Water tank seal component and water heater using same

A technology for sealing components and water heaters, applied in fluid heaters, lighting and heating equipment, pipes/pipe joints/fittings, etc., can solve problems such as aggravated leakage, easy corrosion of welds, and leaking gaps in pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

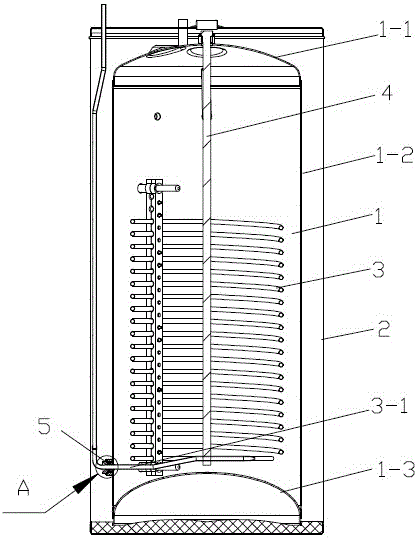

[0013] The present embodiment adopts the heat pump water heater of water tank sealing assembly such as figure 1 As shown, a water tank 1 (commonly known as an inner tank) composed of a cylinder body 1-2, a top cover 1-1 and a bottom cover 1-3 is installed in the shell 2. A spiral heat exchange coil 3 is placed in the water tank 1, and the top cover 1-1 vertically insert the anode rod 4 for anti-corrosion. The two ends of the coil pipe 3 pass through the water tank sealing assembly 5 located in the cylinder body 1-2 respectively through the connecting pipe 3-1, and are externally connected to the heat pump circulation system (only one place is shown in the figure due to the section view).

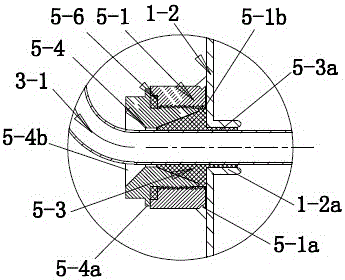

[0014] The concrete structure of water tank sealing assembly 5 is as figure 2 As shown, the pipe seat 5-1 and the water tank cylinder 1-2 are made of stainless steel, and one end adjacent to the water heater tank cylinder 1-2 is formed with a circumferential V-shaped groove 5-1a, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com