Patents

Literature

74results about How to "Guaranteed curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

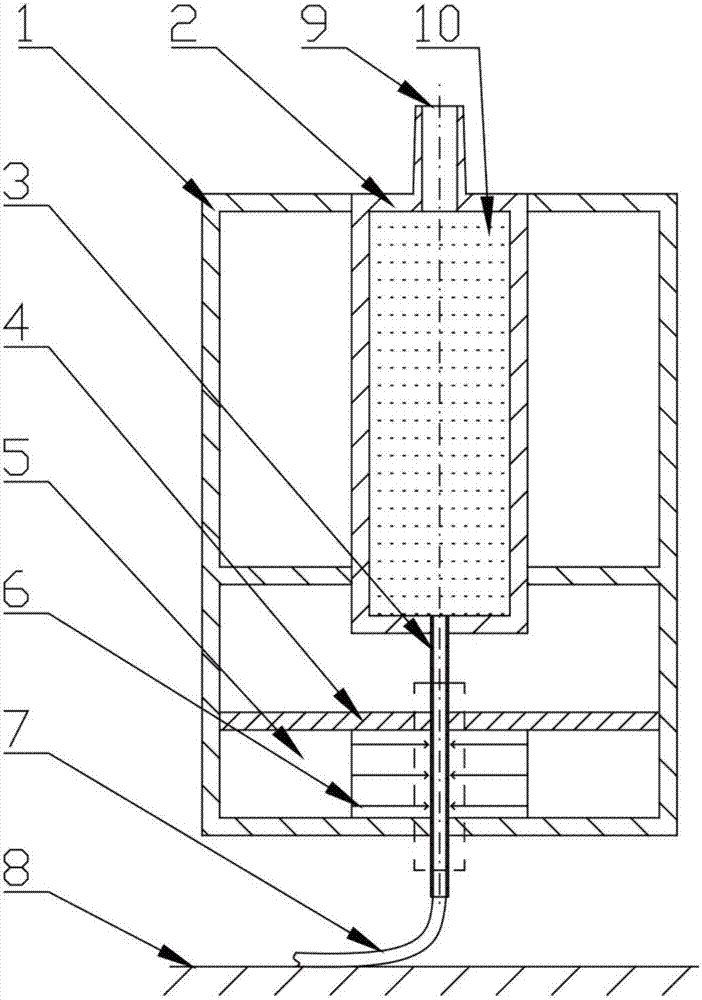

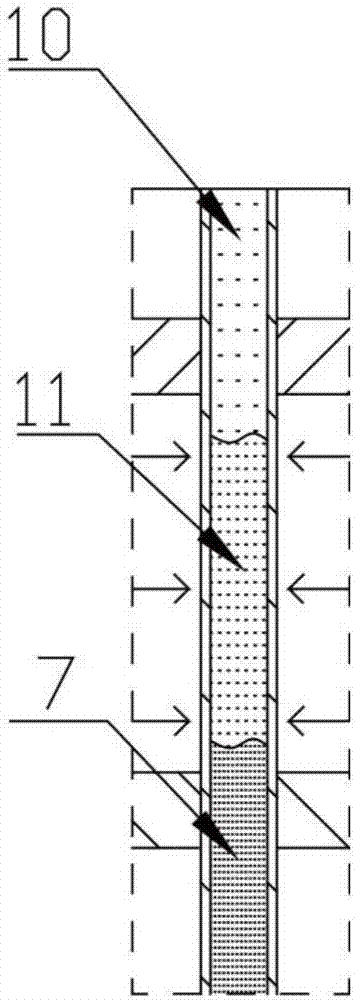

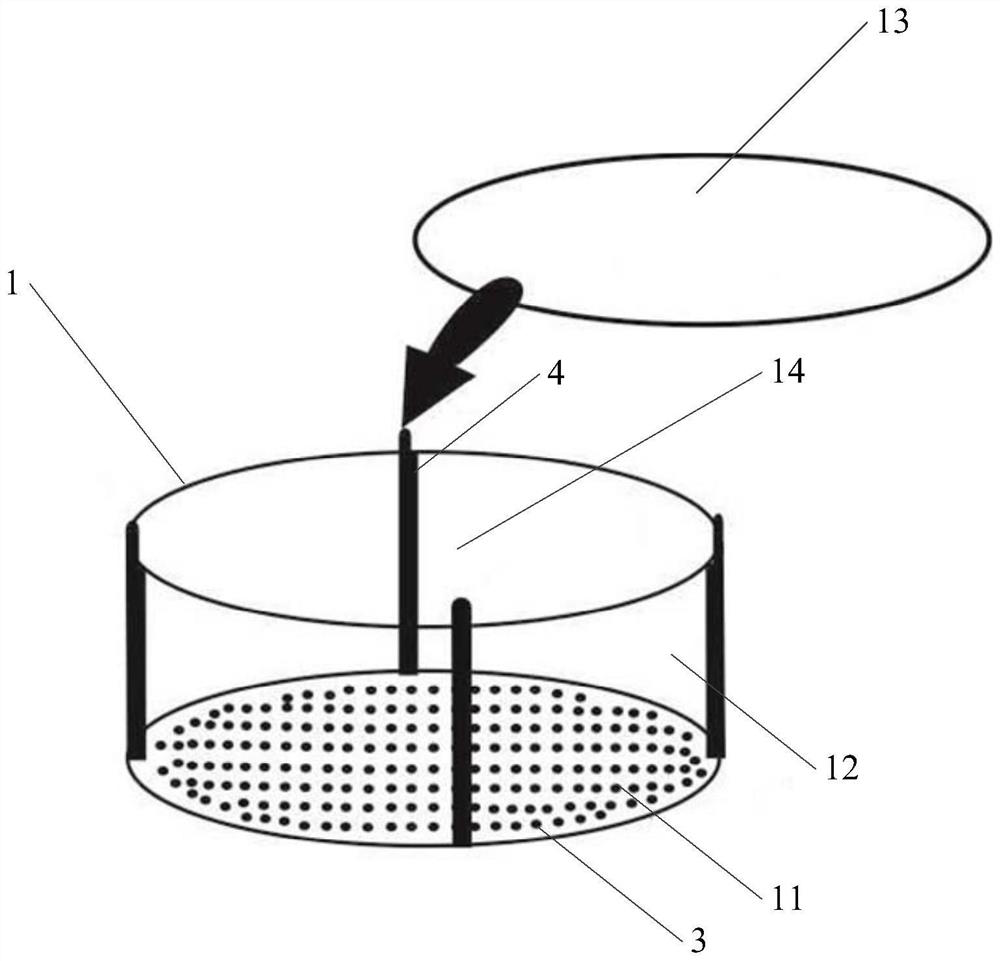

Production process for composite insulator solid core rob

InactiveCN101483089AEnsure solidificationGuaranteed curingSuspension/strain insulatorsDomestic articlesGlass fiberComposite insulators

The invention discloses a method for preparation of composite insulator solid mandril, including: leading-out setting quantity of epoxy glass fiber to a dipping tank for dipping, the epoxy glass fiber after dipping entering into a mould pressing machine, arranging in a preheat die coated with release agent; the mould pressing machine further heating the die, simultaneously applying the identical pressure to the top and bottom of the die, after heating the die at 80 DEG C - 180 DEG C for 4 - 8 hours, maintaining pressure at 180 DEG C - 120 DEG C for 1 to 3 hours to complete the mandril by one time molding; after the one time molding of the mandril, stating the mould pressing machine, separating the dies, drawing the molding epoxy glass fiber from the die, and performing second curing by microwave heating. To ensure complete curing in the internal of the mandrel, intermittent pultrusion technology is combined with the flat-plate heating molding technology, to realize the production of large-diameter epoxy glass fiber composite insulator mandril.

Owner:陕西泰普瑞电工技术有限公司

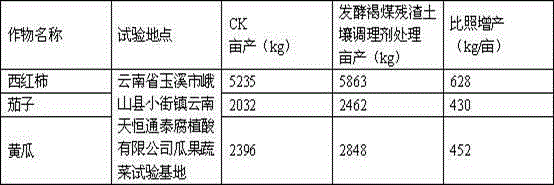

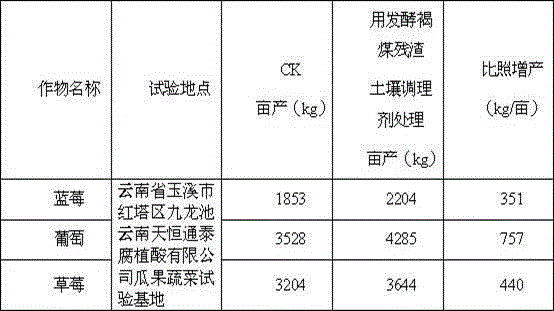

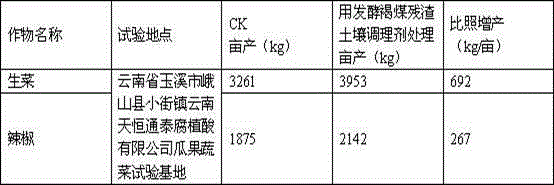

Fermented brown coal residue soil conditioner and processing method thereof

ActiveCN104312589AImprove permeabilityImprove adsorption capacityAgriculture tools and machinesOrganic fertilisersBrown coalMicroorganism

A fermented brown coal residue soil conditioner is prepared by evenly mixing brown coal residues, brown coal essence liquid, medical stone, composite bone meal, dry sapropel, and a composite microorganism inoculant according to a certain weight ratio and then fermenting the mixture. The absorbing performance and salt-base exchange performance of the soil conditioner are strong, the soil conditioner can improve the soil breathability, the crop respiratory effect is improved, the absorbing performance of roots is enhanced, the lateral root growth is promoted, the crop photosynthetic effect is effectively improved, the nutrients for plants are balanced, and the growth is promoted. The wastes (brown coal residues and brown coal essence liquid), which are generated during the brown coal processing process, are utilized, the wastes are converted into valuable resources, the product addition value is increased, an income increasing method is developed for humic acid producing entrepreneurs, a novel thinking is provided for developing soil conditioner, and the soil conditioner eventually improves the soil quality and increases the economic profits.

Owner:YUNNAN SHANGCHENG BIOTECH

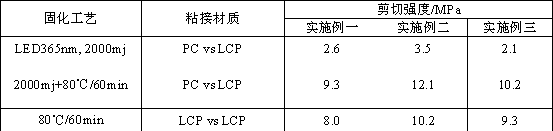

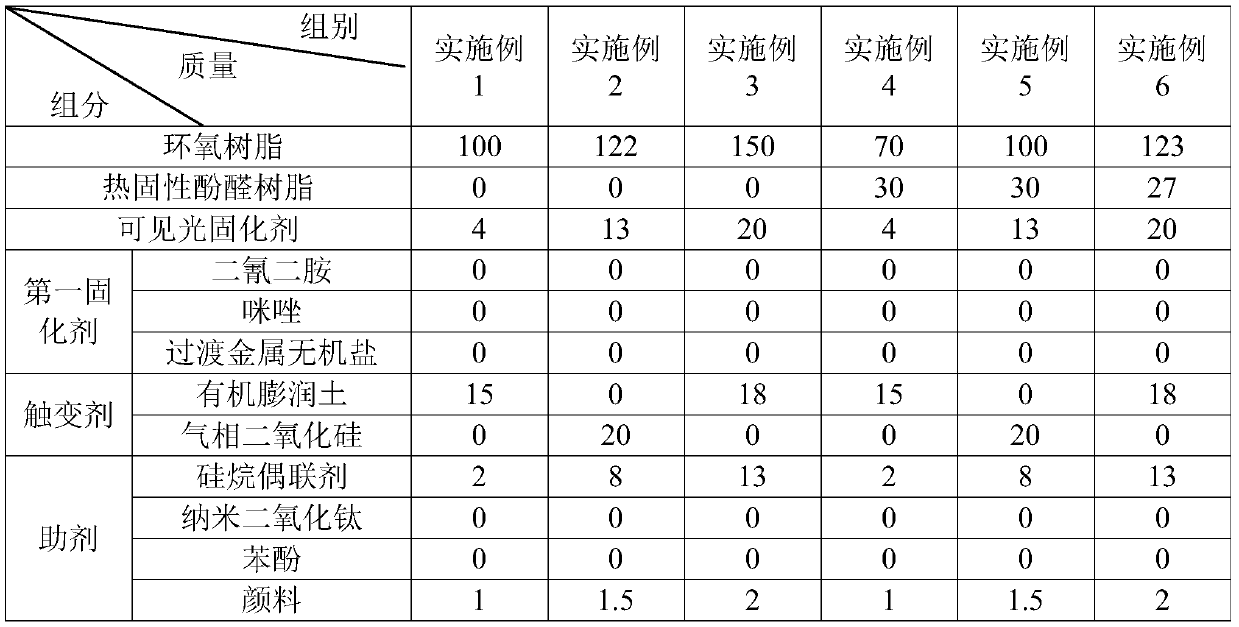

Ultraviolet light/heating double-curing adhesive

InactiveCN109233648AImprove toughnessAdhesive applicationNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyAdhesive

The invention relates to an ultraviolet light / heating double-curing adhesive. The adhesive contains the following raw materials in parts by mass: 40-70 parts of toughening-type epoxy premix, 15-35 parts of acrylate monomer, 0.1-1 part of photoinitiator, 0.1-1 part of thermal initiator, 10-35 parts of latent initiator and 1-10 parts of thixotropic agent, wherein the toughening-type epoxy premix contains bifunctional epoxy resin, liquid crystal epoxy resin and core-shell rubber particles. According to the adhesive disclosed by the invention, by adopting an epoxy / acrylate hybrid system, a heat curing epoxy component with high toughness and high adhesion strength to an LCP (Liquid Crystal Polymer) is obtained by introducing core-shell rubber and liquid crystal epoxy; through the fast photocuring positioning ability of an acrylate system, the applications of photocuring technology to opaque media, complex-shaped substrates, ultra-thick adhesive layers and colored adhesive layers are expanded; and the adhesive is especially suitable for electronic automated high-speed operations and adhesion of components with complex structures.

Owner:YANTAI DARBOND TECH

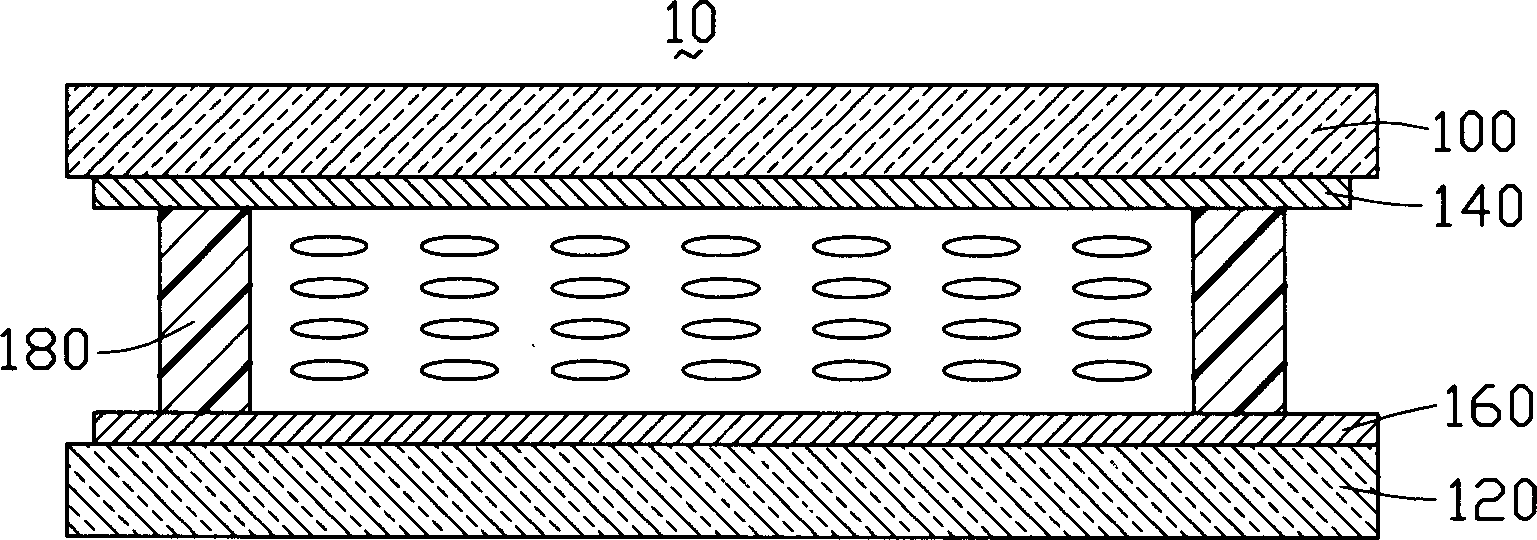

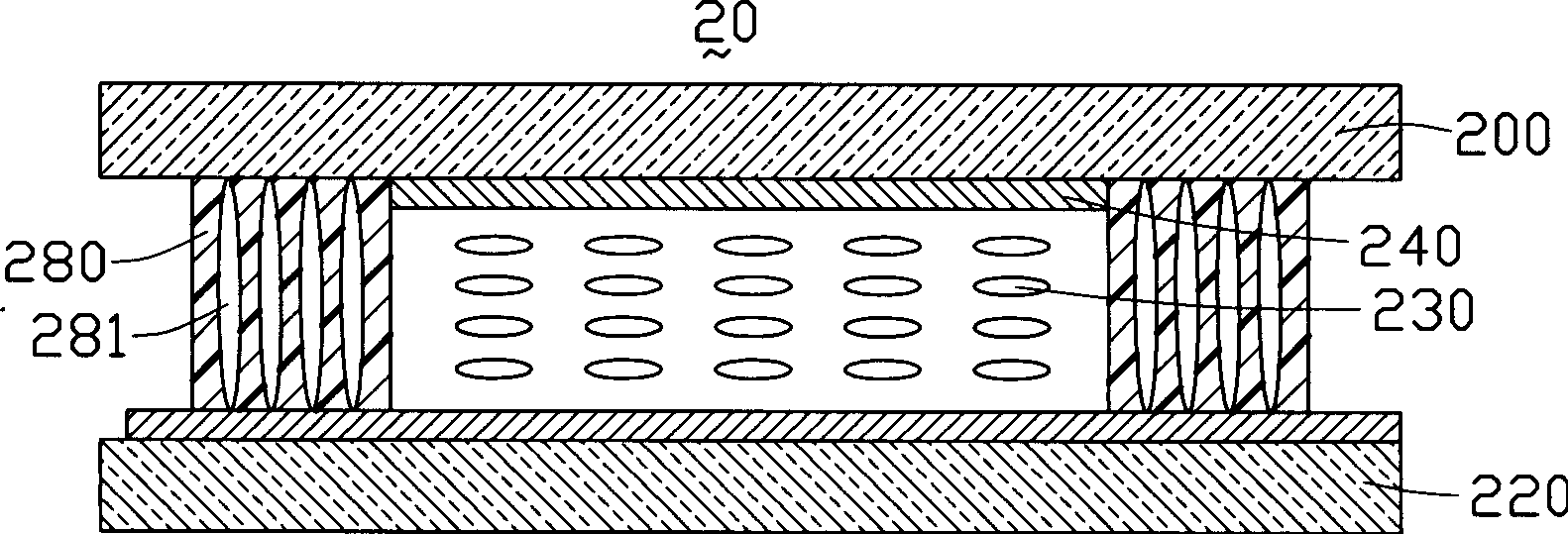

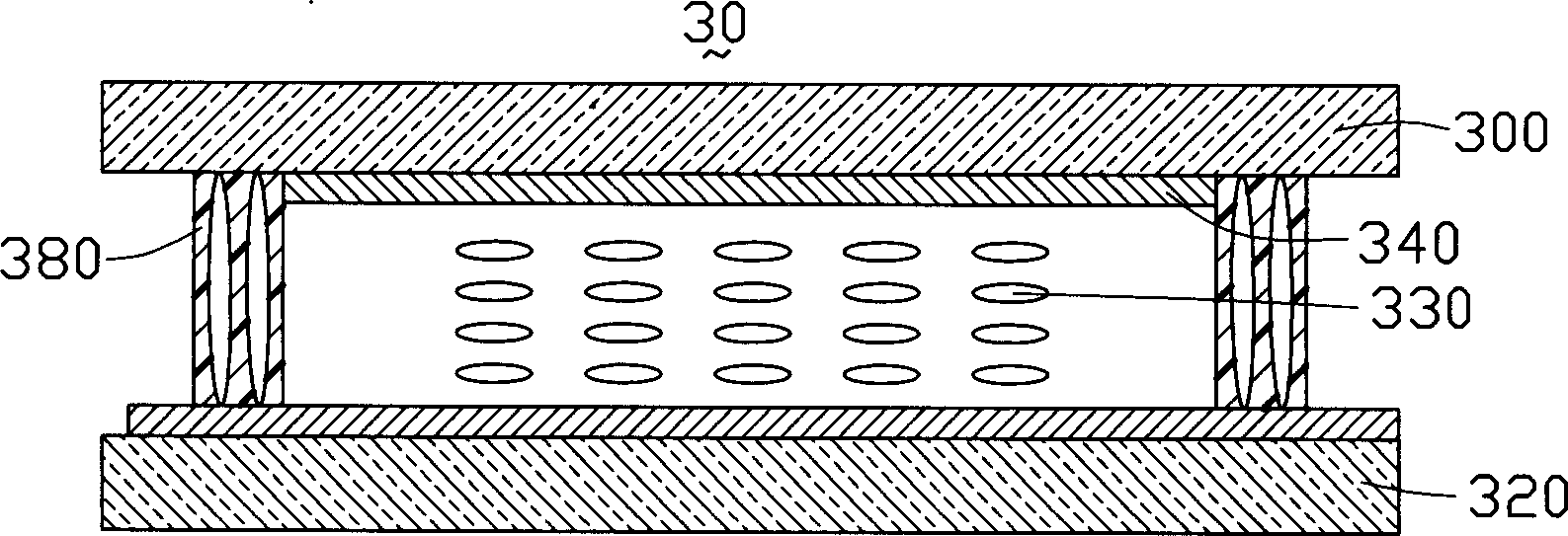

LCD faceplate

InactiveCN1797078AShortened outer widthGuaranteed curingStatic indicating devicesLiquid-crystal displayEngineering

The invention reveals a liquid crystal display panel, comprising: a first substrate whose one surface is provided with a black matrix whose outside extends to the edge of a display region; a second substrate; nontransparent frame glue, arranged around the black matrix to connect with the first and second substrates. The invention need not occupy the glass substrate to coat the frame glue, thus raising the utilization ratio of the glass substrate. In addition, the frame glue is arranged outside the black matrix, thus able to assure it can completely cure in the manufacturing process.

Owner:INNOCOM TECH SHENZHEN +1

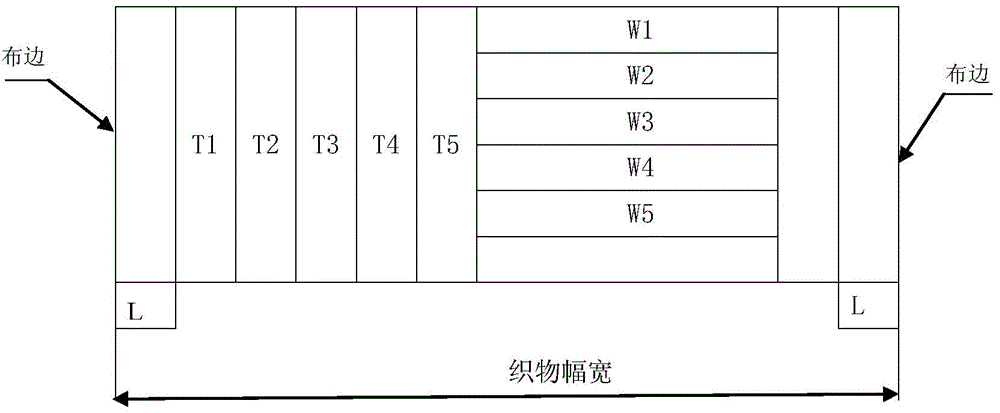

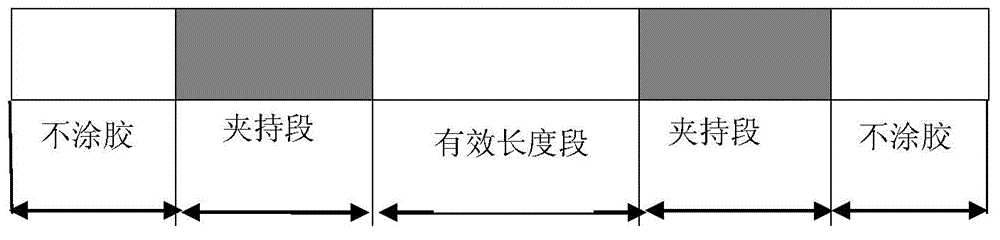

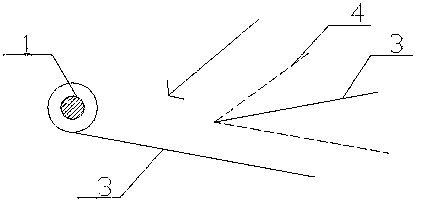

Method for detecting tensile breaking force of polyacrylonitrile-based carbon fiber cloth

InactiveCN104833573AImproves integrity and strengthAvoid uneven forceMaterial strength using tensile/compressive forcesAdhesiveEngineering

The invention provides a method which can be implemented in a laboratory, is simple and feasible to operate and used for detecting the tensile breaking force of polyacrylonitrile-based carbon fiber cloth. The method comprises the following steps: 1, taking a sample, namely, cutting a plurality of warp-direction samples in a direction which serves as a sample length direction and is parallel to the direction of warps, and cutting a plurality of weft samples in a direction which serves as a sample length direction and is parallel to the direction of wefts; 2, treating the samples, namely, respectively intensifying the clamping sections of the wrap samples and the weft samples, uniformly coating an adhesive on the clamping sections of the samples in intensification treatment, putting the samples subjected to the adhesive coating treatment in an experiment environment to adjust the moisture content, and drying the adhesive; and 3, performing tensile experiment, clamping coated parts of the samples by using plate clamps on a testing machine, drawing the test samples at a constant speed until the samples are broken, recording the maximum force exerted when the samples are broken, respectively detecting the wrap samples and the weft samples so as to obtain multiple groups of data, and taking the average values of the data, thereby obtaining the wrap and weft tensile breaking forces of the carbon fiber cloth.

Owner:SHAANXI FAST GEAR CO

Non post cure epoxy resin casting system

The invention provides a non post cure epoxy resin casting system including a formula toughening epoxy resin and a formula toughening anhydride curing agent; the formula toughening epoxy resin is milk white to pale yellow solvent-free pre-acceleration liquid epoxy resin; the formula toughening anhydride curing agent is an improved pre-acceleration anhydride liquid curing agent; components are mixed at the lower temperature in the desired quantity, are defoamed under vacuum condition for 0.5 to 2 hours after even mixing, and then are poured into a mold for curing reaction. The non post cure epoxy resin casting system has the following main characteristics: after demoulding, curing is not needed, the comprehensive energy consumption of electrical equipment manufacturing plants can be reduced, the production cycle time can be shortened by more than 20%, the product delivery time can be shortened, the product cost and labor intensity of workers can be reduced.

Owner:广州仑利奇合成树脂有限公司

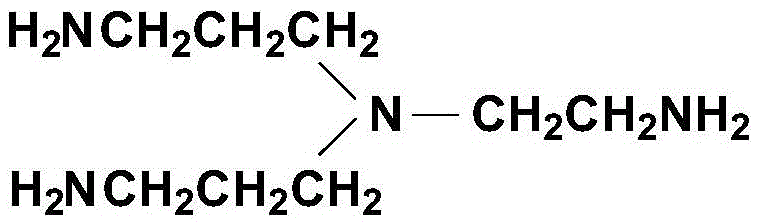

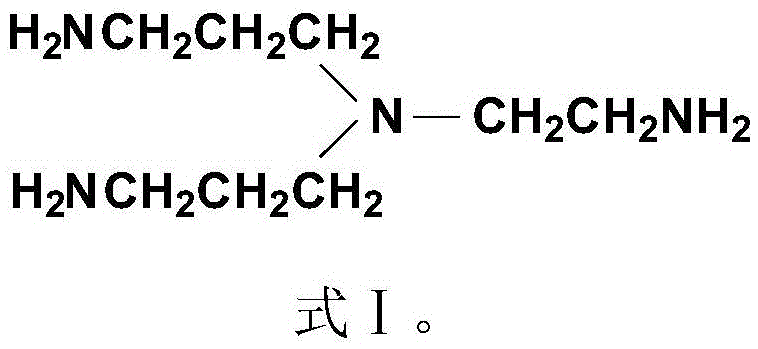

Phenol formaldehyde amine epoxy curing agent and preparation method thereof

ActiveCN105646845AHigh hardnessHigh strengthOrganic compound preparationEpoxy resin adhesivesTemperature resistanceChemistry

The invention discloses a phenol formaldehyde amine epoxy curing agent which is prepared from the following raw materials in parts by weight: 30-60 parts of N,N-di(3-aminopropyl)ethylenediamine, 5-30 parts of formyl compound and 20-60 parts of phenolic group compound. The combination of the curing agent and the epoxy resin has the advantages of very high scratch resistance, high wear resistance and high temperature resistance.

Owner:雅安市弘利展化工有限公司

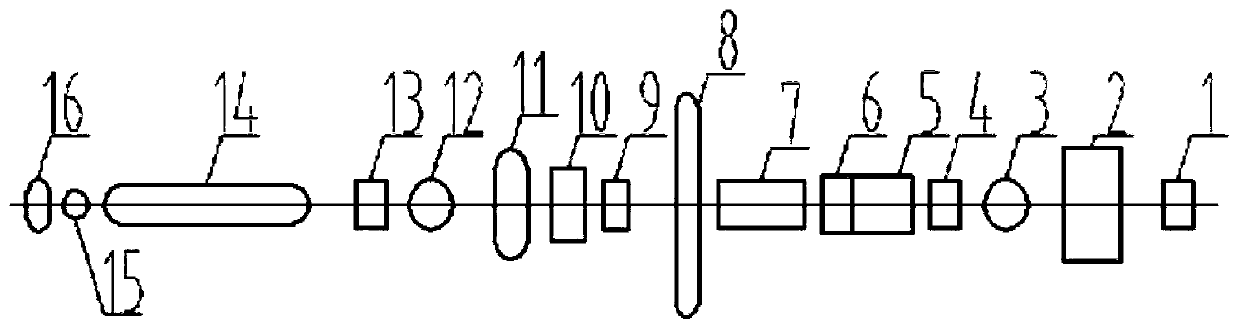

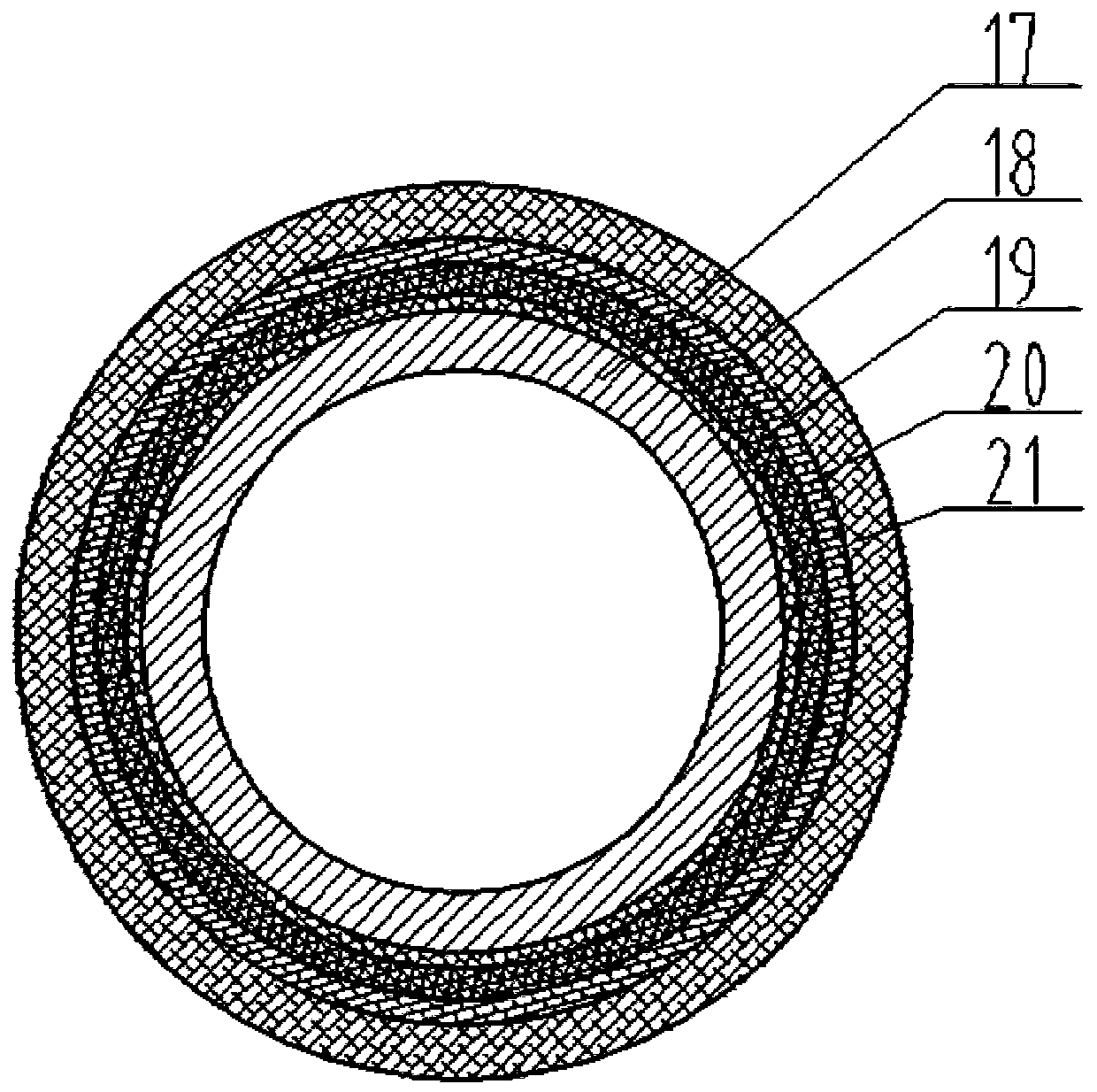

Novel steel pipe outer surface 3PE full powder anticorrosion production line and anticorrosion technology

InactiveCN109772634AImprove rust removal effectAvoid oilPretreated surfacesSpecial surfacesProduction lineIntermediate frequency

The invention discloses a novel steel pipe outer surface 3PE full powder anticorrosion production line which comprises a flame preheating furnace, a shot blasting machine, an in-pipe cleaning device,an intermediate frequency heating furnace I, a pickling phosphating chamber, a high-pressure water cleaning and air drying chamber, a medium frequency heating furnace II, an epoxy powder electrostaticspraying device, a coating heating furnace I, an adhesive powder coating device, a coating heating furnace II, a polyethylene powder coating device, a coating leveling furnace, a water cooling device, an electric spark leak detecting device and a pipe end grinding device which are arranged in sequence. The invention further discloses a novel steel pipe outer surface 3PE full powder anticorrosiontechnology. The technology includes the following steps of preheating, shot blasting, purging, re-preheating, pickling phosphating, water cleaning, air drying, heating, powder electrostatic spraying,coating heating I, adhesive coating, coating heating II, polyethylene coating, coating leveling, water cooling, anti-corrosion layer leak detection and end hitting; and the problems that the 3PE coating thickness is uneven and defects exist in a welding line of a steel pipe are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

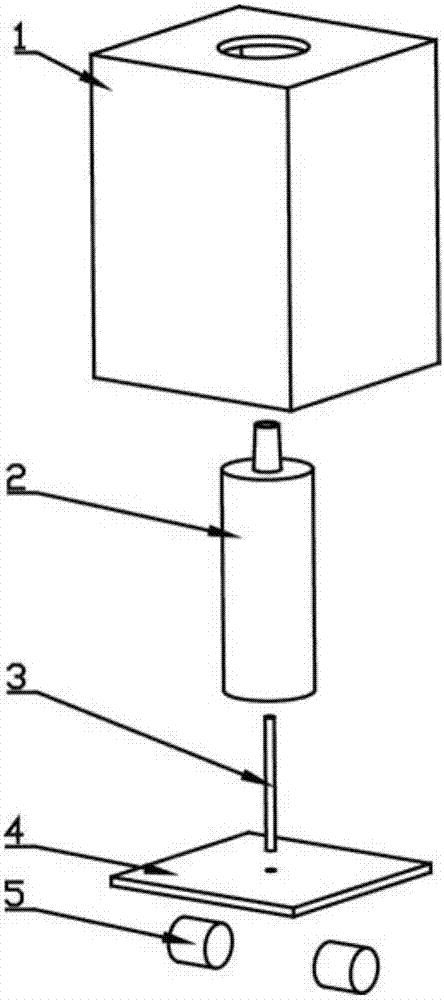

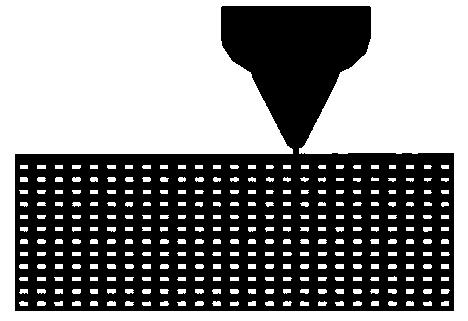

In-situ light curing extrusion nozzle

InactiveCN107127971AExpanded size rangeImprove printing accuracy3D object support structuresApplying layer meansLiquid stateUltraviolet lights

The invention discloses an in-situ light curing extrusion nozzle. The in-situ light curing extrusion nozzle comprises a shell, a liquid chamber, a transparent / semitransparent slim tube, a light source and a light shading plate, wherein the liquid chamber, the transparent / semitransparent slim tube, the light source and the light shading plate are arranged in the shell. The transparent / semitransparent slim tube communicates with the liquid chamber. The light source perpendicularly irradiates on the transparent / semitransparent slim tube, and is arranged in the circumferential direction of the transparent / semitransparent slim tube and used for perpendicularly irradiating on the transparent / semitransparent slim tube. The light shading plate is arranged between the light source and the liquid chamber. When the in-situ light curing extrusion nozzle works, the liquid chamber is internally provided with a liquid light curing material, and the liquid light curing material passes the transparent / semitransparent slim tube and is cured to form a solid filament to be extruded after being irradiated by ultraviolet light emitted from the light source. In-situ light curing refers to that light curing reaction is conducted in the nozzle, thus, the liquid light curing material can be input, and the solid filament can be directly printed out. The size range of the printed filament is greatly expanded through the transparent / semitransparent slim tube with the set size, and the size precision of the extruded filament is ensured.

Owner:XI AN JIAOTONG UNIV

Preparation method for first cathode layer of solid electrolyte capacitor

The invention aims at providing a preparation method of a first cathode layer of an electrode of a solid electrolytic capacitor; the preparation raw materials of a cathode consist of a conductive non-metal, a resin adhesive and an adhesive solvent; the preparation steps are as follows: the raw materials are evenly mixed to prepare preparation emulsion of the cathode layer; the electrode which needs to prepare the first cathode layer adopts the impregnation method in the preparation emulsion to cover a first cathode carbon layer, the air drying at the room temperature, the drying and the curing are carried out to prepare the first cathode layer; the method adopts resin as the adhesive and adopts the organic solvent as the solvent, thereby improving the binding force between the carbon layer and a polymer layer and between the carbon layer and a silver paste layer, reducing the contact resistance and increasing the heat resistance; furthermore, the raw materials are reasonable, and the preparation steps are simple, thereby being suitable for large-scale popularization and application.

Owner:福建国光新业科技股份有限公司

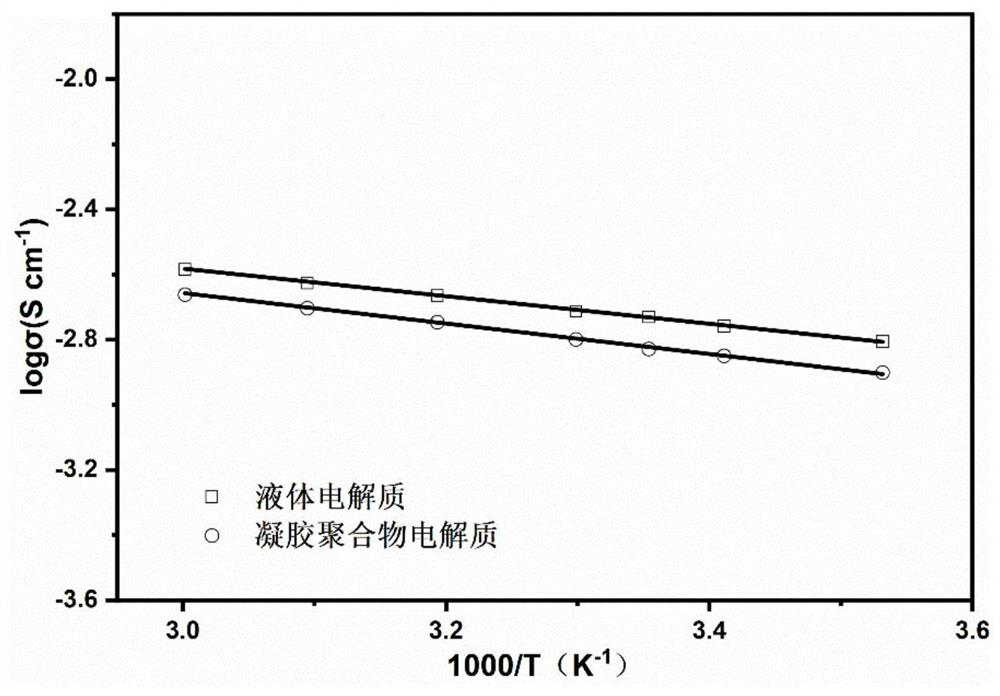

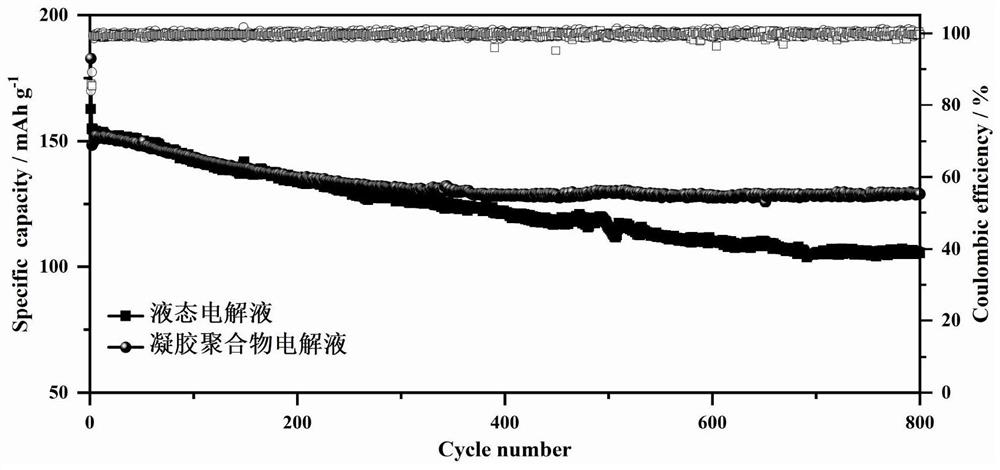

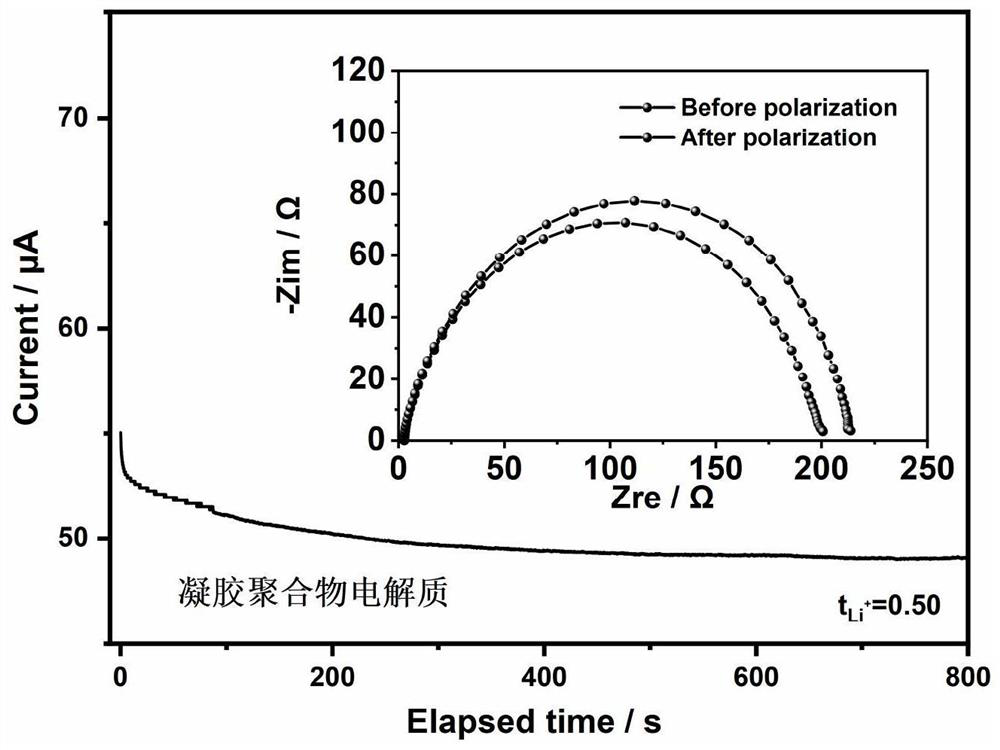

Preparation method of polyamide-based gel polymer electrolyte with multi-network structure

PendingCN112838262AImprove antioxidant capacitySimple preparation processSolid electrolytesSecondary cellsElectrolytic agentPolymer electrolytes

The invention relates to a polyamide-based gel polymer electrolyte with a multi-network structure and a preparation method of the polyamide-based gel polymer electrolyte, and belongs to the technical field of high-performance battery development. The gel polymer electrolyte is formed by polymerizing an amido monomer material, and hydrogen-bond interaction is formed between the amido monomer material and the porous support material. The preparation method comprises: fully and uniformly mixing the amido monomer material and the lithium ion battery liquid electrolyte which are prepared according to the designed components, polymerizing on the porous support material rich in hydroxyl and carboxyl to form a film, and obtaining the interface enhanced polyamide gel polymer electrolyte with the multi-network structure and high strength. The gel polymer electrolyte is reasonable in component design, the preparation process is simple and controllable, the obtained product is excellent in performance, and large-scale industrial production is facilitated.

Owner:广东聚圣科技有限公司

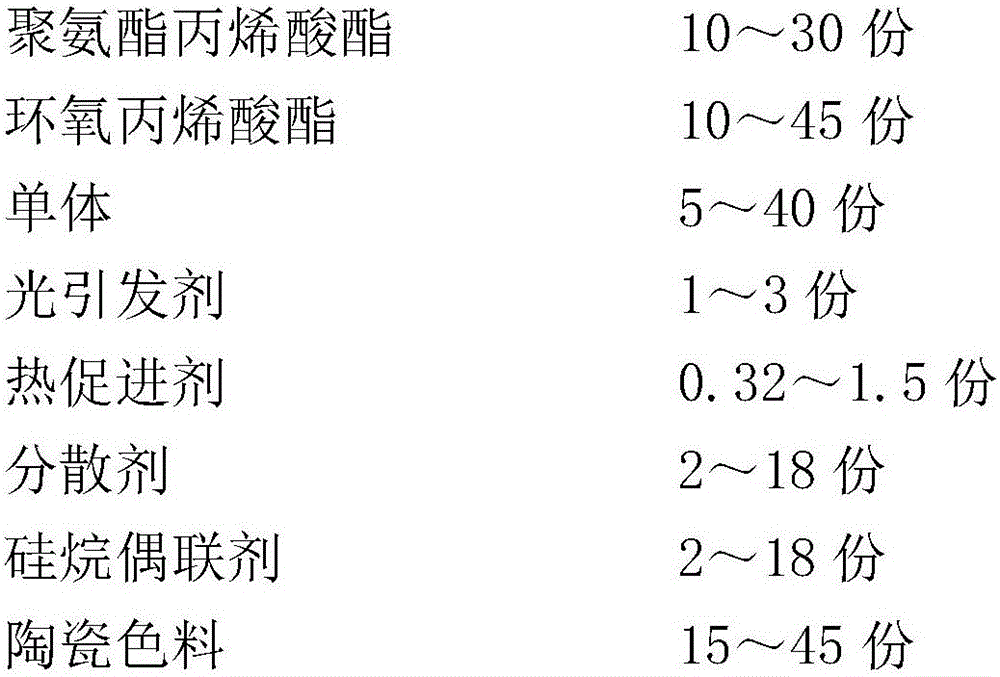

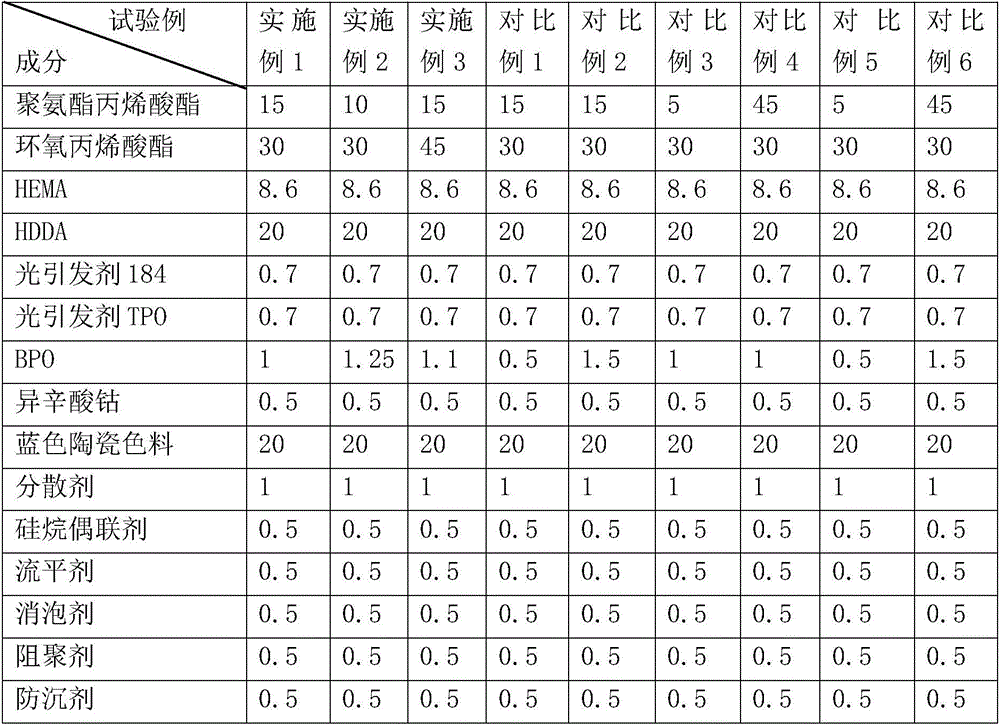

UV photo-thermal dual-curing ceramic ink-jet ink and preparation method thereof

The invention discloses UV photo-thermal dual-curing ceramic ink-jet ink and a preparation method thereof and relates to the technical field of ceramic ink. The ceramic ink-jet ink comprises the following components in parts by weight: 10-30 parts of urethane acrylate, 10-45 parts of epoxy acrylate, 5-40 parts of monomer, 1-3 parts of photoinitiator, 0.8-3 parts of thermal initiator, 0.32-1.5 part of thermal accelerant, 2-18 parts of dispersant, 2-18 parts of silane coupling agent, 15-45 parts of ceramic pigment and 1-4 parts of auxiliary, wherein the monomer is one or a combination of more of low-viscosity acrylate with single functional group, acrylate with two functional groups and acrylate with three or more functional groups; and the ratio of the thermal initiator to the thermal accelerant is (2-2.5):1. In the invention, the ultraviolet curing and thermal curing technologies are combined, polymerization can be performed under ultraviolet irradiation before thermal curing, and complete curing in a shadow area is guaranteed; and by applying the ceramic ink-jet ink to ceramic production, a delicate and vivid stereoscopic decoration effect with a strong color effect can be realized.

Owner:FOSHAN CAIGUI NEW MATERIAL CO LTD

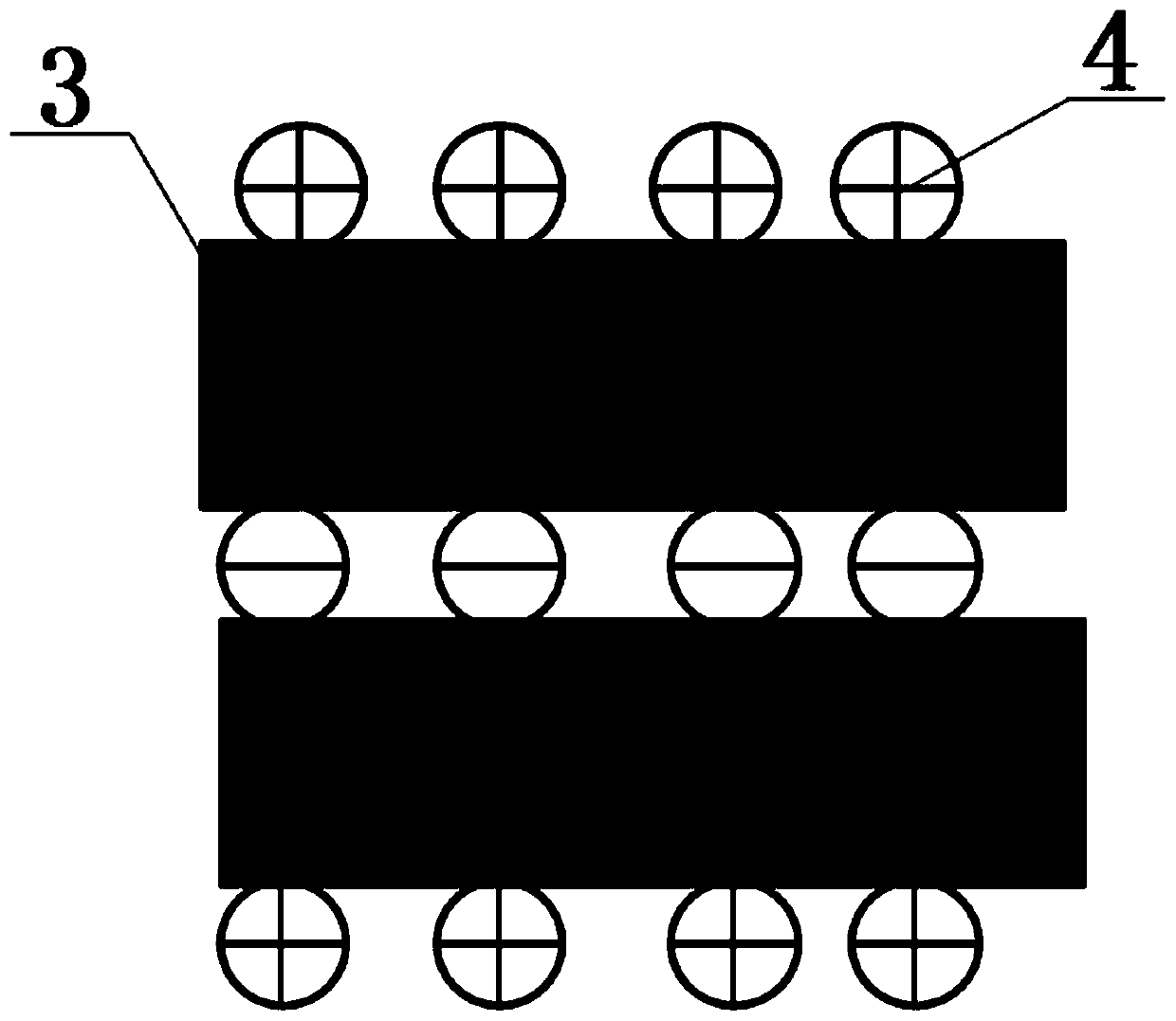

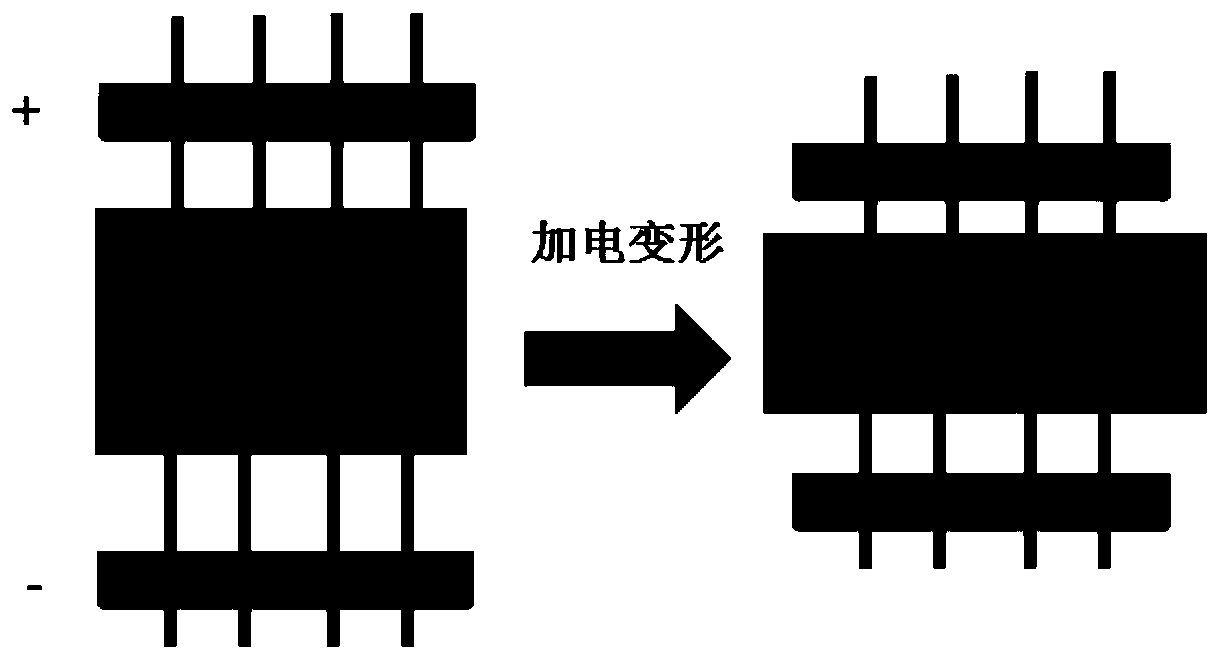

PVC-gel artificial muscle integrated printing method

ActiveCN109795103AGuaranteed rigidityRealize rapid prototypingAdditive manufacturing apparatus3D object support structuresGel electrodeCarbon nanotube

The invention discloses a PVC-gel artificial muscle integrated printing method. The method includes the steps that polyvinyl chloride, adiponitrile poly butylene terephthalate and tetrahydrofuran areused as PVC-gel core layer materials, carbon nanotubes and silicon rubber or polyvinyl chloride and ultra-long carbon tubes and adiponitrile poly butylene terephthalate are used as electrode raw materials, and fully flexible integrated PVC-gel artificial muscles are prepared through a 3D direct writing device printing process. According to the PVC-gel artificial muscle integrated printing method,a 3D printing technology is combined with the fully flexible PVC-gel artificial muscles, the 3D printing technology is applied into an integrated preparation process of a PVC-gel electrode and a corelayer, rapid prototyping of structures of the fully flexible PVC-gel artificial muscles is realized, the cost of manufacturing the fully flexible PVC-gel structures is lowered, and application of thematerial in the fields such as medical treatment, aerospace, soft robots is expanded.

Owner:XI AN JIAOTONG UNIV

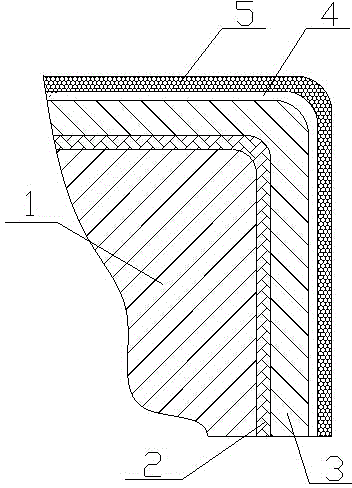

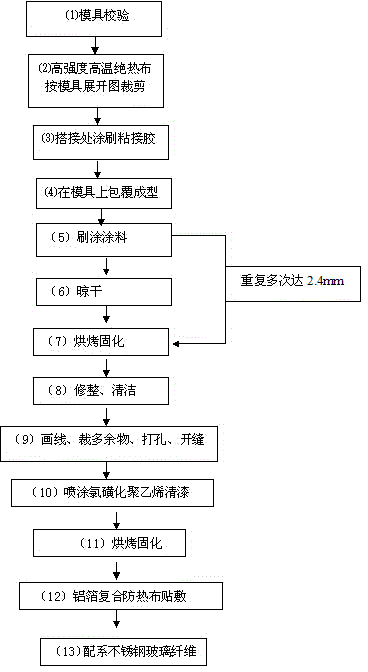

Aluminum foil composite heat-proof sleeve and manufacturing method thereof

ActiveCN104676194AGuaranteed curingEasy to installThermal insulationPipe protection by thermal insulationHeat flowMetallurgy

Owner:HUNAN XINGXIN AETROSPECE NEW MATERIAL CO LTD

High heat conductive epoxy sealant, and preparation method thereof

InactiveCN109705788AImprove thermal conductivityExpand the scope of applicationNon-macromolecular adhesive additivesEpoxy resin adhesivesCvd grapheneOxide

The invention provides a high heat conductive epoxy sealant. The high heat conductive epoxy sealant comprises following raw materials: epoxy resin, a high heat conductive filling material, a curing agent, an antifoaming agent, and a wetting dispersant; the epoxy resin is one or a mixture of two components selected from bisphenol A epoxy resin and bisphenol F epoxy resin; the high heat conductive filling material is one or a mixture of a plurality of components selected from silica, alumina, zinc oxide, copper powder, and graphene; the curing agent is one or a mixture of a plurality of components selected from dicyandiamide, imidazole, and carbamide. The heat conductive performance of the high heat conductive epoxy sealant is obviously better that that of commercially available products, and is as high as 2.0W / (m.k); cost is low, and the cost is 1 / 3 of that of foreign products; the high heat conductive epoxy sealant is a single component material; middle and low temperature curing can be realized; the curing technology is simple; product suitable range is wide; using is convenient; low temperature storage time can be longer than 6 months; the high heat conductive epoxy sealant is convenient to store; and waste is avoided.

Owner:SHANGHAI JORLE FINE CHEM

Method for preparing ionic pressure array sensor based on 3D printing

ActiveCN109878071AHigh precisionHas shear thinning propertiesAdditive manufacturing apparatus3D object support structuresBoiling pointEngineering

The invention discloses a method for preparing an ionic pressure array sensor based on 3D printing. An ionic polymer solution Nafion and high-boiling-point solvent are used as ion sensing raw materials, pluronic F 127 is used as a printing supporting layer raw material, and the ionic pressure array sensor can be prepared through 3D composite printing. According to the method, the printing Nafion solution and printing supporting gel F-127 are combined, the problems occurring in array structure manufacturing with the pure printing Nafion solution are solved, the method is suitable for manufacturing different types of Nafion polymer microstructure arrays and therefore great utilization potentiality is achieved in the fields of artificial skin, flexible sensing and the like.

Owner:XI AN JIAOTONG UNIV

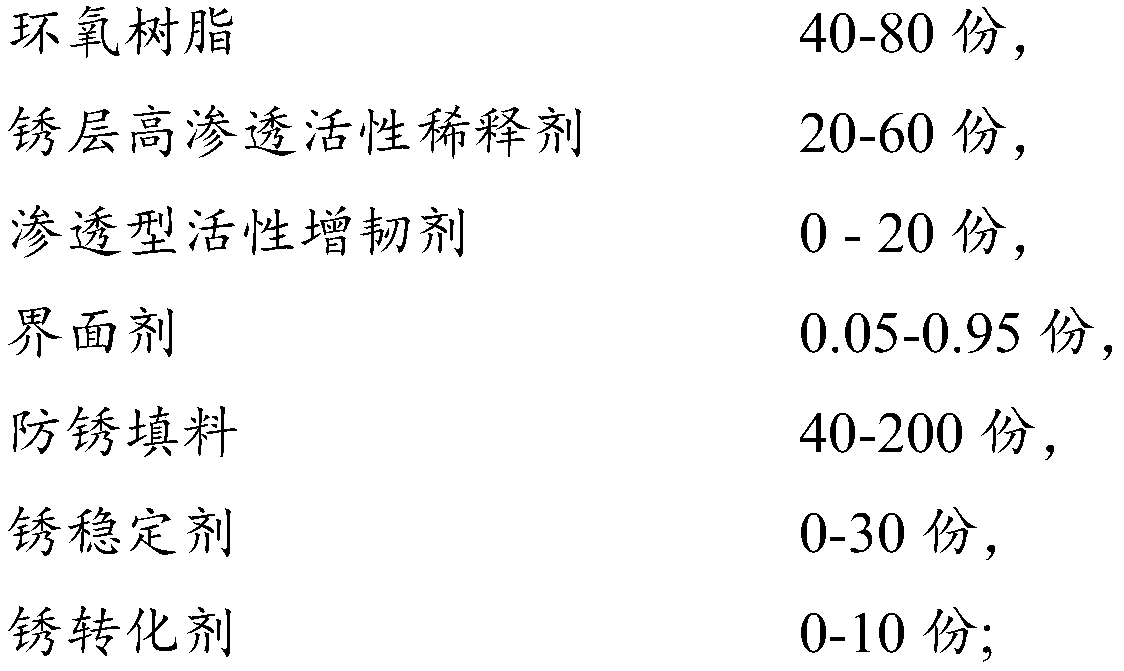

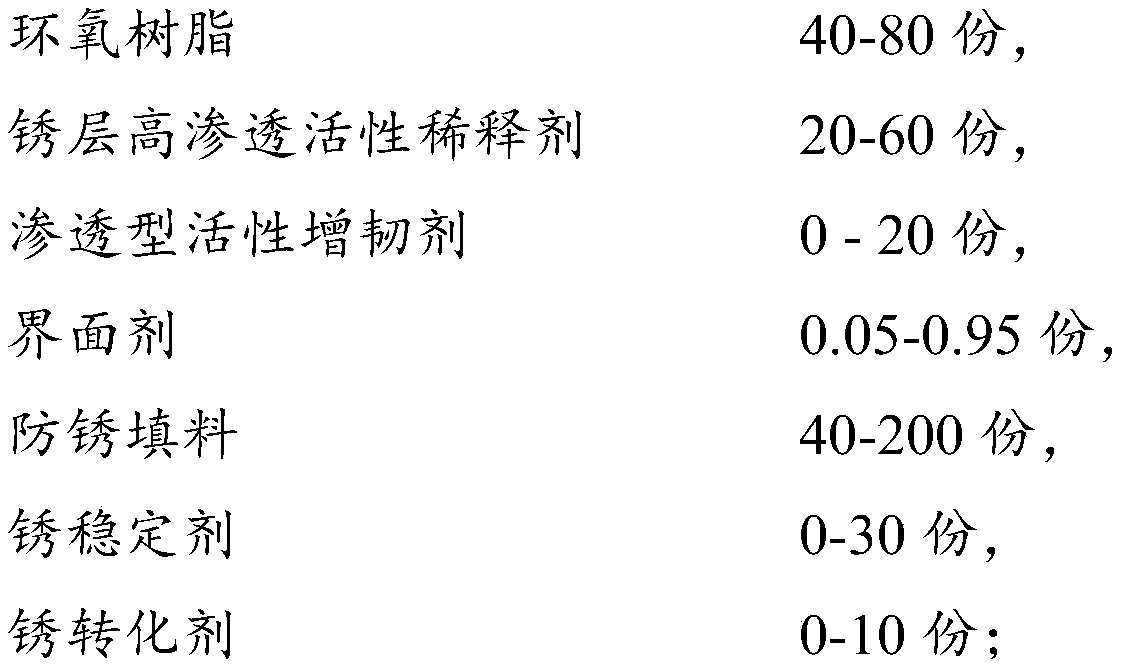

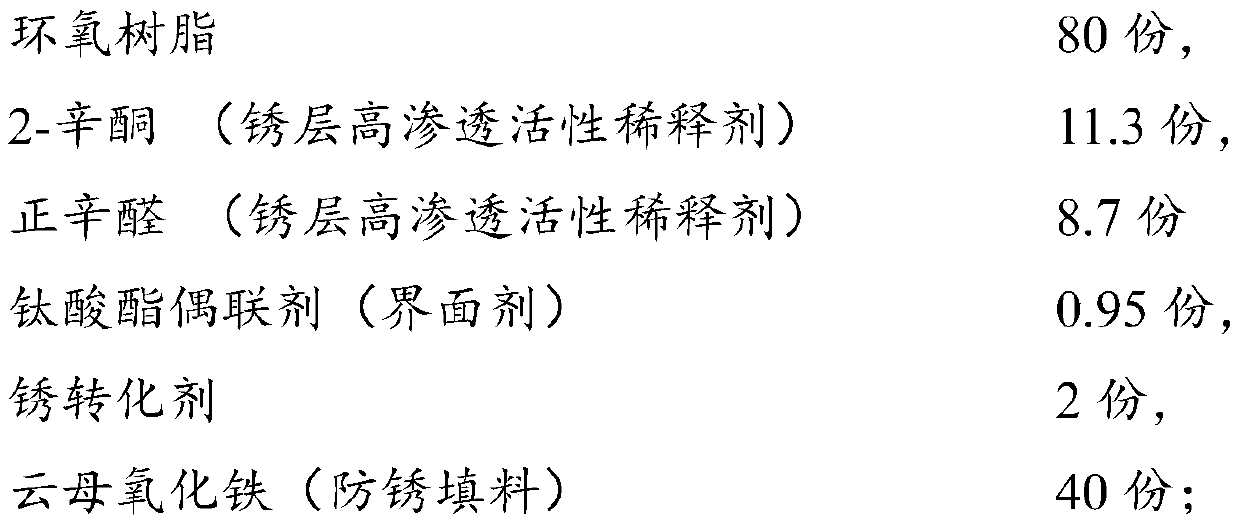

Environmentally-friendly high-permeability modified epoxy rusty coating

InactiveCN110835490AImprove mechanical propertiesGood adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceGlycidyl ethers

The invention provides an environmentally-friendly high-permeability modified epoxy rusty coating, and belongs to the technical field of coatings. The coating is composed of a component A and a component B, the component A comprises at least one of a glycidyl ether compound and a mixture of an aldehyde compound and a ketone compound, at least one of a rust stabilizer and a rust conversion agent, epoxy resin, an interface agent and an antirust filler, and the component B comprises an amine curing agent, a curing accelerator and a moisture-consuming functional curing agent. The aldehyde compound, the ketone compound and the glycidyl ether compound enable the coating to have excellent permeability, and also can participate in system reactions under the action of the amine curing agent, so that the problem of environmental pollution caused by VOCs generated in the film forming process is greatly reduced, and the flexibility and the adhesive property of the coating are improved; and the moisture-consuming functional curing agent can consume moisture in a rust layer, so it is ensured that the rust layer is not rusted any more, and the curing of the epoxy resin is also ensured.

Owner:广州永科新材料科技有限公司

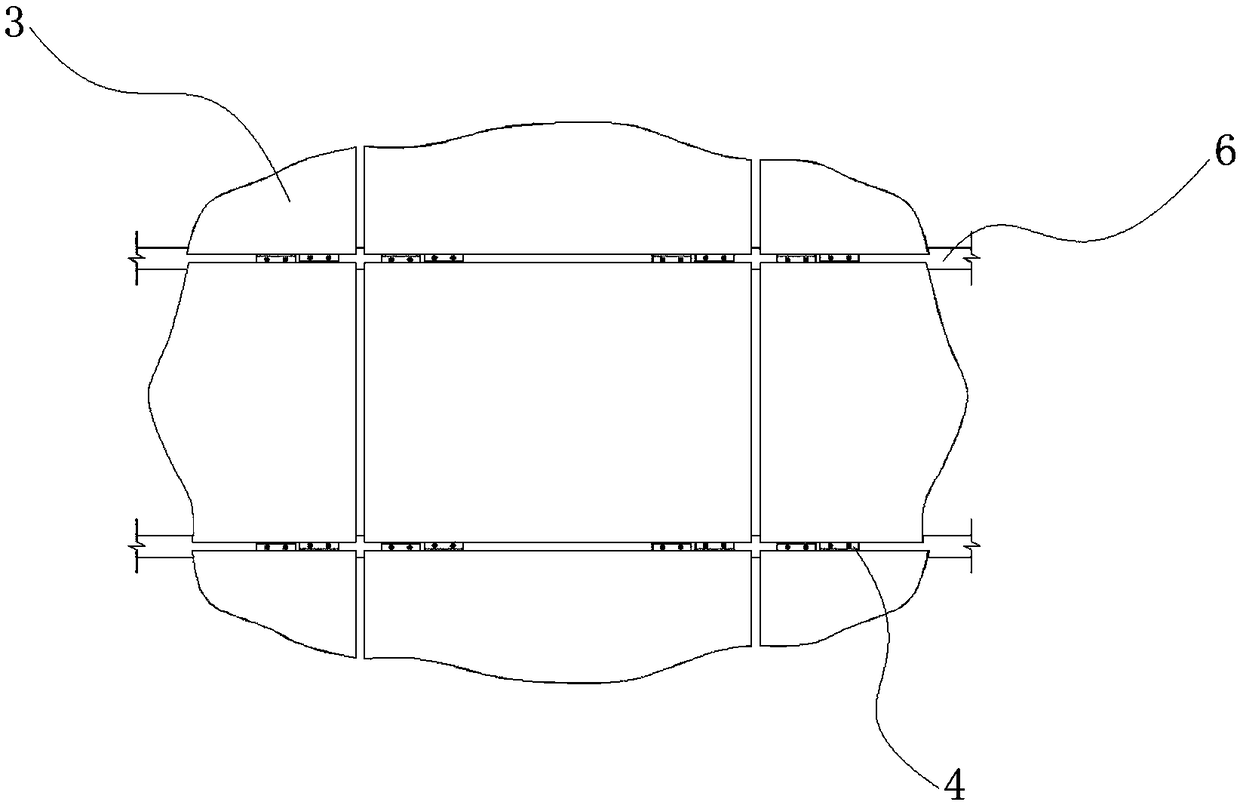

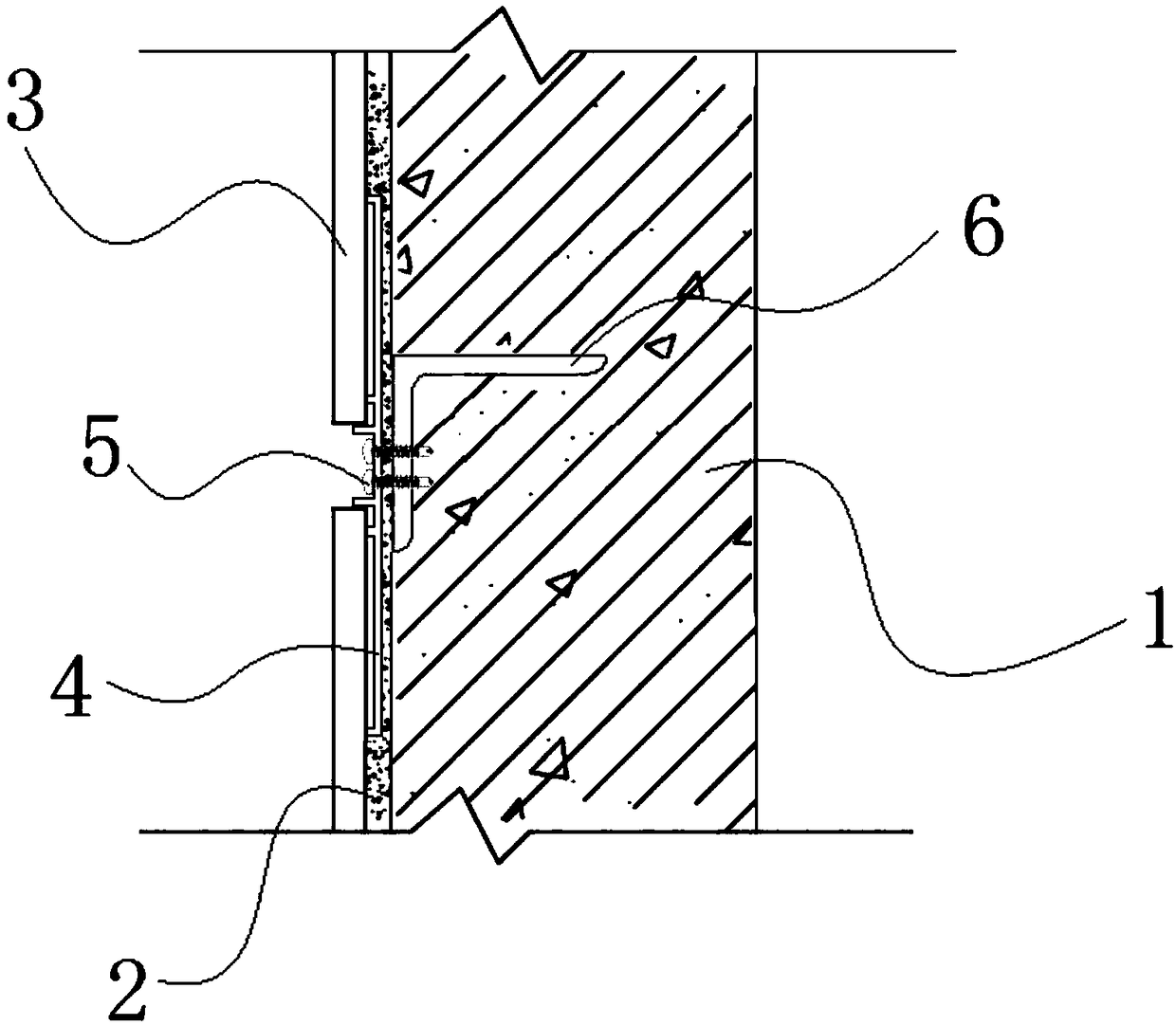

Bonding and anchoring combined ceramic thin plate faced wall and mounting method thereof

PendingCN109403520AGuaranteed curingHigh bonding strengthCovering/liningsWallsHigh riseSelf-tapping screw

The invention provides a bonding and anchoring combined ceramic thin plate faced wall and a mounting method thereof. The bonding and anchoring combined ceramic thin plate faced wall comprises a base layer wall body, and further comprises bonder layers and a ceramic thin plate layer which are sequentially arranged on the outer side of the base layer wall body; a plurality of connecting pieces are pre-buried in the base layer wall body; the ceramic thin plate layer comprises a plurality of ceramic thin plates; a plurality of aluminum alloy pendants are fixed to the upper and lower ends of each ceramic thin plate correspondingly; the bonder layers are arranged on the back faces of the ceramic thin plates in a mode of being scraped in batches; during working, the ceramic thin plates are laid and pasted on the wall surface of the base layer wall body through the bonder layers; and self-tapping screws sequentially penetrate through mounting holes and the connecting pieces to mechanically connect the aluminum alloy pendants with the base layer wall body. The mounting method of the wall comprises the steps of structural adhesive filling, aluminum alloy pendant pasting, bonder scraping in batches, ceramic thin plate laying and pasting and the like. The bonding and anchoring combined ceramic thin plate faced wall is high in reliability degree and security degree, can be suitable for high-rise buildings with the height exceeding 24 meters, and has great engineering significance and practical value.

Owner:魏来仪

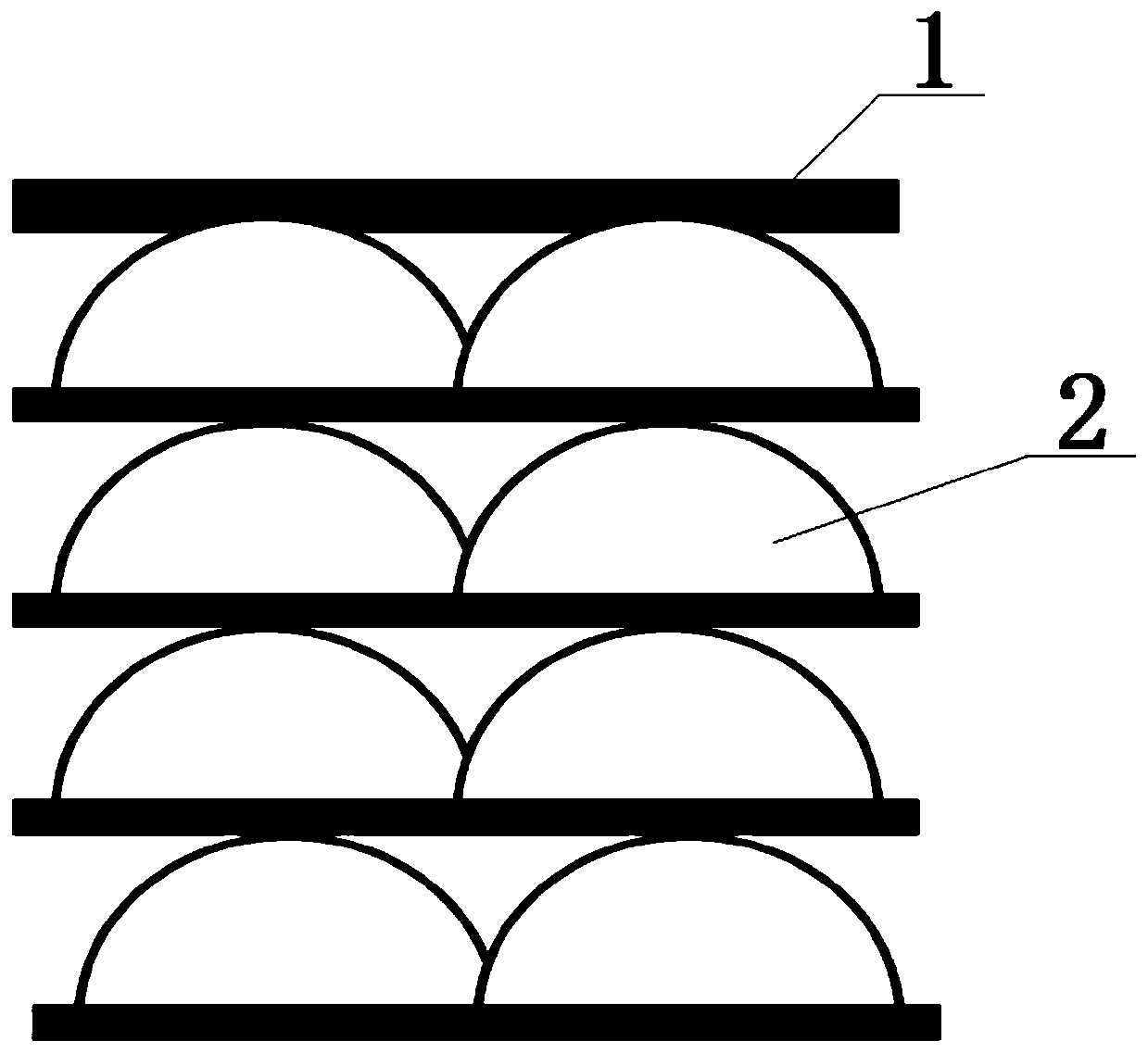

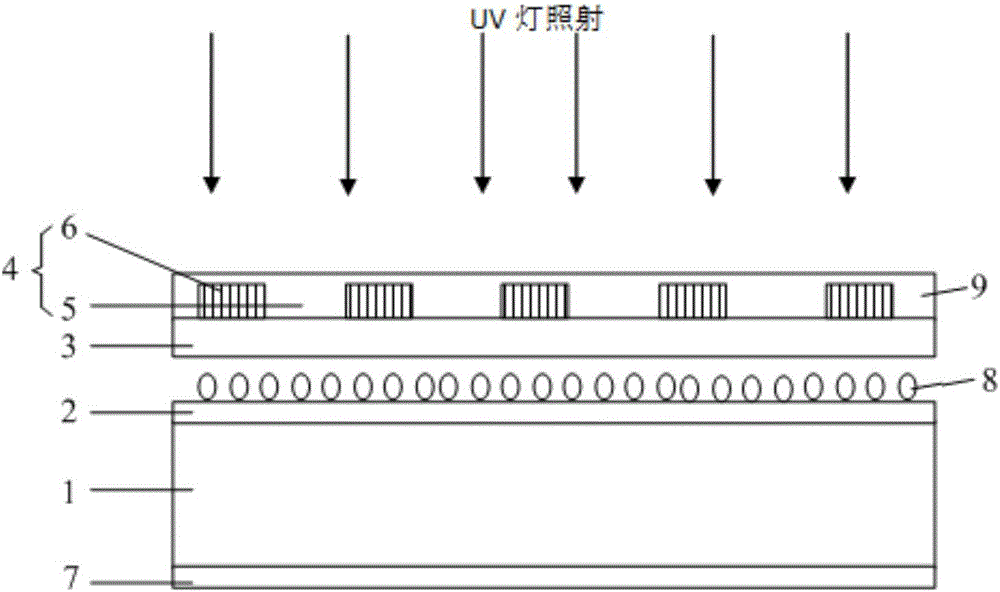

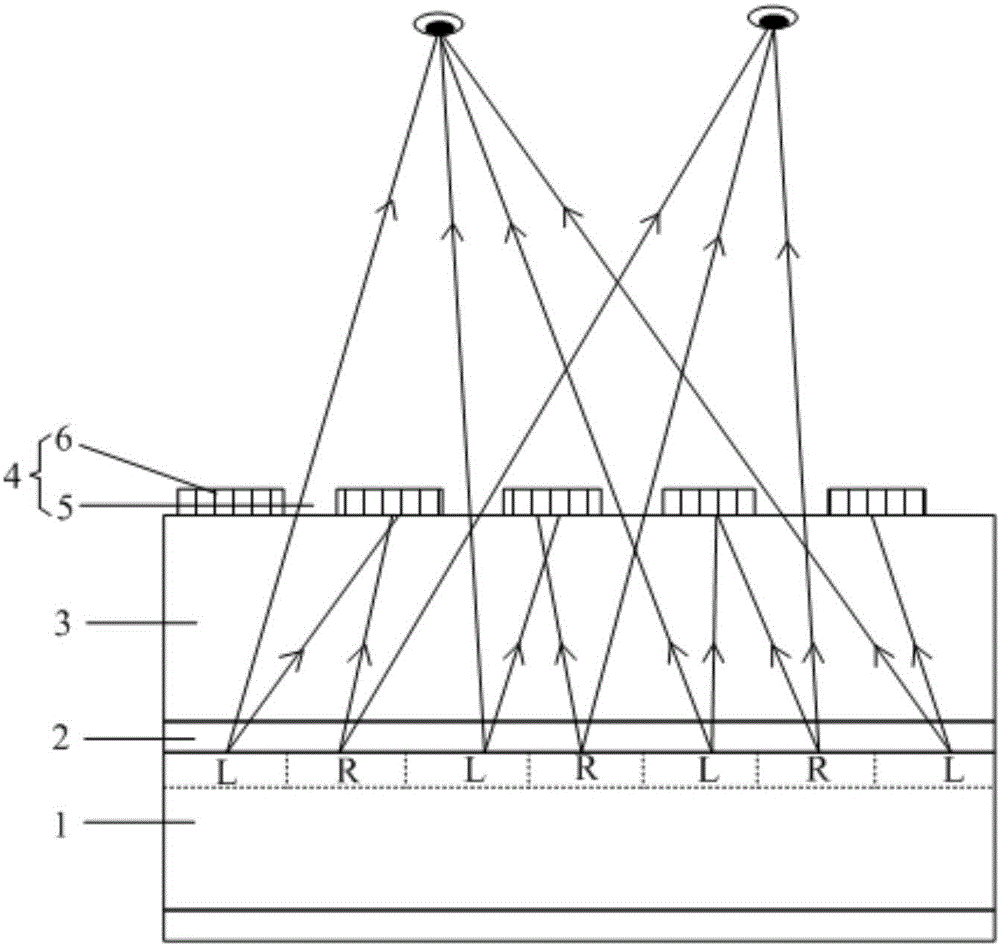

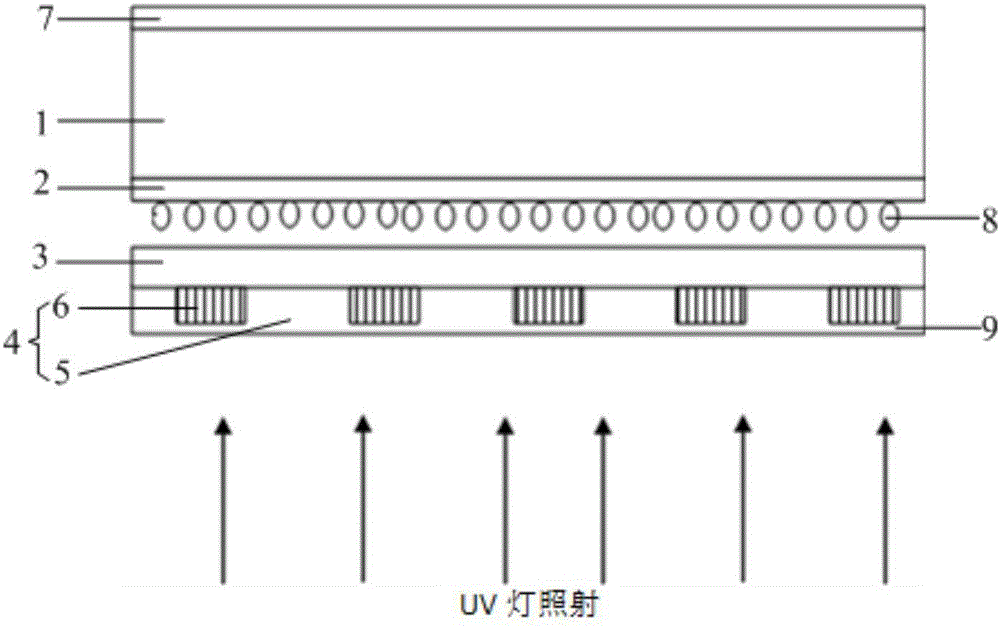

3D display panel, preparation method thereof, and 3D display device

The invention discloses a 3D display panel, a preparation method thereof, and a 3D display device. The 3D display panel comprises a 2D display panel, a first polarizer, a spacer substrate, and a polarizing layer. The first polarizer is at one side of the 2D display panel. The spacer substrate is at one side of the first polarizer opposite to the display panel, and the polarizing layer is at one side of the spacer substrate opposite to the first polarizer. The polarizing layer comprises a plurality of transparent areas and a plurality of polarizing areas, and the transparent areas and the polarizing areas are alternately arranged in parallel. Each of the polarizing areas is provided with a polarizing structure, and all polarizing structures are arranged in parallel. The first polarizer has a first polarizing shaft, the polarizing structures comprise second polarizing shafts, and the first polarizing shaft is perpendicular to the second polarizing shafts. According to the technical scheme of the invention, the naked-eye 3D display can be realized, when UV glue is used to fix the first polarizer and space glass, the solidification of each area in the UV glue can be ensured, and thus the firmness of fixation between the space glass and the display panel and the uniformity of emitted light are improved.

Owner:BOE TECH GRP CO LTD

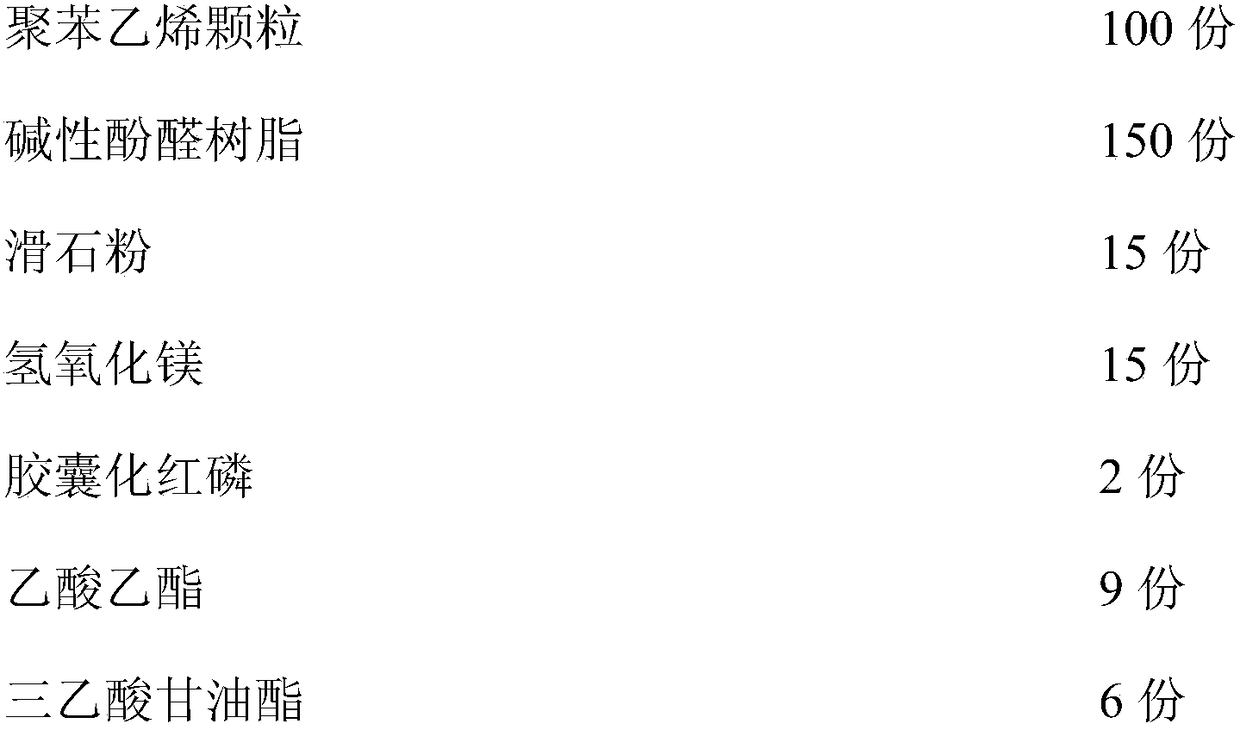

Modified polystyrene board and preparation method thereof

The invention provides a modified polystyrene board and a preparation method thereof. The modified polystyrene board comprises preparation raw materials in parts by weight as follows: 80-120 parts ofpolystyrene granules, 25-200 parts of alkaline phenolic resin, 5-45 parts of inorganic filler, 1-5 parts of a flame retardant and 10-20 parts of a curing agent. The modified polystyrene board preparedwith the method does not need an acid curing agent, pH is larger than 10, the polystyrene board shows strong basicity, so that a thin plastering system is more stable, board falling caused by reaction between the board and mortar is prevented, and adhesion is stronger.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Manufacturing process for cylinder battery

InactiveCN102945980AGuaranteed curingReduce process stepsFinal product manufactureElectrolyte accumulators manufactureMechanical engineeringBattery cell

The invention relates to a manufacturing process for a battery, mainly relates to a manufacturing process for a cylinder battery, and belongs to the lithium battery manufacturing field. The manufacturing process for the cylinder battery successively comprises the following steps of a manufacturing process of a battery rolling needle, a battery winding process, a battery pre-charging process and a battery sealing process, wherein the manufacturing process of the battery rolling needle comprises the steps of firstly welding the rolling needle onto a positive polar plate or a negative polar plate; and then cascading a circular insulating plate having the same diameter with the inner diameter of the battery on the upper end of the rolling needle at a position without welding the positive polar plate or the negative polar plate. The rolling needle passes through the circular insulating plate; and passed through part of the rolling needle is led out to the outer surface of the battery to form a positive terminal or a negative terminal of the battery. The manufacturing process for the cylinder battery is simple and reliable in process and low in cost, and has good battery sealing properties.

Owner:蔡明军

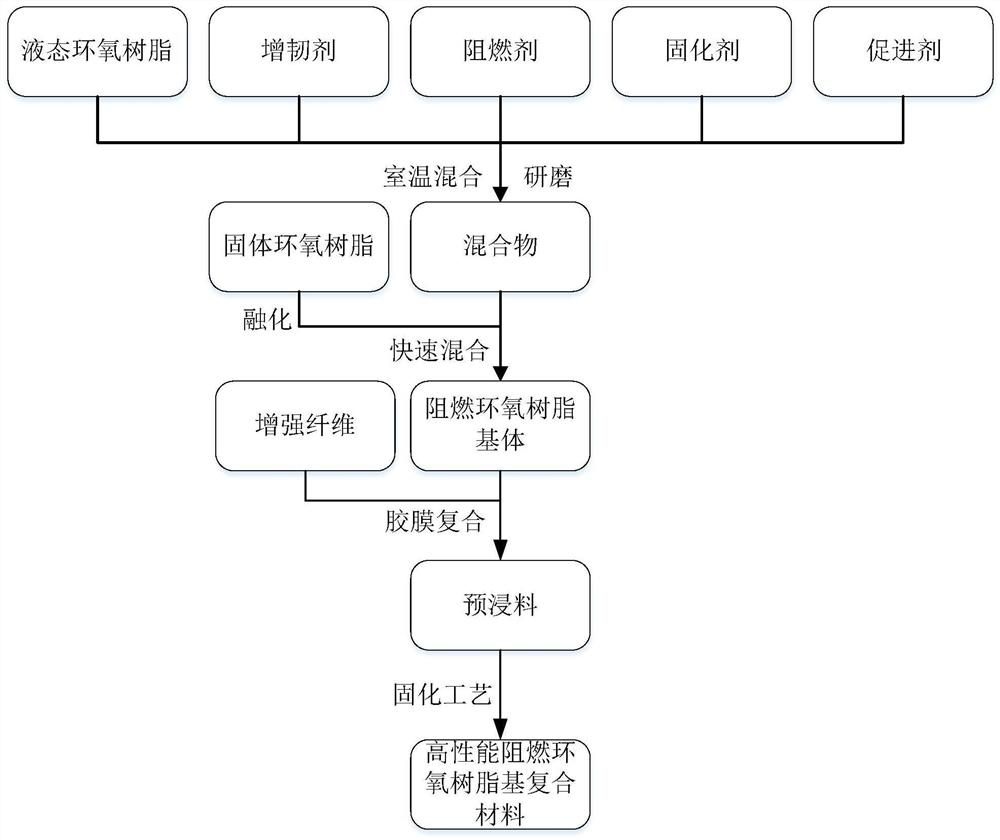

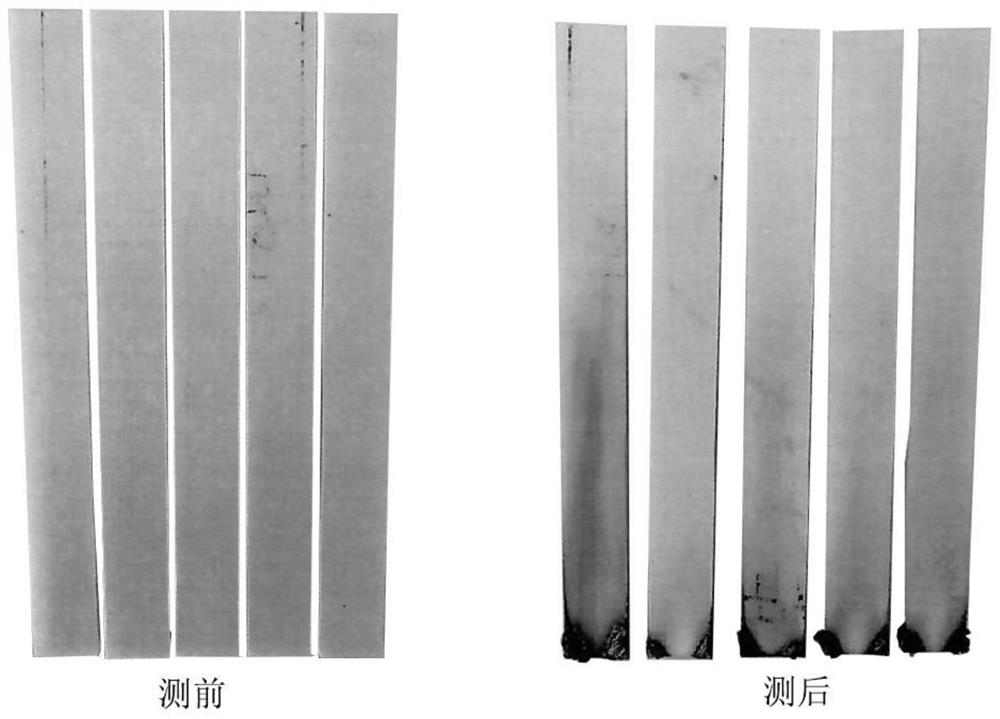

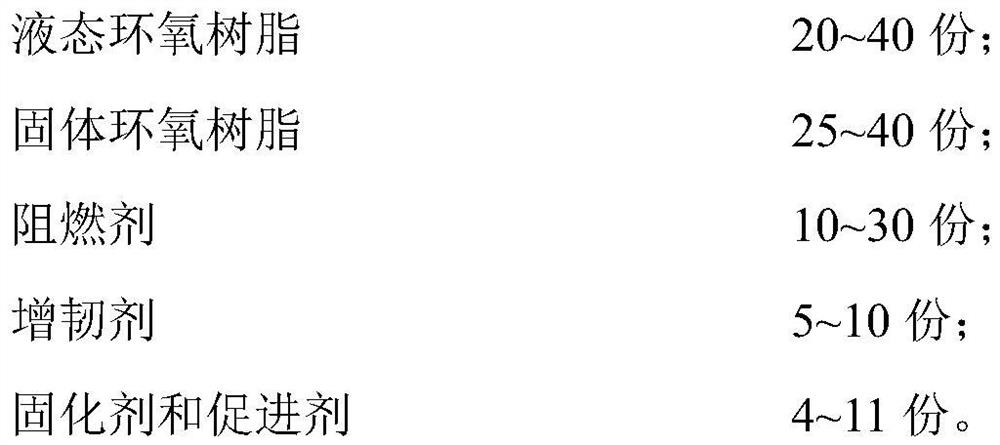

High-performance flame-retardant epoxy resin-based composite material and preparation method thereof

The invention discloses a high-performance flame-retardant epoxy resin-based composite material and a preparation method thereof, and belongs to the technical field of composite materials. The epoxy resin-based composite material comprises a resin matrix and reinforced fibers, and the resin matrix comprises liquid epoxy resin, solid epoxy resin, a flame retardant, a flexibilizer, a curing agent and an accelerant. The epoxy resin-based composite material has the effects of high flame-retardant efficiency and good mechanical property, meets the highest-grade flame-retardant requirement in the standard requirements of UL94, EN45545 and the like, and has good impact resistance and creep resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

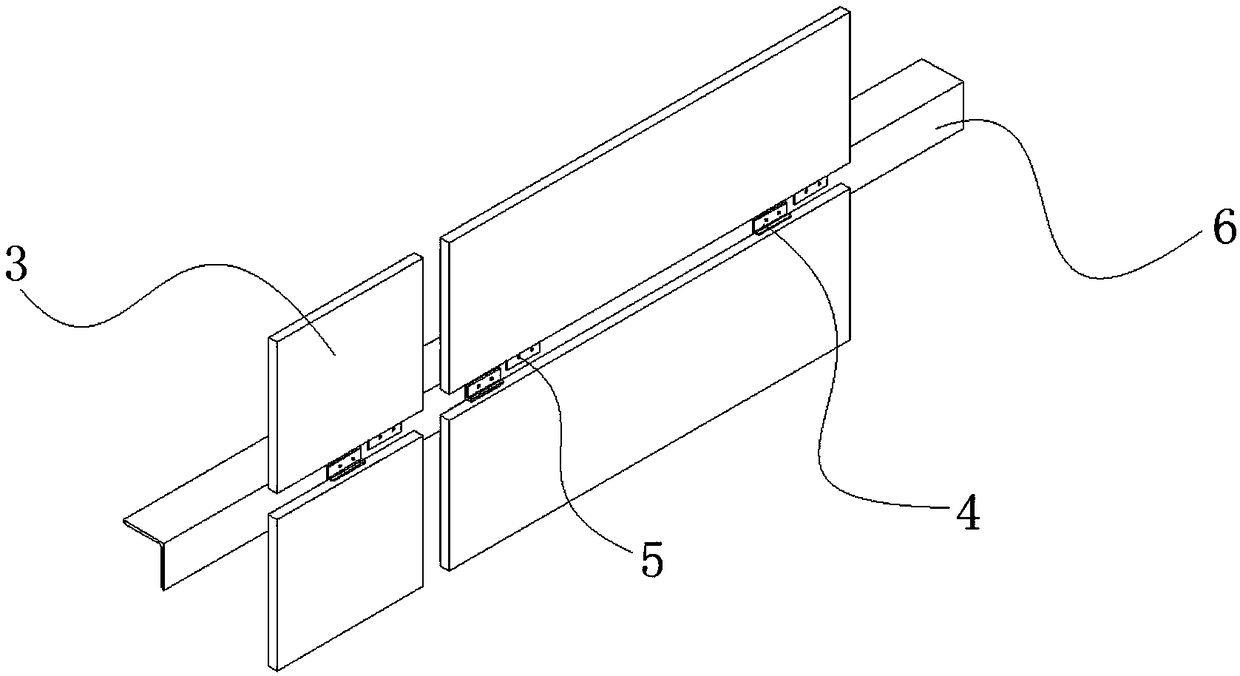

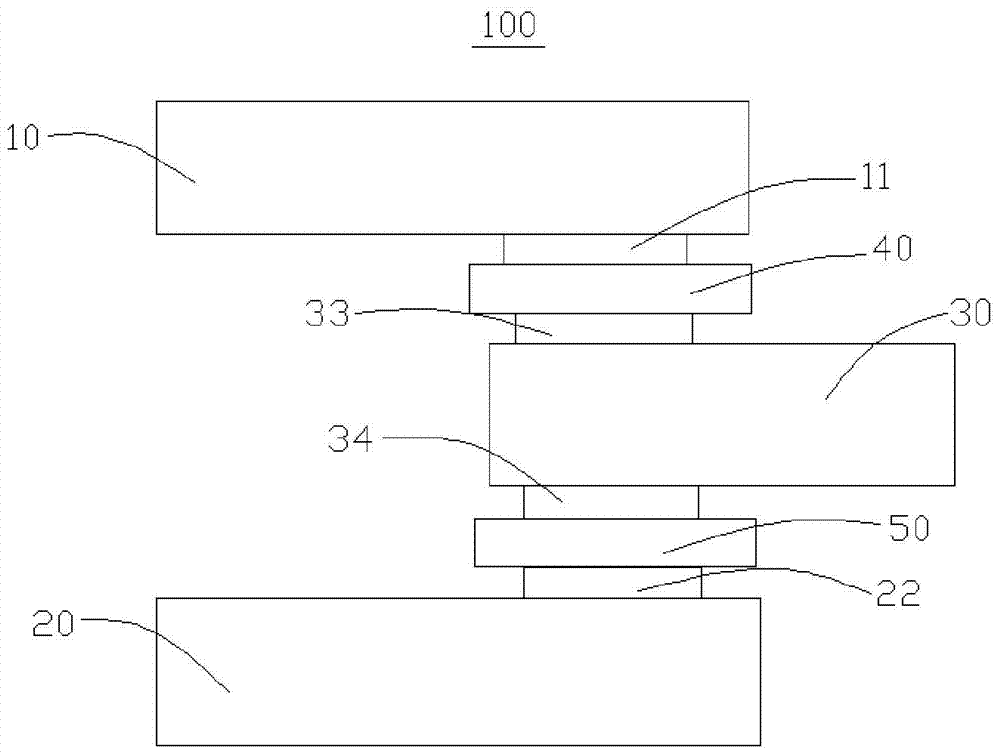

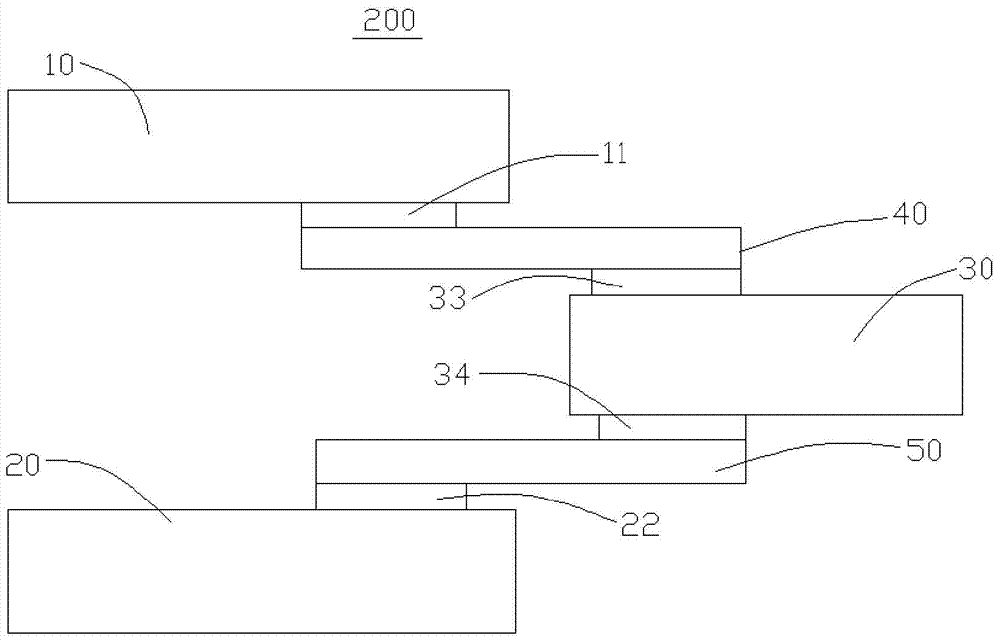

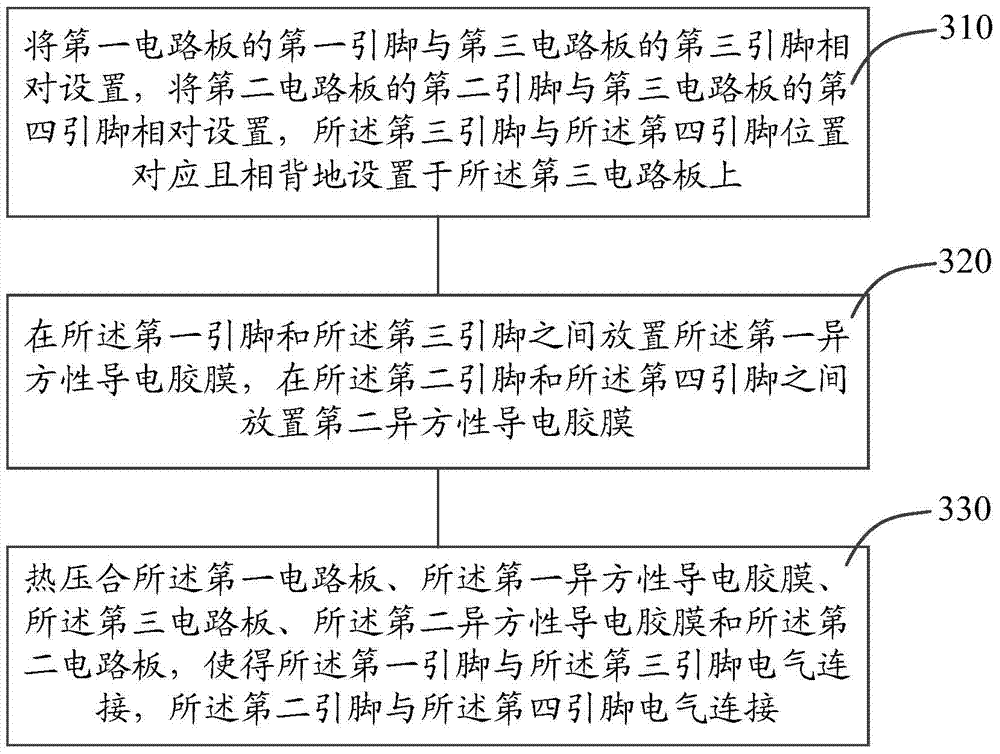

Electronic equipment and circuit board connection method

ActiveCN104852172AAvoid occupyingGuaranteed curingFixed connectionsAnisotropic conductive adhesiveElectric equipment

The invention discloses electronic equipment and a circuit board connection method. The electronic equipment comprises a first circuit board, a second circuit board, a third circuit board, a first anisotropic conductive adhesive film and a second anisotropic conductive adhesive film. The first circuit board comprises a first pin. The second circuit board comprises a second pin. The third circuit board is arranged between the first circuit board and the second circuit board. The third circuit board is provided with a third pin and a fourth pin corresponding to and opposite to the third pin in position. The first anisotropic conductive adhesive film is arranged between the first pin and the third pin and is used for connecting the first pin with the third pin. The second anisotropic conductive adhesive film is arranged between the second pin and the fourth pin and is used for connecting the second pin with the fourth pin.

Owner:LENOVO (BEIJING) LTD

PCB mounting process and mounting glue applied to mounting process

ActiveCN110248496AAchieve solidificationLow temperature requirementPrinted circuit assemblingEpoxyEngineering

The invention discloses a PCB mounting process and a mounting glue applied to the mounting process, belonging to the field of PCBs. The problem that an additive affects the curing degree of epoxy resin in the prior art is solved. The mounting process includes the following steps of (S1) printing a solder paste on an A side of a PCB, (S2) dispensing the mounting glue to the A side of the PCB, mounting components of the A side, and allowing the PCB to enter a reflow furnace with A side up for reflow soldering, and (S3) printing a solder paste on a B side of the PCB, mounting components of the B side, and allowing the PCB to enter the reflow furnace with B side up for reflow soldering, wherein illumination equipment is set in the reflow furnace and is arranged in front of a reflow soldering zone in the reflow furnace and is at two sides of a conveyor belt, and the residence time of the A side of the PCB in a heating zone is 2 to 4 minutes. The mounting glue can achieve a sufficient degree of curing before the components in the obtained PCB of the present invention enter the reflow soldering zone.

Owner:深圳市英创立电子有限公司

Preparation method of press-molded board

InactiveCN108215247AMeet the requirements of shapingReduce thicknessCoatingsOrganic solventMolding machine

The invention relates to a preparation method of a press-molded board, which includes the following steps: 1) mixing 1-10 parts by weight of a curing agent and 10-50 parts by weight of an organic solution, and stirring the mixture to prepare a mixed liquid A; 2) mixing 200-250 parts by weight of resin with 10-50 parts by weight of the organic solution and stirring the mixture to prepare a mixed liquid B, wherein the resin is one or a mixture including more than one of unsaturated polyester resin, polyurethane resin and polypropylene resin; 3) mixing the mixed liquid A with the mixed liquid B and stirring the mixture to prepare resin gum liquid; 4) impregnating a reinforcing material in the resin gum liquid to prepare a prepreg which is a semi-cured sheet; 5) placing at least one layer of the prepreg, in a stacking manner, in a mold of a thermal molding machine, and performing hot-pressing to prepare the press-molded board. The press-molded board has good size stability, is free of rebounding during shaping, has high strength, is good in temperature and humidity resistance, and has excellent anti-impact property; in addition, the press-molded board is environment-friendly and satisfies ROHS and halogen-free demands.

Owner:HUIZHOU ZONGSHENG ELECTRONICS MATERIAL CO LTD

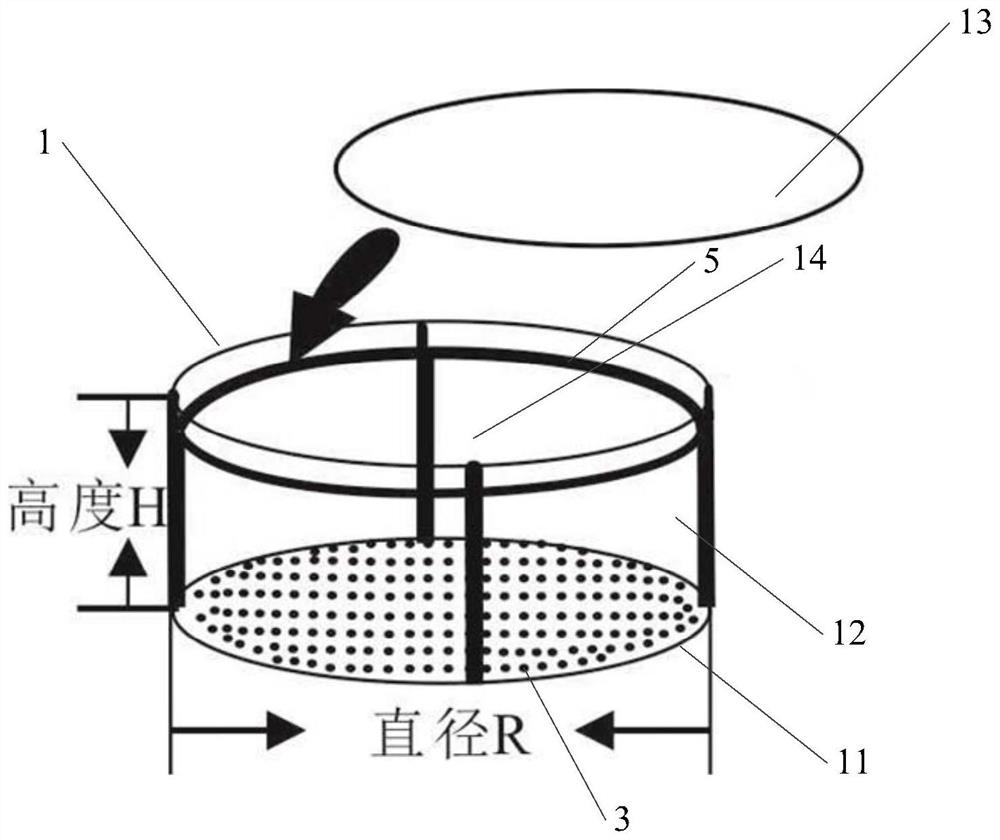

Rock debris sample containing device and rock debris casting slice making method using same

PendingCN112539979AMake sure not to mix with each otherIndependentPreparing sample for investigationRigid containersEngineeringMineralogy

The invention discloses a rock debris sample containing device and a rock debris casting slice making method using the same. The invention provides a rock debris casting slice making method. The rockdebris casting slice making method comprises the following steps of: 1) pretreating a rock debris sample; 2) putting the pretreated rock debris sample into a rock debris sample containing device, andputting the rock debris sample containing device into a glass test tube; 3) preparing a casting by adopting a standard rock slicing method, injecting the casting into the glass test tube containing the rock debris sample containing device, and performing curing to obtain a casting sample; and 4) separating the casting sample from the glass test tube, and slicing the separated casting sample to obtain a rock debris casting slice. The invention further provides a rock debris sample containing device. The rock debris sample containing device disclosed by the invention has independence, permeability, applicability, economy and easiness in cutting, and can be used for quickly and economically finishing the manufacturing of rock debris casting slices in batches and serving oil-gas exploration and development.

Owner:PETROCHINA CO LTD

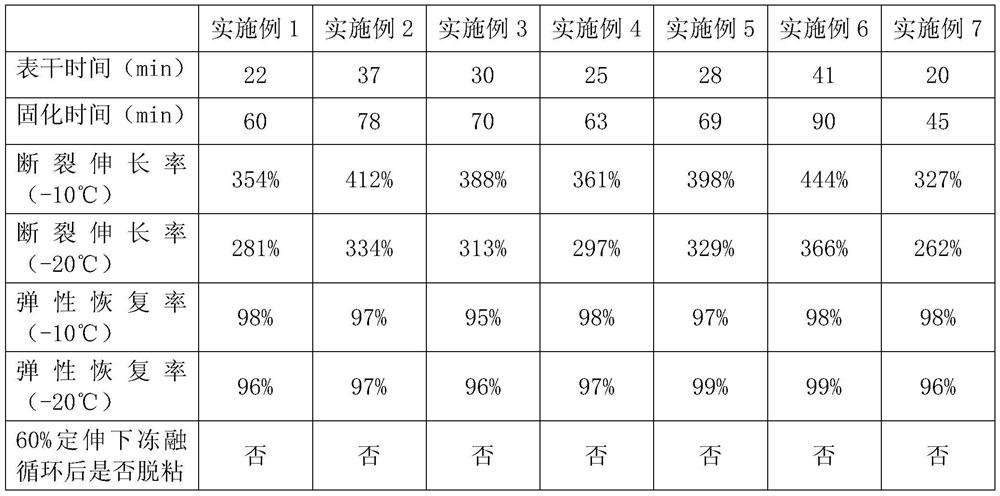

Bridge expansion joint protective pouring system

PendingCN113652191AImprove adhesionAvoid debondingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a bridge expansion joint protective pouring system which is a mixture of a component A, a component B and a component C. The component A comprises, by mass, 30-60 parts of a polyurethane prepolymer, 5-10 parts of a plasticizer, 1-5 parts of a catalyst, 1-5 parts of a defoaming agent, 0.5-2 parts of a water removal agent and 7-20 parts of filler. The component B comprises 10-20 parts by mass of epoxy resin, 1-8 parts by mass of a diluent and 1-3 parts by mass of a thixotropic agent; the component C comprises 1-5 parts by mass of a high-activity curing agent; 1-5 parts by mass of a medium-activity curing agent; and 0.5-2 parts by mass of a coupling agent. After the component B and the component C are mixed, epoxy groups can react with amino groups for curing; the epoxy resin and the metal have excellent bonding performance, so that the component B and the component C can be firmly bonded with a steel structure of the expansion joint after being cured.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +1

Fiber modified thermosetting rubber

The invention discloses fiber modified thermosetting rubber. The formula of the fiber modified thermosetting rubber is that 20 to 30 parts of vinyl phenyl silicon resin, 11 to 15 parts of melamine formaldehyde resin, 8 to 11 parts of methyl silicon hydroxy terminated silicone resin, 30 to 50 parts of solvents, 3 to 5 parts of chain transfer agents, 1 to 3 parts of catalysts, 2 to 4 parts of initiators, 12 to 18 parts of graphene fibers, 18 to 26 parts of ethanediamine, 3 to 5 parts of dispersants and 2 to 4 parts of thickeners. The invention further provides specific implementation materials and implementation manners. The fiber modified thermosetting rubber is simple in method, mild in process conditions, low in production cost, high in material structure stability, not destroyed by high temperature and improved stably in temperature resistance and toughness.

Owner:俞潮军

Manufacturing process for cylinder battery

InactiveCN102945980BReduce process stepsSteps to reduce sealingFinal product manufactureElectrolyte accumulators manufactureMechanical engineeringBattery cell

The invention relates to a manufacturing process for a battery, mainly relates to a manufacturing process for a cylinder battery, and belongs to the lithium battery manufacturing field. The manufacturing process for the cylinder battery successively comprises the following steps of a manufacturing process of a battery rolling needle, a battery winding process, a battery pre-charging process and a battery sealing process, wherein the manufacturing process of the battery rolling needle comprises the steps of firstly welding the rolling needle onto a positive polar plate or a negative polar plate; and then cascading a circular insulating plate having the same diameter with the inner diameter of the battery on the upper end of the rolling needle at a position without welding the positive polar plate or the negative polar plate. The rolling needle passes through the circular insulating plate; and passed through part of the rolling needle is led out to the outer surface of the battery to form a positive terminal or a negative terminal of the battery. The manufacturing process for the cylinder battery is simple and reliable in process and low in cost, and has good battery sealing properties.

Owner:蔡明军

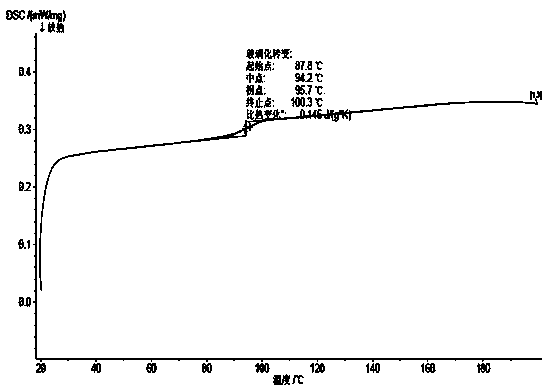

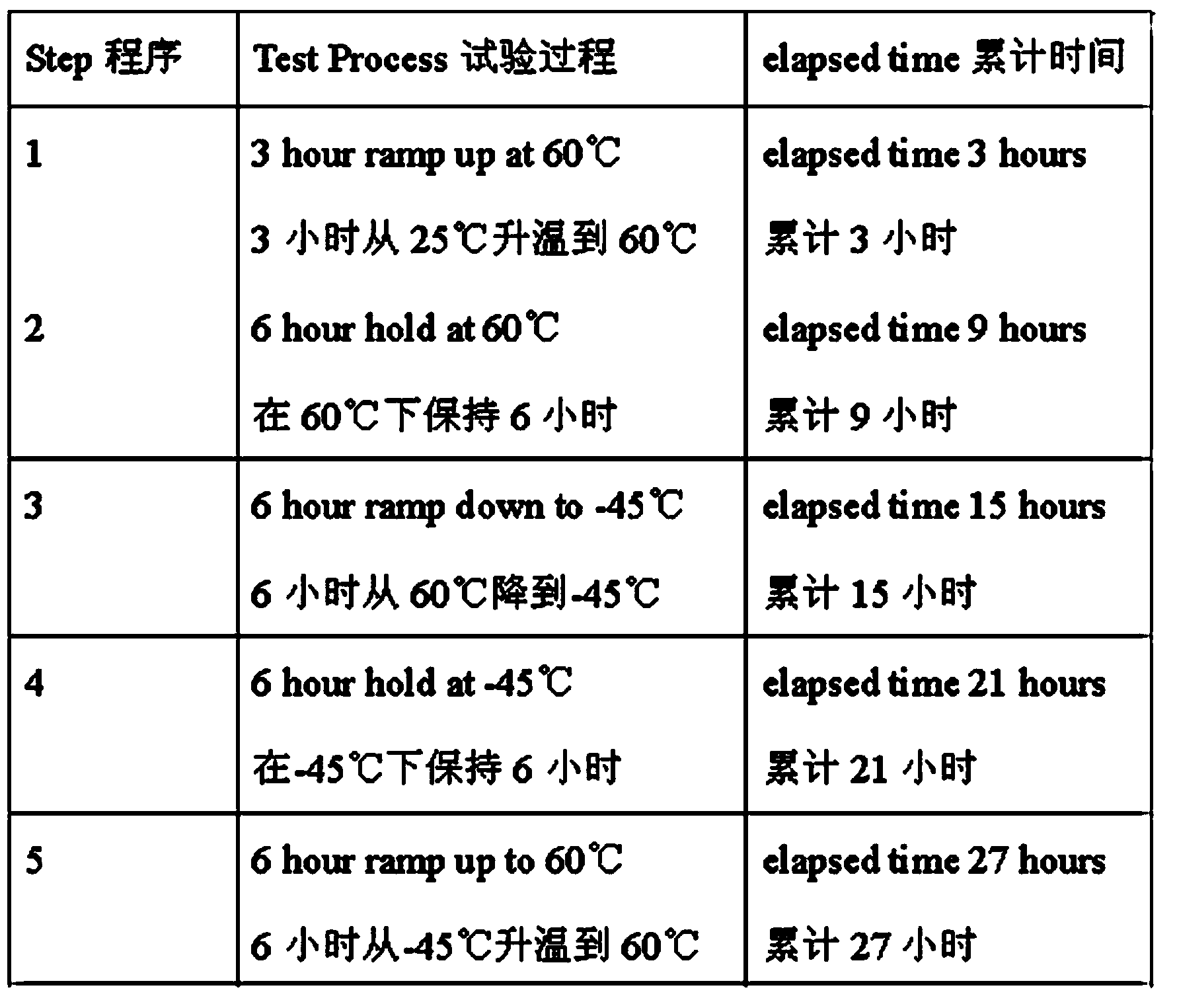

Heating curing method of epoxy resin system for resin-based composite

InactiveCN107652415AChange the status quo that can only be cured at room temperatureShorten curing cycleEpoxyGlass fiber

The invention belongs to the technical field of aviation manufacturing and relates to a heating curing method of an epoxy resin system for resin-based composite. The epoxy resin system is suitable forthe manufacturing of glass fiber resin-based composite. The heating curing method is suitable for heating curing of the epoxy resin system. The epoxy resin system is only applicable to room temperature curing previously; by providing the heating curing method, richer curing methods are provided for the epoxy resin system. The heating curing method has the advantages that the curing time of the epoxy resin system can be effectively shortened from 72 h to 24 h and below, full curing of the epoxy resin system is guaranteed, and zero implosion occurs during curing.

Owner:SHAANXI AIRCRAFT CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com