Patents

Literature

96 results about "Alkadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkadienes are acyclic branched or unbranched hydrocarbons having two carbon-carbon double bonds. A cumulated alkadienes is having two double bonds attached to the same carbon atom same as the example given below. The simplest example is 1,2-propadiene.

End Use Applications Prepared From Certain Block Copolymers

InactiveUS20090093584A1Low energy surfaceImprove cohesive strengthFilm/foil adhesivesEpoxy resin adhesivesAlkadieneBackbone chain

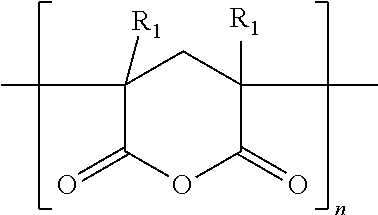

The present invention relates to various end use applications prepared from certain block copolymers. The block copolymers include one or more A or A′ blocks or B blocks plus one or more terminal M blocks. Each A and A′ is a block or segment comprising predominantly a polymerized alkenyl aromatic compound, each B is a block or segment comprising predominantly a polymerized conjugated alkadiene, and each M is a six membered anhydride ring and / or acid group. The anhydride rings are prepared by thermally decomposing adjacent units of (1-methyl-1-alkyl)alkyl acrylic esters such as t-butylmethylacrylate. A wide variety of polymers are disclosed having the stable anhydride rings in the polymer backbone. The invention relates specifically to various end uses prepared from the reaction product of such block copolymers with various reactive resins, reactive monomers and metal derivatives.

Owner:KRATON POLYMERS US LLC

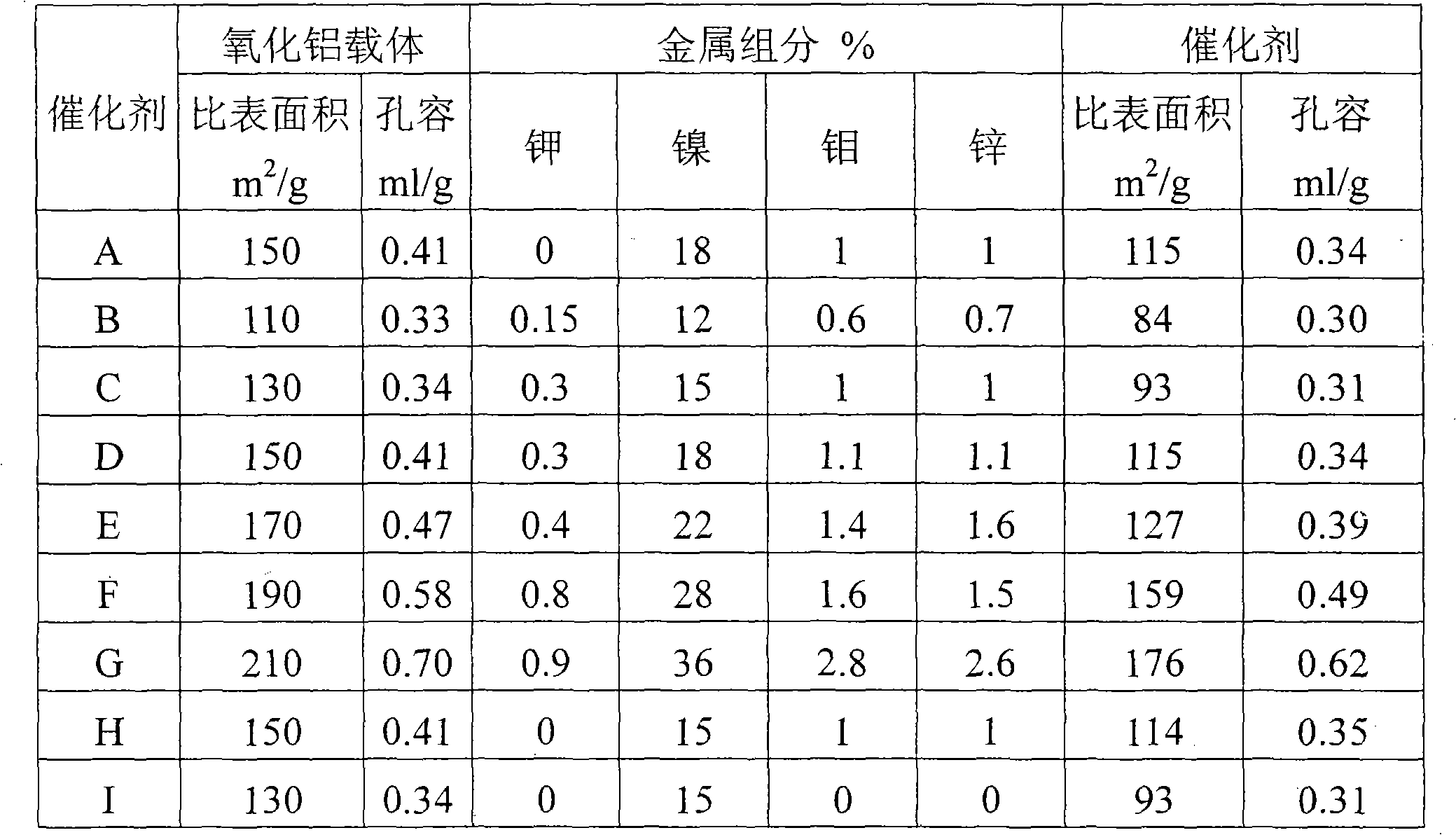

Selective hydrogenation catalyst for alkadiene

ActiveCN1631526AImprove hydrogenation activityHydrocarbon by hydrogenationGaseous mixture working upAlkadieneHydrogen

This is about a kind of catalyst of adding hydrogen of choosing. The catalyst includes a kind of Oxidize the aluminum placer and Gu and / or Ni in ó°, Mu and / or Wu in ó÷ and alkali metal. Its feature is: the catalyst includes 0.5--8% by weight that is chosen Gu and / or Ni in ó°, 2--15% is chosen Mu and / or Wu in ó÷, >2--8% alkali metal. Compared to the current catalyst, the catalyst offend in the invention has much higher choosing ability and activity in adding hydrogen of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

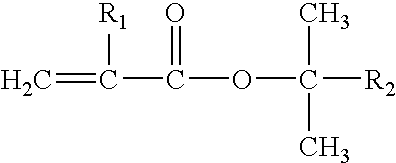

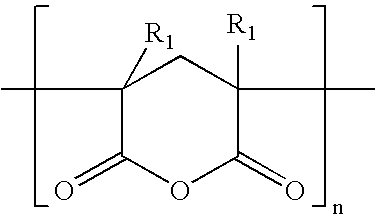

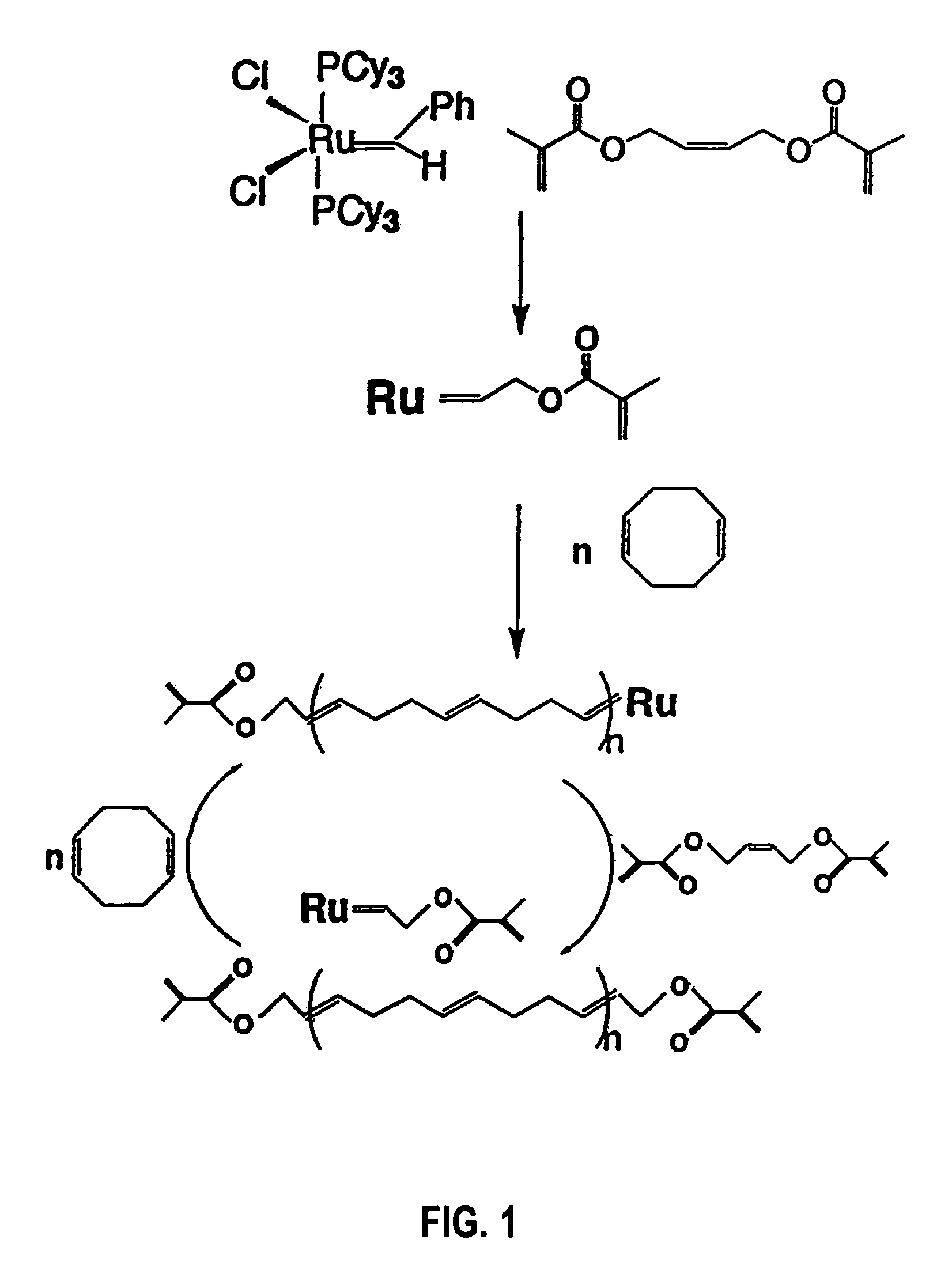

Telechelic alkadiene polymers with crosslinkable end groups and methods for making the same

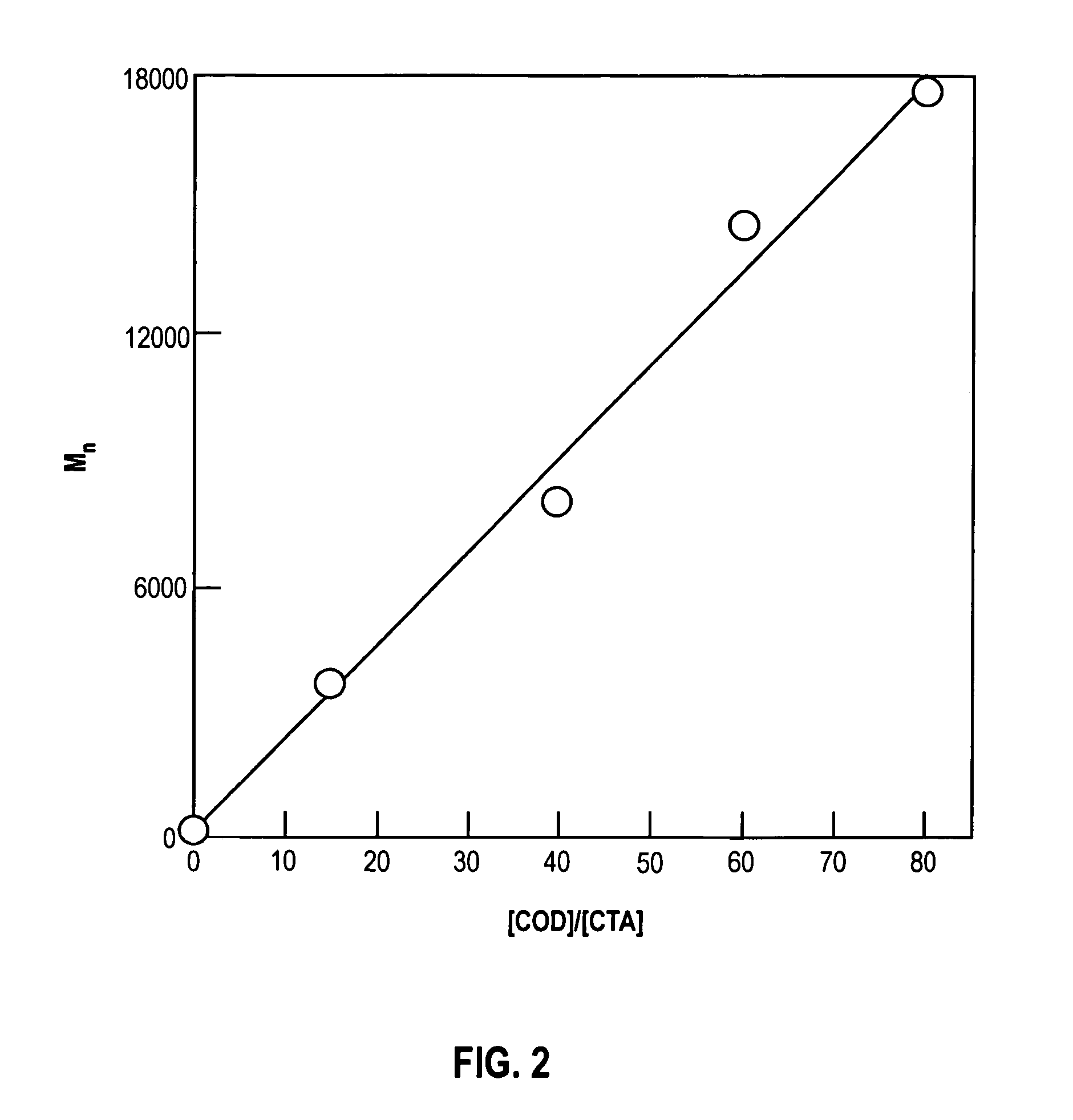

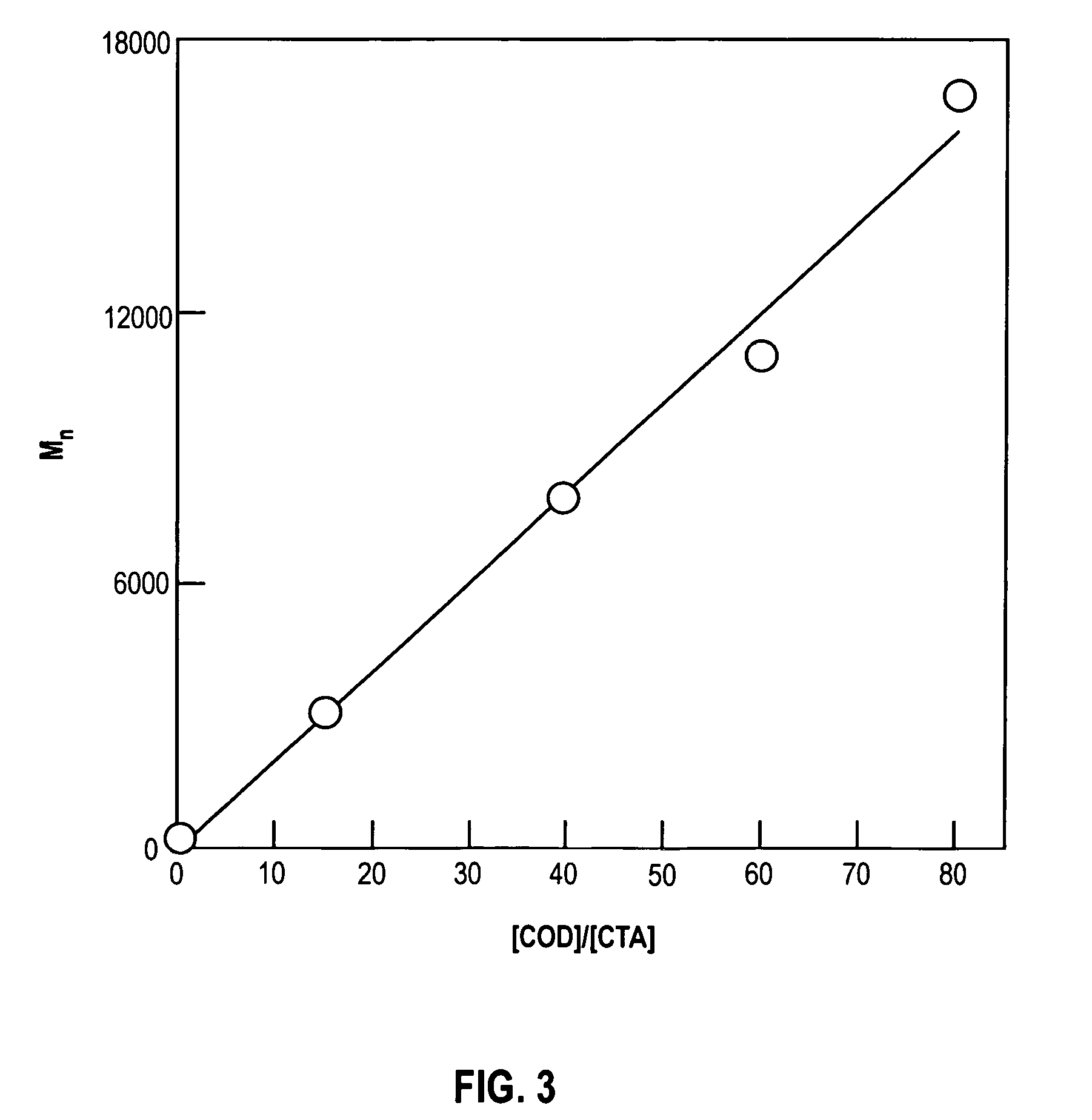

The present invention relates to telechelic polymers having crosslinkable end groups of the formula and methods for preparing the same wherein n is an integer; is an alkadienyl group; Y is an alkyl group; and Z is crosslinkable end group. In general, the inventive synthesis involves reacting a functionalized chain transfer agent having crosslinkable ends with a cycloalkene in the presence of a ruthenium or osmium catalyst of the formula wherein:M is ruthenium or osmium;X and X1 are independently any anionic ligand;L and L1 are any neutral electron donor ligand;R and R1 are each hydrogen or a substituted or unsubstituted substituent wherein the substituent is selected from the group consisting of C1–C20 alkyl, C2–C20 alkenyl, C2–C20 alkynyl, aryl, C1–C20 carboxylate, C1–C20 alkoxy, C1–C20 alkenyloxy, C2–C20 alkynyloxy, aryloxy, C2–C20 alkoxycarbonyl, C1–C20 alkylthio, C1–C20 alkylsulfonyl and C1–C20 alkylsulfinyl. In another aspect of the invention, methods for controlling the molecular weight of the resulting telechelic polymer are also presented.

Owner:CALIFORNIA INST OF TECH

Method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from petroleum fractions and application

ActiveCN102173984AHigh CN valueApparent output ratioOrganic chemistryOrganic compound preparationDistillates petroleumChemical industry

The invention belongs to the technical fields of energy chemical industry and clean diesel components and in particular relates to a method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from main raw materials such as a petroleum C4 component, an alkadiene-removed petroleum C5 component, a catalytic cracking light petroleum 30-90-DEC C fraction low-carbon monoolefine and the like. The structural general formula of the low-polymerization-degree polyformaldehyde dialkyl ether is CnH2n+1O(CH2O)mCnH2n+1, wherein m is an integer from 1 to 5; and n is an integer from 2 to 5. The low-polymerization-degree polyformaldehyde dialkyl ether prepared by the method has a higher CN value, can be applied to diesel fuel widely and effectively without high polymerization degree andhas a relatively simple preparation process. The byproducts petroleum C4 and C5 in the petroleum cracking ethylene process and the catalytic cracking petroleum 30-90-DEC C light fraction serve as theraw materials, so production cost is greatly saved by using low-carbon olefin in the raw materials, a good technical route is provided for comprehensive utilization of a large number of byproducts inthe petroleum cracking process, and remarkable economic significance is achieved.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

Selective hydrogenation catalyst and application thereof

ActiveCN101844081ASignificant selection of hydrogenation activityReduce contentHydrocarbon by hydrogenationChemical recyclingAlkyneNon precious metal

The invention discloses a selective hydrogenation catalyst and application thereof, belonging to the technical field of hydrogenation. In order to satisfy the demand of non-precious metal catalysts for selective hydrogenation of alkyne and alkadiene in hydrocarbon flow, the invention discloses a supported catalyst which takes nickel, molybdenum and zinc as catalytic components. Through adding two assistants, i.e. molybdenum and zinc in nickel active component, the activity, the selectivity and the stability of the catalyst are obviously improved. If alkali metal compounds are used for treating carriers or alkali metals are added in the nickel active component, the stability of the catalyst can be further improved and the regeneration period of the catalyst can be prolonged. The invention additionally discloses the application of the catalyst in the hydrogenation of gasoline and the selective hydrogenation of C4 and C5 fractions, pyrolysis gas and C3 fractions. The catalyst of the invention has the advantages of excellent catalytic activity and selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

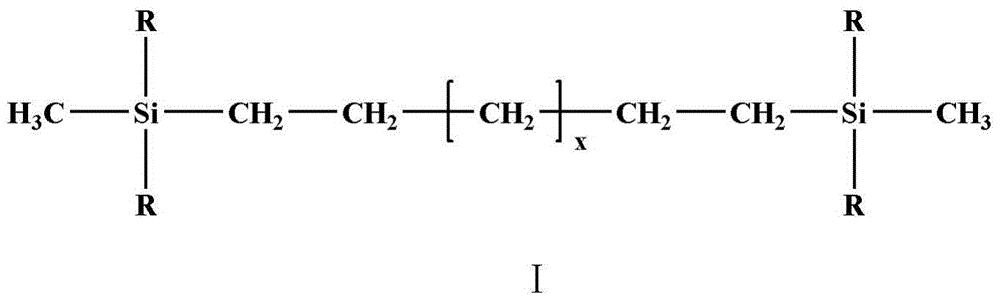

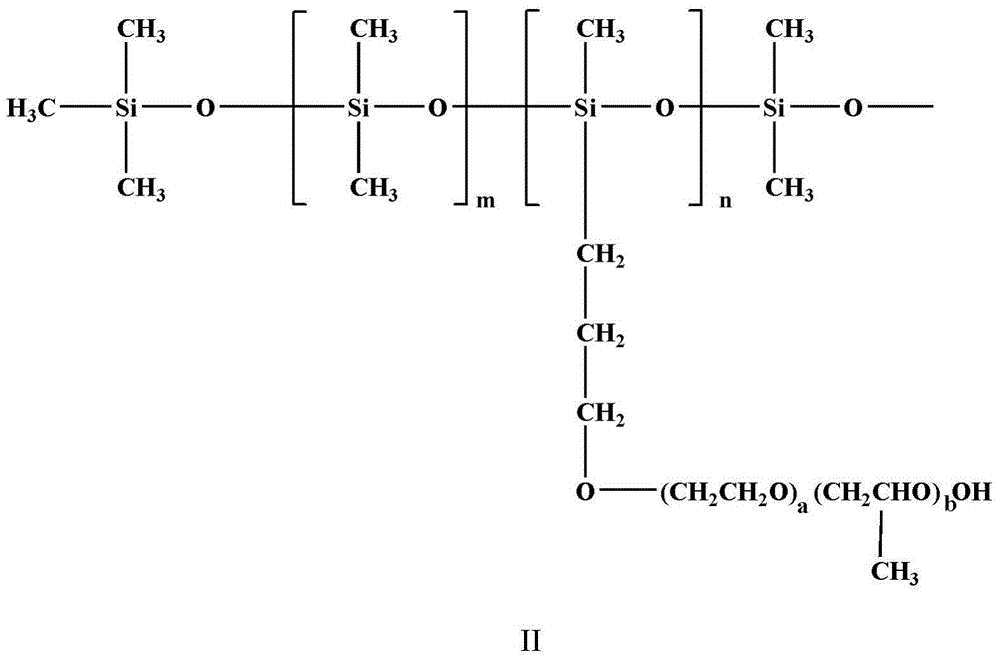

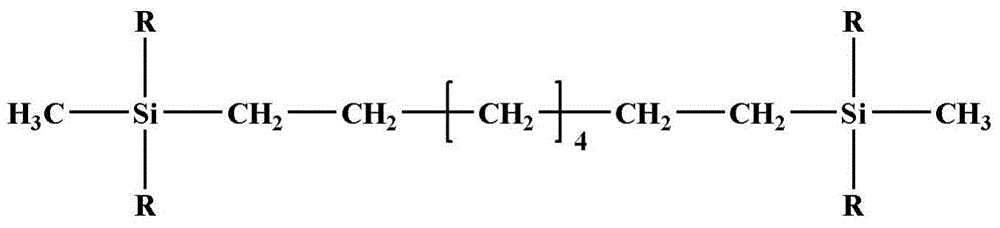

Starlike pectinate polyether-organosilicone copolymer and preparation method thereof

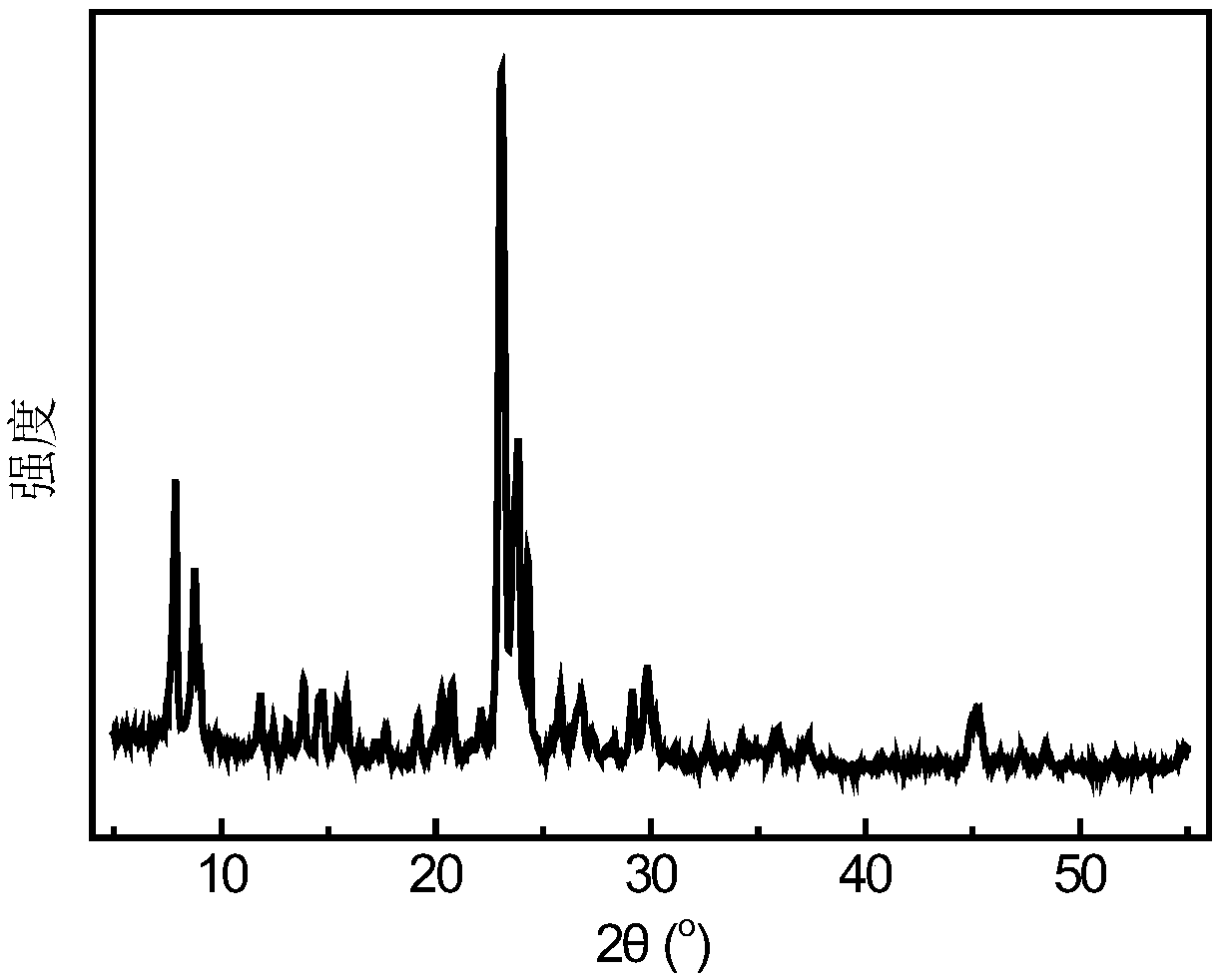

ActiveCN104448323AAvoid problems that easily cause environmental pollutionMild reaction conditionsEther preparation from oxiranesCrystallographyAlkadiene

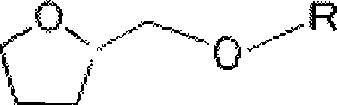

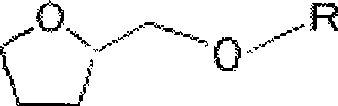

The invention discloses a starlike pectinate polyether-organosilicone copolymer. A branch point (starlike copolymer initiator) in the copolymer is composed of alkadiene and heptamethyltrisiloxane, which are connected by a silicon-carbon bond; a branched chain is a polysiloxane chain and is connected to the branch point by a silicon-oxygen-silicon chain; a side chain is a polyether chain and is connected to the polysiloxane chain by the silicon-carbon bond. The starlike pectinate polyether-organosilicone copolymer disclosed by the invention has a structure with the structural formula I described in the description, wherein in the structural formula I, the value of x is 7-20, R is a structure with a structural formula II described in the description, and in the structural formula II, the value of m is 10-40, the value of n is 1-8, the value of a is 4-30, the value of b is 0-10, the value of m+n is 11-48, and the value of a+b is 4-40.

Owner:JIANGSU MAYSTA CHEM

Selective hydrogenation catalyst for removing alkadiene in mixed c4 and preparation method thereof

InactiveCN101850250AEasy to prepareExtended service lifeHydrocarbon purification/separationHydrocarbonsAlkadieneSurface layer

The invention relates to a selective hydrogenation catalyst for removing alkadiene in mixed C4, which consists of carrier and the following active components measured with the carrier as a reference: 0.1 to 2.0 percent by weight of Pd and 0.1 to 1.0 percent by weight of Pb; the carrier is alumina, the surface layer of which is covered by magnesia-alumina spinel, and the carrier contains 5 to 15 percent by weight of the magnesia-alumina spinel. The catalyst is used for the selective hydrogenation of alkadiene, and has the advantages of high activity and selectivity, high sulphur resistance and long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

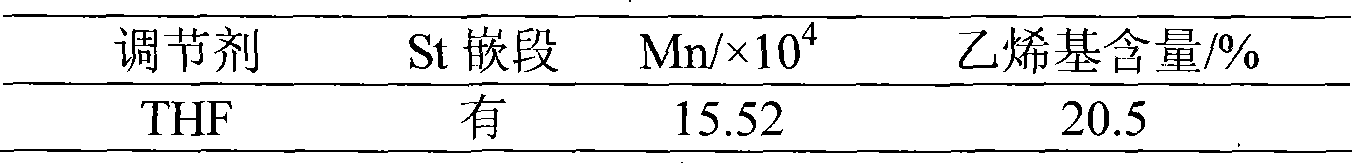

Method for preparing high vinyl solution polymerized butylbenzene by high temperature continuous polymerization technique

The invention discloses a method for preparing high-vinyl solution styrene butadiene through a high-temperature continuous polymerization process. Butyl lithium is taken as an initiator of anionic polymerization, an alkyl tetrahydrofurfuryl ether is taken as a polarity regulator, and the continuous polymerization process is adopted to synthesize high-vinyl solution butadiene styrene at a polymerization temperature of between 100 and 130 DEG C. The vinyl content can reach more than 30 percent, thereby meeting the practical production requirements. The method has the advantages that the alkyl tetrahydrofurfuryl ether is taken as the anion regulator for the homopolymerization of alkadiene or the copolymerization of alkadiene and other olefins; under the condition of the high-temperature continuous polymerization, higher activity is still maintained so as to effectively regulate the vinyl content in the alkadiene.

Owner:DALIAN MARITIME UNIVERSITY

Catalysts for selective hydrogenation of alkynes and alkadienes

InactiveUS7153807B2Maintain and improve conversionMinimization requirementsHydrocarbon by hydrogenationHydrocarbon purification/separationOligomerAlkadiene

Catalysts have been discovered that are useful in hydrogenation reactions, and particularly for the selective hydrogenation of acetylene and / or methyl acetylene (MA) and / or propadiene (PD) in light olefin-rich feedstreams. These catalysts can selectively hydrogenate acetylene with less selectivity to making oligomers (green oil) as compared with existing commercial catalysts, particularly palladium catalysts. These catalysts are non-palladium catalysts, and have three different constituents that are metal or metal-based components. The metal of the first constituent may be nickel or platinum, the metal of the second constituent may be from Groups 1–10, and the metal of the third constituent may be from Groups 11–12, where the Groups are of the Periodic Table of Elements (new IUPAC notation).

Owner:EXXONMOBIL CHEM PAT INC

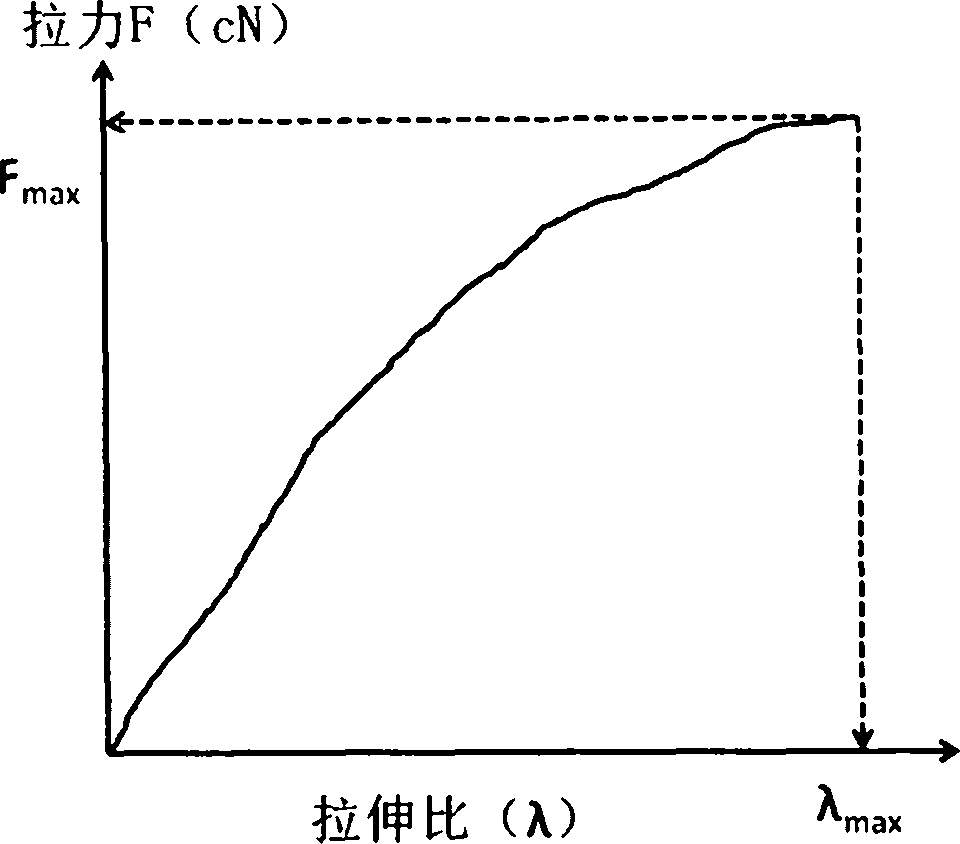

Method for preparing polypropylene melt with high melt strength

The embodiment of the invention discloses a method for preparing polypropylene melt with high melt strength, which uses alkadiene as a modified monomer, thus improving the tensile property of the polypropylene melt with high melt strength due to good compatibility of the alkadiene and polypropylene resin. In addition, the alkadiene monomers can perform grafting reaction with the polypropylene melt, and the alkadiene monomer has lower activity, thus inhibiting cross-linkage reaction so as to expedite the grafting reaction in a certain degree and ensure polypropylene to have higher melt strength. Therefore, the polypropylene melt with high melt strength prepared by the method provided by the invention not only has higher melt strength, but also has larger draw ratio and excellent melt ductility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing propylene from methanol

ActiveCN102875307AExtended regeneration cycleFaster inactivationHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsUnsaturated hydrocarbonFixed bed

The invention relates to a method for preparing propylene from methanol and mainly solves the problem that a present fixed bed technology has disadvantages of short catalyst regeneration period and low propylene yield and a present moving bed technology has disadvantages of large difficulty in continuous coke-burning control of a catalyst and complex flow. According to the method, C5 and the following hydrocarbons obtained from separation of methanol conversion reaction products are subjected to selective hydrogenation treatment, highly unsaturated hydrocarbons such as alkadiene, alkyne and the like are selectively converted into corresponding olefins, and the olefins are recycled. By the adoption of the technical scheme, the above problem is solved well. The method provided by the invention can be applied in industrial production of propylene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

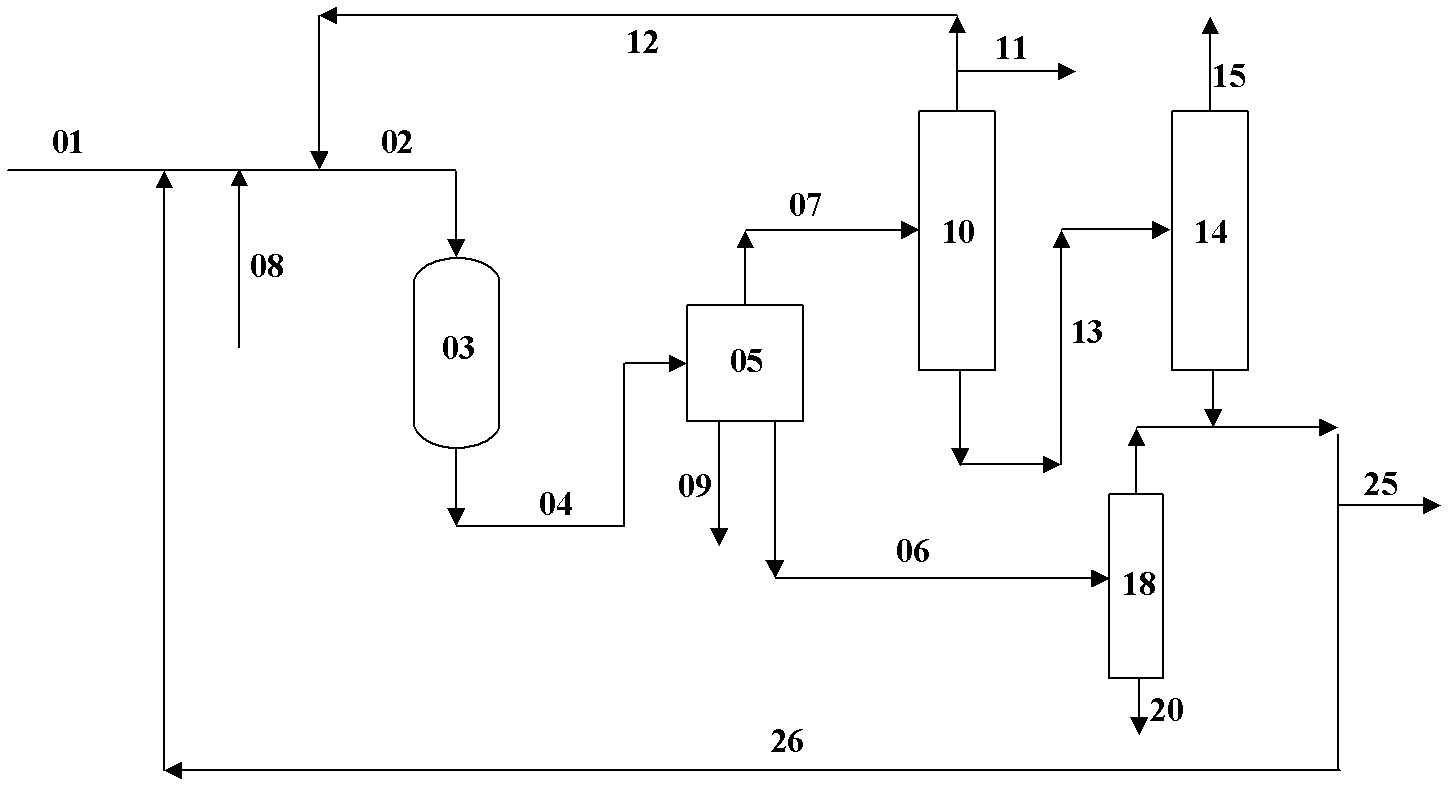

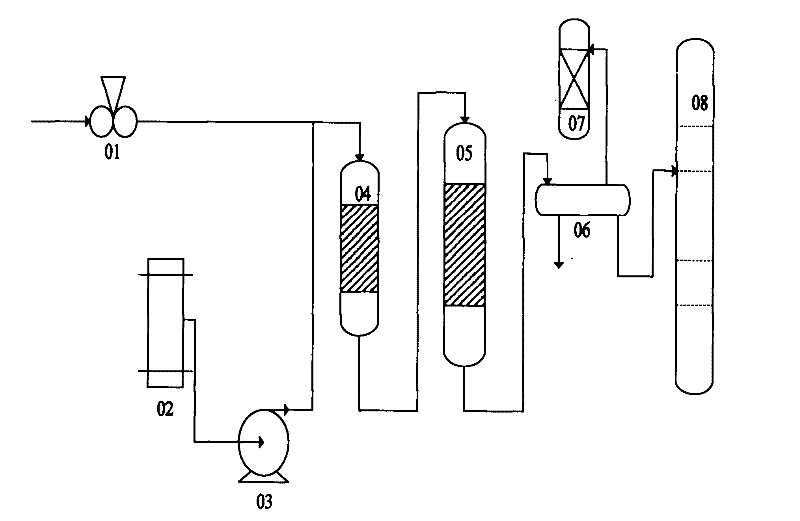

Cleaning method of full-range FCC (Fluid Catalytic Cracking) gasoline

ActiveCN108219841AKeep octaneRealize ultra-deep desulfurizationMolecular sieve catalystsTreatment with hydrotreatment processesIsomerizationCleaning methods

The invention relates to a cleaning method of full-range FCC (Fluid Catalytic Cracking) gasoline. The cleaning method comprises the following process: firstly, removing alkadiene in the full-range FCC(Fluid Catalytic Cracking) gasoline through a prehydrogenation reactor; then, carrying out hydro-adsorption desulfurization on a prehydrogenation product, thus removing sulfide; then carrying out isomerization on reaction effluent under the action of an olefin isomerization catalyst by using a weakly acidic mesoporous H-shaped Zn-ZSM-5 molecular sieve or an improved weakly acidic mesoporous H-shaped Zn-ZSM-5 molecular sieve as a carrier, thus converting olefin into isohydrocarbons, wherein an isomerization reaction product is clean gasoline meeting national standard VI.

Owner:FUZHOU UNIV

Rare earth catalysis system and application thereof in preparation of conjugated diene liquid rubber

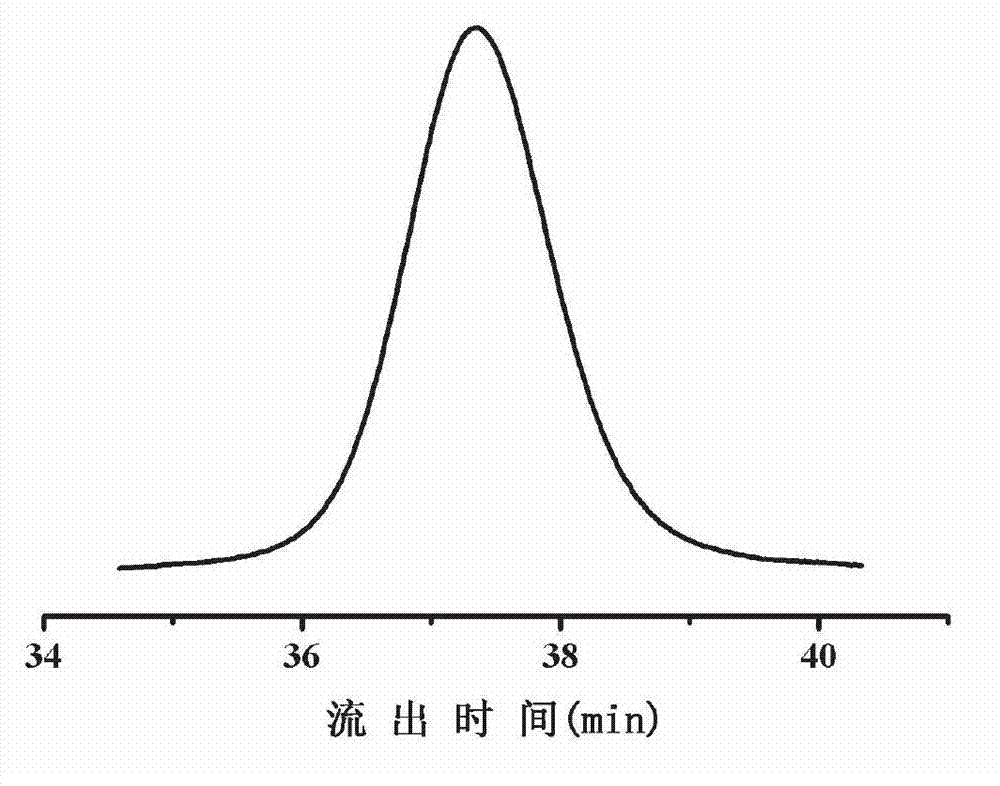

The invention provides a rare earth catalysis system and application of the rare earth catalysis system in preparation of conjugated diene liquid rubber, and relates to the field of catalysts, aiming at solving the problem that the rubber which is low in molecular weight and narrow in molecular weight distribution is hard to prepare by the existing catalysis system. The rare earth catalysis system comprises an alkoxy rare earth compound, a hydrogenated alkyl aluminum compound, chloride and conjugated alkadiene. The alkoxy rare earth compound is ethoxy neodymium, n-propyloxy neodymium, n-propyloxy lanthanum, n-propyloxy samarium, isopropoxy neodymium, isopropoxy lanthanum, isopropoxy samarium, isobutoxy neodymium, isobutoxy lanthanum, isobutoxy samarium, tert-butoxy neodymium, iso-octyl oxygroup neodymium, iso-octyl oxygroup lanthanum or iso-octyl oxygroup samarium. The invention further provides the application of the rare earth catalysis system in the preparation of the conjugated diene liquid rubber. The molecular weight of the prepared conjugated diene liquid rubber is 1.0*10<3>-8.22*10<3>, and the molecular weight dispersion index of the prepared conjugated diene liquid rubber is 1.1-1.4.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

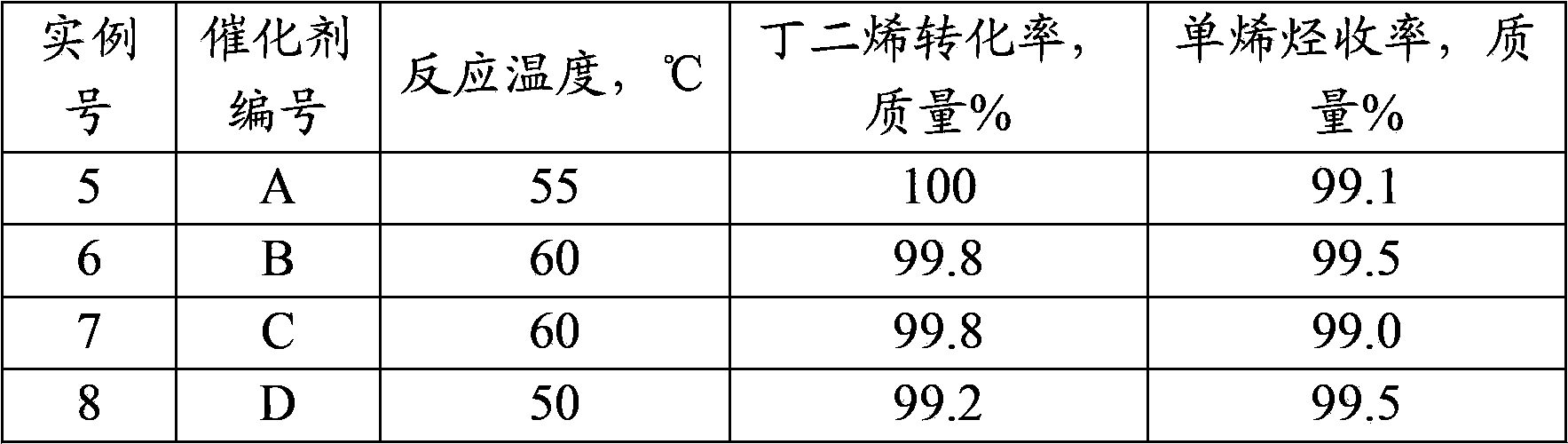

Catalyst for removing alkadiene in C4 and preparation method thereof

ActiveCN103418379AGood choiceHigh monoolefin yieldHydrocarbon purification/separationHydrocarbonsAlkadieneActive component

A catalyst for removing alkadiene in mixed C4. The catalyst comprises a composite carrier and the following active components, calculated by using the composite carrier as a basis: 0.05-1.0 wt% of Pd and 0.1-5.0 wt% of WO3; and the composite carrier comprises 90-99 wt% of alumina and 1-10 wt% of oxygen calcium. The catalyst is used for removing alkadiene in mixed C4 through selective hydrogenation, and has high activity, selectivity and resistance to sulfur poisoning, and excellent service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

A crosslinkable polyethylene composition, method of making the same, and articles made therefrom

The instant invention is a crosslinkable polyethylene composition, a method of making the same, and articles made therefrom. The crosslinkable polyethylene composition according to instant invention includes a polyethylene component, a crosslinking agent, and a crosslinking coagent. The crosslinking agent is an organic peroxide, and the crosslinking coagent is an alkadiene, alkatriene, or alkatetraene compound comprising at least two terminal carbon-carbon double bonds. The crosslinkable polyethylene composition may, optionally, further include a scorch inhibitor, a cure booster, a stable free radical, one or more conventional additives, blends thereof, and / or combinations thereof. The method for producing a crosslinkable polyethylene composition according to instant invention includes the steps of: (1) providing a polyethylene component; (2) providing a crosslinking agent, wherein the crosslinking agent is an organic peroxide; (3) providing a crosslinking coagent, wherein the crosslinking coagent is an alkadiene, alkatriene, or alkatetraene compound comprising at least two terminal carbon-carbon double bonds; (4) melt blending the a polyethylene component, the crosslinking agent, and the crosslinking coagent at a temperature in the range of less than the decomposition temperature of the crosslinking agent; and (5) thereby forming the crosslinkable polyethylene composition. The article according to instant invention includes the crosslinked product of a polyethylene component; a crosslinking agent, wherein the crosslinking agent is an organic peroxide; and a crosslinking coagent, wherein the crosslinking coagent is an alkadiene, alkatriene, or alkatetraene compound comprising at least two terminal carbon-carbon double bonds.

Owner:DOW GLOBAL TECH LLC

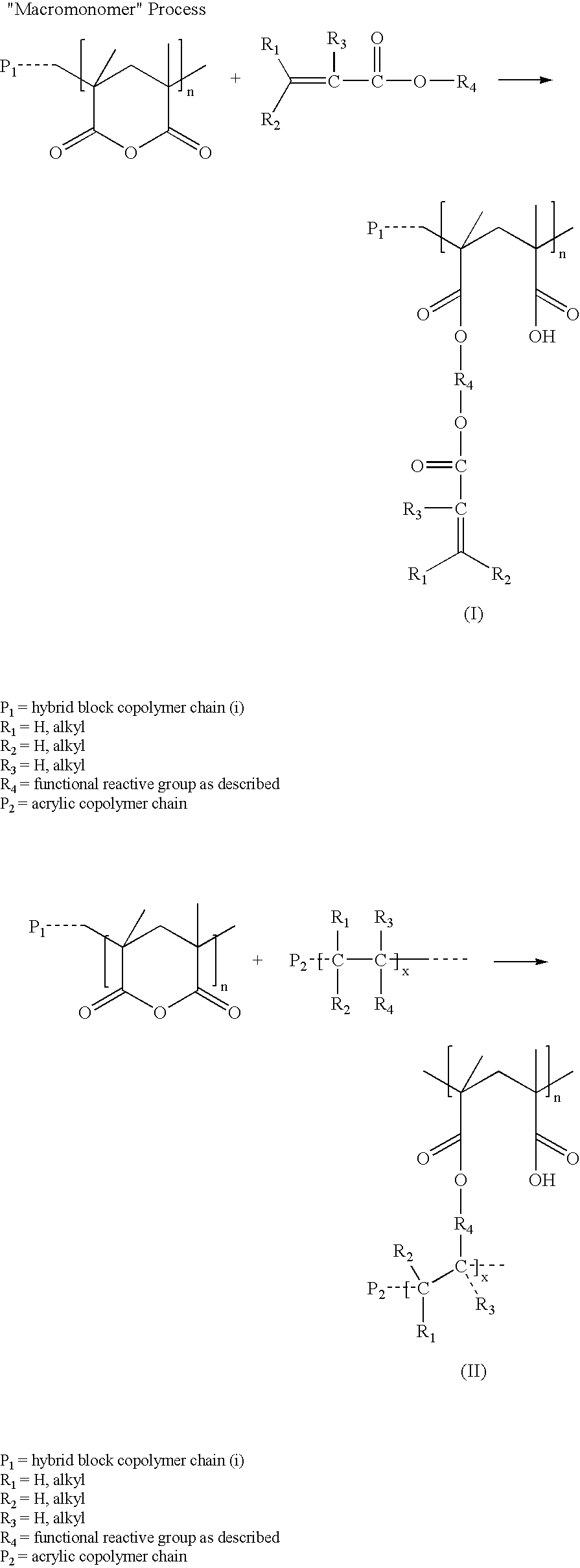

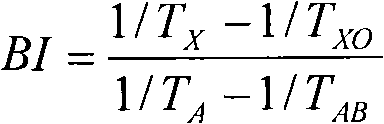

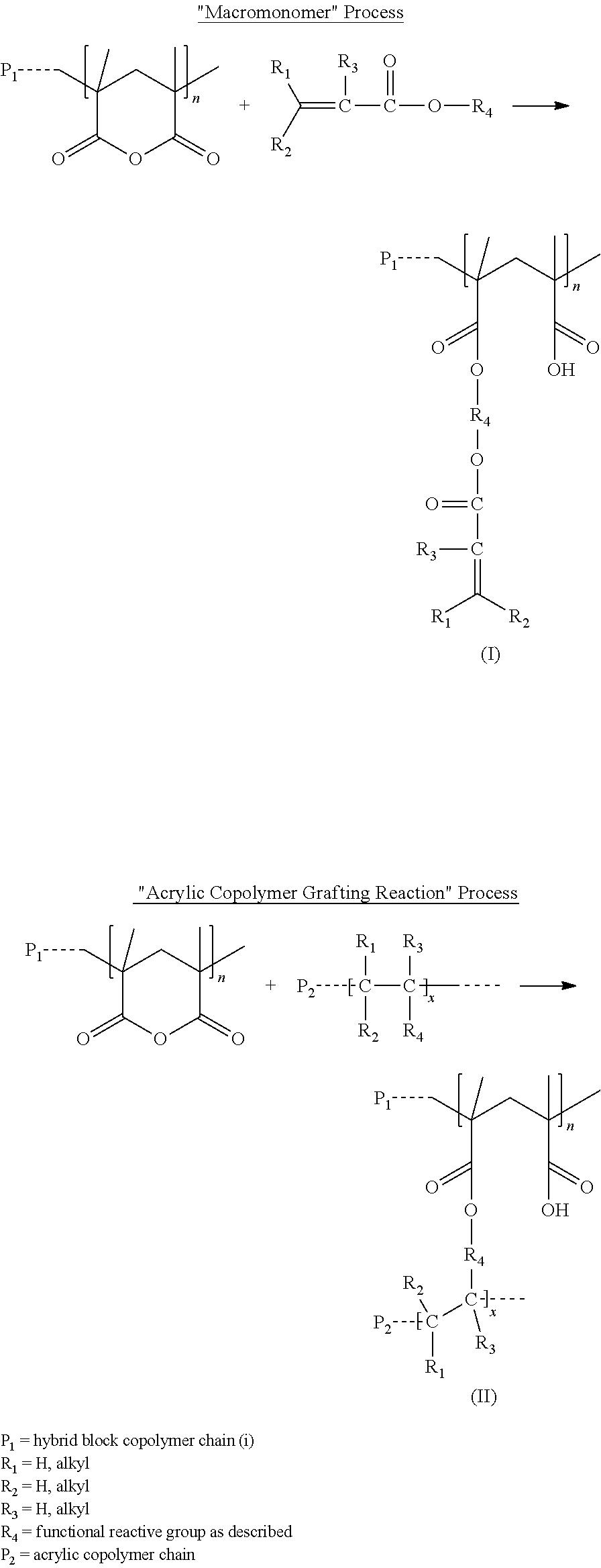

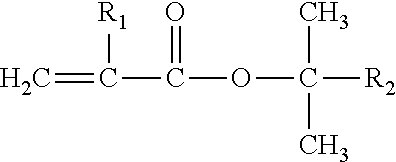

Polymer Composition prepared from acrylic polymer grafted with a functionalized block copolymers

The present invention relates to various end use applications prepared from certain block copolymers. The block copolymers include one or more A or A′ blocks or B blocks plus one or more terminal M blocks. Each A and A′ is a block or segment comprising predominantly a polymerized alkenyl aromatic compound, each B is a block or segment comprising predominantly a polymerized conjugated alkadiene, and each M is a six membered anhydride ring and / or acid group. The anhydride rings are prepared by thermally decomposing adjacent units of (1-methyl-1-alkyl)alkyl acrylic esters such as t-butylmethylacrylate. A wide variety of polymers are disclosed having the stable anhydride rings in the polymer backbone. The invention relates specifically to various end uses prepared from the reaction product of such block copolymers with various reactive resins, reactive monomers and metal derivatives.

Owner:KRATON POLYMERS US LLC

Ultra-deep desulfurization absorbent containing C 4 conjugated dienes raw material and production method and use thereof

InactiveCN101450303AHigh adsorption selectivityImprove adsorption capacityOther chemical processesAdsorption purification/separationAlkadieneSorbent

The invention relates to an adsorbent for deep desulfurization of materials containing C5 conjugated alkadiene, a preparation method and application thereof. The adsorbent for desulfurization consists of reduced VIII transition metal, reduced IB transition metal which activate sulfur-containing molecules, and alumina carrier. The adsorbent can adsorb nearly all sulfur compounds in the materials containing C5 conjugated alkadiene to get the materials containing C5 conjugated alkadiene with sulfur content lower than 10ng / mu l.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Crosslinkable polyethylene composition, method of making the same, and articles made therefrom

The instant invention is a crosslinkable polyethylene composition, a method of making the same, and articles made therefrom. The crosslinkable polyethylene composition according to instant invention includes a polyethylene component, a crosslinking agent, and a crosslinking coagent. The crosslinking agent is an organic peroxide, and the crosslinking coagent is an alkadiene, alkatriene, or alkatetraene compound comprising at least two terminal carbon-carbon double bonds. The crosslinkable polyethylene composition may, optionally, further include a scorch inhibitor, a cure booster, a stable free radical, one or more conventional additives, blends thereof, and / or combinations thereof. The method for producing a crosslinkable polyethylene composition according to instant invention includes the steps of: (1) providing a polyethylene component; (2) providing a crosslinking agent, wherein the crosslinking agent is an organic peroxide; (3) providing a crosslinking coagent, wherein the crosslinking coagent is an alkadiene, alkatriene, or alkatetraene compound comprising at least two terminal carbon-carbon double bonds; (4) melt blending the a polyethylene component, the crosslinking agent, and the crosslinking coagent at a temperature in the range of less than the decomposition temperature of the crosslinking agent; and (5) thereby forming the crosslinkable polyethylene composition. The article according to instant invention includes the crosslinked product of a polyethylene component; a crosslinking agent, wherein the crosslinking agent is an organic peroxide; and a crosslinking coagent, wherein the crosslinking coagent is an alkadiene, alkatriene, or alkatetraene compound comprising at least two terminal carbon-carbon double bonds.

Owner:DOW GLOBAL TECH LLC

Neodymium-based homogeneous phase rare earth catalyst and preparation method and application thereof

The invention relates to a rare earth catalyst used for conjugation alkadiene polymerization, a preparation method thereof and a method for combining a high cis-form gathering conjugate alkadiene elastic body. The rare earth catalyst is composed of carboxylic acid neodymium, alkyl aluminum, halogen-containing compound and conjugate alkadiene, can be prepared under the condition that the molar ratio of the alkyl aluminum and the carboxylic acid neodymium is smaller than or equal to 10, has relatively higher catalytic activity and enables polymerization conversion rate of the conjugate alkadiene to be larger than 80%. The catalyst has the advantages of homogeneous phase, good stability and high directionality. The catalyst is used for conjugate alkadiene polymerization and can prepare the gathering conjugate alkadiene elastic body with the cis-form structure content larger than 98%.

Owner:CHINA PETROLEUM & CHEM CORP +1

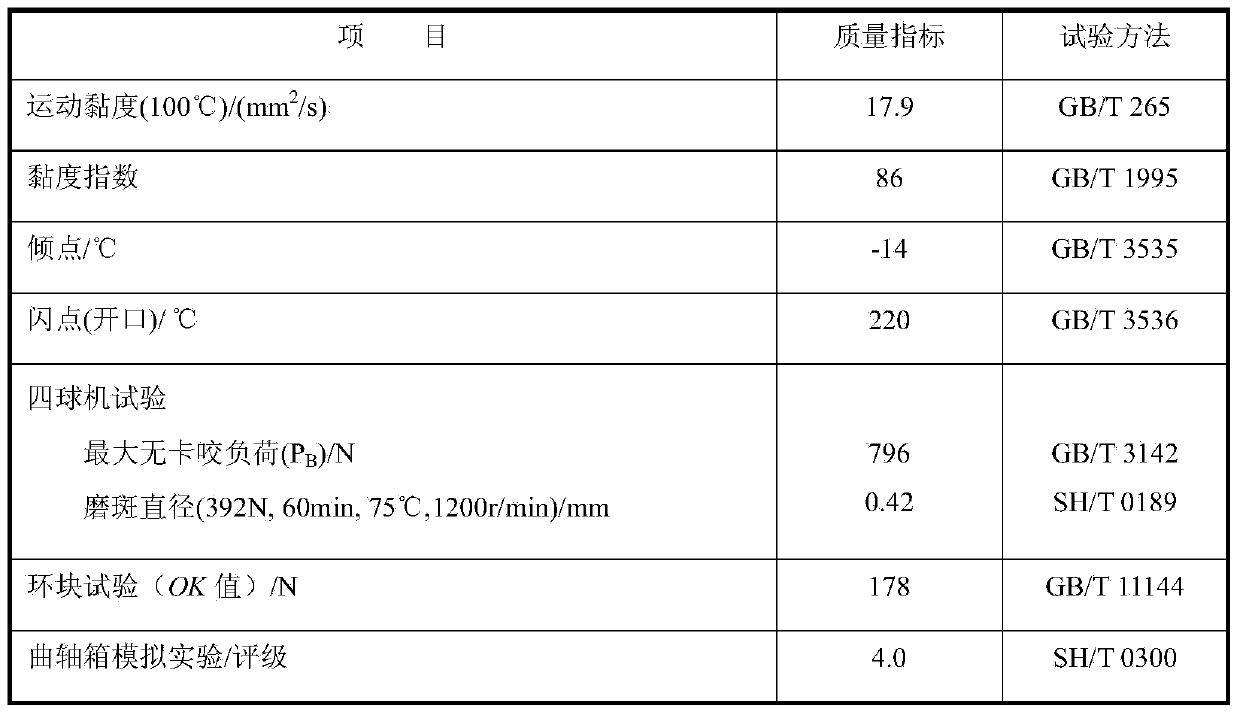

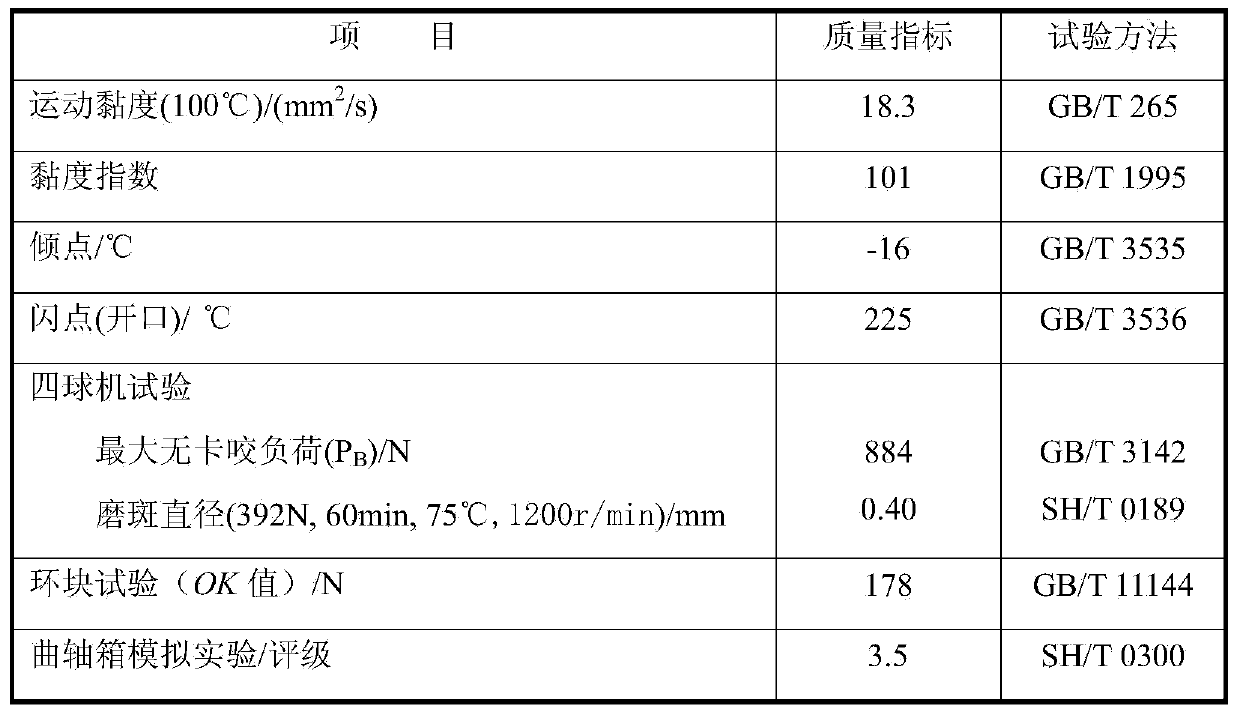

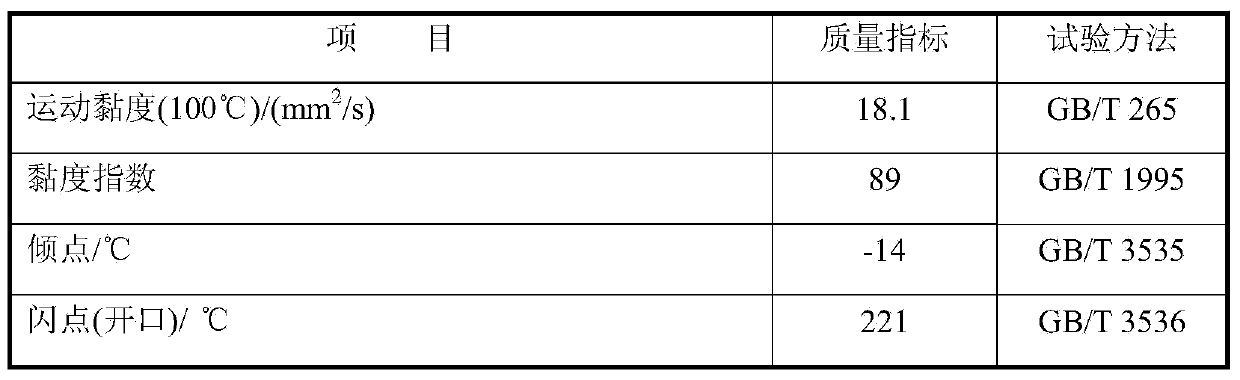

All-purpose lubricating oil for motor and gear case of mini-tiller

InactiveCN103695136AAchieve universalImprove key performanceLubricant compositionMooney viscosityDimethyl siloxane

The invention relates to all-purpose lubricating oil for a motor and a gear case of a mini-tiller. The all-purpose lubricating oil comprises the following components by mass percent: 89.0-93.6% of base oil and a plurality of additives, wherein the kinematic viscosity of the base oil at 100 DEG C is 15-17mm<2> / s; the first additive is 1.0-2.0% of synthetic calcium sulfonate with high base number; the second additive is 2.0-3.0% of sulfurized calcium alkyl phenol with high base number; the third additive is 1.0-2.0% of polyisobutene bissuccinimide; the fourth additive is 1.0-2.0% of sulfurphosphorousbutyloctyl zinc salt; the fifth additive is 1.0-1.5% of amino monothioester; the sixth additive is 0.2-1.0% of terpolymer of ethylene, propylene and non-conjugated alkadiene, wherein the mooney viscosity (ML(1+4) 100 DEG C) of the sixth additive is 25-35; the seventh additive is 0.0001-0.0002% of polydimethylsiloxane. The invention also relates to a preparation method of the lubricating oil. The all-purpose lubricating oil can be used as the lubricating oil for a gasoline engine and a gear case of a mini-tiller, and also can be used as the lubricating oil for a diesel engine and the gear case of the mini-tiller.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +1

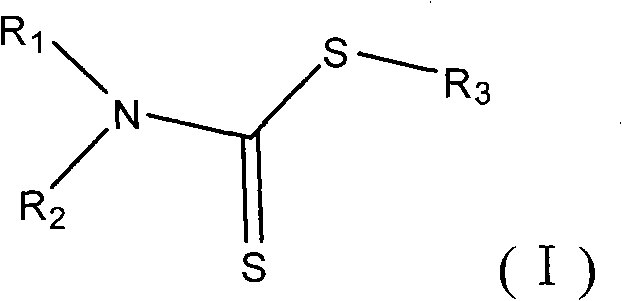

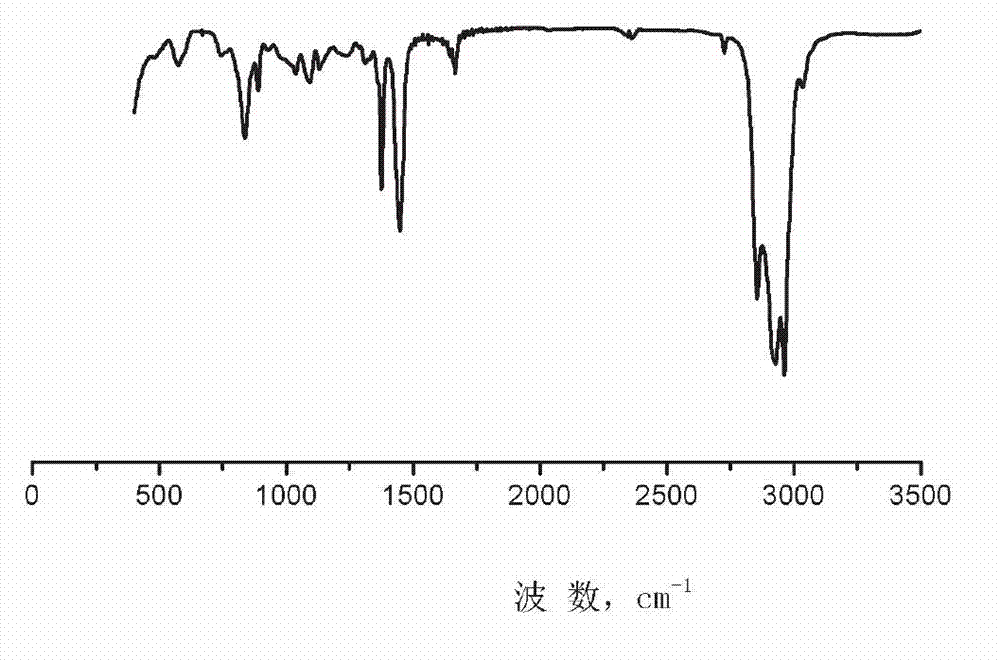

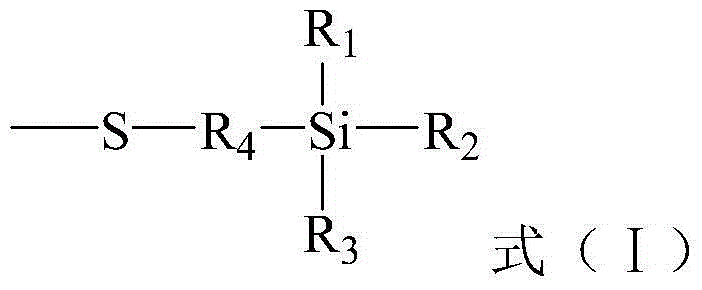

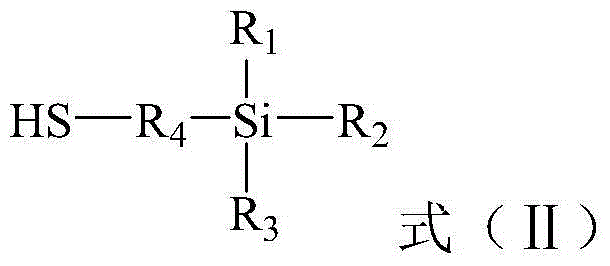

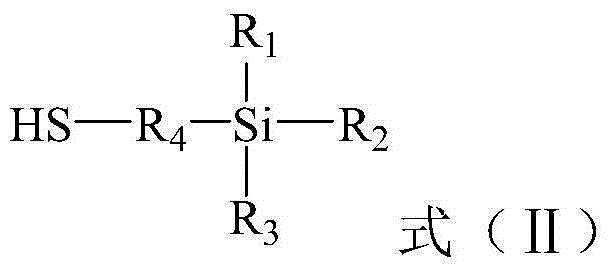

Modified alkadiene polymer as well as preparation method and application thereof

The invention provides a modified alkadiene polymer, a preparation method of the modified alkadiene polymer and application of the modified alkadiene polymer as base rubber. A molecular chain of the modified alkadiene polymer comprises a monovinyl aromatic hydrocarbon structure unit, a conjugated alkadiene structure unit and a silane coupling agent shown in a formula (I), wherein the number-average molecular weight of the modified alkadiene polymer is 50000-1000,000; R1-R4 is C1-C20 linear chain or branched chain alkyl or heteroatom-containing C1-C20 linear chain or branched chain alkyl; the heteroatoms are selected from one or more of halogen, oxygen, sulphur, silicon and phosphorus. The modified alkadiene polymer can be used for effectively balancing the relation between wet-skid resistance and rolling resistance and can also be used for improving unpleasant odor generated by using the silane coupling agent in the rubber mixing process. The formula (I) is as shown in the description.

Owner:CHINA PETROLEUM & CHEM CORP +1

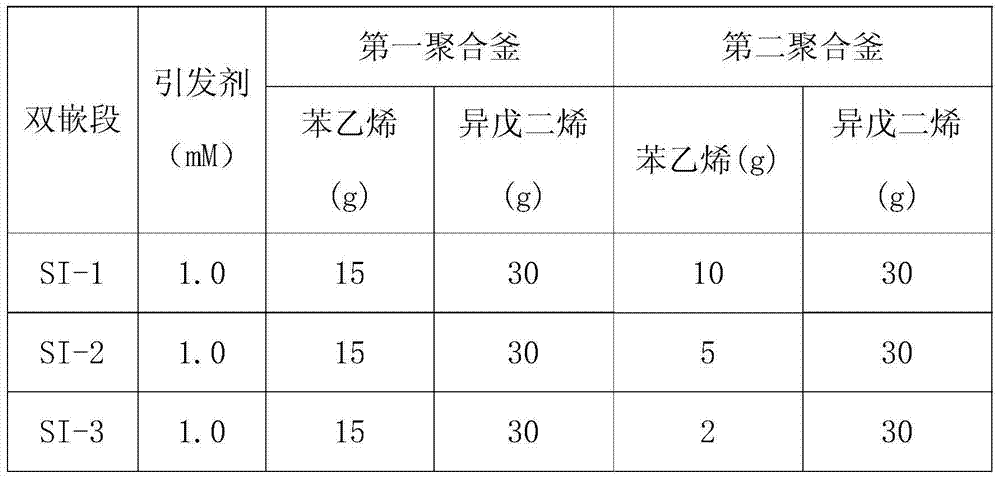

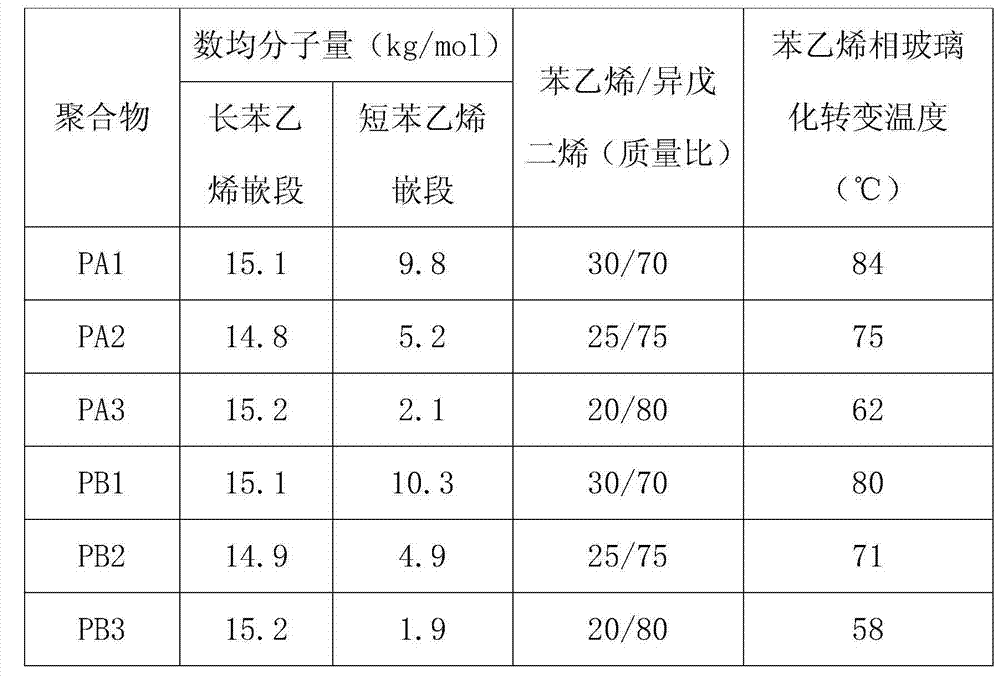

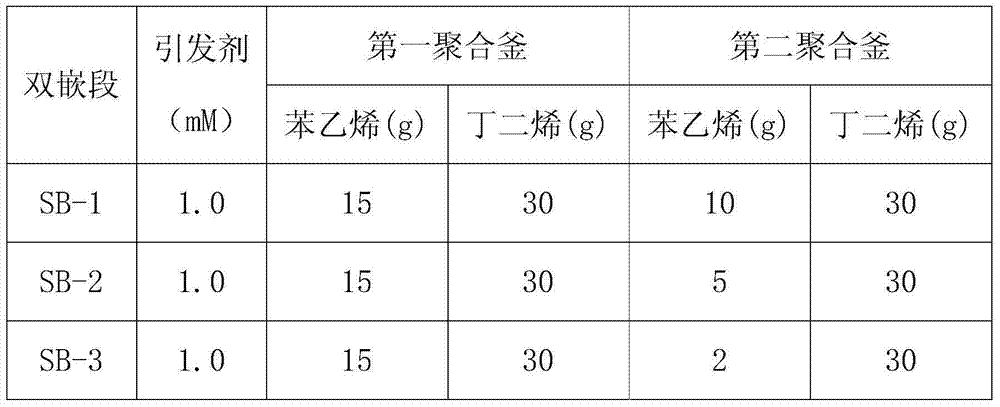

Method for preparing star-shaped styrene thermoplastic elastomer

InactiveCN103773000AAdjust processing temperatureControl processing temperatureAlkadieneThermoplastic elastomer

The invention relates to a method for preparing a star-shaped styrene thermoplastic elastomer, belonging to the technical field of thermoplastic elastomers. The method is characterized in that active styrene-alkadiene dual block mixtures of different structures and lengths are coupled into star-shaped styrene thermoplastic elastomers by dobby coupling agent, so as to form the mixture of an equal-arm star-shaped styrene thermoplastic elastomer with a long styrene block, an equal-arm star-shaped styrene thermoplastic elastomer with a short styrene block, and an unequal-arm star-shaped styrene thermoplastic elastomer with different styrene blocks. The method has the beneficial effects that the long styrene block guarantees that the system has enough physical cross linking points and cohesion strength, the glass-transition temperature is regulated by the length and proportion of the short styrene block at 30-80 DEG C, and the purpose of regulating and controlling the processing temperature of the star-shaped styrene thermoplastic elastomer is realized.

Owner:DALIAN UNIV OF TECH

Preparation method of high-melt strength polypropylene resin with long-chain branched structure characteristic

The invention relates to a preparation method of high-melt strength polypropylene resin with long-chain branched structure characteristic. According to the preparation method, polymerization reactions are carried out section by section based on MgCl2 / TiCl4 type high-efficiency Ziegler-Natta catalysts. The preparation method comprises the following steps of carrying out propylene homo-polymerization, generating a homo-polypropylene matrix framework-linear polypropylene resin matrix, introducing alpha, omega-alkadiene monomer to carry out copolymerization, generating co-polypropylene in which the long chain is branched and some parts are interlinked, and evenly dispersing the co-polypropylene in which the long chain is branched and some parts are interlinked into a linear polypropylene resin-based polypropylene resin body to obtain the high-melt strength polypropylene resin with the long-chain branched structure characteristic. The preparation method is simple in polymerization technique, the high-melt strength polypropylene resin with the long-chain branched structure characteristic has good particle morphology, and the polymer melt has relatively strong strain hardening effect once being stretched.

Owner:INST OF CHEM CHINESE ACAD OF SCI

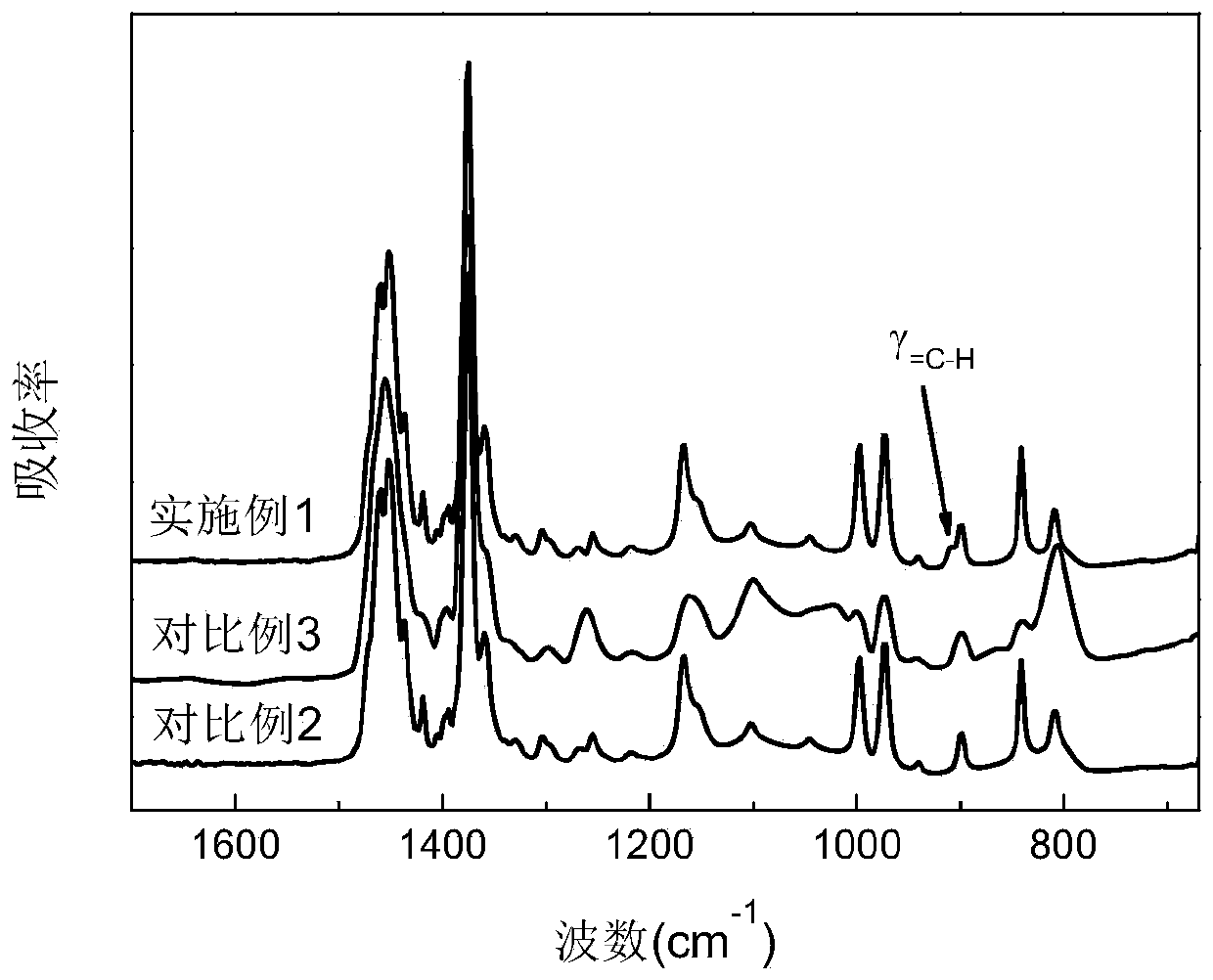

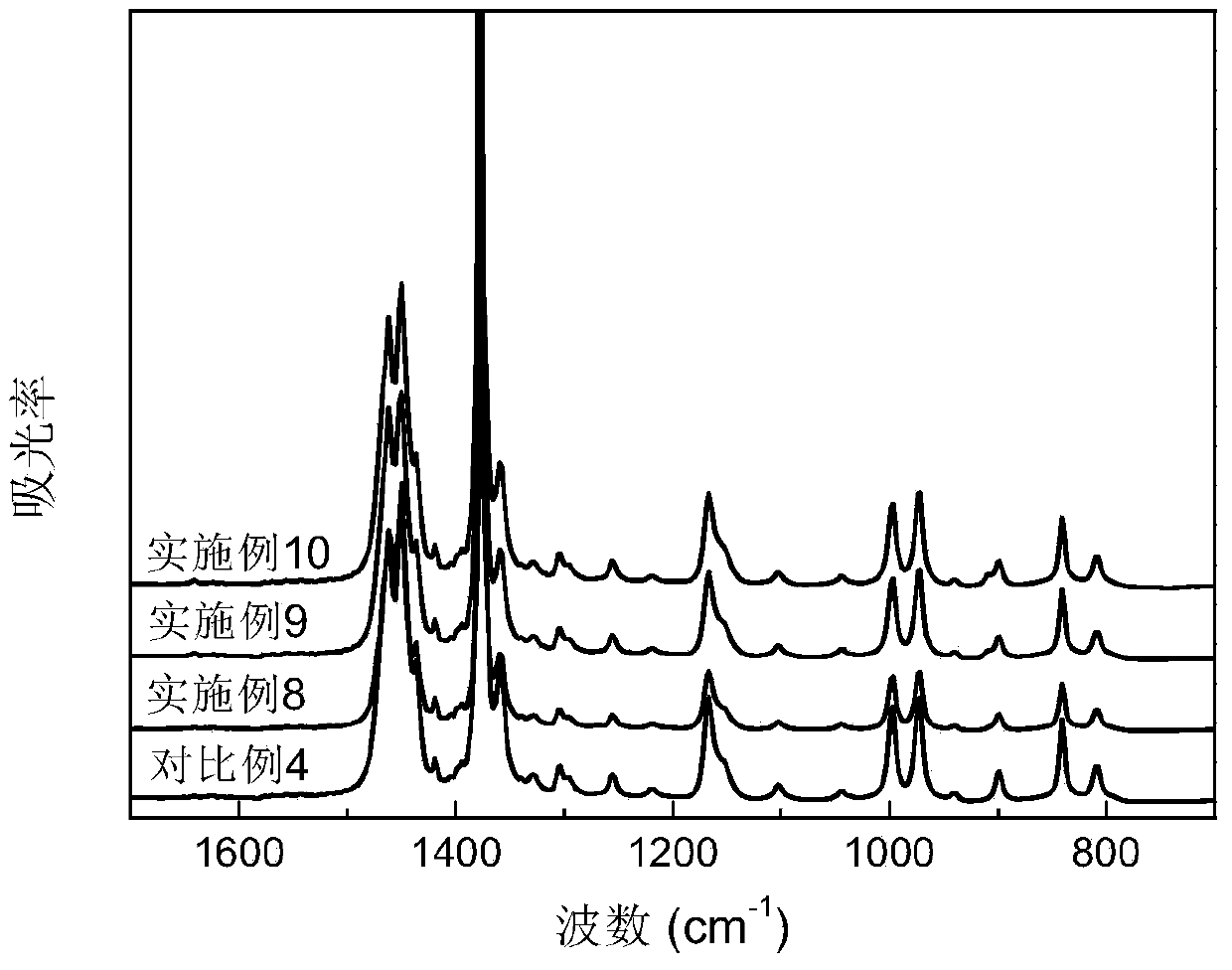

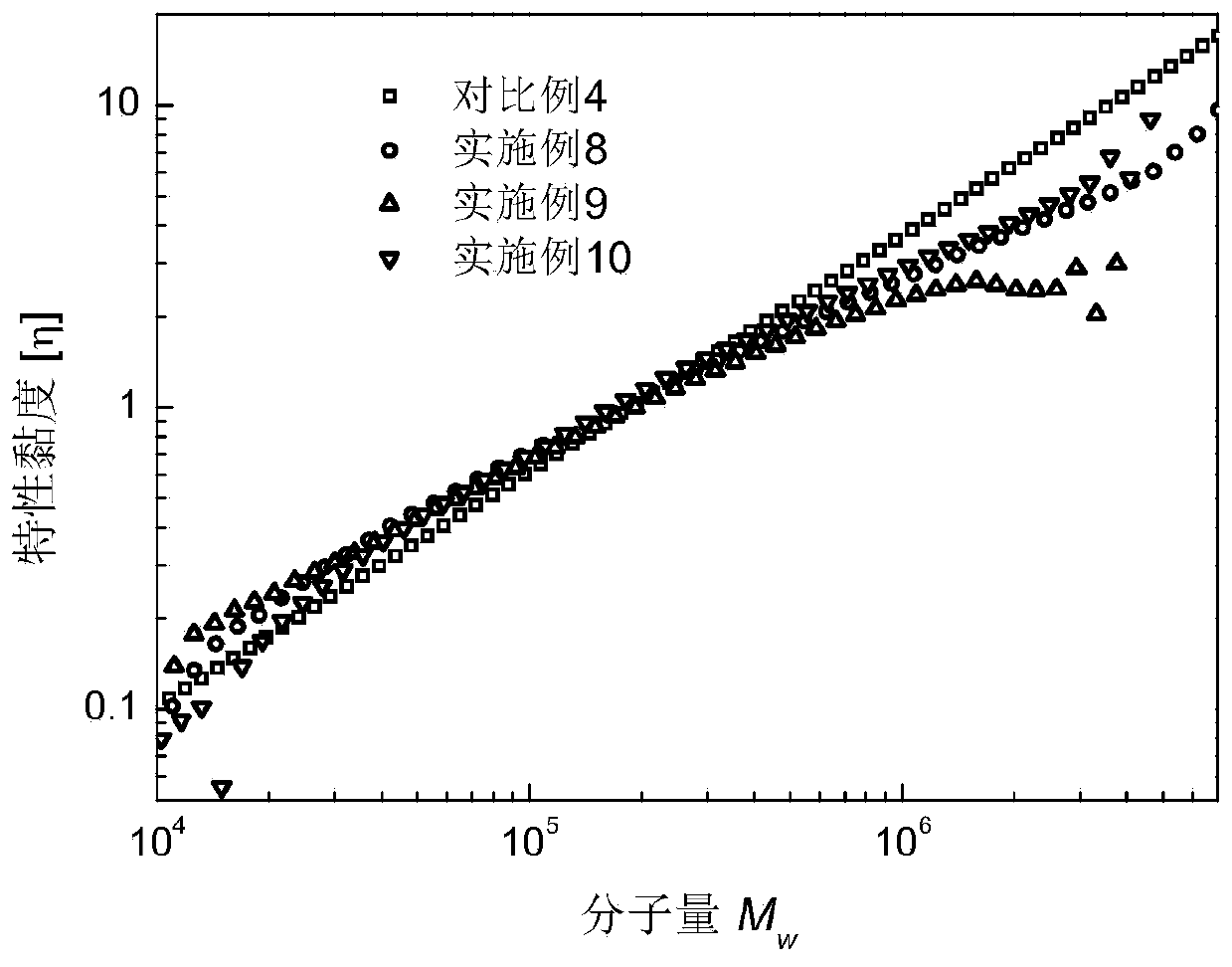

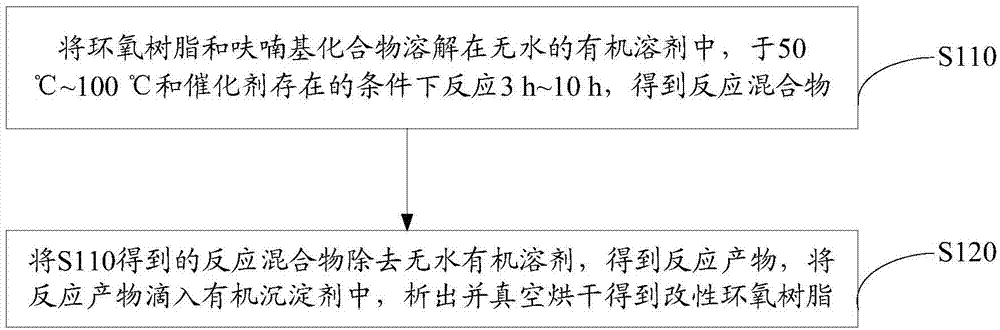

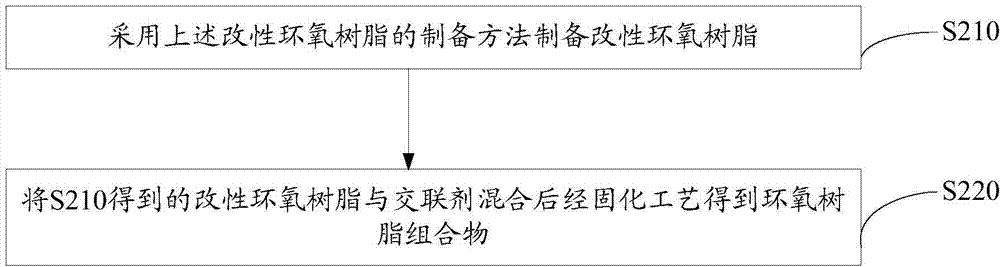

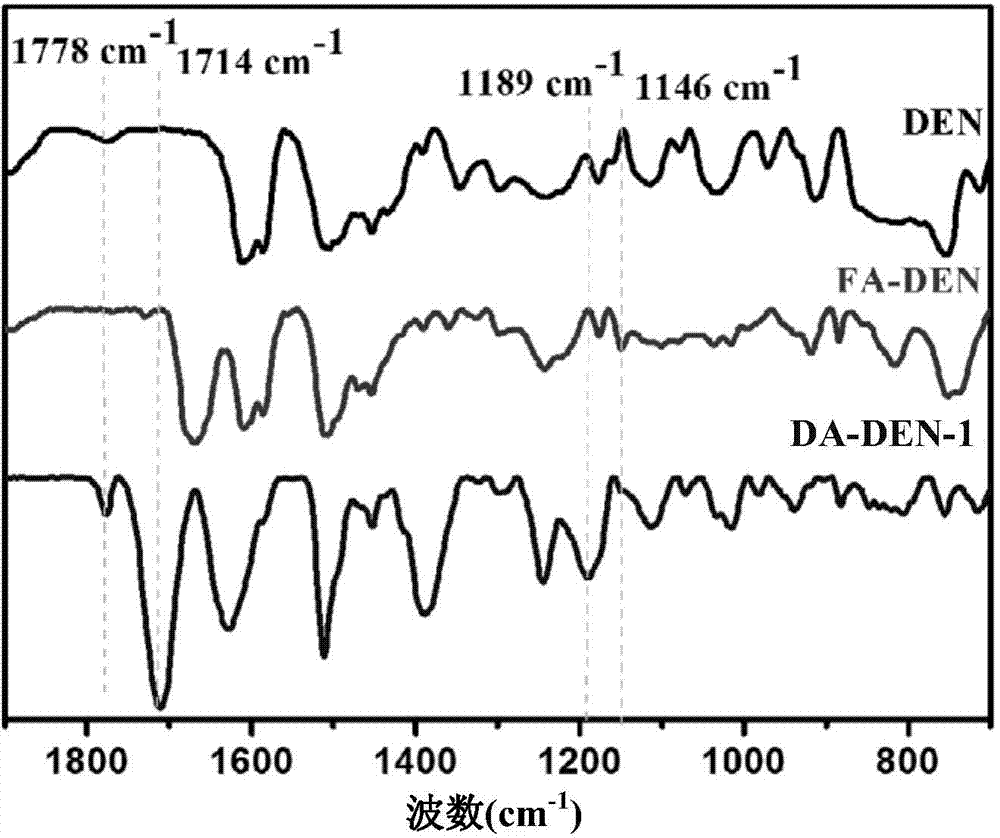

Modified epoxy resin and preparation method thereof, as well as modified epoxy resin composition and preparation method thereof

The invention discloses a preparation method of modified epoxy resin. The preparation method comprises the following steps of dissolving an epoxy resin and furyl compound into an anhydrous organic solvent, and reacting in the existence of a catalyst and at the temperature of 50-100 DEG C for 3-10 hours to obtain a reaction mixture; removing the anhydrous organic solvent in the reaction mixture; dropping the anhydrous organic solvent into an organic precipitator; and separating out and carrying out vacuum drying to obtain modified epoxy resin. According to the preparation method of the modified epoxy resin, the epoxy resin is modified, and active furyl groups are introduced to a molecular structure of the epoxy resin. Furan is a five-membered heterocyclic compound containing oxa-atoms and simultaneously has the chemical performances of aromatic nucleus and alkadiene. Compared with the traditional epoxy resin, the modified epoxy resin prepared by using the preparation method of the modified epoxy resin is relatively high in shrinkage performance and relatively good in thermal stability. The invention also discloses a method for preparing a modified epoxy resin composition by using the prepared modified epoxy resin.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Application of alkadiene polymer in rubber masterbatch, masterbatch and preparation method

The invention relates to an application of an alkadiene polymer in preparing rubber masterbatch, masterbatch based on the application and a preparation method thereof. According to the application of the alkadiene polymer in rubber masterbatch, the alkadiene polymer is a powdery or granular homopolymer and / or copolymer, wherein the melting point is 40-80 DEG C, preferably 50-70 DEG C, and the alkadiene polymer accounts for 10-50wt% of the masterbatch. Transpolyisoprene or polybutadiene used in the invention is of good compatibility with almost diene rubber, so that no negative influence on performance of rubber products is caused. The melting point of TPI (Transpolyisoprene) is about 70 DEG C, so that the masterbatch is not adhered under a storage condition without a separant. At the mixing temperature of common rubber, the masterbatch is crystallized and melted and easy to disperse.

Owner:QINGDAO UNIV OF SCI & TECH

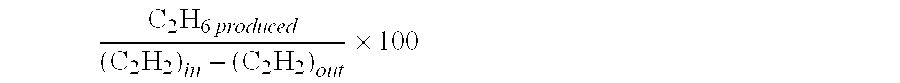

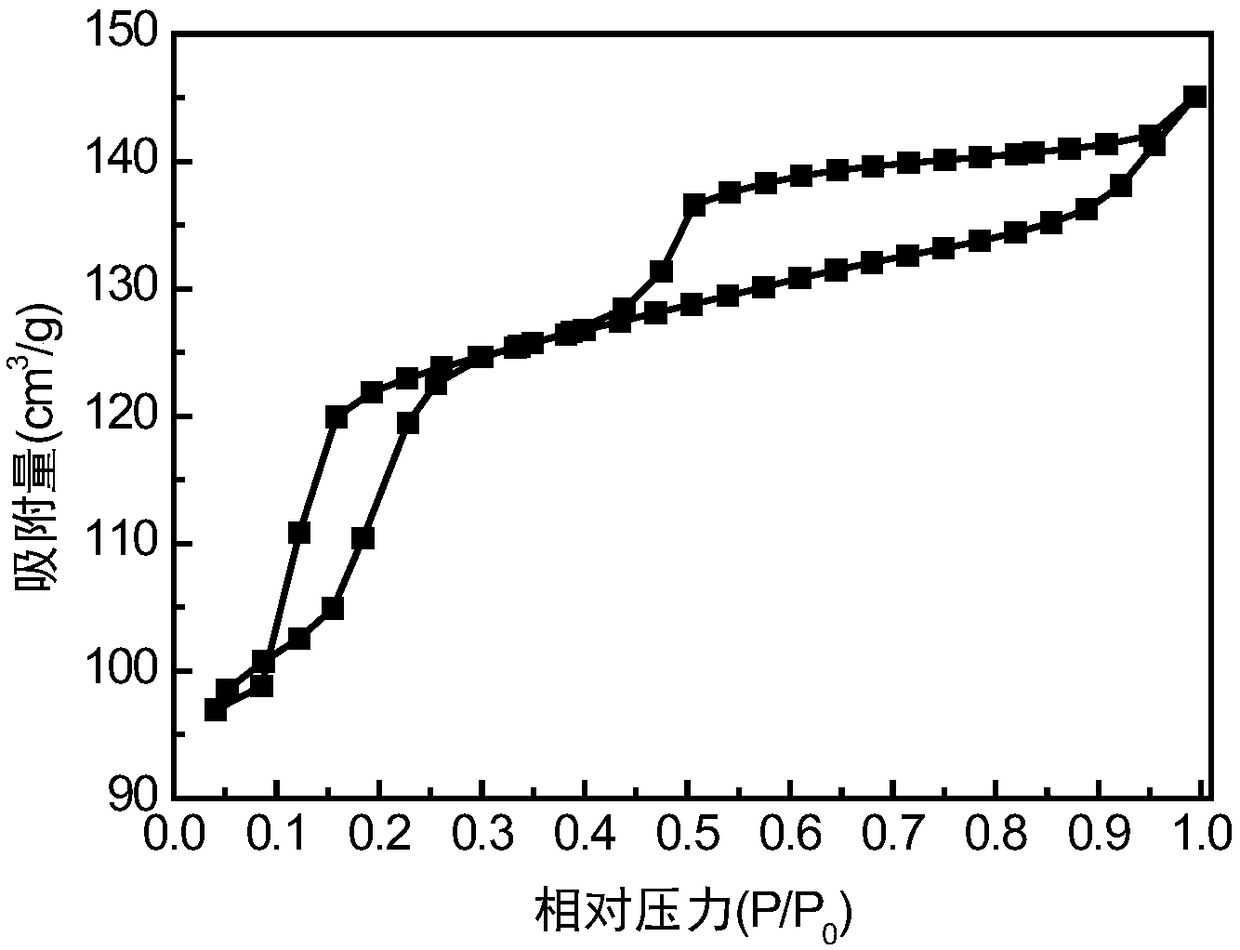

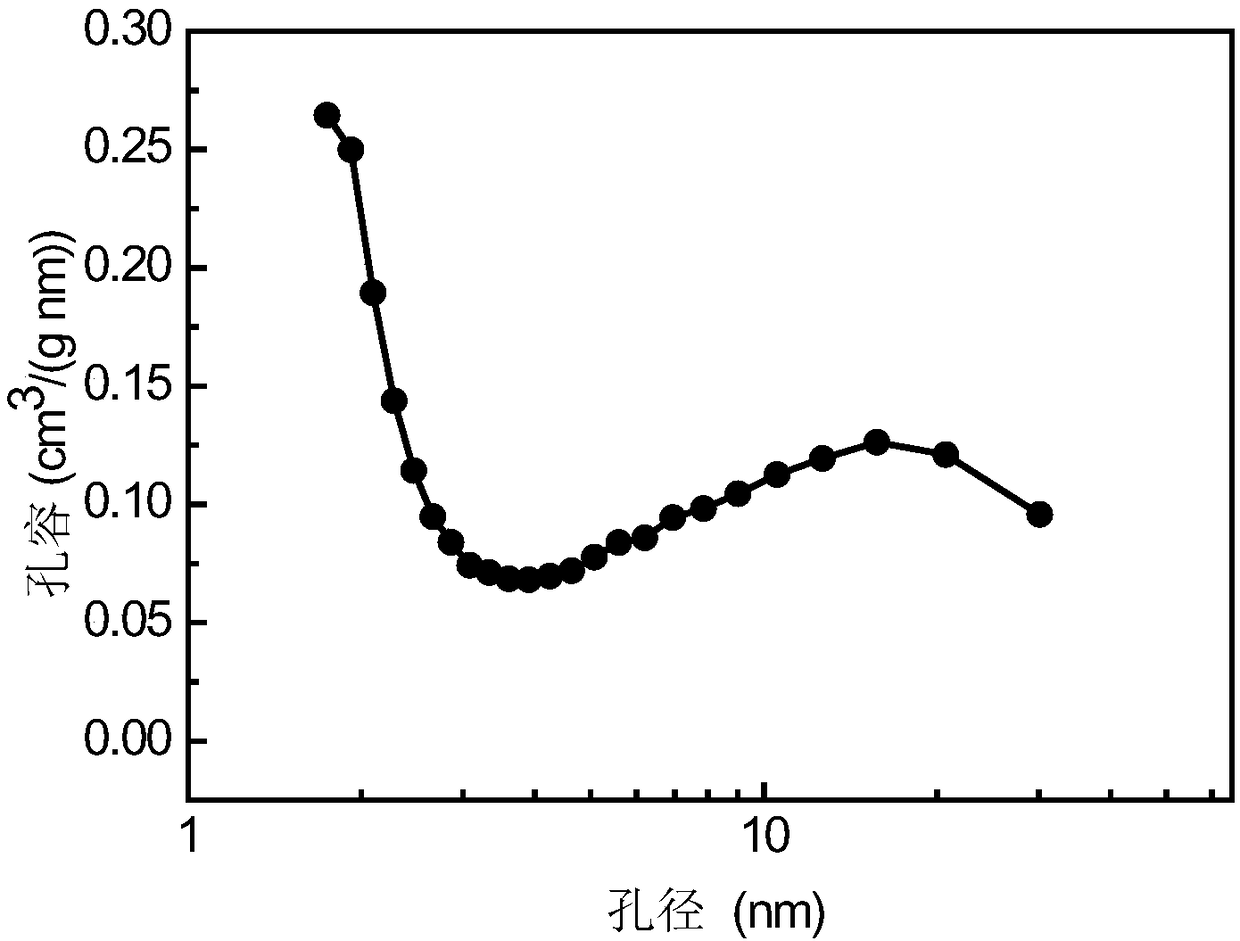

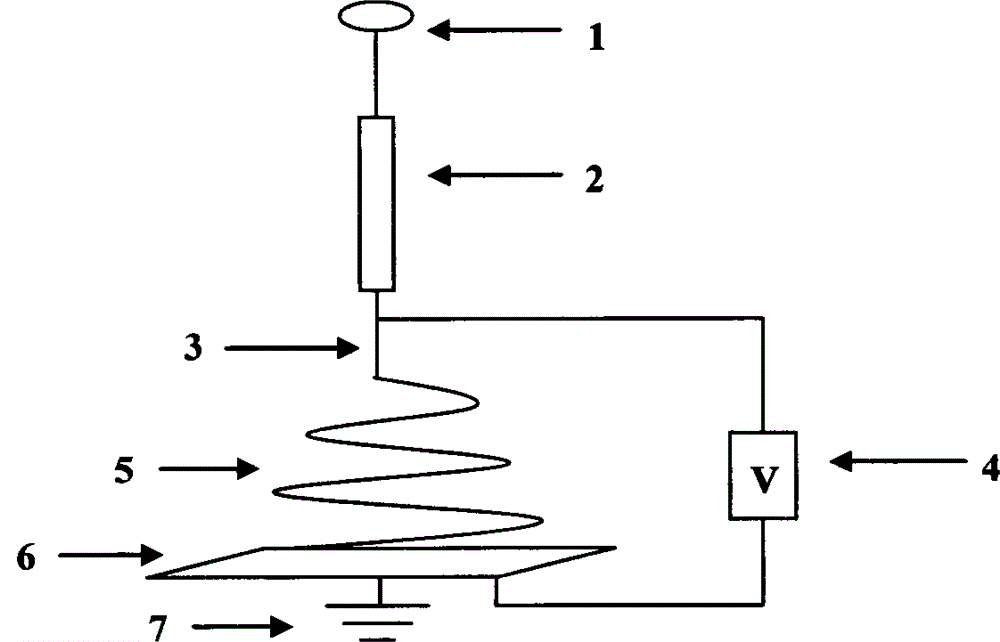

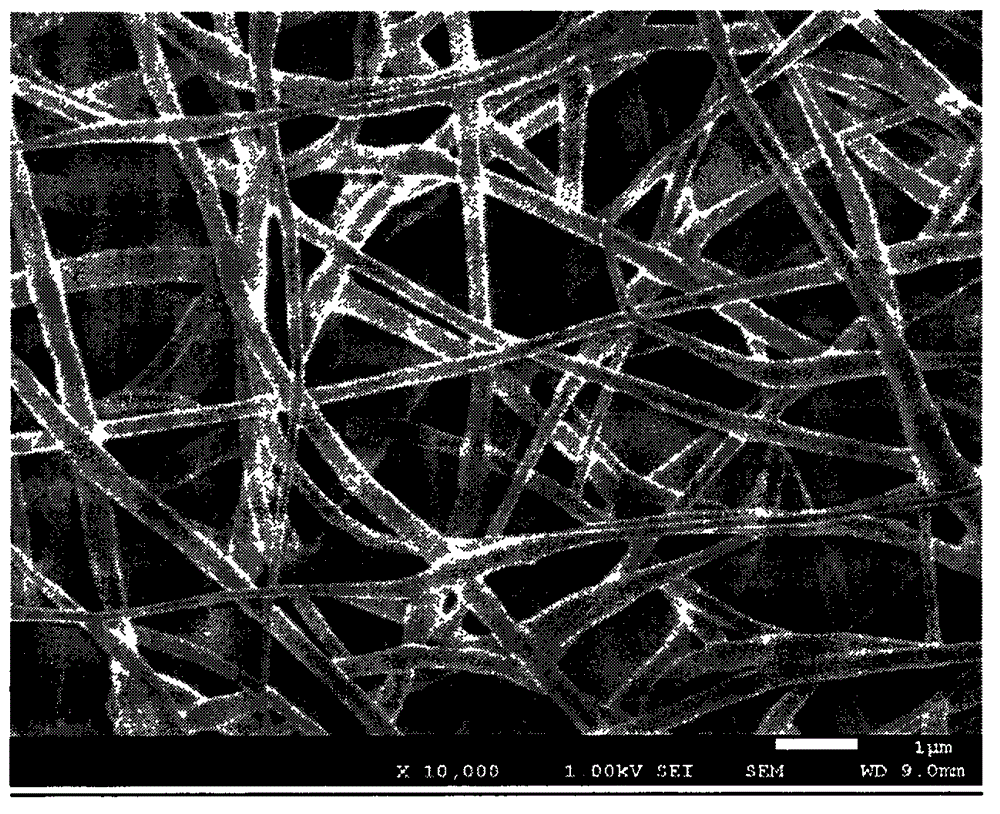

Trans-rubber fiber material, preparation method and applications thereof

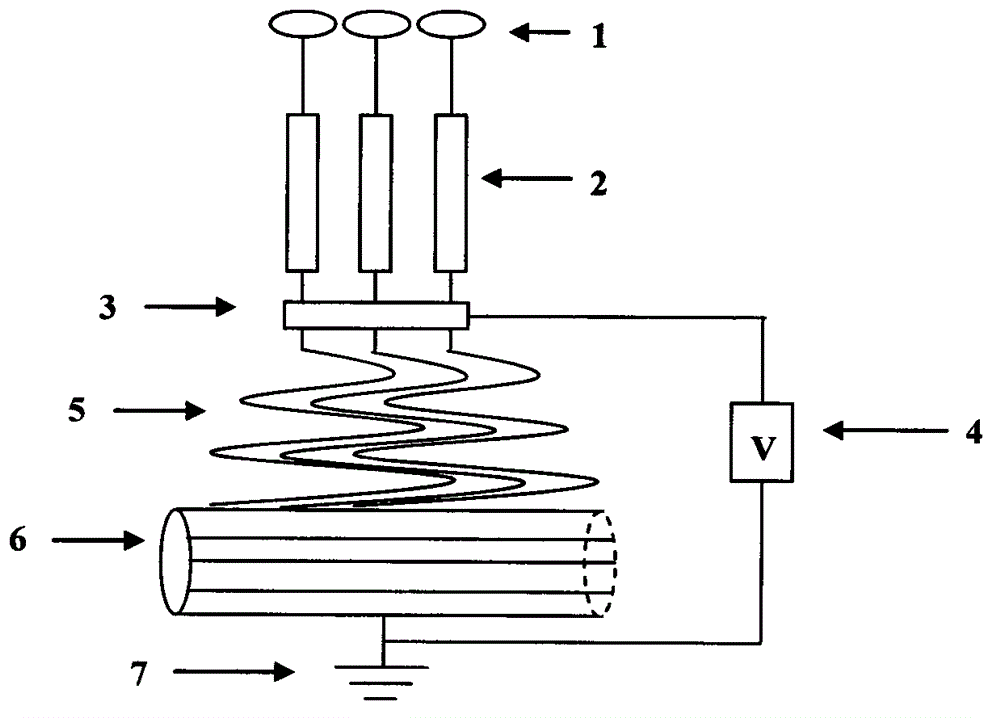

InactiveCN103911766AControl diameterControl speedNew-spun product collectionFilament/thread formingFiberPorosity

The invention provides a trans-rubber fiber material. The trans-rubber is selected from one or more of trans-1, 4-polyisoprene, trans-1, 4-polybutadiene, trans-1, 4-butadiene-isoprene copolymerization rubber, trans-1, 4-butadiene-piperylene copolymerization rubber, trans-1, 4-polydiolefin rubber alloy and trans-1, 4-alkadiene homopolymer and / or homopolymer epoxidation or chlorination modified derivatives and derivatives. The diameter of the trans-rubber is in a range of 100nm to 10 microns. The invention further provides a preparation method and applications of the trans-rubber fiber material. The trans-rubber fiber material has the advantages of being fine in diameter, low in weight, large in specific surface area, large in porosity, small in mass-to-volume ratio, capable of maintaining good fiber morphology after being put for a period and free of fiber dissolving and deformation of other fibers in the prior art.

Owner:QINGDAO UNIV OF SCI & TECH

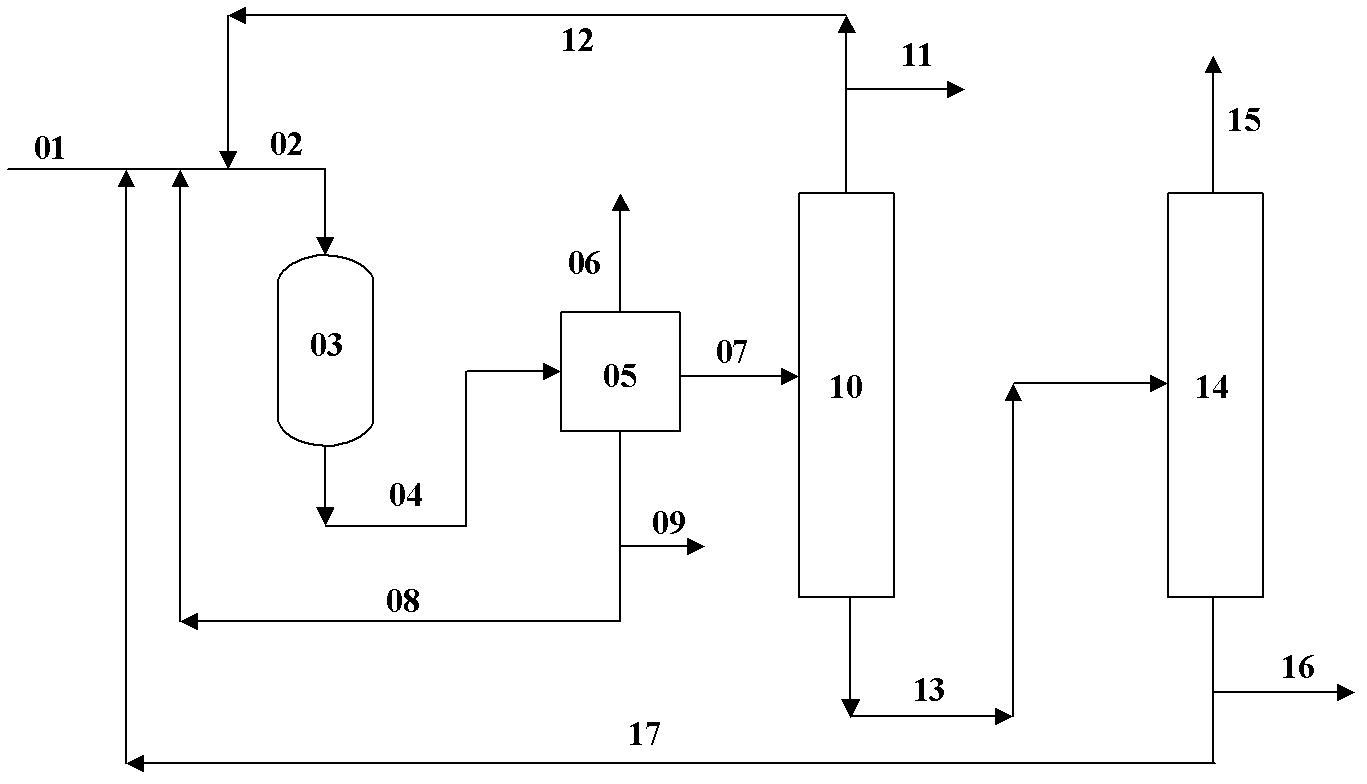

Method for producing ultralow-sulfur cleaning gasoline through full-distilling hydrogen desulfurization of catalytic gasoline

InactiveCN102649914AReduce lossesSimple processTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a method for producing ultralow-sulfur cleaning gasoline through full-distilling hydrogen desulfurization of catalytic gasoline. The method mainly solves the problems of the prior art that the process flow of hydrogen desulfurization of catalytic gasoline is complex, the reaction condition is rigorous, the saturation ratio of the gasoline olefin after being subjected to hydrogen desulfurization is ultrahigh, the loss of octane value is big, and the like. The method comprises the following steps of: firstly, mixing hydrogen with the full-distilling catalytic gasoline, and then entering into a hydrogenation unit; removing alkadiene in the mixture while causing a part of hydrocarbon to perform isomerization reaction; placing a product obtained by pre-hydrogenating into a selective hydrogenating desulfurization unit; removing majority of sulfides in the product by performing the selective hydrogenating desulfurization reaction while maximally protecting the olefin from being saturated; and finally removing the hydrogen sulfide from the gasoline after being subjected to the selective hydrogenating desulfurization by a hydrogen sulfide removing unit, thereby obtaining a cleaning product of gasoline. According to the technical scheme, the problem is more efficiently solved. The method is suitable for the industrial production of the catalytic gasoline with low-sulfur high-octane value.

Owner:江苏佳誉信实业有限公司

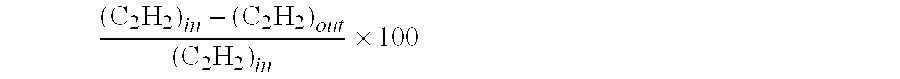

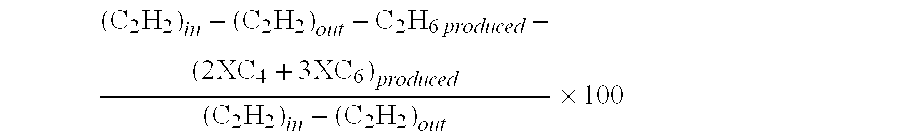

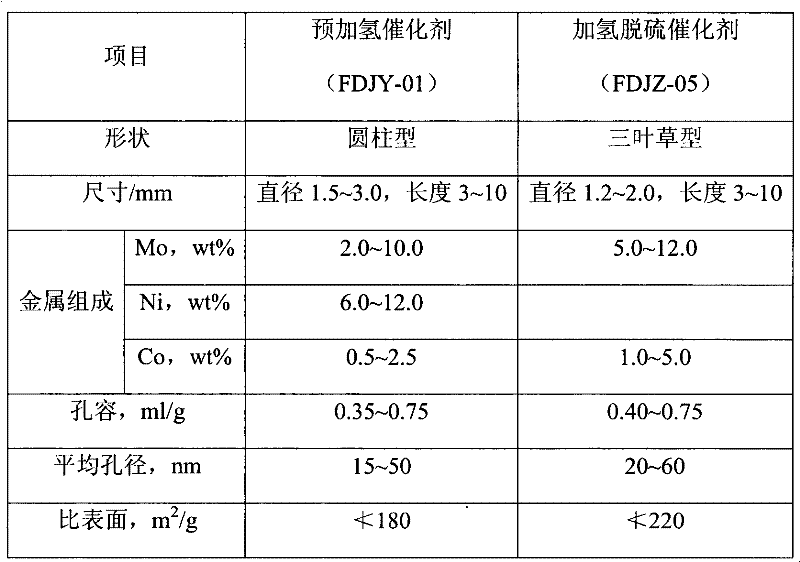

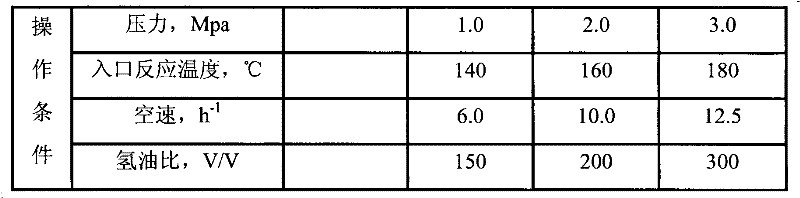

Method for hydrogenation dialkene removal of catalytically cracked gasoline

ActiveCN101323797AImprove hydrogenation activityLower octaneRefining by selective hydrogenationDifferential pressureReaction temperature

The invention relates to a method for catalyzing and cracking gasoline which is added with hydeogen for extracting alkadiene; catalyzed and cracked gasoline distillate with an alkadiene value of 2.56gI.(100g)<-1> is added with the hydrogen for extracting the alkadiene at a reaction temperature of 120 DEG C to 280 DEG C and at a hydrogen differential pressure of 1.0Mpa to 5.0 Mpa, an liquid hourly space velocity of 1.0h<-1> to 20.0h<-1> and volume ratio of hydrogen to oil of 10 to 400; the catalyst takes alumina and Y molecular sieve as composite carriers loading 3.35 percent of cobaltous oxide, 10.03 percent of molybdenum oxide, 0.86 percent of magnesia and 1.01 percent of nickel oxide, and the total weight of the catalyst is 100 percent; atomic ratio of magnesium to cobalt and nickel is 6.8; the average value of the alkadiene of the produced oil is reduced to be less than 0.2gI.(100g)<-1>; the selectivity of extracting the alkadien reaches 95.1 percent; the octane number of the raw oil (RON) is reduced to be not more than 1, monoolefine is reduced to be not more than 3v percent and the average value of the liquid yield of the gasoline is 99.6 mass percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Alkadiene removal method for FCC gasoline light fractions

ActiveCN109468144AImprove anti-glue abilityReduce surface coking processMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsReaction temperatureSilicon oxide

The invention relates to an alkadiene removal method for FCC gasoline light fractions. Gasoline is firstly cut into light and heavy fractions, the cutting temperature is 70 DEG C, the light fractionsof gasoline enter into a reactor to carry out an alkadiene removal reaction, a used catalyst is a nickel-molybdenum hydrogenation catalyst, and the catalyst comprises a silicon oxide-aluminum oxide carrier and metal active components, such as nickel, molybdenum and strontium, loaded on the carrier; and the technological conditions of the reaction are as follows: the reaction temperature is 120 to210 DEG C, the reaction pressure is 1.5 to 3.5 MPa, the airspeed of liquid volume is 1.0 to 25.0 h<-1>, and the volume ratio of hydrogen to oil is (4 to 300): 1. The alkadiene removal method for FCC gasoline light fractions is well-adapted for different raw oil and high in alkadiene removal rate, the catalyst is unlikely to poison, and the catalytic performance is stable.

Owner:博兴兴业精细化工产业发展有限公司

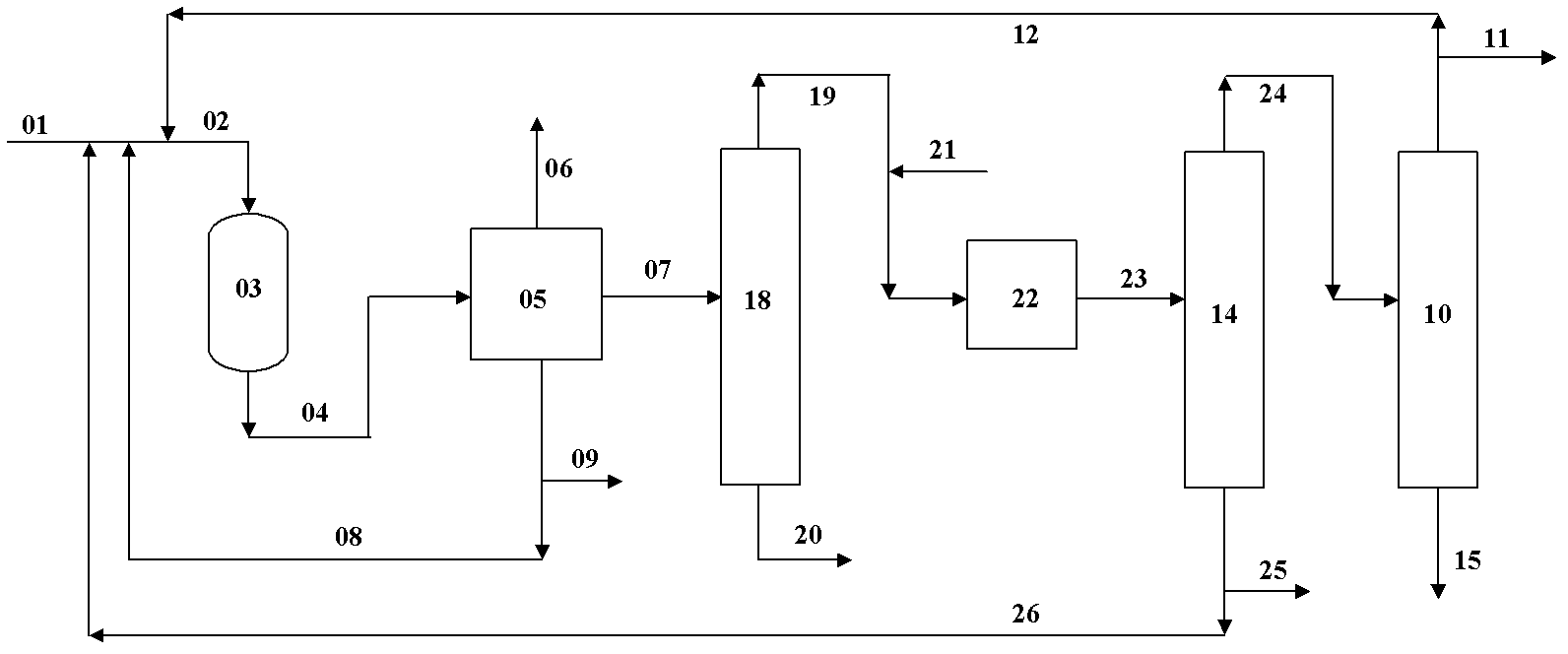

Selective hydrogenation method for C5 fraction of ethylene cracking by-product

ActiveCN102911714ASolve the problem of easy aggregationProblems that affect the life cycleRefining by selective hydrogenationAlkaneAlkadiene

The invention discloses a selective hydrogenation method for C5 fraction of an ethylene cracking by-product. The selective hydrogenation method comprises the following steps of (1) performing selective hydrogenation by using the C5 fraction of the ethylene cracking by-product as a raw material to remove alkadiene and alkyne, wherein catalyst is arranged in 3-5 reaction sections along flow direction of reaction materials; catalyst volume content in each reaction section is increased by 5-30% than that in the former adjacent reaction section successively; the amount of the catalyst in a first section is 8%-20% of a total volume of the catalyst; and the amount of the catalyst in last section is 40%-65% of the total volume of the catalyst; (2) adding a diluent in the raw material, wherein the diluent is a saturated alkane; and (3) adding a polymerization inhibitor selectively in the raw material. The method can remove alkadiene and alkyne from the C5 fraction with high content of alkadiene and alkyne via selective hydrogenation, simultaneously solves the easy coking problem of the catalyst, and can guarantee that a reaction apparatus runs stably for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com