Automatic manufactured sand gradation fine controller

A fine control and controller technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve problems such as instability, changes, hidden dangers of engineering and construction safety, and achieve lower concrete costs, beneficial economic and social benefits, The effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

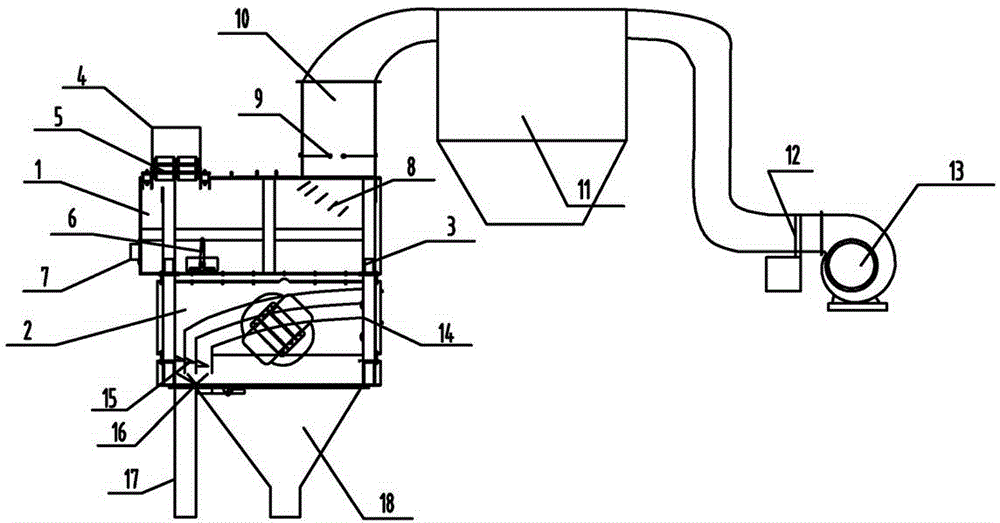

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the pre-division control room 1 and the fine control room 2 are integrated into one body through a soft connection 3 .

[0019] Raw materials are put into the initial pre-division control chamber 1 through the feed port 4, coarse sand, fine sand, and stone powder are broken up by the vibrating disperser 5, and mixed in the initial pre-division control chamber 1.

[0020] Blower fan 13 draws wind and just pre-divides control room 1 and becomes negative pressure zone, and wind enters just pre-divided control room from air inlet 7, then discharges from air outlet 10. According to the analysis of fluid mechanics and particle force, the smaller particle size is easy to be blown away, while the larger particle size is the opposite. There is a louver-type baffle 8 near the air outlet, which can effectively prevent fine particles exceeding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com