High-performance flame-retardant epoxy resin-based composite material and preparation method thereof

A technology for epoxy resin and composite materials, applied in the field of composite materials, can solve the problems of adverse effects of gel curing of composite materials, increase in viscosity of epoxy resin system, and decrease in resin process performance, etc., to achieve high bond strength and improve tensile strength Effects of modulus, good toughness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

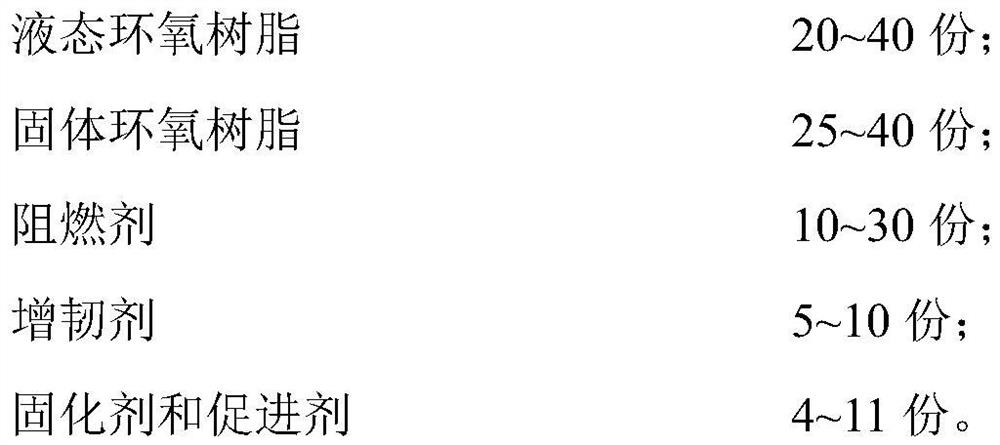

[0031] This embodiment discloses a high-performance flame-retardant epoxy resin-based composite material, including 30 parts of resin matrix and 70 parts of reinforcing fiber, the reinforcing fiber adopts SW300 glass fiber, and the formula of the resin matrix is as follows (statistics in parts by mass) :

[0032]

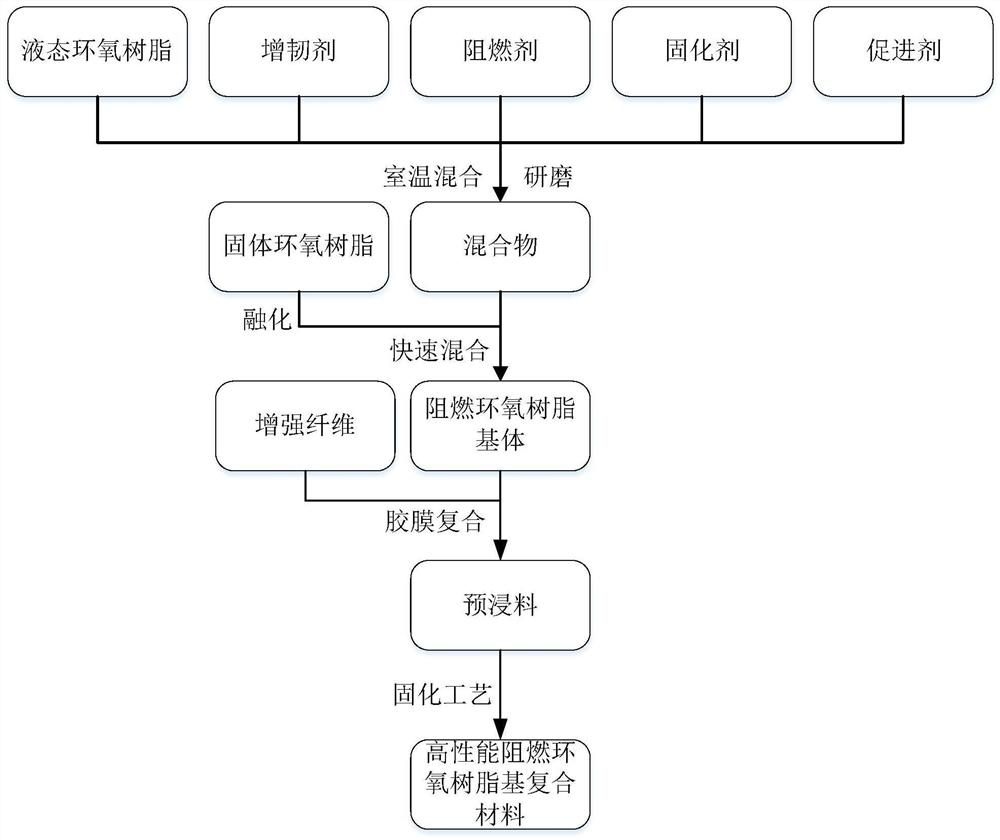

[0033] figure 1 To prepare the flow chart, the specific preparation steps are as follows:

[0034] The first step is to weigh 15 parts of bisphenol A liquid epoxy resin E-51, 16 parts of four-functional liquid epoxy resin AG-80, 7 parts of toughening agent, 20 parts of intumescent flame retardant and 4 parts of curing agent. 2 parts and 2 parts of accelerator were mixed uniformly at room temperature, and passed through a three-roll mill twice to obtain a mixture;

[0035] The second step is to weigh 35 parts of solid epoxy resin E-20, heat up to 120°C to melt, add it to the mixture, and quickly mix it evenly to obtain a flame-retardant epoxy resin matrix;

...

Embodiment 2

[0043] A high-performance flame-retardant epoxy resin-based composite material disclosed in this embodiment includes 40 parts of resin matrix and 60 parts of reinforcing fiber, the reinforcing fiber adopts SW300 glass fiber, and the formula of its resin matrix is as follows (statistics in parts by mass) :

[0044]

[0045] The preparation steps are as follows:

[0046] The first step is to weigh 20 parts of bisphenol A liquid epoxy resin E-52, 20 parts of four-functional liquid epoxy resin AG-80, 10 parts of toughening agent, 10 parts of intumescent flame retardant and 8 parts of curing agent. 1 part and 1 part of accelerator were mixed uniformly at room temperature, and passed through a three-roll mill twice to obtain a mixture;

[0047] The second step is to weigh 40 parts of solid epoxy resin E-14, heat up to 130°C to melt, add it to the mixture, and quickly mix it evenly to obtain a flame-retardant epoxy resin matrix;

[0048] In the third step, the flame-retardant ...

Embodiment 3

[0052] A high-performance flame-retardant epoxy resin-based composite material disclosed in this embodiment includes 50 parts of resin matrix and 50 parts of reinforcing fiber, the reinforcing fiber adopts DSCCP-200 plain weave carbon cloth, and the formula of its resin matrix is as follows (by mass parts statistics):

[0053]

[0054]

[0055] The preparation steps are as follows:

[0056] The first step is to weigh 10 parts of bisphenol A liquid epoxy resin E-54, 10 parts of four-functional liquid epoxy resin AG-80, 5 parts of toughening agent, 30 parts of intumescent flame retardant and 3 parts of curing agent. 3 parts and 3 parts of accelerator were mixed uniformly at room temperature, and passed through a three-roller mill twice to obtain a mixture;

[0057] The second step is to weigh 25 parts of solid epoxy resin JF-45, heat up to 90°C to melt, add it to the mixture, and quickly mix it evenly to obtain a flame-retardant epoxy resin matrix;

[0058] In the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com