Method for preparing self pore-forming calcium phosphate cement bracket

A technology of calcium phosphate bone cement and bone cement, applied in medical science, prosthesis and other directions, can solve the problems that the physical and chemical properties of calcium sulfate hemihydrate need to be improved, it is difficult to provide the mechanical strength of repair parts, weak biological activity, etc., to meet the needs of surgical operations. Need, promote body fluid circulation, the effect of uniform distribution of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

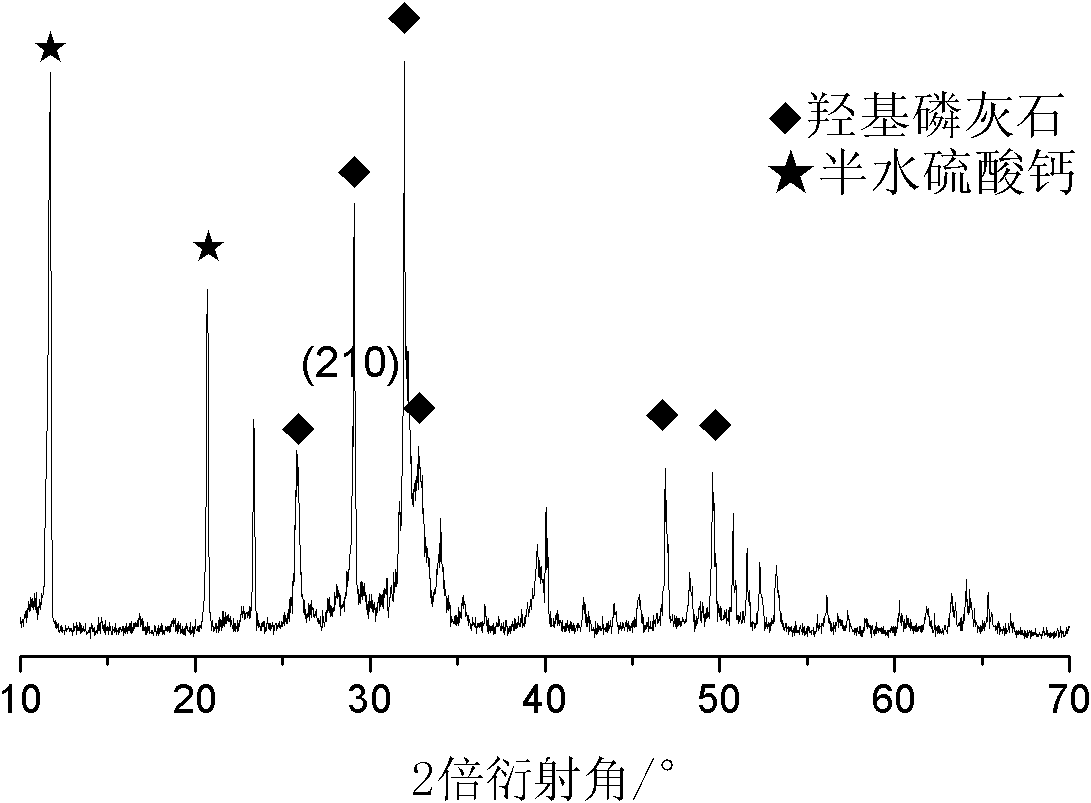

[0026] Step 1: Configuration of bone cement composite powder

[0027] Bone cement composite powders include calcium sulfate hemihydrate (α-CaSO 4 1 / 2H 2 O) and tricalcium phosphate bone cement powder. Taking the total mass as 25 grams, weigh 0.75 grams of α-CaSO at a mass ratio of 3:97 4 1 / 2H 2 O and 24.25 grams of alpha-tricalcium phosphate bone cement powder. The α-tricalcium phosphate bone cement powder includes α-tricalcium phosphate (α-TCP), Ca(H 2 PO 4 ) 2 ·H 2 O, calcium carbonate and hydroxyapatite powder, are 86:5:5:4 by mass ratio; Take by weighing 20.86 gram α-TCP powders, 1.21 gram analytically pure Ca(H 2 PO 4 ) 2 ·H 2 O, 1.21 grams of analytically pure CaCO 3 Prepare bone cement with 0.97 g of hydroxyapatite powder, grind the bone cement composite powder evenly in an agate mortar, and set aside. The specific preparation process of α-tricalcium phosphate powder and hydroxyapatite powder can be prepared according to the methods disclosed in the invento...

Embodiment 2

[0031] Step 1: Configuration of bone cement composite powder

[0032] Calcium sulfate hemihydrate (α-CaSO 4 1 / 2H 2 O) Except that the mixing ratio with the tricalcium phosphate bone cement powder is different, the rest of the preparation method is the same as step 1 of Example 1. Taking the total mass as 25 grams, weigh 1.25 grams of α-CaSO at a mass ratio of 5:95 4 1 / 2H 2 O and 23.75 grams of alpha-tricalcium phosphate bone cement powder. The tricalcium phosphate bone cement powder includes α-tricalcium phosphate (α-TCP), Ca(H 2 PO 4 ) 2 ·H 2 O, calcium carbonate and hydroxyapatite powder, are 86:5:5:4 by mass ratio; Take by weighing 20.42 gram α-TCP powders, 1.19 gram analytically pure Ca(H 2 PO 4 ) 2 ·H 2 O, 1.19 grams of analytically pure CaCO 3 Prepare bone cement with 0.95 g of hydroxyapatite powder, grind the bone cement composite powder evenly in an agate mortar, and set aside.

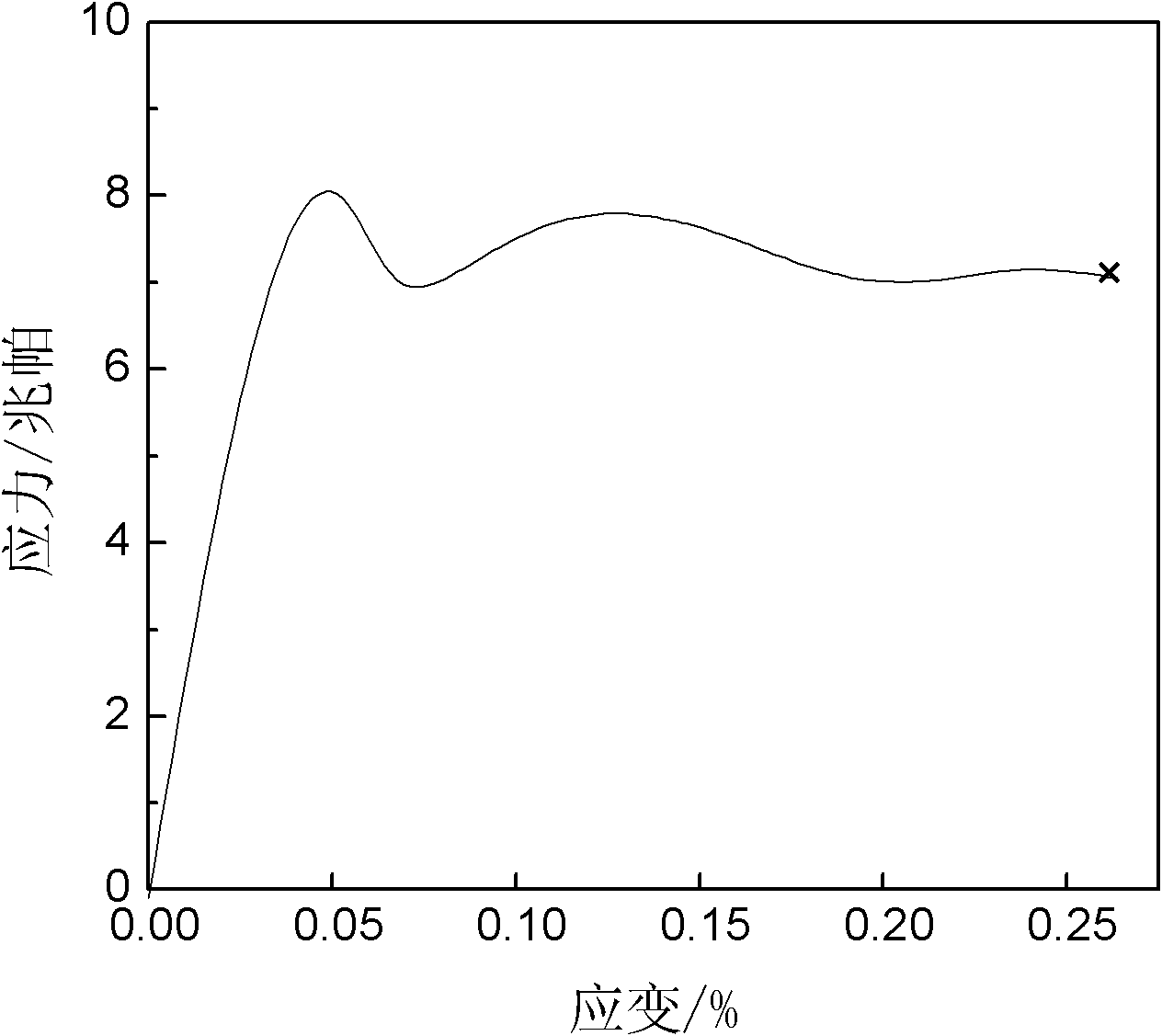

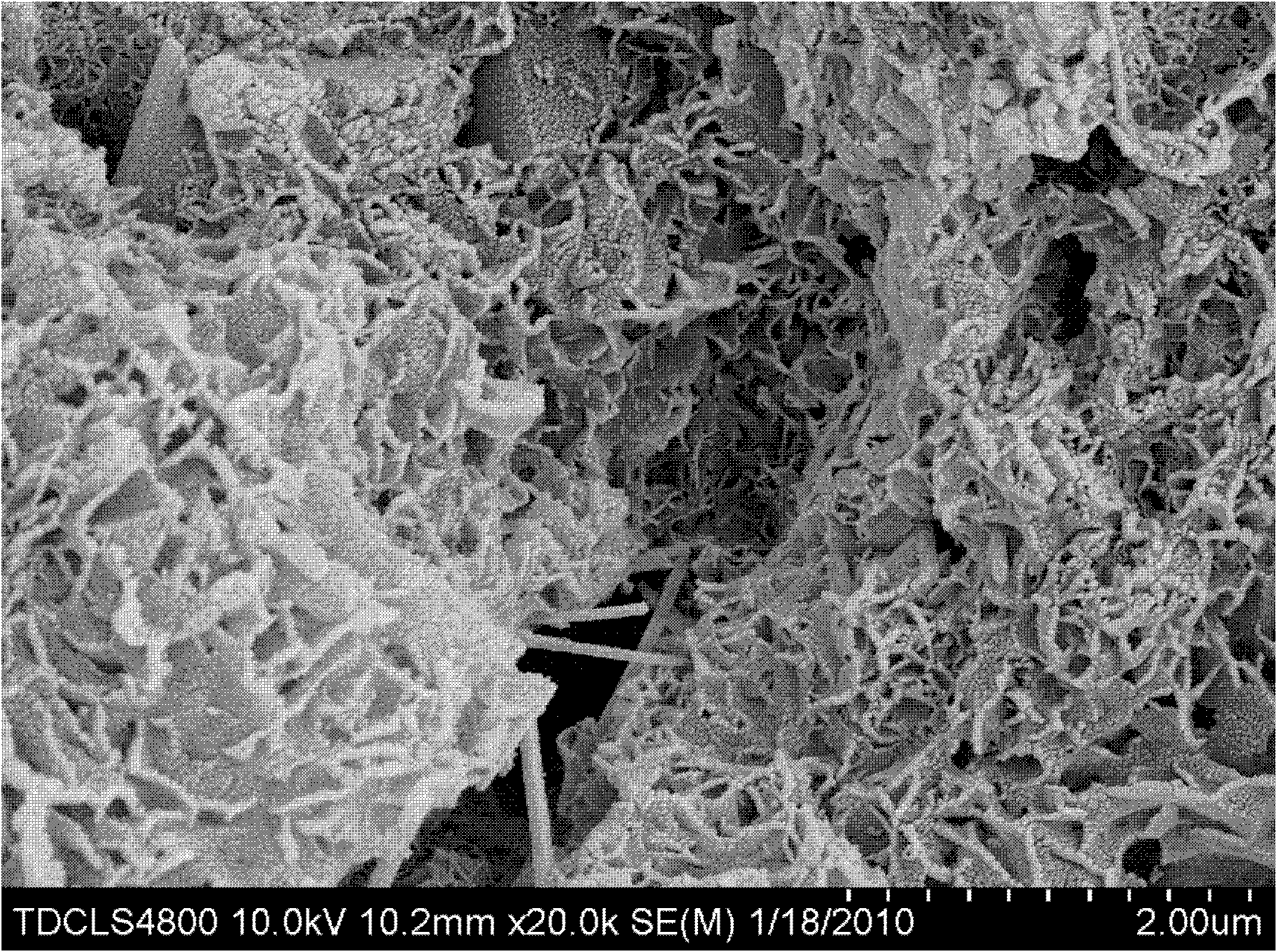

[0033] Step 3: Preparation of self-forming calcium phosphate bone cement scaf...

Embodiment 3

[0036] Step 1: Configuration of bone cement composite powder

[0037] Calcium sulfate hemihydrate (α-CaSO 4 1 / 2H 2 O) Except that the mixing ratio with the tricalcium phosphate bone cement powder is different, the rest of the preparation method is the same as step 1 of Example 1. Taking the total mass as 25 grams, weigh 5 grams of α-CaSO in a mass ratio of 20:80 4 1 / 2H 2 O and 20 g of α-tricalcium phosphate bone cement powder. The tricalcium phosphate bone cement powder includes α-tricalcium phosphate (α-TCP), Ca(H 2 PO 4 ) 2 ·H 2 O, calcium carbonate and hydroxyapatite powder, are 86:5:5:4 by mass ratio; Take by weighing 17.2 gram α-TCP powders, 1 gram analytically pure Ca(H 2 PO 4 ) 2 ·H 2 O, 1 gram of analytically pure CaCO 3 Prepare bone cement with 0.8 g of hydroxyapatite powder, grind the bone cement composite powder evenly in an agate mortar, and set aside.

[0038] Step 3: Preparation of self-forming calcium phosphate bone cement scaffold

[0039] 3.4g ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com