Patents

Literature

739results about "Glue vessels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

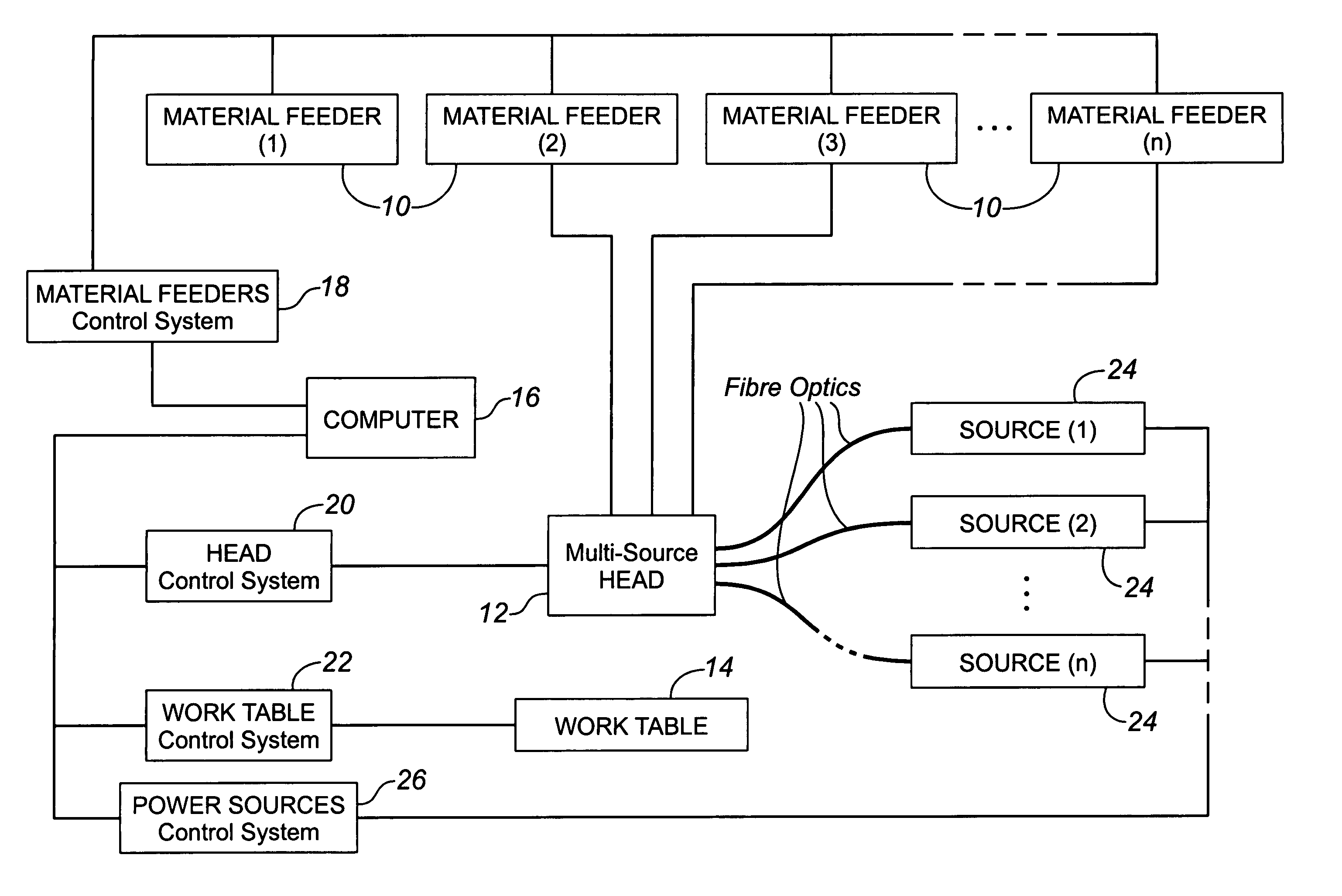

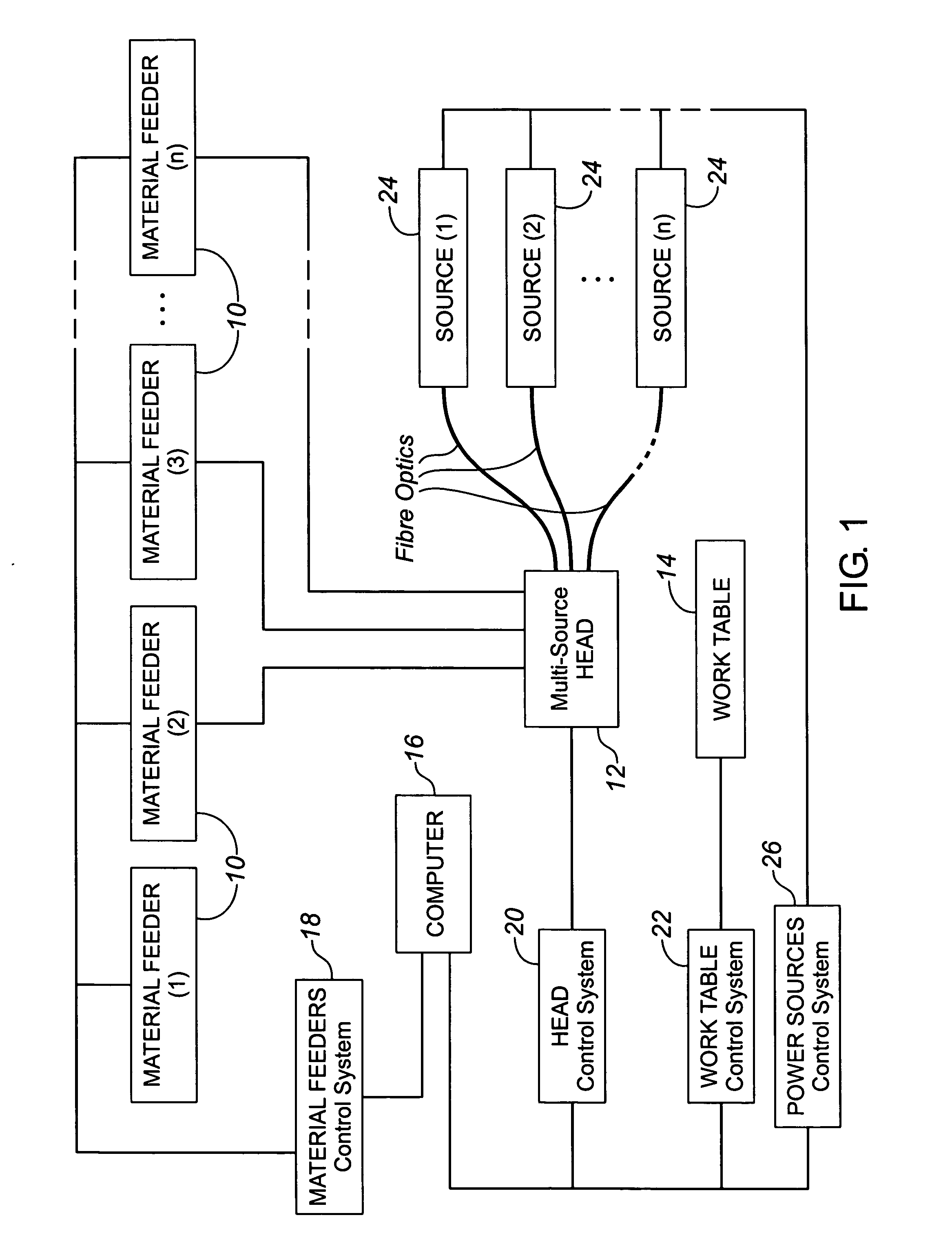

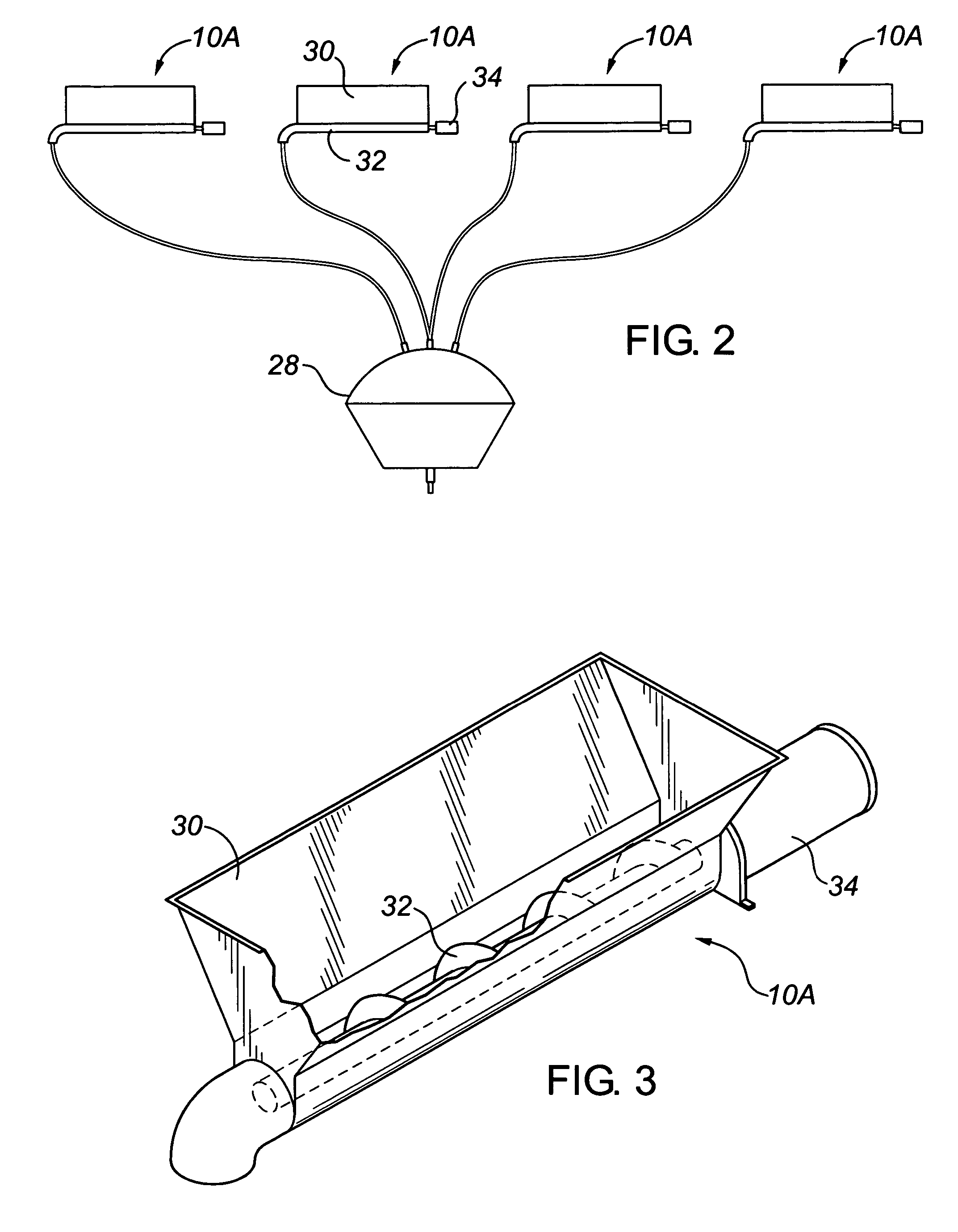

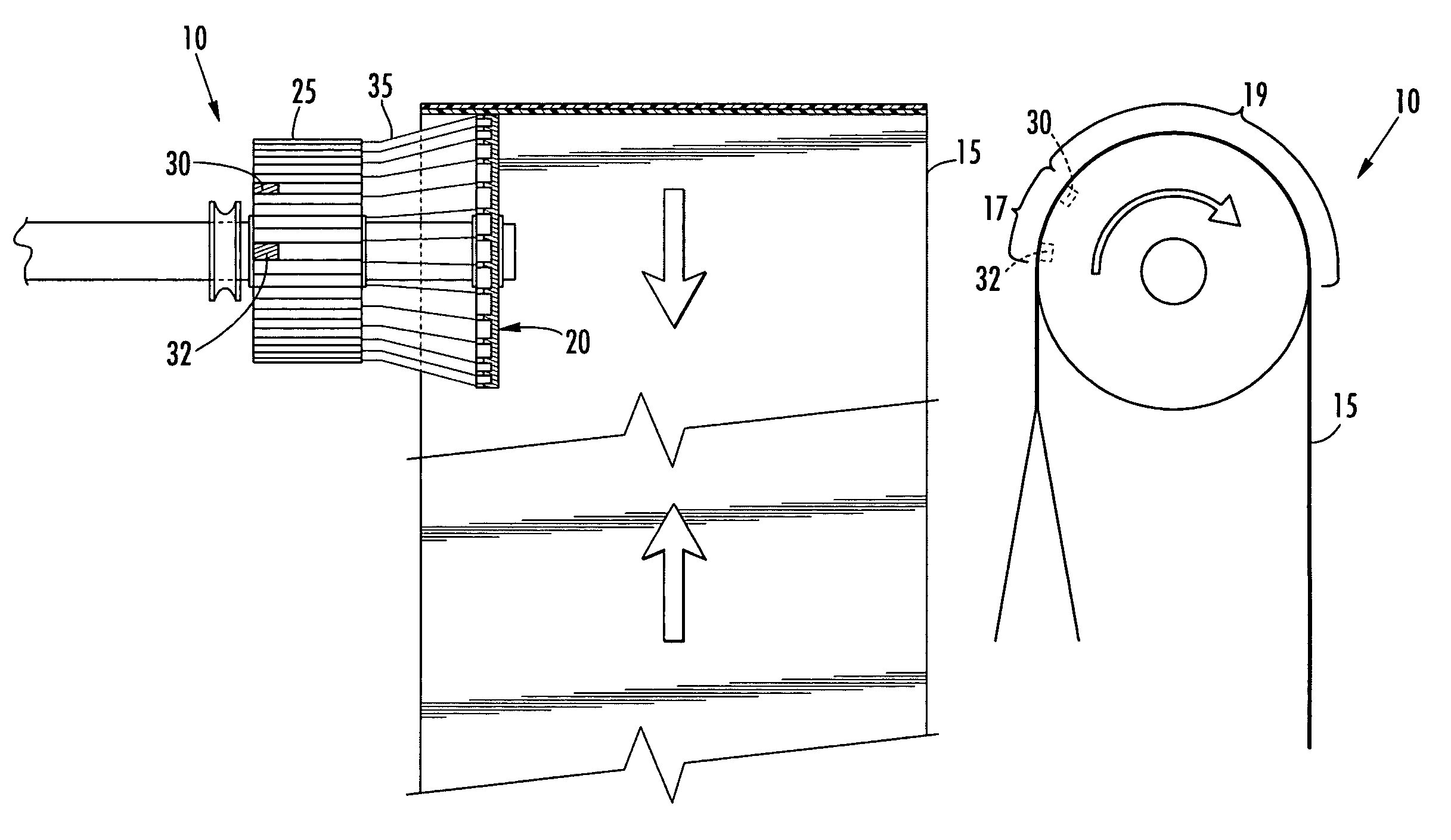

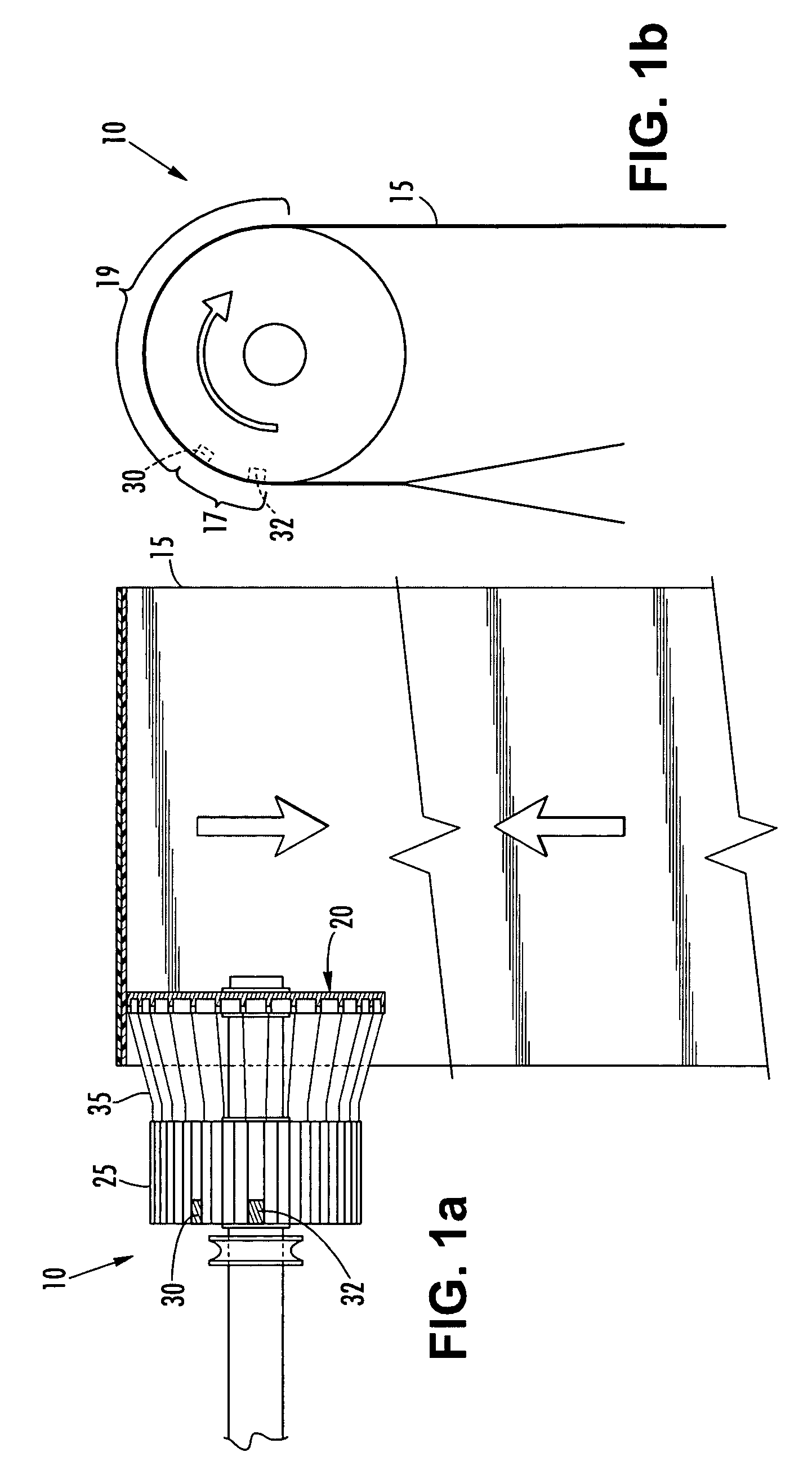

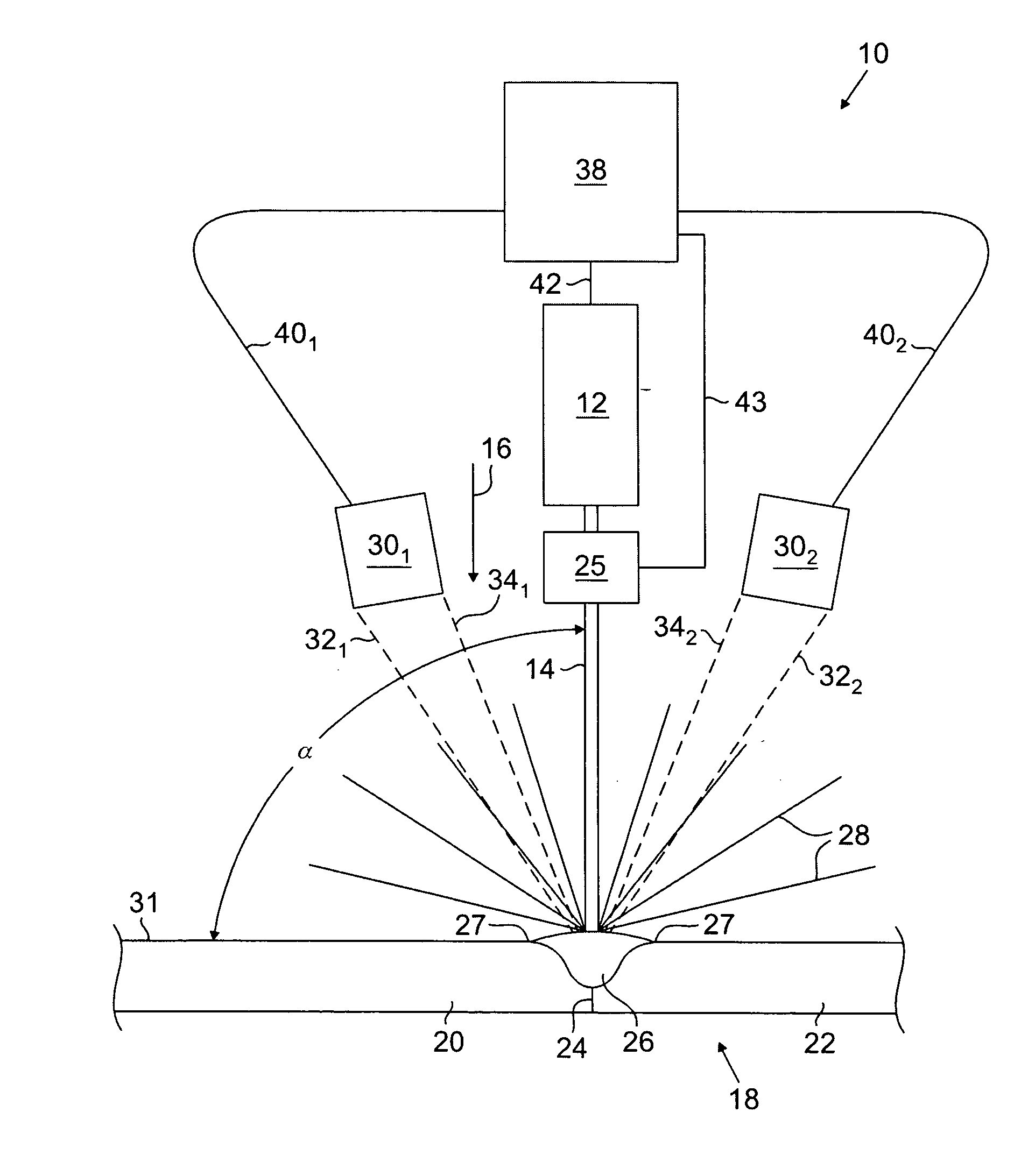

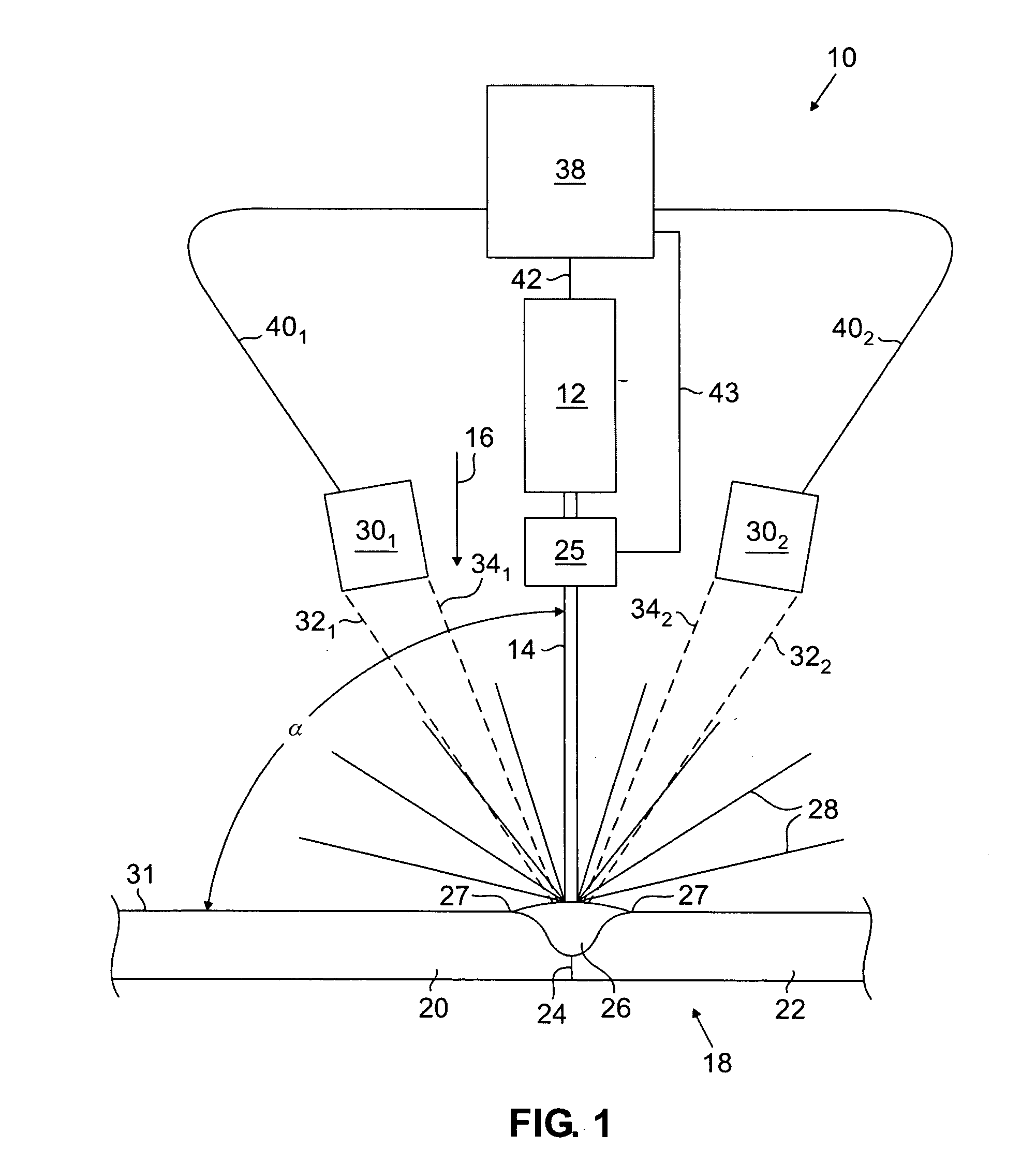

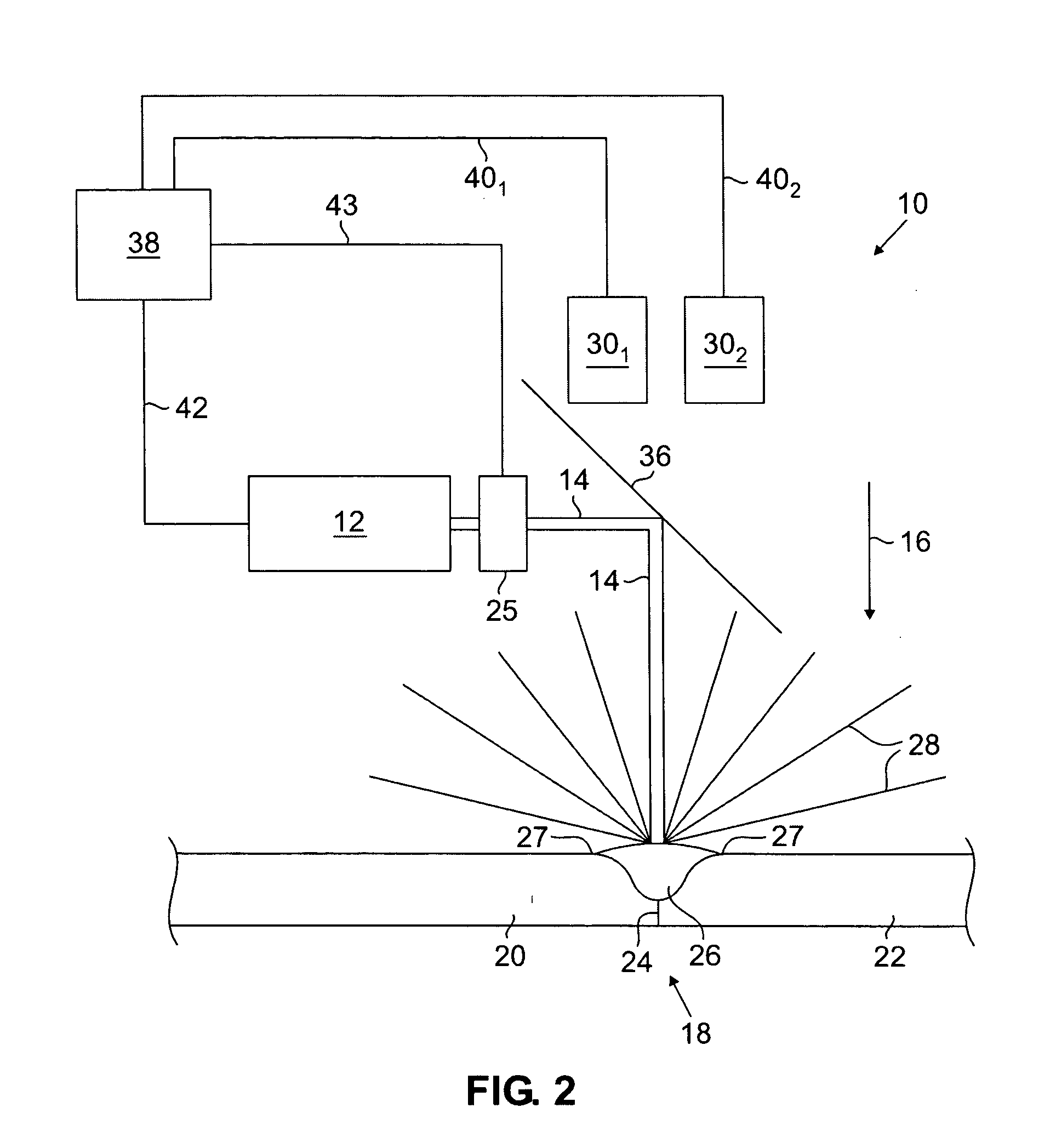

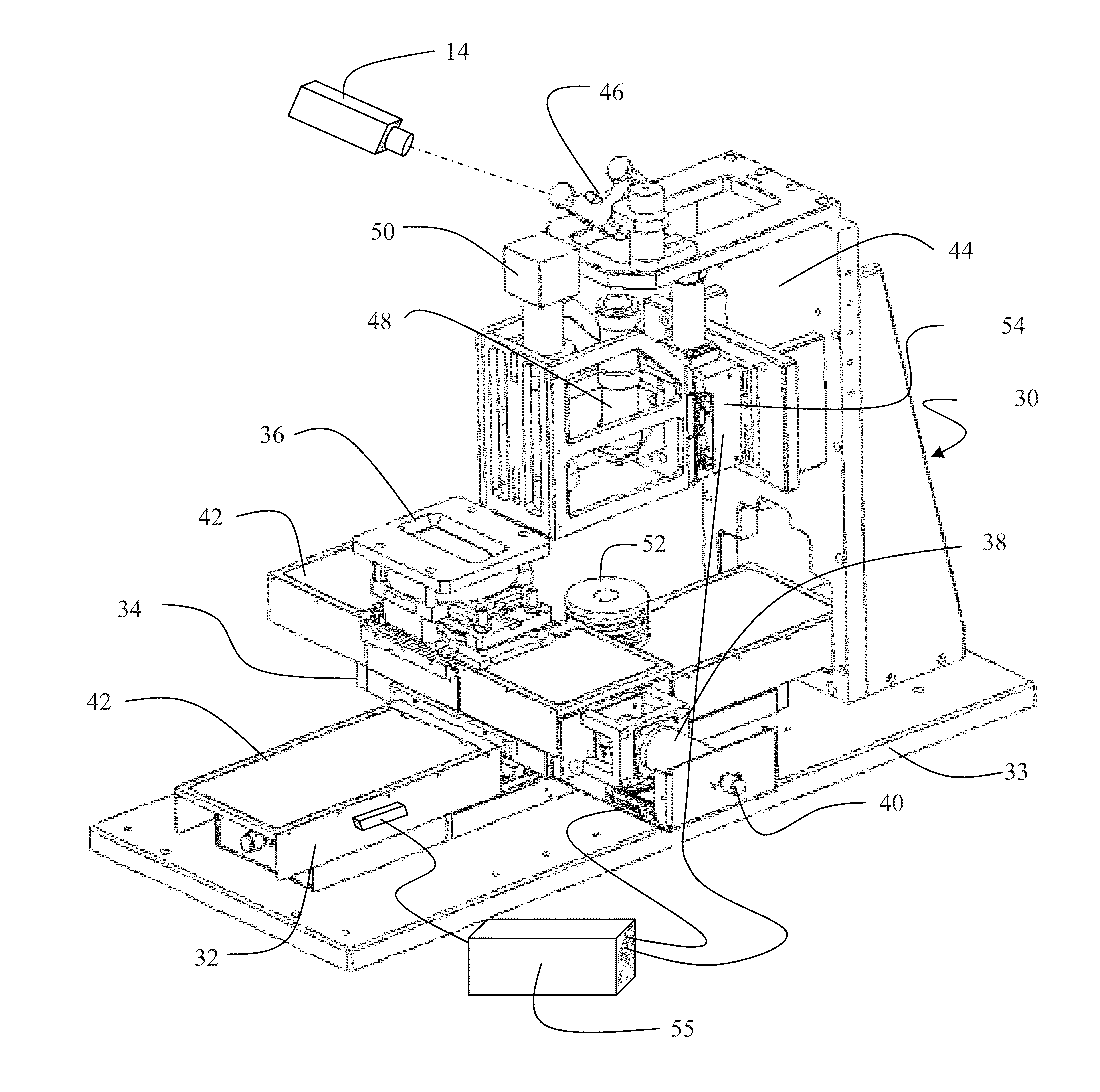

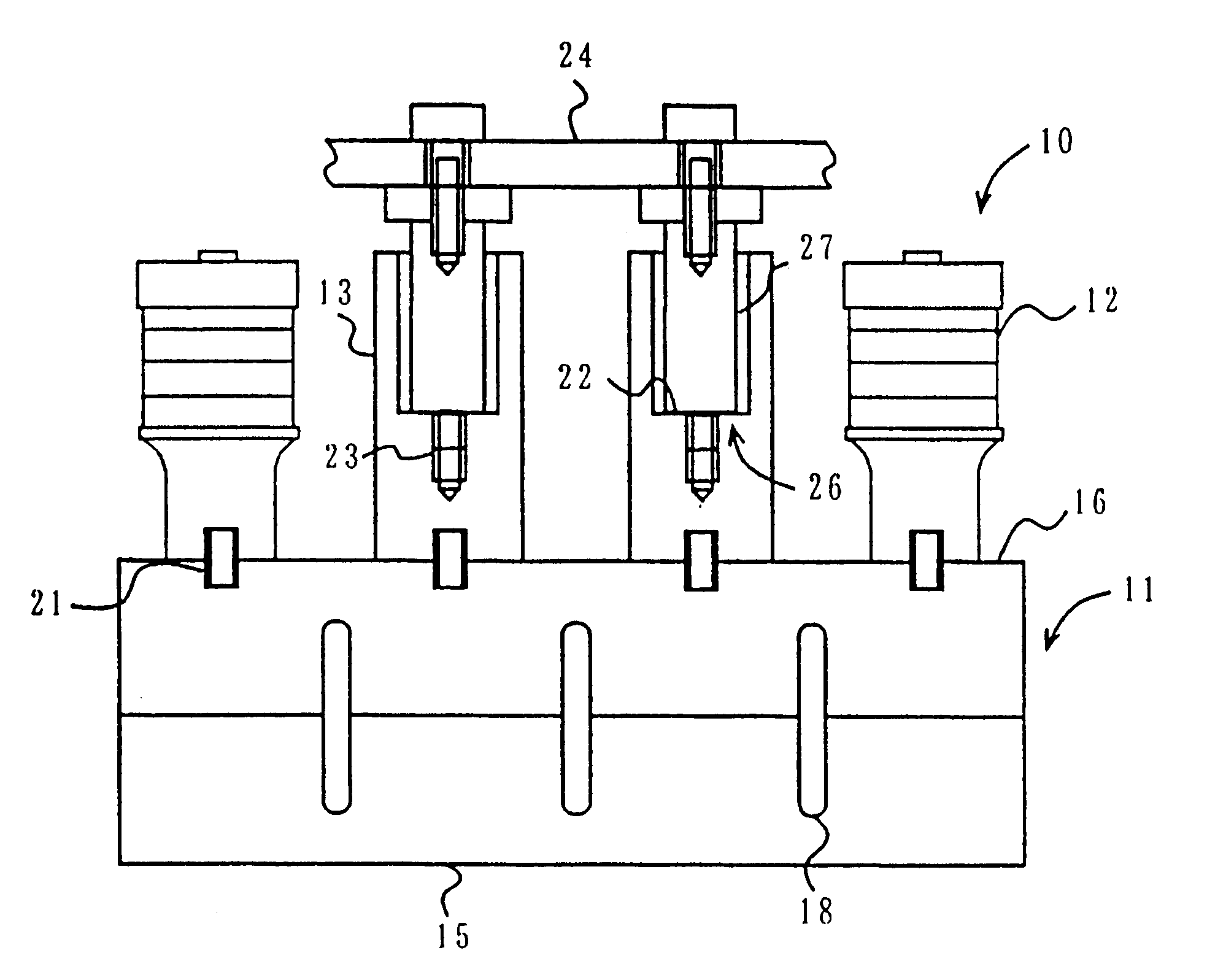

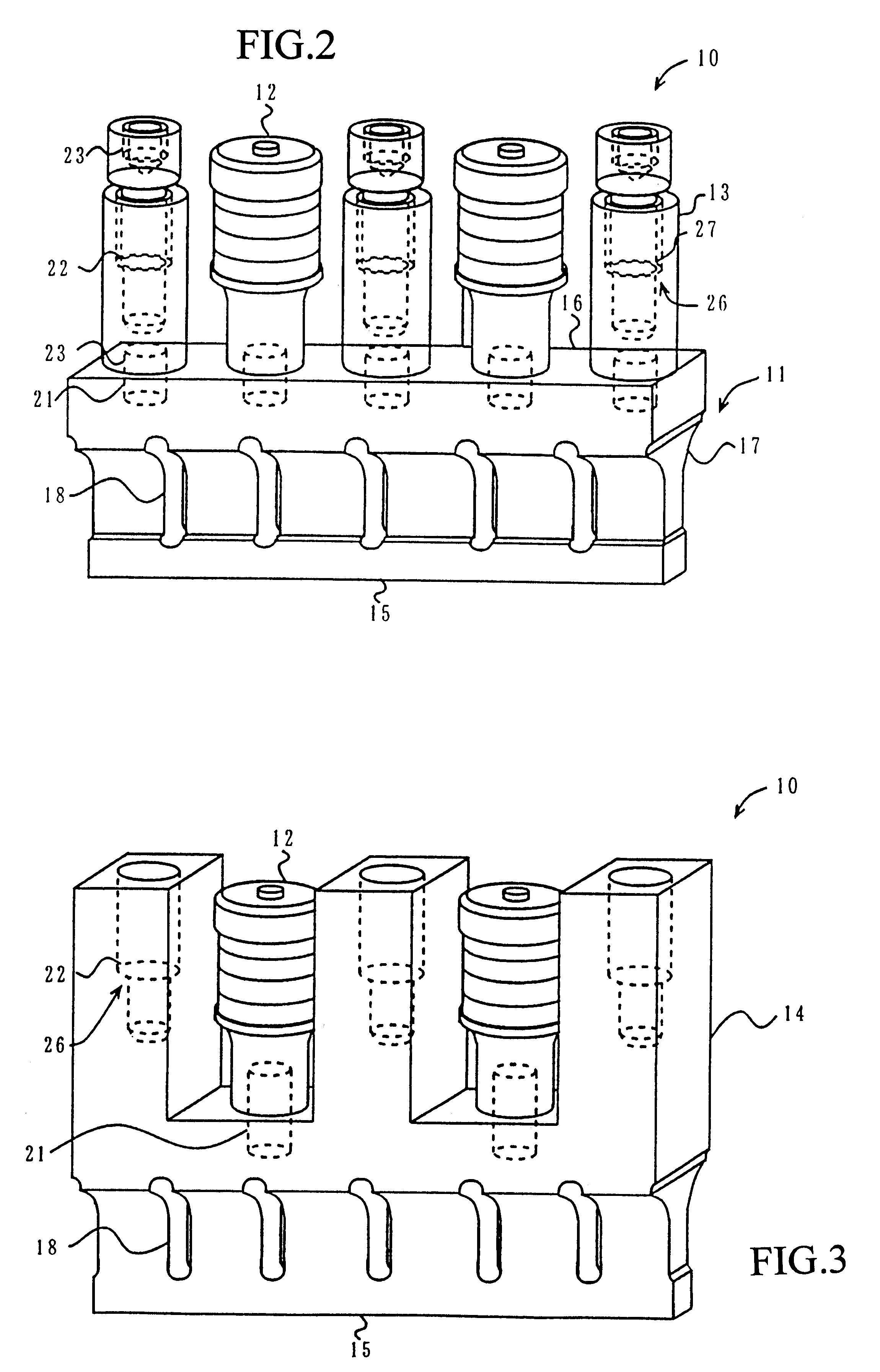

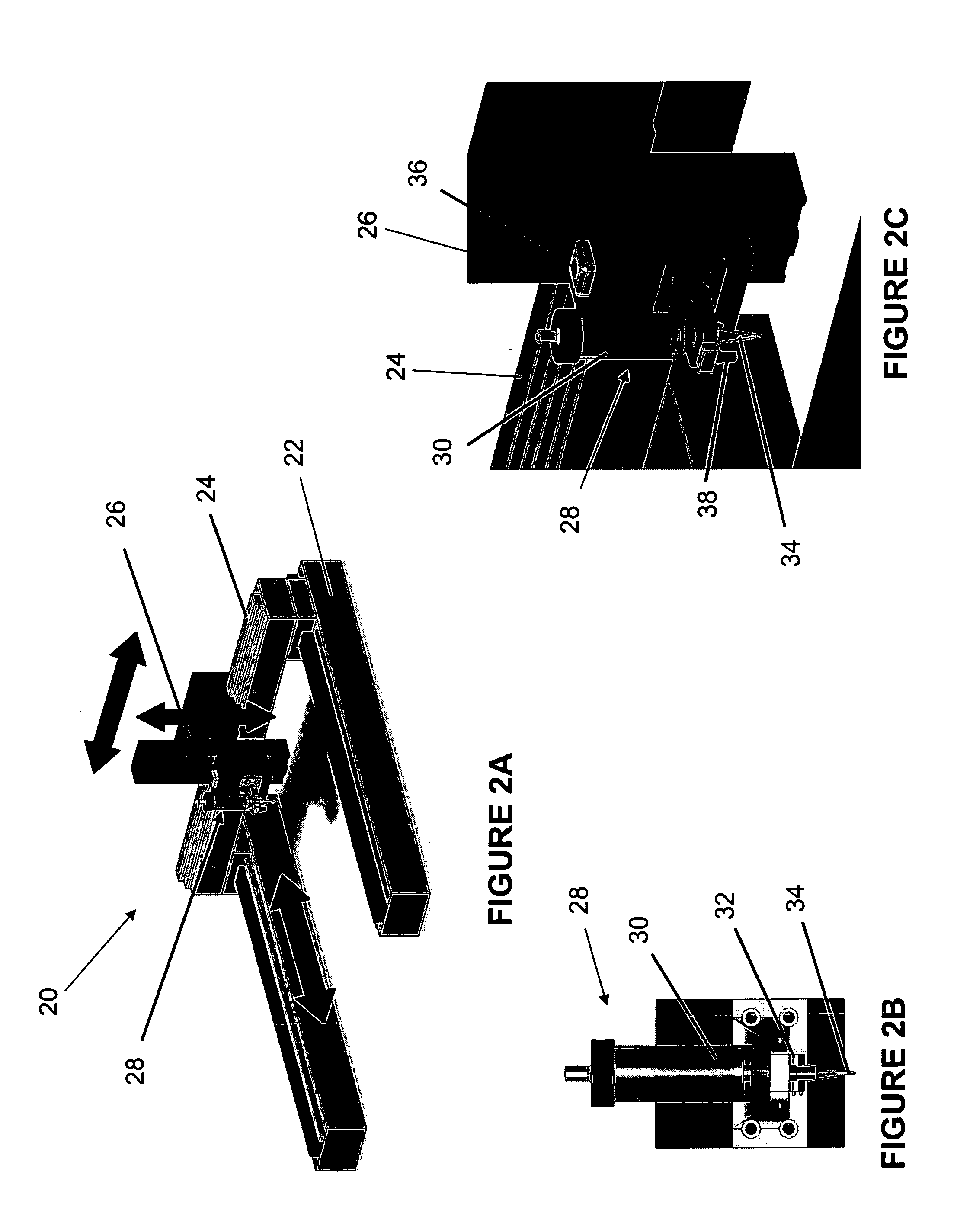

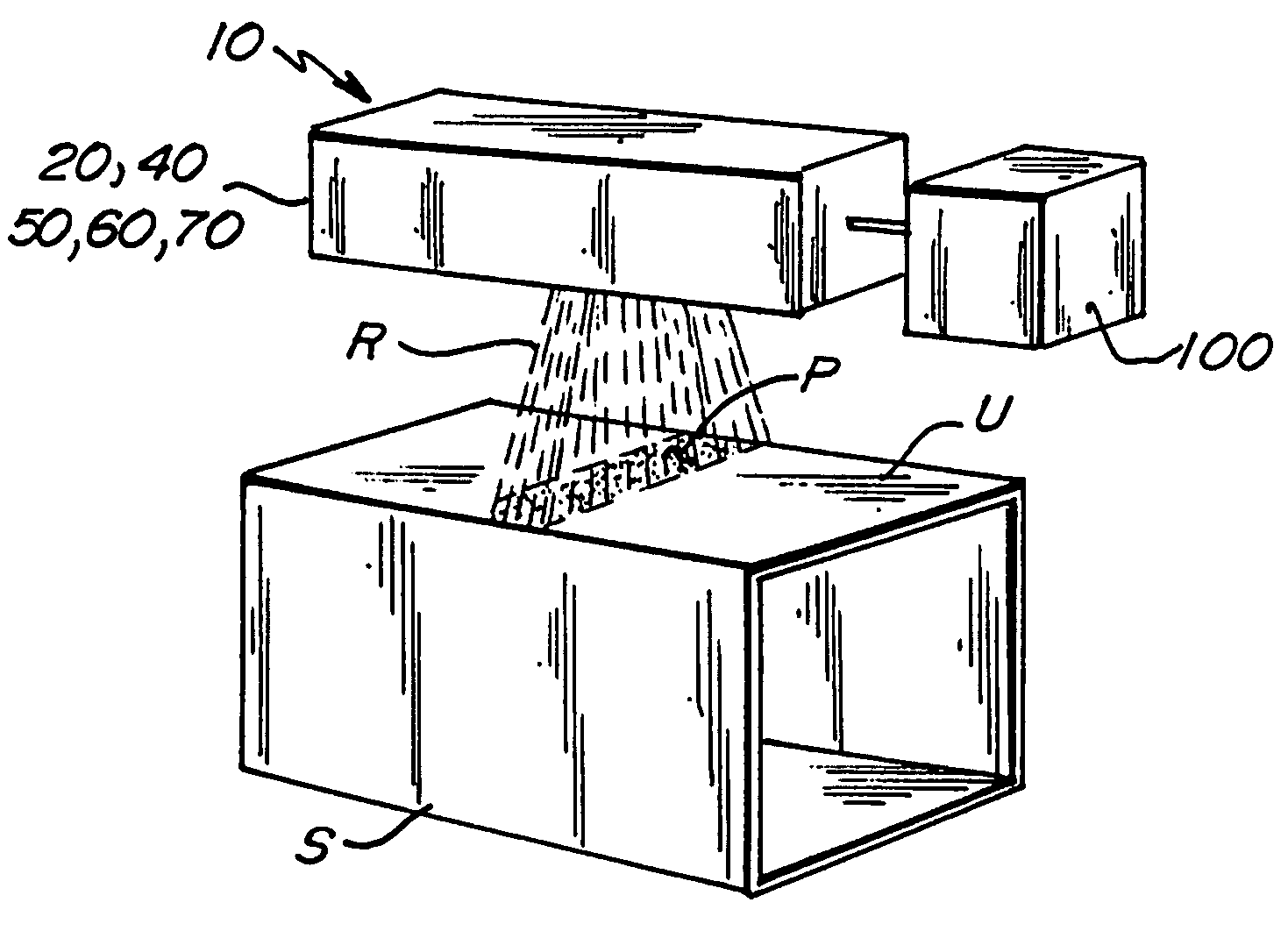

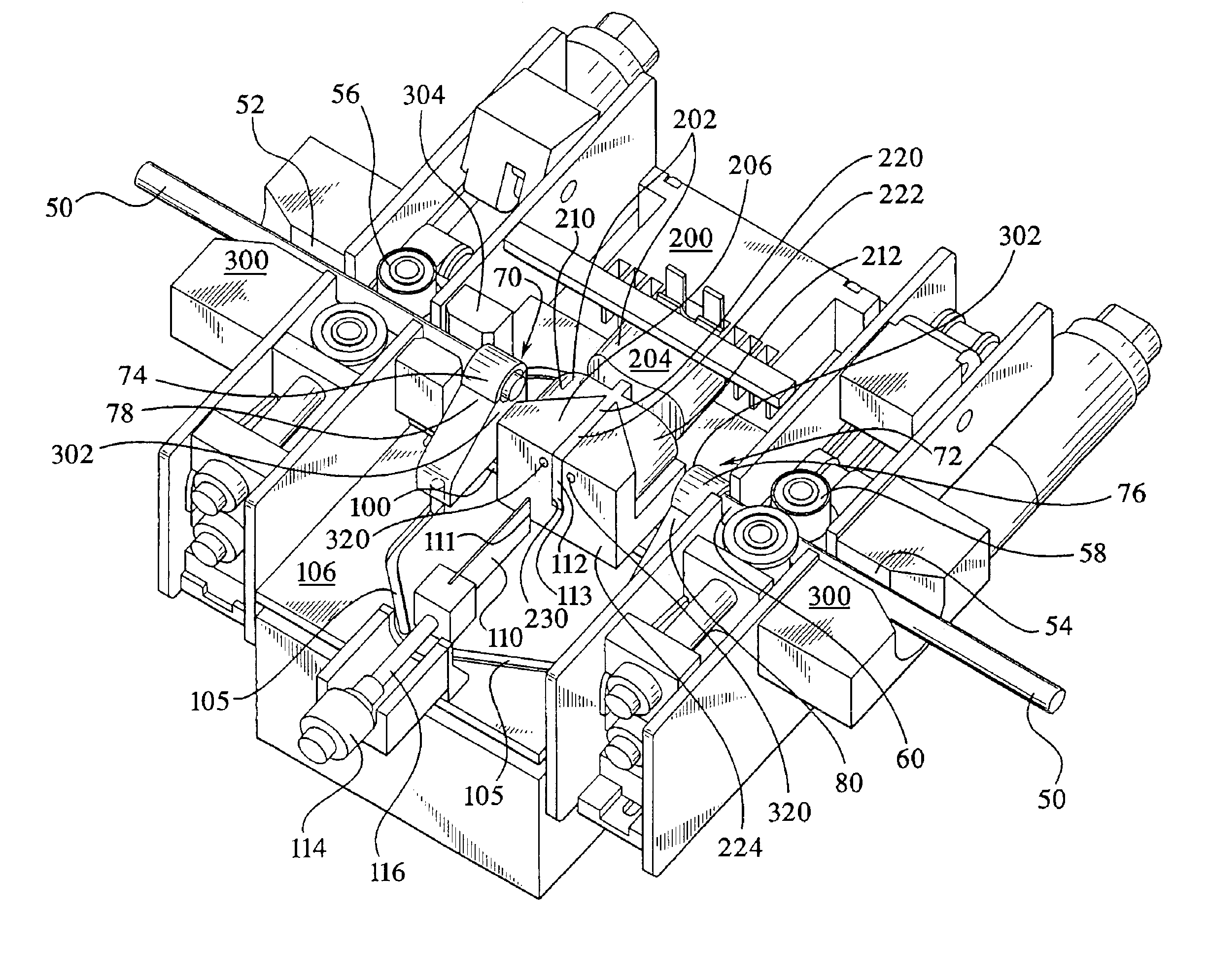

Multisource and multimaterial freeform fabrication

InactiveUS20050104257A1Liquid surface applicatorsMechanical working/deformationControl systemEngineering

An apparatus for forming freeform solid articles includes a head unit having a plurality of arc-shaped support arms. The support arms mount material feeders and power sources which are directed at a work table. The material feeders, power sources and movement of the head unit and work table are controlled by a computerized control system.

Owner:UNIV TECH INT

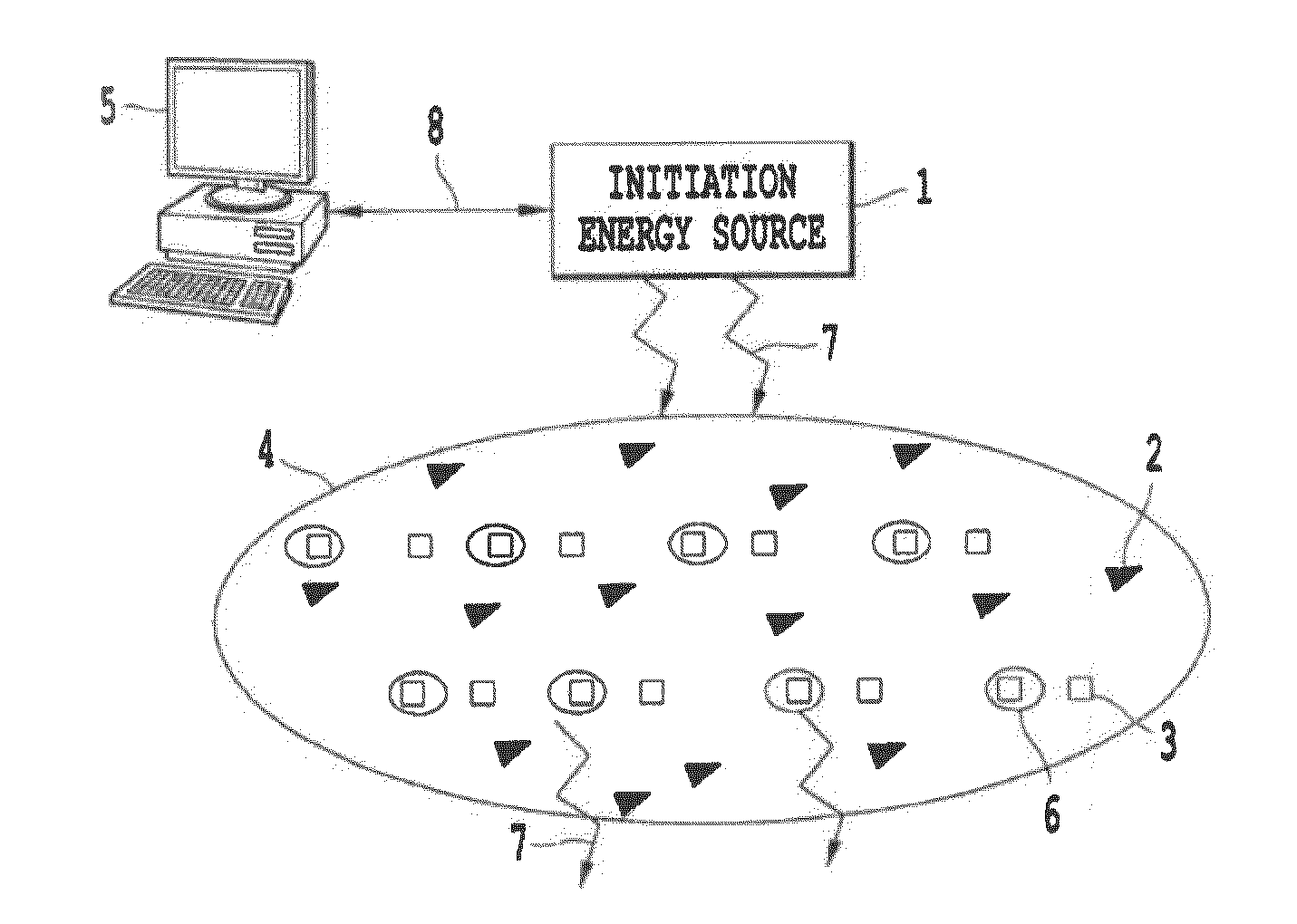

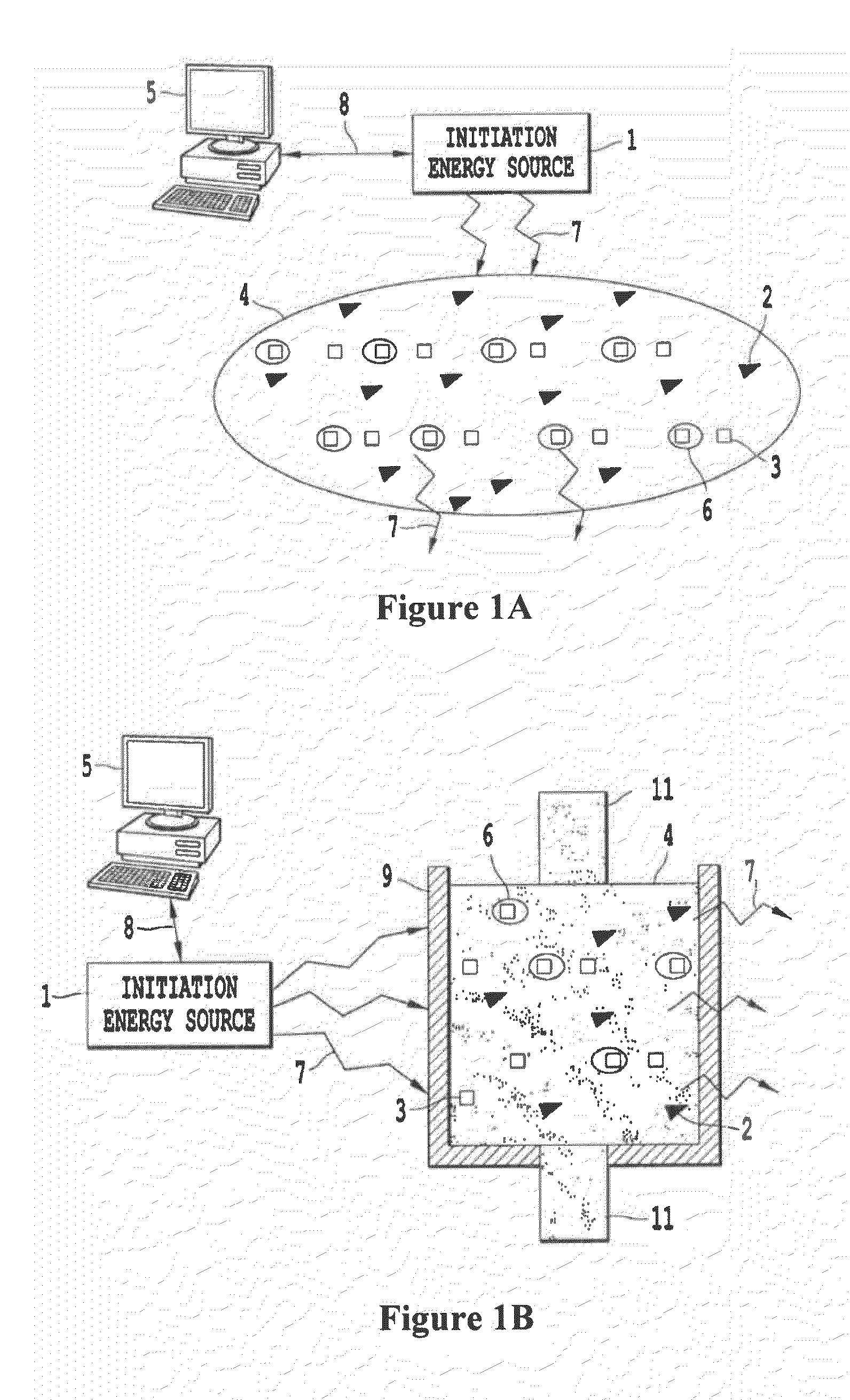

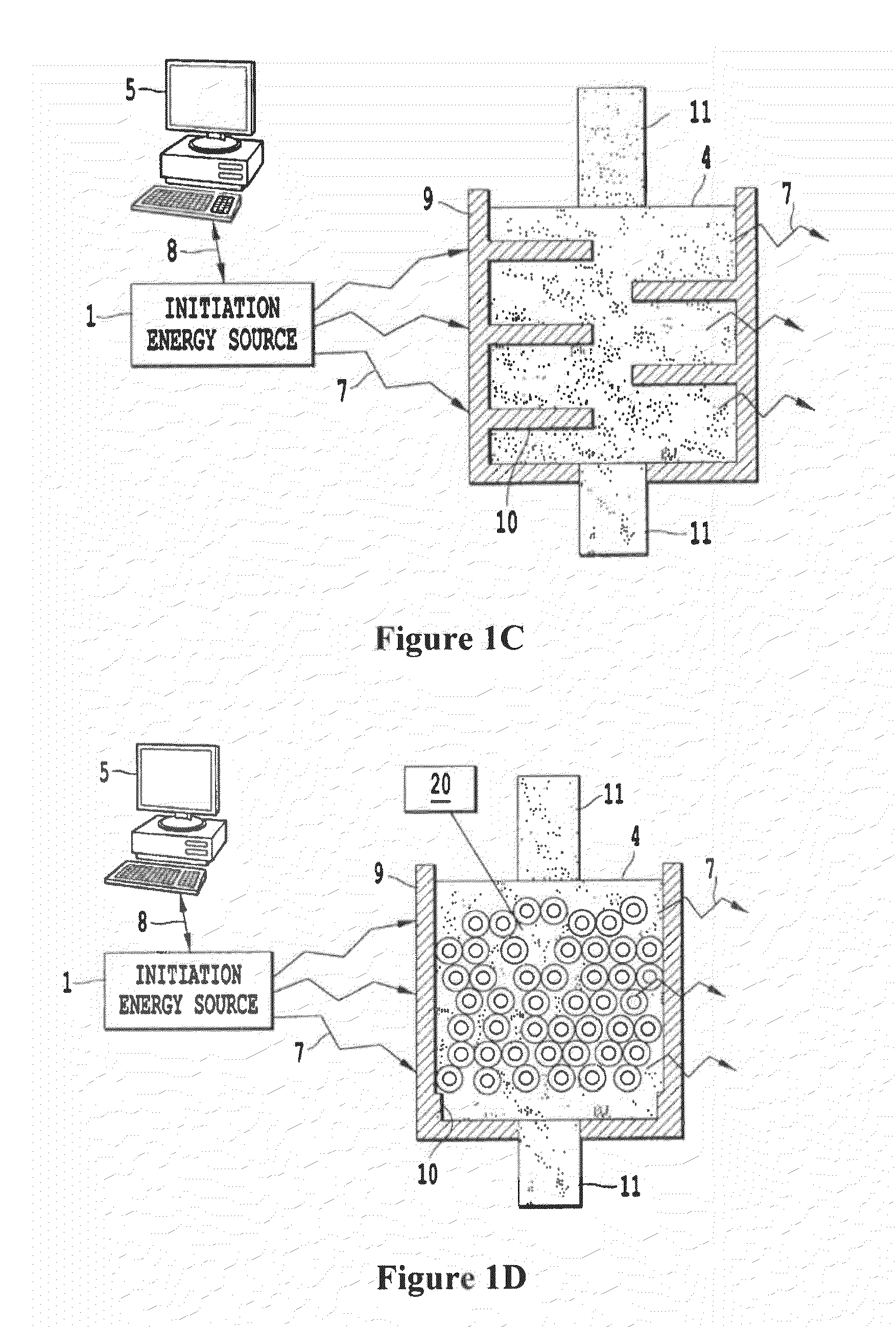

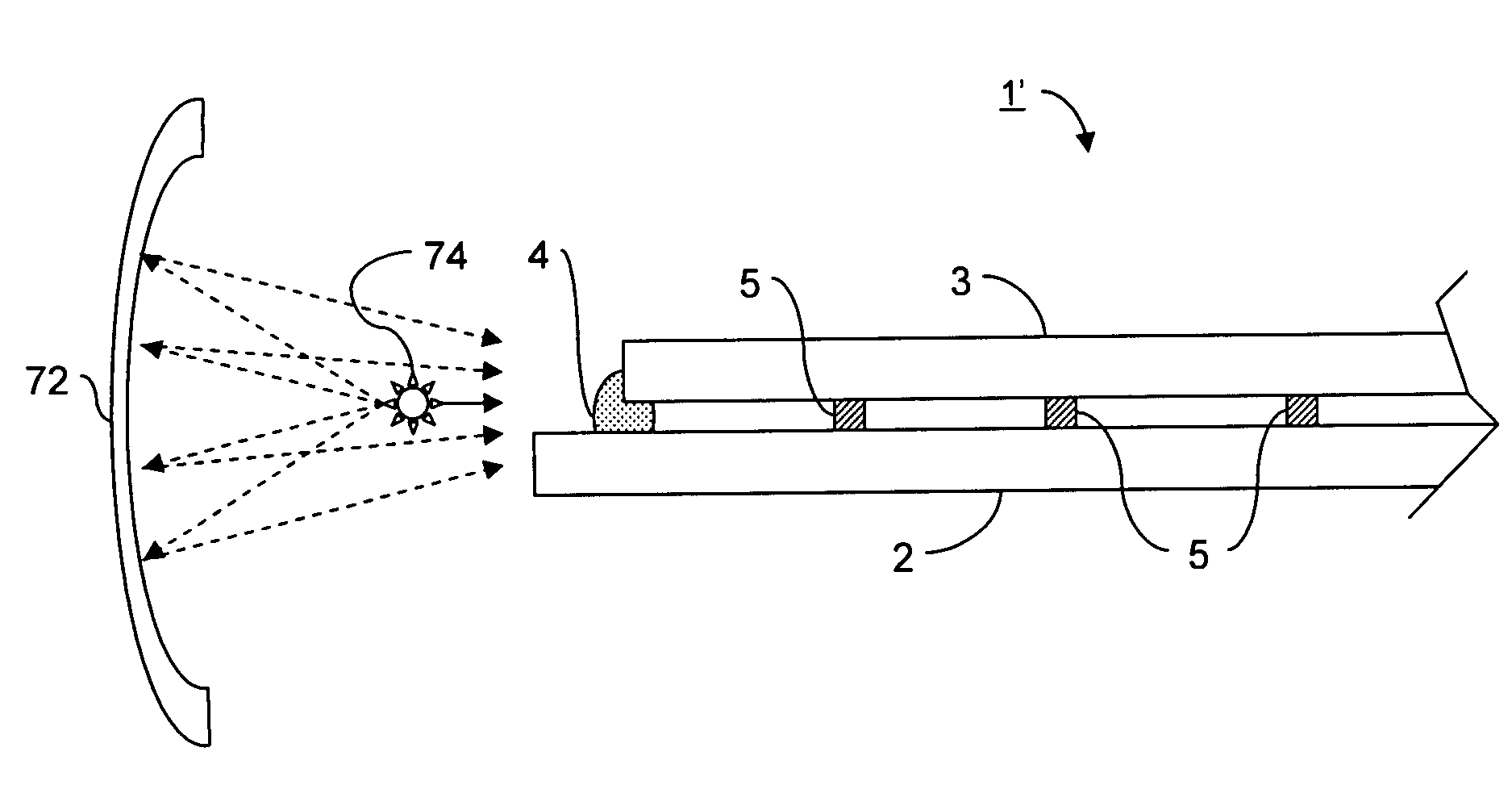

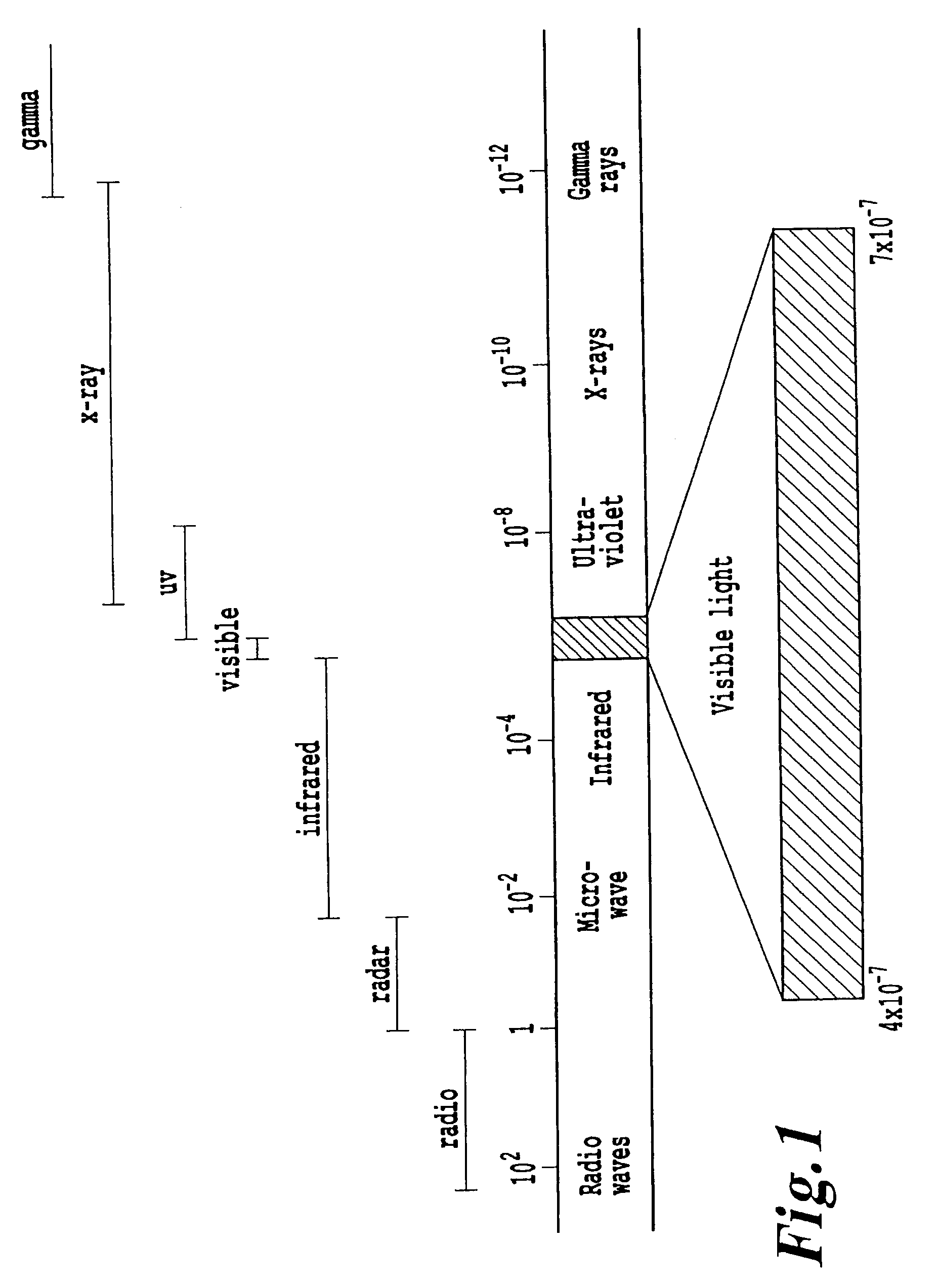

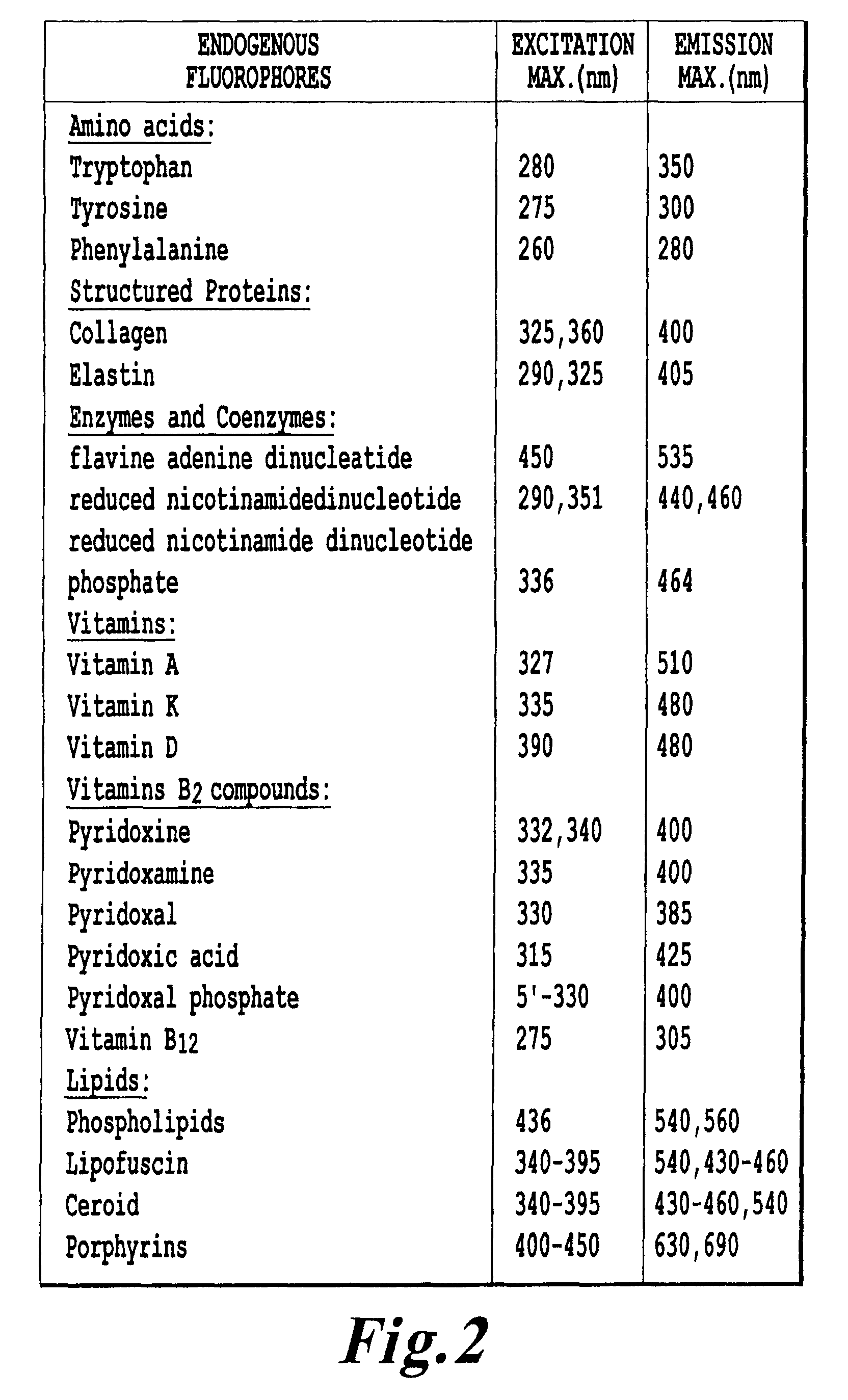

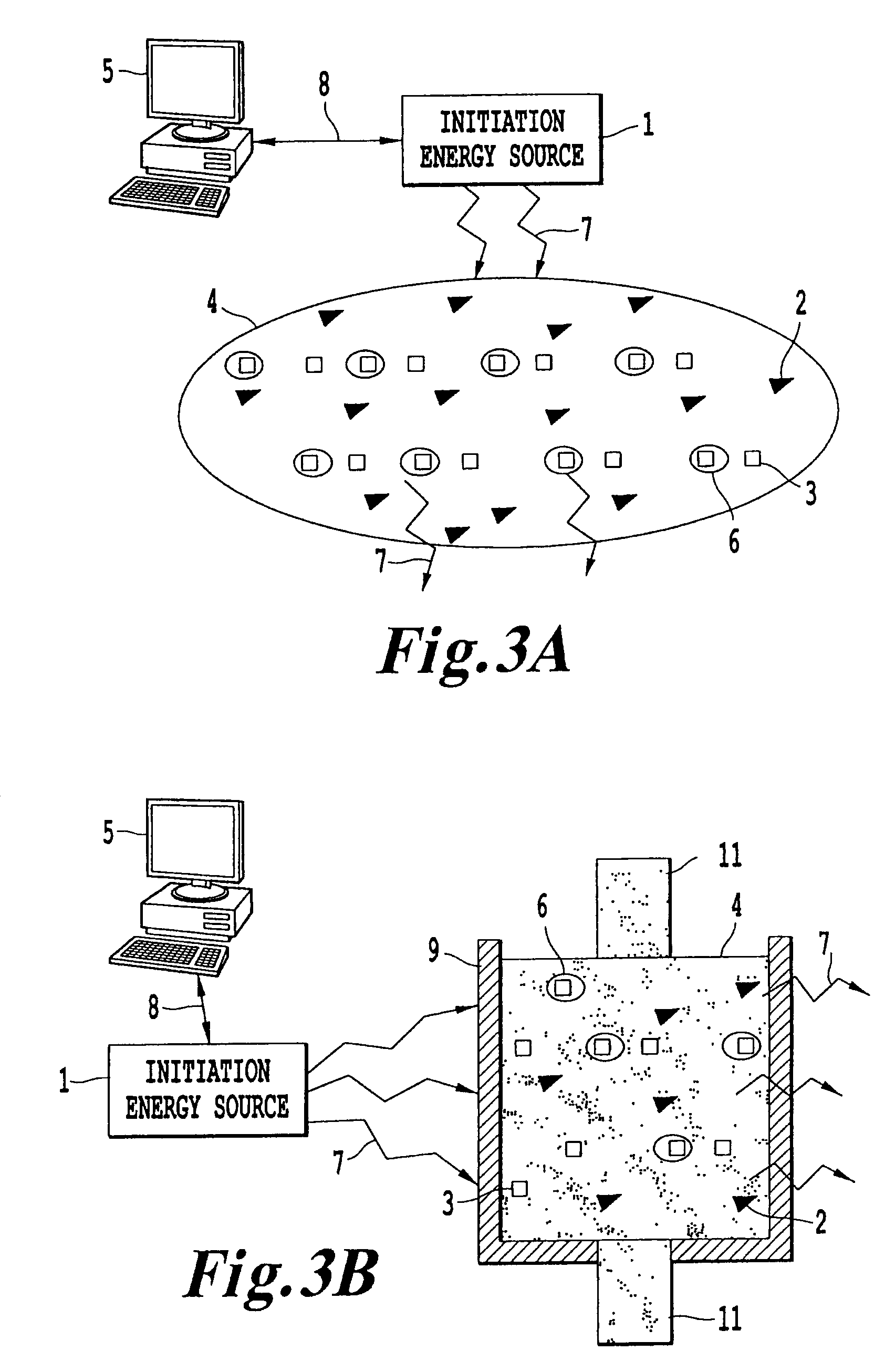

Up and down conversion systems for production of emitted light from various energy sources including radio frequency, microwave energy and magnetic induction sources for upconversion

Methods and systems for producing a change in a medium. A first method and system (1) place in a vicinity of the medium at least one upconverter including a gas for plasma ignition, with the upconverter being configured, upon exposure to initiation energy, to generate light for emission into the medium, and (2) apply the initiation energy from an energy source including the first wavelength λ1 to the medium, wherein the emitted light directly or indirectly produces the change in the medium. A second method and system (1) place in a vicinity of the medium an agent receptive to microwave radiation or radiofrequency radiation, and (2) apply as an initiation energy the microwave radiation or radiofrequency radiation by which the agent directly or indirectly generates emitted light in the infrared, visible, or ultraviolet range to produce at least one of physical and biological changes in the medium.

Owner:IMMUNOLIGTHT LLC +1

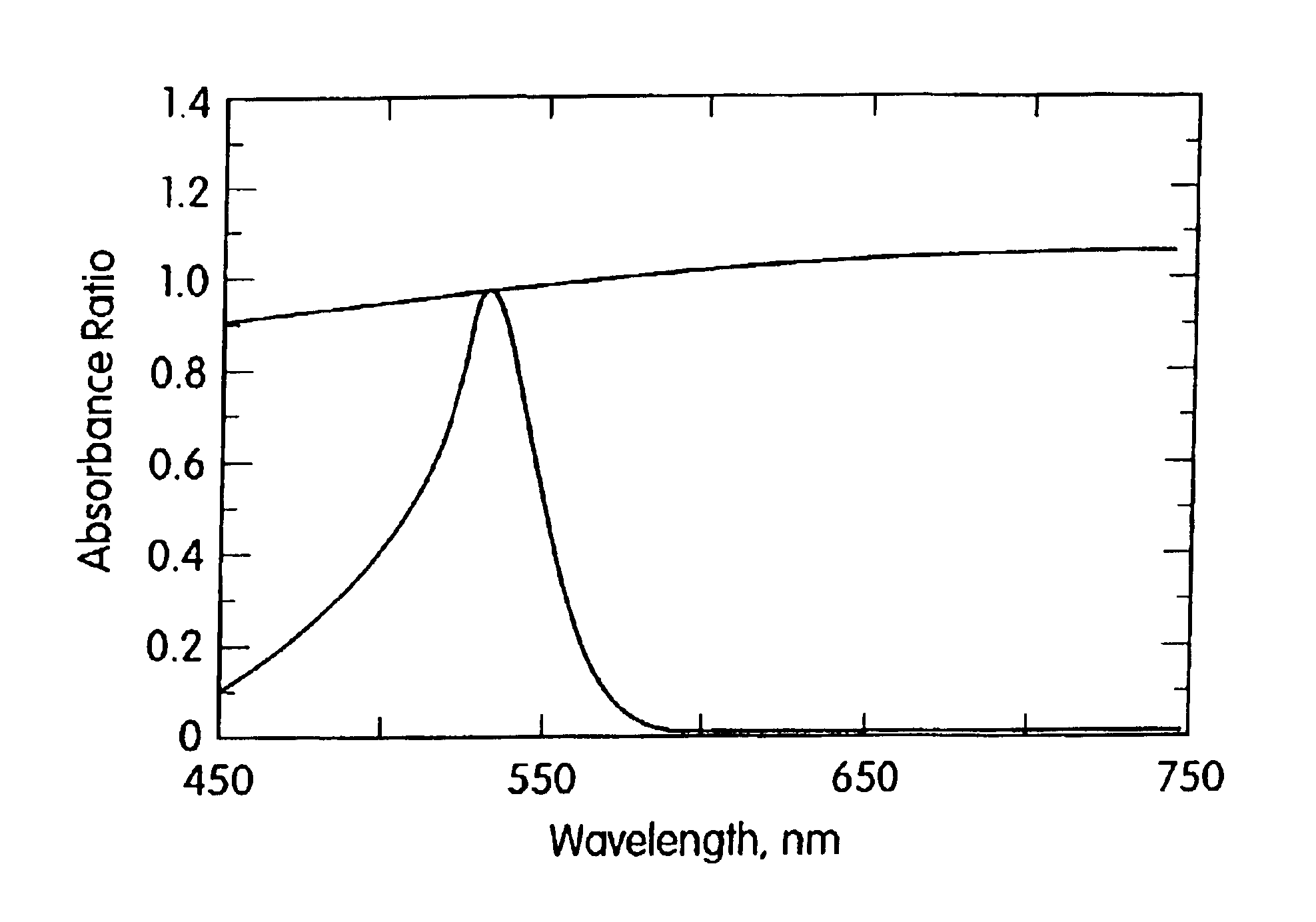

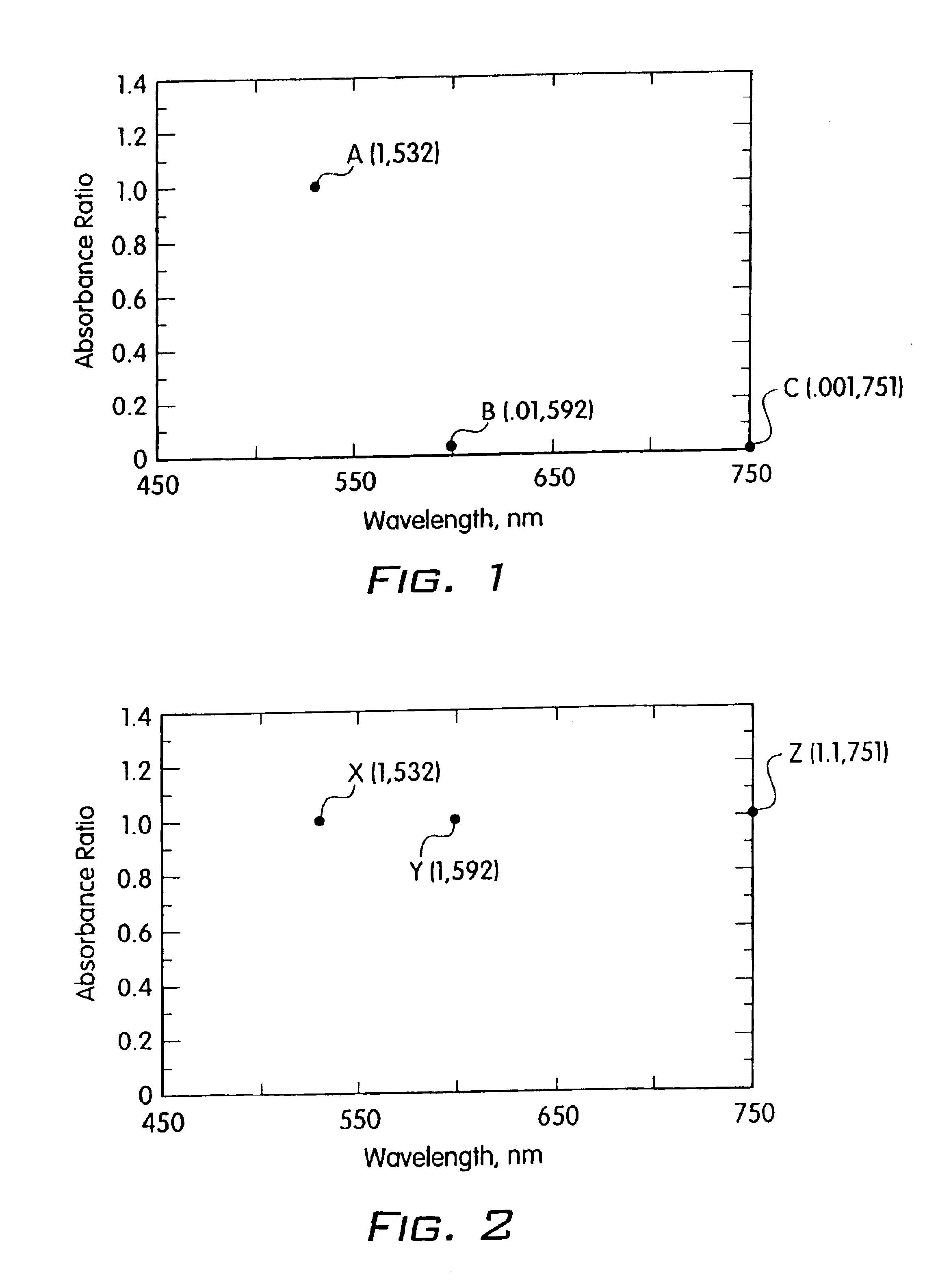

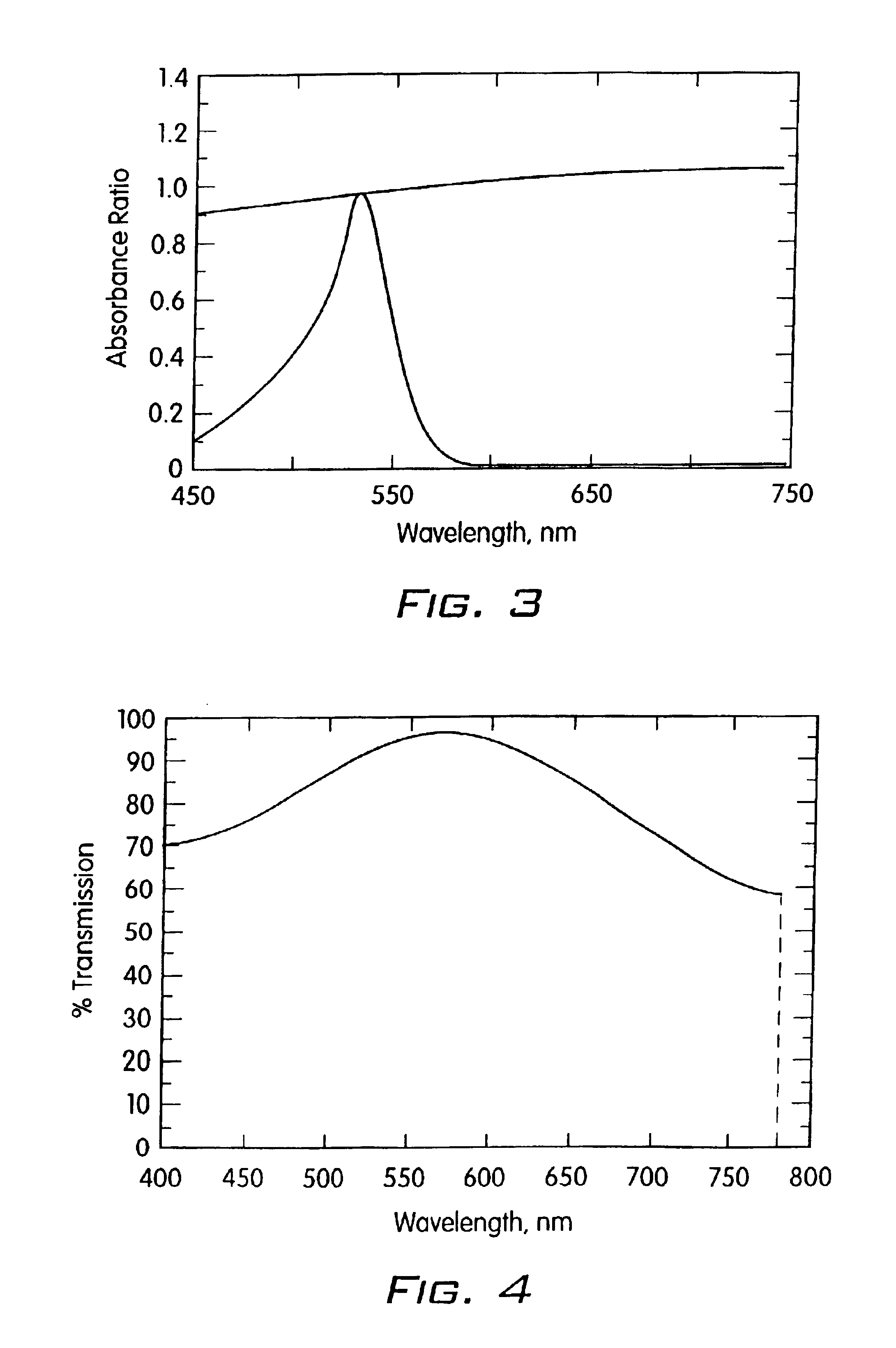

Visibly transparent dyes for through-transmission laser welding

InactiveUS6911262B2Add little or no light scatteringEffective radiationMechanical working/deformationLamination ancillary operationsSelection criterionThrough transmission

Owner:GENTEX CORP

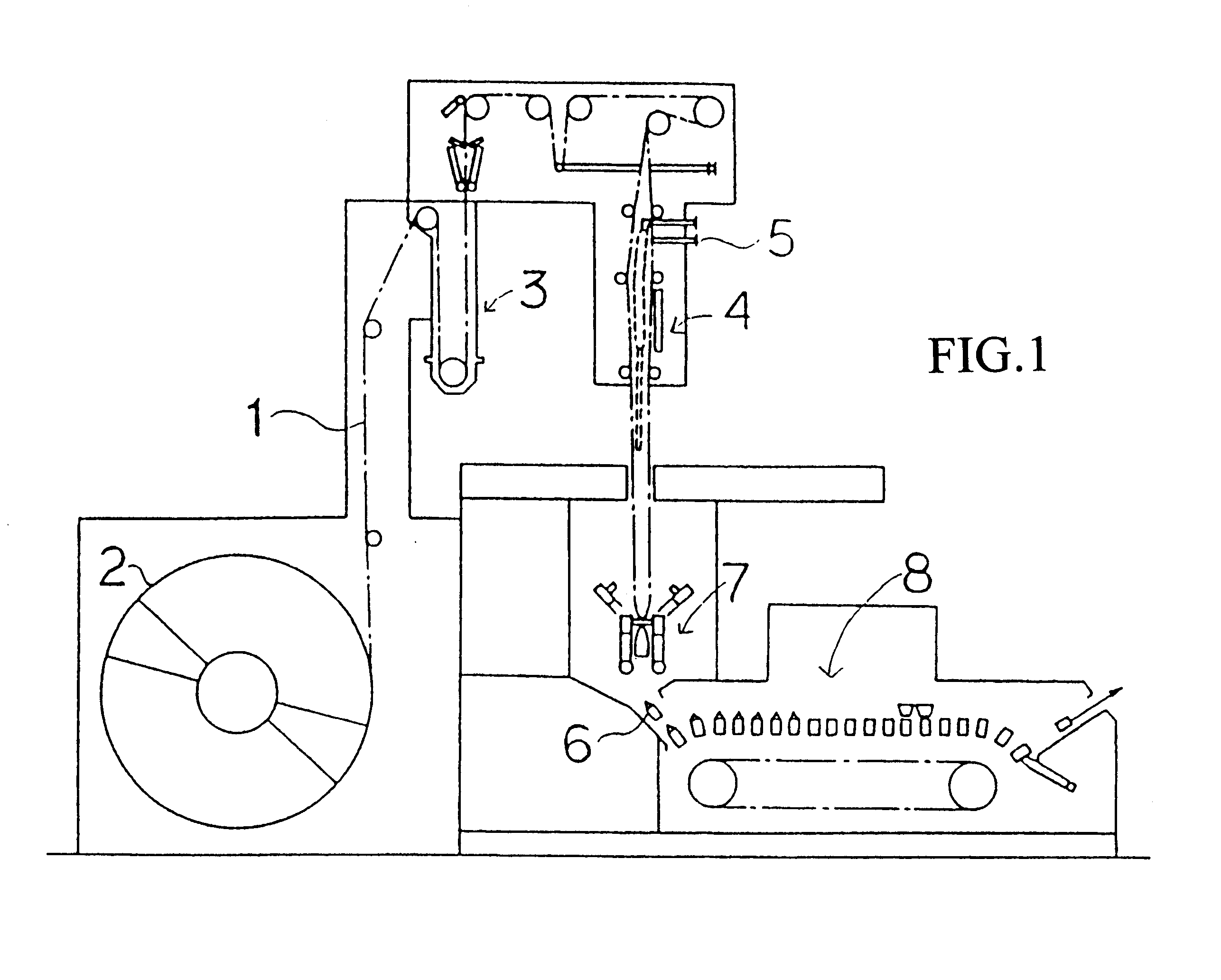

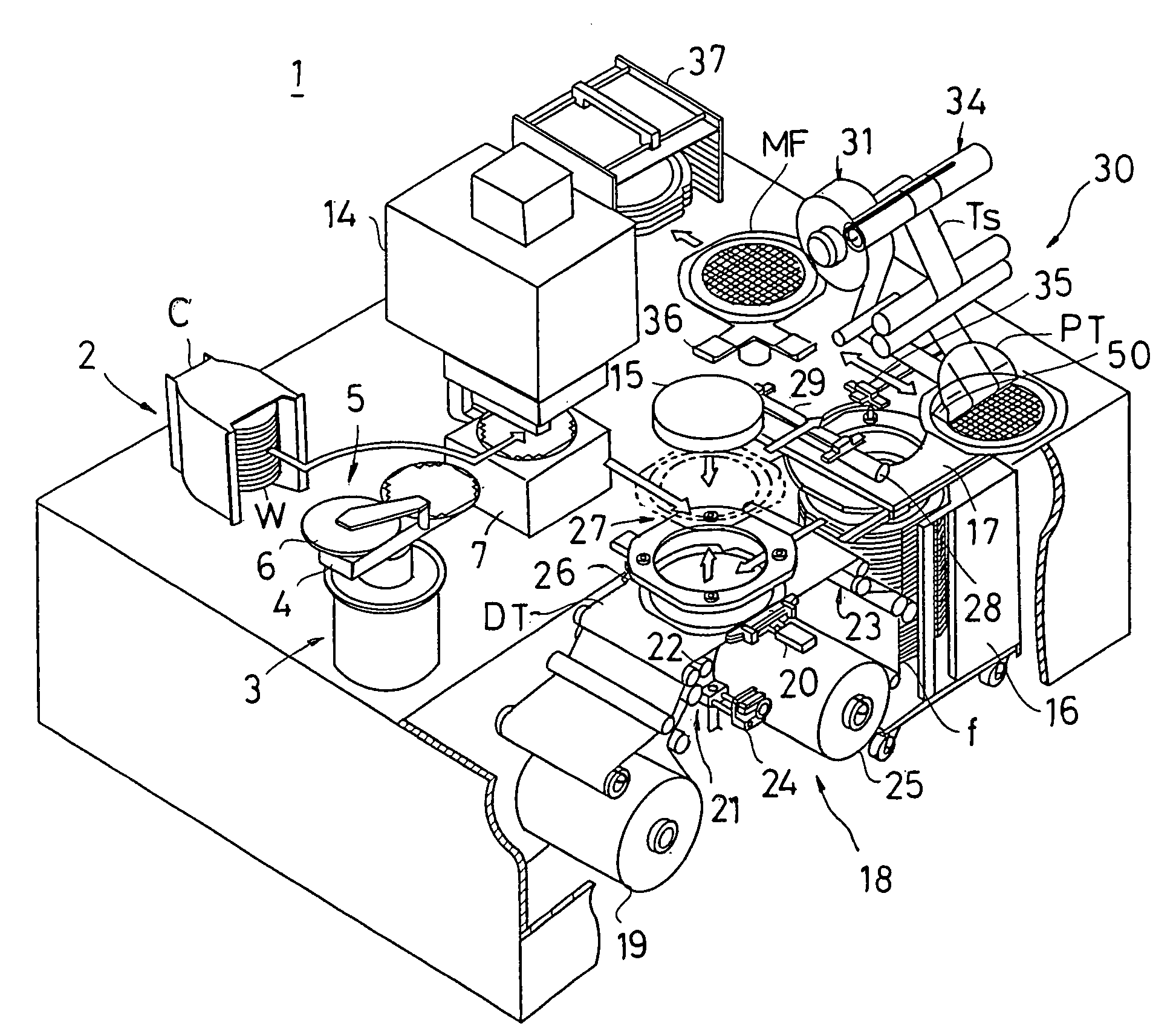

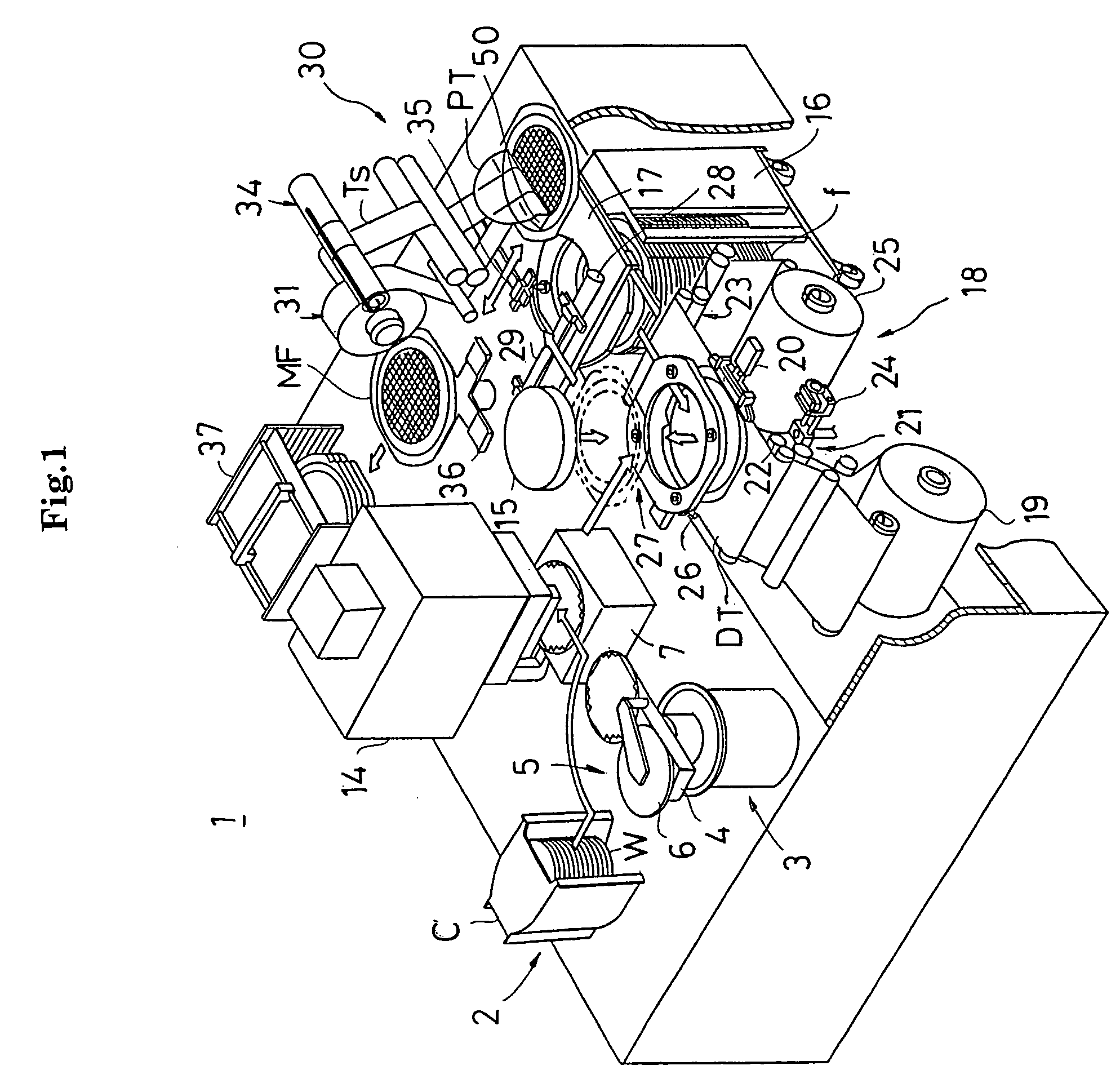

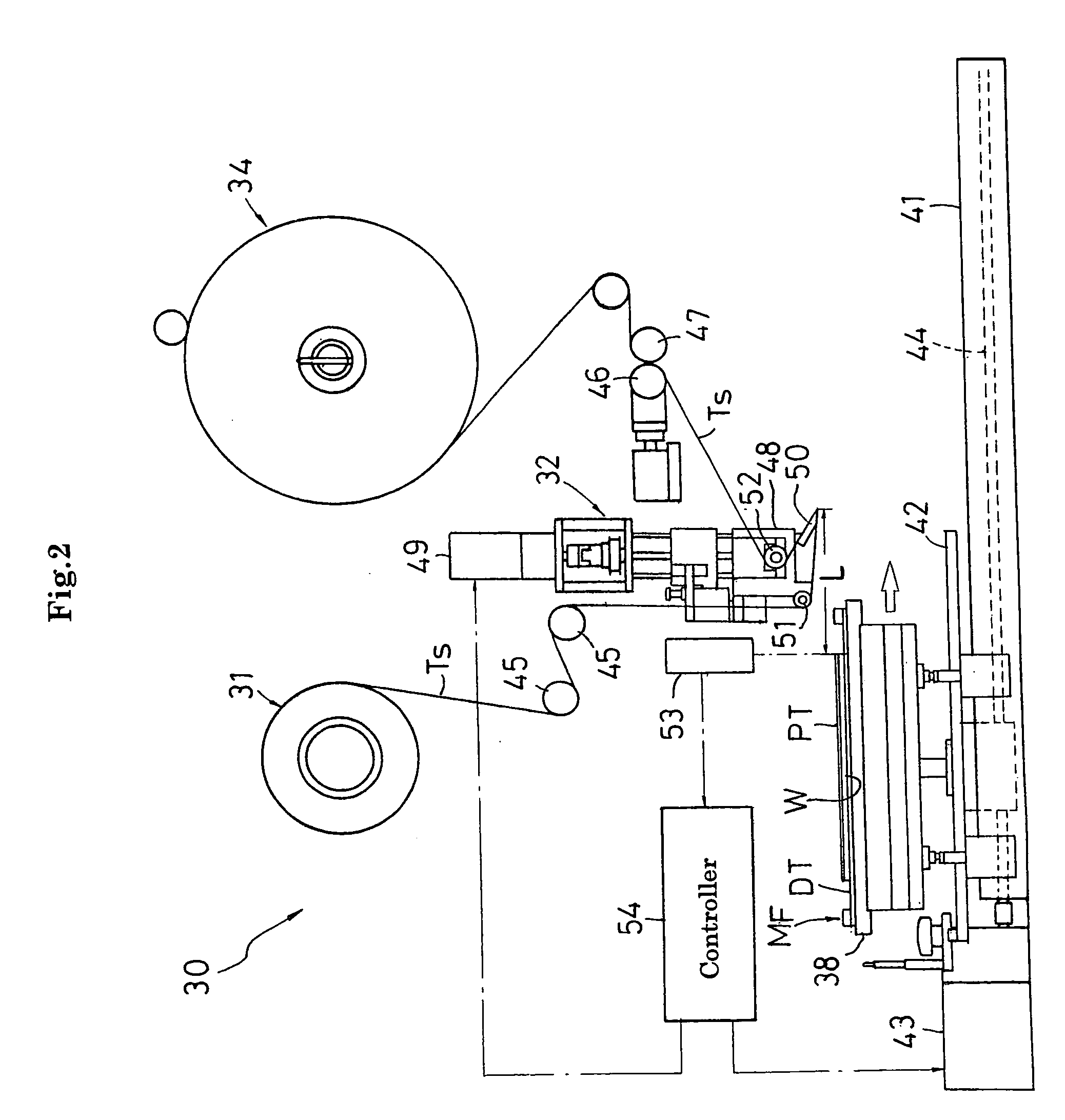

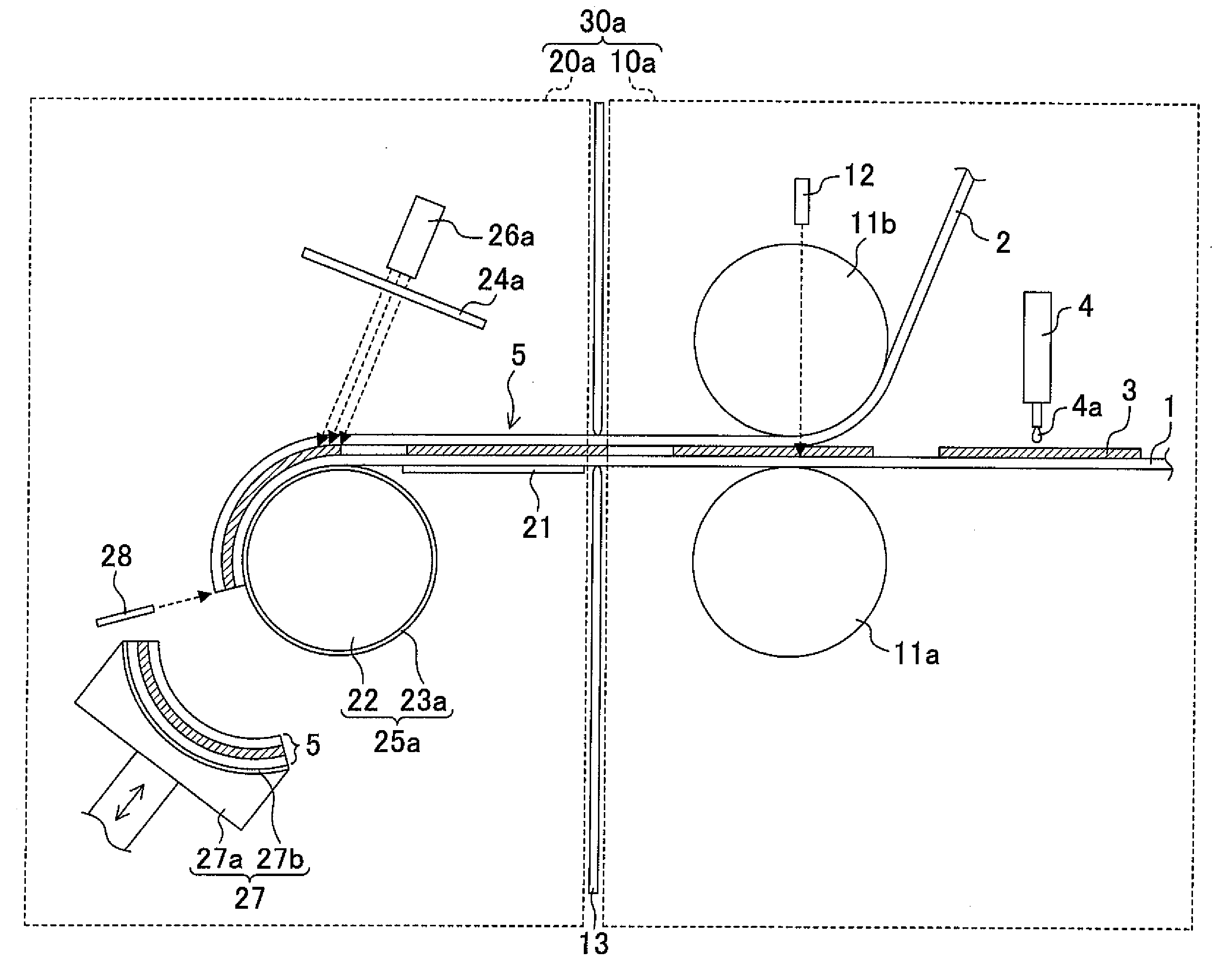

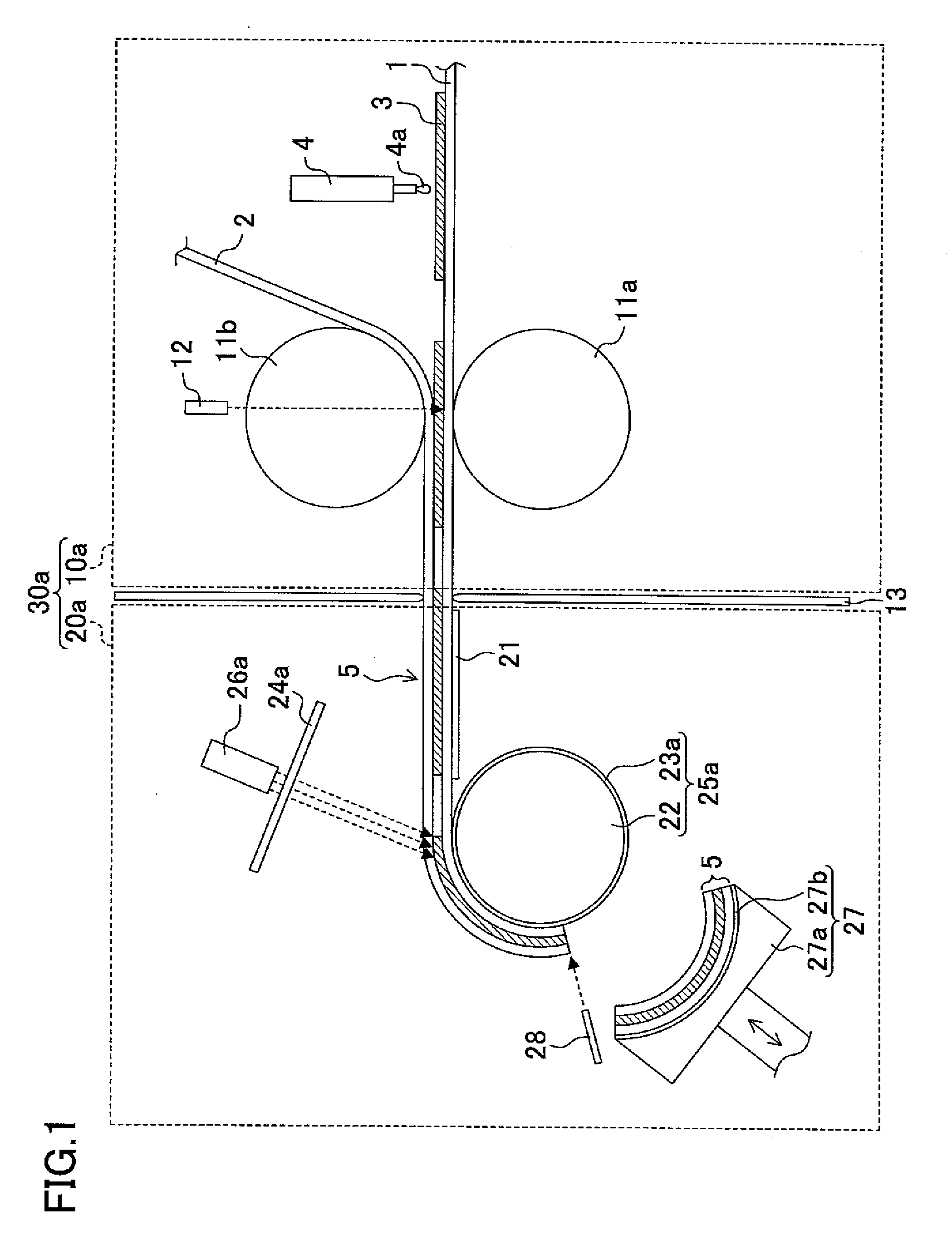

Method and apparatus for producing composite structure

ActiveUS20140039437A1Simple structureQuality improvementLiquid surface applicatorsMechanical working/deformationParticulatesFEMININE HYGIENE

The present invention relates to a method and apparatus for forming a composite structure, preferably for use in an absorbent structure used within the personal hygiene industry, such as for instance feminine hygiene garments, baby diapers and pants and adult incontinence garments. The present invention preferably provides a method and apparatus for depositing and positioning particulate materials in a desired pattern onto a moving carrier layer. The method allows accurate forming of a pattern of particulate material clusters at high production speed having improved attachment properties, with reduced raw material usage and relative low cost. The present invention foresees in the need for improved thin, flexible, lightweight absorbent structure having optimal absorption, distribution and retention.

Owner:DRYLOCK TECHNILOGIES NV

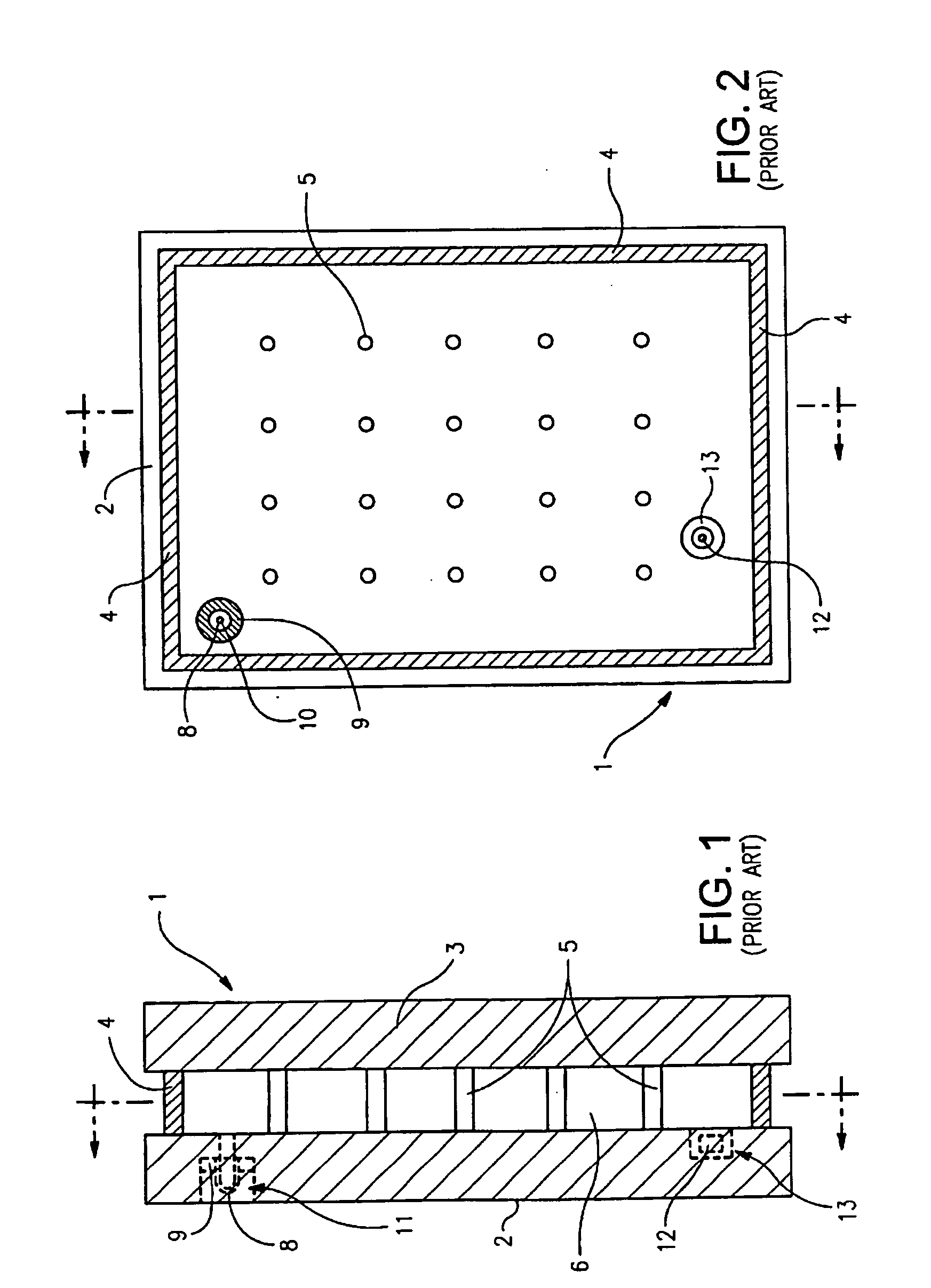

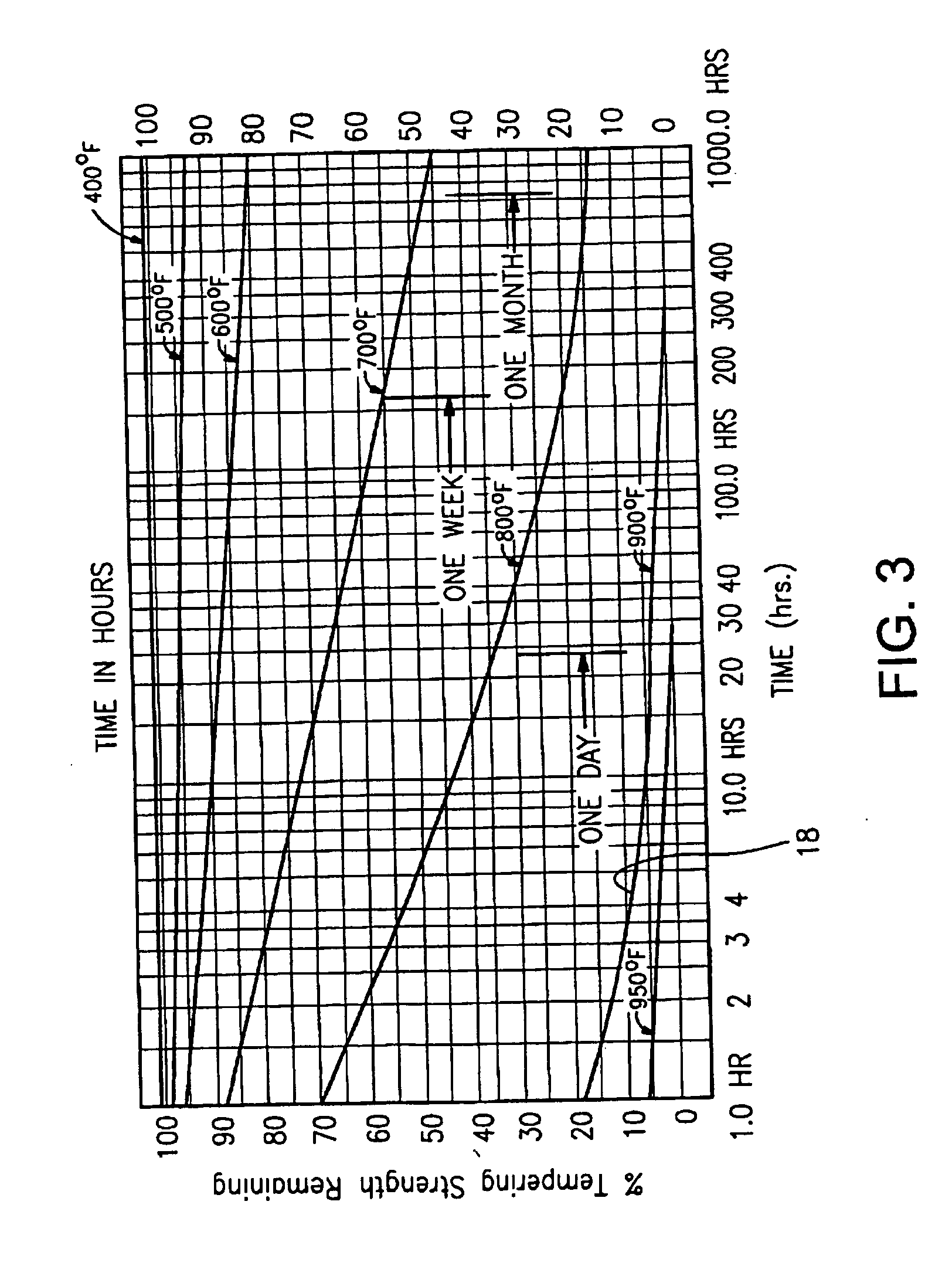

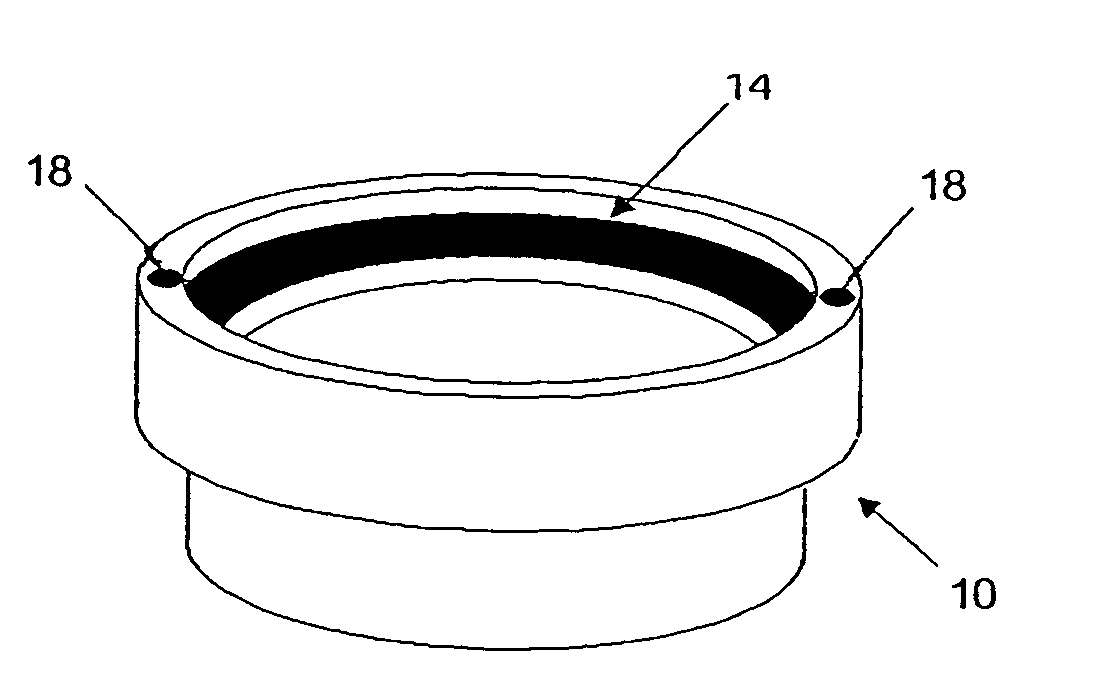

Localized heating of edge seals for a vacuum insulating glass unit, and/or unitized oven for accomplishing the same

ActiveUS20090151854A1Reduce the temperatureAccelerate breakageMechanical working/deformationClimate change adaptationEngineeringTemperature gradient

Certain example embodiments of this invention relate to edge sealing techniques for vacuum insulating glass (VIG) units. More particularly, certain example embodiments relate to techniques for providing localized heating to edge seals of units, and / or unitized ovens for accomplishing the same. In certain example embodiments, a unit is pre-heated to one or more intermediate temperatures, localized heating (e.g., from one or more substantially linear focused IR heat sources) is provided proximate to the peripheral edges of the unit so as to melt frits placed thereon, and cooled. In certain non-limiting implementations, the pre-heating and / or cooling may be provided in one or more steps. An oven for accomplishing the same may include multiple zones for performing the above-noted steps, each zone optionally including one or more chambers. Accordingly, in certain example embodiments, a temperature gradient proximate to the edges of the unit is created, thereby reducing the chances of breakage and / or at least some de-tempering of the substrates.

Owner:GUARDIAN GLASS LLC

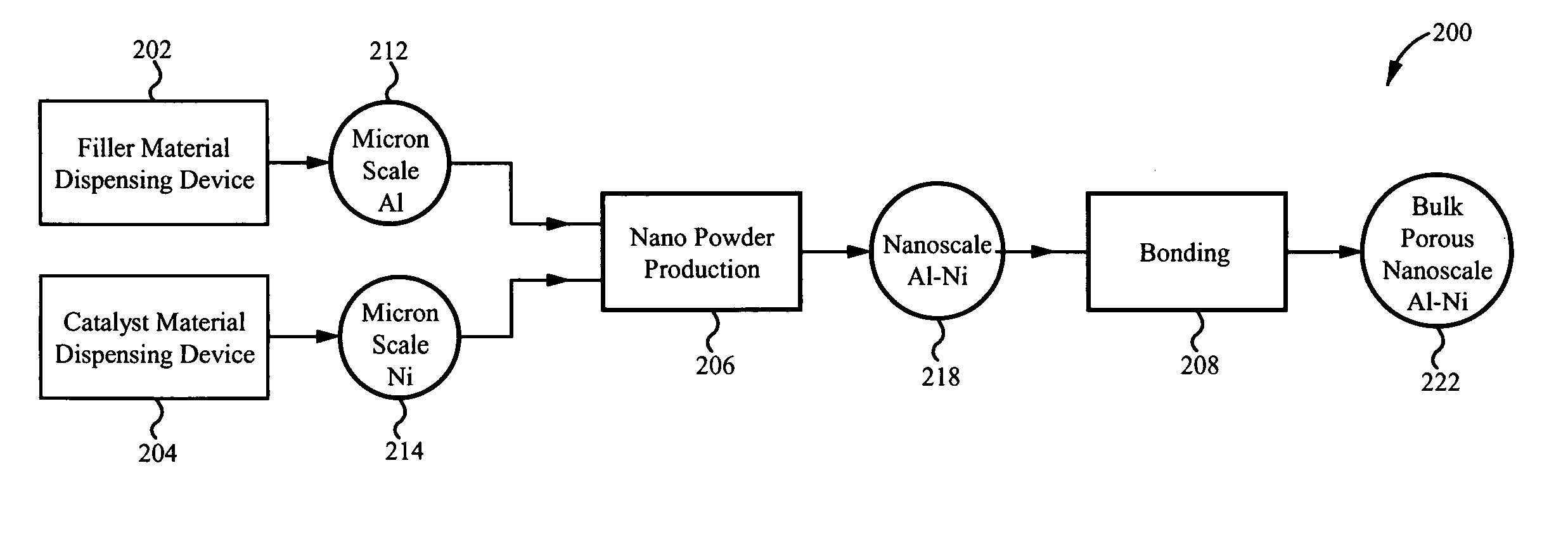

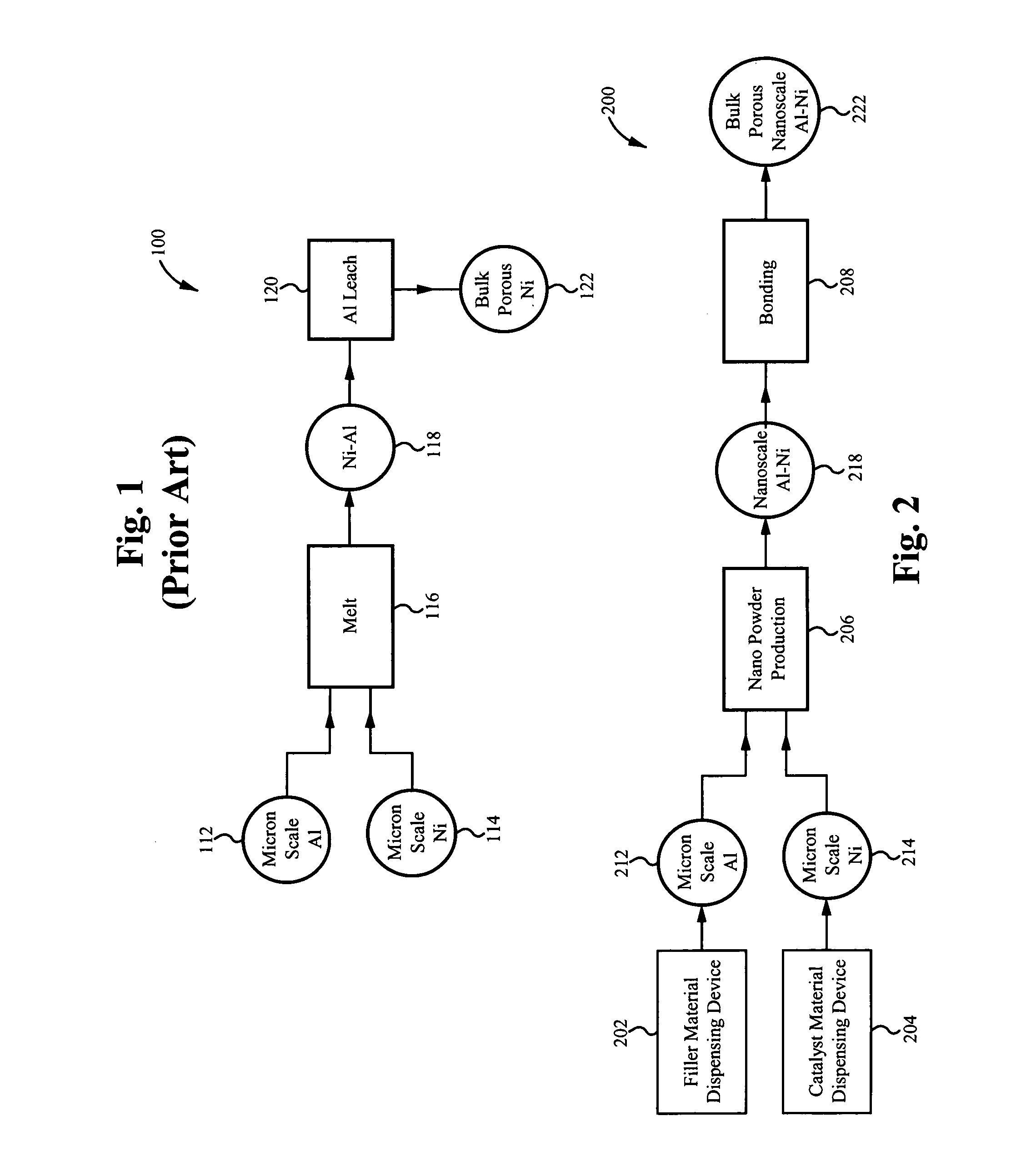

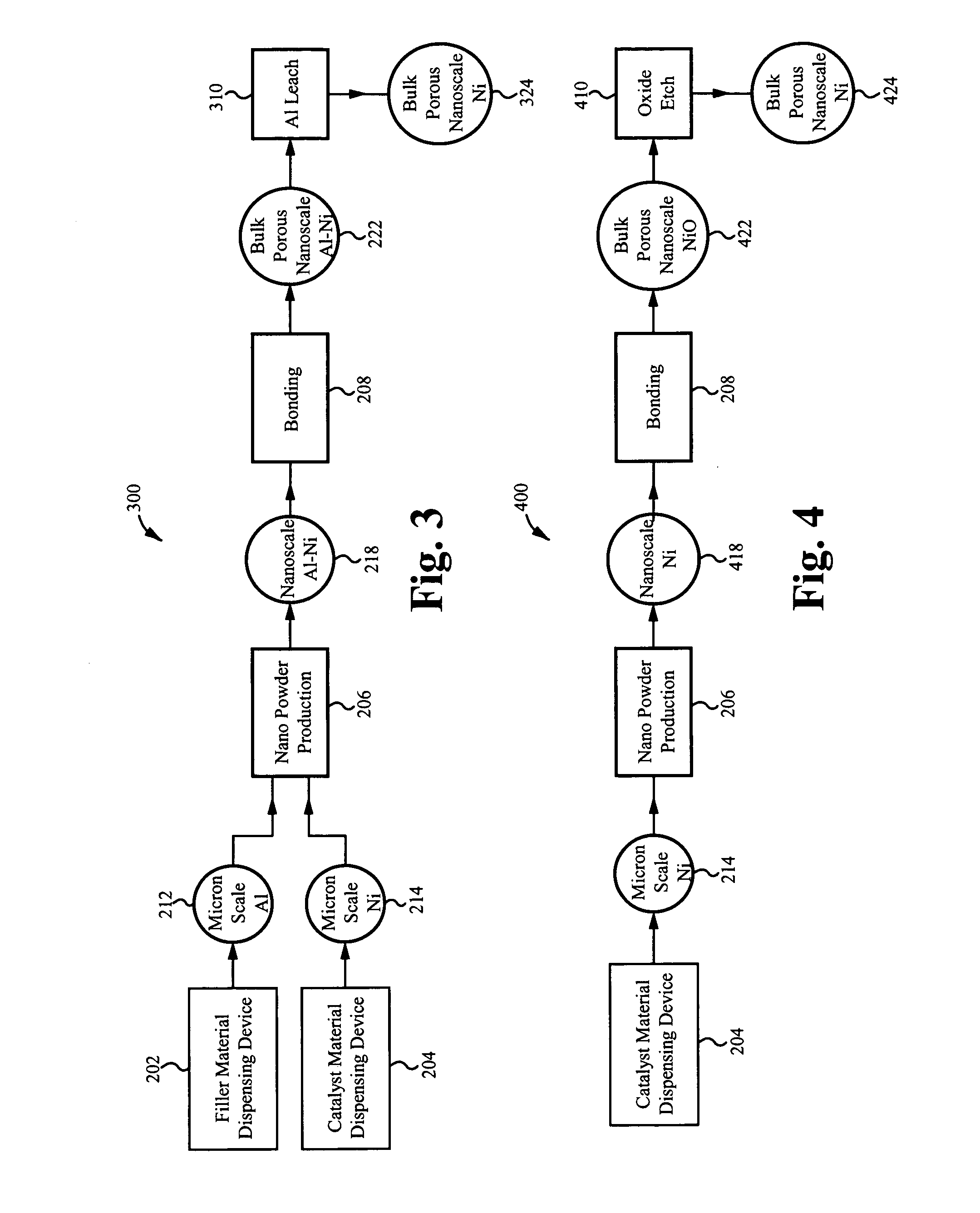

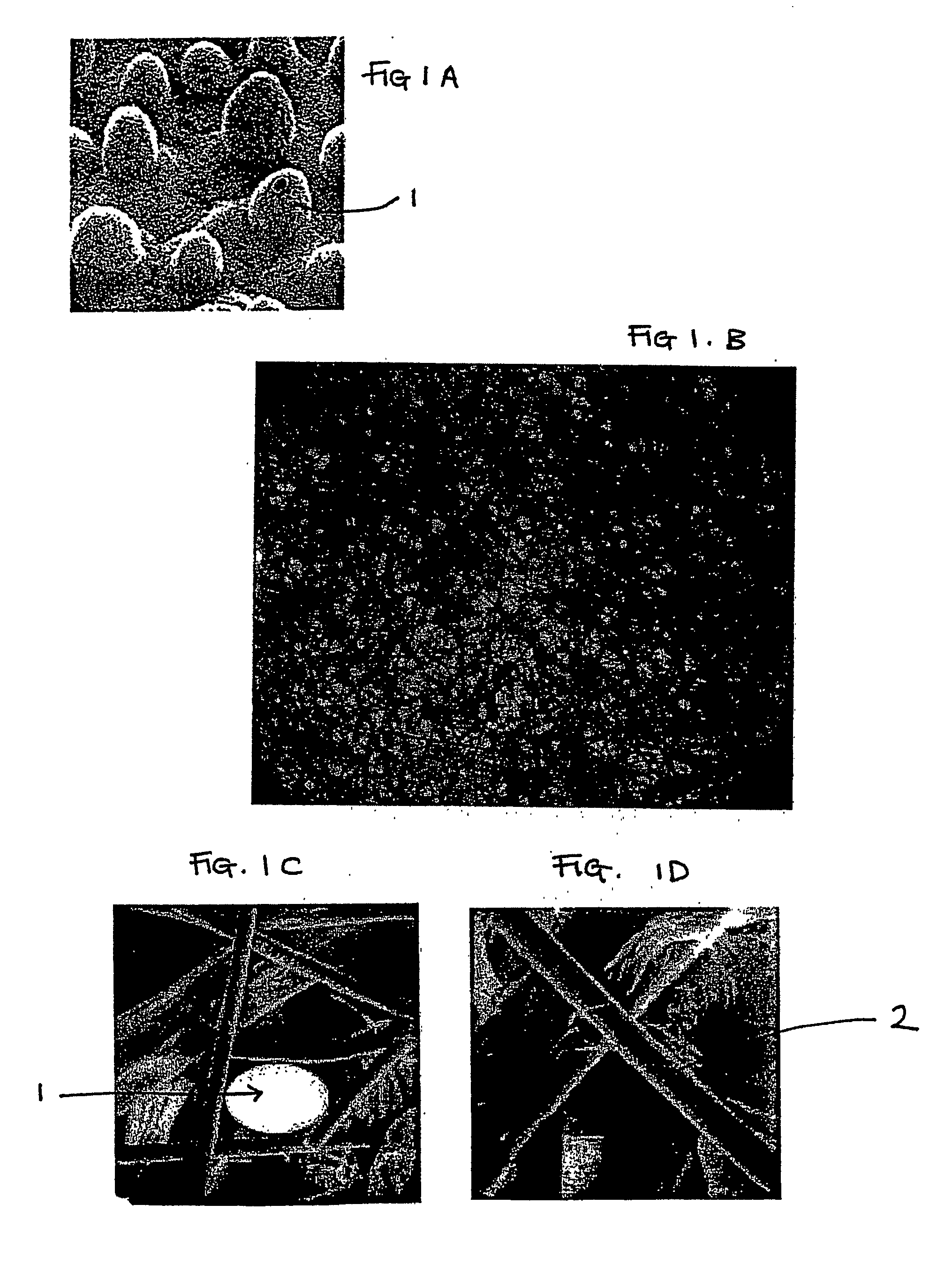

Nano-skeletal catalyst

ActiveUS20080280756A1Increase surface areaMassive costMechanical working/deformationSemiconductor/solid-state device manufacturingPolymer scienceScale structure

A method of producing a catalyst material with nano-scale structure, the method comprising: introducing a starting powder into a nano-powder production reactor, the starting powder comprising a catalyst material; the nano-powder production reactor nano-sizing the starting powder, thereby producing a nano-powder from the starting powder, the nano-powder comprising a plurality of nano-particles, each nano-particle comprising the catalyst material; and forming a catalyst precursor material from the nano-powder, wherein the catalyst precursor material is a densified bulk porous structure comprising the catalyst material, the catalyst material having a nano-scale structure.

Owner:SDC MATERIALS +1

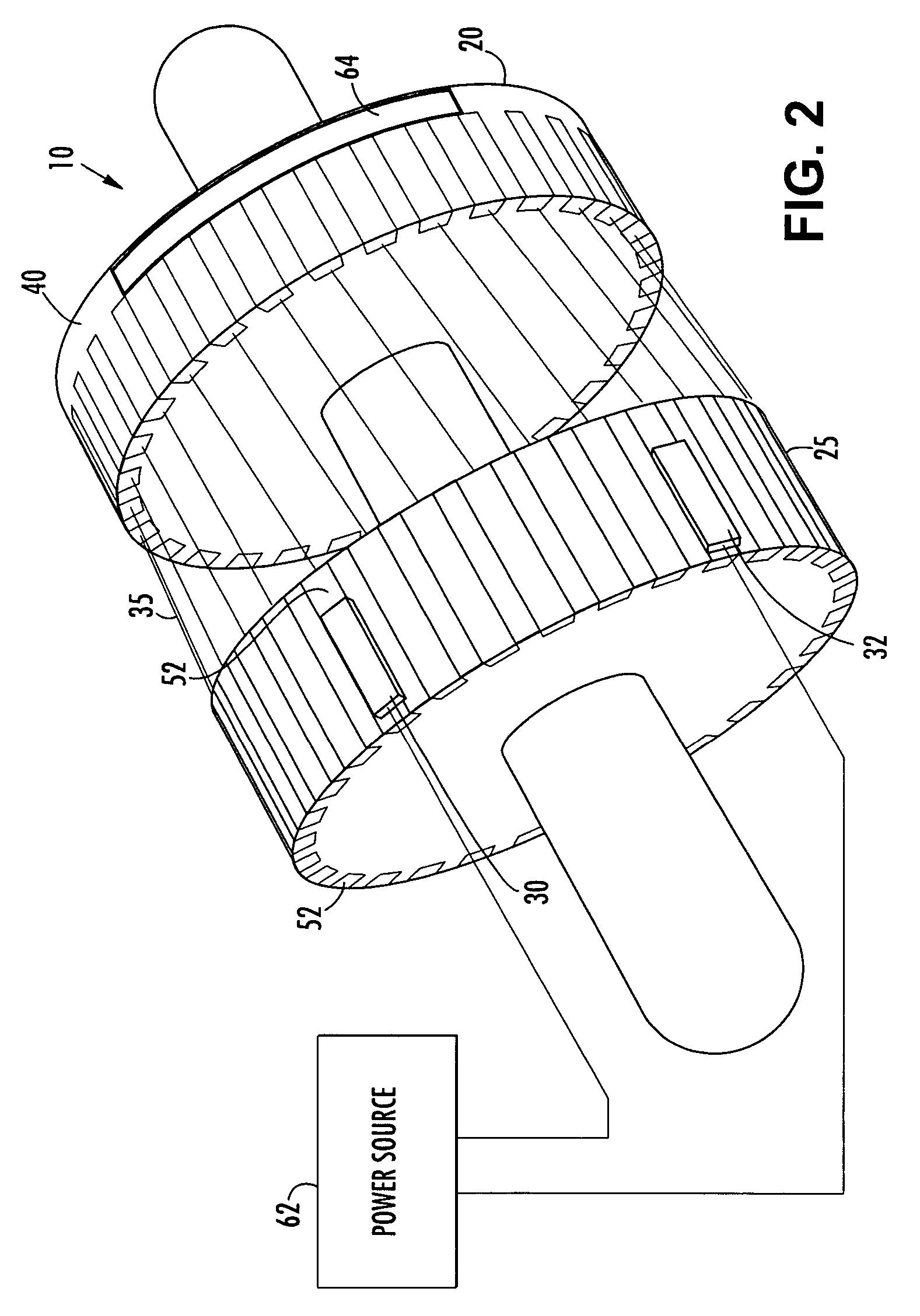

Rotary impulse sealer

ActiveUS7247219B2Increase or decrease sizeMechanical working/deformationLaminationElectrical resistance and conductanceEngineering

Owner:SEALED AIR U S

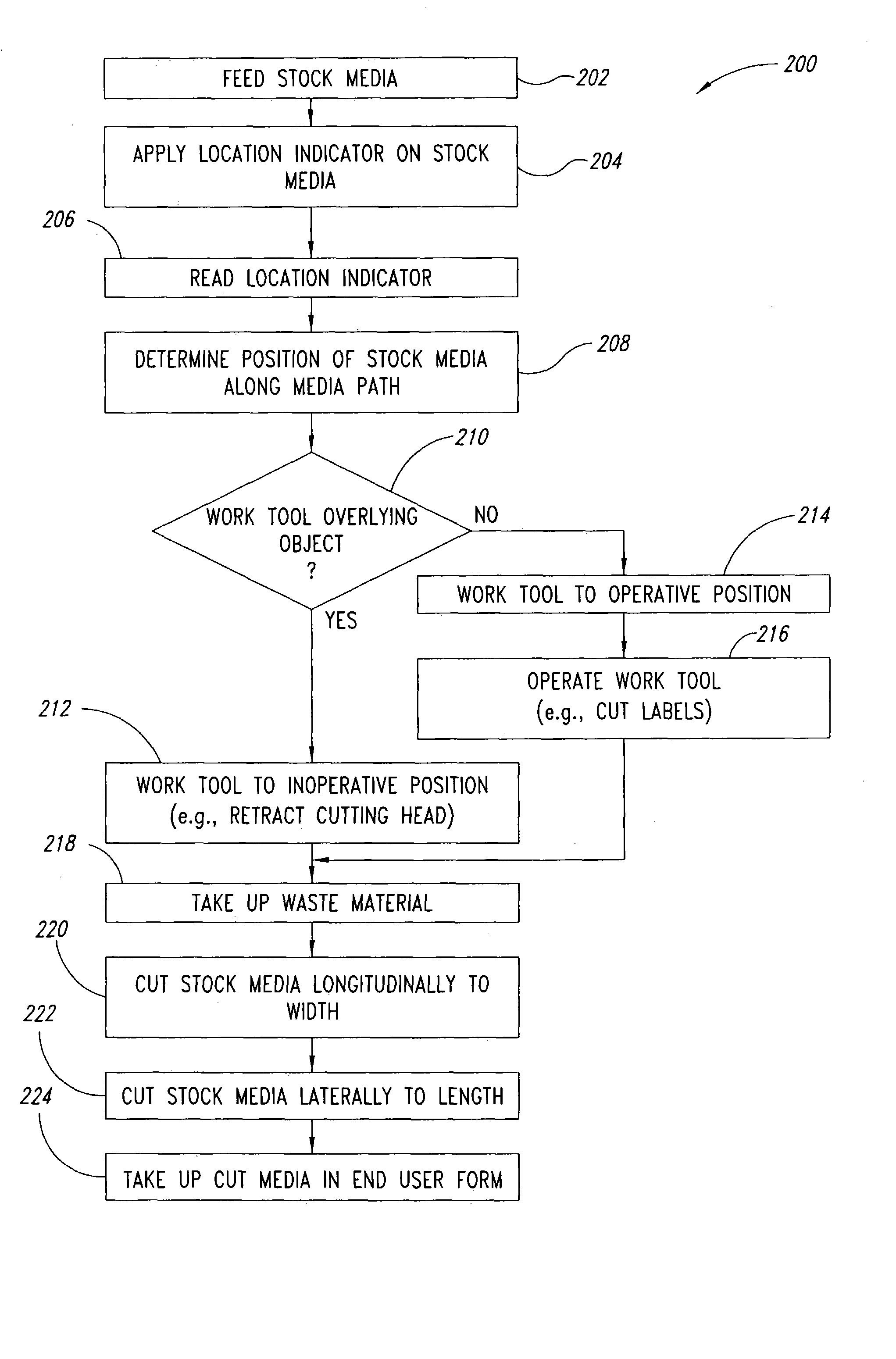

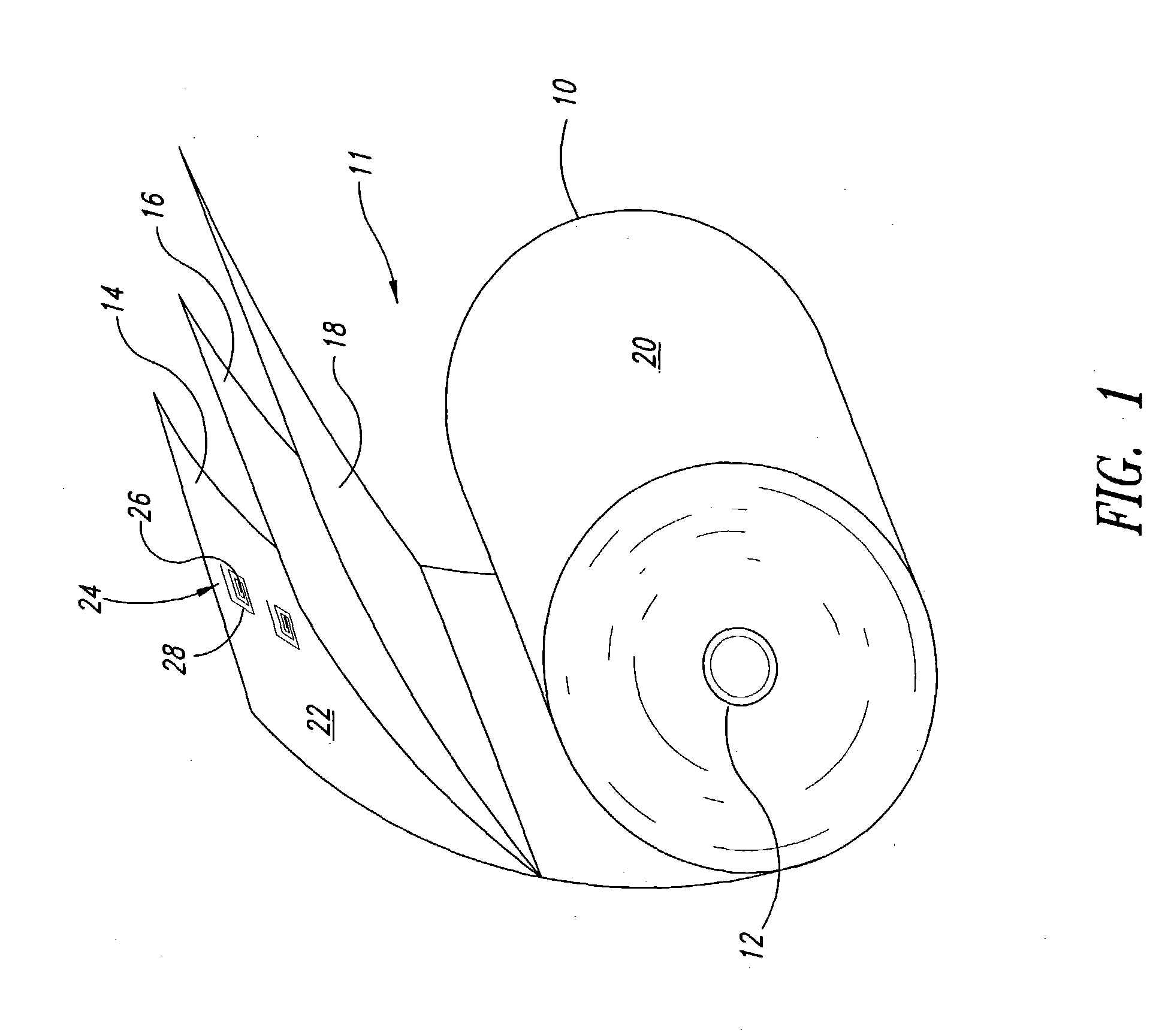

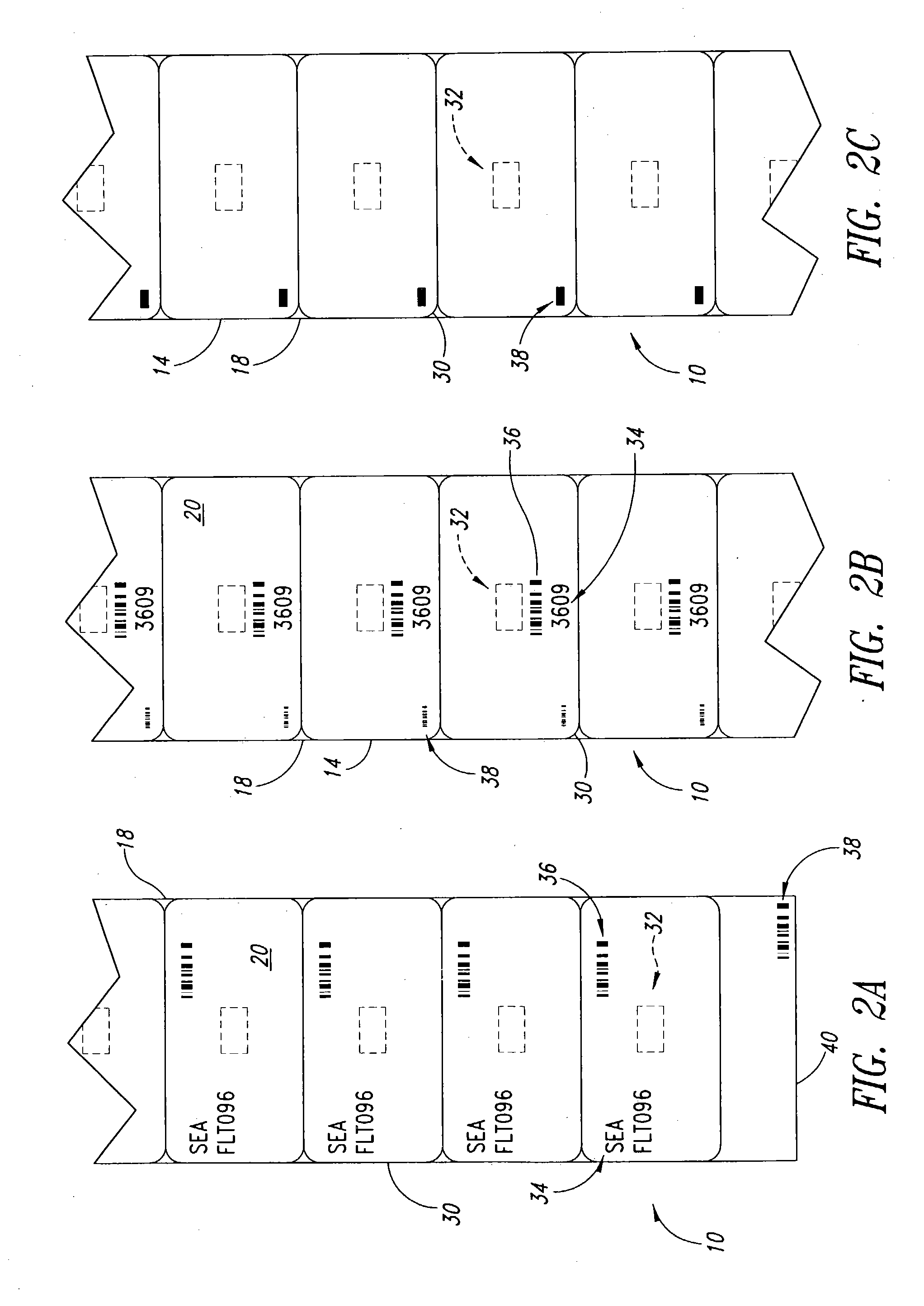

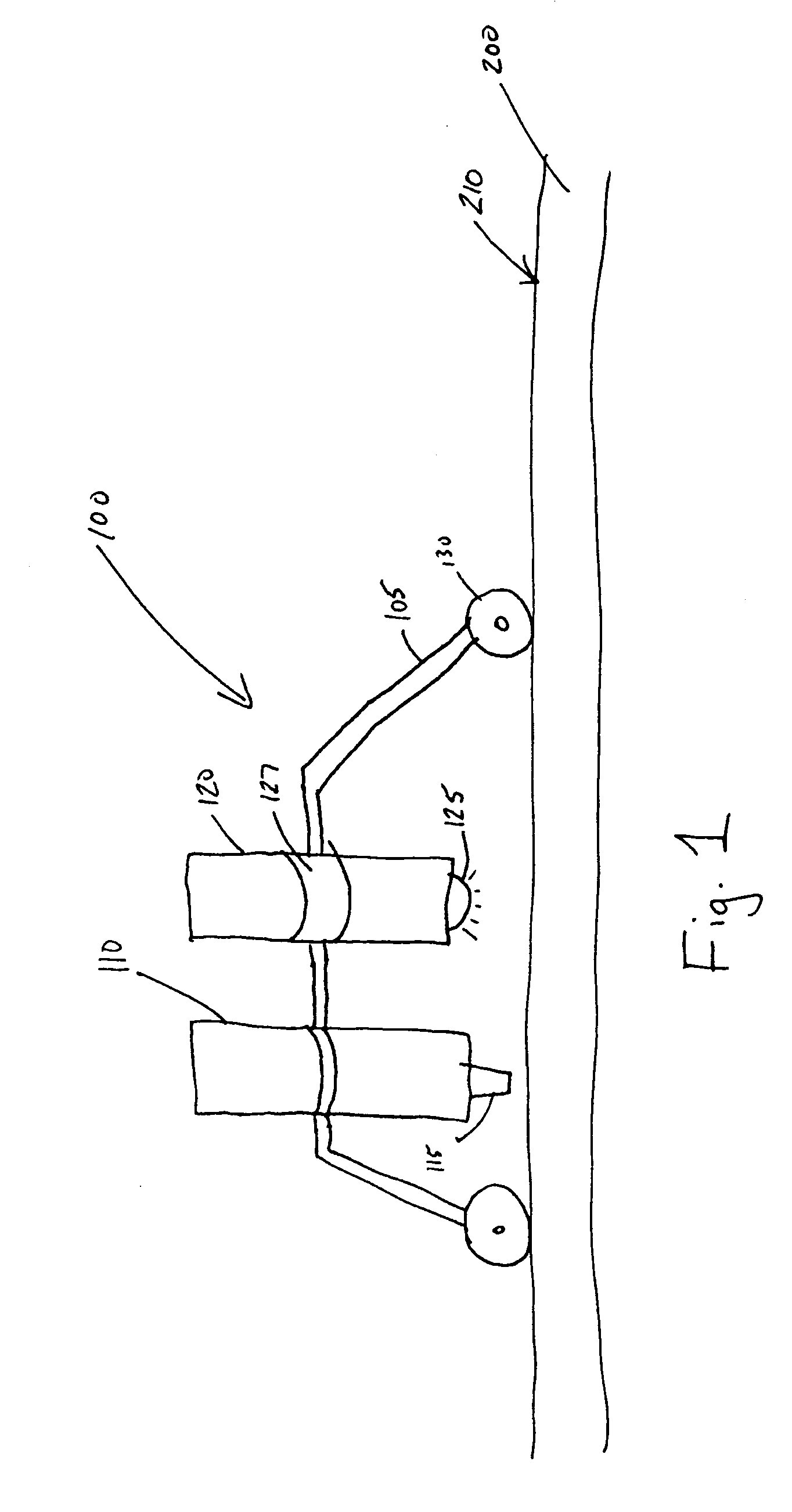

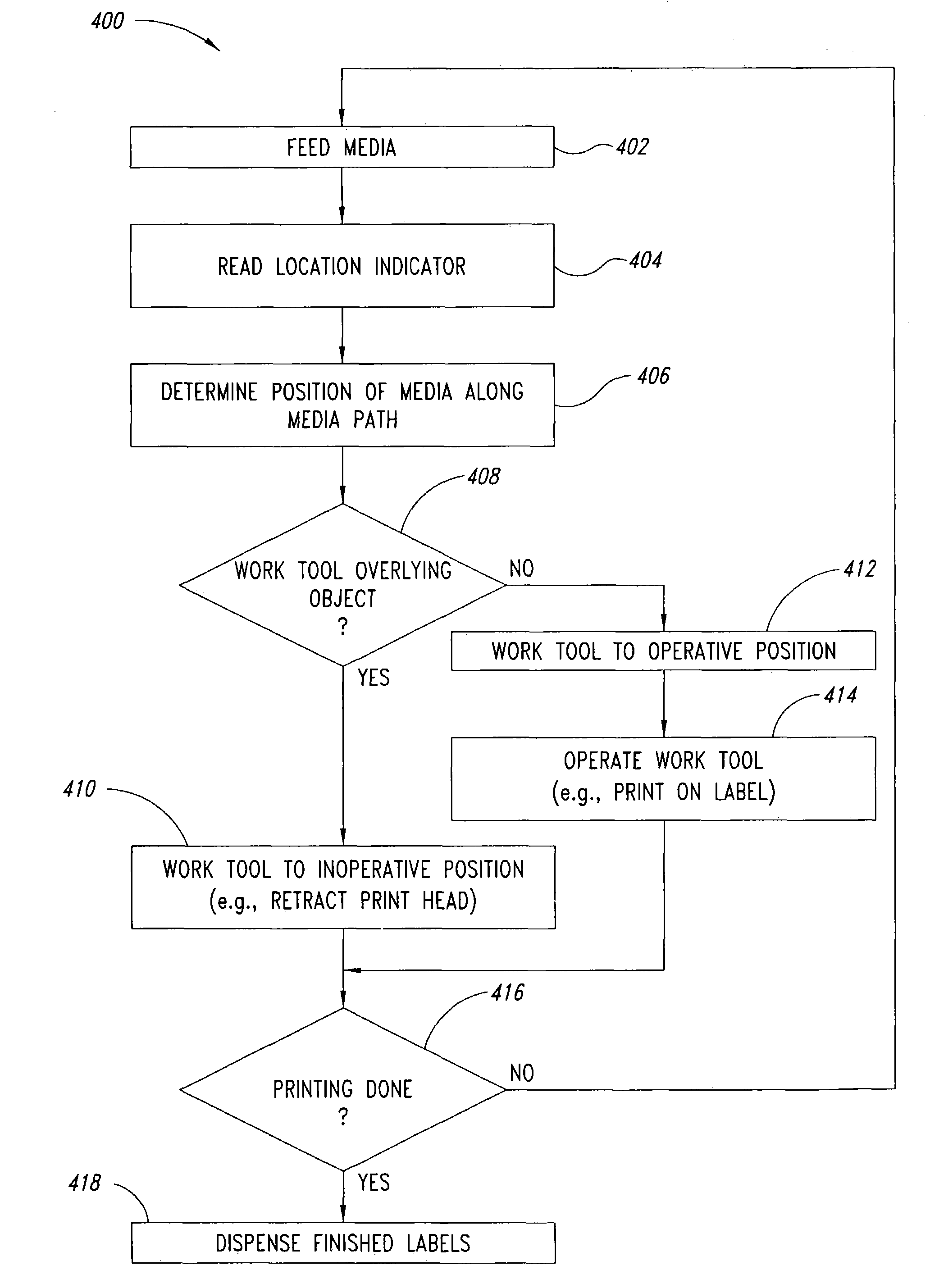

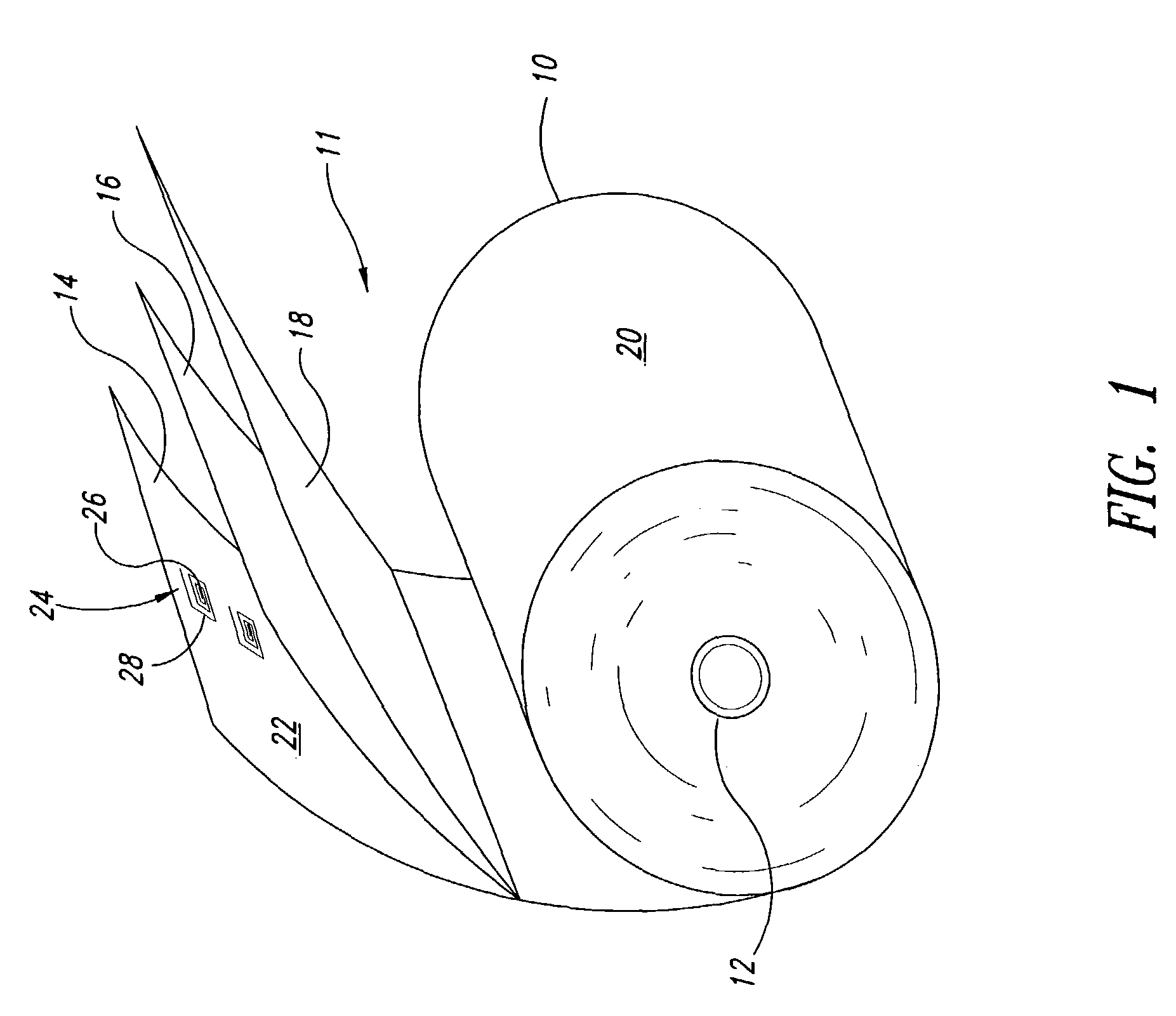

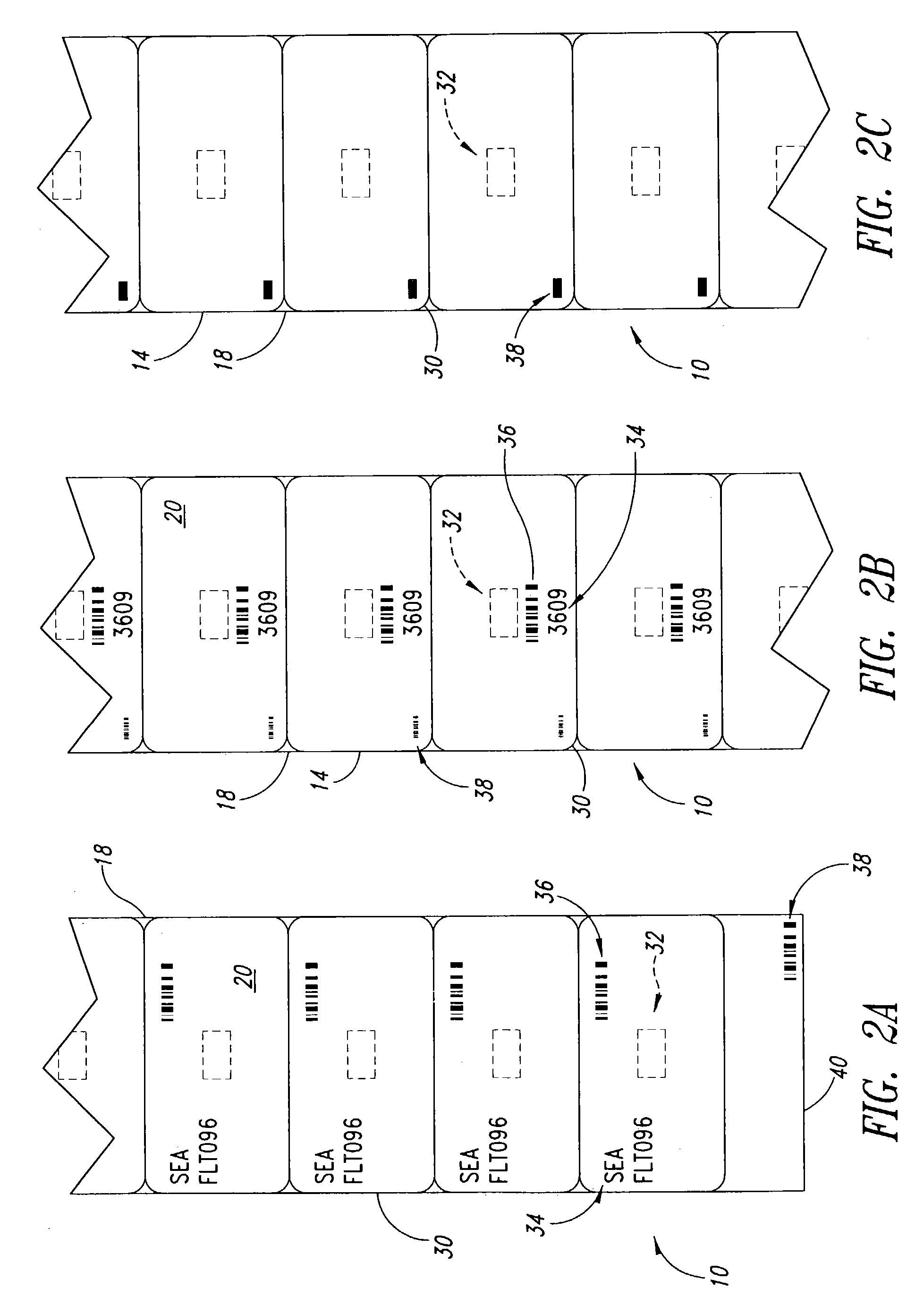

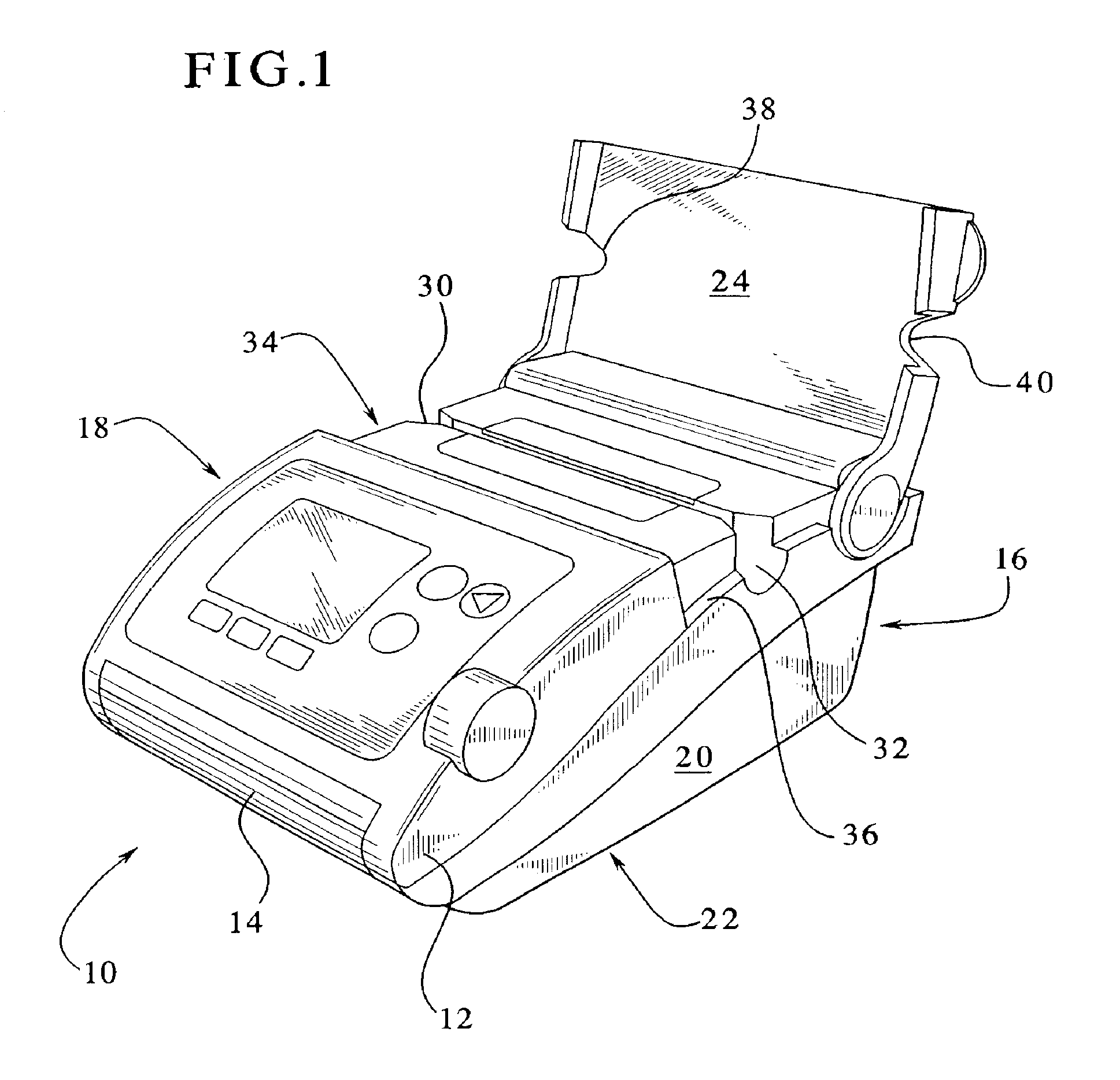

Method and apparatus for preparing media

ActiveUS20050021172A1Increase distanceReduce distanceMechanical working/deformationLamination ancillary operationsEngineeringHead parts

Work tools such as a printhead, platen, and / or cutting head are spaced normally with respect to a media path based on a location of one or more objects carried by the media, and the position of the media with respect to the work tool. Additionally or alternatively the work tools are selectively operated based on a location of one or more objects carried by the media, and the position of the media with respect to the work tool. The approaches are suitable for the manufacture and use of RFID tags and labels.

Owner:INTERMEC IP

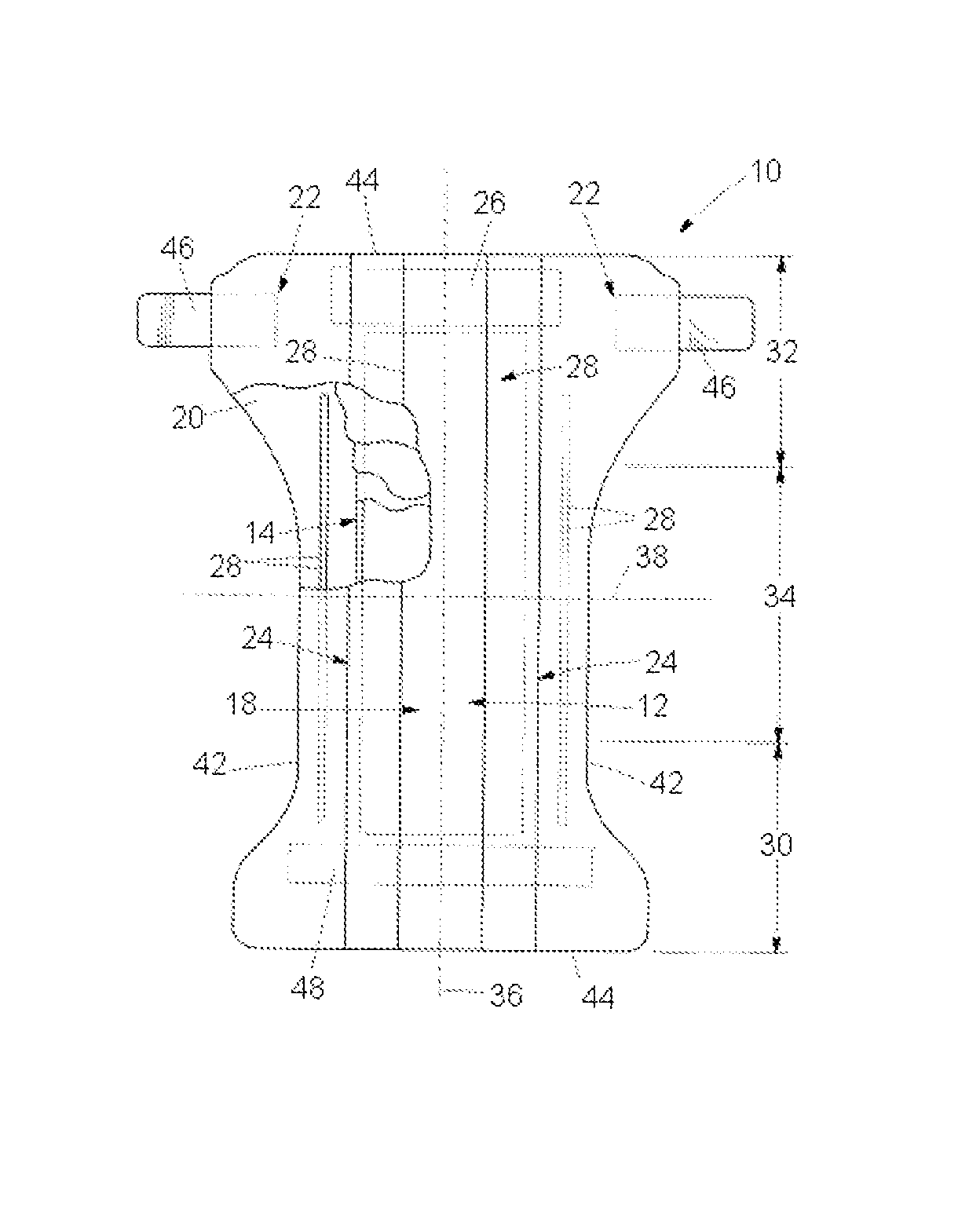

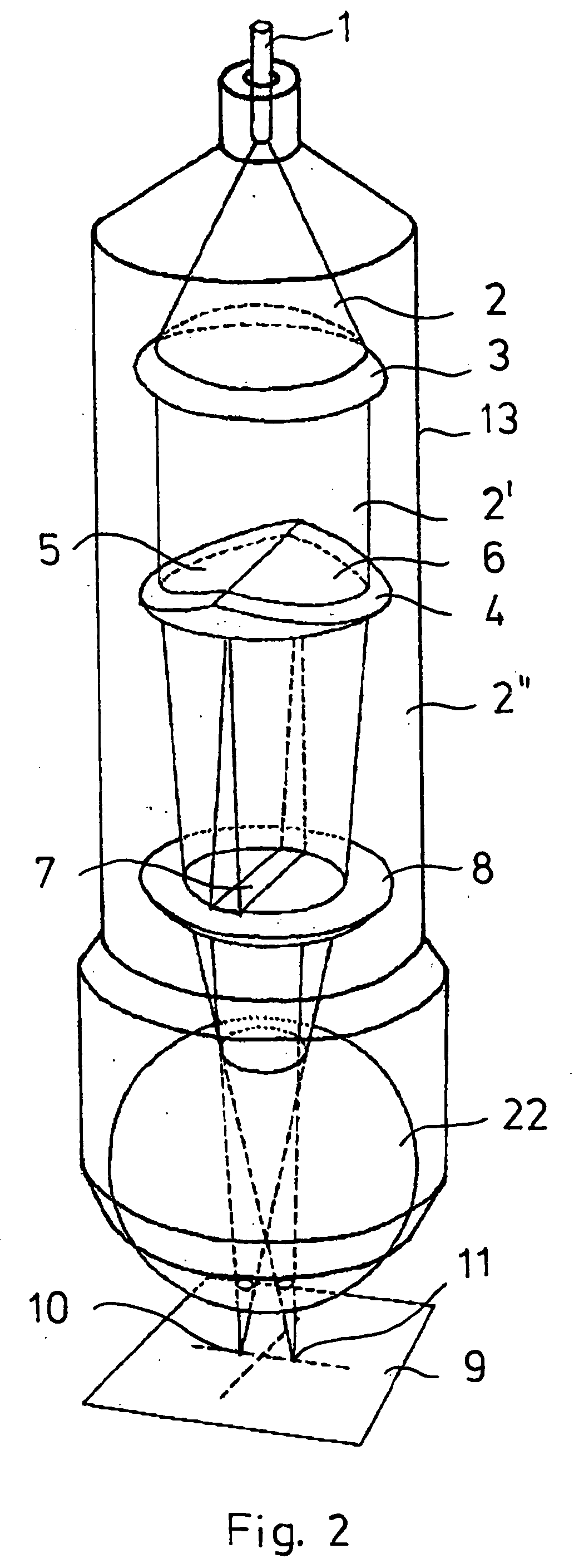

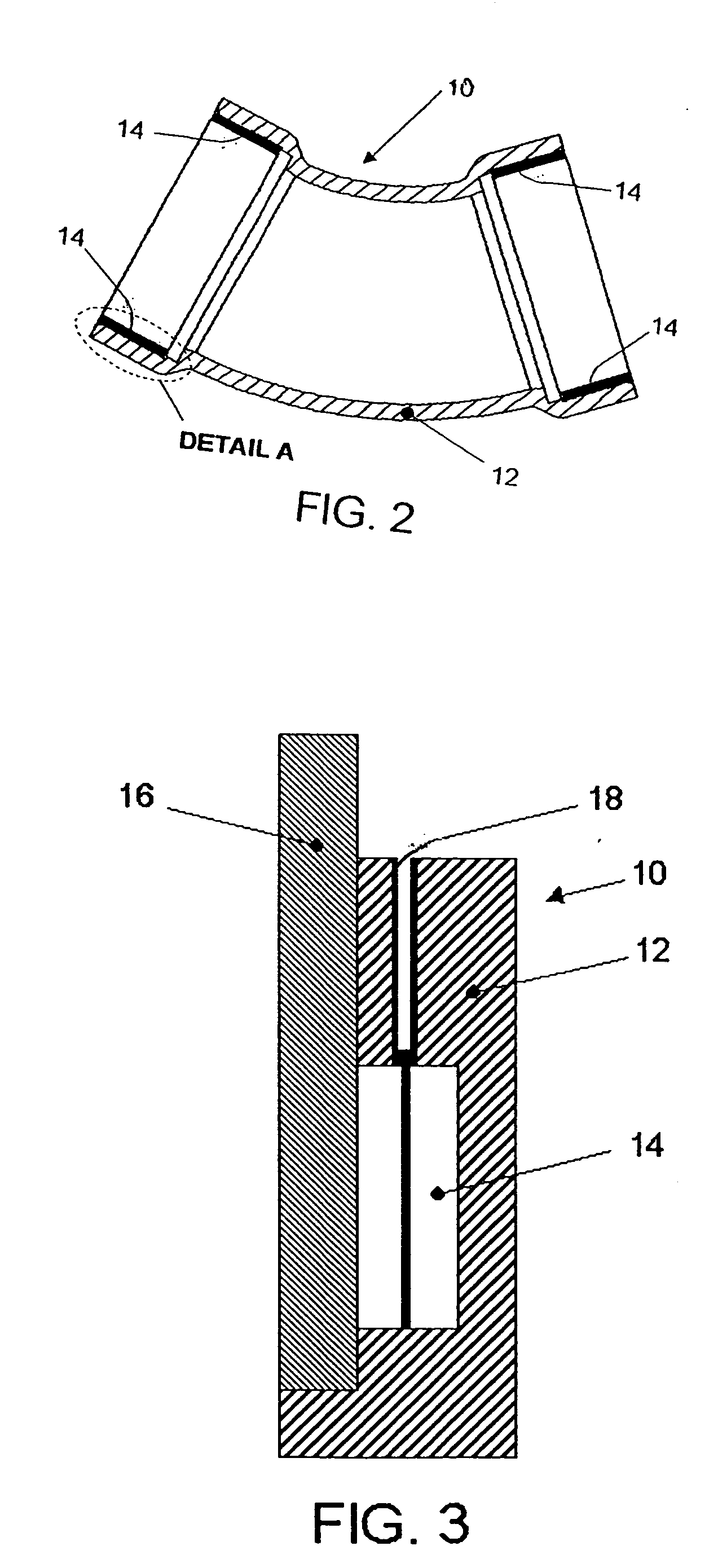

Method and apparatus for controlling and adjusting the intensity profile of a laser beam employed in a laser welder for welding polymeric and metallic components

InactiveUS20060000812A1Enhanced signalImprove signal-to-noise ratioMechanical working/deformationLamination ancillary operationsLight beamOptoelectronics

A method and apparatus is provided for forming a fusion bond between two materials such as two components of a catheter. The method begins by forming a bond site by positioning a portion of a first body with respect to a portion of a second body so that a fusion bond site is formed. A laser beam is generated that has an intensity profile across its width. The laser beam is directed onto at least a portion of the first and second bodies within the bond site so that a fusion zone having an increased temperature is formed. After the laser beam is generated, the intensity profile of the laser beam that is directed onto the bond site is controllably adjusted by an optical element such as a dynamically-adjustable beam shaping element

Owner:BOSTON SCI SCIMED INC

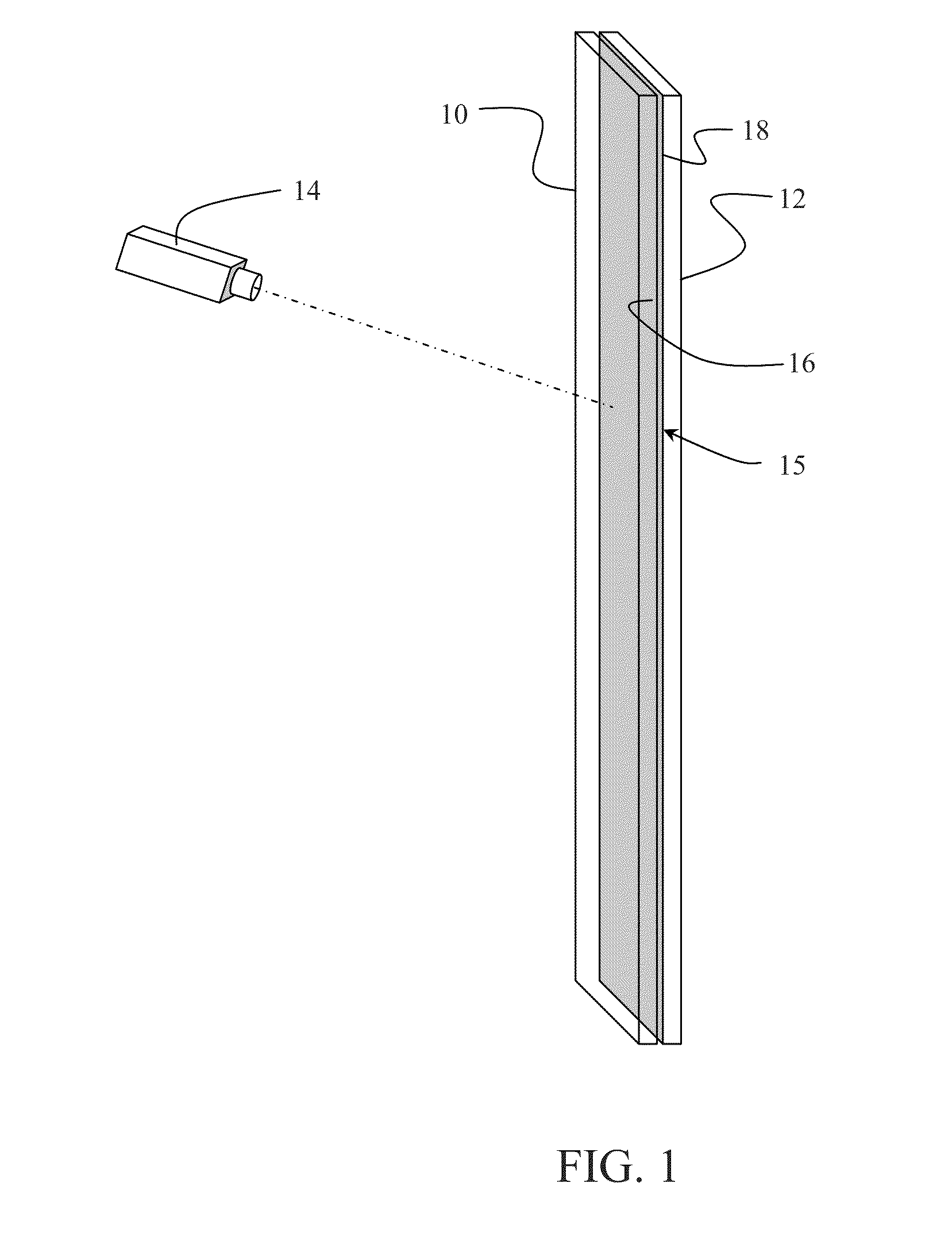

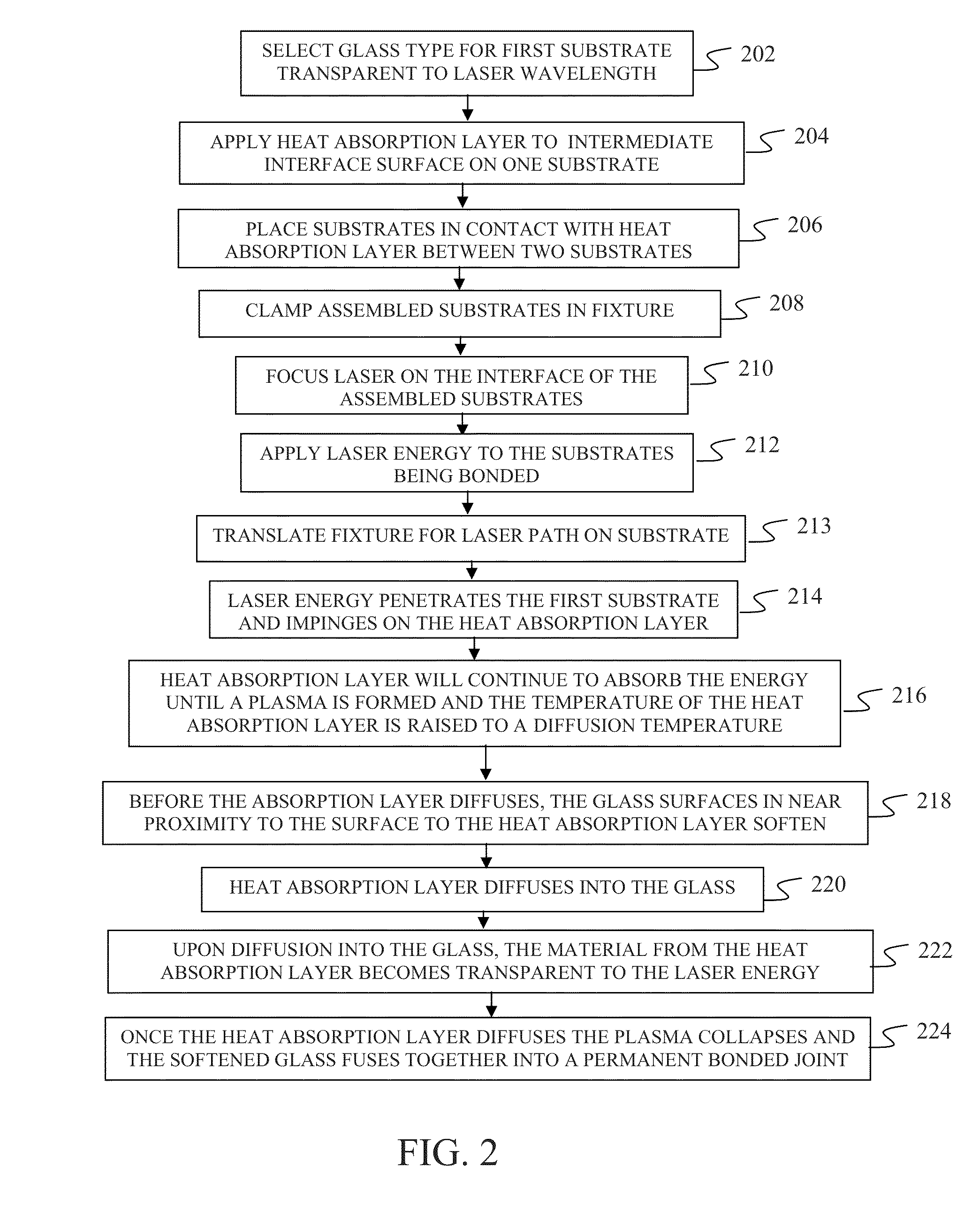

Room temperature glass-to-glass, glass-to-plastic and glass-to-ceramic/semiconductor bonding

ActiveUS20130112650A1Index may changeMechanical working/deformationWelding/cutting auxillary devicesTransmittanceRoom temperature

A process for room temperature substrate bonding employs a first substrate substantially transparent to a laser wavelength is selected. A second substrate for mating at an interface with the first substrate is then selected. A transmissivity change at the interface is created and the first and second substrates are mated at the interface. The first substrate is then irradiated with a laser of the transparency wavelength substantially focused at the interface and a localized high temperature at the interface from energy supplied by the laser is created. The first and second substrates immediately adjacent the interface are softened with diffusion across the interface to fuse the substrates.

Owner:CORNING INC

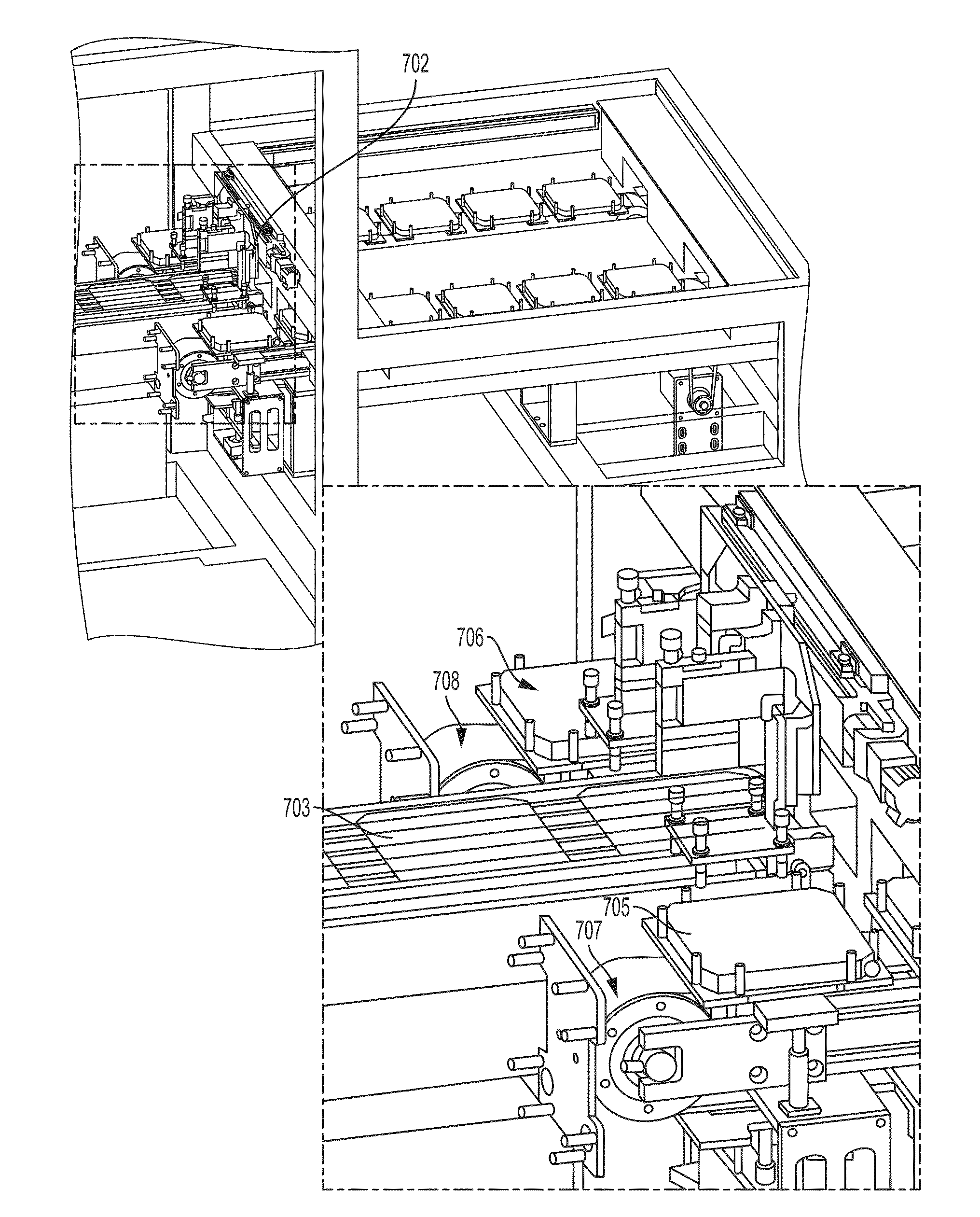

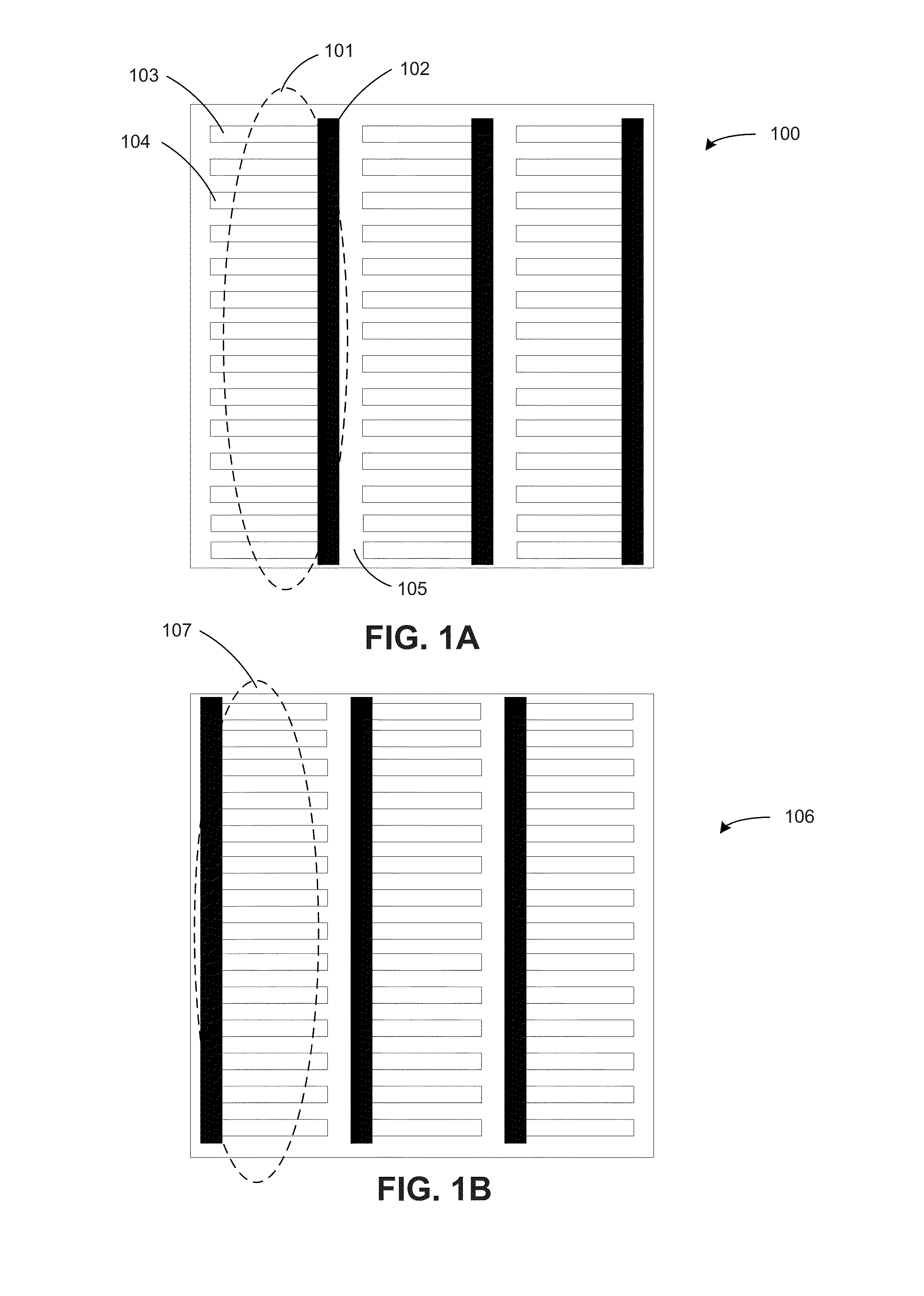

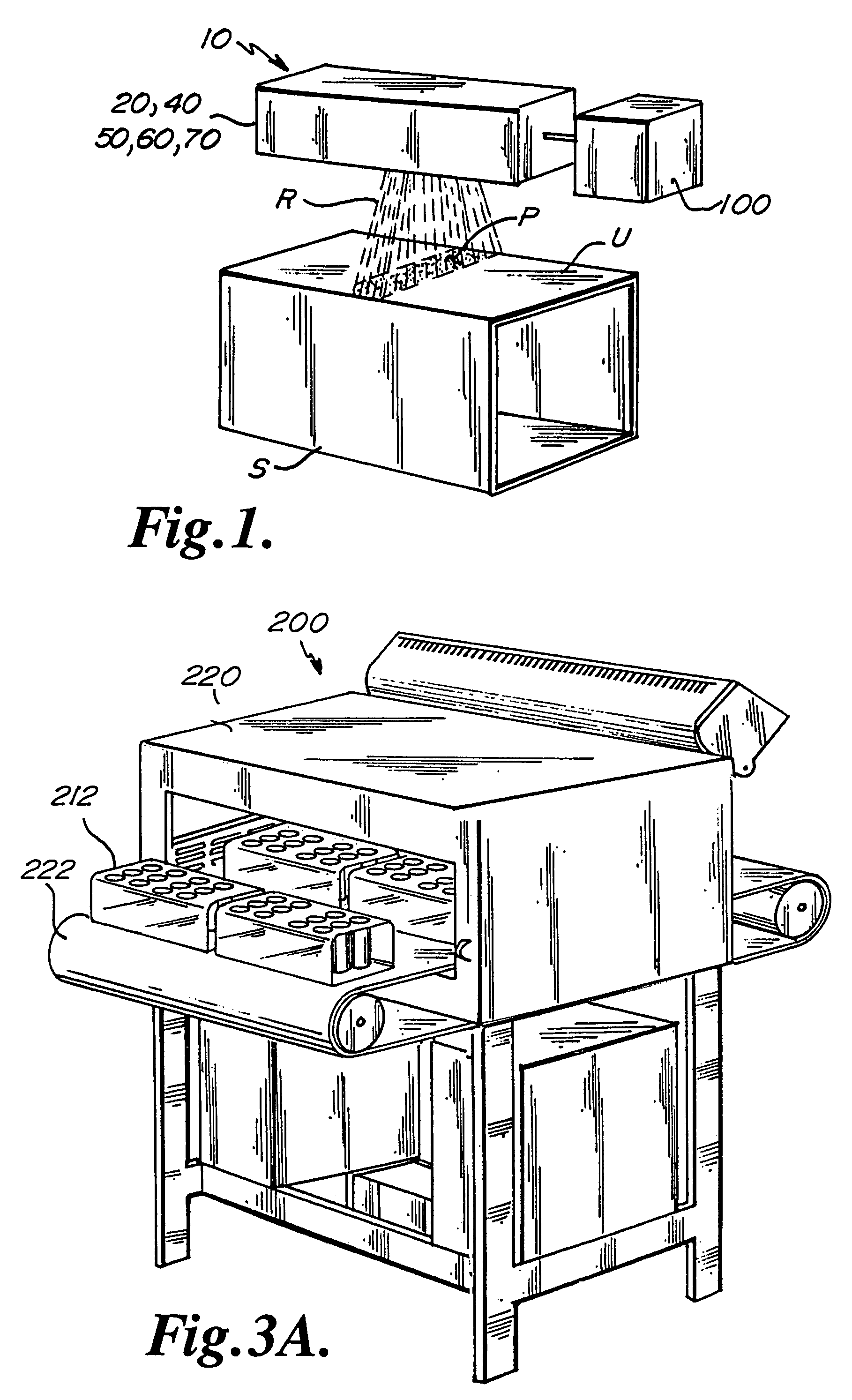

Systems, methods and apparatus for precision automation of manufacturing solar panels

Systems and methods for manufacturing solar panels are disclosed. Solar cells are placed on a conveyor that transports the cells from a start point to an end point. A laser scribing module scribes the cells at a predetermined depth. A paste dispensing module deposits a predetermined amount of conductive paste on the surface of the solar cells. A cleaving apparatus divides the cells into smaller strips. A shingling module creates a string of cells by overlapping the strips. A targeted annealing module cures the paste, and a layup module places the strings on a backsheet. A glass cover is then added to one side of the strings.

Owner:TESLA INC

Conductive adhesive bonding

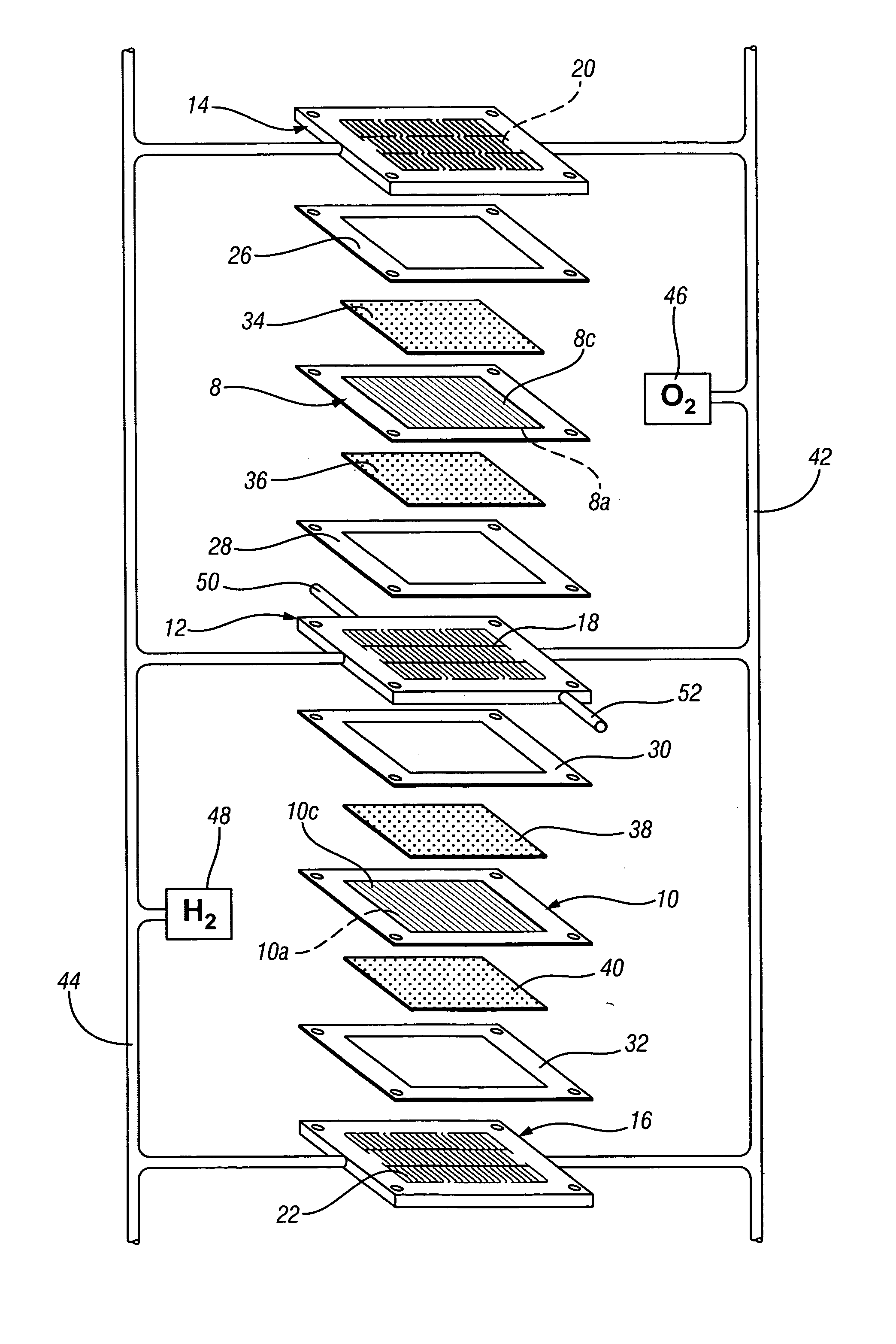

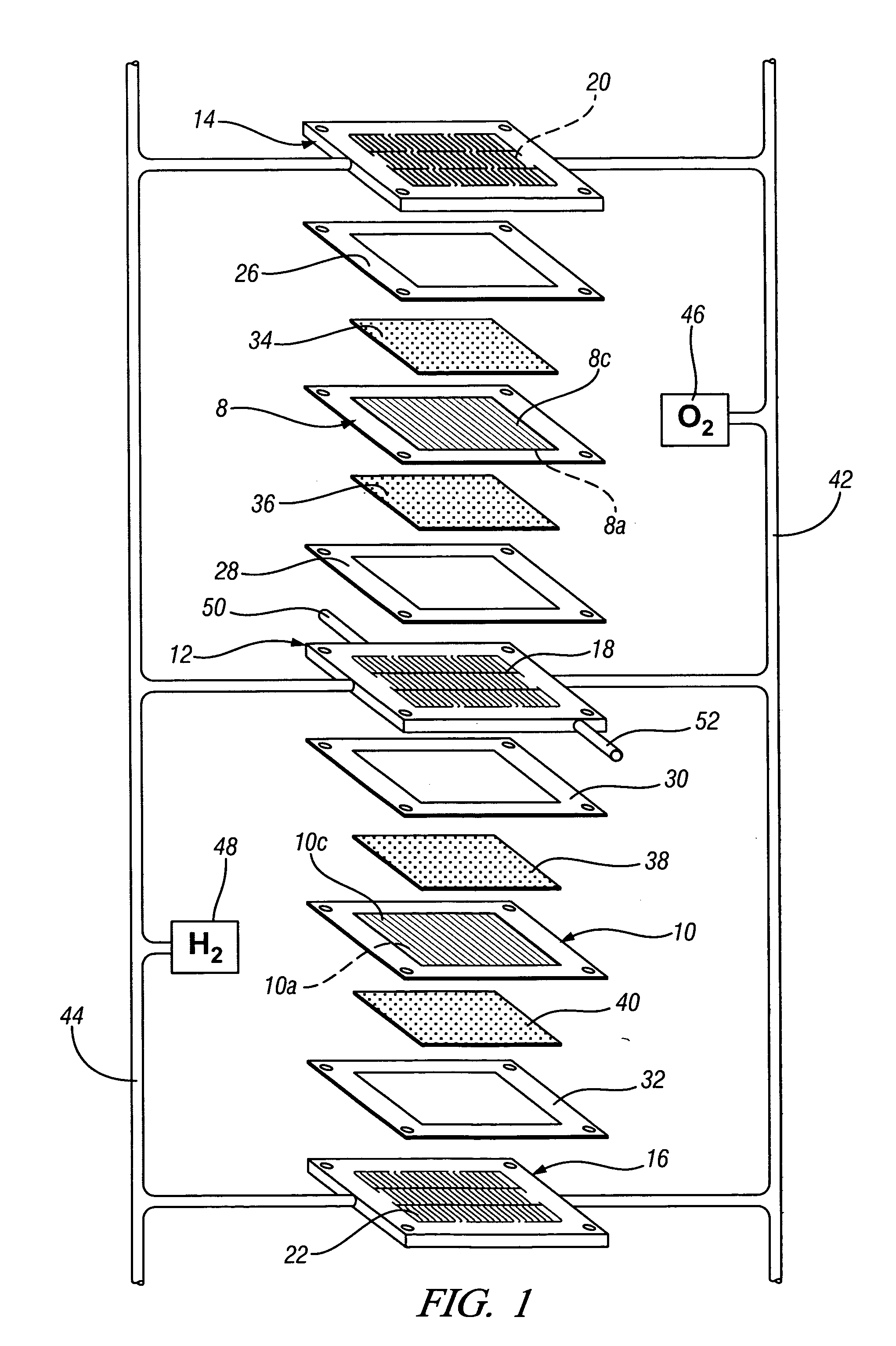

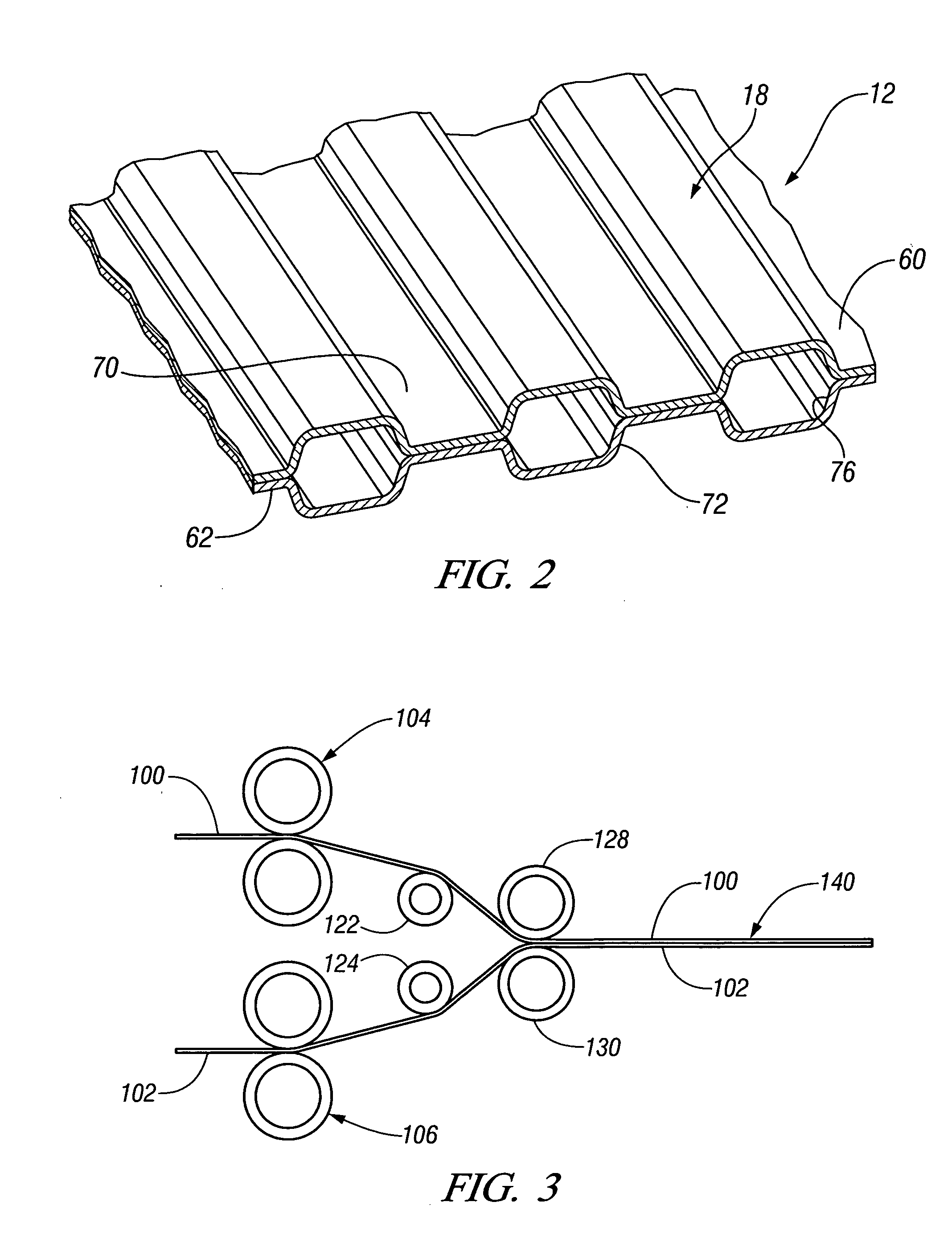

InactiveUS20060060296A1Reduce resistanceMechanical working/deformationLamination ancillary operationsSurface reactionFuel cells

Electrically conductive workpieces with facing surfaces are bonded with an adhesive that is filled with conductive metal particles that are reactive with the surfaces of the workpieces. In the bonding process the surfaces are coated with the adhesive, pressed together and an electric current passed between them to momentarily melt the conductive particles. The molten droplets agglomerate and wet the facing surfaces. When the molten clusters re-solidify, electrically conductive paths are formed between the workpieces. For example, the practice is useful for bonding ferrous-based or aluminum-based alloy sheets, strips or plates in making products such as bipolar plates for fuel cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

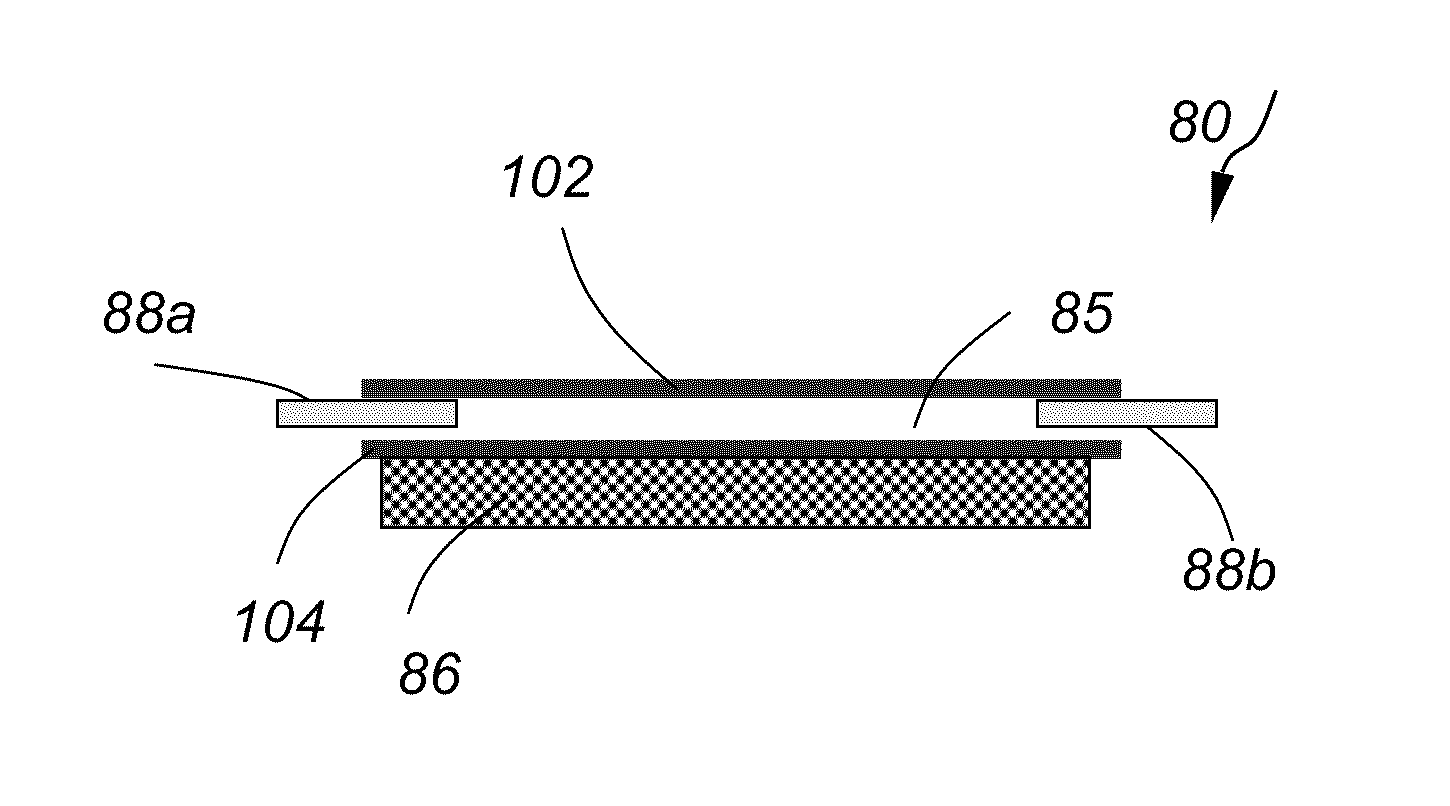

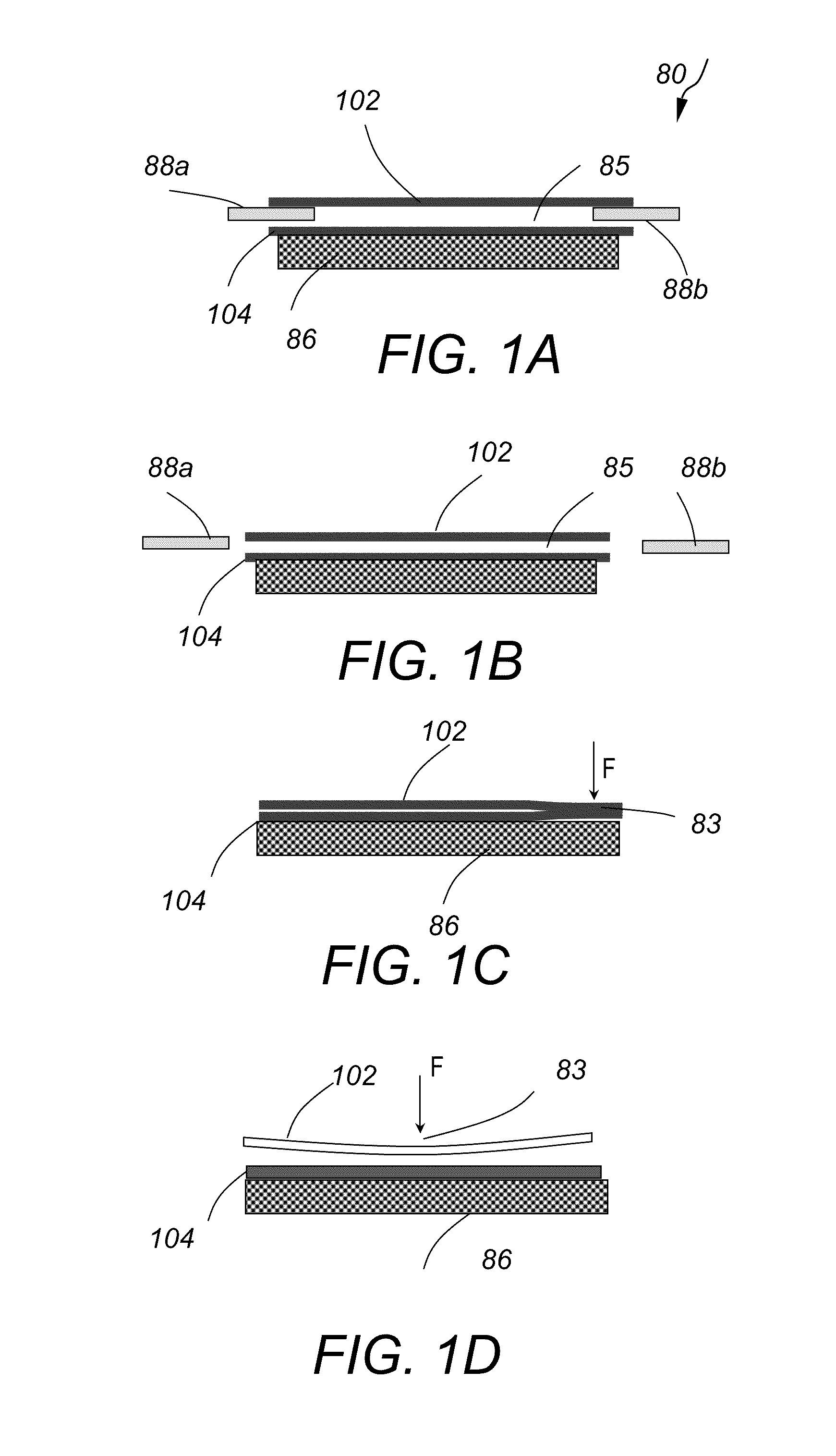

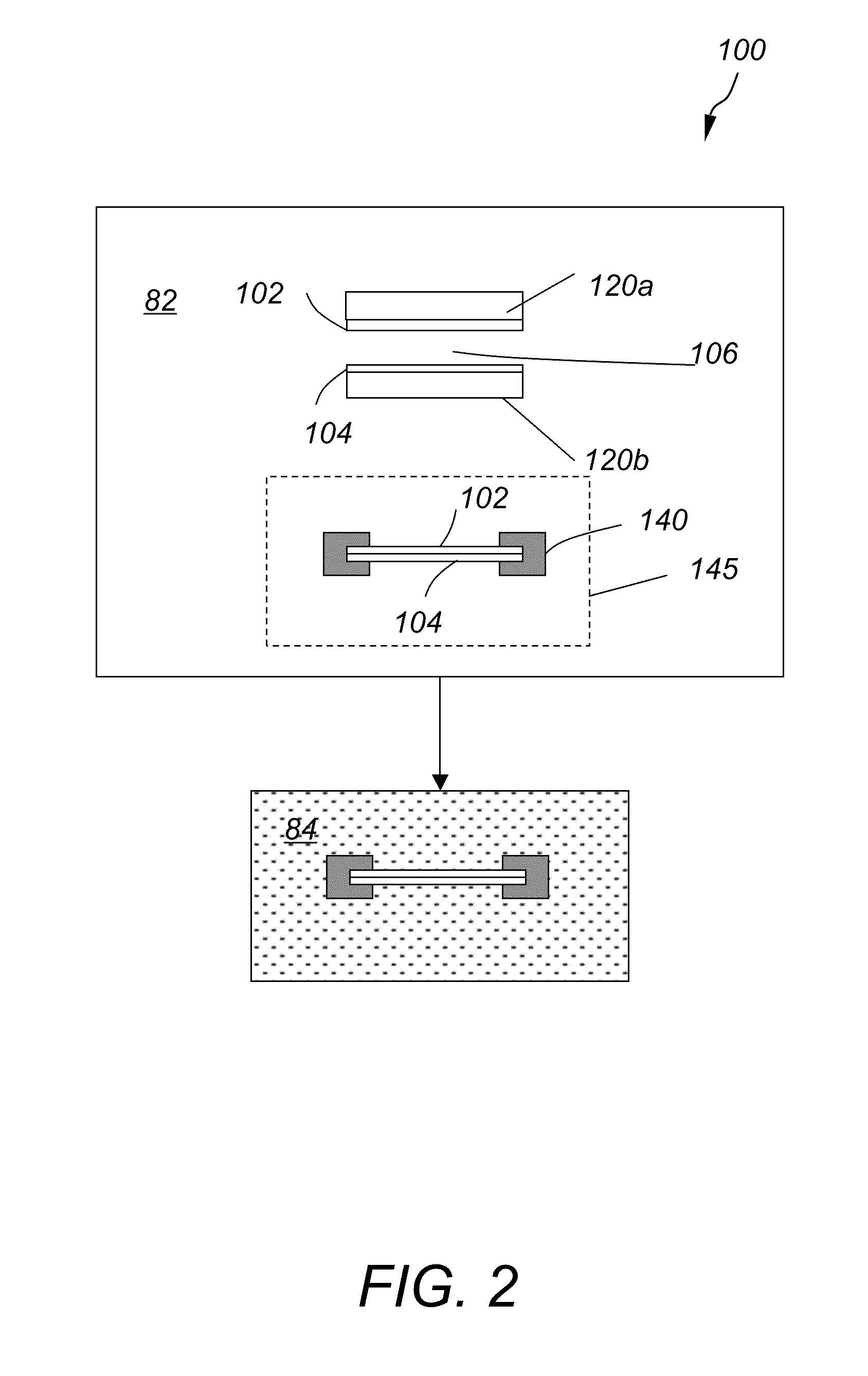

Method and apparatus for wafer bonding with enhanced wafer mating

ActiveUS20100122762A1Reduce pressureAccuracy in alignmentPrinted circuit assemblingMechanical working/deformationWafer dicingEngineering

An improved wafer-to-wafer bonding method includes aligning an upper and a lower wafer and initiating a bond at a single point by applying pressure to a single point of the upper wafer via the flow of pressurized gas through a port terminating at the single point. The bond-front propagates radially across the aligned oppositely oriented wafer surfaces at a set radial velocity rate bringing the two wafer surfaces into full atomic contact by controlling the gas pressure and / or controlling the velocity of the motion of the lower wafer up toward the upper wafer.

Owner:SUSS MICRO TEC LITHOGRAPHY

Ultrasonic sealer

InactiveUS6605178B1Increase powerUniform sealing effectMechanical working/deformationPiezoelectric/electrostriction/magnetostriction machinesWavelengthUltrasound

An ultrasonic sealing apparatus comprises at least one horn having an elongated sealing face for sealing a packing material. Plural converters are erected on a side of the horn opposite to the sealing face for resonating the horn with a vibrating frequency. The ultrasonic sealing apparatus has a length that is one wavelength of the vibrating frequency and is fixed in position to a sealing jaw at a nodal plane of the vibrating frequency.

Owner:SHIKOKU KAKOOKI CO LTD

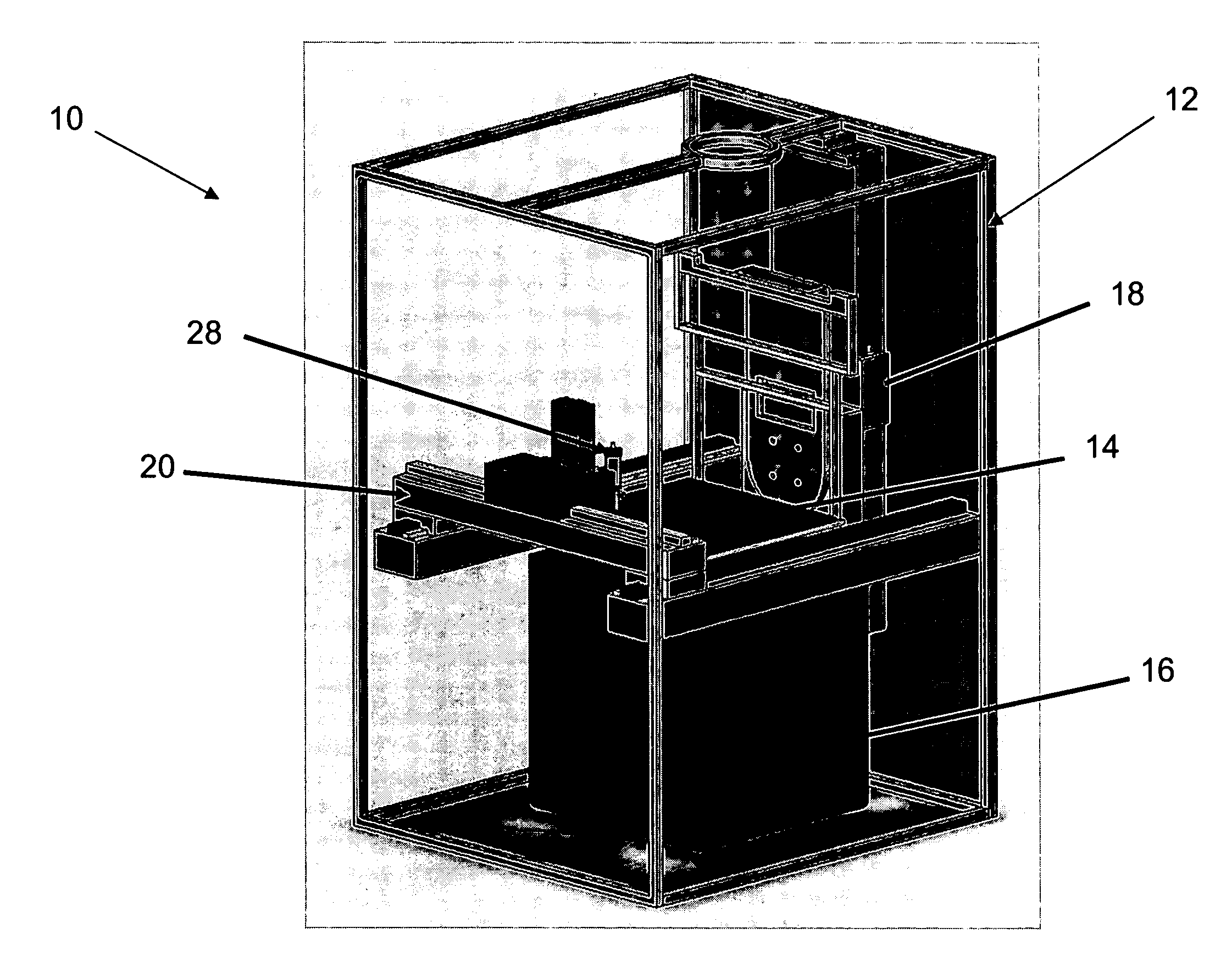

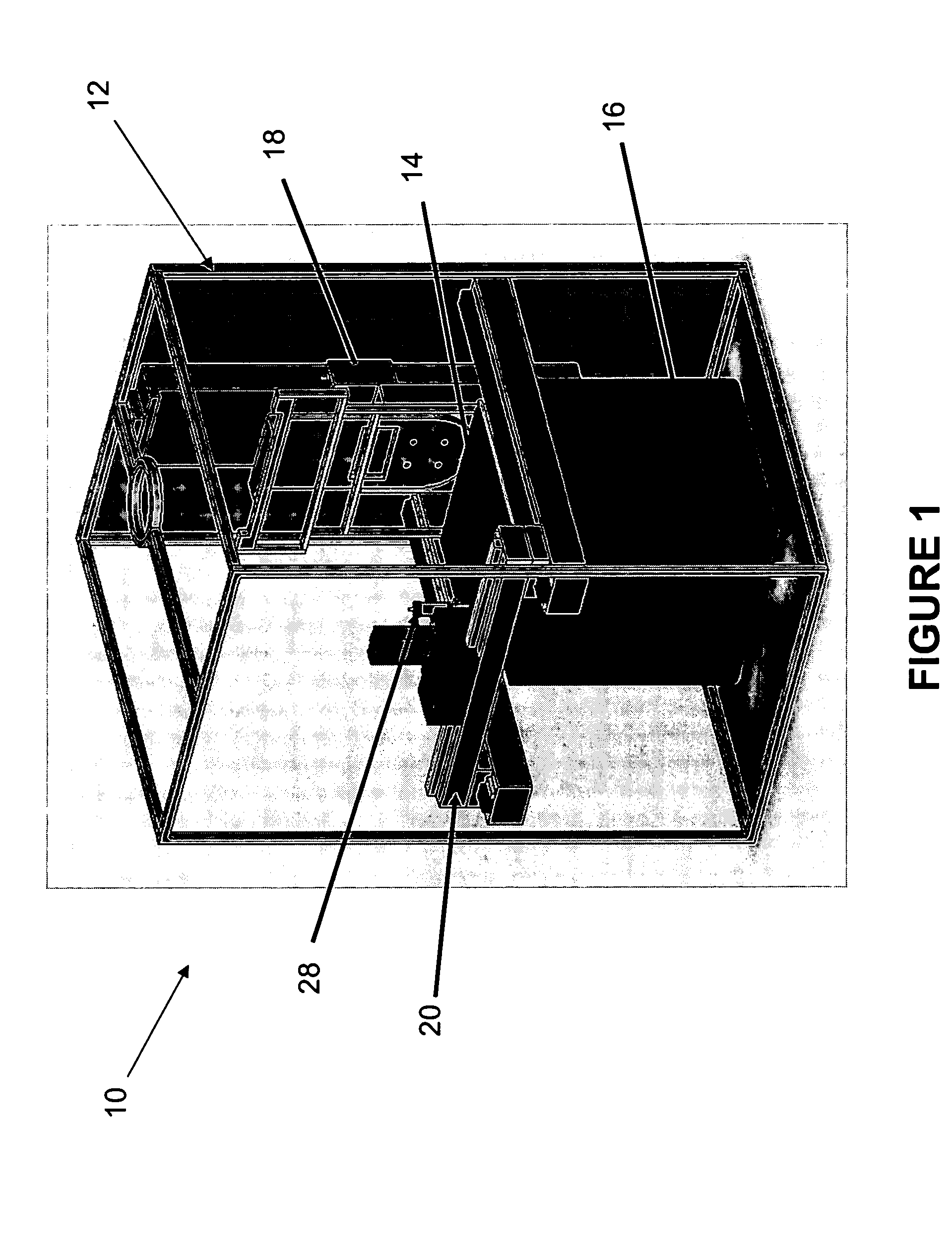

Methods and systems for integrating fluid dispensing technology with stereolithography

InactiveUS20060225834A1Increased micro-fabricationEfficient and effectiveAdhesive processesMechanical working/deformationMulti materialLaser sensor

An integrated system and method of integrating fluid dispensing technologies (e.g., direct-write (DW)) with rapid prototyping (RP) technologies (e.g., stereolithography (SL)) without part registration comprising: an SL apparatus and a fluid dispensing apparatus further comprising a translation mechanism adapted to translate the fluid dispensing apparatus along the Z-, Y- and Z-axes. The fluid dispensing apparatus comprises: a pressurized fluid container; a valve mechanism adapted to control the flow of fluid from the pressurized fluid container; and a dispensing nozzle adapted to deposit the fluid in a desired location. To aid in calibration, the integrated system includes a laser sensor and a mechanical switch. The method further comprises building a second part layer on top of the fluid deposits and optionally accommodating multi-layered circuitry by incorporating a connector trace. Thus, the present invention is capable of efficiently building single and multi-material SL fabricated parts embedded with complex three-dimensional circuitry using DW.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

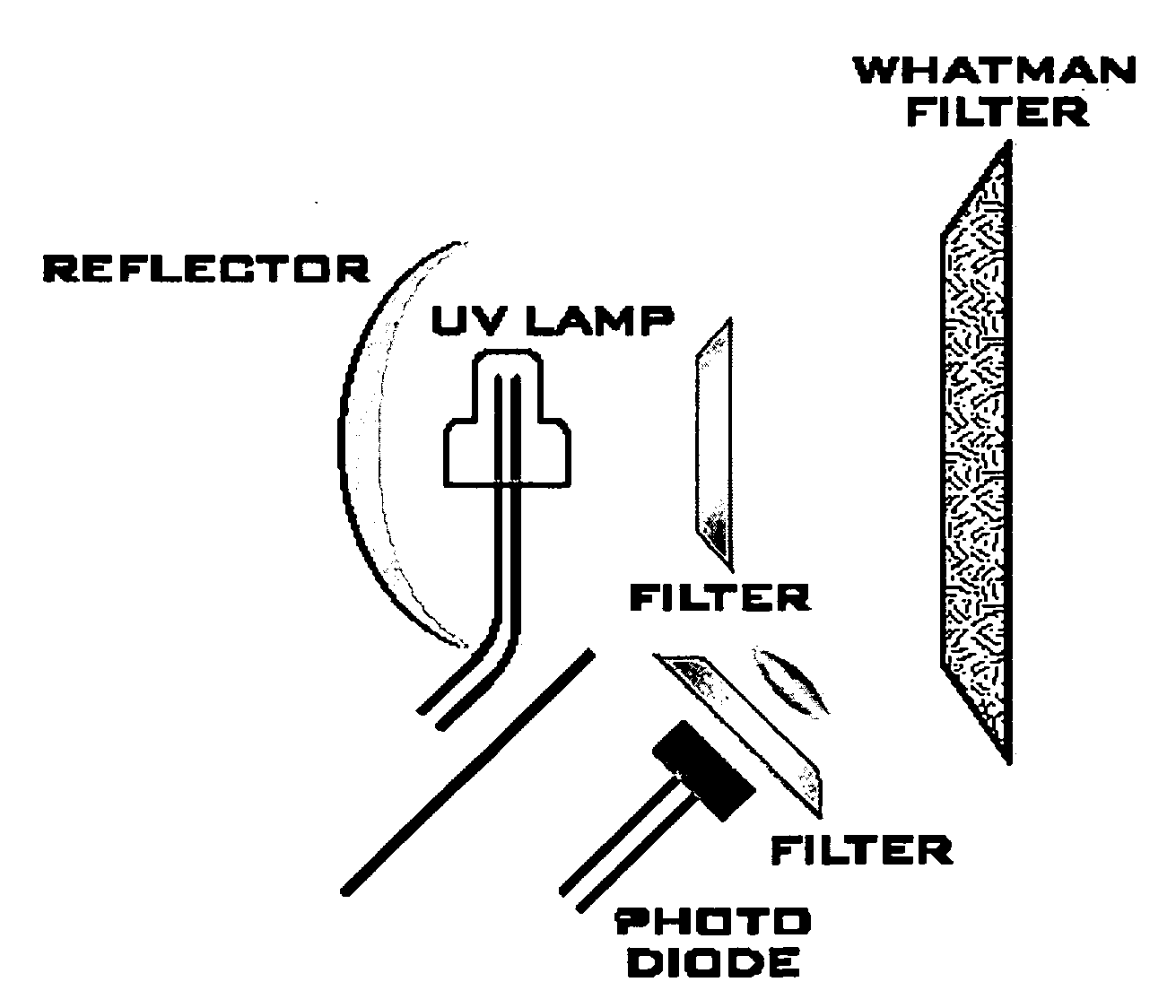

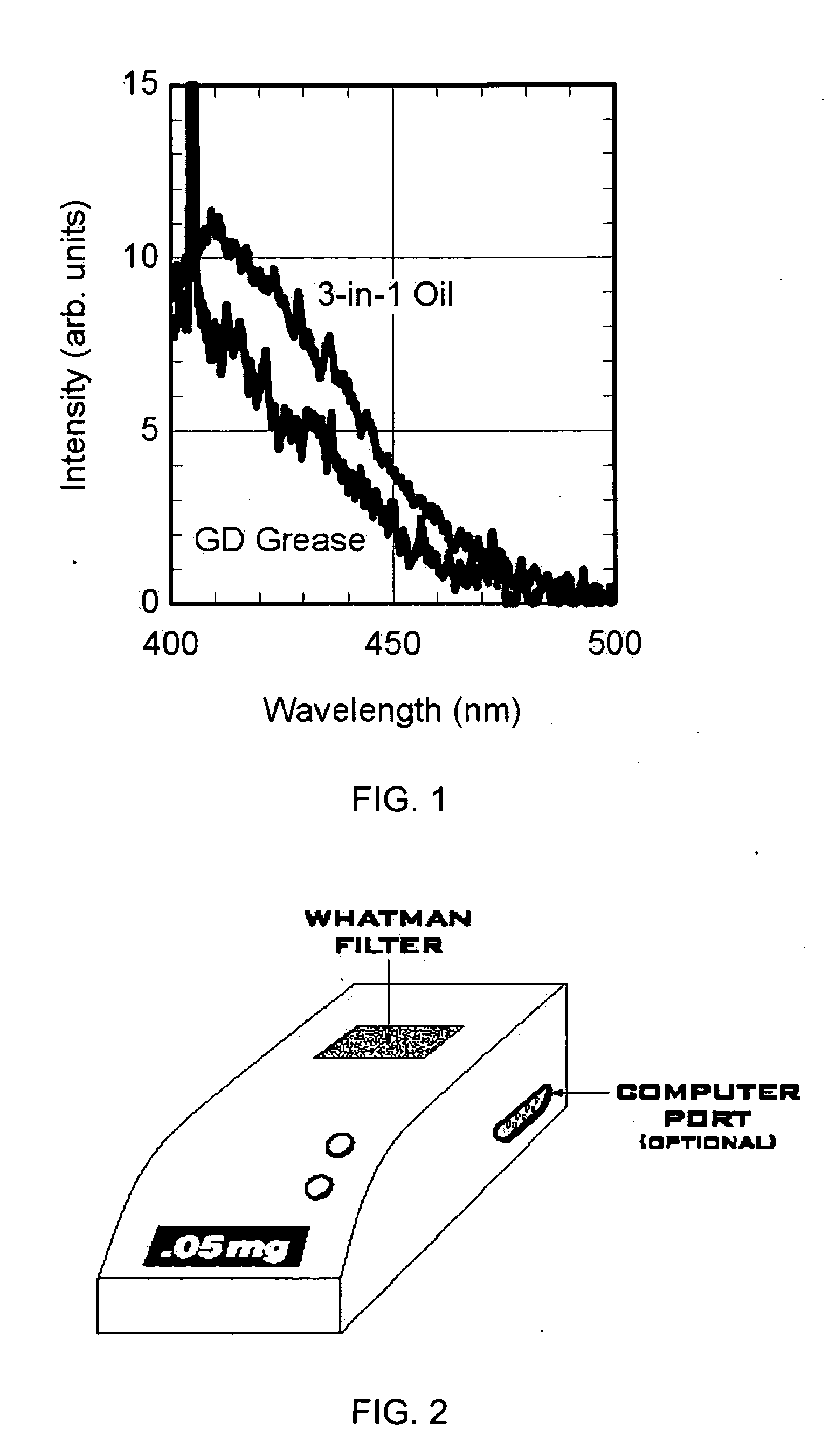

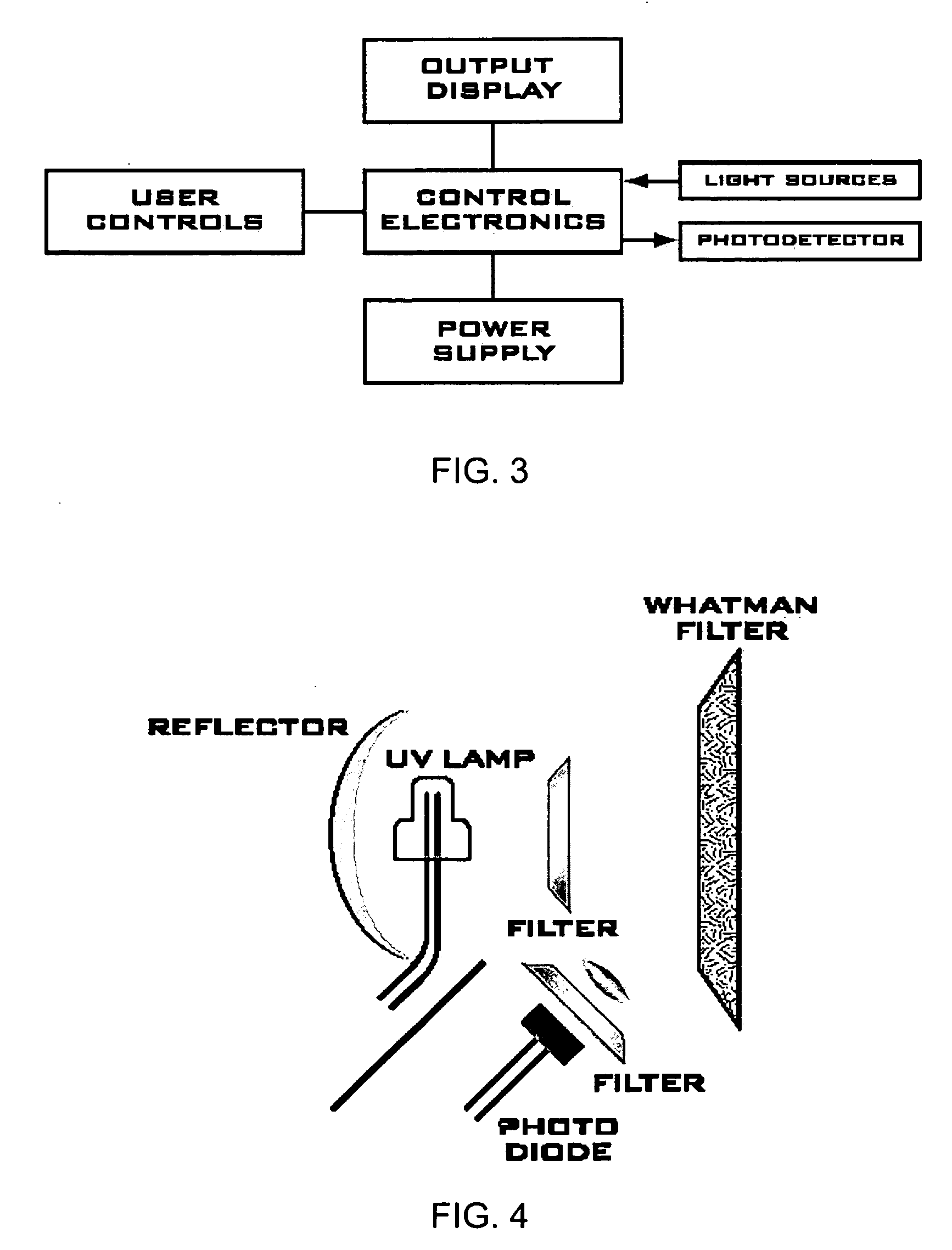

Device and method for quantifying a surface's cleanliness

ActiveUS20090223635A1Optical radiation measurementMechanical working/deformationSurface cleaningFluorescence

Provided are devices and methods for quantifying a surface's cleanliness relative to a contaminant. Such devices and methods may comprising and use a source of interrogating radiation to which the contaminant is responsive, a means for directing the interrogating radiation, a detector, and an analyzer. Radiation emitted from the source is directed by the radiation means toward the surface or a surface cleaner that may hold the contaminant. The detector detects radiation from the surface or the surface cleaner produced in response to the interrogating radiation by the contaminant, e.g., fluorescent or phosphorescent radiation, and generate a corresponding signal that is compared by the analyzer relative to an electronic standard that corresponds to the surface in an acceptably clean state so as to quantify the surface's cleanliness.

Owner:LAWLESS JOHN L

Protective tape separating method and apparatus using the same

InactiveUS20060219359A1Accurate separationReliable separationMechanical working/deformationSolid-state devicesEngineeringSemiconductor

During relative and horizontal movement of a mount frame, in which a semiconductor wafer with a protective tape is supported on a ring frame through a supporting adhesive tape, and a joining member, a position of an end edge of the protective tape is detected in a non-contact manner. Based on the detection result, a joining member is stopped in the position of the end edge of the protective tape and is moved close to the semiconductor wafer to press and bring a separation tape against and into contact with an end of the protective tape. In this state, the mount frame and the joining member are relatively and horizontally moved to join the separation tape onto the protective tape. Then, the mount frame and the joining member are relatively and horizontally moved to separate the separation tape together with the protective tape from a surface of the semiconductor wafer.

Owner:NITTO DENKO CORP

Apparatus and method for manufacturing display panel, and display panel manufactured by the method

InactiveUS20100208190A1Apparatus cost be reducedReduce manufacturing costEngine sealsMechanical working/deformationLiquid-crystal displayManufactured apparatus

A liquid crystal display panel manufacturing apparatus for successively bonding a pair of film substrates, each having a plurality of display regions defined at least along a longitudinal direction, along the longitudinal direction through a sealant formed in every display region of one of the film substrates includes: a first processing unit arranged to form a bonded body by bonding the film substrates so that the respective display regions are superimposed on each other; and a second processing unit including a molding roll configured to hold the bonded body formed in the first processing unit onto a peripheral wall thereof, and arranged to mold the bonded body into a curved shape along the peripheral wall of the molding roll by curing the sealant while holding the bonded body on the peripheral wall of the molding roll.

Owner:SHARP KK

Apparatus and method for selective processing of materials with radiant energy

InactiveUS7823366B2Maximize contactReduce capacityWrappers shrinkageMechanical working/deformationControl systemDna testing

Apparatus selectively processes a substrate using radiant energy. The substrate can consist of any target material having a portion to be processed using the radiant energy and a larger portion to be unprocessed. The apparatus includes a source of radiant energy (preferably a quantum cascade laser) that has a customizable spectrum that can be configured to be specifically absorbed only by the portion to be processed, and a control system for targeting the radiant energy only at the portion to be processed. Specific examples of the use of the apparatus and method are in the technologies of heat-shrinking polyethylene film, fusing toner to paper in a laser printer, heating reaction vessels in DNA testing, and temperature profiling bottle pre-forms.

Owner:DOUGLAS MACHINE LIABILITY

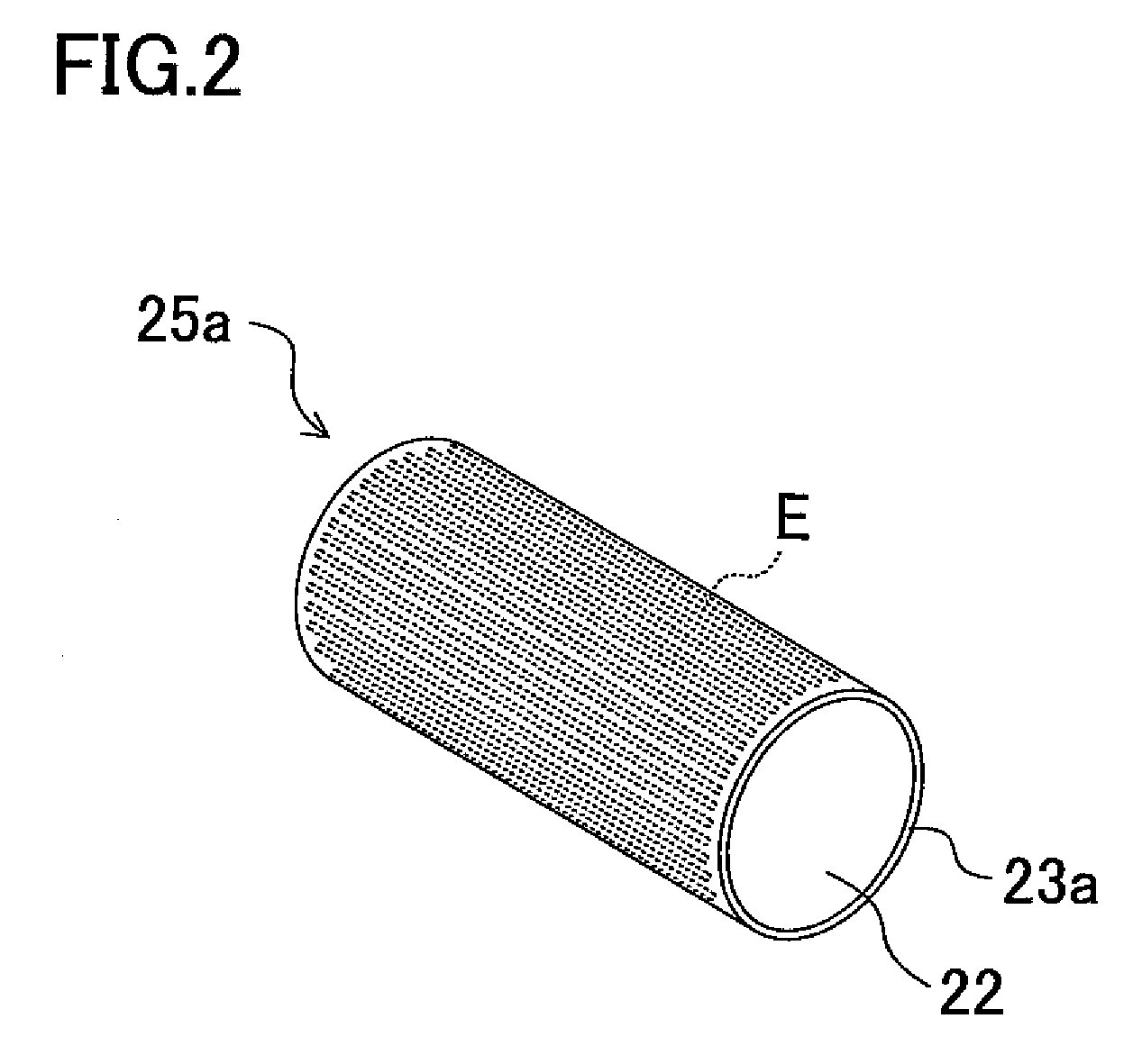

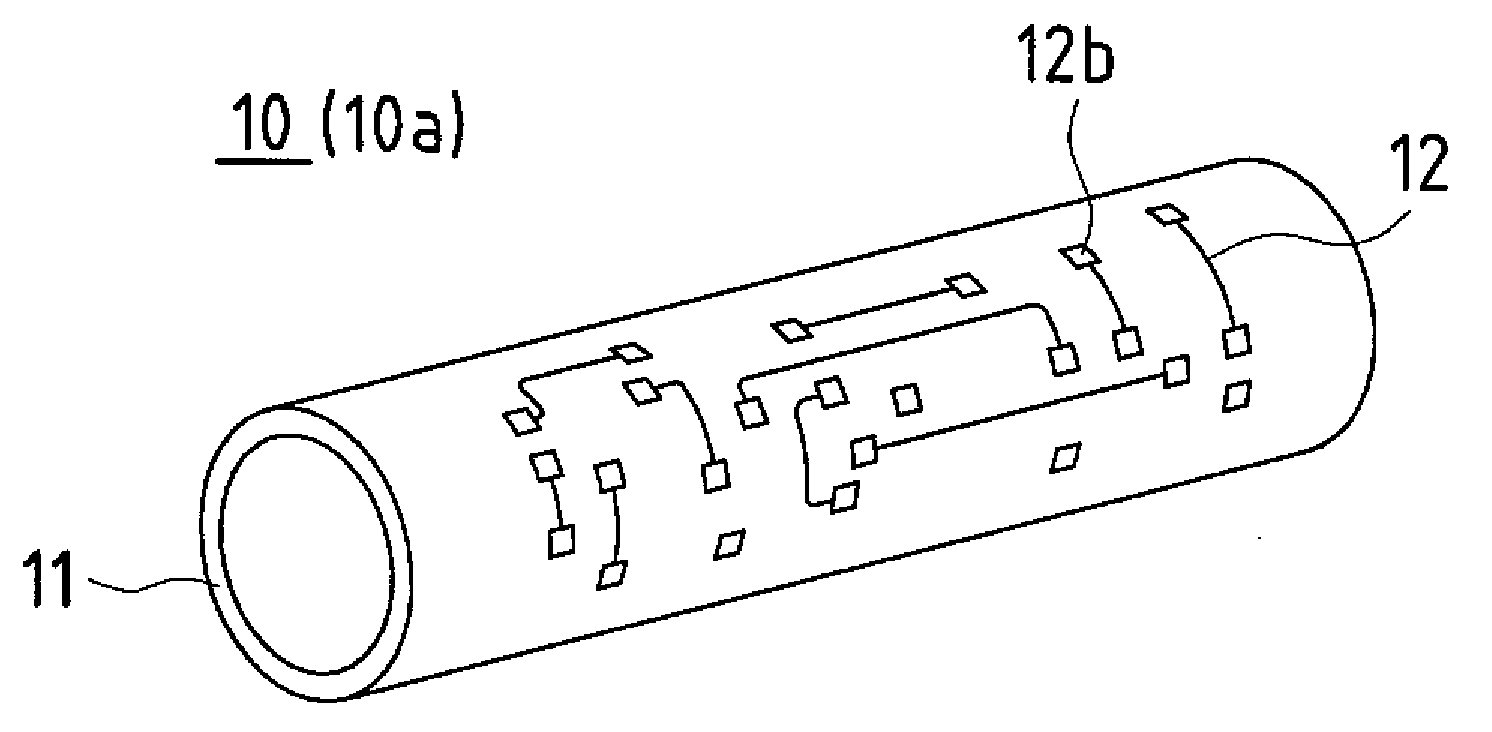

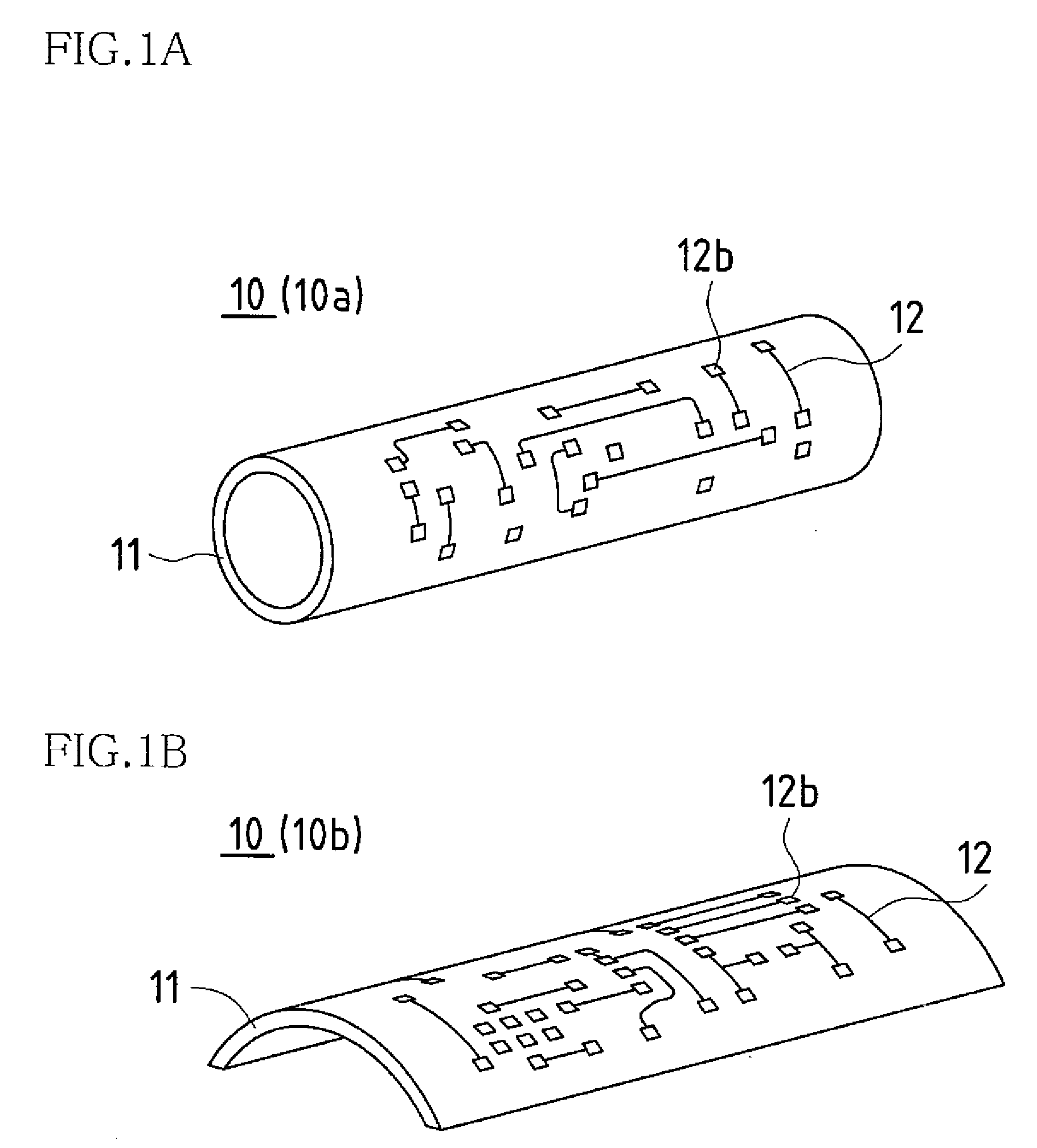

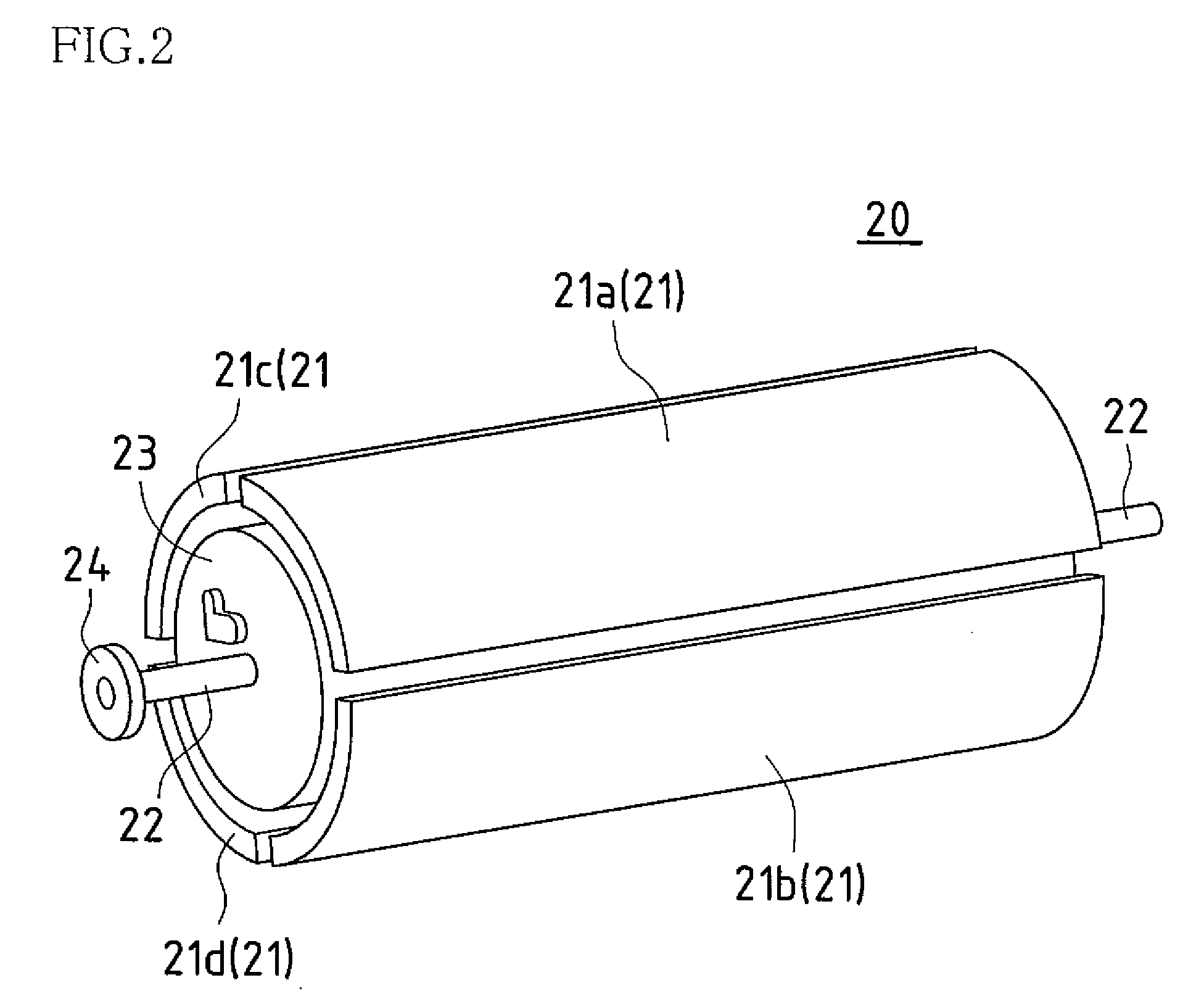

Printed wiring board manufacturing apparatus, printed wiring board, method for manufacturing printed wiring board, and electronic device

InactiveUS20080118681A1Easy to manufactureAdaptableMechanical working/deformationWelding/cutting auxillary devicesEngineeringElectronic equipment

According to an embodiment of the present invention, a printed wiring board manufacturing apparatus being provided with a drum unit having a processing cylinder that holds the printed wiring board material and comprises a cylinder outer circumference and a processing unit that performs processing on the printed wiring board material held by the processing cylinder.

Owner:SHARP KK

Plasmonic assisted systems and methods for interior energy-activation from an exterior source

Owner:DUKE UNIV +1

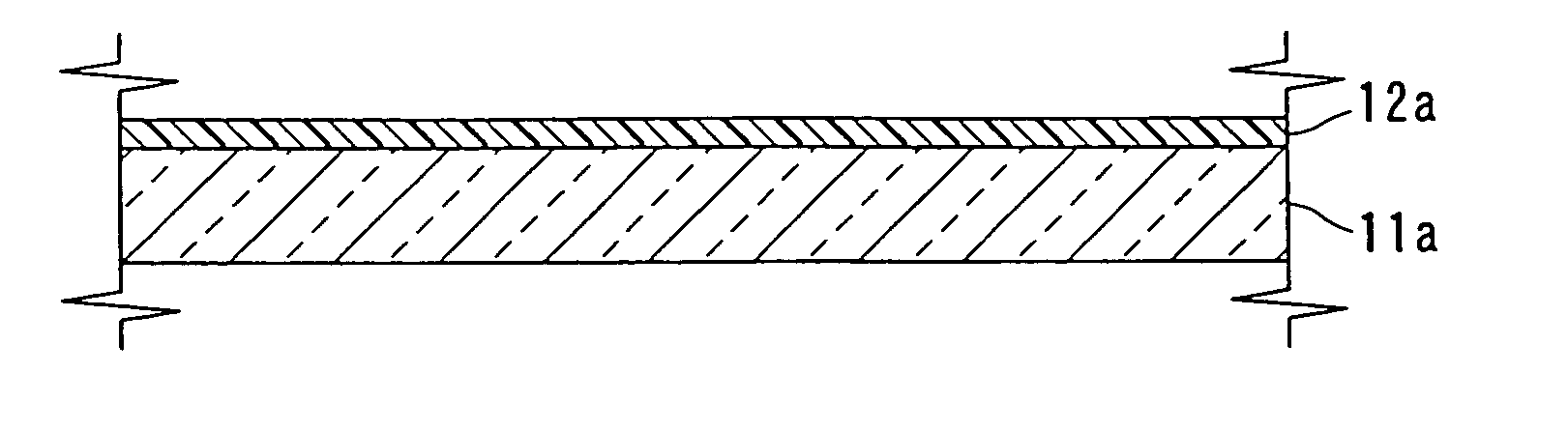

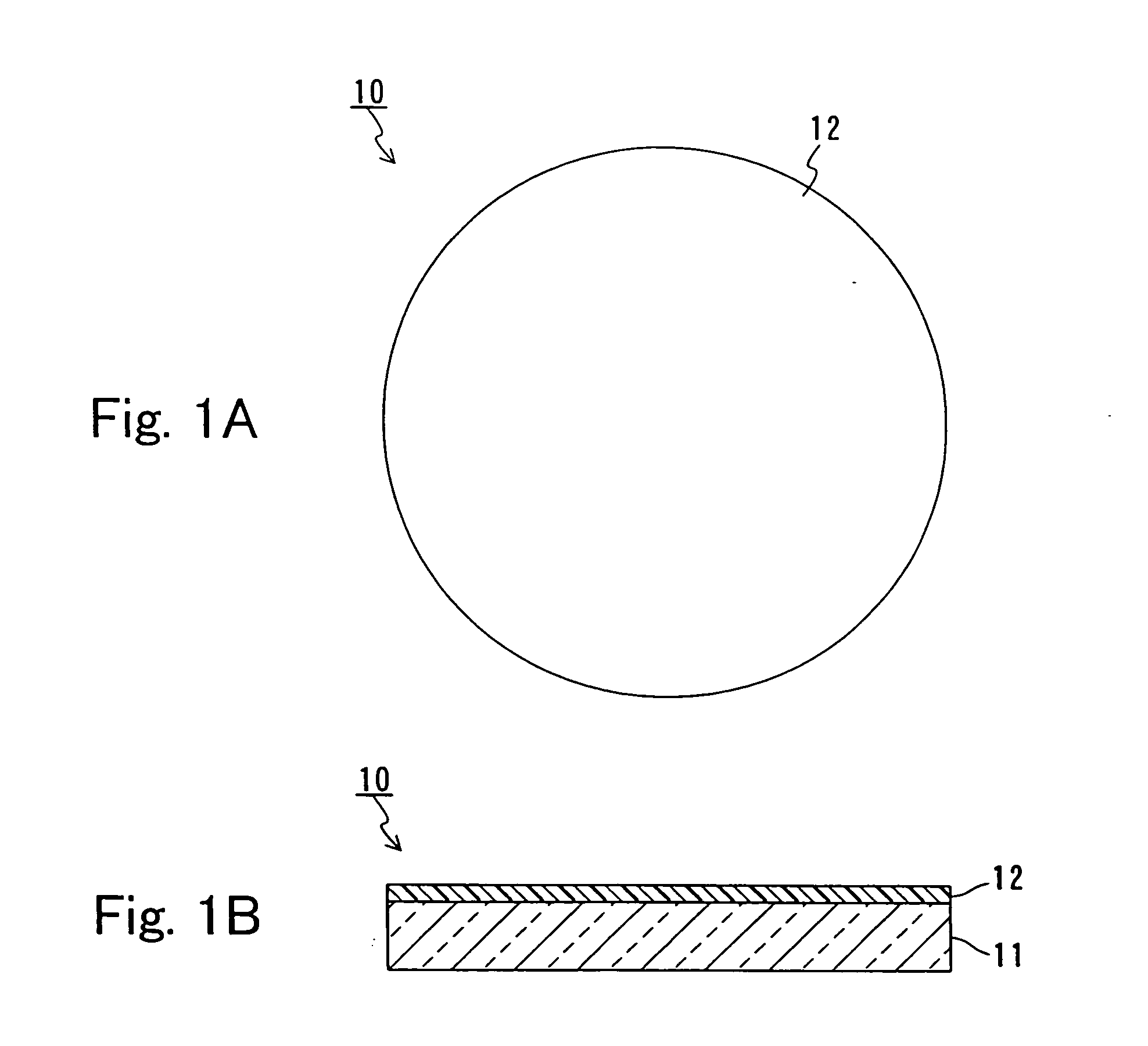

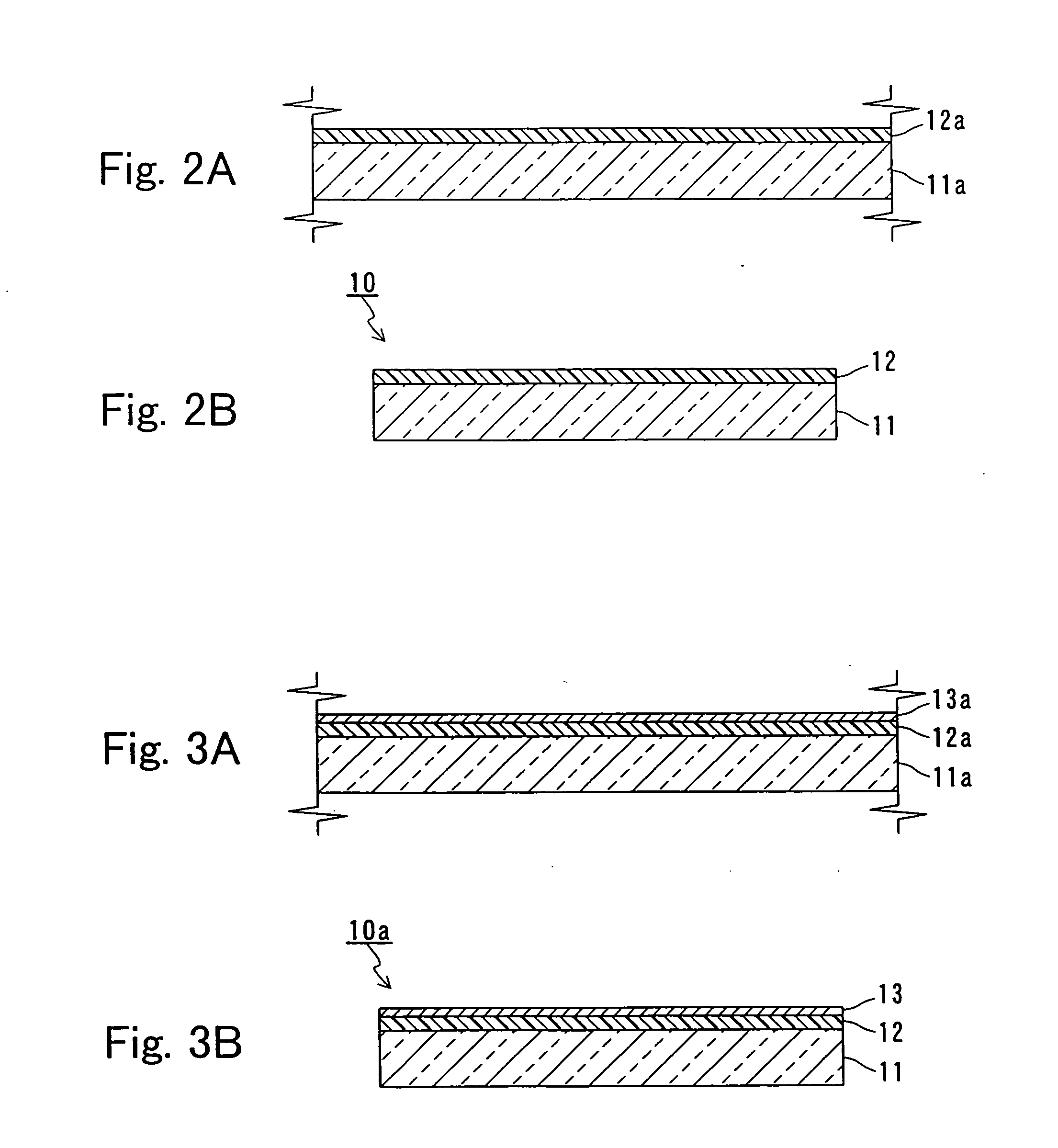

Method of manufacturing disk substrate, and method and device for manufacturing optical disk

InactiveUS20050031777A1Thin substrateAvoid damageMechanical working/deformationRecord carriersOptoelectronicsOptical disc

A method for producing a disk-shaped substrate 10 used for producing an optical disk includes: (a) forming a protective layer 12a that is larger in area than the disk-shaped substrate 10 on a surface of a transparent plate 11a; and (b) cutting a portion of the plate 11a with the protective layer 12a formed thereon other than an outer edge portion of the protective layer 12a to form a disk shape. According to this producing method, a thin substrate can be prevented from being damaged by forming a protective layer. Furthermore, according to this producing method, a protective layer with a uniform thickness can be formed.

Owner:PANASONIC CORP

Method and apparatus for bonding and debonding adhesive interface surfaces

InactiveUS20060219350A1Shorten the timeEvenly distributedEngine sealsNanostructure manufactureThermal energyMicrosphere

The present invention relates to a system and a method of improving the debonding of two or more surfaces together. The invention utilises thermoexpanadable microspheres and thermal energy to debond interfaces in an adhesive system or as vehicle carriers. It also discloses a method of curing the adhesive system prior to the debonding step so that the same adhesive system may be used for both phases. It is especially useful in the automotive industry for end of vehicle life dismantling.

Owner:BAIN & COMPANY

UVV curable coating compositions and method for coating flooring and other substrates with same

InactiveUS20100276059A1Reduce power consumptionComposition is limitedOrganic chemistryMechanical working/deformationCoated surfacePolymer science

A floor covering includes a wear layer including a resin and a photoinitiator in which the composition of the wear layer is curable by radiation having the strongest wavelength in the UVV range of 400 to 450 nm. The gloss of the wear layer can be controlled by controlling the amount of flatting agent in the composition applied to the surface, the amount of power applied to the surface coated with the composition or the temperature of the surface coated with the composition when the coated surface is subjected to the UVV radiation.

Owner:AFI LICENSING

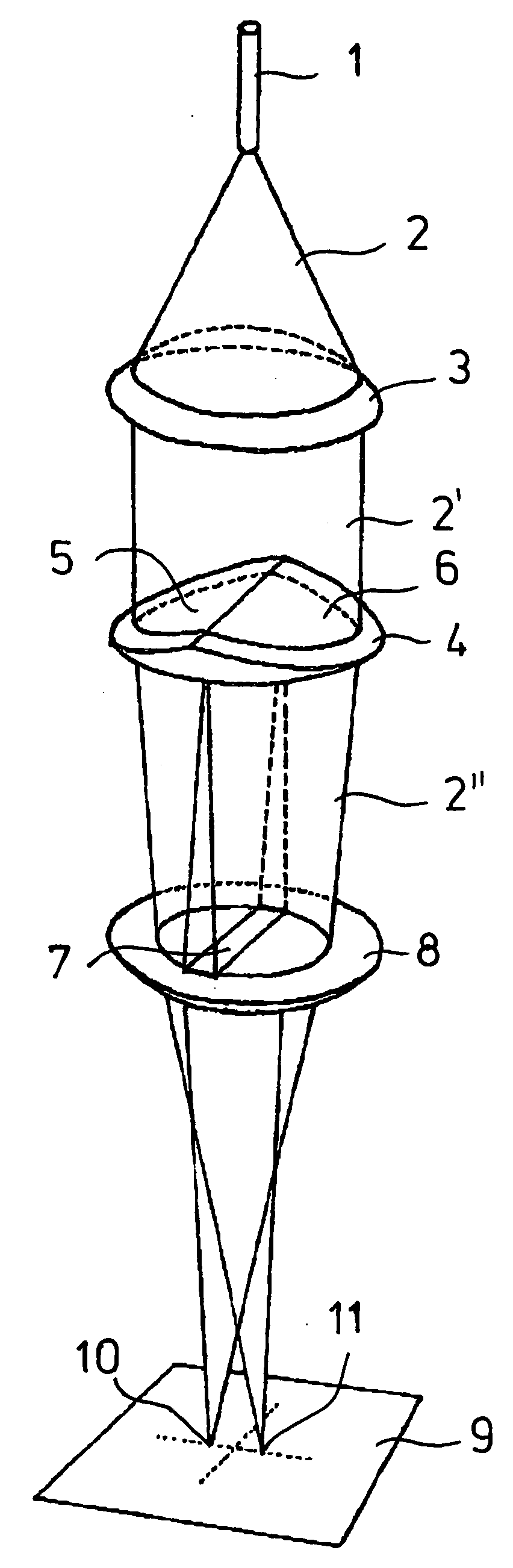

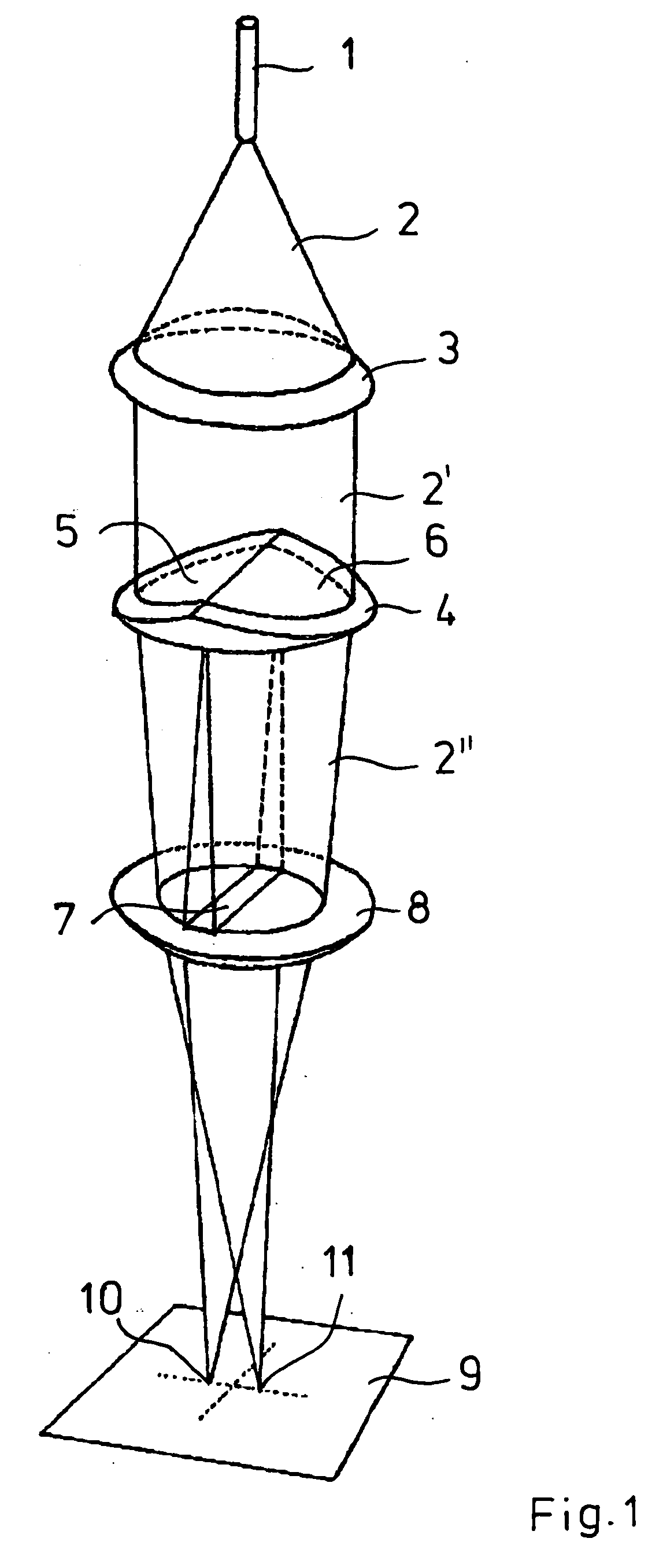

Method and apparatus for heating plastics by means of laser beams

InactiveUS20050098260A1Easy to handleEnjoys full flexibility of movementMechanical working/deformationLamination ancillary operationsOptoelectronicsLaser beams

Method and apparatus for heating plastic by laser beams with the aid of a number of laser points on the focal plane, the laser points being produced by an optical arrangement with the aid of a multiple wedge plate. The arrangement can be integrated in a processing head.

Owner:LEISTER TECHNOLOGIES

Method and apparatus for preparing media

ActiveUS7245227B2Increase distanceReduce distanceMechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

Work tools such as a printhead, platen, and / or cutting head are spaced normally with respect to a media path based on a location of one or more objects carried by the media, and the position of the media with respect to the work tool. Additionally or alternatively the work tools are selectively operated based on a location of one or more objects carried by the media, and the position of the media with respect to the work tool. The approaches are suitable for the manufacture and use of RFID tags and labels.

Owner:INTERMEC IP

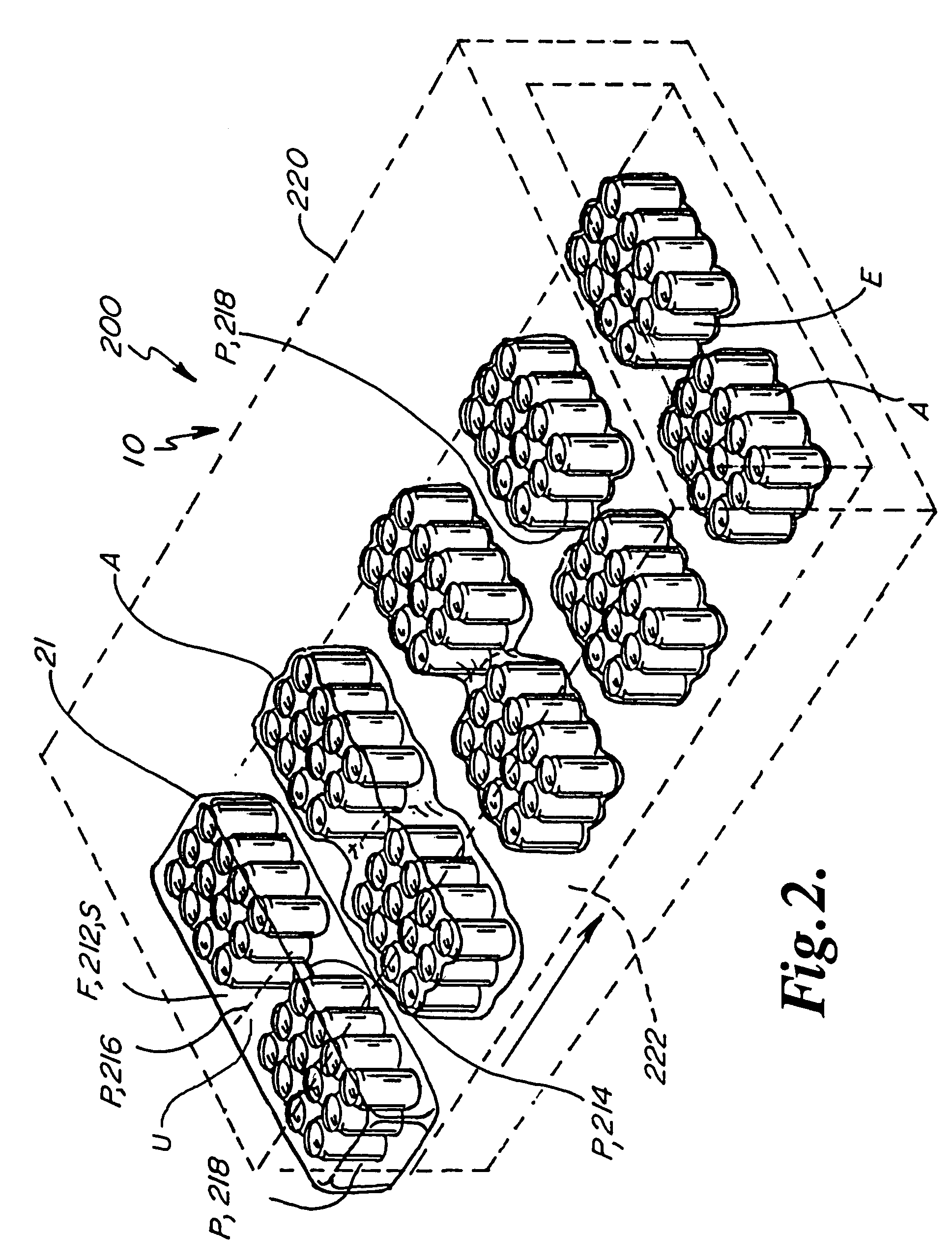

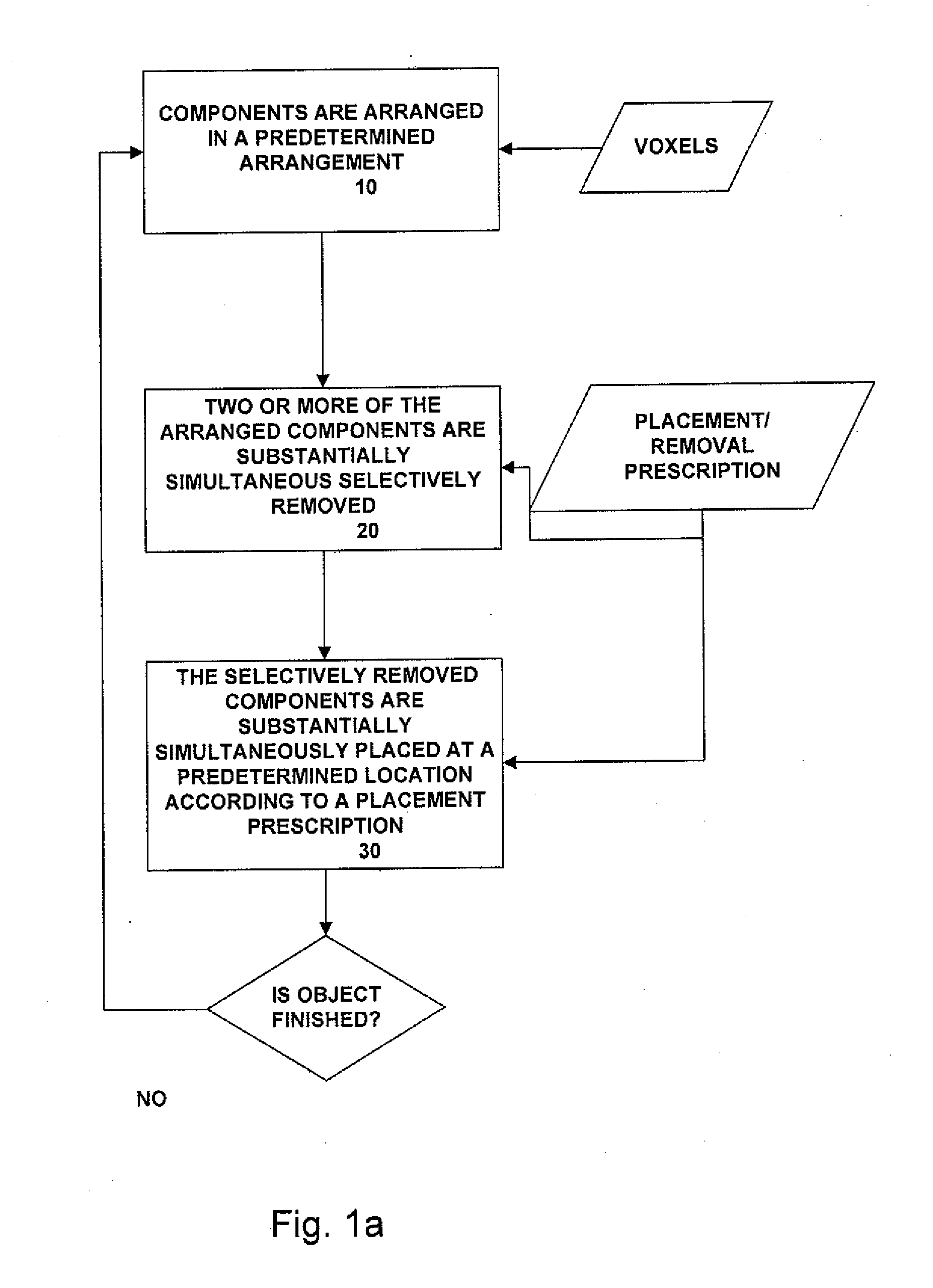

Apparatus and methods for digital manufacturing

ActiveUS20110123794A1Liquid surface applicatorsMechanical working/deformationEngineeringDigital manufacturing

A method for manufacturing objects / materials includes selectively arranging the predetermined components in a staging area, substantially simultaneously selectively removing two or more of the selectively arranged predetermined components according to a predetermined removal plan and substantially simultaneously placing the selectively removed components, the removed components being substantially simultaneously placed at a predetermined location. A system for practicing the method includes a supply of the predetermined components, an arranging subsystem receiving the predetermined components and arranging the predetermined components according to a predetermined arrangement, a selective removal subsystem for selectively removing at least two of the selectively arranged predetermined components, the selectively removing occurring substantially simultaneously and according to a predetermined removal prescription, and a placement subsystem for substantially simultaneously placing the selectively removed components at a predetermined location.

Owner:CORNELL UNIVERSITY

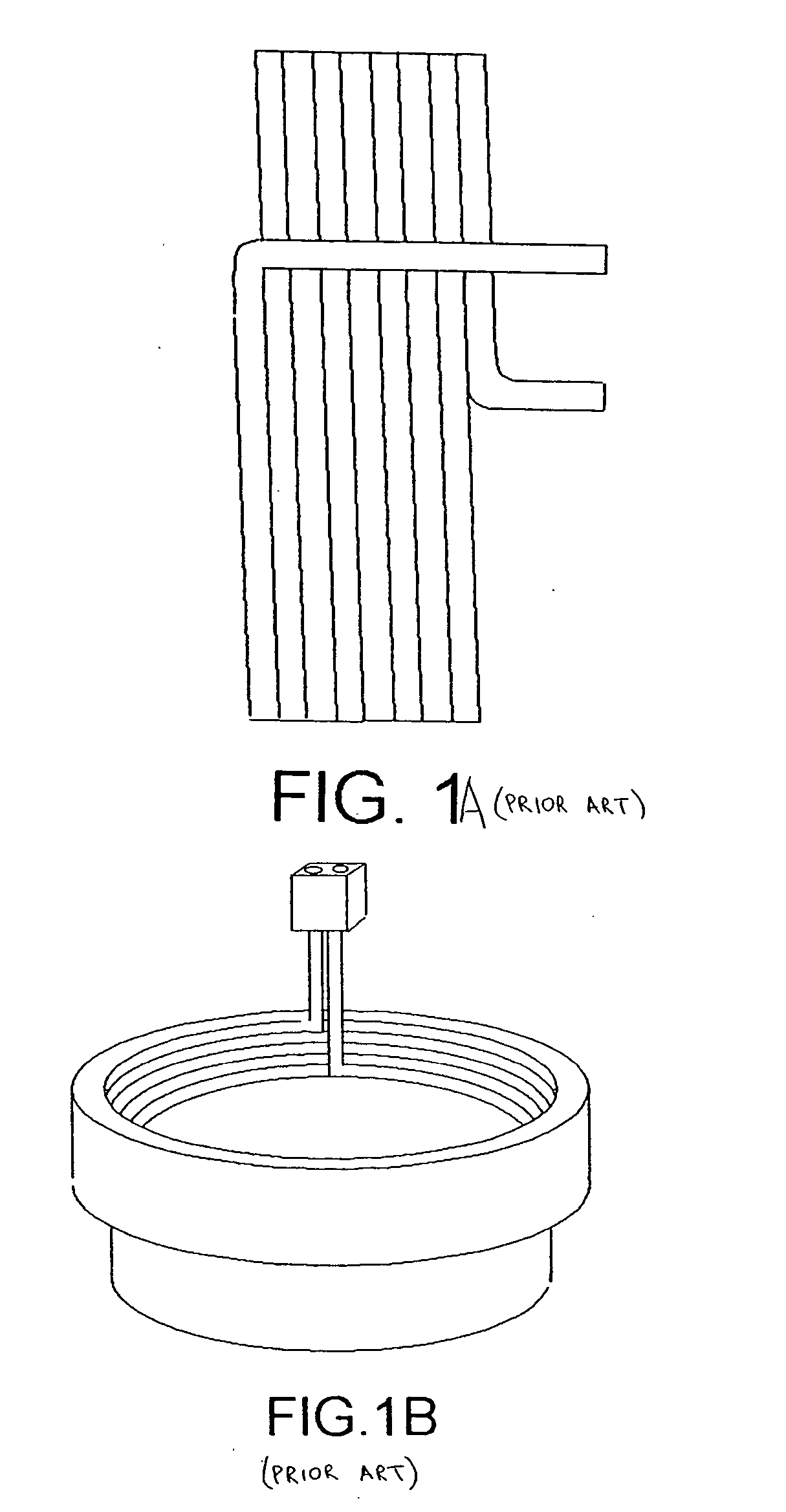

Electrofusion pipe-fitting joining system and method utilizing conductive polymeric resin

InactiveUS20060016552A1Material nanotechnologyMechanical working/deformationConductive polymer compositePipe fitting

A joining device for electrofusion of at least one end of a pipe to a fitting is provided which includes a fitting of a polymeric material and a collar adapted to receive the end of the pipe. The collar is fabricated from a conductive polymer composite material and positioned within the fitting. A connector for connecting the collar to a source of current may be provided which may be integral to the fitting. Likewise, the collar may be integral to the fitting. All three of the connector, collar and fitting are preferably an integral unit. A method of making the joining device and a method of using the joining device are also provided.

Owner:GEORGE FISCHER SLOANE

Apparatus and method for connecting and disconnecting flexible tubing

InactiveUS6913056B2Mechanical working/deformationWelding/cutting auxillary devicesMechanical engineeringLaser optics

A laser strikes and aseptically heats or sterilizes the end of two flexible tube ends for connection. Tube holders are pushed toward each other to bring the tube ends into contact. A weld detector checks the characteristics of the weld. A laser optics assembly may be used to change the direction of the laser and focus the laser at the tube ends. In addition, a crimping device is used to compress a single flexible tube for disconnection. The laser strikes the compressed area. The crimping device continues to pinch the area and forms a seal in the tube. The tube is separated into two tube segments, each segment has a sealed end.

Owner:BAXTER HEALTHCARE SA +1

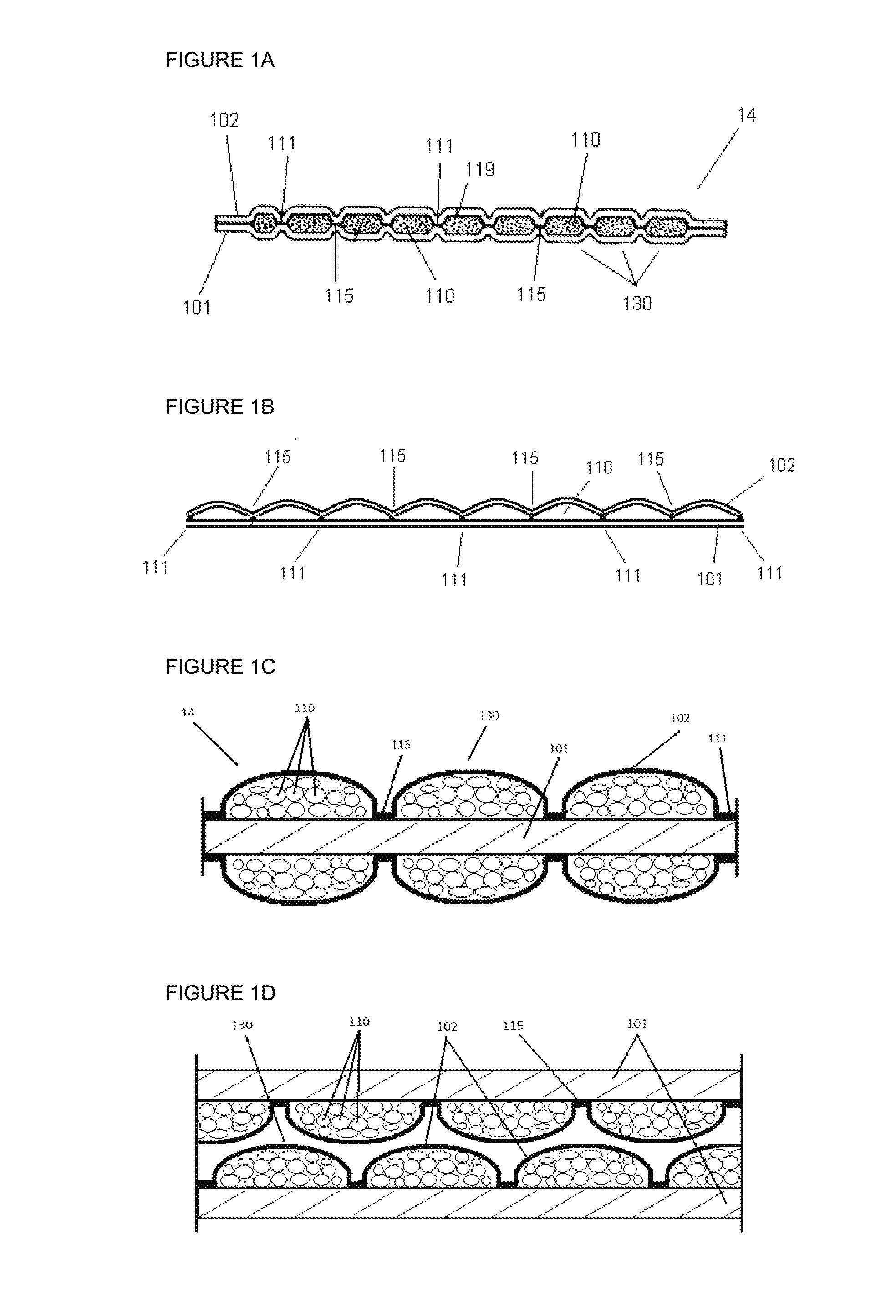

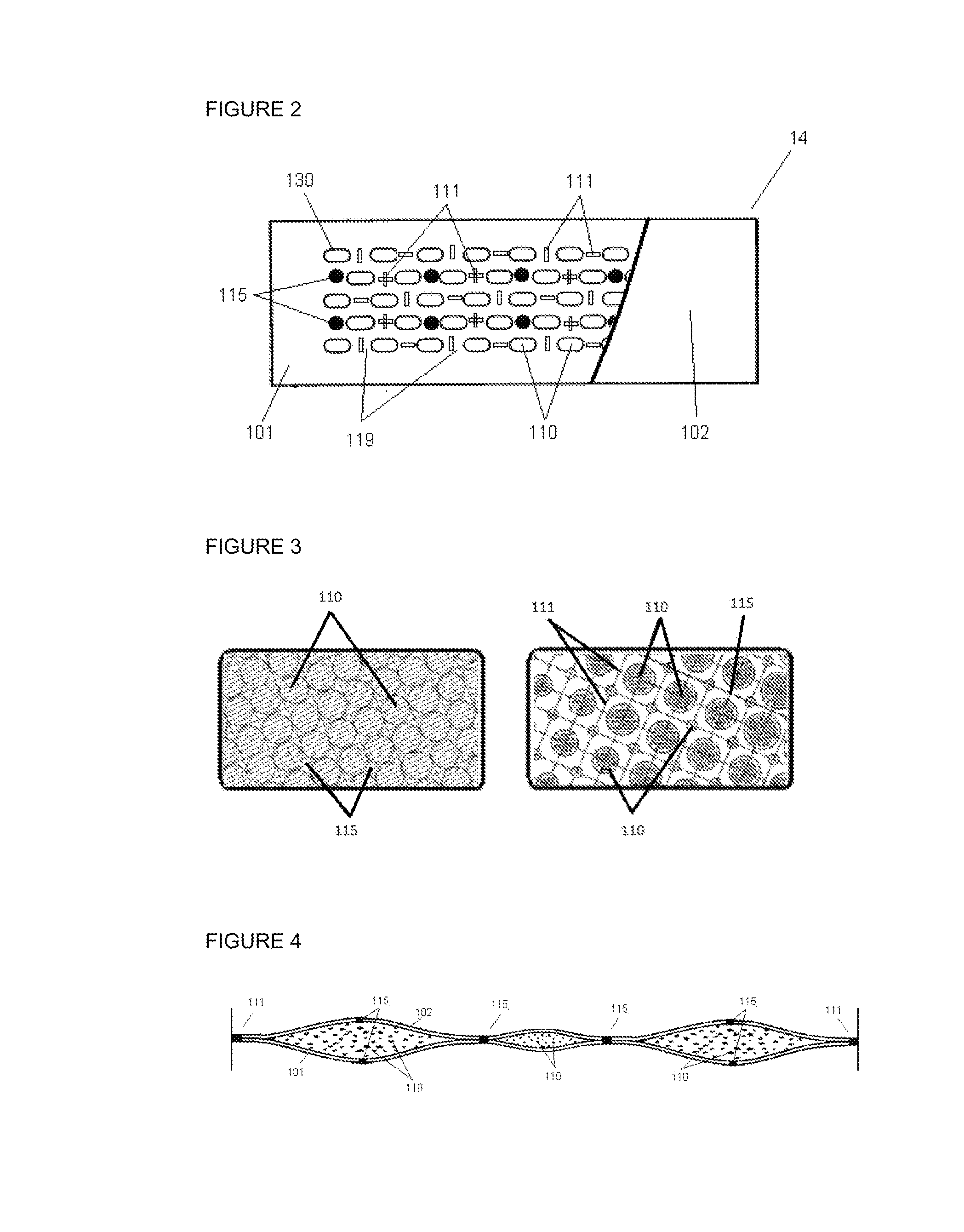

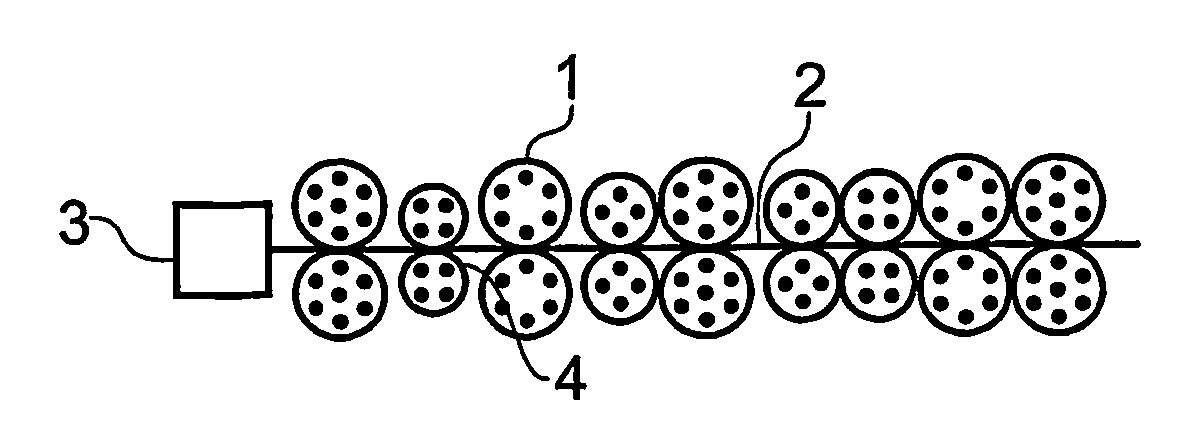

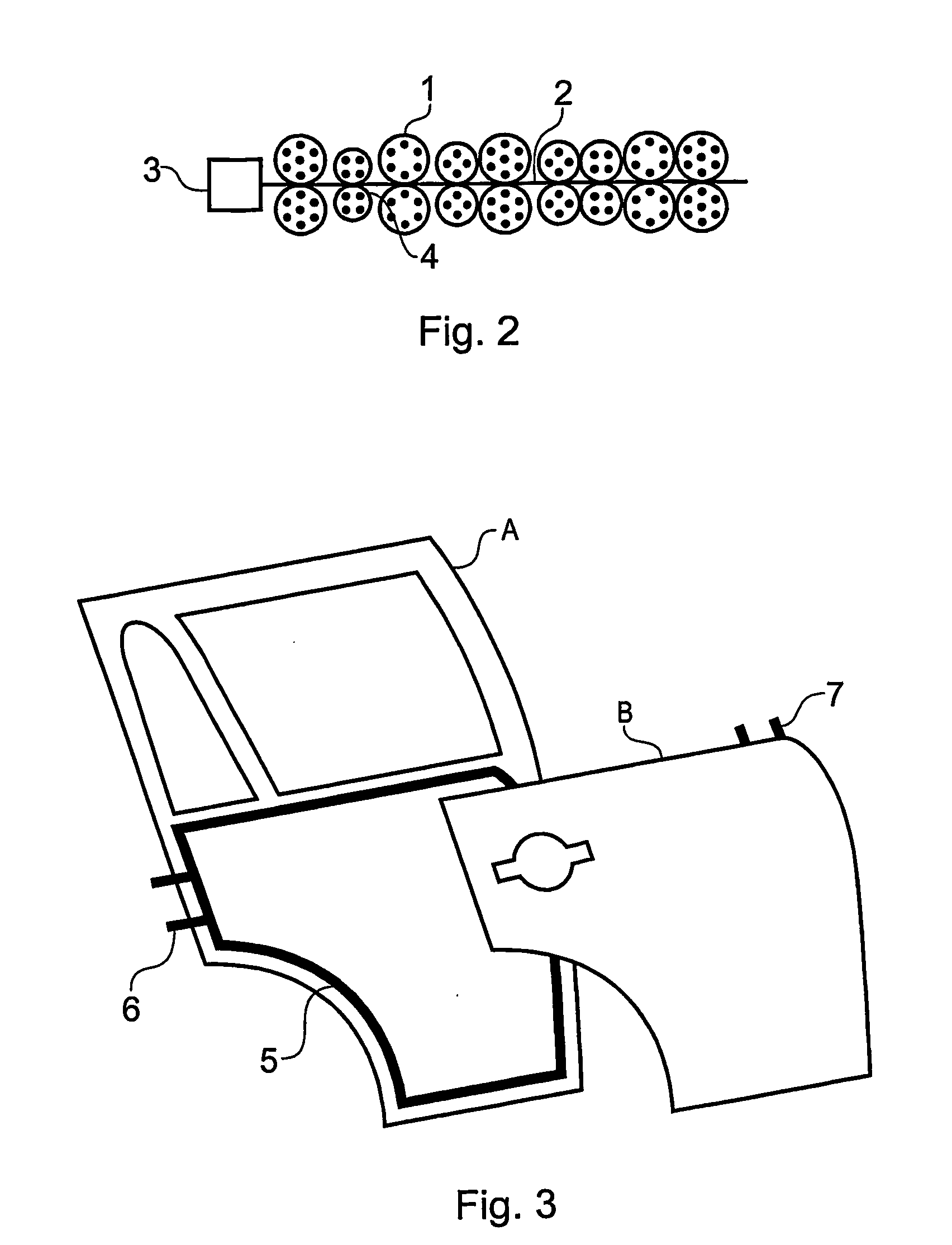

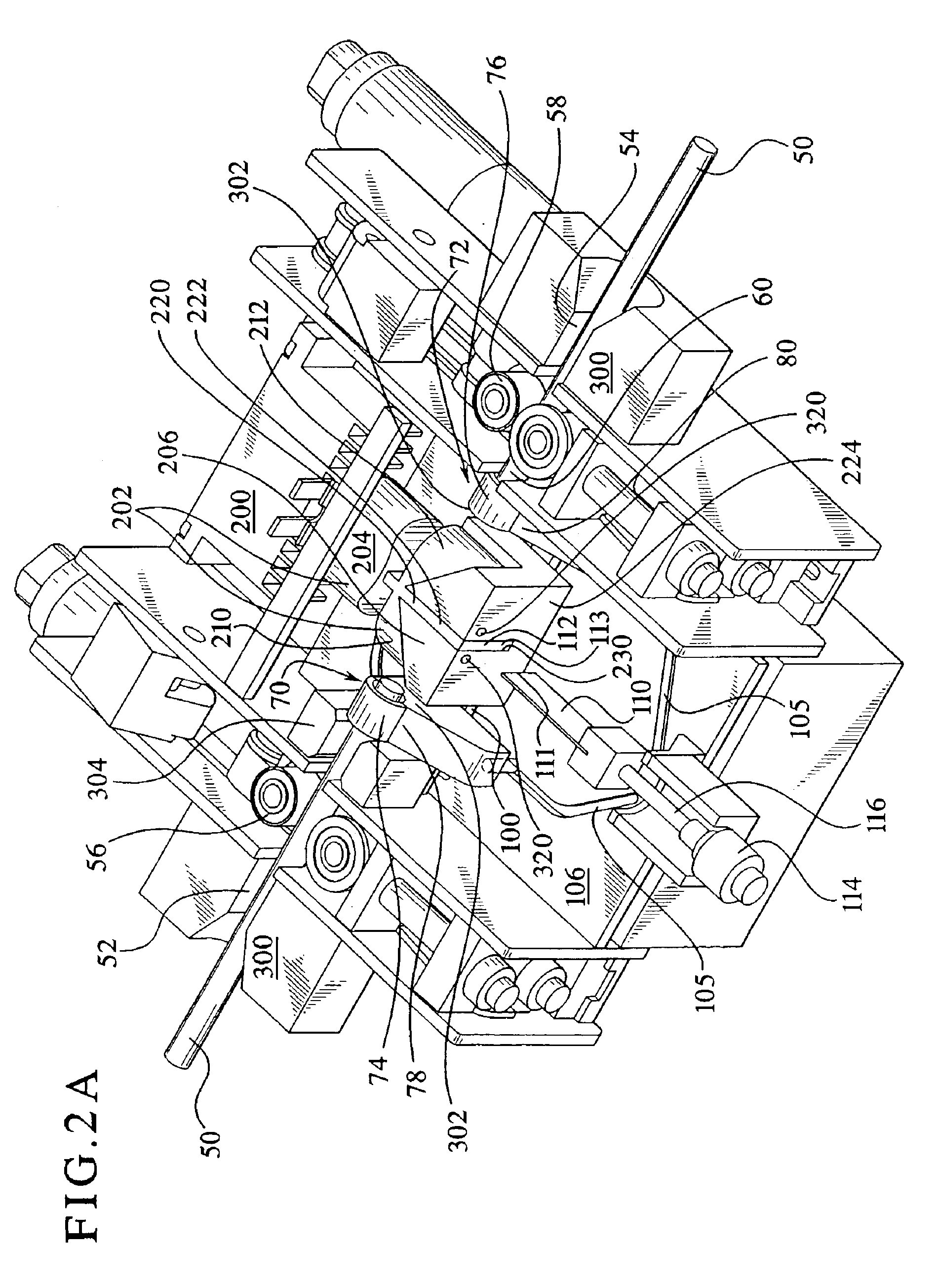

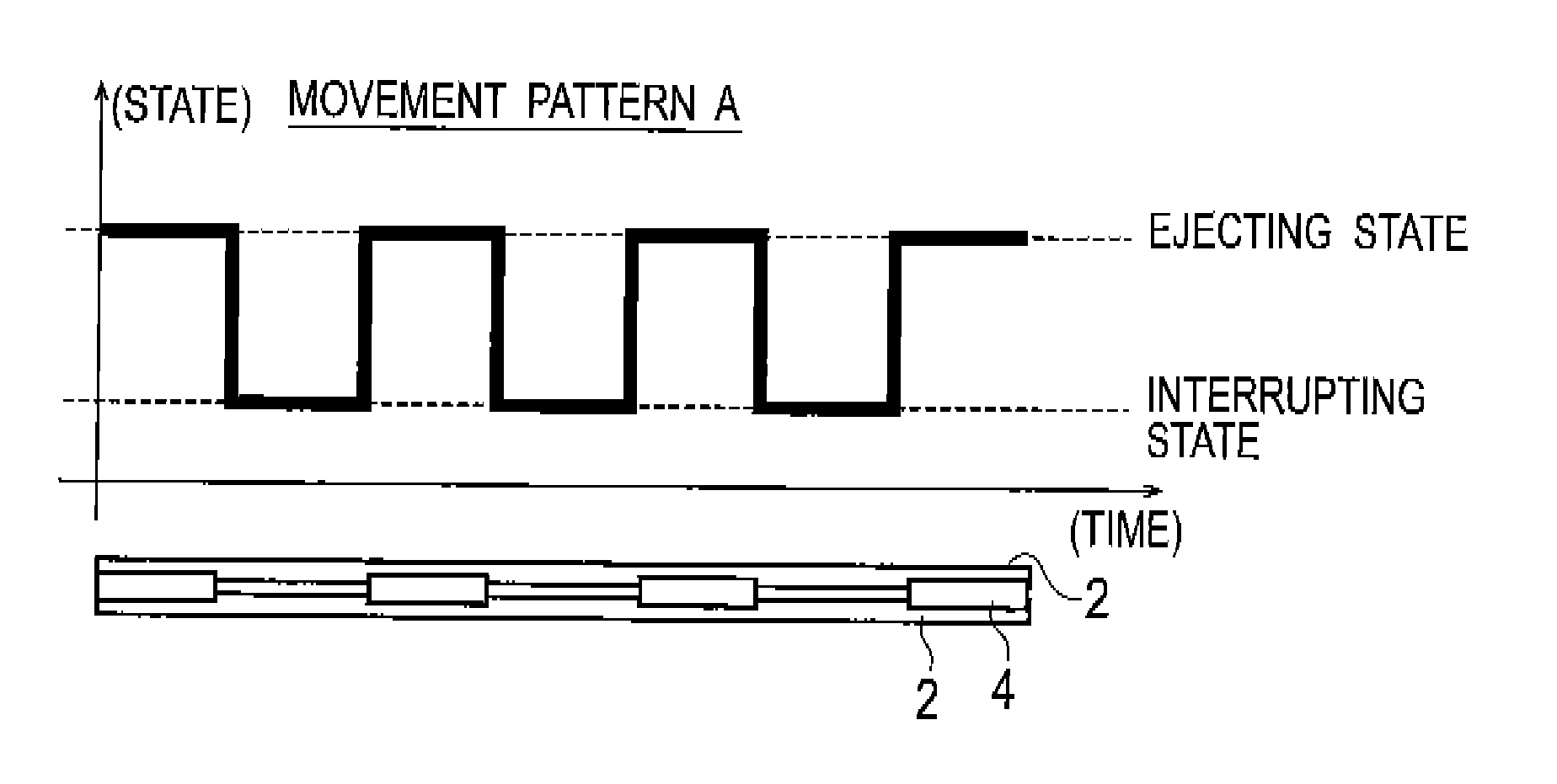

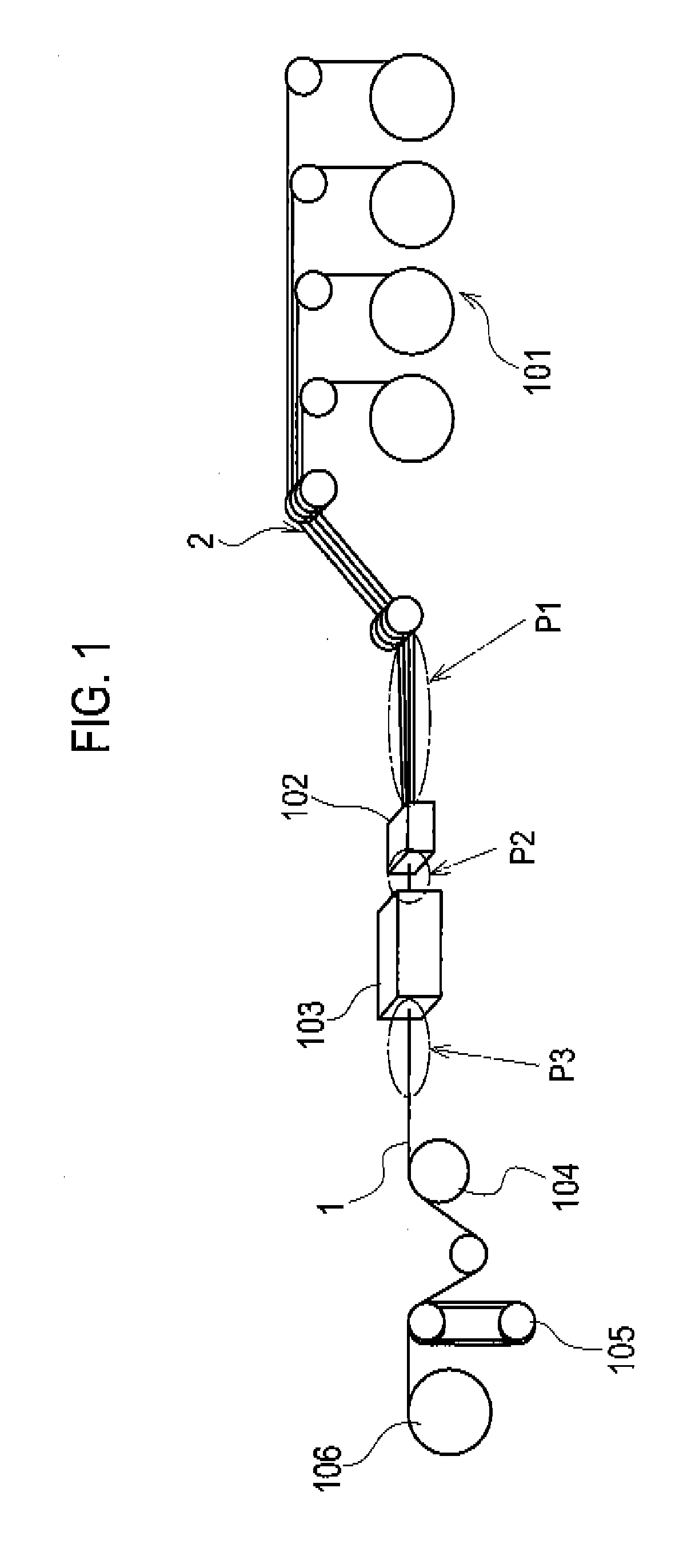

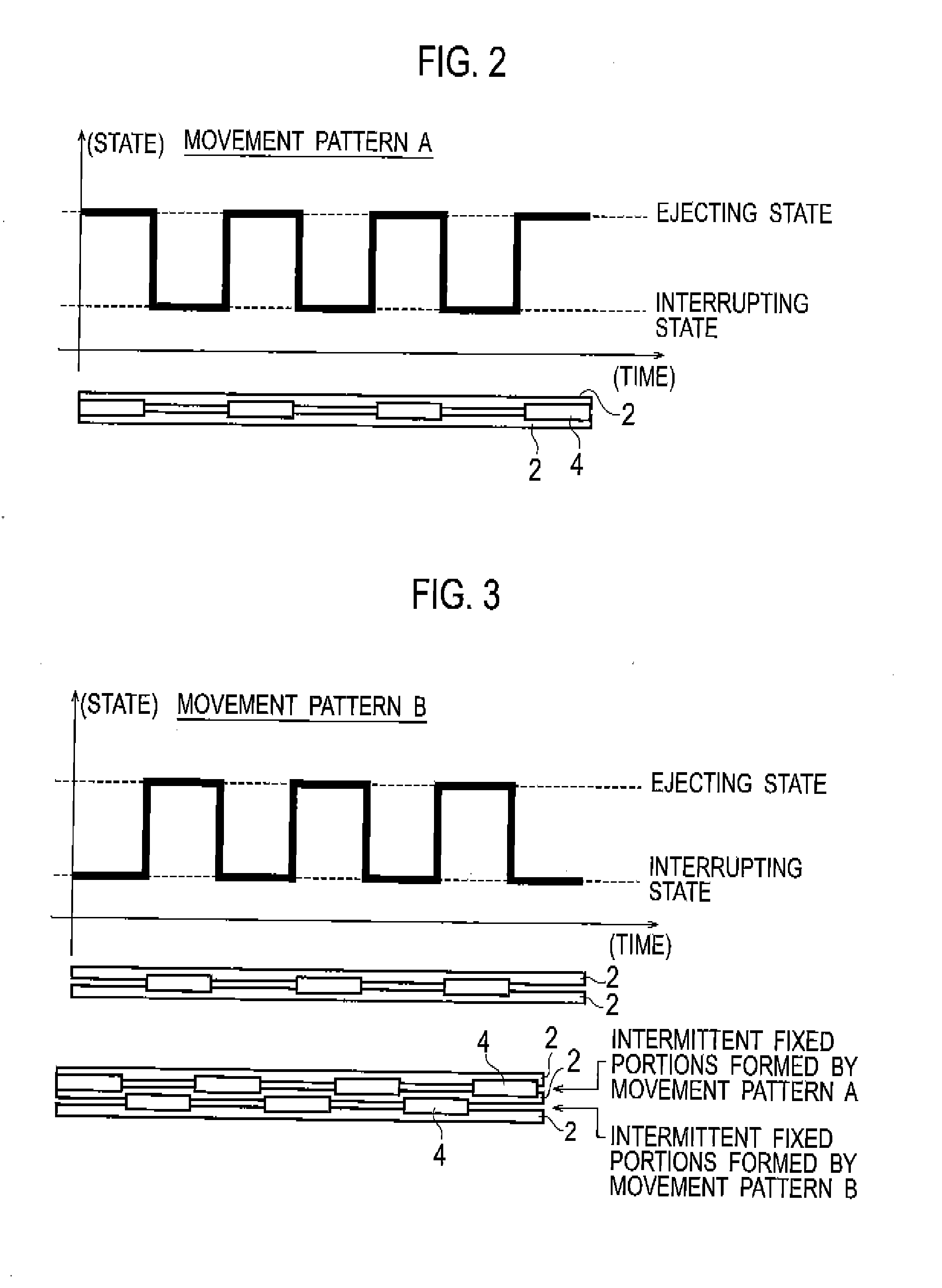

Manufacturing method of optical fiber ribbon, manufacturing device for optical fiber ribbon implementing said manufacturing method, and optical fiber ribbon manufactured with said manufacturing method

A manufacturing method for an optical fiber ribbon, in which: a plurality of optical fibers are arranged in parallel and the neighboring optical fibers are partially coupled with each other at given intervals in a longitudinal direction to form a subunit; and the optical fibers positioned at side edges of the neighboring subunits are partially coupled with each other at a given intervals in the longitudinal direction, includes: sending out the optical fibers in a parallel manner with intervals provided therebetween, applying an uncured resin to the optical fibers, continuously changing positions at which the uncured resin is interrupted by a plurality of interrupt members, and forming coupled portions at which the optical fibers are coupled to each other by irradiating resin curing energy, wherein a moving period or phase of the interrupt members is changed for every arbitrary optical fibers.

Owner:THE FUJIKURA CABLE WORKS LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com