Water turbine blade blank profile measuring and machining allowance analyzing method

A technology of machining allowance and analysis method, which is applied in measuring devices, instruments, and optical devices, etc., can solve the problems of high equipment cost, inconsistent calculation results, and difficulty in measuring large blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

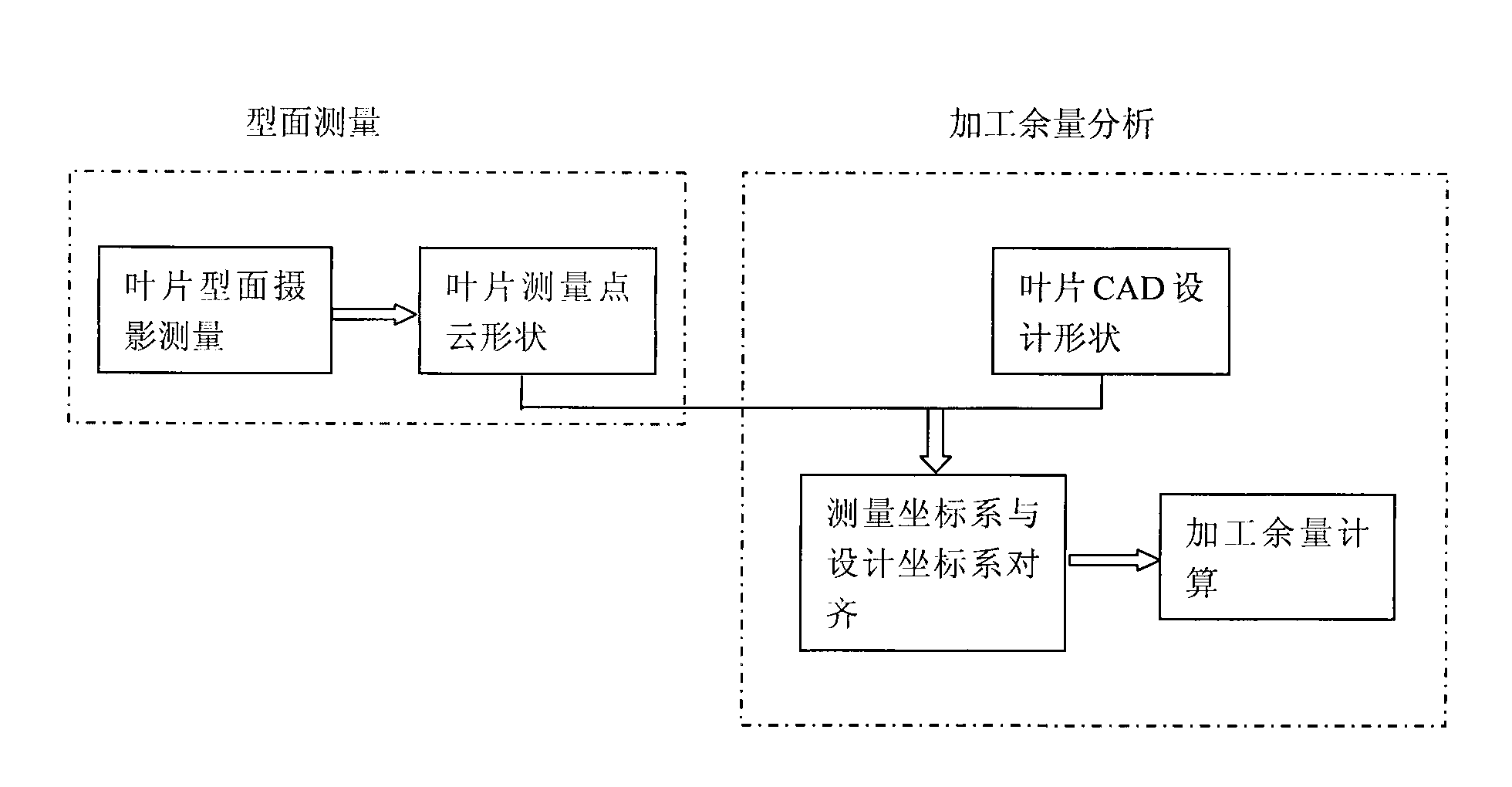

[0014] Depend on figure 1 Provide, the present invention comprises profile measurement and machining allowance analysis, and profile measurement is to carry out photogrammetry to blade profile, then make the blade point cloud shape measurement coordinate system (software model) of photogrammetry, then to blade CAD design Shape, design the machining allowance calculation design coordinate system (software model), and then align the measurement coordinate system with the design coordinate system, so as to realize the machining allowance calculation. The specific steps are:

[0015] Step 1: Carry out digital close-range photogrammetry on the blank of the blade to be detected, and obtain the shape of the measured point cloud (data shape) of the blade. The method is:

[0016] A circular reflective mark for photogrammetry is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com