Preservative for natural rubber latex and environment-friendly rubber

A natural rubber and antistaling agent technology, applied in the field of rubber production, can solve the problems of reducing the dry content of fresh latex, polluting the environment with ammonia water, increasing production costs, etc., and achieve the effects of increasing total solid content, simple production process, and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments.

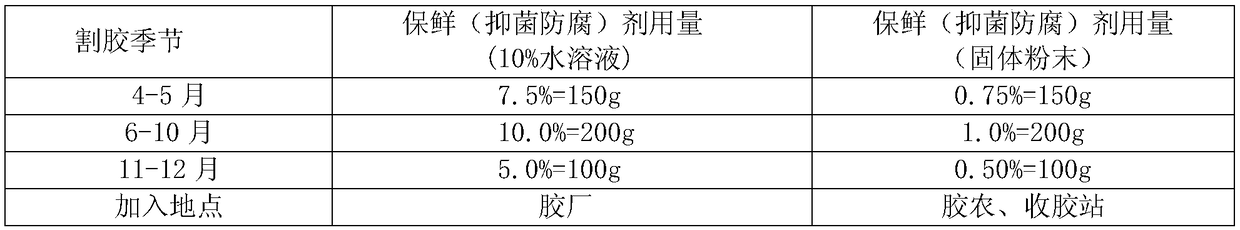

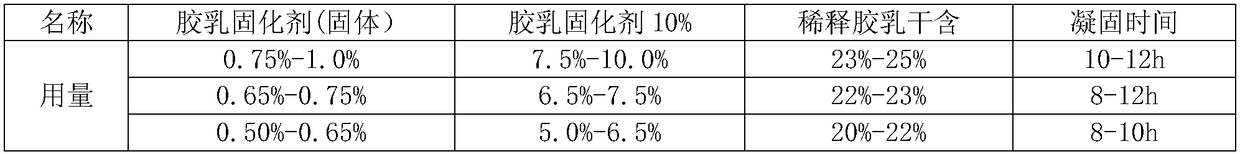

[0030] 1. Preservation: The following two methods can be used to preserve the freshness of natural rubber latex.

[0031] 1. The natural rubber latex can be kept fresh on site (the preservative can be directly added to the latex)

[0032] Add preservative on site: the time from tapping to harvesting is about 4-5 hours, you can put preservative in the rubber collecting barrel in advance, the general size of the rubber barrel is 20-25 kg, you can put the preservative when tapping the rubber as needed About 100-200g (different from season to season), when putting the latex into the rubber barrel, stir to make the preservative fully and evenly in the latex.

[0033] The formula of the antistaling agent is 2kg of nano-titanium dioxide, 5kg of ethylparaben, 30kg of chitosan, 25kg of lysozyme, 10kg of pentaerythritol ester, 8kg of sodium dithionite, 18kg of benzoic acid, and 2kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com