Decorative aggregate concrete surface preparation process

a concrete surface and decorative aggregate technology, applied in manufacturing tools, construction, roads, etc., can solve the problems of a large amount of installation and added expense, unable to incorporate the application of decorative or seeded aggregate, and the coarse aggregate in the concrete surface can be too abrasive, so as to reduce the potential for random cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

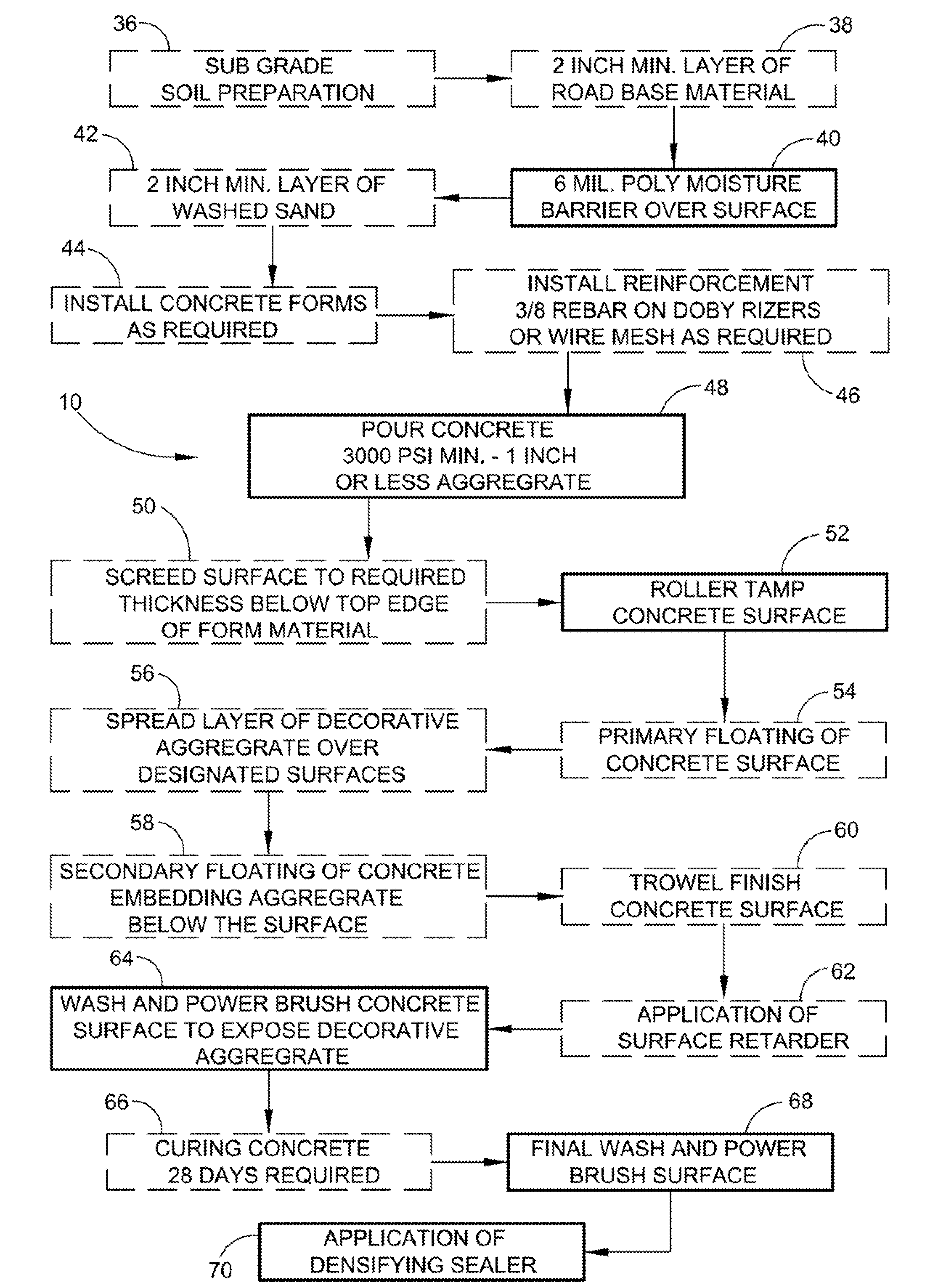

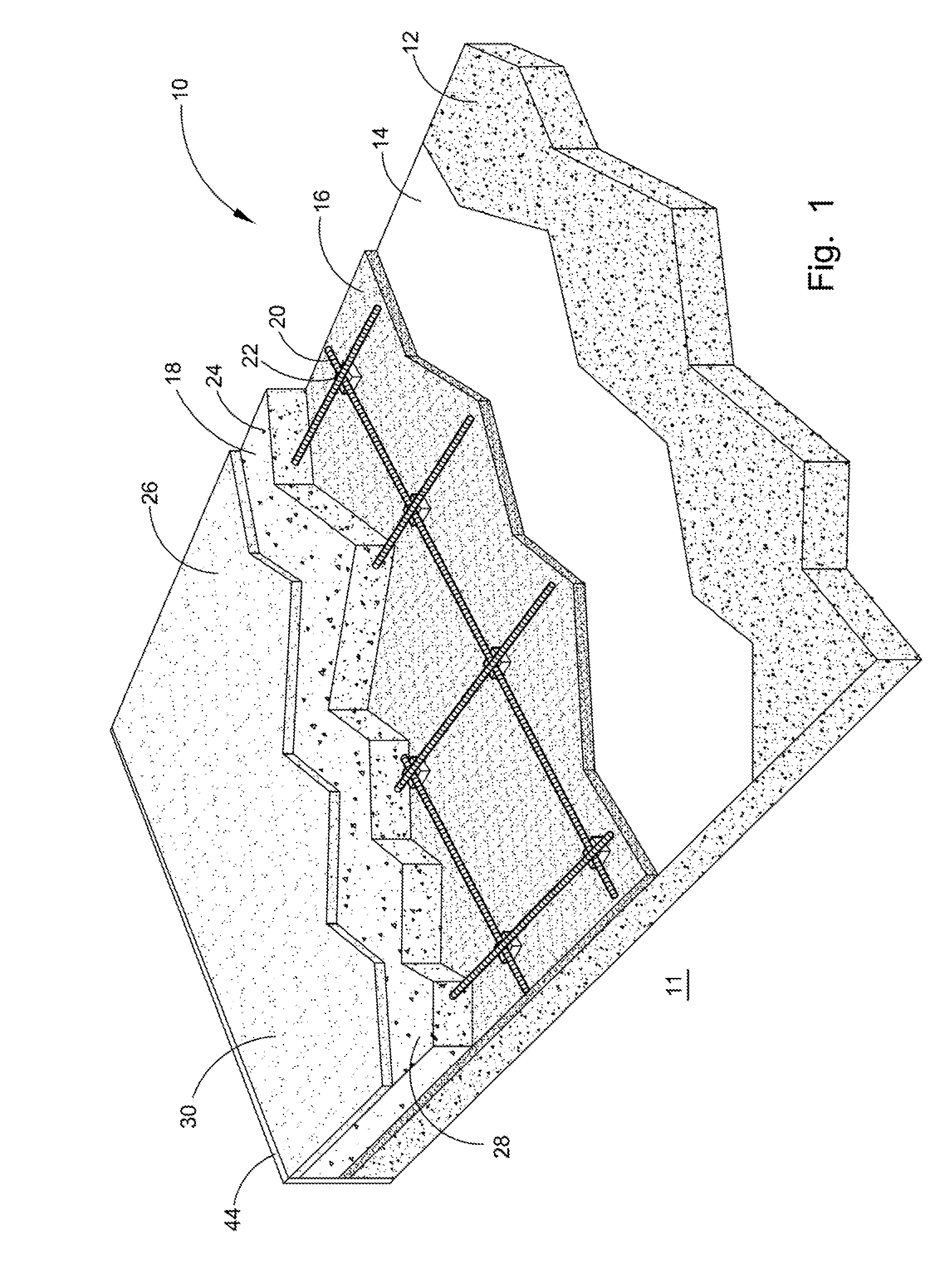

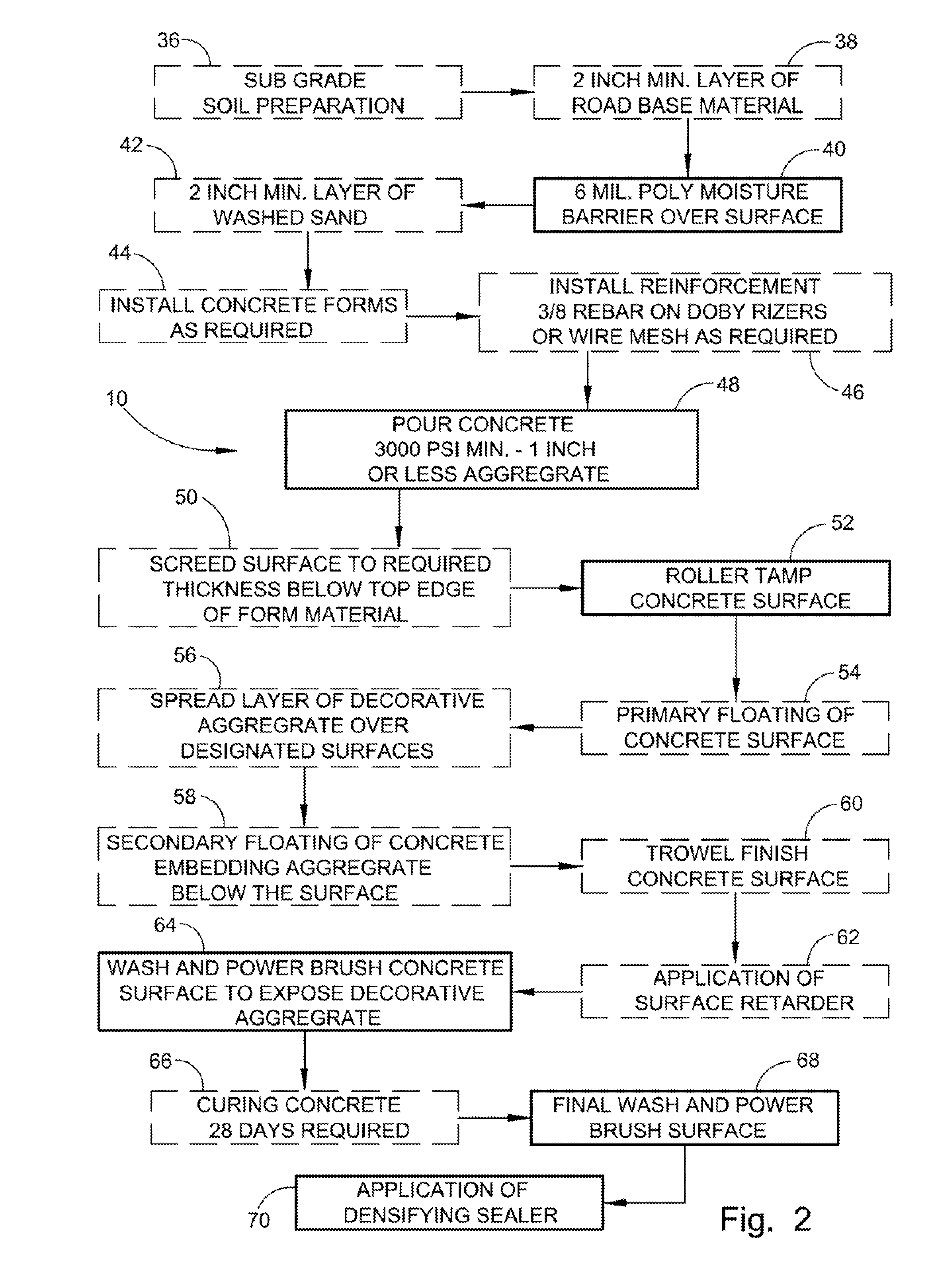

[0046]Referring now to the drawings, wherein similar parts of the decorative aggregate concrete surface preparation 10 are identified by like reference numerals, there is seen in FIG. 1 a perspective view of the decorative aggregate concrete surface preparation 10 illustrating the varying layers of the process, as it applies to a ground concrete installation. Above the existing soil 11 will be a suggested layer of road base material 12 at the required thickness compacted to a minimum of 90% compaction. A moisture barrier 14 of 6-mil poly (Visqueen) is layered over the road base material 12 and covered with a layer of two inches clean washed sand 16 to be fine graded in place to allow for the proper thickness of concrete 18. The rebar mat 20 is placed on adobe risers 22 elevating the rebar off the surface and not allowing any of the rebar mat 20 to extend below the lower surface of the concrete. This is important because if any of the metal surface of the rebar mat 20 is exposed the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com