Patents

Literature

1724results about "Sealing/support means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

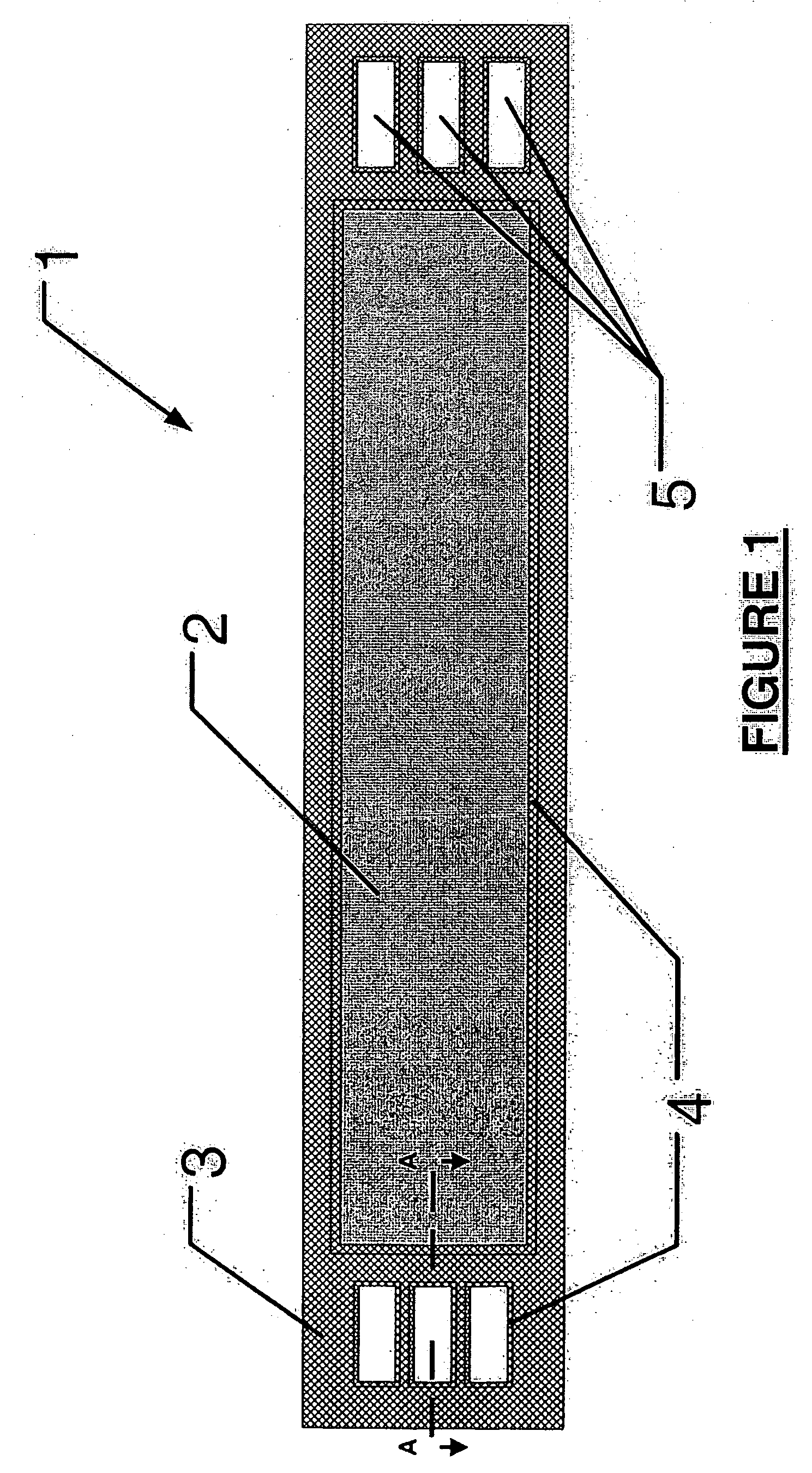

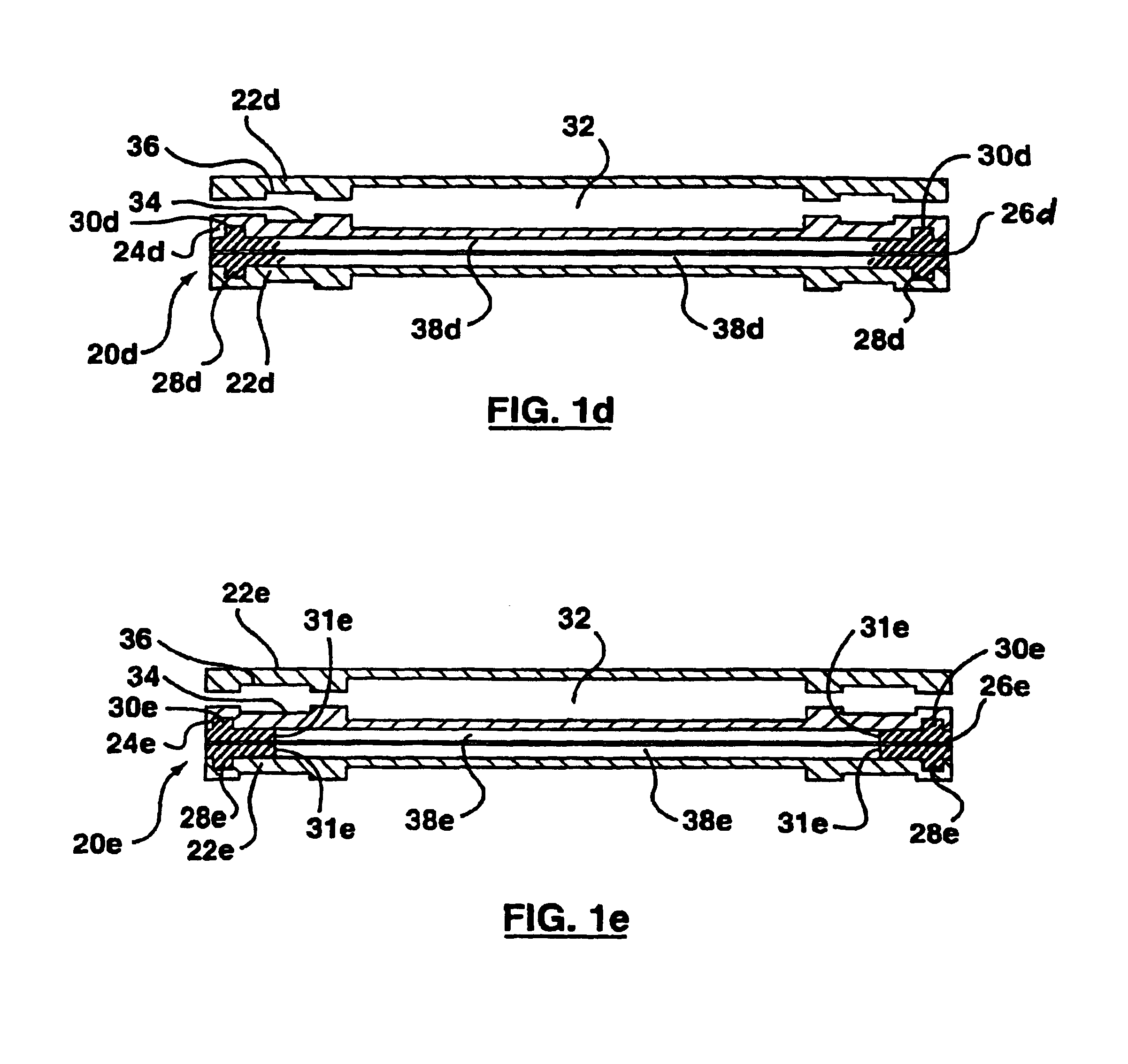

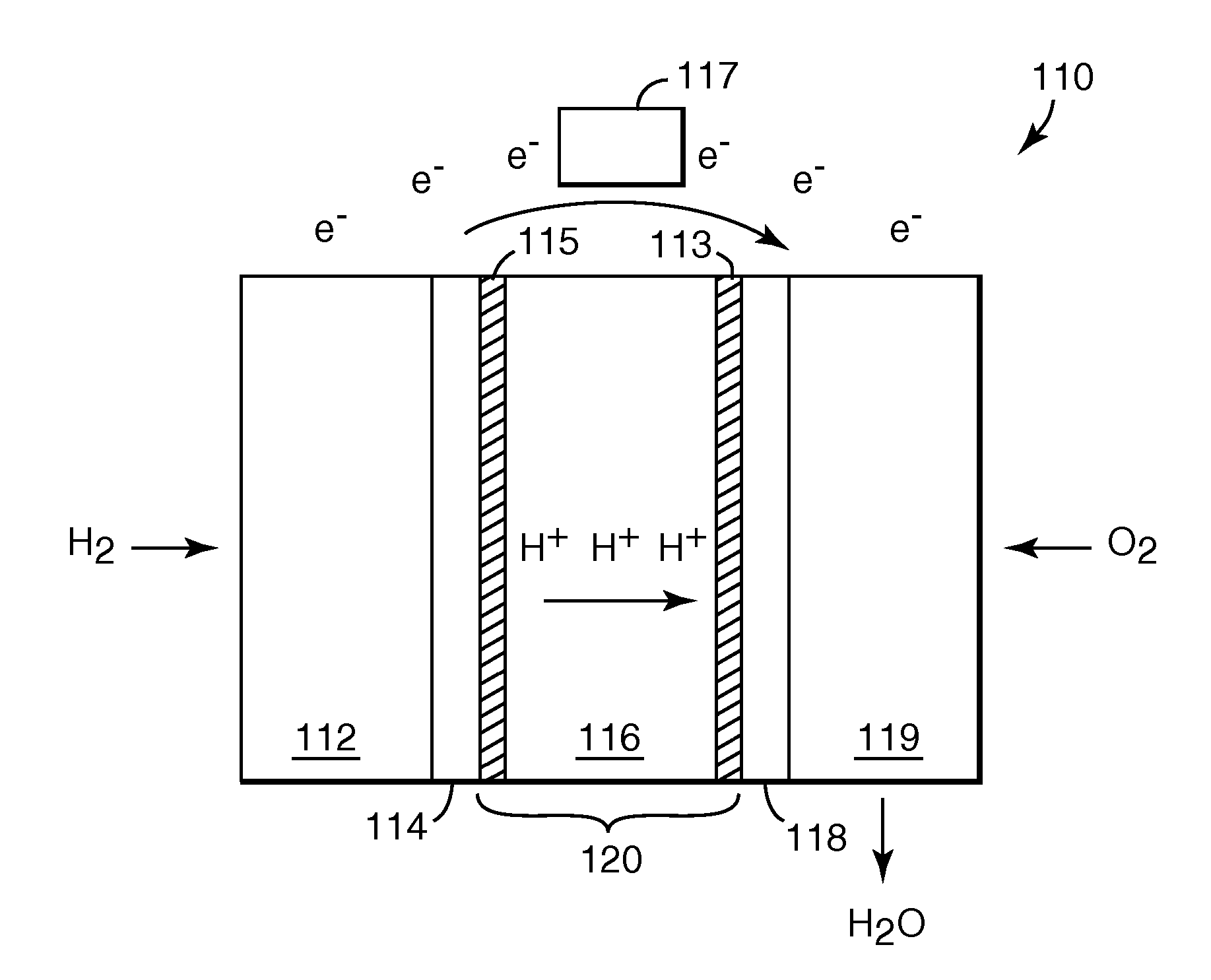

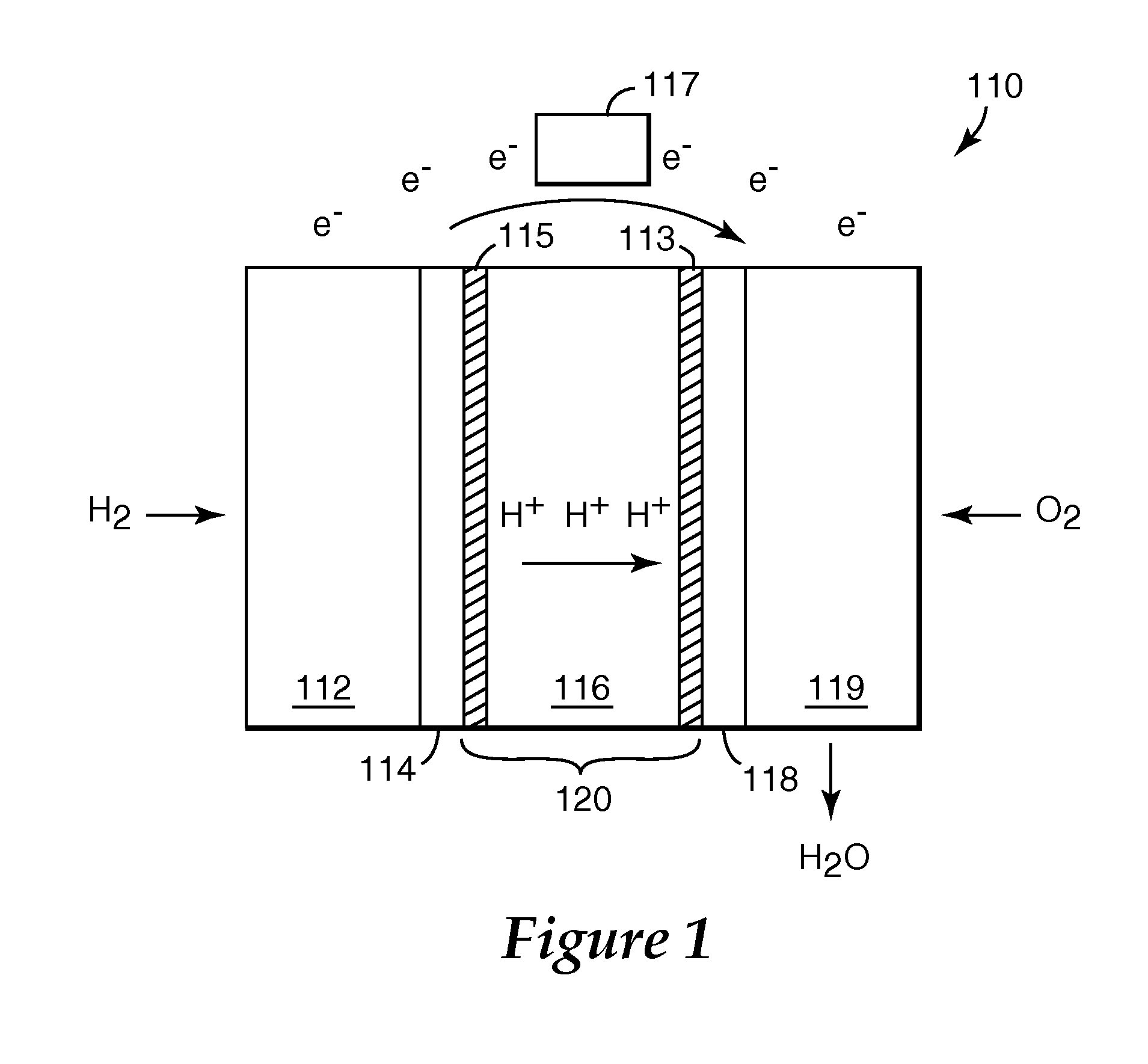

Membrane electrode unit for electrochemical equipment

InactiveUS20050014056A1Good design conceptOvercome disadvantagesCellsFuse device manufactureSpecial designEngineering

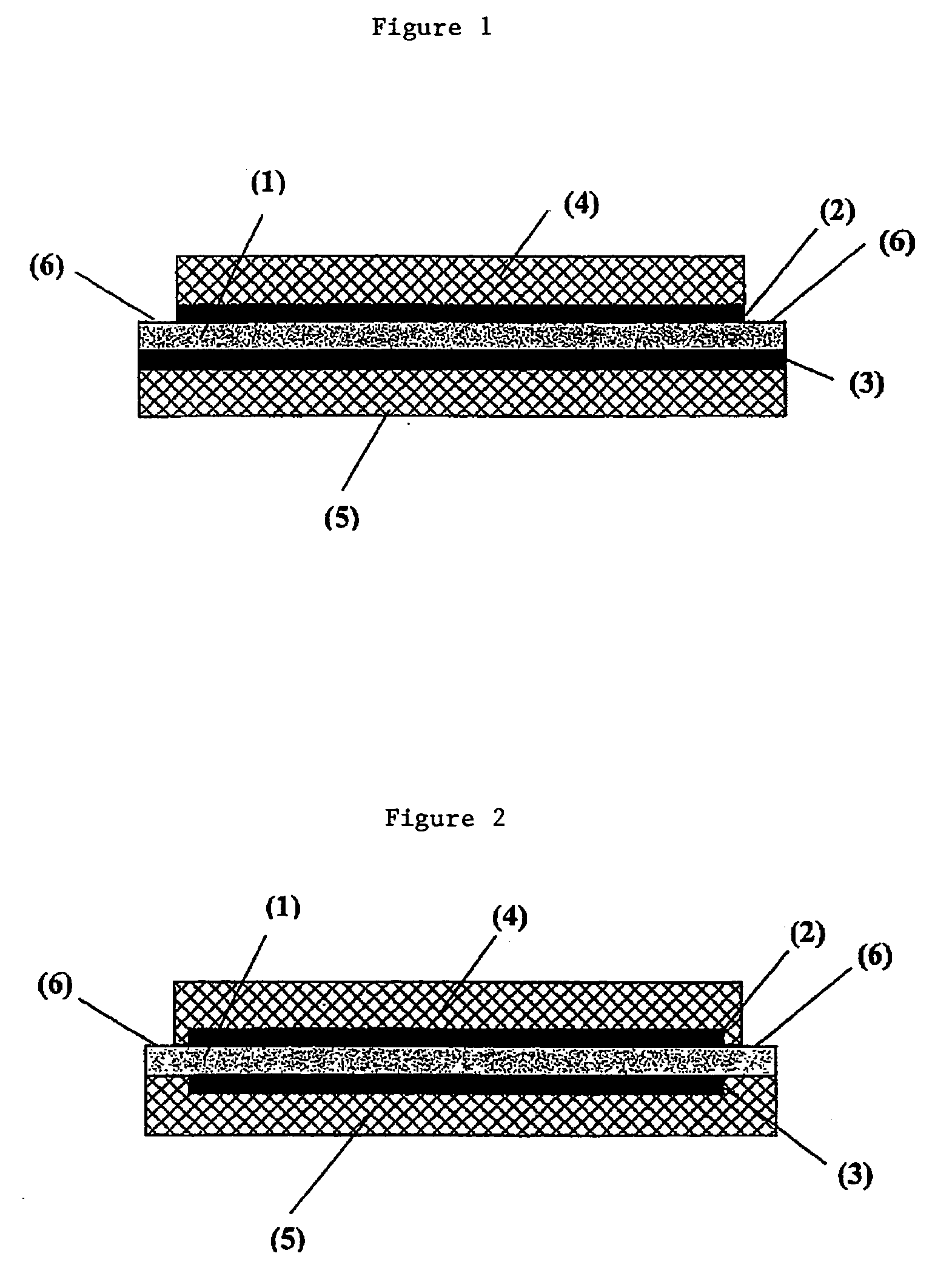

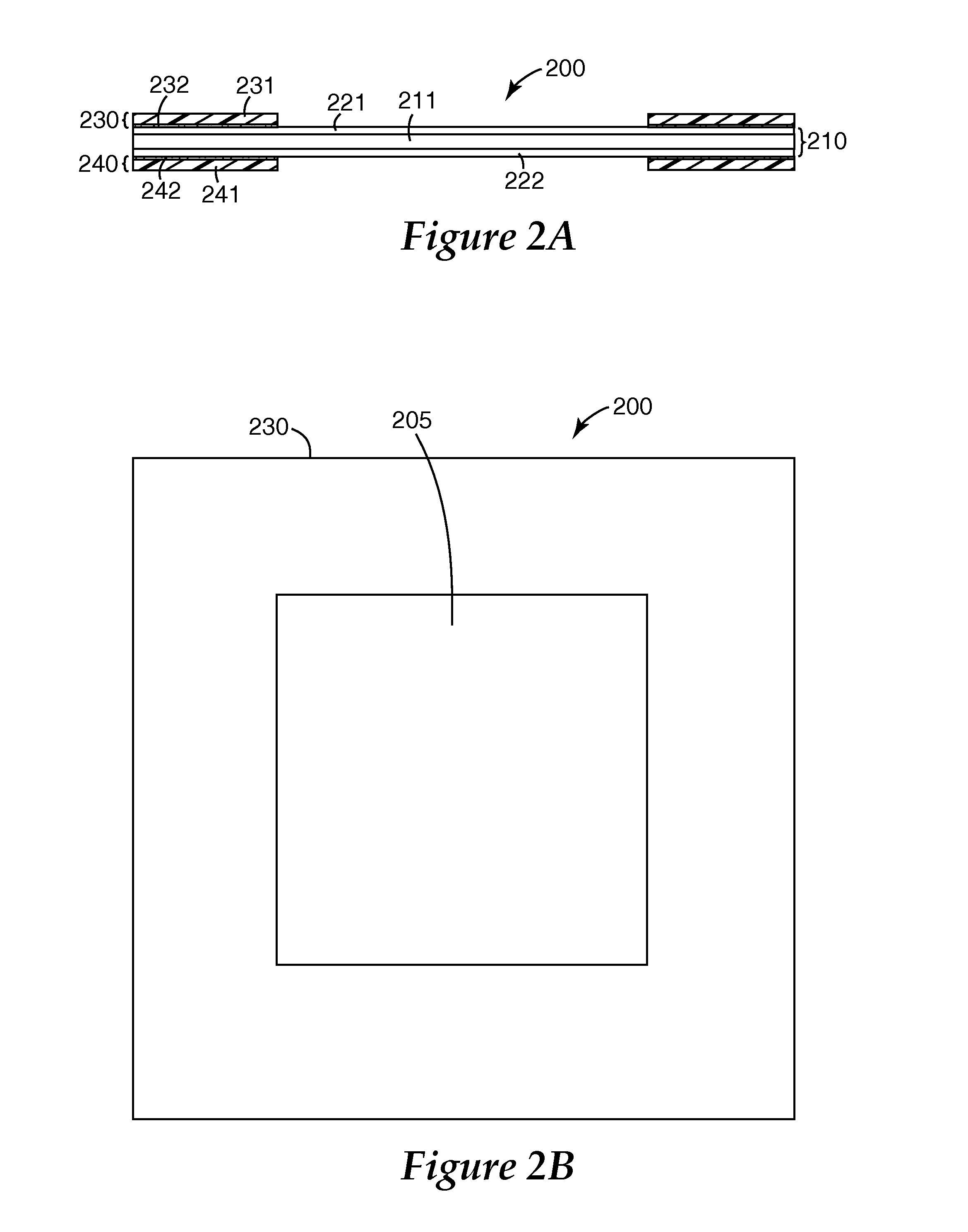

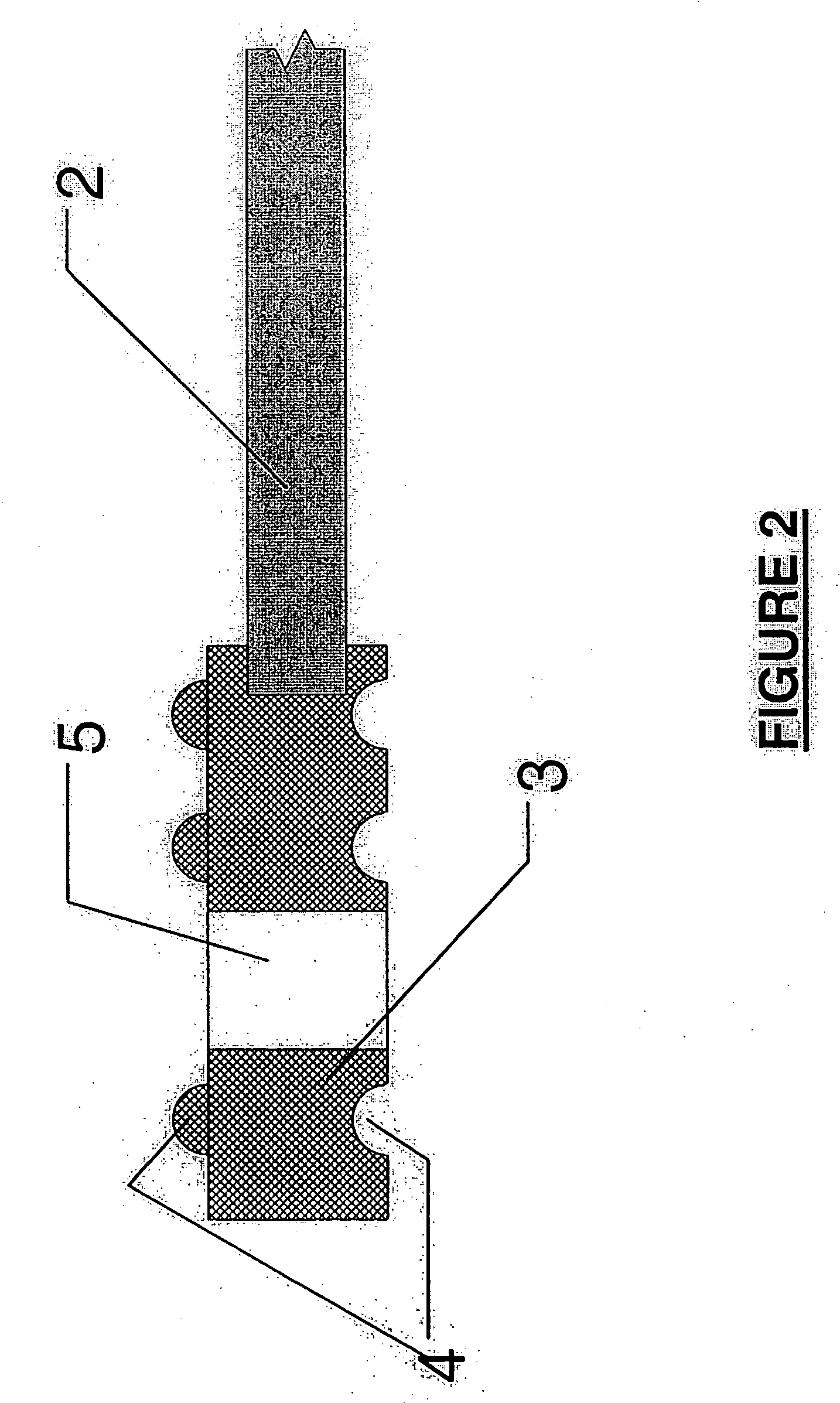

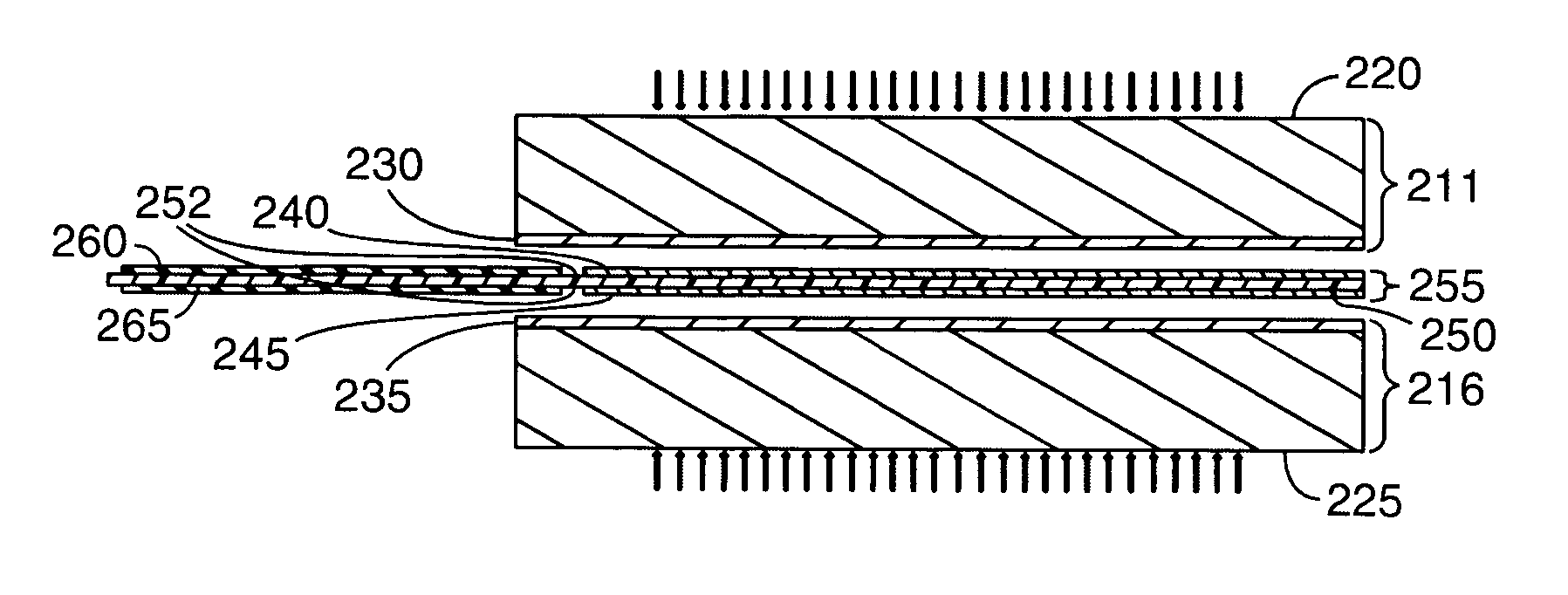

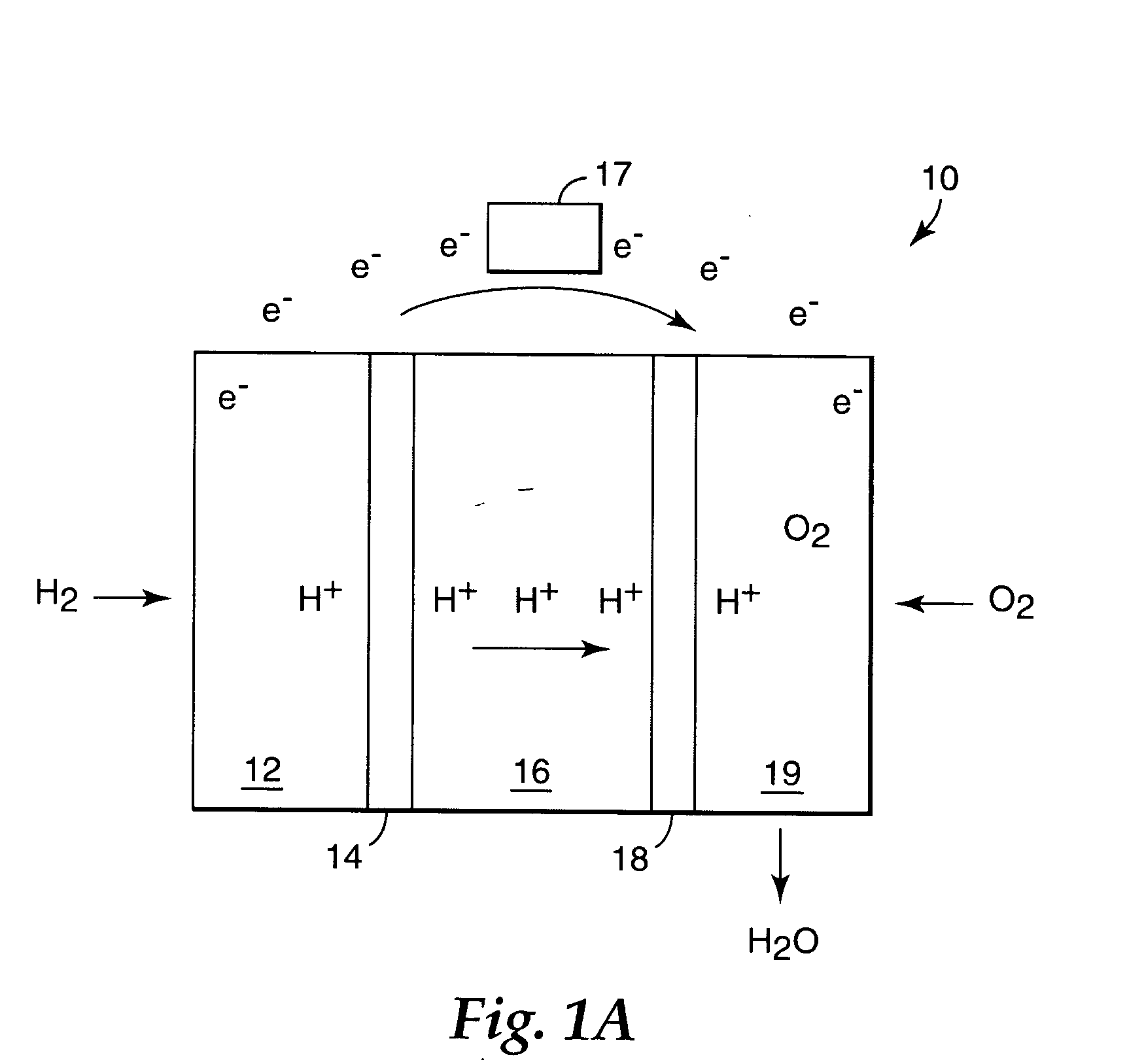

The invention concerns a membrane electrode unit (MEU) for electrochemical equipment, especially for membrane fuel cells. The membrane electrode unit has a “semi-coextensive” design and contains an ionically conductive membrane, two catalyst layers, and gas distributor substrates of different sizes on the front and back sides. The first gas distributor substrate has smaller surface dimensions than the ionically conductive membrane, while the second gas distributor substrate has the same area as the ionically conductive membrane. The membrane electrode unit has, because of its special design, a stable structure that can be handled well, and which exhibits advantages for sealing the reactive gases off from each other and in its electrical properties. In particular, the hydrogen penetration current is distinctly reduced. The membrane electrode unit is used in PEM fuel cells, direct methanol fuel cells, electrolyzers, and other electrochemical equipment.

Owner:UMICORE AG & CO KG

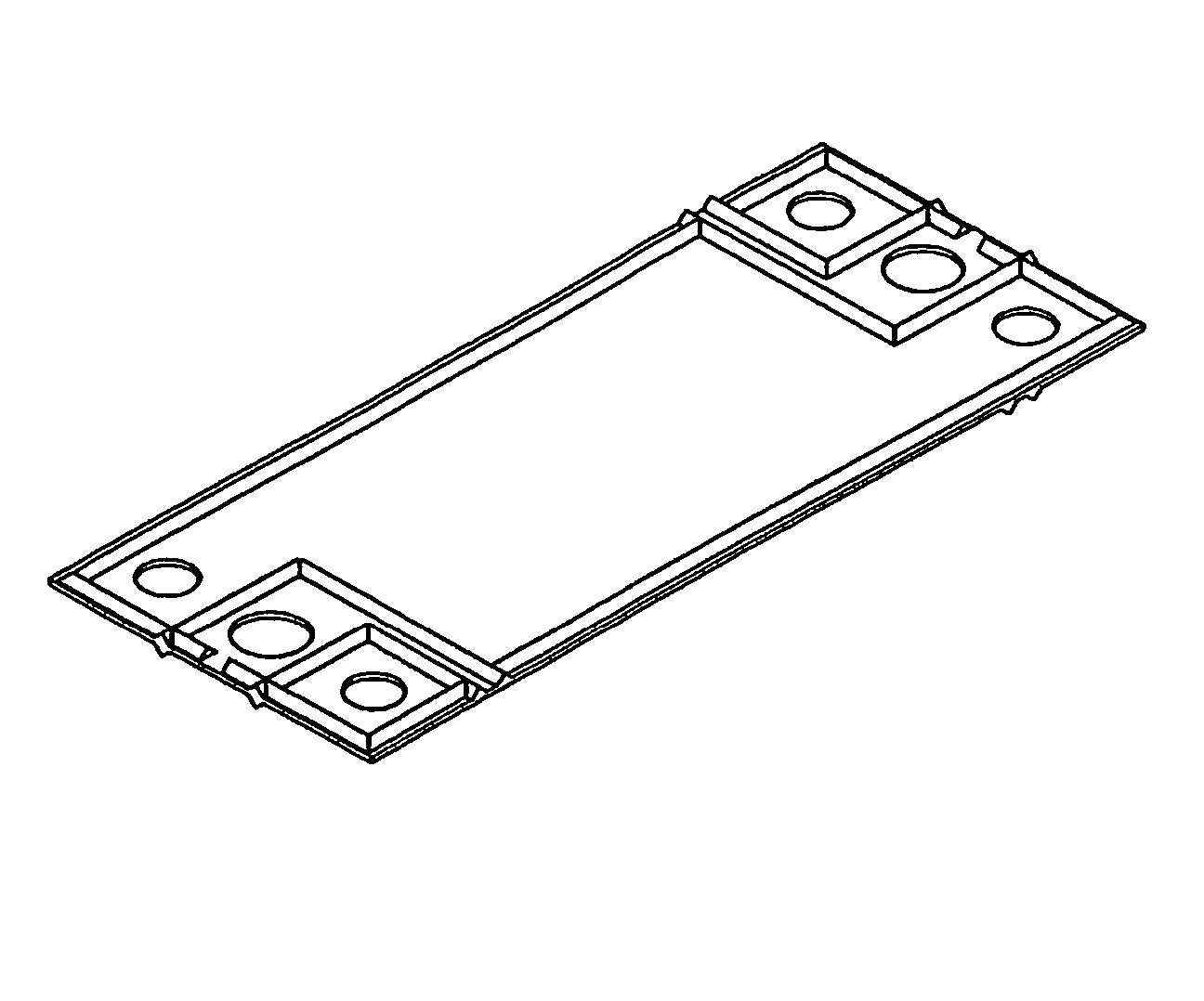

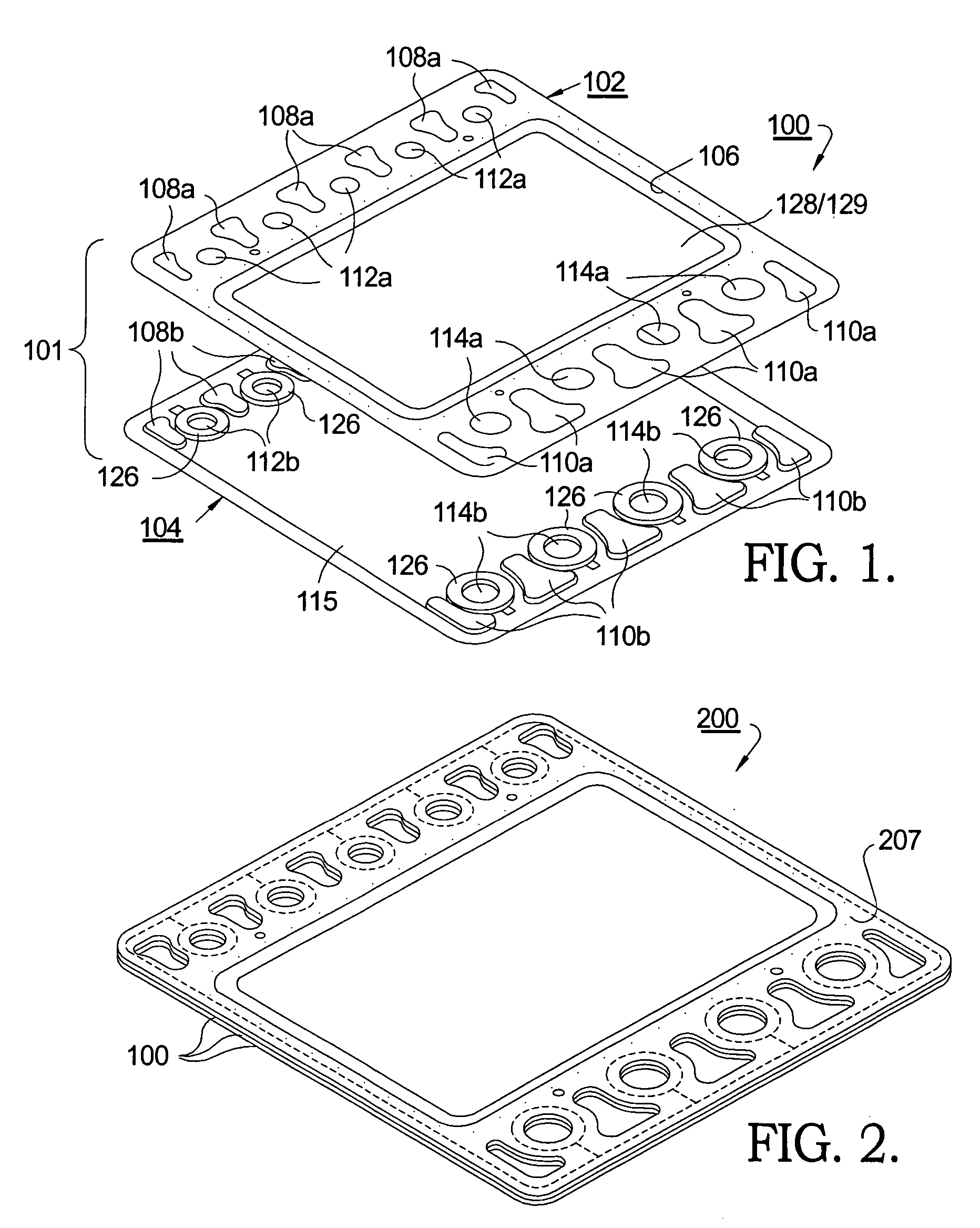

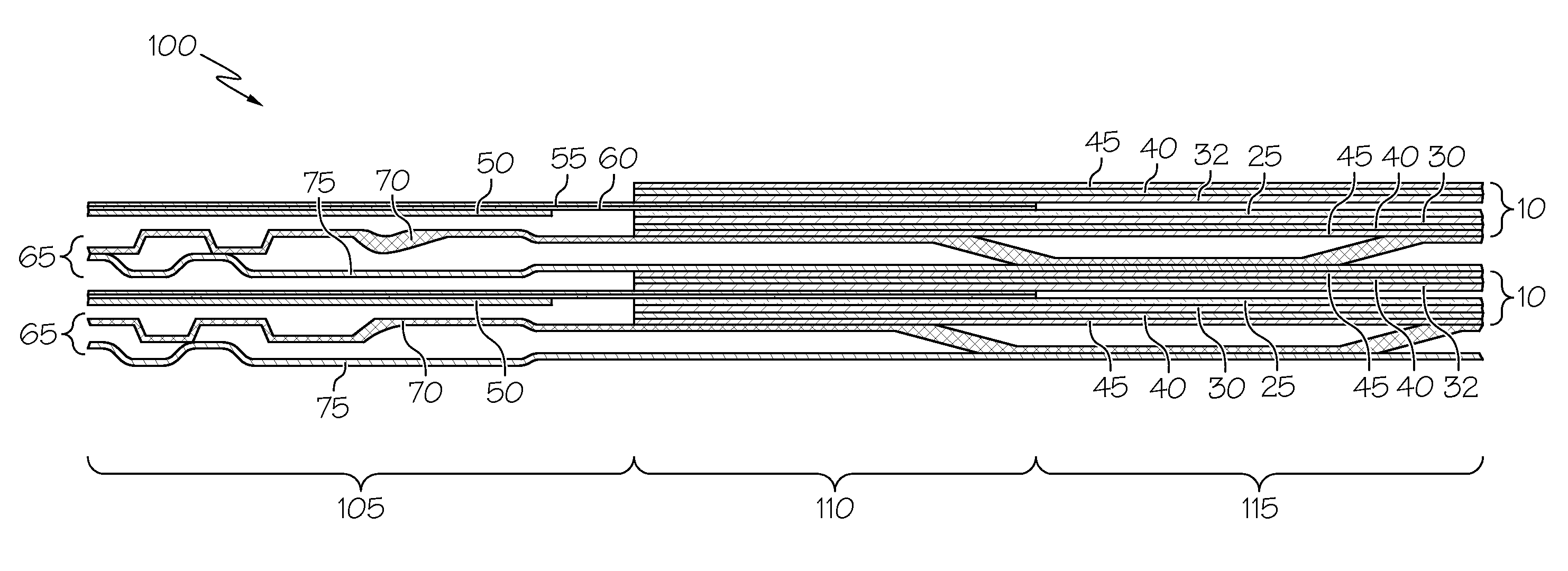

Processing methods and systems for assembling fuel cell perimeter gaskets

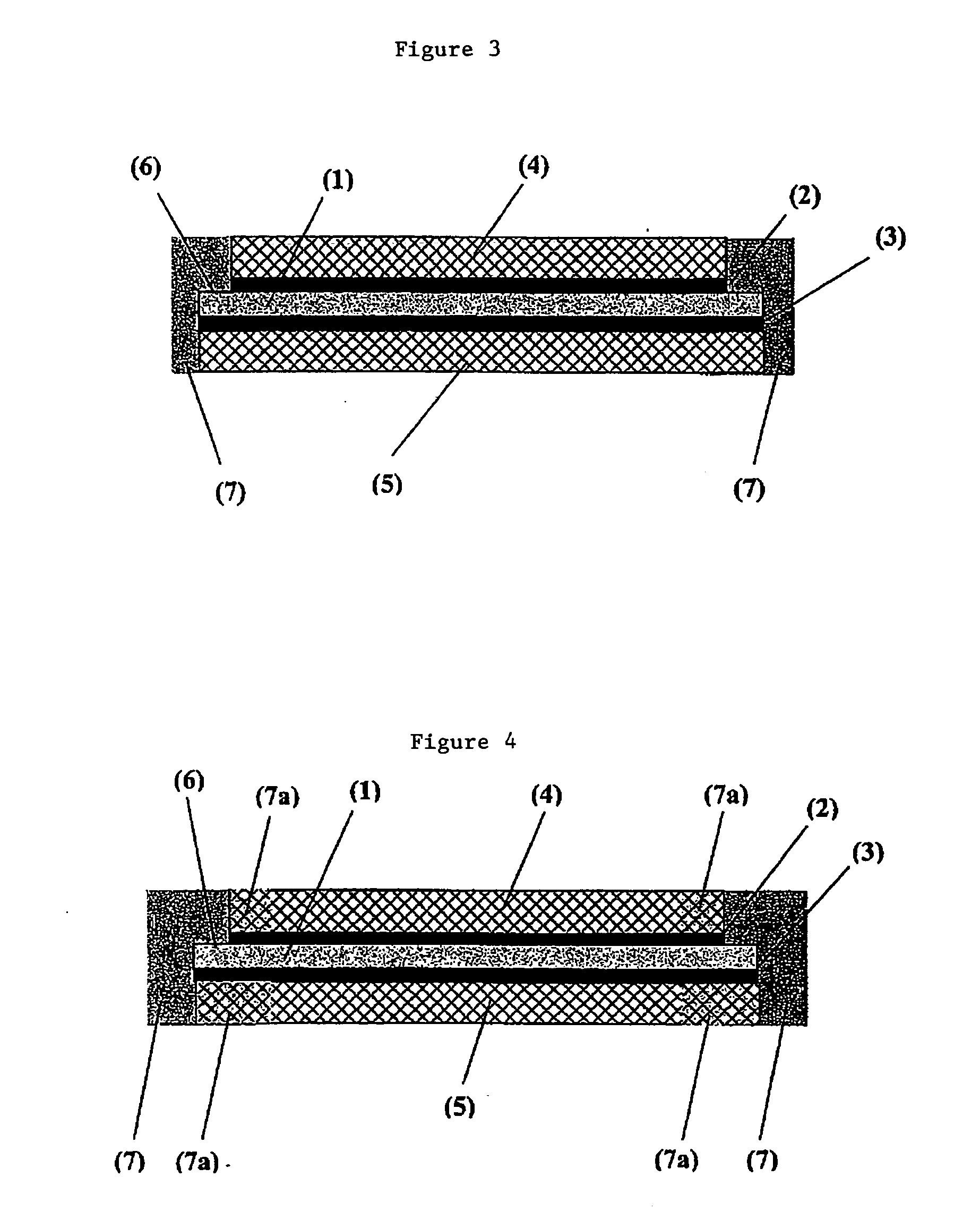

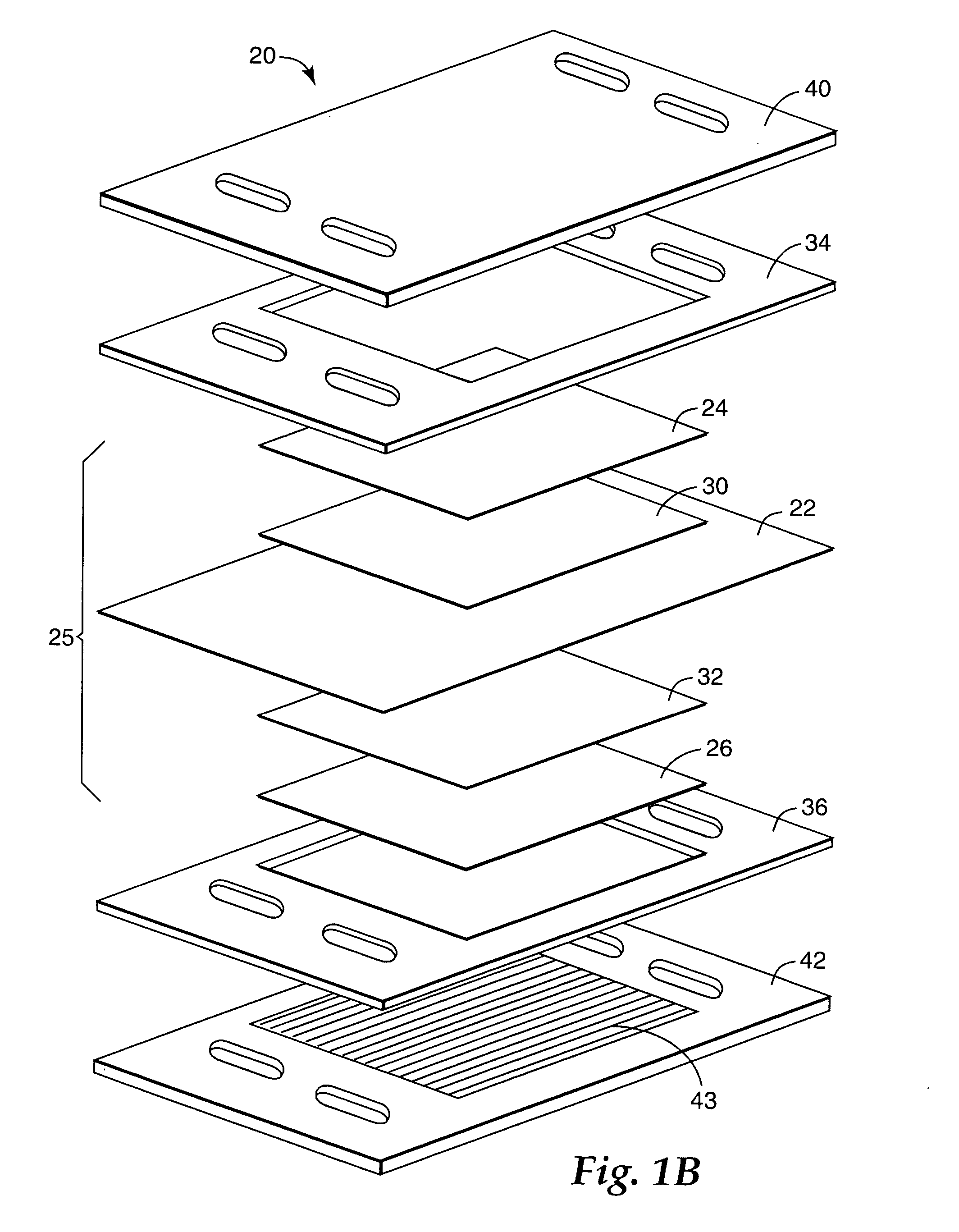

A method and apparatus for making fuel cell components via a roll to roll process are described. Spaced apart apertures are cut in first and second gasket webs that each include adhesives. The first and second gasket webs are transported to a bonding station on conveyers. A membrane web that includes at least an electrolyte membrane is also transported to the bonding station. At the bonding station, a gasketed membrane web is formed by attaching the first and second gasket webs to the membrane web. The first gasket web is attached to a first surface of the membrane web via the adhesive layer of the first gasket web. The second gasket web is attached to a second surface of the membrane web via the adhesive layer of the second gasket web.

Owner:3M INNOVATIVE PROPERTIES CO

Alkali-Free Composite Sealant Materials for Solid Oxide Fuel Cells

A sealant composition for use in sealing solid oxide fuel cells is provided which comprises a glass component which comprises a mixture of alkali-free inorganic oxides, and an optional filler component dispersed in the glass component, said filler component being up to 40% by weight of the composition. The glass component can include, on a mole basis, 20 to 50% BaO, 1 to 10% Y2P3, 5 to 20% B2O3, 10 to 30% SiO2, 3 to 35% MgO, 2 to 20% CaO, 1 to 10% ZnO, and 0 to 5% ZrO2, and exemplary filler components include zirconia, alumina, barium titanate, strontium titanate, and combinations thereof.

Owner:CUMMINS ENTERPRISE LLC

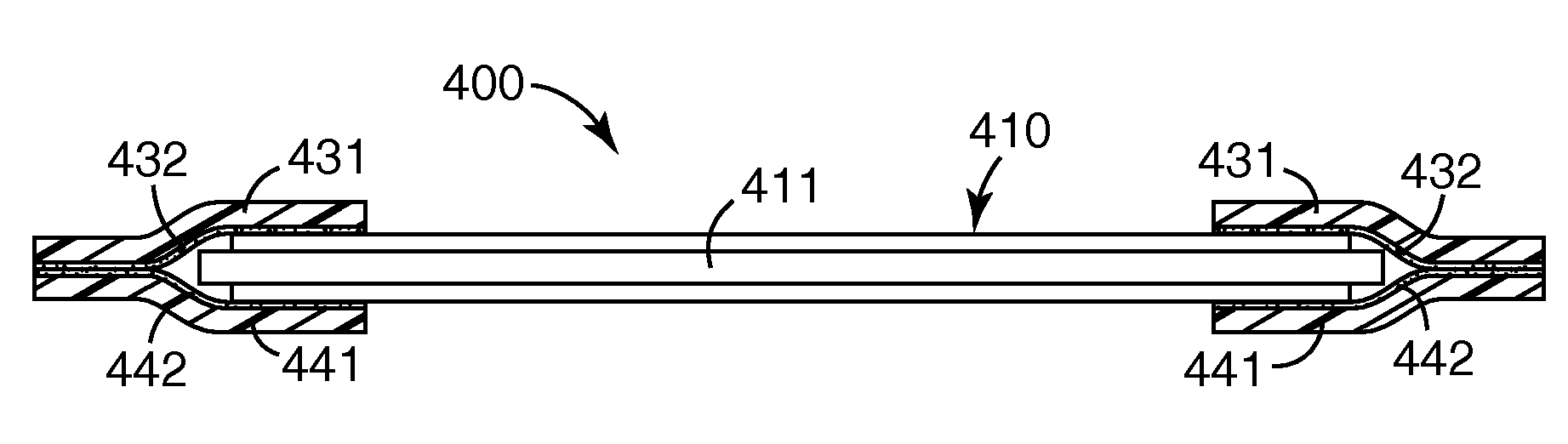

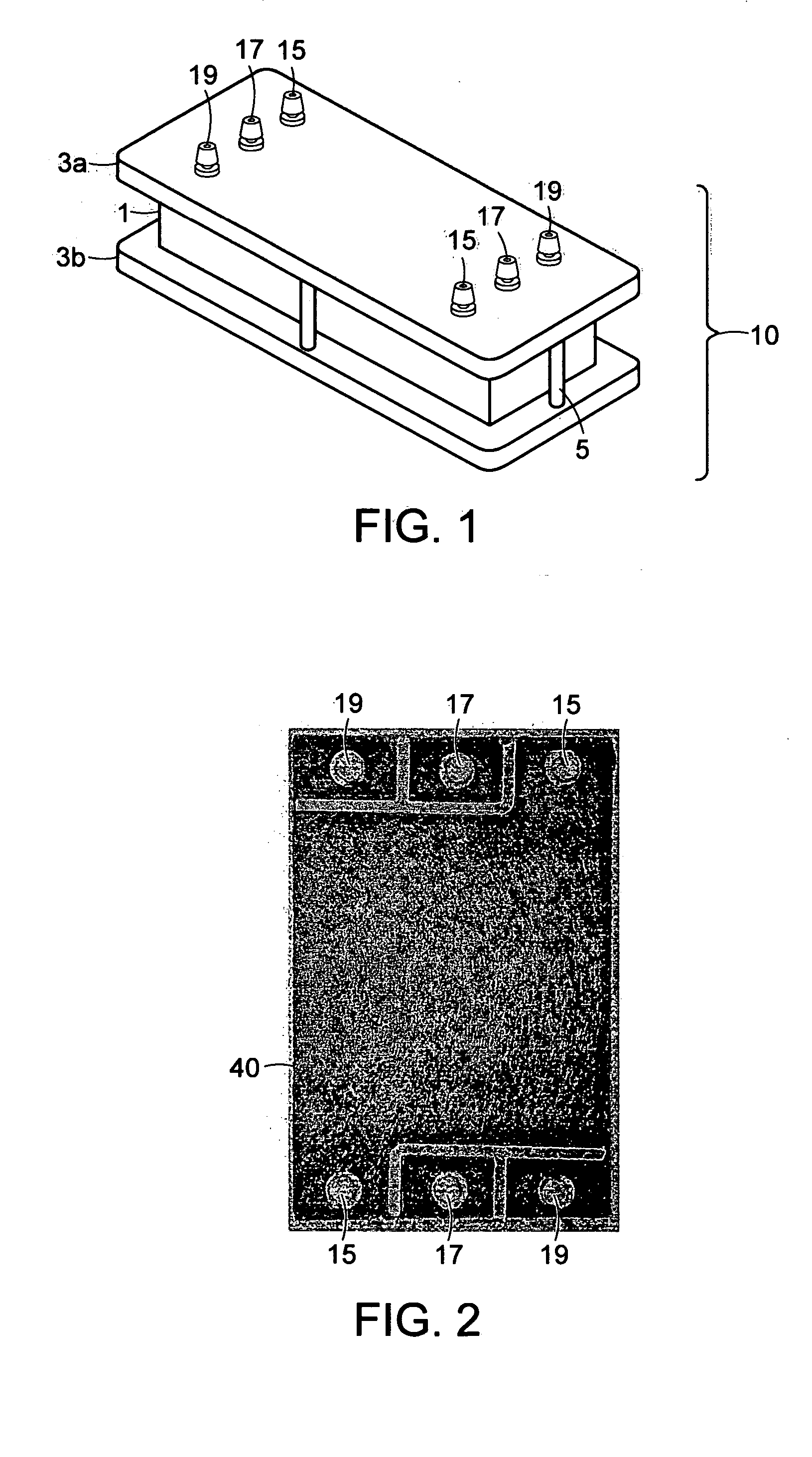

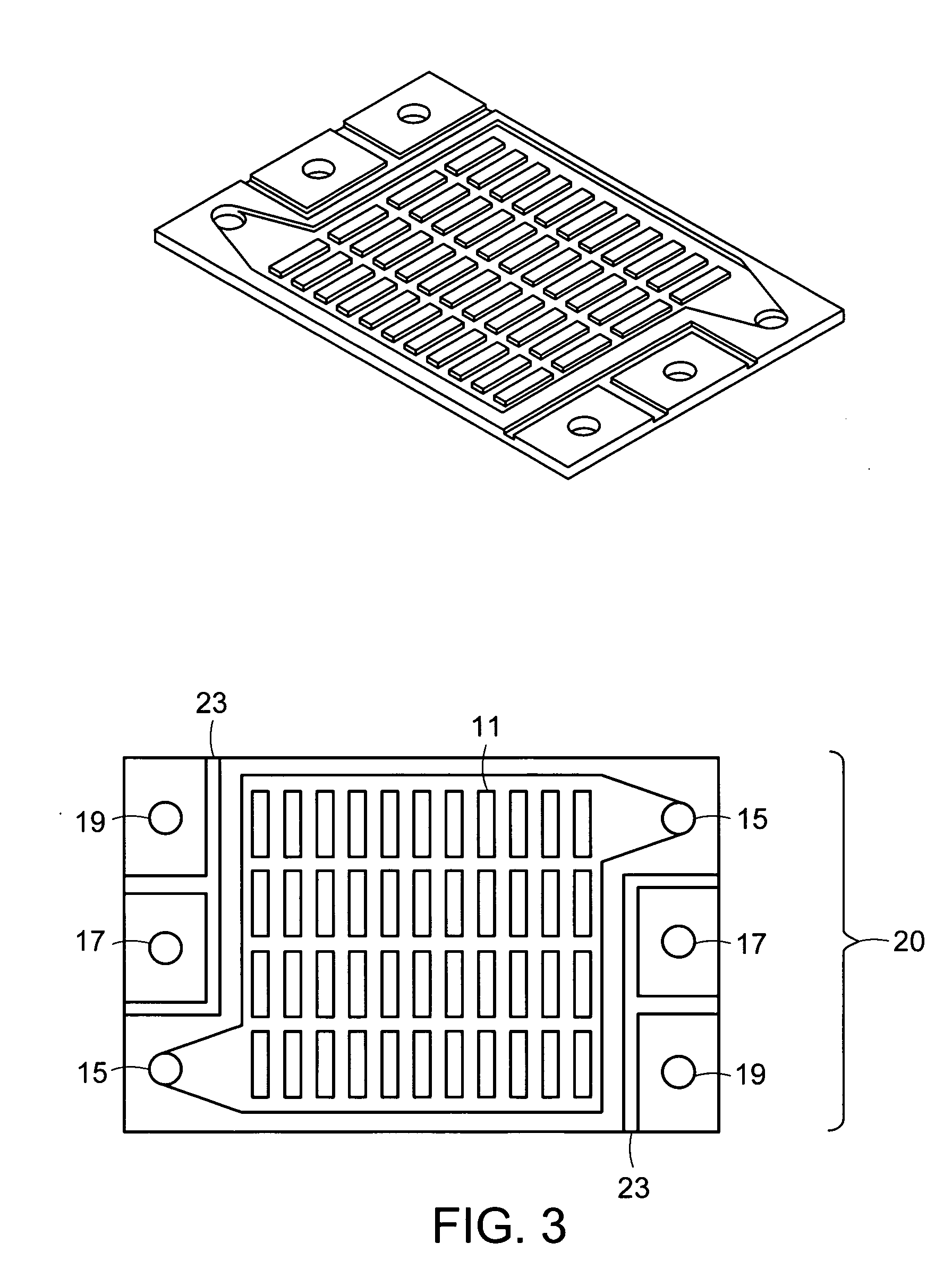

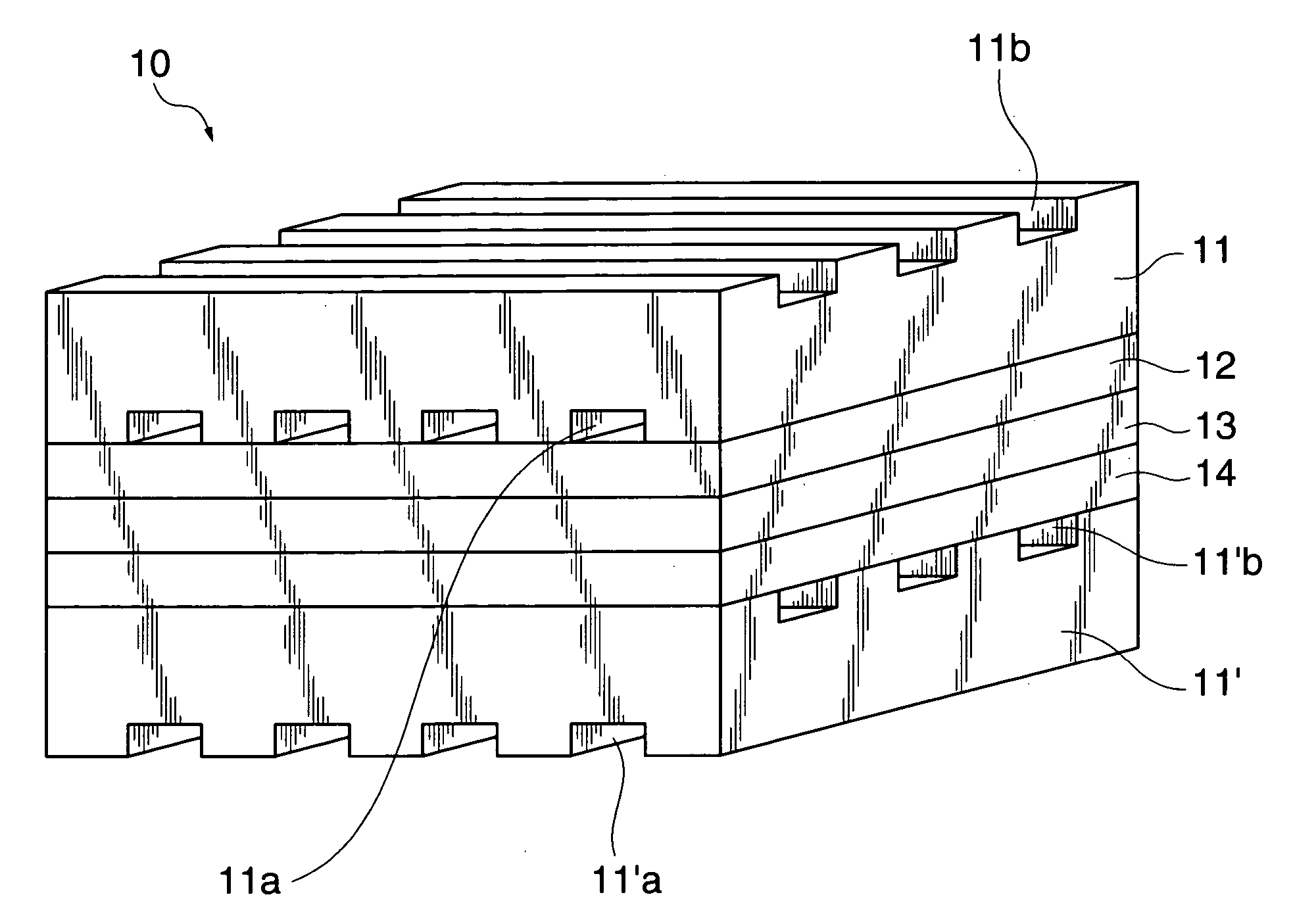

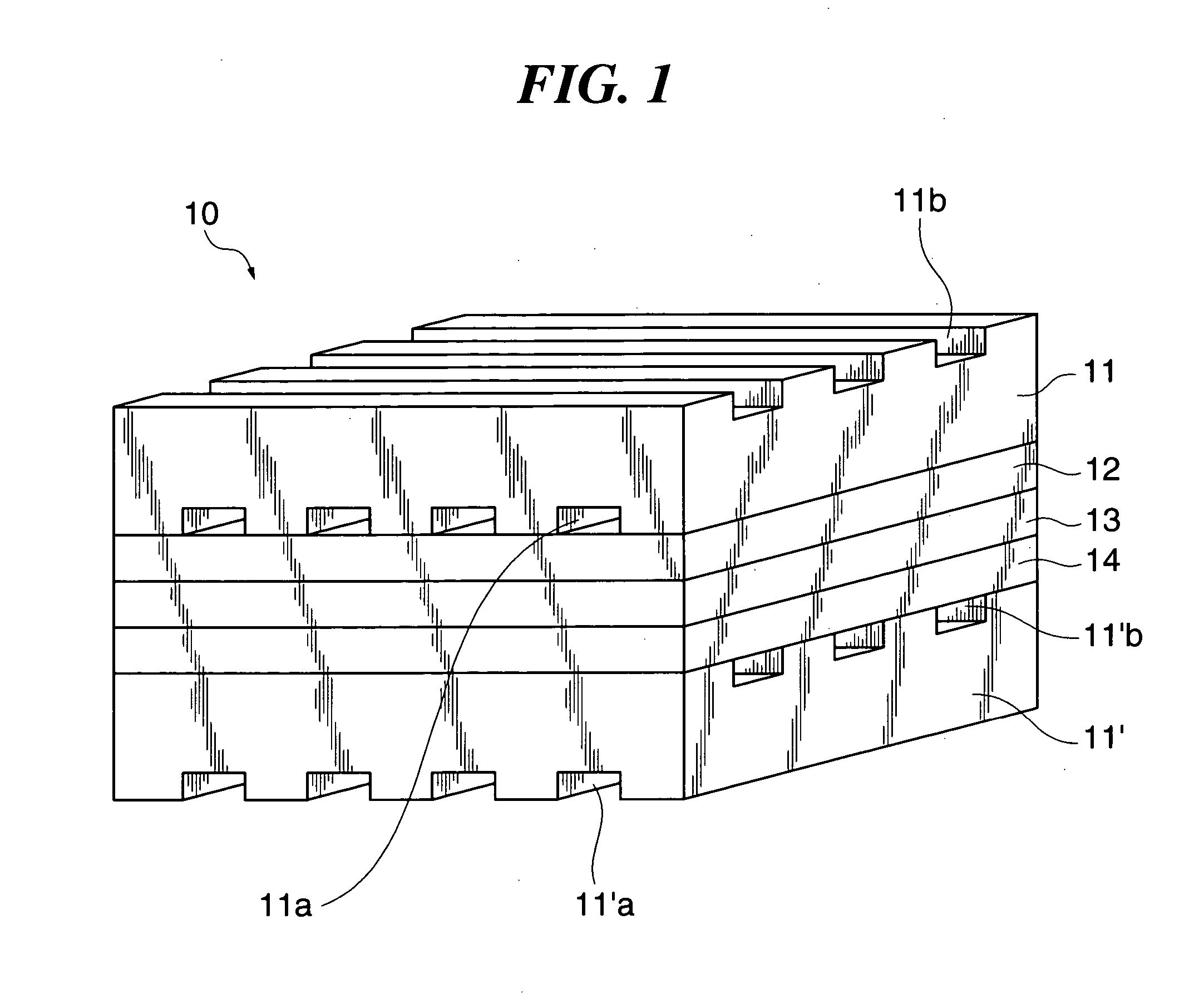

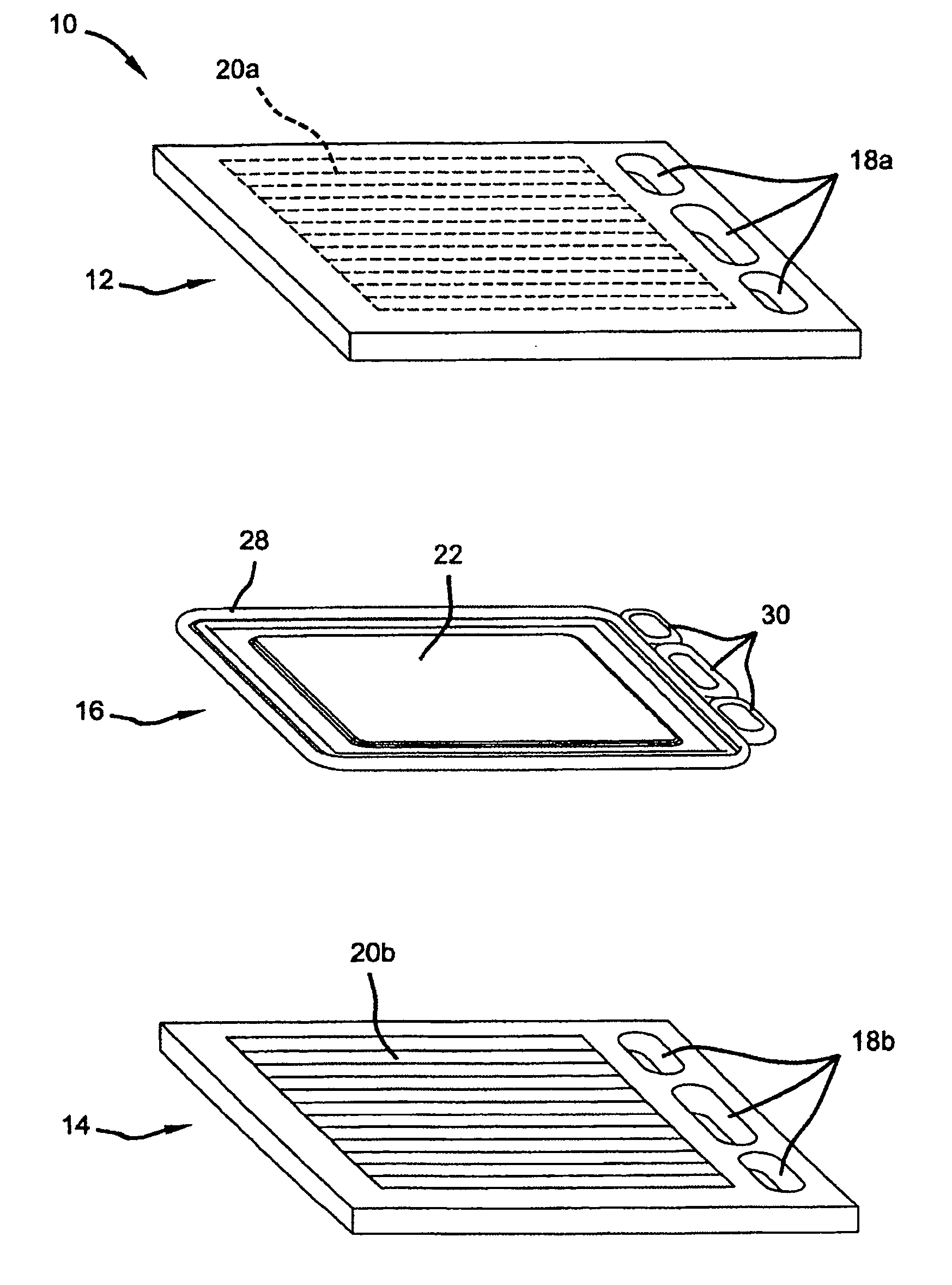

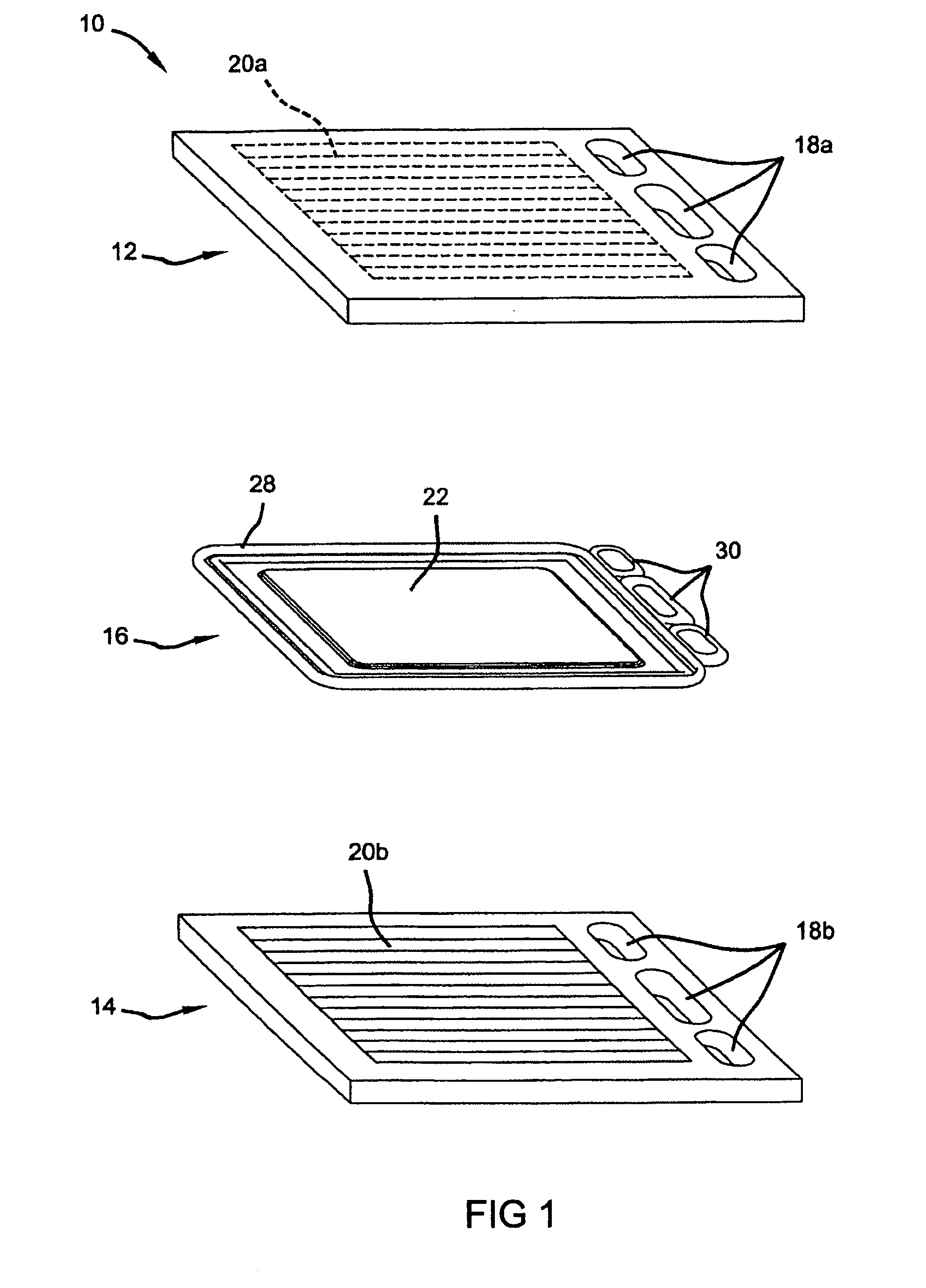

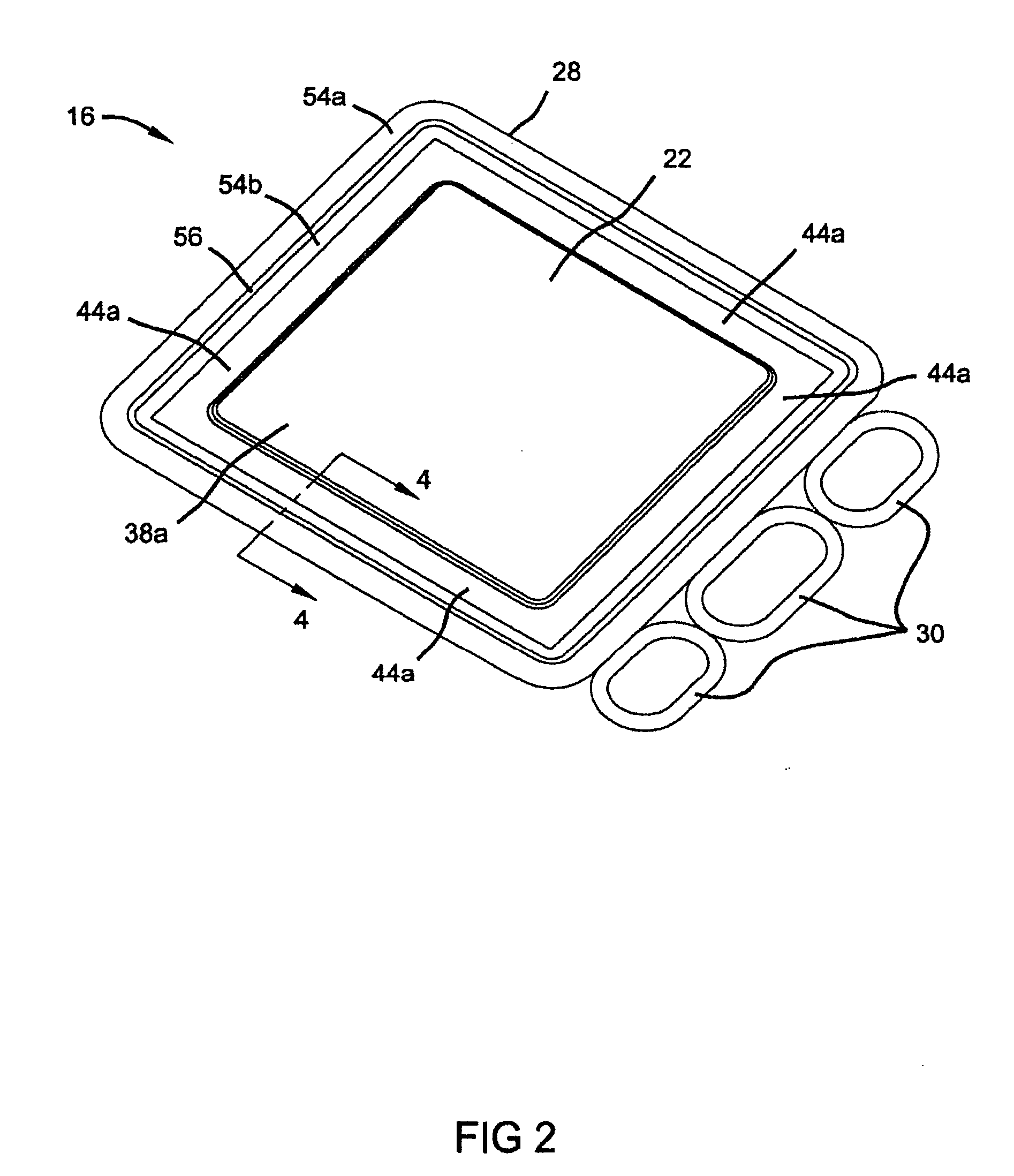

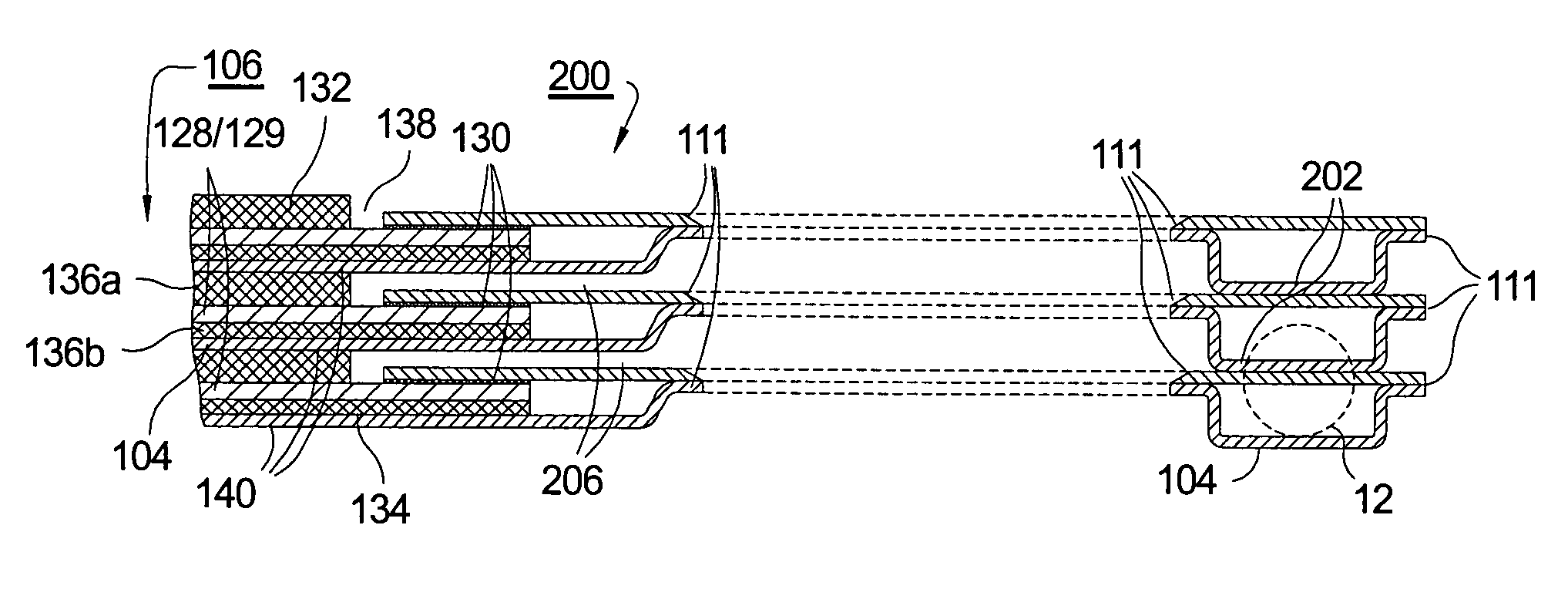

Membrane based electrochemical cell stacks

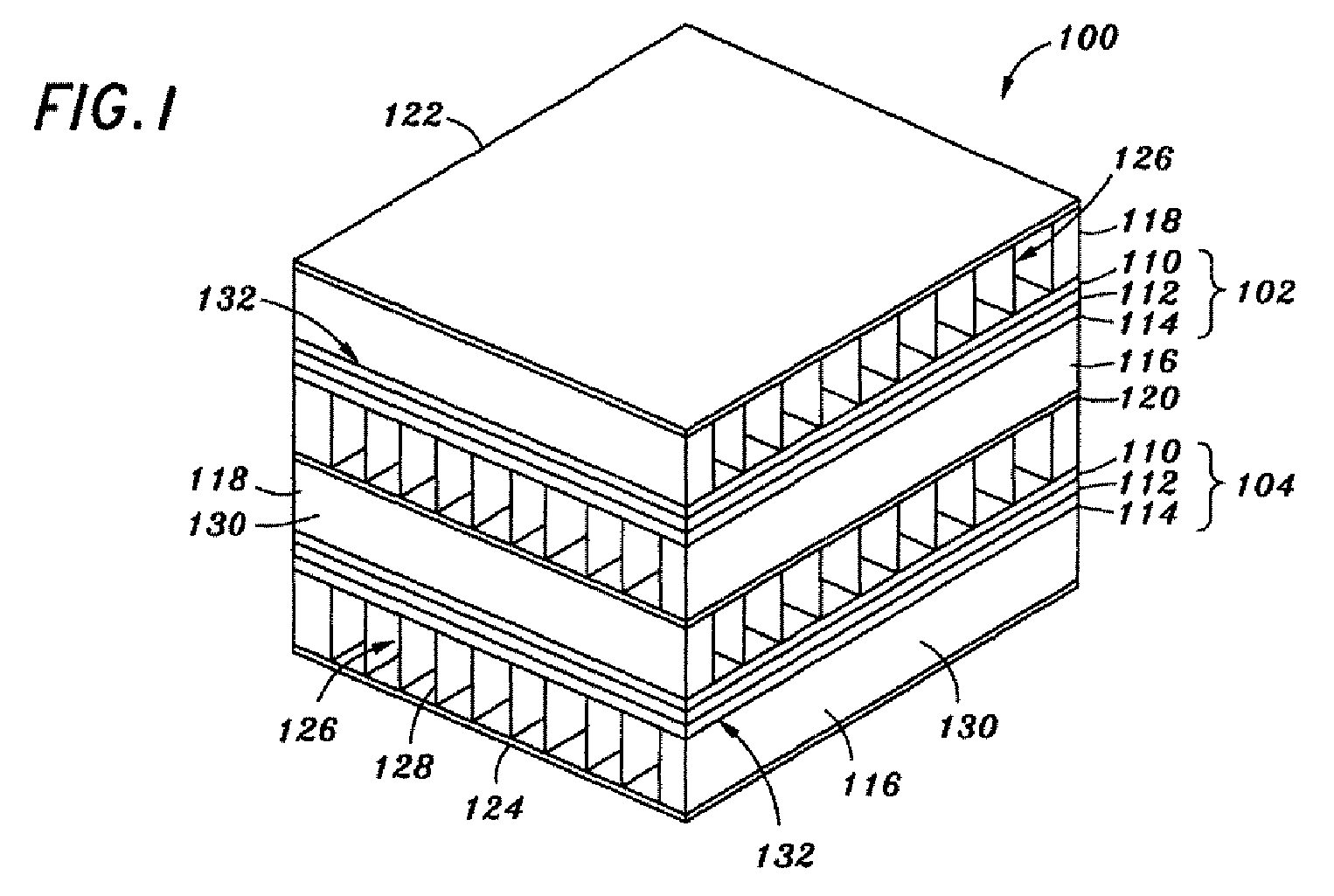

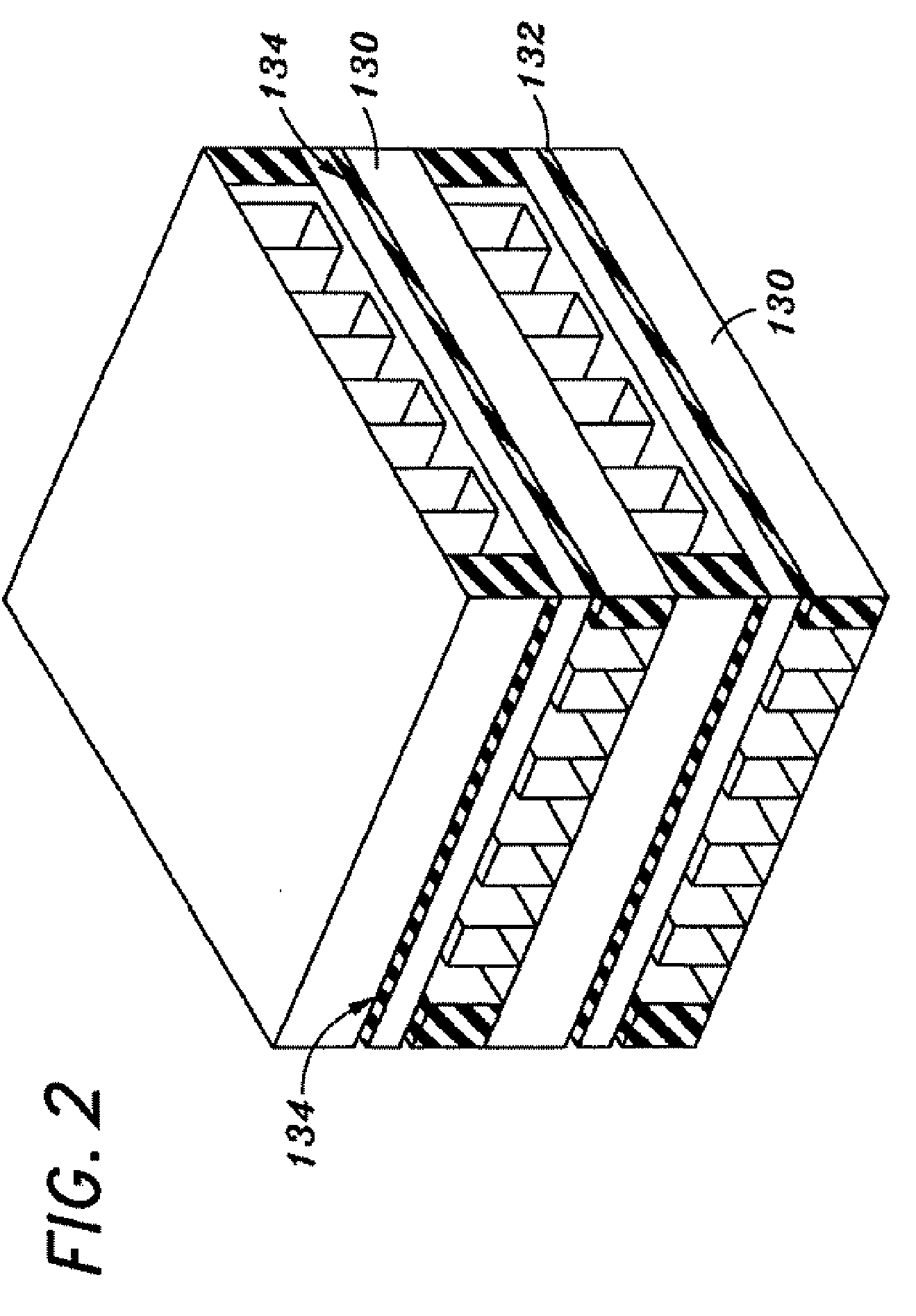

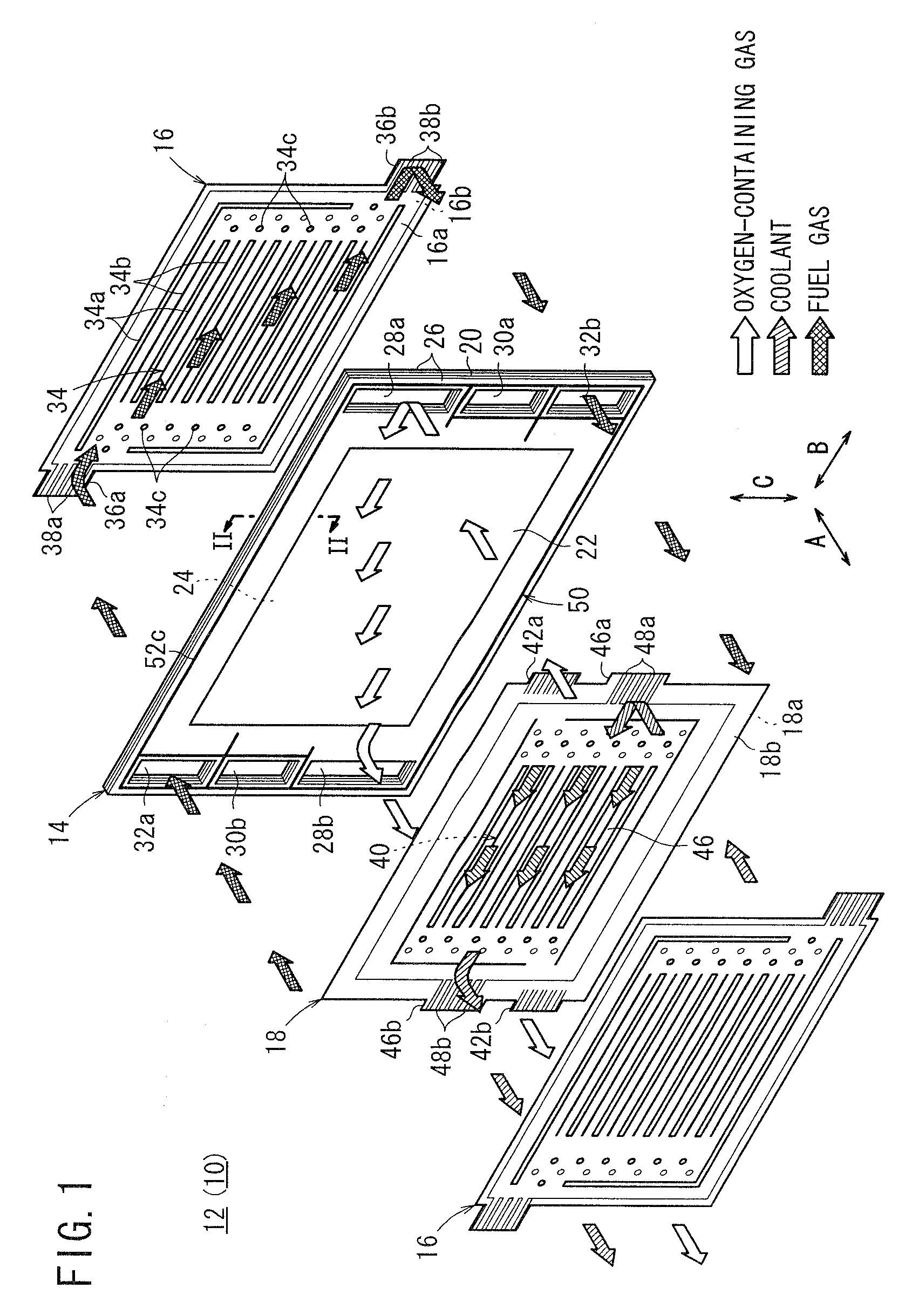

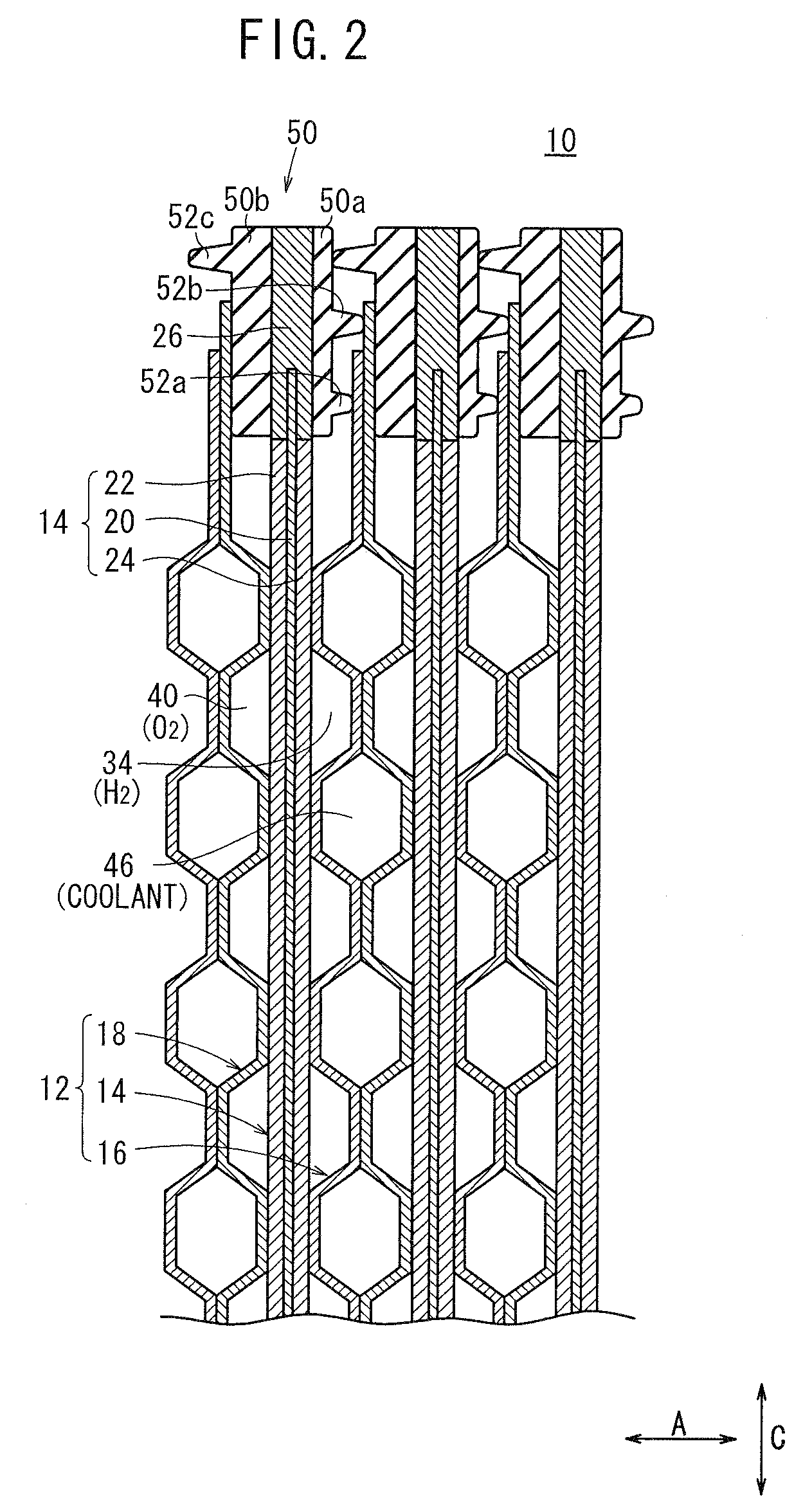

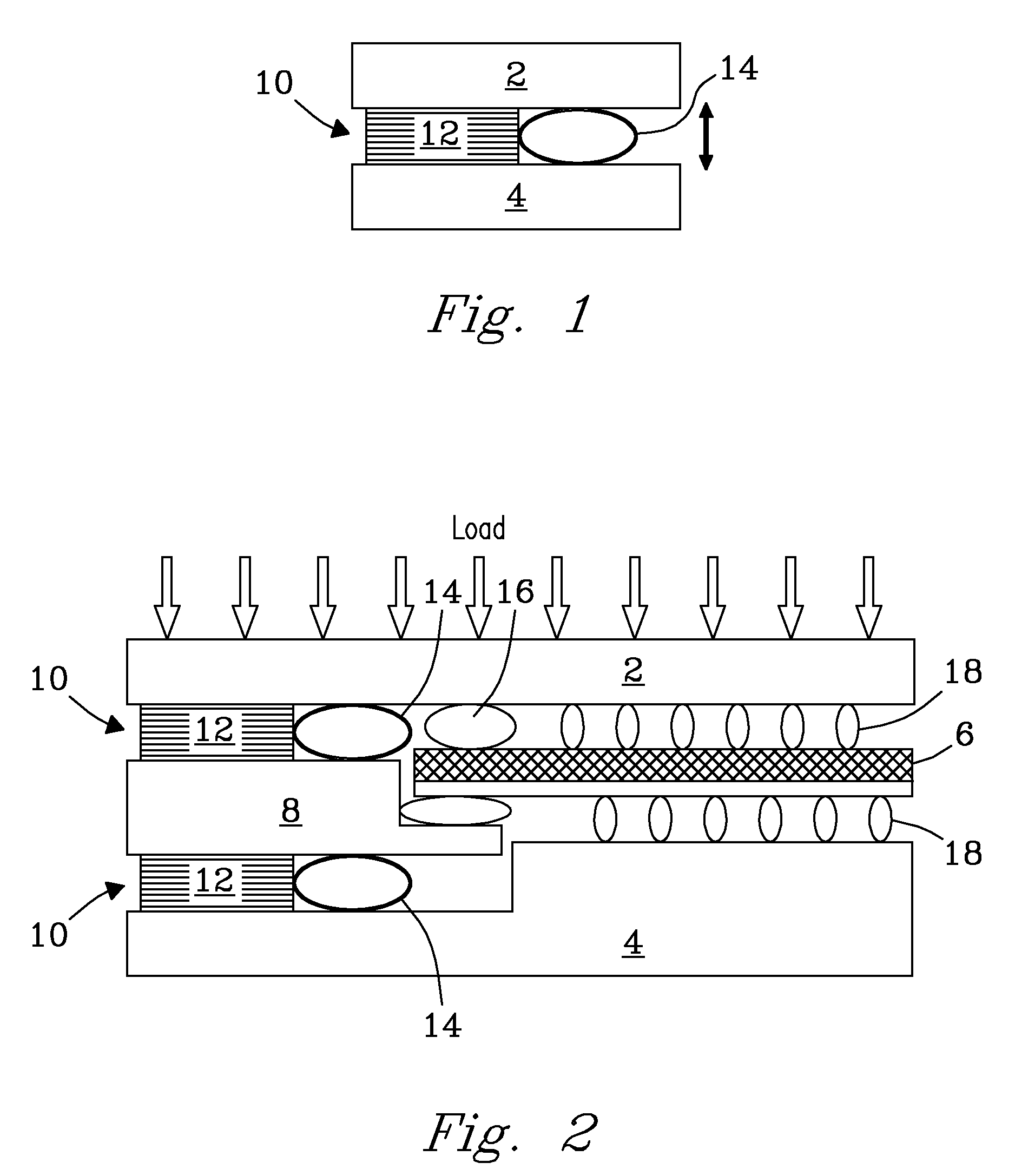

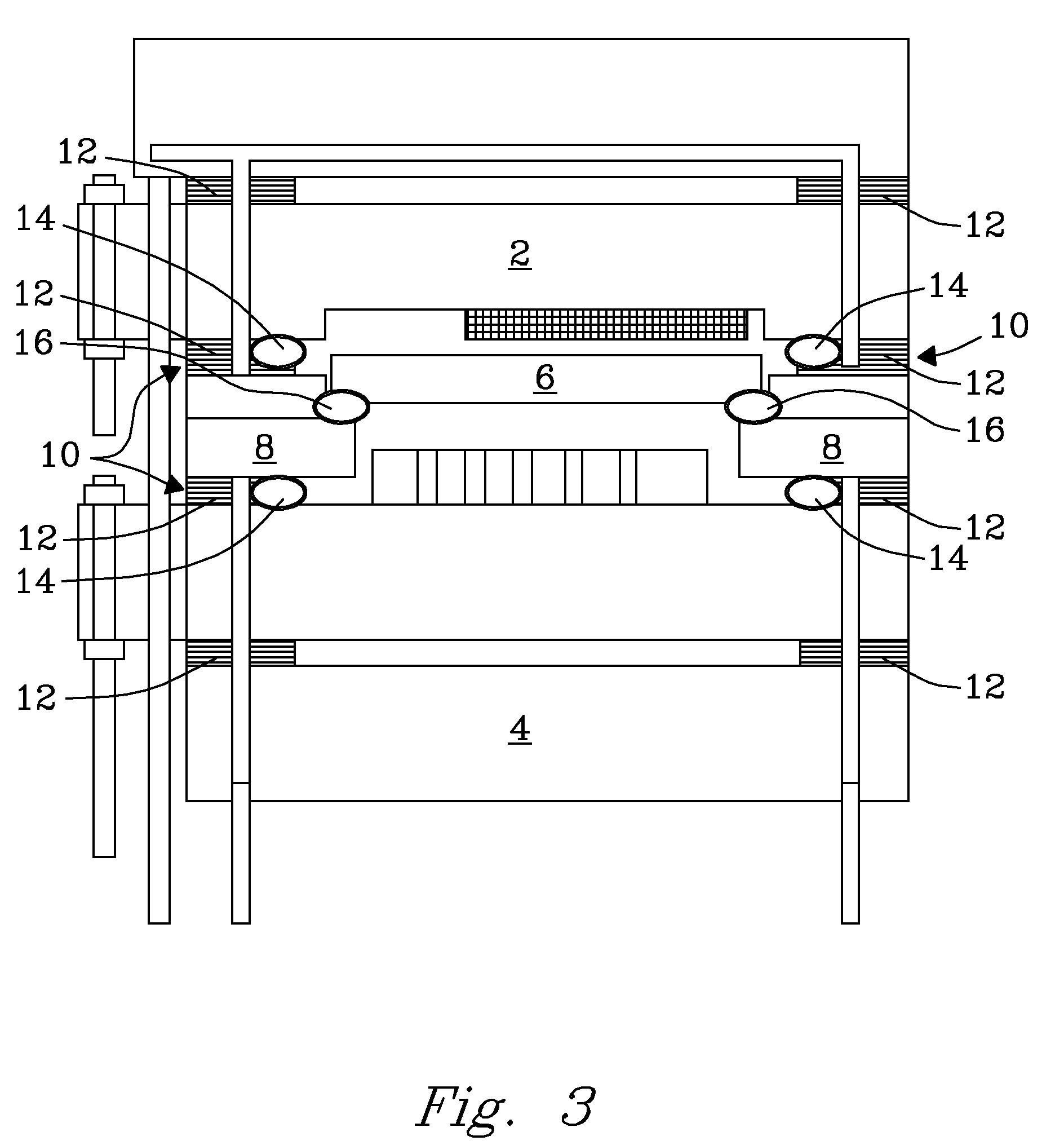

ActiveUS20050244703A1Eliminate needImprove the ease of assemblyFuel cell heat exchangeReactant parameters controlFuel cellsDesign improvement

The present invention provides membrane cassettes and stacks thereof which are suitable for a use in a variety of electrochemical applications. The invention further provides membrane cassettes which comprise one or more bipolar plates which have one or two reactant or coolant flow fields consisting of at least one groove in opposing surfaces of the bipolar plate. In certain preferred embodiments, the invention provides cassettes and stacks which are suitable for use in fuel cell applications. Particularly preferred embodiments of the invention include design improvements which enhance the performance and reliability of certain components of the fuel cell stack.

Owner:SILICON VALLEY BANK

Fuel cell metallic separator

The invention provides a fuel cell metallic separator, wherein the metallic plate's edges include a resin portion comprising the communication ports. The resin portion around the communication ports is shaped so as to be capable of interlocking with a fuel cell stack component adjacently located in a fuel cell system. The invention also provides a resin portion capable of press fitting or thermal bonding with adjacent a fuel cell stack components.

Owner:CELLCENTRIC GMBH & CO KG +1

Membrane based electrochemical cell stacks

ActiveUS20060127735A1Simplification of the other portions of the stackSimple processFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

The present invention provides membrane cassettes and stacks thereof which are suitable for a use in a variety of electrochemical applications. The invention further provides membrane cassettes which comprise one or more composite membrane electrode assemblies which have a peripheral gasket where the gasket has at least one groove or channel for introducing and distributing a sealant about the cassette. In certain preferred embodiments, the invention provides cassettes and stacks which are suitable for use in fuel cell applications.

Owner:SILICON VALLEY BANK

Separator for fuel cell, single cell unit for fuel cell, short stack unit for fuel cell, and production methods of separator for fuel cell and cell unit (single cell unit or short stack unit) for fuel cell

ActiveUS20100047650A1Increase speedSolve the real problemMaterial nanotechnologyFinal product manufactureMolten stateFuel cells

A high-performance separator for a fuel cell and a high-performance cell unit (single cell unit or short stack unit) for a fuel cell, each ensuring lightweight and compact fabrication necessary to enhance output density, enabling stacking without use of a gas seal member and making the insulating treatment of the outer circumference of the stack not necessary, and production methods thereof are provided.By a processing method of forming a thermoplastic resin composition highly filled with a carbonaceous material into a thin sheet form, heating the sheet to a melted state, and cold-shaping the melt at a high speed, a lightweight, compact and high-performance thin fuel cell separator having a corrugated flow path may be provided. Also, a separator for a fuel cell and a cell unit (single cell unit or short stack unit) for a fuel cell, where a stacked body of separator and MEA can be integrated by injection molding or heat welding and the outer circumferential part is covered with an insulating thermoplastic resin composition, may be provided.

Owner:SHOWA DENKO KK +1

Sealing glass composition, sealing glass frit, and sealing glass sheet

A sealing glass composition which has an alkali metal oxide content kept down as much as possible, and can stably join metal or ceramic members together in a temperature range of 600 to 900° C. The sealing glass composition is used to join together members each selected from the group consisting of metal members and ceramic members, and comprises, as essential components, 20 to 50 mol % of SiO2, 1 to 9 mol % of Al2O3, 5 to 25 mol % of B2O3, 10 to 40 mol % of BaO, and 5 to 20 mol % of SrO. ZnO content is 0 to 10 mol %. An alkali metal oxide content is not more than 5 mol %. PbO is substantially not contained. The total content of MgO, CaO, SrO, BaO and ZnO is 30 to 50 mol %.

Owner:NIPPON SHEET GLASS CO LTD

Apparatus for and method of forming seals in fuel cells and fuel cell stacks

InactiveUS6852439B2Good chemical resistanceImprove robustnessCellsEngine sealsFuel cellsProbable Case

A sealing technique is provided for forming complex and multiple seal configurations for fuel cells and other electrochemical cells. To provide a seal, for sealing chambers for oxidant, fuel and / or coolant, a groove network is provided extending through the various elements of the fuel cell assembly. A source of seal material is then connected to an external filling port and injected into the groove network, and the seal material is then cured to form the seal. There is thus formed a “seal in place”, that is robust and can accommodate variations in tolerances and dimensions, and that can be bonded, where possible, to individual elements of the fuel cell assembly. This avoids the difficulty, labor intensive cost and complexity of manually assembling many individual gaskets into complex groove shapes and the like. The seal material can be selected to be comparable with a wide variety of gases, liquid coolants and the like.

Owner:HYDROGENICS CORP

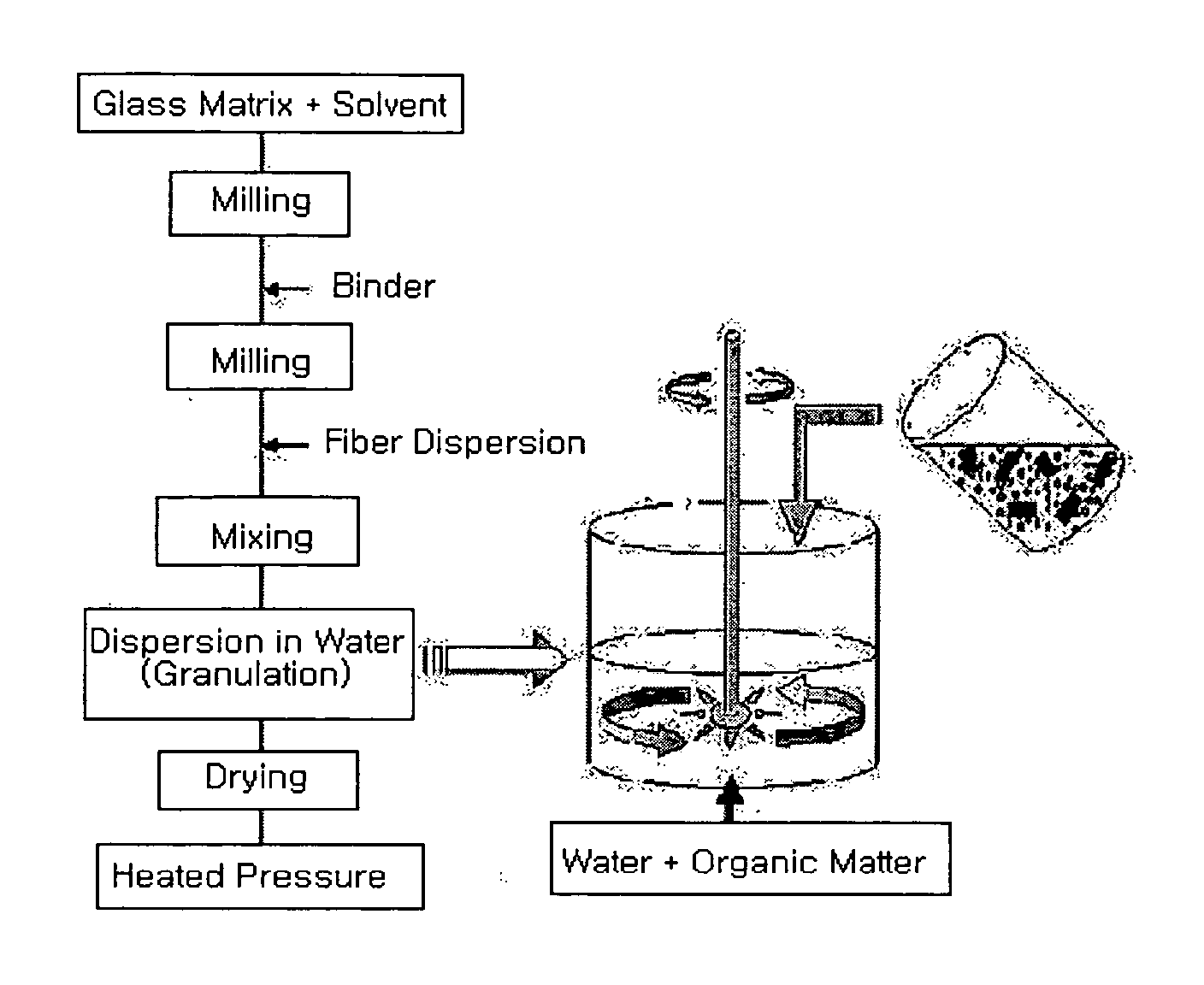

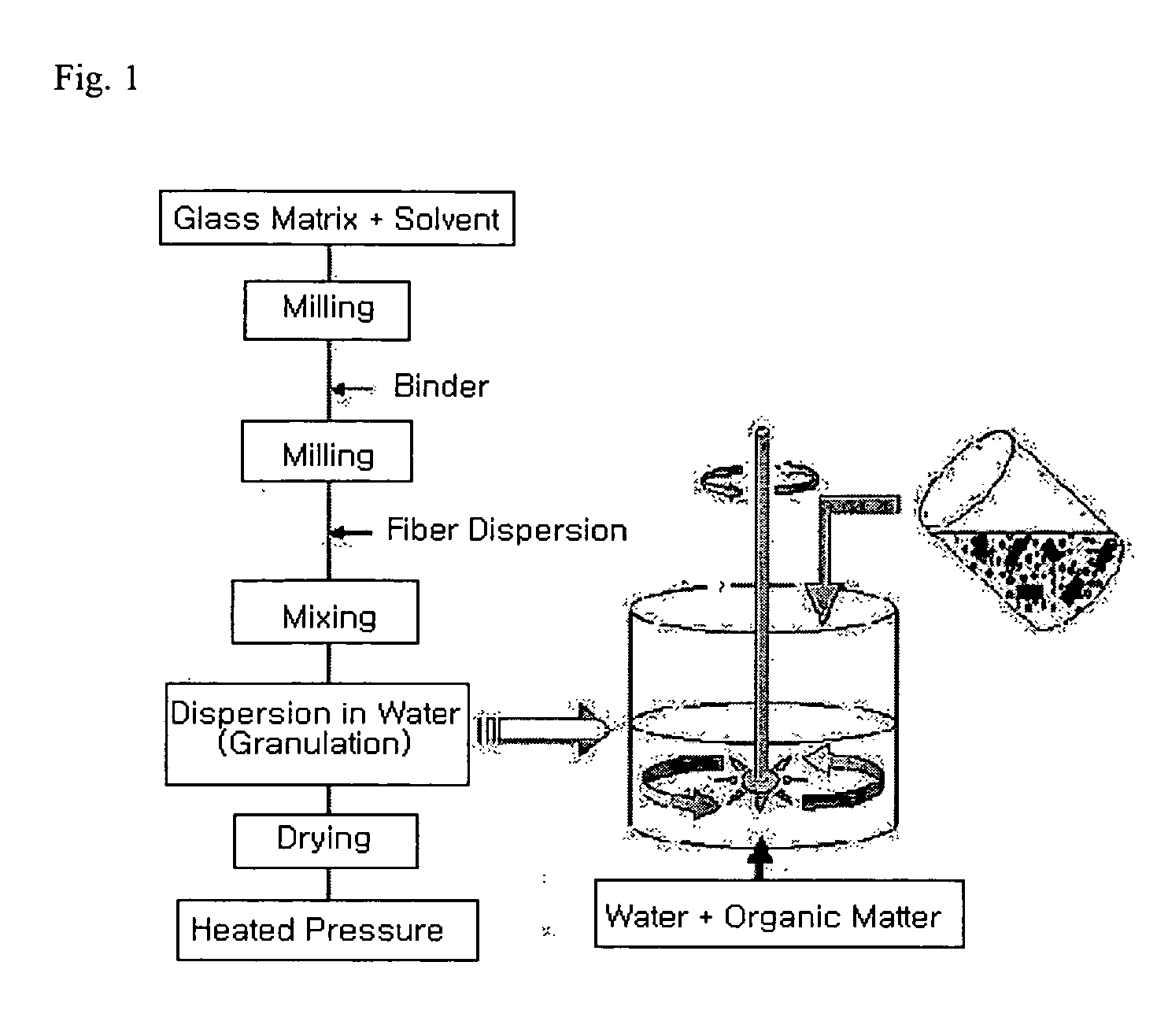

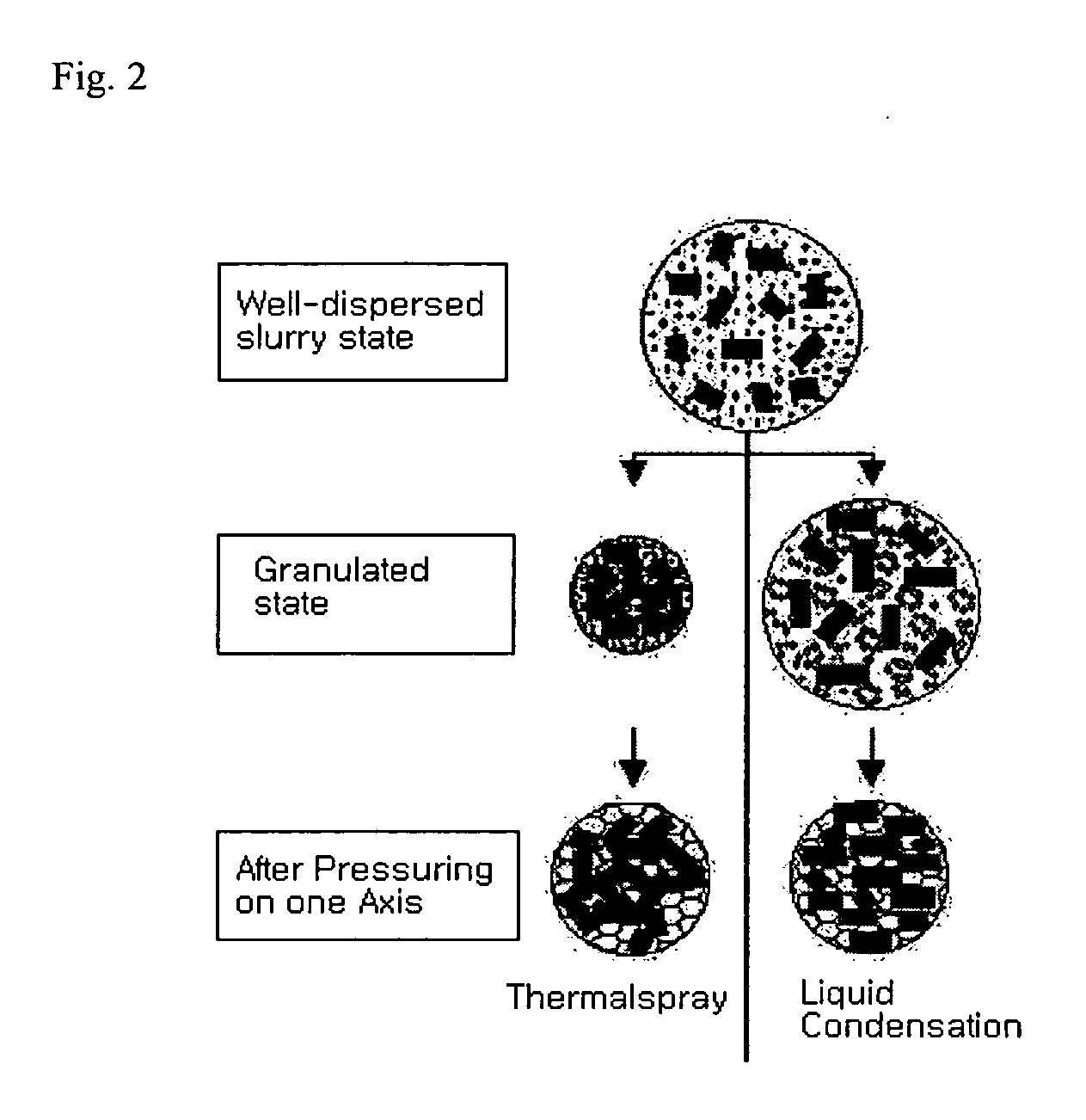

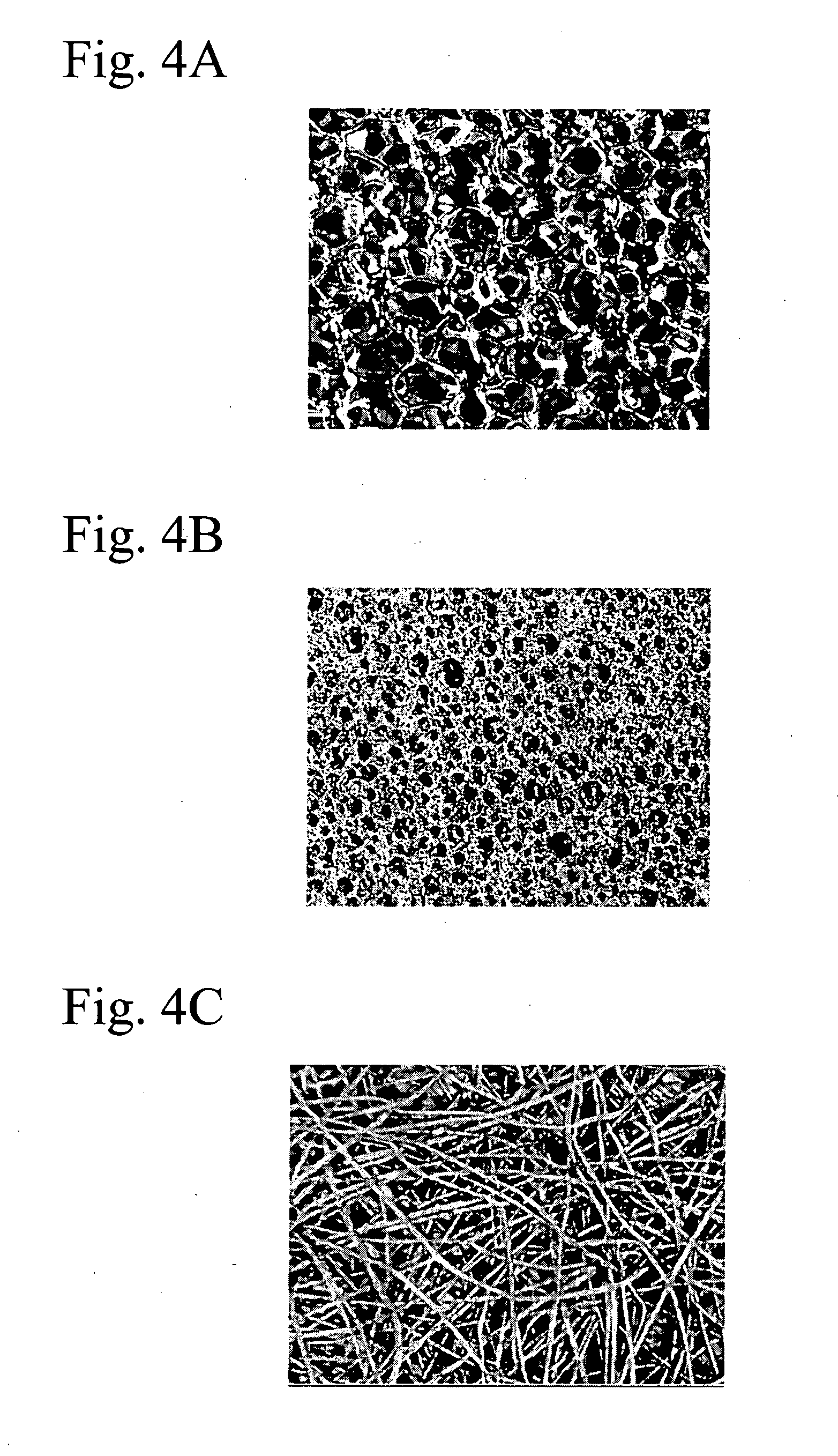

Solid oxide fuel cell sealant comprising glass matrix and ceramic fiber and method of manufacturing the same

InactiveUS20050147866A1Efficiently prevent and minimize viscous flowAccurate locationTime-programme switchesFinal product manufactureFiberFuel cells

Sealant compositions particularly suitable for solid oxide fuel cell sealant are provided and preferably comprise glass matrix and ceramic fiber, wherein glass matrix and ceramic fiber are mixed in an volume ratio of 25:75-75:25 in the sealant, and the ceramic fibers are preferably uniformly dispersed in the sealant to exhibit an orientation. Methods to manufacture the sealant compositions also are provided. Particularly preferred sealant compositions of the invention can efficiently avoid undesired viscous flow of glass matrix, precisely locate the stack of fuel cell on the region to be sealed, and maintain uniform sealing ability under various changes in size of the fuel cell stack.

Owner:HYUNDAI MOTOR CO LTD +1

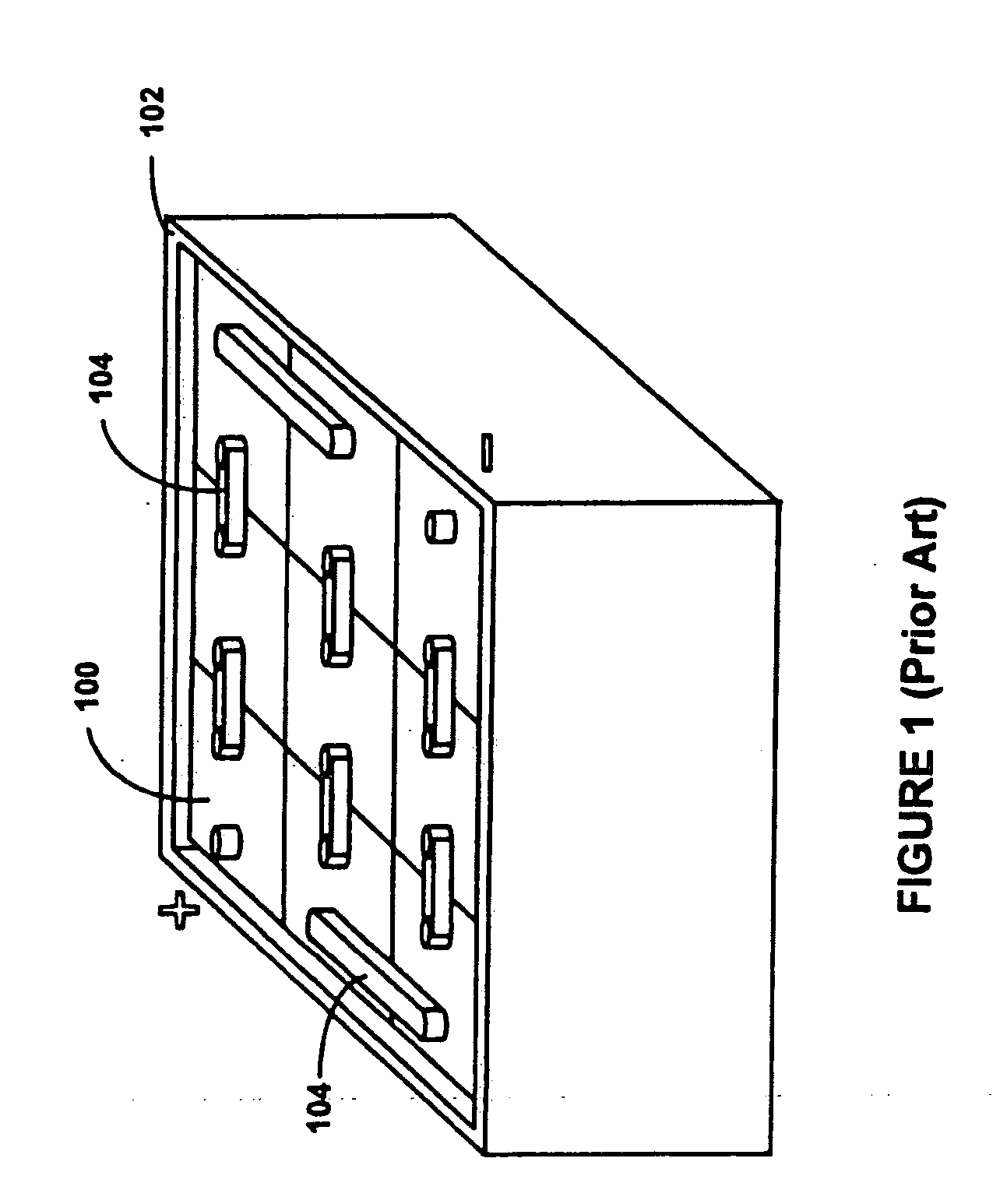

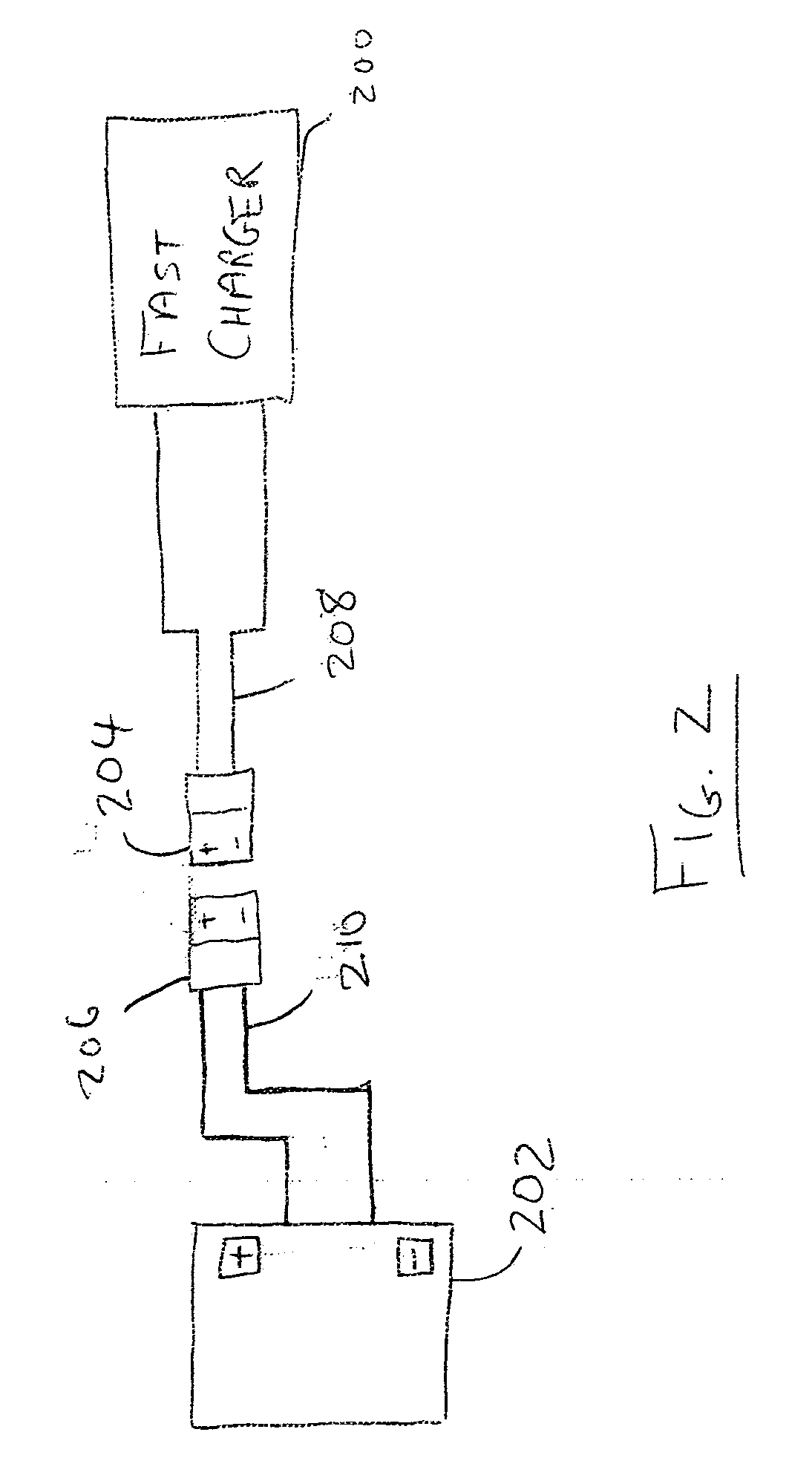

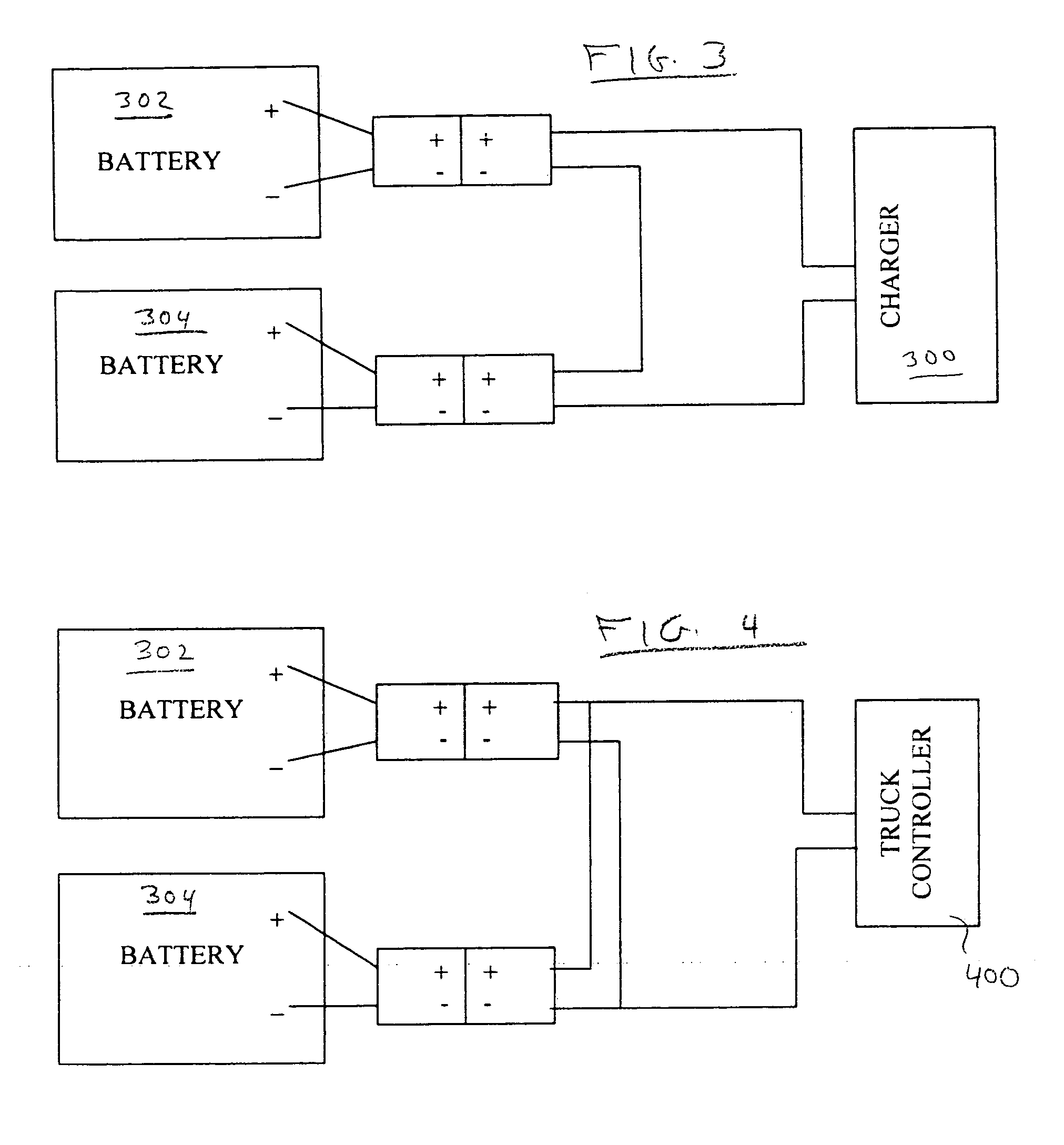

Motive power dual battery pack

A fast charge configuration for a power supply includes a serial connection to a pair of batteries each having an output that is half that required by the device, such as the electric vehicle, in which the batteries are to be used. When the batteries in then connected to the vehicle, they are connected in parallel

Owner:AEROVIRONMENT INC

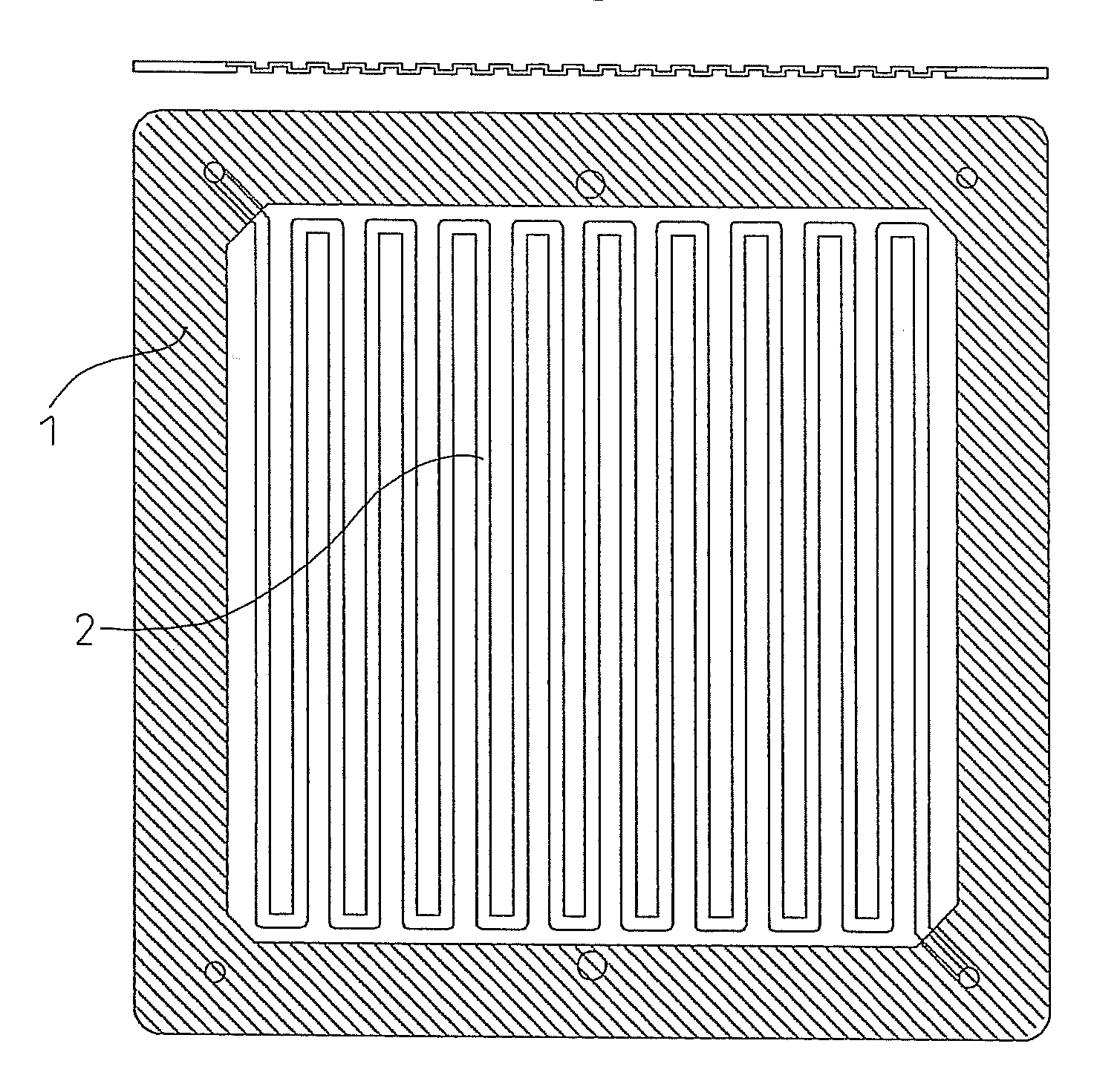

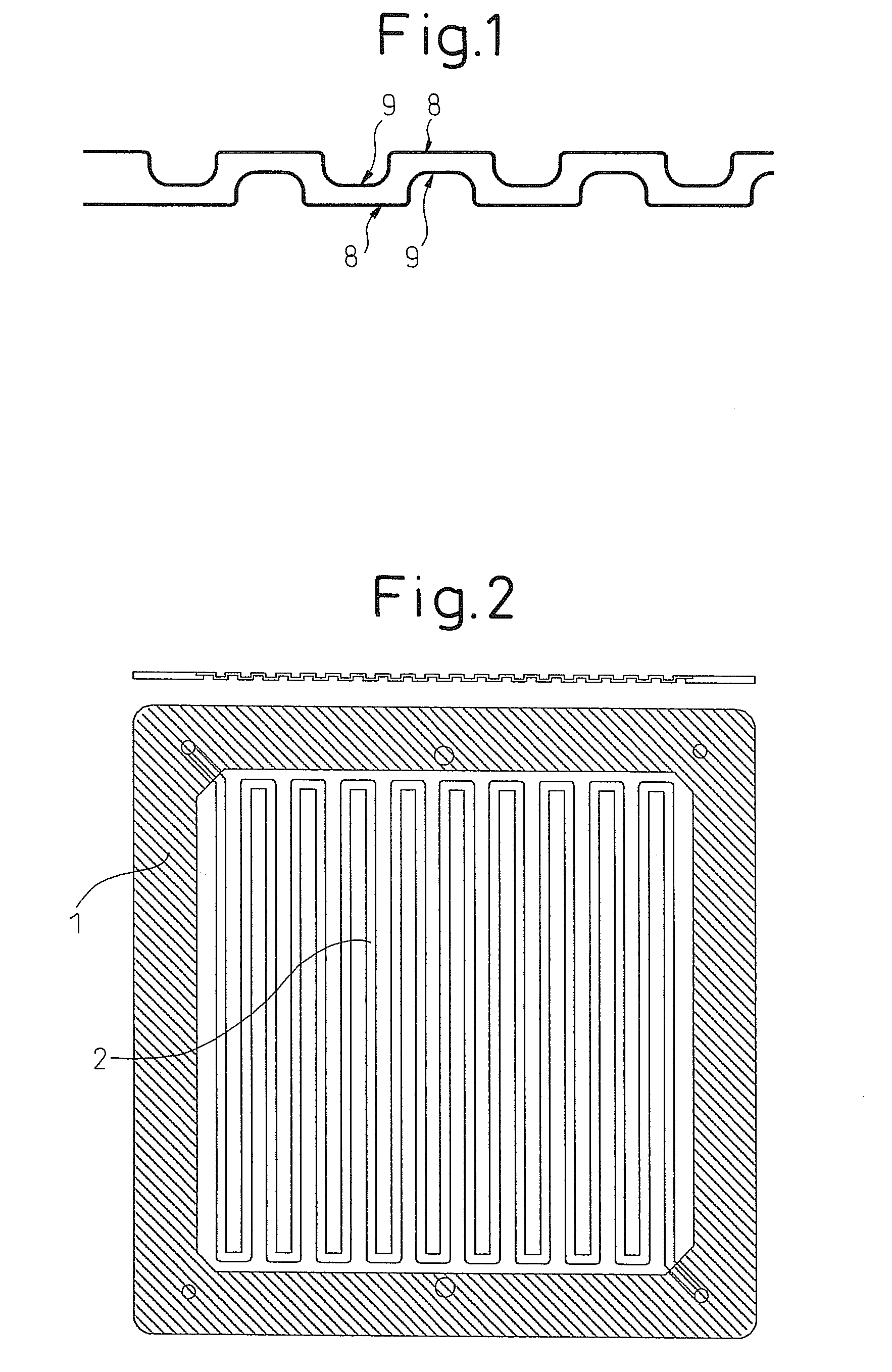

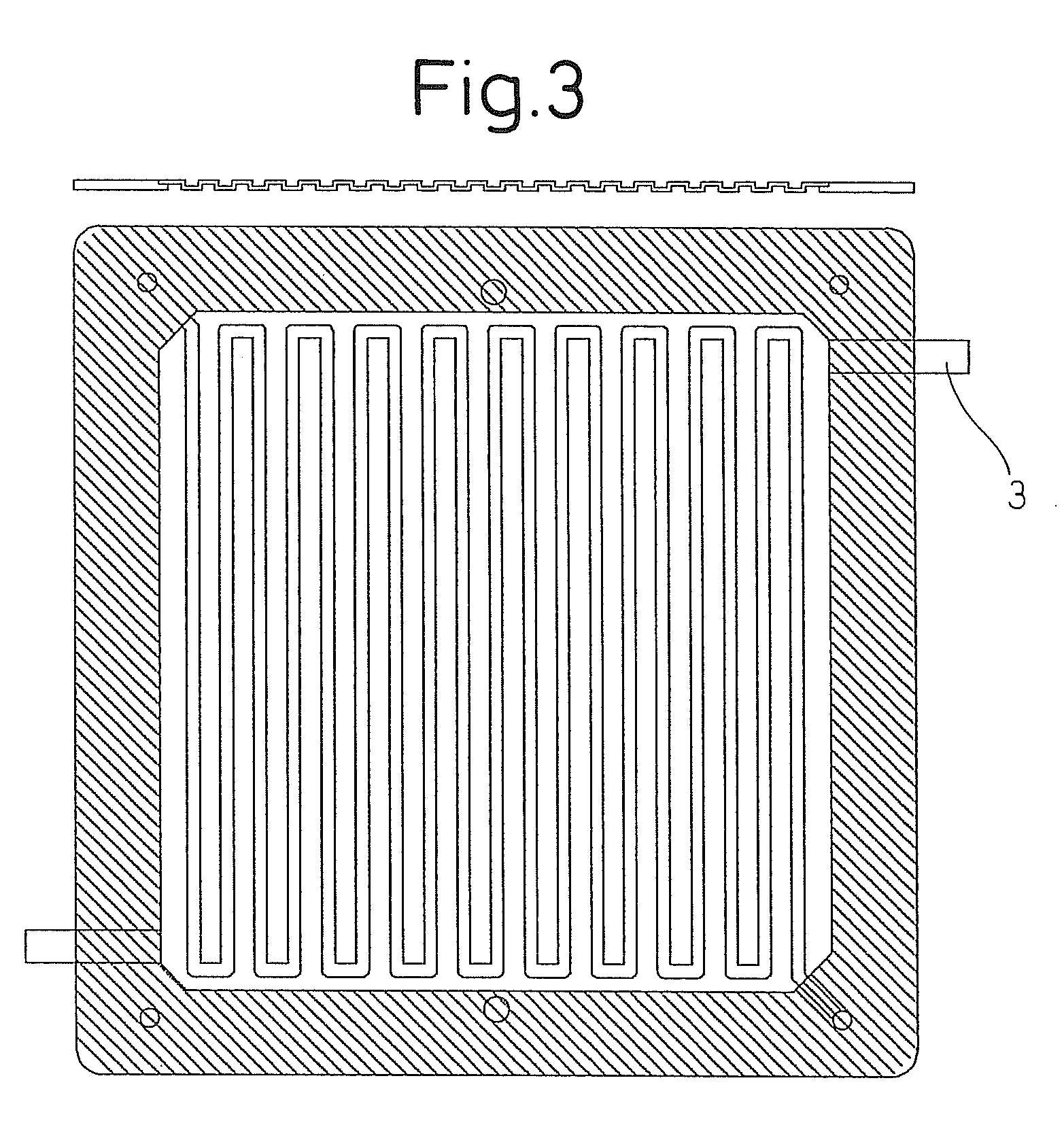

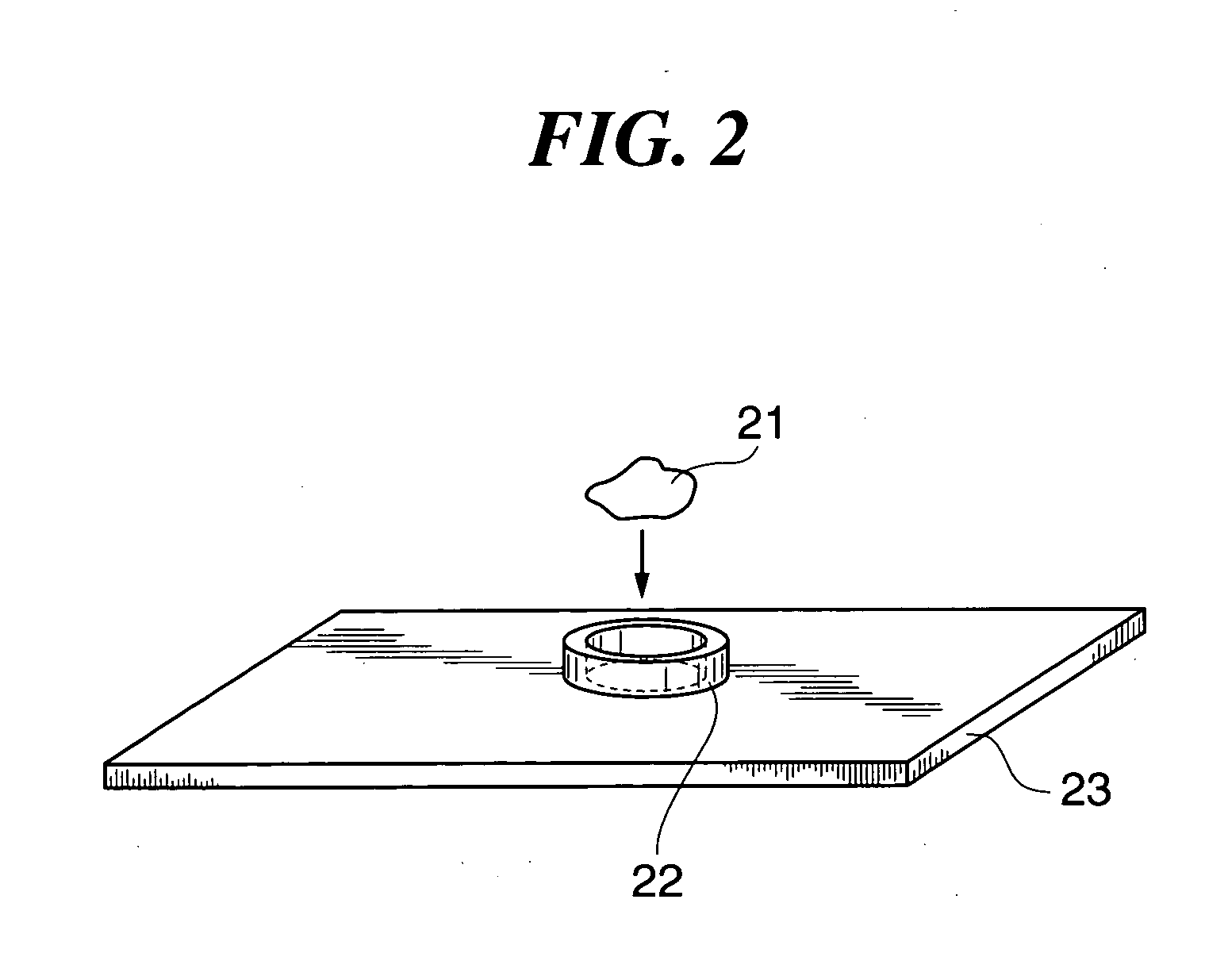

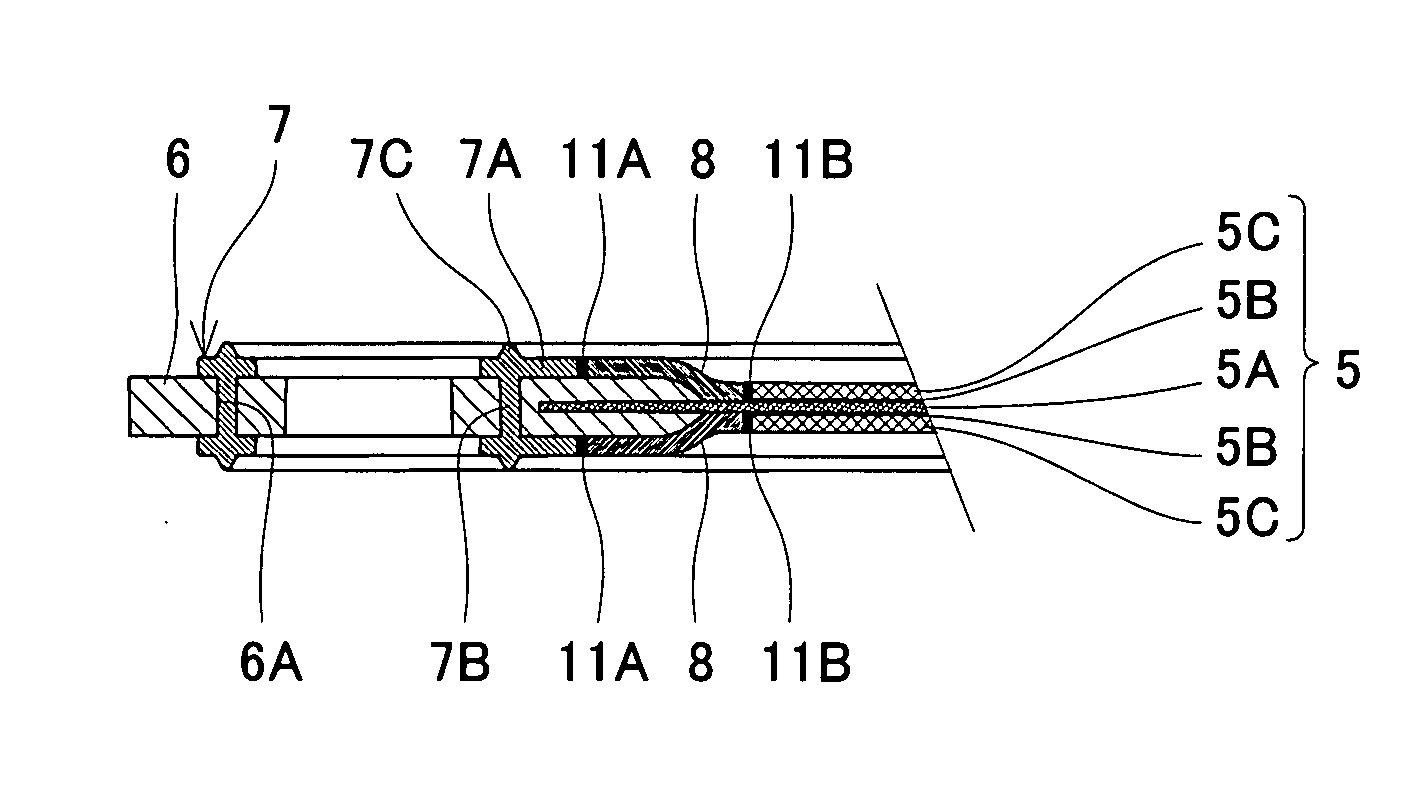

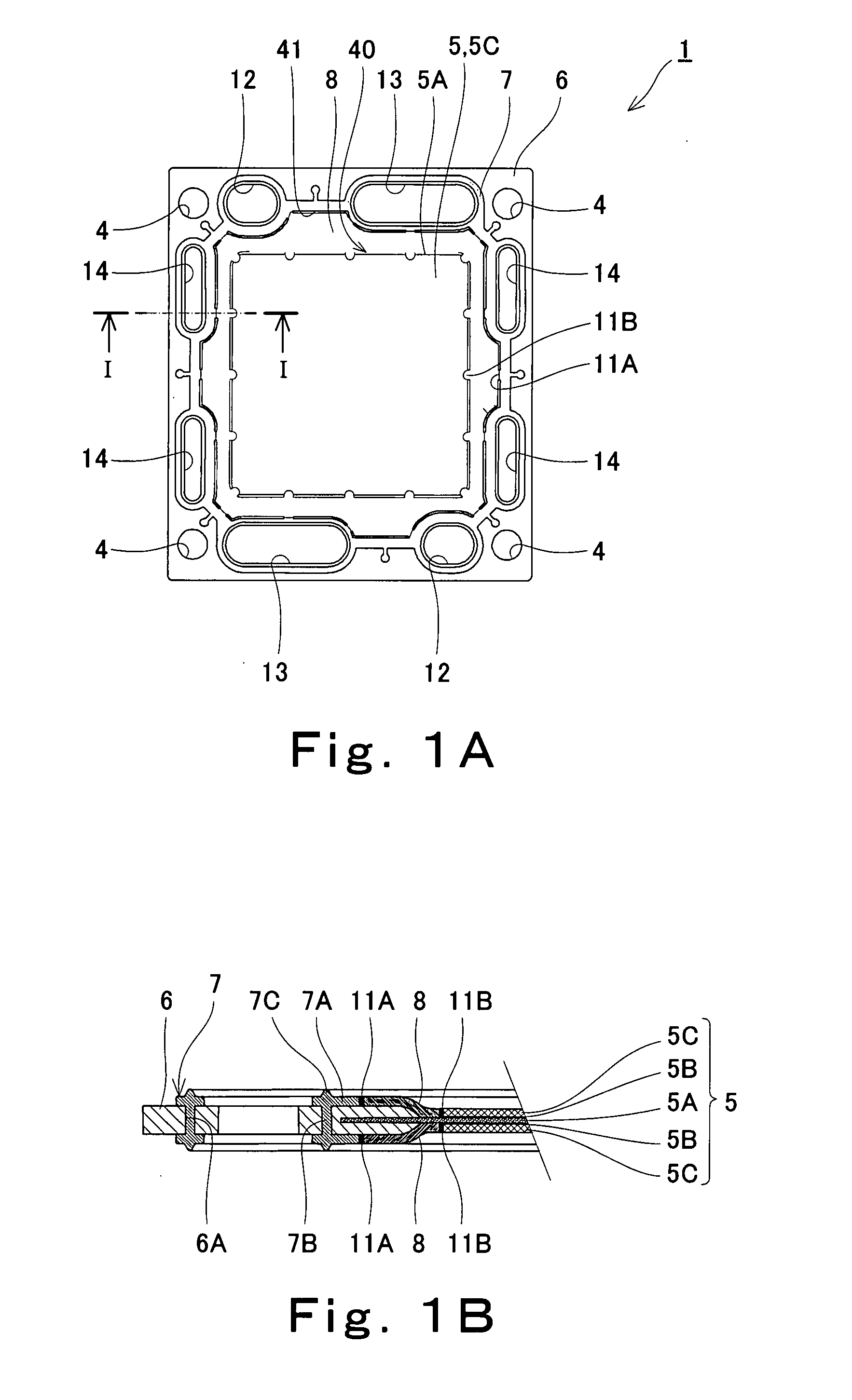

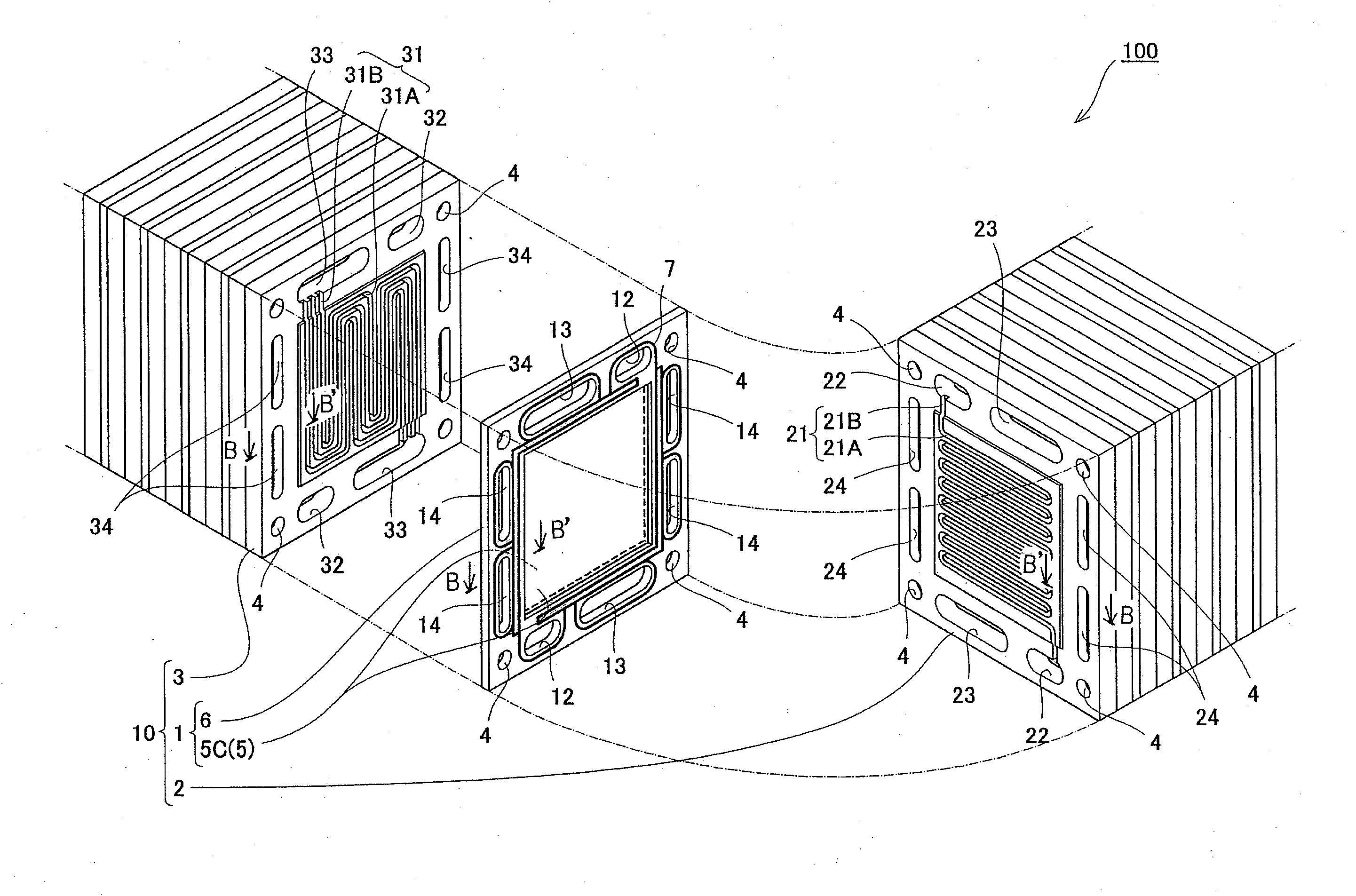

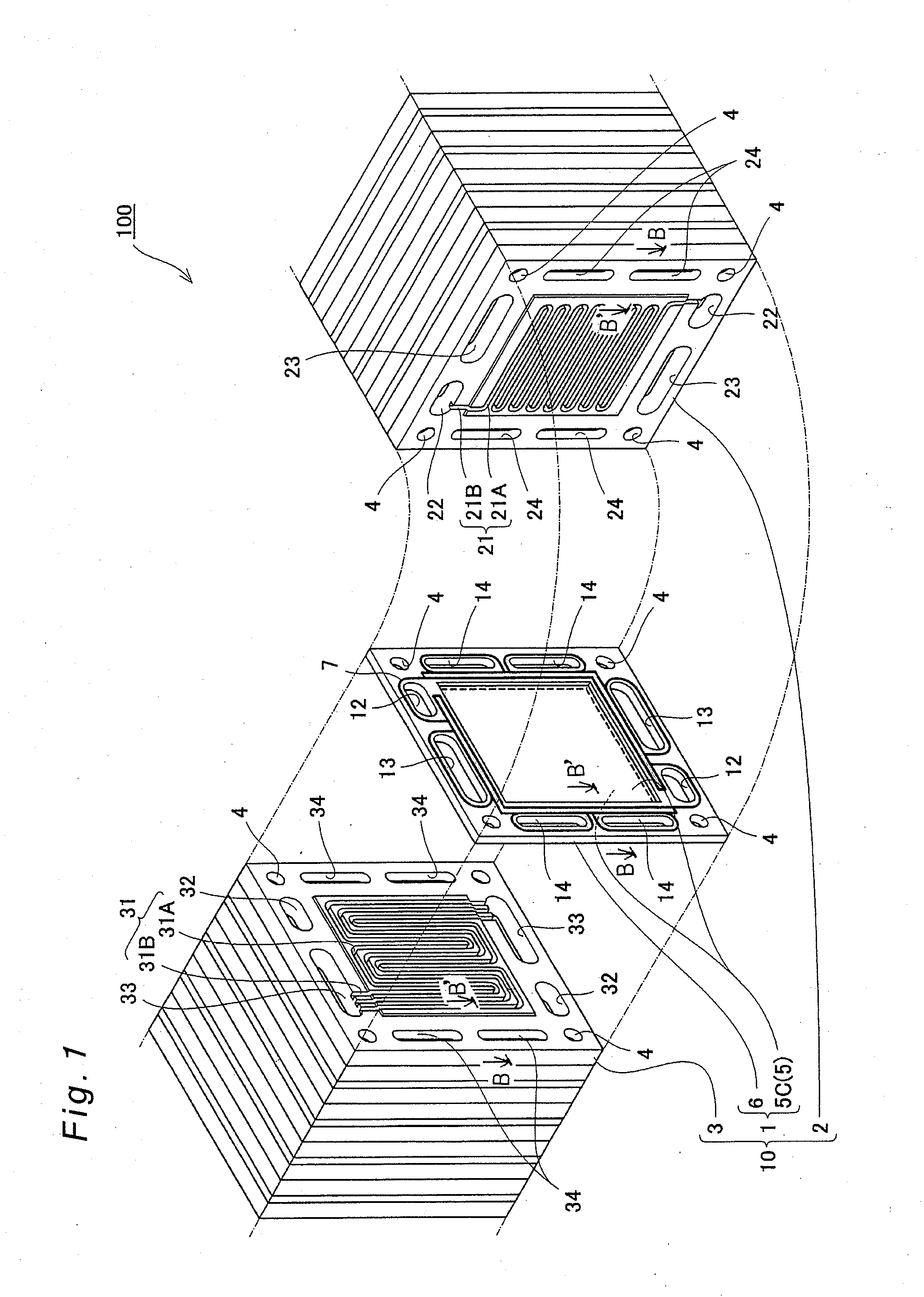

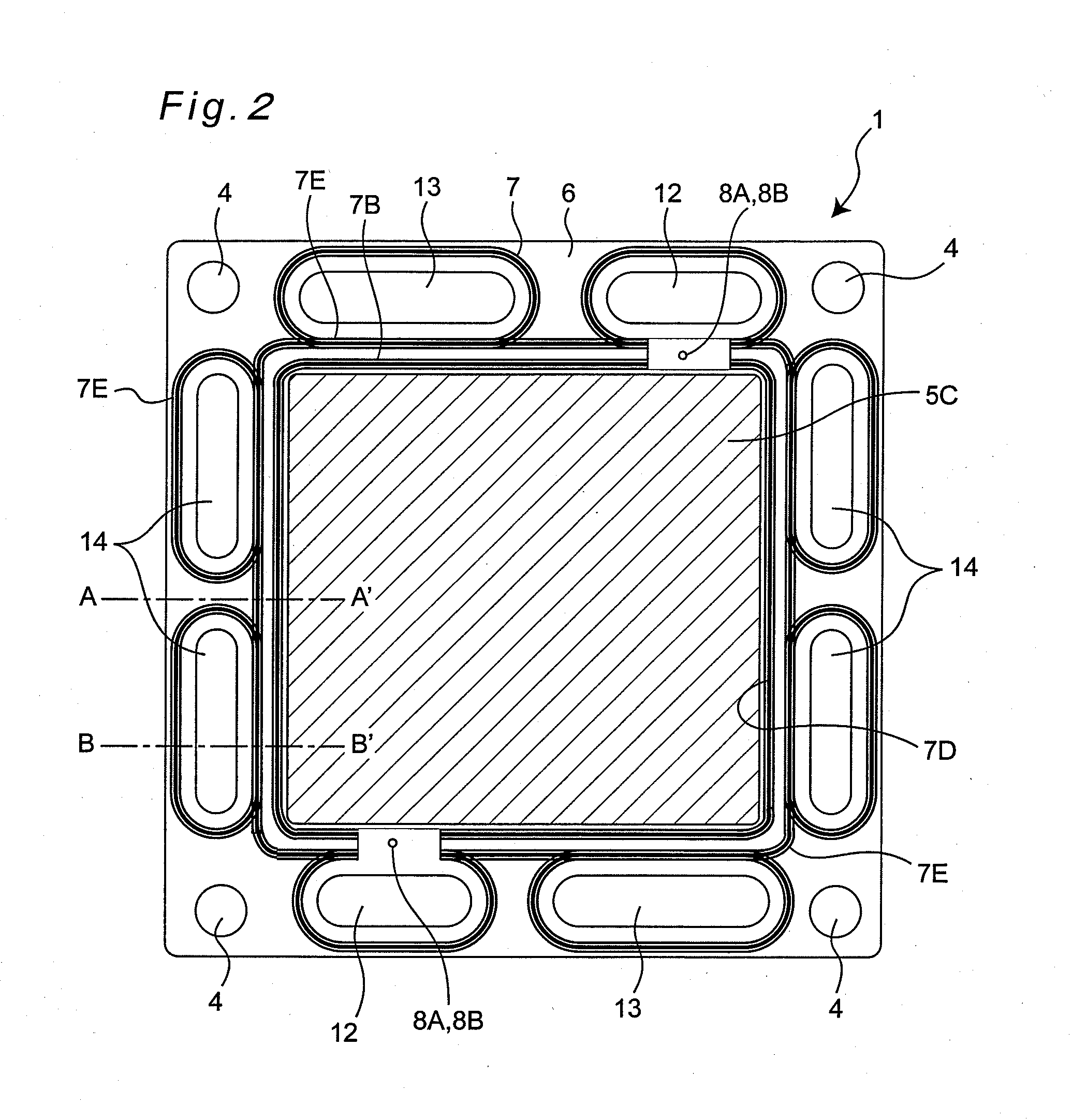

Mea-Gasket Assembly and Polymer Electrolyte Fuel Cell Using Same

InactiveUS20070264557A1Simple structureAvoid flowFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

The invention provides an MEA-gasket assembly (1) comprising: an MEA (5) having a polymer electrolyte membrane (5A), catalyst layers and gas diffusing layers (5C); a plate-like frame (6) which is joined to a portion of the polymer electrolyte membrane (5A) so as to enclose the MEA (5), the portion being located in a peripheral region of the MEA (5) and which has a plurality of fluid manifold holes (12, 13, 14); and an annular gasket (7) formed on both faces of the frame (6), wherein an annular gap formed between the inner peripheral edge of the annular gasket (7) and the outer peripheral edges of the gas diffusing layers (5C) is at least partially closed.

Owner:PANASONIC CORP

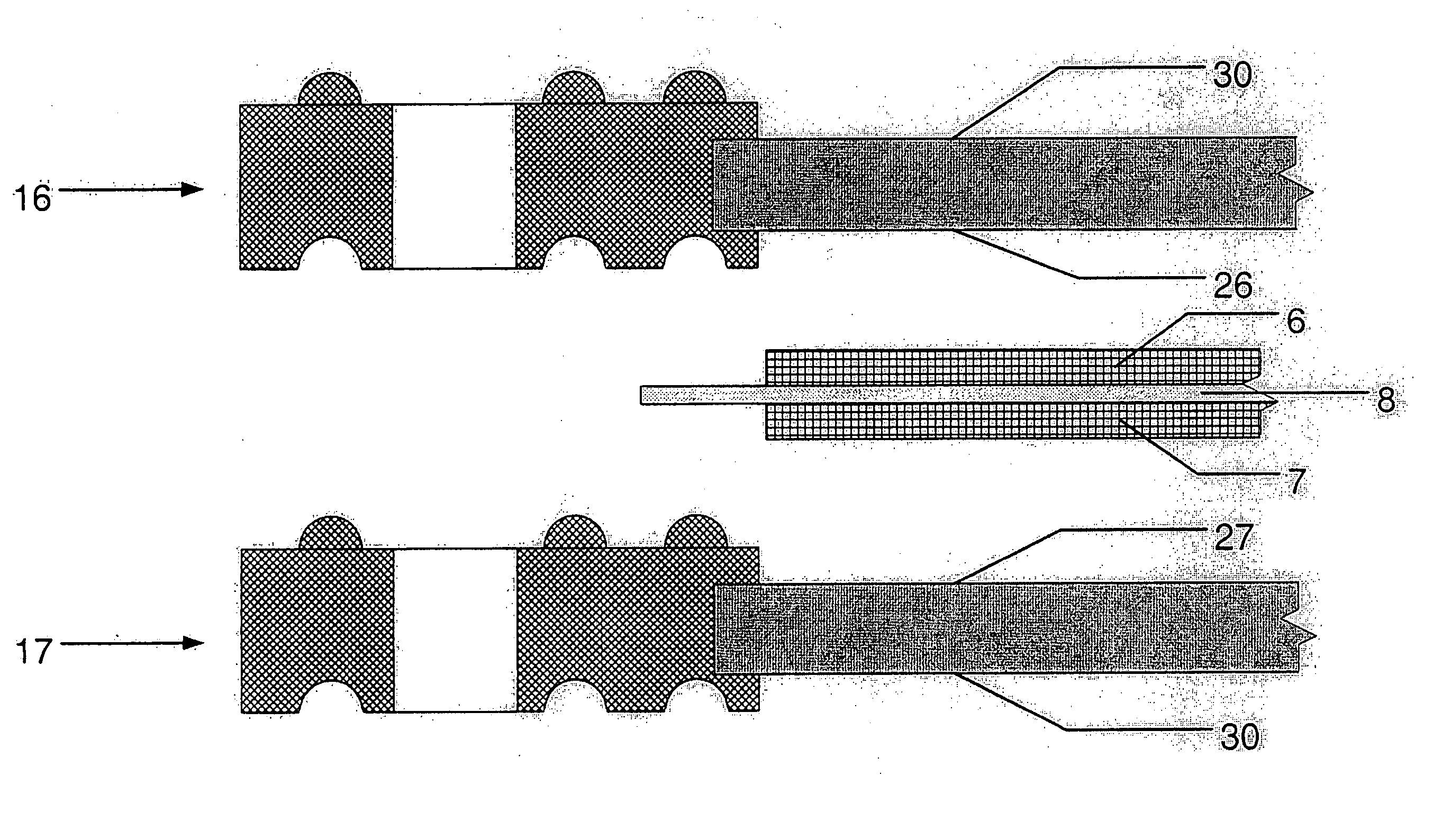

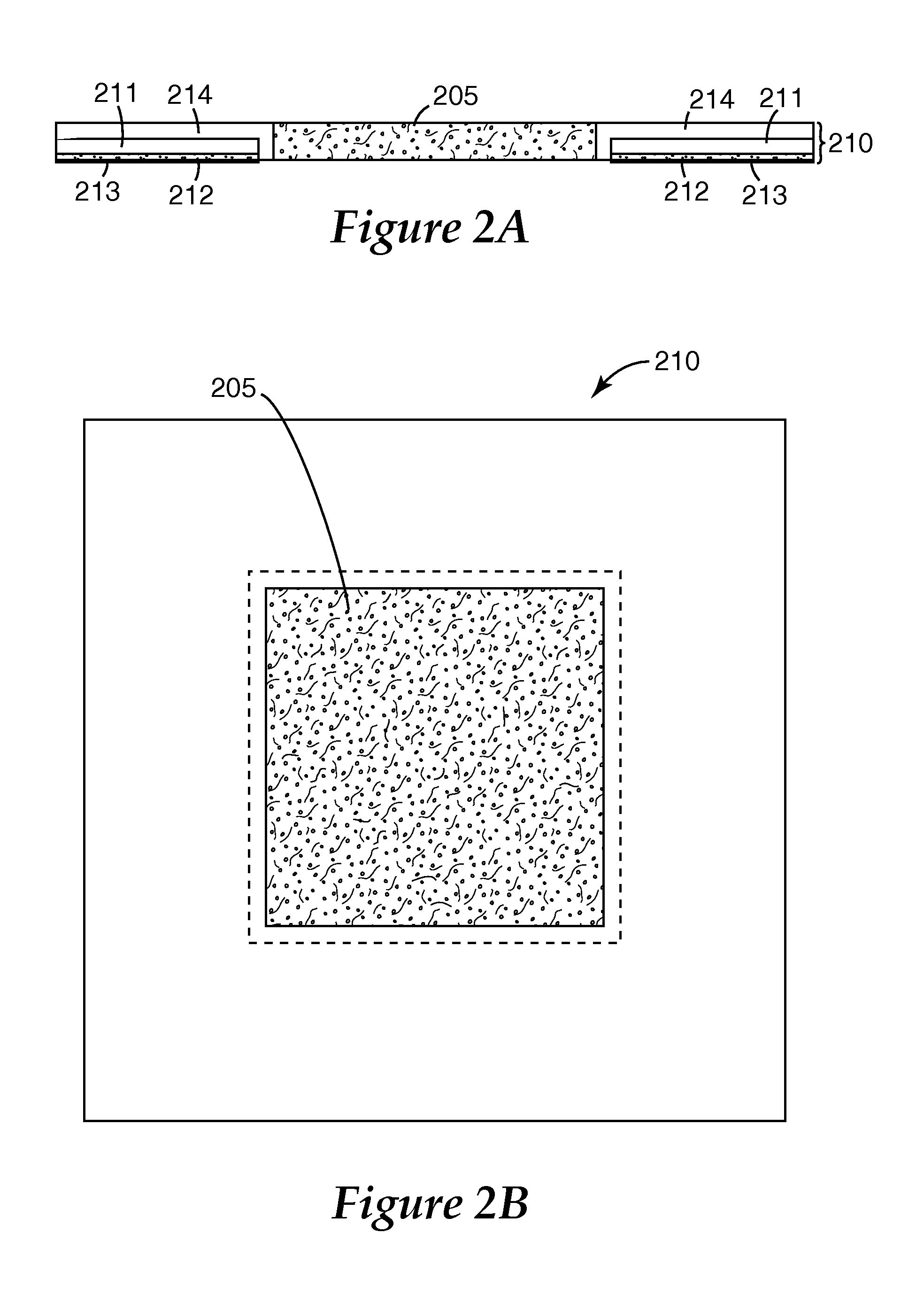

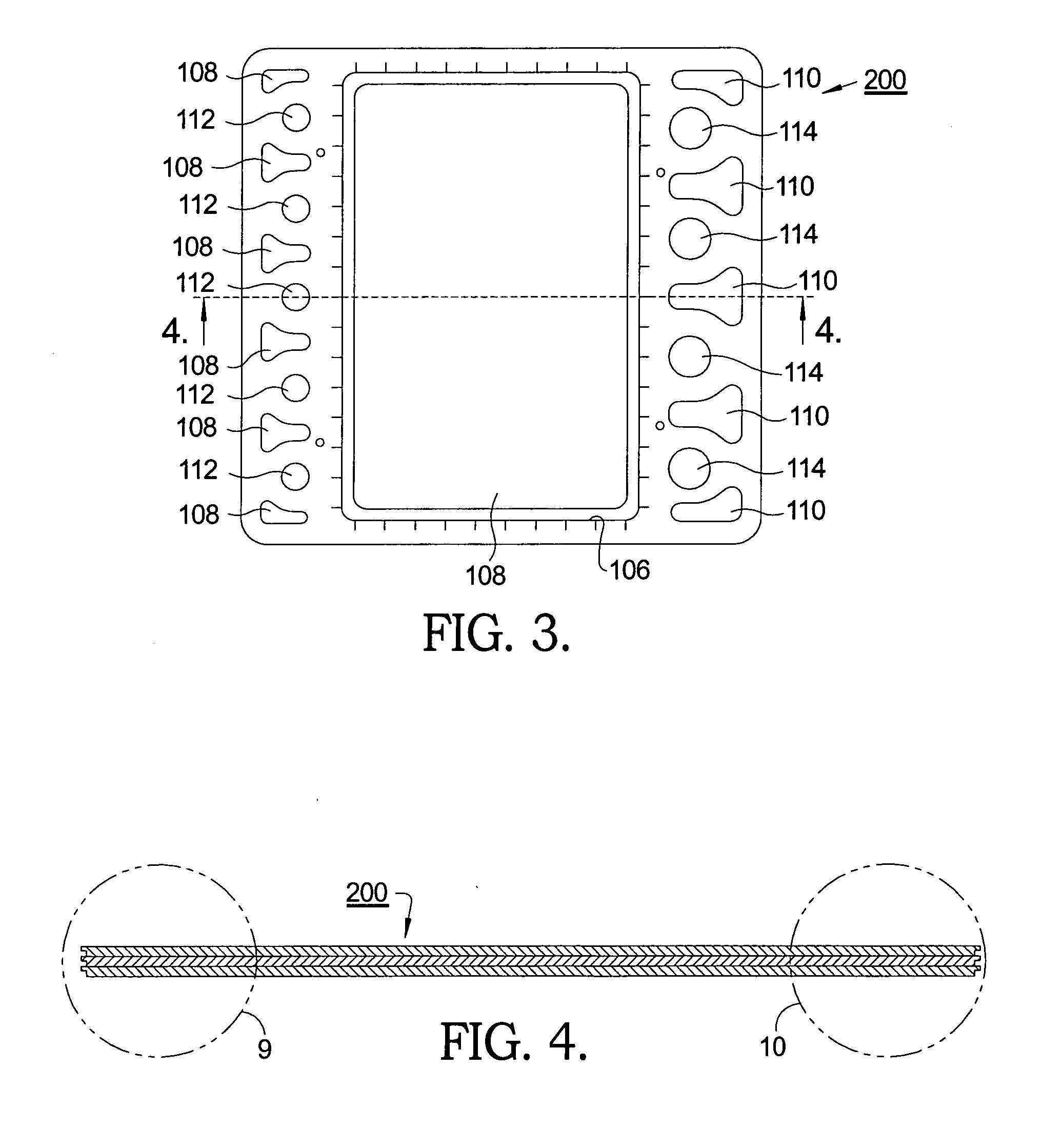

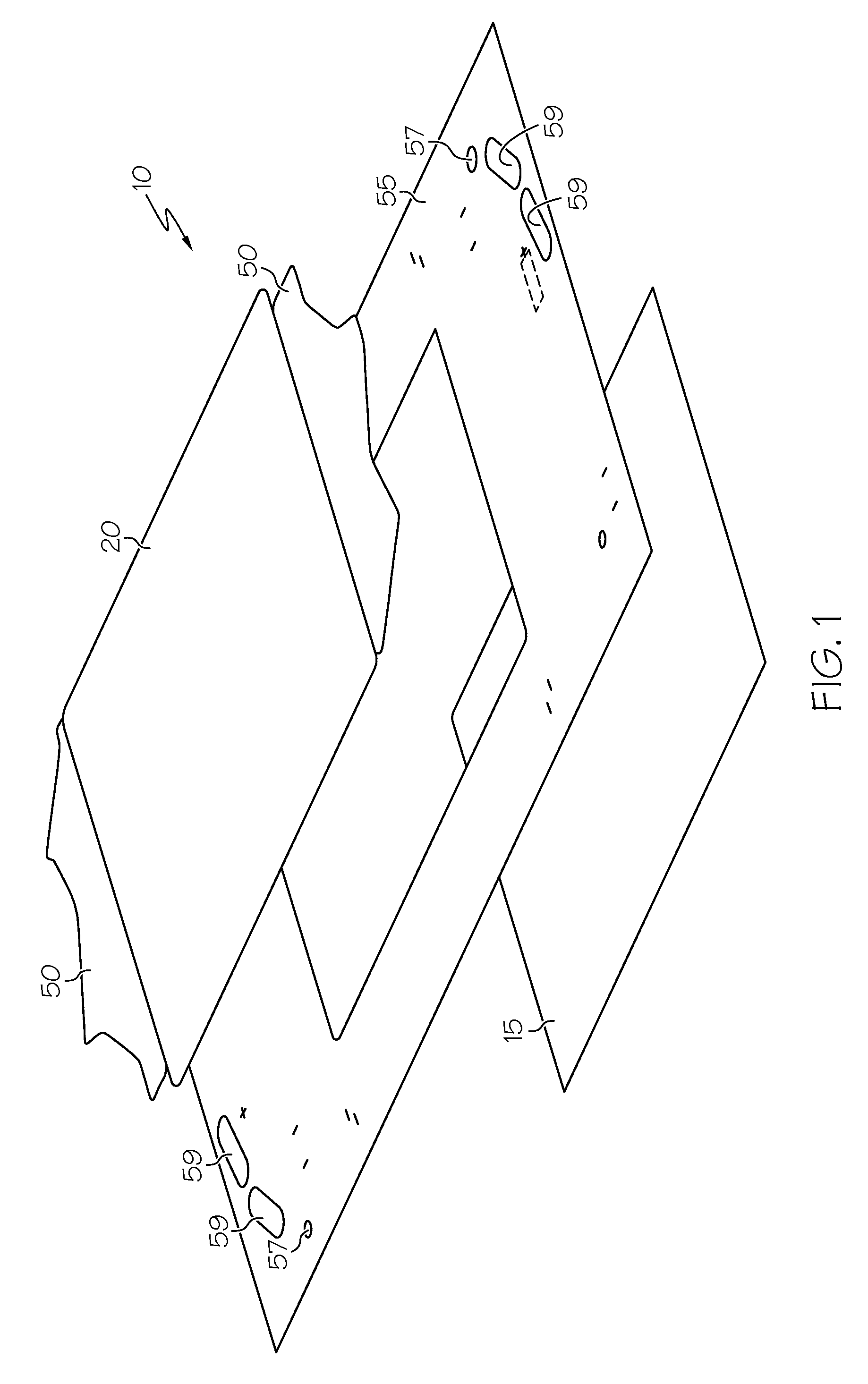

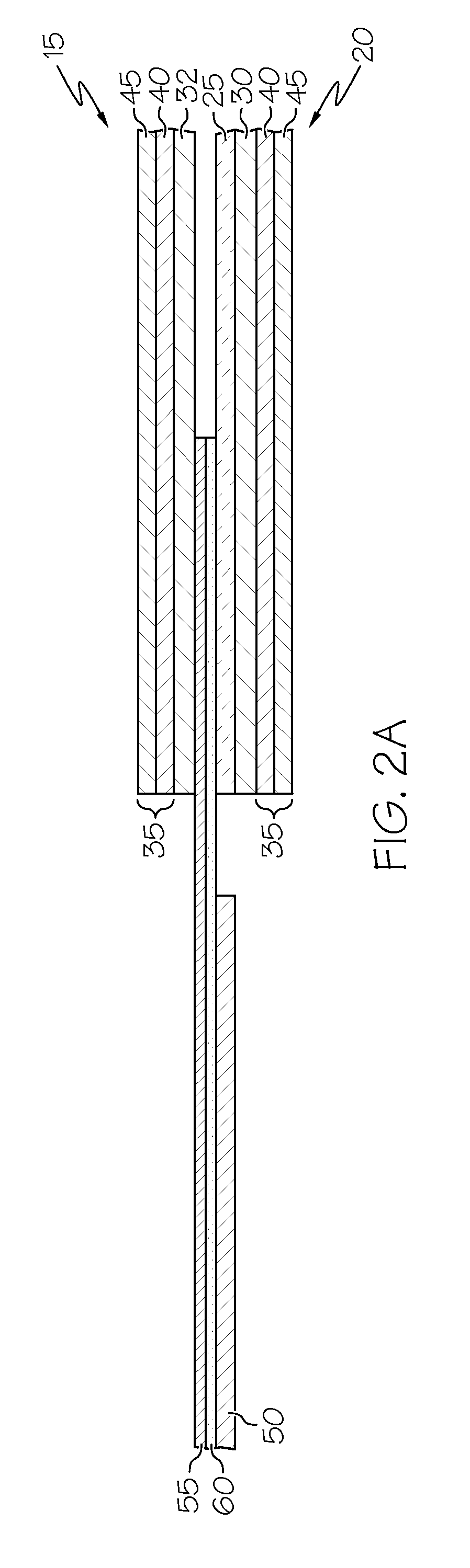

Gas diffusion layer incorporating a gasket

InactiveUS20080143061A1Facilitate achieving a predetermined thickness of the subassembly componentsEngine sealsFuel cells groupingMembrane electrode assemblyElectrical and Electronics engineering

A gas diffusion layer incorporating a gasket (GIG) is described along with assemblies incorporating the GIG subassembly. Processes for making the GIG and membrane electrode assemblies (MEAs) incorporating the GIG are also described. A GIG subassembly includes a gas diffusion layer (GDL) and a gasket bonded to the GDL. The gasket includes a first gasket layer and a second gasket layer. The second gasket layer is formed of a gasket material in contact with the first gasket layer and the GDL. The gasket material of the second gasket layer bonds the GDL to the first gasket layer. An adhesive layer, and optionally a removable adhesive liner, is disposed on a surface of the first gasket layer opposite the second gasket layer. In some MEA configurations, the GDL is disposed within an aperture in the first gasket layer.

Owner:3M INNOVATIVE PROPERTIES CO

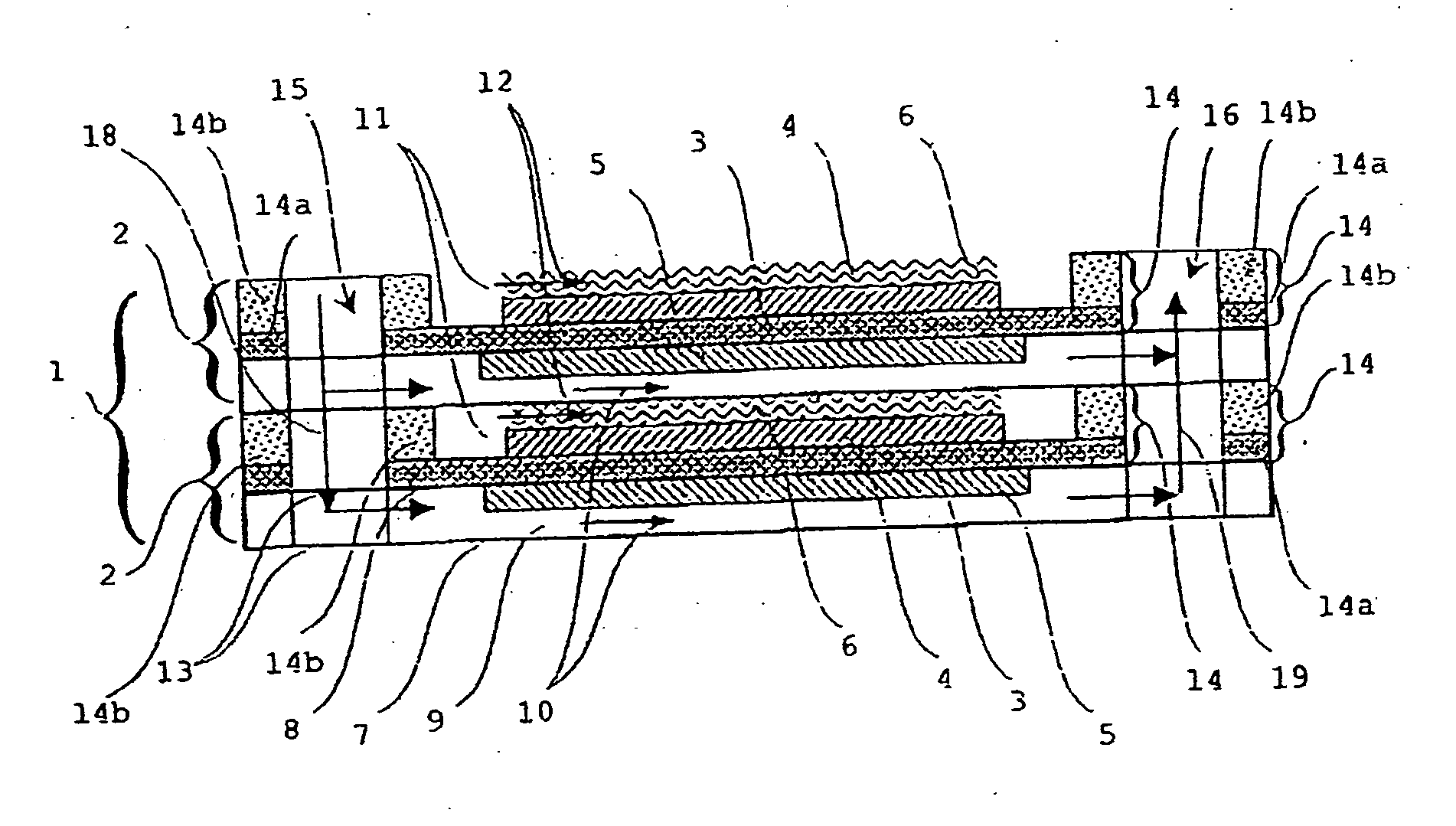

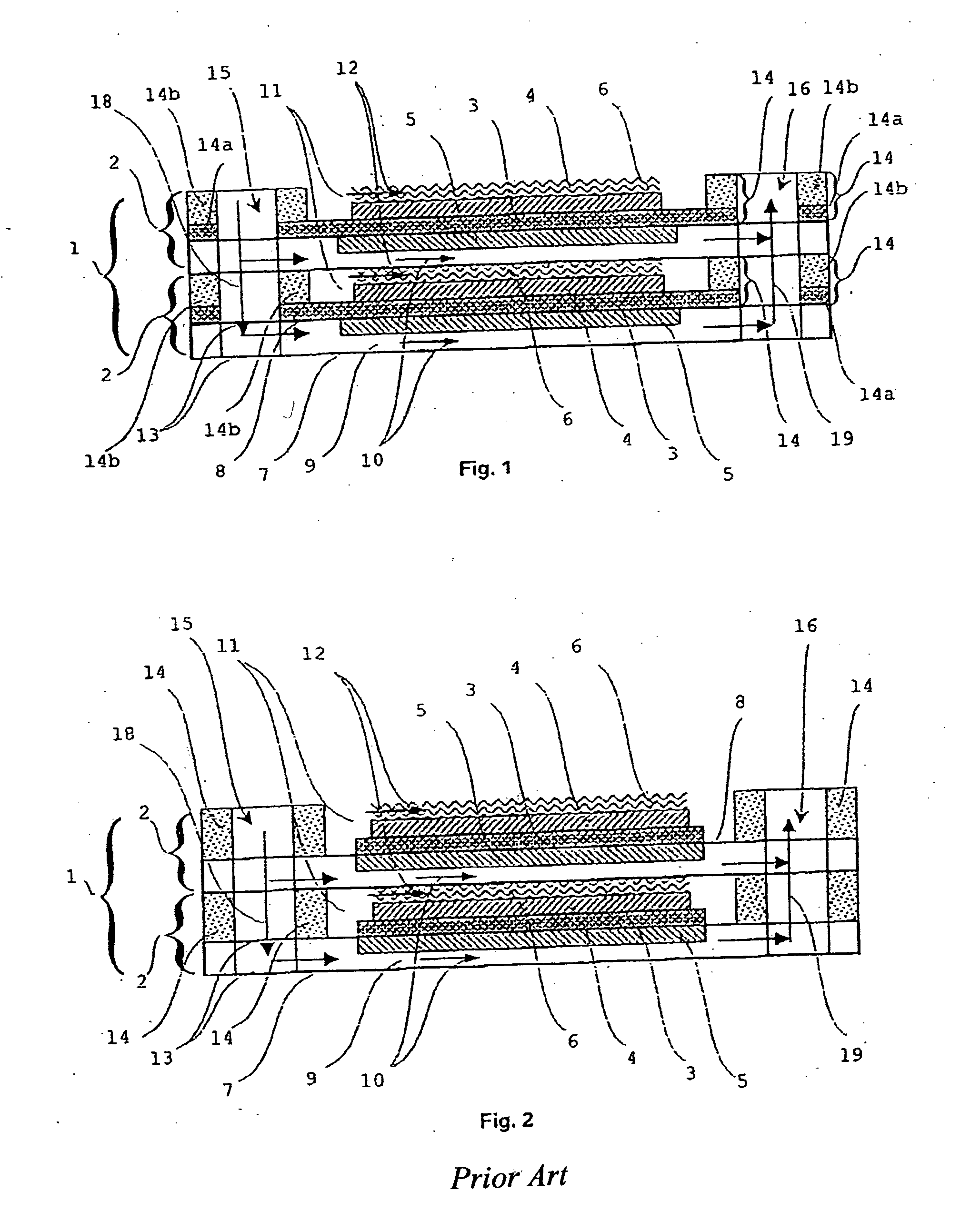

Sealing structure for a fuel cell, as well as a method for producing it, and a fuel cell with the sealing structure

A sealing structure for a fuel cell and / or an electrolyzer, in particular a solid electrolyte fuel cell and / or a solid electrolyte electrolyzer, wherein the sealing structure (14a, 14b) is arranged between adjoining separator plates (7, 8) of a cell stack (1), wherein the sealing structure (14, 14a, 14b) is embodied in at least two layers and has at least one insulating layer (14a) and at least one sealing layer (14b), wherein the insulating layer (14a) is arranged on a separator plate (7, 8).

Owner:ELRINGKLINGER AG

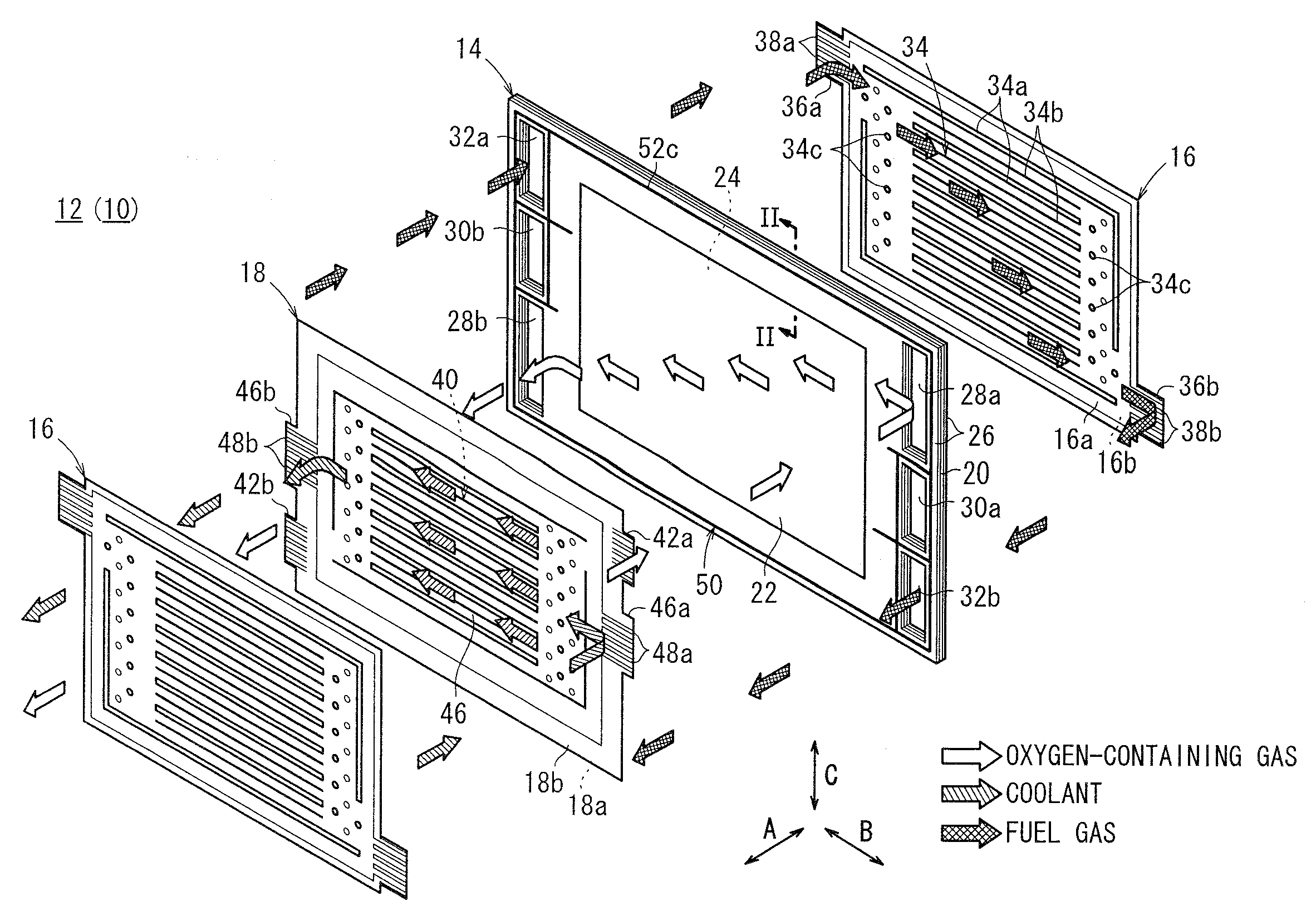

Fuel cell

InactiveUS20090004539A1Desired performanceReduce thicknessFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A unit cell of a fuel cell is formed by stacking a membrane electrode assembly between a first metal separator and a second metal separator in a stacking direction. A frame is provided in an outer end of the membrane electrode assembly. A seal member is formed on the frame. The seal member includes a first seal as a fuel gas seal, a second seal as a coolant seal, and a third seal as an oxygen-containing gas seal. The first seal, the second seal, and the third seal are offset from each other in the stacking direction.

Owner:HONDA MOTOR CO LTD

Method for joining laser transmitting resin member and porous member, method for joining thermoplastic resin, and fuel cell

InactiveUS20050208361A1Decrease productivityImprove productivityLamination ancillary operationsFuel cells groupingFuel cellsLaser beams

A method for joining a resin member and a porous member can prevent peeling in a specified direction. When a thermoplastic laser transmitting resin member and a porous member are joined, the laser transmitting resin layer and the porous member are laminated, and a laser beam is emitted at a side of the laser transmitting resin member. The porous member is heated so that the laser transmitting resin member is melted, and the melted resin is impregnated with holes of the porous member. The resin is cooled so as to solidify.

Owner:HONDA MOTOR CO LTD

Integrally molded gasket for a fuel cell assembly

InactiveUS20070003821A1Damaging the MEAFuel cells groupingActive material electrodesFuel cellsHigh density

A fuel cell membrane electrode assembly (MEA) comprising first and second gas diffusion layers and an ion exchange membrane disposed between the diffusion layers. Each diffusion layer includes an inner surface facing the membrane, an outer surface opposite the inner surface, and a side surface defining a perimeter of the diffusion layers. An outboard region extends about the diffusion layers at the perimeter. The outboard region surrounds an inboard region. The outboard region has a low density region proximate to the side surface and a high density region between the low density region and the inboard portion. A seal is mounted at the low density region. The high density region prevents portions of the seal from entering the inboard region thereby damaging the MEA. The seal includes a first rim having a smaller radius than a second rim. The smaller radius allows the seal to fit between adjacent support plates and increases the durability of the seal.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

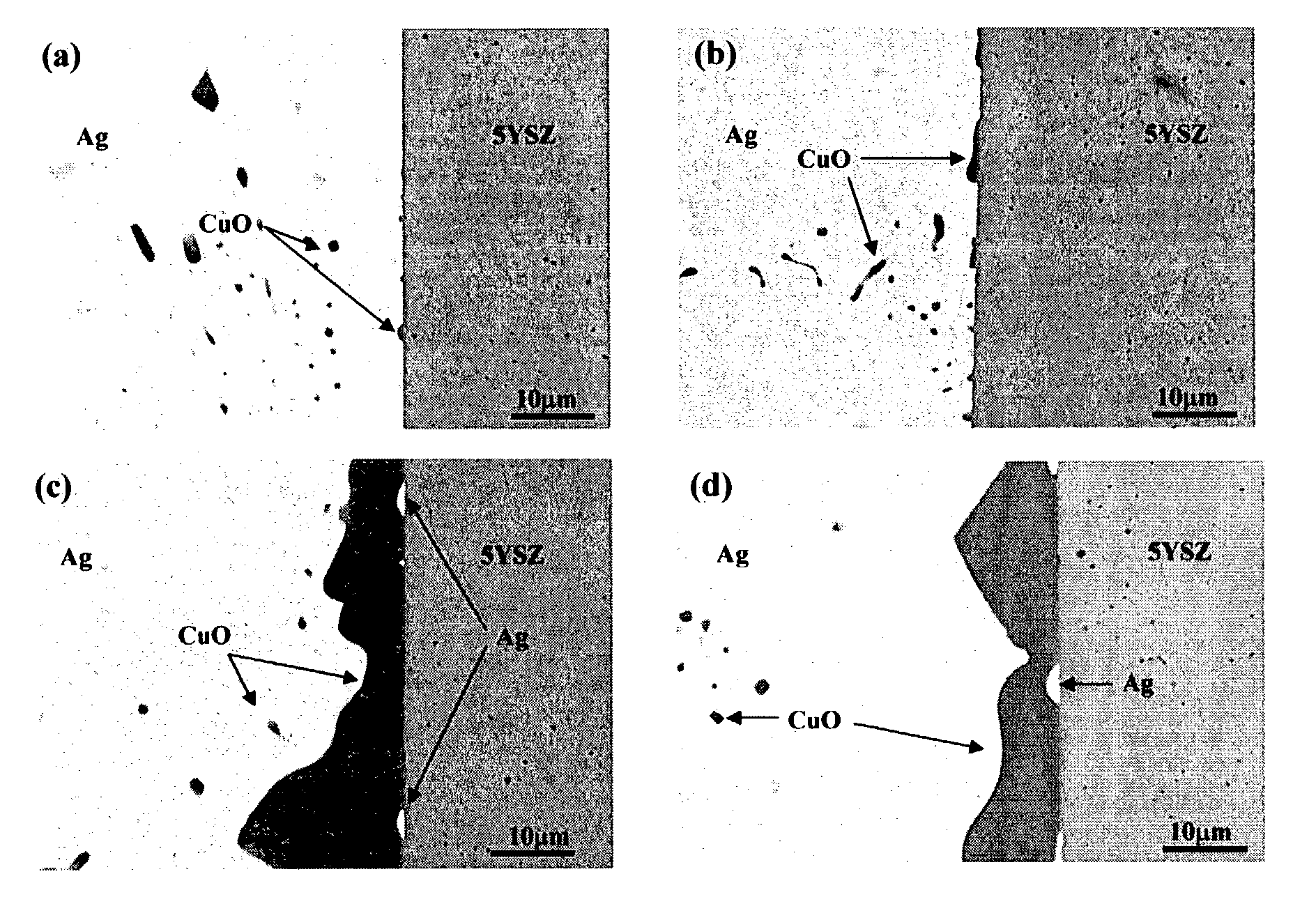

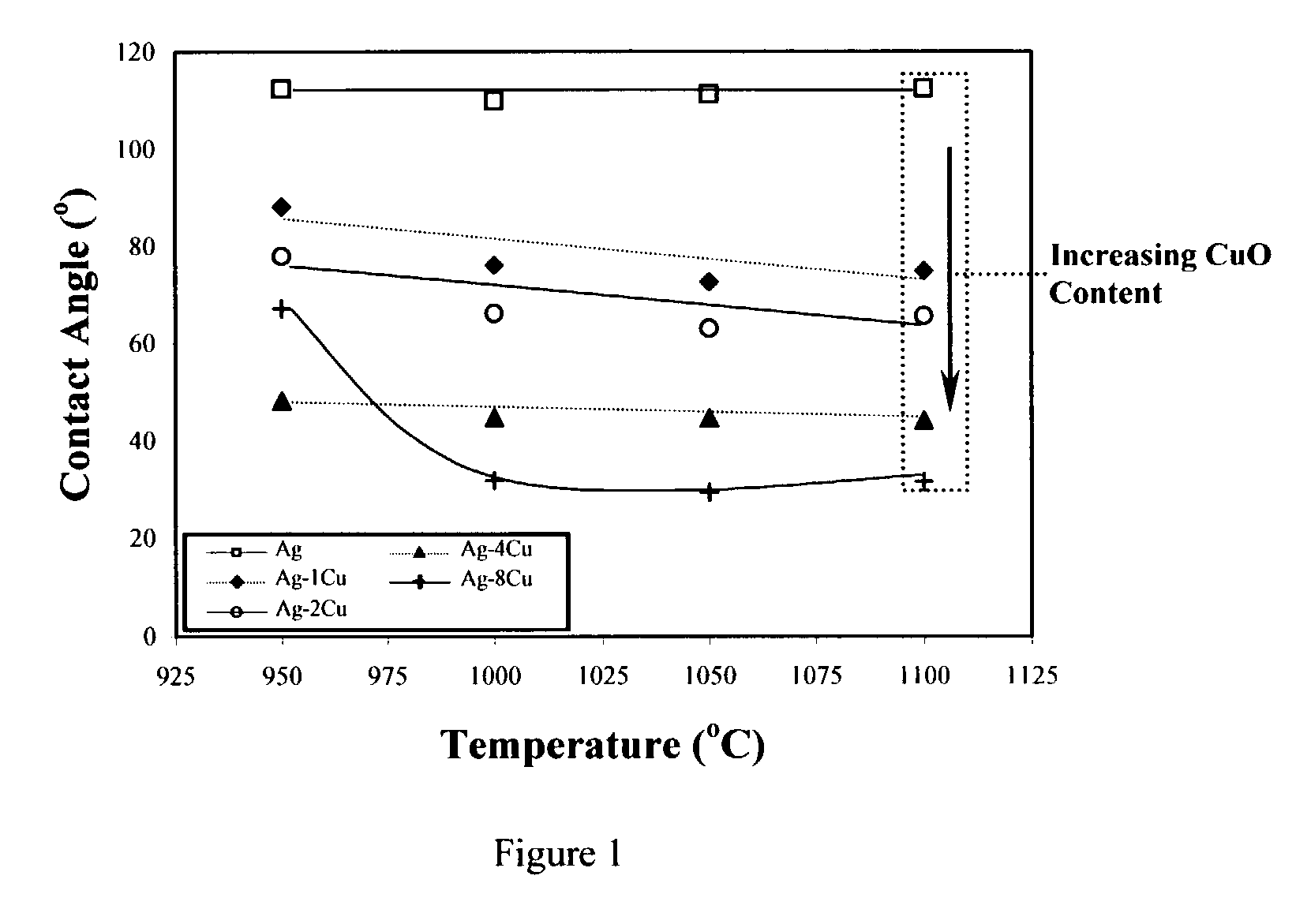

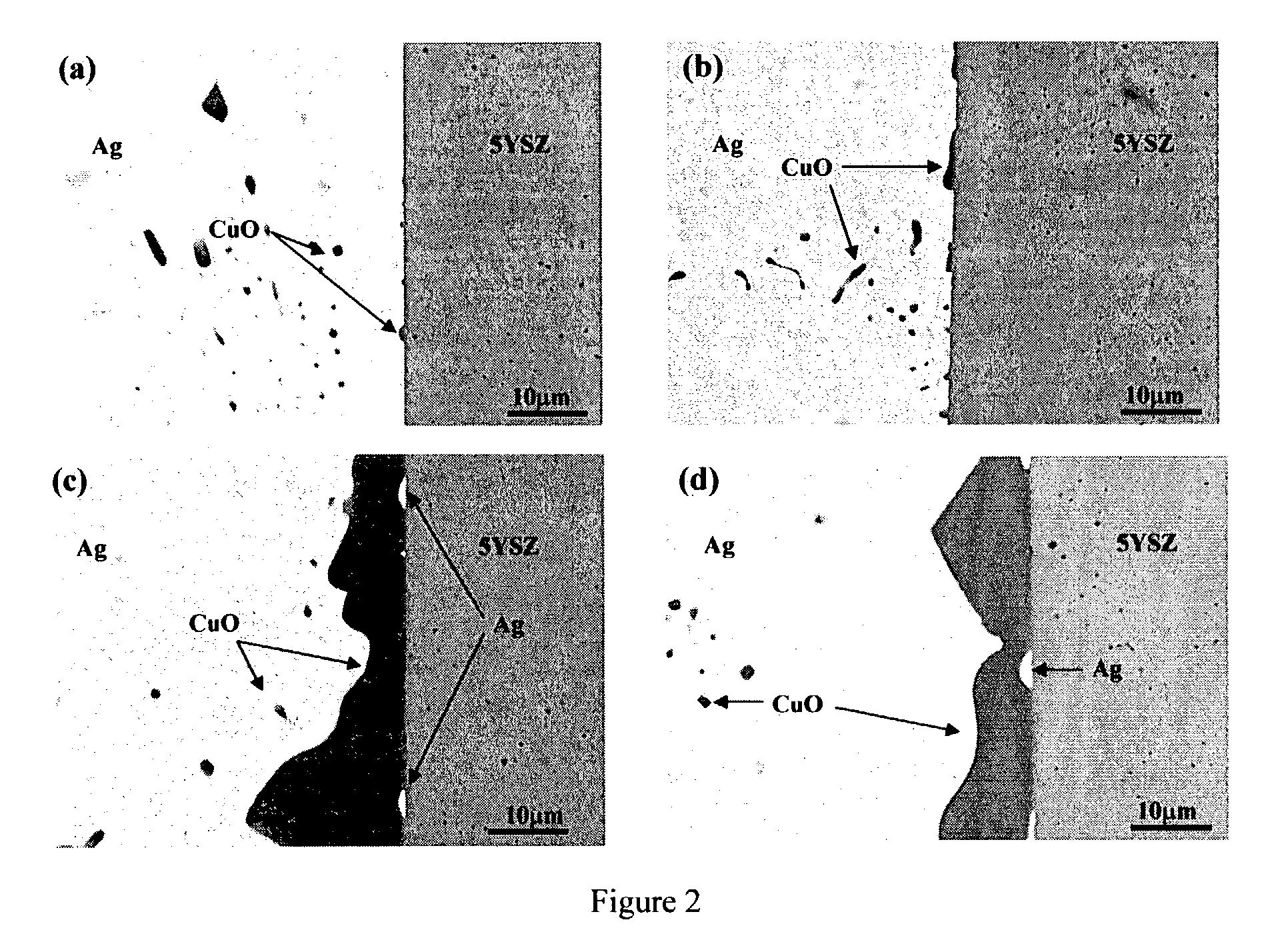

Oxidation ceramic to metal braze seals for applications in high temperature electrochemical devices and method of making

InactiveUS7055733B2Improve sealingEasy to wetFinal product manufactureLayered productsElectrochemistrySuperalloy

A method of joining metal and ceramic parts, wherein an alumina forming metal part and a ceramic part are provided. A braze material in placed between the alumina forming metal part and the ceramic part, and the combination is then heated in an oxidizing atmosphere, preferably in air at a temperature of between 500° C. and 1300° C. The alumina forming metal parts are selected from the group consisting of high temperature stainless steels, such as Durafoil (alpha-4), Fecralloy, Alumina-coated 430 stainless steel and Crofer-22APU, and high temperature superalloys such as Haynes 214, Nicrofer 6025, and Ducraloy. The braze material is selected as a metal oxide-noble metal mixture, preferably Ag—CuO, Ag—V2O5, and Pt—Nb2O5, and more preferably between 30.65 to 100 mole % Ag in CuO.

Owner:BATTELLE MEMORIAL INST

Sealing glass frit

InactiveUS20050277541A1Reduce decreaseSolid electrolyte fuel cellsSealing/support meansFritRoom temperature

A sealing glass frit which is capable of stably joining metal members or ceramic members at temperatures thereof not higher than 1000° C., and at the same time stably maintaining the joined state of the members at temperatures ranging from room temperature to 700 or 800° C. A raw material in an amount of MG 300 g is prepared such that it has a composition of 40 to 70 mol % of SiO2, 5 to 20 mol % of Al2O3, 4 to 20 mol % of Na2O, 4 to 20 mol % of K2O, 5 to 20 mol % of ZnO, and 0.5 to 5 mol % of ZrO2, and the total content of Na2O and K2O is not lower than 12 mol %. The raw material is melted in a platinum crucible at 1550° C. for 8 hours, cast in a mold of stainless steel, held at 650° C. for 2 hours, and then cooled to room temperature at 5° C. / minute. The cooled raw material is pulverized in a mortar to obtain powder having a particle diameter 10 to 20 μm as a sealing glass frit.

Owner:NIPPON SHEET GLASS CO LTD

Curable subgasket for a membrane electrode assembly

InactiveUS20060078781A1Cell electrodesCell component detailsPolymer electrolytesMembrane configuration

A subgasket for a membrane electrode assembly is deposited on a surface of a MEA component and cured in situ. A membrane electrode subassembly includes a polymer electrolyte membrane, a gas diffusion layer and a catalyst layer between the polymer electrolyte membrane and the gas diffusion layer. The membrane electrode subassembly includes a subgasket, disposed over one or more components of the membrane electrode subassembly. The subgasket is made of a layer of material that is depositable and curable in situ. A peripheral edge of the gas diffusion layer overlaps the subgasket.

Owner:3M INNOVATIVE PROPERTIES CO

SOFC Double Seal with Dimensional Control for Superior Thermal Cycle Stability

InactiveUS20090311570A1Improved thermal cycling stabilityEngine sealsFuel cells groupingFuel cellsHermetic seal

A seal for devices such as a solid oxide fuel cells. The seal is a double seal having a first sealing material having a first preselected characteristic and a second sealing material having a second sealing characteristic. In one embodiment of the invention the first sealing material is a compressive sealing material and the second sealing material is a hermetic sealing material. In some embodiments a dimensional stabilizer may also be included as a part of the seal. In use these double seals provide superior thermal cycling stability in electrochemical devices where gasses must be separated from each other.

Owner:BATTELLE MEMORIAL INST

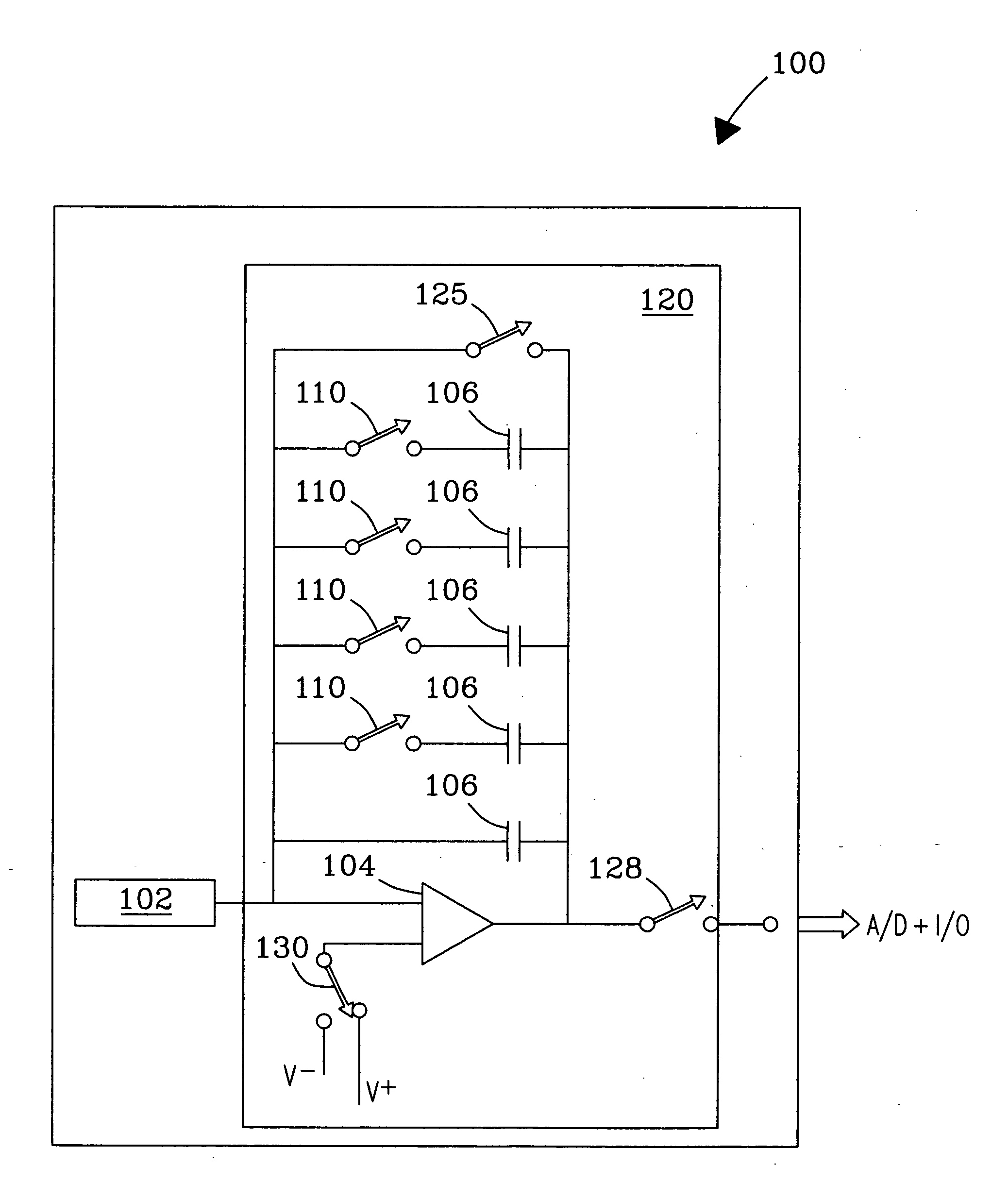

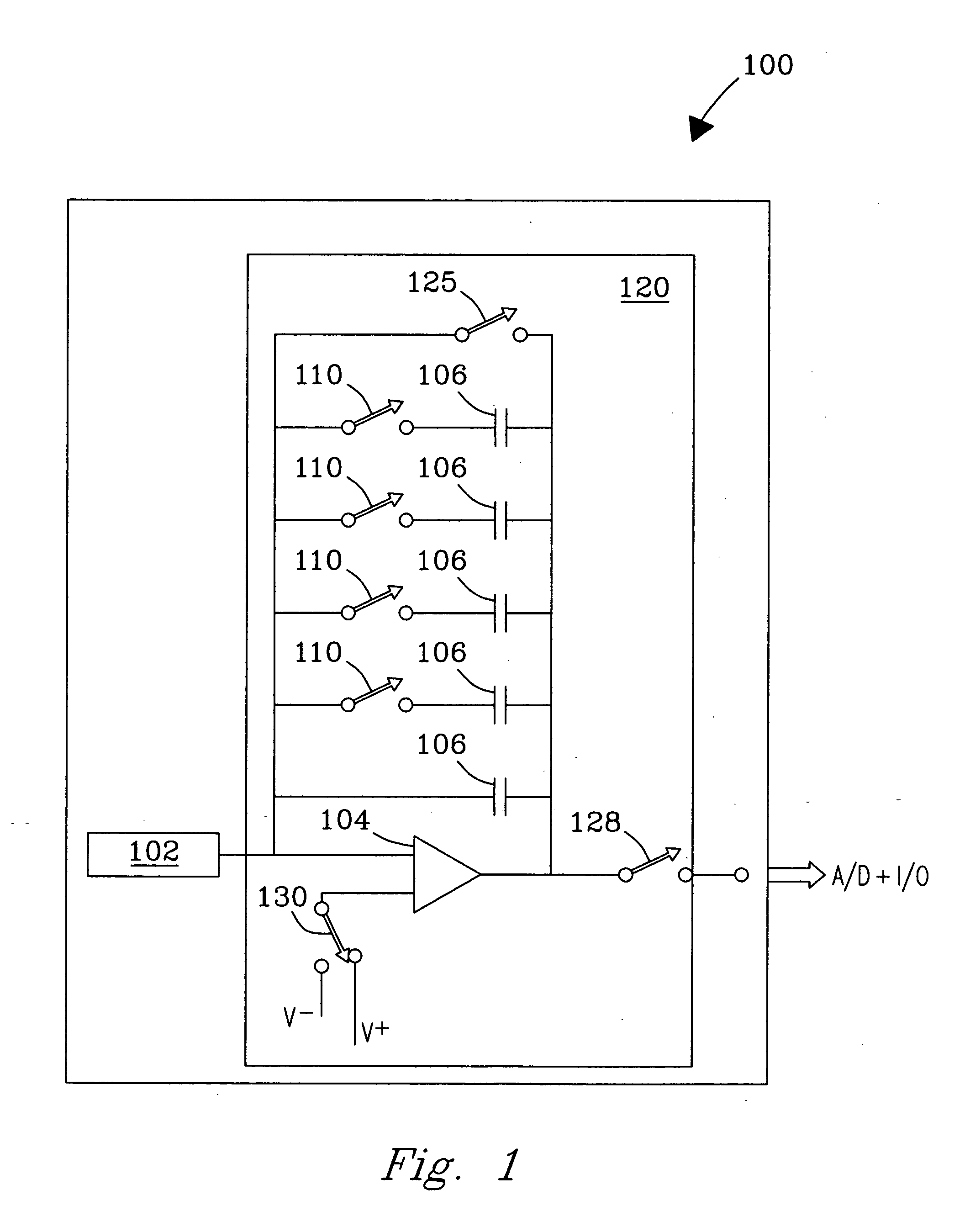

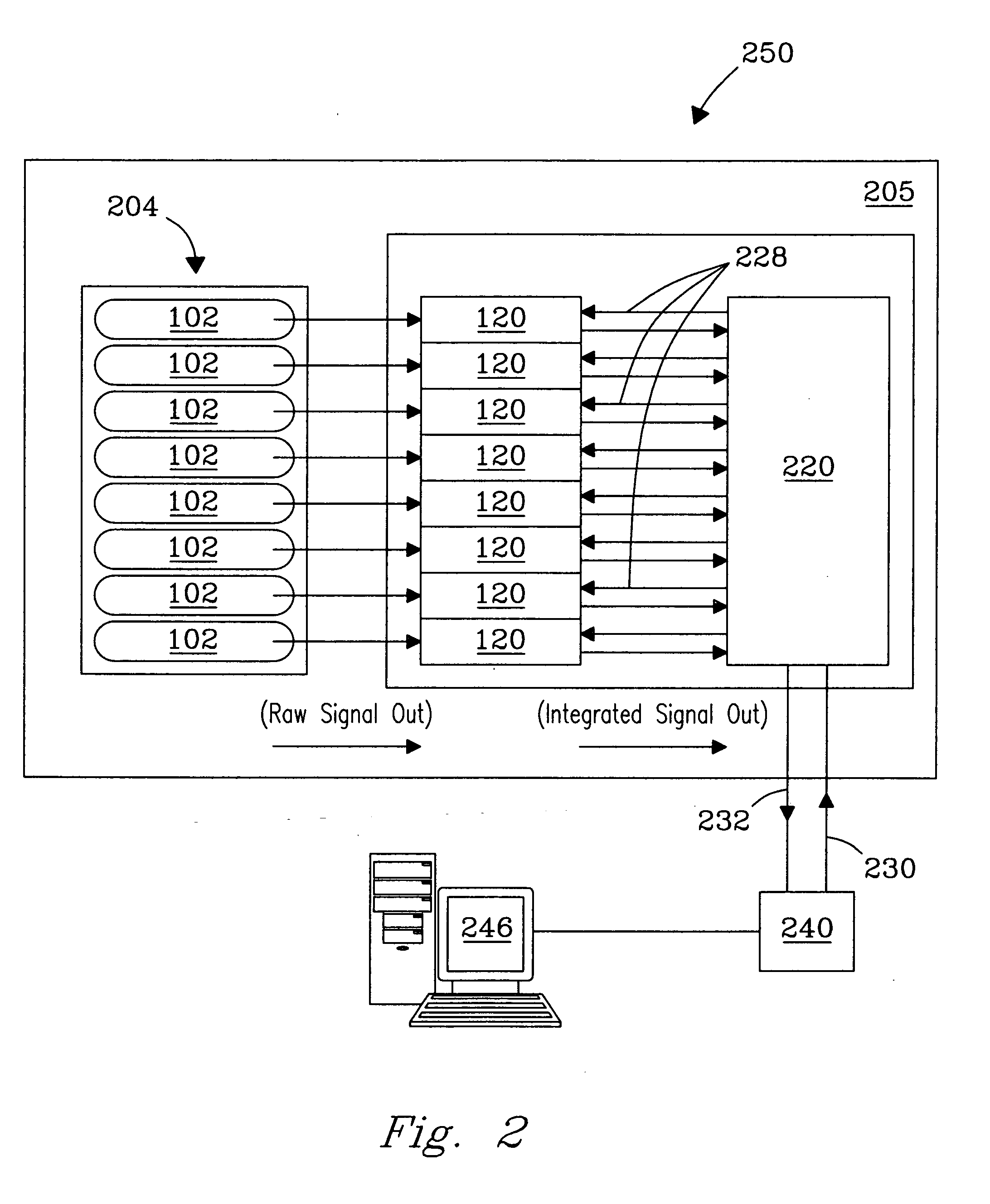

Method and apparatus for simultaneous detection and measurement of charged particles at one or more levels of particle flux for analysis of same

InactiveUS20080073548A1Solve the low detection efficiencyVariation can be minimizedThermometer detailsSpectrometer detectorsCharged particle detectorsParticle physics

A charged particle detector and method are disclosed providing for simultaneous detection and measurement of charged particles at one or more levels of particle flux in a measurement cycle. The detector provides multiple and independently selectable levels of integration and / or gain in a fully addressable readout manner.

Owner:INDIANA UNIV RES & TECH CORP +2

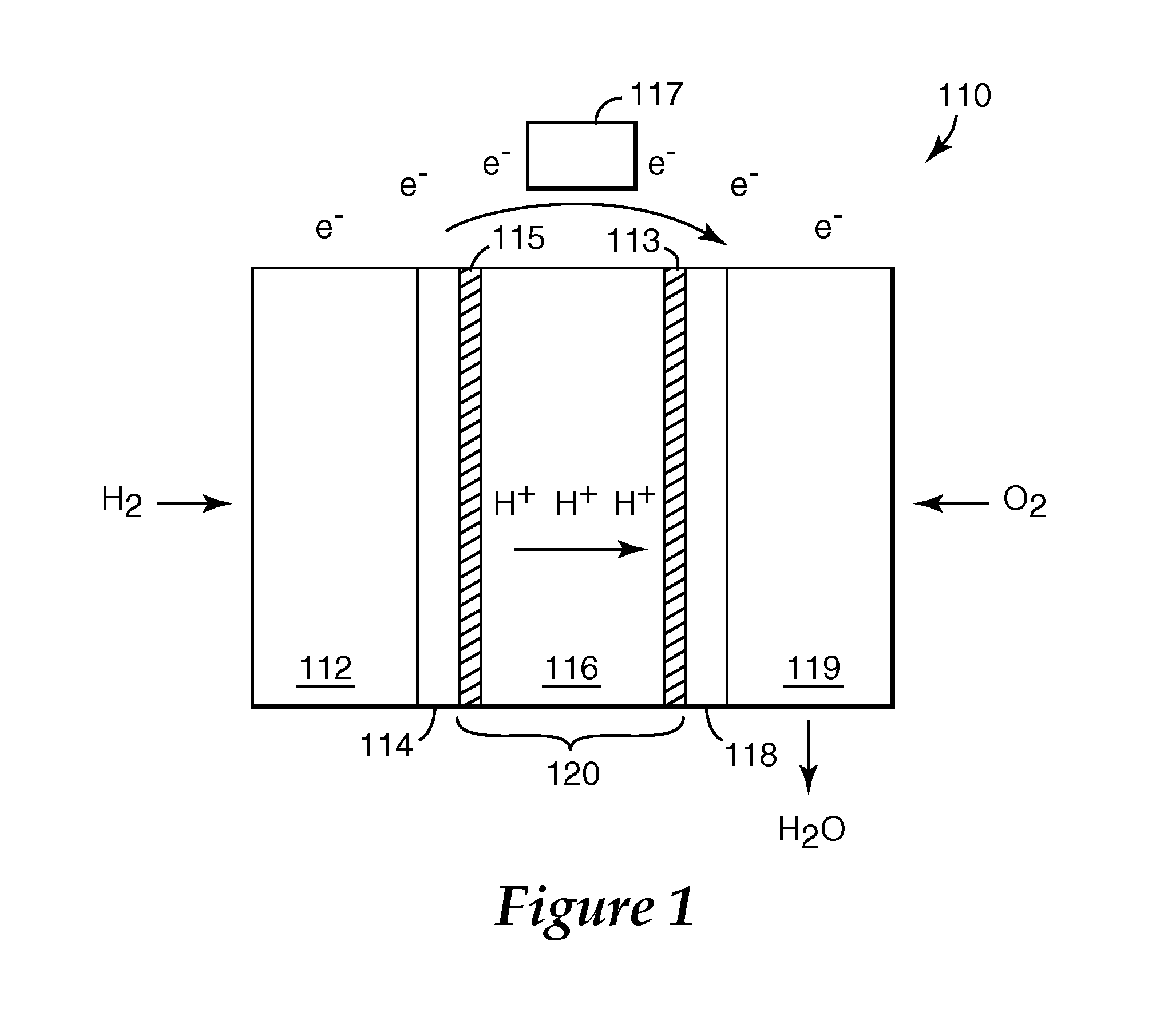

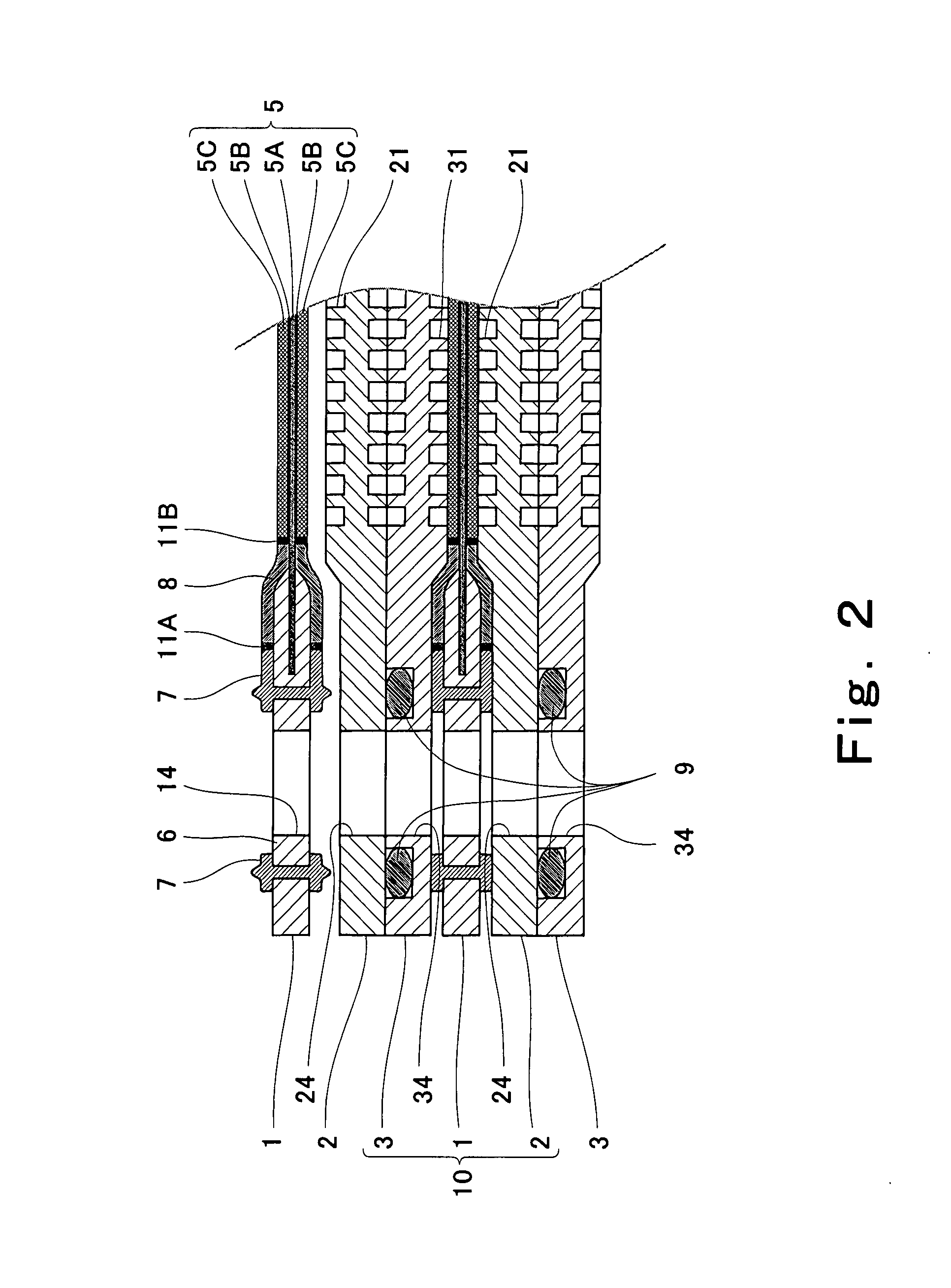

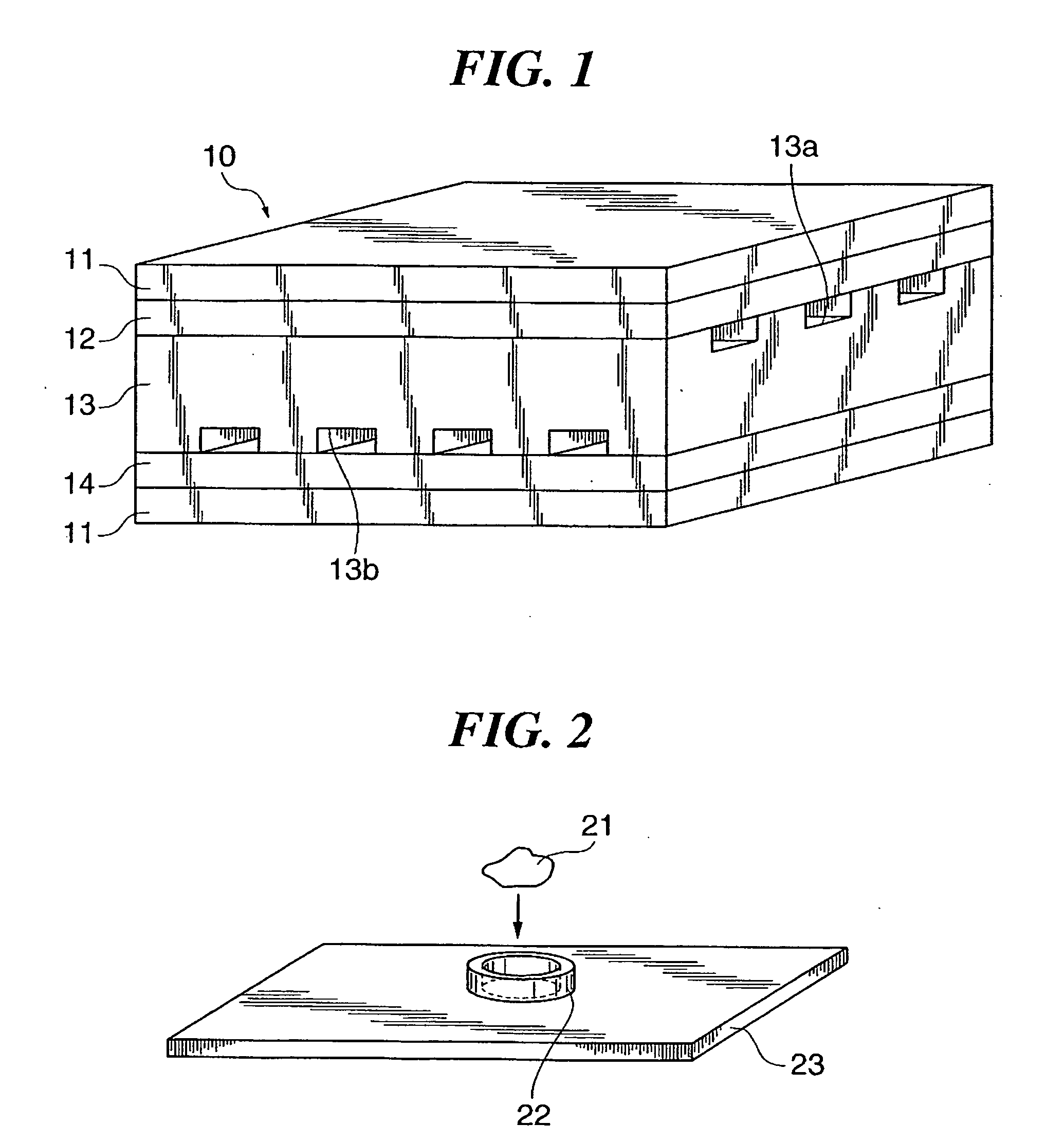

Electrode-membrane-frame assembly for fuel cell, polyelectrolyte fuel cell and manufacturing method therefor

ActiveUS20080305384A1Facilitated releaseYield in manufacturing can be improvedFinal product manufacturePrimary cellsPolyelectrolyteFuel cells

An electrode-membrane-frame assembly for a polyelectrolyte fuel cell which is held between one pair of separators and constitutes an electric cell module in the fuel cell is constituted of a membrane electrode assembly, a first frame body which has a separator-side surface on which a sealing member for sealing between the member and one separator and a membrane-side surface located on one surface of the peripheral edge portion of the membrane electrode assembly and is formed of a thermoplastic resin material, and a second frame body that has a separator-side surface on which a sealing member for sealing between the member and the other separator and a membrane-side surface located on the other surface of the peripheral edge portion of the membrane electrode assembly and is formed of a thermoplastic resin material and fitted to the first frame body holding the peripheral edge portion of the membrane electrode assembly between the second frame body and the first frame body.

Owner:PANASONIC CORP

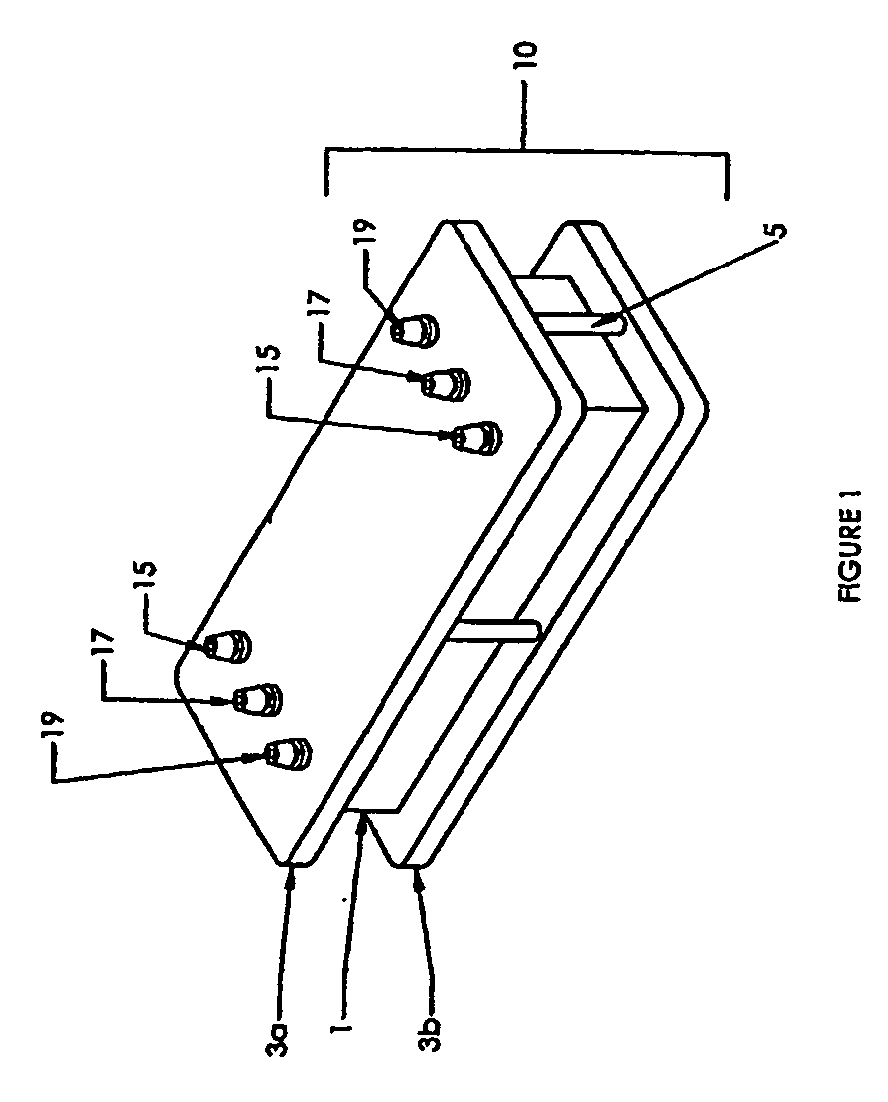

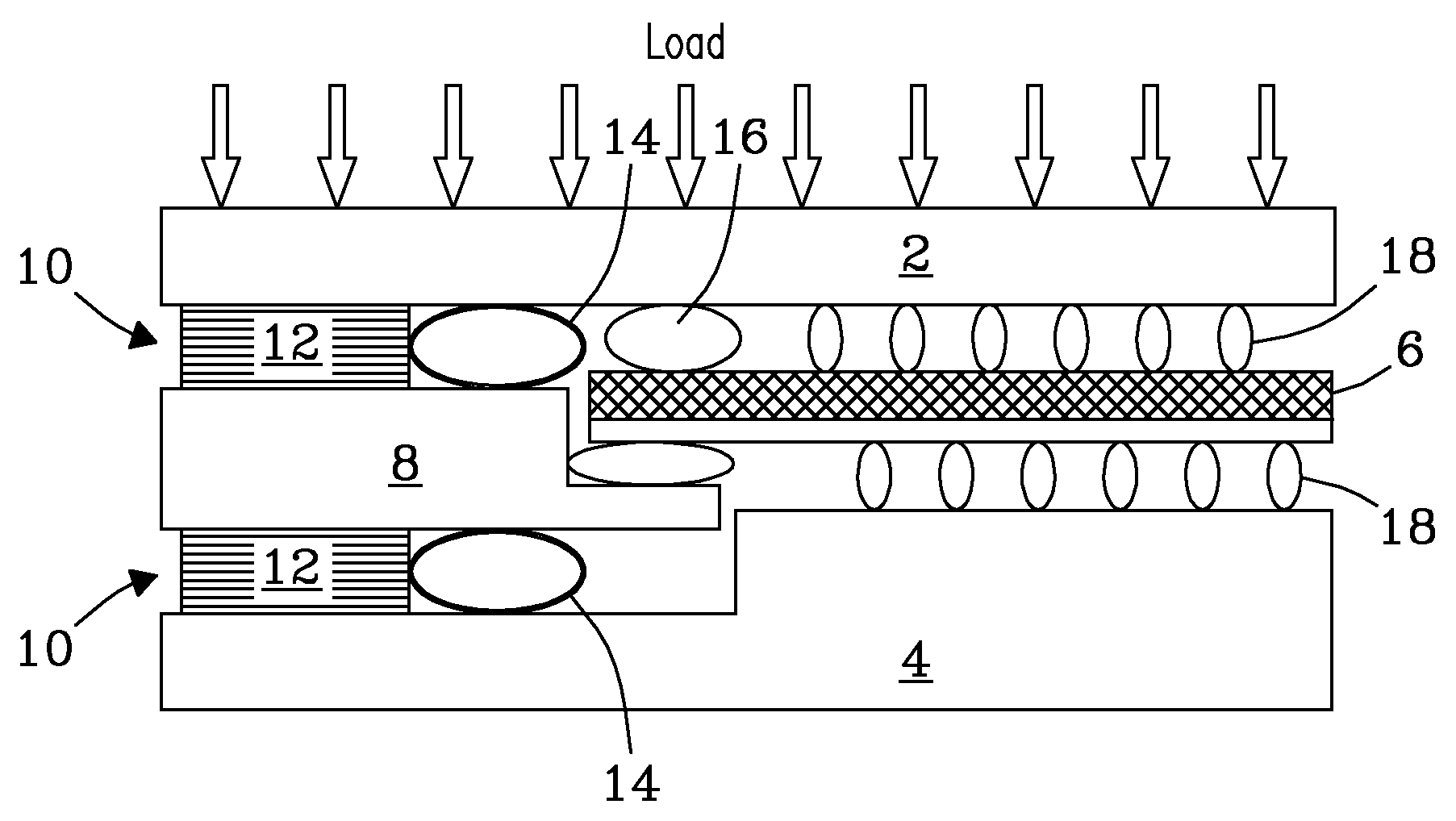

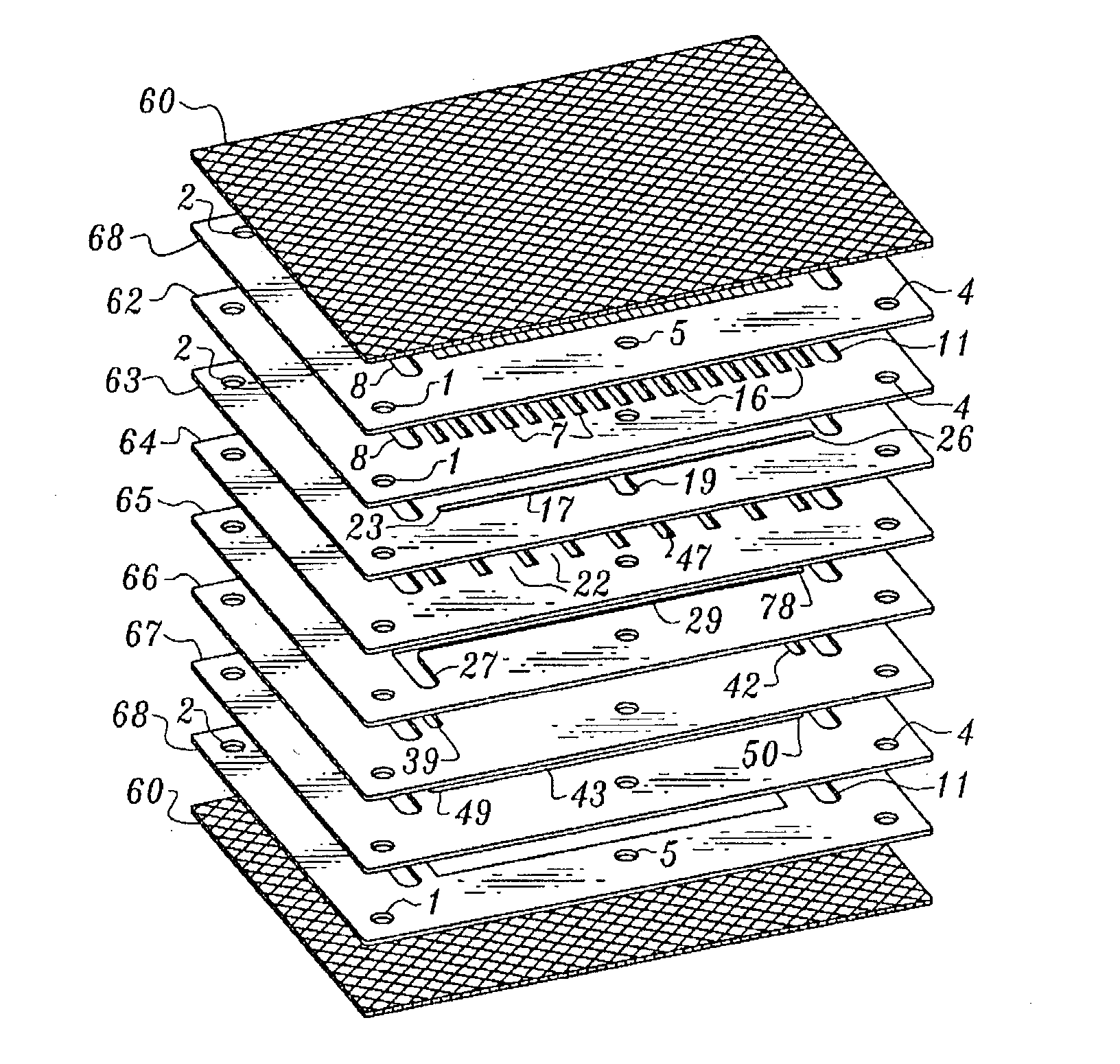

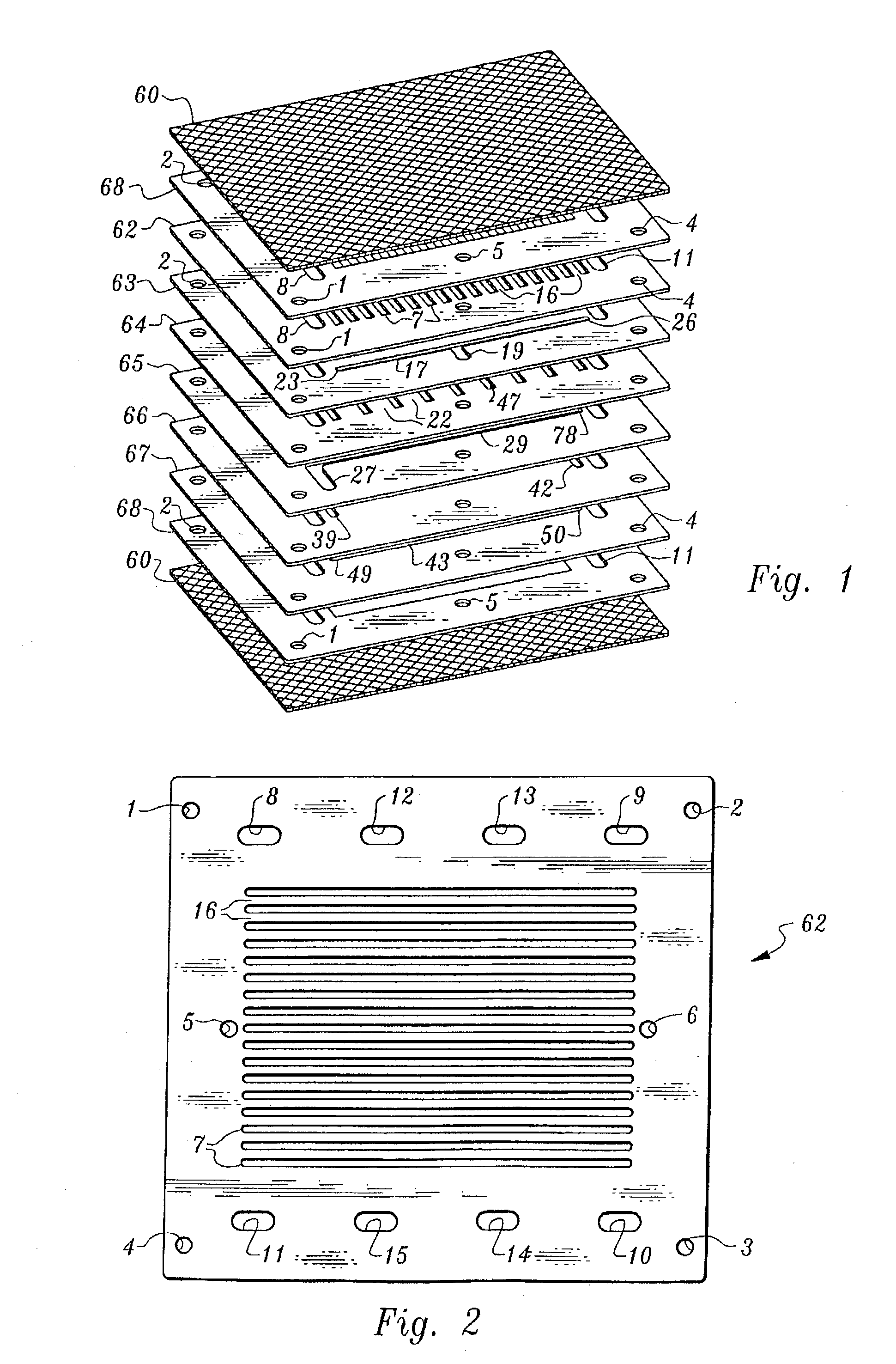

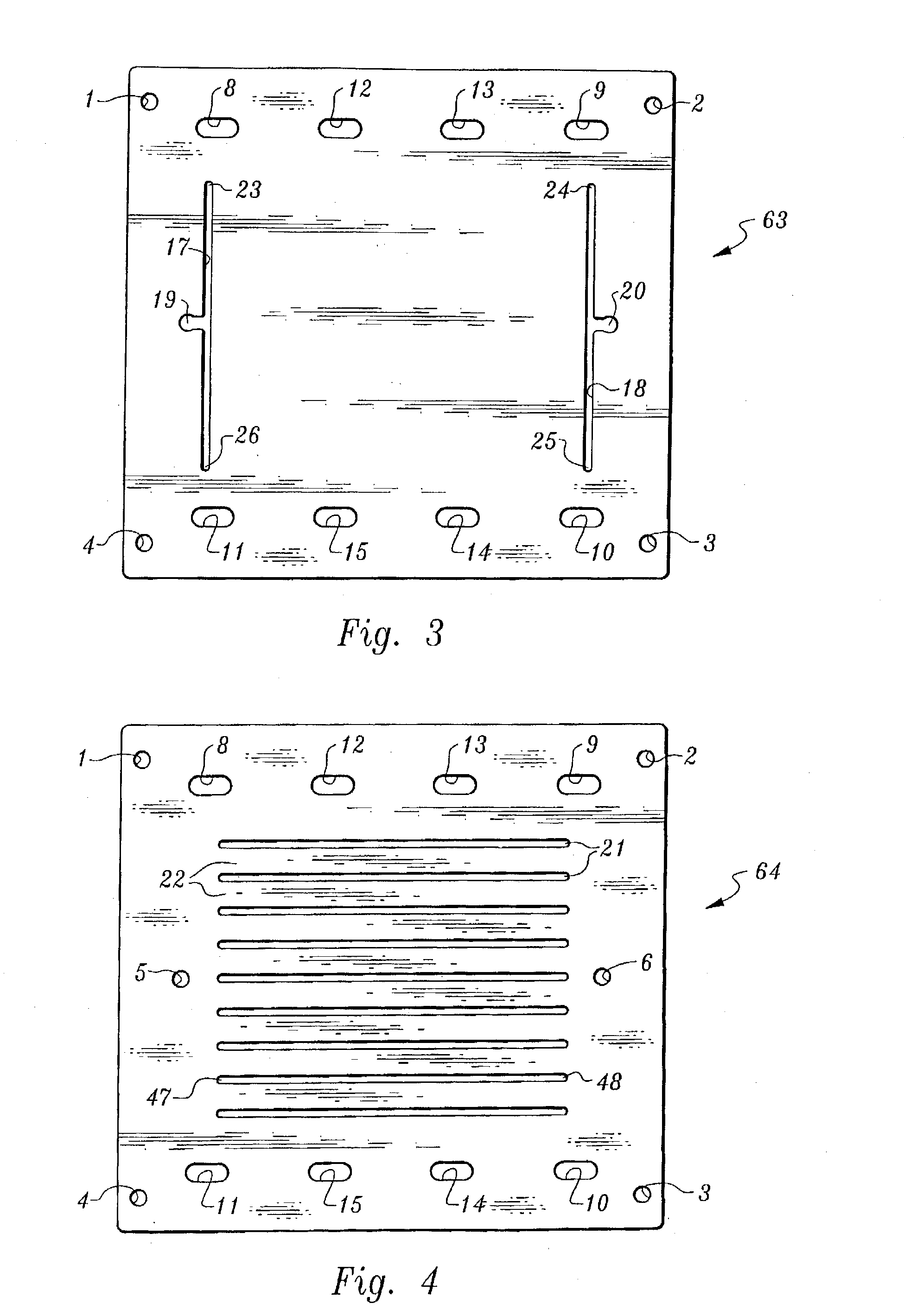

Electrochemical fuel cell comprised of a series of conductive compression gaskets and method of manufacture

InactiveUS20040018412A1Avoid Insufficient SealingEase of mass productionFuel cells groupingFinal product manufactureFluid migrationEngineering

A novel electrochemical fuel cell comprising at least one fuel cell assembly comprising a Membrane Electrode Assembly (MEA) interposed between an anode separator and a cathode separator. The Membrane Electrode Assembly comprises a solid polymer electrolyte or Proton Exchange Membrane (PEM) interposed between an anode and a cathode, each electrode comprising electrocatalyst. The anode separator contains the fuel flow field distribution features necessary to communicate the fuel to said anode. The cathode separator contains the oxidant flow field distribution features necessary to communicate the oxidant to said cathode. In addition, a Heat Transfer (HT) separator may be integrated into said fuel cell assembly. The Heat Transfer separator contains the flow field distribution features necessary to communicate Heat Transfer Fluid (HTF) through a Heat Transfer Zone (HTZ) in said fuel cell assembly in order to control the thermal conditions of the fuel cell assembly and stack. Each of the said anode, cathode and Heat Transfer separators are made up of a respective series of multiple conductive compression gaskets possessing inter-related fluid distribution channel and manifold features that form intra-communicating systems for the distribution of fuel, oxidant and Heat Transfer Fluid throughout the fuel cell separator and stack. Under sufficient mechanical load, the respective series of multiple compression gaskets are consolidated into fuel cell separators that demonstrate sufficient structural integrity to contain the PEMFC fluids under substantial pressure; that demonstrate sufficient electrical and thermal conductivity to enable the operation of a high-performing Proton Exchange Membrane Fuel Cell; that demonstrate sufficient material obduracy to bear the compressive load necessary to seal the fuel cell assembly and fuel cell stack; and that demonstrate sufficient fluid impermeability in order prevent fluid migration through the gasket material. Within the consolidated fuel cell separators, the inter-related channel and manifold features form an intra-communicating system for the distribution of fuel, oxidant and Heat Transfer Fluid throughout the fuel cell assembly and fuel cell stack. In addition, the present invention includes methods of manufacturing said electrochemical fuel cell.

Owner:TETROS INNOVATIONS LLC

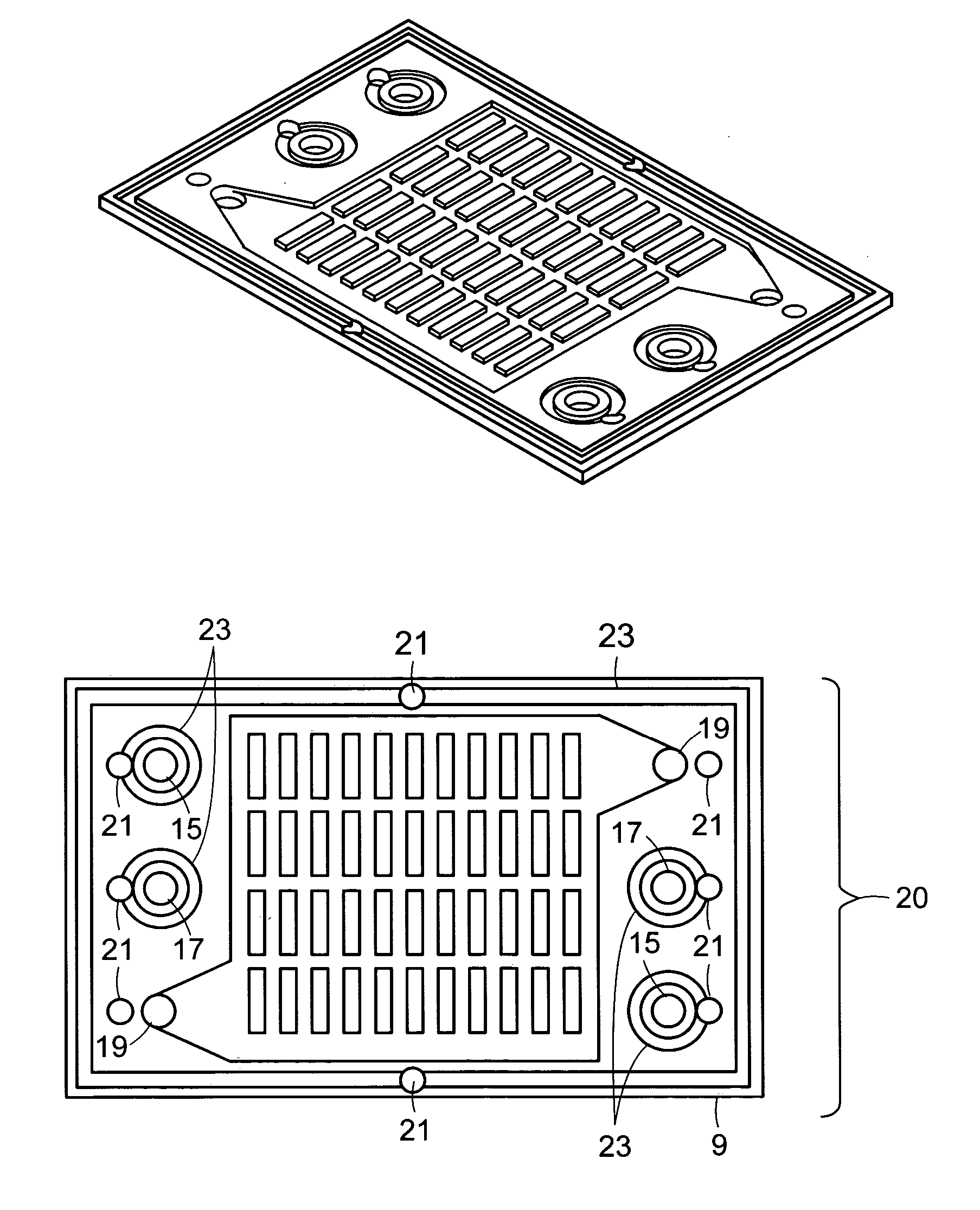

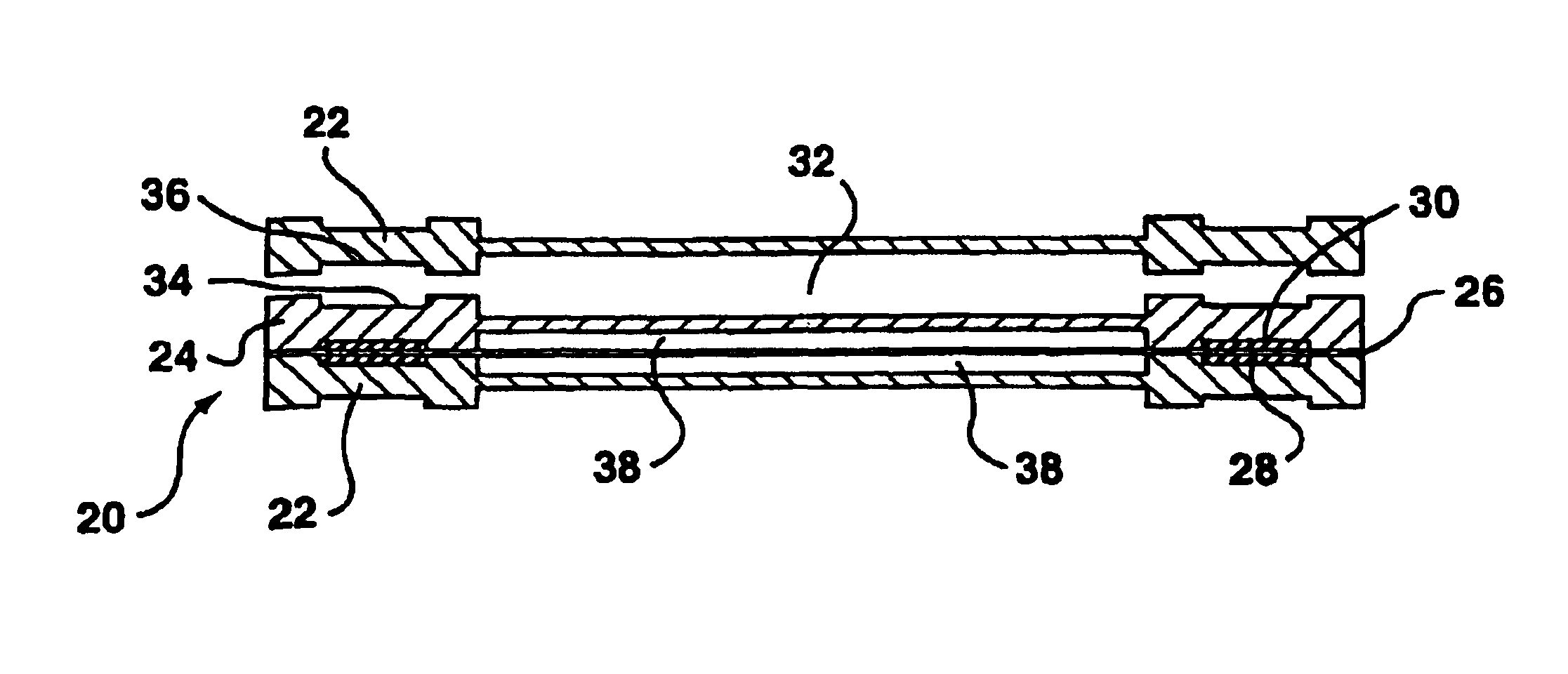

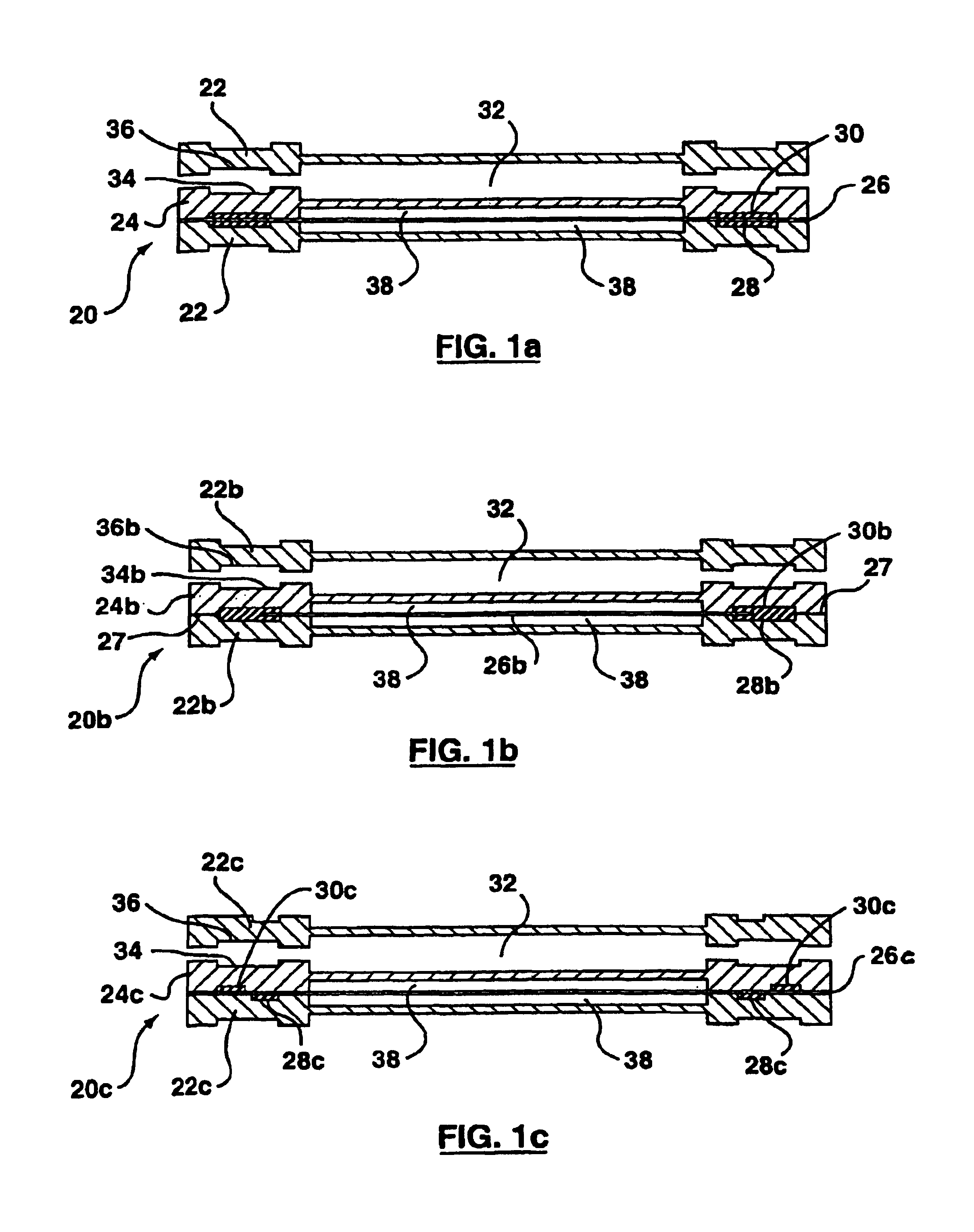

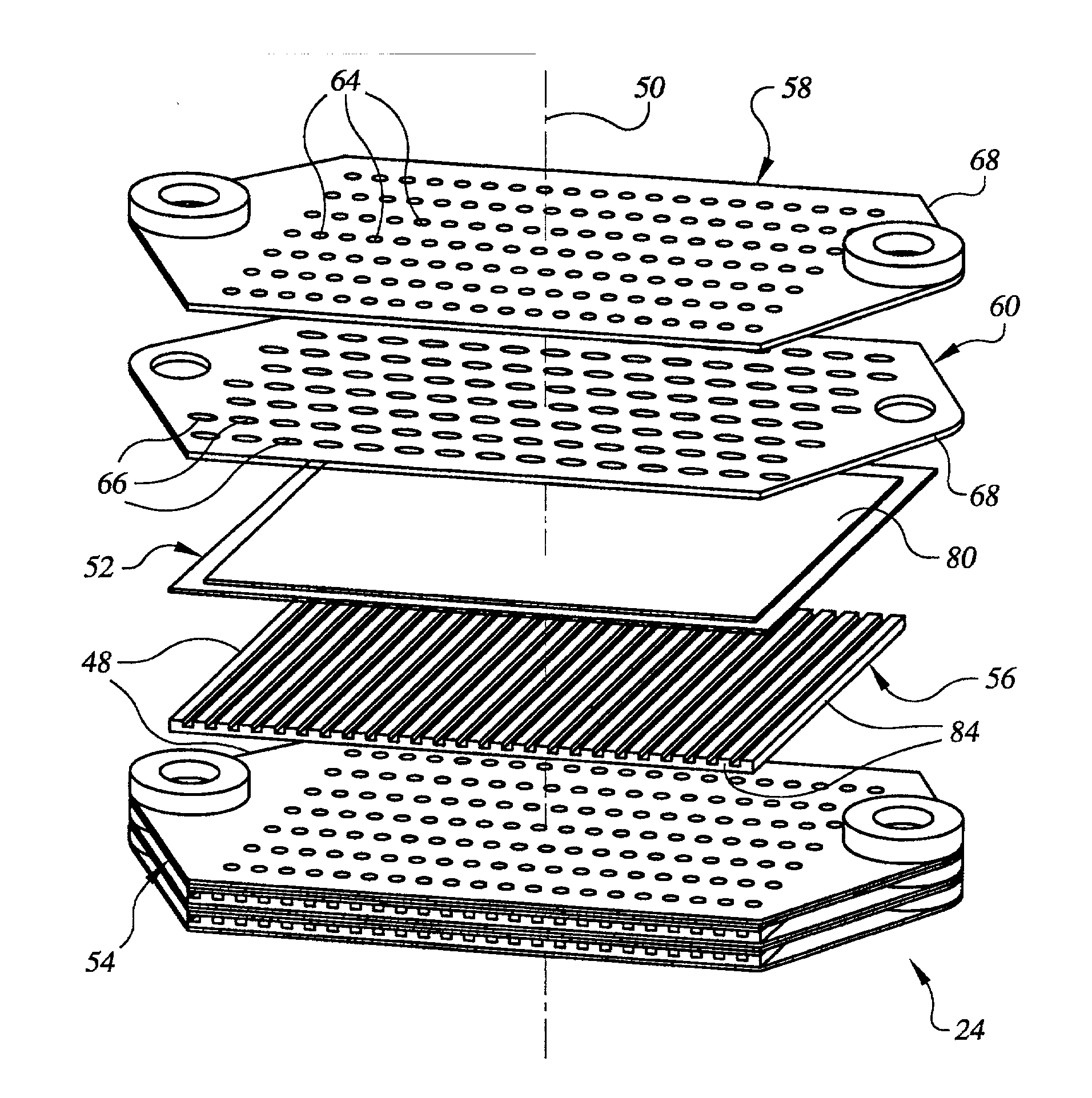

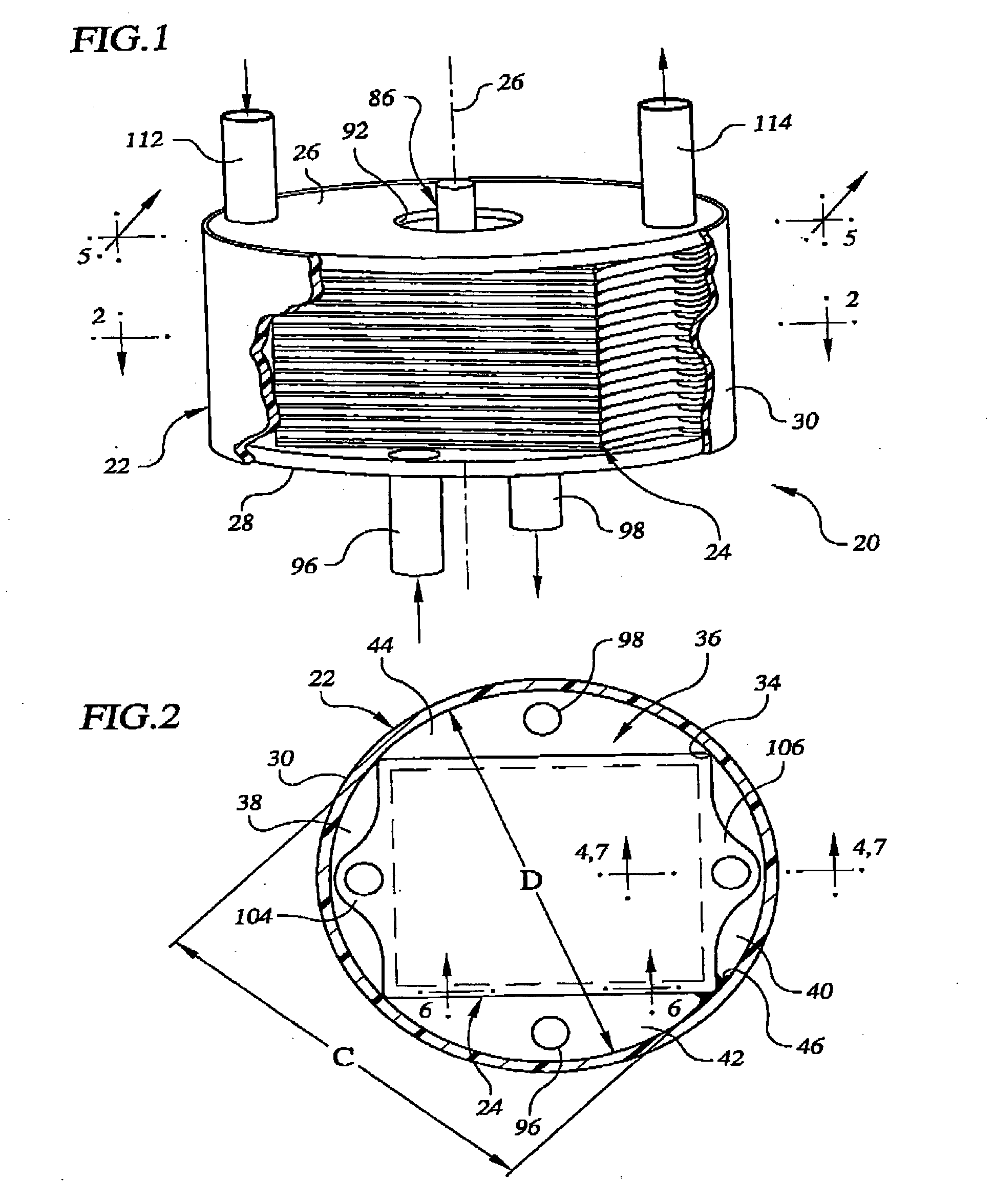

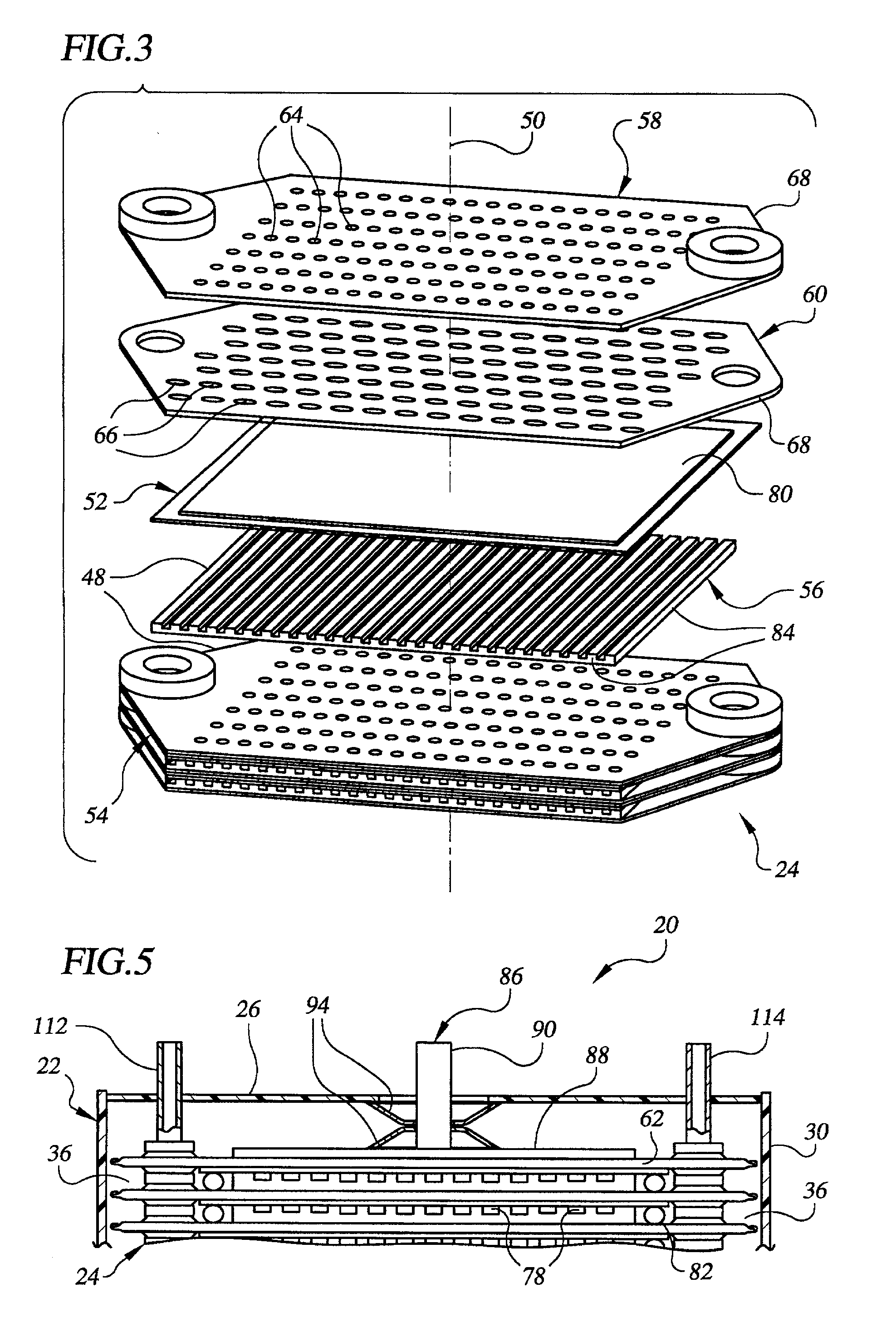

Lightweight direct methanol fuel cell and supporting systems

InactiveUS20070015035A1Fuel cell heat exchangeReactant parameters controlHandling systemCompression member

A lightweight direct methanol fuel cell unit (20) comprising a fuel cell stack (24) enclosed within a housing (22). In one embodiment the fuel cell stack includes a plurality of polymer electrolyte membrane electrode assemblies (52) stacked alternatingly with a plurality of bipolar plates (48). Each bipolar plate includes a cathode flow field (78) defined by a porous cathode flow field structure (56) and an anode flow field (62) defined by an upper plate (58) and a lower plate (60) separated from one another by a plurality of spacers (64). The anode flow fields are manifolded with one another via manifold embossments (118, 120) that are hermetically sealed with one another with a gasket (126). The fuel cell stack and housing are shaped so as to form four manifold regions (36) in the spaces between the fuel cell stack and housing. The fuel cell stack is compressed within the housing by compression members (94) located between the fuel cell stack and housing so as to place the sidewall (30) of the housing into tension. Supporting systems for the fuel cell unit include a fuel handling system (502), an oxidant handling system (600), and a liquid inventory control system (700).

Owner:CREARE INC

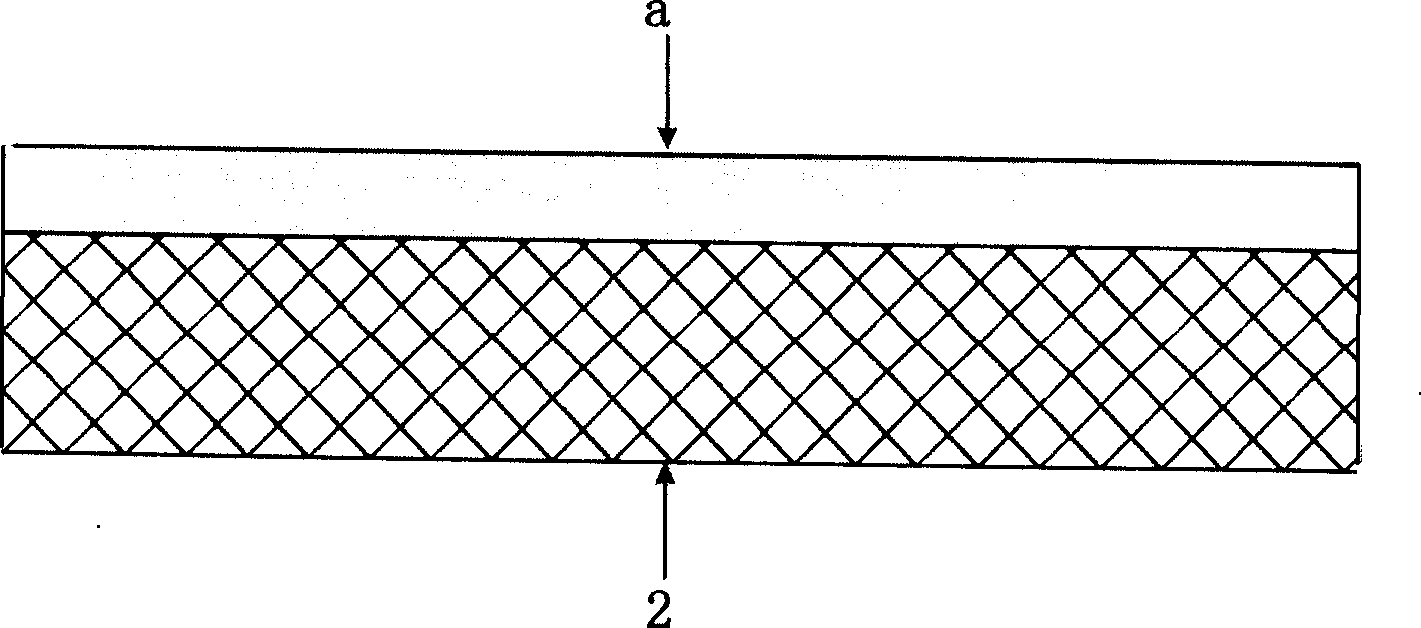

Core component having sealed frame and membrane electrode prepared thereby

ActiveCN101393989AStable supportDimensional stabilitySolid electrolyte fuel cellsSealing/support meansPhysical chemistryCore component

The invention relates to a core component with a sealed frame and a membrane electrode prepared by using the core component. A method for preparing the membrane electrode of the core component with the sealed frame is characterized in that a sealed frame material coated with a sticky glue layer on one surface thereof at the normal temperature is adopted, and a strengthened underlay is attached to the other surface thereof. The sealed frame is overlapped on two surfaces of an ion exchange membrane under the condition that one surface of the ion exchange film is supported. Then, an active area of the ion exchange membrane is coated with a catalyst, and the core component (CCM) with the sealed frame is prepared, and then carries out the hot pressing with a gas diffusion layer with a micropore layer and a gas diffusion layer (GDL), so as to prepare the membrane electrode (MEA).

Owner:武汉理工新能源有限公司

Ceramic coatings for insulating modular fuel cell cassettes in a solid-oxide fuel cell stack

ActiveUS20070134537A1Improve adhesionEngine sealsFuel cells groupingCeramic coatingSurface oxidation

In assembling an SOFC fuel cell stack from a plurality of cassettes, the mounting plate of one cassette is attached to, and insulated from, the separator plate of the next-adjacent cassette by a peripheral dielectric seal consisting of a ceramic coating and a metal braze. Materials suitable for the ceramic coating include yttrium stabilized zirconia (YSZ), zirconia toughened alumina, magnesium silicates such as the mineral forsterite, magnesium aluminates, magnesium aluminosilicates and lanthanum zirconate. The ceramic coating may be applied to the cassette's outer surface in known fashion as by physical vapor deposition, chemical vapor deposition, sputtering, and various methods of plasma spray. An underlayer of alumina may also be used to provide a redundant layer of electrical insulation.

Owner:BATTELLE MEMORIAL INST +1

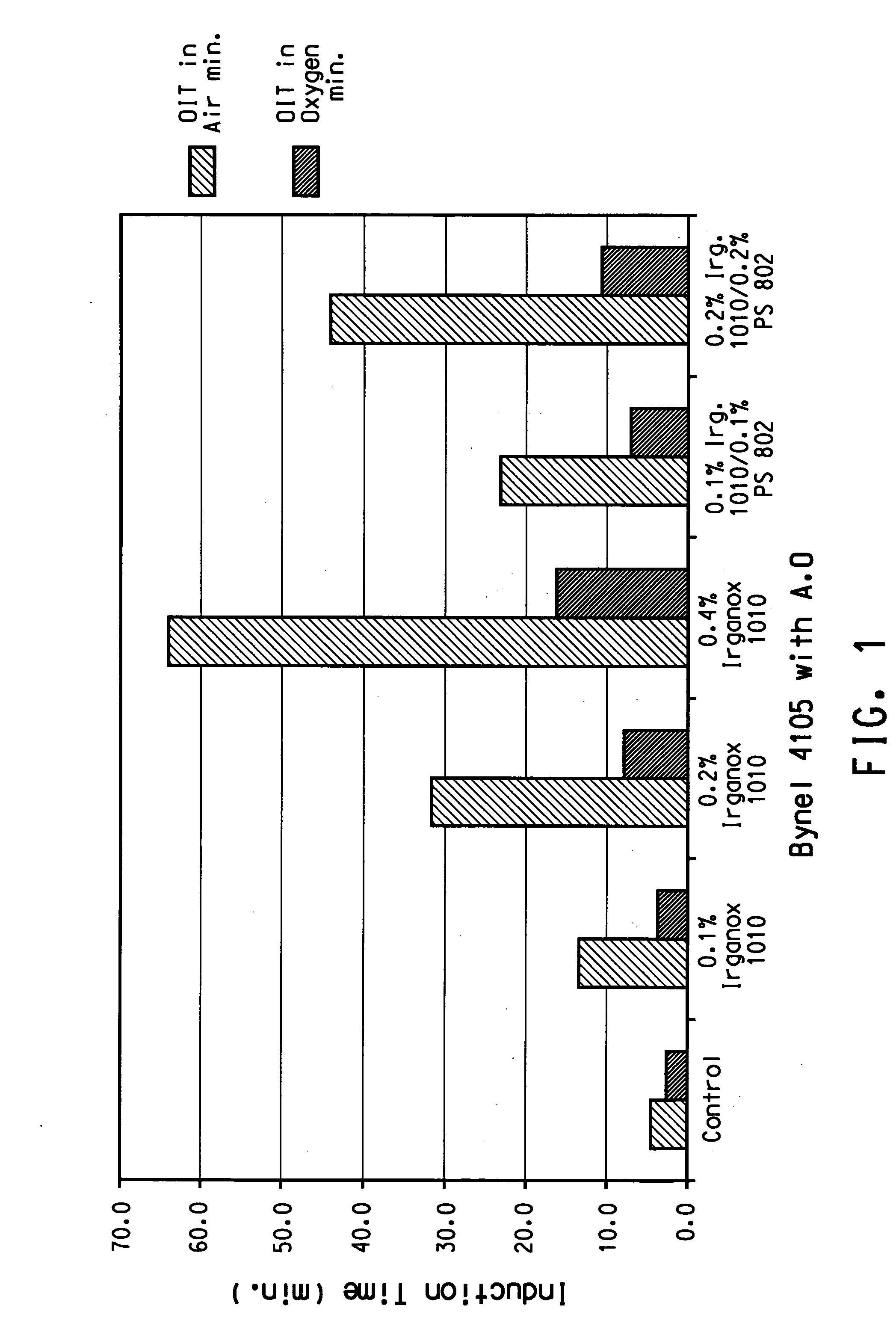

Novel sealant material for electrochemical cell components

Multipurpose sealing adhesive materials for sealing different components of an electrochemical cell are provided. The sealing materials are acid, acid anhydride, acid ester or metallocene modified polyolefins that are capable of providing multiple sealing functionalities in a heat activated sealing process. These sealing polymers are capable of adhering to plain and textured metal, graphite and graphite-filled polymer composite separator plates.

Owner:EI DU PONT DE NEMOURS & CO

Glass-ceramic seals for use in solid oxide fuel cells

The invention is directed to highly crystalline, frit-sintered glass-ceramic materials and seals made using them that are suitable for solid oxide fuel cell applications. The seals have a coefficient of thermal expansion in the range of 70-130×10−7° C., preferably 85-115×10−7° C. The glass-ceramic materials have a crystalline component and a glass component, the crystalline component being >50% of the glass-ceramic and the glass component being <50%. In one preferred embodiment the crystalline component is >75%. Regarding the crystalline component only, >50% of the crystals in the crystalline component of the glass-ceramic has a structure selected from the structural groups represented by walstromite, cyclowollastonite, μ-(Ca,Sr)SiO3, kalsilite, kaliophilite and wollastonite (the primary crystalline phase) and the remaining <50% of the crystalline component is at least one secondary crystalline phase. Generally, the glass-ceramics of the invention are useful as metal-to-metal, metal-to-ceramic and ceramic-to-ceramic sealing agents.

Owner:CORNING INC

Integrated fuel cell assembly and method of making

An integrated fuel cell assembly is described. The integrated fuel cell assembly includes a polymer membrane; an anode electrode and a cathode electrode on opposite sides of the polymer membrane; a pair of gas diffusion media on opposite sides of the polymer membrane, the gas diffusion media comprising a microporous layer and a gas diffusion layer, the anode electrode and the cathode electrode positioned between the polymer membrane and the pair of gas diffusion media; a subgasket positioned around a perimeter of one of the gas diffusion media, the subgasket defining an active area inside the perimeter, the subgasket having a layer of thermally activated adhesive thereon; and a bipolar plate sealed to the subgasket by the layer of thermally activated adhesive. Methods of making the integrated fuel cell assembly and assembling fuel cell stacks are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com