Grain-graded zirconium oxide toughened aluminum oxide ceramic substrate and preparation process thereof

A technology of alumina ceramics and zirconia, applied in the field of grain-graded zirconia toughened alumina ceramic substrates and its preparation technology, can solve problems such as breakdown of heating elements, reduce sintering temperature, and facilitate industrial production , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

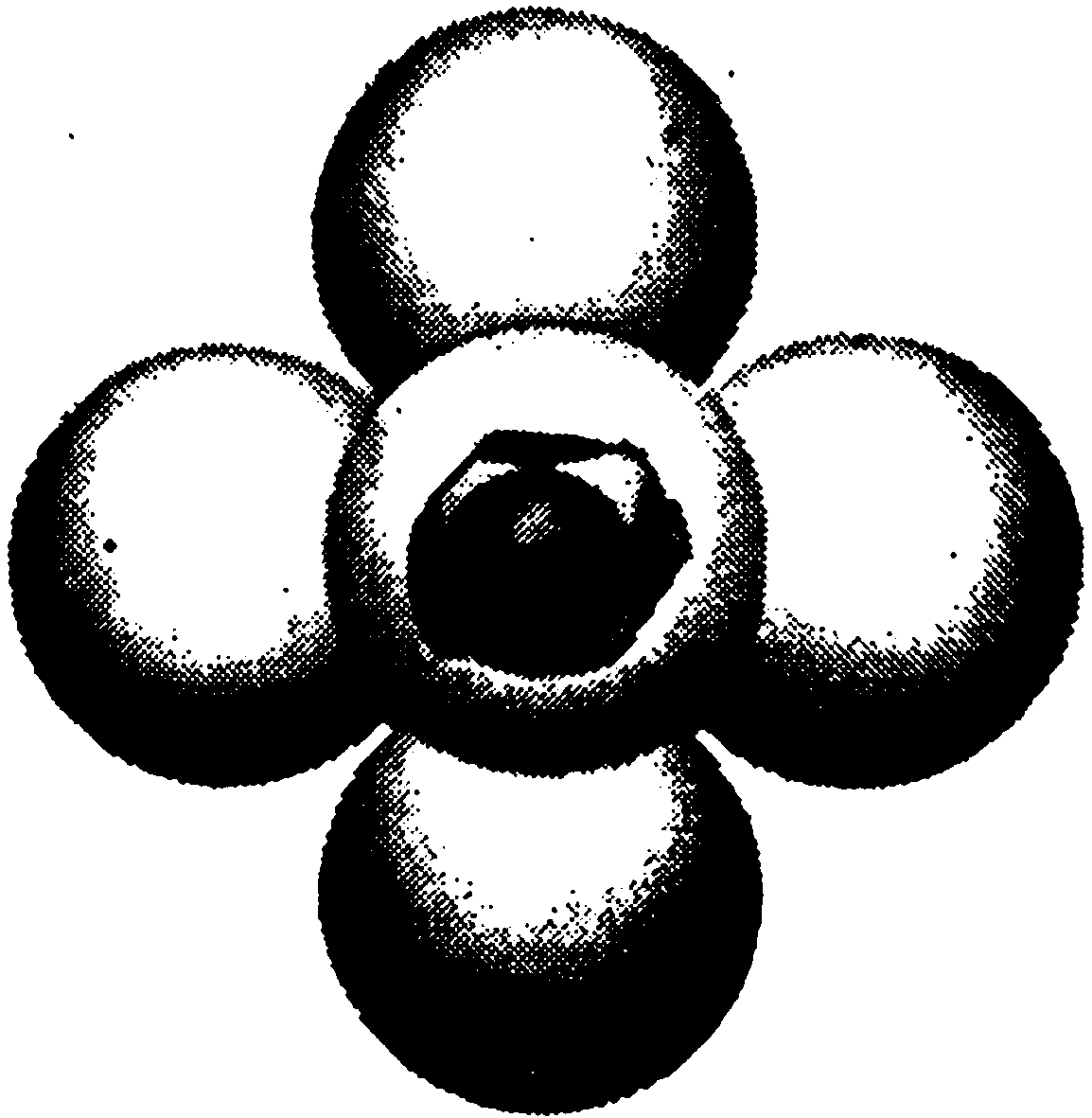

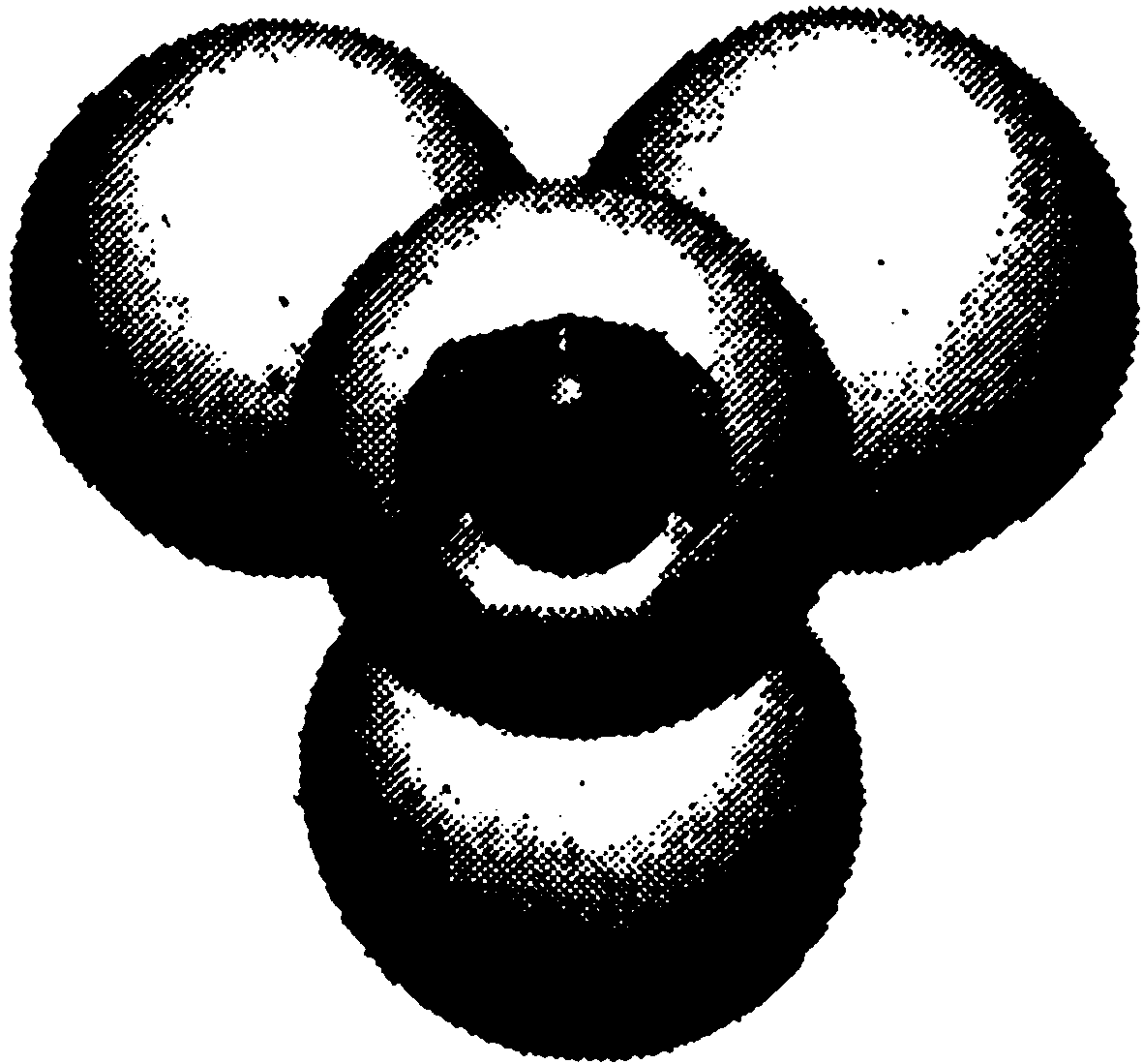

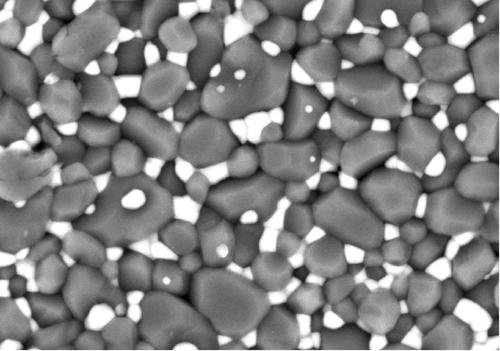

Image

Examples

Embodiment 1

[0029] Example 1: A zirconia-doped alumina ceramic substrate, using alumina powder as the main phase material, zirconia powder as the second phase material, magnesia alumina spinel powder as the sintering aid, and absolute ethanol and methyl ethyl ketone The binary azeotropic mixture is used as solvent, phosphate ester is used as dispersant, polyvinyl butyral is used as binder, and dibutyl phthalate is used as plasticizer.

[0030] Specifically, it is prepared with the following raw materials: 3.30% volume percentage of 3Y zirconia powder (particle size 0.25μm), 96.7% volume percentage content of α~alumina powder (particle size 0.7μm), plus 3Y zirconia 0.1% of the total weight of powder and alumina powder as a flux of magnesia-aluminum spinel powder to form an inorganic powder; and add a solvent composed of a binary azeotropic mixture of absolute ethanol and methyl ethyl ketone with 20% of the total weight of inorganic powder , Add 0.5% of the total weight of inorganic powder as ...

Embodiment 2

[0031] Example 2: A zirconia-doped alumina ceramic substrate, which specifically includes the following raw materials, is prepared: 8% by volume of 3Y zirconia powder (particle size 0.25μm), 92% by volume of α ~Alumina powder (particle size 0.7μm), plus 2% magnesia-aluminum spinel powder flux based on the total weight of 3Y zirconia powder and alumina powder to form an inorganic powder; and add 25% of the total weight of inorganic powder Solvent consisting of a binary azeotropic mixture of absolute ethanol and methyl ethyl ketone, adding 1.0% of the total weight of inorganic powder as a dispersant, and ball milling for 32 hours; then adding 8% of the total weight of inorganic powder as a bonding agent The total weight of polyvinyl butyral and inorganic powder 4% of the total weight of dibutyl phthalate as a plasticizer, secondary ball milling for 48 hours; discharged from the ball mill, through vacuum degassing to obtain a viscosity of 22000mPa •S casting slurry; cast on a cast...

Embodiment 3

[0032] Example 3: A zirconia-doped alumina ceramic substrate, which specifically includes the following raw materials, is prepared: 13% by volume of 3Y zirconia powder (particle size 0.25μm), 87% by volume of α ~Alumina powder (particle size 0.7μm), plus 3Y zirconia powder and 3% of the total weight of alumina powder magnesia-aluminum spinel powder flux, together to form an inorganic powder; and adding 30% of the total weight of inorganic powder A solvent consisting of a binary azeotropic mixture of absolute ethanol and methyl ethyl ketone, adding 1.5% of the total weight of inorganic powder as a dispersant, and ball milling for 40 hours; then adding 12% of the total weight of inorganic powder as a bonding agent Polyvinyl butyral and 5% of the total weight of inorganic powder as plasticizer dibutyl phthalate, secondary ball milling for 48 hours; the material is discharged from the ball mill, and the viscosity is 24000mPa through vacuum degassing •S casting slurry; cast on a cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com