Patents

Literature

329results about How to "Extend curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

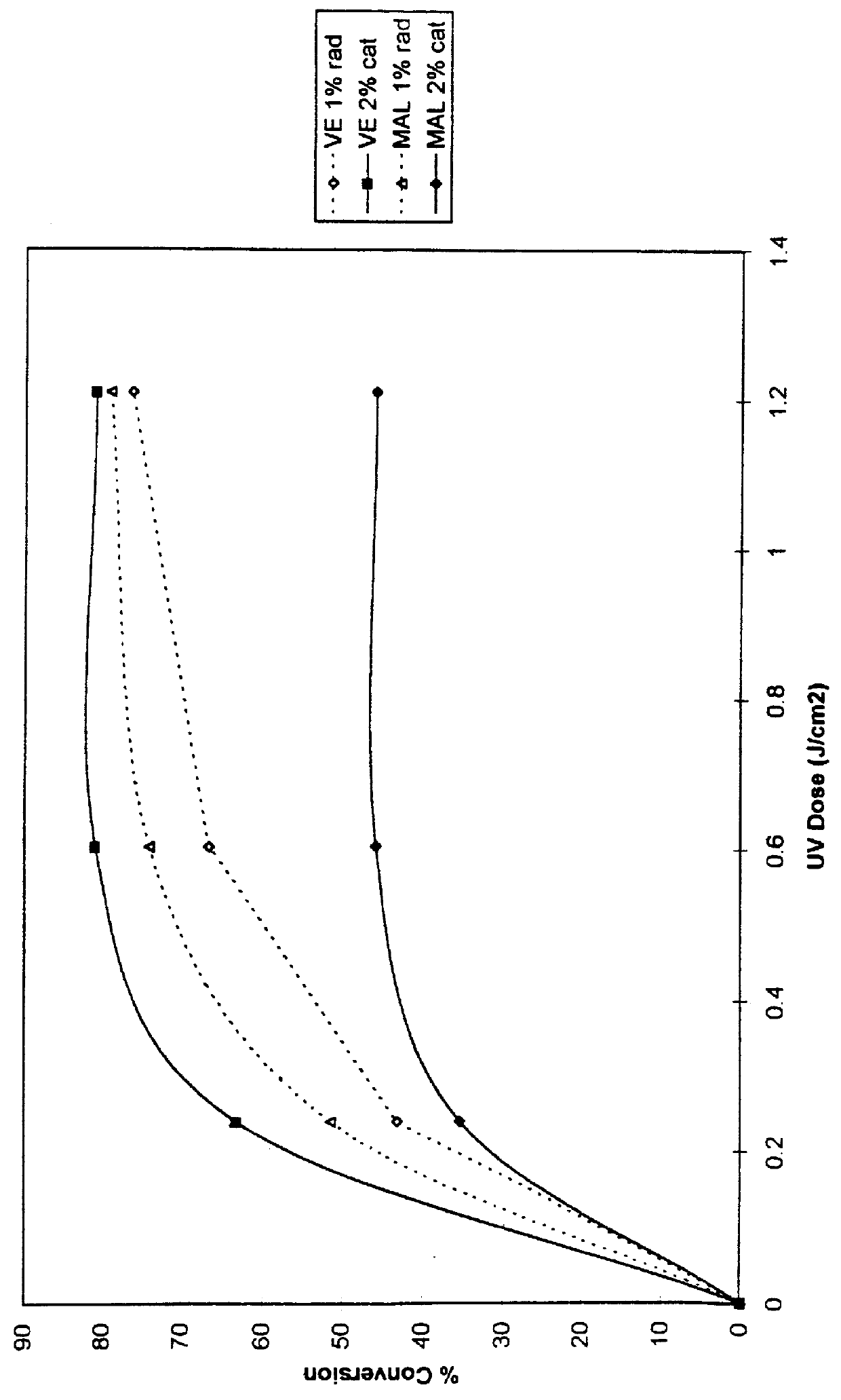

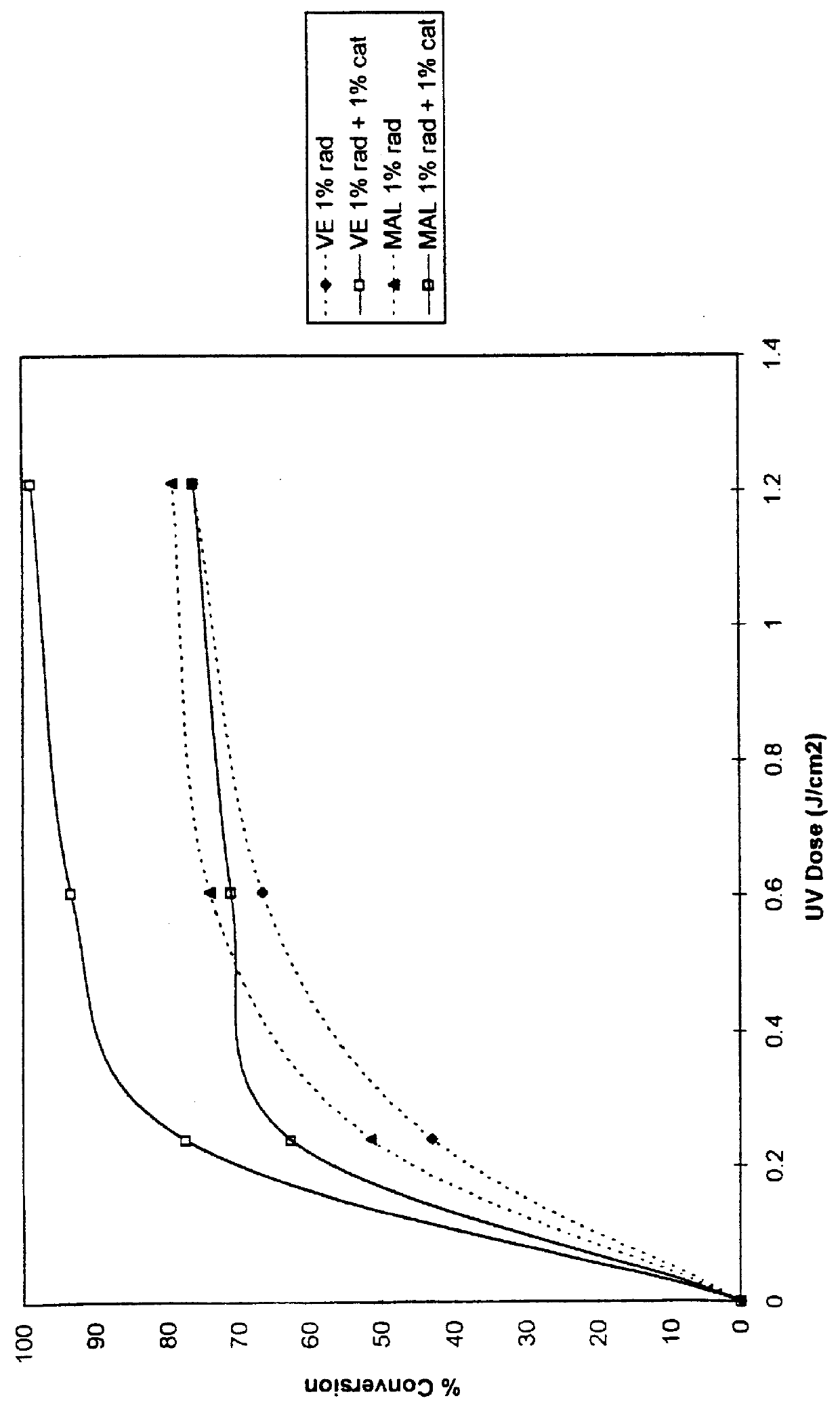

Photopolymerization process and composition employing a charge transfer complex and cationic photoinitiator

InactiveUS6127447AAccelerating polymerizationExtend curing timePhotomechanical apparatusOptical articlesVinyl etherCharge-transfer complex

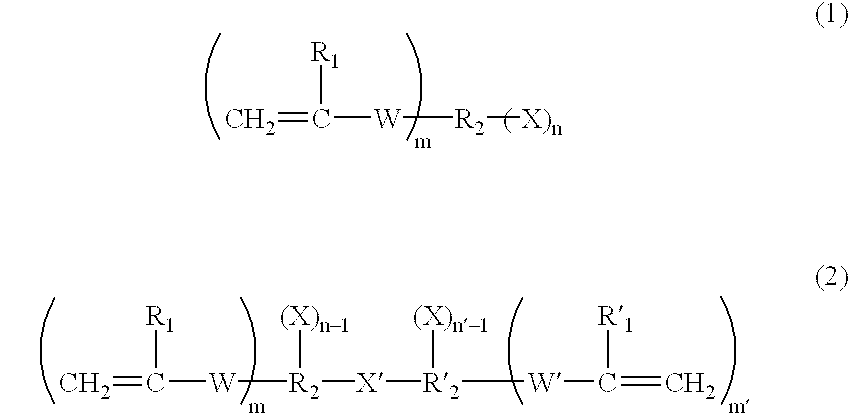

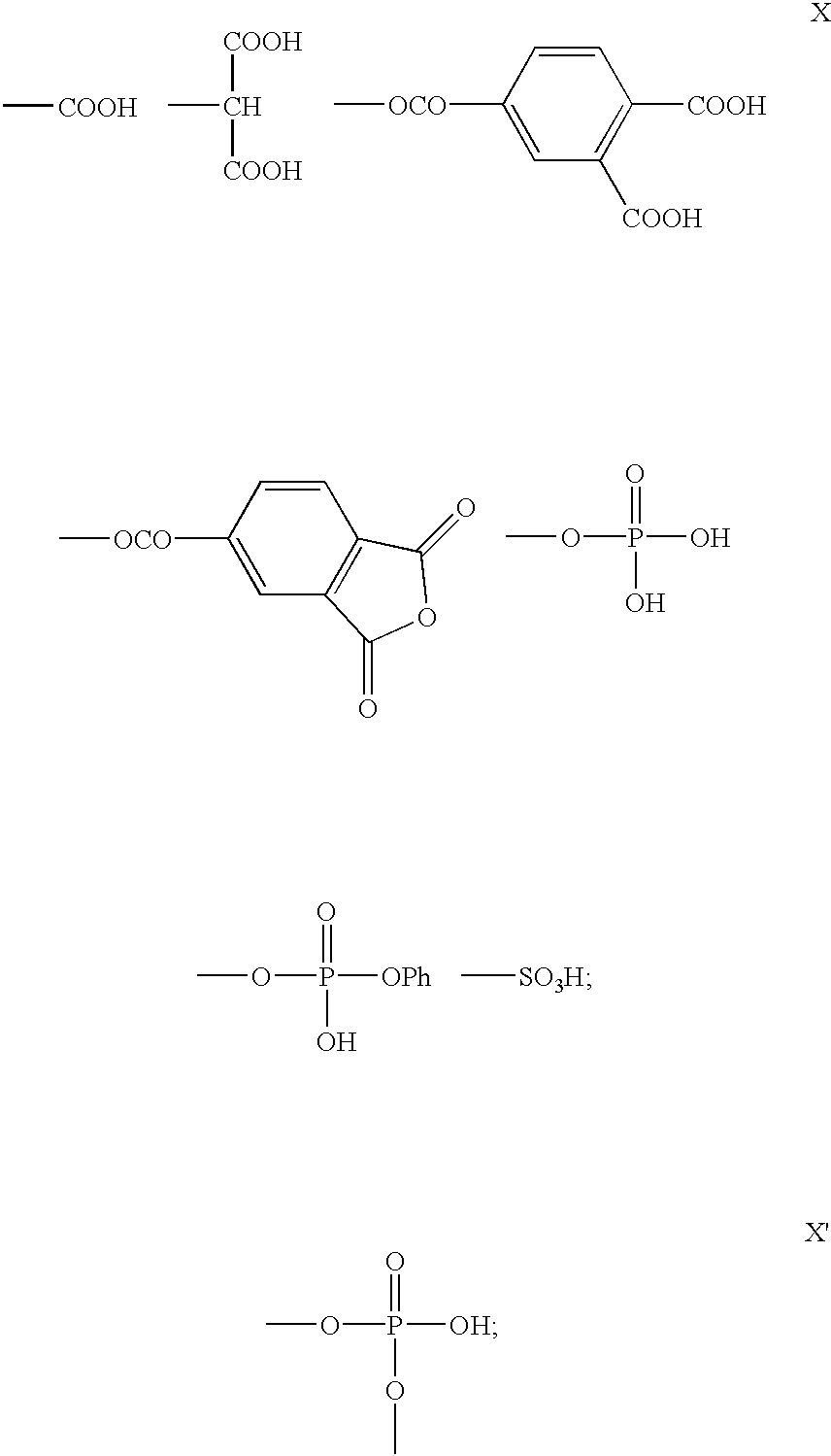

A radiation curable coating composition is provided and includes an effective amount of cationic photoinitiator, in combination with a charge transfer complex, the charge transfer complex comprising at least one electron withdrawing reactant component and at least one electron donating reactant component free radically reactive therewith, the electron withdrawing reactant component comprising an unsaturated nitrogen containing compound and the electron donating reactant component comprising an unsaturated compound having at least one vinyl ether group, the electron donating reactant component may be separate from or structurally incorporated within the electron withdrawing reactant component and an effective amount of a cationic photoinitiator. A photopolymerization process employing the composition is also provided.

Owner:FUSION UV SYST

Dental adhesive composition

InactiveUS20030050359A1Short working hoursOptimize working timeImpression capsTeeth fillingArylAdhesive

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

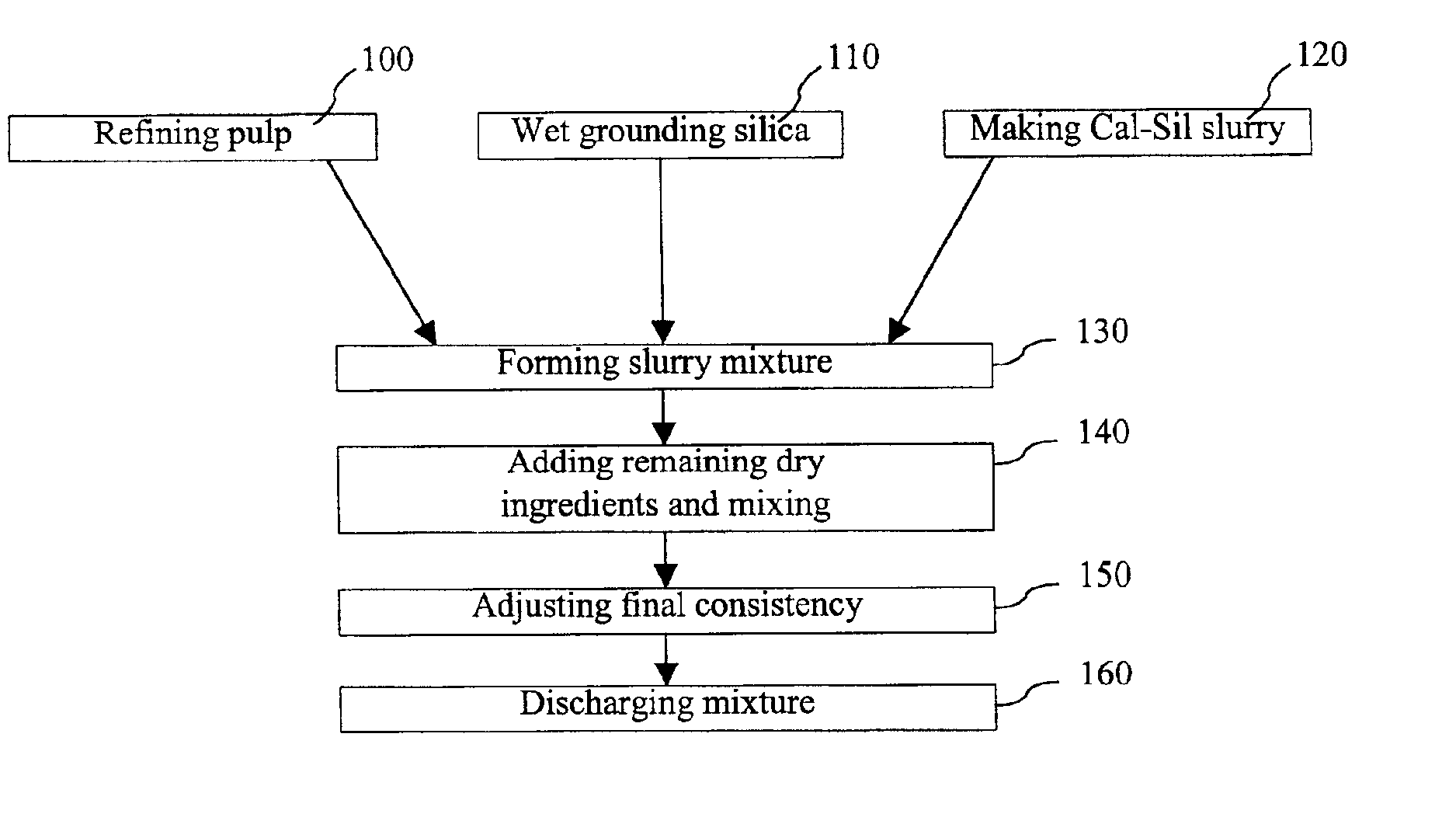

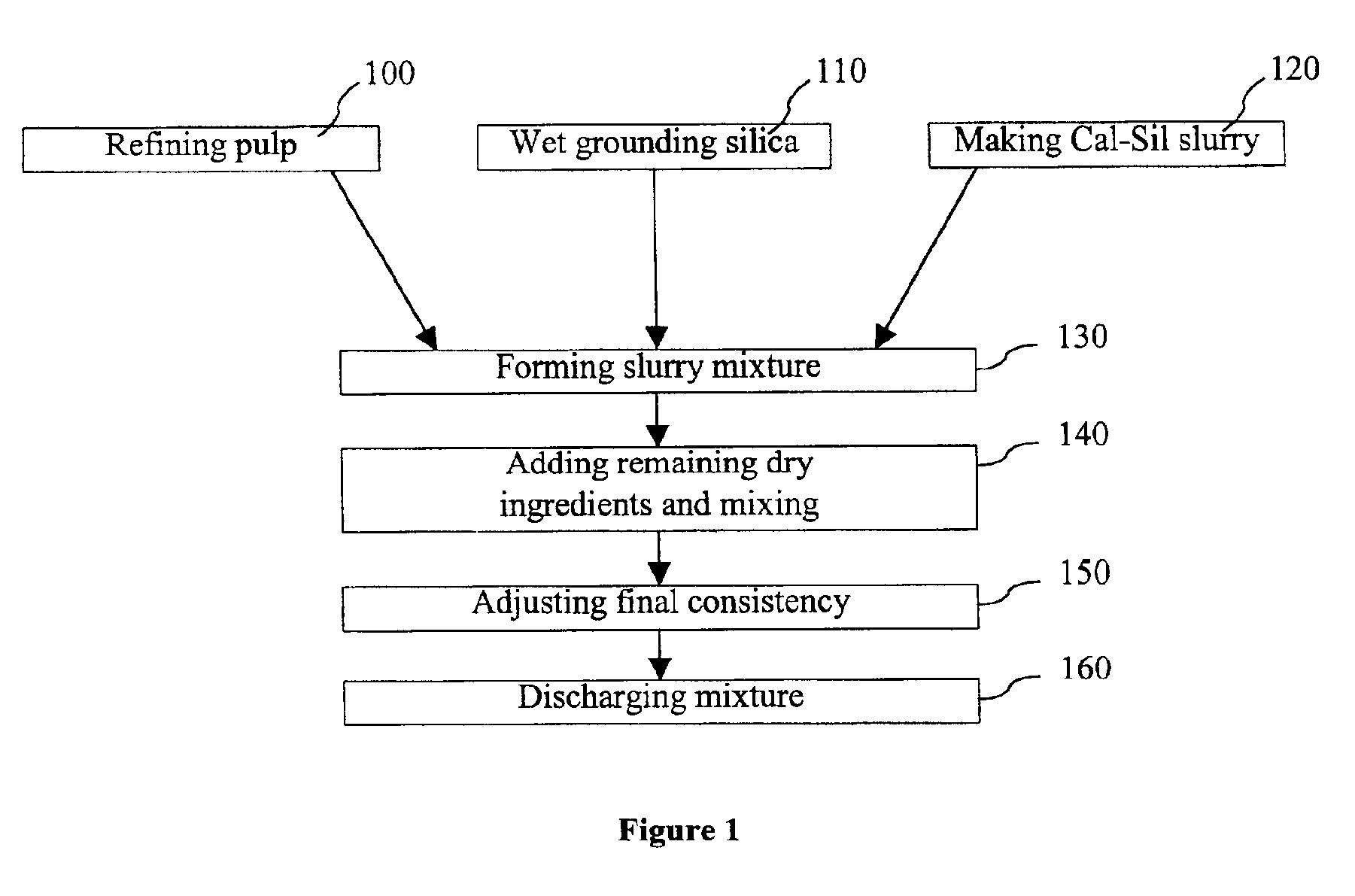

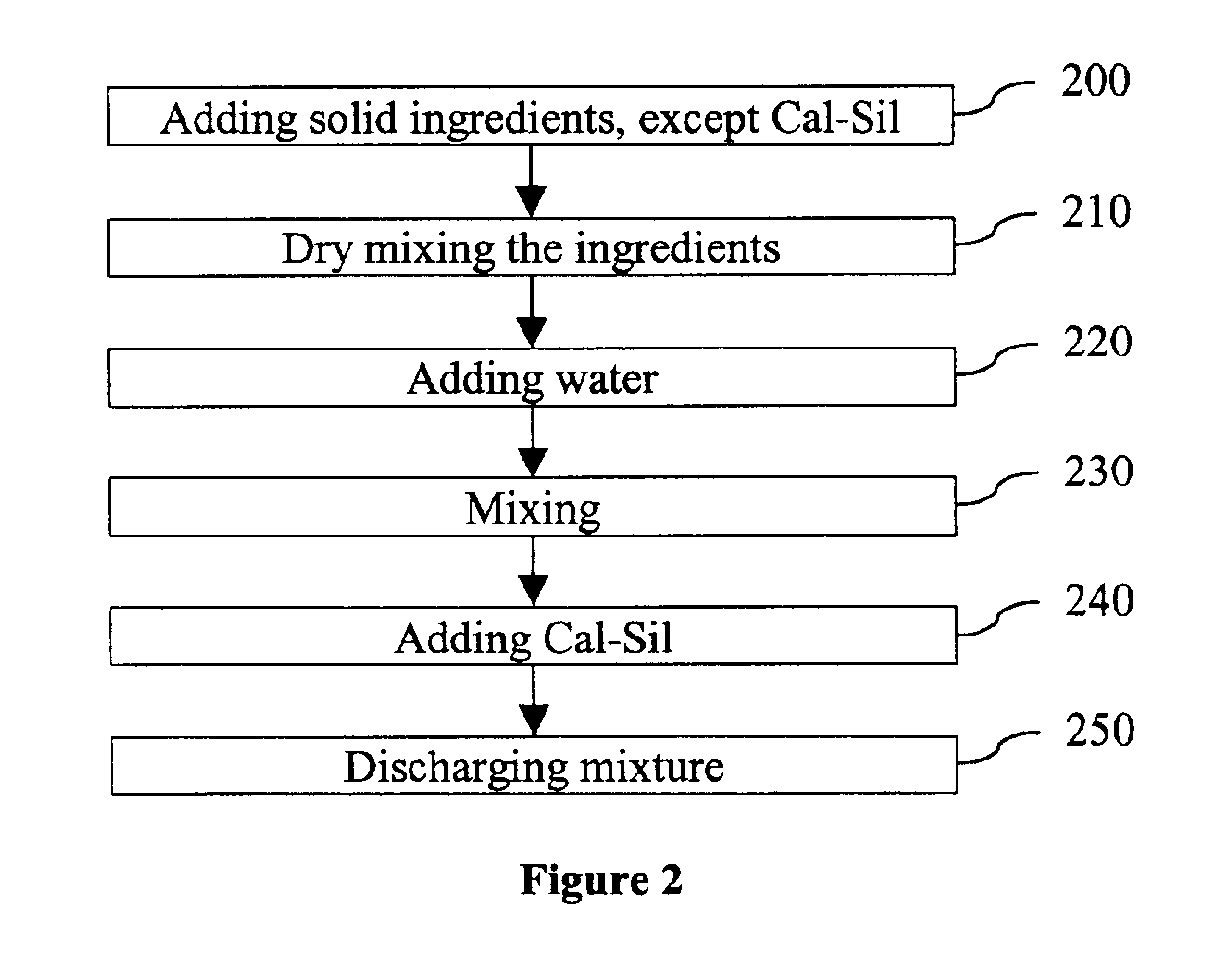

Low density accelerant and strength enhancing additive for cementitious products and methods of using same

InactiveUS7041167B2Extend curing timeOvercomes retarding effectSolid waste managementAlkali metal silicate coatingsFiberMaterials science

Disclosed are concrete and fiber cement formulations and products comprising low-density calcium silicate hydrate, and methods for producing these formulations and products. The disclosed formulations exhibit accelerated curing times. Other advantages of the disclosed formulations include improved dimensional stability in extruded products, reduced cracking, and reduced wash-out in underwater applications. The products of the disclosed formulation have lower cost of production and faster time to market.

Owner:JAMES HARDIE TECH LTD

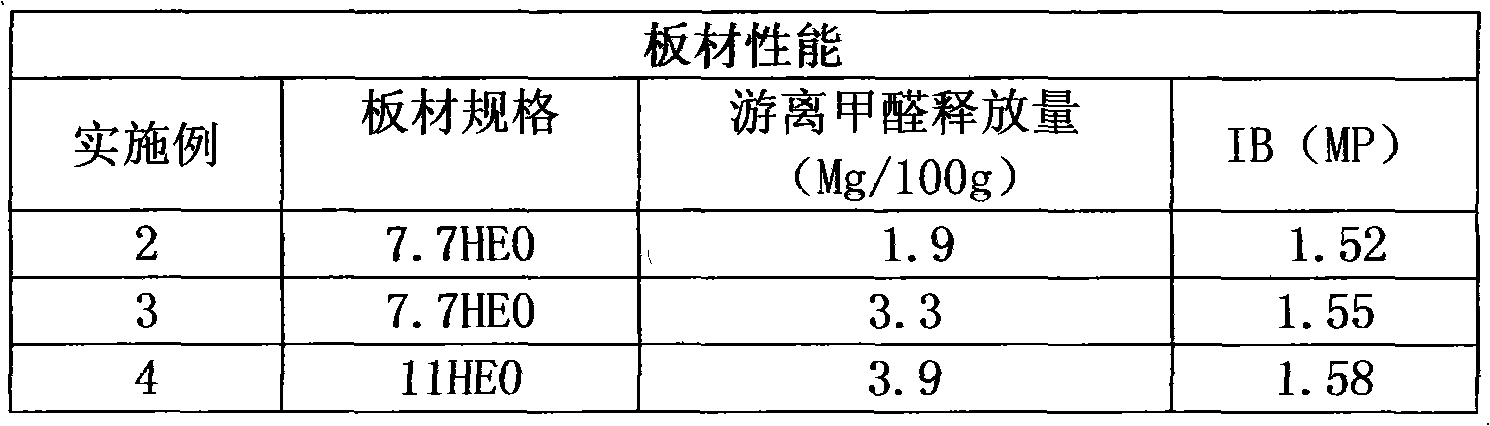

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

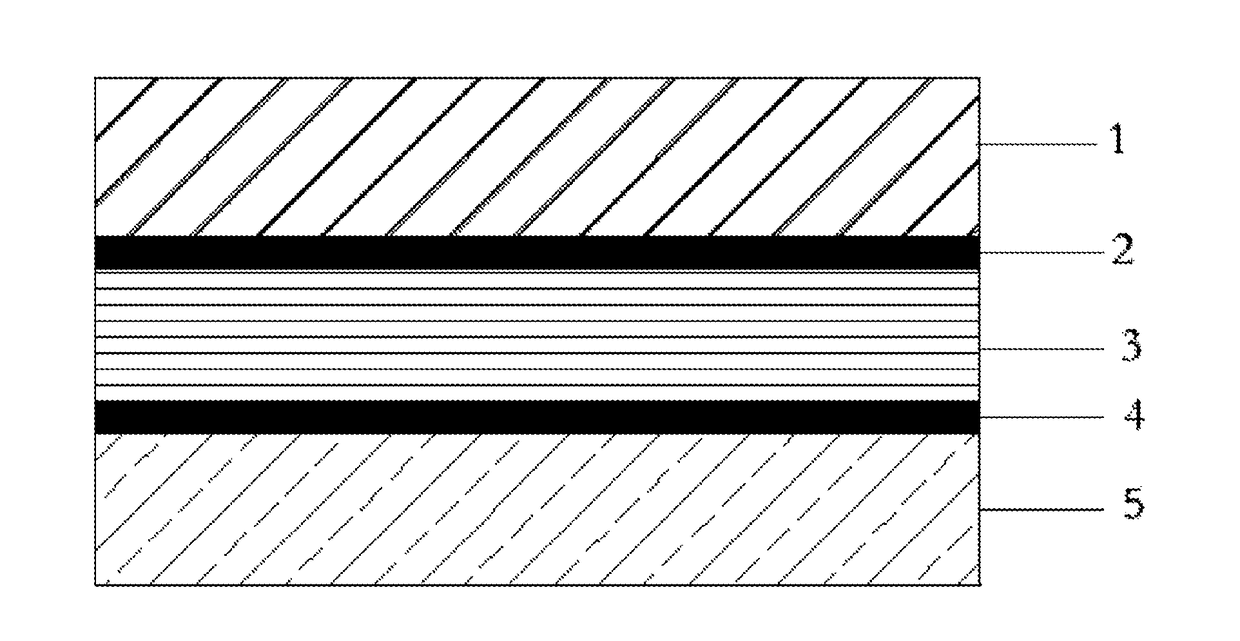

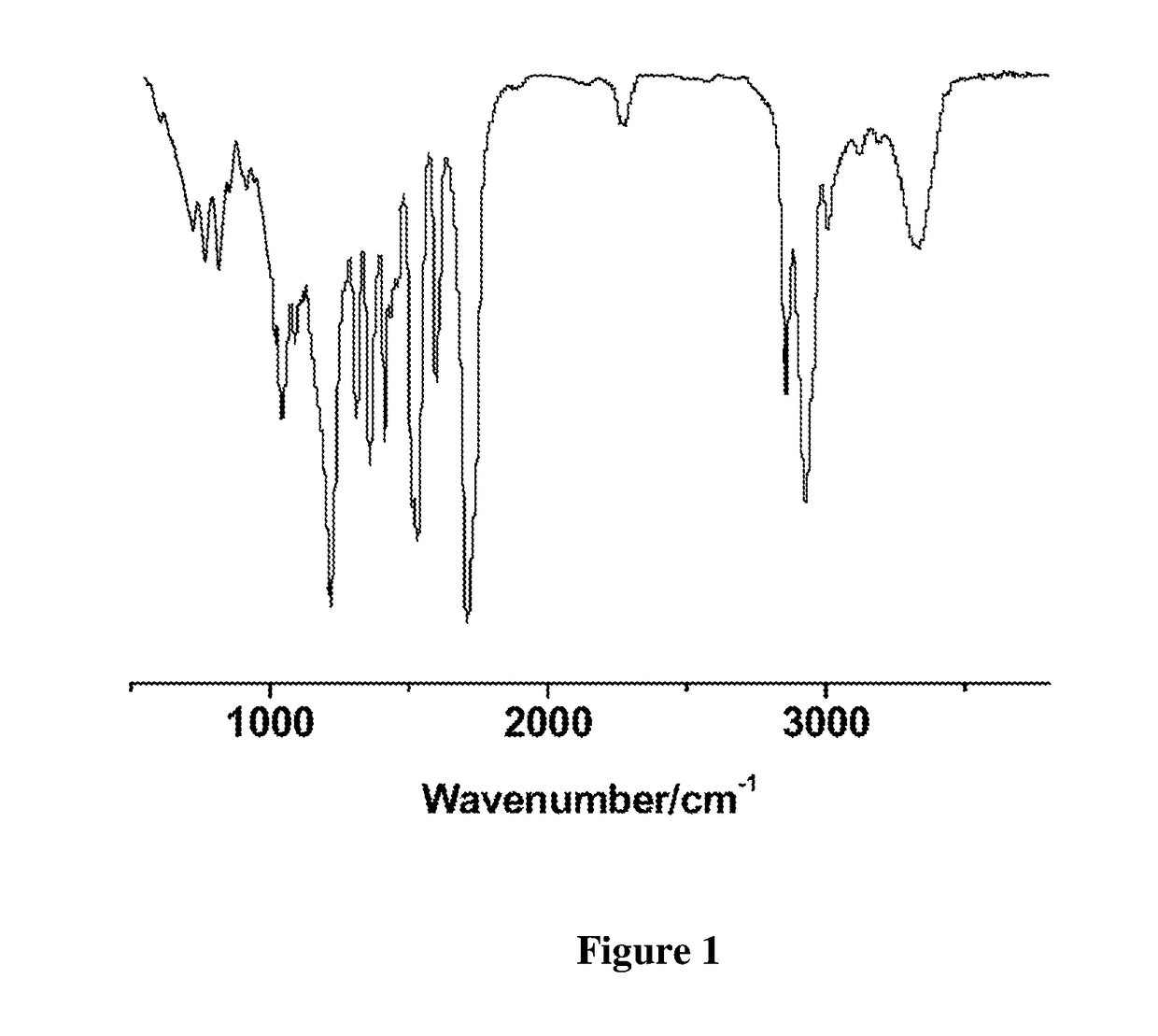

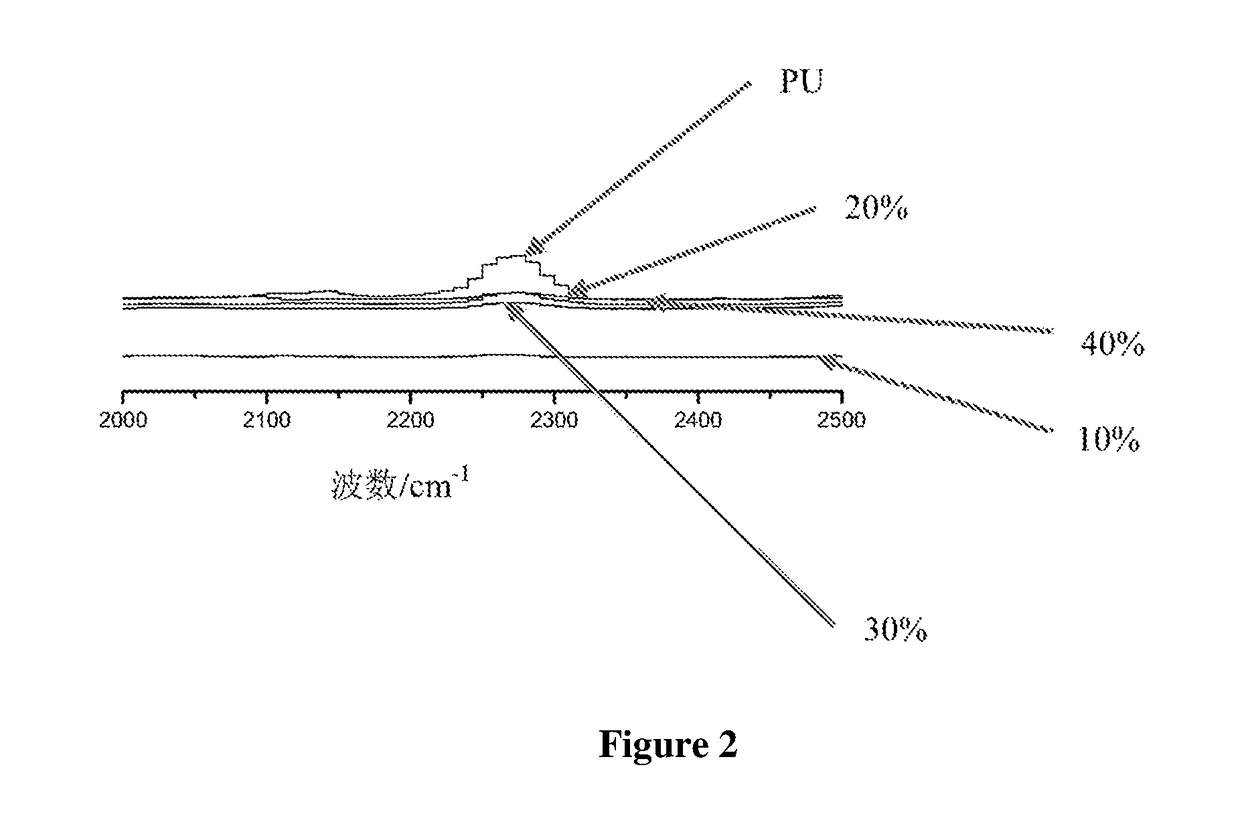

Polyurethane, modified asphalt and mixture material containing same and pavement structure

InactiveUS20180312437A1High strengthExtended service lifeIn situ pavingsBuilding insulationsHydrogenPolyol

A polyurethane is obtained by continuously reacting a polyurethane prepolymer in an asphalt or asphalt mixture material system under high temperature. The prepolymer is prepared by: adding a polymerization inhibitor, catalyst and isocyanate component in a reaction container, adding a polyol to the reactor while stirring at room temperature under nitrogen, increasing the temperature to 50-80° C., and maintaining the temperature to react for 0.5-6 hours. A polyurethane modified asphalt, a mixture material containing the polyurethane and a polyurethane modified asphalt pavement structure can be prepared. The synthesis condition of the polyurethane is mild, and a secondary reaction with the air and an active hydrogen component in the asphalt can occur during maintenance and formation to further increase the strength of a mixture material. The standard Marshall stability at 60° C. meets the petroleum asphalt requirement, such that a service life of the asphalt pavement can be increased.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD +1

Preparation method of anticorrosive polyurea coating

InactiveCN102786870AHigh bonding strengthSimple processPretreated surfacesPolyurea/polyurethane coatingsSurface layerSand blasting

The invention belongs to the field of metal corrosion and protection and discloses a preparation method of an anticorrosive polyurea coating. The preparation method comprises processes of preprocessing a metal structure, removing oil, performing sand blasting, treating a metal surface, drying, spraying bottom polyurea paint and spraying surface polyurea paint. The preparation method is characterized in that an inositol phosphate solution is adopted in the metal surface treatment to form a chemical conversion film of inositol phosphate on the surface a the metal structure substrate; the bottom polyurea paint is aromatic polyurea paint; the surface polyurea paint is an aliphatic polyurea paint; the metal comprises steel, aluminum alloy and a zinc-plated steel structure; and the coating is 500-1500 mu m thick, the bottom layer is 300-1200 mu m thick, the surface layer is 200-400 mu m thick, and the bonding strength of the coating is higher than 10MPa. The preparation method provided by the invention is simple in process, convenient to operate and free from coating a primer.

Owner:SHANDONG UNIV +1

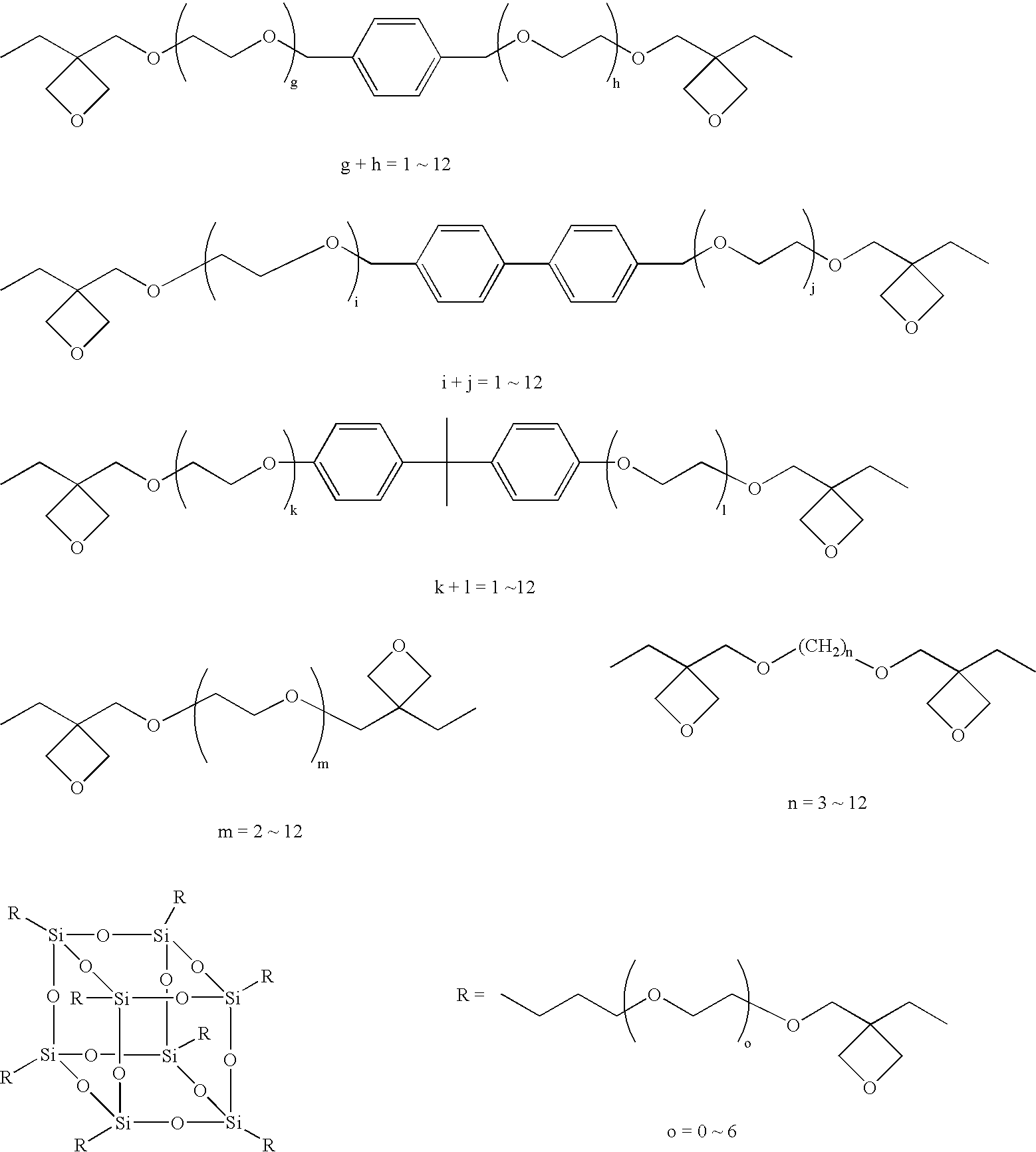

Cationically curable composition for dental use

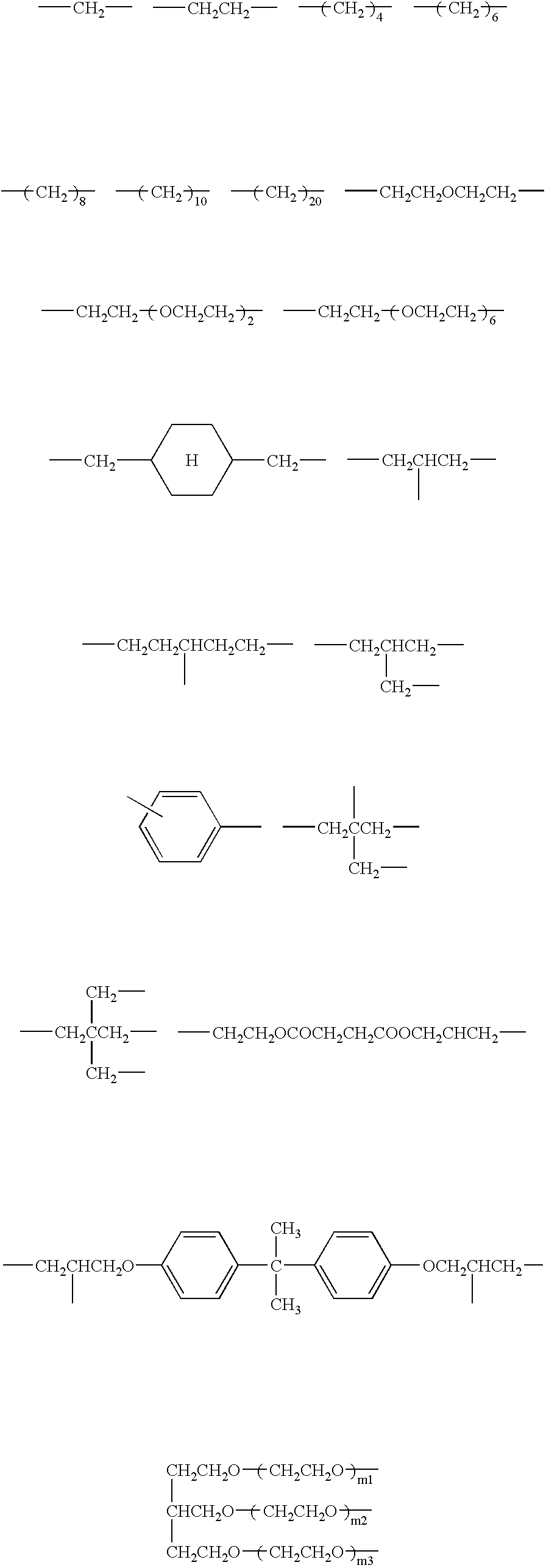

ActiveUS20050250868A1Improve aesthetic appearanceExtend curing timeCosmetic preparationsImpression capsEpoxyCationic polymerization

A cationically curable composition for dental use containing a cationic polymerization initiator (I) and cationically polymerizable monomers (II), the cationically polymerizable monomers (II) containing an oxetane compound and an epoxy compound or an alkenyl ether compound at a ratio of amounts that satisfy the conditions expressed by the following formula, (a×A):(b×B)=91:9 to 45:55 wherein A is a mol number of the oxetane compound, “a” is an average number of the oxetane functional group contained in one molecule of the oxetane compound, B is a mol number of the epoxy compound or the alkenyl ether compound, and “b” is an average number of the epoxy functional group contained in one molecule of the epoxy compound or an average number of the alkenyl ether functional group contained in one molecule of the alkenyl ether compound. The composition is not hindered by oxygen from being polymerized, cures quickly even without using a special polymerizable monomer or a particular polymerization initiator, little forms an unpolymerized layer on the surface even when polymerized and cured in a highly humid environment such as in the oral cavity, and is suited as a filling / restorative material for dental use.

Owner:TOKUYAMA CORP +1

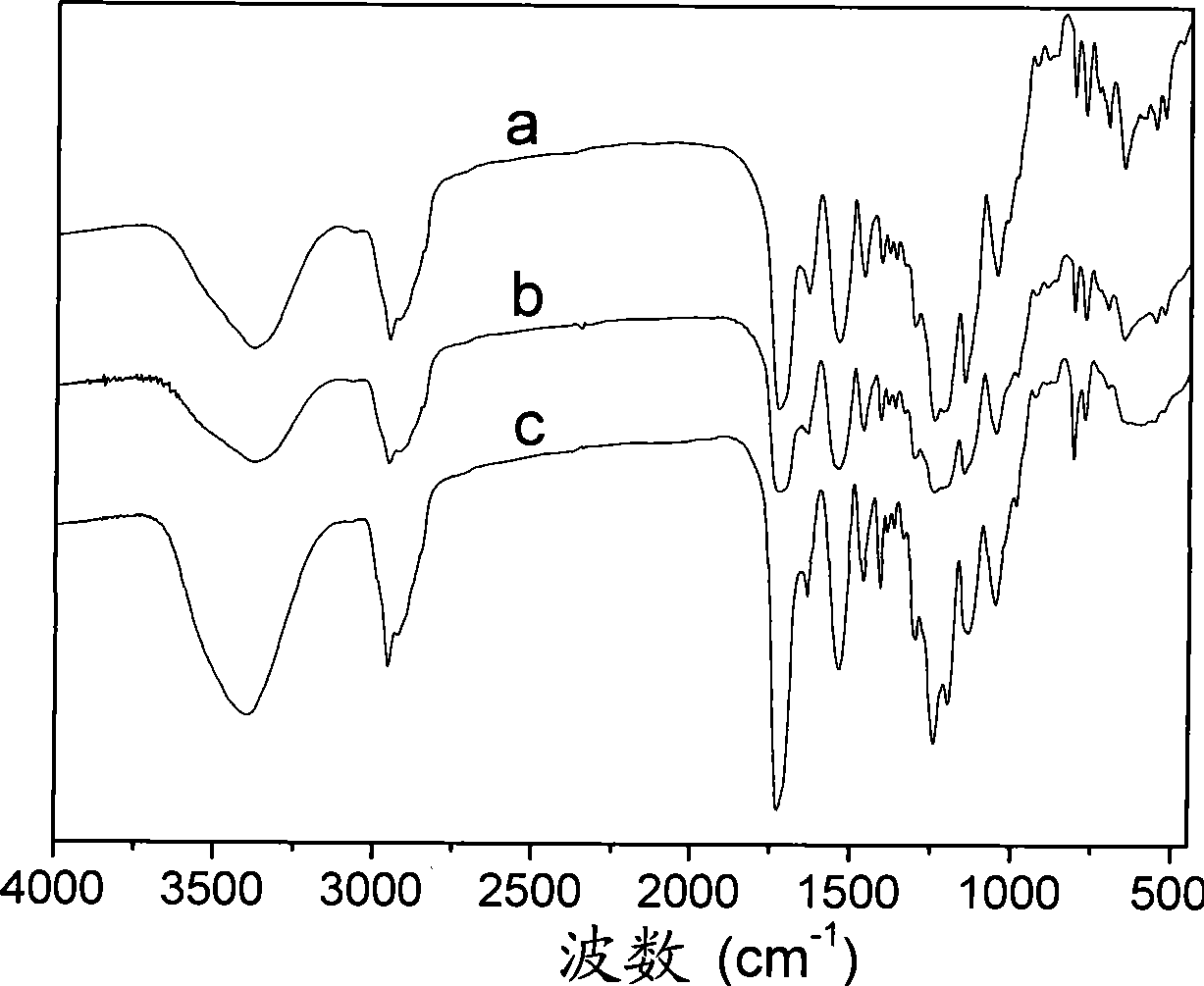

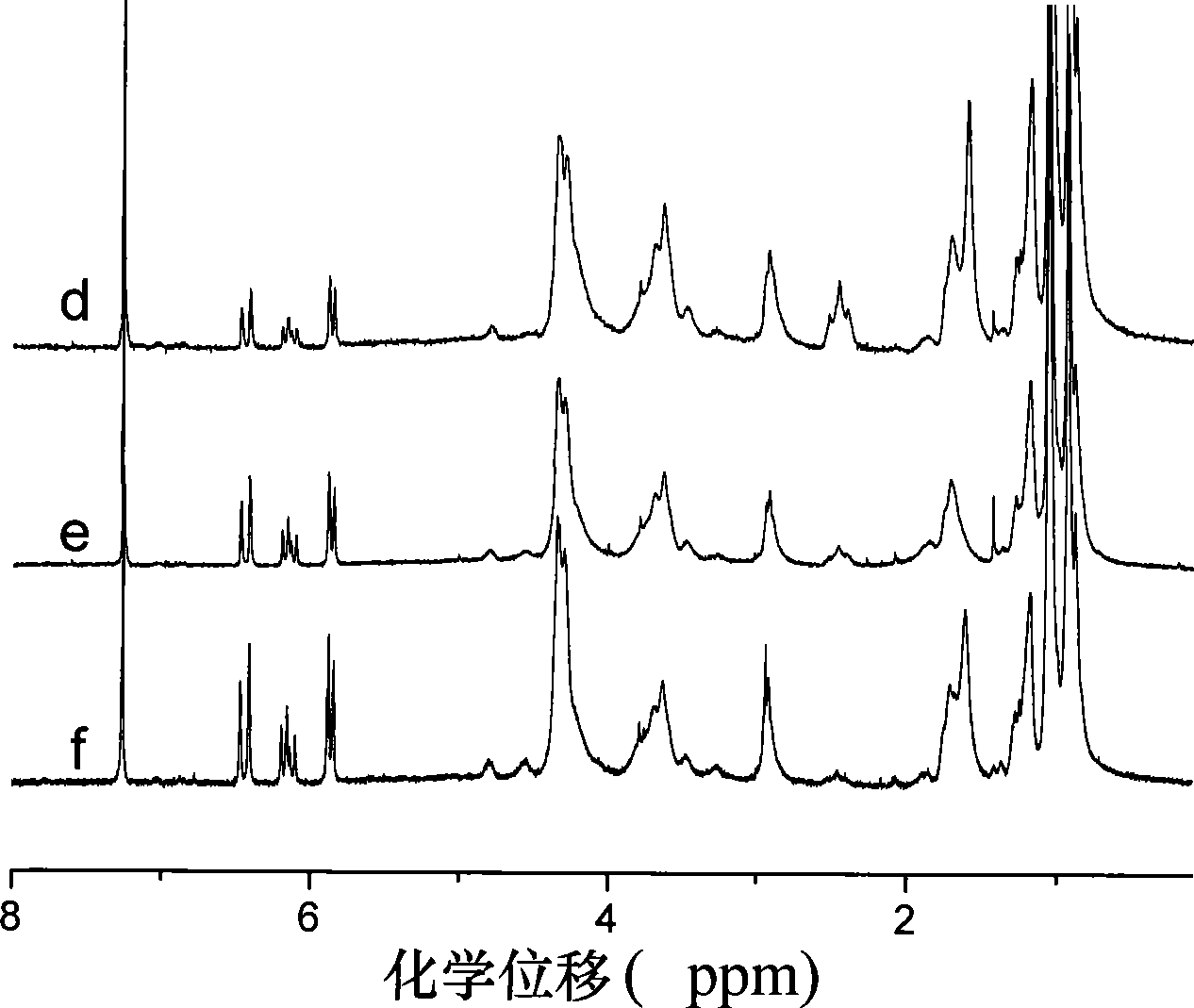

Fluorine-containing hyperbranched polyester acrylic ester and method of preparing the same

The invention discloses fluorinated hyperbranched polyester acrylate and a preparation method thereof. Fluoride-alcohol and hydroxy acrylate are chosen to react with diisocyanate respectively to achieve two semi-additive products, and the two semi-additive products in proper proportions are used to react with hydroxyl-terminated hyperbranched polymer, to achieve hyperbranched polymer fluorine terminated bases with acrylic acid ester base groups and halothane base groups linked to the hyperbranched molecular framework through carbamate base groups as well as acrylic acid modified hyperbranched polymer. The iso-cyan acid radical reaction of the method has high activity, the Fluoro-alcohol conversion rate is high, the raw materials are cheap and easy to obtain, the operation is easy, and capable of facilitating industrial production. The fluoric hyperbranched polyester acrylate achieved by the method can be applied to ultraviolet-light solidification coating, the achieved coating has sound hydrophobic and oleophobic performances, and the industrial application is very broad.

Owner:UNIV OF SCI & TECH OF CHINA

In-mold appearance coatings for nylon and nylon based thermoplastic substrates

InactiveUS6863981B2Extend curing timeShorten the curing timeLiquid surface applicatorsSynthetic resin layered productsPolymer chemistryOligomer

An in-mold coating composition particularly useful for in-mold coating of molded nylon based substrates comprises a coreactive addition polymerizable composition of urethane-acrylate oligomer having at least two acrylate and / or methacrylate terminal groups, at least 0.2% of a sulfonic acid functional acrylate or methacrylate, at least 0.2% of acrylic and / or methacrylic acid, with the balance being coreactive polymerizable diacrylate(s) and / or ethylenically unsaturated monomer(s).

Owner:OMNOVA SOLUTIONS INC

Polyurea adhesive composition and preparation method thereof

InactiveCN106905911ASolve the shortcomings of fast reaction time and short gel timeReduce shrinkage stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNano siliconPolyaspartic

The invention discloses a polyurea adhesive composition and a preparation method thereof. The polyurea adhesive composition is mainly prepared from polyaspartic ester, nanofiller and a curing agent. The polyaspartic ester is prepared by enabling an organic diamine compound and maleate to make a Michael addition reaction; the curing agent is prepared from an organic diisocyanate or polyisocyanate component, and can be a monomer, a polymer, a derivative of isocyanate, a prepolymer or a semi-prepolymer; the nanofiller is selected from nano-silicon dioxide, nano-titanium dioxide and nano-silicon carbide. By utilizing the Michael addition reaction of the organic diamine compound and the maleate, primary amine is transformed into secondary amine on the one hand, and a group having higher steric hindrance is introduced on the other hand, so that the defects that a polyurea material is rapid in reaction time and short in gelation time are overcome; the nanofiller is added into the polyurea adhesive composition, so that the stress shrinkage caused during the curing of an adhesive film is effectively reduced, and the polyurea adhesive composition is high in bonding strength.

Owner:北京奥润联创微电子科技开发有限公司

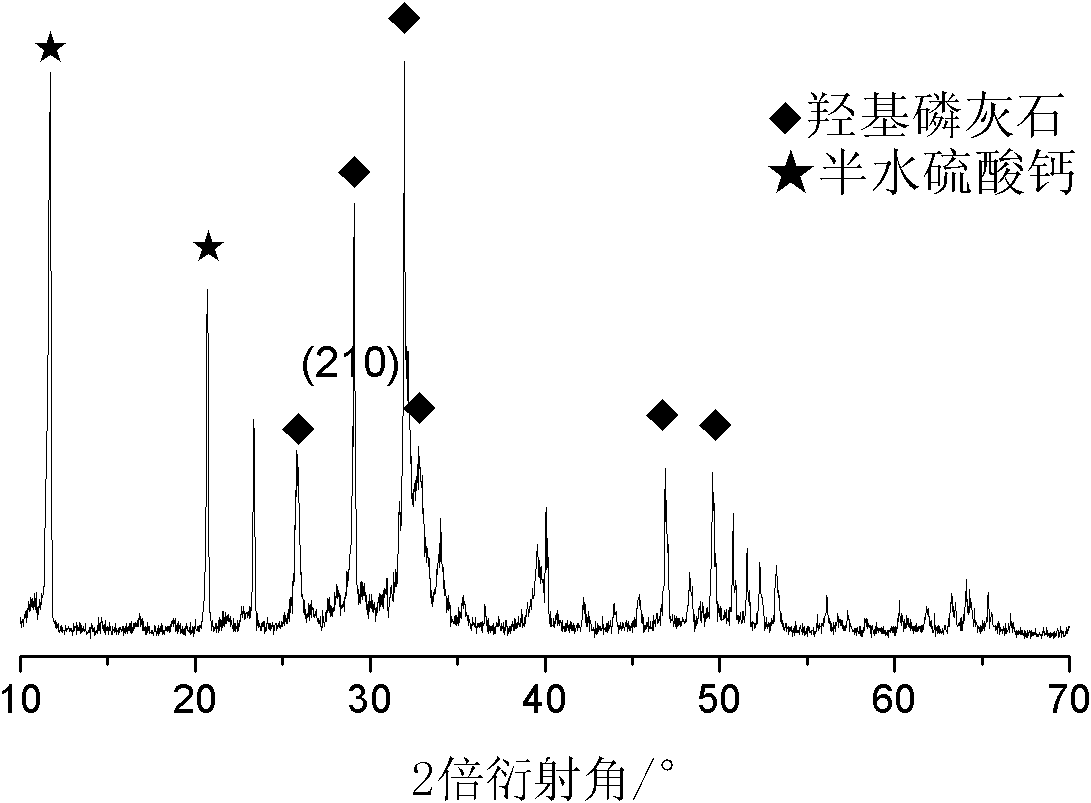

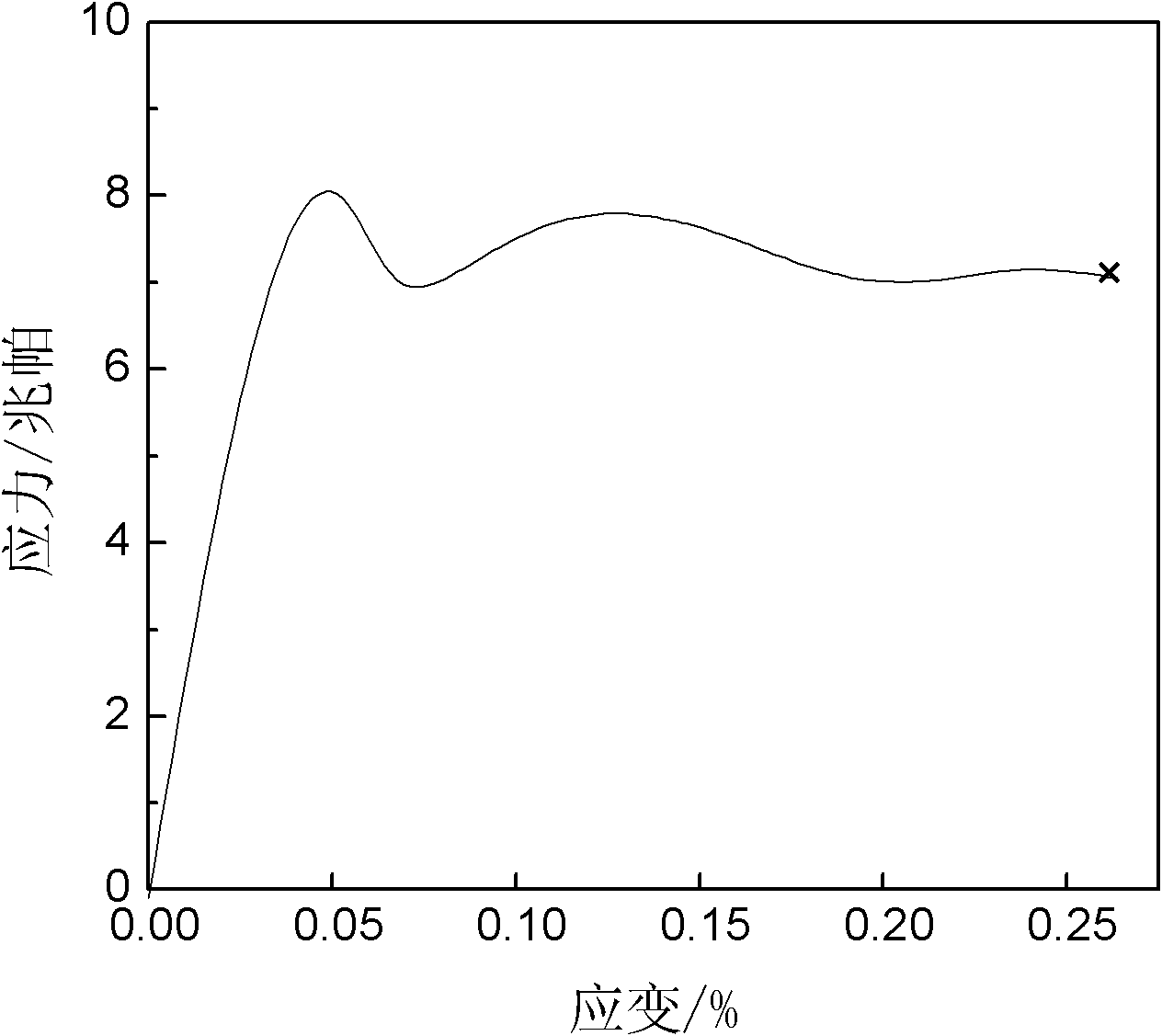

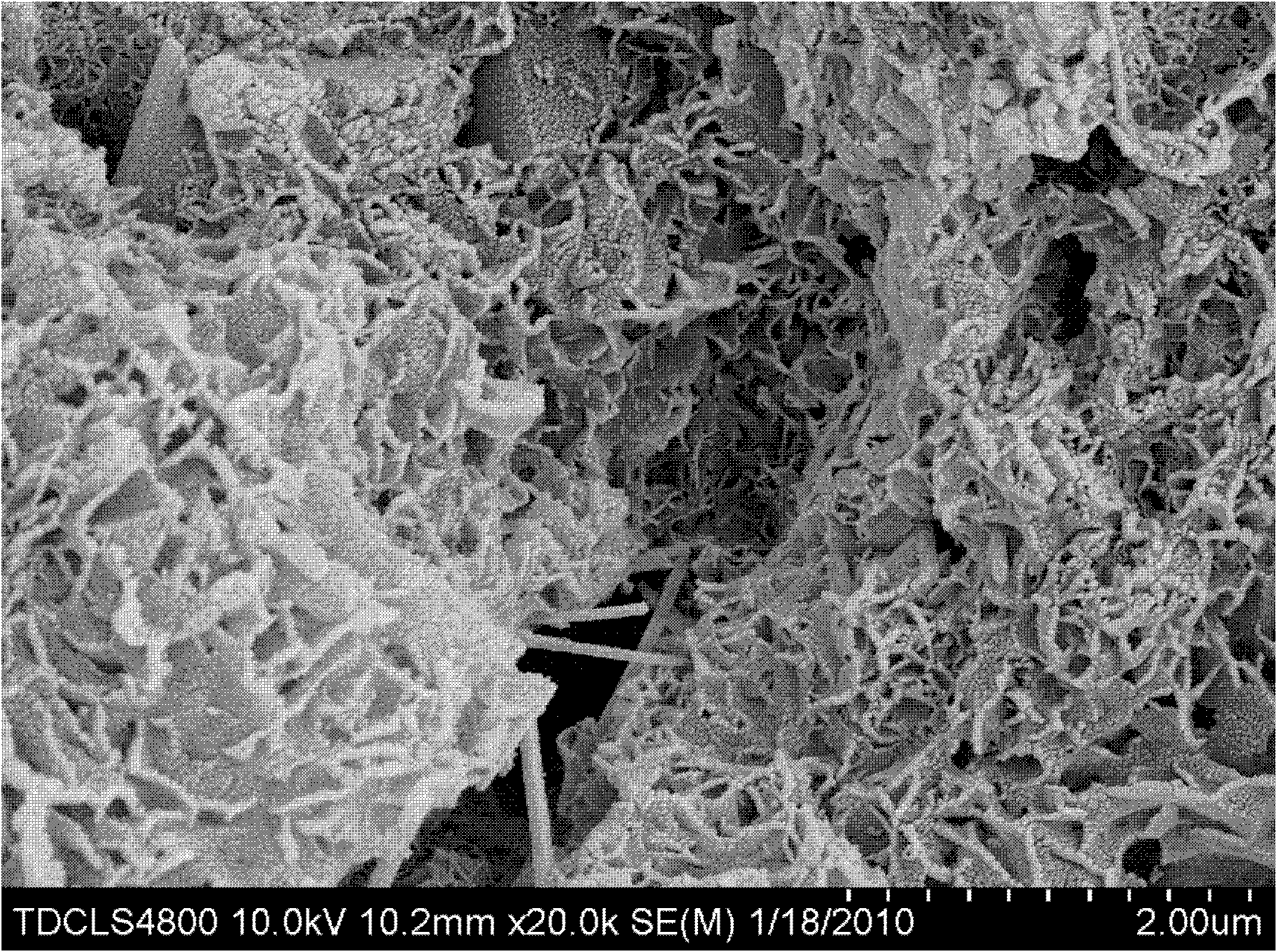

Method for preparing self pore-forming calcium phosphate cement bracket

The invention relates to a method for preparing a self pore-forming calcium phosphate cement bracket, which comprises the following steps of: 1) uniformly mixing calcium sulfate hemihydrate and tricalcium phosphate cement powder to obtain the mixed cement powder; 2) heating gelatin and NaH2PO4 with stirring in water at the temperature of between 45 and 50 DEG C until the gelatin and the NaH2PO4 are dissolved completely to obtain mixed solution; 3) uniformly mixing the mixed cement powder obtained by the step 1) and the solution obtained by the step 2), adding 25 to 50 percent aqueous solution of glutaraldehyde immediately, injecting the mixed cement powder slurry into a steel mould, then mixing the slurry at room temperature for 60 to 90 seconds, keeping the temperature of the slurry to be 37 DEG C after taking out, and then curing the slurry for 1 to 2 hours under the condition that the humidity is 100 percent to obtain the composite bracket. When the porosity is 71 percent, the average value of the compression strength can be increased to 8.1MPa; the bracket has high porosity and compression strength, and plays a better role in supporting in a human body, and the macropore diameter is between 100 and 300 mu m; and the self pore-forming calcium phosphate cement bracket prepared by the invention can be used as a repairing material of a human hard tissue.

Owner:TIANJIN UNIV

Resin glue adhesive for E0 grade fibre board

InactiveCN101307215ALow water resistanceLow aging resistanceAldehyde/ketone condensation polymer adhesivesDomestic articlesFirming agentUltimate tensile strength

The invention discloses a synthetic resin cementing compound used for an EO-stage fiberboard. The synthetic resin cementing compound consists of melamine modified urea resin and a firming agent and is characterized in that the compositions of reaction material of the urea resin by weight percentage are: 4.0 to 6.0 percent of the melamine, 40.0 to 42.0 percent of urea, 52.0 to 56.0 percent of formaldehyde, and 0.4 to 0.6 percent of an accelerating agent; acid and alkali are appropriate and the total mol ratio is between 0.90 and 0.93; and the cementing compound is obtained by the systemization and reaction of the materials. The cementing compound has good cementation strength, appropriate curing time, and the content of 0.06 to 0.08 percent of free formaldehyde, etc. E1 and the E0-stage fiberboard with good quality can be produced stably and have the advantages of low glue feeding amount, strong adaptability to the hot press molding technology and high curing speed in the hot press molding process, etc., thereby meeting the need of the market on products of high environmental performance fiberboards.

Owner:DARE TECH

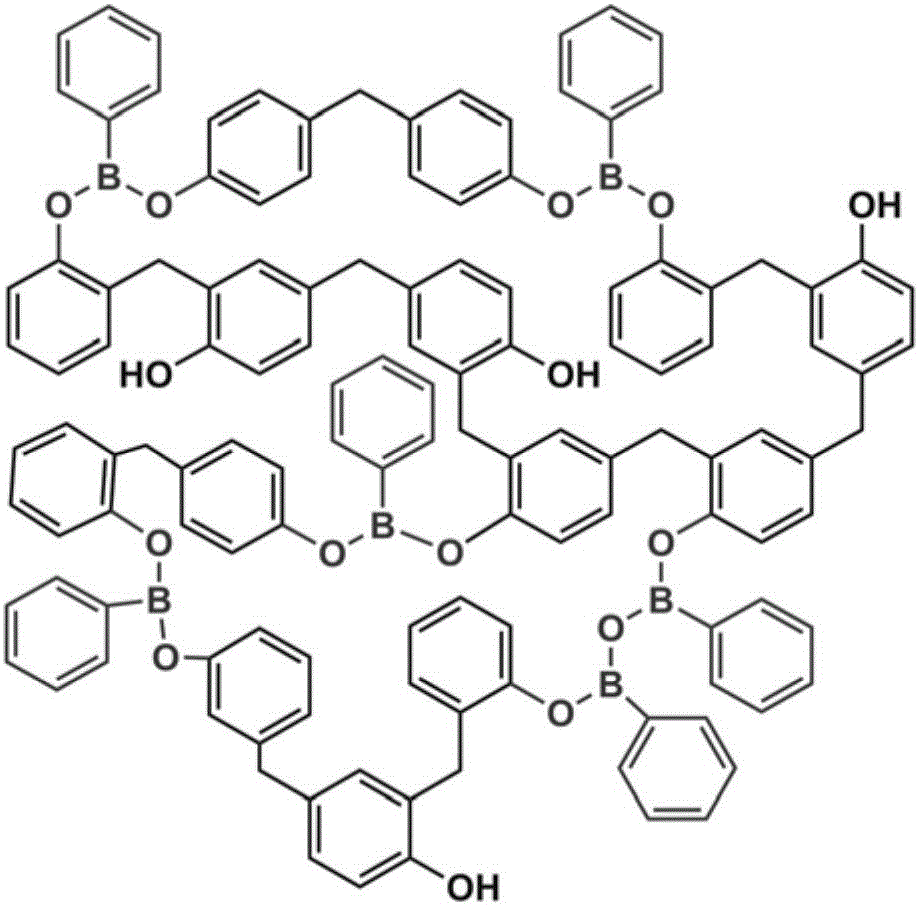

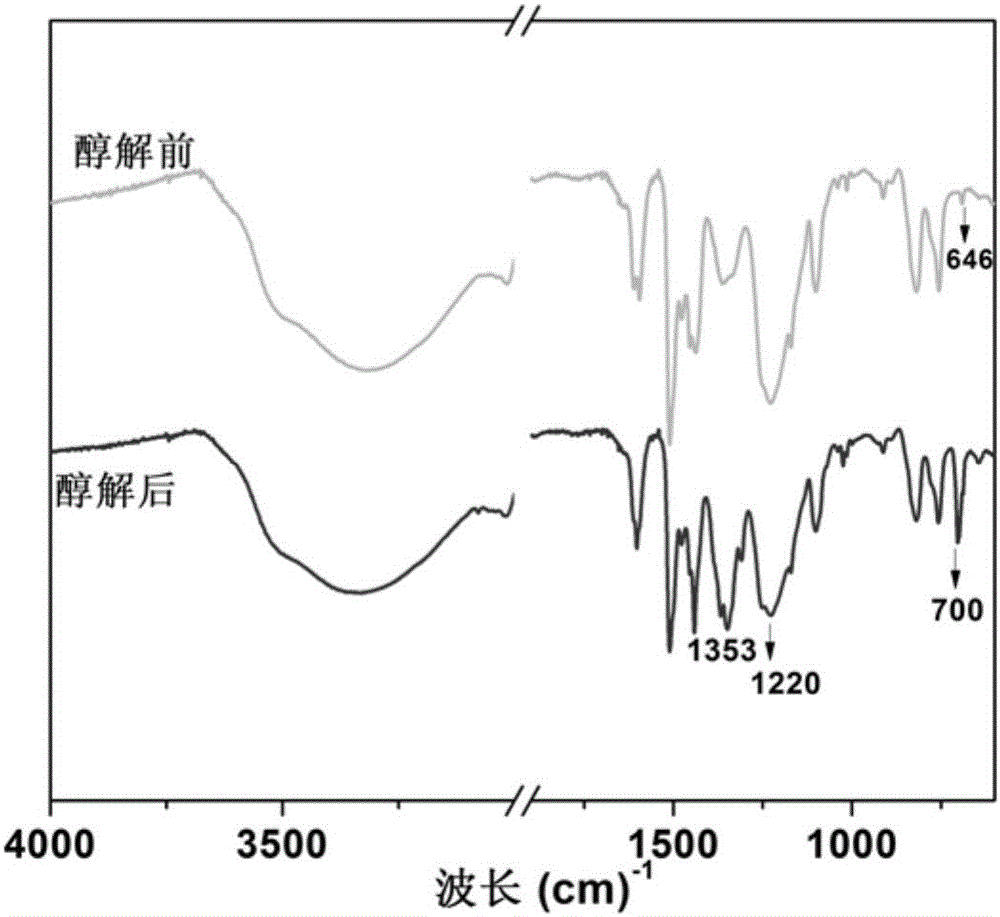

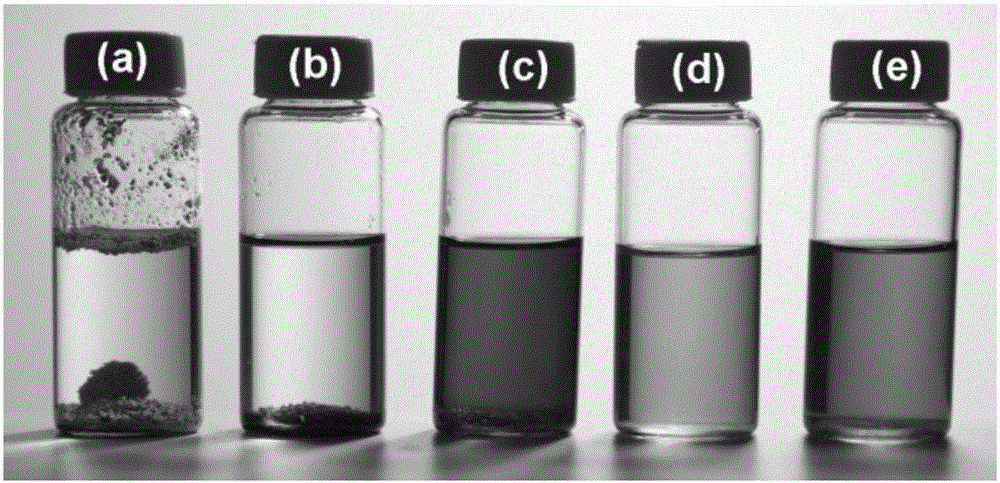

Preparation method of room-temperature regenerated phenolic resin and recycling technology and application thereof

ActiveCN106750064ALow softening temperatureReduce melt viscosityPlastic recyclingOrganic solventAlcohol

The invention relates to a preparation method of room-temperature regenerated phenolic resin and a recycling technology and application thereof. The preparation method comprises the following steps of according to parts by mass, melting and blending 100 parts of thermoplastic phenolic resin and 18.4 to 55 parts of boric acid compound at the temperature of 60 to 100 DEG C, so as to obtain boron-containing thermoplastic phenolic resin; or, dissolving 100 parts of thermoplastic phenolic resin and 20 to 50 parts of boric acid compound into an organic solvent with low boiling point at the temperature of 40 to 60 DEG C, so as to obtain the boron-containing thermoplastic phenolic resin; curing, so as to obtain the room-temperature regenerated phenolic resin. The preparation method has the advantages that the preparation technology of the resin is simple; the resin is dissolved into the mixing solvent of ethyl alcohol and water at room temperature, so that the resin can be recycled; the resin can be used for preparing the recyclable fiber reinforced boron-containing thermoplastic phenolic resin-based composite material. The prepared boron-containing thermoplastic phenolic resin has the advantages that the function of arylboronic acid ester structure promoting the heat-resistant property of the thermoplastic phenolic resin is fully realized, and the technology of the resin and the mechanical property of the composite material can be simultaneously realized.

Owner:XI AN JIAOTONG UNIV +1

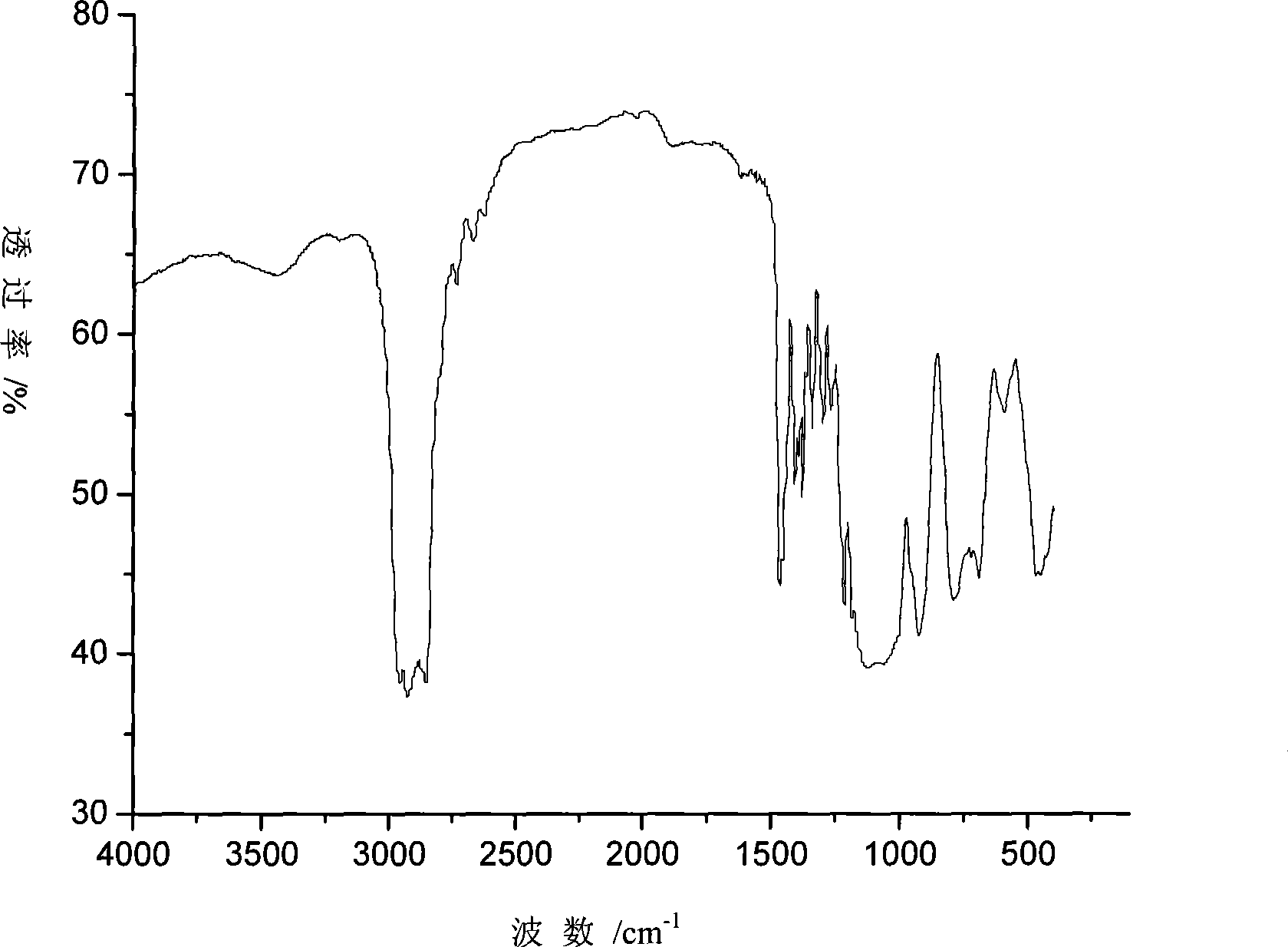

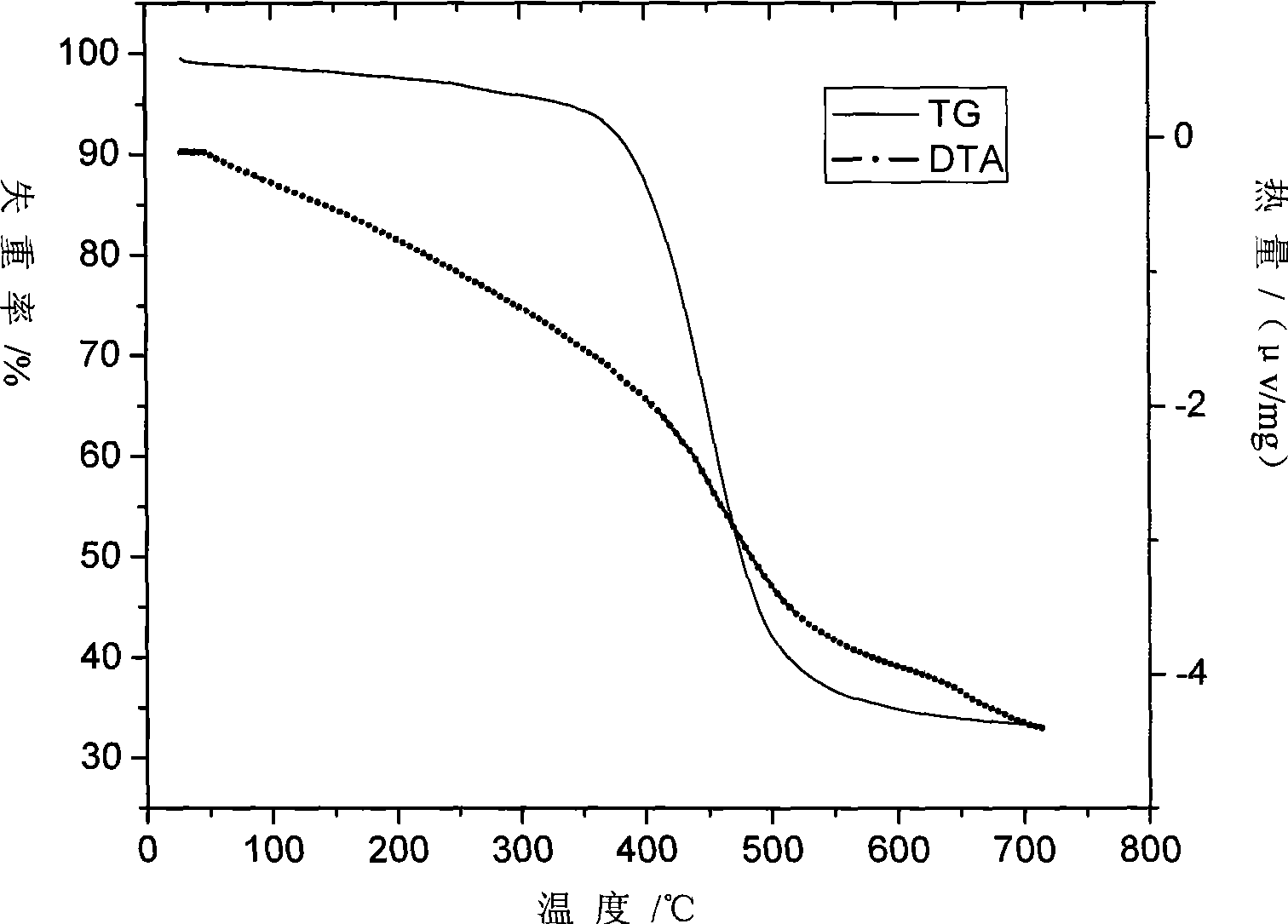

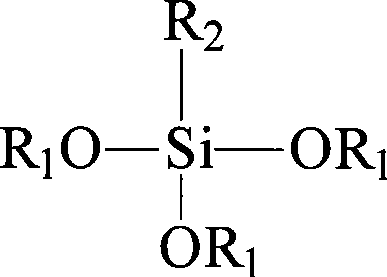

Preparation method for organic silicon resin with high curing activity and high temperature resistance

The invention discloses a preparation method for an organic silicon resin with high curing activity and high temperature resistance, which comprises the following steps: carrying out hydrolytic polycondensation on two kinds of alkyl alkoxy silane and one kind of metal acid ester to polymerize into a silicone resin polymer with proper molecular weight; and using a low-toxic organic solvent as a diluting agent, and adding a curing agent into the low-toxic organic solvent so as to obtain the organic silicon resin with high curing activity and high temperature resistance which can be used as a coating matrix resin. Compared with the common organic silicon resin, the synthetical organic resin has the advantages of excellent heat resistance, high curing activity, good adhesive force, considerable stability, excellent light stability, and excellent environmental friendliness; the preparation method has simpler synthetic route, easily-obtained raw materials, and low price; and the synthetical silicon resin is a low-cost and high performance resin, and is suitable for large-scale preparation and industrialized production.

Owner:GUANGDONG UNIV OF TECH

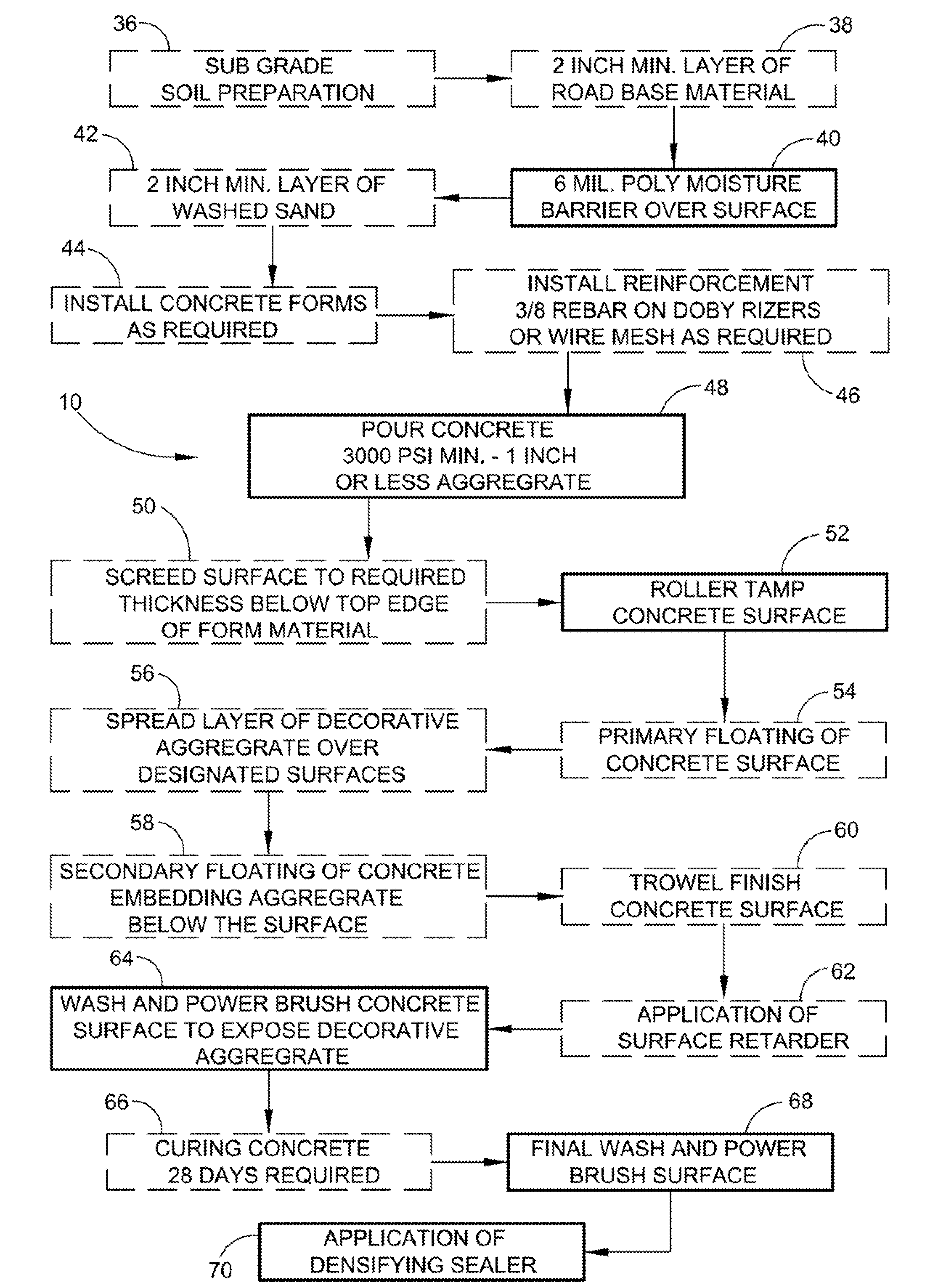

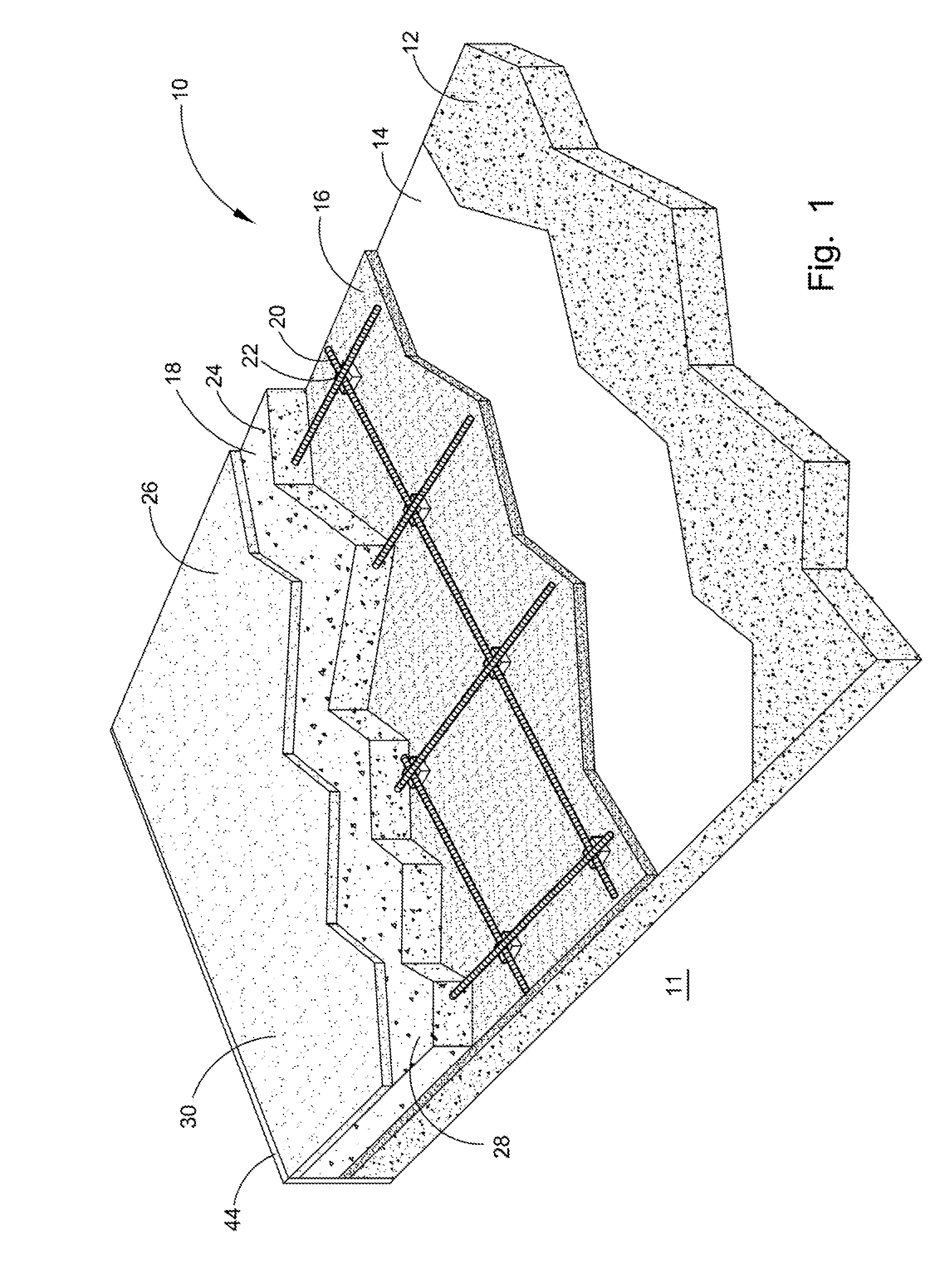

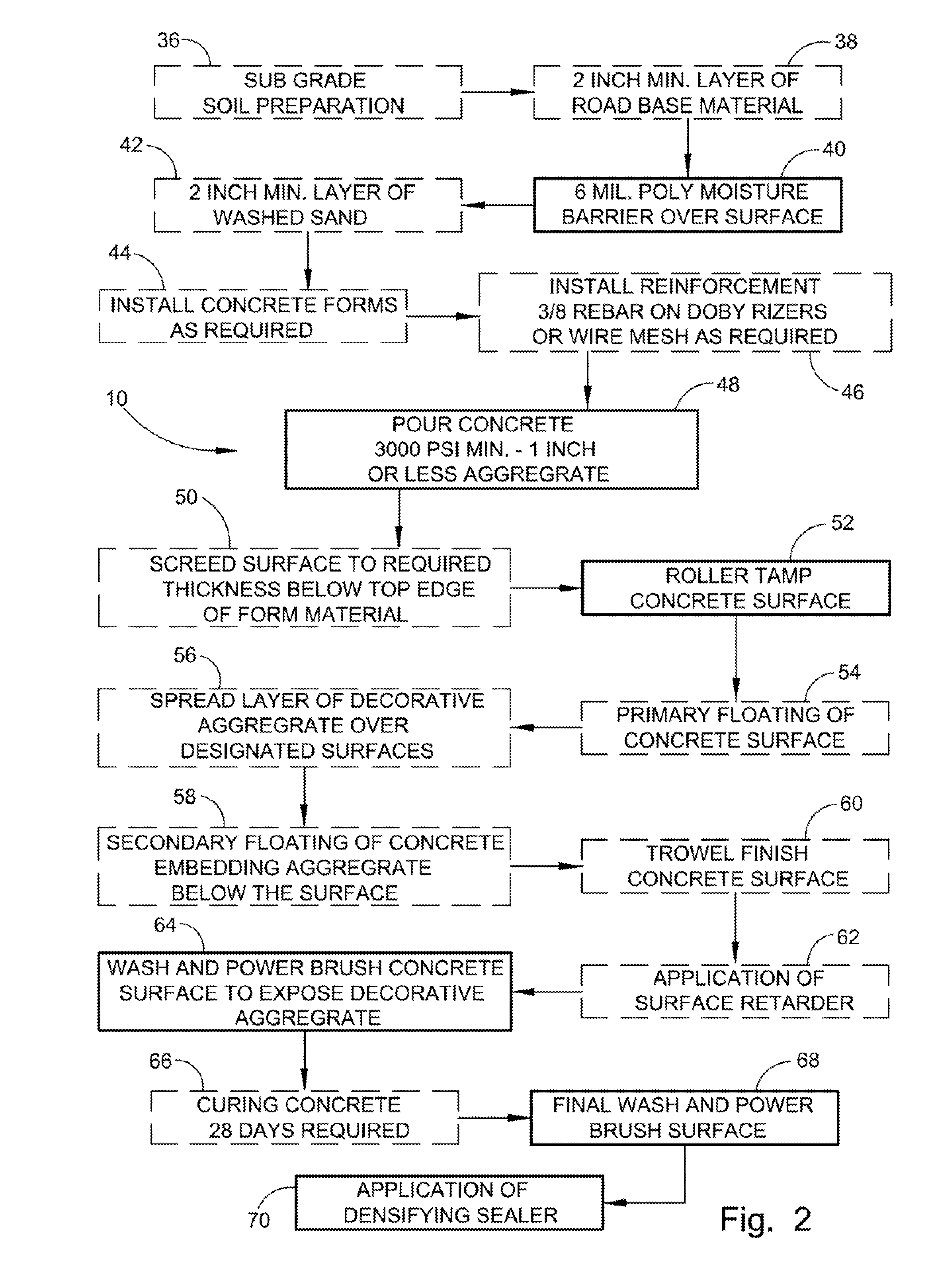

Decorative aggregate concrete surface preparation process

InactiveUS20140000214A1Increases adhesion potentialReduces the potential for shrinkageIn situ pavingsBuilding repairsWood veneerPolypropylene

The present invention is directed to a process of creating a decorative aggregate concrete surface. The preparation includes washed decorative aggregate surfaces using a variety of decorative aggregate materials imbedded within a standard concrete mix having a one inch maximum aggregate. A 6-mil polypropylene sheet Visqueen material covered with a two-inch layer of sand is used directly below the concrete to retard the curing time. Roller tamping is used to move the large aggregate below the surface of the concrete material. Power brushes are then used to expose the decorative aggregate prior to the final process of applying a densifing sealer. This process has been designed to reduce installation time, as well as overall labor and material costs.

Owner:VASQUEZ JR RICARDO +1

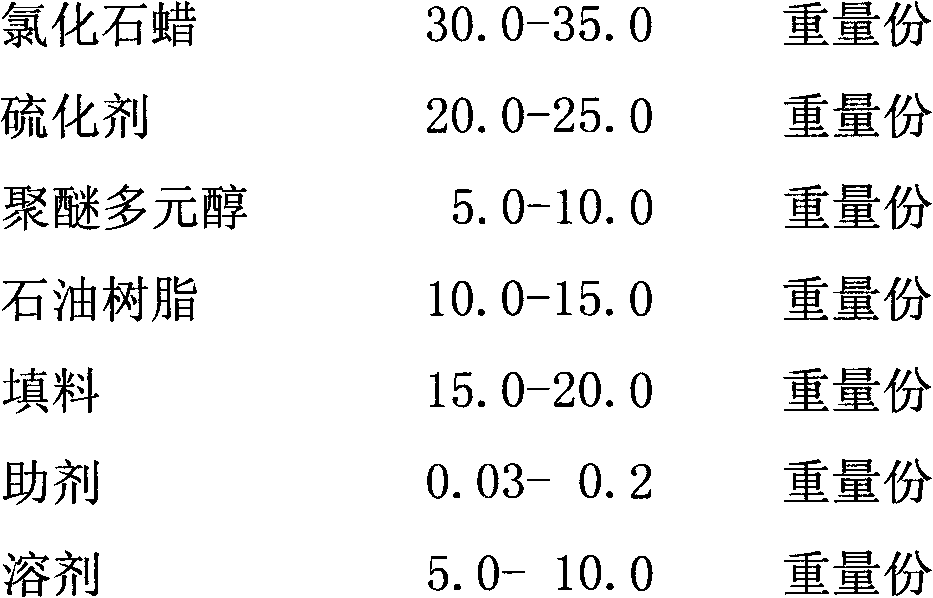

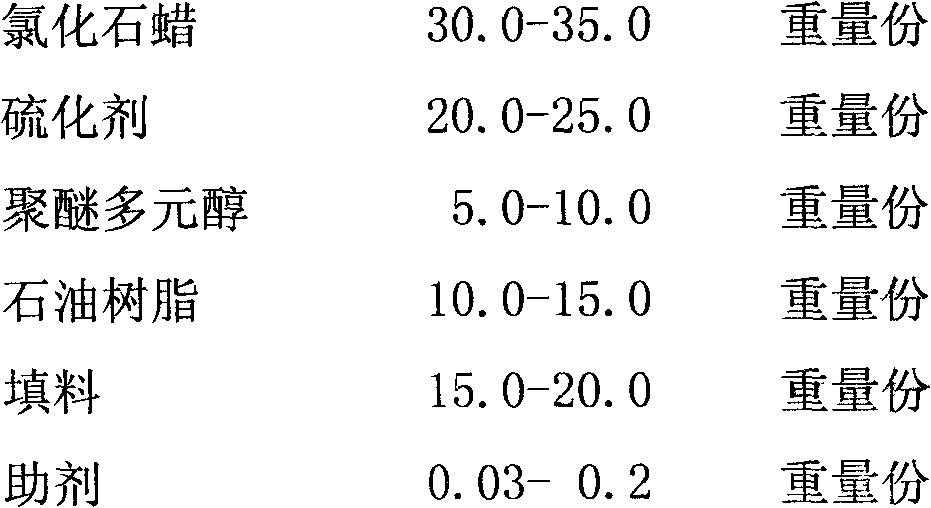

Super-strength polyurethane waterproof coating and preparation method thereof

InactiveCN102433061AElastomerImprove strong adhesionPolyurea/polyurethane coatingsSolventChlorinated paraffins

The invention relates to a super-strength two-component polyurethane waterproof coating which is made of petroleum resin. The polyurethane waterproof coating is prepared by the following method. The raw materials of the polyurethane waterproof coating comprise a component A and a component B, wherein the component A contains 60.0-70.0 parts of polyether diol, 10.0-20.0 parts of polyether polyol and 15.0-25.0 parts of chain extender by weight; and the component B contains 30.0-35.0 parts of chlorinated paraffin, 20.0-25.0 parts of vulcanizing agent, 5.0-10.0 parts of polyether polyol, 10.0-15.0 parts of petroleum resin, 15.0-20.0 parts of filler, 0.03-0.1 parts of assistant and 5.0-10.0 parts of solvent by weight. Since the petroleum resin is added into the raw materials of the super-strength two-component polyurethane waterproof coating and has unsaturated bonds which can be bonded with polyurethane in the generation process of the polyurethane to increase the length of molecular chains, the tensile strength and the elongation at break of the coating film are greatly improved and the mechanical properties are better than that of the product in which the petroleum resin is not added. At the same time, since the price of the petroleum resin is low, the material is convenient to obtain, the cost of the two-component polyurethane waterproof coating product is low and the economic benefit is greater.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

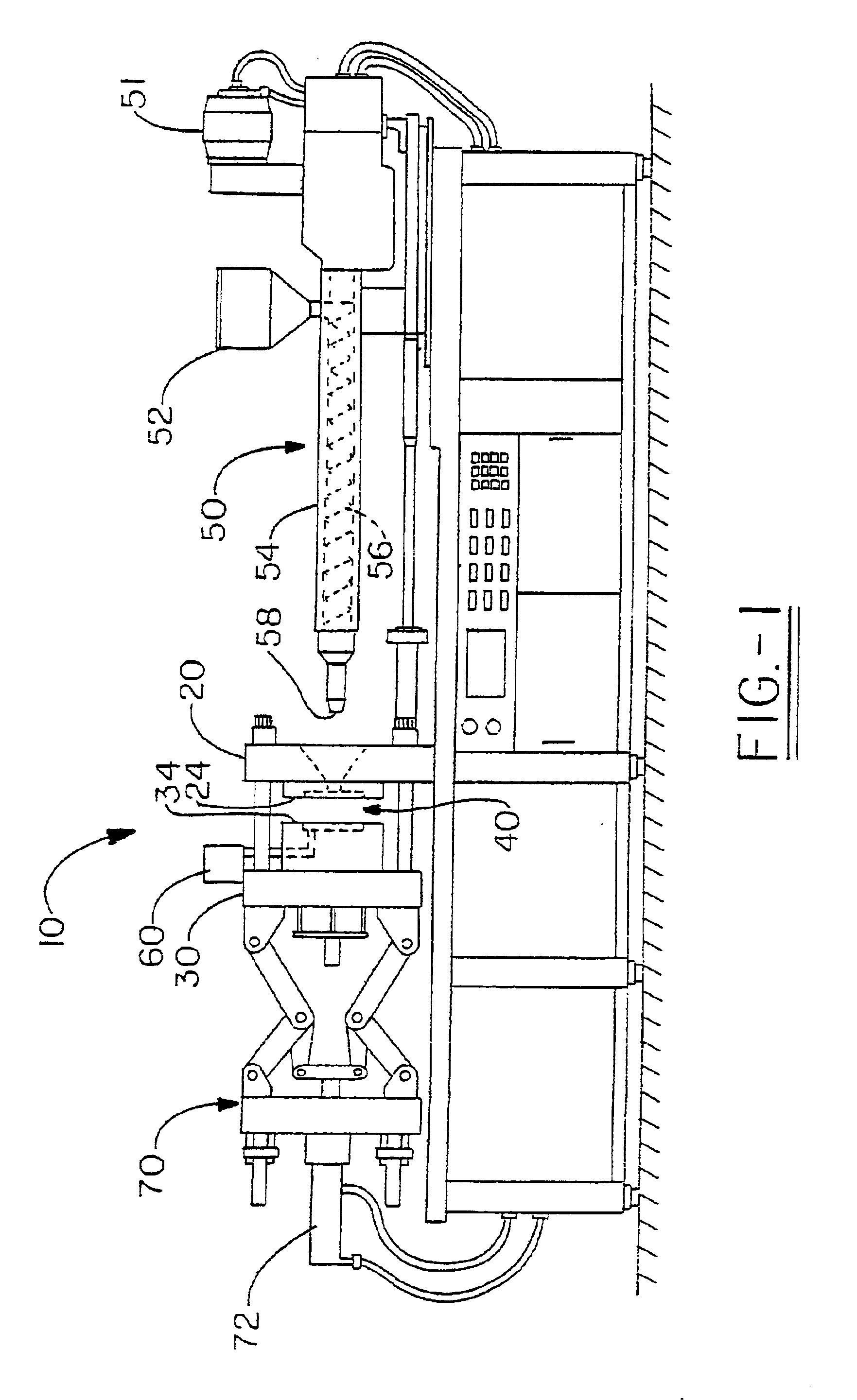

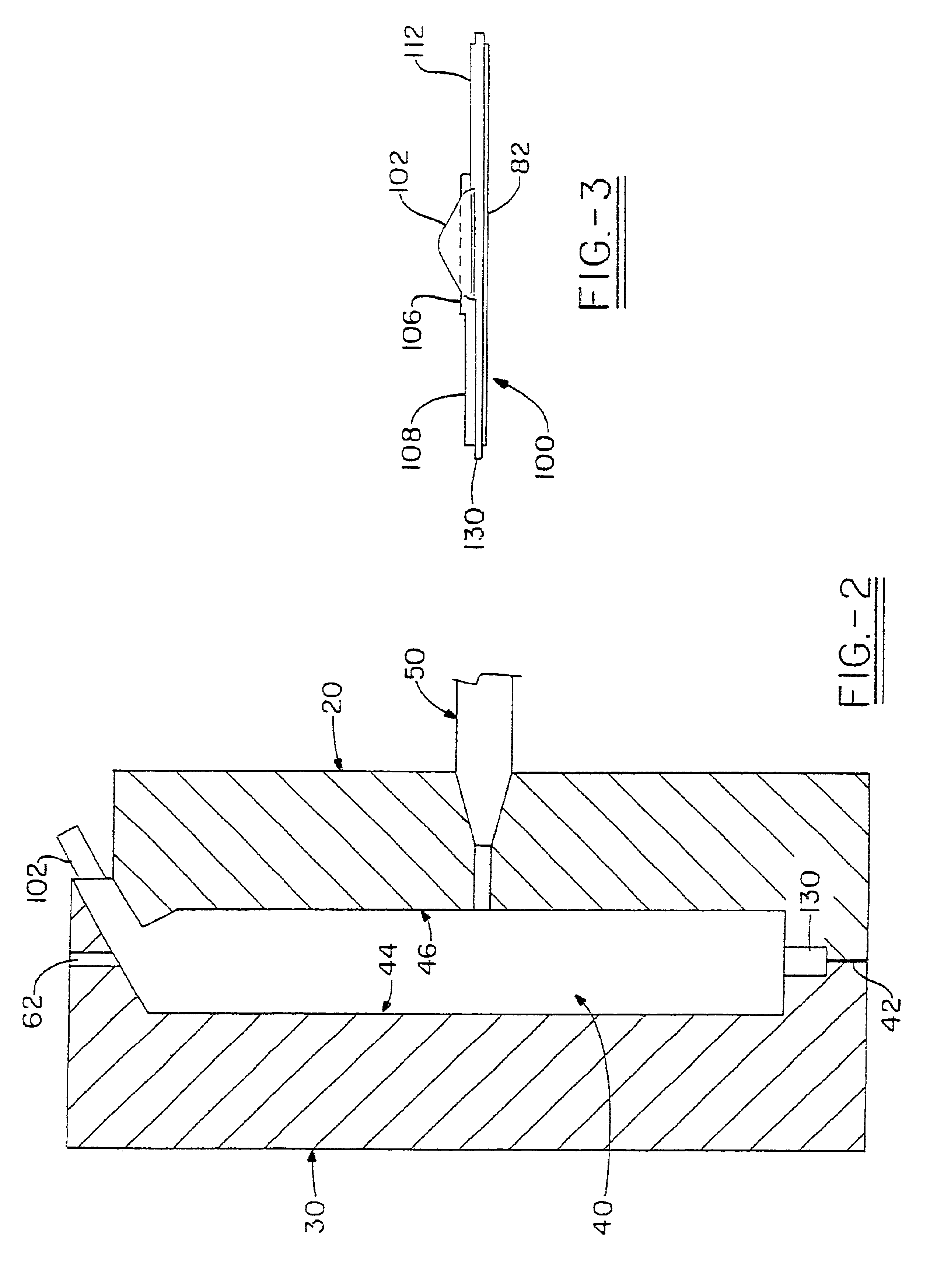

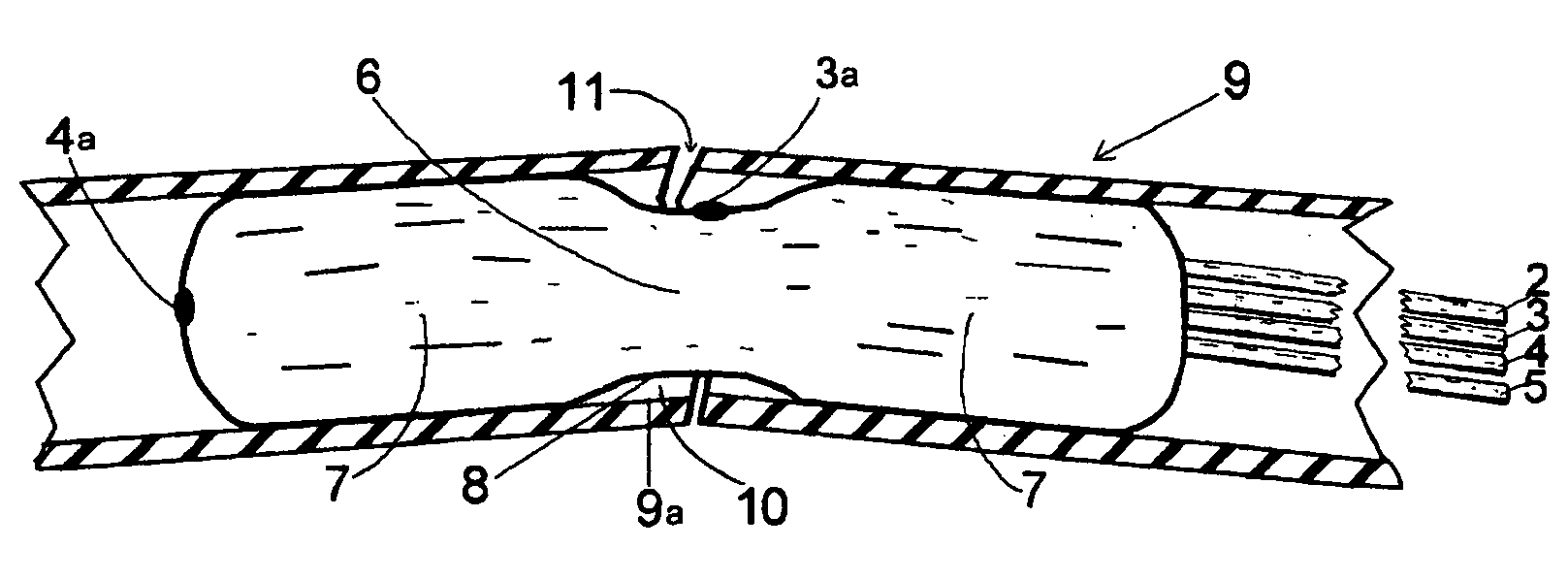

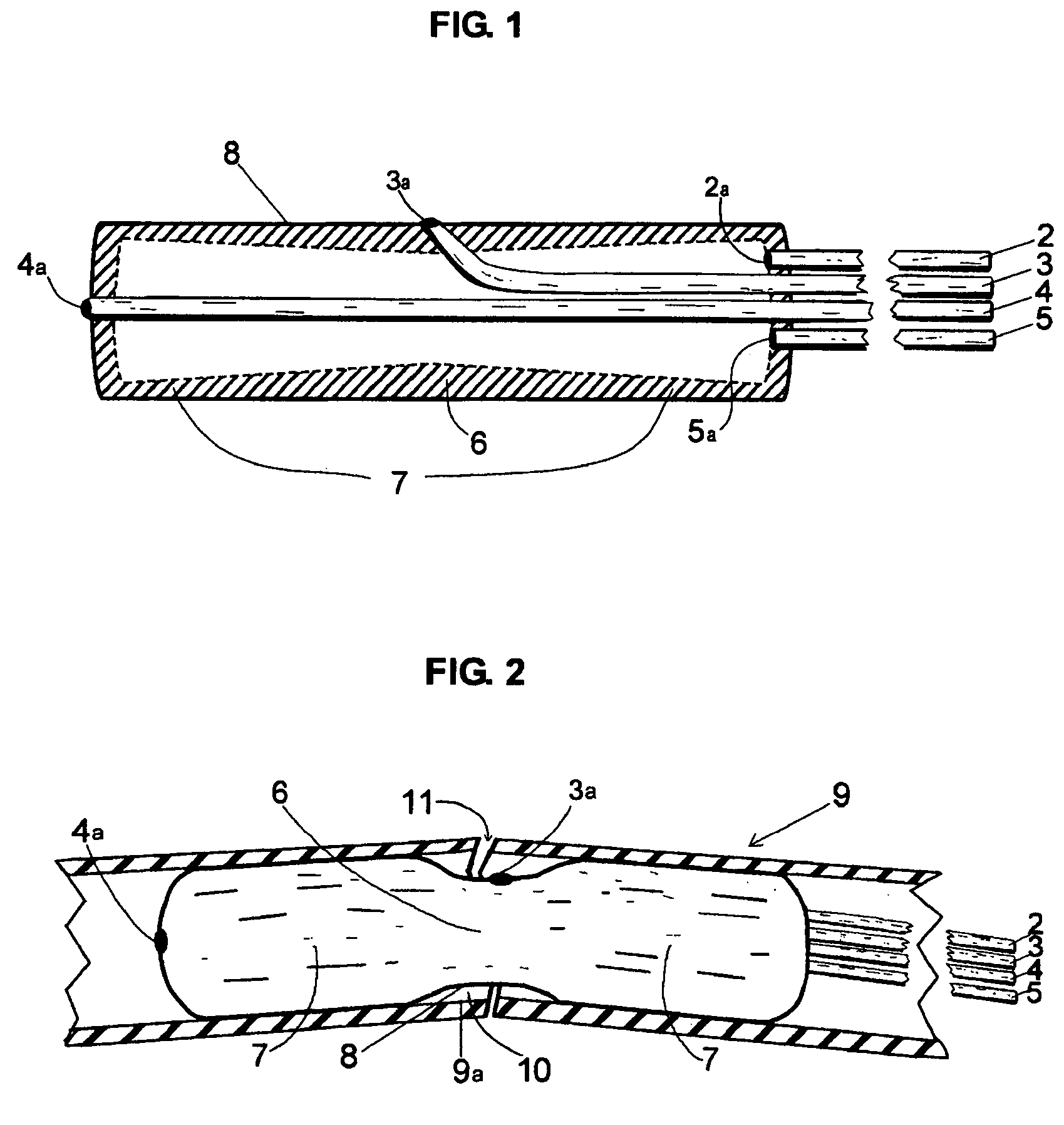

Internal pipe repair method and device

A device and method for internally repairing pipes. The device consists of a reusable, elastomeric shell configurable for two, three, and four-pipe junctions. The design of the device aids in positioning the expandable shell over and helps seal off the leak area inside a pipe. Once inflated into proper position, a sealant is injected into the leak area. Not only does the sealant eventually seal and fortify inside the pipe it also forms a seal around the outside of the pipe. Once the sealant has cured, the device is deflated and removed from the pipe. Minimal pipe preparations are necessary before implementing a repair. The device can also be temperature modulated to enhance sealant cure.

Owner:BEDNARZIK UWE HAROLD

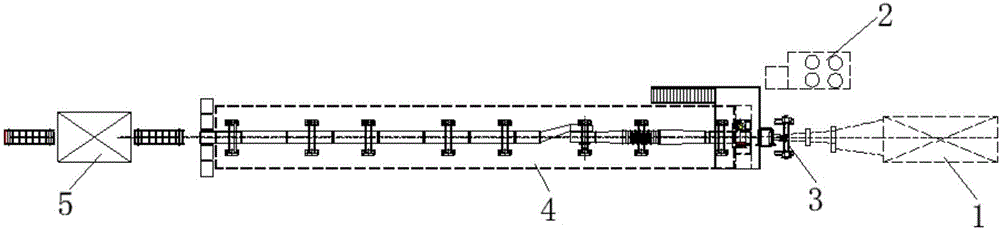

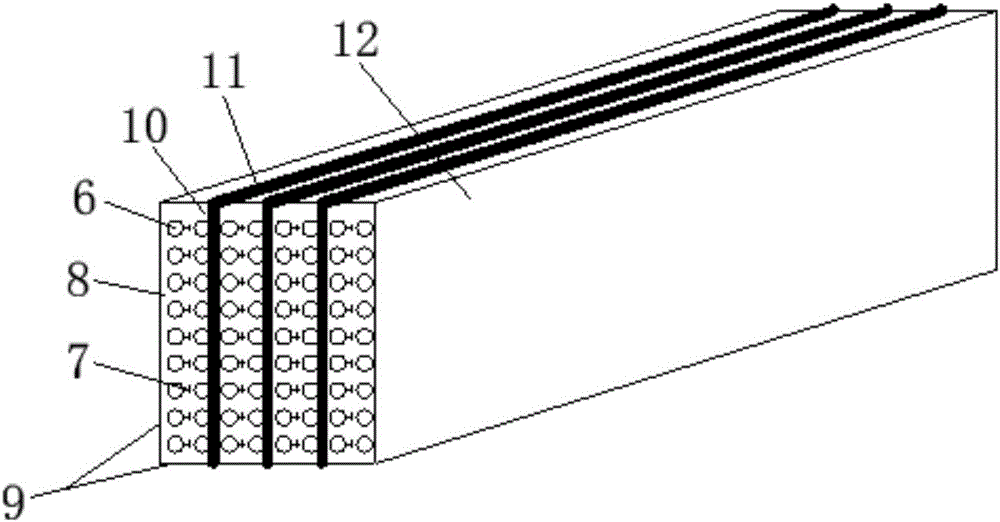

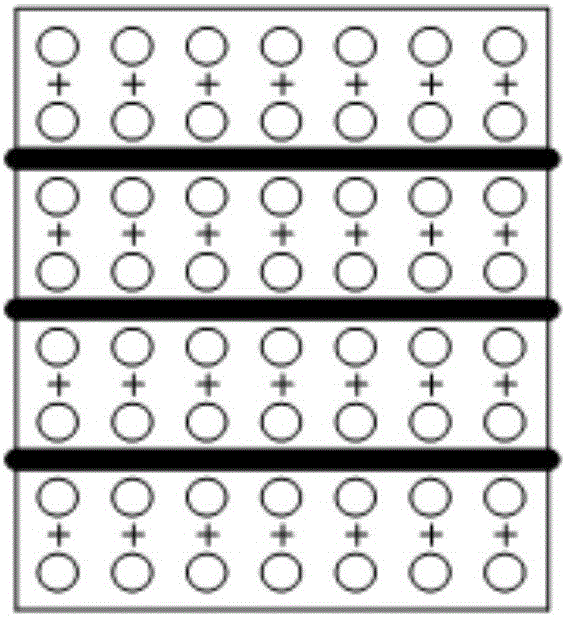

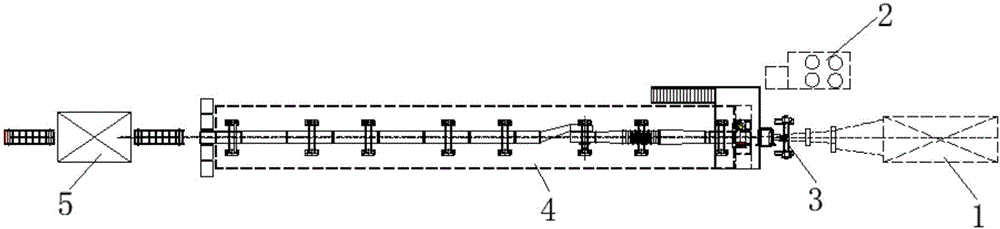

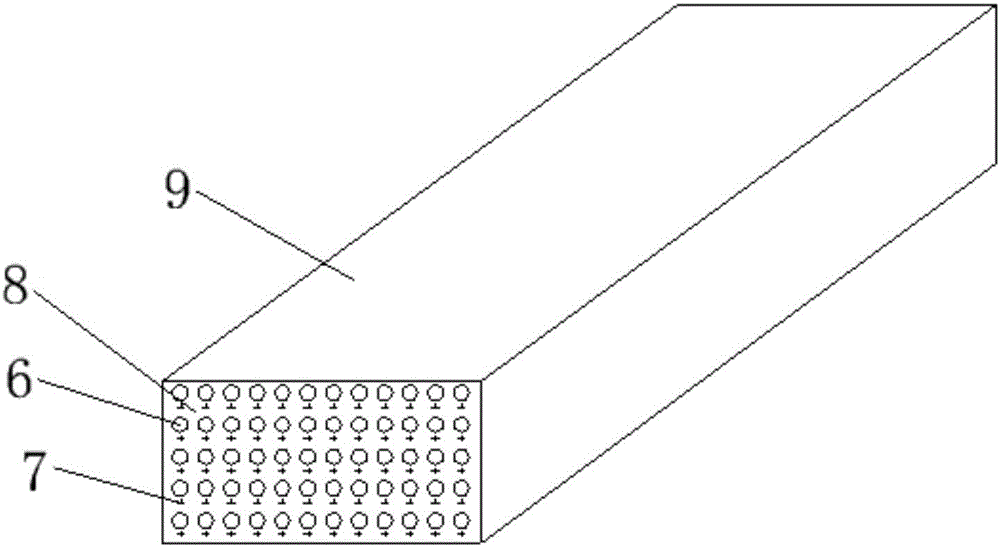

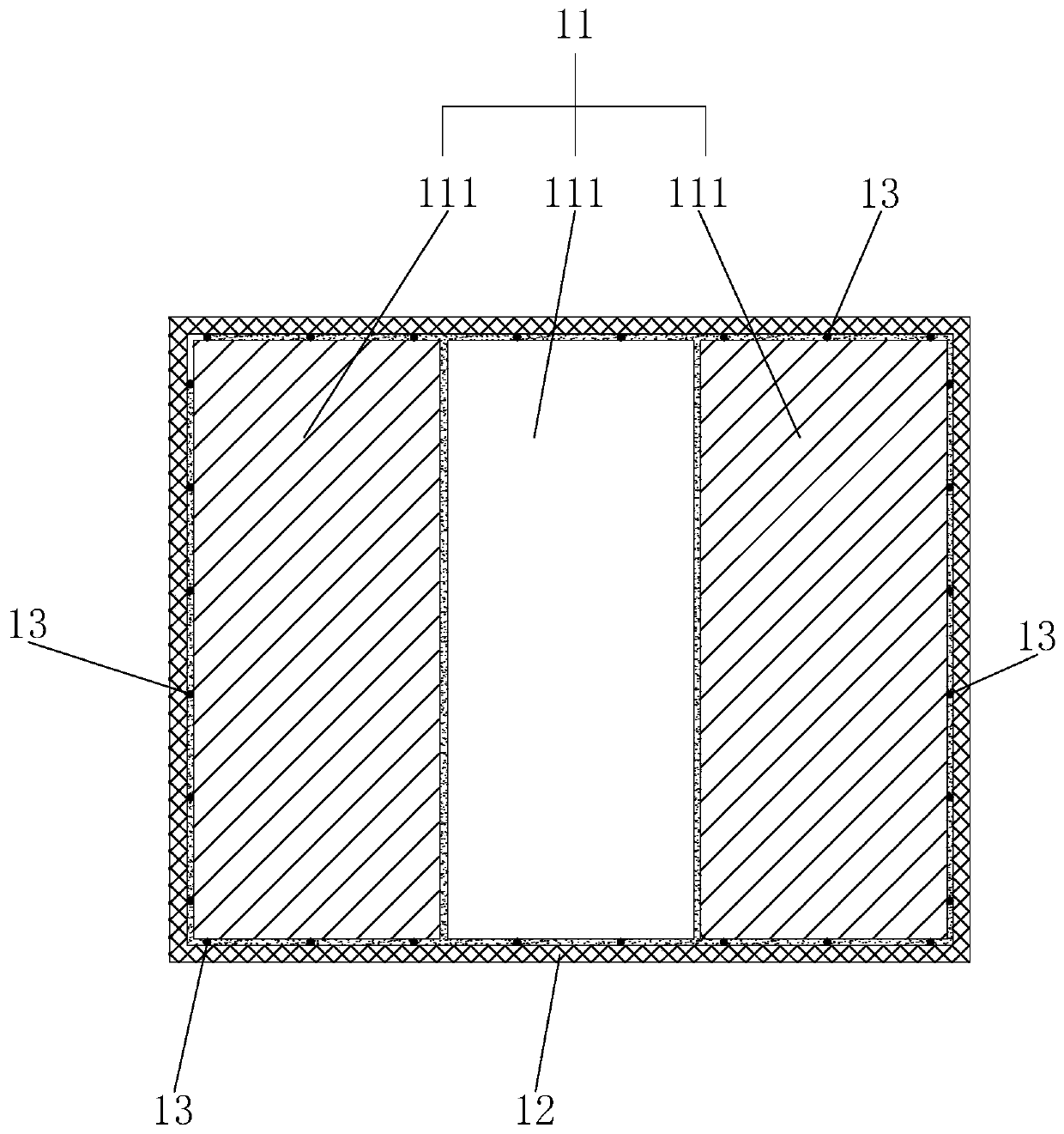

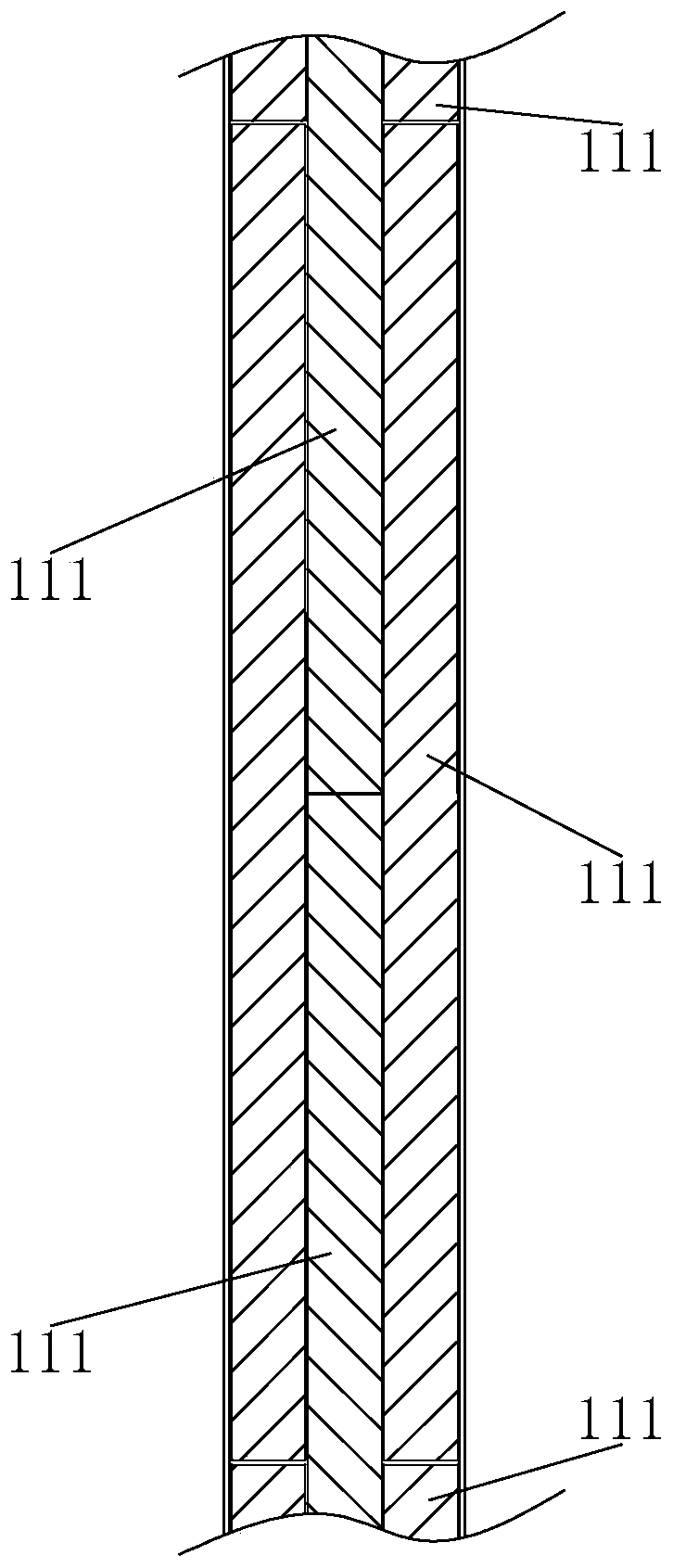

Fiber-reinforced rigid polyurethane foam synthesis sleeper with high fiber content and manufacturing method of sleeper

The invention relates to a fiber-reinforced rigid polyurethane foam synthesis sleeper with the high fiber content and a manufacturing method of the sleeper. The sleeper is formed by bonding multiple fiber-reinforced rigid polyurethane foam synthesis boards with the high fiber content through a bonding agent, an anti-corrosive paint film is arranged on the outer surface of the sleeper, and the fiber-reinforced rigid polyurethane foam synthesis boards with the high fiber content use polyurethane resin and reinforced fibers as base materials. Various technological measures such as mixed type polyether polyol with the low hydroxyl value and the low functionality degree and a coupling agent are adopted, the problem that the polyurethane resin and the reinforced fibers are not sufficiently impregnated is solved, so that the content of the reinforced fibers is increased, a fiber-reinforced rigid polyurethane foam material product with the density higher than 840 kg / m<3> and the content of the reinforced fibers larger than 60% can be manufactured, the technological blank of the fiber-reinforced rigid polyurethane foam synthesis boards is filled up, the standards and the performance of the product of the boards are diverse, and the requirements for different technical indexes are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

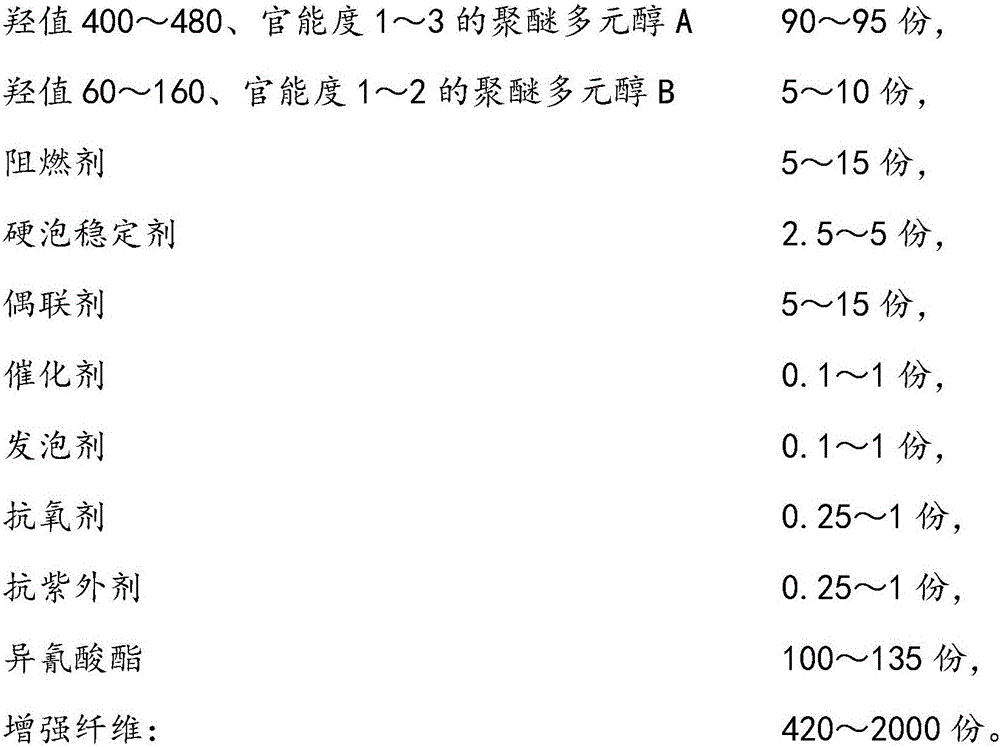

High-fiber-content fiber-reinforced rigid polyurethane foam composite board and manufacturing method thereof

ActiveCN106349446ASolve the problem of insufficient impregnationIncreased reinforcing fiber contentFoaming agentAntioxidant

The invention relates to a high-fiber-content fiber-reinforced rigid polyurethane foam composite board and a manufacturing method thereof; the high-fiber-content fiber-reinforced rigid polyurethane foam composite board is made from polyurethane resin and reinforcing fibers as base materials, as well as hybrid polyether polyol, a flame retardant, a rigid foam stabilizer, a coupling agent, a catalyst, a foaming agent, an antioxidant, an ultraviolet screening agent, an isocyanate, and reinforcing fibers, wherein the content of the reinforcing fibers is greater than 60%; by means of various techniques such as using low-hydroxyl value low-functionality hybrid polyether polyol and using the coupling agent, the problem that polyurethane resin is insufficiently steeped to reinforcing fibers is solved, the content of the reinforcing fibers is increased, a fiber-reinforced rigid polyurethane foam article higher than 840 kg / m<3> in density and higher than 60% in reinforcing fiber content can be manufactured, the technical blank of fiber-reinforced rigid polyurethane foam composite boards is filled, product specifications and properties are diversified, and the different technical index requirements are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

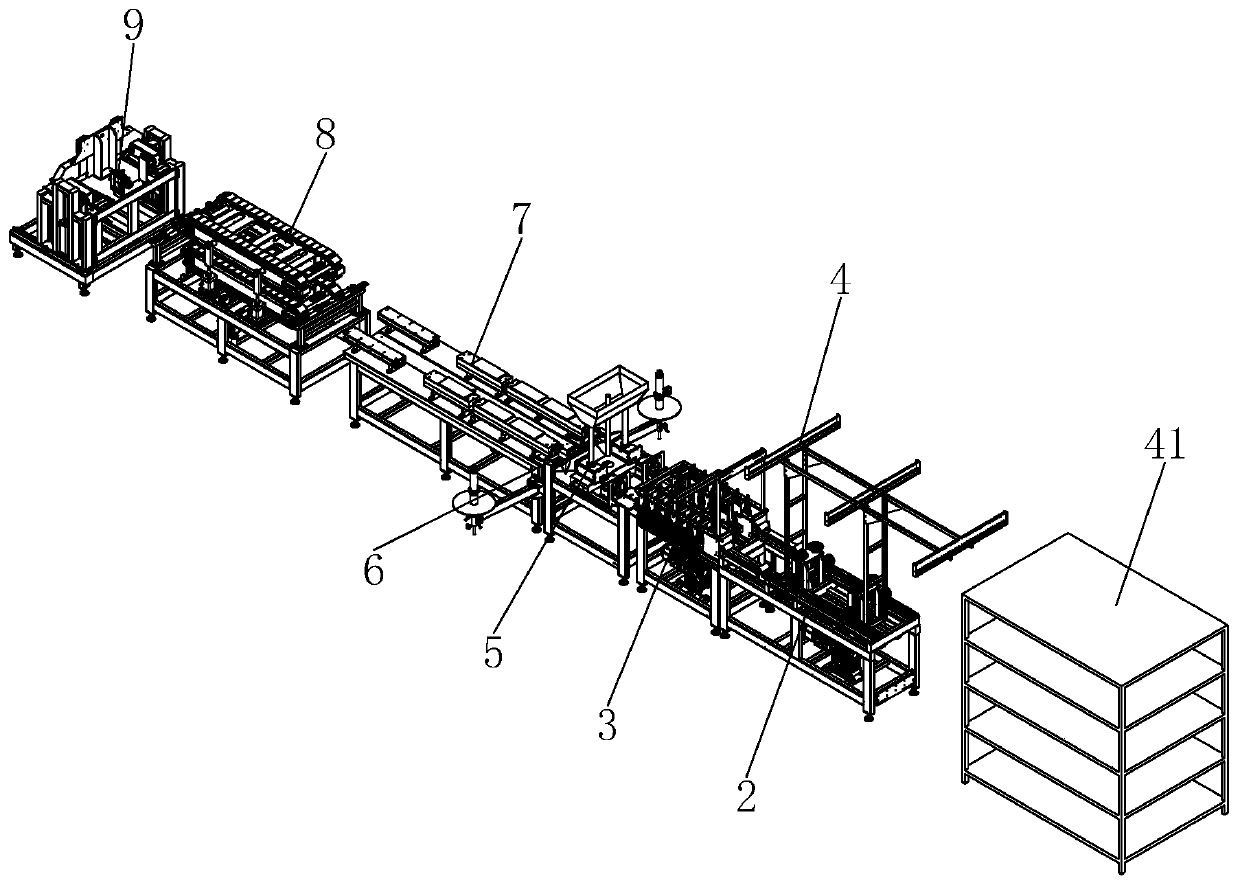

Composite square wood and production line thereof

PendingCN110067385AProne to the problem of rising and openingInhibit swellingOther plywood/veneer working apparatusWood veneer joiningProduction lineGlass fiber

The invention discloses a composite square wood which comprises a square wood body, wherein the square wood body comprises a plurality of closely overlapped wood strips, the mutually spliced wood strips are arranged in the same length direction, the ends of every two adjacent overlapped wood strips are not aligned, the wood strips are bonded by glue, and glass fiber cloth is bonded and wrapped onthe peripheral side surface of the square wood body. The composite square wood has the following advantages and effects that the wood strips in the square wood body are closely overlapped, and duringthe overlapping process, the ends of every two adjacent overlapped wood strips are not aligned, and when the wood strips are overlapped, the wood strips in a plurality of length directions are distributed in a staggered mode, so that the purpose of unlimited square wood length is achieved; meanwhile, the strength of the composite square wood can be improved through glue between the square bodies and the glass fiber cloth wrapped on the surface of the square wood body in a bonding mode. The invention further discloses a composite square wood production line for producing the composite square wood.

Owner:浙江衡昶科技有限公司

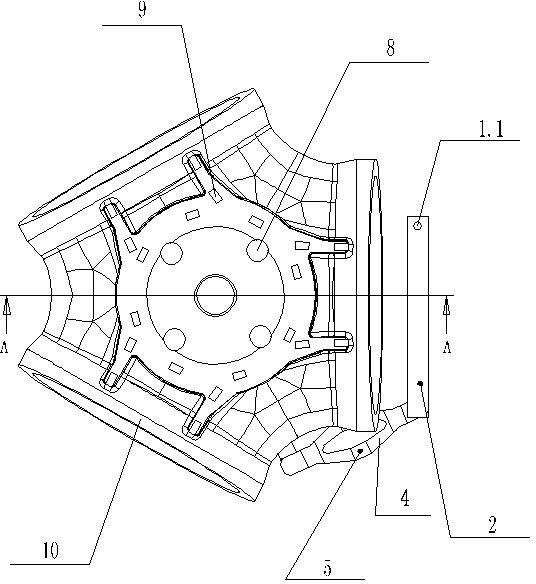

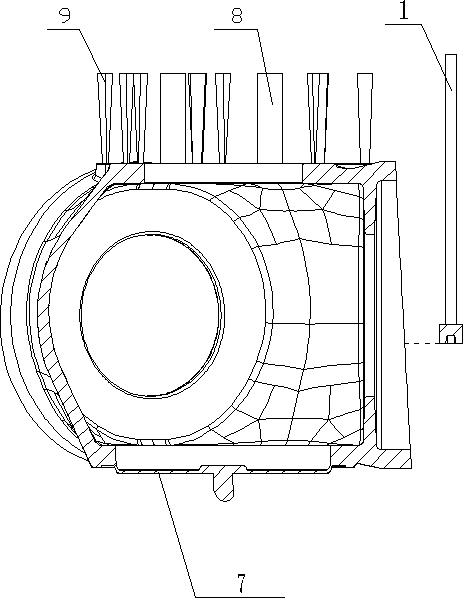

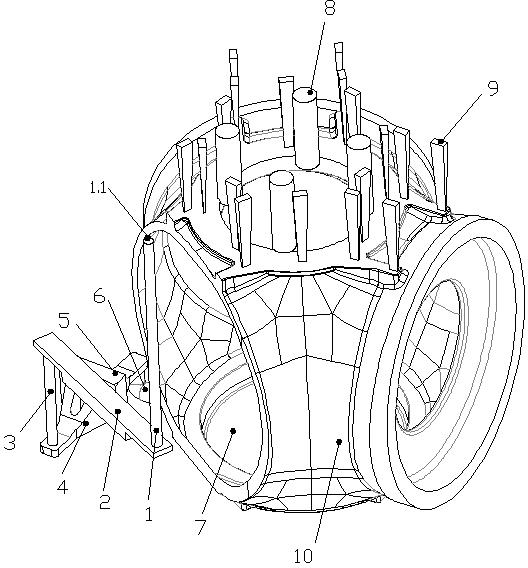

Chill-free processing method of wind-driven generator hub

The invention discloses a chill-free processing method of a wind-driven generator hub, and the method comprises the following steps: manufacture of a mould, manufacture of a sand mould and moulding by casting, wherein in the manufacture of the sand mould, a completely opened bottom gating system is utilized; an ingate is designed to be disc-shaped; a downgate on an upper sprue is a quantitative ladle stopper sprue gate; the ratio of the components is F(straight):F(transverse):F(internal)=1:(1.5-2):(25-28); a rectangular vent hole is arranged at the highest point at the top face of a casting; the total section area of the rectangular vent hole is greater than that of the ingate; a casting head is arranged on the top face of the casting; the height of the single casting head is greater than 400 mm; no chills are discharged during the manufacture procedure; in the moulding by casting, the casting speed of melted iron entering into a casting cavity is controlled within 0.5-1.0 m / s; the casting time is controlled within 150-210 seconds; and the casting temperature is between 1300 and 1310 DEG C. The chill-free processing method of the wind-driven generator hub disclosed by the invention has the advantages that the method adapts to the large scale production of low-temperature ductile iron castings for large wind-driven generator with quite high requirements, the process is simple, and the production cost is low.

Owner:宁波日星铸业有限公司

Preparation method of brushite bone cement

The invention relates to a preparation method of brushite bone cement. The preparation method comprises the following steps: preparing an acidic bone cement solidification liquid by adopting a citric acid solution as a main body and adopting phosphorylated chitosan, hydroxypropyl methyl cellulose and gelatin as modifying agents; fully mixing monohydrate calcium dihydrogen phosphate, beta-tricalcium phosphate and SiO2 to obtain SiO2 modified brushite bone cement solid-phase powder; and mixing the bone cement solid-phase powder with the solidification liquid according to a solid-to-liquid ratio to obtain the brushite bone cement, wherein a solidification product comprises brushite as a main component. By adopting the preparation method disclosed by the invention, the solidification time of the brushite bone cement which adopts a conventional citric acid solution as the solidification liquid can be prolonged to be 6-20 minutes, and the flowability of blended slurry can be increased; and meanwhile, by virtue of complexing action of phosphorylated chitosan, solid-liquid separation of the blended slurry at a certain pressure can be avoided, and the comprehensive performance of the blended slurry can preferably meet the requirements of clinical application.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Ceramic coating material with effects of environmental protection, self-cleaning property, antibacterial property and scratch resistance, and preparation method thereof

InactiveCN110183878AExtend curing timeImprove stain resistanceAntifouling/underwater paintsPaints with biocidesEmulsionOxide

The invention discloses a ceramic coating material with effects of environmental protection, self-cleaning property, antibacterial property and scratch resistance, wherein the ceramic coating materialcomprises a sol, water, a coloring pigment, a filler, an auxiliary agent and alkoxysilane, the sol is one or two selected from a metal oxide sol and a non-metal oxide sol, the emulsion is one or twoselected from an acrylic emulsion and an alkyd emulsion, and the auxiliary agent comprises a dispersant, an anti-settling agent, an antifoaming agent, a thickener, an antibacterial agent, an acid anda film forming auxiliary agent. The invention further discloses a preparation method of the ceramic coating material with effects of environmental protection, self-cleaning property, antibacterial property and scratch resistance. According to the present invention, the prepared ceramic coating material has the characteristics of no formaldehyde, stain resistance, high hardness, sterilization, bacterial inhibition and the like, and can be used for the coating of concrete wall surfaces, calcium silicate boards and concrete members.

Owner:常州天瑞新材料科技有限公司

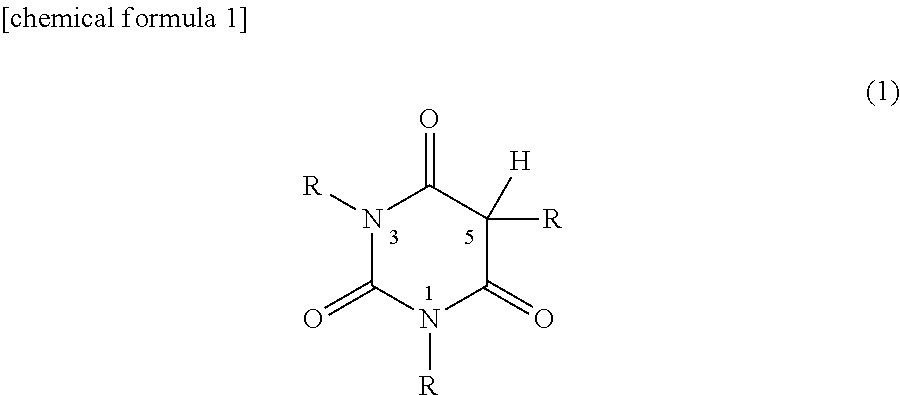

Powder-liquid dental curable material kit

ActiveUS20150038614A1Curing rate can be downCuring timeImpression capsDentistry preparationsMeth-Halogen

A powder-liquid dental curable material kit composed of (A) a liquid material and (B) a powder material, wherein the liquid material (A) contains (a1) a radically polymerizable (meth)acrylic monomer, (a2) an organic halogen compound and (a3) a radical chain transfer agent; the powder material (B) contains (b1) non-crosslinked resin particles, (b2) a pyrimidinetrione compound and (b3) an organic metal compound; and (Z) a peroxide is blended in at least one of the liquid material (A) and the powder material (B). This curable material kit is capable of reducing the heat generation during the curing of a curable material which is a mixture of the liquid material (A) and the powder material (B) and is not susceptible to the excessive prolongation of the curing time even when the curable material is cured by a brush-on technique, thereby ensuring an appropriate curing time for both of a brush-on technique and a kneading technique.

Owner:TOKUYAMA DENTAL CORP

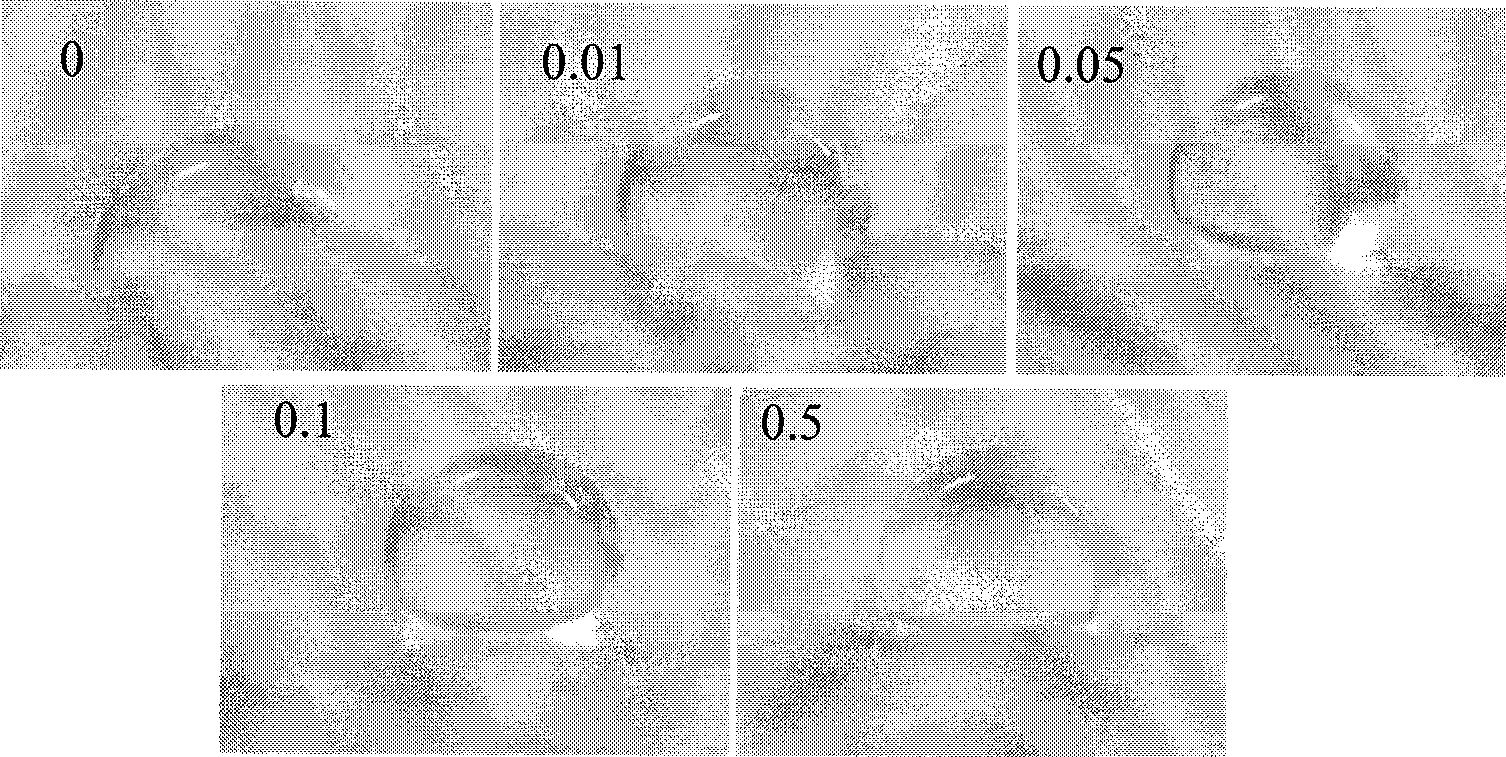

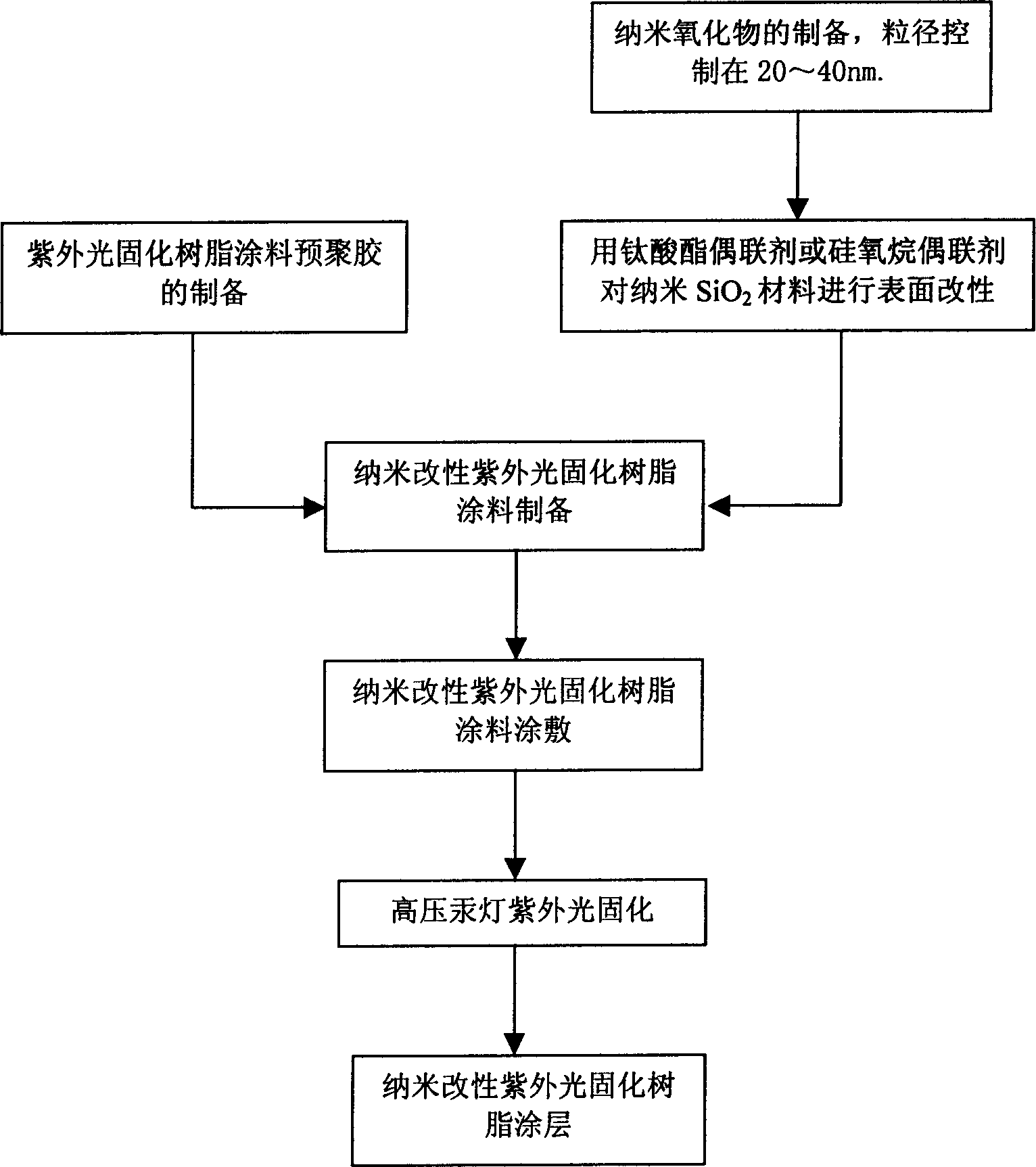

Process for preparing nano modified UV-cured resin coating

The present invention relates to the preparation process of nanometer modified UV cured resin paint. The preparation process includes preparing nanometer oxide through sol-gel process, controlling calcining temperature and adding PVA or gelatin to control the particle size of the nanometer oxide in 20-40 nm; measuring the particle size, crystal form, etc. of the nanometer oxide; surface modifying the nanometer oxide with siloxane or titanate coupling agent; mixing pre-polymerizing glue, active monomer, photosensitive agent, initiator and solvent to form the UV cured resin paint pre-polymer; and adding and ultrasonically dispersing the nanometer oxide to obtain the nanometer modified UV cured resin paint. The nanometer modified UV cured resin paint of the present invention has prolonged curing period, complete curing, homogeneous coating thickness, high coating hardness, high heat resistance, and high wear resistance.

Owner:NANJING UNIV OF SCI & TECH

Emulsified asphalt modified by carbon nanometer fiber and preparing method thereof

InactiveCN105315684AExtend curing timeEnhanced high temperature deformation propertiesBuilding insulationsFiberCarbon fibers

The invention relates to emulsified asphalt modified by carbon nanometer fiber and a preparing method thereof. The nanometer material characteristic of the nanometer carbon fiber and the characteristic of nanometer carbon materials are utilized for modifying emulsified asphalt, high-temperature performance and low-temperature performance of the emulsified asphalt can be improved, pavement materials short in curing time and high in curing strength are obtained, site cold mixing and cold laying can be achieved during construction of fast patching of asphalt road pits and repair of municipal road observation well lids, construction time is short, and the asphalt has a better application effect and has considerable application prospects.

Owner:重庆市六工新材料有限公司

Novel wood adhesive

InactiveCN106147651AObvious price advantageWide variety of sourcesNon-macromolecular adhesive additivesStarch adhesivesUreaChemistry

The invention discloses a novel wood adhesive, which is prepared from the following raw materials in parts by weight: 104 to 162 parts of Chinese yam starch, 13 to 18 parts of dimethyl glutarate, 11 to 15 parts of N,N-dimethyl acetamide, 2 to 5 parts of sodium hydroxide, 3 to 7 parts of epoxy chlorobutane, 2 to 5 parts of urea, 0.3 to 0.7 part of coupling agents, 0.1 to 0.4 part of initiating agents, 0.1 to 0.3 part of catalysts, 0.1 to 0.4 part of stabilizing agents, 0.5 to 1 part of antifoaming agents, 0.6 to 1.2 parts of plasticizers, 0.5 to 0.9 part of toughening agents and 0.4 to 0.8 part of thickening agents. The novel wood adhesive has the advantages that the bonding strength is high; the water resistance performance is high; the novel wood adhesive completely conforms to relevant standards in GB / T14732-2006; the strength of produced plywood is much higher than that of China type II artificial board standards. The novel wood adhesive can be widely applied to the production of artificial boards, plywoods and cellulose boards, and replaces tridecanal glue to be used.

Owner:广西南宁桂尔创环保科技有限公司

Fireproof coating

ActiveCN113480928ALarge specific surface areaMicroporous Ratio DecreaseFireproof paintsPolyurea/polyurethane coatingsCellulosePolymer science

The invention provides a fireproof coating, and belongs to the field of fireproof building materials. The fireproof coating comprises the following components in percentage by weight: 40-60% of water-based resin emulsion, 5-20% of fireproof sepiolite fiber slurry, 10-30% of a coating additive and other fillers, and 10-30% of water. A preparation method of the slurry comprises the following steps: (1) preparing modified sepiolite fabric: mixing sepiolite with a mixed acid solution 1 of hydrochloric acid and phosphoric acid; (2) conducting alkali neutralization: mixing the sepiolite slurry subjected to acid activation with ammonia water; and (3) sequentially adding talcum powder, vegetable gelatin powder, polypropylene fibers, cellulose ether and a surfactant into the sepiolite slurry while stirring to obtain the fireproof sepiolite fiber slurry. The fireproof coating has good fireproof performance.

Owner:石家庄易辰防火保温材料有限公司

Low formaldehyde emission adhesive system

InactiveUS20110198028A1Extend curing timeImprove curing speedMonocarboxylic acid ester polymer adhesivesAdhesive processesChemistryCOMPONENT II

The invention relates to an improved two component adhesive system, a kit comprising said two adhesive components, its use and a method for production of interior wood products, in particular form-pressed products, parquet floor elements and solid wood panels with very low formaldehyde emission and to the interior wood products obtainable having improved properties.The two-component adhesive system comprises adhesive component I comprising a 50-70 wt % melamine-formaldehyde (MF) type resin in 25-40 wt % water and adhesive component II comprising 25-40 wt % of a water based dispersion adhesive, 15-40 wt % of a formaldehyde scavenger and an acidic compound in an amount such that the pH of adhesive component II is 1.5-6.5, wherein adhesive component I and II are to be applied in a weight ratio I:II of 1:0.5 to 1:1.5 and the adhesive system has a molar ratio of formaldehyde (F) to total amino group (F / NH2) between 0.2 and 0.7.

Owner:DYNEA

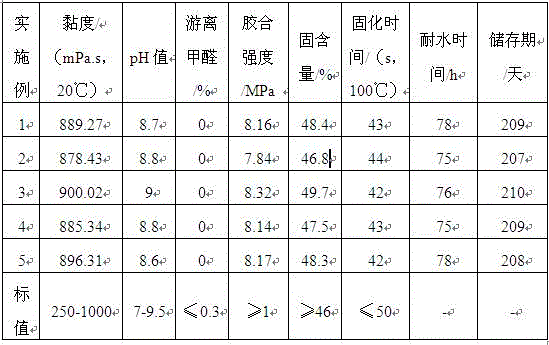

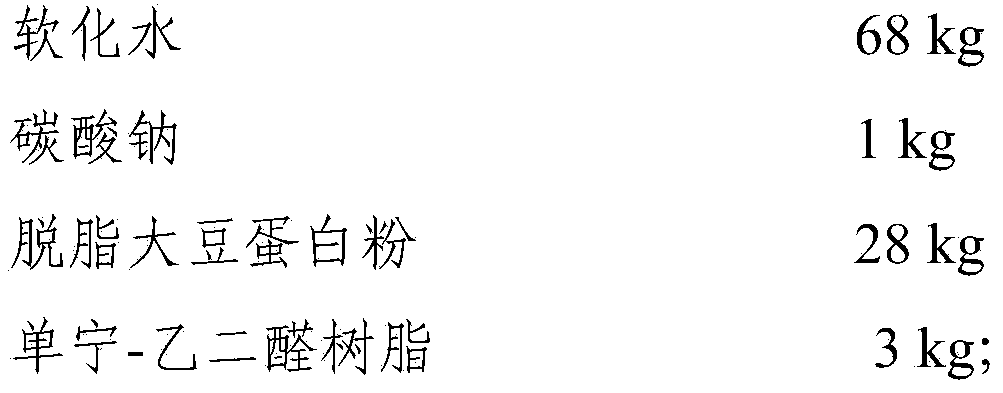

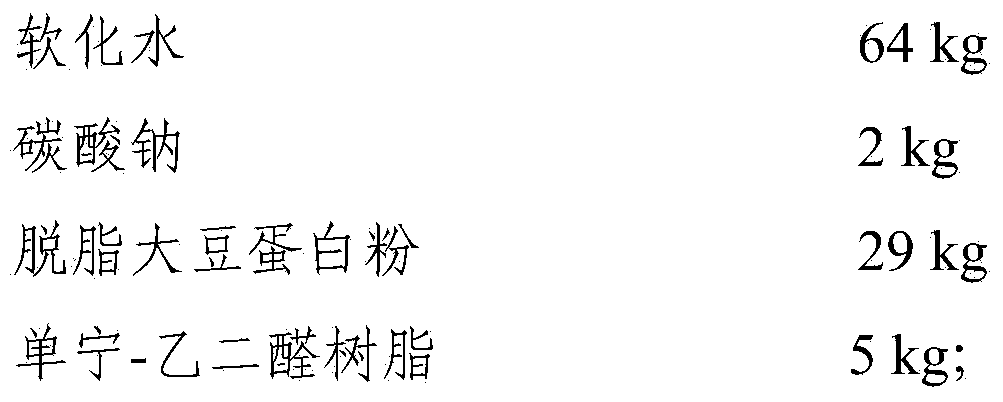

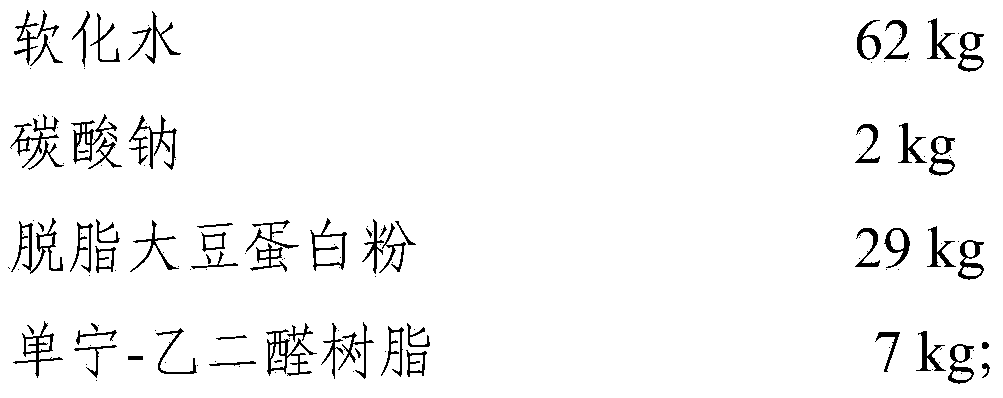

Adhesive for artificial boards, and preparation method and application thereof

ActiveCN103740324AComprehensive utilization of resourcesReduce manufacturing costNon-macromolecular adhesive additivesProtein adhesivesChemistryWater resistance

The invention relates to an adhesive for artificial boards, and a preparation method and application thereof. The adhesive for artificial boards is prepared from a dispersion medium, a protein substance, an alkaline compound and a crosslinking reinforcer, wherein the crosslinking reinforcer is a tannin-glyoxal resin. The adhesive for artificial boards is free of formaldehyde, is mainly prepared from renewable substances, and thus, is an environment-friendly adhesive for artificial boards; the adhesive provided by the invention thoroughly solves the problem of formaldehyde pollution when in use, and ensures water resistance, adhesion strength and other practical properties of the adhesive; compared with the prior art, the components have favorable synergetic effects, so that the effect is enhanced; the preparation method is simple, does not need very long curing time, is convenient to operate and has high production efficiency; and generally, the method comprehensively utilizes the resources, saves the production cost, conforms to the principles of environmental protection and sustainable development, and has favorable application prospects.

Owner:XUZHOU ANLIAN WOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com