Electric rubber tapping knife

A tapping knife and electric technology, applied in forestry, application, agriculture, etc., can solve the problems of increased labor cost, high labor intensity, and no cutting if there is glue, so as to save labor cost, reduce labor intensity and save labor cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to describe the technical content and structural features of the present invention in detail, the following will be further described in conjunction with the embodiments and accompanying drawings.

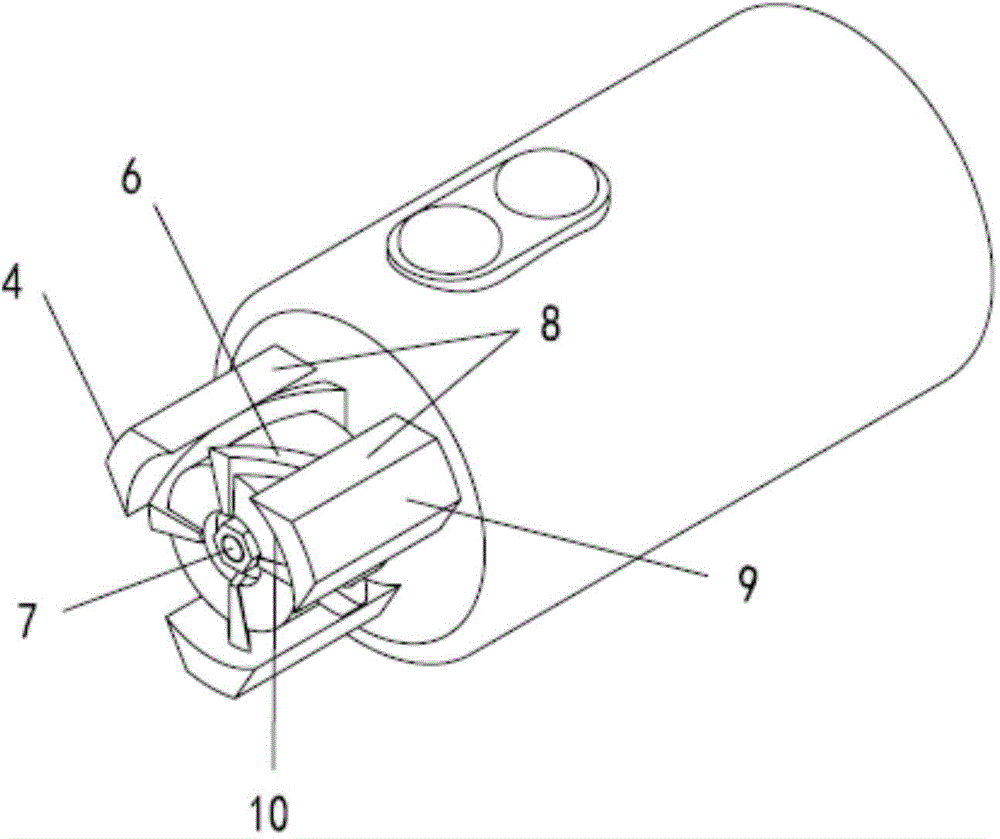

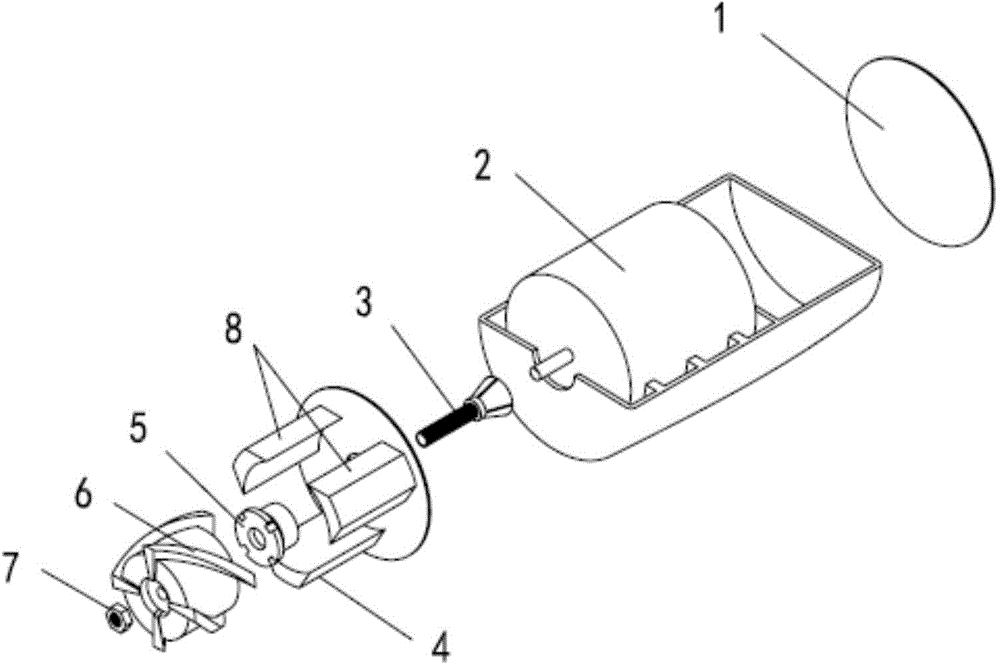

[0012] Such as figure 1 , 2 As shown, the rubber electric tapping knife of the present invention includes a motor 2, a guide device and a rotary cutter head; the guide device is connected to the motor 2 shell through a fixing screw, the rotary cutter head is located in the guide device, and the rotary cutter head is connected to the motor through a rotating shaft; The guide device is made up of several arc trapezoidal guide pieces 4; each guide piece 4 is made up of an outer arc surface 9, an inner arc surface 10 and two waist surfaces 8; gaps are formed between adjacent guide pieces 4; Adjacent waist surfaces between adjacent guide pieces form a limit surface 8 on the same plane, and the limit surface 8 is parallel to the axis; the rotary cutter head is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com