Patents

Literature

161 results about "Particle size ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

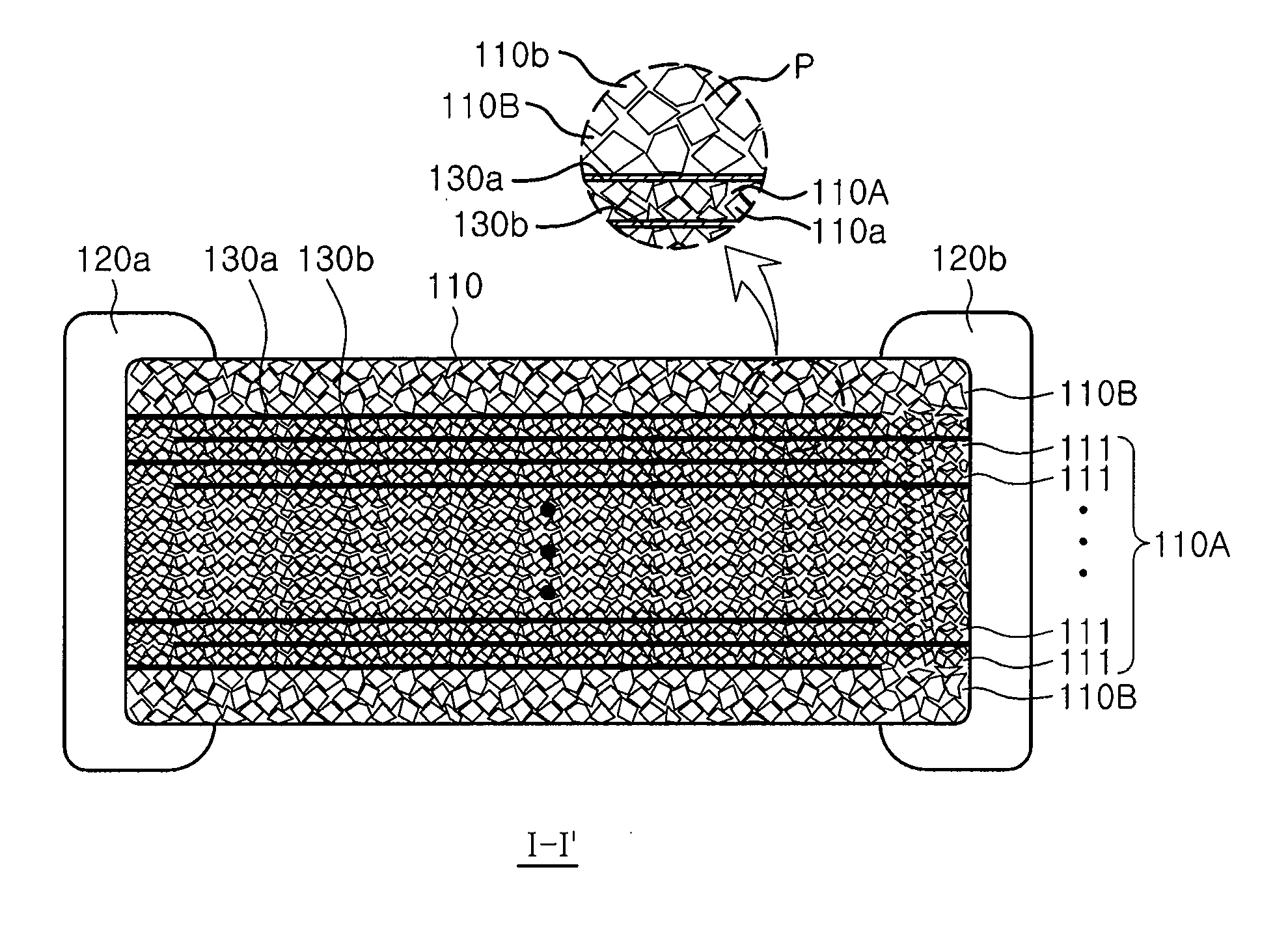

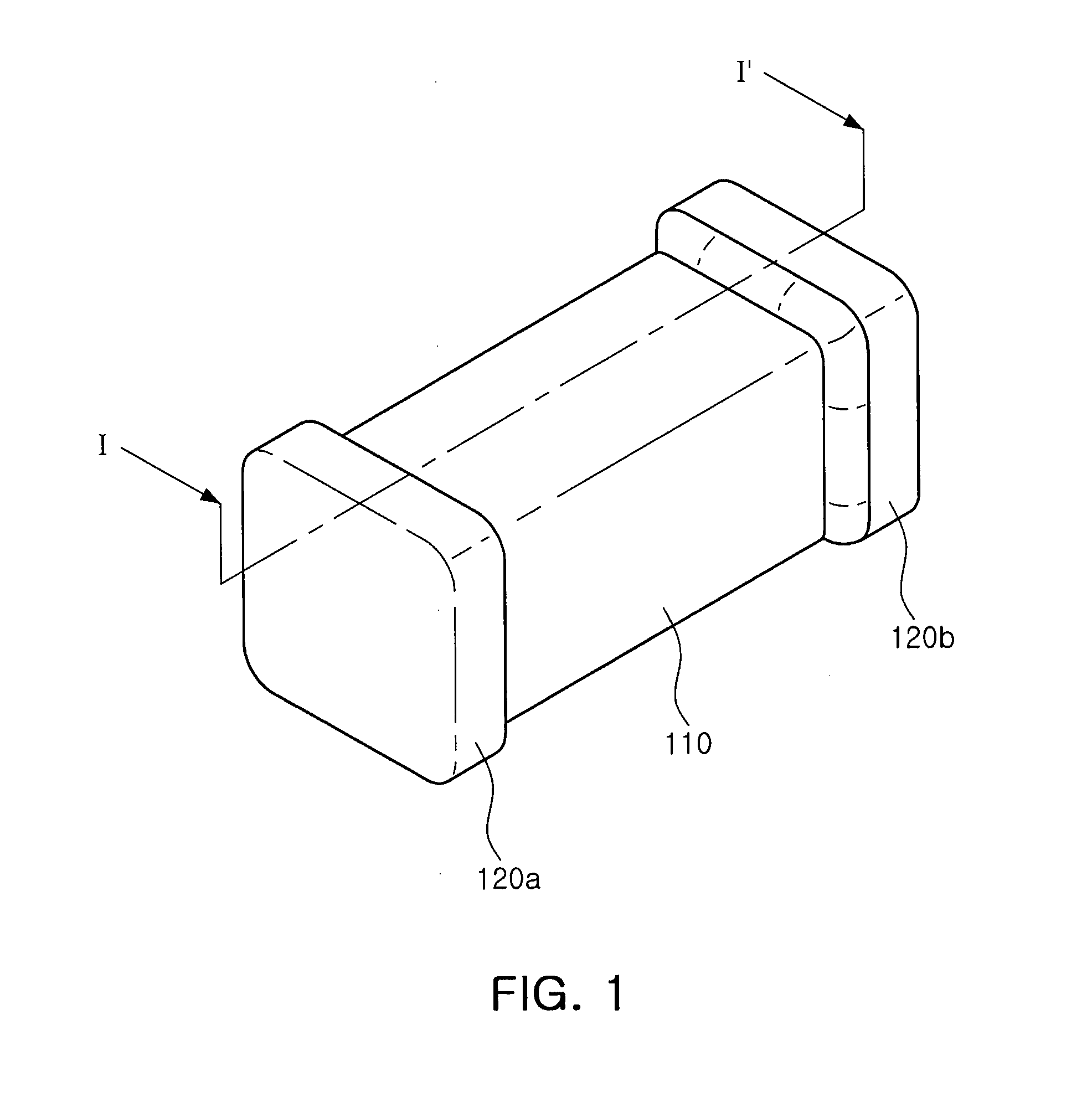

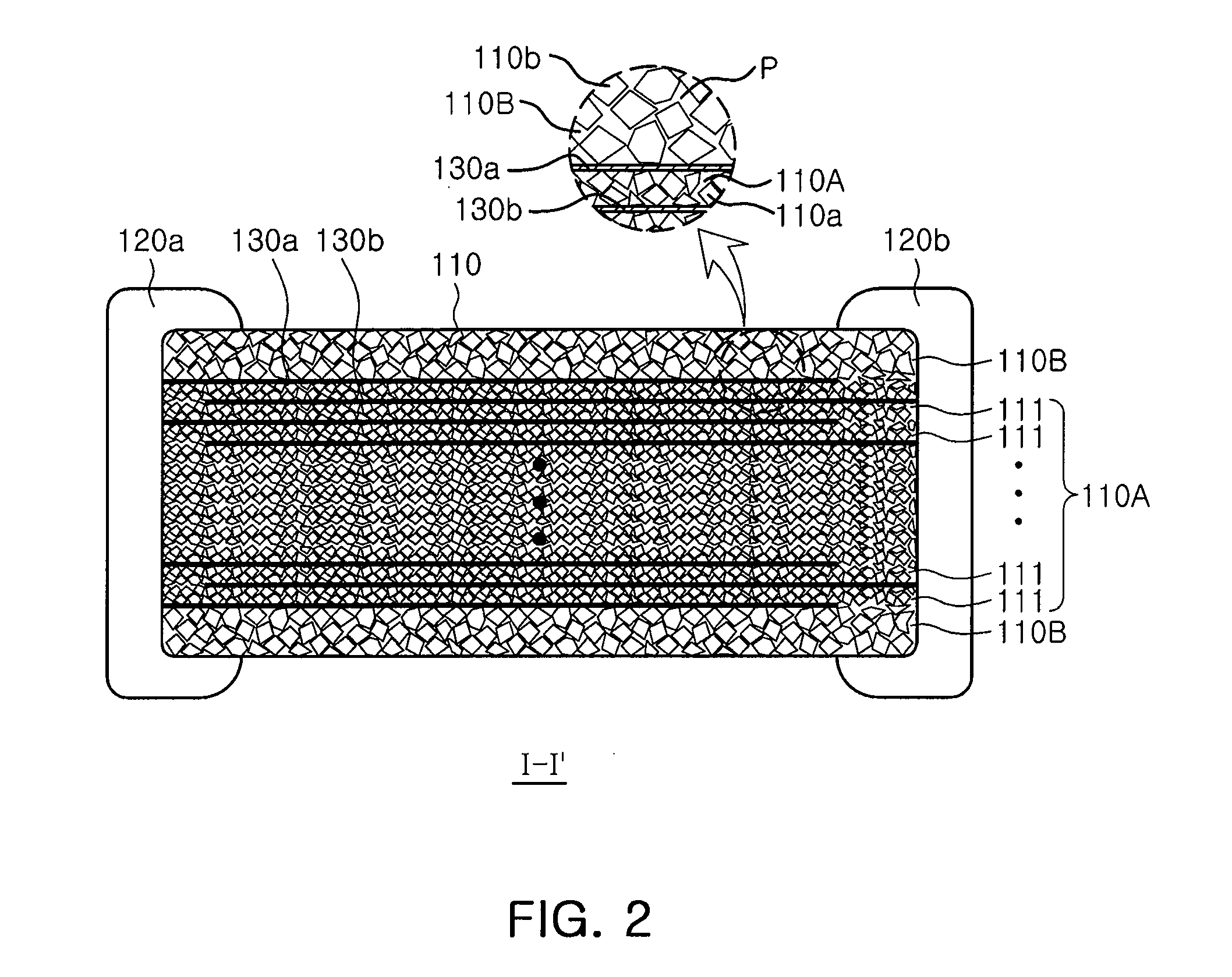

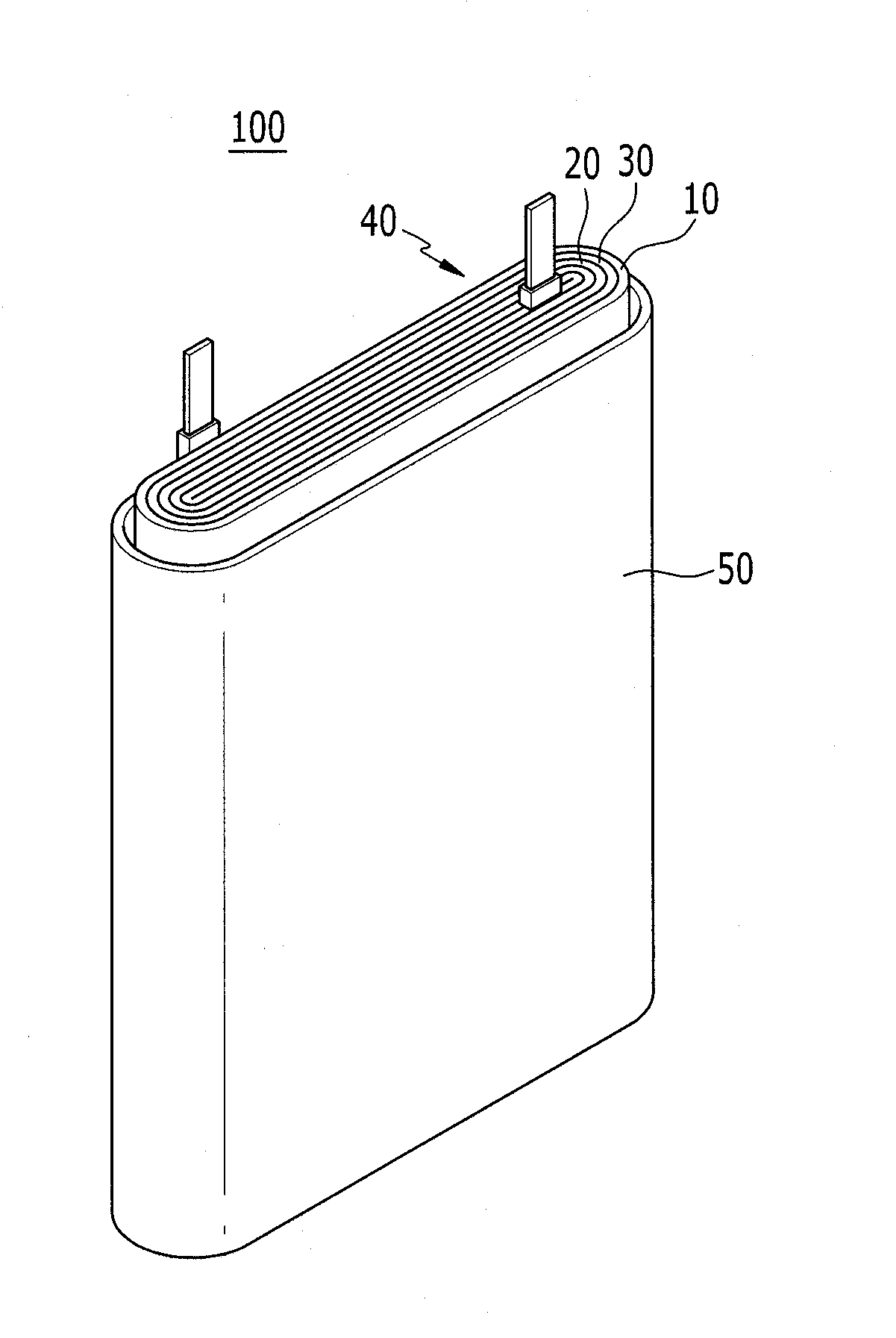

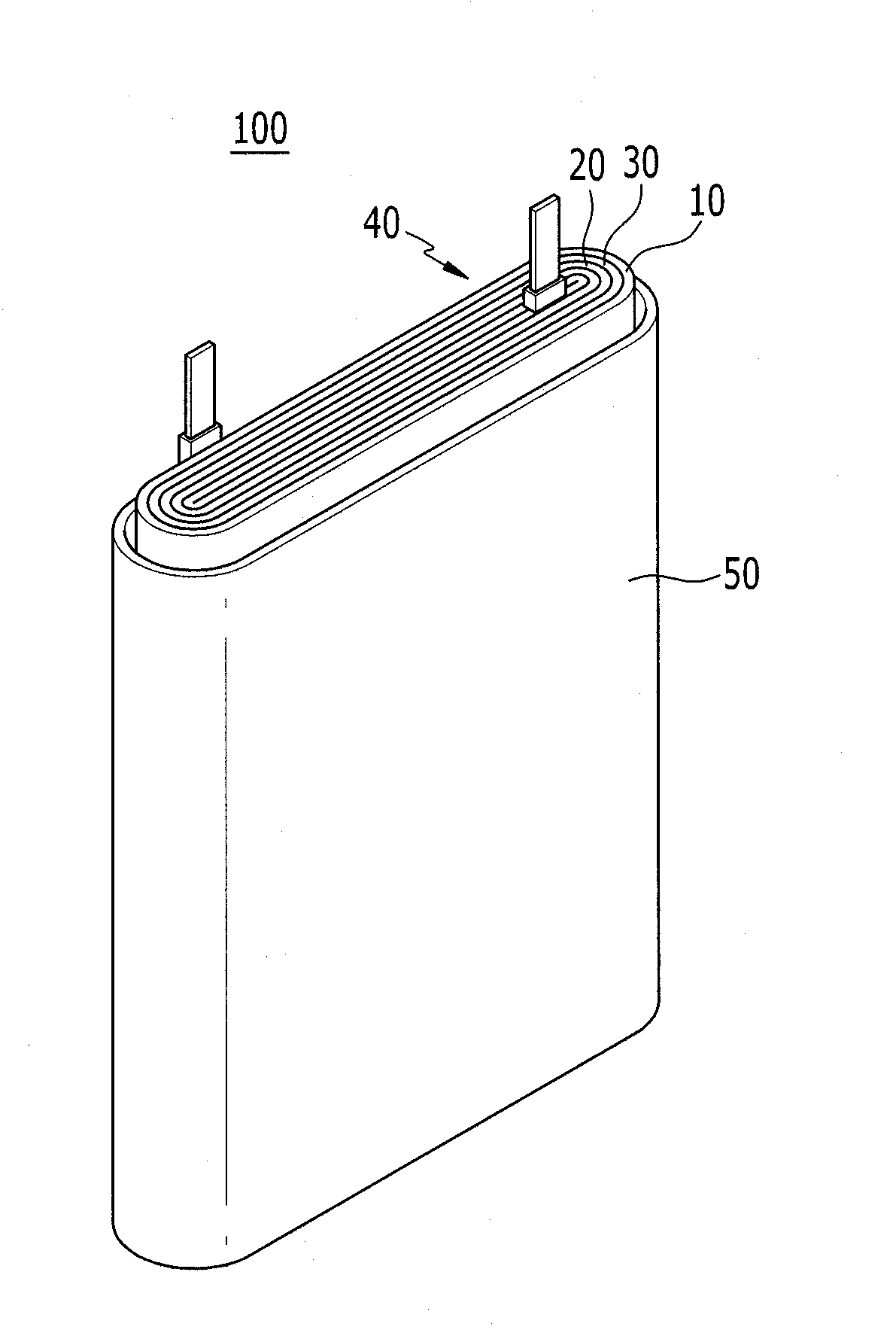

Multilayer ceramic capacitor

InactiveUS20110141655A1Improve reliabilityLow crack occurrence rateThin/thick film capacitorFixed capacitor electrodesParticle size ratioCapacitance

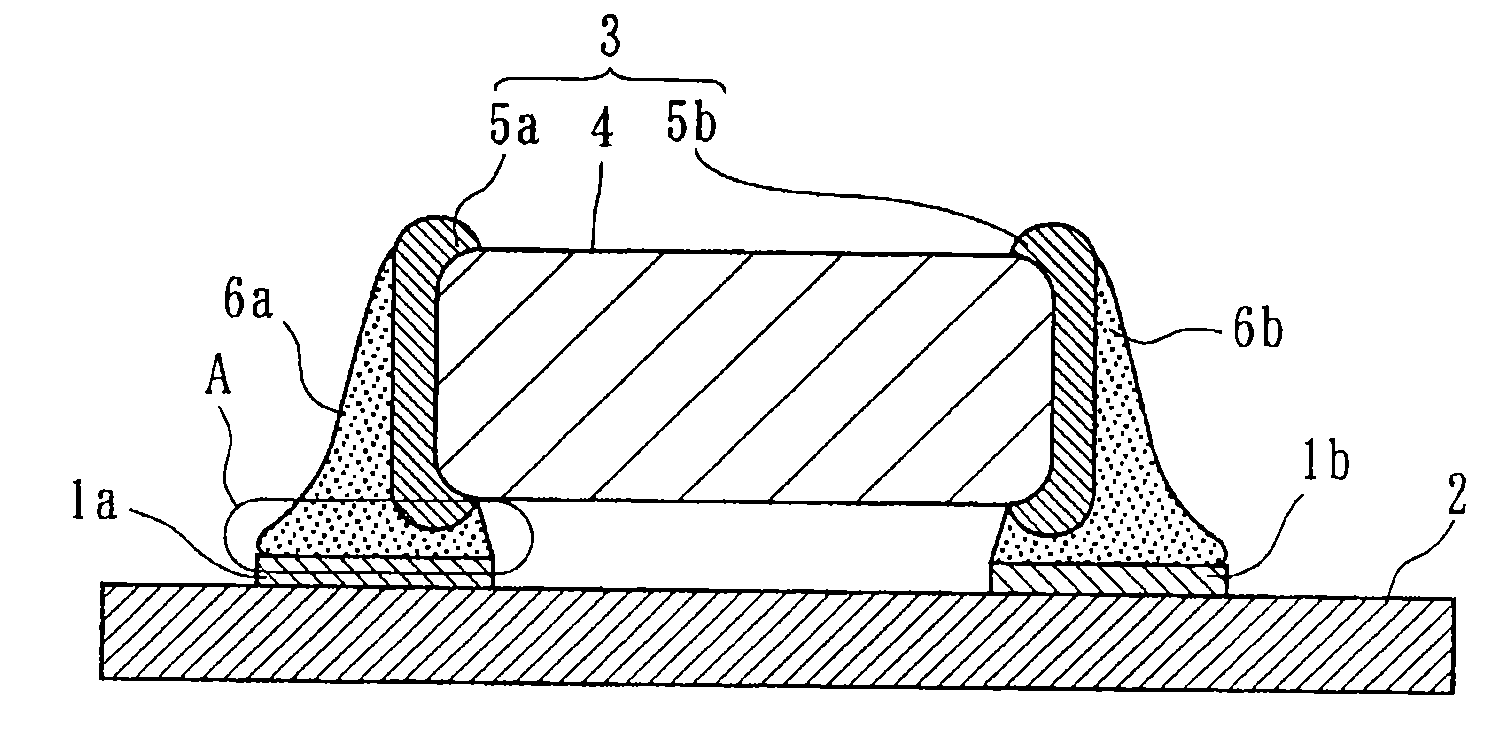

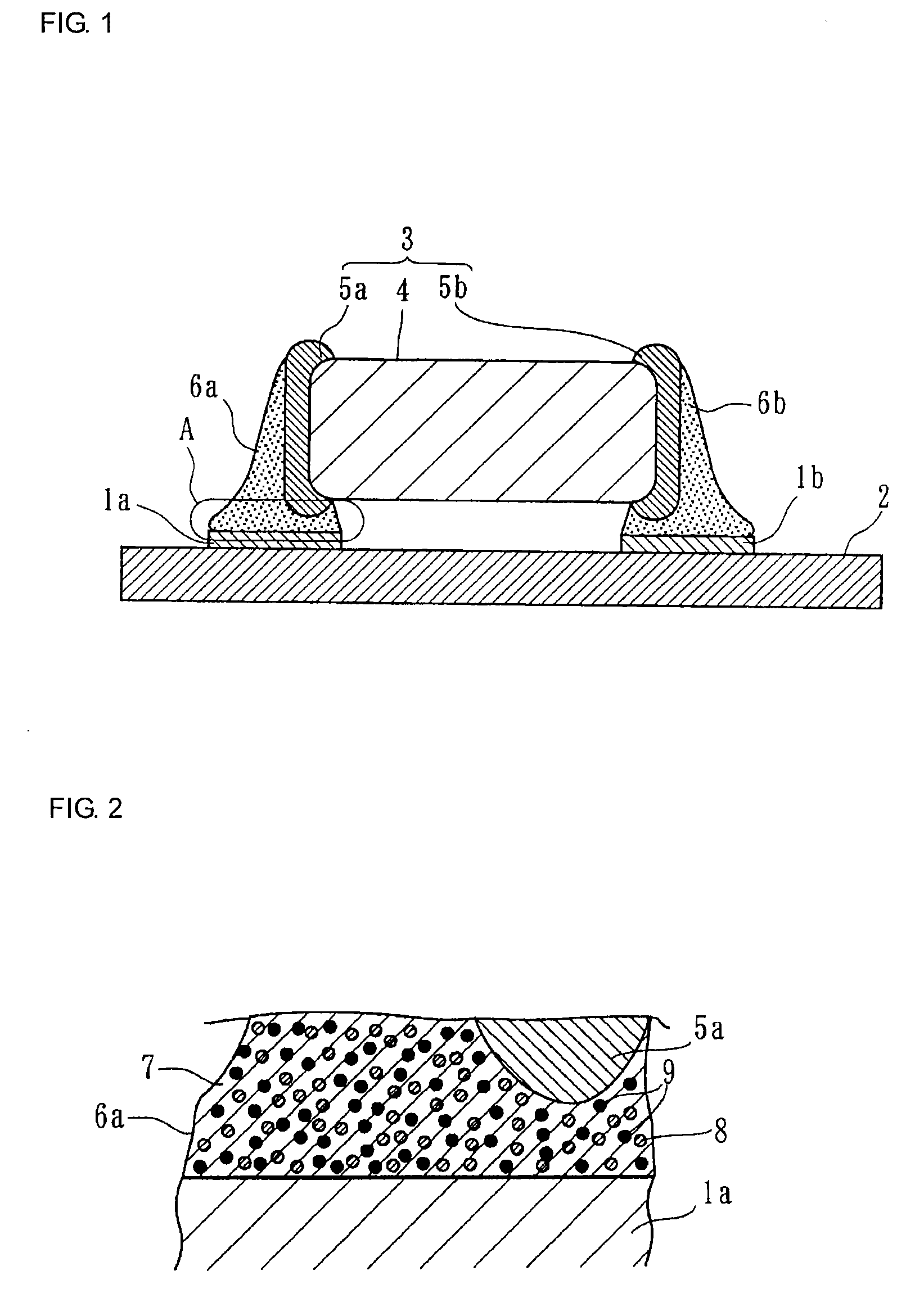

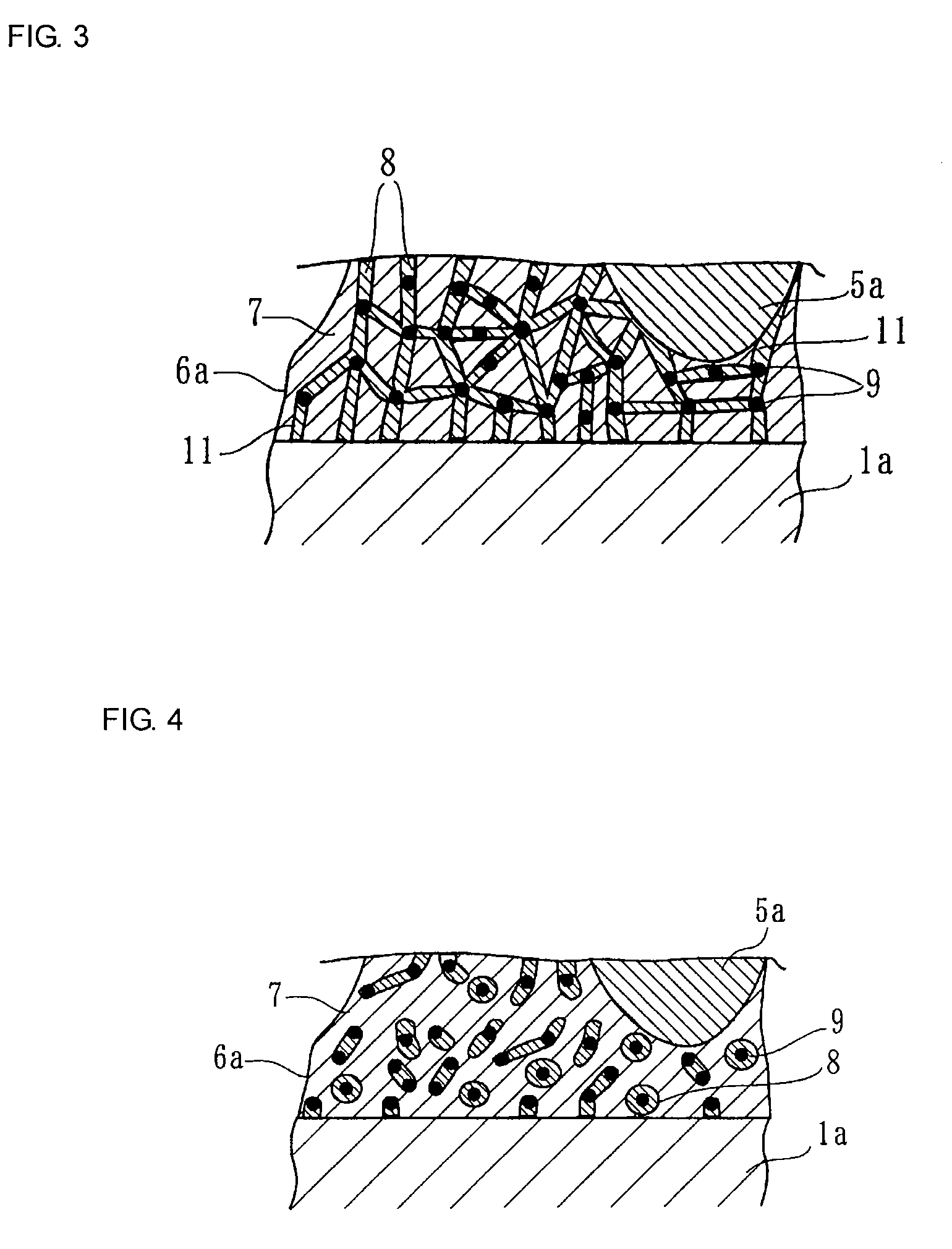

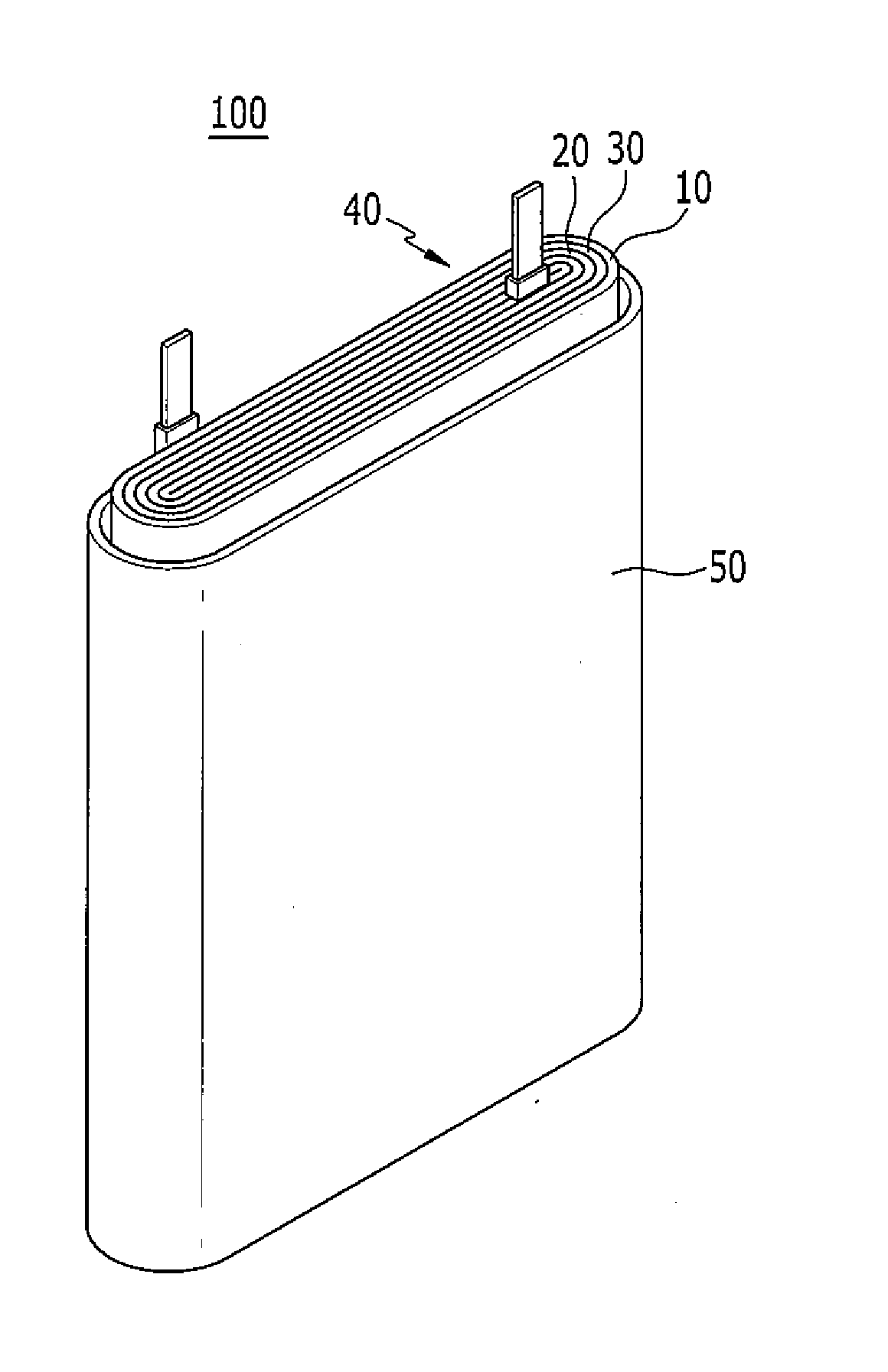

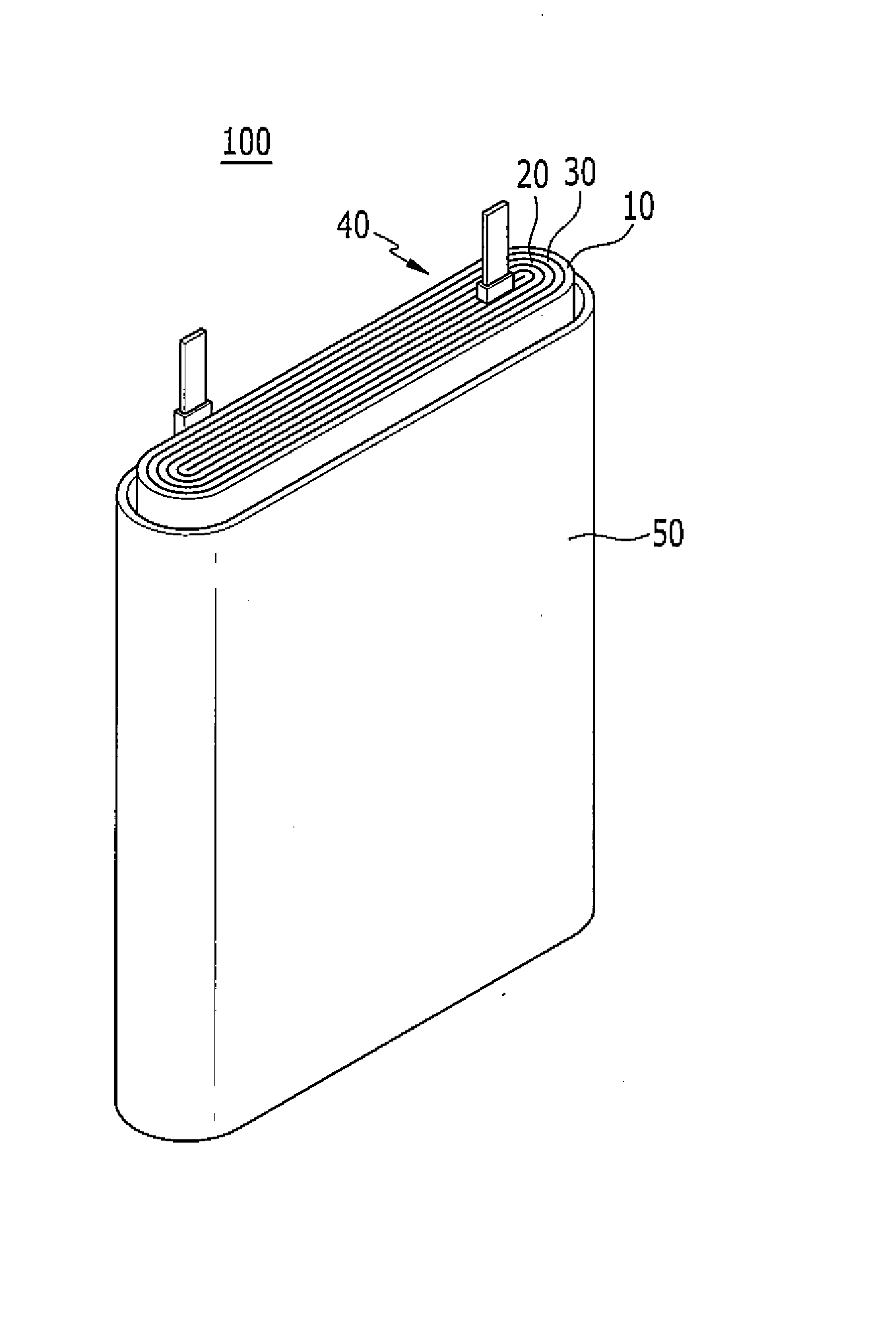

Disclosed is multilayer ceramic capacitor. The multilayer ceramic capacitor includes a capacitive part including dielectric layers and first and second internal electrodes alternately laminated therein, wherein the dielectric layers include first ceramic particles having an average particle size of 0.1 μm to 0.3 μm, and one set of ends of the first internal electrodes and one set of ends of the second internal electrodes are exposed in a lamination direction of the dielectric layers, a protective layer formed on at least one of top and bottom surfaces of the capacitive part, including second ceramic particles and having a porosity of 2% to 4%, wherein an average particle size ratio of the second ceramic particles to the first ceramic particles ranges from 1.1 to 1.3; and first and second external electrodes electrically connected to the first and second internal electrodes exposed in the lamination direction of the dielectric layers.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

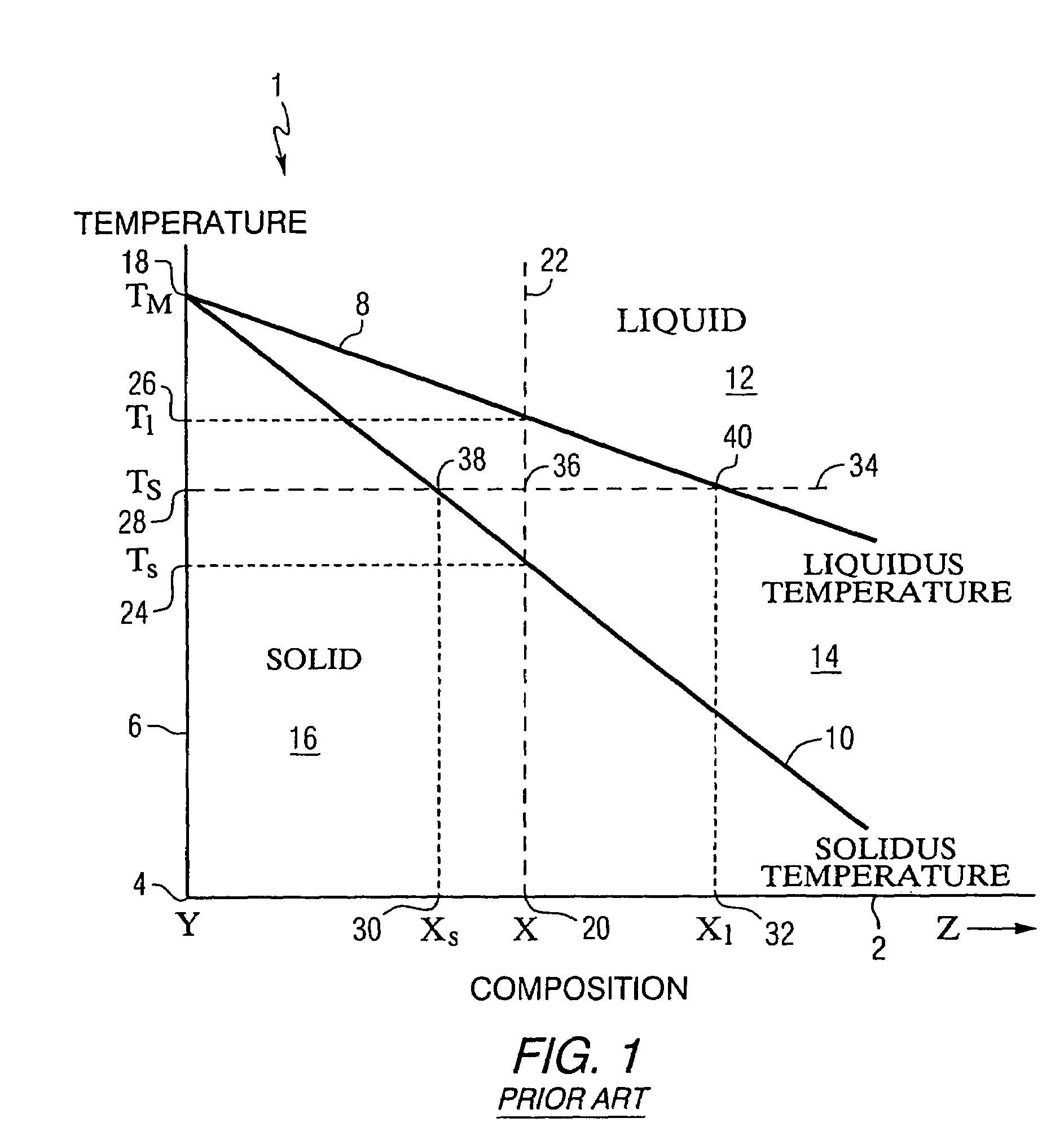

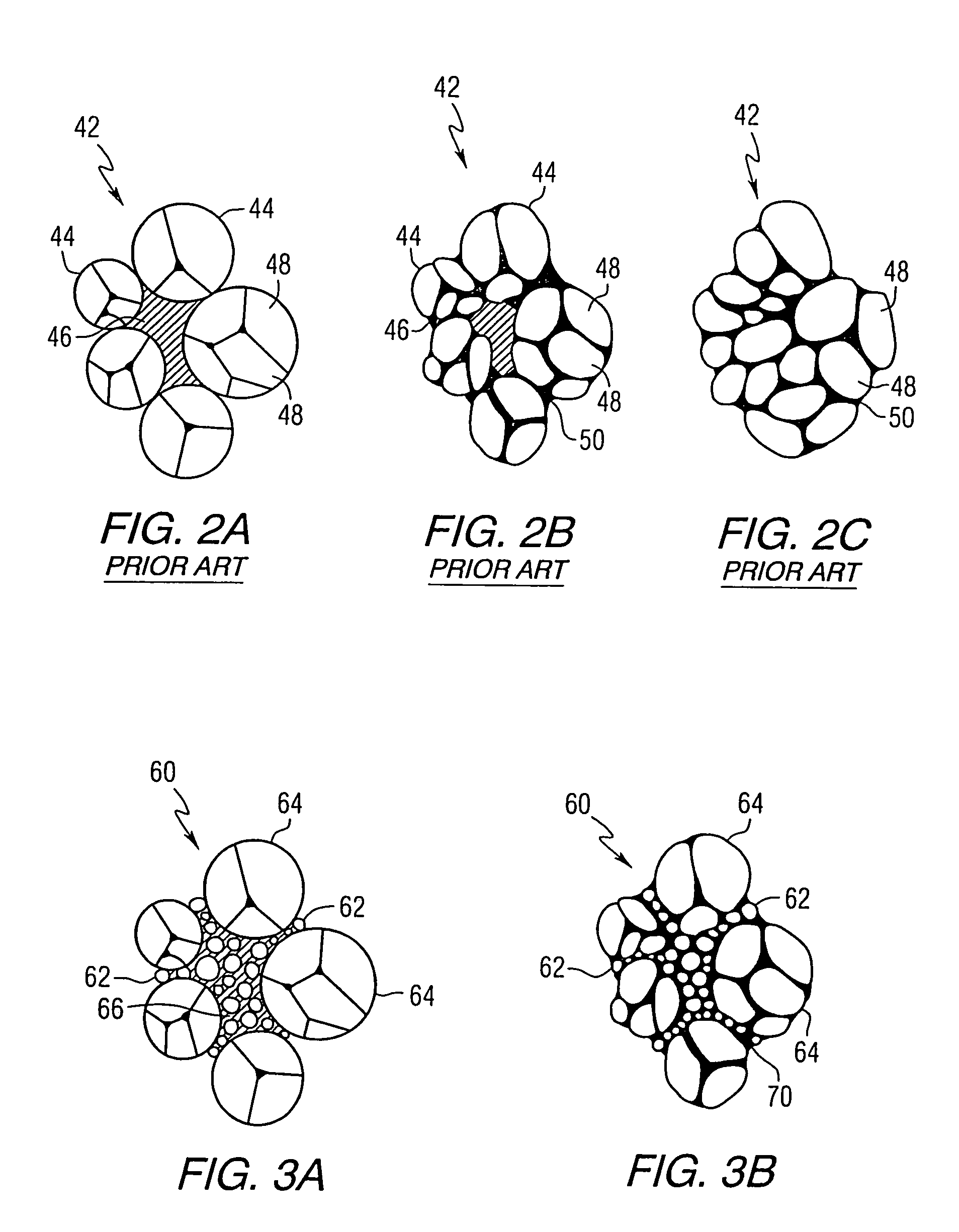

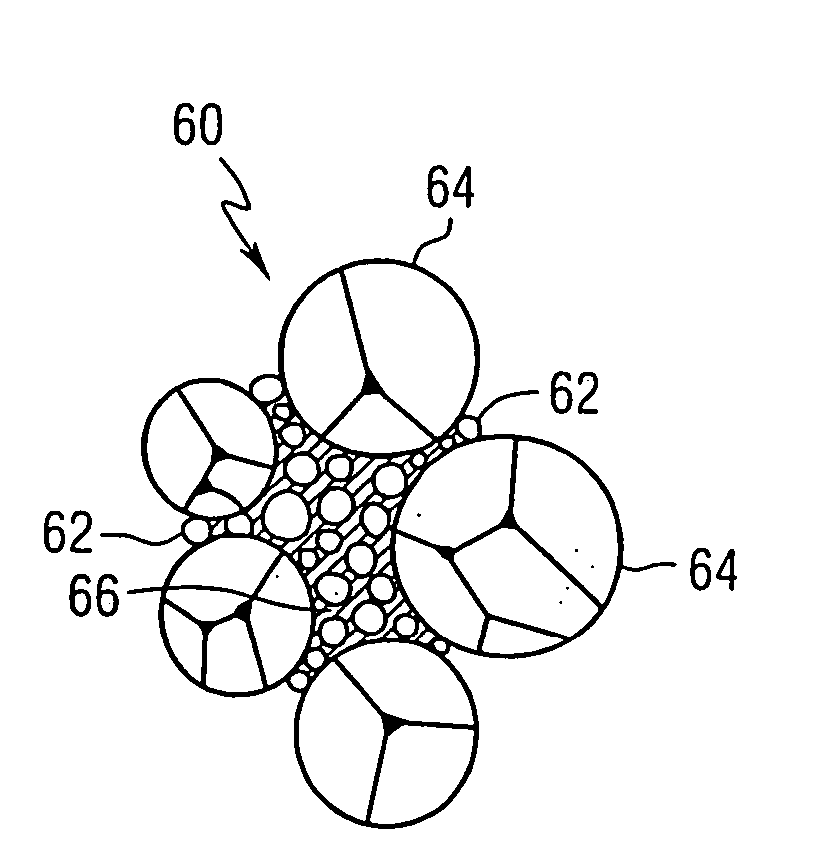

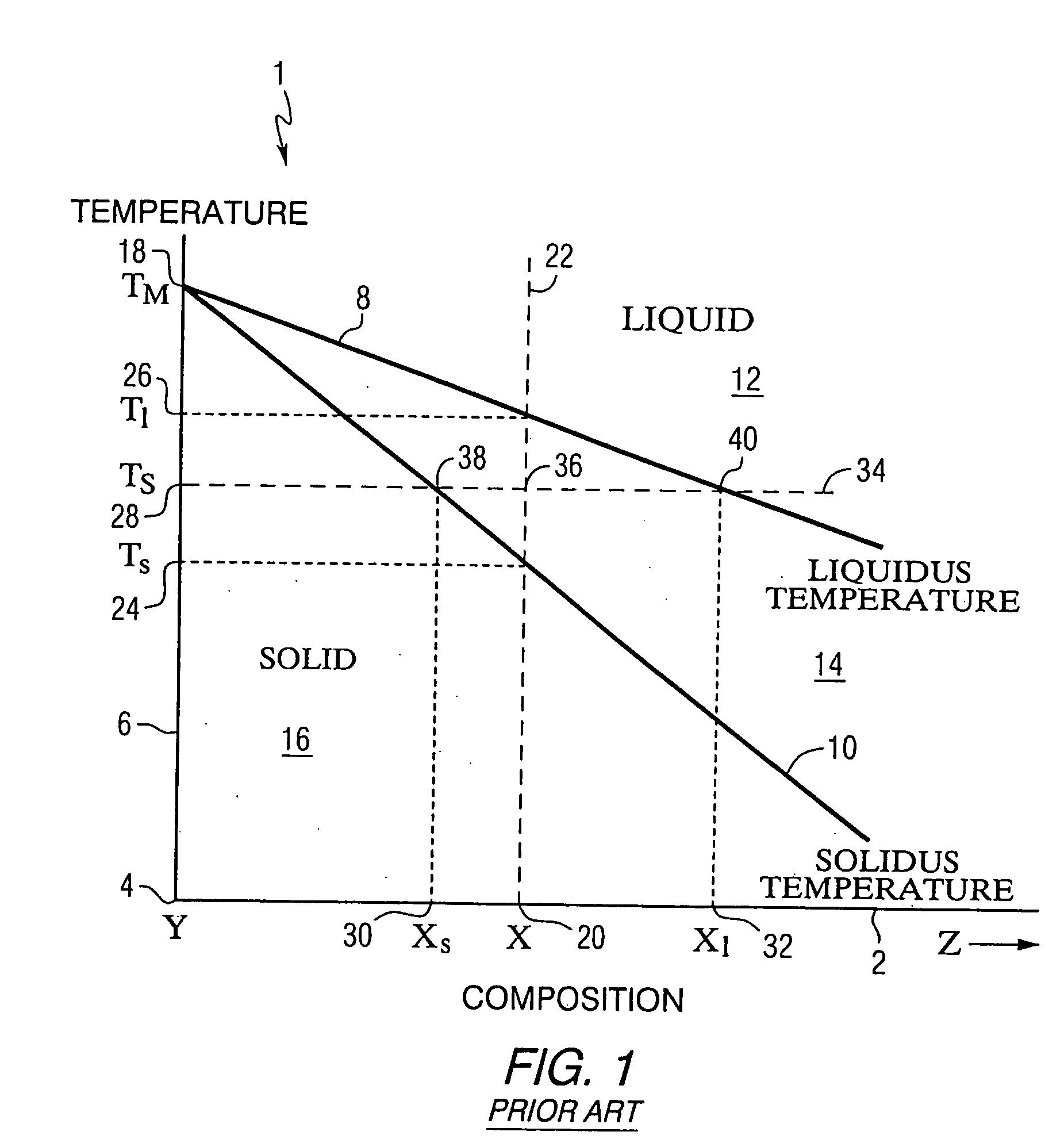

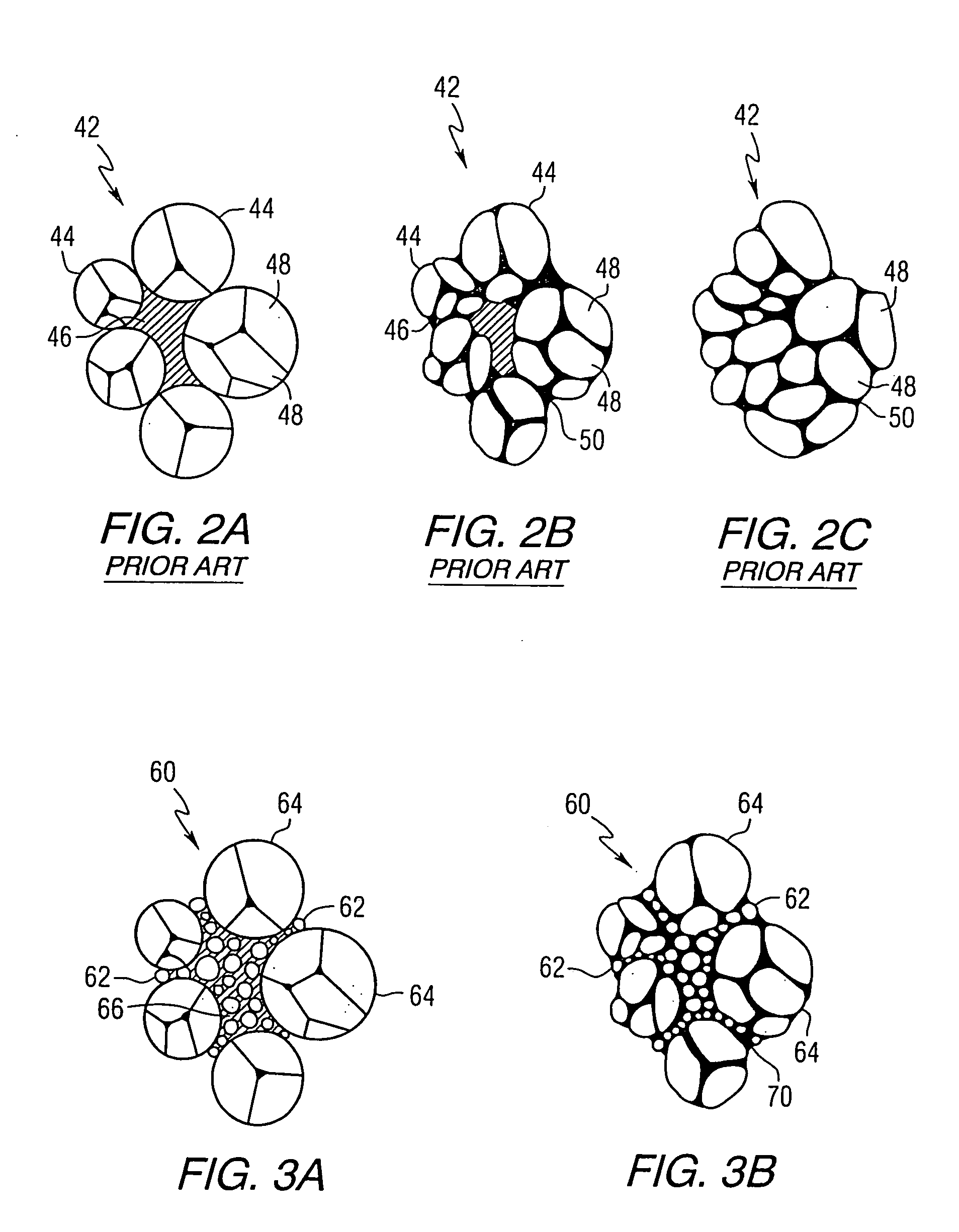

Blended powder solid-supersolidus liquid phase sintering

InactiveUS7070734B2Deleterious effectHigh densityAdditive manufacturing apparatusTransportation and packagingPowder mixtureAlloy

A green article comprising an A-B powder mixture and methods of manufacturing such green articles and corresponding sintered articles are disclosed. The A-B powder mixture consists of a minor volume fraction of a relatively fine powder A and a complementary major volume fraction of a relatively coarse prealloyed powder B wherein the A-B powder mean particle size ratio is at least about 1:5. Metal powder A consists of one or more elemental metals or alloys which has a melting or solidus temperature above the highest sintering temperature at which the A-B powder mixture may be sintered without slumping. Prealloyed metal powder B consists of one or more alloys which are amenable to supersolidus liquid phase sintering. Green articles made from the A-B powder have a wider sintering temperature window than do articles made from prealloyed metal powder B alone.

Owner:THE EX ONE

Blended powder solid-supersolidus liquid phase sintering

InactiveUS20060083652A1Deleterious effectHigh densityAdditive manufacturing apparatusTransportation and packagingPowder mixtureAlloy

A green article comprising an A-B powder mixture and methods of manufacturing such green articles and corresponding sintered articles are disclosed. The A-B powder mixture consists of a minor volume fraction of a relatively fine powder A and a complementary major volume fraction of a relatively coarse prealloyed powder B wherein the A-B powder mean particle size ratio is at least about 1:5. Metal powder A consists of one or more elemental metals or alloys which has a melting or solidus temperature above the highest sintering temperature at which the A-B powder mixture may be sintered without slumping. Prealloyed metal powder B consists of one or more alloys which are amenable to supersolidus liquid phase sintering. Green articles made from the A-B powder have a wider sintering temperature window than do articles made from prealloyed metal powder B alone.

Owner:THE EX ONE

Electroconductive Bonding Material and Electronic Apparatus

ActiveUS20090155608A1High bonding strengthWell formedNon-macromolecular adhesive additivesFinal product manufactureUltimate tensile strengthMetal powder

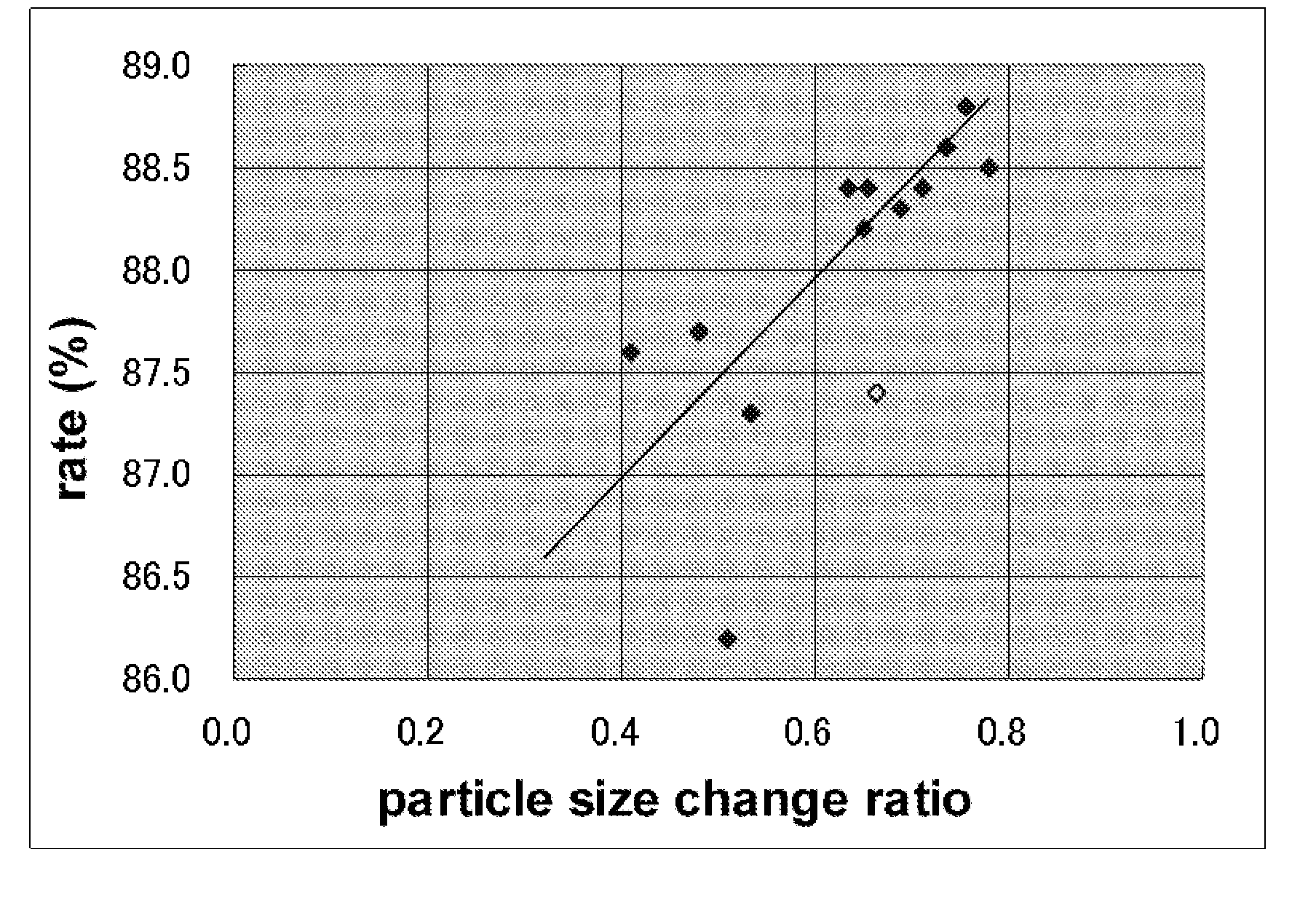

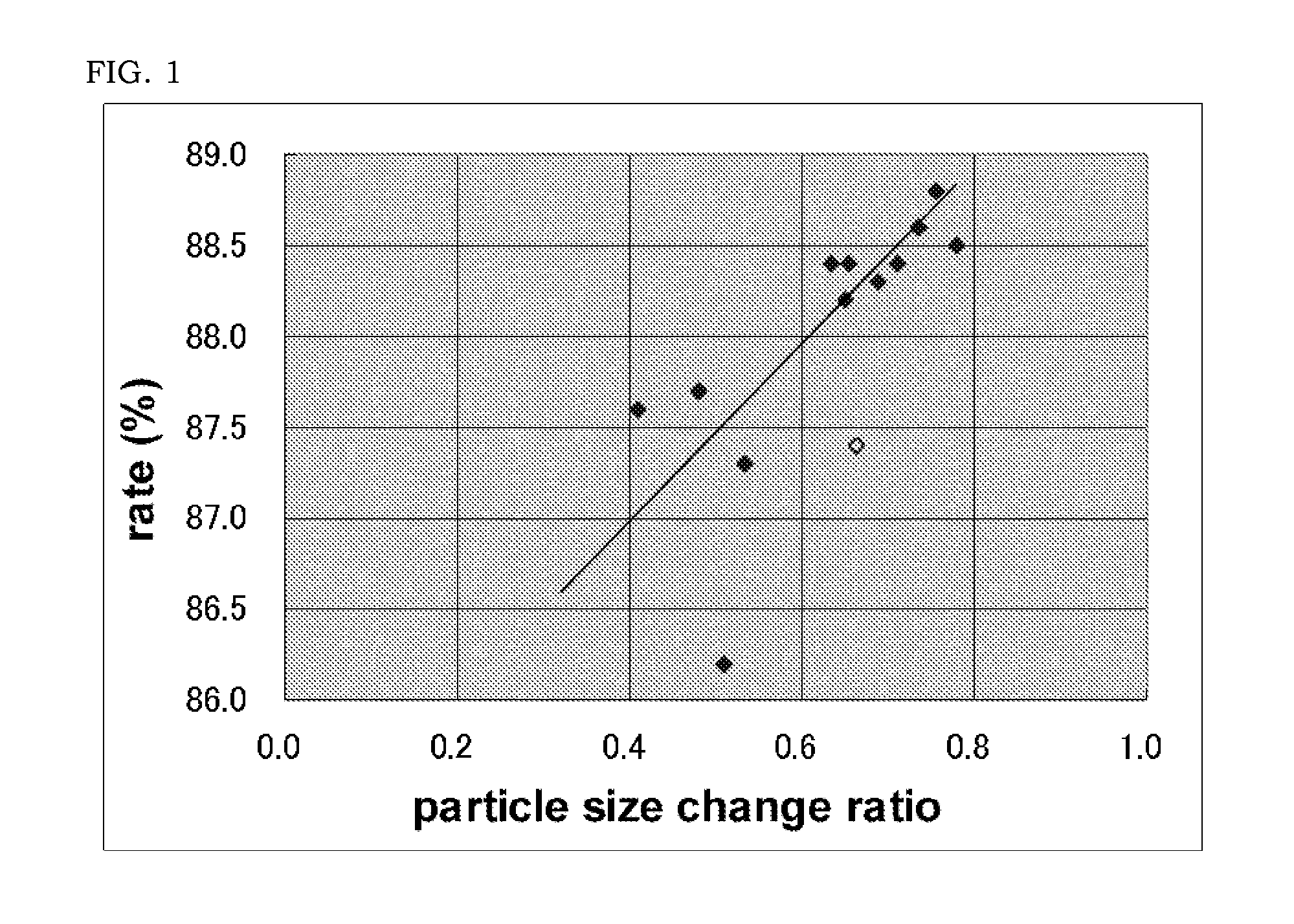

An electroconductive bonding material contains a thermosetting resin, a low-melting-point metal powder which is melted at a temperature equal to or lower than the thermosetting temperature of the thermosetting resin, a high-melting-point metal powder which is not melted at a temperature equal to or lower than the thermosetting temperature of the thermosetting resin and which reacts with the low-melting-point metal powder to form a reaction product having a high melting point of 300° C. or higher during heat-hardening of the thermosetting resin, and a reducing substance which removes an oxide formed on the surface of the high-melting-point metal powder. The total content of the low-melting-point metal powder and the high-melting-point metal powder is 75% to 88% by weight, and the particle size ratio D1 / D2 of the average particle size D1 of the low-melting-point metal powder to the average particle size D2 of the high-melting-point metal powder is 0.5 to 6.0. Thereby, an electroconductive bonding material is provided which has good conduction properties and high connection strength even when reflow heat treatment is repeatedly carried out or thermal shock accompanied with a rapid temperature change is applied to the electroconductive bonding material, and an electronic apparatus using such an electroconductive bonding material.

Owner:MURATA MFG CO LTD

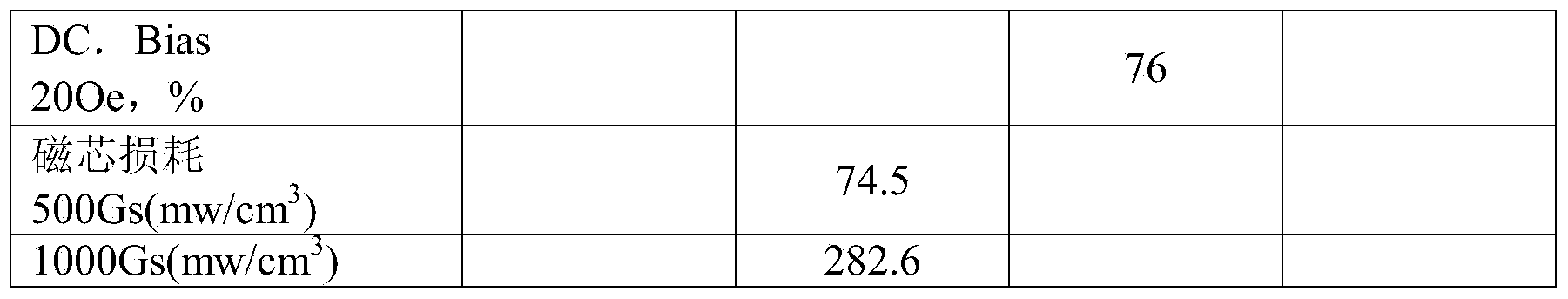

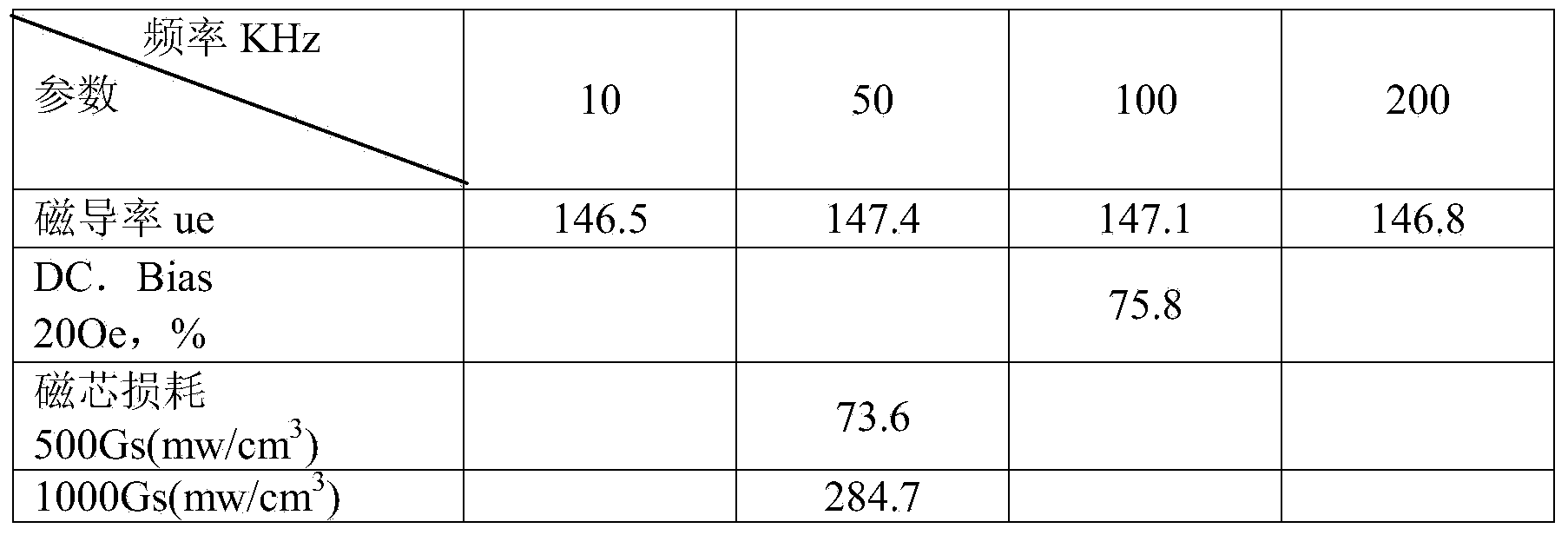

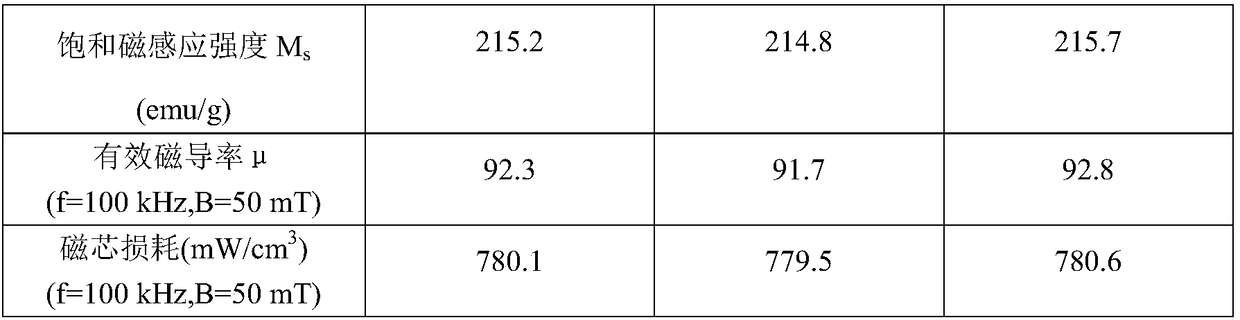

Preparation method of low-loss high permeability Fe-Si-Al magnetic powder core

InactiveCN104361968ALess smelting costEasy to operateInorganic material magnetismVolumetric Mass DensityInduction furnace

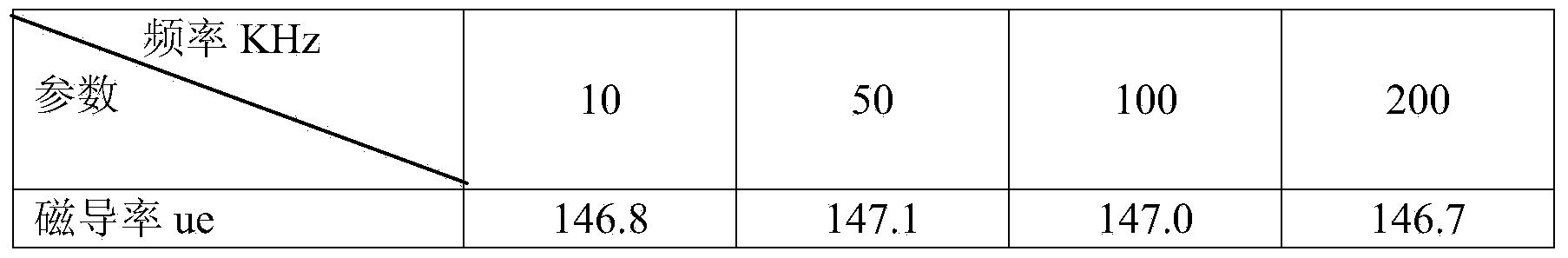

The invention belongs to the technical field of preparation of magnetic materials and discloses a preparation method of a low-loss high permeability Fe-Si-Al magnetic powder core. The method comprises the following steps: (1), adopting a medium-frequency induction furnace, and smelting Fe-Si-Al alloy ingot casting by using casting powder; (2), mechanically crushing the Fe-Si-Al alloy ingot casting into power, performing annealing treatment, screening, and making into Fe-Si-Al alloy powder according to different particle size ratio; (3), performing insulating treatment on the Fe-Si-Al alloy powder, adding an internal lubricant, a releasing agent and then compression moulding forming, preparing into a compression molding product with the density being 6.0-6.2 g / cm<3>; (4), performing heat treatment on the compression molding product, and carrying out surface insulation coating to obtain the Fe-Si-Al magnetic powder core. The preparation method of low-loss high permeability Fe-Si-Al magnetic powder core is low in cost, convenient to operate, high in performance, high in magnetic conductivity and low in high-frequency loss.

Owner:惠州市科力磁元有限公司

Positive Electrode Active Material For Lithium-Ion Battery, Positive Electrode For Lithium-Ion Battery, And Lithium-Ion Battery

ActiveUS20130004849A1Good rate characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryLithium electrode

The present invention provides a positive electrode active material for lithium ion battery having good rate characteristics. The positive electrode active material for lithium ion battery has a layer structure expressed by a composition formula: Lix(NiyMi1-y)Oz, wherein M represents Mn and Co, x represents 0.9 to 1.2, y represents 0.6 to 0.9, and z represents 1.8 to 2.4. The positive electrode active material has a particle size ratio D50P / D50 of 0.60 or more, wherein D50 is the average secondary particle size of the positive electrode active material powder, and D50P is the average secondary particle size of the positive electrode active material powder after pressing at 100 MPa. The positive electrode active material contains 3% or less particles having a particle size of 0.4 μm or less in terms of the volume ratio after pressing at 100 MPa.

Owner:JX NIPPON MINING& METALS CORP

Silica sol and silica-containing epoxy resin composition

ActiveUS20160068664A1Lower emission rateSmall moisture absorption coefficientOther chemical processesSilicon compoundsEpoxySilica particle

The silica sol of the invention contains silica particles having a mean primary particle size of 20 to 100 nm and which has a silica particle size / mean primary particle size ratio, determined through dynamic light scattering, of 3.0 or less, wherein the silica particles are surface-treated with an organic silane compound and have an α-ray emission rate of 0.005 counts / cm2·hr or less and a moisture absorption coefficient, determined after allowing the silica particles to stand for 48 hours at 23° C. and a relative humidity of 50 RH %, of 0.5 mass % or lower.

Owner:NISSAN CHEM IND LTD

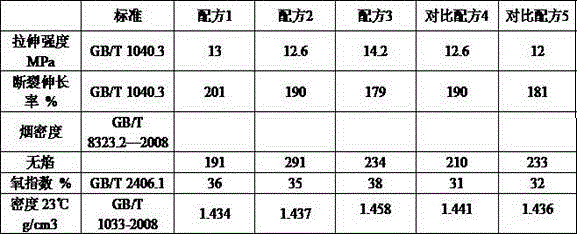

High-oxygen index thermoplastic low-smoke halogen-free polyolefin cable material and preparation method thereof

InactiveCN106750850AImprove flame retardant performancePlastic/resin/waxes insulatorsLinear low-density polyethylenePolyolefin

The invention relates to a high-oxygen index thermoplastic low-smoke halogen-free polyolefin cable material and a preparation method thereof. The material is prepared from the following components: 40-60 parts of ethylene-vinyl acetate copolymer (EVA), 10-35 parts of linear low-density polyethylene (LLDPE), 2-25 parts of ethylene-octylene copolymer (POE), 10-30 parts of an interfacial compatibilizer (grafting material and silicone master batches), 100-180 parts of aluminum hydroxide (the aluminum hydroxide of which the particle sizes are smaller than 1 micron accounts for about 0-50% and the aluminum hydroxide of which the particles sizes are 1-10 microns accounts for 50-100%), 0-50 parts of other fire retardants, 0-4 parts of an antioxidant and 1-10 parts of other mill base and the like. Compared with the prior art, the high-oxygen index thermoplastic low-smoke halogen-free polyolefin cable material has the advantages that the aluminum hydroxide materials with different particle size ratios are selected, so that a product has the characteristics of a high oxygen index, high mechanical strength, good processability and the like. The product can be applied to sheaths or insulating materials of a power cable, a control cable, an optical cable, a local cable, a signal cable and various transmission cables, plays a structural flame retardant role and is used for improving the flame resistance of the cable.

Owner:BAOSHENG SCI & TECH INNOVATION +2

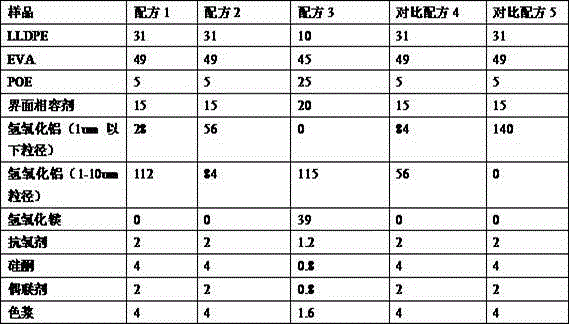

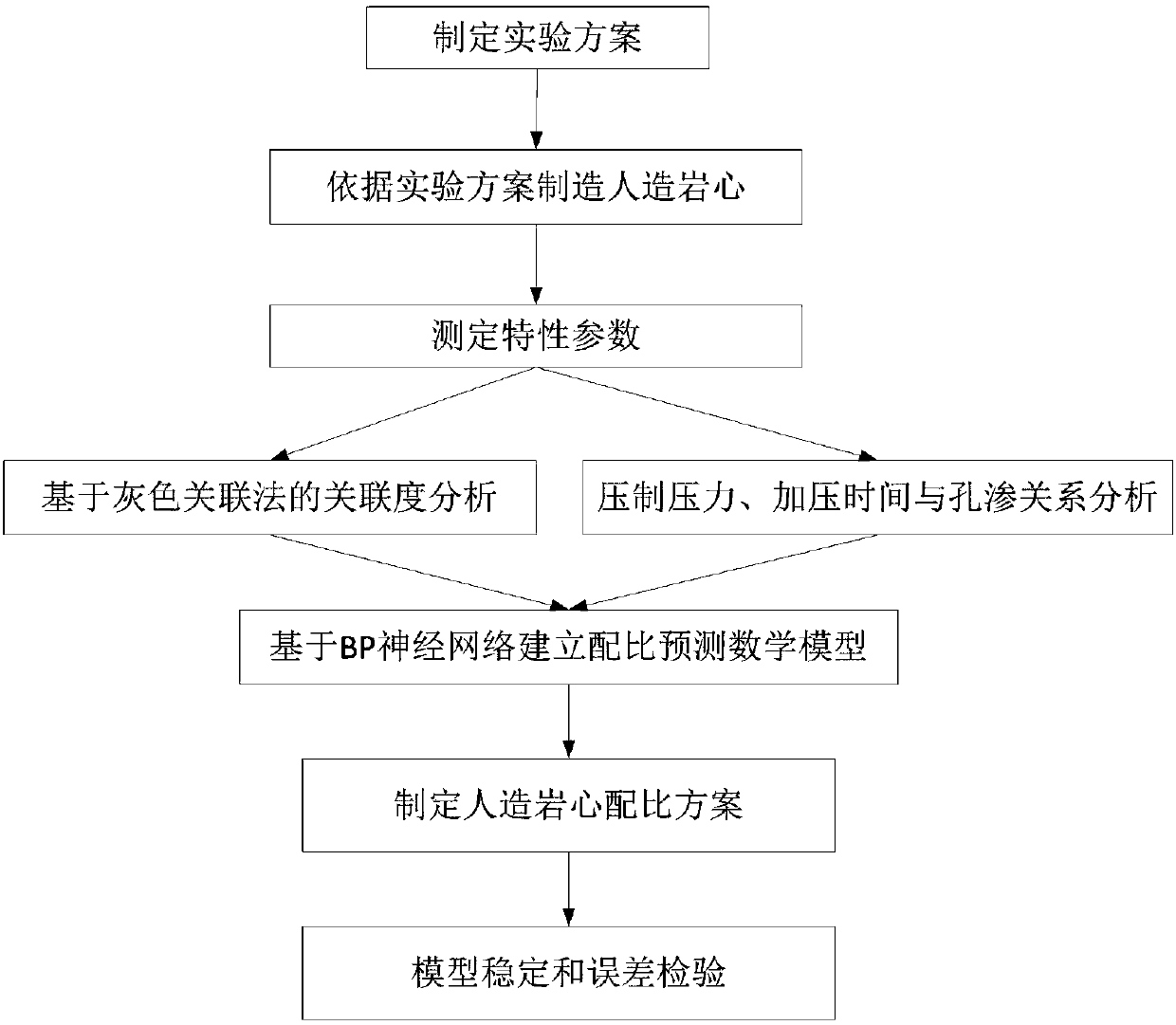

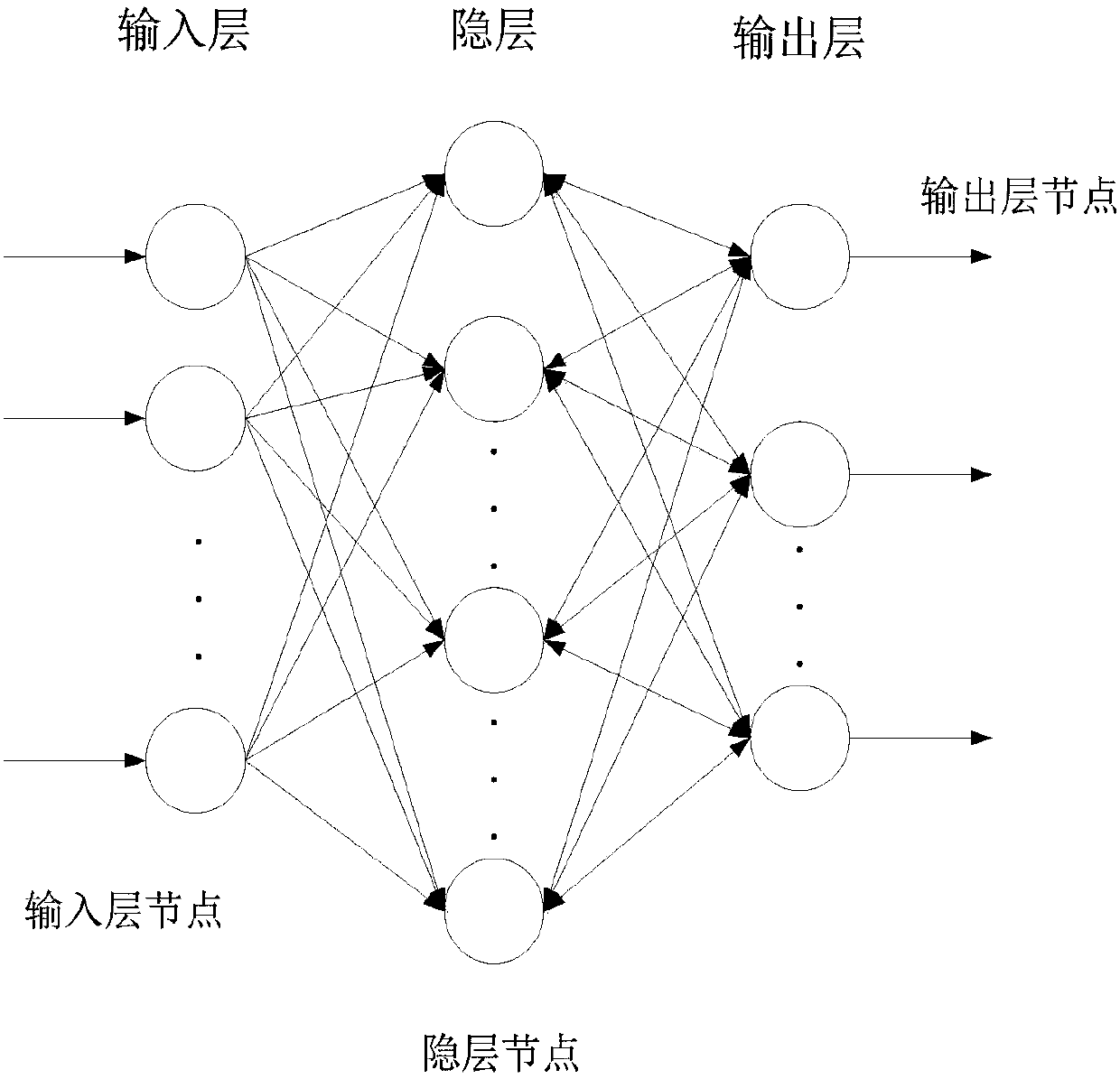

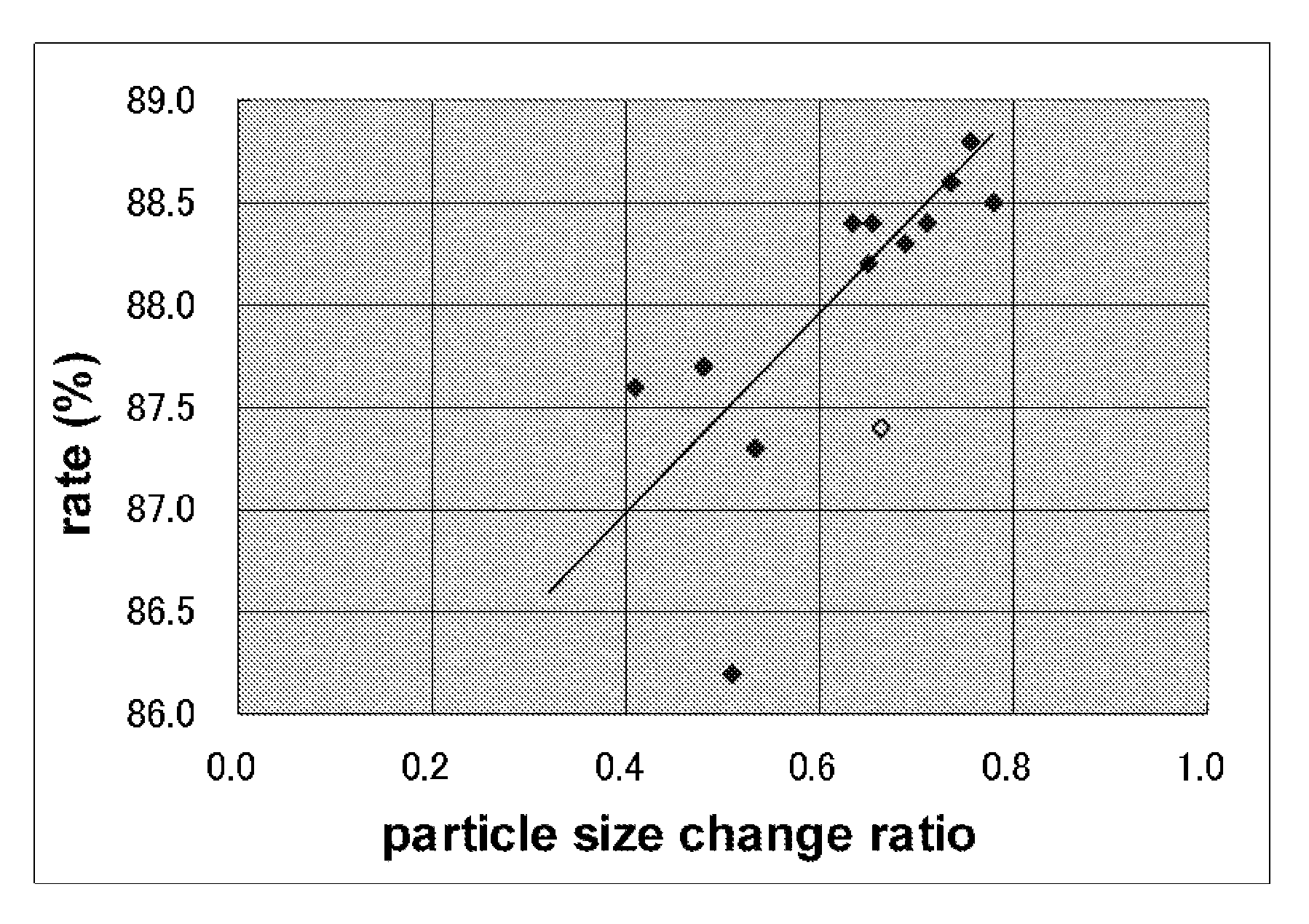

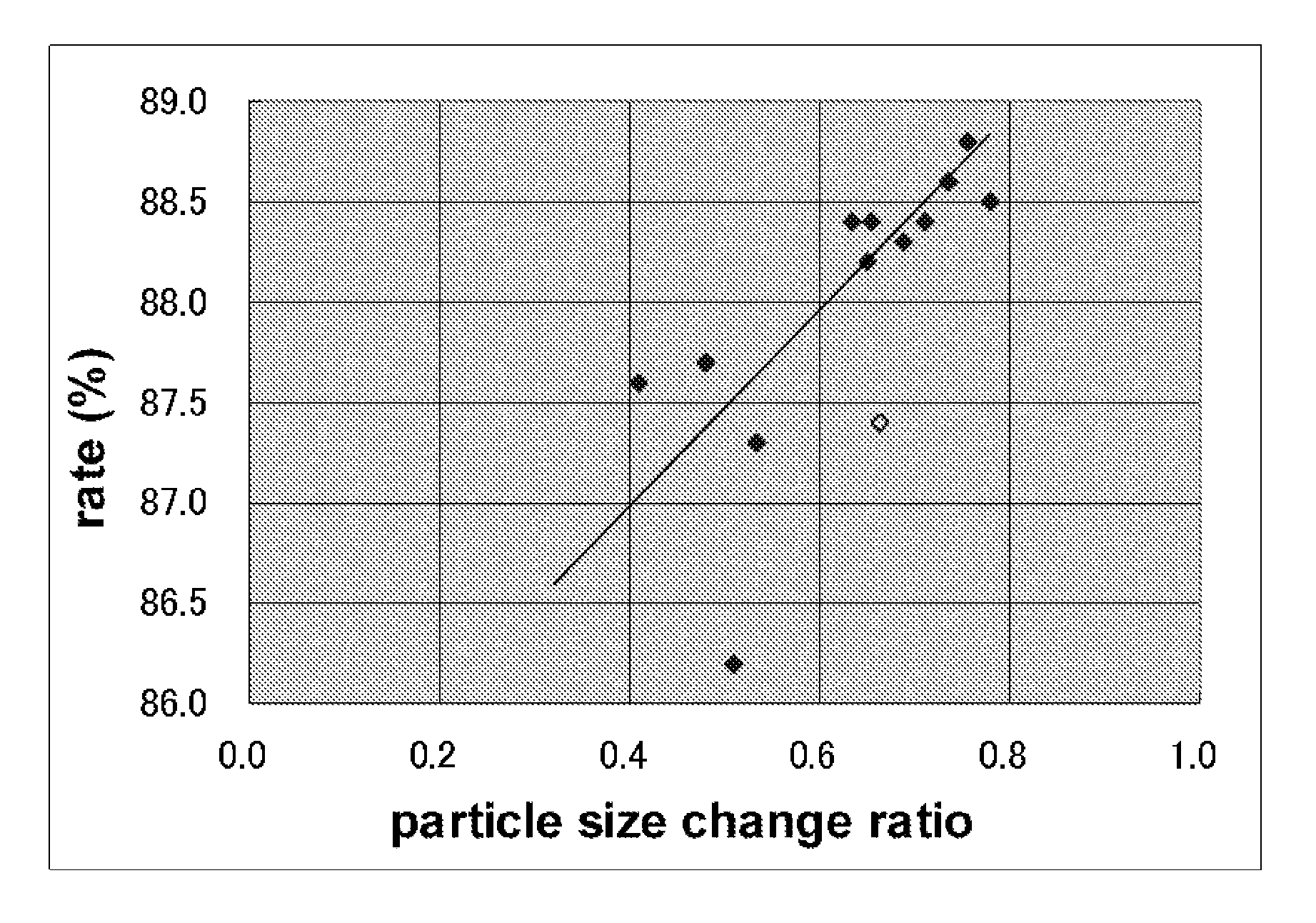

Displacement experiment artificial core analysis preparing method based on experimental and mathematical algorithms

ActiveCN107742031AImprove error precisionReasonableness of judgmentDesign optimisation/simulationSpecial data processing applicationsStatistical analysisMathematical model

The invention discloses a displacement experiment artificial core analysis preparing method based on experimental and mathematical algorithms, and the method combines qualitation with quantitation. The method comprises the steps that physical parameters of an artificial core are used as target parameters for preparation of the artificial core; influencing factors of the physical parameters of theartificial core are determined; multiple sets of combined experiment schemes are made, and the artificial core is prepared according to all the combined experiment schemes, and the physical parametersof the artificial core are measured after preparation is completed; preparation condition parameters of all the combined experiment schemes are used as basis, and based on a gray correlation analysismethod, relevancy degrees of all the influencing factors and all the target parameters are determined; according to the relevancy degree rank of all the influencing factors and the target parameters,larger influencing factors and smaller influencing factors are determined; based on a statistic analysis result of the gray correlation analysis method and a BP neural network theory, a particle sizeratio prediction mathematical model is built; a matching prediction result is calculated through the particle size ratio prediction mathematical model and serves as a reference which provides data support for artificial core manufacturing.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

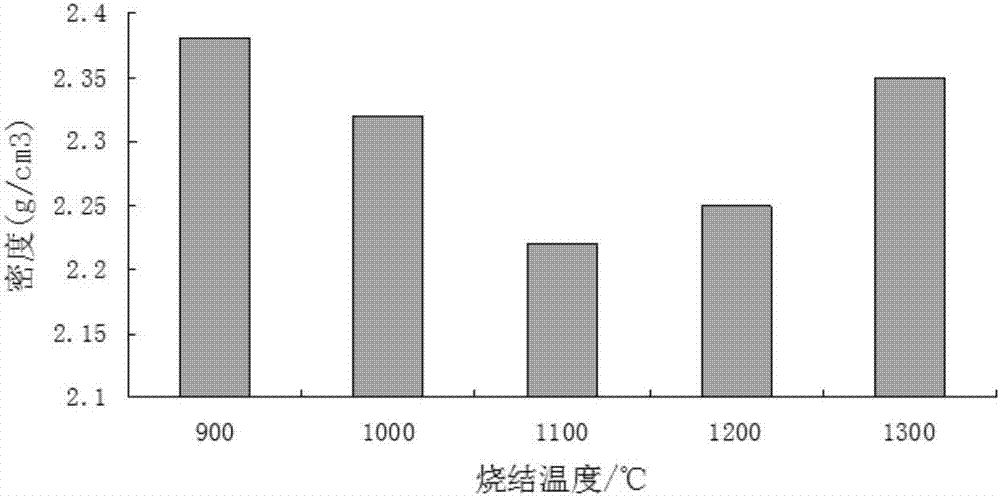

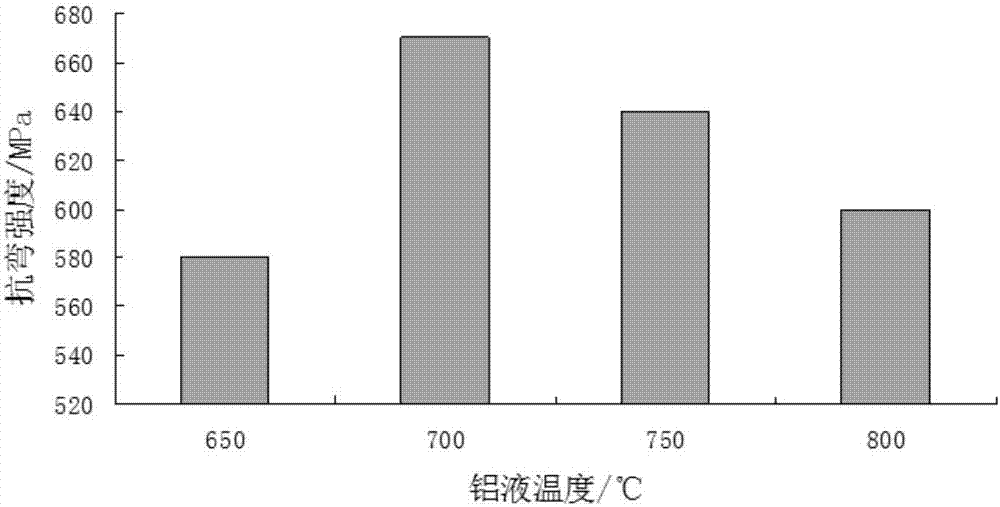

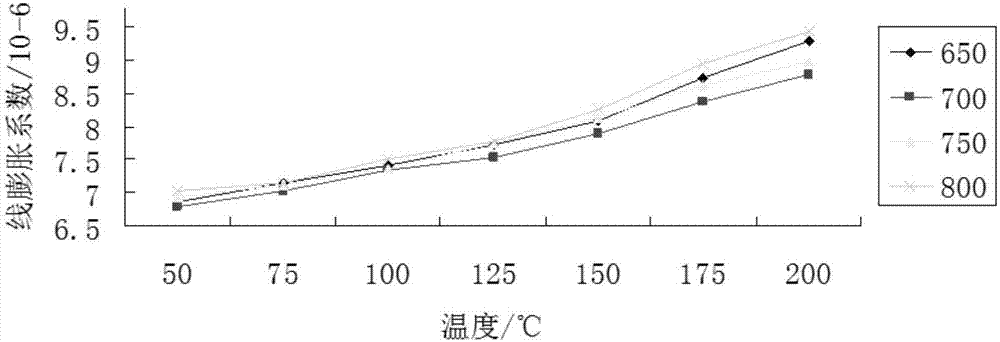

Preparation method of hollow aluminum oxide ball/silicon carbide synergetically enhanced aluminum-based composite material

The invention provides a preparation method of a hollow aluminum oxide ball / silicon carbide synergetically enhanced aluminum-based composite material. Hollow aluminum oxide balls and micron-level silicon carbide with different sizes are used as enhancement bodies, so that the overall density of the composite material is reduced on the premise of guaranteeing the mechanical property and a low thermal expansion coefficient. The adoption of the hollow aluminum oxide balls aims at reducing the density of the whole material to the maximum extent due to the characteristic of high strength of used aluminum oxide ceramic and the hollow structures of hollow aluminum oxide balls; furthermore, the interface activation energy of aluminum oxide and aluminum is relatively low; and after silicon carbide particles are added, the composite interface activation energy can be enhanced, so that the mechanical property of the composite material is higher. Due to different particle size ratios, the volume fractions of the enhancement bodies can be increased to the maximum extent, so that the mechanical strength of the composite material is enhanced, and the toughness of the aluminum and the rigidity of the enhancement bodies can reach the optimal ratios.

Owner:西安明科微电子材料有限公司

Enhanced thermal conducting formulations

InactiveUS7462294B2Low viscosityOther chemical processesSemiconductor/solid-state device detailsElectrical conductorAdhesive

A thermal conducting mixture is provided which is used to make thermal conducting formulations such as a paste having a high thermal conductivity and a relatively low viscosity. The paste is used to provide a thermal conductor connection between an electronic component and a cooling device to increase the heat transfer rate between the component and the device cooling the electronic component. The formulation contains the mixture of thermally conductive particles in various particle size ranges typically dispersed in a non-aqueous dielectric carrier containing an antioxidant and a dispersant with the thermally conductive particles mixture being specially correlated in the mixture by volume % based on particle size range and by particle size ratio of each particle size range. The mixture may be used to make other similar products such as thermal gels, adhesives, slurries and composites, for electronic and cosmetics, pharmaceuticals, automotive, and like products.

Owner:INT BUSINESS MASCH CORP

Sintered mixture preparation method, sintered mixture distribution apparatus and sintered mixture distribution method

ActiveCN108396136AEnhanced granulationIncrease the ratio of reasonable granularityCharge composition/stateCharge manipulationMaterial distributionDistributor

The invention relates to a sintered mixture preparation method, a sintered mixture distribution apparatus and a sintered mixture distribution method, wherein the raw materials of the sintered mixturecomprise iron ore powder, coke powder, return ore, quicklime and limestone. The sintered mixture preparation method comprises: placing iron ore powder, quicklime, return ore with a particle size of less than 3 mm after wetting, coke powder with a particle size of less than 3 mm, limestone and water to a primary mixer, and uniformly mixing to obtain a primary mixture; and placing the primary mixture, return ore with a particle size of 3-5 mm after wetting, coke powder with a particle size of more than 3 mm, limestone with a particle size of greater than 3 mm and water to a secondary intensive mixer, and uniformly mixing to prepare the sintered mixture. The sintered mixture distribution method comprises: distributing the sintered mixture onto a sintering machine in layers through the sintered mixture distribution apparatus comprising three sets of multi-roller material distributors, wherein the particle sizes of the layers are sequentially reduced from bottom to top, the particle size ofthe first layer is more than 8 mm, the particle size of the second layer is 5-8 mm, the particle size of the third layer is 3-5 mm, and the particle size of the uppermost layer is less than 3 mm. According to the present invention, the particle size ratio of the sintered mixture is improved, the precise segregation multi-layer material distribution is achieved, and the gas permeability and the sintering utilization coefficient of the sintered mixture are improved.

Owner:ANGANG STEEL CO LTD

Positive electrode active material for lithium-ion battery, positive electrode for lithium-ion battery, and lithium-ion battery

ActiveUS9090481B2Good rate characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesPhysical chemistryLithium-ion battery

The present invention provides a positive electrode active material for lithium ion battery having good rate characteristics. The positive electrode active material for lithium ion battery has a layer structure expressed by a composition formula: Lix(NiyM1-y)Oz, wherein M represents Mn and Co, x represents 0.9 to 1.2, y represents 0.6 to 0.9, and z represents 1.8 to 2.4. The positive electrode active material has a particle size ratio D50P / D50 of 0.60 or more, wherein D50 is the average secondary particle size of the positive electrode active material powder, and D50P is the average secondary particle size of the positive electrode active material powder after pressing at 100 MPa. The positive electrode active material contains 3% or less particles having a particle size of 0.4 μm or less in terms of the volume ratio after pressing at 100 MPa.

Owner:JX NIPPON MINING & METALS CORP

Preparation method for non-close-packed SiO2 photonic crystals

ActiveCN102417309ALess prone to damageSimple production processPhotonic crystal structureCrystal structure

The invention relates to a preparation method for non-close-packed SiO2 photonic crystals. The preparation method comprises the following steps: taking tetraethoxysilane as a raw material, thereby preparing SiO2 nanometer and submicron sphere grains; ultrasonically and automatically assembling two SiO2 sphere grains at a certain particle size ratio, thereby obtaining a double-size photonic crystal structure; and roasting, etching and cleaning the double-size photonic crystal structure, thereby obtaining the non-close-packed SiO2 photonic crystals. The preparation method provided by the invention is short in preparation period and simple in processing equipment.

Owner:江苏优耐机械制造有限公司

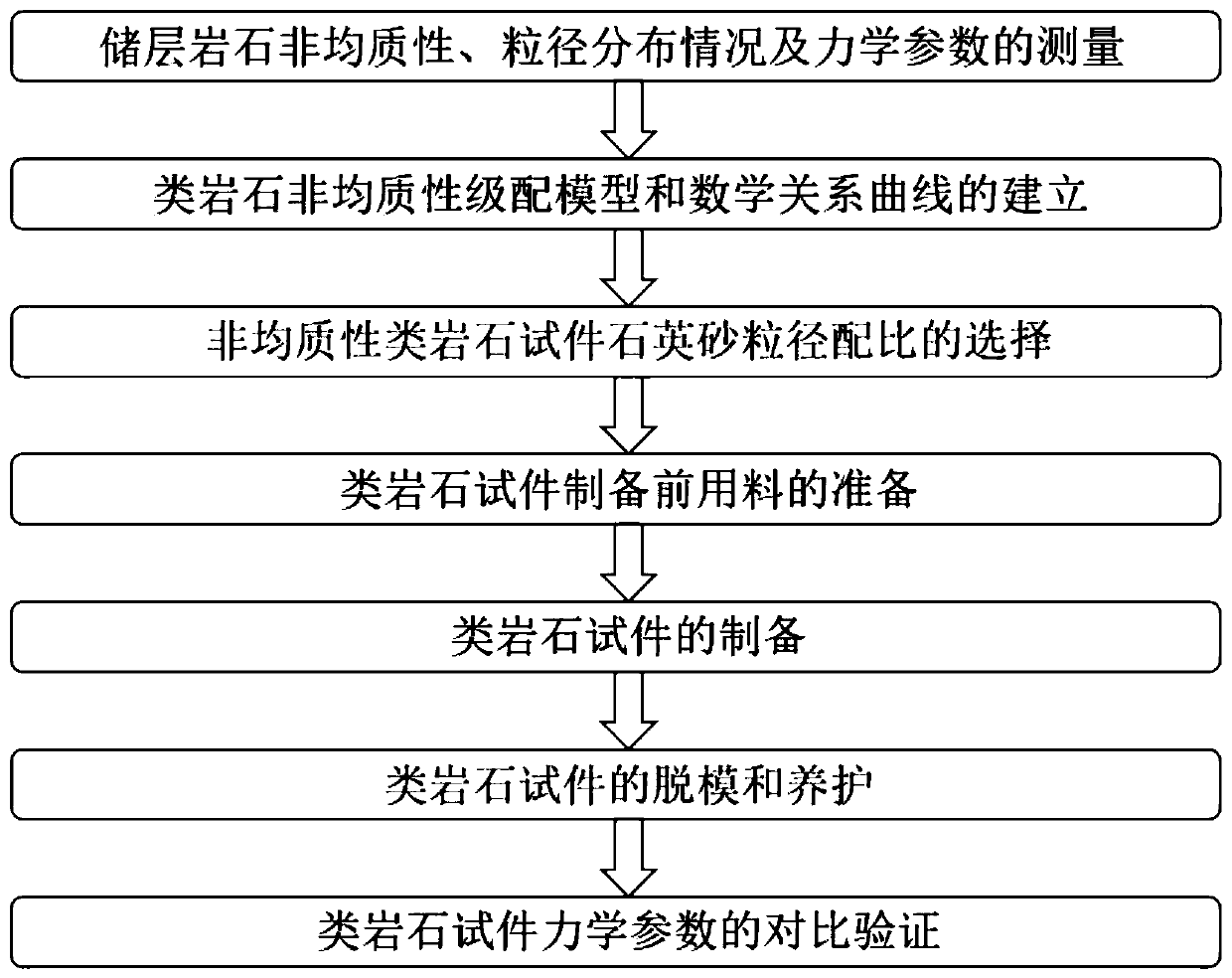

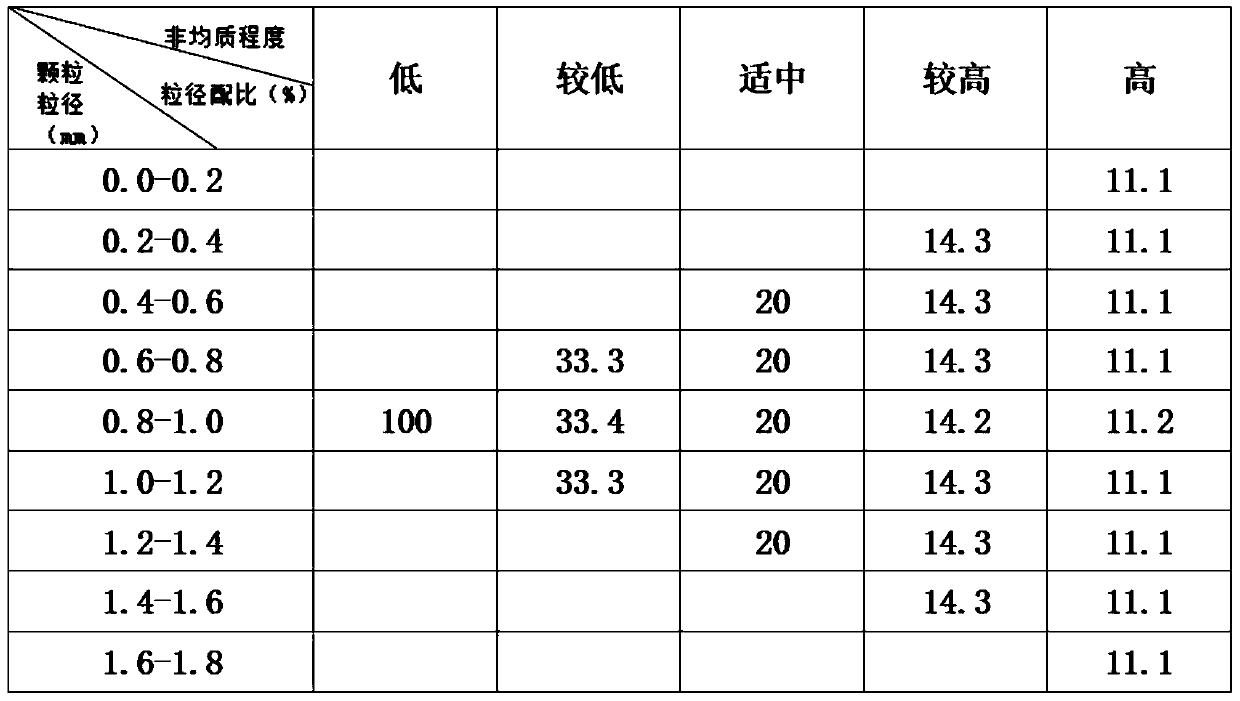

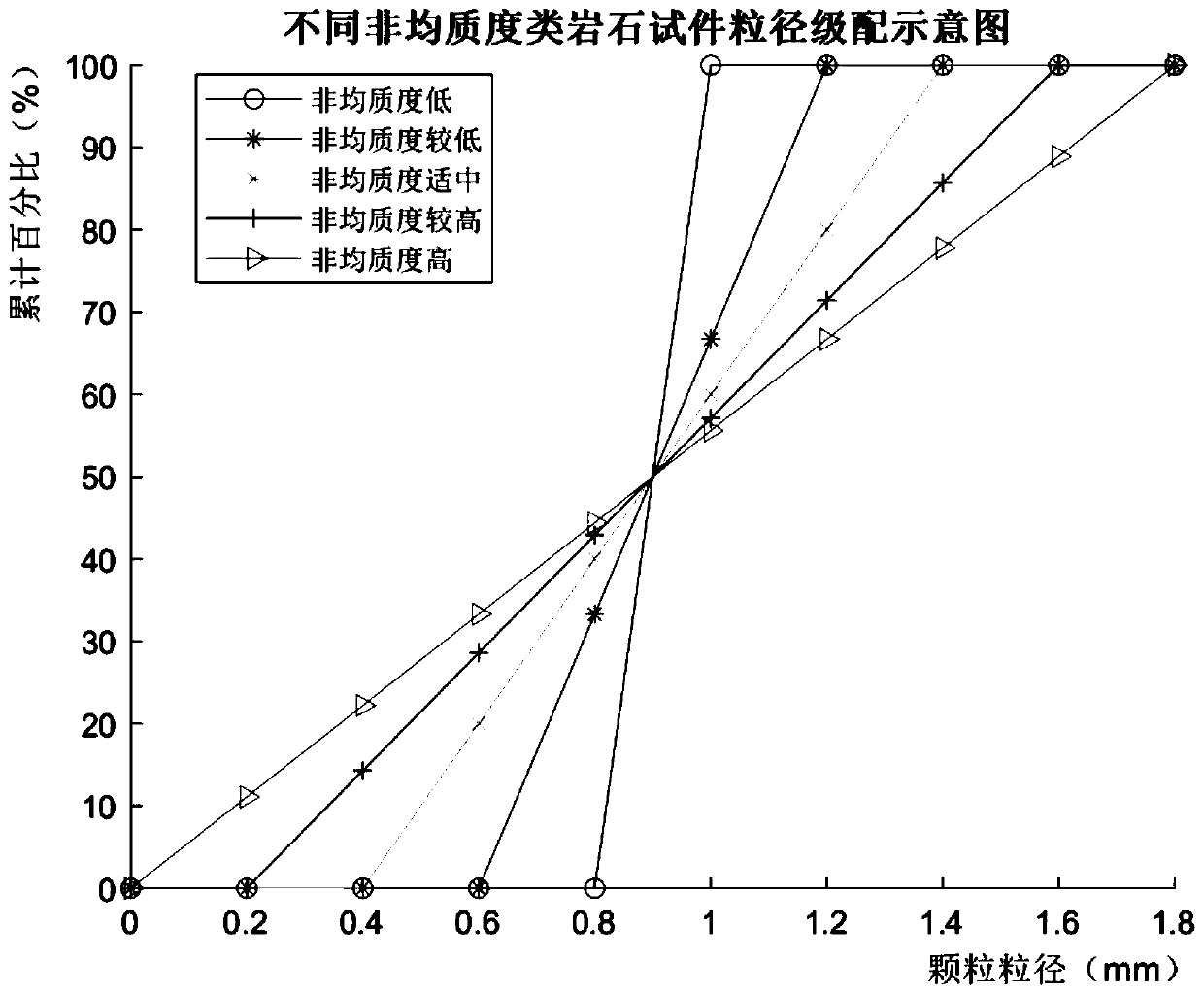

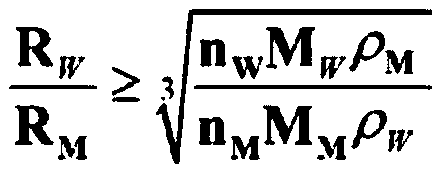

Rock-like material for simulating reservoir rock heterogeneity and test piece preparation method

ActiveCN111579374AEasy to makeLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesPelletsParticle-size distribution

The invention relates to a rock-like material for simulating reservoir rock heterogeneity and a test piece preparation method, and belongs to the field of rock-like material preparation. The method comprises the following steps: measuring reservoir rock heterogeneity, particle size distribution condition and mechanical parameters; analyzing the influence of the particle size ratio degree on the reservoir rock heterogeneity and the mechanical parameter sensitivity of the rock-like material, and establishing a grading model and a mathematical relationship curve of the rock-like material with different heterogeneity degrees under different particle size ratio conditions by taking the particle size of the quartz sand particles as an index; referring to a fracturing test, and selecting quartz sand particles with corresponding particle sizes to perform aggregate proportioning by using a heterogeneous degree of rock and a rock-like specimen aggregate particle size grading schematic table; preparing a rock-like test piece by taking the quartz sand particles as aggregate, and carrying out maintaining and demolding operation to obtain the rock-like material. The heterogeneous rock-like material provided by the invention can well reflect the control effect of the particle size on the rock heterogeneity, and can accurately describe heterogeneity characteristics of a complex lithologic stratum.

Owner:SHANDONG UNIV

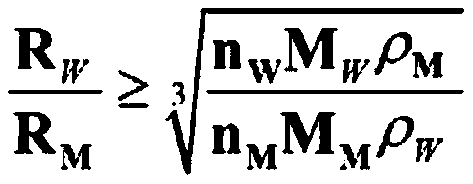

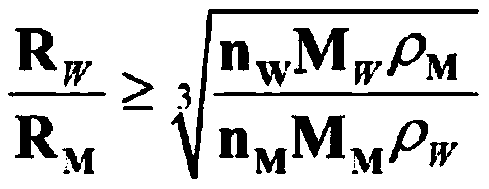

Doped tungsten oxide target material and preparation method thereof

The invention relates to a doped tungsten oxide target material and a preparation method thereof. The preparation method comprises the following steps: activating and grinding tungsten oxide to obtainactivated tungsten oxide; activating and grinding a doped oxide to obtain activated doped oxide, wherein the doped oxide is an oxide composed of one or more of titanium, nickel, tantalum, rhenium, iridium, molybdenum, niobium, silicon, tin, zinc, zirconium and germanium; uniformly mixing the activated tungsten oxide with the activated doped oxide, and pressing the obtained mixture to obtain a green body; and sintering the green body to obtain the doped tungsten oxide target material, wherein a relationship between the particle size ratio and the molar ratio of the activated tungsten oxide tothe activated doped oxide is shown in the description. The electrochromic doped tungsten oxide target material with a uniform composition and a high density is obtained by establishing the relationship between the particle size ratio and the molar ratio; and the doped tungsten oxide target material has a certain conductivity, and can be used in direct current or medium-frequency power supplies.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of compound reducing agent applied to industrial silicon smelting production

ActiveCN105329897AImprove chemical reactivityReduce depositionSilicon compoundsChemical reactionAdhesive

The invention relates to a preparation method of a compound reducing agent applied to industrial silicon smelting production, and belongs to the technical field of non-ferrous metal smelting. According to the particle size ratio of petroleum coke materials, the ratio of the petroleum coke with the particle size smaller than 0.1 mm is 60-75wt%, and the ratio of the petroleum coke with the particle size larger than or equal to 0.1 mm is 25-40wt%. According to the particle size ratio of anthracite / bituminous coal materials, the ratio of the anthracite / bituminous coal materials with the particle size being 0.15-0.3 mm is 55-75%, and the ratio of the anthracite / bituminous coal materials with the particle size smaller than or equal to 0.15 mm is 25-45%. Charcoal powder and biomass carbon / carbocoal are mixed according to an arbitrary ratio to obtain charcoal powder mixed materials. According to the particle size ratio of the charcoal powder mixed materials, the ratio of the charcoal powder mixed materials with the particle size ratio smaller than or equal to 0.075 mm is 75-90%, and the ratio of the charcoal powder mixed materials with the particle size ratio larger than or equal to 0.075 mm is 10-25%. The prepared petroleum coke materials, anthracite / bituminous coal materials and the charcoal powder mixed materials are mixed to be uniform to obtain mixed materials, an organic adhesive, an additive and water are added into the mixed materials, the mixture is stirred to be uniform and then prepared into pellets, and the pellets are dried to obtain the compound reducing agent. The compound reducing agent has the advantages of being high in fixed carbon content, high in chemical reactivity, low in ash content and volatile content and the like.

Owner:KUNMING UNIV OF SCI & TECH

Rechargeable lithium battery with controlled particle size ratio of activated carbon to positive active material

ActiveUS20150263336A1Improved high-rate capability and cycle-life characteristicExcellent characteristicsNegative electrodesSecondary cellsActivated carbonLithium iron phosphate

A rechargeable lithium battery that includes: a negative electrode including a negative active material, and a positive electrode including a positive active material and activated carbon. When the positive active material includes a lithium iron phosphate-based compound, the average particle diameter of the activated carbon is greater than or equal to about 1000% and less than or equal to about 3000% of the average particle diameter of the positive active material.

Owner:SAMSUNG SDI CO LTD

Active material and lithium ion battery

ActiveCN110120497ASecondary cellsNon-aqueous electrolyte accumulator electrodesPole pieceLithium-ion battery

The invention provides an active material, a pole piece and a lithium ion battery. The particle size of the active material satisfies the following formula (1): (Dv90-Dv50)- And (Dv50-Dv10) is less than or equal to 2.5. The compaction density and the initial discharge capacity of the pole piece are improved by adjusting the particle size ratio of the first particles to the second particles in theactive material, so that the energy density (ED) of the battery is improved; by adjusting the types and contents of doping elements of the first particles and the second particles, the first particlesare more stable, and the 500-time circulating discharge capacity of the pole piece is improved, so that the characteristics of the battery are not deteriorated.

Owner:NINGDE AMPEREX TECH

Rechargeable lithium battery with controlled particle size ratio of activated carbon to positive active material

InactiveUS20150010818A1Improved high-rate capability and cycle-life characteristicExcellent characteristicsCarbon compoundsSecondary cellsActivated carbonLithium iron phosphate

A rechargeable lithium battery that includes: a negative electrode including a negative active material, and a positive electrode including a positive active material and activated carbon. When the positive active material includes a lithium nickel-based oxide, a lithium cobalt-based oxide, a lithium manganese-based oxide, a lithium titanium-based oxide, a lithium nickel manganese-based oxide, a lithium nickel cobalt manganese-based oxide, a lithium nickel cobalt aluminum-based oxide, or a combination thereof, the average particle diameter of the activated carbon is greater than about 100% and less than about 1000% of the average particle diameter of the positive active material. When the positive active material includes a lithium iron phosphate-based compound, the average particle diameter of the activated carbon is greater than or equal to about 1000% and less than or equal to about 3000% of the average particle diameter of the positive active material.

Owner:SAMSUNG SDI CO LTD

Thermoplastic resin composition

A thermoplastic resin composition comprising:(A) 30 to 80 parts by mass of a polyamide;(B) 20 to 70 parts by mass of a polyphenylene ether;(C) 0 to 40 parts by mass, based on 100 parts by mass of the total amount of the polyamide (A) and the polyphenylene ether (B), of a rubbery polymer; and(D) 10 to 50 parts by mass, based on 100 parts by mass of the total amount of the polyamide (A) and the polyphenylene ether (B), of a platy inorganic filler having an average particle size of 9 to 20 μm, and having a particle size ratio (d75% / d25%) of the particle size (d75%) at 75% counted from smaller particle size to the particle size (d25%) at 25% of 1.0 or more and 2.5 or less.

Owner:ASAHI KASEI CHEM CORP

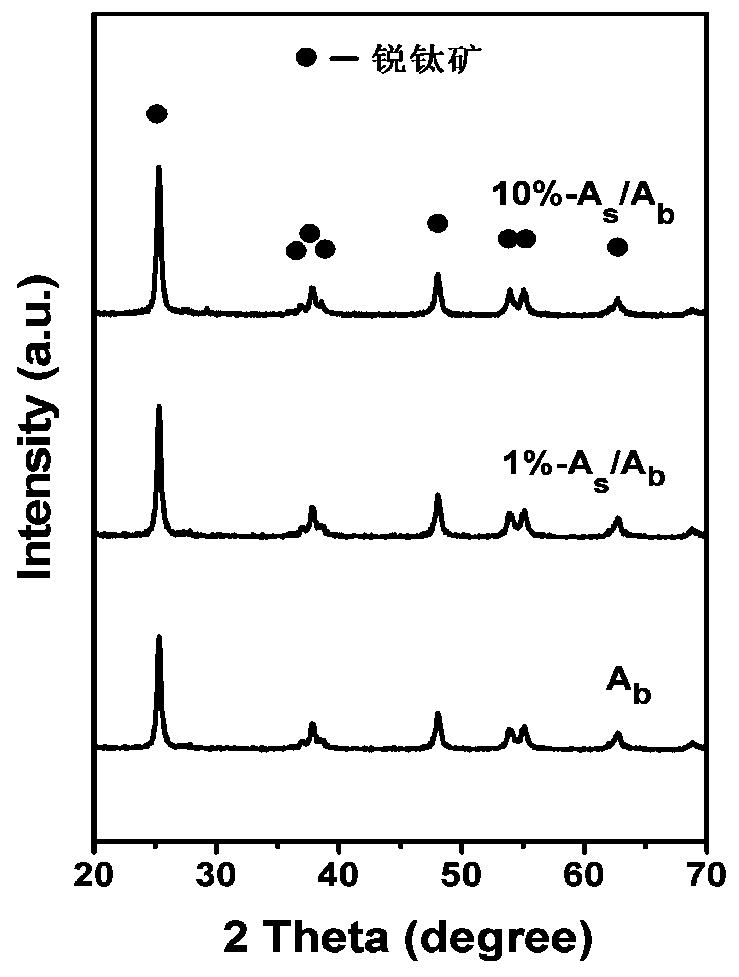

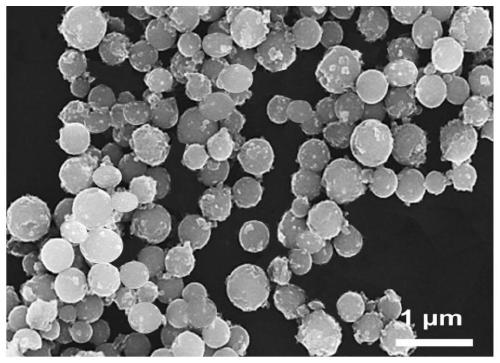

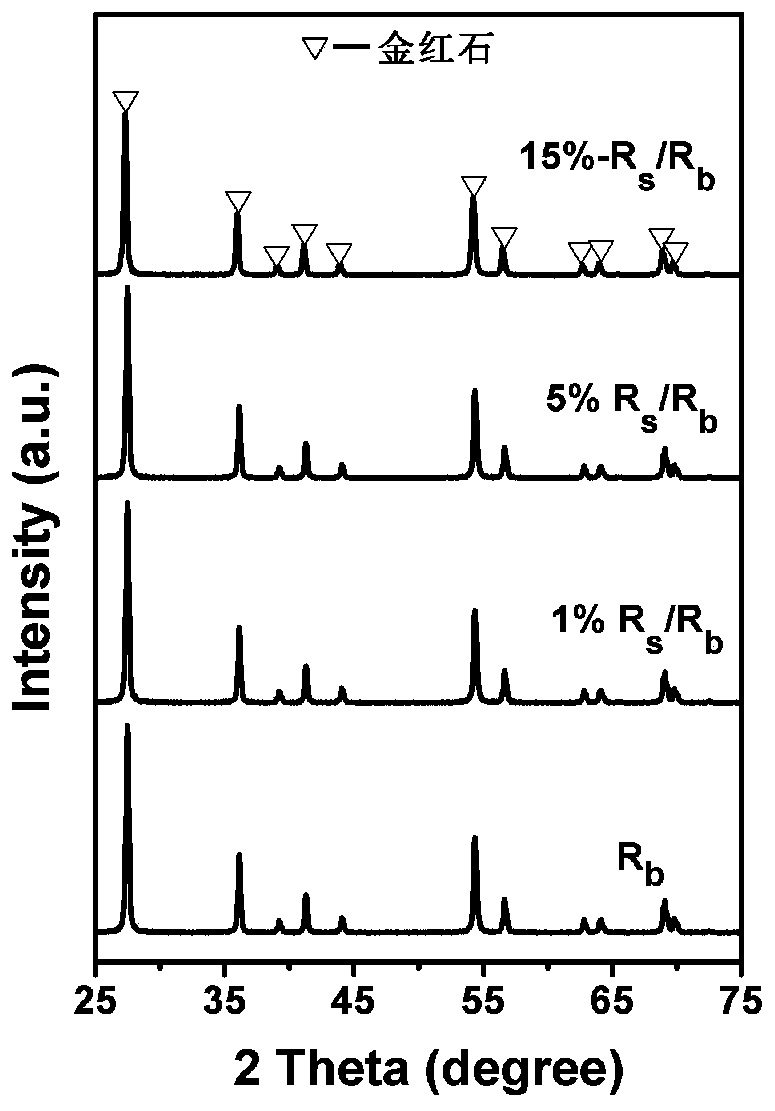

In-phase junction photocatalyst, preparation method and application thereof

ActiveCN109731563AImprove photocatalytic performanceEasy to separateWater/sewage treatment by irradiationWater contaminantsHydrogenSemiconductor materials

The invention belongs to the technical field of photocatalysis, in particular to an in-phase junction photocatalyst, a preparation method and an application thereof. The in-phase junction photocatalyst comprises in-phase semiconductor materials with different particle diameters, wherein the small particle diameter semiconductor material is loaded on the surface of the large particle diameter semiconductor material; and the particle size ratio of the large particle size semiconductor material to the small particle size semiconductor material is (40-100): 1. The same crystal phase semiconductormaterials with different particle sizes are utilized to form junctions, so that the efficiency of separating photogenerated electrons and holes can be effectively promoted, and the photocatalytic performance of the materials is obviously improved. The embodiment results show that when the in-phase junction photocatalyst is used for photocatalytic decomposition of water, the hydrogen generation amount can reach 150 umol / h / g.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

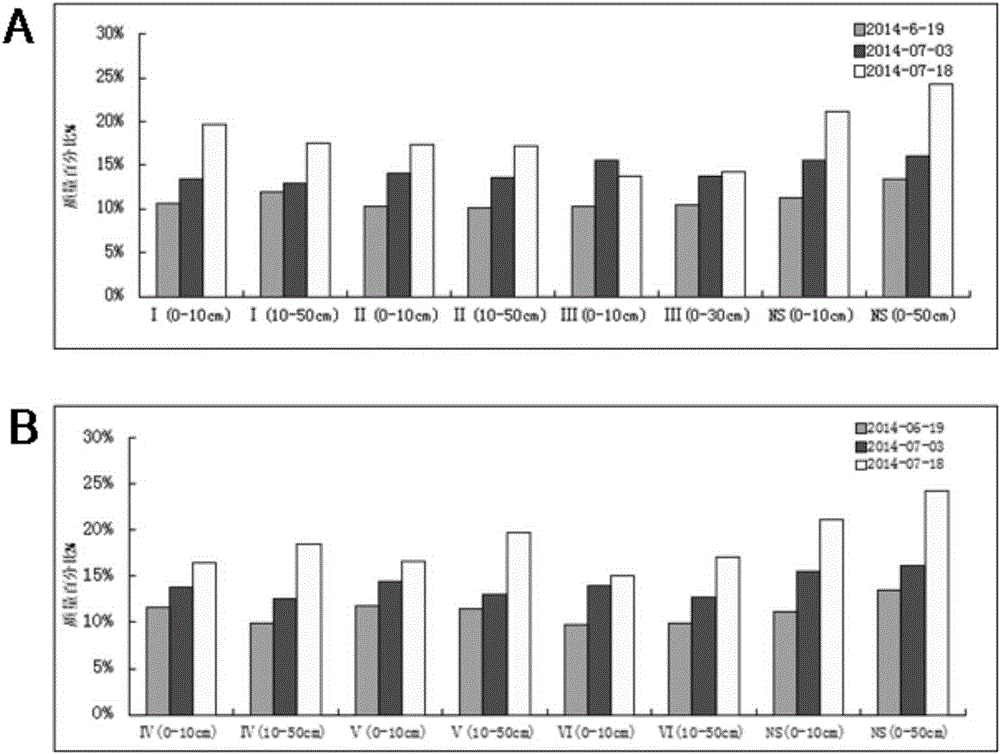

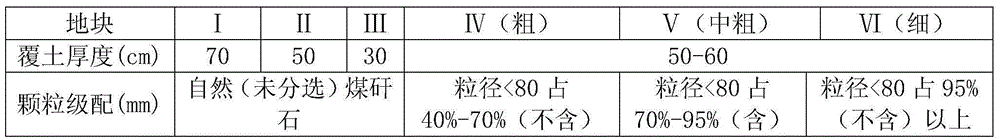

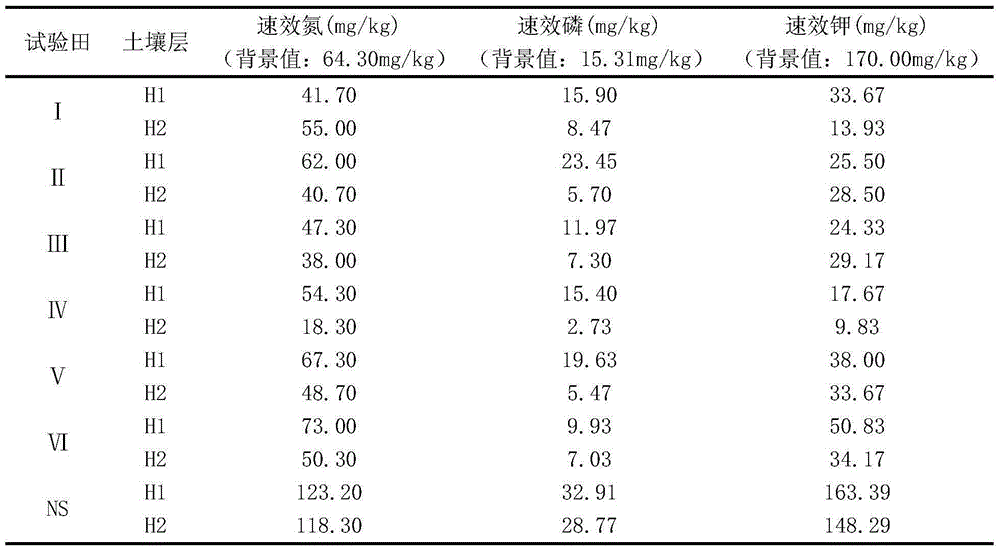

Coal mining subsidence area filling reclamation method based on coal gangue

InactiveCN105165164AImprove water retentionImprove breathabilitySoil-working methodsMining engineeringNatural state

The invention discloses a coal mining subsidence area filling reclamation method based on coal gangue. According to the method, the coal gangue is taken as a filling substrate to fill a coal mining subsidence area, and then the filling substrate is covered with soil, wherein the coal gangue with the particle size smaller than 80 mm accounts for more than 40% of the filling substrate. The coal mining subsidence area filling reclamation method based on the coal gangue utilizes the coal gangue with different particle size ratios as the filling substrate, so that the filling substrate has better water and fertilizer retention capability and air permeability than the coal gangue in a natural state, especially the coal gangue containing 70%-95% of the coal gangue with the particle size smaller than 80 mm accounting for 70%-95% is taken as the filling substrate, accordingly, physio-ecological characteristics of crops cultivated by reconstructed soil are good, and the reconstructed soil obtained with the filling method is more favorable for growth of the crops.

Owner:ANHUI UNIV OF SCI & TECH

Transfer sheet material

A phosphorescent transfer sheet includes a support, and a transfer layer detachable from the support, wherein the transfer layer includes hot melt adhesive particles and phosphorescent pigments. The average particle diameter of the hot melt adhesive particles may be about 30 to 150 μm, and the average particle diameter of the phosphorescent pigment may be about 5 to 40 μm. The average particle size ratio of the hot melt adhesive particles to the phosphorescent pigment is about 1 / 1 to 10 / 1. Phosphorescent pigments include strontium-containing phosphorescent pigments. In the transfer layer, a protective layer detachable from the support may be interposed between the support and the transfer layer. Phosphorescent transfer sheets ensure clear glossy or glossy images even in dark places after transfer.

Owner:DAICEL CHEM IND LTD

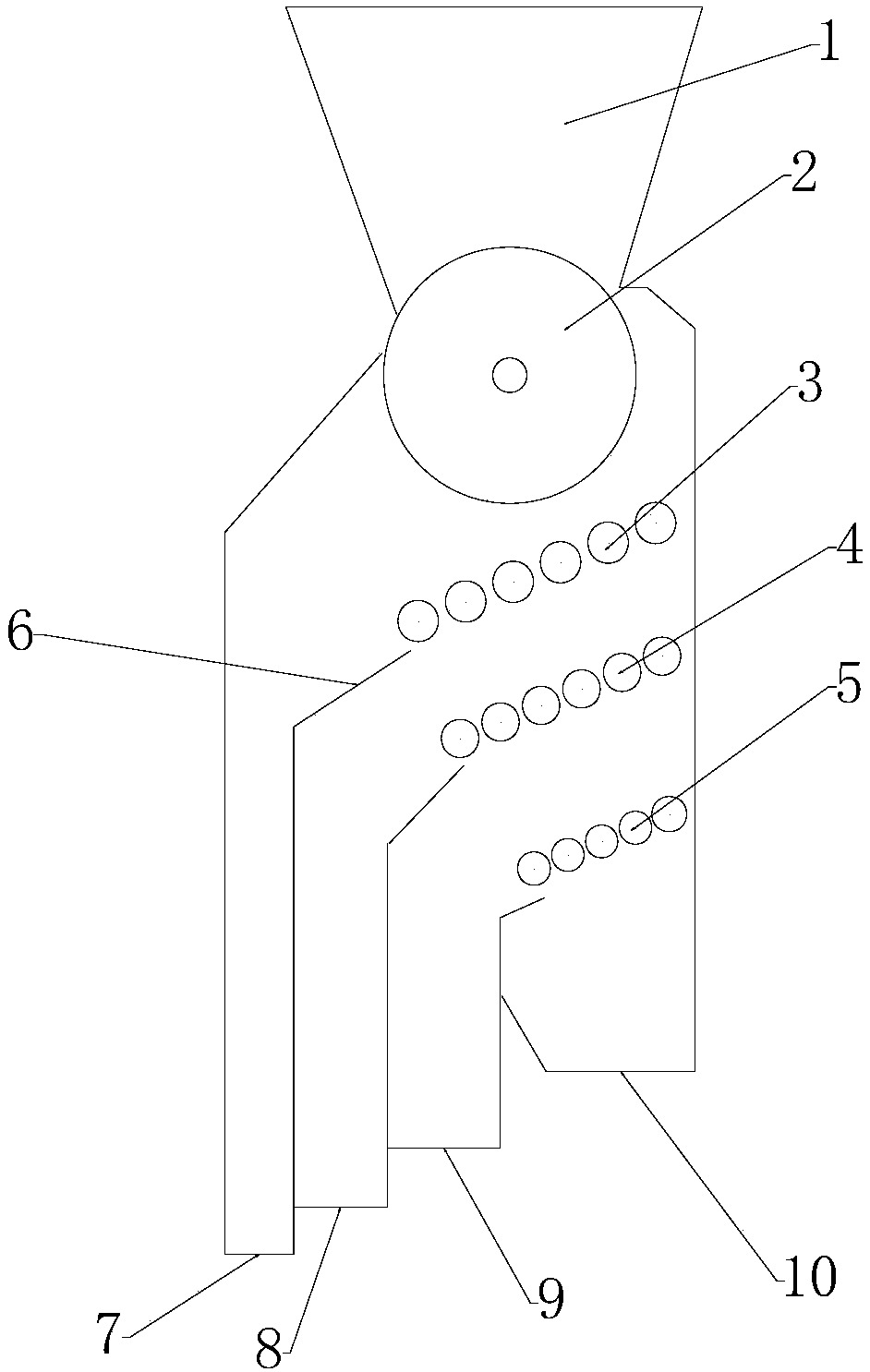

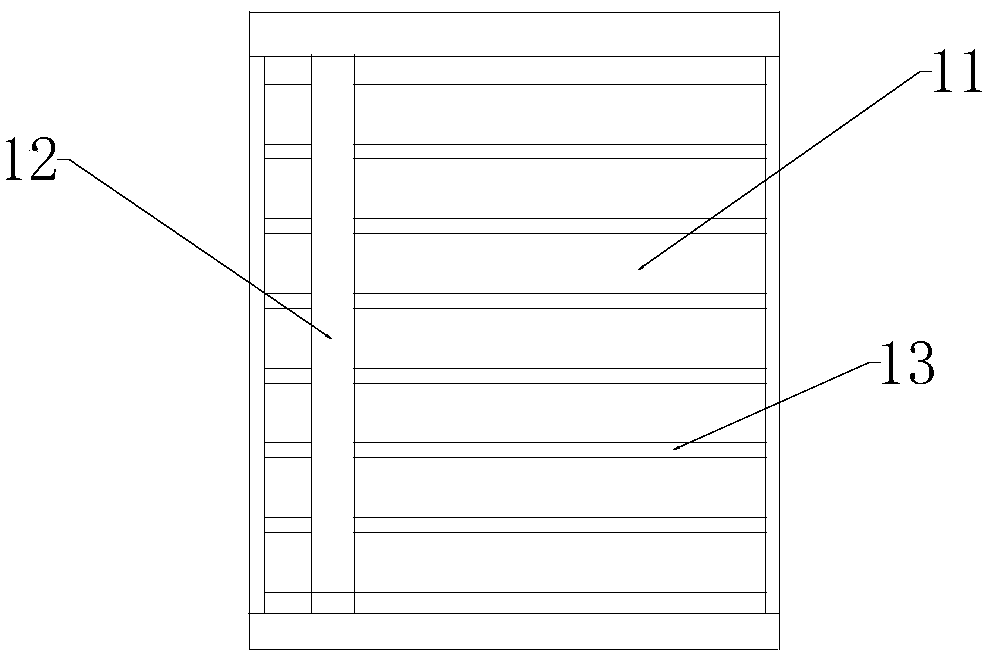

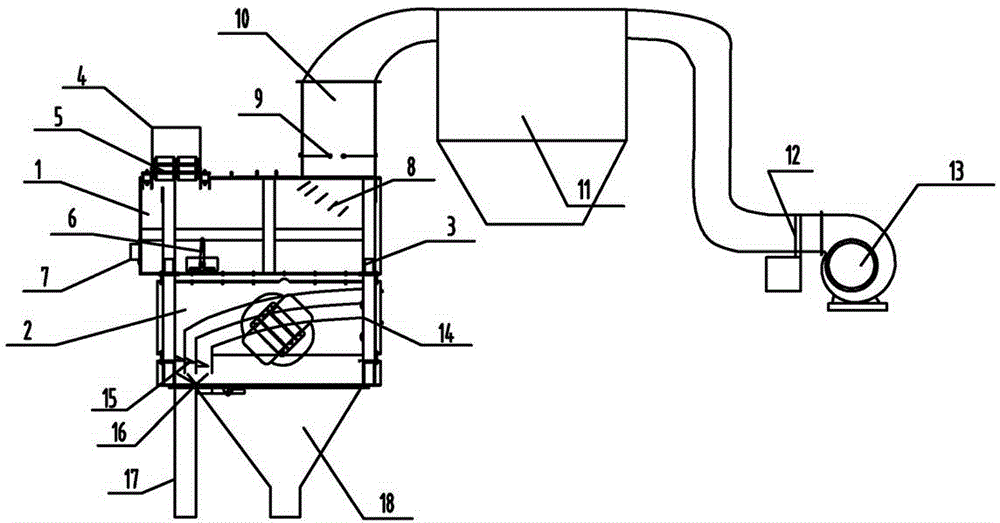

Automatic manufactured sand gradation fine controller

InactiveCN104607388AAutomated fine control of contentContent fine controlSievingGas current separationSocial benefitsAutomatic control

The invention discloses an automatic manufactured sand gradation fine controller. The automatic manufactured sand gradation fine controller comprises a primary presorting control chamber, a fine control chamber and a rock flour separation system. The primary presorting control chamber is changed to negative pressure area by an air draft fan; and particles are stressed to flow to the direction of the fan along a pipe. Fine sand and rock flour are separated by a louvered baffle plate. The relationship between the wind speed of the pipe and the content of the rock flour is calibrated at the beginning; a wind speed signal of the pipe is returned to an electric wind way opening adjusting valve through a wind speed sensor; and the wind speed is adjusted by changing the opening size of the pipe so as to automatically control the content of the rock flour. Thick sand and fine sand are primarily separated by a thick and fine sand separation plate in the primary presorting control chamber; all particle sizes of manufactured sand are separated by screens; the flows of the sand on all layers of the screens are dynamically measured by an impact flow meter; and a flow signal is automatically connected with the size of an electric outlet valve so as to realize automatic fine control of all particle size ratios of the manufactured sand. Concrete is prepared by using the manufactured sand, so that the concrete cost can be reduced, the working performance of the concrete is improved, and the beneficial economic and social benefits are generated.

Owner:世邦工业科技集团股份有限公司

Preparation method of double-shell soft magnetic composite material

ActiveCN108057878AImprove magnetismHigh resistivityTransportation and packagingMetal-working apparatusOxygenFerromagnetism

The invention discloses a preparation method of a double-shell soft magnetic composite material. A nitride / oxide double-shell structure is prepared on the surface of high-purity iron powder by a chemical heat treatment process, wherein nitride on the inner layer is used as a transitional layer, and is matched with matrix lattices; and by oxide on the outer layer, the resistivity of an iron power core is further increased on the basis of nitriding, and loss of the iron powder core is reduced favorably. Meanwhile, double shells of nitriding and oxidizing have ferromagnetism, a magnetic dilutioneffect is greatly reduced, and the saturation flux density of the composite material is improved. The preparation method comprises the following key steps: (1) reducing iron powder with a certain particle size ratio in high-purity hydrogen to remove surface oxide; (2) feeding mixed gas of ammonia gas and hydrogen to carry out surface nitriding so as to obtain a Fe4N thin layer on the surface of the iron powder; (3) feeding an oxygen-containing atmosphere to carry out surface oxidizing so as to obtain a double-shell core-shell structure of which the inner shell is Fe4n and the outer shell is Fe3O4; and (4) adding a binder and a lubricating agent in the prepared iron powder, pressing to obtain a soft magnetic composite material and then carrying out vacuum heat treatment.

Owner:ZHEJIANG UNIV

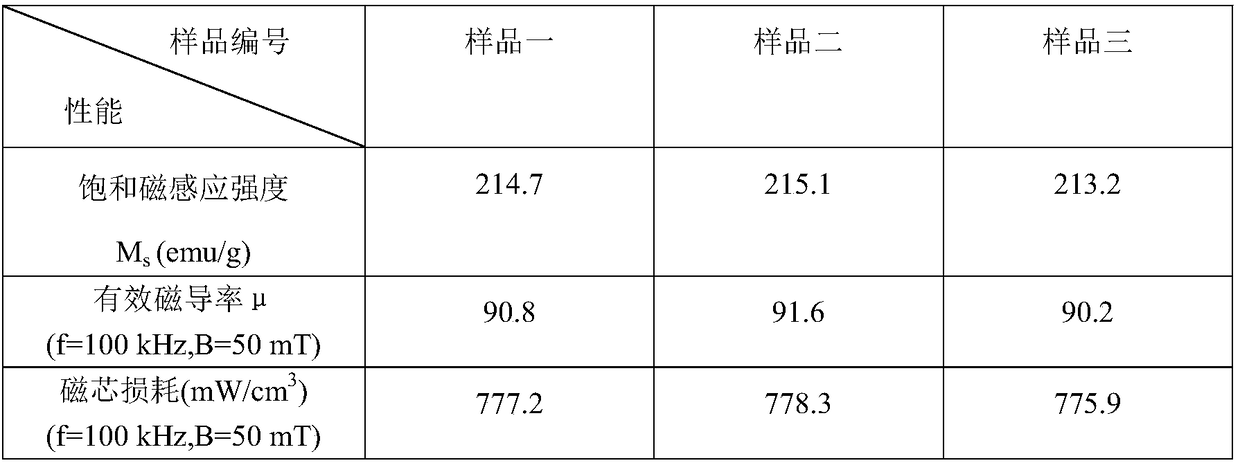

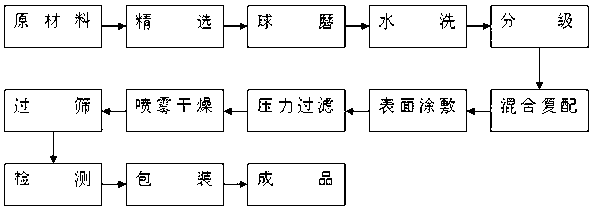

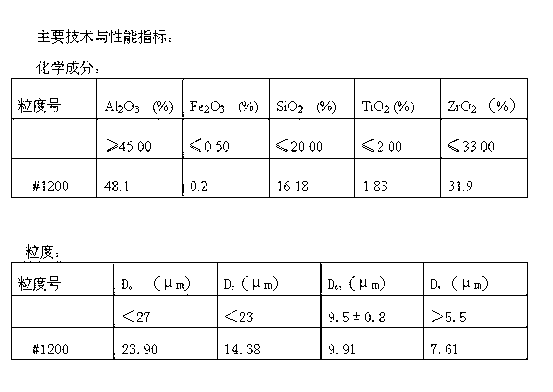

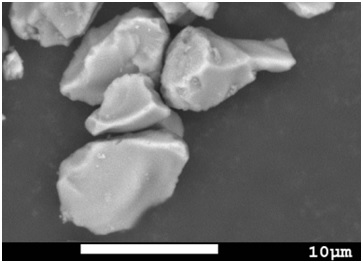

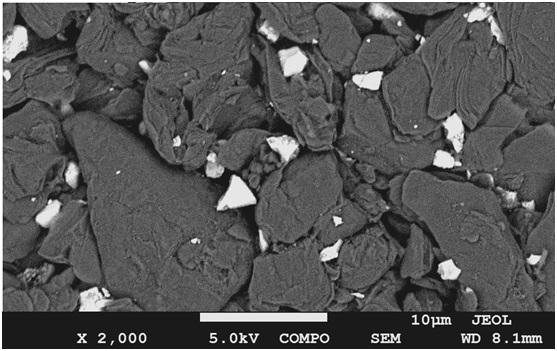

Special zirconium-aluminium composite ground micro-powder for optoelectronic industry and production method for same

ActiveCN103342987AStrong grinding forceImprove grinding efficiencyOther chemical processesManufactured materialSpray dried

The invention discloses special zirconium-aluminium composite ground micro-powder for the optoelectronic industry and a production method for the same. The special zirconium-aluminium composite ground micro-powder for optoelectronic industry is produced from two main raw materials, namely, fused alumina and zirconium silicate, via ball-milling, water-washing, grading, compounding, surface coating, filtering, spray-drying and sieving, wherein the compounding ratios of the contents of the raw materials are as follows: the content of alumina particles is 30-50%, and the content of zirconium silicate particles is 70-50%. The product disclosed by the invention is reasonable in particle shape collocation, wide in particle size distribution, stable in median diameter, high in basic particle size ratio, without large particles and ultrafine particles, excellent in interparticle lubrication property, and especially suitable for grinding and polishing high-tech products in the optoelectronic industry.

Owner:ZIBO JINJIYUAN ABRASIVES

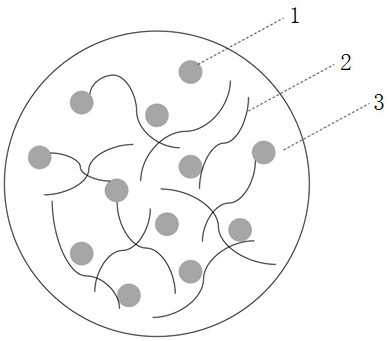

Preparation of silicon composite material and negative plate containing silicon composite material

ActiveCN112310402AMake full use of the high gram capacityImprove conductivityMaterial nanotechnologyElectrode thermal treatmentLithium oxideSilicon oxide

The invention discloses preparation of a silicon composite material and a negative plate containing the silicon composite material, and relates to the field of silicon-based composite materials. The silicon-based composite material comprises silicon nanoparticles, carbon nanotubes, silicon oxide, lithium oxide and lithium silicate, wherein the carbon nanotubes and the silicon nanoparticles are dispersed and crosslinked to form a three-dimensional network structure; and the silicon oxide, the lithium oxide and the lithium silicate coat the three-dimensional network structure to form secondary particles. The silicon secondary particles and graphite are homogenized and coated according to a specific particle size ratio to prepare the silicon-containing negative plate with high capacity exertion, good conductivity, high coulombic efficiency, small volume expansion and high cycling stability.

Owner:SHANGHAI RUIPU ENERGY CO LTD +1

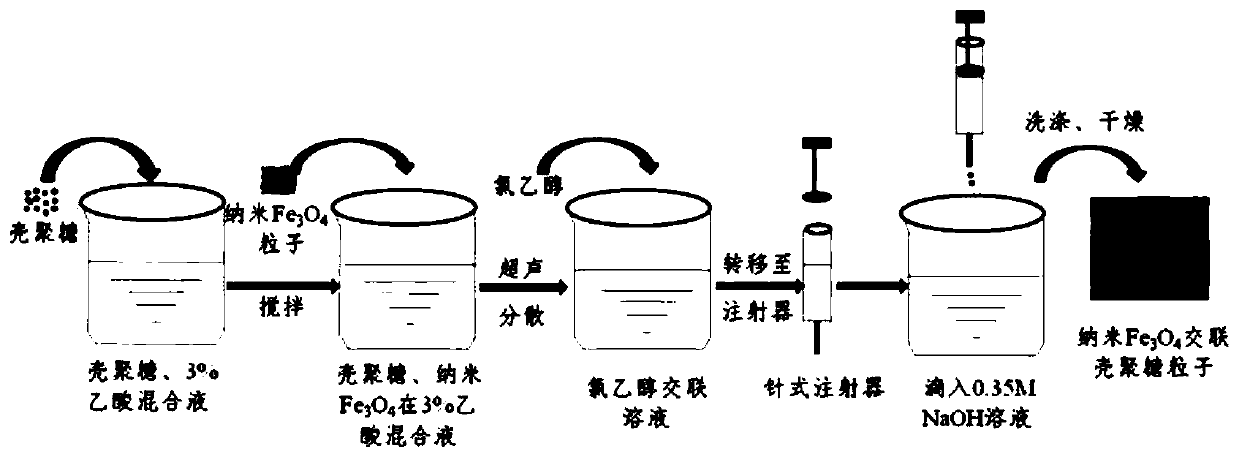

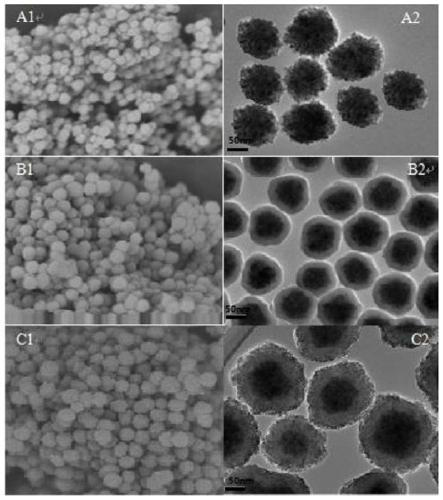

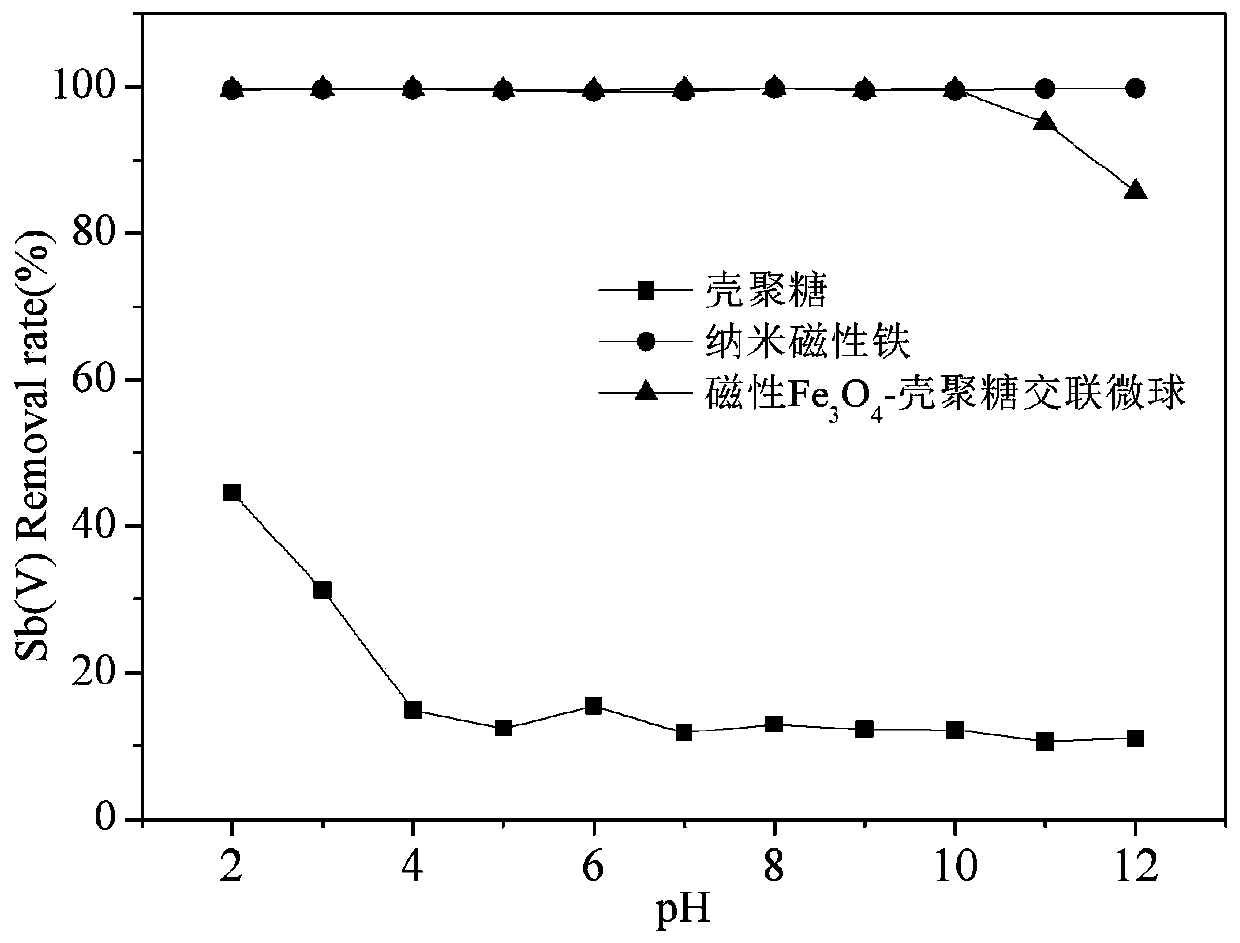

Preparation and application of nano mesoporous Fe3O4-chitosan core-shell crosslinked microsphere material

ActiveCN109876779AImprove stabilityGood dispersionOther chemical processesWater contaminantsSodium acetateCross-link

The invention discloses preparation and application of a nano mesoporous Fe3O4-chitosan core-shell cross-linked microsphere material, and belongs to the field of preparation and water treatment research and application of nano mesoporous Fe3O4-chitosan core-shell cross-linked microspheres. Based on controllable synthesis of mesoporous Fe3O4 microspheres, chitosan is used as a synthesis process regulating agent and a stable matrix for the first time, chloroethanol is used as a cross-linking agent, ferric trichloride, ethylene glycol and sodium acetate are used as reaction raw materials and auxiliary materials, through regulation and control of the growth and cross-linking of nanoparticles, the improvement of the porosity of the nanoparticles, the increase of the specific surface area and the effective crosslinking of the particles are realized. The particle size of the obtained cross-linked microsphere is 200-450 nm, the specific surface area is 6.2 m<2> / g, the pore size is about 7 nm,the particle size distribution is narrow, the cross-linked microsphere has high magnetism (40-85 emu / g), cross-linked chitosan provides a strong matrix, and the physical stability of the cross-linkedmicrosphere is enhanced.

Owner:HUNAN CITY UNIV

Low cost dolomite continuous casting tundish coating

The invention relates to a low cost dolomite continuous casting tundish coating, which is prepared from the following raw materials by weight: 50%-65% of dolomite particles, 30%-45% of magnesium chromium waste brick particles, 1%-3.5% of bauxite, 1%-3.5% of soft clay, 1%-2% of high alumina cement, 0.2%-1.5% of sodium tripolyphosphate, and 0.5%-1.5% of paper fibers. The dolomite particles and the magnesium chromium waste brick particles have a particle size ratio, by weight, as the following: the particles with a particle size of 3-2mm account for 35%-45%, the particles with a particle size of 2-1mm account for 45%-55%; and the balance is fine powder particles with a particle size of less than 1mm. Compared with the prior coatings, the dolomite continuous casting tundish coating provided by the invention has the advantages of low production cost and good use performance, and realizes recycling of magnesium chromium waste bricks, thus having good economic and social benefits.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com