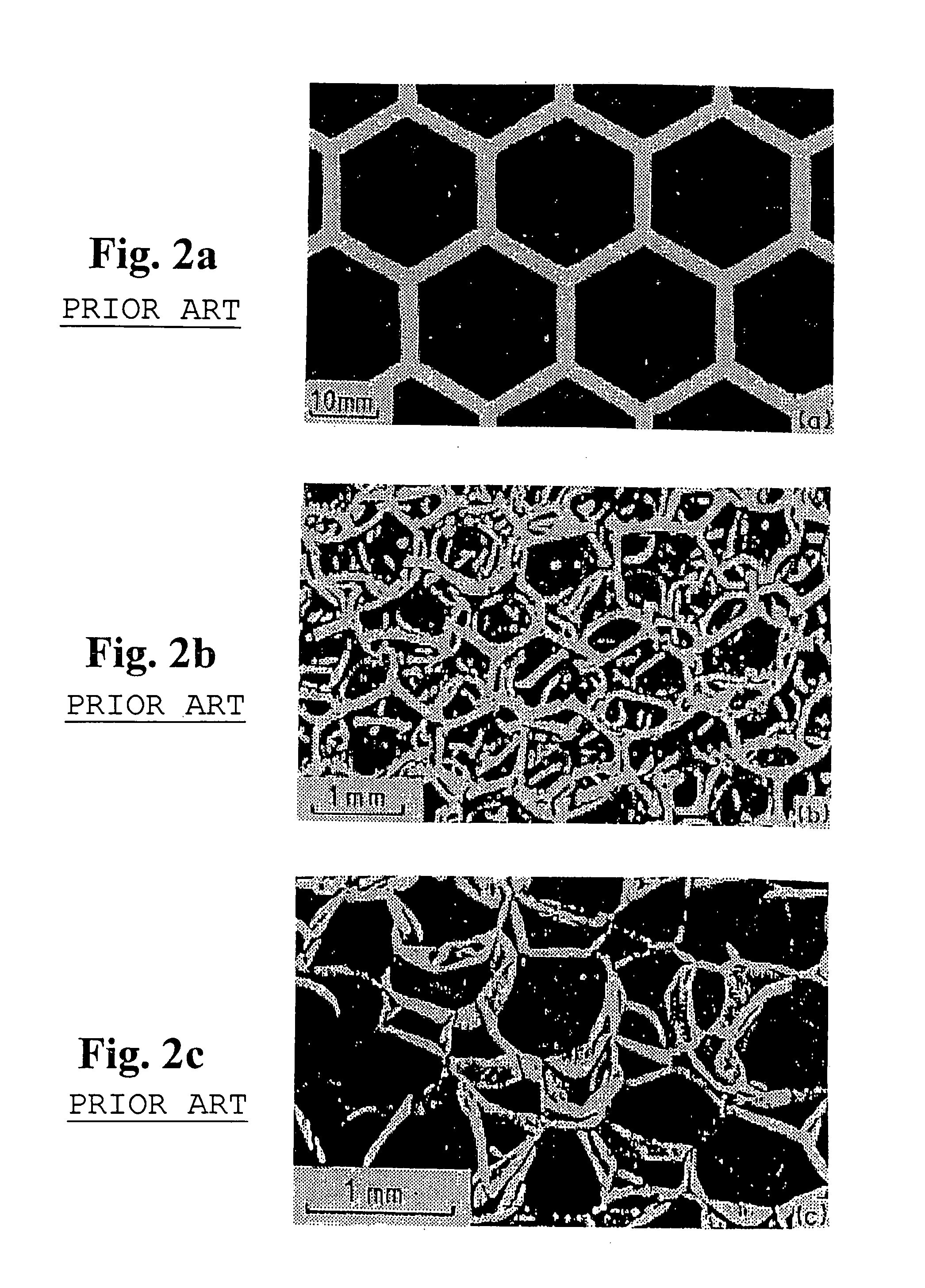

A light-weight armor system for retrofitting onto light vehicles, such as HMMWVs, trucks, or helicopters, or incorporating into a vehicle to protect against HEAT or high explosive warheads. The armor system comprises multiple layers of a thin metal film. The front side of the thin metal sheet facing away from the vehicle is coated with a layer of zirconium nanoparticles and imprinted with a network of hollow packets filled with water and sealed. The back side of the thin metal sheet is coated with a layer of potassium bicarbonate powder. The multiple layers of metal film are imbedded in a matrix of composite foam to form a honeycomb structure that can be retrofitted onto light vehicles or used in new designs.

Owner:FOI GRP

Metal/carbonyl composite foaming material and preparation method thereof

InactiveCN101104893AImprove machinabilityImprove acid and alkali corrosion resistanceMetal coatingMetallic materials

The invention relates to the field of foamed metal materials, specifically metal / carbon-based composite foamed material and the preparation method thereof. The preparation method comprises processing a foamed carbon blank from foamed plastic as matrix, and forming a metal coating on the foamed carbon by direct electroplating method after the foamed carbon is molded to obtain a metal / carbon-based composite foamed material. The composite foamed material is constituted by foamed carbon and metal coating thereon. The ratio of carbon to metal, by weight percentage, is (20-90):(80-10). In this invention, the metal coating is formed uniformly and continuously on the surface of the foamed carbon matrix by electroplating method, so as to obtain a novel metal / carbon-based composite foamed material; and the toughness and heat conduction capacity of material are improved greatly without changing the appearance of foamed carbon. The inventive metal / carbon-based composite foamed material can not only used as an electronic element in radiator but also a heat exchanger for industrial and domestic uses, additionally can be used as electrode, electronic shield, catalyst and catalyst carrier in automobile, chemical and aerospace industries.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Sports board with integral laminated stiffening element

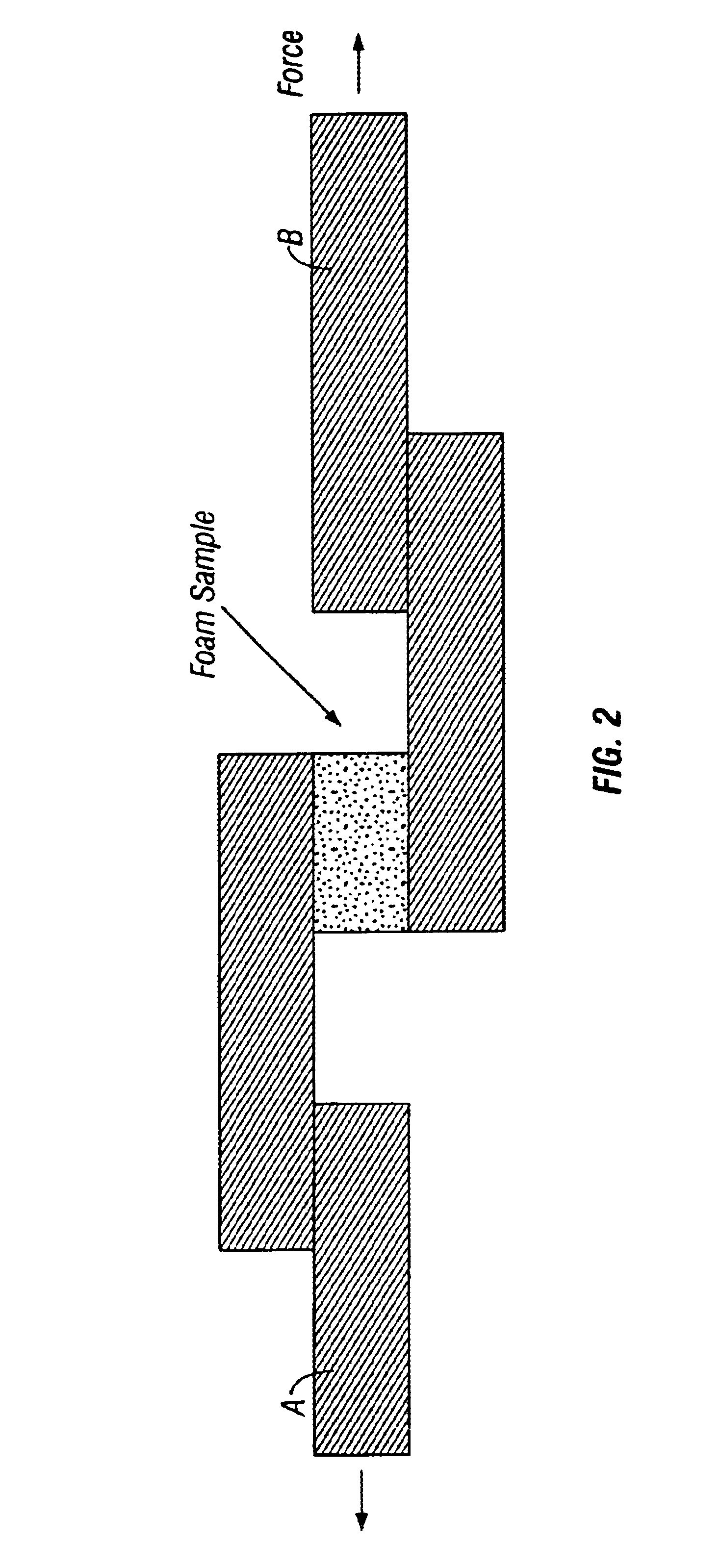

InactiveUS7246568B1Uniform stiffnessImproves compression resistanceNon-magnetic metal hullsWater sport boardsPolyolefinPliability

A sport board for snow sledding or surf body boarding comprises a multi-layered laminated composite foam core coupled with stiffening elements for mechanical strengthening of the board. The composite foam core comprises laminates of polyolefin foam base and stiffening elements composed of substantially polymer foam and has substantial higher compressive strength and flexural strength than the foam base. A front section may be made of the same blank material as the low density polyolefin foam base and is bonded to the front end of the foam core complex to give a full frontal flexibility for a higher directional control by the rider and improved shock absorbing property. Upper and lower polyethylene foam sheets wrap the foam core complex subassembly and head section for sled integrity and graphic film finishes the sled top, the bottom is also finished with a polyethylene sheet for slickness.

Owner:CHEUNG WAH KAN

Heat-preserving composite foam concrete and preparation method thereof

InactiveCN101805203AImprove thermal insulationLight weightSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses a formula of heat-preserving composite foam concrete, which comprises the following components based on parts by weight: 500-1000 parts of concrete, 500-1000 parts of admixture, 5-20 parts of additive, 1-30 parts of polyurethane grains, 5-20 parts of foaming agent and 500-900 parts of water. The preparation method the foam concrete comprises the following steps of: preparing foaming agent water solution, smashing the polyurethane into grains, and adjusting the sizes of the grains as required, wherein the diameters of the grains are 1-3mm; adding the polyurethane grains into the concrete, the residual water after preparing the foaming agent water solution, the additive and the admixture, and evenly stirring to obtain slurry; mixing and stirring the slurry with the foam prepared by the foaming agent water solution; and maintaining, pouring and shaping into the cast-in-situ foam concrete. The invention solves the problems of the coordination between the intensity of the foam concrete and the heat-conducting property and the treatment of the waste polyurethane. The foam concrete can guarantee the intensity and has better heat-insulating effect.

Owner:建研建材有限公司 +1

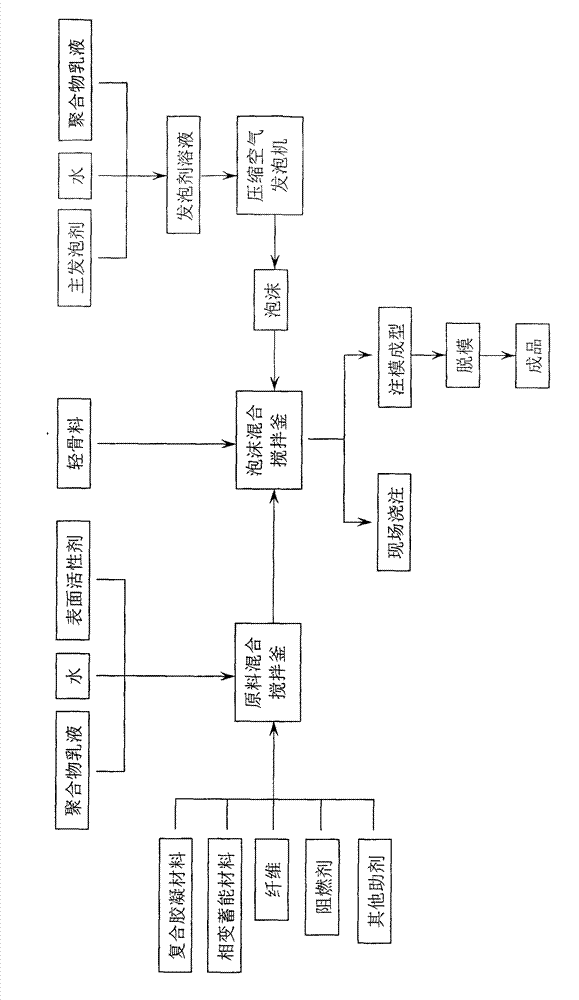

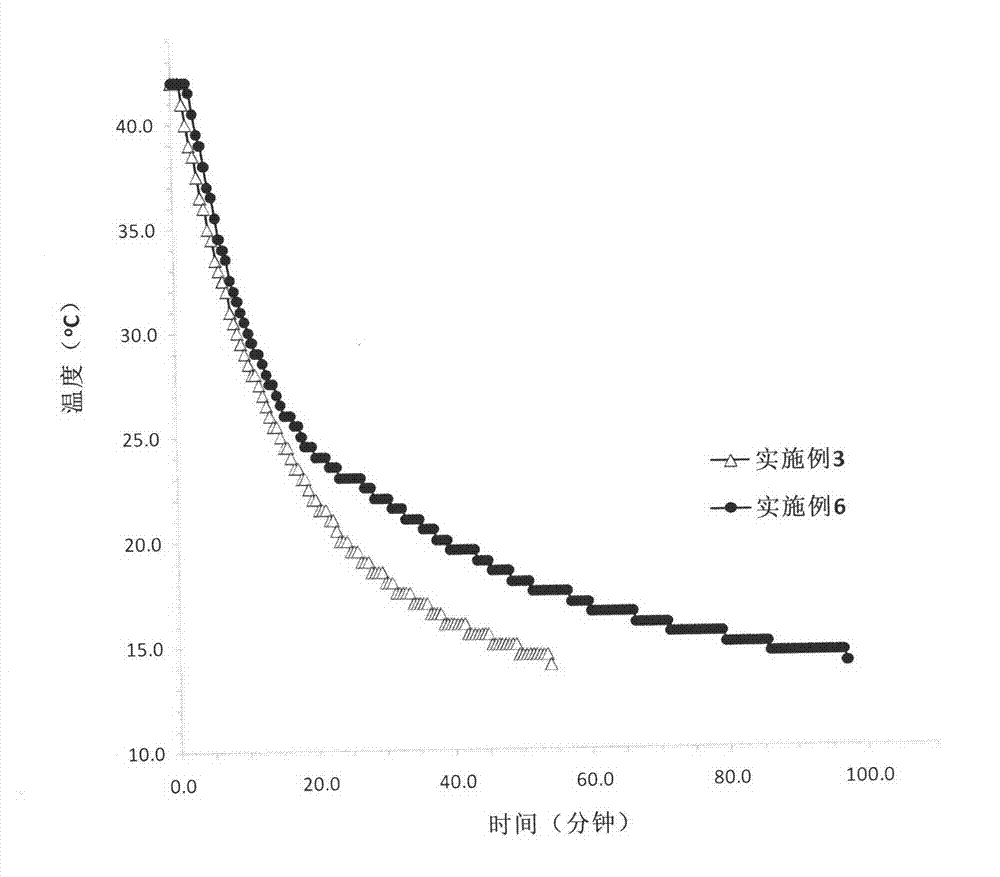

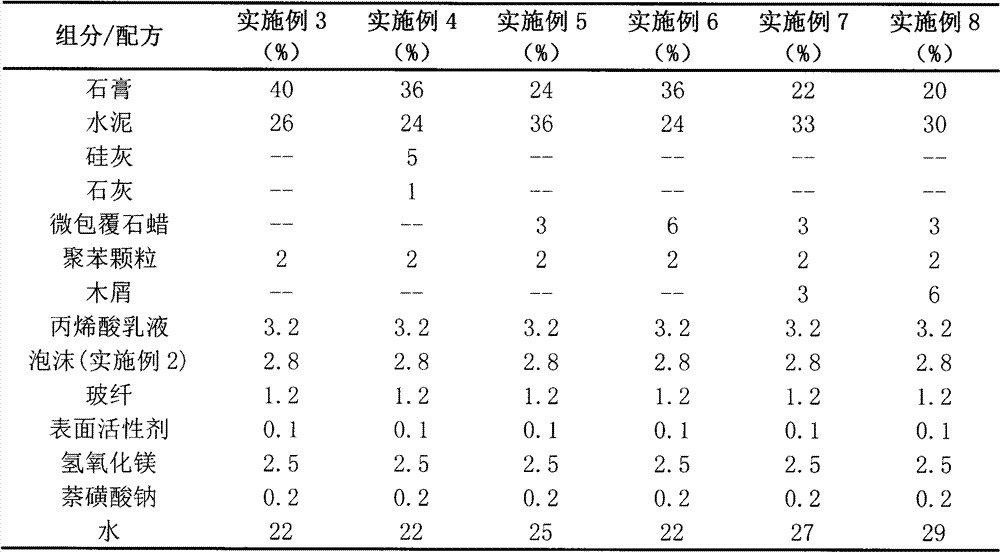

Energy storage energy-efficient foam gypsum cement composite material and preparation method thereof

ActiveCN102765959AImprove fire performancePrevent high temperature penetrationCeramicwareInsulation layerThermal insulation

The invention relates to an energy storage energy-efficient foam gypsum cement composite material and a preparation method thereof. The formula thereof is composed of a composite cementing material, lightweight aggregate, a phase change energy storage material, polymer latex, foam and a foaming agent. The composite cementing material is mainly composed of semi-hydrated gypsum and cement. The preparation method thereof comprises the steps of: preparing a foaming agent solution to prepare stable foam; thoroughly mixing water, polymer emulsion and other liquid state components with the composite cementing material, the phase change energy storage material and other additives such as solid-state components; and sending the solid-liquid mixed slurry to a foam-mixing kettle filled with the lightweight aggregate, while introducing the foam, to prepare the foam gypsum cement composite slurry. The inorganic composite foam material of the present invention has an energy storage function absorbing heat during the day and radiating heat at night, so as to effectively maintain a comfortable indoor temperature, is fire-proof, heat preservative, humidity-adjustable, good in water-resistance, and high in strength, and can be used for manufacturing fireproof insulation layers or fireproof insulation zones for interior and exterior walls of buildings, heat insulation, fire proof and heat preservation wallboards, door panels and core materials, steel structure fireproof cladding materials and the like.

Owner:南京依科国特新材料科技有限公司

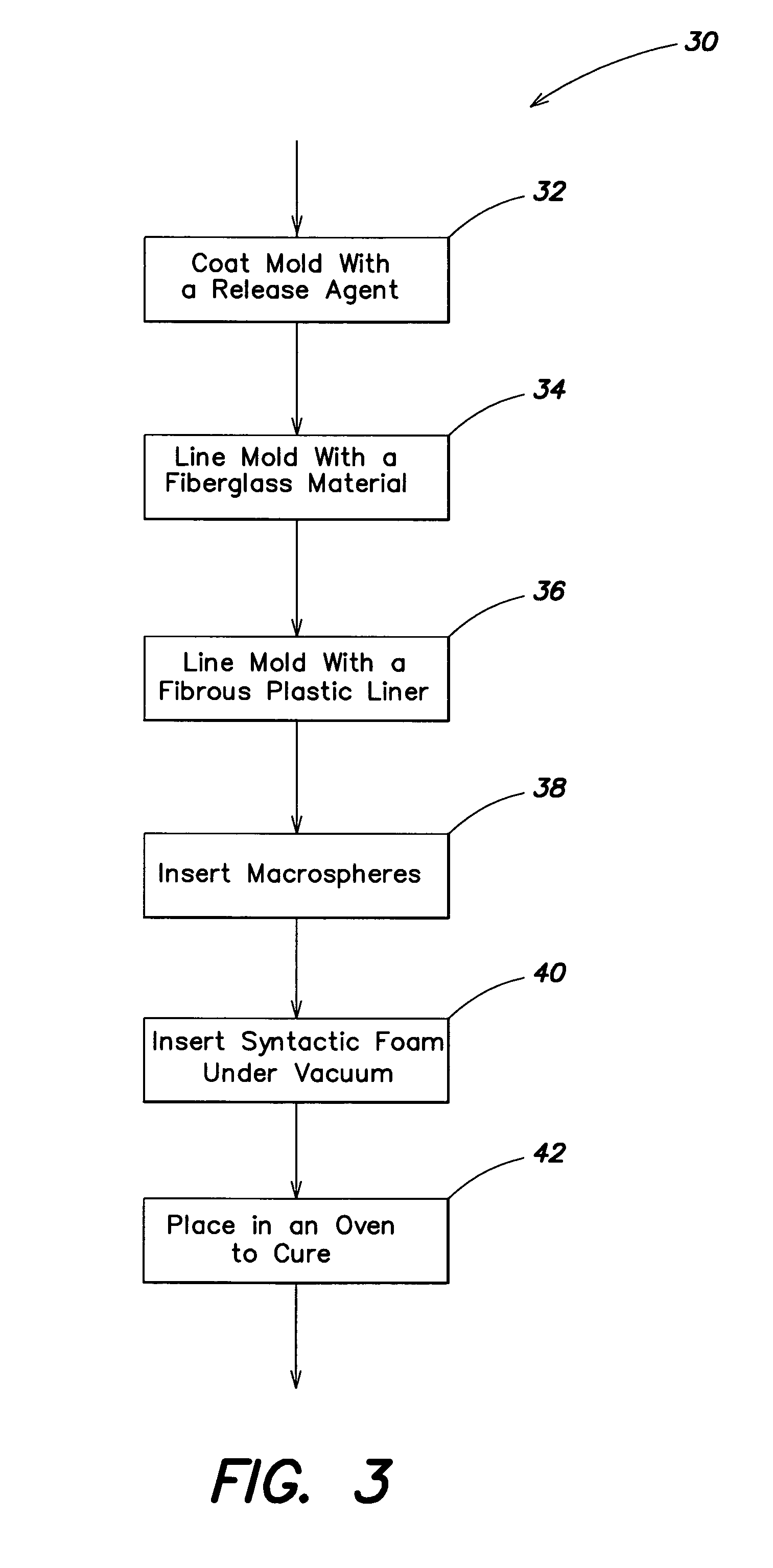

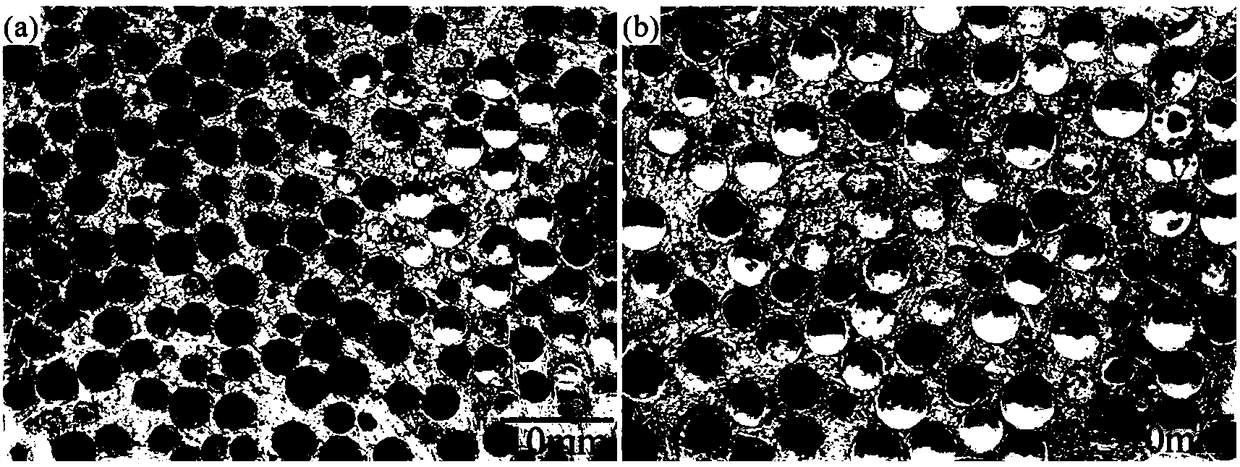

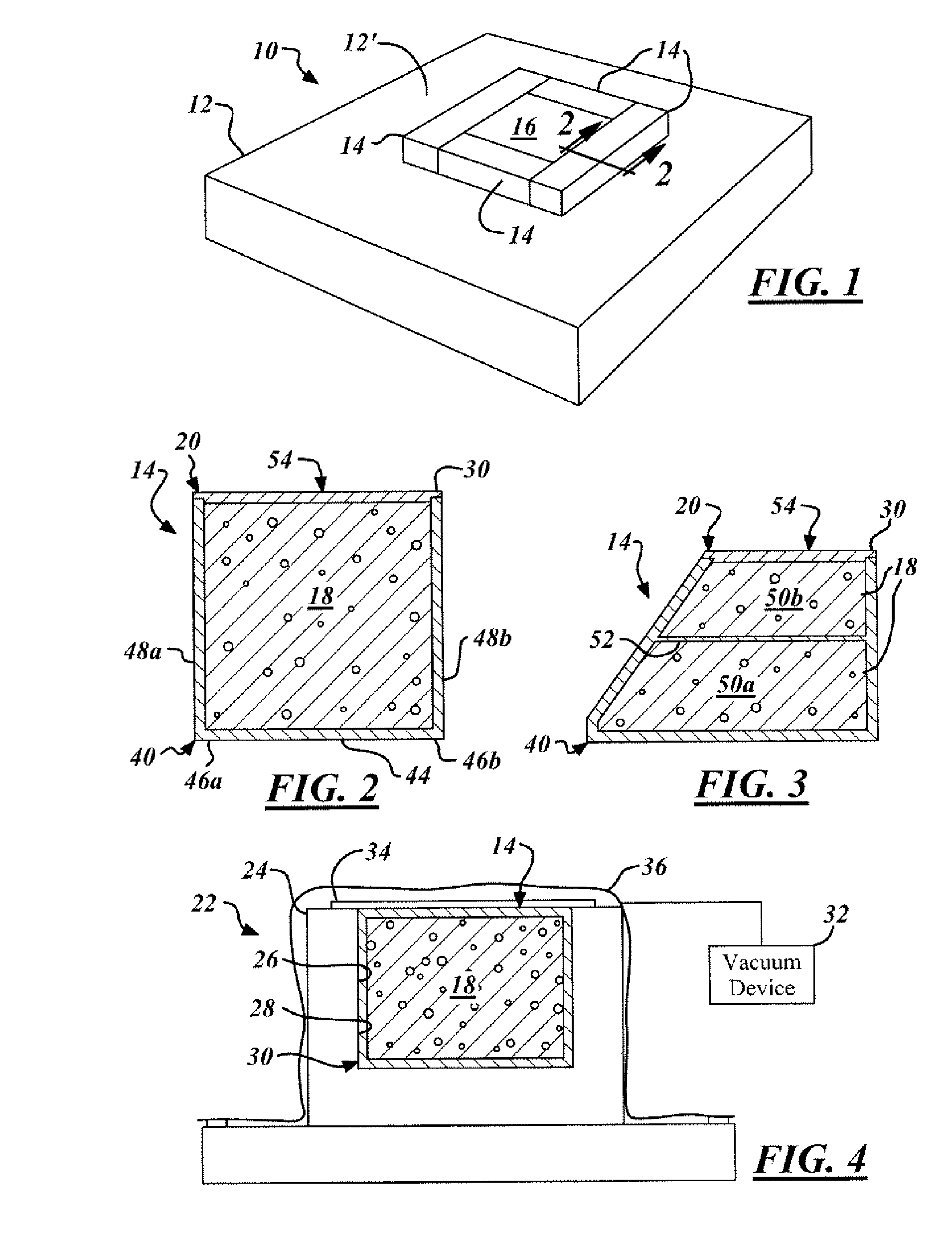

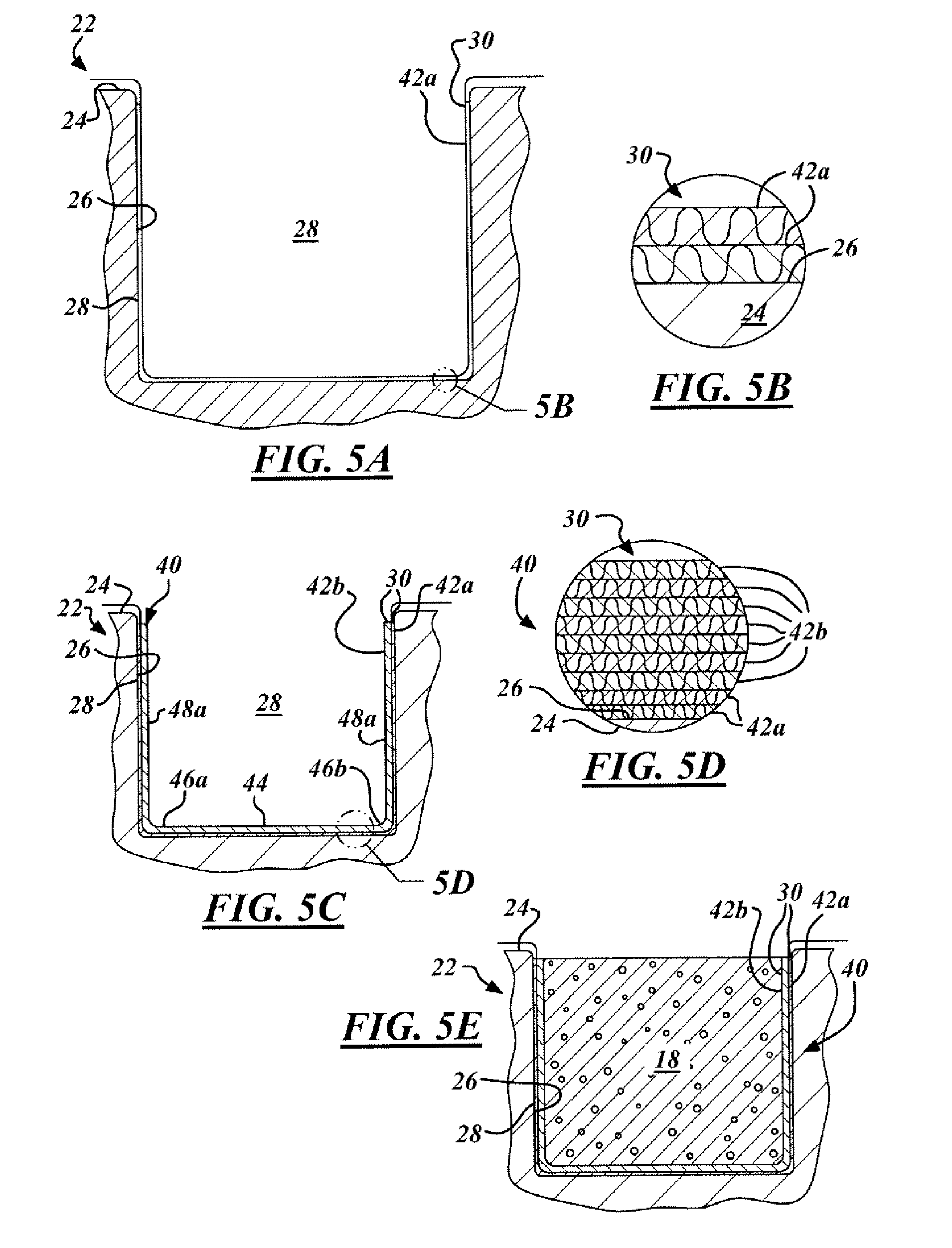

Rugged foam buoyancy modules and method of manufacture

InactiveUS7121767B1Increased durabilityImprove reinforcementDrilling rodsWaterborne vesselsFiberGlass fiber

A buoyancy module comprises a multi-layer outer protective shell that has an exterior surface and an interior surface. A first layer of foam buoyancy material is located adjacent to the interior surface. A second layer of foam buoyancy material that includes macrospheres and syntactic foam is surrounded by the first layer of foam buoyancy material. The multi-layer outer protective shell can include a layer of fiberglass backed by a fibrous plastic liner. In this embodiment, the layer of fiberglass provides the exterior surface of the multi-layer outer protective shell, while the fibrous plastic liner provides the interior surface of the protective shell. The second layer of foam buoyancy material can be a precast material. The precast material can include for example macrospheres and syntactic foam. The first layer of foam buoyancy material is preferably a stronger layer than the second layer of foam buoyancy material. Advantageously, the buoyancy module has a plurality of different layers, wherein the components of greatest strength and density are located on the outside. The multi-component system improves ruggedness of the buoyancy material, and provides increased reinforcement at locations subject to increased bending strengths, and provides a buoyancy module of longer life. In addition the buoyancy module may also include steel support members where bolting loads and other forces are brought to bear when parts are attached.

Owner:CUMING CORP

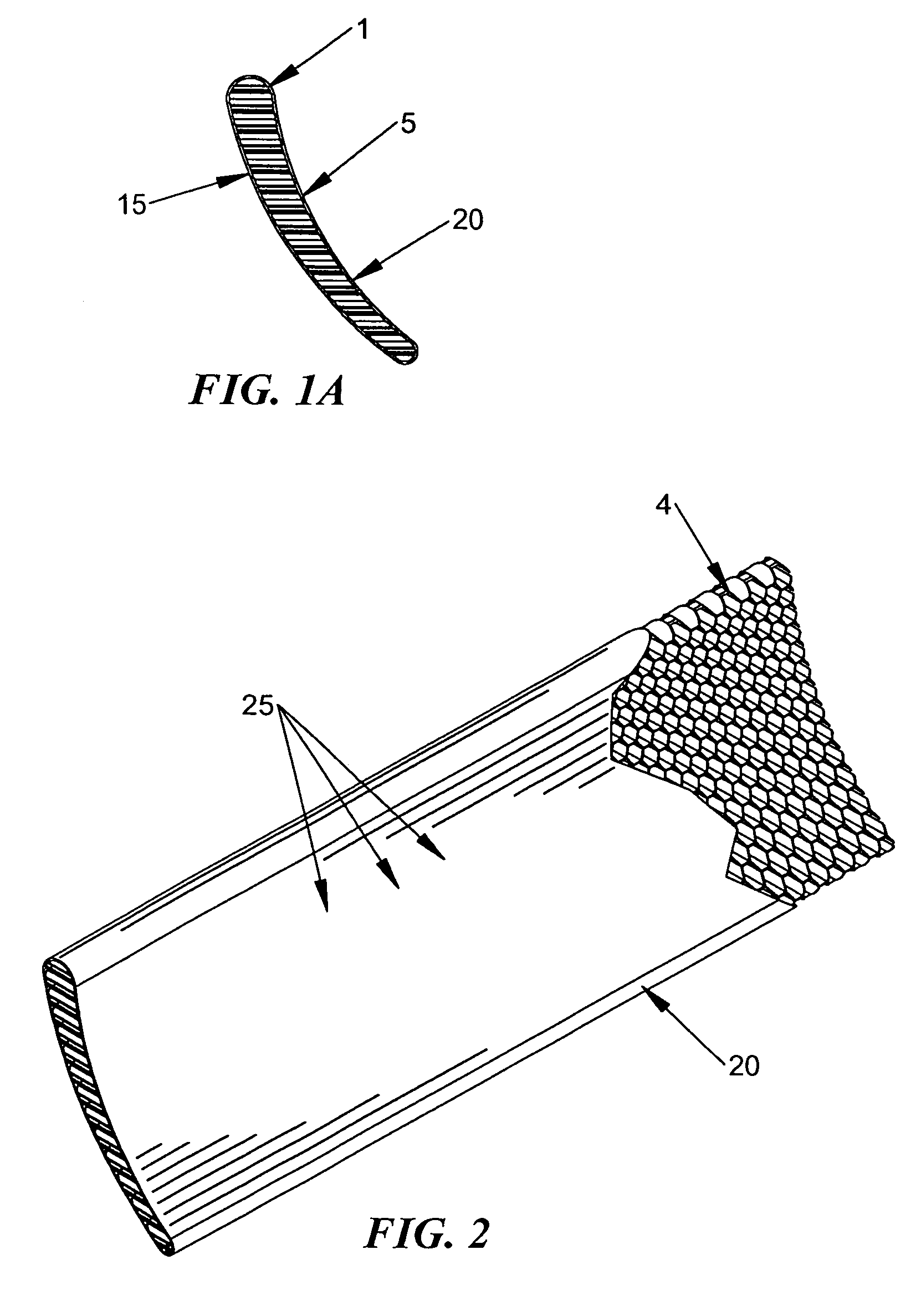

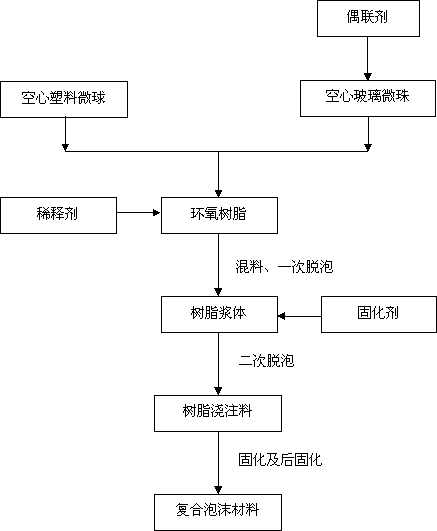

Hollow-microsphere-filled epoxy resin composite foam material and preparation method thereof

The invention discloses a hollow-microsphere-filled epoxy resin composite foam material and a preparation method thereof, belonging to the field of foam materials. The composite foam material comprises hollow polystyrene microspheres, hollow glass microspheres, an epoxy resin, a curing agent, a diluter and a coupling agent. The invention also discloses a preparation method of the composite foam material, which is characterized by comprising the following steps: 1) hollow glass microsphere modification; 2) mixing and primary defoaming; and 3) secondary defoaming and curing formation. The composite foam material has the characteristics of higher compression strength, lower density, excellent properties, lower cost, simple preparation process, uniform distribution of the filled microspheres, and the like, and provides a new option for deep-sea buoyancy materials.

Owner:UNIV OF JINAN

Polystyrene/thermosetting resin syntactic foam and method for preparing same

InactiveCN102863706ASolving Burning DripsImprove flame retardant performanceCoatingsPolystyrene beadPolystyrene particle

The invention discloses polystyrene / thermosetting resin syntactic foam and a method for preparing the same, and belongs to the field of flame retardant materials. The formula of the syntactic foam comprises expandable polystyrene, resin monomers or prepolymers and a curing agent. The invention also discloses a method for preparing the syntactic foam. The preparation method comprises the following steps of: pre-foaming the expandable polystyrene particles to obtain polystyrene beads; and uniformly coating the polystyrene beads with the curing agent-contained resin monomers or prepolymers, and curing the polystyrene beads to obtain the syntactic foam. The syntactic foam can fundamentally solve the problem that the polystyrene is combusted and drips, has a high flame retardant property, and is low in cost and excellent in performance, so that the syntactic foam becomes a new selection for exterior wall heat-insulating materials.

Owner:赵毅 +1

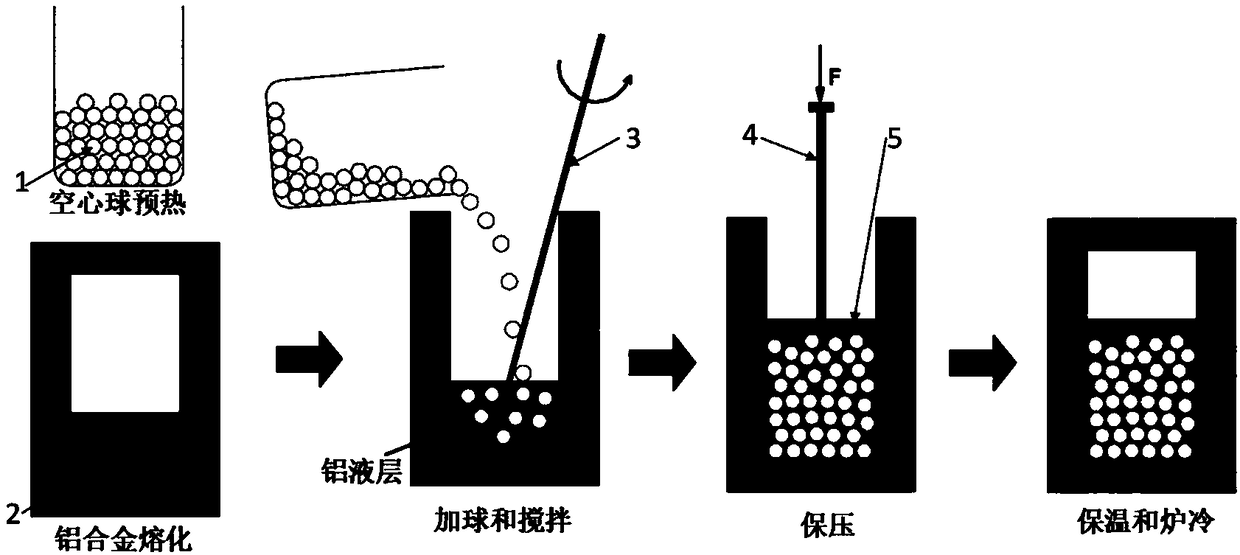

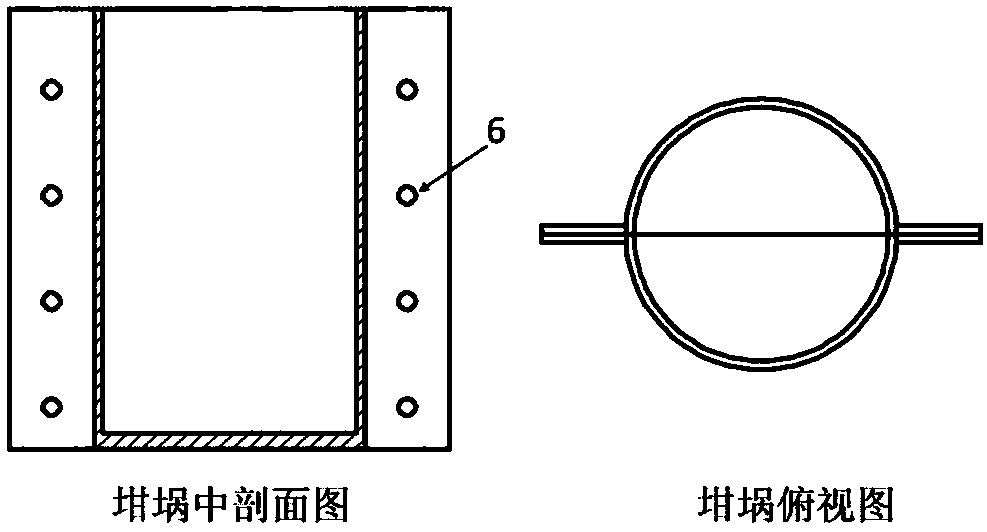

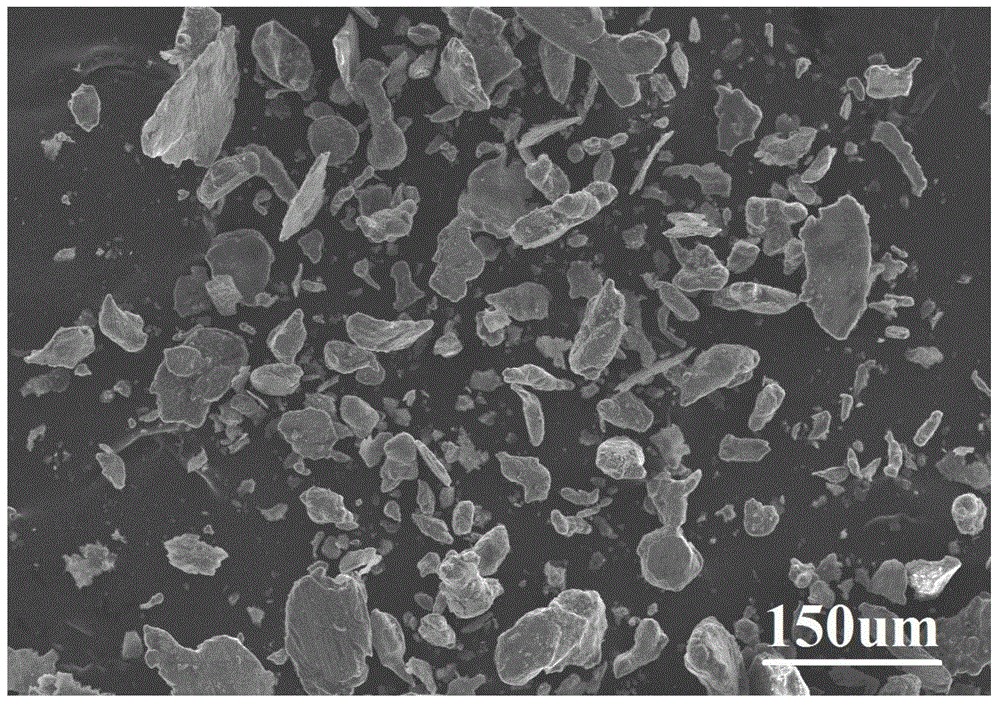

Metal-based hollow-ball composite foam material and preparation method thereof

The invention relates to a metal-based hollow-ball composite foam material and a preparation method thereof. The composite foam material comprises a metal matrix and ceramic hollow balls, wherein theceramic hollow balls are uniformly distributed in the metal matrix. The preparation method has the advantages of simple operation and low cost. In the prepared aluminum-based / aluminum oxide hollow-ball composite foam material, the interface bonding of an aluminum matrix and the hollow balls is good, the grain size of the hollow balls is larger, and the volume fraction of the hollow balls is larger. The plateau stress in a compressive stress-strain curve can reach 46MPa, the plateau phase is flat and long, and the prepared aluminum-based / aluminum oxide hollow-ball composite foam material is anexcellent light energy absorbing material. Under impulse load, the plateau stress of the composite foam can be increased to about 60MPa. The composite foam material has a significant advantage and a good application prospect in the field of shock resistance and explosion protection.

Owner:TSINGHUA UNIV

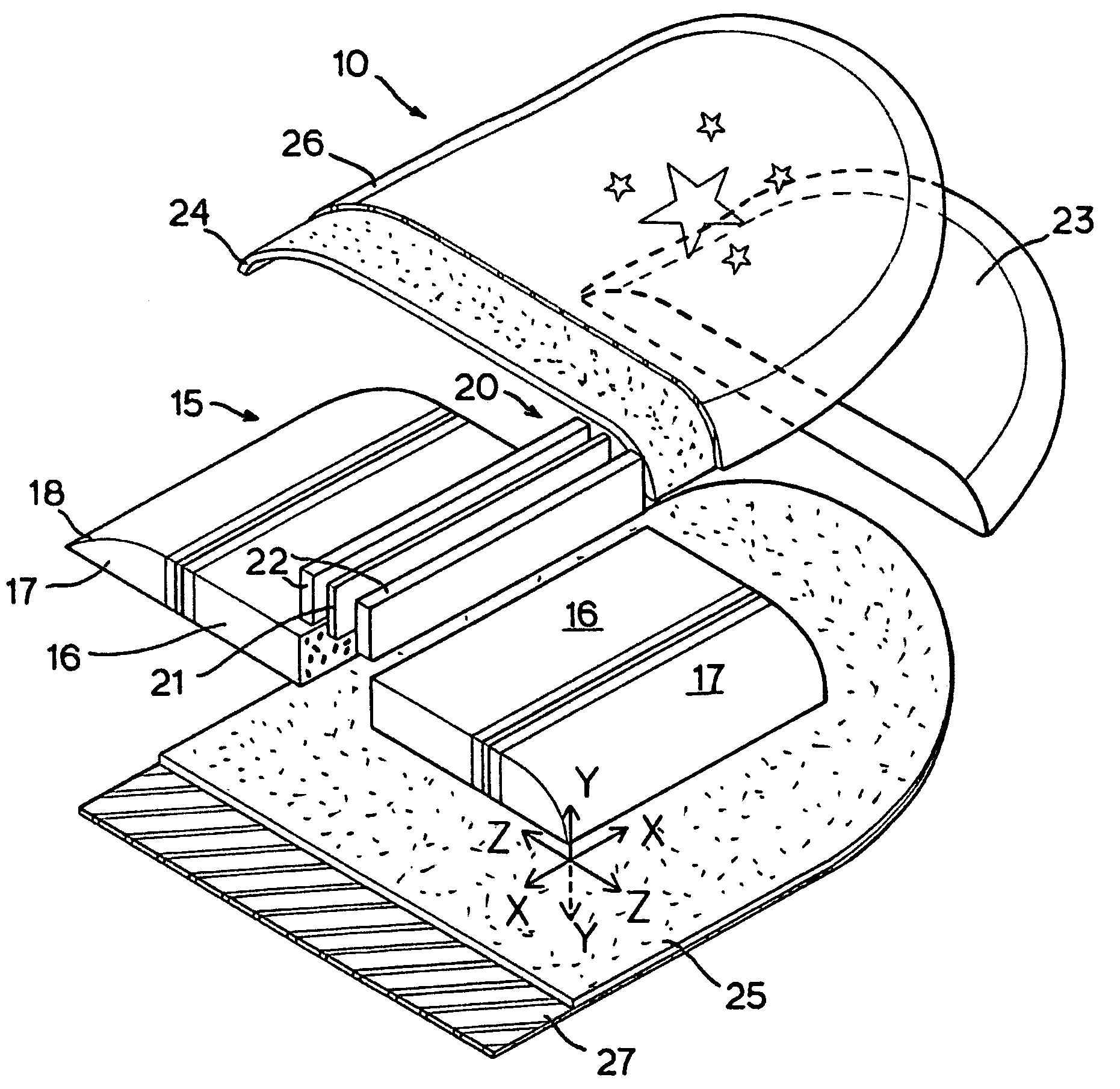

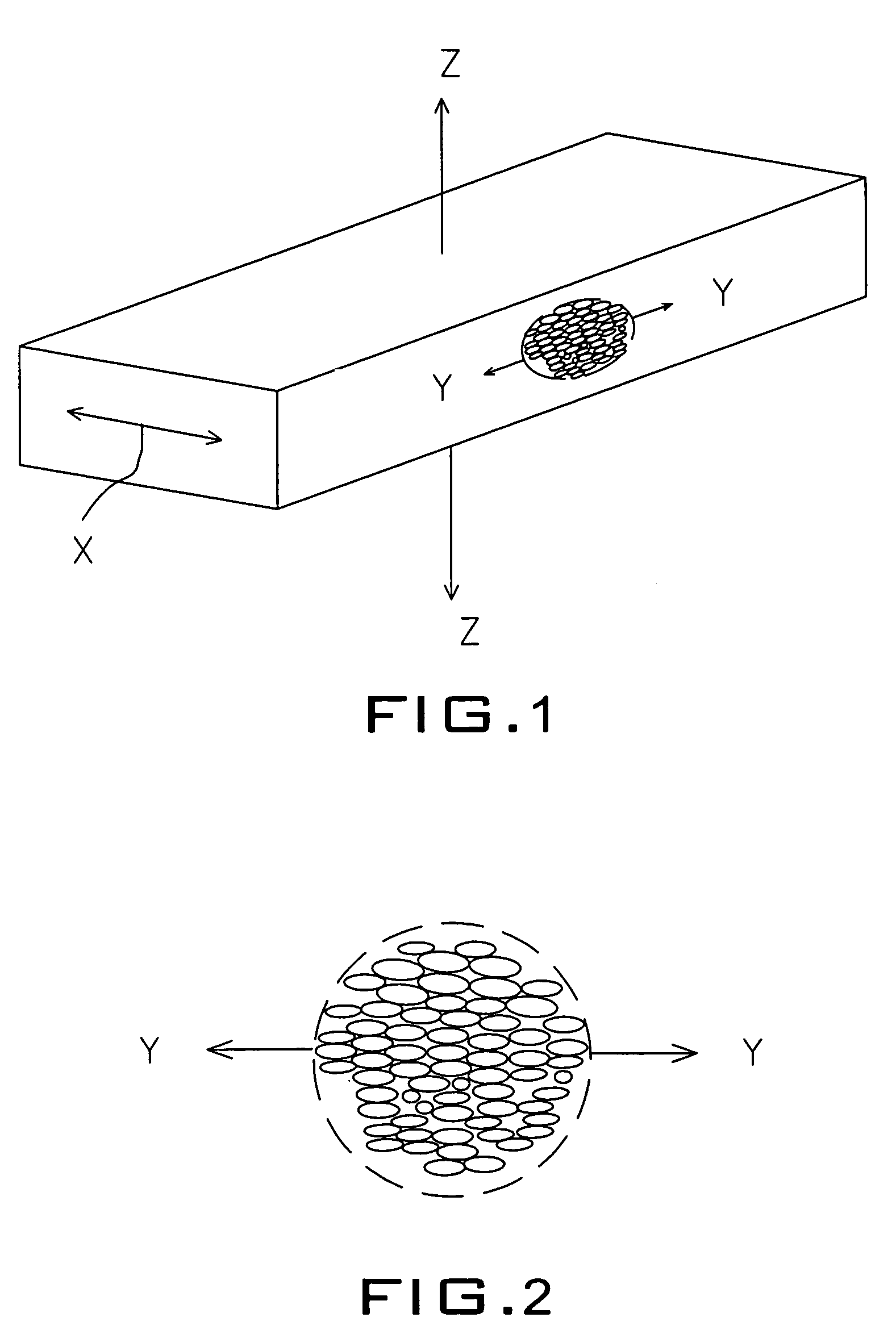

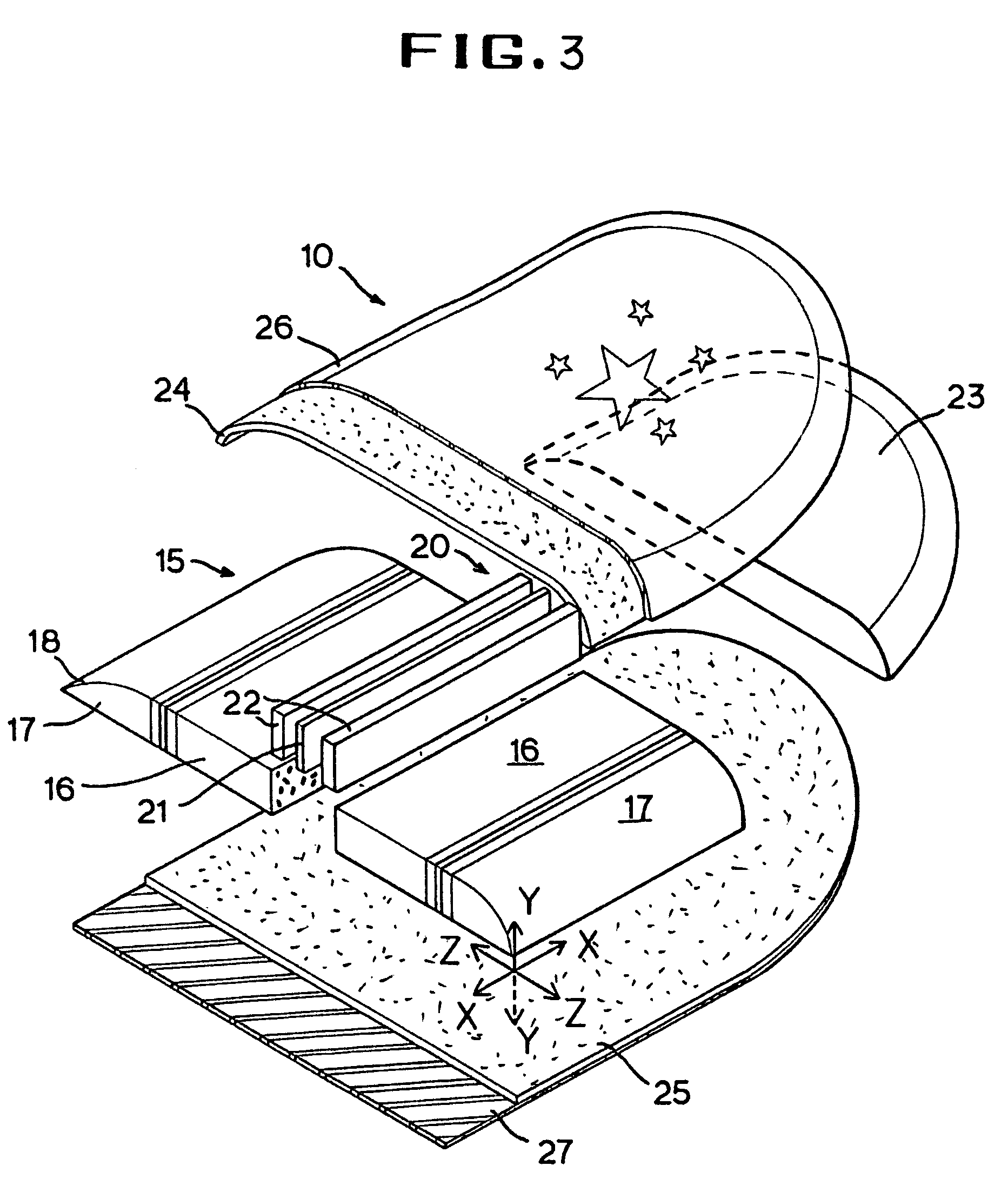

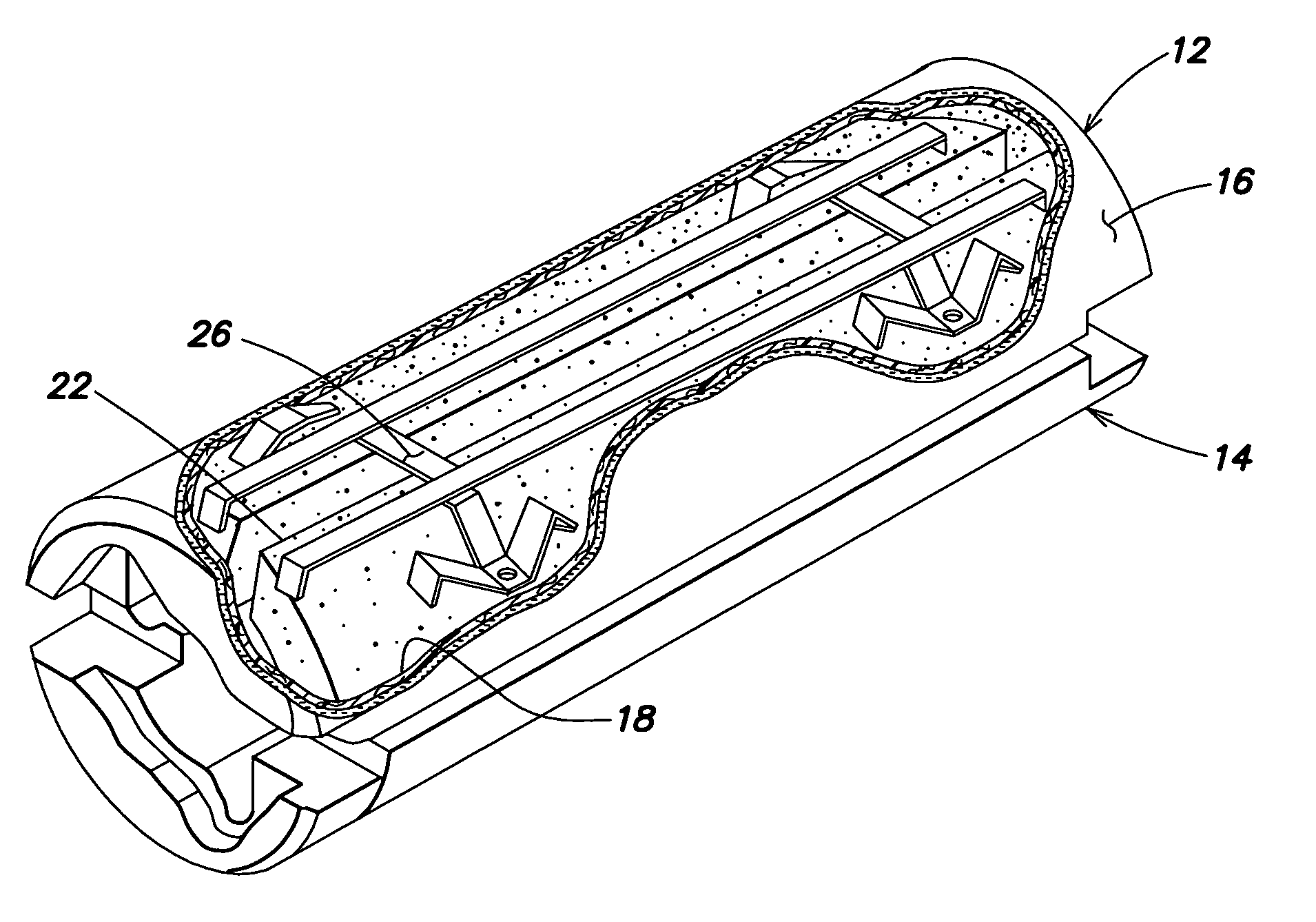

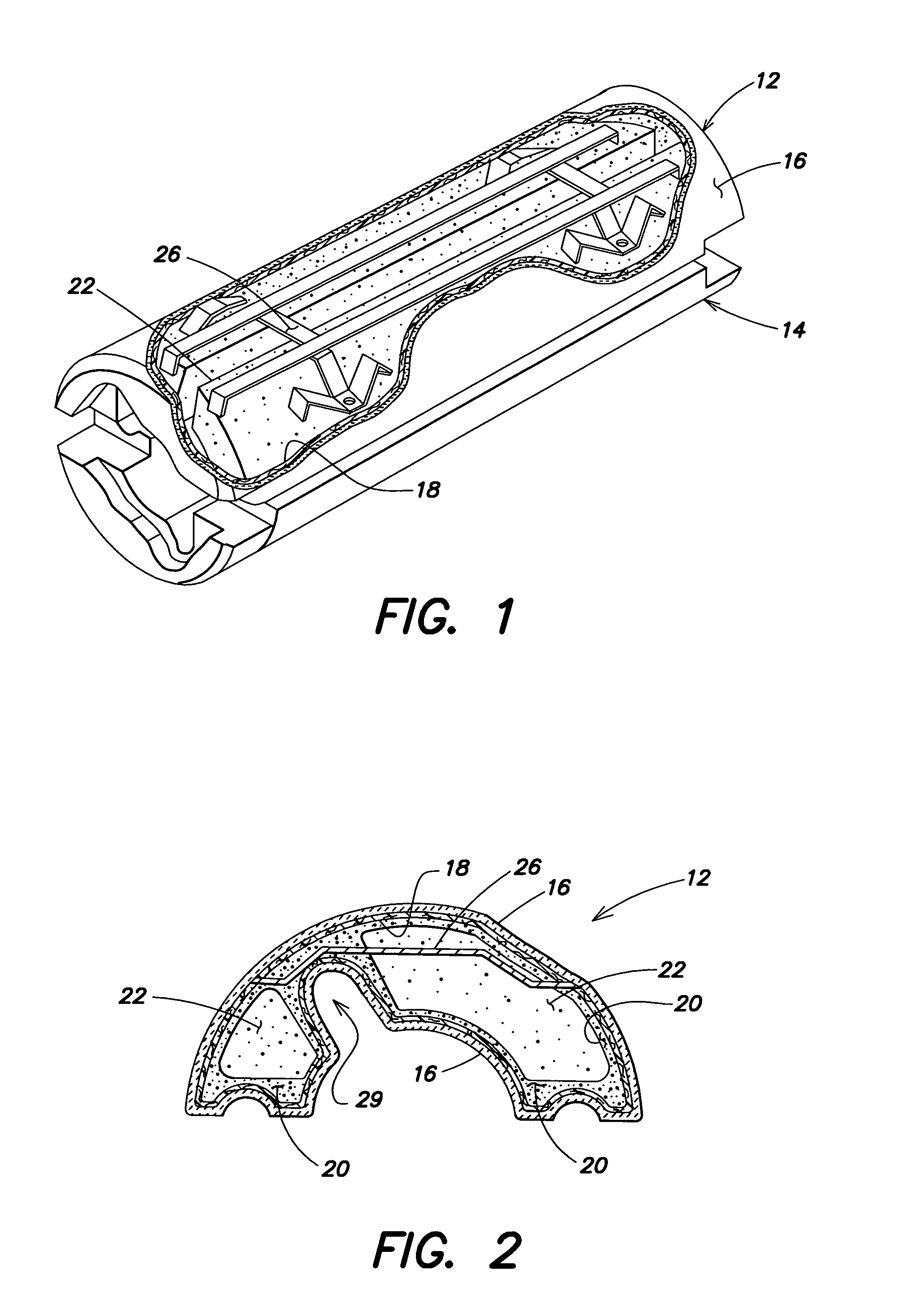

Lightweight composite fairing bar an method for manufacturing the same

InactiveUS20060280927A1Short flow timeReduce manufacturing costConfectioneryMeat processingEpoxyVolumetric Mass Density

A lightweight composite fairing bar (14) for use in fabricating a composite component (16) of an aircraft. The fairing bar (14) includes a core (18) and an elongated outer shell (20) surrounding the core (18). The outer shell (20) is comprised of a laminate material, and the core (18) is comprised of epoxy syntactic foam having a lower density than that of the laminate material. The outer shell (20) is configured for supporting the composite component (16) during the manufacture of the same.

Owner:THE BOEING CO

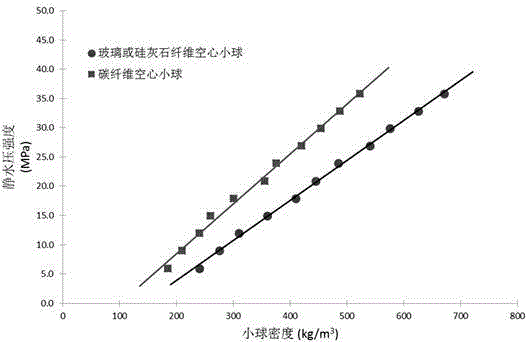

Fiber-reinforced resin composite material hollow ball and preparation method thereof

The invention relates to a fiber-reinforced resin composite material hollow ball and a preparation method thereof. According to the fiber-reinforced resin composite material hollow ball, a small polystyrene ball which is expanded and foamed through steam serves as a spherical core of the composite material hollow ball, and the outer surface of the spherical core is evenly coated with a plurality of layers of fiber-reinforced resin mixtures from inside to outside until the small ball reaches the targeted density. The fiber-reinforced resin mixtures are formed by mixing liquid state epoxy resin, amine curing agents and reinforced fibers. The nominal diameter of the composite material hollow ball is 2.0-50.0 mm, the wall thickness is 0.5-2.5 mm, and the density is 100-600 kg / m<3>. The raw materials of the hollow ball are simple, the preparation technology is simple, and operation is convenient. The obtained hollow ball can be combined with artificial composite foamed resin to be made into composite buoyancy materials to be applied to underwater equipment, and particularly applied to vertical tube buoyancy modules.

Owner:TAIZHOU CBM FUTURE NEW MATERIALS S & T CO LTD

Production method of hollow ball metal composite foamed material

PendingCN109513906AIncrease productivityReduce the amount of subsequent machiningMetal foamMaterials science

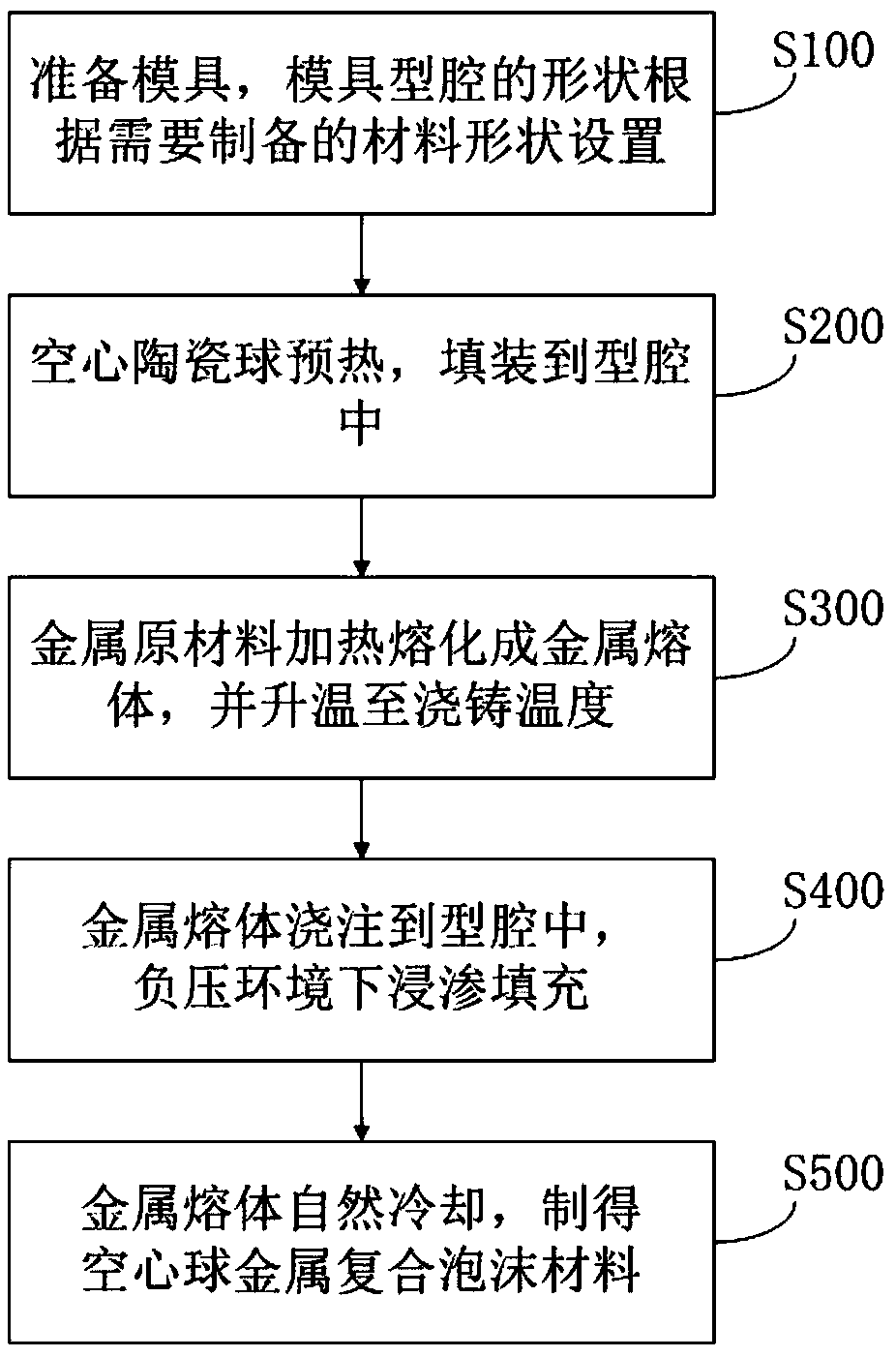

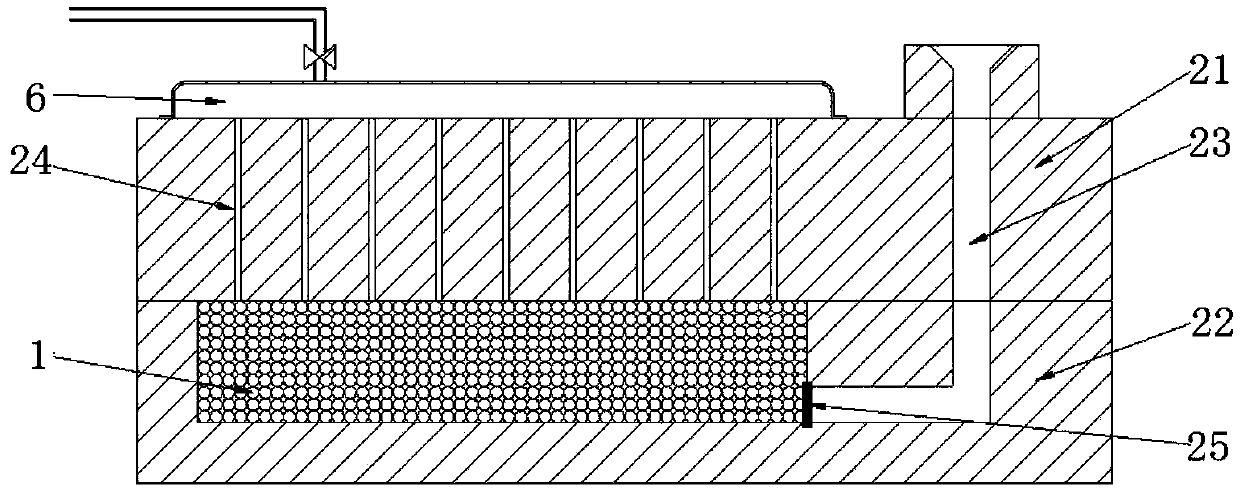

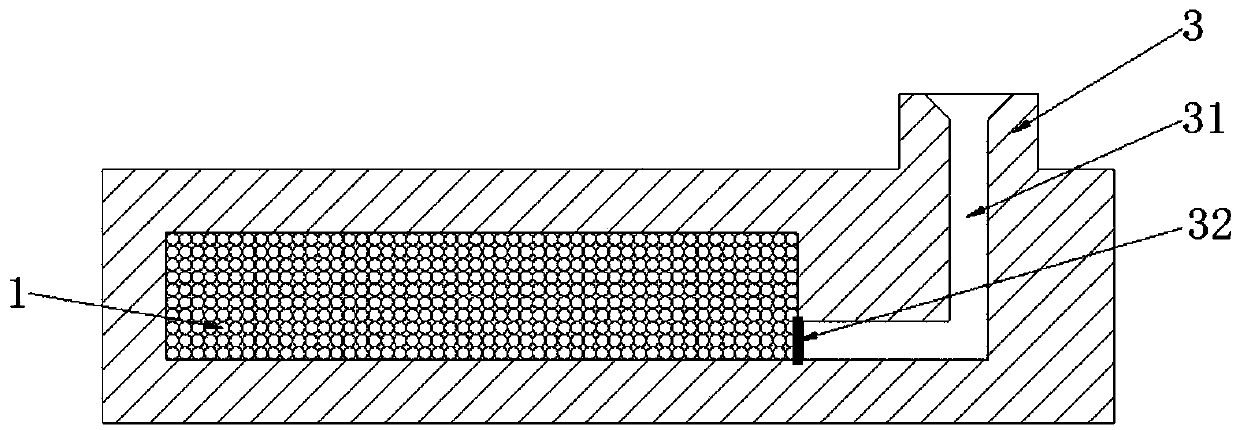

The invention discloses a production method of a hollow ball metal composite foamed material. The production method comprises the following steps: S100, preparing a mould, wherein the mould is provided with a cavity, and the shape of the cavity is set according to the shape of a to-be-prepared structural component; S200, preheating hollow ceramic balls, filling the cavity with the hollow ceramic balls, and closely arranging the hollow ceramic balls; S300, heating a metal raw material into a metal melt, and raising the temperature of the metal melt to casting temperature; S400, pouring the metal melt into the cavity, pumping the pressure of the cavity to negative pressure, and filling the clearances of the hollow ceramic balls with the metal melt in a negative pressure environment through infiltration; and S500, naturally cooling the metal melt, and carrying out demoulding to obtain the hollow ball metal composite foamed material. The one-step integral casting molding of different shapes of specially shaped structural components can be realized through the porous structure composite material, the production cost is reduced, the practicability is high, and technical support is provided for the engineering popularization and application of the hollow ball composite metal foamed material.

Owner:SAFENET NINGBO NEW MATERIAL TECH CO LTD

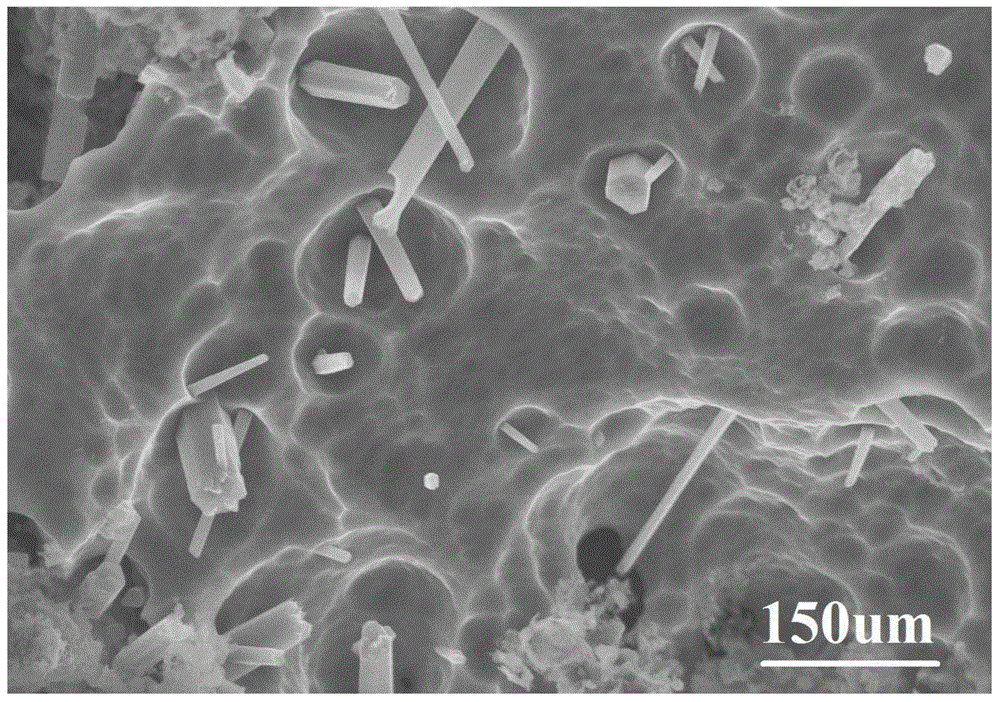

In-situ synthesized spinel whisker reinforced aluminum-based composite foam and preparation method thereof

The invention relates to a method for preparing spinel whisker reinforced aluminum-based composite foam by in-situ synthesis. The method comprises the following steps of preparing Al-Mg powder according to the mass ratio of 7.4-16 to 1; dropping PVA (Polyvinyl Alcohol) solution with the mass fraction of 3 to 5 percent into the Al-Mg powder according to the mass-to-volume ratio of 13-14g to 1-2ml, grinding the mixture and drying the mixture under the air condition to obtain composite powder, then uniformly mixing the composite powder and NaCl particles according to the mass ratio of 0.29 to 1.16 and pressing the mixture at room temperature and the pressure of 300 to 400MPa into bulk materials; raising the temperature of the bulk materials to be 600 to 800DEG C at the temperature rise rate of 5 to 10DEG C / Min under the atmosphere of argon gases, sintering the bulk materials at the above temperature for 1 to 4 hours and then cooling the sintered materials along with the furnace to obtain an Al-Mg composite material bulk; cleaning the Al-Mg composite material bulk. The method disclosed by the invention has the advantages that the process of preparing foamed aluminium is simple and controllable, and the porosity is adjustable.

Owner:TIANJIN UNIV

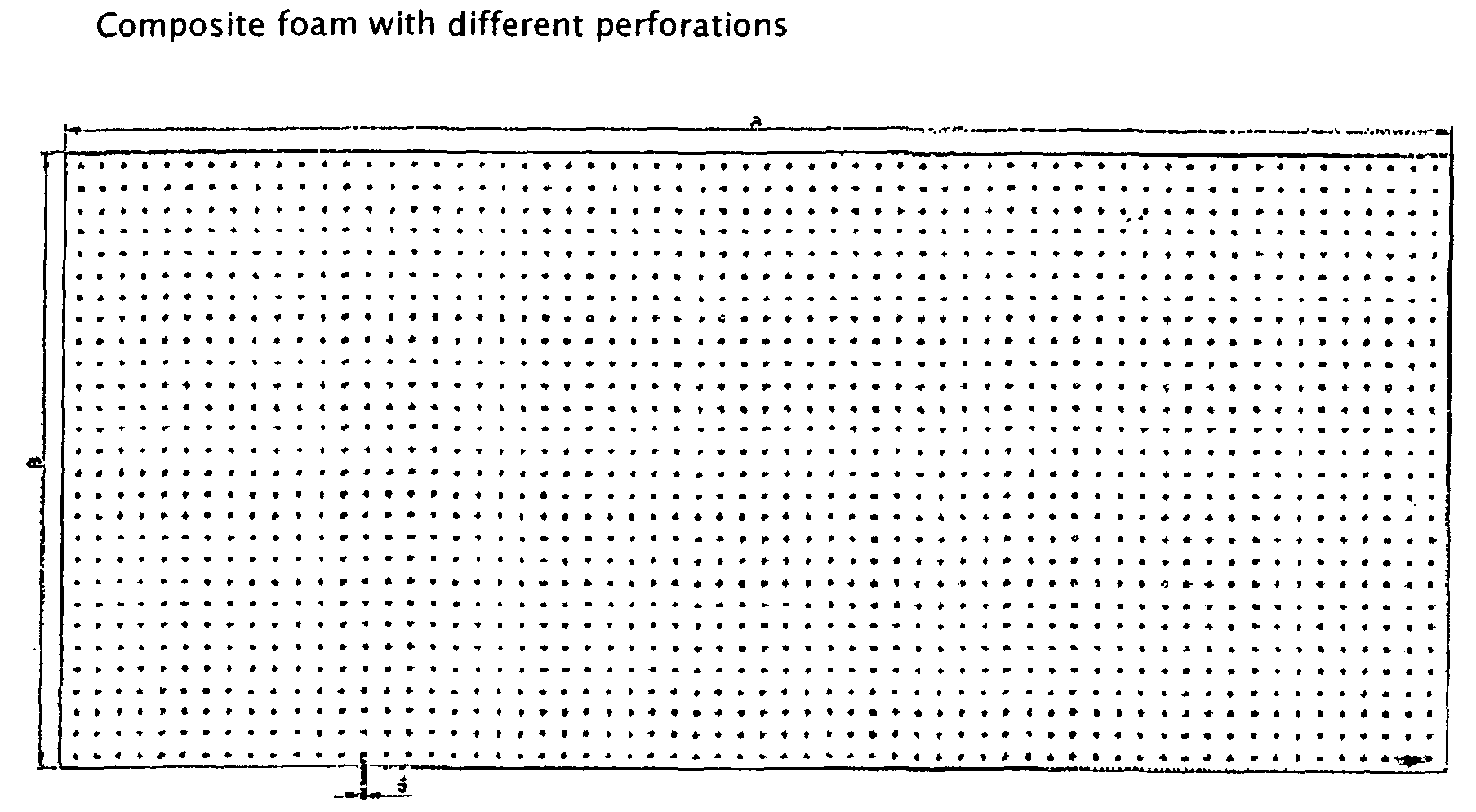

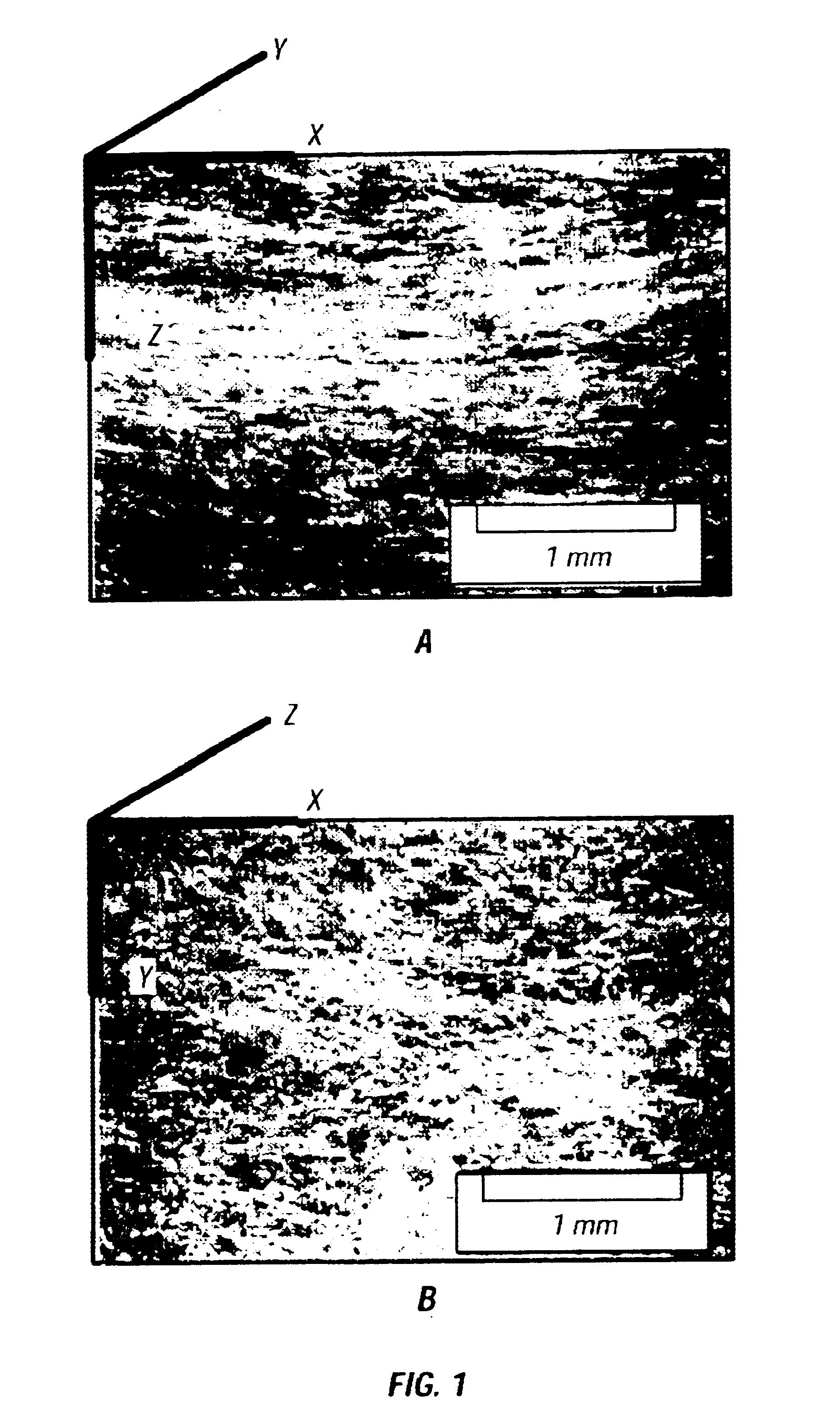

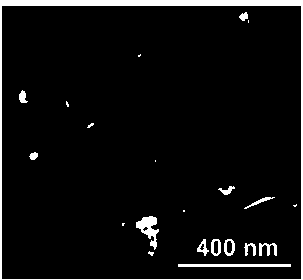

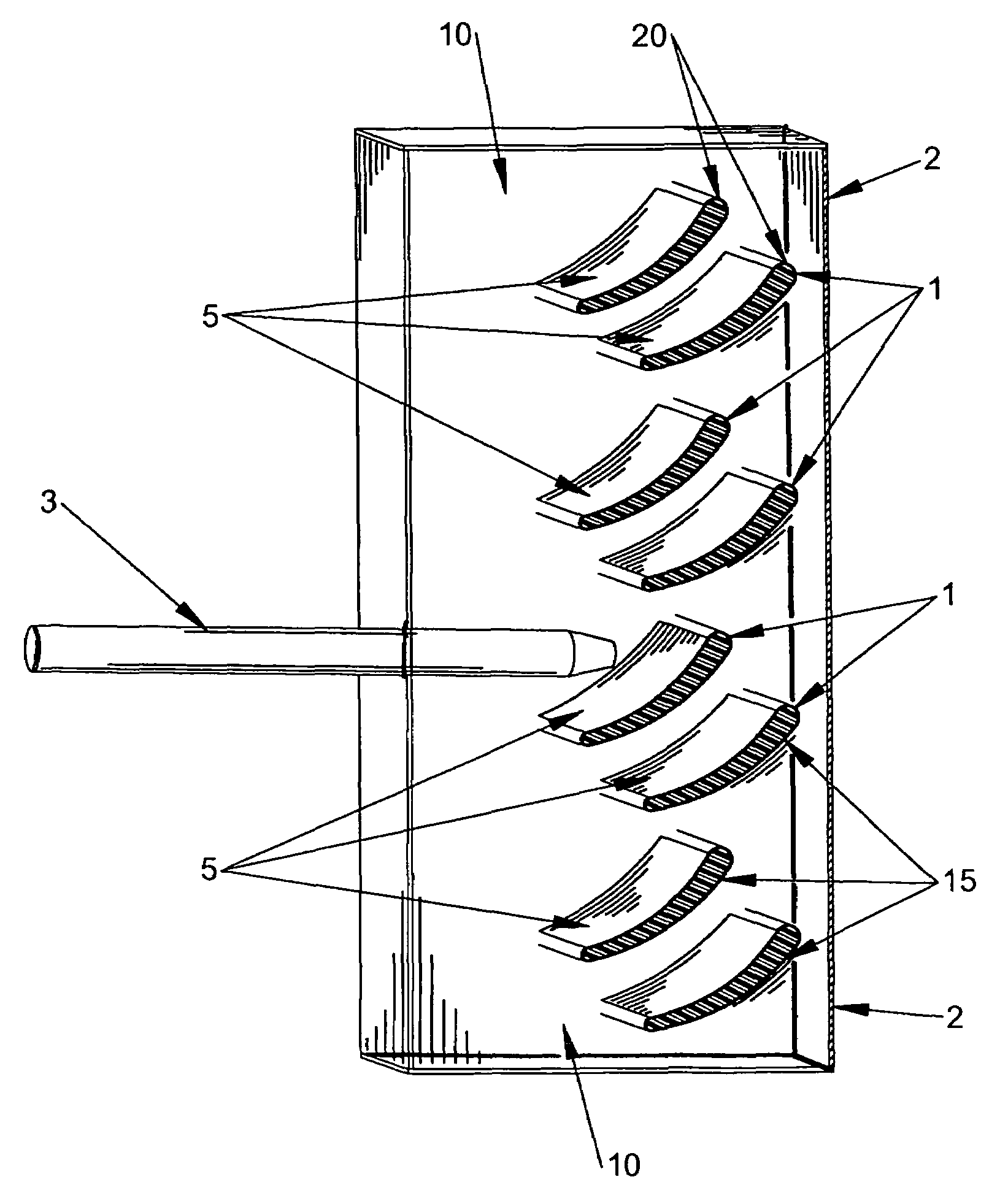

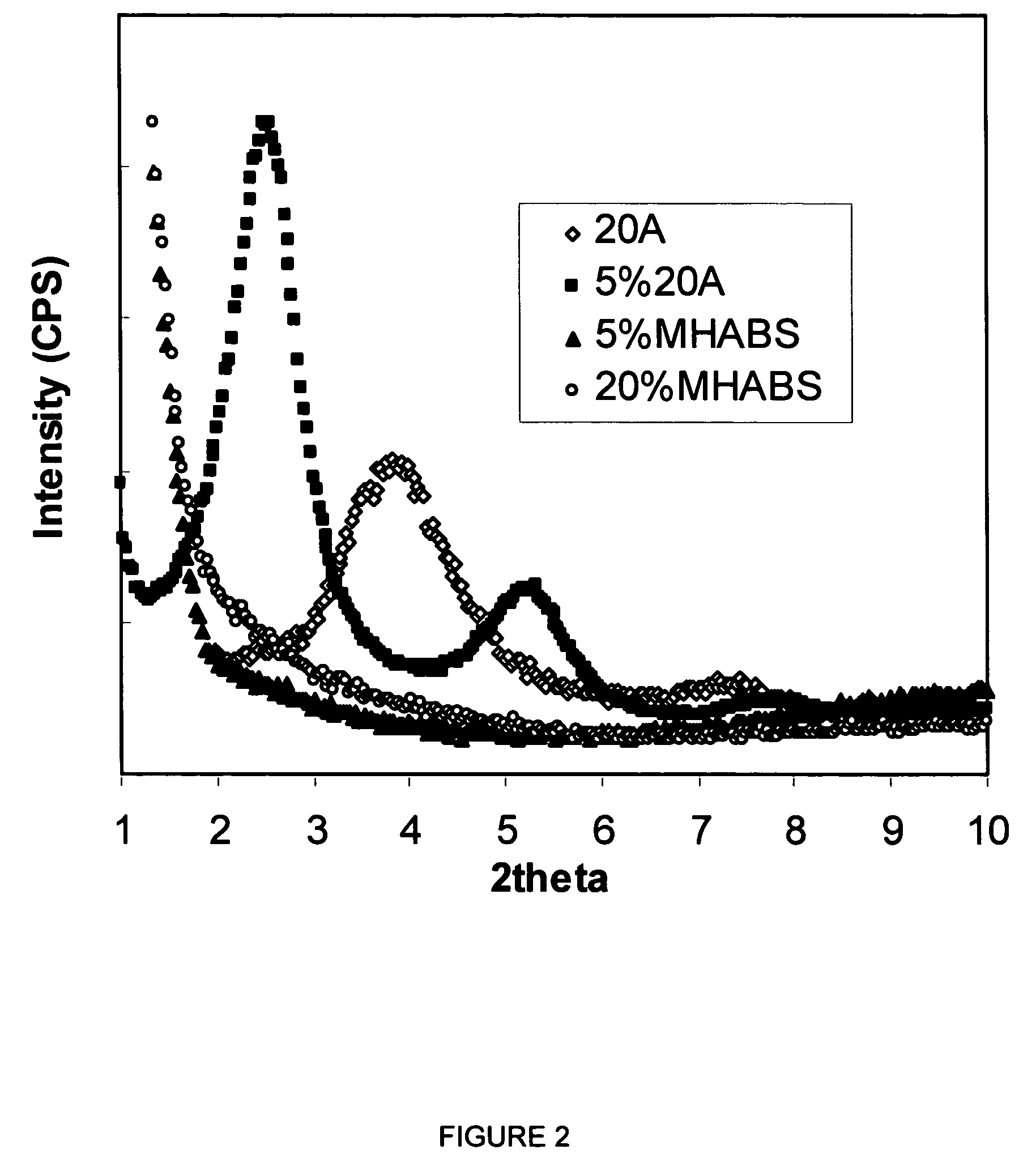

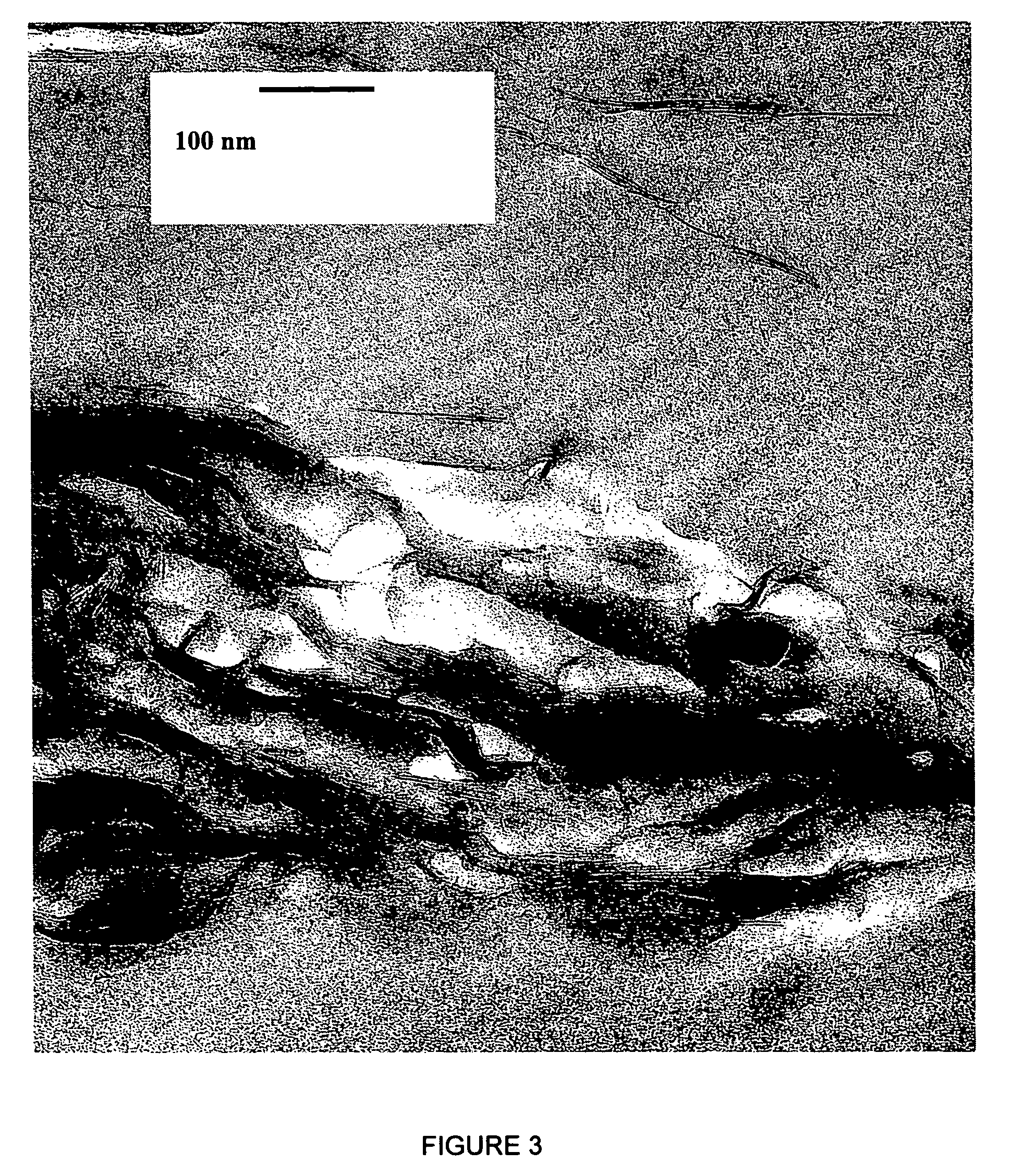

Polymer nanocomposite foams

Nano-sized particles such as nano-clays can be mixed with polymers through either melt compounding or in-situ polymerization. By modifying the particle surface with various surfactants and controlling processing conditions, we are able to achieve either intercalated (partial dispersion) or exfoliated (full dispersion) nano-clay distribution in polymers with the clay content up to 35% by weight. When a blowing agent is injected into the nanocomposite in an extruder (a continuous mixer) or a batch mixer, polymeric foam can be produced. Supercritical carbon dioxide, an environmentally friendly, low-cost, non-flammable, chemically benign gas is used as the blowing agent. This process forms a microcellular foam with very high cell density (>109 cells / cc) and small cell size (<5 microns) can be achieved by controlling the CO2 content, melt and die temperature, and pressure drop rate.

Owner:THE OHIO STATE UNIV RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com