Patents

Literature

523results about How to "Improve wet skid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High shock-resistant, wear-resistant sport shoe sole material and manufacturing method thereof

InactiveCN101885865AWide glass transition temperature rangeImprove loss factorSolesActive agentButadiene-styrene rubber

The invention relates to a method for manufacturing a rubber sole material, in particular to a method for manufacturing a medium- and high-grade sport shoe sole with higher requirements on shock resistance and wear resistance. The high shock-resistant, wear-resistant sport shoe sole material consists of butadiene rubber, natural rubber, styrene butadiene rubber, brominated butyl rubber, softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizing agent, a vulcanization accelerator, a tackifier and an age resister. On the basis of the rubbers, the softening oil and the reinforcing agent, a series of the high shock-resistant, wear-resistant shoe sole materials are prepared by screening rubber composition ratio, the coupling agent, the accelerator and an active agent and controlling the process reasonably; and in a dynamic viscoelastic property test, the maximum value of a dissipation factor is 0.3 to 0.5, and the DIN abrasion is less than or equal to 120 mm<3>. The high shock-resistant, wear-resistant shoe sole material has the advantages of alleviation of the shock to a brain during a strenuous exercise, high shock resistance, high wear resistance, improvement on wet skid resistance and increase of comfortableness during the strenuous exercise.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

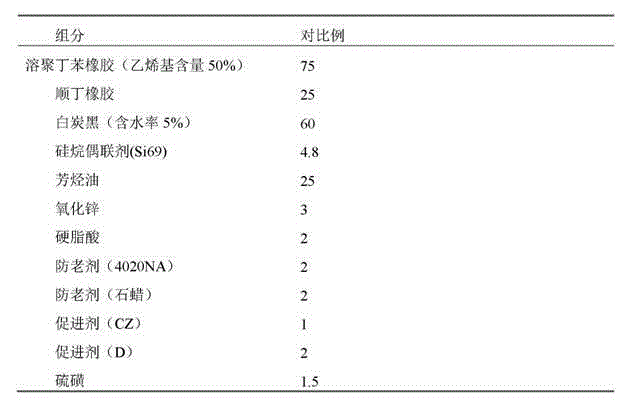

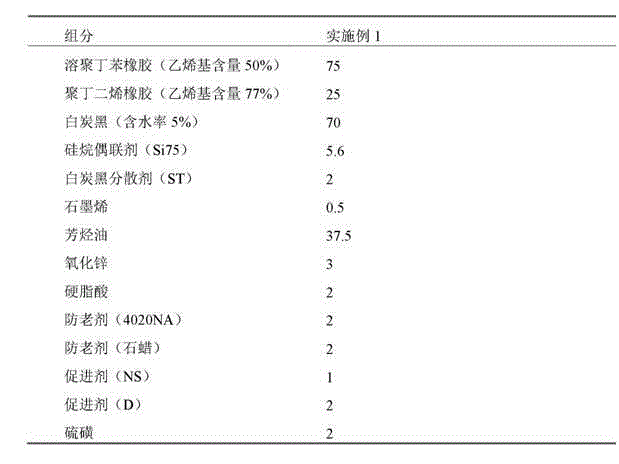

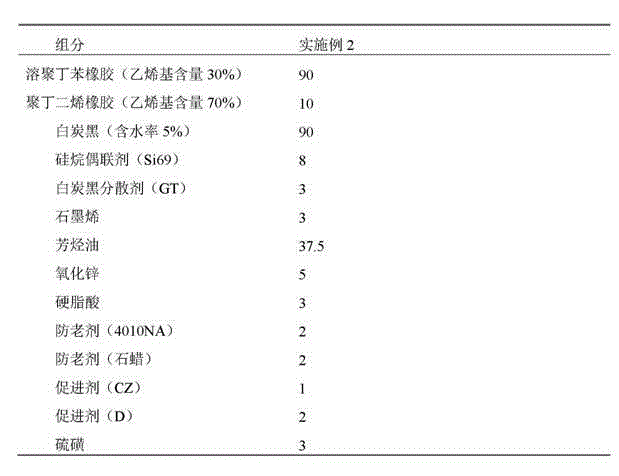

Antistatic low-rolling-resistance tyre tread material and preparation method thereof

ActiveCN102911411AReduce rolling resistanceSolve static electricity accumulationRolling resistance optimizationChemistryButadiene-styrene rubber

The invention relates to the technical field of rubber, in particular to an antistatic low-rolling-resistance tyre tread material and a preparation method thereof. The material is characterized by comprising the following constituents in parts by weight: 40-90 parts of solution polymerized styrene-butadiene rubber, 10-60 parts of polybutadiene rubber, 50-90 parts of white carbon black, 4-8 parts of silane coupling agent, 0.5-3 parts of graphene, 1-3 parts of white carbon black dispersing agent, 10-37.5 parts of aromatic oil, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4 parts of anti-aging agent, 2-4 parts of accelerant and 1-3 parts of sulphur. Sizing materials are mixed by an internal mixer, the rotor speed, the sizing material mixing time and the temperature are controlled, and a composite material is prepared by the four-section mixing method. The rolling resistance of a tyre can be reduced; more importantly, the problem that the white carbon black filling tread composite material has static accumulation is solved by using the graphene; and the wet-skid resistance and the abrasion resistance of a tyre tread of a passenger vehicle can be improved.

Owner:BEIJING UNIV OF CHEM TECH

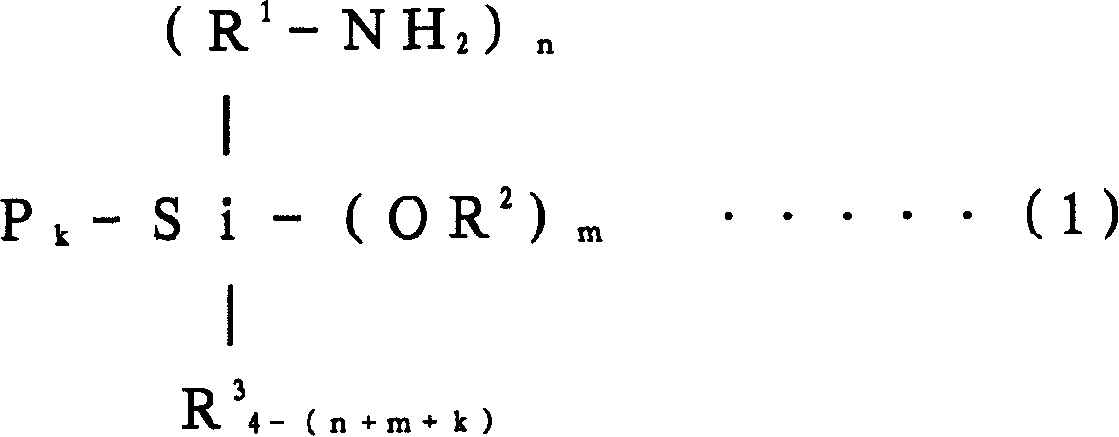

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

InactiveCN1578790ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

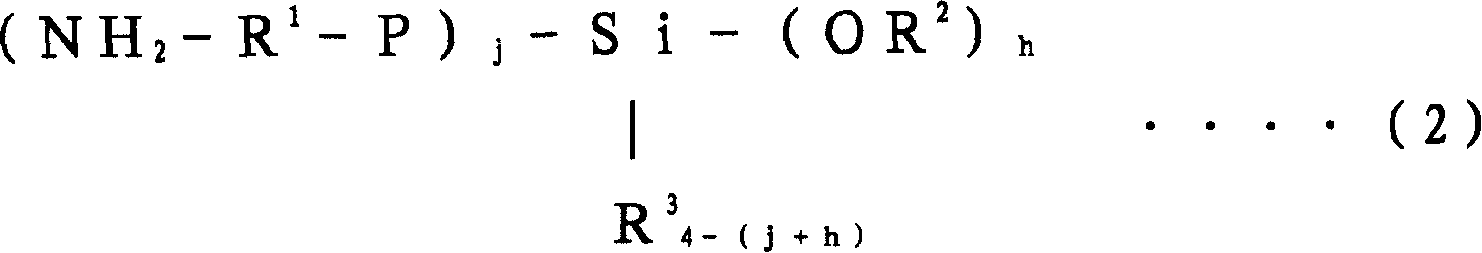

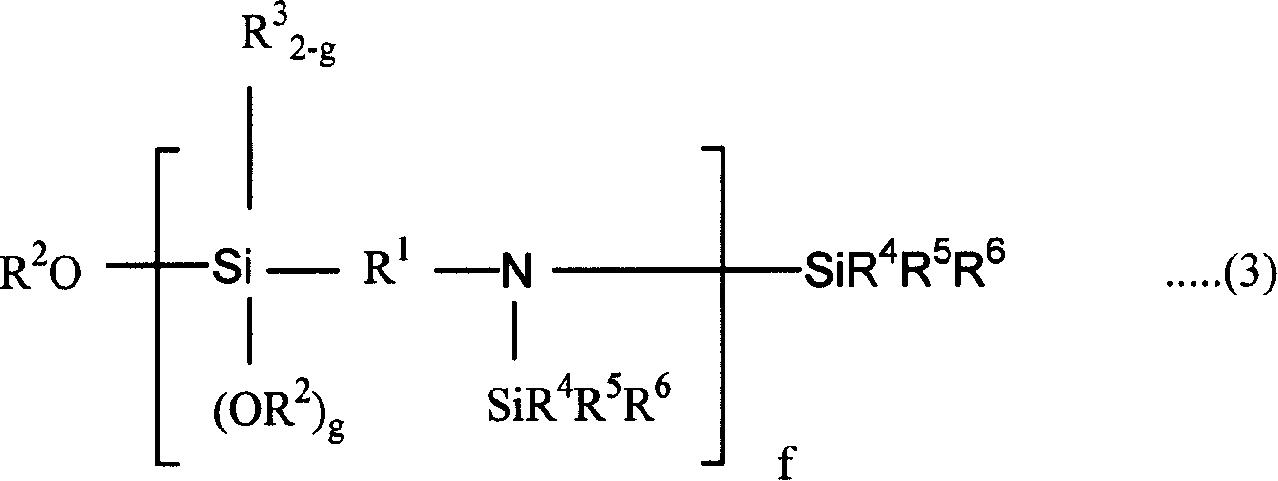

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

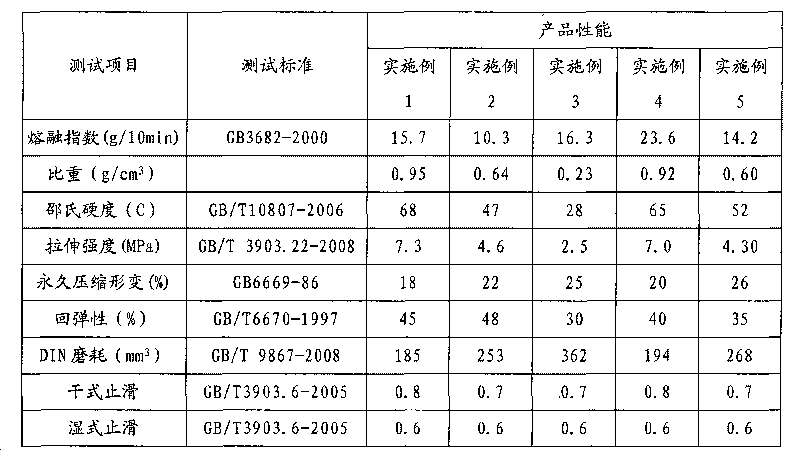

High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

ActiveCN103059470AImprove wear resistanceImprove wet skid resistancePolymer sciencePolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and a preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials. The modified materials comprise following raw materials, by weight, 80-120 parts of PVC resin, 5-15 parts of stuffing bulking agents, 31-70 parts of plasticizer, 1-10 parts of abrasion resistant modifying agents, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 10-20 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to the weight and are blended, after the raw materials are stirred, the stirred raw materials are extruded to be granulated into particles through a double-screw extruder to produce the modified materials. The prepared modified materials are good in abrasion resistant property, environment-friendly, high in strength, good in flame retardant efficiency, strong in compression property and toughness, good in processing property, and good in comprehensive property. The preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials is simple in craft, convenient to operate and control, stable in quality and high in production efficiency and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

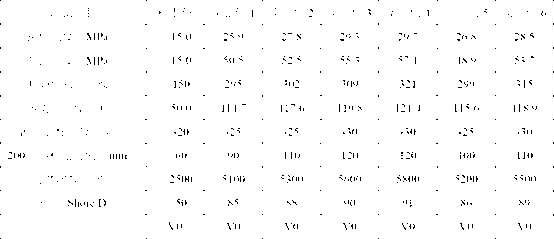

Styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, preparation method and application method thereof

The invention discloses a styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, a preparation method and an application method thereof. The preparation method takes styrene-butadiene copolymer mixing random structure with block structure as base material, and adds flow modifier or softener to regulate the fluidity of rubber. Rubber compositions manufactured by the method have good fluidity and can be molded directly through injection. Chemical foaming agents added reduces product density and effectively achieves the aim of obtaining lightweight material. Post partial chemical crosslinking can be performed so as to improve the stress cracking resistance and wear resistance of the material. Meanwhile, as the partial physical crosslinking of the styrene-butadiene copolymer allows the material to overcome the defect that all-chemical crosslinked rubber cannot be regenerated, the material can be recycled and regenerated.

Owner:浙江仕峰实业有限公司

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

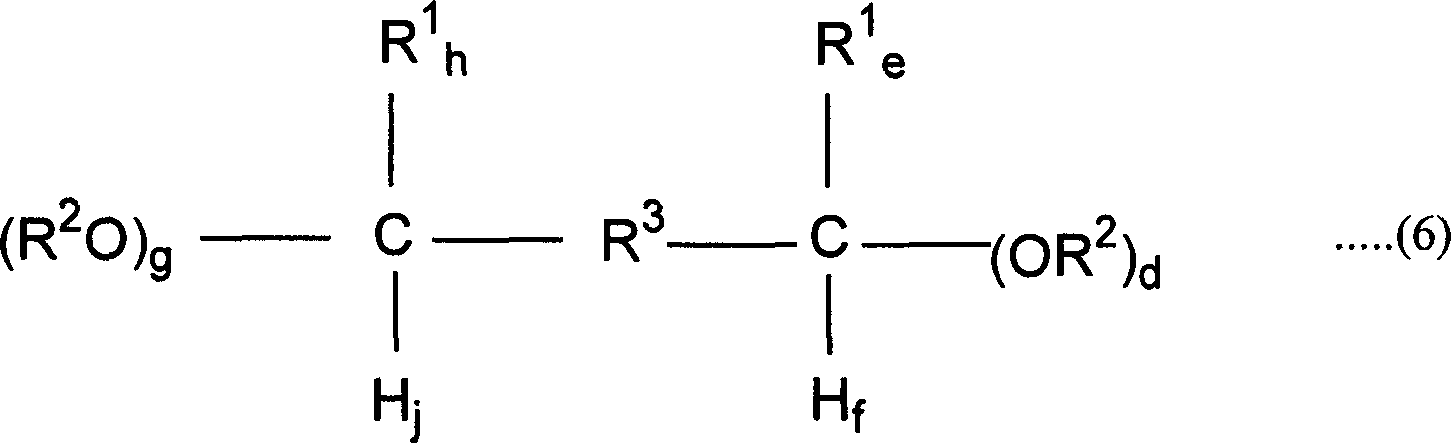

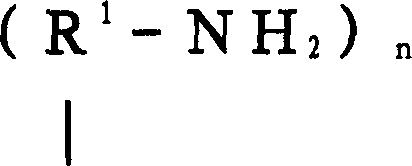

InactiveCN1789293ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationPolymer scienceAlkoxy group

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reinforcing performance of tread rubber of lorry tyre by resin acceptor modified white carbon black

InactiveCN101555363AImprove compactnessImprove mechanical propertiesPigment treatment with organosilicon compoundsPolymer scienceHardness

The invention relates to a method for reinforcing performance of a tread rubber of a lorry tyre by resin acceptor modified white carbon black, belonging to the technical field of nanometer material modified rubber process. The method comprises the following steps that: nanometer white carbon black is dried to remove moisture in vacuum at 120 DEG C, and is subjected to surface treating of a resin acceptor, wherein the dosage of the resin acceptor is 1 to 10 percent of the nanometer white carbon black powder by weight; on the basis of maintaining the prior production formula and the production flow of rubber, the nanometer white carbon black composite powder modified by the resin acceptor with 20 to 30 percent of unvulcanized rubber by weight is added in the process of mixing rubber. Testing results prove that after addition of the composite nanometer white carbon black, the tread rubber of the lorry tyre is greatly improved in tensile strength, tearing strength, hardness and the like.

Owner:SHANGHAI UNIV

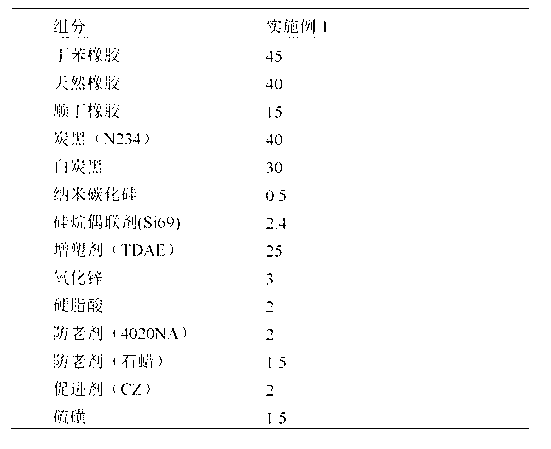

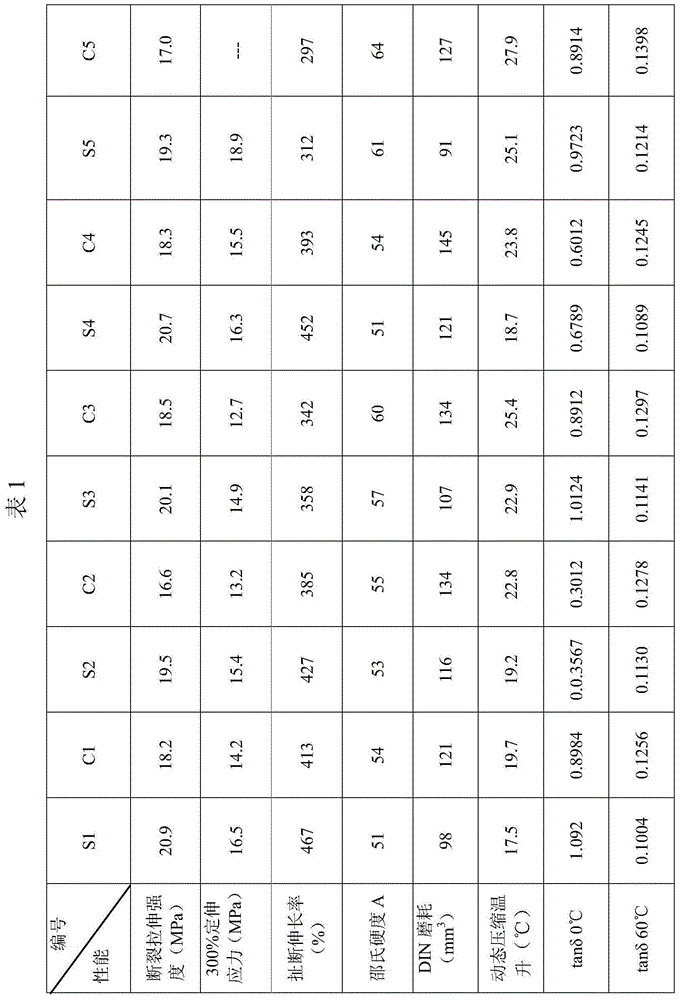

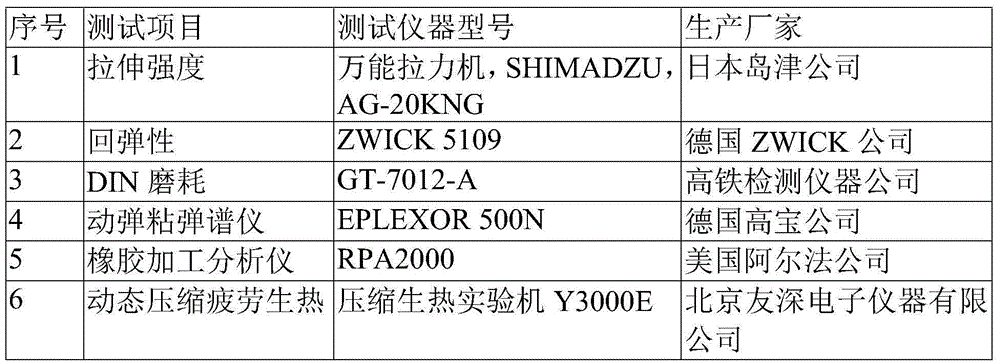

Tire tread material with high wet and skid resistance and preparation method of material

ActiveCN103159998AImprove wet skid resistanceReduce rolling resistanceRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of rubber and particularly relates to a preparation method of a tire tread composite material with high wet and skid resistance. The composite material is characterized by containing the following materials in parts by weight: 100 parts of dienes rubber (concretely including styrene butadiene rubber, butadiene rubber, natural rubber, integrated rubber and a composite of the integrated rubber), 50-80 parts of stuffing (concretely including carbon black, white carbon black and a composite of the white carbon black), 0-6.4 parts of silane coupling agent, 0.5-3 parts of silicon carbide,10-40 parts of plasticizer, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4 parts of anti-aging agent, 2-4 parts of accelerant and 1-3 parts of sulphur. By adoption of the material prepared by the method, the rolling resistance of a tire can be reduced, the wear-resisting property of the tire tread is not affected simultaneously, and especially, the wet and skid resistance of the tire is greatly increased by utilizing the nano silicon carbide material.

Owner:BEIJING UNIV OF CHEM TECH

Gross rubber for high wearable tyre and its prepn.

InactiveCN1834140AExcellent abnormal temperature crystallization performanceIncrease stressSpecial tyresVulcanizationPolymer science

This invention relates to a kind of high wear-resistant tyre rubber and its preparation method. Eucommia ulmoides gum is blended with natural rubber, styrene-butadiene rubber, nitrile-butadiene rubber and cis-1, 4-polybutadiene rubber and vulcanized; and by varying the ratio of eucommia ulmoides gum to rubber additive 1 and eucommia ulmoides gum to rubber additive 2 in the ingredients, high wear-resistant tyre rubber is obtained. It has the technique characteristics of eucommia ulmoides gum, rubber additive 1, rubber additive 2, sulphur-containing enhancer and antioxidant. The preparation method is that, raw materials according to the ingredients mentioned above is blended in a double-roller machine for common rubber processing at a temperature of 50~80 deg. C and heated on a plate vulcanization machine to produce the desired high wear-resistant tyre rubber. It has the advantages of abundant raw materials source and simple preparation method. The obtained rubber is uniquely of extraordinary wear resistance and little rolling friction. It also has low dynamic compression heat, good fatigue resistance and skid resistance and comprehensive properties for tyre driving, and is a perfect kind of tyre materials for aviation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Oil-proof antiskid rubber sole and preparation method thereof

ActiveCN104277274AImprove wear resistanceImprove wet skid resistanceSolesPolymer scienceVulcanization

The invention relates to a sole, and discloses an oil-proof antiskid rubber sole and a preparation method thereof. The oil-proof antiskid rubber sole comprises: butadiene-acrylonitrile rubber, epoxidized rubber, brominated butyl rubber, nanosilicon dioxide, a plasticizer, an antiaging agent, a white smoke activator, a silane coupling agent, polyethylene wax, zinc oxide, sulfur and a vulcanization accelerant. Compared with the prior art, by adopting the epoxidized rubber as base rubber and combining the butadiene-acrylonitrile rubber with high acrylonitrile content, the sole is excellent in oil-proof property, has good antiskid performance on the oil-polluted interfaces, can keep excellent wear-resistant property while having high oil-proof and antiskid properties, and is wide in application range including places such as ships, petrochemical plants, motor car repair shops, oil plants where oil is accumulated or splashes, the oil-proof antiskid rubber sole can protect people who walk and work on oil dirt areas from difficultly falling down, and the oil-proof antiskid rubber sole is simple in production procedures, easy in industrial production and has good market prospects.

Owner:MAOTAI FUJIAN SOLES CO LTD

Method for preparing reactive nano calcium carbonate-native rubber composite material

The invention provides a preparation method for a reactive nanometer calcium carbonate-natural rubber composite material, which is characterized in that, the nanometer calcium carbonate or proper amount of coupler or anionic surfactant is added to deionized water to be stirred and ultrasonically dispersed, and then proper amount of emulsion epoxidized natural rubber is added to be continuously stirred and ultrasonically dispersed to prepare nanometer calcium carbonate aqueous dispersion; meanwhile, proper amount of non-ionic surfactant is used for stabilizing the proper amount of emulsion natural rubber; the nanometer calcium carbonate aqueous dispersion is uniformly mixed to the emulsion natural rubber under the condition of continuous stirring; the unsaturated carboxylic acid neutralizing solution with the pH value adjusted by potassium hydroxide and a triggered cross linker are dropped into the mixture under 60 DEG C of water bath condition to obtain the latex-stated nanometer calcium carbonate-natural rubber composite material. The vulcanizing film of the composite material can reach 25-30MPa of tensile strength, 800-950 percent of maximum elongation and 3.5-6.0MPa of 300 percent stretching stress.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

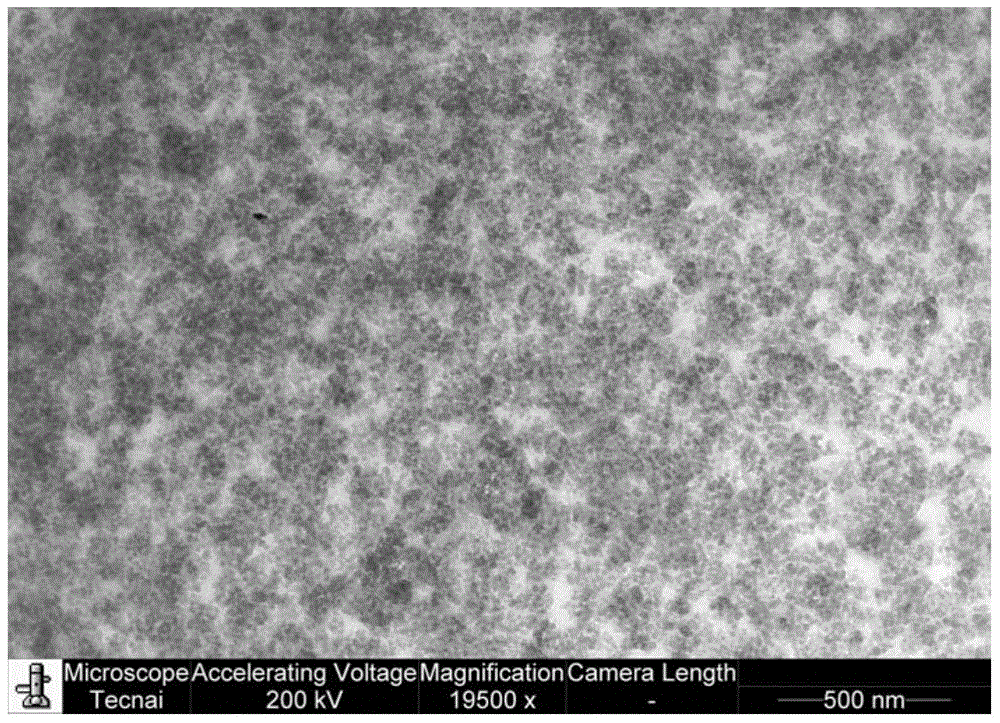

Nanometer composite material and preparation method thereof, vulcanized rubber and applications thereof

InactiveCN105368097AGood dispersionGood compatibilitySpecial tyresPigment treatment with organosilicon compoundsMaterials preparationWear resistance

The present invention discloses a nanometer composite material and a preparation method thereof, the nanometer composite material prepared through the method, and a vulcanized rubber containing the nanometer composite material and applications thereof. According to the present invention, the nanometer composite material contains white carbon black, graphene oxide, and a surface modifier attached onto the surface of the white carbon black and / or graphene oxide; the nanometer composite material preparation method comprises uniformly mixing the white carbon black and the graphene oxide in water, carrying out spray drying to obtain a solid, mixing the obtained solid and the surface modifier, and drying; the present invention further provides the vulcanized rubber and applications of the vulcanized rubber in tire material preparation, wherein the mixture containing the nanometer composite material, a raw material rubber, a vulcanizing agent and an accelerator is subjected to mixing and vulcanizing to form the product, ie., the vulcanized rubber; the nanometer composite material has excellent dispersion property and excellent compatibility; and the vulcanized rubber has characteristics of good tensile property, good abrasion resistance and good dynamic mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

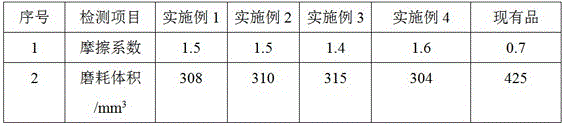

High-anti-slippery abrasion-resistant material for shoes and preparation method thereof

ActiveCN105778172AIncrease internal resistanceImprove mechanical propertiesSolesCarbide siliconOrganosilicon

The invention discloses a high-anti-slippery abrasion-resistant material for shoes and a preparation method thereof.The high-anti-slippery abrasion-resistant material is prepared from, by weight, 20-40 parts of natural rubber, 20-40 parts of styrene-butadiene rubber, 20-40 parts of butadiene rubber, 15-25 parts of halogenated butyl rubber, 20-30 parts of nanometer calcium carbonate, 10-20 parts of rubber oil, 10-20 parts of white carbon black, 3-8 parts of an activator, 3-5 parts of silicon carbide, 2-4 parts of organic siloxane, 1-5 parts of an accelerant, 1-3 parts of an antiager, 1-3 parts of sulfur and 0.5-1.5 parts of stearic acid.The raw materials required by the prepared high-anti-slippery abrasion-resistant material for the shoes are low in price and easy to obtain, the preparation process is simple, the strength is high, the anti-slippery performance is good, the abrasion-resistant performance and processing performance are excellent, the friction coefficient is 1.4-1.6, the friction volume is 304-315 / mm<3>, and the material can be used for production of high-anti-slippery abrasion-resistant shoe soles and other auxiliary materials.

Owner:QUANZHOU JIYOU SHOES CO LTD

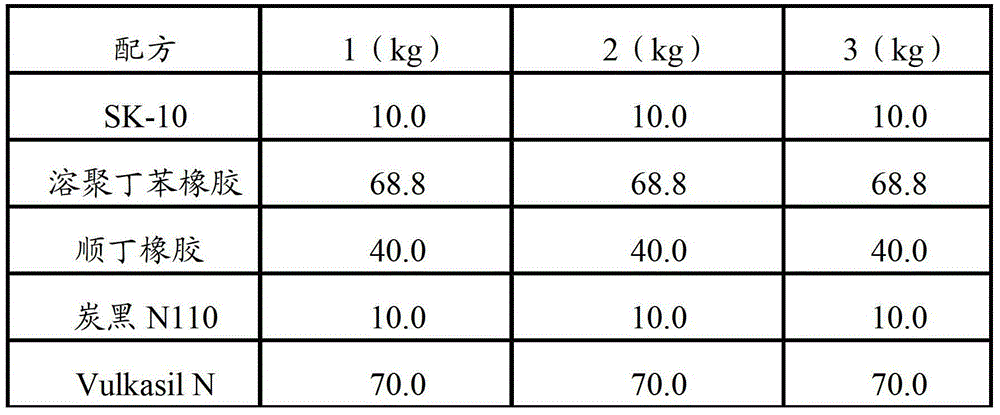

Rubber composition and preparation method thereof, and vulcanized rubber

The present invention discloses a rubber composition and a preparation method thereof, and a vulcanized rubber. The rubber composition preparation method comprises: (1) carrying out first mixing on solution polymerized styrene-butadiene rubber, white carbon black, a surface modifier and an optional cis-polybutadiene rubber to prepare white carbon black rubber master batch; (2) carrying out second mixing on the white carbon black rubber master batch, an activator, an anti-aging agent, a softening agent and an optional carbon black to prepare a second-stage rubber master batch; and (3) carrying out third mixing on the second-stage rubber master batch, an accelerator and a vulcanizing agent to obtain the final mixed rubber. According to the present invention, in the processing process, the effect of the surface modifier can be well provided, the complete interaction between the white carbon black and the polymer can be easily achieved, the strength of the vulcanized rubber prepared through the vulcanization can be improved, the heat generation of the vulcanized rubber can be reduced, and the wet skid resistance of the vulcanized rubber can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

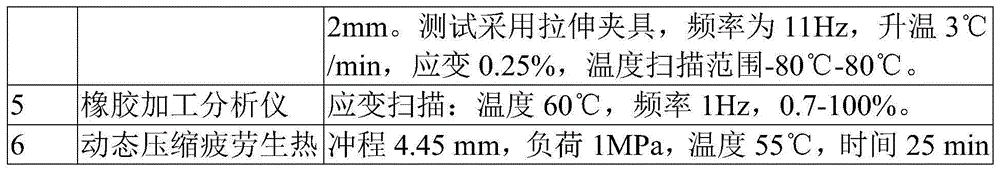

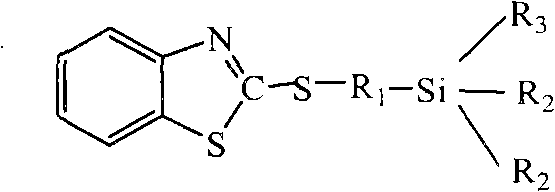

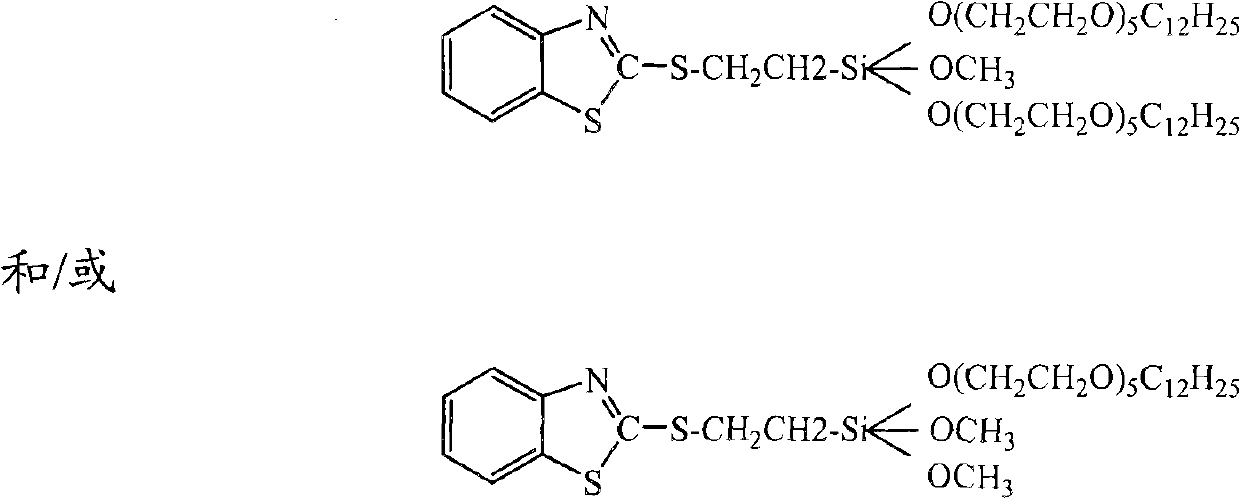

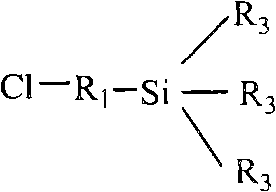

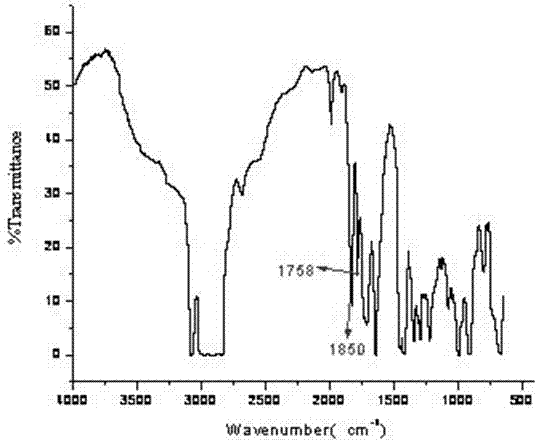

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Master batch and preparation method thereof, and vulcanized rubber and applications thereof

ActiveCN103159994AReduce rolling resistanceGood wet skid resistanceSpecial tyresRolling resistance optimizationSilane couplingCarbon black

The invention provides a master batch and a preparation method thereof. The method comprises the following steps that: (1) under a condensation condition, white carbon black contacts a silane coupling agent; (2) a layered silicate mineral, a quaternary ammonium salt and water are mixed and dried; (3) the product obtained from the step (2) and a rubber liquid obtained through solution polymerization are mixed to obtain a suspension, wherein the rubber liquid comprises a polymer and a first organic solvent; and (4) the contacting product obtained from the step (1) and the suspension obtained from the step (3) are mixed and dried. The present invention further provides a vulcanized rubber and applications of the vulcanized rubber in tire preparation, wherein the vulcanized rubber is prepared by carrying out mixing and vulcanization on a mixture, and the mixture comprises the master batch, a vulcanizing agent, a vulcanization activator, an accelerator and an anti-aging agent. With the present invention, the obtained vulcanized rubber has characteristics of low rolling resistance, good wet skid resistance and excellent abrasion resistance, wherein rolling resistance, fuel consumption and the like of the tire prepared by the vulcanized rubber can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

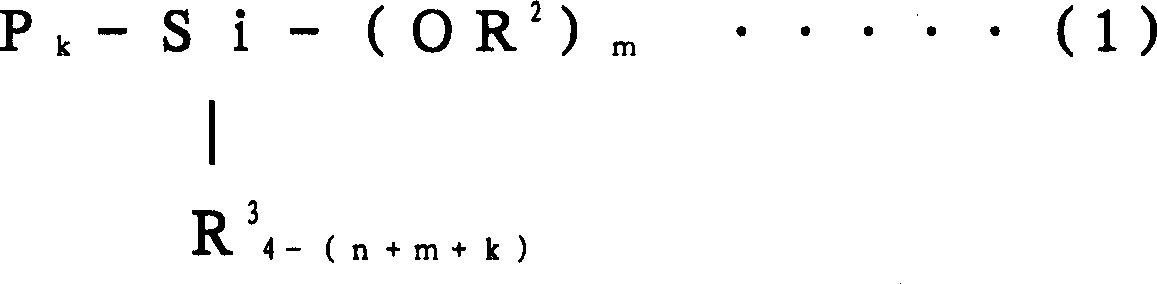

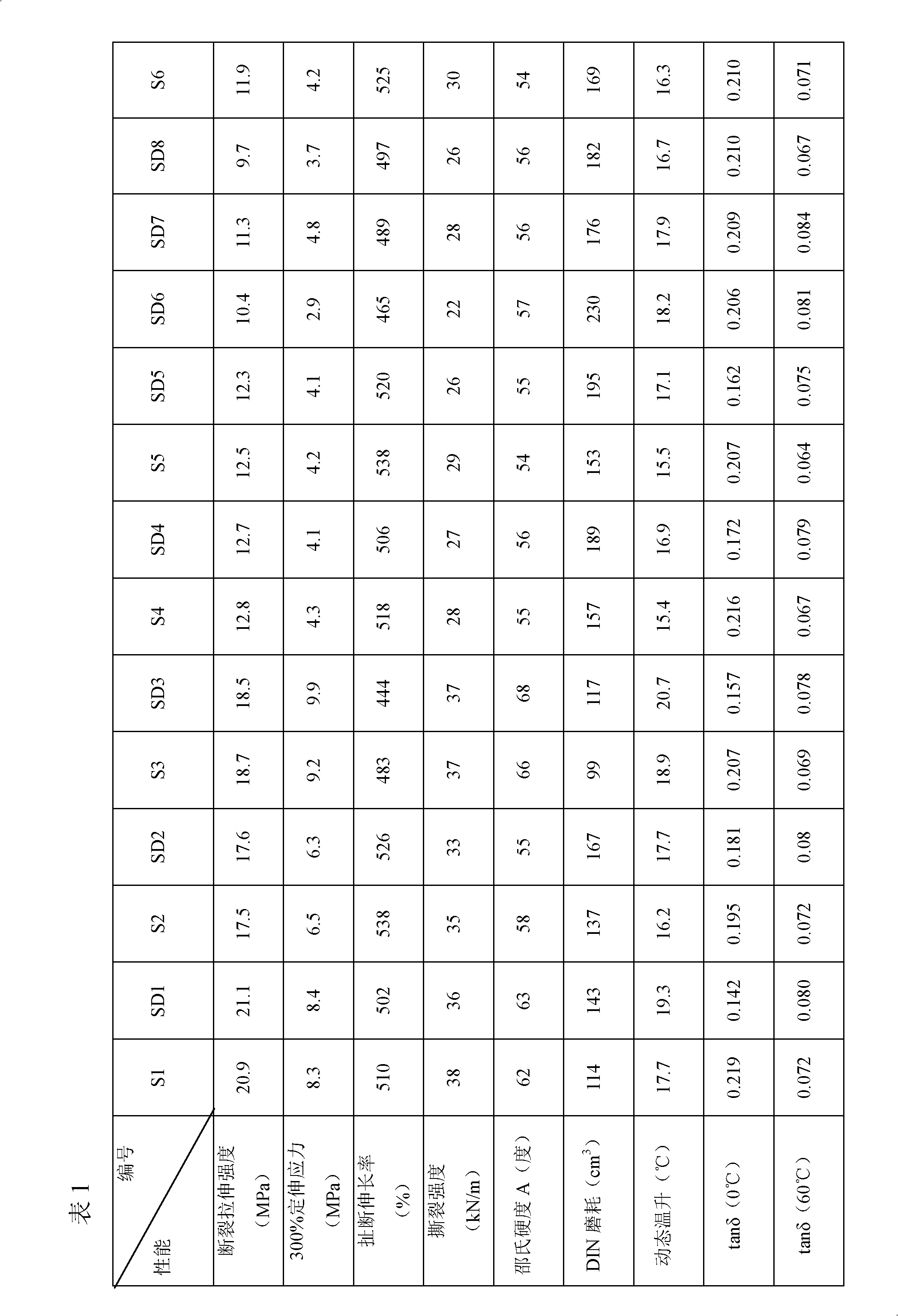

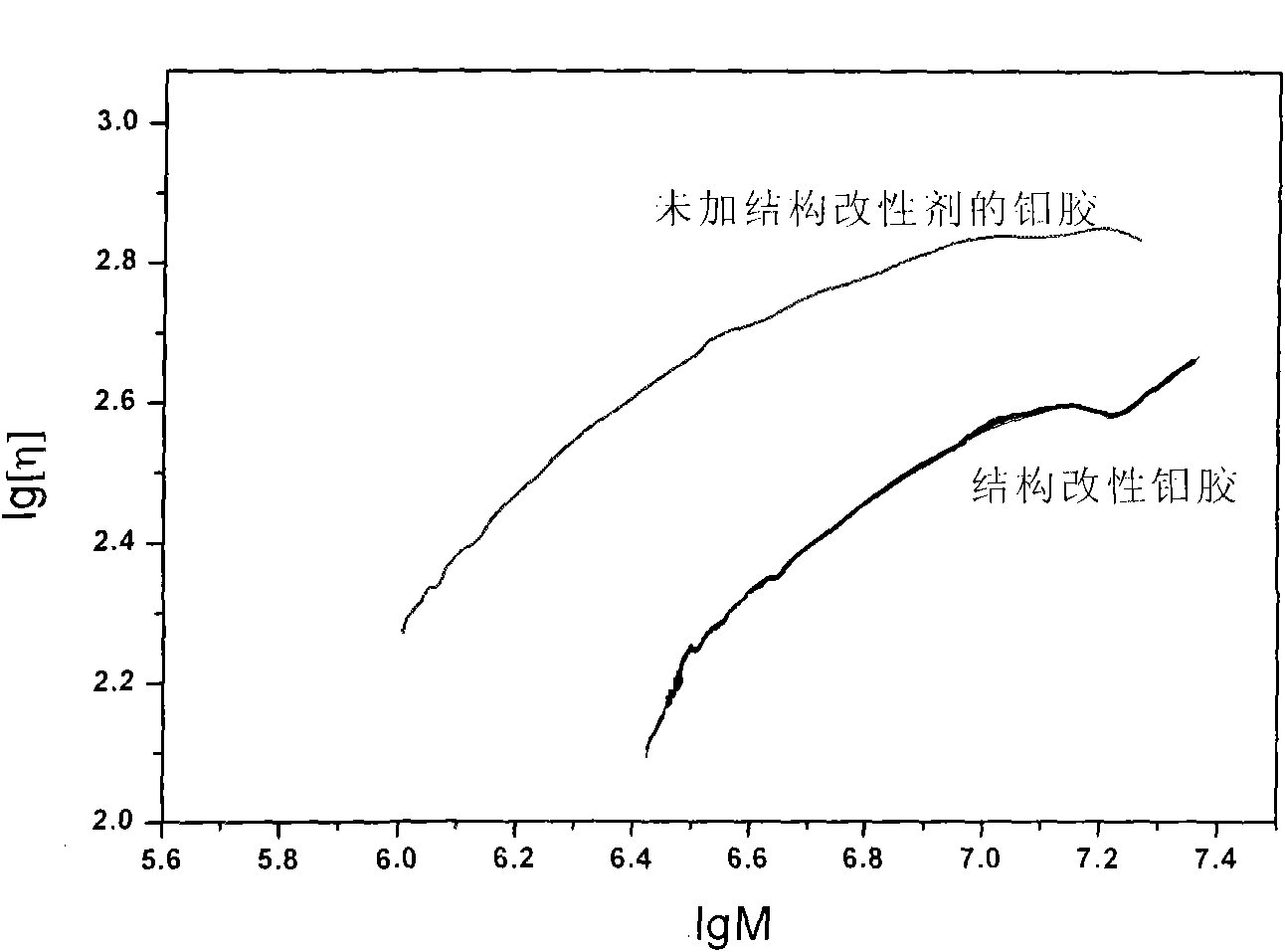

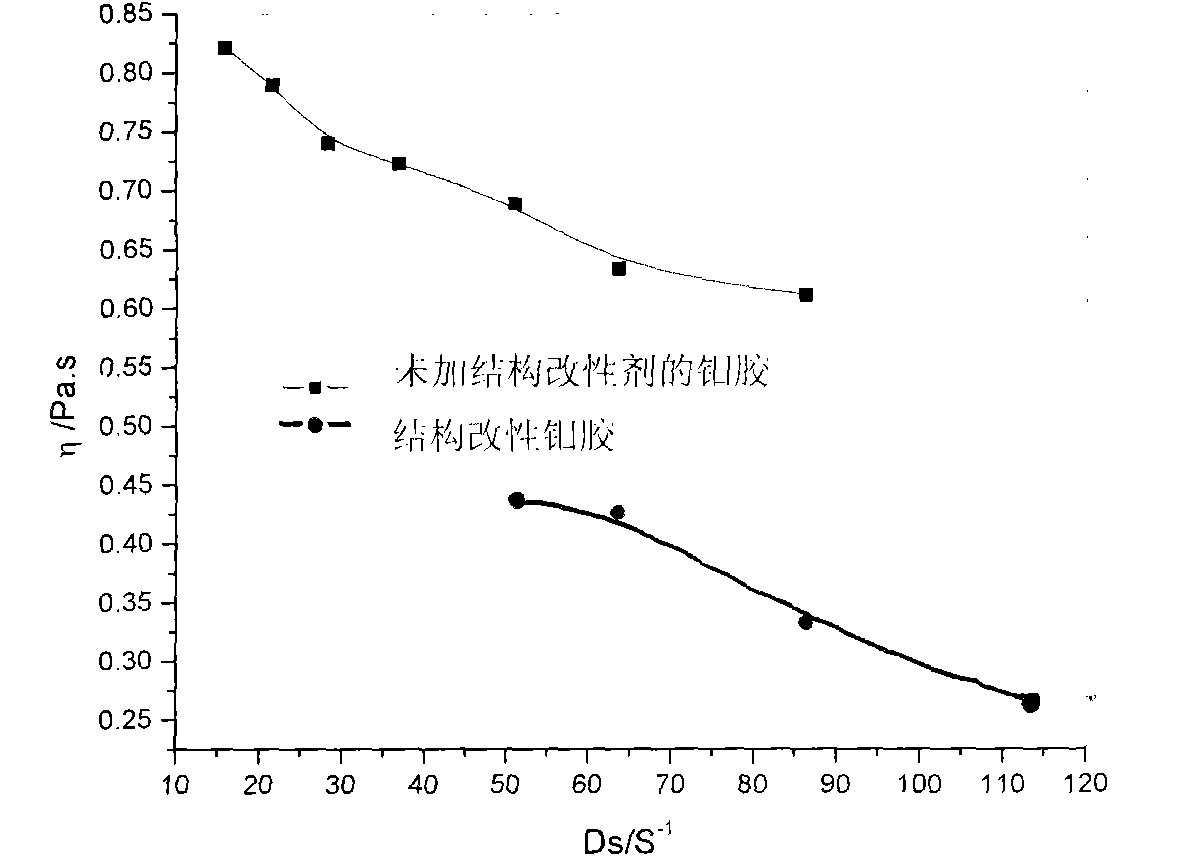

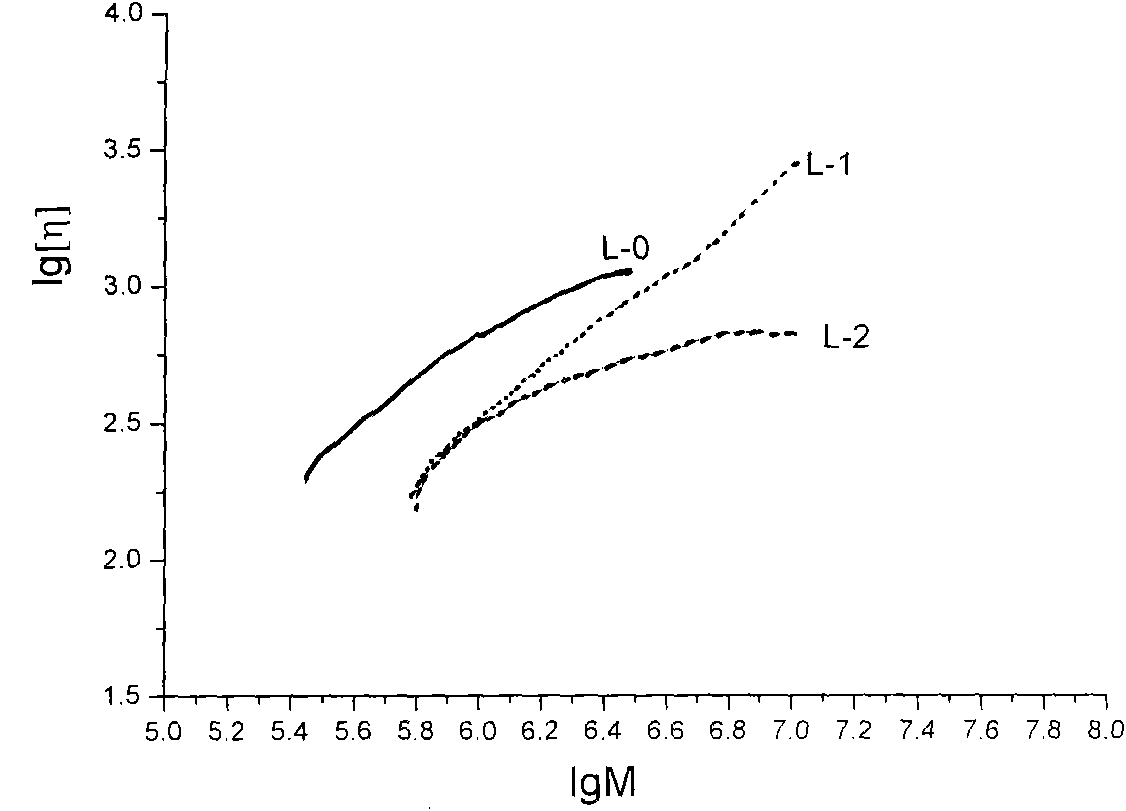

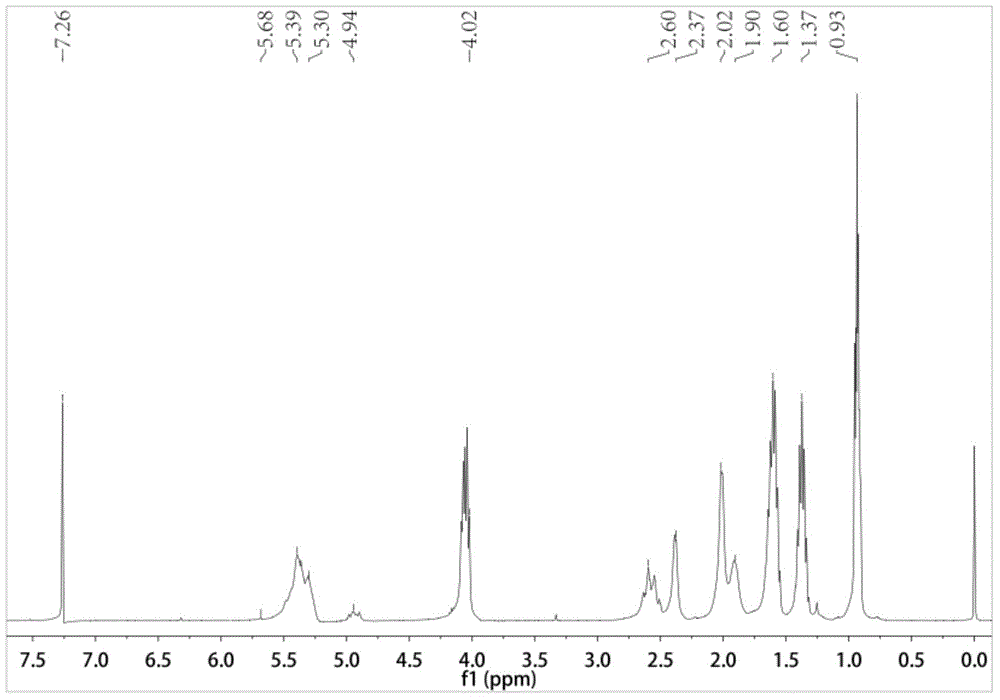

Preparation method of structure-modified 1,2-polybutadiene rubber

The invention relates to a preparation method of structure-modified 1,2-polybutadiene rubber, belongs to a macromolecular compound obtained by carbon-carbon unsaturated bond reaction, relates to a preparation method of butadiene homopolymers, and is characterized by comprising (1) raw materials used; (2) the preparation method of the structure-modified 1,2-polybutadiene rubber; (3) a preparation method of mixed stock of the structure-modified 1,2-polybutadiene rubber. The invention provides a molybdenum catalyst system which can substantially raise the activity of the catalysis system, reduce the molecular weight of a polymerization product, widen molecular weight distribution and decrease the polymerization glue solution viscosity, and simultaneously also provides a structure modifier for improving cold-flow performance and processability of a polymer and wet traction and aging resistance of vulcanized rubber and greatly increasing the service life of the rubber by generating a branched structure of the polymer, so as to realize the industrial preparation method of the structure-modified 1,2-polybutadiene rubber product by molybdenum catalytic synthesis.

Owner:CHINA PETROLEUM & CHEM CORP

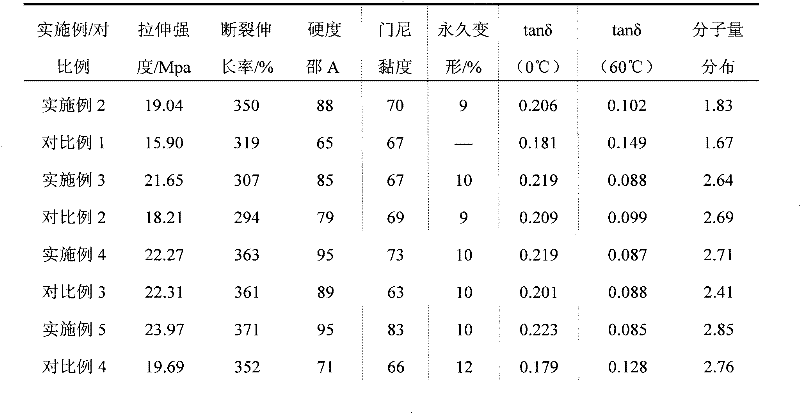

Itaconate/butadiene copolymer type bioengineering rubber and preparation method thereof

ActiveCN104945817AImprove mechanical propertiesImprove wet skid resistanceConveyorsSpecial tyresPolymer scienceEmulsion polymerization

The invention discloses itaconate / butadiene copolymer type bioengineering rubber and a preparation method thereof, and belongs to the field of bioengineering rubber. The bioengineering rubber provided by the invention is formed by performing chemical crosslinking on a copolymer formed through emulsion polymerization of itaconate and butadiene, the number-average molecular weight of the itaconate / butadiene copolymer is 53000-1640000, and the weight-average molecular weight of the itaconate / butadiene copolymer is 110000-2892000. The preparation method comprises the following steps: an itaconate monomer and butadiene are subjected to emulsion polymerization to prepare the itaconate / butadiene copolymer; then, the itaconate / butadiene copolymer is subjected to the chemical crosslinking to prepare the bioengineering rubber, wherein the chemical crosslinking process can be implemented by adding a traditional sulfuration / accelerant sulfuration system. The bioengineering rubber provided by the invention is high in molecular weight and low in glass-transition temperature, can be sulfurized by the sulfuration / accelerant sulfuration system, is enabled to have the physical and mechanical properties and processing performance equivalent to those of the conventional synthetic rubber, and can meet the requirements for engineering application such as tire treads and conveyor belts.

Owner:BEIJING UNIV OF CHEM TECH

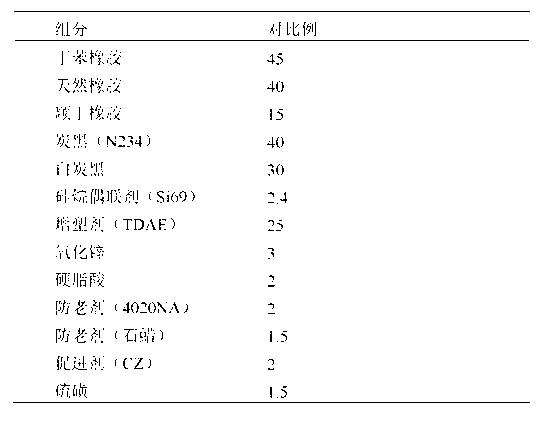

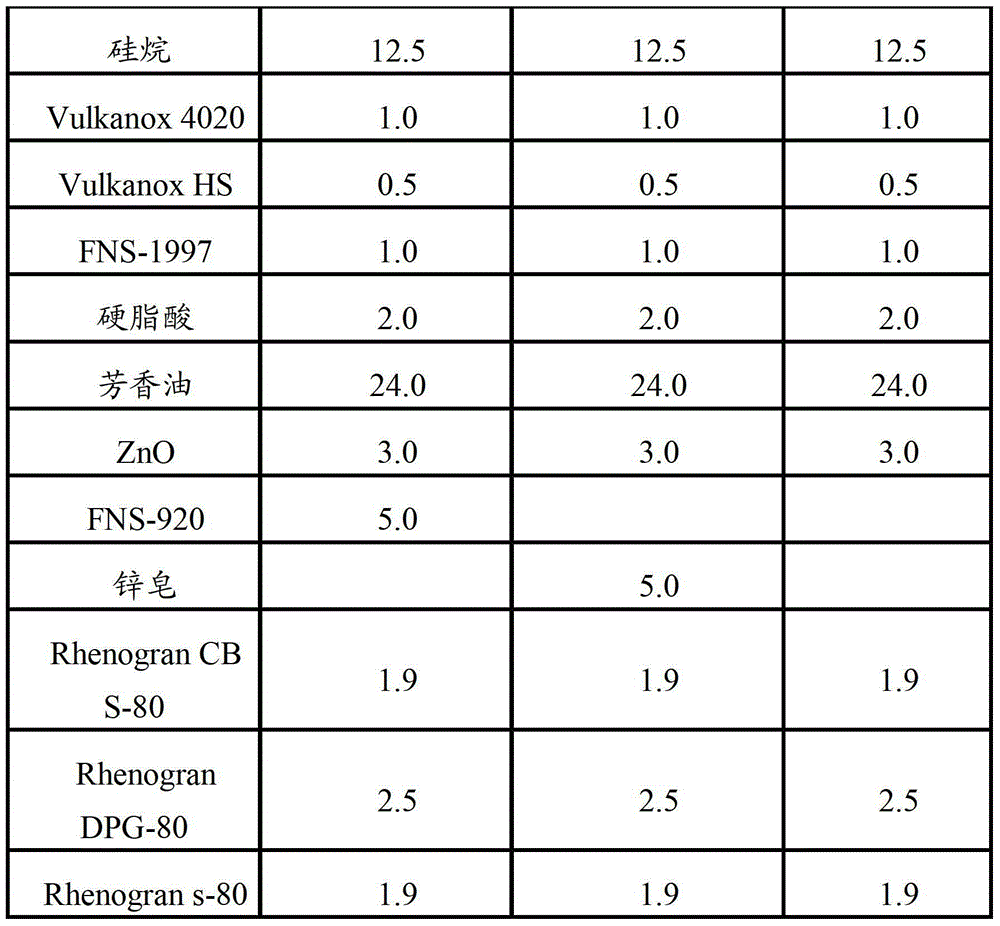

Rubber composition for high-performance tire and production process thereof

InactiveCN105218902AExcellent wet skid resistance of the tireReduce rolling resistanceSpecial tyresRolling resistance optimizationChemistryCarbon black

The invention discloses a rubber composition for a high-performance tire and a production process thereof. The composition comprises the following raw materials in parts by weight: 60 to 100 parts of SSBR, 0 to 20 parts of high cis-1,-4-nickle or neodymium cis-butadiene rubber, 0 to 20 parts of natural rubber, 0 to 20 parts of ultra anti-abrasion carbon black, 50 to 110 parts of low-polymer high-dispersion silicon dioxide, 5 to 15 parts of silane coupling agent, 0 to 40 parts of TDAE oil, 2.0 to 5.5 parts of zinc oxide, 1.0 to 3.5 parts of stearate, 1.0 to 3.5 parts of pre-dispersion sulfur, 2.0 to 6.0 parts of pre-dispersion accelerant and 0.5 to 2.0 parts of anti-aging agent. The tire adopting the tread formula is excellent in slippery resistance, excellent in brake distance, bend performance and high-speed stability, capable of acquiring optimum land grabbing performance on dry land or wet land, relatively low in rolling resistance and relatively good in wear resistance.

Owner:AEOLUS TIRE

White carbon black dispersant and preparation method thereof

The invention discloses a white carbon black dispersant. The white carbon black dispersant comprises, by mass, 40 to 60% of C8-C22 fatty acid, 5 to 25% of protection wax, 10 to 28.8% of fatty acid ester, 6 to 10% of an inorganic filling material and 0.96 to 5% of an anti-oxidant. The invention also discloses a preparation of the white carbon black dispersant having a good white carbon black dispersion effect. The white carbon black dispersant is an environmentally-friendly high-dispersibility zinc-free white carbon black dispersant, can improve dispersibility of a filling material and rubber chemicals in rubber in rubber mixing, is suitable for improvement of dispersibility of rubber containing high-activity white carbon black, avoids re-condensation, improves wet-skid resistance of a tyre surface, and avoids the pollution produced heavy metal zinc on the environment.

Owner:青岛福凯橡塑新材料有限公司

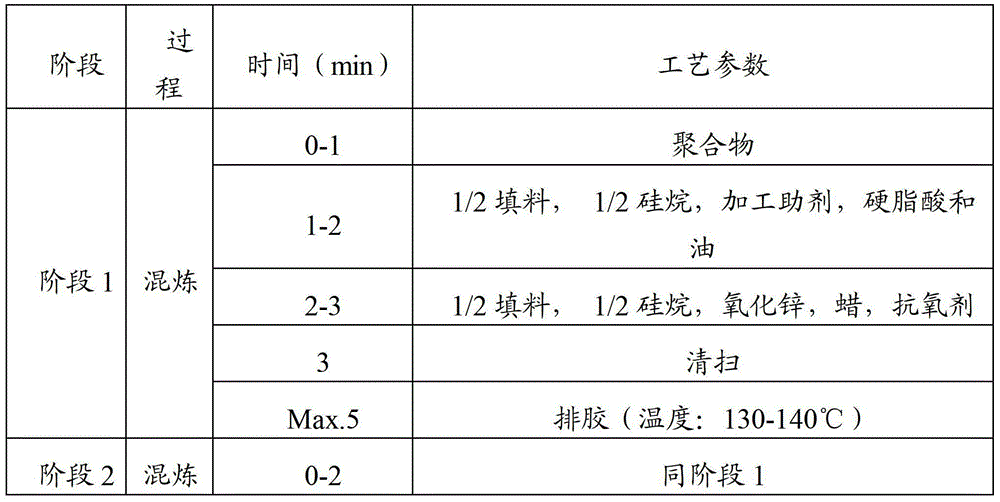

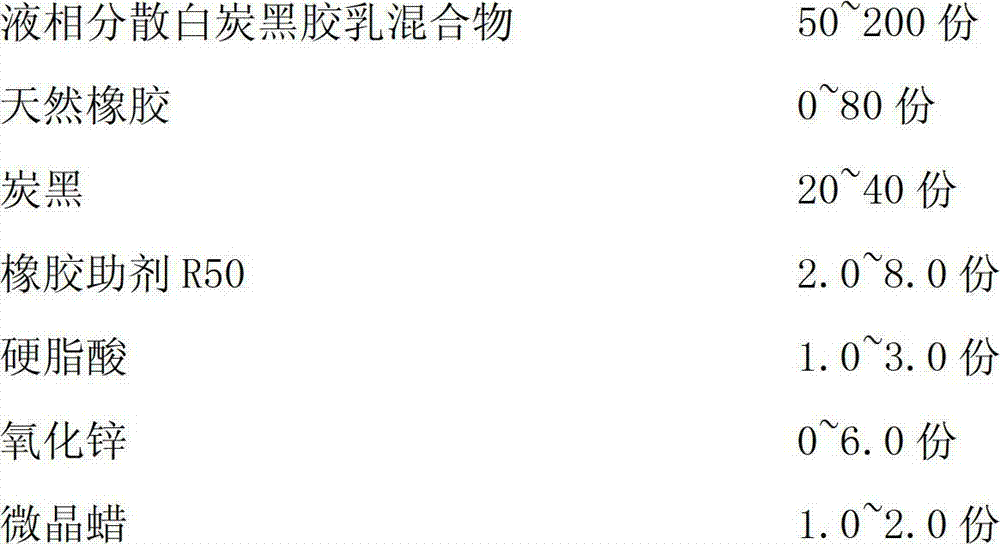

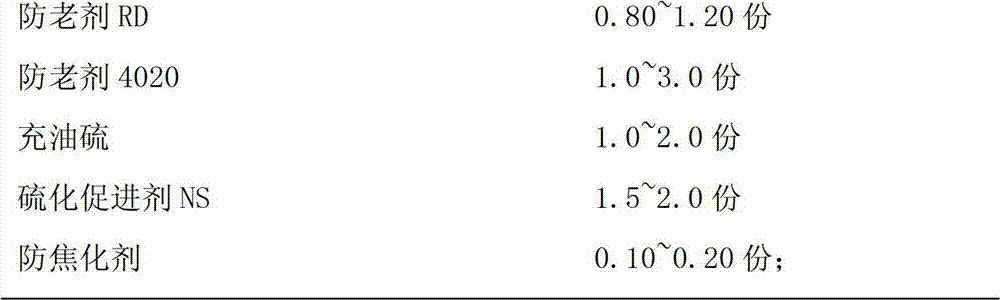

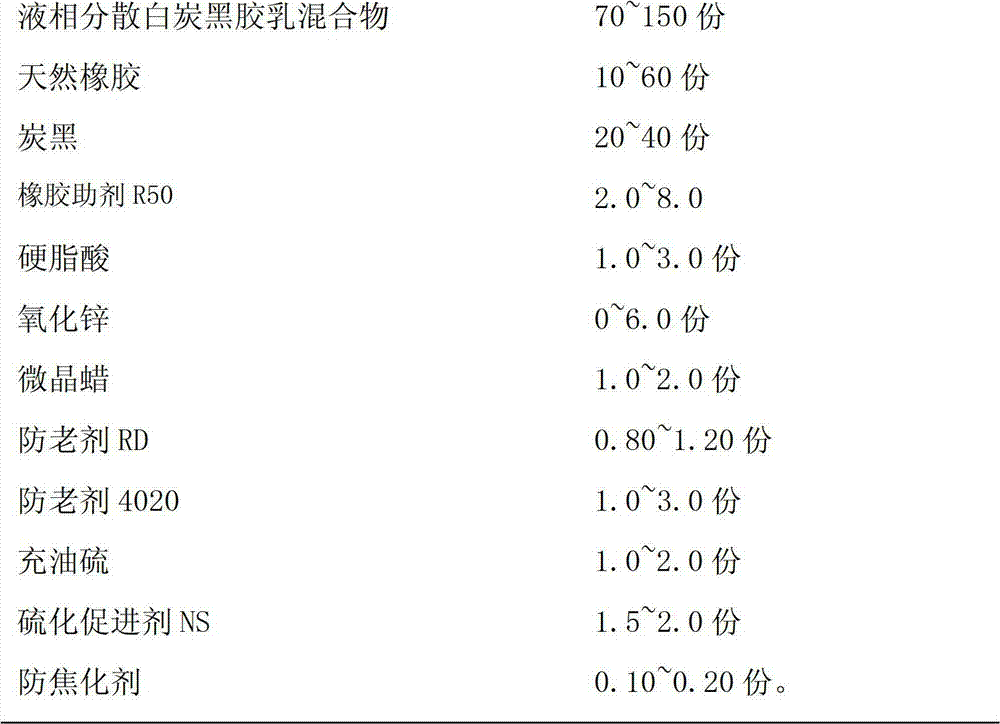

Liquid-phase dispersion white carbon black latex mixture contained mine tire tread rubber compound and preparation method and application thereof

ActiveCN102807689AReduce rolling resistanceReduced effectSpecial tyresRolling resistance optimizationRolling resistanceVulcanization

The invention relates to the field of production of tire rubber compounds, in particular to a mine tire tread rubber compound and a preparation method and the application thereof. The liquid-phase dispersion white carbon black latex mixture contained mine tire tread rubber compound is prepared by plasticating and mixing, by weight, 50-200 parts of liquid-phase dispersion white carbon black latex mixture, 0-80 parts of natural rubber, 20-40 parts of carbon black, 2.0-8.0 parts of rubber assistant R50, 1.0-3.0 parts of stearic acid, 0-6.0 parts of zinc oxide, 1.0-2.0 parts of microcrystalline wax, 0.80-1.20 parts of antiagerRD, 1.0-3.0 parts of antiager4020, 1.0-2.0 parts of oil filled sulfur, 1.5-2.0 parts of vulcanization accelerator and 0.10-0.20 part of anti-coking agent. White carbon black is adopted to totally replace or most replace carbon black to lower rolling resistance of tires and improve wet-skid resistance and abrasive resistance to produce energy-saving and environment-friendly tires.

Owner:ZHONGCE RUBBER GRP CO LTD

Improved preparation method of epoxy trans isoprene rubber

The invention provides an improved preparation method of epoxy trans isoprene rubber, and relates to the field of polymer materials. A first preparation method comprises the following steps: dissolving trans isoprene rubber in a solvent, slowly adding an organic acid and hydrogen peroxide under a stirring and / or ultrasonic action, reacting at a temperature of 0-80 DEG C for 0.1-12 hours, adding sodium carbonate to regulate the pH of the system to 7 after the reaction, removing a sweller and water by use of a vaporizing extract process, repeatedly eluting, pelleting and drying, and epoxy trans isoprene rubber with epoxy groups uniformly distributed in a polymer is obtained by the preparation method; a second preparation method comprises the following steps: partially dissolving the trans isoprene rubber in the sweller, wherein the rest steps are the same as those in the first method; a third preparation method comprises the following steps: prefabricating the trans isoprene rubber to emulsion, wherein the rest steps are the same as those in the first method. The epoxy groups are introduced to increase the wet skid resistance and air tightness of the trans isoprene rubber and the binding power of polar compounds, and the epoxy trans isoprene rubber can be applied on such occasions as a conveyor belt, a tire and a damping material.

Owner:QINGDAO UNIV OF SCI & TECH

Antiskid EVA sole and preparation method thereof

ActiveCN104277316AImprove anti-slipExtended service lifeSolesDomestic footwearCross-linkWear resistant

The invention belongs to the technical field of an organic high-molecular compound, and particularly relates to an antiskid EVA sole and a preparation method thereof. The antiskid EVA sole is prepared from the following raw materials: EVA, liquid rubber, a thermoplastic elastomer, a tackifier, chlorinated polyethylene, hemp stem core superfine powder, an AC foaming agent, a cross-linking agent, nanozinc oxide, zinc stearate, stearic acid, a wear-resistant agent and inorganic fillers. The preparation method comprises the following steps: banbury-mixing and open-milling the raw materials, pelletizing to obtain antiskid EVA particles, and then performing heating foaming and secondary oil-pressure forming to the antiskid EVA particles, to obtain the antiskid EVA sole. The antiskid EVA sole has the characteristics of being light in mass, high in antiskid property, good in handfeel and size stability and the like, as well as excellent in tensile strength and tearing strength, is especially suitable for application on aspects of various shoe accessories, sole materials and the like, and is good in comfortableness and long in service life.

Owner:茂泰(福建)新材料科技有限公司

Butadiene rubber

The invention relates to a butadiene rubber including following components: 30-50 parts of a cis-polybutadiene mixture, 5-9 parts of cyclohexane, 1-3 parts of cobalt oxide, 2-5 parts of zinc oxide, 3-7 parts of sulfur, 1-3 parts of stearic acid, 1-5 parts of nickel naphthenate, 5-9 parts of triisobutyl aluminium, 2-4 parts of boron trifluoride diethyl etherate, 2-6 parts of heptane, 3-8 parts of hydrogenated gasoline, 15-19 parts of an accelerant NS, 10-13 parts of HAF, 11-15 parts of ASTM-typed 103 oil, 2-8 parts of an aluminum oxygen clinker and 2-5 parts of chloroxylenol. The cis-polybutadiene mixture consists of cis-1,4-polybutadiene and cis-1,3-polybutadiene, wherein a weight ratio of the cis-1,4-polybutadiene to the cis-1,3-polybutadiene is 2:5 in the mixture. The butadiene rubber contains the cis-polybutadiene mixture so that the butadiene rubber is effectively reduced in tear strength, is enhanced in anti-slippery performance and adhesive property, and is low in heat-generating property.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

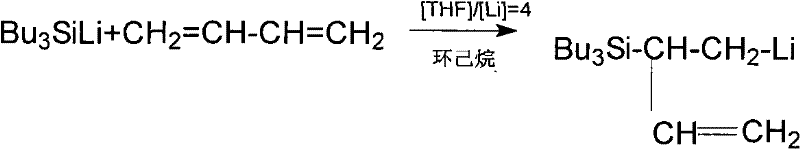

Preparation method of star-shaped solution polymerized butadiene styrene rubber with wide molecular weight distribution

The invention provides a preparation method of star-shaped solution polymerized butadiene styrene rubber (SSBR) with wide molecular weight distribution. The star-shaped SSBR is prepared through adopting a combined initiator system comprising an organic monolithium compound and a silicon lithium initiator, adding the initiator system in a multi-time dropwise mode, and carrying out a coupling reaction by adding a coupling agent in a multi-time adding mode after finishing polymerization. The star-shaped SSBR with wide molecular weight distribution, which can be processed under common conditions without adding low molecular weight polymers to improve the processing performance of the star-shaped SSBR and has the advantages of good tensile strength, balanced comprehensive mechanical property, good dynamic mechanical property, and combination of two properties of wet skid resistance and rolling resistance, is special rubber for tyres which has excellent properties. The star-shaped SSBR can be filled with carbon black, liquid rubber and the like, so the cost can be further saved, properties of rigidity, hardness and wear resistance of rubber products are improved, and the shrinkage of the rubber products is reduced, thereby the star-shaped SSBR can be widely applied to the shoemaking industry, the tyre industry and other industries.

Owner:PETROCHINA CO LTD

Material for high-wear-resistant rare earth rubber shoes and preparation method thereof

ActiveCN107216504AIncrease the amount addedGuaranteed basic physical propertiesSolesDomestic footwearVulcanizationPolymer science

The invention discloses a material for high-wear-resistant rare earth rubber shoes and a preparation method thereof. The material is prepared from rare earth polybutadiene rubber (NdBR), isoprene rubber (IR), solution polymerized butadiene styrene rubber (SSBR), a softening agent, an activating agent, a coupling agent, a vulcanizing agent, a vulcanization accelerator, an anti-aging agent and surface modified ground rubber. The invention adopts a die pressing method to prepare a series of rubber shoe sole materials with wear resistance (DIN wear is 30 to 120mm<3>), slip limit (dry slip is 0.6 to 1.1, and wet slip is 0.3 to 0.6), and moderate hardness (Shore A) 60 to 70; the material has the following advantages that (1) the wear resistance is better; (2) the slip limit is improved; (3) the comfort is increased; (4) the production cost can be remarkably reduced, the profit space is improved, and the energy is saved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST JINJIANG CO LTD +1

Method for preparing maleic anhydride-grafted 1,2-polybutadiene

InactiveCN104262543AImproved low rolling resistanceImprove wet skid resistancePolymer scienceButadiene Dioxide

The invention discloses a method for preparing maleic anhydride-grafted1,2-polybutadiene and relates to a method for preparing polymer materials. The invention provides a synthesis of 1,2-polybutadiene modified with maleic anhydride and a preparation method of 1,2-polybutadiene modified with maleic anhydride. The maleic anhydride-grafted 1,2-polybutadiene is prepared by virtue of a solution blending grafting method, a reactive polar maleic anhydride group is grafted to a double bond on a macromolecular branched chain of 1,2-polybutadiene; due to introduction of the reactive polar maleic anhydride group, the polarity of 1,2-polybutadiene is changed and thus certain novel special properties such as improved heat resistance, fatigue resistance, aging resistance, solvent resistance and processing properties are endowed on 1,2-polybutadiene. The maleic anhydride-grafted 1,2-polybutadiene prepared by the invention can be used for toughening modification of other polymer materials (such as nylon and epoxy resin).

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Butadiene styrene rubber composition with wear-resisting characteristic and preparation method thereof

ActiveCN102432927AReduce rolling resistanceImprove wet skid resistanceSpecial tyresRolling resistance optimizationPotassium persulfatePolymer science

The invention provides a butadiene styrene rubber composition with a wear-resisting characteristic and a preparation method thereof. The butadiene styrene rubber composition comprises the following components in parts by weight: 100 parts of butadiene styrene rubber, 1-30 parts of modified butylbenzene powdered rubber and can also comprise 1-30 parts of hydroxyl-terminated liquid butadiene styrene rubber and the like. In the butadiene styrene rubber, the content of the bound styrene is 15-50%, and the Mooney viscosity is 30-90; the modified butylbenzene powdered rubber is obtained by modifying the surface of the butylbenzene powdered rubber prepared by a radiation crosslinking method by using ethanthiol and potassium persulfate under the existence of polyethylene glycol, wherein the content of the bound styrene is 15-60% and the average particle size is 50-300nm; and the content of gel is 70-98%. The butylbenzene vulcanized rubber can well achieve the balance among the rolling resistance, the slippery resistance and the wear resistance, and is suitably used for tread rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com