Patents

Literature

86 results about "Zirconia Toughened Alumina" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

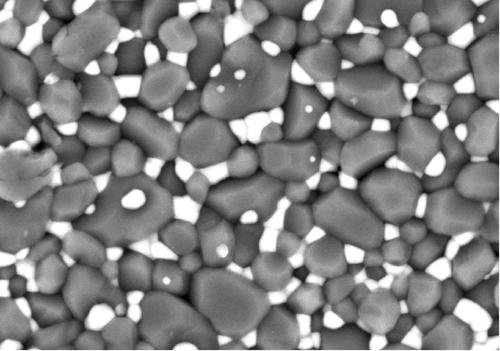

Zirconia toughened alumina is a ceramic material comprising alumina and zirconia. It is a composite ceramic material with zirconia grains in the alumina matrix. It is also known in industry as ZTA. Zirconia aluminia (or zirconia toughened alumina), a combination of zirconium oxide and aluminum oxide, is part of a class of composite ceramics called AZ composites. Noted for their mechanical properties, AZ composites are commonly used in structural applications, as cutting tools, and in many medical applications. Additionally, AZ composites feature high strength, fracture toughness, elasticity, hardness, and wear resistance. Zirconia toughened alumina (ZTA), in particular, offers several key properties.

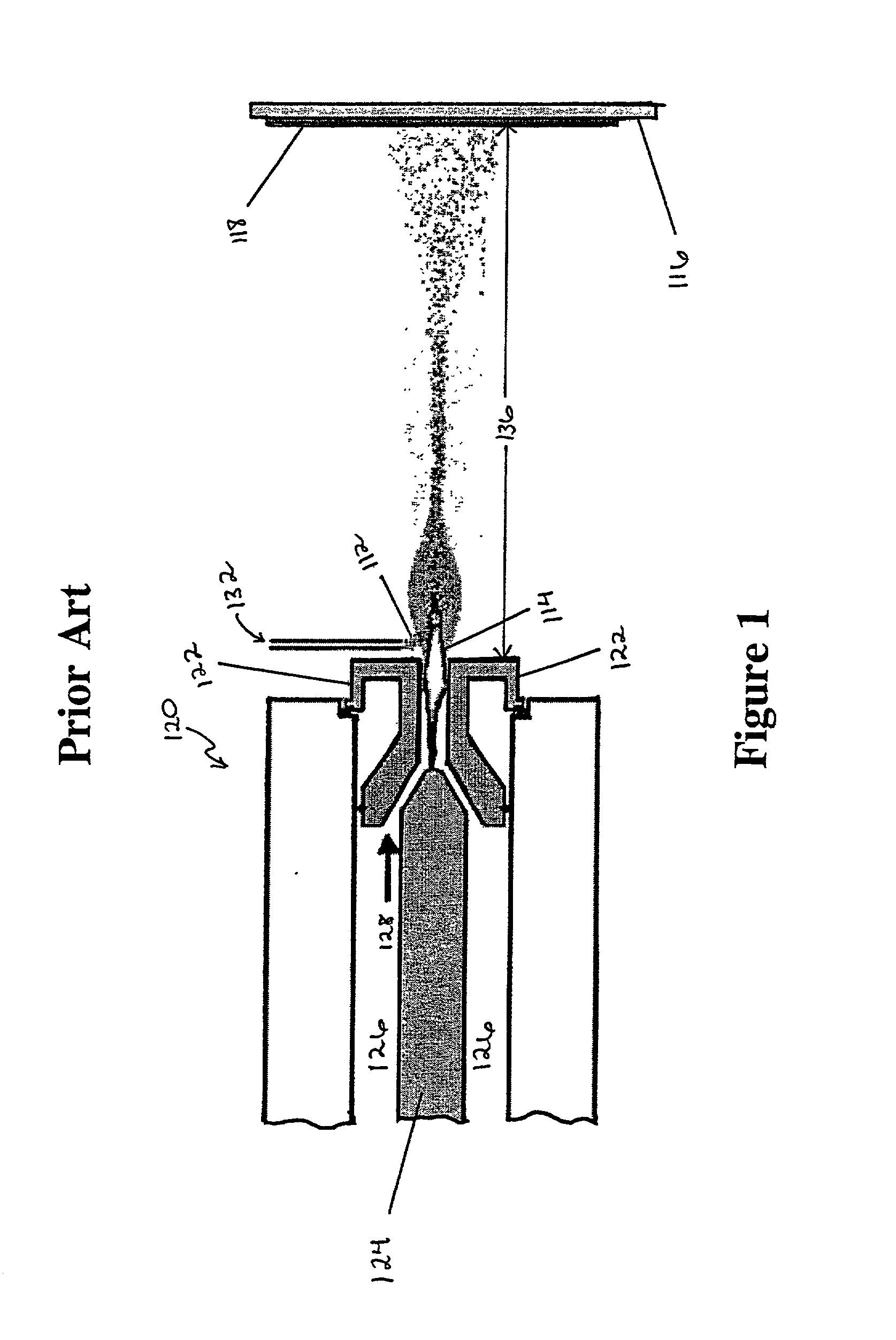

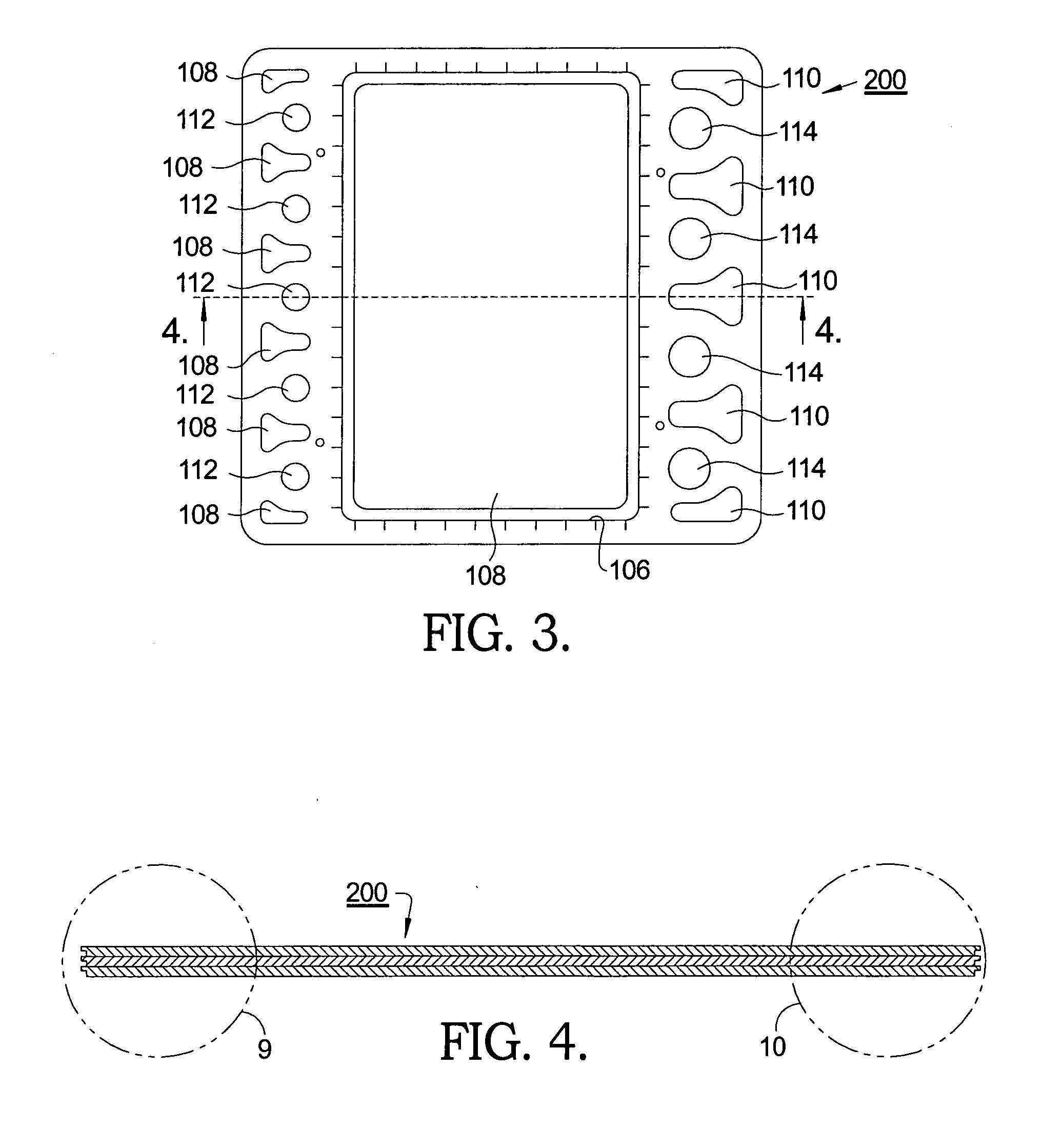

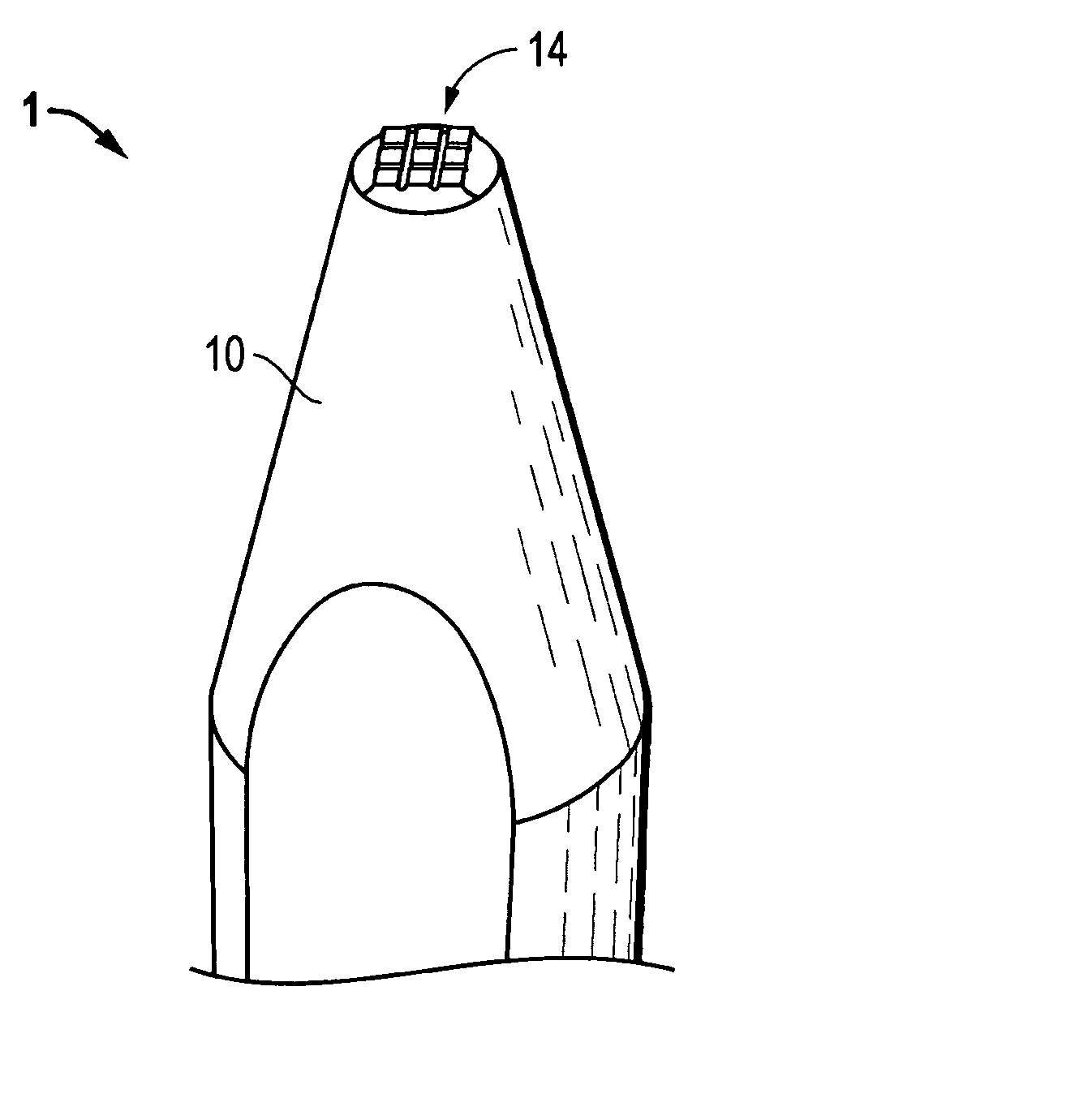

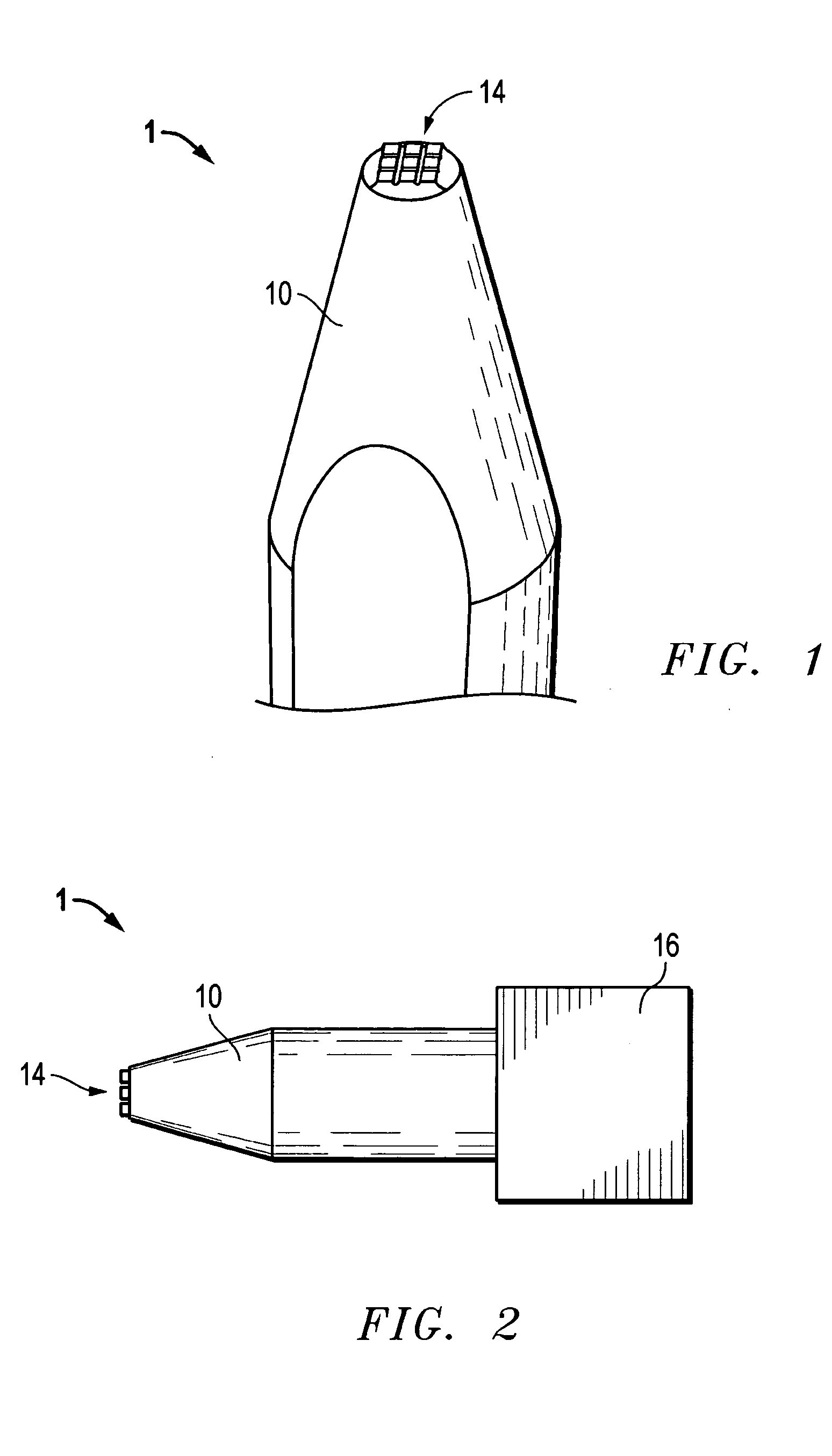

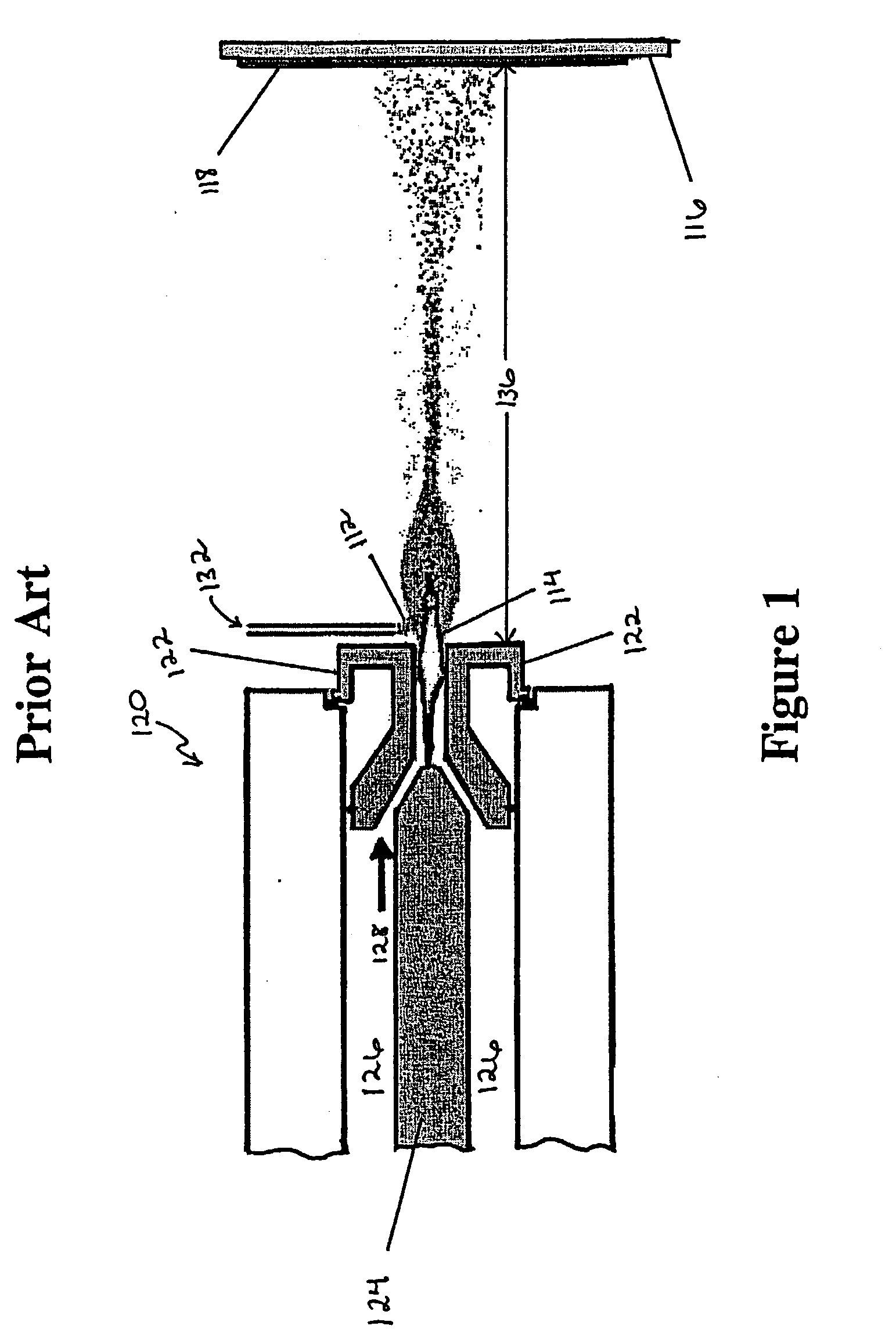

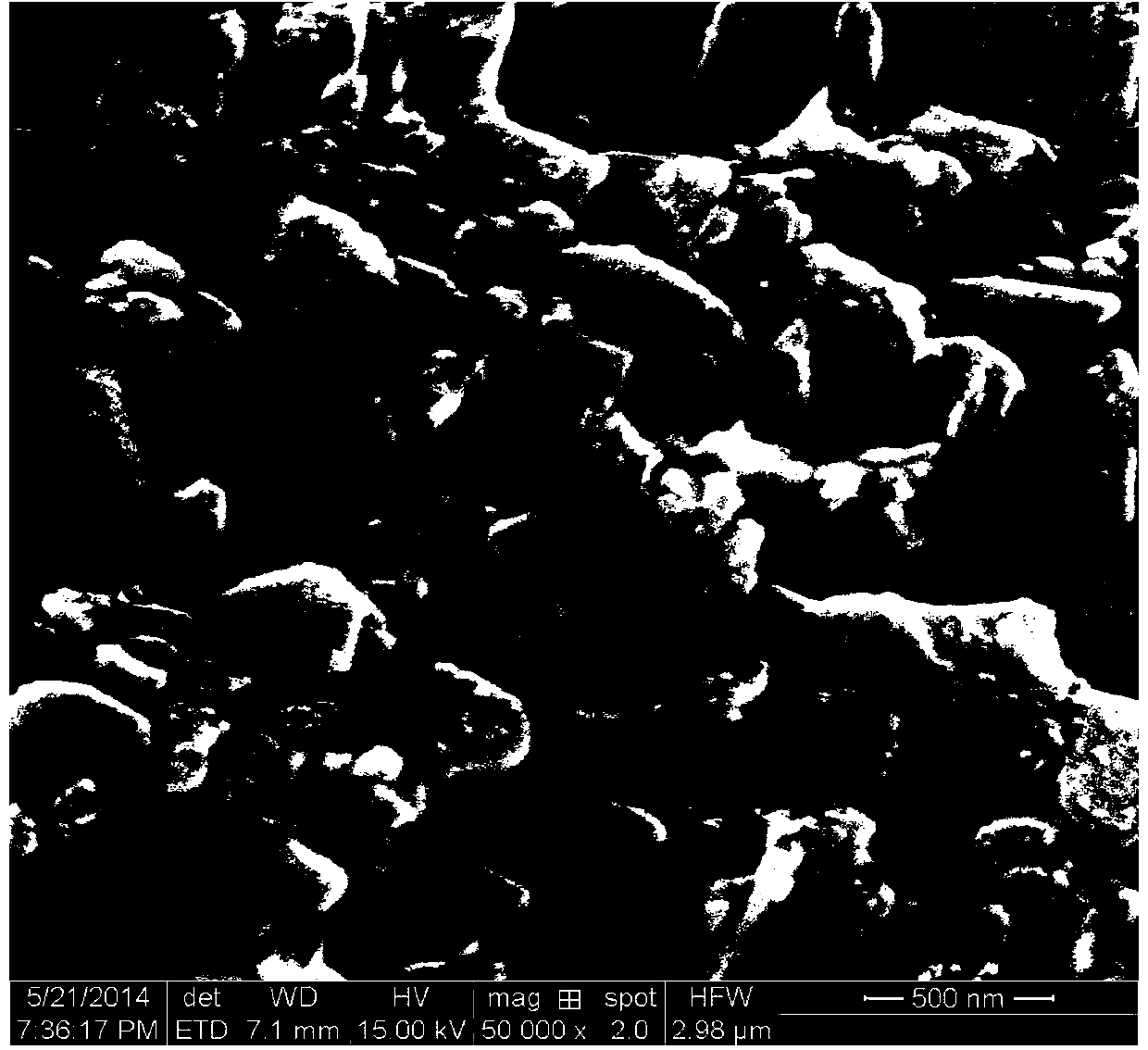

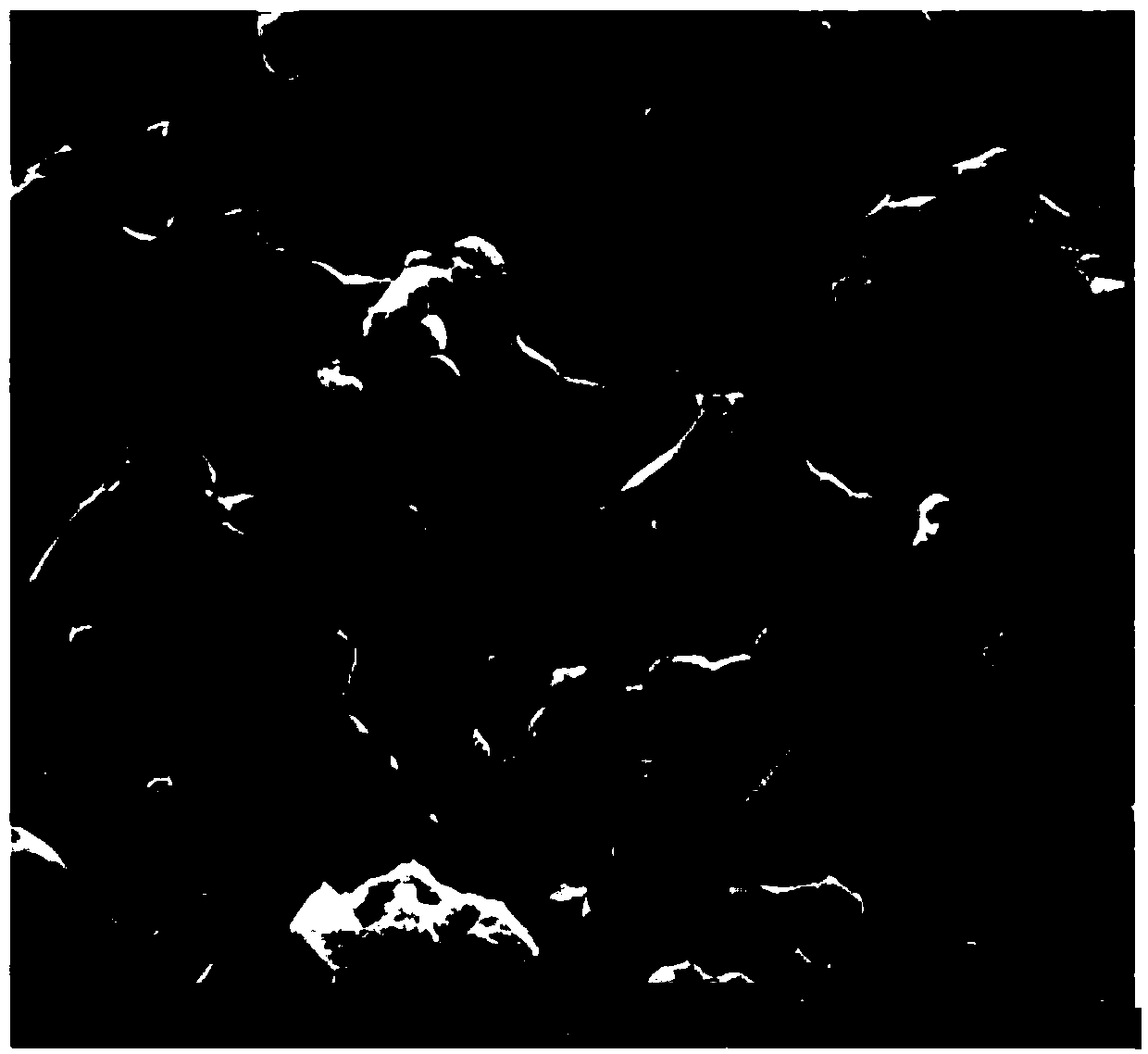

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

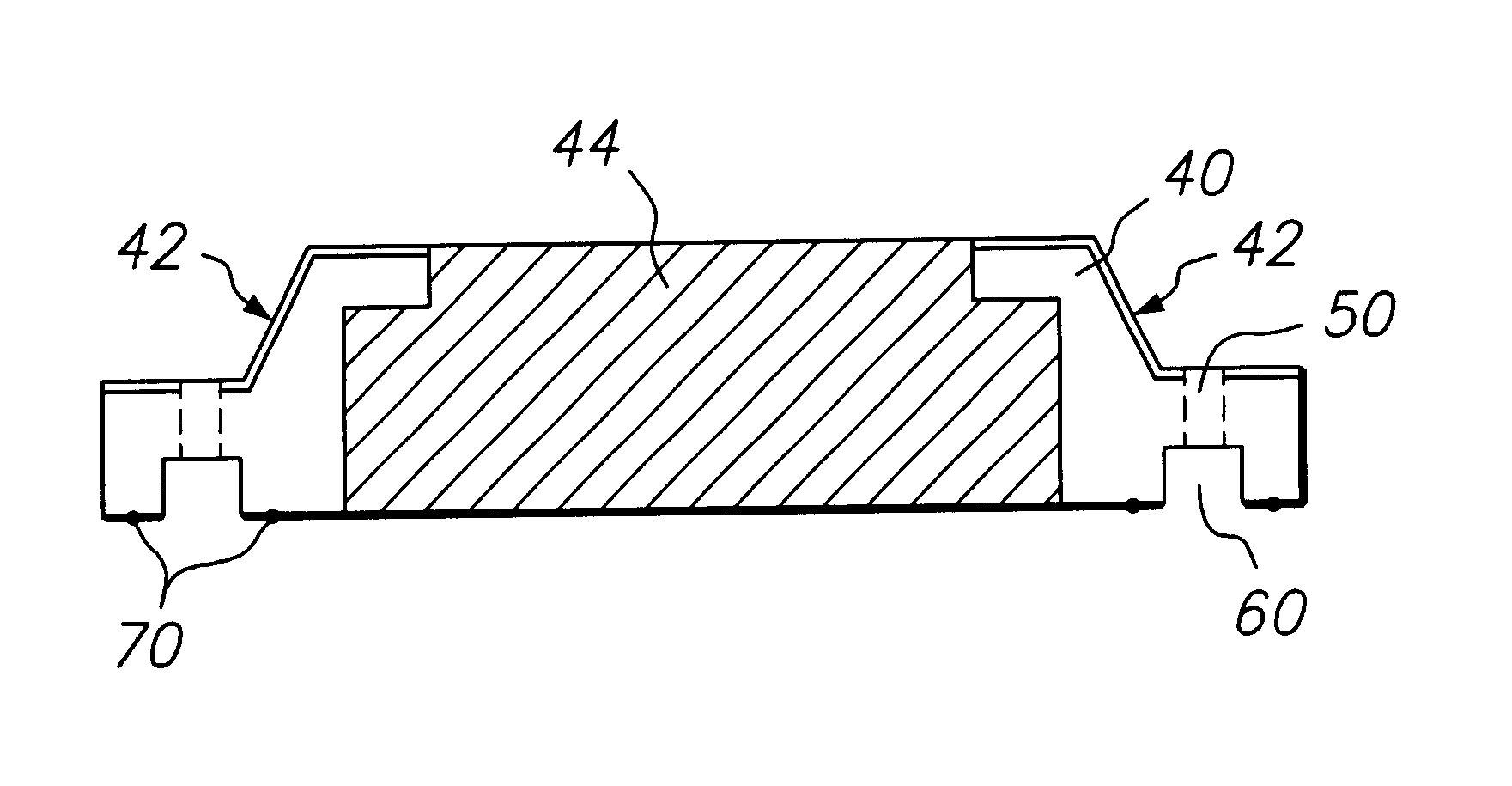

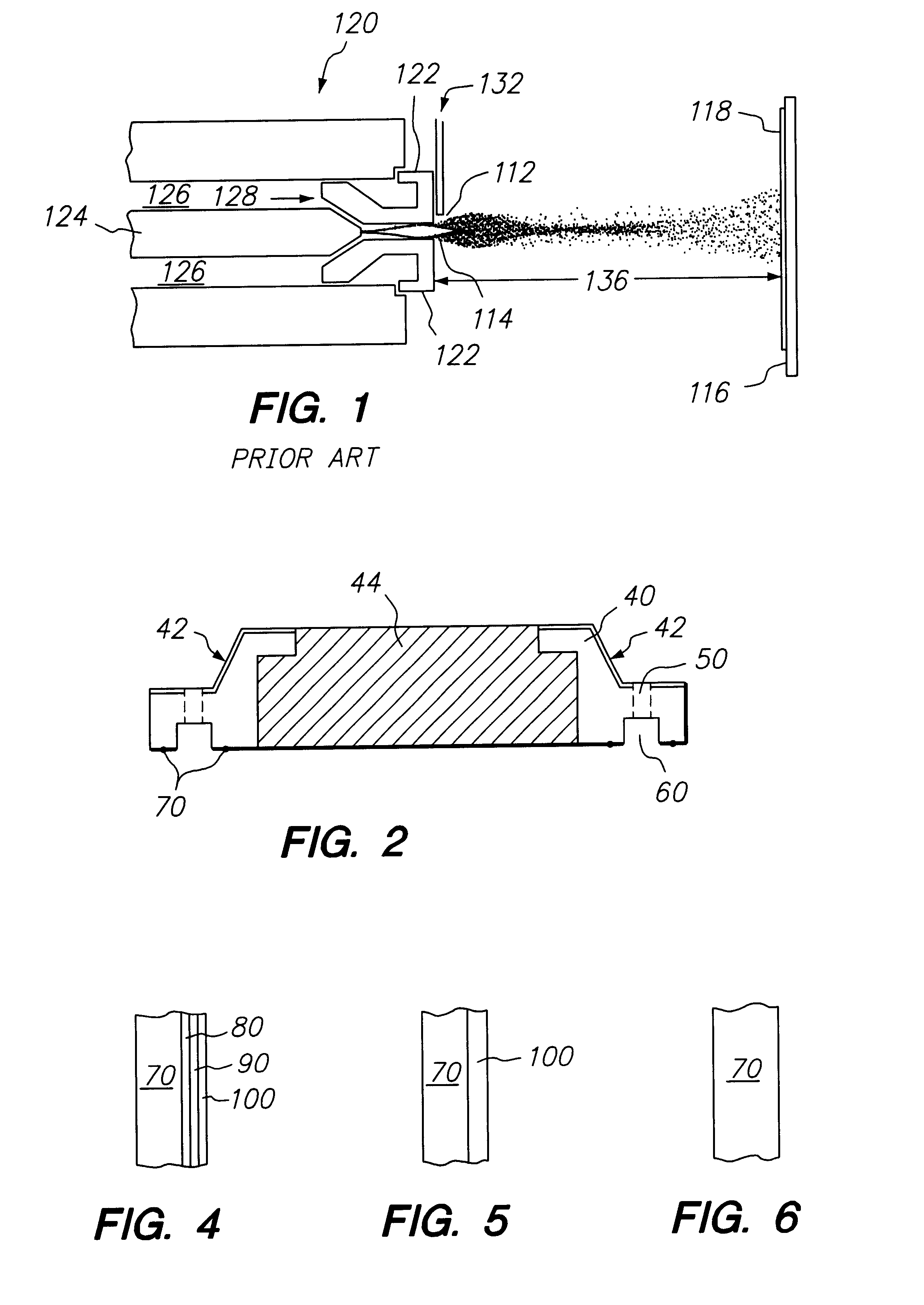

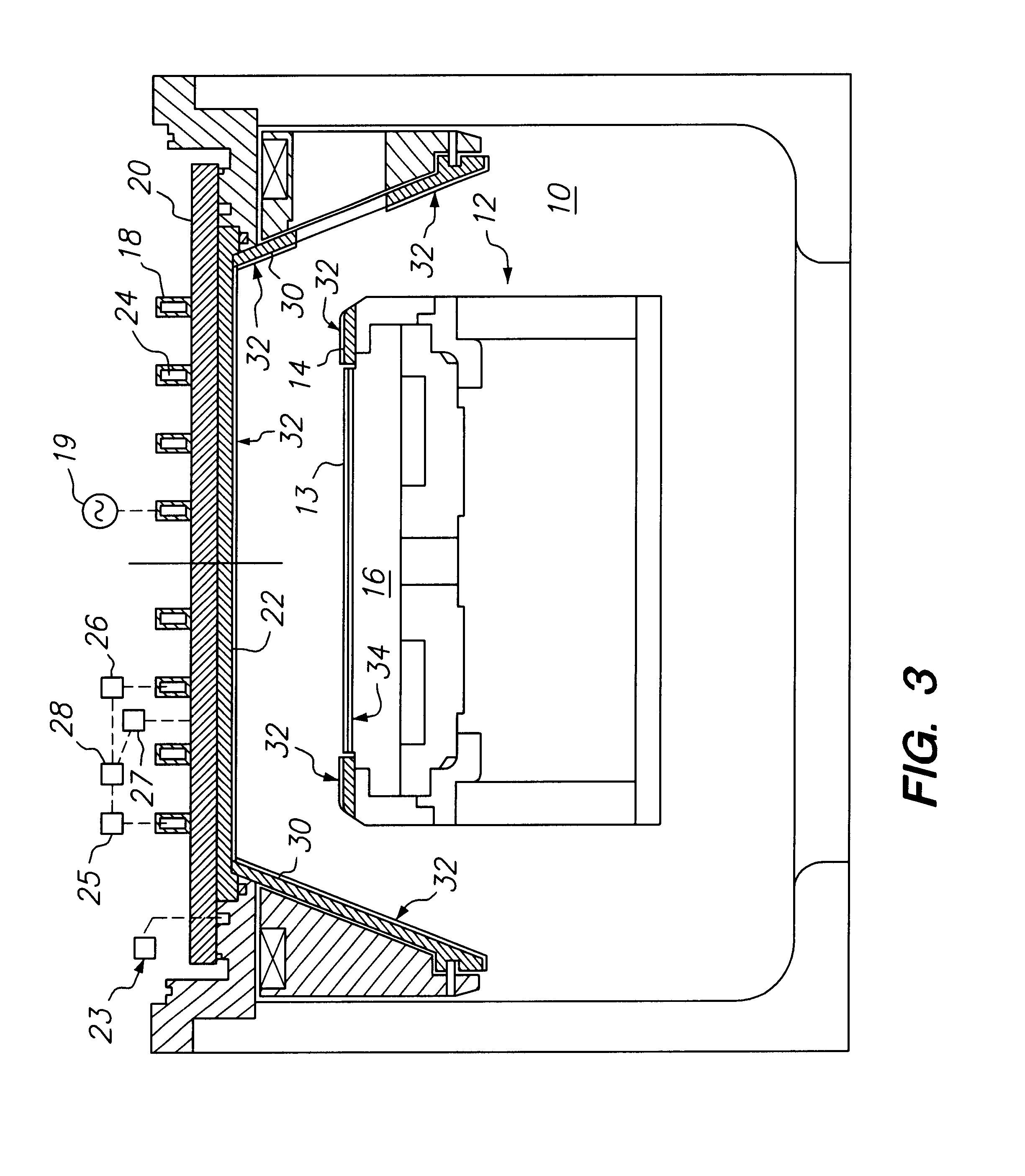

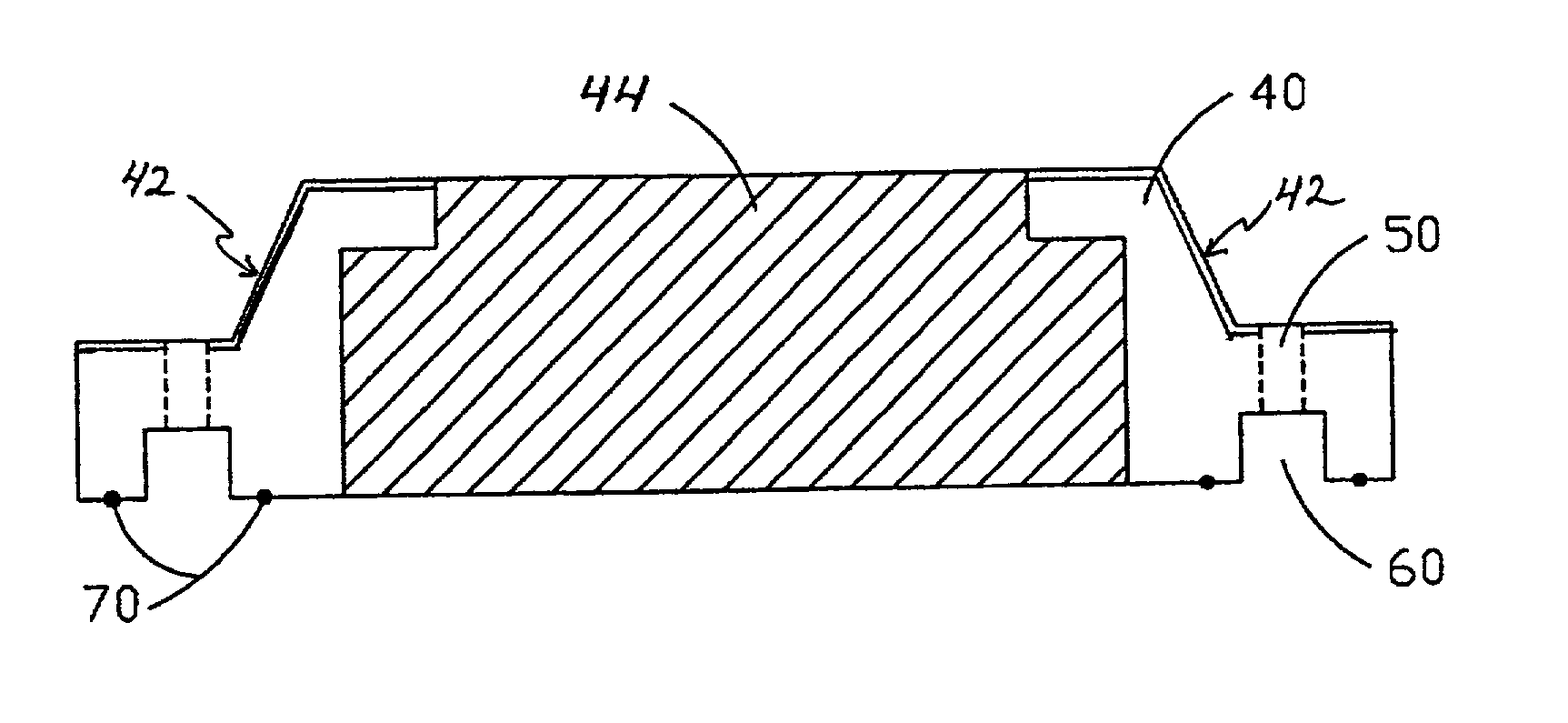

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

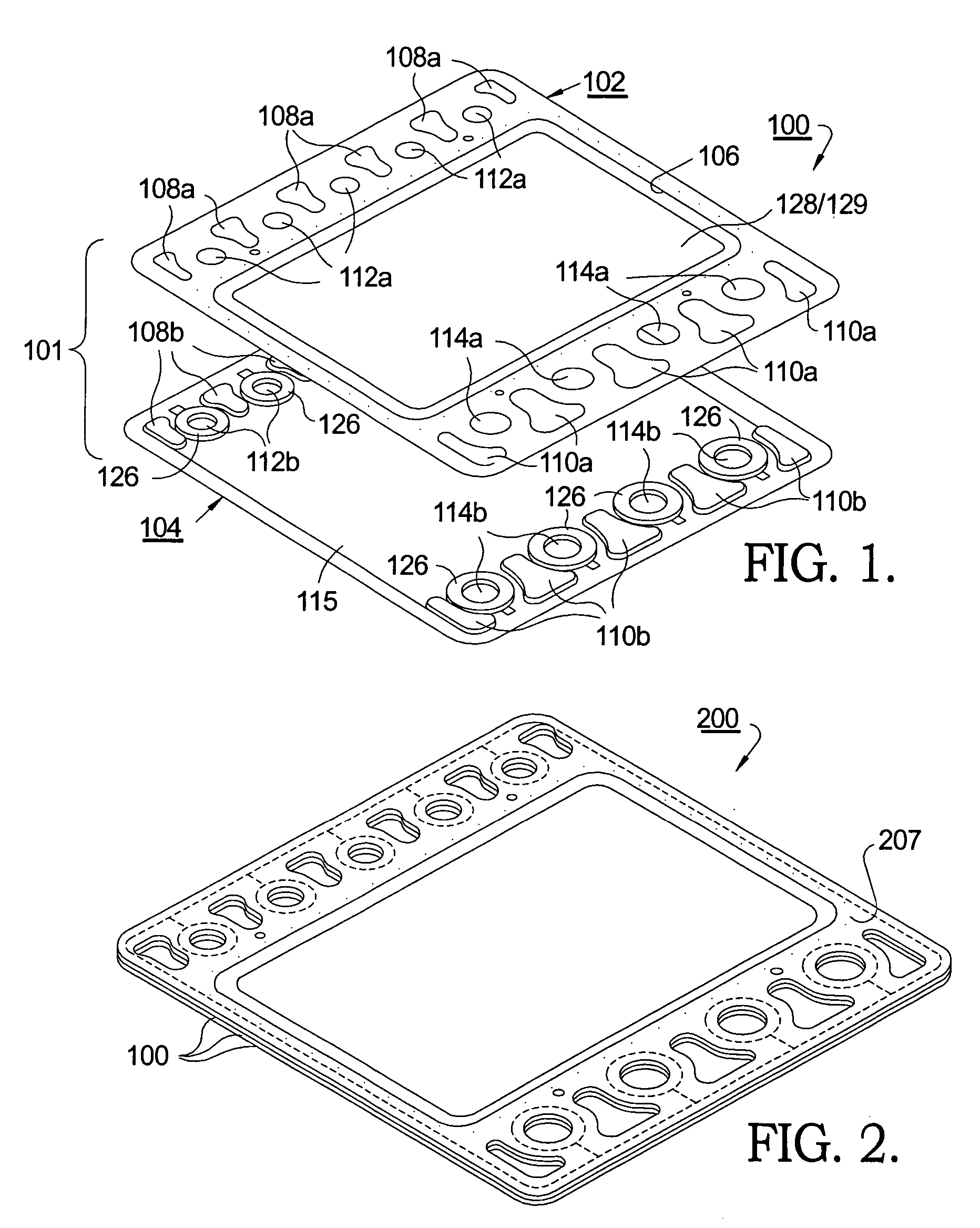

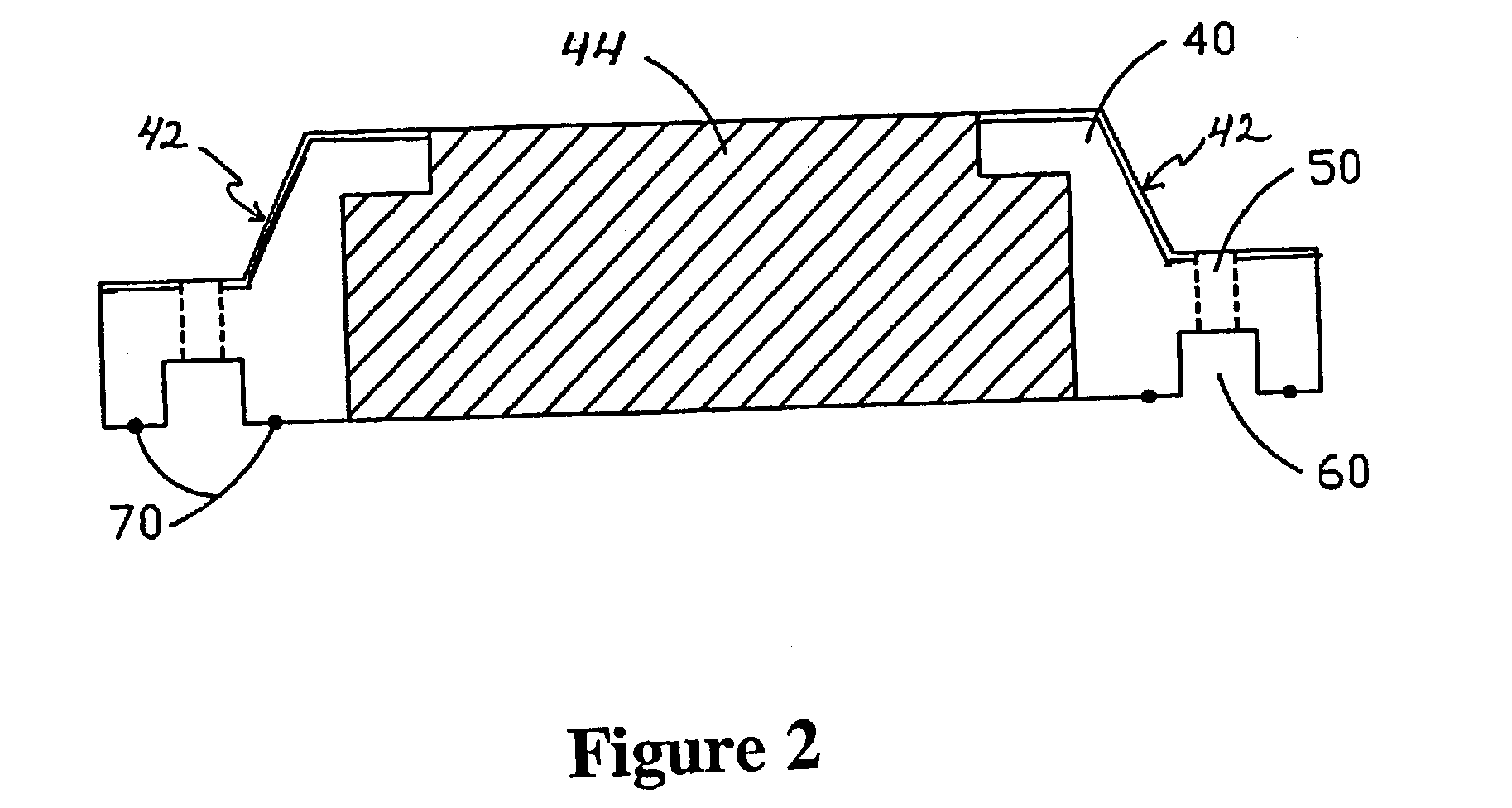

Ceramic coatings for insulating modular fuel cell cassettes in a solid-oxide fuel cell stack

ActiveUS20070134537A1Improve adhesionEngine sealsFuel cells groupingCeramic coatingSurface oxidation

In assembling an SOFC fuel cell stack from a plurality of cassettes, the mounting plate of one cassette is attached to, and insulated from, the separator plate of the next-adjacent cassette by a peripheral dielectric seal consisting of a ceramic coating and a metal braze. Materials suitable for the ceramic coating include yttrium stabilized zirconia (YSZ), zirconia toughened alumina, magnesium silicates such as the mineral forsterite, magnesium aluminates, magnesium aluminosilicates and lanthanum zirconate. The ceramic coating may be applied to the cassette's outer surface in known fashion as by physical vapor deposition, chemical vapor deposition, sputtering, and various methods of plasma spray. An underlayer of alumina may also be used to provide a redundant layer of electrical insulation.

Owner:BATTELLE MEMORIAL INST +1

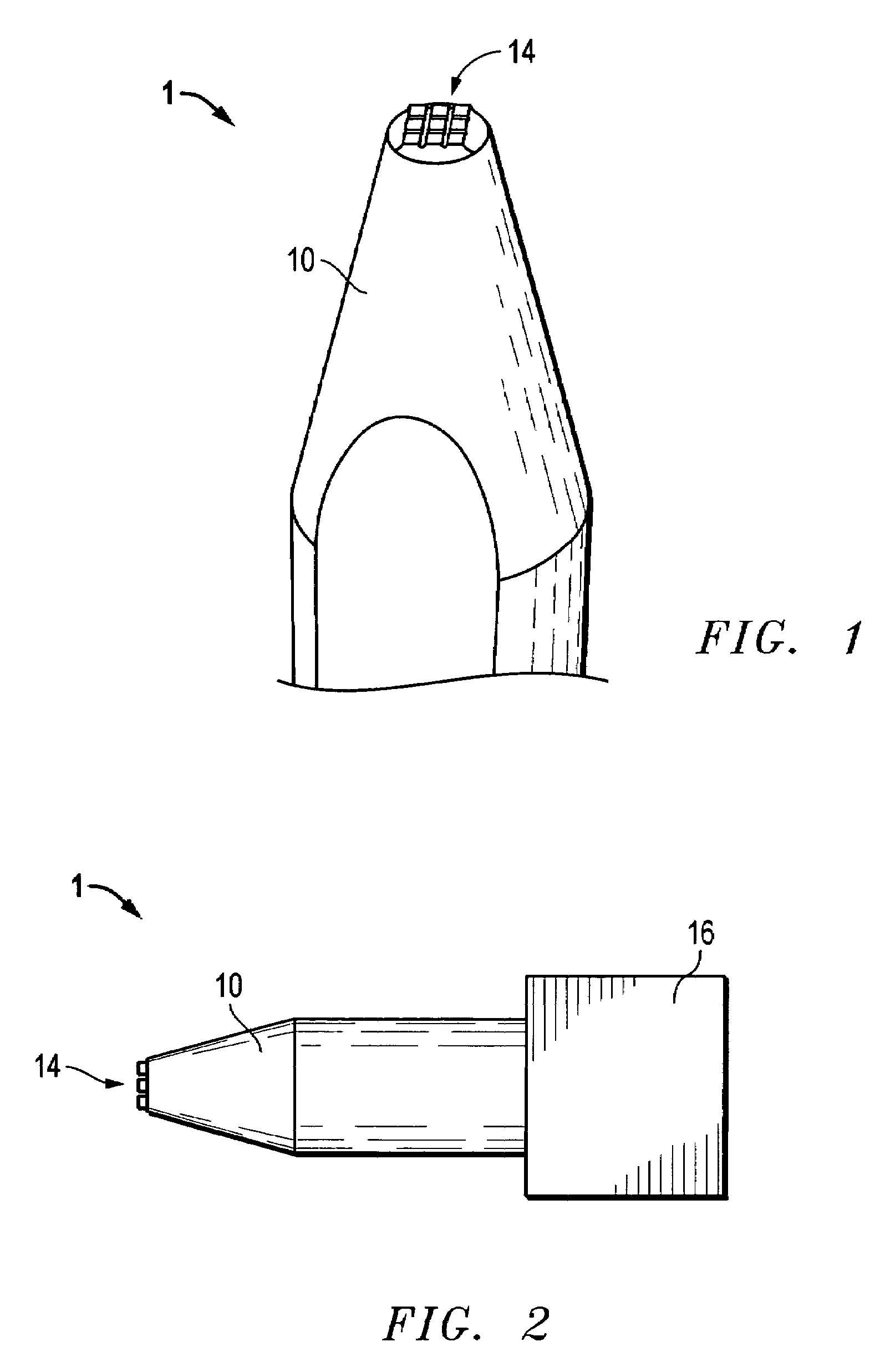

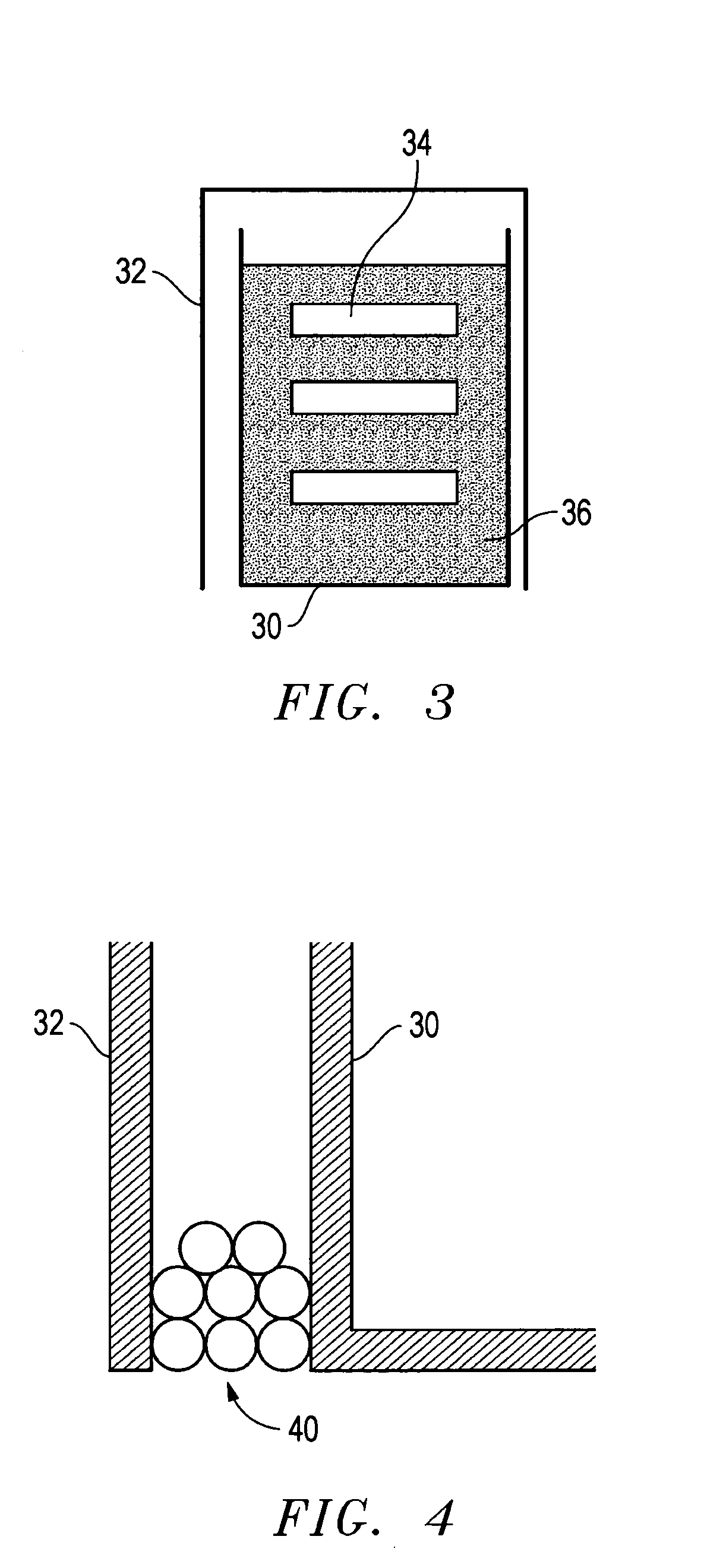

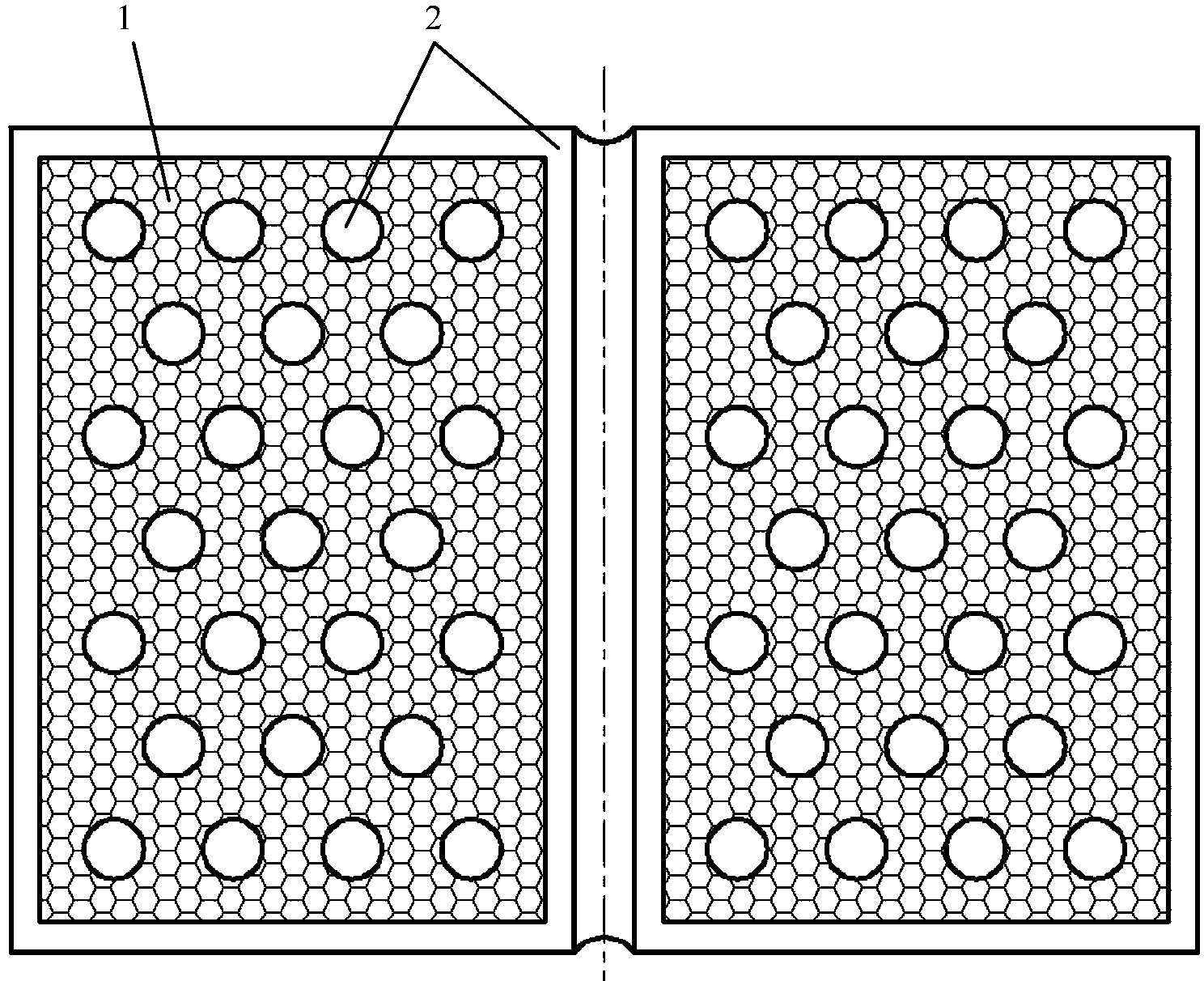

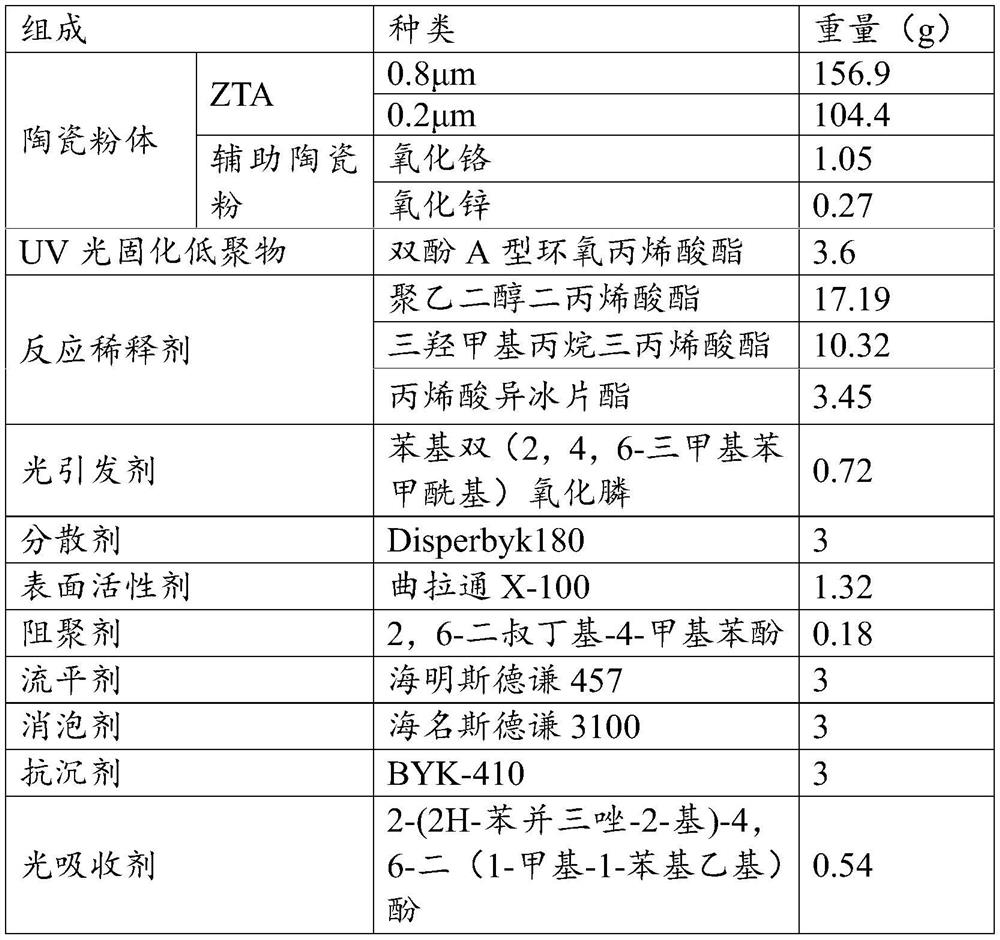

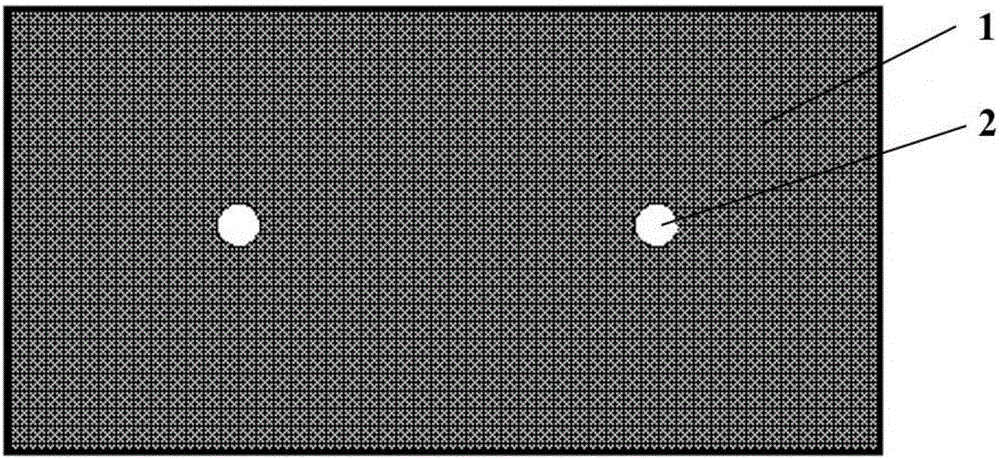

Preparation method for active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and grinding disk

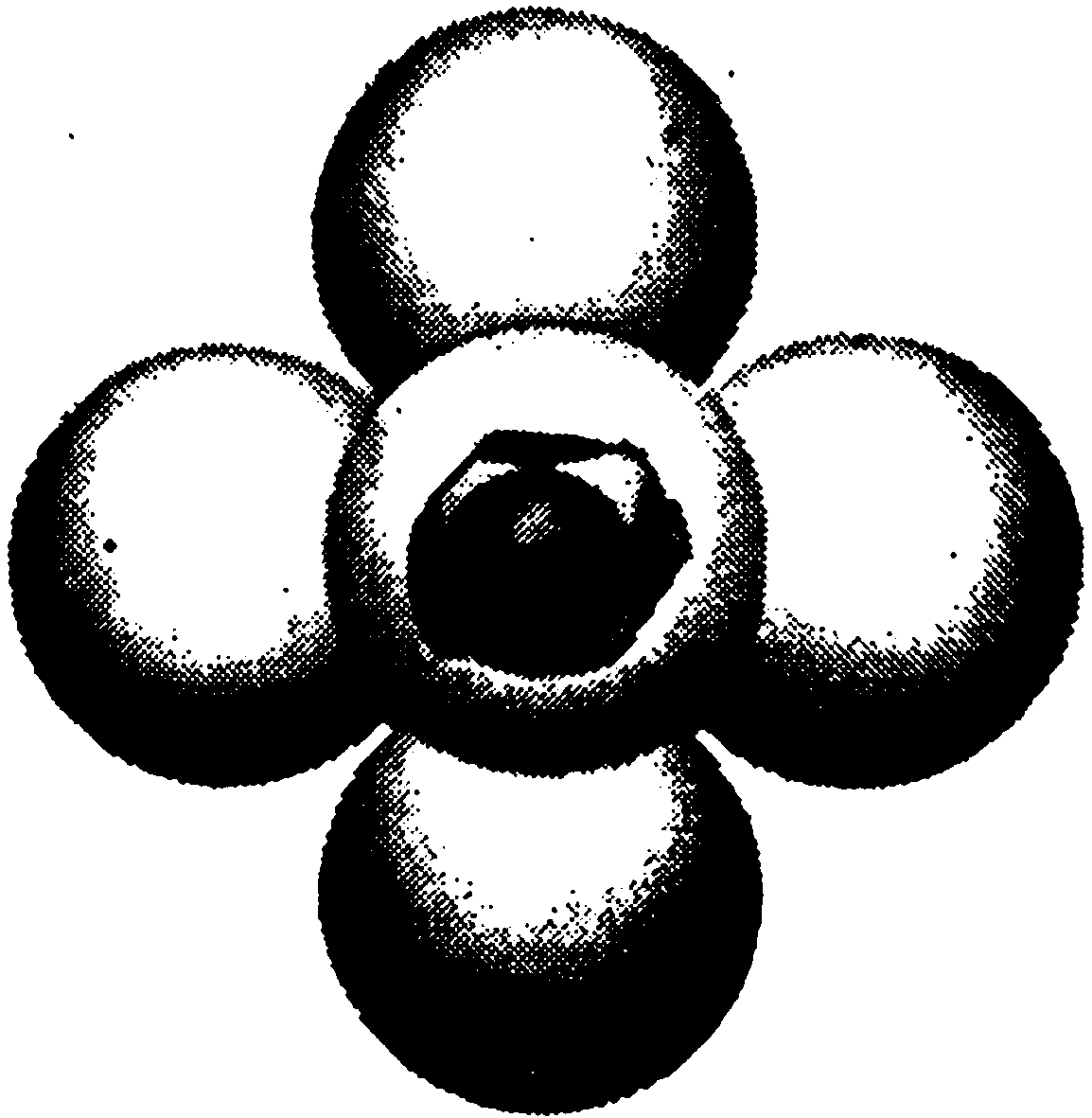

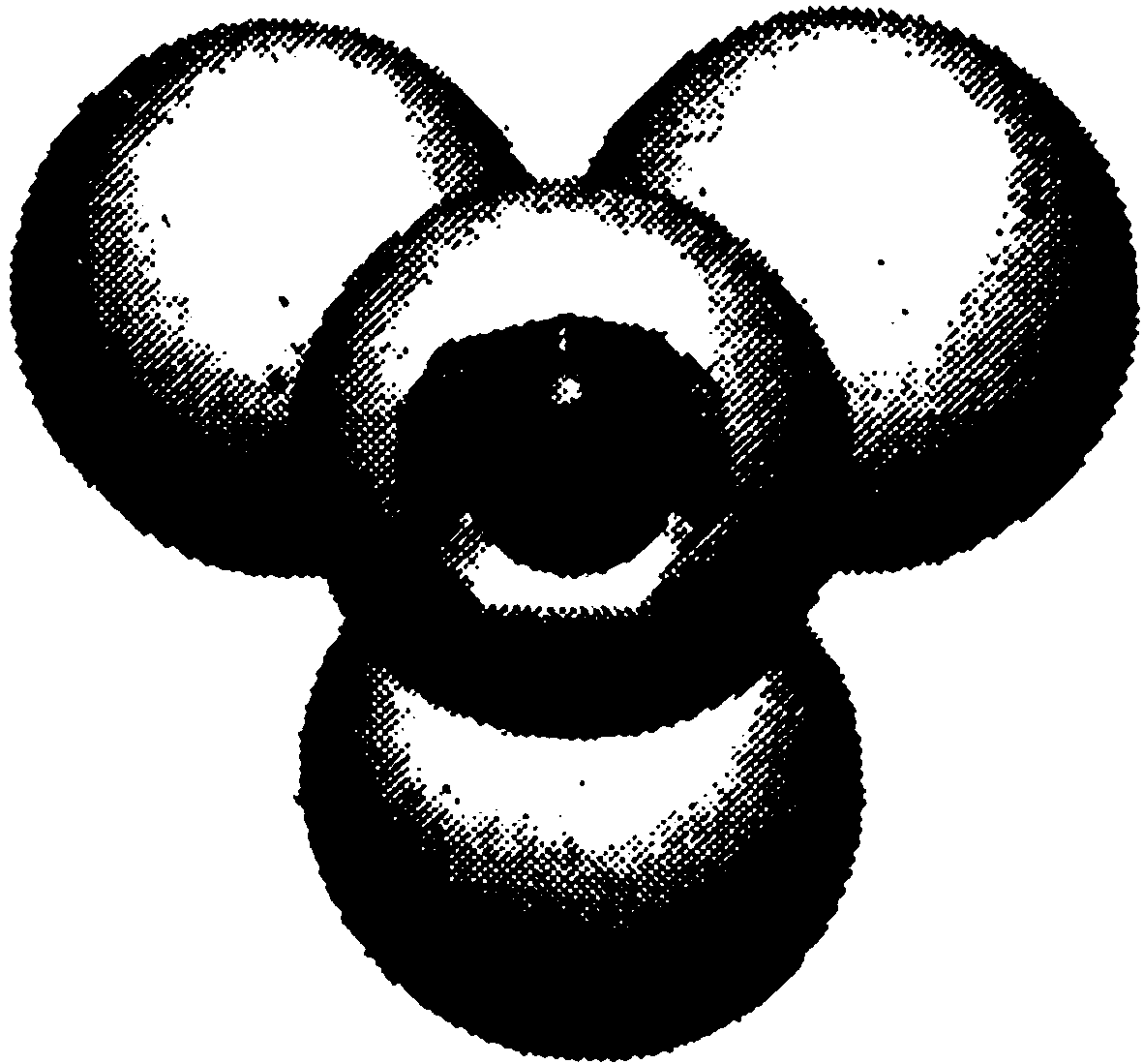

The invention discloses a preparation method for an active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and a grinding disk. The preparation method comprises the following steps: 1) uniformly mixing multiple active element powder, and then adding a defined amount of binding agents and fully mixing with ZTA particulates so as to uniformly cover the active element powder on the surfaces of the particulates, filling into a graphite mould, pressing, and then drying; 2) sintering, thereby obtaining a porous precast block; 3) fixing the precast block on a specific casting position and pouring molten metal, cooling and de-molding, thereby obtaining the compound grinding roller or grinding disk. According to the preparation method, the shape and size of the ZTA particulate precast block can be controlled through the mould and the technique is simple and has higher production efficiency, yield and practicability. Besides, the active element introduced into the interface can increase the wettability and binding strength of the interface and a compound layer structure with interactive distributed enhanced phase and base can ensure the longer service life of the grinding roller and the grinding disk under high stress effect.

Owner:XI AN JIAOTONG UNIV +1

Zirconia toughened alumina ESD safe ceramic composition, component, and methods for making same

ActiveUS7247588B2Conductive materialSemiconductor/solid-state device manufacturingMetallurgySecondary component

Owner:COORSTEK INC

Zirconia toughened alumina ESD safe ceramic composition, component, and methods for making same

ActiveUS20060175584A1Conductive materialSemiconductor/solid-state device manufacturingAll ceramicZirconia Toughened Alumina

ESD safe ceramic component is provided which includes a sintered composition which is formed of a base material and a resistivity modifier. The base material includes a primary component and a secondary component, the primary component including Al2O3 and the secondary component including tetragonal-ZrO2.

Owner:COORSTEK INC

Zirconia toughened ceramic components and coatings in semiconductor processing equipment and method of manufacture thereof

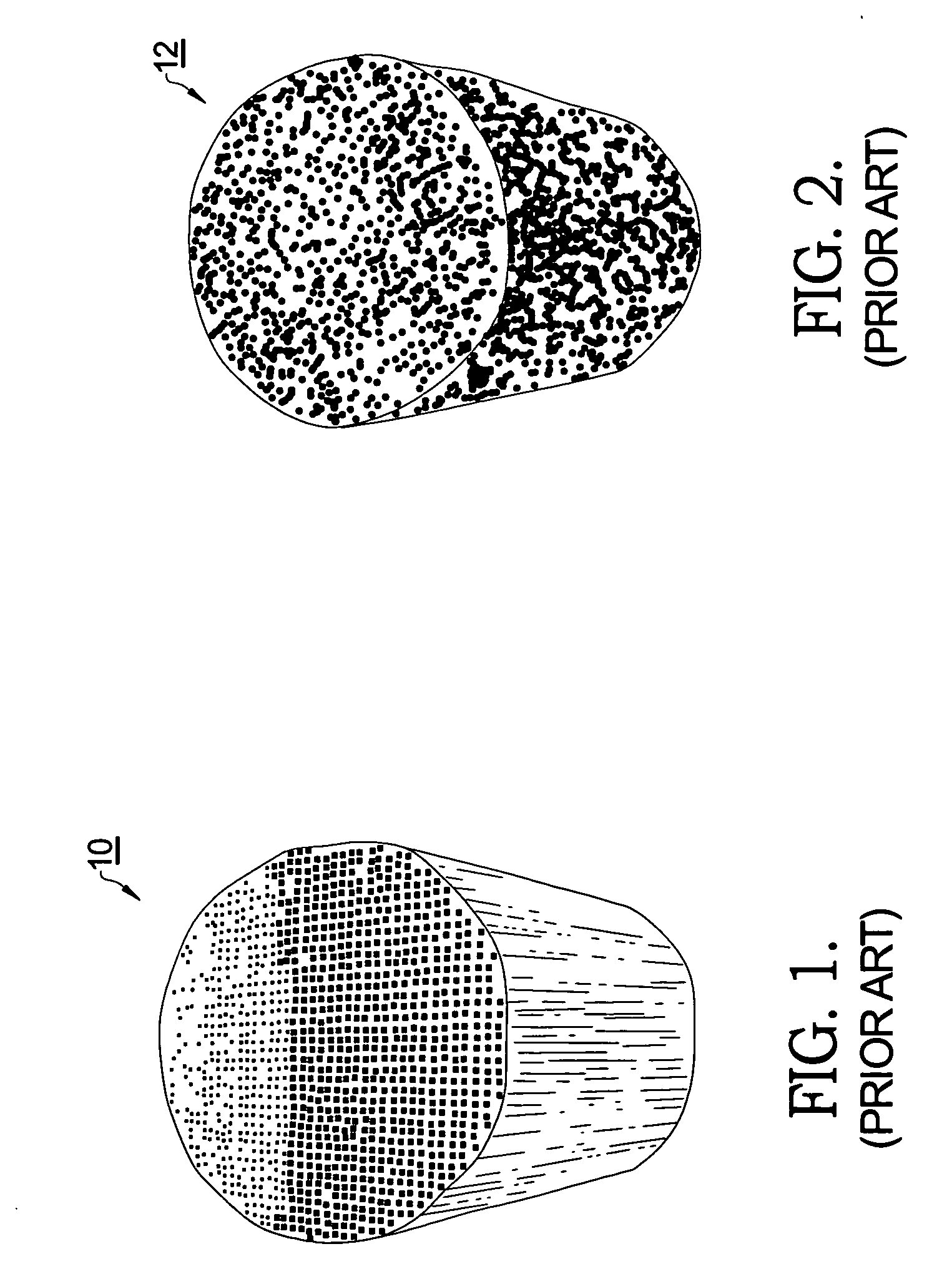

InactiveUS20040023047A1Electric discharge tubesVacuum evaporation coatingCeramic coatingPlasma chamber

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises zirconia toughened ceramic material as an outermost surface of the component. The component can be made entirely of the ceramic material or the ceramic material can be provided as a coating on a substrate such as aluminum or aluminum alloy, stainless steel, or refractory metal. The zirconia toughened ceramic can be tetragonal zirconia polycrystalline (TZP) material, partially-stabilized zirconia (PSZ), or a zirconia dispersion toughened ceramic (ZTC) such as zirconia-toughened alumina (tetragonal zirconia particles dispersed in Al2O3). In the case of a ceramic zirconia toughened coating, one or more intermediate layers may be provided between the component and the ceramic coating. To promote adhesion of the ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

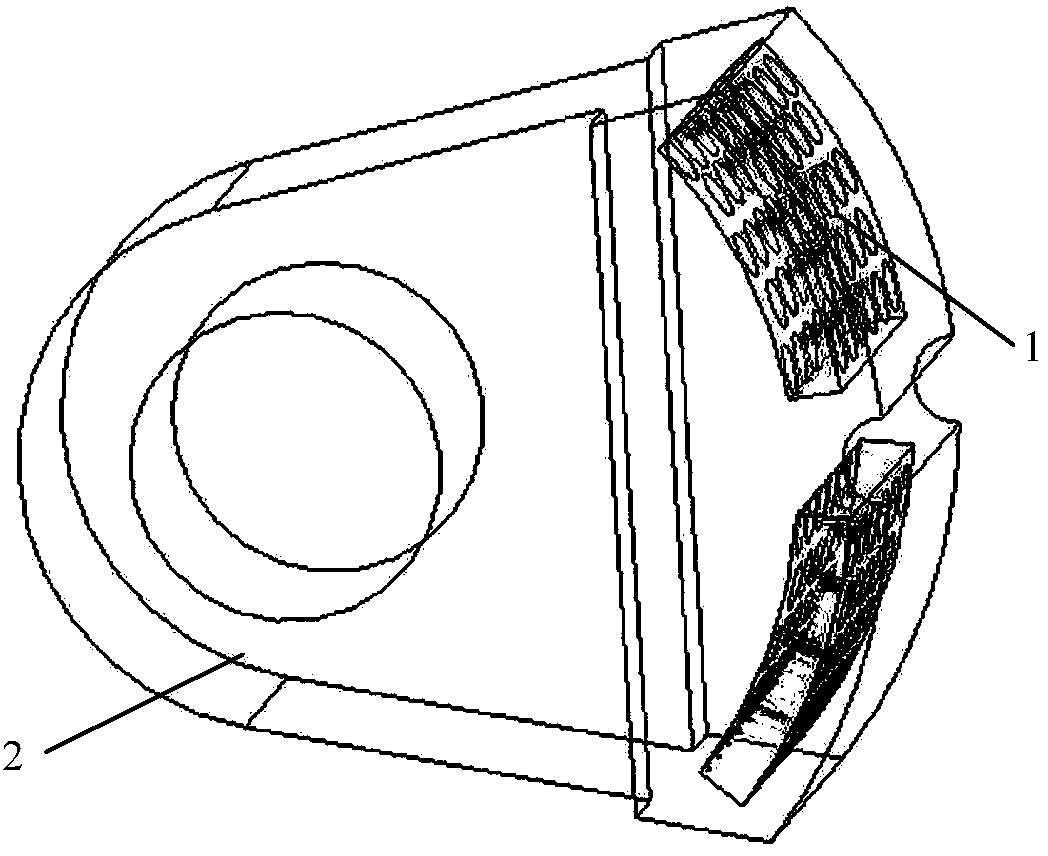

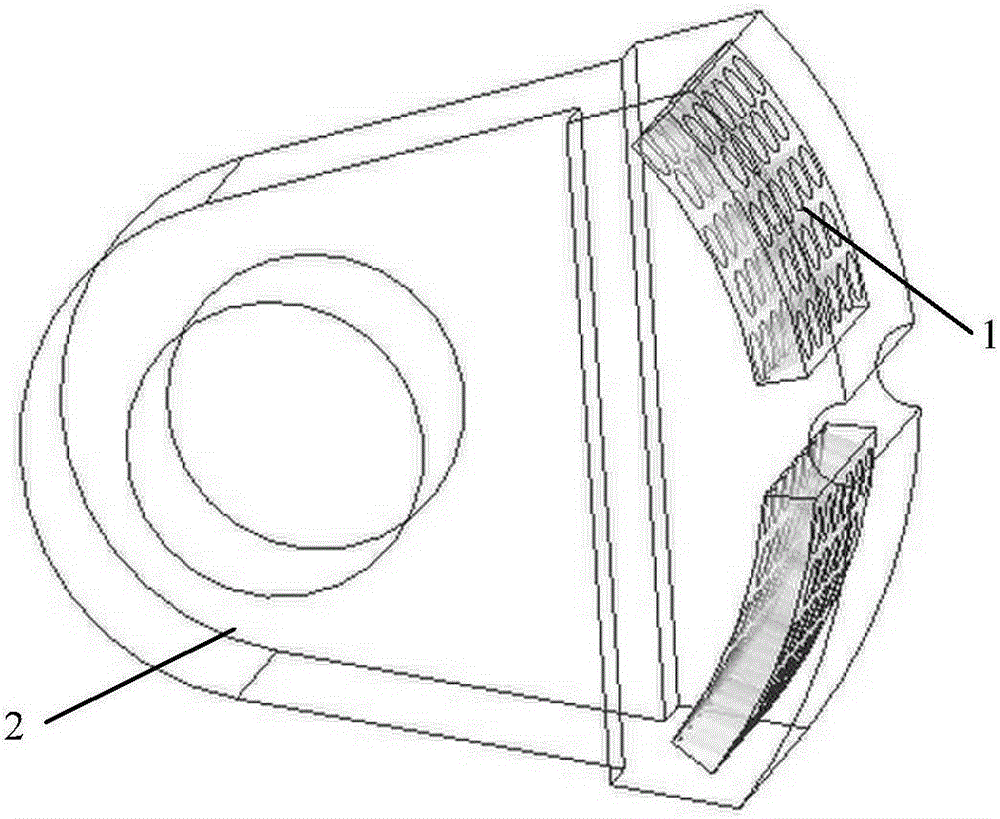

Preparation method for active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound hammer

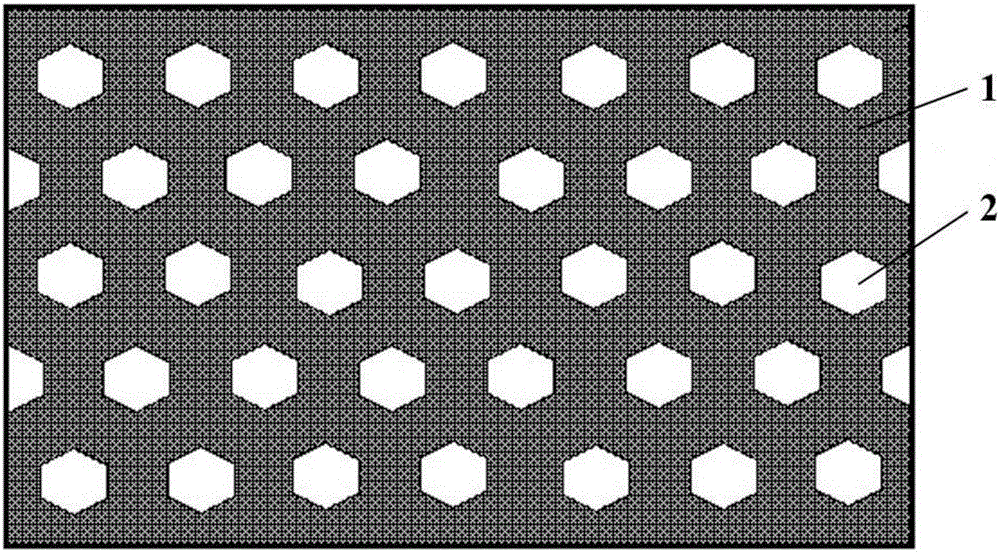

InactiveCN103769562AImprove the bonding strength of the interfaceImprove impact resistanceParticulatesHoneycomb

The invention discloses a preparation method for an active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound hammer. The preparation method comprises the following steps: uniformly mixing active element powder; adding a defined amount of binding agents, mixing and stirring with ZTA particulates; filling into a honeycomb-shaped mould, pressing and then drying; sintering to obtain a honeycomb-shaped precast block; fixing the honeycomb-shaped precast block on a reserved casting position and pouring molten metal; cooling and de-molding, thereby obtaining a compound hammer. According to the preparation method, a sintering technique for the ZTA particulate precast block is simple; the shape and size of the precast block can be controlled through the mould; the casting seeping technique for the compound hammer has higher production efficiency, yield and universality. Besides, the active element introduced into the interface can increase the interface bonding strength and a compound layer structure with a pinning effect can endow the compound hammer with better impact resistance.

Owner:XI AN JIAOTONG UNIV +1

Preparation method of zirconium oxide toughening aluminum oxide hollow balls

The invention discloses a preparation method of zirconium oxide toughening aluminum oxide hollow balls. The method uses industrial aluminum oxide as major raw materials, zirconium-containing toughening materials are introduced to be smelted in a three-phase AC electric arc furnace or a DC electric arc furnace, air is used for blasting during furnace turndown, and then, 0.2 to 5mm zirconium oxide toughening aluminum oxide hollow balls are obtained through sieving separation. Compared with aluminum oxide hollow balls produced by pure industrial aluminum oxide, the hollow balls have the advantages that the intensity and the toughness are better, the thermal shock resistance performance is greatly improved, and the hollow balls are particularly applicable to sharp quenching and sharp heating parts, have high use temperature, and can be widely applied to various light bricks and heat insulation casting materials.

Owner:ZHEJIANG UNIV

Process for preparing punching die by using ZTA material

InactiveCN101289320AAvoid reunionEvenly dispersedMixing operation control apparatusClay processing apparatusHigh fractureTemperature resistance

The invention discloses a method for preparing press tool by using ZTA material. The method of the invention has the following procedures: a coprecipitation method is adopted to prepare zirconium hydroxide and yttrium hydroxide collosol; yttrium stable zirconia collosol and nano-alumina powder are mixed evenly according to the mixture ratio of 75 to 95 percent weight content of A12O3 in ZTA powder materials, and calcined at the temperature of 500 to 900 DEG C to obtain the ZTA powder in which zirconia is evenly distributed; then zirconia-toughened alumina ceramics is formed by baking at the temperature of 1500 to 1600 DEG C after the isostatic pressing at the pressure of 150MPa to 250MPa. The ZTA material prepared by the method has the advantages of high strength, high fracture toughness property, high hardness, high temperature resistance, corrosion resistance and anti-abrasive property, etc. By using ZTA ceramics materials to prepare alkaline cells and tablet press tool used in pharmaceuticals industry, the abrasive resistance property of the tool is greatly increased and the life service is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

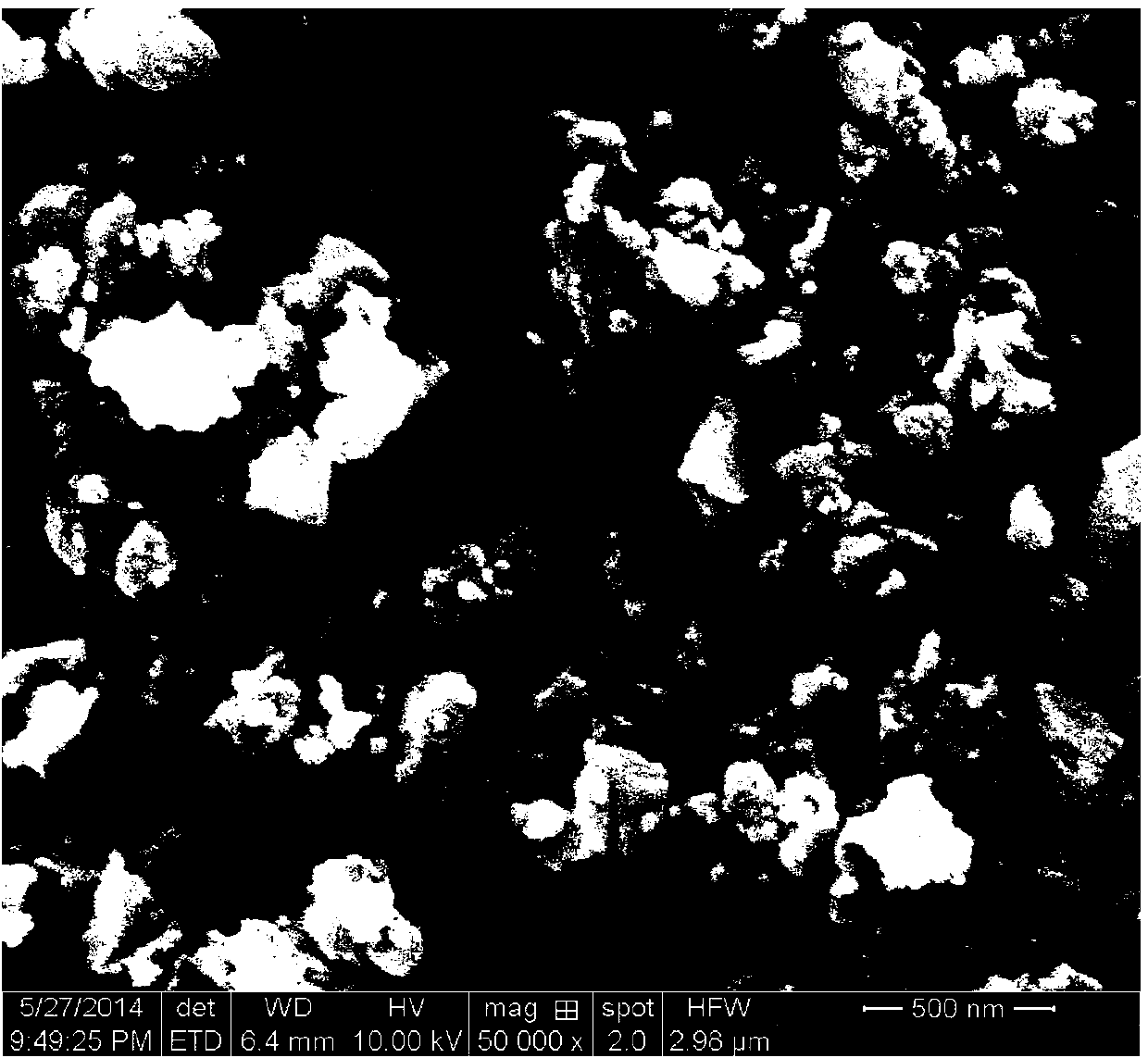

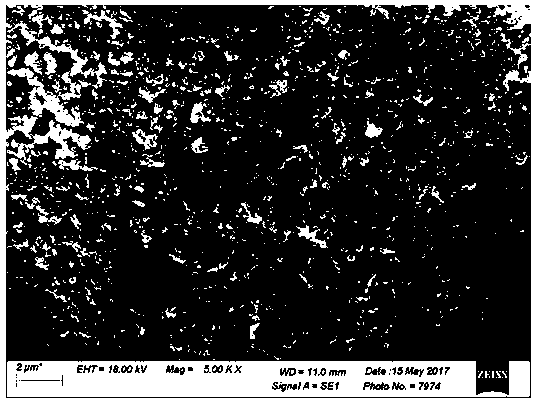

Spray granulation preparation method for zirconium oxide toughened aluminum oxide powder

The invention discloses a spray granulation preparation method for zirconium oxide toughened aluminum oxide powder. The method comprises the following steps of: preparing nano zirconium nitrate and yttrium hydroxide mixed gel by adopting a co-precipitation method, adding nano aluminum oxide, mixing uniformly by using a wet ball milling method to form Zr(OH)4+Y(OH)3 / Al2O3 slurry, performing spray drying granulation and calcination on the slurry, and thus obtaining the zirconium oxide toughened aluminum oxide powder with fine zirconium oxide crystal, uniform distribution of the zirconium oxide crystal in the aluminum oxide, high sintering activity and good forming performance. The method for preparing the zirconium oxide toughened aluminum oxide granulated composite powder overcomes the defects of low uniformity, zirconium oxide agglomeration and the like caused by directly mixing and granulating zirconium oxide powder and aluminum oxide powder in the conventional method, powder making and granulation processes are integrated, the method is simple, and the zirconium oxide is dispersed uniformly and is low in granularity and high in sintering activity.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for local ceramic reinforced aluminum matrix composite wear-resistant part

A preparation method for a local ceramic reinforced aluminum matrix composite wear-resistant part includes: firstly, preparing a zirconia toughened alumina (ZTA) preformed part; secondly, fixing the ZTA preformed part in a die forging die and vacuumizing the interior of the die forging die; and finally, injecting aluminum liquid into a runner of the die forging die, squeezing the aluminum liquid into a cavity of the die forging die under high pressure first, then using the forging die for forging and stamping until the aluminum liquid completely solidifies, and separating a male die from a female die so as to fetch the composite wear-resistant part out from the forging die when composite materials completely solidify. By using the preparation method, not only wear-resistant performance of the surface of the composite wear-resistant part is improved, but also effects of the character of high toughness of ZTA particles are simultaneously brought into full play, and probability of internal fragmentation of ceramic is greatly reduced, overall impact resistance of the composite wear-resistant part is improved, and furthermore due to the fact that the composite wear-resistant part is prepared through a method of combining low vacuum die forging with extrusion die forging, the aluminum liquid can be fully composited with the ZTA particles, and the number of internal interstices of the wear-resistant part is decreased. Accordingly, overall intensity of the composite wear-resistant part is improved, and service life of the composite wear-resistant part is prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

Ceramic composite material for high-flexibility artificial skeleton joint and preparation method

InactiveCN108689699AHigh hardnessZirconia has good toughnessTissue regenerationProsthesisCeramic compositeBiocompatibility Testing

The invention discloses a ceramic composite material for a high-flexibility artificial skeleton joint and a preparation method. Raw materials are formed by the following components by mass percentage:30-40% of hydroxyapatite, 30-40% of zirconia-toughened aluminum oxide powder or yttria-stabilized zirconia powder, 5-10% of ceramic whisker, 5-10% of nano titanium oxide, 0-10% of oyster shell powder, 0-10% of magnesium oxide, and 0-10% of calcium oxide; the zirconia-toughened aluminum oxide powder is prepared from 60-70wt% of aluminum oxide and 30-40wt% of zirconium oxide, and is prepared by preparing mixed gel through a coprecipitation method, and spray-drying; the yttria-stabilized zirconia powder is prepared from 97wt% of the zirconium oxide and 3wt% of yttrium oxide. The prepared artificial skeleton joint ceramic composite material has good biocompatibility and flexibility, good shock resistance, and good heat stability and corrosion resistance, wherein the bending strength can reach1250-1400 MPa, the breaking tenacity can reach 16.5-17.5 MPa / m<2>, and the compressive strength reaches 750-900 HV; the material can prepare an artificial skeleton or a joint instead of a metal or ceramic.

Owner:湖南鹏登生物科技股份有限公司

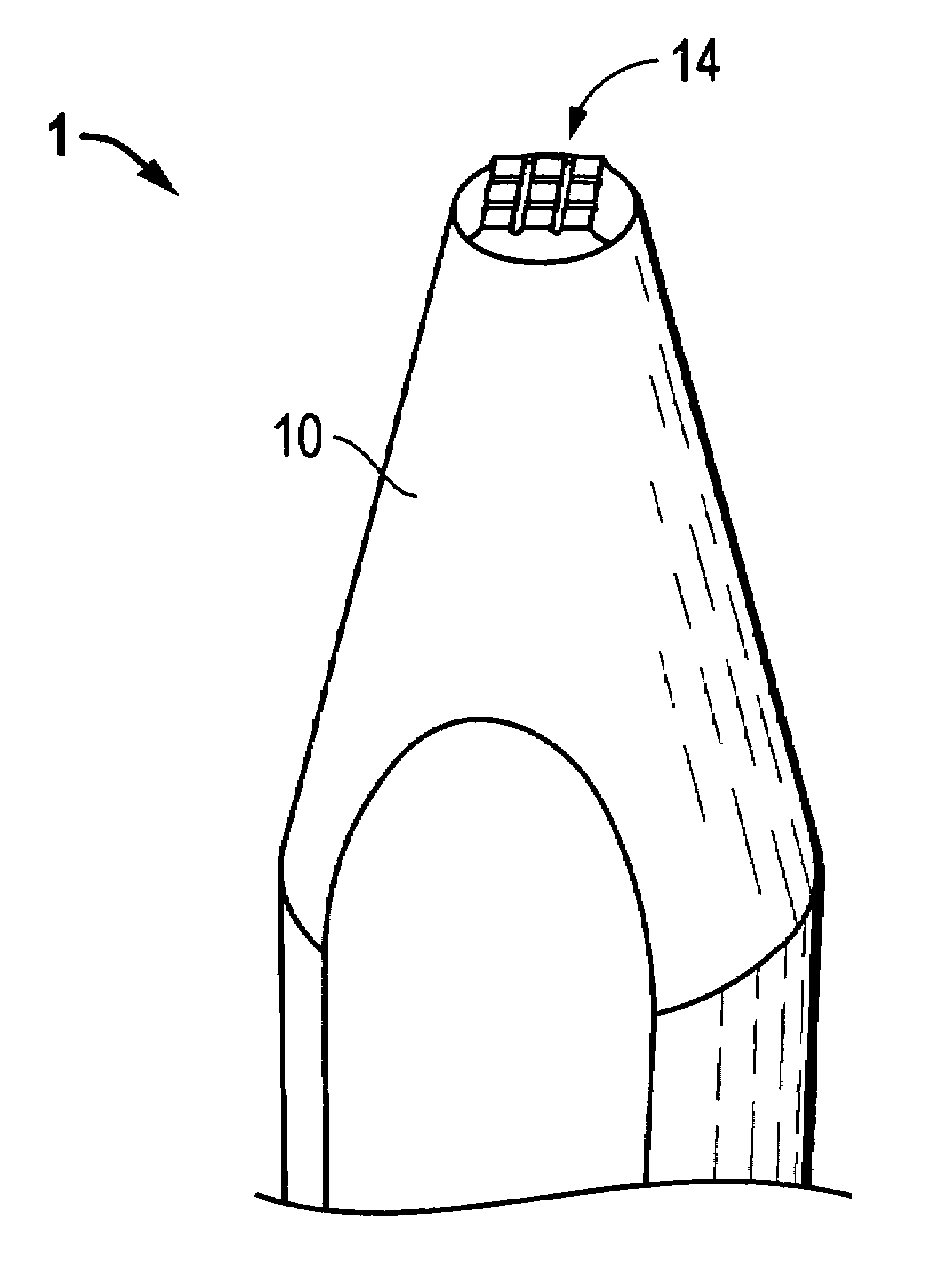

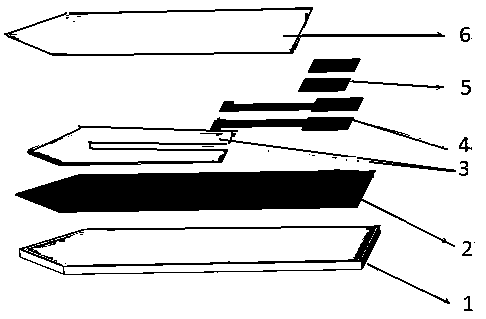

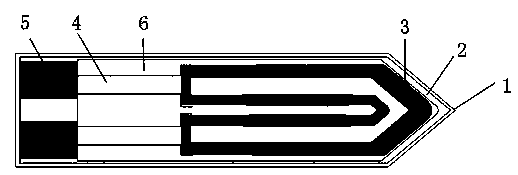

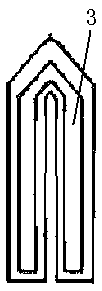

Electronic cigarette heater

PendingCN110200331AHigh strengthImprove thermal conductivityTobacco devicesOptoelectronicsElectronic cigarette

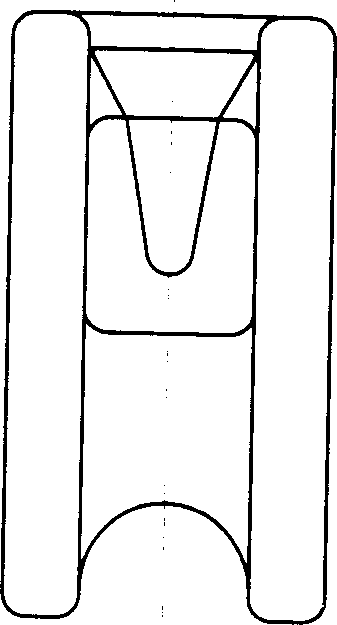

The invention relates to an electronic cigarette heater. The electronic cigarette heater at least comprises a ceramic substrate (1), wherein the ceramic substrate (1) is composed of a zirconia toughened alumina (ZTA) ceramic substrate, a bottom insulating layer (2), an upper electrode layer (3), a lower electrode layer (4), a weldable layer (5) and a surface insulating layer (6), wherein the bottom insulating layer (2), the upper electrode layer (3),the lower electrode layer (4), the weldable layer (5) and the surface insulating layer (6) are sequentially printed on the surface of the ceramicsubstrate (1), and the upper electrode layer (3) is connected with the lower electrode layer (4); and the weldable layer (5) coincides with the lower electrode layer (4). The electronic cigarette heater has high strength and good thermal conductivity.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

Preparation method of low-cost zirconium dioxide toughened alumina ceramic granular powder

The invention relates to a preparation method of low-cost zirconium dioxide toughened alumina ceramic granular powder, belonging to the technical field of ceramic wear-resistant materials. The method comprises the following steps: by using 3 mol% yttrium-oxide-stable zirconium dioxide powder, microcrystalline alumina powder and binder as main raw materials and water as a dispersion medium, carrying out ball milling and mixing at room temperature to obtain a uniformly mixed paste; transferring the mixed paste into a stirring barrel, adding the adhesive, and stirring to obtain a uniformly mixed slurry; and carrying out pressure atomization or centrifugal atomization on the slurry in a spray granulation tower, and carrying out spray granulation to obtain the granular powder. The spray granulation technique and equipment are simple and cheap, and can easily implement automatic operation. The prepared zirconium dioxide toughened alumina ceramic granular powder has the advantages of high purity, favorable sphericity, fine original grain size and favorable formability.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

Making process of woven ceramic product of zirconia flexibilized alumina ceramic

The production process of ceramic product of zirconia flexibilized alumina ceramic for textile use includes: weighing material and grinding into powder in a ball mill; adding adhesive and mixing into mixed material; forming biscuit; trimming; high temperature sintering; and final polishing. The ceramic product for textile use has high wear resistance and shearing strength and long service life and its use can improve the quality of fiber and textile.

Owner:上海施迈尔精密陶瓷有限公司

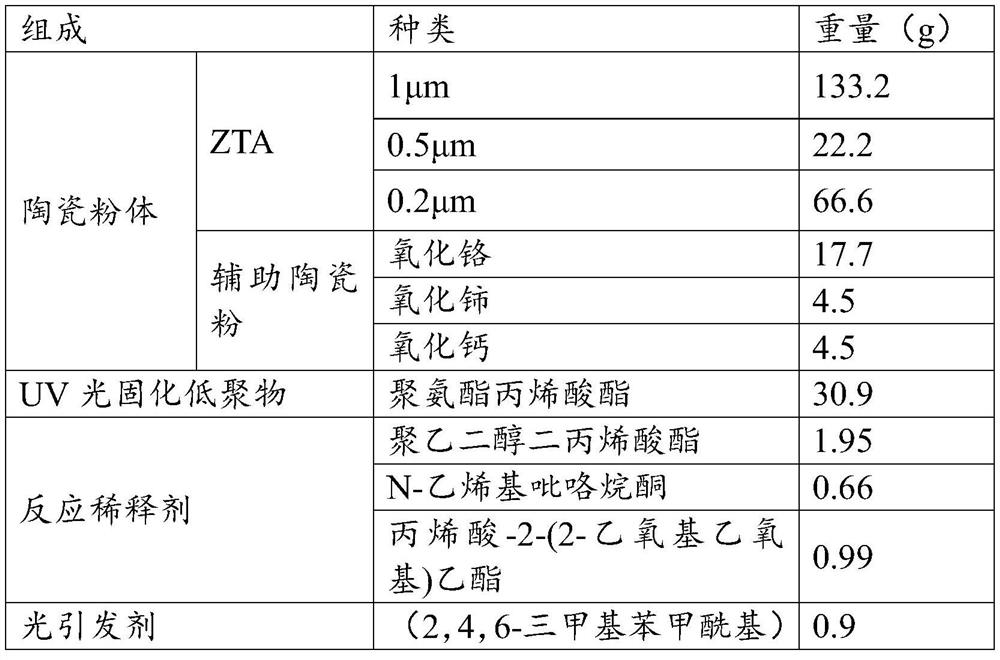

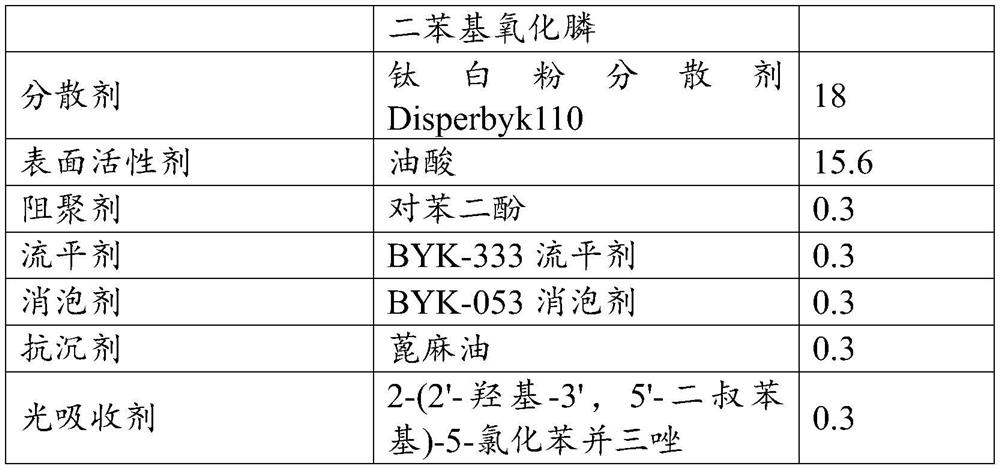

Grain-graded zirconium oxide toughened aluminum oxide ceramic substrate and preparation process thereof

The invention relates to a grain-graded zirconium oxide toughened aluminum oxide ceramic substrate and a preparation process thereof. Alumina powder is used as a main phase and zirconia powder is usedas a second phase material; magnesium aluminate spinel powder is used as a sintering aid; taking a binary azeotropic mixture of absolute ethyl alcohol and butanone as a solvent; phosphate esters as dispersants, polyvinyl butyral is used as an adhesive; dibutyl phthalate is used as a plasticizer; the volume ratio of the alumina powder to the zirconia powder is 82.44%-96.7%; the content of the zirconia powder is 3.30%-17.56%; the magnesium aluminate spinel powder accounts for 0.1-4.0% of the total weight of the alumina powder and the zirconia powder; the alumina powder, the zirconia powder andthe magnesium aluminate spinel powder form inorganic powder; the solvent accounts for 20-35% of the total weight of the inorganic powder; a dispersing agent accounts for 0.5-2.0% of the total weight of the inorganic powder, an adhesive accounts for 5-15% of the total weight of the inorganic powder, a plasticizer accounts for 2-6% of the total weight of the inorganic powder, wherein the particle size ratio of alumina powder to zirconia powder is 2.415-4.444, so that ZrO2 can be used as a toughening phase, no leakage current is generated, and the requirements of a ZTA ceramic copper-clad substrate and a heating element on mechanical and electrical properties can be met.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

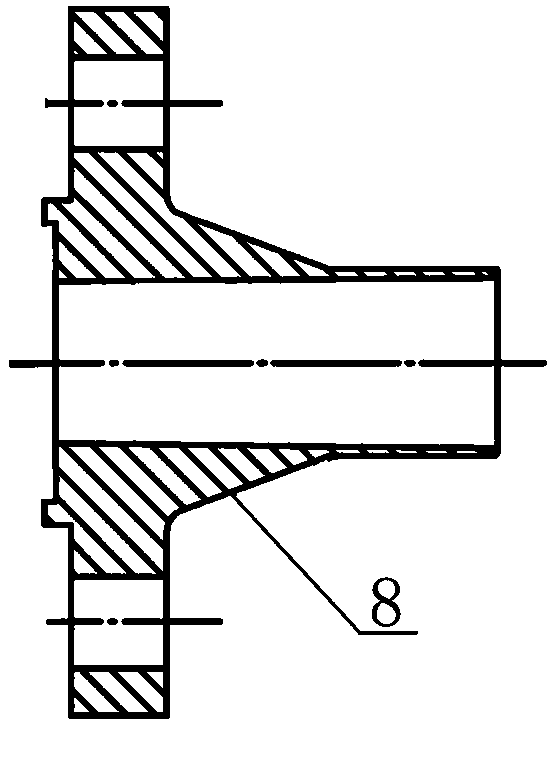

Process for preparing lining of ceramic cylinder jacket

InactiveCN1448365AHigh hardnessHigh strengthPositive displacement pump componentsLiquid fuel engine componentsSolventPetroleum

The present invention relates to zirconia toughened alumina ceramic cylinder liner and its preparation and is especially one ceramic cylinder liner used to replace double-metal cylinder liner in petroleum well drilling field. The main material used includes zirconia, alumina, silica powder, and during the production, monomer, cross-linking agent, initiator, dispersant and solvent are mixed, the mixture is gel molded, sintered in two steps into product. During the sintering, the first step has relatively low temperature and the deformation is corrected to ensure the sintered sizes. The ceramic cylinder liner thus produced has strength up to 320 MPa, toughness of 6.30 MPa, Vickers hardness up to 1200 MPa, simple production process, controlled sintering, and other advantages.

Owner:QINGDAO UNIV

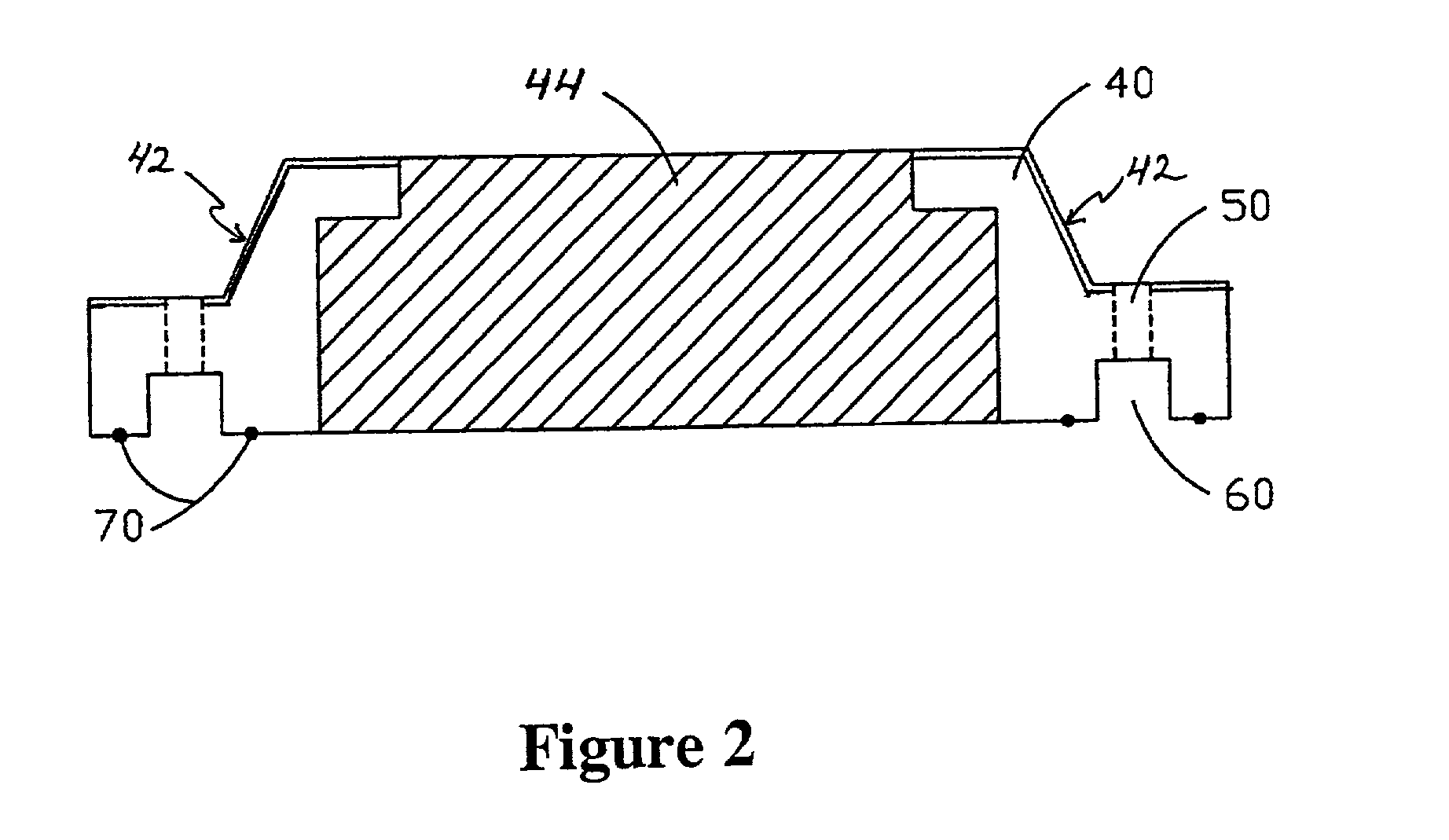

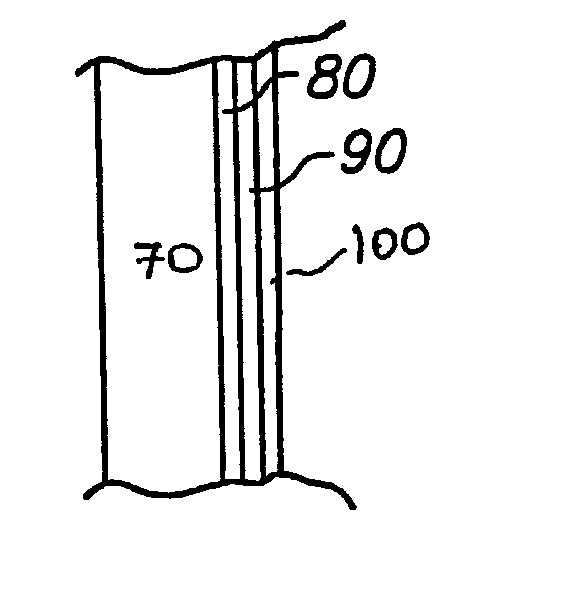

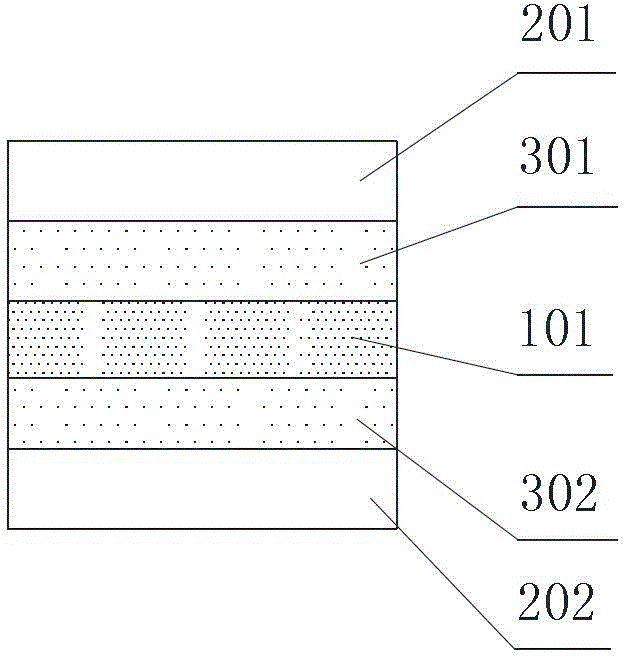

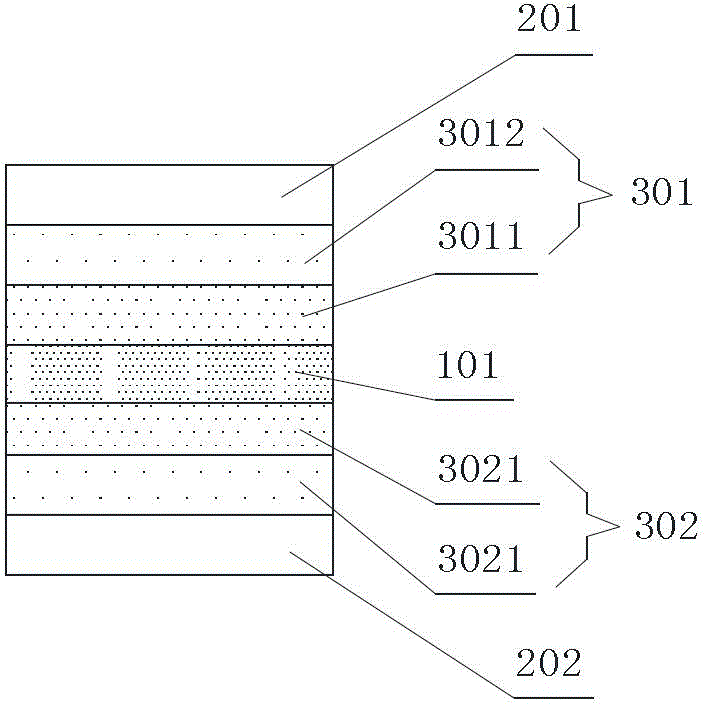

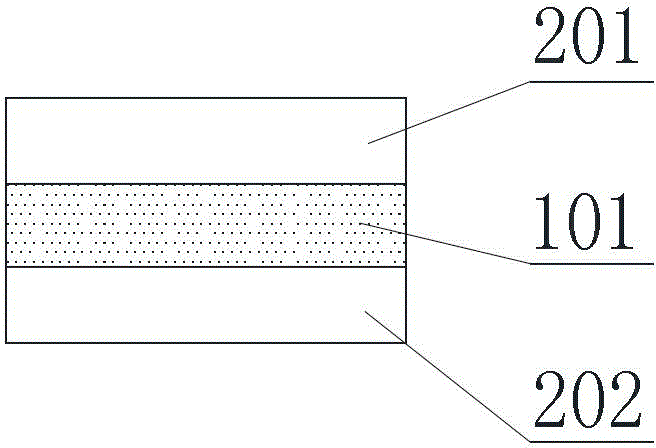

Ceramic substrate and preparation method thereof, and power module

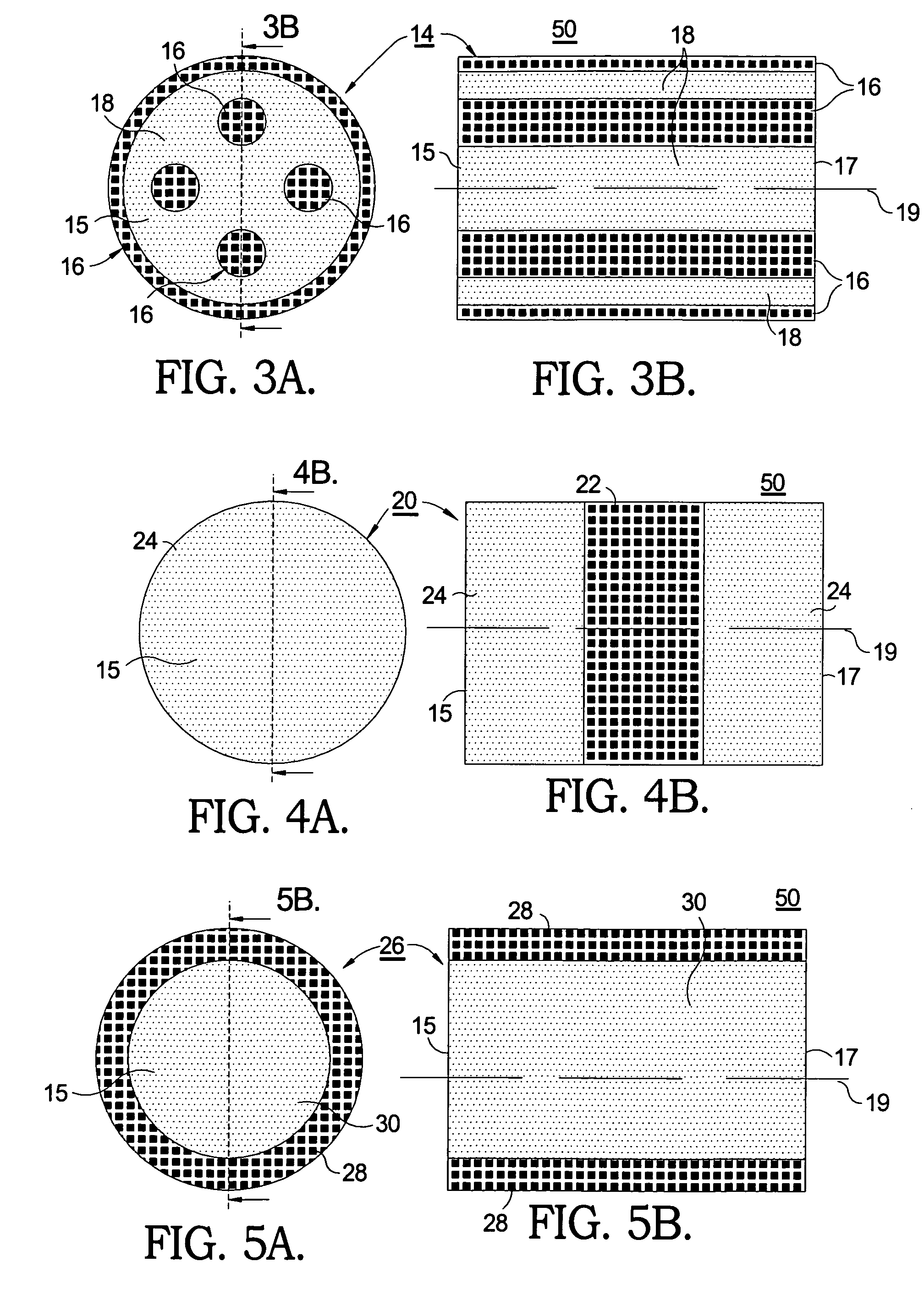

ActiveCN105459515AImprove toughnessHigh strengthCeramic layered productsSurface layerUltimate tensile strength

The invention provides a ceramic substrate and a preparation method thereof. The ceramic substrate comprises, from interior to exterior, a core layer, transition layers and surface layers in an integrated structure, wherein the transition layers comprise an upper transition layer and a lower transition layer symmetrically distributed at two sides of the core layer, the surface layers comprise an upper surface layer and a lower surface layer symmetrically distributed at two sides of the upper and lower transition layers, the surface layers are made of alumina, the transition layers and the core layer are made of zirconia-toughened alumina, and the content of zirconia in the core layer is higher the content of zirconia in the transition layers. The invention also provides a power module using the ceramic substrate. The ceramic substrate provided by the invention uses alumina ceramic as the surface layers and zirconia-toughened alumina ceramic as the transition layers and the core layer, and the contents of zirconia gradiently increase from exterior to interior, so the ceramic substrate has higher strength and toughness and can be extensively applied to the power module.

Owner:BYD CO LTD

Zirconia toughened alumina ceramic cylinder sleeve

InactiveCN103496952AOvercome chalkingOvercome the disadvantage of low fracture toughnessLiquid mediumHigh pressure

The invention belongs to the technical field of preparation processes of ceramics and specifically relates to a zirconia toughened alumina ceramic cylinder sleeve. The zirconia toughened alumina ceramic cylinder sleeve comprises the following components in percentage by weight: 60-70% of alumina, 20-30% of zirconia, 1.2-1.5% of yttrium oxide, 0.5% of lanthanum oxide and 3-3.3% of magnesium carbonate and is prepared by the process flow comprising the steps of ball milling, mixing, granulation, molding and sintering. The produced ceramic cylinder sleeve has the advantages of corrosion resistance, acid and alkali resistance and high temperature resistance, and can work in drilling mud or other liquid media with strong corrosiveness, and the hardness is sufficient to resist grinding or scoring of various solid-phase particles with sharpness or strong grinding property in the high-pressure mud. The ceramic microstructure is uniform, and the surface gloss is high, so that the zirconia toughened alumina ceramic cylinder sleeve is favorable to prolonging the service life of a piston. The ceramic cylinder sleeve is high in working pressure and can meet the requirements of drilling deep wells and ultra-deep wells.

Owner:HEFEI JINGCHUANG CERAMIC EQUIP TECH

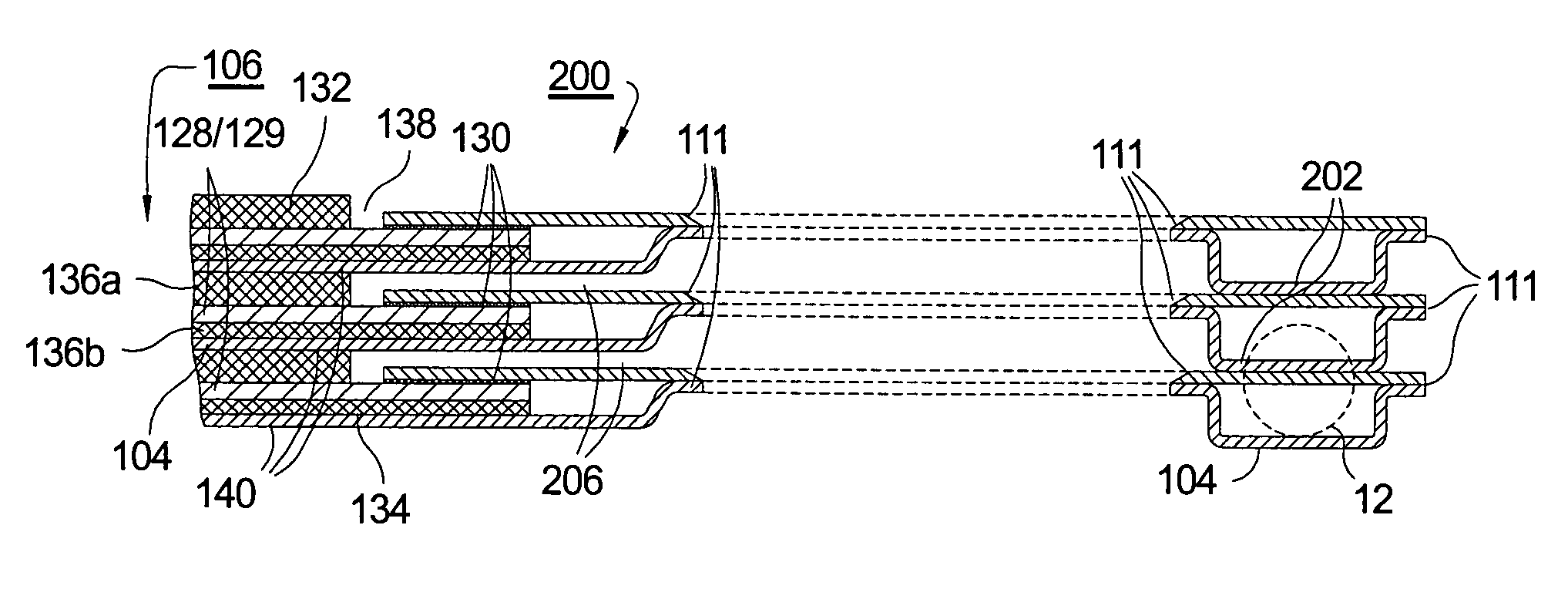

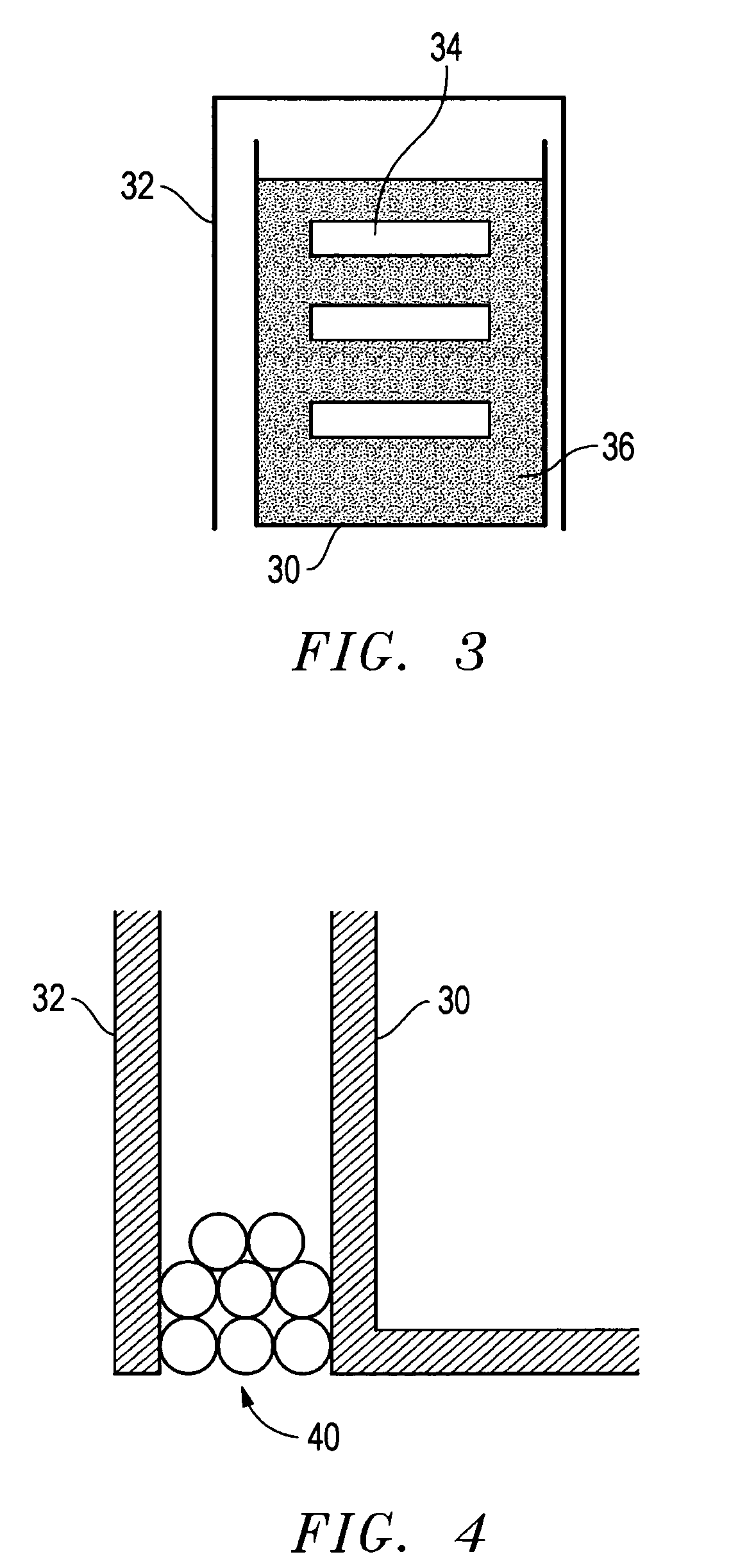

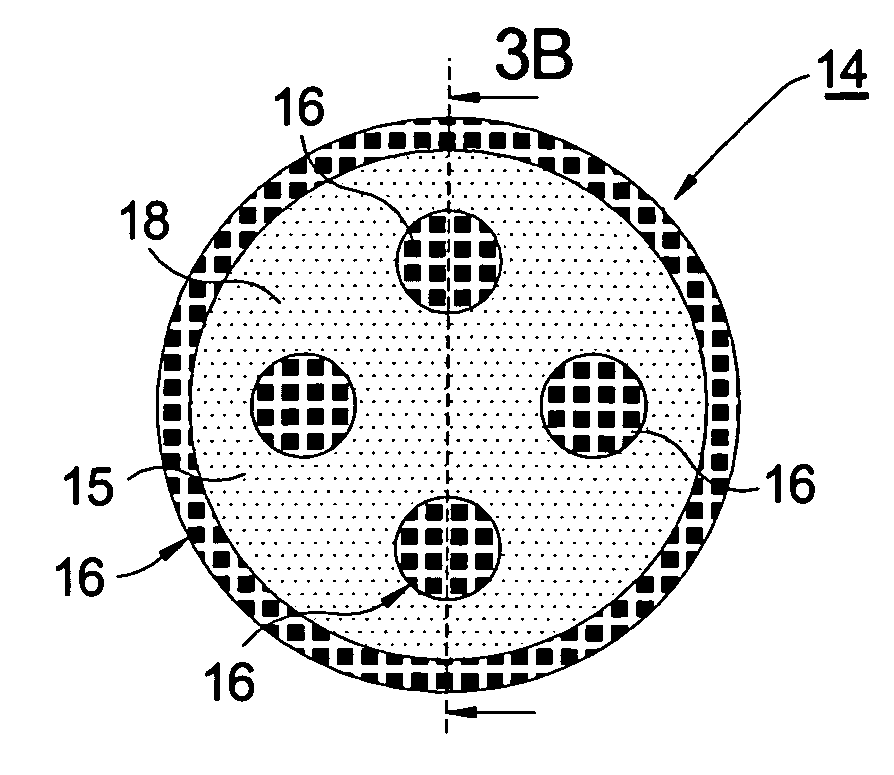

Hydrocarbon reformer substrate having a graded structure for thermal control

InactiveUS20100062212A1Reduce heat lossQuality improvementHydrogenPhysical/chemical process catalystsRadiative heat lossMullite

A reformer substrate for supporting a catalyst in a hydrocarbon reformer, comprising a graded structure that is inhomogeneous either radially, longitudinally, or both. The inhomogeous graded structure components are selected and arranged to maintain the catalyst operating temperature during extended periods of catalytic inactivity. Selection is based primarily on heat capacity and / or thermal loss properties. Generally, the perimeter of the substrate, radially and / or longitudinally comprises a thick wall of high thermal mass materials to reduce conductive and radiated heat loss, and a high thermal capacity material within the substrate to reduce radiated heat loss. Preferred materials are open-cell rigid foams such as zirconia-toughened alumina reticulated foam, for negative thermal loads in endothermic reaction regimes, and zirconia-mullite honeycomb monolith, for positive or neutral thermal loads in exothermic or autothermic reaction regimes.

Owner:DELPHI TECH INC

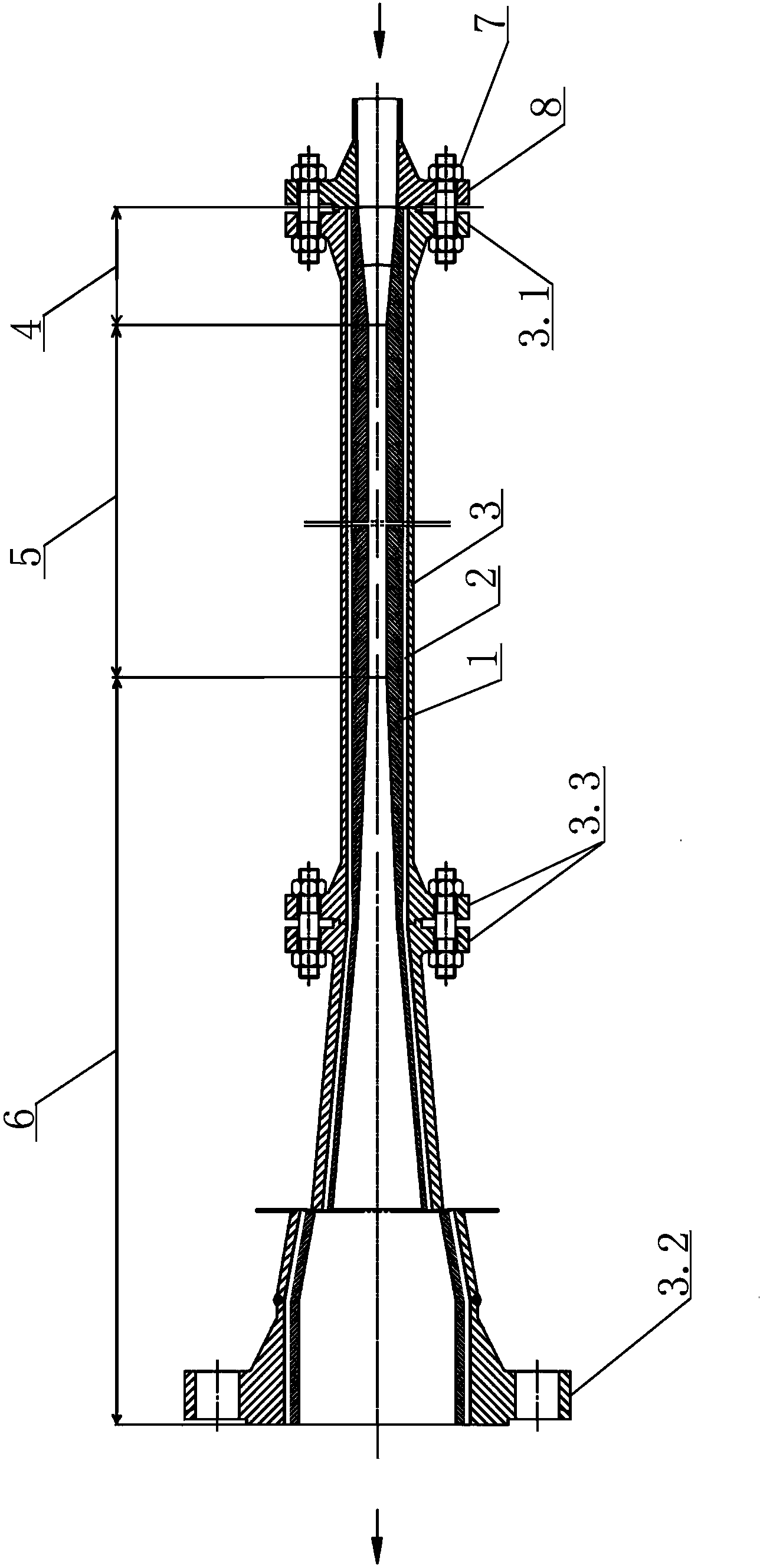

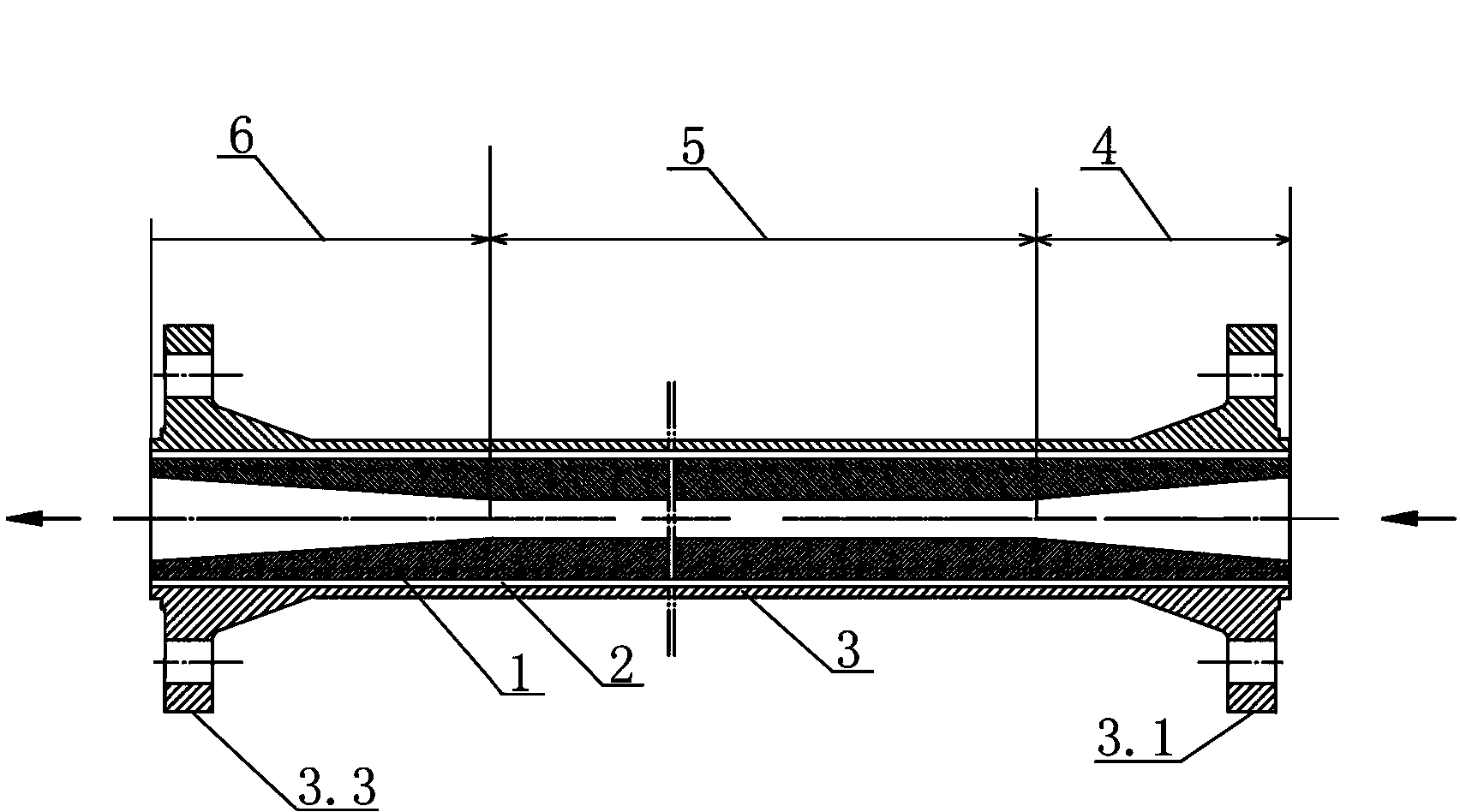

Multi-layer composite wear-resistant pressure reduction pipe and manufacturing method thereof

ActiveCN103727321ANo looseningIncreased durabilityPreformed elementsRigid pipesWear resistantMetallic materials

The invention discloses a multi-layer composite wear-resistant pressure reduction pipe and a manufacturing method of the multi-layer composite wear-resistant pressure reduction pipe. The multi-layer composite wear-resistant pressure reduction pipe is sequentially formed by a wear-resistant ceramic inner layer, a micro-expansion combination layer and a metal outer layer from inside to outside in a composite mode. The multi-layer composite wear-resistant pressure reduction pipe sequentially comprises a diameter reduction section, a straight pipe section and a diameter increasing section from the inlet end to the outlet end, and the portion, located at the inlet end, of the metal outer layer and the portion, located at the outlet end, of the metal outer layer are provided with an inlet connecting flange and an outlet connecting flange respectively. The wear-resistant ceramic inner layer, the combination layer and the metal outer layer are seamlessly combined, integrality of the product is embodied, and the phenomenon that the inner layer and the outer layer are loosened can not occur. The ceramic layer can be made of zirconia toughened alumina ceramic, and excellent durability of the product is achieved due to the rigidity and wear resistance of the product. The inner layer ceramic material, the combination layer and the outer layer metal material are firmly combined together due to the micro-expansion combination layer through the adhering action and the micro-expansion action. The multi-layer composite wear-resistant pressure reduction pipe can be of a multi-section combination structure, and therefore a pipeline can be conveniently manufactured, and machining accuracy of the pipeline is improved.

Owner:曹海亮

Ceramic substrate and preparation method thereof, and power module

ActiveCN105459516AHigh strengthImprove toughnessCeramic layered productsSurface layerUltimate tensile strength

The invention provides a ceramic substrate and a preparation method thereof. The ceramic substrate comprises surface layers and a core layer in an integrated structure, wherein the surface layers are symmetrically distributed at two sides of the core layer, the surface layers are made of alumina, the core layer is made of zirconia-toughened alumina, and the zirconia-toughened alumina chemically comprises more than 0 wt% and no more than 40 wt% of ZrO2 and no less than 60 wt% and less than 100 wt% of Al2O3. The invention also provides a power module using the ceramic substrate. The ceramic substrate provided by the invention uses alumina ceramic as the surface layers and zirconia-toughened alumina ceramic as the core layer, so the ceramic substrate has higher strength and toughness and can be extensively applied to the power module.

Owner:BYD CO LTD

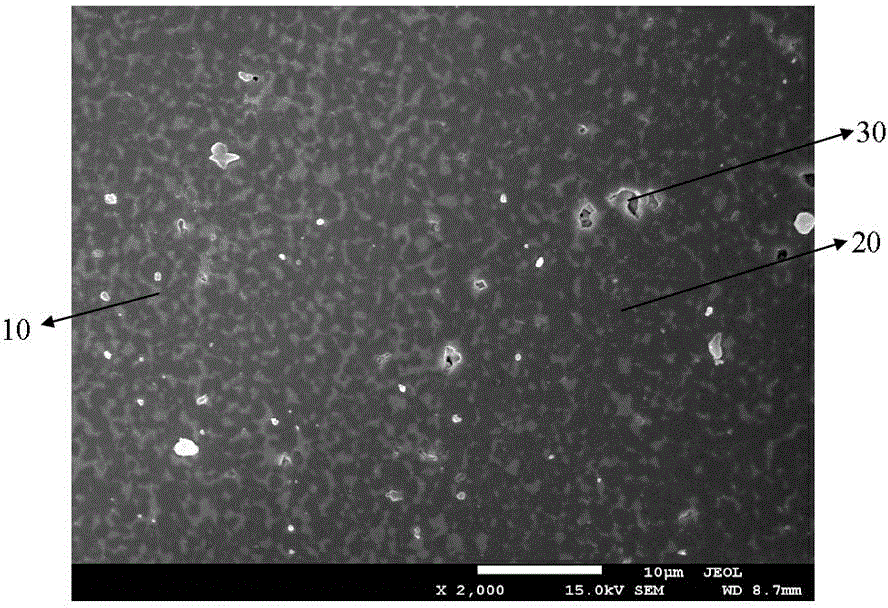

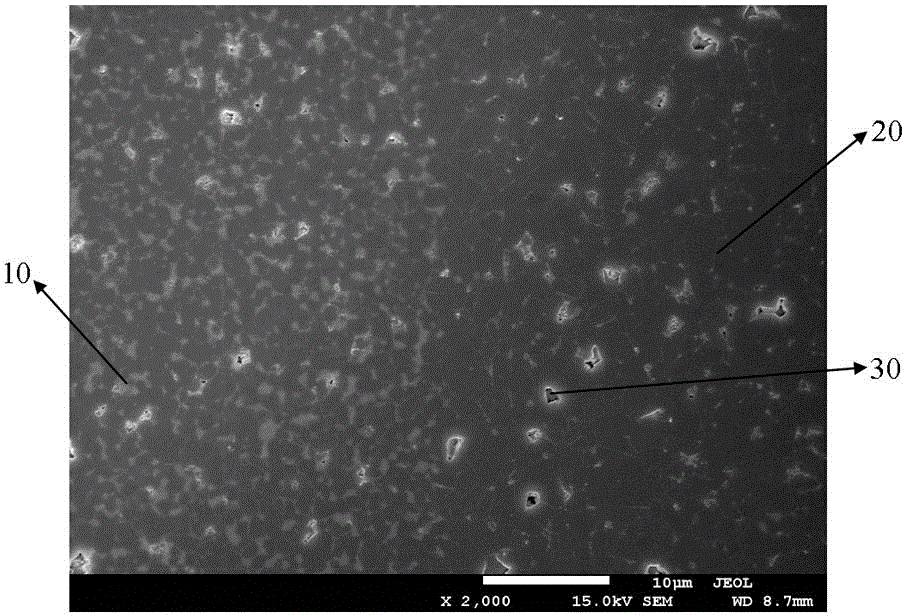

Preparation method of modified ZTA complex-phase ceramic having good wettability with steel melts

InactiveCN108585808AImprove interface responsivenessImprove wettabilityRare earthMetal matrix composite

The invention discloses a preparation method of a modified zirconia toughened alumina (ZTA) complex-phase ceramic having good wettability with steel melts, and belongs to the technical fields of ceramic-based composite materials and metal-based composite materials. The preparation method comprises the following steps: firstly, preparing yttria-stabilized zirconia (YSZ) powder by using a soft chemistry method, adding an rare-earth oxide in the process of preparing the YSZ powder, carrying out drying and calcinating, then uniformly carrying out mixing with Al2O3 and TiO2 powder, carrying out pre-pressing and pressing on the mixed powder, and carrying out high-temperature sintering to obtain a modified ZTA complex-phase ceramic block having good wettability with steel melts. The modified ZTAcomplex-phase ceramic prepared by the invention is low in cost, simple in process and high in production efficiency, has good wettability with steel melts under the condition of not changing the original toughness of ZTA particles, and can be directly used to prepare ceramic particle reinforced steel-based composite materials.

Owner:KUNMING UNIV OF SCI & TECH

Zirconia tenacity-increasing alumina oxide dental ceramics substrate crown gelcasting forming method

The invention discloses a zirconia tenacity-increasing alumina oxide dental ceramics substrate crown gelcasting forming method; the method comprises the following steps: dipping a special provided ceramic slurry by a stack porcelainsmall brush to compost all ceramic crown inner core on a dental die surface of a clinical patient and standing the dental die; absorbing the water content on the surface of the slurry and densifying to form embryonic core, and then drying the embryonic core at a constant temperature, taking off the all ceramic crown from the dental die, and sintering the all ceramic crown at a high temperature to prepare the ceramics substrate crown. In the invention, gel systems composed of organic monomer and crosslinker are used, high solid content and strongly plastic core biscuit is obtained by the free radical polymerization reaction, nano-ceramic particles are used as dispersed phase to introduce micron ceramic matrix to prepare a nano-composite ceramic, and the nano-composite ceramic has good strenghing and toughing effect, high strength material and high toughness, small change of sintering volume, moreover the forming method of the invention is easy and fast to operate, and can prepare dental ceramics substrate crown into various complicated shapes and approach net size forming.

Owner:温州医科大学附属口腔医院

Preparation method of ceramic material

ActiveCN114380583AHigh hardnessHigh densityAdditive manufacturing apparatusCeramic shaping apparatusOxide ceramicAluminum Ion

The invention belongs to the technical field of ceramics, and provides a preparation method of a ceramic material, which comprises the following steps: degumming a zirconium oxide toughened aluminum oxide ceramic blank, pre-sintering, soaking in steeping liquor and sintering, wherein the impregnation liquid comprises a zirconium ion salt solution, an aluminum ion salt solution and urea. According to the preparation method of the ceramic material, the mixed solution of the zirconium ion salt solution, the aluminum ion salt solution and the urea is adopted as the steeping liquor to carry out post-treatment on the zirconium oxide toughened aluminum oxide ceramic green body, the compactness of the ceramic material is improved, and the defect that a ceramic product prepared through a traditional 3D printing technology is low in hardness is overcome.

Owner:重庆恩辰新材料科技有限责任公司 +1

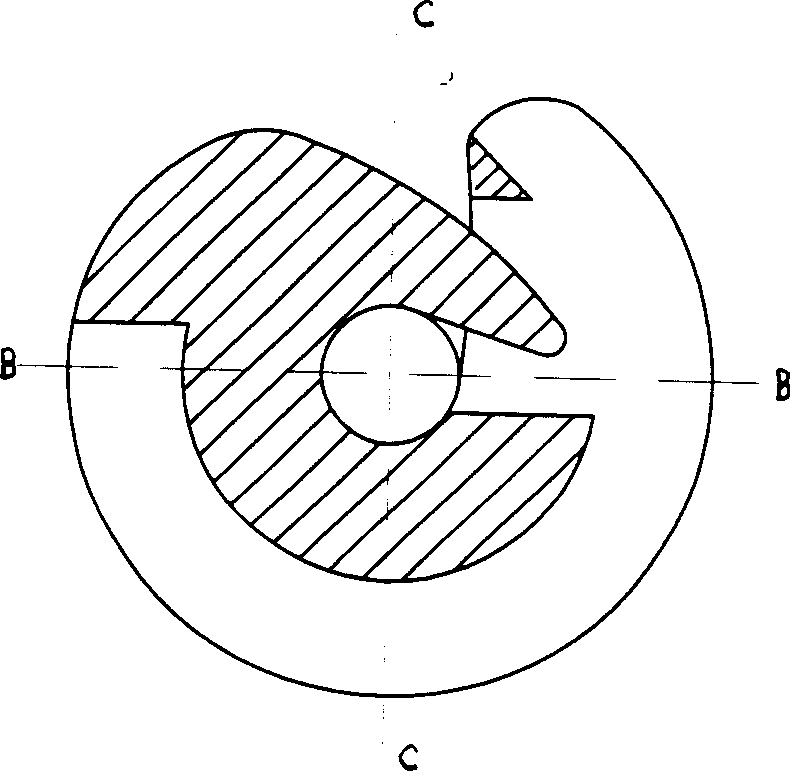

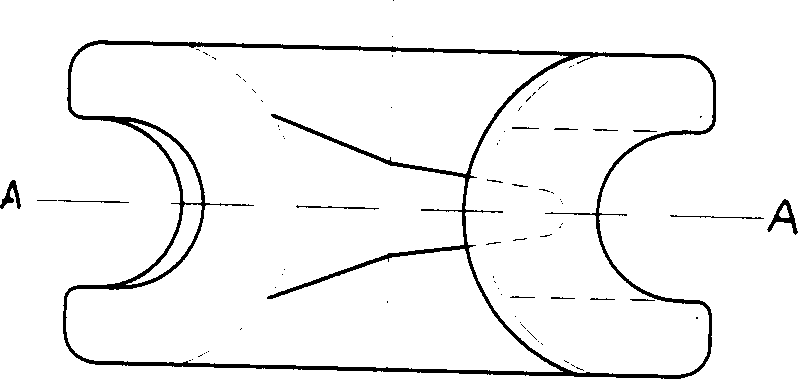

Toughened alumina ceramic overlapping curved pipe of high-performance zirconium oxide and its production

ActiveCN101073939AIncreasing the thicknessSimple processPrinting press partsParticulatesManufacturing cost reduction

The invention is concerned with high capability zirconia particulates toughened alumina ceramic net wave tube and its production method. According to the requirement of net wave tube to wear resistance, intension and toughness of stuff, and thinking about to reduce cost, select zirconia particulates toughened alumina ceramic stuff to produce the ceramic net wave tube and get ZrO2 toughened Al2O3 composite ceramic. Its weight and cost is lower than zirconia ceramic and its wear resistance, intension and toughness are better than alumina ceramic coating. The three point bending intension is larger or equal to 500 to 600Mpa, the rupture toughness is larger or equal to 6.8 to 10MPa.m1 / 2, and the rigidity is larger or equal to 1200 to 1500Gma. The process is producing ZrO2 toughened Al2O3 composite ceramic powder, milling, preparing high solid ceramic plasm by mixing round (adding dispersant, adjusting the value of pH), gel to pour the module, dryness, sinter, rubbing and getting ceramic net wave tube with high precision.

Owner:湖南华联特种陶瓷有限公司

A kind of preparation method of active element sintered ZTA particles reinforced steel matrix composite hammer head

InactiveCN103769562BImprove the bonding strength of the interfaceImprove impact resistanceParticulatesHoneycomb

The invention discloses a preparation method for an active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound hammer. The preparation method comprises the following steps: uniformly mixing active element powder; adding a defined amount of binding agents, mixing and stirring with ZTA particulates; filling into a honeycomb-shaped mould, pressing and then drying; sintering to obtain a honeycomb-shaped precast block; fixing the honeycomb-shaped precast block on a reserved casting position and pouring molten metal; cooling and de-molding, thereby obtaining a compound hammer. According to the preparation method, a sintering technique for the ZTA particulate precast block is simple; the shape and size of the precast block can be controlled through the mould; the casting seeping technique for the compound hammer has higher production efficiency, yield and universality. Besides, the active element introduced into the interface can increase the interface bonding strength and a compound layer structure with a pinning effect can endow the compound hammer with better impact resistance.

Owner:XI AN JIAOTONG UNIV +1

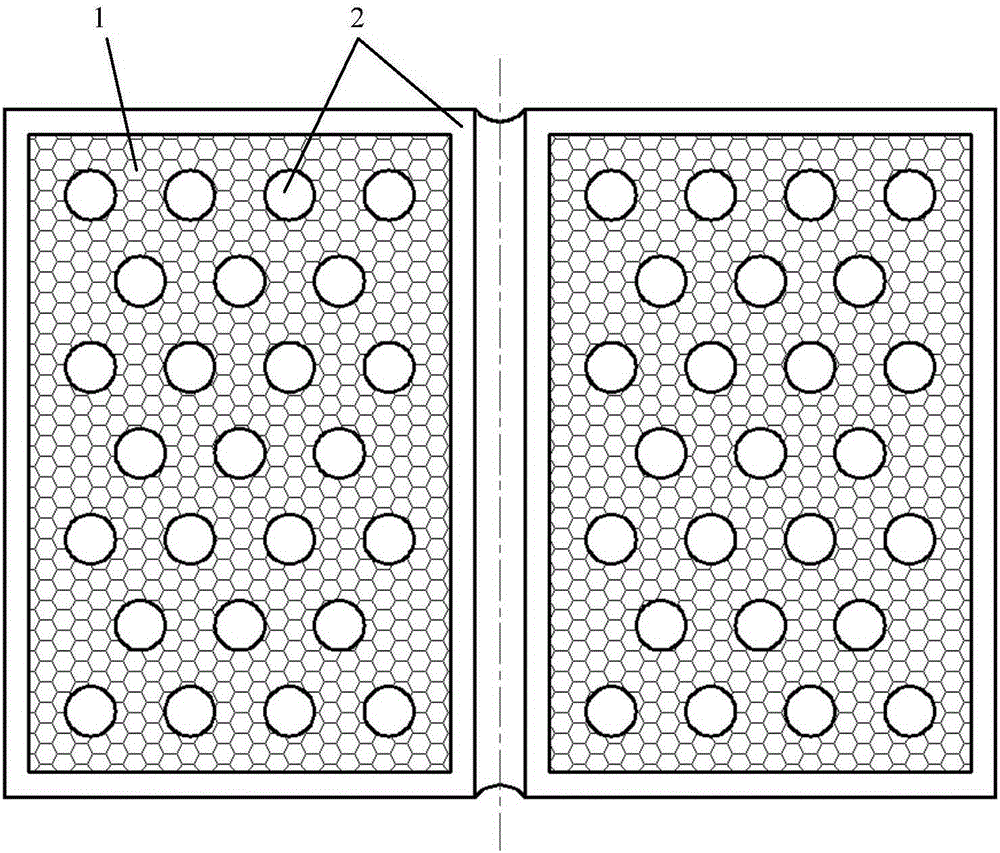

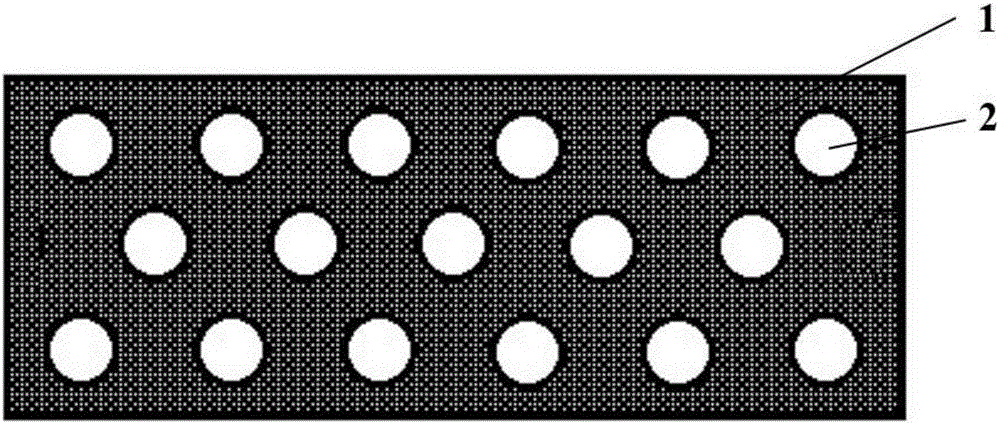

Ceramic particle reinforced wear-resisting insert and manufacturing method thereof

ActiveCN106392061AImprove flexural strengthImprove fracture toughnessTransportation and packagingMetal-working apparatusMolding machineWear resistance

The invention discloses a ceramic particle reinforced wear-resisting insert and a manufacturing method thereof. The manufacturing method comprises the following steps of: 1) determining the shape, the structure and the dimension of the insert according to the shape of a cast product, and manufacturing the mould for pressing the insert by aluminum alloy; 2) carrying out oil removal, chemical nickel plating, and cleaning and drying on zirconium oxide toughened aluminum oxide ceramic particles; 3) preparing mould materials for the insert; 4) filling a mould cavity of the mould in the step 1) with the mould materials, compacting and pressing the mould materials by a vibrating-pressing type out-of-the-box molding machine, and de-molding to obtain preform; 5) putting the preform into a hot-blast stove, and sufficiently drying the preform; and 6) putting the dried preform into a vacuum sintering furnace, carrying out vacuum sintering, and cooling and discharging, thereby obtaining the ceramic particle reinforced wear-resisting insert. The manufacturing method is high in efficiency, is stable in shaping, and is good in casting-penetration effect; and the manufactured ceramic particle reinforced wear-resisting insert has good high temperature collapsibility resistance, is good in wetting property with molten metal and is excellent in wear resistance.

Owner:GUANGZHOU PANYU POLYTECHNIC

Preparation method of high pressure slurry pump ceramic cylinder jacket for well drilling

InactiveCN1948756AWith uniformityDensePositive displacement pump componentsLiquid fuel engine componentsWell drillingSludge

The invention relates to a manufacture method of the ceramic cylinder jacket of high-pressure sludge pump for drilling, in which using zirconium oxide plasticized alumina (a-Al 203) as a matrix, leading in Zr 02 and Y 203-La 203 rare earth composite additive by using the modern plasticizing and reinforcing technology and adopting the isostatic compaction technology makes green bodies have uniformity and compactness. Because of using the atmospheric high-temp. drawer kiln once-through sintered, the temperature is distributed uniformly.

Owner:湖南泰鑫瓷业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com