Patents

Literature

222 results about "Rubber tapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber tapping is the process by which latex is collected from a rubber tree. The latex is harvested by slicing a groove into the bark of the tree at a depth of a quarter inch with a hooked knife and peeling back the bark. Trees must be approximately six years old and six inches in diameter in order to be tapped for latex.

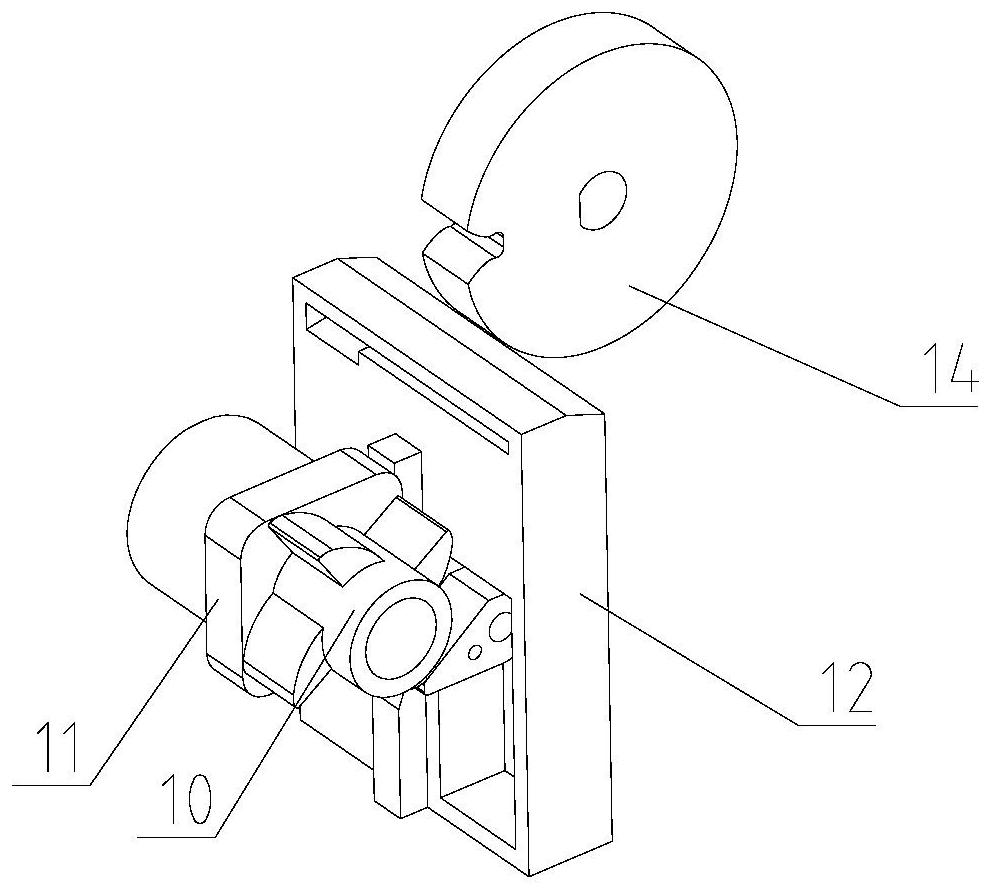

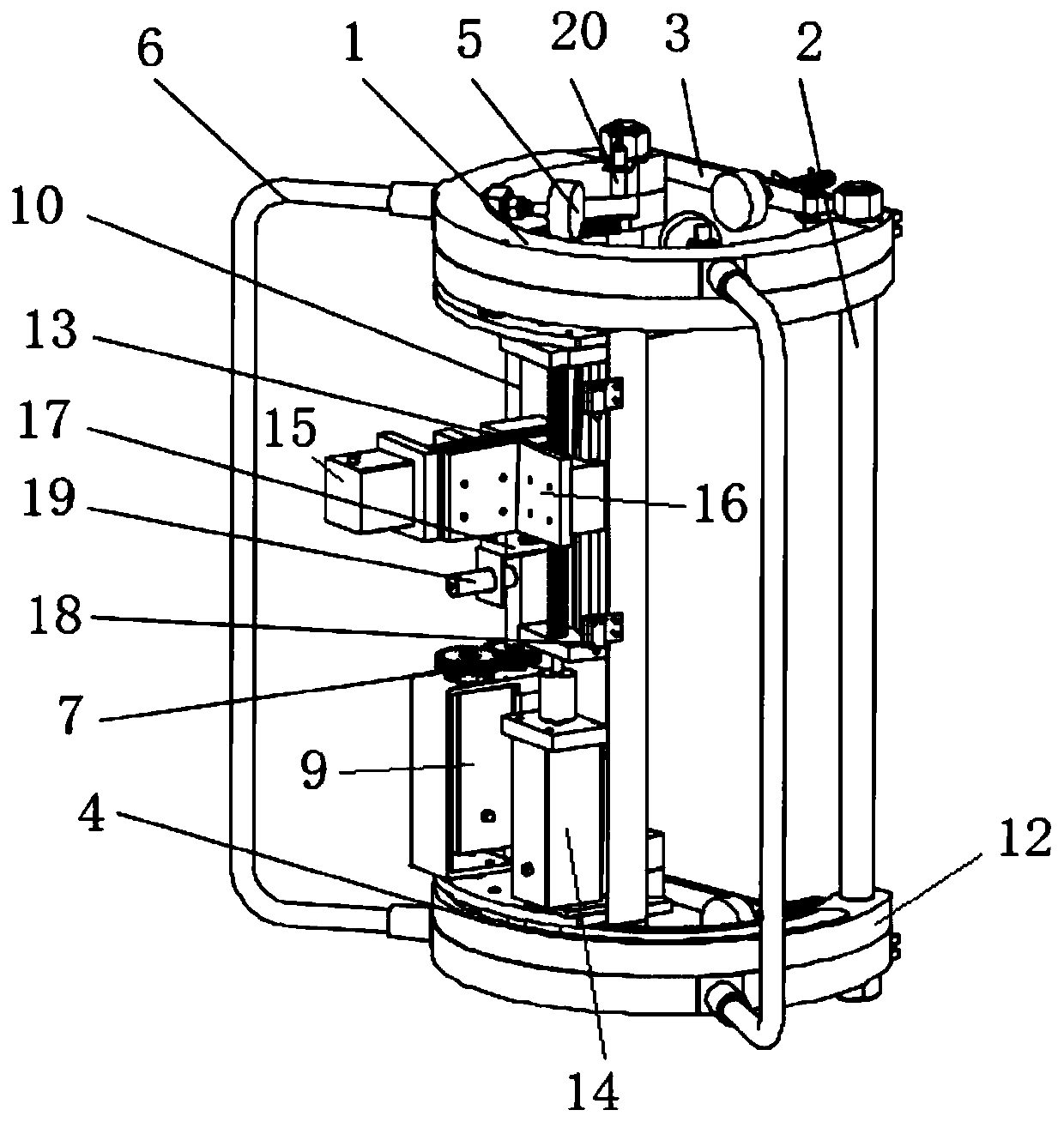

Rubber tapping machine

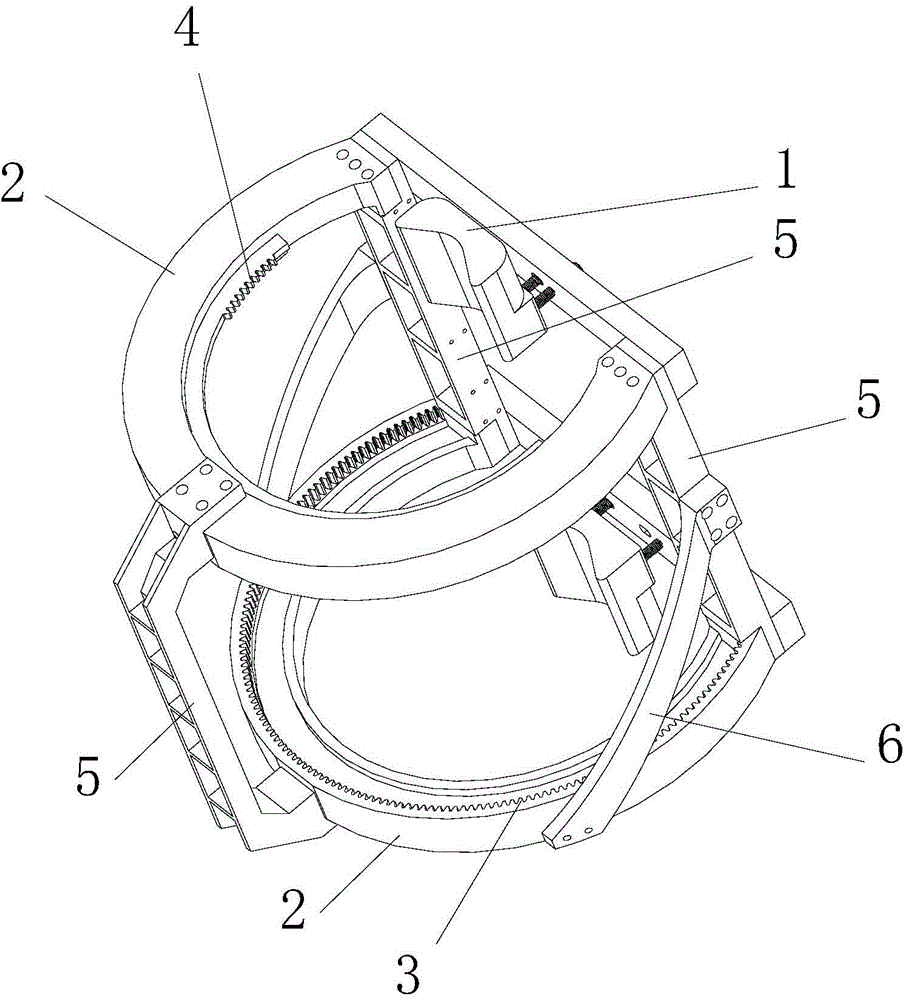

ActiveCN104429813ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryAutomatic controlControl system

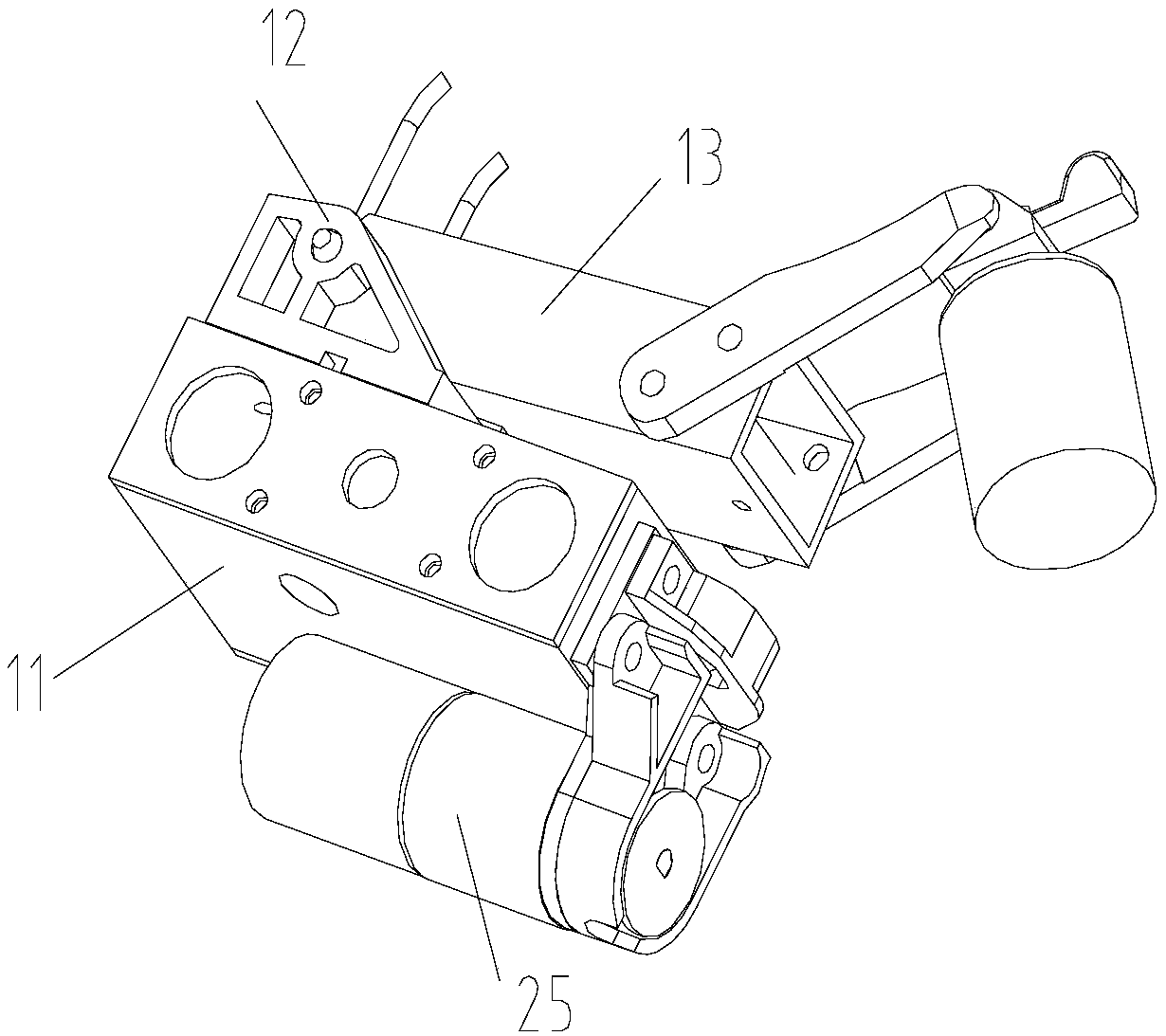

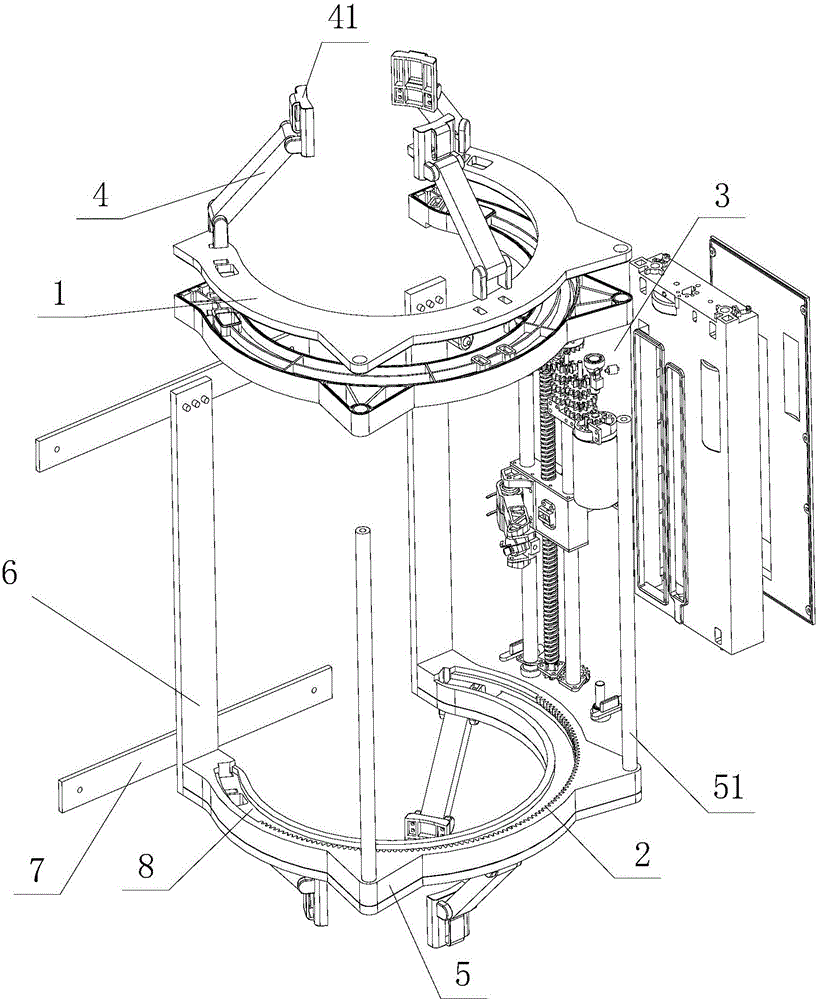

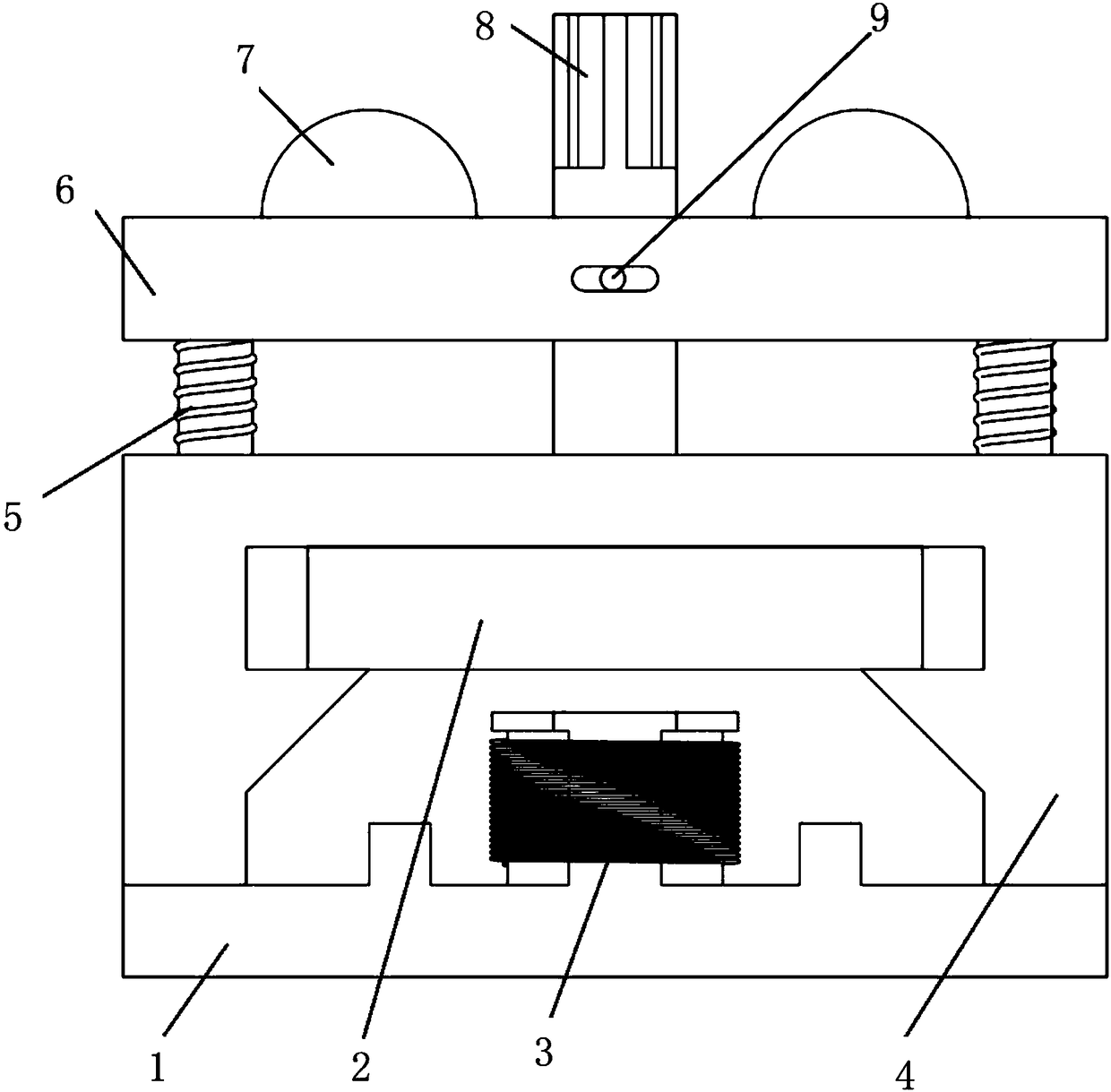

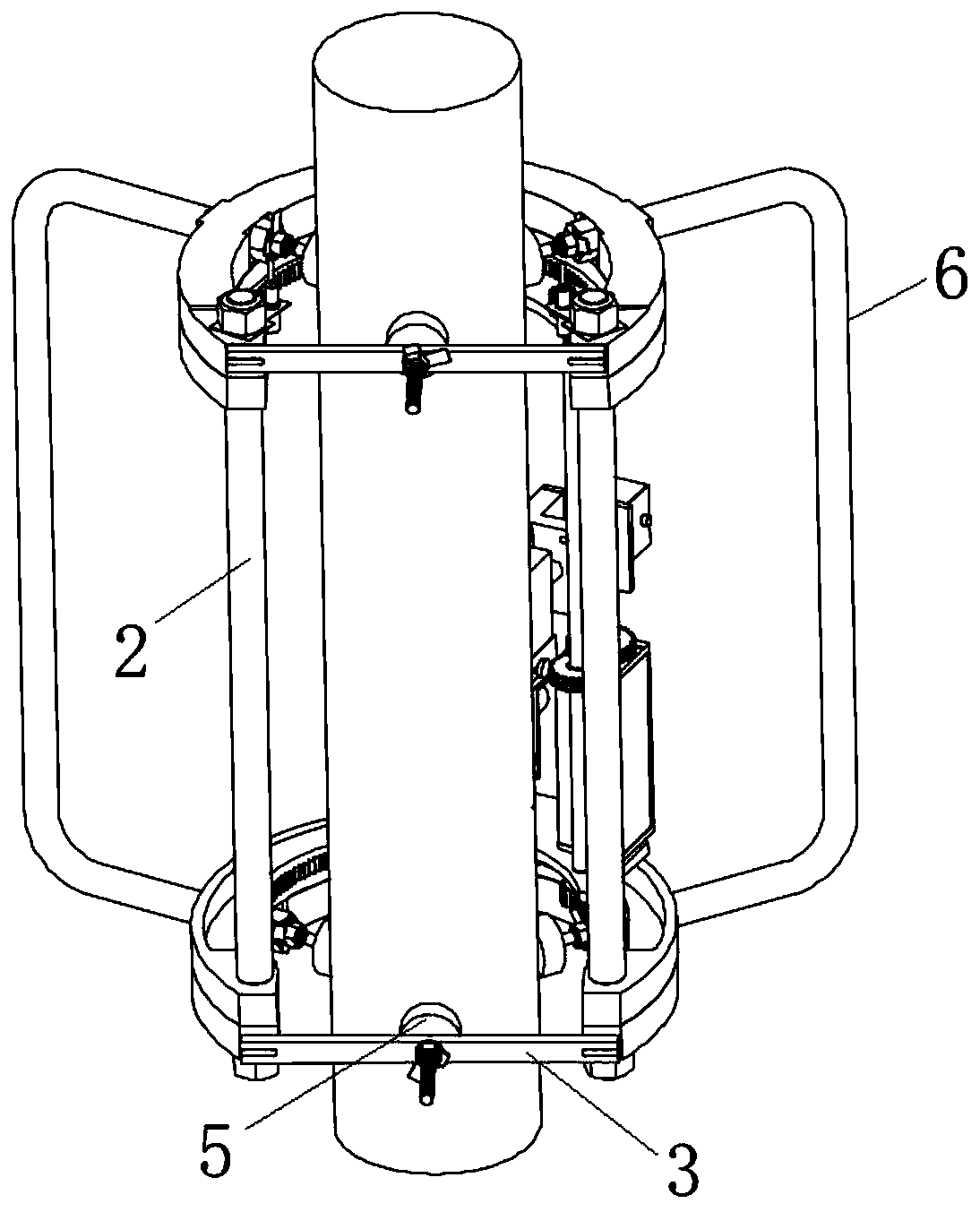

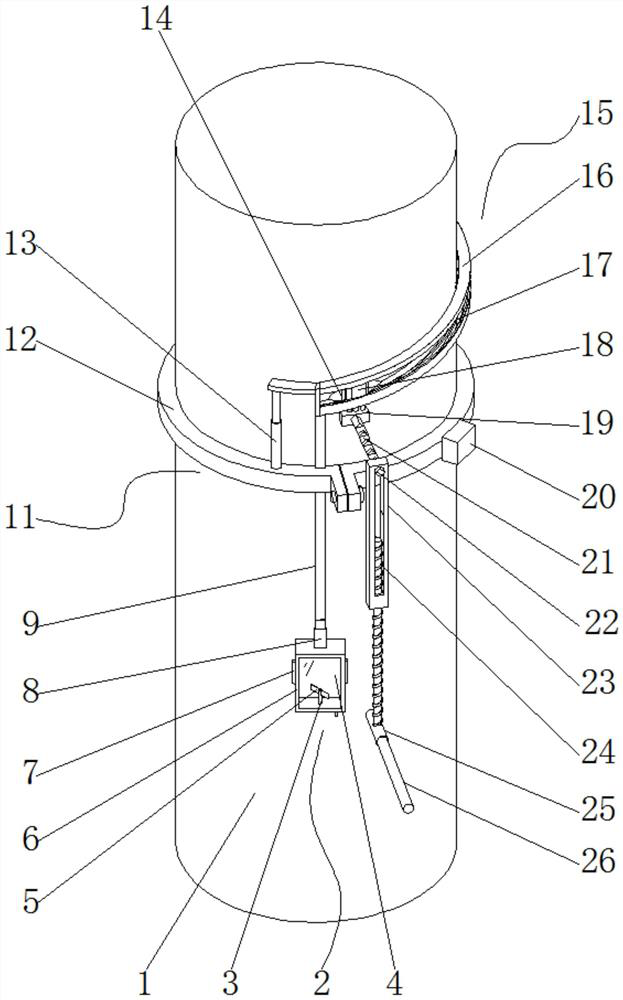

The invention discloses a rubber tapping machine. The rubber tapping machine comprises a tree binding fixing frame and two annular planetary gear outer shells installed at the upper end and the lower end of the tree binding fixing frame respectively. A vector movement knife rest assembly is arranged between the two annular planetary gear outer shells. A gear shaft is arranged on the vector movement knife rest assembly, a motor and a rubber tapping knife rest with a gear rack are arranged in the vector movement knife rest assembly, a rubber tapping knife assembly is arranged in the rubber tapping knife rest, a lead screw is connected to the top end of the rubber tapping assembly, and the rubber tapping knife assembly can vertically move in the rubber tapping knife rest by rotating the lead screw. By means of the rubber tapping machine, manual operation is not needed, and starting, stopping, forward rotating and backward rotating of the motor and starting, stopping, the spraying time and the spraying amount of a catalyst spraying assembly can be controlled by an automatic control system according to a set program. In addition, the automatic control system can be in communication with the exterior through an input-output module, receive a command of an upper computer, update internal program setting and transmit various working states of the rubber tapping machine outwards at any time.

Owner:NINGBO CIHEVEA TECH CO LTD

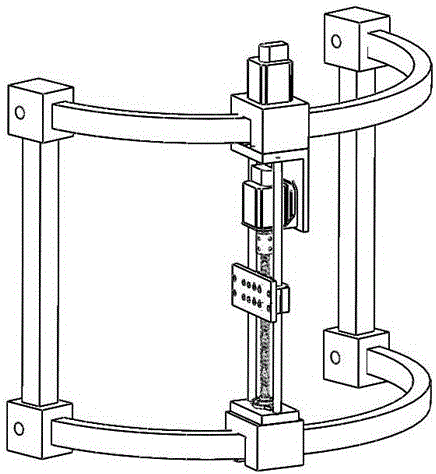

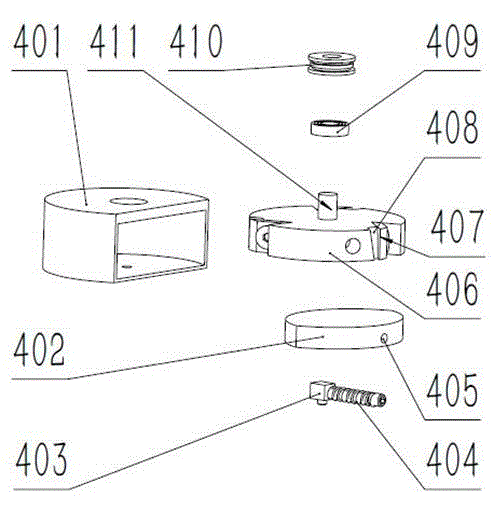

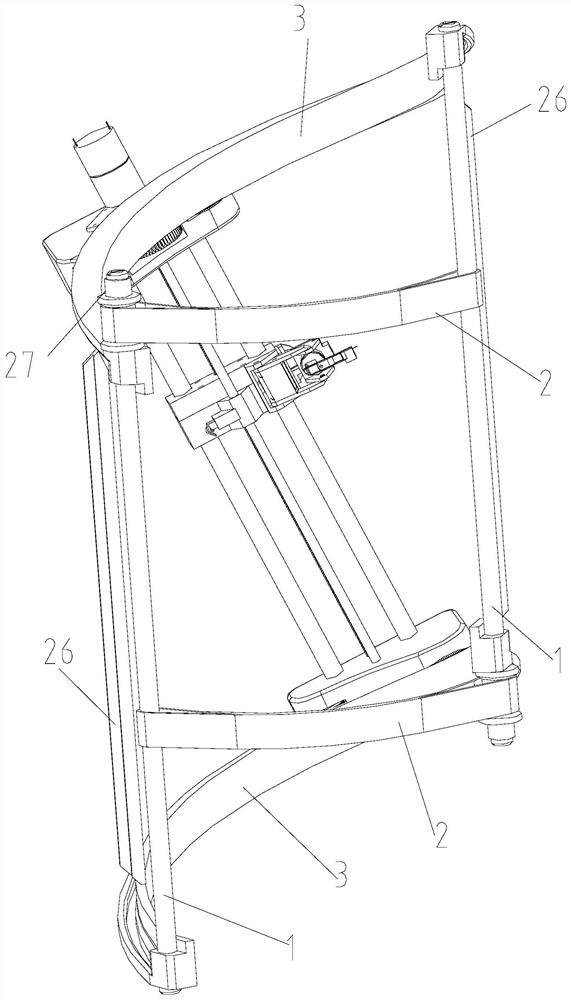

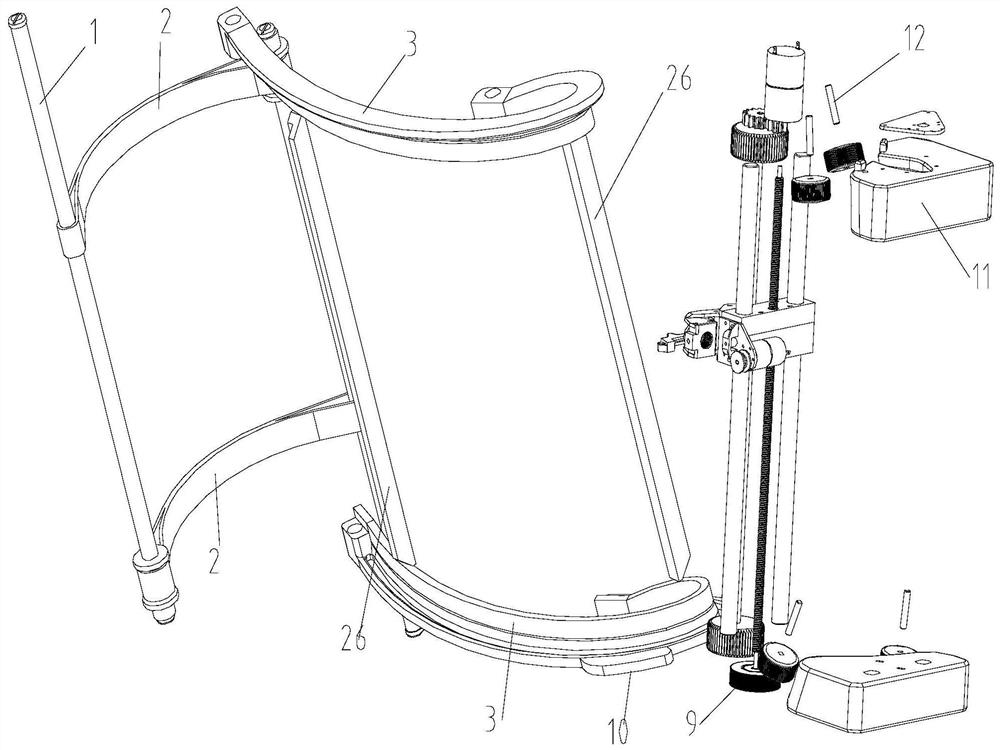

Automatic rubber cutting robot

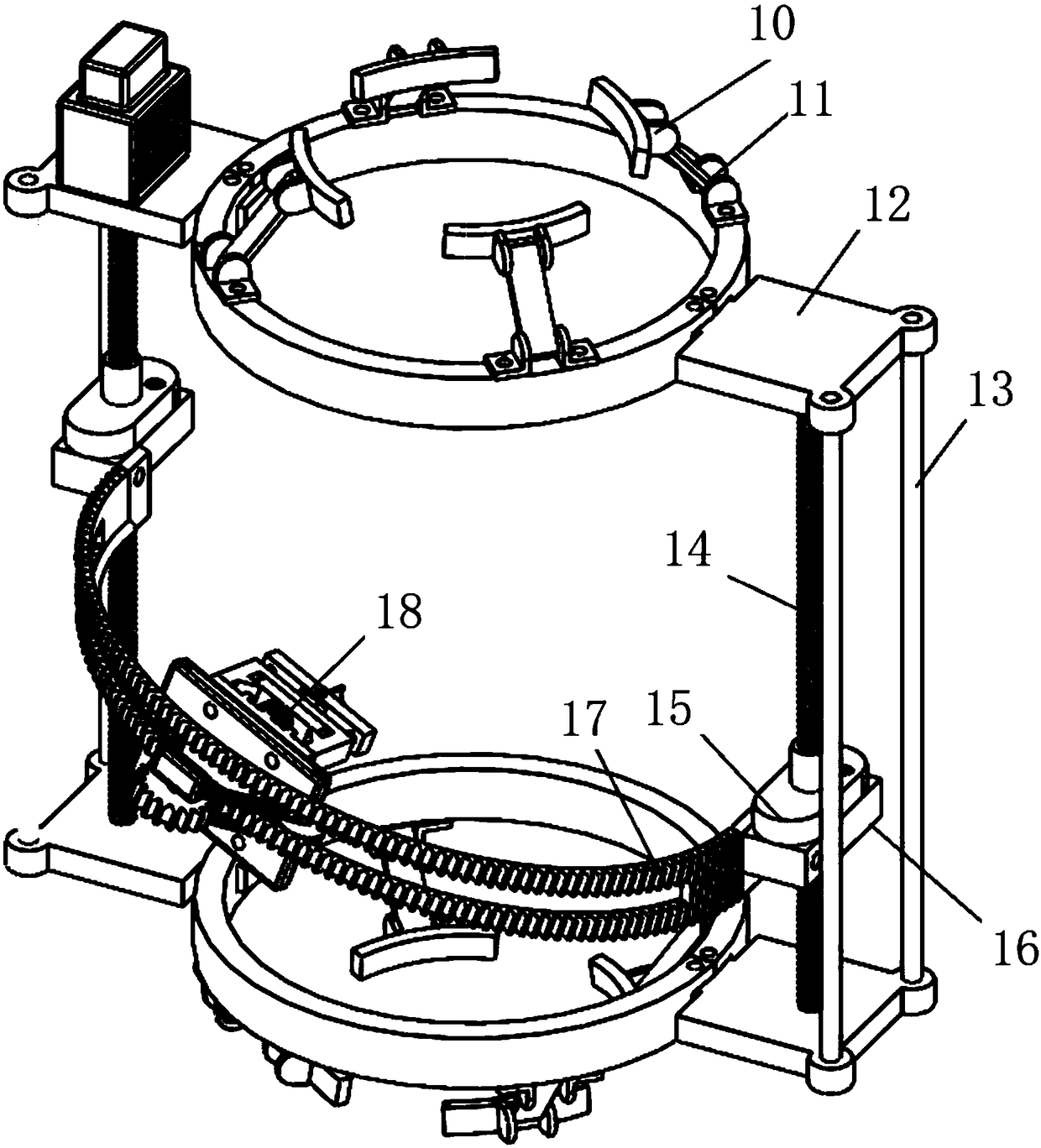

The invention provides an automatic rubber cutting robot, and belongs to the field of agricultural machinery. The automatic rubber cutting robot is characterized by comprising a clamping mechanism, a cutting depth adjusting mechanism, a power device and a cutting trajectory control mechanism, wherein the clamping mechanism consists of rotating blocks and supporting rods; the cutting depth adjusting mechanism consists of a rotating disk with scales, a movable positioning wheel and a knife rest; power is provided by stepping motors; and the cutting trajectory control mechanism comprises an upper annular track, a lower annular track, bogie driving mechanisms and a screw and nut mechanism. The automatic rubber cutting robot is tightly clamped to a rubber tree through the clamping mechanism, a cutting trajectory is a helix through the cutting trajectory control mechanism, then line-change cutting of the automatic rubber cutting robot is realized through screws and nuts, finally appropriate cutting depth is adjusted through the cutting depth adjusting mechanism, and automatic rubber cutting is realized. The automatic rubber cutting robot can automatically adjust the rubber cutting depth, can automatically change lines, is adapted to different tree diameters, and has the characteristics of being simple in structure, convenient to control, low in cost, reliable and practical.

Owner:武汉市享昱科技有限公司

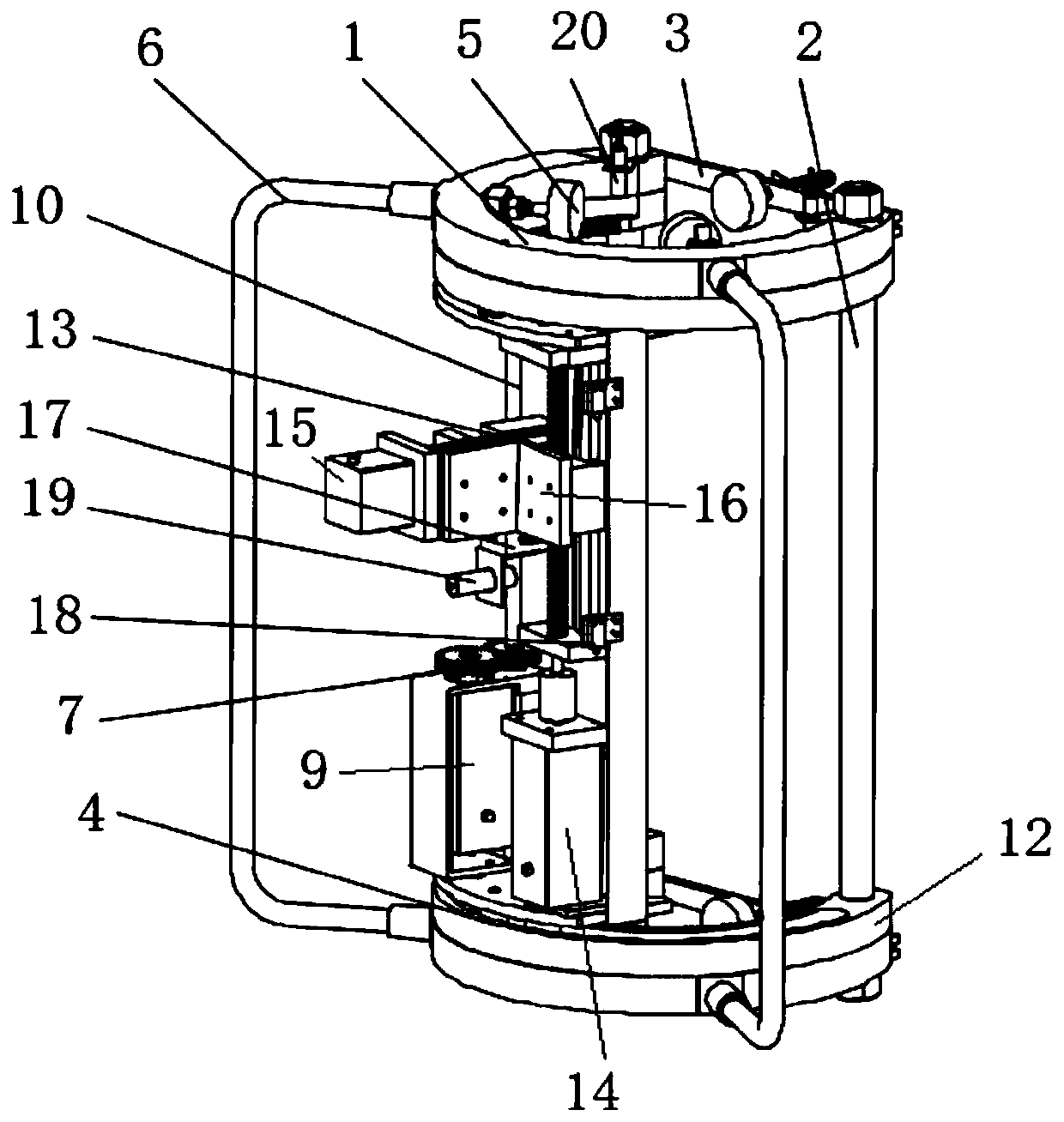

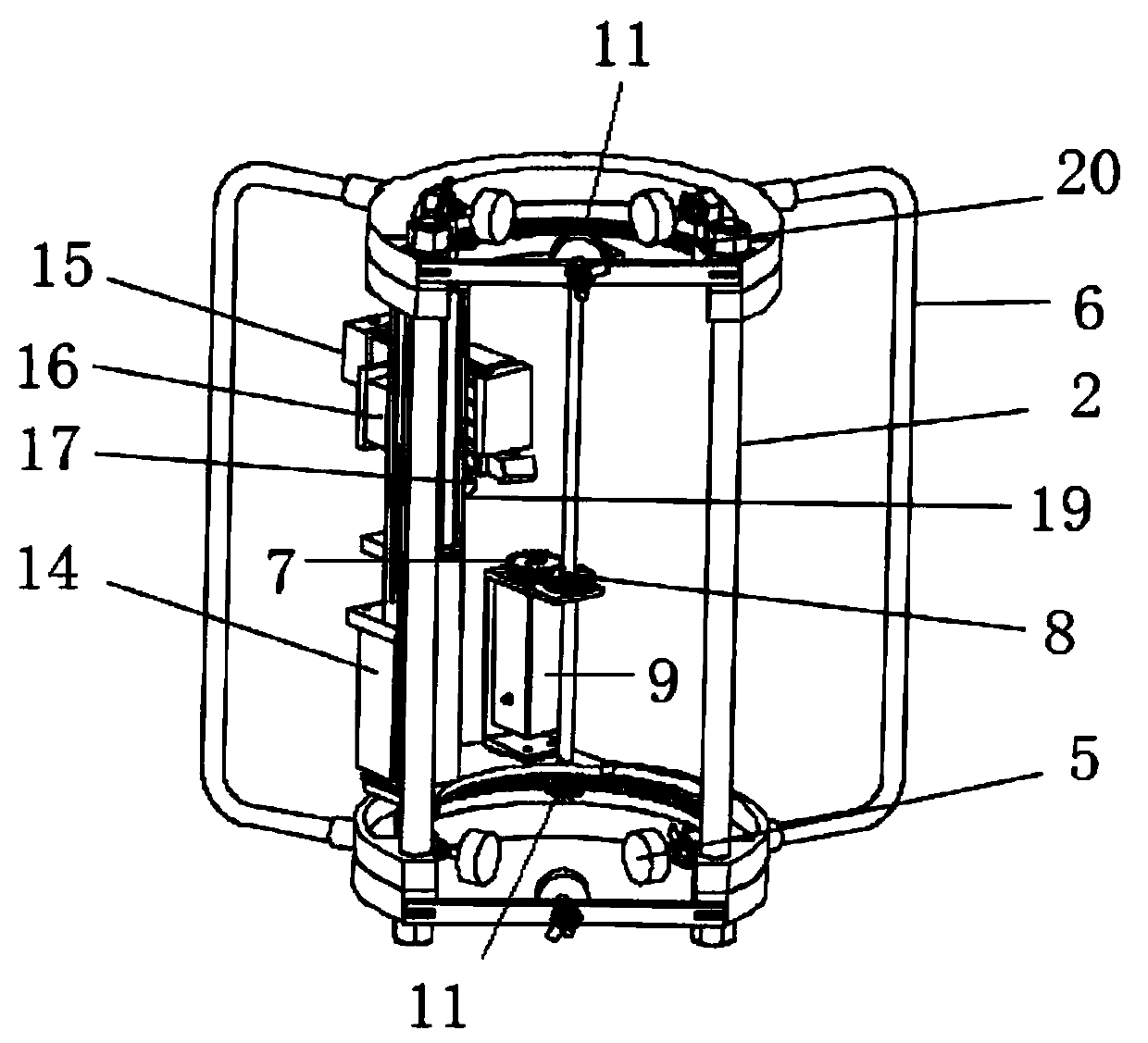

Automatic rubber tapping machine for rubber tree rubber picking

ActiveCN104067904AReduce laborAchieving Micro-Cost RequirementsRenewable energy machinesForestryEngineeringSolar power

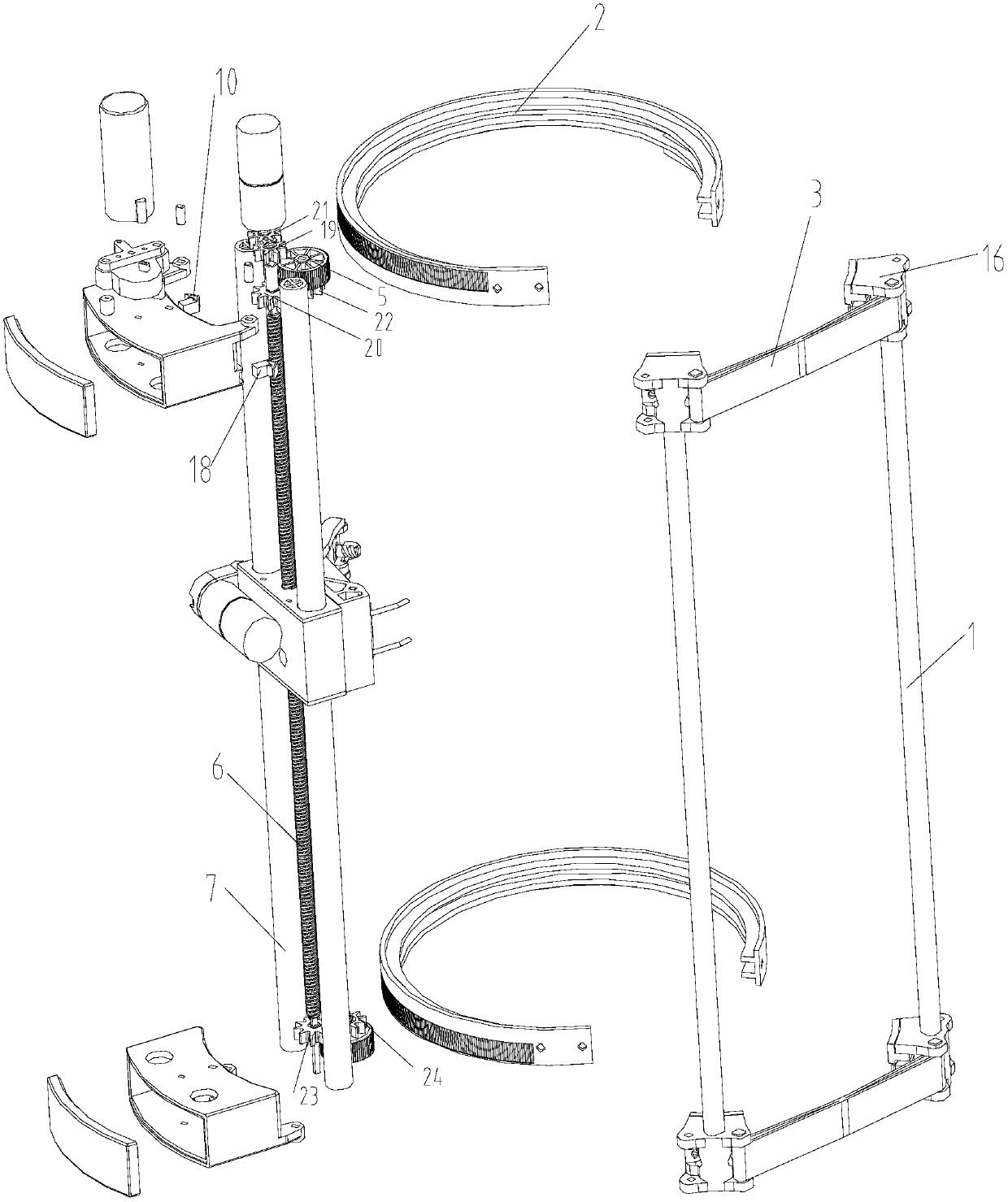

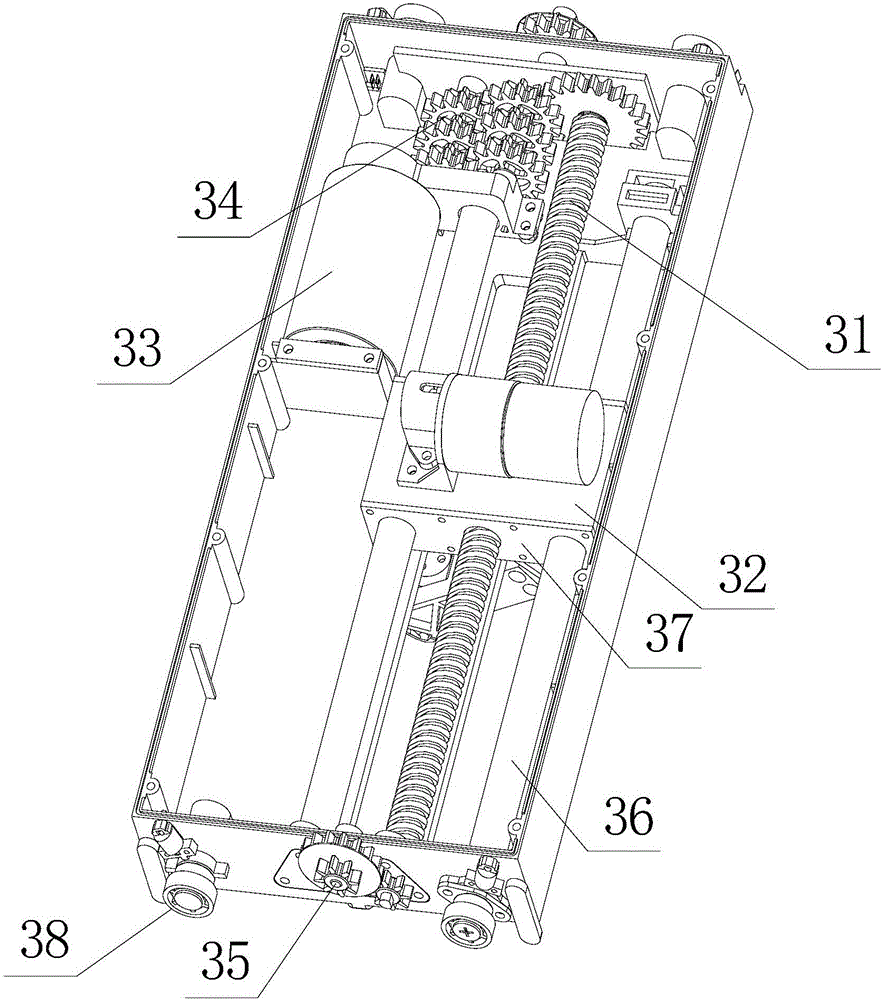

The invention relates to an automatic rubber tapping machine for rubber tree rubber picking. The machine comprises a tapping frame and is characterized in that the tapping frame is formed by a support rod and a support arm. A cut depth location structure, a curved cutter moving structure, an automatic line feed location structure, an end point detection structure, a solar power structure and a control structure are arranged on the tapping frame. The end point detection structure is used for detecting the moving track of a cutter in the curved cutter moving structure, and the signal output end of the end point detection structure is connected with the signal input end of the control structure. The control output end of the control structure is connected with the control input ends of the cut depth location structure, the curved cutter moving structure and the automatic line feed location structure through driving mechanisms. The cut depth location structure is provided with a cutter tapping depth adjusting and locating mechanism. The curved cutter moving structure is provided with a mechanism capable of achieving arc movement, lateral movement and vertical movement simultaneously. Therefore, the automatic rubber tapping machine allowing cut depth location, end point detection limiting, automatic line feed location and the arc tapping track is formed. The automatic rubber tapping machine has the advantages of being capable of reducing labor quantity of rubber picking workers and lays a device foundation for large scale rubber automatic production and the like.

Owner:宁国市吉思知识产权运营有限公司

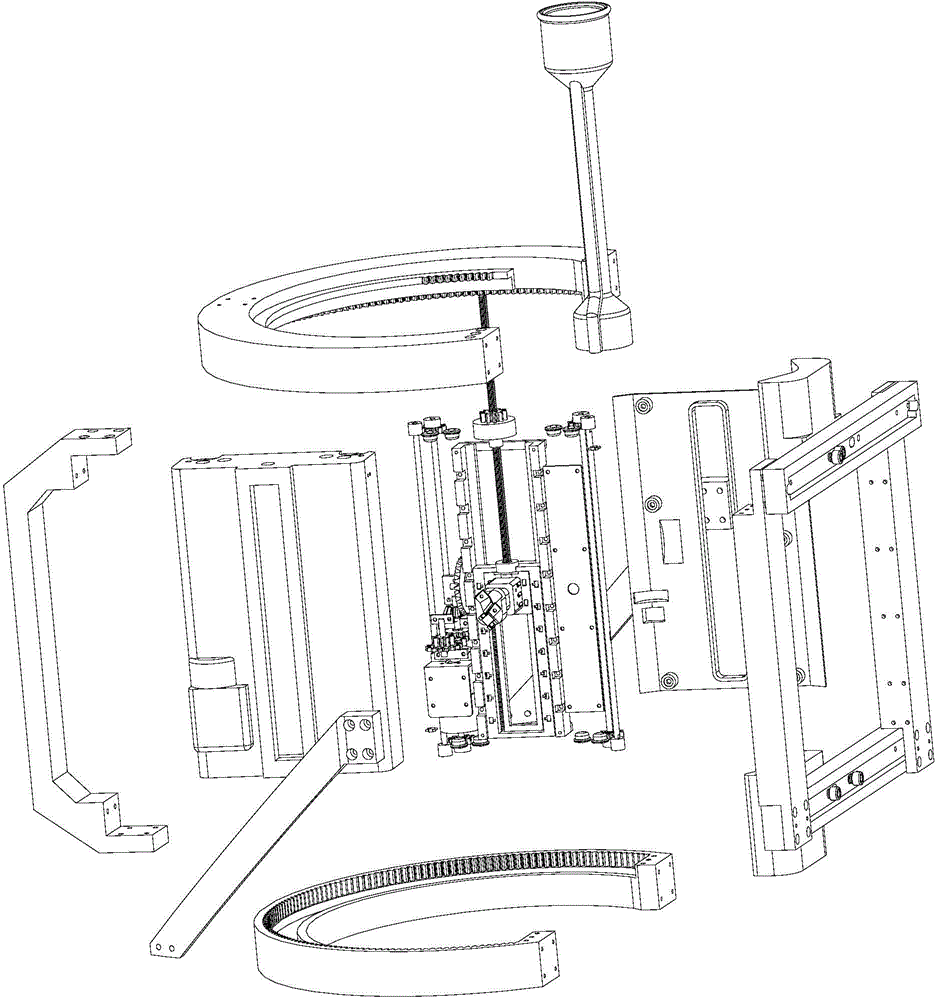

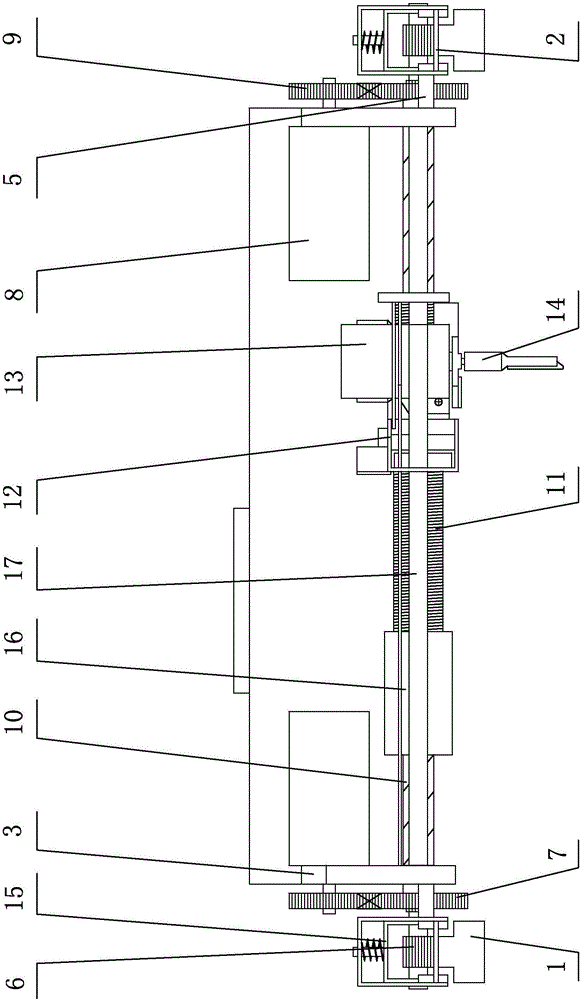

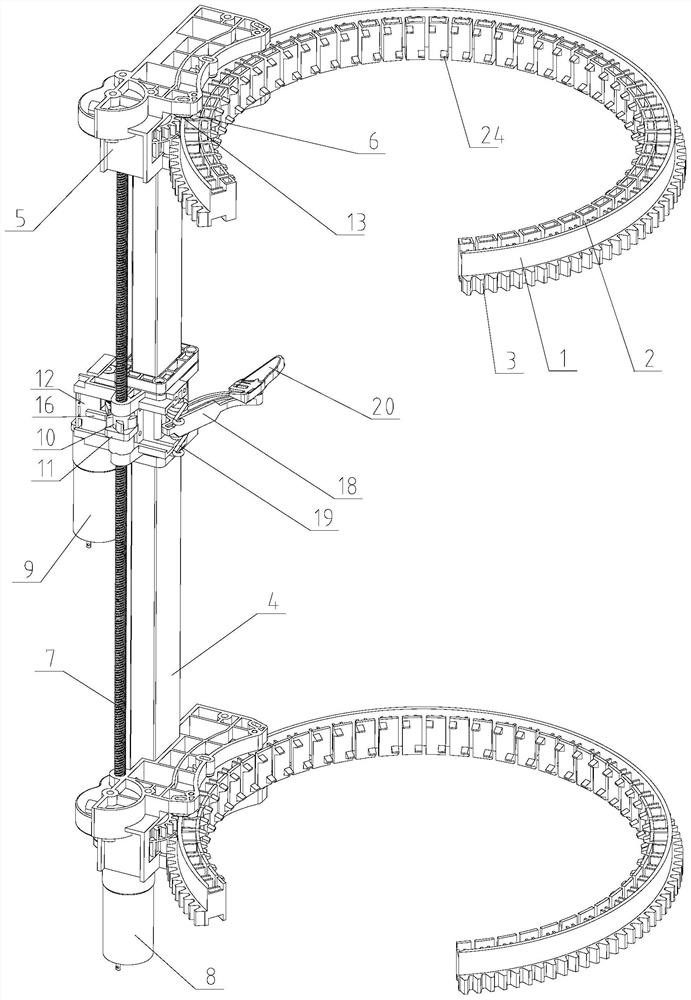

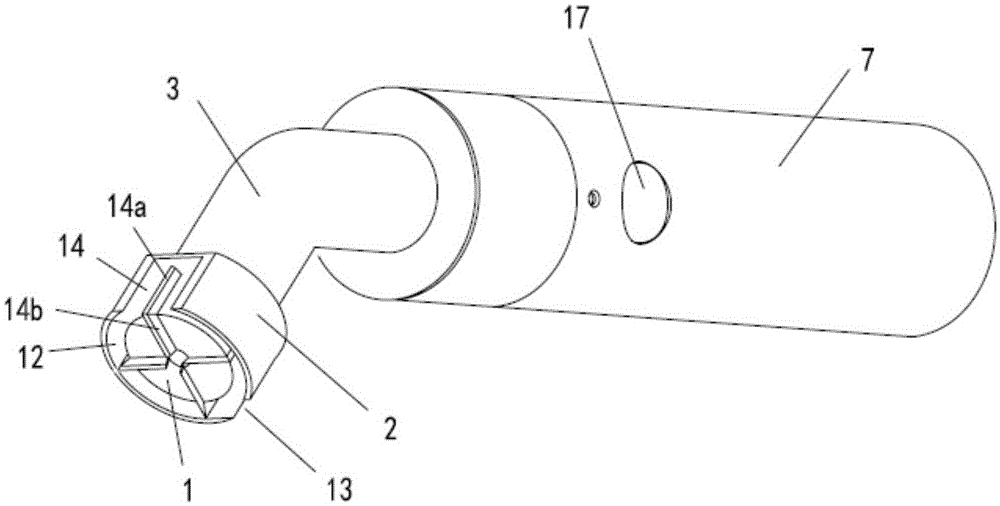

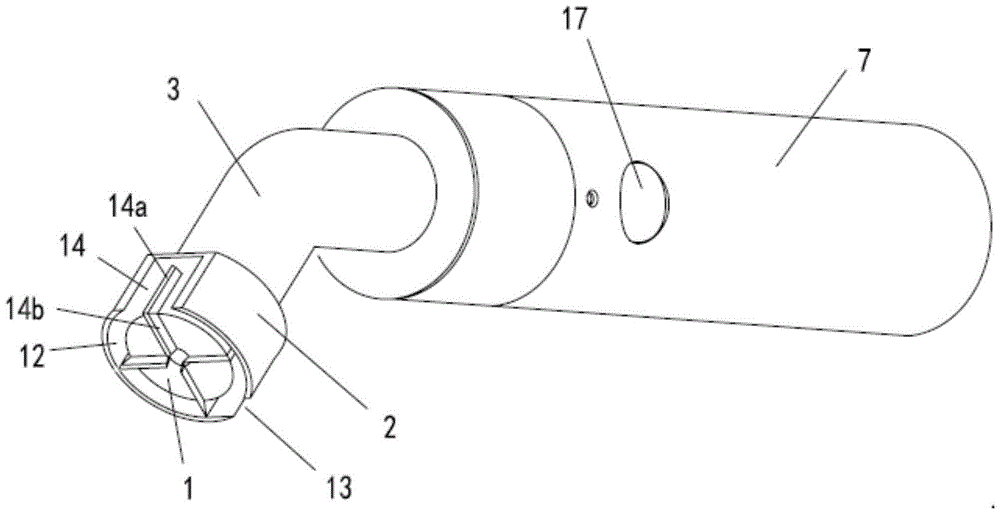

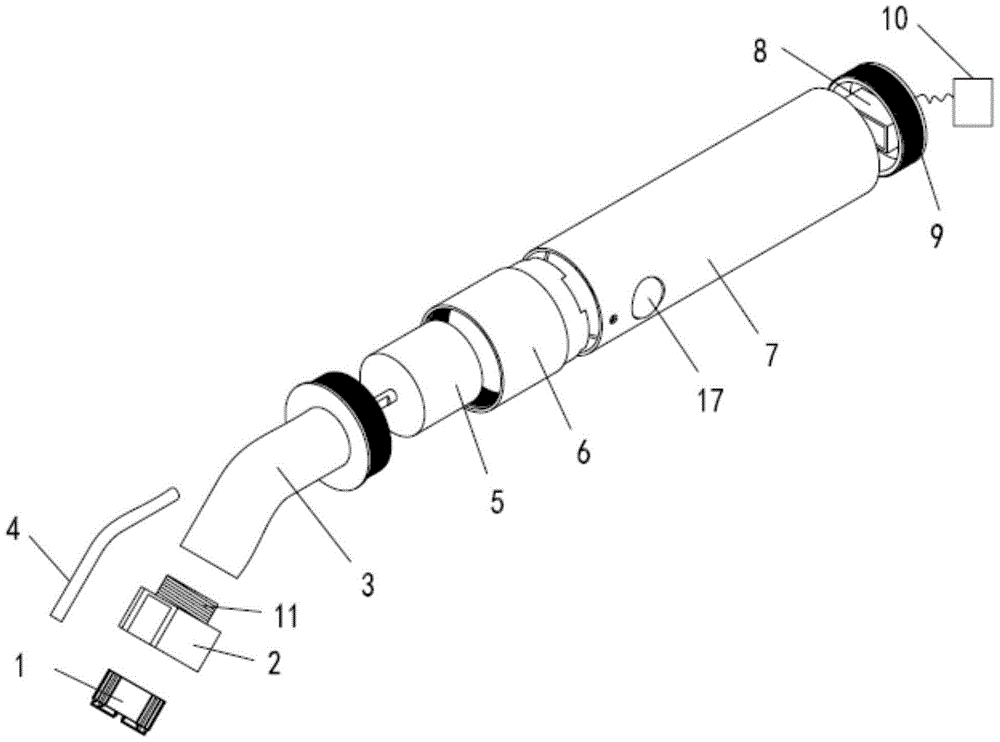

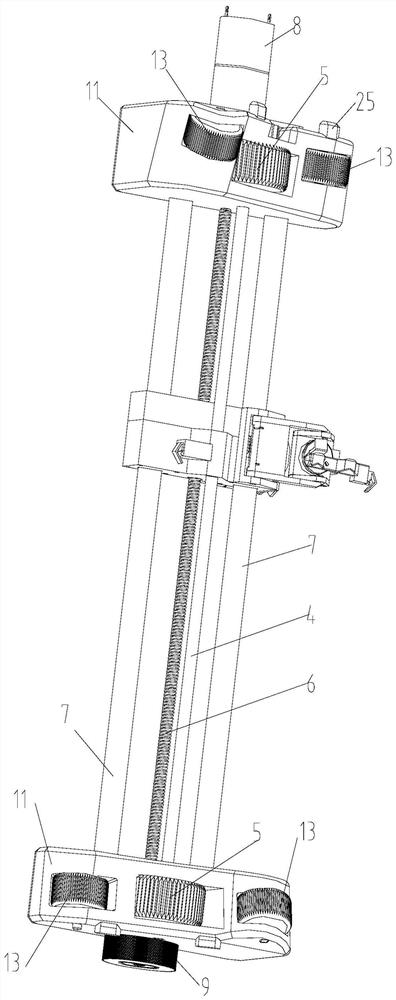

Rubber tapping machine and rubber tapping method

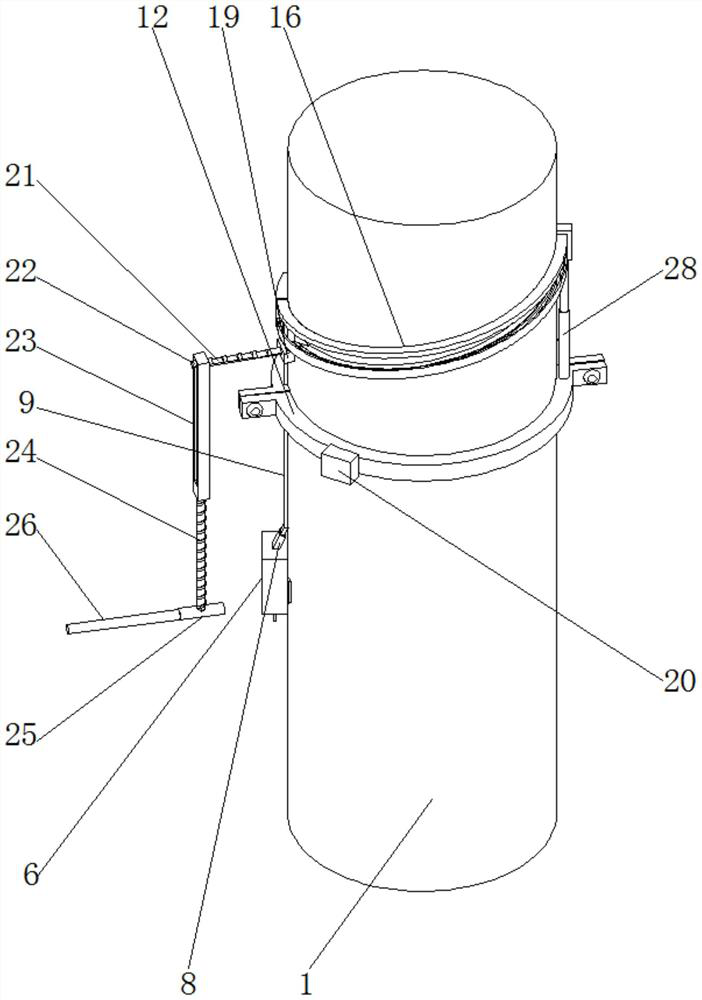

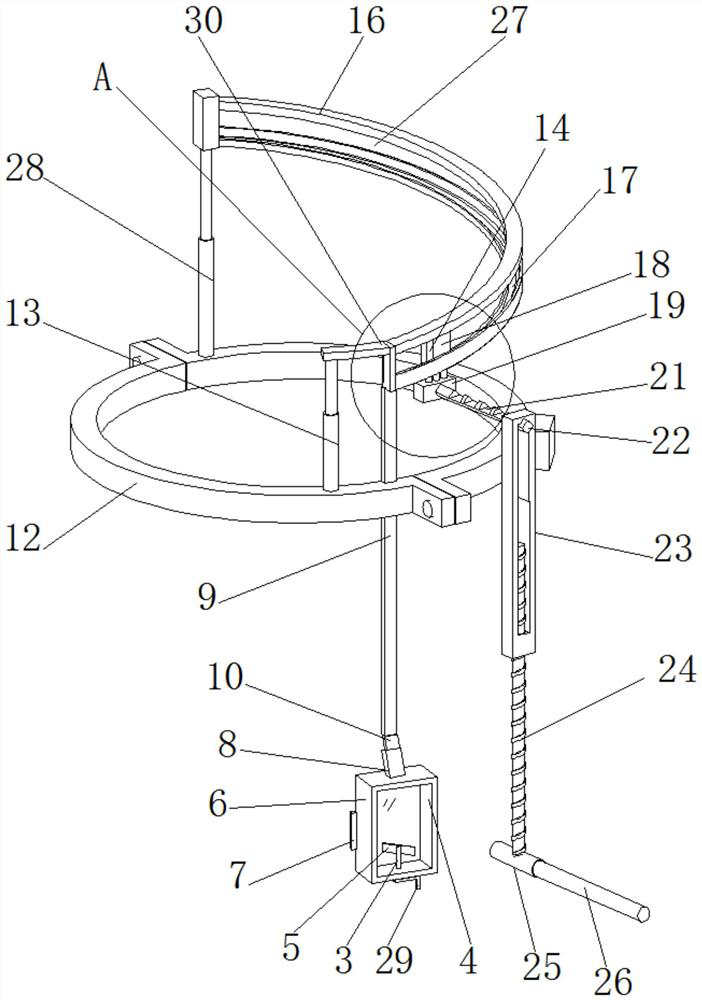

PendingCN107711410ARealize unmanned automatic tappingSolve labor intensityForestryEngineeringUltimate tensile strength

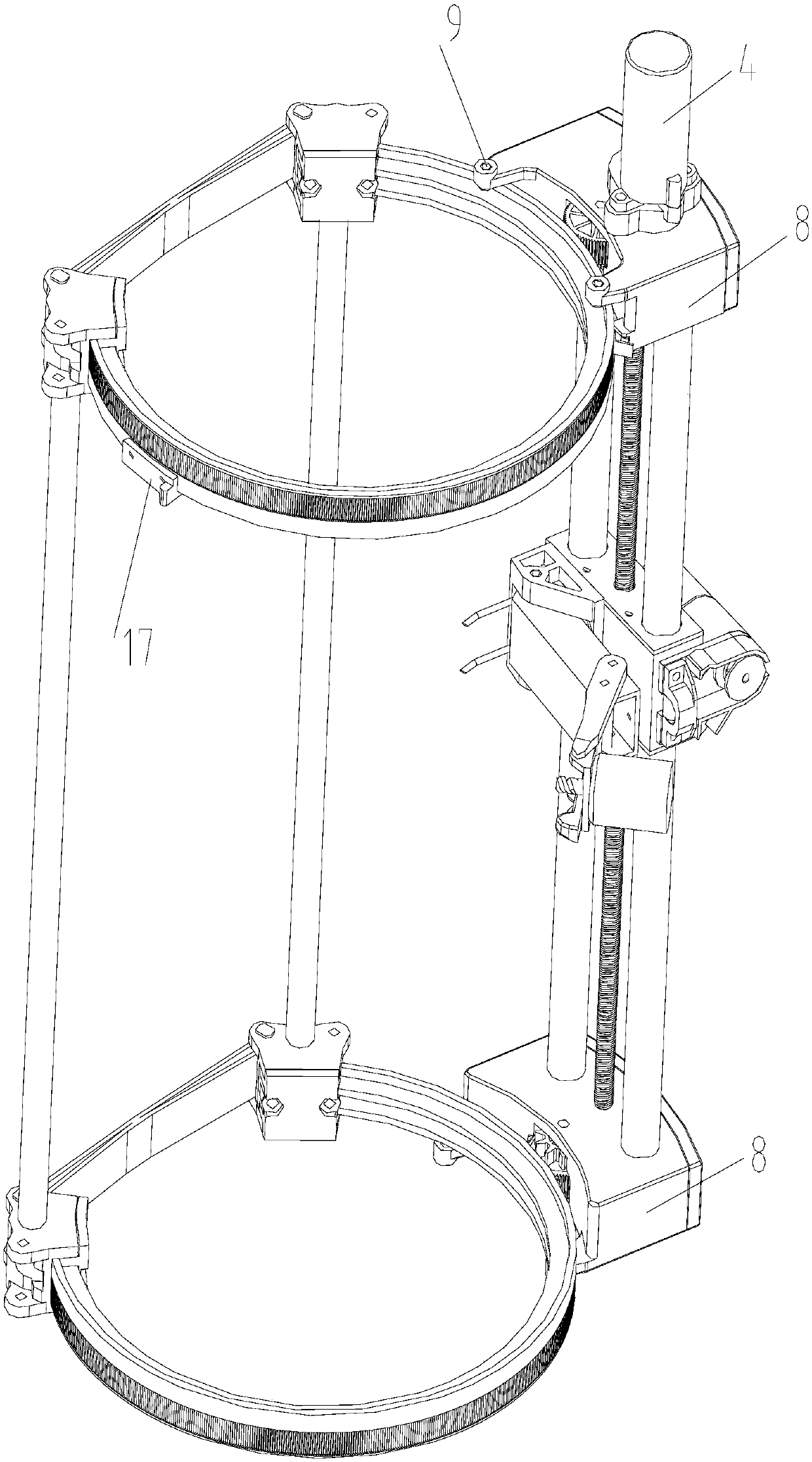

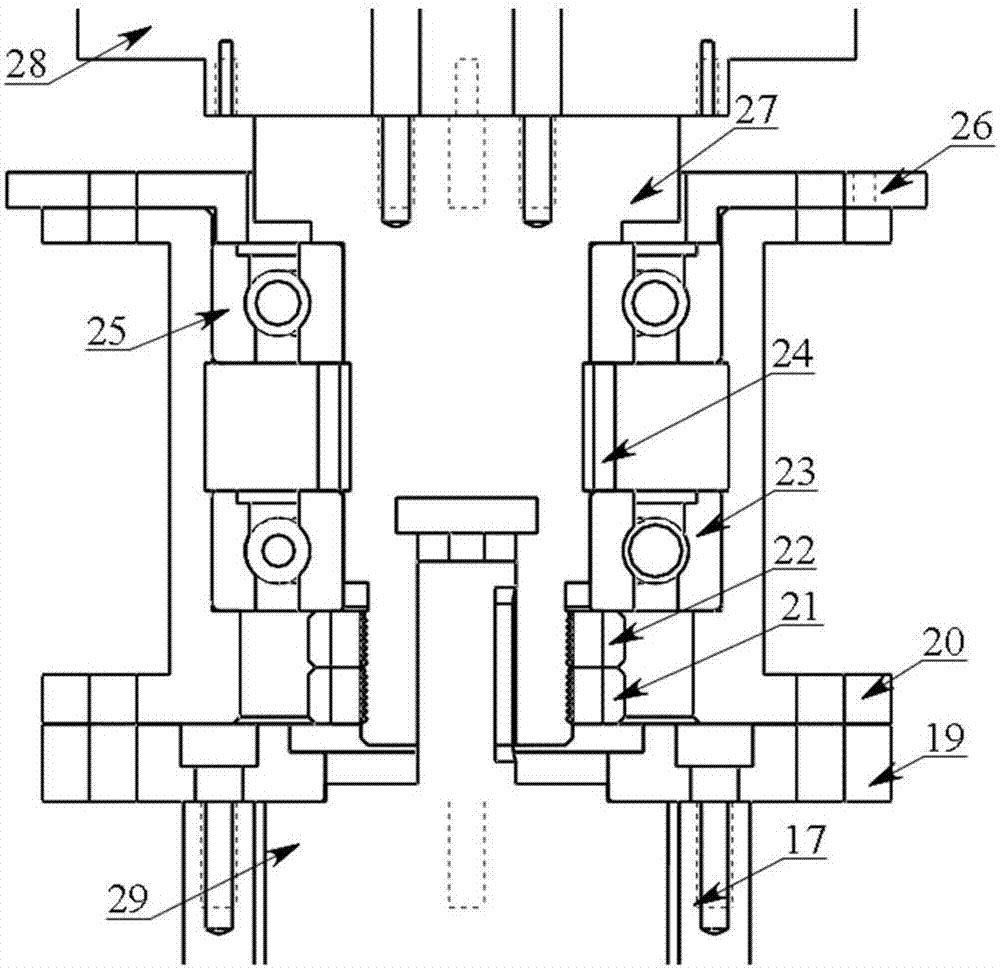

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises support rods, a knife rest assembly and a rubber tapping knife assembly. A side of one of the support rods is connected with a side of the other support rod by flexible guide rails, the other side of each support rod is connected with the other side of the other support rod by tightening belts, and the flexible guide rails are opposite to the tightening belts on the sides opposite to the flexible guide rails; the knife rest assembly is provided with a motor, two track wheels capable of rolling along the outer sides of the flexible guide rails are mounted at the upper end and the lower end of the knife rest assembly, a lead screw and more than one fixing rod are further mountedin the knife rest assembly along the vertical directions, and the track wheels and the lead screw can be driven by the motor in the knife rest assembly to rotate. The rubber tapping machine and the rubber tapping method have the advantages that labor can be replaced by automatic machinery, accordingly, rubber can be automatically tapped from rubber trees in an unmanned manner, and the problems ofhigh labor intensity of manual rubber tapping and insufficient fineness of manual rubber tapping can be solved to the greatest extent.

Owner:NINGBO CIHEVEA TECH CO LTD

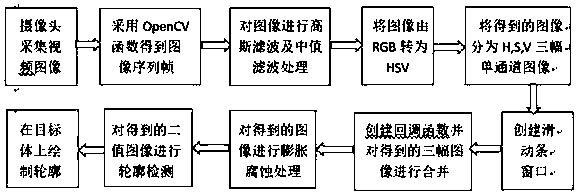

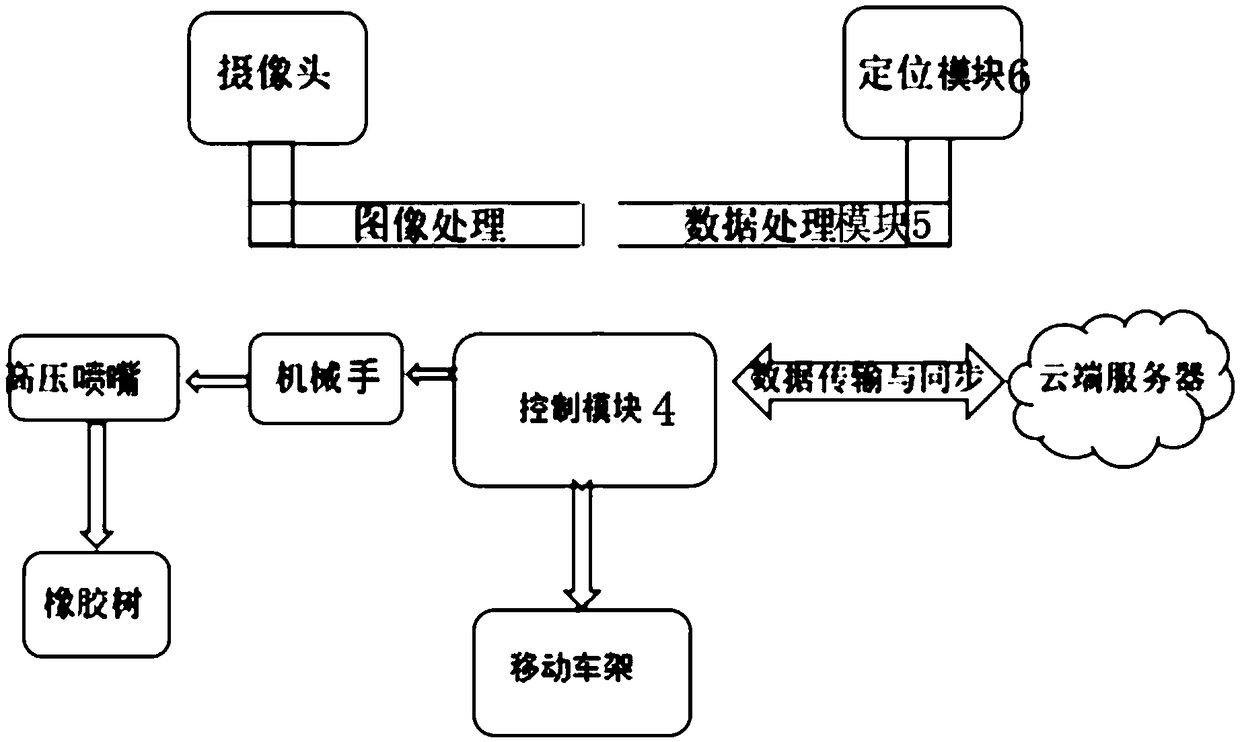

Intelligent rubber tapping system for rubber tree and control method thereof

ActiveCN109328973AImprove anti-interference abilityReduce power consumptionCharacter and pattern recognitionForestryAutomatic controlEngineering

The invention discloses an intelligent rubber tapping system for a rubber tree and a control method thereof. The rubber tapping system comprises a moving vehicle frame, an image acquisition module, ahigh pressure water cutting module, a control module and a data processing module; the method comprises the steps that the control module controls the moving vehicle frame to the portion under the rubber tree not subjected to rubber tapping and controls the high pressure water cutting module to perform rubber tapping on the rubber tree. Compared with the prior art, the intelligent rubber tapping system and method for the rubber tree have the advantages that the power dissipation is low, transmission is accurate, the anti-interference performance is high, the rubber tapping system is convenientto control, efficient and practical, achieves stable and controllable rubber tapping with the best mode, and replaces manpower with a robot to work in the optimum time quantum, monitoring and automatic control functions are added on the basis of rubber tapping, it is achieved that the dynamic condition of the rubber tree is grasped all-directionally, the manual input cost is reduced, the production efficiency is improved, and the promotion and use value is better.

Owner:XIANGTAN UNIV

Rubber tapping robot system and rubber tapping method

InactiveCN110122256AImprove automationImprove intelligenceForestryManipulatorEngineeringUltimate tensile strength

The invention relates to the technical field of natural rubber tapping and discloses a rubber tapping robot system and a rubber tapping method. The system comprises a moving car body, wherein a mechanical arm and a controller are arranged on the moving car body; a reader-writer matched with a label corresponding to a rubber tree is arranged on the moving car body; a rubber tapping knife is arranged at the tail end of the mechanical arm; the controller is connected with the moving car body, the mechanical arm and the reader-writer and used for adjusting moving parameters of the mechanical arm for driving the rubber tapping knife to tap rubber according to tree information of the rubber tree corresponding to the label recognized by the reader-writer. According to the rubber tapping robot system and the rubber tapping method, a specific adaptive rubber tapping track can be generated by aiming at each rubber tree, automatic rubber tapping precision is guaranteed, and automation and intelligence of the rubber tapping are improved; the overall system is stable and controllable in operation, can replace manual rubber tapping and reduces labor intensity.

Owner:CHINA AGRI UNIV

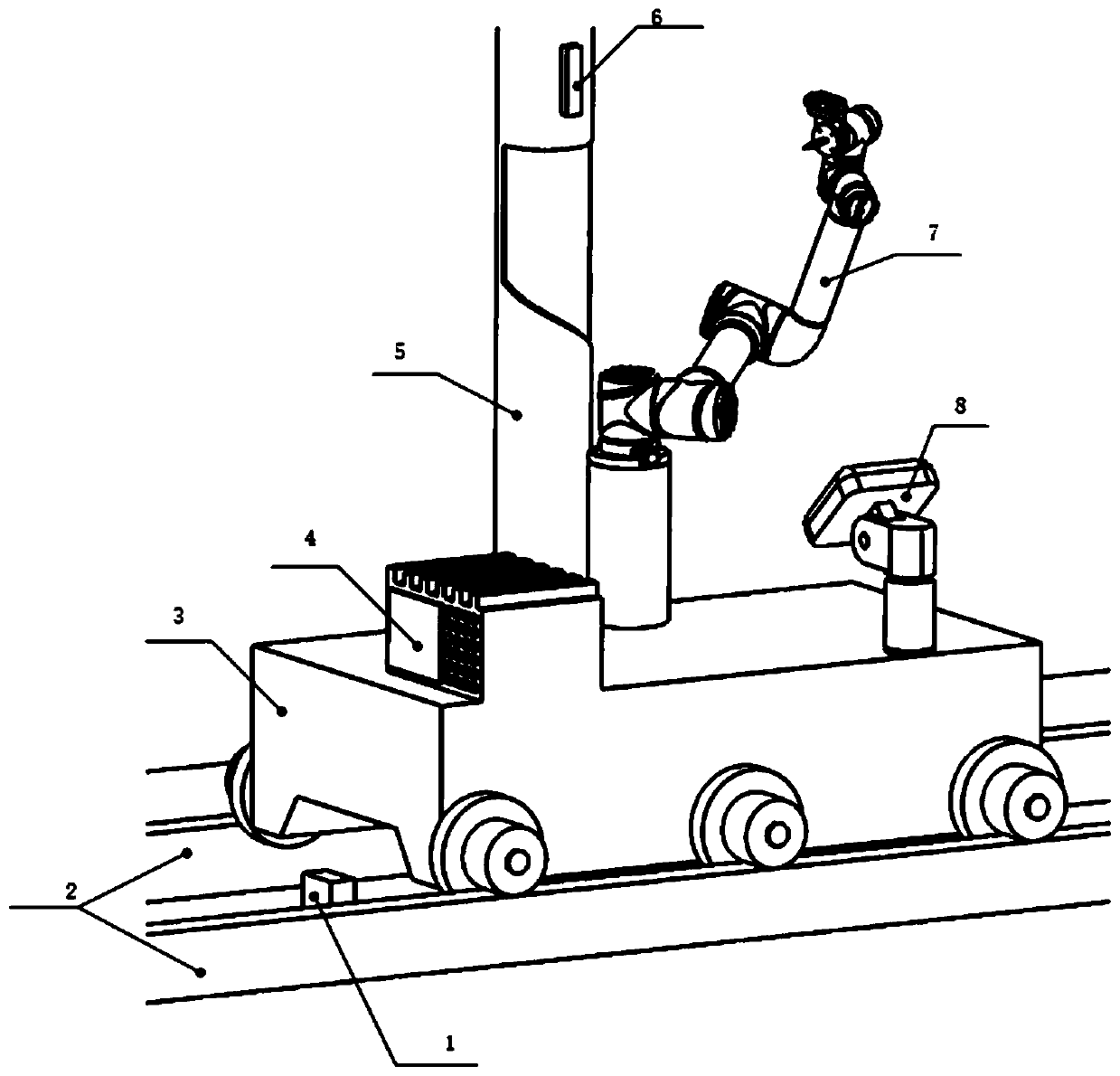

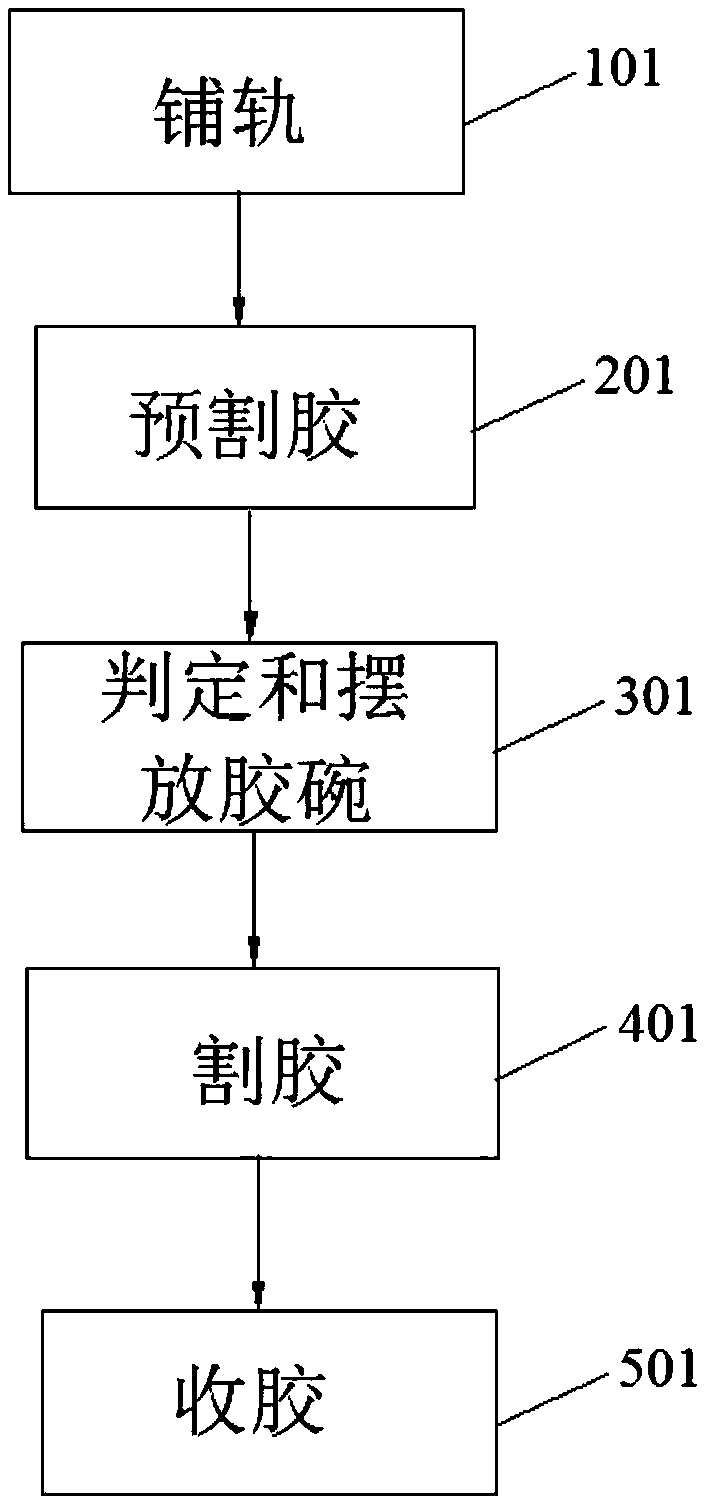

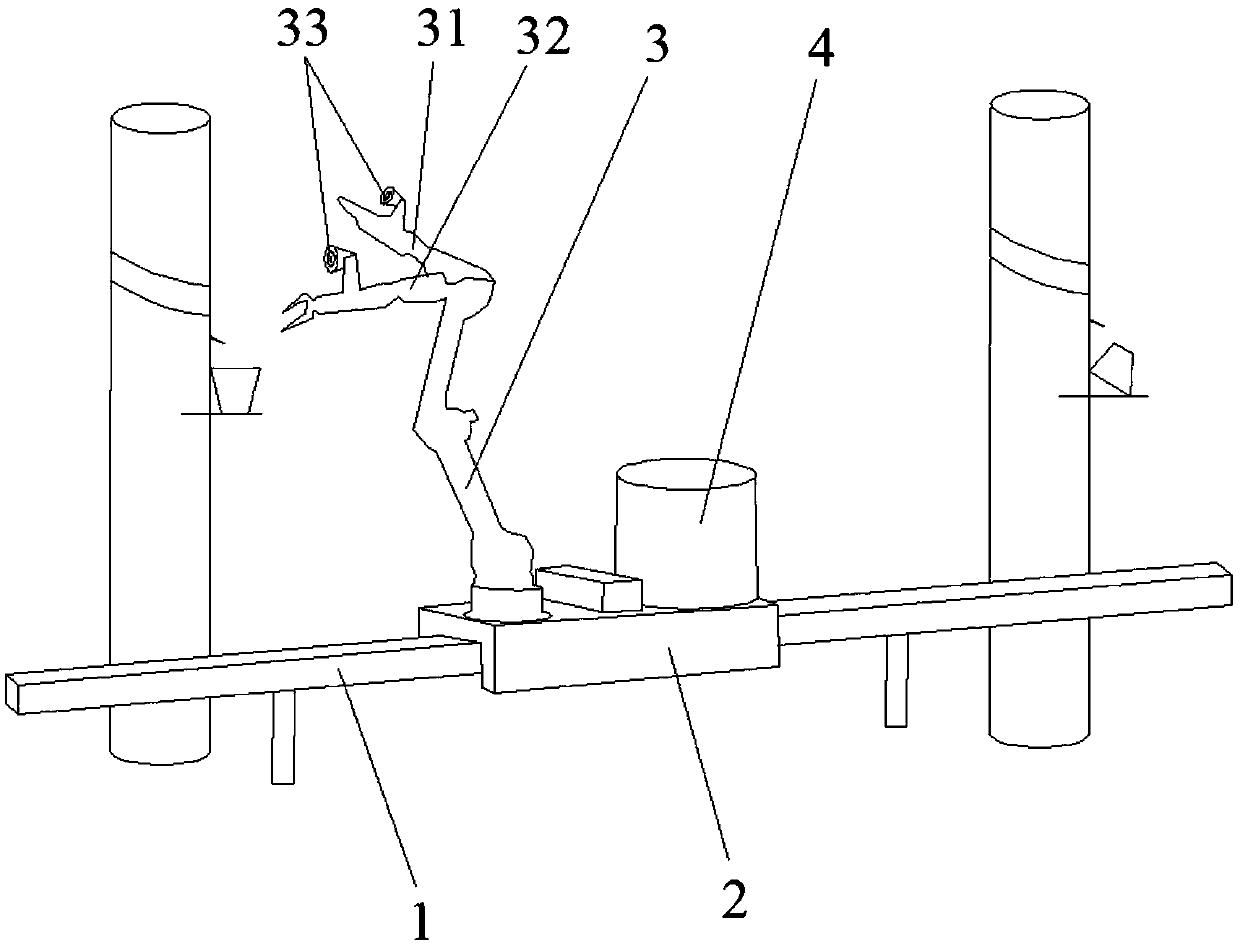

Automatic integrated rubber tapping and collecting method based on image identification and automatic integrated rubber tapping and collecting device based on image identification

The invention discloses an automatic integrated rubber tapping and collecting method based on image identification. The method comprises the following steps: firstly, through a camera identification system on a rubber collecting manipulator carried on a work platform which can move along rails, determining the positions of rubber trees, the placement positions and directions of rubber bowls and other parameters, and sending an instruction to the rubber collecting manipulator to decide whether a tree is subjected to rubber tapping or not and a rubber bowl is well placed or not; then, by use of a rubber tapping manipulator with a camera identification system carried on the work platform which can move along the rails, sending an instruction to the rubber tapping manipulator through the camera identification system, and performing rubber tapping by the rubber tapping manipulator according to the instruction; and then, by use of the rubber collecting manipulator with the camera identification system carried on the work platform which can move along the rails, sending an instruction to the rubber collecting manipulator through the camera identification system, and collecting rubber by the rubber collecting manipulator according to the instruction. According to the method and the device, the automation of rubber tapping and collecting can be realized, and the method and the device have the characteristics of full-automatic implementation and high efficiency. Meanwhile, the technology disclosed by the invention can be applied to other economic tree species.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

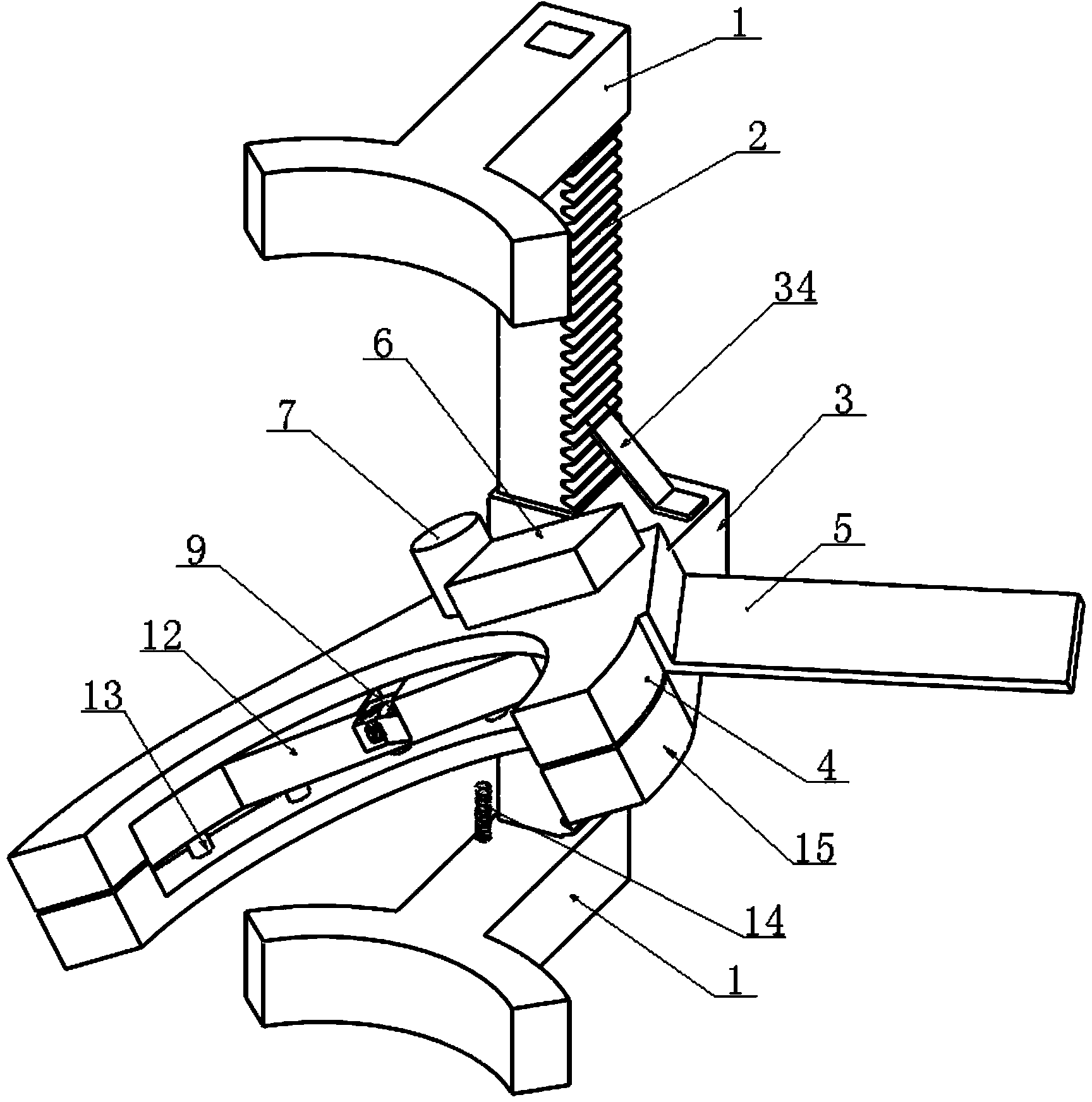

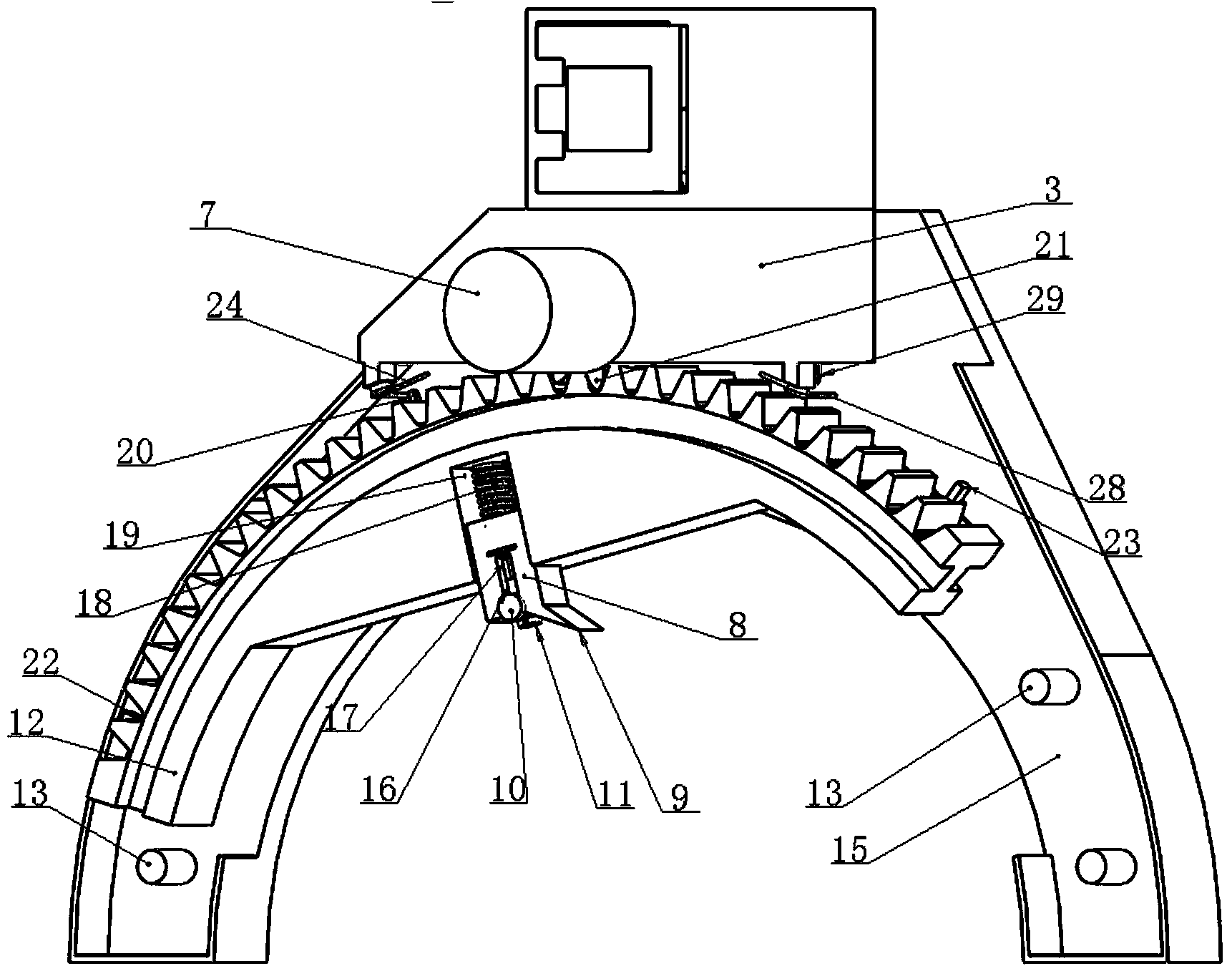

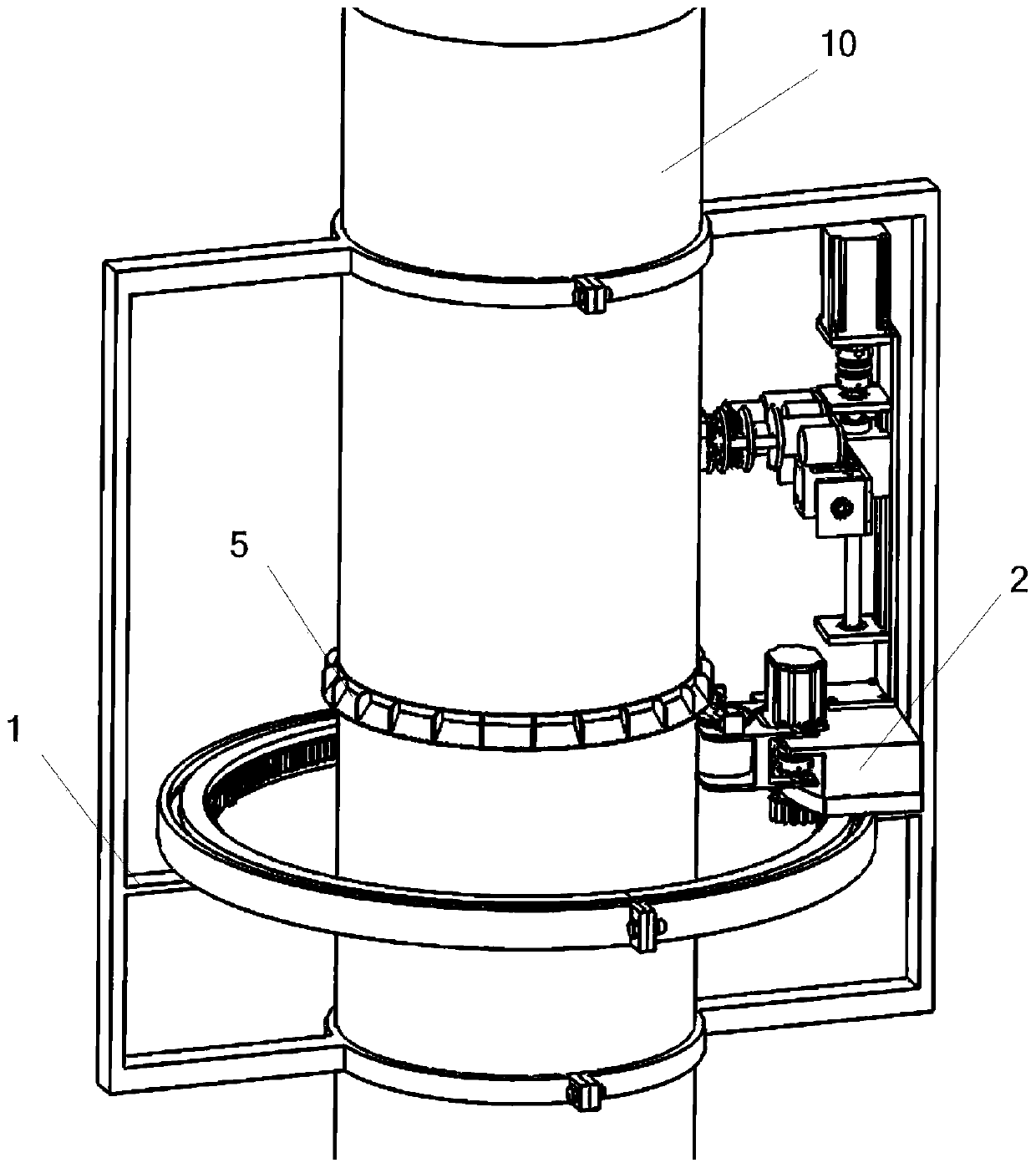

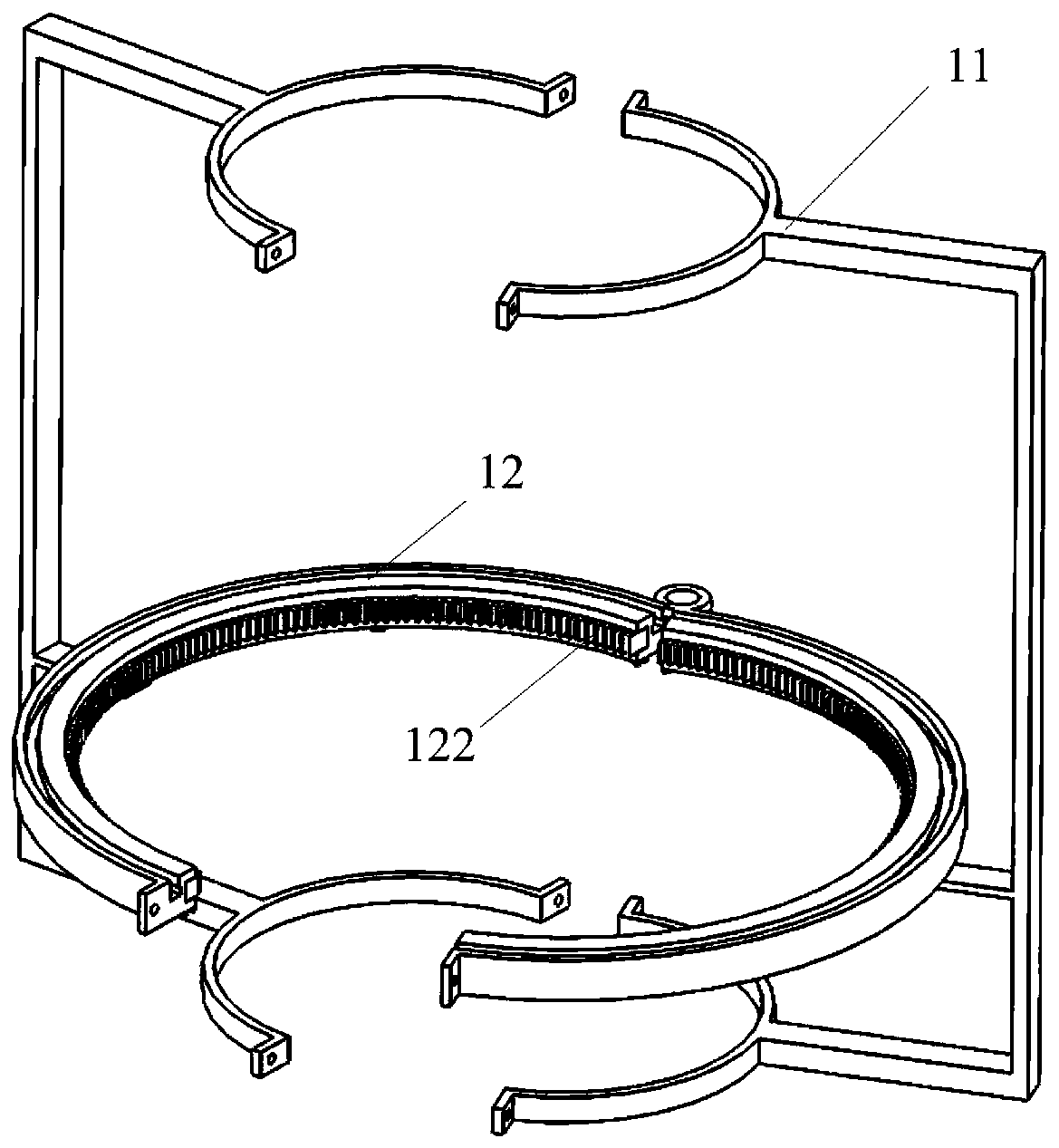

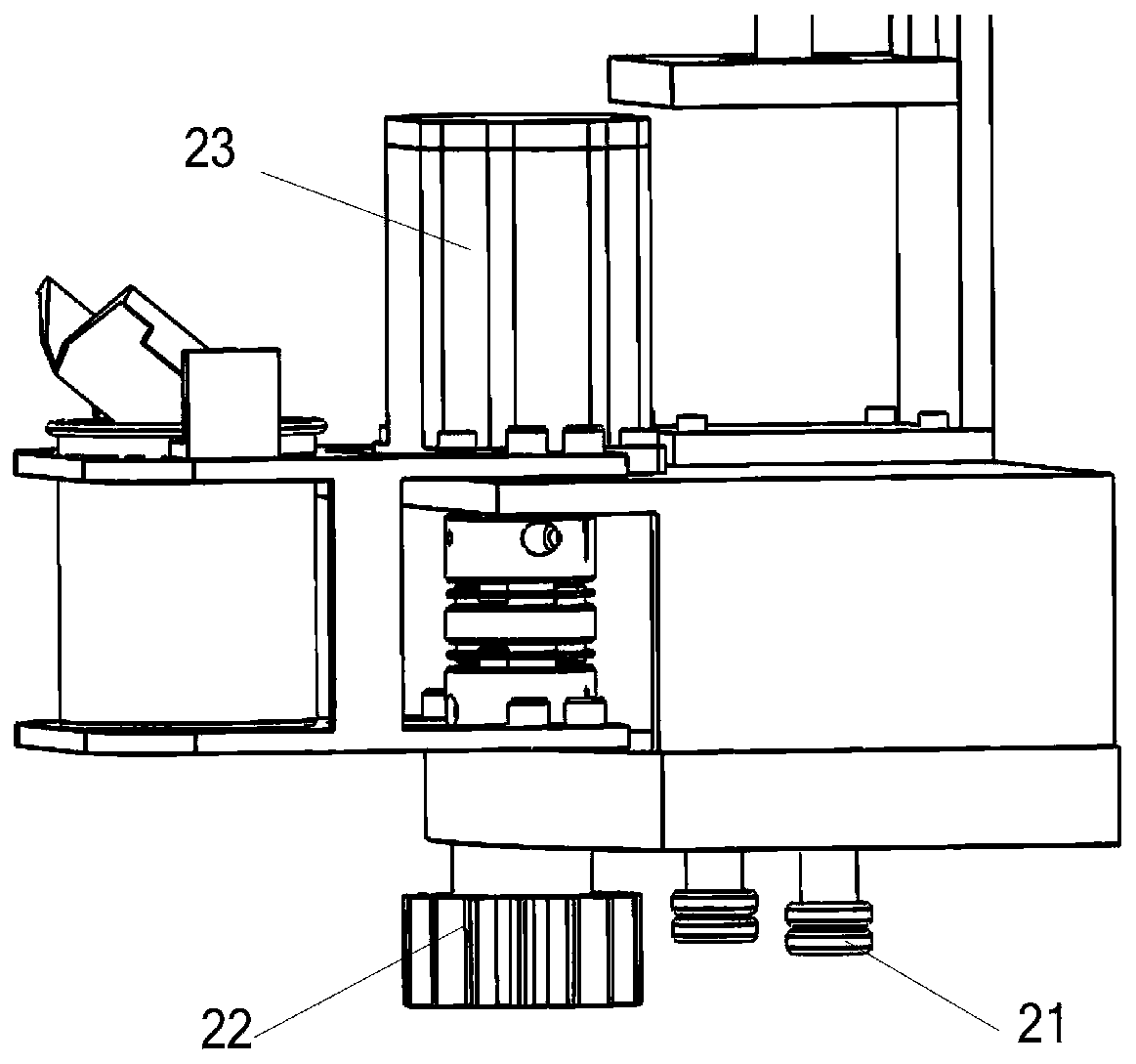

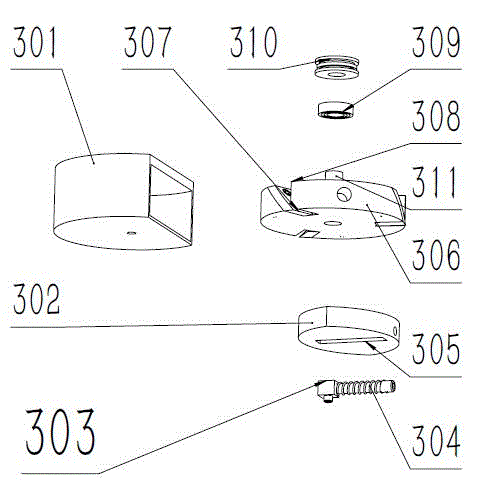

Rubber tapping machine and rubber tapping method

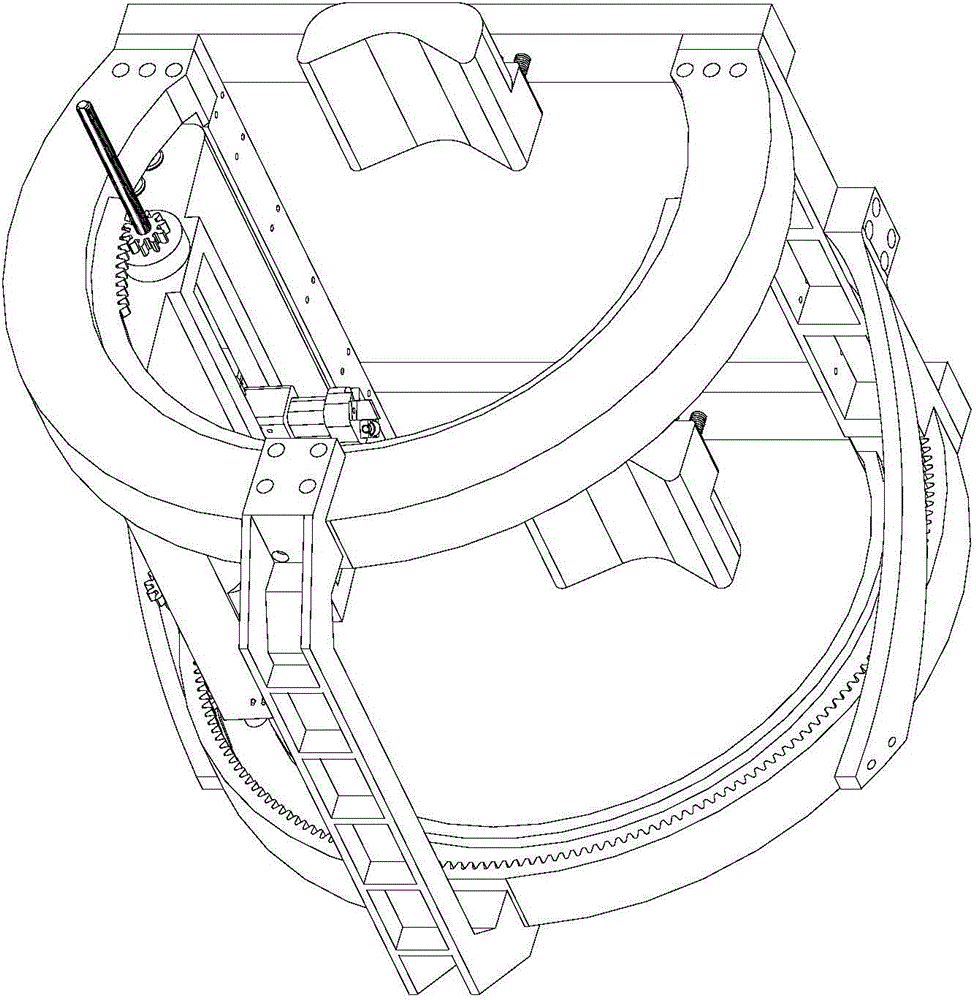

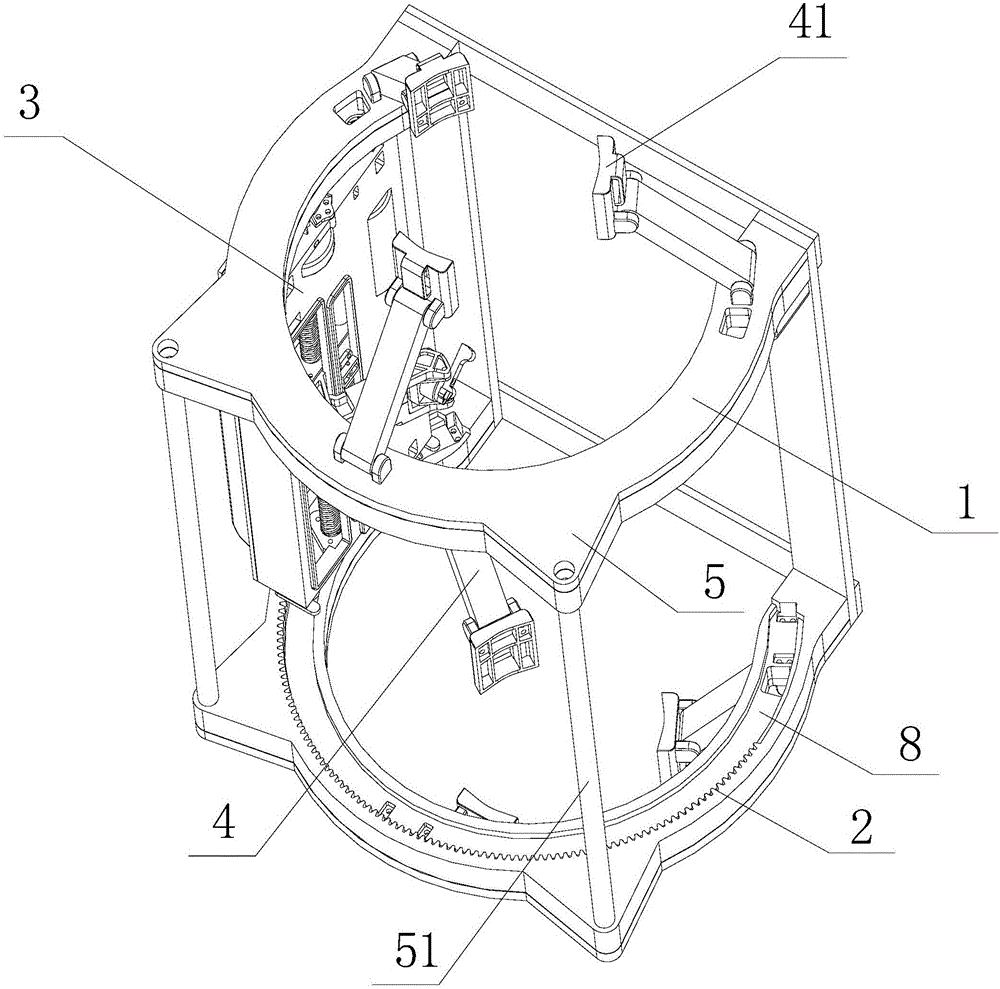

ActiveCN106034978ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryEngineeringUltimate tensile strength

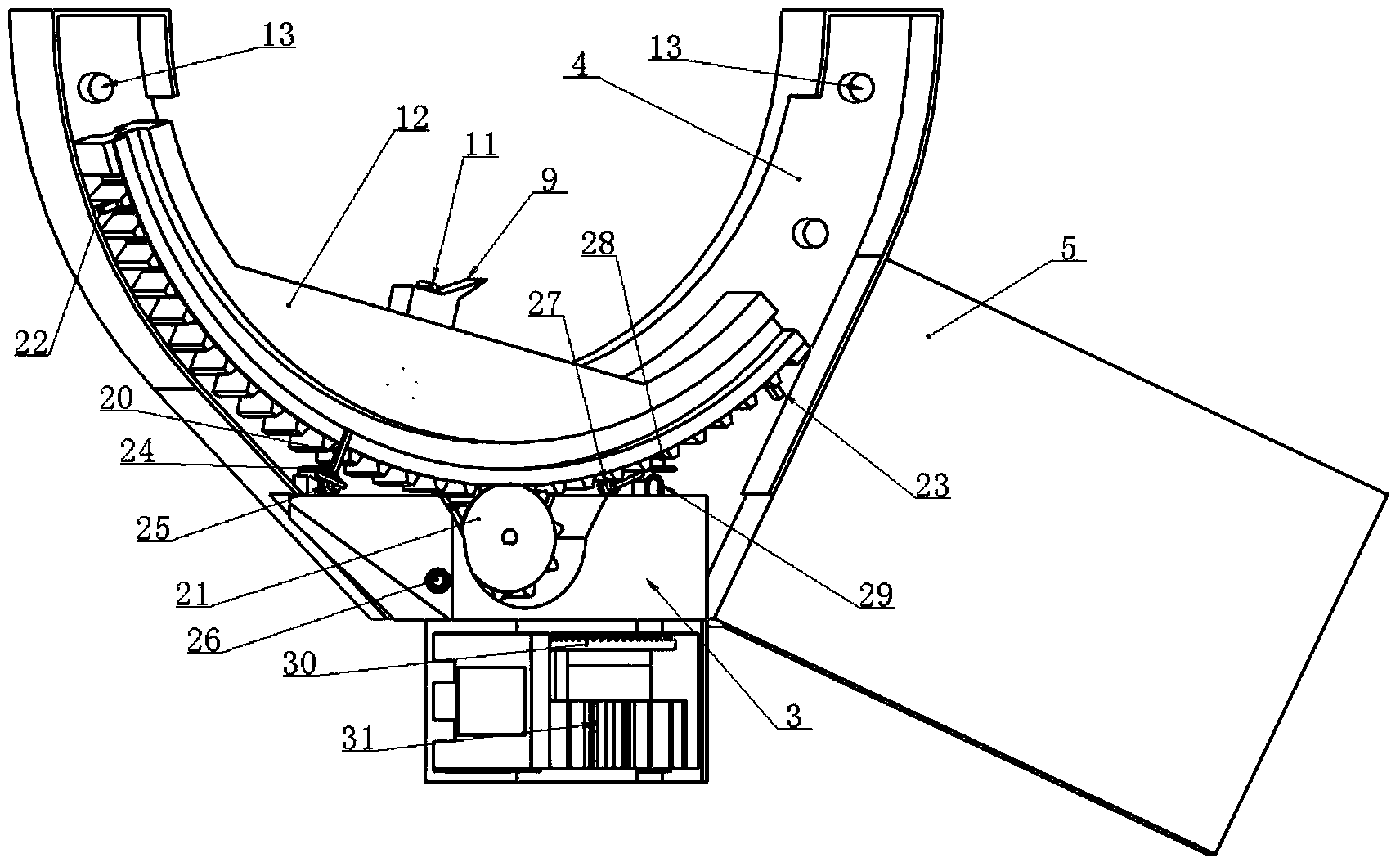

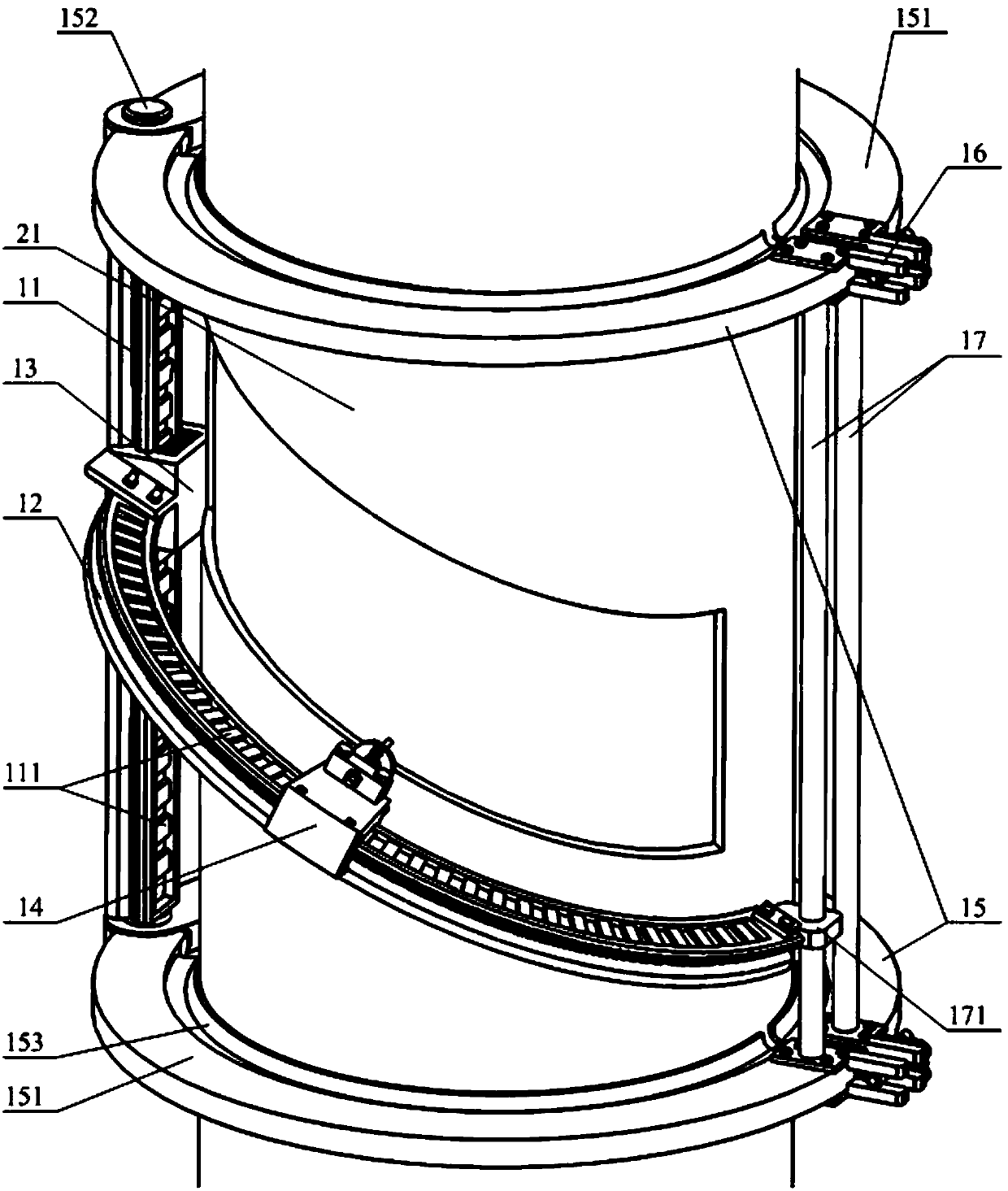

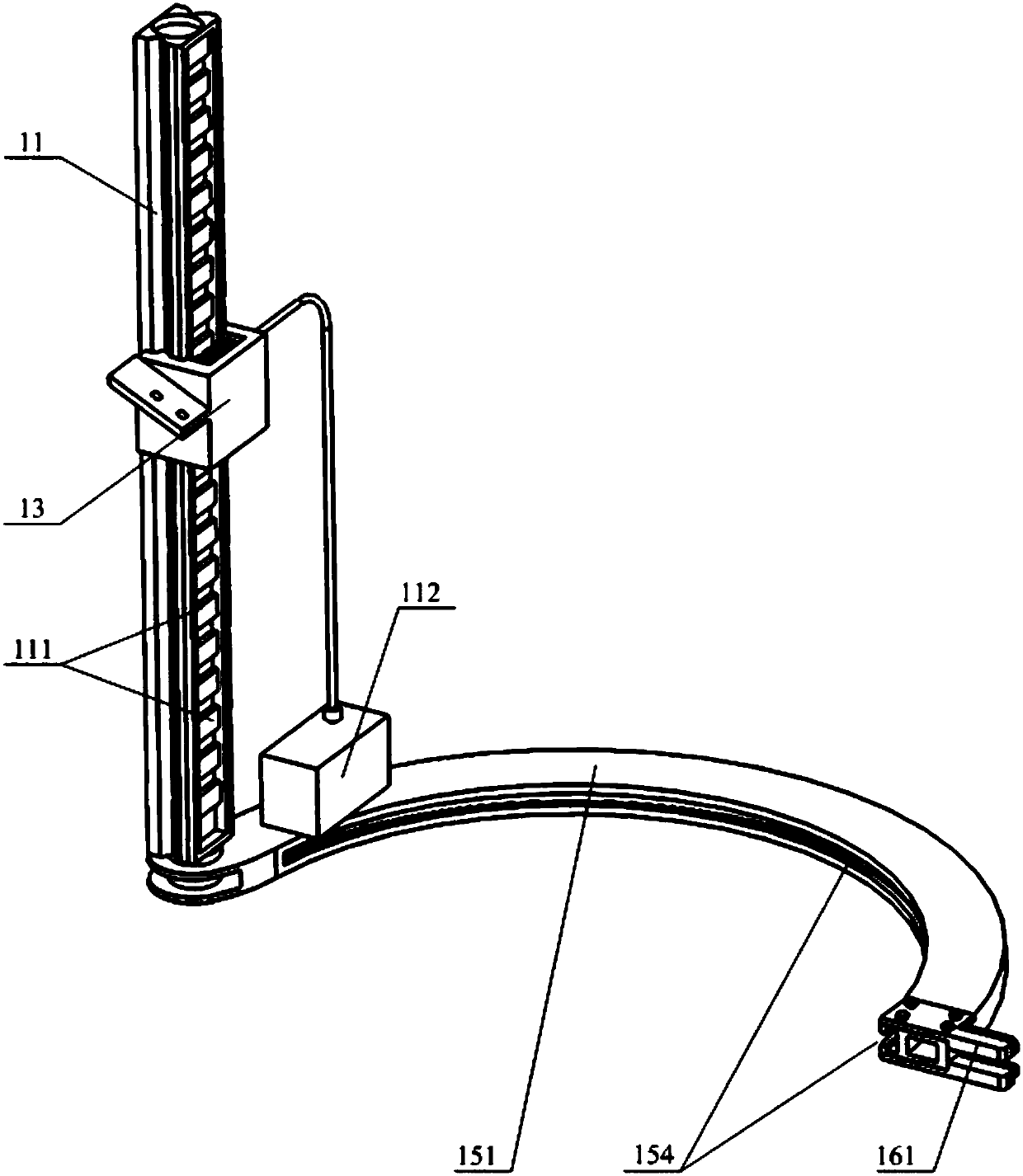

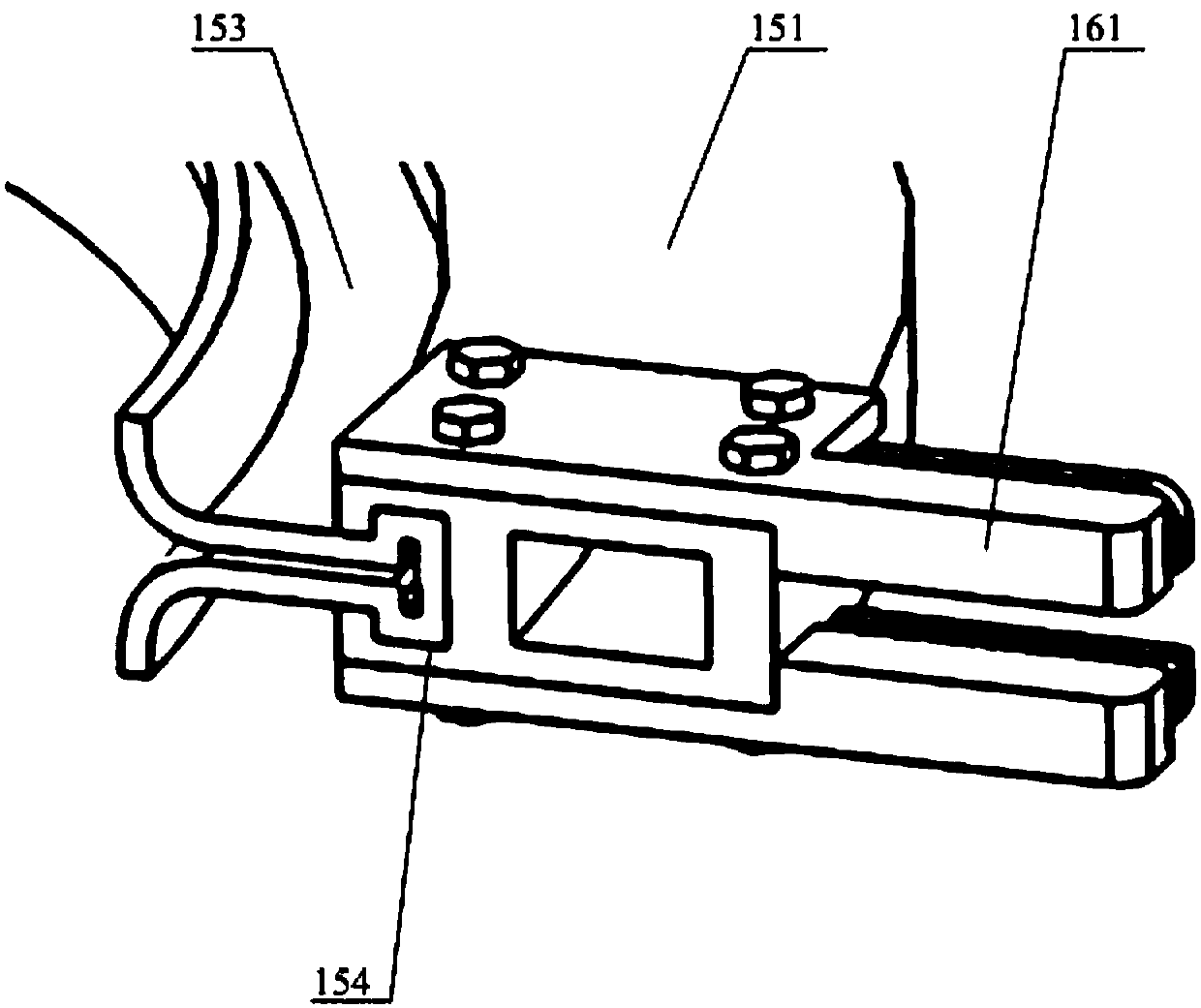

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises a fixation frame, the top surface and the bottom surface of the fixation frame are respectively provided with annular planet gears in opposite arrangement, a knife rest assembly is installed between the top surface and the bottom surface of the fixation frame, the knife rest assembly is internally provided with a leading screw along a vertical direction, a rubber tapping assembly is installed on the leading screw and can be driven by the leading screw to vertically move along the leading screw, the rubber tapping assembly comprises a knife rest which is installed on the leading screw and can move vertically along the leading screw, one side of a cutter head swing arm is hinged to the knife rest through a torsion spring, the other side is hinged to a swing seat, the swing seat is provided with a cutter head angle adjustment seat, the top end of the cutter head angle adjustment seat is provided with a cutter head and a knife depth limiting member, and the knife rest is also provided with a knife collecting assembly which can overcome an elastic force of the torsion spring to draw the cutter head swing arm to the knife rest. The rubber tapping machine disclosed by the invention replaces labor with automatic machinery, realizes unmanned automatic rubber tapping for rubber trees, and solves the problems of large manual rubber tapping labor intensity and low manual rubber tapping precision to the maximum degree.

Owner:NINGBO CIHEVEA TECH CO LTD

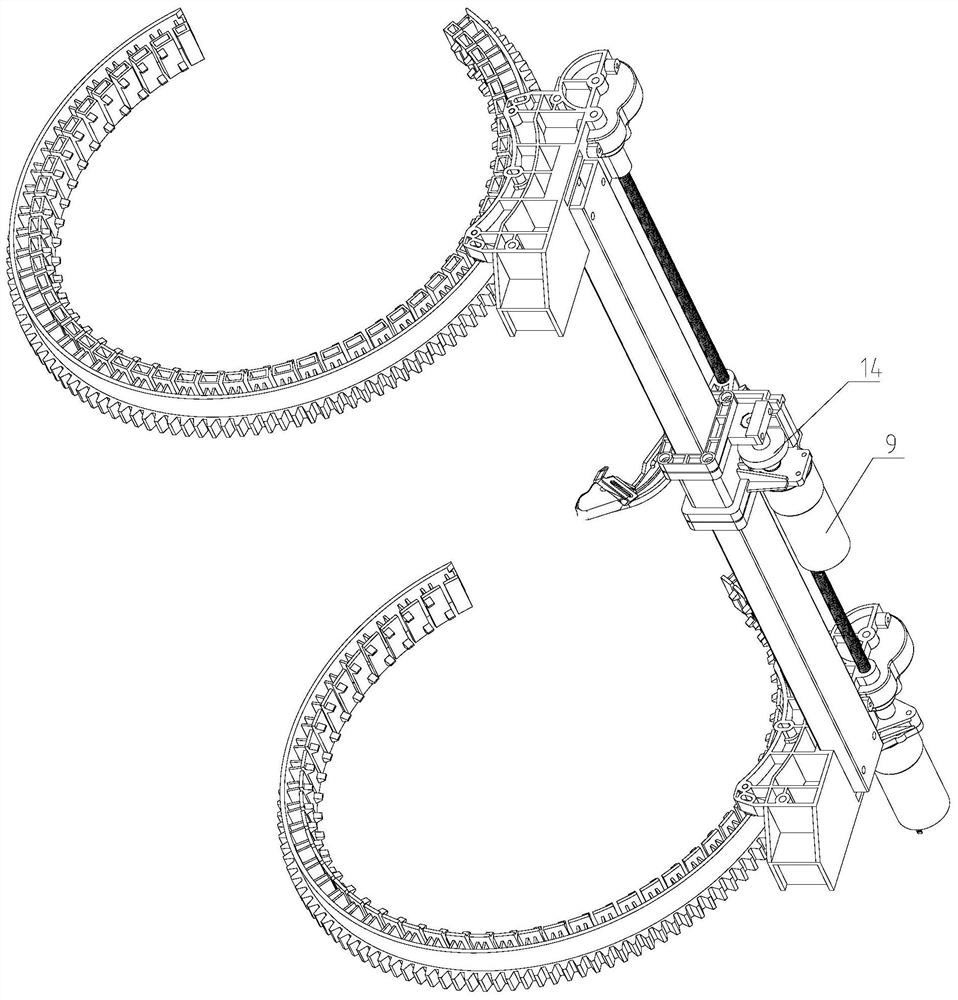

Automatic rubber tapping machine for rubber trees

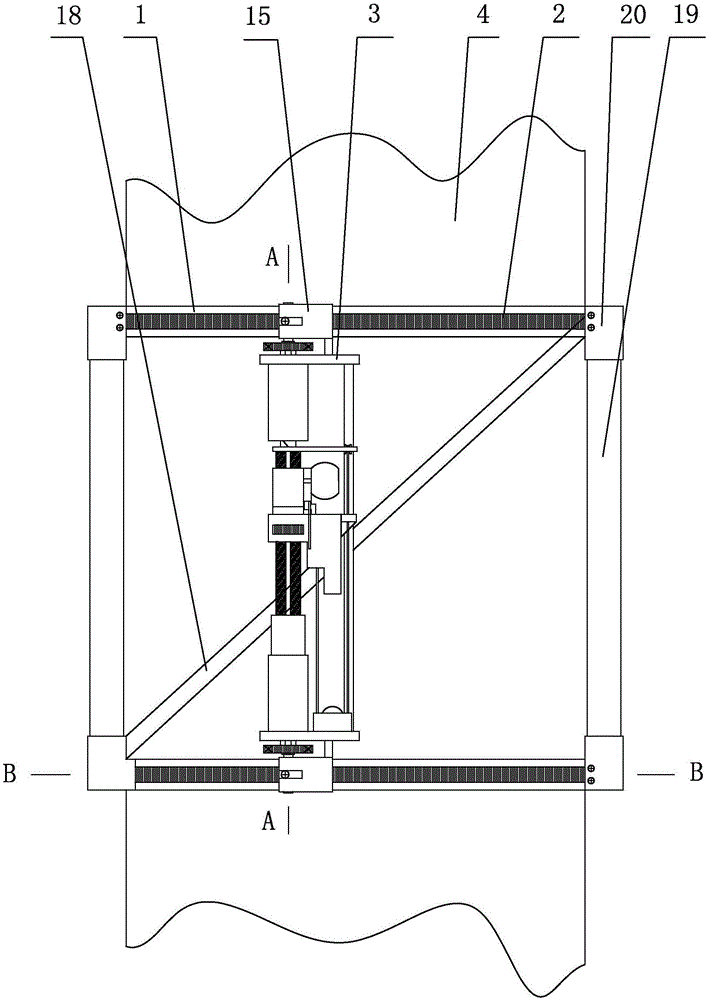

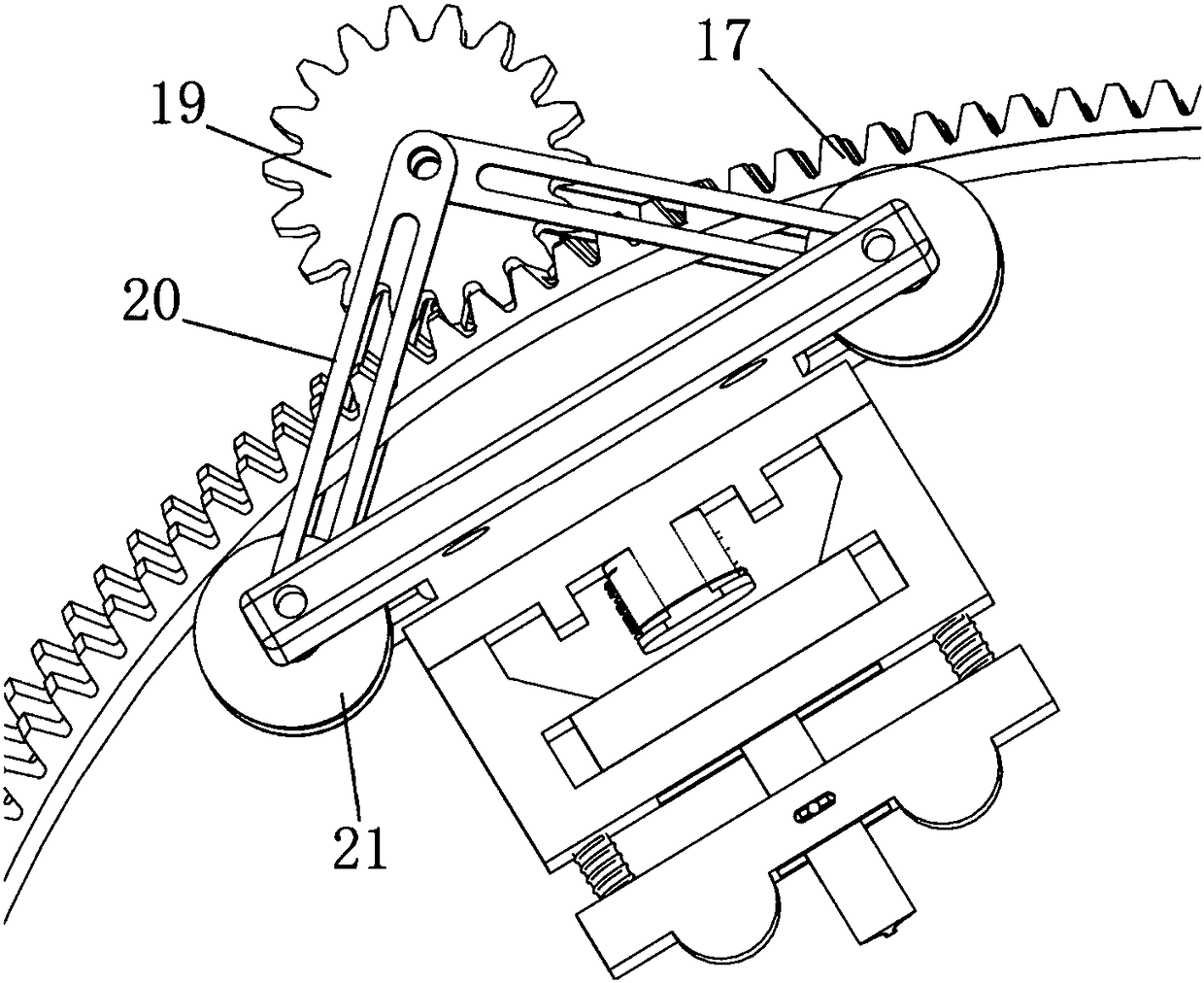

The invention discloses an automatic rubber tapping machine for rubber trees. The automatic rubber tapping machine comprises a guide track device, a travel device and a cutting device, wherein the guide track device comprises an upper arc track, a lower arc track, an upper arc rack and a lower arc rack. The travel device comprises a travel frame arranged between the upper arc track and the lower arc track, the travel frame is mounted on an arc track through a guide frame, and a travel mechanism is arranged between the arc track and the travel frame. The cutting device comprises a cutting mechanism mounted on the travel frame through a lifting mechanism, the lifting mechanism comprises a lead screw, a nut sleeve and a lifting frame, the lead screw and the nut sleeve are screwed, the lifting frame is connected with the nut sleeve, the cutting mechanism comprises a tool bit directly driven by a cutting motor, and the cutting motor is mounted on the lifting frame through a radial guide mechanism and driven to radially move by a radial feed mechanism. The automatic rubber tapping machine is simple in structure, complete in function and convenient to operate, rubber can be individually tapped for each rubber tree, and the automatic rubber tapping machine can adapt to rubber tapping operation of the rubber trees with different diameters.

Owner:胡银星

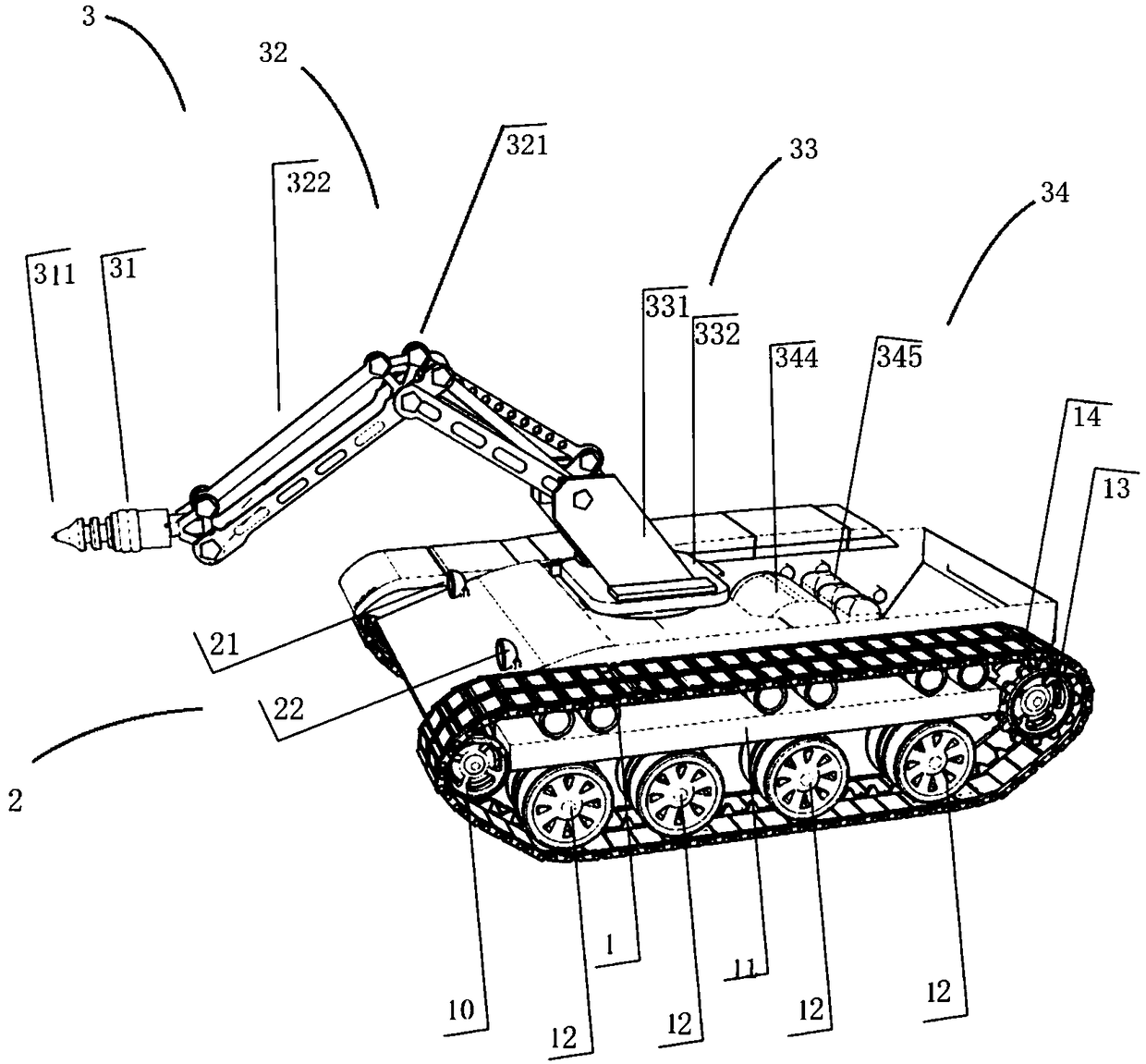

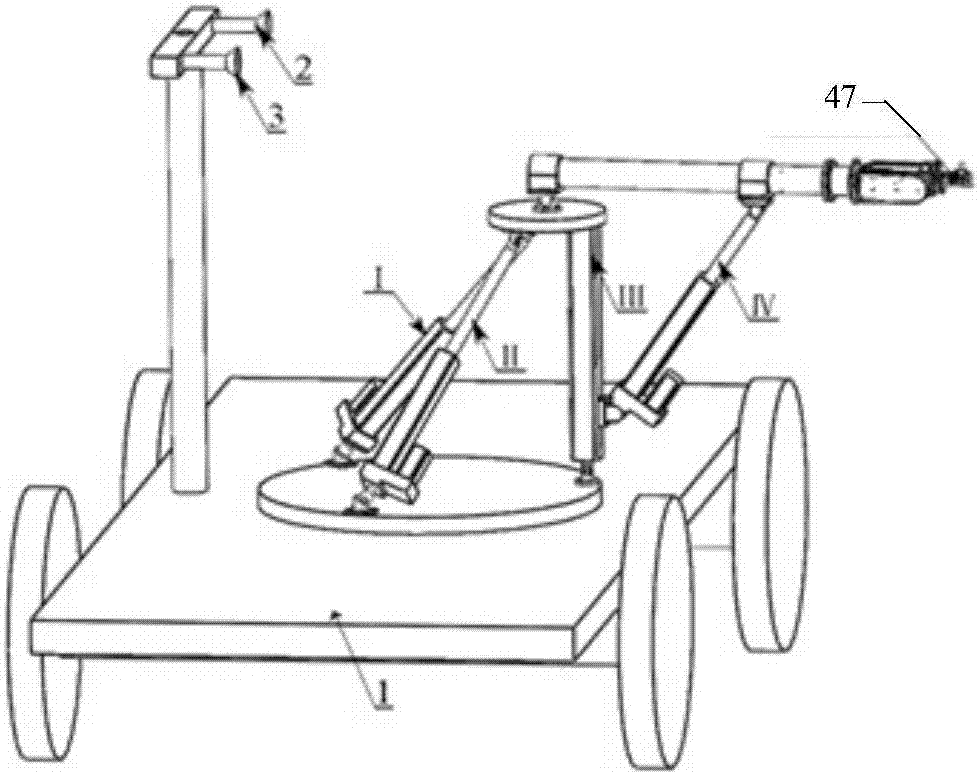

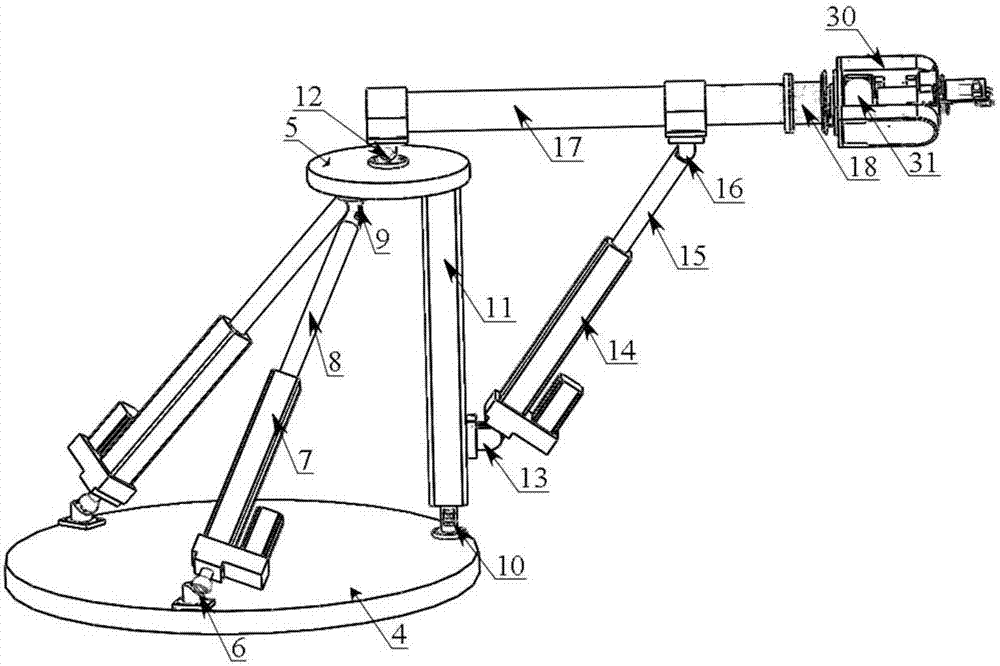

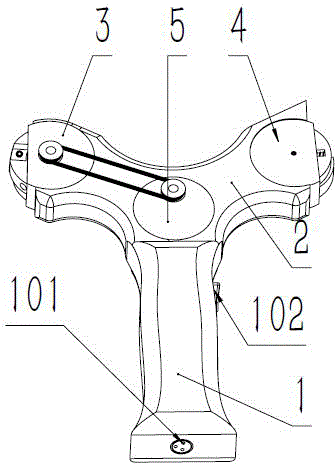

Rubber tapping robot

The invention provides a rubber tapping robot. The robot comprises a mobile small vehicle, an image collecting device, a five-freedom-degree hybrid mechanism and a tail end actuator, the image collecting device and the five-freedom-degree hybrid mechanism are fixed to the mobile small vehicle, and the five-freedom-degree hybrid mechanism is connected with the tail end actuator; the image collecting device is used to collect rubber tree rubber tapping space initial position information and control the rubber tapping robot to move to a rubber tree rubber tapping space initial position according to the collected rubber tree rubber tapping space initial position information; the five-freedom-degree hybrid mechanism comprises a two-freedom-degree parallel mechanism and a three-freedom-degree serial mechanism, and the two-freedom-degree parallel mechanism and the three-freedom-degree serial mechanism adjust the position and the working attitude of the tail end actuator together; and the tail end actuator is used to tap rubber. The rubber tapping robot has the characteristics of having a simple structure, having high rigidity, having full automation, having high efficiency, being applied to different tree diameters and the like, and the robot can replace artificial rubber tapping, realize rubber tapping automation, and improve labor efficiency.

Owner:CHINA AGRI UNIV

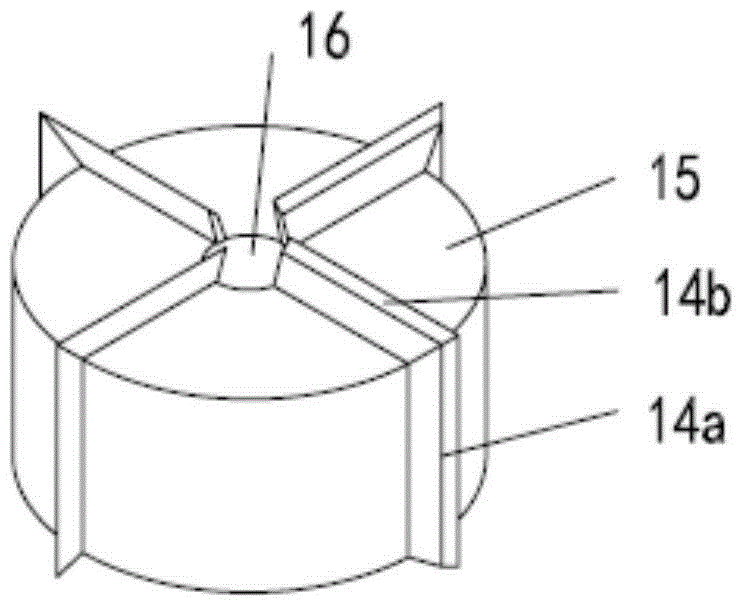

Automatic rubber tapping robot

The invention discloses an automatic rubber tapping robot. The automatic rubber tapping robot comprises a magnetic suspension knife head and a knife head installation mechanism, wherein the knife headinstallation mechanism is used for making the magnetic suspension knife head attached to a tree trunk and guiding movement of the magnetic suspension knife head along the surface of the tree trunk. The magnetic suspension knife head comprises a base, a knife rest and a cutting knife, wherein the knife rest is elastically connected to the base, and the cutting knife reciprocates in a form of single degree of freedom and is slidably matched with the knife rest; the base is provided with a permanent magnet and an electromagnet opposite to the permanent magnet; the electromagnet drives the cutting knife connected with the permanent magnet to vibrate by continually changing polarity, so that cutting motion is completed. By means of the robot, the problems can be solved that in an existing automatic rubber tapping machine, the structure of a knife head is complicated, the rubber tapping efficiency is low, the service life of a motor is short, and the existing automatic rubber tapping machine is complicated in structure, difficult to control and high in cost.

Owner:CHONGQING UNIV

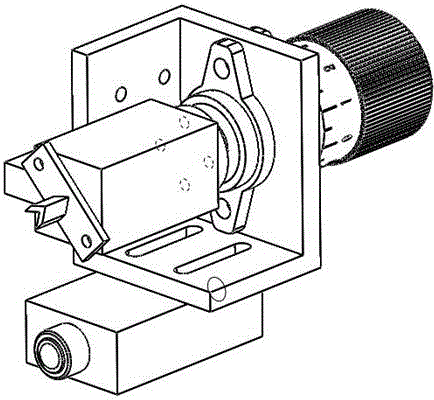

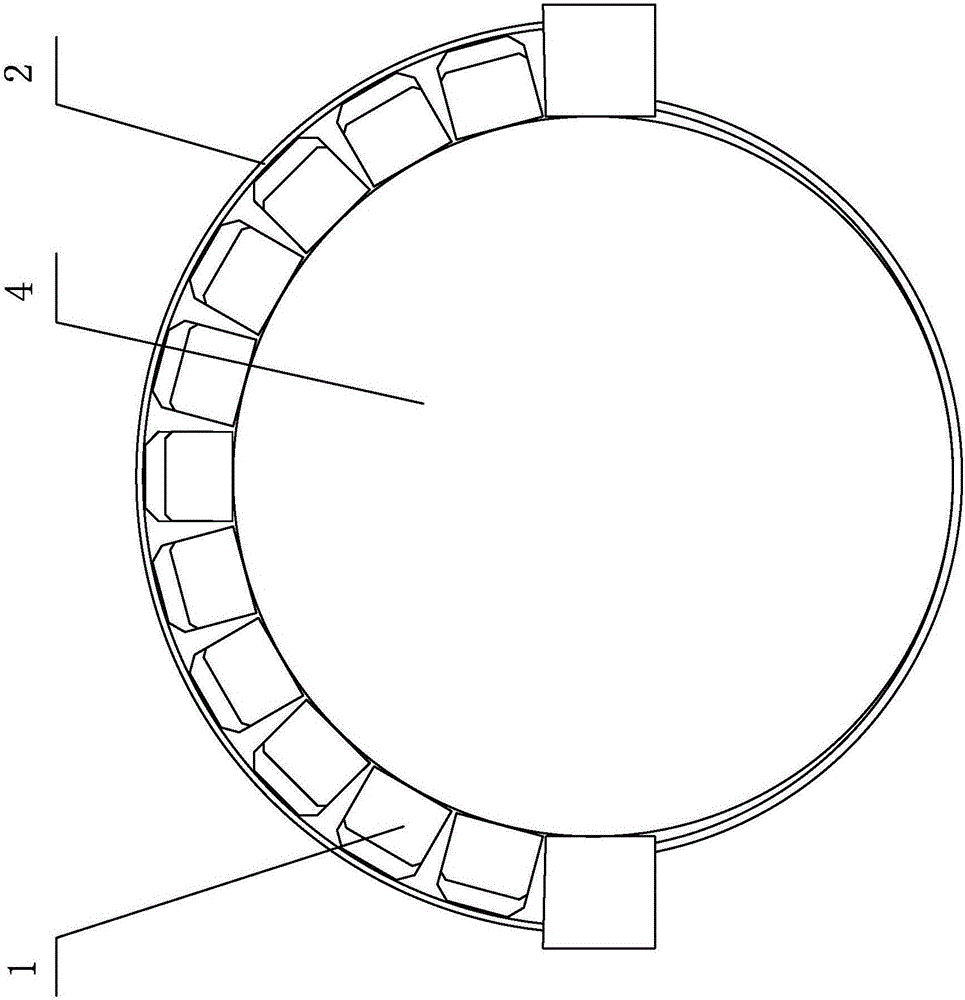

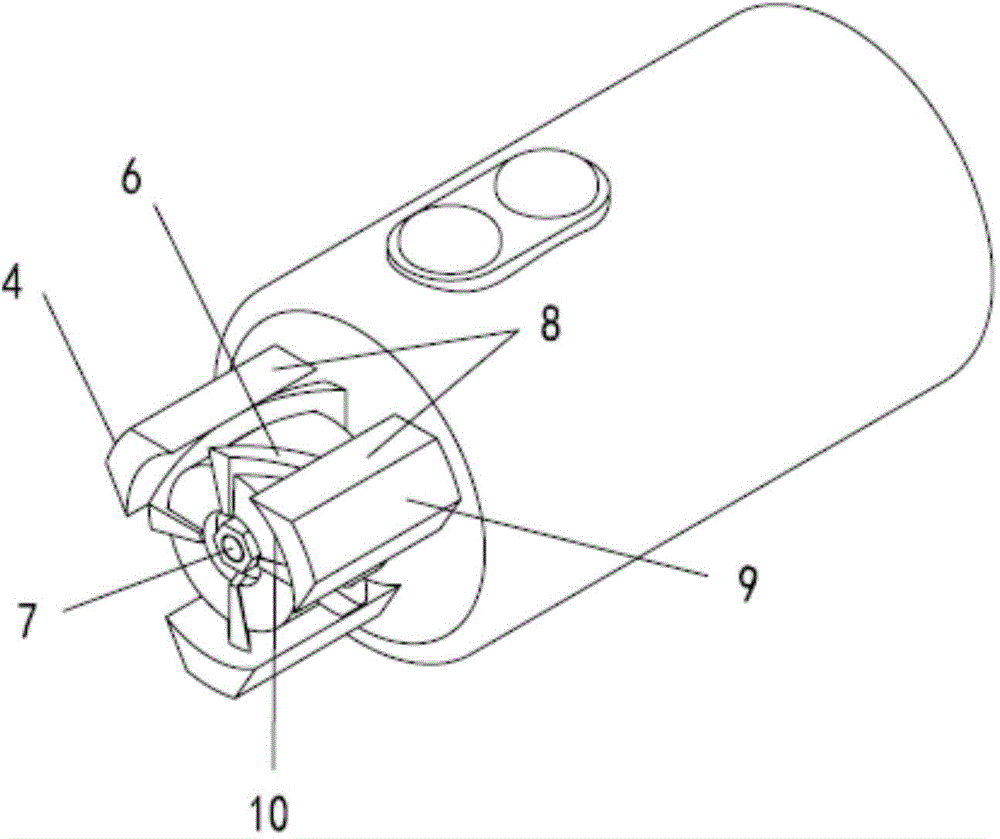

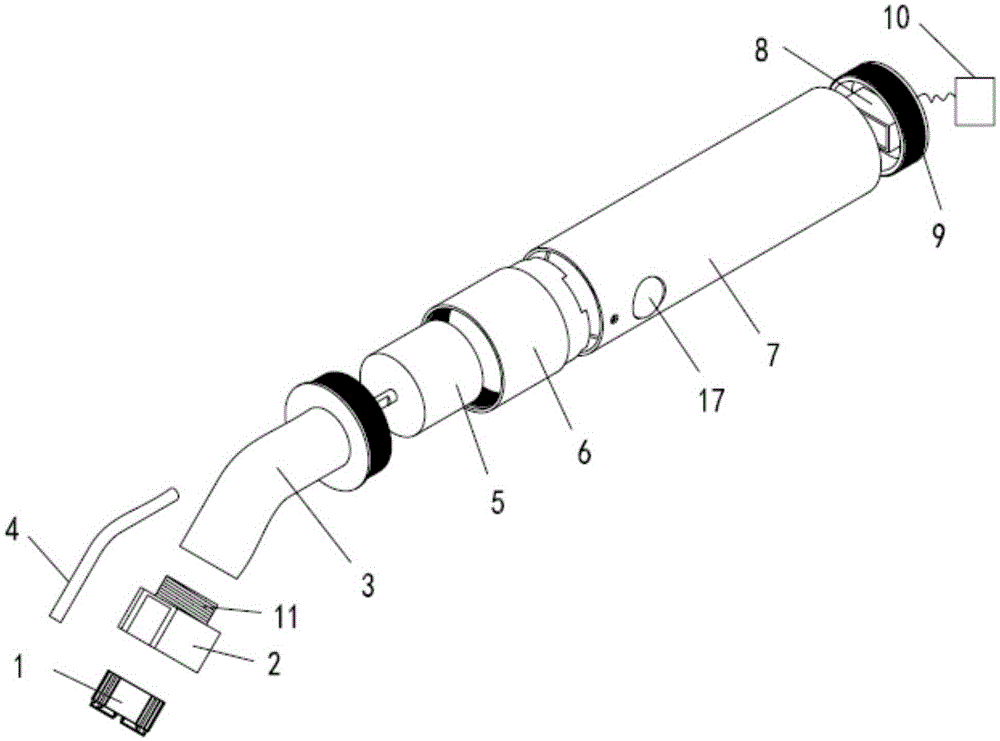

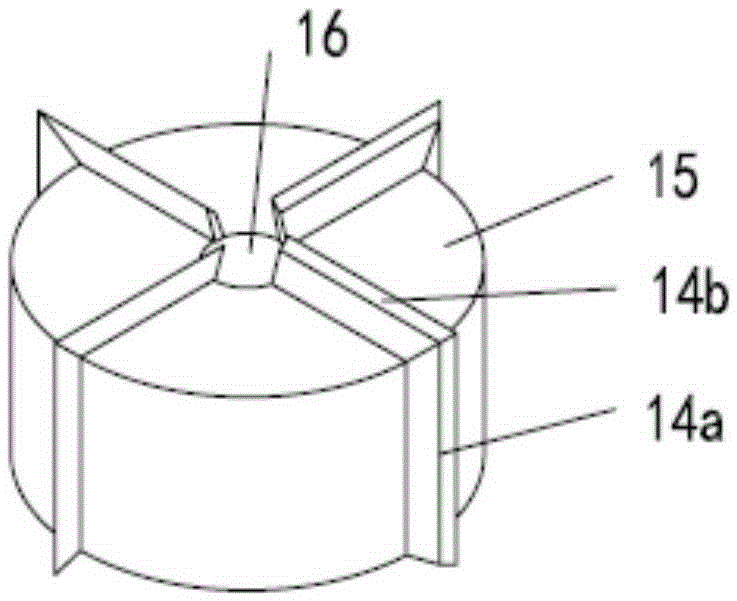

Electric rubber tapping knife

ActiveCN104620937AImprove efficiencyTapping is quick and easyForestryEngineeringUltimate tensile strength

The invention discloses an electric rubber tapping knife. The electric rubber tapping knife comprises a motor, a guide device and a rotating knife head. The guide device is connected with an outer shell of the motor through a fixing screw, and the rotating knife head is arranged in the guide device. The guide device is composed of a plurality of arc-shaped trapezoidal guide sheets. Each guide sheet is composed of an outer arc face, an inner arc face and two waist faces. A notch is formed between every two adjacent guide sheets. Limiting faces on the same plane are formed by the adjacent waist faces between every two adjacent guide sheets and are parallel to the axis. A screw blade is arranged at the rotating knife head. The electric rubber tapping knife is used for replacing traditional manual rubber tree bark tapping and traditional V-shaped-knife rubber tree bark tapping, rubber tapping is easily, conveniently, rapidly and efficiently carried out, the labor intensity is reduced, the requirement for the rubber tapping technology is reduced, the labor cost is saved accordingly, and the benefits of the natural rubber industry is accordingly improved.

Owner:曹建华 +3

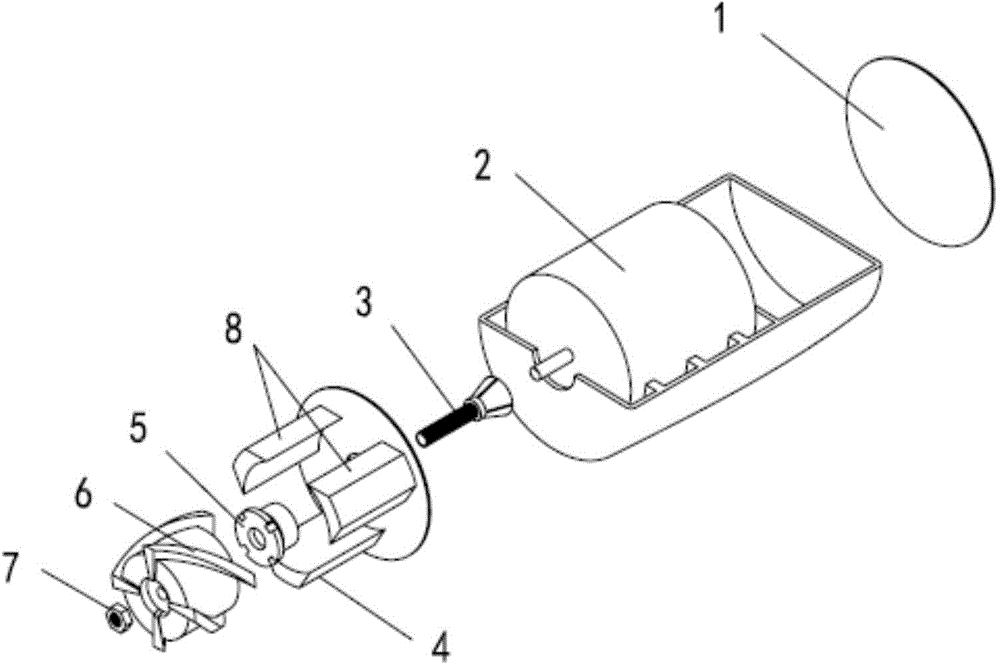

Method for cultivating Ganoderma lucidum Antler in rubber forest

InactiveCN104303823ASolve technical problemsCultivating equipmentsMushroom cultivationManagement processEdible mushroom

The invention belongs to the field of crop cultivation, and relates to a method for cultivating Ganoderma lucidum Antler in a rubber forest. The method comprises a mushroom bag production process, a Ganoderma lucidum bed arrangement process and a plantation management process. An intercropping mode in the rubber forest is adopted, and the measures of mushroom bed cultivation technology, culture medium, mushroom bed shedding and film covering and the like are organically integrated, so that the technical problem that the Ganoderma lucidum Antler is difficultly cultivated under high-temperature and high-moisture environments in the rubber forest is solved, a successful technical reference is provided for economy in a rubber tapping plantation development forest, the planting of edible mushrooms in Hainan forests is promoted, and a new mode is provided for developing the forest economy and the production of the edible mushrooms.

Owner:HAINAN NONGKEN TECH DEV CO LTD

Rubber tapping machine and rubber tapping method

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises an upper deformable guide rail and a lower deformable guide rail; a sliding groove isformed between the inner wall and the outer wall of each deformable guide rail, and teeth are arranged on the outer side of the outer wall of each deformable guide rail; the rubber tapping machine further comprises a longitudinal guide rail; an upper guide rail frame and a lower guide rail frame are installed at two ends of the longitudinal guide rail respectively; inner grooves and transverse limiting wheels are arranged on the guide rail frames; gears in the guide rail frames are meshed with the teeth on the outer walls of the deformable guide rails, and the transverse limiting wheels are embedded into the corresponding sliding grooves in the deformable guide rails; in addition, a lead screw is installed between the upper and lower guide rail frames, one end of the lead screw is fixedlyconnected with motor teeth of a motor I, and the other end of the lead screw is fixedly connected with a driving gear; and the rubber tapping machine further comprises a tool rest assembly arranged on the longitudinal guide rail and the lead screw in a sleeving mode. According to the rubber tapping machine disclosed by the invention, the deformable guide rails are used, so that the rubber tappingmachine can be suitable for trunks with different thicknesses and shapes; the whole rubber tapping machine can be firmly fixed on the trunks by cooperation with a tightening belt; and in addition, the deformable guide rails also play a transmission role in a rubber tapping process.

Owner:NINGBO CIHEVEA TECH CO LTD

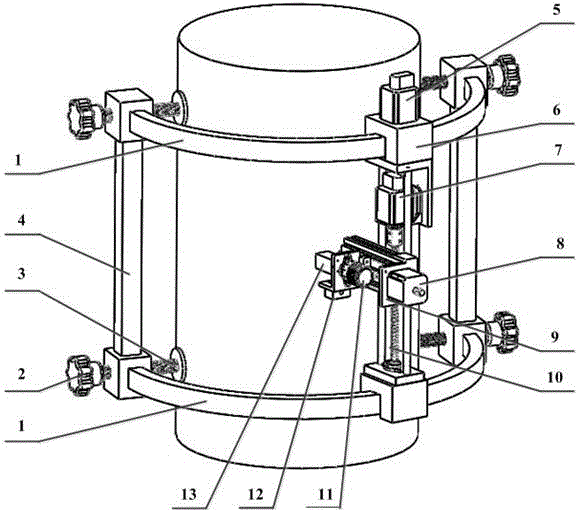

Rubber cutting robot

ActiveCN110696008AImprove accuracyExtend your lifeForestryManipulatorControl systemControl engineering

The invention relates to a rubber cutting robot which comprises a clamping mechanism, a cutting mechanism, a moving mechanism, a measuring and limiting module and an existing control system. The rubber cutting robot is fixed to a rubber tree through the clamping mechanism. The moving mechanism and the measuring and limiting module are arranged on the clamping mechanism and both connected with theexisting control system. The measuring and limiting module transmits a received signal into the existing control system, and the existing control system controls the moving mechanism to act accordingto the received measurement signal. The cutting mechanism is arranged on the moving mechanism and driven by the moving mechanism to do spiral movements on the clamping mechanism. The cutting mechanismis connected with the existing control system and controlled by the existing control system to work. The rubber cutting accuracy can be improved, and the waste of rubber liquid and the damage to rubber latex vessel tissue caused by artificial operation errors are avoided, and the repeated cutting rate is effectively increased.

Owner:BEIJING INFORMATION SCI & TECH UNIV

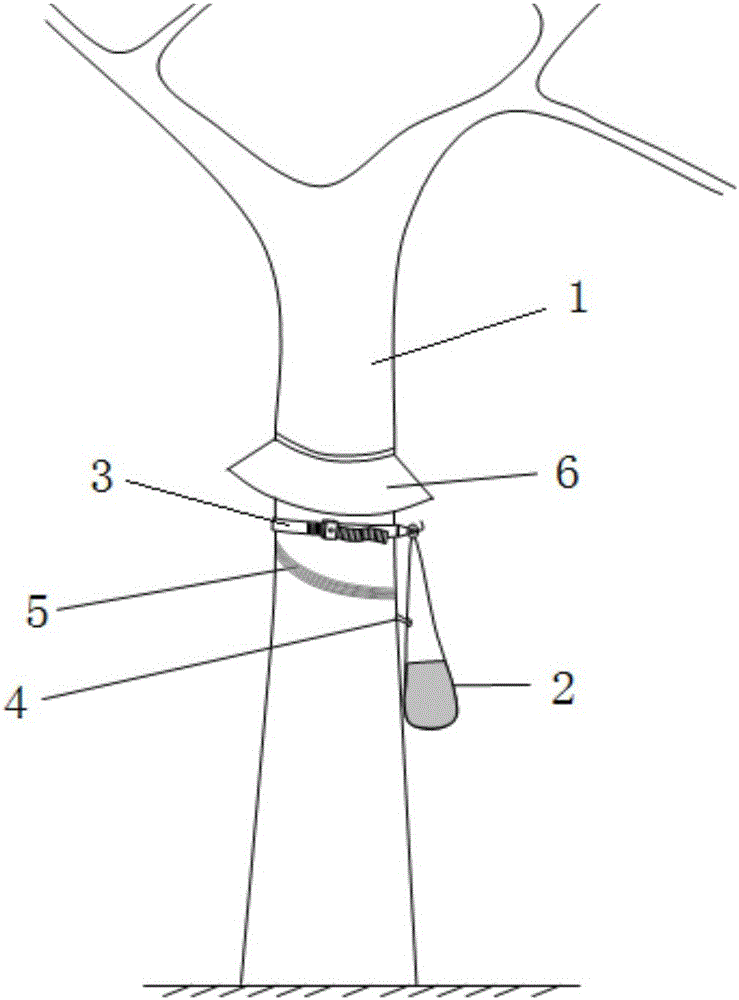

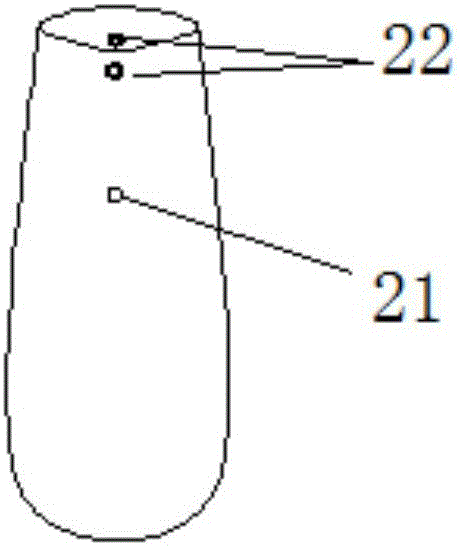

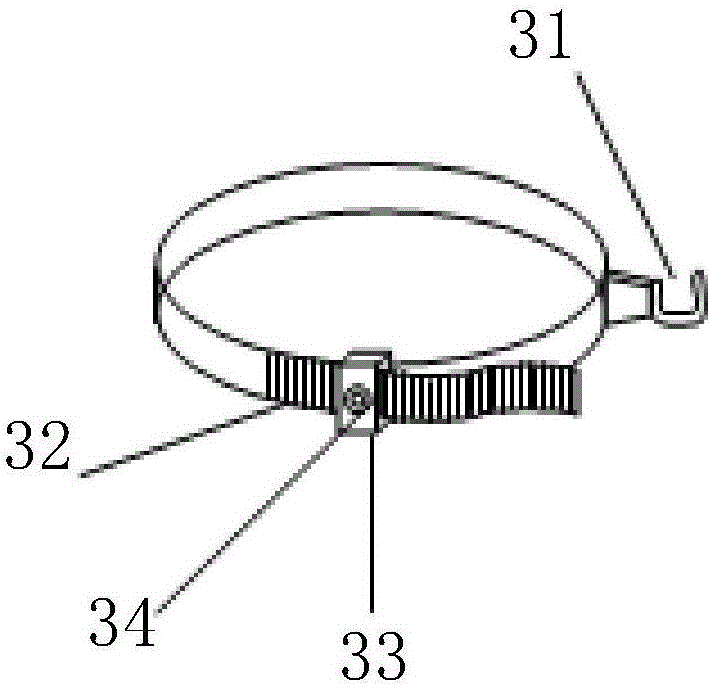

Method and device for collection of natural rubber latex

The invention discloses a collection method for a natural rubber latex. The collection method comprises the following steps: collecting the latex flowing along a rubber tapping line after rubber tapping by utilizing a flexible plastic container; and allowing the latex in the flexible plastic container to solidify under natural conditions. Through the collection method for the latex provided by the invention, the collected latex can be solidified under natural conditions, and addition of a chemical substance used for promoting the latex to solidify is not needed, so the purity of the latex is improved. The invention also discloses a collection device used for realizing the above-mentioned collection method for the natural rubber latex. The collection device comprises the flexible plastic container used for collection of the latex, a fixing unit which is used for fixing the flexible plastic container and detachably connected with the flexible plastic container, and a rubber tongue which is used for guiding the latex to enter the flexible plastic container, wherein the side wall of the flexible plastic container is provided with a latex inlet hole; the fixing unit is fixedly arranged on a rubber tree; one end of the rubber tongue is positioned below the bottom part of the rubber tapping line of the rubber tree; and the other end of the rubber tongue is positioned inside the rubber inlet hole.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

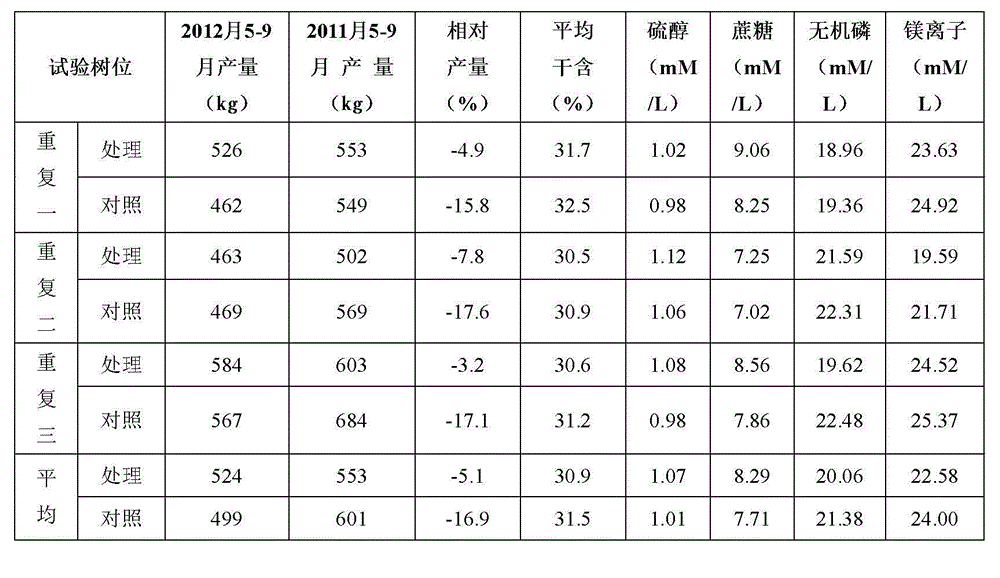

Nutrition agent for healing of rubber tree

InactiveCN102144636AIncrease productionLong growth cycleBiocidePlant growth regulatorsSodium metasilicateThird generation

The invention relates to a nutrition agent for healing of a rubber tree. The adopted technical scheme for solving the technical problems is as follows: the nutrition agent is composed of 1g-10g marine algae, 1g-12g sorbic acid, 50-80 ml alcohol, 10g-30g sodium benzoate, 1g-22g sodium metasilicate, 1g-25g sodium pyrosulfite, 3g-36g boric acid and 1g-23g citric acid. The nutrition agent for healingof the rubber tree has the following beneficial effects: after tapping off the rubber from the rubber tree, the tapped part is coated with the nutrition agent for healing of the rubber tree, so that the rubber tree is protected from invasion of noxious bacteria and pathogenic mycete, various fungi are killed, and nutrition is supplemented for the rubber tree, and the tapped part can be healed quickly. In this way, the yield of the rubber tree is improved, and simultaneously, the growth cycle of the rubber tree is prolonged. Many tests prove that the nutrition agent has very obvious effect.

Owner:王向前 +3

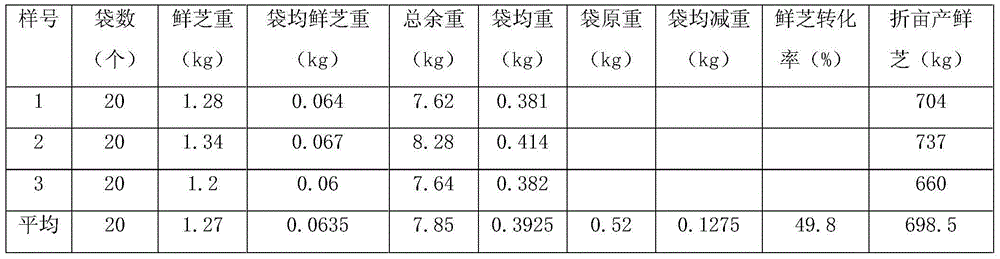

Portable electric rubber tapping knife

The invention discloses a portable electric rubber tapping knife which comprises a rotary knife head, a limit device, a transmission assembly, a power assembly, a connecting assembly and a handle. The rotary knife head is composed of a cylindrical knife body and screw blades radially distributed on the cylindrical knife body, and each screw blade is composed of an axial blade body and a radial blade body; a limit cover arranged on the exterior of the rotary knife head in a sleeving mode serves as the limit device, one end of the limit device is provided with a screwed joint, the other end of the limit device is provided with a circular opening, and the side face of the limit device is provided with an axial cutting opening and a chip discharging opening; the axial blade bodies are located at the axial cutting opening of the limit device, and the radial blade bodies are located at the circular opening of the limit device. The rubber tapping knife is simple in structure, convenient to use, low in requirement for a rubber tapping technique of a rubber tapping worker and capable of significantly improving the rubber tapping efficiency, saving the production cost, meeting the usage of inclined upward tapping and inclined downward tapping and the requirements of body mechanics and being reused.

Owner:曹建华

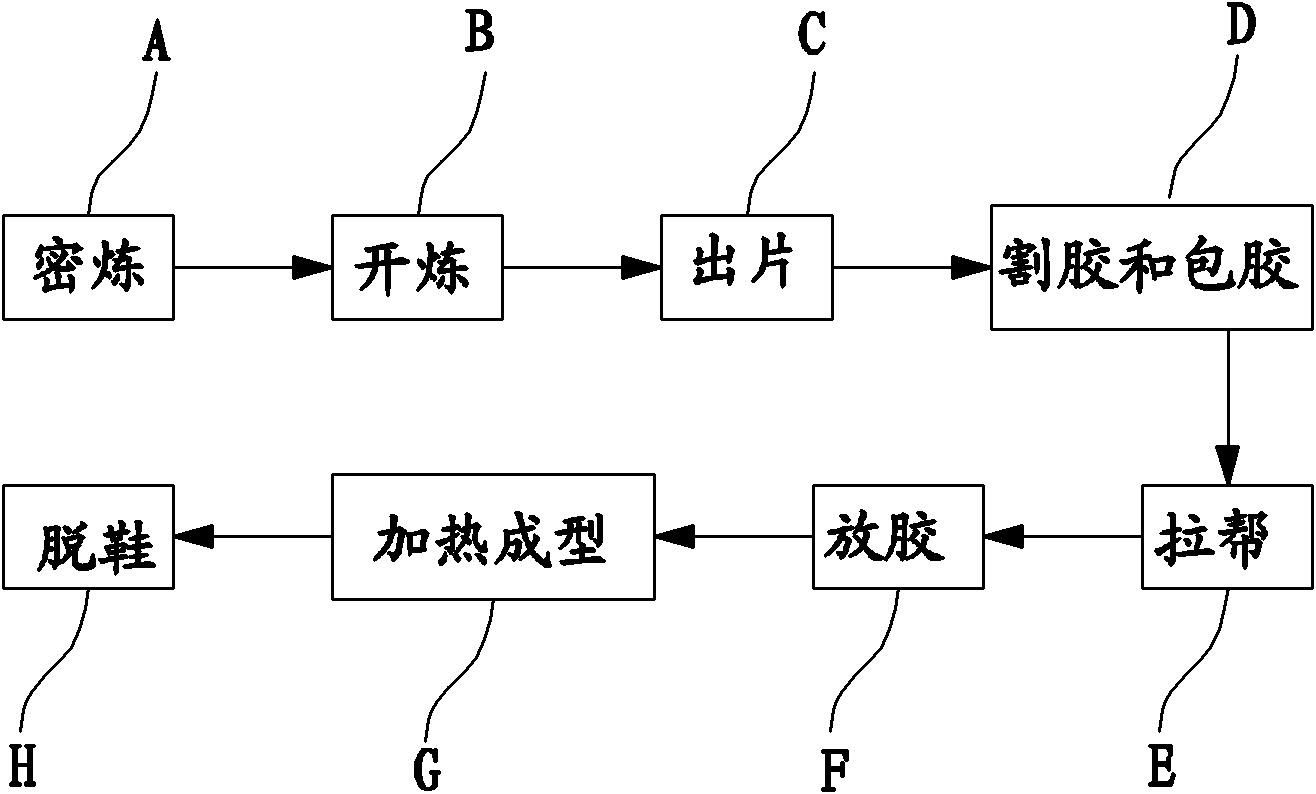

Sole formula and production process thereof

The invention discloses a sole formula and a production process thereof. The formula comprises the following components: 3-5 parts of natural rubber, 10-13.8 parts of isoprene rubber, 5-7 parts of talc powder, 10-14.5 parts of nano ointment, 3-5.6 parts of white carbon black, 0.94-1.2 parts of zinc carbonate, 0.1-0.3 part of flow promoter, 0.01-0.03 part of DCP (Dicumyl Peroxide), 0.188-0.276 part of anti-aging agent, 0.125-0.25 part of protective wax, 0.05-0.08 part of p-toluenesulfonyl, 0.1-0.2 part of sulfur and 0.025-0.05 part of foaming agent. The production process comprises the procedures of banburying, open milling, sheet discharging, rubber tapping, rubber coating, bringing up, sizing, heating, molding, taking off shoes and the like. The sole produced by adopting the production process has the characteristics of high binding property, high elasticity, high stretching strength, high tear resistance, high electrical insulating property, high wear resistance, high drought resistance, low temperature resistance, noise resistance, high processability and the like.

Owner:福建晋江市越峰鞋塑有限公司

Automatic rubber tapping machine

The invention discloses an automatic rubber tapping machine. The automatic rubber taping machine comprises a support detachably matched with a trunk, wherein a longitudinal track which extends in thevertical direction and is in clearance fit with the outer surface of the trunk is arranged on the support, a spiral track which is in clearance fit with the outer surface of the trunk is further arranged on the support, one end of the spiral track is connected with a longitudinal sliding block movably arranged on the longitudinal track, and the spiral track is linked with the longitudinal slidingblock; a cutter is movably arranged on the spiral track, and a blade is arranged on the cutter; permanent magnets which are sequentially and uniformly distributed in the extending directions of the respective tracks are respectively arranged in the longitudinal track and the spiral track, the magnetisms of the two adjacent permanent magnets is opposite, magnetic induction coils matched with the permanent magnets are respectively arranged in the longitudinal sliding block and the cutter, and the automatic rubber tapping machine further comprises a controller matched with the magnetic inductioncoils. The automatic rubber tapping machine is simple, convenient and feasible to operate and is accurate and efficient, the labor intensity of workers can be reduced effectively, and the rubber tapping operation precision and operation efficiency are improved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Cutting mechanism and method for collecting natural rubber at high position

InactiveCN111631110AImprove growth efficiencyMaintain healthForestryTree trunkStructural engineering

The invention provides a cutting mechanism and method for collecting natural rubber at a high position. The cutting mechanism for collecting the natural rubber at the high position is arranged on a trunk part, higher than the normal body height, of a rubber tree. The cutting mechanism comprises a cutting mechanism body and a fixing assembly. The rubber tree is sleeved with the fixing assembly, andthe cutting mechanism is arranged on the fixing assembly. The cutting mechanism body comprises a spiral sliding way, a scraper, a sliding block, a connecting rod, a threaded rod, a fixing sleeve, a handle and a connecting block. According to the cutting mechanism and method for collecting the natural rubber at the high position, through cooperation of the spiral sliding way, the scraper, the sliding block, the connecting rod, the threaded rod, the fixing sleeve, the handle and the connecting block, the selection range of the rubber tapping position can be expanded; meanwhile, a certain periodof time can be reserved for self-repairing of bark tissues damaged after rubber tapping at a low position originally, so that the growth efficiency of the rubber tree is improved, and meanwhile, thehealth state of the rubber tree is guaranteed; and therefore, the rubber production efficiency is indirectly improved.

Owner:诸暨市惠中智能科技有限公司

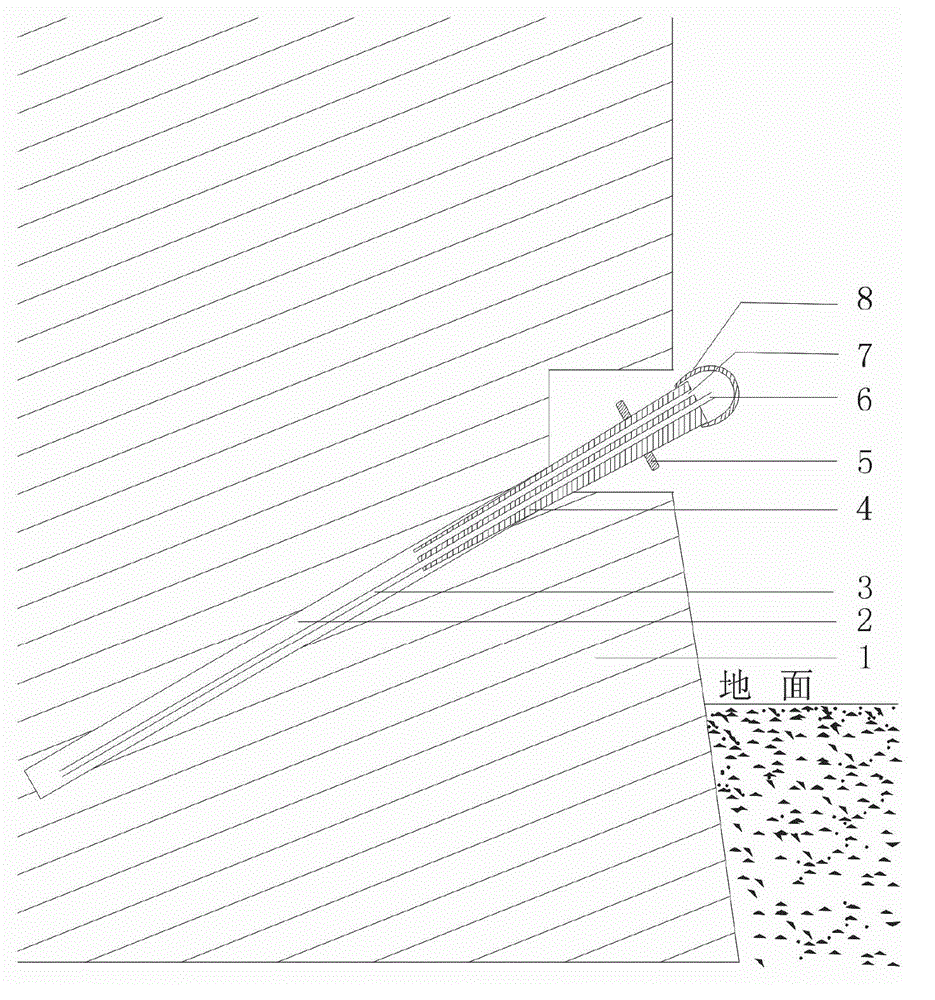

Method for collecting latex from old rubber trees

The invention discloses a novel method for collecting latex from old rubber trees. Specifically, the method comprises the steps of drilling a drill hole (2) with the diameter being about 0.8 cm and the depth being 15 cm on a tree head (1), and implanting a set of new plastic tube device in the drill hole (2); and the device is characterized by comprising a thin plastic tube (3) with the length being about 20 cm and the inner diameter being about 0.15 cm; the outer tail end of the thin plastic tube is sleeved with a conical tubular plug (4) with the length being about 8 cm and the diameter in the maximum position being about 1 cm; two handles (5) are formed on the plug; a liquid inlet (6) with the diameter being about 0.15 cm and a liquid outlet (7) with the diameter being about 0.15 cm are formed at the outer tail end of the plug; the thin plastic tube (3) and the liquid inlet (6) form a liquid inlet pipeline; excess liquid in the drill hole (2) can be discharged from the liquid outlet (7); and a plastic cover (8) covers the outer tail end of the plastic tube device. A certain amount of ethephon preparation is injected through the plastic tube device, so as to stimulate a rubber tree, latex is collected through methods, such as short line rubber tapping, low-frequency rubber tapping, acupuncture rubber collection and the like as required, and the collection position can be any position of a trunk bast. According to the method, the purposes of increasing in yield, improving efficiency, reducing the bark consumption and the like are achieved.

Owner:海南省农垦科学院

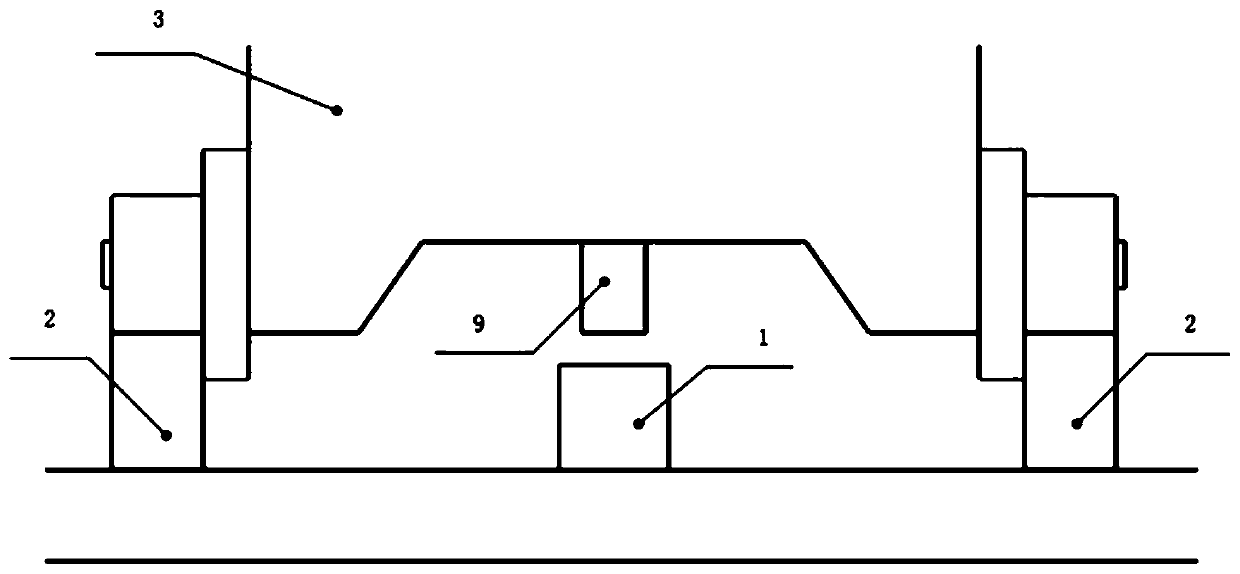

Full-automatic puncture tapping machine

PendingCN109952935AGood application effectRealize "micro-cutting" rubber miningForestryIntegrated operationsEngineering

The invention discloses a full-automatic puncture tapping machine. The full-automatic puncture tapping machine comprises a rail machine frame, a movable carrying platform and a puncture tapping system, wherein the rail machine frame is used for being fixed to a rubber tree, the movable carrying platform can be movably arranged on the rail machine frame, and the puncture tapping system is arrangedon the movable carrying platform. The full-automatic puncture tapping machine has the advantages that the functions of rubber tree rossing, rubber latex output increasing agent coating, puncture tapping, rubber latex collecting and the like are integrated, and the integrated operation functions of pesticide application and rubber latex tapping and collecting are achieved; and puncture groups whichare arranged according to the production specification and has a certain thickness are arranged on the puncture tapping system arranged on the movable carrying platform, the drilling and rubber latextaking operation can be carried out on the surface of bark of the rubber tree, the rubber tapping operation is carried out by replacing a traditional bark cutting mode with a drilling mode, so that the technical difficulty of the rubber tapping operation can be greatly lowered, the problems that the profiling design is poor in other types of rubber tapping machine designs, the cutting depth of the bark is difficult to control, the operation precision is difficult to guarantee, and the like can be solved, and the practical application effect of rubber tapping and collecting of a rubber tappingmachine is enhanced.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Electric rubber cutting machine

The invention discloses an electric rubber cutting machine. The electric rubber cutting machine comprises a handle, a machine base, a motor, a rubber cutting tool bit and a waterline tool bit. The electric rubber cutting machine is characterized in that the rubber cutting tool bit and the waterline tool bit are connected with the motor through a well-known power transmission method, the motor, the rubber cutting tool bit and the waterline tool bit are fixed to the machine base, and a switch and a power supply plug are arranged on the handle. In the rubber cutting process, a waterline can be formed for a newly-cut rubber tree through the waterline tool bit, or dry rubber dried on the bark can be taken out and then cut through the rubber cutting tool bit. Due to the work efficiency of the electric cutting machine, work conducted by 2 to 3 skilled rubber cutting workers can be conducted through the electric rubber cutting machine, and people without work experience can easily operate the machine to cut rubber.

Owner:潘朝鼎

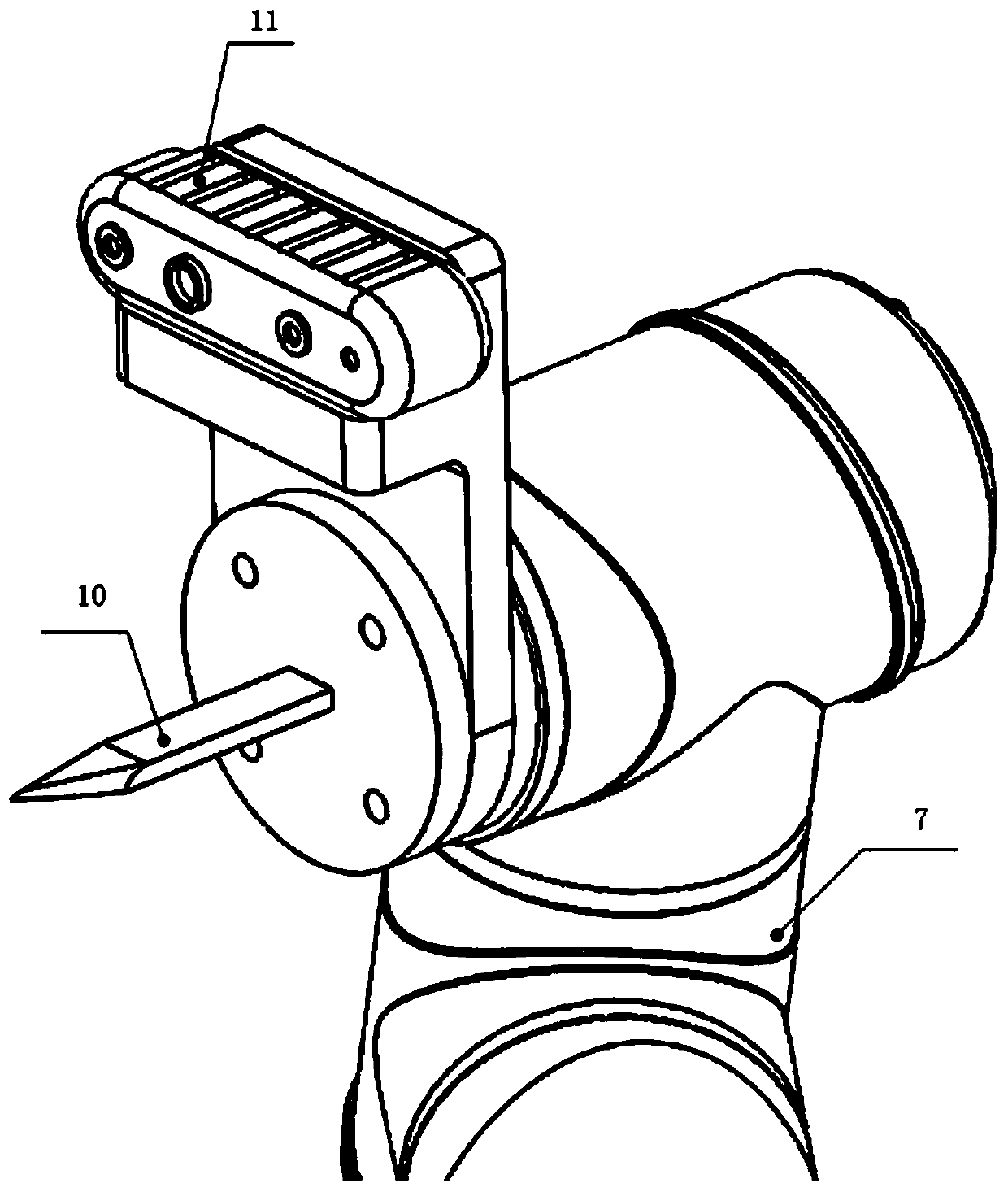

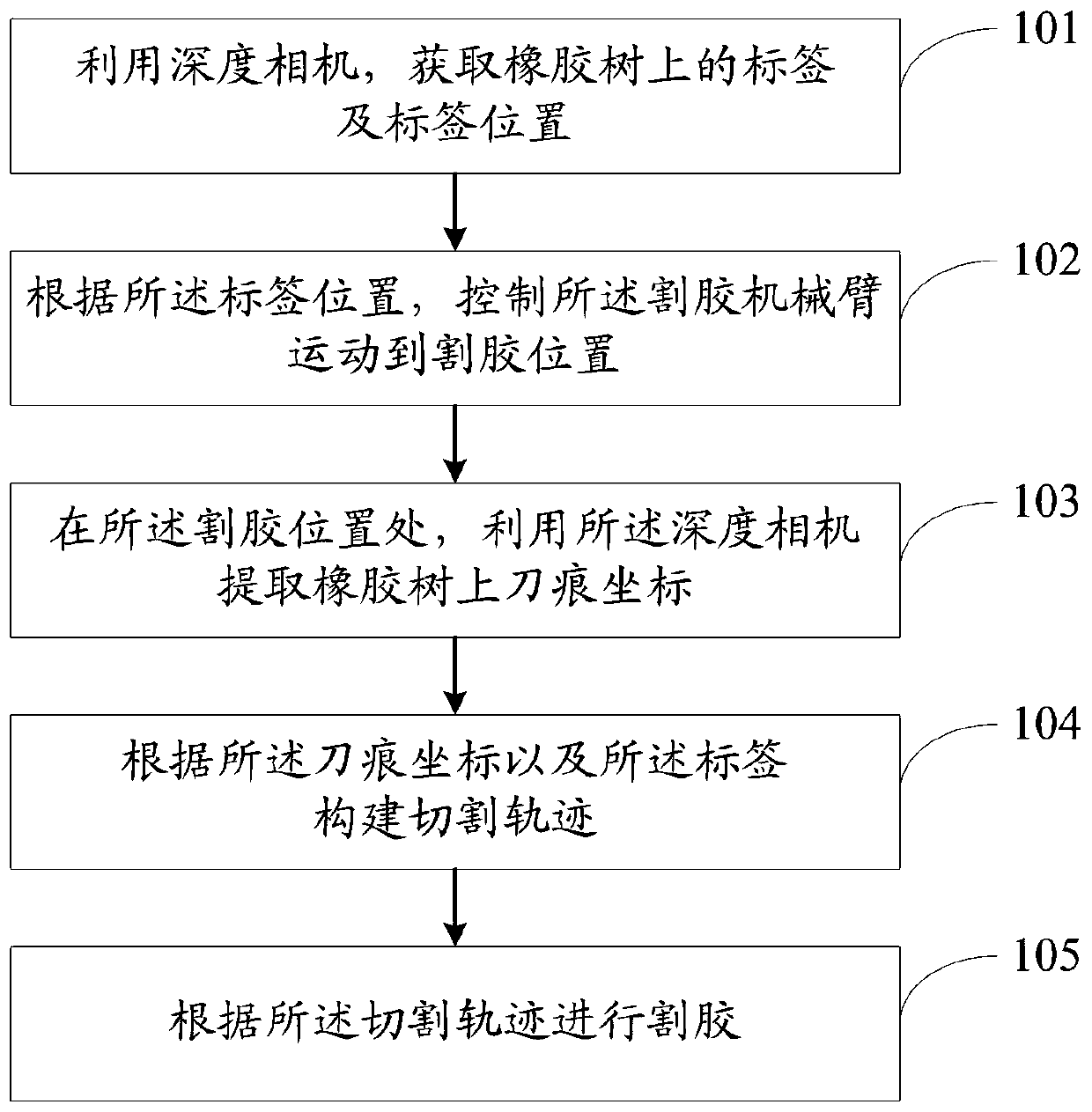

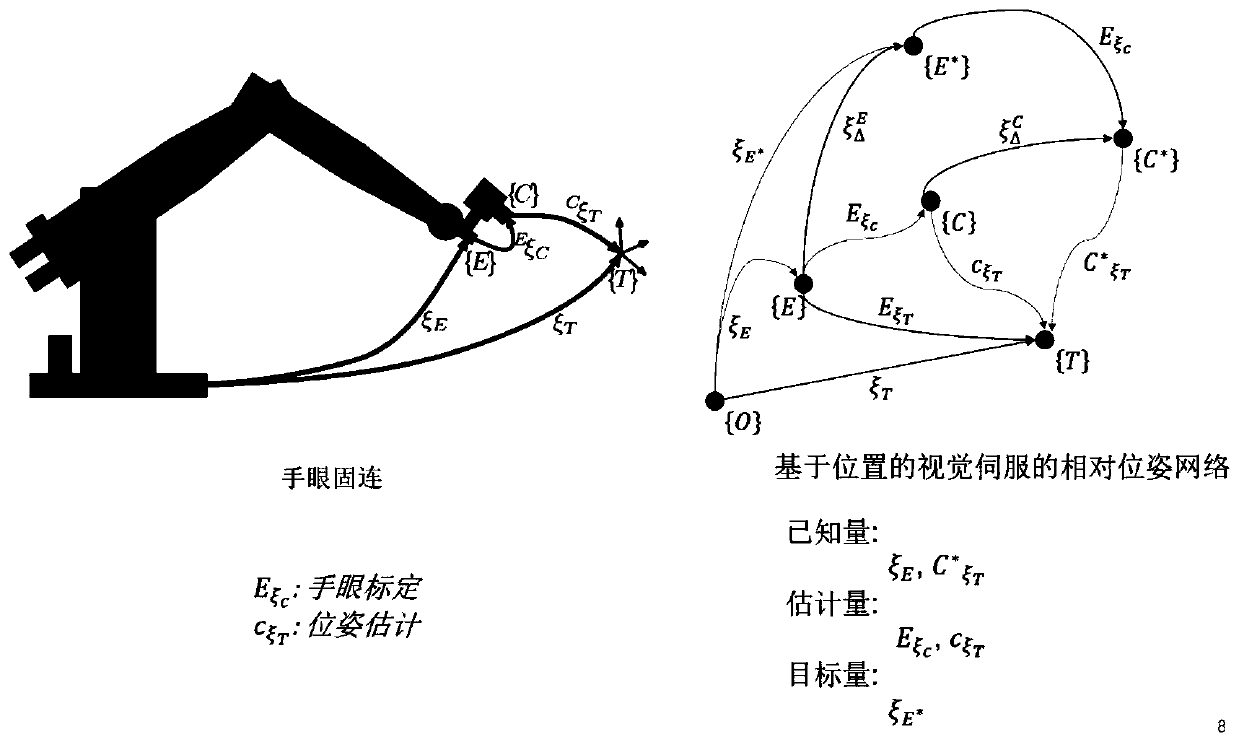

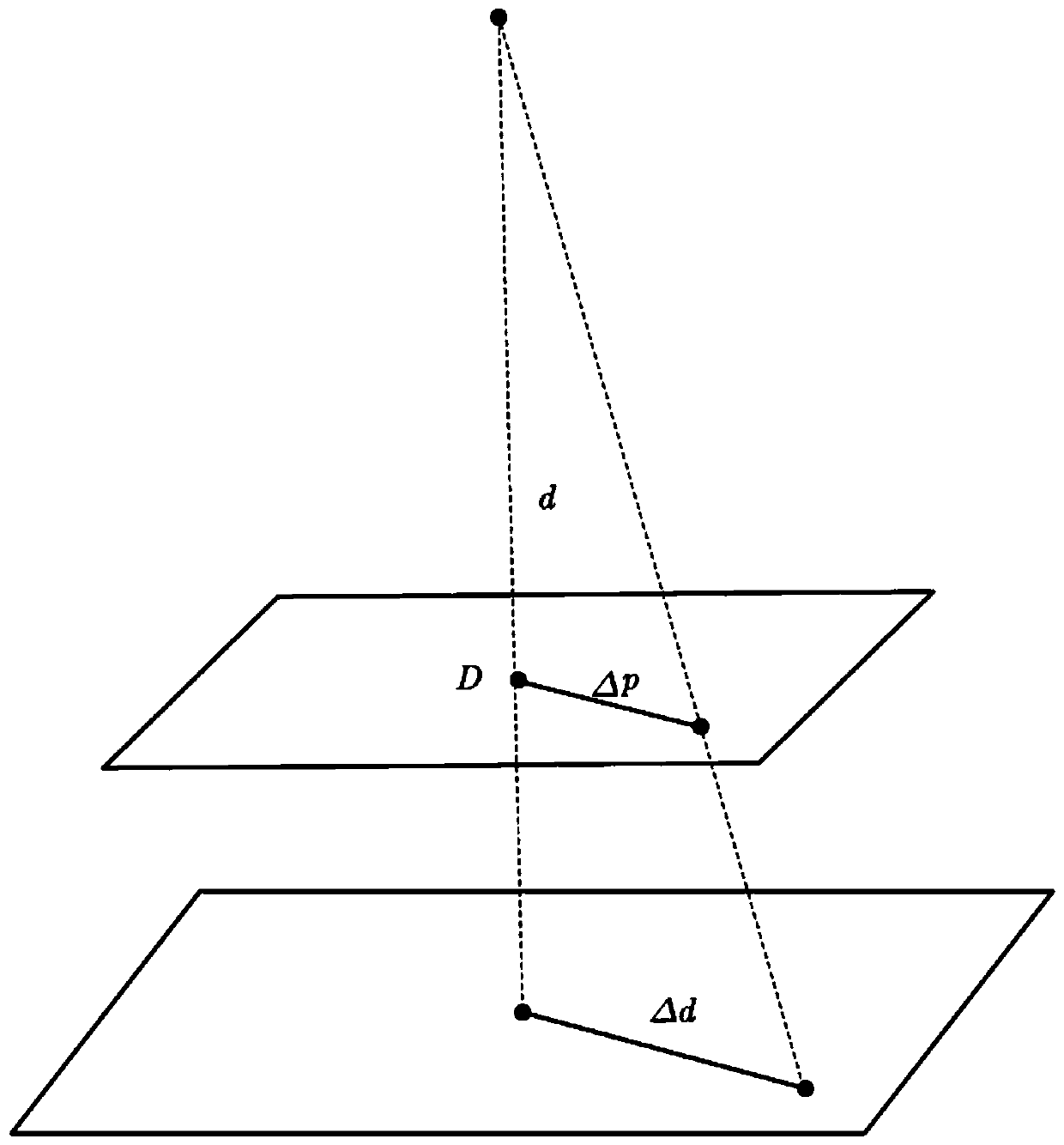

Rubber tapping method and system based on rubber tapping mechanical arm

ActiveCN110651686AImprove productivityReduce labor intensityForestryEngineeringMechanical engineering

The invention discloses a rubber tapping method and system based on a rubber tapping mechanical arm. The rubber tapping method includes: utilizing a depth camera to acquire a label on a rubber tree and a position of the label, wherein the label is number information; according to the position of the label, controlling the rubber tapping mechanical arm to move to a rubber tapping position; at the rubber tapping position, utilizing the depth camera to extract cut mark coordinates on the rubber tree; establishing cutting trails according to the cut mark coordinates and the label; performing rubber tapping according to the cutting trails. By adopting the rubber tapping method and system, labor intensity of artificial rubber tapping can be lowered, and rubber tapping productivity can be improved.

Owner:自走科技(北京)有限公司

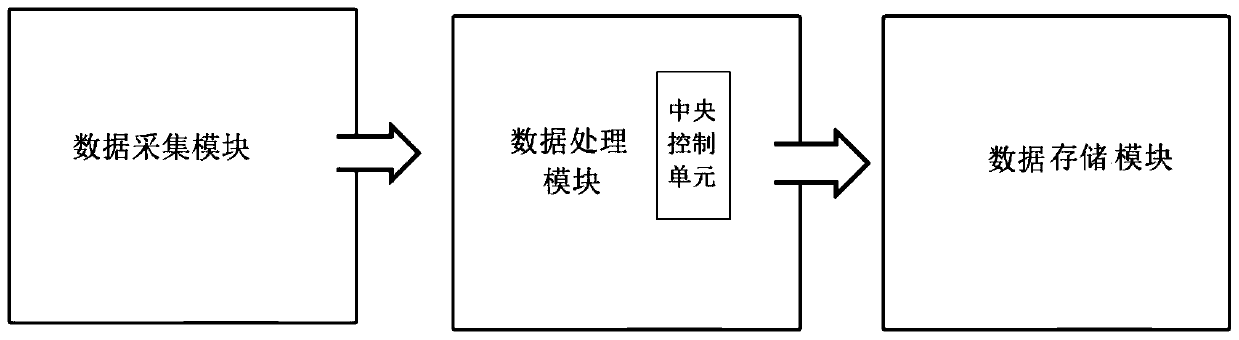

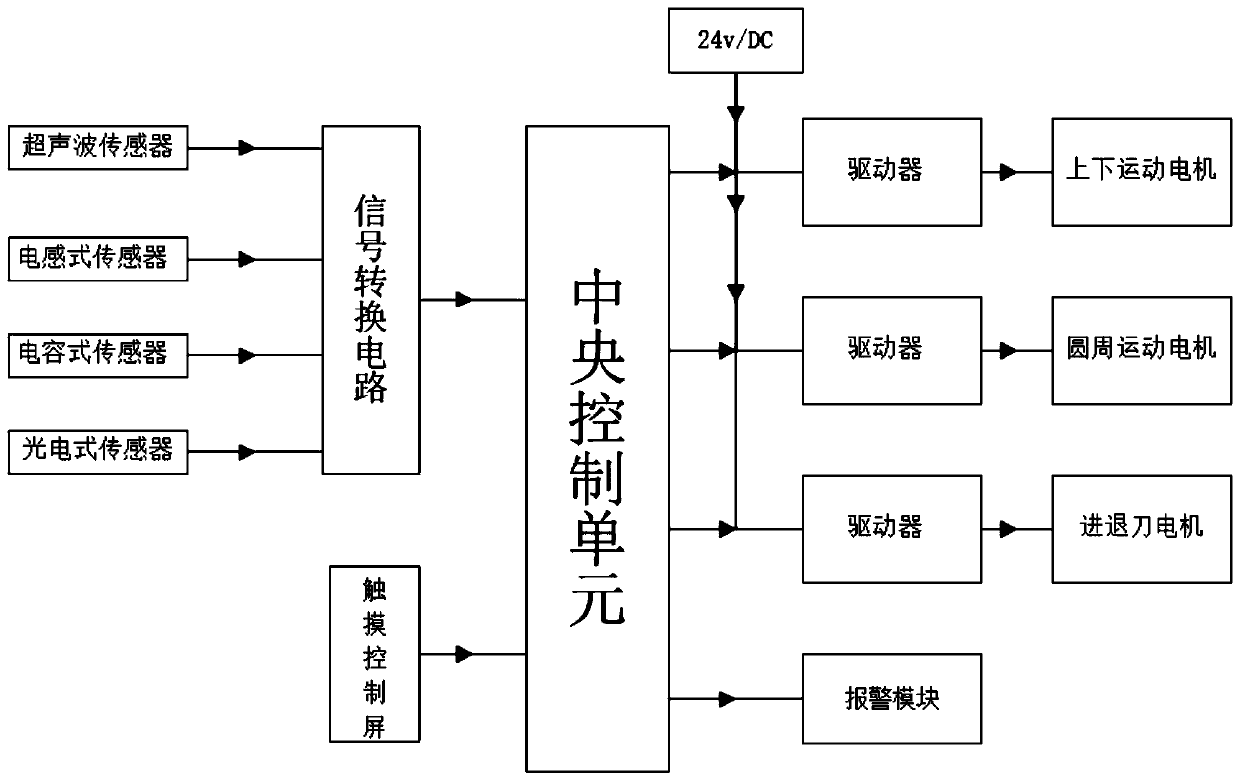

Rubber tapping robot control system and method

ActiveCN110682302ANo interferenceStable controlProgramme-controlled manipulatorForestryControl systemData acquisition

The invention relates to a rubber tapping robot control system and method. The system involves a data acquisition module, a data processing module, a data storage module and a power supply battery, wherein the power supply battery is used for supplying power to each module; the data acquisition module transmits collected rubber tapping information to the data processing module, the collected rubber tapping information is transmitted to a rubber tapping robot and the data storage module after being processed by the data processing module; and the rubber tapping robot carries out rubber tappingoperation according to the received control information, and the data storage module is used for data storage. According to the rubber tapping robot control system and method, the required requirements of the rubber tapping are met through the movement control over three directions of circumference direction surrounding a tree, direction parallel to the tree and direction perpendicular to the treeand the control over the rubber tapping depth and trajectory, the principle is simple, the control is sensitive and the safety stability is good; and the system and method can be can be widely applied to the fields such as the depth, the trajectory and the spiral rise angle of the novel natural rubber tapping robot.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Portable electric rubber tapping knife for rubber

PendingCN105165550AReduce labor intensityImprove tapping efficiencyForestryBody mechanicsSpiral blade

The invention discloses a portable electric rubber tapping knife for rubber. The portable electric rubber tapping knife comprises a rotating knife head, a limiting device, a transmission component, a power component, a connecting component and a handle, wherein the rotating knife head comprises a cylindrical knife body and spiral blades radially distributed on the cylindrical knife body; each spiral blade comprises an axial blade and a radial blade; the limiting device is a limiting cover sleeving the outer part of the rotating knife head; a threaded joint is arranged at one end of the limiting device, and the other end of the limiting device is a circular opening; an axial cutting opening and a debris discharge opening are formed in the side face of the limiting device; the axial blades are positioned in the axial cutting opening of the limiting device; the radial blades are positioned in the circular opening of the limiting device. The rubber tapping knife is simple in structure and convenient to use, the requirement on the rubber tapping technique of rubber workers is low, the rubber tapping efficiency can be greatly improved, the production cost is reduced, the use of both upward rubber tapping and downward rubber tapping is met, the requirement on body mechanics is met, and the portable electric rubber tapping knife can be repeatedly used.

Owner:CHINESE ACAD OF TROPICAL AGRI SCI

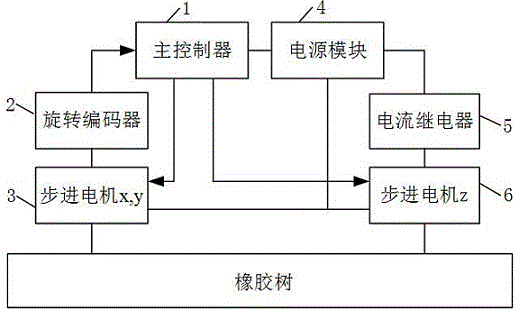

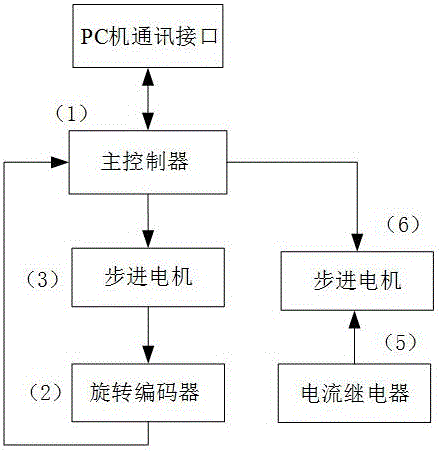

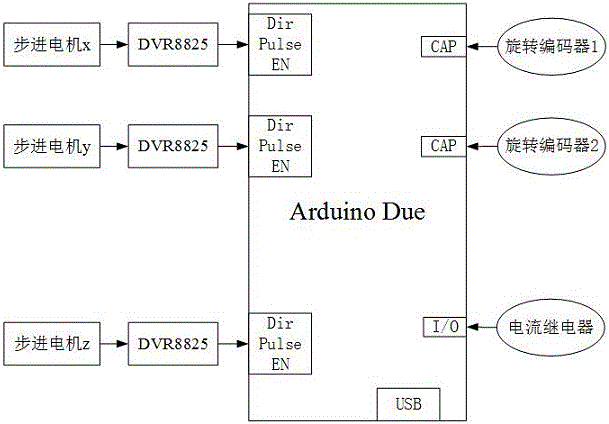

Control system of automatic rubber tapping robot

InactiveCN105961139AEasy to controlRenewable energy machinesForestryControl system designSolar power

The invention discloses a control system of an automatic rubber tapping robot, and belongs to the field of specialized robot control. The control system is characterized by comprising a main controller, a rotary encoder, a current relay module and a power module. The main controller is mainly used for receiving various operation instructions and controlling all mechanisms of the automatic rubber tapping robot to cooperatively move; the rotary encoder is mainly used for detecting the motion conditions and positions of stepping motors and feeding relevant information back to the main controller to be processed; the current relay module is mainly used for controlling the tool tapping depth when the rubber tapping robot starts primary tapping; the power module is a small solar power generating system and is used for supplying a power supply to the control system. The cleaning robot control system controls the rubber tapping depth by cooperating with the current relay module through a program in a control panel, collects and processes information fed back by the rotary encoder and then sends an instruction to precisely control the stepping motors in real time to cooperate with one another to conduct tapping, after primary tapping is finished, the main controller controls a tool to return along an original path, and after delaying is conducted, the tool moves downwards by 1.1 mm for next tapping. The control system is simple in design and easy to operate.

Owner:武汉市享昱科技有限公司

Rubber tapping machine and rubber tapping method

PendingCN111972250ARealize unmanned automatic tappingSolve labor intensityForestryElectric machineryEngineering

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises two supporting steel pipes, wherein one sides of the two supporting steel pipes are connected through binding belts, the other sides of the two supporting steel pipes are connected through an upper spiral guide rail and a lower spiral guide rail, and the positions of the spiral guiderails are opposite to the positions of the binding belts on the opposite sides of the spiral guide rails; the rubber tapping machine further comprises a knife rest assembly with a motor and a limit switch; the upper end and the lower end of a power steel shaft of the knife rest assembly are provided with power wheels capable of rolling along the spiral guide rails respectively; in addition, the knife rest assembly is further provided with a lead screw and more than one fixing rod in the vertical direction; the upper end and the lower end of the knife rest assembly penetrate through the lead screw and the fixing rod to be provided with main machine shells respectively; the main machine shells are clamped in grooves of the spiral guide rails; guide roller shafts are arranged in the main machine shells; guide rollers are arranged on the corresponding guide roller shafts; and the rubber tapping machine further comprises a rubber tapping knife assembly. According to the rubber tapping machine, manual work is replaced with automatic machinery, unmanned automatic rubber tapping of a rubber tree is achieved, and the problems that the labor intensity of manual rubber tapping is large and manual rubber tapping is not refined enough are solved to the maximum extent.

Owner:NINGBO CIHEVEA TECH CO LTD

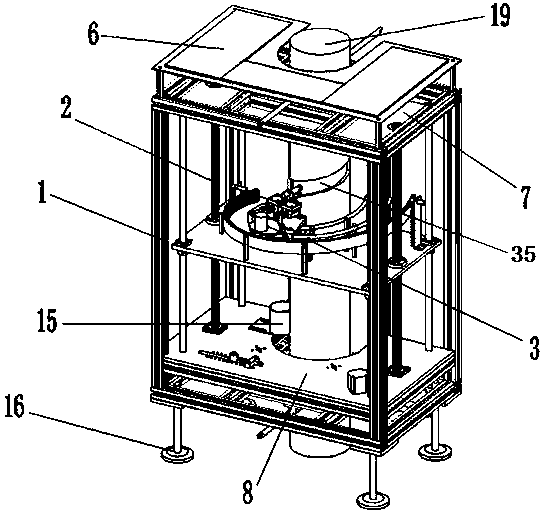

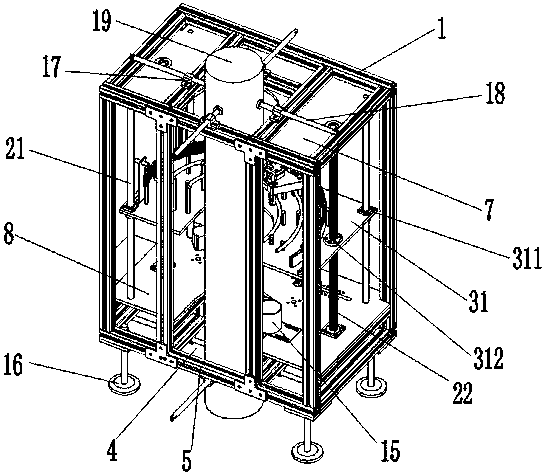

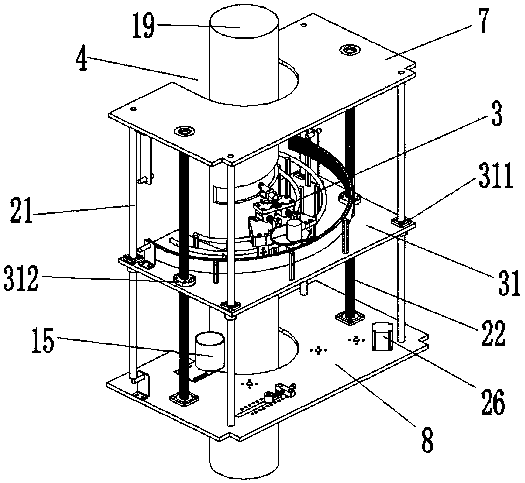

Rubber tapping equipment with double-knife-edge structure

PendingCN108432590AComplete lift movement wellAvoid the disadvantages of unbalanced transmissionForestryRenewable energy machinesControl systemTree trunk

The invention provides rubber tapping equipment with a double-knife-edge structure. The equipment comprises an outer frame, a vertical lifting work feeder arranged on the outer frame and a spiral rubber-tapping device arranged on the vertical lifting work feeder and capable of vertical lifting along the vertical lifting work feeder; and the spiral rubber-tapping device is provided with a rubber-tapping knife with an adjustable extending distance and a double-sided knife edge, the outer frame is provided with a tree trunk fixing position used for accommodating a tree trunk of a rubber tree, theposition, corresponding to the tree trunk fixing position, of one side of the outer frame is provided with a detachable movable baffle, the top end of the outer frame is provided with a solar panel and a control system, the vertical lifting work feeder and the spiral rubber-tapping device are connected with the solar panel and the control system, and the part, located at the edge position of thetree trunk fixing position, of the bottom of the outer frame is provided with a rubber collecting barrel. The equipment provided by the invention can replace manual rubber tapping, not only improves rubber tapping efficiency, but also improves rubber tapping quality; and the equipment is provided with the rubber tapping knife with a front knife edge and back knife blade structure, so that the equipment facilitates effective and high-efficiency cutting of the rubber tree.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com