Patents

Literature

161 results about "Sodium dithionite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium dithionite (also known as sodium hydrosulfite) is a white crystalline powder with a weak sulfurous odor. Although it is stable in the absence of air, it decomposes in hot water and in acid solutions.

Cyclic process for the production of taurine from ethylene oxide

ActiveUS9061976B1Organic compound preparationSulfonic acids salts preparationCyclic processSodium dithionite

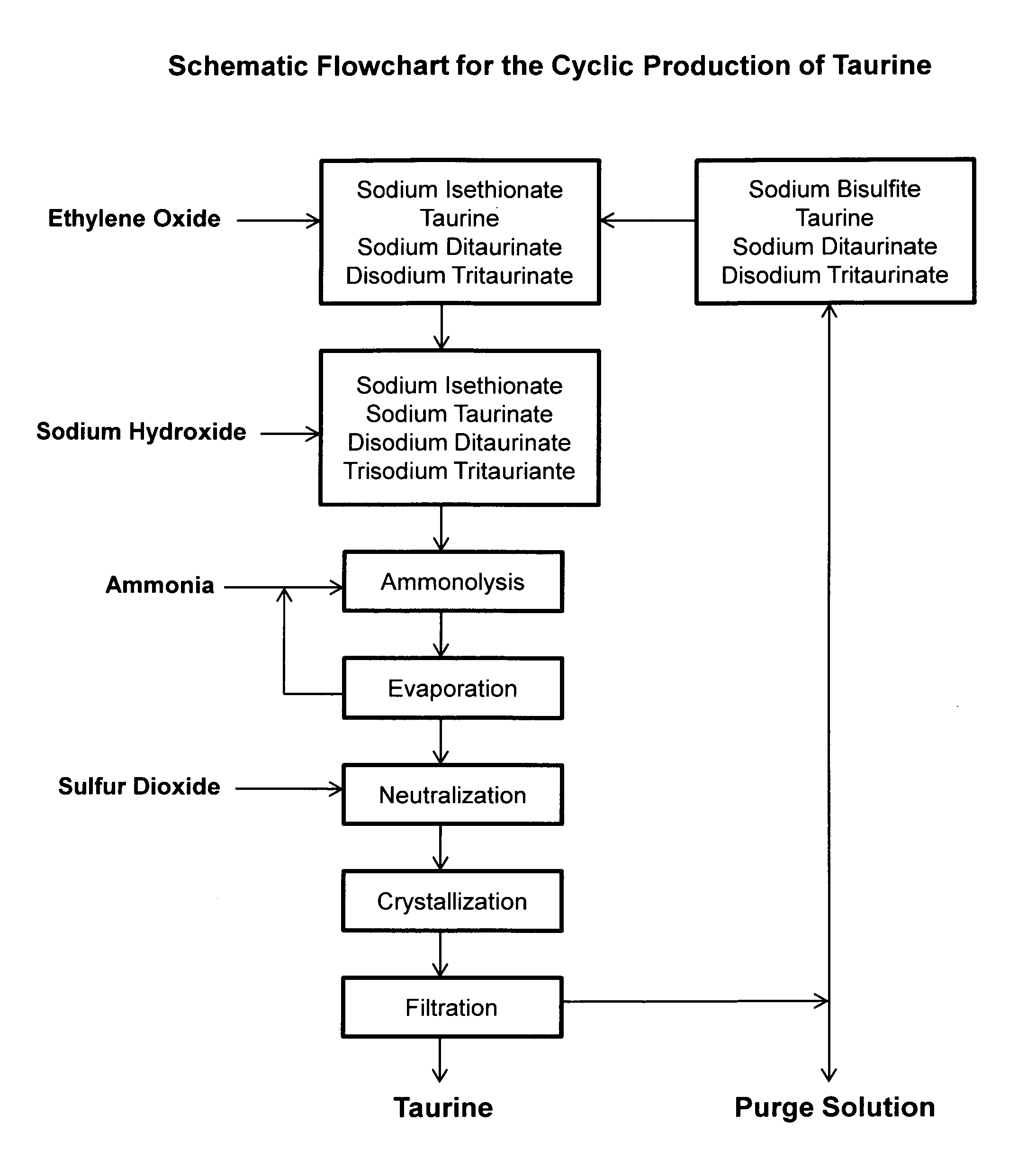

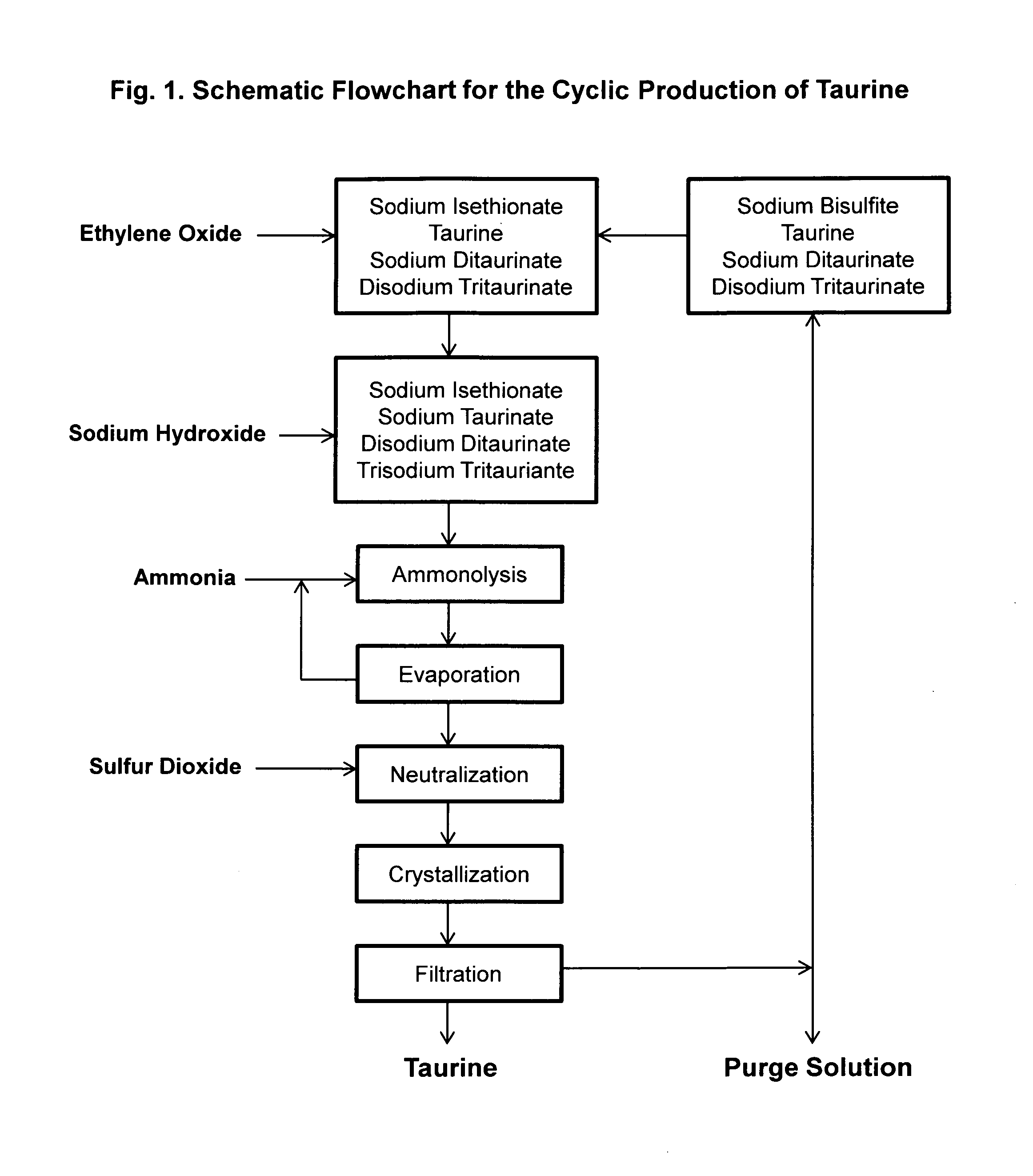

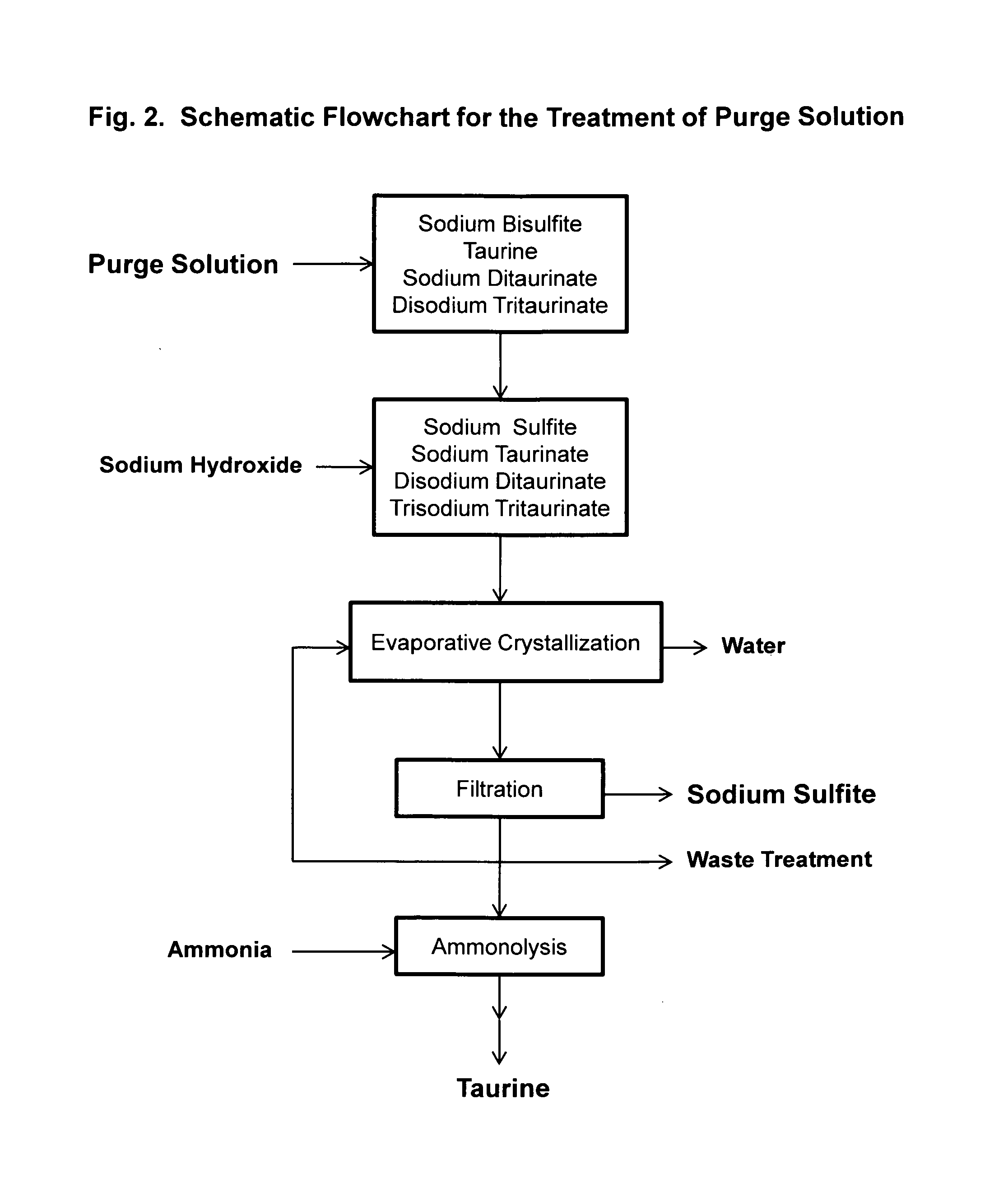

The present invention discloses a cyclic process for the production of taurine from ethylene oxide in a high yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. The cyclic process is completed by using sulfur dioxide or sulfurous acid to neutralize sodium taurinates to recover taurine and to regenerate sodium bisulfite, which is then reacted with ethylene oxide.

Owner:VITAWORKS IP LLC

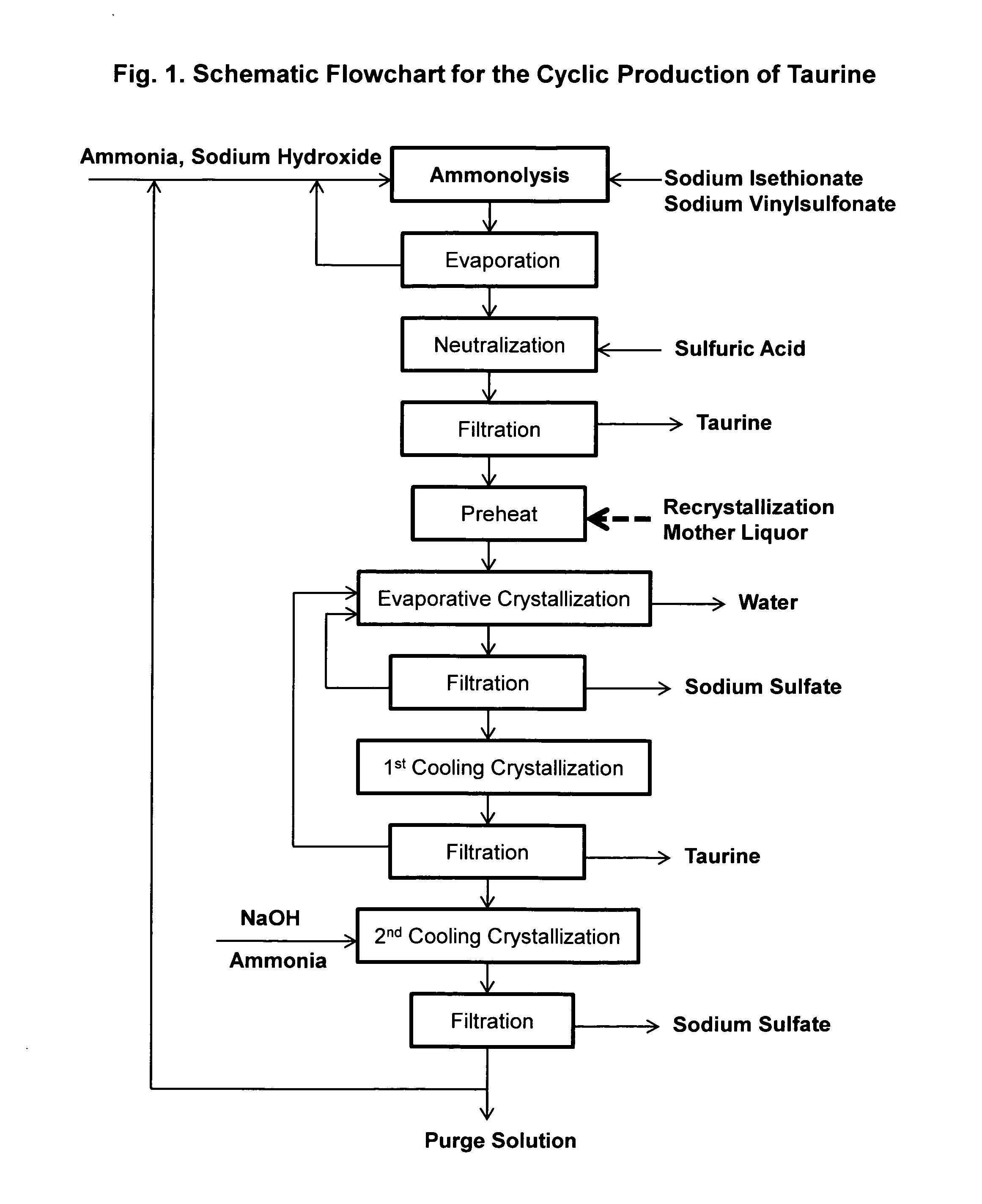

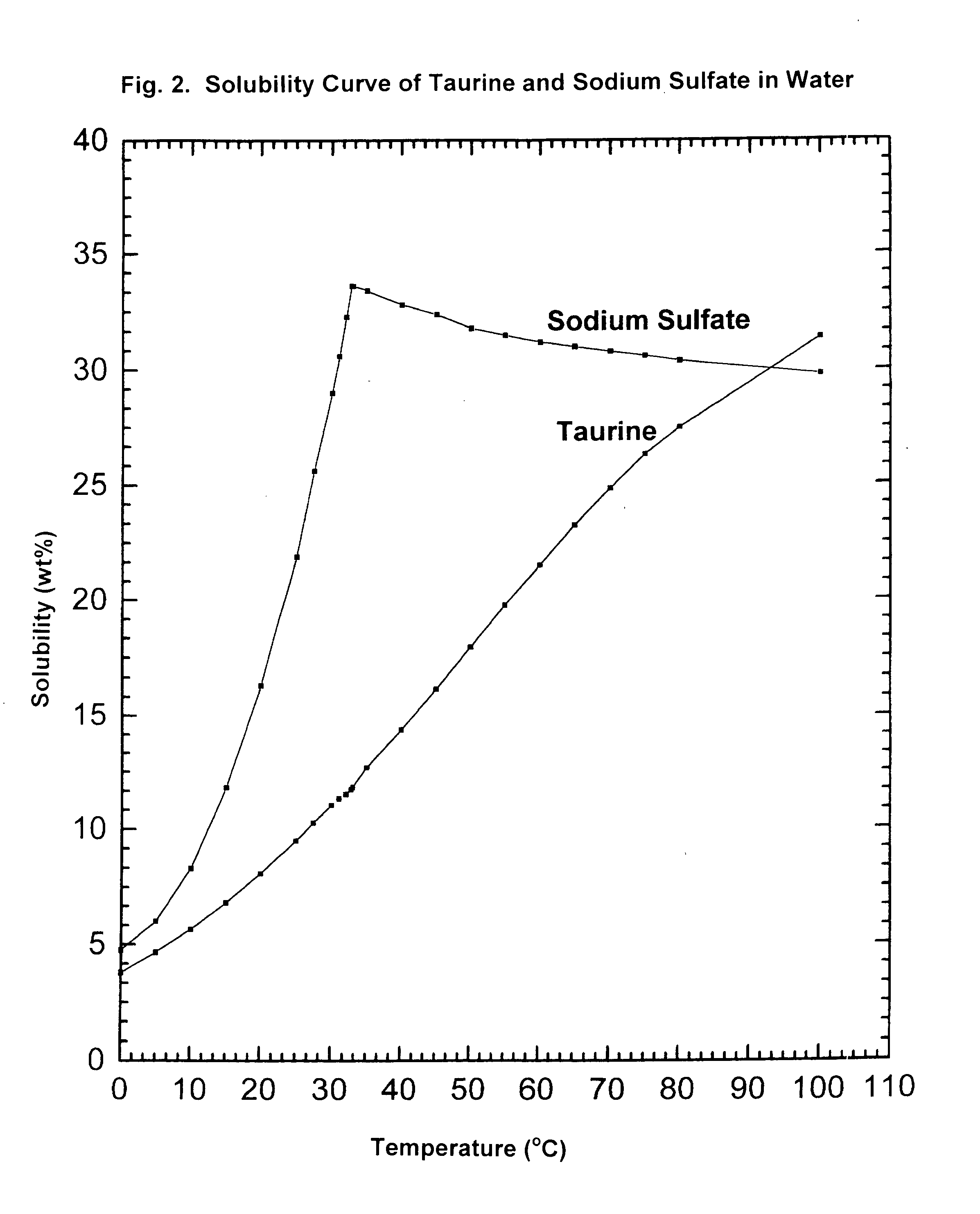

Cyclic process for the production of taurine from alkali isethionate and alkali vinyl sulfonate

ActiveUS20150299114A1Facilitate cooling crystallizationOrganic compound preparationSulfonic acids salts preparationCyclic processSulfonate

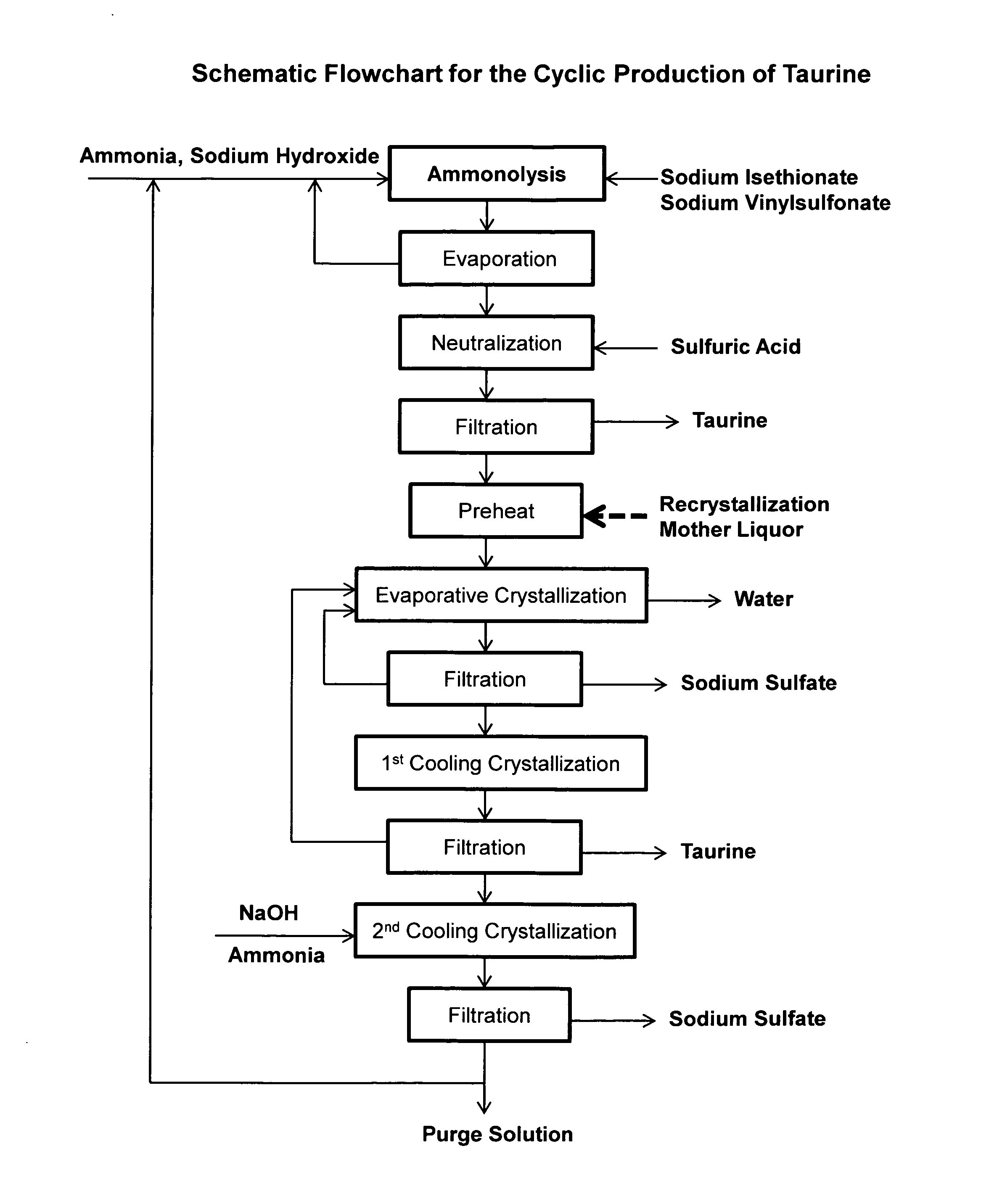

The present invention discloses a cyclic process for the production of taurine from alkali isethionate and alkali vinyl sulfonate in a high overall yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. Sodium sulfate and residual taurine in the crystallization mother liquor are efficiently separated by converting taurine into a highly soluble form of sodium taurinate or ammonium taurinate while selectively crystallizing sodium sulfate.

Owner:VITAWORKS IP LLC

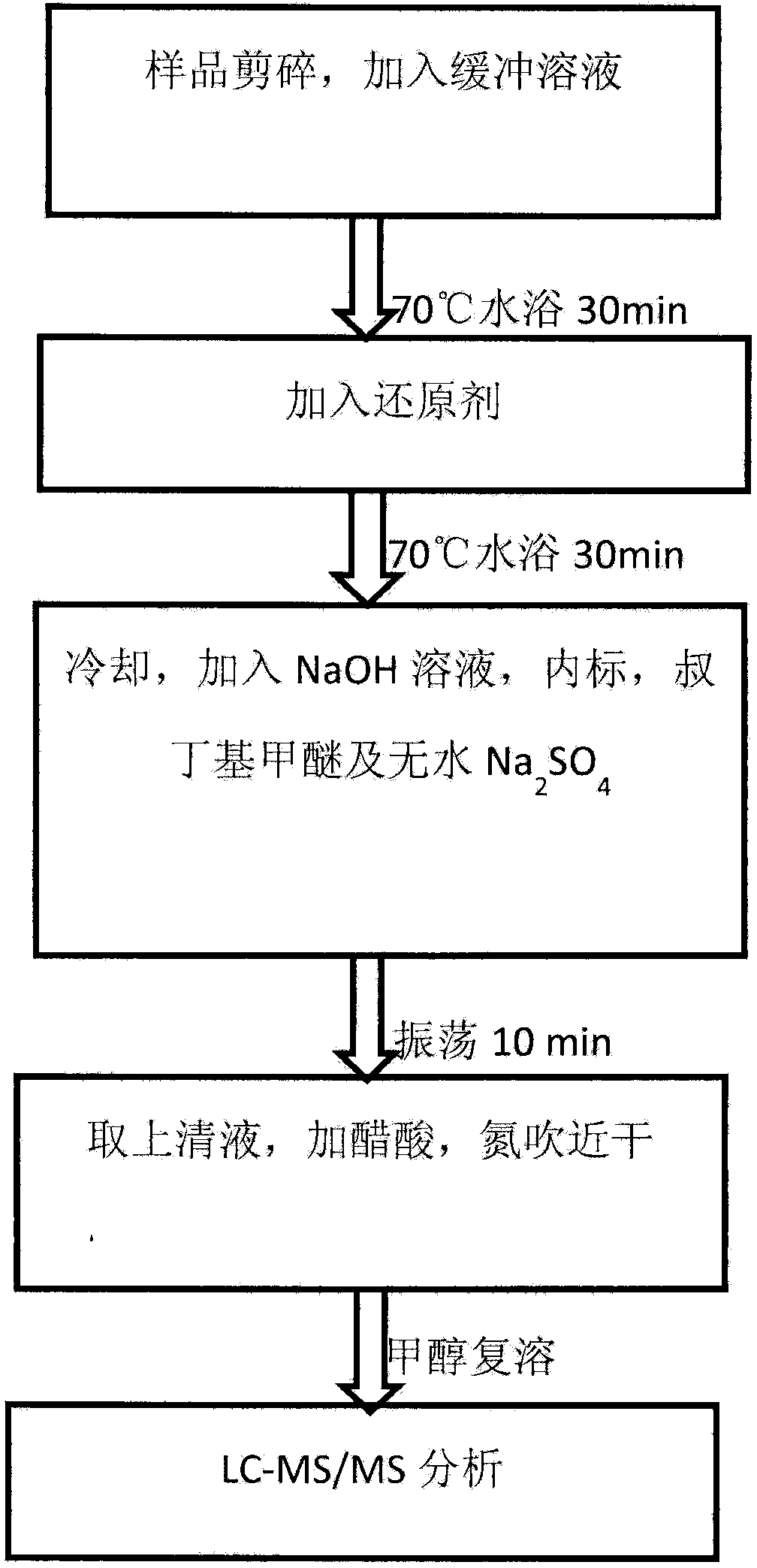

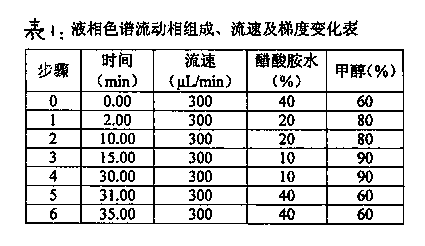

Test method of banned azo-dye in cigarette paper

ActiveCN103760288AEasy to handleEasy processing conditionsComponent separationSodium dithioniteHazardous substance

The invention discloses a test method of a banned azo-dye in cigarette paper and belongs to the technical field of physical and chemical inspection of harmful substance residues in lined paper, tipping paper and carton packaging paper for cigarettes. The test method is characterized by comprising the following steps: cutting a cigarette paper sample, adding a reduction solution, reducing an azo substance into aromatic amine by sodium hydrosulfite in a citric acid buffer solution, extracting aromatic amine from the solution by a liquid-liquid extraction method, concentrating, redissolving by methanol, testing by a liquid chromatography-tandem mass spectrometry combined instrument, and quantifying by an internal standard method. According to the method, the deficiencies of a sample treatment method in the prior art are overcome, and a sample pre-treatment method and instrument test conditions are optimized for the tipping paper, the lined paper and the carton packaging paper for the cigarettes; as a solid-phase extraction column does not need to be passed, cumbersome purification and concentration steps such as rotary evaporation are not required, and the method has the advantages of accuracy for operation, high recovery rate, quickness, simplicity, convenience, high sensitivity and the like.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

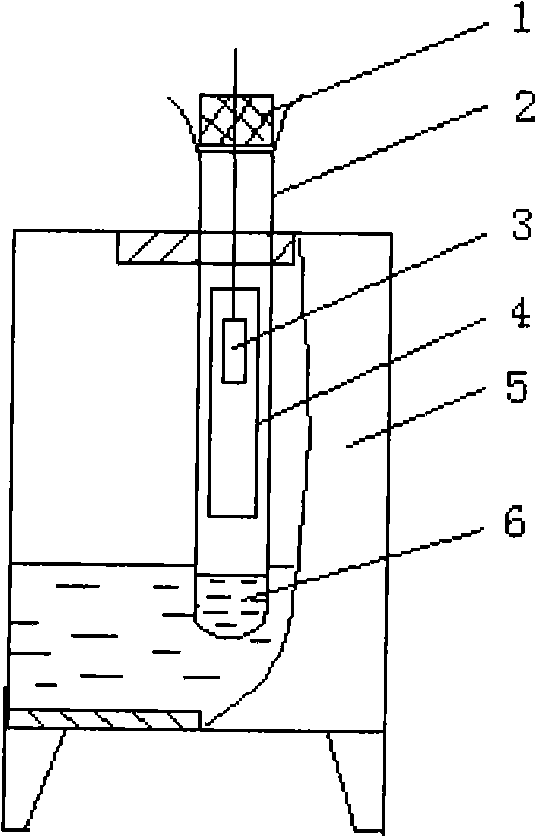

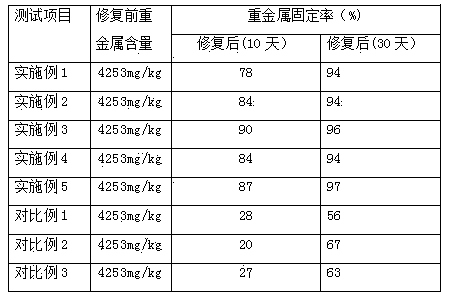

Technology for preparing mineral composite solid lubricant for well drilling on basis of by-products in chemical industry

InactiveCN102199417ALow costConvenient storage and transportationDrilling compositionChemical industrySodium dithionite

The invention relates to a technology for preparing a mineral composite solid lubricant for well drilling on the basis of by-products in chemical industry. The solid lubricant is prepared by taking by-product residue (or residual liquid) of sodium dithionite powder distillation as a main ingredient, adopting graphite and / or expanded graphite mineraloid as a loading material, taking animal oil or vegetable oil or oil based surfactants derived from the animal oil or the vegetable oil as a lubricating property regulator, and adding a certain amount of a combined drilling-fluid property regulator prepared by matching special fluid loss additive for drilling fluid, a collapse preventing agent and an emulsifying agent according to a specific proportion through processes such as mixing, extrusion, kneading, and the like. The preparation method comprises a cross blending method, a kneading method, a twin-screw-rod extrusion method, a single-screw-rod extrusion method, and the like. Compared with the prior art, the invention has the advantages of simultaneously enhancing two lubricating properties of the adhesion coefficient reducing rate and the friction resistance coefficient reducing rate of the drilling fluid lubricant, and the collapse preventing property, and has the characteristics of low price, simplicity for production process, convenience for field transport and storage of petroleum drilling and geological prospecting drilling, and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

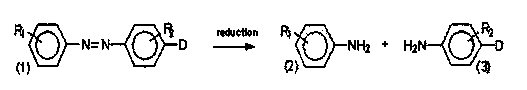

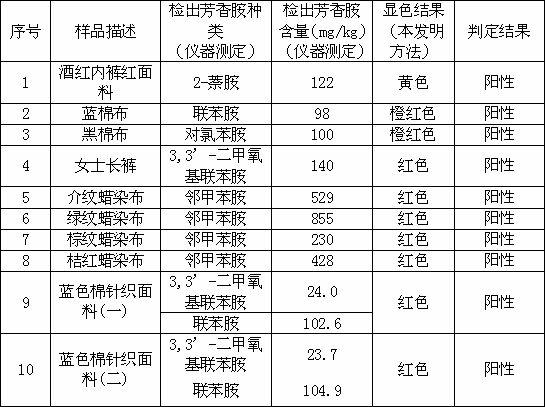

Rapid detection kit and detection method of forbidden azo dyes in dyed textiles

InactiveCN102507561ASimple technologySimple stepsMaterial analysis by observing effect on chemical indicatorAromatic amineReducing agent

The invention discloses a rapid detection method of forbidden azo dyes in dyed textiles, which uses the following reagents: 1) an extracting reagent A: 10 mL of methyl ten-butyl ether; 2) an extracting reagent B: 5 mL of 0.1-1.0 mol / L hydrochloric acid solution; 3) a reagent 1: 0.05 mL of 50 g / L NaNO2 solution; 4) a reagent 2: 0.5 mL of 25 g / L NH4SO3NH2 solution; 5) a reagent 3: 1 mL of o-metoxyphenol ethanol aqueous solution with volume percentage concentration of 2%; 6) a reagent 4: 1 mL of 0.5 mol / L NaOH solution; 7) a reducing agent 1: 16 mL of 0.06 mol / L citrate buffering solution with pH of 6.0; and 8) a reducing agent 2: 3.0 mL of 200 mg / L sodium hydrosulfite solution. According to the invention, the pre-treatment is realized by liquid-liquid extraction of textile reduction solution and discoloring, and the aromatic amine is measured by coloration; the pre-treatment is simple and rapid enough to greatly simplify the original steps, and no instrument or equipment is necessary in the measurement so as to realize the quick screening detection of forbidden azo dyes in textiles.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Dyeing method for suspension cotton yarn by reduced dye

InactiveCN107476094AAdaptableModerate reduction rateDyeing processVegetal fibresYarnSodium dithionite

The invention discloses a dyeing method for suspension cotton yarn by reduced dye. The dyeing method comprises the following steps: slacking, pretreatment, and dyeing. The bath ratio in the pretreatment step is 1:(6 to 10), and the bath ratio in the dyeing step is 1:(6 to 10). The dyeing method comprises the following specific steps: adding a reefing agent for operating, then adding alkali for operating, raising the temperature, adding hydrogen peroxide for operating, and carrying out acid pickling and water washing; operating for a period of time, then sequentially adding a dye leveler, sodium hydroxide and sodium dithionite, and then raising the temperature for operating; draining, adding water again, and then adding the hydrogen peroxide for operating; adding a soaping agent, and finally draining liquid to obtain dyed cone yarns. The method has the advantages of simple steps, simple dyeing operation, high production efficiency and good dyeing effect.

Owner:XINJIANG RUYI TEXTILE GARMENT CO LTD +2

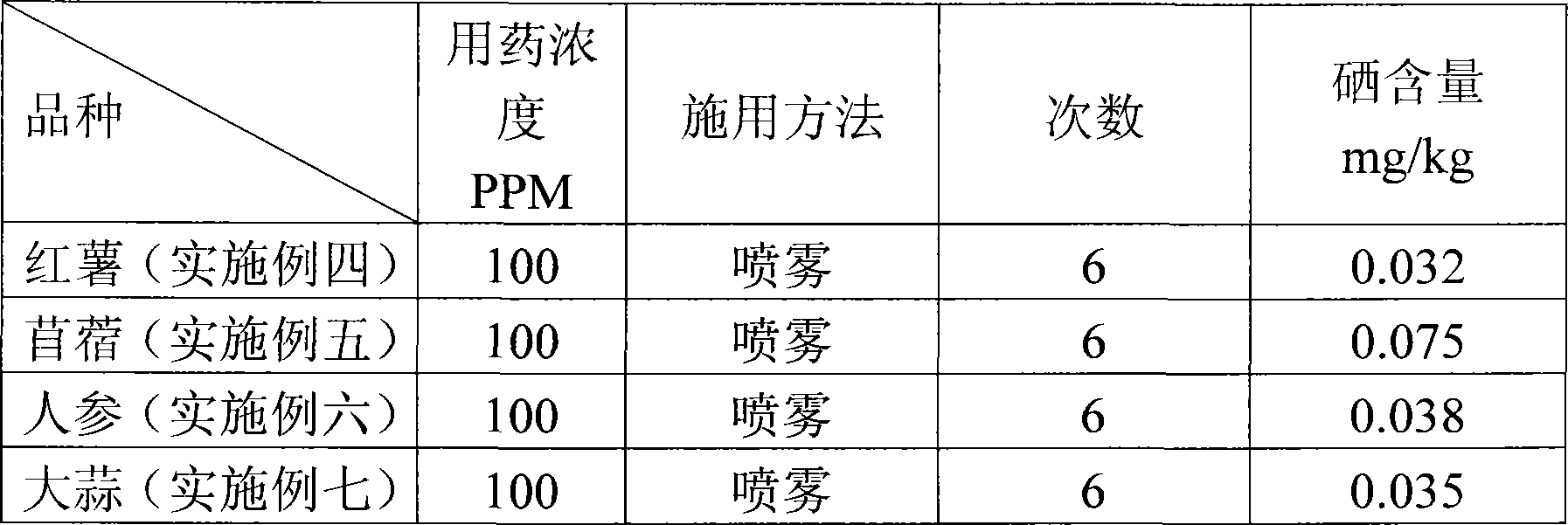

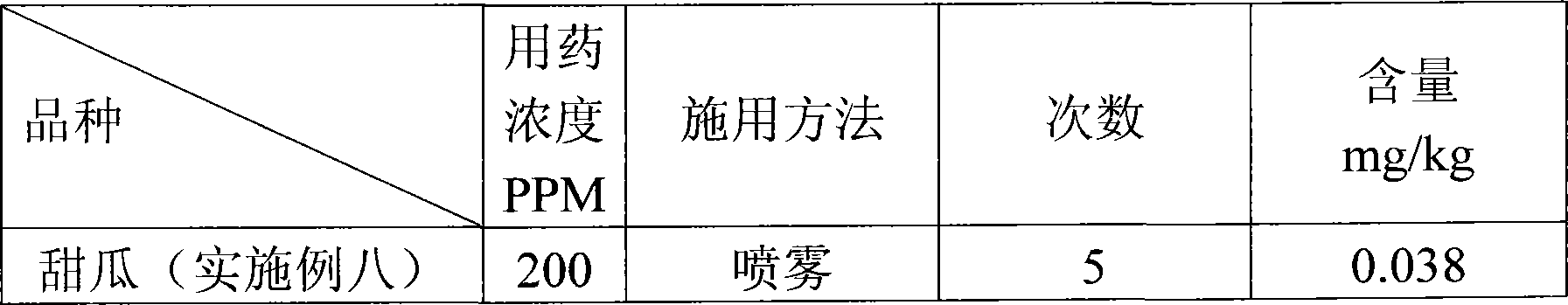

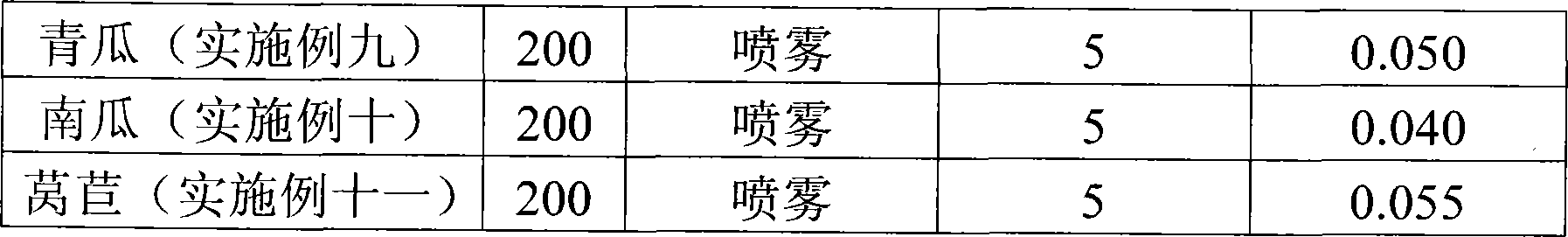

Selenium-enriched fertile solution and application method for selenium-enriched agricultural product production

InactiveCN101182246AIncrease selenium contentThe preparation method is simple and easySodium dithioniteInorganic selenium

A selenium-enriched fertilizer liquid is produced according to the steps as follows: coal ash granules are washed down from a coal flue by water; the obtained coal ash granules are aired, crushed and sieved through an eighty-mesh sieve; the coal ash after sieving is added into extract liquid which contains sodium hydroxide and sodium dithionite; sodium hyposulfite is added into the solution; the solution after being disposed by the sodium hyposulfite is put into a sedimentation barrel to be placed statically for 24 hours, and clear liquid at the upper layer is taken; the clear liquid at the upper layer which is obtained from last step is neutralized by vitriol, the pH value is adjusted to be 8 to 8.5, and the selenium-enriched fertilizer liquid is obtained. The method of applying the selenium-enriched fertilizer liquid to the production of the selenium-enriched agricultural products is that before the agricultural products are harvested, the selenium-enriched fertilizer liquid is diluted till 100ppm to 200ppm and sprayed at the agricultural products. The invention adopts the coal ash which is washed down from the coal flue by water to extract inorganic selenium, the manufacturing method of which is simple with very low cost, and the selenium content of the agricultural products can be improved effectively by spraying the manufactured selenium-enriched fertilizer liquid at the crop.

Owner:慈溪市蔬菜开发有限公司

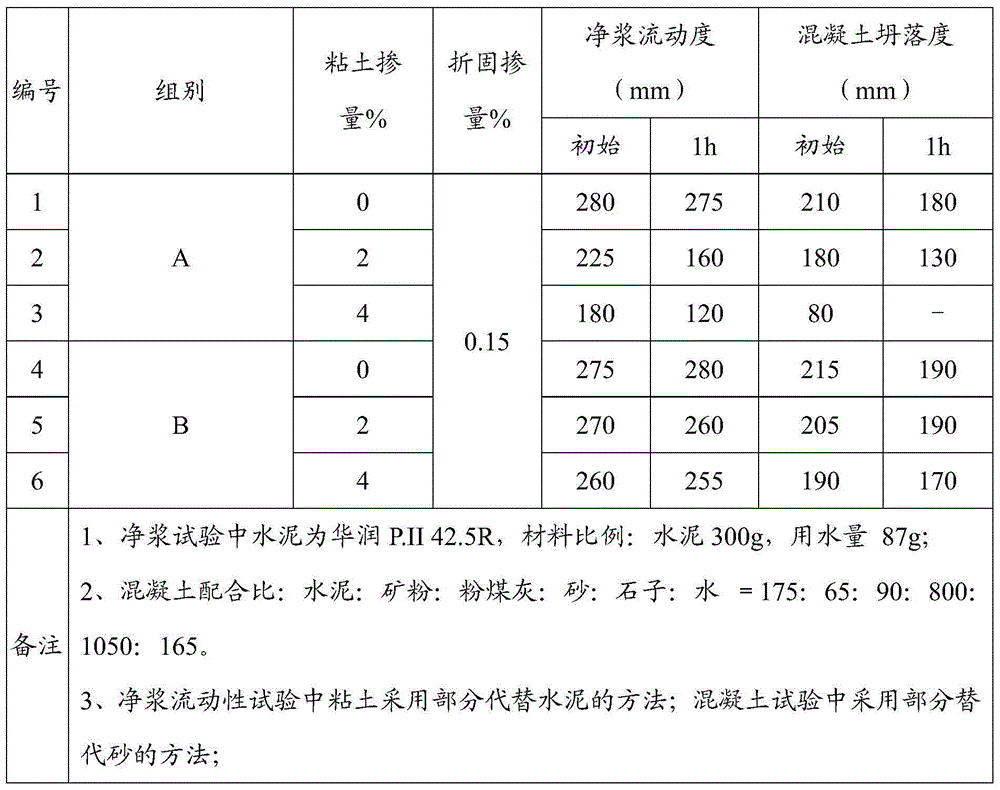

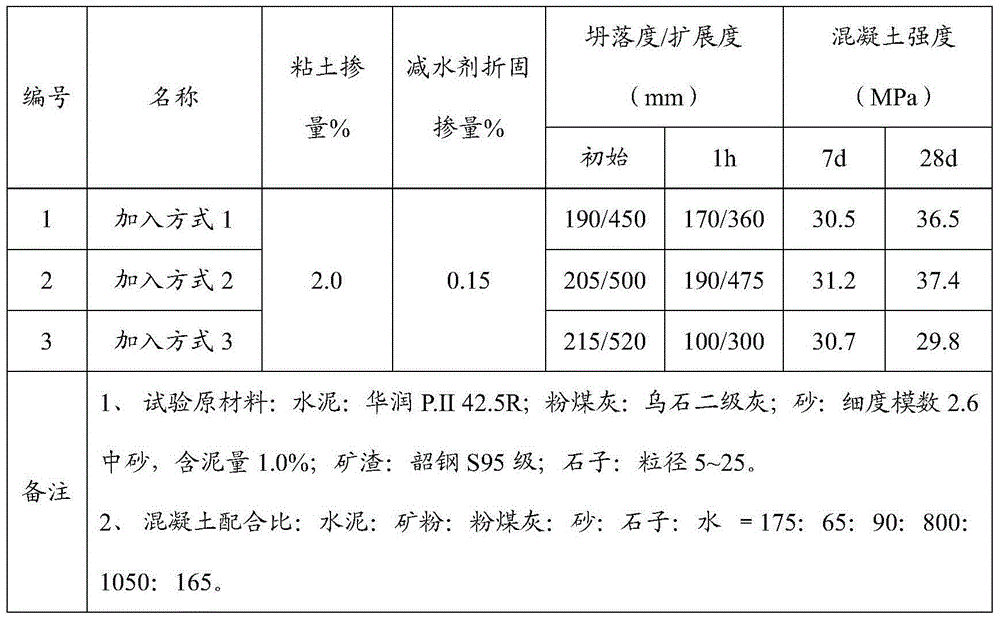

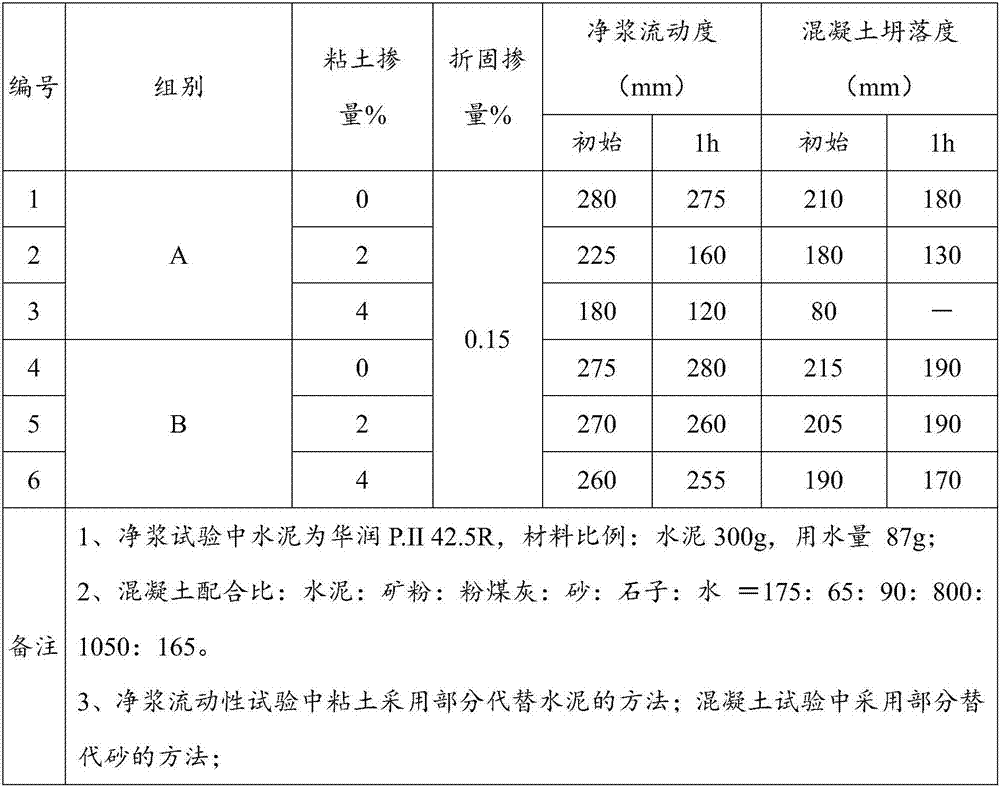

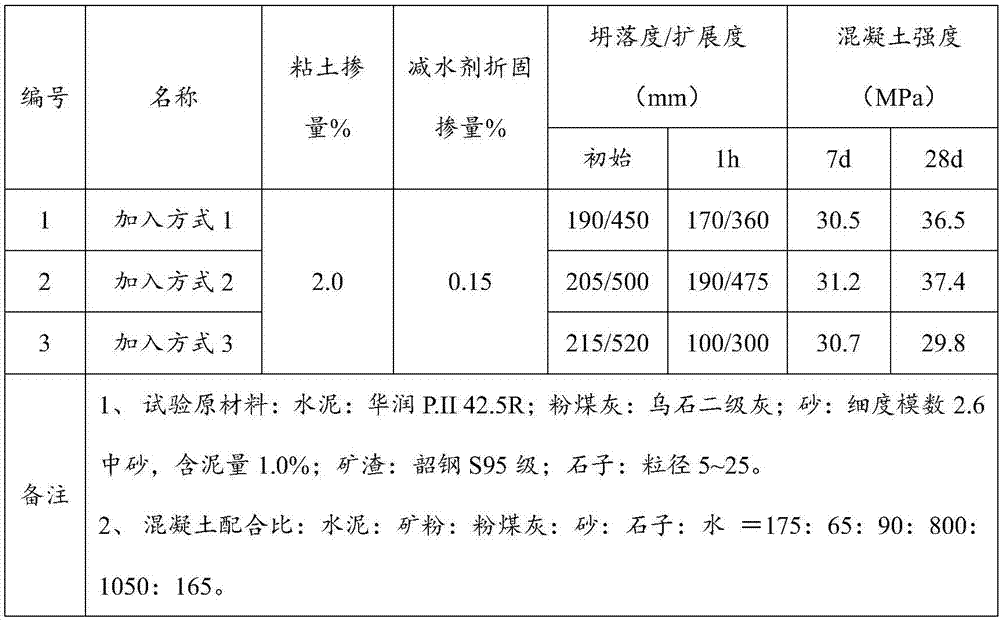

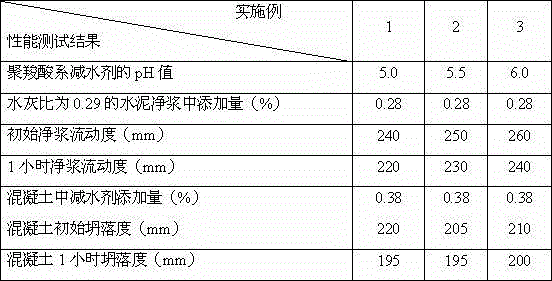

Preparation method for anti-mud-type polycarboxylic-acid water-reducing agent and application thereof

The invention discloses a preparation method for an anti-mud-type polycarboxylic-acid water-reducing agent and application thereof. The method is used to improve production efficiency of the anti-mud-type polycarboxylic-acid water-reducing agent, save energy and reinforce anti-mud performance and gradual plasticity-maintaining property of the anti-mud-type polycarboxylic-acid water-reducing agent. The preparation method for the anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention comprises the following steps: under the normal temperature condition of 5 to 35 DEG C, mixing isobutylene alcohol polyoxyethylene ether and maleic anhydride-beta-cyclodextrin and then dissolving the mixture in water; adding a mixed solution of acrylic acid and p-styryl formate; adding hydrogen peroxide; under the protection of nitrogen, adding a mixed solution of mercaptopropionic acid and ascorbic acid, a mixed solution of acylic acid and p-styryl formate, and sodium dithionite; and adding an aqueous sodium hydroxide solution and adjusting the pH value to 6 to 7 so as to obtain the anti-mud-type polycarboxylic-acid water-reducing agent. The anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention has a cup-shaped structure.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

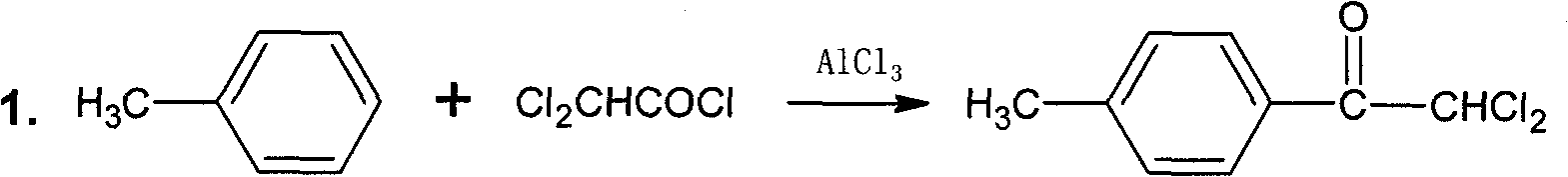

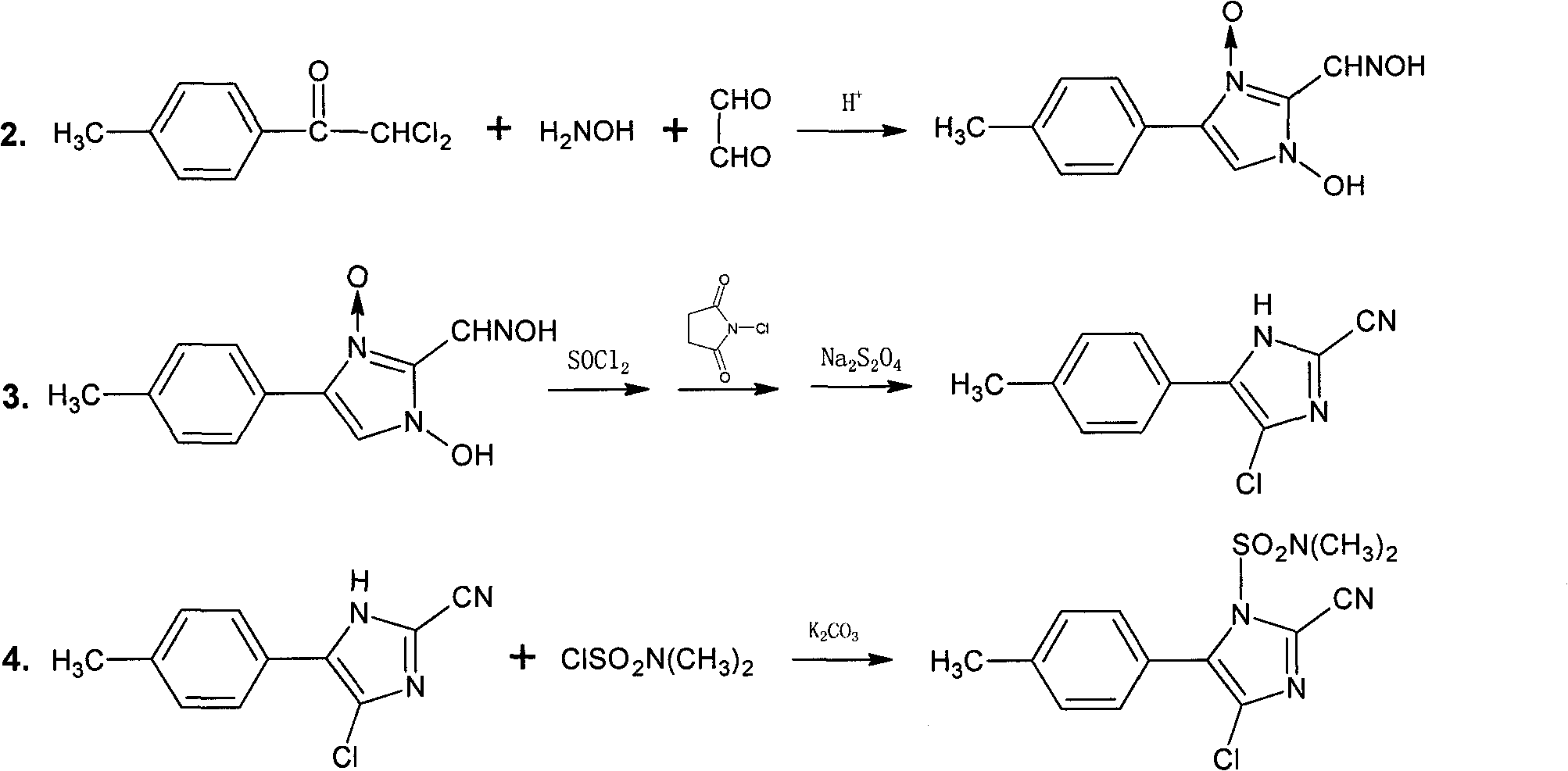

Synthesis method of 4-chloro-2-cyano-1-dimethylamino-sulfonyl-5-(4-methylphenyl)imidazo

ActiveCN102424671AEmission reductionShort reaction timeOrganic chemistrySodium dithioniteN-Chlorosuccinimide

The invention discloses a synthesis method of 4-chloro-2-cyano-1-dimethylamino-sulfonyl-5-(4-methylphenyl)imidazo, which aims to solve the technical problems of long reaction time, low yield and environment pollution of the prior art. The method is used for preparing 2,2-dichloro-4'-methyl acetophenone as an intermediate through an acylation reaction of methylbenzene and dchloroethanoyl chloride and preparing 4(5)-chloro-2-cyano-5(4)-(4-methylphenyl)imidazo as an intermediate by taking ethyl acetate and the like as solvent, N-succinchlorimide as chlorinating agent and sodium dithionite and the like as reductant. The synthesis method has short reaction time, high yield and total yield up to 61.7% and is mainly used for preparing the 4-chloro-2-cyano-1-dimethylamino-sulfonyl-5-(4-methylphenyl)imidazo.

Owner:XIAN MODERN CHEM RES INST

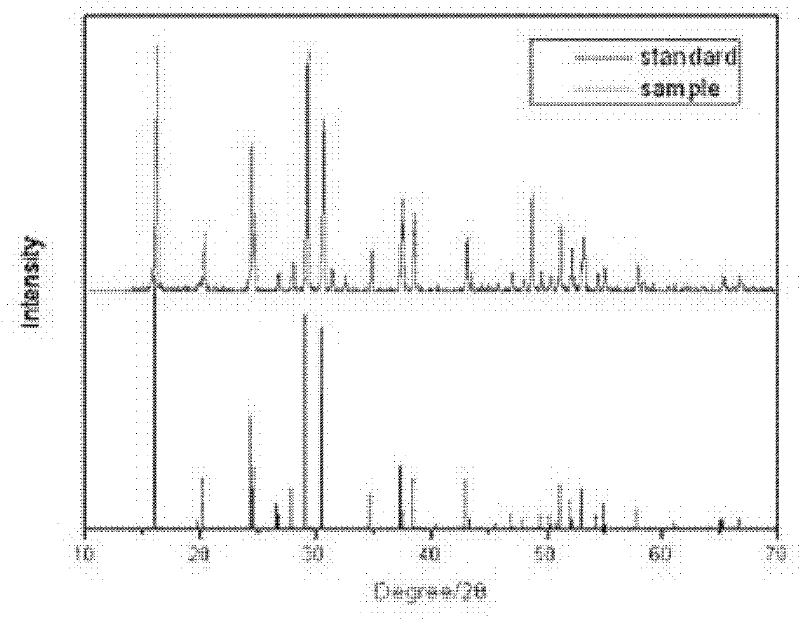

Method for preparing kaoline

ActiveCN101798096AReduce viscosityPhysical/chemical process catalystsAluminium silicatesSodium dithionitePtru catalyst

The invention provides a method for preparing kaoline. The method comprises the following steps: mining impurity removal, in which, soft kaoline mineral aggregate is extracted, clay and impurities are primarily separated to obtain a base material; pulping and grit removal, in which, the base material is subjected to pulping and grit removal to obtain an ore pulp primary material; chemical bleaching, in which, the ore pulp primary material is delivered to a high-speed stirring tank for pulp storage, sulfuric acid solution and sodium hydrosulfite solution are added to the high-speed stirring tank, wherein the mass ratio of the sulfuric acid solution to the ore pulp primary material is 0.3:100-0.8:100 and the mass ratio of the sodium hydrosulfite solution to the kaoline ore pulp primary material is 0.6:100-1.0:100, and the mixed solution with the pH value of between 2.0 and 3.0 is adjusted, and is stirred at the speed of between 140 and 180 revolution / minute for 40 to 45 minutes to prepare an ore pulp concentrated material; cleaning and dehydration, in which, the ore pulp concentrated material is subjected to circulated cleaning and dehydration to prepare an ore pulp finished material; and the ore pulp finished material is dried to prepare powder, and is filtered and dehydrated to prepared a kaoline filter cake, and the kaoline filter cake is crushed and collected after the kaoline filter cake is dried to prepare the kaoline finished product. The kaoline prepared by the method has the viscosity content of about 52 percent, and is suitable for making catalyst or cracking agent.

Owner:茂名市茂群高岭土有限公司

Dyeing process of ultrafine wool fiber wool tops

InactiveCN105316964AHigh color fastnessImprove dyeing uniformityDyeing processSodium dithioniteSorbitan

The invention discloses a dyeing process of ultrafine wool fiber wool tops. The dyeing process comprises the following steps: (1) adding the following components into a dye vat in parts by weight: 3.4 parts of polyacrylamide, 25 parts of water, 2.2 parts of polydiallyldimethylammonium chloride, 1.8 parts of sodium dithionite, 2.6 parts of camphor tree leaf extracting liquid, 13 parts of a natural plant pigment, 2.2 parts of N-methyl pyrrolidone and 1.9 parts of polyoxyethylene sorbitan fatty acid ester, and uniformly stirring; (2) immersing wool tops into the dye vat for 25 minutes; (3) drying the immersed wool tops at 60 DEG C; (4) immersing the dried wool tops into clean water and rinsing for 15 minutes; and (5) taking out the rinsed wool tops and naturally airing. According to the dyeing process of the ultrafine wool fiber wool tops, provided by the invention, the dyed wool tops have high color fastness and good dyeing uniformity and have no dyeing defects.

Owner:常熟市新华源有色毛条厂

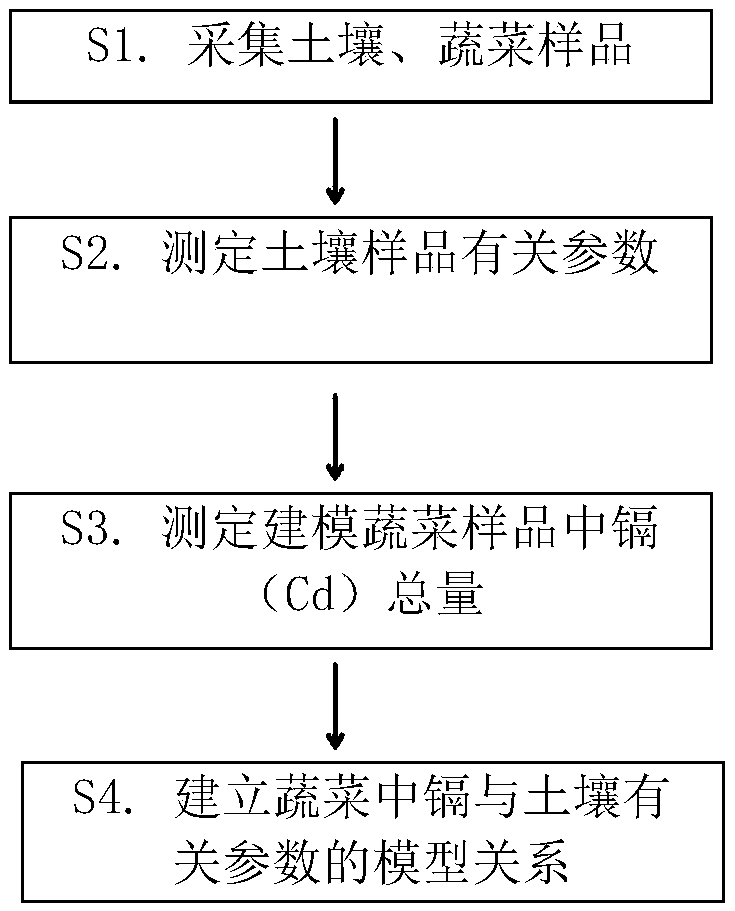

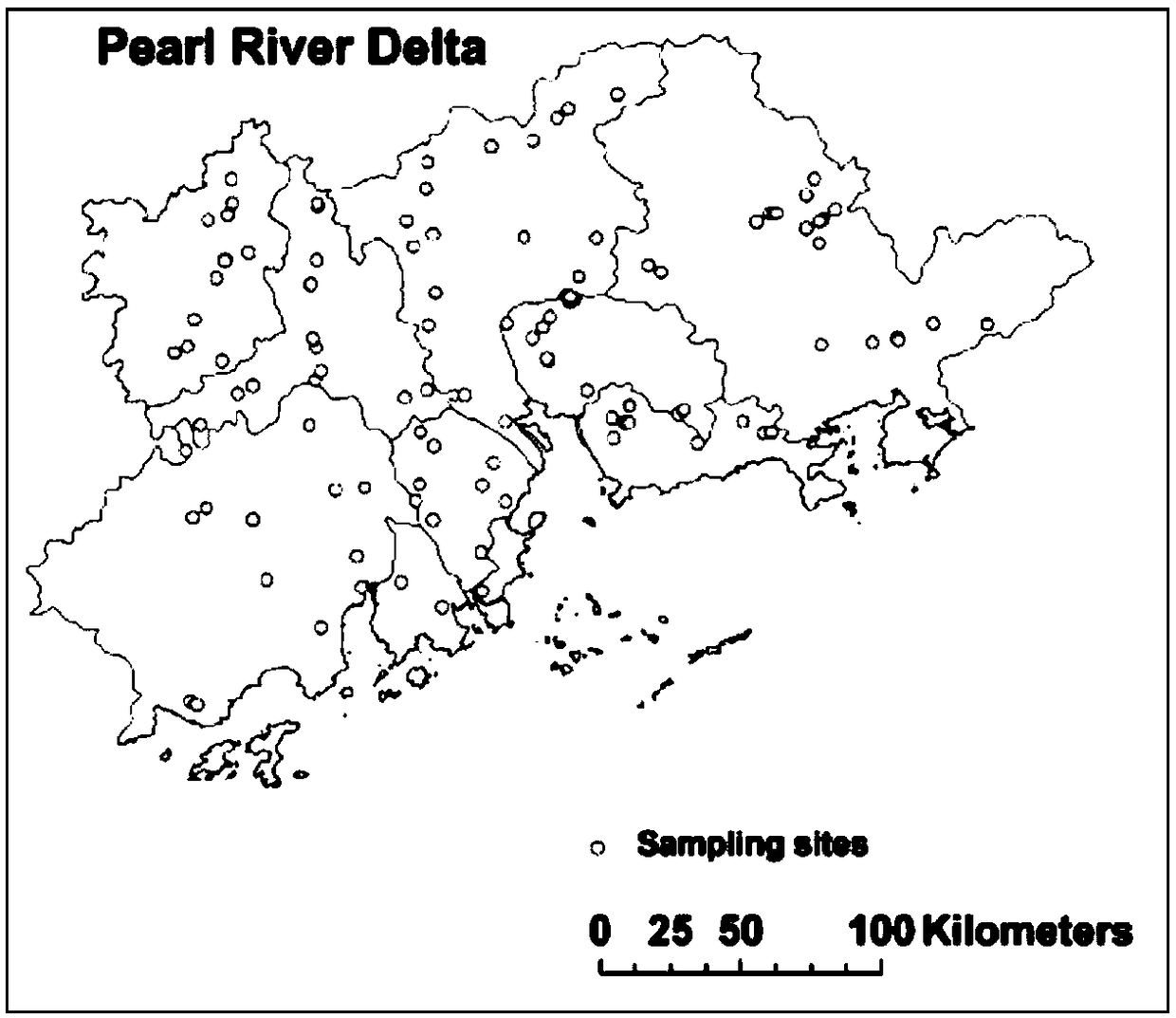

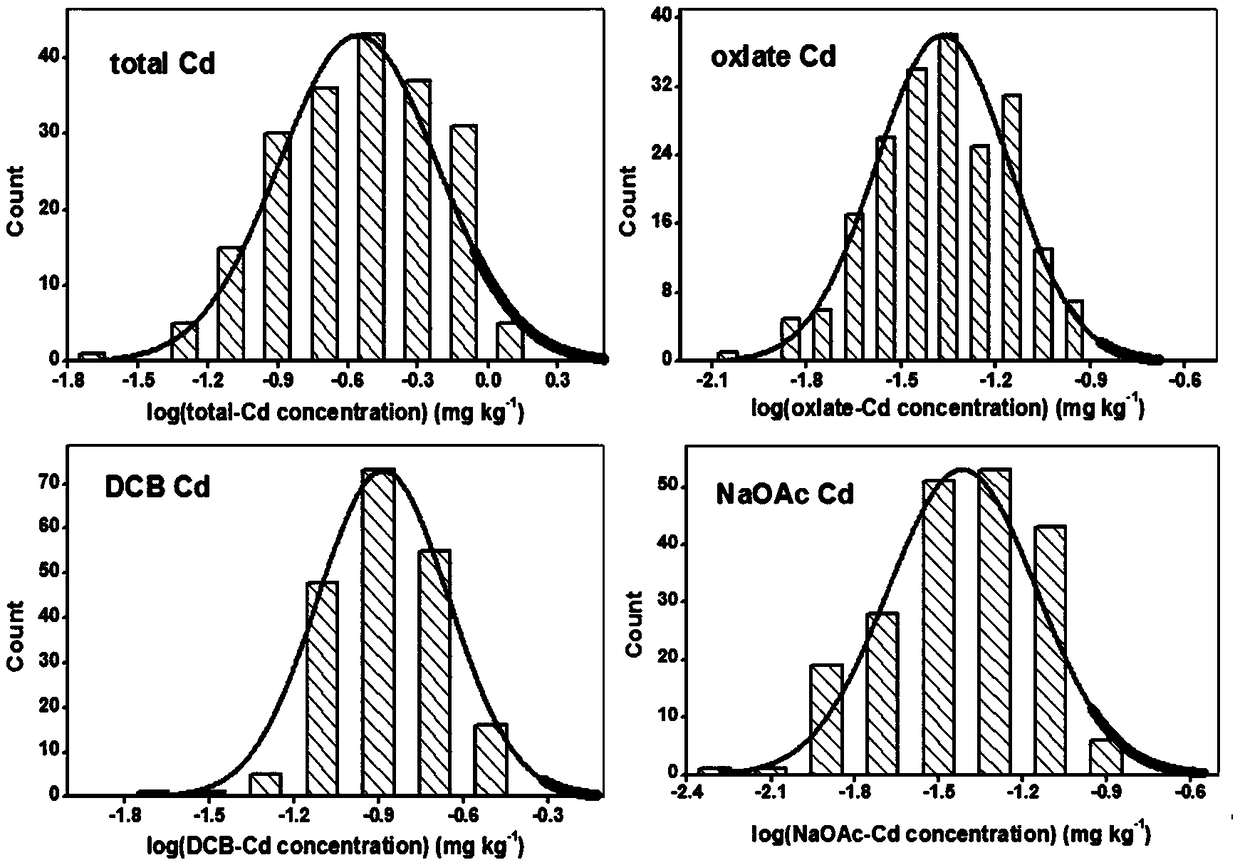

Modeling method for prediction model of cadmium content in vegetables and application thereof

InactiveCN109142650AEarly warning riskReduced enrichmentMaterial analysis by electric/magnetic meansEarth material testingSodium acetateSodium bicarbonate

The invention belongs to the field of agriculture and environment, and relates to a modeling method for a prediction model of the cadmium content in vegetables and application thereof. The modeling method comprises the following steps that a soil sample is collected, the iron-extractable (FeDCB-soil) content of sodium hydrosulfite-trisodium citrate-sodium bicarbonate (DCB) in soil, the cadmium-extractable (Cdoxalate-soil) content of oxalic acid / ammonium oxalate (Oxalate) and the aluminum-extractable (AlNaoac-soil) content of acetic acid / sodium acetate (NaOAc) in the soil are measured, and a model relationship among the content of FeDCB-soil, Cdoxalate-soil and AlNaoac-soil and the content of vegetable cadmium (Cdplant) is established. The formula of the established model is shown in the formula. The model is suitable for the prediction of the cadmium content of the vegetables in the soil, can improve the prediction accuracy of the cadmium content of the vegetables, and provide reference for vegetable safety production layout.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

A kind of preparation method and application of mud-resistant polycarboxylate superplasticizer

The invention discloses a preparation method for an anti-mud-type polycarboxylic-acid water-reducing agent and application thereof. The method is used to improve production efficiency of the anti-mud-type polycarboxylic-acid water-reducing agent, save energy and reinforce anti-mud performance and gradual plasticity-maintaining property of the anti-mud-type polycarboxylic-acid water-reducing agent. The preparation method for the anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention comprises the following steps: under the normal temperature condition of 5 to 35 DEG C, mixing isobutylene alcohol polyoxyethylene ether and maleic anhydride-beta-cyclodextrin and then dissolving the mixture in water; adding a mixed solution of acrylic acid and p-styryl formate; adding hydrogen peroxide; under the protection of nitrogen, adding a mixed solution of mercaptopropionic acid and ascorbic acid, a mixed solution of acylic acid and p-styryl formate, and sodium dithionite; and adding an aqueous sodium hydroxide solution and adjusting the pH value to 6 to 7 so as to obtain the anti-mud-type polycarboxylic-acid water-reducing agent. The anti-mud-type polycarboxylic-acid water-reducing agent provided by the invention has a cup-shaped structure.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

Nano-selenium leaf fertilizer and preparation method thereof

The invention relates to a method for preparing a nano-selenium leaf fertilizer through utilizing sodium dithionite as a reducing agent. The method has the advantages of quick reaction, easiness in implementation and low cost. The nano-selenium leaf fertilizer is prepared according to the following steps: mixing nano-selenium with biogel with strong adhesiveness to form a solution, wherein the content of nano-selenium is 5.0%-10%; and reacting a selenium source reactant with a reducing agent and the biogel, reducing and dispersing.

Owner:北京中国科学院老专家技术中心

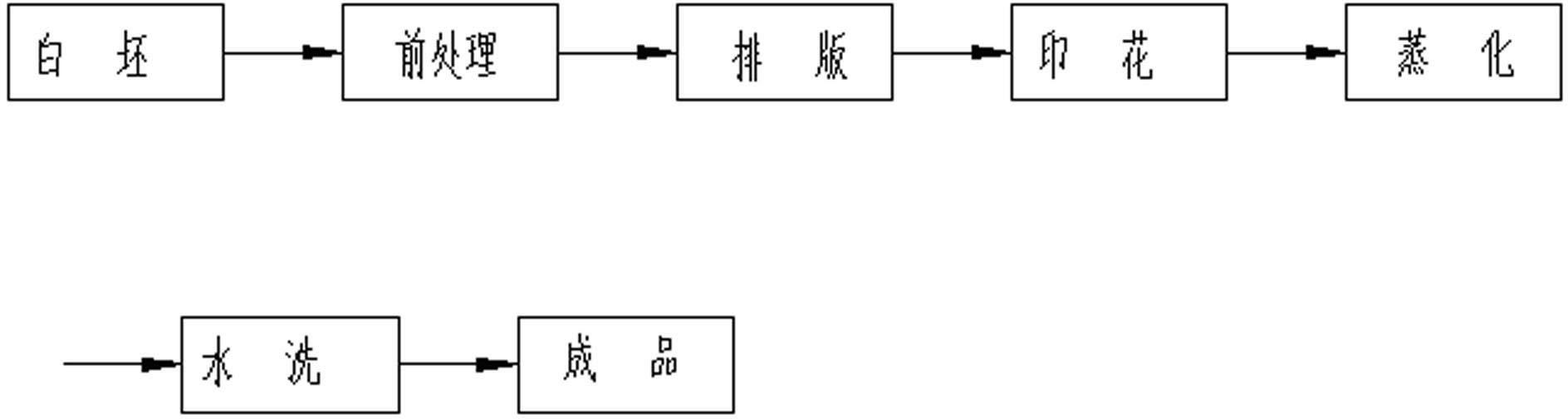

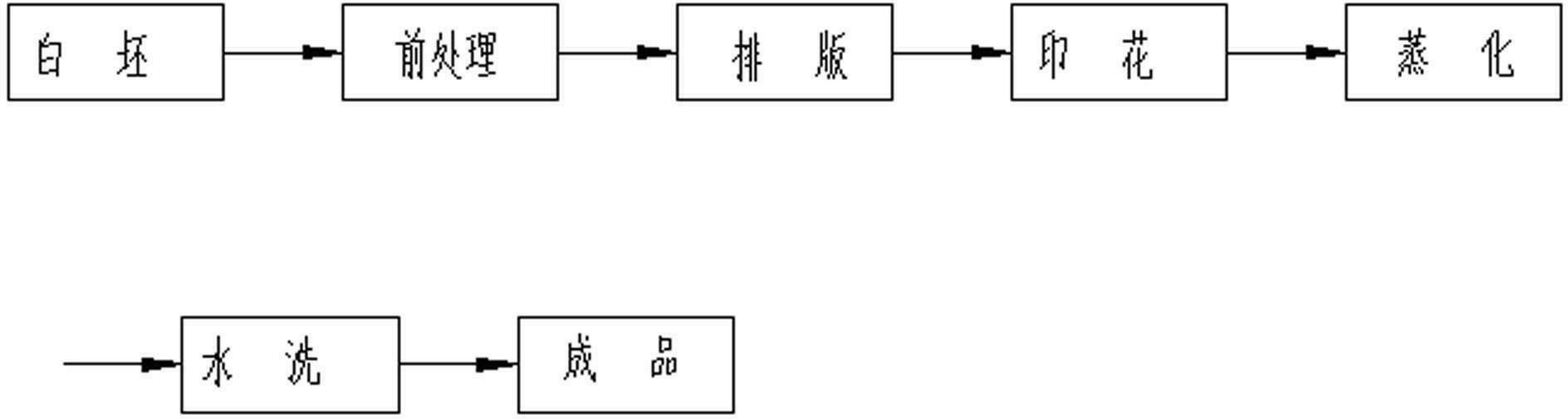

Process for printing far infrared detection prevention camouflage fabric

ActiveCN102628226AGood security camouflage effectDry-cleaning apparatus for textilesDyeing processPolyesterSodium dithionite

The invention relates to a process for printing a far infrared detection prevention camouflage fabric. The process is characterized by comprising the following processing steps of: (1) pretreatment, to be specific, baking and presetting a polyester filament oxford grey fabric, and preparing printing paste; (2) layout, to be specific, arranging a dye screen in front of a coating screen according to a process flow direction; (3) printing, to be specific, printing the printing paste on the pretreated grey fabric by using the dye screen and the coating screen; (4) ageing, to be specific, ageing the printed oxford fabric by using an ageing machine; and (5) washing, to be specific, washing the aged oxford fabric by using a washing machine, wherein washing liquor comprises 2 mass percent of soda, 0.5 to 0.8 mass percent of sodium dithionite, 1 mass percent of nonionic cleaning agent and the balance of water, and washing temperature is 60 to 70 DEG C. By adopting the unique printing process, the camouflage fabric capable of preventing the detection of a far infrared detection instrument can be obtained, and a person and an object covered by the camouflage fabric can be invisible in a complex battlefield environment, so that a good safe camouflage effect can be achieved.

Owner:SHENGHONG GRP CO LTD

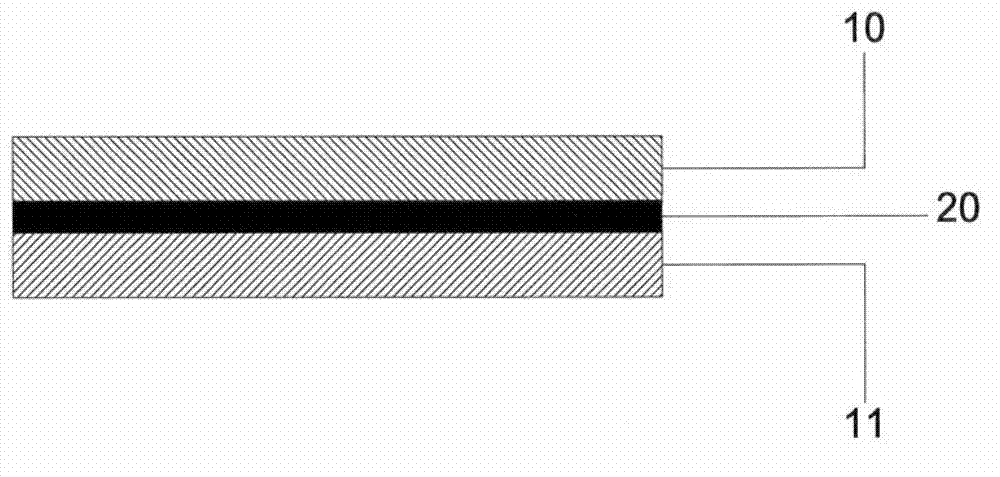

Preparation of conductive gas-phase anti-rust membrane

The invention discloses an electric conduction gas phase rust prevention film which can prevent static and rust. The film is obtained by ingredients such as polyolefin resin, superfine carbon black, a vapor phase inhibitor, chemical inhibitor 1010, light stabilizer 6911, aluminate coupling agent; the polyolefin resin comprises 95% of blending polyolefine (low density polyethylene: linearity low density polyethylene equals to 3:7) and 5% of polyethylene wax; ultrafine grinding and wind force screening are carried out on carbon black powder by a whirlwind mill to obtain the superfine carbon black, the fineness of which reaches 5000 mesh. The vapor phase inhibitor comprises ammonium molybdate 5-30%, sodium benzoate 2-10% , the mixture of hydroxy triazole 5-20%, decanedioic acid sodium 28-45%, oxygen absorbent 5-20%, chrome acid tert-butyl ester 15-35%, and aluminate coupling agent 1-2%; the oxygen absorbent is sodium hydrosulfite or green copperas. The main processing comprises: the solid constituents of the vapor phase inhibitor are ground and coupled; the vapor phase inhibitor and the polyolefin resin are coupled, blended and co-extruded; the superfine carbon black and the polyolefin resin are coupled, blended and co-extruded; a three-layer co-extrusion blown film device is used for putting the polyolefin resin containing the vapor phase inhibitor and the carbon black in a feeding hole for blow molding. The film has the advantages that (1) the film is suitable for the rust prevention of various metals such as various steel, copper, aluminum, chromeplate, does not have undesirable impact on other non-metal materials such as optical equipment, rubber materials, electronic devices and components, and has good compatibility; (2) the film can be suitable for rust prevention packaging of various electronic equipment; the surface resistivity of the packaging film can reach 10 omega; and has excellent static-free and magnetic prevention performances on built-in devices.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Kaolin for preparing heavy-oil catalytic cracking catalyst

The invention discloses kaolin for preparing a heavy-oil catalytic cracking catalyst. Preparation comprises the steps: firstly, digging a Songhua kaolin mineral aggregate, and initially separating out clay and impurities, to obtain a kaolin base material, mixing the base material and a dispersant, slurrying, then removing sand, and thus obtaining a kaolin mineral slurry initial material; transporting the kaolin mineral slurry initial material to a slurry storage tank, stirring, adding an oxidant and a sodium hyposulfite solution, and carrying out chemical bleaching, to obtain a kaolin mineral slurry concentrate; washing the kaolin mineral slurry concentrate obtained through chemical bleaching, carrying out press filtration and dewatering, and thus obtaining a filter cake; and after the filter cake is dried, crushing, and thus obtaining the finished product. The kaolin has good dispersibility and stability, can meet requirements of a catalytic cracking device on catalyst physicochemical properties, and has lower production cost; and in a gelation process, the colloid gelation time is short, the product wear index is low, and the finally-obtained catalyst has better heavy oil conversion ability and heavy metal pollution resistant ability.

Owner:茂名市茂群高岭土有限公司

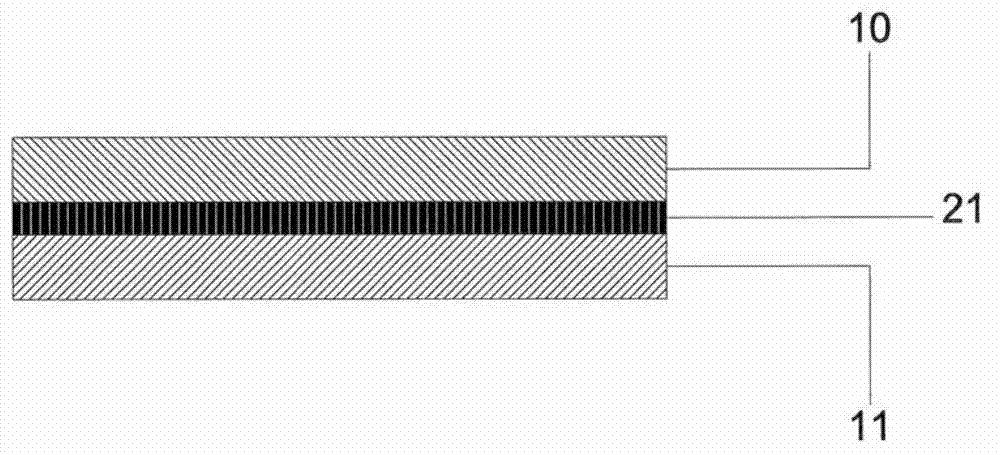

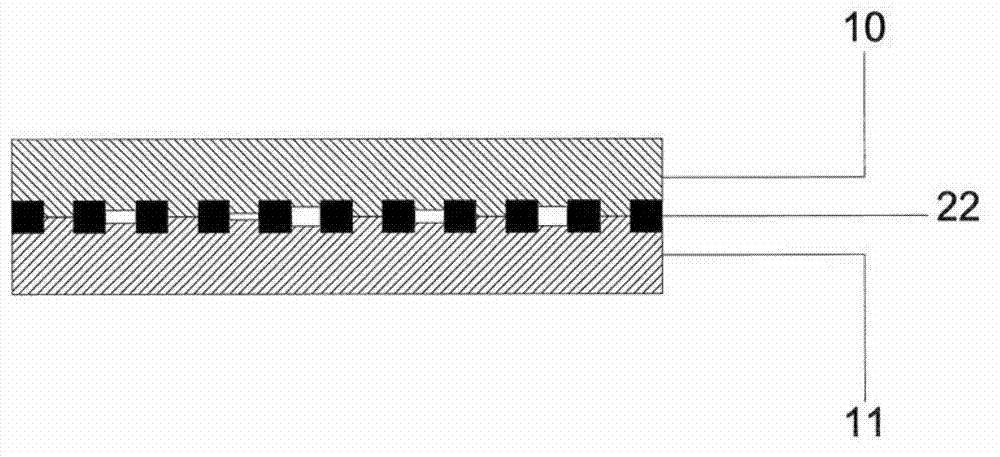

Liner for the protection of adhesive masses

ActiveCN103173150AMeasured value indication by color changeNon-macromolecular adhesive additivesSodium dithioniteIndium

In the case of a liner for the protection of adhesives, the protective effect is to be enhanced in respect of permeates originating from the environment and also permeates included during winding or stacking and other processing steps. This enhancement is accomplished through provision of a liner which comprises at least one adhesive release layer and at least one layer of a getter material capable of sorbing at least one permeable substance. The getter material is selected from lithium, beryllium, boron, sodium, magnesium, silicon, potassium, calcium, manganese, iron, nickel, zinc, gallium, germanium, cadmium, indium, cesium, barium, boron oxide, calcium oxide, chromium oxide, manganese oxide, iron oxide, copper oxide, silver oxide, indium oxide, barium oxide, lead oxide, phosphorous oxide, sodium hydroxide, potassium hydroxide, metal salts, metal hydrides, anhydrides of mono- and polycarboxylic acids, sodium dithionite, carbohydrazide, ascorbates, gallic acid, zeolites, carbon nanotubes, activated carbon, and carbodiimides, and mixtures of two or more substances selected from the above.

Owner:TESA SE

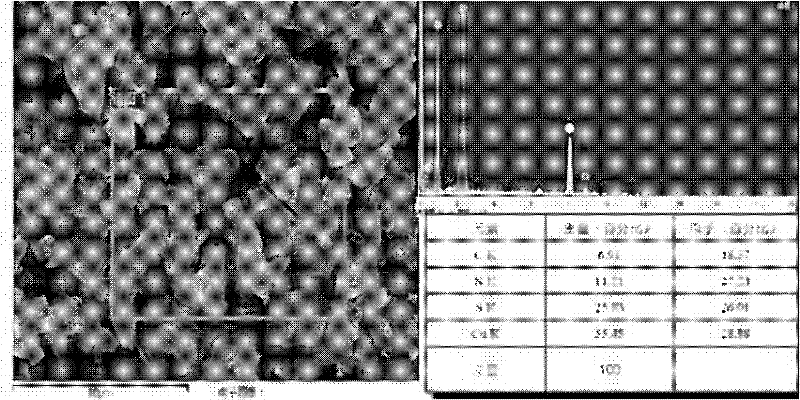

Preparation method for high-oil-factor ultra-fine kaolin

ActiveCN103496710AIt will not cause the sieve residue to exceed the standardWill not cause excessiveSilicon compoundsSodium dithioniteSlurry

The invention discloses a preparation method for high-oil-factor ultra-fine kaolin. The preparation method comprises the following steps of (1) drying kaolin raw ores in a drying box, and then smashing the kaolin raw ores; (2) mixing the smashed kaolin and water to obtain serous fluid, adding sodium dithionite and sodium polyacrylate in the serous fluid, electrically stirring the mixture at normal temperature, then adding sulfuric acids or hydrochloric acids and hydrogen peroxide in the mixture, and continuing stirring the mixture intensely; (3) pumping the serous fluid prepared from the step (2) in a grinding mill, grinding the serous fluid, and adding sodium dodecyl sulfate in the serous fluid in a grinding process; (4) performing solid and fluid separation on the serous fluid prepared from the step (3) by using a filter press to obtain filter cakes; (5) drying and distributing the filter cakes, and spraying the filter cakes by using a spraying machine to obtain kaolin raw powder; and (6) scattering and roasting the kaolin raw powder, annealing naturally, cooling the roasted kaolin powder at normal temperature, and scattering the kaolin powder to obtain the high-oil-factor ultra-fine kaolin products. In a preparation process, screen tailings of the products do not exceed standards, the obtained products is non-corrosive, is low in viscosity, and can be scattered in liquor easily.

Owner:广东科进应用技术研究有限公司

Aqueous degradable environment-friendly ink and decoloring agent thereof

InactiveCN102838900ASafe to useStable in natureChemical paints/ink removersInksSodium dithioniteOrganic solvent

The invention provides aqueous degradable environment-friendly ink for printing, a special decoloring agent and a preparation method of the ink. The degradable environment-friendly ink contains dye, wherein the dye is azo-dye or triphenylmethane dye, or macromolecular dye synthesized by one of azo-dye or triphenylmethane dye, and aqueous macromolecular material. The preparation method of the degradable environment-friendly ink comprises the steps of dispersing, grinding and filtering aqueous acrylic resin, dye, de-ionized water, an antifoaming agent, a flatting agent, surfactant and amine materials in a high-speed disperser and a sand mill in sequence. The special decoloring agent is sodium dithionite or 2Na2CO3.3H2O2. The ink has the advantages of environment friendliness, no harmfulness, good safety, stable performance and good printing effect. When waste papers is recycled, the ink can be decoloured quickly under the action of the matching decoloring agent, and therefore, the problems that organic solvent in the oily ink volatilizes, the waste paper is difficult to deink and sewage pollution is serious are solved.

Owner:SHANXI UNIV

One bath process-based desizing dyeing method of size-containing polyester fabrics and special auxiliaries for dyeing method

ActiveCN104195850AEvenly suspendedAggregation does not occurDry-cleaning apparatus for textilesDyeing processSodium carbonateSodium polyacrylate

The invention discloses a one-bath process-based desizing dyeing method of size-containing polyester fabrics and special auxiliaries for the dyeing method. The method comprises the following steps: putting the size-containing polyester fabrics in water, adding one bath auxiliary A to the water, mixing thoroughly and then adding a dye to the water, mixing thoroughly again and then orderly performing heating, heat preservation and cooling treatment on the obtained system containing the fabrics; next, adding one bath auxiliary B and sodium hydrosulfite to the cooled system for reductive cleaning; and finally, discharging residual liquid and cleaning with warm water, thereby obtaining the desized and dyed polyester fabrics. The one bath auxiliary A comprises the following components in percentage by mass: 15%-20% of wetting emulsifier, 15%-20% of level dyeing diffusant, 4%-6% of chelating disperse agent and the balance being water. The one bath auxiliary B comprises the following components in percentage by mass: 15%-30% of sodium polyacrylate, 20%-40% of sodium hydroxide and 40%-60% of sodium carbonate. The one-bath process-based desizing dyeing method of the size-containing polyester fabrics is only carried out in one bath, and therefore, the processing time is obviously shortened and the quality of the fabrics can be guaranteed favorably; a low amount of water is used and water can be saved by 80%; the energy consumption is low; few types of auxiliaries are utilized.

Owner:BEIJING CTA TEX CHEM

Room-temperature synthetic type polycarboxylic high performance water-reducing agent and preparation method thereof

The invention relates to a room-temperature synthetic type polycarboxylic high performance water-reducing agent and a preparation method thereof. The room-temperature synthetic type polycarboxylic high performance water-reducing agent is prepared form the following components including isopentenol polyoxyethylene ether, acrylic acid, methacrylic acid, sodium allylsulfonate, sodium methallyl sulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, sodium dithionite, mercaptoacetic acid, mercaptopropionic acid, sodium hydroxide and water. The room-temperature synthetic type polycarboxylic high performance water-reducing agent is suitable for synthesis and production at room temperature, is high in product water-reducing rate and good in slump loss resistant property, has wide market prospect as the production process has a series of advantages of saving energy, lowering consumption, improving the efficiency, being green and environment-friendly and the like and is widely suitable for high-quality concrete of commercial concrete in various grades, high-speed railways, expressways, large bridges, precast elements, airports, port construction and the like.

Owner:河南新汉材料科技有限公司

Fiber-reinforced polylactic-acid composite material and preparation method thereof

The invention discloses a fiber-reinforced polylactic-acid composite material. The fiber-reinforced polylactic-acid composite material is prepared from the ingredients in parts by weight: polylactic-acid resin, kapok fibers, Shengma fibers, nano cellulose, silicon carbide powder, nano zinc phosphate, epoxy resin E44, epoxy chloropropane, lithium chloride, phenyl salicylate, isophorone diamine, polyamide wax, a coupling agent, 0.5mol / L potassium hydroxide, sodium dithionite and barium stearate. The prepared fiber-reinforced polylactic-acid composite material has the breaking elongation of 243.5 percent to 301.4 percent, the tensile strength of 48.2MPa to 53.4MPa and the notch impact strength of 149.2J / m to 201.7J / m, and the comprehensive mechanical properties are good, so that the problem of the traditional composite materials that the rupture strength and ductility are poor due to poor interface compatibility between polylactic acid and fibers is solved, and the needs of actual applications are met.

Owner:顺达塑胶制品(深圳)有限公司

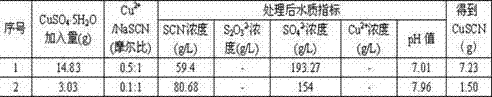

Comprehensive utilization method of desulfurization waste liquid

InactiveCN102225798AReduce salt concentrationIncrease added valueThiocyanic acidWater/sewage treatment by flocculation/precipitationHigh concentrationSodium bicarbonate

The desulfurization waste liquid of a sodium carbonate-sodium bicarbonate solution which contains high concentrations of sodium thiosulfate, sodium thiocyanide and sodium sulfate loses the absorption capability to hydrogen sulfide, and can not be directly discharged, thus a difficult problem emerges. The invention provides a treatment method for recycling the desulfurization waste liquid which is characterized by comprising the following steps of: adding an appropriate amount of copper sulfate to the desulfurization waste liquid to form high-purity cuprous thiocyanate precipitate; separating the precipitate, wherein the concentrations of sodium thiosulfate and sodium thiocyanate in the water body are significantly reduced and part of sodium thiosulfate and sodium thiocyanate is converted into sodium sulfate, so that sodium sulfate in the water body is saturated; and then removing the majority of sodium sulfate by using low-temperature crystallization or other industrially realizable methods to greatly reduce the salt concentration of the water body, wherein the water body can be used as desulfurization liquid after the supplementation of sodium carbonate, thus avoiding or reducing discharge.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting silver from silver-extracted sediment

InactiveCN102181645AReduce pollutionLow costProcess efficiency improvementSodium dithioniteLeaching rate

The invention provides a method for extracting silver in silver-extracted sediment. In the method, sodium thiosulfate and copper sulfate which serve as leachate are leached twice to extract the silver, so the method is high in the leaching rate of the silver and environment-friendly; and the silver is reduced by adopting sodium dithionite and the reduced liquid is regenerated to be used for leaching, so the cost is saved greatly.

Owner:GEM CO LTD

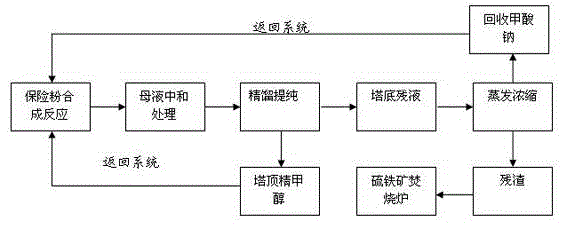

Method for recycling residues of sodium dithionite

InactiveCN103058146AReduce manufacturing costAchieve emission standardsThiosulfates/dithionites/polythionitesActivated carbonSodium dithionite

The invention relates to a method for recycling residues of sodium dithionite. The method comprises the following steps of (1) putting the residues into an incinerator for incinerating, and removing organic salts in the residues; (2) feeding the material residues into a reactor in a stirring state, heating until the material residues boil, adding sulfur of which the weight is 5 to 15 percent of that of the residues, continuously heating, stirring and reacting for 1 to 2 h; (3) feeding solution obtained in step (3) into an oxidation reactor, oxidizing by air at the temperature of between 70 and 80 DEG C, and stopping oxidizing until the color of reaction solution is changed into white, and the pH value is between 7 and 8; and (4) performing vacuum evaporation, activated carbon decolorizing, filter pressing, cooling, crystallizing, centrifugal separation and screening on the oxidized reaction solution, and thus obtaining an industrial-class sodium thiosulfate product; and returning mother solution to the oxidation reactor. According to the treatment method provided by the invention, the residues generated in the production process of the sodium dithionite can be recycled, and can be discharged on standard after being subjected to a series of recycling comprehensive utilization, and higher economic benefit can be reached.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

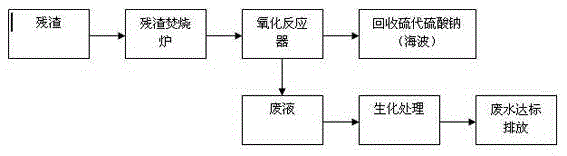

Heavy metal contaminated acidic soil remediation agent, and preparation method and application method thereof

InactiveCN105368455AGood restorativeShort repair timeOrganic fertilisersSoil conditioning compositionsSodium dithioniteSodium metasilicate

The invention discloses a heavy metal contaminated acidic soil remediation agent, and a preparation method and an application method thereof. The heavy metal contaminated acidic soil remediation agent contains the following materials by weight: 20-30 parts of fly ash, 20-28 parts of bentonite, 18-25 parts of hydroxyapatite, 4-9 parts of magnesium aluminosilicate, 3-6 parts of sodium aluminum carbonate, basic, 2-3 parts of zirconium potassium fluoride, 1-2 parts of sodium metasilicate, 1-2 parts of coal gangue, and 0.8-2 parts of sodium dithionite. The present invention also provides a preparation method of the heavy metal contaminated acidic soil remediation agent.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

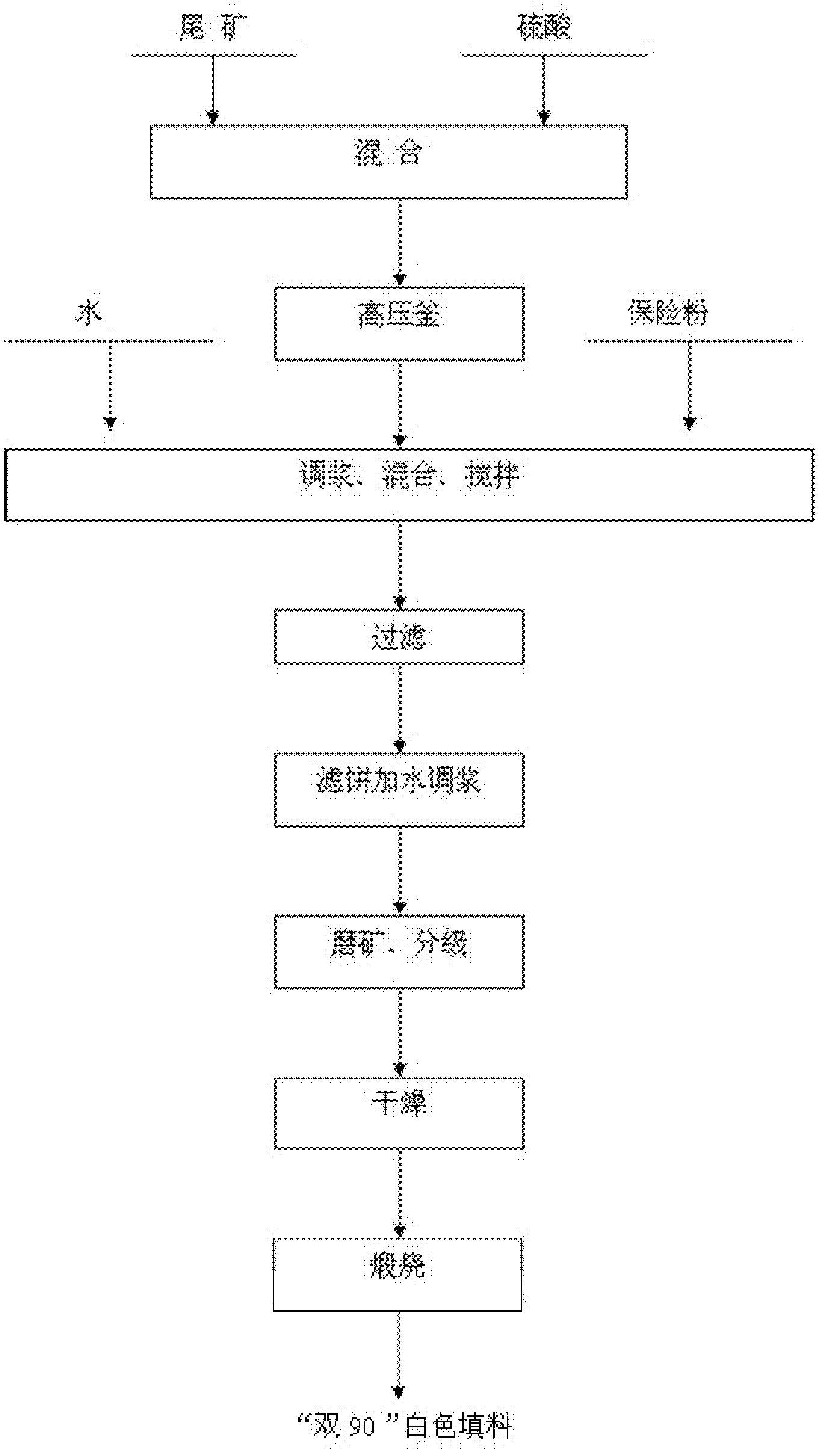

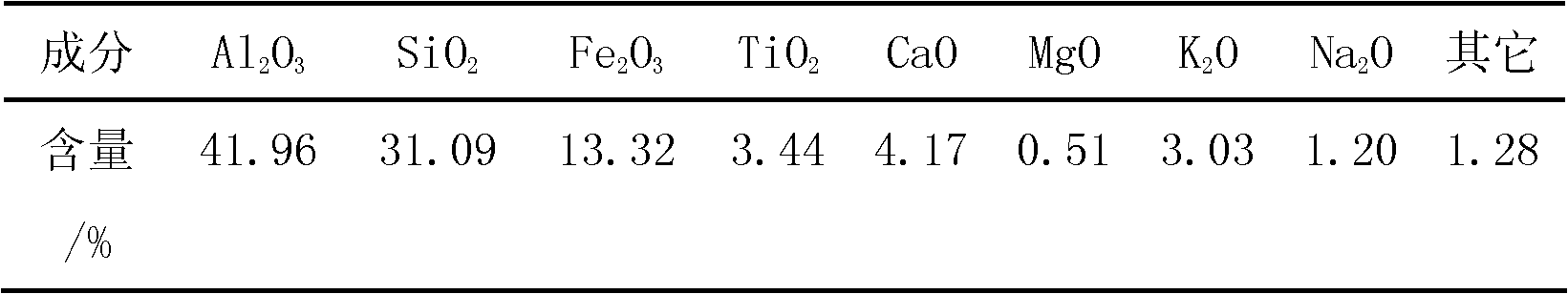

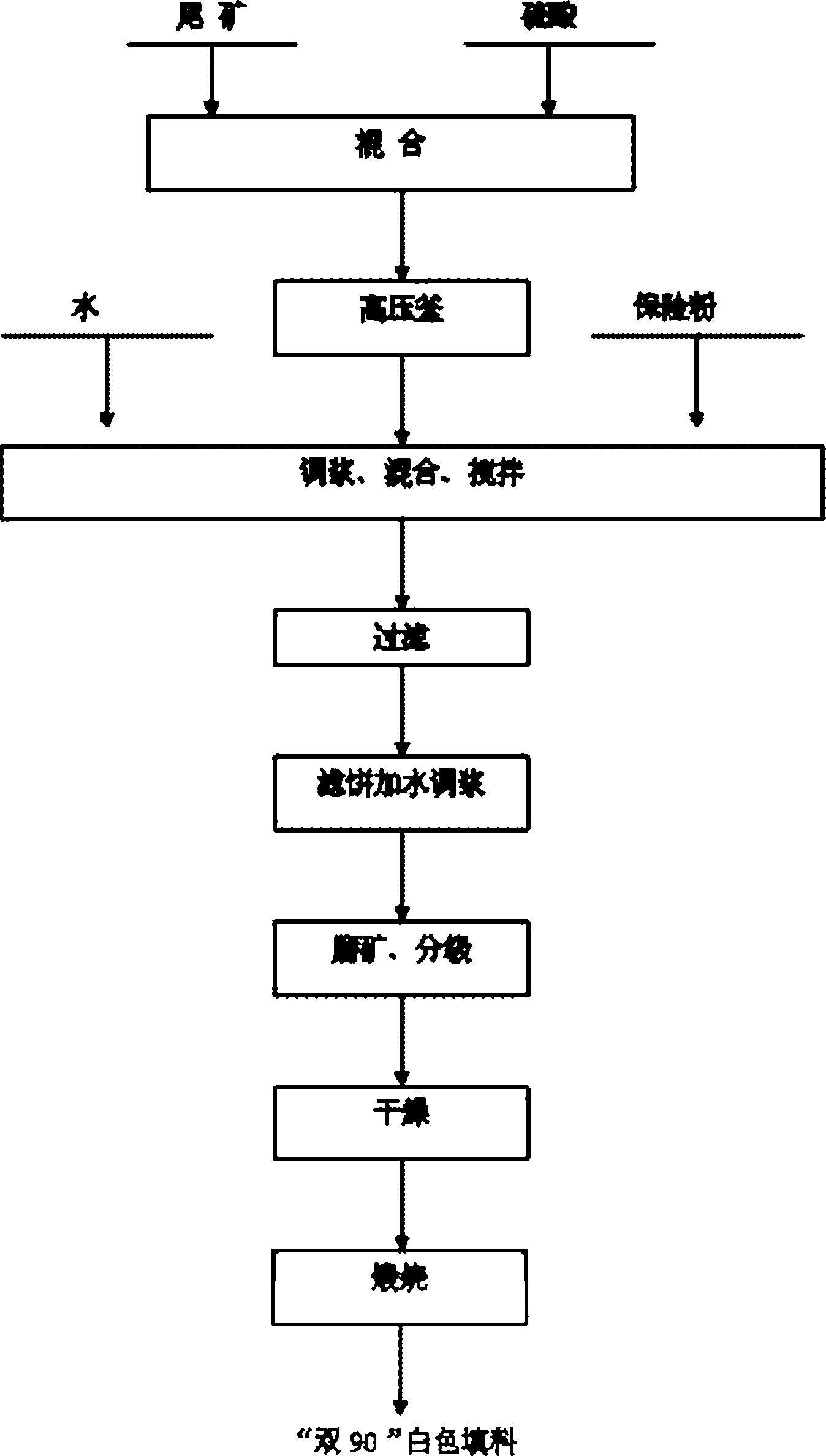

Method for preparing double-90 white filler from bauxite tailing

InactiveCN102675930AEffective iron removalEasy to removePigment physical treatmentSocial benefitsSodium dithionite

A method for preparing double-90 white filler from bauxite tailing comprises the following steps: firstly, heating the bauxite tailing and sulfuric acid at the temperature of 150-300 DEG C for 4-24 hours; secondly, adding water to adjust the pulp density and the pH value; adding sodium dithionite, performing reaction at the temperature of 25-90 DEG C and then filtering to obtain an ore sludge filter cake; adding water into the ore sludge filter cake and mixing to form ore pulp; grinding, grading and drying the ore pulp to obtain superfine powder with the grading content of 0.2 Mum and the whiteness of more than 90 percent; and finally, calcining the superfine powder at the temperature of 800-1000 DEG C to obtain the double-90 white filler. The double-90 white filler produced by the method disclosed by the invention has a high added value, can be applied to the fields of high-grade coating and paint, plastic, rubber and the like and has favorable economic benefits and social benefits. The method disclosed by the invention has the advantages of simple process, low cost, less investment and easiness in realization of industrial production. According to the method disclosed by the invention, the bauxite tailing can be treated in a large batch, the waste can be changed into valuables and a favorable technical path for treating and comprehensively utilizing the bauxite tailing is provided.

Owner:CENT SOUTH UNIV

Reductive dye dyeing process for all-cotton fabric

InactiveCN106120380ASimple processImprove dyeing effectDry-cleaning apparatus for textilesDyeing processSodium dithioniteAqueous solution

The invention discloses a reductive dye dyeing process for an all-cotton fabric. The reductive dye dyeing process comprises the following steps: first, placing the all-cotton fabric in water; then, heating water to 80 DEG C, adding a reductive dye, and preserving heat; next, adding auxiliary agents into an aqueous solution of the all-cotton fabric, wherein the auxiliary agents comprise caustic soda, sodium dithionite and a dispersing agent, the using amount of the caustic soda is 20 to 60 g for each liter of water, the using amount of the sodium dithionite is 5 to 20 g for each liter of the water, and the using amount of the dispersing agent is 1 g for each liter of the water; later on, preserving the heat, and performing oxidation treatment after water washing treatment; finally, performing soaping. The reductive dye dyeing process for the all-cotton fabric disclosed by the invention has the advantages of good dyeing effect, high-temperature water washing resistance and fastness to chlorine-bleaching.

Owner:安徽融创化工科技股份有限公司

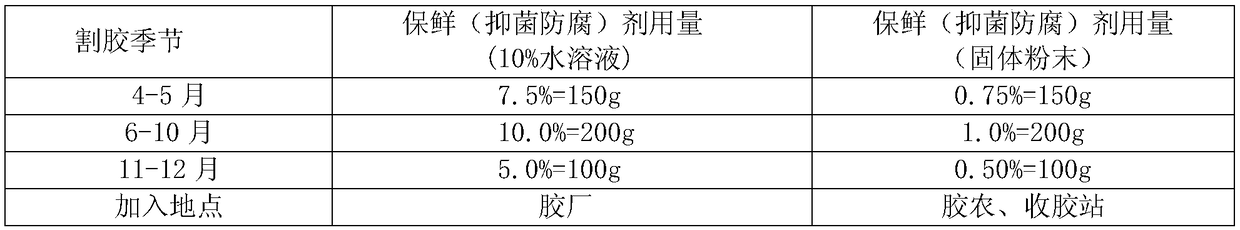

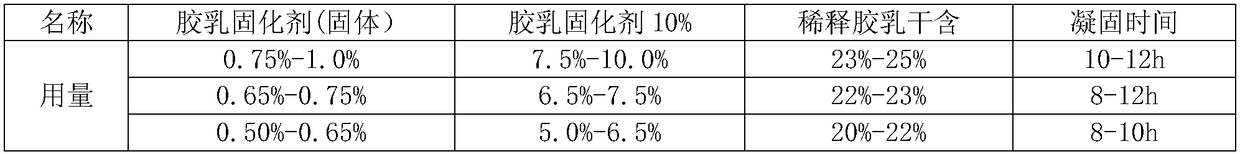

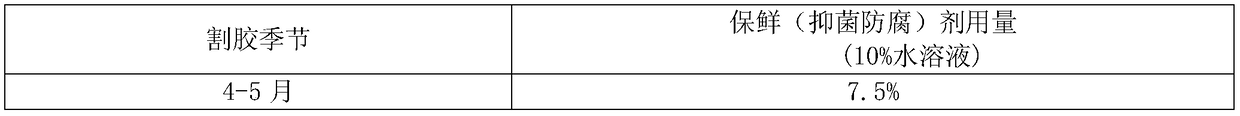

Preservative for natural rubber latex and environment-friendly rubber

The invention provides a preservative for natural rubber latex. The preservative comprises the following ingredients: 1-3% of nano titanium dioxide, 4-6% of ethylparaben, 30-35% of chitosan, 25-28% oflysozyme, 10-12% of pentaerythritol ester, 8-10% of sodium dithionite, 18-20% of benzoic acid and 2-4% of potassium ferrocyanide. The environment-friendly rubber has a simple production process, andafter the ingredients are added according to the specified amounts, full stirring is conducted, so that the dry content of the rubber and the content of total solid in the rubber are increased, the quality of the rubber is improved, and especially the strength, wear resistance, aging resistance are improved greatly.

Owner:青岛金瑞纳橡胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com