Patents

Literature

142 results about "High diaphragm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick Answer. An elevated diaphragm is usually a congenital condition, but atrophy, paralysis and lack of development in certain muscle fibers can also cause an elevated diaphragm, explains National Center for Biotechnology Information.

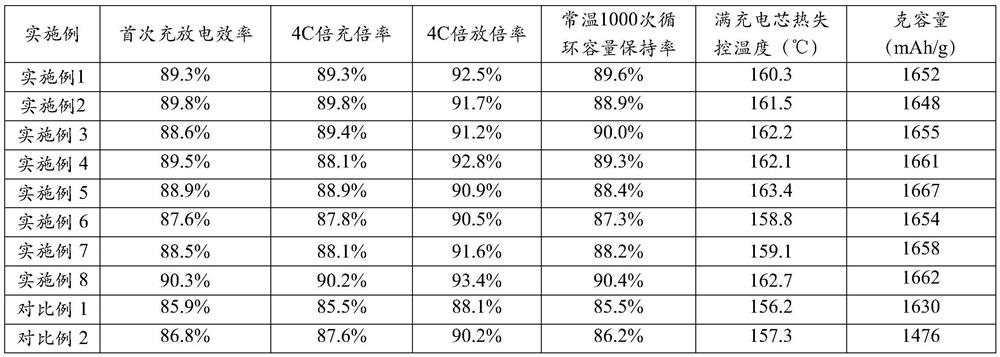

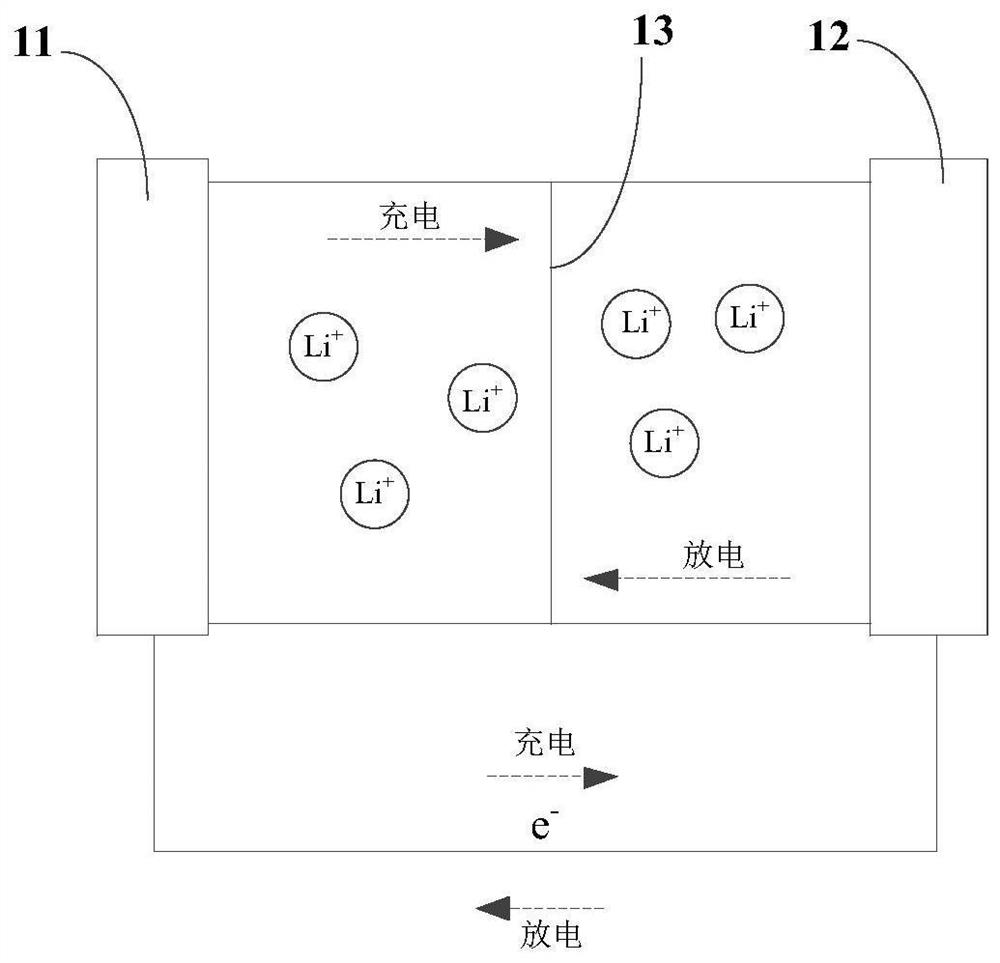

Porous composite diaphragm for lithium ion secondary battery and preparation method thereof

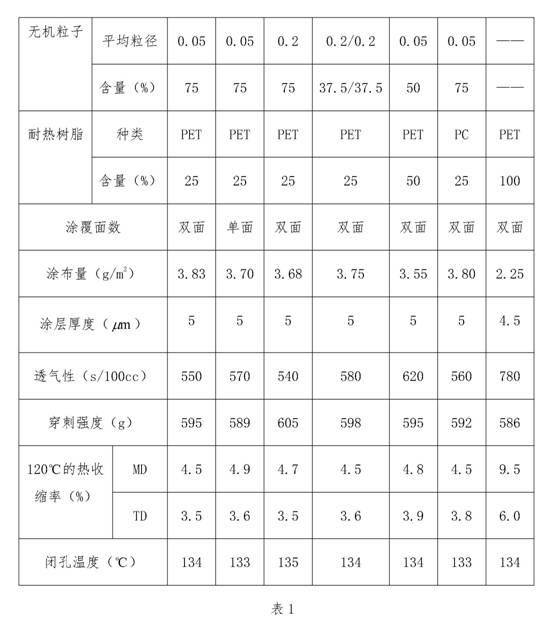

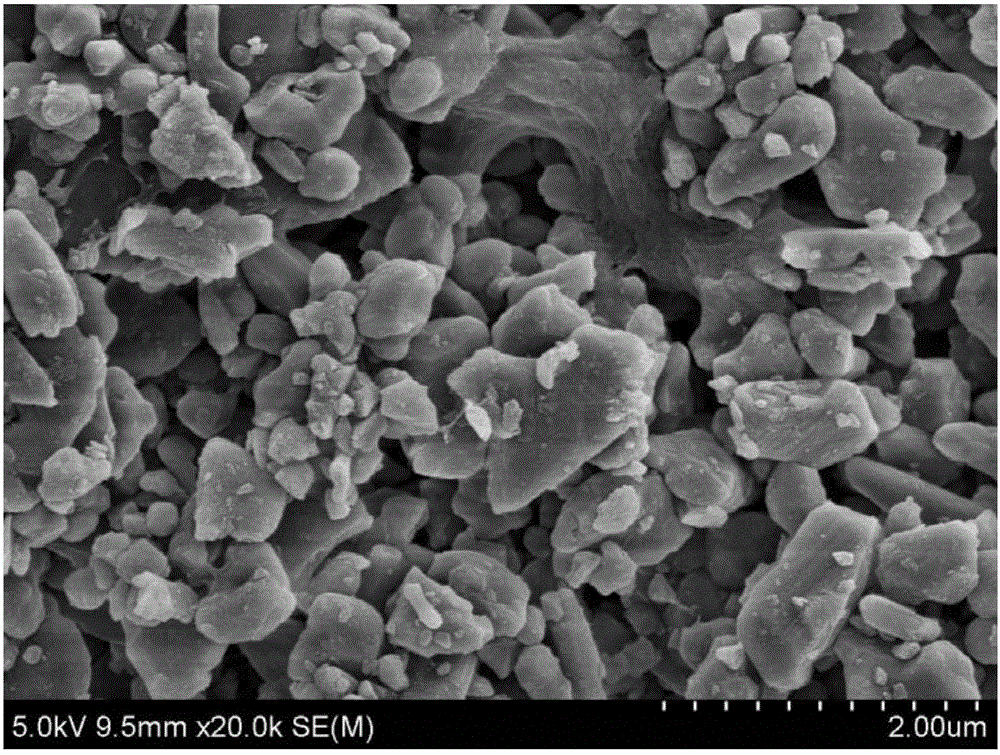

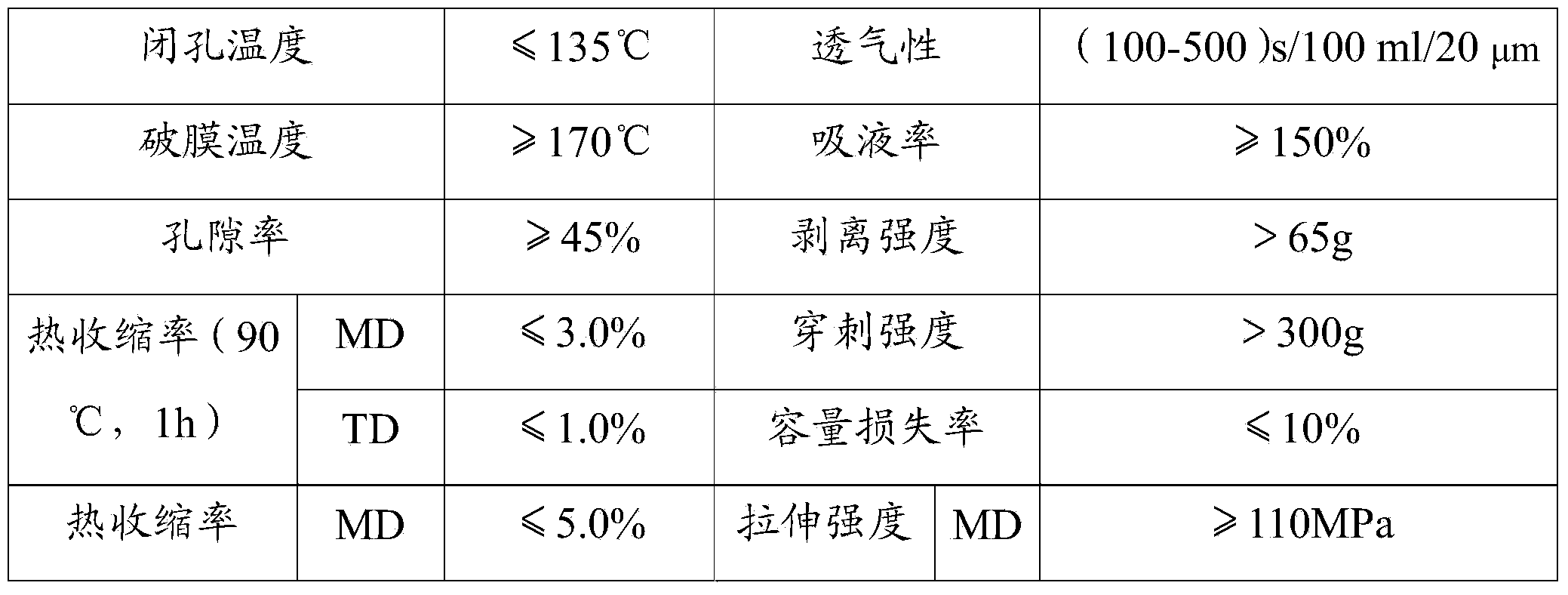

The invention discloses a porous composite diaphragm for a lithium ion secondary battery and a preparation method thereof. The porous composite diaphragm comprises a polyethylene microporous membrane; and single surface or two surfaces of the polyethylene microporous membrane is / are covered with a heat-resistant coating layer containing heat-resistant resin and inorganic non-conductive insulated particles. Due to use of the composite diaphragm, the mechanical performance, the aperture and the porosity of a base layer can be controlled, the thickness, the aperture and the porosity of the coating layer can be similarly controlled. The diaphragm has the advantages of low hole-closing temperature, high diaphragm-breaking temperature and less heat shrinkage; and the diaphragm used for the lithium ion secondary battery has excellent safety performance.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

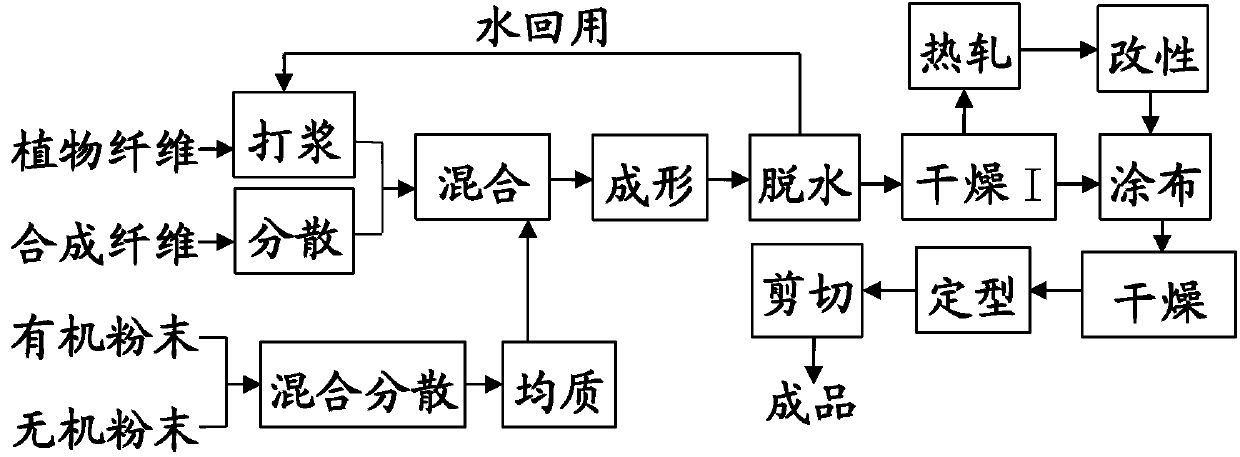

Battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and preparation method of filter material

InactiveCN103100264AImprove uniformityHigh strengthCoatings with pigmentsElectrolytic capacitorsSocial benefitsHigh diaphragm

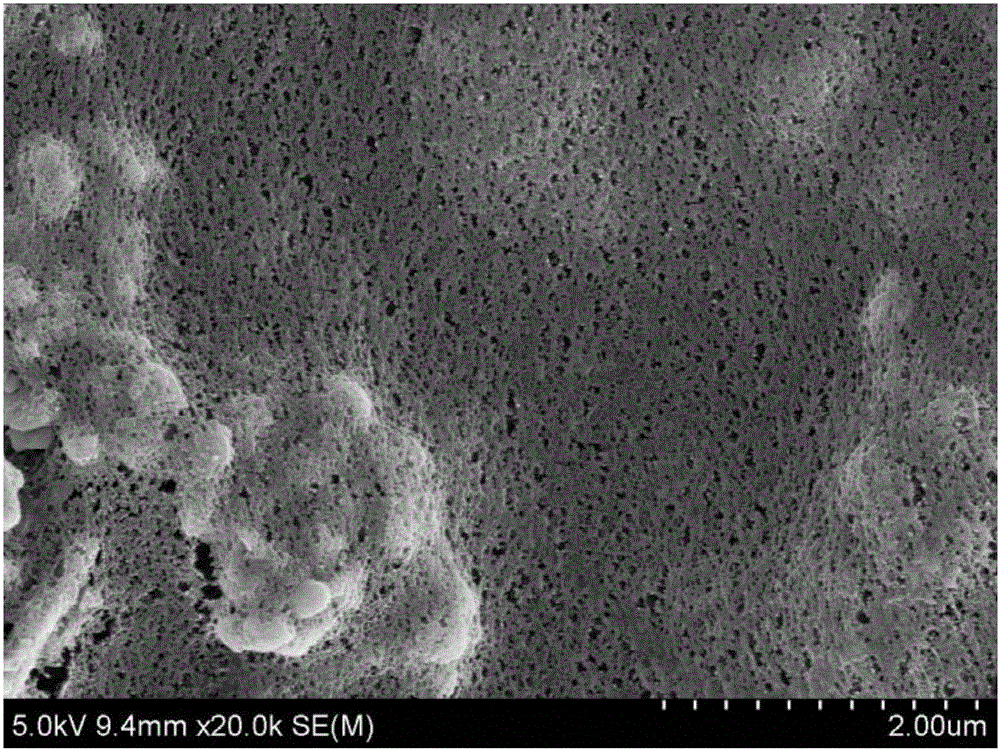

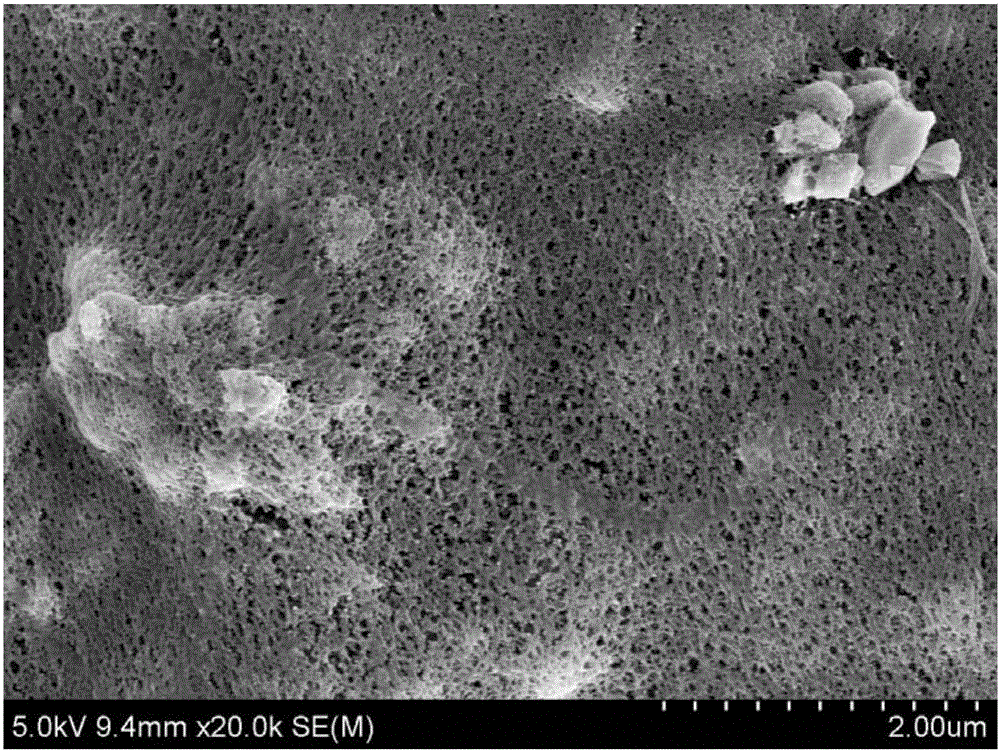

The invention discloses a battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and a preparation method of the filter material. The fiber materials are as follows in percentage by weight: 0.1%-2.5% of plant fibers and 80%-99.9% of synthetic fibers, inorganic powder being 45%-1000% of the weight of the fiber, organic powder being 0-50% of the weight of the fibers, and strengthening binder being 0.5%-15% of the weight of the fibers. The preparation method of the filter material comprises the following steps of: pulping the plant fiber and the synthetic fibers, respectively; homogenizing and mixing the inorganic powder with the organic powder under high pressure, and forming the mixture into a single layer or a plurality of layers by a mixer; coating, thermally rolling and modifying the mixture, so that various physical and chemical indexes of the diagram are improved, the pore diameter size can be effectively controlled and the uniformity of the pore diameter is improved; moreover, treelike crystals can be prevented from being generated by maze type bent holes; the filtering precision and the efficiency are high; the inner resistance of the diagram is high; the liquid retaining rate and the high temperature resistance of the diagram are improved; the over-temperature closed-cell protection is improved; the dimension deformation is small; the service life is long; and the economic benefits and the social benefits are better.

Owner:吕凯

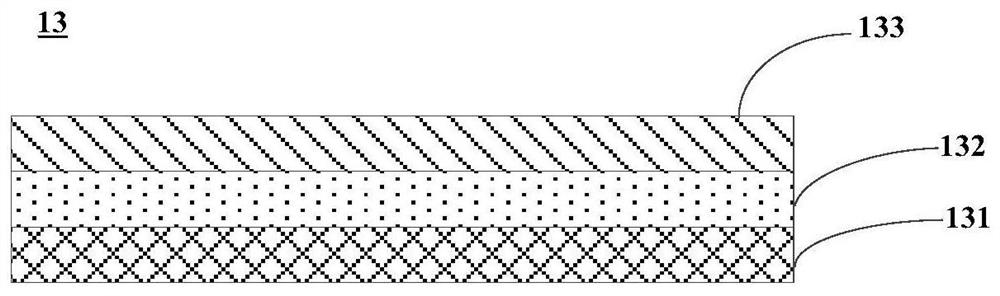

High-temperature-resistant composite lithium battery diaphragm and preparation method for same

InactiveCN106025149AHigh liquid absorptionIncrease fluid retentionSecondary cellsCell component detailsHeat resistancePorous membrane

The invention discloses a high-temperature-resistant composite lithium battery diaphragm and a preparation method for the same. The diaphragm comprises a base membrane and a high-temperature-resistant resin layer with which at least one surface of the base membrane is coated, wherein the base membrane is a thermoplastic resin porous membrane, and the high-temperature-resistant resin layer is a coating containing high-temperature-resistant resin. The diaphragm has stronger strength, the heat resistance of the diaphragm is greatly improved, and when the diaphragm is used, puncturing of the diaphragm by burrs and short-circuit caused by shrinkage of the diaphragm at high temperature can be reduced, and the using safety of the diaphragm can be improved; the composite diaphragm with high wettability is high in liquid absorption rate and liquid retention rate; the composite diaphragm with high anti-oxidation performance can be adapted to various application environments, and the service life of a corresponding battery is also prolonged.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

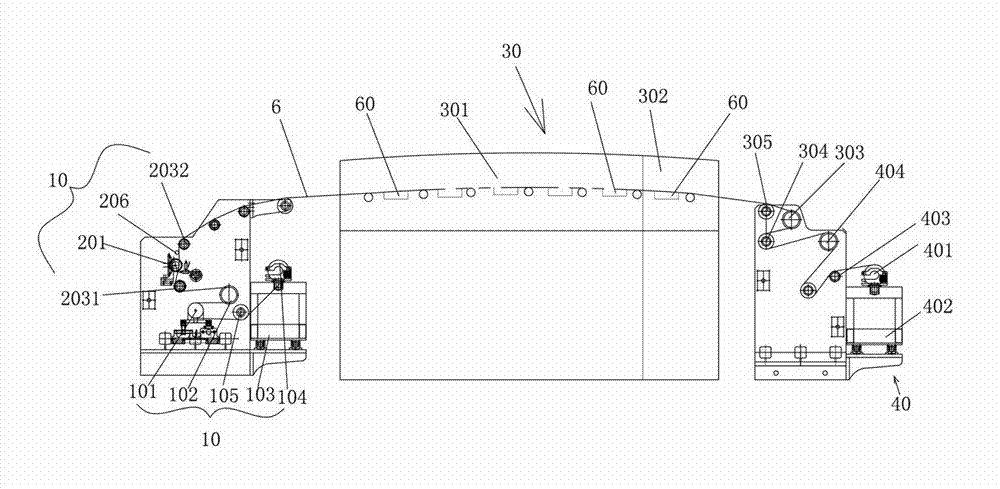

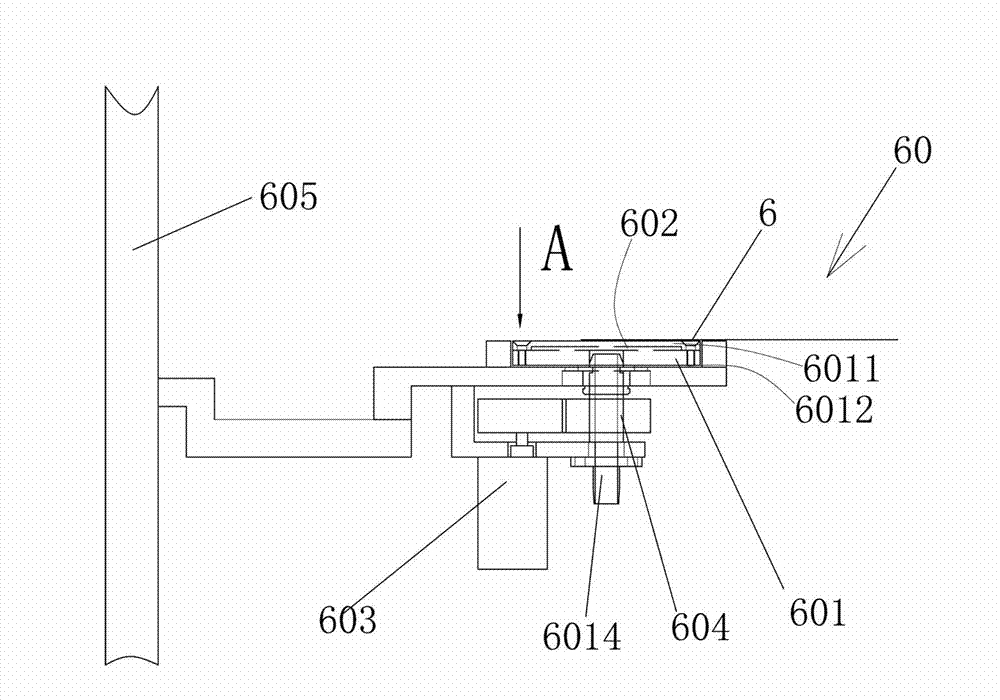

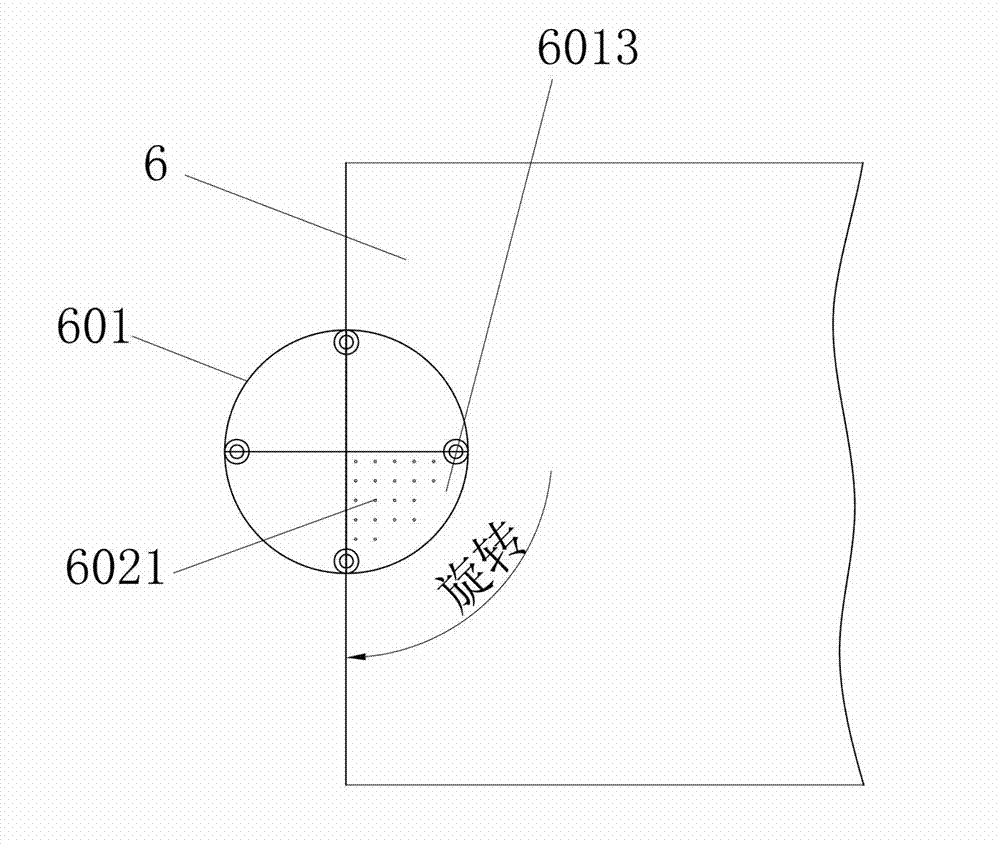

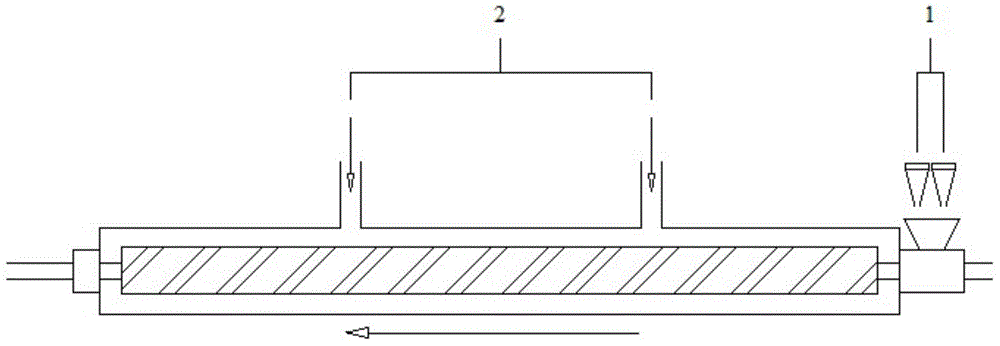

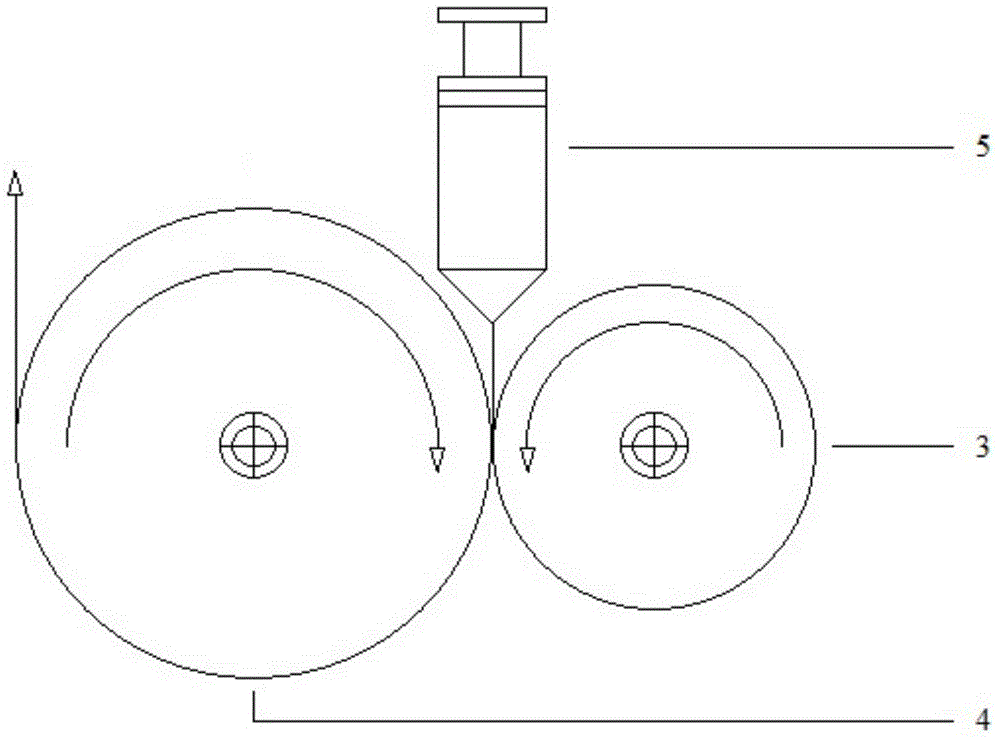

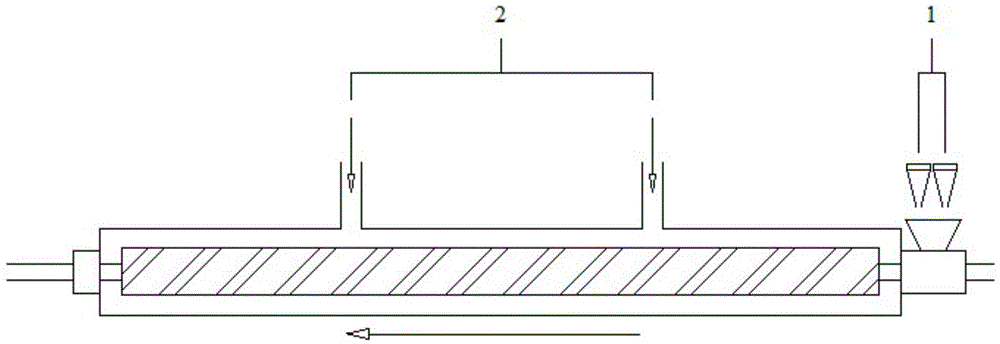

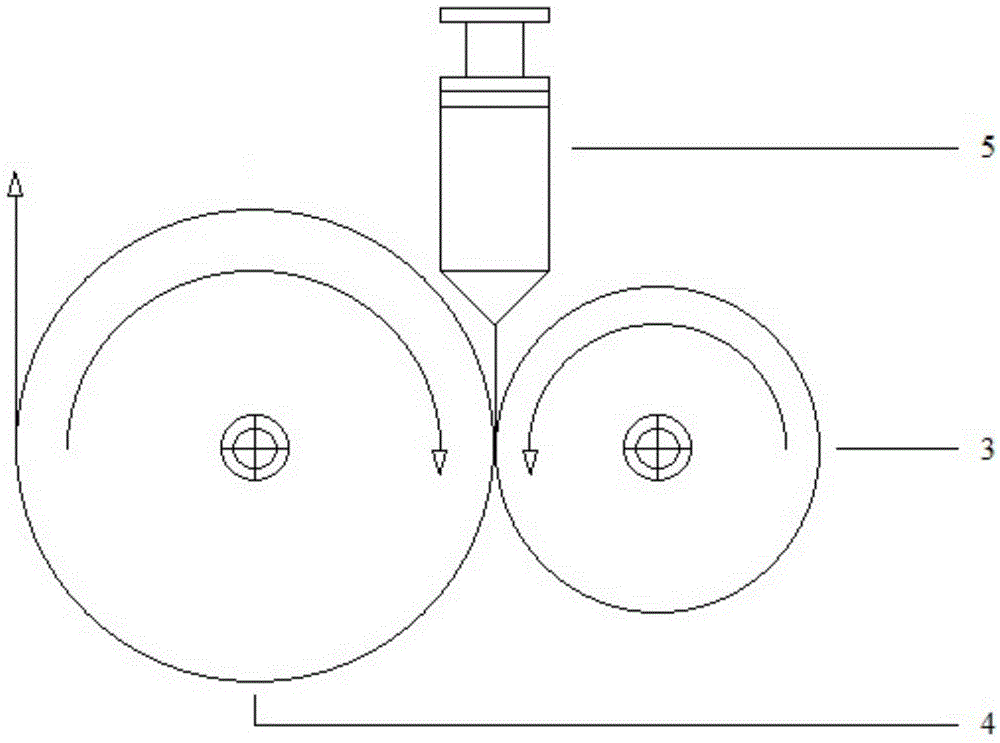

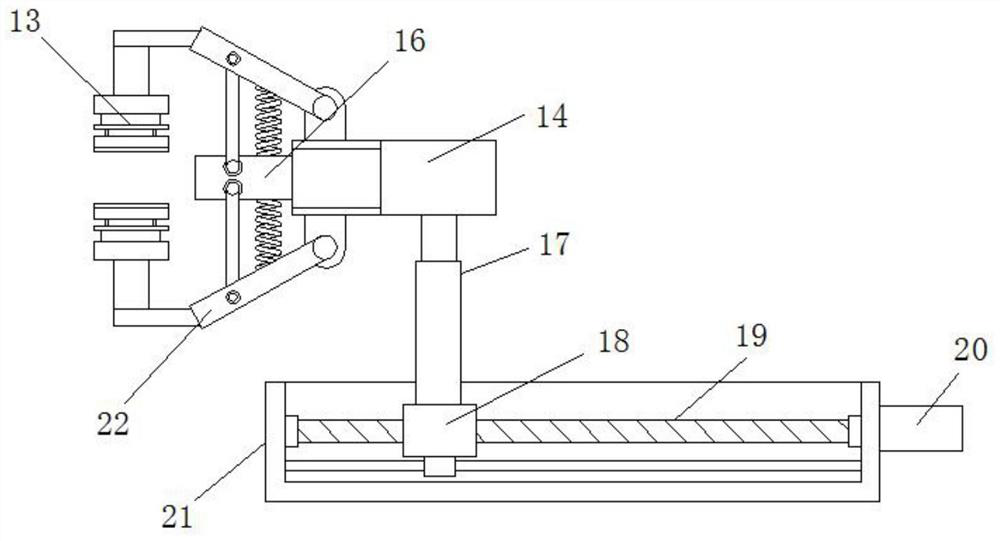

Micro-gravure coating machine

The invention discloses a micro-gravure coating machine, which comprises an unwinding device, a micro-gravure coating head, a baking-cooling box and a winding device. A diaphragm is put out of the winding device, coated with slurry by the micro-gravure coating head, then baked and cooled, and put in the winding device to wind. A flattening system of the micro-gravure coating machine comprises a first flattening roller and a second flattening roller located on two sides of a micro-gravure ceramic anilox roller of the micro-gravure coating head, and more than one vacuum flattening devices located on two sides of the diaphragm in the baking-cooling box and attached to the lower bottom surface closely. The vacuum flattening devices comprise a negative pressure source component connected with a negative pressure source and an absorption part provided with a plurality of absorption apertures. The absorption part moves against the negative pressure source component, and part of absorption apertures on the absorption part is selectively controlled by the negative pressure source component to be communicated with the outside world. The comprehensive flattening technology is adopted in the process of coating and proceeding diaphragm by the micro-gravure coating machine, so that the flattening effect of the diaphragm is enhanced.

Owner:SHENZHEN XINYUREN TECH

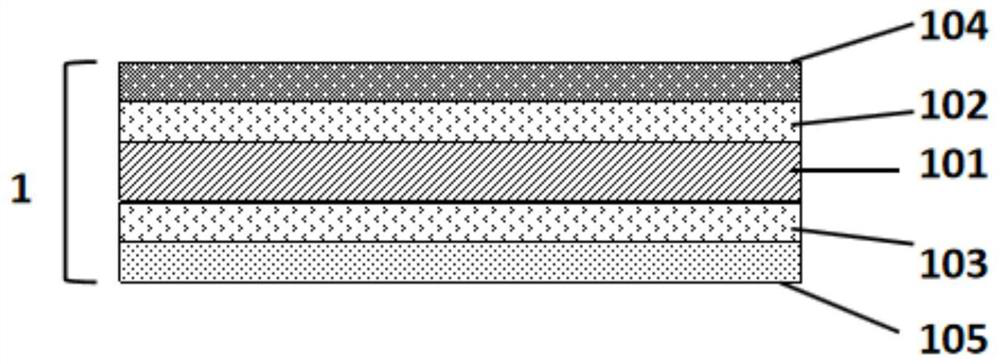

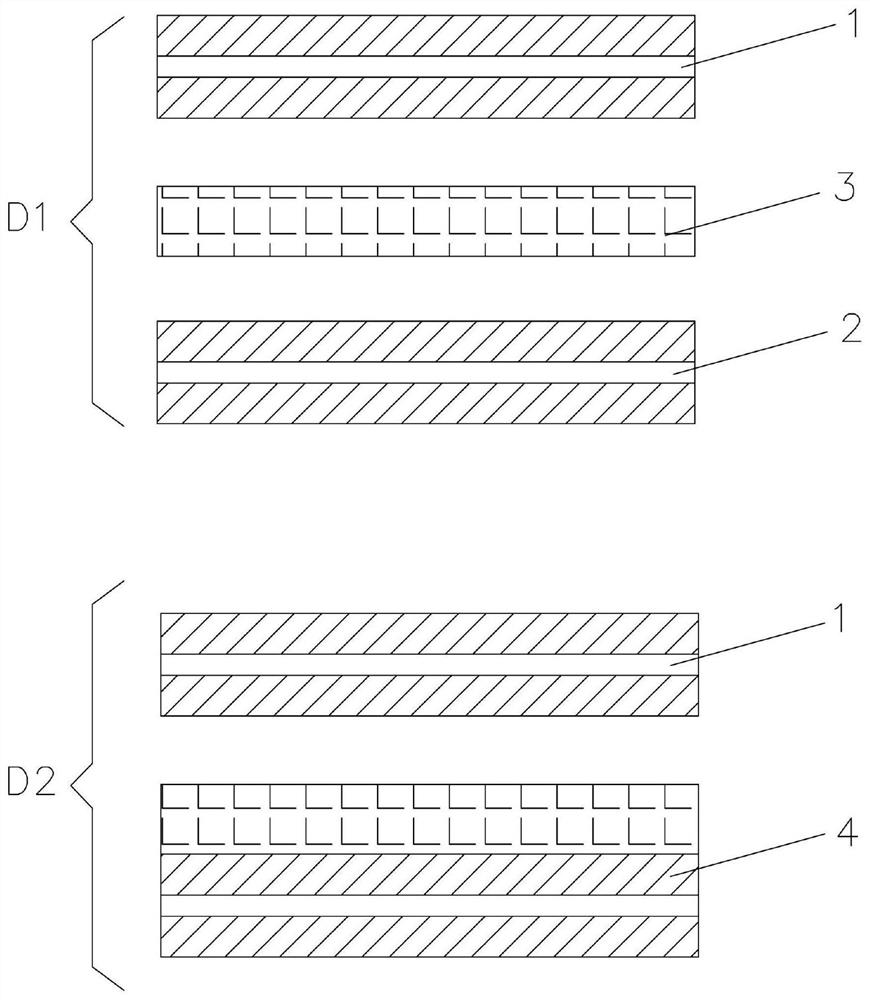

Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

ActiveCN103531735AWith ion acceleration functionExcellent Adhesive FunctionCell component detailsPolyolefinHigh diaphragm

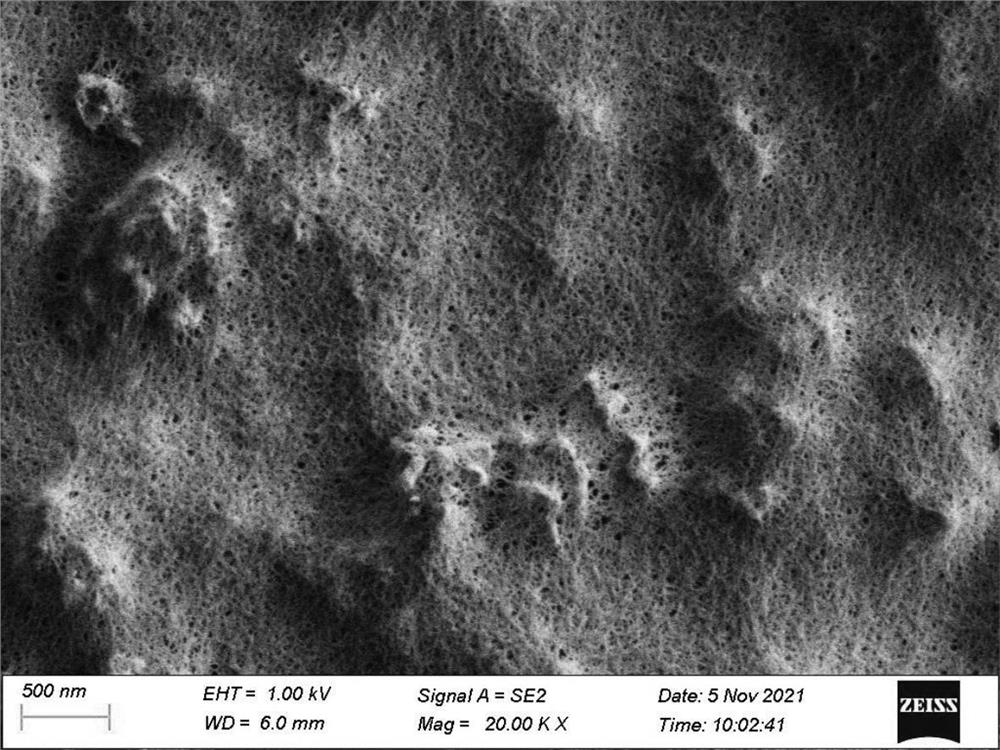

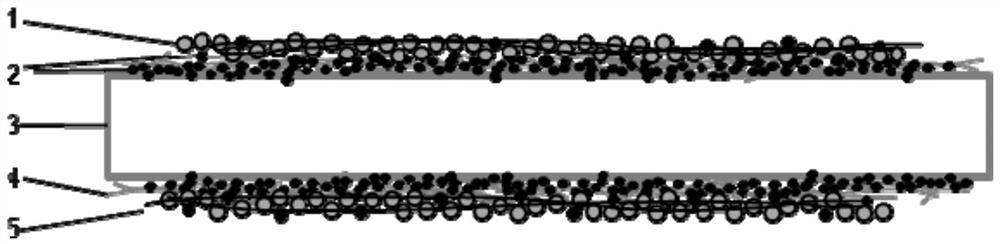

The invention relates to a polyolefin multilayer micro porous diaphragm for a lithium ion battery and a preparation method of the polyolefin multilayer micro porous diaphragm. The polyolefin multilayer micro porous diaphragm comprises a polyethylene micro porous layer, wherein an ion acceleration layer is arranged on each of the upper surface and the lower surface of the polyethylene micro porous layer, and a polypropylene micro porous layer is arranged on the outer surface of each ion acceleration layer. According to the polyolefin multilayer micro porous diaphragm, due to the adoption of a five-layer structure, a low hole closing temperature and a high diaphragm breaking temperature of the diaphragm can be provided, thus a safety window of the diaphragm is increased and the good safety performance is provided; and meanwhile, the ion acceleration layers provide low resistance, high electron conduction rate and good solution absorption performance and solution maintaining performance of the diaphragm, thus the charge-discharge power and the cycle service life of the lithium ion battery can be improved; and the ion acceleration layers have micro porous net-shaped structures and have excellent lyophilic performance and adhering performance, the ion transmission performance of the diaphragm is improved when all layers of the multilayer micro porous diaphragm are well compounded, and good gas permeability is kept.

Owner:河南惠强新能源材料科技股份有限公司

Method for manufacturing porous multilayer composite diaphragm for lithium battery and diaphragm

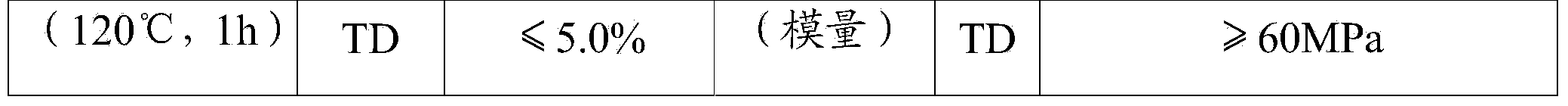

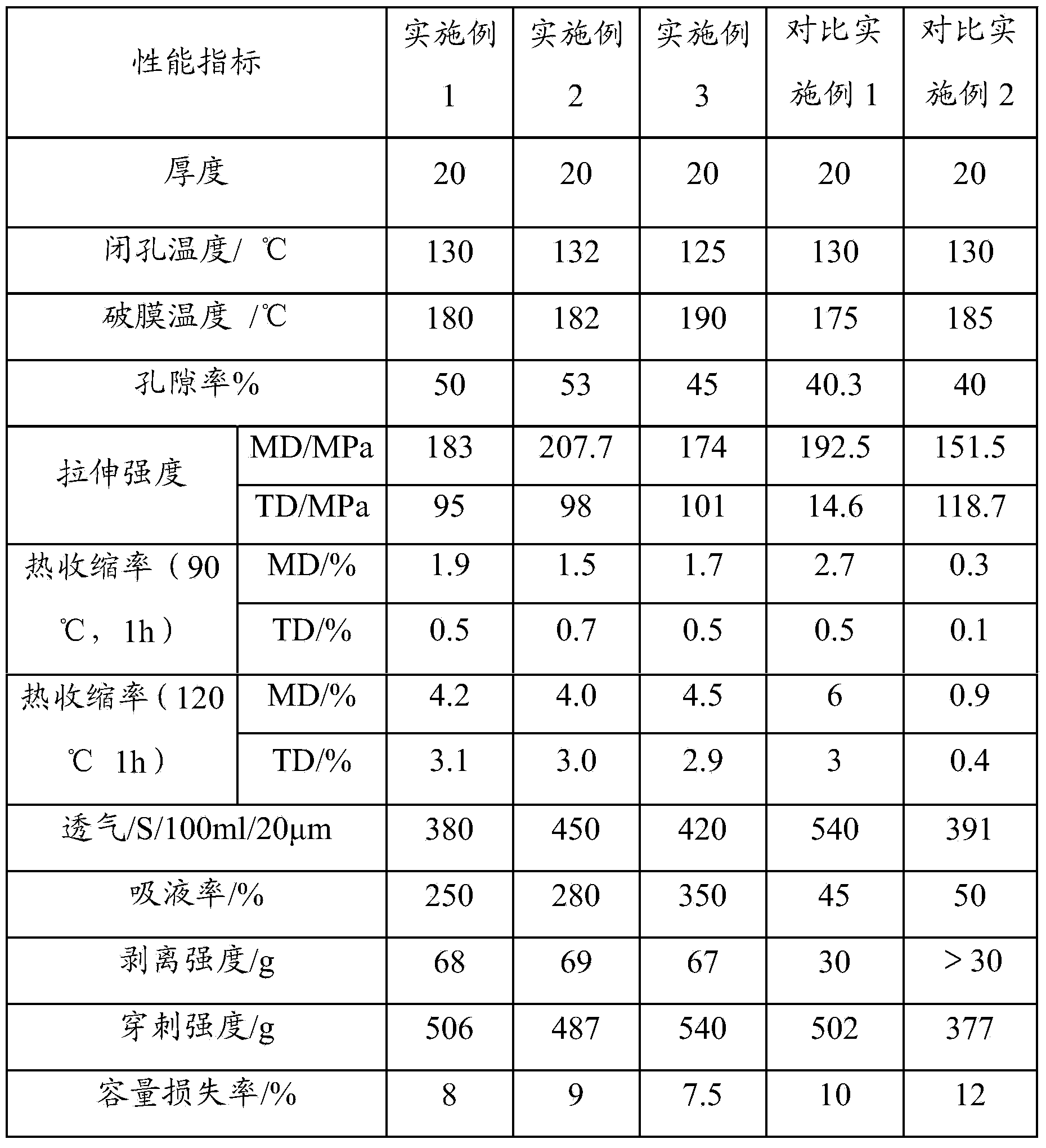

The invention discloses a method for manufacturing a porous multilayer composite diaphragm for a lithium battery and a diaphragm manufactured by the same. In the method, polyethylene mixed with solvent and heat-resistant resin mixed with the solvent are extruded by using a multilayer die head of a double-screw extruder, and the extruded products are subjected to chill casting, two-way stretch, washing, drying and heat setting to manufacture the porous multilayer composite diaphragm. An integral structure of the manufactured diaphragm comprises a polyethylene layer and a heat-resistant resin layer, has low closed-cell temperature given by the polyethylene and high diaphragm breaking temperature given by the heat-resistant resin layer simultaneously. Simultaneously, the addition of the heat-resistant resin layer reduces the heat contractibility of the multilayer diaphragm and improves the puncture strength of the multilayer diaphragm, so the multilayer diaphragm has more excellent performance.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Lithium supplementing composite diaphragm and preparation method thereof

PendingCN112271405AIncrease transfer rateIncrease gram capacitySecondary cellsCell component detailsHigh diaphragmLithium-ion battery

The invention discloses a lithium supplementing composite diaphragm and a preparation method thereof. The lithium supplementing composite diaphragm comprises a base membrane, one side, facing a positive electrode, of the base membrane is coated with a lithium supplementing layer, the material of the lithium supplementing layer comprises a lithium supplementing active substance and a binder, and the lithium supplementing active substance is metal oxide lithium salt. The lithium supplementing active substance adopts the metal oxide lithium salt, so that the gram volume of the positive electrodematerial can be improved, the lithium ion transmission rate is increased, and the rate capability and the cycle performance of the lithium ion battery are improved; on the other hand, the mechanical property of the diaphragm can be effectively enhanced, the temperature resistance of the diaphragm is improved, and the safety performance of the lithium ion battery is enhanced; besides, compared witha traditional method that the surface of the positive electrode material is coated with the metal oxide lithium salt serving as the lithium supplementing active substance, the metal oxide lithium salt is applied to the diaphragm, the mass of the positive electrode material cannot be increased, and therefore reduction of the gram volume of the positive electrode material due to addition of the lithium supplementing active substance can be avoided.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

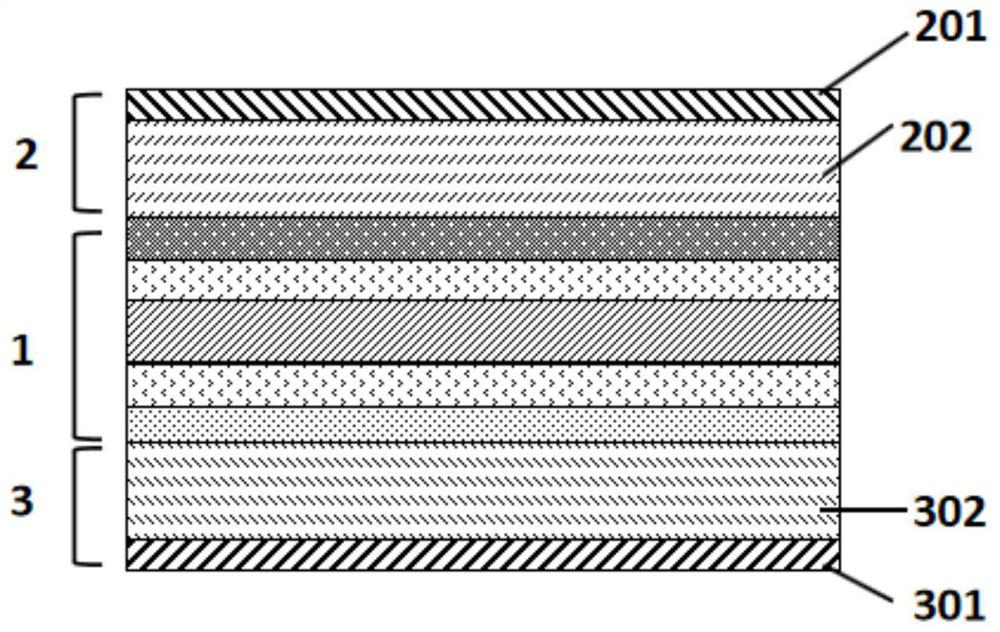

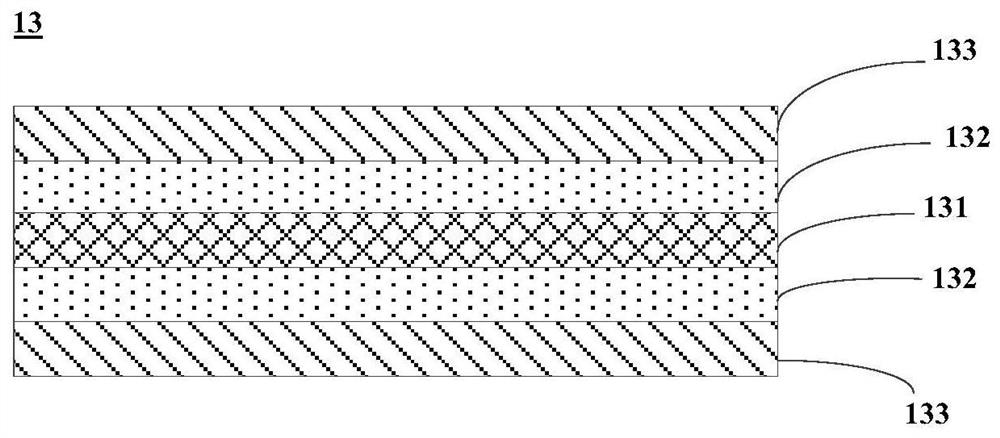

Composite diaphragm with lithium supplementing effect, and preparation method thereof and lithium ion battery

PendingCN112599928AImprove electrochemical performanceGood chemical propertiesElectrolyte/reactants regenerationCell component detailsHigh diaphragmCeramic coating

The invention provides a composite diaphragm with a lithium supplementing effect. The composite diaphragm comprises a base membrane, a first ceramic coating and a second ceramic coating which are respectively positioned on the upper surface and the lower surface of the base membrane, a lithium supplementing gel coating positioned on the upper surface of the first ceramic coating, and a gel coatingpositioned on the lower surface of the second ceramic coating. According to the invention, with the ceramic coating in the diaphragm, the temperature resistance of the diaphragm is improved, the thermal shrinkage of the diaphragm is improved, explosion caused by short circuit due to direct contact between a positive electrode and a negative electrode due to diaphragm deformation caused by thermalcontraction of the diaphragm at a high temperature is prevented, the lithium supplementing gel coating can realize uniform and accurate lithium supplementing of a silicon-carbon negative electrode sheet, a silicon-carbon negative electrode is prevented from being excessively lithiated to cause lithium precipitation, after lithium supplementing is finished, the gel coating and the electrode sheethave higher bonding force under the action of hot-pressing shaping, and the lithium ion good conductor powder remained in the lithium supplementing coating has good ionic conductivity, so that the conduction of lithium ions is promoted.

Owner:TIANJIN ENERGIES

Lithium ion battery diaphragm and preparation method thereof

InactiveCN111192999AThe process steps are simpleIncrease productivitySecondary cellsCell component detailsHigh diaphragmPhysical chemistry

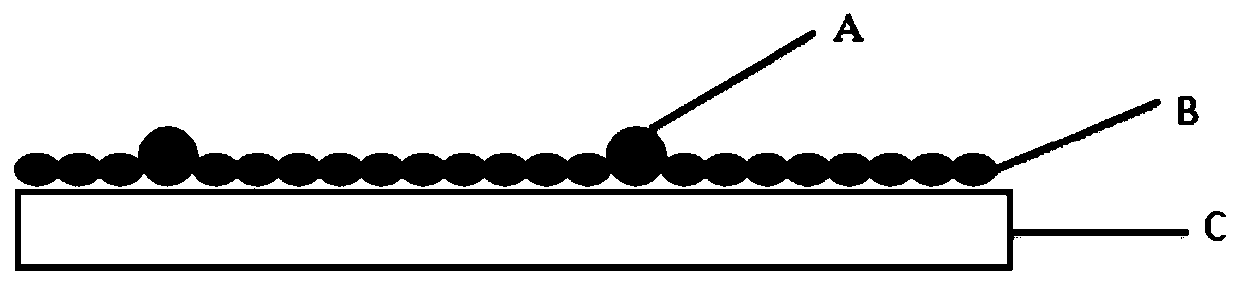

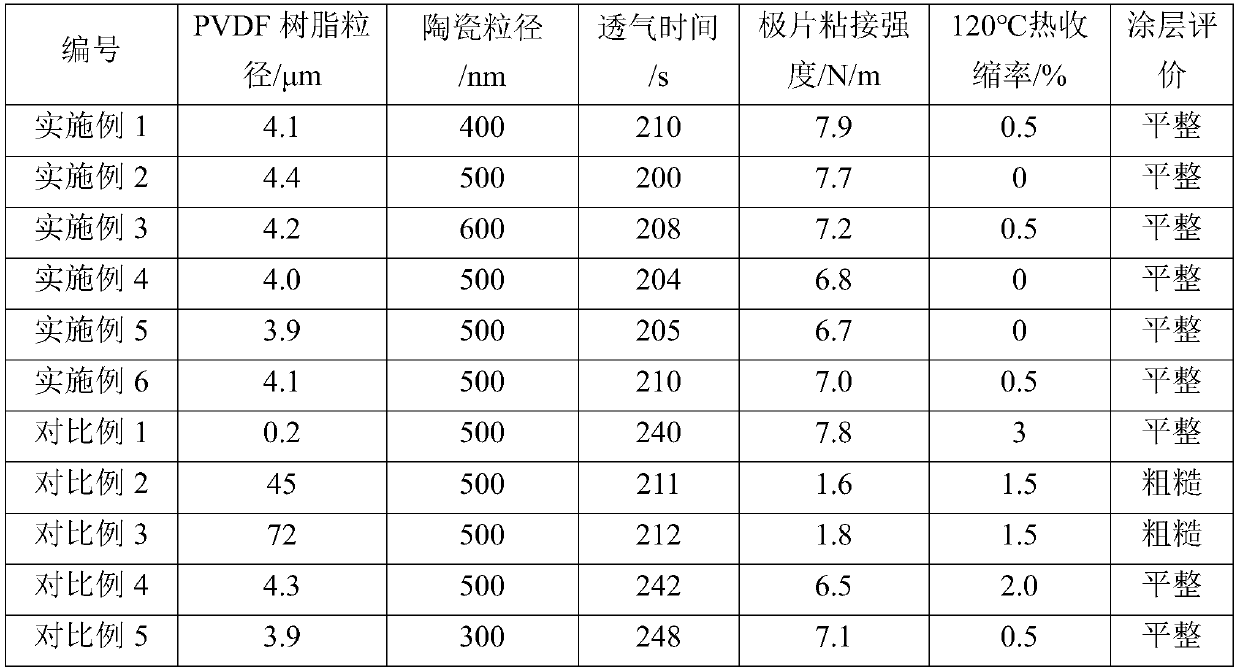

The invention provides a lithium ion battery diaphragm and a preparation method thereof. The diaphragm comprises a base material and a coating coated on at least one surface of the base material, thecoating comprises ceramic particles and PVDF copolymer resin, the ceramic particles are continuously distributed in the coating, and the PVDF copolymer resin is embedded in the ceramic particles and protrudes out of the coating. The invention also provides a preparation method of the diaphragm. In the diaphragm, the small molecule accumulation effect of large-particle PVDF is weakened, the air permeability of the diaphragm is improved, PVDF particles protruding out of a coating play a role in bonding with a pole piece, the diaphragm has good heat resistance and pole piece bonding performance at the same time, and the additional value of a diaphragm product can be remarkably improved. And the preparation method adopts one-time coating, the process is simple, and the production efficiency ishigh.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

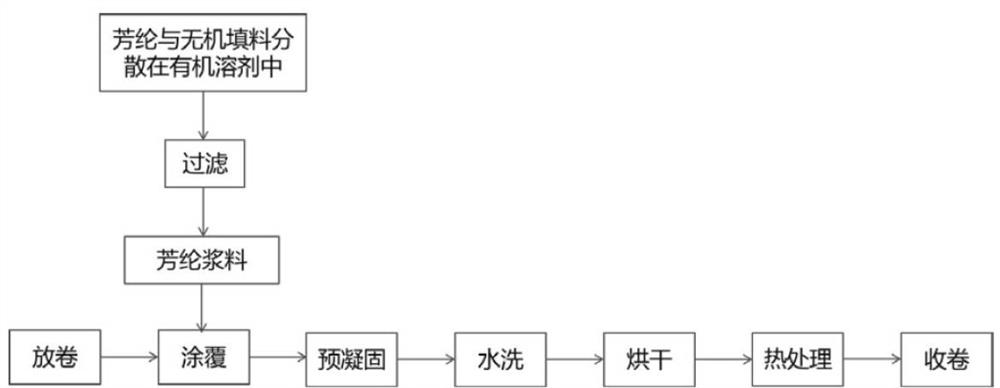

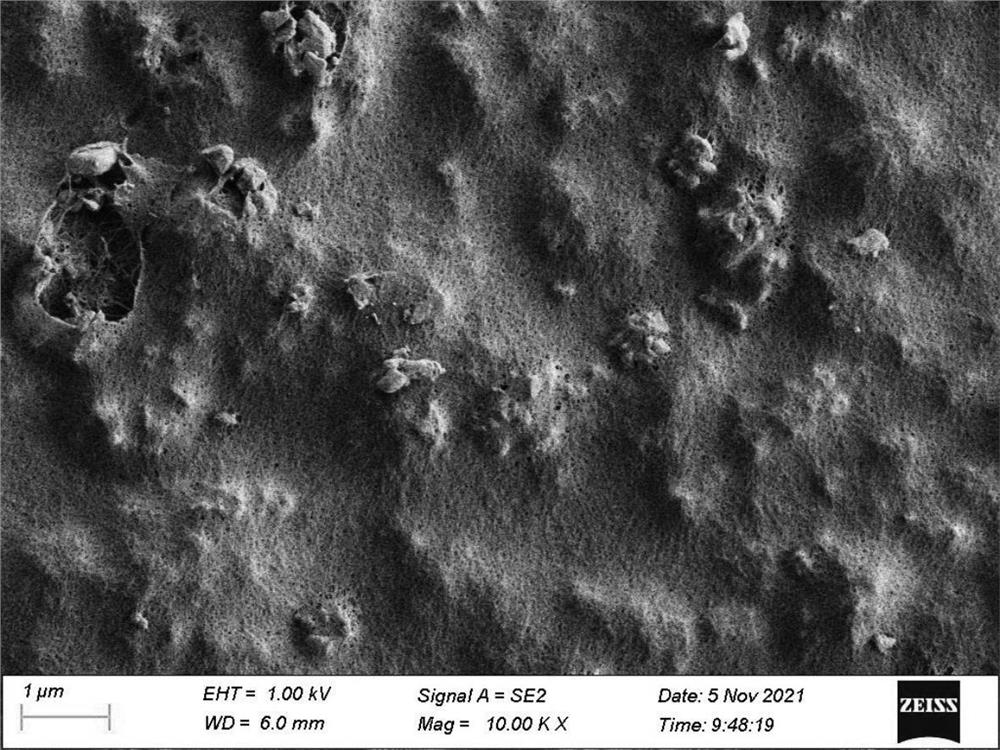

High-breakdown-strength aramid diaphragm as well as preparation method and application thereof

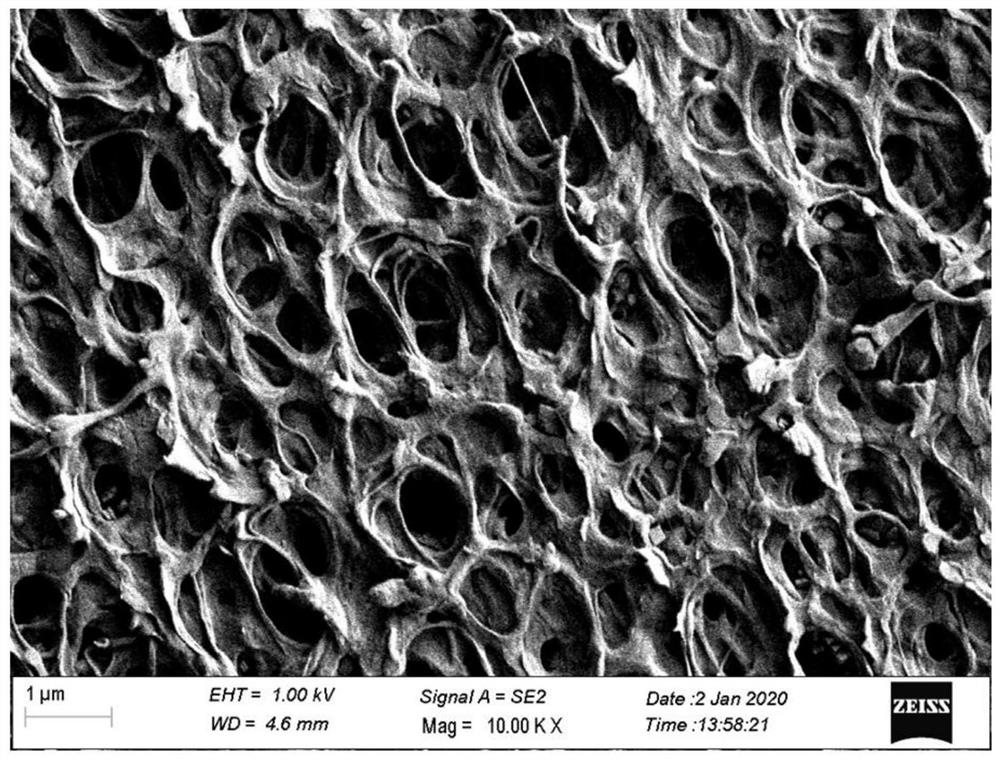

ActiveCN114243093AHigh breakdown strengthImprove securityHybrid capacitor separatorsSecondary cellsPolymer scienceHigh diaphragm

The invention provides a high-breakdown-strength aramid diaphragm as well as a preparation method and application thereof, and relates to the technical field of diaphragms, the high-breakdown-strength aramid diaphragm comprises a base membrane and an aramid coating arranged on one side or two sides of the base membrane; the outer layer of the aramid fiber coating is of a dense porous structure, and the interior of the aramid fiber coating is of a fibrous porous structure; the added value of the air permeability of the aramid fiber coating of the high-breakdown-strength aramid fiber diaphragm is 20-30 s / 100 cc / mu m, and the breakdown strength of the aramid fiber coating of the high-breakdown-strength aramid fiber diaphragm is 0.24-0.3 kv / mu m. On the basis of not abnormally increasing the air permeability of the aramid fiber coating diaphragm, the breakdown strength of the diaphragm can be improved, and the safety performance is improved.

Owner:中材锂膜(宁乡)有限公司

Heat-shrinkage-resistant lithium ion battery diaphragm and polyethylene composition adopted by same

ActiveCN106328859ALow costWide variety of sourcesCell seperators/membranes/diaphragms/spacersSecondary cellsHigh diaphragmPhysical chemistry

The invention provides a polyethylene composition for preparing a heat-shrinkage-resistant lithium ion battery diaphragm. The composition comprises high-molecular polyethylene, ultra-high-molecular polyethylene and an optional additive. The lithium ion battery diaphragm prepared from the composition has high heat shrinkage resistance, high tensile strength, high puncture strength, relatively high diaphragm-rupture temperature and relatively low closed-hole temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

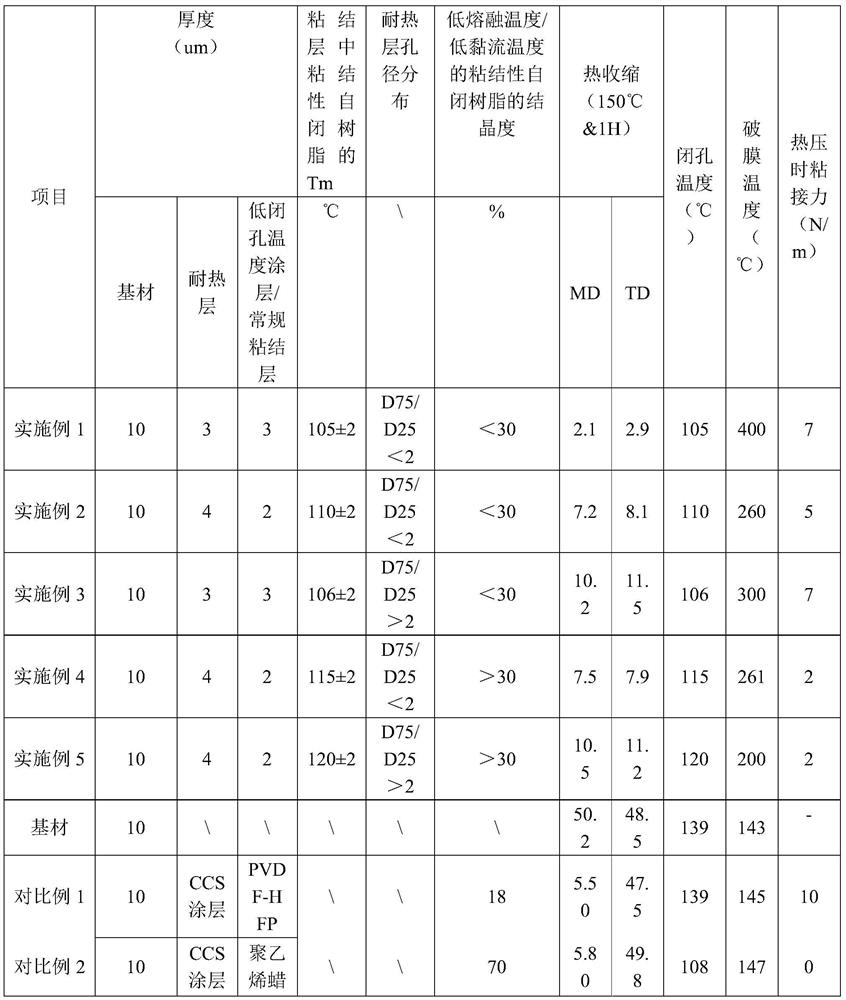

High-safety diaphragm and battery

PendingCN113054324AIncrease temperatureImprove heat resistanceSecondary cellsCell component detailsPorous substrateHigh diaphragm

The invention relates to the field of battery diaphragms, in particular to a high-safety diaphragm and a battery, the high-safety diaphragm comprises a porous base material, a heat-resistant coating coated on at least one side of the porous base material, and a low-hole-closing-temperature coating coated on the porous base material or the heat-resistant coating; the heat-resistant coating comprises heat-resistant resin; the low-hole-closing-temperature coating comprises a self-hole-closing material; and the self-closing material comprises cohesive self-closing resin with a low melting temperature or a low viscous flow temperature. The diaphragm rupture temperature and the heat-resistant shrinkage performance of the diaphragm are improved by arranging the heat-resistant coating, meanwhile, the low-pore-closing-temperature coating is introduced, and cohesive self-closing resin with low melting temperature or low viscous flow temperature can be rapidly melted or softened at a certain temperature to close pores of the porous base membrane, so that the purpose of reducing the pore closing temperature is achieved, the difference value between the hole closing temperature and the membrane breaking temperature is increased, and the high-safety diaphragm is obtained, so that the safety of the battery is enhanced.

Owner:ZHUHAI ENERGY NEW MATERIALS TECH CO LTD

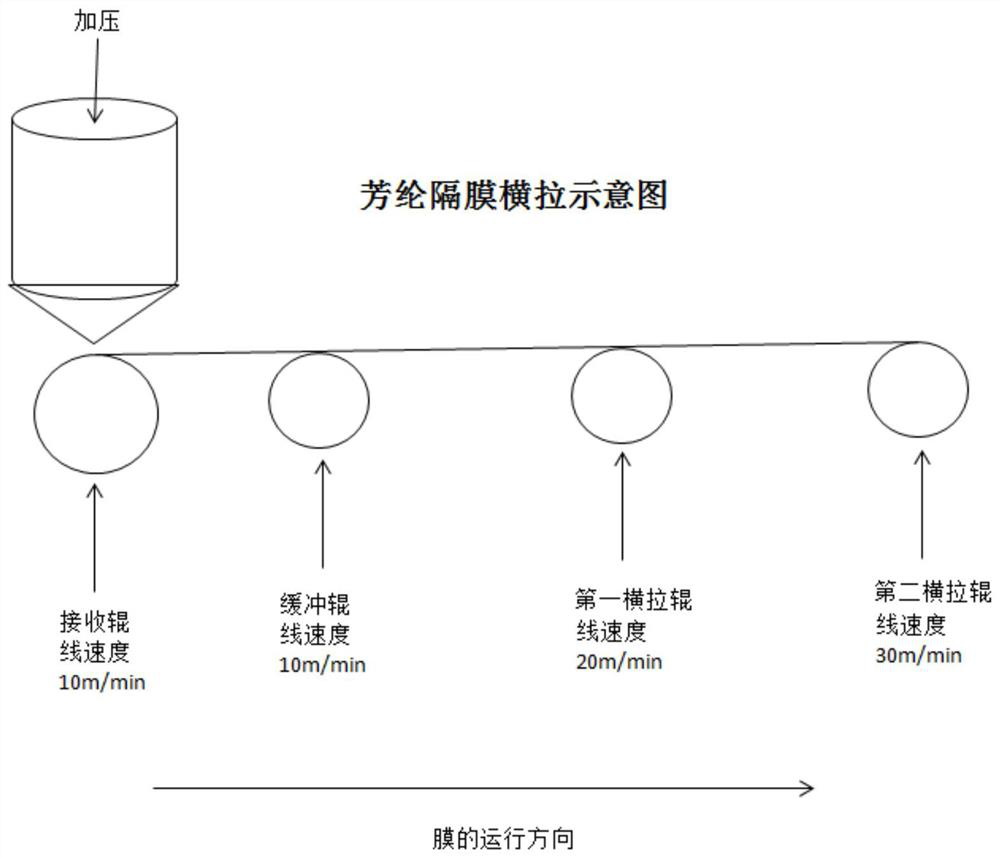

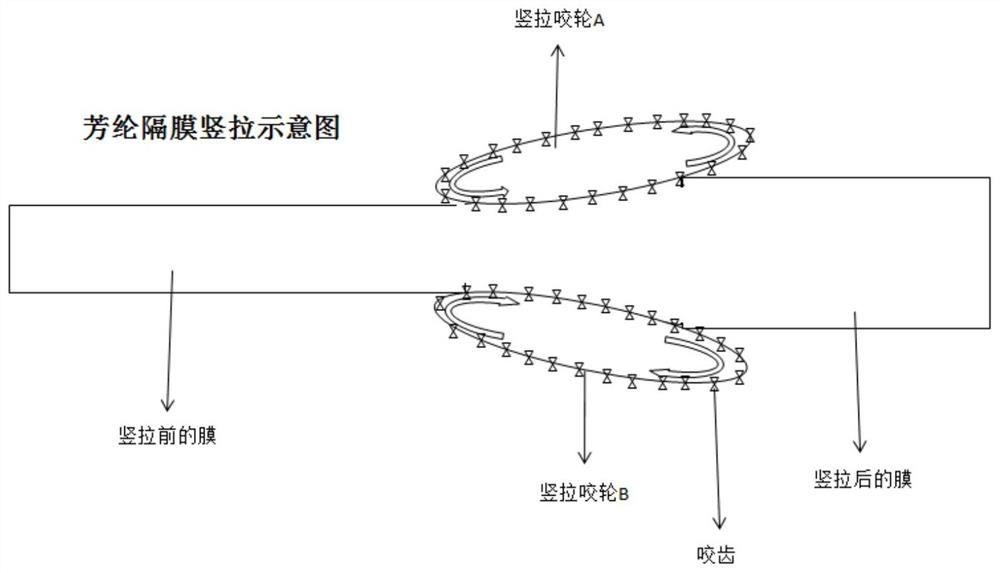

Meta-aramid diaphragm and preparation method thereof

InactiveCN111668425AHigh molecular weightReduce internal stressCell component detailsArtifical filament manufactureCalcium hydroxidePolymer science

The invention discloses a preparation method of a meta-aramid diaphragm. The method comprises the following steps: reacting m-phenylenediamine, isophthaloyl dichloride and calcium hydroxide in dimethylacetamide to obtain a meta-aramid solution; uniformly mixing the meta-aramid solution with dimethyl carbonate, and adjusting the viscosity to 25000-30000 mpa.s to obtain meta-aramid slurry; extrudingthe meta-aramid slurry to obtain a cast sheet, and transversely stretching the cast sheet to obtain a diaphragm precursor; vertically stretching the diaphragm precursor to obtain a diaphragm semi-finished product; and carrying out extraction curing on the semi-finished diaphragm product, drying, and rolling to obtain the meta-aramid diaphragm. According to the invention, a considerable amount ofcalcium hydroxide is added in a synthesis process of meta-aramid to form a calcium salt system in a meta-aramid solution, so that the molecular weight of the meta-aramid is improved, and the viscosityand toughness of the slurry of the meta-aramid are improved; and transverse and vertical stretching is carried out in the membrane preparation process, so that the slurry forms a membrane uniformly,the internal stress during extraction and curing is reduced, pores are formed in the membrane uniformly, and the high-temperature resistance of the membrane is remarkably improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

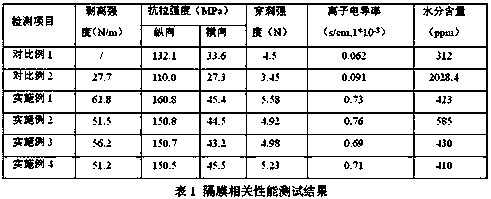

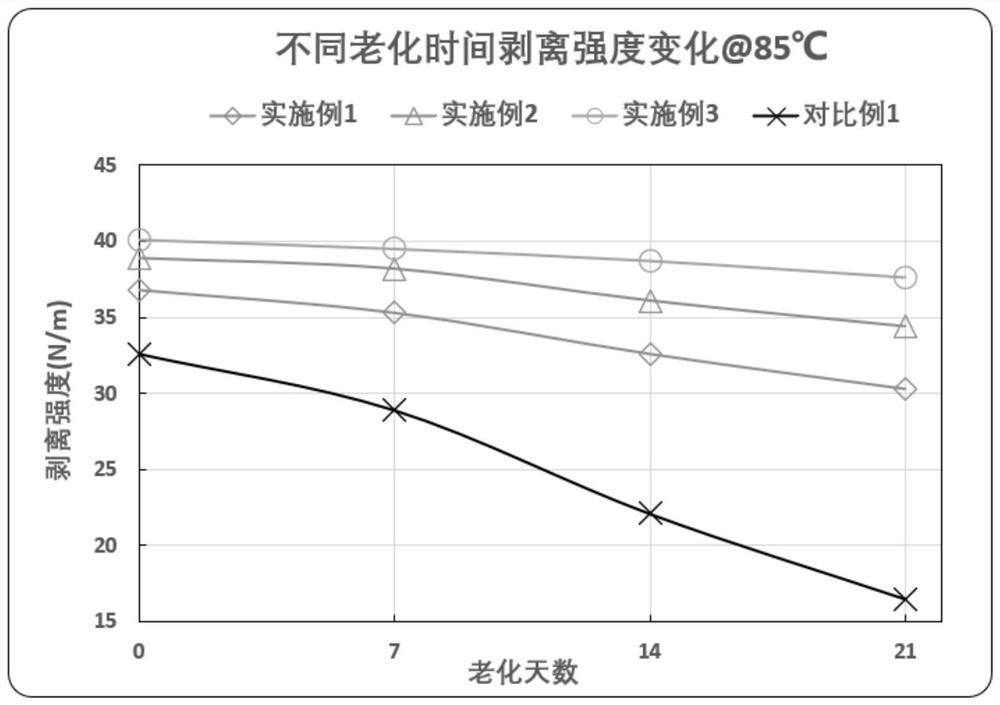

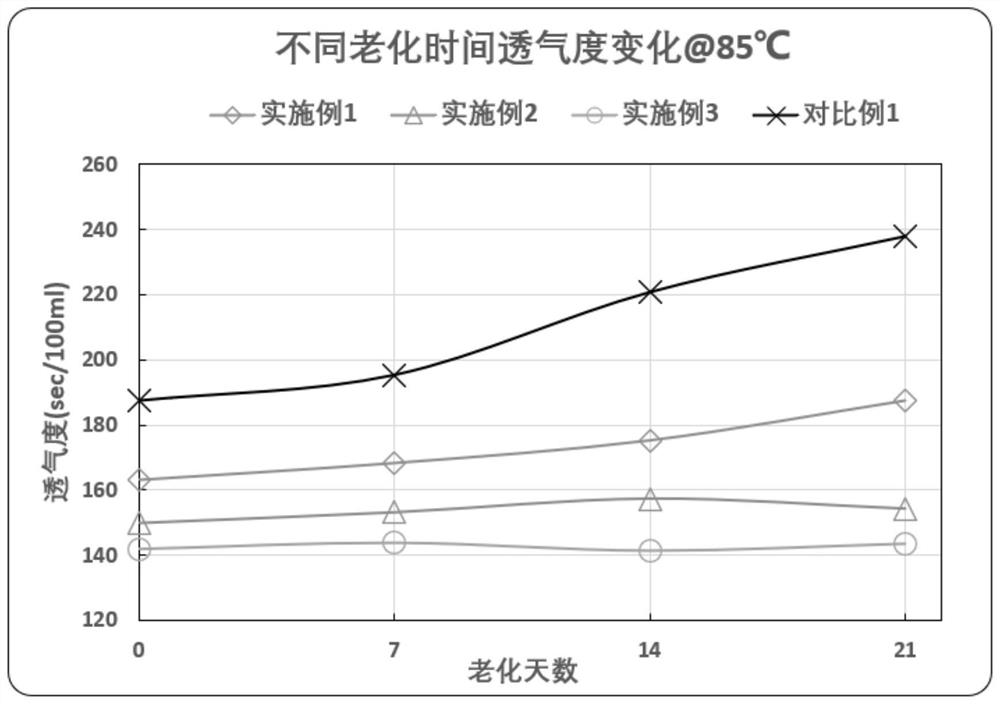

Diaphragm containing organic-inorganic coating for lithium battery and preparation method of same

The invention discloses a diaphragm containing an organic-inorganic coating for a lithium battery and a preparation method of the diaphragm. The preparation method comprises the following steps: treating ceramic particles with a plant phenolic acid compound, carrying out a cross-linking reaction on the treated ceramic particles and isocyanate to obtain a functionalized ceramic material, carrying out self-crosslinking on the functionalized ceramic material, polyphosphazene and derivatives thereof to form a polyphosphazene / functionalized ceramic composite coating, and treating with a surface glyceride compound to obtain the diaphragm coating. According to the invention, the organic-inorganic coating is introduced to one side or two sides of the polyolefin diaphragm, so that the adhesion strength, mechanical properties and ionic conductivity of the diaphragm coating are further improved on the premise of not influencing other properties, and the moisture content of the diaphragm is reduced; and furthermore, the electrochemical performance is improved, so that the performance requirements of the lithium ion battery diaphragm can be better met.

Owner:XINXIANG ZHONGKE SCI&TECH

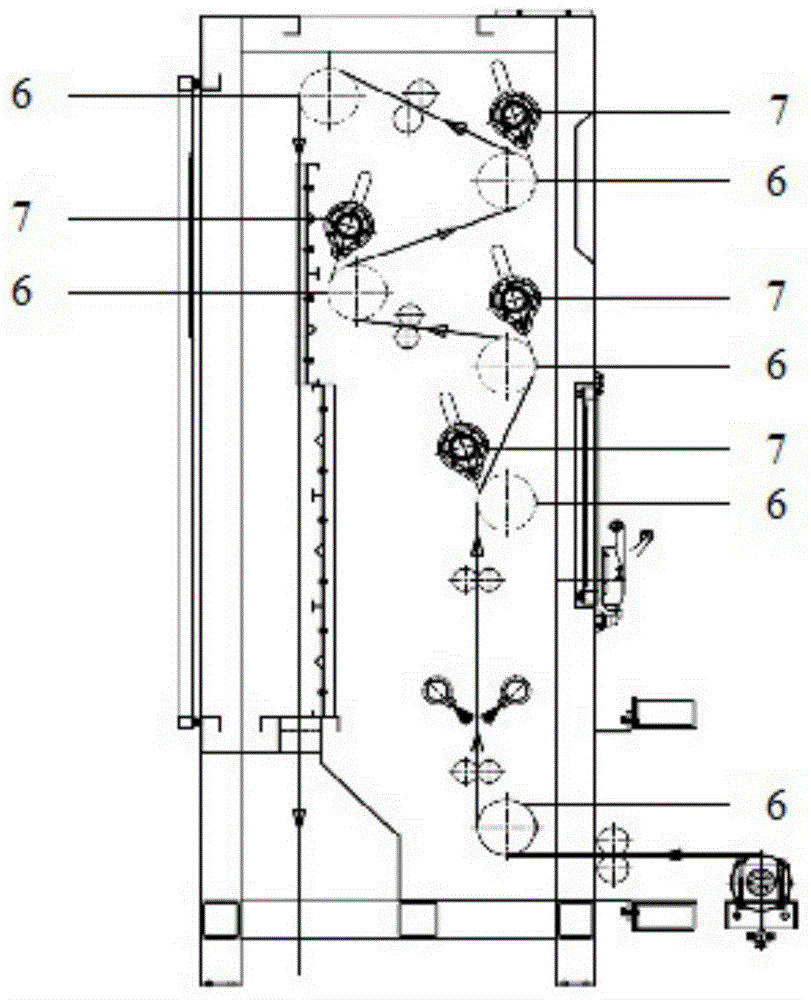

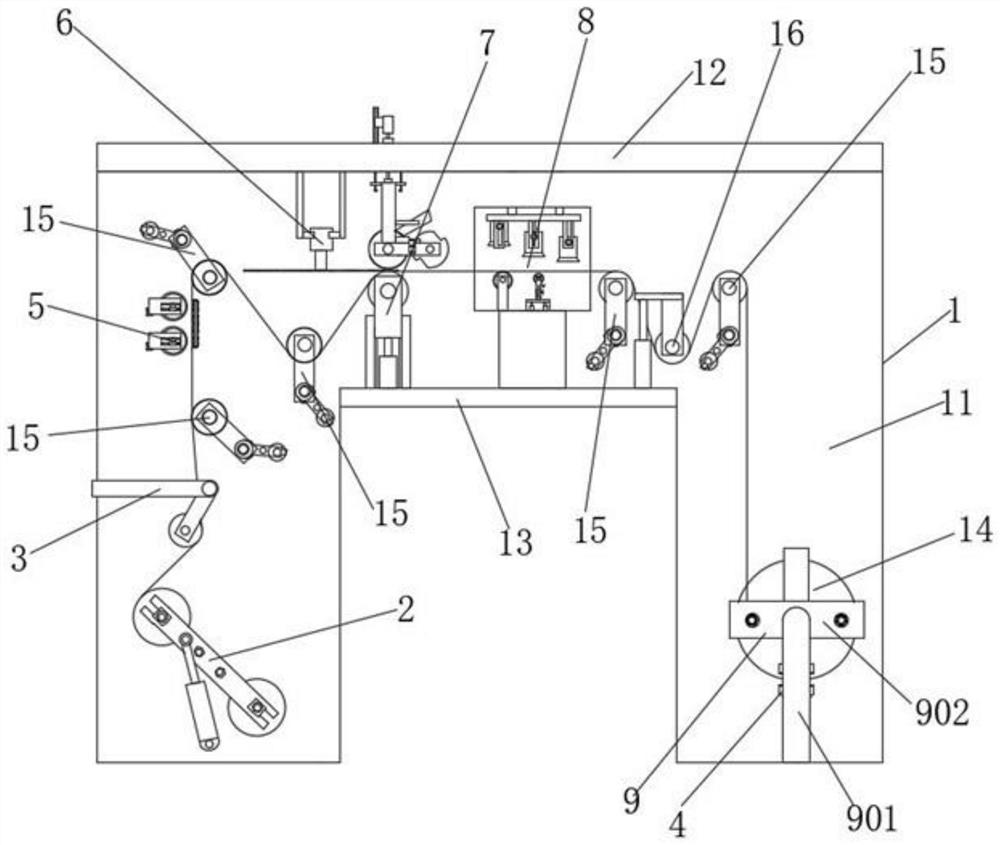

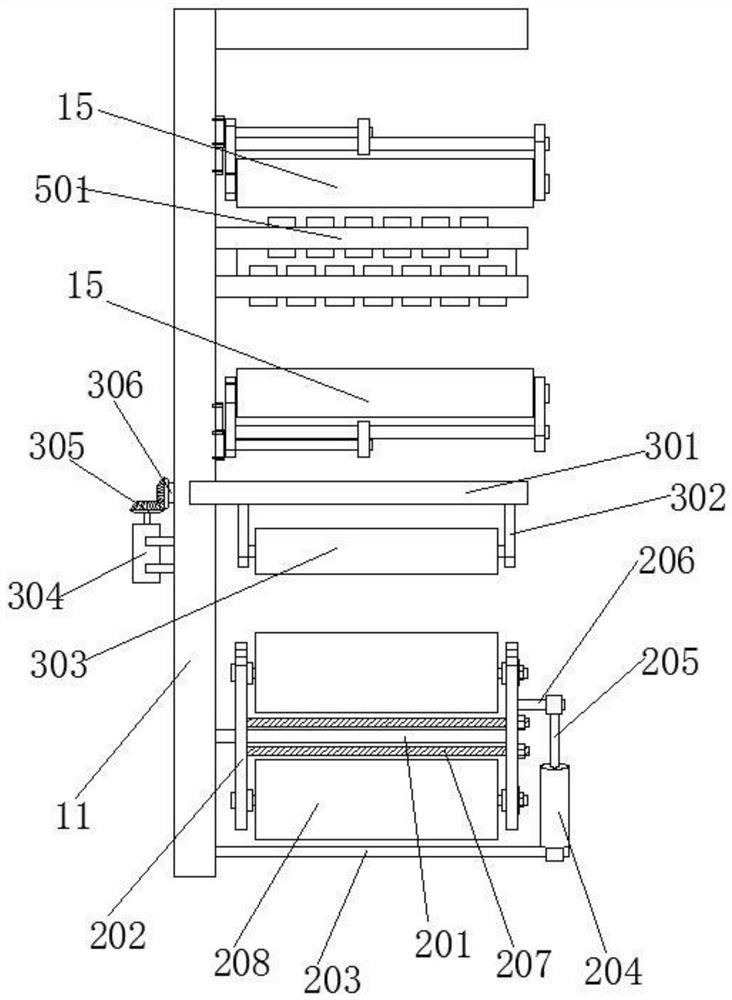

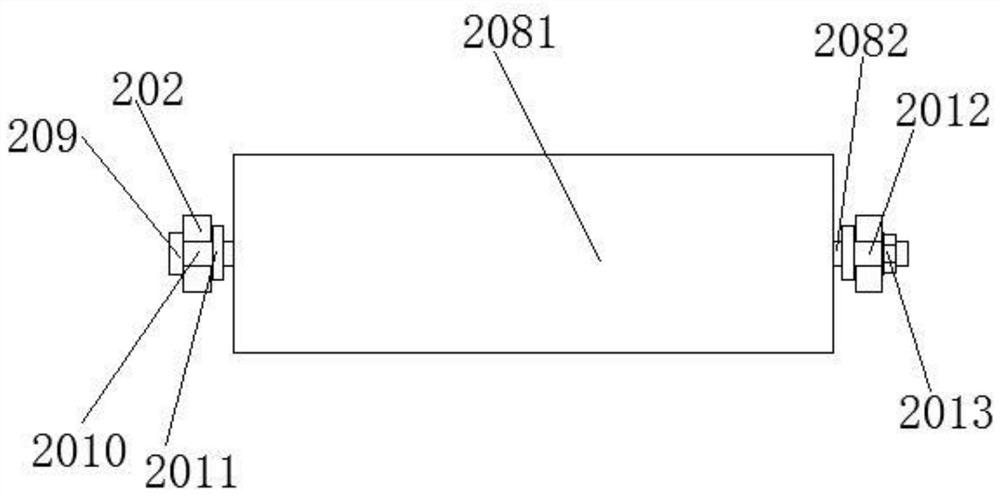

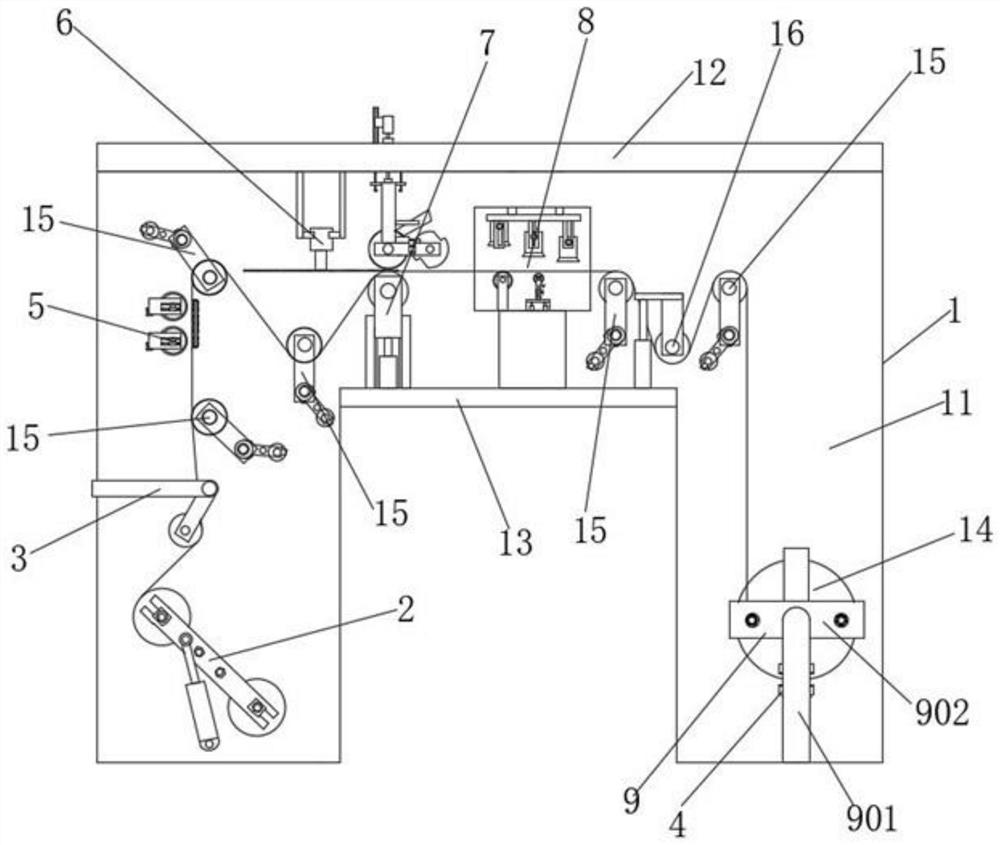

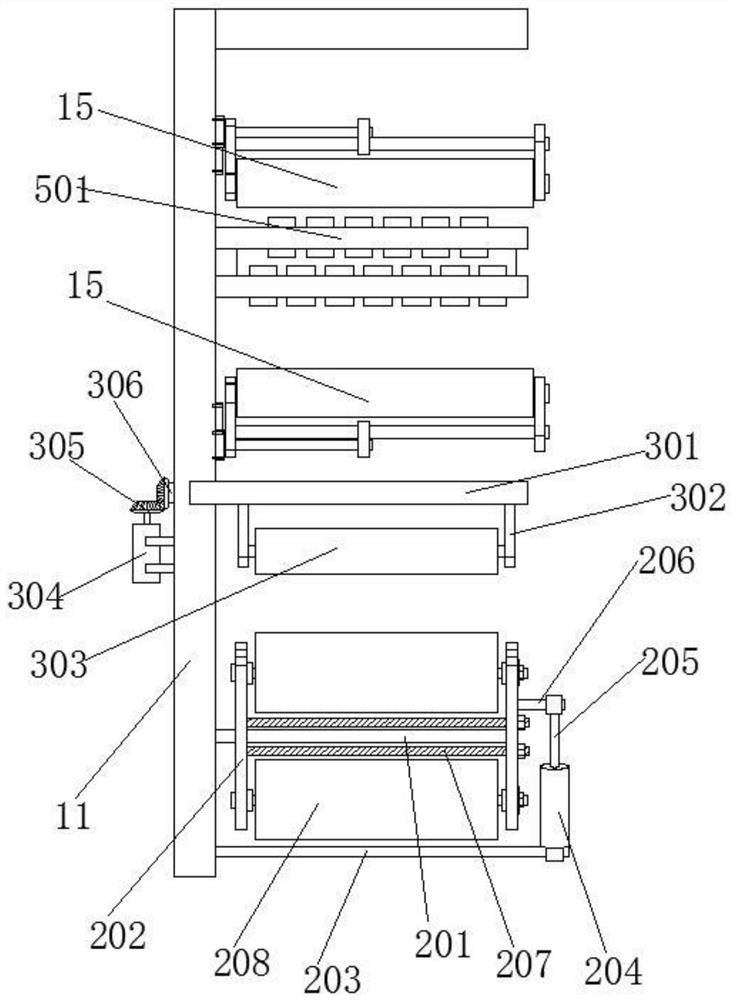

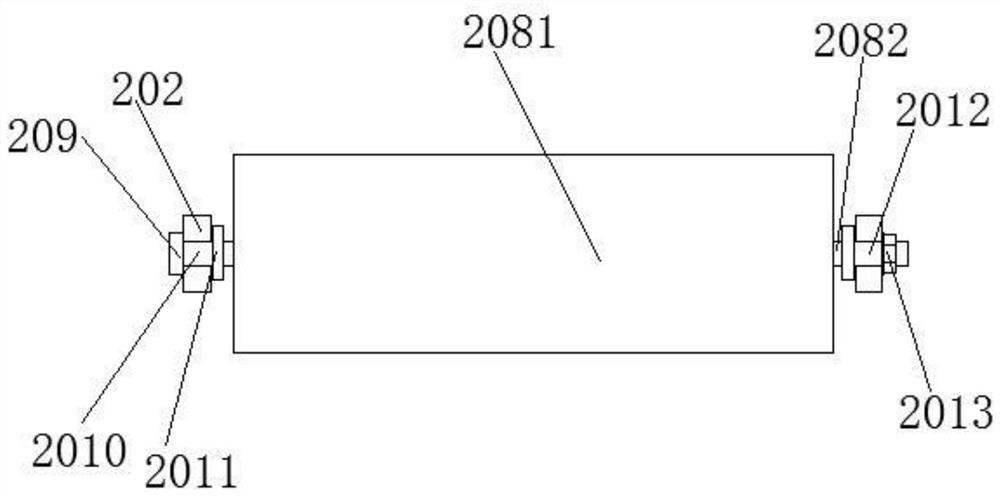

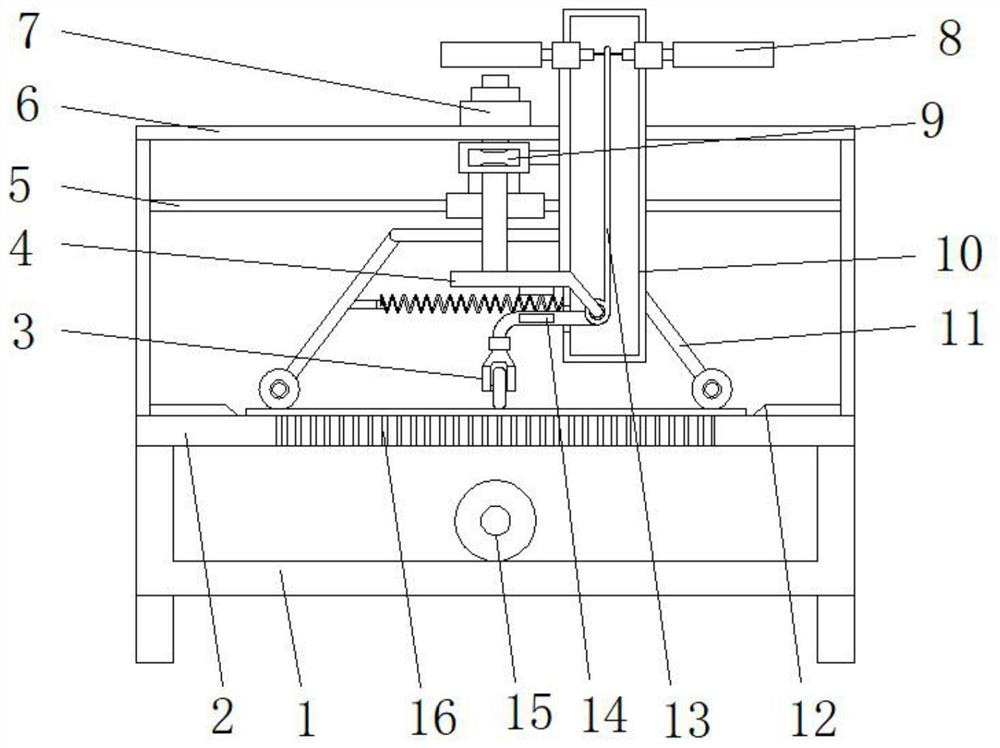

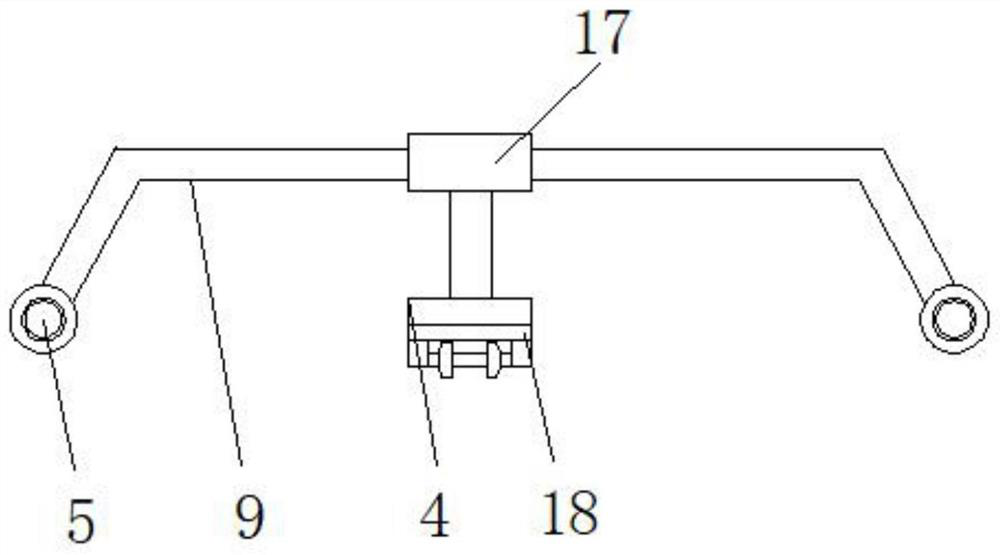

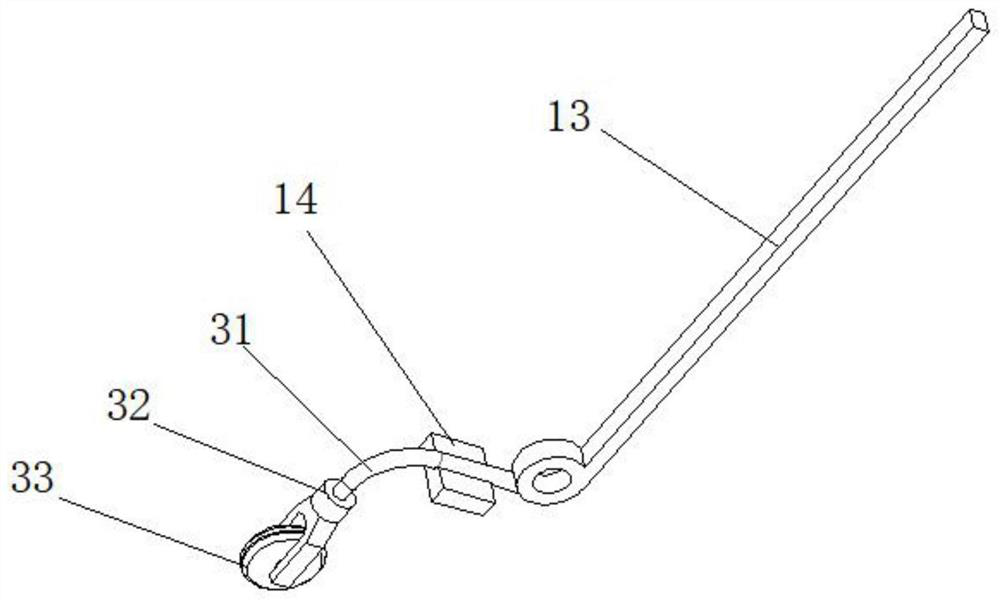

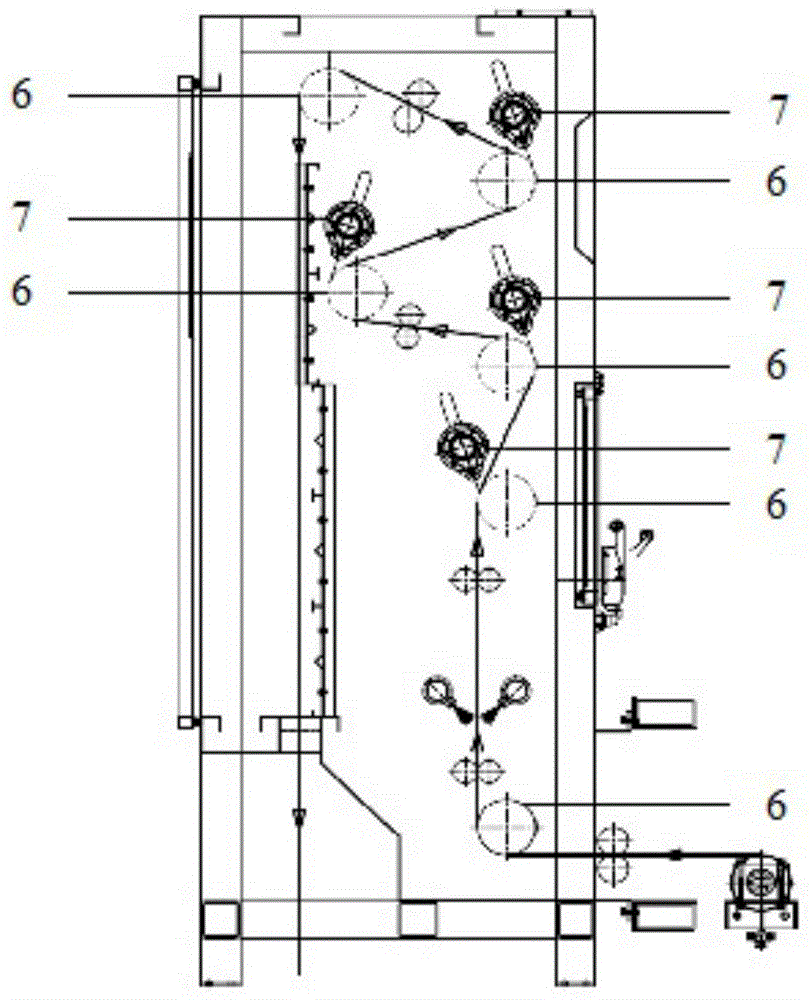

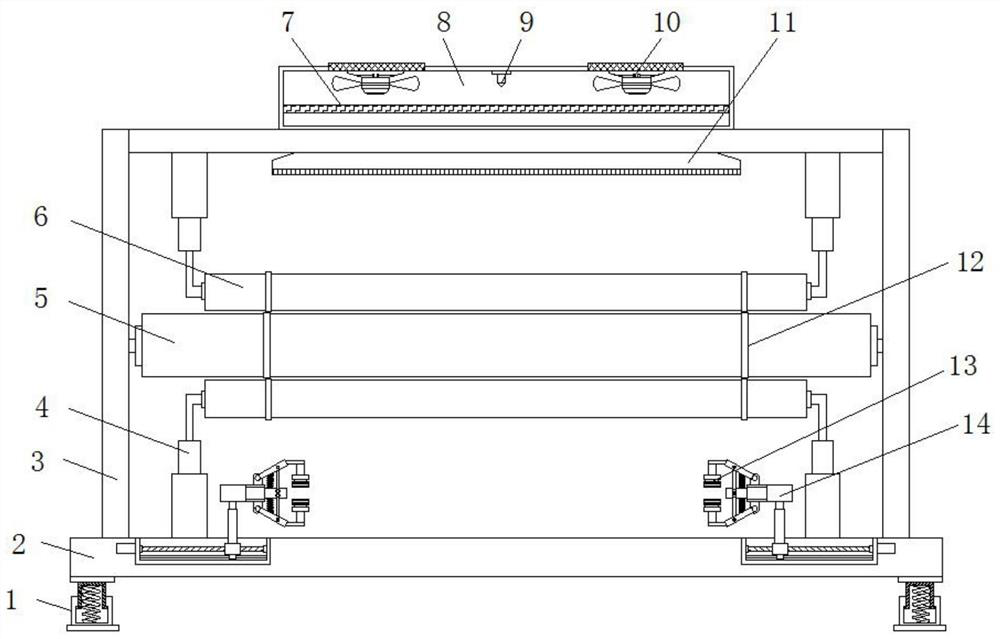

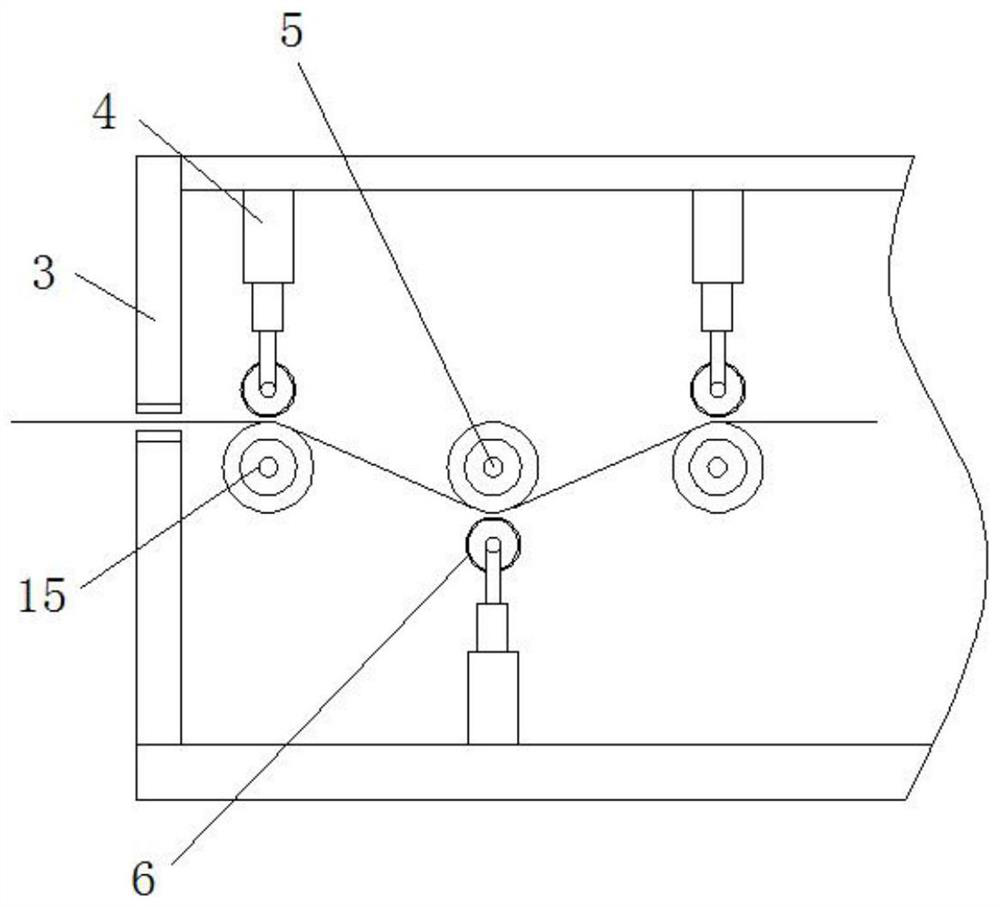

Coating device for PVDF diaphragm for lithium battery

InactiveCN112076954ALiquid surface applicatorsCleaning using toolsHigh diaphragmStructural engineering

The invention discloses a coating device for a PVDF diaphragm for a lithium battery. The coating device is characterized by comprising a rack, wherein an unwinding mechanism, a swinging mechanism, a cleaning mechanism, a coating conversion mechanism, a coating mechanism, a drying mechanism, a cutting mechanism and a winding mechanism are arranged on the rack according to the advancing direction ofthe diaphragm; the rack comprises a vertical plate, a top plate and a supporting plate, wherein the top plate and the supporting plate are vertically arranged on the vertical plate; a plurality of guide rollers used for guiding the conveying direction of the diaphragm are arranged on the vertical plate; the unwinding mechanism comprises a rotating rod and a supporting rod which are fixed on the vertical plate; two mounting plates are rotationally arranged on the rotating rod; two connecting rods are connected between the two mounting plates; a hinge rod is connected to the mounting plate on the outer side; a rotating air cylinder is hinged to the outer end of the supporting rod; a rotating air cylinder piston rod is arranged in the rotating air cylinder; the upper end of the rotating aircylinder piston rod is hinged to the hinge rod; and two unwinding rollers are rotationally arranged between the two mounting plates. The coating device has the advantages that the automation degree ishigh, and the production efficiency of the diaphragm is obviously improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Device for coating lithium battery diaphragm with PVDF coating

InactiveCN112076955ALiquid surface applicatorsCleaning using toolsHigh diaphragmStructural engineering

The invention discloses a device for coating a lithium battery diaphragm with a PVDF coating. The device is characterized by comprising a rack, wherein an unwinding mechanism, a swinging mechanism, acleaning mechanism, a coating conversion mechanism, a coating mechanism, a drying mechanism, a cutting mechanism and a winding mechanism are arranged on the rack in the advancing direction of the diaphragm; the rack comprises a vertical plate, a top plate and a supporting plate, wherein the top plate and the supporting plate are vertically arranged on the vertical plate; a plurality of guide rollers used for guiding the conveying direction of the diaphragm are arranged on the vertical plate; the unwinding mechanism comprises a rotating rod and a supporting rod which are fixed on the vertical plate; two mounting plates are rotationally arranged on the rotating rod; two connecting rods are connected between the two mounting plates; a hinge rod is connected to the mounting plate on the outerside; a rotating air cylinder is hinged to the outer end of the supporting rod; a rotating air cylinder piston rod is arranged in the rotating air cylinder; the upper end of the rotating air cylinderpiston rod is hinged to the hinge rod; and two unwinding rollers are rotationally arranged between the two mounting plates. The device is high in automation degree, and the production efficiency of the diaphragm is obviously improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Diaphragm, preparation method thereof, secondary battery and electric equipment

The invention provides a diaphragm, a preparation method thereof, a secondary battery and electric equipment. The diaphragm comprises a base film, at least one inorganic coating and at least one organic coating, the base film, the inorganic coating and the organic coating are laminated, at least one side surface of the base film is in contact with the inorganic coating, the organic coating contains organic heat-resistant resin, and the lower one of the melting point and the decomposition temperature of the organic heat-resistant resin is greater than or equal to 200 DEG C. The diaphragm with the structure can improve the high-temperature shrinkage performance of the diaphragm while increasing the diaphragm rupture temperature of the diaphragm.

Owner:HUAWEI TECH CO LTD

Preparation method of diaphragm with high porosity and safety performance

InactiveCN111525080AAvoid cloggingGuaranteed porositySecondary cellsCell component detailsPorous substrateHigh diaphragm

The invention relates to a preparation method of a diaphragm with high porosity and safety performance, and belongs to the technical field of lithium ion batteries. The method comprises: pre-immersinga porous base material in a solvent medium, so that the micropores of the base material are filled with the solvent medium; coating the base material filled with the pre-immersing medium with a layerof ceramic slurry and / or glue slurry; heating the diaphragm coated with the ceramic or the glue, wherein a cross-linking agent acts, so that the molecules of the binder are cross-linked together; andheating to a high temperature, and drying to obtain the ceramic and / or glued diaphragm with high porosity and high mechanical properties. According to the invention, a base material pre-impregnationmedium is adopted, so that pores of the base material can be prevented from being blocked by surface coating slurry, and the porosity of the original base material is ensured; binder molecules are cross-linked together by utilizing a cross-linking agent, so that the overall tensile strength and puncture strength of the diaphragm are improved; and the porosity of the surface coating is ensured by utilizing a pore-forming agent, so that the coated diaphragm with high porosity and high safety performance can be finally obtained.

Owner:华鼎国联四川动力电池有限公司

Self-supporting diaphragm, preparation method thereof, composite pole piece and secondary battery

PendingCN113794034AImprove thermal stabilityImprove ionic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesHigh diaphragmEngineering

The invention belongs to the technical field of secondary batteries, and particularly relates to a self-supporting diaphragm, a preparation method thereof, a composite pole piece and a secondary battery. The self-supporting diaphragm is prepared from, by weight, 40-60 parts of an ionic liquid, 30-50 parts of lignocellulose and 5-20 parts of a binder. The self-supporting diaphragm disclosed by the invention has good thermal stability, ionic conductivity, dimensional stability and wettability, the conditions of short positive and negative electrodes and spontaneous combustion of a battery cell under a high-temperature condition are greatly reduced, and the practicability of the diaphragm and the battery cell is improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Ultrathin coated diaphragm and preparation method thereof

ActiveCN114709566AImprove heat resistanceImproved thermal dimensional stabilitySecondary cellsCell component detailsElectrolytic agentPolyetherimide

According to the ultrathin coating diaphragm and the preparation method thereof provided by the invention, the ultrathin coating diaphragm with high heat resistance, thermal dimensional stability and high wettability is prepared by limiting components and a process; the base membrane is coated with slurry prepared from superfine aluminum oxide particles and multi-walled carbon nanotubes, so that the coated diaphragm has thermal shrinkage resistance, high liquid retention and low internal resistance; small-particle aluminum oxide is hydroxylated, the hydroxylated aluminum oxide is coated and modified by carbomer, and the surface electrostatic repulsion of the hydroxylated aluminum oxide effectively improves the dispersion uniformity of the small-particle aluminum oxide in the diaphragm and synergistically improves the crosslinking complexity of each component in the diaphragm under the conditions of not adding a dispersing agent and reducing a binder; the mechanical strength and the electrolyte wettability of the diaphragm are improved; through electrostatic spinning and in-situ growth, polybenzimidazole and polyetherimide are utilized to prepare a porous diaphragm with a pseudo-boehmite two-dimensional nanosheet layer grown on the surface, and the porous diaphragm is used as a base membrane.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

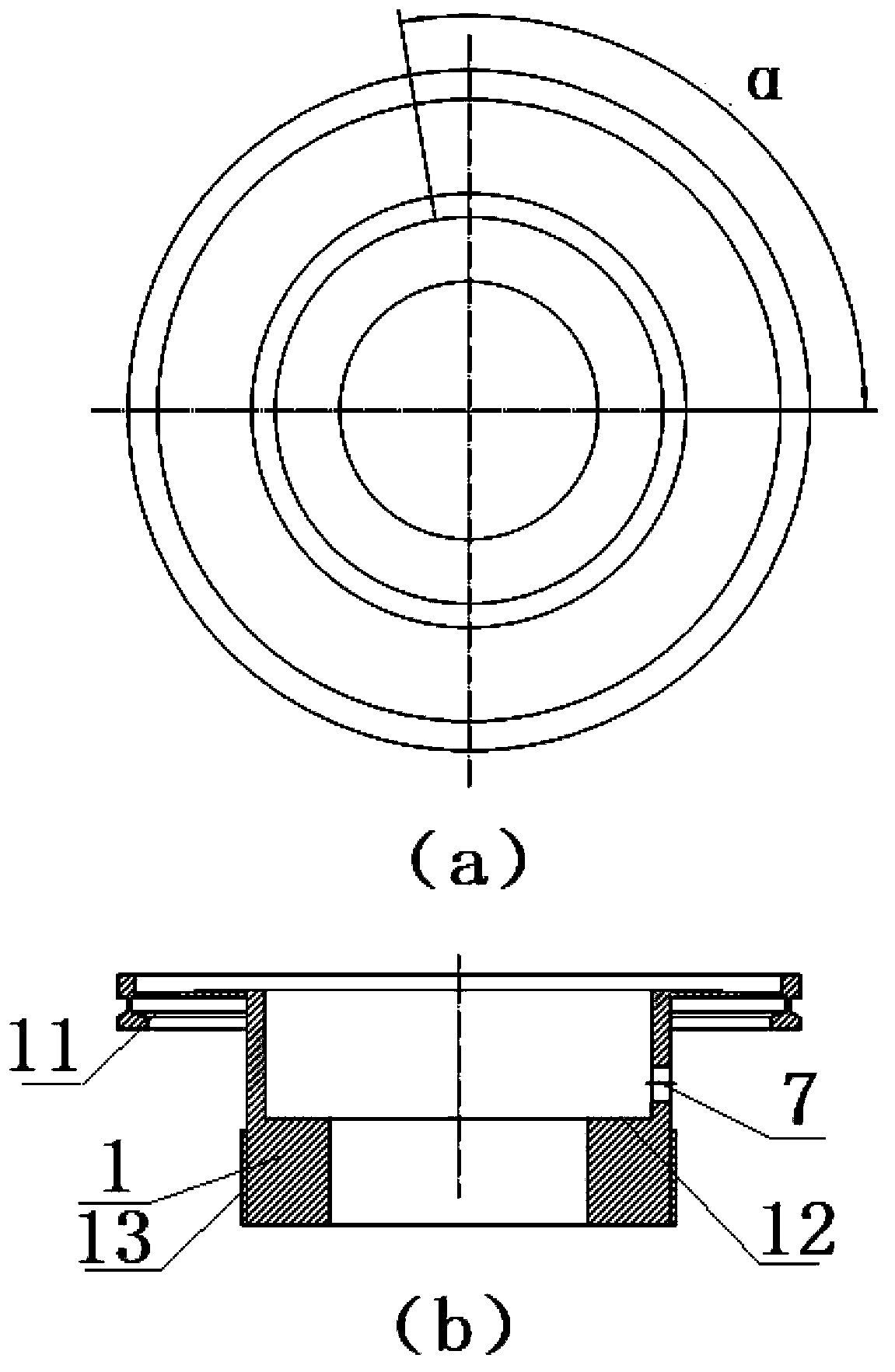

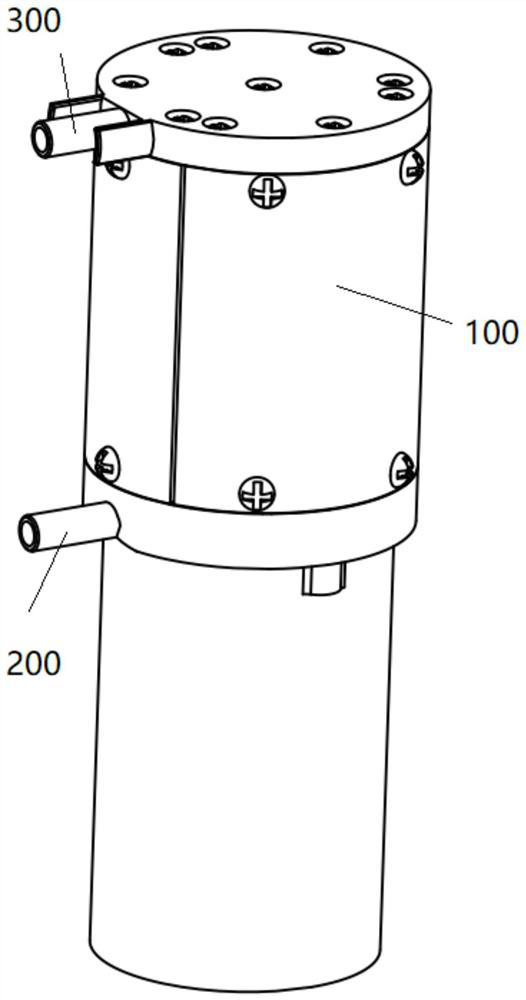

Threaded hollow revolution type travelling wave ultrasound motor

InactiveCN102751906BAchieve throughLarge hollow diameterPiezoelectric/electrostriction/magnetostriction machinesHigh diaphragmEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

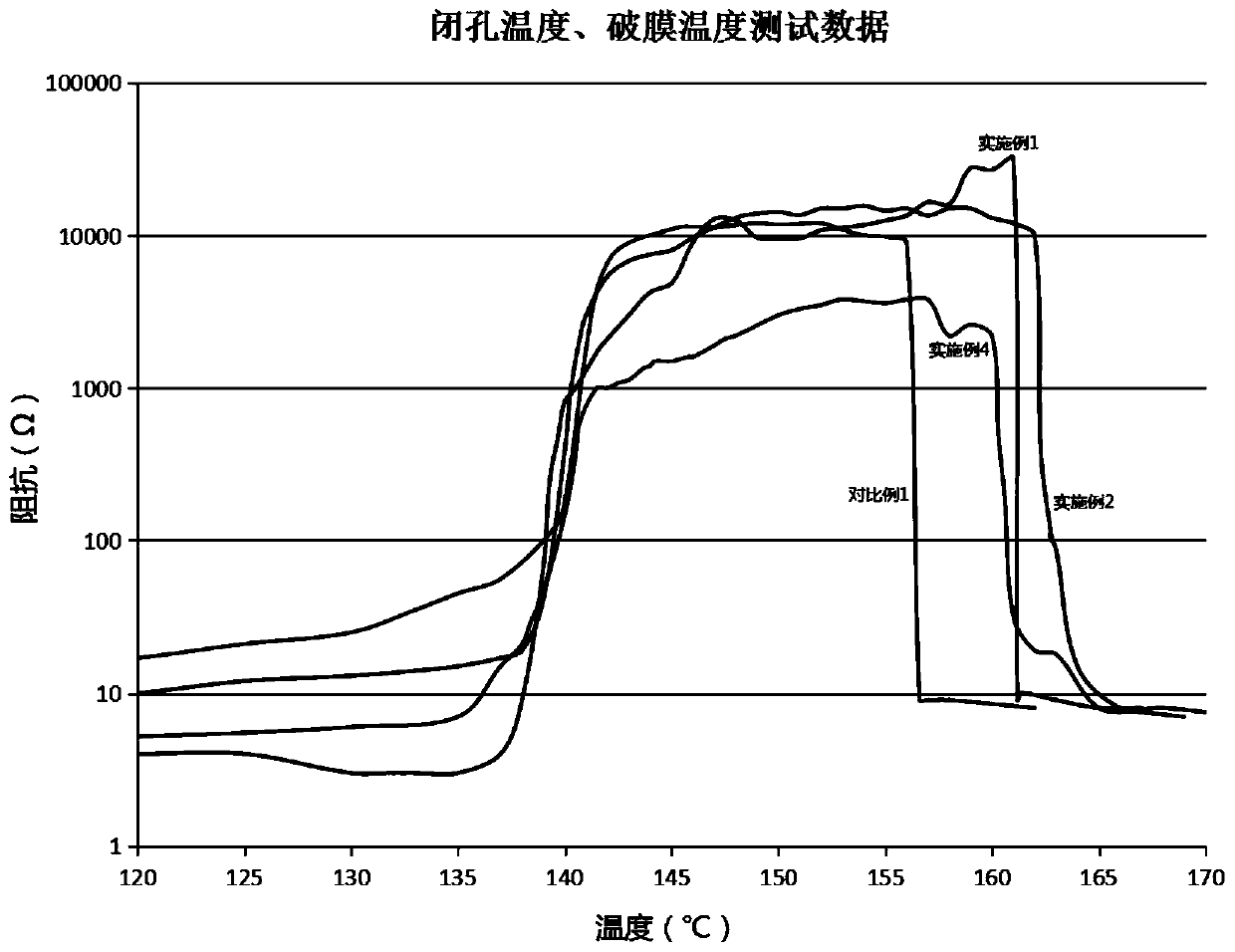

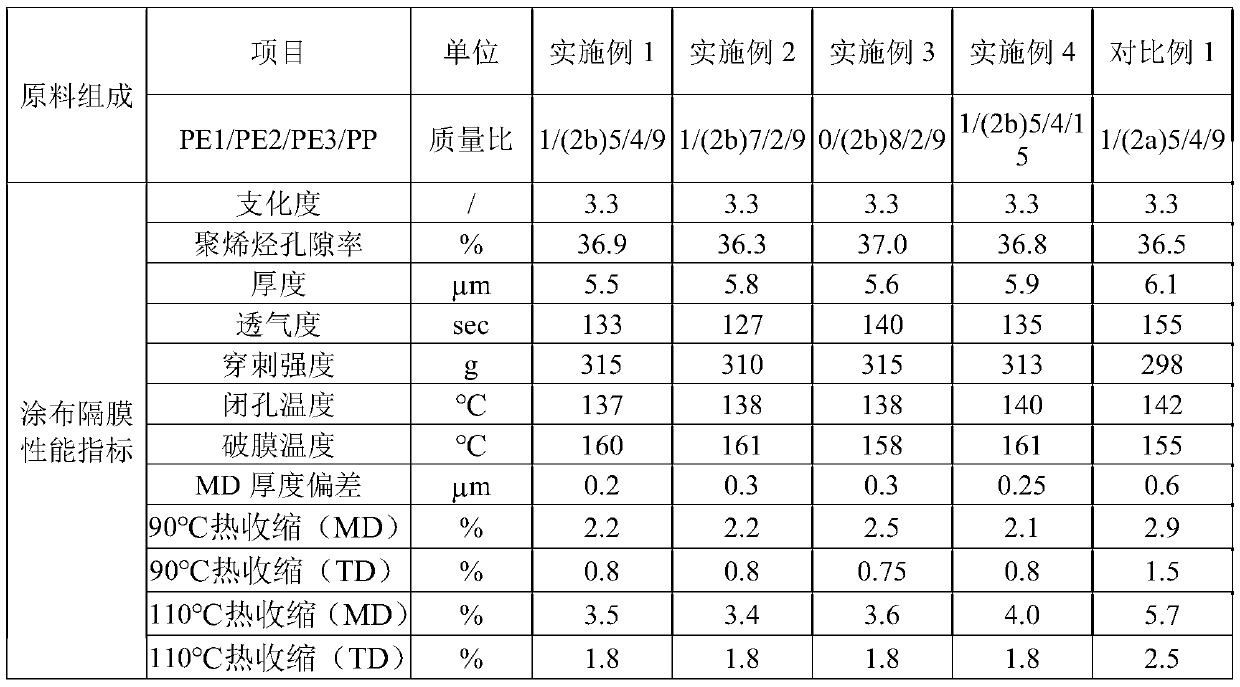

Low-pore closing high-diaphragm splitting polyolefin diaphragm and preparation method thereof

ActiveCN110649211AFix compatibility issuesAvoid breakingCell component detailsPolymer sciencePolyolefin

The invention discloses a low-pore closing high-diaphragm splitting polyolefin diaphragm and a preparation method thereof. The polyolefin diaphragm is mainly formed by blending polyethylene, polypropylene and polypropylene grafted branched polyethylene; and the polyethylene comprises low-melting-point polyethylene and high-melting-point polyethylene. Thus, the problem of compatibility of polyethylene and polypropylene is solved, the homogeneous phase capability of polyethylene and polypropylene in a molten state is improved, so that polypropylene molecular chains are interspersed among polyethylene molecular chains, a rigid skeleton supporting effect is achieved, and the diaphragm is prevented from being split, thereby acquiring relatively high diaphragm splitting temperature and excellentthermal shrinkage performance. In addition, through blending of high / low melting point polyethylene, the melting starting temperature of the blended polyethylene is reduced, the melting range is prolonged, the duration of the pore closing process is prolonged, and the continuous pore closing characteristic is formed.

Owner:CHONGQING YUNTIANHUA NEWMI-TECH CO LTD

Thickness detection device for battery diaphragm

PendingCN114659428AImprove detection efficiencyHigh precisionMechanical thickness measurementsHigh diaphragmStructural engineering

The invention discloses a thickness detection device for a battery diaphragm, and relates to the technical field of battery diaphragm production. The problems that in the detection process, pressing concave holes are easily formed in the surface of a diaphragm, and the detection precision is affected are solved. The device specifically comprises a supporting rack, the supporting rack is of a box body structure, a detection plate is fixedly installed at the top end of the supporting rack, a limiting film frame is fixedly installed at the top end of the detection plate, supporting rods are fixedly installed on the two sides of the top of the supporting rack, and a limiting sliding rod is fixedly installed between every two adjacent supporting rods; and a top plate is fixedly mounted between the top ends of the two supporting rods. According to the invention, the verticality displayed by the probe of the electronic dial indicator when the detection rod mechanism encounters an uneven diaphragm or unqualified thickness of the diaphragm is increased, tiny flaws are amplified and displayed, the diaphragm thickness verification precision of the device is enhanced, the device is simple in structure and convenient to operate, and the diaphragm thickness detection efficiency is improved.

Owner:襄阳惠强新能源材料科技有限公司

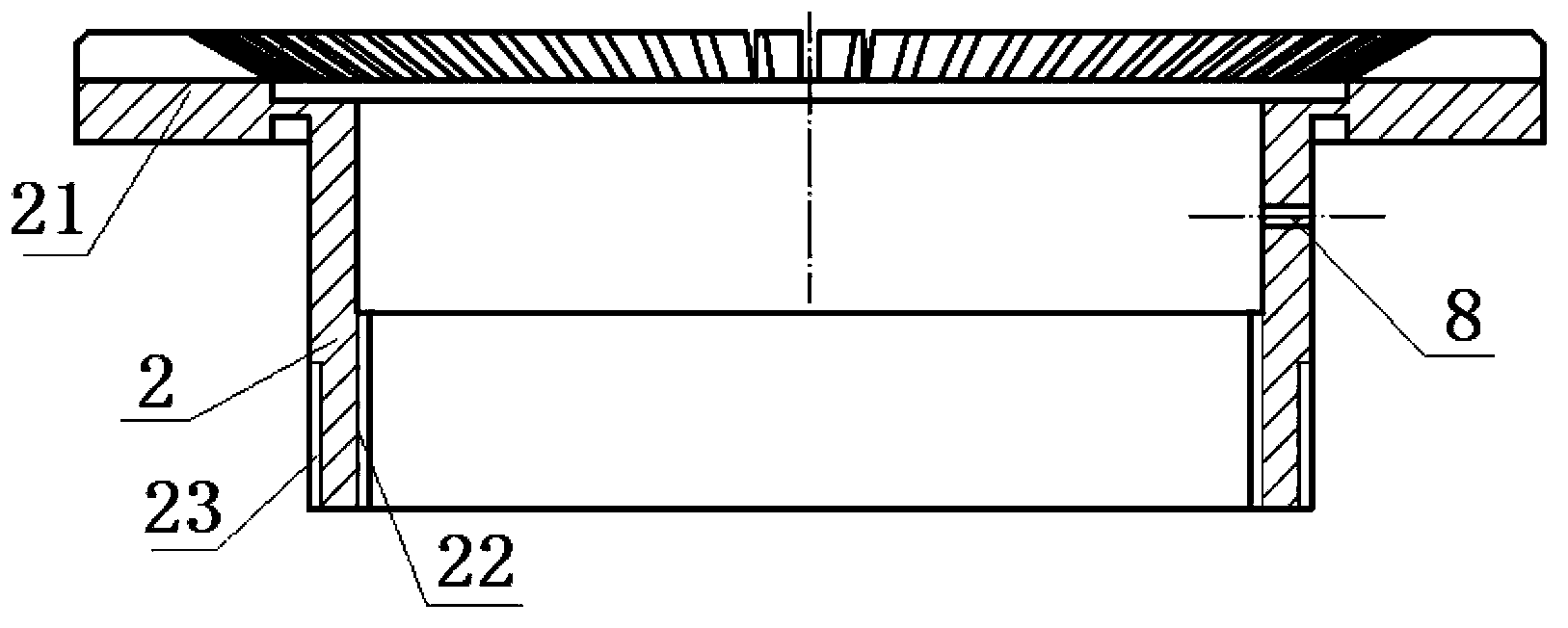

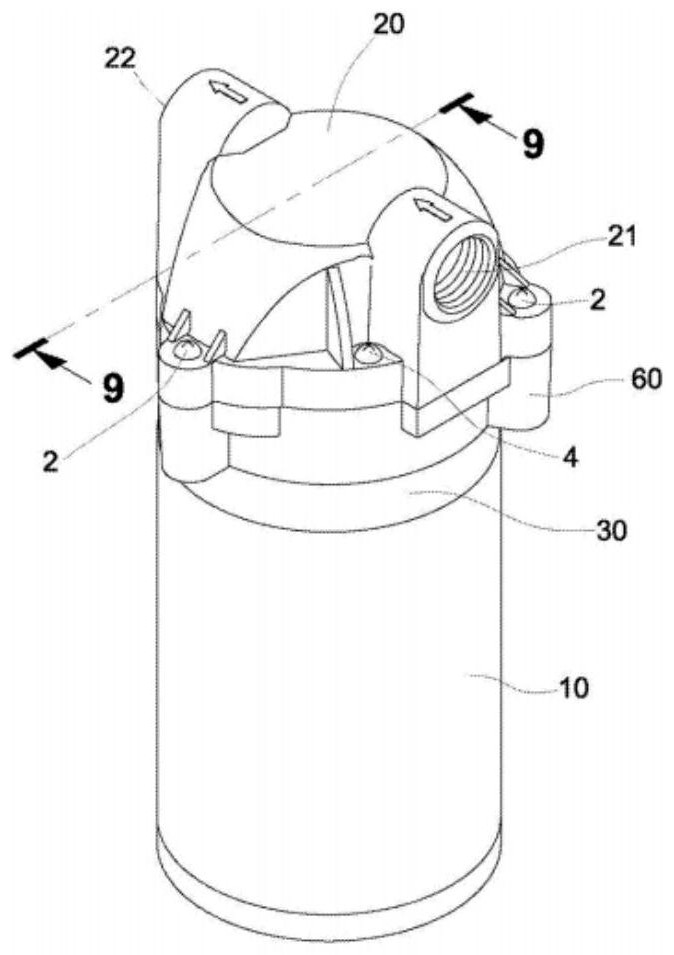

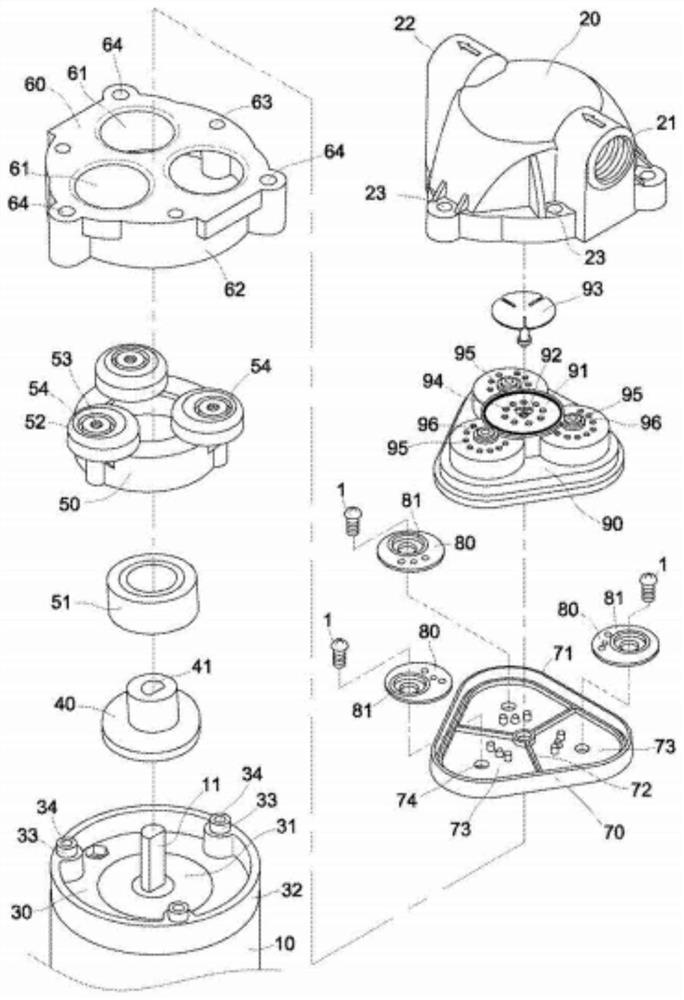

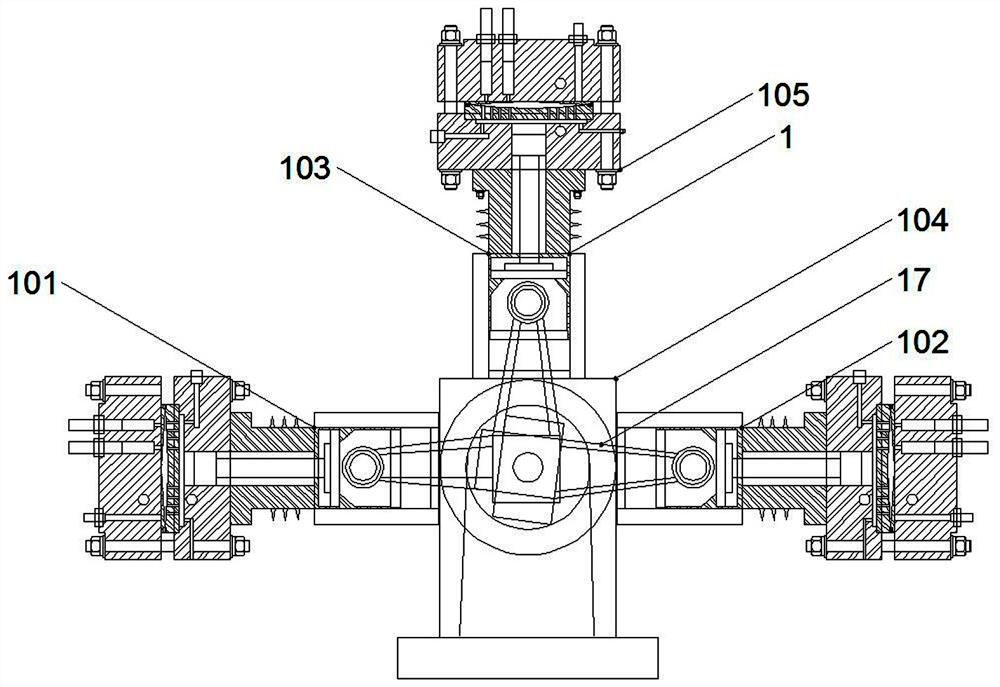

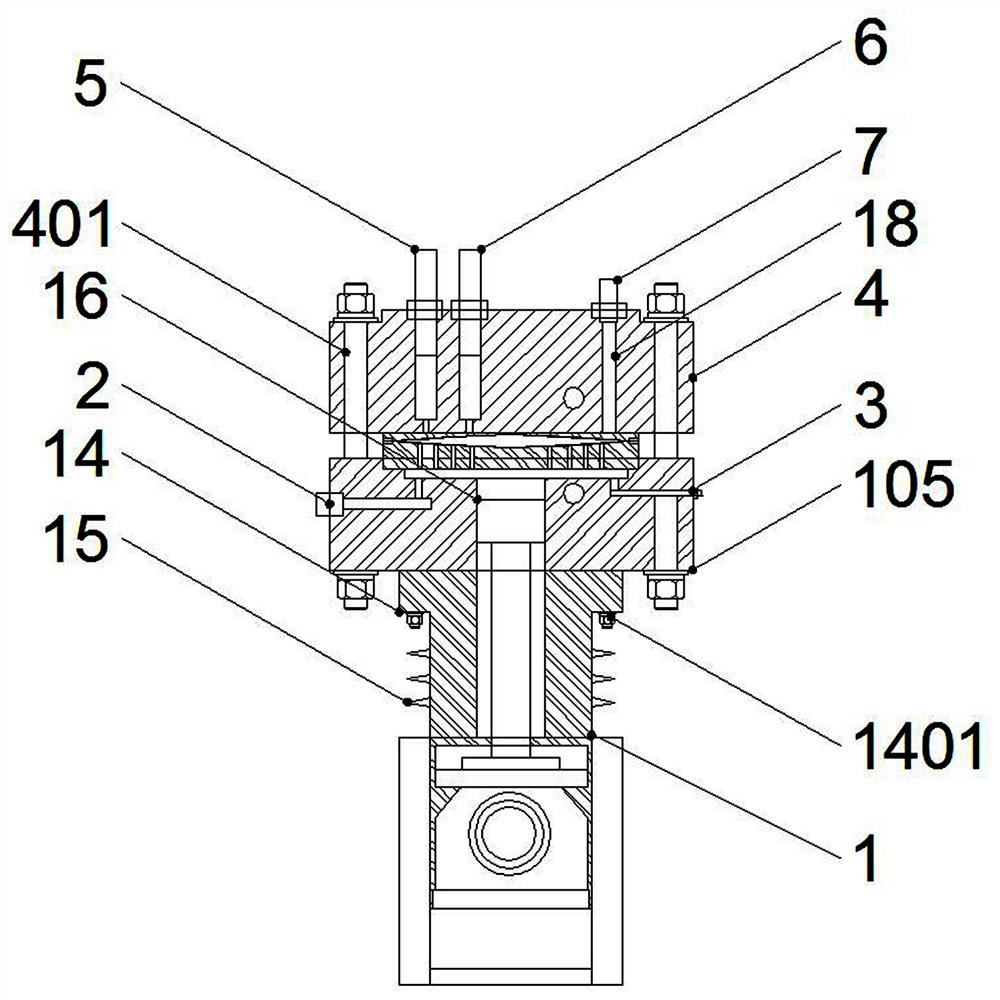

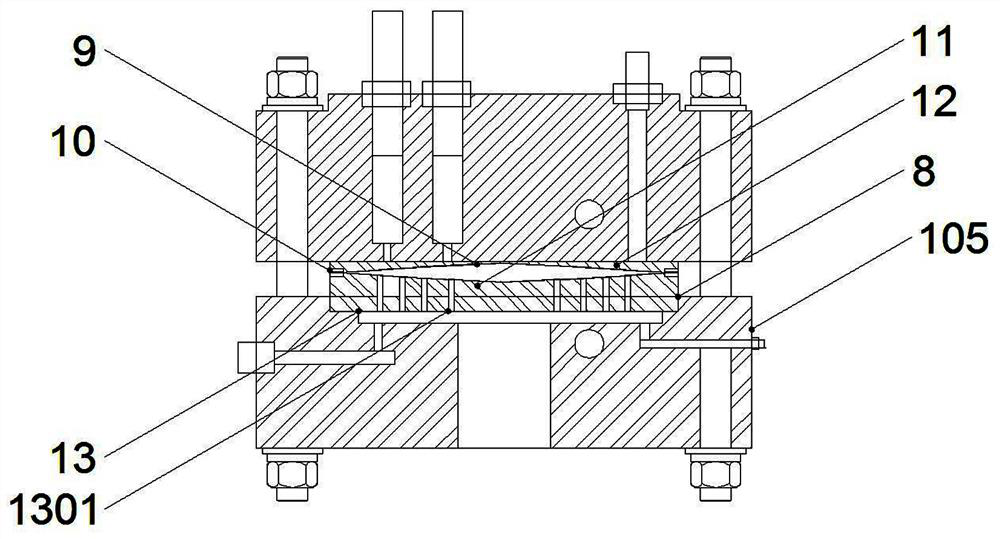

Pump head of diaphragm booster pump, diaphragm booster pump and water treatment device

InactiveCN112696341AHigh trafficIncrease the deformation areaPositive displacement pump componentsFlexible member pumpsRadial motionHigh diaphragm

The invention relates to a pump head of a diaphragm booster pump, the diaphragm booster pump and a water treatment device. The pump head comprises a piston chamber, wherein a pressurizing cavity is formed in the inner wall of the piston chamber; a diaphragm piece, sealed to form the pressurizing cavity, wherein the pressurizing cavity is expanded or compressed in the radial direction; eccentric wheels, including the first eccentric wheel and the second eccentric wheel, wherein the eccentricity of the first eccentric wheel is opposite to the eccentricity of the second eccentric wheel, and a first balance wheel and a second balance wheel which correspond to the first eccentric wheel and the second eccentric wheel respectively move in opposite directions. By the radial movements of the diaphragm piece, the pressurizing cavity is expanded or compressed, the flow of the diaphragm booster pump is increased, and vibration and noise generated when the diaphragm booster pump works are reduced.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

Heat-shrinkage-resistant lithium ion battery diaphragm and pore-forming agent composition adopted by same

ActiveCN106328860AHigh porosityImprove ventilationCell seperators/membranes/diaphragms/spacersHigh diaphragmBoiling point

The invention discloses a heat-shrinkage-resistant lithium ion battery diaphragm and a pore-forming agent composition adopted by the same. The pore-forming agent composition comprises an organic pore-forming agent and an inorganic pore-forming agent, wherein the organic pore-forming agent is high-boiling-point low molecular weight organic matter preferably; the inorganic pore-forming agent is water-soluble inorganic nanoparticles preferably; and the pore-forming agent and the optional additive are jointly added to a film-forming material to form a lithium ion battery diaphragm with three kinds of microporous structures through processing of casting pieces. In addition, the heat-shrinkage-resistant lithium ion battery diaphragm has relatively low closed-hole temperature, high heat shrinkage resistance, high tensile strength, high puncture strength and relatively high diaphragm-rupture temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Novel diaphragm compressor

PendingCN112502948AAvoid damageStrong impactPositive displacement pump componentsFlexible member pumpsHigh diaphragmCylinder head

The invention discloses a novel diaphragm compressor. The novel diaphragm compressor comprises a cylinder body, a first-stage cylinder, a second-stage cylinder and a third-stage cylinder. The first-stage cylinder, the second-stage cylinder and the third-stage cylinder are all fixedly installed on one side of a base, a cylinder head is arranged on one side of the cylinder body, an oil overflow valve is arranged on one side of the cylinder head, and an oil supplementing valve is arranged on the other side of the cylinder body. One side of the cylinder body is provided with a cylinder cover, andone side of the cylinder cover is provided with an air inlet valve. According to the novel diaphragm compressor, when liquid is brought into the air cylinder of the compressor in the compression process, the liquid is discharged by arranging a liquid discharging valve, and the situation that the liquid is forced by a piston in the air cylinder to generate strong impact and the machine body vibrates violently and thus is damaged is prevented. By adding the cylinder parts, the total compression ratio of the diaphragm compressor can be effectively improved to meet the requirement of high-pressureoutput. The cylinder cover is made of L-shaped stainless steel and is good in hydrogen embrittlement resistance. The upper portion of the cylinder cover is provided with a flange for connection, thestructure of the cylinder body is more stable and firmer, and the effect on the high-pressure or ultrahigh-pressure diaphragm compressor is particularly outstanding.

Owner:ANHUI KEHAI COMPRESSOR MFG

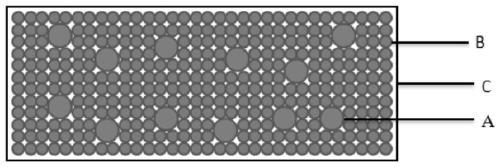

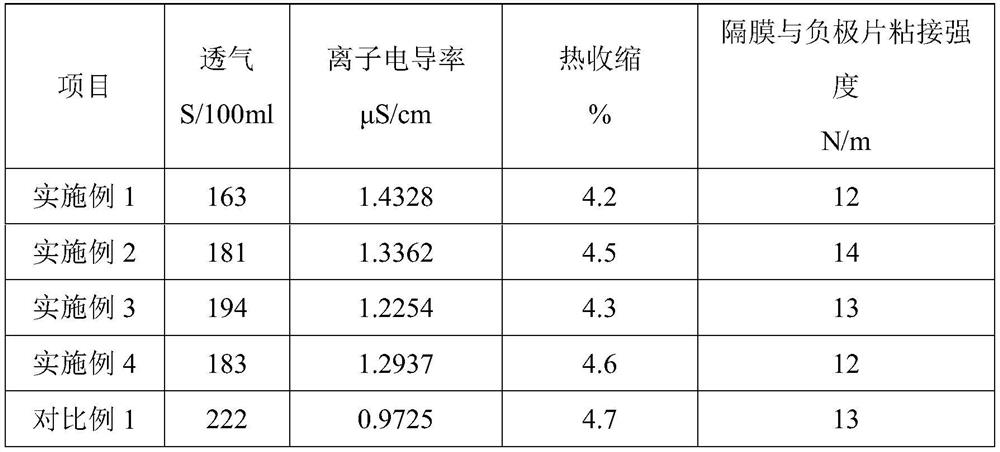

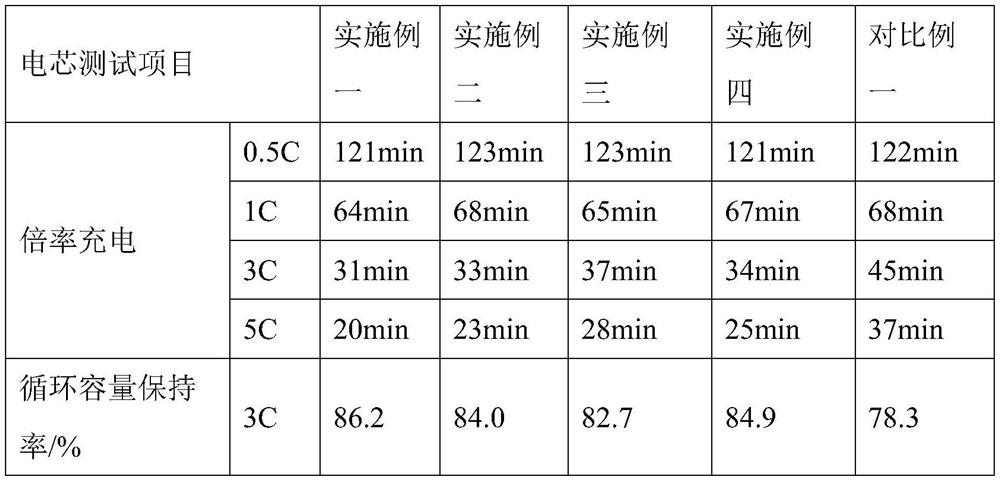

Coated diaphragm and preparation method thereof

PendingCN114361706AGood heat shrinkabilityImproved magnification performanceCell seperators/membranes/diaphragms/spacersElectrolytic agentHigh diaphragm

The invention provides a lithium battery diaphragm, and particularly relates to a coated diaphragm. The coated diaphragm at least comprises a base membrane and a coating layer coated on at least one side of the base membrane, the coating layer at least comprises porous PMMA microspheres, ceramic particles, a thickening agent, a water-based adhesive and a wetting agent, the particle size D50 of the porous PMMA microspheres is 1.0-4.0 [mu] m, the porosity is 10-40%, and the average pore size is 30-150 nm. According to the coating layer, the thermal shrinkage performance of the diaphragm can be improved, the porous PMMA microspheres in the coating layer provide better circulation and liquid retention channels for electrolyte, the electrolyte wettability of the diaphragm is improved, rapid liquid injection can be achieved, meanwhile, the adverse effect of the polymer coating layer on the air permeability can be reduced, the ionic conductivity of the polymer coating layer is improved, and the service life of the diaphragm is prolonged. The rate capability and the cycle performance of the battery cell are improved. In addition, the coating layer can improve the bonding performance of the diaphragm and the pole piece, reduce the deformation risk of the battery cell and improve the safety performance of the battery cell.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

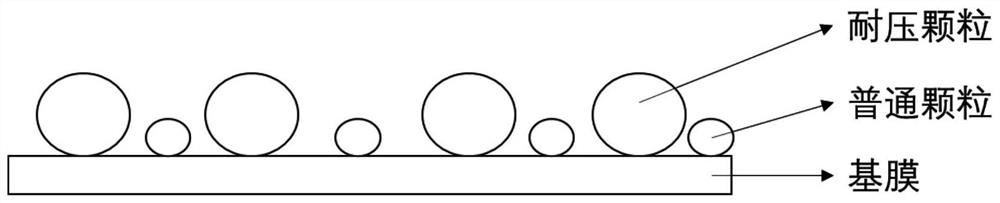

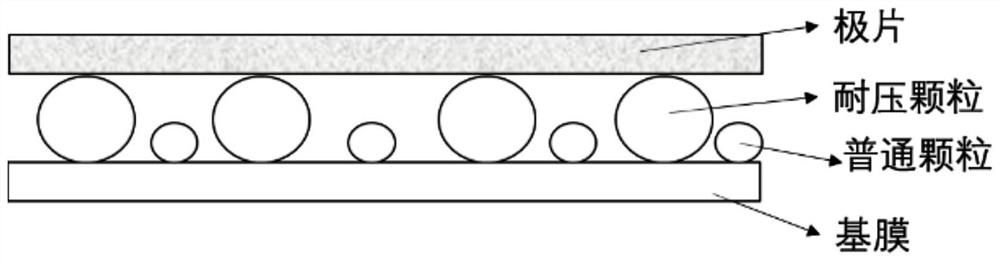

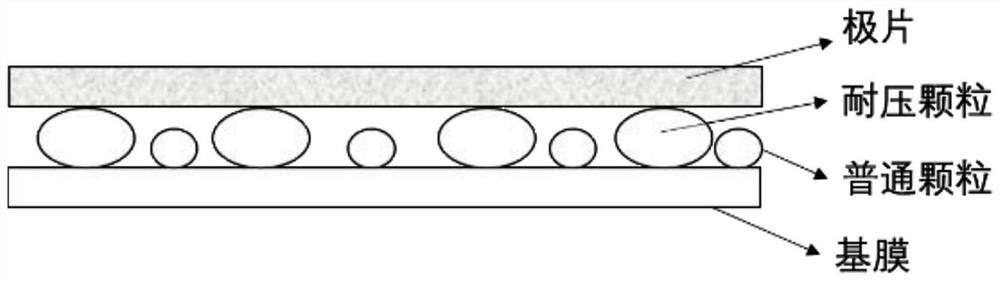

Coated diaphragm with high liquid storage rate as well as preparation method and application thereof

InactiveCN113258211AIncreased liquid storage rateGuaranteed bonding effectSecondary cellsCell component detailsPolymer scienceHigh diaphragm

The invention provides a coated diaphragm with a high liquid storage rate, which comprises a base membrane and a coating compounded on the surface of the base membrane. The coating is prepared from a binder containing pressure-resistant particles, and the pressure-resistant particles comprise one or more of a polyacrylate binder, PVDF, SBR, aramid fibers, polyacrylonitrile and polyacrylic acid. The particle size of the pressure-resistant particles is 0.2-10 [mu] m. The compression ratio of the coating ranges from 0.4 to 0.99. According to the invention, a relatively high coating compression ratio is obtained through a special coating design, and the liquid storage rate of the diaphragm is greatly improved while the adhesive force of the diaphragm and a pole piece is maintained, so that the electrical performance of a battery is improved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Stretching device for lithium battery diaphragm

InactiveCN112644007AIncrease temperatureReduce tensionCell component detailsHigh diaphragmClassical mechanics

The invention discloses a stretching device for a lithium battery diaphragm. A base, a second guide roller, a preheating box and clamps are included, a cover body is fixed to the top of the base, the second guide roller is arranged in the center of one side of the interior of the cover body, and first guide rollers are arranged at the positions, on the two sides of the second guide roller, in the cover body; and fixing grooves are evenly formed in the two sides of the end, away from the second guide roller, of the top of the base, threaded lead screws are arranged in the fixing grooves correspondingly, the threaded lead screws are sleeved with driving blocks correspondingly, adjusting arms are hinged to the two sides of each air cylinder correspondingly, and the clamps are arranged on the adjusting arms correspondingly. By installing the base, the cover body, the first guide rollers, the second guide roller, the fixing grooves, the threaded lead screws, the driving blocks, hydraulic telescopic rods, the air cylinders, telescopic columns, connecting rods, the adjusting arms and the clamps, the diaphragm can be stretched more comprehensively and thoroughly, the smoothness of the diaphragm is improved, and the stretching quality of the diaphragm is improved.

Owner:湖北江升新材料有限公司

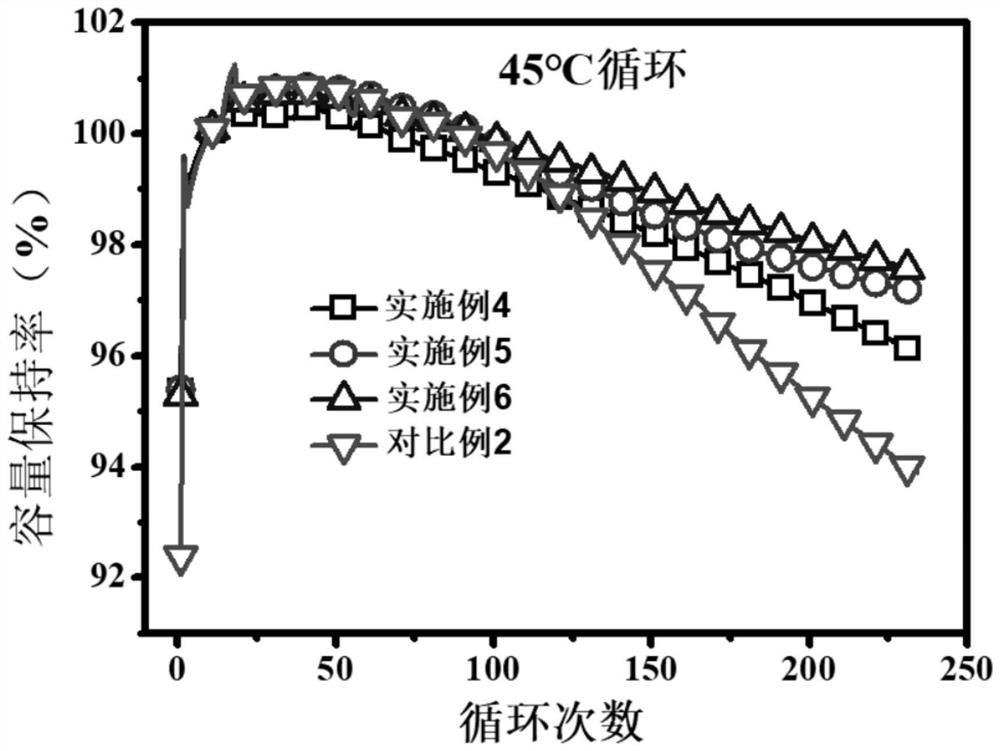

Preparation method and application of long-durability polyolefin-coated diaphragm

PendingCN112864532AImprove aging resistancePrevent movementSecondary cellsCell component detailsElectrolytic agentPolymer science

The invention provides a preparation method and application of a long-durability polyolefin-coated diaphragm. According to the invention, a layer of crosslinked polyethylene and ceramic mixture coats on one side or two sides of a base diaphragm, and the crosslinked polyethylene is prepared by irradiation crosslinking or siloxane crosslinking. The crosslinked polyethylene coating the surface of the base diaphragm can greatly improve the electrolyte-resistant size stability of the diaphragm, decrease the moisture content of the diaphragm, reduce the risk that the diaphragm is stabbed under pressurization, and enhance the quality and electrochemical stability of the coated diaphragm, so the long-durability battery diaphragm has better electrolyte aging resistance and is more beneficial for improving the high-temperature cycle performance, the high-temperature storage performance and the like of the lithium ion battery.

Owner:TIANJIN ENERGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com