Patents

Literature

56results about How to "Uniform sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

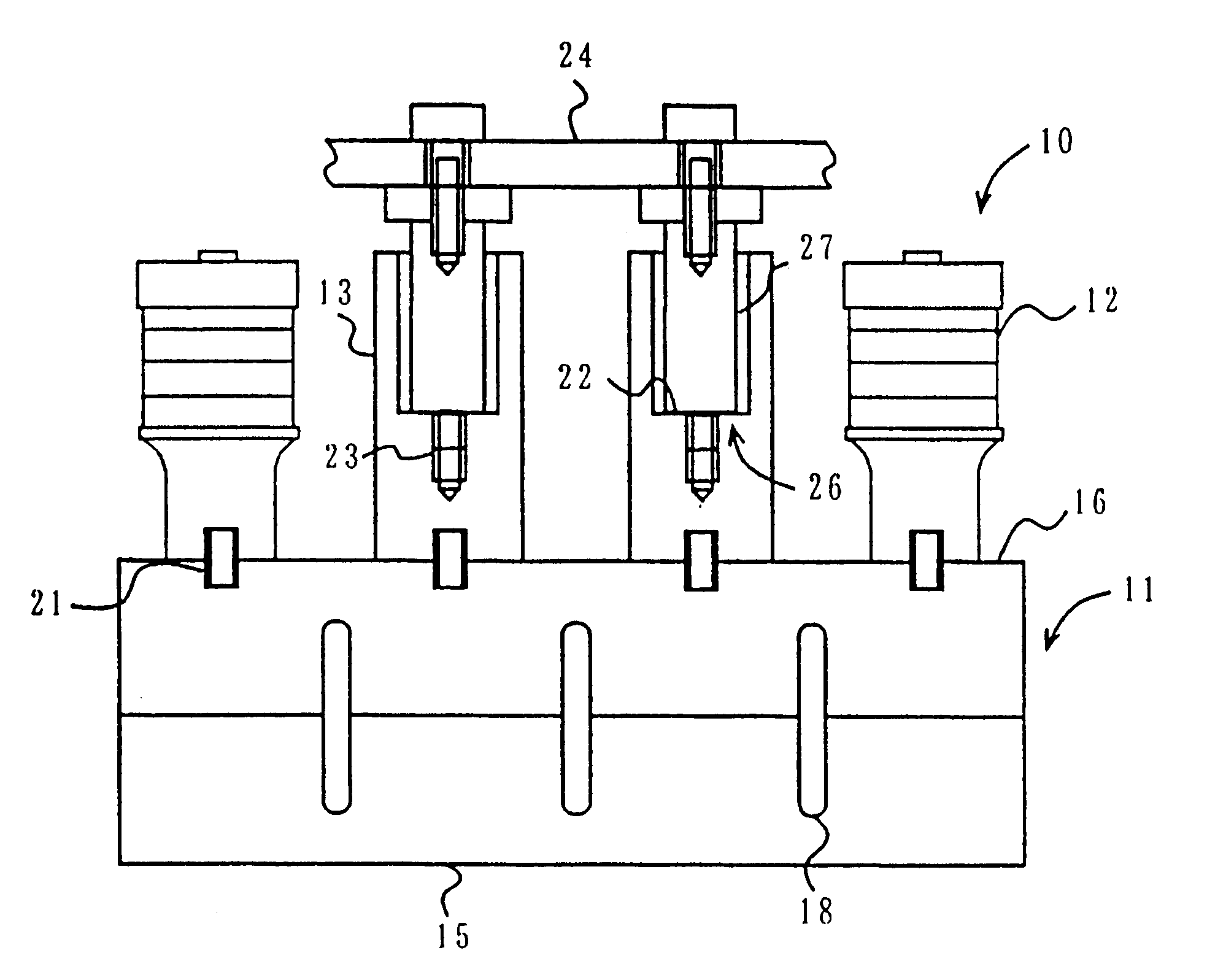

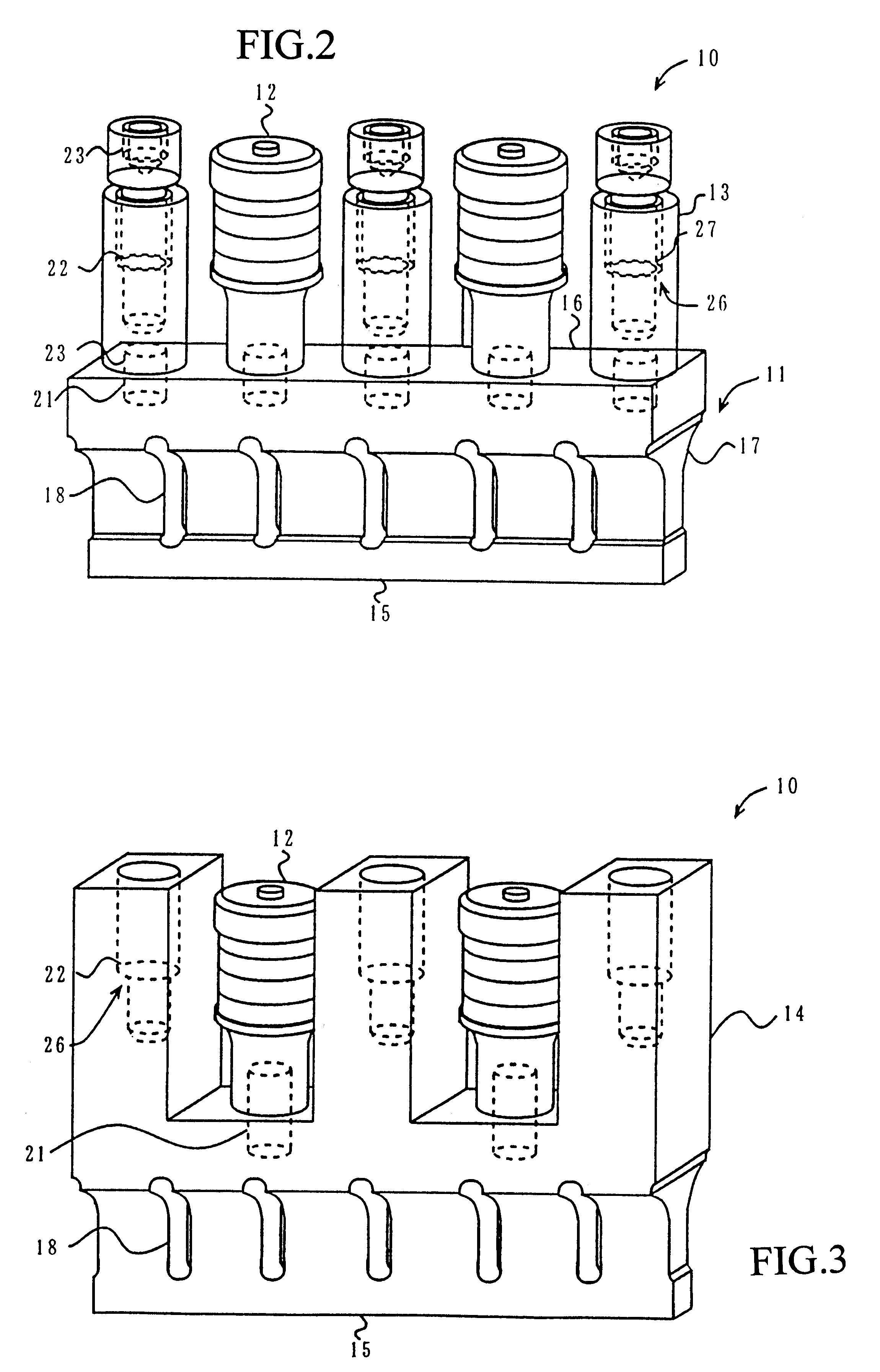

Ultrasonic sealer

InactiveUS6605178B1Increase powerUniform sealing effectMechanical working/deformationPiezoelectric/electrostriction/magnetostriction machinesWavelengthUltrasound

An ultrasonic sealing apparatus comprises at least one horn having an elongated sealing face for sealing a packing material. Plural converters are erected on a side of the horn opposite to the sealing face for resonating the horn with a vibrating frequency. The ultrasonic sealing apparatus has a length that is one wavelength of the vibrating frequency and is fixed in position to a sealing jaw at a nodal plane of the vibrating frequency.

Owner:SHIKOKU KAKOOKI CO LTD

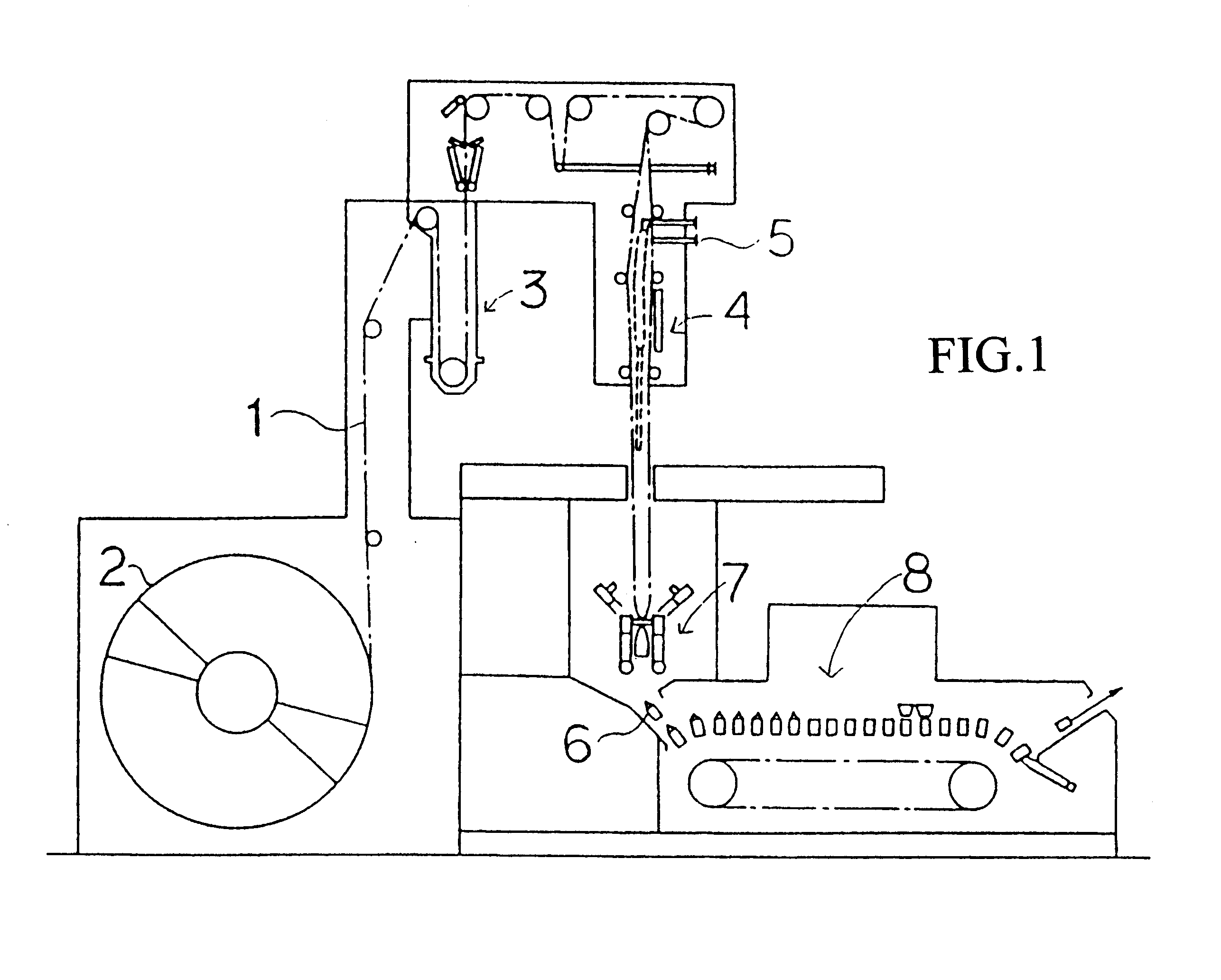

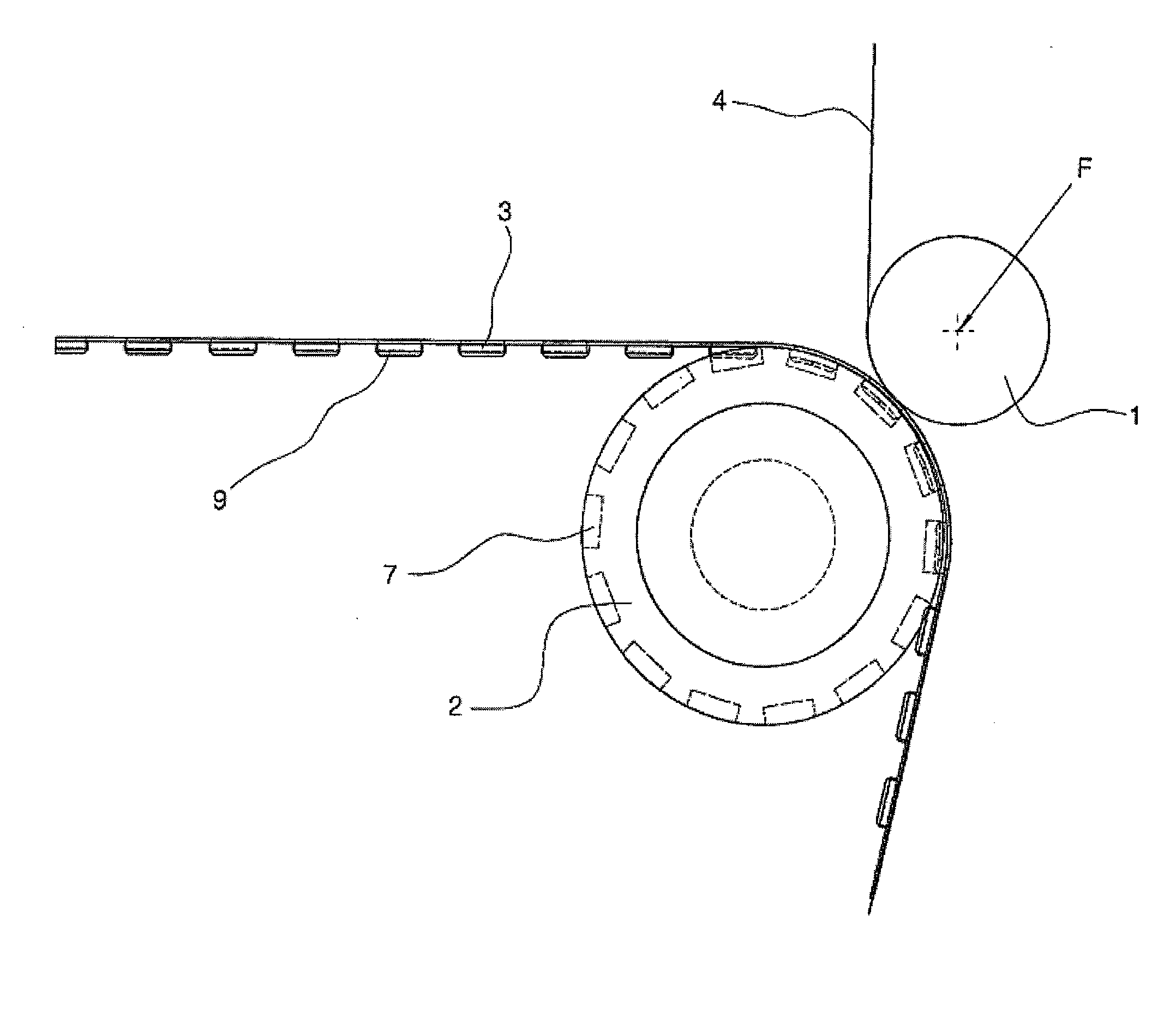

Device for the roll-sealing of sheets

InactiveUS20100107558A1Simple designUniform sealing effectWrapper twisting/gatheringDomestic articlesEngineeringBlisters

The device for the roll-sealing of sheets has a mating roll and a sealing roll, which presses against the mating roll with a sealing force, so that a molded sheet and a cover sheet can be guided between the sealing roll and the mating roll and sealed to form a sealed composite sheet structure. The surface of the mating roll has recesses to accept blister pockets of the molded sheet and a rippled structure. The elevations formed by the rippled structure comprise contact areas of different sizes.

Owner:UHLMANN PAC SYST

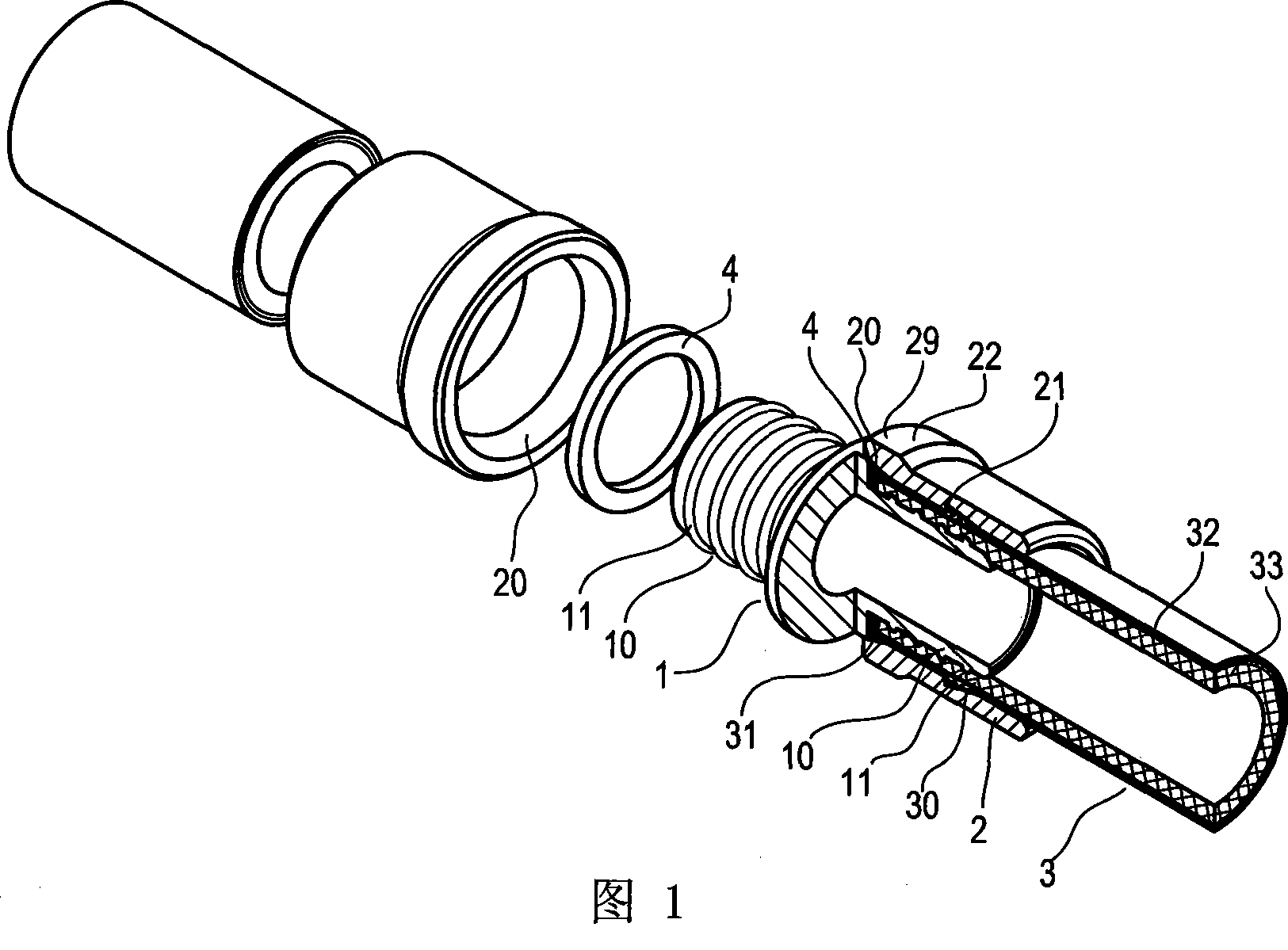

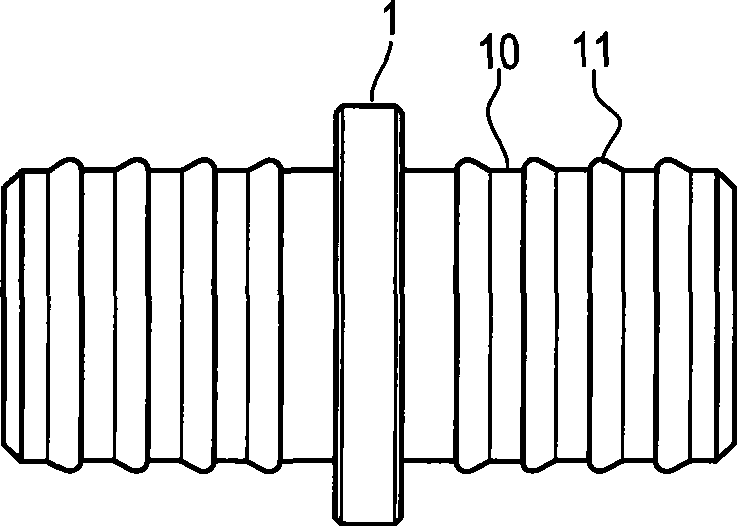

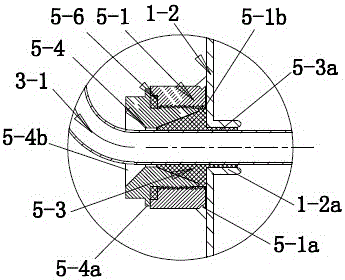

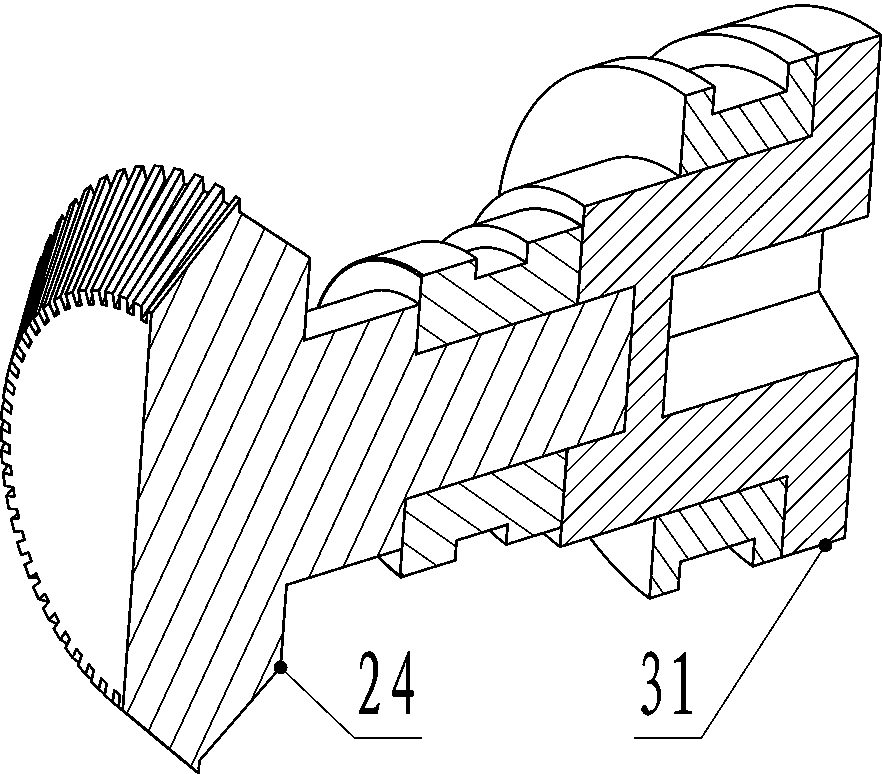

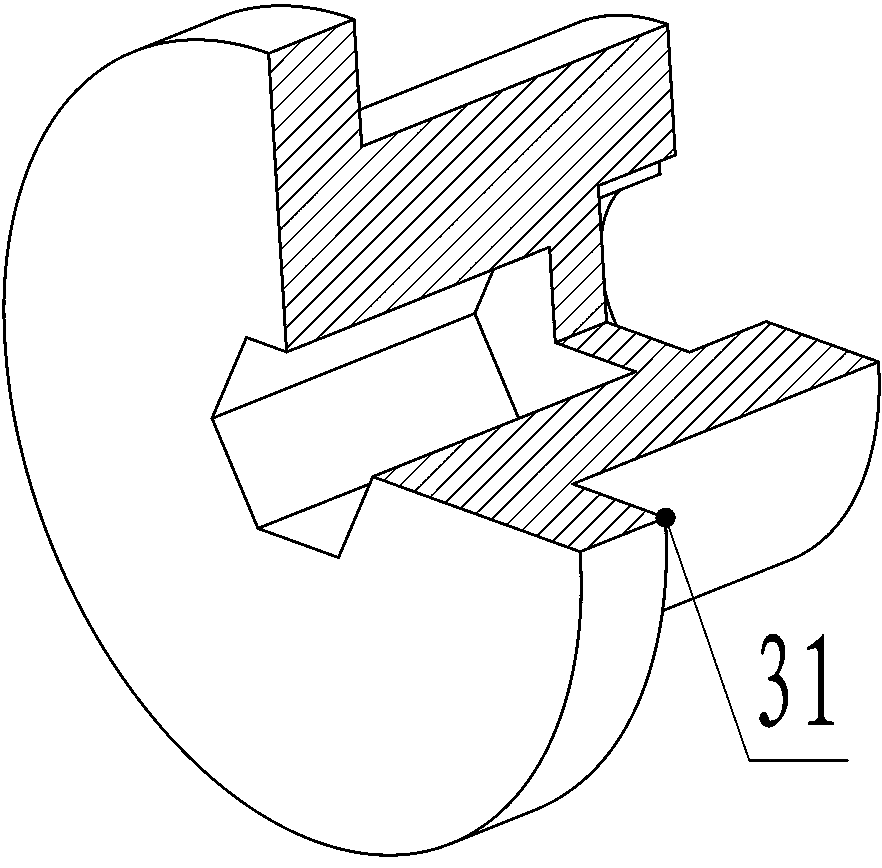

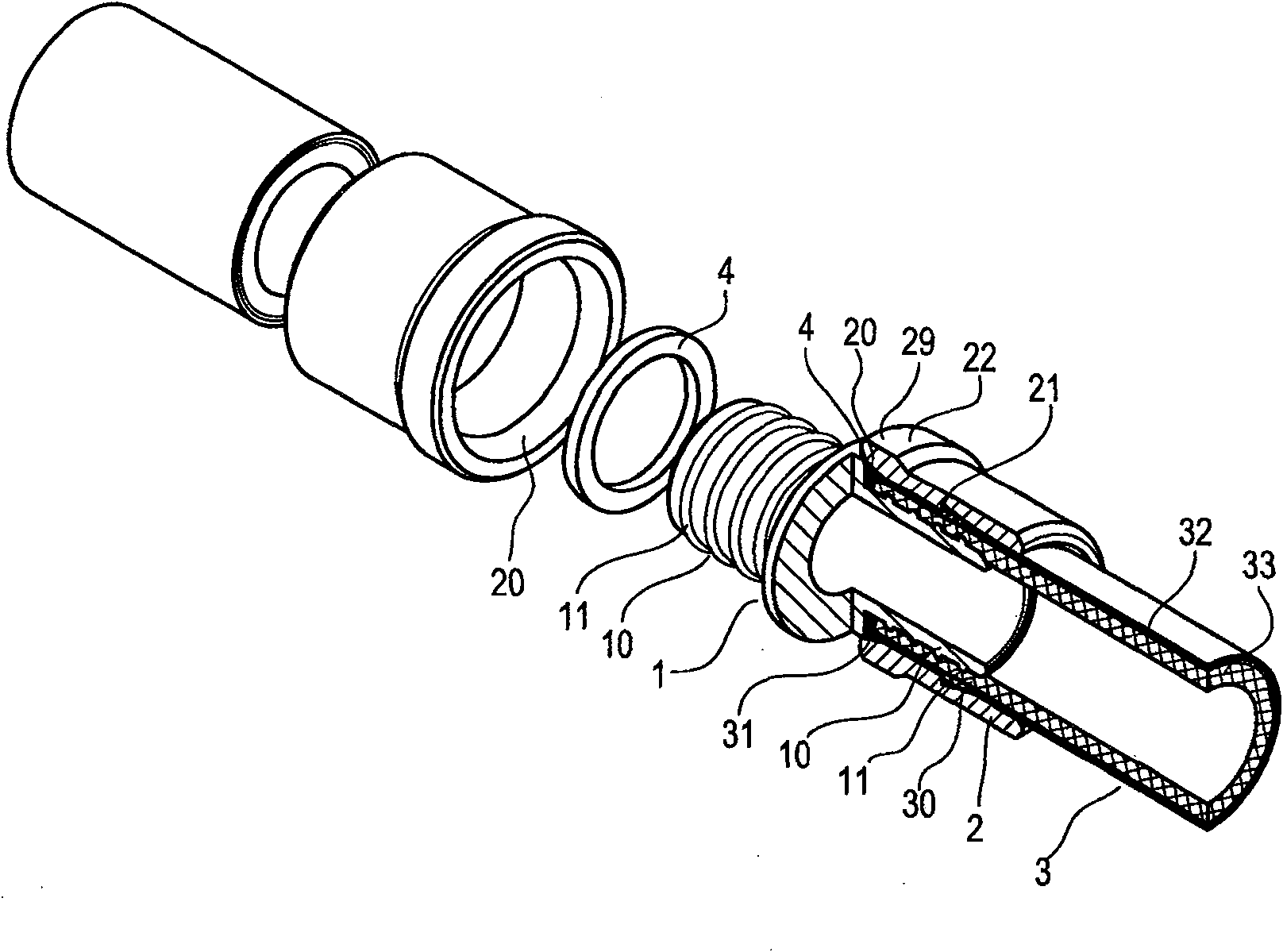

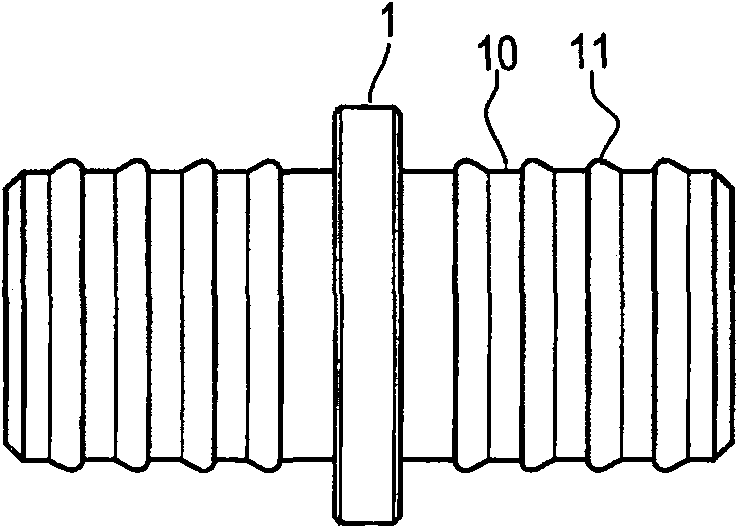

Sliding type aluminium plastic composite pipe fittings

ActiveCN101430035AUniform sealing effectImprove safety and reliabilityHose connectionsPipe connection arrangementsAluminiumEngineering

The invention relates to a pipeline connecting technique, in particular to a sliding compact type aluminum-plastic laminated pipe fitting, comprising a main pipe fitting body (1) provided with a pipe internal stay (10) on at least one end, an element rest (11) which is arranged at the outside diameter of the pipe internal stay (10) and is pressed into a port (31) of an aluminum-plastic laminated pipe (3) that is enlarged in a cold way when in installation, a ring-shaped sliding compact blocking sleeve (2) that is matched with the pipe internal stay (10) and can be sheathed into the external diameter of the aluminum-plastic laminated pipe (3) in a way of clearance fit, and a chamfer angle (20) is arranged at the port of the inner wall at the left end (29) of the sliding compact blocking sleeve (2) that is fixed at a part (30) of the aluminum-plastic laminated pipe (3) enlarged in a cold way after being installed. Compared with the prior art, the sliding compact type aluminum-plastic laminated pipe fitting has the advantages of small diameter shrinkage, even connection stress as well as better applicability and market prospect, and is suitable for being surface mounted and buried in a hiding way, so as to be safer and more reliable.

Owner:浙江世进水控股份有限公司

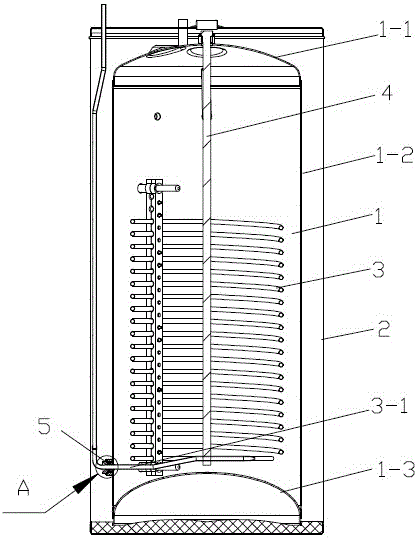

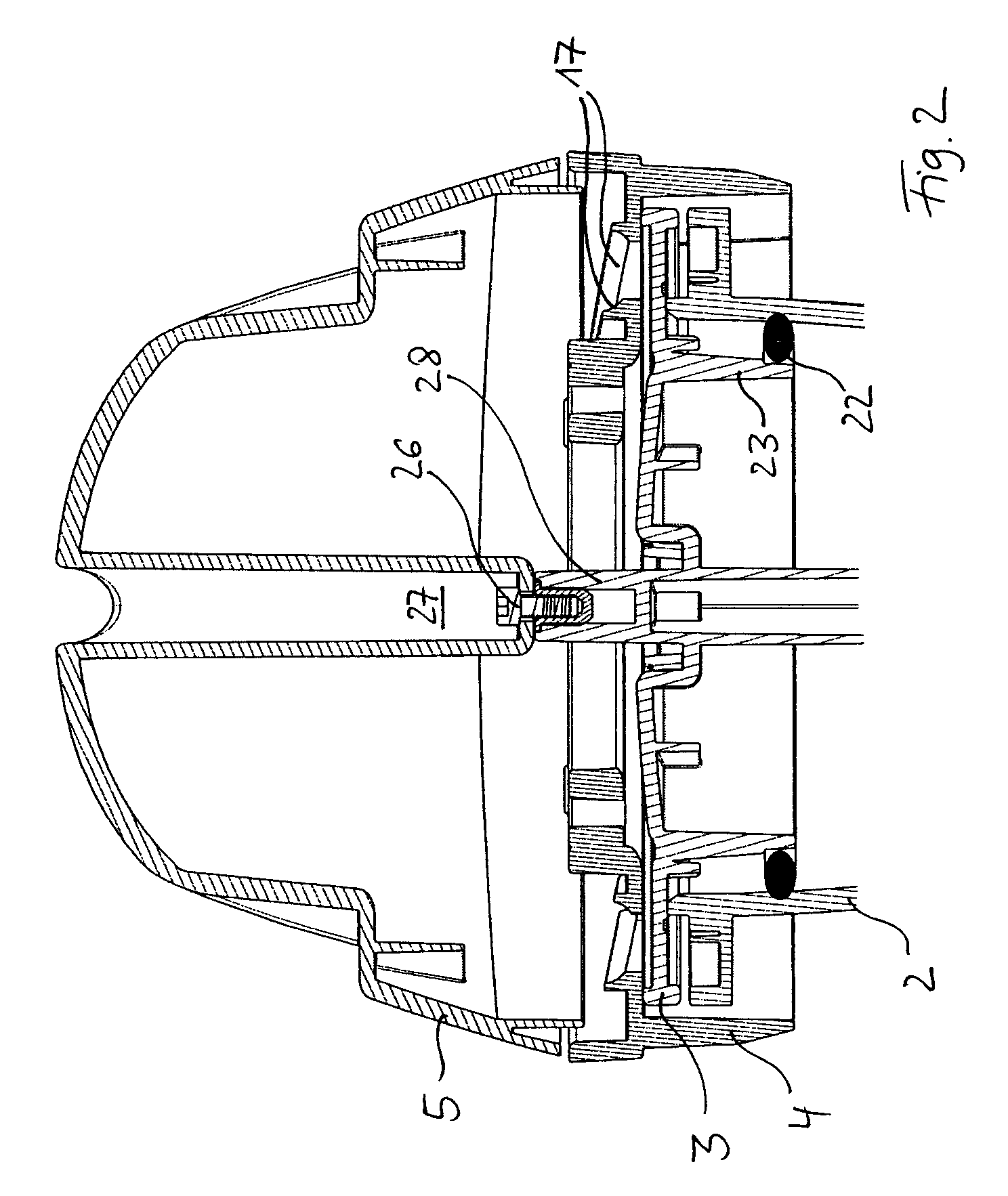

Water tank seal component and water heater using same

ActiveCN105042199AConsistent compression in all directionsUniform sealing effectFluid heatersPipesPositive pressureAxial force

The invention relates to a water tank seal component and a water heater using the same and belongs to the technical field of water heaters. The water tank seal component comprises a tube seat which is welded on the outside of a penetration hole of a water tank cylinder of the water heater, the tube seat and the water tank cylinder are made of the same materials, and the penetration hole is provided with a circular inner flange. An inner threaded hole with the drift diameter larger than the diameter of the penetration hole is formed in the tube seat. A seal plug with a central through hole is arranged in the tube seat and comprises an outer taper and a lining ring, wherein the small end of the outer taper is outward, the lining ring extends into the penetration hole from the through hole, and a round tube stretching into a barrel of a water tank of the water heater is inserted into the through hole. By means of the water tank seal component and the water heater using the same, radial and axial force components are produced by the outer taper surface of the seal plug, positive pressure between a seal plug inner hole and the outer circle surface of the round tube as well as between the inner end surface of the seal plug and the outer surface of the water tank cylinder is formed, and accordingly the reliable radial and axial seal is guaranteed; moreover, the circular tube vibration is completely separated from the water tank while electrochemical corrosion is eradicated, and accordingly, an ideal vibration absorption effect is provided.

Owner:JIANGSU GMO HI TECH

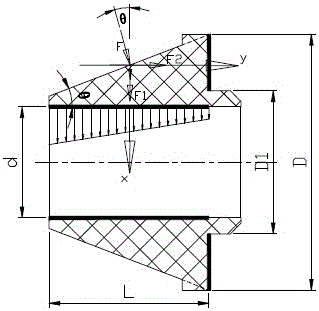

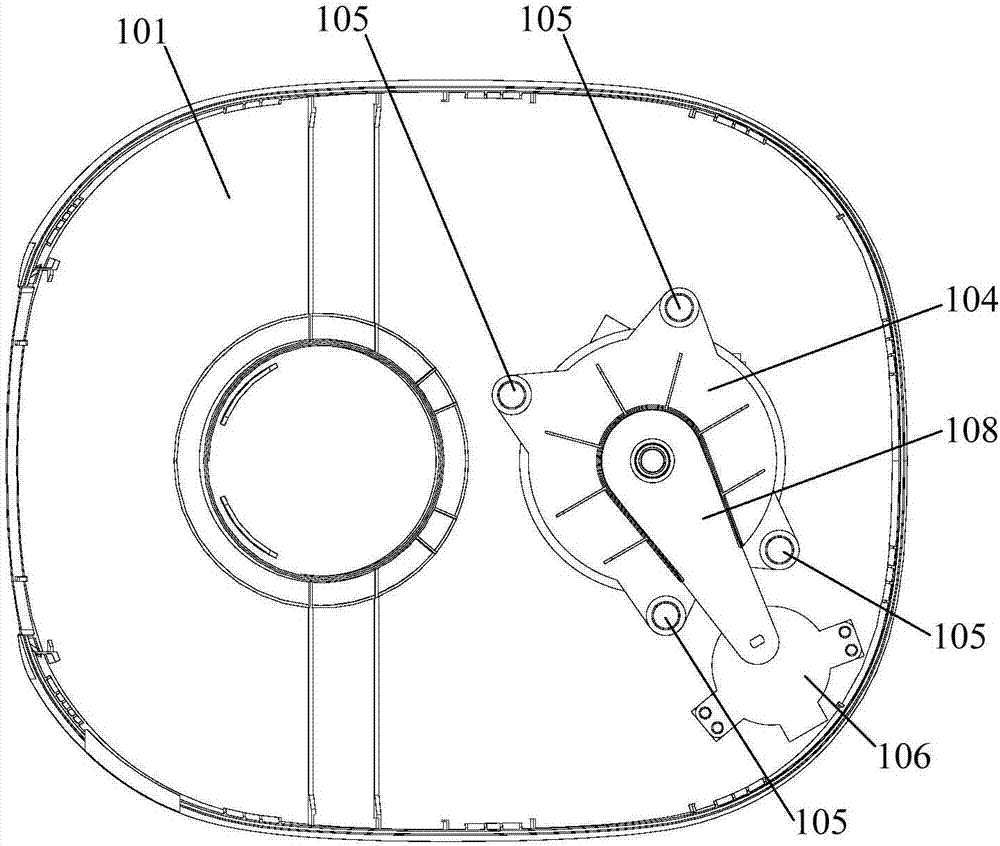

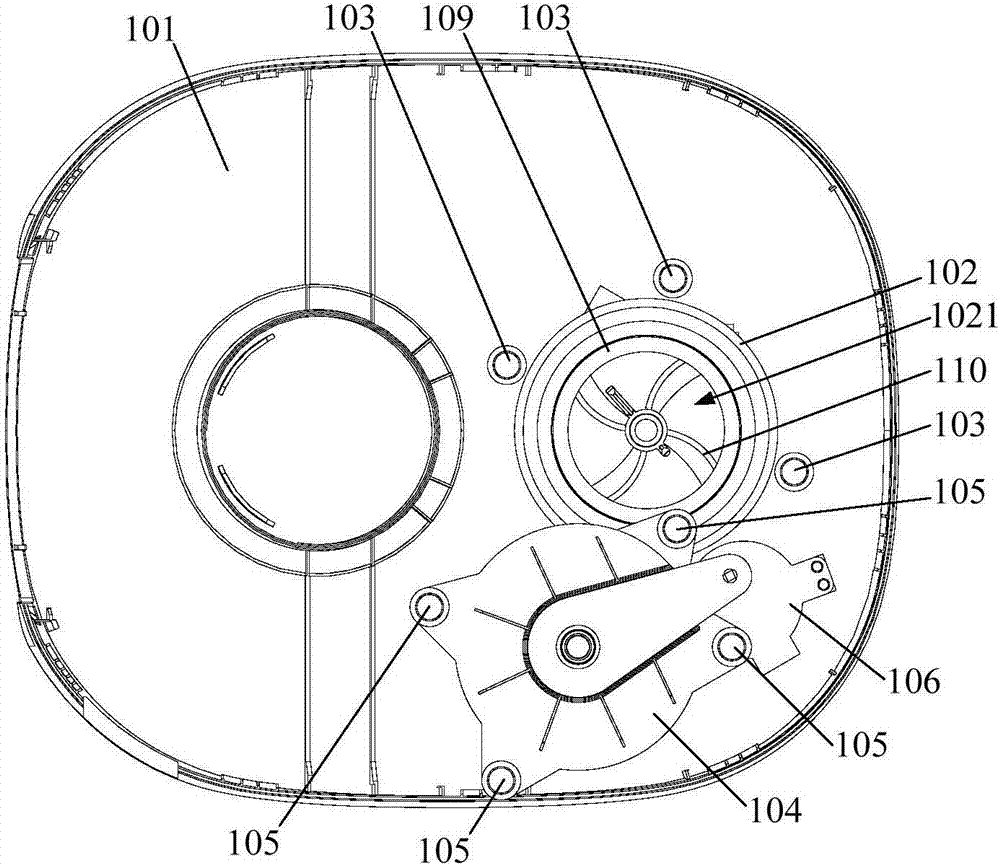

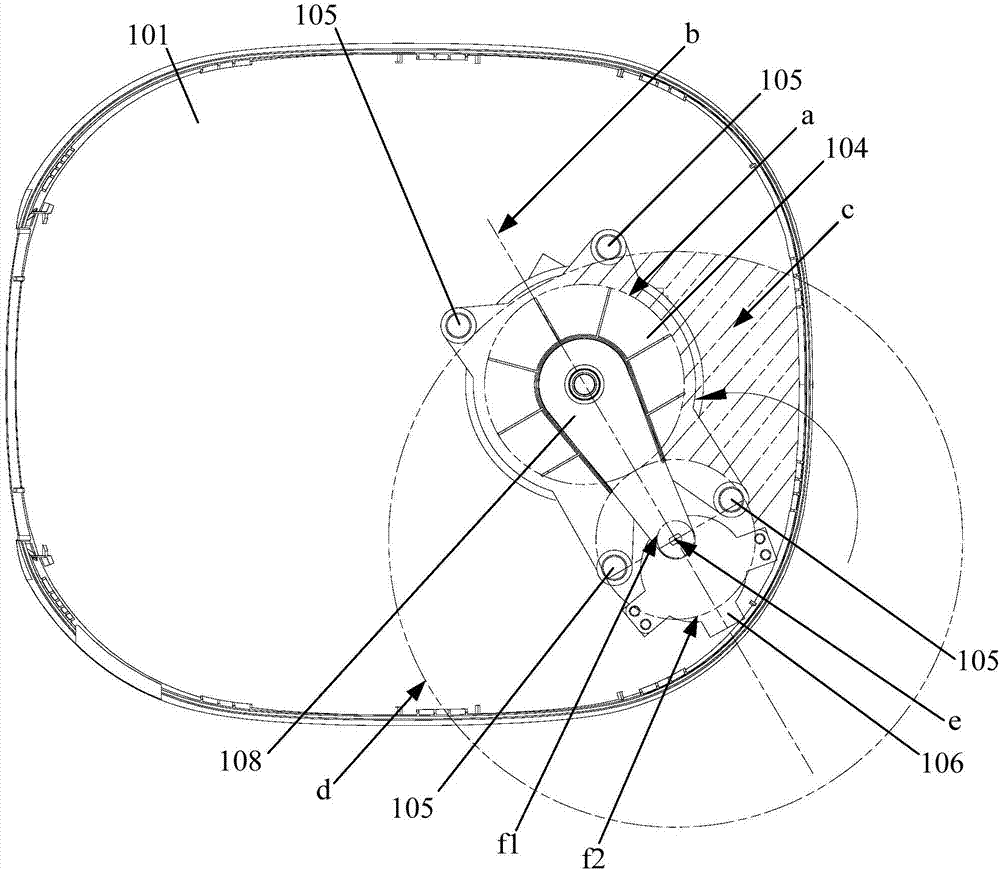

Seal device of clothes dryer roller end

ActiveCN101377053AUniform sealing effectImprove sealingTextiles and paperLaundry driersWear resistantWork time

The invention relates to a sealing device of a dryer, in particular to a sealing device applied on the end of a dryer tumble. The sealing device comprises a tumble support ring; the side surface of the tumble support ring is evenly provided with a wear resistant elastic part; the end of the tumble is arranged on the tumble support ring; the end face of the tumble is axially extruded on the wear resistant elastic part. The wear resistant elastic part comprises a wear resistant felt layer and an elastic felt layer. Because of the structure, the sealing device on the end of the dryer tumble can seal evenly; in addition, in the device, a wear resistant double-layered sealing strip is adopted, so that the sealing device on the end of the tumble can automatically compensate the wear of the tumble to the sealing strip, and the sealing does not become uneven because of longer working time; the device has better sealing effect to the end of the dryer tumble.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

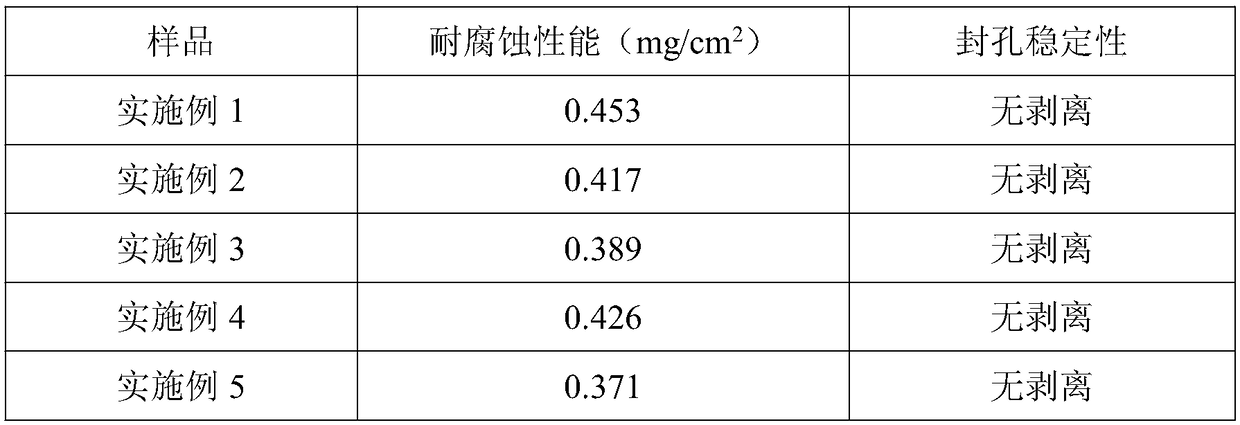

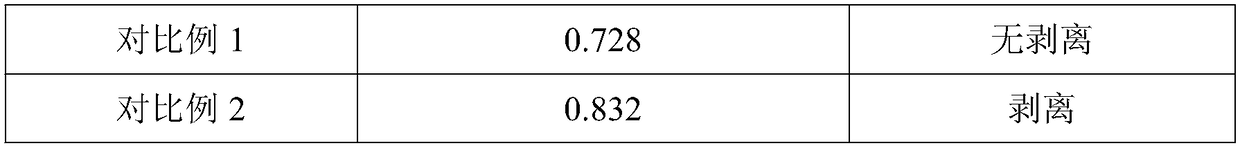

Hole sealing process for magnesium-aluminum alloy

InactiveCN108441923AGood adhesionImprove compactnessSurface reaction electrolytic coatingStearic acidMaterials science

The invention discloses a hole sealing process for magnesium-aluminum alloy. The hole sealing process comprises the following steps of: washing the magnesium-aluminum alloy by using water; degreasingthe magnesium-aluminum alloy by using alkaline liquid; polishing the magnesium-aluminum alloy by using an electrolyte and subsequently carrying out anodic oxidation; washing the magnesium-aluminum alloy by using deionized water and drying the magnesium-aluminum alloy by cold air to obtain film-coated magnesium-aluminum alloy for later use; by weight, adding 10-13 parts of tetraethoxysilane into 40parts of ethanol; subsequently adding acetic acid to regulate the pH value to be 4.6 to 5.3; continuously mixing for 30 min to 40 min to obtain sol A; adding 5-7 parts of butyl titanate into 60 partsof ethanol; mixing the butyl titanate with the ethanol uniformly; afterwards slowly adding the acetic acid to regulate the pH value to 3.5 to 4; continuously mixing for 30 min to 40 min to obtain solB; dissolving stearic acid by using isopropanol; adding the sol A and the soil B into the isopropanol to obtain hole sealing liquid; and carrying out hole sealing on the magnesium-aluminum alloy by using the hole sealing liquid. The hole sealing process disclosed by the invention has the characteristics of being free of fluorine, free of heavy metal pollution, stable in hole sealing effect and low in energy consumption.

Owner:长沙小新新能源科技有限公司

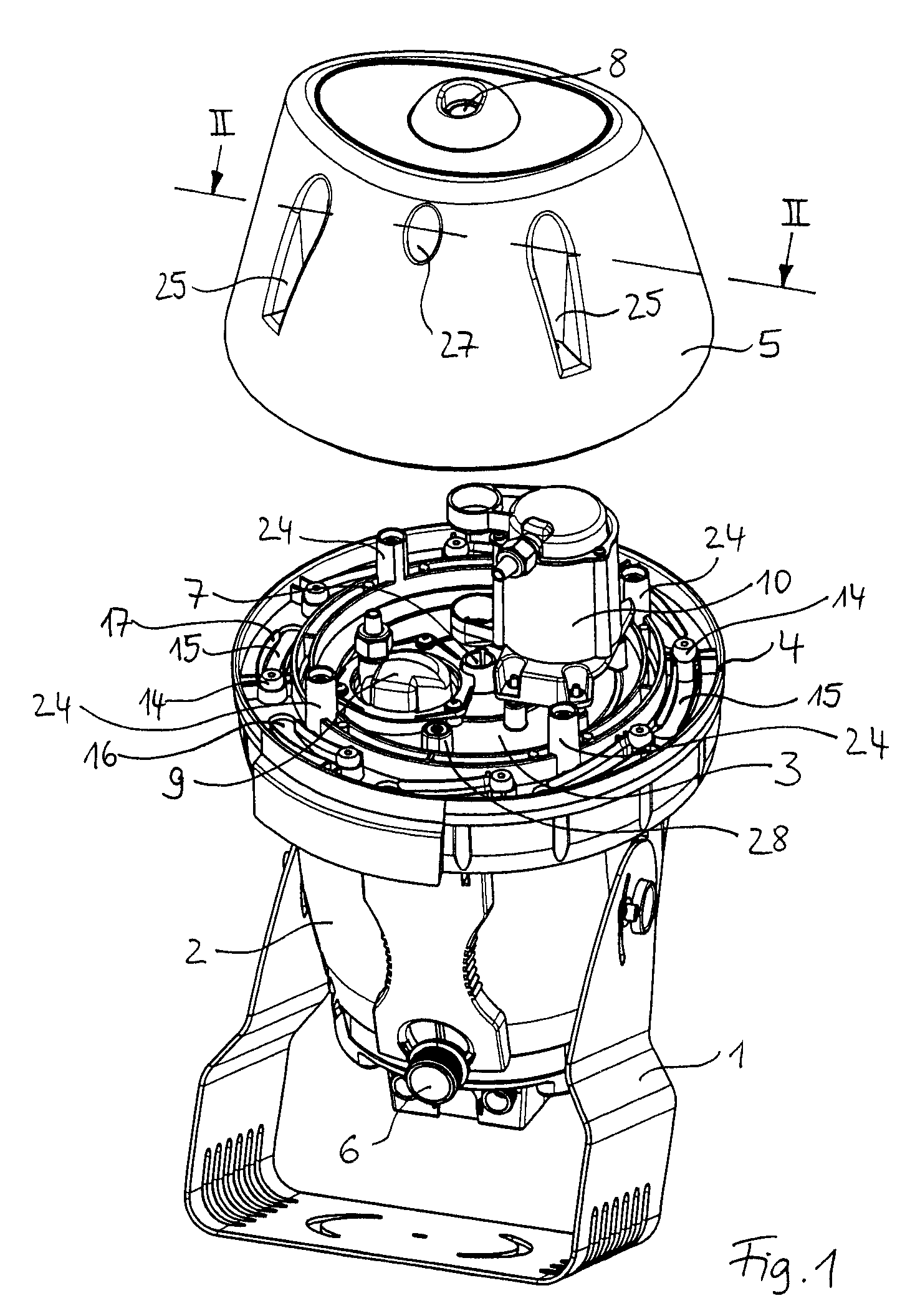

Cooking utensil and upper cover thereof

PendingCN107960850ACover firmlyAvoid fatigueCooking-vessel lids/coversBeverage vesselsEngineeringEnergy consumption

The invention provides a cooking utensil and an upper cover of the cooking utensil. The upper cover of the cooking utensil comprises an upper face cover, a first actuation part, a material discharge cavity door and a second actuation part, wherein the upper face cover is provided with a washing cavity body, and the washing cavity body is provided with a material discharge hole for discharging materials; the first actuation part is arranged on the upper face cover; the material discharge cavity door can cover the material discharge hole, or can translate in a plane vertical to the central axisof the material discharge hole to be separated from the material discharge hole, so that the material discharge hole is open; the second actuation part is fixed on the material discharge cavity door,is used for realizing actuation and fixing with the first actuation part when the material discharge cavity door covers the material discharge hole, and is separated from the first actuation part whenthe material discharge cavity door is separated from the material discharge hole. For the upper cover of the cooking utensil provided by the technical scheme, by utilizing the actuation and fixing ofthe first actuation part and the second actuation part, the stable covering of the material discharge cavity door with the material discharge hole can be guaranteed, and meanwhile, the purposes of reducing driving energy consumption and reducing fatigue damage of a power device are achieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

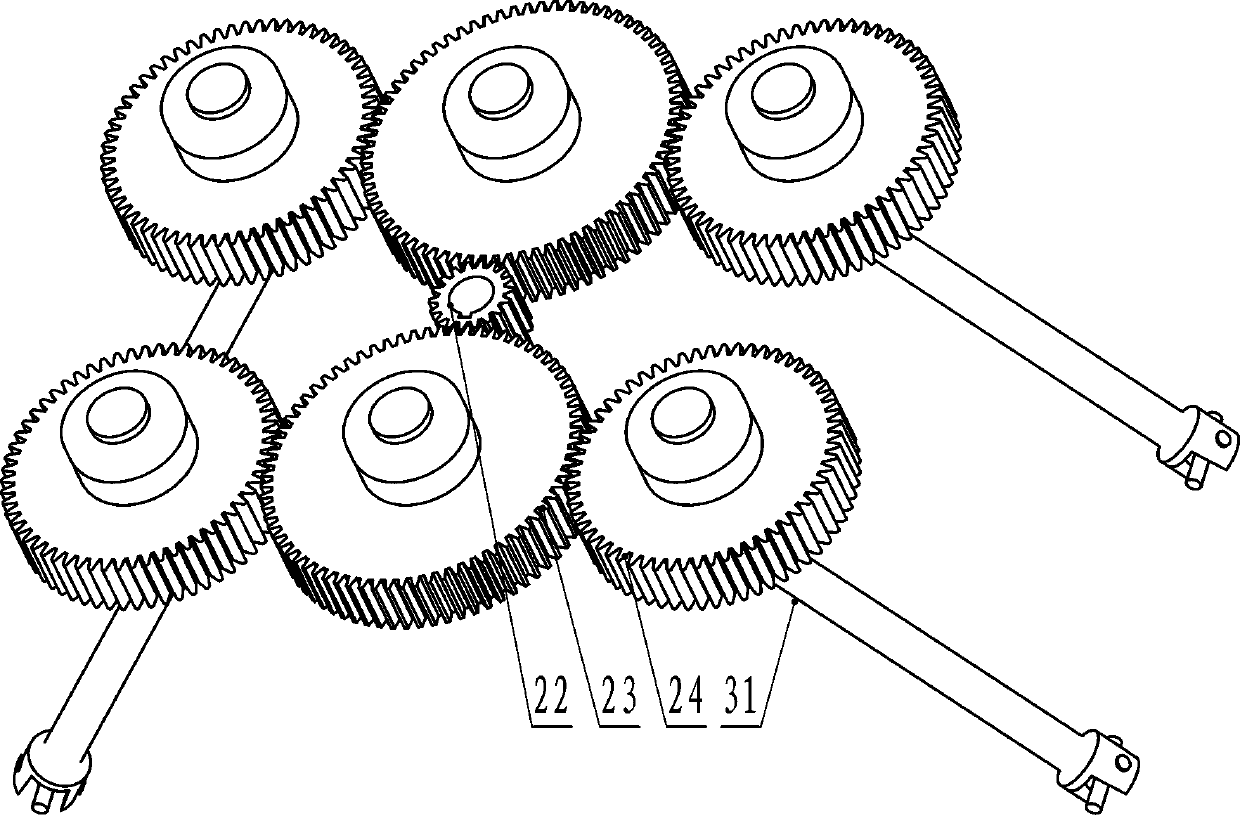

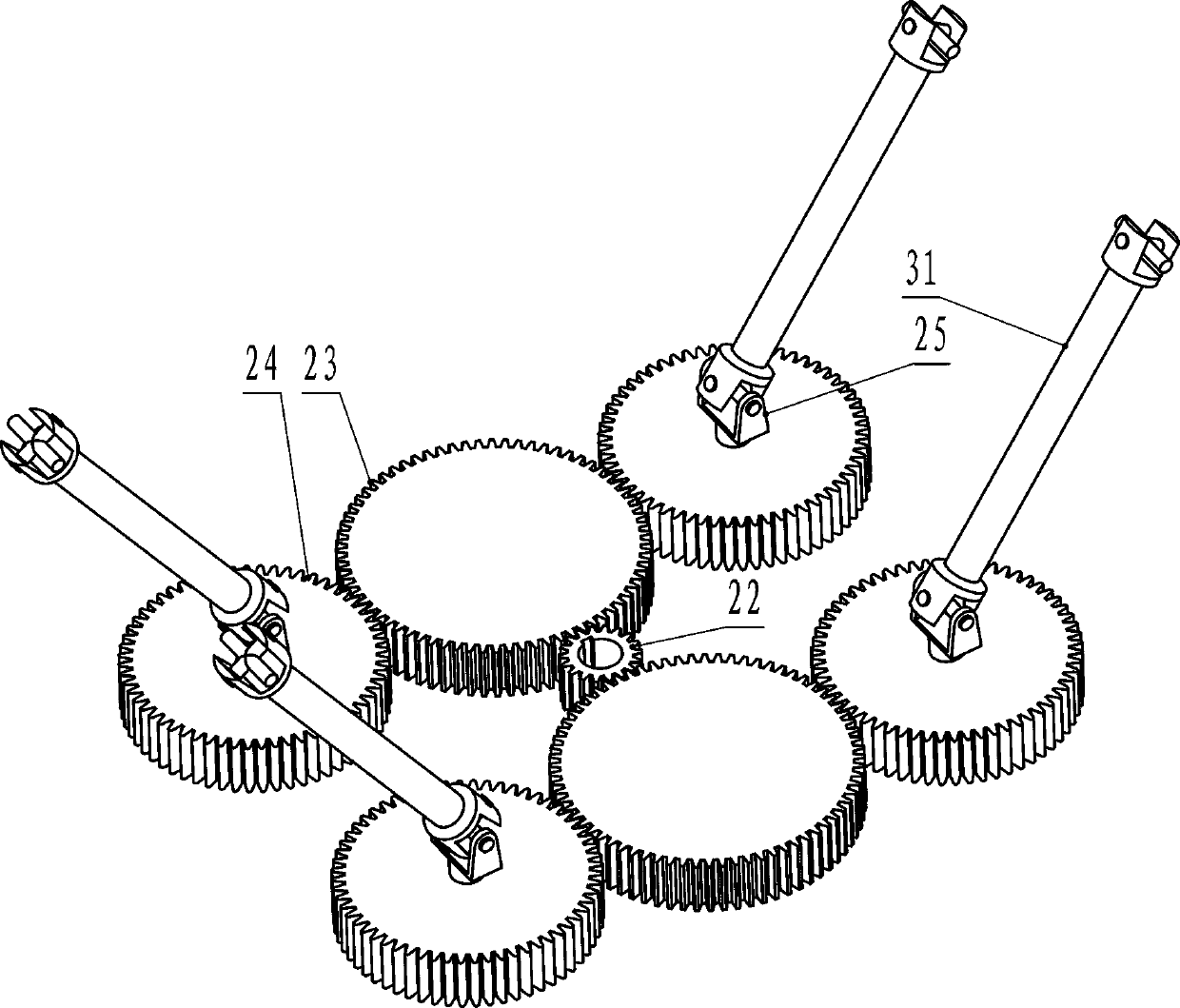

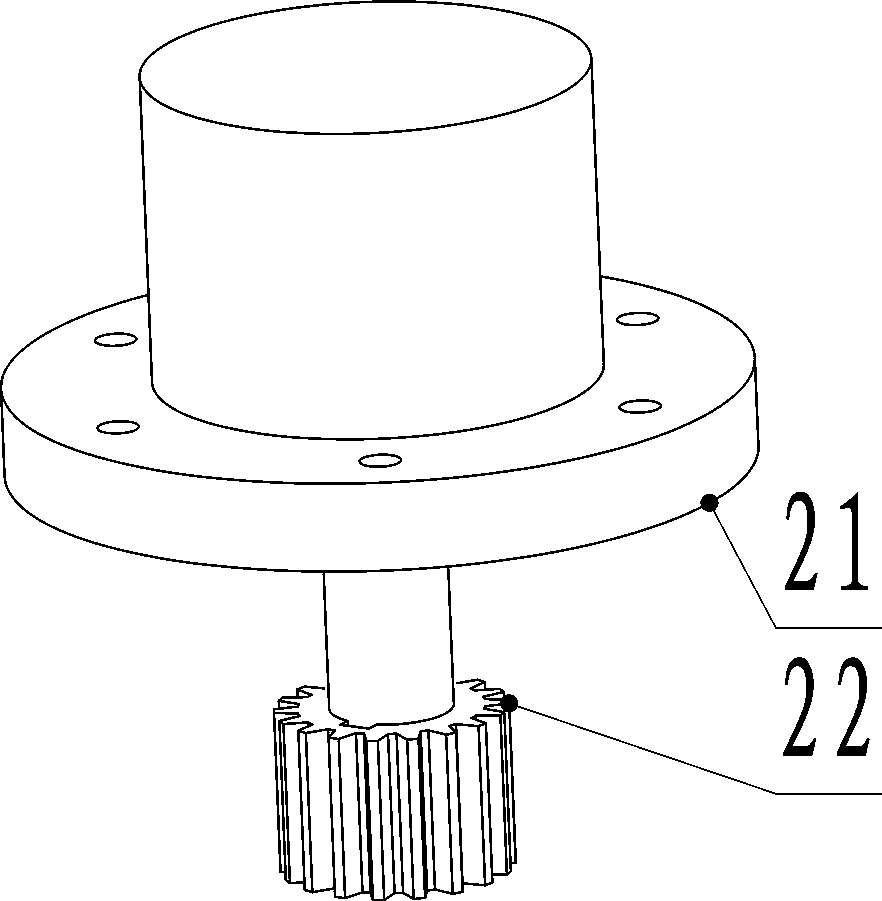

Bolt pretensioner for clamp connectors

InactiveCN107701853AQuick preloadReduced underwater aid connection timePipe elementsState of artHydraulic motor

The invention relates to a bolt pretensioner for clamp connectors, comprising a housing system, a reduction system and a tightening system and characterized in that the reduction system is mounted inthe housing system and is connected with the tightening system through keys, and bolts are fitly mounted in the tightening system. According to the operating principle of the bolt pretentioner, a hydraulic motor rotates and drives a small gear to rotate, the small gear drives a reduction gear to rotate, the reduction gear drives a transmission gear to rotate, the transmission gear drives a tightening socket to rotate, the tightening socket drives a bolt to rotate, and simultaneous pretensioning of multiple bolts is achieved. Compared with the prior art, the bolt pretensioner can provide rapidbolt pretensioning for submarine clamp connectors so that underwater auxiliary connection takes less time, submarine pipelines are quickly repaired and connected, submarine pipeline repair cycle is shortened, and integrated cost of marine oil-gas delivery is decreased.

Owner:SOUTHWEST PETROLEUM UNIV

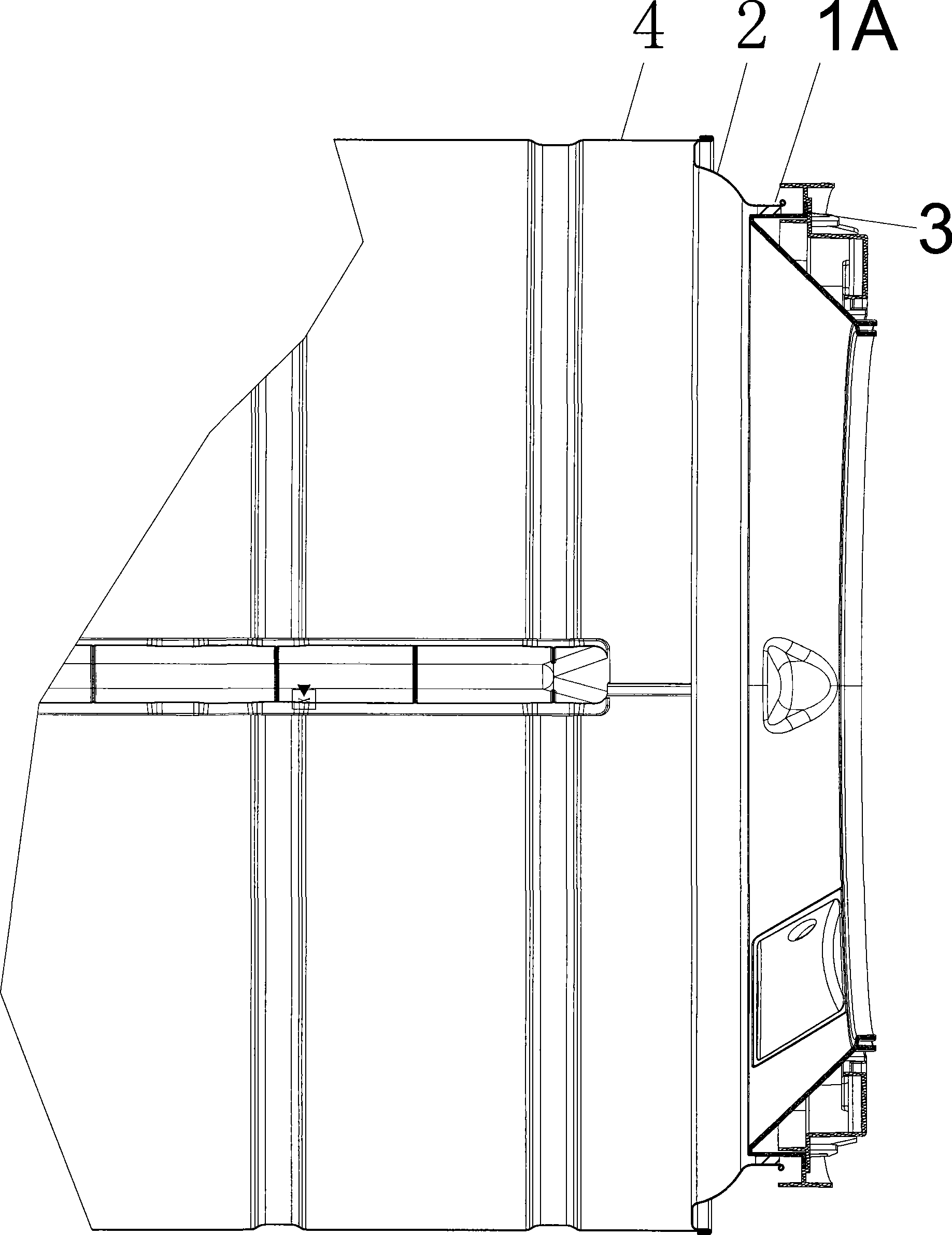

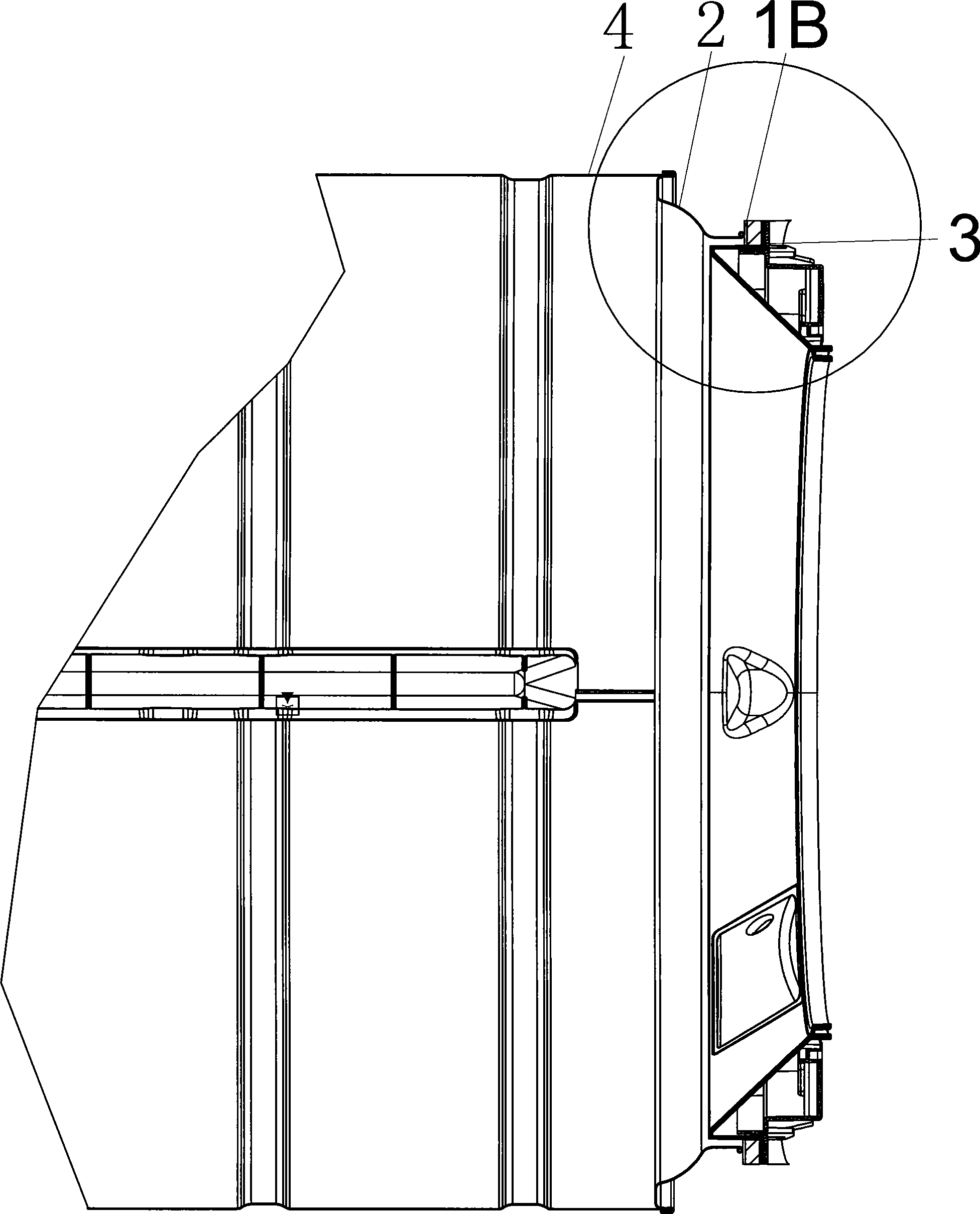

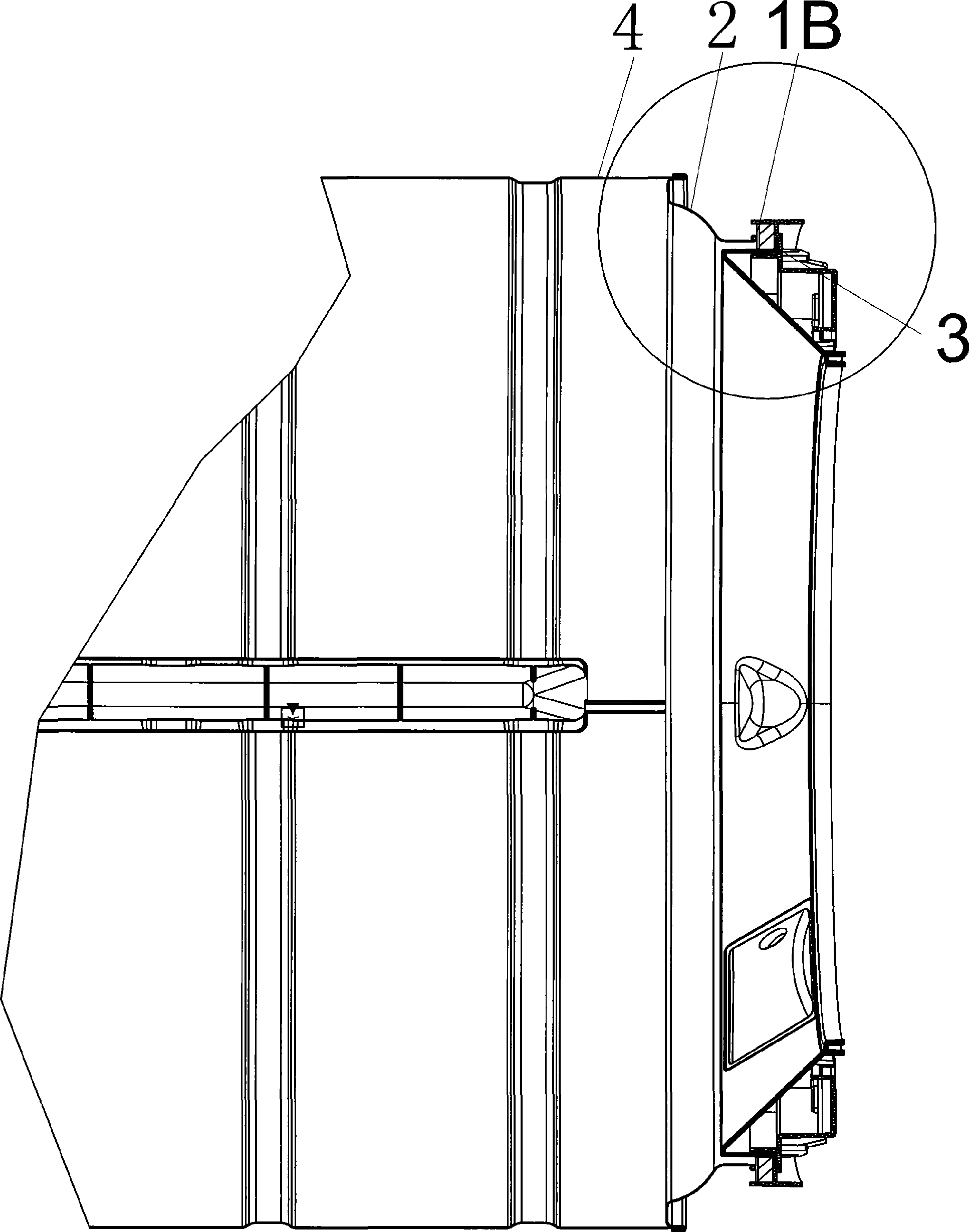

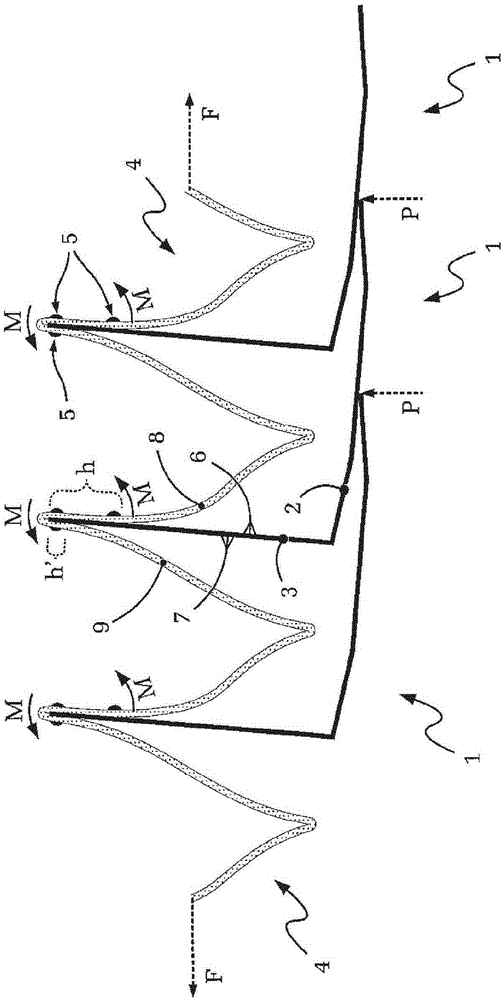

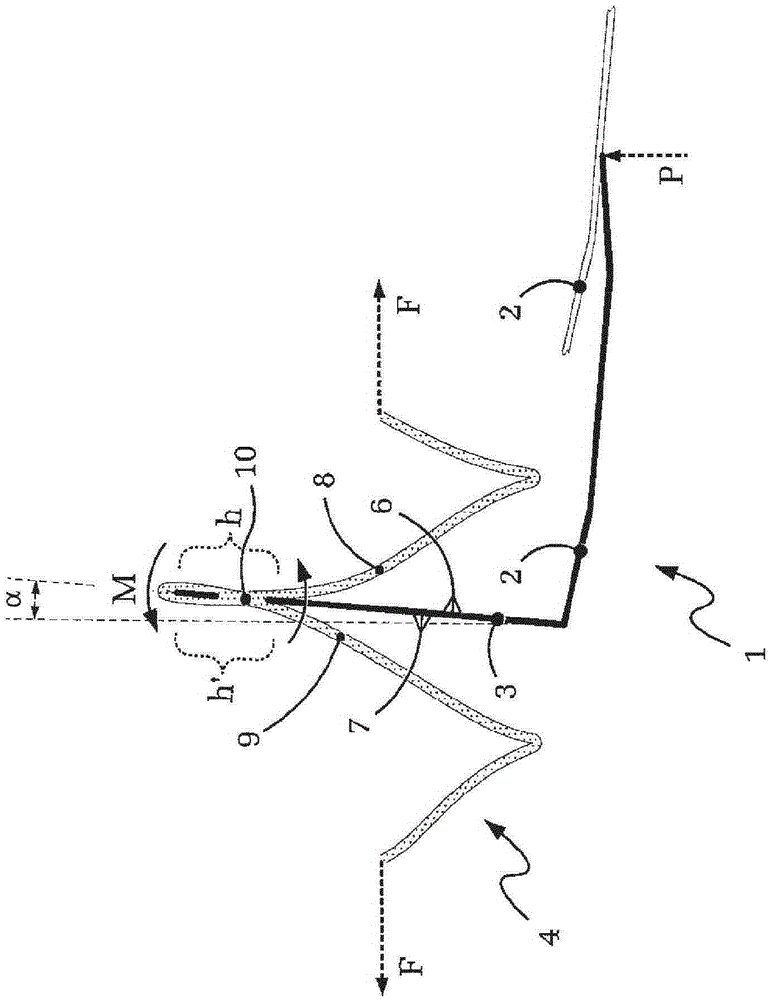

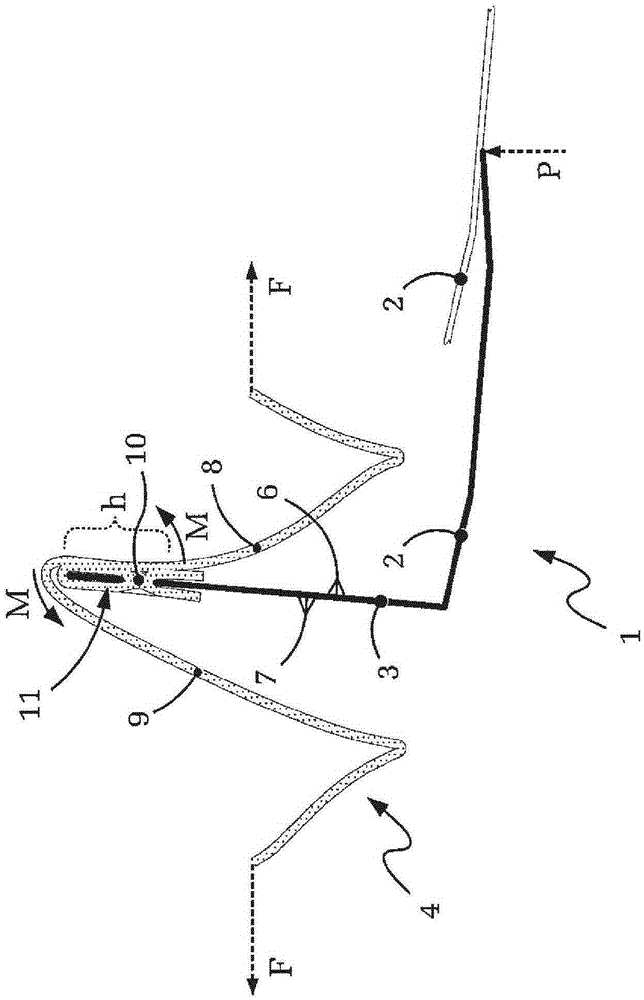

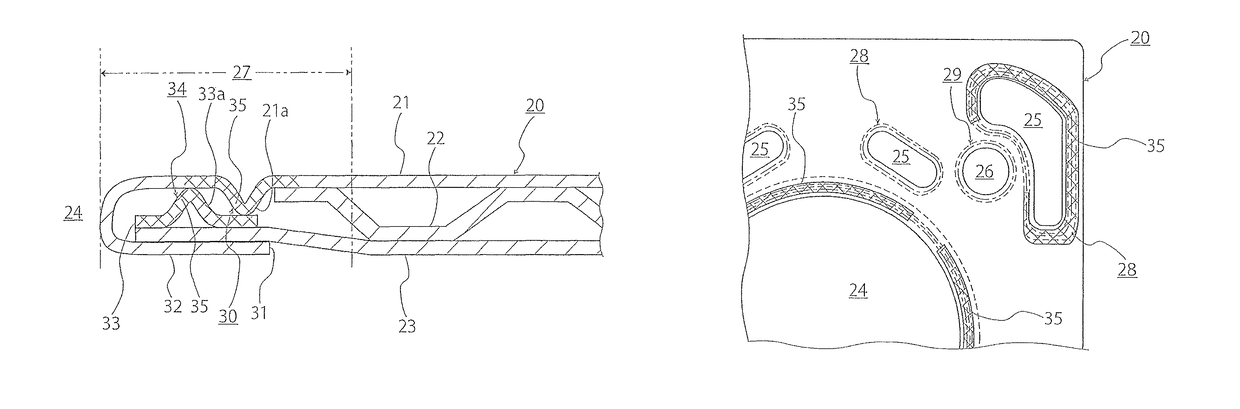

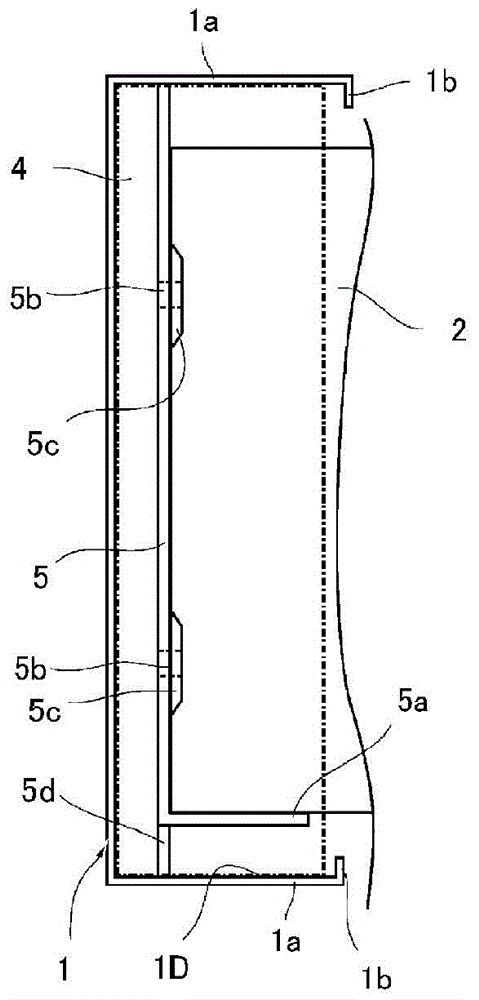

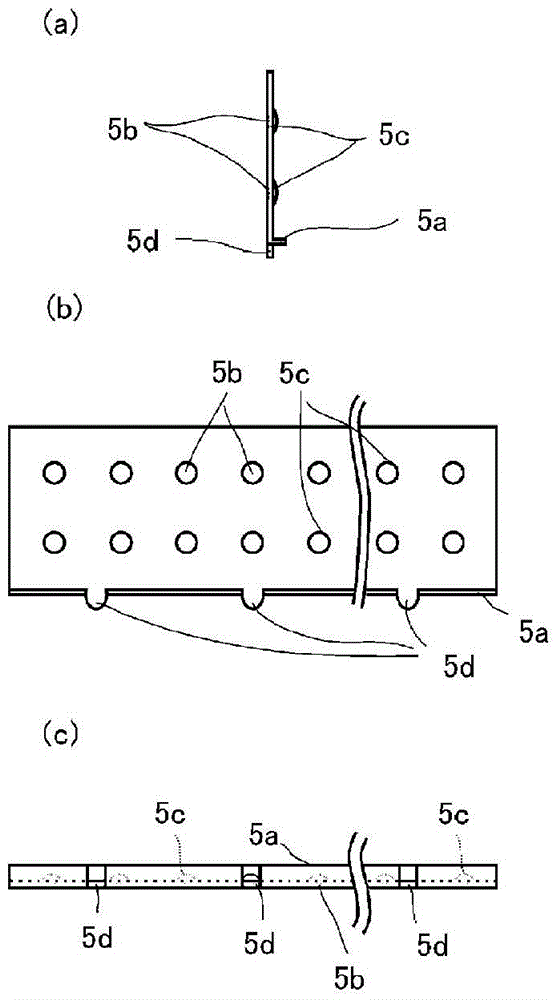

Inherently rigid telescopic protective cover

ActiveCN105408059AReliable closureHermetically closedCosmetic preparationsToilet preparationsEngineeringFlexural rigidity

The invention relates to a protective cover, comprising a plurality of protective cover segments (1), which can be moved in relation to one another telescopically and which each have a covering leg (2) and a supporting leg (3), and comprising a connecting element or bellows (4). When the protective cover is telescopically extended, an elastic restoring element produces a torque (M) and transfers said torque to the supporting leg (3). The invention is characterized in that the elastic restoring element is an integral component of the connecting element (4), in that the connecting element (4) has flexural rigidity and is connected to the supporting leg in a planar manner along a height range (H) of the supporting leg (3). Because of the invention, an additional elastic restoring element and the fastening thereof to the supporting leg are no longer necessary. Thus, the fully compressed size, weight, and production complexity of the protective cover can be reduced, and the leak-tightness and operational reliability are improved.

Owner:ARNO ARNOLD

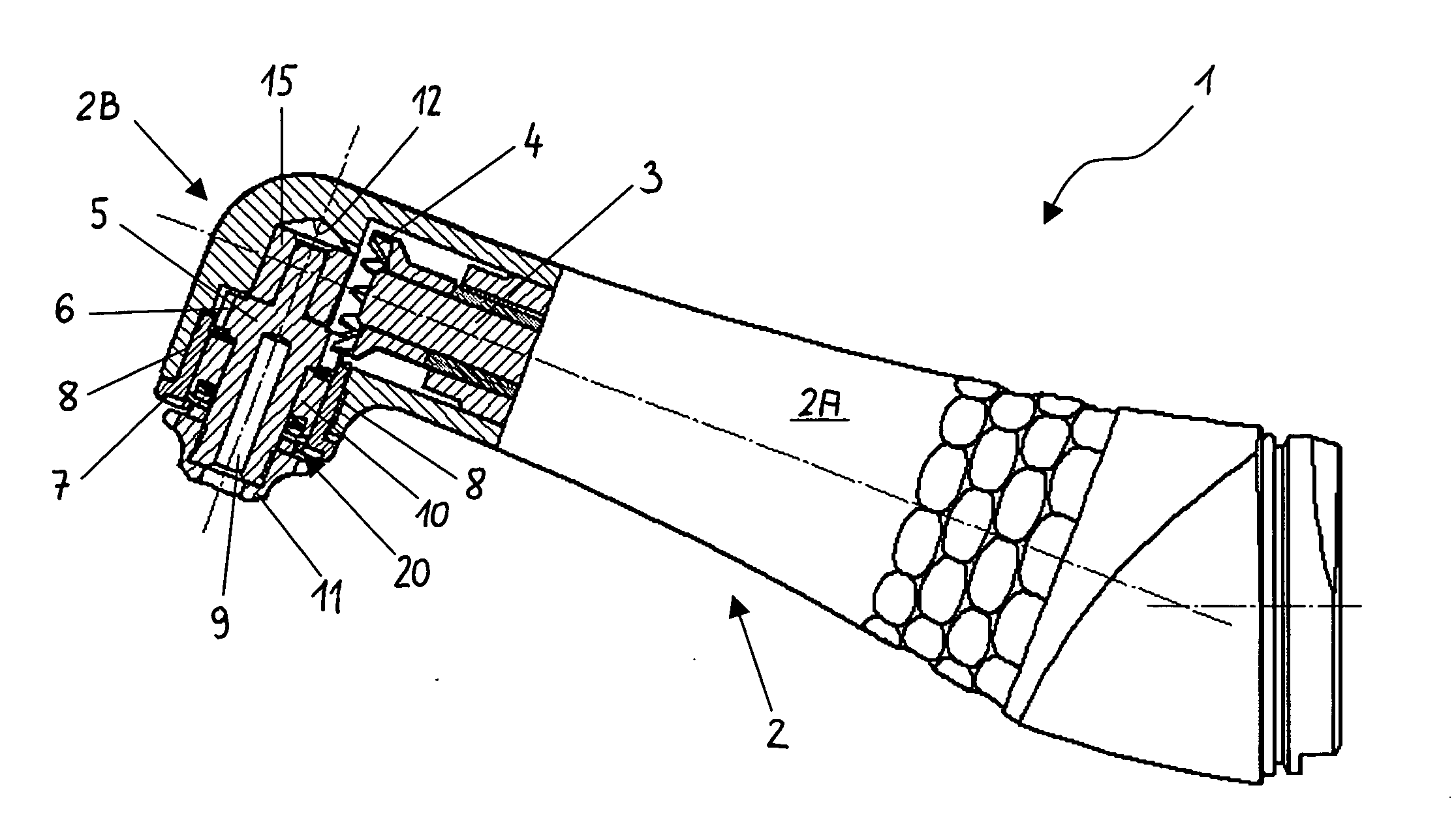

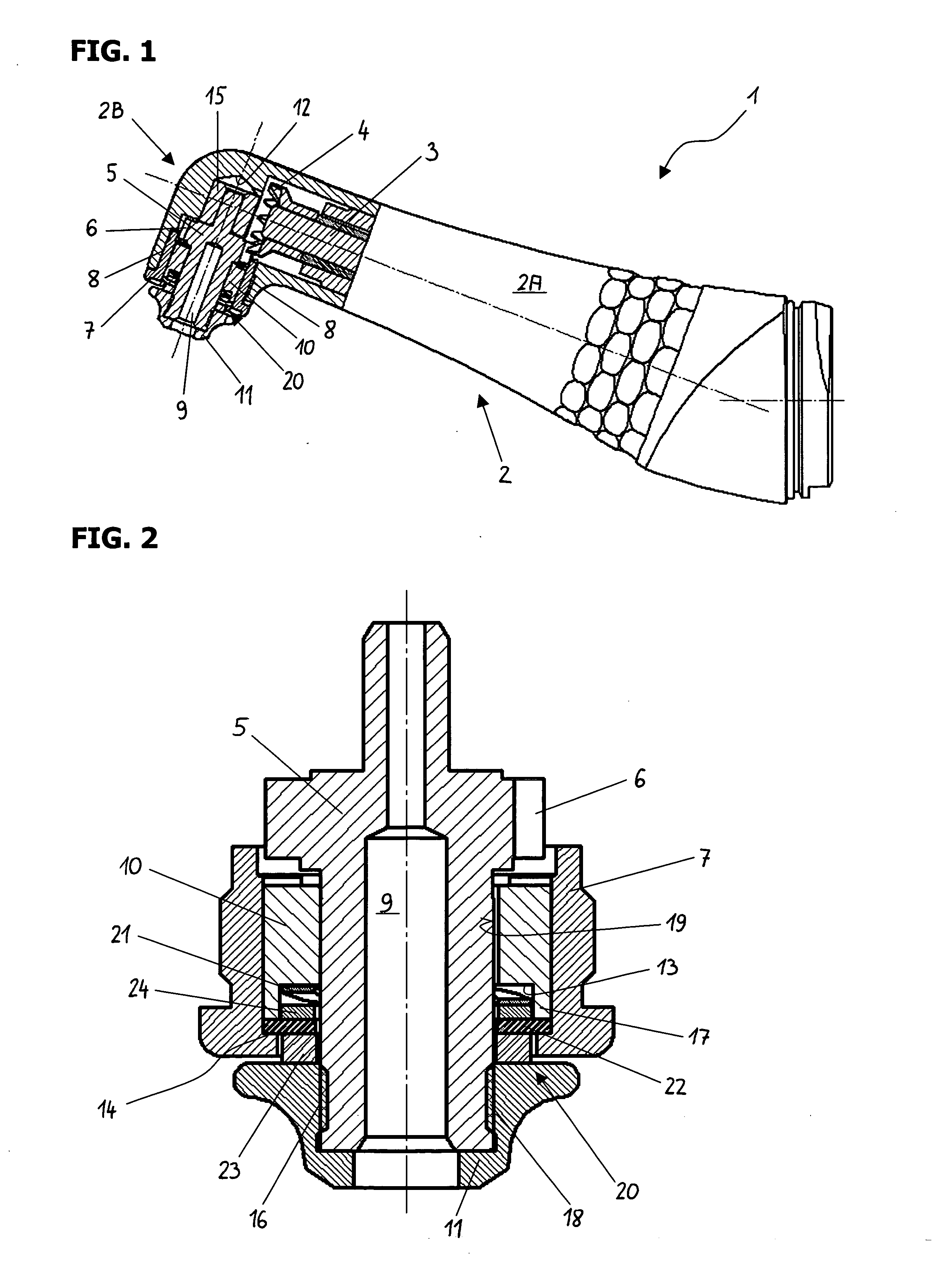

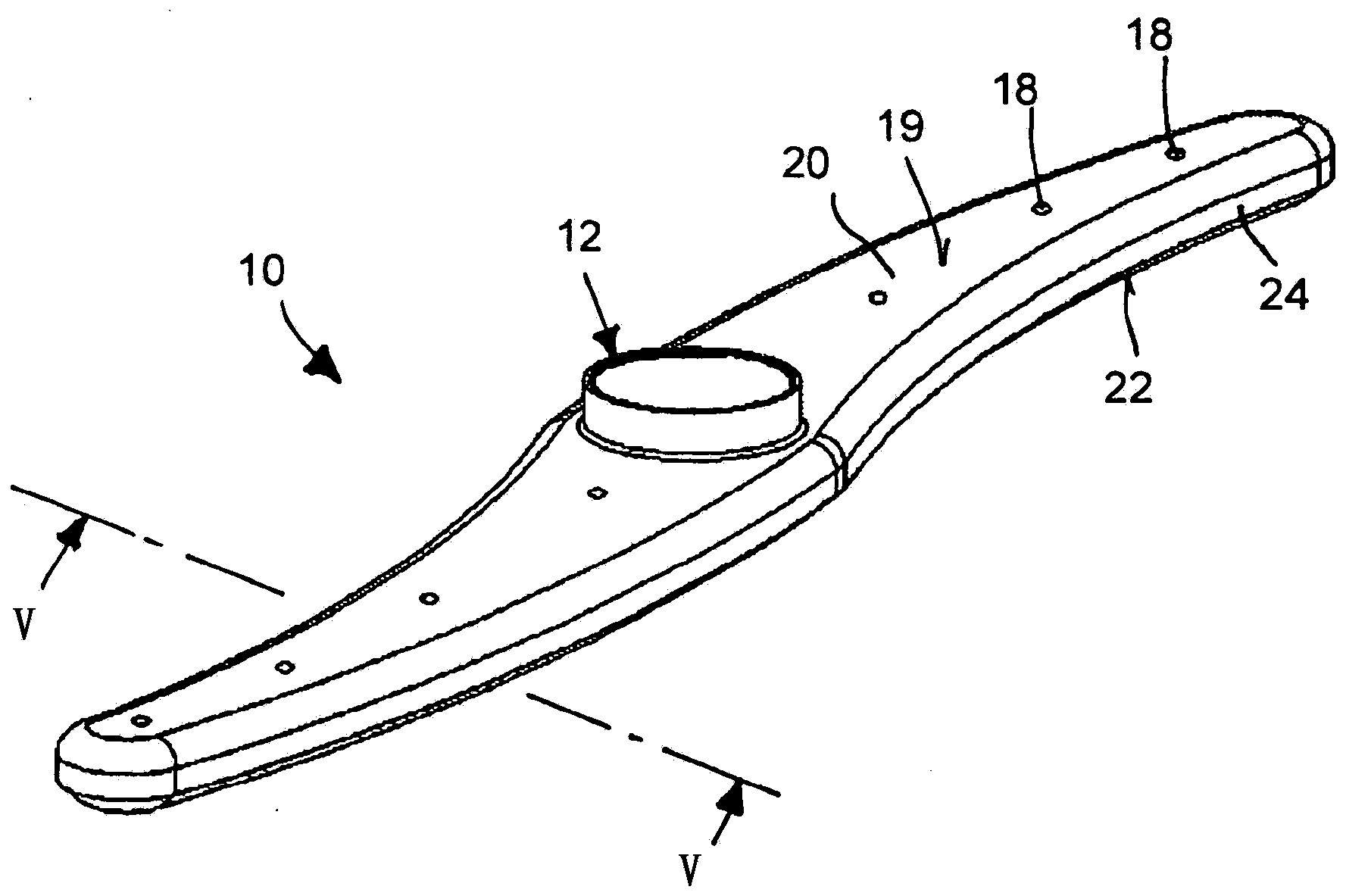

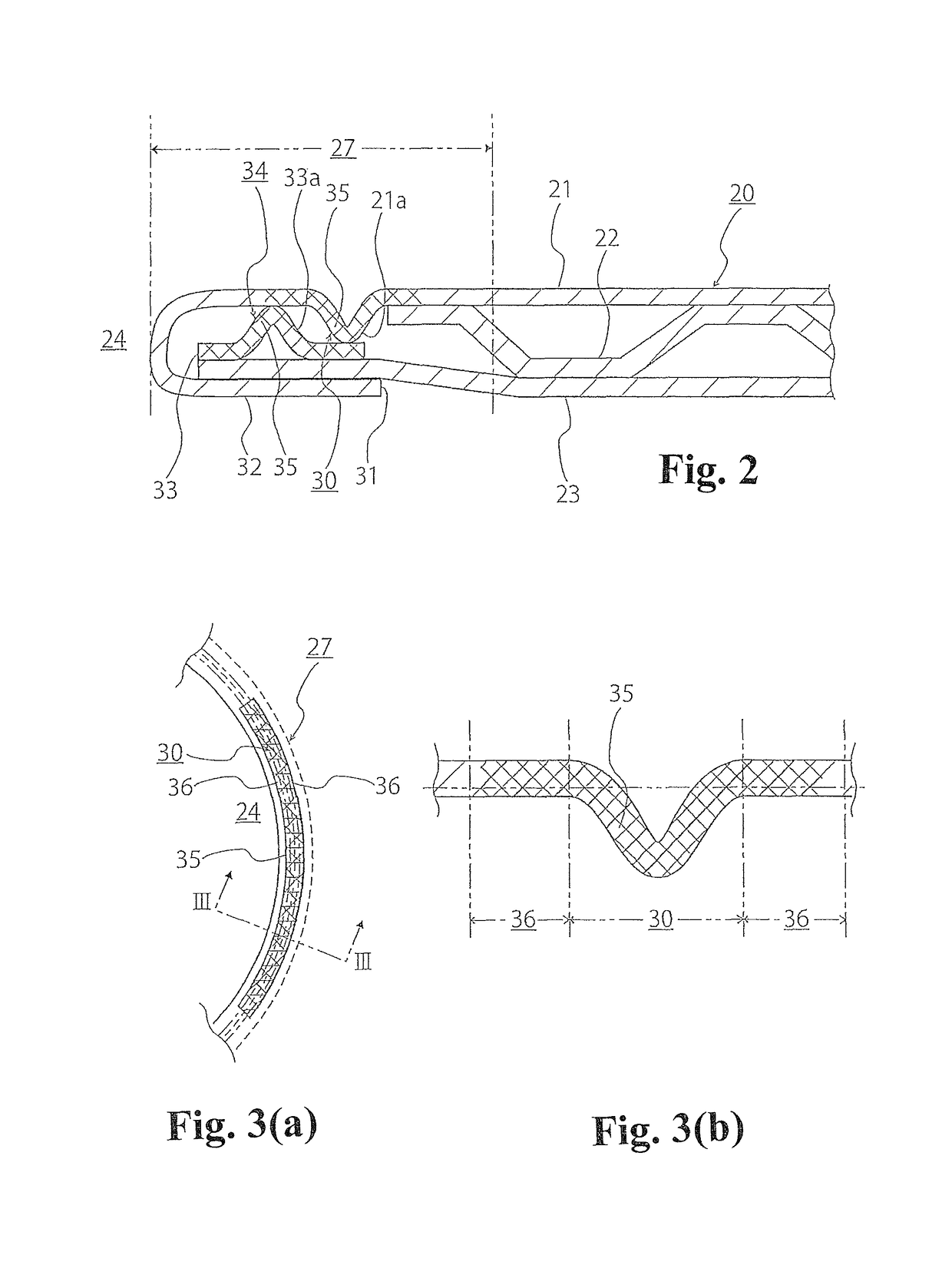

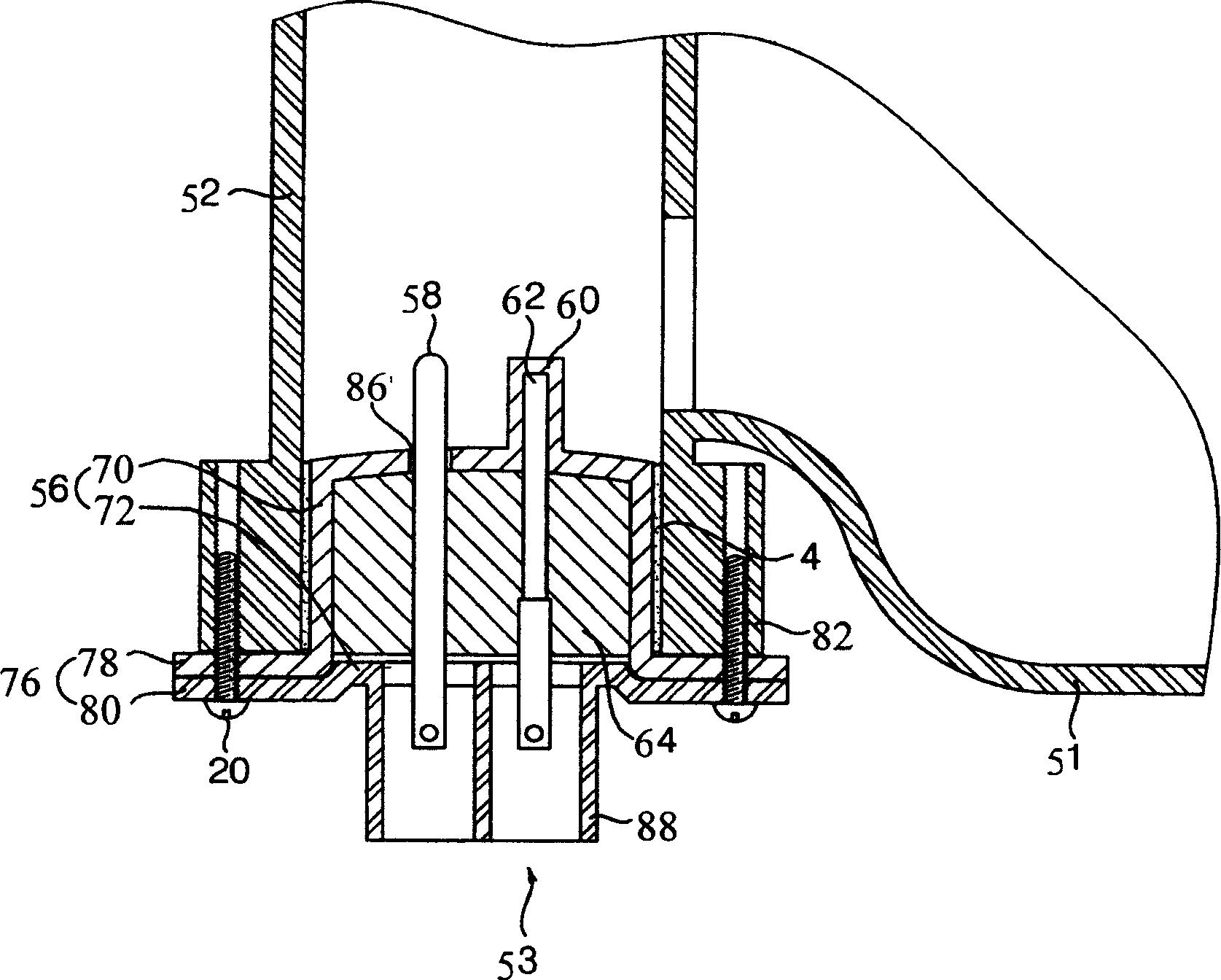

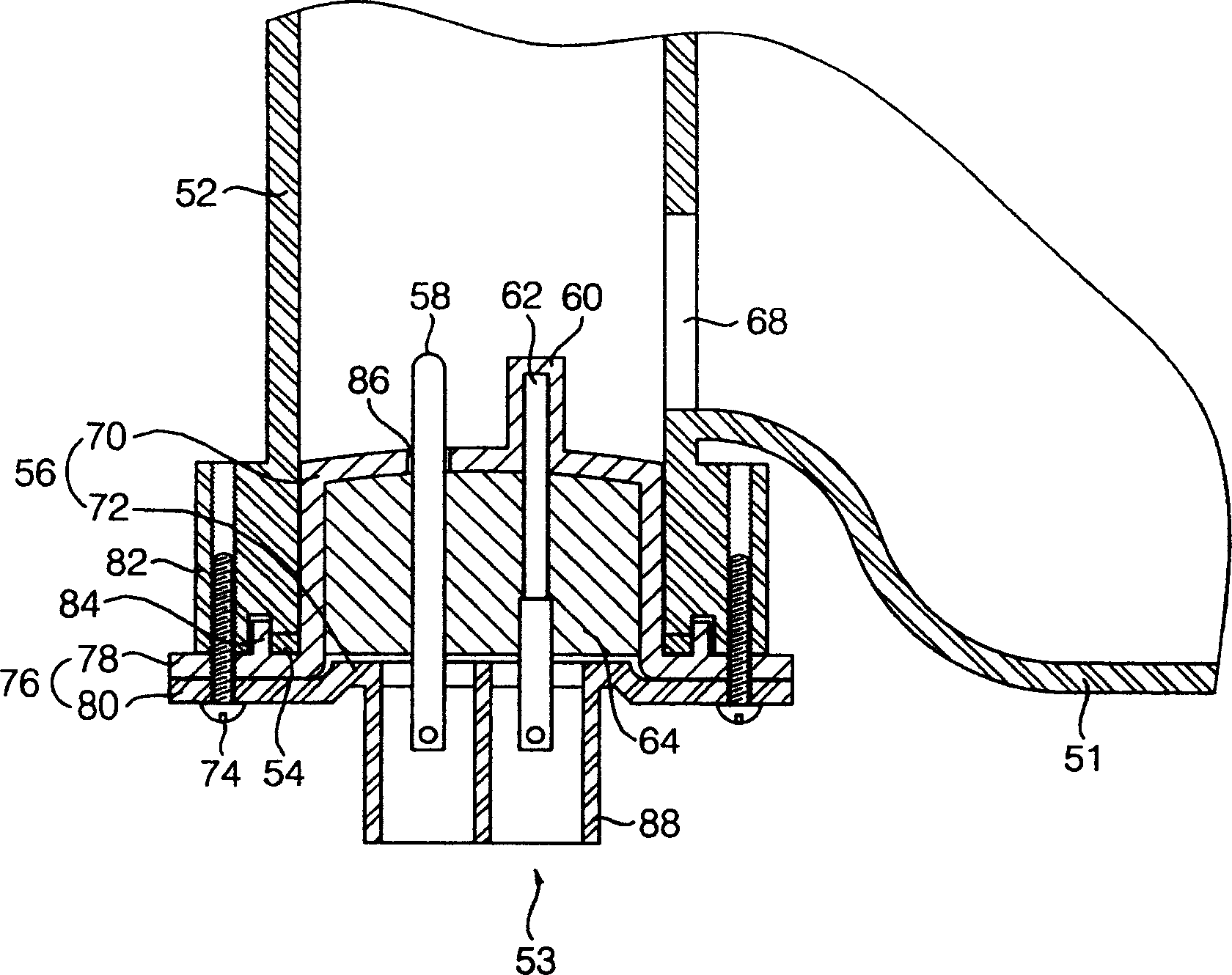

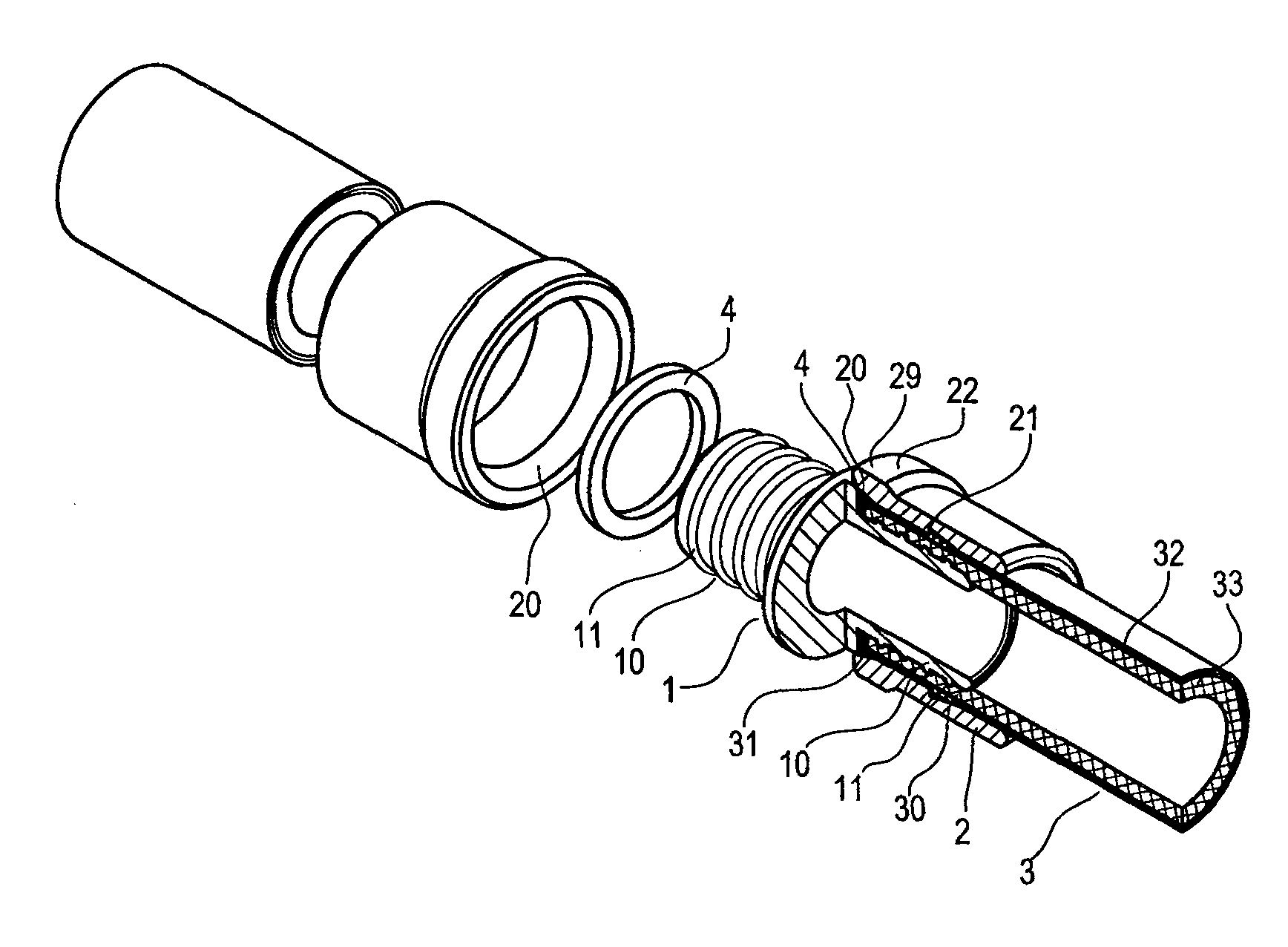

Seal for a medical handpiece

InactiveUS20050026110A1Improve sealingUniform quality sealing effectBoring toolsMedical treatmentGasket

The present invention relates to a seal in the tool side of a straight or contra angle handpiece head for sealing the interior of straight or contra angle handpieces. The seal is characterised by a spring, which prestresses a gasket of compressible elastic material against a fixed component and a rotating disk located in the immediate vicinity of the seal. Moreover, the present invention relates to a straight or contra angle handpiece with such a seal.

Owner:W&H DENTALWERK

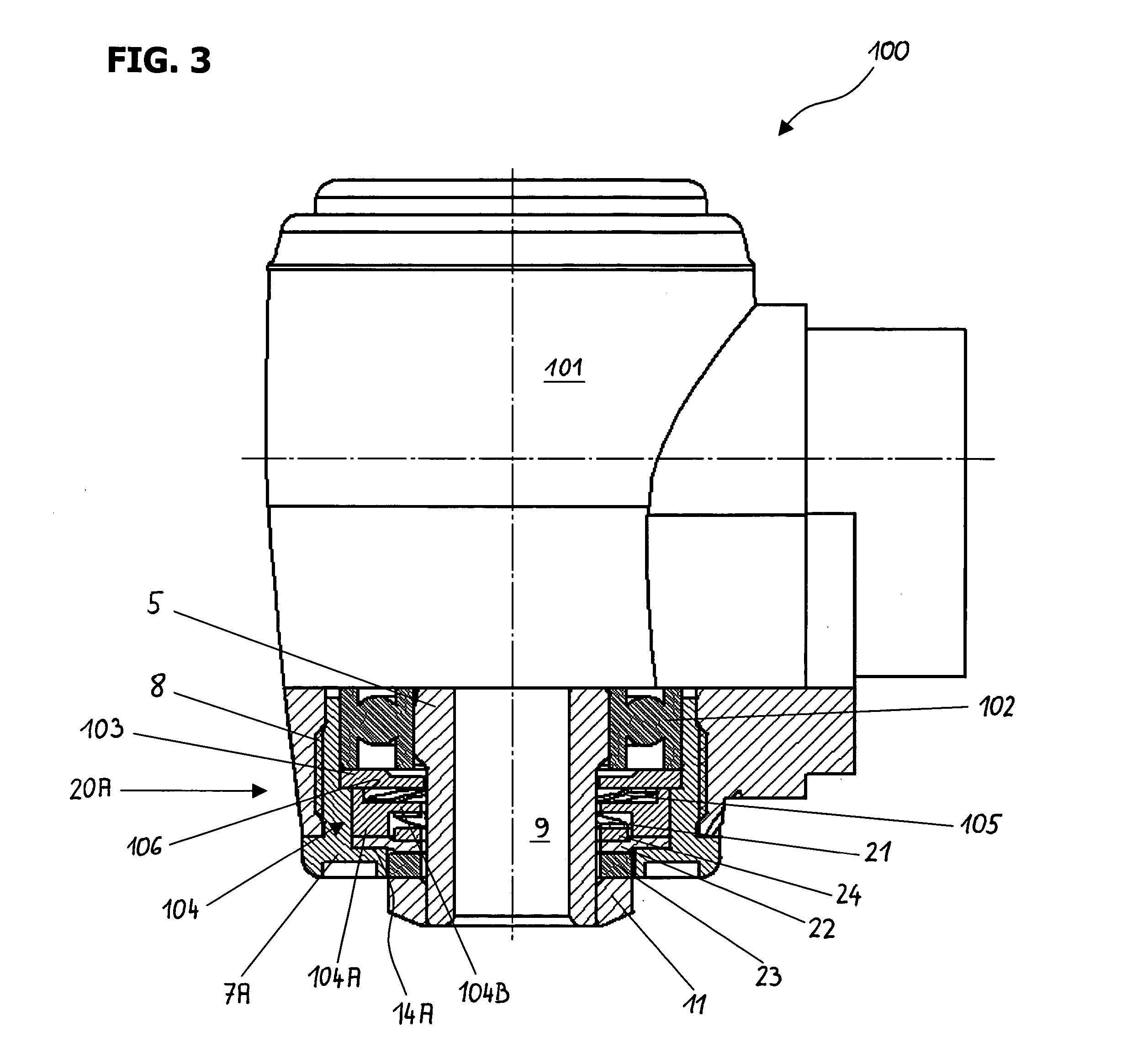

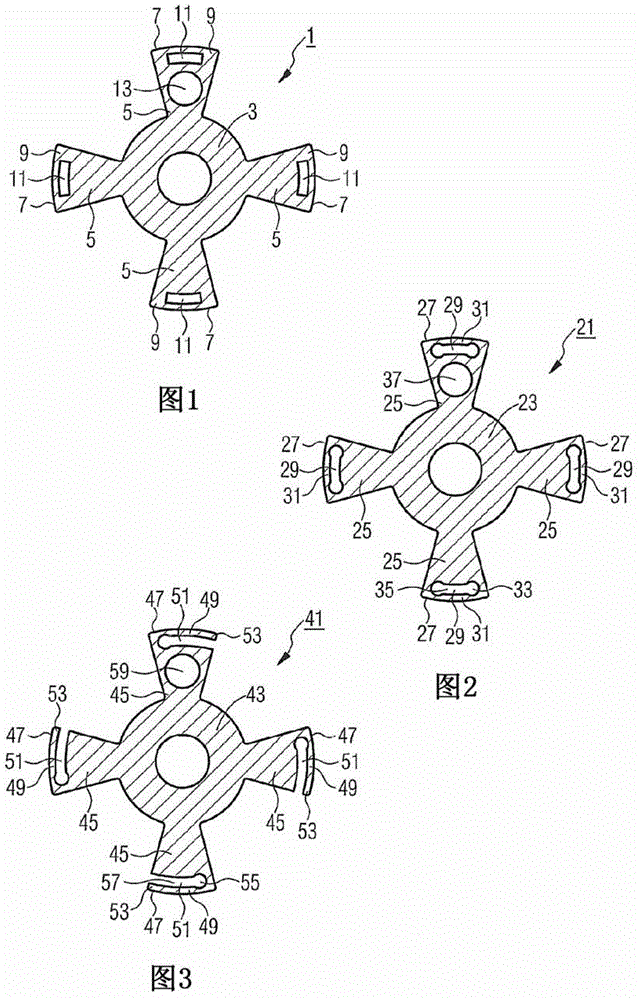

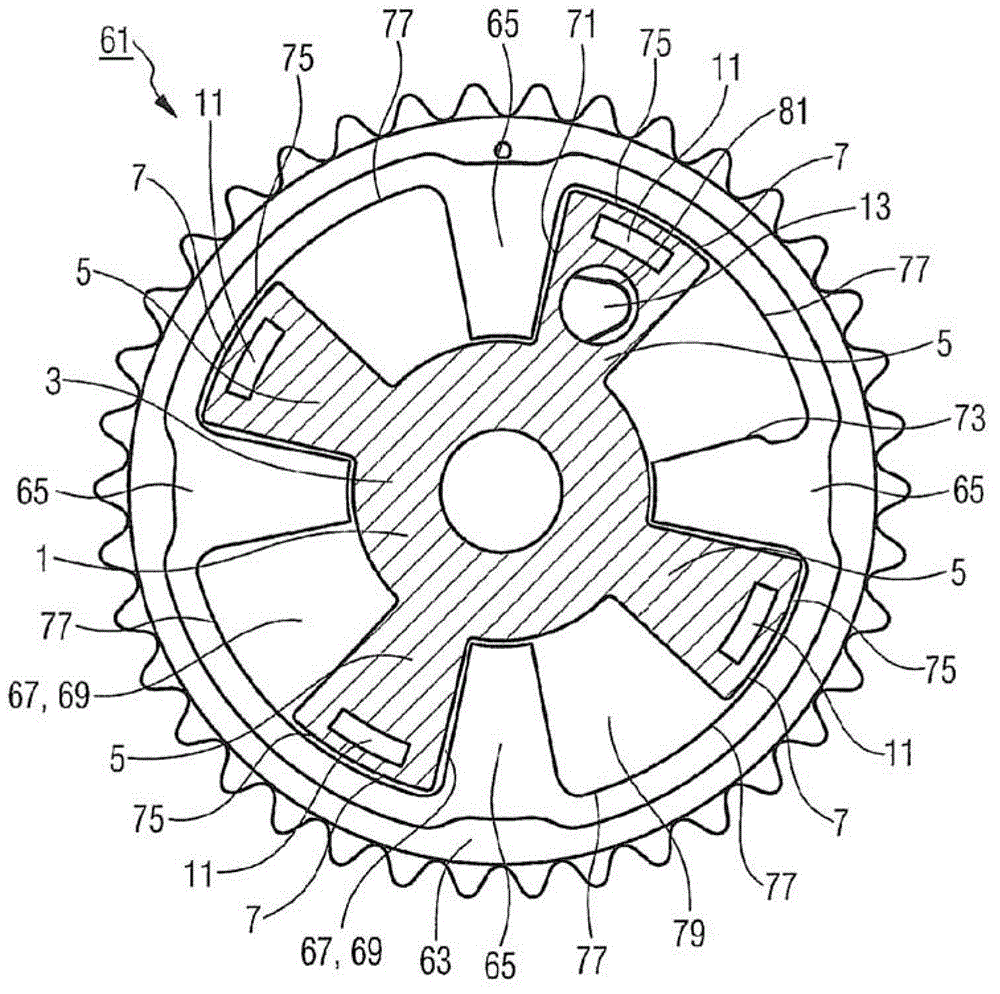

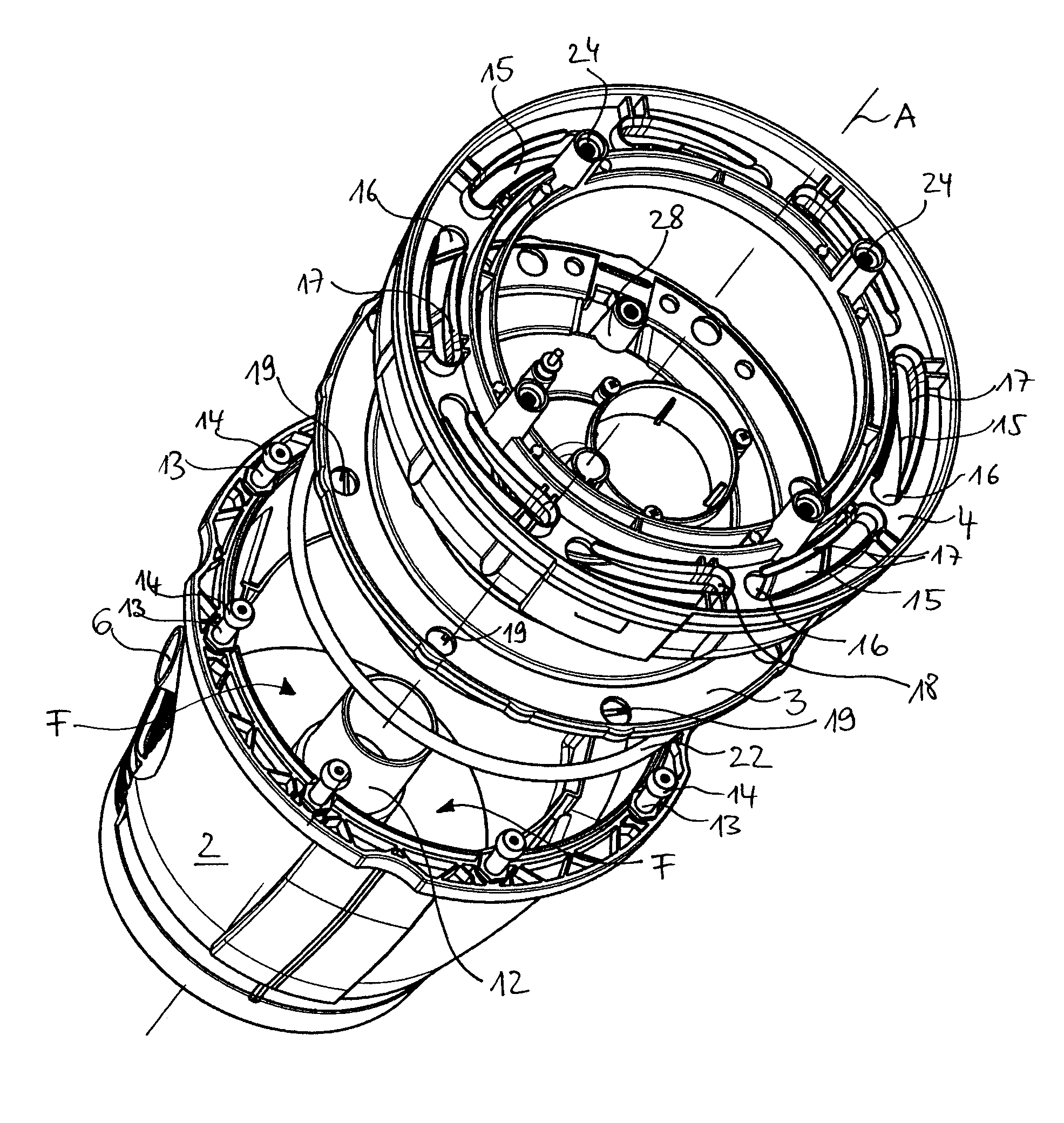

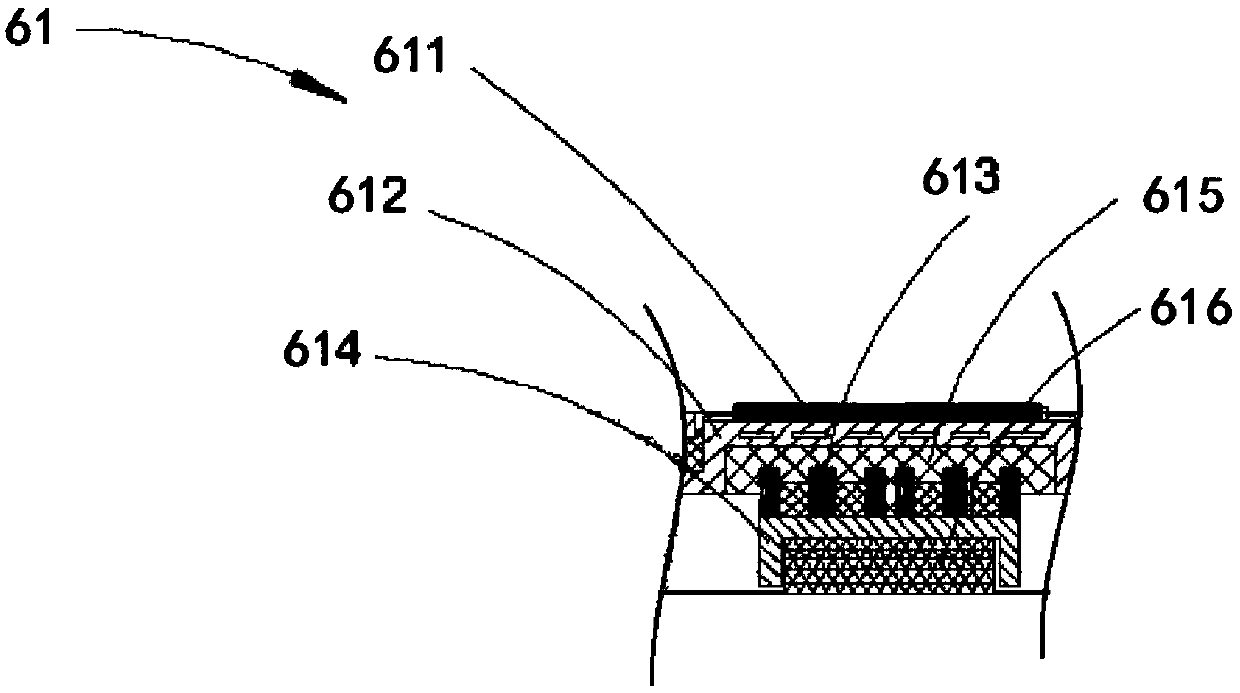

Rotor for a camshaft adjuster and camshaft adjuster

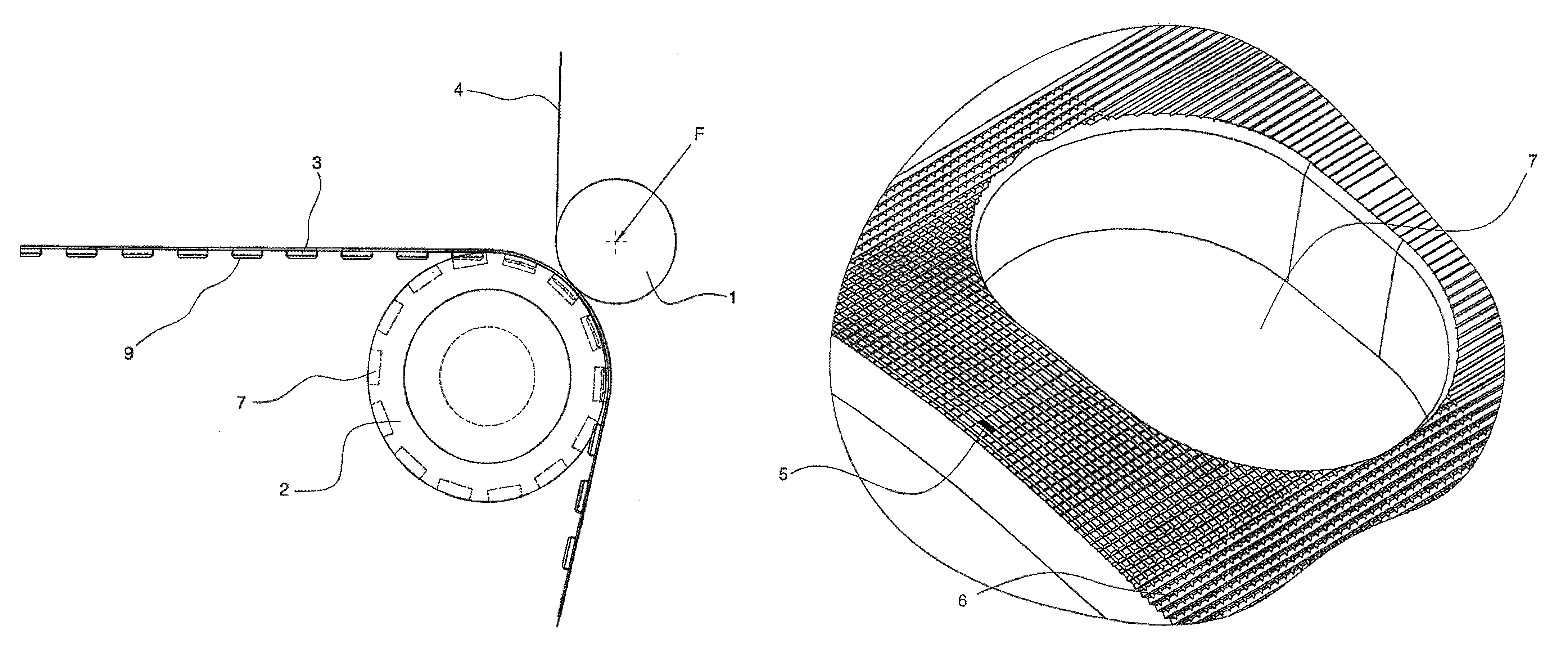

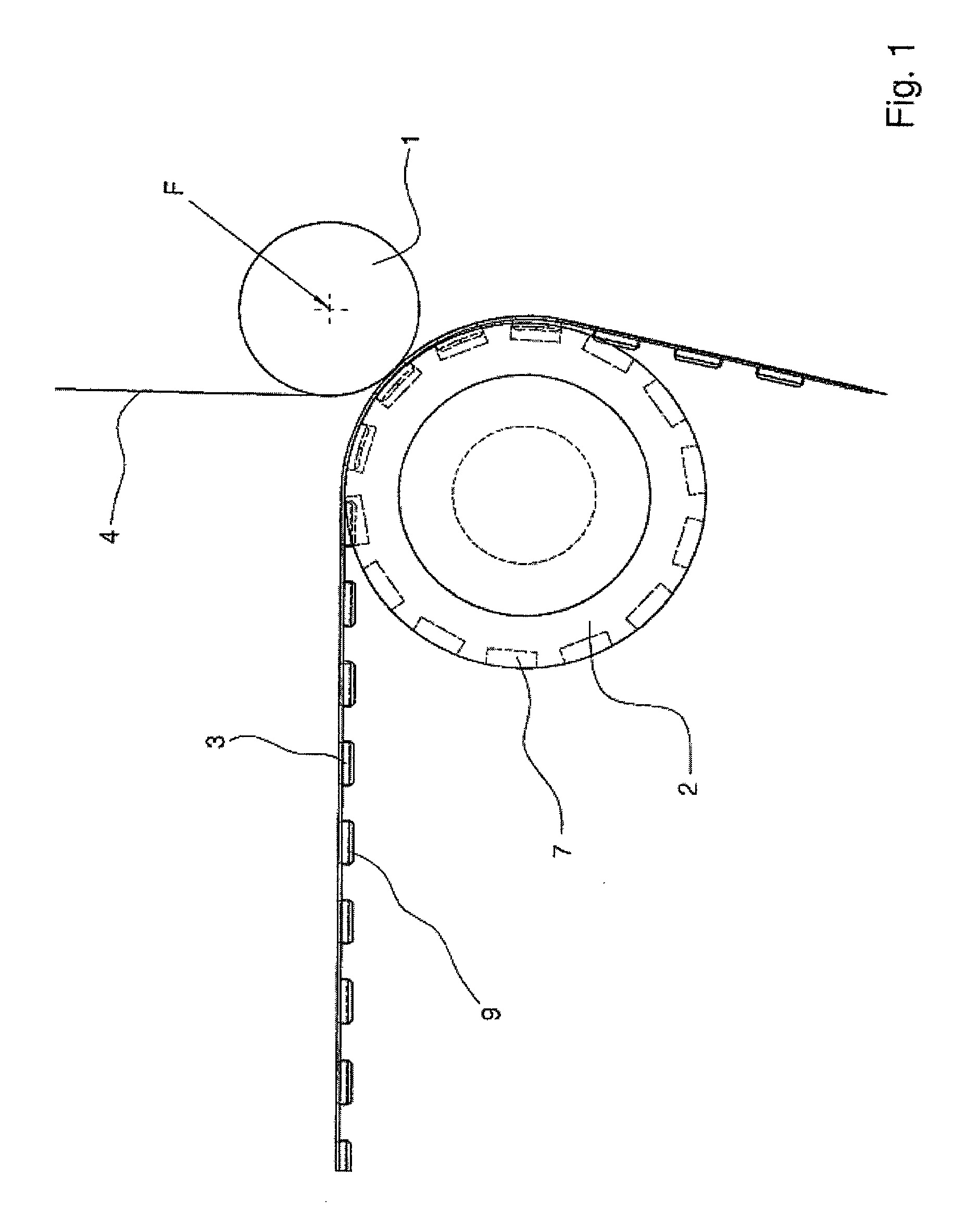

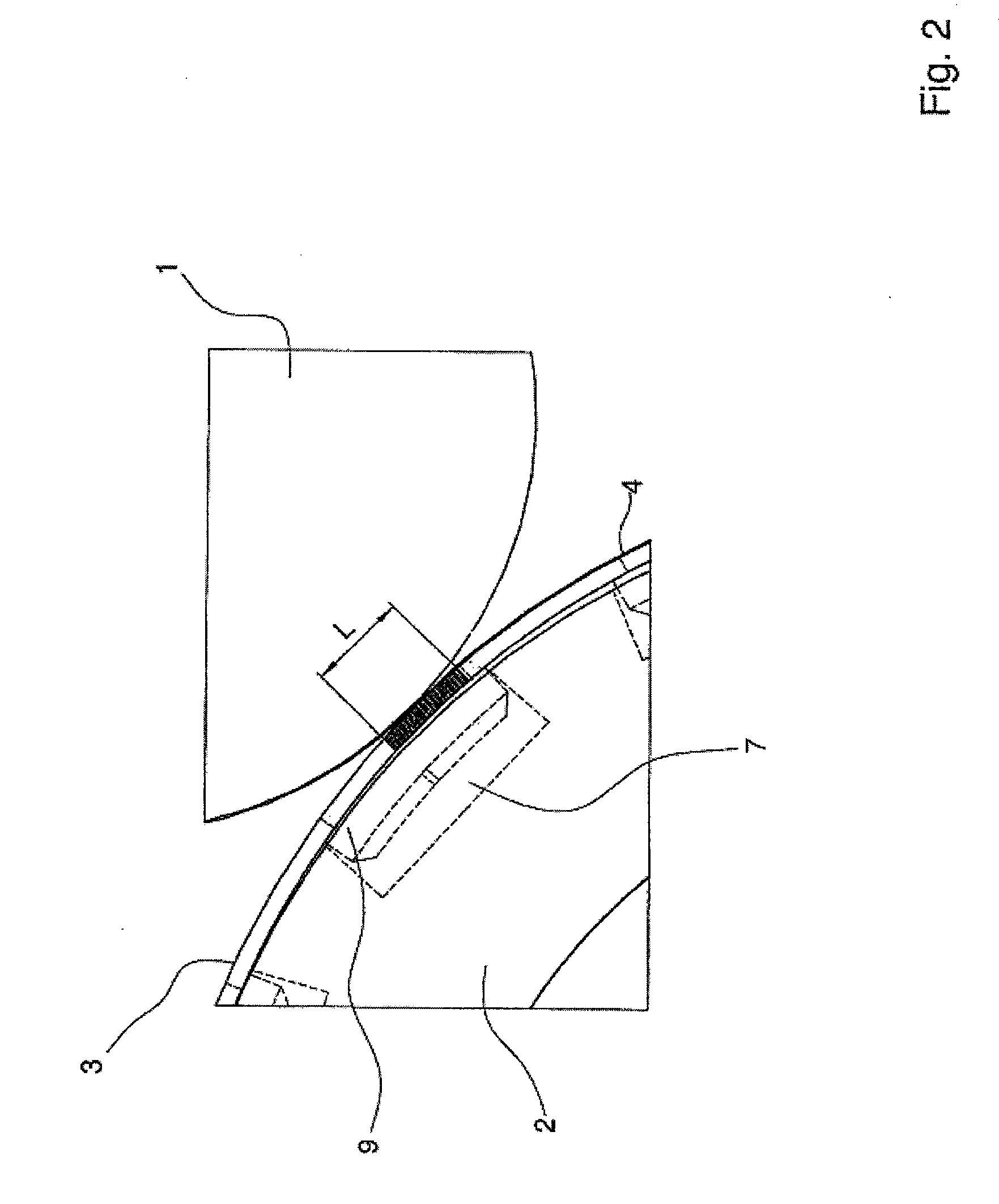

InactiveCN102947553AAvoid leaningGuaranteed elastic deformabilityValve arrangementsMachines/enginesEngineeringInternal combustion engine

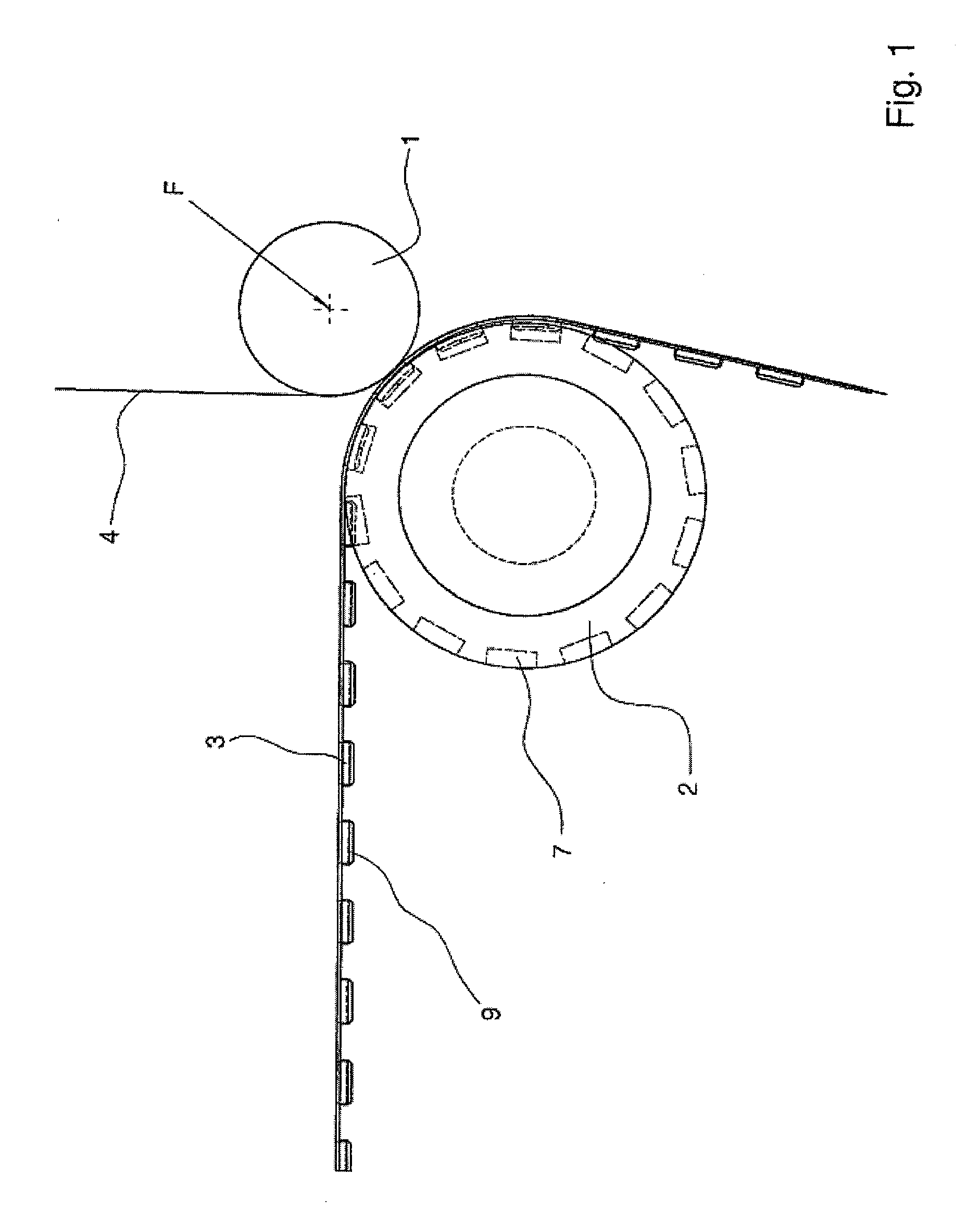

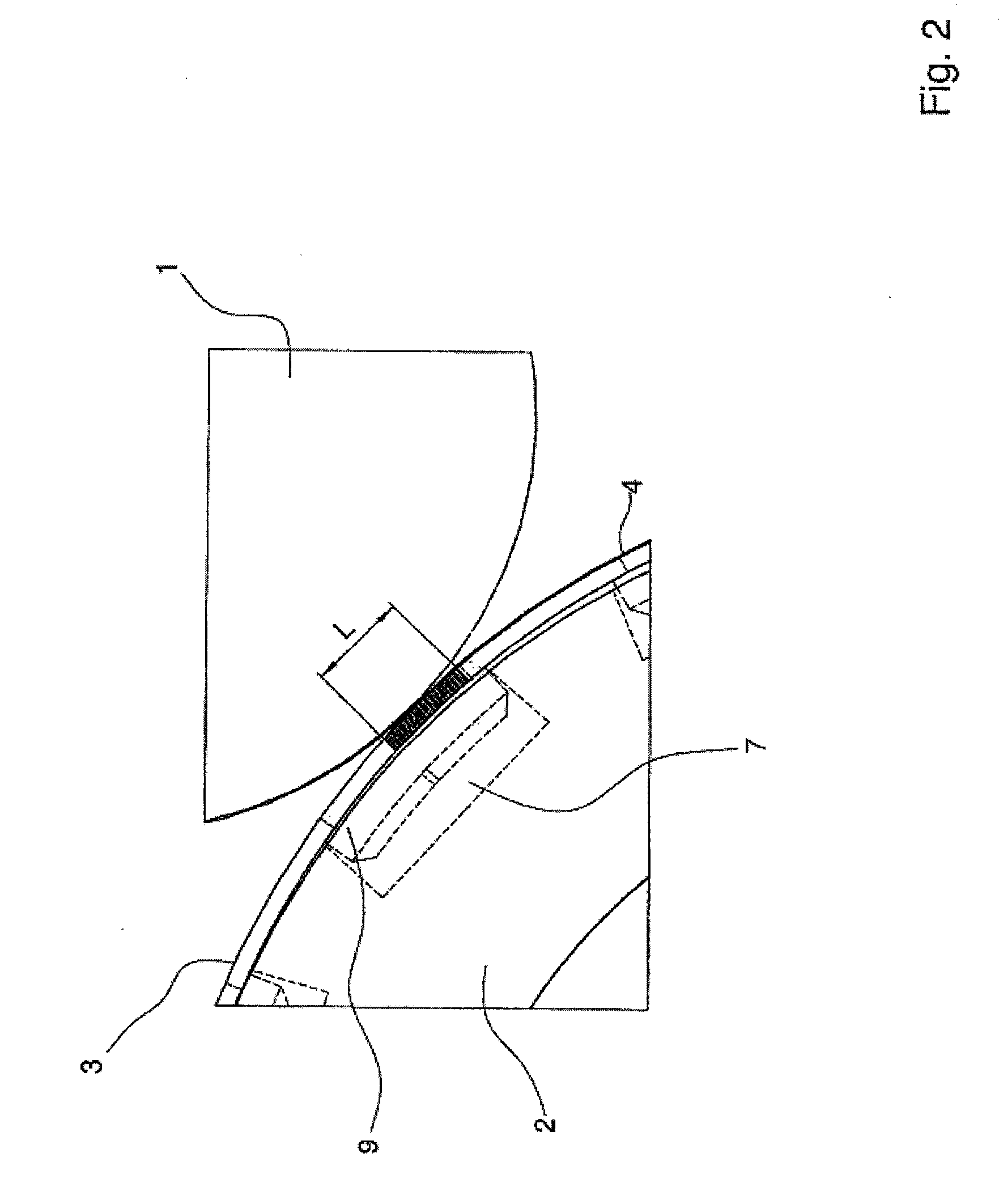

The invention relates to a rotor (1, 21, 41) for a camshaft adjuster (61), comprising a rotor base body (3, 23, 43) and a number of rotor blades (5, 25, 45) extending radially outwards and located on the rotor base body (3, 23, 43), each of said blades having a blade end (7, 27, 47). To reduce leakage, the blade ends (7, 27, 47) of the rotor blades (5, 25, 45) take the form of sealing fins (9, 31, 49) that can be deformed radially outwards. A rotor (1, 21, 41) of this type affords the possibility of reducing leakage in a camshaft adjuster (61) using simple engineering and without added costs. The invention also relates to a camshaft adjuster (61) for an internal combustion engine, comprising a rotor (1, 21, 41) of this type.

Owner:SCHAEFFLER TECH AG & CO KG

Bolt pre-tightening tool for submarine hoop connector

InactiveCN107838669AQuick preloadReduced underwater aid connection timeMetal working apparatusHydraulic motorOcean bottom

The invention relates to a bolt pre-tightening tool for a submarine hoop connector. The tool comprises a casing system, a speed reducing system, a transmission system and a tightening system; the speed reducing system is mounted in a casing and is connected with the upper end of the transmission system through universal joint pins; the lower end of the transmission system is connected with the tightening system through universal joint pins; and the tightening system is mounted in a lower casing. The working principle of the tool is as follows: a hydraulic motor rotates to drive a pinion to rotate, the pinion is decelerated by reduction gears to transfer motion to transmission gears, the transmission gears transfer the rotating motion to transmission shafts, then the transmission shafts transfer the rotating motion to tightening sleeves, finally, bolts are driven by the tightening sleeves to rotate, and then the purpose of tightening the multiple bolts simultaneously is achieved. Compared with the prior art, the tool has the advantages as follows: the bolts can be pre-tightened quickly for the submarine hoop connector, then the underwater auxiliary connecting time can be shortened,quick repair and connection of a submarine pipeline can be realized, the repair cycle of the submarine pipeline can be shortened, and the comprehensive cost for ocean oil and gas transmission can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV

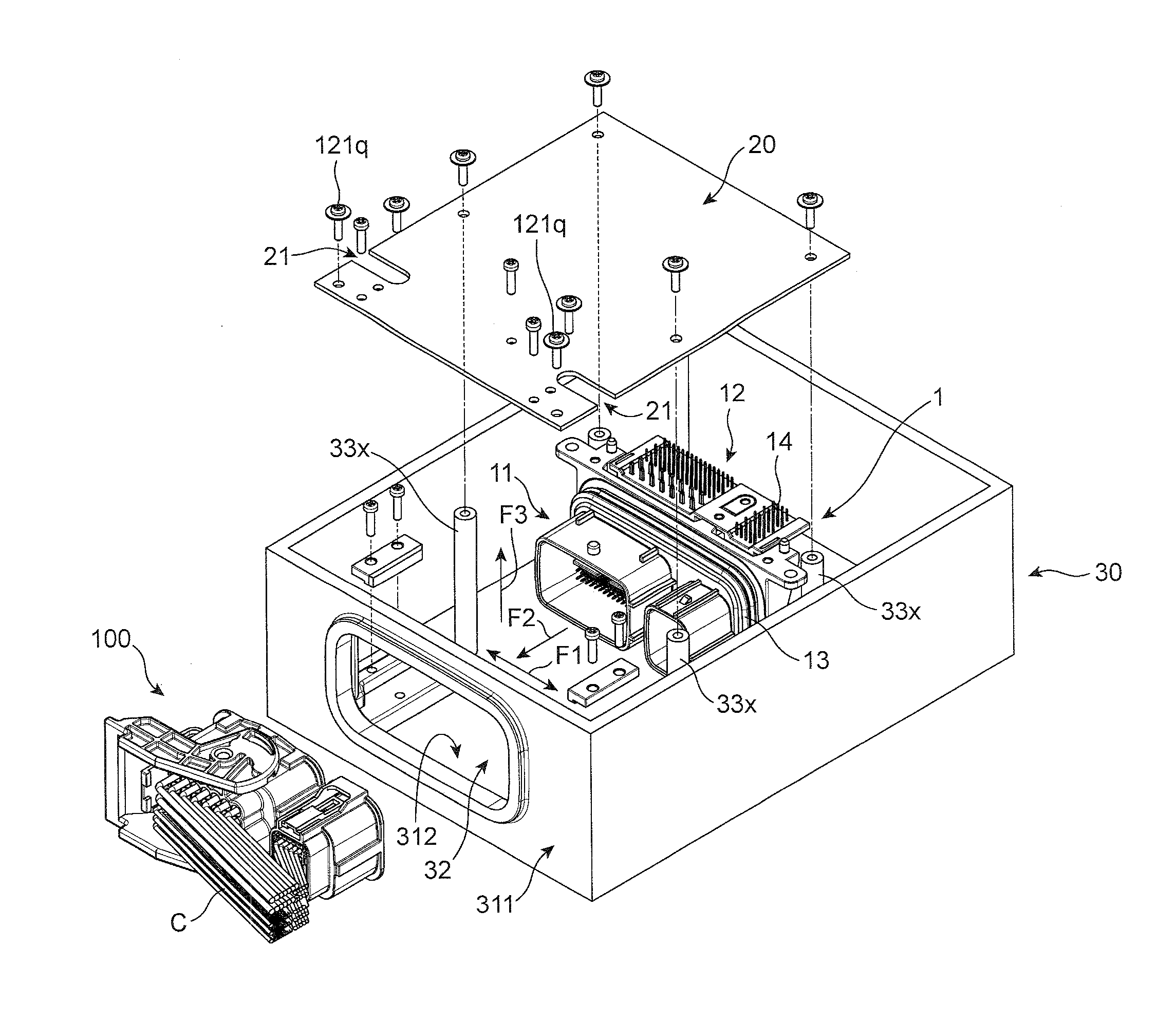

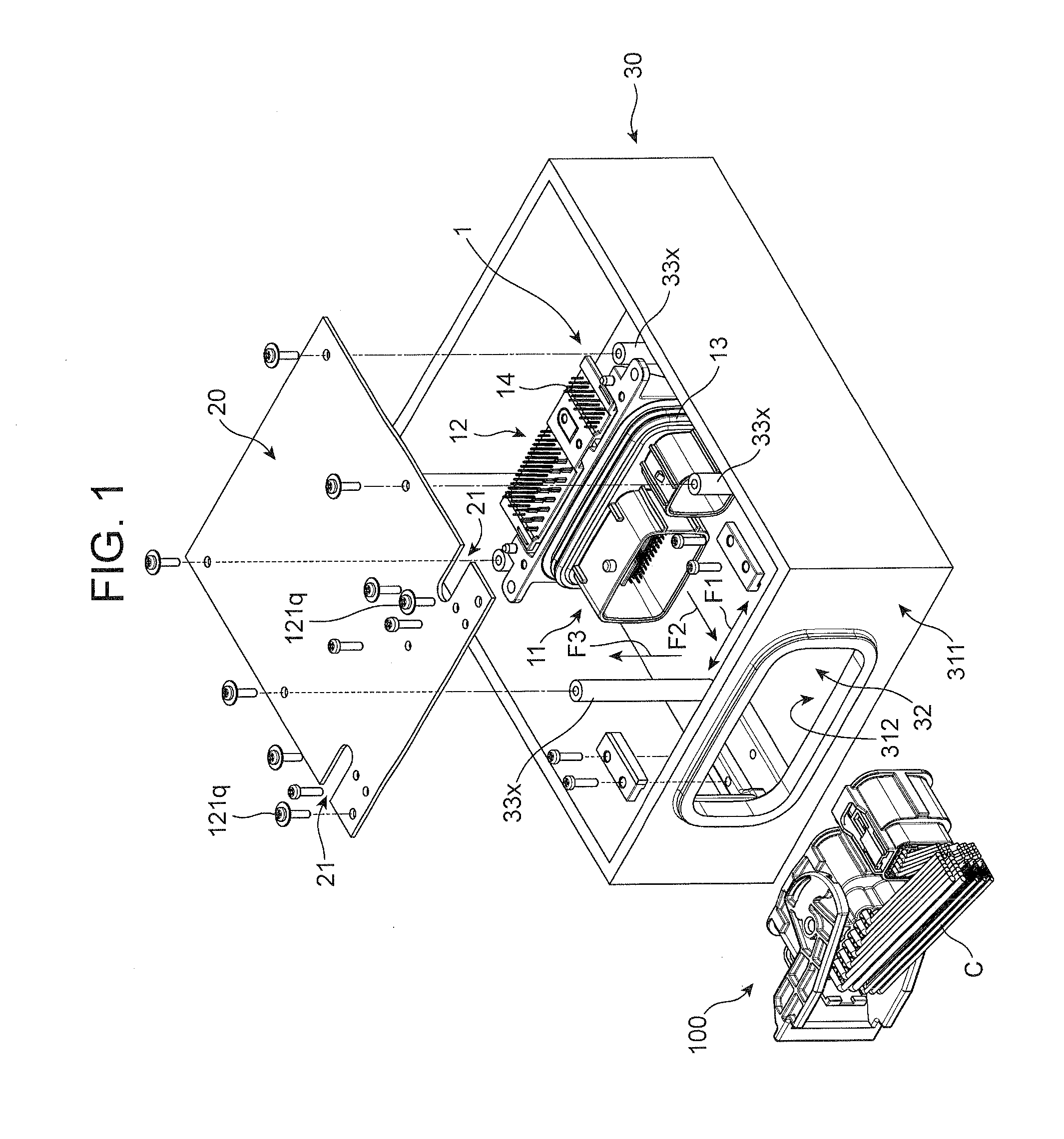

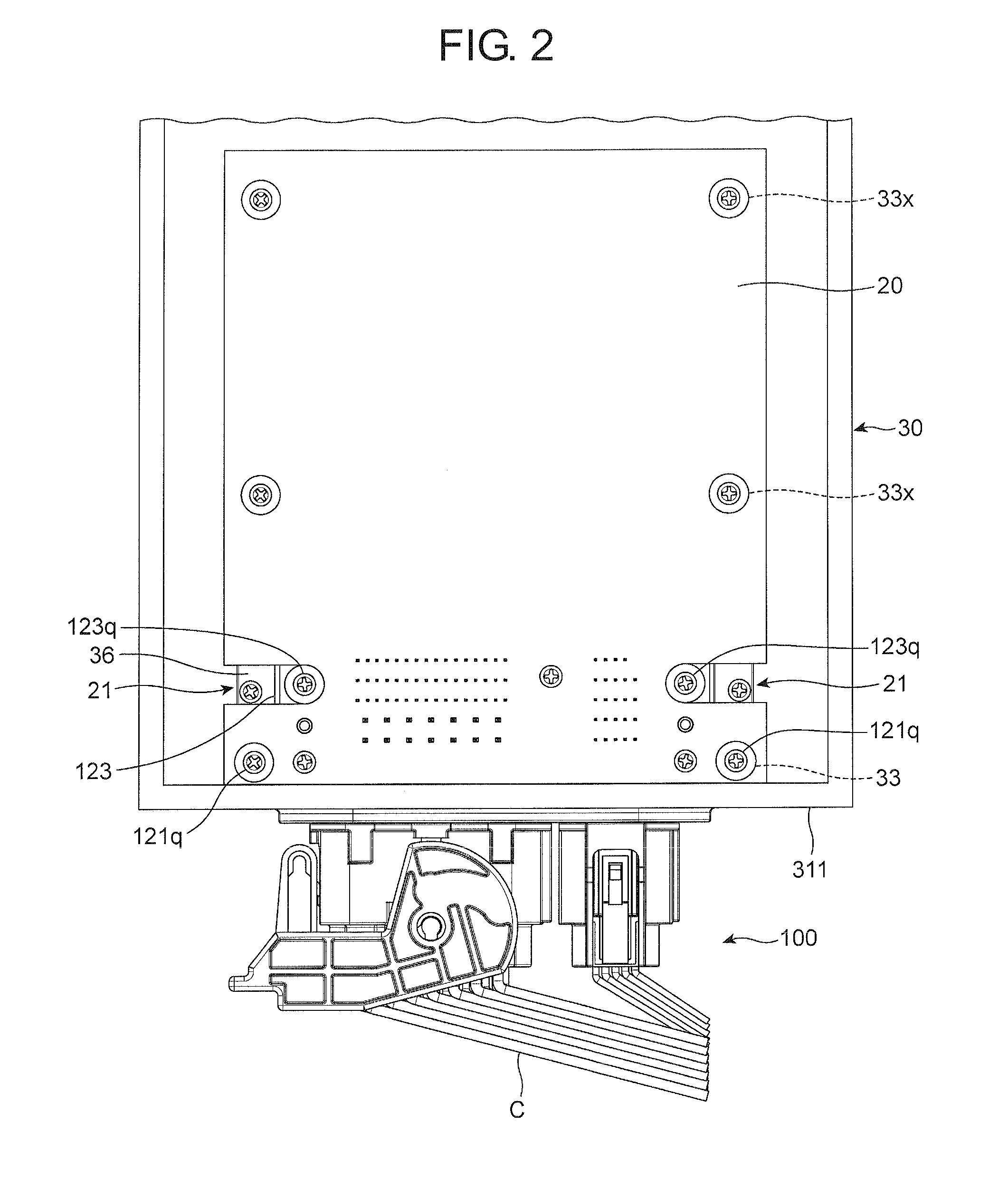

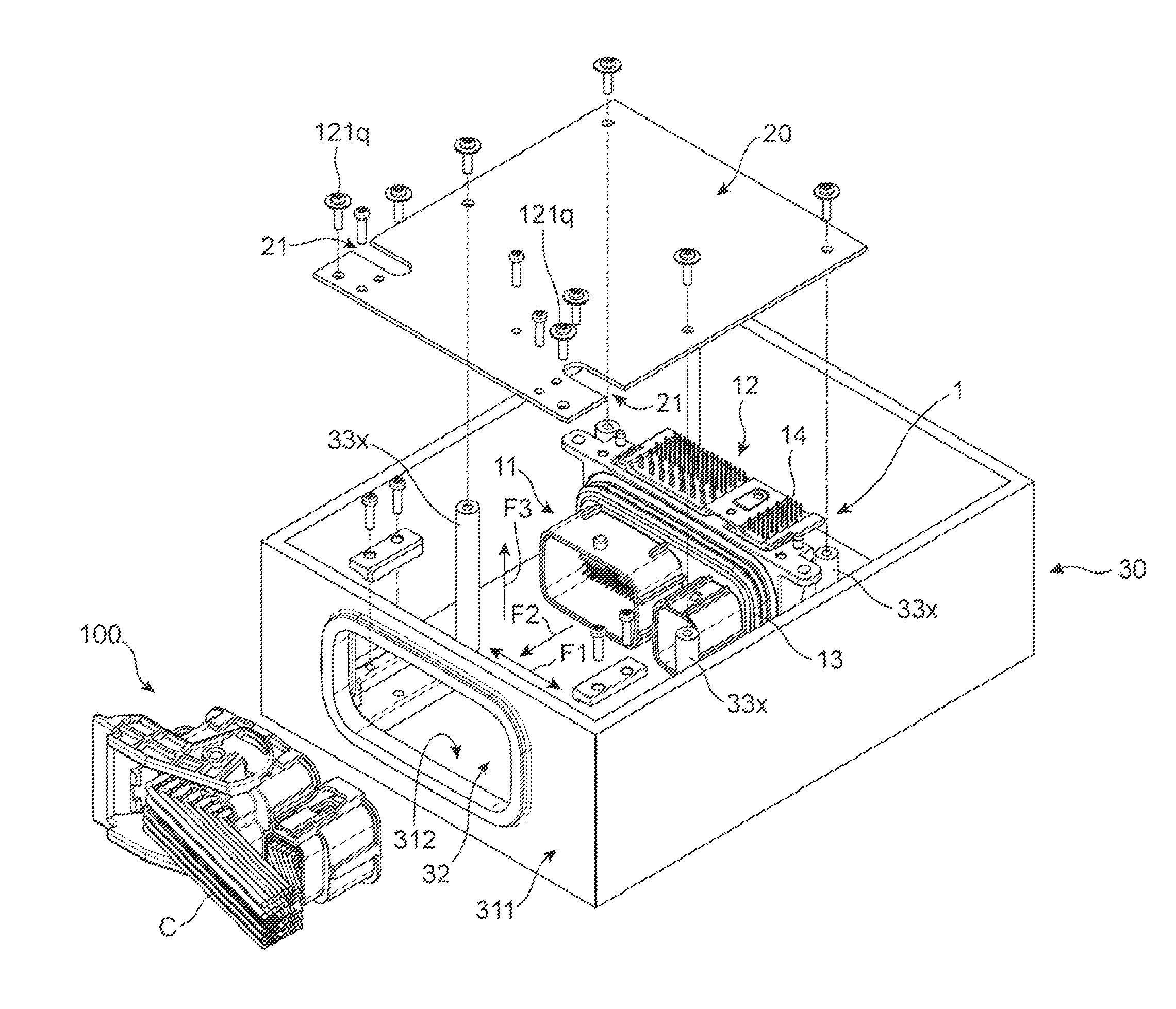

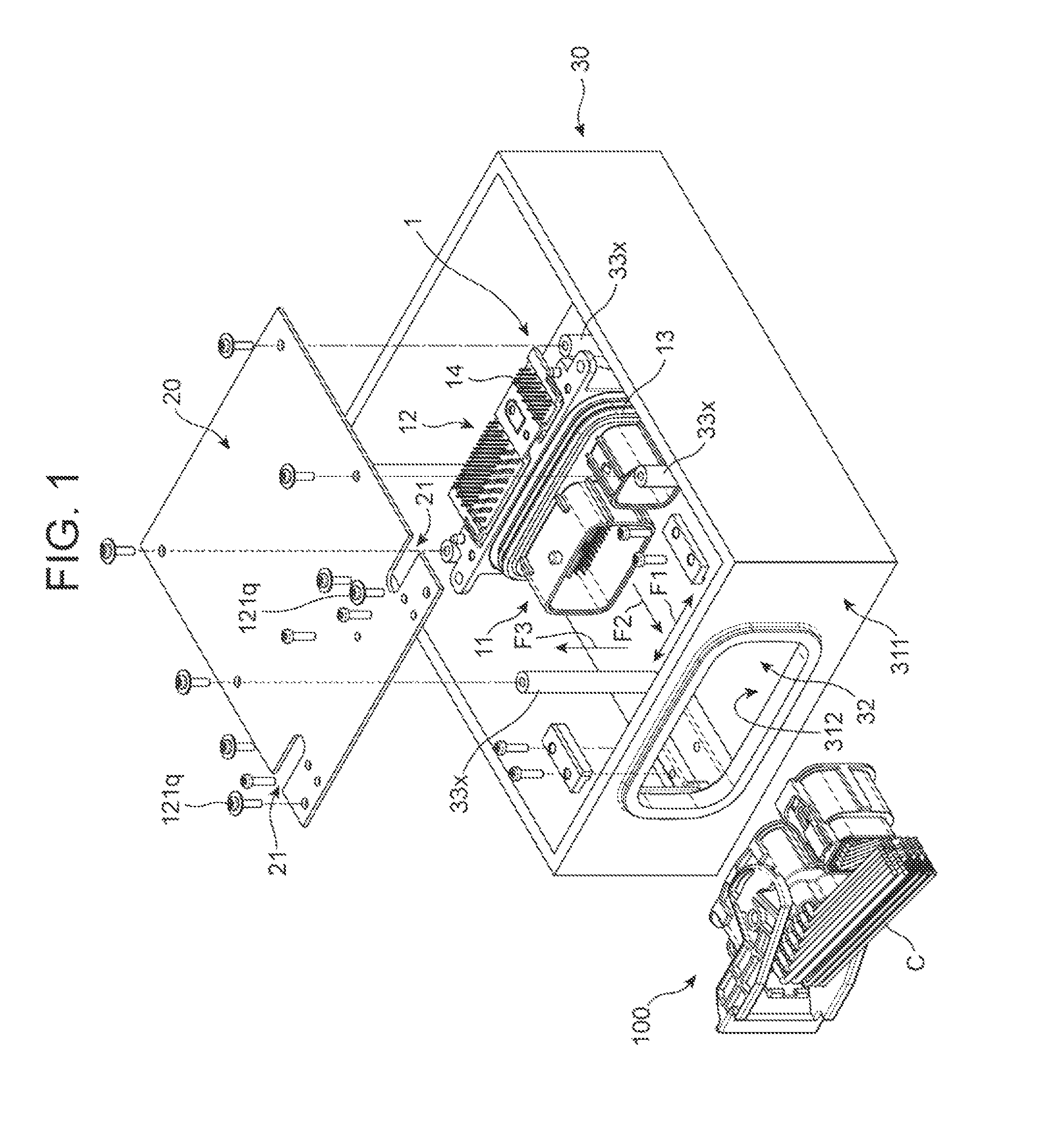

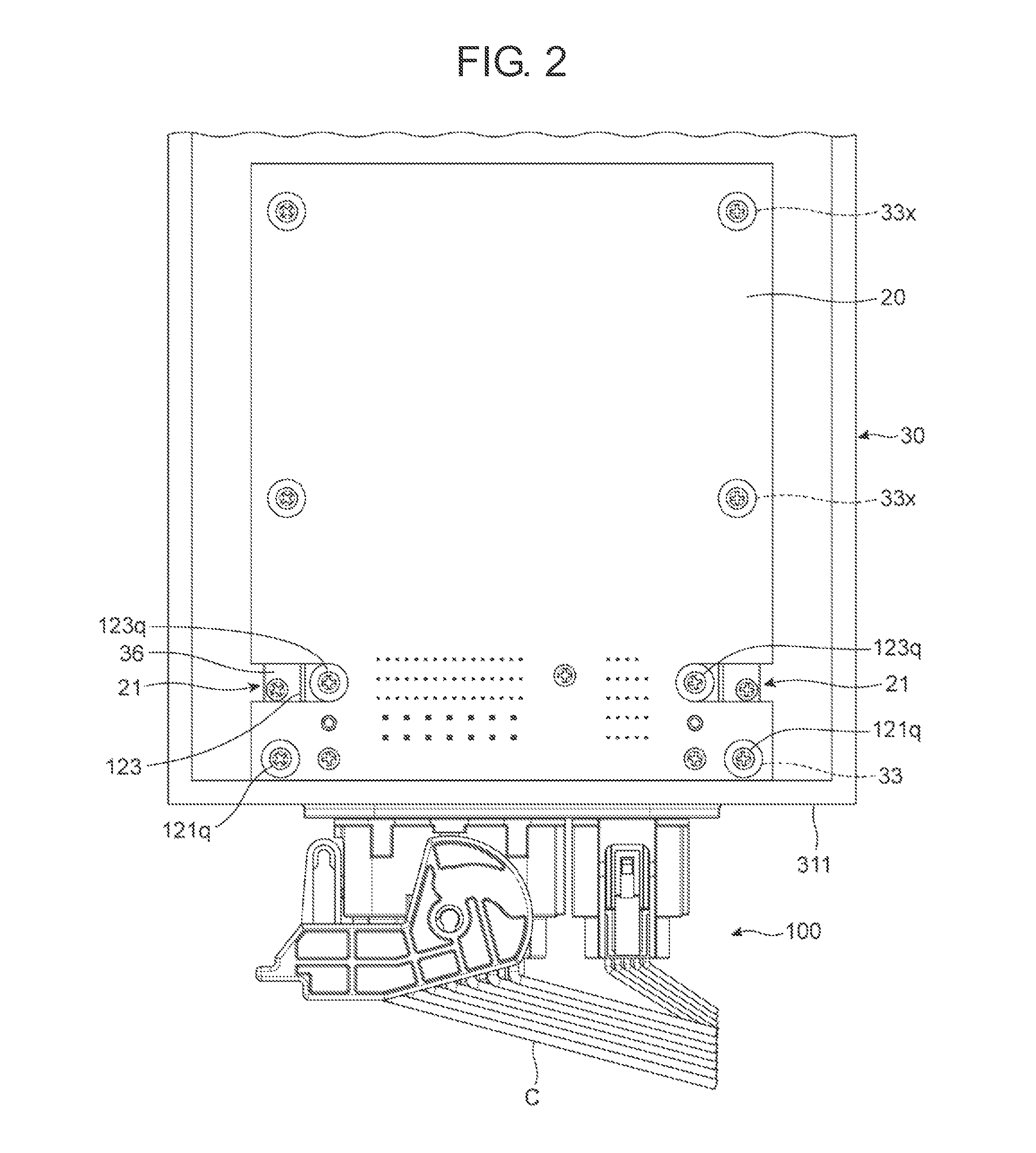

Casing for electric connector

InactiveUS20150180156A1Uniform sealing effectSmall distanceVehicle connectorsSubstation/switching arrangement detailsMechanical engineeringClose contact

A casing in which an electric connector is housed, including a floor, and a wall standing perpendicular to the floor, the wall being formed with an opening, when a part of the electric connector projects outwardly through the opening, a seal formed around the part making close contact with an inner edge of the opening, the casing further including a first positioning unit for positioning the electric connector relative to the opening in a first direction defined as a length-wise direction of the wall, and a second positioning unit for positioning the electric connector relative to the opening in a height-wise direction of the wall.

Owner:DAIICHI SEIKO CO LTD

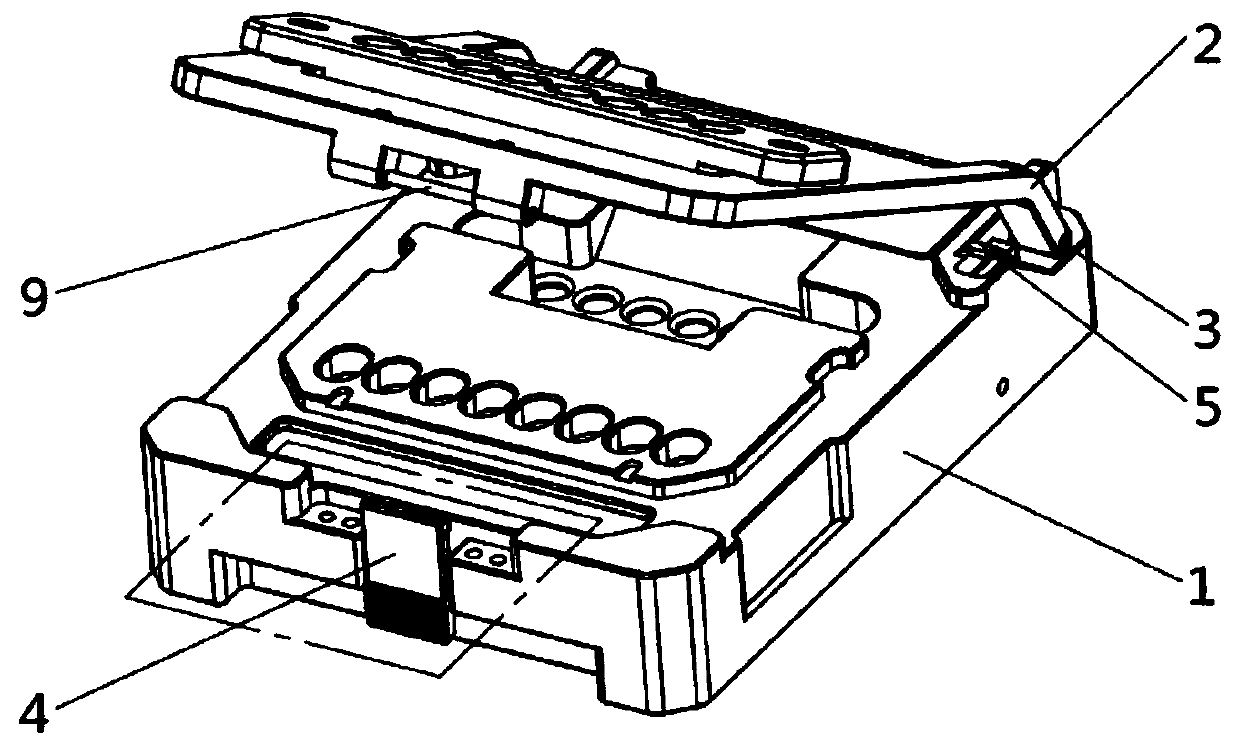

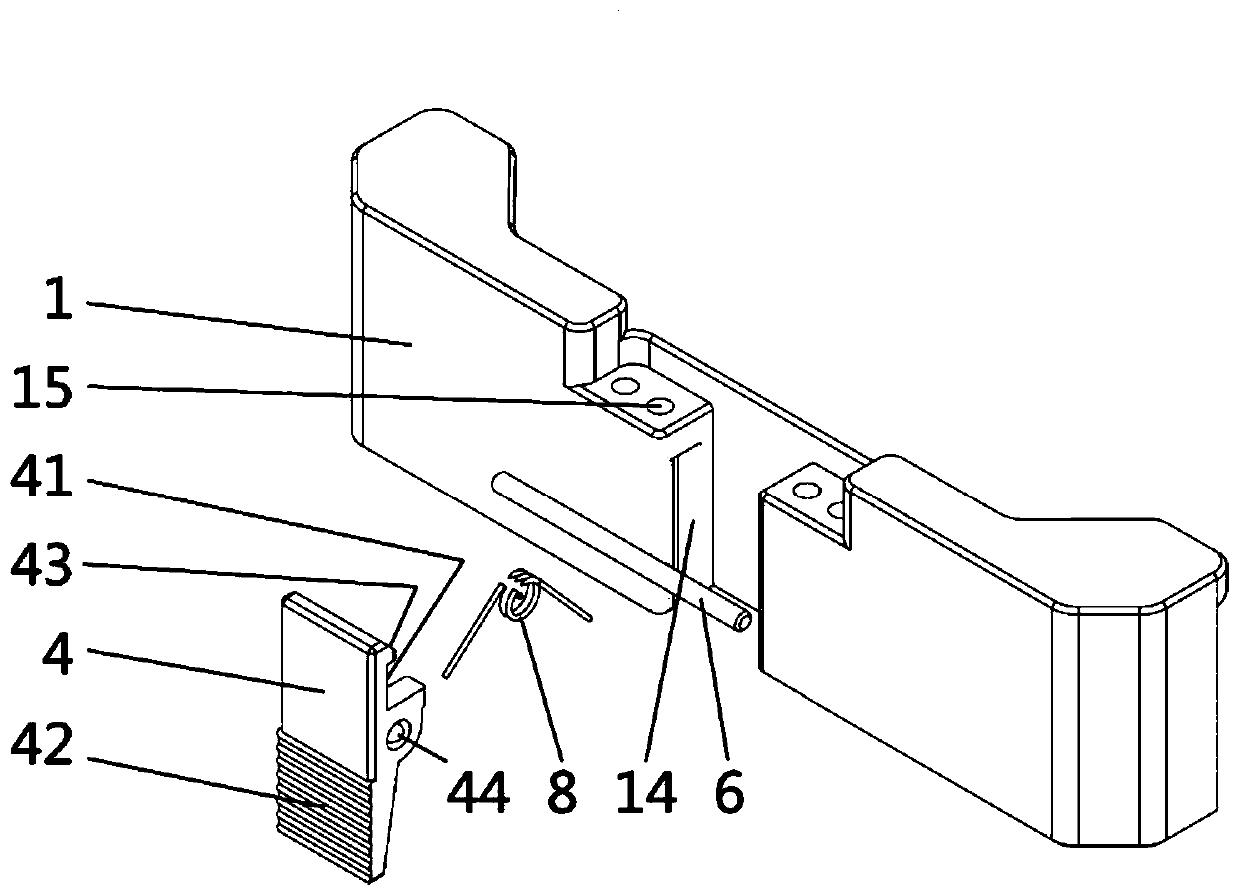

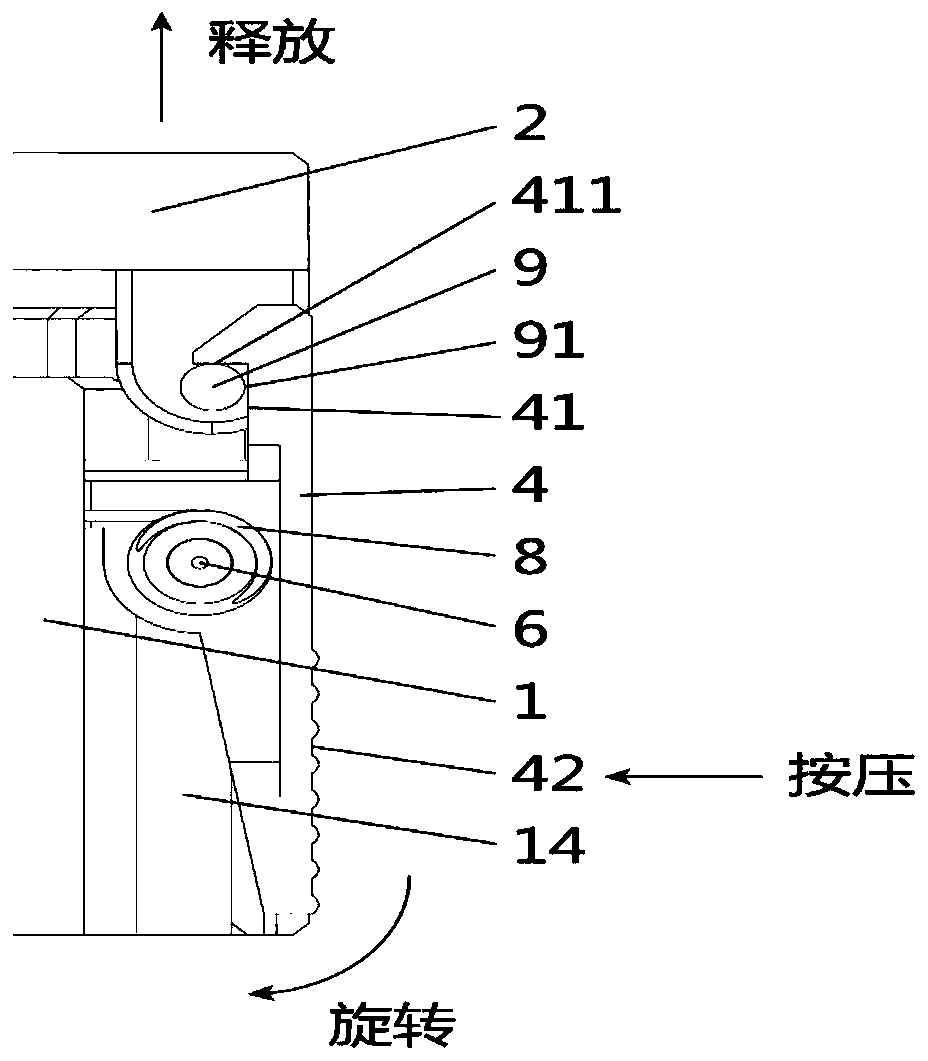

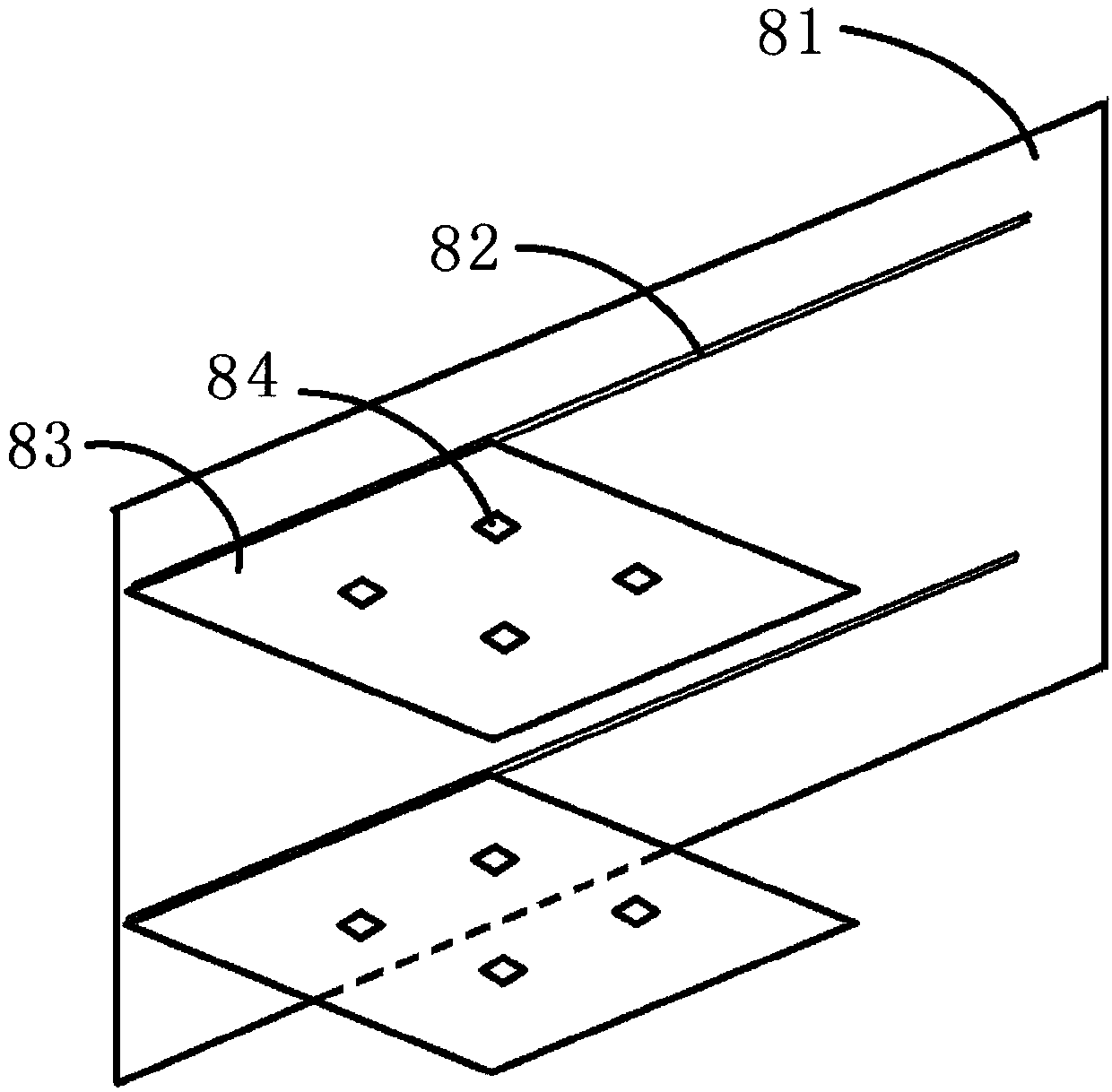

Fixing device for micro-drop detection chip

PendingCN110694703AEliminate toleranceTest results are stableLaboratory glasswaresSupporting apparatusStructural engineeringMechanical engineering

The invention provides a fixing device for a micro-drop detection chip. The fixing device comprises a rigid bottom plate and a rigid flip cover, and the rear ends of the rigid bottom plate and the rigid flip cover are connected through a rotating shaft to form a rotating pair; the bottom plate is used for accommodating the micro-drop detection chip, and the bottom plate and the flip cover are matched to realize rigid clamping of the micro-drop detection chip; when the micro-drop detection chip is detected, a connecting pipe comprising at least two detection pipes is placed, a groove for accommodating the micro-drop detection chip is arranged on the bottom plate, and an elastic device is arranged at the bottom of each groove for eliminating bottom tolerance for accommodating the micro-dropdetection chip. The elastic device is additionally arranged at the bottom of each pipe of the connecting pipe, so that the overall tolerance between the connecting pipe and the chip plane can be compensated, the sealing force is more uniform, the sealing effect is more uniform, the flow of liquid in all flow channels of the chip is more uniform, and the detection result of the whole instrument ismore stable.

Owner:TARGETINGONE TECH (BEIJING) CORP

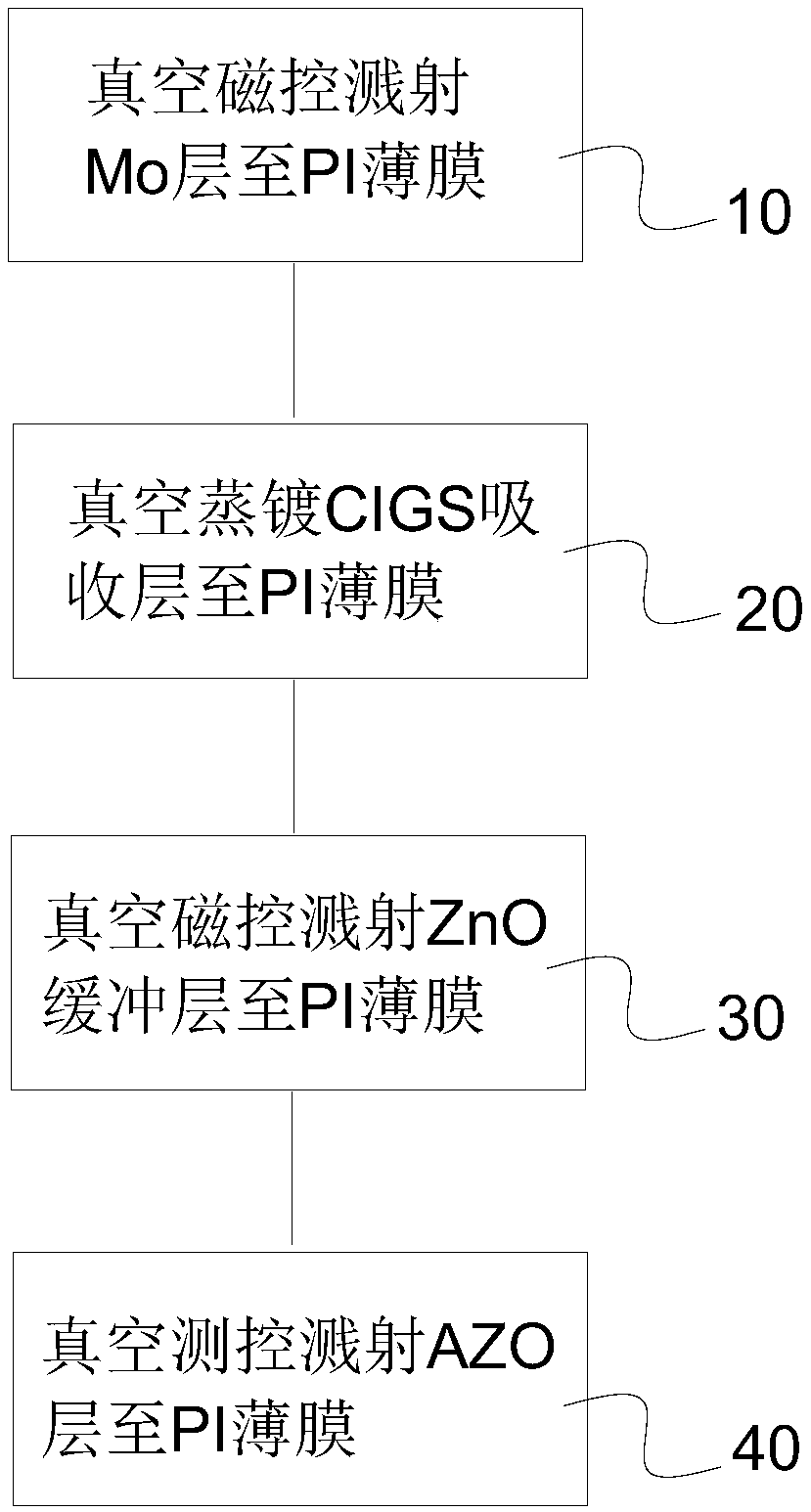

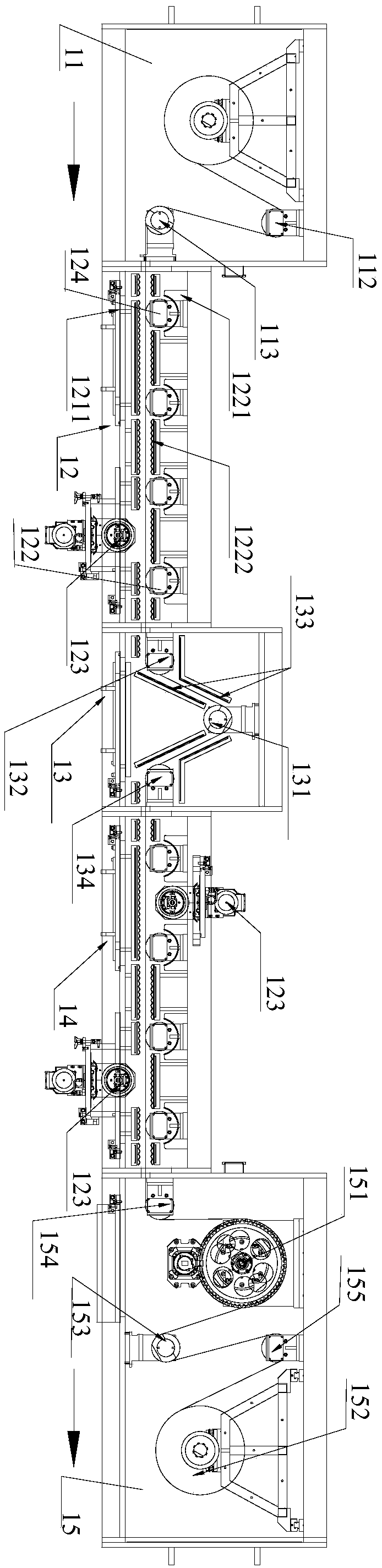

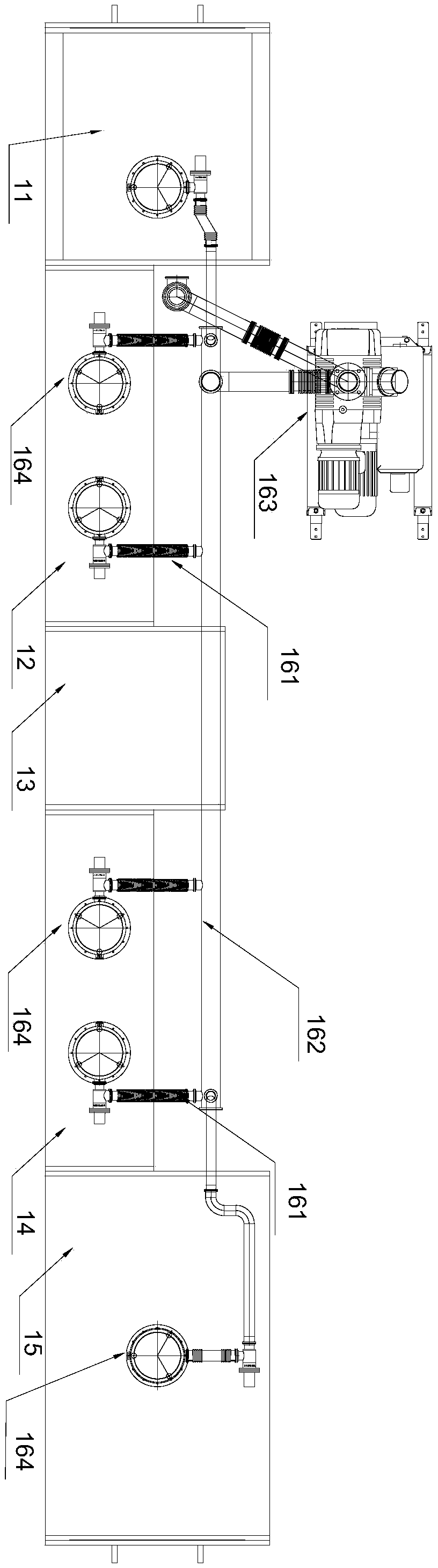

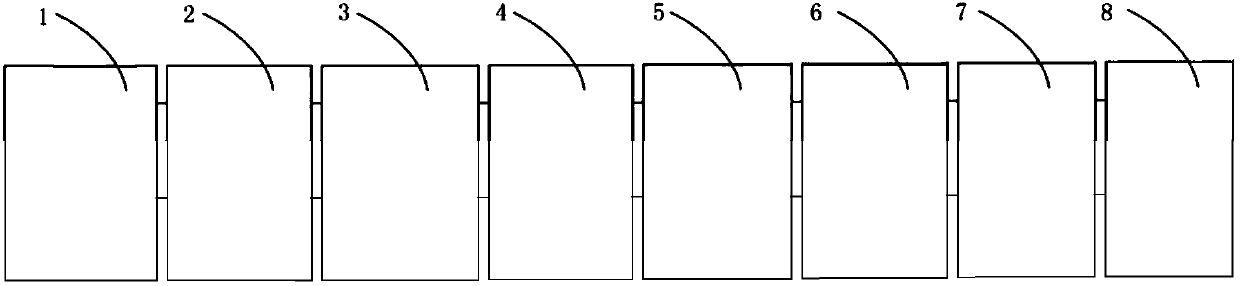

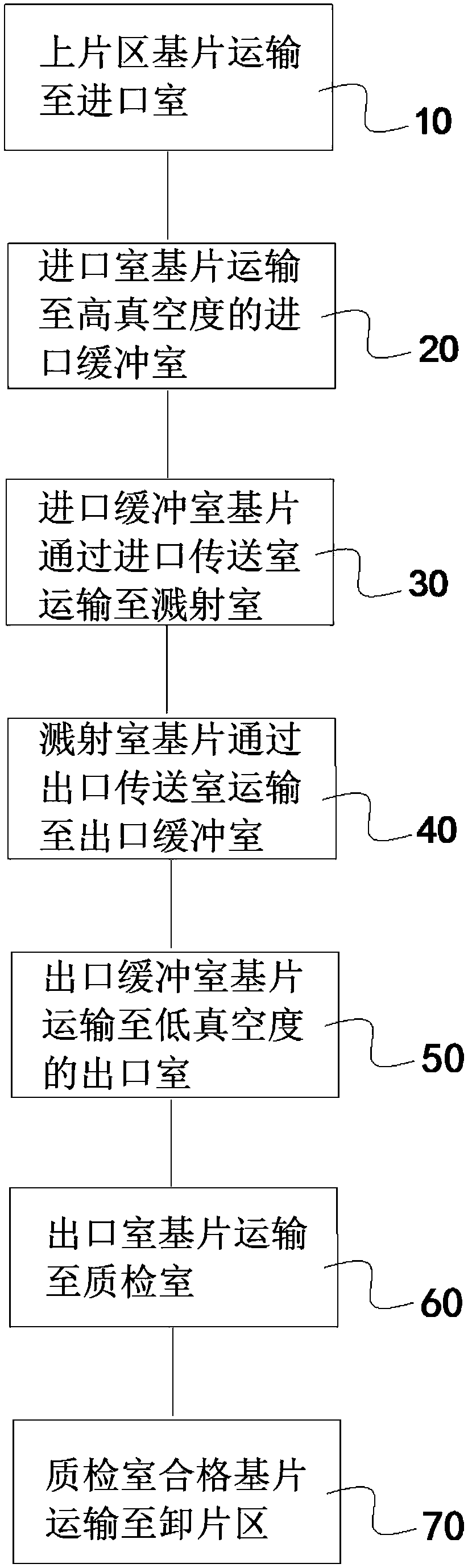

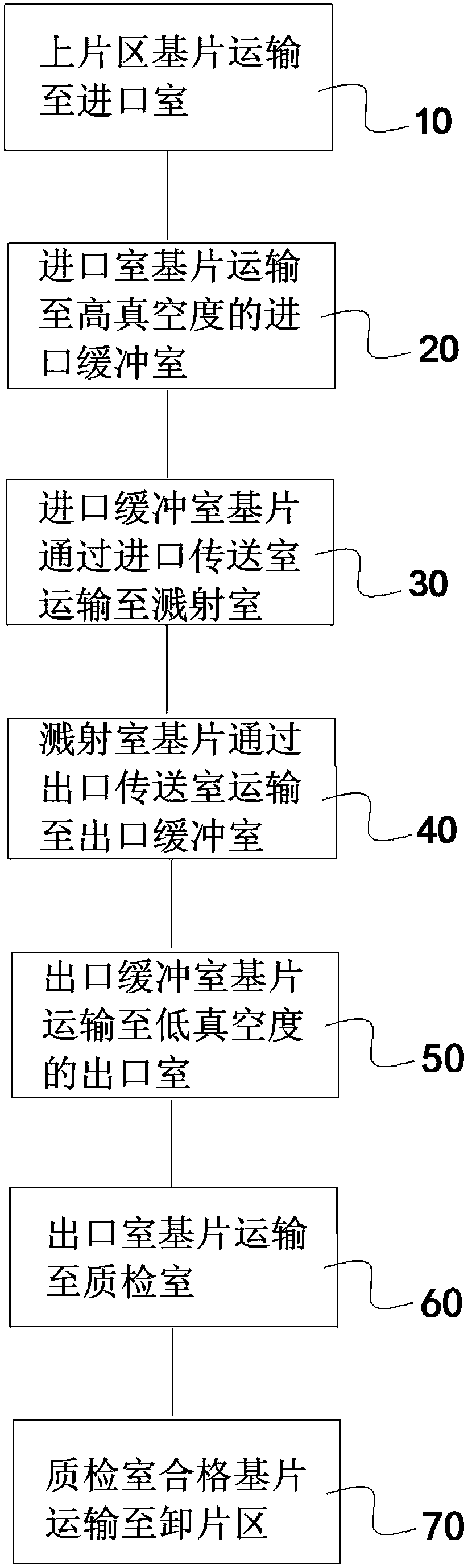

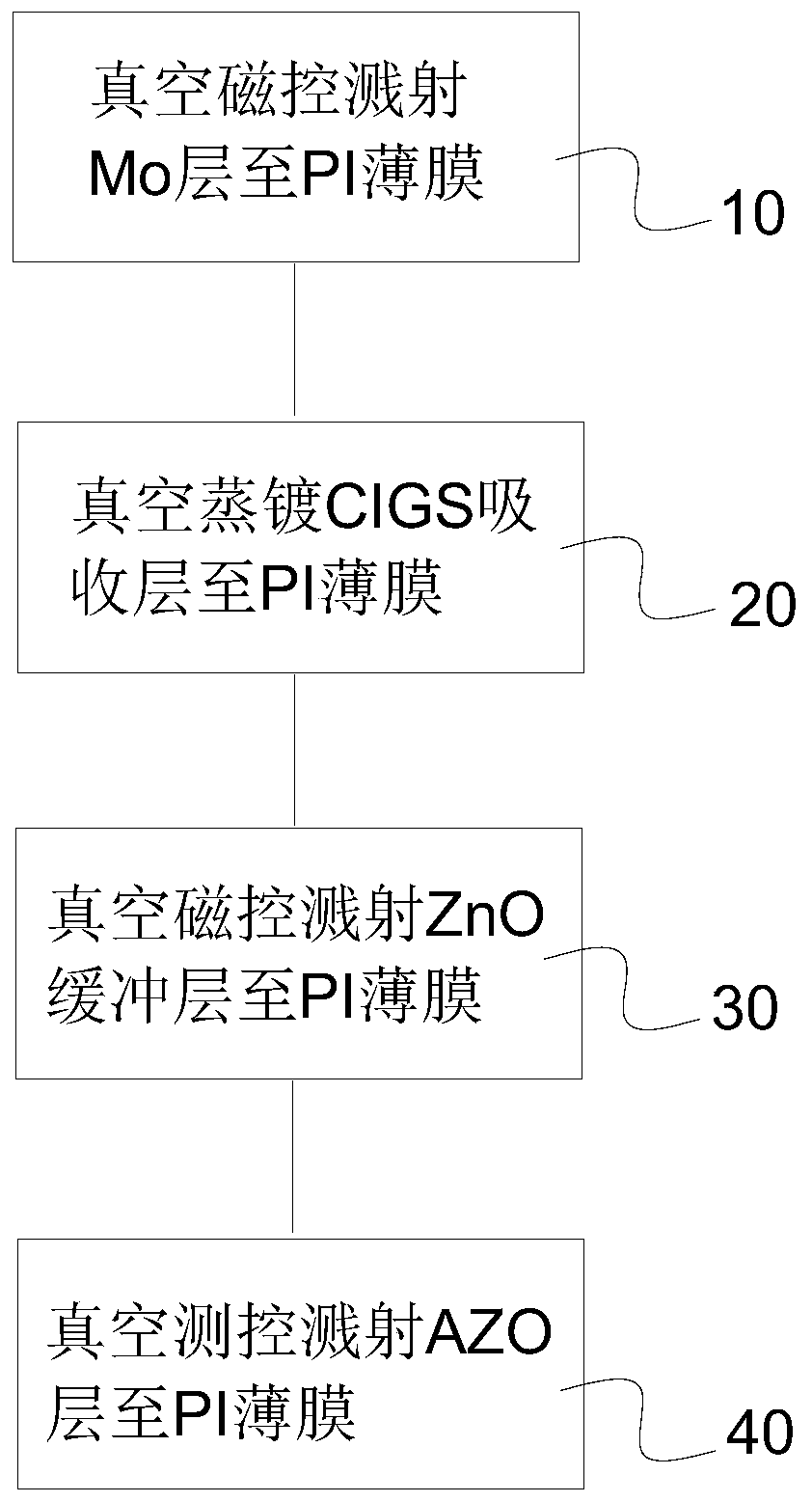

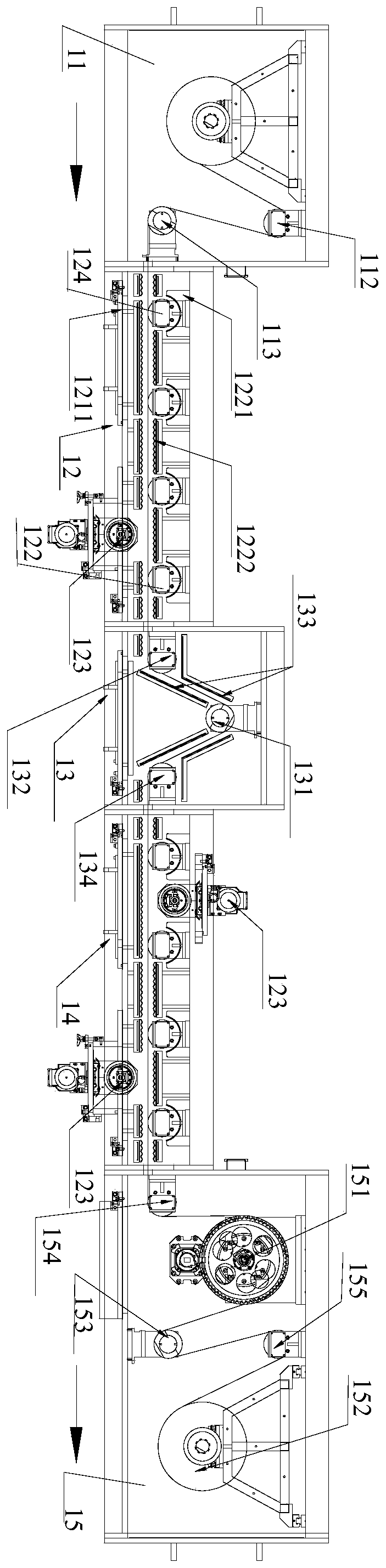

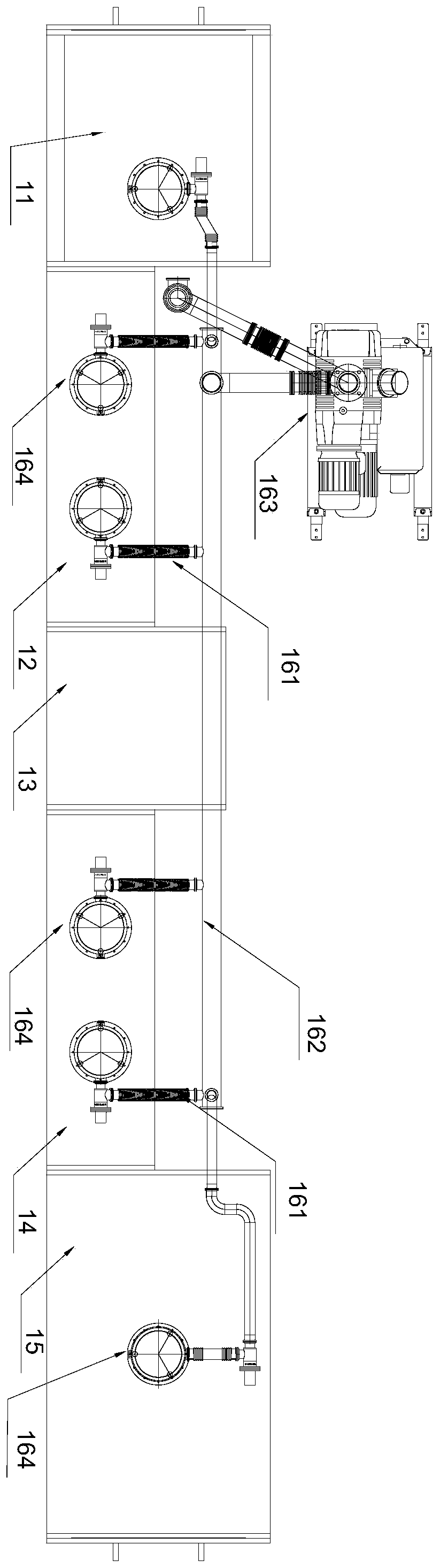

cigs solar cell film production line

ActiveCN106319473BReduce exposureAvoid destructionFinal product manufactureVacuum evaporation coatingProduction lineEvaporation

The invention discloses a CIGS solar cell film production line. The CIGS solar cell film production line comprises a plurality of coating sub-lines. The sub-lines sequentially and independently conduct vertical coating on a film. Each sub-line at least comprises an unreeling chamber, a coating chamber and a reeling chamber in the film unfolding direction, wherein a main drive roller is arranged in the unreeling chamber and the reeling chamber, a plurality of transmission rollers are arranged in cavities of the sub-line, and a tension detection roller and a tension adjusting roller are arranged in at least one cavity of the sub-line. The tension detection rollers are adjacent to the tension adjusting rollers, the tension detection rollers are used for monitoring the tension of the film in real time, and the tension adjusting rollers adjust the rotation speed of the tension adjusting rollers according to the feedback of the tension detection rollers so as to adjust the transmission speed of the film in the cavities; and the tension adjusting rollers are non-transmission rollers, and the unfolding track that the film passes the tension detection rollers and the tension adjusting rollers is the nonlinear track. According to the provided CIGS solar cell film production line, the element diffusion path is short, intermediate products are avoided, element evaporation is avoided, the film efficiency is high, and the CIGS solar cell film production line is particularly suitable for large-area scale industrial production.

Owner:旭科新能源股份有限公司 +1

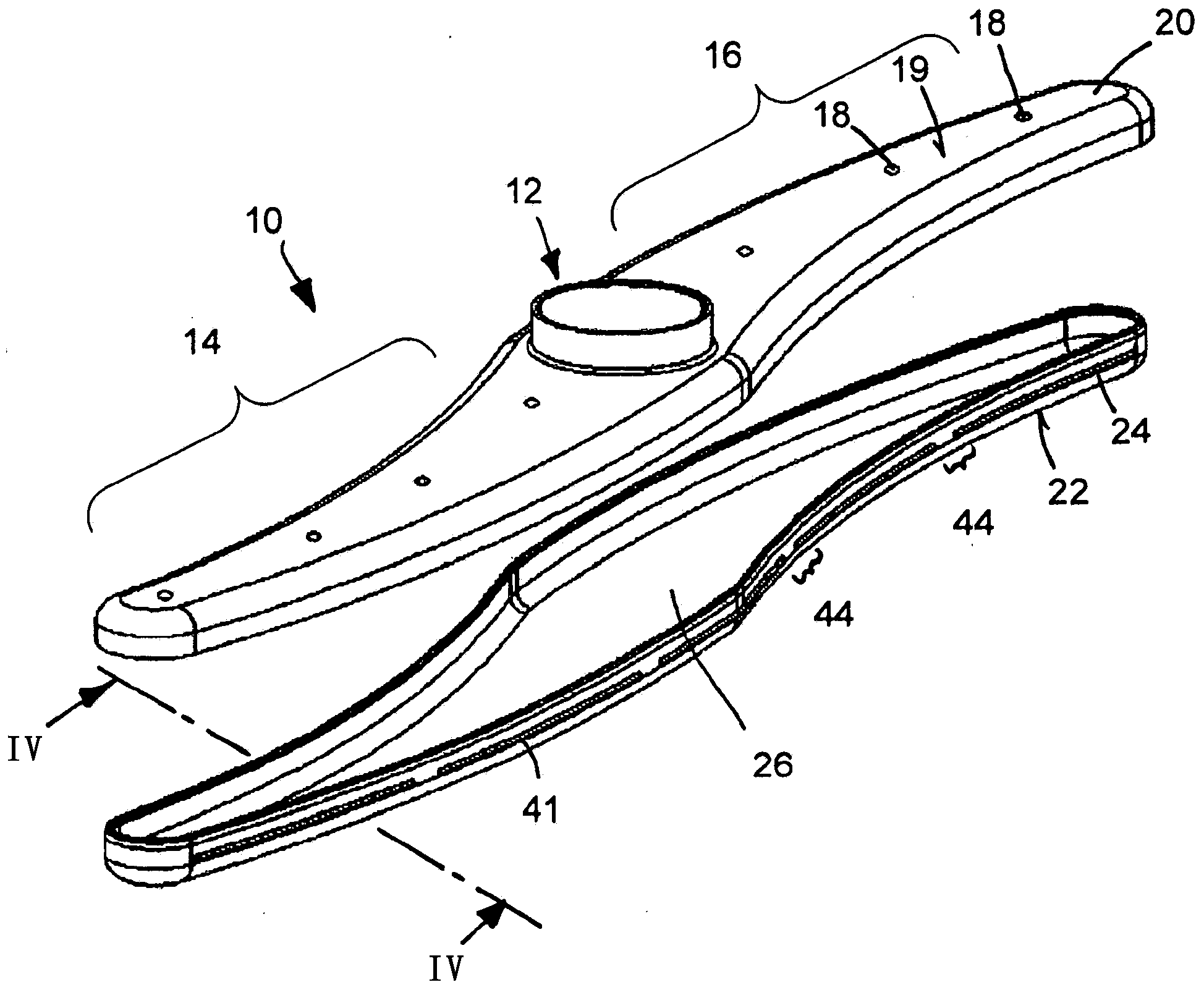

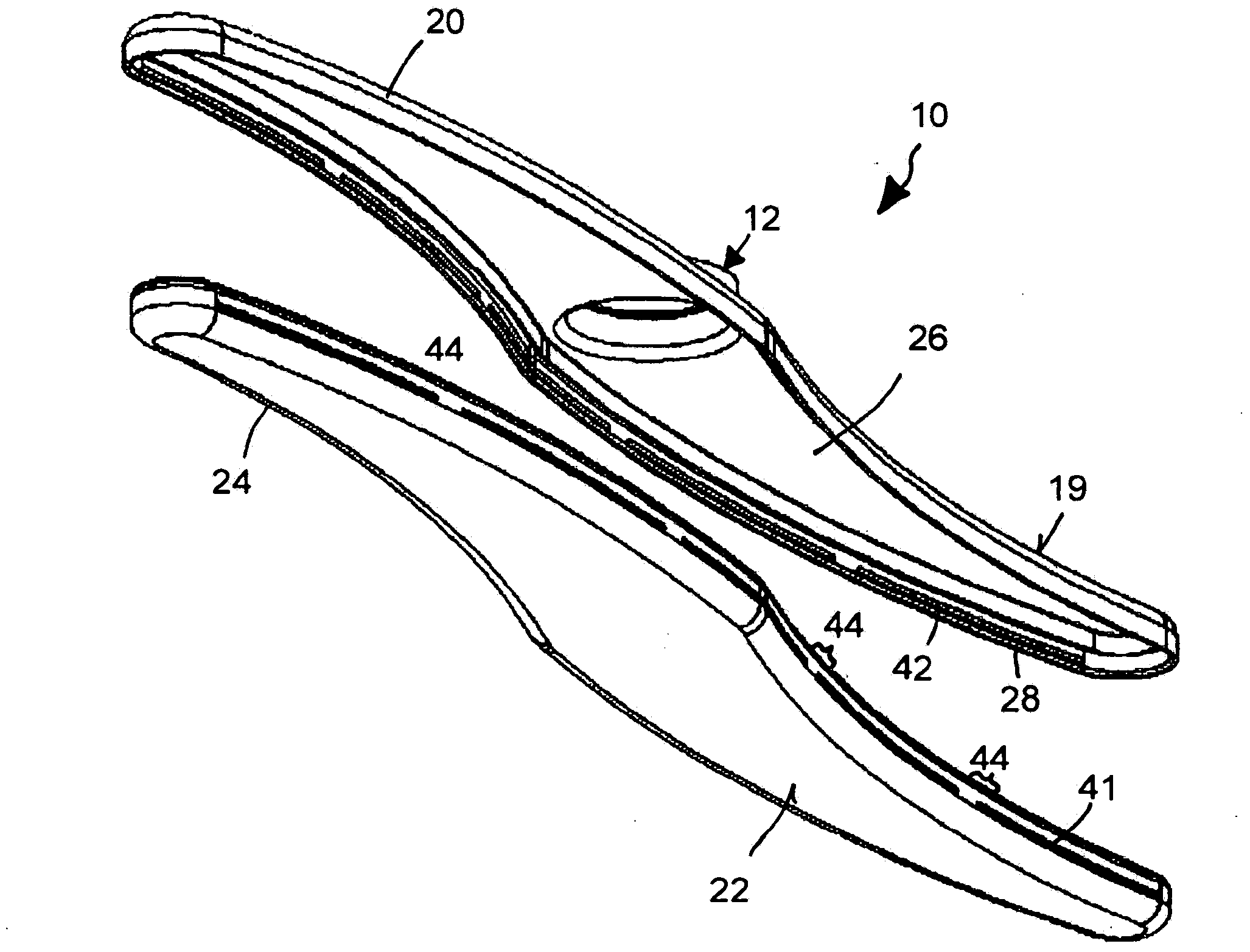

Spray arm for a dishwasher having two spray-arm parts

ActiveCN104302222AHigh strengthAvoid tightnessTableware washing/rinsing machinesEngineeringMechanical engineering

Owner:ETIMEX TECHN COMPONENTS

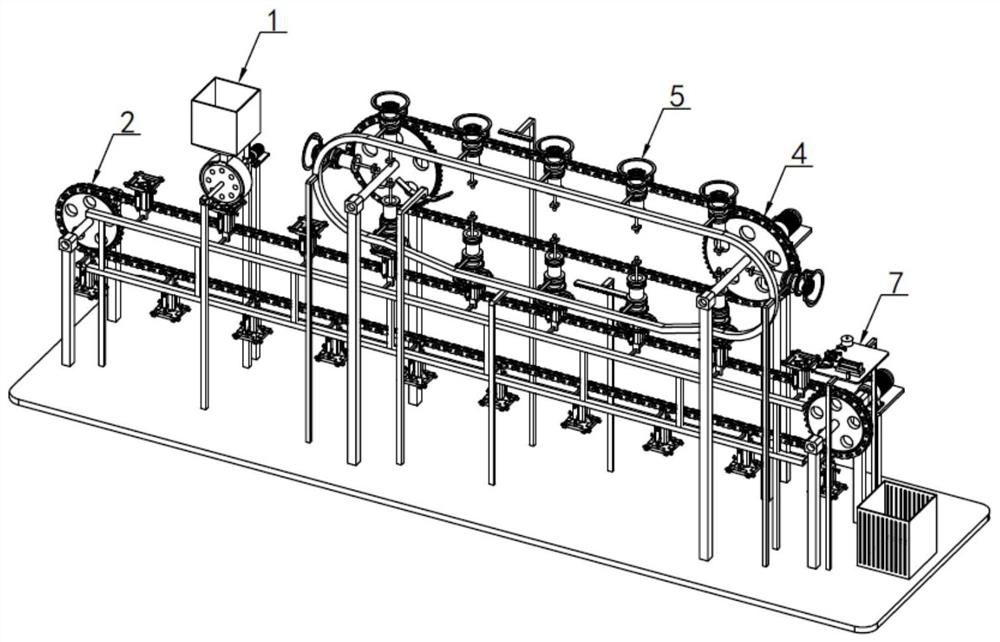

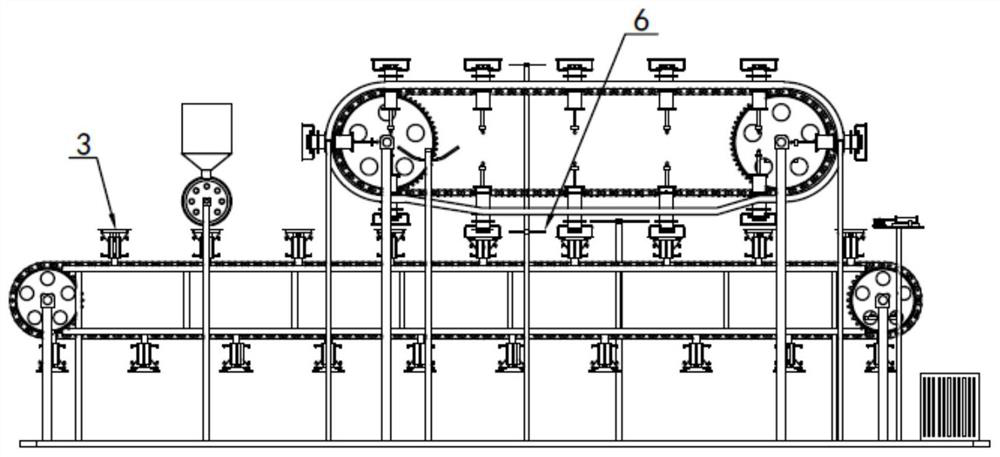

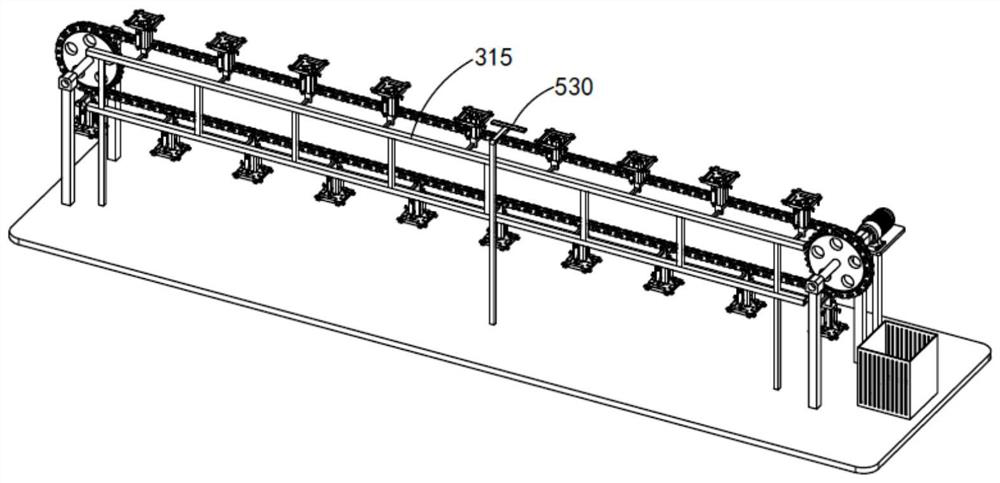

Continuous tea dragon bead packaging production line

PendingCN112744383ASave manpower and timeImprove packaging processing efficiencyWrappingWrapper twisting/gatheringProcess engineeringManufacturing line

The invention relates to a continuous tea dragon bead packaging production line which comprises a feeding device. A first rotary device is arranged below the feeding device, wrapping mechanisms are arranged on the first rotary device, and each wrapping mechanism comprises a limiting assembly and a supporting assembly. A second rotary device cooperating with the first rotary device is further arranged above the first rotary device, and screwing mechanisms are arranged on the second rotary device. A screwing channel is formed between the first rotary device and the second rotary device. Each screwing mechanism comprises a pressing assembly, a tightening assembly and a rotation assembly. A bundling mechanism cooperating with the screwing mechanisms is further arranged at the position, on the rear side of the screwing channel, of the moving path of the first rotary device. Through the arrangement of the feeding device, the first rotary device, the wrapping mechanisms, the second rotary device, the screwing mechanisms and the bundling mechanism, the defect that in the prior art, tea dragon bead packaging still needs manual operation is effectively overcome, a large amount of manpower and time are saved through automatic production, the packaging processing efficiency is improved, and better market benefits can be obtained.

Owner:胡承超

Casing for electric connector coupled to a cable

InactiveUS9287653B2Uniform sealing effectSmall distanceVehicle connectorsCouplings bases/casesElectricityEngineering

A casing in which an electric connector is housed, including a floor, and a wall standing perpendicular to the floor, the wall being formed with an opening, when a part of the electric connector projects outwardly through the opening, a seal formed around the part making close contact with an inner edge of the opening, the casing further including a first positioning unit for positioning the electric connector relative to the opening in a first direction defined as a length-wise direction of the wall, and a second positioning unit for positioning the electric connector relative to the opening in a height-wise direction of the wall.

Owner:DAIICHI SEIKO CO LTD

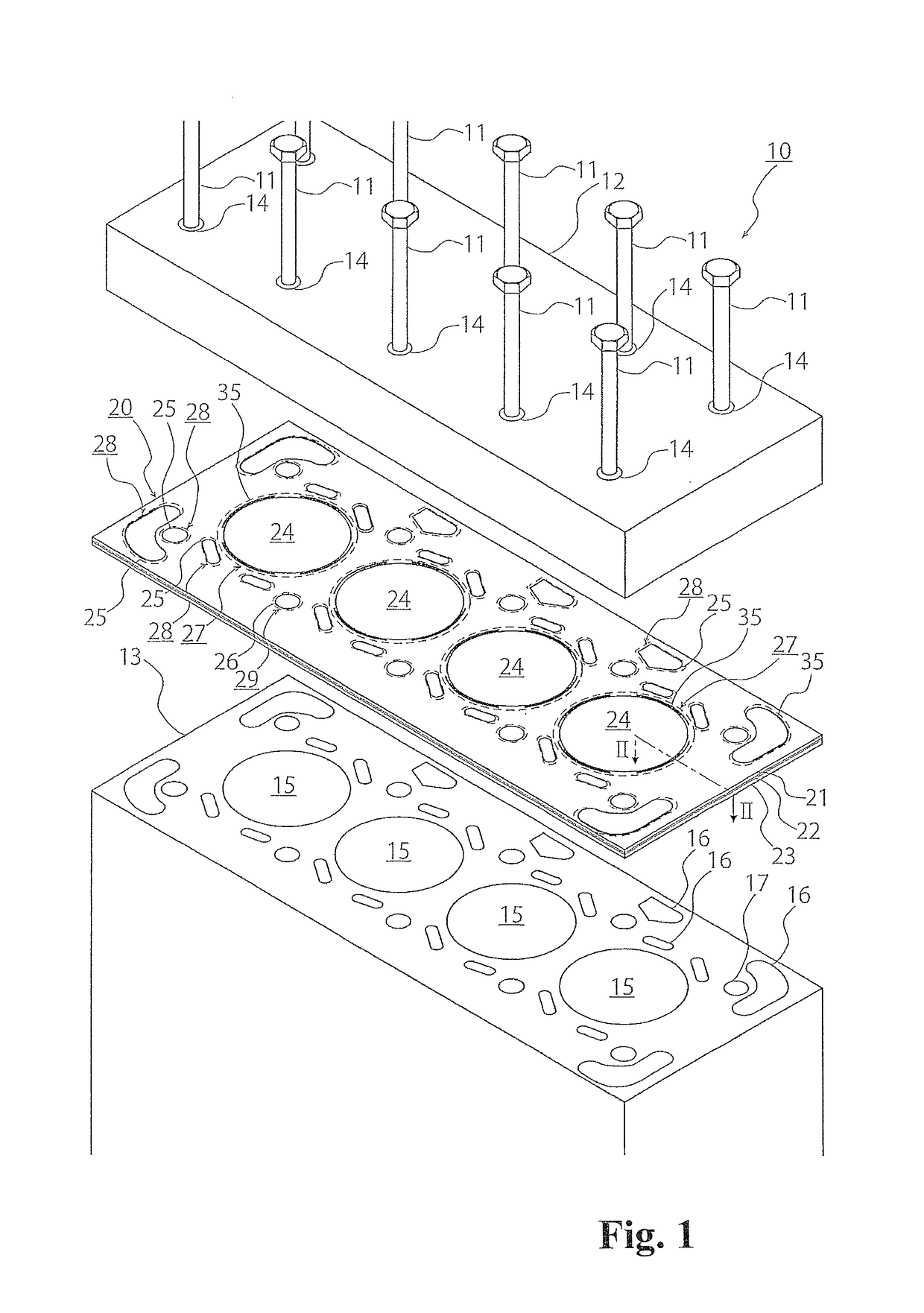

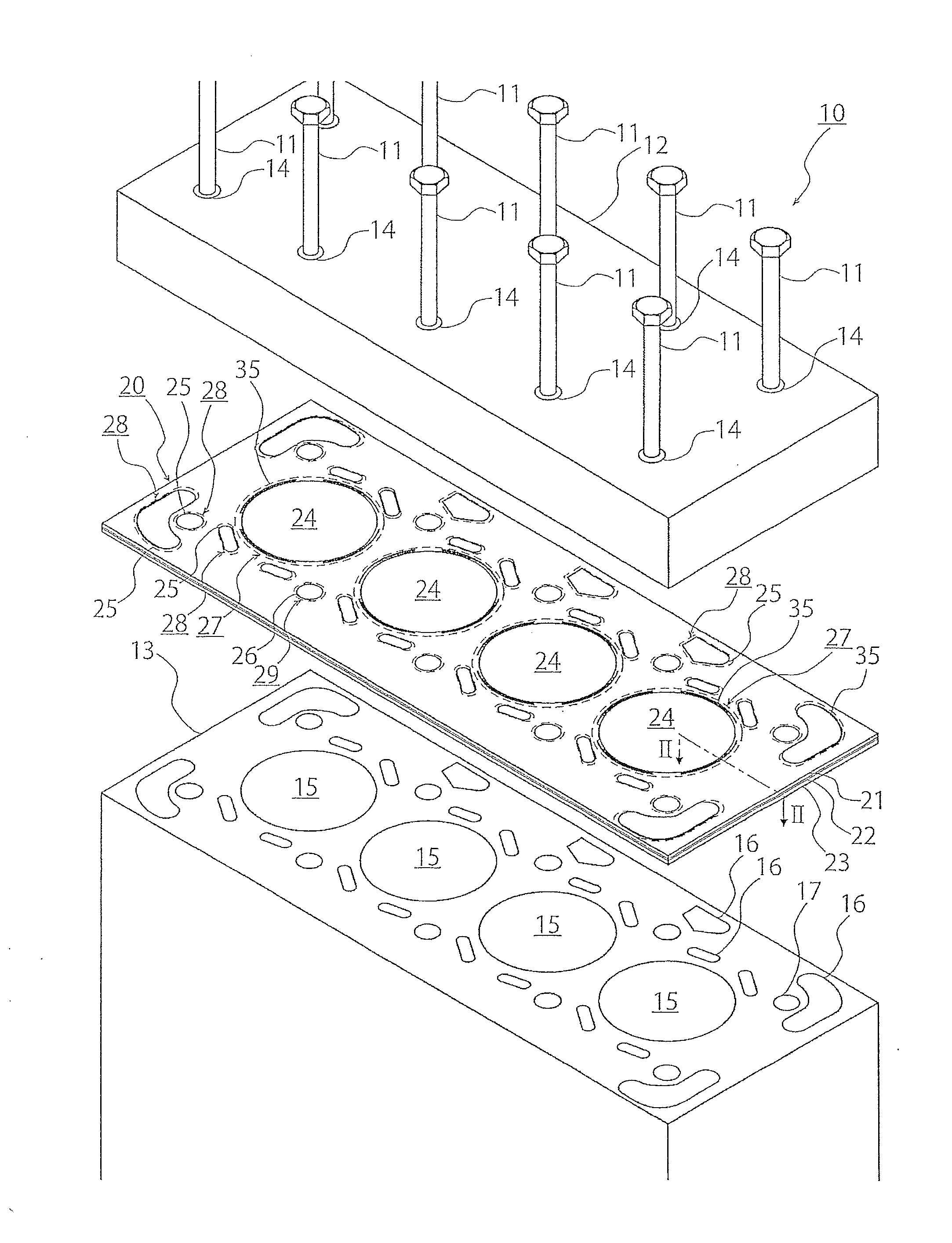

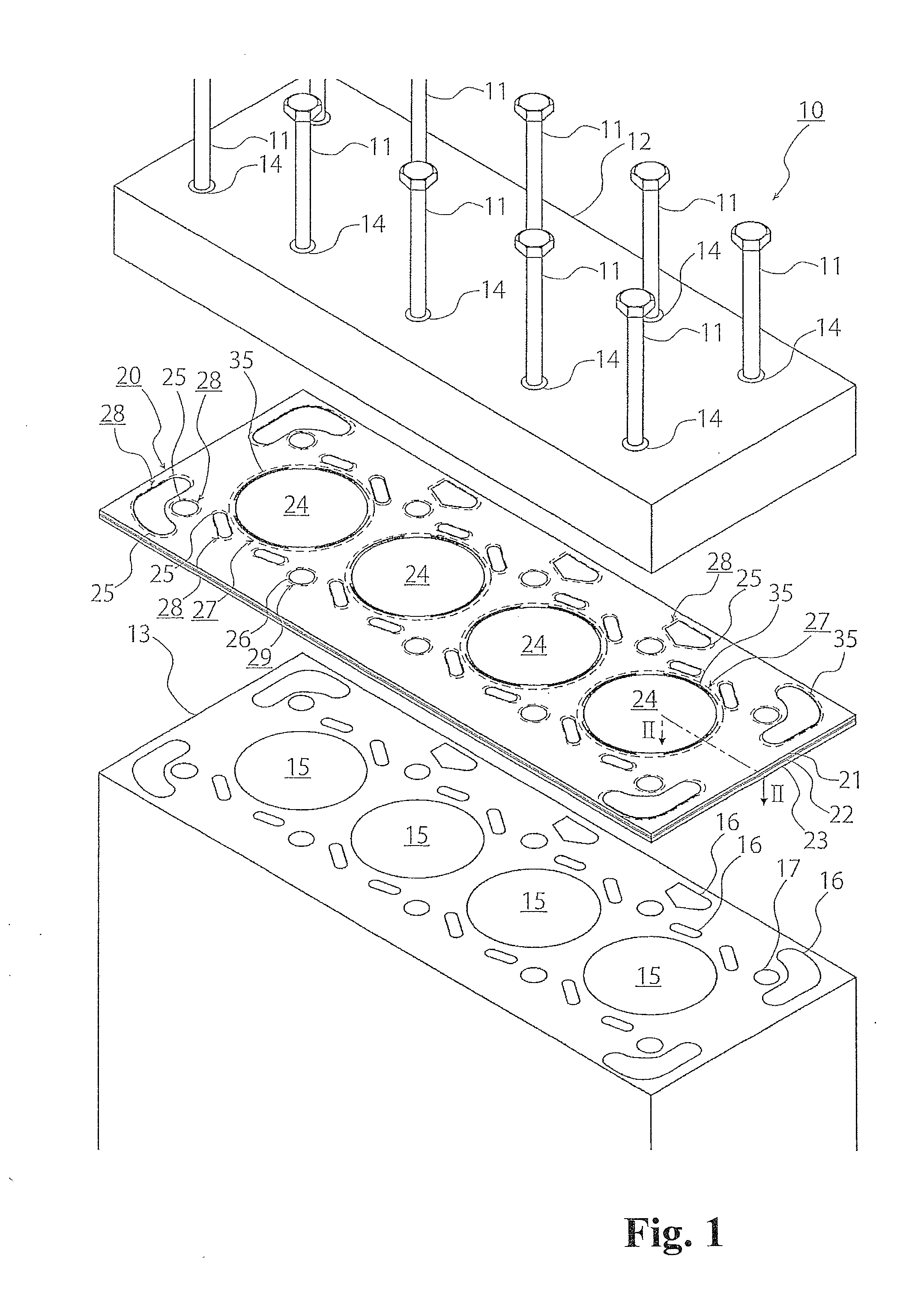

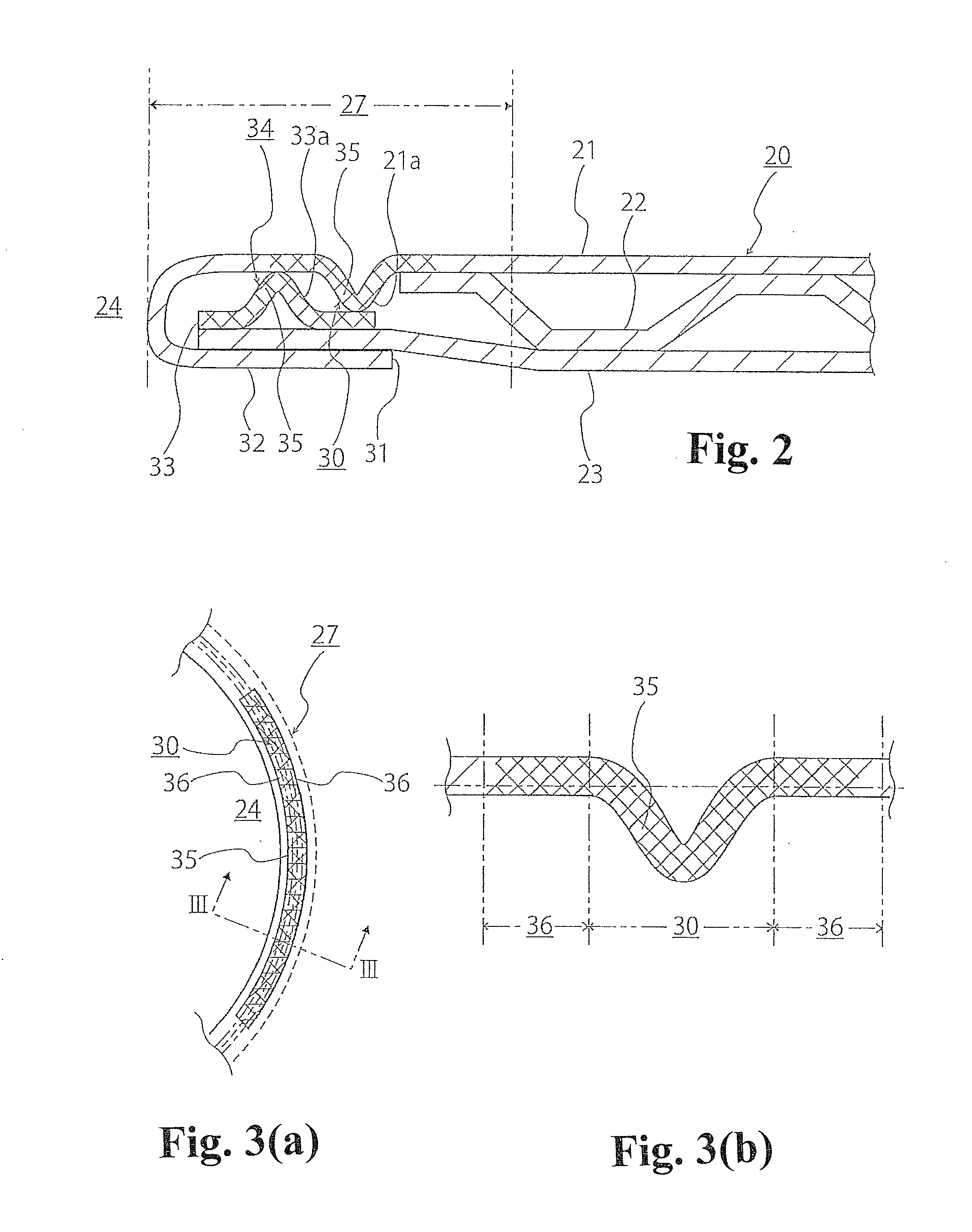

Gasket

ActiveUS10125871B2High hardnessReduce hardnessEngine sealsSealing arrangements for enginesMartensitic stainless steelEngineering

Owner:ISHIKAWA GASKET CO LTD

Water leakage preventing structure for hardness sensor of washing machine

InactiveCN1683639APrevent water leakageUniform sealing effectOther washing machinesMeasurement apparatus housingsWater leakageHardness

The water leakage preventing structure for hardness sensor of washing machine consists of air chamber, hardness sensor and sealing ring. The air chamber is set on one side of the drum in washing machine, the hardness sensor detects the hardness of water fed to the drum, and the sealing ring is installed on the side of the hardness sensor. In one other water leakage preventing structure, the cylindrical air chamber with downward opening is set in the lower side of the drum, the hardness sensor is inserted in the air chamber. The present invention has hardness sensor in easy to install structure and no water leakage between the sensor and the drum.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Pressurized water container

ActiveUS8251405B2Safe closureUniform sealing effectFluid pressure sealed jointsBoltsEngineeringMechanical engineering

Owner:OASE GMBH

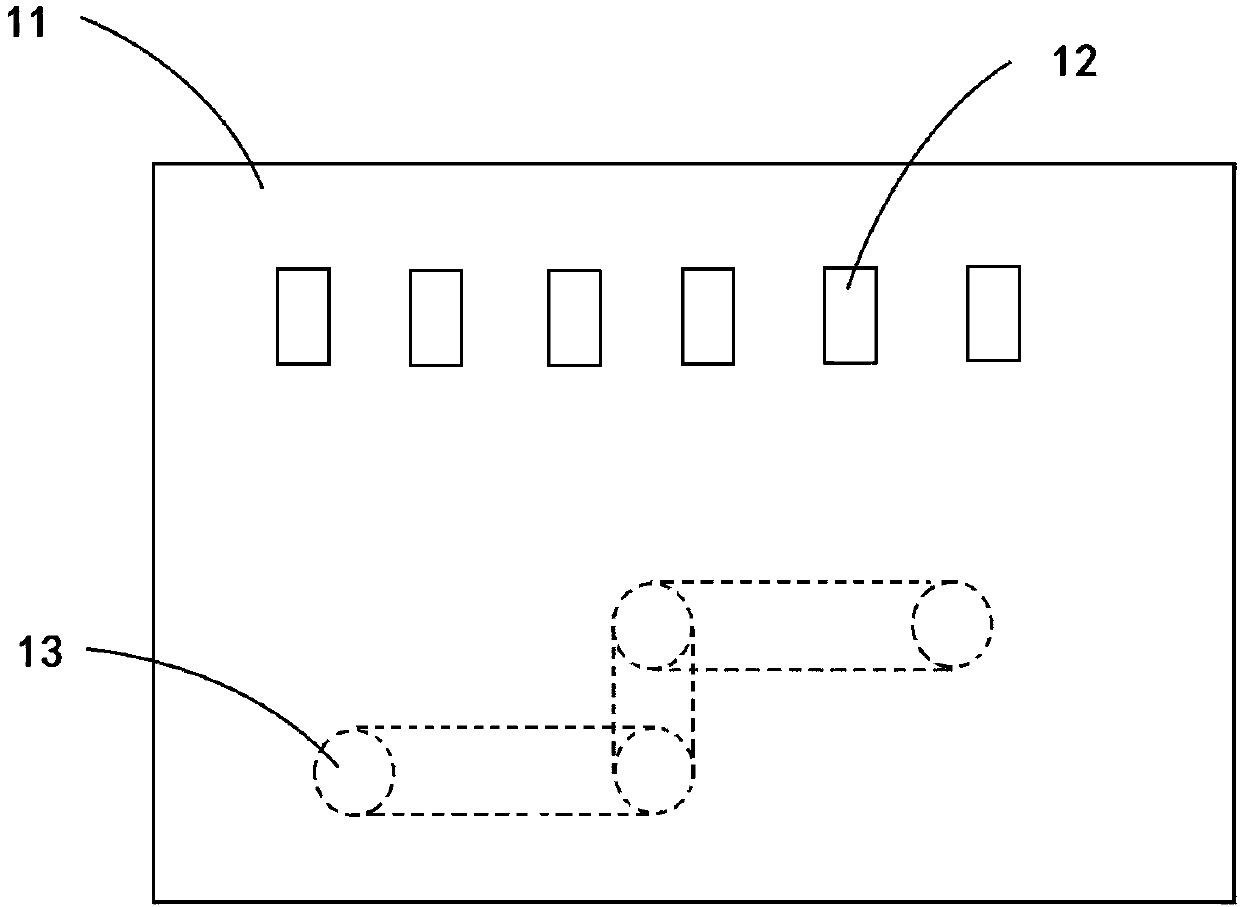

Vacuum magnetron sputtering coating production line for arc-shaped glass

InactiveCN109957769AIncrease profitAvoid formingVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention discloses a vacuum magnetron sputtering coating production line for arc-shaped glass. The production line comprises a loading area, an inlet cavity, an inlet buffer cavity, an inlet conveying cavity, a sputtering cavity, an outlet conveying cavity, an outlet buffer cavity, an outlet cavity, a quality inspection cavity and an unloading area which are connected in sequence, transmission tables connected in sequence are arranged in the loading area, the inlet cavity, the inlet buffer cavity, the inlet conveying cavity, the sputtering cavity, the outlet conveying cavity, the outlet buffer cavity, the outlet cavity and the unloading area, a coating quality inspection table and a quality inspection system are arranged in the quality inspection cavity, and the transmission table inthe outlet cavity is connected with the coating quality inspection table. The vacuum magnetron sputtering coating production line for arc-shaped glass provided by the invention can realize large-batchand low-cost production of various coatings, and is high in sputtering deposition rate, high in process universality and particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

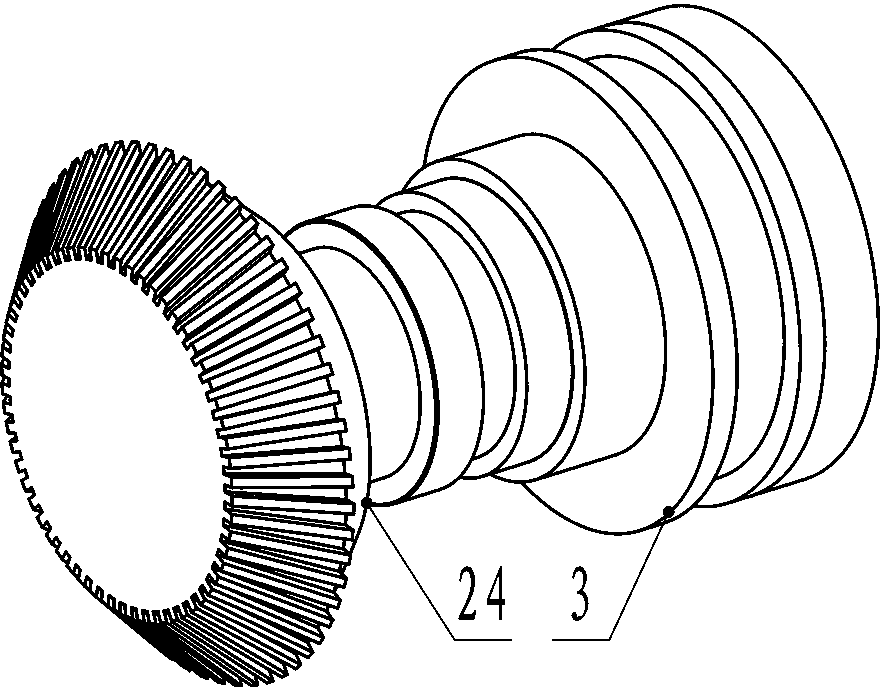

Sliding type aluminium plastic composite pipe fittings

ActiveCN101430035BUniform sealing effectImprove safety and reliabilityHose connectionsPipe connection arrangementsSurface mountingPipe fitting

The invention relates to a pipeline connecting technique, in particular to a sliding compact type aluminum-plastic laminated pipe fitting, comprising a main pipe fitting body (1) provided with a pipe internal stay (10) on at least one end, an element rest (11) which is arranged at the outside diameter of the pipe internal stay (10) and is pressed into a port (31) of an aluminum-plastic laminated pipe (3) that is enlarged in a cold way when in installation, a ring-shaped sliding compact blocking sleeve (2) that is matched with the pipe internal stay (10) and can be sheathed into the external diameter of the aluminum-plastic laminated pipe (3) in a way of clearance fit, and a chamfer angle (20) is arranged at the port of the inner wall at the left end (29) of the sliding compact blocking sleeve (2) that is fixed at a part (30) of the aluminum-plastic laminated pipe (3) enlarged in a cold way after being installed. Compared with the prior art, the sliding compact type aluminum-plastic laminated pipe fitting has the advantages of small diameter shrinkage, even connection stress as well as better applicability and market prospect, and is suitable for being surface mounted and buried ina hiding way, so as to be safer and more reliable.

Owner:浙江世进水控股份有限公司

Large-area AZO glass coating film production line

The invention discloses a large-area AZO glass coating film production line, which comprises a coating film line and a conveying line, wherein the coating film line comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a sputtering chamber, an outlet conveying chamber, an outlet buffer chamber, an outlet chamber and a quality inspection chamber, the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber, the outlet chamber and the quality inspection chamber are sequentiallyconnected, at least a valve is arranged between the adjacent chambers, the conveying line comprises transmission rollers and a coating film quality inspection roller, the sequentially connected transmission rollers are respectively arranged in the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber, the coating film quality inspection roller is arranged in the quality inspection chamber, the transmission roller in the outlet chamber is connected to the coating film qualityinspection roller, and the transmission rollers and the coating film quality inspection roller are used for conveying a coating film substrate. According to the present invention, with the large-areaAZO glass coating film production line, the large-batch and low-cost production of various large-area coating films can be achieved, the sputter deposition rate is high, the process has strong versatility, the diffusion path is short, no intermediate product is generated, and no element is evaporated, such that the preparation is fast, the efficiency is high, the yield rate is over 95%, and the production line is especially suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

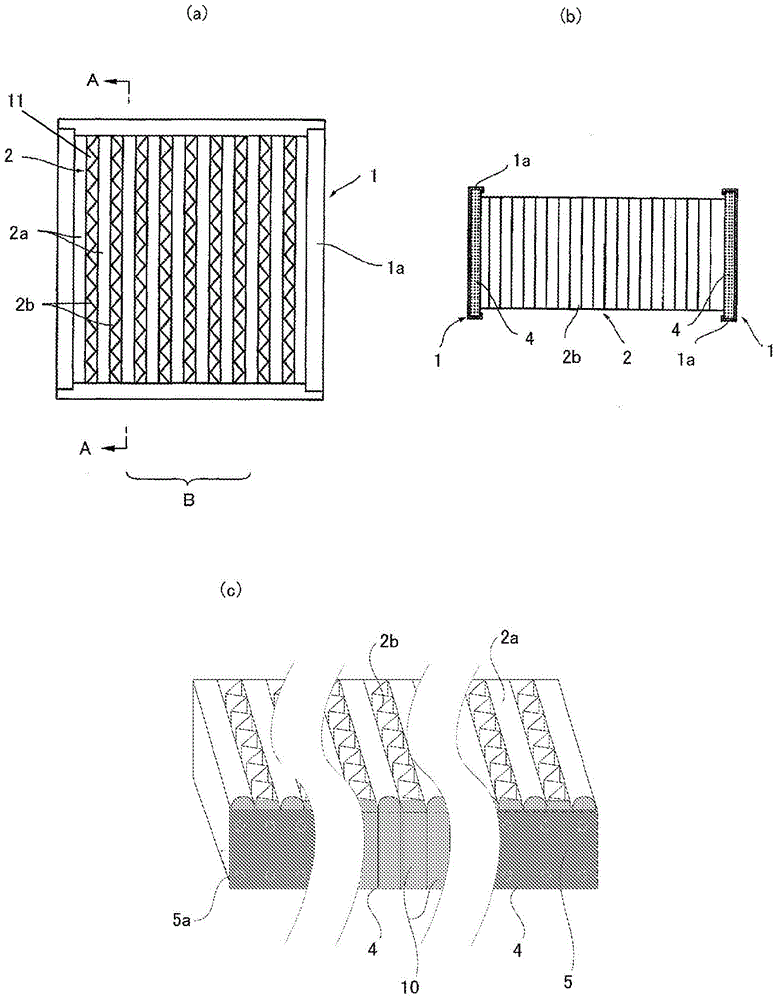

Gasket and method for manufacturing gasket

ActiveUS20160138717A1Improve sealingHigh hardnessEngine sealsSealing arrangements for enginesMartensitic stainless steelEngineering

A gasket includes at least one metal plate to be clamped between two members fastened by fastening devices, an opening portion corresponding to a sealing hole provided in the at least one metal member, a seal bead protruding outwardly from a flat surface of the at least one metal plate, and annularly surrounding the opening portion, and insertion holes through which the fastening devices pass. At least one metal plate is formed by a martensitic stainless steel plate, and a high hardness portion having a hardness higher than that of the stainless steel plate is formed in at least one portion of the seal bead formed in the stainless steel plate.

Owner:ISHIKAWA GASKET CO LTD

Multipurpose metal film layer vacuum coating production line

InactiveCN109913846AReduce the impactIncrease profitVacuum evaporation coatingSputtering coatingProduction lineEvaporation

The invention discloses a multipurpose metal film layer vacuum coating production line. The production line comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a sputtering chamber, an outlet conveying chamber, an outlet buffer chamber, an outlet chamber and a quality inspection chamber, wherein the inlet chamber, the inlet buffer chamber, the inlet conveying chamber,the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber are connected in sequence; transferring rollers connected with each other are arranged in the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber; a film coating quality inspection roller and a quality inspection system are arranged in the quality inspection chamber; the transferring roller in the outlet chamber is connected with the film coating quality inspection roller;and the transferring rollers and the film coating quality inspection roller are used for transferring a film coating substrate. According to the multipurpose metal film layer vacuum coating productionline, mass and low-cost production of various coatings are achieved with high sputtering deposition rate and strong process universality; an element diffusion path is short with no intermediate product and no element evaporation, so that the preparation speed and the efficiency are high, the yield is 95% or above, and the production line is particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

air filter

ActiveCN103796729BSolve sheddingSolve problems like air leaksEngine sealsDispersed particle filtrationGlass fiberAir filter

To provide an air filter in which a filter pack is not moved in use as well as in which the filter pack does not fall off when used in horizontal direction. An air filter in which a sheet-shaped sealing material made of glass fibers is inserted into a zigzag-shaped end surface of a filter pack formed by folding a filter medium in zigzag shape and by inserting corrugated separators into folding spaces, and at least the zigzag-shaped end surface of the filter pack is surrounded by a filter frame having a C-shape in cross section and including folded portions formed by inwardly folding open ends, which includes a stopper between the folded portion in a downstream side and the filter pack and strip-shaped sealing materials made of glass fibers are embedded between the sheet-shaped sealing material and the filter pack so as to closely contact the separators in the folding spaces of the filter pack.

Owner:NIPPON MUKI CO LTD

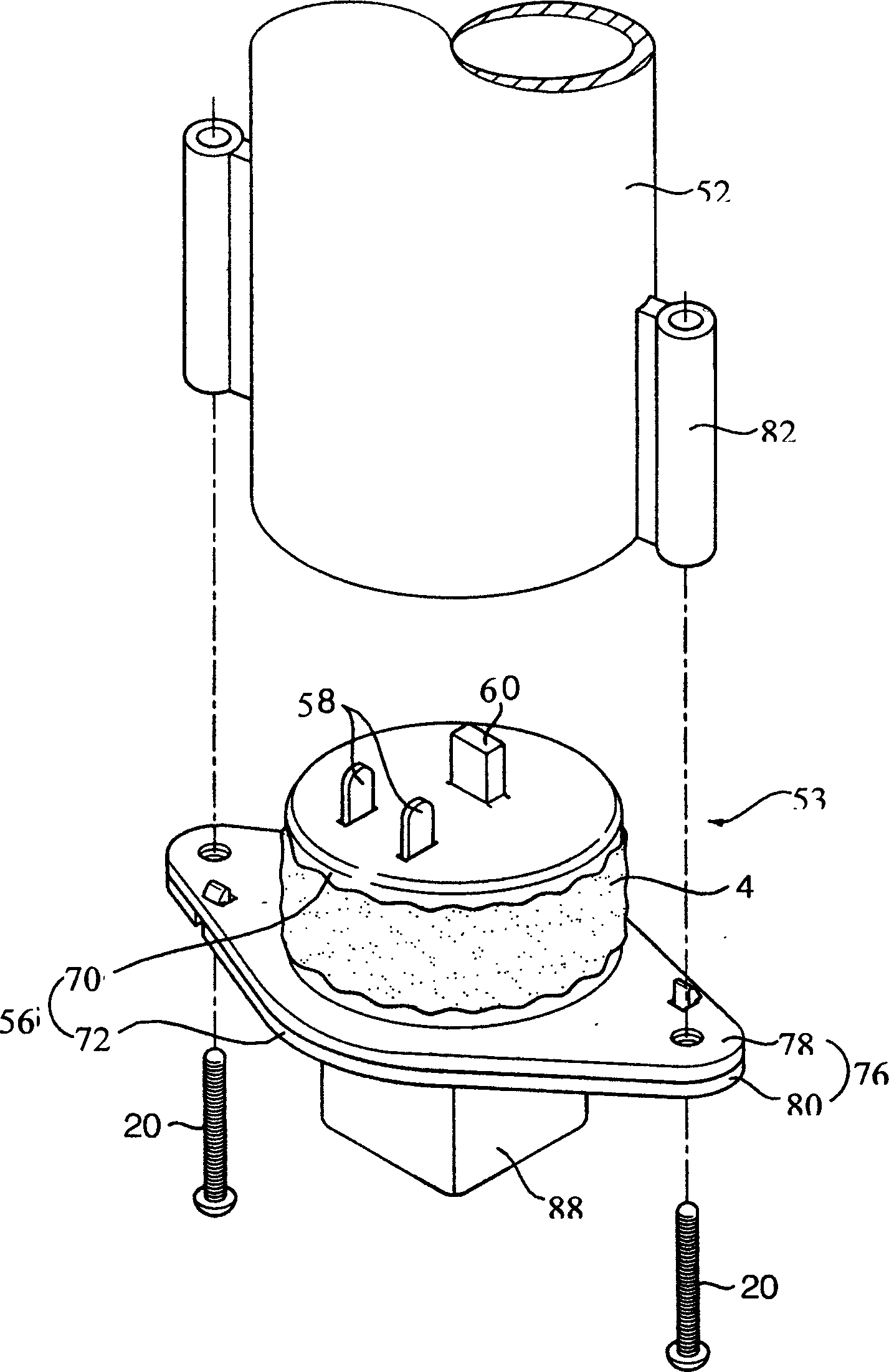

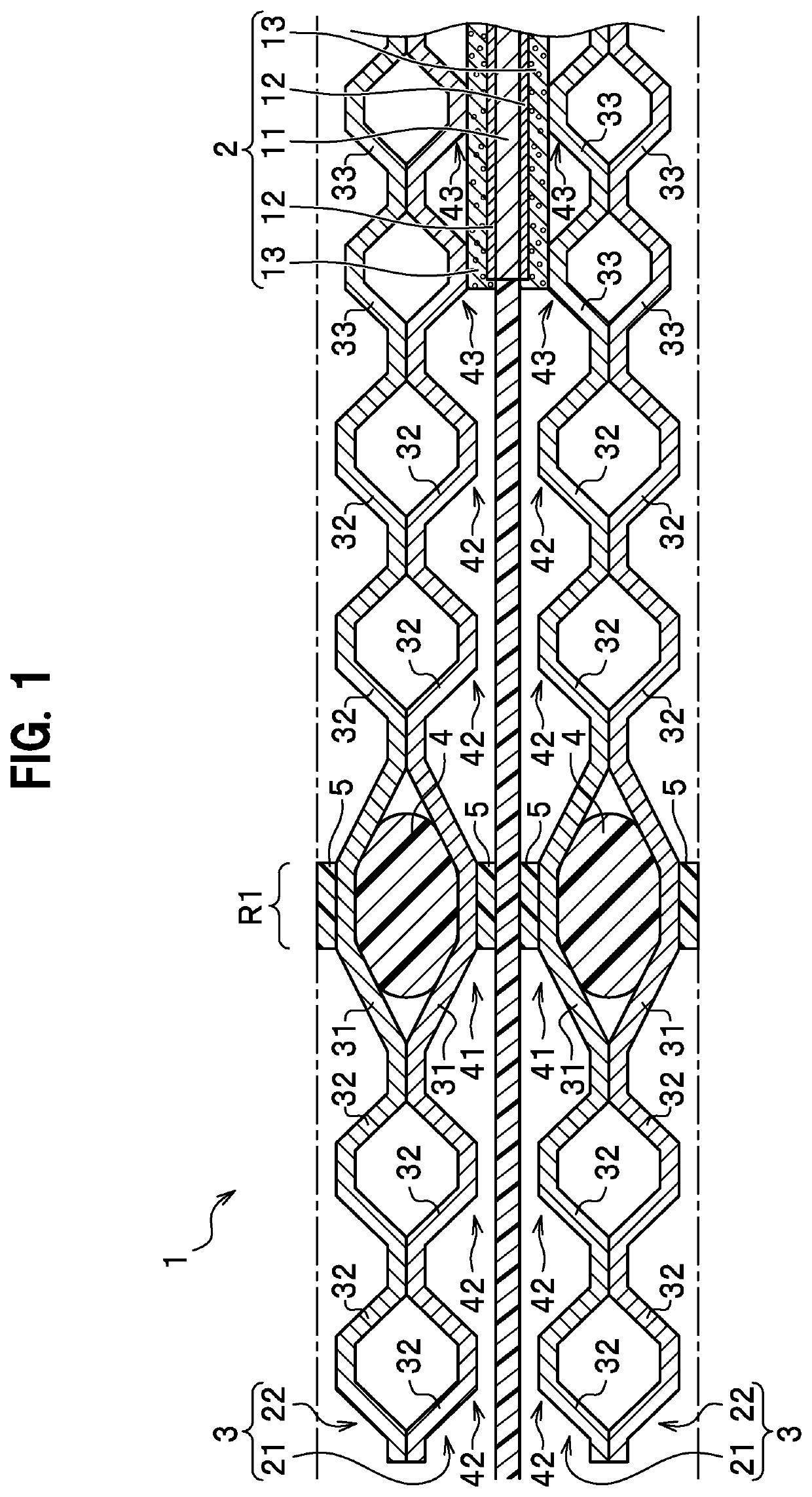

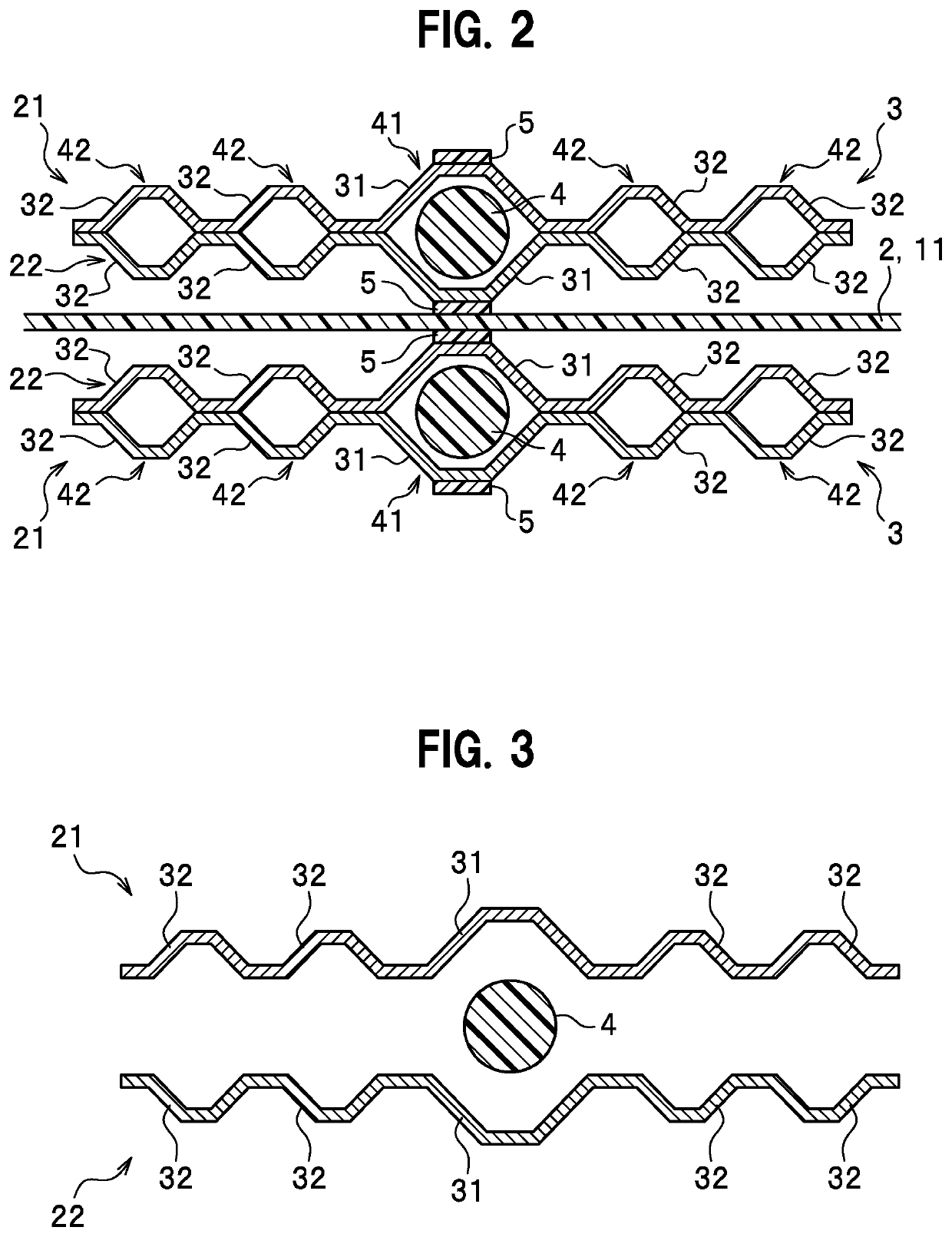

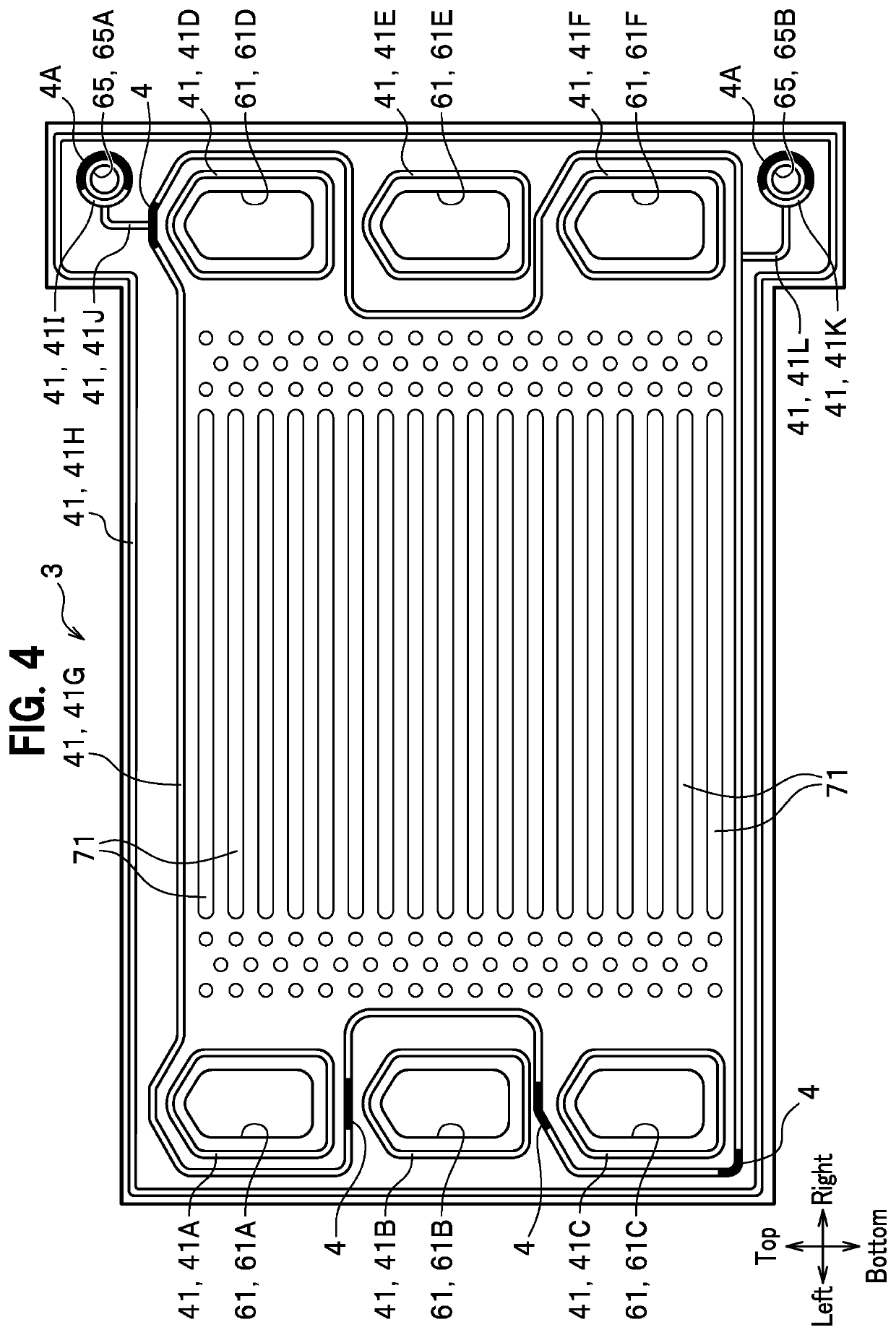

Separator assembly used for fuel cell

ActiveUS20210194020A1Increase surface pressureReduce surface variationCollectors/separatorsSealing/support meansFuel cellsEngineering

A separator assembly used for a fuel cell includes one pair of metal separators joined together and including a bead seal section including one pair of seal bead portions projecting in opposite directions respectively, an elastic body disposed in the bead seal section, and a first communication hole which extends through the separator assembly in a thickness direction of the separator assembly and which allows a reaction gas or a coolant to flow through the separator assembly. The bead seal section is disposed along an outer periphery of the separator assembly and along a shape of the first communication hole. The elastic body of a predetermined length is disposed in the bead seal section.

Owner:NOK CORP +1

Flexible film vertical vacuum coating production line

ActiveCN107794510BReduce exposureAvoid destructionFinal product manufactureVacuum evaporation coatingProduction lineThin membrane

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Device for the roll-sealing of sheets

InactiveUS8322116B2Simple designUniform sealing effectWrapper twisting/gatheringDomestic articlesEngineeringMechanical engineering

The device for the roll-sealing of sheets has a mating roll and a sealing roll, which presses against the mating roll with a sealing force, so that a molded sheet and a cover sheet can be guided between the sealing roll and the mating roll and sealed to form a sealed composite sheet structure. The surface of the mating roll has recesses to accept blister pockets of the molded sheet and a rippled structure. The elevations formed by the rippled structure comprise contact areas of different sizes.

Owner:UHLMANN PAC SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com