Coated diaphragm with high liquid storage rate as well as preparation method and application thereof

A technology with high liquid storage rate and liquid storage rate, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of reducing battery electrical performance and increasing battery internal resistance, so as to improve electrical performance and increase liquid storage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Prepare coating solution;

[0052] Select 15g of polyvinylidene fluoride particles with a particle size of 3 μm as pressure-resistant particles, and uniformly disperse them in 85g of ultrapure water to obtain a coating solution;

[0053] 2. Preparation of coated separator

[0054] The coating solution was coated on the surface of a 9 μm polyethylene-based film by micro-gravure roll coating, and dried at 65 degrees Celsius to obtain a coated separator, marked as S1.

[0055] Among them, the coverage of the coating is 100%, the coating thickness is 1.5μm, and the surface density is 1.0g / m 2 .

Embodiment 2

[0057] 1. Prepare coating solution;

[0058] Select 15g of polyvinylidene fluoride particles with a particle size of 3 μm as pressure-resistant particles, and uniformly disperse them in 85g of ultrapure water to obtain a coating solution;

[0059] 2. Preparation of coated separator

[0060] The coating solution was coated on the surface of a 9 μm polyethylene-based film by micro-gravure roll coating, and dried at 65 degrees Celsius to obtain a coated separator, marked as S2.

[0061] Among them, the coverage of the coating is 15%, the coating thickness is 1.5μm, and the surface density is 1.0g / m 2 .

Embodiment 3

[0063] 1. Prepare coating solution;

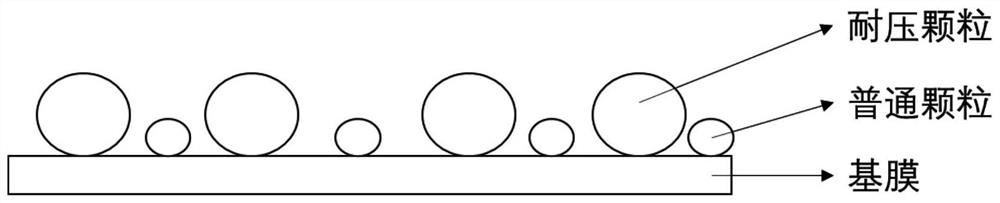

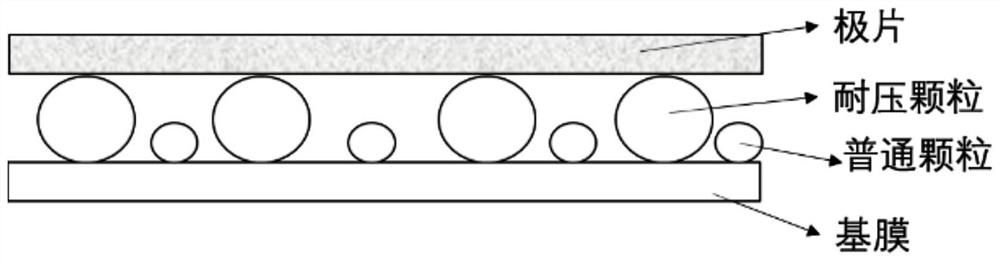

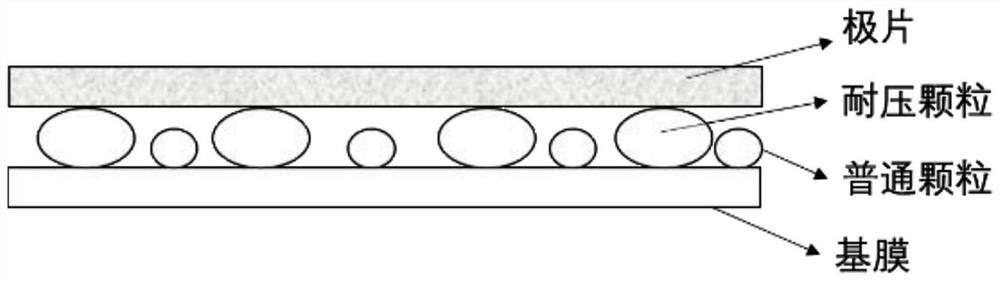

[0064] Select 3g of PVDF particles with a particle size of 3μm as pressure-resistant particles, and 12g of alumina as ordinary particles with a particle size of 0.8μm, and uniformly disperse them in 85g of ultrapure water to obtain a coating solution; Among them, pressure-resistant particles: ordinary particles The mass ratio of = 1:4;

[0065] 2. Preparation of coated separator

[0066] The coating solution was coated on the surface of a 9 μm polyethylene-based film by micro-gravure roll coating, and dried at 65 degrees Celsius to obtain a coated separator, marked as S3.

[0067] Among them, the coverage of the coating is 100%, the coating thickness is 1.5μm, and the surface density is 1.0g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com