Resin glue adhesive for E0 grade fibre board

A technology for synthetic resins and adhesives, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., which can solve the problems of water resistance, aging resistance, deterioration of mechanical properties of wood-based panels, and reduction of free formaldehyde Content and other issues, to achieve the effect of fast curing speed, suitable curing time and acid-base buffer volume, and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 is a synthetic resin adhesive for grade E0 fiberboard according to the present invention, which consists of 98.5% melamine-modified urea-formaldehyde resin and 1.5% ammonium sulfate by weight percentage.

[0029] The mass proportioning of melamine modified urea-formaldehyde resin reaction material is, 99.8% melamine 5.3%, 98.0% urea 40.6%, 37.0% formaldehyde 53.6%, accelerator 0.5%, and total molar ratio is 0.925; Accelerator is can buy from the market The mf-01 accelerator produced by Zhenyang Printing and Dyeing Auxiliary Factory, Qiting Town, Yixing City, Jiangsu Province. The above materials are reacted to prepare a synthetic resin adhesive.

[0030] The method of preparation is as follows:

[0031] Feed amount of reaction materials

[0032] 1. Formaldehyde: 11800KG;

[0033] 2. Urea: U11=200KG, U12=3700KG, U2=2150KG, U3=3000KG

[0034] 3. Melamine: M1=850KG, M2=200KG

[0035] 4. High-efficiency accelerator: the first time: 25KG, the second time: 25KG...

Embodiment 2~4

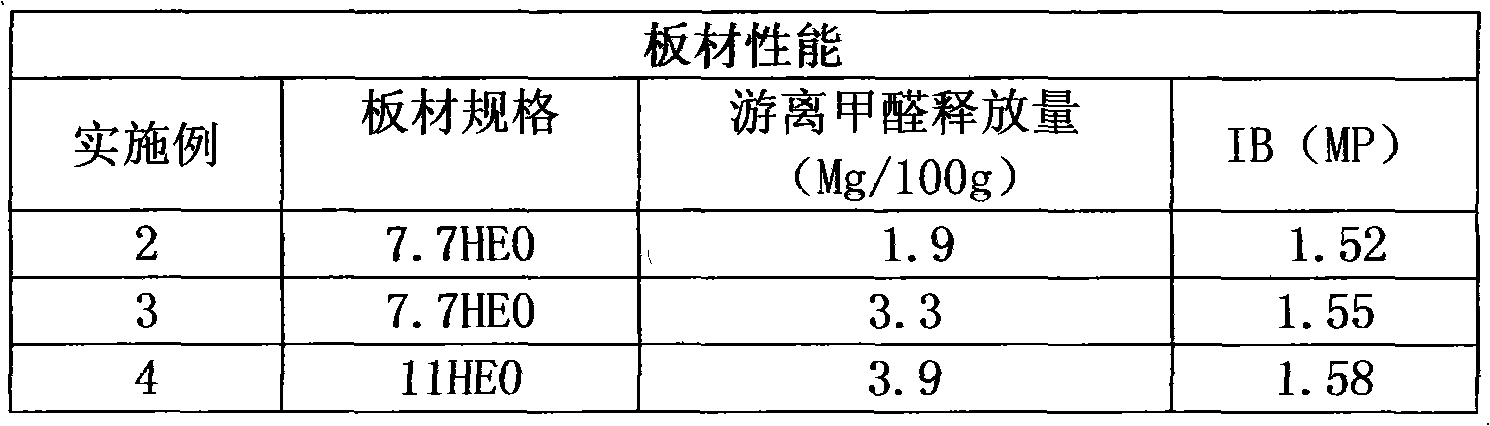

[0047] The preparation method of the synthetic resin adhesive for E0 grade fiberboard is the same as in Example 1, except that the mass ratio of the melamine-modified urea-formaldehyde resin reaction material is adjusted, and the mass ratio and the free formaldehyde content (%) in the adhesive are as follows 2 shows:

[0048] Free formaldehyde content (%) in the synthetic resin adhesive of table 2

[0049]

Example

Amine content

(%)

urea

content

(%)

formaldehyde

content

(%)

total moles

Compare

Accelerator

content

(%)

Free formazan

Aldehyde content

(%)

2

5.5

40.4

52.9

0.90

0.5

0.060

3

5.0

40.8

53.8

0.928

0.5

0.065

4

4.8

40.9

53.9

0.930

0.5

0.072

[0050] The adhesive in the above-mentioned each embodiment is manufactured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com