Itaconate/butadiene copolymer type bioengineering rubber and preparation method thereof

An itaconate, bioengineering technology, applied in transportation and packaging, special tires, tire parts, etc., to achieve the effect of improving mechanical properties, broad market prospects, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

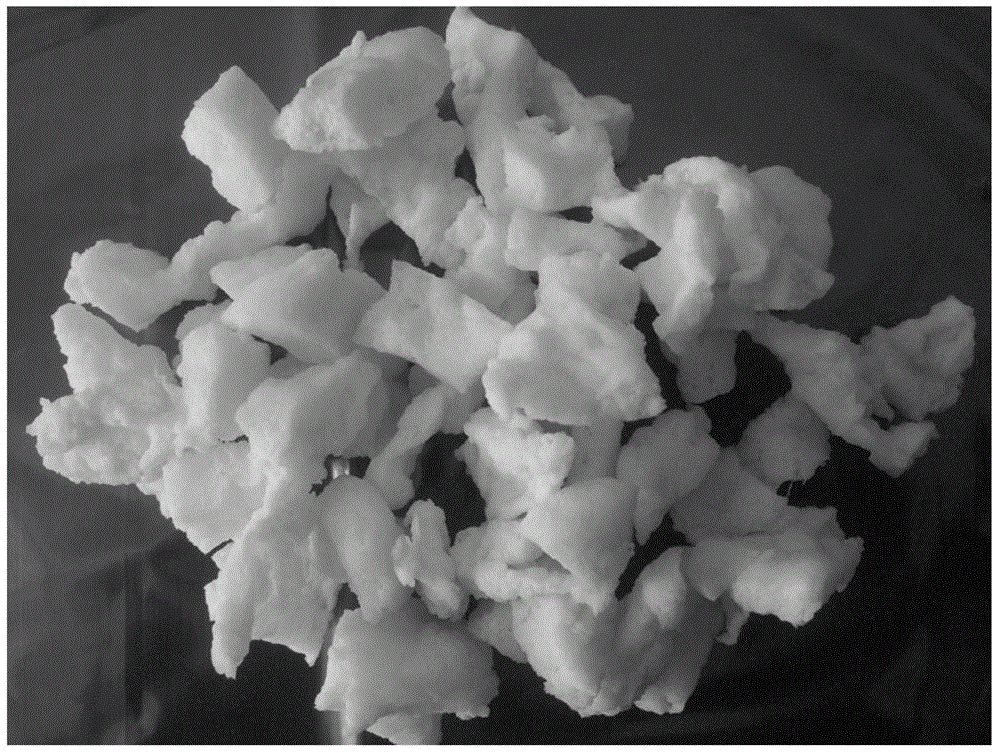

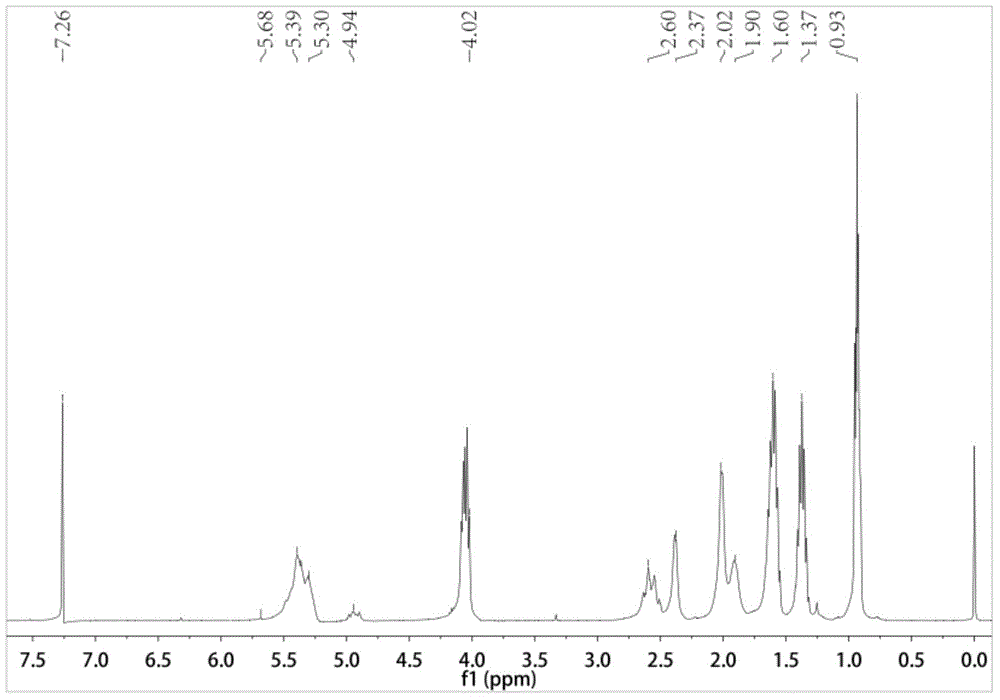

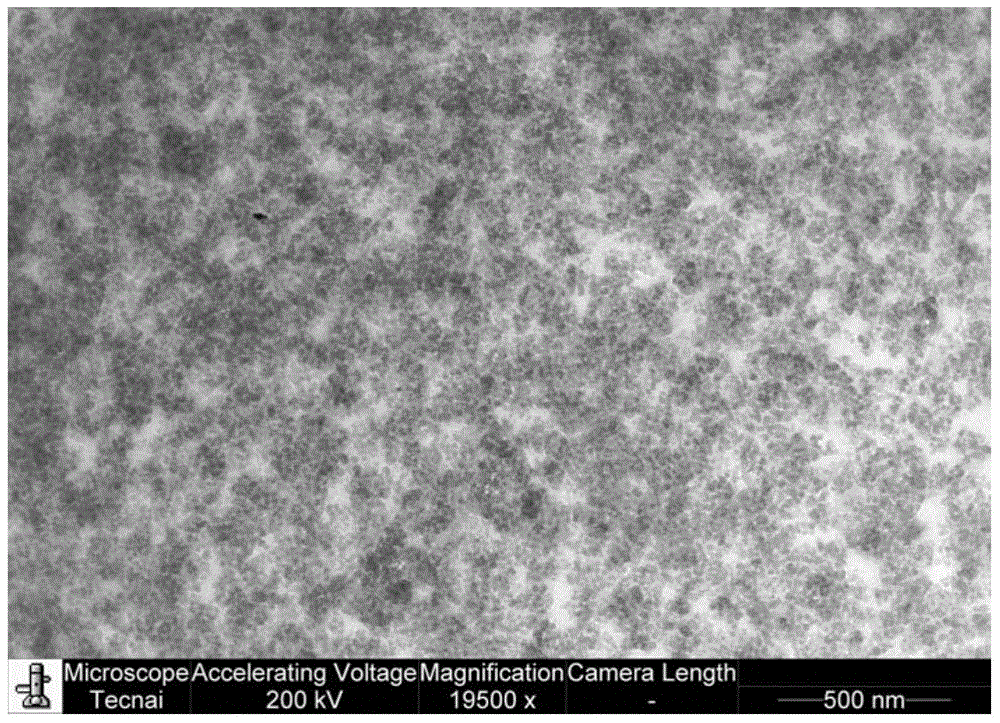

Embodiment 1

[0037] In a 1-liter polymerization device, add 500 grams of deionized water, 150 grams of methyl itaconate, 3 grams of fatty acid potassium soap, 4 grams of fatty acid sodium soap, 2 grams of H 3 PO 4 , 1.2 grams of KOH, 0.02 grams of EDTA, 0.25 grams of TAOM-L, 0.01 grams of EDTA-Fe, 0.05 grams of sodium formaldehyde sulfoxylate; after sealing the device, vacuumize and fill with nitrogen, operate once, and then add 50 grams of butane Alkene, 0.02 gram of sodium dithionite and 0.03 gram of hydroperoxide p-menthane were reacted for 15 hours at 1 °C and 0.1 MPa pressure, and 1 gram of hydroxylamine was added to terminate the reaction to obtain methyl itaconate / butadiene copolymer type Bioengineering rubber latex, the latex is poured into 0.1mol / L hydrochloric acid solution to demulsify and dry to obtain methyl itaconate / butadiene copolymer bioengineering rubber raw rubber.

[0038] 100 grams of the above methyl itaconate / butadiene copolymer bioengineering rubber raw rubber, 5 g...

Embodiment 2

[0040] In a 1-liter polymerization device, add 500 grams of deionized water, 160 grams of ethyl itaconate, 5 grams of fatty acid potassium soap, 5 grams of disproportionated abietic acid sodium soap, 0.3 grams of K 3 PO 4 , 0.15 g of KCl, 0.03 g of EDTA, 0.25 g of TAOM-L, 1 g of EDTA-Fe Na, 4 g of sodium formaldehyde sulfoxylate; after sealing the device, vacuumize and fill with nitrogen, operate continuously for 3 times, and then add 40 1 gram of butadiene, 0.01 gram of sodium dithionite and 0.05 gram of hydroperoxide p-menthane, reacted for 10 hours at 5° C. under 1 MPa pressure conditions, added 5 gram of hydroxylamine to terminate the reaction, and obtained ethyl itaconate / butadiene copolymer Pour the latex into absolute ethanol to break the emulsion and dry to obtain the ethyl itaconate / butadiene copolymer bioengineering rubber latex.

[0041] With 100 grams of above-mentioned ethyl itaconate / butadiene copolymer bioengineering rubber raw rubber, 5 grams of zinc oxide, 2 ...

Embodiment 3

[0043] In a 1-liter polymerization device, add 500 grams of deionized water, 140 grams of butyl itaconate, 3 grams of fatty acid potassium soap, 4 grams of fatty acid sodium soap, 0.2 grams of H 3 PO 4 , 0.12 grams of KOH, 0.02 grams of EDTA, 0.25 grams of TAOM-L, 0.01 grams of EDTA-Fe, 0.05 grams of sodium formaldehyde sulfoxylate; after sealing the device, vacuumize and fill with nitrogen, operate continuously for 5 times, and then add 60 grams of butane Diene, 2 grams of sodium dithionite and 5 grams of p-menthane hydrogen peroxide, reacted at 5 ° C and 1 MPa pressure for 8 hours, added 3 grams of hydroxylamine to terminate the reaction, and obtained butyl itaconate / butadiene copolymer Bioengineering rubber latex, the latex is poured into 1wt% calcium chloride solution to demulsify and dry to obtain butyl itaconate / butadiene copolymer bioengineering rubber raw rubber.

[0044] 100 grams of the above-mentioned butyl itaconate / butadiene copolymer bioengineering rubber raw ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com