Modified polystyrene board and preparation method thereof

A polystyrene board, modified technology, applied in the field of building materials, can solve the problems affecting the flatness of the board, mixed resin agglomeration, acidity of the board, etc., and achieve the effect of stable board performance, strong adhesion and excellent performance of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

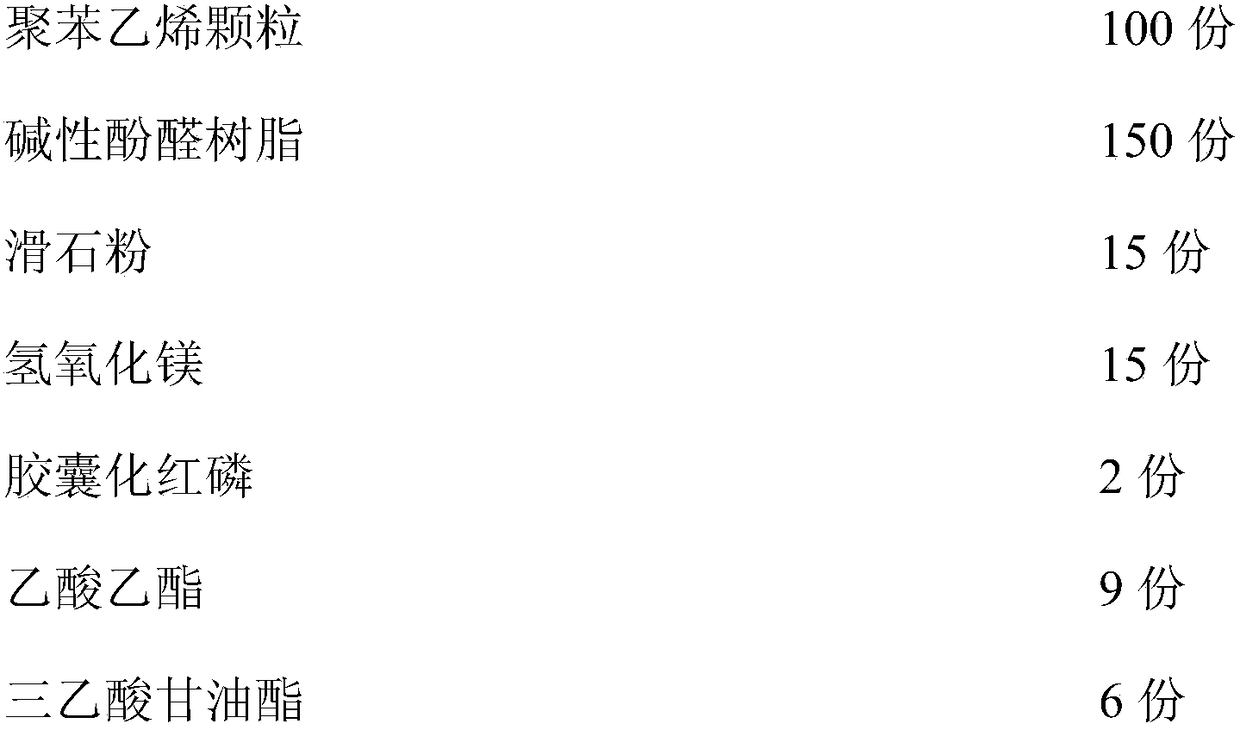

[0050] The preparation raw material of present embodiment comprises the following components by weight:

[0051]

[0052] This embodiment prepares the modified polystyrene board through the following steps:

[0053] (1) Pre-expand polystyrene particles under 0.3MPa pressure for 15 minutes to obtain a pre-expansion density of 10kg / m 3 polystyrene beads;

[0054] (2) Alkaline phenolic resin (the molar ratio of formaldehyde and phenol is 2:1, the viscosity is 800mPa·s), talcum powder, magnesium hydroxide and encapsulated red phosphorus are mixed to form a coating material;

[0055] (3) Fully mix the coating material obtained in step (2) with ethyl acetate and glycerol triacetate (wherein the mass ratio of ethyl acetate to glycerol triacetate is 3:2), and then mix with polystyrene beads The mass ratio of polystyrene beads to coating material is 1:2, a layer of coating layer is attached to the surface of polystyrene beads, dried at 70°C, and molded at a pressure of 0.05MPa for...

Embodiment 2

[0057] The preparation raw material of present embodiment comprises the following components by weight:

[0058]

[0059]

[0060] This embodiment prepares the modified polystyrene board through the following steps:

[0061] (1) Pre-expand polystyrene particles under 0.6MPa pressure for 1min to obtain a pre-expansion density of 18kg / m 3 polystyrene beads;

[0062] (2) Alkaline phenolic resin (wherein the molar ratio of formaldehyde and phenol is 2.7:1, viscosity is 500mPa·s), barite, aluminum hydroxide and encapsulated red phosphorus are mixed to form coating material;

[0063] (3) Fully mix the coating material obtained in step (2) with butyl acetate, and then mix it with polystyrene beads, wherein the mass ratio of polystyrene beads to coating material is 1:1, polystyrene A coating layer was attached to the surface of the vinyl beads, dried at 60°C, and molded at a pressure of 0.03MPa for 1000s to obtain a modified polystyrene board with a pH of 10.3.

Embodiment 3

[0065] The preparation raw material of present embodiment comprises the following components by weight:

[0066]

[0067] This embodiment prepares the modified polystyrene board through the following steps:

[0068] (1) Pre-expand the polystyrene particles under 0.03MPa pressure for 30 minutes to obtain a pre-expanded density of 4kg / m 3 polystyrene beads;

[0069] (2) Alkaline phenolic resin (wherein the molar ratio of formaldehyde and phenol is 2.7:1, viscosity is 700mPa·s), barite, talcum powder, aluminum hydroxide and encapsulated red phosphorus are mixed to form coating material;

[0070] (3) The coating material obtained in step (2) is fully mixed with 1-methoxypropyl acetate, and then mixed with polystyrene beads, wherein the mass ratio of polystyrene beads to coating material is 1 :5, a layer of coating layer is attached to the surface of polystyrene beads, dried at 80°C, and molded at a pressure of 0.08MPa for 300s to obtain a modified polystyrene board with pH=10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com