All-steel radial tire belt compound rubber composition and production method thereof

A technology of rubber composition and belt layer rubber, applied in special tires, tire parts, rolling resistance optimization, etc., can solve the problem of low material utilization rate, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

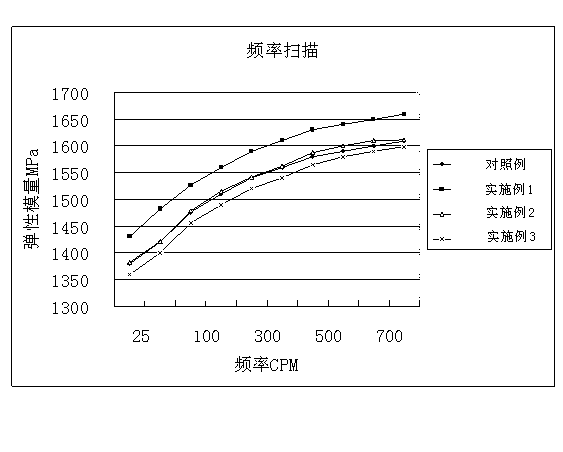

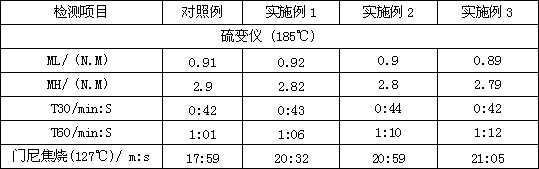

Examples

Embodiment

[0046] 1. The present invention is described in detail below in conjunction with embodiment, but the present invention is not limited to these embodiments.

[0047] 2. Use the above-mentioned environment-friendly resin as a methylene acceptor to make an all-steel radial tire belt sizing compound, which is characterized in that it uses a four-stage mixing method, including the following mixing steps:

[0048] One-stage mixing: the rotor speed of the internal mixer is 50 rpm, and the pressure of the top bolt is 0.65MPa. Put 100 parts of 20# standard rubber into the internal mixer chamber and knead for 35-40 seconds, then put in 30-60 parts of carbon black, 7-10 parts of zinc oxide, 1-3 parts of antioxidant 4020, and 1-2 parts of environmentally friendly resin , 5-15 parts of white carbon black, 1-2 parts of cobalt decanoate, kneading for 40-45 seconds, lifting the bolt for 6-10 seconds, then kneading for 30-35 seconds, degumming, the degumming temperature is controlled below 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com