Composite square wood and production line thereof

A production line and wood cube technology, which can be used in wood processing appliances, wood veneer bonding, other plywood/plywood appliances, etc., and can solve the problem of inability to process composite wood cubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

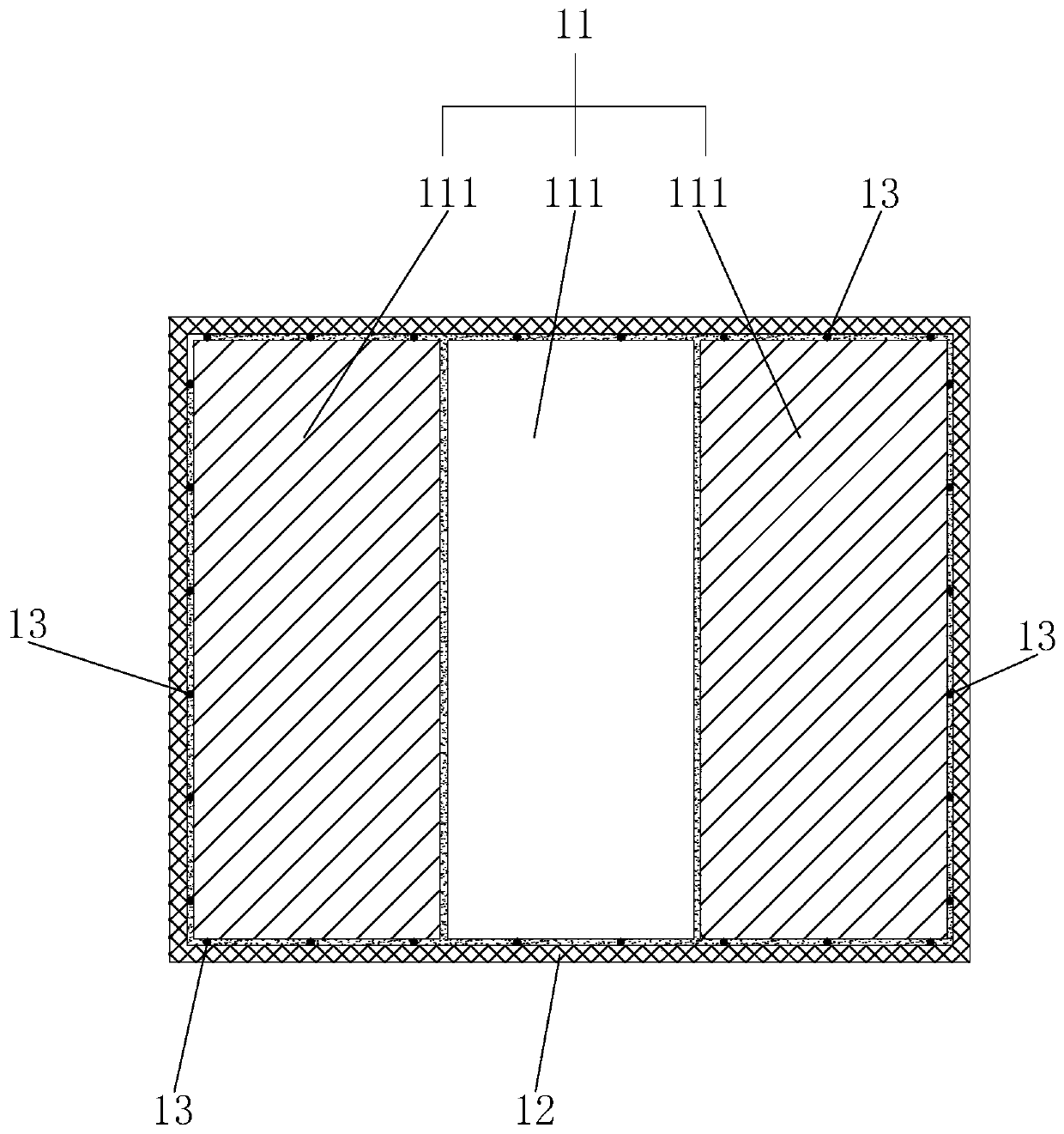

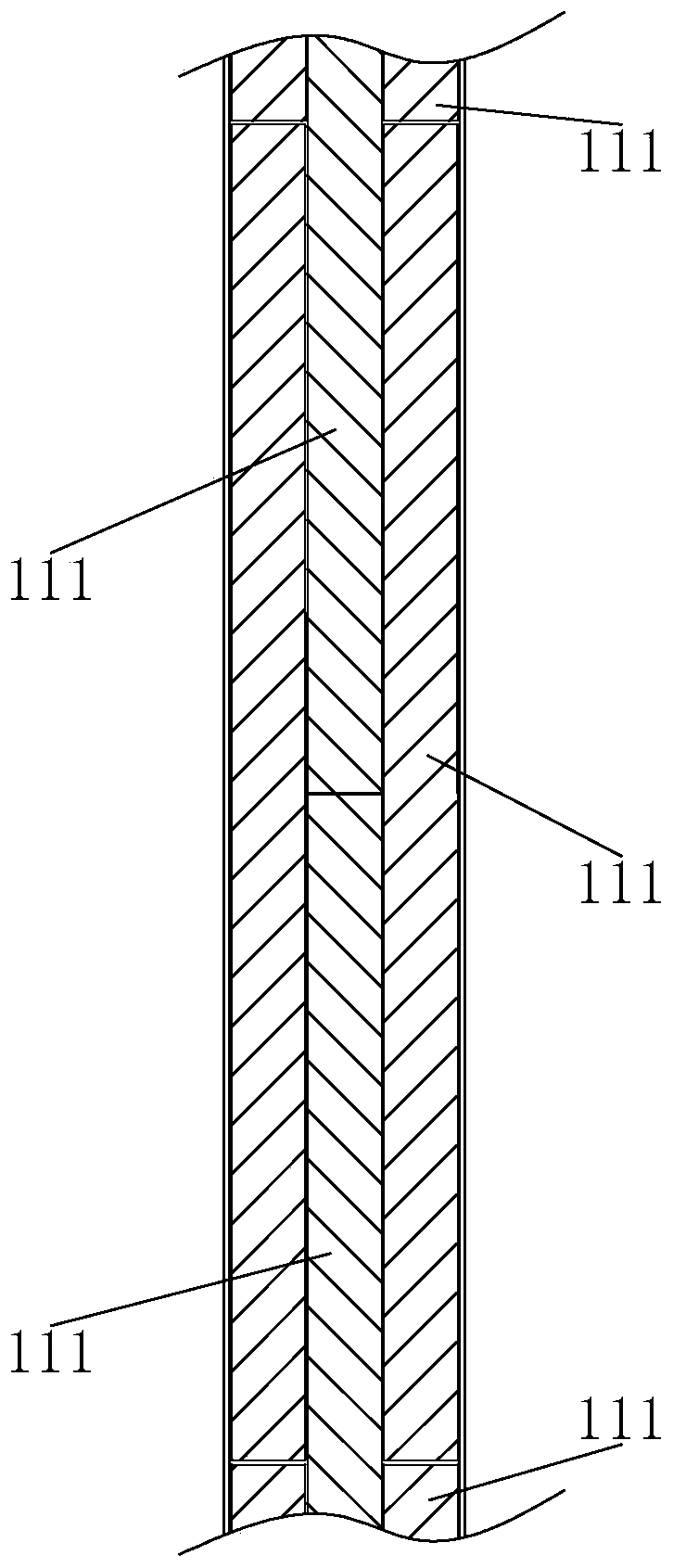

[0050] Embodiment 1: a kind of composite wood side, such as figure 1 with figure 2 As shown, the wooden cube body 11 is included, and the wooden cube body 11 includes a plurality of closely overlapping wooden strips 111, and has a plurality of mutually spliced wooden strips 111 in the same length direction; and when overlapping, two adjacent overlapping wooden strips 111 The ends of the wooden strips 111 are not aligned, and the end of one wooden strip 111 is located in the middle of the lengthwise direction of adjacent overlapping wooden strips 111 . At the same time, the contact surfaces of multiple wooden squares are fixed by glue bonding.

[0051] Such as figure 1 As shown, there are glues on the four sides of the wooden body 11, up, down, left, and right, and a plurality of glass fiber filaments 13 extending along the length direction of the wooden body 11 are bonded to the four sides of the wooden body 11. Each strand of glass The fiber filaments 13 are composed of...

Embodiment 2

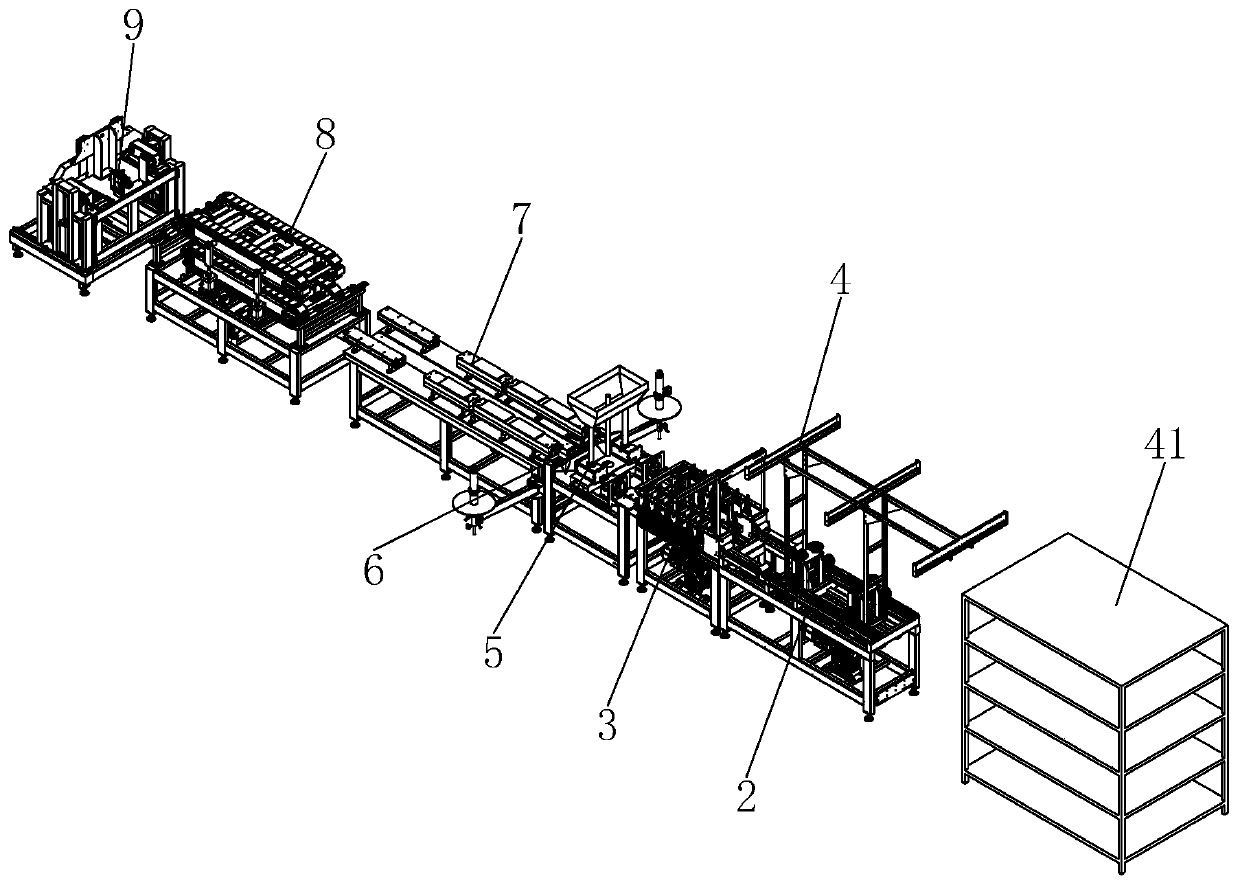

[0053] Embodiment 2: a kind of composite wood production line, such as image 3 As shown, it includes a wooden strip conveying device 2, a wooden body pressure feeding device 3, a glass fiber filament compounding device 4, a wooden body gluing device 5, a glass fiber cloth compounding device 6, a thermocompression forming device 7, a traction device 8, Cutting device 9.

[0054] Such as image 3 with Figure 4 As shown, the wooden strip conveying device 2 includes a conveying frame 21, two splitting groove assemblies 22 fixedly arranged on both sides of the conveying frame 21, and a plurality of wooden strip conveying mechanisms 23 respectively arranged on both sides of the conveying frame 21. . There are a plurality of partitions 221 inside the splitting trough assembly 22 for a plurality of wood strips to be placed in, and the number of partitions 221 is reduced during the transportation of the wooden strips, and the width of the splitting slot assembly 22 is also gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com