Rare earth catalysis system and application thereof in preparation of conjugated diene liquid rubber

A technology of rare earth catalysis and conjugated dienes, which is applied in the field of catalysts and can solve problems such as rubber difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

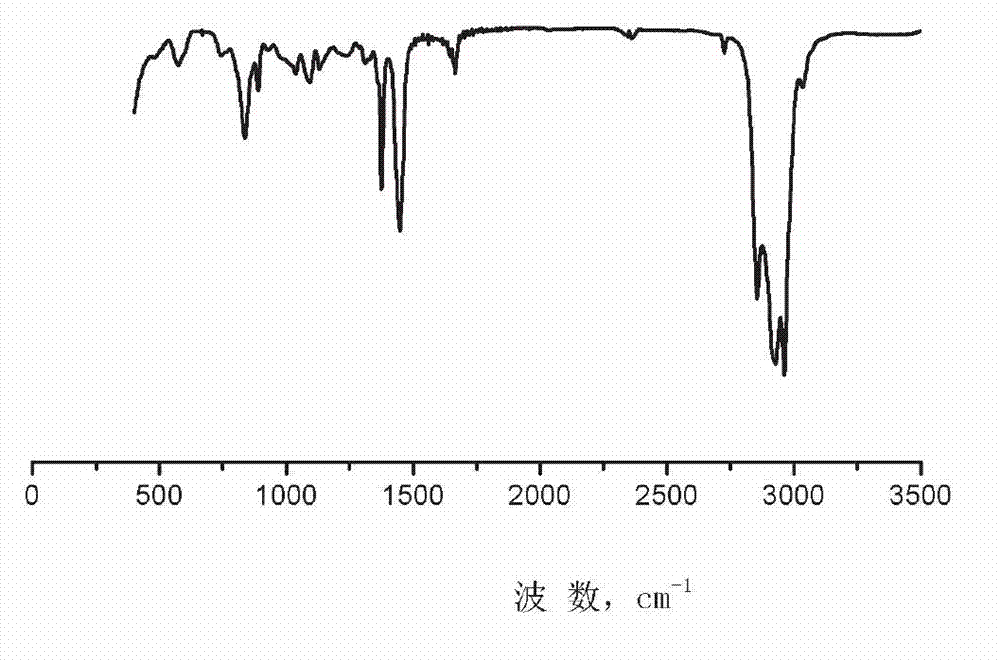

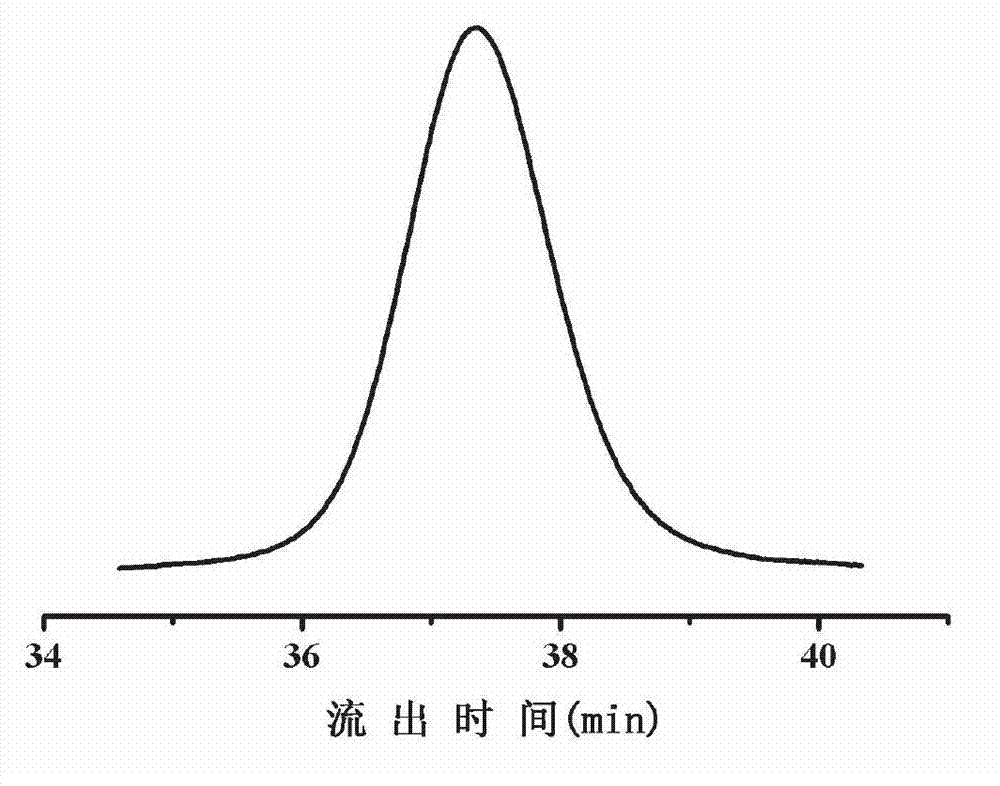

Image

Examples

Embodiment 1

[0036] In the 10mL catalyst reaction bottle filled with nitrogen after vacuum baking, add neodymium isopropoxide (Nd), isoprene (IP) and diisobutylaluminum hydride (Al), dichlorodimethyl Silane (Cl), react in a constant temperature water bath at 20°C for 60 minutes to obtain a homogeneous rare earth catalyst, the molar ratio of [Nd] / [Al] / [Cl] / [IP] in this catalyst is 1 / 10 / 4 / 3 .

Embodiment 2

[0038] In the 10mL catalyst reaction bottle filled with nitrogen after vacuum baking, add lanthanum isopropoxide (La), isoprene (IP) and diisobutylaluminum hydride (Al), carbon tetrachloride ( Cl), react in a constant temperature water bath at 20°C for 60 minutes to obtain a homogeneous rare earth catalyst, and the molar ratio of [La] / [Al] / [Cl] / [IP] in this catalyst is 1 / 10 / 4 / 3.

Embodiment 3

[0040] In the 10mL catalyst reaction bottle filled with nitrogen after vacuum baking, add samarium n-propoxide (Sm), isoprene (IP) and diethylaluminum hydride (Al), dichlorodimethylsilane in sequence (Cl), react in a constant temperature water bath at 60°C for 20 minutes to obtain a homogeneous rare earth catalyst, and the molar ratio of [Sm] / [Al] / [Cl] / [IP] in this catalyst is 1 / 5 / 4 / 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com